A method for enriching Thiobacillus ferrooxidans with a hollow fiber membrane to form a biofilm, a hollow fiber membrane reactor and its application

A technology of Thiobacillus ferrooxidans and fiber membrane reactor, applied in the direction of microorganism-based method, method of supporting/immobilizing microorganism, bioreactor/fermenter combination, etc., can solve the problem that the culture medium cannot be reused, and achieve Reduce operating requirements and management costs, simple operation, and solve the effect that cannot be recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

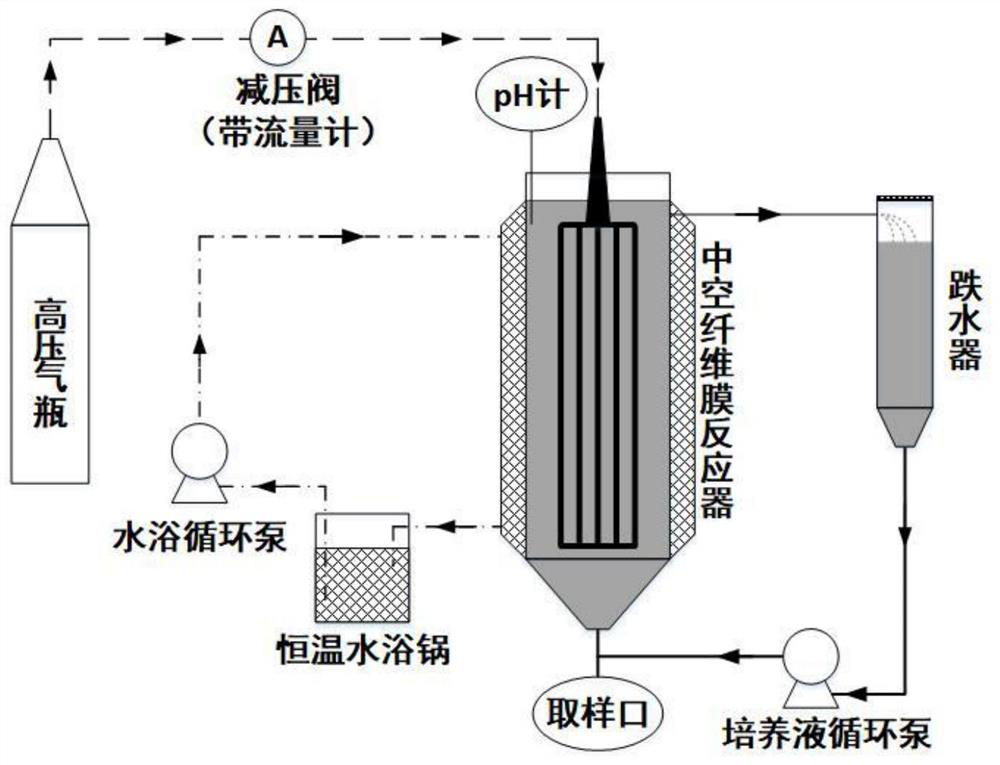

[0046] Enrichment and biofilm formation of Thiobacillus ferrooxidans:

[0047] Attached figure 1 Construct the reaction system with the hollow fiber membrane reactor as the core, then add 450mL liquid culture medium (the composition is: (NH 4 ) 2 SO 4 ,132;K 2 HPO 4 ,41; MgSO 4 ·7H 2 O,490; CaCl 2 2H 2 O,9; KCl,52; ZnSO 4 ·7H 2 O,1; CuSO 4 ·5H 2 O,2; MnSO 4 ·H 2 O,1; FeSO 4 ·7H 2 O,70; NaMoO 4 ·5H 2 O,0.5; CoCl 2 ·6H 2 O, 0.5; Na 2 SeO 4 10H 2 O,1; NiCl 2 ·6H 2 O, 1, the balance is water (unit: mg / L, the pH of the medium is adjusted to 2.0 with 5mol / L sulfuric acid)) and 50mL of acidic mine wastewater, turn on the culture medium circulation pump, and carry out enrichment culture and biofilm formation Open the valve of the high-pressure gas cylinder, adjust the pressure reducing valve to control the inlet pressure to be 0.06Mpa, supply the mixed gas of hydrogen and carbon dioxide (the volume ratio of hydrogen and carbon dioxide in the mixed gas is 4 : ...

Embodiment 2

[0050] Generate ferric sulfate leach solution that can be used for bioleaching, including intermittent flow mode (high concentration ferric sulfate leach solution) and continuous flow mode (low concentration ferric sulfate leach solution):

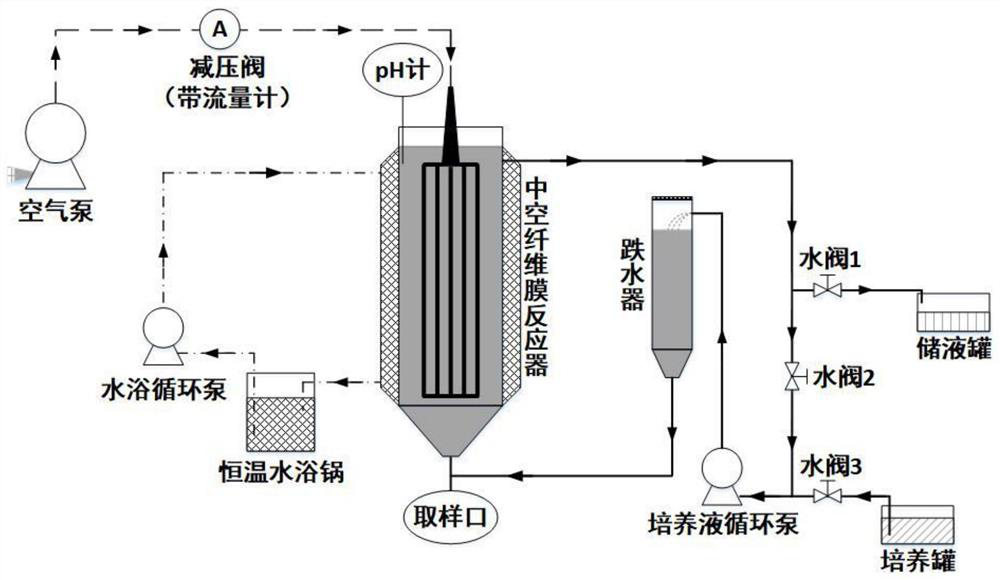

[0051] (1) Concrete steps under the discontinuous flow mode: the hollow fiber membrane reactor attached to the biofilm is pressed figure 2 Build a new reaction system; add 500mL ferrous sulfate solution (Fe in the solution) by the sampling port of the reaction system 2+ Concentration is 9g / L, and adjusts pH=2.0 with the sulfuric acid of 5mol / L), then open culture fluid circulation pump and water valve 2 (water valve 1 and water valve 3 are closed), start ferrous ion oxidation; Open air pump (air The air inlet of the pump is provided with a filter membrane to prevent dust from entering the air pump), adjust the pressure reducing valve to control the air inlet pressure, and supply air through the hollow fiber membrane reactor in a way of ai...

Embodiment 3

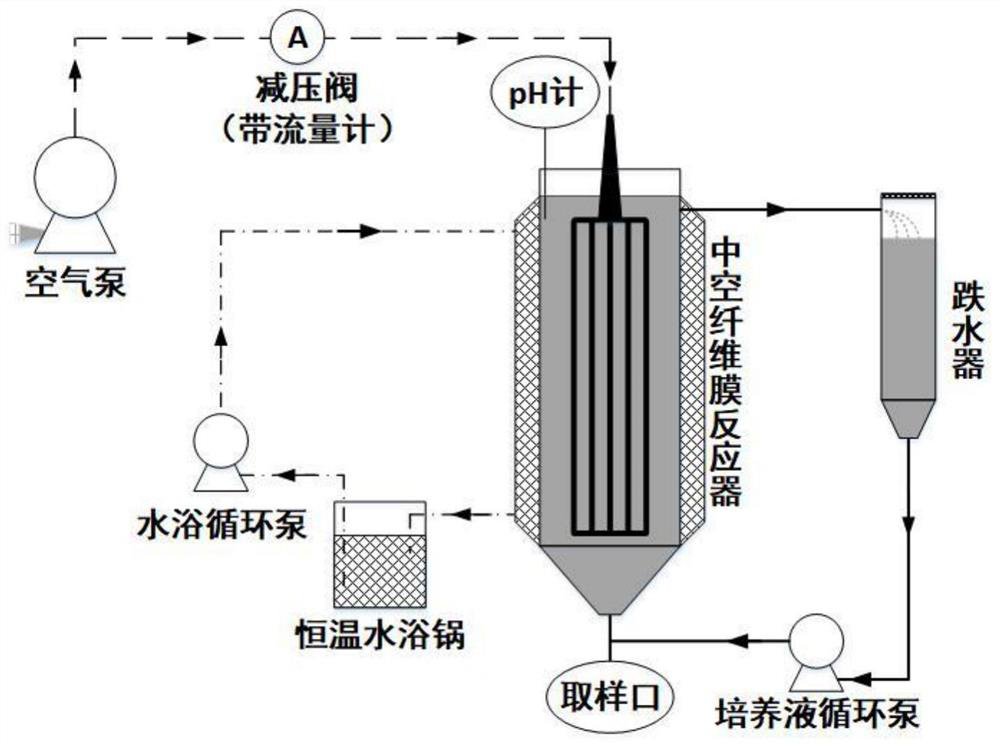

[0057] Generate schizite:

[0058] (1) The hollow fiber membrane reactor attached to the biofilm image 3 Build a new reaction system; add 500mL of ferrous sulfate solution (solution Fe 2+ The concentration is 9g / L, and the sulfuric acid of 5mol / L is used to adjust the pH=3.0), then turn on the circulation pump of the culture solution to start the oxidation of ferrous ions; turn on the air pump to feed air into the hollow fiber membrane, and adjust the pressure reducing valve to make the hollow fiber membrane No bubbles out; then turn on the water bath circulation system, and stabilize the temperature of the hollow fiber membrane reactor at 25-35°C by means of water bath heating; after 48 hours of reaction, turn off the culture medium circulation pump, and separate the minerals at the bottom of the reactor through the sampling port; minerals After cleaning and drying, the Shi's mineral is obtained, and the appearance of the Shi's mineral is as attached Image 6 shown.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com