Patents

Literature

164results about How to "No turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

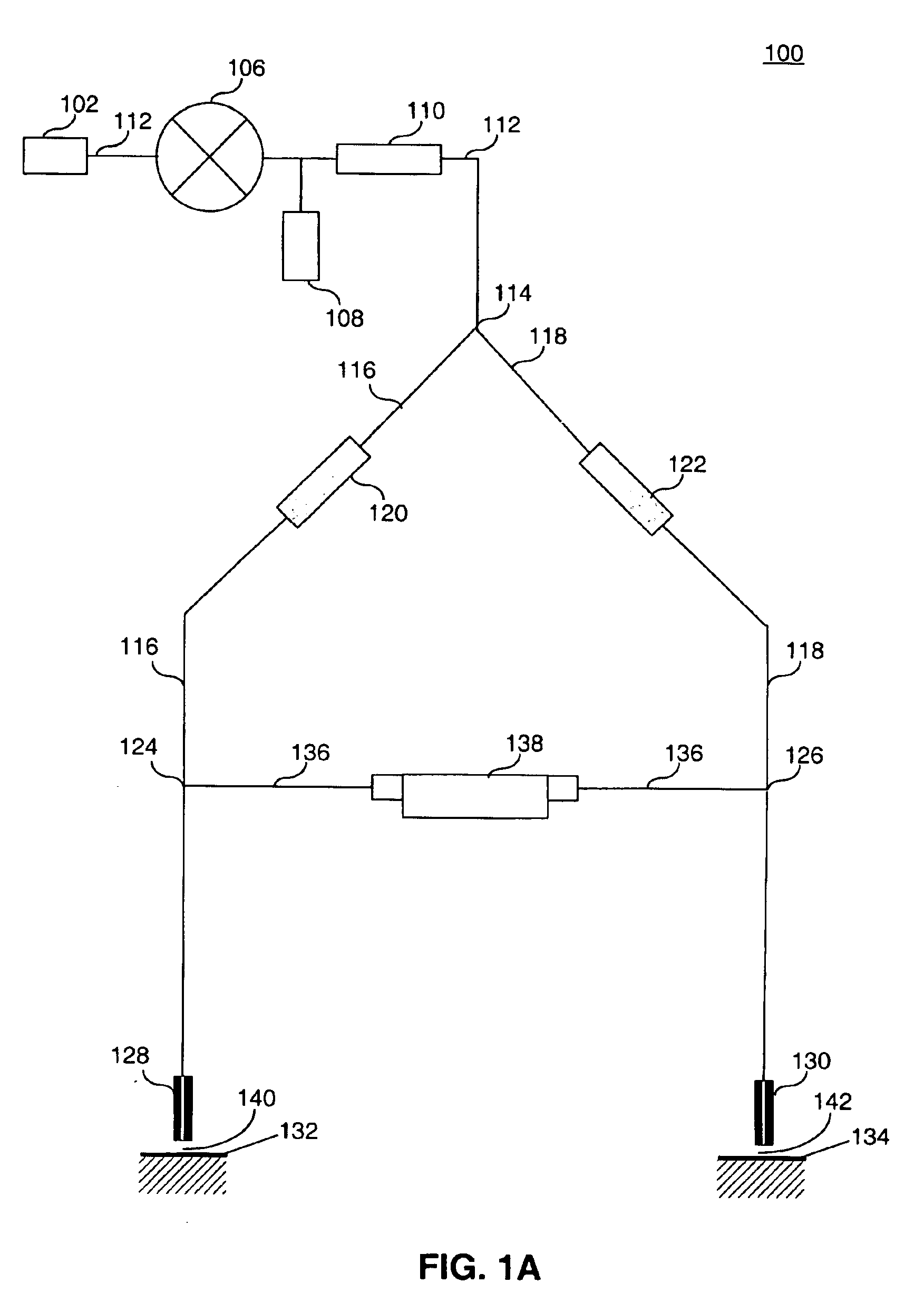

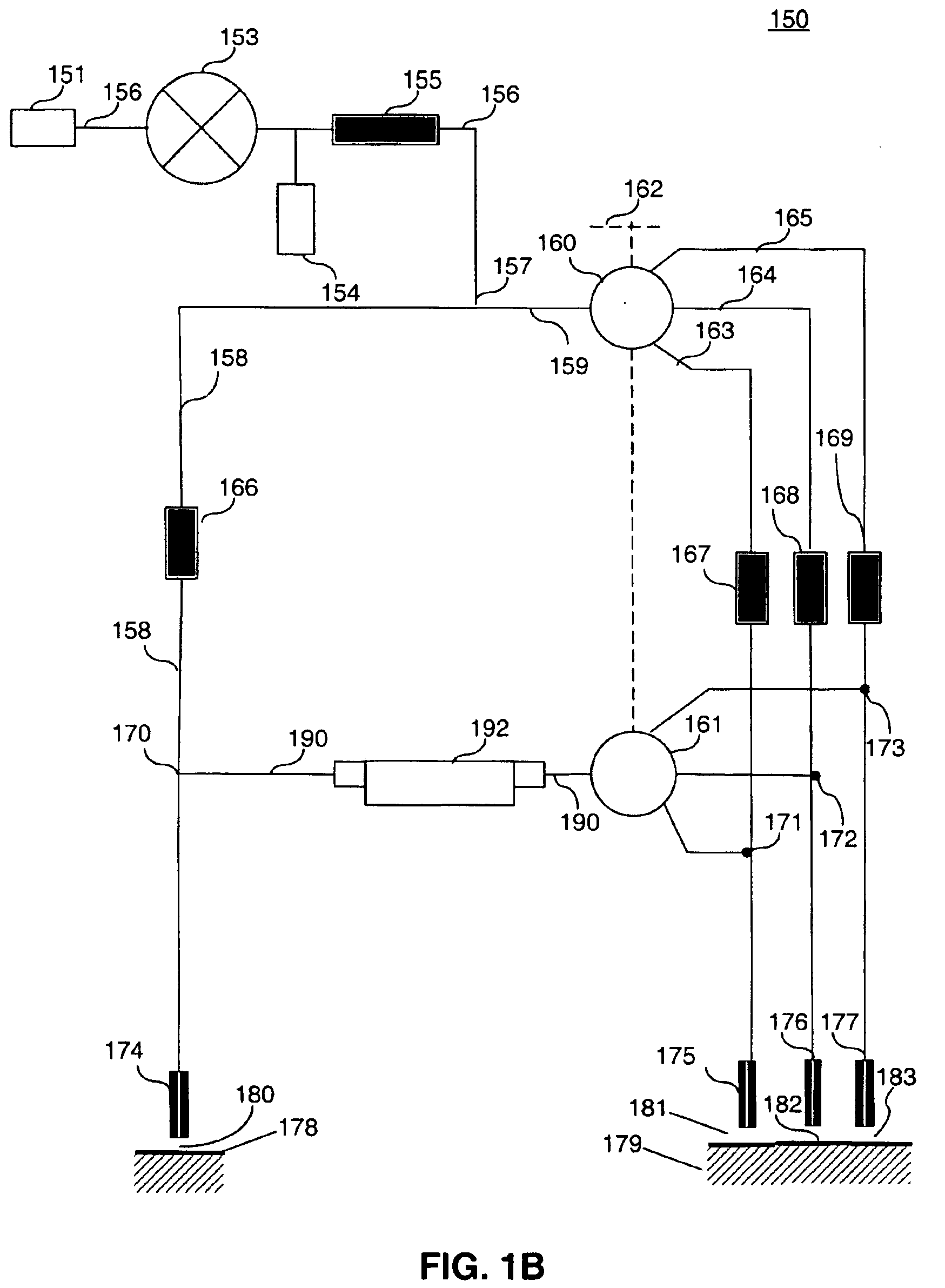

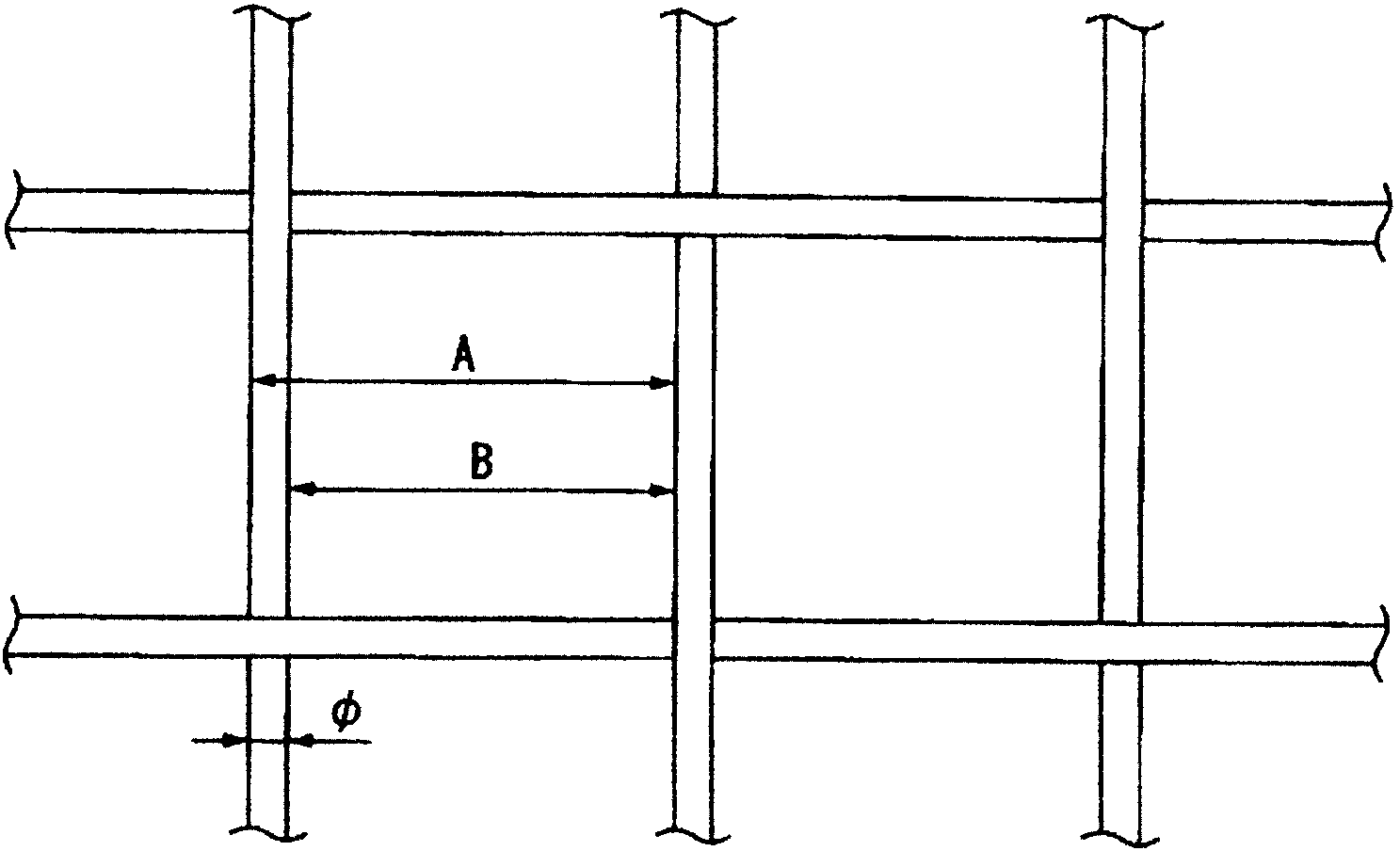

High-resolution gas gauge proximity sensor

InactiveUS7010958B2No turbulenceReduce noiseVolume/mass flow measurementSemiconductor/solid-state device manufacturingProximity sensorEngineering

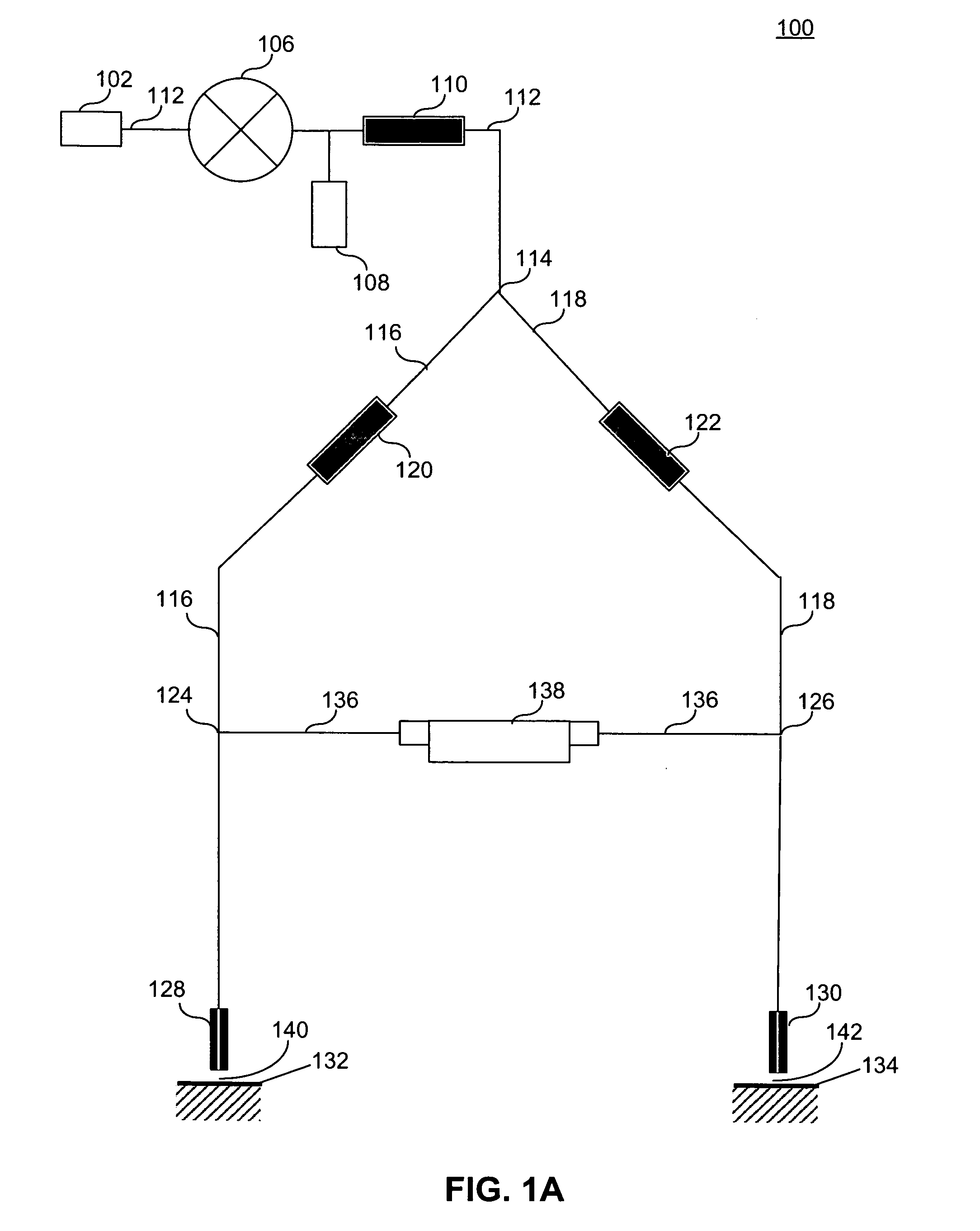

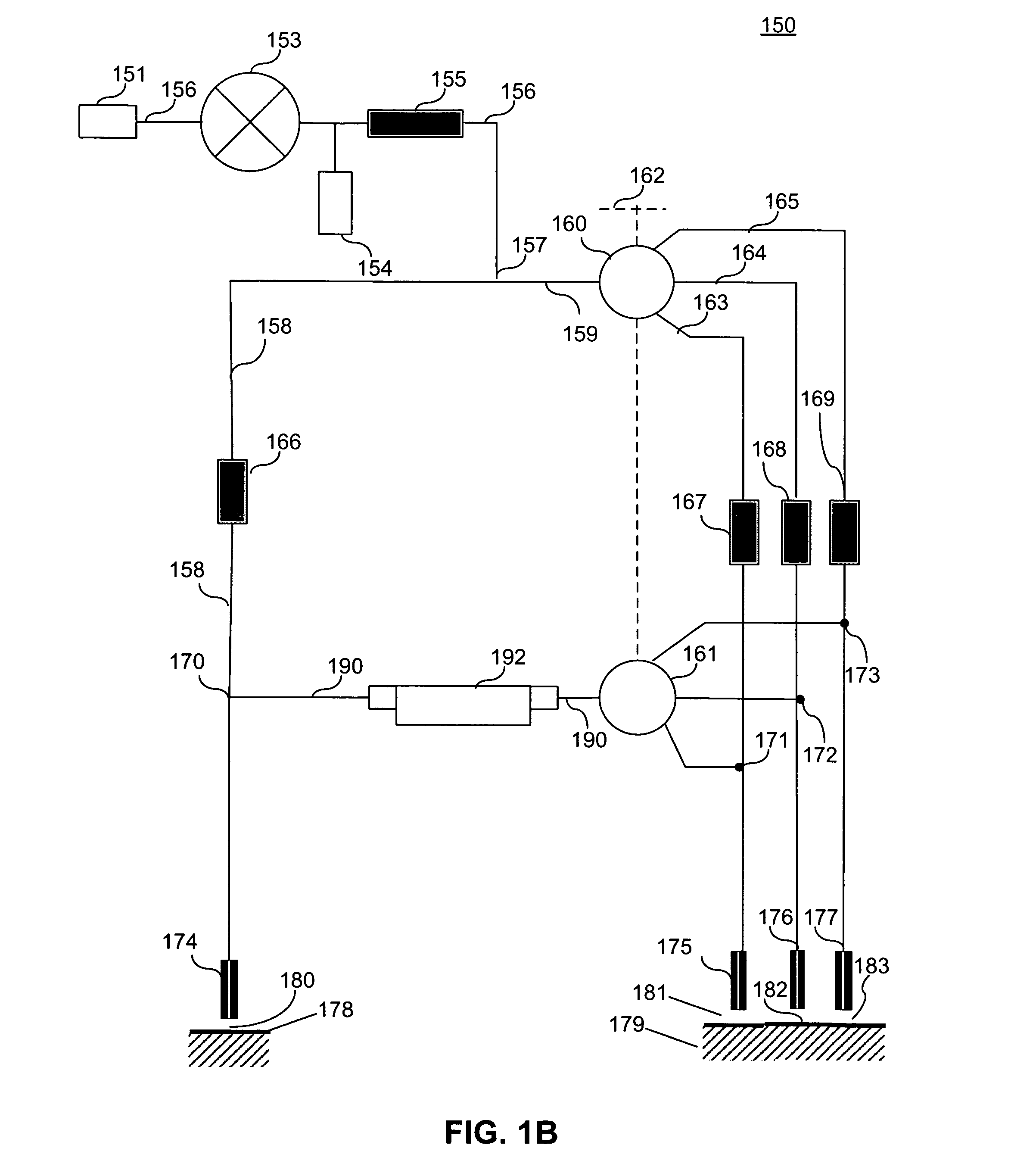

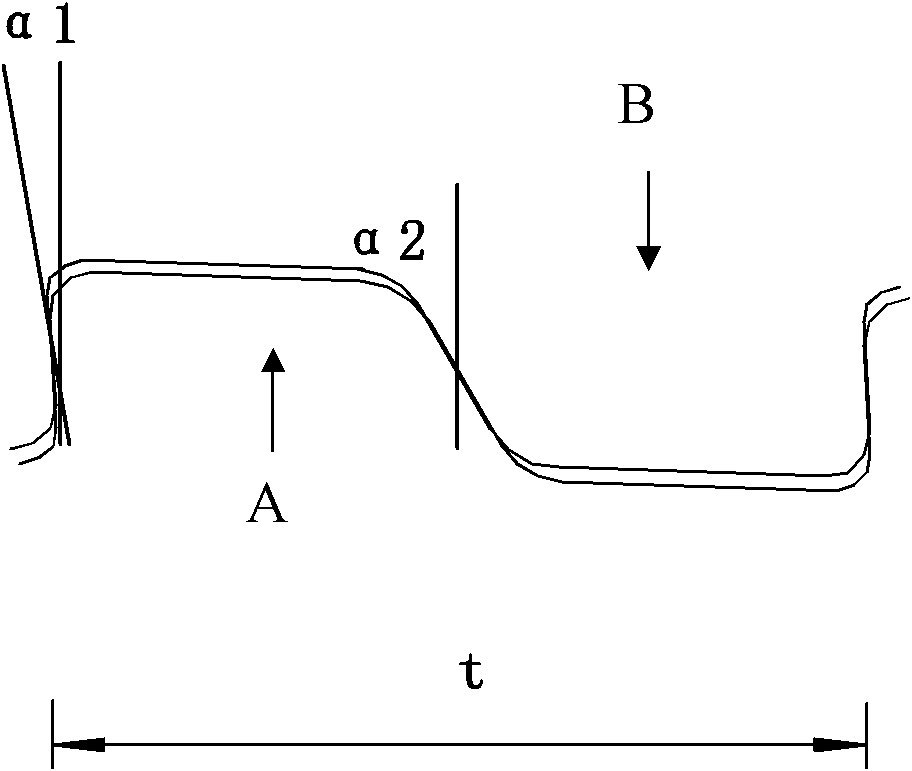

An apparatus and method for precisely detecting very small distances between a measurement probe and a surface, and more particularly to a proximity sensor using a constant gas flow and sensing a mass flow rate within a pneumatic bridge to detect very small distances. Within the apparatus the use of a flow restrictor, and / or snubber made of porous material, and / or a mass flow rate controller enables detection of very small distances in the nanometer to sub-nanometer range. A further embodiment wherein a measurement channel of a proximity sensor is connected to multiple measurement branches.

Owner:ASML HLDG NV

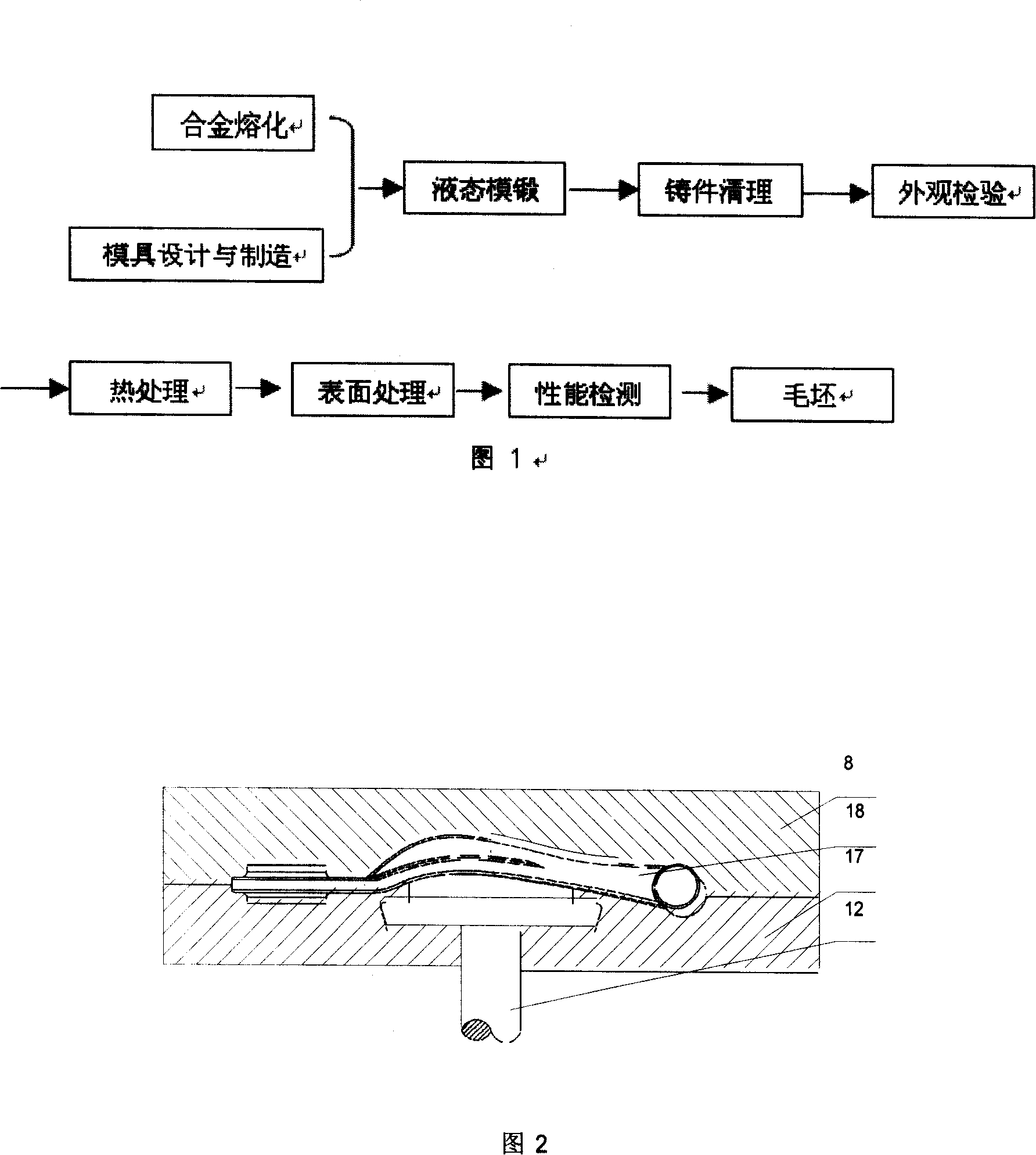

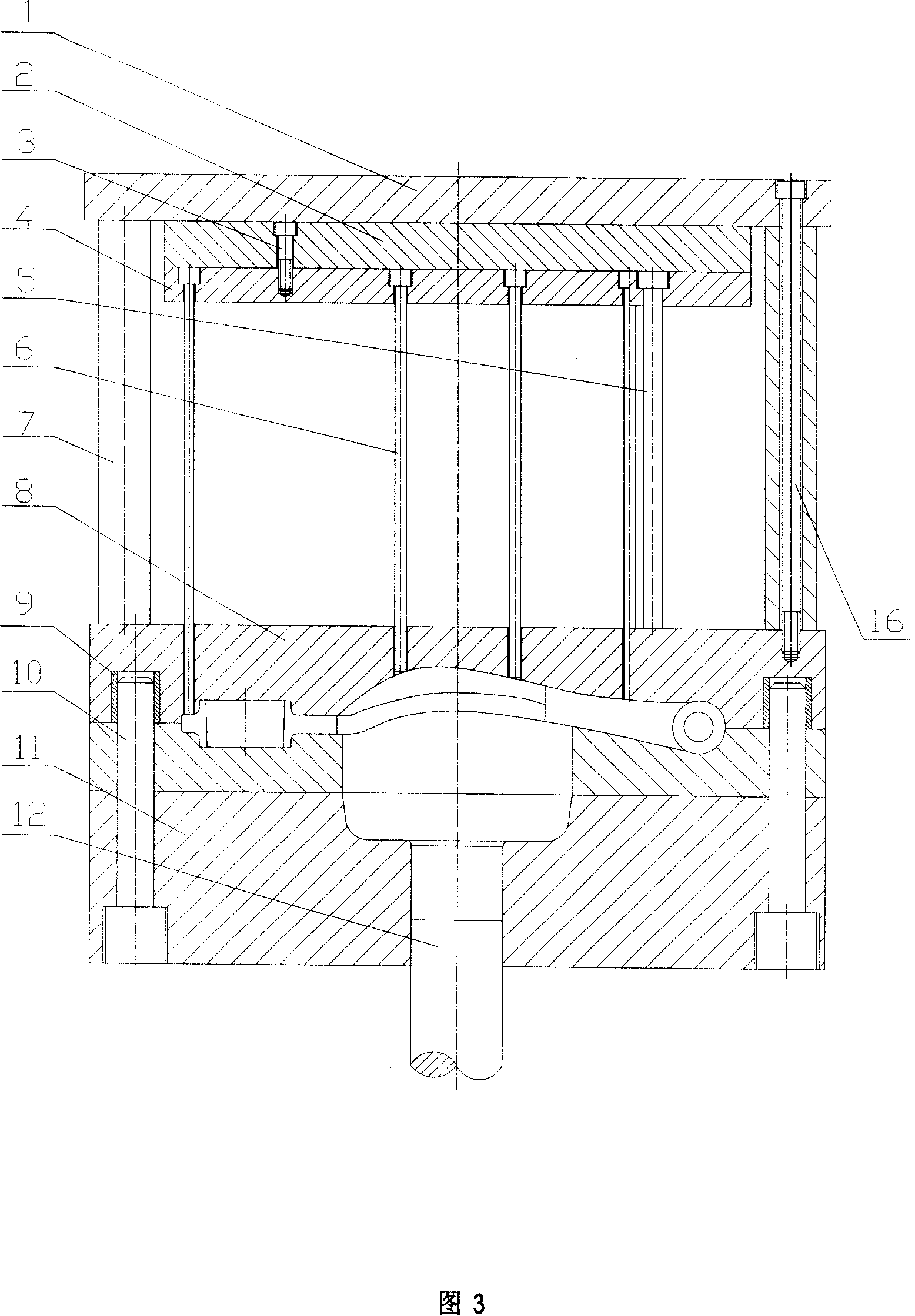

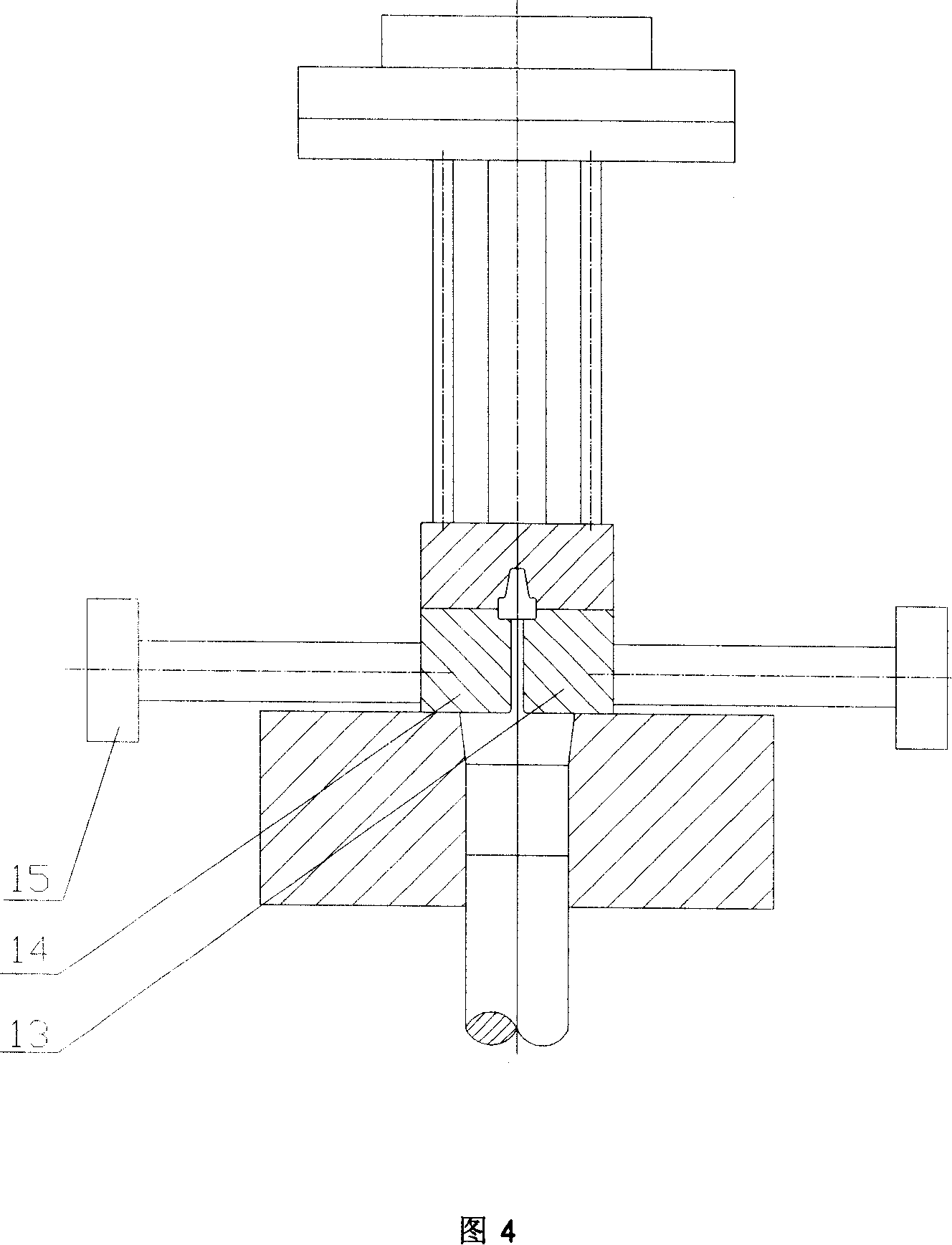

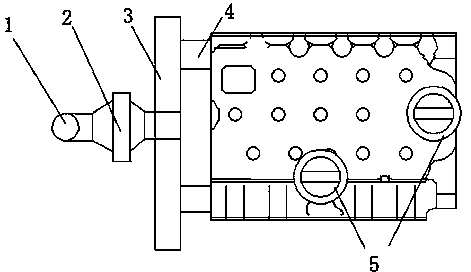

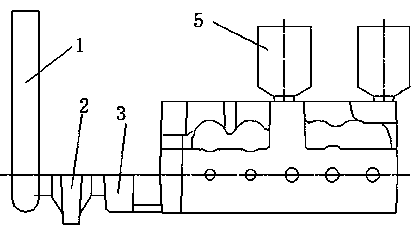

Aluminum alloy precast-forging forming technique and mold thereof

The invention relates to a forging technology and a device, in particular to aluminum alloy liquid forging molding technology and a module. In light of the technical problems that the prior art adopts complex module and process not suitable for aluminum alloy liquid forging, etc., the invention provides the forging module with simple structure and easy operation as well as the aluminum alloy liquid forging molding technology with reasonable process. The main technical proposal of the invention is as follows: a lower left module and a lower right module are arranged and fixed on a lower template in parallel, and a cylinder bottom punch gets through the lower template and is arranged between the lower left module and the lower right module; liquid aluminum alloy is injected into a cavity through a pouring port between the lower left module and the lower right module; an upper module is arranged on the lower left module and the lower right module and a pillar is also arranged and fixed; when in forging, the cylinder bottom punch conducts upward squeezing movement on liquid aluminum alloy; after meeting forging requirement, pressure can be maintained for 30 to 50 minutes.

Owner:宁波拓普隔音系统有限公司

Slag conglomerating and skimming method and device

The invention relates to the field of molten iron pretreatment desulfurization processes, in particular to a slag conglomerating and skimming method and a device. The slag conglomerating and skimming method sets a traveling wave magnetic field; the phase of the magnetic field is controlled to enable the moving direction of molten iron driven by the traveling wave magnetic field to point to a ladle port; the traveling wave magnetic field enables the molten iron to flow to the ladle port under the effect of electromagnetic force, so that molten iron slag is conglomerated in the ladle port; and when the conglomerated molten iron slag is higher than the ladle port, the molten iron slag can overflow a ladle to enter a slag receiving tank so as to realize the ladle slag skimming. The slag conglomerating and skimming device comprises an electromagnetic winding and the slag receiving tank; the electromagnetic winding is arranged above the ladle; the magnetic force line of a magnetic field generated by the electromagnetic winding is pointed to an area of the ladle port; and the slag receiving tank is arranged below the ladle port. The slag conglomerating and skimming process is finished under non-contact conditions without generating the molten iron oscillation phenomenon; the molten iron nearly has no loss; the precise slag conglomerating and skimming operation is realized without polluting the molten iron; and the ton steel energy consumption can be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

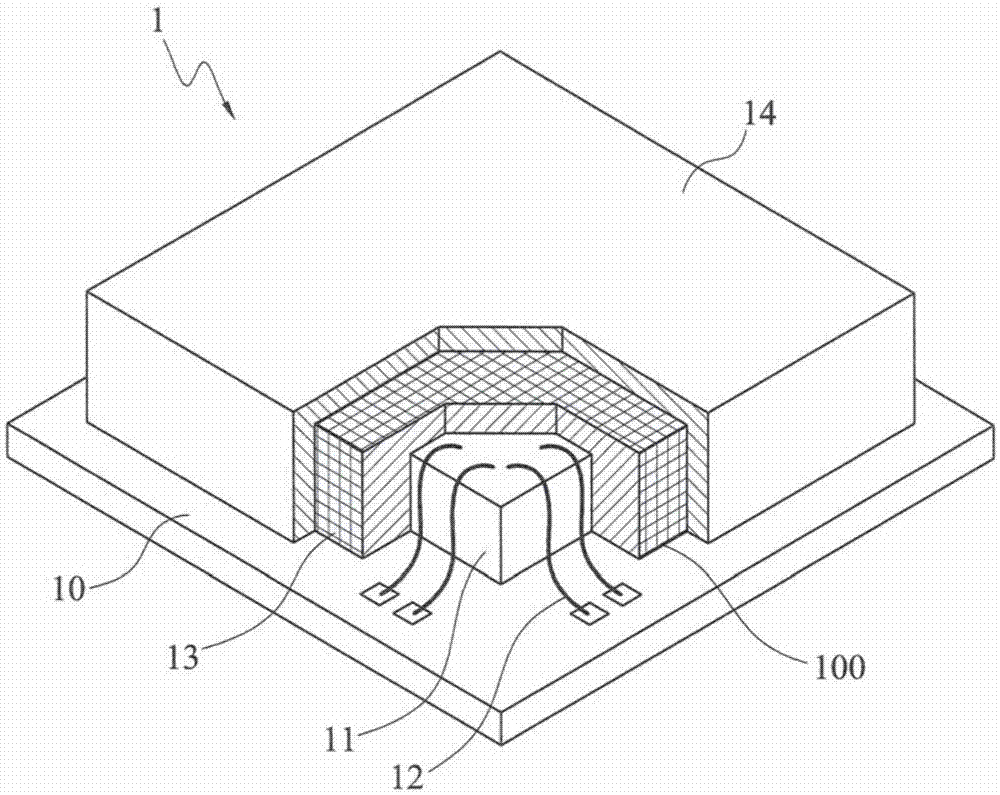

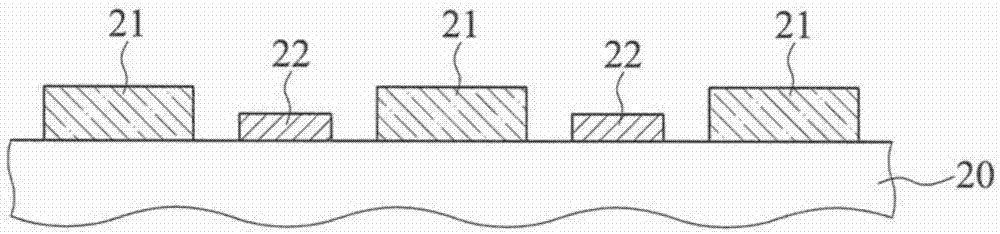

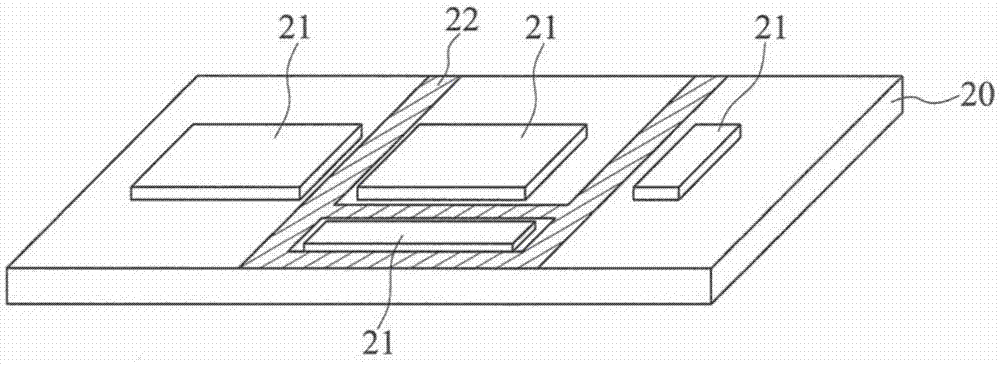

Packaging structure and preparation method thereof

InactiveCN107104094AEasy to manufactureEMI suppressionSemiconductor/solid-state device detailsSolid-state devicesElectromagnetic interferenceElectronic component

A packaging structure and preparation method thereof. The packaging structure includes a bearing piece whose surface is provided with a metal layer and an electronic component, a wrapping layer which warps the electronic component and a shielding layer arranged on the wrapping layer. The metal layer surrounds the electronic component and is exposed out of the wrapping layer, the shielding layer is in contact with the metal layer, so as to suppress electromagnetic interference, thereby preventing the electronic component from electromagnetic wave interference.

Owner:SILICONWARE PRECISION IND CO LTD

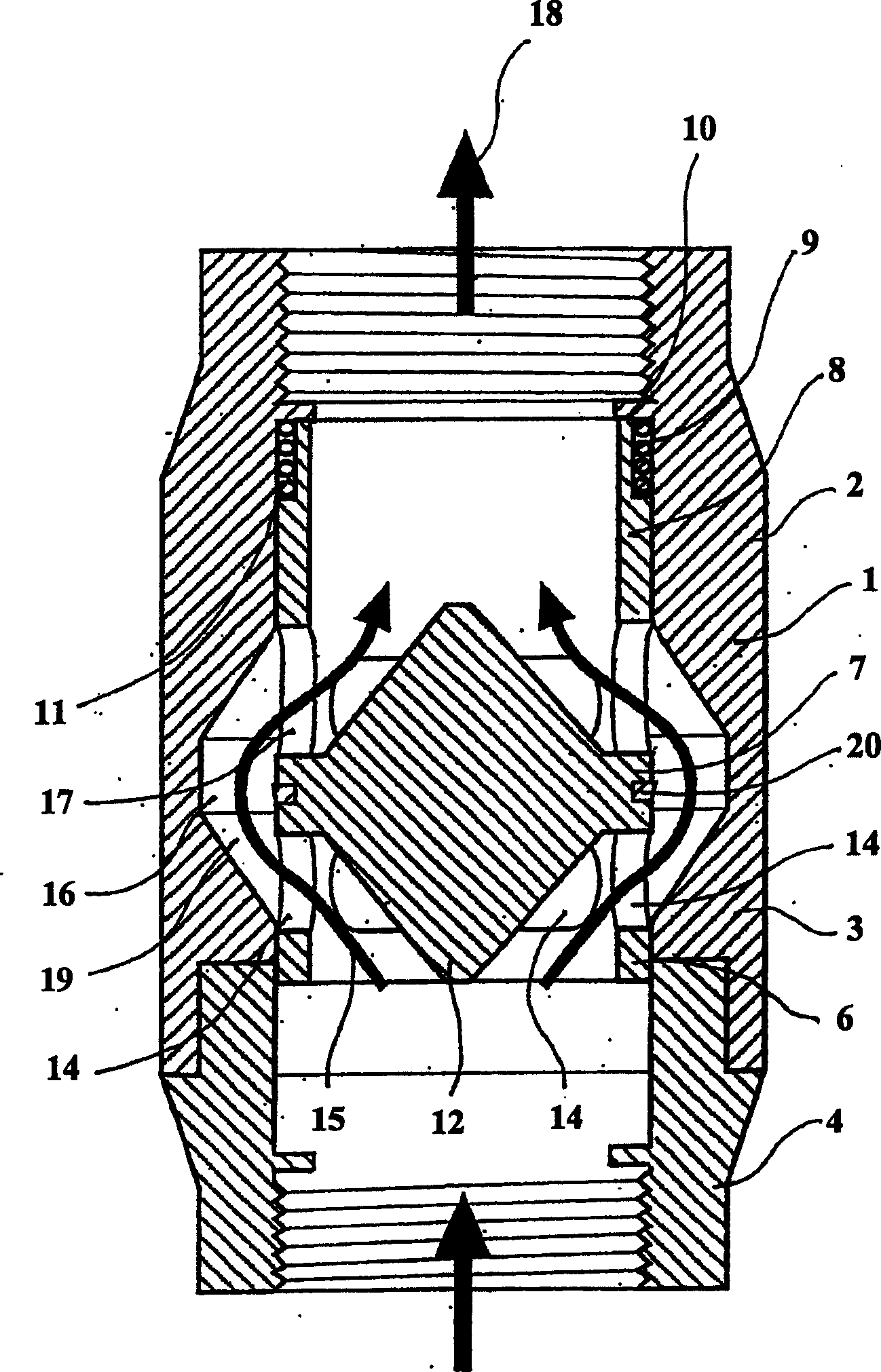

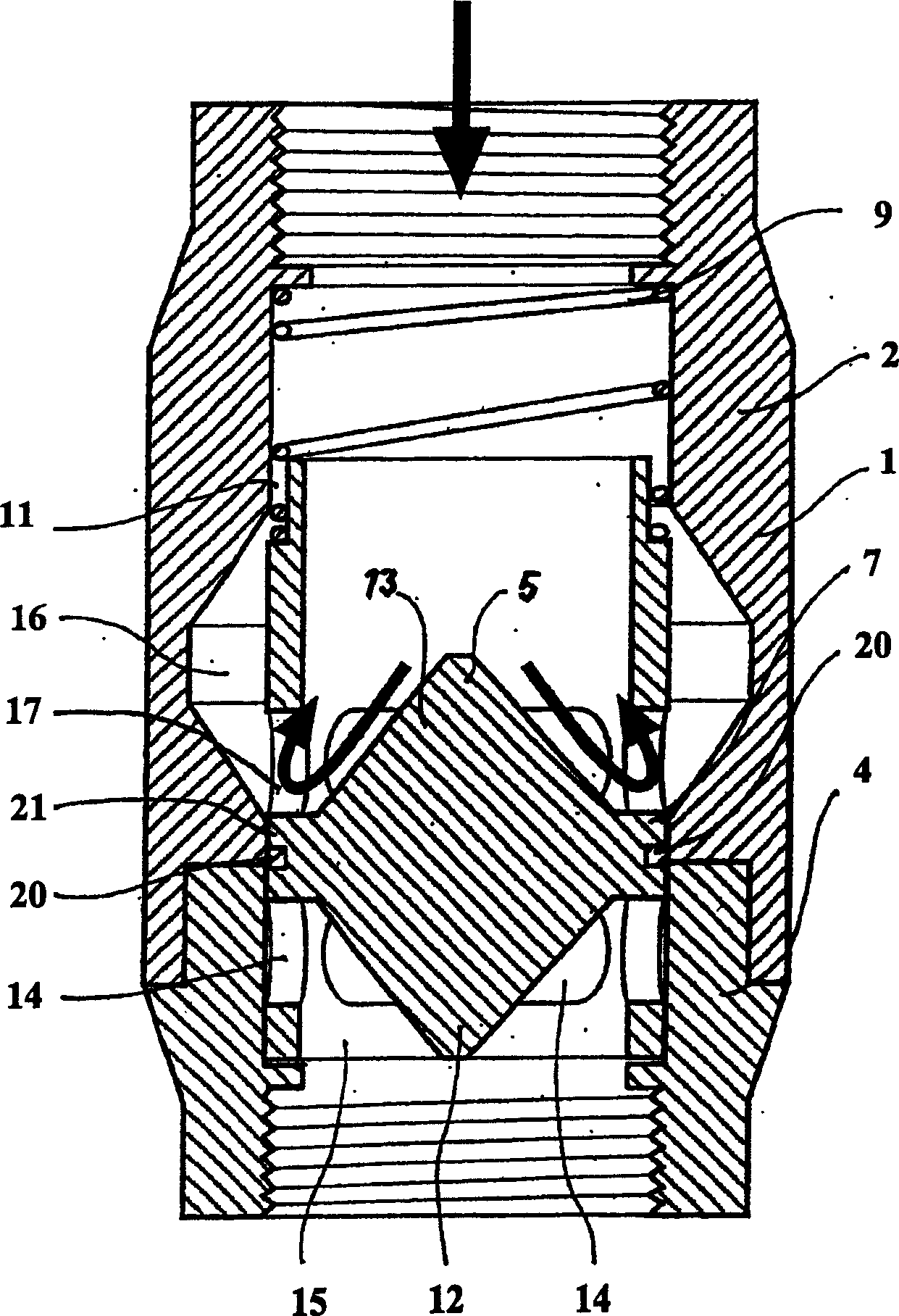

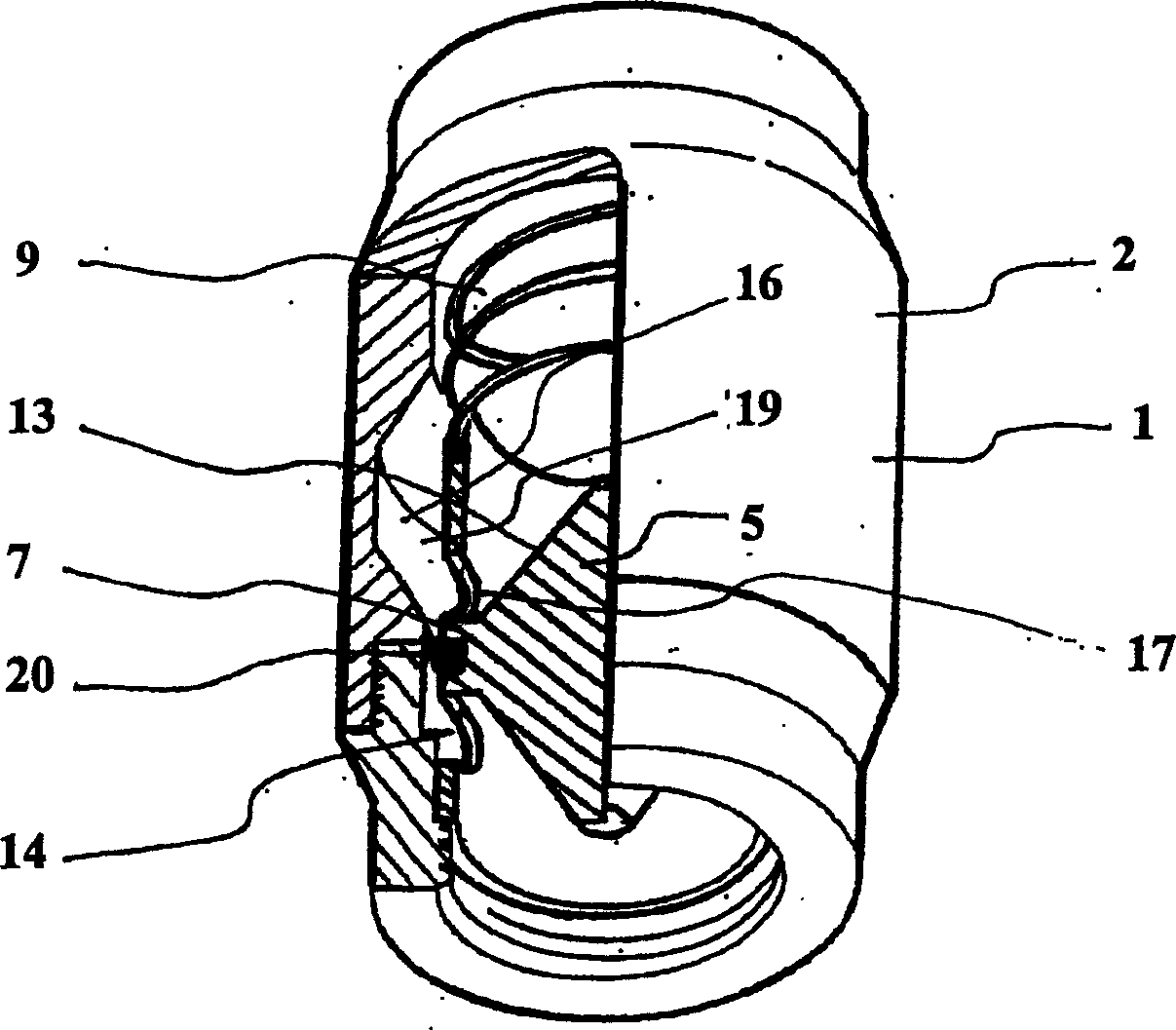

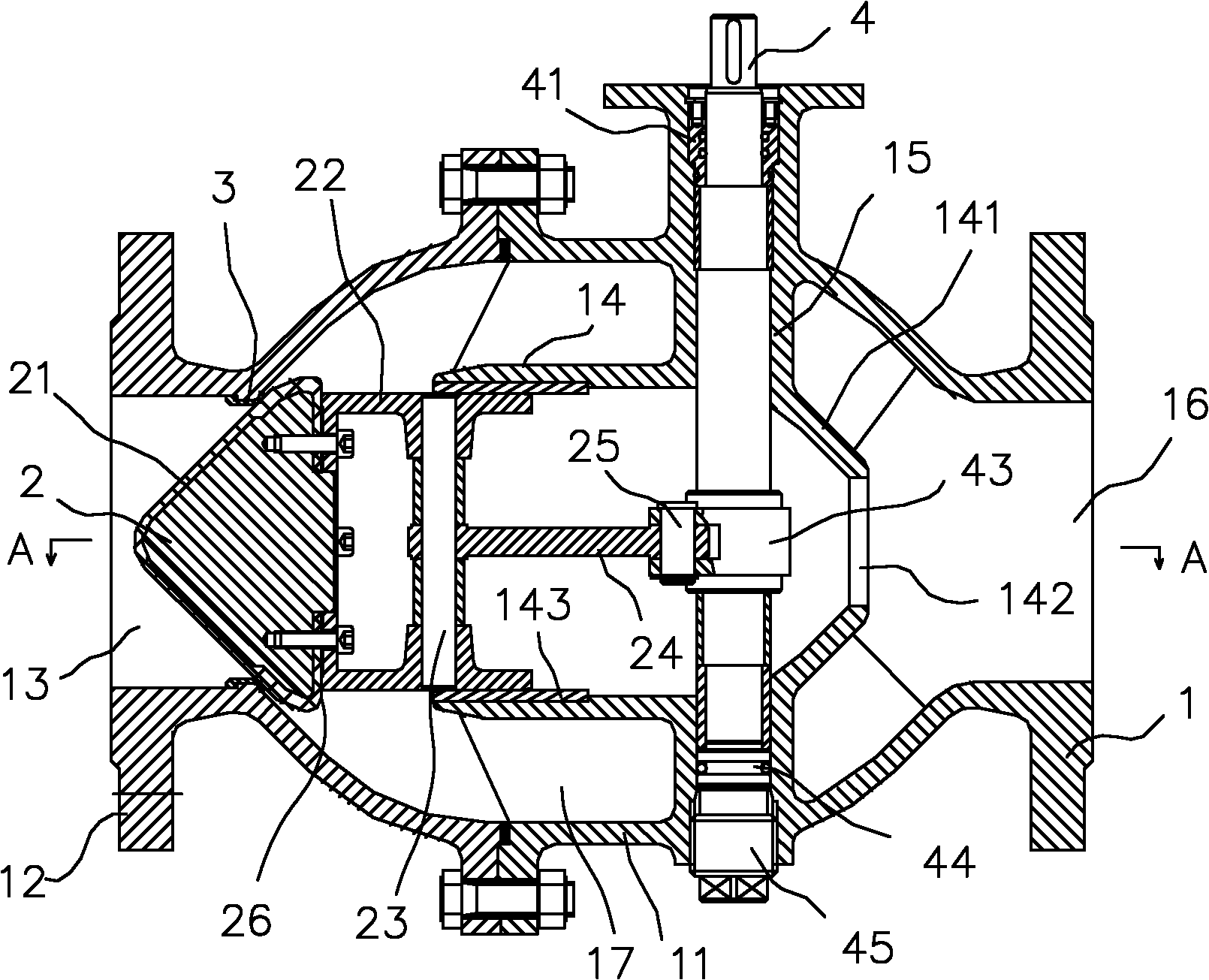

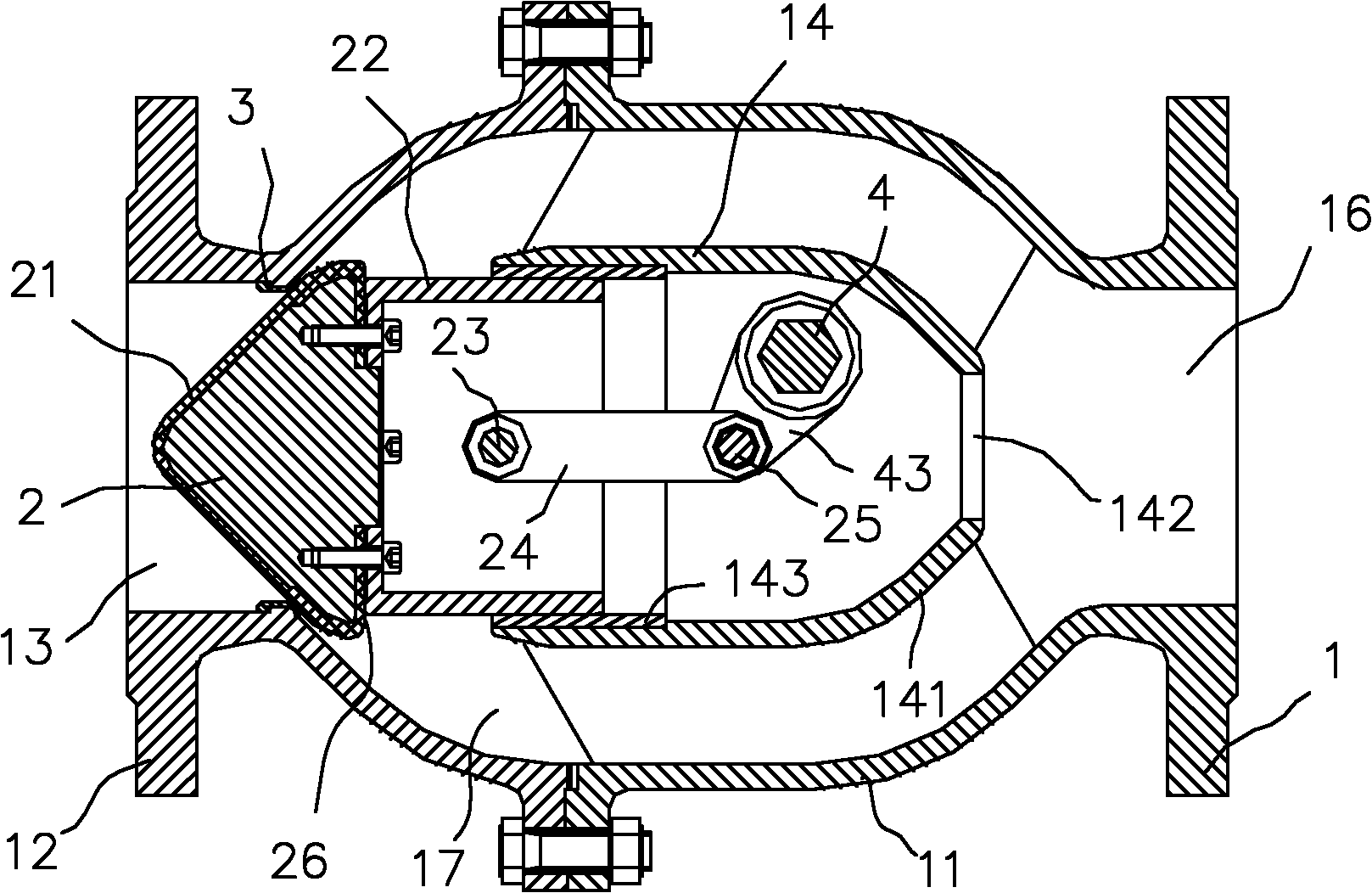

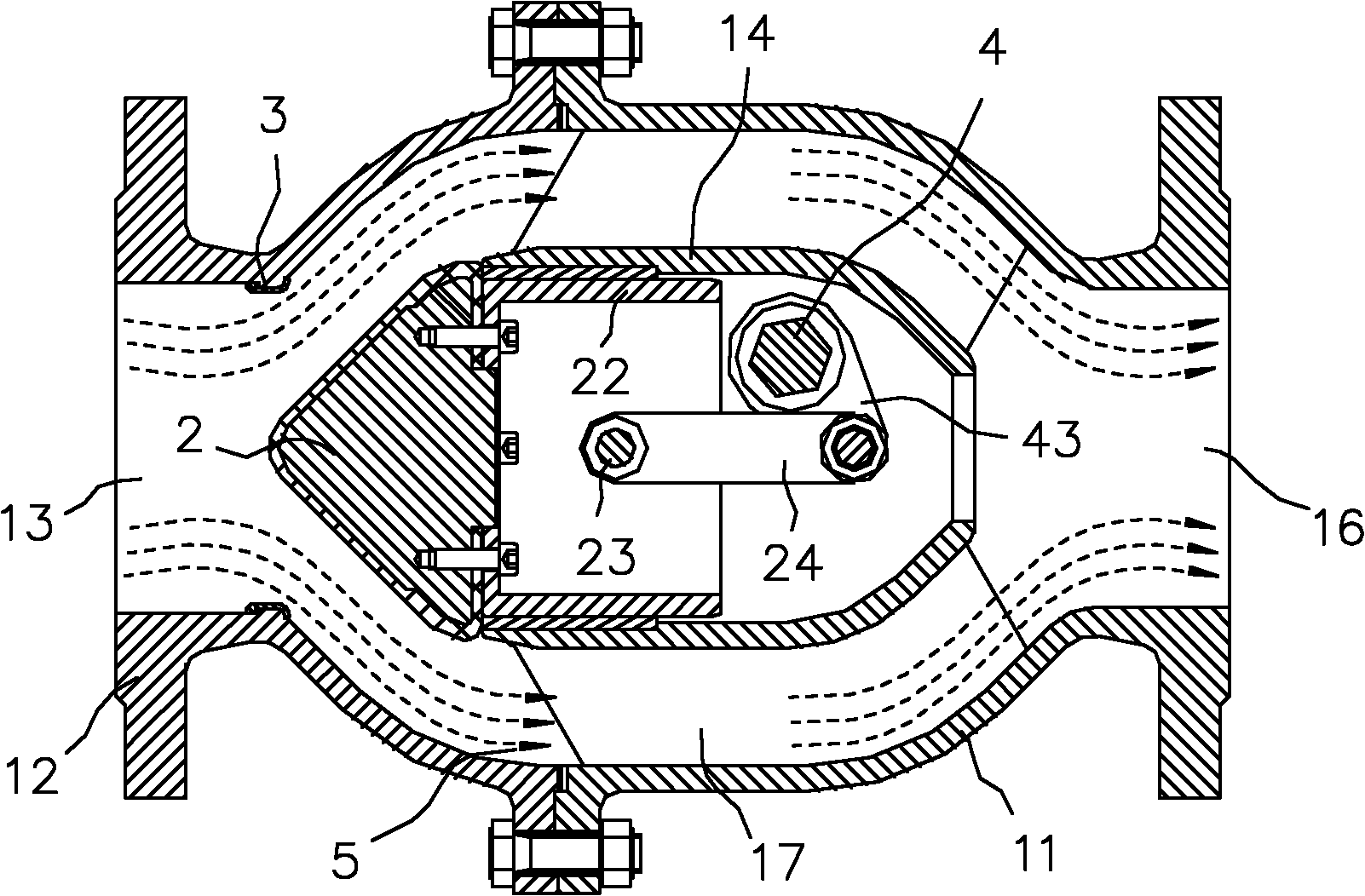

A check valve

A check valve comprising an outer body having an inner bore, and a reciprocating slide disposed within the inner bore for a closed position relative to the inner bore to prevent liquid flow through the valve and to allow liquid flow through the valve. Elastic means for moving between open positions of the valve and biasing the position of the reciprocating slide towards the closed position, characterized in that the reciprocating slide has a downstream portion, an upstream portion and an intermediate portion, each portion sliding fit in engagement with the bore and such that, when in the closed position, the intermediate portion sealingly engages the bore, and when in the open position, is configured to allow fluid to flow through a passage around the intermediate portion comprising at least The path through this external body.

Owner:HYDRO FLO HLDG

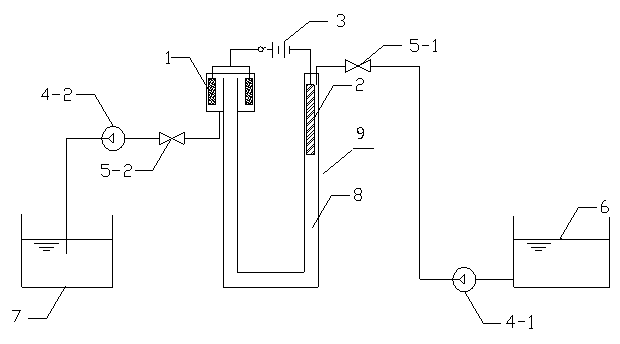

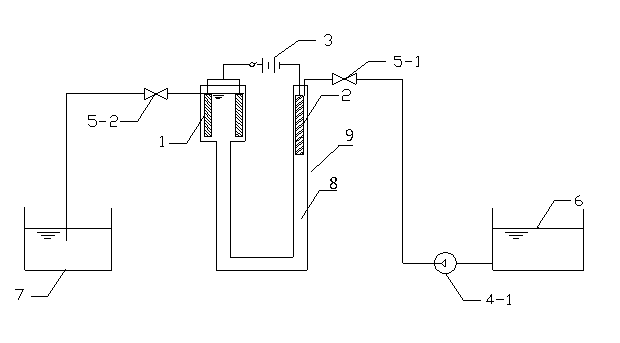

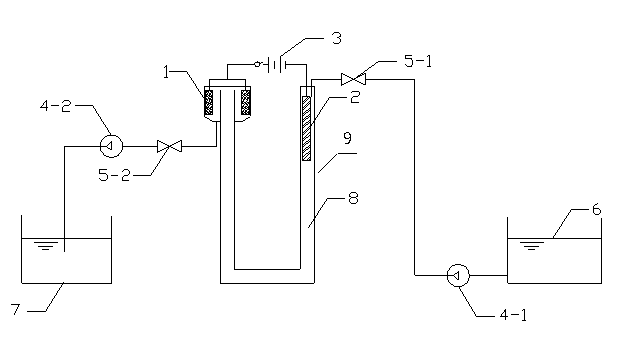

Device and process for preparing liquid ferrate through electrolysis method

The invention relates to a device for preparing liquid ferrate through an electrolysis method. The device is characterized in that an electrolyzer is a U-shaped pipe electrolyzer, an alkali liquor inlet of an alkali liquor storage tank is communicated with the alkali liquor inlet of the U-shaped pipe electrolyzer through an alkali liquor delivery pump and an alkali liquor control valve which are arranged on a pipeline, the liquid ferrate outlet of the U-shaped pipe electrolyzer is communicated with a liquid ferrate storage tank through a liquid ferrate control valve and a liquid ferrate delivery pump which are arranged on the pipeline, a side pipeline of the alkali liquor inlet of the U-shaped pipe electrolyzer is a cathode chamber, a cathode electrode is arranged in the cathode chamber of the U-shaped pipe electrolyzer, a side pipeline of the liquid ferrate outlet of the U-shaped pipe electrolyzer is an anode chamber, at least one anode electrode is arranged in an enlarged containing groove of the anode chamber of the U-shaped pipe electrolyzer, and the cathode electrode and the anode electrode are connected with a direct current power source. The device is simple in structure, economical and applicable, scientific and reasonable in technologic process, and low in operation cost, has high current efficiency and good effect, and can be widely used for interval or continuous production.

Owner:NORTHEAST DIANLI UNIVERSITY

Chill-free processing method of wind-driven generator hub

The invention discloses a chill-free processing method of a wind-driven generator hub, and the method comprises the following steps: manufacture of a mould, manufacture of a sand mould and moulding by casting, wherein in the manufacture of the sand mould, a completely opened bottom gating system is utilized; an ingate is designed to be disc-shaped; a downgate on an upper sprue is a quantitative ladle stopper sprue gate; the ratio of the components is F(straight):F(transverse):F(internal)=1:(1.5-2):(25-28); a rectangular vent hole is arranged at the highest point at the top face of a casting; the total section area of the rectangular vent hole is greater than that of the ingate; a casting head is arranged on the top face of the casting; the height of the single casting head is greater than 400 mm; no chills are discharged during the manufacture procedure; in the moulding by casting, the casting speed of melted iron entering into a casting cavity is controlled within 0.5-1.0 m / s; the casting time is controlled within 150-210 seconds; and the casting temperature is between 1300 and 1310 DEG C. The chill-free processing method of the wind-driven generator hub disclosed by the invention has the advantages that the method adapts to the large scale production of low-temperature ductile iron castings for large wind-driven generator with quite high requirements, the process is simple, and the production cost is low.

Owner:宁波日星铸业有限公司

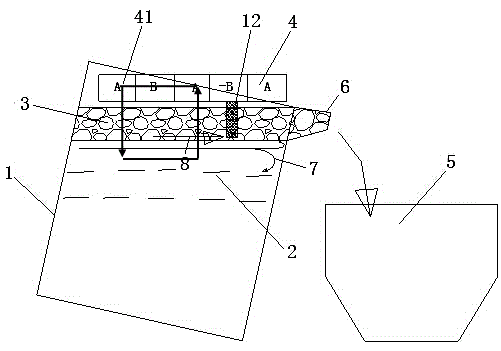

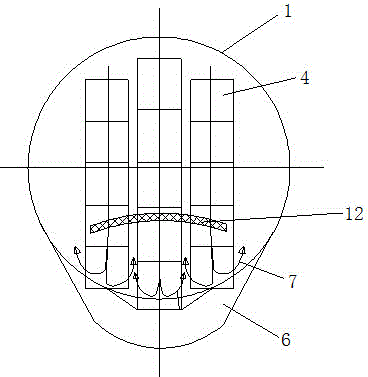

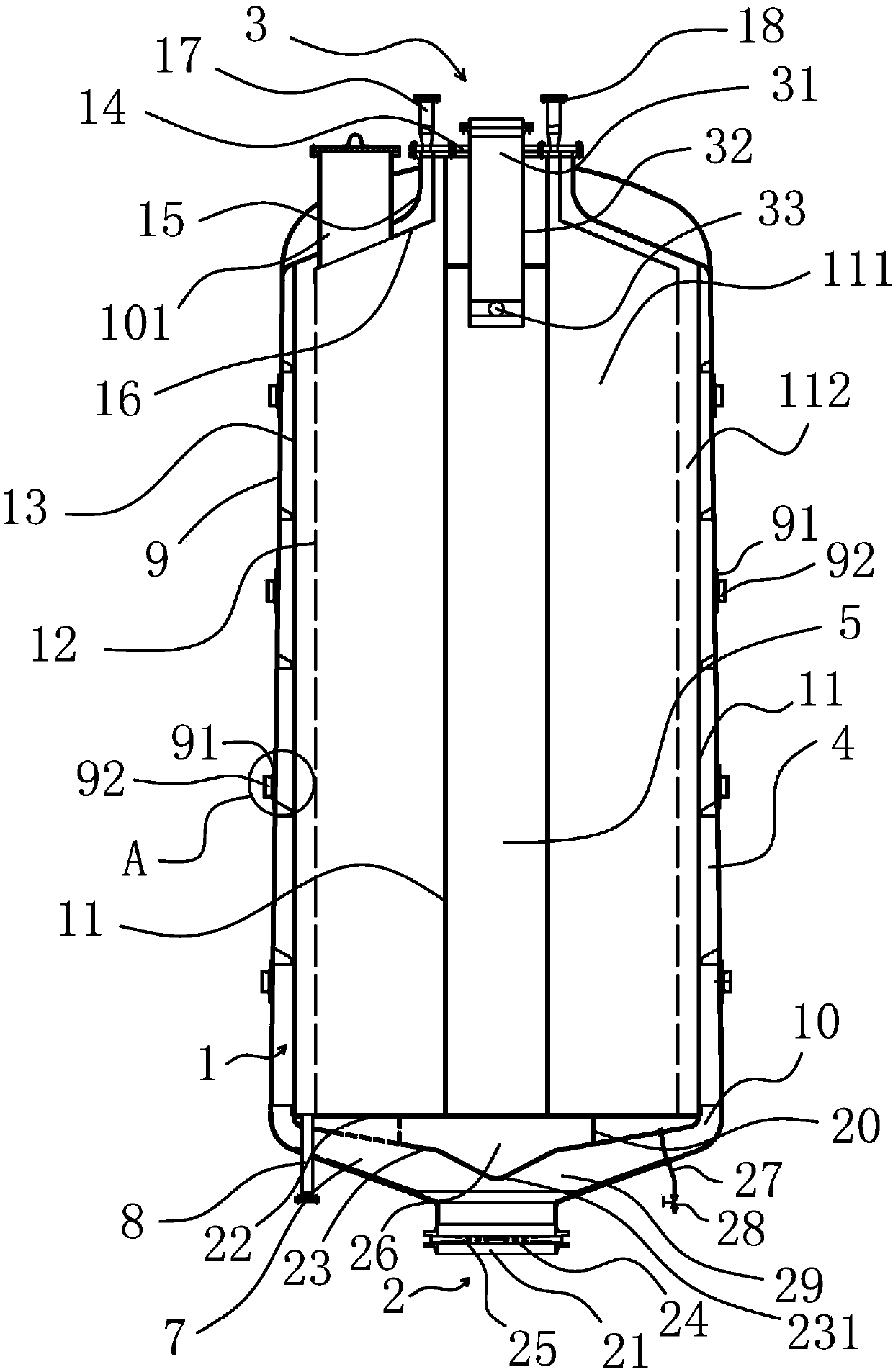

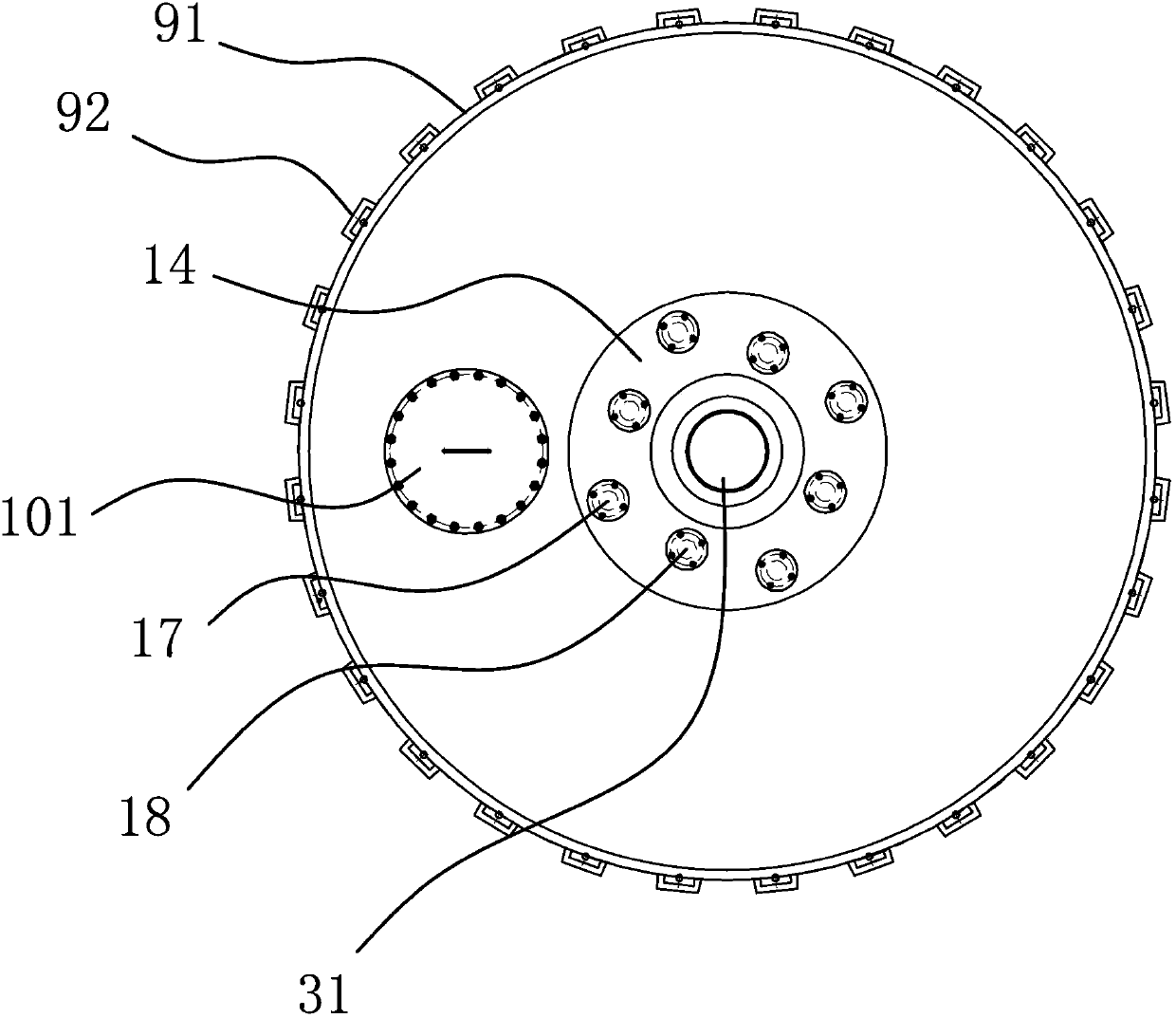

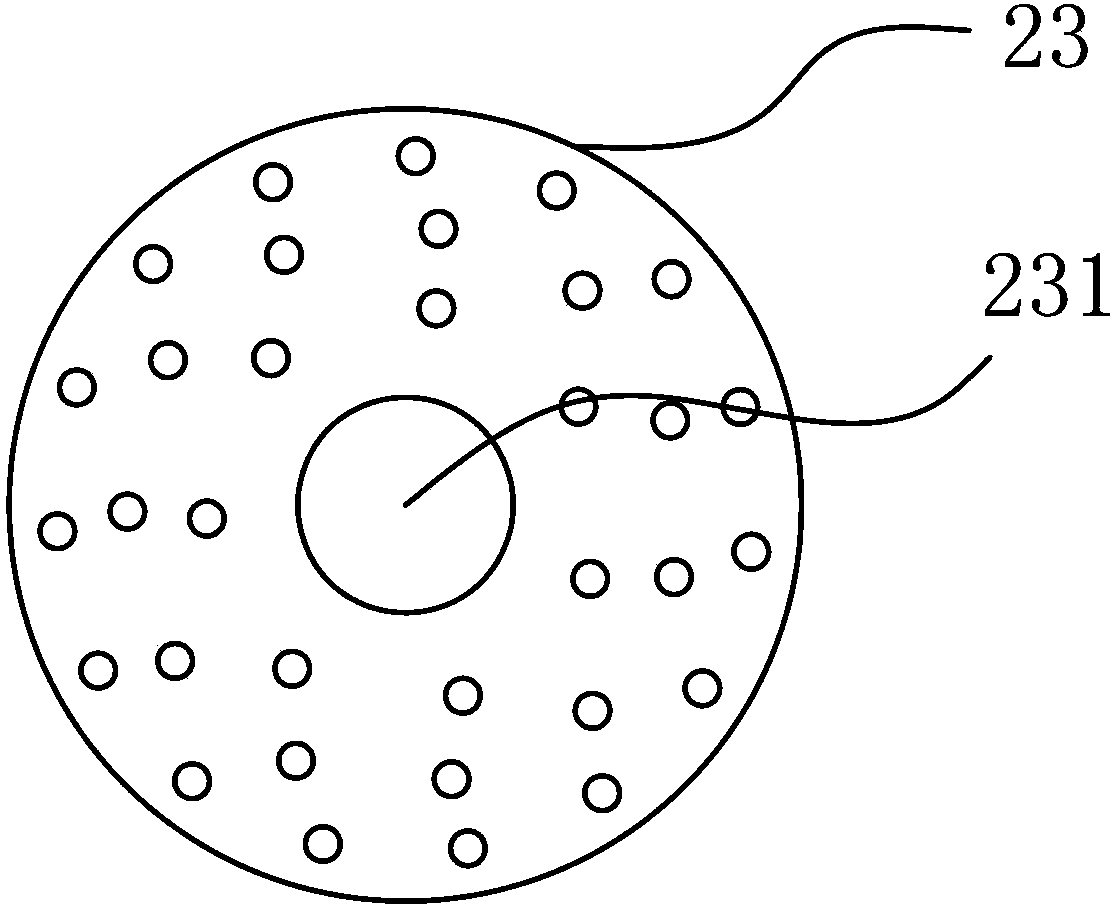

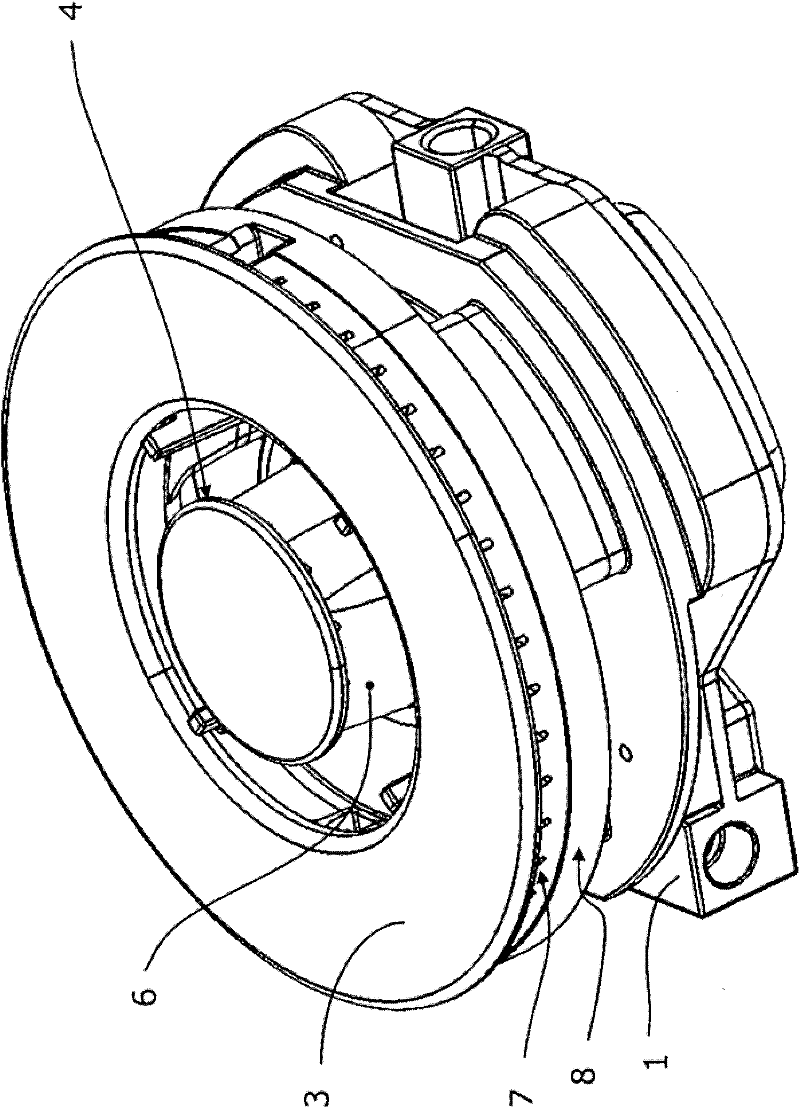

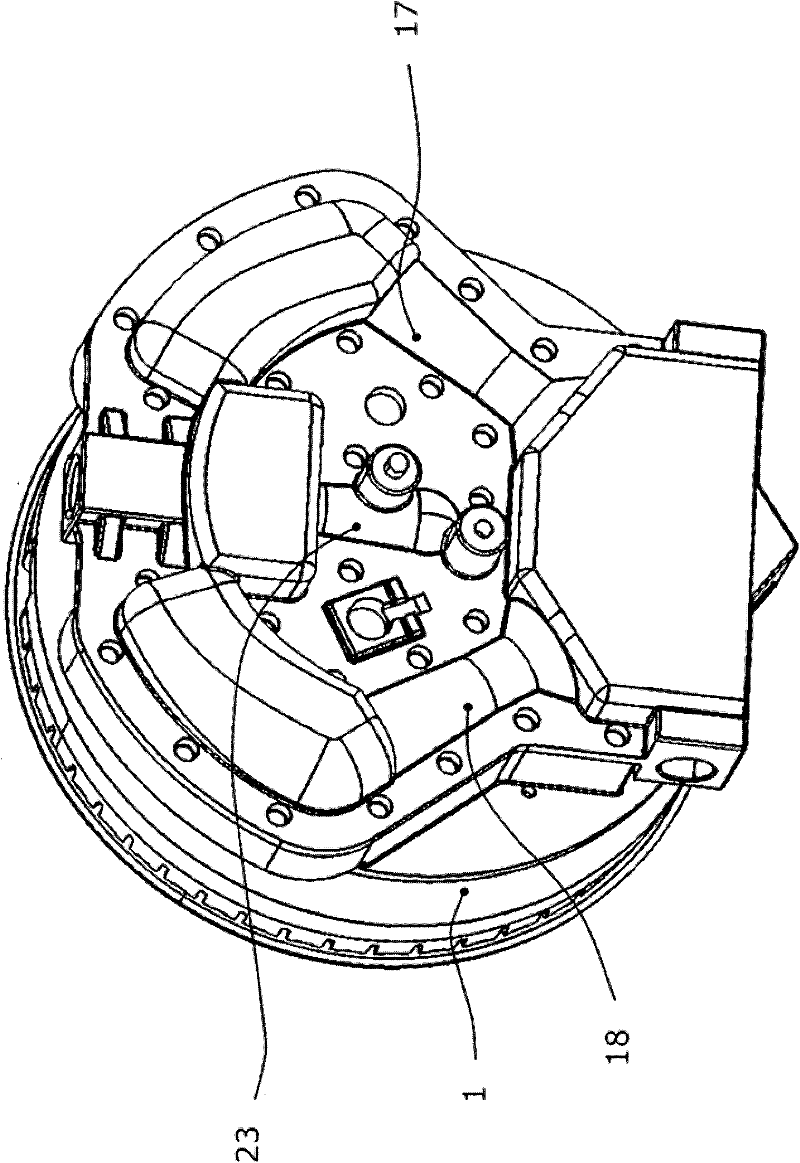

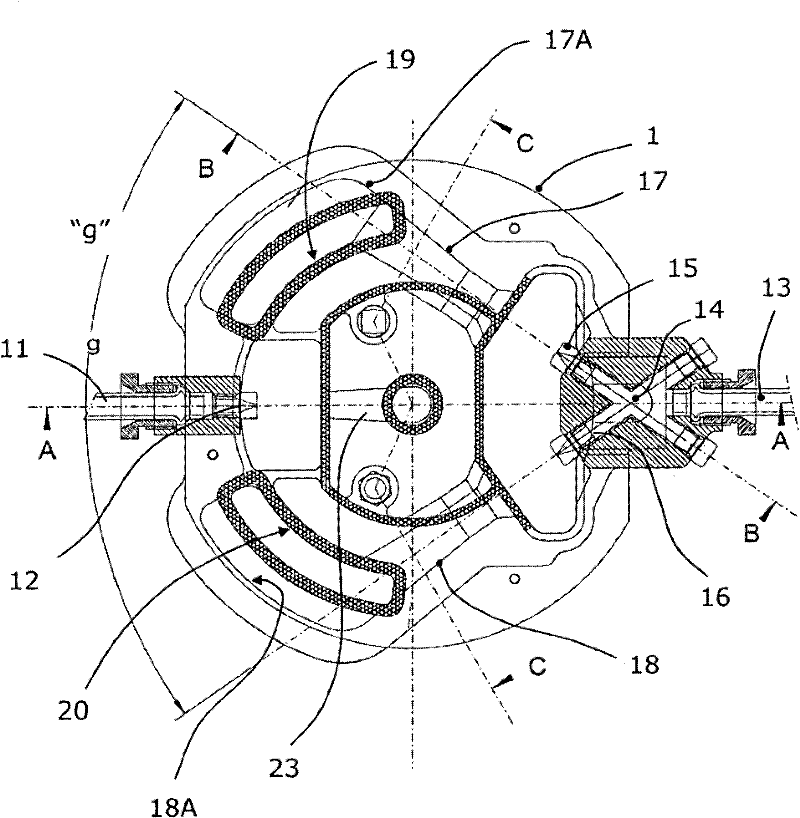

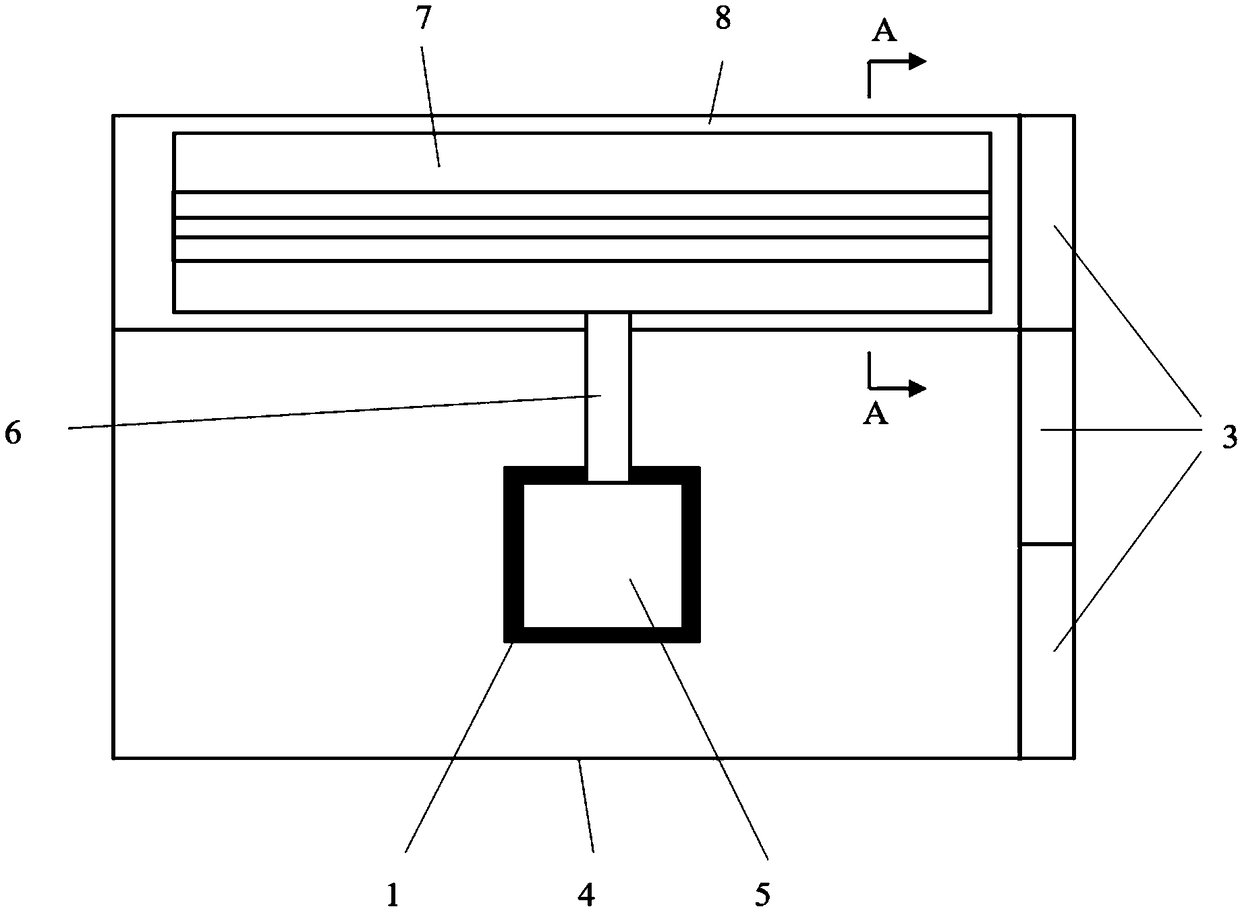

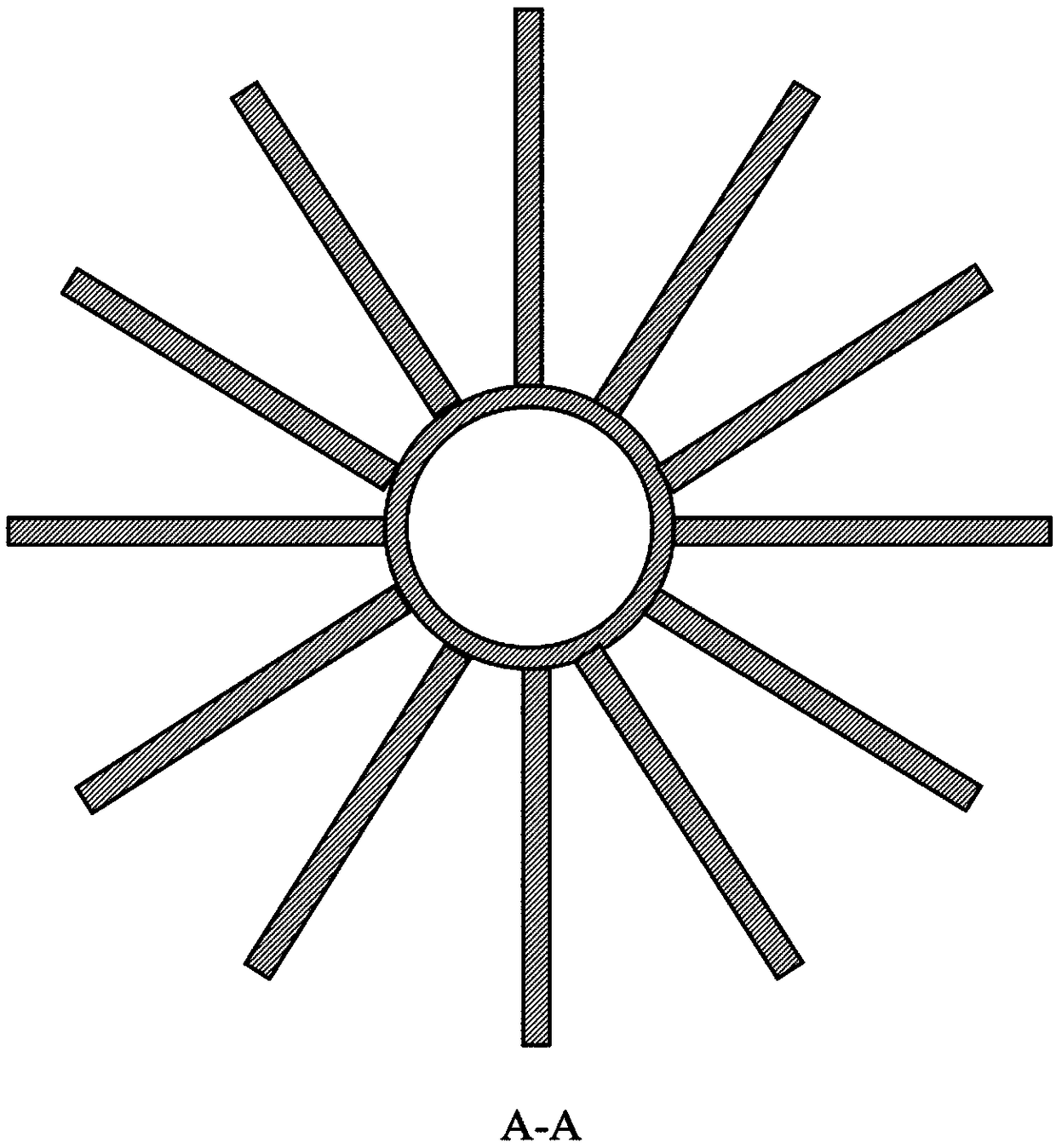

Radial oxygen production adsorption tower

ActiveCN103357243AUniform adsorptionImprove adsorption efficiencyDispersed particle separationOxygen preparationDiameter ratioMechanical equipment

The invention provides a radial oxygen production adsorption tower, belongs to the technical field of mechanical equipment, and solves the technical problems of too small height-diameter ratio, too large occupied floor space, non-uniform adsorption and the like in the prior art. The oxygen production adsorption tower comprises a cylindrical tower body, an gas inlet assembly disposed at the bottom of the tower body, an gas outlet assembly disposed at the top of the adsorption assembly, an adsorption assembly disposed in the tower body and a circular gas transportation cavity formed between the inner wall of the tower body and the outer wall of the adsorption wall, wherein the gas inlet assembly is provided with a circular gas vent disposed at the periphery of the lower end of the adsorption assembly; the circular gas vent is communicated with the gas transportation cavity; a gas flow can be transported to the adsorption assembly radially by the gas transportation cavity; two ends of the adsorption assembly are sealed; the center of the adsorption assembly is provided with a gas collection channel for collecting finished product oxygen; the lower end of the gas collection channel is sealed; and the upper end of the gas collection channel is communicated with the gas outlet assembly. The radial oxygen production adsorption tower has the advantages of uniform adsorption, high adsorption efficiency, small occupied floor space, large-scale designability, etc.

Owner:杭州普菲科空分设备有限公司

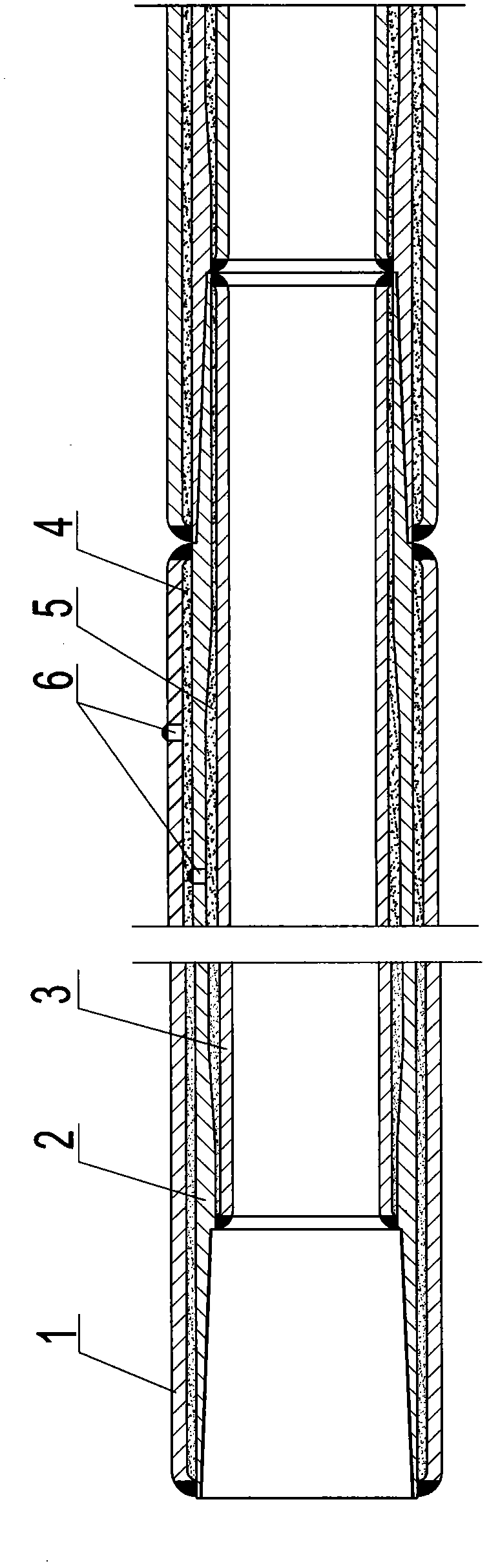

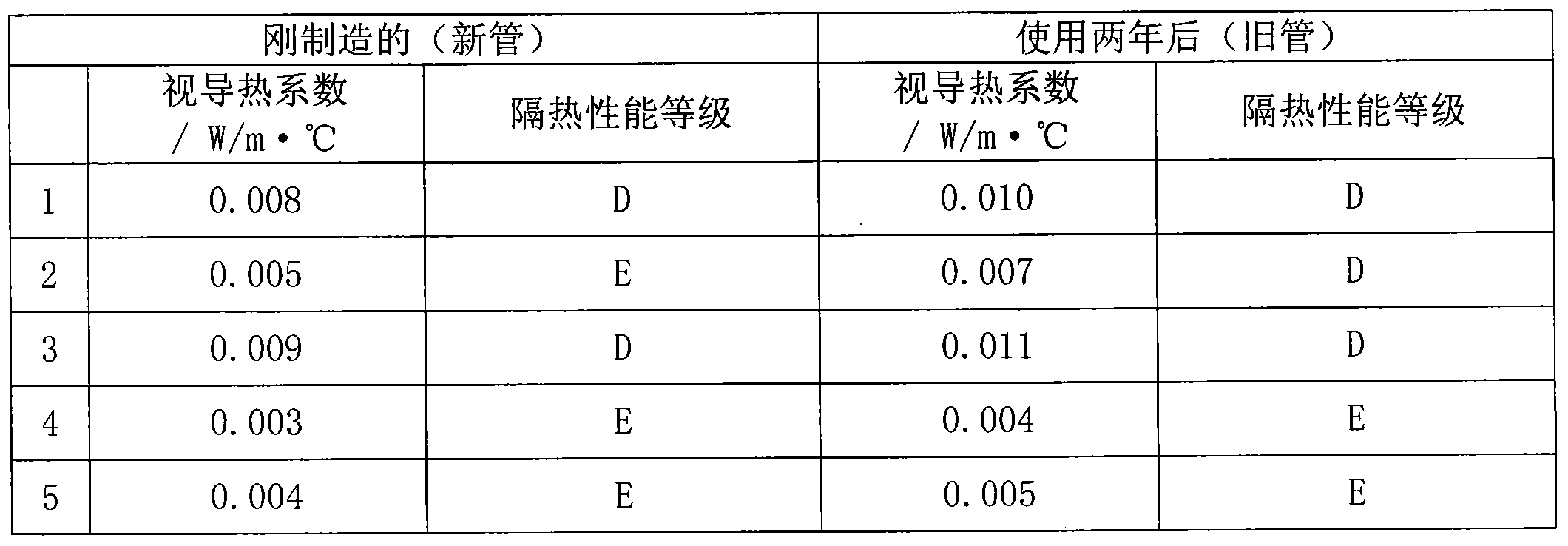

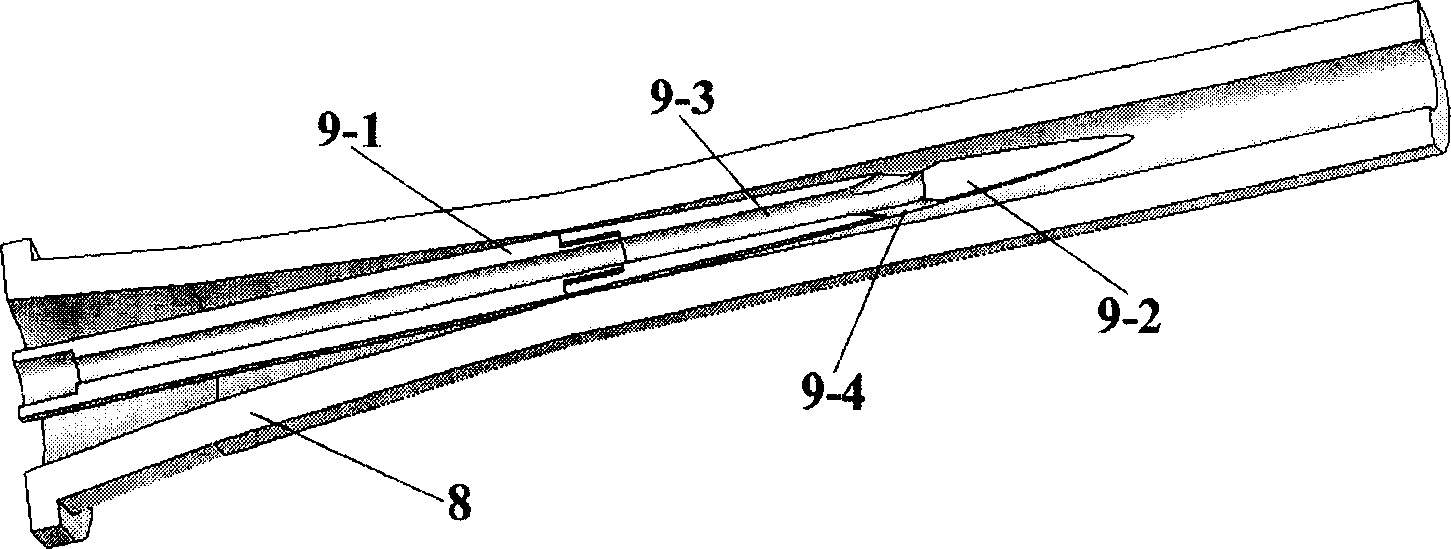

Heat-insulating oil sleeve and manufacturing method thereof

ActiveCN103850653AImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsEngineeringScrew thread

The invention relates to a heat-insulating oil sleeve. The heat-insulating oil sleeve is characterized by comprising an outer pipe, an intermediate pipe and an inner pipe which are sleeved in a clearance fit way; internal threads are machined at one end of the intermediate pipe; external threads are machined at the other end of the intermediate pipe; one end, provided with the internal threads, of the intermediate pipe is welded with the outer pipe at a pipe end, and is welded with the inner pipe at the length position of the preserved internal threads; one end, provided with the external threads, of the intermediate pipe is welded with the outer pipe at the length position of the preserved external threads, and is welded with the inner pipe at the pipe end; an annular cavity formed by the outer pipe and the intermediate pipe is filled with a heat-insulating material and is vacuumized to form a first heat-insulating layer; an annular cavity formed between the intermediate pipe and the inner pipe is vacuumized and is injected with inert gas to form a second heat-insulating layer. A manufacturing method for the heat-insulating oil sleeve comprises the following steps in sequence: performing pretreatment on the three pipes, sleeving and welding the inner pipe and the intermediate pipe, treating the annular cavity between the inner pipe and the intermediate pipe, sleeving and welding the outer pipe and the intermediate pipe, treating the annular cavity between the outer pipe and the intermediate pipe, testing an apparent heat conductivity coefficient and machining threads at the two ends of the intermediate pipe. The heat-insulating oil sleeve has a structure with three layers of steel tubes and double layers of heat-insulating layers, high heat insulation performance, long heat insulation life and high performance.

Owner:淄博孚瑞特热能科技有限公司

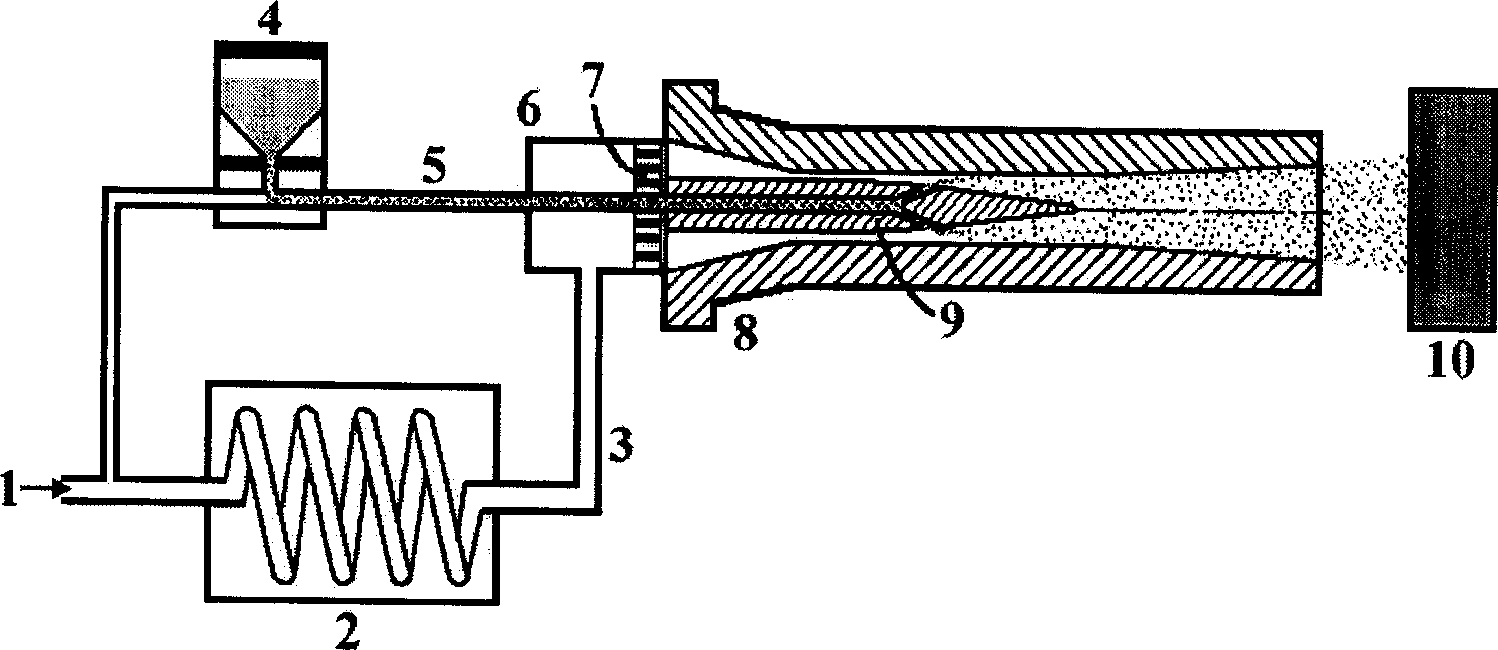

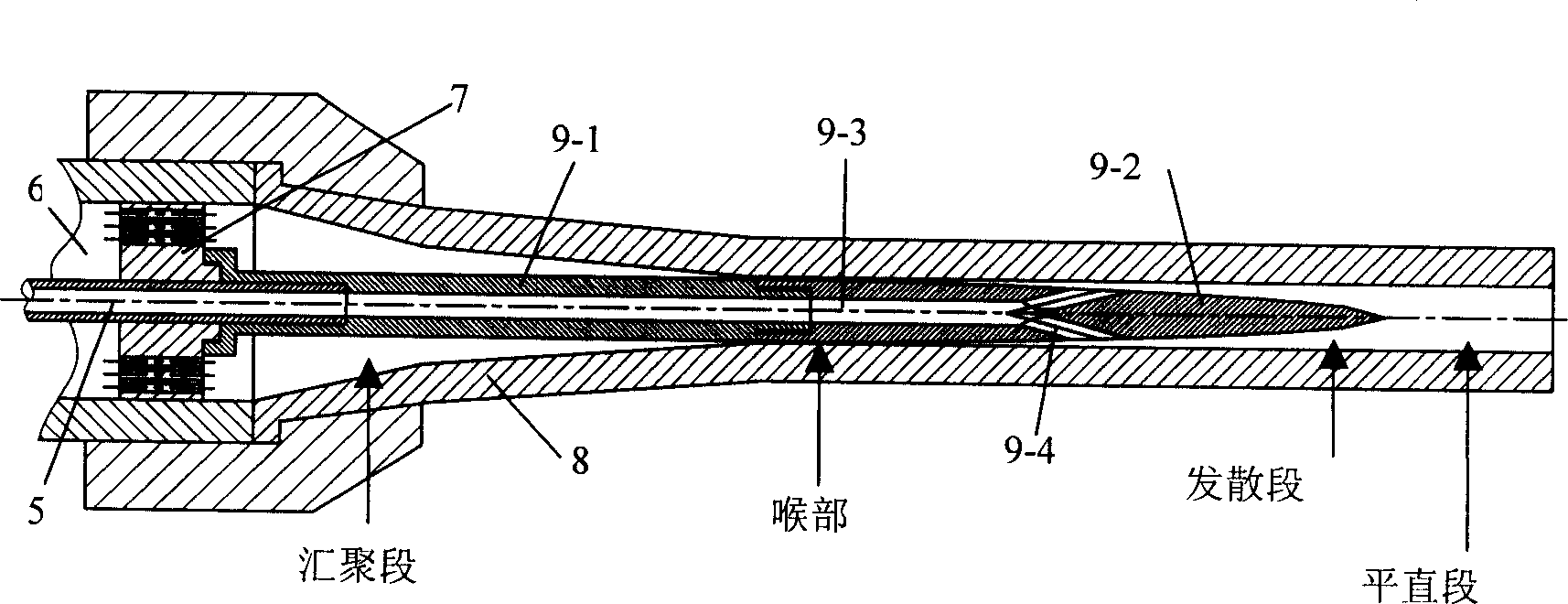

Cold air powered spraying method and device

The present invention relates to cold gas powered spraying method and device for spraying metal powder to the surface of sample or workpiece to form coating. The present invention features that work gas is first heated, then fed to the converging section in the upstream of the nozzle flow passage, and expanded and speeded in the divergent section of the nozzle, while the metal powder to be sprayed is fed directly to the converging section in the upstream of the nozzle through the powder feeding channel and two powder exhausting holes in some angle with the axis of the nozzle. The present invention has no contamination and jamming of the nozzle caused by the sprayed powder and easy manufacture of the nozzle.

Owner:BAOSHAN IRON & STEEL CO LTD

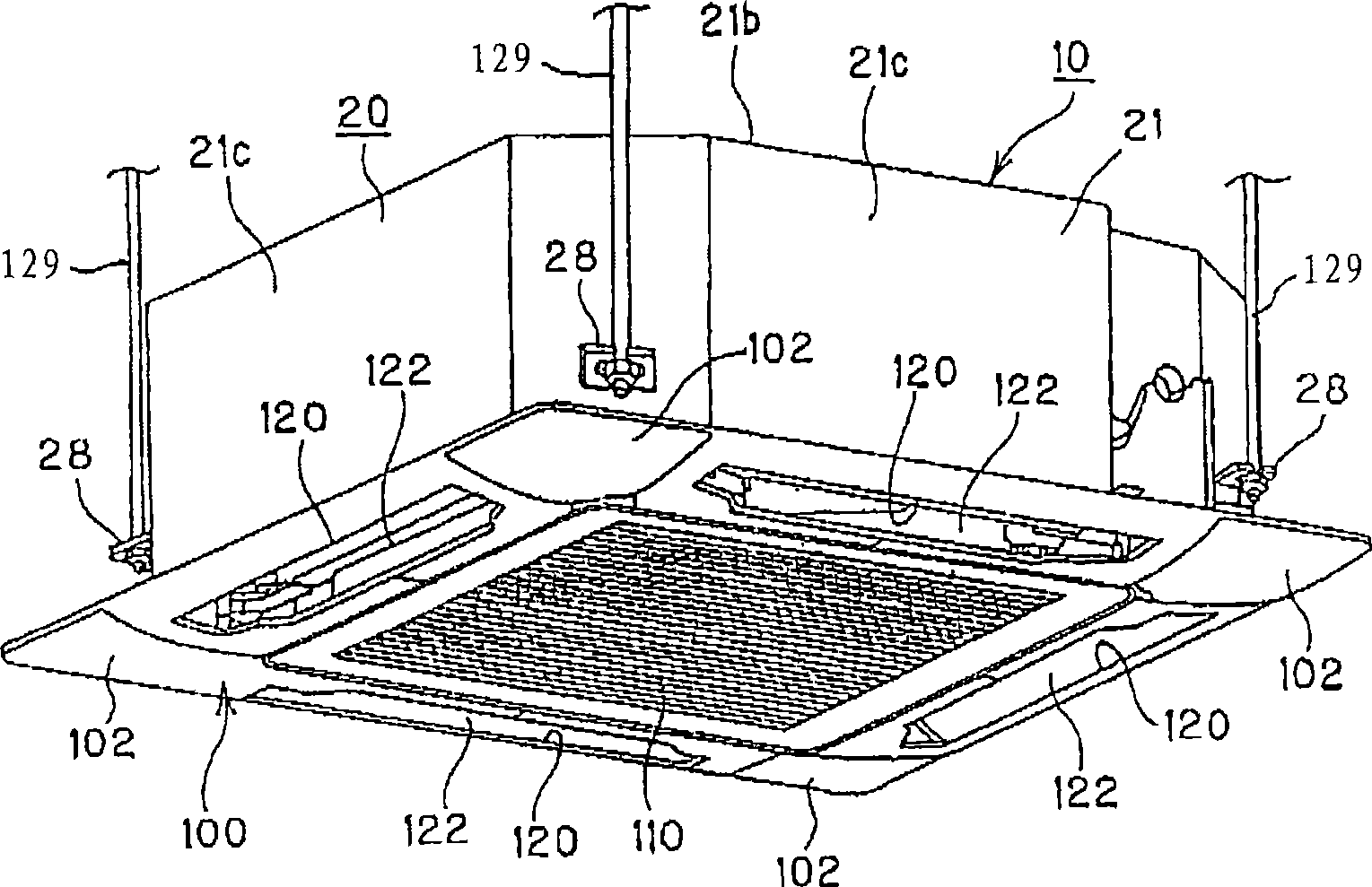

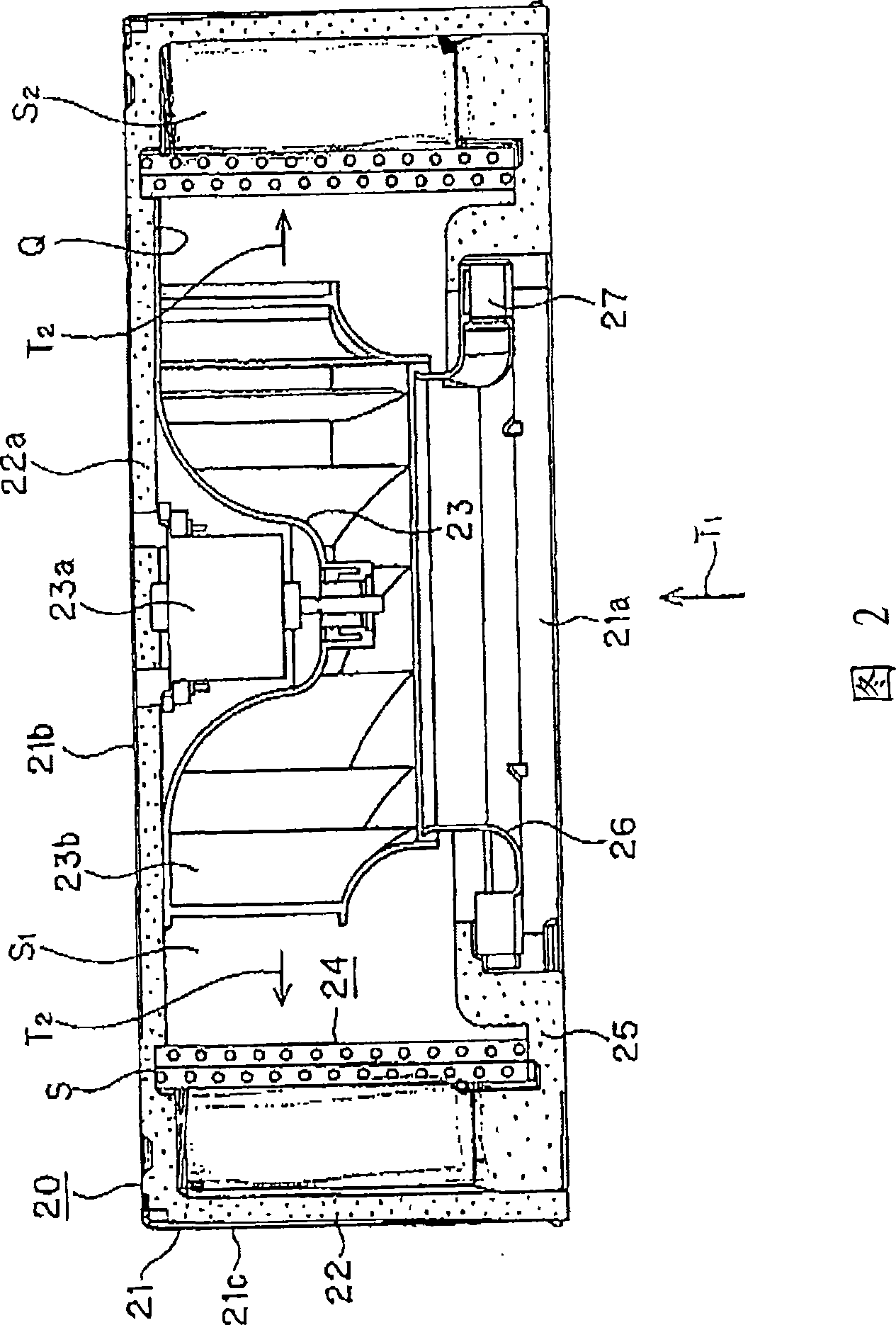

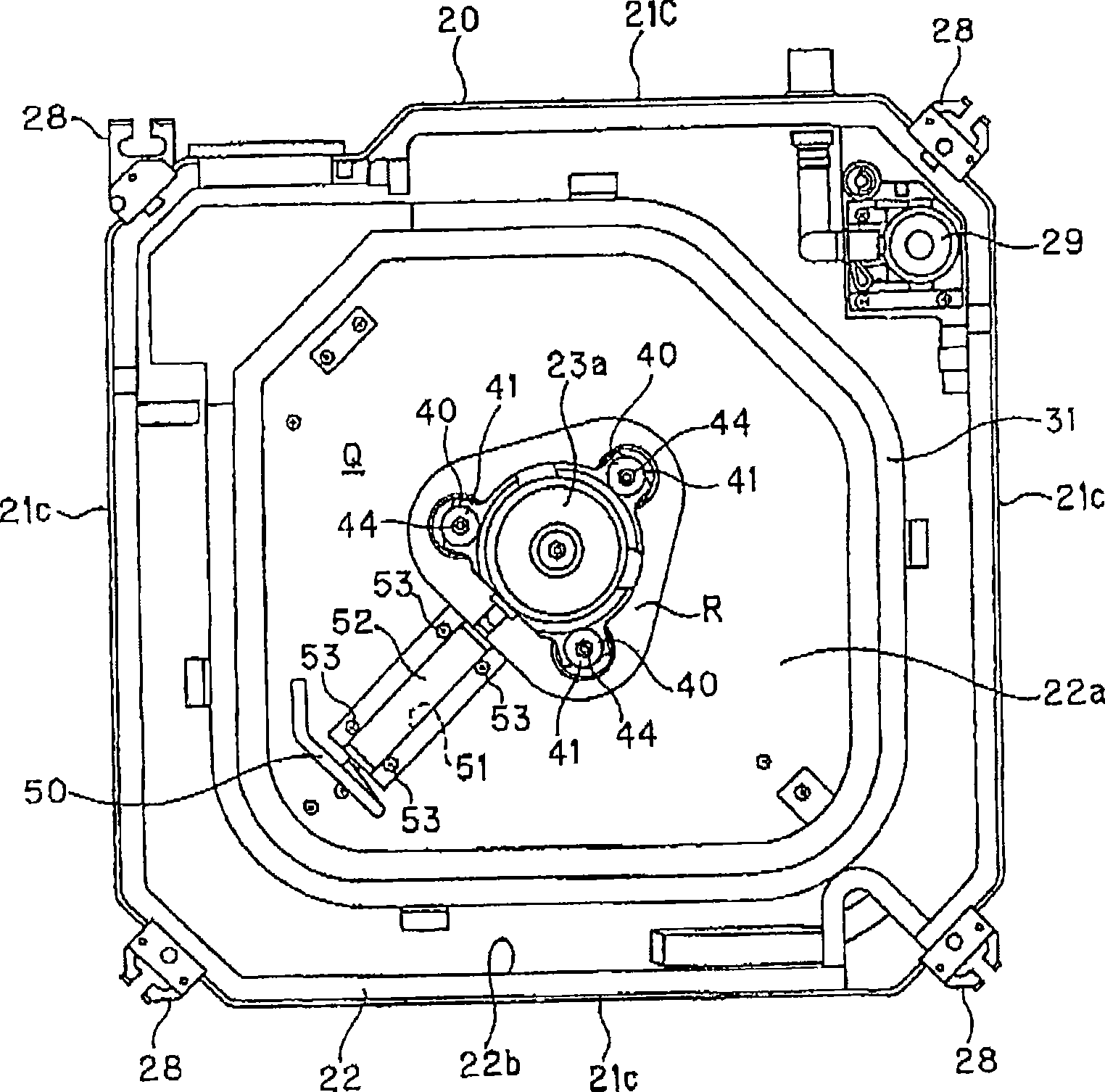

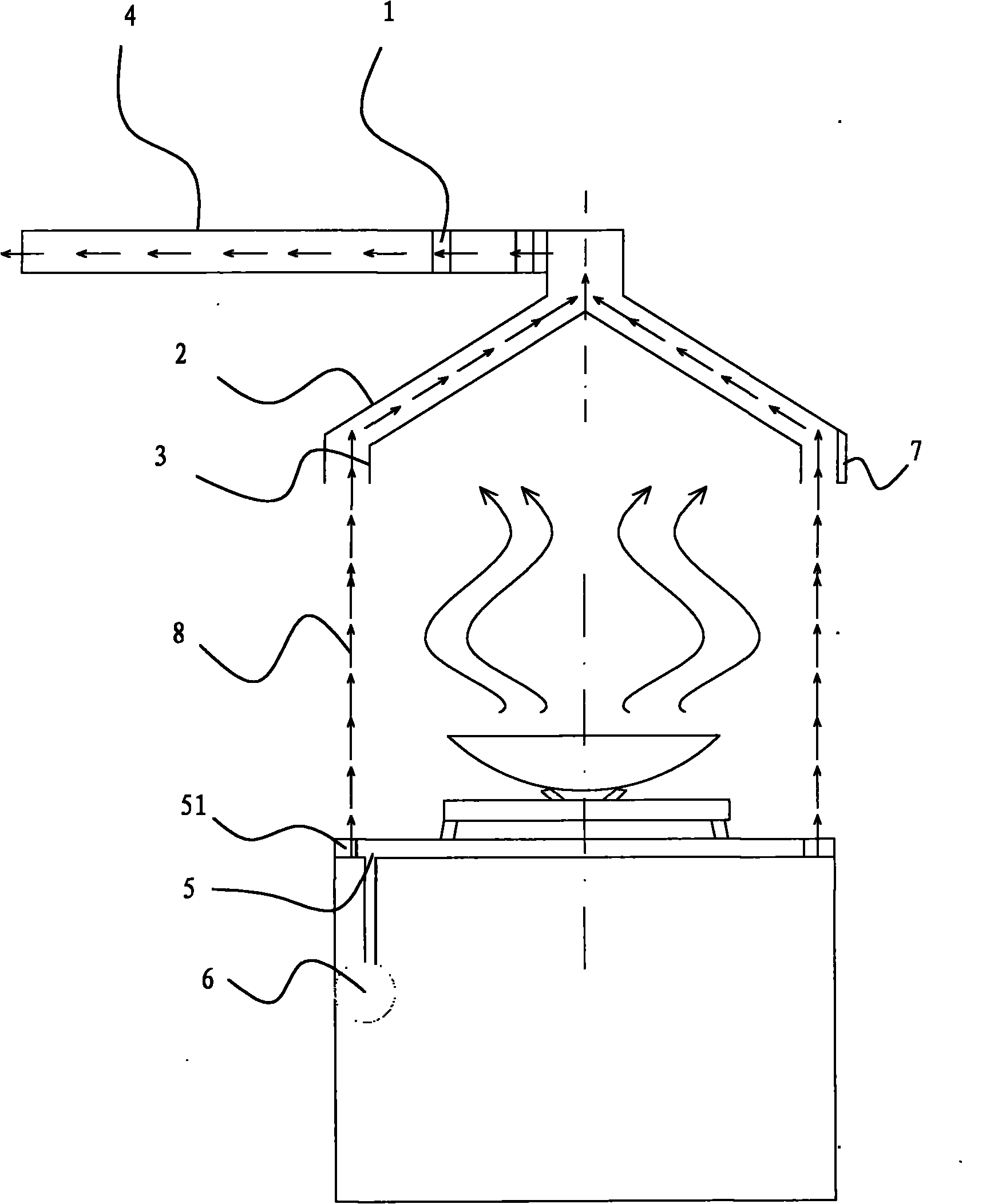

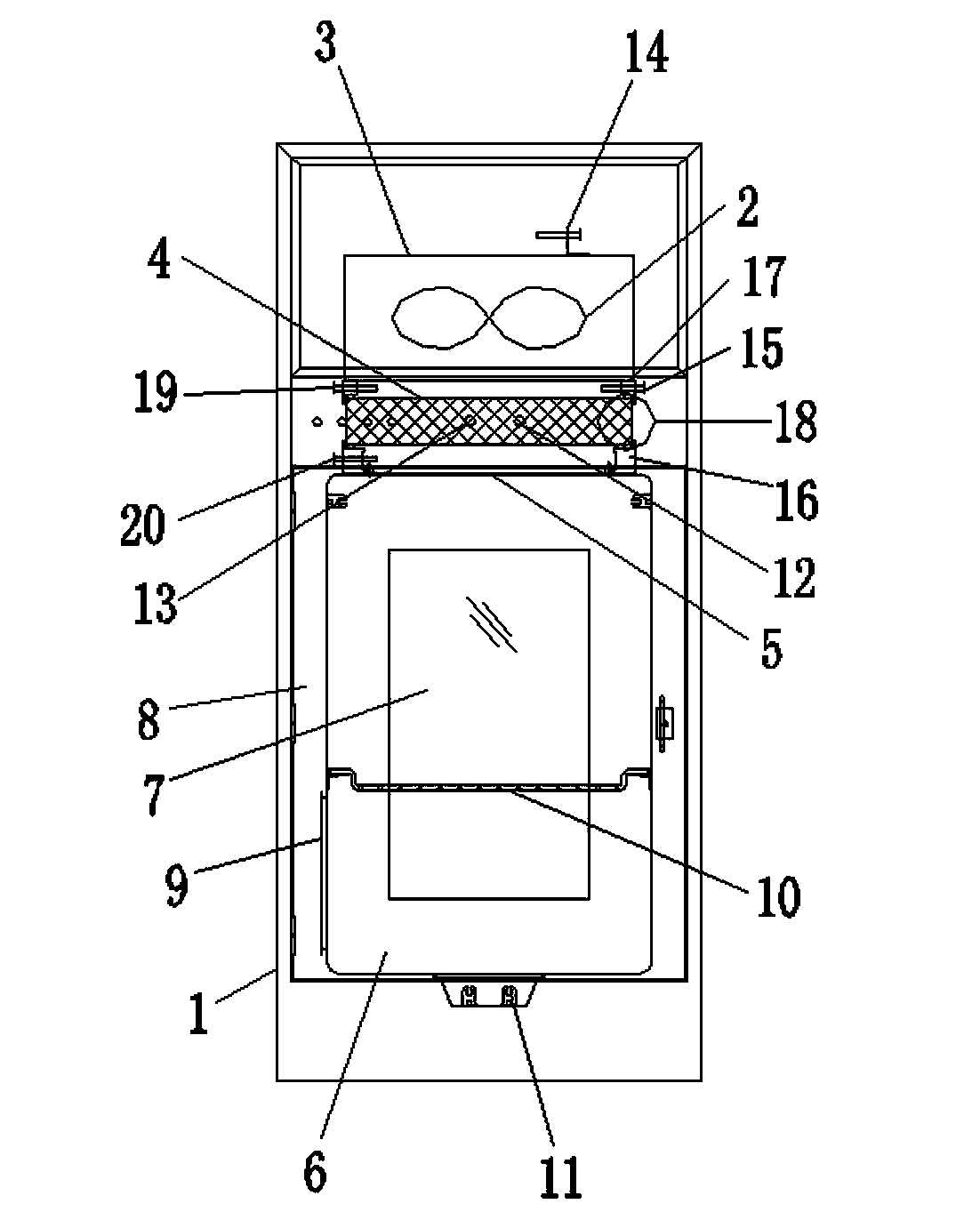

In-ceiling mount type air conditioner and indoor unit thereof

ActiveCN101387425ASmall volumnNo turbulenceThermal insulationHeating and ventilation casings/coversCeiling mountEngineering

An indoor unit of an in-ceiling mount type air conditioner includes a box-shaped housing having a top plate portion, a side plate portion and an opening portion at the lower portion thereof, a face panel detachably mounted on the opening portion of the housing, an indoor heat exchanger through which the inside of the housing is compartmented into a primary side and a secondary side, and an air blower secured to the top plate portion of the housing that faces the primary side, has a primary side heat insulating material is provided to the top plate portion so as to face the primary side of the housing and a secondary side heat insulating material provided to the side plate portion so as to face the secondary side of the housing, wherein the primary side heat insulating material is provided with an opening portion through which the air blower is fixed to the top plate portion.

Owner:SANYO ELECTRIC CO LTD

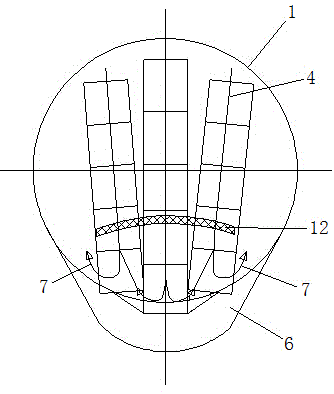

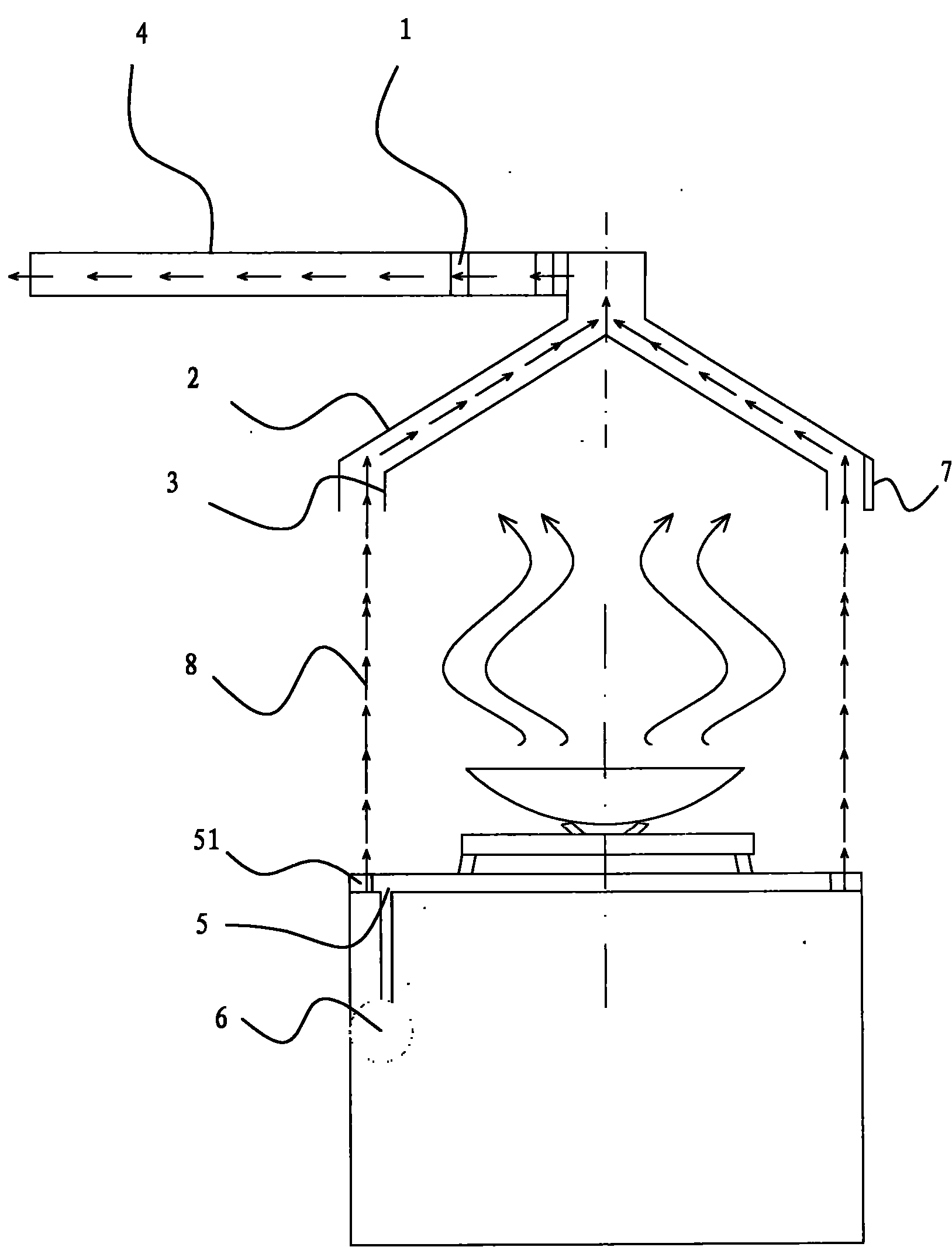

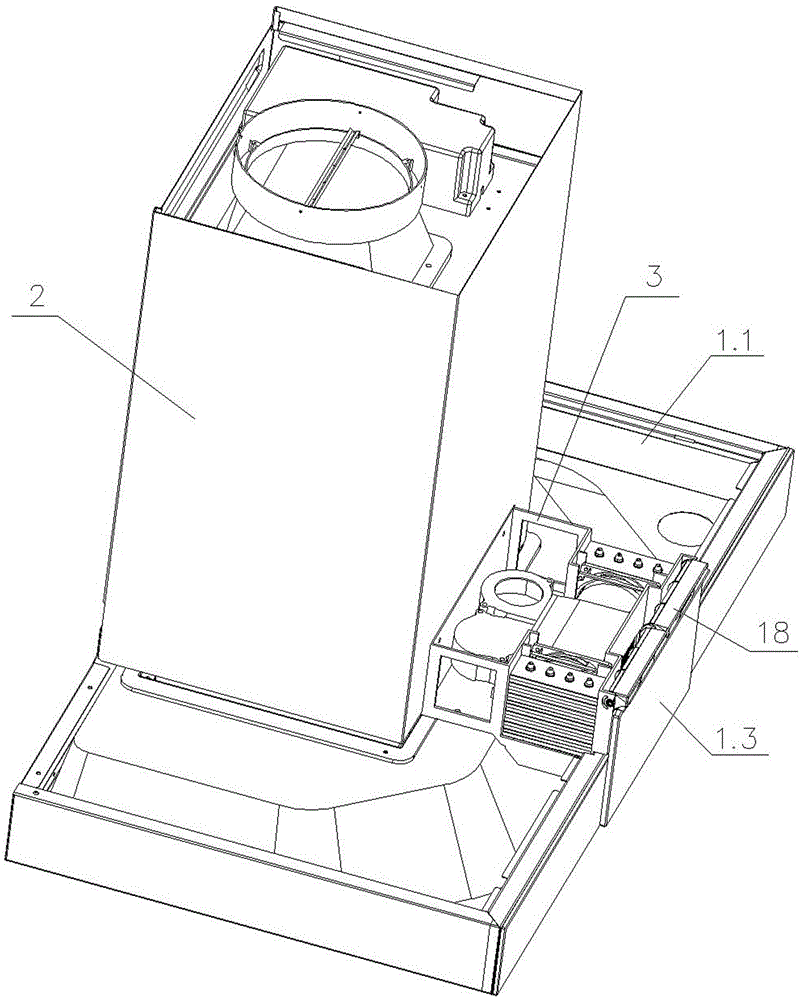

Smoke exhaust ventilator and air curtain device

InactiveCN101936563ASmall diameterLow costDomestic stoves or rangesLighting and heating apparatusSuction forceElectrical control

The invention discloses a smoke exhaust ventilator which comprises a collecting hood, at least two air exhaust fans, a smoke exhaust tube and an electrical control device. The air exhaust fans are arranged in the smoke exhaust tube along the axis of the smoke exhaust tube. The invention also discloses an air curtain device of the smoke exhaust ventilator, which comprises an air blowing tube bank arranged below a cooking range and an air blowing fan connected with the air blowing tube bank and used for providing wind power. The air blowing tube bank is provided with an air outlet with an opening around the cooking range and corresponding to the collecting hood, and at least one air exhaust fan is installed in the smoke exhaust tube. Because the adopted air exhaust fans have small diameter and low cost and are arranged in the smoke exhaust tube simultaneously, the smoke exhaust ventilator has no turbulence, high air exhaust efficiency, energy saving and high smoke removal rate, and the air flow and the negative suction force of the smoke exhaust ventilator can be conveniently adjusted. After an air curtain is adopted on the cooking range, the smoke is limited within the range of the collecting hood, and the smoke removal rate is greatly increased.

Owner:东莞市瑞通电子五金有限公司

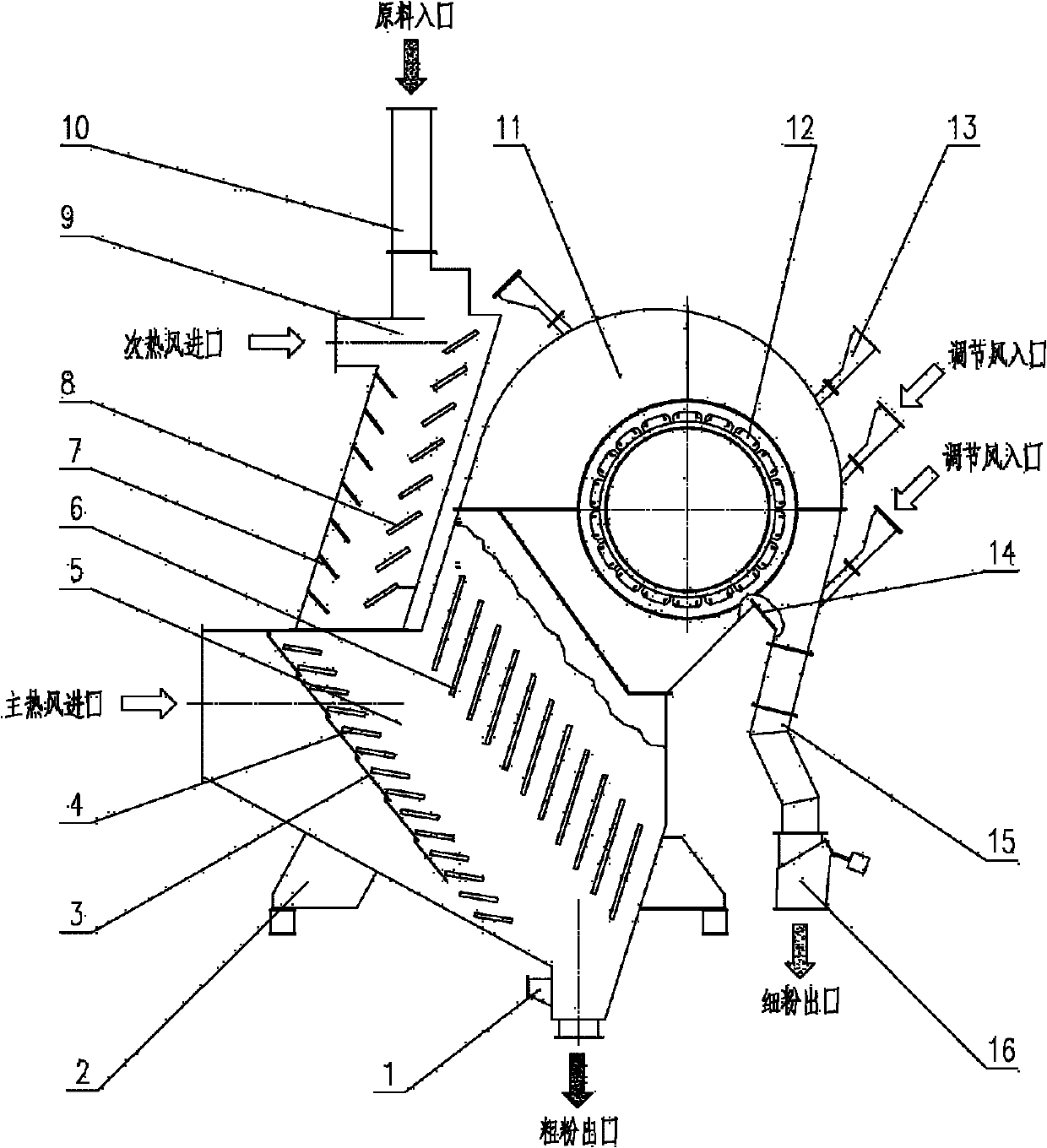

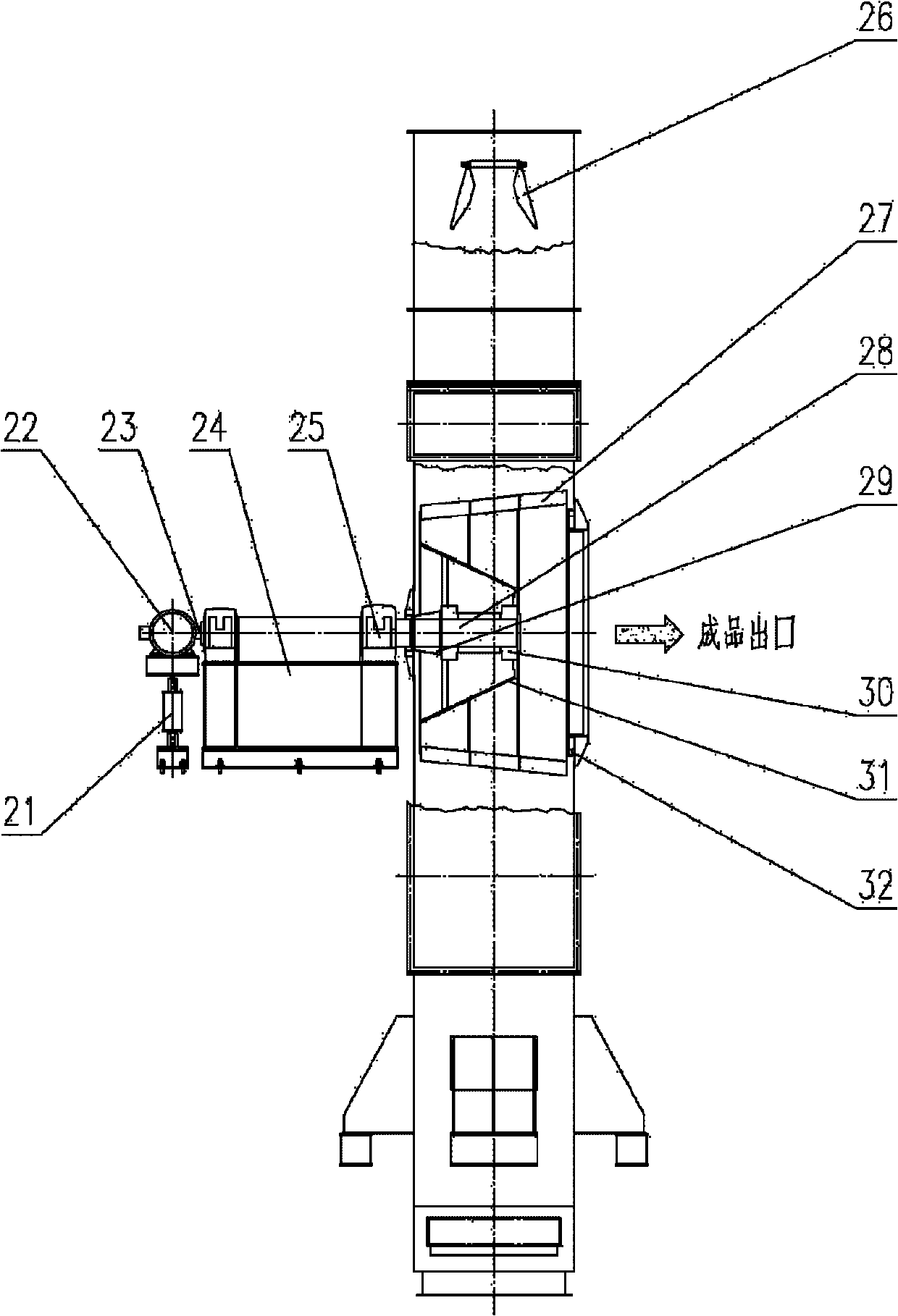

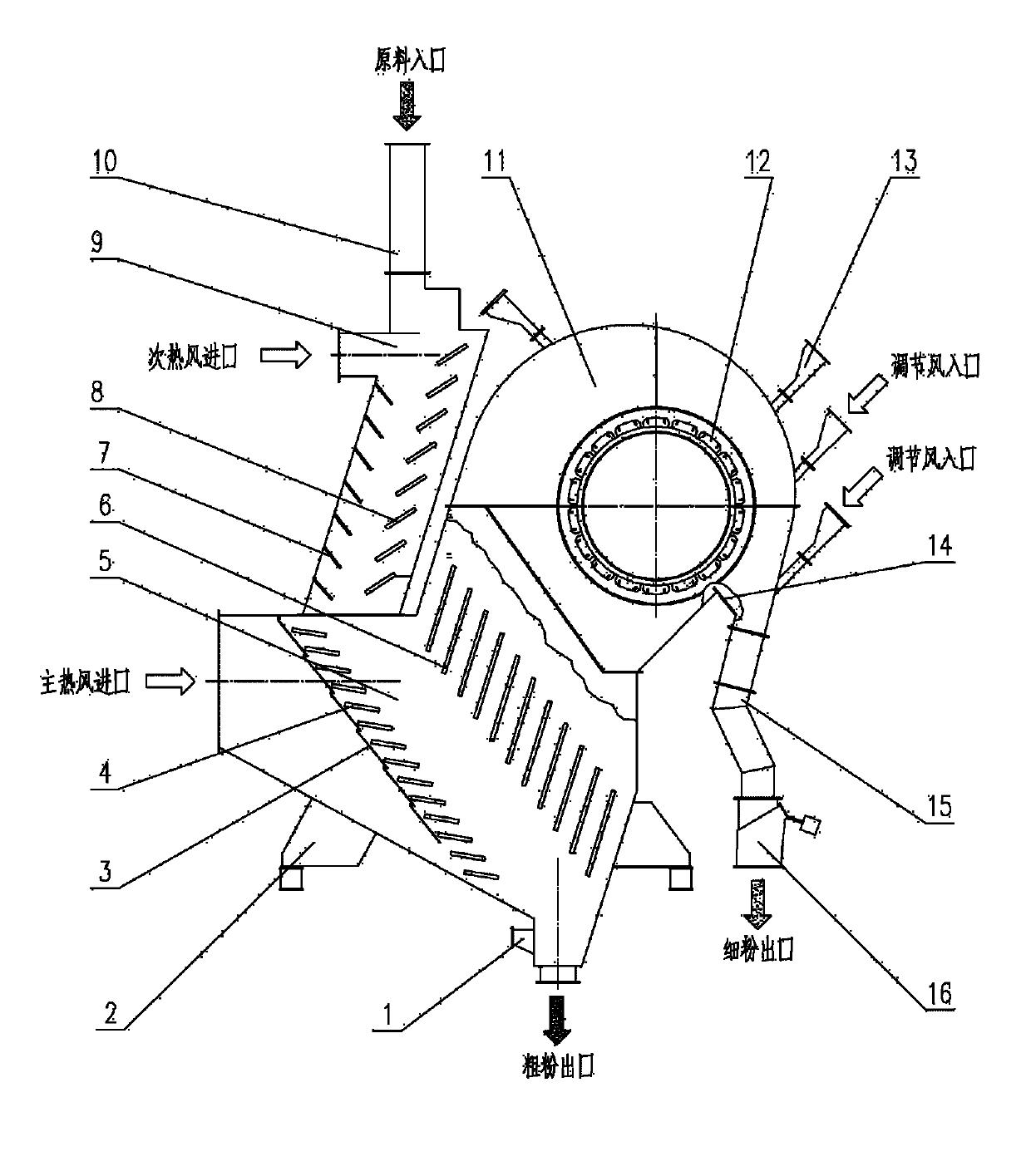

Powder concentrator integrating functions of scattering, drying and grading into whole

InactiveCN101767093AExtended drying and breaking up pathGood sorting efficiencyDrying solid materials with heatGas current separationMain bearingEngineering

The invention relates to a powder concentrator integrating the functions of scattering, drying and grading into a whole, which mainly comprises a drying area casing, a scattering area casing, a raw material splitting tube, a splitting device, a volute body, a grading rotor, a main shaft and a main bearing bracket. The powder concentrator is characterized in that the drying area casing is in a V-shaped structure, one side of the drying area casing is joined with the volute body, the upper part of the other side of the drying area casing is connected with the scattering area casing which is slantways arranged, and the upper part of the scattering area casing is connected with the raw material splitting tube in which the splitting device is arranged. An eccentric position in the volute body is vertically provided with the grading rotor which is in a conical structure, and a cantilever of the main shaft of the grading rotor is supported on a bearing pedestal on the main bearing bracket. The invention has the advantages of good material adaptability, strong drying and scattering capabilities, high powder concentration efficiency, low pressure loss of a system, small maintenance quantity of equipment, compact and reasonable structure, large adaptability to materials and the like.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

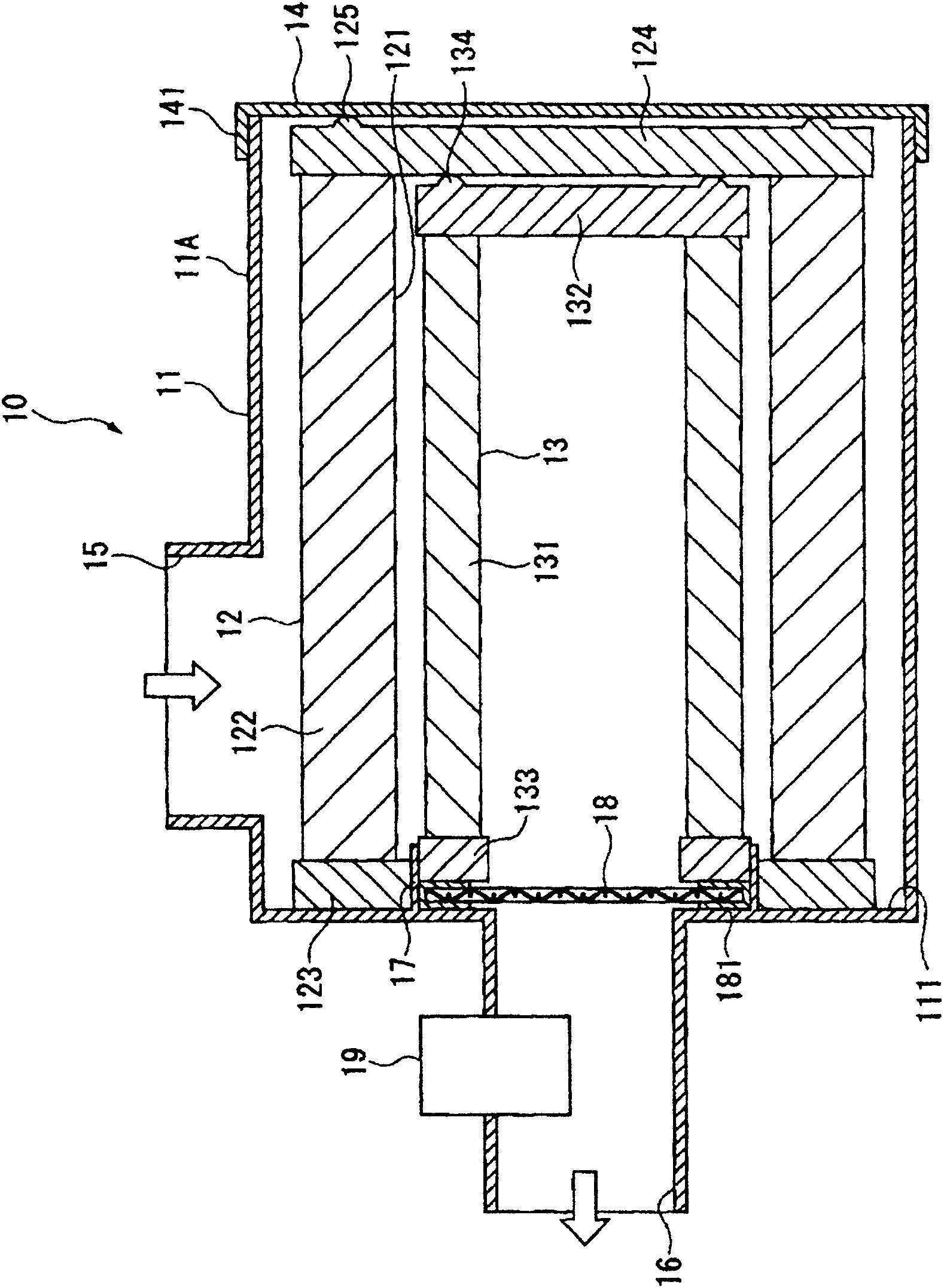

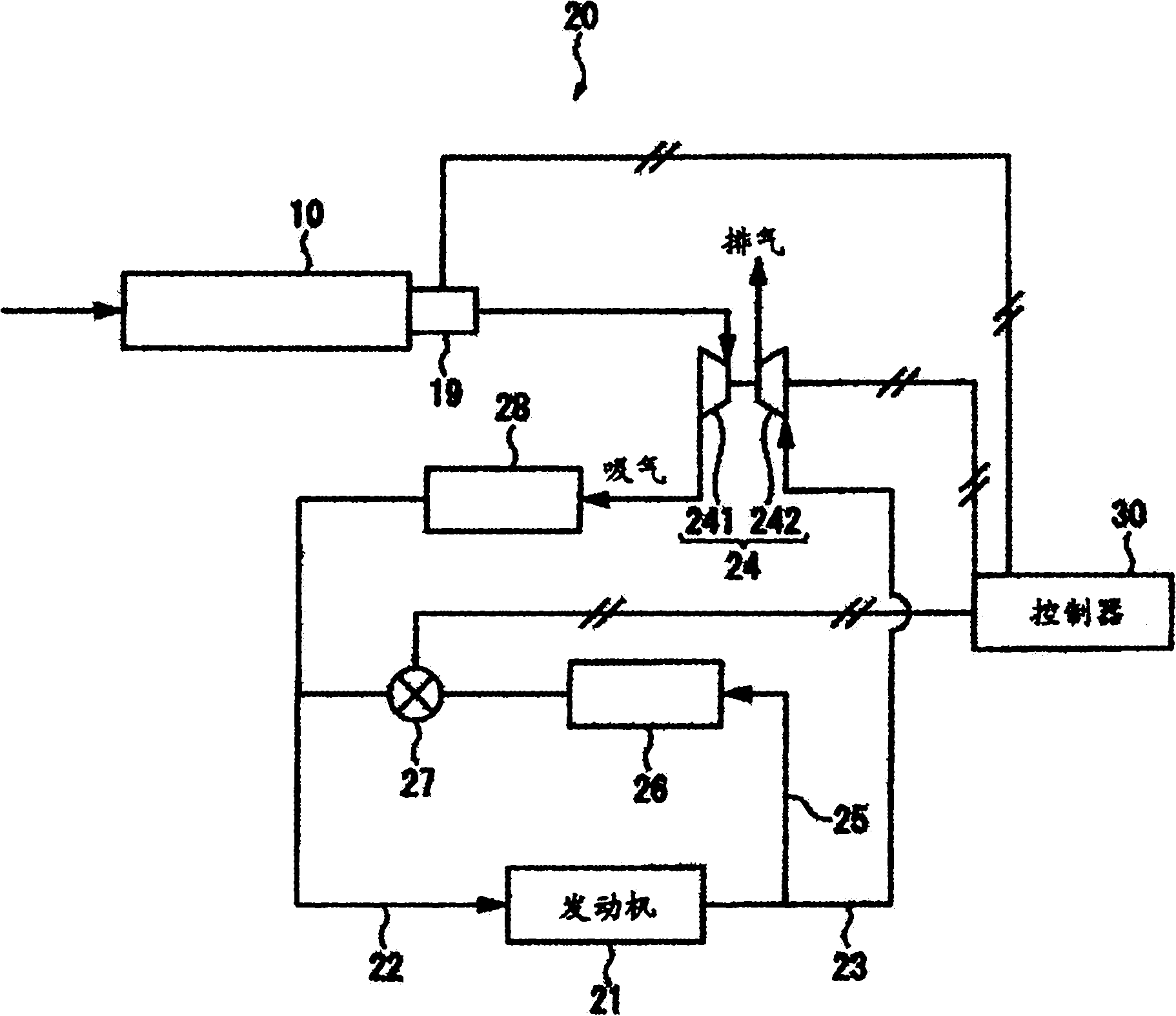

Air cleaner, and engine control system

ActiveCN102105667AHigh precision measurementImprove cleanlinessElectrical controlNon-fuel substance addition to fuelControl systemAir filter

The invention relates to an air cleaner and an engine control system. The air cleaner (10) is provided with a housing (11) for housing therein an inner tube filter (13) and an outer tube filter (12) and comprising a case body (11A) having an open end face closed by a lid member (14). The housing (11) is provided with an air intake opening (15) provided in the outer peripheral surface of the case body (11A) and taking in outside air, and also with an air discharge opening (16) provided in a bottom surface (111) of the case body (11A), which bottom surface is located on the air flow downstream side of the case body, and discharging the air taken in from the air intake opening (15) and filtered by both the inner tube filter (13) and the outer tube filter (12). Inside the air discharge opening (16) is provided a mass flow rate sensor (19) for measuring the flow rate of the air. On the upstream of the mass flow rate sensor (19) is provided a flow regulating grid (18) for regulating the flow of the air.

Owner:KOMATSU LTD

Through type rapid cut-off valve

ActiveCN102102764AGood shunt effectFast cut-offOperating means/releasing devices for valvesLift valveEngineeringCylinder block

The invention discloses a through type rapid cut-off valve for emergently cutting off a pipeline, which comprises a valve body, a valve core and a valve rod, wherein a liquid inlet and a liquid outlet are formed at the two ends of the valve body respectively; the valve rod is fixed on the valve body; the liquid inlet end of a valve cavity is provided with a valve seat; the front end of the valve core is provided with a conical surface matched with the valve seat; a piston is fixed at the rear end of the valve core; a cylinder body matched with the piston of the valve core is arranged in the valve cavity and is fixed on the valve body through a connecting rod; the symmetric center of the cylinder body is coincided with the symmetric center of a flow passage of the valve cavity; the valve rod is fixed at the rear end of the cylinder body; a swing arm is fixed on the valve rod; and the other end of the swing arm is hinged with the piston of the valve core through a connecting rod. A valve core opening and closing mechanism has a piston structure, so that the pipeline can be extremely quickly cut off; and the conical surface at the front end of the valve core has a good flow distribution effect and low flow resistance, so that the valve can be stably operated and turbulence and vibration are avoided in the medium circulation process.

Owner:ANHUI TONGDU FLOW TECH

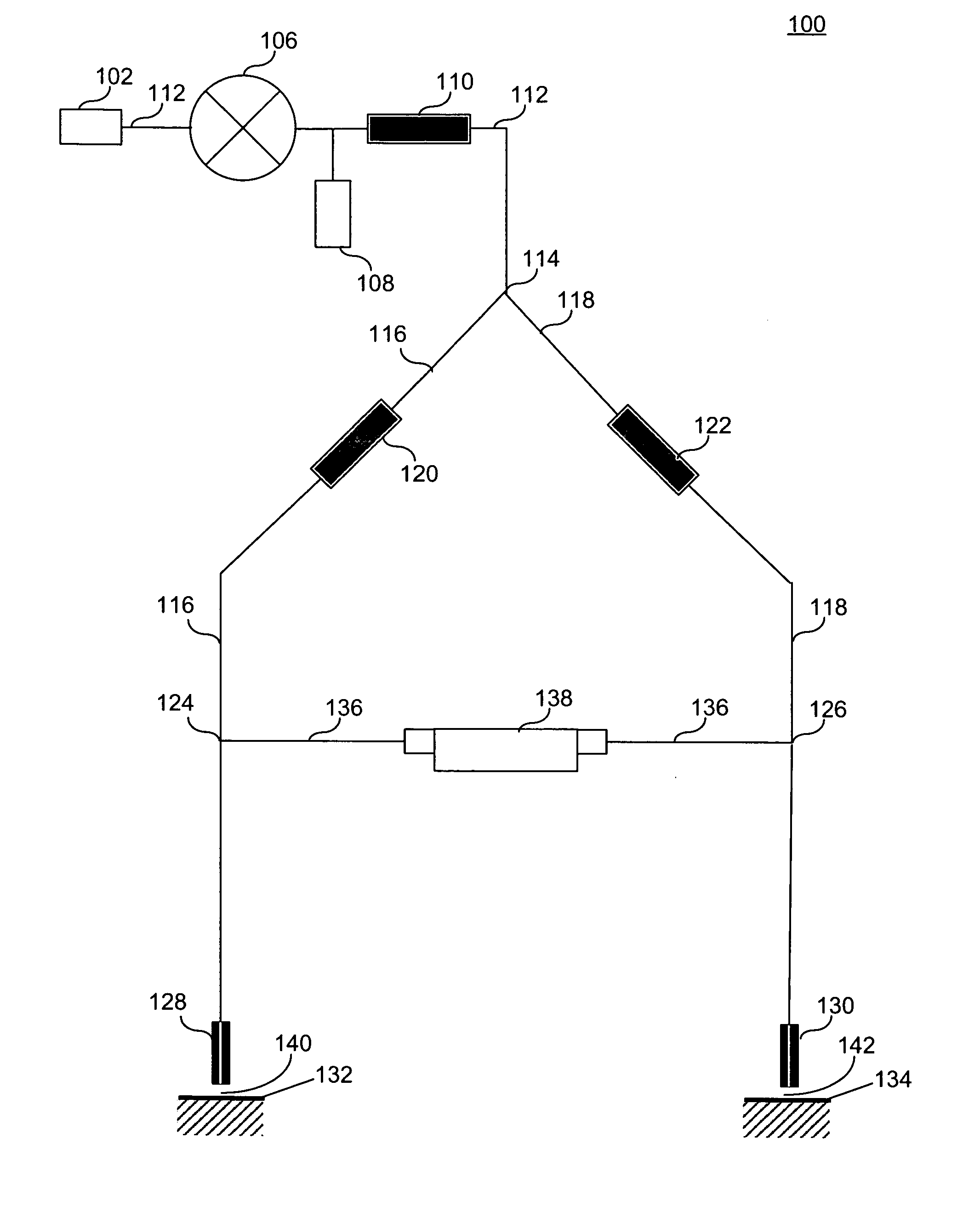

High-resolution gas gauge proximity sensor

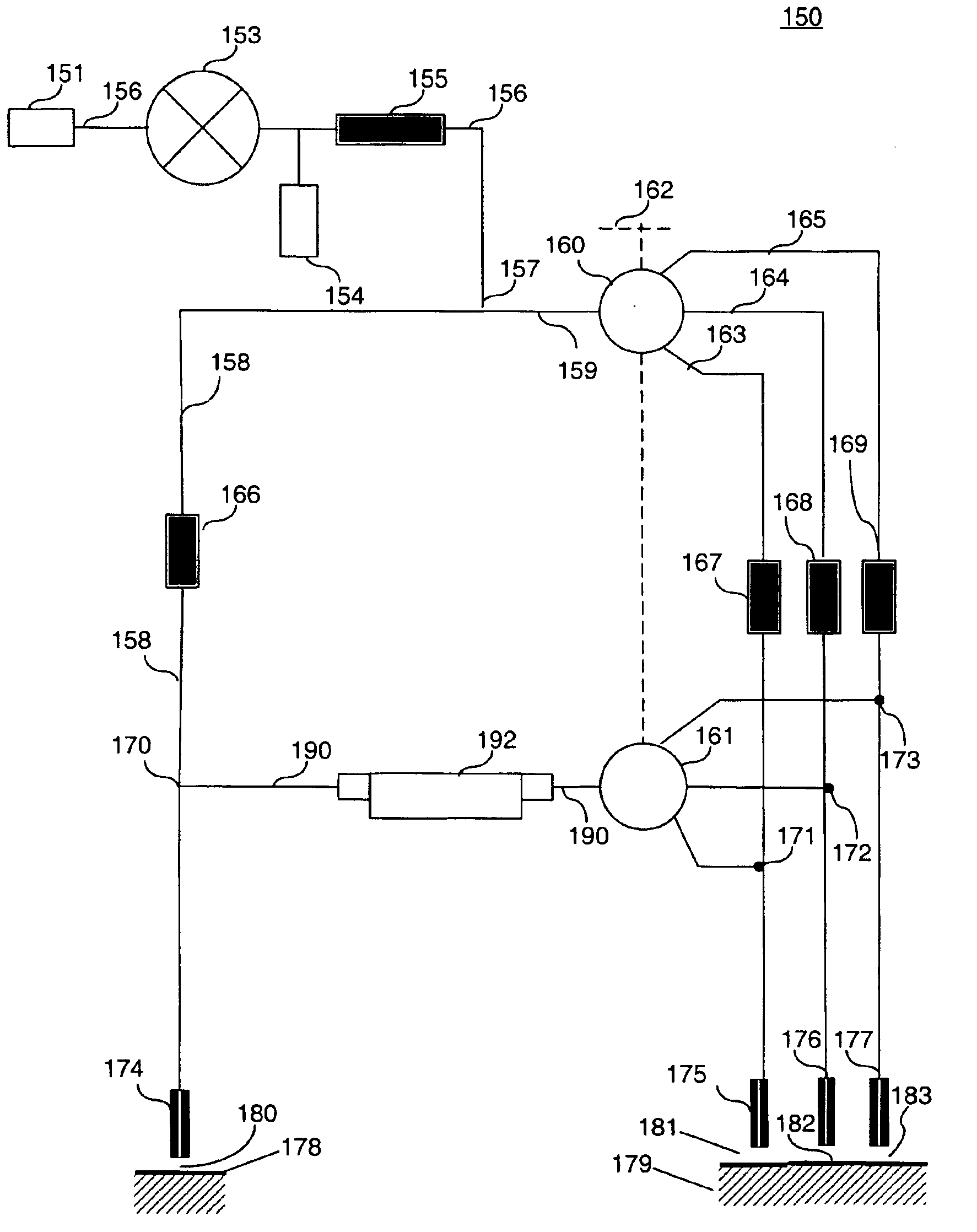

InactiveUS20050268698A1Easy to adaptImprove abilitiesVolume/mass flow measurementSemiconductor/solid-state device manufacturingProximity sensorEngineering

An apparatus and method for precisely detecting very small distances between a measurement probe and a surface, and more particularly to a proximity sensor using a constant gas flow and sensing a mass flow rate within a pneumatic bridge to detect very small distances. Within the apparatus the use of a flow restrictor and / or snubber made of porous material and / or a mass flow rate controller enables detection of very small distances in the nanometer to sub-nanometer range. A further embodiment wherein a measurement channel of a proximity sensor is connected to multiple measurement branches.

Owner:ASML HLDG NV

Casting process for hydraulic main control valve blank

PendingCN103962504AReduce the effect of dimensional changesImprove appearance qualityFoundry mouldsFoundry coresFree coolingSize change

The invention discloses a casting process for a hydraulic main control valve blank. The process comprises the following steps: selecting molding sand used by a pouring system, wherein the molding sand is resin sand; constructing a sand mold casting cavity of the hydraulic main control valve blank by the resin sand; pouring into the sand mold casting cavity; and breaking a mold to obtain the finished product after cooling naturally. According to the casting process, the defects that a hydraulic main control valve blank is likely to contract, a core is easily broken, the size is out of tolerance and the like in the production in the prior art are overcome. The resin sand mold can effectively alleviate the size change influence caused by the expansion and the contraction of molten iron. Meanwhile, the appearance quality of a casting is greatly improved. By virtue of bottom casting, the molten iron enters the mold cavity smoothly; the core and the mold cavity are eroded slightly; meanwhile, the turbulent flow is avoided; gas and dregs are prevented from being involved in. A heat insulation riser is used at a contraction position; the casting yield is improved from 60 percent to 72 percent.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Improved gas burner

ActiveCN102348932ALower the altitudeNo turbulenceDomestic stoves or rangesDamper arrangementEngineeringGas burner

Gas burner provided with a plurality of concentric circular flame crowns, with a burner body apt to be mounted on the surface of a cooking plate, a burner body apt to be mounted on the surface of a cooking plate and provided with a first chamber for the diffusion of the air / gas mixture, and whose top is closed by a first cover, a second outer annular burner surrounding said central burner, a first gas inlet in communication with said body, a first gas injector able of injecting a gas flow into a respective Venturi pipe to said first central burner, a second gas inlet in communication with said body, wherein said second annular burner is provided with two separate diffusion chambers, and whose top is closed by a second cover, wherein said second gas inlet is in communication with said two separate chambers which are not in communication to each other, two distinct injectors connected with said second gas inlet and placed on the same end position of said second gas inlet, two respective horizontally oriented Venturi pipes, each of which being able of supplying with an air / gas mixture a respective of said two diffusion chambers; said first gas injector and the respective Venturi pipe for the central burner are horizontally oriented, and preferably they are positioned between the two Venturi pipes dedicated to said two diffusion chambers. Said two horizontally oriented Venturi pipes for the outer annular burner and the relevant gas injectors are angled to each other, and this angle is over 70 DEG . Preferably the Venturi pipes for the annular burner admit into respective curved chambers provided with respective vertical gas passages, extended for the whole length of said curved chamber, connecting them to respective diffusion chambers.

Owner:ELECTROLUX HOME PROD CORP NV

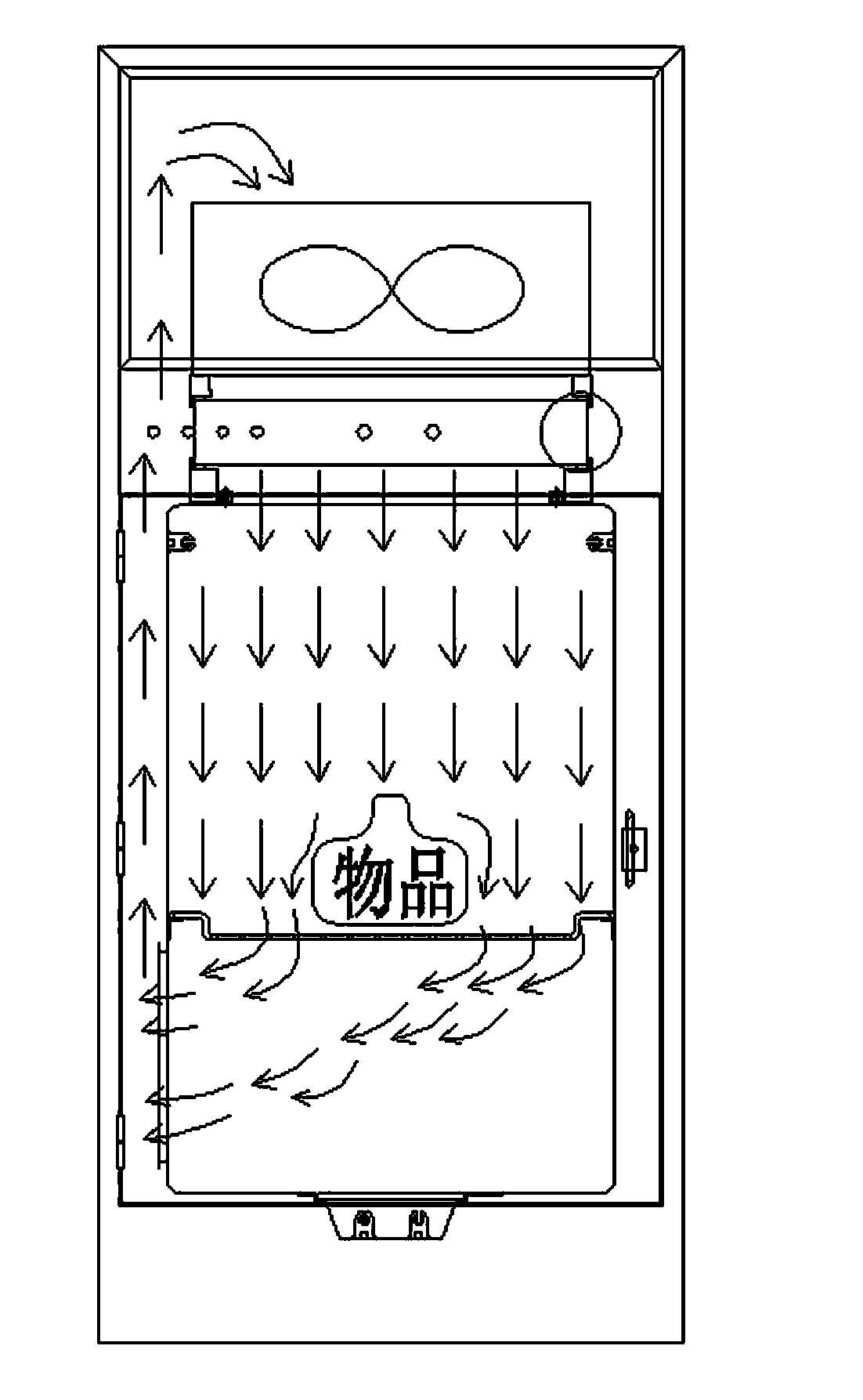

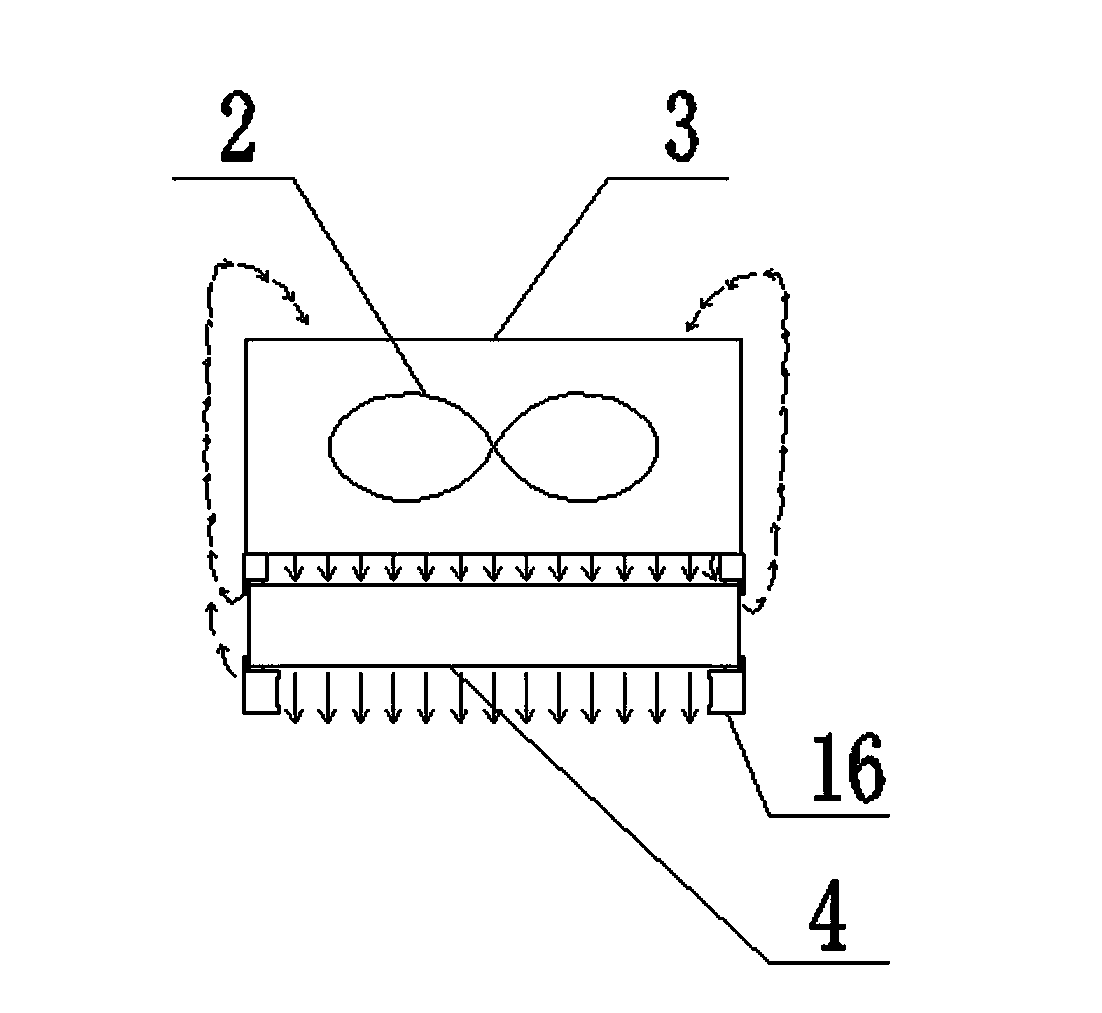

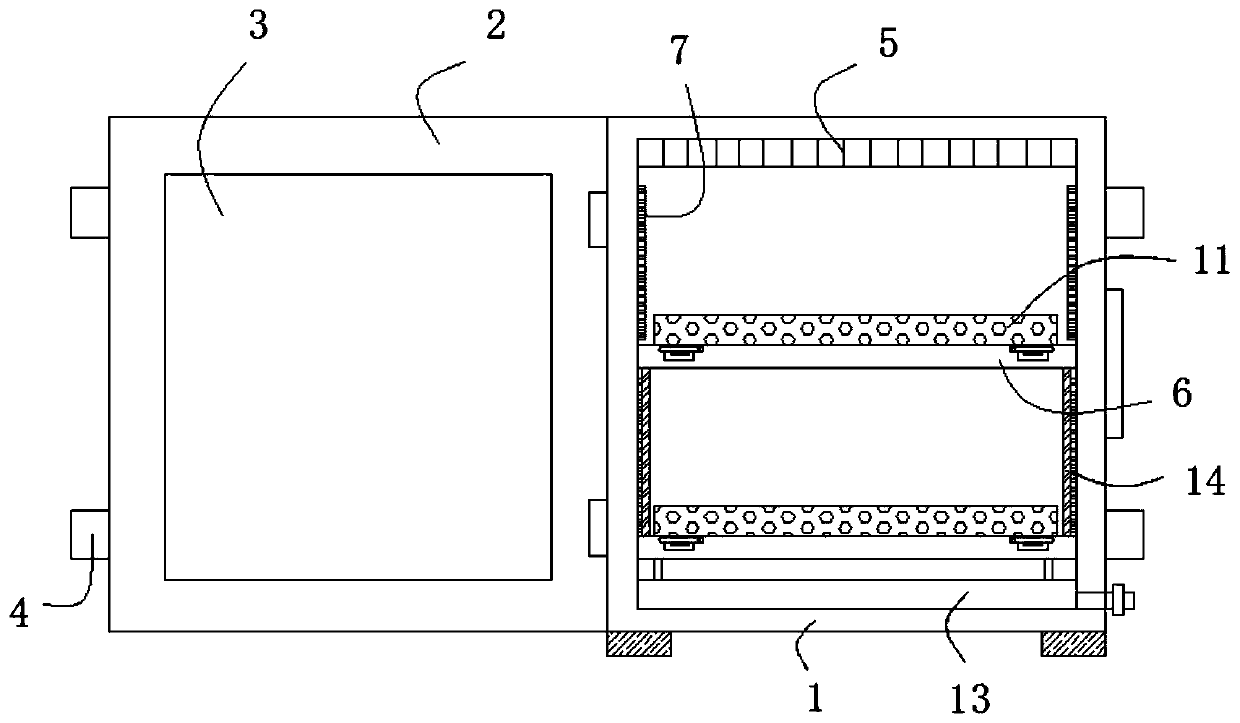

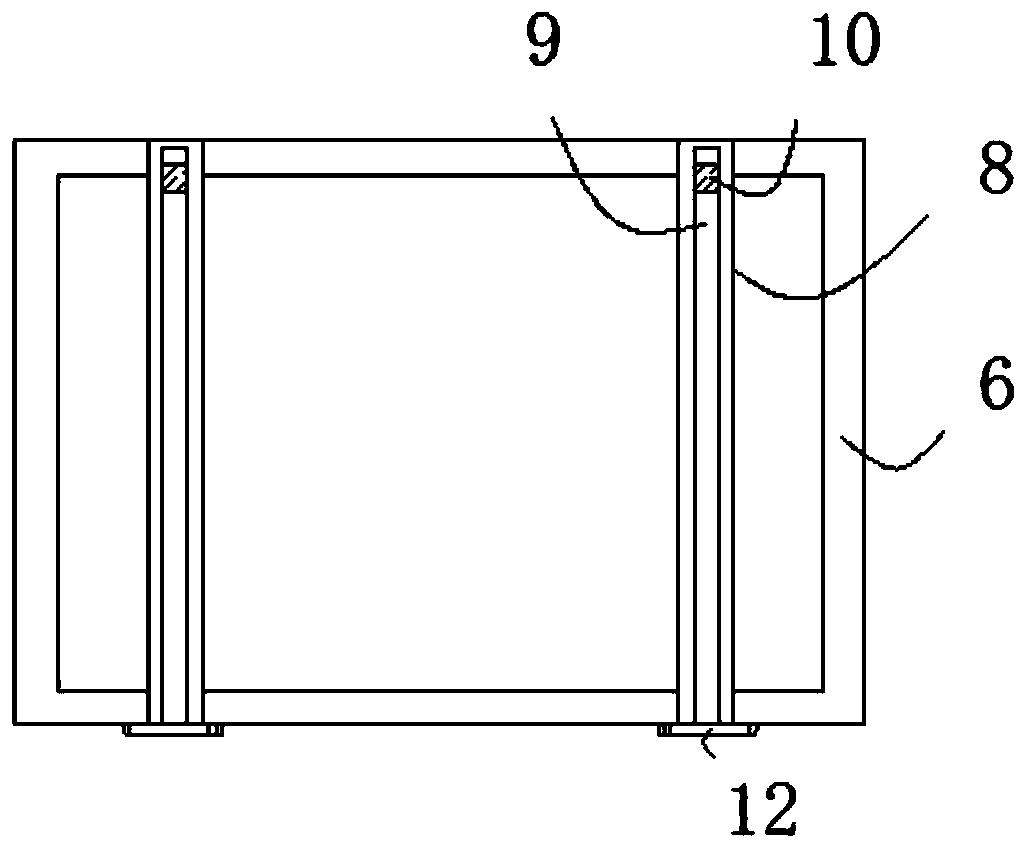

Pass box special for clean room of pharmaceutical factory

InactiveCN103381411AEasy to cleanConvenient verificationDispersed particle filtrationCleaning using gasesVena contracta diameterEngineering

The invention discloses a pass box special for a clean room of a pharmaceutical factory. The pass box comprises a box body, wherein a fan box body, an efficient filter, an air supply orifice plate and an article delivery cavity are arranged in the box body in sequence from the top down; the fan box body is used for accommodating a fans; the efficient filter is used for purifying air; the air supply orifice plate is used for transmitting airflows; the article delivery cavity is used for delivering articles; gas tight doors, which are used for picking and placing articles and can be locked by each other, are respectively arranged on two opposite outer side surfaces, corresponding to the article delivery cavity, on the box body; perspective double-layered windows are respectively arranged in the middles of the two gas tight doors; an air return passage is arranged between the outer side surface of the article delivery cavity and the inner side surface of the box body, wherein the outer side surface of the article delivery cavity is perpendicular to the gas tight doors; the upper end of the air return passage is communicated with the air inlet of the fan; an air return orifice plate is arranged below the side surface, corresponding to the air return passage, of the article delivery cavity, so as to enable the article delivery cavity to in airflow communication with the air return passage. According to the pass box, the structure of the airflow box body is more reasonable in design; online leak detection can be easily performed; the pressure difference of the efficient filter can be monitored in real time.

Owner:KUNSHAN MAX METAL

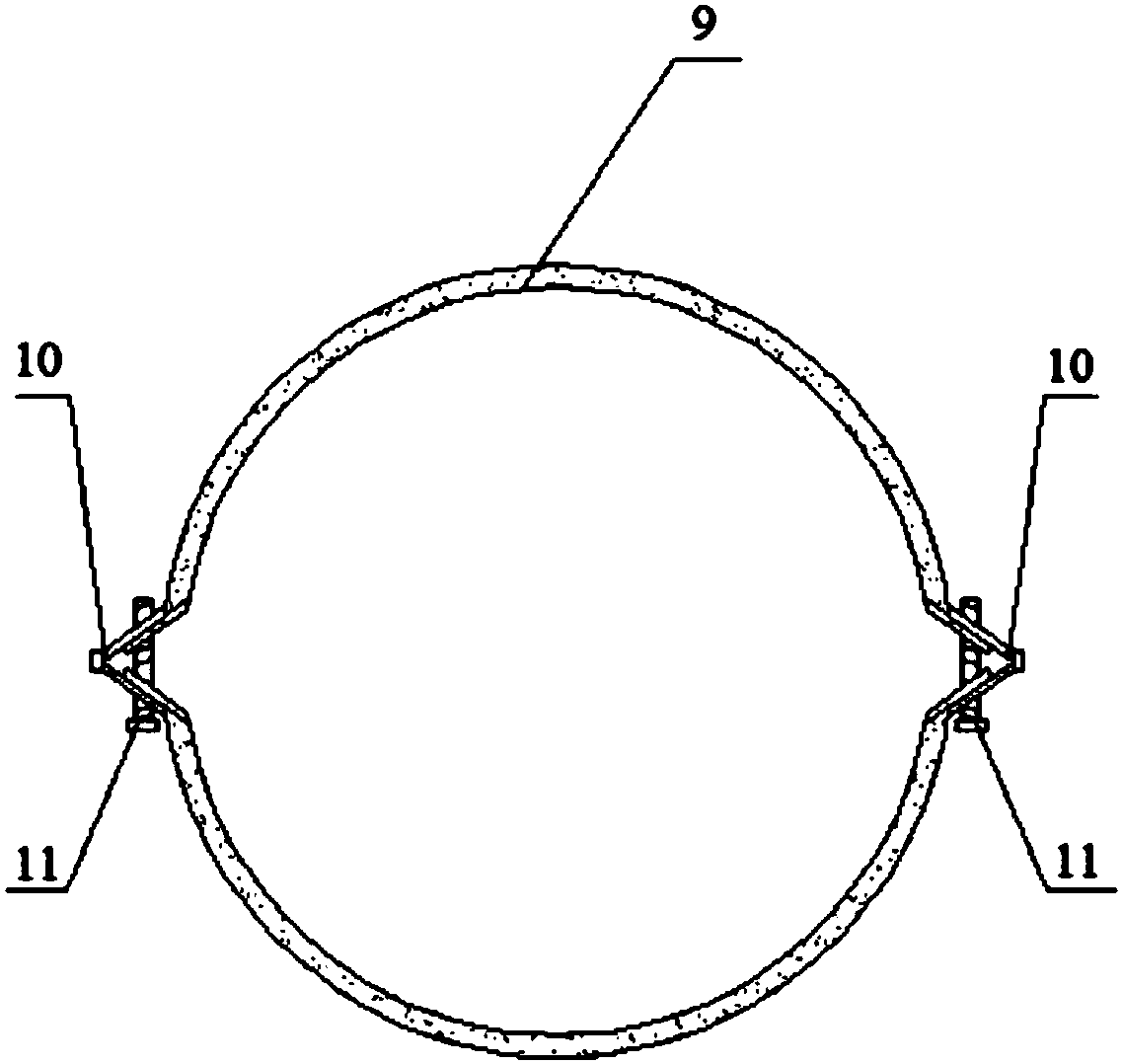

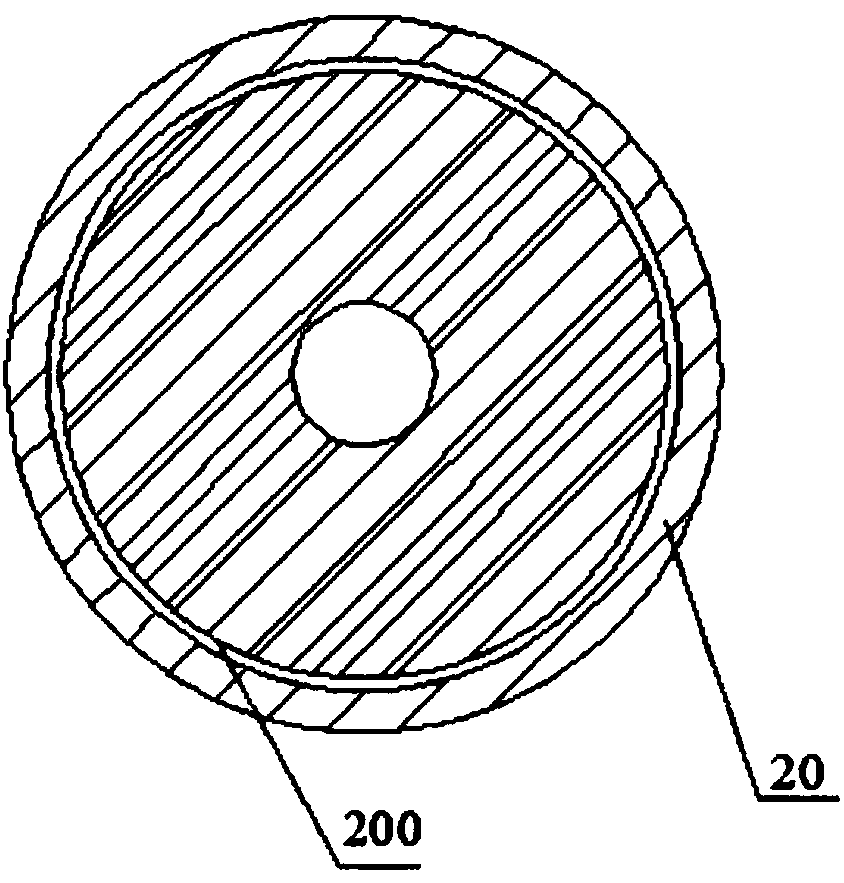

Synthesis kettle with sufficient stirring function

ActiveCN108295796AStir fully and stablySame rotation rateChemical/physical/physico-chemical stationary reactorsReaction rateMechanical energy

The invention discloses a synthesis kettle with a sufficient stirring function. The synthesis kettle comprises a buffer outer tank, a heating interlayer, a synthesis inner kettle, a first motor, a first rotating shaft and a base. An electric control telescopic cylinder is arranged between the outer wall of the bottom of the heating interlayer and the inner wall of the bottom of the buffer outer tank; a fastening hoop surrounds the side wall of the heating interlayer, and a V-shaped plate is arranged on the side wall of the buffer outer tank; a mounting hole is formed in the V-shaped plate, andthe fastening hoop is fixedly connected with the V-shaped plate through a bolt penetrating through the mounting hole; the lower end of the first rotating shaft is connected with a first coupler, anda first stirring assembly is arranged at the lower end of the first coupler; the first stirring assembly comprises a main stirring rod, a first stirring blade set and a second stirring blade set. Thesynthesis kettle promotes sufficient and stable stirring of reaction materials in the synthesis kettle, electric energy and mechanical energy are saved, it is guaranteed that large turbulence is not generated in the kettle, and the reaction rate is increased.

Owner:NANJING FORESTRY UNIV

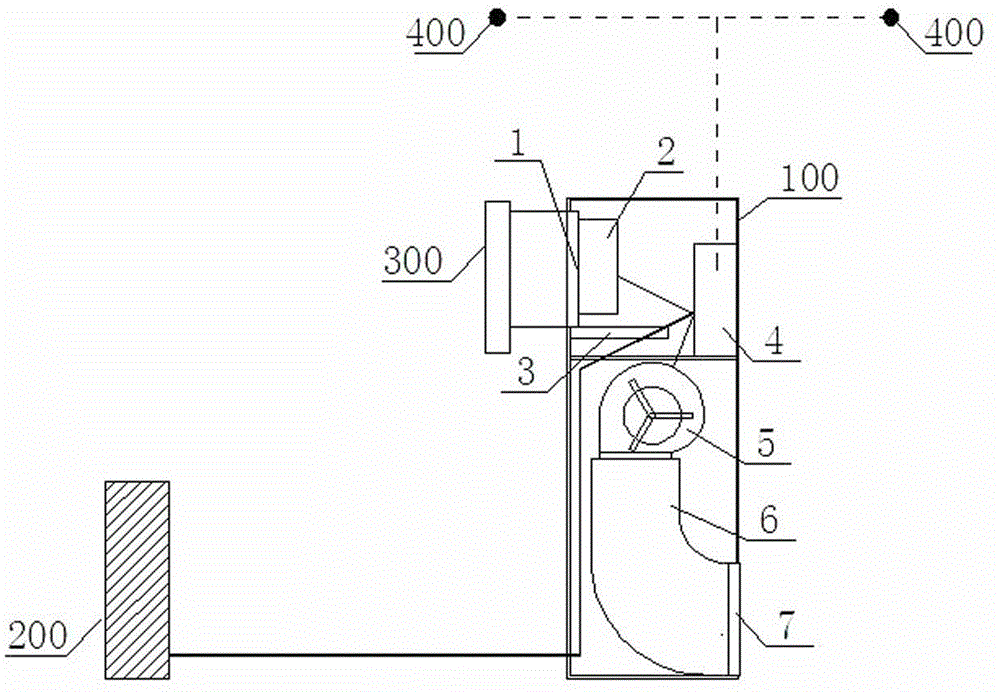

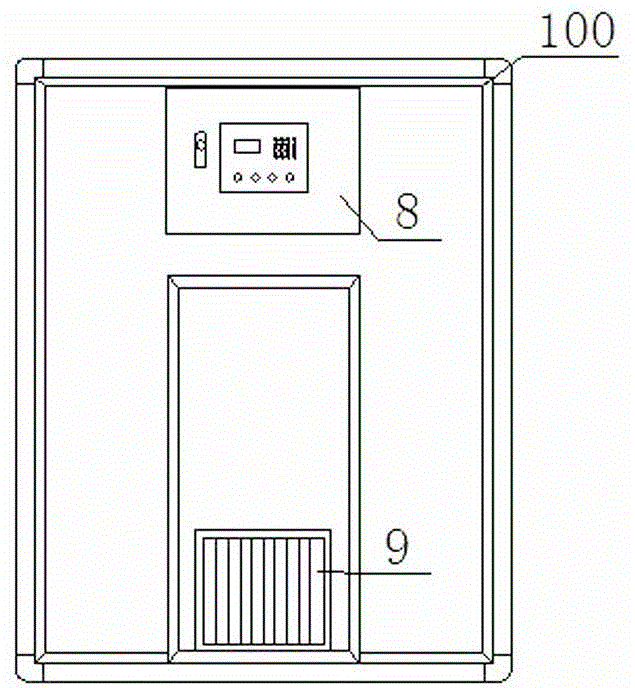

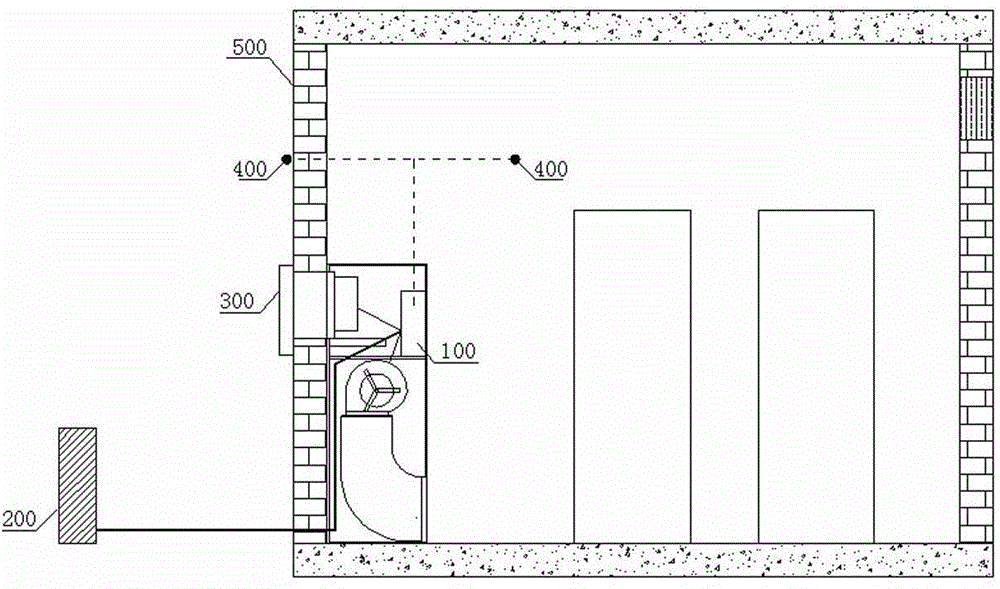

Substation indoor environment intelligent control device

InactiveCN104456832ANo excessive coolingSave energyMechanical apparatusSpace heating and ventilation safety systemsElectricityEngineering

The invention relates to a substation indoor environment intelligent control device which is characterized in that an indoor unit, an outdoor unit and a sensor set are included. The indoor unit comprises a box, an air inlet is formed in the upper portion of the box, an air outlet is formed in the lower portion of the box, the inside of the box is sequentially provided with an evaporator, a water collecting plate, a fan and a silencing pipeline from top to bottom, the evaporator corresponds to the air inlet in position, the water collecting plate is located under the evaporator, the upper end of the silencing pipeline is connected with the fan in a sealed mode, the lower end of the silencing pipeline is connected with the air outlet in a sealed mode, a controller is disposed in the box, a compressor is arranged in the outdoor unit, the sensor set comprises an outdoor temperature and humidity sensor and an indoor temperature and humidity sensor, and the evaporator, the fan, the compressor, the outdoor temperature and humidity sensor and the indoor temperature and humidity sensor are electrically connected with the controller. Environment control is performed on indoor space in a substation by means of the intelligent control device, potential safety hazards do not exist, energy can be saved, meanwhile, air outflow amount and air speed are easy to control, and eddies and turbulent flow can not be generated.

Owner:JIANGSU TAIPUDA TECH

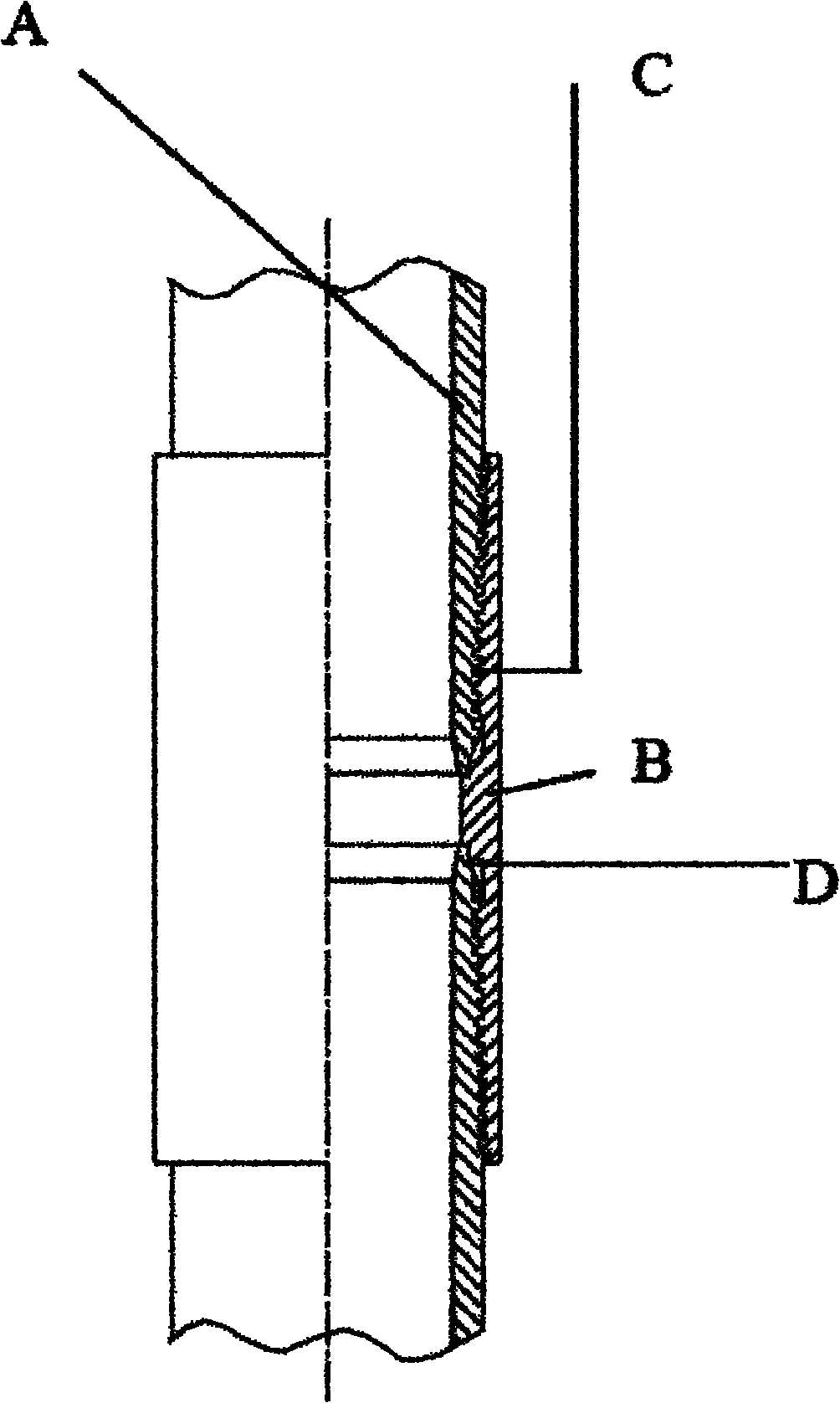

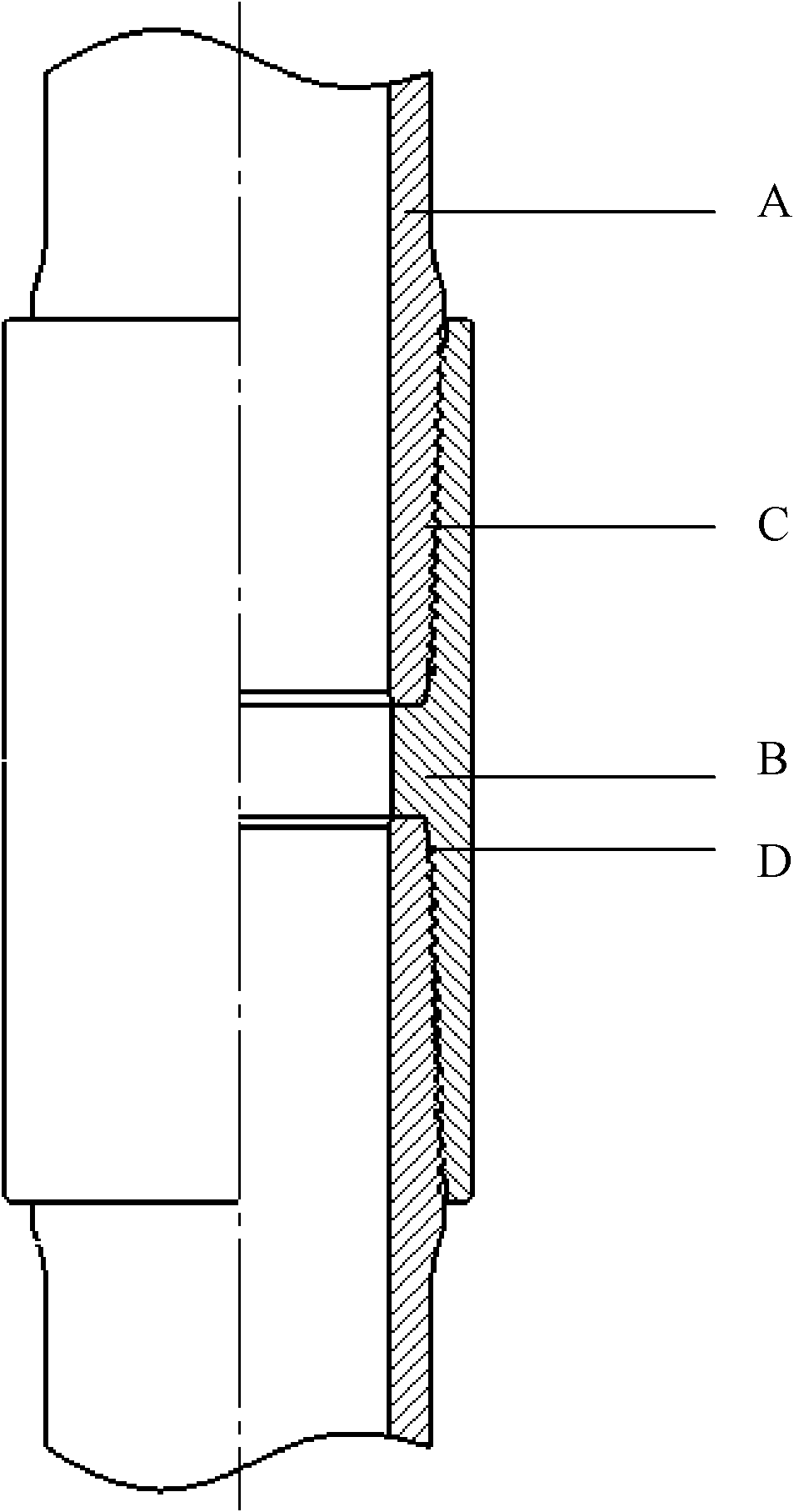

Thread joint structure for high-performance oil casing

The invention provides a thread joint structure of high-performance oil casing. The structure comprises a casing of which one end is provided with external threads and a coupling with internal threads, wherein the casing and the coupling are screwed together; the external threads at the end part of the casing and the internal threads of the coupling are both negative-angle taper threads; the threads are designed to be tooth-side interference; and the internal threads of the coupling are provided with a torque-stop shoulder. Due to the simultaneous adoption of the negative-angle thread design and the tooth-side interference design, the thread structural design is optimized, the stability of sealing performance of a sealing surface under a stretching and compression load is improved, and the use of the oil casing under extreme conditions is facilitated. As the stretching and compression performance is improved, the bending resistance is enhanced; the torque-stop shoulder is arranged at a corresponding position of the coupling so as to ensure a screwing position; and the connection efficiency of the joint is maximized and the compression performance is optimized.

Owner:TIANJIN PIPE (GROUP) CORP

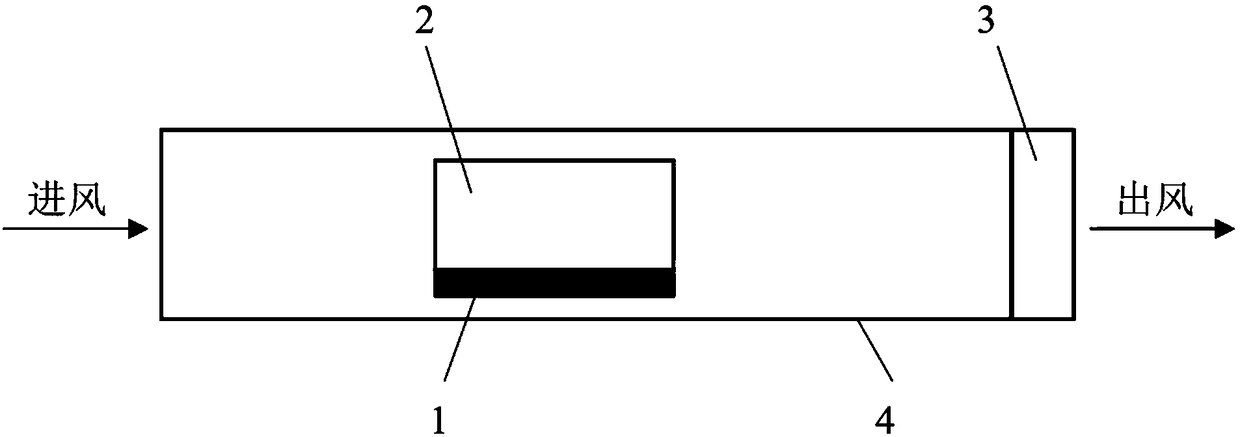

Central processing unit chip heat dissipation device for blade server

PendingCN108762454AEasy dischargeSolution areaDigital data processing detailsHeating effectEngineering

The invention relates to a central processing unit chip heat dissipation device for a blade server, and belongs to the technical field of integrated circuit chip heat dissipation. The heat dissipationdevice for the blade server comprises an evaporator, a heat pipe, a condenser and a heat dissipation air duct. Heat generated by a CPU chip is absorbed through the evaporator; a liquid working mediumin an evaporator cavity is rapidly vaporized into steam after being heated; and the heat pipe is used for transmitting working medium steam to the condenser for condensing, liquefying and heat releasing. Since the vapor and liquid phase change of the working medium is utilized to transfer heat, the thermal resistance is very small and the heat conduction capability is very high. The heat dissipation air duct is of a straight-through structure, the wind power is unidirectional and has no turbulence phenomenon, so that the condenser can quickly and fully dissipate heat, and the heat generated by the CPU chip can be rapidly discharged. The heat dissipation air duct is physically isolated from a circuit space of the blade server; the heat dissipation air flow only flows in the heat dissipation air duct, and does not enter the circuit space of the blade server, thus the problems that the existing heat dissipation device has a cascade heating effect, low heat dissipation efficiency, large fan noises and the like are solved.

Owner:UNISPLENDOUR CO LTD

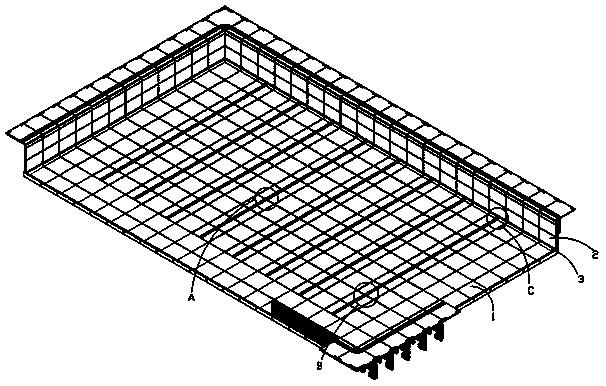

Water supply and drainage mechanism at pool bottom of assembly type swimming pool.

PendingCN110017039AIncrease the areaEasy to assembleGymnasiumSwimming poolsMarine engineeringWater flow

The invention discloses a water supply and drainage mechanism at the pool bottom of an assembly type swimming pool. The water supply and drainage mechanism comprises a swimming pool bottom formed by splicing a plurality of pool bottom plates, an inner coaming vertically surround the periphery of the swimming pool bottom, and pool edge plates connected between the edge part of the swimming pool bottom and the lower edge part of the inner coaming. The pool bottom plates and the pool edge plates in the same row or column are provided with water supply / drainage grooves, a water supply pipeline isarranged on the outer side of the inner coaming, a circulating water pump is arranged on the water supply pipeline, the pool edge plate on one side is provided with a through hole for communicating the water supply pipeline with the water supply / drainage groove, the water supply / drainage groove is covered with a cover plate, and the cover plate is provided with a perforation through which water flows, so that the disassembly and assembly are convenient, and a water supply / drainage pipeline is easy to be processed on the pool bottom plates, so that the water supply / drainage of the swimming poolis convenient.

Owner:江阴四方游泳康复产业股份有限公司

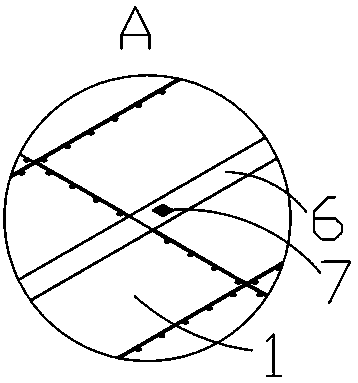

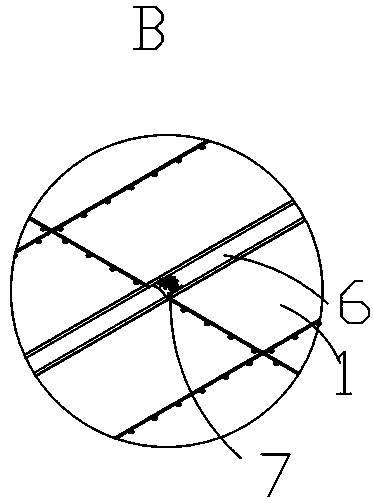

Method and acid distributor for uniformly distributing sulfuric acid

ActiveCN106044722AEvenly distributedDistribution does not affectSulfur compoundsDistributorChemistry

The invention discloses a method and an acid distributor for uniformly distributing sulfuric acid. The method for uniformly distributing the sulfuric acid is implemented by the aid of a pre-distribution cavity. A main acid distribution component which is communicated with the pre-distribution cavity is arranged on the lower side of the pre-distribution cavity, and a plurality of acid distribution branch pipes with equal heights are arranged on the main acid distribution component; the pre-distribution cavity, a cavity of the main acid distribution component and cavities of the acid distribution branch pipes are connected with one another to form a closed acid liquor channel, only acid liquor inlets are only formed in the pre-distribution cavity, and acid liquor outlets are uniformly formed in the lower portions of the acid distribution branch pipes; the circulation cross section of the pre-distribution cavity, the total circulation cross section of the main acid distribution component and the total circulation cross section of the acid distribution branch pipes are larger than the section of the acid liquor inlets. The method and the acid distributor have the advantages that acid liquor can be uniformly distributed by the aid of the method and the acid distributor; the flow rate of the acid liquor is controlled, the acid liquor in the pre-distribution cavity, the main acid distribution component and the acid distribution branch pipes is in un-full states, partial air in acid liquor unfilled spaces is exhausted, and accordingly stable flow of acid liquor discharged from the various acid liquor outlets can be uniformly distributed.

Owner:云南化铸科技有限责任公司

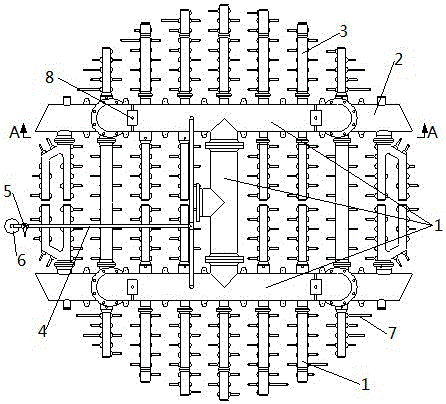

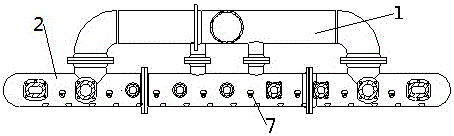

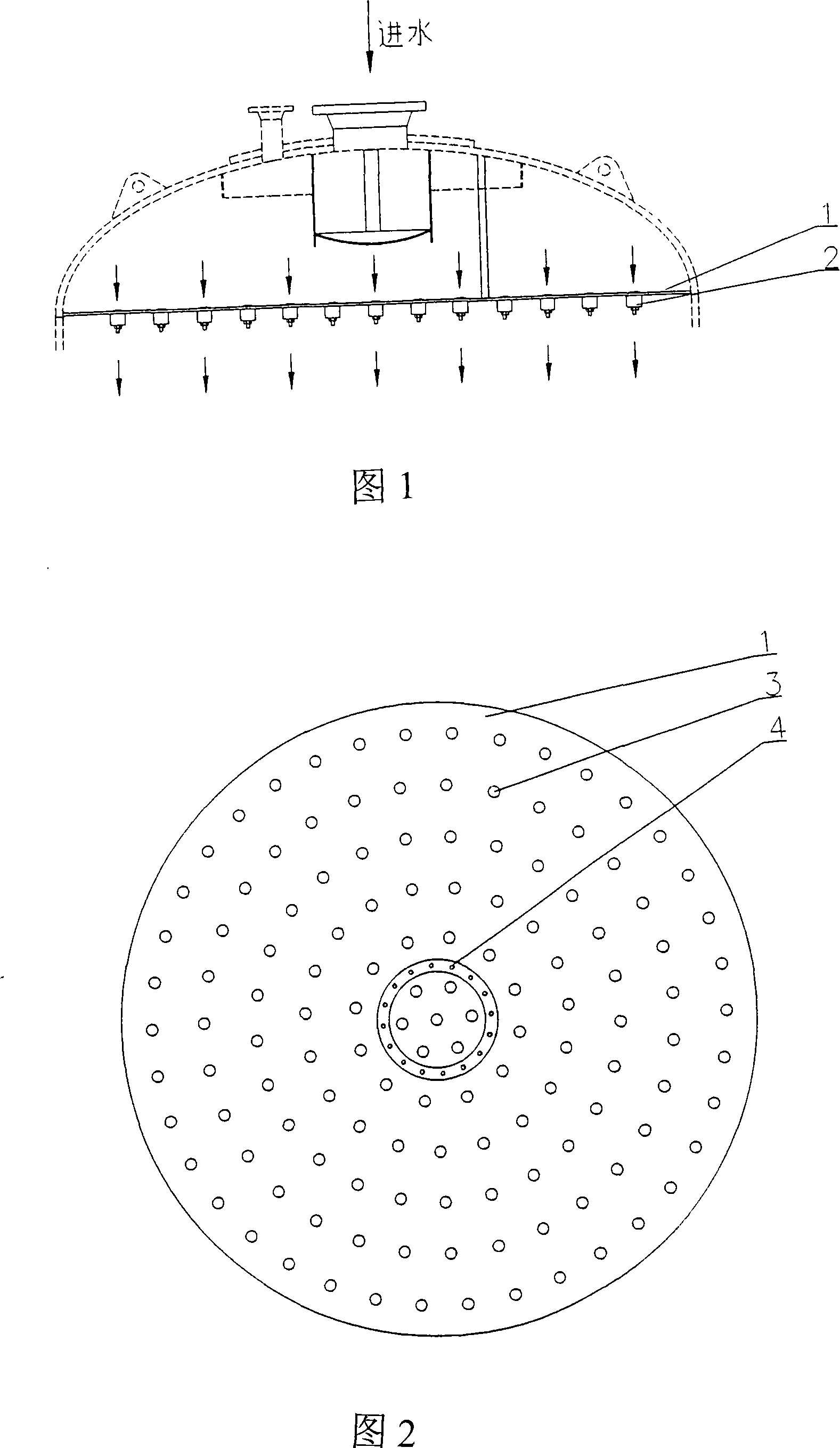

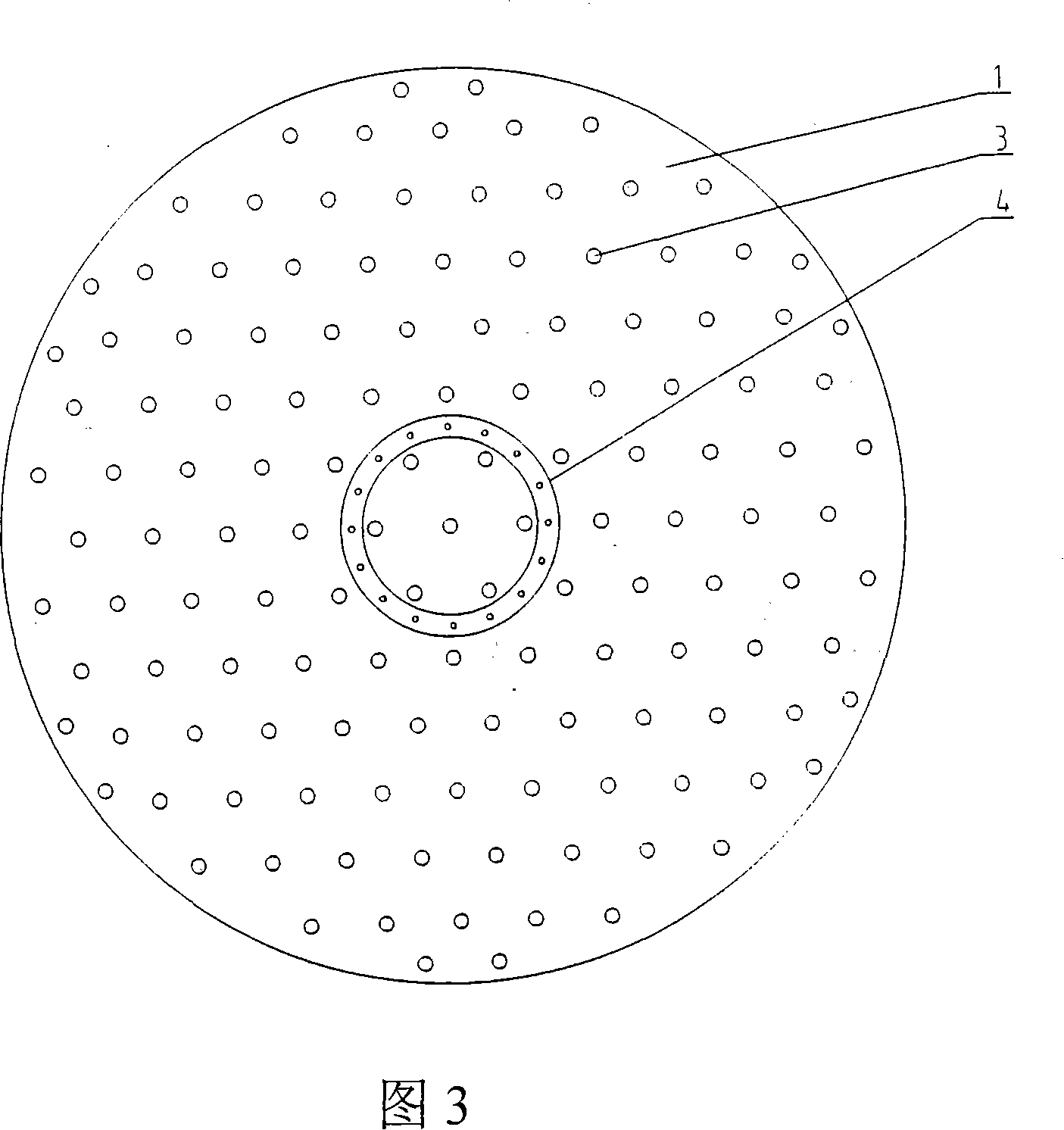

Water distributing plate used for high flow velocity equipment

InactiveCN101130440AGuaranteed tightnessEvenly distributedWater/sewage treatmentPower stationWater flow

The invention discloses a water distribution board of power station condensate fine disposal equipment under high-flow velocity in the industrial water disposal domain, which is composed of water distribution board plane 1 and water distributor 2, wherein the assembling hole 3 is set on the water distribution board plane 1 with the water distributor 2 under the assembling hole; the water distribution board plane 1 is integral structure to ensure the evenness of water distribution, which reduces the abrasion of equipment due to flow, therefore improving the water quality and quantity and lengthening the life of the equipment.

Owner:华电水处理技术工程有限公司 +1

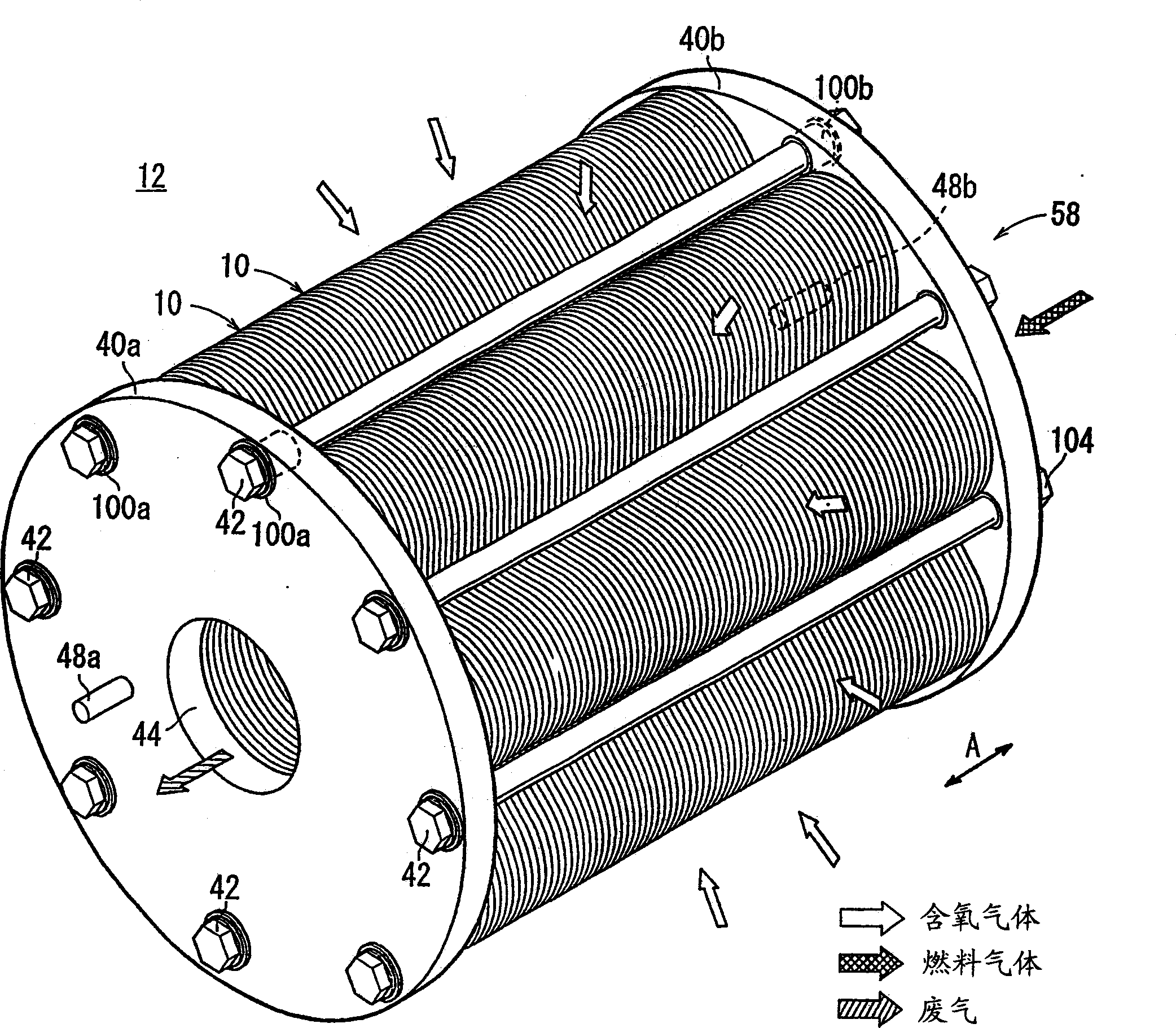

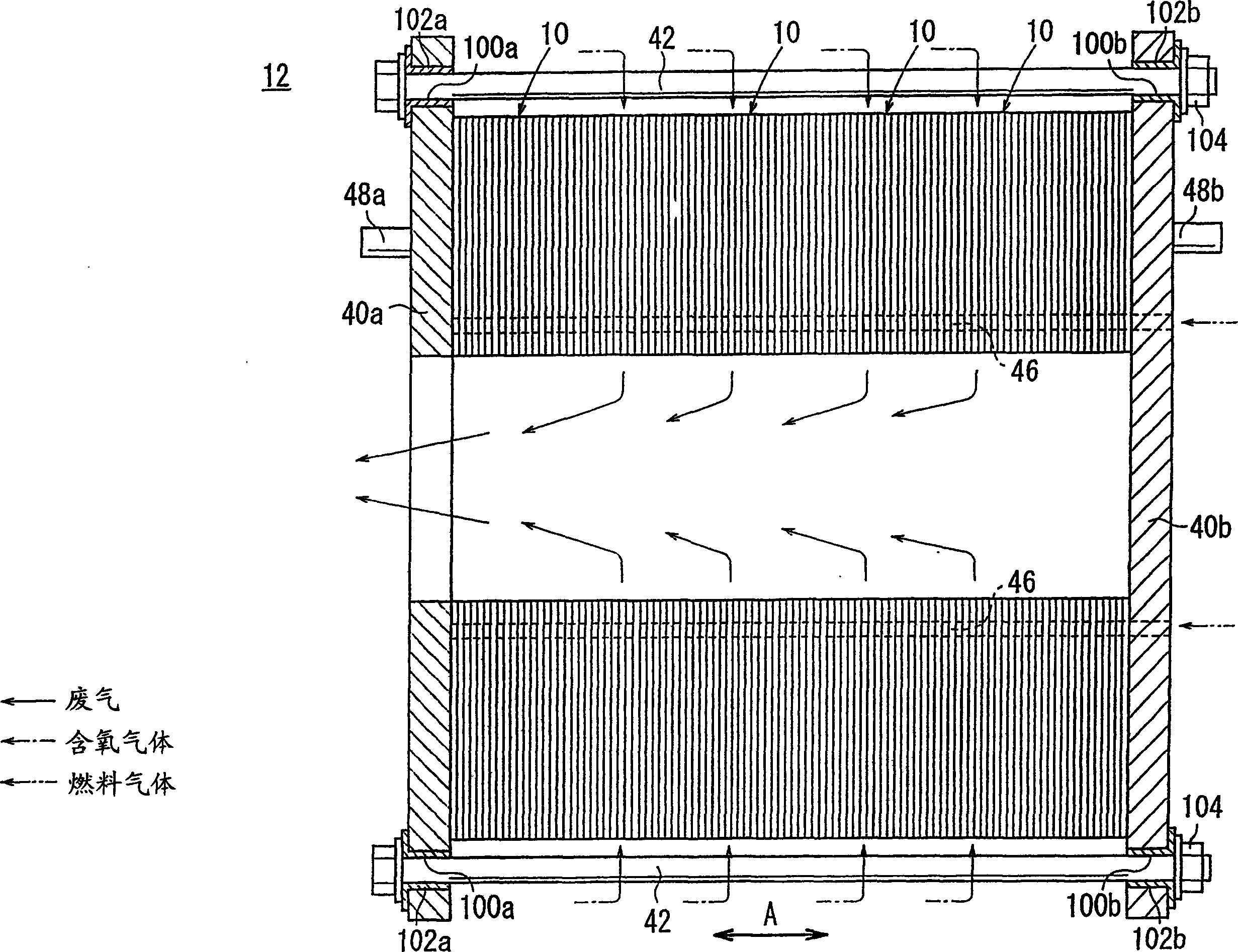

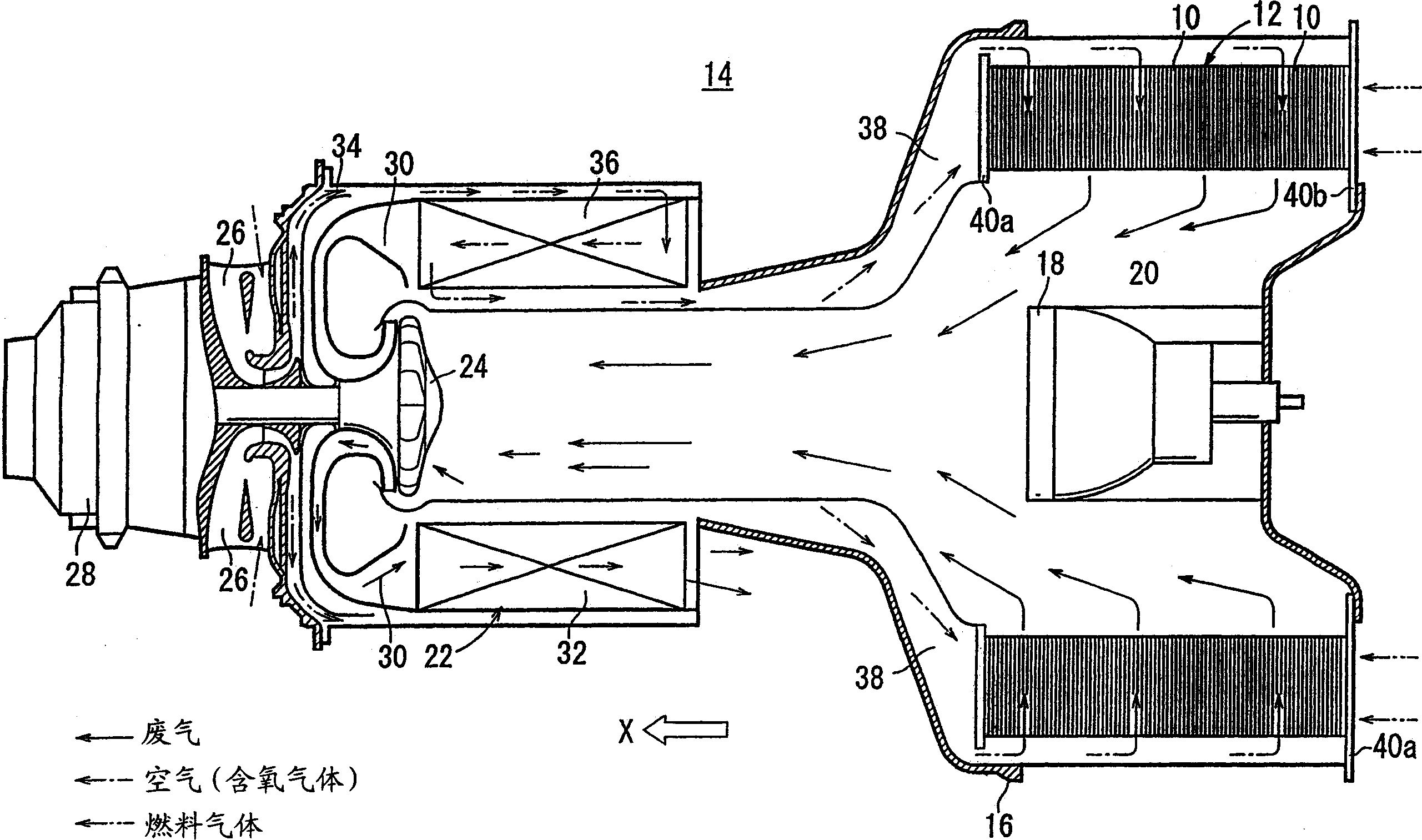

Fuel cell and fuel cell stack

InactiveCN1666366AAvoid damageUniform temperature distributionFuel cells groupingFuel cell auxillariesFuel cellsOxygen

A fuel cell includes a pair of separators and a plurality of electrolyte electrode assemblies between the separators. The electrolyte electrode assemblies has a small circular disk shape. Eight electrolyte electrode assemblies are arranged along an inner circle and eight electrolyte electrode assemblies are arranged along an outer circle concentric with a circular hole. Each of the separators includes a plurality of plates stacked together. A fuel gas channel for supplying a fuel gas to anodes of the electrolyte electrode assemblies, an oxygen-containing gas channel for supplying an oxygen-containing gas to cathodes of the electrolyte electrode assemblies are formed between the plates.

Owner:HONDA MOTOR CO LTD

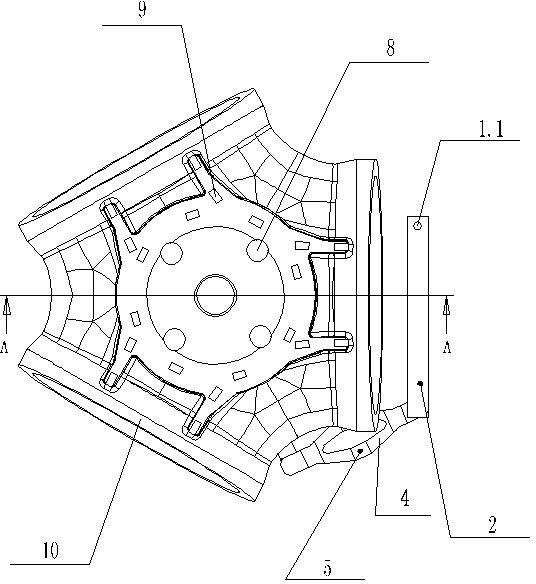

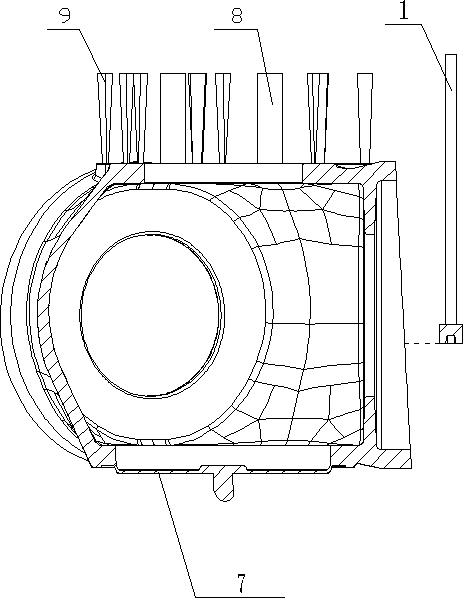

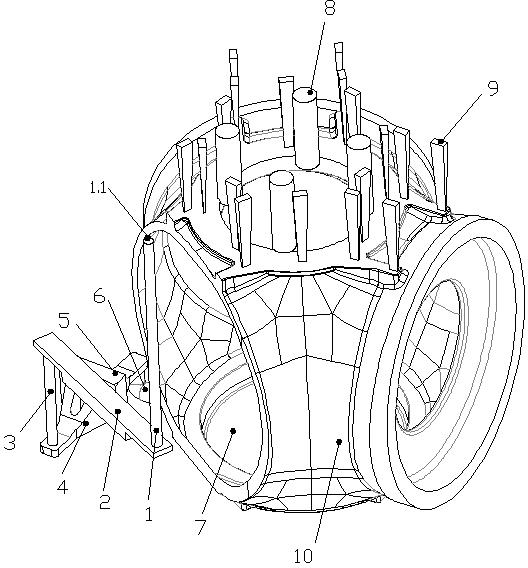

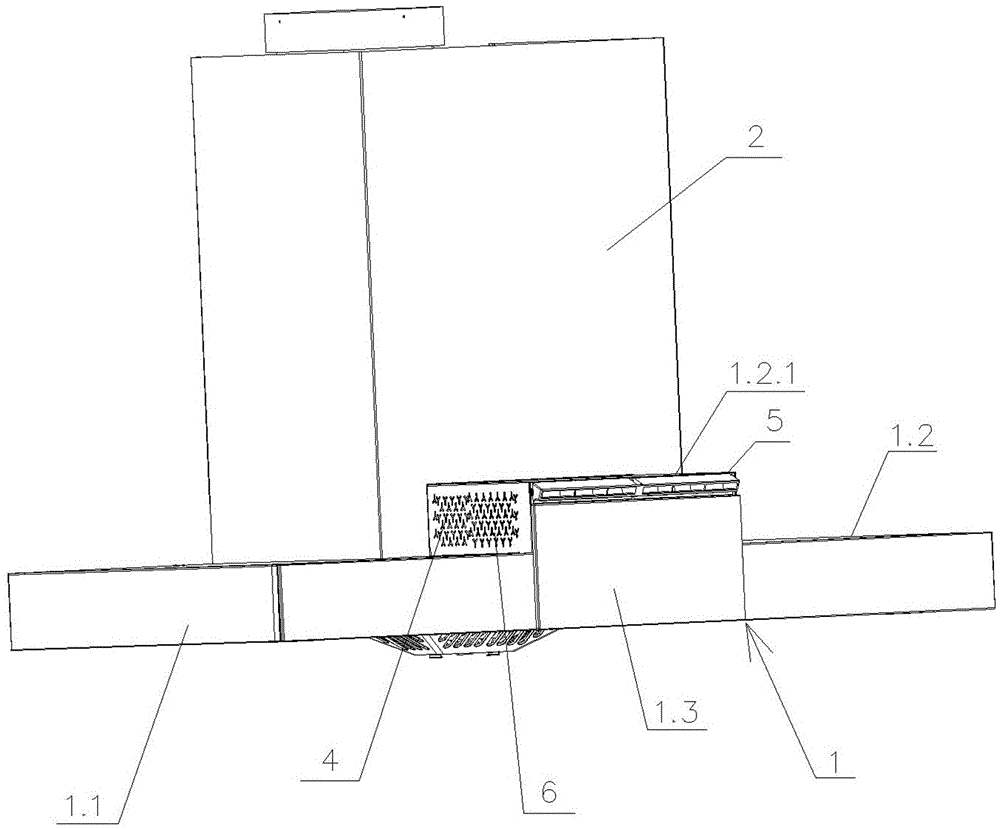

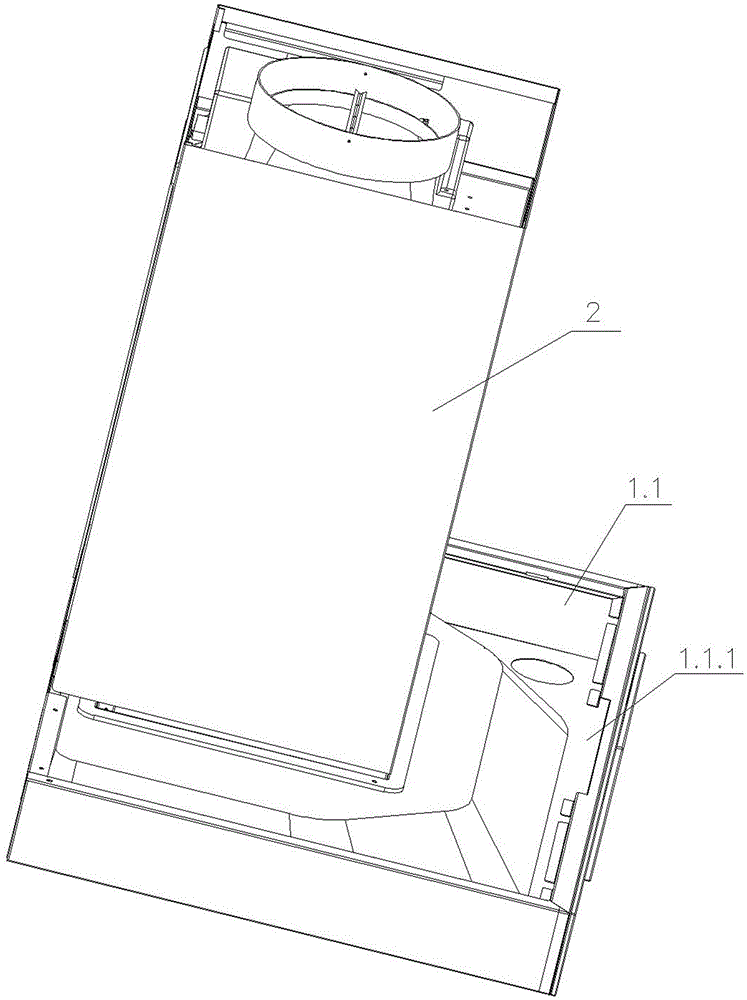

Range hood with refrigeration function

ActiveCN105526612AReduce volumeSmall footprintDomestic stoves or rangesLighting and heating apparatusCold airEngineering

The invention discloses a range hood with a refrigeration function. The range hood comprises a hood body (1) and a hood box assembly (2). The hood body (1) comprises a machine body (1.1) and a cover plate (1.2). The machine body (1.1) is covered with the cover plate (1.2). The range hood further comprises a box body (3) and a semiconductor refrigeration device. The semiconductor refrigeration device is arranged in the box body (3). A slot (1.1.1) matched with the box body (3) is formed in the machine body (1.1). The box body (3) is installed in the machine body (1.1) and connected in the slot (1.1.1) in an inserted mode. According to the range hood, a cold air device is integrated in the hood body, so that the range hood is small in whole size, compact in structure and small in occupied space. Blown cold air is close to a user, so that the experience feeling of the user is good.

Owner:NINGBO OULIN KITCHEN APPLIANCE

Ultraviolet disinfection cabinet

InactiveCN110384810AEasy to removeEasy to collectLavatory sanitoryRadiationWater flowUv disinfection

The invention discloses an ultraviolet disinfection cabinet. Aiming at solving the problem that existing disinfection objects are inconvenient to move out, a scheme is currently proposed as follows: the ultraviolet disinfection cabinet comprises a box body, and an opening is formed in the front face of the box body; a box cover is hinged to one side of the opening, and a water receiving tank bodyis fixed to the inner wall of the bottom of the box body; one side of the water receiving tank body is connected with a water drainage pipe extending out of the outer wall of the box body, and a firstultraviolet lamp strip is mounted on the inner wall of the top of the box body; and two supporting tank bodies arranged in the up-down direction are fixed between the inner walls of the box body, a connecting pipe is connected between the two supporting tank bodies, and second ultraviolet lamp strips which are fixed to the inner walls on the two sides of the box body are arranged on the upper parts of the two ends of the two supporting tank bodies correspondingly. According to the ultraviolet disinfection cabinet, placement and taking can be convenient, meanwhile, a water flow is convenientlycollected, thus the situation that the water flow flows disorderly, and consequently cross contamination is caused is avoided, the placement tank bodies are convenient to move out, clearing is convenient, and thus the ultraviolet disinfection cabinet meets using demands better.

Owner:佛山市南海四度机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com