Casting process for hydraulic main control valve blank

A casting process and main control valve technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as shrinkage porosity, out of tolerance, broken core, etc., to reduce the impact of dimensional changes, enter the cavity smoothly, Small washout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

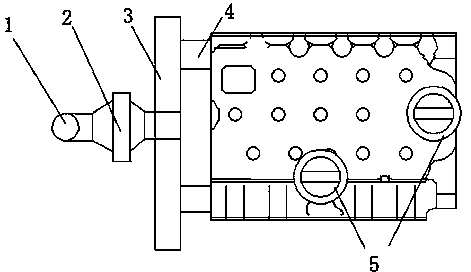

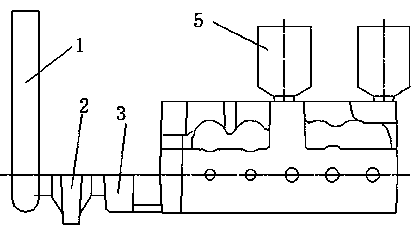

[0025] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0026] like Figure 1-2 As shown, the blank casting process of the hydraulic main control valve includes the steps of: selecting the molding sand used in the pouring system, and the molding sand is resin sand; using resin sand to construct the sand casting cavity of the hydraulic main control valve blank; Pouring, then cooling naturally and breaking out of the finished product.

[0027] The sand casting cavity includes a main cavity and a runner, the runner communicates with the main cavity, and there are at least two thermal insulation risers 5 on the main cavity. The sprue includes a sprue 1, a runner 3, and an ingate 4, the sprue is arranged vertically, and is connected to the runner and the ingate in sequence, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com