Anti-air-erosion dewatering regulating valve

A technology of anti-cavitation and regulating valve, which is applied in the directions of steam traps, sliding valves, valve details, etc., can solve the problems of cavitation, non-applicable zero leakage, sealing ring damage, etc. Corrosion, prolong service life, reduce the effect of erosion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

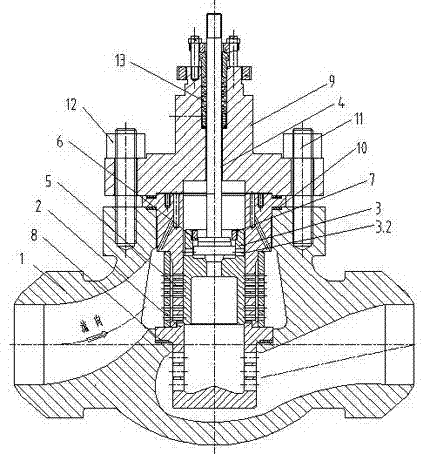

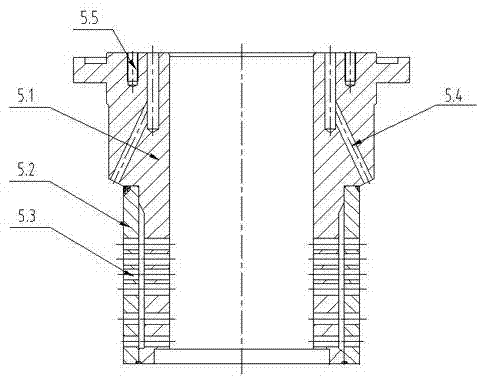

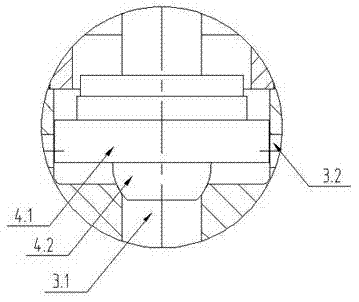

[0028] see Figure 1-4 , the present invention provides an anti-cavitation and water-repelling regulating valve, comprising a valve body 1, a valve seat 2 fixed in the valve cavity surrounded by the valve body, and its sealing surface and the sealing surface of the valve seat constitute the main seal The auxiliary valve disc 3 and the valve stem 4 that drives the valve disc to rise and fall in a straight line, a throttling sleeve 5 is fixed in the valve cavity on the medium inlet side, and a section of the outer diameter of the throttle sleeve is matched with a section of the inner wall of the valve cavity. Maintaining coaxiality, the lower end of the throttling sleeve abuts against the non-sealing surface of the upper end of the valve seat. The throttling sleeve and the valve seat divide the medium inlet side valve cavity into two parts, the inner part and the outer part of the throttling sleeve. The throttling sleeve is welded by the inner sleeve 5.1 and the outer sleeve 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com