Patents

Literature

478 results about "Plant factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plant factory is a closed growing system which enables a plantsman to achieve constant production of vegetables all year around. The facility utilizes artificial control of light, temperature, moisture, and carbon dioxide concentrations.

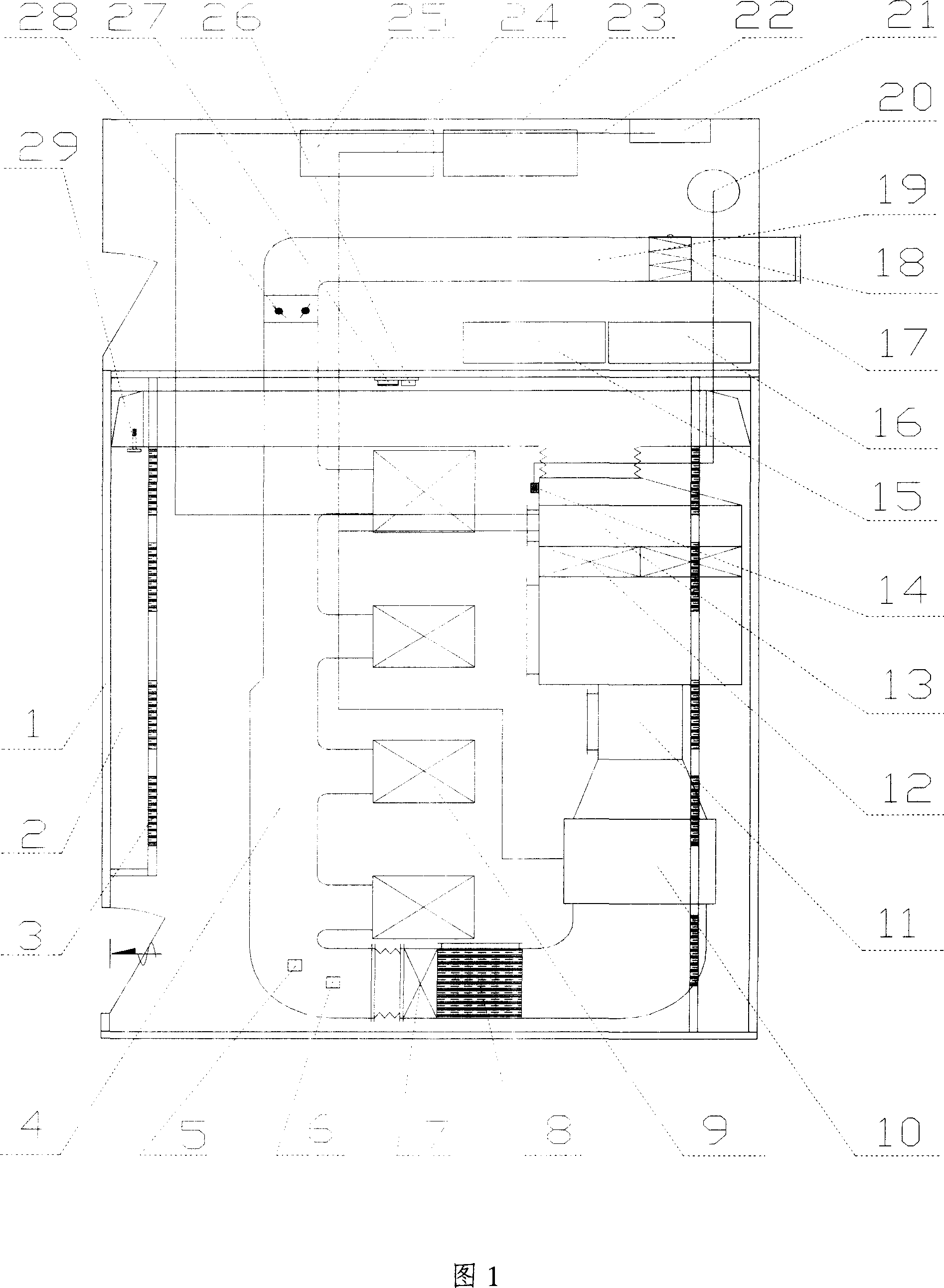

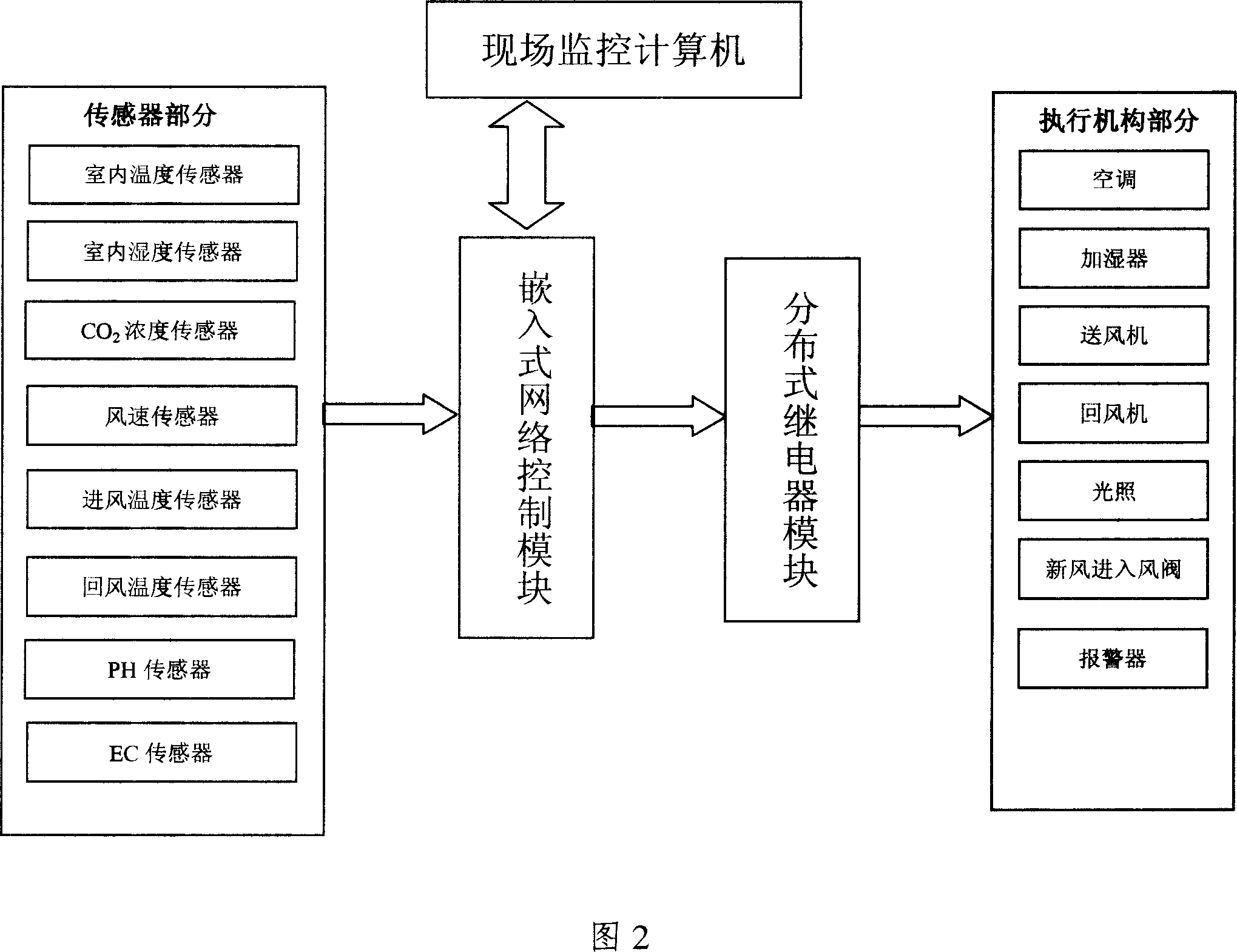

Closed type fully using artificial light environment controlled plant factory

ActiveCN101057550AControl light timeControl light intensityClimate change adaptationSaving energy measuresAir cycleEngineering

The invention discloses an environment control plant factory through seal-typed artificial light, which comprises the following parts: fender structure, air circulating system, temperature adjusting system, moisture adjusting system, CO2 supplying system, light supplying system, control system based on inserted network technique and automatic power-metering system, wherein the systems are seal, heat-proof and light-tight, which provides clean and fitful growing environment for plant. The invention saves cost and energy consumption, which realizes normalized and standardized cultivating management and planning manufacturing.

Owner:CHINA AGRI UNIV

Soilless vegetable cultivation machine

InactiveCN103733971APesticide freeHormone freeAgriculture gas emission reductionCultivating equipmentsTemperature controlPlant factory

The invention relates to a soilless vegetable cultivation machine which comprises a cultivation rack and a constant-temperature tank. A plurality of vertically arrayed cultivation layers are arranged in the cultivation rack and are sequentially connected with one another by drain pipes, a culture fluid tank is communicated with a spray pipe in the uppermost cultivation layer via a suction pipe, and a lowermost culture fluid groove is communicated with the culture fluid tank via a drain pipe; the constant-temperature tank is arranged at the bottom of the cultivation rack, and a temperature control assembly b and a temperature sensor b are arranged inside the constant-temperature tank; the culture fluid tank and a seedling raising assembly are arranged inside the constant-temperature tank, and a filter box is further arranged in the culture fluid tank; the constant-temperature tank is communicated with a temperature control chamber via an air channel, and the temperature control chamber is positioned on the top of the cultivation rack; an air outlet is formed in a side wall of each cultivation layer and is connected with a pipe of the air channel. The soilless vegetable cultivation machine has the advantages that the soilless vegetable cultivation machine is applicable to domestic and small-scale vegetable cultivation and vegetable production of indoor medium and large plant factories and is low-nitrate, green and healthful vegetable production equipment free of pesticides, hormone and heavy metal residues.

Owner:汪蕾

Self-adaptive light supplementing system and method for plant factory

ActiveCN103563685AReduce labor intensityLow pollution rateGreenhouse cultivationPlant factoryEngineering

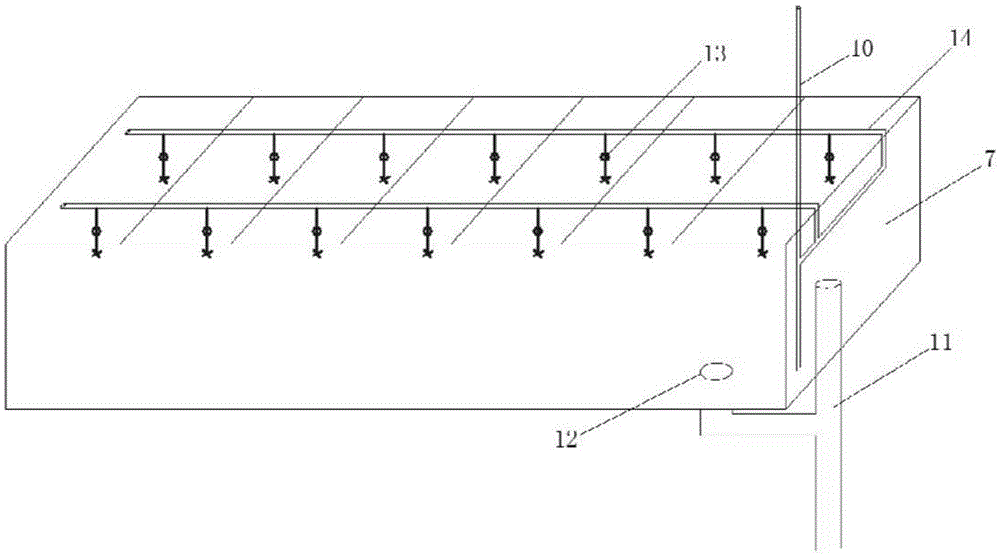

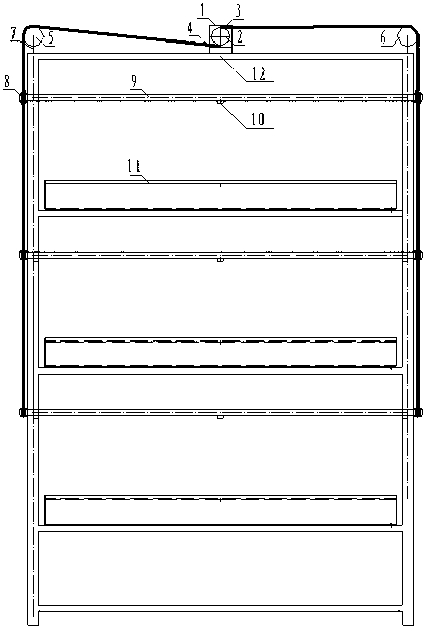

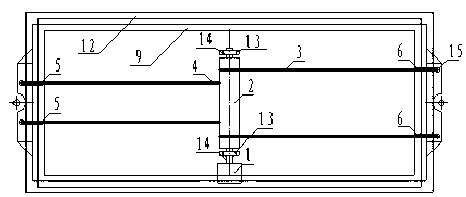

The invention discloses a self-adaptive light supplementing system and method for a plant factory. The distance between a light supplementing lamp 1 and plants 12 planted on a culture bed 10 is measured through distance measuring sensors 11, and a stepping motor 4 is driven to operate so as to drive a winding shaft 3 to rotate, so that the light supplementing lamp 1 is driven by steel wires 6 winding round winders 2 to rise or fall; and meanwhile, the light supplementing system can measure and calculate the illumination intensity of a plant canopy through an illumination intensity sensor 13, and then the illumination intensity of the light supplementing lamp 1 is adjusted to be adapted to light intensity requirements of different crops. The method is simple and practical, and the illumination intensity of the light supplementing lamp 1 and the distance between the light supplementing lamp 1 and the plants 12 can be adjusted, so that only set values of system software are required to be changed, and then culture requirements of the different plants for the space and the illumination intensity can be met. The system and the method are applicable to light supplementing for culture of the various plants in the plant factory.

Owner:JIANGSU UNIV

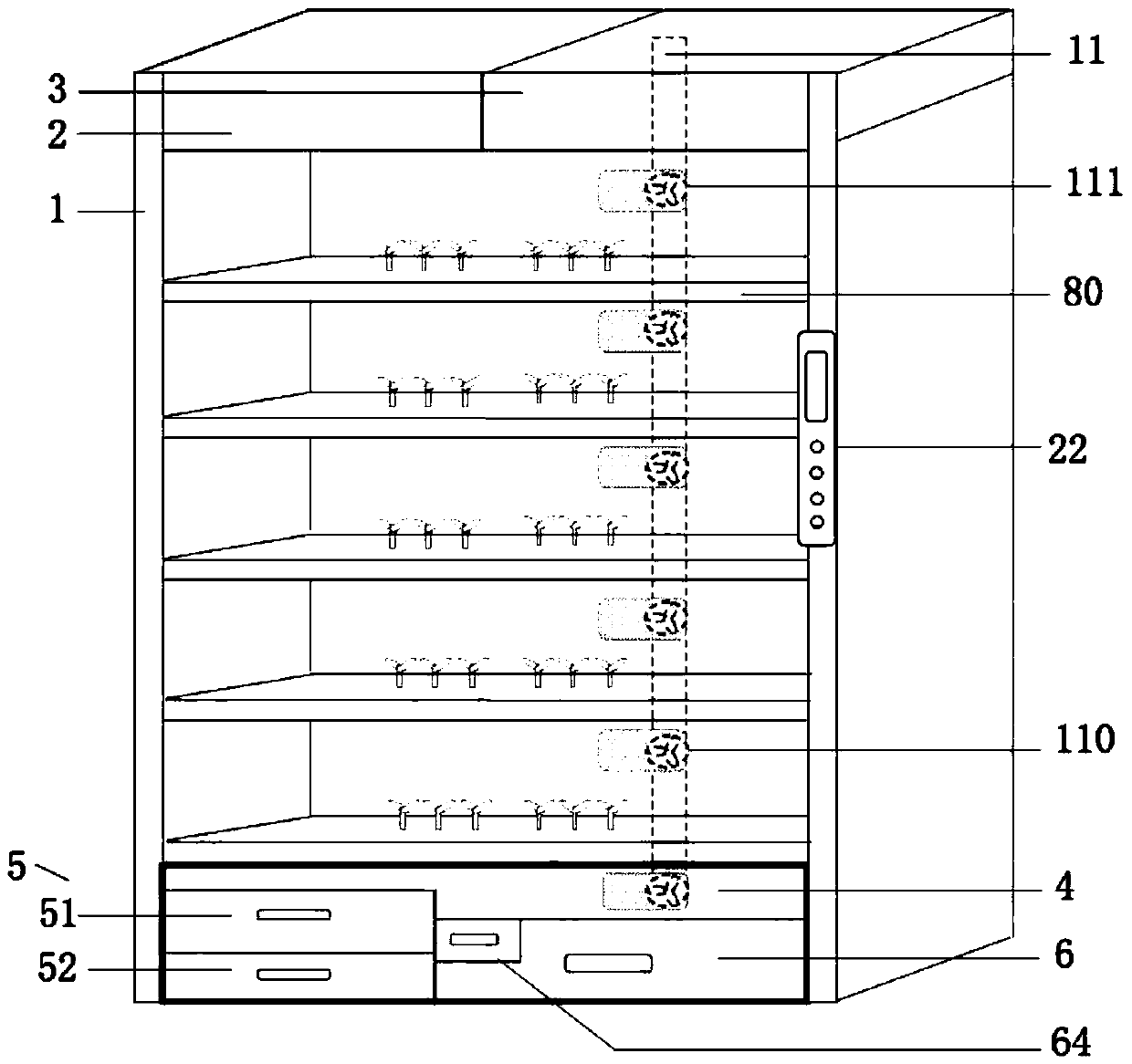

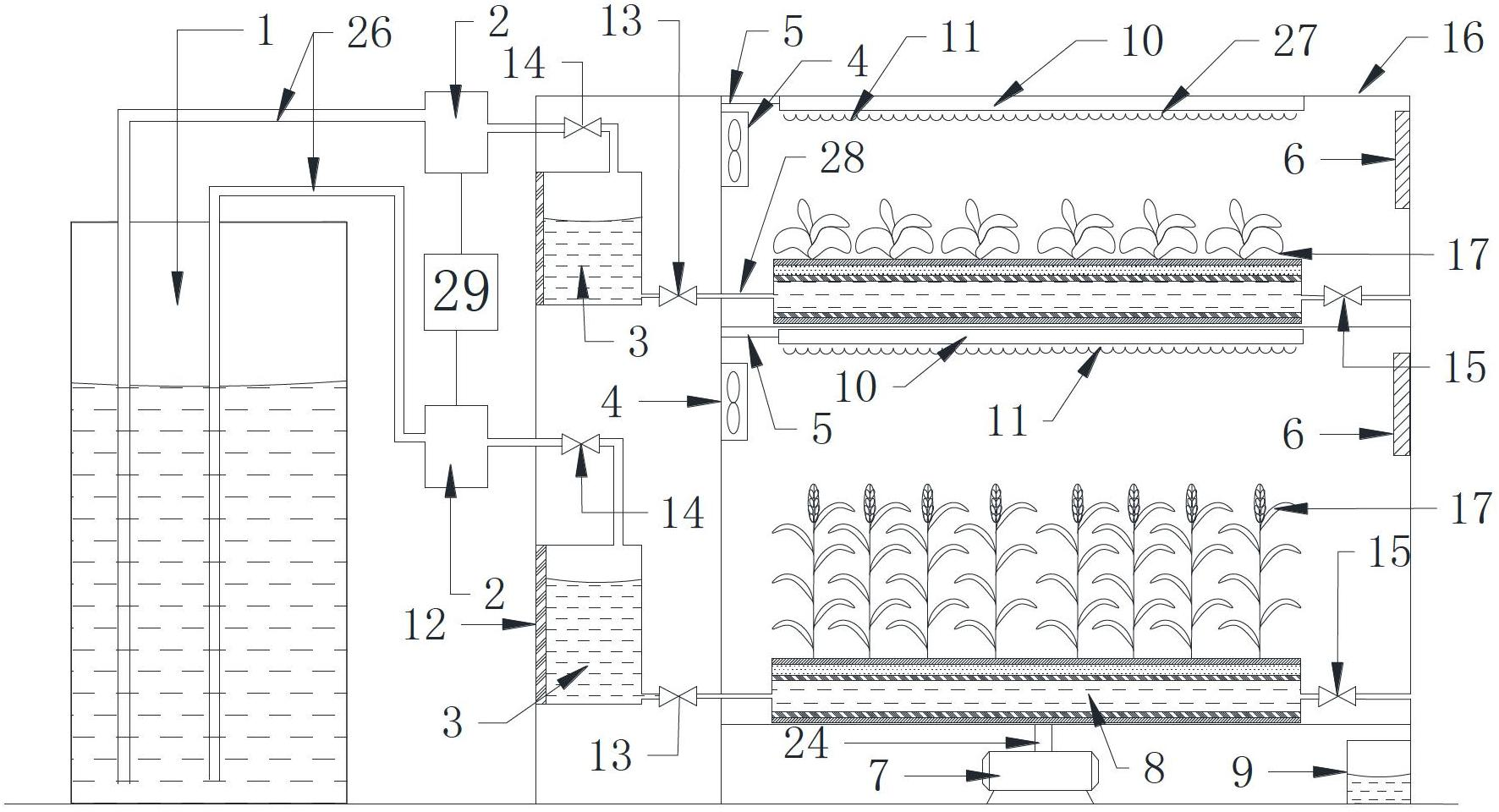

Miniature light-emitting diode (LED) plant factory

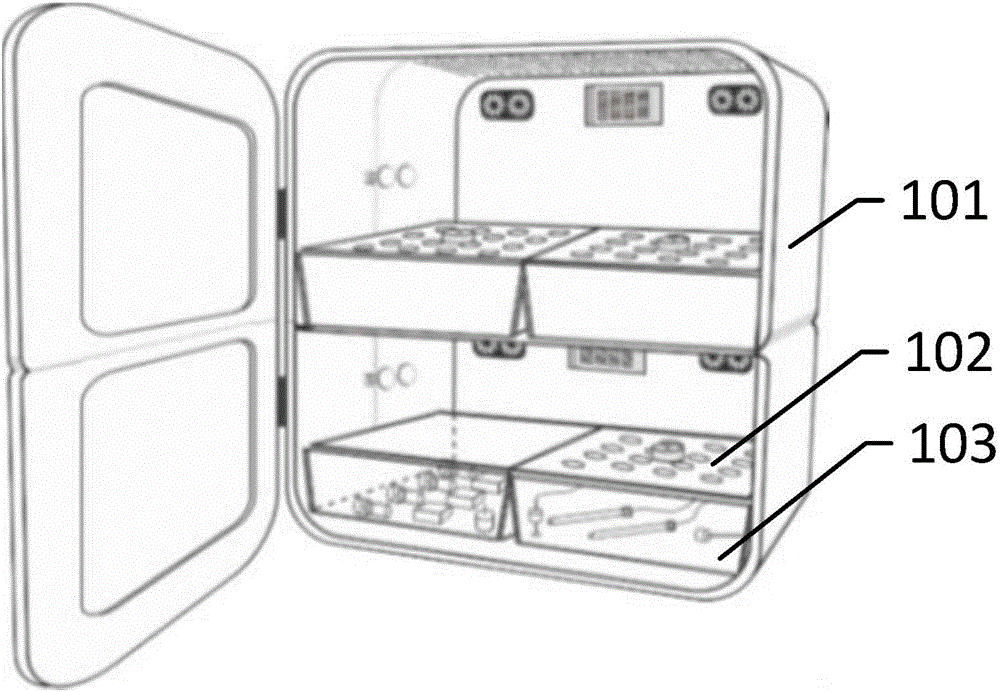

InactiveCN103098693AReduce human laborSmall footprintAgriculture gas emission reductionCultivating equipmentsPlant rootsNutrient solution

The invention relates to a miniature light-emitting diode (LED) plant factory. In the process of planting agricultural products, growing of plants is often limited by various needed factors. The miniature LED plant factory comprises an LED plant lamp, nutrient solution, a nutrient solution automatic cyclic utilization system, nutrient solution heating and sterilization, planting plate vermiculite substrate for fixing root systems, a temperature control system, a humidity control system, an automation control circuit, software control cultivation procedures of different vegetable planting processes and a temperature and humidity sensor. The LED plant lamp is used as a light source. A miniature water pump is utilized in the nutrient solution automatic cyclic utilization system, three-layer water level is controlled by a liquid valve, and the nutrient solution cyclic utilization system is communicated with a water tank. An electric heater unit is installed in the water tank and used for heating and sterilizing the nutrient solution regularly. The plant root systems are fixed and supplied with nutrient by applying of a vermiculite substrate. Temperature and humidity can be monitored and regulated, and matched control cultivation procedures can be called. The miniature LED plant factory can be suitable for growing of various plants, manpower work quantity is reduced, and lands are saved. The miniature LED plant factory is green, safe, energy-saving, environment-friendly and beneficial for popularization.

Owner:HUIZHOU WAI CHI ELECTRONICS CO LTD

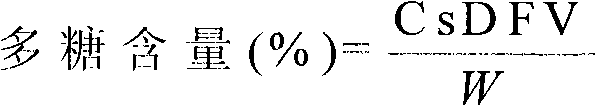

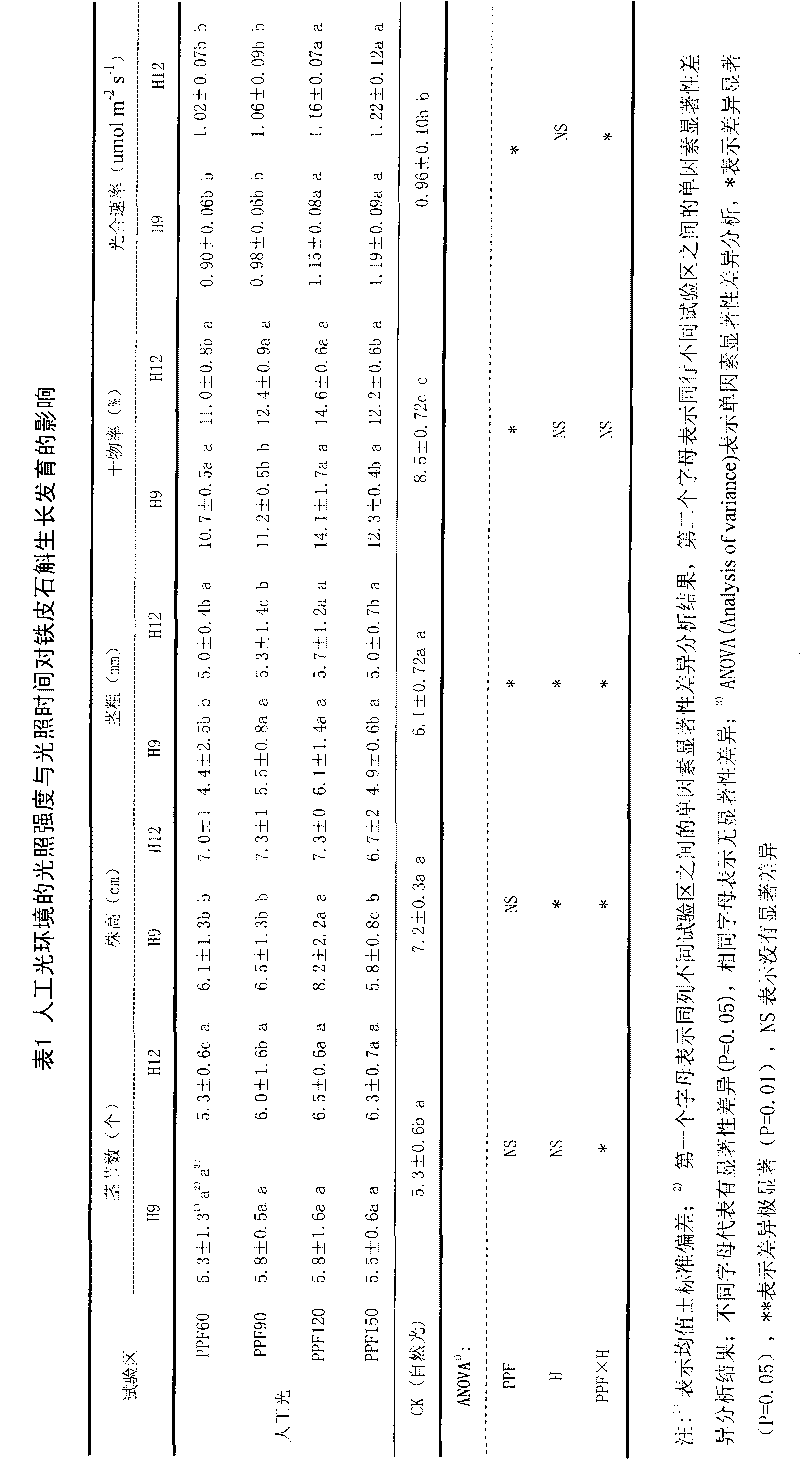

Artificial light cultivating method of dendrobium candidum

ActiveCN101699984AShorten the production cycleUniform qualityColor/spectral properties measurementsAgriculture gas emission reductionAir velocityNutrition

The invention discloses an artificial light cultivating method of dendrobium candidum, belonging to the technical field of medical plant cultivation. The method comprises the following steps: naturalized young plants are transplanted to a nutrition pot or a potted tray containing base material and placed in a three-dimensional cultivating shelf of an artificial light closed plant factory; wherein cultivating conditions are as follows: the illumination intensity is 60-150 mu mol.m-2.s-1; the illumination time is 9-12h.d-1, the temperature is 24-27 DEG C; the relative humidity is 65-80%; the CO2 concentration is 400-800 mu mol.m-1; and the air velocity is 0.3-0.6 m.s-1; after the young plants are transplanted, atomizing keeps the humidifying state of leaf surfaces of the young plants before 2 weeks; after two weeks, the young plants are watered; according to the principle of keeping the humidification of the base material, macroelement nutrient solution is applied every 7 to 15 days; microelement nutrient solution is applied every 25 to 35 days; bottom surface is watered every 3 to 5 days; the young plants are harvested after being cultivated for 1.5 to 2 years and every half year is a picking time. The method shortens the production period, guarantees the uniform quality of the products, increases the yield, and is easy to realize standardization, industrialization and scale production.

Owner:CHINA AGRI UNIV

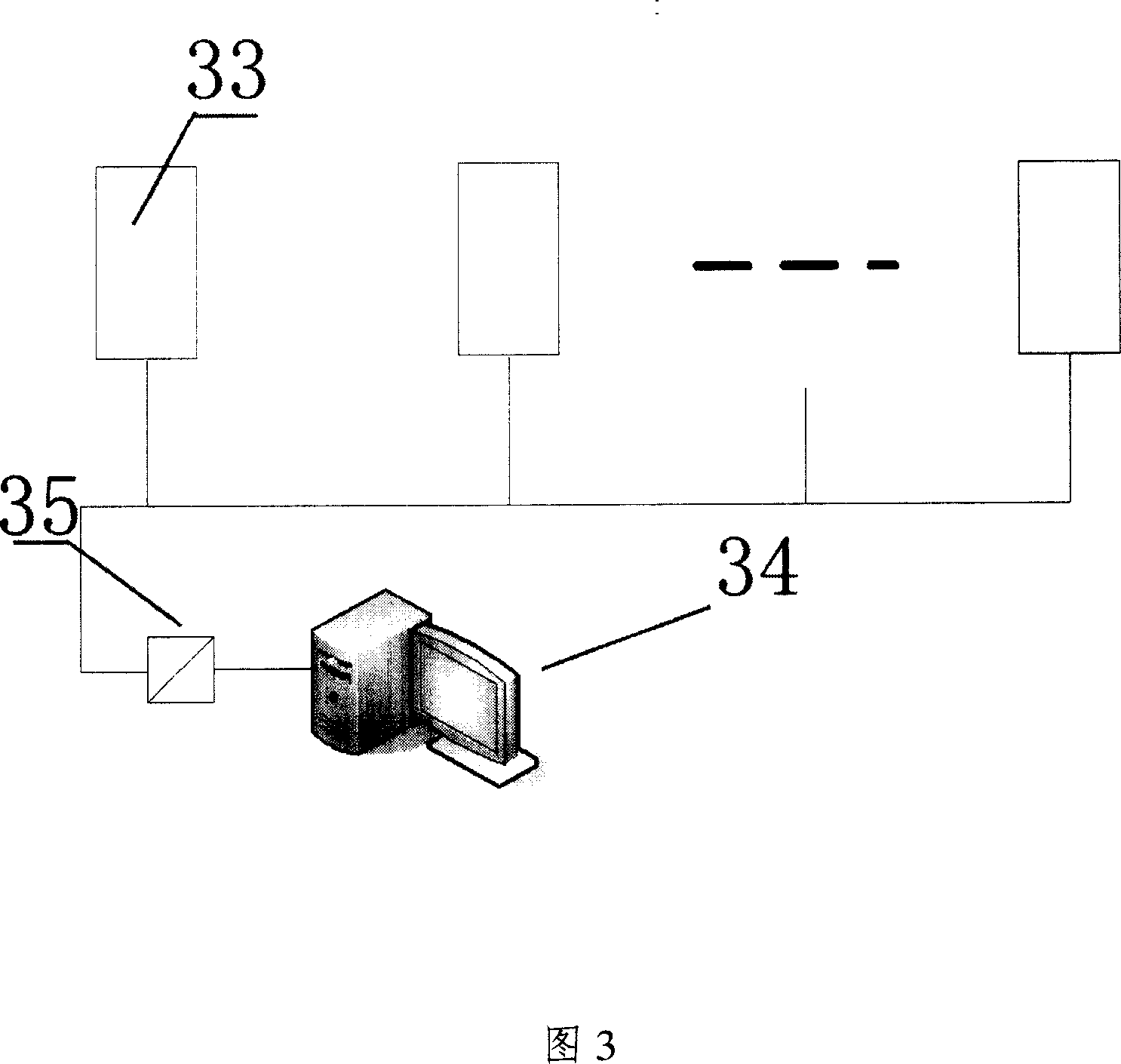

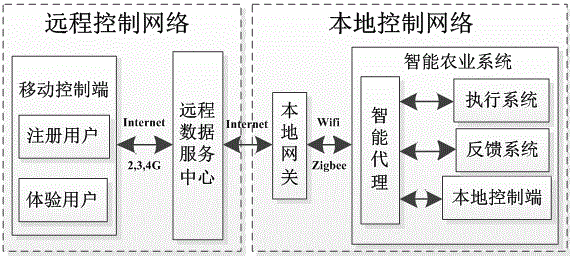

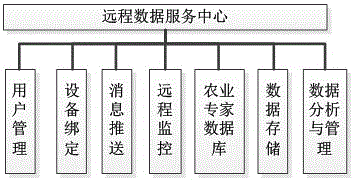

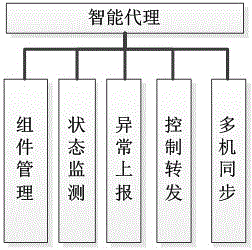

Wholly artificial light type plant factory intelligent monitoring system based on Internet of Things (IOT)

ActiveCN105897901ARealize remote intelligent monitoringEasy to controlData switching networksArea networkAgricultural engineering

The invention discloses a wholly artificial light type plant factory intelligent monitoring system based on the Internet of Things (IOT). The wholly artificial light type plant factory intelligent monitoring system includes a remote control network and a local control network. A user can log in a mobile control terminal using a smart phone, a tablet or a laptop to connect to a remote data service center to acquire real-time data of a local agriculture system, and achieve remote control of the local agriculture device, and when entering a local area network, a user can complete real-time monitoring of the agriculture system through an intelligent agent. The system can grow plants in a closed environment completely using an artificial LED light source, and provides a clean, pure and optimal growth environment for the plants by reasonably controlling the lighting, temperature, humidity, nutrient solution and other environmental factors. The invention has the advantages of low cost and low energy consumption, allows the plants to be free from the environmental restrictions of seasons, regions and the like, enables continuous production throughout the year without being affected by natural disasters, and achieves industrialized and intelligent agricultural production.

Owner:秦皇岛小马物联网科技开发有限公司

Plant factory

ActiveCN102668964ASimple structureEasy to operateAgriculture gas emission reductionCultivating equipmentsHigh energyPlant factory

The invention discloses a plant factory, which mainly comprises a rising plant cultivation module unit, an on-demand automatic nutrient solution supply block unit, an adjustable light source module unit, a shell protection cover and a refrigeration system. The plant factory can be adopted by supermarkets and dining rooms to independently plant and sell various plant foods, or be suitable for environment conditions of special zones such as plateaus, deserts, the underground, the south pole, the north pole and space bases to meet the requirements on continuous plant food supply and air purification of personnel having activities in the special environments for a long time, or be adopted by families to plant fresh vegetables independently. The plant factory has a simple structure, is convenient to operate and achieves a high energy utilization rate.

Owner:BEIHANG UNIV

Multifunctional agricultural LED (light-emitting diode) lighting device

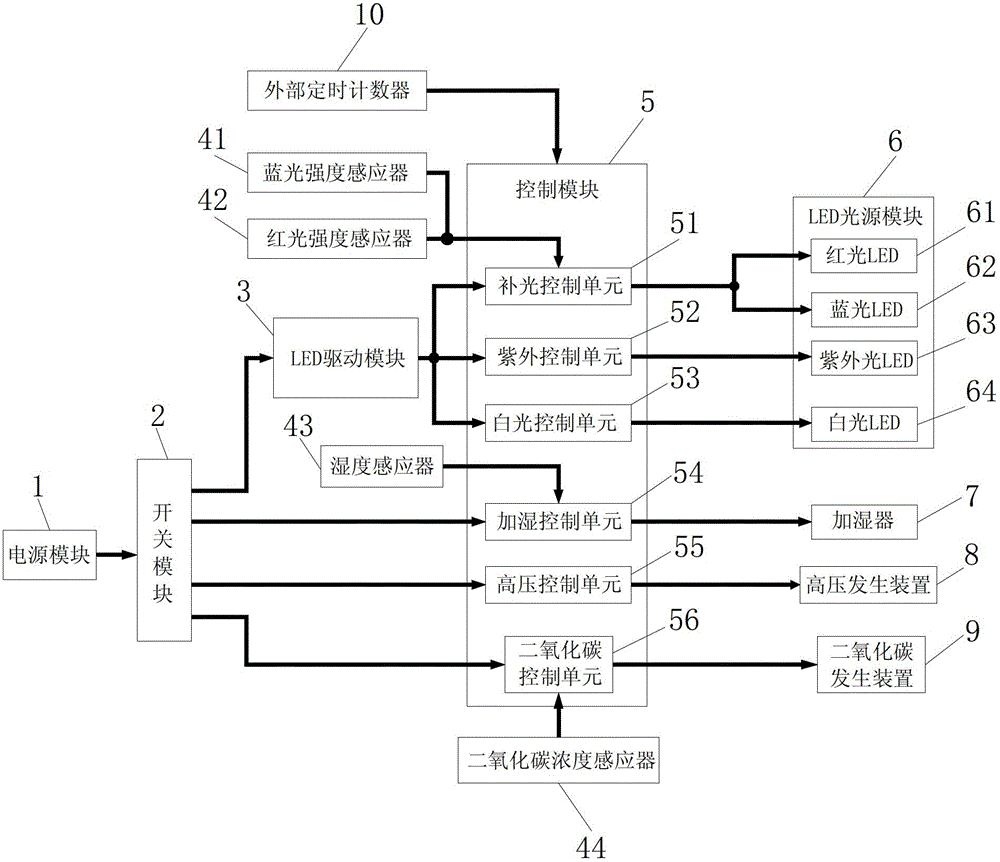

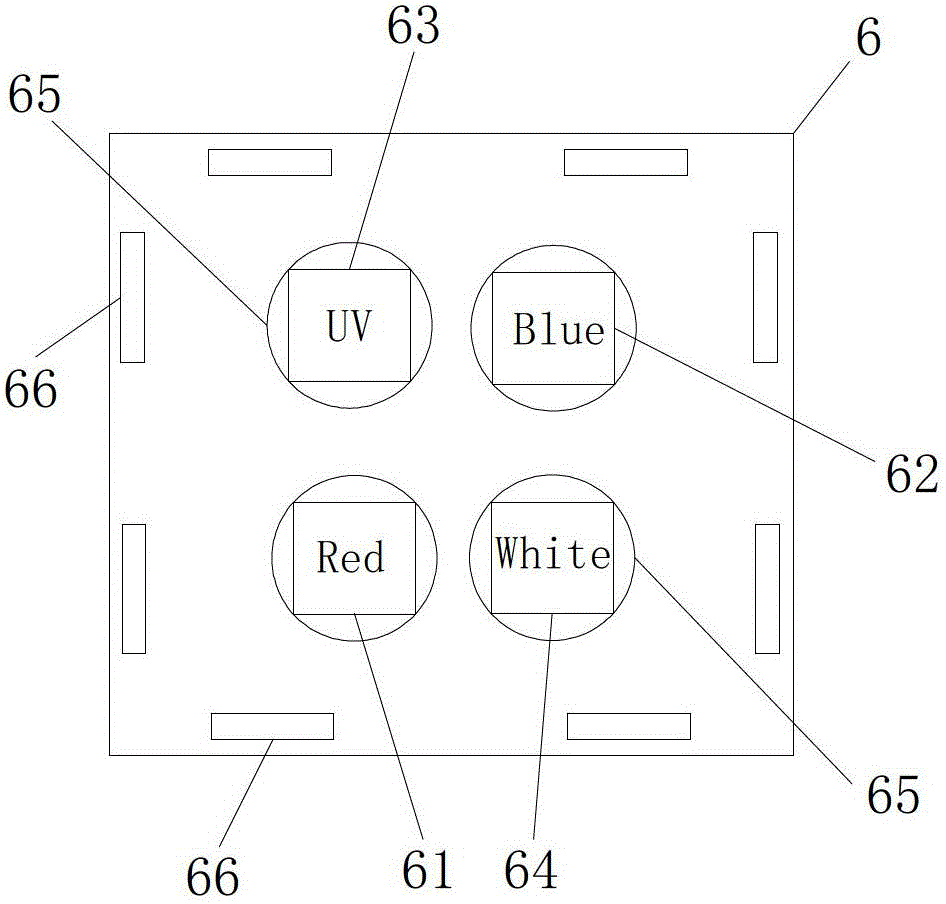

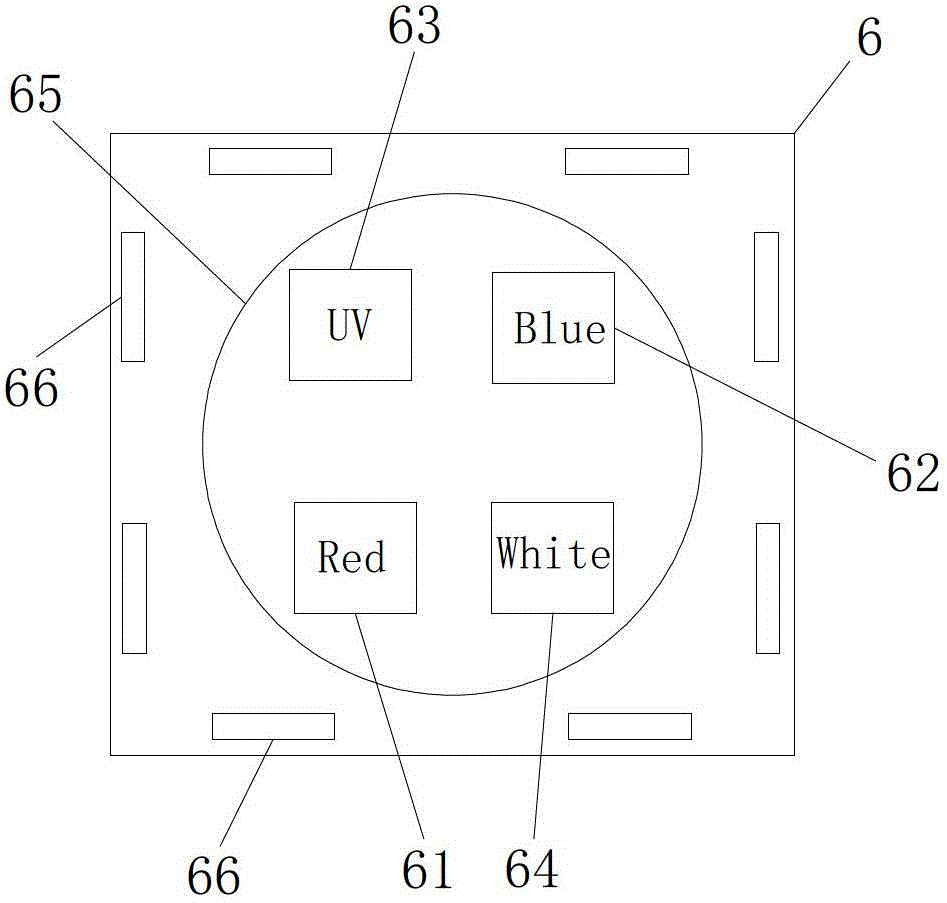

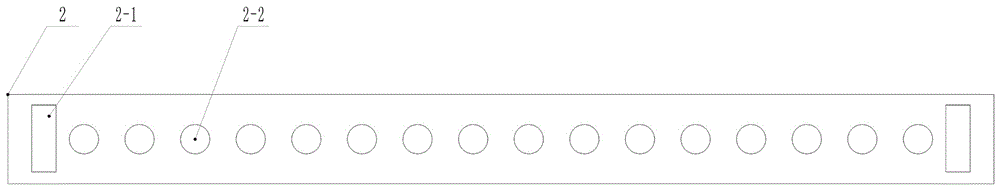

InactiveCN102748627ARealize artificial intelligence managementPoint-like light sourceElectric circuit arrangementsAgricultural engineeringUltraviolet lights

The invention belongs to the technical field of agricultural lighting, and particularly discloses a multifunctional agricultural LED (light-emitting diode) lighting device. The multifunctional agricultural LED lighting device comprises an LED light source module, a control module, a high voltage generator, a blue light intensity sensor, a red light intensity sensor, an LED driving module, an external timing and counting device, a power module and a switch module, wherein an red light LED, a blue light LED, an ultraviolet light LED and a white light LED are arranged on the LED power module. According to the multifunctional agricultural LED lighting device, the modules are matched with each other to achieve the effects of light supplementing, pest killing, sterilizing and disinfecting and the like in the growth process of plants. The multifunctional agricultural LED lighting device integrates the functions of light supplementing, pest killing, sterilizing and lighting, thus meeting the requirements on the development of a plant factory.

Owner:APT ELECTRONICS

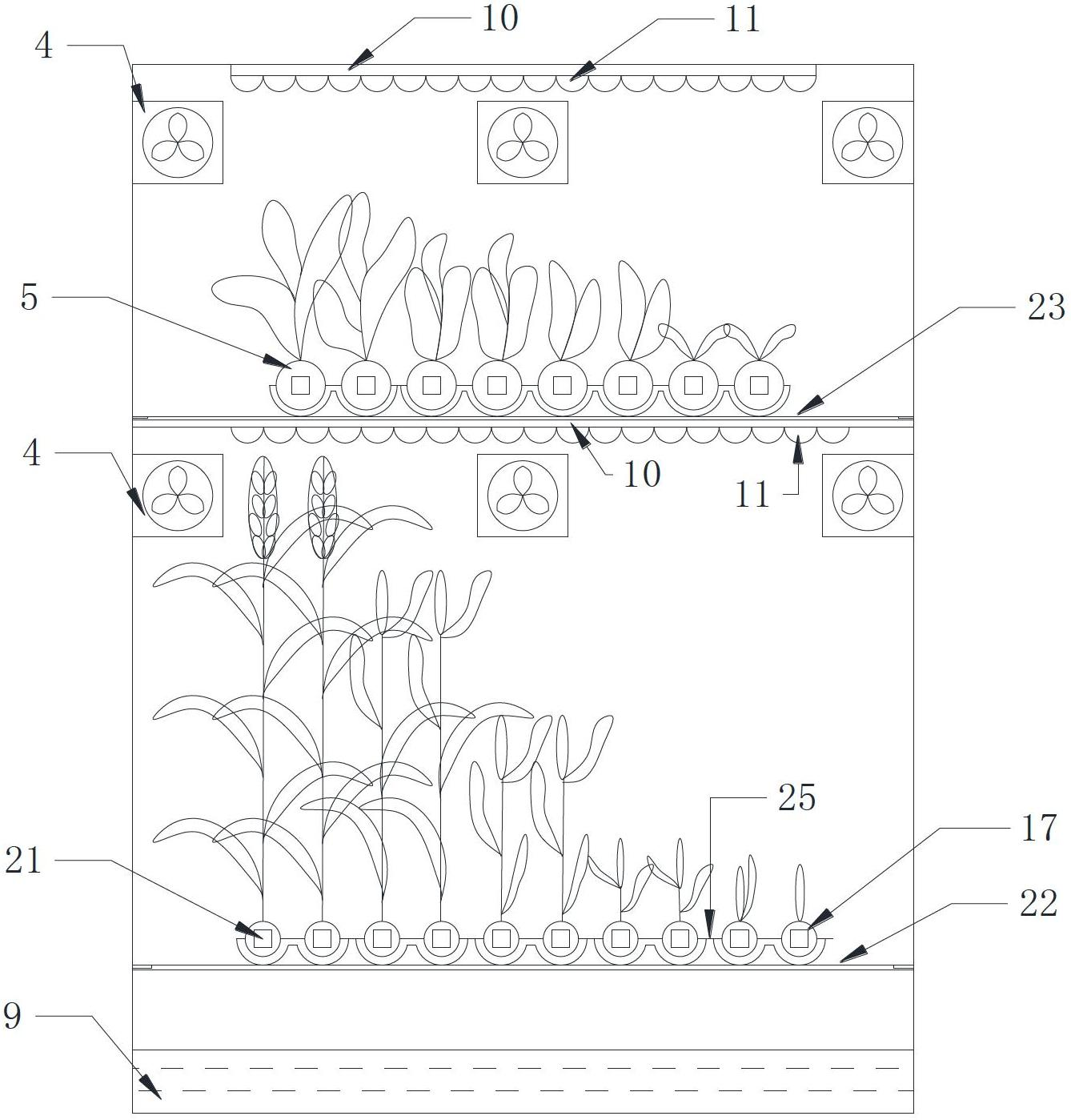

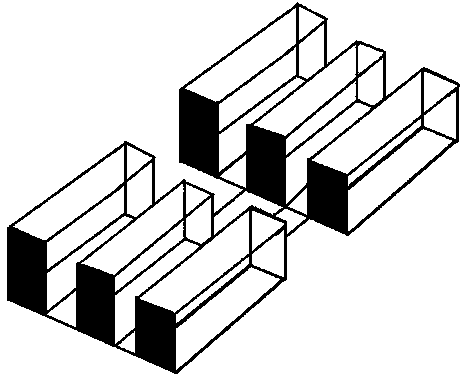

Automatic three-dimensional layer frame type plant factory

InactiveCN105746246AHealthy growthGrow fastClimate change adaptationAgriculture gas emission reductionPlant factoryEconomic benefits

The invention discloses an automatic three-dimensional layer frame type plant factory which comprises three-dimensional layer frame type culture layer frames.The plant factory is characterized by further comprising planting groove bodies, three-dimensional groove frame conveyers and three-dimensional groove rack pipelines.The planting groove bodies are movably arranged on the culture layer frames.Each three-dimensional groove frame conveyer comprises a transverse conveying mechanism which can drive the planting groove bodies to move horizontally, and a longitudinal conveying mechanism which can drive the planting groove bodies to move vertically.Each three-dimensional groove frame pipeline comprises but not limited to a nutrient solution conveying pipeline.One ends of the nutrient solution conveying pipelines are communicated with the planting groove bodies, and the other ends of the nutrient solution conveying pipelines are communicated with nutrient solution mixing grooves.The plant factory has the advantages of being high in economic benefit, low in labor intensity of workers and high in production efficiency and safety.

Owner:桂林明莹生物科技开发有限公司

Method for cultivating mesembryanthemum crystallinum L. using LED light source

InactiveCN105265290AEnergy savingWith monochromatic lightPoint-like light sourceSaving energy measuresMesembryanthemum cristallinumNutrient solution

The invention relates to a method for cultivating mesembryanthemum crystallinum L. using an LED light source, and belongs to the field of cultivation of medicinal plants. The method comprises sowing seeds of the mesembryanthemum crystallinum L. in a flat plate or a plug tray taking vermiculite as a matrix, watering to make the matrix totally wet, putting the flat plate or the plug tray on a three-dimensional cultivation shelf in a plant factory having an LED light source, and spraying water to keep the matrix wet, wherein the temperature in the plant factory is within the range from 20 DEG C to 23 DEG C; irradiating seedlings after the seeds germinate, and spraying a nutrient solution to cultivating the seedlings; distributing the seedlings after two leaves and one core grows up on each seedling, cleaning the matrix on roots of the seedlings, fixedly planting the seedlings on field planting plates of a three-dimensional multilayer hydroponic system in the plant factory via sterilized sponge, irradiating the seedlings, supplying a nutrient solution by an automatic circulatory system, cultivating; and harvesting in 60 to 70 days after sowing. The production period of the mesembryanthemum crystallinum L. can be fixed, the mesembryanthemum crystallinum L. can be produced and supplied year round, the mesembryanthemum crystallinum L. is safe without pesticides, and contains no heavy metal, more functional substances of the mesembryanthemum crystallinum L. can be accumulated in a controllable environment.

Owner:BEIJING IEDA PROTECTED HORTICULTURE

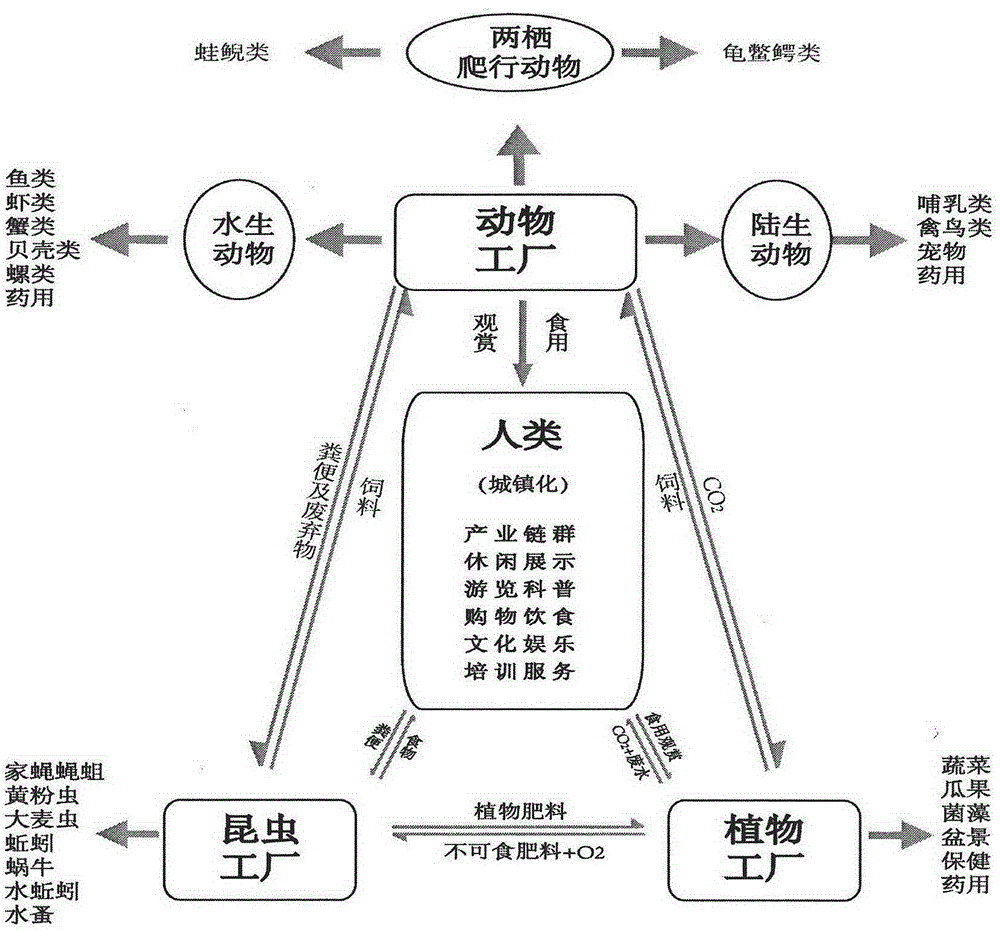

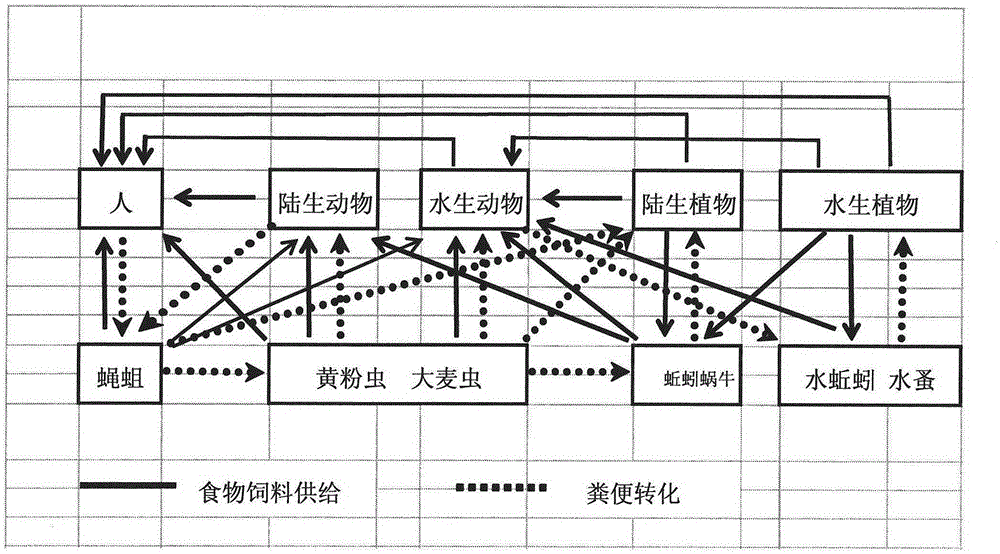

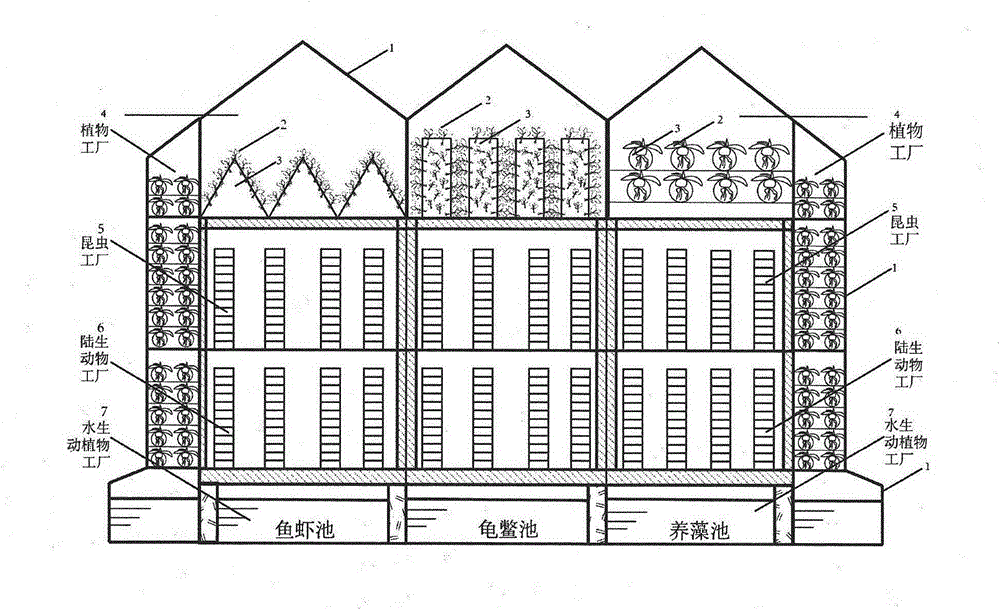

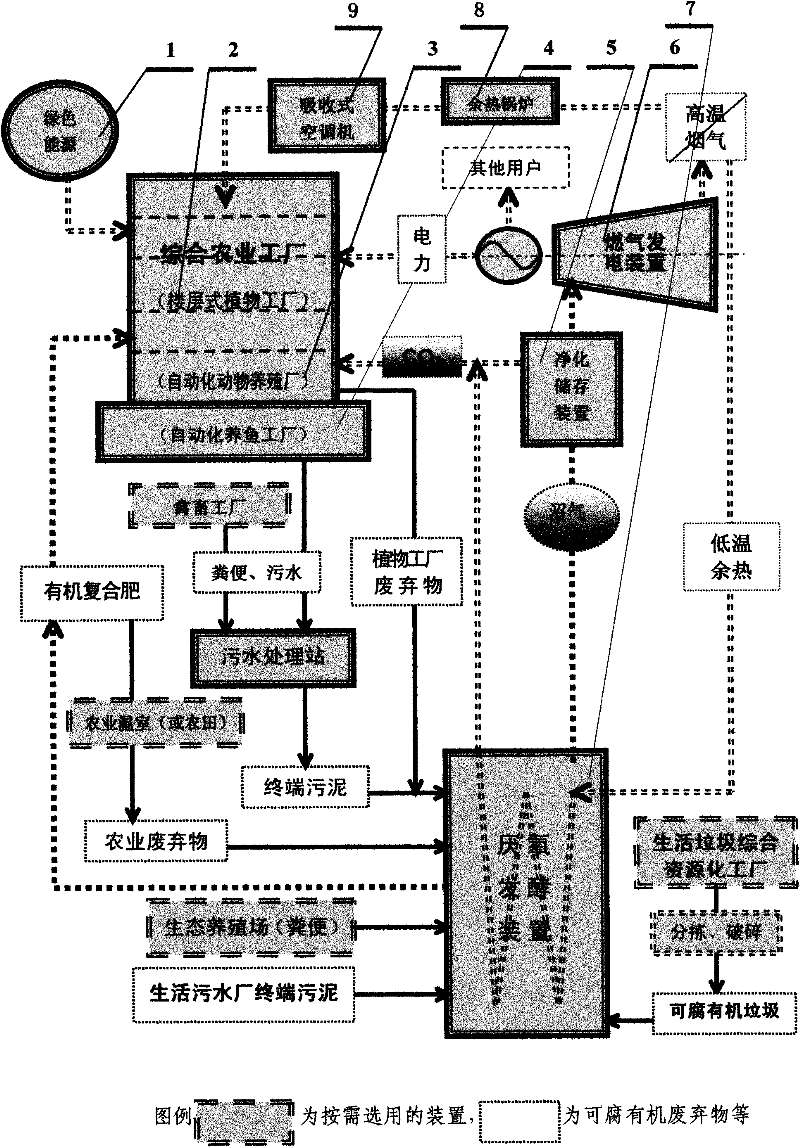

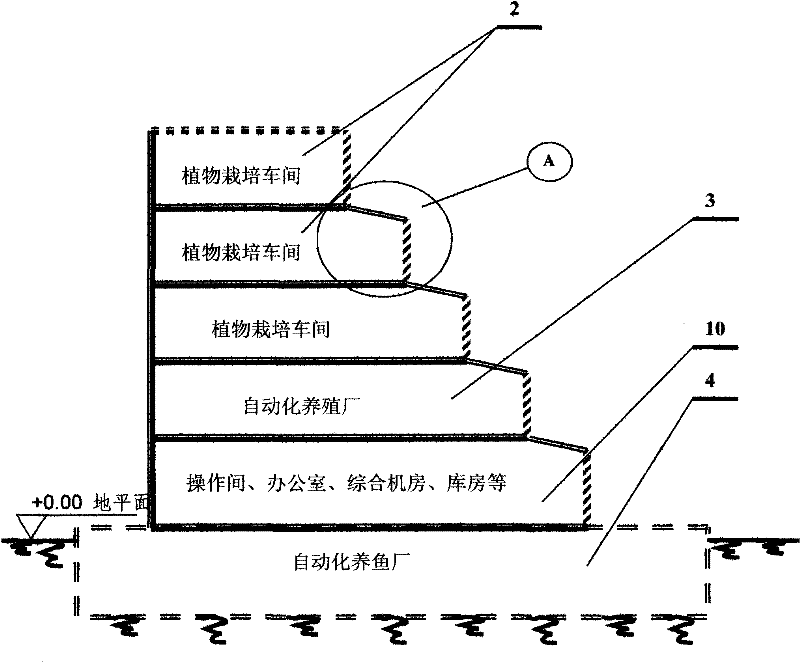

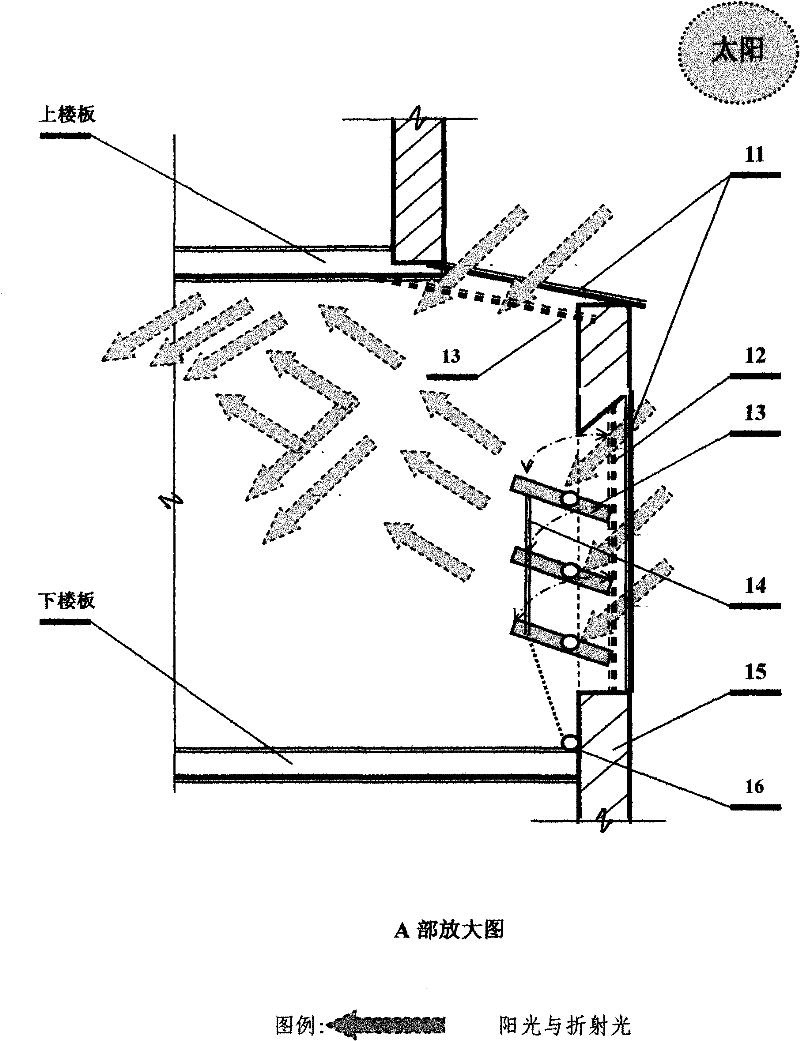

Circular agriculture system and implementation method thereof

InactiveCN104969907ABuild upBuild processabilityAnimal feeding stuffAnimal housingLandscape designFeces

The invention relates to a circular agriculture system and an implementation method thereof. According to a characteristic that different biological wastes can be highly efficiently cycled by various insects and small animals, an insect breeding factory is constructed; and insect and small animal proteasome and insect feces residue organic fertilizer are respectively utilized as an animal factory protein feed and a plant factory organic fertilizer. Therefore, carious animal and plant products with high added values can be produced with high yields. With modern advanced agricultural technologies and equipment, stereo cultivation is usually carried out with rare species, such that a unit yield of the types of factories reaches more than a hundred times that of conventional agriculture. With the products from the three types of factories, a wide variety of series downstream industry chain group can be developed, such that best economic benefit can be ensured. The three types of factories, downstream industry chain spaces and farmer residential spaces can be arranged in a rise building. The buildings can form a highly clustered production, management, residence, agriculture, industry and business integral community. With farmland novel industry and landscape designs outside the buildings, a novel intensive town is formed.

Owner:张懋

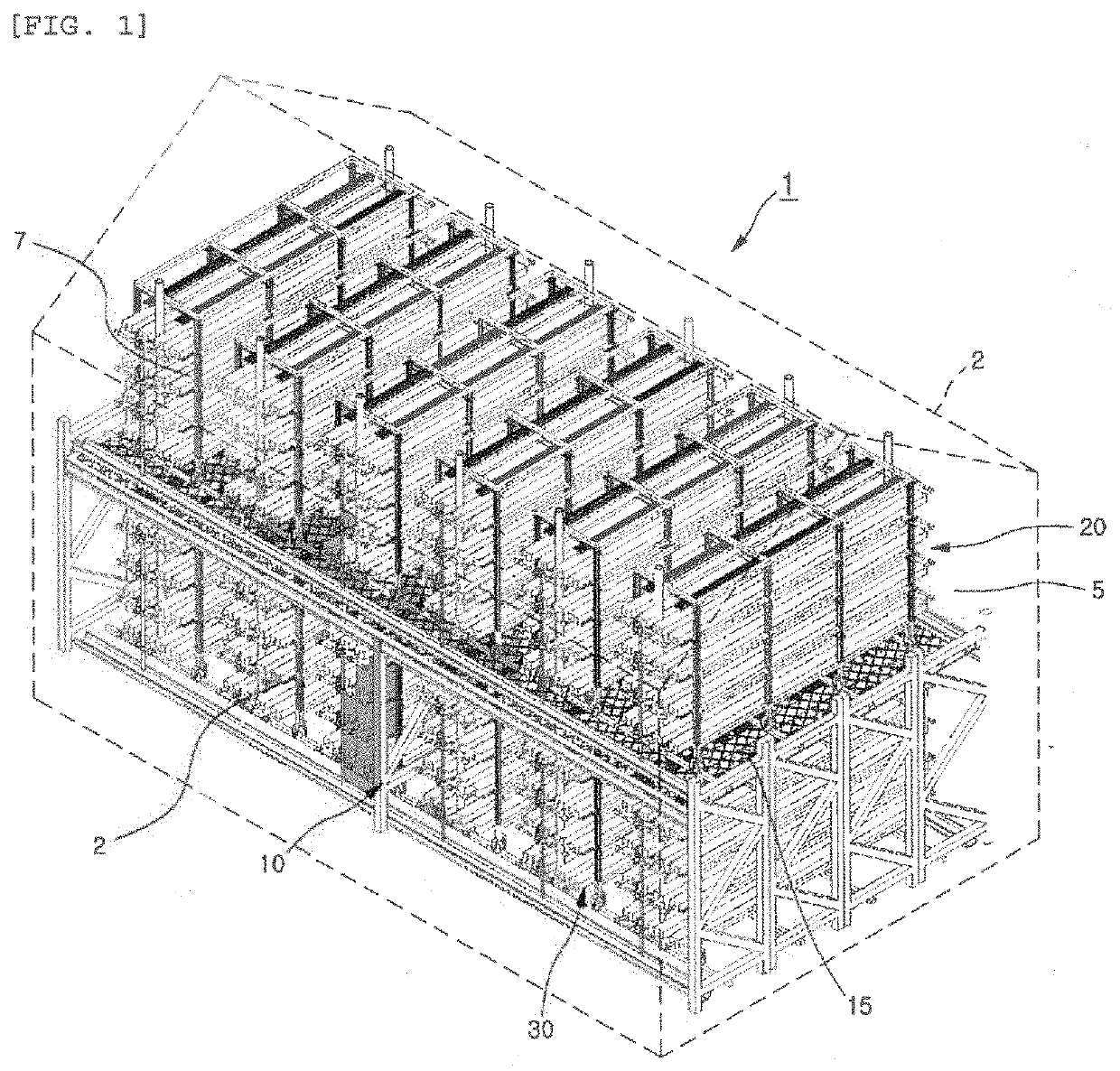

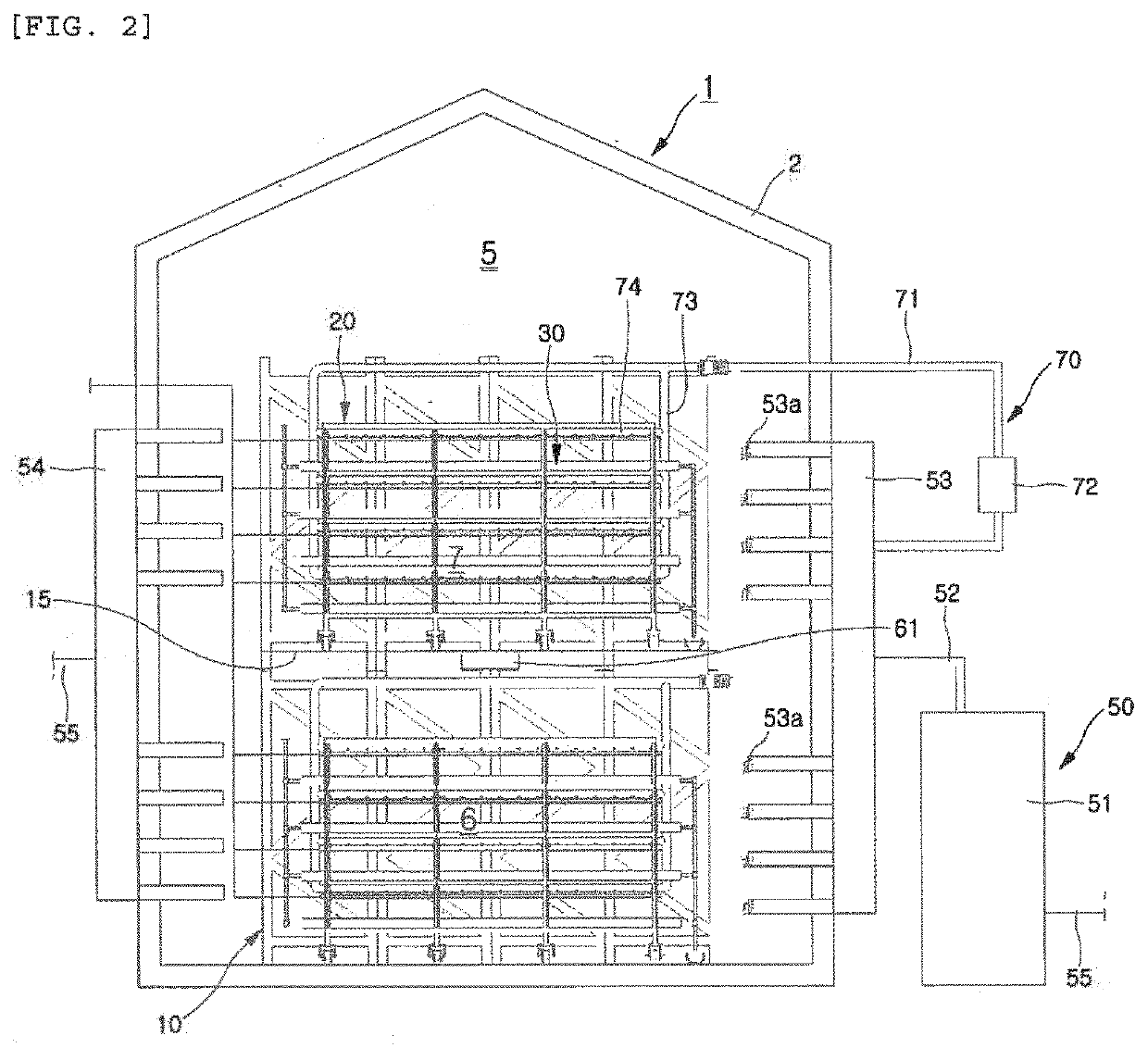

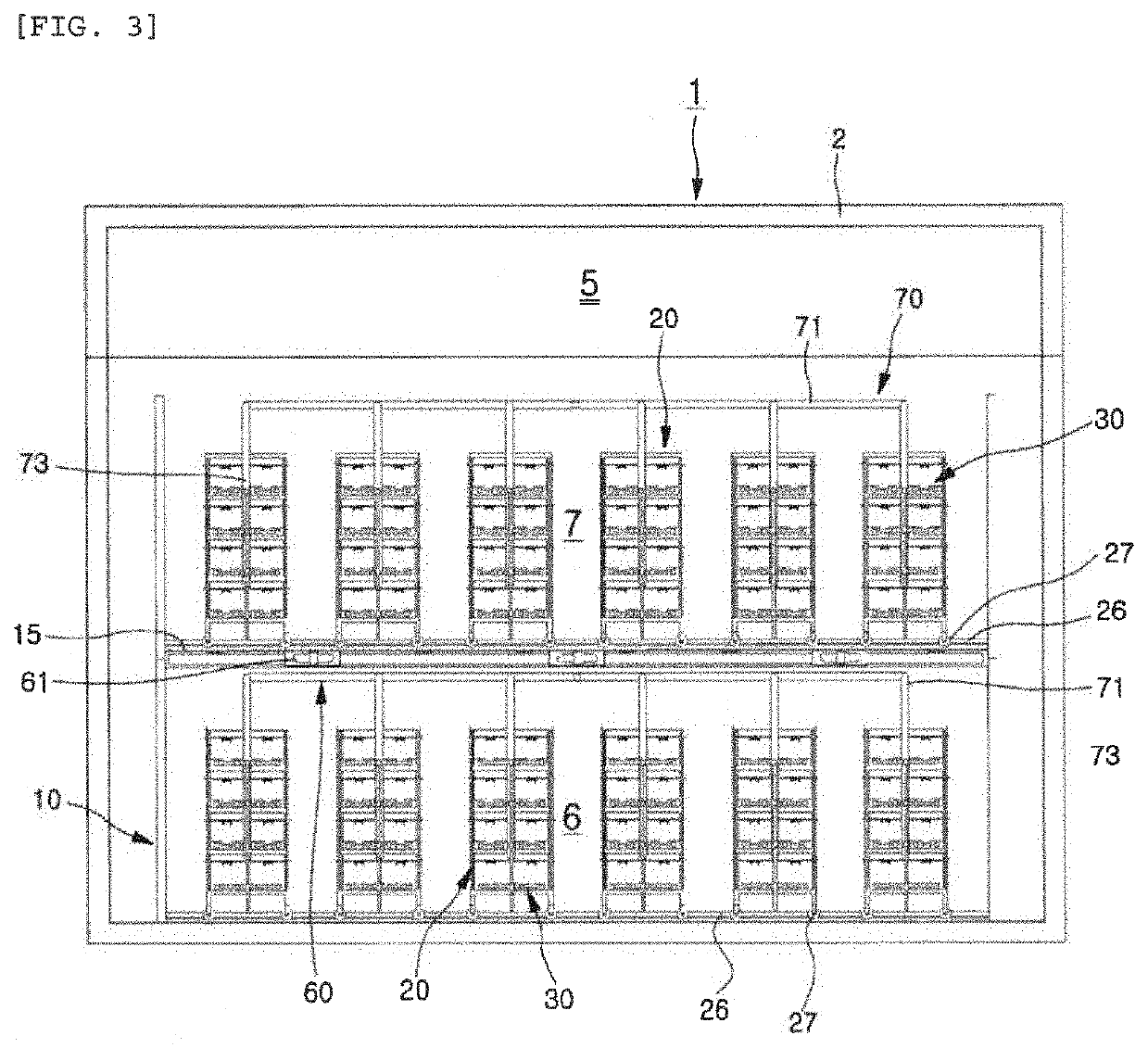

Plant factory

ActiveUS20200214228A1Minimizing input resourceSpace maximizationGreenhouse cultivationCultivating equipmentsAgricultural sciencePlant factory

Owner:CHO YOUNG CHAI +1

Environmental protection and agriculture combination device with ecological circulation

InactiveCN102477813ANo pollution in the processLong-term environmental benefitsSolid waste disposalGas production bioreactorsOrganic farmingCogeneration

The invention discloses an environmental protection and agriculture combination device with ecological circulation, which selects various efficient agriculture livestock and fishery factories (plant factories, farms, fish farms, etc.) according to circumstances or is optimally integrated with advanced engineering technology of house refuse comprehensive utilization (containing anaerobic digestion to produce marsh gas for power generation) factories and the like, so as to intensively carry out anaerobic digestion to produce marsh gas on agriculture livestock and fishery factories wastes or corrodible organic wastes sorted from the house refuses, and be assisted by green energy resource to form an efficient energy system with cogeneration of heat power and cool; all CO2 in the device and CO2 exhausted by an automation animal farm are intensively processed to be used by the plant factories and greenhouses; biogas slurry and biogas residues are process into organic compound fertilizer for promoting organic agriculture production; intensification land is realized on a floor type agricultural factory building, and green organic products can be produced high-efficiently; an advanced level of whole recycling 'three wasters' is achieved; and sustainable development taking energy, environment and efficiency into consideration is realized, and the excellent economic benefit and environmental benefit are achieved.

Owner:周诗忠

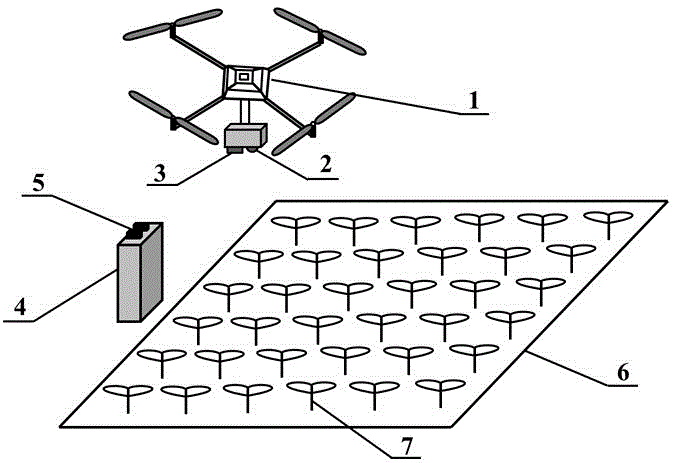

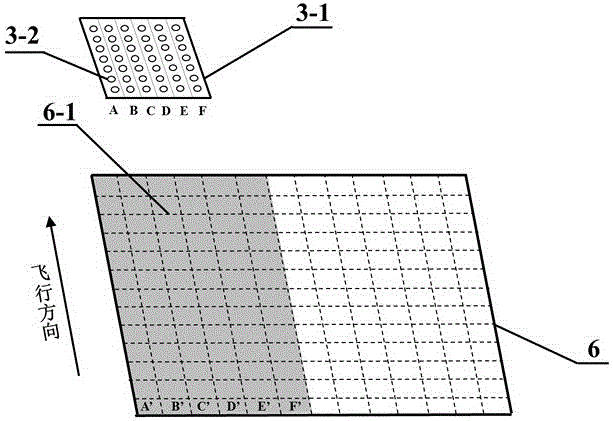

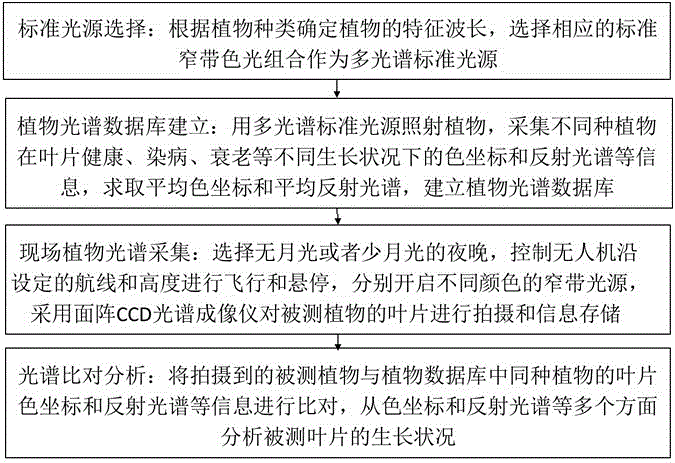

Method for monitoring plant growth by using unmanned aerial vehicle with multispectral light source

InactiveCN106596412ASimple flight pathReduce error rateMaterial analysis by optical meansWavelengthColored light

The invention specifically provides a method for monitoring plant growth by using an unmanned aerial vehicle with a multispectral light source, belonging to the technical field of monitoring of plant growth. The method comprises the following steps: determining the characteristic wavelengths of plants according to the species of the plants and selecting a corresponding standard narrowband colored light combination as a standard multispectral light source; irradiating the plants with the standard multispectral light source, acquiring information like the chromaticity coordinates and reflection spectra of the plants of different species and establishing a plant spectrum database; controlling the unmanned aerial vehicle to shoot a detected plant by using an area-array CCD spectral imager and to store information; and comparing the information of the shot detected plant with information like the chromaticity coordinates and reflection spectra of leaves of a plant of a same species in the plant spectrum database so as to analyze the growth condition of detected leaves. According to the invention, the unmanned aerial vehicle carries the multispectral light source and the area-array CCD spectral imager for monitoring, so the coverage area of a single scanning is great and measuring precision is high; the unmanned aerial vehicle is simple in flight route, easy to control and low in cost; thus, the method is applicable to monitoring of plant growth during current agricultural plantation in fields, greenhouses, plant factories, etc.

Owner:上海复展智能科技股份有限公司 +1

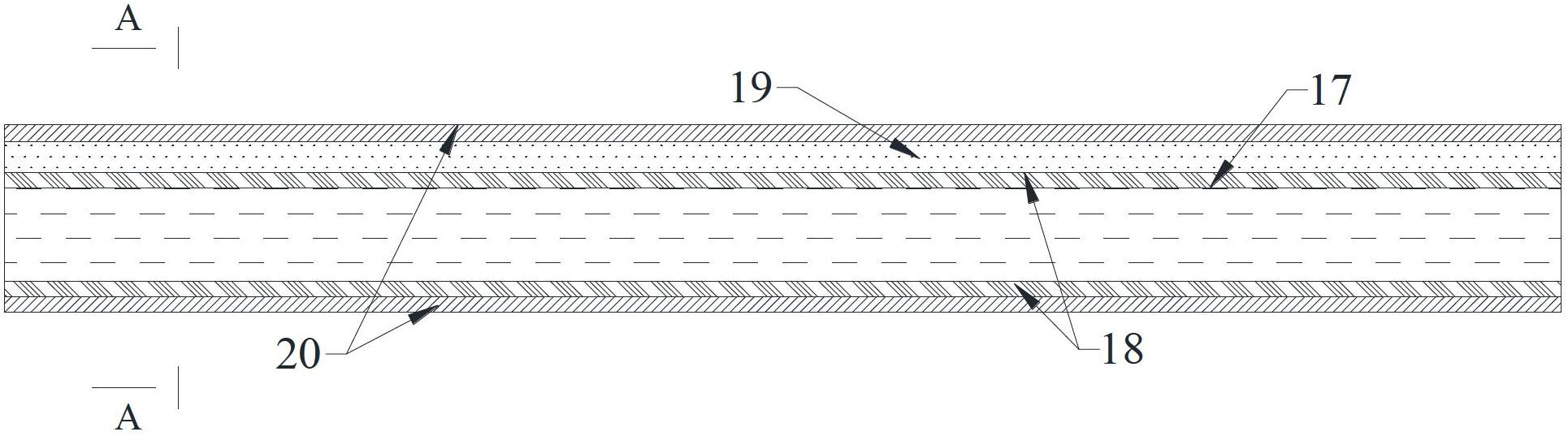

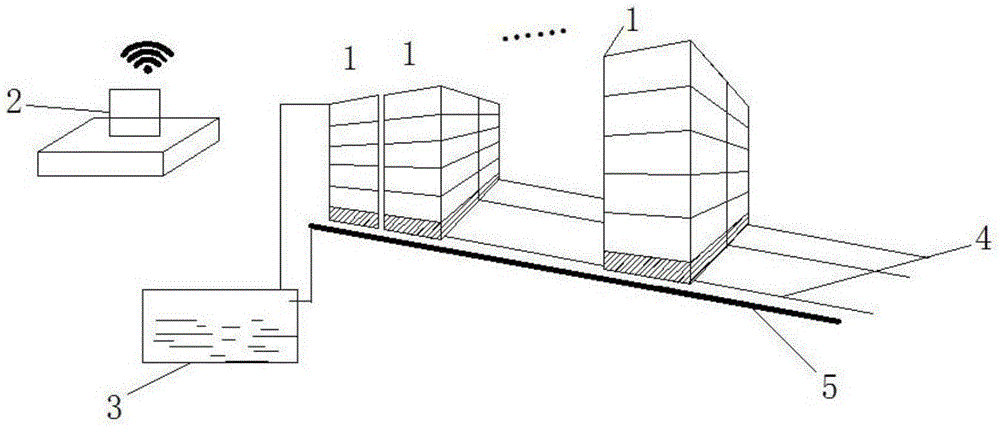

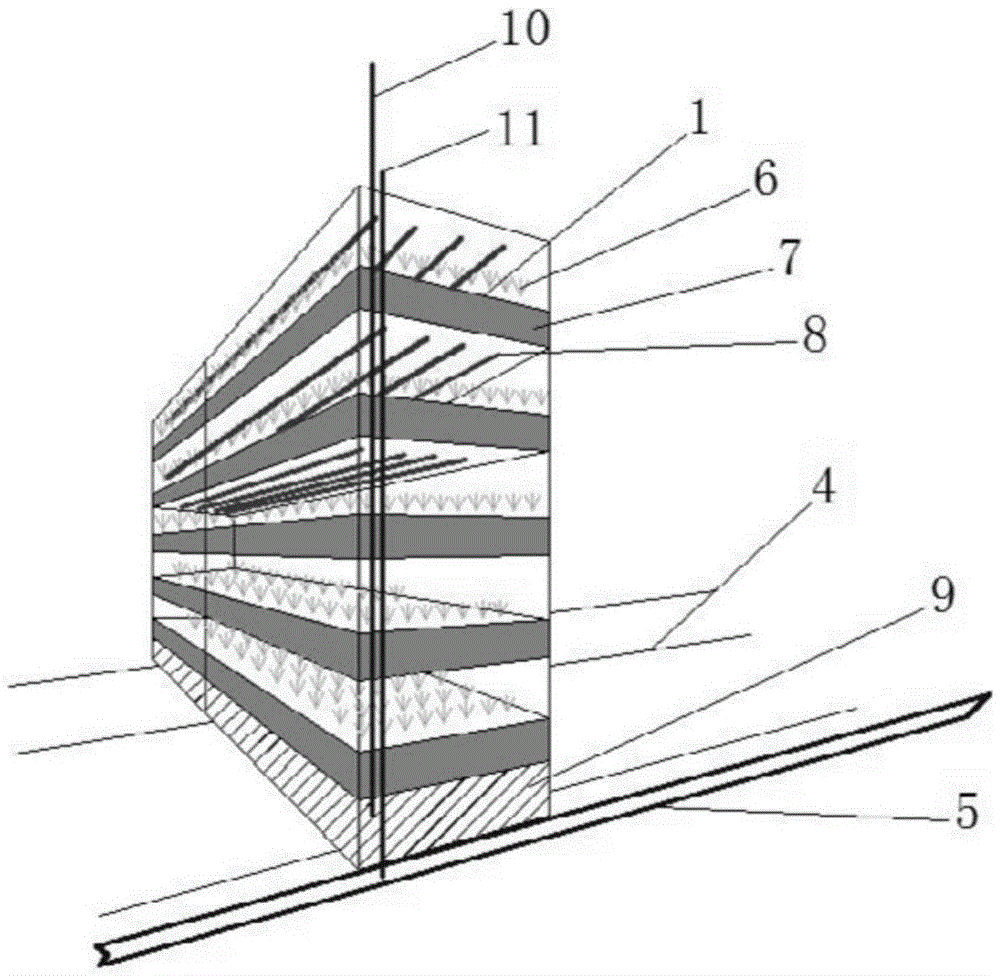

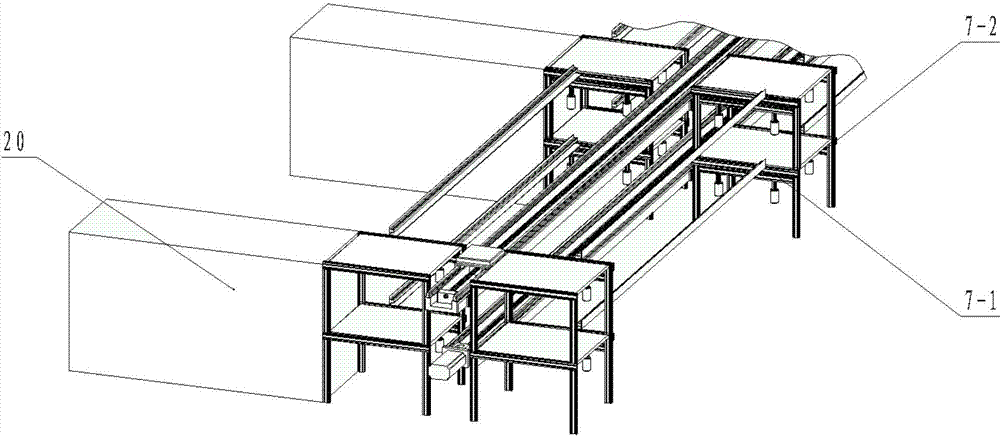

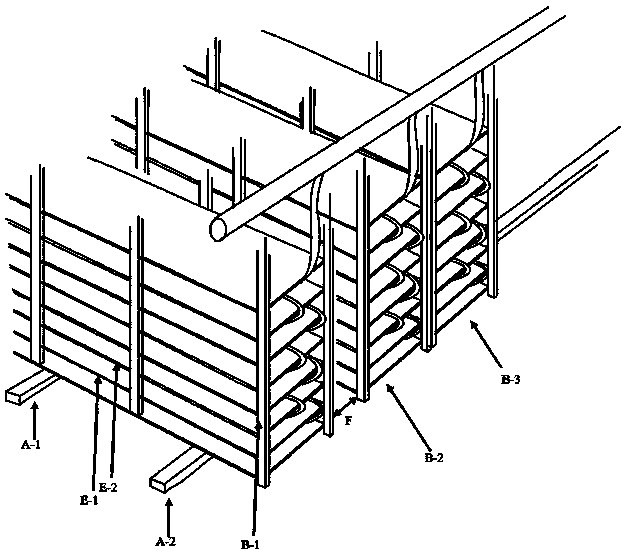

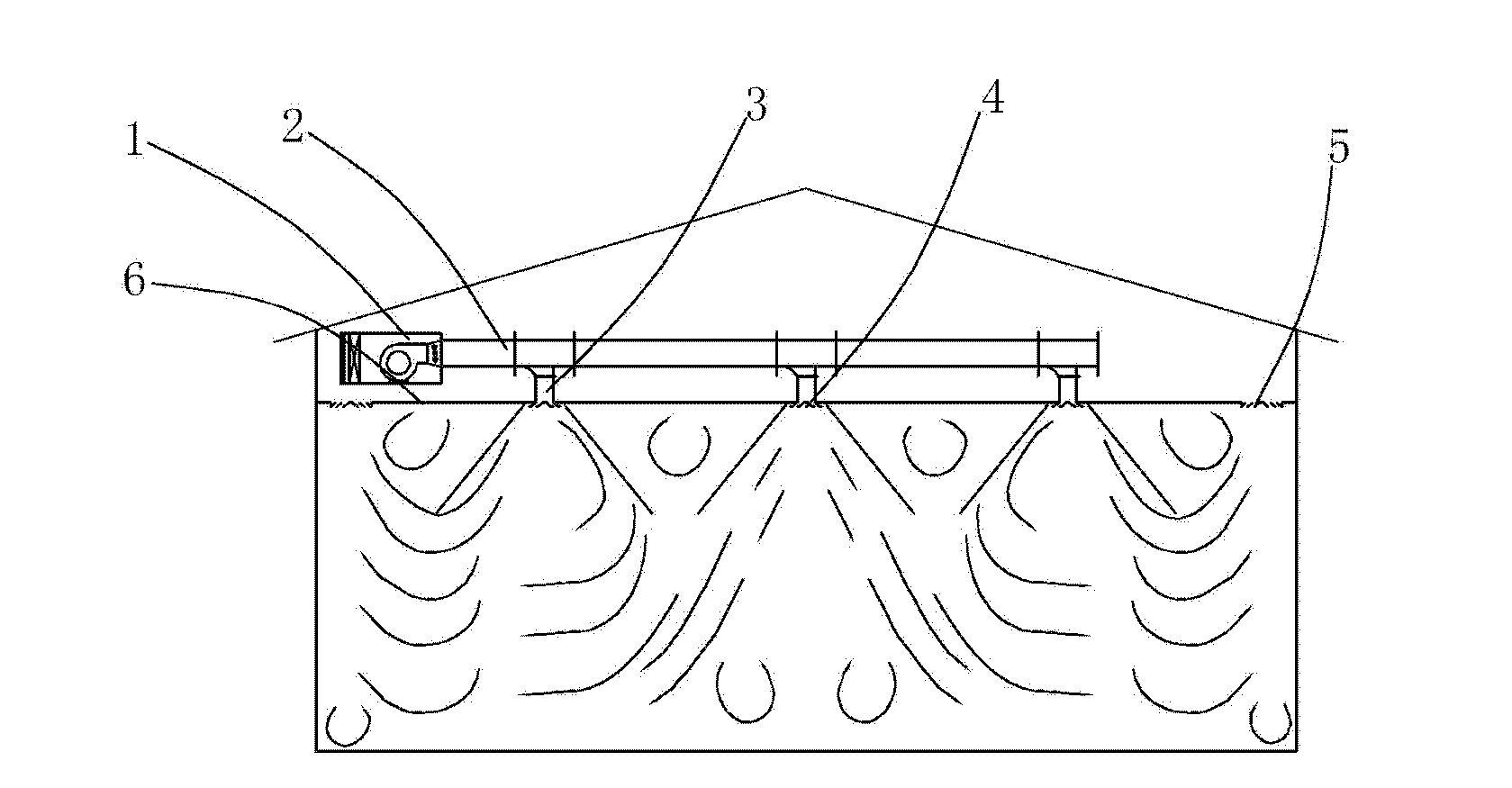

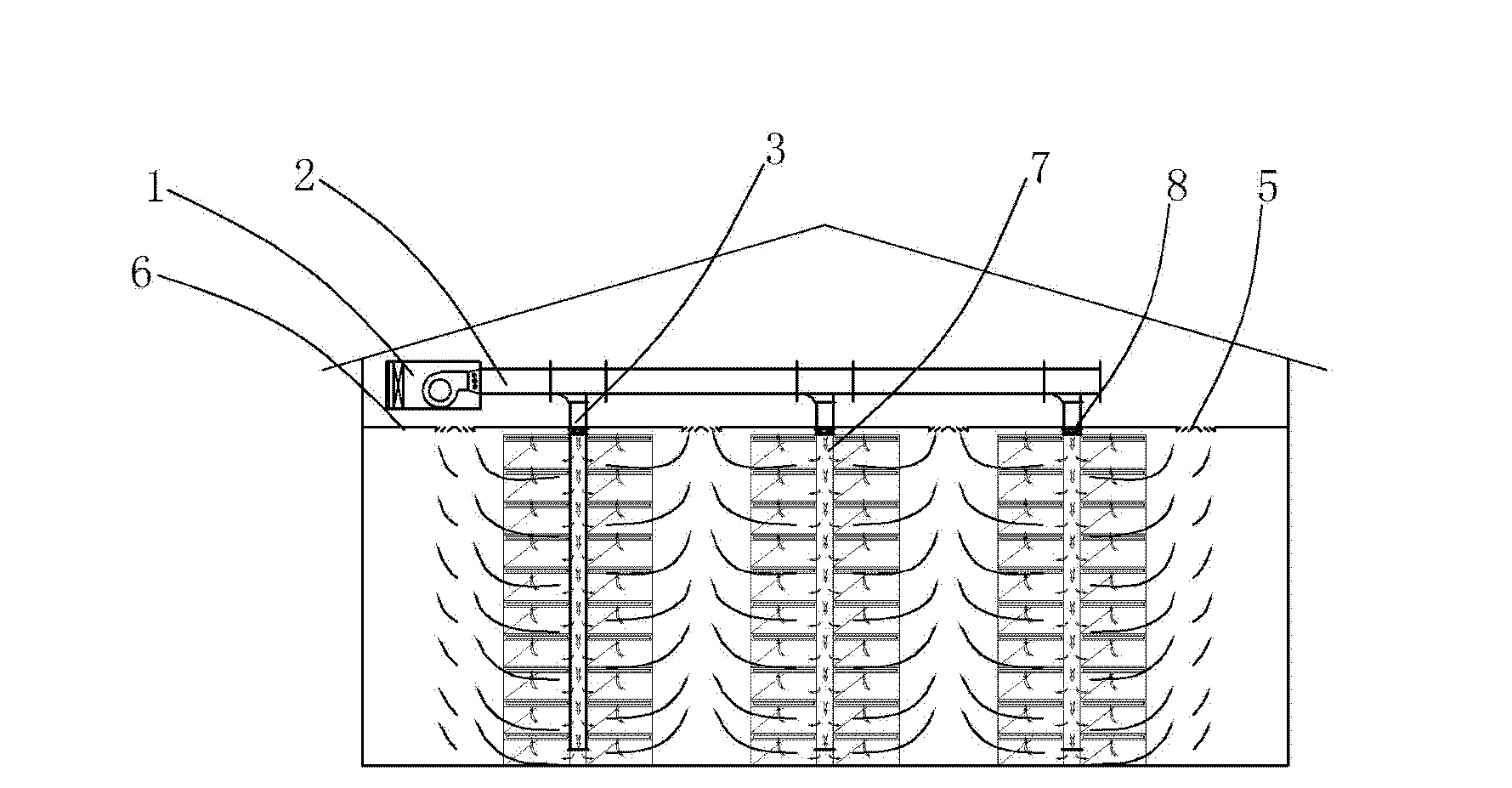

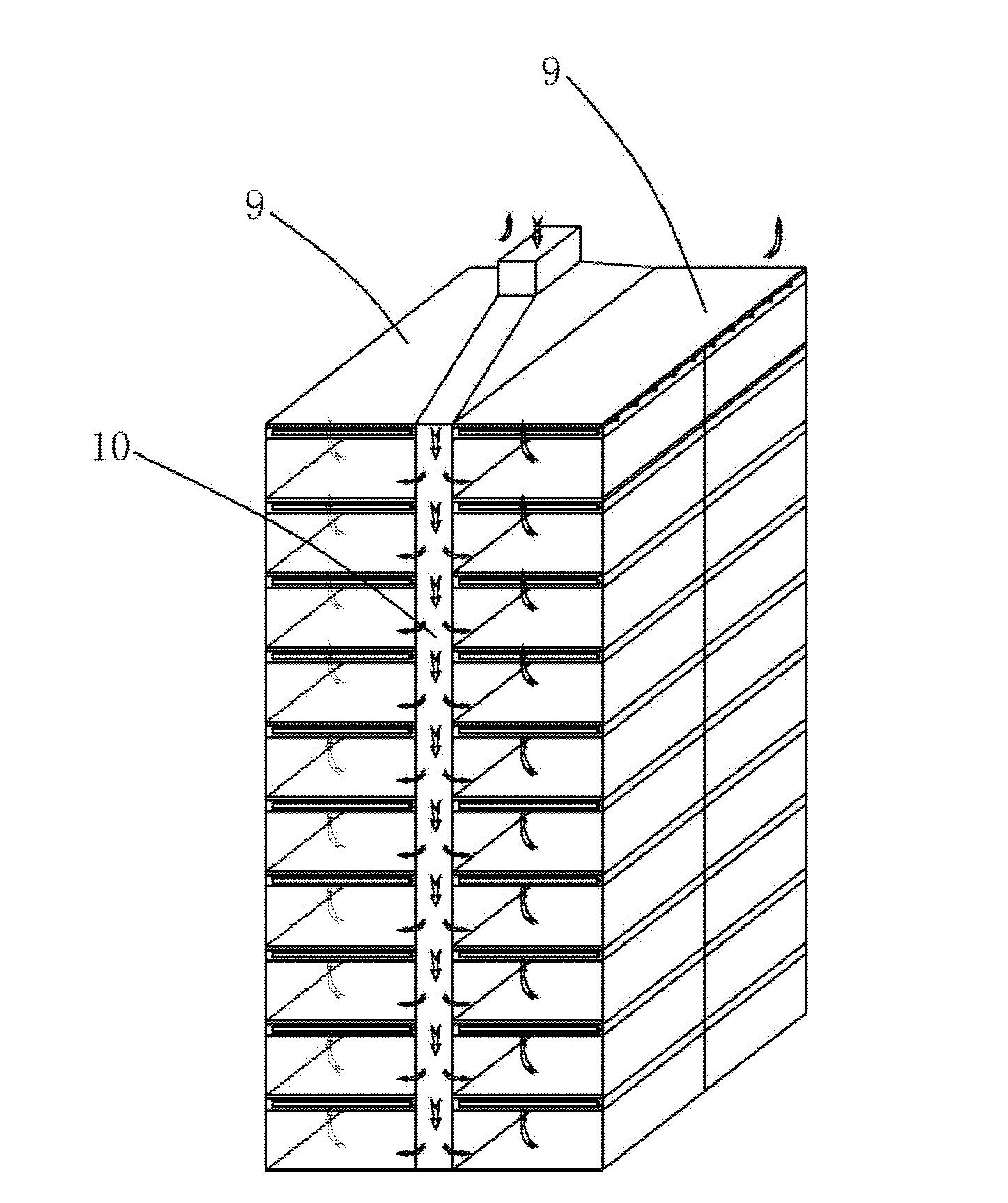

Movable stereoscopic multi-layered aeroponic system for artificial-light plant factory

InactiveCN105638429ASmall footprintIncrease planting areaAgriculture gas emission reductionCultivating equipmentsComputer control systemPlant factory

The invention discloses a movable stereoscopic multi-layered aeroponic system for an artificial-light plant factory. The movable stereoscopic multi-layered aeroponic system comprises a plurality of cultivation racks, a plurality of groups of ground tracks for movement of the cultivation racks, a nutrient solution pool for accommodating a nutrient solution, a ground drainage channel and a computer control system. The movable stereoscopic multi-layered aeroponic system not only adopts an artificial light source, realizes multi-layer stereoscopic cultivation in a closed artificial-light plant factory, and increases the yield of unit area, but also achieves movable cultivation and avoids the phenomenon that sidewalks are specially reserved between the cultivation racks in the plant factory, so that the planting area of the plant factory is increased, the land utilization rate is improved, and the cost of a unit product is lowered.

Owner:ZHEJIANG UNIV

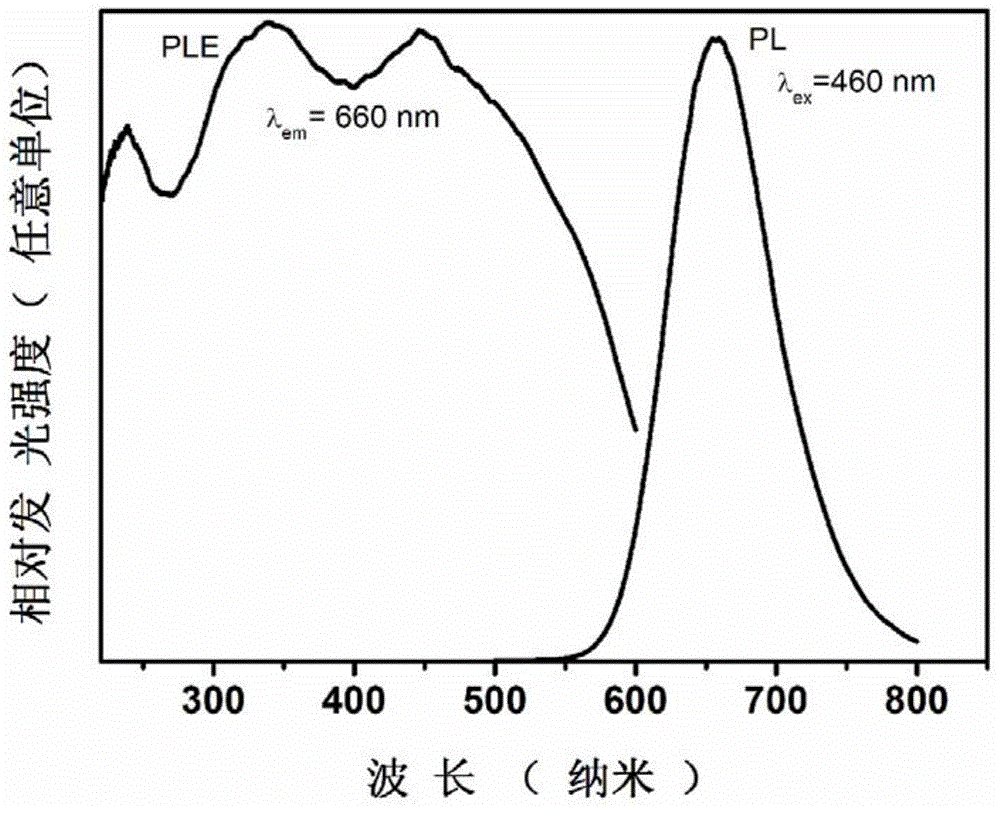

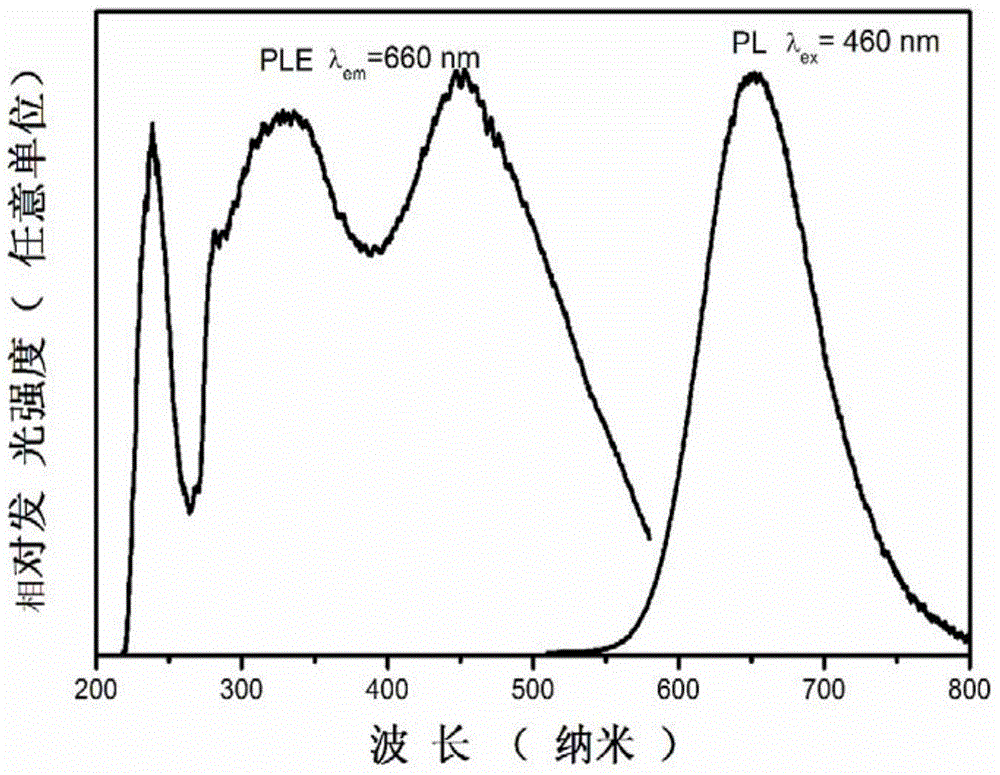

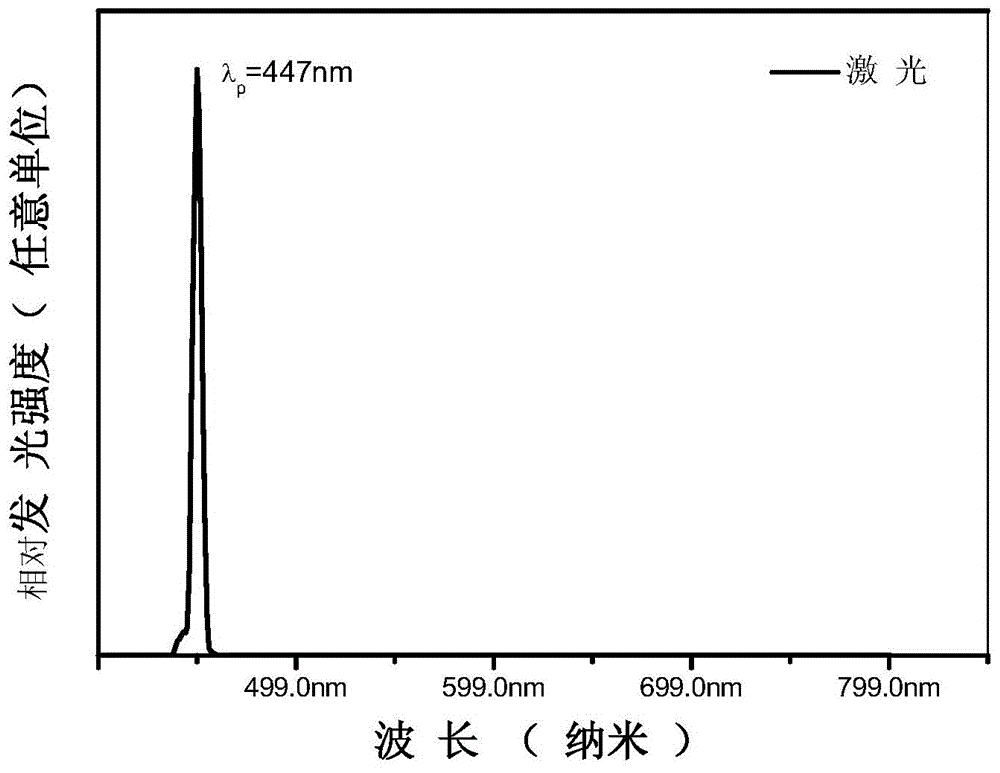

Plant laser lighting fluorescent glass-ceramics and preparation method thereof

Plant laser lighting fluorescent glass-ceramics is composed of 5-30wt% of red fluorescent powder and the balance of a glass matrix; the red fluorescent powder emits 660nm wide spectrum deep red light under excitation of a blue laser light source, the full width at half maximum is wider than 60nm; and red fluorescent powder crystalline grains are uniformly embedded in the glass matrix. The advantages of the plant laser lighting fluorescent glass-ceramics are that: the fluorescent glass-ceramics emits high brightness 660nm wide spectrum red light under excitation of a blue semiconductor laser, partly-transmitted-out blue laser and the red light emitted by the fluorescent glass-ceramics are matched with effective spectrum of plant photosynthesis, at the same time, the plant laser lighting fluorescent glass-ceramics can obtain a high brightness plant laser lighting source under excitation of high energy density laser, and has potential application in the fields such as a plant factory, vertical planting, a greenhouse, a glass cultivation room, and the like.

Owner:深圳惠农智光科技有限公司

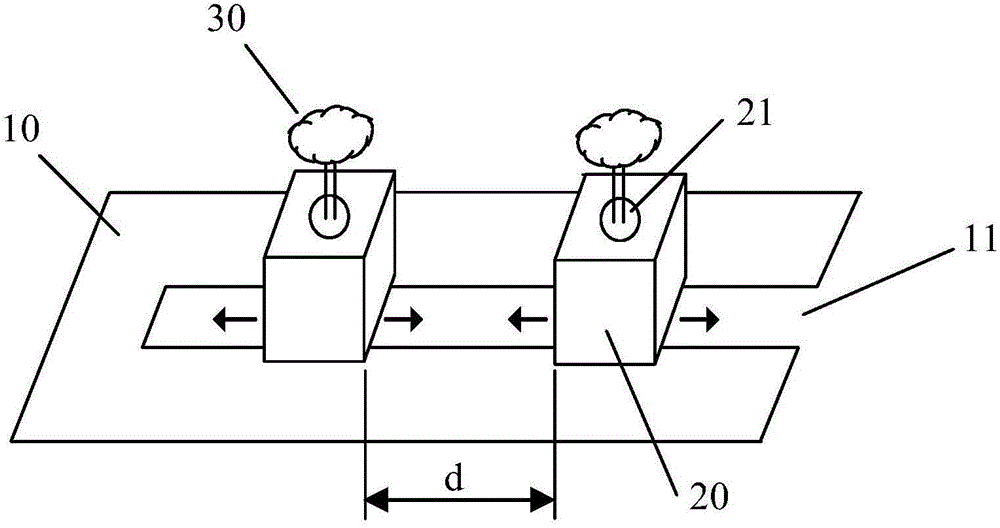

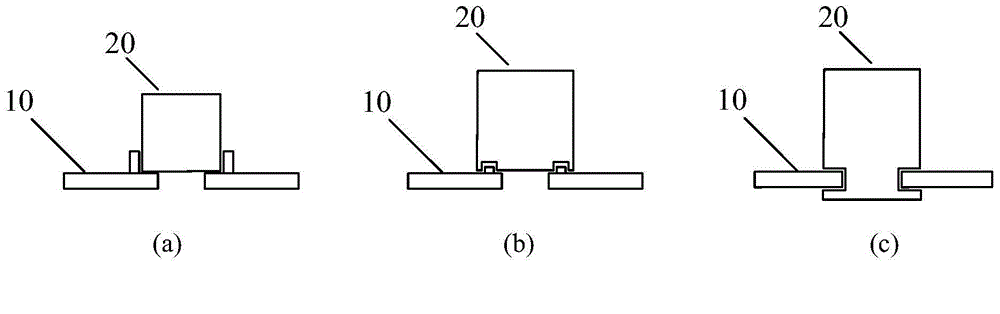

Device and method for regulating and controlling density of soilless cultured plants of plant factory

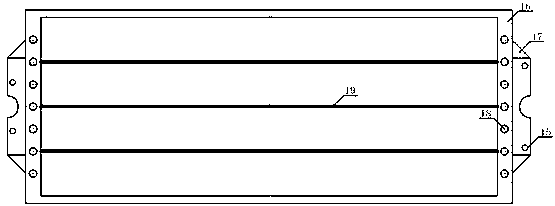

InactiveCN104798674AReduce light wasteEasily adjust the distanceAgriculture gas emission reductionCultivating equipmentsPlant factoryFishery

The invention relates to a device and a method for regulating and controlling the density of soilless cultured plants of a plant factory. The device comprises at least one culturing plate and at least two culturing units, wherein each culturing unit is provided with a culturing hole; each culturing plate is provided with a strip-shaped opening; the culturing units are erected on the strip-shaped openings and can move along the strip-shaped openings so as to regulate the interval; at least one additional culturing plate for regulating the interval between the culturing plates is arranged between the culturing plates; the culturing plates and the culturing units can be provided with matched guide rails for providing convenience for sliding. According to the device disclosed by the invention, each culturing unit moves along the strip-shaped opening of each culturing plate so as to regulate the planting distance; line spacing can be regulated by adding or reducing the additional culturing plates, so that the distance between the soilless cultured plants can be conveniently regulated; a culturing space can be saved; the utilization rate of electric energy of a light source can be increased.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

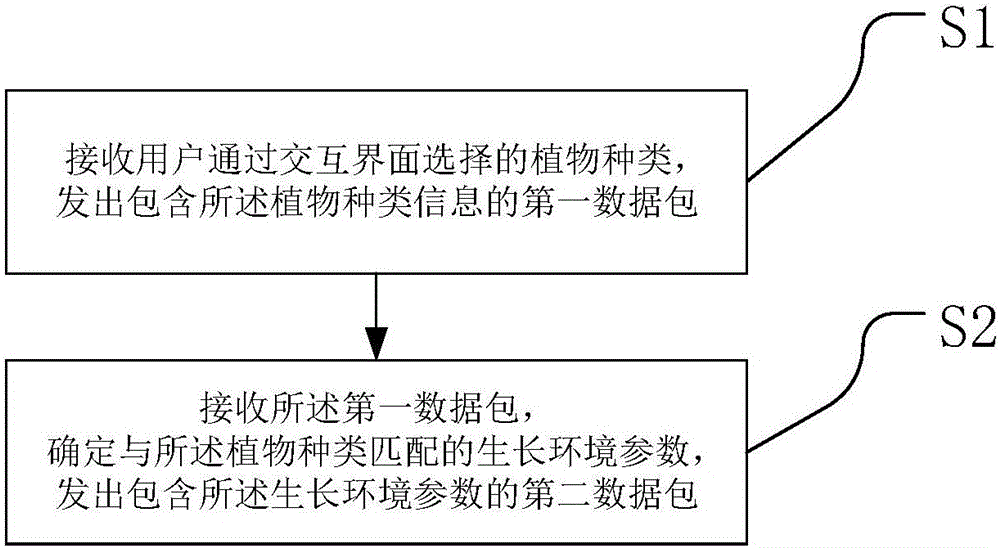

Household type plant factory, remote control method, controller and control system

InactiveCN105867144ARealize automatic adjustmentImprove performanceComputer controlProgramme total factory controlPlant factoryRemote control

The invention provides a household type plant factory, a remote control method, a controller and a control system. The remote control method of the household type plant factory comprises the following steps: a mode selection step, i.e., receiving a plant type selected by a user through an interaction interface, and emitting a first data packet including information of the plant type; and a parameter confirmation step, i.e., receiving the first data packet, determining growth environment parameters matching the plant type, and emitting a second data packet including the growth environment parameters, wherein the second data packet is used for arranging standard growth environment parameters of the household type plant factory. According to the remote control method of the household type plant factory, types of plants which can be cultured by the household type plant factory are not restricted to hardware, the standard growth environment parameters can be updated according to needs, a mode can be changed accordingly, a plant type database can be upgraded and expanded, performance of the household type plant factory is optimized, and control of the growth environment parameters is more accurate.

Owner:YUNSHANG HOUJI BEIJING TECH CO LTD

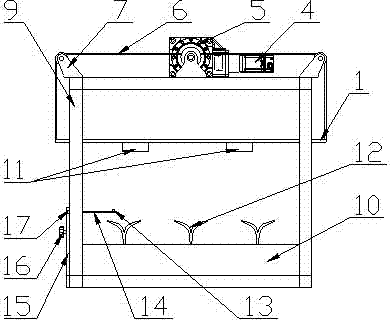

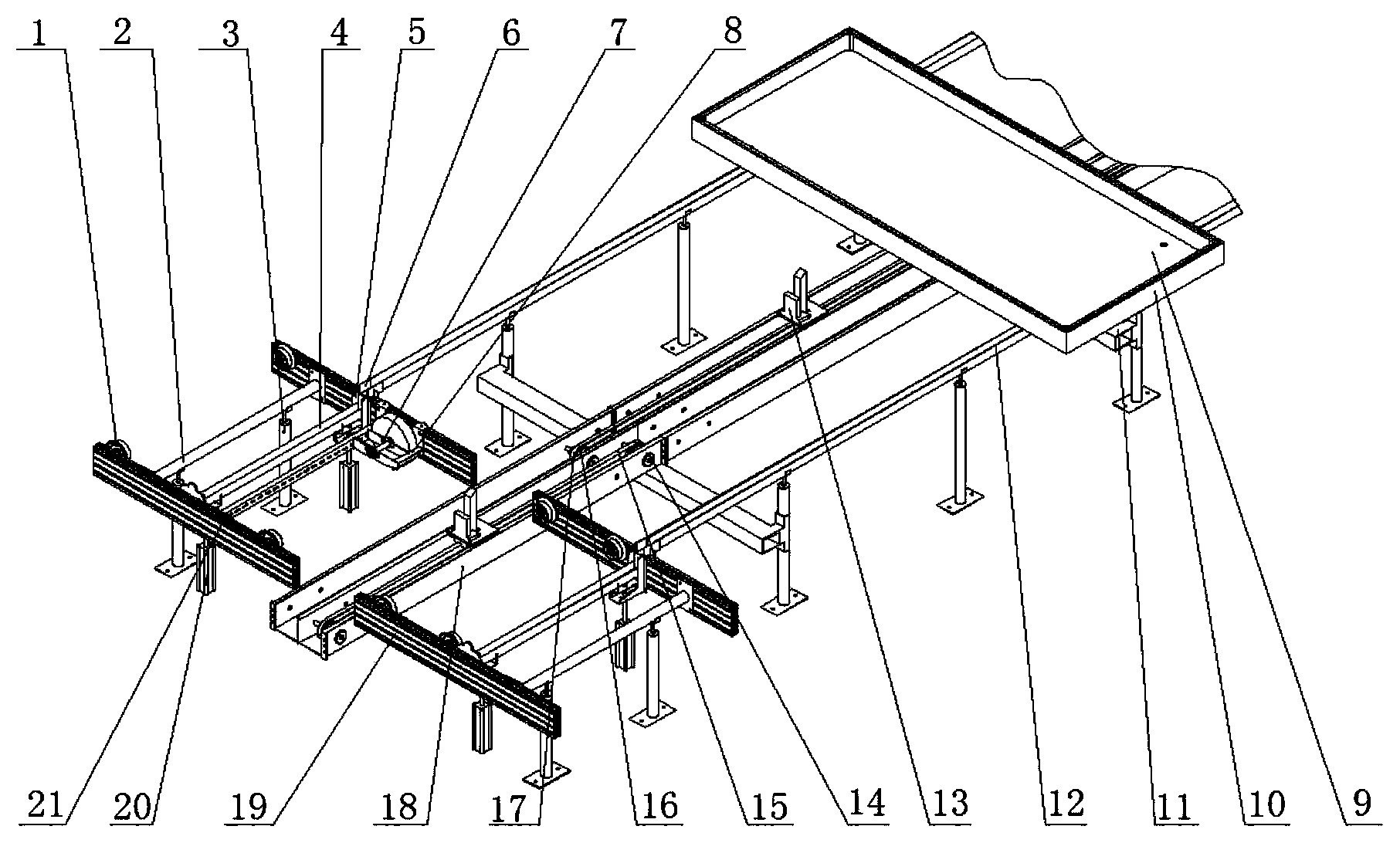

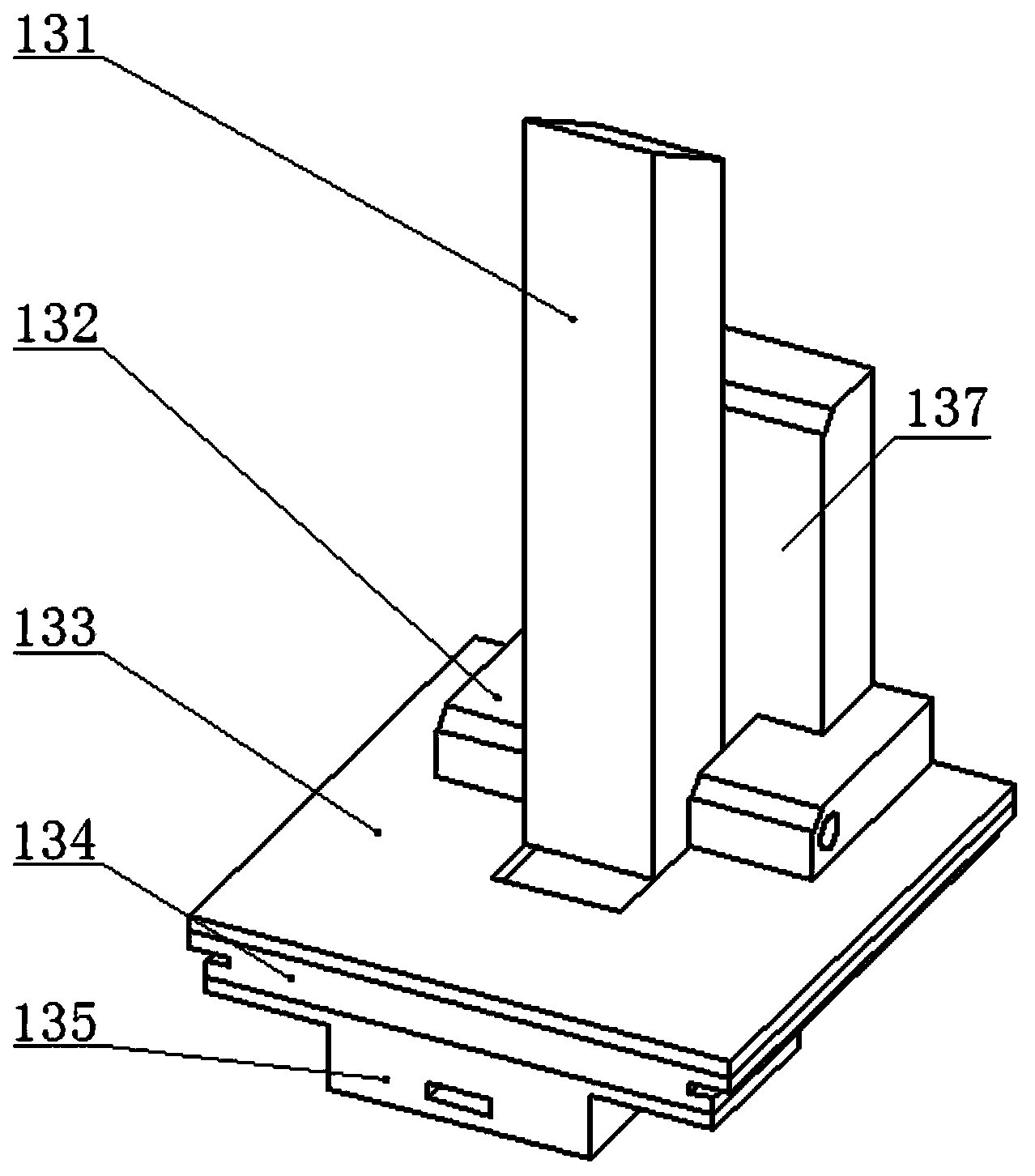

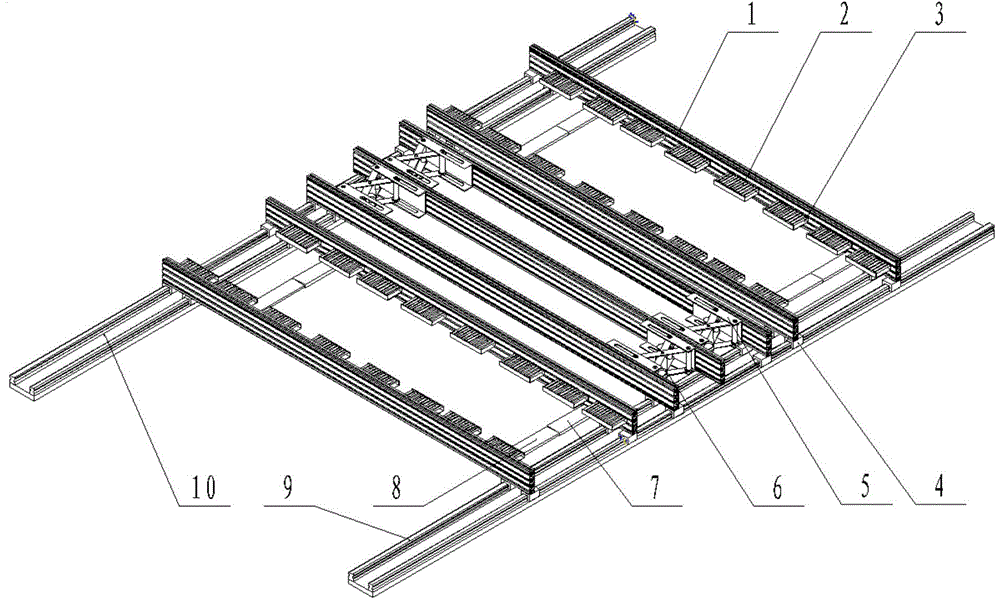

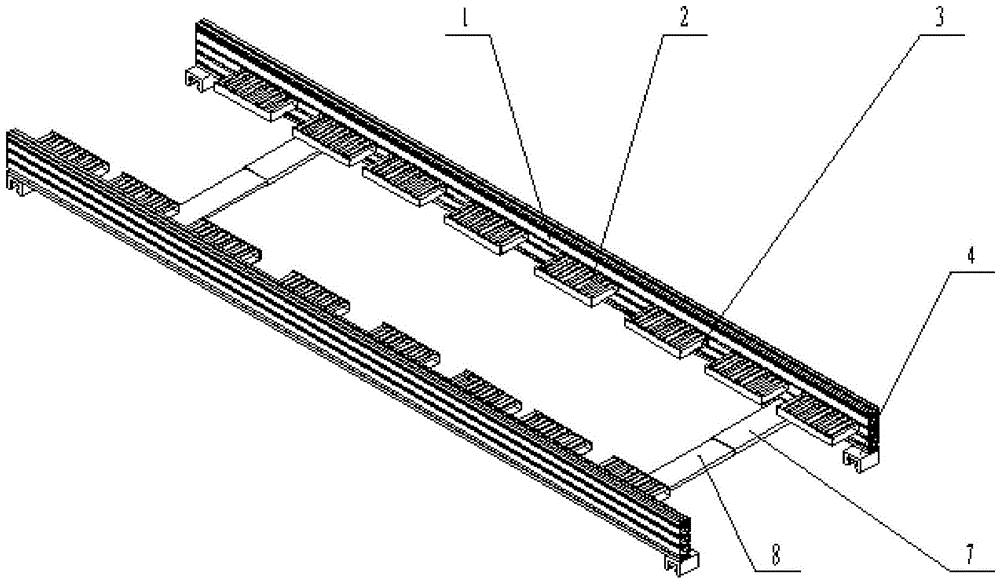

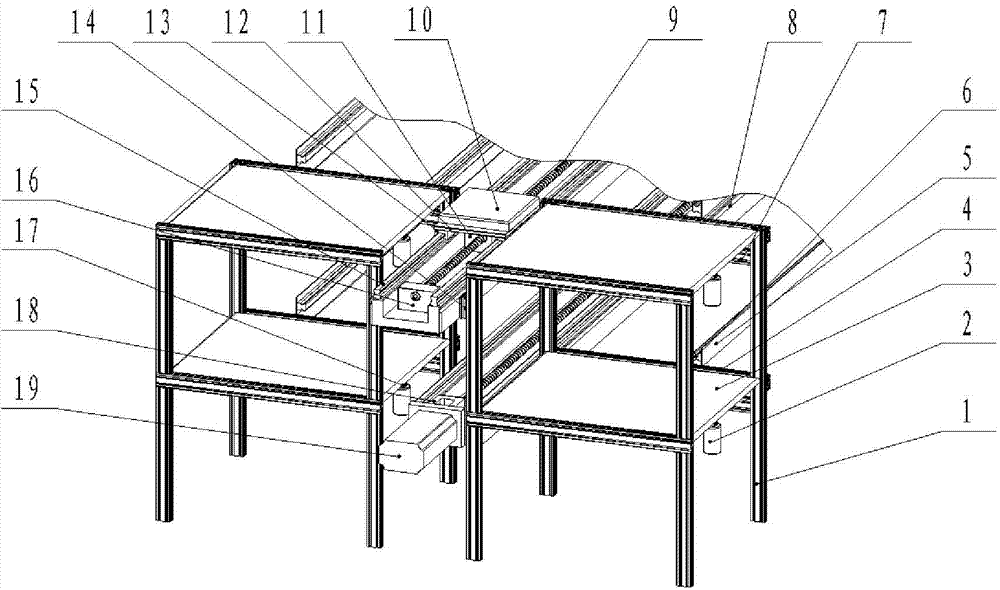

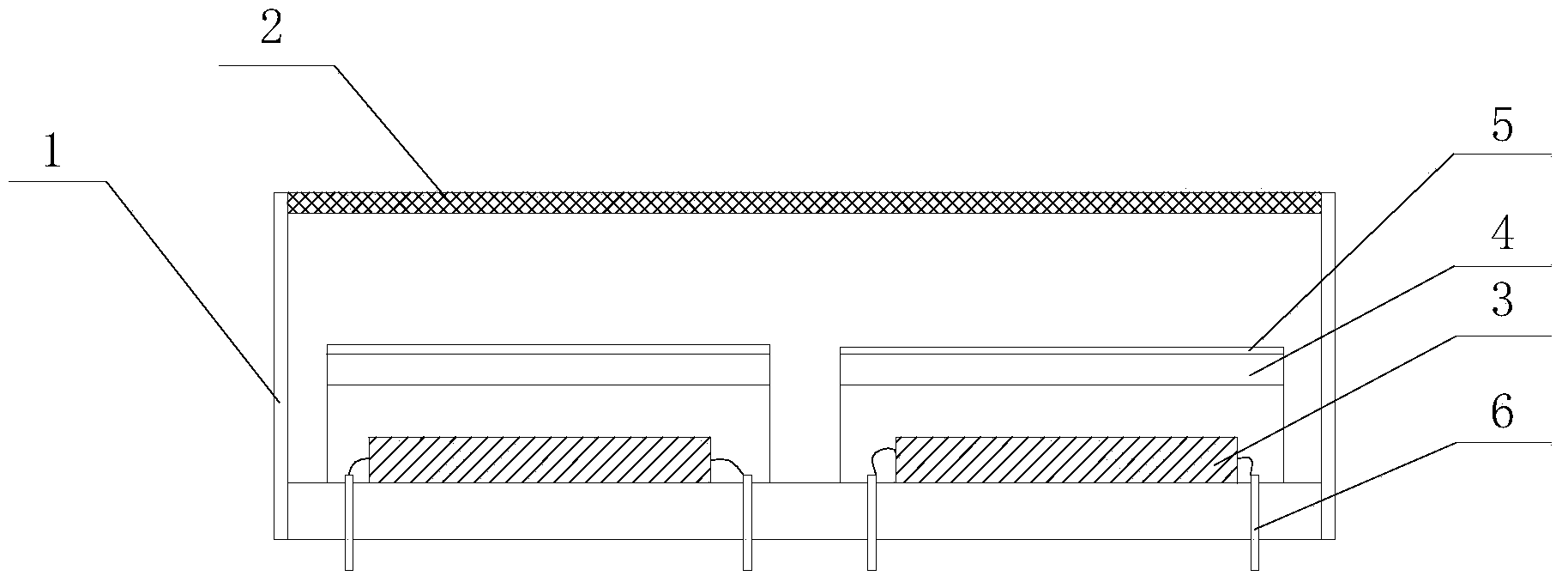

Rail-spliced type automatic seedbed moving system

The invention relates to a rail-spliced type automatic seedbed moving system. The rail-spliced type automatic seedbed moving system comprises an inlet unit, an outlet unit, a cultivating unit, a single seedbed and sensing positioning devices, wherein the inlet unit and the outlet unit are arranged at the front and rear ends of the cultivating unit respectively and are identical in structure and both comprise longitudinal seedbed sliding rails and driving devices driving the single seedbed to slide. The cultivating unit comprises transverse seedbed sliding rails, chain rail racks and pushing devices arranged on the chain rail racks to push the single seedbed to move. The single seedbed enters the transverse seedbed sliding rails of the cultivating unit through the longitudinal seedbed sliding rails of the inlet unit and moves out through the longitudinal seedbed sliding rails of the outlet unit after cultivating. The sensing positioning devices are used for positioning the single seedbed. Compared with the prior art, the rail-spliced type automatic seedbed moving system is capable of automatically moving the seedbed to the appointed position and being docked with an auxiliary worktable, and conforms to development trend from a conventional greenhouse to a large plant factory.

Owner:TONGJI UNIV

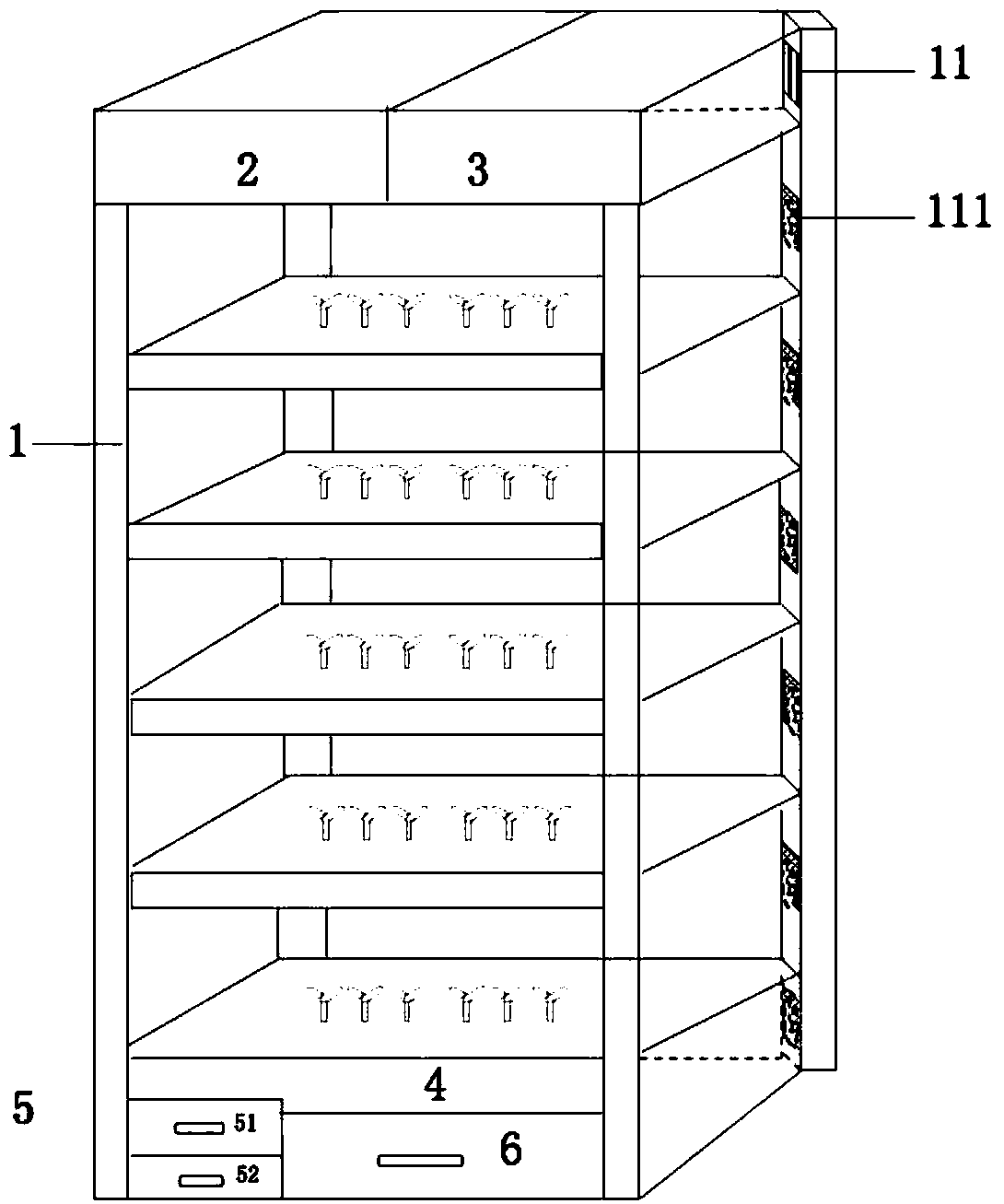

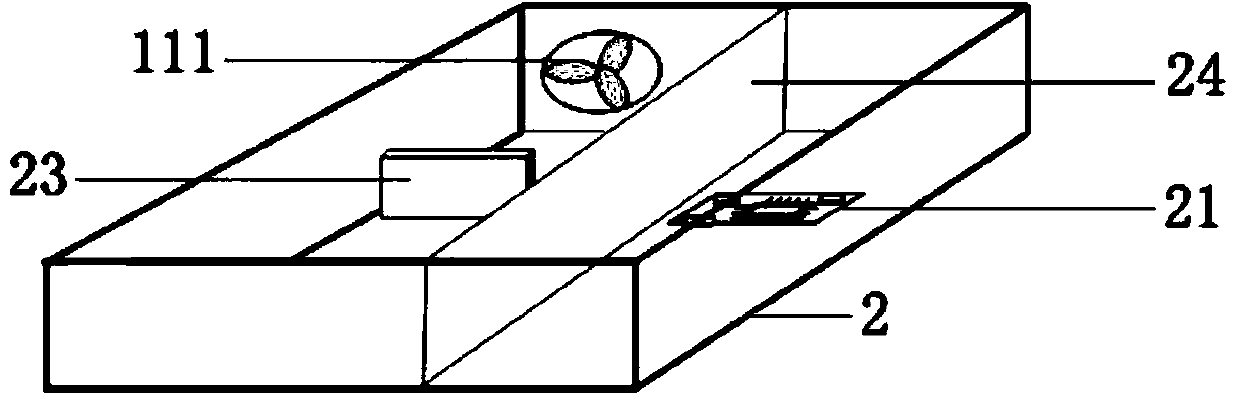

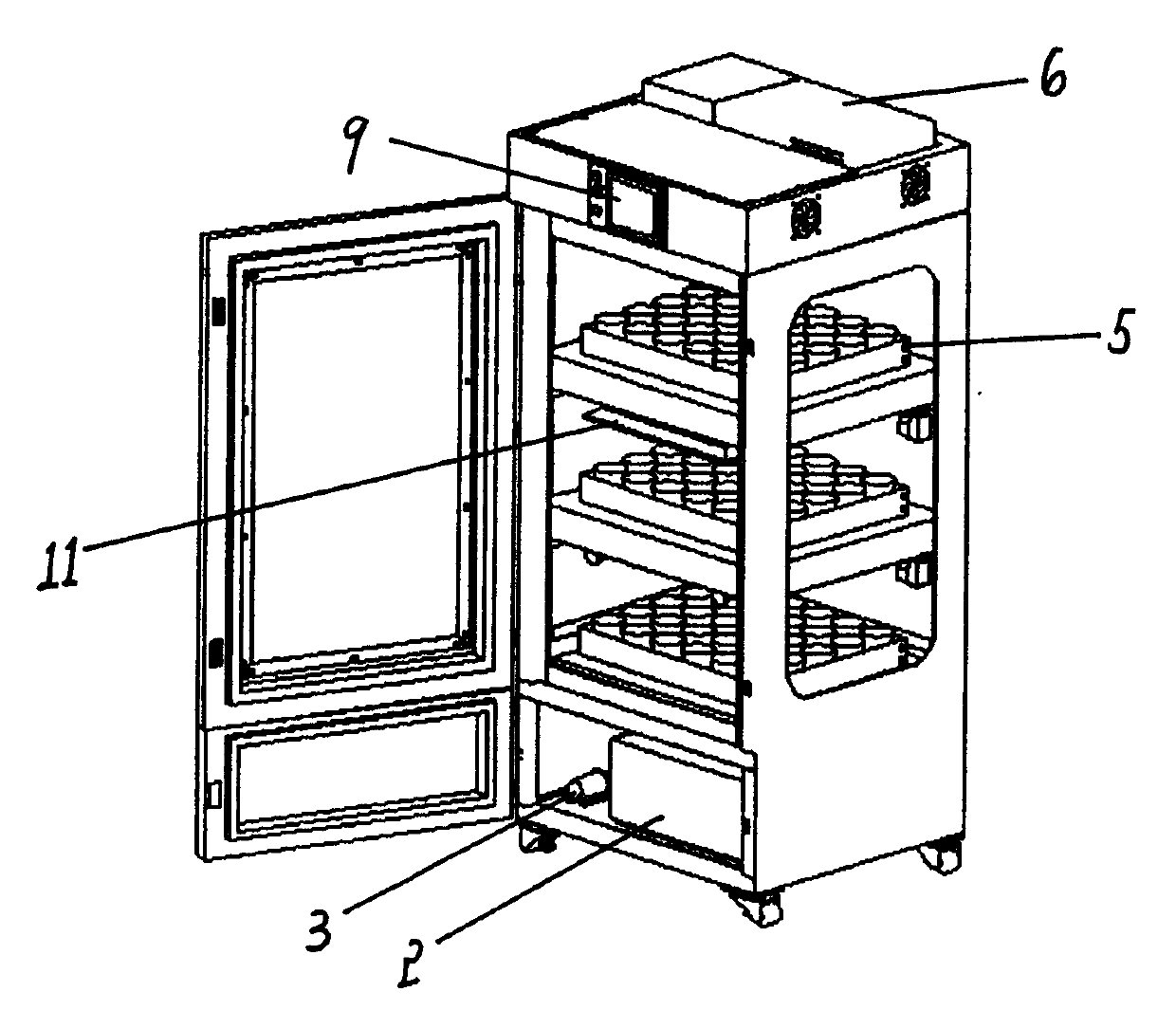

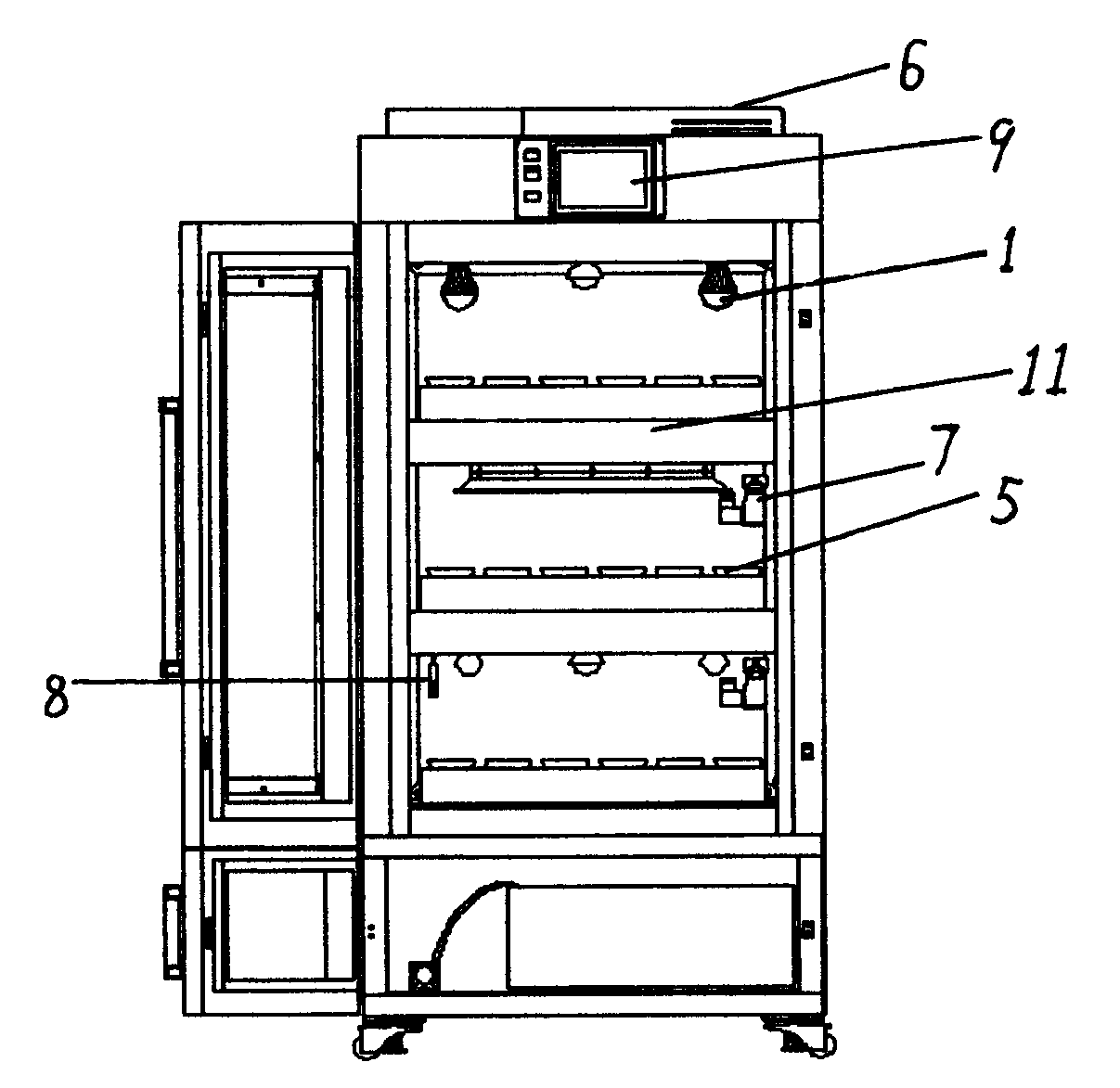

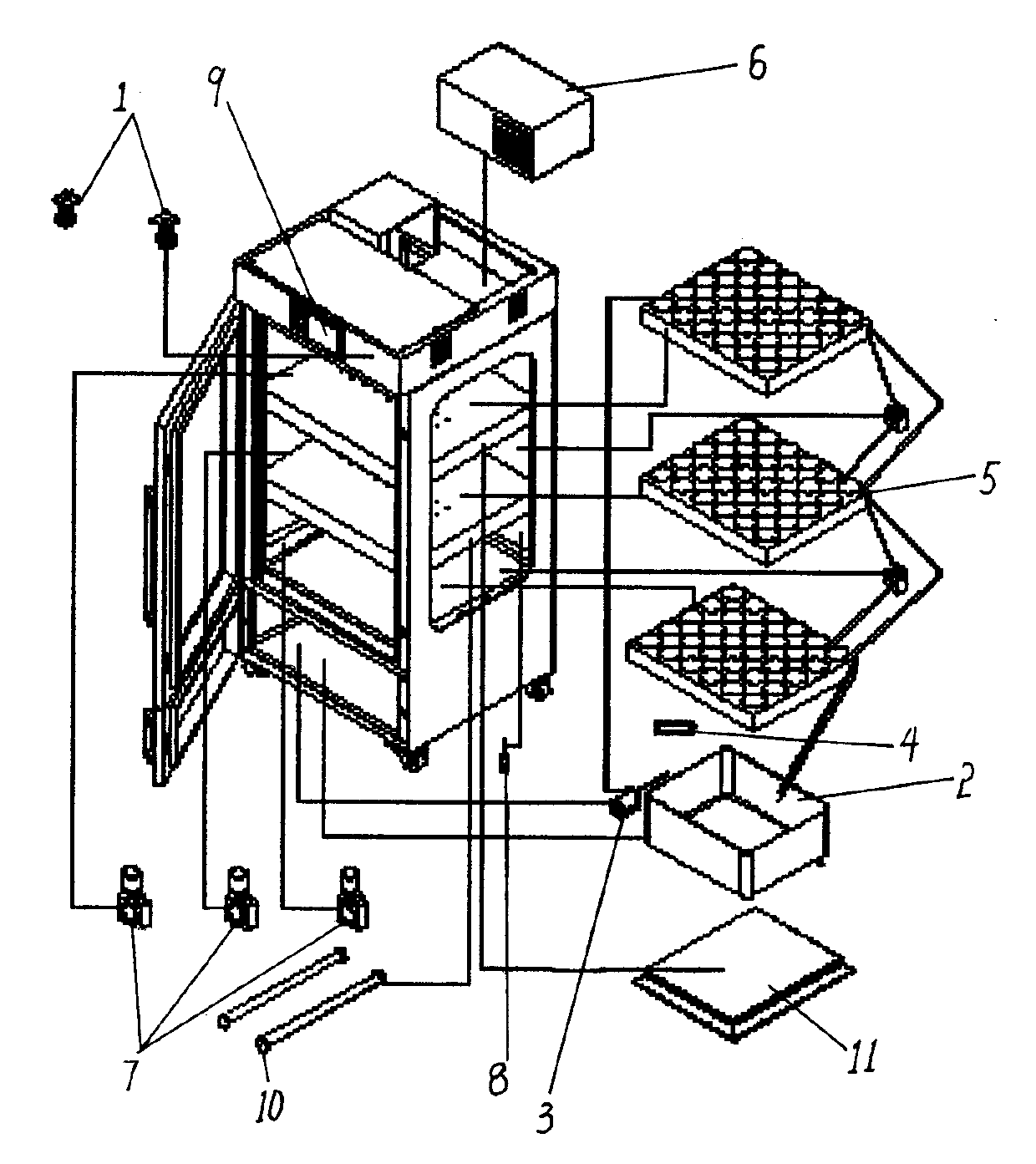

Intelligent miniature sterile plant factory

InactiveCN104351033ASave plant areaGood for healthAgriculture gas emission reductionCultivating equipmentsTemperature controlDrive wheel

The invention relates to an intelligent miniature sterile plant factory, which comprises a cabinet body with a sealed window, wherein a vegetable culture device, a nutrient solution circulation device, a temperature control device and an illumination device are arranged in the cabinet body, the cabinet body is provided with an air inlet and an air outlet, the air inlet is communicated with external air through a sterile air filter, the vegetable culture device comprises a planting disc and a conveying device, the conveying device comprises a plurality of support rods, an annular transmission device and a driving motor, the support rods are rotationally arranged in the cabinet body in a mutually parallel way and are connected with the driving motor, a driving wheel is arranged on each support rod, the annular transmission device is surrounded on the support rods and is matched with the driving wheel, in addition, the planting disc is detachably arranged on the transmission device, and when the driving motor drives the driving wheels to rotate, the planting disc arranged on the transmission device can be driven to do annular movement. The intelligent miniature sterile plant factory provided by the invention overcomes the defects of low space utilization rate and management inconvenience of the existing plant factory.

Owner:WUHAN YOUSHI AGRI TECH

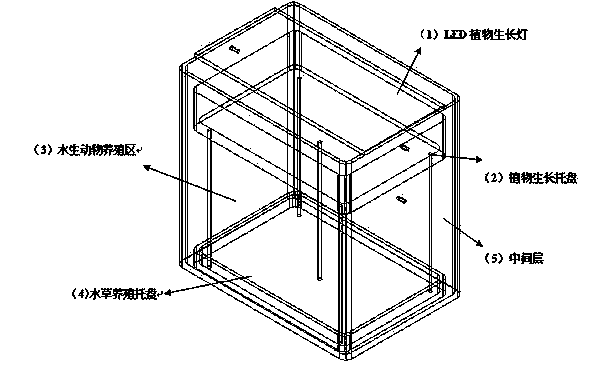

Intelligent ecological fish-vegetable intergrowth culture box

InactiveCN103621456AOvercoming the problem of single plantingAchieve natural circulationPisciculture and aquariaAgriculture gas emission reductionAquaponicsPlant growth

The invention relates to an intelligent ecological fish-vegetable intergrowth culture box, which comprises an LED (light emitting diode) plant growth lamp (1), a plant growth tray (2), an aquatic animal culture area (3) and an aquatic plant cultivation tray (4). The LED plant growth lamp (1) is hung above the culture box through a barb member, the plant growth tray (2) is connected to the aquatic plant cultivation tray through five cylinders, the aquatic animal growth area (3) is the space of the culture box, the aquatic plant cultivation tray (4) can be paved with filter materials such as perlite, cobblestone and active carbon. The LED plant growth lamp (1) adopts a wireless network signal receiver to receive the light quality of a computer host, and the light source is automatically adjusted through a luminescence signal. The plant growth tray (2) is in a barrier form, and materials such as sponge, foam plates and fibers can be used as the culture medium. The aquatic animal culture area (3) is provided with an EC sensor, a water level adjusting device and a temperature sensor. The intelligent ecological fish-vegetable intergrowth culture box is used for the planting and cultivation in high mountains, grassland, plant factories, greenhouses, households and regions which are lack of water.

Owner:SUZHOU KEDA WEILONG INFORMATION TECH

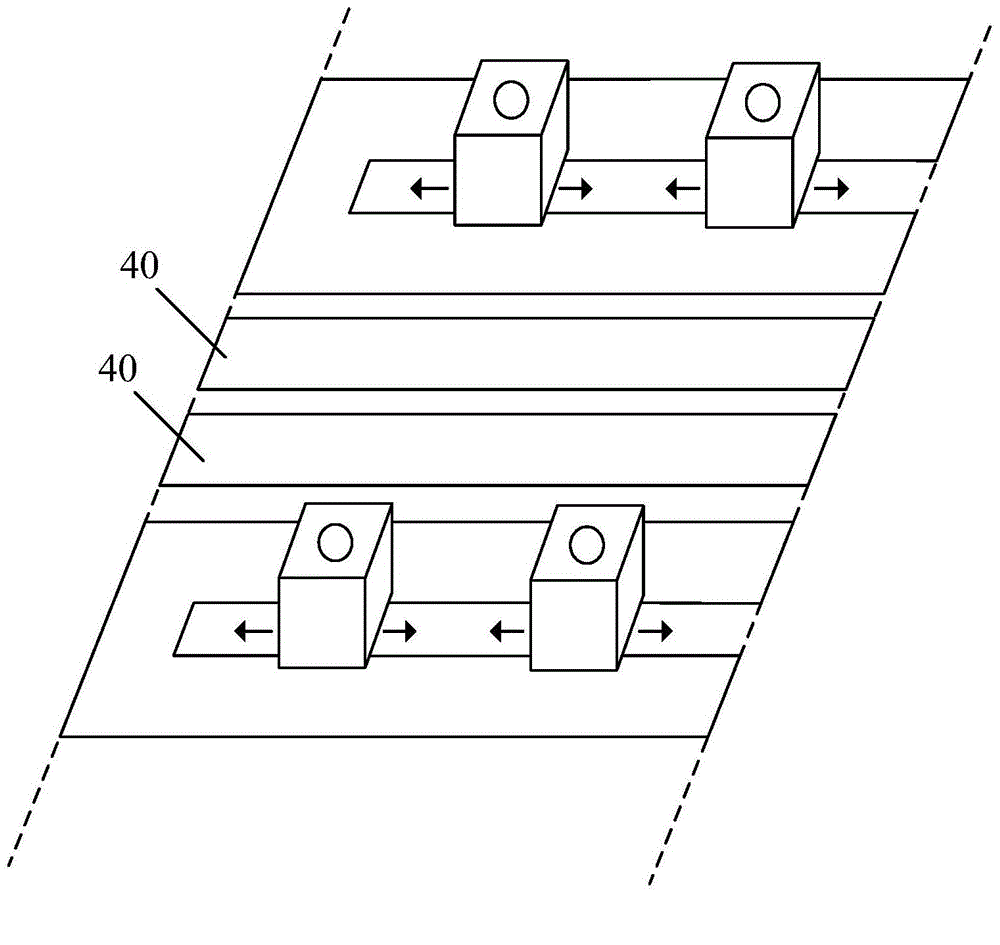

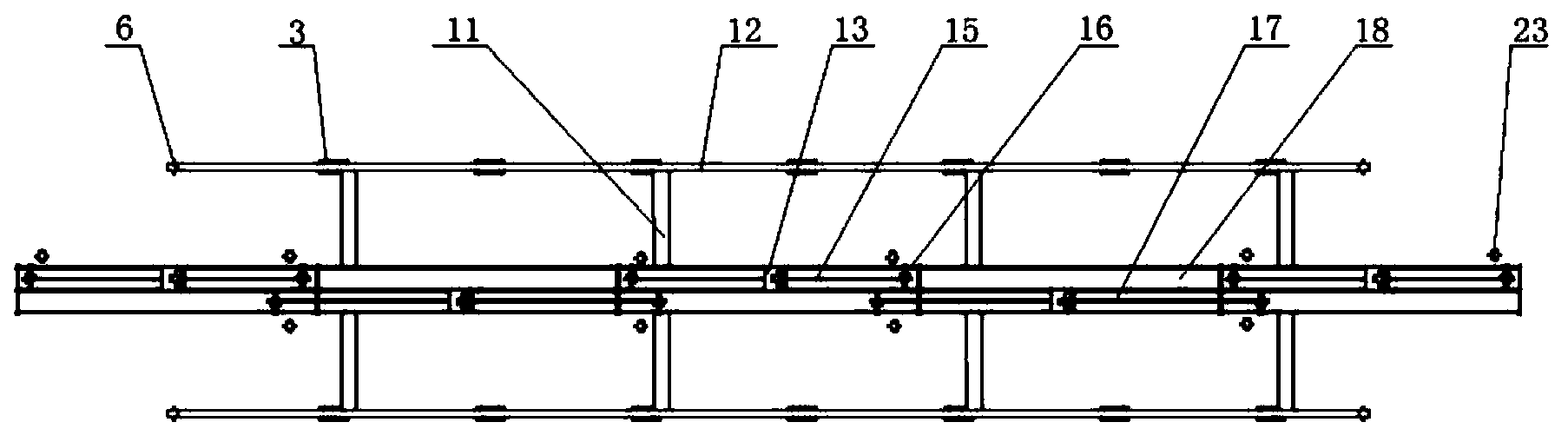

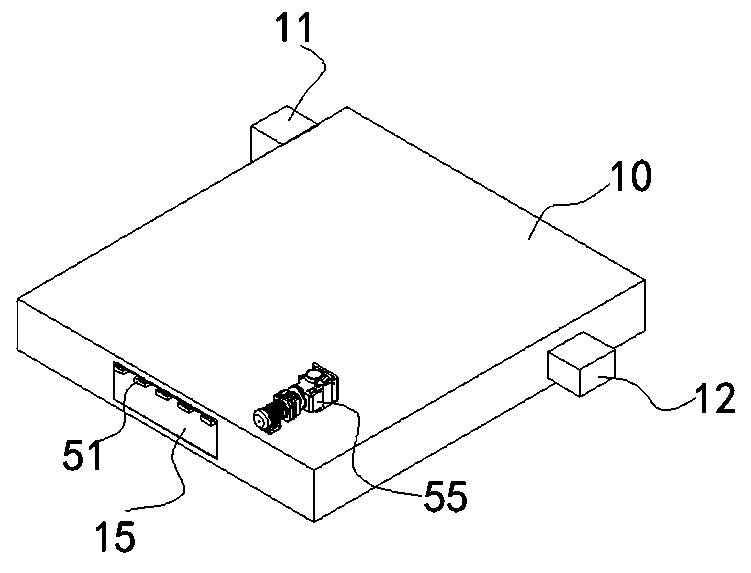

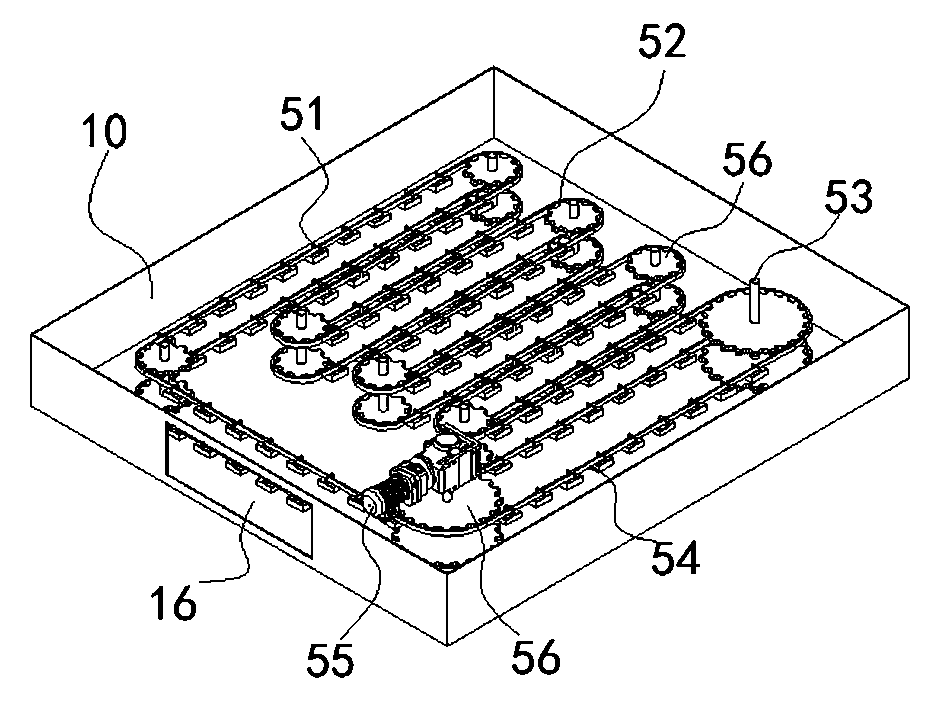

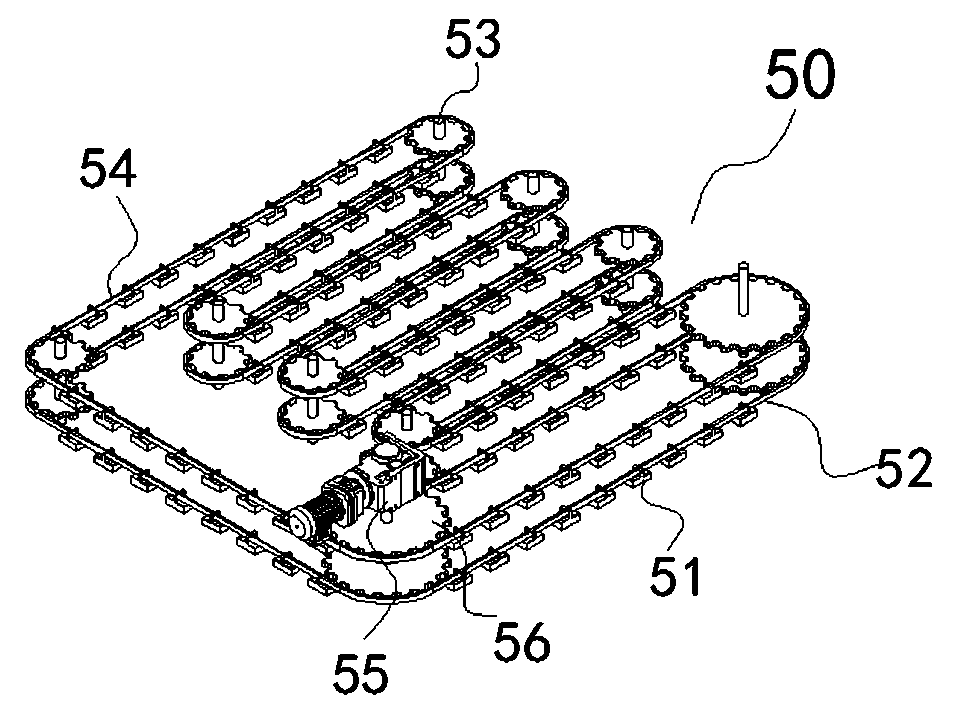

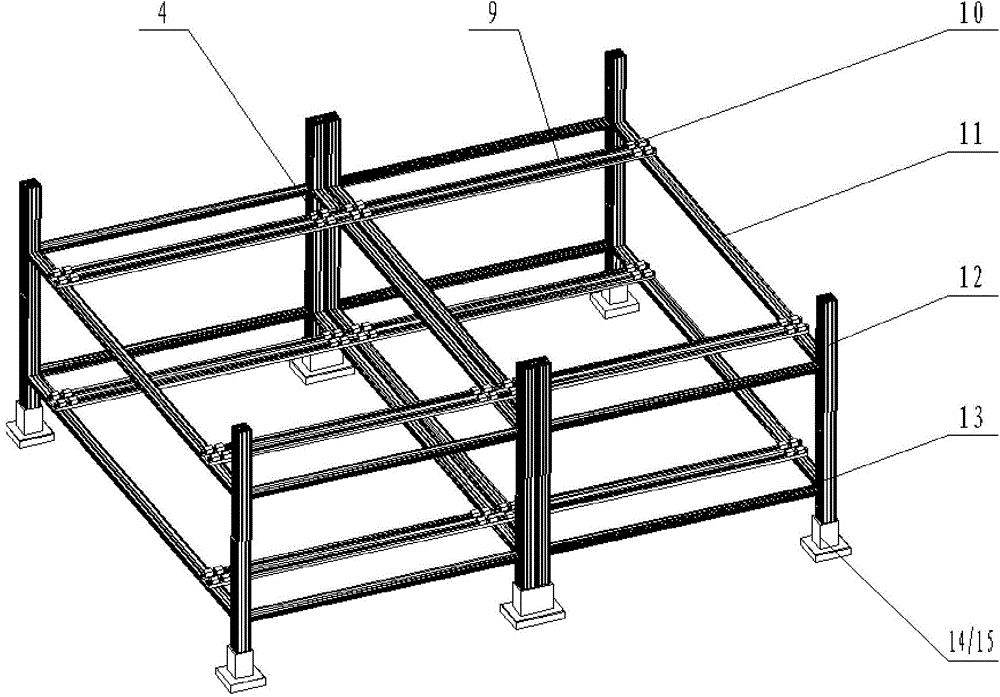

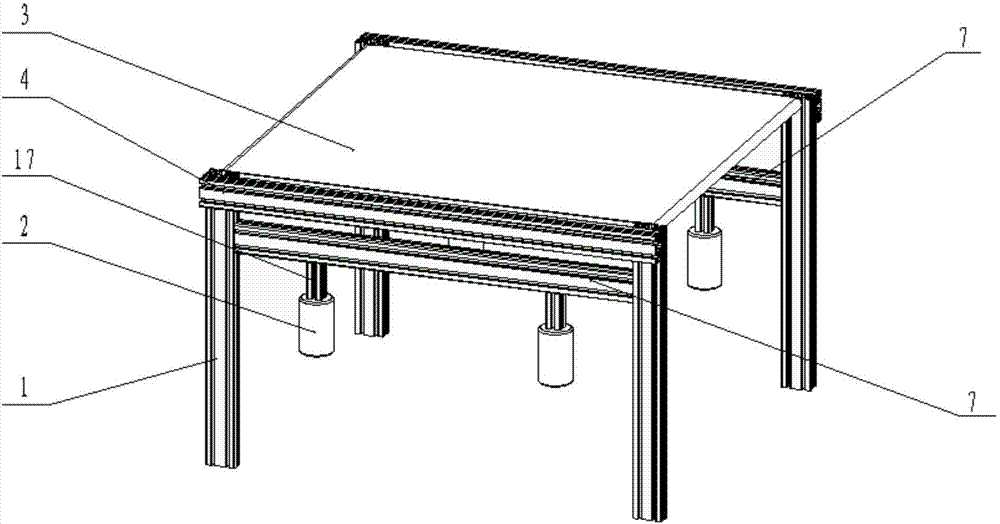

Automatically-moving three-dimensional seedbed system with adjustable light transmittance

InactiveCN104604598AIncrease flexibilityChange footprintSaving energy measuresCultivating equipmentsPlant factoryGreenhouse

The invention relates to an automatically-moving three-dimensional seedbed system with the adjustable light transmittance. The automatically-moving three-dimensional seedbed system comprises a three-dimensional frame body, linear guide rails, seedbed conveying units, single seedbeds and sensing and positioning devices. The linear guide rails are arranged on the three-dimensional frame body in a layered mode through supporting plates. Each seedbed conveying unit comprises two side plates arranged in parallel, wherein the distance between the two side plates is regulated according to the depth by which corresponding interval insertion plate inner plates are inserted into corresponding interval insertion plate outer plates, wheels used for rolling to convey the corresponding single seedbed are arranged on the inner sides of the side plates, and the side plates are connected to the corresponding linear guide rail in a sliding mode through slide blocks. The sensing and positioning devices are arranged on the three-dimensional frame body, the seedbed conveying units and the single seedbeds to position the single seedbeds. Compared with the prior art, the seedbeds can be moved to the assigned seedbed positions, the positions of the seedbeds can be automatically adjusted according to the growth condition of plants, the illumination receiving rate of the seedbeds is increased, and the automatically-moving three-dimensional seedbed system conforms to the tendency that traditional greenhouses are developed towards large-scale plant factories.

Owner:TONGJI UNIV

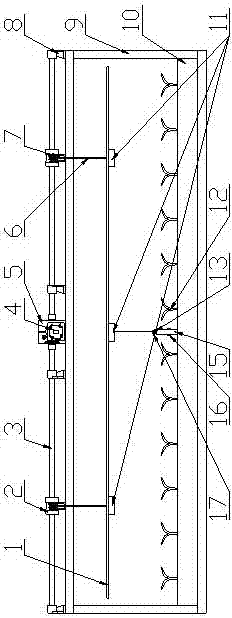

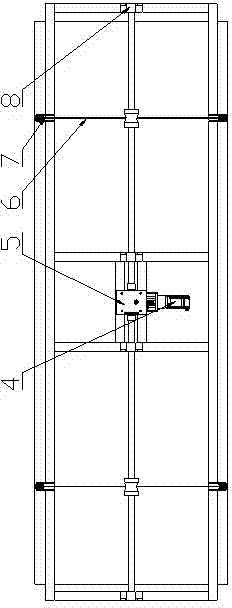

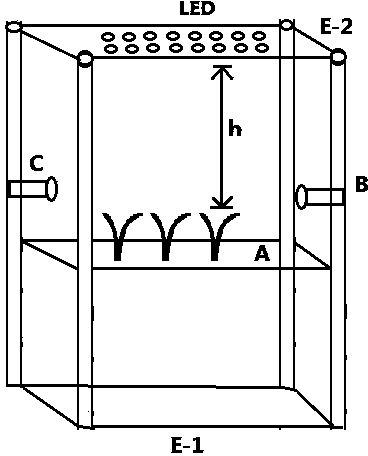

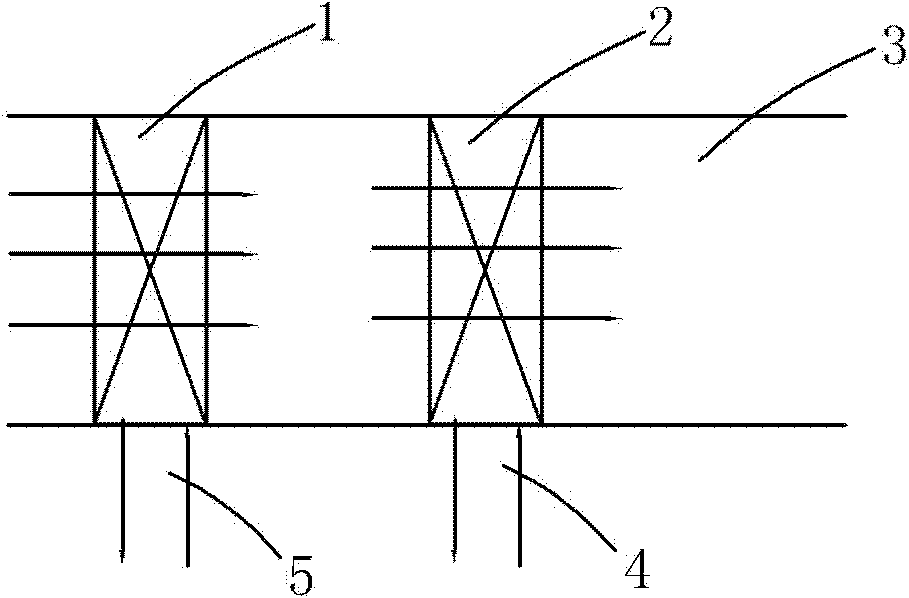

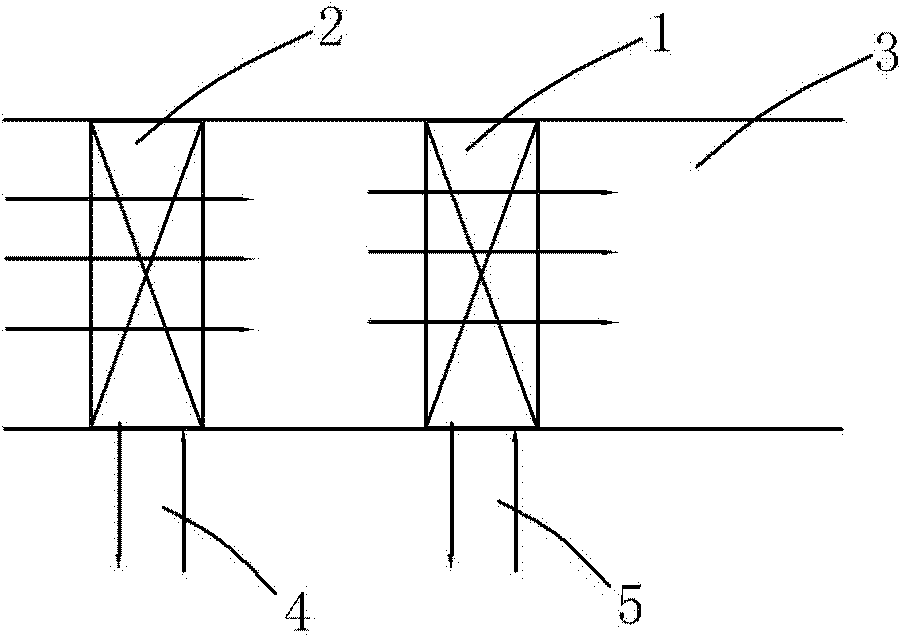

Intelligent LEDs lamp holder adjusting and controlling system for plant factory cultivation frame

InactiveCN103250600AKeep a reasonable heightAutomatically adjust the positionControl using feedbackGreenhouse cultivationPlant factoryControl system

Provided is an intelligent LEDs lamp holder adjusting and controlling system for a plant factory cultivation frame. The LEDs lamp holder adjusting and controlling system comprises a drive set, a transmission set, a lamp holder set, an ultrasonic distance measuring sensor (10), a system controller, cultivation frames (12) and cultivation grooves (11). The drive set comprises a stepping motor (1), a rotary drum (2), rotary drum supporting bearings (13) and rotary drum shafts (14). The transmission set comprises a left flexible suspension wire rope (3), a right flexible suspension wire rope (4), a left supporting idler wheel (5), a right supporting idler wheel (6) and supporting idler wheel supports (7). The lamp holder set comprises adjustable lamp holder suspension locking devices (8), LEDs lamp holders (9) and suspension locking device installing holes (15). The ultrasonic distance measuring sensor is used for detecting the heights of lamp plates and canopies of cultivation plants so that positions of the lamp plates can be automatically adjusted along with change of the growing heights of the plants, and reasonable heights of light sources of the lamp plates and the canopies of the plants can be conveniently kept.

Owner:NANJING AGRICULTURAL UNIVERSITY

Quick and precise positioning automatic movement three-dimensional seedbed system

InactiveCN104488593AStrong suctionGreat suctionCultivating equipmentsMechanical conveyorsPlant factoryButt joint

The invention relates to a quick and precise positioning automatic movement three-dimensional seedbed system. The system comprises a cultivation unit, a front conveying unit, a rear conveying unit, a single seedbed and a sensor positioning device, wherein the cultivation unit comprises an L-shaped track and a pushing device; the L-shaped track is used for supporting the single seedbed to slide; the pushing device is used for pushing the single seedbed to move transversely on the L-shaped track; the front conveying unit and the rear conveying unit are the same in structure and are arranged at the front and rear ends of the cultivation unit respectively to drive the single seedbed to move longitudinally; the sensor positioning device is arranged on the front conveying unit, the rear conveying unit and the cultivation unit to position the single seedbed; the pushing device is a lead screw device. Compared with the prior art, the system has the advantages that the seedbed can be quickly and accurately positioned and automatically moved to a specific position and can be automatically butt-jointed to an auxiliary working table, the device has good maneuverability, mass production can be modularized according to specific production requirements, the production site can be expanded or saved in the directions of three dimensions, and the system conforms to the trend of development of the conventional greenhouse to a large-sized plant factory.

Owner:TONGJI UNIV

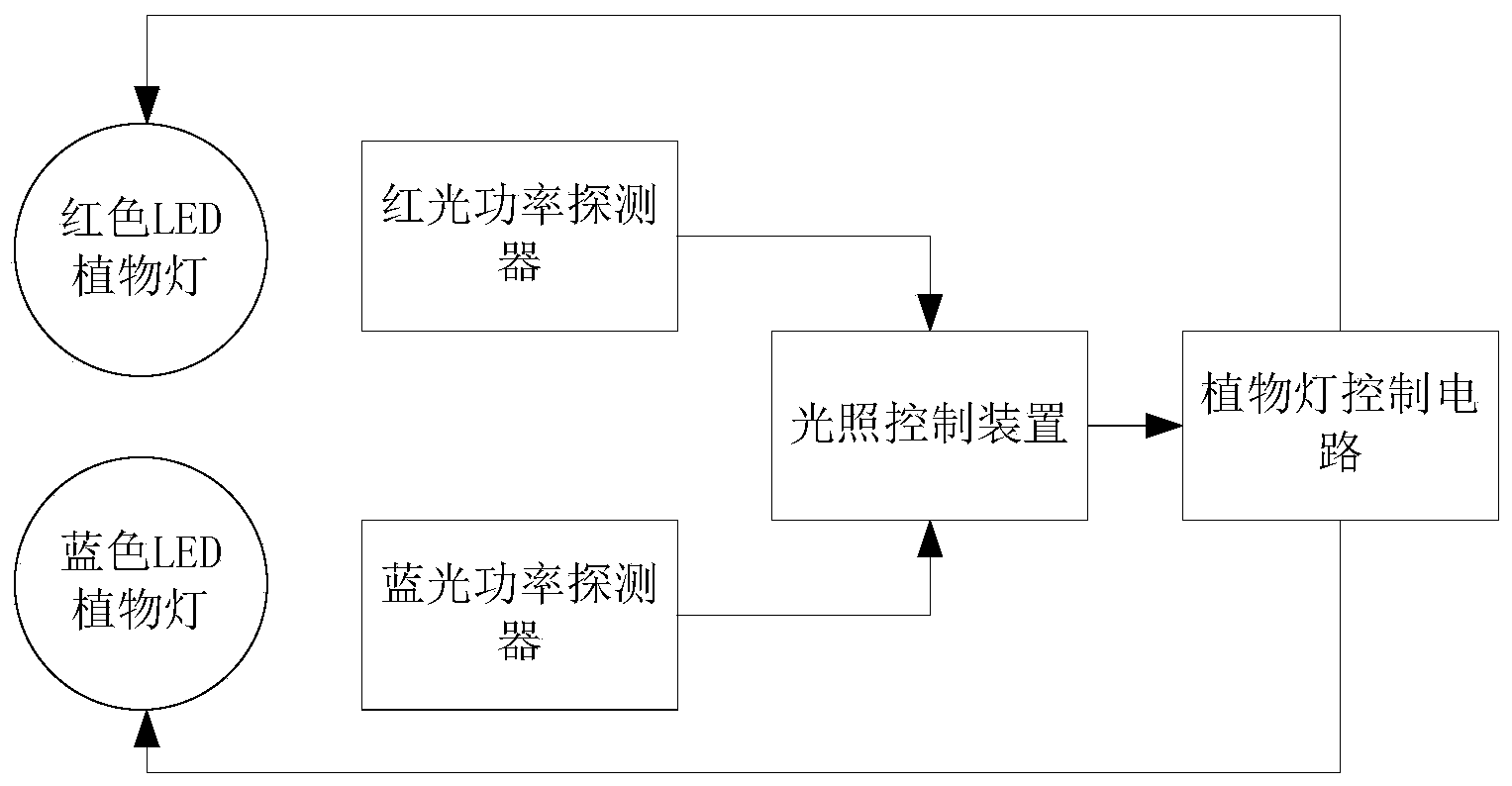

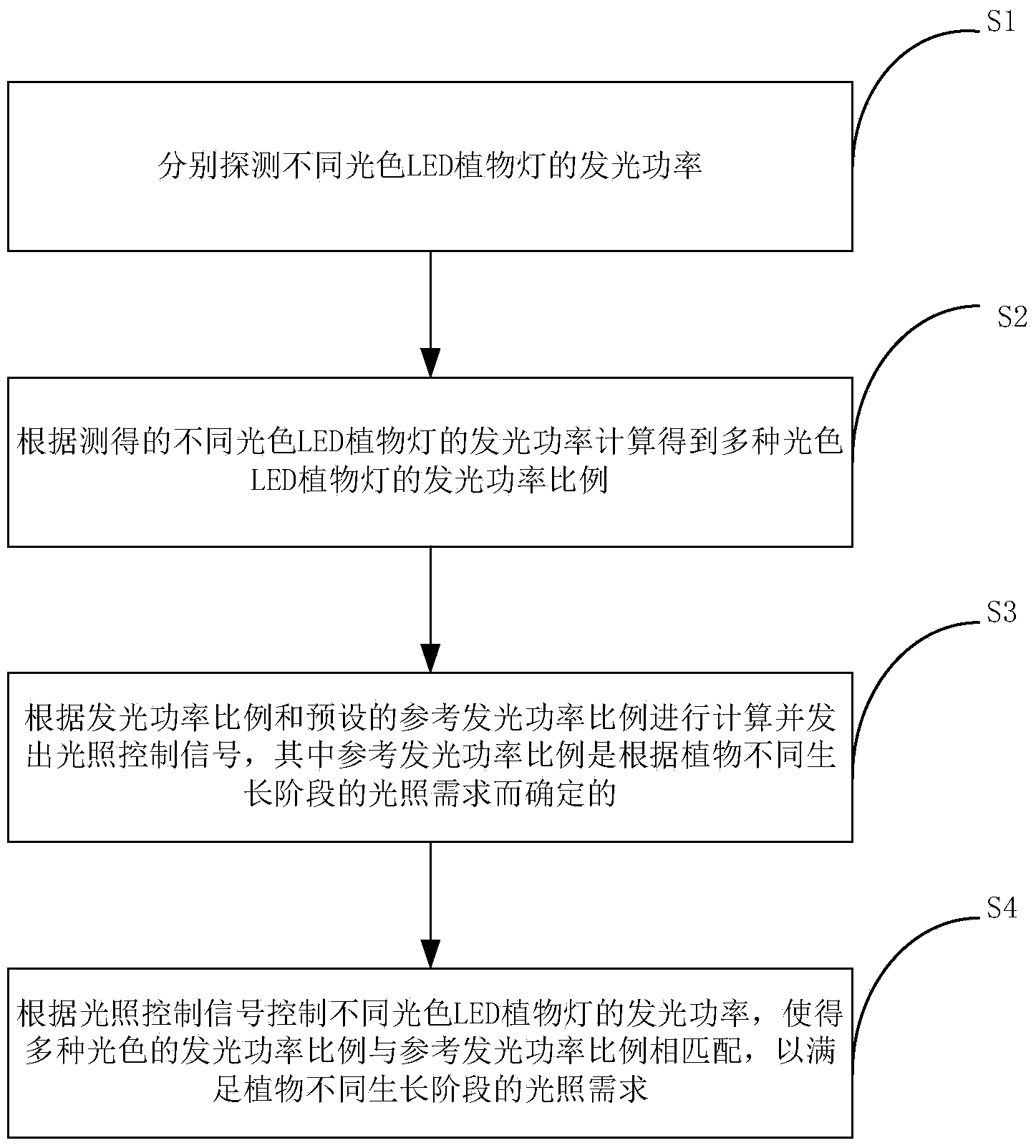

Illumination control system and method for intelligent plant factory with multi-color LEDs

ActiveCN104302062AMeet lighting needsPromote growthSaving energy measuresElectric light circuit arrangementPlant factoryControl system

The invention discloses an illumination control system and method for an intelligent plant factory with multi-color LEDs. The light-emitting power proportions of a plurality of light colors are calculated by detecting the light-emitting power of LED plant lamps with different light colors, calculation is carried out according to the light-emitting power proportions of the LED plant lamps with various light colors and the preset reference light-emitting power proportion, and an illumination control signal is sent out and controls the light-emitting power of the LED plant lamps with different light colors, and the light-emitting power proportions of the light colors are matched with the reference light-emitting power proportion so that the requirement for illumination of different growing stages of plants can be met. Due to the fact that the light-emitting power of the LED plant lamps with the light colors is continuously detected online in real time, the light-emitting power of the LED plant lamps with the light colors is adjusted according to the requirement for illumination of different growing stages of the plants, the plants in the plant factory can be in an optimal growing state, the energy utilization rate of the plant factory is increased, and energy resources are saved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

Intensive plant factory with high light-energy utilization rate

The invention relates to an intensive plant factory with a high light-energy utilization rate. The intensive plant factory is characterized in that the intensive plant factory comprises a plant workshop composed of a plant cultivation shelf set; the plant cultivation shelf set comprises a plurality of rows of cultivation shelves capable of translating on a guide rail; the plant cultivation shelf set is only provided with a slidable and movable adjusting channel with one unit width; each cultivation shelf has N layers, LED sources are arranged on each layer to provide illumination for the corresponding layer; a liftable plant cultivation tray and a limiting device are arranged on each layer; the limiting devices are used for recognizing positions of the tops of plants to cooperate with a control system to provide illumination needed by the plants. According to the technical scheme, small LED power can be adopted to satisfy illumination intensity needed by growth of the plants to achieve energy conservation, and different needs of the plants for the illumination intensity in different growing periods can be met, so that the plants can be optimally irradiated in each growing period, and the requirement on rapid growth of the plants is met.

Owner:FUJIAN AGRI & FORESTRY UNIV

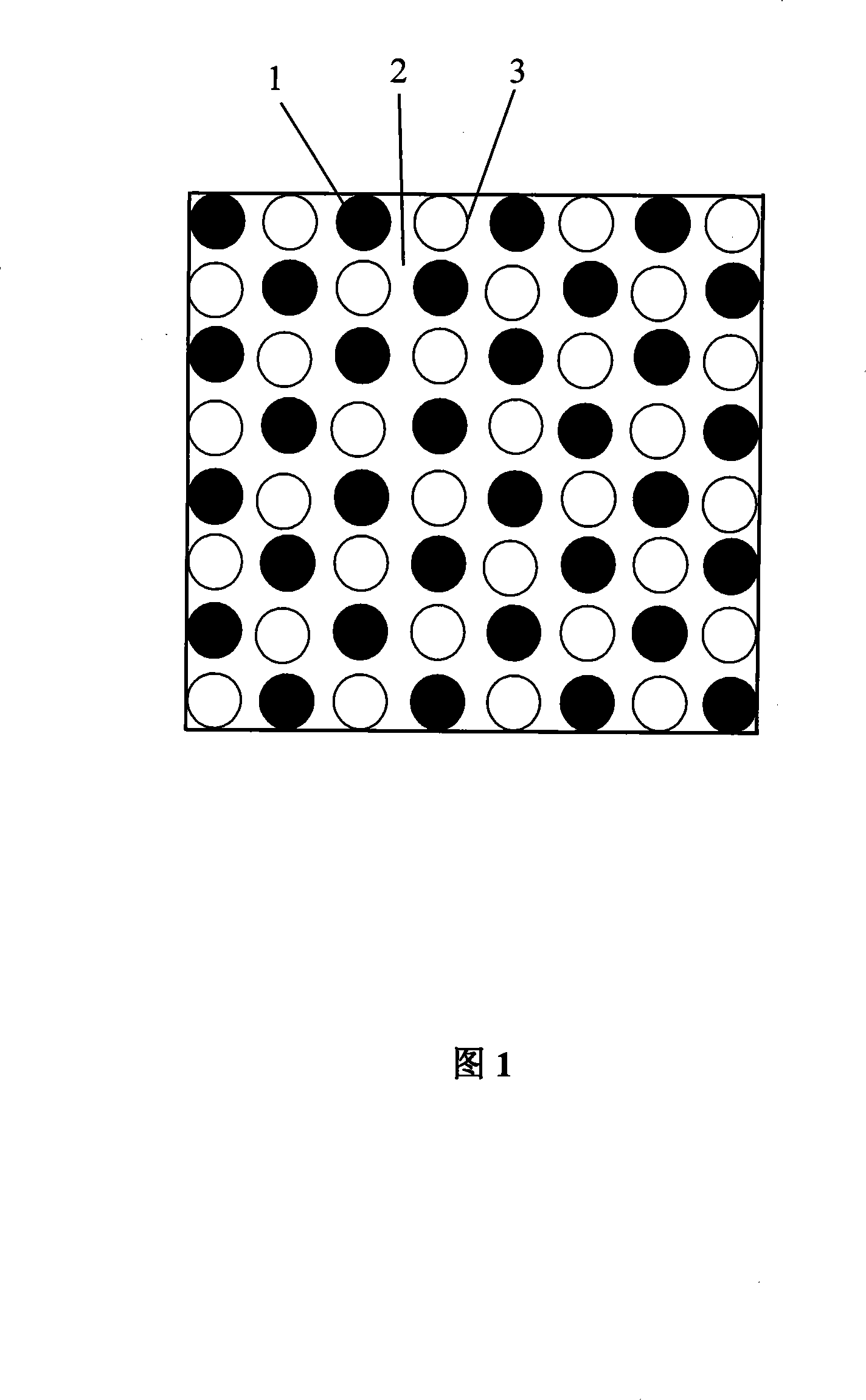

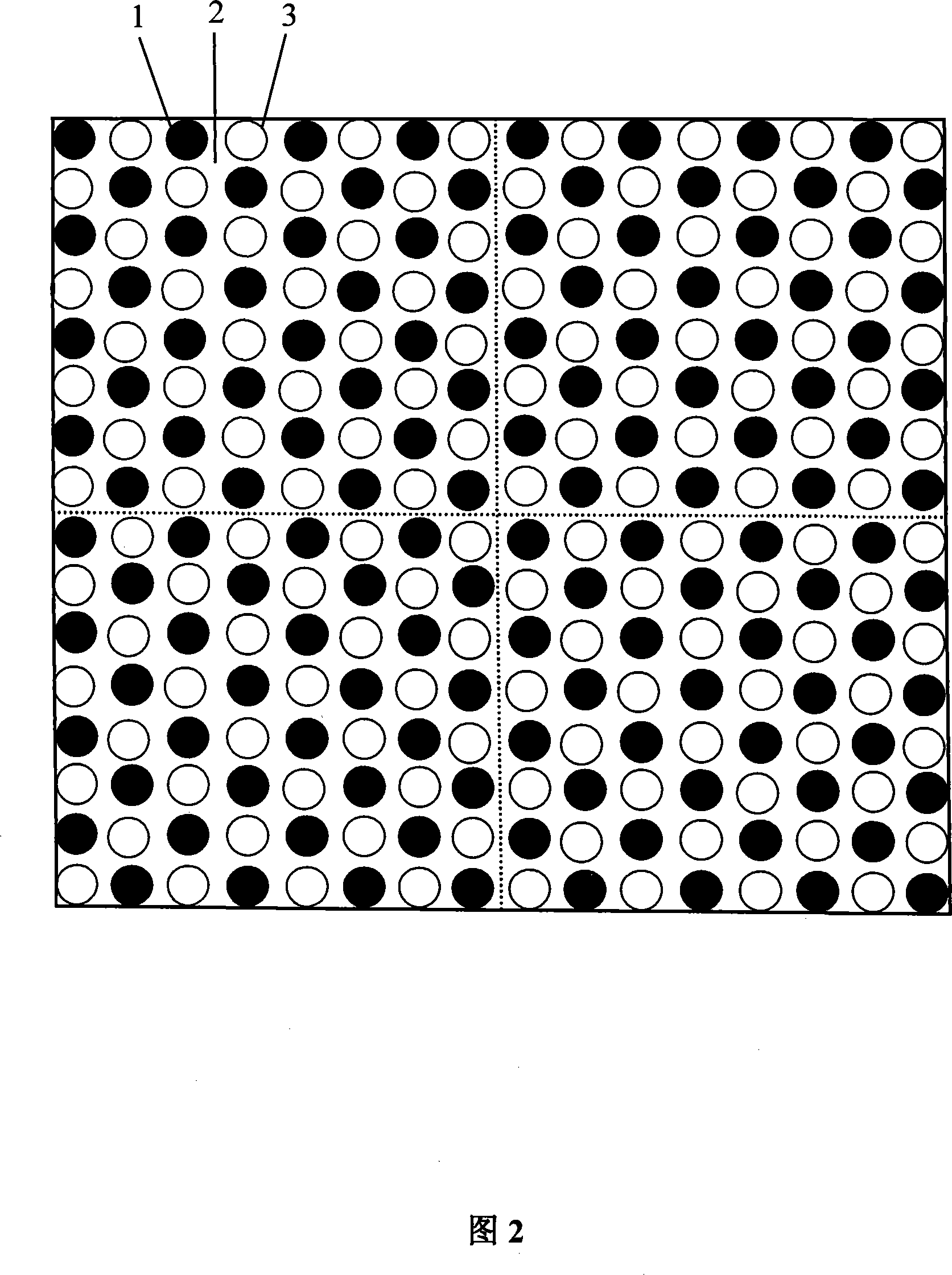

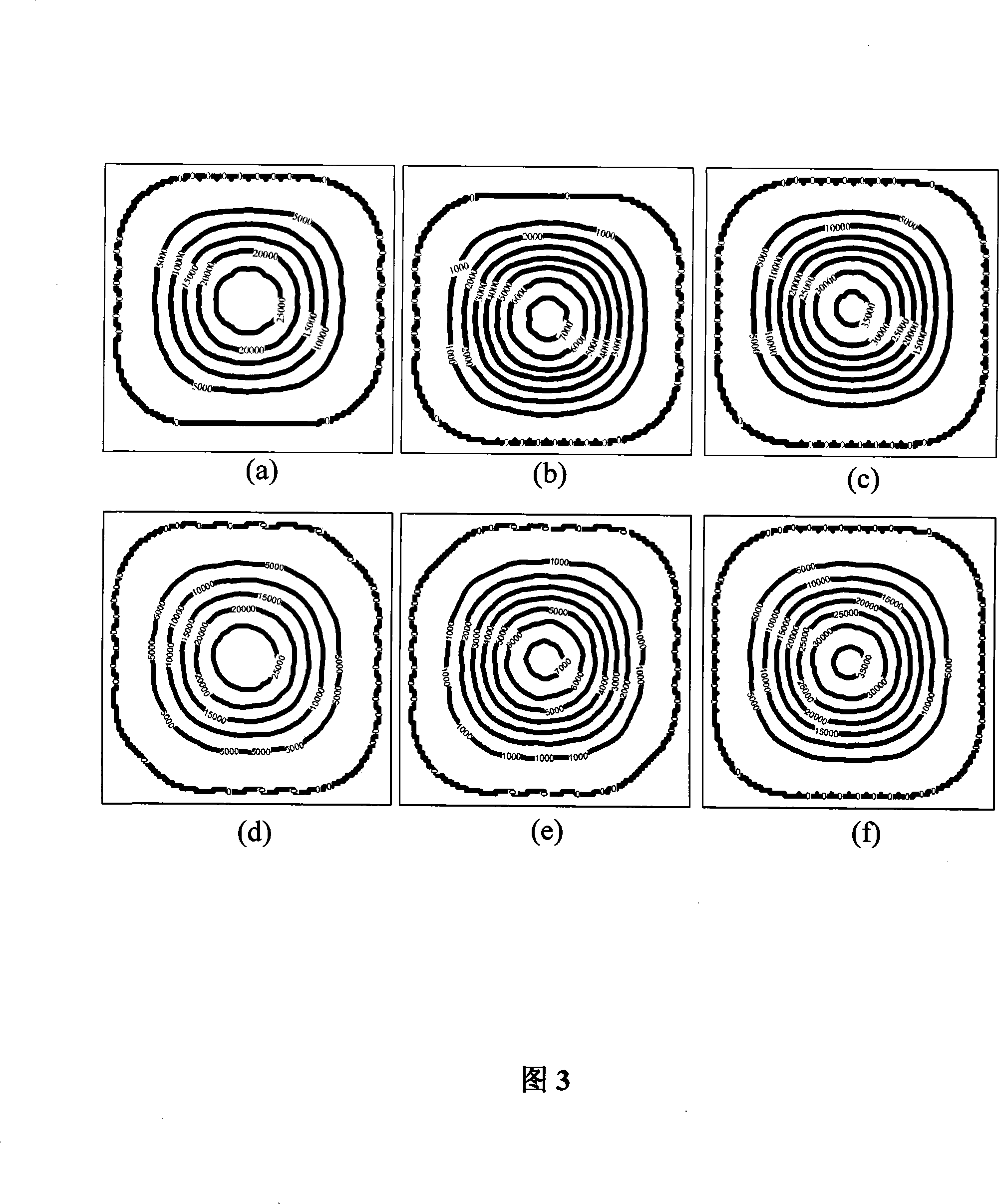

Method for combining LED with homogeneous proportion of red blue light as well as module thereof

InactiveCN101251241AEasy to control automaticallyQuick installationPlanar light sourcesLight source combinationsPlant factoryGreenhouse

The present invention discloses a light emitting diode combining method enabling uniform proportion between red light and blue light. Firstly, selecting single LED, an extra-bright circular lamp with a half-value angle of 7 degrees, a diameter of 5 mm and a wavelength of 636 nm is selected for the red light LED; an extra-bright circular lamp with a half-value angle of 7 degrees, a diameter of 5 mm and a wavelength of 459 nm is selected for the blue light LED; secondly, eight LEDs are arranged on each line and each row, and each red LED and each blue LED are evenly arranged at intervals, the surrounding of each LED are LEDs with the other color, the spacing between two adjacent LEDs is no more than 2.5 mm, 64 LEDs with the arranging manner form a 8x8 array to be arranged on a circuit board so as to be made into a light emitting diode combining module, and the module is used as a unit module which can be assembled or expanded longitudinally and / or transversely according to needs, and the uniformity of the distribution of the ratio R / B between the red light and blue light photons flux is not changed. The method is suitable for being used as light source for photosynthesis of plants in a greenhouse and being an illumination light source for plant factories. The method has the advantages of convenient mounting, replacing, assembly and expansion, and uniform distribution of R / B ratio.

Owner:ZHEJIANG FORESTRY UNIVERSITY

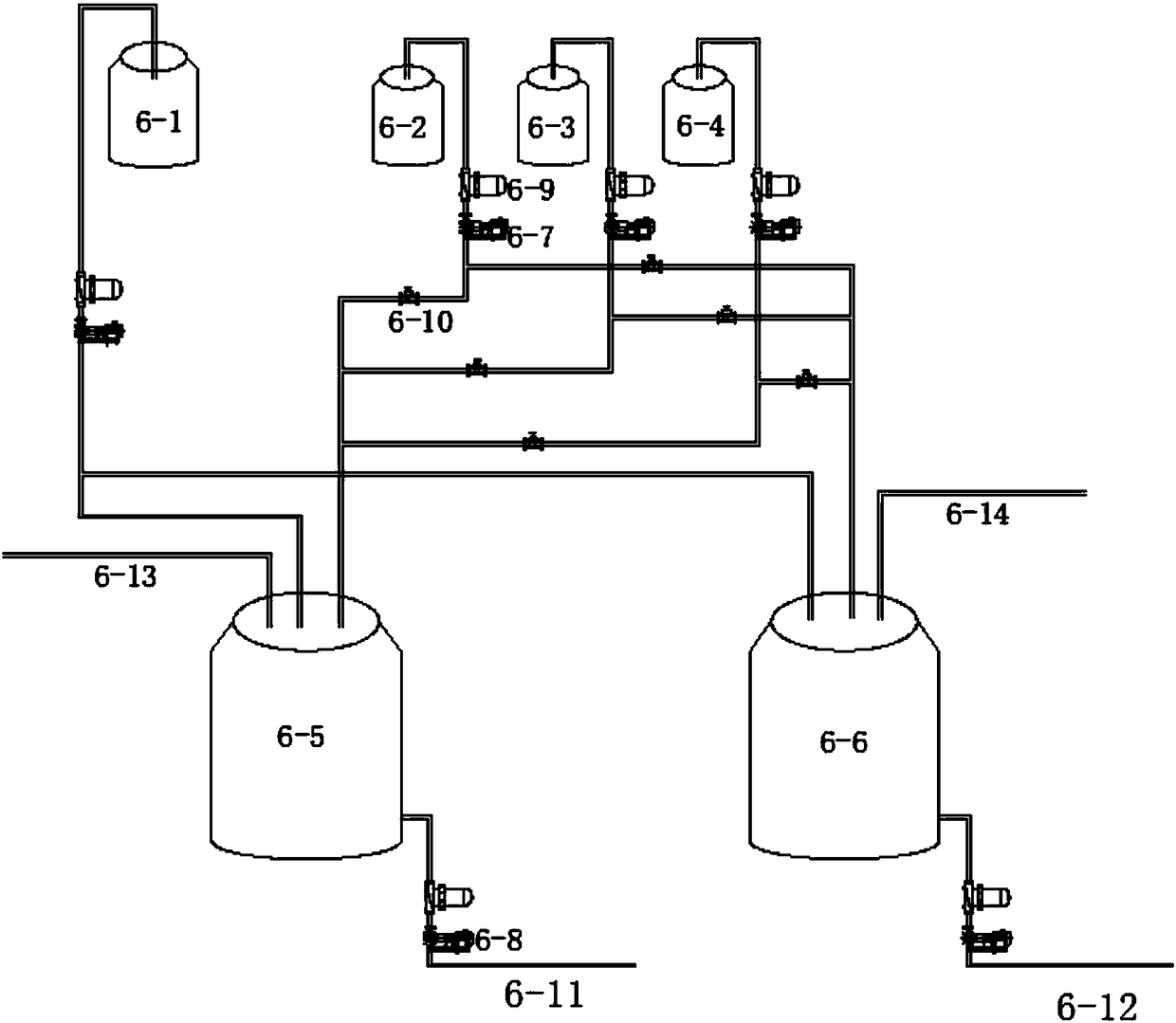

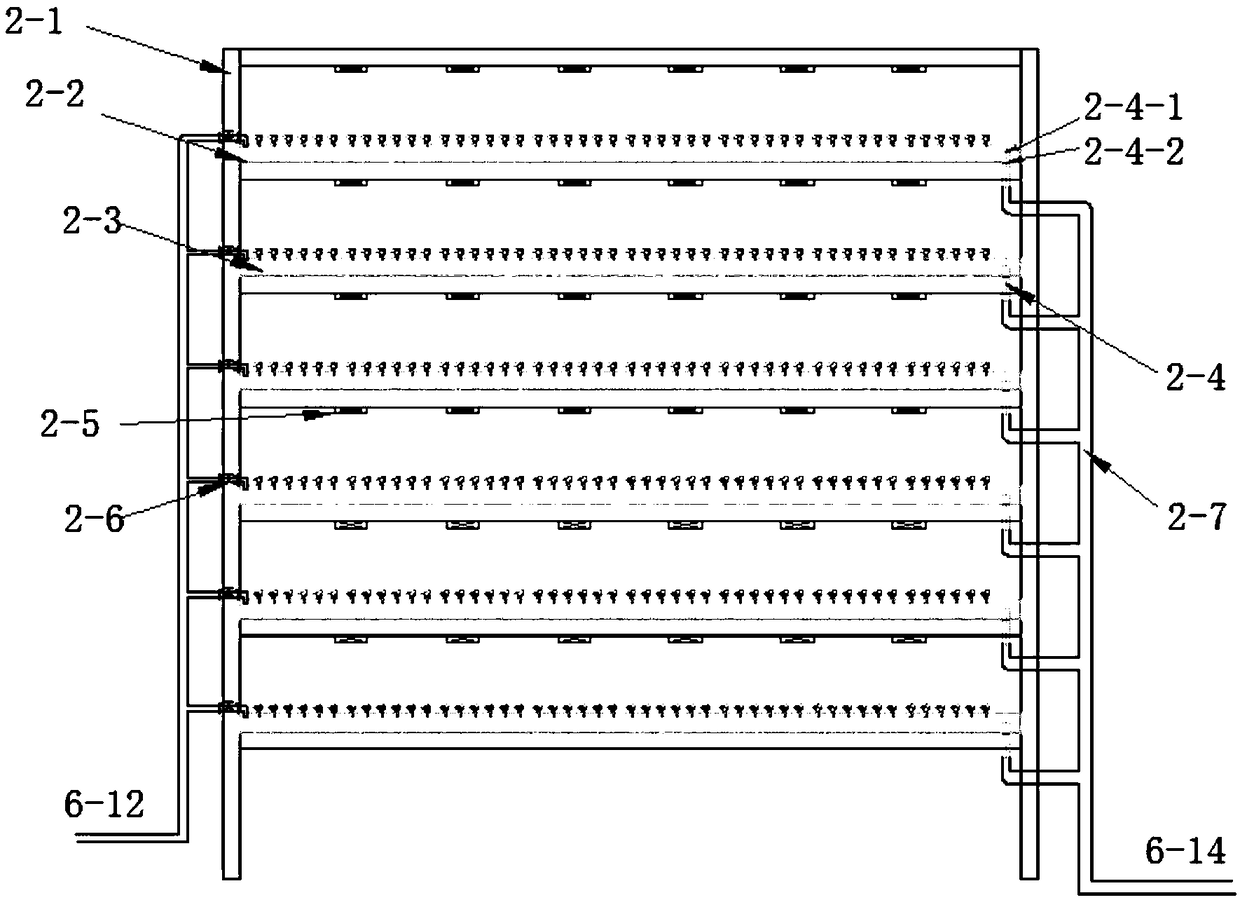

Indoor plant factory system

ActiveCN108575725AHigh degree of automationSave human effortAgriculture gas emission reductionCultivating equipmentsNutrient solutionHouse plants

The invention provides an indoor plant factory system. The system comprises a planting room, a nutrient solution room and a control system, wherein the planting room comprises a seeding room, a seedling room, a cultivation room, a harvesting room, a cleaning room, and is a planting place of plants; the nutrient solution chamber is provided with a mother liquid tank, a nutrient liquid tank and an assorted water supply and drainage system, and is a preparation and control place for a nutrient solution; the control system comprises an HVAC control system, a nutrient solution control system and anLED growth lamp illumination system, and is used for monitoring, adjusting and controlling environmental parameters in a plant factory and a nutrient solution system. The indoor plant factory systemhas the advantages that the degree of automation is high; an assorted loading and unloading device and cultivation groove transport equipment are arranged, so that the manpower is reduced; the nutrient solution, the environmental temperature and humidity, the LED fill-in light, the CO2 gas fertilizer and the like are highly automatically controlled, so that the manpower is reduced, errors caused by human operation are avoided, the space utilization is high, the planting row spacing can be adjusted along with the growth of vegetables, and compared with a conventional planting method, planting amount can be increased by 50% per unit area.

Owner:LIUHEFENG TIANJIN TECH CO LTD

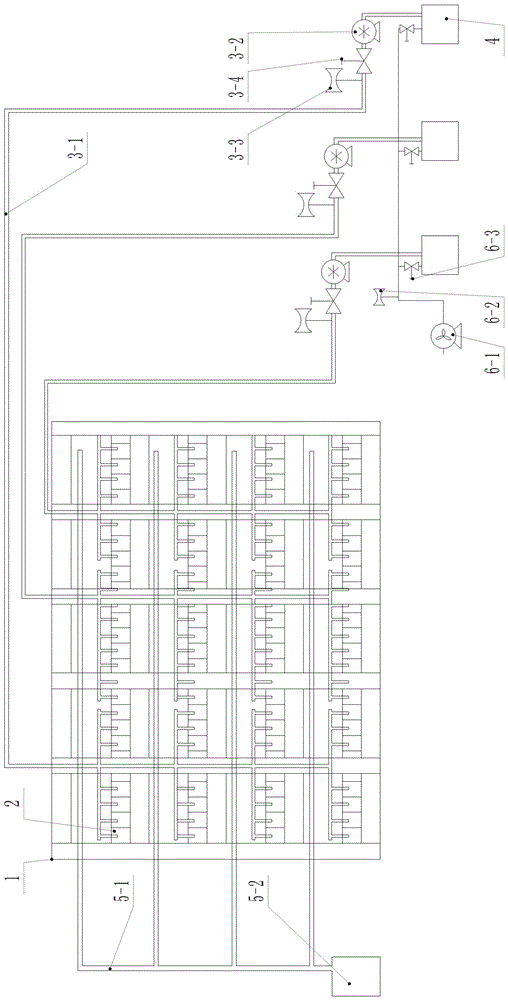

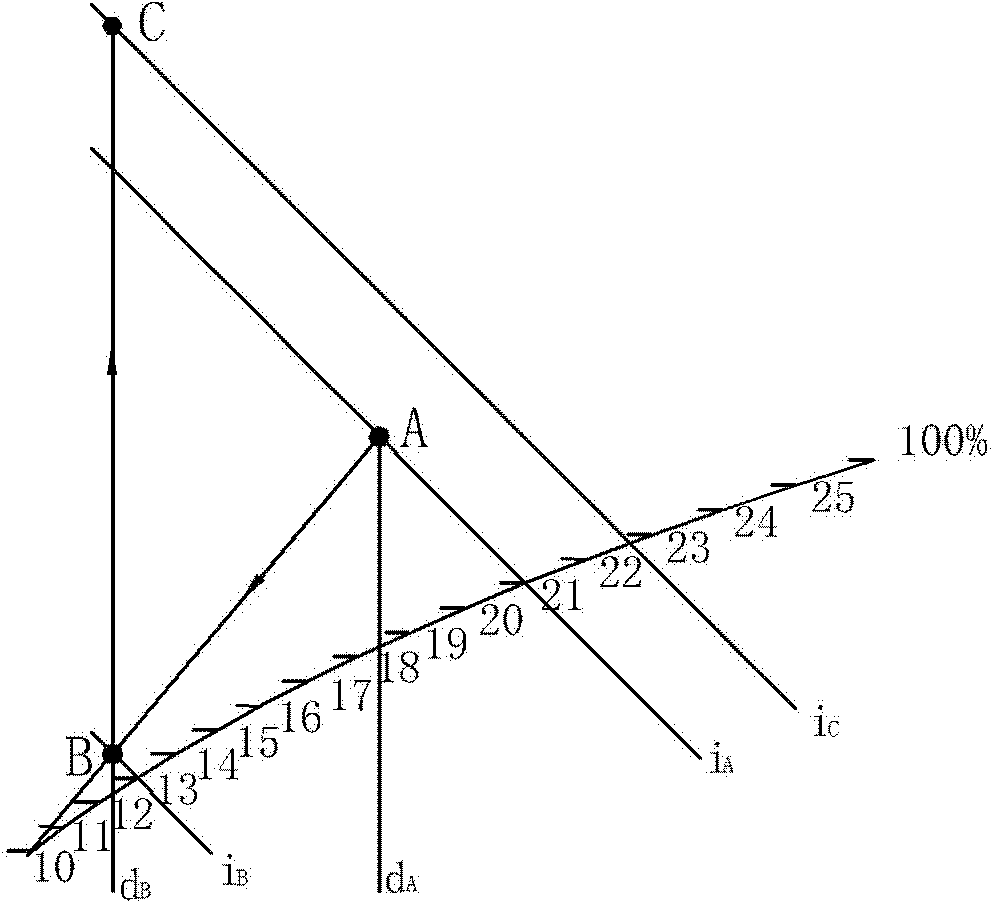

Air conditioner air supply and air return system for plant factory

InactiveCN102318523AUniform temperature/humidityConvenient zone controlClimate change adaptationGreenhouse cultivationPlant factoryAir treatment

The invention discloses an air conditioner air supply and air return system for a plant factory, which comprises an air processing machine set, a horizontal air supply main pipe, a plurality of vertical air supply branch pipes, multiple rows and multiple layers of plant culture frames and a plurality of air return grids, wherein the horizontal air supply main pipe is arranged above a factory building ceiling and is communicated with the air processing machine set, the vertical air supply branch pipes are communicated onto each horizontal air supply main pipe, the plant culture frames are arranged under the factory building ceiling, one vertical air supply branch pipe is arranged between every two rows of culture frames, one independent air condition unit is formed between every upper layer and lower layer of each row of culture frame, each vertical air supply branch pipe supplies air from the side part of each independent air condition unit and outputs the air from two side parts of each independent air condition unit at the front side and the back side, and the air return grids are arranged on the factory building ceiling. The air supply and air return system has the advantages that a high and large space is actually divided into a plurality of independent air condition units, the temperature / humidity uniformity of the the airflow tissue in the region can be easily realized by each unit through a simple technical method, and further, the temperature / humidity uniformity of the airflow tissue in the whole high and large space is ensured.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

Air cooling-dehumidifying method and cooling-dehumidifying air-conditioning system for plant factory

ActiveCN102177825ARaise the temperature of the cold sourceImprove energy efficiency ratioEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsHigh humidityPlant factory

The invention discloses an air cooling-dehumidifying method for a plant factory. Two groups of heat exchangers sharing a common air flow channel are arranged in the plant factory; the two groups of heat exchangers are connected in series from front to back in the common air flow channel; for the two groups of heat exchangers, the first heat exchanger is set to be a heating coil which is firstly contacted with air so as to heat the air and the second heat exchanger is set to be a cooling coil which cools and dehumidifies the air at the outlet of the heating coil; and the heat source of the heating coil is the condensation heat of a refrigerating unit in the plant factory or the radiation heat of an artificial light source. The invention solves the difficulties that the existing dehumidifying equipment is poor in dehumidification effect or even can not achieve humidification in the environment with low temperature and high humidity.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com