Patents

Literature

1051results about How to "Reduce washout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

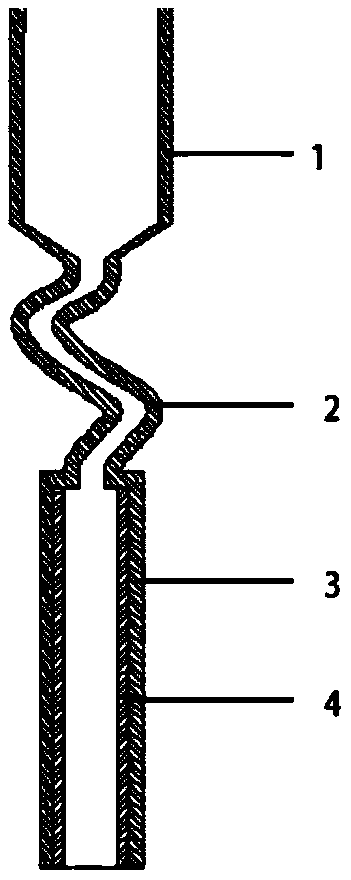

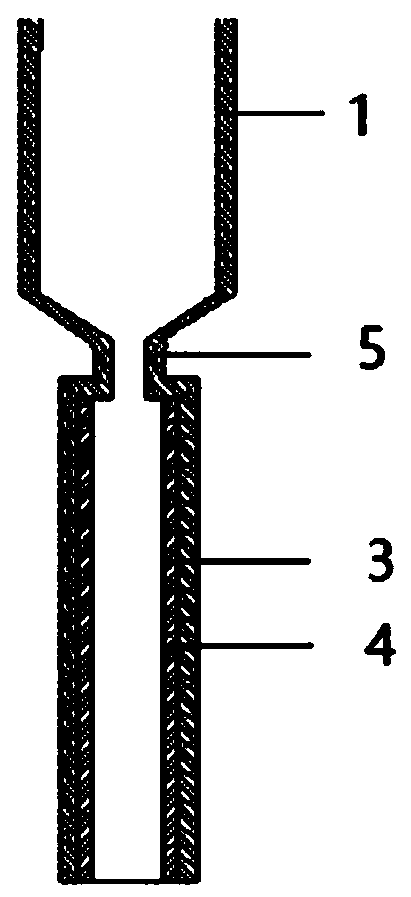

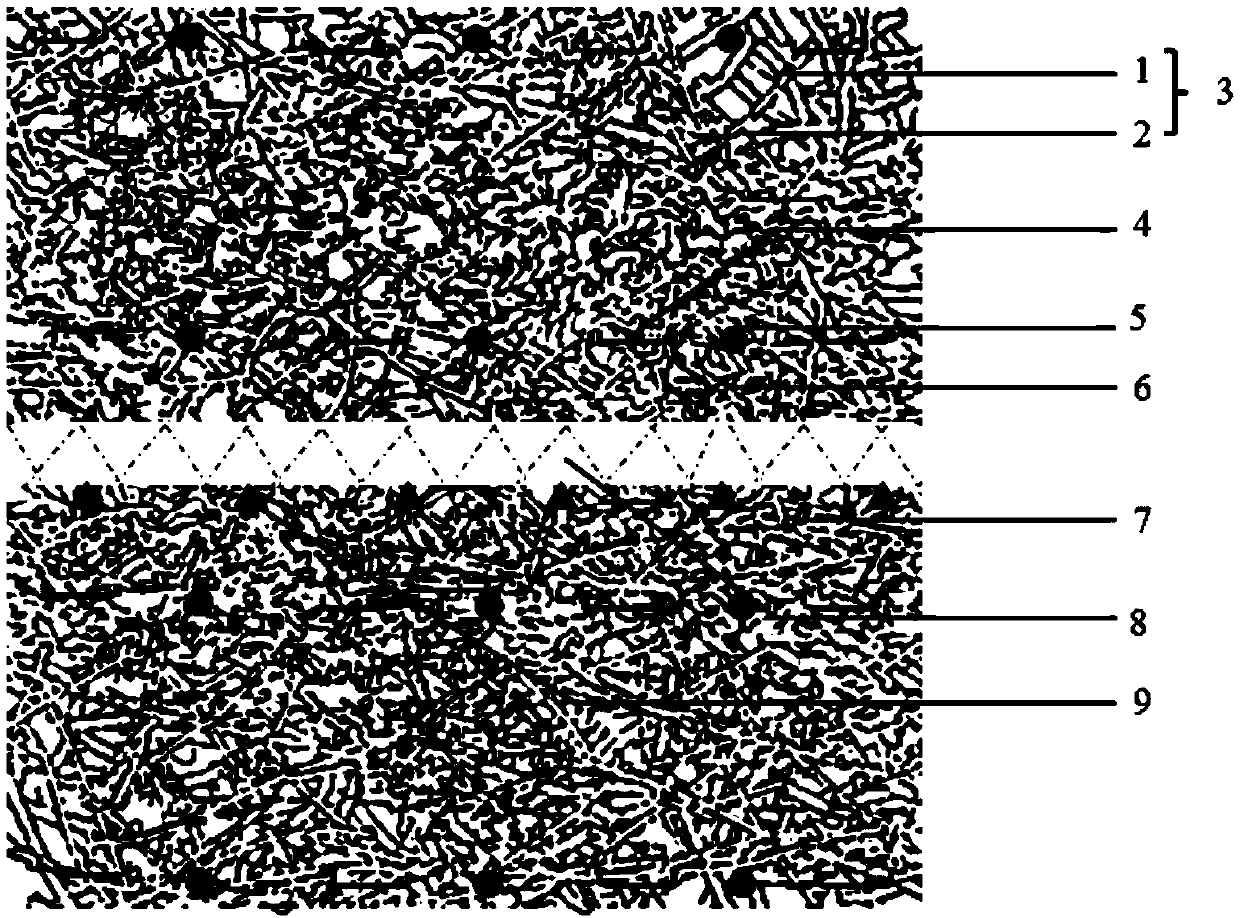

Filter for the separation of leukocytes from whole blood or blood preparations, method for production of said filter, corresponding device and use thereof

ActiveUS7775376B2Simple and inexpensive to produceLong durabilitySemi-permeable membranesOther blood circulation devicesHydrophilic monomerWhite blood cell

Owner:FRESENIUS HEMOCARE ITAL

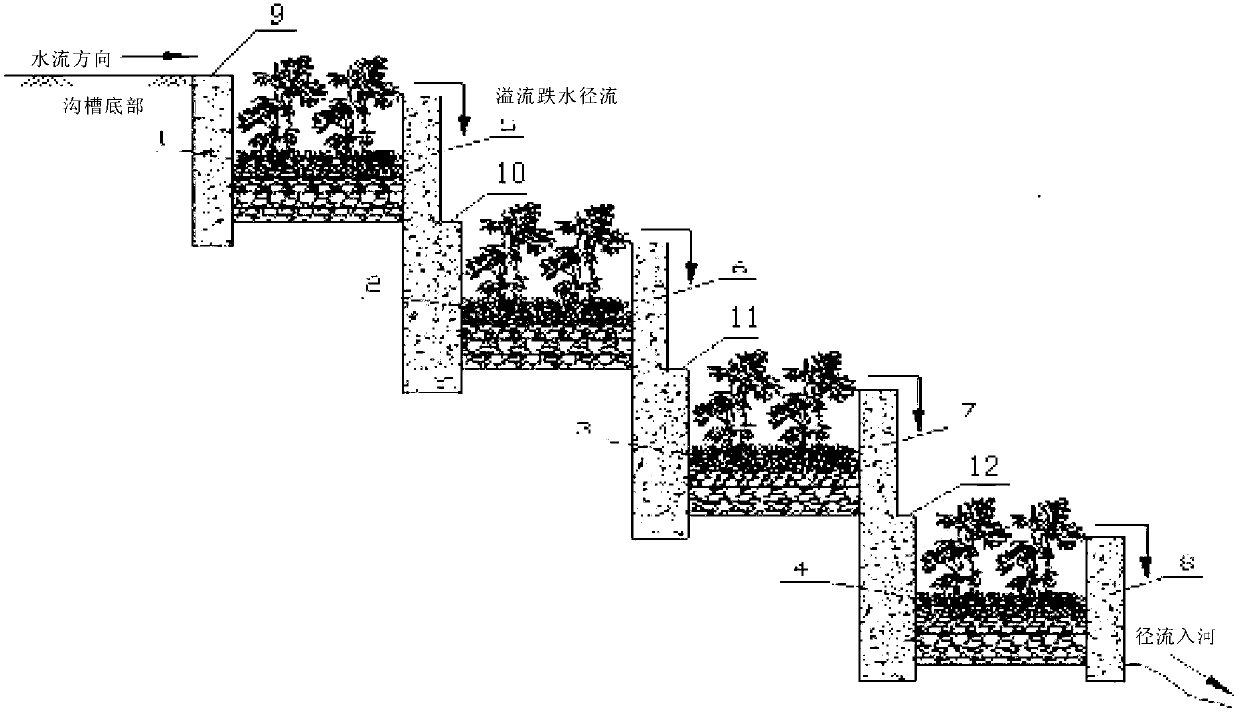

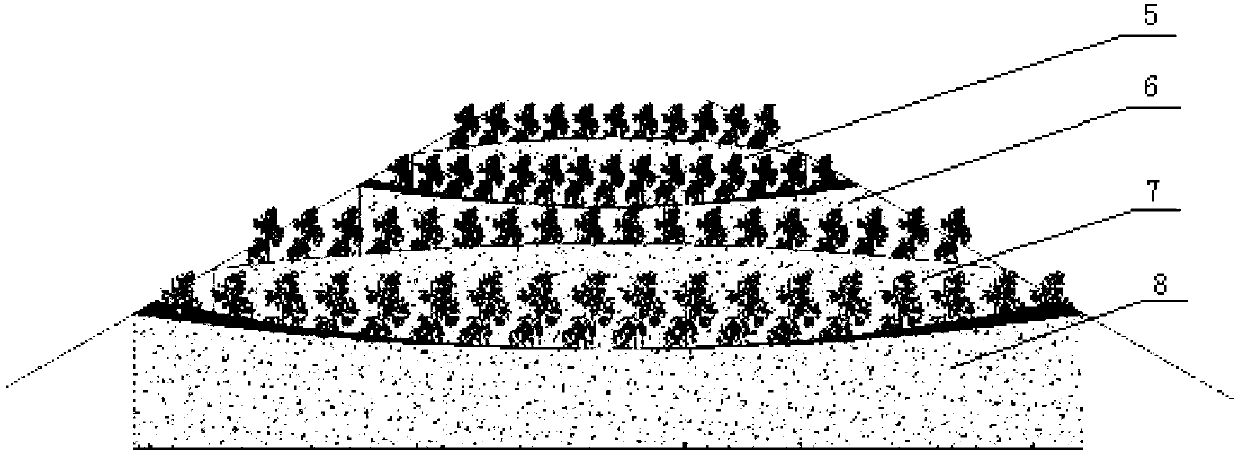

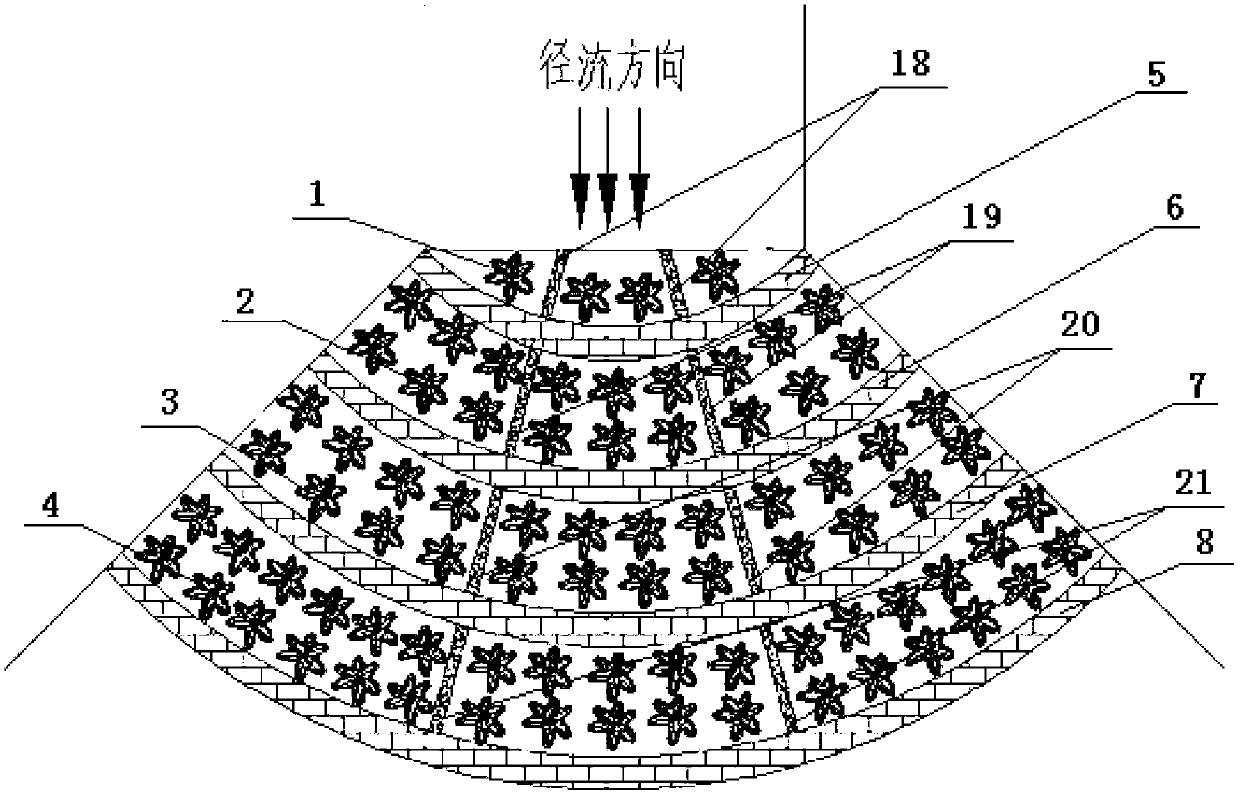

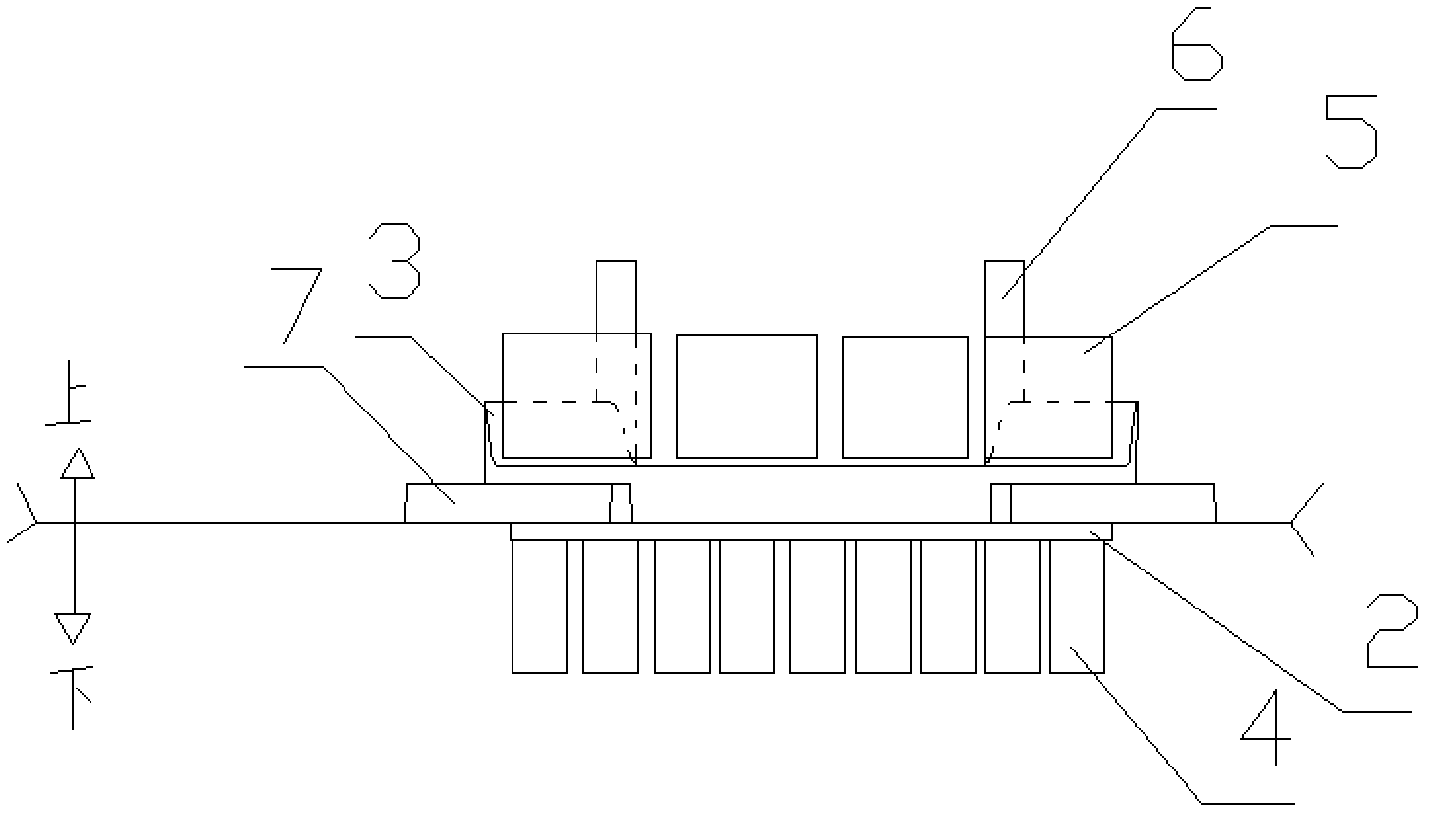

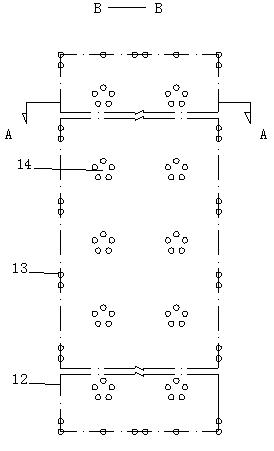

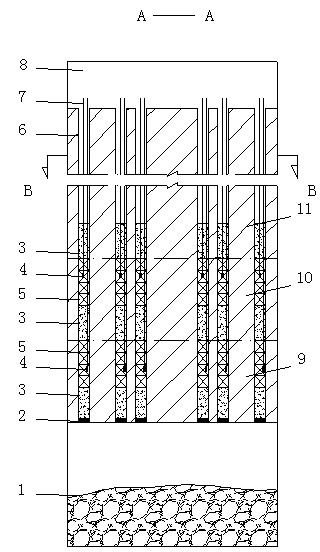

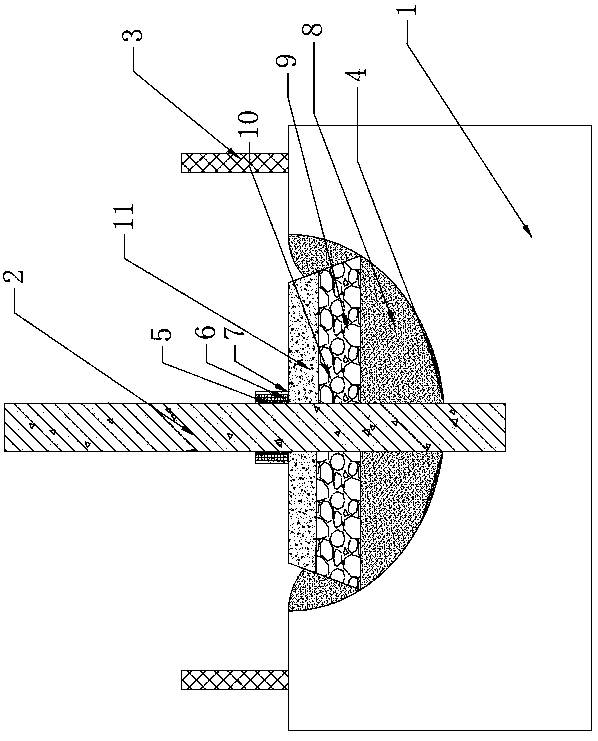

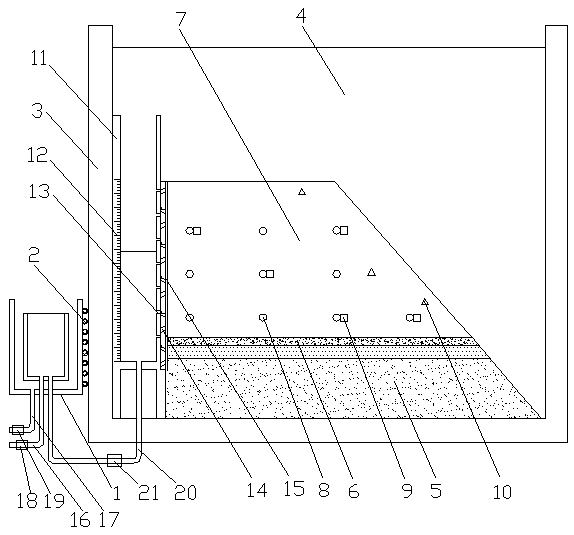

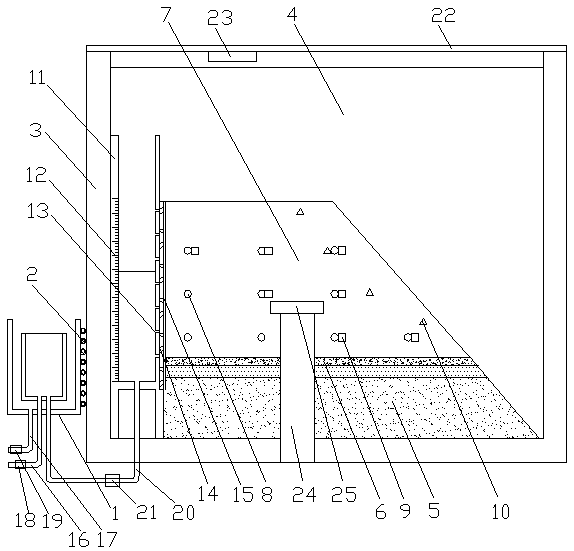

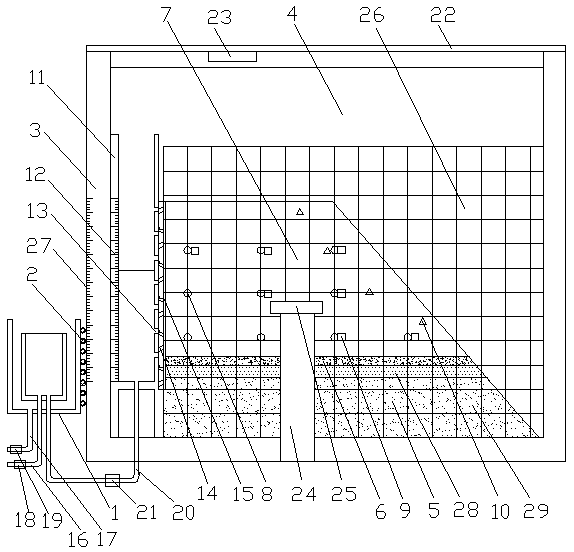

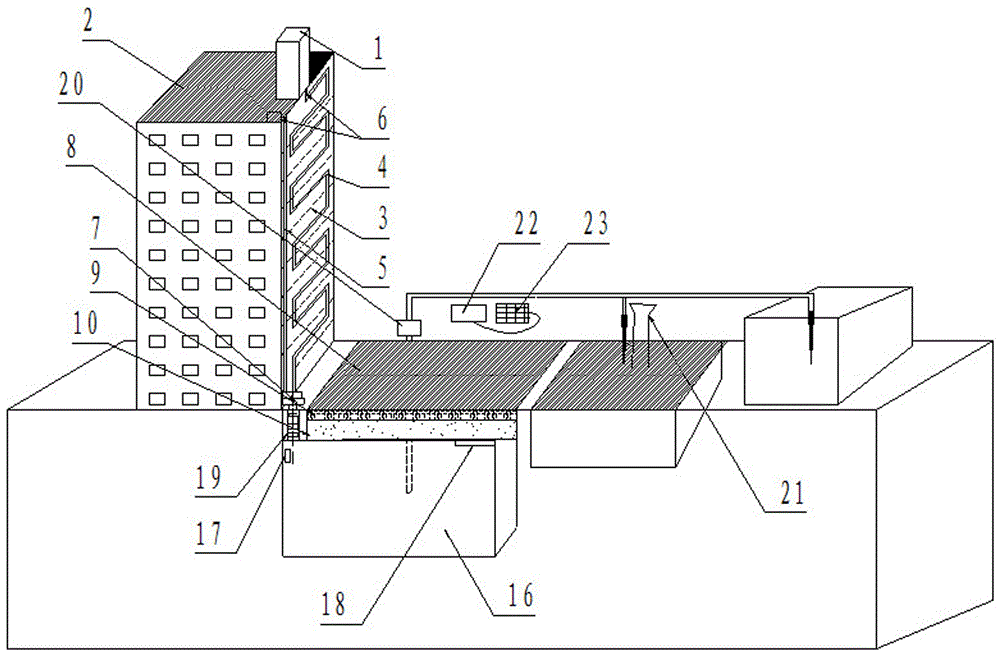

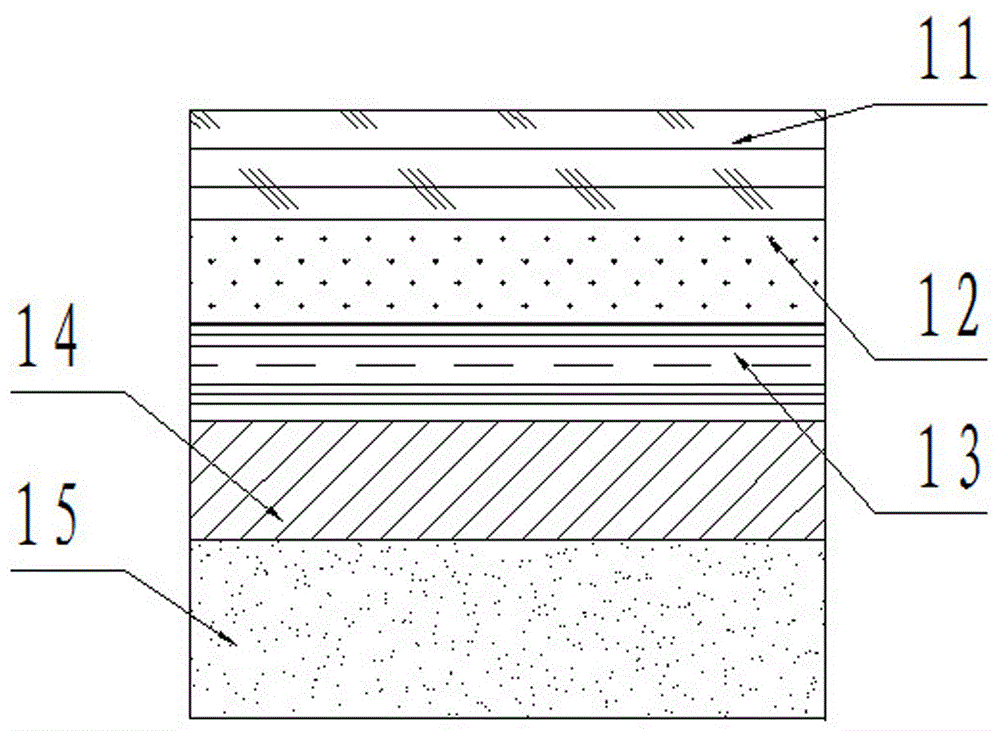

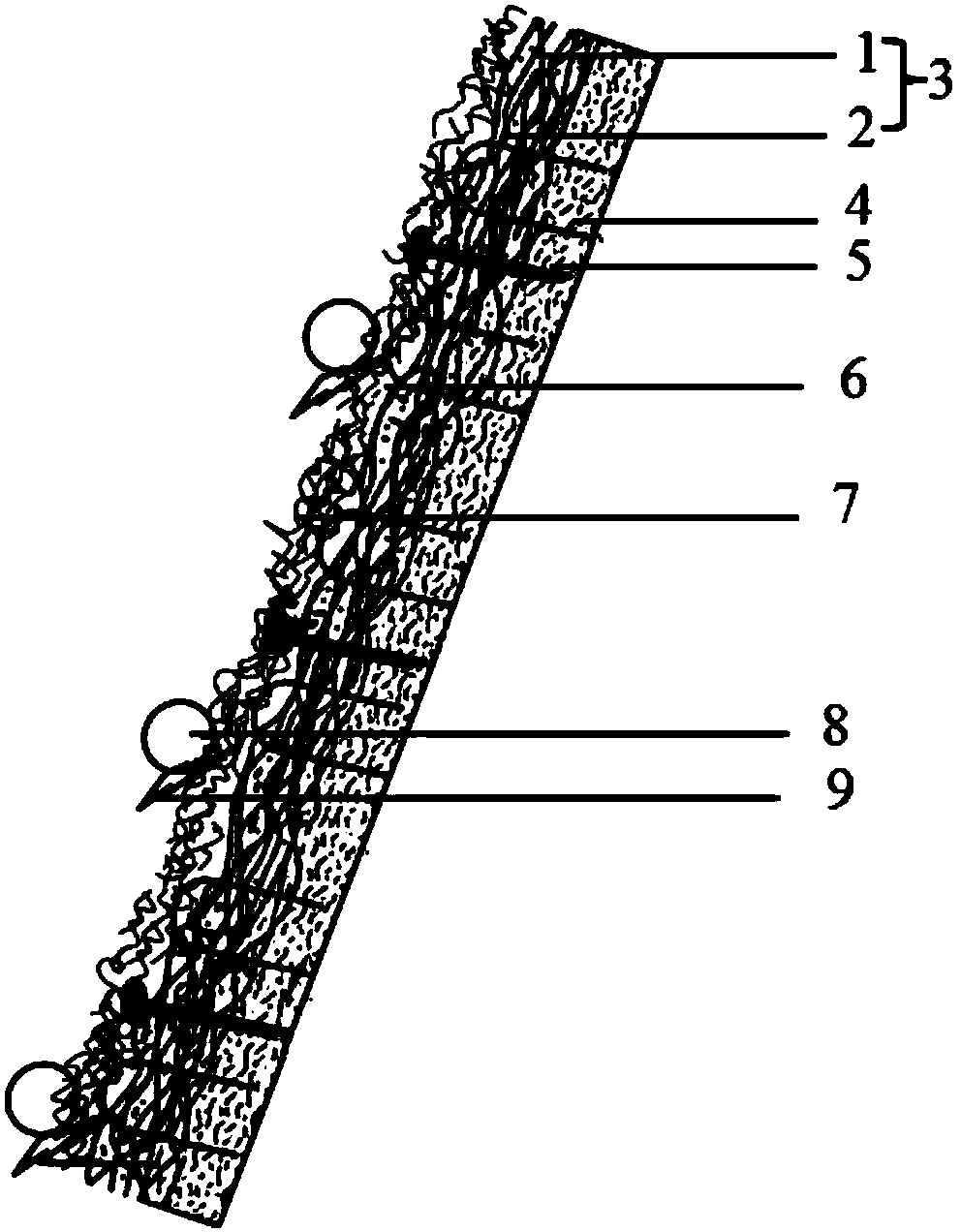

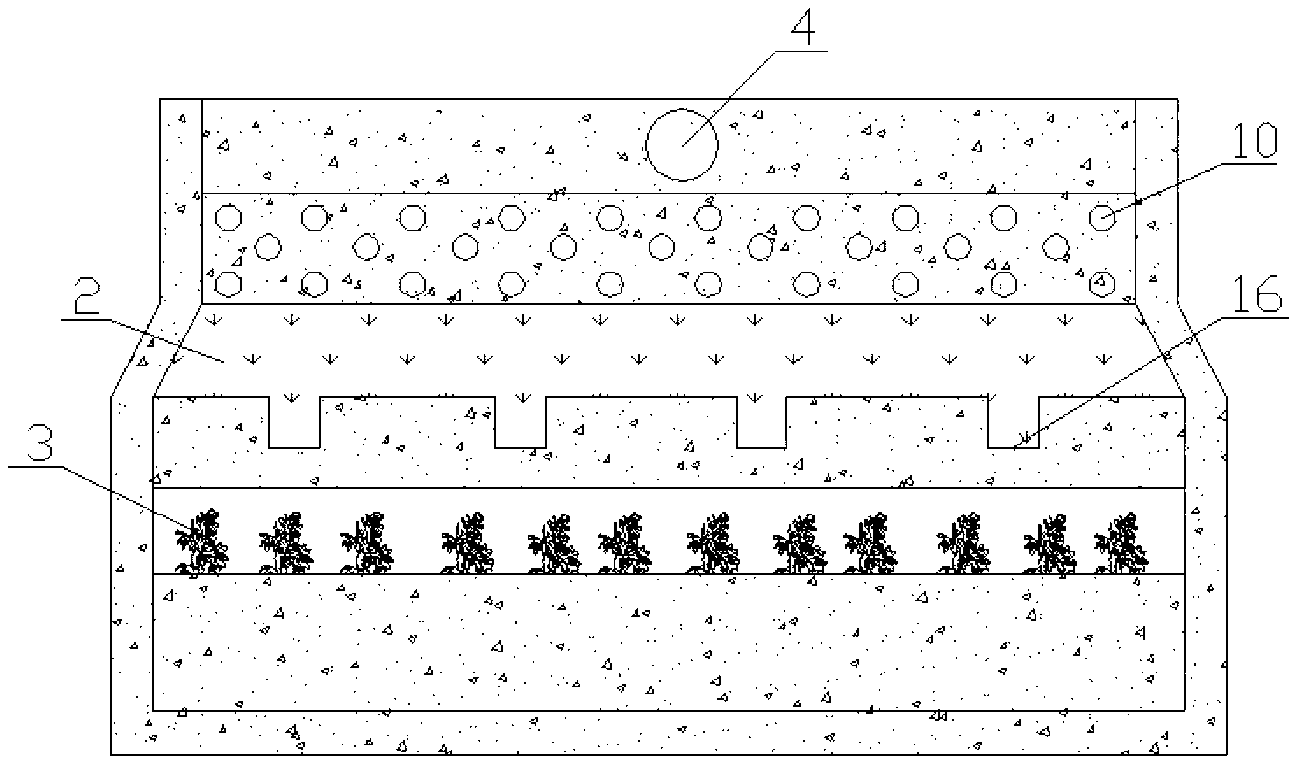

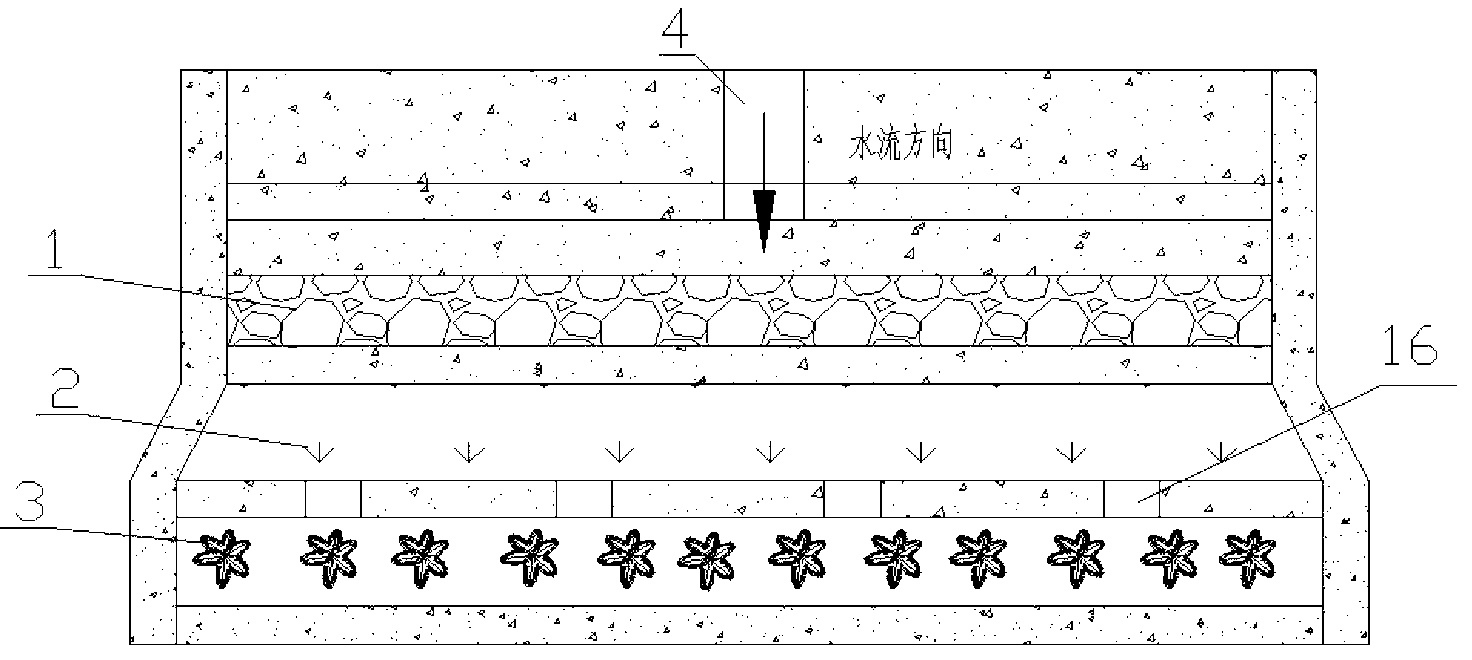

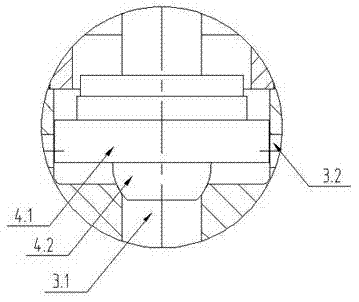

Sectored multi-step ecological buffer revetment system

InactiveCN103215920AMeet safety requirementsGood interception and purification effectClimate change adaptationCoastlines protectionEngineeringFlood water

The invention discloses a sectored multi-step ecological buffer type revetment system. The revetment system is provided with at least four levels of steps, blocking walls are sequentially arranged on the outer sides of the steps, one plant planting zone is arranged in the blocking wall of each level, soil matrix is arranged in the upper layer of each plant planting zone, yellow sand, ceramsite, soft rock and zeolite are sequentially in the lower layer of the plant planting zone of each level, and emersed landscape plants and submergence-tolerant plants are arranged in the plant planting zone of each level; hydraulic drop platforms are sequentially arranged in the corresponding positions of spaced plant planting zones of the blocking walls; and one guide plate is arranged between each blocking wall and the corresponding hydraulic drop platform; the plant planting zone of the first level is connected with a farmland drainage canal and is sectored towards the downstream to form a hydraulic-drop type hierarchical structure in an open sectored shape, the sector radius is 5-8 m, and the central angle is 45 degrees-75 degrees; and the blocking wall of the last level is connected with a river channel. The sectored multi-step ecological buffer type revetment system not only has the efficacies of protecting river channel side slope, and realizing flood water drainage and water and soil conservation, but also has good purification and landscape effects.

Owner:TIANJIN UNIV

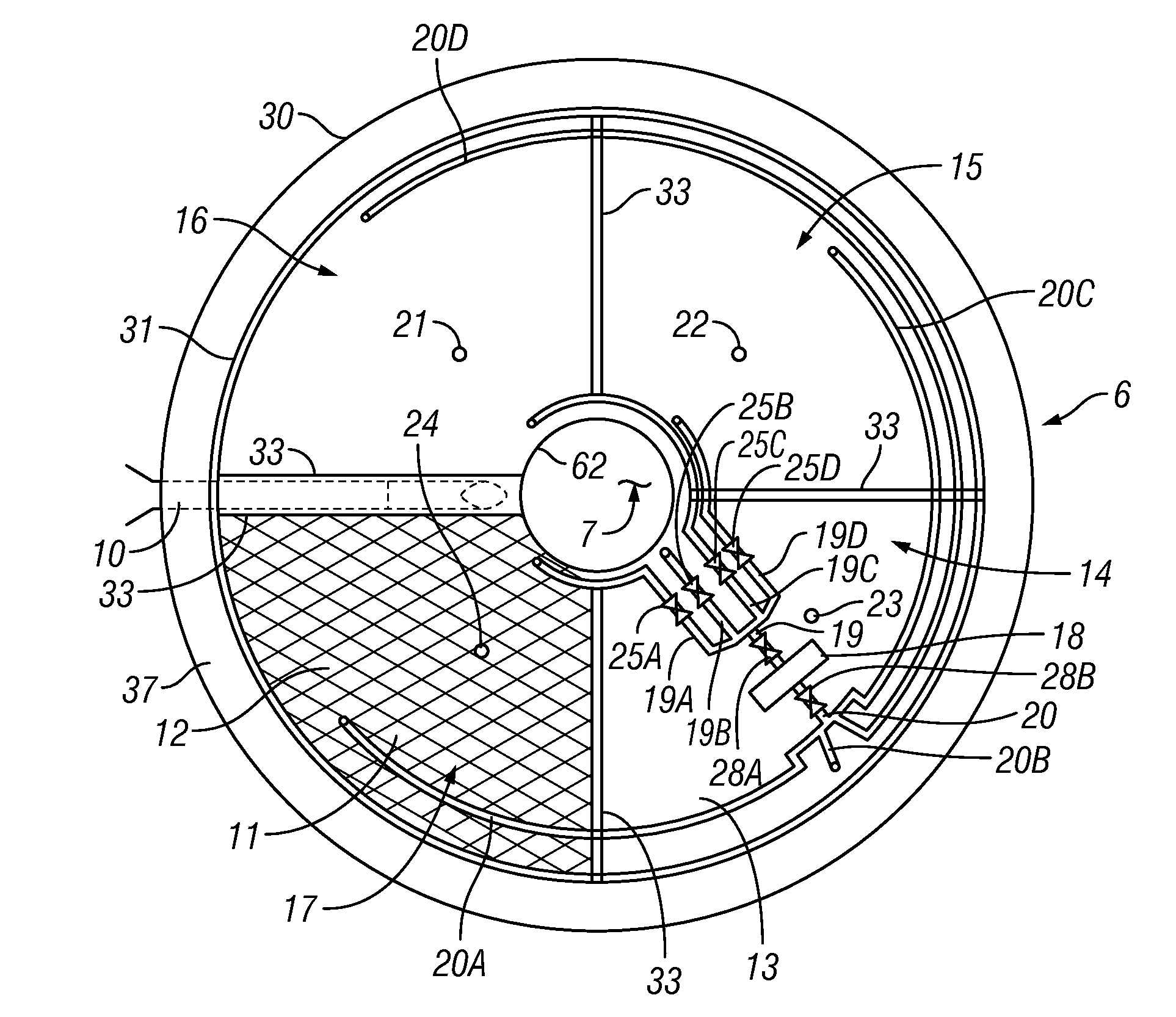

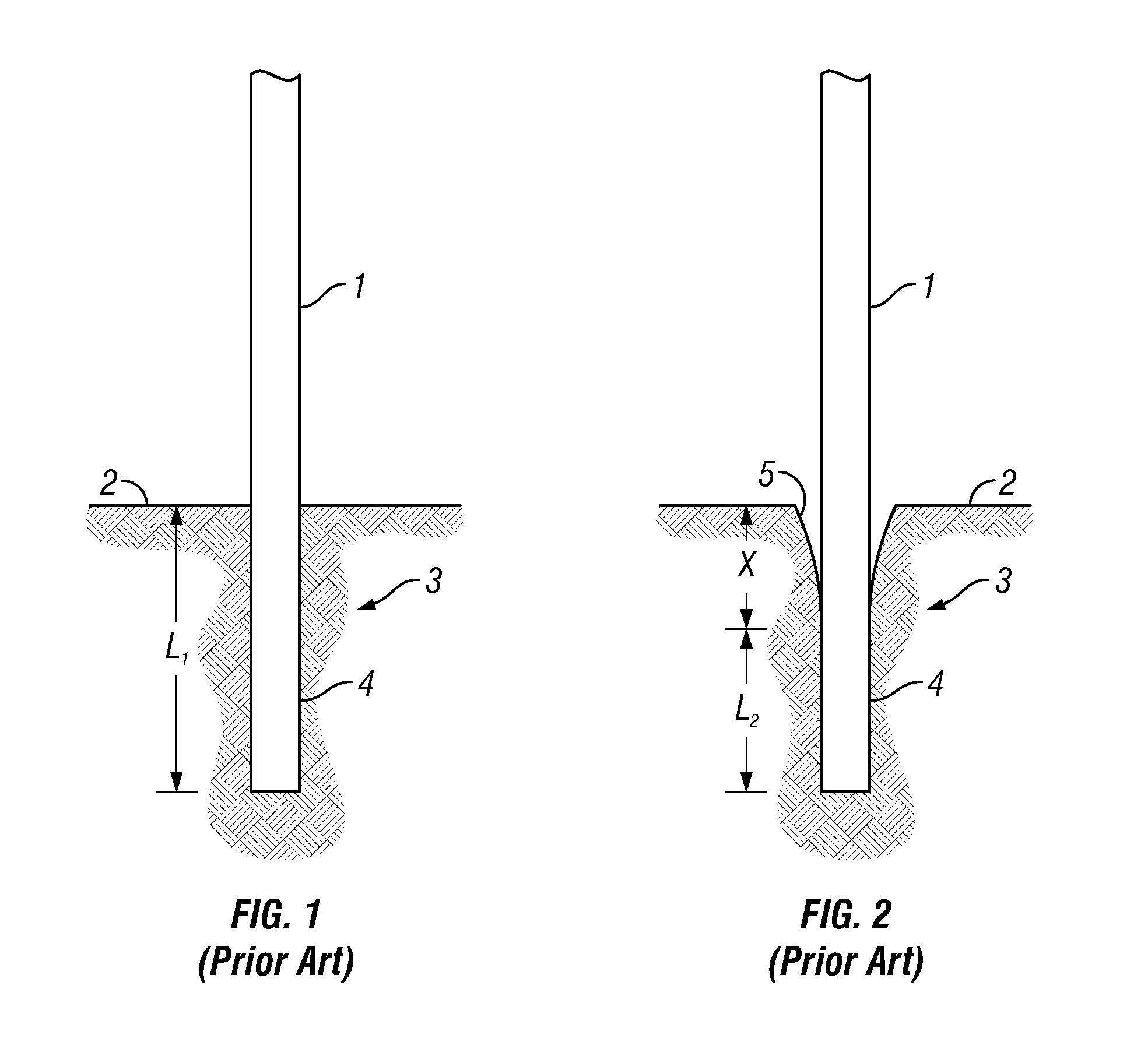

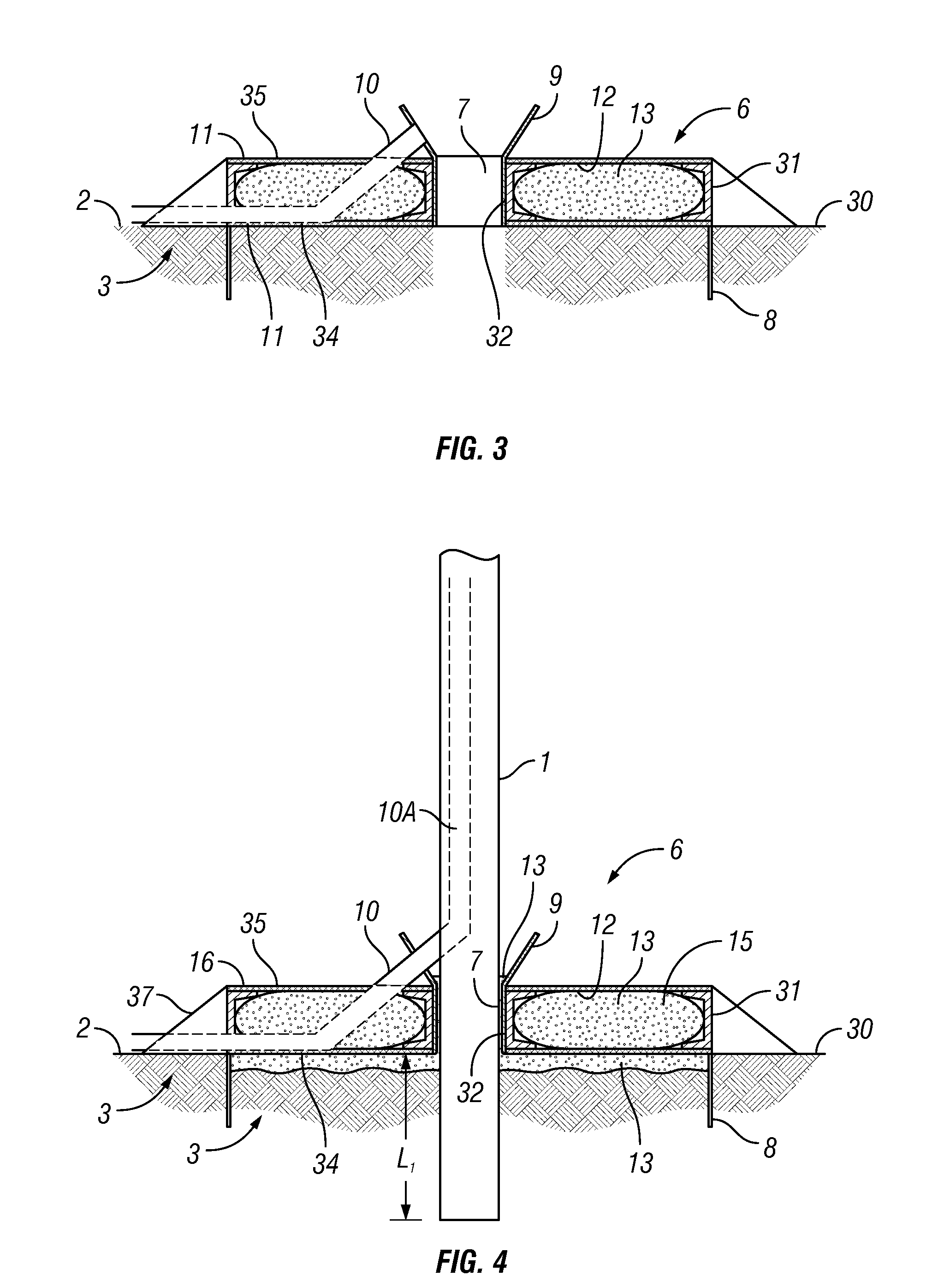

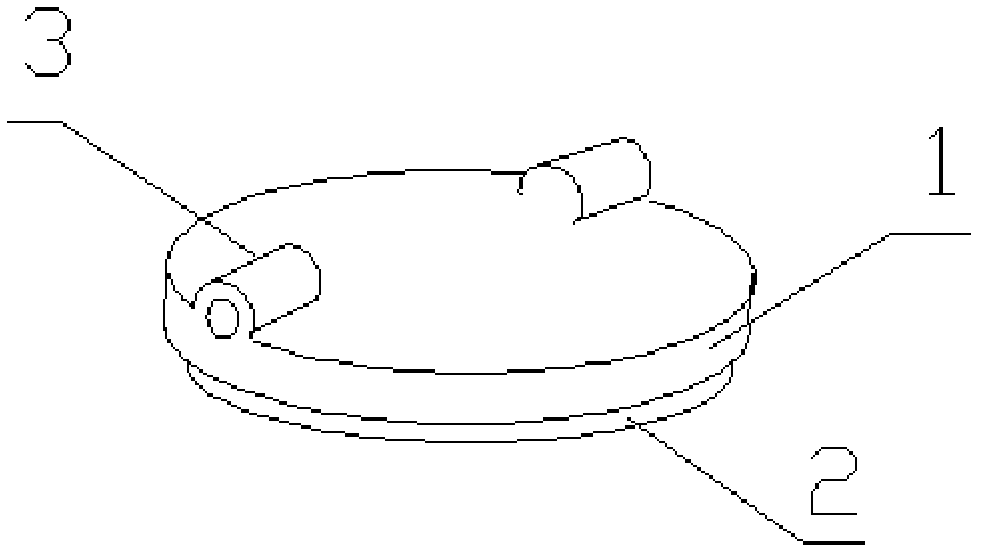

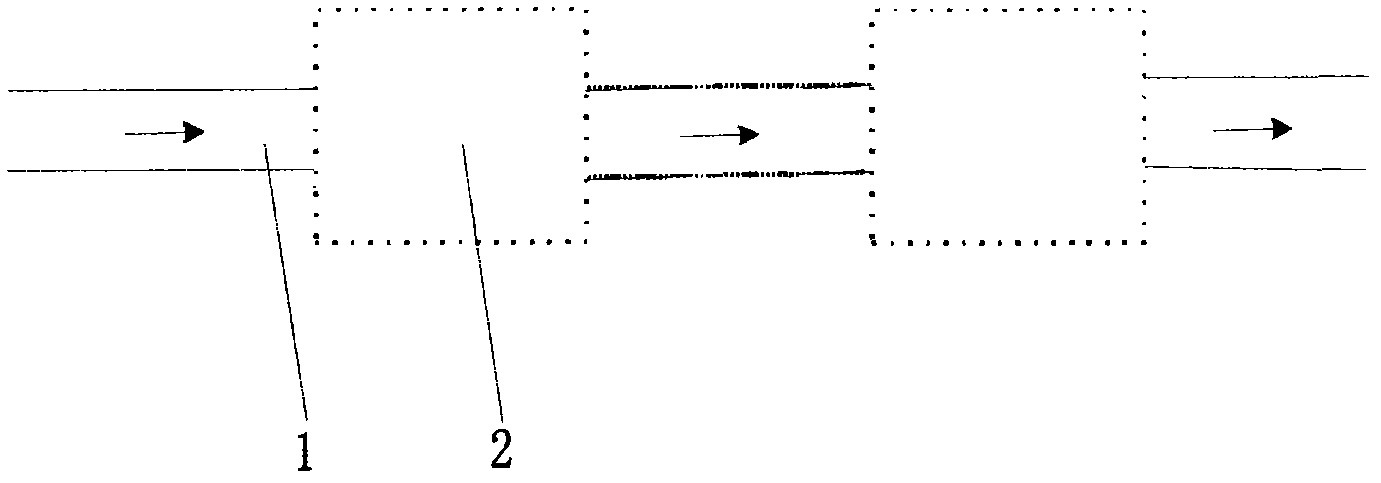

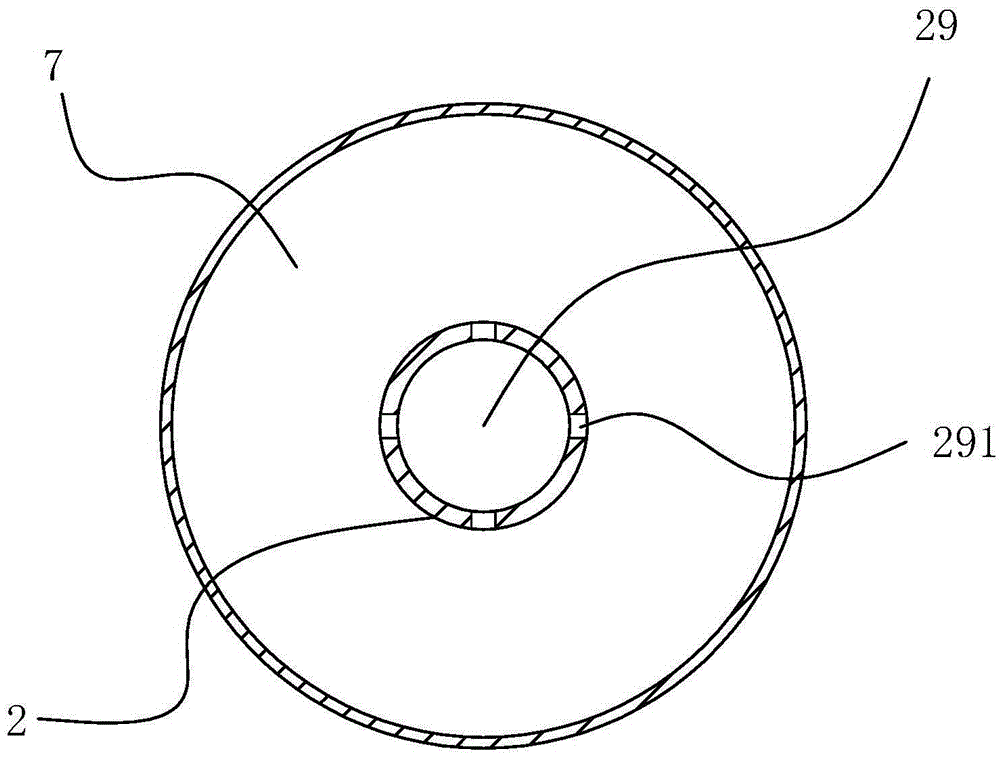

Anti-scour disk and method

ActiveUS20120128436A1Reduce washoutGreat cross-sectional dimensionProtective foundationExcavationsFilling materialsMechanical engineering

The present disclosure provides a disk for reducing scour around a pile, such as a monopole, installed in the seabed. The disk has a pile opening through which the pile protrudes. The disk includes a peripheral skirt for embedding into the seabed below the portion of the disk installed above the seabed. The disk can include partitions for segmenting chambers of the disk. The disk can include mesh on the top, bottom, or both surfaces with one or more fill bags installed in the chambers. The disk can include chambers that can be filled with fluidized fill material, such as grout or concrete. The fill material can be inserted into the fill bags through conduits with valves that can be remotely operated with an ROV. The fill material can also be injected below the disk using the conduits for support on the seabed.

Owner:TECH FRANCE SA

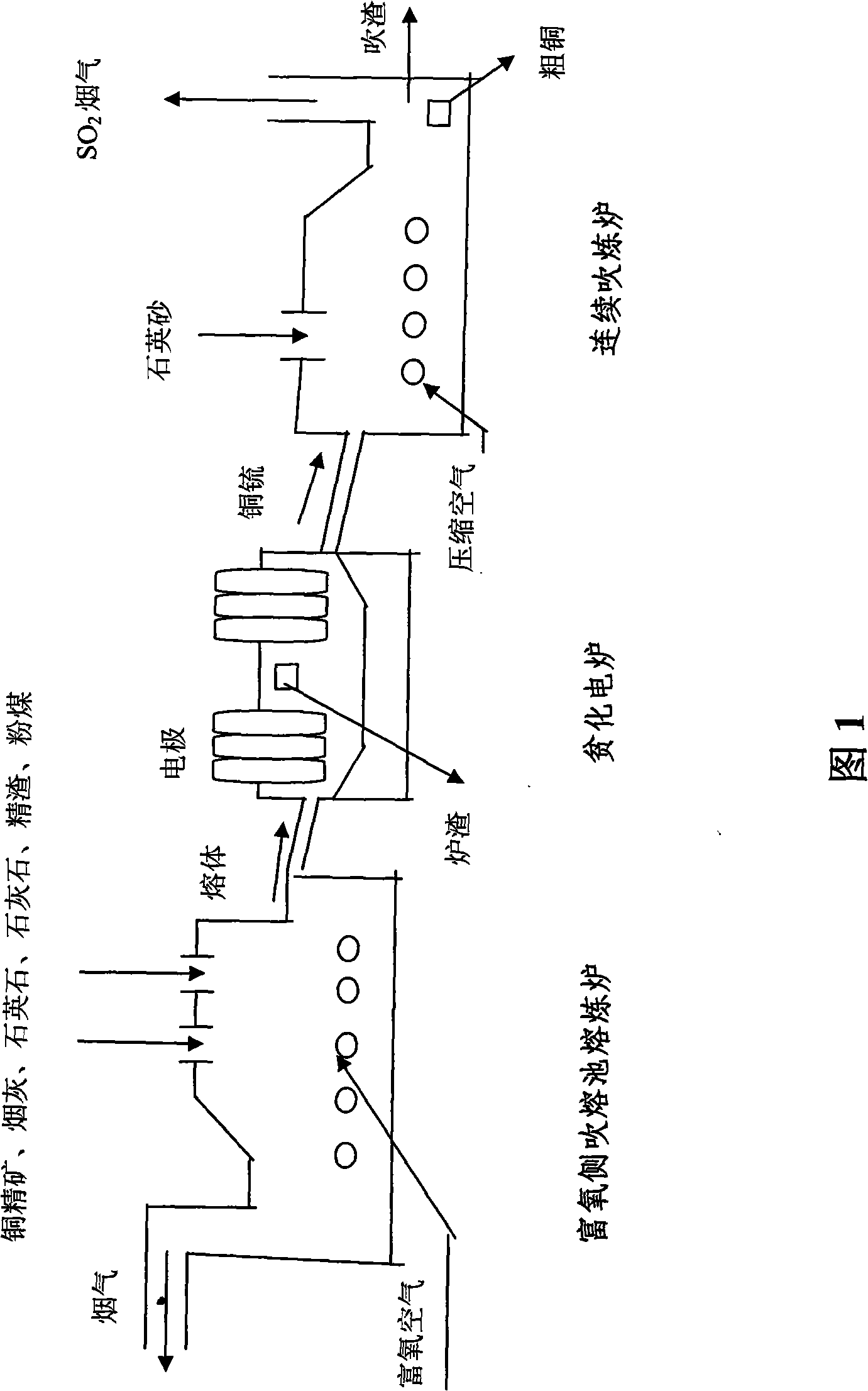

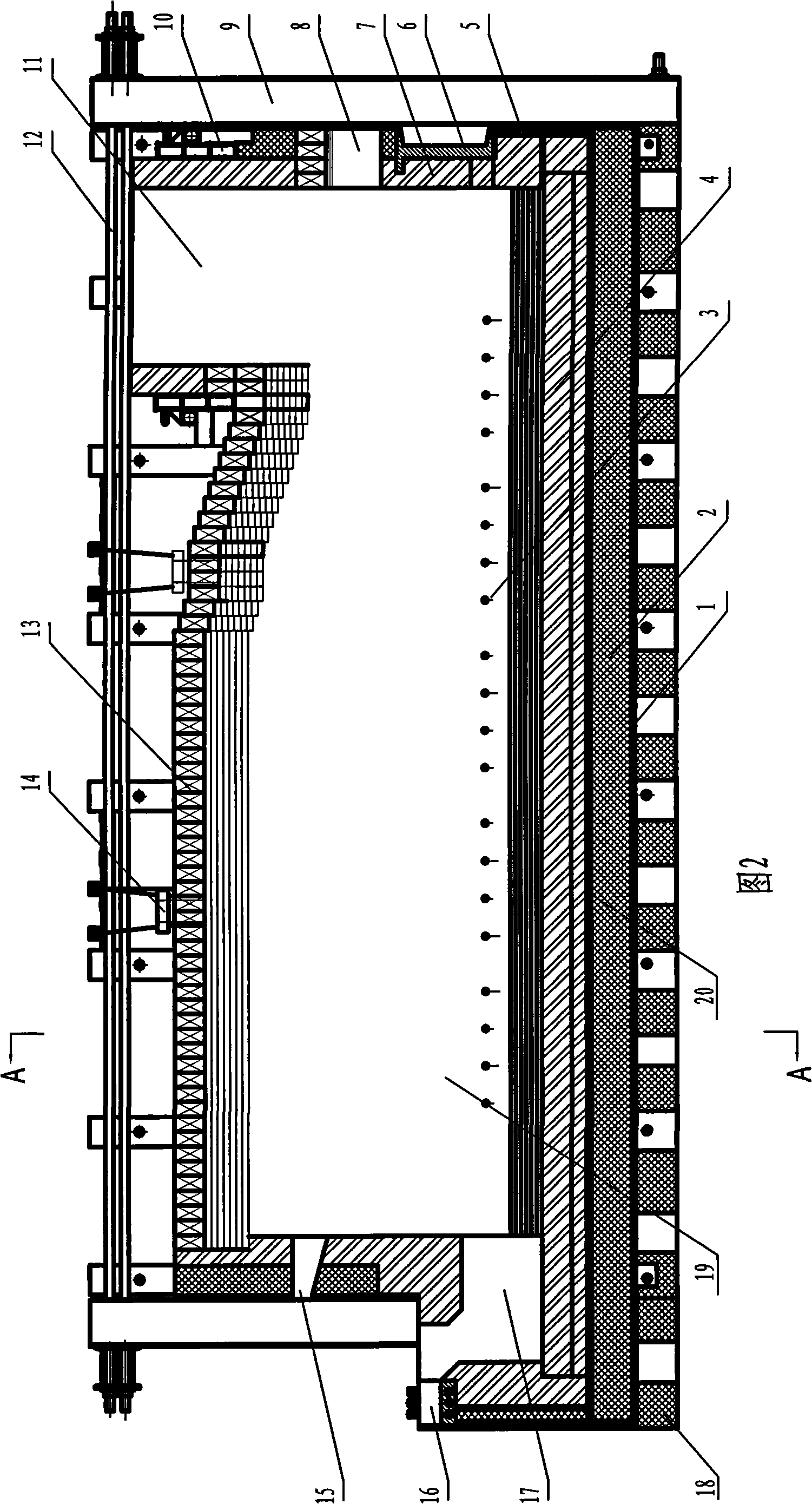

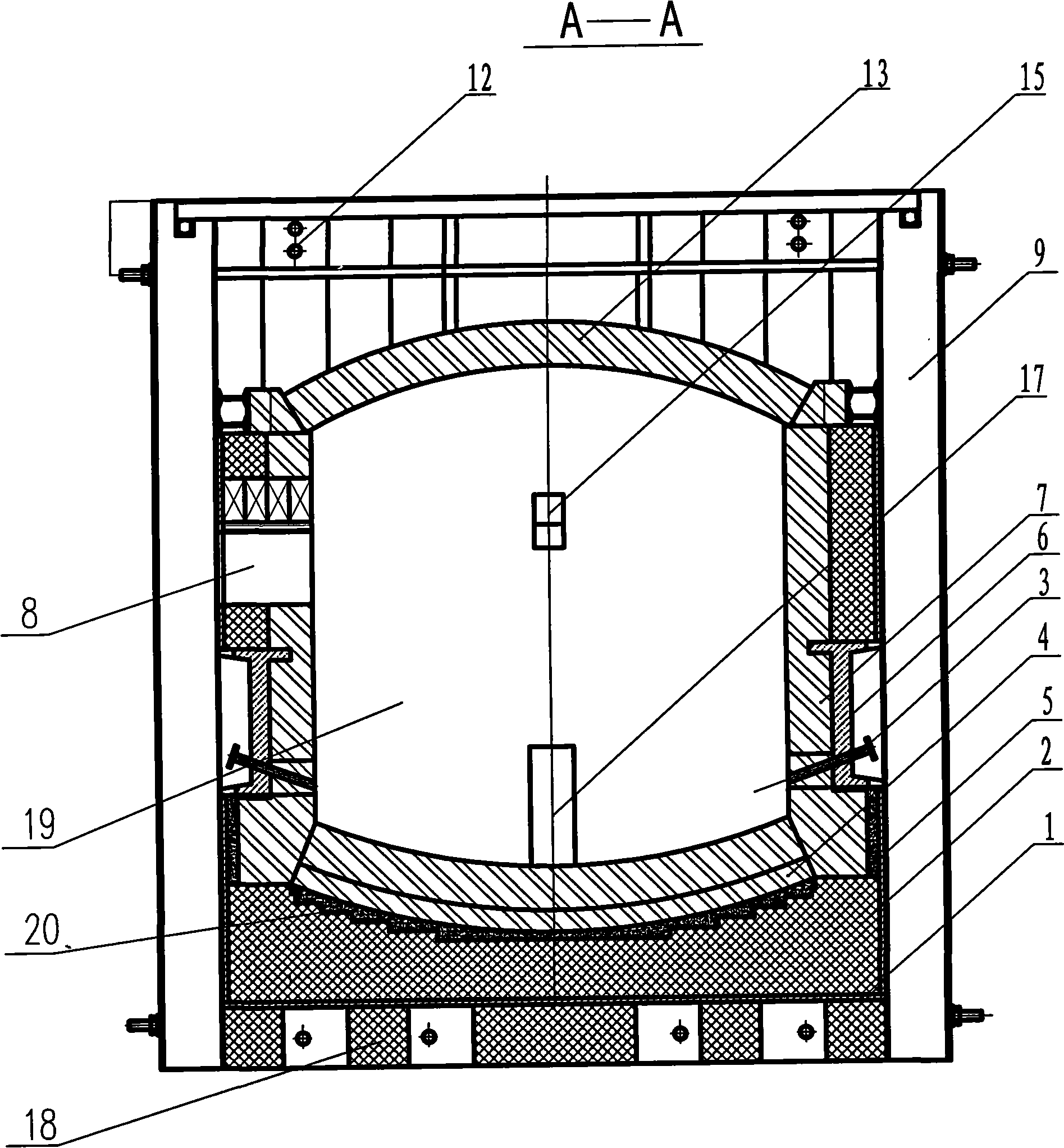

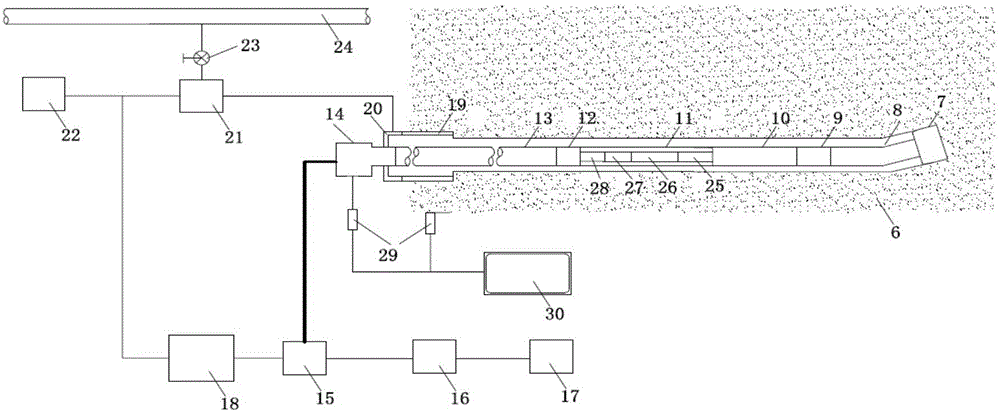

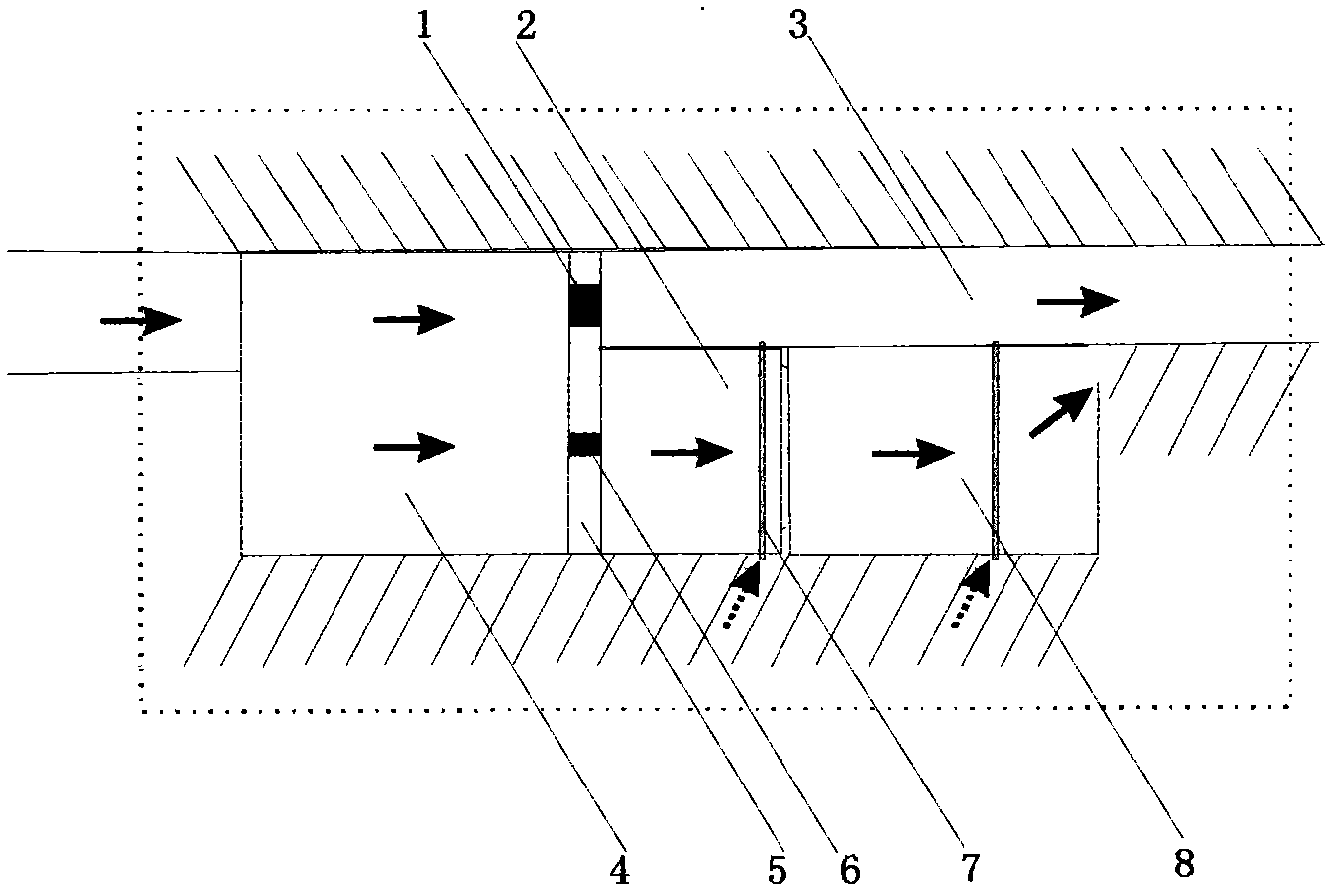

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185ALess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure oxygen

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the high pressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnace through a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

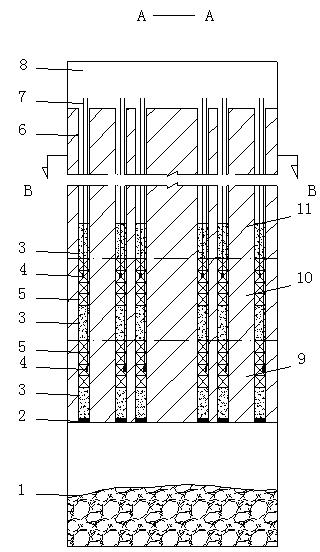

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

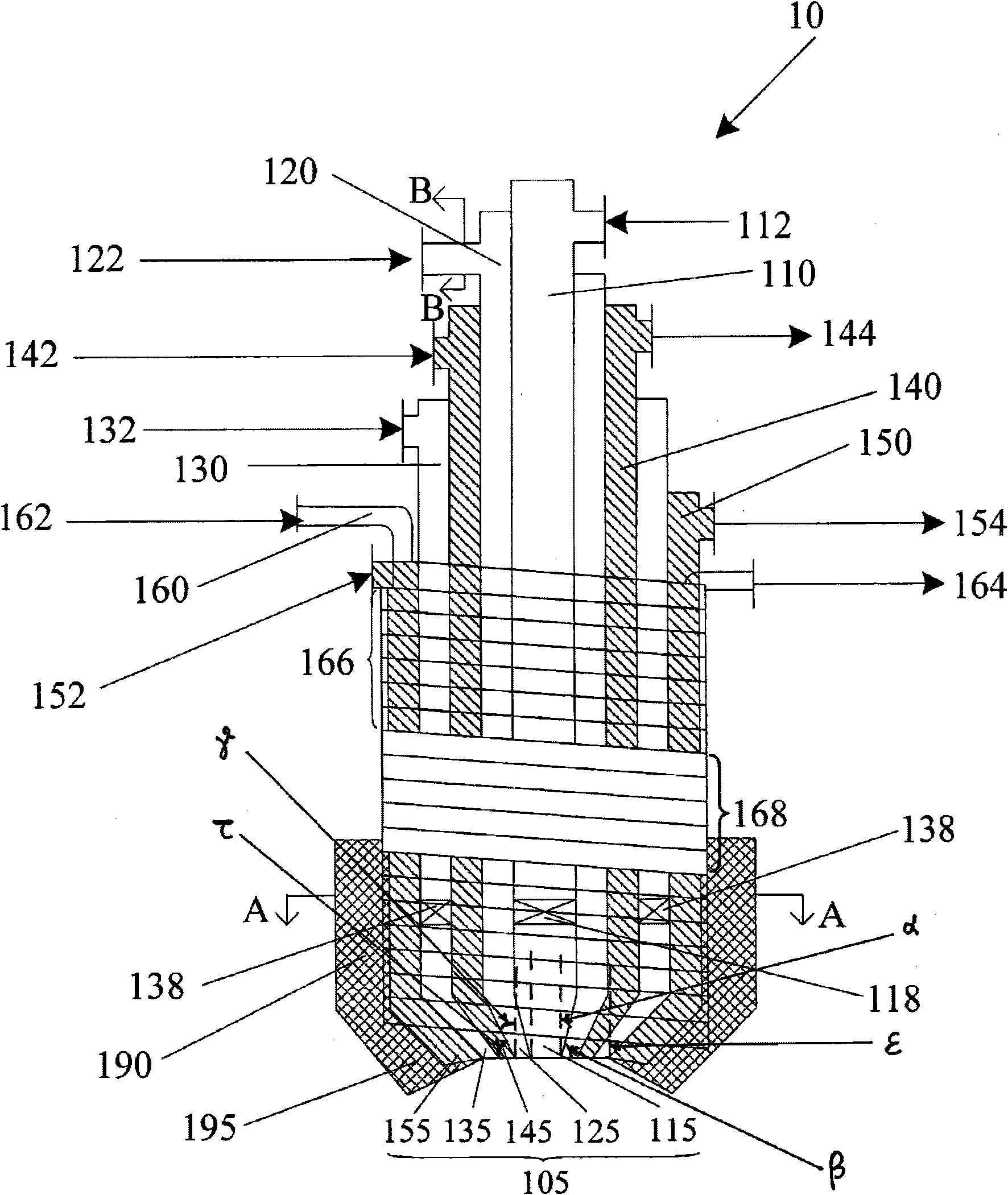

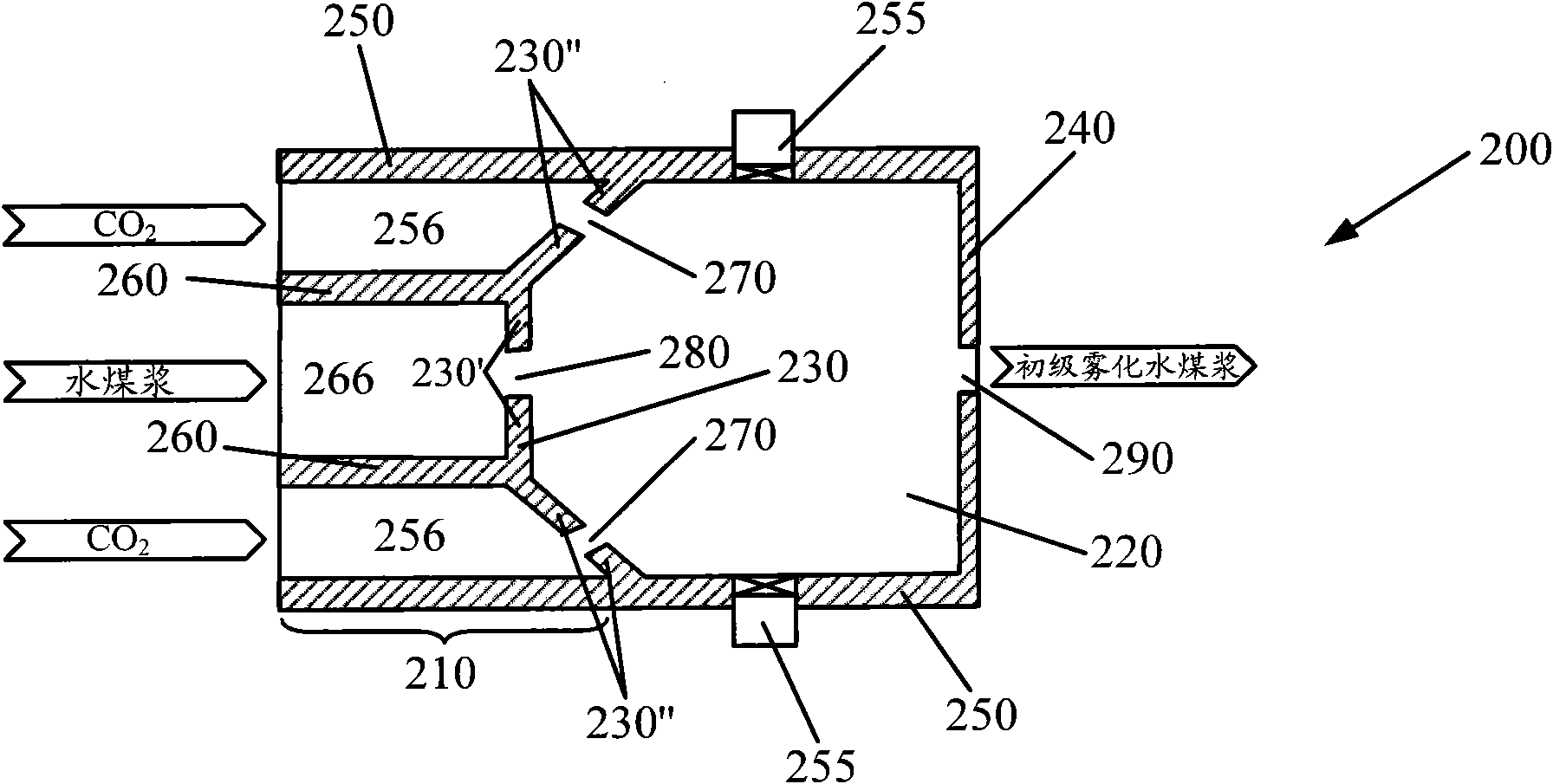

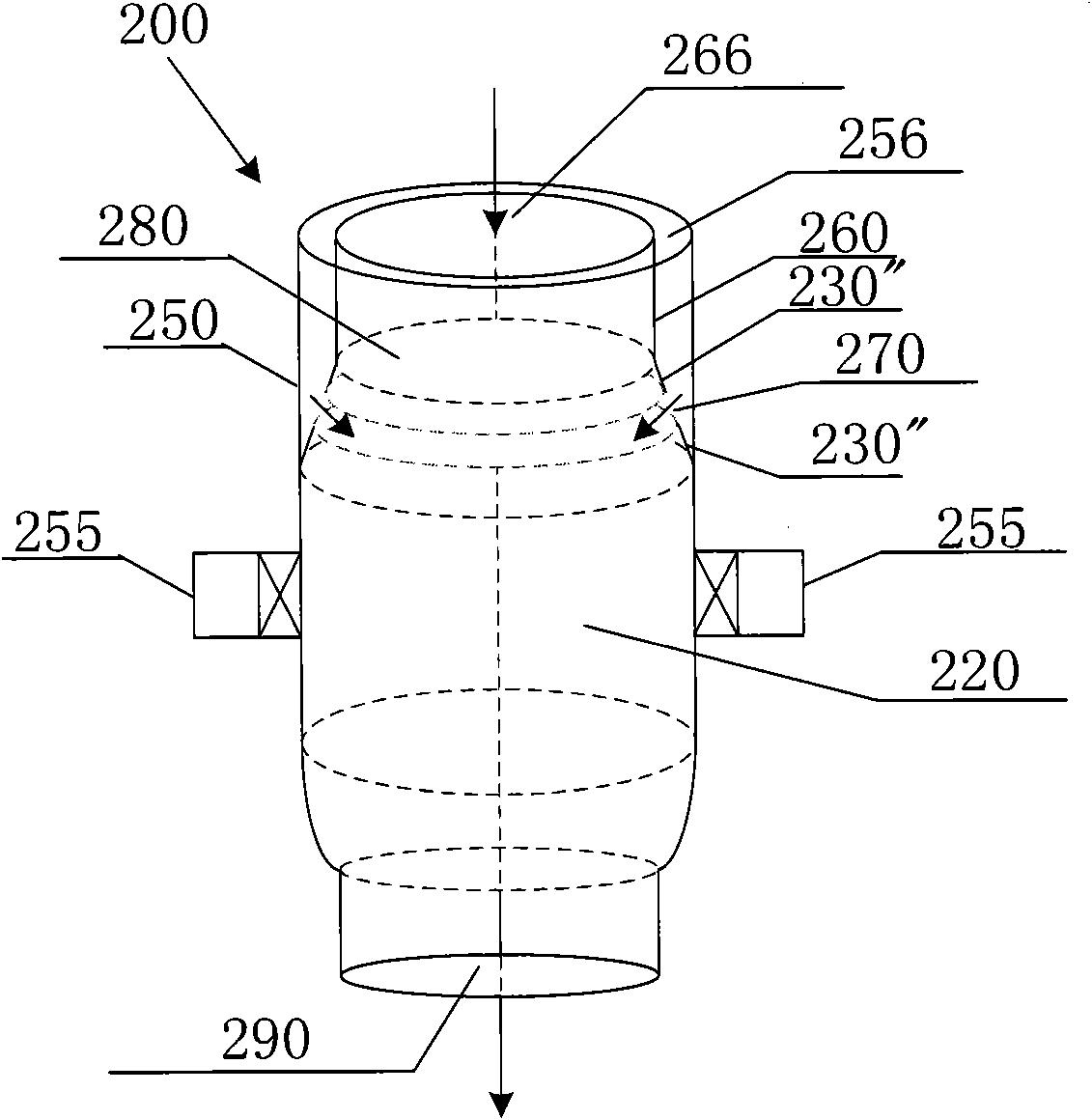

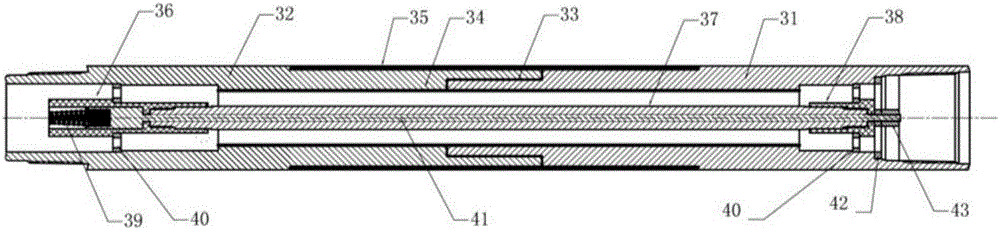

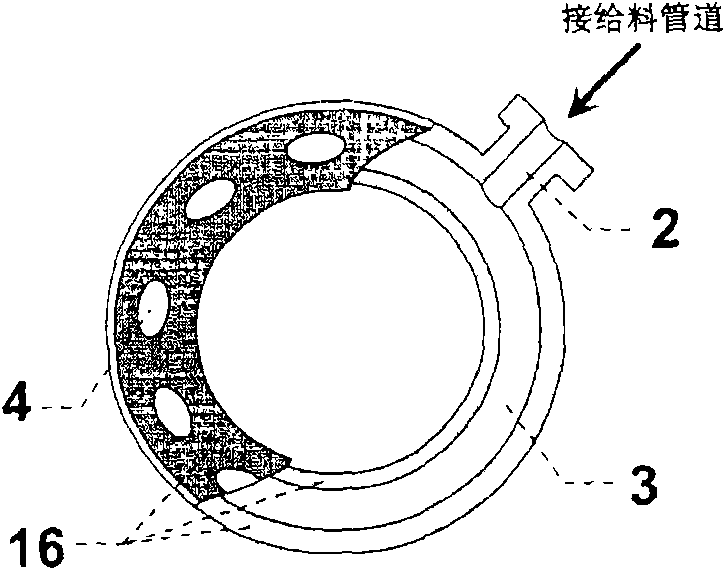

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Multilayer blasting method for bundle holes

InactiveCN102221315AQuality improvementImprove production capacity of stopeBlastingDetonatorDetonation

The invention discloses a multilayer blasting method for bundle holes, comprising the following steps: a) 5-8 blast holes with the diameter of 120-165mm are opened in the middle of a stope; the annular bundle holes are composed by the blast holes, wherein the spacing in the bundle holes is 0.5-0.86m; the spacing of the bundle holes, namely the distance between the central points of two adjacent annular bundle holes, is 6.5-7.5m; dual holes with the spacing of 0.5-0.86m are arranged along the boundary of the stope; the spacing of the dual holes is 6.5-7.5m; the dual holes are staggered with the bundle holes; and each stopping plug is arranged at the bottom of each blast hole; b) each blast hole is divided into multiple layers; the height of each layer is 6.5-7.5m; fillers and dynamite are arranged in each layer from bottom to top; detonators are embedded in the dynamites, wherein the thickness of the filler is 3-4m; and c) the blast holes in the same layer are detonated simultaneously; differential spaced detonation is adopted between the layers with the differential time interval of 25-50ms. The multilayer blasting method for bundle holes is used for mining and has the advantages of solving the problem of frequent blasting during the delaminated mining process, shortening the mining cycle in the stope, and improving mining intensity.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

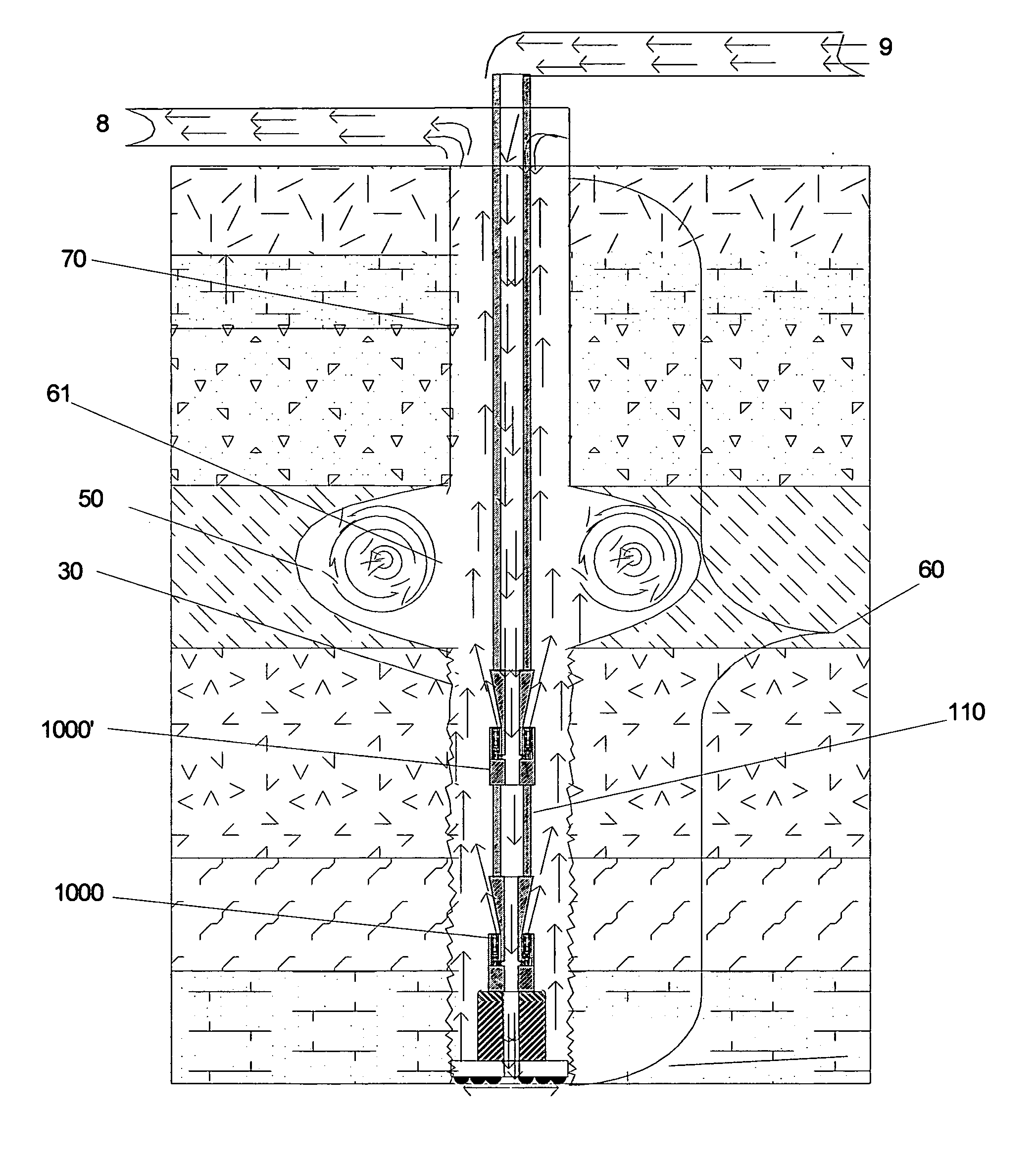

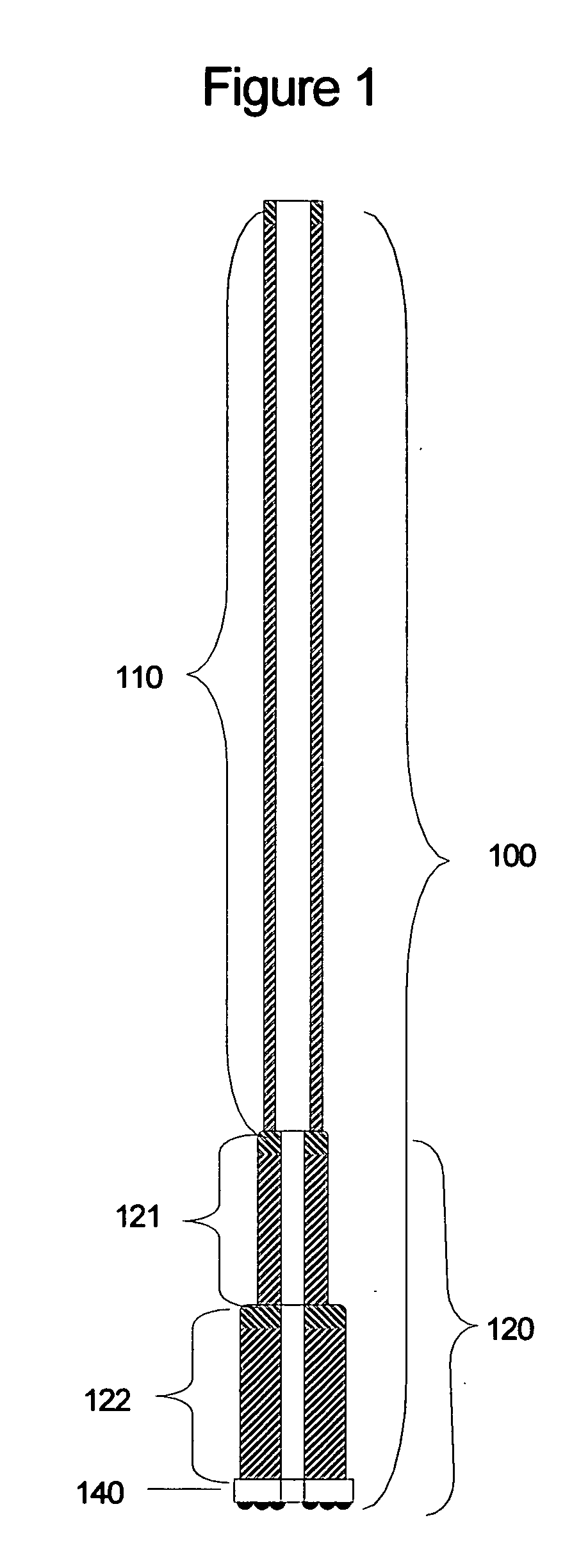

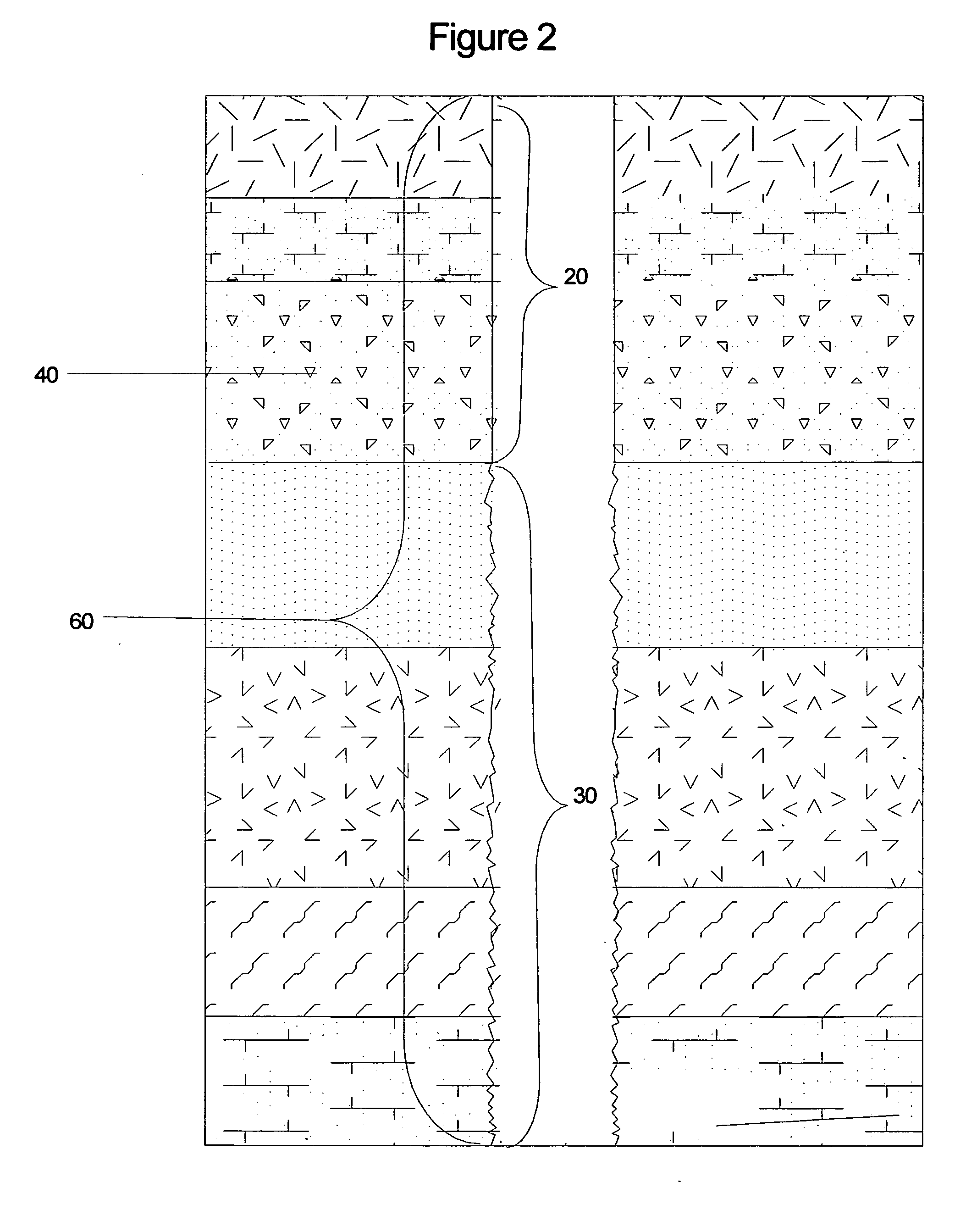

Method for repairing pile foundation and scour pit underwater

InactiveCN108411802AEasy constructionEasy to processFoundation repairBridge structural detailsUnderwaterPortland cement

The invention relates to a method for repairing a pile foundation and a scour pit underwater. The method includes the following steps that (1), a steel plate pile cofferdam is adopted for conducting construction around the local scour pit of a pier needing to be repaired; (2), a concrete cushion layer is laid within the range 2 m away from the pier; (3), the condition that the pier is damaged dueto scouring and corrosion is checked, and the pier is repaired firstly; (4), natural backfill soil is packed in the scour pit; (5), multiple stones are packed in the scour pit; and (6) ordinary Portland cement mortar is laid flatly on a macadam grouting protection layer, an RPC material is packed in the portion at the depth 15% of the remaining depth of the scour pit, an RPC layer is formed untilthe RPC layer is flush with the bottom face of a riverbed, and a soil layer is backfilled in the portion, around the RPC layer, in the scour pit. By the adoption of the method, the effect that the scoured and damaged pier foundation and the scour pit can be repaired, the bearing capacity of the original structure is improved, the service life of the structure can be prolonged by the adoption of the RPC material, and maintenance cost is saved.

Owner:YANGZHOU UNIV

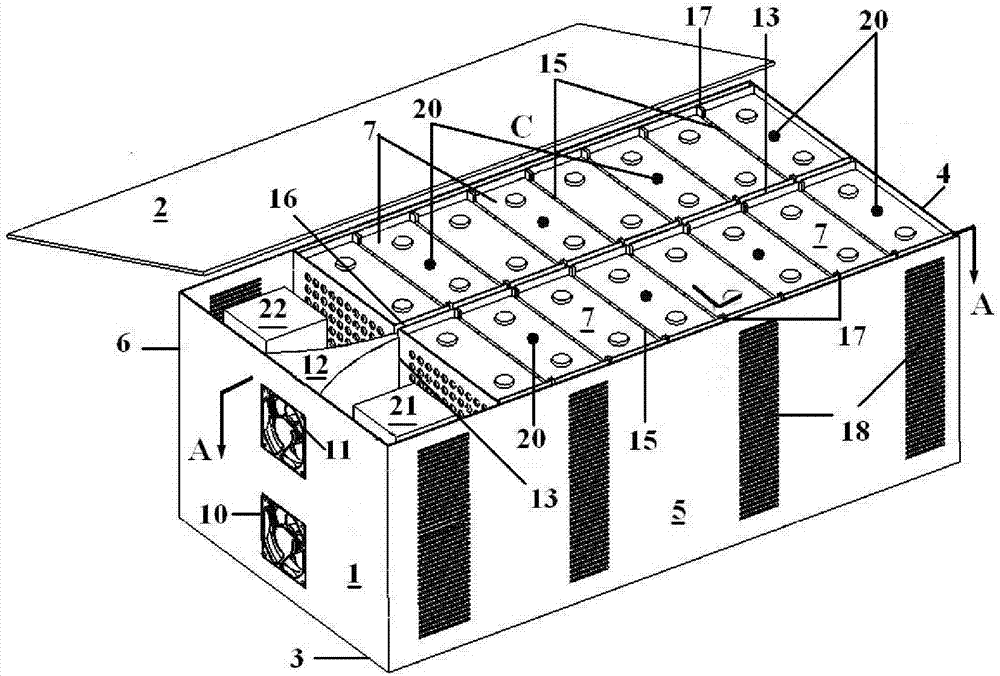

Forced air cooling battery box, and box body and cooling plates thereof

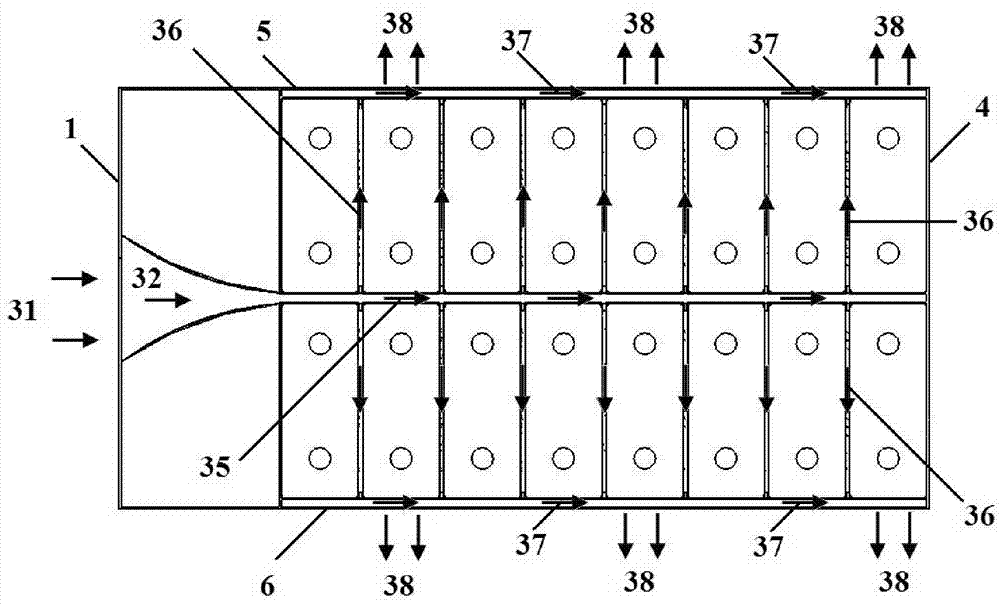

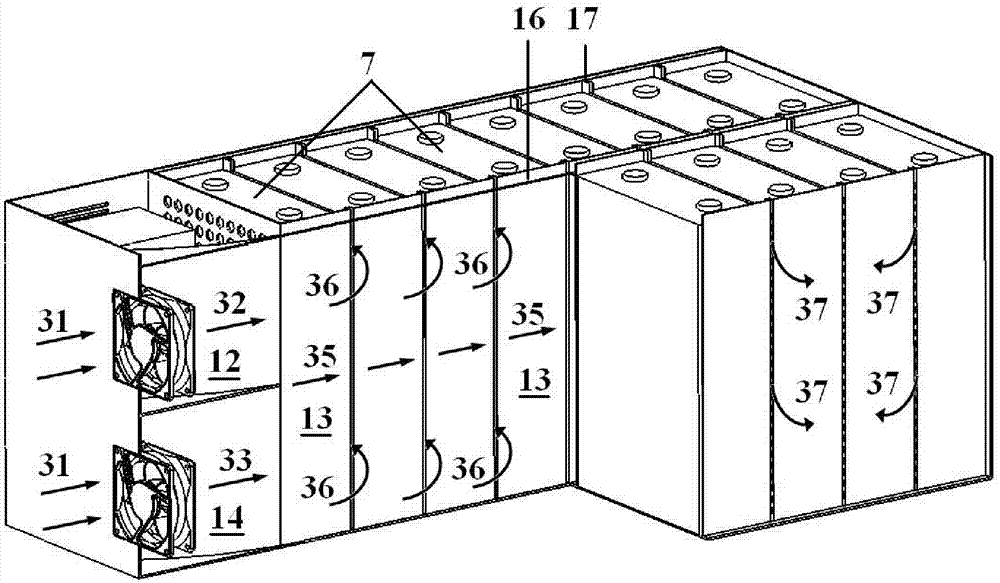

ActiveCN104300190AReduce washoutReduce erosionSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsCold airBlock effect

The invention discloses a forced air cooling battery box, and a box body and cooling plates thereof. The cooling plates are arranged in air ducts of the box body; each cooling plate comprises two thermal conductive boards which are adhered to opposite side surfaces of two adjacent battery cells, and a thermal conductive core portion disposed between the two thermal conductive boards; the thermal conductive core portion is provided with cold air channels penetrating through two opposite end surfaces; the thermal conductive boards are side sealing surfaces used for preventing cold air in the cold air channels from being leaked out of the boards, so that the cold air in the cold air channels can achieve a predetermined effect of forced air cooling on the battery cells; the cold air in the cold air channels can be prevented from being leaked out of the cold boards under a blocking effect of the thermal conductive boards; the cold air can not scour the side surfaces of the battery cells; and impurities in the cold air do not erode the sides surface of the battery cells. Therefore, the cooling plates provided by the invention can increase a cooling effect of the cold air on the battery cells and uniformity of the temperature of the battery cells and reduce scouring of the surfaces of the battery cells by the cold air sucked in the battery box, so as to reduce erosion of the battery cells by the impurities in the cold air.

Owner:HENAN UNIV OF SCI & TECH

Filter for the separation of leukocytes from whole blood or blood preparations, method for production of said filter, corresponding device and use thereof

ActiveUS20060207937A1Long durabilityReduce washoutSemi-permeable membranesOther blood circulation devicesHydrophilic monomerWhite blood cell

The invention relates to a filter for the separation of leukocytes from whole blood, comprising a hydrophobic support material and a polymeric coating material, whereby the surface of the filter has a critical surface wetting tension in the range 50 to 80 dyn / cm and the polymeric coating material may be obtained by polymerisation reaction of mixtures comprising hydrophobic and hydrophilic monomers. The invention further relates to a method for production of said filter and devices for the separation of leukocytes from whole blood and the use of the filter.

Owner:FRESENIUS HEMOCARE ITAL

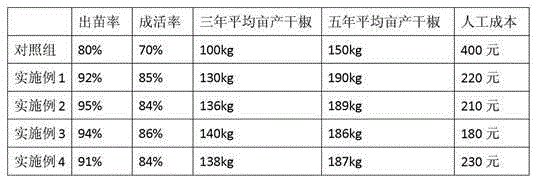

Planting method for Zanthoxylum bungeanum

InactiveCN105284372AGrowth inhibitionReduce washoutSeed and root treatmentFertilising methodsControl releaseZanthoxylum bungeanum

The invention discloses a planting method for Zanthoxylum bungeanum. The planting method which is used for breeding in a picking period or in spring comprises the following steps: (1) seed collection; (2) seed treatment: treating seeds by a plurality of methods; (3) breeding; (4) thinning; (5) garden construction; (6) fertilizing in good time: applying special slow or controlled released fertilizers to the Zanthoxylum bungeanum regularly; (7) stem determining; (8) shaping and trimming: trimming by a reasonable method; (9) prevention and treatment of plant diseases and insect pests: comprising physical prevention and treatment, chemical prevention and treatment and biological prevention and treatment; (10) other management: respectively spraying soil non-deep-tilling conditioner once on the ground of a whole garden in spring and autumn; and (11) picking and storing. According to the planting method for Zanthoxylum bungeanum, through refined management, an advanced production technology and scientific planting, the survival rate of the Zanthoxylum bungeanum is improved, the yield of the Zanthoxylum bungeanum is also improved, labor cost of the Zanthoxylum bungeanum is reduced, and a current situation that demand exceeds supply is relieved.

Owner:ZUNYI JINSU TRADE CO LTD DAOZHEN HONGLIANG BRANCH

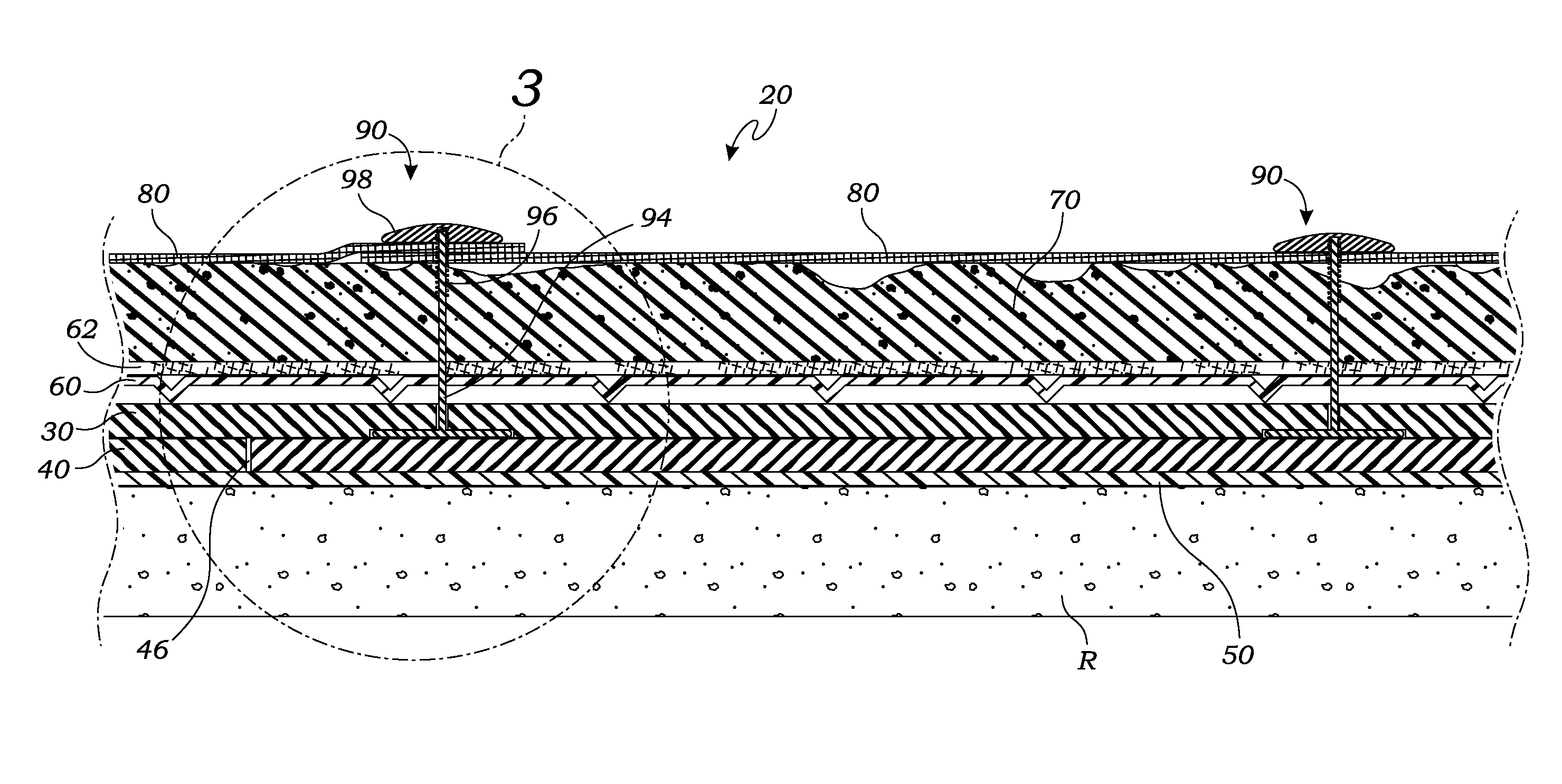

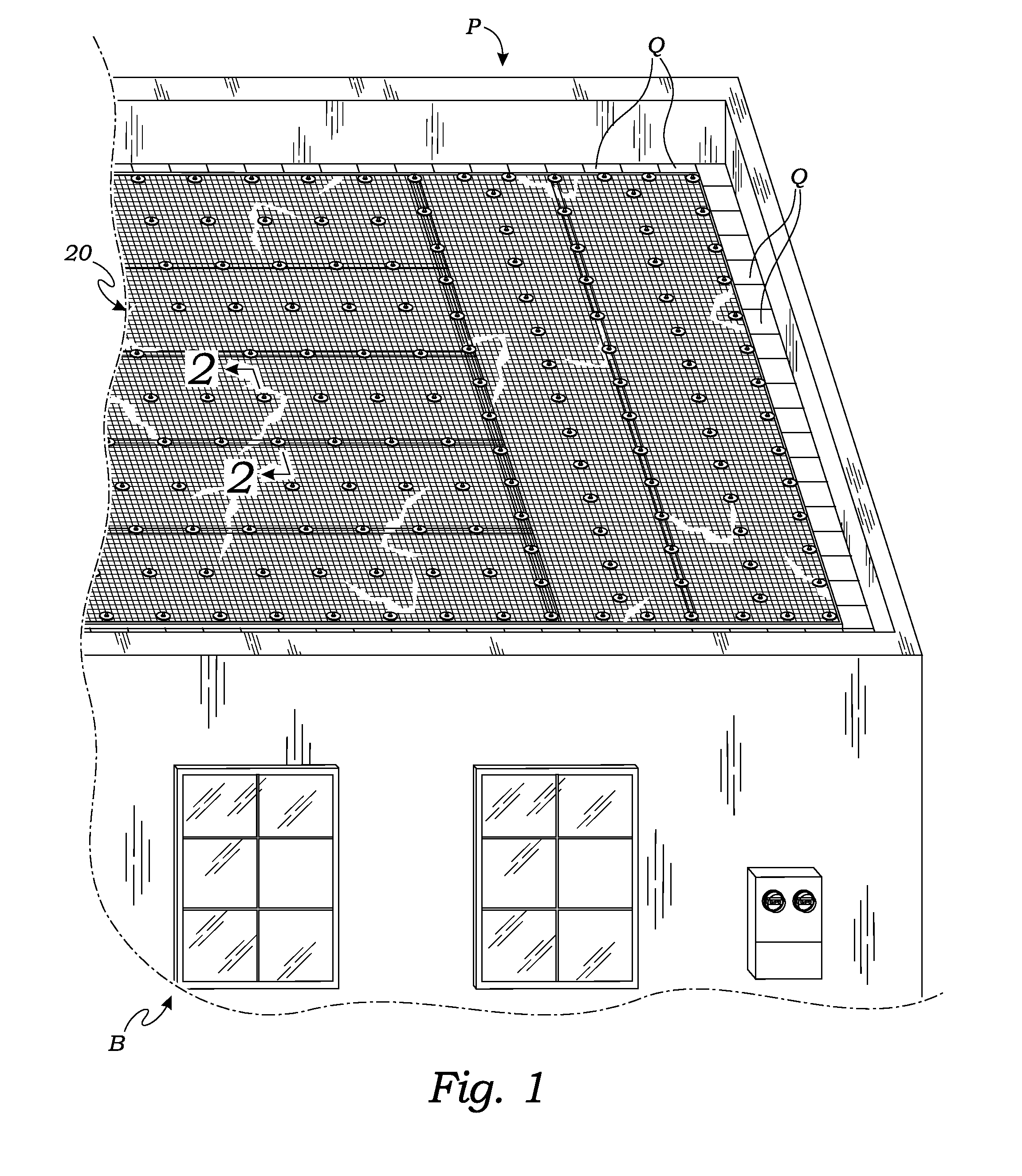

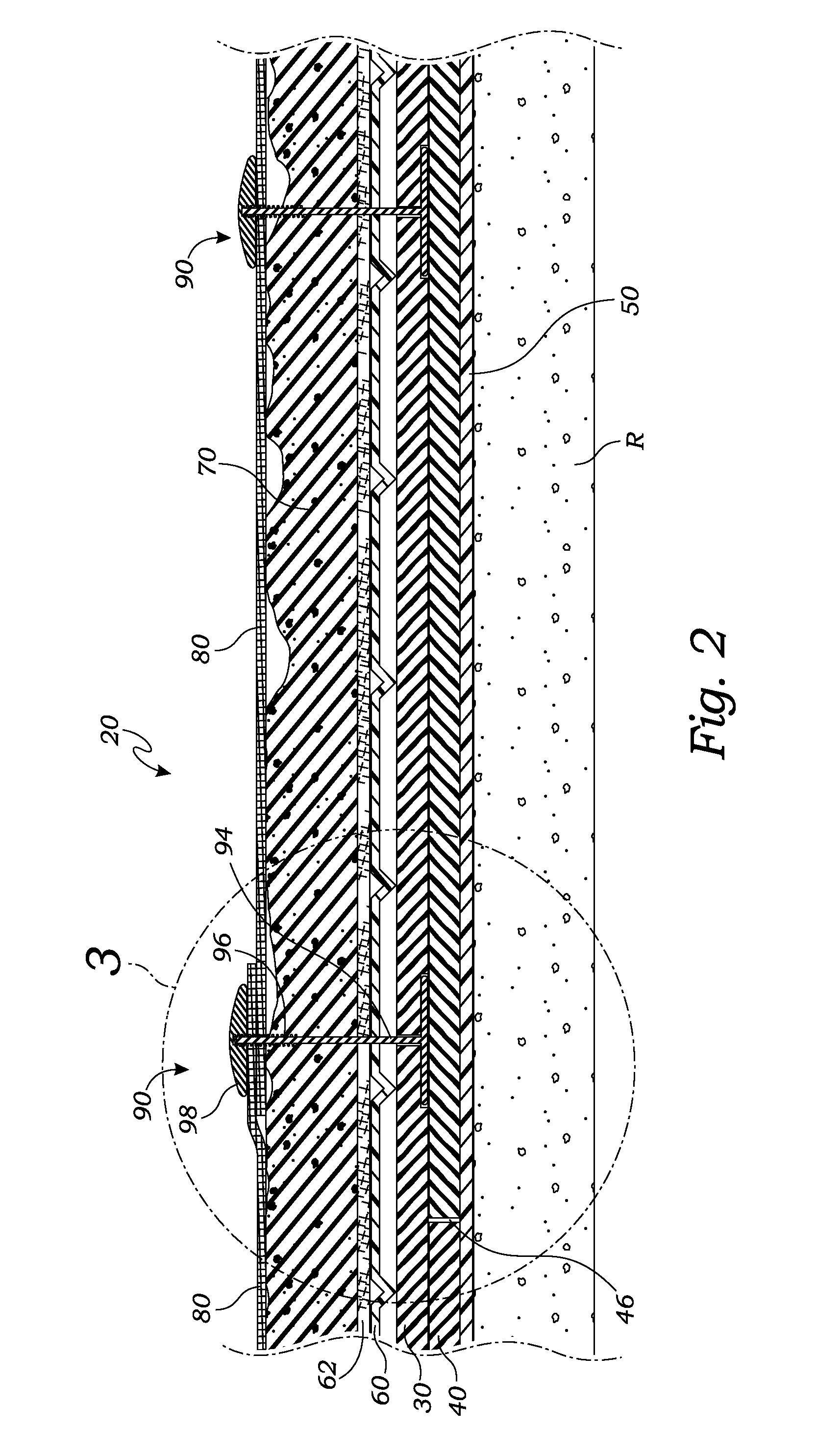

Protected membrane roof system

ActiveUS8863442B2Increase resistanceReduce washoutRoof covering using slabs/sheetsBuilding roofsTectorial membraneMembrane roofing

A protected membrane roof system for installation on a roof decking comprising an upper insulation board having an upwardly-facing upper board top surface and an opposite downwardly-facing upper board bottom surface and at least one through-hole communicating therebetween, a ballast material positioned over the upper insulation board, a netting positioned over the ballast material, and at least one fastener assembly having a base seated substantially adjacent the upper board bottom surface, a rod extending substantially vertically from the base of sufficient size so as to extend through the through-hole of the upper insulation board, the ballast material, and the netting, and a cap engaged with the rod above the netting, whereby the wind uplift resistance of the protected membrane roof system is improved and scour of the ballast material is reduced by effectively anchoring the netting to the upper insulation board beneath the ballast material.

Owner:FREEMAN THURMAN W

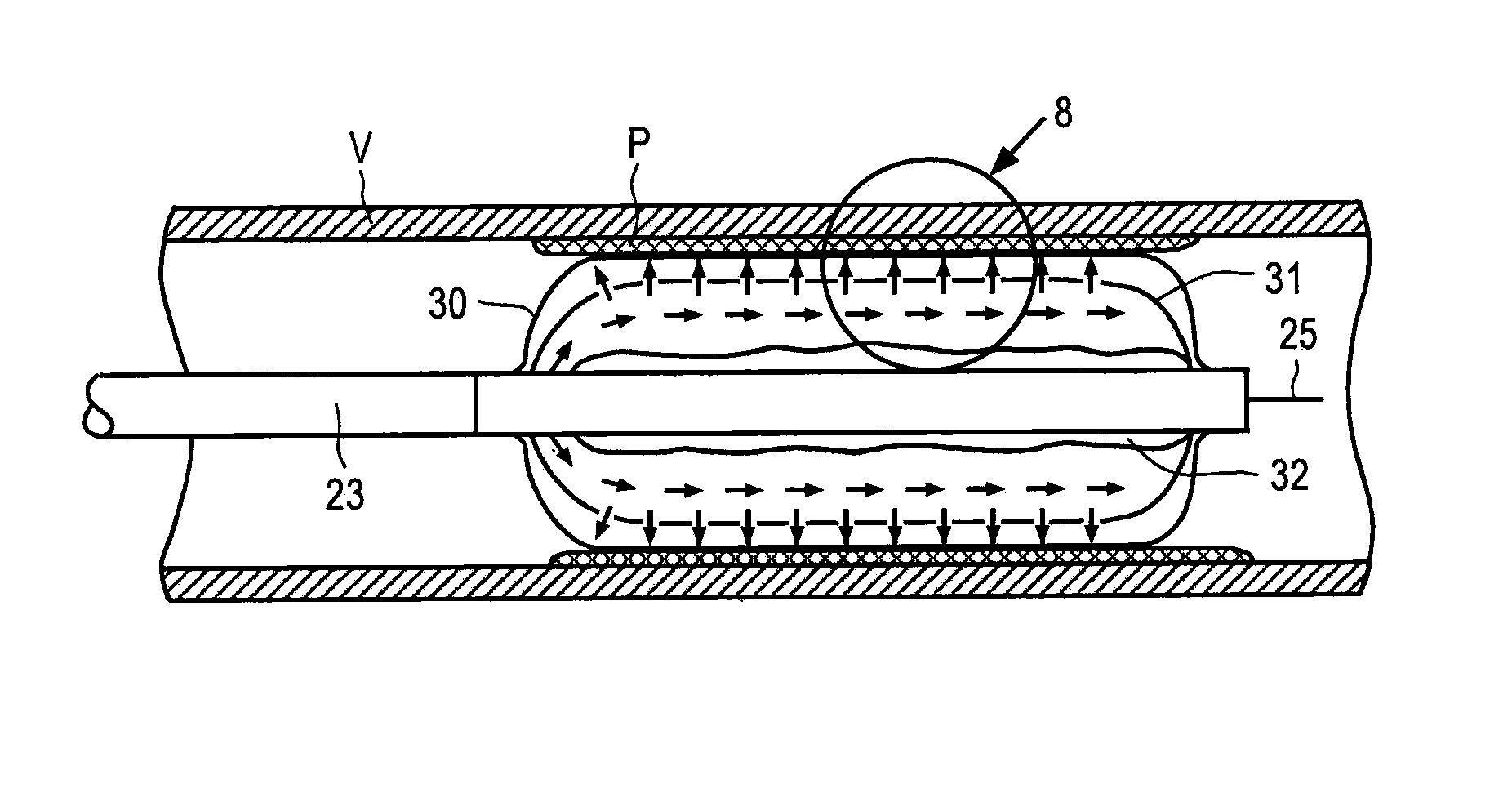

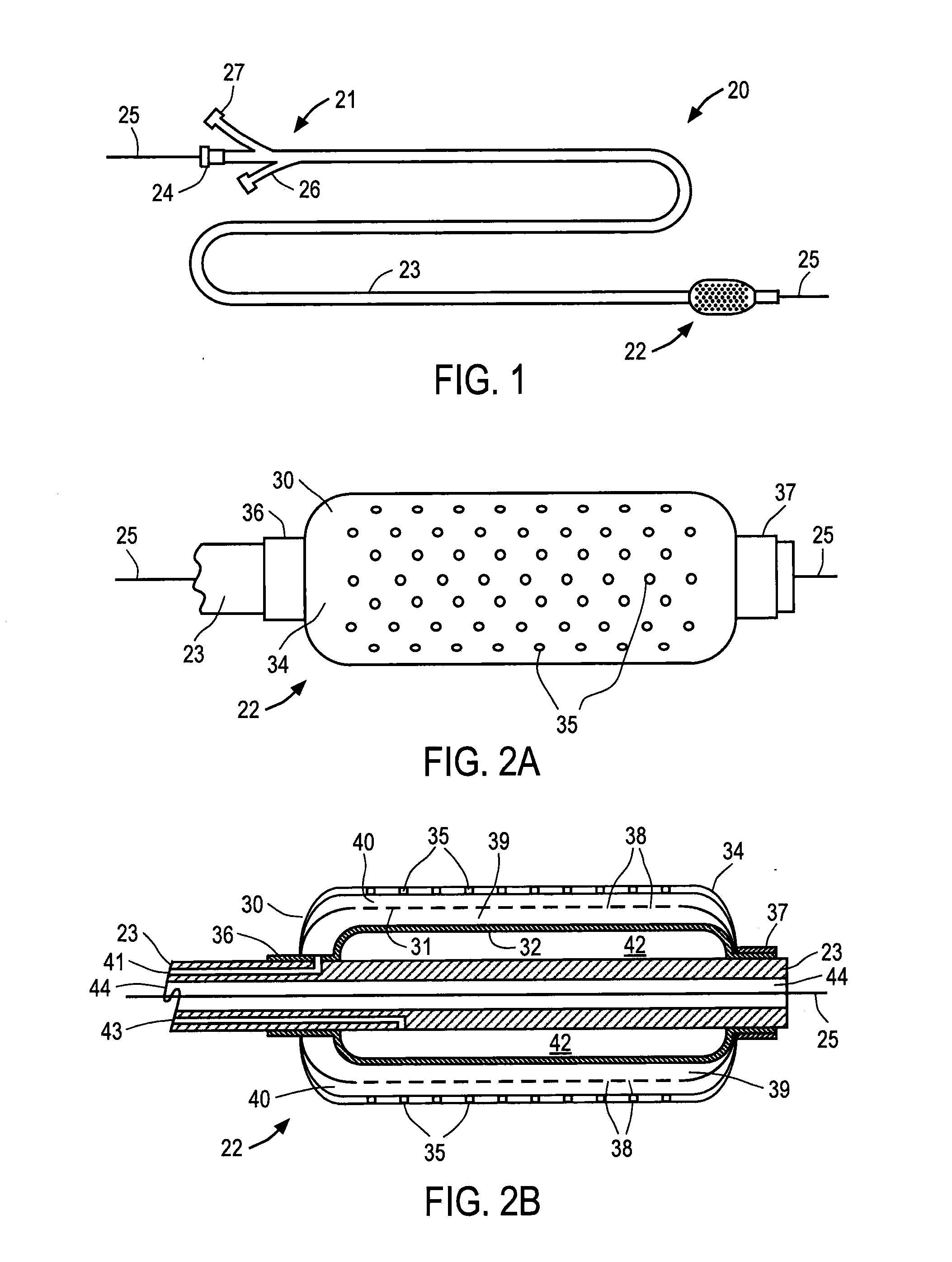

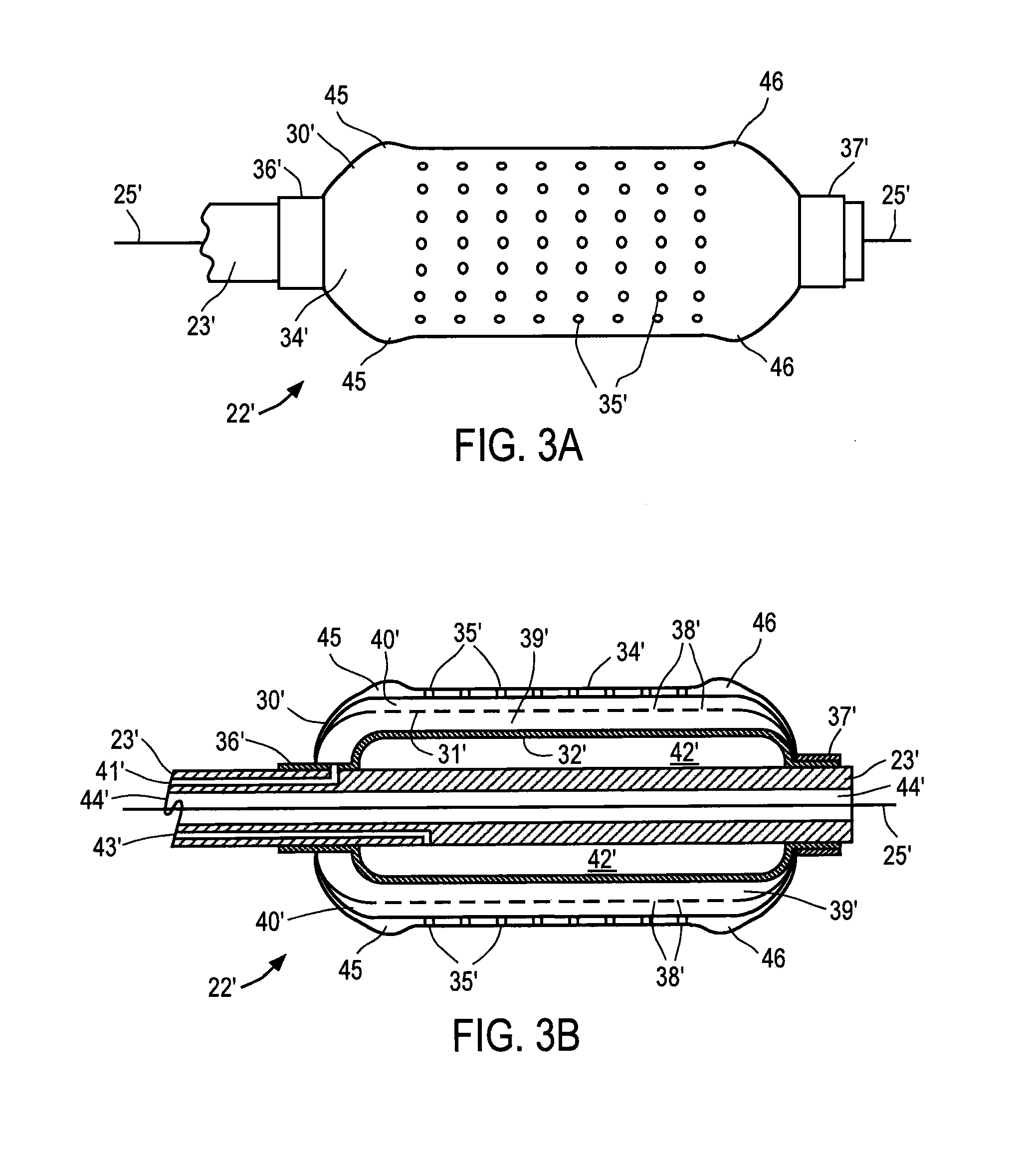

Apparatus and method for delivering intraluminal therapy

InactiveUS20140200504A1Reduce washoutReduce occurrenceStentsUltrasound therapyTreatment effectVascular wall

A catheter and methods for luminal therapy are provided wherein a catheter has an outer balloon with a multiplicity of apertures for infusing one or more therapeutic agents into a vessel wall, an intermediate balloon having a multiplicity of apertures offset from the apertures of outer balloon to serve as a baffle that reduces jetting and promotes uniform distribution of therapeutic agent exiting through the outer balloon, and an impermeable inner balloon disposed within the intermediate balloon that enables the intermediate and outer balloons to be forced into engagement with the vessel wall to dilate the vessel and disrupt plaque lining the vessel wall and to also facilitate the uniform delivery of the therapeutic agent. The outer balloon may include protrusions that contact the vessel wall to disrupt the plaque, bumpers to reduce washout during infusion of therapeutic agents; the intermediate balloon may include a texture, ribs or protrusions on its outer surface to prevent adhesion to the outer balloon during dilation of the vessel; and the catheter may include a guide wire lumen sized to accept an energy delivery device to delivery energy that enhances uptake of the therapeutic agent or prolongs therapeutic effectiveness of the agent.

Owner:ROCHA SINGH KRISHNA

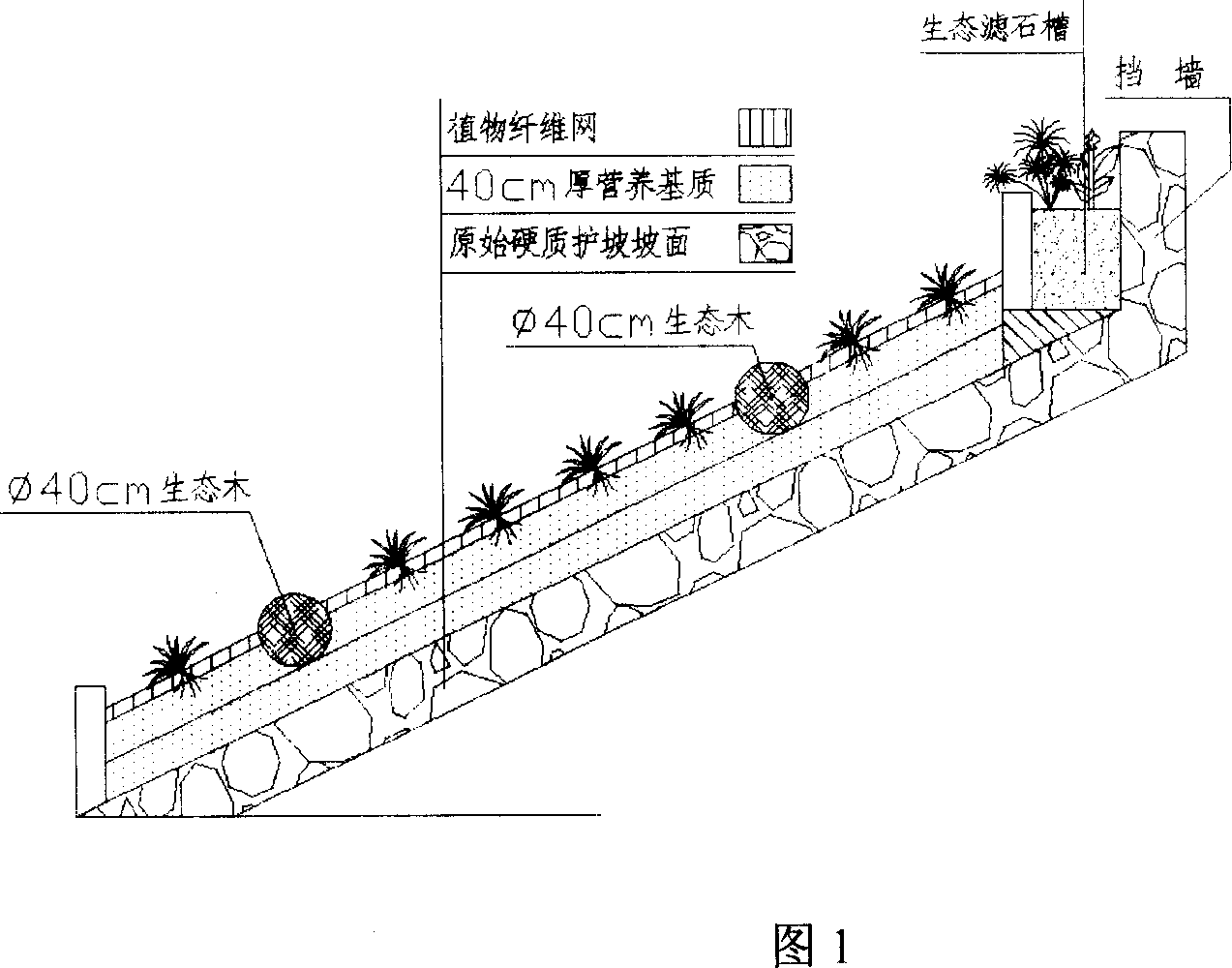

Method for slope protecting natural simulating ecological constitution and taking account of surface source pollution control

InactiveCN1974935AReduce washoutPrevent slipping and shiftingCoastlines protectionExcavationsPollutantPre treatment

The present invention relates to a method for constructing artificial natural ecologic revetment with the functions of raising revetment stability and controlling area-source pollution. Said method includes the following steps: (1), in the revetment top position close to vertical retaining wall constructing ecological filter broken stone channel and using it as pretreatment equipment for making area-source pollution control; (2), on the hard revetment laying matrix crushed gravel layer whose thickness is 40 plus or minus 20 cm; (3), laying and fixing fiber web or plant fiber web on the matrix crushed gravel layer and (4) on the plant fiber web area spreading and sowing herbaceous plant seeds and making cultivation.

Owner:国家环境保护总局华南环境科学研究所

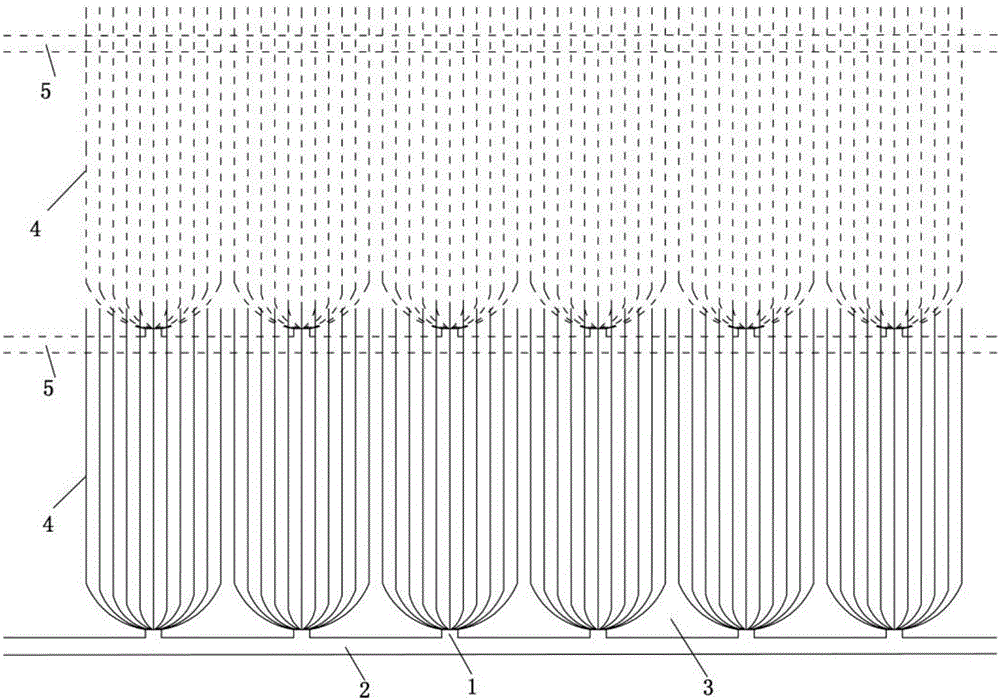

Underground progressive gas pre-extraction and directional hole drilling system and method for broken and soft coal seam

ActiveCN105971517AImprove hole depthHigh hole forming precisionSurveyDrilling rodsRock cuttingEngineering

The invention relates to an underground progressive gas pre-extraction and directional hole drilling system and method for a broken and soft coal seam. An orifice bubble filling system is utilized to provide a continuous bubble flow for a drill hole to drive hole bottom grooving air screw motor to perform rapid drilling, and scouring to the hole wall of the broken and soft coal seam is reduced. A triquetrum auger stem is used for strengthening residue discharge. An orifice bubble-eliminating extraction system is utilized to eliminate bubbles, remove rock cuttings and perform gas extraction, and construction safety is guaranteed. A dual-drive compound directional drilling technology is combined to regulate and control a drilling trajectory and ensure that the drill hole extends along the designed trajectory and penetrates through and covers an unmined working face and a roadway to be excavated. The hole forming depth, the hole forming precision, hole forming efficiency and hole forming rate of the broken and soft coal seam with the Platts hardness coefficient f greater than or equal to 0.5 but smaller than or equal to 0.8 are wholly improved, the formed hole is used for progressive gas pre-extraction in a broken and soft coal seam zone, and a standard-reaching period of the working face of the broken and soft coal seam and coal roadway driving gas extraction is shortened.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Environment-friendly stemming for blast furnace and preparation method thereof

The invention provides environment-friendly stemming for a blast furnace. The stemming is prepared from aggregate, silicon carbide, titanium dioxide, white mud, coke dust, micropowder and a binding agent. The method for preparing the stemming comprises the following steps: proportioning aggregate, silicon carbide, titanium dioxide, white mud, coke dust and micropowder according to the mass percentage; performing dry mixing and grinding, adding the binding agent, and performing wet mixing and grinding to obtain the environment-friendly stemming for a blast furnace. The stemming has the advantages of small shrinkage rate, excellent thermal shock resistance, excellent washing resistance and excellent erosion resistance, and once tapping time reaches 100-180 minutes; in-situ generated TiC has an effect of protecting the furnace, and the service life of the furnace can be prolonged; T60 carbon-containing resin and phenolic resin are used as the binding agent to reduce generation of cancerogenic smoke and improve the operation environment.

Owner:BEIJING JINGYEYUAN NEW MATERIALS

Method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment

ActiveCN108624959AOvercome the need to set up a spiral crystal selector to suppress the formation of miscellaneous crystals below the remelting interface inside the seed crystalOvercoming the problem of stray crystal formation below the remelt interfacePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses a method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment. The method is characterized in that the original structurestate of seed crystal is converted into a uniform structure from a thick seed crystal structure through a solid-solution thermal treatment way, so that a structure on the upper part of a mushy zone under a melting-back interface forms a complex network shaped structure in a seed crystal single-crystal preparation process; un-melted solid phases are connected with each other to improve ability ofresisting deformation, so that flow speed when melt is poured to the upper end of the seed crystal does not need to limit, and therefore, the purpose of removing a spiral crystal selector structure ina mould shell is achieved. In a process of preparing the single-crystal high-temperature alloy, the seed crystal re-melting region is completely inhibited to form mixed crystal, so that the structureof the corresponding mould shell is simplified, mechanical degree and assembly precision of shell making are improved, and cost is reduced, and therefore, the defect of using a spiral crystal selecting section in the mould shell in a process of producing single-crystal high-temperature alloy by repeatedly using seed crystal is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pre-reservoir series system of purification for non-point source pollution in hilly and mountainous area agriculture

InactiveCN102874972AAvoid damageReduce washoutMultistage water/sewage treatmentSustainable biological treatmentParticulatesDry season

The invention discloses a pre-reservoir series system of purification for non-point source pollution in small watershed agriculture of hilly and mountainous areas. The system comprises a series of small-size pre-reservoir units in series, wherein each pre-reservoir unit mainly comprises four parts: (1) an ecological reservoir and a spillway sluice: by building a water retaining dam to construct the ecological reservoir used fro storing water for dry seasons, retaining for rain seasons and settling sediments and suspended solids in runoff; (2) a setting pond for removing particulate matters and sediments to protect the aquatic vegetation of the pre-reservoir area to a certain degree; (3) flood discharge ditches (ecological ditches and flood discharge pipes) for preventing flood from damaging the pre-reservoir from the front and from the side when heavy rain falls; and (4) a pre-reservoir area: the aquatic vegetation with strong adaptive capacity under stress conditions, good purification effect, and developed root system for recovering the water level. The invention provides a technical reference for non-point source pollution control in small watershed agriculture of extremely difficult hilly and mountainous area, and has the advantages of simple construction, strong pertinence, harmony between the flood discharge and purification, etc.

Owner:LINYI UNIVERSITY

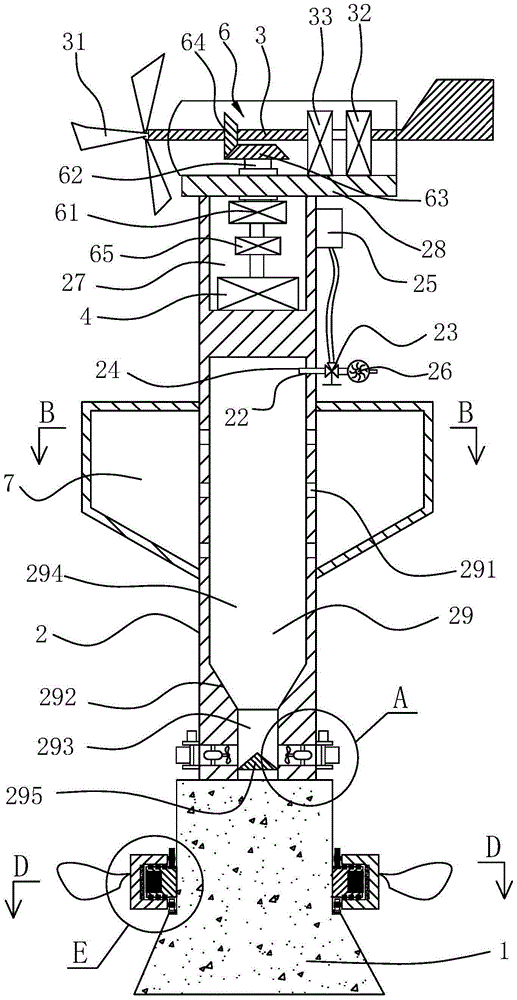

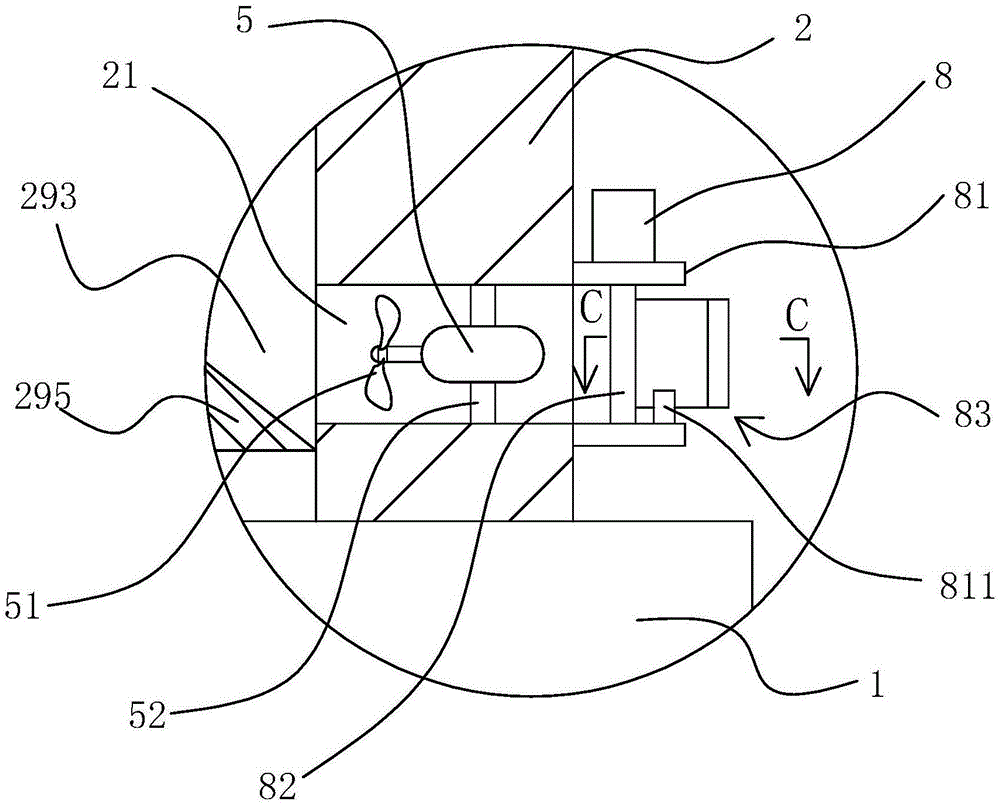

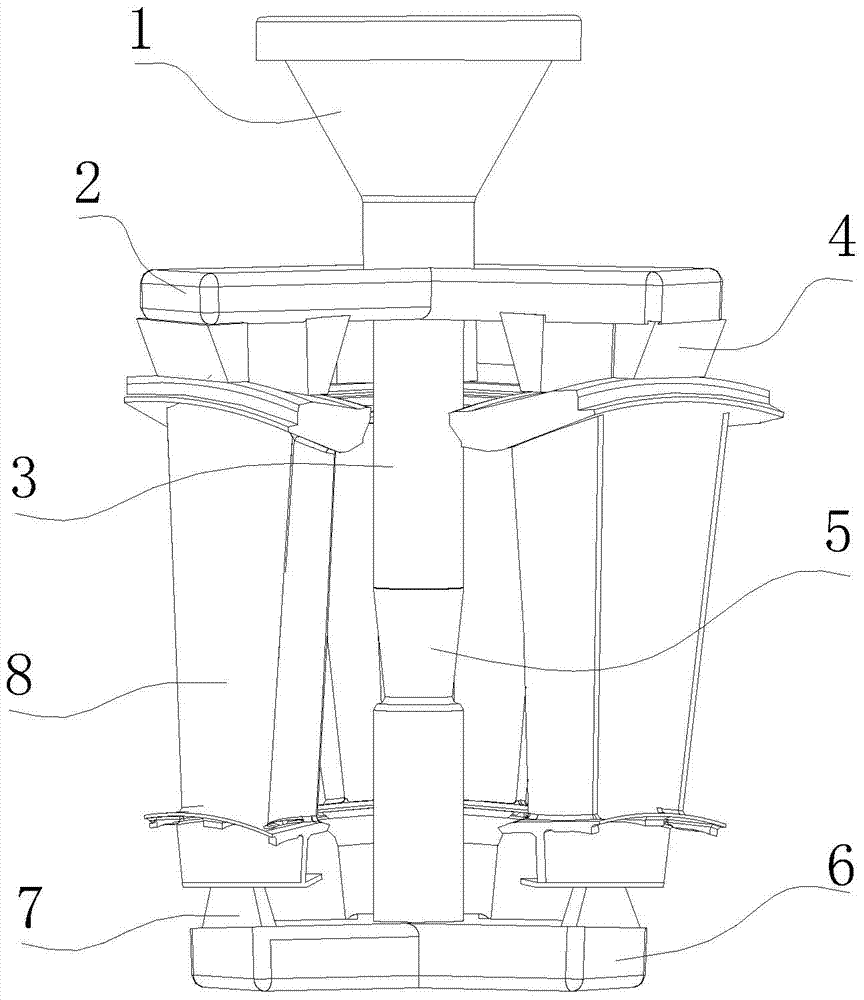

Combined type ocean power generation device

InactiveCN105626367AReduce washoutIncrease profitWater-power plantsHydro energy generationReduction driveEngineering

The invention provides a combined type ocean power generation device. The combined type ocean power generation device comprises a base and a main body, wherein the main body is fixedly connected with the base; an upper cavity is arranged in the upper end of the main body; a lower cavity is arranged in the lower end of the main body; a sealing plate is arranged at the upper end of the upper cavity and rotationally connected with a rotary shaft; the rotary shaft is horizontally arranged, one end of the rotary shaft is fixedly connected with vanes, and the rotary shaft is connected with an input shaft of a generator through a speed reducer; a generator II is arranged in the upper cavity, a transmission structure capable of driving an input shaft of the generator II to rotate when the rotary shaft rotates is arranged between the input shaft of the generator II and the rotary shaft; a through hole is horizontally formed in the lateral wall of the lower end of the lower cavity, and a generator III is arranged in the through hole; a swinging generator is arranged at the outer end of the through hole; a ventilation hole is formed in the lateral wall of the main body and fixedly connected with a valve capable of controlling the ventilation hole to open and close; a plurality of base protecting devices are further arranged on the base. According to the combined type ocean power generation device, scouring of ocean currents to the base can be reduced, and wind energy and tidal energy are fully used for power generation.

Owner:ZHEJIANG OCEAN UNIV

Method for simulating soil slope instability induced by groundwater

InactiveCN108828189AShorten test timeImprove test efficiencyEarth material testingPhysical modelInstability

The invention discloses a method for simulating soil slope instability induced by groundwater. The method is characterized by comprising the following steps: a, putting a physical model on a centrifugal machine; b, raising the height of an external water tank, opening a water outlet valve and a water inlet valve, carrying out water seepage into a soil layer according to the thickness of a saturated soil layer and completing the saturation process of a soil mass; c, closing the water inlet valve, reducing the height of the external water tank, improving the centrifugal acceleration to solidifyand disperse the internal pore water pressure of the physical model; d, after the solidification is finished, opening the water inlet valve, raising the height of the external water tank to the corresponding height according to the preset water level height of an internal water tank; obtaining different infiltration capacity of the water to the slope when the water in the internal water tank seepsinto the soil layer and stays at different heights, and observing the wetting front change and the slope deformation condition of the physical model. The method disclosed by the invention has the advantages that the height of the groundwater level can be accurately adjusted in real time and washing of water current to the slope body is prevented; in the whole test process, high operability, highreliability and good test effect are realized.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for cooling air film of turbine blade of aircraft engine

InactiveCN101832154AReduce lossesImprove cooling efficiencyTurbine/propulsion engine coolingBlade accessoriesAviationTurbine blade

The invention discloses a method for cooling an air film of a turbine blade of an aircraft engine. In the cooling method, the solid working medium NH4HCO3 is used as the resource of the cooling working medium; an annular cavity disposed inside the external casing of the engine and outside the tailpipe of the engine is used as the back-heating cavity, and the solid working medium is input into theback-heating cavity. The solid working medium is heated and decomposed into the intermediate-temperature and high-pressure working medium by the waste heat of the tail gas of the engine; the cooling working medium is driven by the pressure to enter the original air supplying channel for cooling the air film via an air channel communicated with the outlet of the back-heating cavity and the coolingair inlet of the turbine blade, so that the air film is cooled by the turbine blade of the aircraft engine. The endothermic decomposition reaction occurs in the cooling course, so that the cooling efficiency is improved remarkably; and the cooling working medium is the thermal decomposition product. The invention can completely or partially replace the cooling of the air film and can cool the members having highest heat loads of the aircraft engine such as a first-stage guide blade and a first-stage rotor blade when the amount of the cooling air cannot be further increased and the higher cooling efficiency must be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

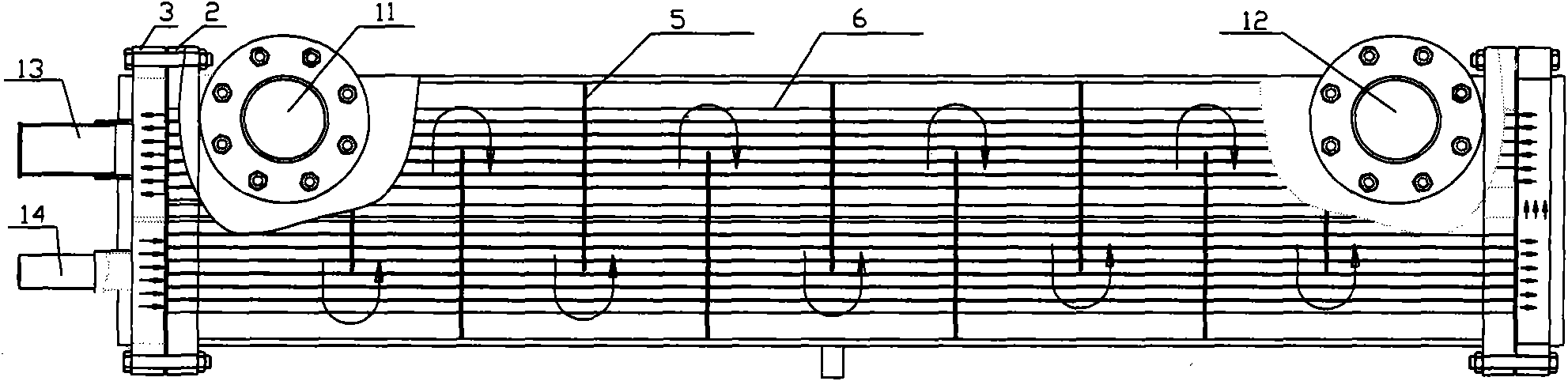

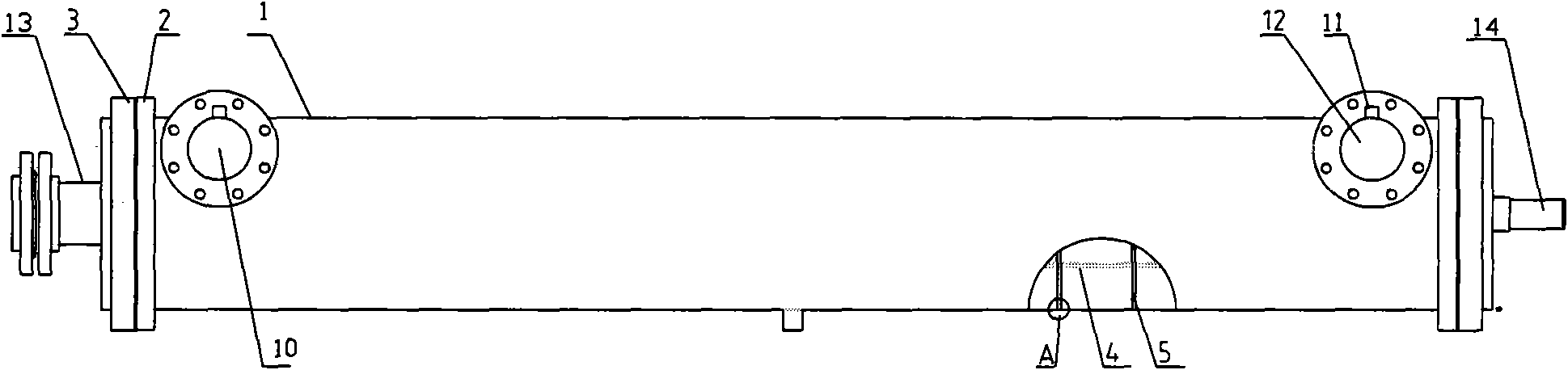

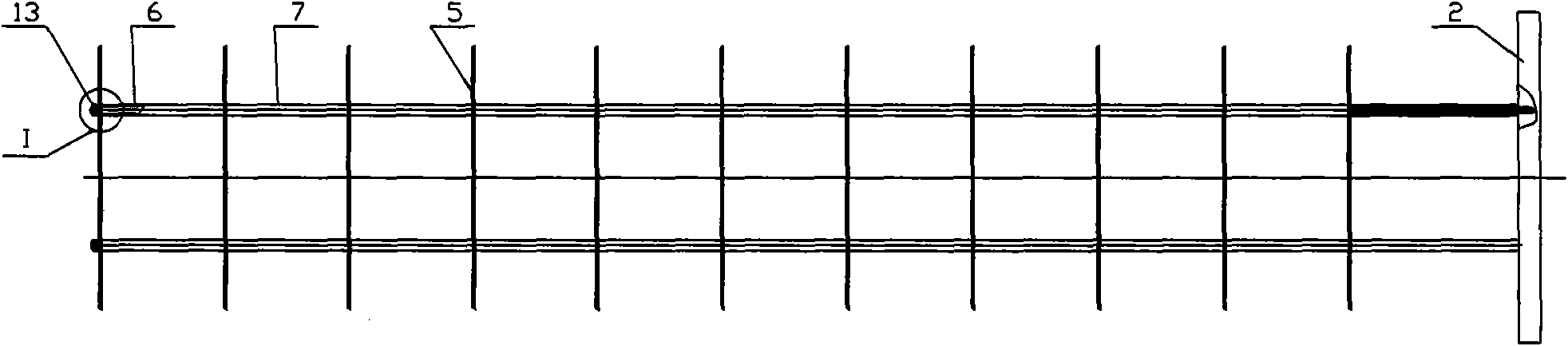

Shell-and-tube heat exchanger

InactiveCN101650138AAvoid short circuit shunt phenomenonImprove heat transfer efficiencyEvaporators/condensersHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

A shell-and-tube heat exchanger comprises a tubular shell, tube sheets arranged along two ends of the tubular shell and an end cover which is fixedly connected to the end of the tubular shell on the outer side of the tube sheets. A cavity of the shell and the tube sheet are provided with a whirl plate, a hollow coil heat exchanger bundle, a pull rod and a pipe spacer. Pores are uniformly arrangedon the whirl plate and periphery of the whirl plate is provided with a soft edge. The hollow coil heat exchanger bundle passes through the pore on the whirl plate and is fixed between two tube sheets.The hollow heat exchanger is the hollow coil heat exchanger bundle, tube wall of which has a continuous spiral slot shape and the external surface of which also has a spiral slot shape. The inventionavoids short circuit and split stream of flow media formed in the shell, and water is forced to spirally flow from a flowing pore gap, which is formed between the pore on the whirl plate and the spiral heat exchanger bundle, through the heat exchanger bundle. The invention improves heat-exchanging efficiency, enables shell side fluid to flow through a reasonable passage, reduces local scour, andeffectively prevents corrosion of the whirl plate, with clean and pollution-free water.

Owner:广州联合冷热设备有限公司

Intelligent rainwater purification landscape system

PendingCN106746205AExtension of timeDelay bufferTreatment involving filtrationEnergy based wastewater treatmentRainwater harvestingStormwater

The invention discloses an intelligent rainwater purification landscape system. The intelligent rainwater purification landscape system comprises a firefighting impounding reservoir, a roof plant greening layer, a wall vertical greening layer, an S-shaped rainwater pipeline, a rainwater falling pipe, a primary deposition oxidization pond, a rainwater storage unit, an intelligent rainwater control module, a solar cell panel and a landscape fountain oxygen aeration unit which are arranged on a roof. According to the technical scheme, rainwater is collected, filtered, stored, purified and used by utilizing different filtering layers, so that the collected and purified rainwater can be used for providing irrigation water for garden greening. The utilization rate of rainwater resources can be improved, the municipal water consumption problem can be relieved, and the rainwater resource waste and urban water logging problems can be solved while landscapes are formed.

Owner:ANQING NORMAL UNIV

Precision casting gating system

ActiveCN103658542AEffective control of the rendezvous interfaceRealize reasonable diversionFoundry mouldsFoundry coresAlloyMaterials science

The invention discloses a precision casting gating system. The precision casting gating system mainly comprises a pouring cup, a gate sprue, a cross gate and an inner runner, wherein the gate sprue is connected with the pouring cup and arranged below the pouring cup; the cross gate comprises an upper cross gate and a lower cross gate; the upper cross gate and the lower cross gate are respectively arranged above and below the gate sprue; the inner runner comprises an upper inner runner and a lower inner runner; the upper inner runner is arranged below the upper cross gate; the lower inner runner is arranged above the lower cross gate; a reduced section is arranged on the gate sprue. By providing the reduced section on the gate sprue of the composite gating system, and adjusting the ratio of the upper and lower cross gates and the inner runners of the gating system, shunting of alloy liquid in the pouring process is achieved. The height of the reduced section on the gate sprue is adjusted, so as to achieve precision control of the meeting interface position of the alloy liquid. The set preferential solidification part is preferentially solidified, so that metallurgical defects such as looseness and cold shut at the position are avoided, and the qualified rate of casting is improved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Down hole air diverter

InactiveUS20050247487A1Type of reductionReduce environmental impactDrill bitsDrilling rodsImproved methodHole drilling method

The present invention provides an improved method of and apparatus for, pneumatic drilling. The present invention includes a down hole air diverter of improved design, a corresponding computer modeling program, and method of application to optimally achieve the benefits of controlled gradient pneumatic drilling.

Owner:MELLOTT JOSEPH C

High and steep slope reinforcing and greening device and method

ActiveCN107711170AImprove water retentionWith filter functionFlowers cultivationHops/wine cultivationFiberLandslide

The invention relates to the field of environment protection, and discloses a high and steep slope reinforcing and greening device and method. The high and steep slope reinforcing and greening devicecomprises reinforced three-dimensional polypropylene gauze pads, U-shaped nails, anchor rods, vegetation seeds, soil improvement fiber mixtures, erosion-resistant fiber mixtures, fiber filtering tubesand wedges. The high and steep slope reinforcing and greening device is simple in construction process and convenient to operate; after the reinforced three-dimensional polypropylene gauze pads are fixedly arranged on a slope surface of a high and steep slope by the anchor rods and the U-shaped nails, the fiber filter tubes are laid, and then a mixture of the vegetation seed and the soil improvedfiber mixture and a mixture of the vegetation seeds and the erosion-resistant fiber mixture are successively sprayed and sowed. A soil living condition for growth of plants can be improved effectively, nutrient elements required for growth and metabolism are provided for the plants, and the technical problems that by an existing high and steep slope reinforcing method, the slope is easily washedby rainstorm, secondary landslide is caused, the collapse water-retaining property is poor, and meanwhile, secondary pollution to the environment will be caused are solved.

Owner:JOFO GREEN CO LTD

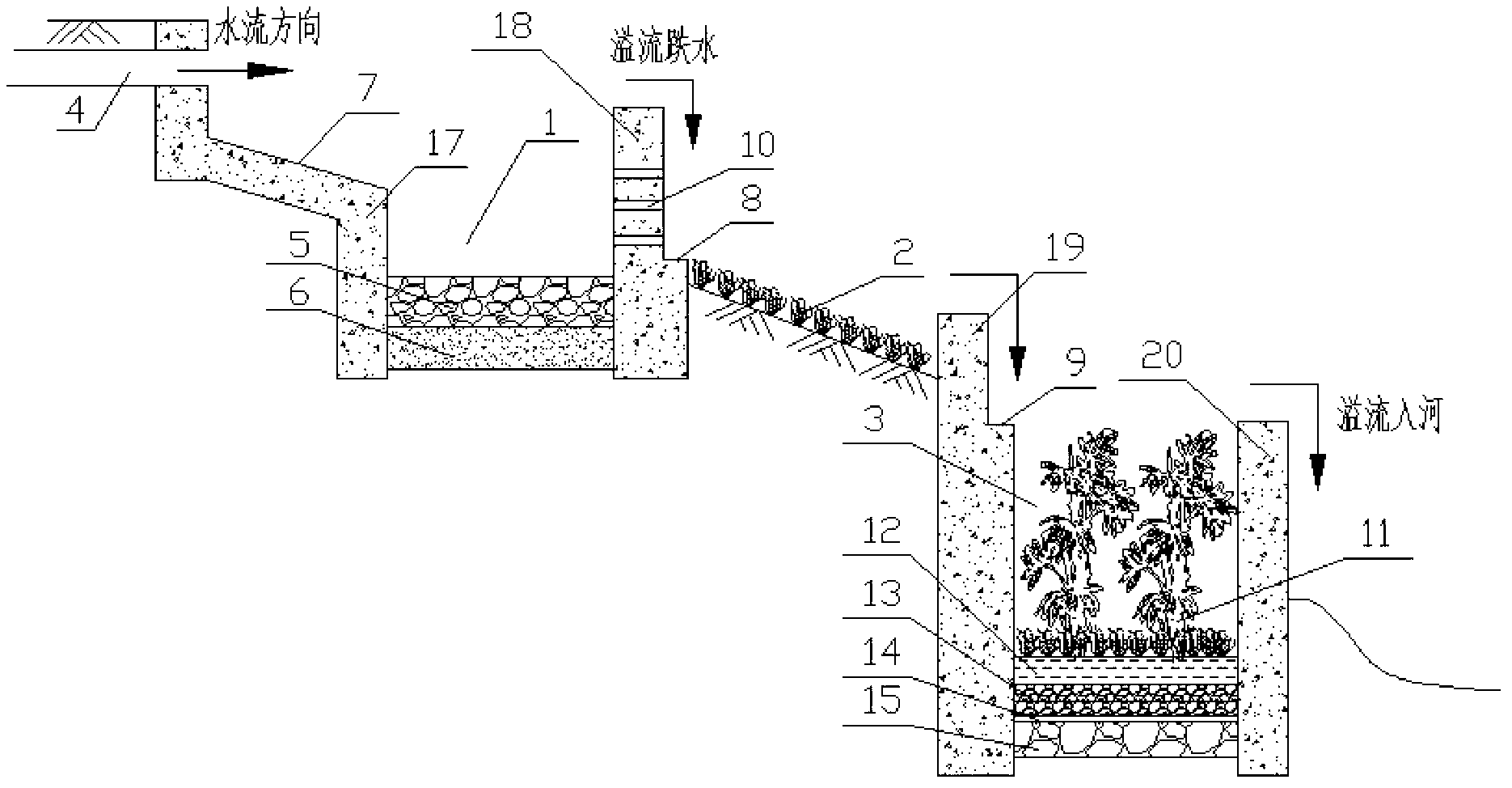

Multidimensional ecological drainage system for intercepting and controlling separate system rainwater pollutants into river

InactiveCN103306360AReduce the risk of polluted runoff directly entering the riverReduce impact damageSustainable biological treatmentSewage drainingEnvironment of AlbaniaWater pipe

The invention discloses a multidimensional ecological drainage system for intercepting and controlling separate system rainwater pollutants into a river. The system is arranged on one side of a river bank and takes a stair-step shape along the river bank; rainwater in pipe networks flows into a first-stage water drop platform by rain-water pipes, enters a storage pond, flows into an ecological buffer zone by a second-stage water drop platform, and lastly flows into a plant growth detention pond; and the first-stage water drop platform and the ecological buffer zone are slope-shaped, and plants are planted in the plant growth detention pond. The system not only ensures drainage, but also reduces the risk that rainwater polluted run-offs directly flow into the river, reduces impact and damage to water quality of the water body in a river channel, effectively controls the pollutants in the river, effectively improves the water environment, and enhances the urban water landscape value.

Owner:TIANJIN UNIV

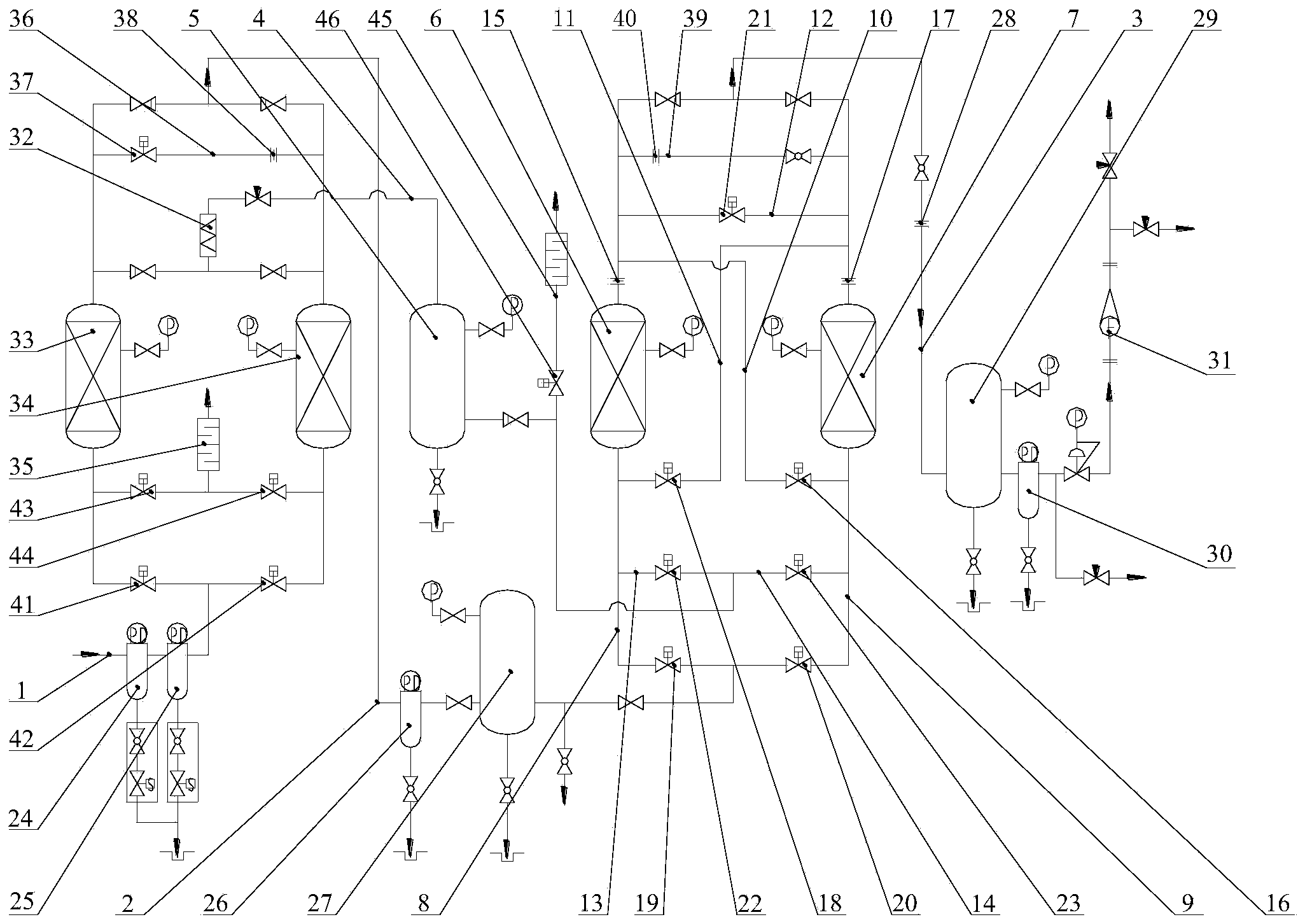

Pressure swing adsorption oxygen generating equipment and method

ActiveCN104340961AEfficient use ofIncrease profitDispersed particle separationSpecific gas purification/separationLow speedProcess engineering

The invention provides pressure swing adsorption oxygen generating equipment and method. The equipment comprises an intake pipeline, a heat regenerative adsorption type dryer, a gas conveying pipeline, a pressure swing adsorption oxygen generating host, a finished gas output pipeline, a regenerating pipeline and an exhaust gas recovery tank, wherein an inlet of the heat regenerative adsorption type dryer is connected with the intake pipeline, and an outlet of the heat regenerative adsorption type dryer is connected with the gas conveying pipeline; an inlet of the pressure swing adsorption oxygen generating host is connected with the gas conveying pipeline, and an outlet of the pressure swing adsorption oxygen generating host is connected with the finished gas output pipeline; the pressure swing adsorption oxygen generating host also comprises a first adsorption tower and a second adsorption tower, and an outlet of the first adsorption tower is connected with an inlet of the second adsorption tower through a third pipeline; an outlet of the second adsorption tower is connected with an inlet of the first adsorption tower through a fourth pipeline, and the exhaust gas recovery tank is arranged on the regenerating pipeline. By adopting an exhaust recovery device, a seven-valve two-step non-equipotential voltage-sharing process, and a low-speed voltage-sharing control technology, the unit energy consumption of oxygen generation can be substantially reduced, and the air utilization rate and the equipment reliability are improved.

Owner:WUHAN HENGYETONG GAS EQUIP

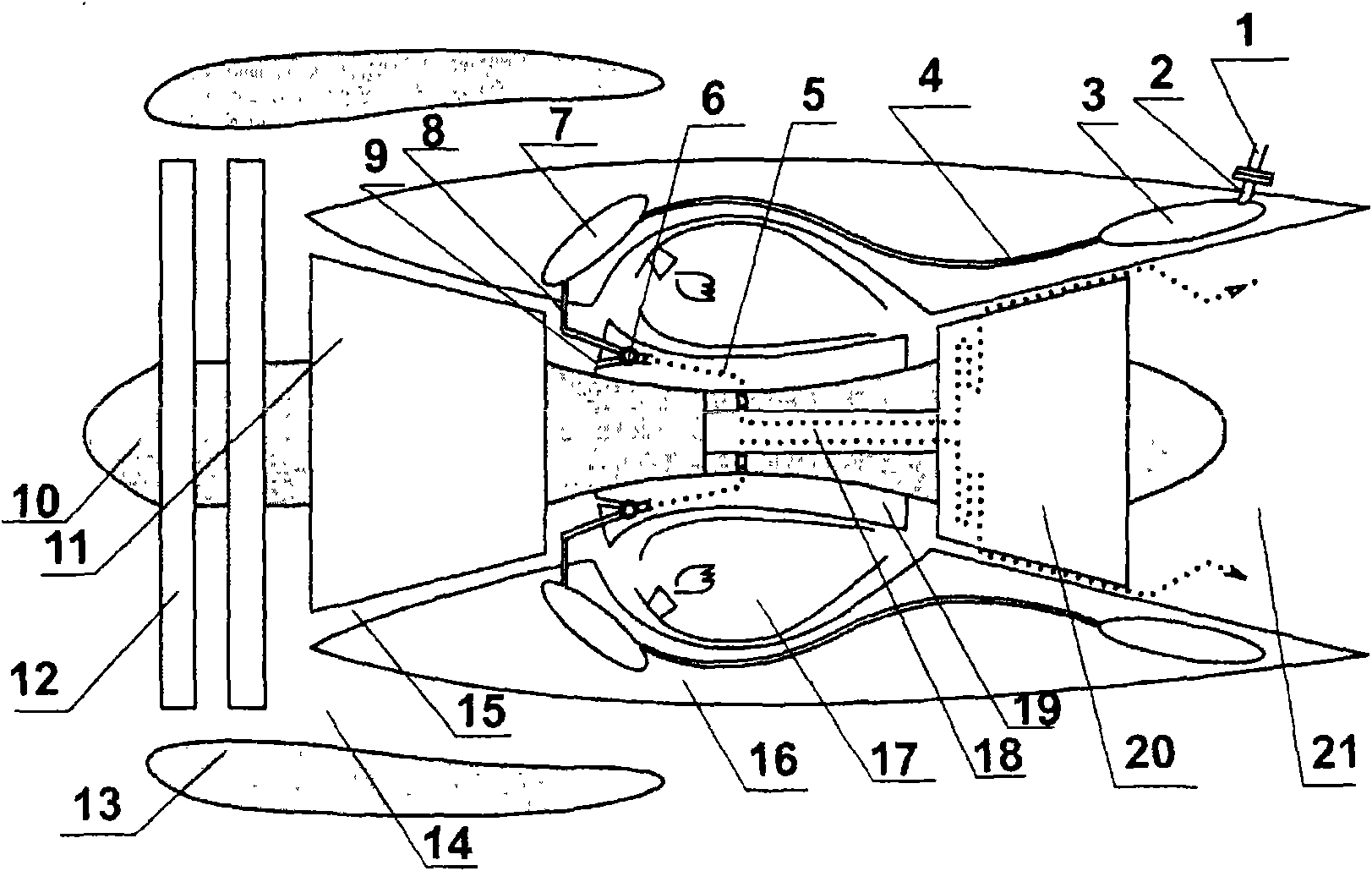

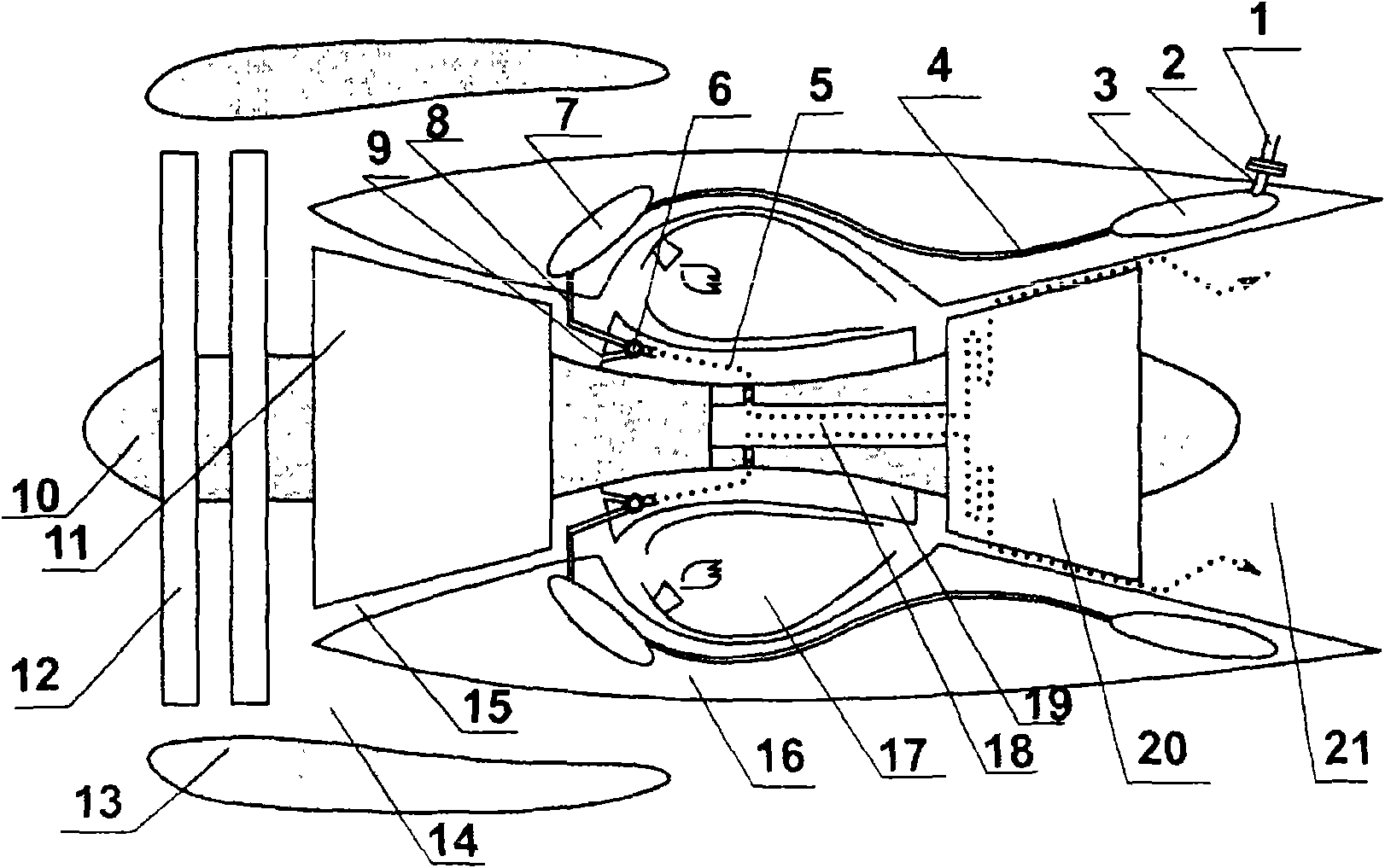

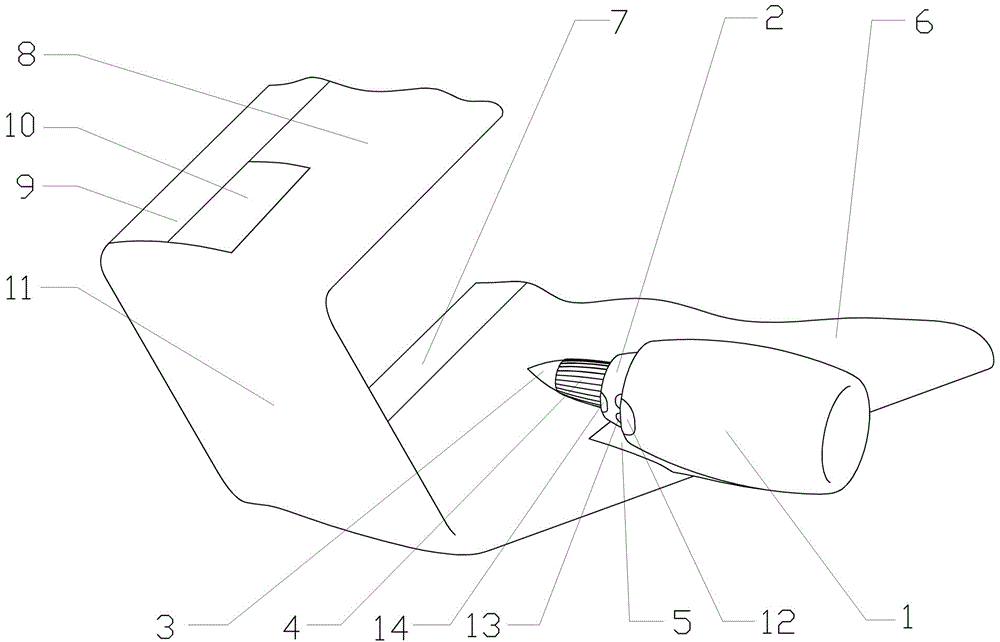

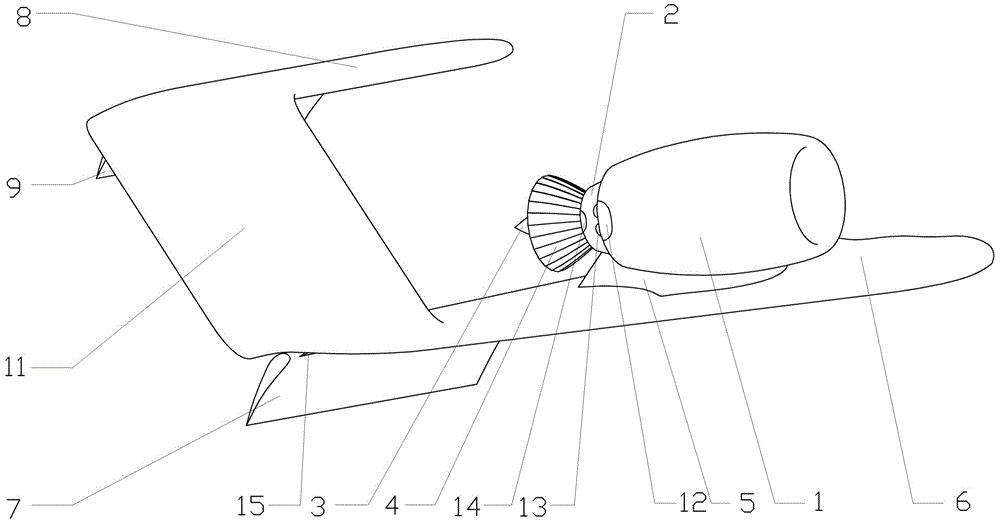

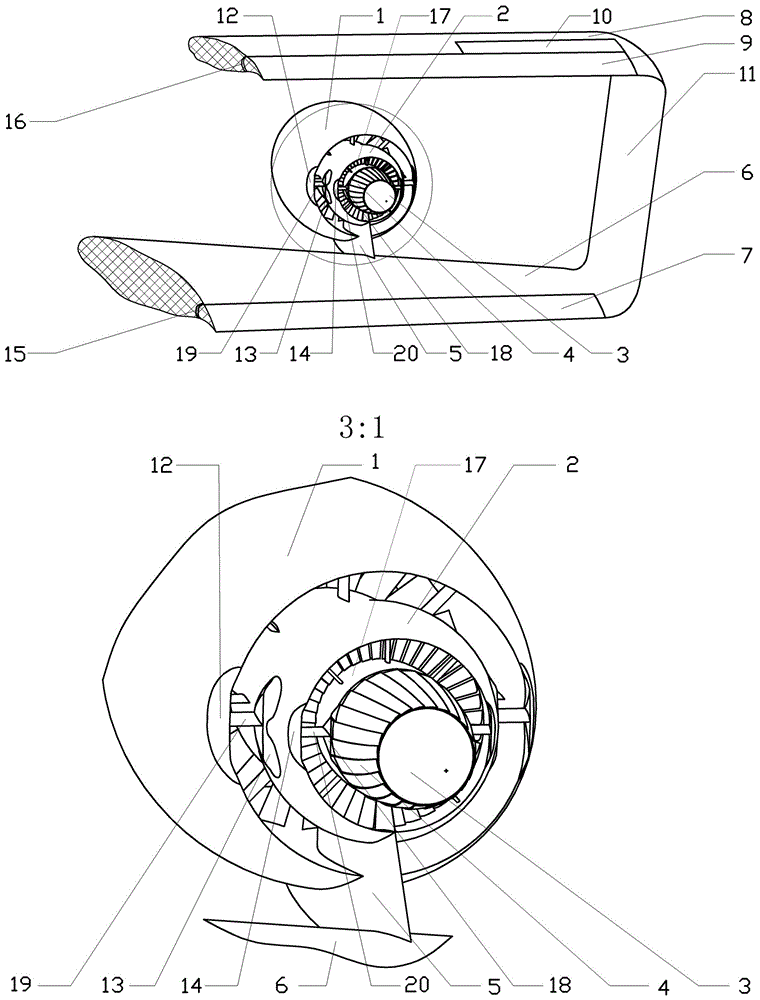

Jet-propelled flap lift augmentation joined wing system and aircraft thereof

The invention discloses a jet-propelled flap lift augmentation joined wing system. The jet-propelled flap lift augmentation joined wing system comprises a turbofan engine, an airfoil, a hanger and a turbine shaft rectifying cone, wherein the airfoil is provided with a rear-edge flap, the turbine shaft rectifying cone extends backwards for a given length and is provided with a plurality of scale-type convergence dispersion spray pipes, the left side and the right side of an outer duct spray opening are respectively provided with an airflow convergence dispersion apparatus consisting of an outer front edge and two outer convergence dispersion sheets, the left side and the right side of an inner duct spray opening are respectively provided with an airflow convergence dispersion apparatus consisting of an inner front edge and two inner convergence dispersion sheets, the airfoil is a joined wing. When the jet-propelled flap lift augmentation joined wing system takes off and lands perpendicularly, an upward lift resultant force can be generated; when the jet-propelled flap lift augmentation joined wing system flies in a level cruising manner, a thrust force and a lift force can be generated; an aircraft utilizing the jet-propelled flap lift augmentation joined wing system disclosed by the invention can vertically take off and land and fly at a high speed and can be stably switched between the vertical taking-off and landing and high-speed flight.

Owner:江苏中孚动力产业链有限公司

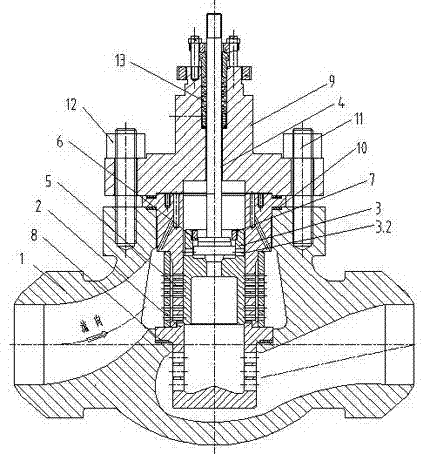

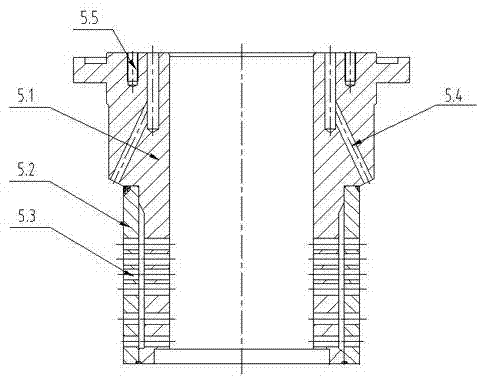

Anti-air-erosion dewatering regulating valve

ActiveCN103244748AAvoid direct impactReduce noisePressure relieving devices on sealing facesValve members for absorbing fluid energyWashoutEngineering

The invention relates to an anti-air-erosion dewatering regulating valve comprising a valve body, a valve seat, valve clacks and a valve rod. The valve seat is fixed in a valve cavity encircled by the valve body, the sealing surfaces of the valve clacks and the sealing surface of the valve seat form a main sealing pair, the valve rod drives the valve clacks straightly up and down, a orifice sleeve is fixedly arranged in a valve cavity at a medium inlet, the lower end of the orifice sleeve is abutted against the non-sealing surface of the upper end of the valve seat, the valve cavity at the medium inlet is divided into an inner portion and an outer portion by the orifice sleeve and the valve seat, multilayer sleeves are sleeved layer by layer to form the orifice sleeve, a gap is reserved between each layer of the lower portion of the orifice sleeve, a plurality of orifices are radially reserved on the sleeve wall of each sleeve layer, and external diameter surfaces of the valve clacks are slidingly matched with the inner diameter surfaces of the orifice sleeve. The anti-air-erosion dewatering regulating valve has the advantages of no erosion, small required executive force, reliable sealability, wear resistance, washout proof, simple structure, convenient mounting, long service life and the like. Erosion can be avoided under the working condition of big differential and the anti-air-erosion dewatering regulating valve can be driven by a small actuator.

Owner:HARBIN SONGLIN POWER STATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com