Patents

Literature

2957 results about "Culture fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Culture fluid. a fluid in which microscopic organisms are made to develop, either for purposes of study or as a means of modifying their virulence. If the fluid is gelled by, for example, the use of agar, it then is called, depending on the vessel in which the gelled medium is contained, a plate, a slant, or a stab.

Microbial culture liquors containing microorganisms differing in characteristics and living in symbiosis and metabolites thereof, carriers and adsorbents containing the active components of the culture liquors and utilization of the same

Solutions containing microorganisms differing in characteristics from each other and living in symbiosis with each other and enzymes characterized by containing aerobic microorganisms, anaerobic microorganisms and at least one basidiomycete belonging to the family Pleurotaceae living in symbiosis, metabolites thereof and enzymes; carriers obtained by adsorbing the components of the above solutions onto finely ground carbonaceous materials; and porous materials obtained by adsorbing the components of the above solutions onto porous materials. Because of having various effects of absorbing, adsorbing and decomposing harmful matters, deodorizing, decolorizing, etc., these materials are applicable to various uses in the fields of agriculture and environment.

Owner:ORIENT GREEN

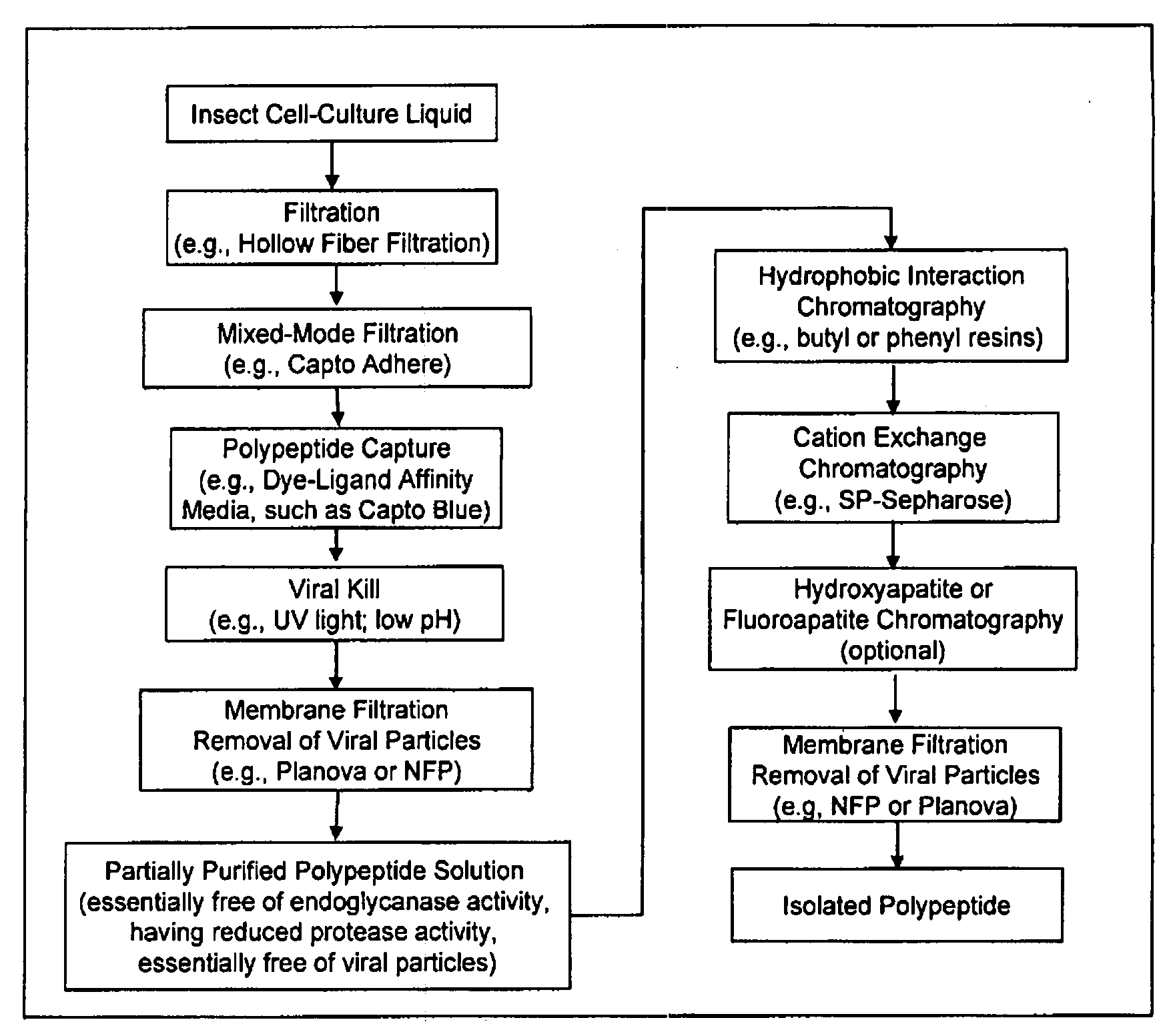

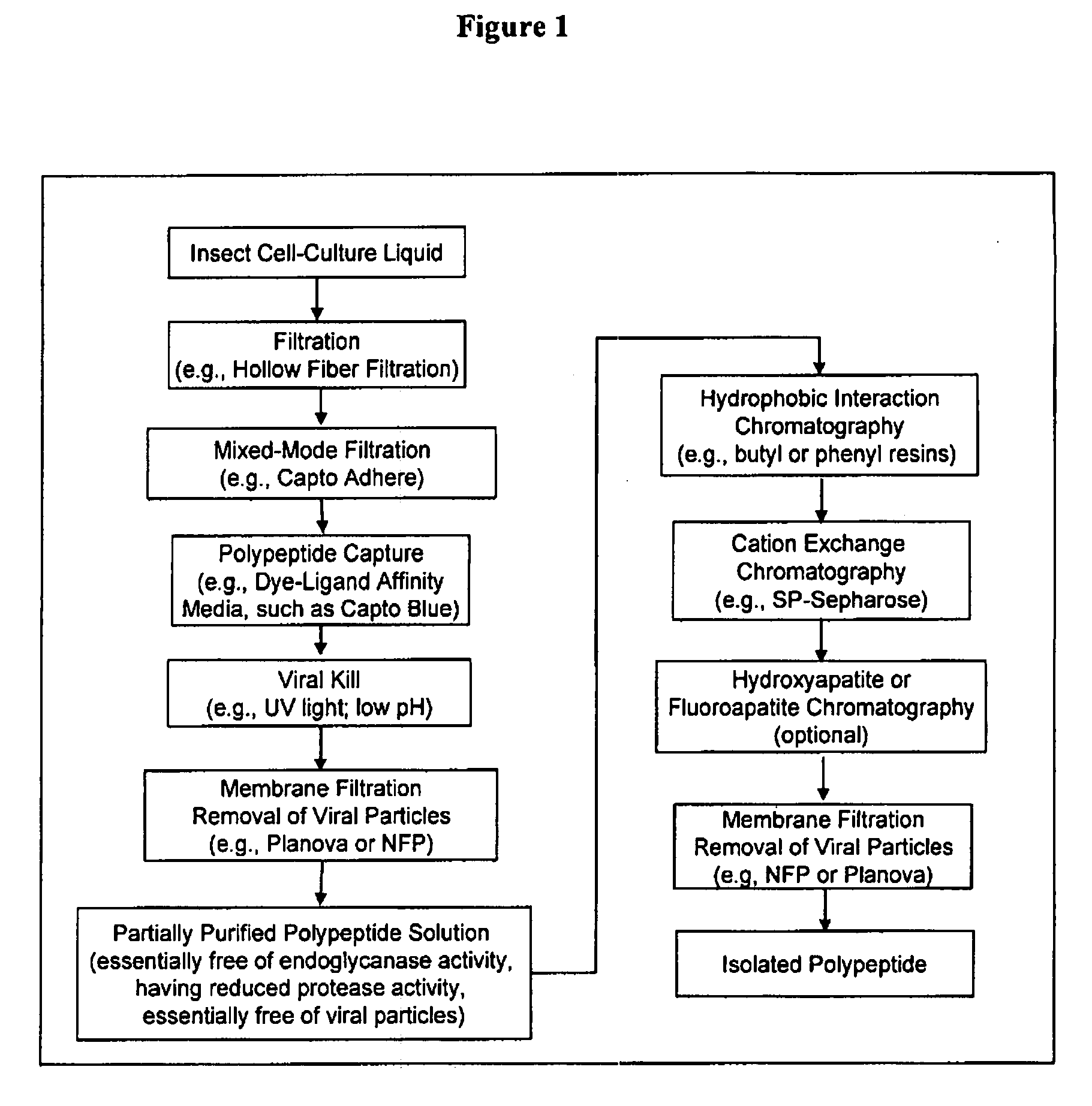

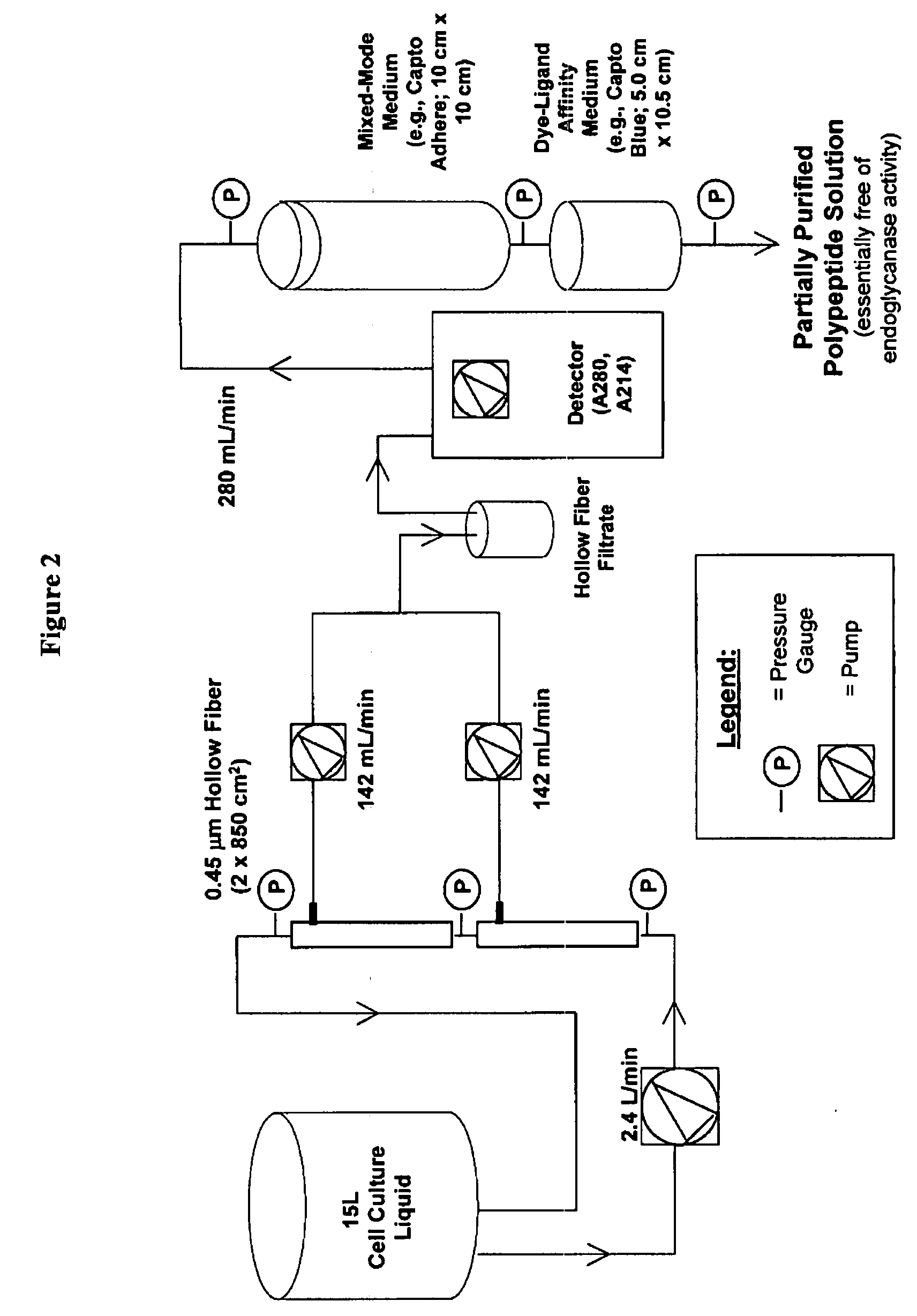

Manufacturing process for the production of polypeptides expressed in insect cell-lines

InactiveUS20080207487A1Promote recoveryReduce manufacturing costPeptide/protein ingredientsDepsipeptidesFiberCulture fluid

The present invention provides a manufacturing method for polypeptides that are produced in insect cells using a baculoviral expression system. In one example, the insect cell culture is supplemented with a lipid mixture immediately prior to infection (e.g., one hour prior to infection). The polypeptides are isolated from the insect cell culture using a method that employs anion exchange or mixed-mode chromatography early in the purification process. This process step is useful to remove insect-cell derived endoglycanases and proteases and thus reduces the loss of desired polypeptide due to enzymatic degradation. In another example, mixed-mode chromatography is combined with dye-ligand affinity chromatography in a continuous-flow manner to allow for rapid processing of the insect-cell culture liquid and capture of the polypeptide. In yet another example, a polypeptide is isolated from an insect cell culture liquid using a process that combines hollow fiber filtration, mixed-mode chromatography and dye-ligand affinity in a single unit operation producing a polypeptide solution that is essentially free of endoglycanase and proteolytic activities. In a further example, the isolated polypeptides are glycopeptides having an insect specific glycosylation pattern, which are optionally conjugated to a modifying group, such as a polymer (e.g., PEG) using a glycosyltransferase and a modified nucleotide sugar.

Owner:NOVO NORDISK AS

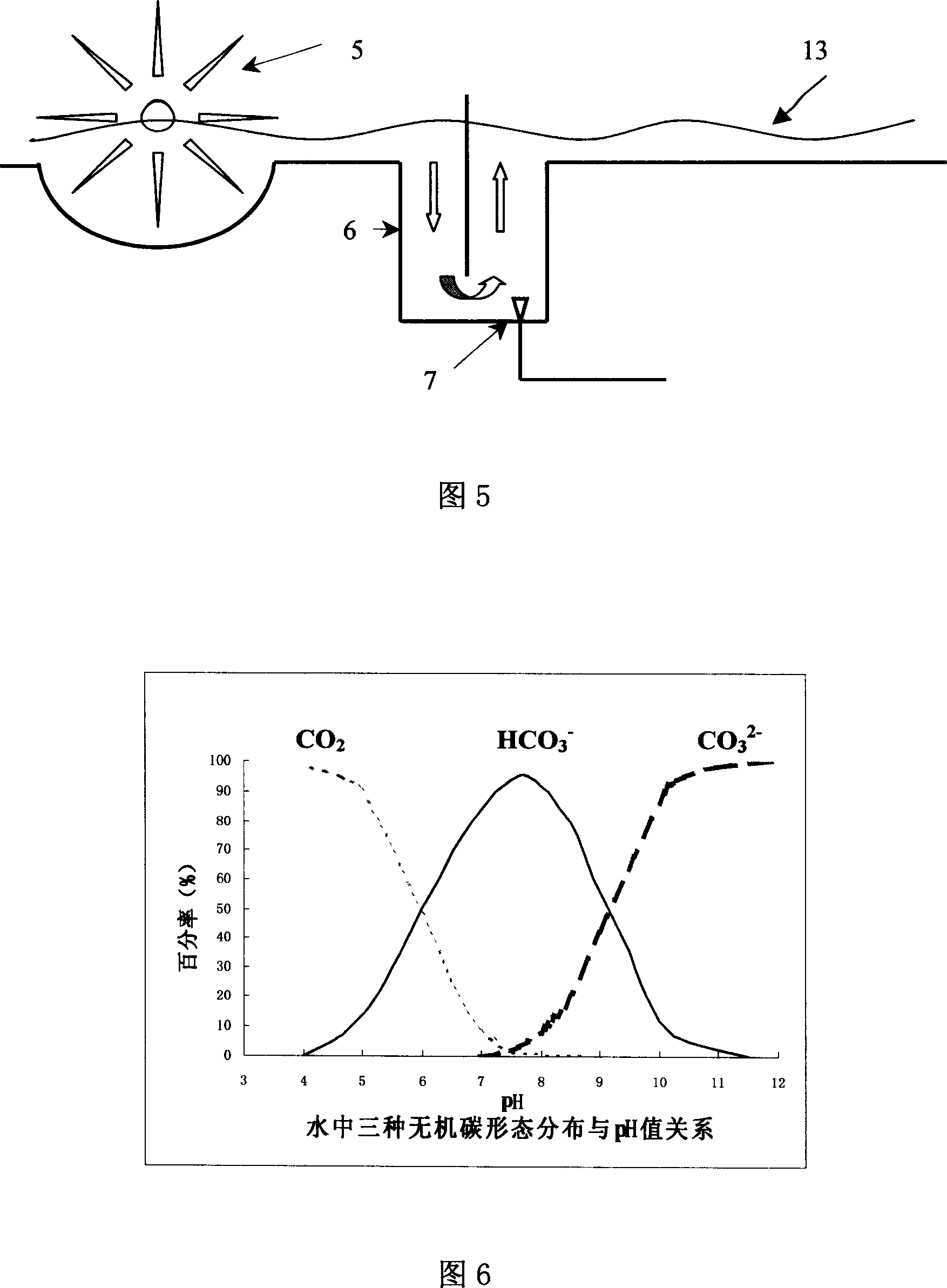

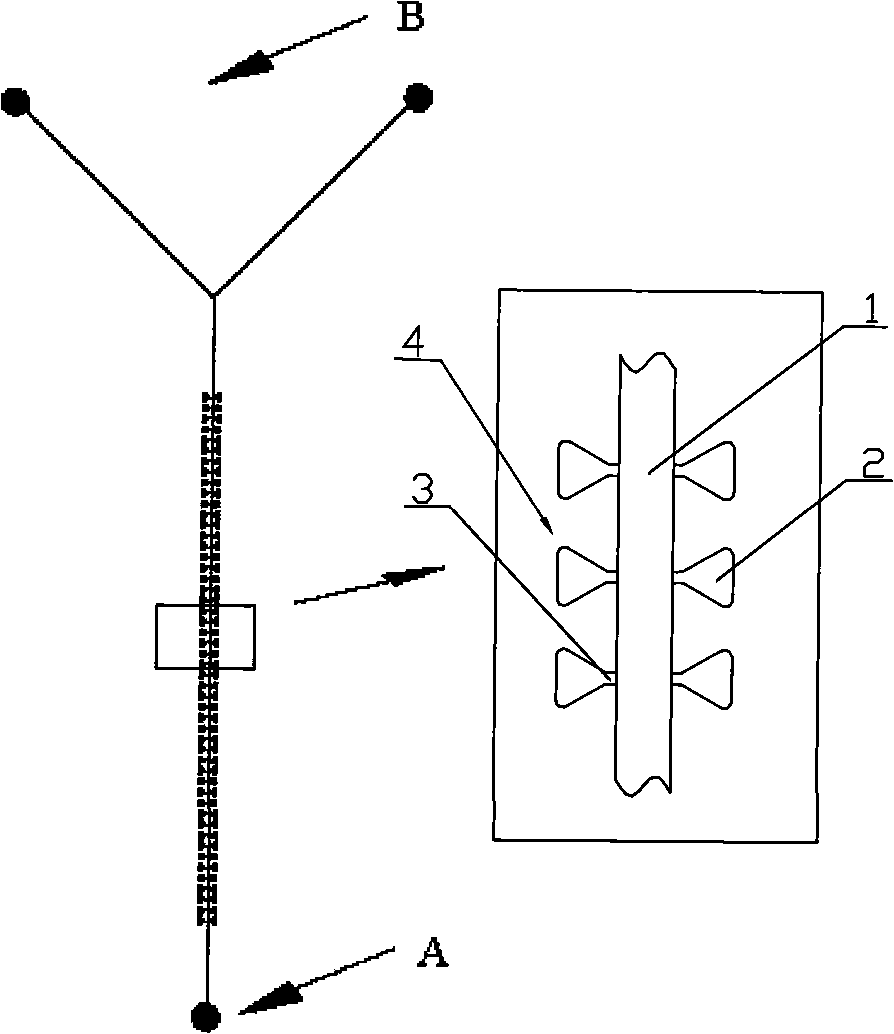

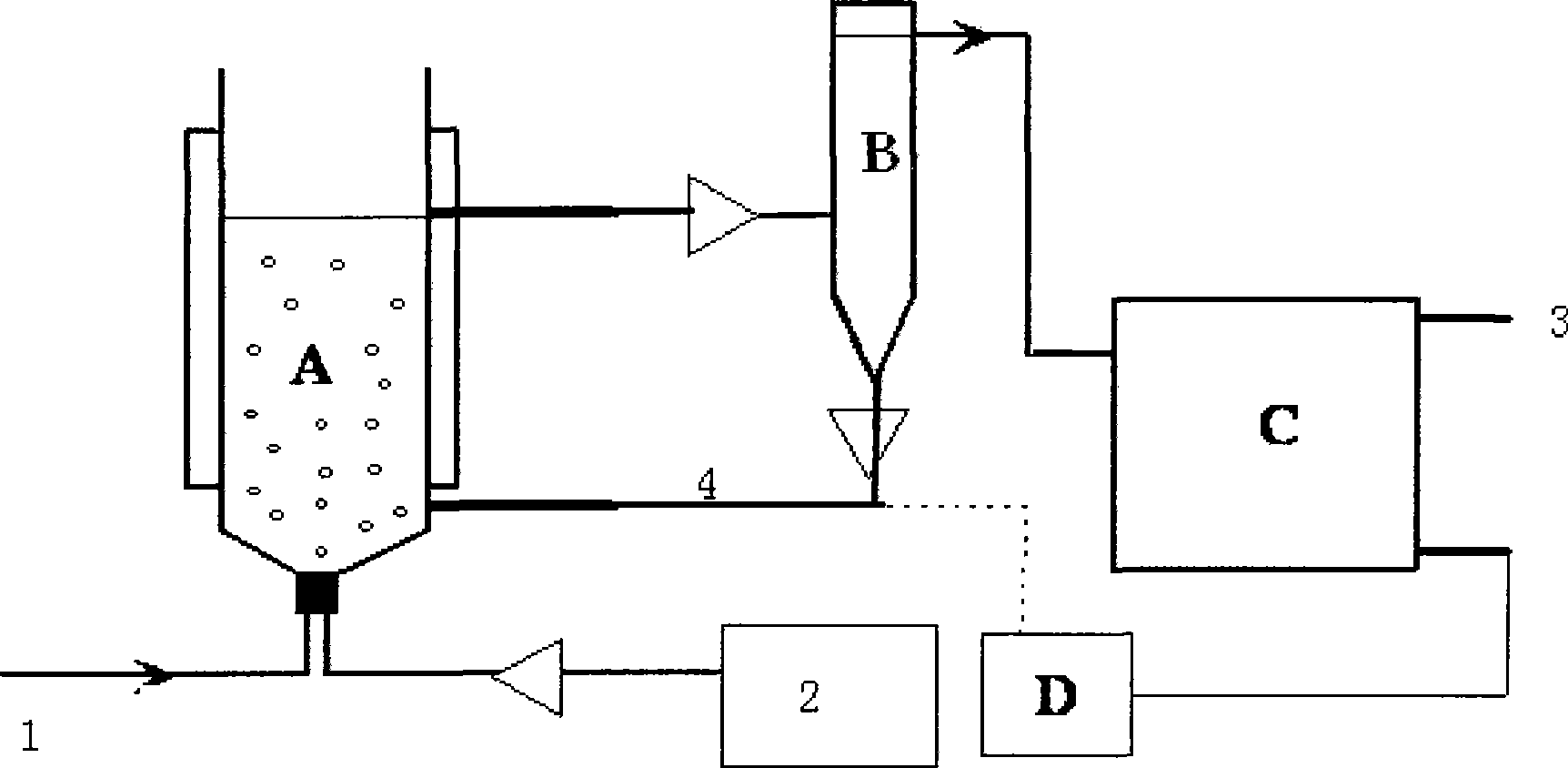

Carbon compensator for large-scale culturing micro-algae, its utilization and use

InactiveCN1982432AIncrease profitReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsVapor liquidContact time

A carbon supplementing apparatus for supplying carbon dioxide efficiently in micro-algae culturing tank, its usage and use are disclosed. A vertical baffle plate is installed above in the container with 10-50 cm gap, gas distributor is arrange at bottom of tank, the apparatus is built-in the bottom of tank, whose upper edge is aligned with the tank bottom, baffler plate is above culturing level of tank so as to pass culturing fluid to the apparatus with agitator driven. It has longer vapor-liquid contact time, more vapor-liquid contact area and higher carbon dioxide efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Bacillus amyloliquefaciens growing in disease-preventing and growth-promoting plant and application thereof

ActiveCN101948771AHas development and application valueImprove efficiencyBiocideBacteriaDiseaseCulture fluid

The invention relates to a bacillus amyloliquefaciens growing in a disease-preventing and growth-promoting plant and application thereof, relating to bacillus amyloliquefaciens and the application thereof. The bacillus amyloliquefaciens TF28 growing in the disease-preventing and growth-promoting plant belongs to bacillus, has the storage number of CGMCC No.4038 and the storage data of July 26, 2010. The application of the bacillus amyloliquefaciens TF28 comprises the following steps of: (1) preparing activated bacilli liquid; (2) inoculating the activated bacilli liquid in an NYD culture fluid to obtain a strain fermentation solution; and (3) soaking seeds in a dilution solution 50 times of the strain fermentation solution. The strain TF28 in the invention can be colonized, reproduced and transmitted in plants, can simultaneously generate two antibacterial substances, i.e. antimicrobial proteins and lipopeptide antibiotic and has the multiple efficacy of preventing diseases, stimulating growth, increasing the yield, improving the quality, widening an antibacterial spectrum, and the like. Rice seeds treated by the dilution solution 50 times of the fermentation solution of the strain TF28 reach a room-temperature bakana resistance rate over 84.6 percent.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

Micro-ecological fruit-vegetable enzyme preparation method

InactiveCN103859404ARich sourcesLess investmentFood ingredient functionsFood preparationCulture fluidAdditive ingredient

The invention discloses a micro-ecological fruit-vegetable enzyme preparation method. The method comprises the steps of culturing 4 to 6 of six probiotics including lactobacillus acidophilus, bacillus coagulans, bacillus natto, saccharomyces cerevisiae, enterococcus faecium and bifidobacterium in a culture medium comprising ingredients such as brown sugar, liquorice and fresh sweet potato, and then culturing the probiotics through a diluted culture liquid containing brown sugar and liquorice in an activating manner to prepare a micro-ecological preparation, wherein the prepared micro-ecological preparation is a fermenting agent which is used for fermenting fruit pulp of fresh fruit and vegetable and traditional Chinese herbs. The microorganism enzyme in the ecological preparation and the natural vegetable enzyme in fruits, vegetables and Chinese herbs are compounded into a composite enzyme supplement by utilizing a micro-ecological fermentation technology, i.e. the micro-ecological fruit-vegetable enzyme. The micro-ecological fruit-vegetable enzyme can be made into a liquid type or a solid type (powder). An ideal effect is achieved in the fields such as medicine, healthcare and beauty.

Owner:JUNZHU DALIAN BIOLOGICAL IND CO LTD

Method for producing astaxanthin by cultivating haematococcus pulvialis

InactiveCN1392244AEmission reductionSimple processUnicellular algaeChemical recyclingCulture fluidProper treatment

Owner:中国科学院武汉植物研究所

Method for preparing edible fungus health-care product

InactiveCN102805335ASimple processLower control costsFood preparationHorticultureSubmerged fermentationCulture fluid

The invention relates to a method for preparing an edible fungus health-care product. The method comprises the following steps of: (A), inoculating edible fungus strains into a culture solution, and performing shake culture on a shaker to obtain strain liquid; (B), inoculating the strain liquid obtained in the step A into a liquid culture medium containing barley malt and soybeans, and performing aerobic culture or anaerobic culture to obtain fermented edible fungus mycelia and edible fungus fermentation liquor; (C), crushing cell tissues of the edible fungus mycelia obtained in the step (B), and extracting by using water to obtain a mycelium extracting solution; and (D), mixing the edible fungus fermentation liquor obtained in the step (B) and the edible fungus mycelium extracting solution obtained in the step (C), and diluting or concentrating a mixed solution to obtain the edible fungus health-care product. Due to the adoption of an industrial liquid submerged fermentation technology of edible fungi, a large number of edible fungus strains can be propagated in the liquid culture medium; and the preparation method is simple in process, stable in quality and low in cost.

Owner:BEIJING UPVALUE INTPROP CONSULTANTSCO

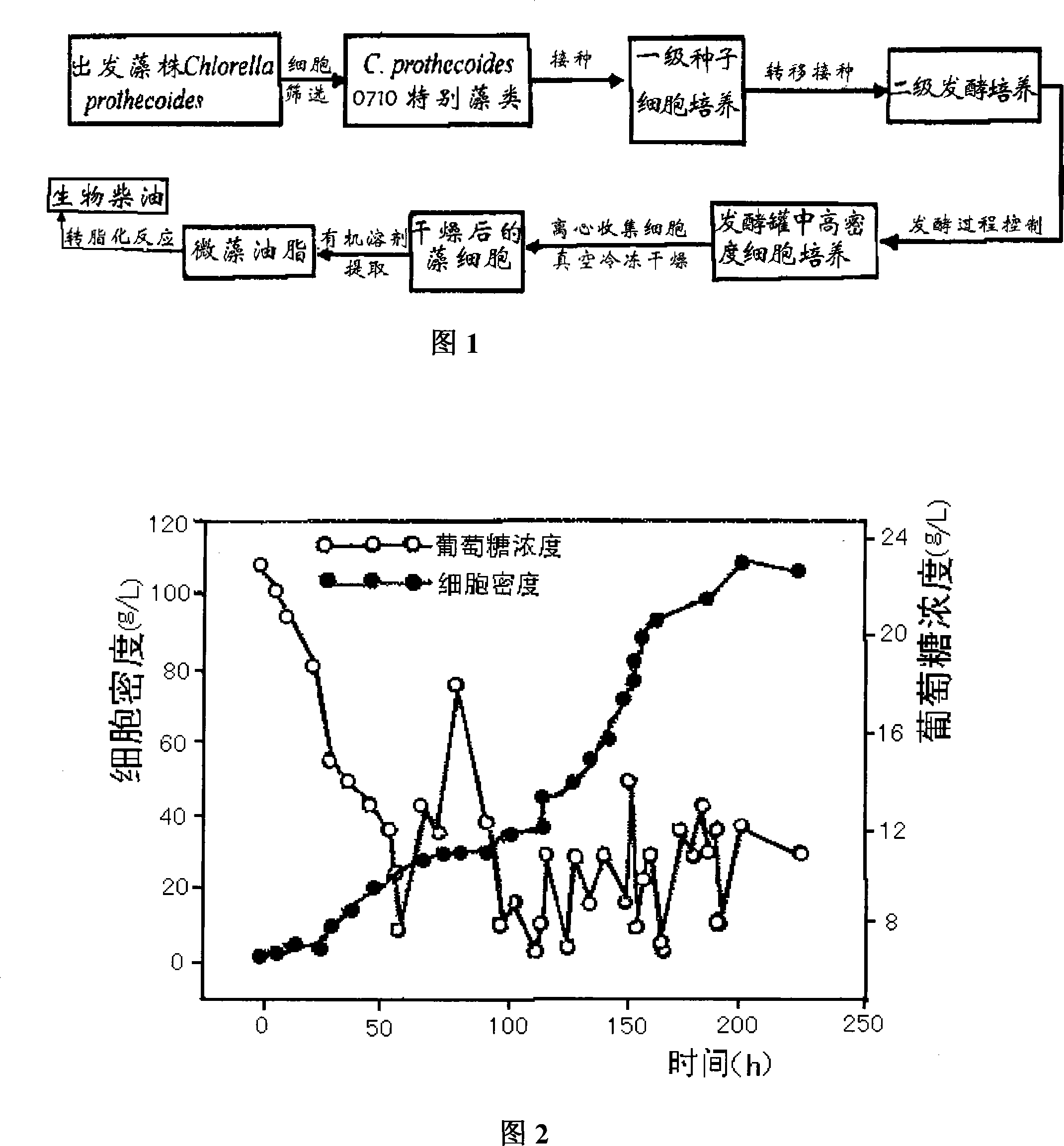

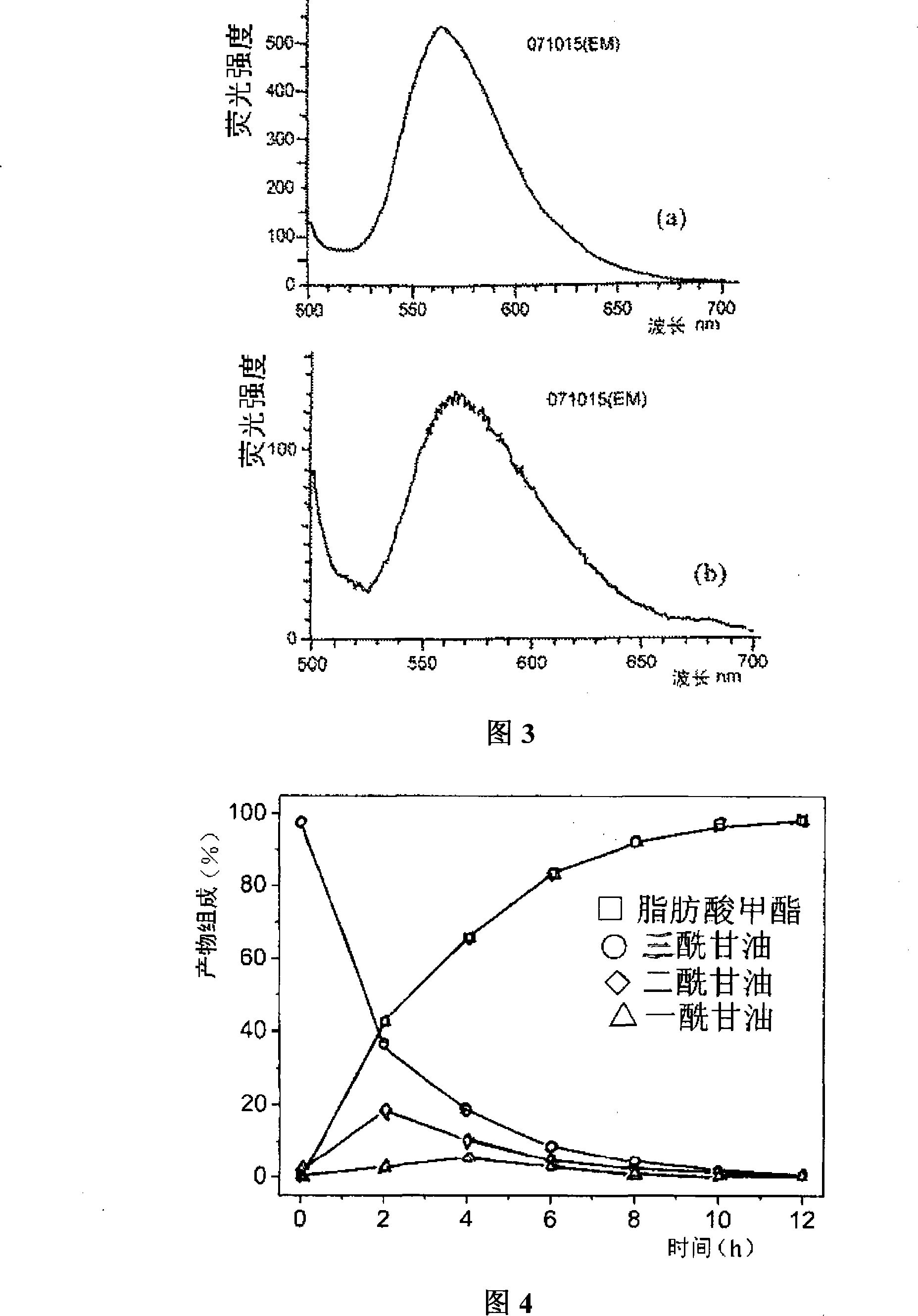

Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

InactiveCN101230364ALow raw material costOptimizing conditions for heterotrophic fermentationFatty acid esterificationUnicellular algaeBiodiesel feedstockBiodiesel

The invention discloses a method of producing bio-diesel by fermenting the heterotrophic chlorella in high density which belongs to the renewable biological energy field. The method uses the heterotrophic chlorella fermented in high density in the bio-reactor as a raw material, which screens the chlorella species having high growth rate and high oil content, directly inoculates into the bottle as the first-class germ to culture then transfers to the fermentation cylinder to undergo the second-glass high density fermentation; the reaction condition is then optimized, and the process is controlled; the culture containing the carbohydrate is dripped to provide the nutrition for the cell growth, therefore the heterotrophic chlorella cells cultured in high density with density of 108g / L and oil content of 61 percent are separated, collected and dried; the algae oil is extracted, and the bio-diesel is produced by transesterification reaction; the invention reduces the cost for the raw material of bio-diesel, and satisfies the demand of industrialized application of producing bio-diesel by heterotrophic chlorella cells, therefore the technique of the invention becomes an economical and effective way of making oils from bio-diesel materials.

Owner:TSINGHUA UNIV

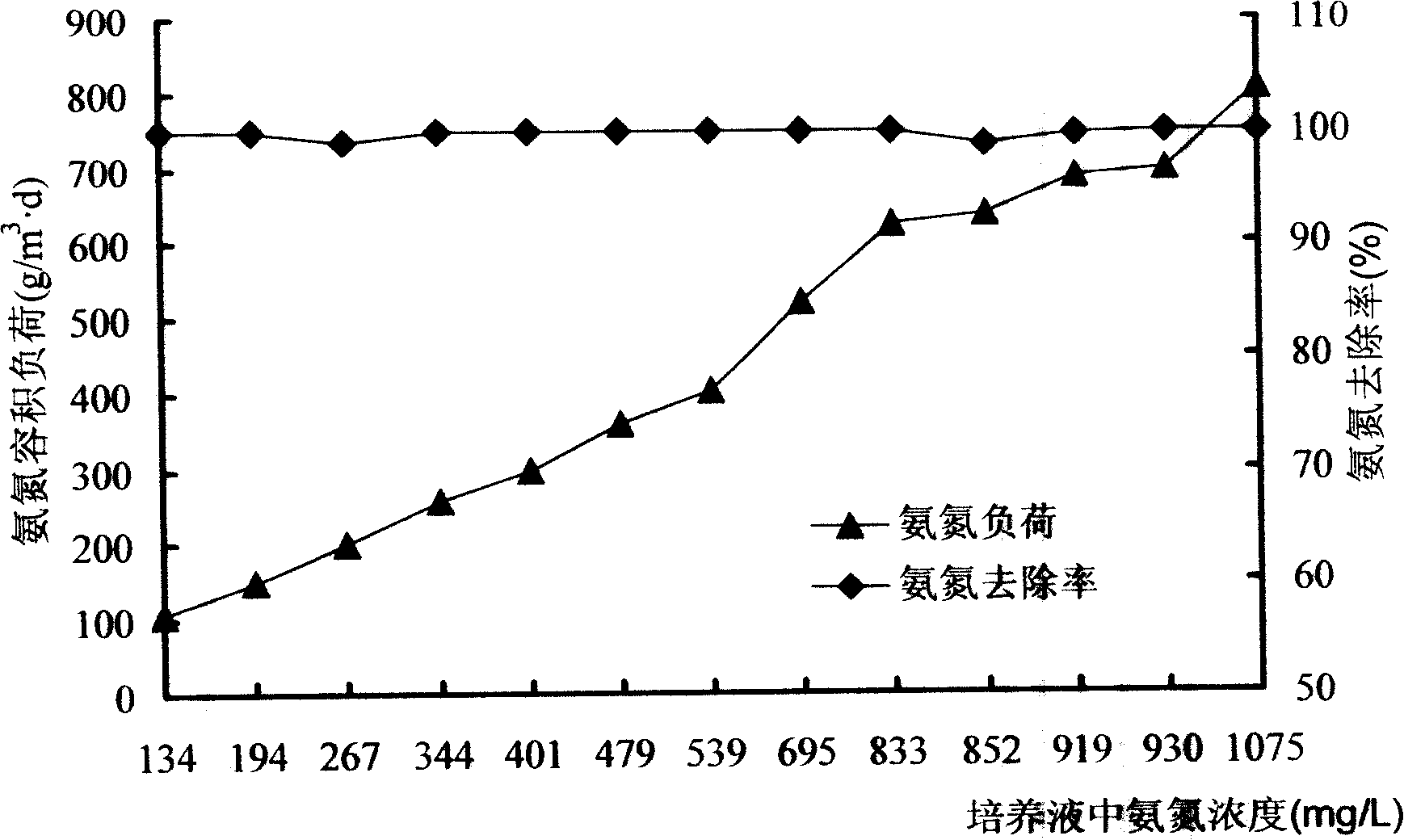

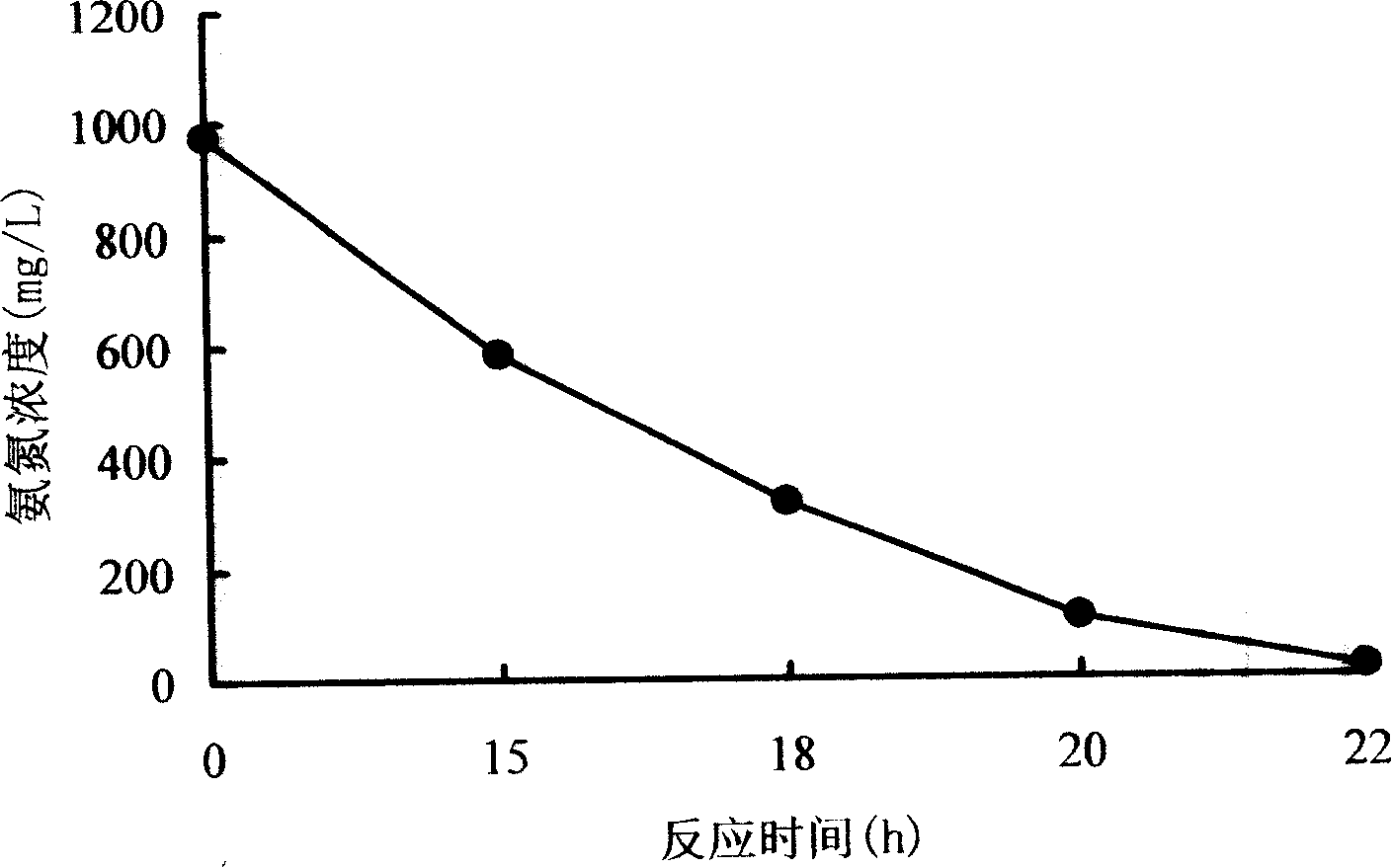

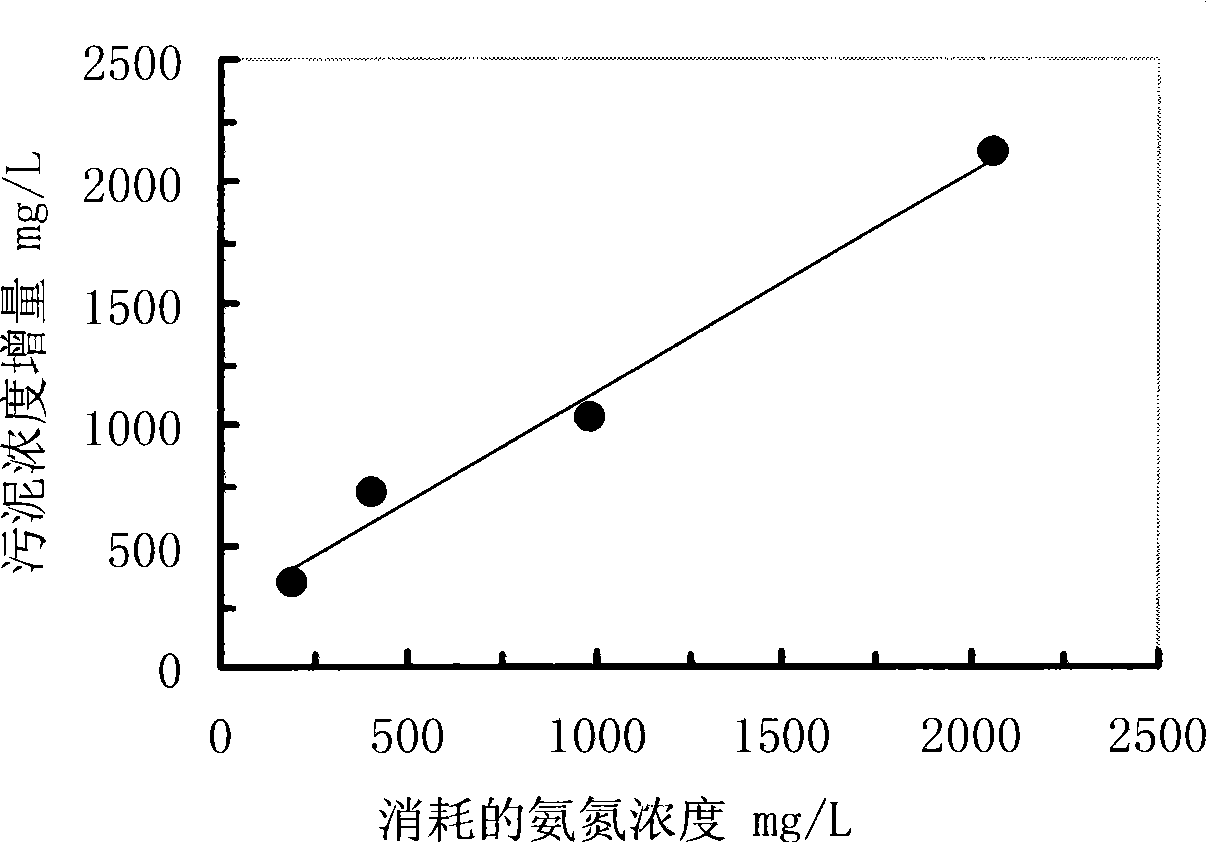

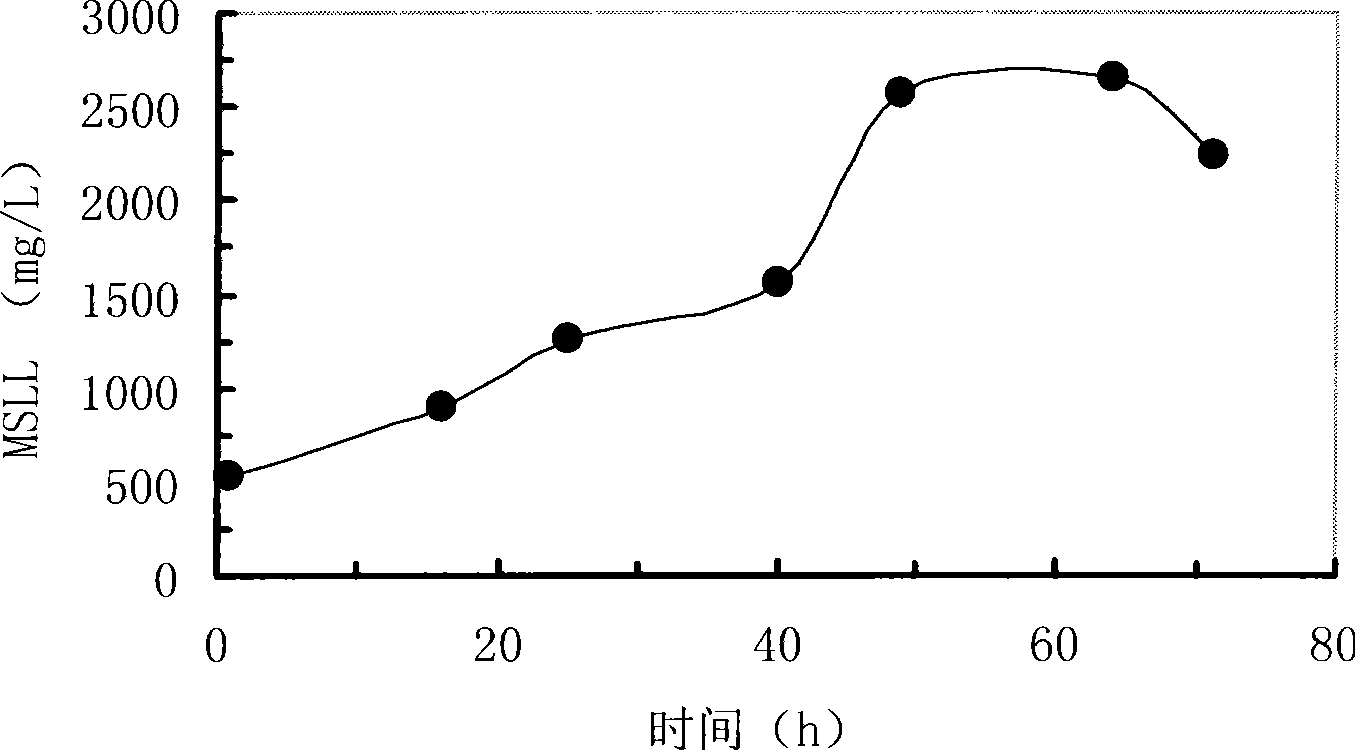

Method for concentrating highly effective nitrobacteria in active sludge

ActiveCN101240253AGrowth inhibitionGood removal effectBacteriaSustainable biological treatmentActivated sludgeHigh concentration

The invention discloses a enrichment method of nitrifying organism. The method adapts discontinuous activated sludge process by gradually improving ammonia nitrogen ph indicator in nutrient fluid to enrich. The main component of the enrichment nutrient fluid is inorganic salt comprising microelement Fe, Mg, Na, K and amortization liquor, in which inceptive concentration of NH(4)(+-N) is 100mg / L to 200mg / L, final concentration is 500mg / L to 1200mg / L and COD is less than or equal to 200mg / L. The method can restrain evidence the growth of sundry bacterium such as carbonizing bacterium, is propitious for nitrifying organism to become ascendency bacterium and resist more and more high ammonia nitrogen concentration, and finally disposing concentration of the ammonia nitrogen wasted water is up to 1200mg / L and high concentration ammonia nitrogen in wasted water can be reduce to less 10mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

Culture solution of nitrosobacteria as well as preparation method and culture method thereof

InactiveCN103898026AGuaranteed normal growthGrow fastBacteriaMicroorganism based processesCulture fluidMicrobiology

The invention relates to a culture solution of a typical nitrosomonaseuropaea and a culture method thereof. The culture method comprises the steps of preparing the culture solution, activating the bacteria and culturing. By adopting the culture solution and the method, the outstanding problems that the existing bacteria is difficult to culture, the requirement is high, the bacteria is easy to be polluted in the culture process and slow to grow, and the like can be solved. The culture solution comprises nutritional substances needed by the growth of the bacteria, a biological buffering agent and a pH indicating agent, and the culture solution can promote the growth of the bacteria, improve the propagation capacity and survival capacity of the bacteria and can judge and adjust the growth state and activity of the bacteria according to the color variation of the indicating agent; in the culture process, the bacteria is activated, so that the activity and the growth rate of the bacteria can be further increased, the culture period can be greatly shortened, the pH can be monitored and adjusted in real time, the survival capacity of the bacteria can be further improved, and the culture efficiency can be improved.

Owner:SOUTHEAST UNIV

Method for preparing stem cell secretion factor for beauty treatment and skin-protection

InactiveCN101461772AMaintain repair activityPromote proliferationCosmetic preparationsToilet preparationsDead cellDecomposition

The invention relates to a preparation method for stem cell secretion factors used for beauty culture and skin protection. The preparation method comprises the following steps: cell separation, stem cell amplification, the acquisition and concentration of a stem cell factor system, and the acquisition of the system containing the stem cell active factors through storage. The system comprises the active factors secreted by various types of currently verified stem cells. The obtained stem cell active factor system neither contains foreign culture solution components nor contains dead cell decomposition components; in addition, the stem cell active factor system can store and maintain the tissue and cell repairing activity for a long period, thereby truly turning the ideal of stem cell beauty culture into a reality, and improving the traditional beauty culture concepts at the biomedical depth. Simultaneously, the preparation method is simple and feasible and is suitable for mass production, thereby providing a shortcut for the stem cells to serve the beauty culture cause.

Owner:天津欧瑞生物科技有限公司

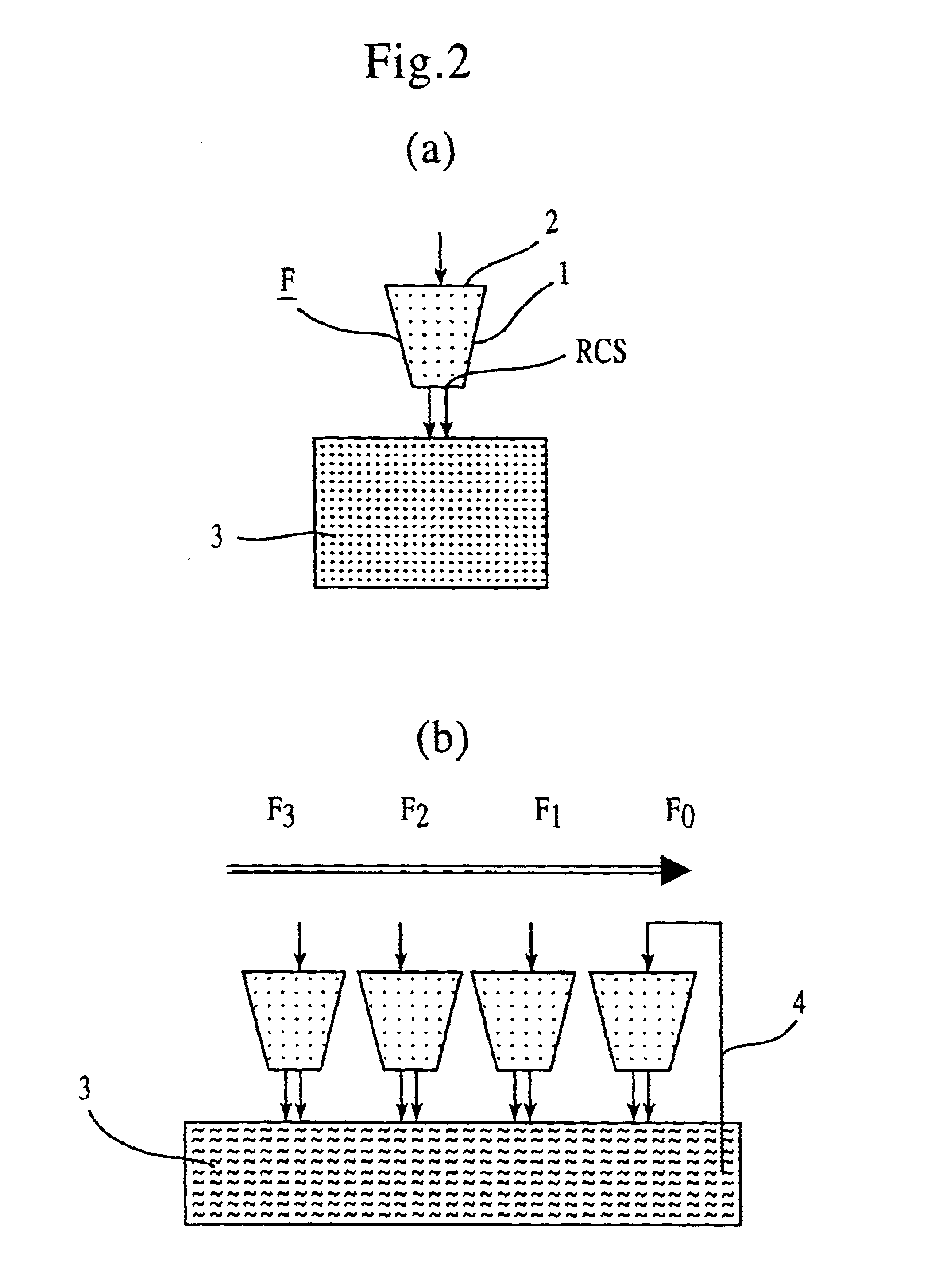

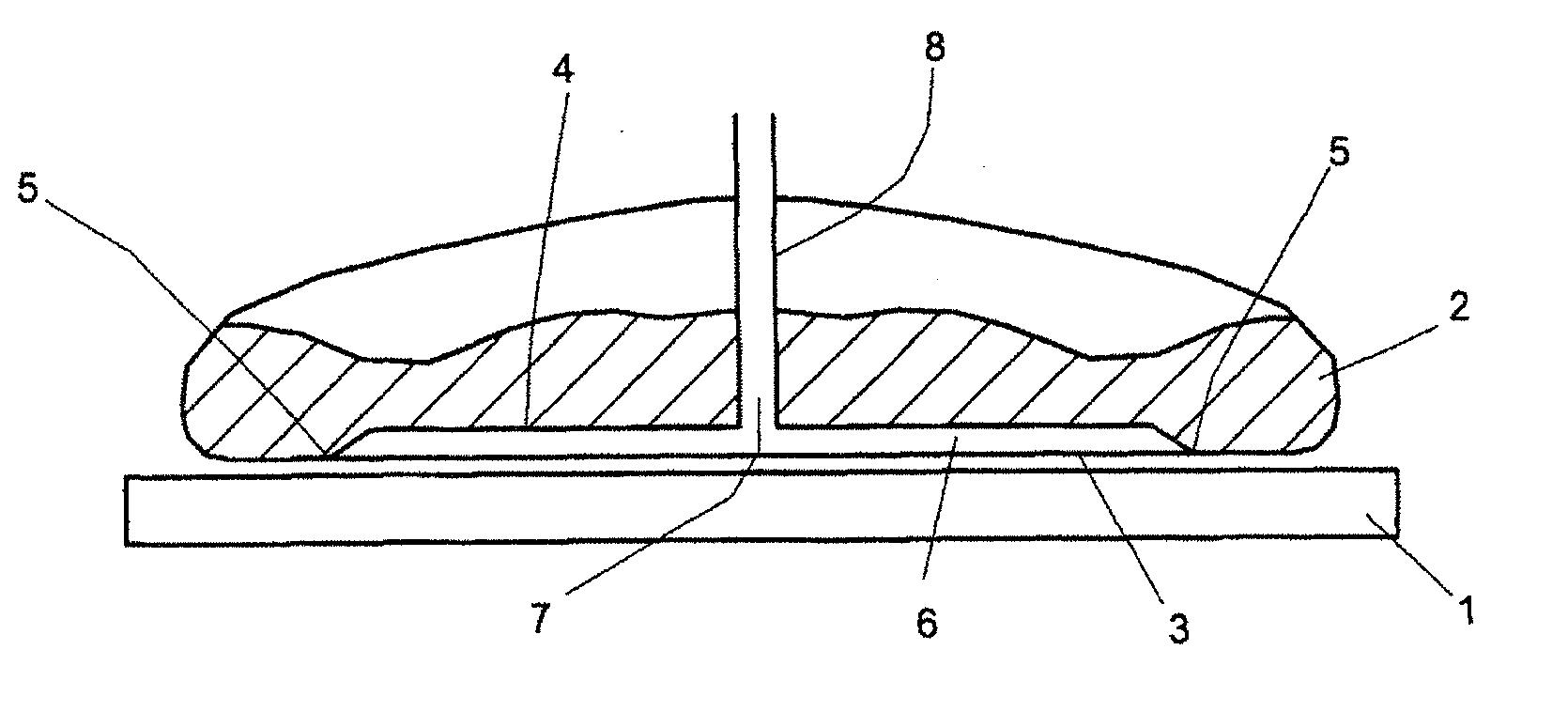

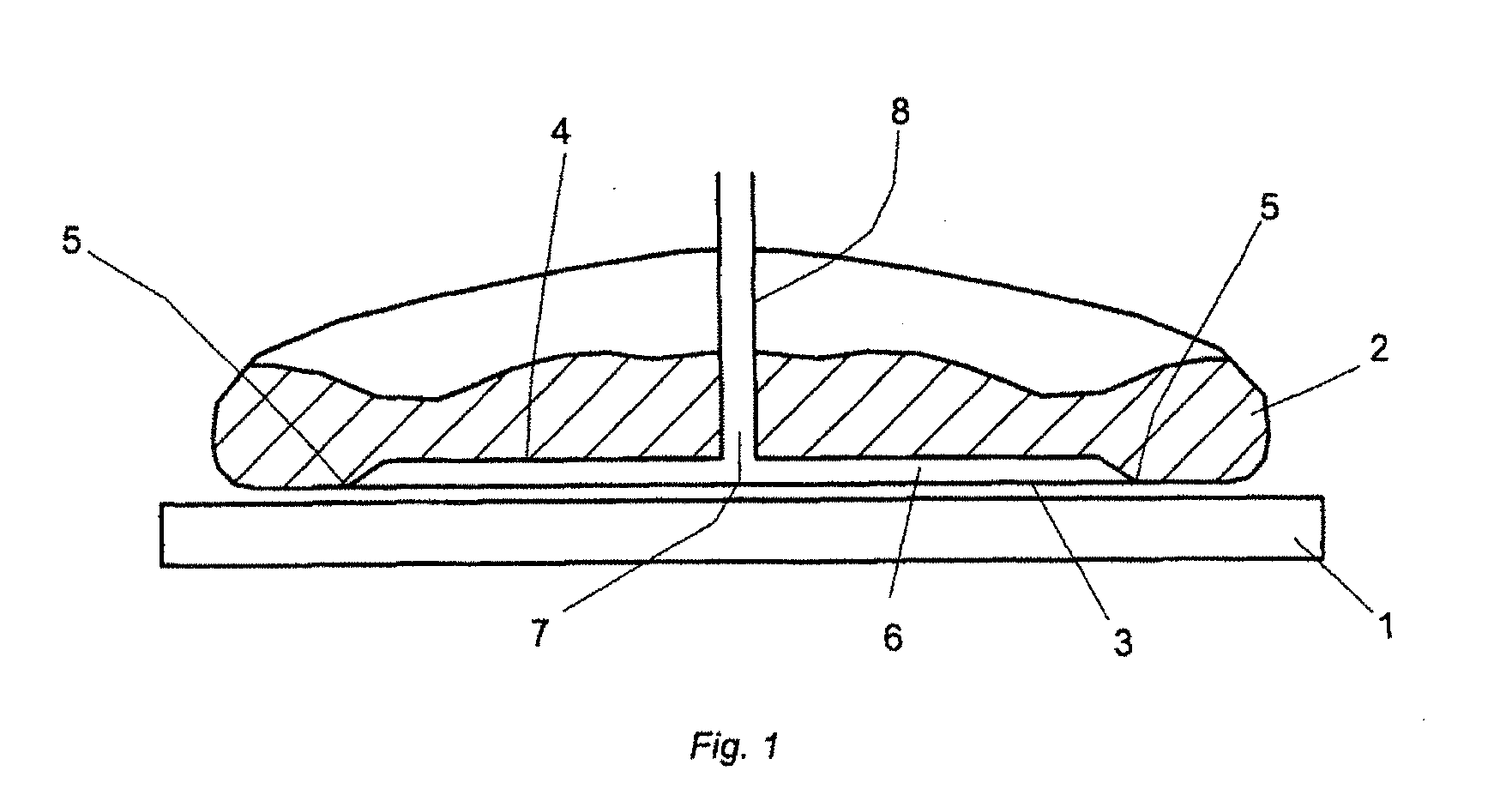

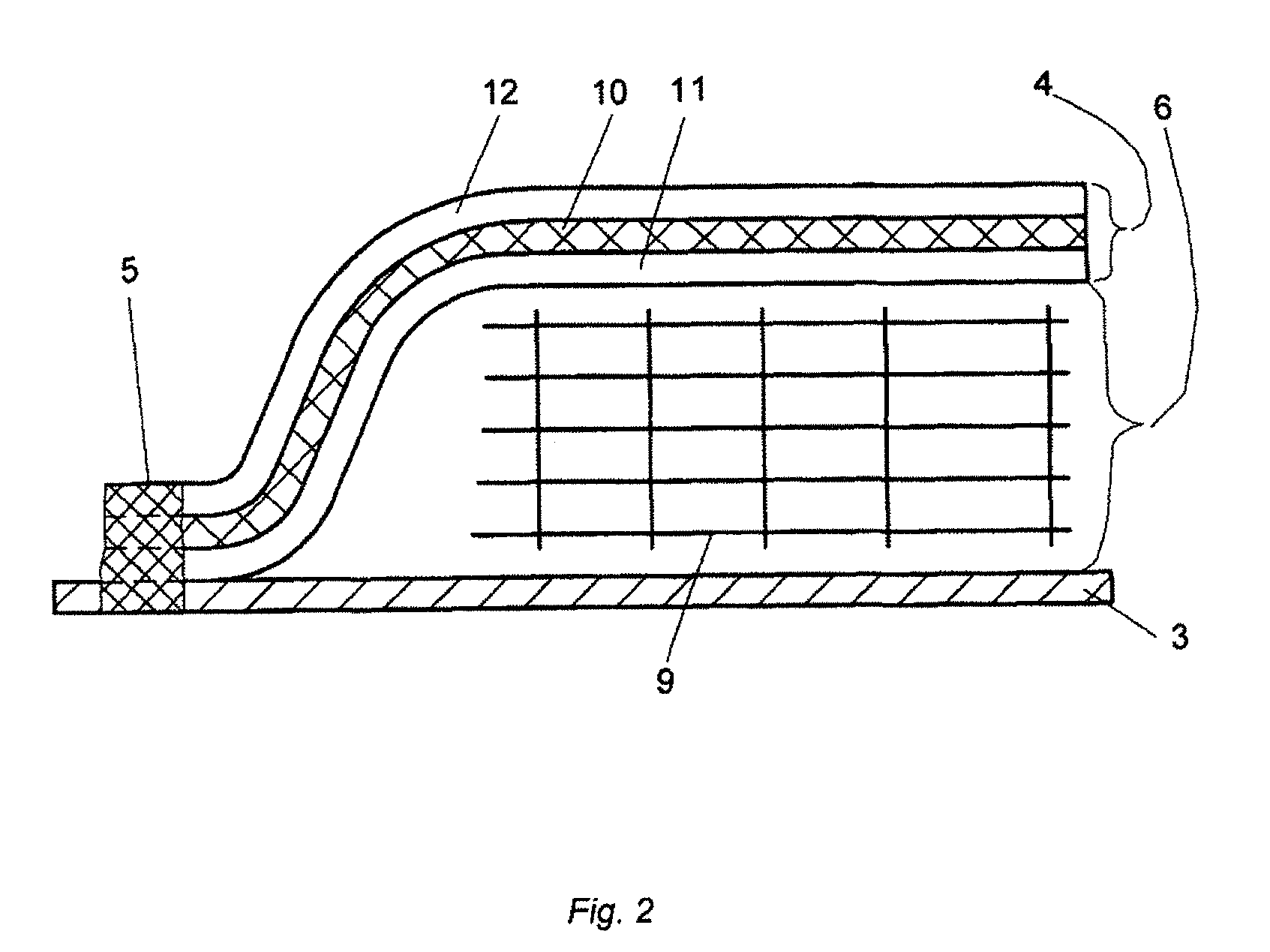

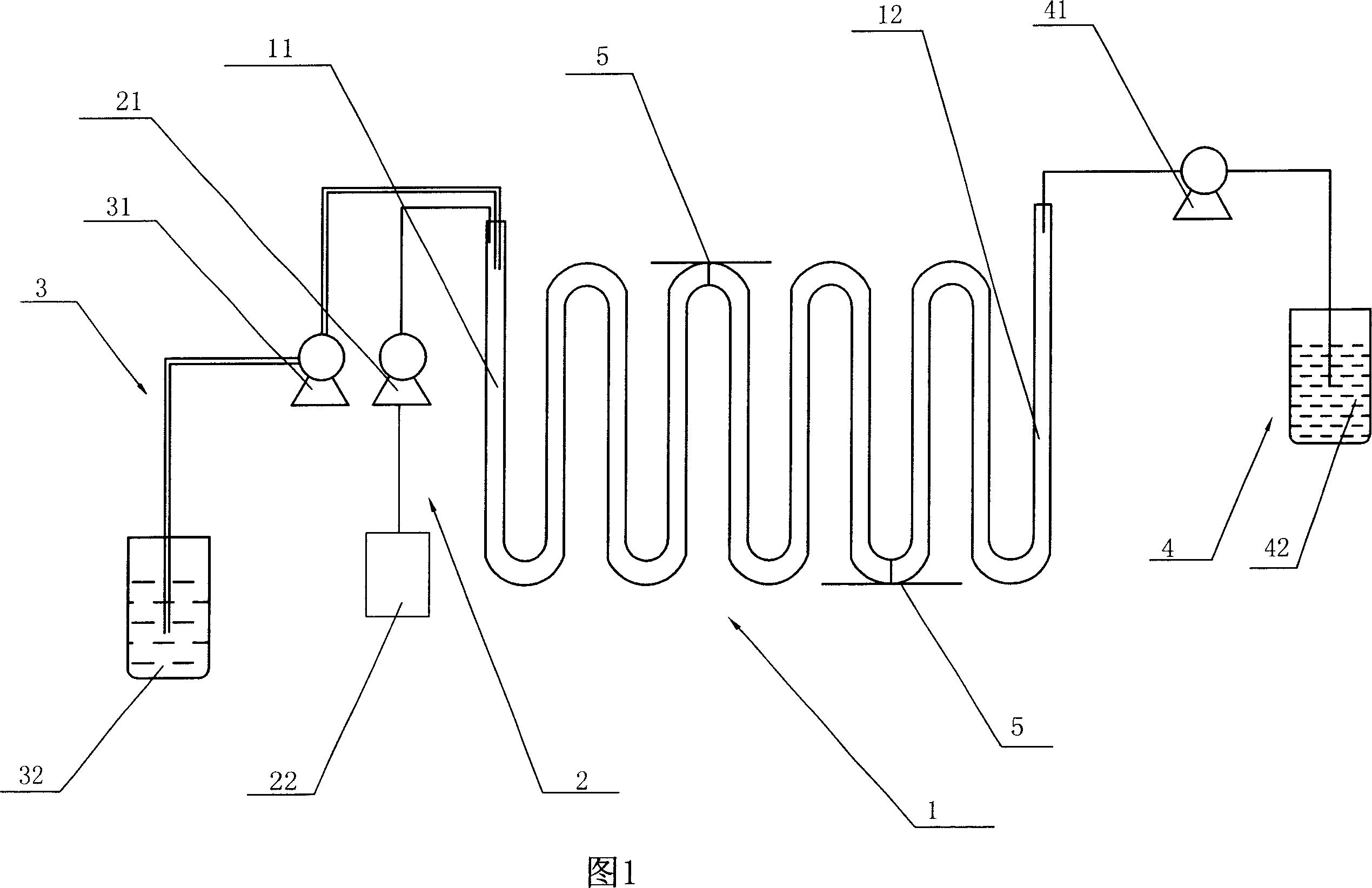

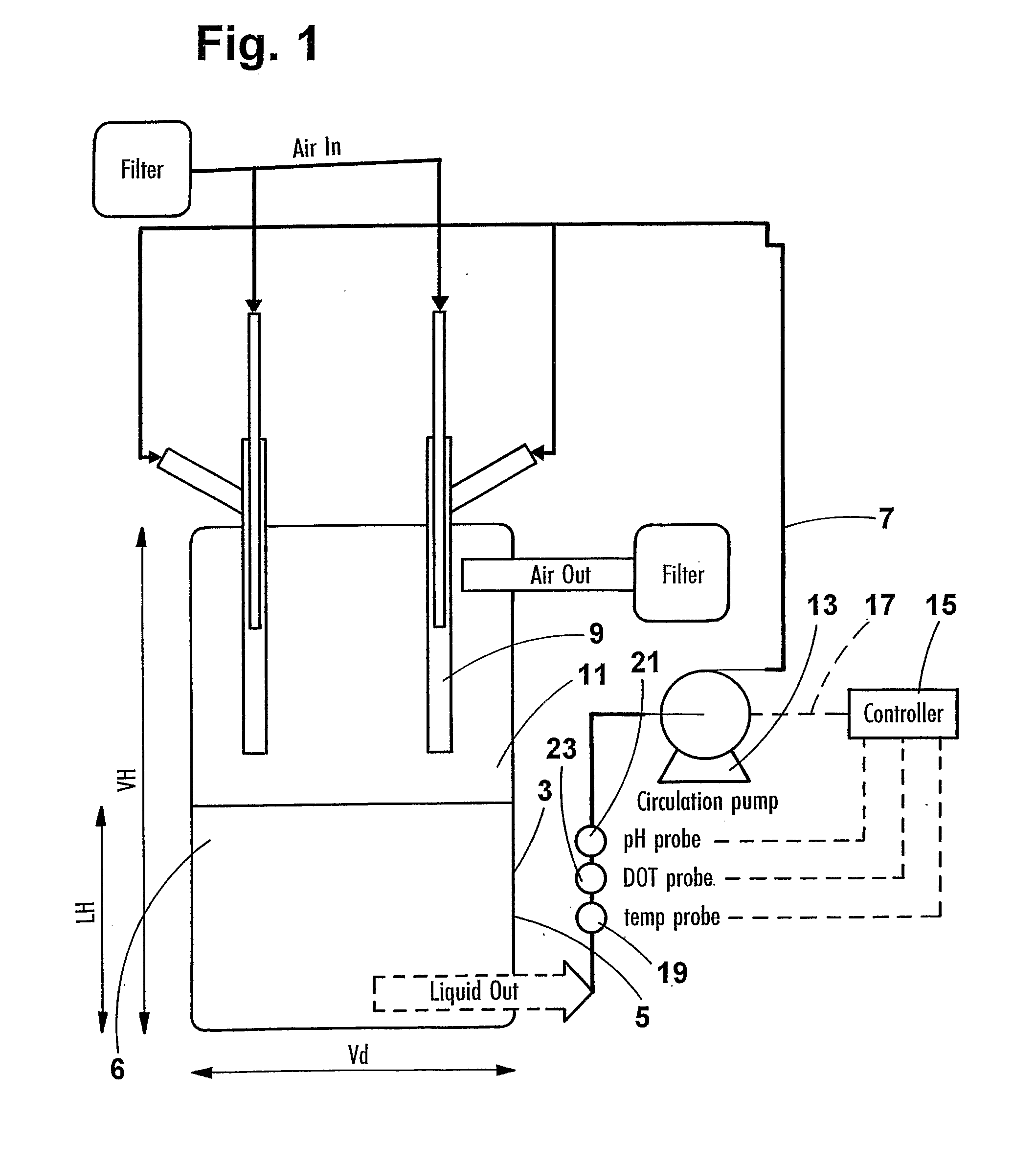

Bioreactor

ActiveUS20110020922A1Inhibition formationFine surfaceBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidFilter media

The invention relates to a bioreactor for cultivating cells having a filter bag for separating culture fluid and cells, the filter medium of the filter bag having a degree of swelling of less than 1%. The bioreactor according to the invention is characterized by a high durability of the filter bag thereof.

Owner:SARTORIUS STEDIM BIOTECH GMBH

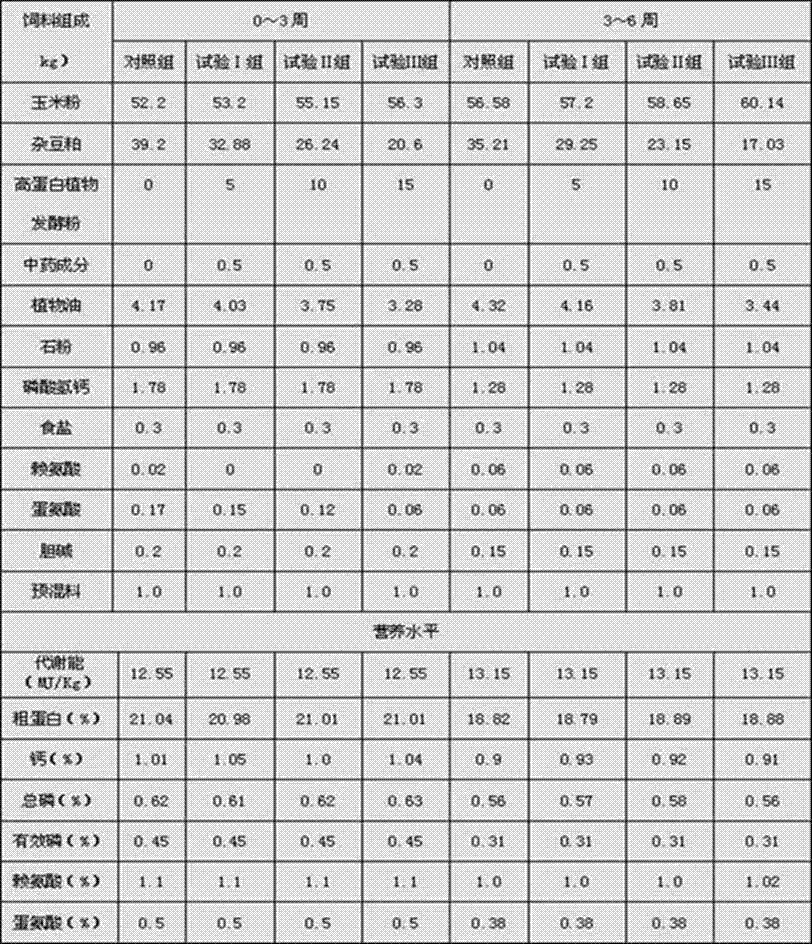

Meat chick granulated feed containing active bacterium fermentation ingredient and traditional Chinese medicine ingredient

ActiveCN102919565AImprove conversion rateImprove immunityAnimal feeding stuffFeed conversion ratioSide effect

The invention discloses a meat chick granulated feed containing an active bacterium fermentation ingredient and a traditional Chinese medicine ingredient. The meat chick granulated feed comprises 5-15 percent of the active bacterium fermentation ingredient, 0.3-1 percent of the traditional Chinese medicine ingredient and the balance of a full value chicken feed. The active bacterium fermentation ingredient is prepared by adopting the following method of: adding an aspergillus niger culture solution, a probiotics culture solution and a yeast culture solution to a fermentation medium respectively according to an inoculation quantity of 5-15 percent for fermentation comprising primary anaerobic fermentation and secondary aerobic fermentation; and after the fermentation, carrying out low-temperature drying at 55 DEG C and smashing on the culture solution to obtain the active bacterium fermentation ingredient. Proved through tests, the feed provided by the invention can be used for obviously improving the food consumption and the daily gain of meat chicken and reducing the feed conversion ratio and the diarrhea rate, does not contain antibiotics, has no toxic and side effects and environmental pollution and can be used for providing high-quality green livestock and poultry products.

Owner:孙萍

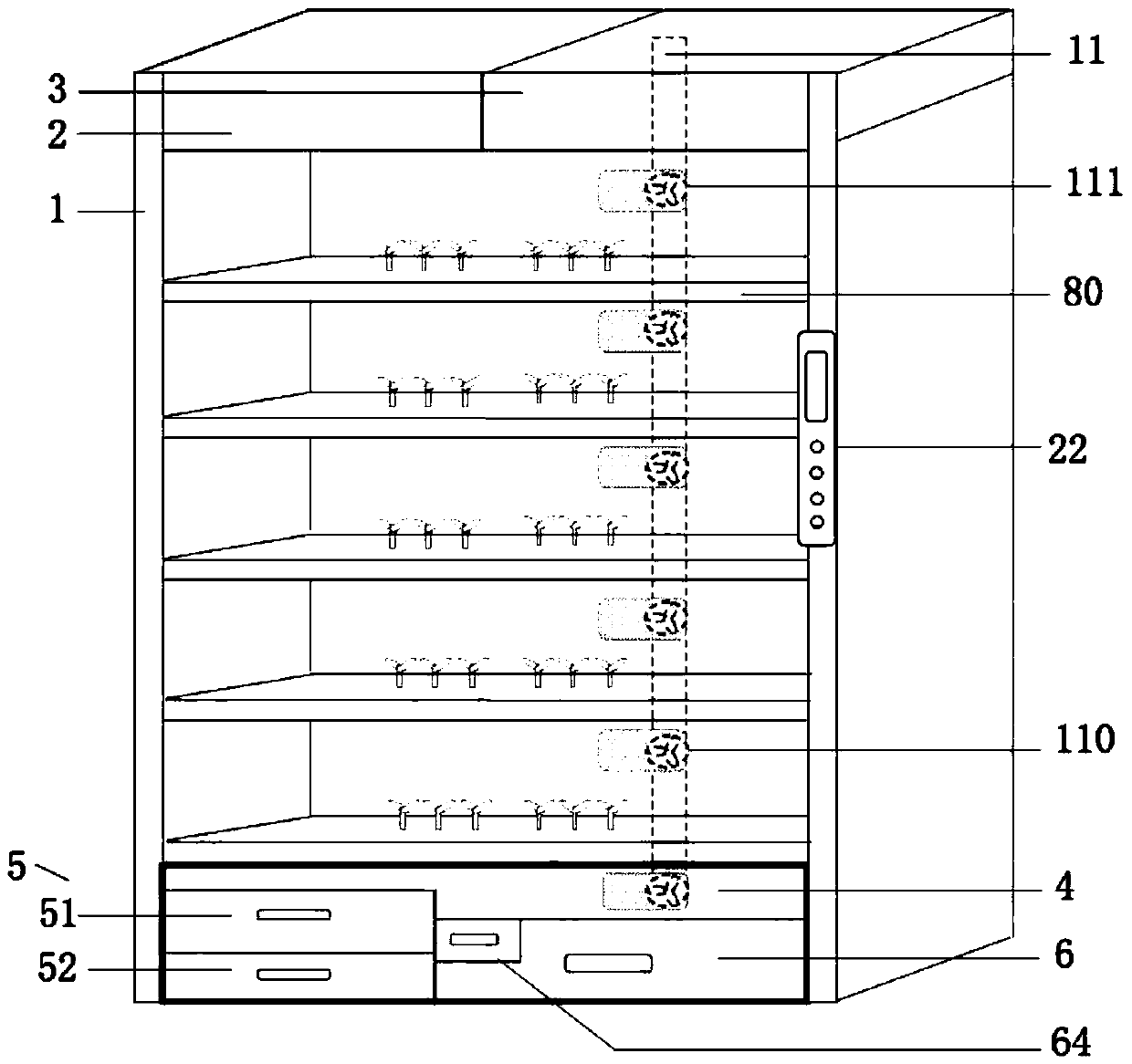

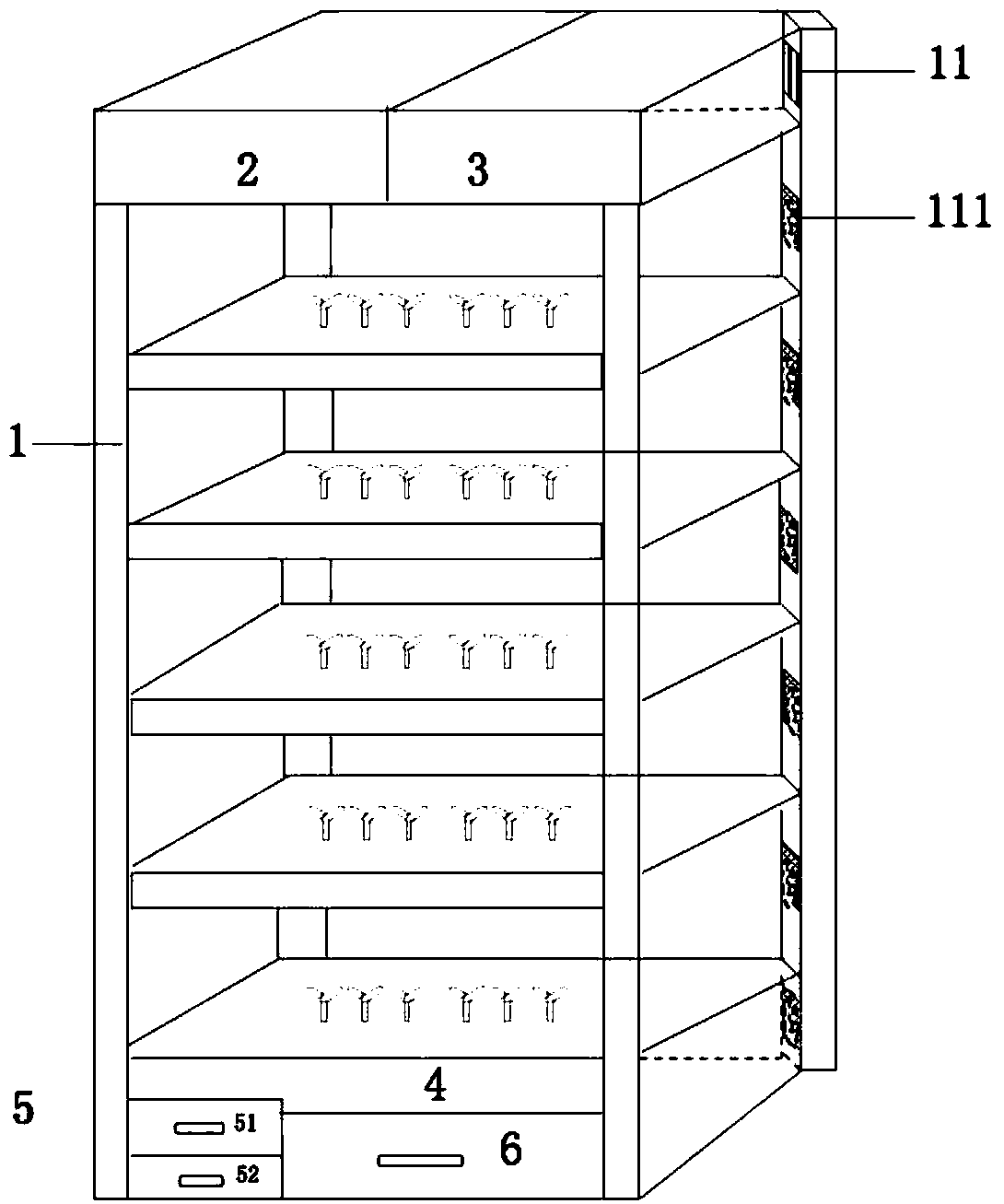

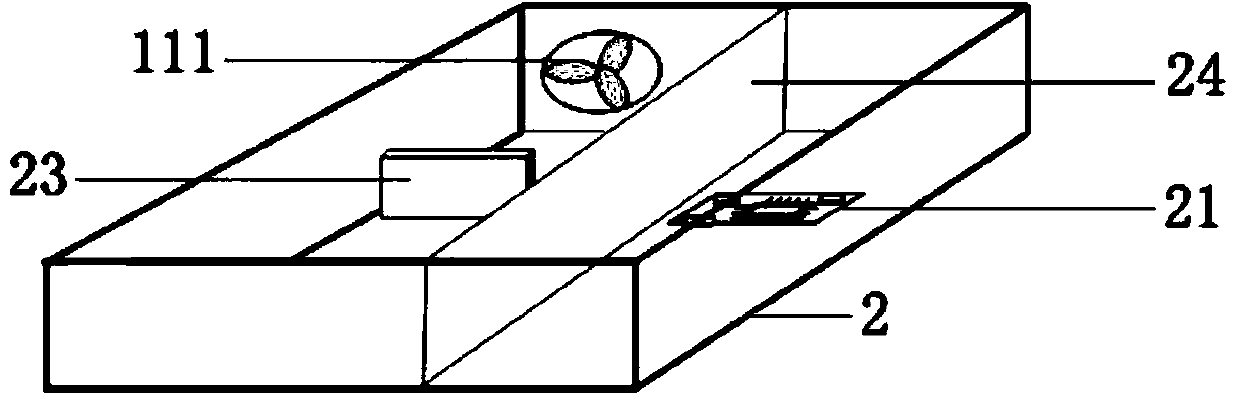

Soilless vegetable cultivation machine

InactiveCN103733971APesticide freeHormone freeAgriculture gas emission reductionCultivating equipmentsTemperature controlPlant factory

The invention relates to a soilless vegetable cultivation machine which comprises a cultivation rack and a constant-temperature tank. A plurality of vertically arrayed cultivation layers are arranged in the cultivation rack and are sequentially connected with one another by drain pipes, a culture fluid tank is communicated with a spray pipe in the uppermost cultivation layer via a suction pipe, and a lowermost culture fluid groove is communicated with the culture fluid tank via a drain pipe; the constant-temperature tank is arranged at the bottom of the cultivation rack, and a temperature control assembly b and a temperature sensor b are arranged inside the constant-temperature tank; the culture fluid tank and a seedling raising assembly are arranged inside the constant-temperature tank, and a filter box is further arranged in the culture fluid tank; the constant-temperature tank is communicated with a temperature control chamber via an air channel, and the temperature control chamber is positioned on the top of the cultivation rack; an air outlet is formed in a side wall of each cultivation layer and is connected with a pipe of the air channel. The soilless vegetable cultivation machine has the advantages that the soilless vegetable cultivation machine is applicable to domestic and small-scale vegetable cultivation and vegetable production of indoor medium and large plant factories and is low-nitrate, green and healthful vegetable production equipment free of pesticides, hormone and heavy metal residues.

Owner:汪蕾

Device and method for large scale culturing Haemotococcum pluvies and converting astaxanthin

ActiveCN1966660AQuick exchangeSynchronous growthUnicellular algaePhotobioreactorsCulture fluidFishery

The invention discloses a set of apparatus and a method for culturing Haematococcus pluvialis and converting astaxanthin in large scale. The apparatus consists of a photo-bioreactor system set on the frisket, aeration equipment, culture fluid inoculation equipment and still cell harvesting equipment. Floating or sunken pulse equipment is set on the frisket. The apparatus don't need establishment of artificial culture pool and other institution, but uses natural water body to culture Haematococcus pluvialis in large scale. It is low cost, the culture temperature, illumination and water flow rate is stable, culture fluid flows with each other, aeration is continuous, culture conditions are precedent, which make the growth and increment of Haematococcus pluvialis almost at equal pace. The growth rate of Haematococcus pluvialis can reach to 25%, biomass increase is fast, doubles 3-5 days. The photo-bioreactor can be hoisted into required depth of the water, which solves the contradiction of difference of temperature, illumination and nutrition of Haematococcus pluvialis culture and astaxanthin conversion.

Owner:LIJIANG CHENGHAI BAOER BIOLOGICAL DEV

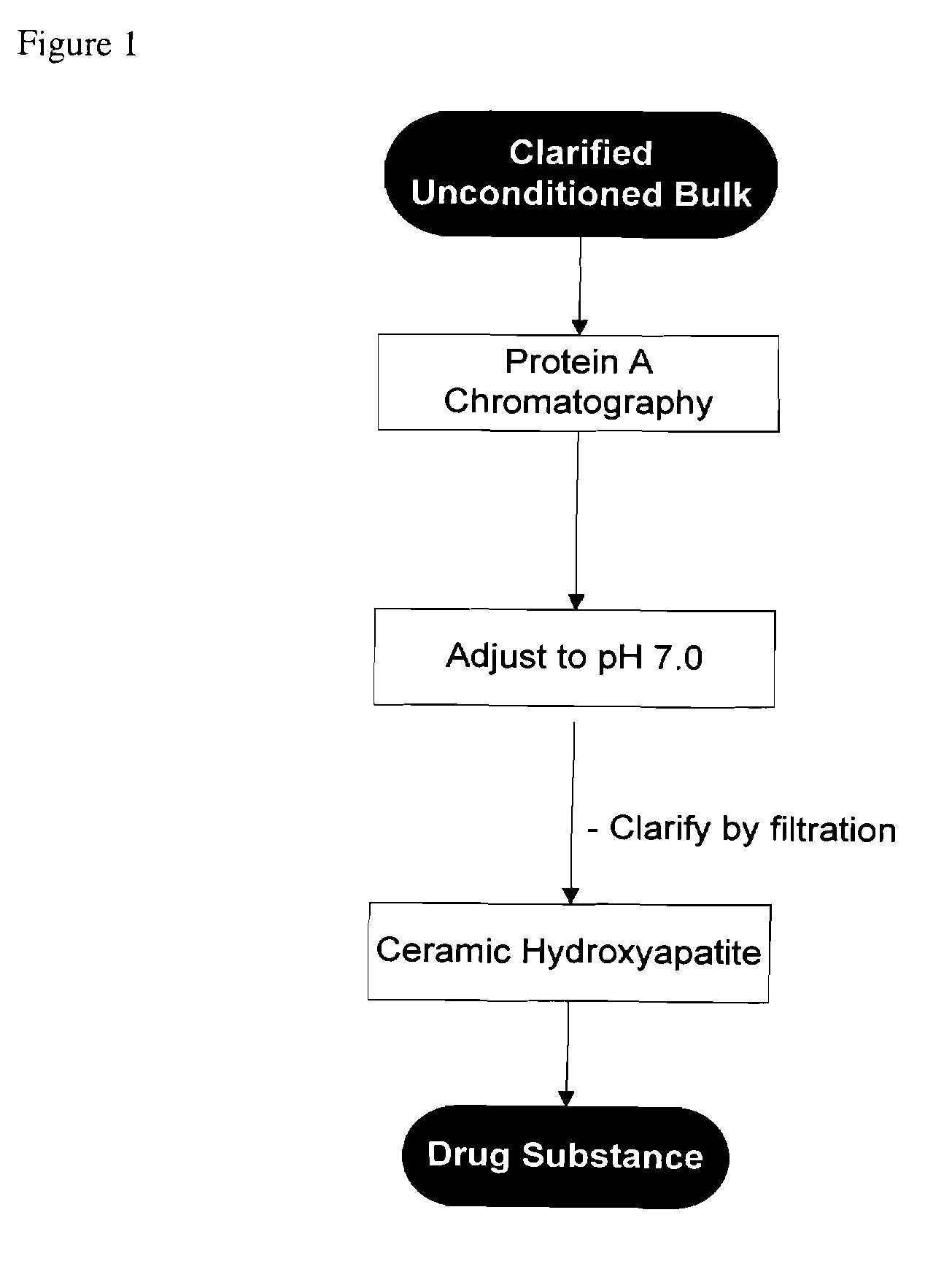

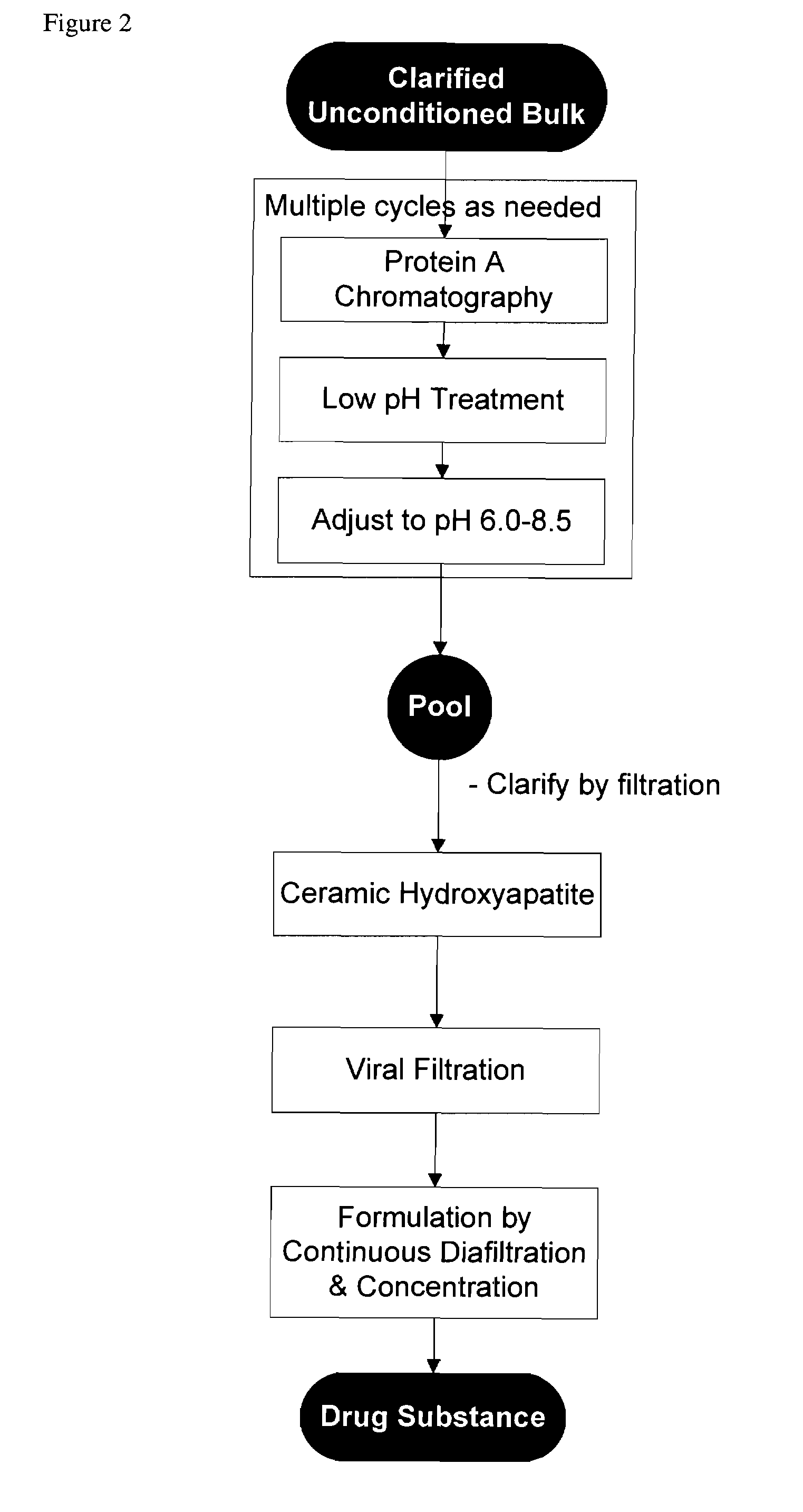

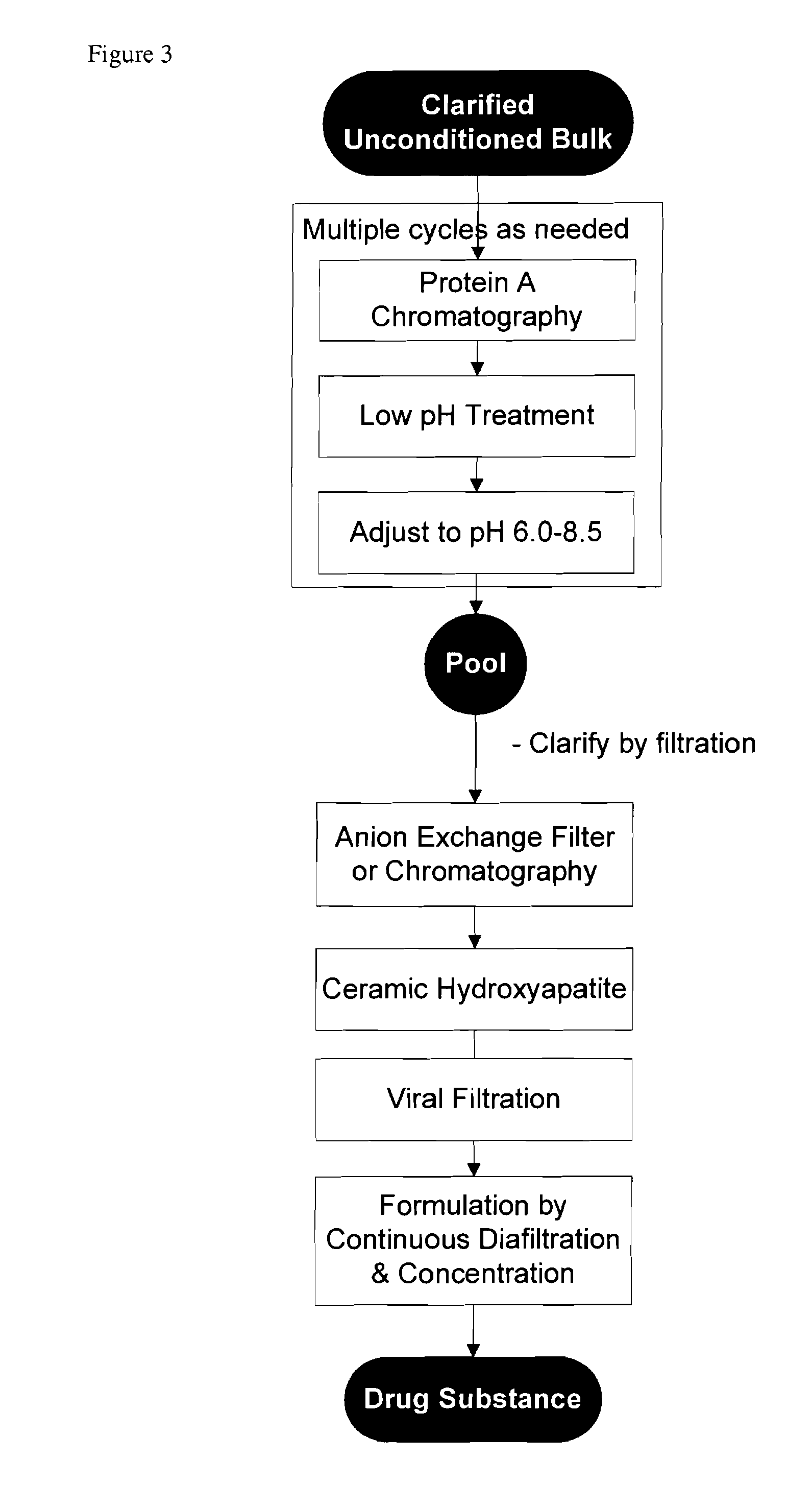

Methods for purifying antibodies using ceramic hydroxyapatite

InactiveUS20100234577A1Increase productionPeptide preparation methodsImmunoglobulinsApatiteCulture fluid

This invention relates to the purification of monoclonal antibodies from mammalian cell culture fluid utilizing sequential, orthogonal chromatography and filtration techniques resulting in material of high purity and quality that is suitable for human administration. The method involves capturing an IgG product using immobilized protein A affinity chromatography, followed by at least one ion exchange technique prior to adsorbing the IgG to hydroxyapatite and selectively eluting the product in a single isocratic step to achieve purification from impurities and simultaneously reducing multiple types of impurities including but not limited to IgG aggregates, residual protein A, non-IgG proteins, host cell proteins, viral particles, and DNA

Owner:SMITHKLINE BECKMAN CORP

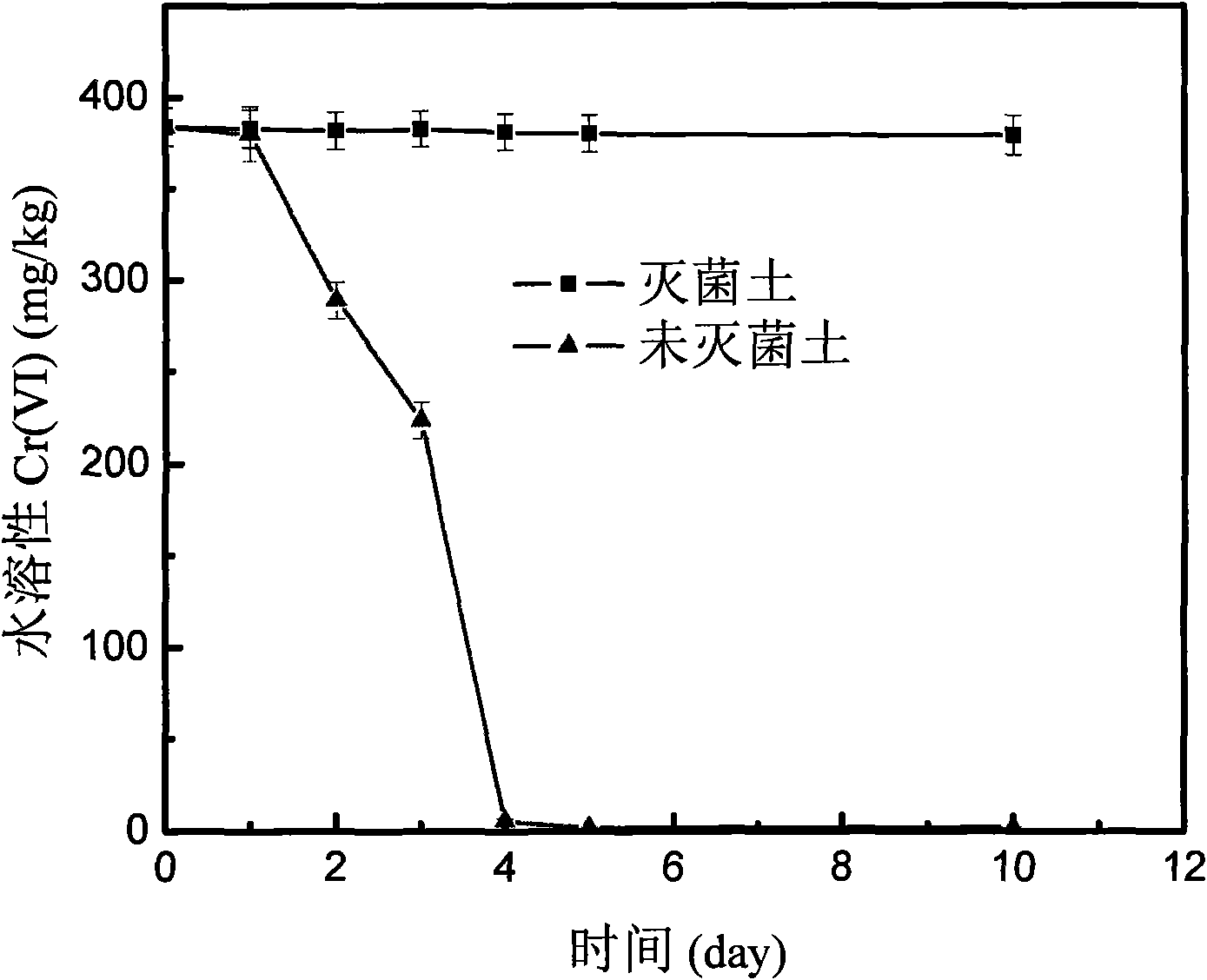

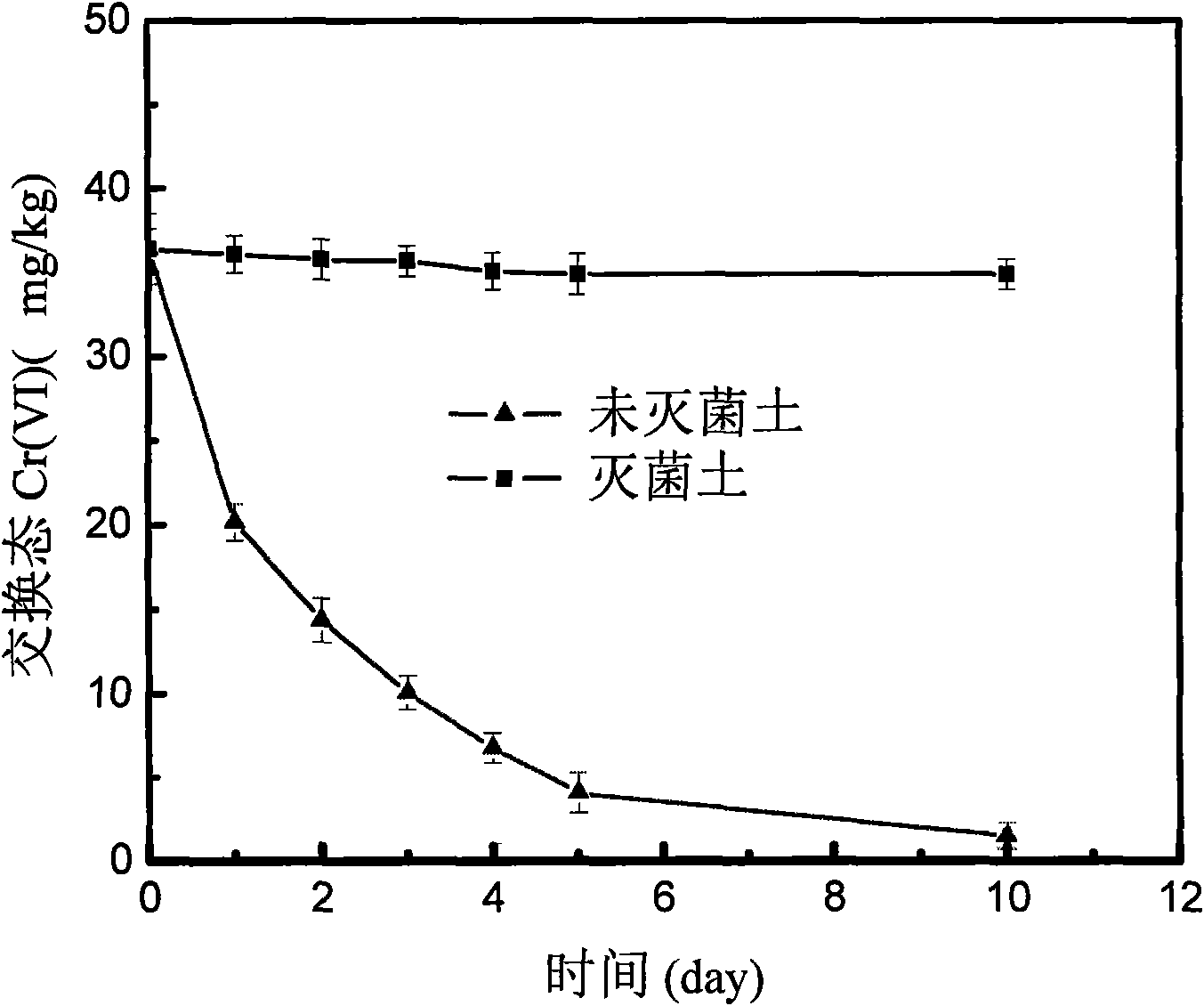

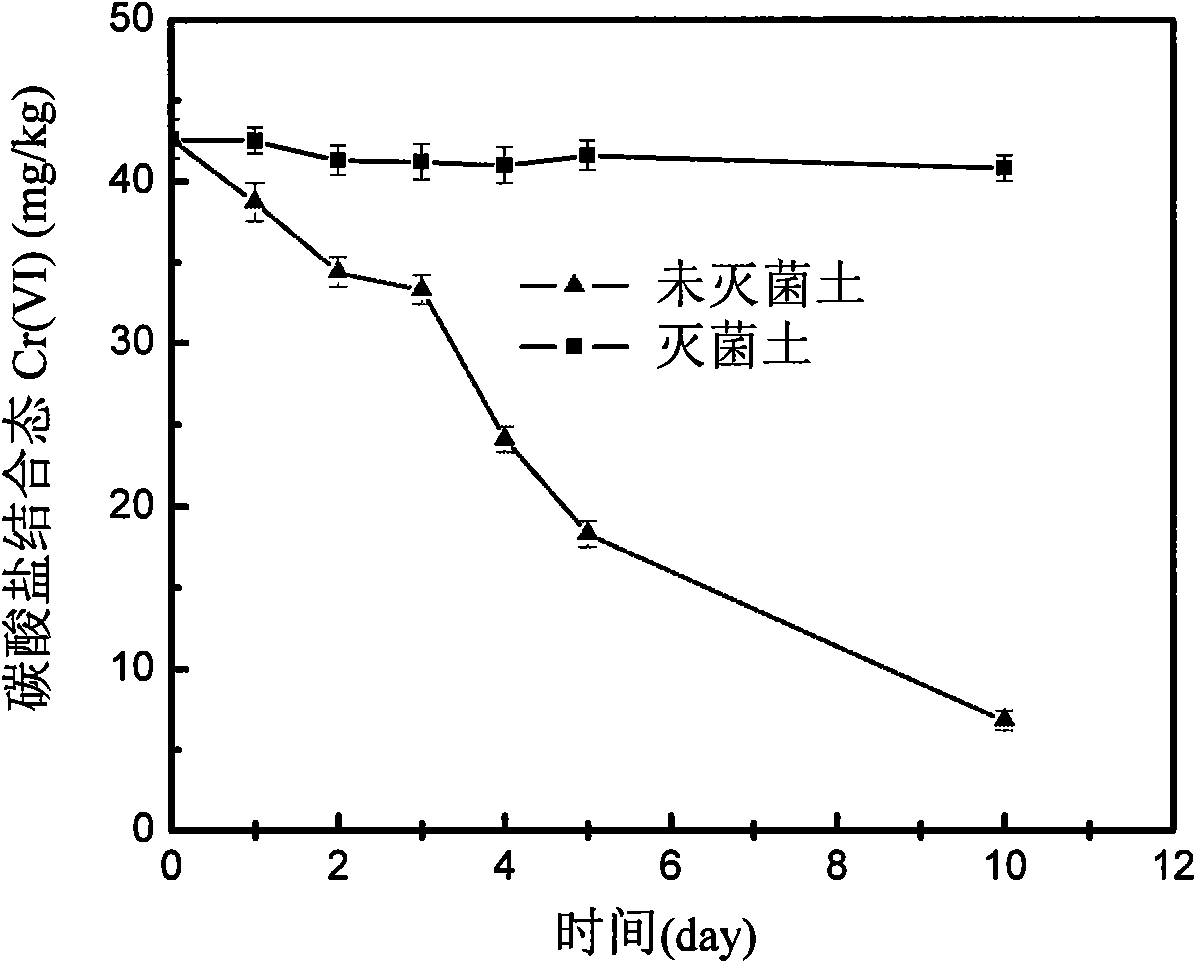

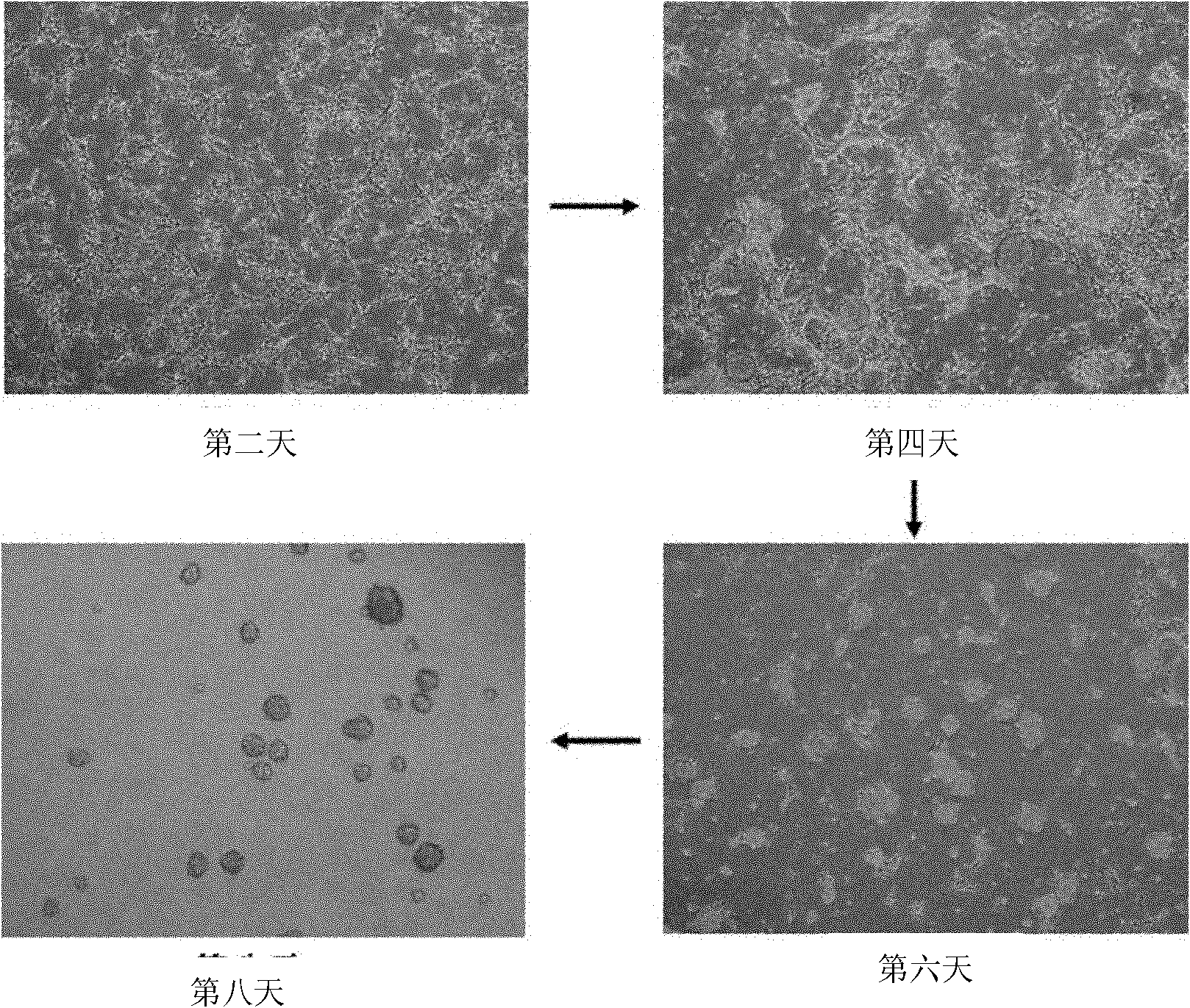

Repairing method of microorganism in contaminated soil of chromium slag storage yard

InactiveCN101602060ADoes not destroy physical and chemical propertiesLow costContaminated soil reclamationSlagCulture fluid

The invention discloses a repairing method of microorganism in contaminated soil of chromium slag storage yard, comprising the steps of selecting Pannonibacter phragmitetus BB single bacterium, dropping the single bacterium in a liquid culture medium containing Cr (VI) of 50-250mg / L for culturing until Cr (VI) is not detected in the culture solution, selecting strains in a bottle for transferring, gradually improving the Cr (VI) concentration for gradient domestication, adding the domesticated Pannonibacter phragmitetus BB lysate in the contaminated soil, and culturing for 4-5 days at a temperature below 30 DEG C, so as to repair the soil, wherein the amount of the added lysate is that the mass-volume ratio (g: mL) of the soil to the lysate is 1: 2. The invention treats and repairs hexavalent chromium-contaminated soil through the strains with hexavalent chromium reducing capacity, the operation is simple and feasible, the cost is low, and the method is an environment-friendly treatment method.

Owner:CENT SOUTH UNIV

Serum-free cell culture fluid suitable for enriching and culturing tumour stem cells

The invention provides a serum-free cell culture fluid suitable for enriching and culturing tumour stem cells. DMEM / f12 serves as the basic culture fluid of the serum-free cell culture fluid and transferrin, insulin and other substances are also added as the components of the serum-free cell culture fluid. The serum-free cell culture fluid provided by the invention can efficiently enrich tumour stem cells from malignant tumour cell strains and tumour tissues. In addition, the serum-free cell culture fluid can promote stable growth of the tumour stem cells and maintain fine cell activity and physiological properties of the tumour stem cells, thus being very suitable for research fields related to tumour cells and tumour stem cells.

Owner:SUN YAT SEN UNIV

Method for recovering cement-based material crack by means of microorganism, culture fluid and repair nutrient fluid

ActiveCN101302484AImprove volume stabilityIncreased durabilityBacteriaBuilding repairsCulture fluidNutrient solution

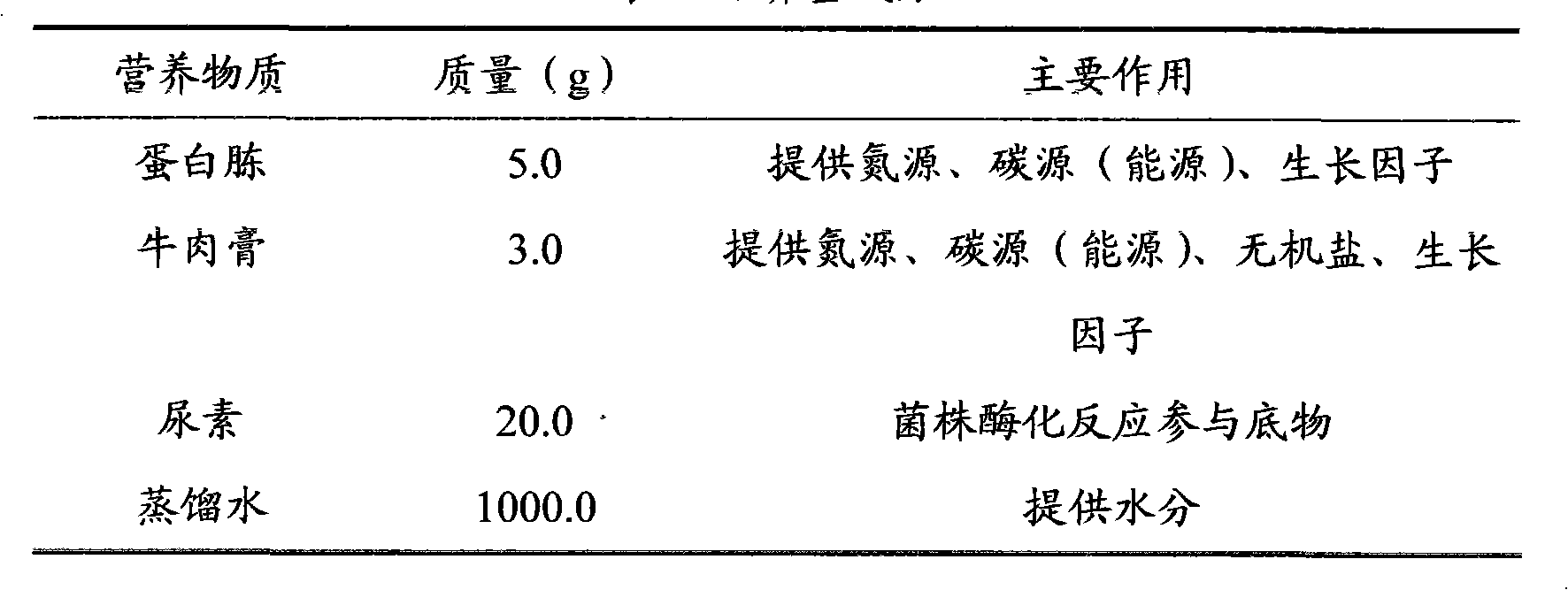

The invention discloses a method for repairing cement-based material cracks, as well as a culture solution and a repair nutrient solution. The method for repairing cement-based material cracks by through microorganisms comprises the following steps that: a Bacillus pasteurii strain is inoculate onto a culture medium provided with a urea-containing substrate; shake cultivation is carried out at a temperature of between 25 and 37 DEG C, and then a culture bacteria solution is taken out and centrifuged and has supernatant fluid removed; strain cells are collected through the culture solution; the concentration of the strain cells is controlled in a range of between 2x10<9> and 1x10<11> cell / ml; standard sand, urea and Ca(NO3)2.4H2O mixture are added to each milliliter of strain cell solution obtained through collection, mixed, stirred into slurry and injected into cement stone cracks; the frequency of the repair nutrient solution injection is not less than two times; finally, maintenance is carried out. In the culture solution, each liter of culture solution contains 4 to 6 g of peptone, 2 to 4 g of beef extract and 20 to 60 g of urea. The method fully utilizes microbial resources in nature; CO3<2-> decomposed out through microbial enzyme can chelate Ca<2+> in a substrate so as to be mineralized and deposit calcium carbonate, and is close in the combination with the substrate and good in stability.

Owner:SOUTHEAST UNIV

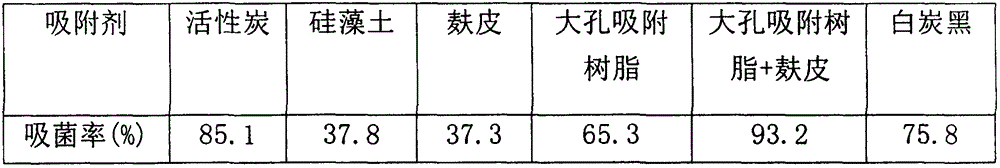

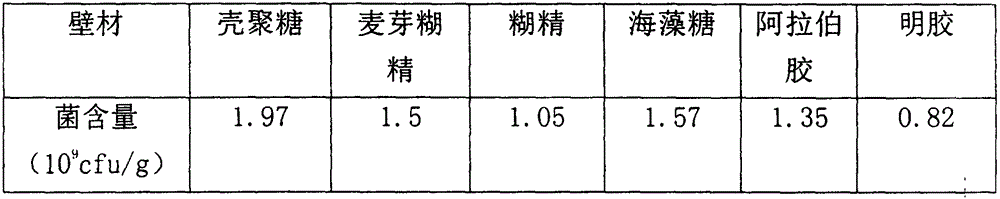

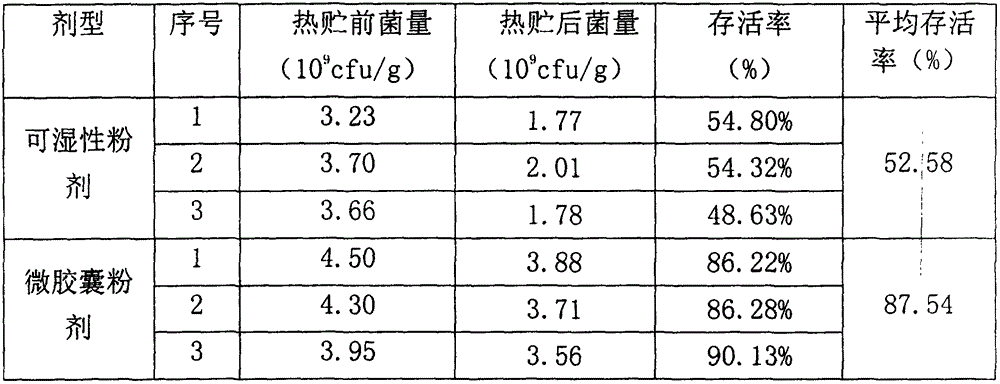

Preparation of microcapsules of viable microbe biopesticide

The invention relates to microcapsules prepared from viable microbes such as pseudomonas, bacillus and paenibacillus serving as main active components, belonging to the technical field of microorganism and biochemistry. The method for preparing microcapsules of viable microbe biopesticide comprises the following steps of: adsorbing microbial fermentation culture solution through an adsorption effect to prepare capsule cores and solidifying the capsule cores, and adding wall materials, so as to prepare a microcapsule preparation. The microcapsule preparation prepared by adopting the method has high content of viable microbes, high storage property and strong high-temperature and ultraviolent resistances, and stable and good prevention and control effect on plant diseases and insect pests.

Owner:成都特普生物科技股份有限公司

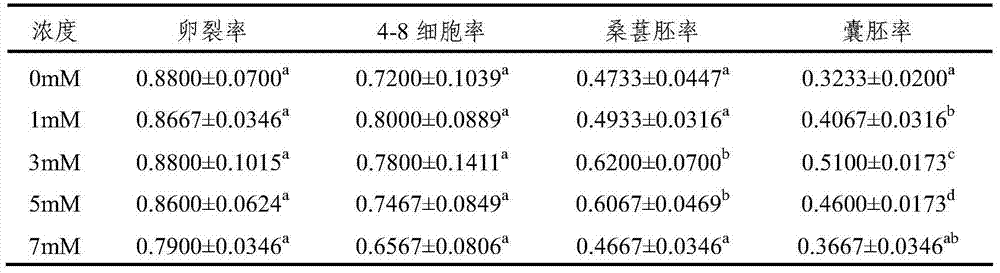

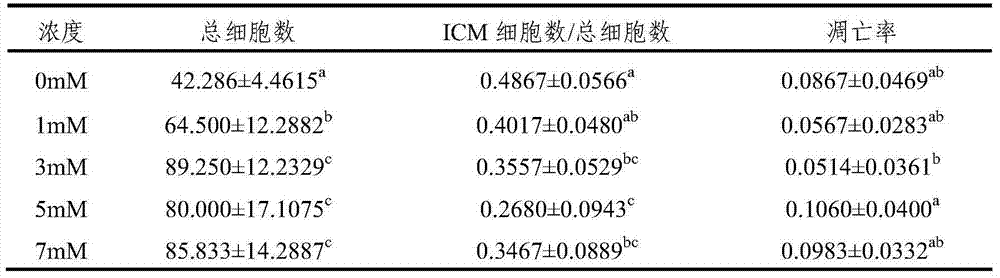

Cow in-vitro fertilization embryo culture fluid and culture method thereof

InactiveCN103898046AImprove developmental abilityIncrease development rateEmbryonic cellsCulture fluidGrossularine-1

The invention provides a culture fluid exclusively used in cow in-vitro fertilization embryos. The culture fluid contains 109.0mM-110mM of NaCl, 2.9mM-3.1mM of KCl, 26.0mM-26.5mM of NaHCO3, 0.5mM-1.0mM of MgCl2.6H2O, 1.0mM-1.3mM of KH2PO3, 0.4mM of sodium pyruvate, 1.5 mM of glucose, 5mM of galacturonic calcium, 10v / v% fetal bovine serum, 1mM of L- glutamine, 2v / v% essential amino-acid, 1v / v% nonessential amino acid and 1mM-10mM of glutathione. The cow in-vitro fertilization embryos are placed into the culture fluid to carry out in-vitro cultivation, and results are shown to be obviously superior to those of a control group which is not added with GSH (glutathione), and therefore, developmental rate of blastula and embryo quality are improved, cost for producing embryos in vitro is lowered, experimental basis is provided for applying a cow IVF (in vitro fertilization) technology to practice, and a genetic breeding process can be greatly accelerated.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

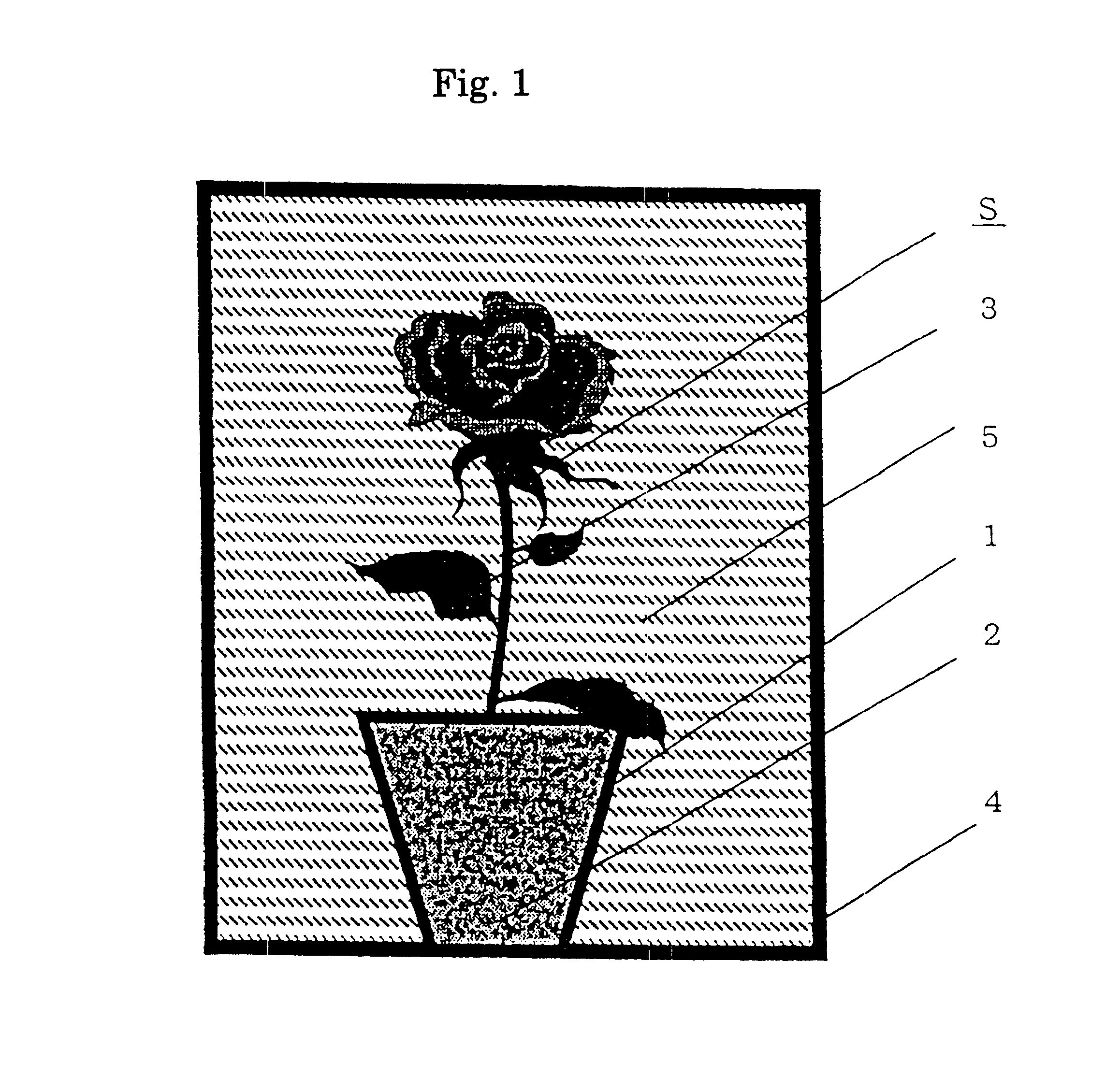

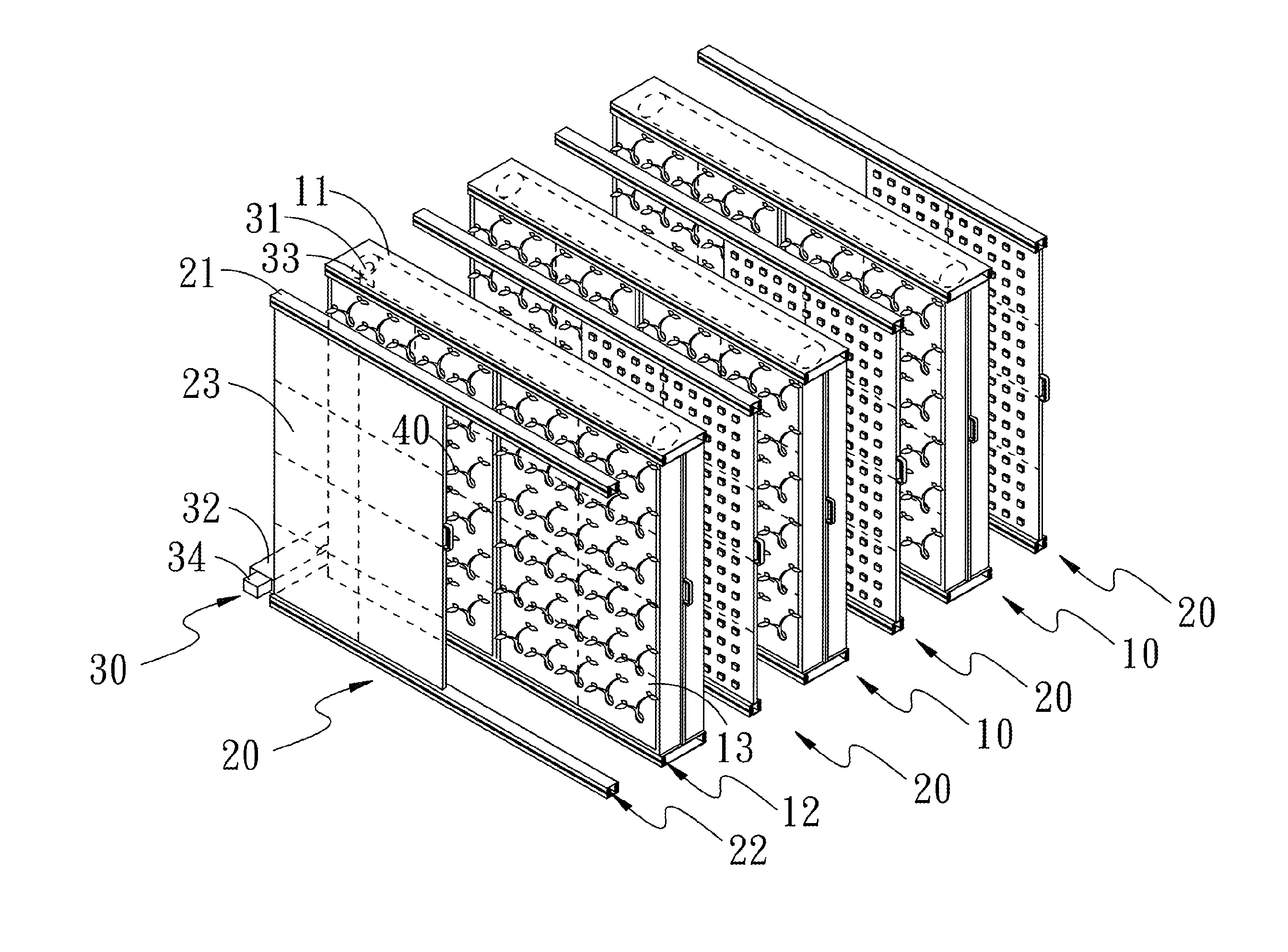

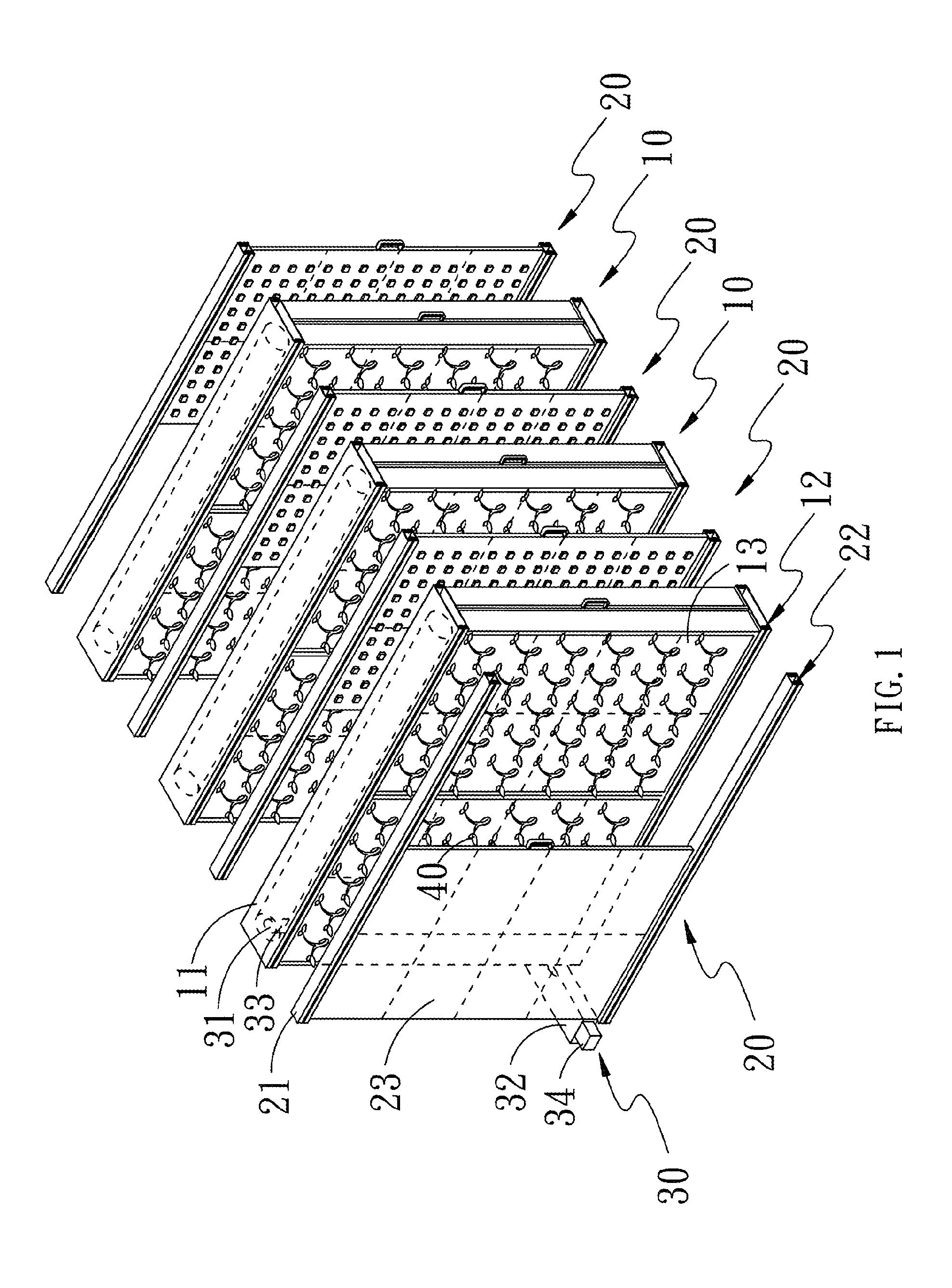

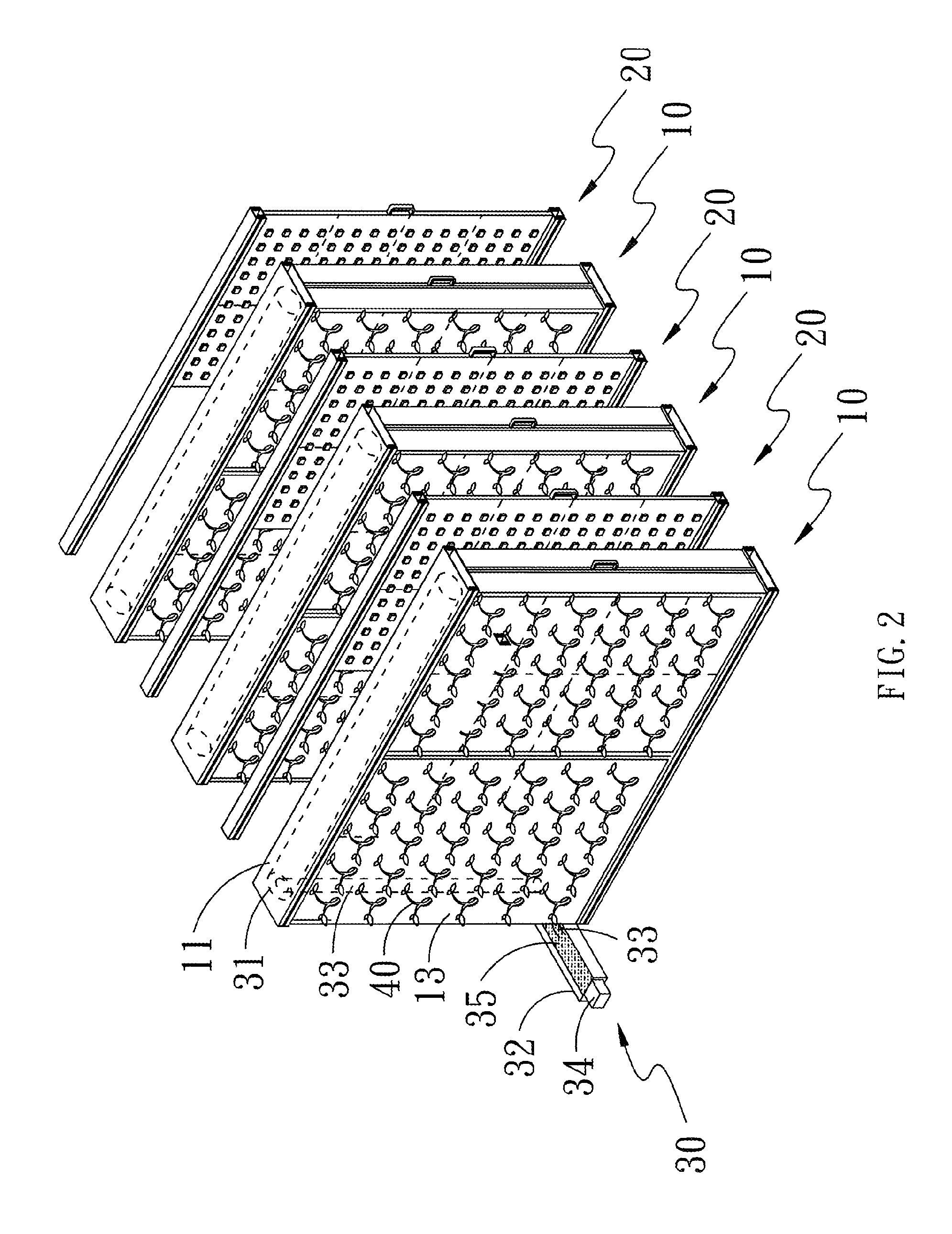

Plant culturing equipment

InactiveUS20140144079A1Control speedSimple materialAgriculture gas emission reductionCultivating equipmentsCulture fluidEngineering

A plant culturing equipment is composed of a plurality of planting walls, a plurality of lamp racks and a circulation fluid supply component, wherein the planting walls are mutually disposed in parallel, and the lamp rack is disposed relative to the planting walls to supply light source to the colonization board. The circulation fluid supply component is composed of connecting a plurality of fluid supply members, a fluid collection member, a plurality of pipes and a motor so as to form a circulation loop for the culture fluid. The fluid supply member is disposed onto the colonization board and fastened to the planting walls. The culture fluid is circularly utilized to supply plants. The plants are illuminated by the light source of the lamp board to replace natural light so as to control the speed of growing plants. The colonization board is pulled and pushed by the first sliding component.

Owner:LIN MING TSUN

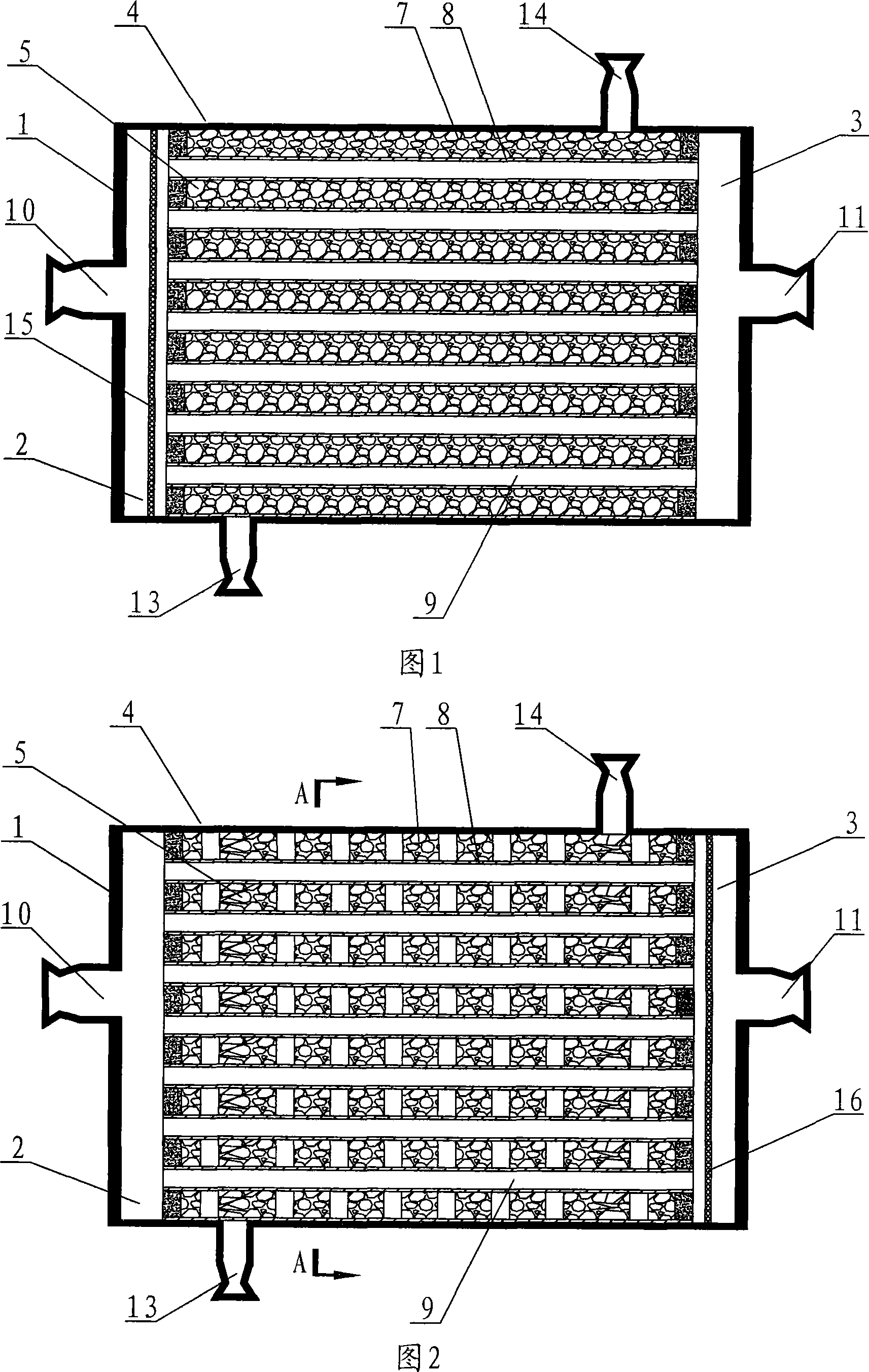

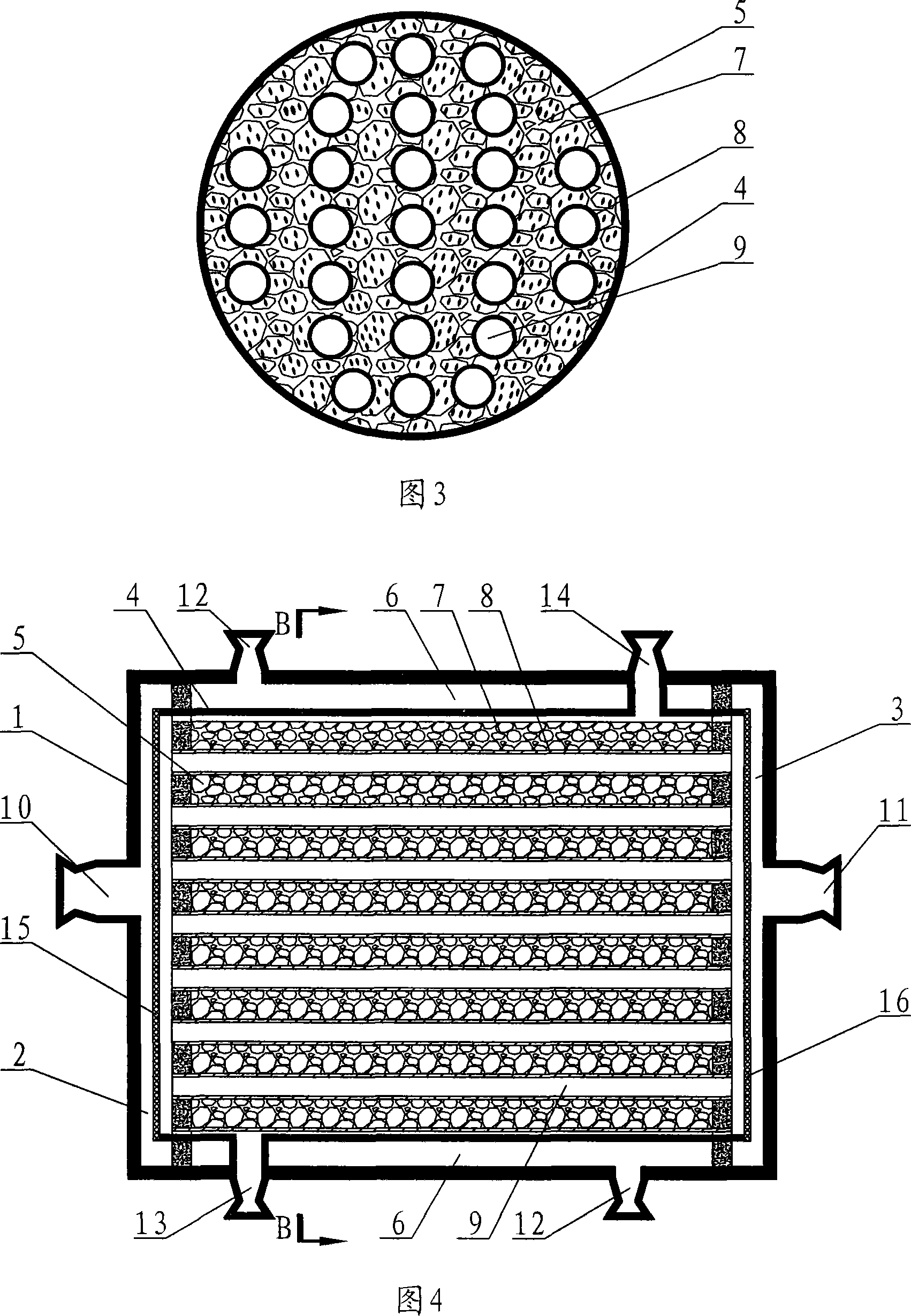

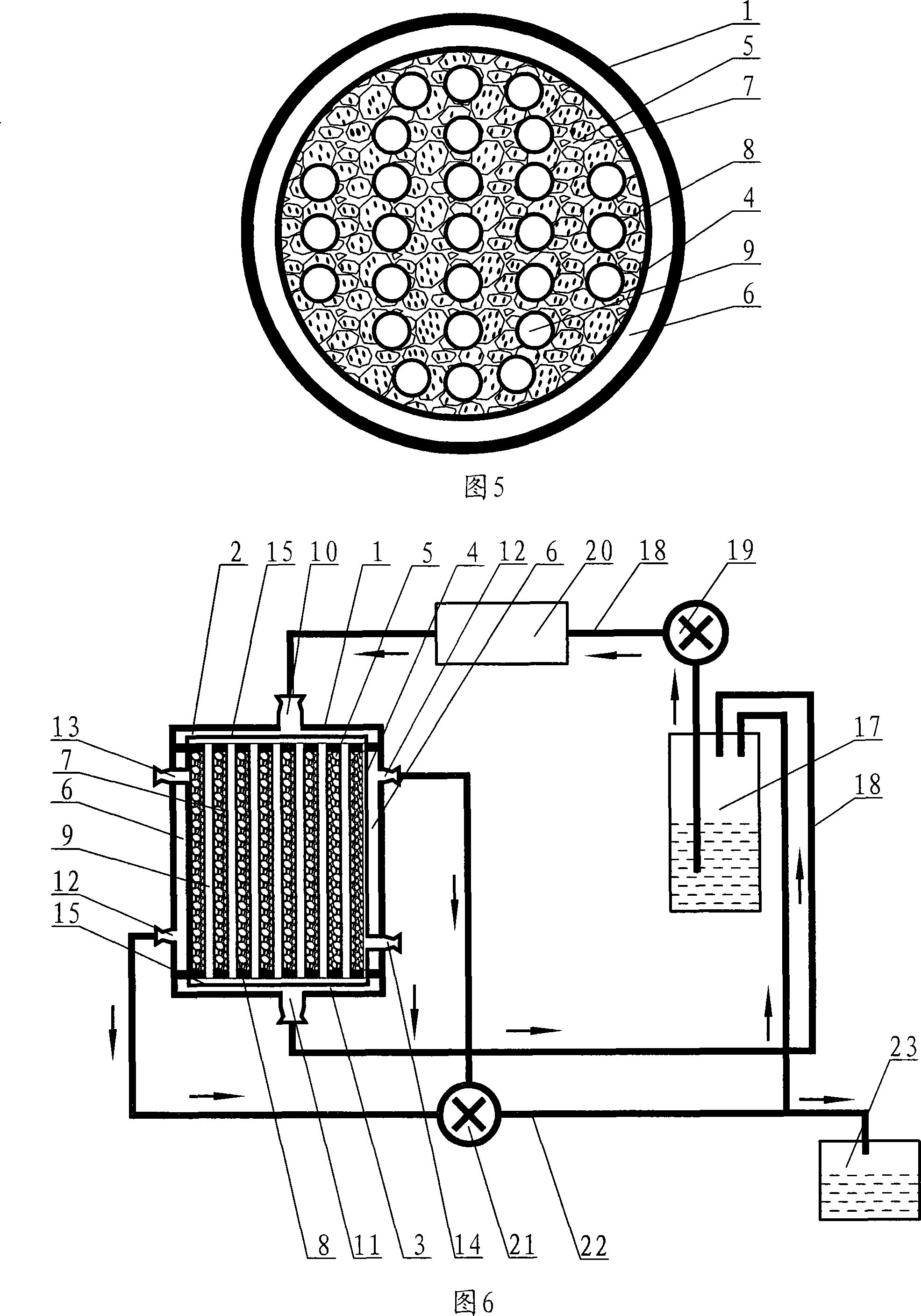

Three-dimensional liver cell culture bioreactor

InactiveCN101199436AHigh densityIncrease biological functionSurgeryDialysis systemsFiberHollow fibre

Disclosed is a 3-D bioreactor to culture hepatic cells, comprising a culture cavity provided with a cell feeding port and a vent, an inflow cavity with a culture fluid inlet and an outflow cavity with a culture fluid outlet which are arranged next to the culture cavity. A plurality of hollow fibers are arranged inside the culture cavity, each with one end communicated with the inflow cavity and the other end communicated with the outflow cavity, forming a culture fluid flow passage which is communicated with the culture cavity through the tiny holes on the hollow fibers. The invention is characterized in that a 3-d bracket with a plurality of holes is arranged inside the culture cavity. The invention can provide a growth and culture condition that accords better with the physiological environment for the hepatic cells, which is good for culturing dense hepatic cells with high activity so as to ensure the therapeutic effect of a bio-artificial liver with the hepatic cells as the core.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

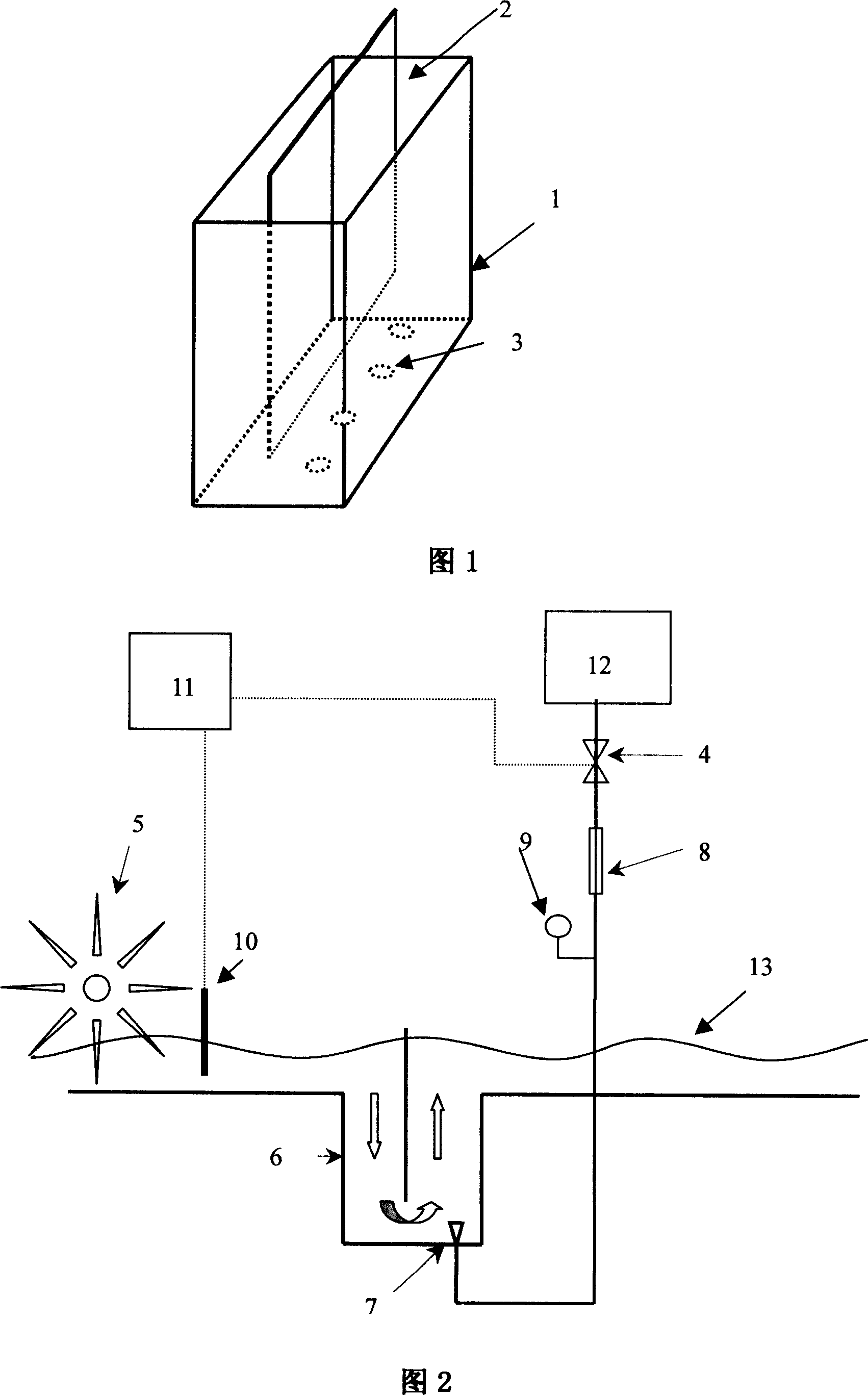

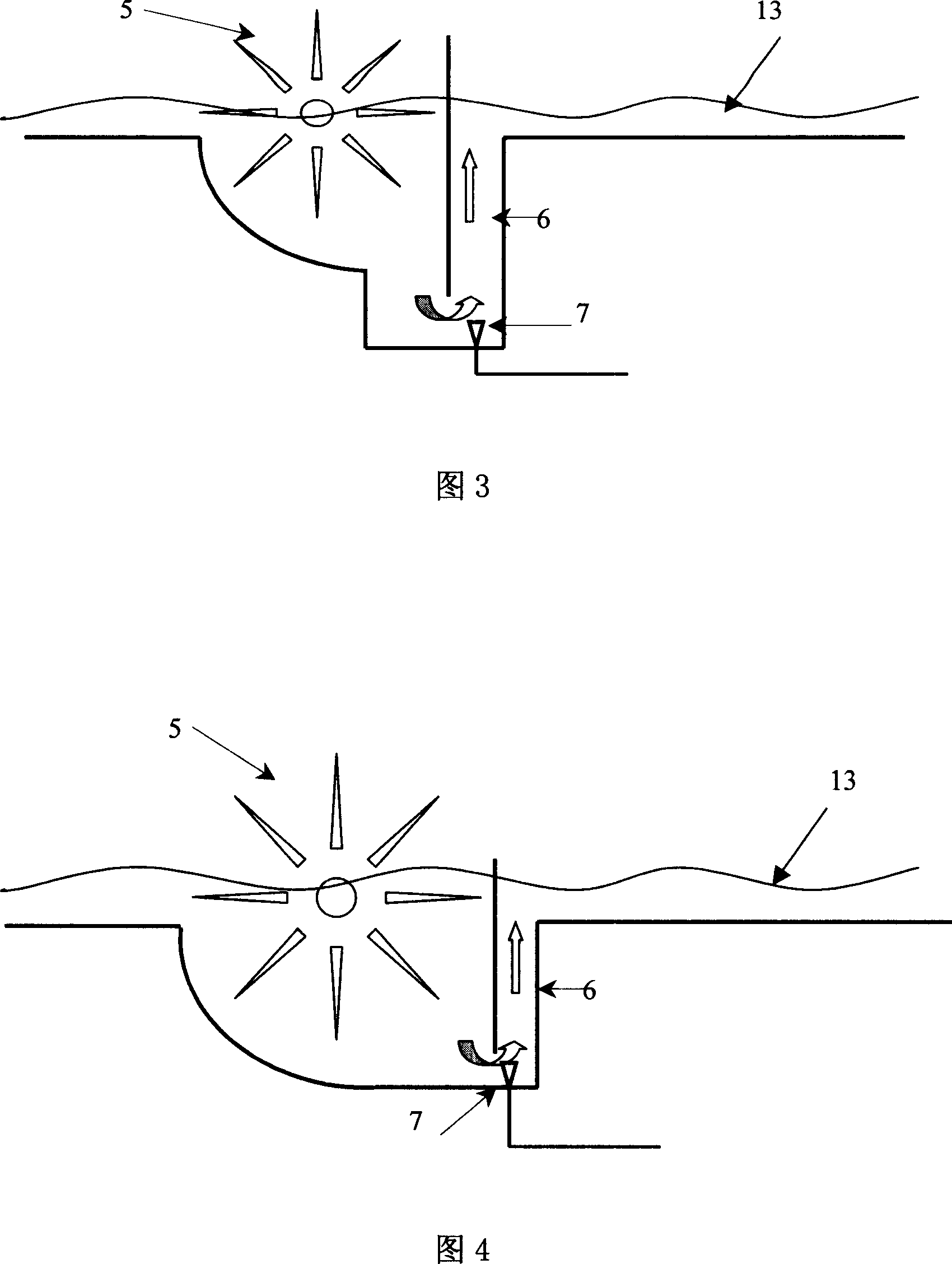

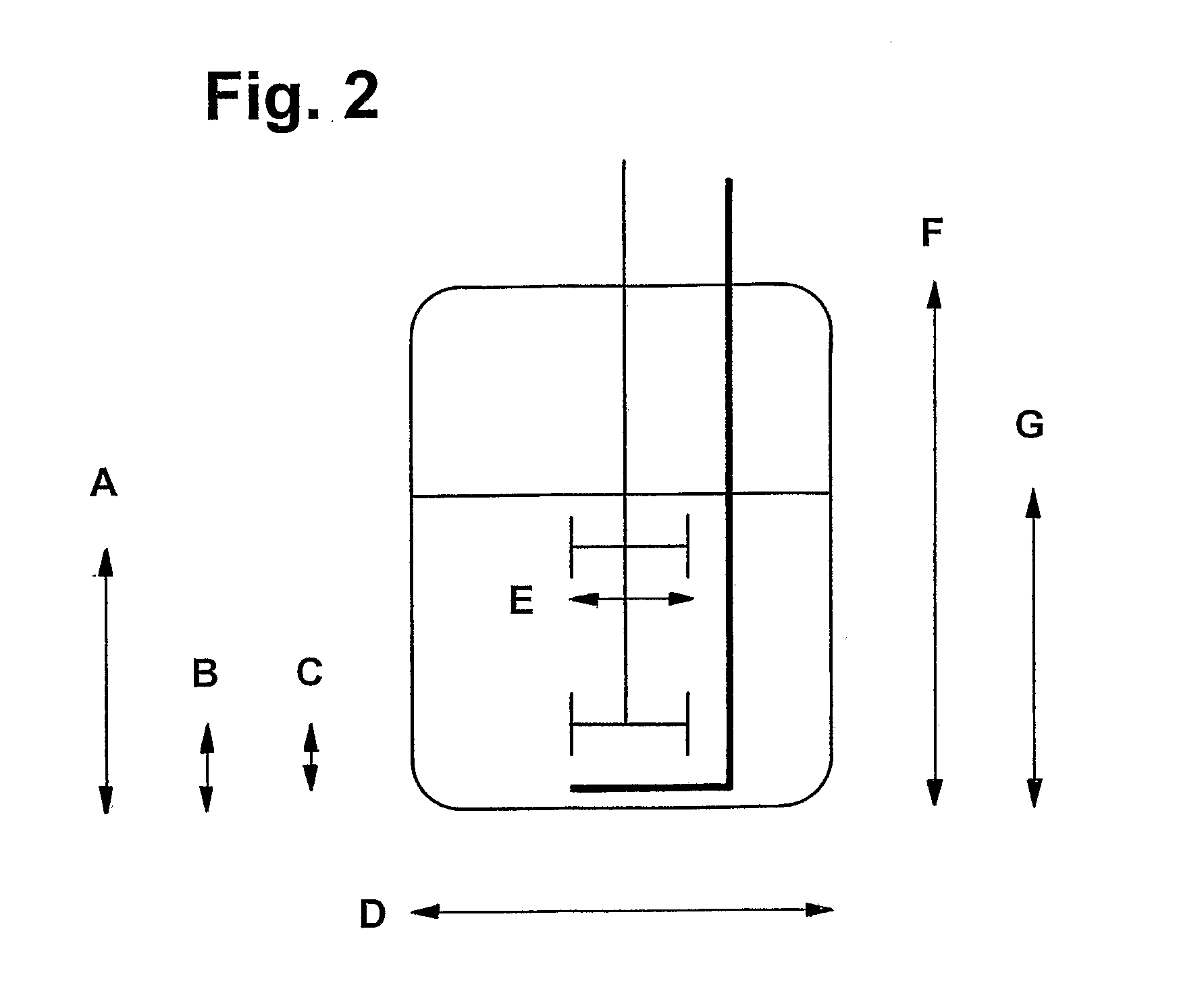

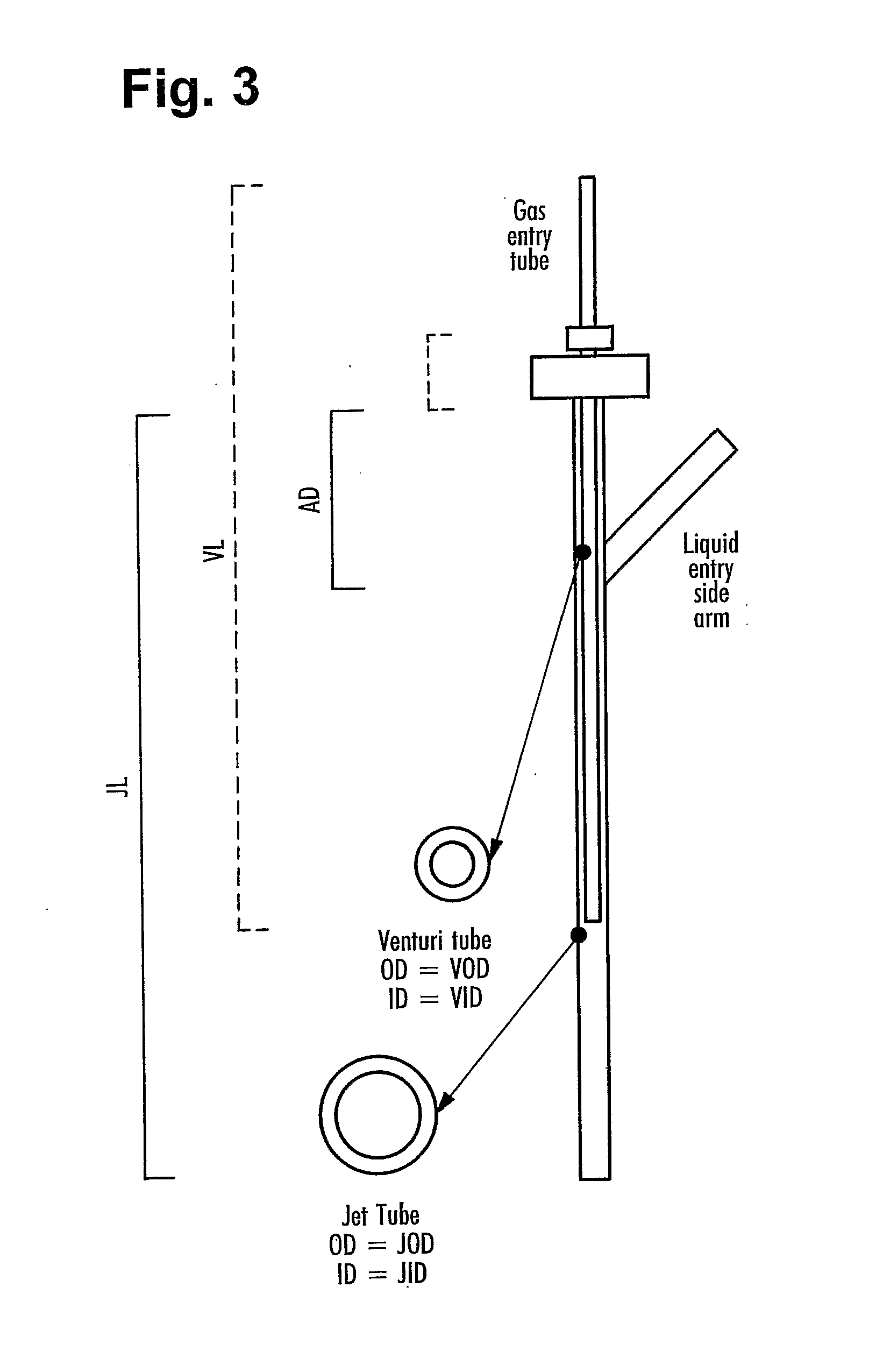

Bioreactor

InactiveUS20070172945A1Easy to useIncrease gas exchangeBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineCulture fluid

The present invention concerns a plunging jet bioreactor (1) comprising a mechanism (4), (5) adapted in use to form culture fluid into a hollow flow stream and to introduce into the hollow of the flow stream an oxygen-containing gas. In some embodiments the mechanism comprises concentrically arranged outer (4) and inner tubes (5) wherein the inner tube is in flow communication with the culture fluid container whereby the culture fluid flows over the inner tube to form the hollow flow stream into which the oxygen from the inner tube is introduced.

Owner:OKENNEDY RONAN DESMOND +1

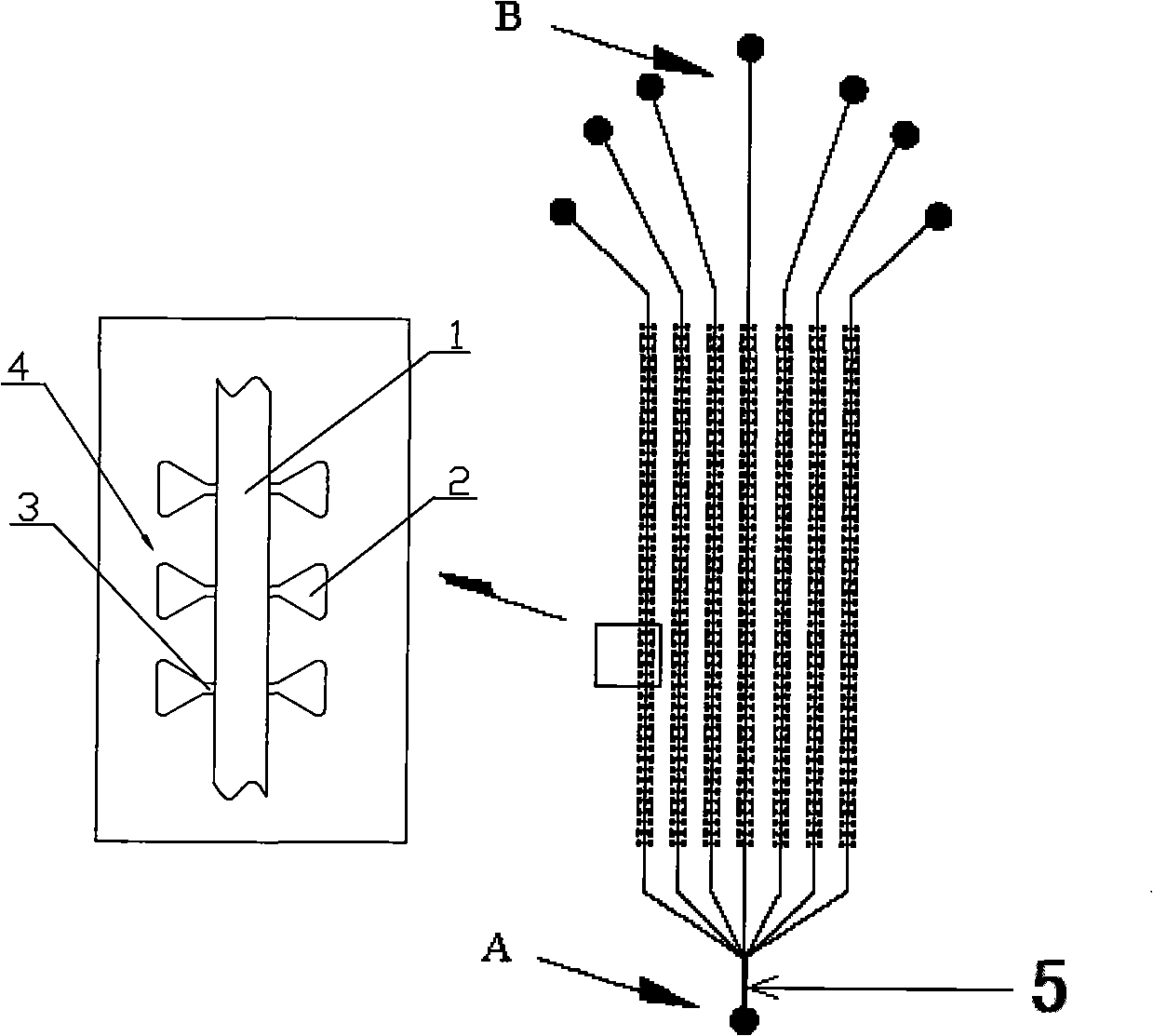

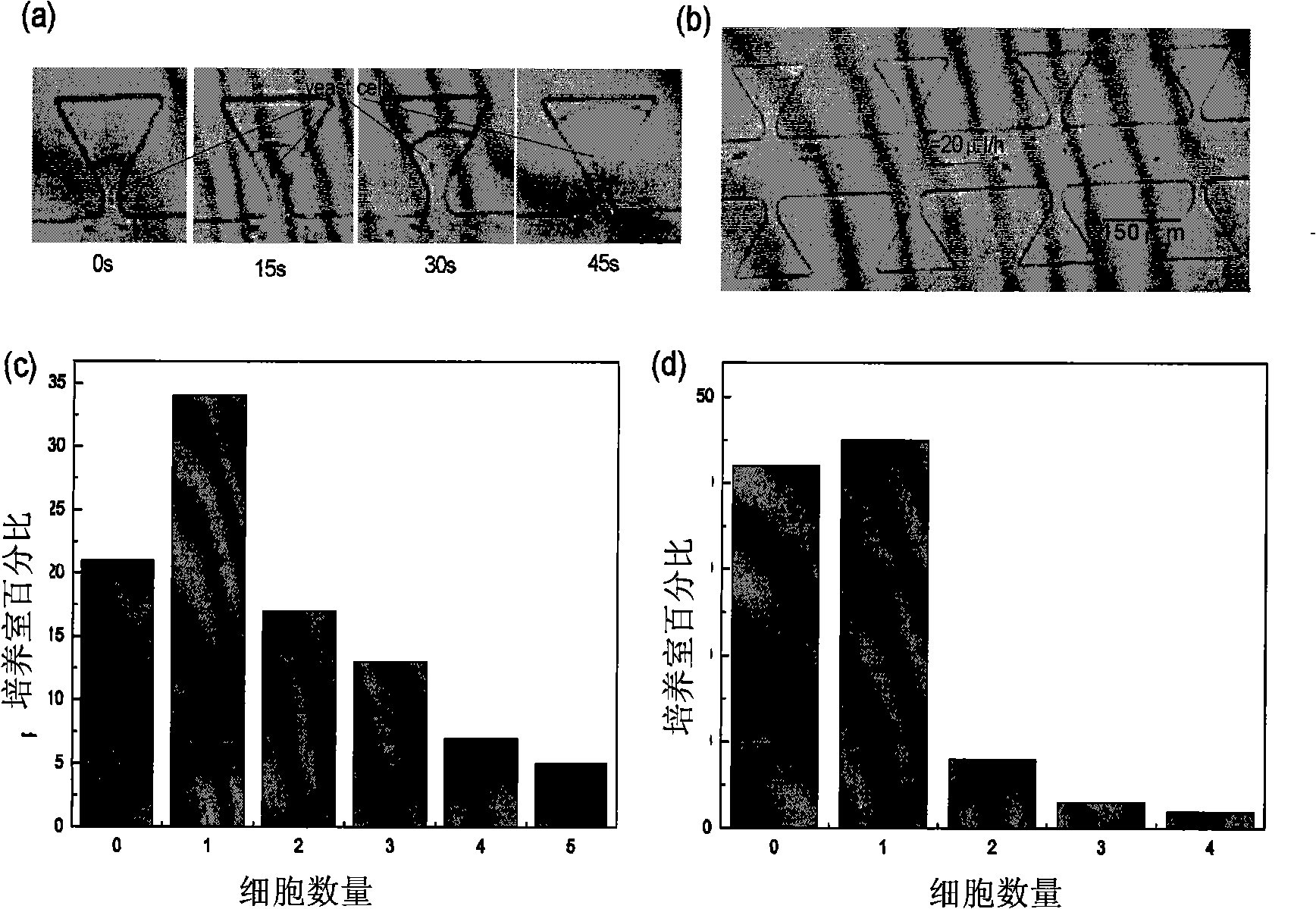

Microflow cell culture array and application thereof

InactiveCN101275114AAchieve single-cell distributionConvenient microscopic observationBioreactor/fermenter combinationsFungiCell phenotypeMicroorganism

The present invention provides a microorganism culture array, including one or more microflow cell culture array units, the microflow cell culture array unit includes a main channel and a plurality of cell culture units connected with the main channel, each culture unit includes a diffusion channel and a cell culture room, the cell culture room is connected with the main channel. The microorganism culture array of the invention not only realizes isolation of single-cell, but also makes the cell locate in zero flow state when the culture liquid or other reagent is changed, bringing greatly convenience for the cell culture and observation especially the culture and observation of non-adherent cells, greatly fit for research work of high throughput screen based on the cell phenotype.

Owner:PEKING UNIV

Method for cultivating nitrosobacteria flora and method for treating wastwater containing ammonia nitrogen

ActiveCN101434915AImproving the Efficiency of Removing Ammonia Nitrogen in Biochemical TreatmentSimple processBacteriaWater contaminantsHigh concentrationCulture fluid

The invention discloses a culture method of a nitrosomonas sp. flora and a treatment method of waste water containing ammonia nitrogen. The ammonia nitrogen concentration and the pH value of a matrix are increased during an enrichment process, and free NH3 with higher concentration is maintained, thereby gradually achieving the purposes of eliminating nitrobacter sp. and enriching nitrosomonas sp. and obtaining a nitrosomonas sp. flora. Then, the obtained nitrosomonas sp. flora is taken as seeds, the expanded culture is carried out by utilizing self-prepared ammonia nitrogen waste water or high ammonia nitrogen waste water as a culture liquid, the nitrosomonas sp. flora after the expanded culture is inoculated into a biochemical treatment pool for improving the removal efficiency of ammonia nitrogen by biochemical treatment, or the nitrosomonas sp. flora after the expanded culture is directly used for removing the ammonia nitrogen of the ammonia nitrogen waste water, and the optimal proposal is used in the aerobic nitrification stage of the shortcut nitrification-denitrification process for accumulating nitrite nitrogen as an electron acceptor for denitrification directly. The method has simple process and outstanding effect of treating the waste water containing the ammonia nitrogen.

Owner:CHINA PETROLEUM & CHEM CORP +1

Trichoderma harzianum strain and use thereof

InactiveCN101503659APromote growth and reproductionIncrease production capacityFungiMicroorganism based processesMicroorganismLignin peroxidase

The invention relates to Trichoderma harzianum Rifai WRF-2 and use thereof. The bacterium strain was preserved in China General Microbiological Culture Collection Center on January 21st, 2009, with a preservation number of CGMCC No.2870. The bacterium belongs to deuteromycetes and is a lower fungus that is short in culture period and quick in growing and propagating speed and produces a large amount of uniform culture liquid for lignin degrading enzyme-generating bacteria in a short time compared with a major part of basidiomycetes to which whiterot fungi belong. The invention also provides a method for culturing and producing lignin peroxydase (Lip) and manganese peroxidase (MnP) by the fermentation of the bacterial strain in a liquid enzyme-generating culture medium, which can produce high-acitivity LiP and MnP in a short time, and is simple in fermentation process, stable, low in cost, and high in yield.

Owner:CHINA AGRI UNIV +1

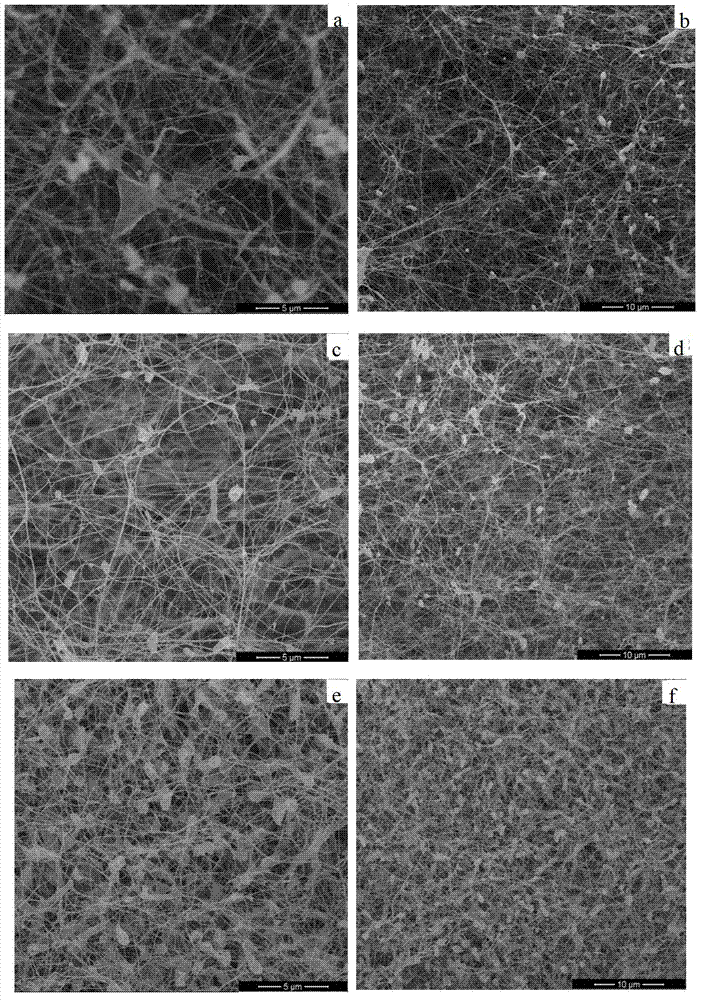

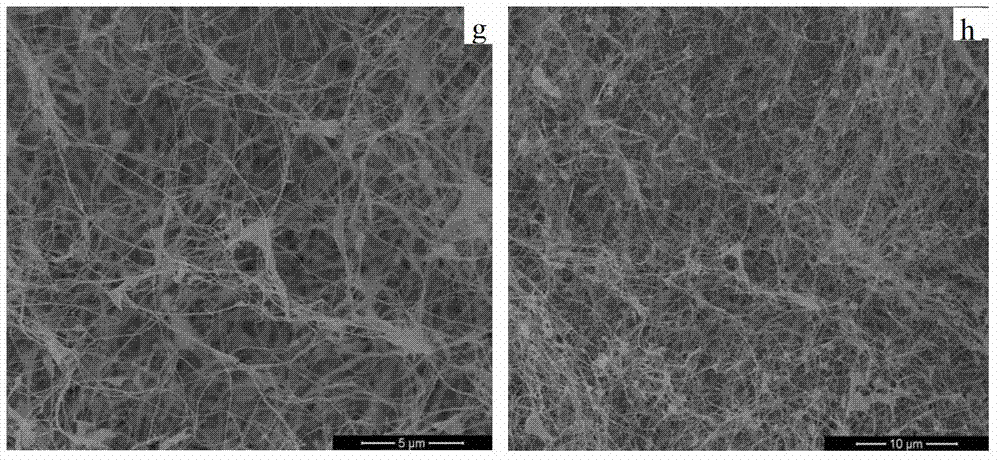

Preparation method of graphene/bacterial cellulose composite material

InactiveCN102924755AInhibition of agglomerationSimple preparation processBiocideOther chemical processesFiberCulture fluid

The invention discloses a preparation method of a graphene / bacterial cellulose composite material. Bacterial cellulose and graphene are co-cultured in situ to obtain the graphene / bacterial cellulose composite material, wherein the graphene evenly grows in the bacterial cellulose reticular fiber structure. The preparation method comprises the following steps: 1) preparing a bacterial cellulose culture fluid, and sterilizing at high temperature under high pressure for 30-60 minutes; 2) inoculating the strain in the bacterial cellulose culture fluid, and rocking in a rocker for 12-48 hours; 3) carrying out ultrasonic treatment on a 0.2mg / ml graphene dispersion liquid for 1-3 hours, and adding the graphene dispersion liquid into the bacterial cellulose culture fluid with the strain, wherein the volume ratio of the graphene dispersion liquid to the bacterial cellulose culture fluid is 1:5-1:10; 4) rocking the mixed liquid in the rocker for 12-24 hours; 5) putting the liquid in a 28 DEG C thermostatic oven, and standing for 1-2 weeks to obtain the graphene / bacterial cellulose composite material; and 6) cleaning the graphene / bacterial cellulose composite material, and carrying out freeze-drying. In the composite material, the graphene is evenly distributed on the bacterial cellulose fibers, thereby effectively inhibiting the defect of high agglomeration tendency of graphene particles.

Owner:EAST CHINA JIAOTONG UNIVERSITY

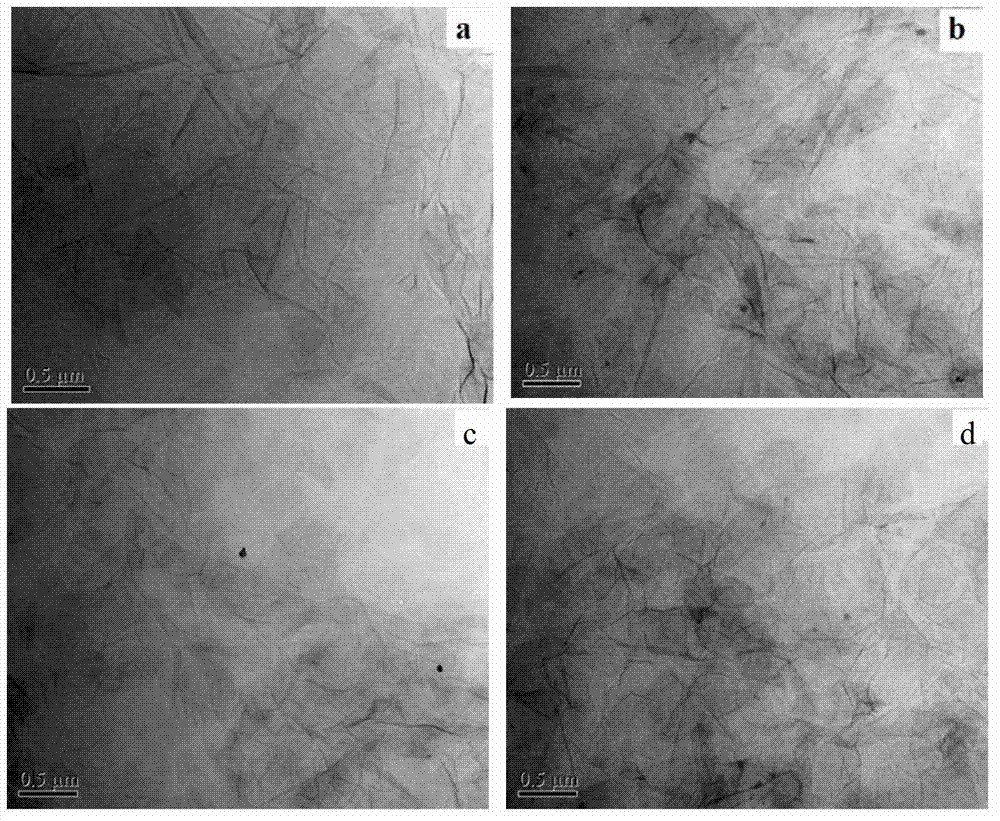

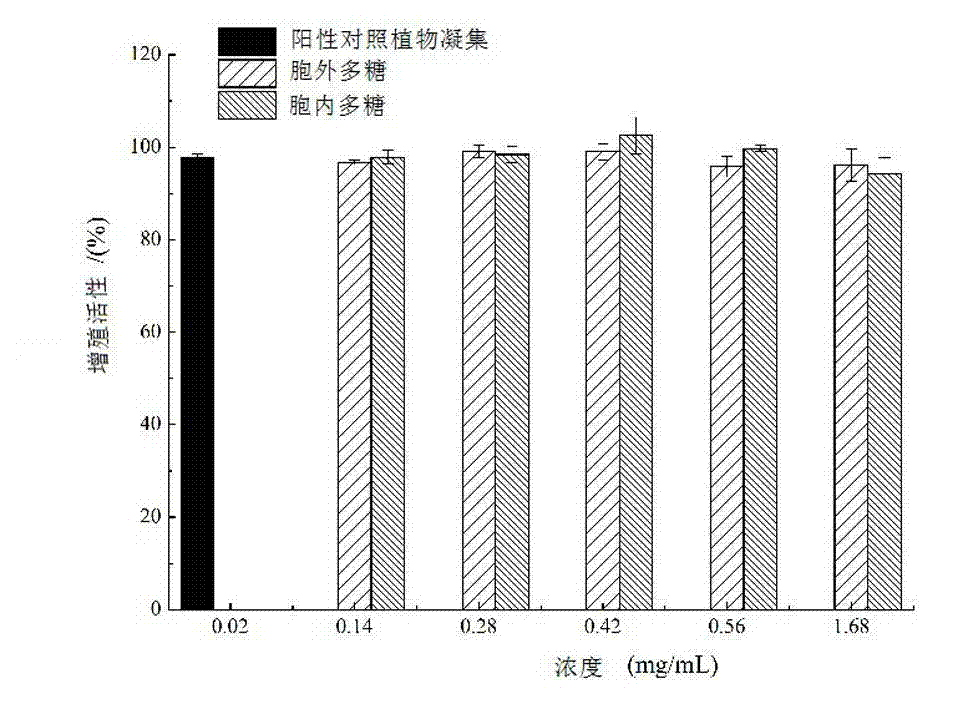

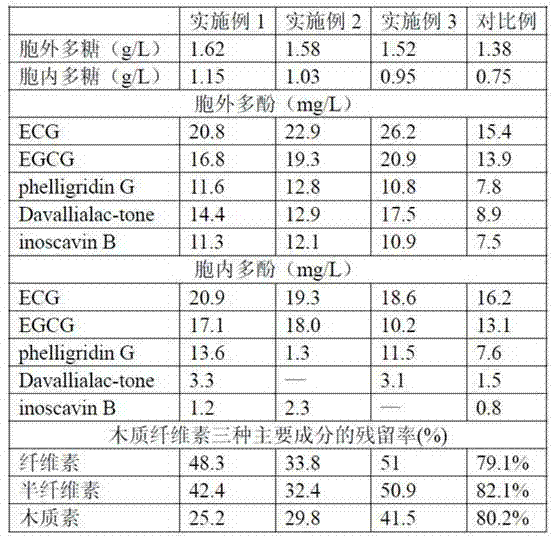

Submerged fermentation technology of producing immunological enhancement active materials of inonotus obliquus

InactiveCN103156052AIncrease productionPromote decompositionAnimal feeding stuffHorticultureBiotechnologySubmerged fermentation

The invention relates to the technical field of fermentation engineering, and discloses a submerged fermentation technology of producing immunological enhancement active materials of inonotus obliquus. The submerged fermentation technology of producing the immunological enhancement active materials of the inonotus obliquus comprises the main steps of culture activation, culture liquid cultivation, submerged fermentation and preparation of the immunological enhancement active materials of the inonotus obliquus and the like. The optimized submerged fermentation technology of producing the immunological enhancement active materials of the inonotus obliquus is high in content of the obtained immunological enhancement active materials, and good in activity of the obtained immunological enhancement active materials, and the obtained immunological enhancement active materials are beneficial for industrial application.

Owner:徐向群

CIK cell, as well as preparation method and cell preparation thereof

InactiveCN101519646AIncrease the number of proliferationPromote cell proliferationMammal material medical ingredientsTissue cultureAbnormal tissue growthPhytohemagglutinins

The invention discloses a CIK cell, as well as a preparation method and a cell preparation thereof. The method for preparing the CIK cell comprises the following steps: placing a separated mononuclear cell in a culture fluid containing phytohemagglutinin; transplanting the mononuclear cell into a culture flask enveloped by antiCD3 monoclonal antibody and antiCD28 monoclonal antibody after the cell is cultured for 24 to 72 hours; and adding a culture fluid containing IL-1alpha and IL-2 into the culture flask to keep on culturing for 5 to 15 days, and separating the cells into different flasks to be cultured every 2 to 3 days. The CIK cell prepared by the method has the characteristics of obvious improved cell proliferation, great increase of CD8 cell proportion, wide antineoplastic spectrum and strengthened antineoplastic activity. The CIK cell and the cell preparation can effectively prevent the metastasis and the recrudescence for of postoperative patients with tumor, can be combined with chemicotherapy to effectively reduce toxic and side effects of the chemicotherapy, strengthens the survivability tolerance of the patients to improve healing efficacy, and can obviously prolong lifecycle to of end-stage patients so as to improve the life living quality.

Owner:上海德嘉生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com