Quick and precise positioning automatic movement three-dimensional seedbed system

A technology of precise positioning and automatic movement, applied in conveyors, cultivation, applications, etc., can solve problems such as low degree of intelligent control, high cost of seedling cultivation, backward seedling cultivation technology, etc., and achieve simple, sensitive and accurate movements, strong environmental adaptability, The effect of low operating and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

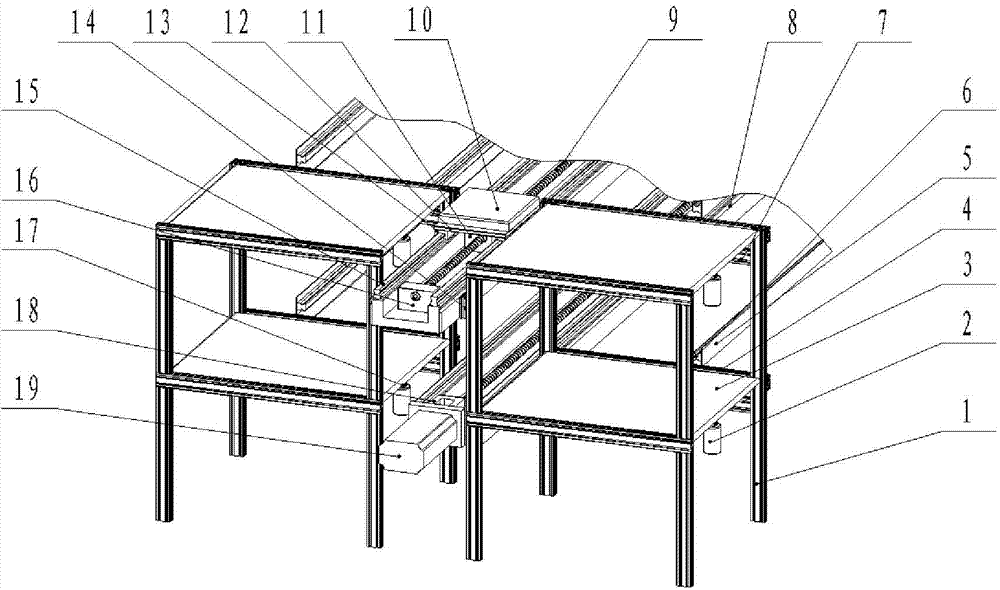

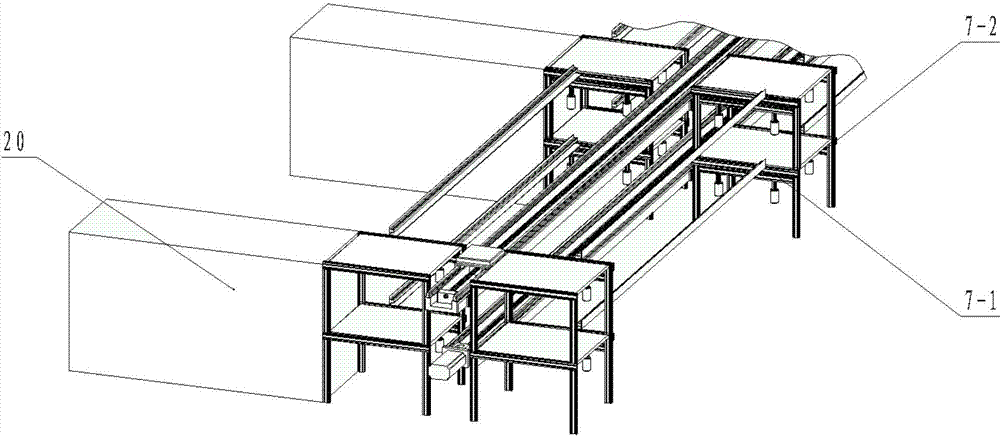

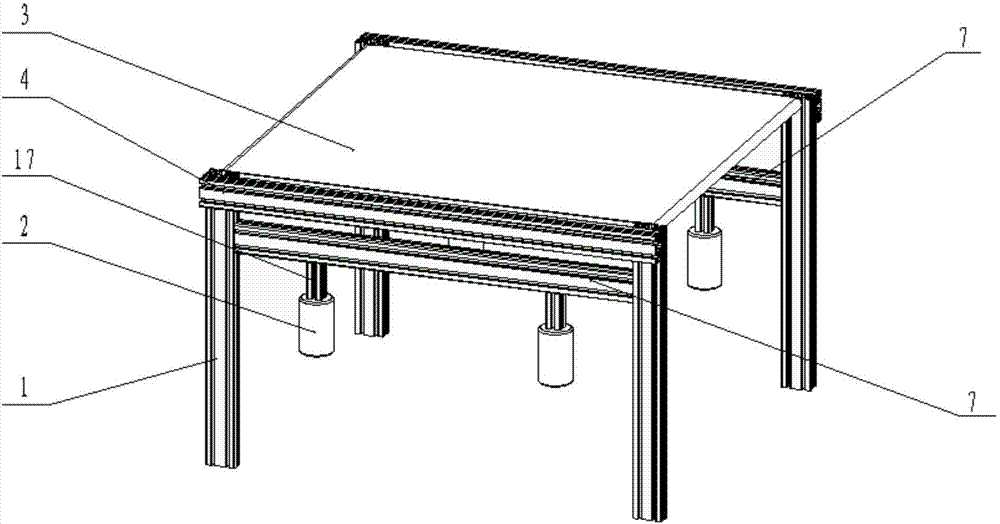

[0059] A fast and precise positioning automatic three-dimensional seedbed system, such as figure 1 , figure 2 Shown, comprise cultivation unit, front conveying unit, middle conveying unit, back conveying unit, monomer seedbed 22 and sensing positioning device, cultivation unit comprises the L-shaped track 5 that supports monomer seedbed 22 slides and promotes monomer seedbed 22 in The propelling device that moves laterally on the L-shaped track 5, the front conveying unit and the rear conveying unit have the same structure, and are respectively arranged at the front and rear ends of the cultivation unit to drive the single seedbed 22 to move longitudinally, and the middle conveying unit is arranged in the middle of the cultivation unit to drive The single seedbed 22 moves longitudinally. Wherein the middle part of the L-shaped track 5 is separated by the middle conveying unit.

[0060] In this embodiment, the seedbed system is a two-layer structure. Each layer is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com