Rock impact resistance spring lattice debris flow blocking structure

A debris flow and lattice technology, applied in dams, gravity dams, etc., can solve problems such as poor resistance to boulder impact, poor energy consumption performance, and easy damage, so as to improve the ability to resist boulder impact, improve safety, and avoid direct impact. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

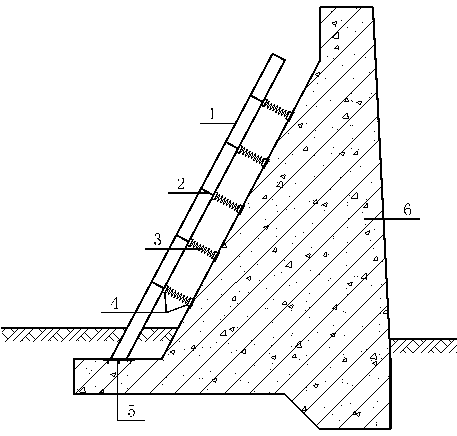

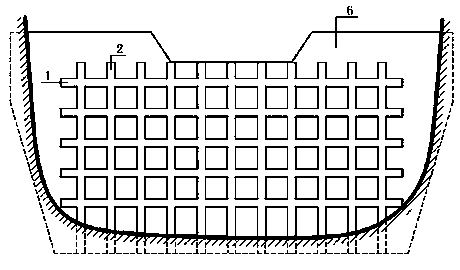

[0009] Such as figure 1 , figure 2 As shown, the present invention is a spring lattice debris flow retaining structure resistant to boulder impact, including connecting nodes 5, and the front part of the spring lattice debris flow retaining structure resistant to boulder impact is an I-shaped steel column 1 and an I-shaped steel column. A plane well-shaped structure composed of beams 2; the front I-shaped steel column 1 and I-shaped steel beam 2 are parallel to the upstream surface of the reinforced concrete dam body 6 at the rear; springs 3 are set at the joints of the well-shaped beams Vertical to the plane of the front well-shaped structure and the facing surface of the reinforced concrete dam body 6 at the rear; spring protective sleeves 4 are arranged at the joints of the well-shaped beams and columns, and the spring protective sleeves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com