Repairing method of microorganism in contaminated soil of chromium slag storage yard

A technology for microbial remediation and contaminated soil, applied in the restoration of contaminated soil, etc., can solve the problems of a large number of chemical reagents, uneconomical, high energy consumption, etc., and achieve the effect of high removal efficiency, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Isolation, purification and domestication of chromium-reducing bacteria of the present invention

[0018] Collect the soil under the chromium slag dump site of Hunan Ferroalloy Factory, weigh 10g of chromium slag soil in a 150mL sterilized Erlenmeyer flask, add 10mL sterilized liquid medium (5g / L sodium lactate, 5g / L yeast extract and 2g / L Sodium chloride, the rest is water, adjust pH=9.5~9.8 with 5mol / L NaOH;), cultivate in 30°C incubator for 4 days. Then take 1mL mud and dilute to 10 -3 、10 -4 、10 -5 、10 -6 、10 -7 、10 -8 , with a pipette from 10 -6 、10 -7 and 10 -8 Take 0.1mL of the diluent and place it in a solution containing 250mg / L Cr(VI) (in K 2 Cr 2 o 7 Solution as chromium source) solid medium, solid medium consists of: 5g / L sodium lactate, 5g / L yeast extract and 2g / L sodium chloride, 15g / L agar. Spread evenly with a triangular stick, and place the plate upside down in a 30°C incubator for 4 days. Bacterial colonies of different forms...

Embodiment 2

[0021] Example 2: Remediation Test of Contaminated Soil in Chromium Slag Stockyard

[0022] Weigh 10g of the soil under the chromium slag dump of Hunan Ferroalloy Factory, put it in a 150mL Erlenmeyer flask filled with 10mL of liquid medium, and place it in an incubator at 30°C for 10 days. On the 5th and 10th days, the cultured soil samples were randomly taken, poured out, spread the soil samples dry, air-dried at room temperature, ground, and passed through a 10-mesh sieve to determine the total hexavalent chromium, water-soluble hexavalent chromium, and exchangeable chromium in the soil. Contents of valent chromium, carbonate-bound hexavalent chromium, iron-manganese bound hexavalent chromium, organic bound hexavalent chromium and residual hexavalent chromium.

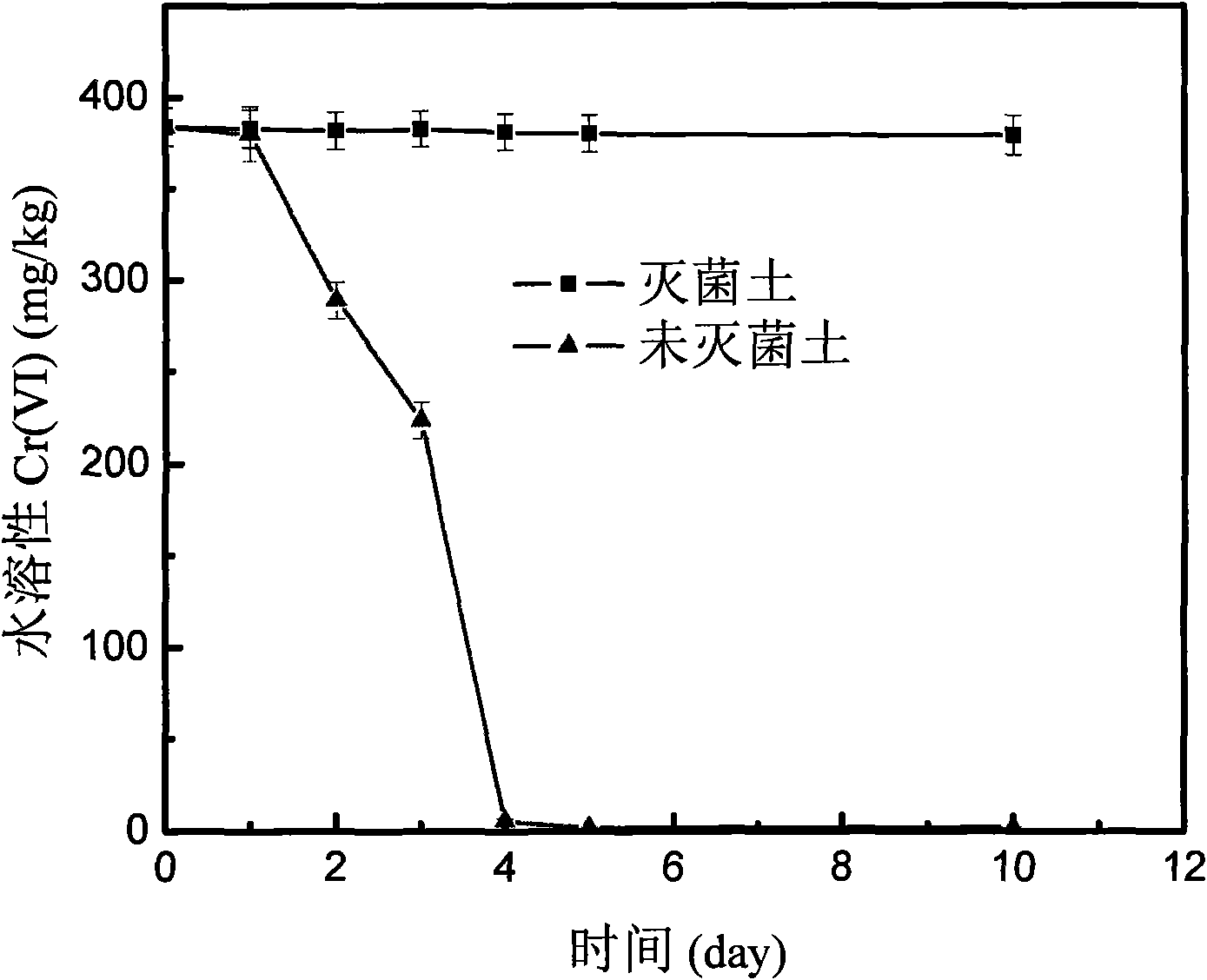

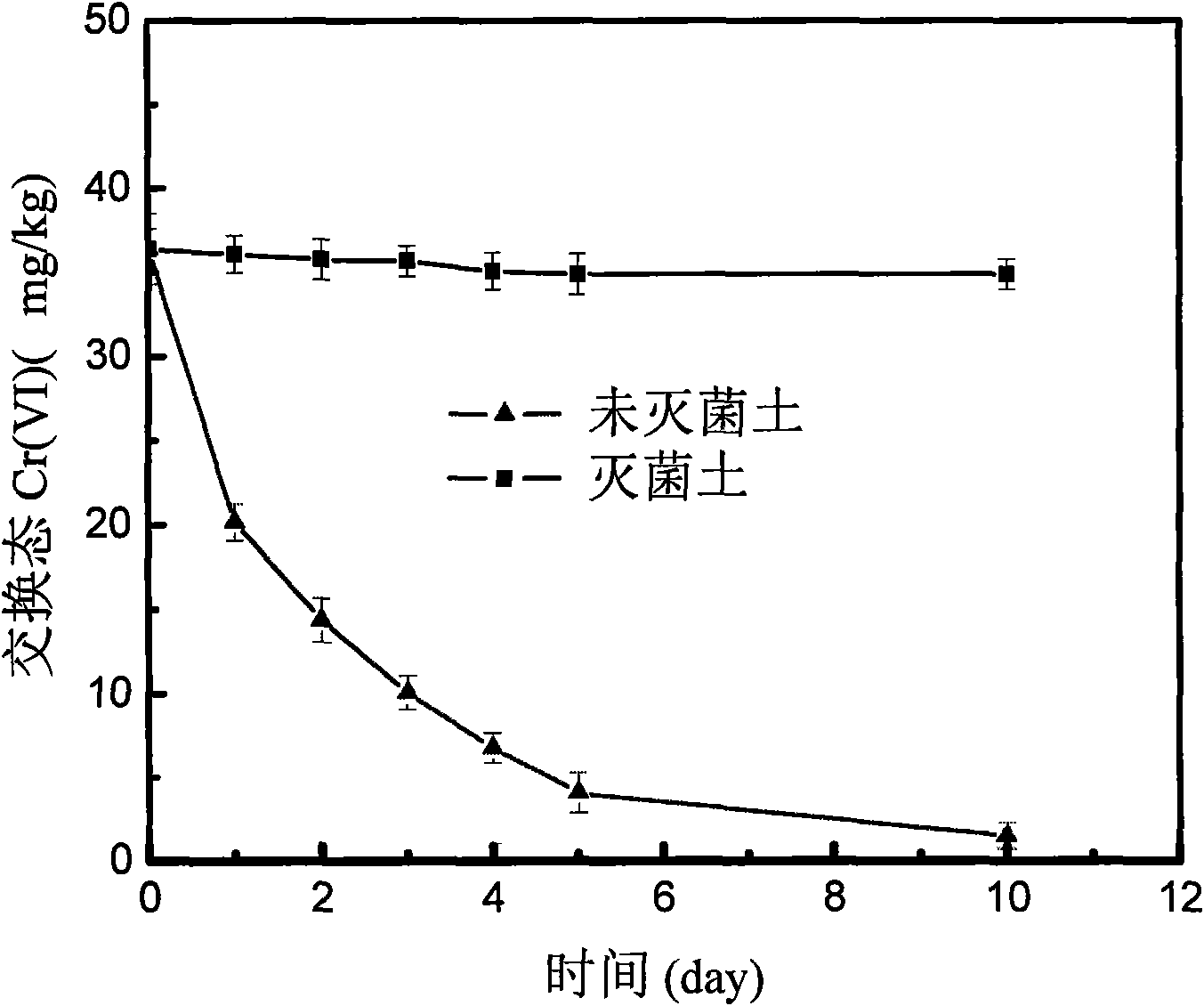

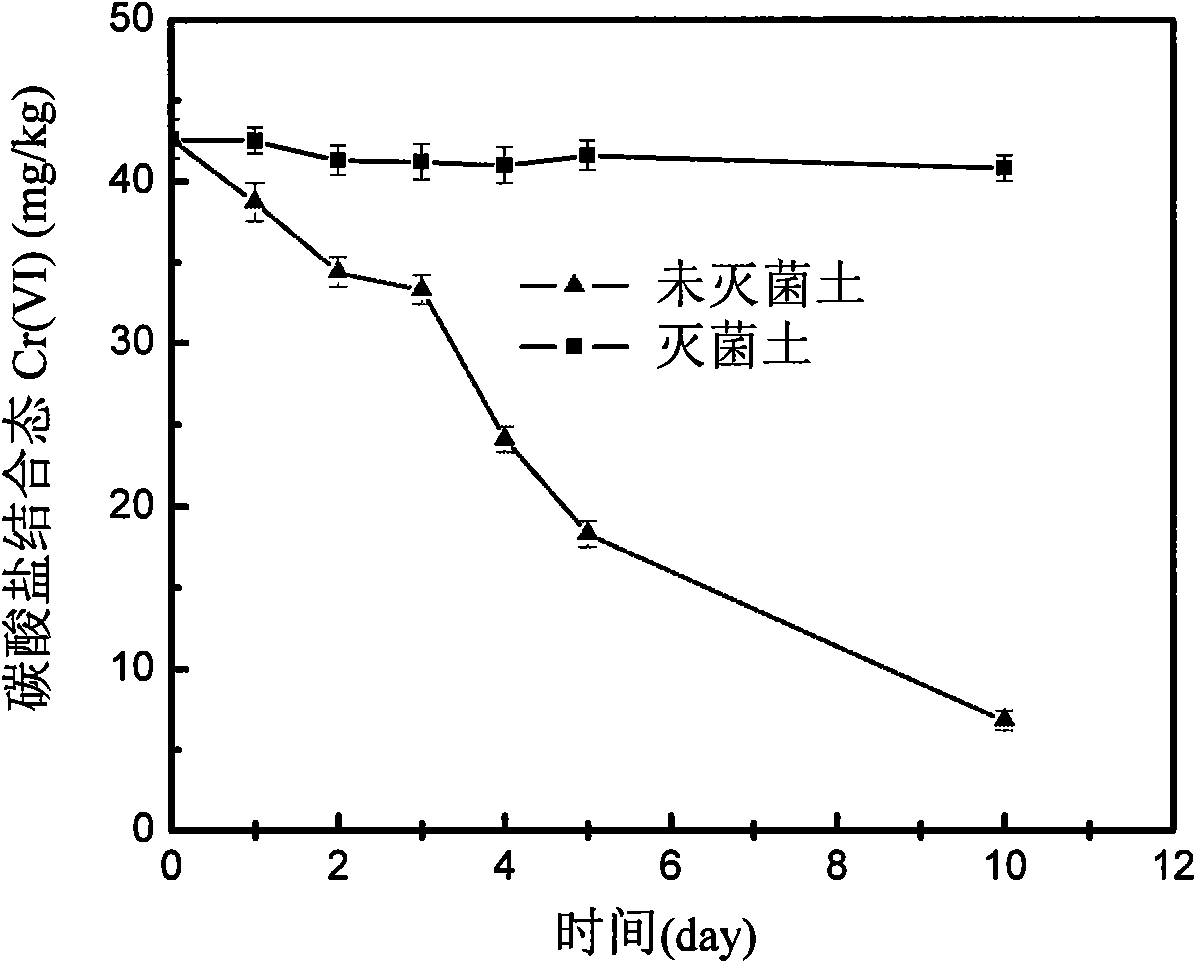

[0023] On the fourth day after cultivation, the removal rate of total hexavalent chromium in the soil reached 92%, and after 10 days, the removal rate reached 98%; after 5 days of cultivation, the water-soluble hexa...

Embodiment 3

[0024] Embodiment 3: simulated chromium-contaminated soil remediation test

[0025] Take uncontaminated soil, air-dry, grind, and pass through a 10-mesh sieve. Potassium dichromate solution was added to the sieved soil to prepare contaminated soil containing Cr(VI) of 210mg / kg, 360mg / kg, 410mg / kg, 610mg / kg, and 1010mg / kg respectively. Weigh 20g of the above soil, add the acclimatized bacterial culture medium (10% inoculum) according to the soil-liquid mass-volume ratio (g:mL) of 1:2, the pH of the medium is 9.5, and place it in an incubator at 30°C The concentration of Cr(VI) in the soil was measured regularly. After 13 days, the removal rates of Cr(VI) were 40%, 63%, 96%, 100% and 100% (as attached Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com