Patents

Literature

154results about How to "Improve axial load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

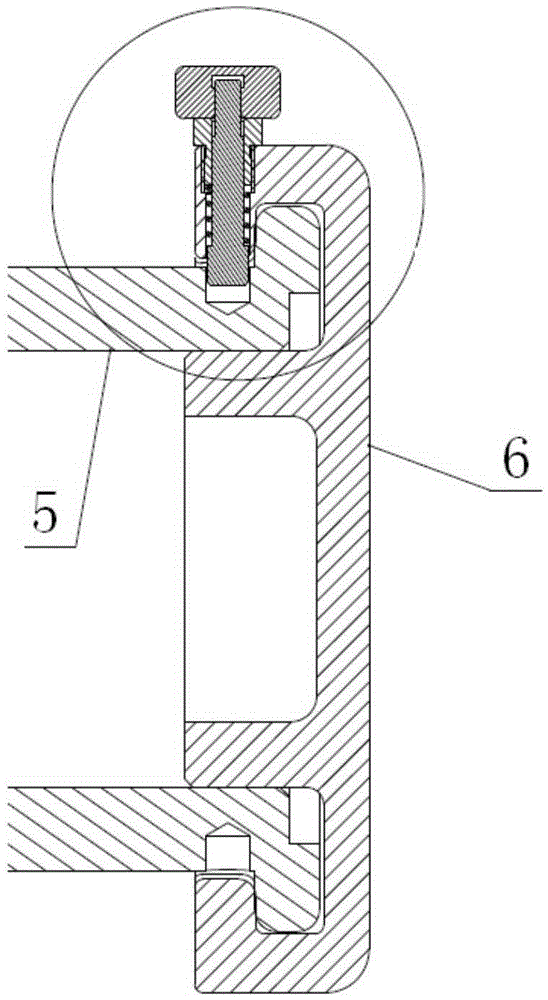

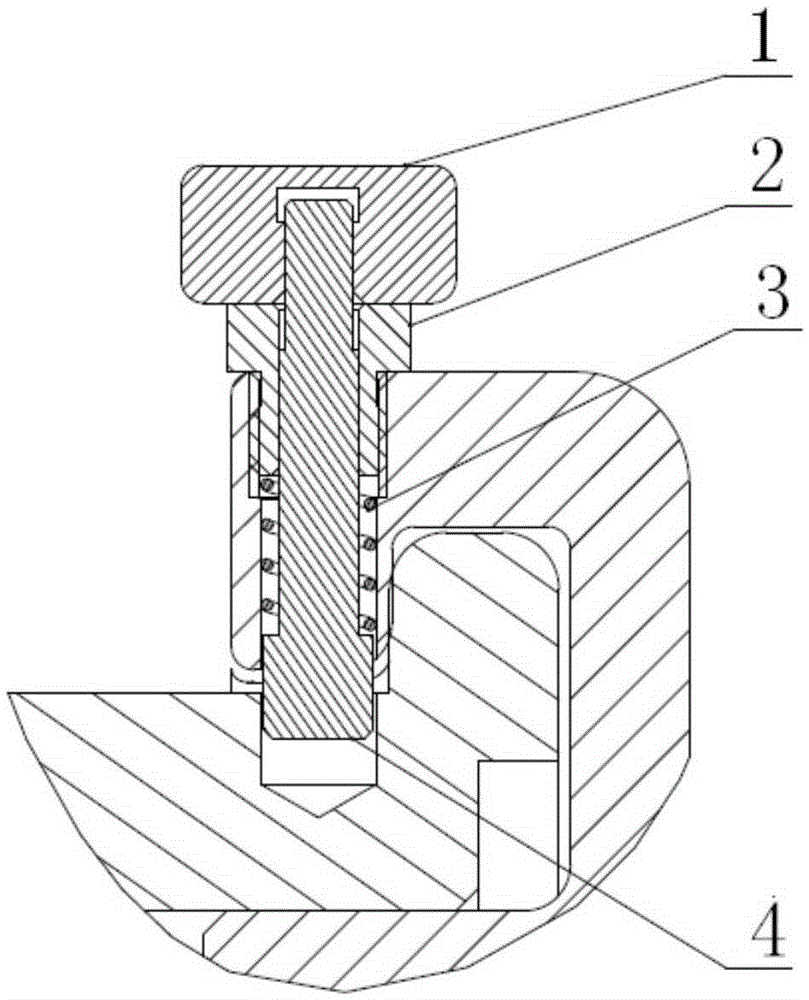

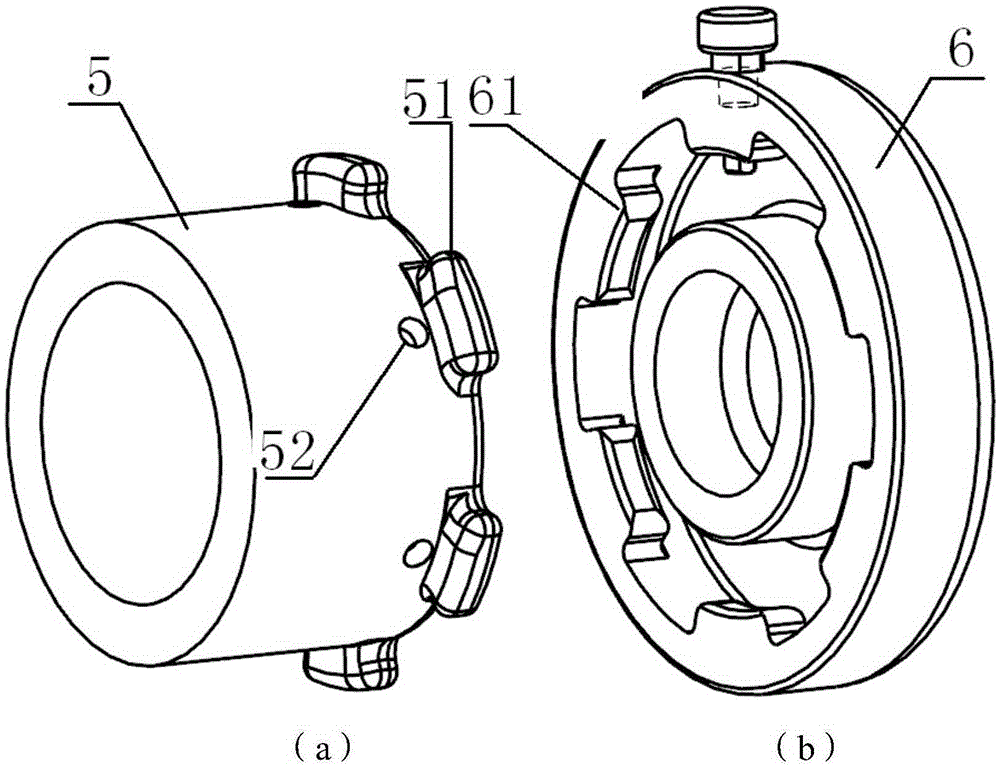

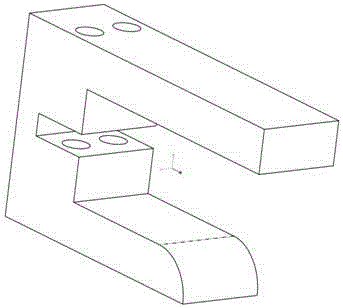

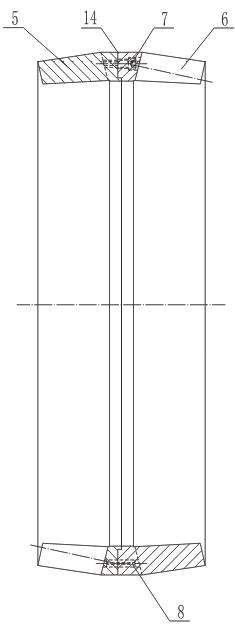

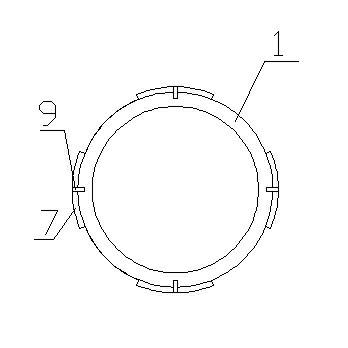

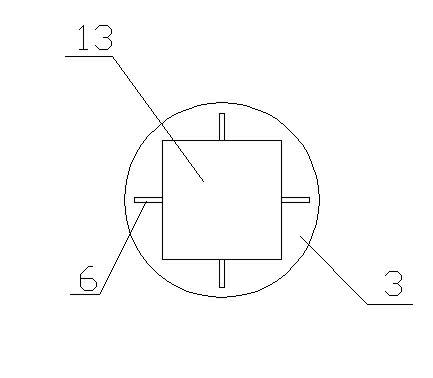

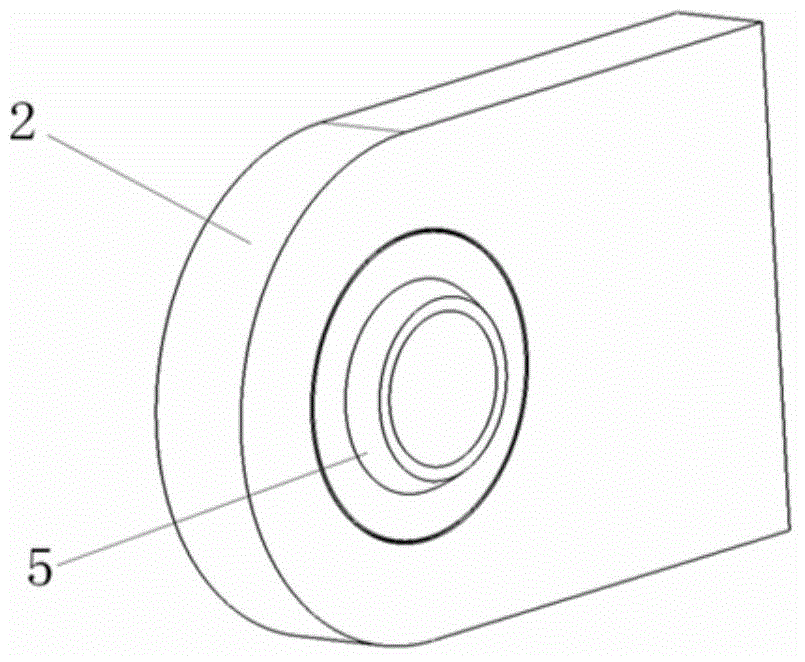

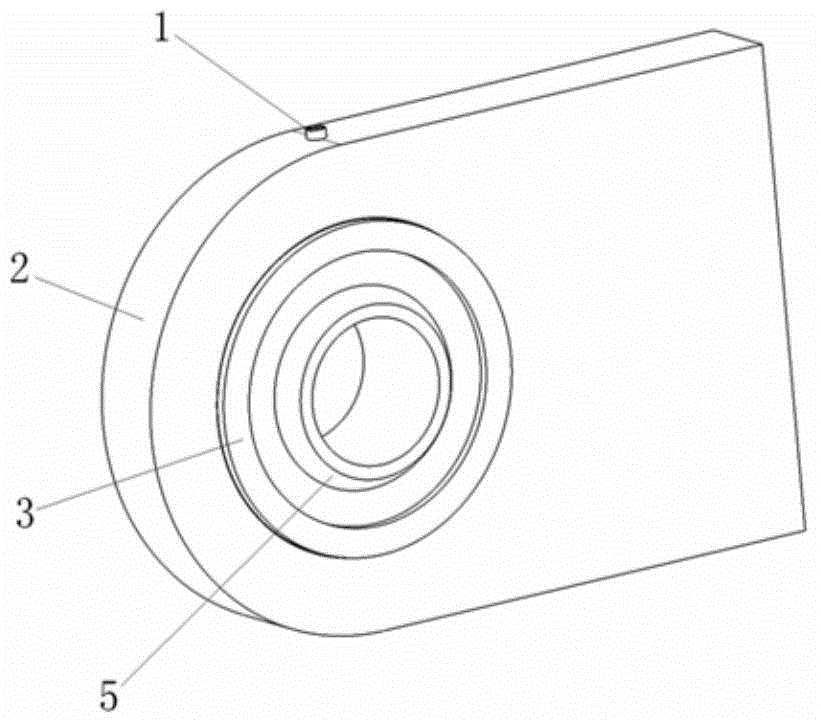

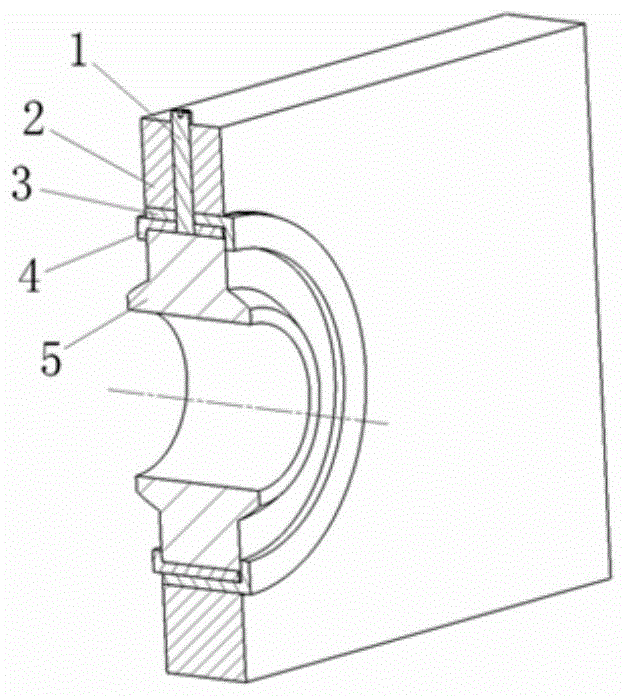

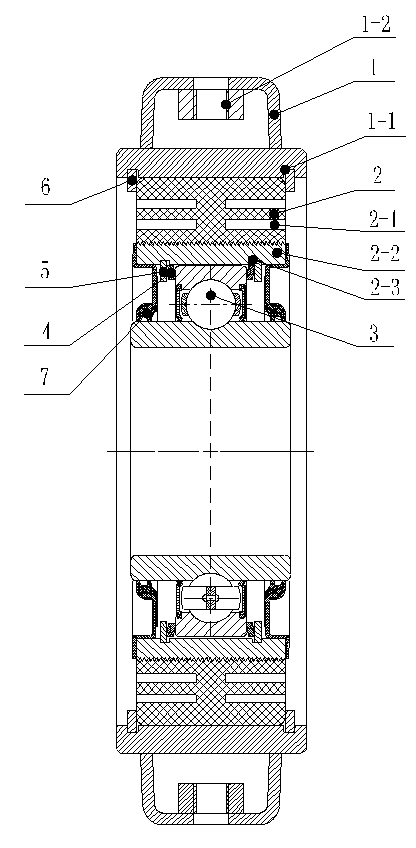

Fast clamping locking device

The invention provides a fast clamping locking device which comprises nuts (1), thread sleeves (2), springs (3), locking pins (4), first clamping supporting rims (61) and second clamping supporting rims (51). One end of each locking pin (4) is fixedly connected with the corresponding nut (1), and the other end of each locking pin (4) is inserted in a locking blind hole (52). Each locking pin (4) is sleeved with the corresponding thread sleeve (2). Each thread sleeve (2) is mounted in a mounting hole of an end cover (6). Each locking pin (4) is sleeved with the corresponding spring (3). One end of each spring (3) is connected with the corresponding thread sleeve (2), and the other end of each spring (3) is connected with the end, inserted in the corresponding locking blind hole (52), of the corresponding locking pin (4). The nuts (1) are pulled out or loosened, the springs (3) are driven to stretch out and draw back, the locking pins (4) are made to move in the mounting holes of the end cover (6), and therefore mounting, dismounting and locking of the end cover (6) and a shell (5) are achieved. Through the fast clamping locking device, high-precision and high-reliability connection between structures is achieved in a narrow space; the fast clamping locking device is compact in structure, easy to operate, capable of being dismounted and mounted repeatedly and good in maintainability.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

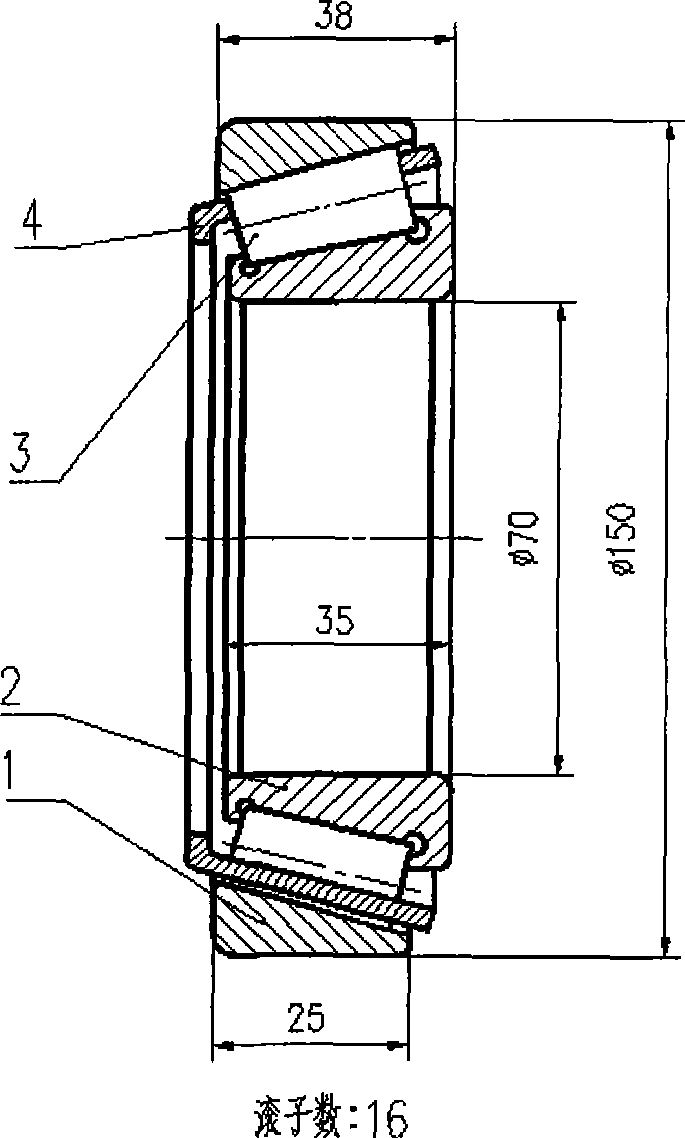

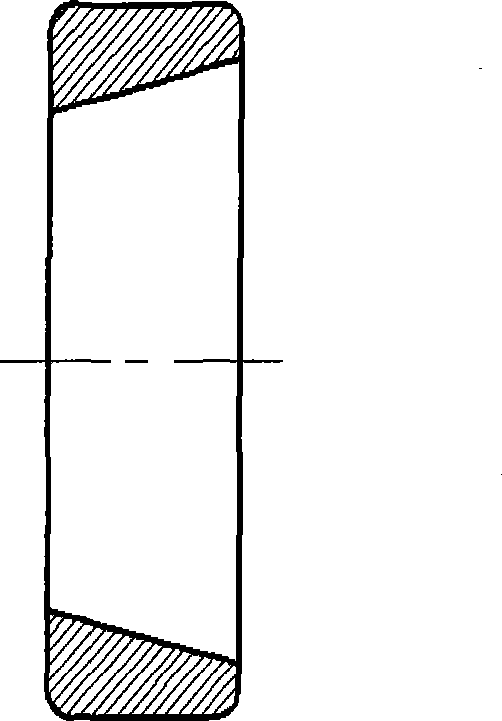

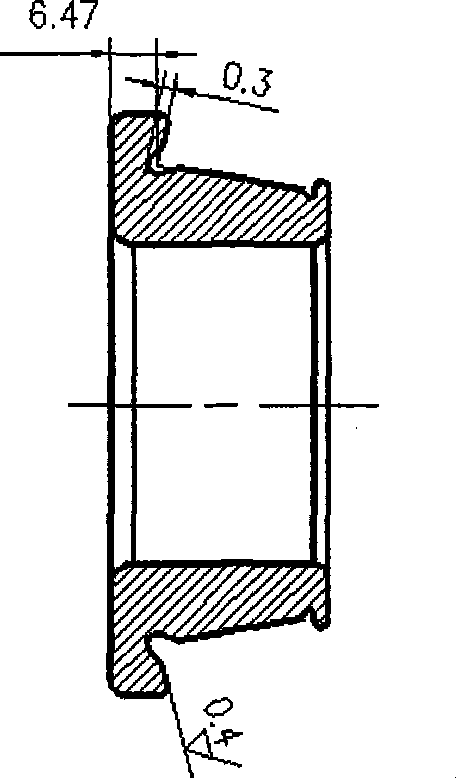

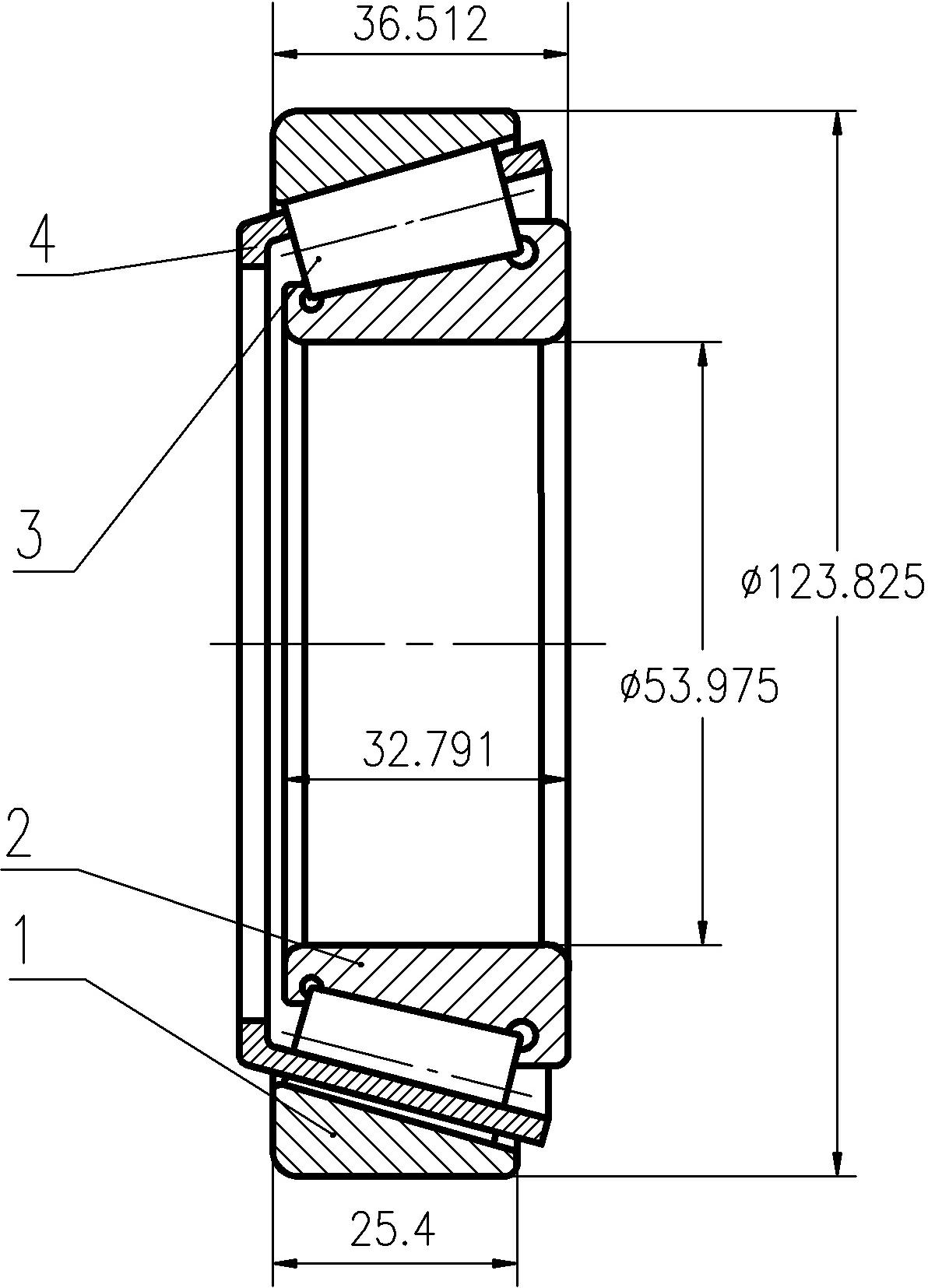

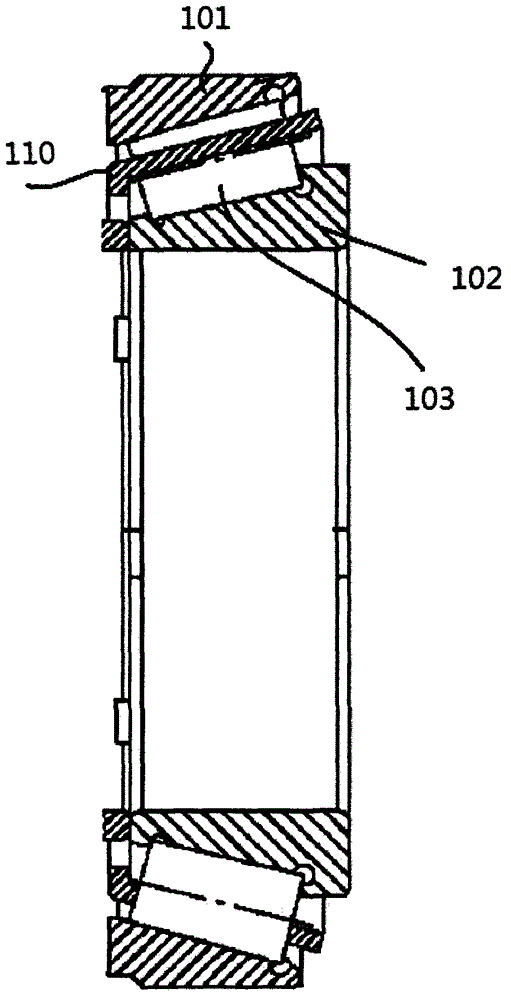

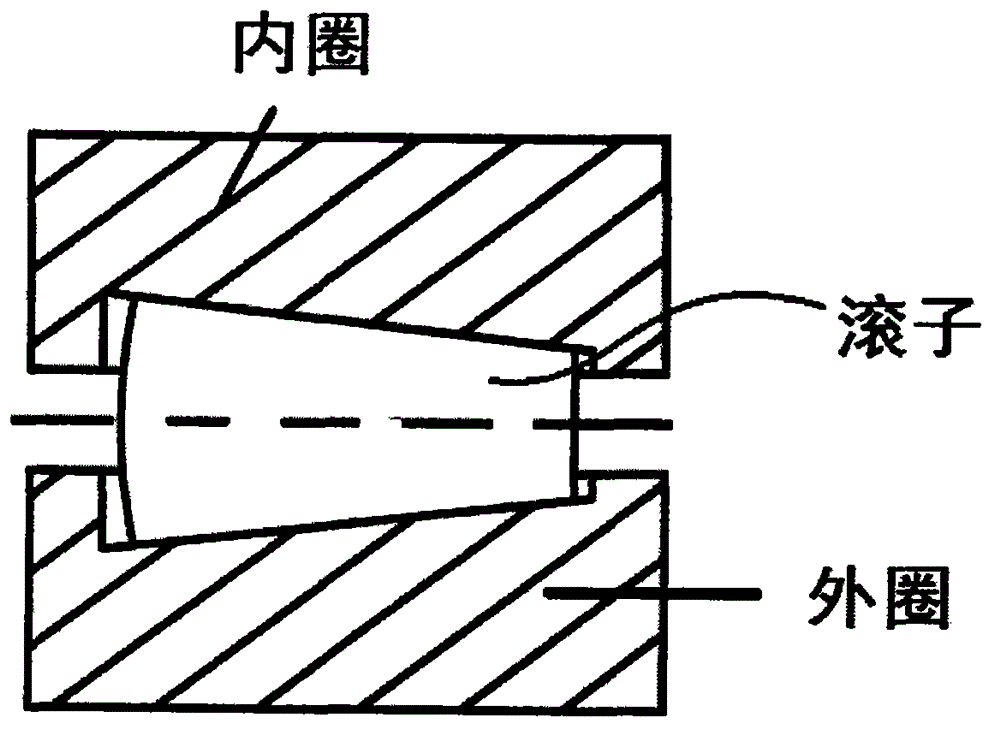

Tapered roller bearing with high strength and low friction torque

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reduces the energy consumption.

Owner:FUJIAN YONGAN BEARING

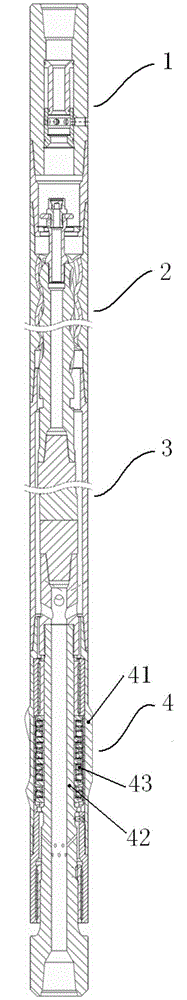

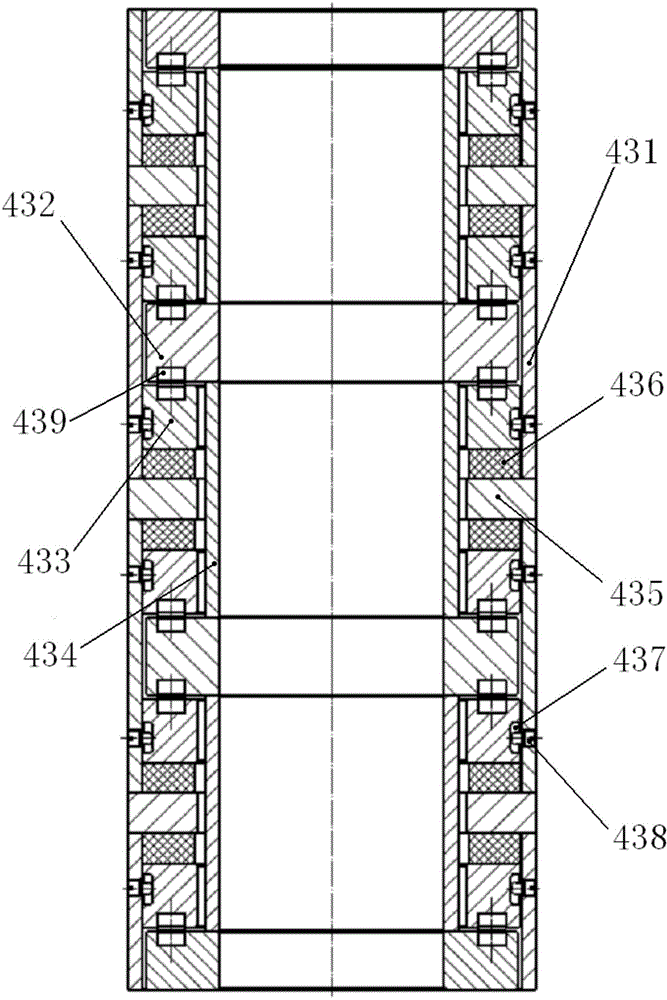

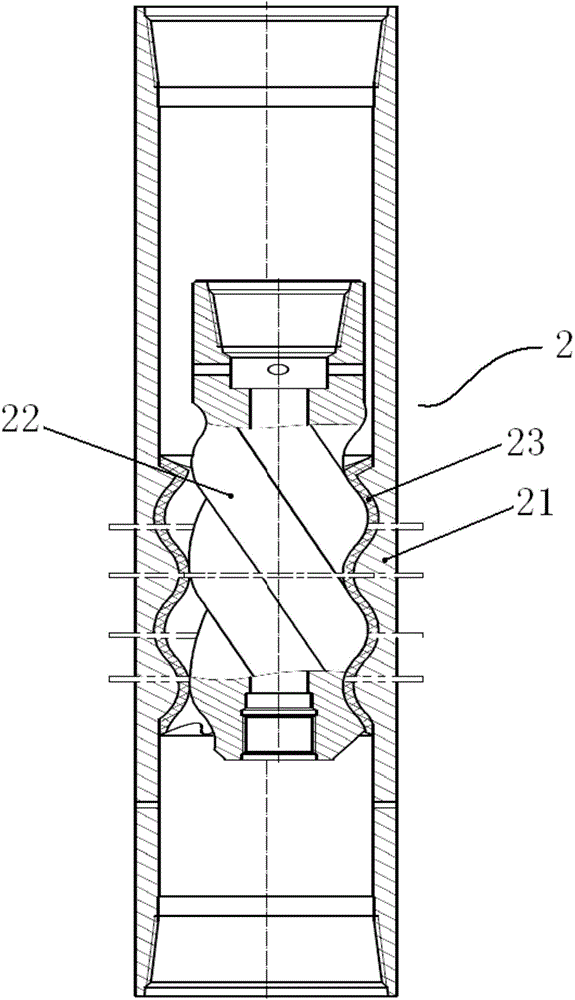

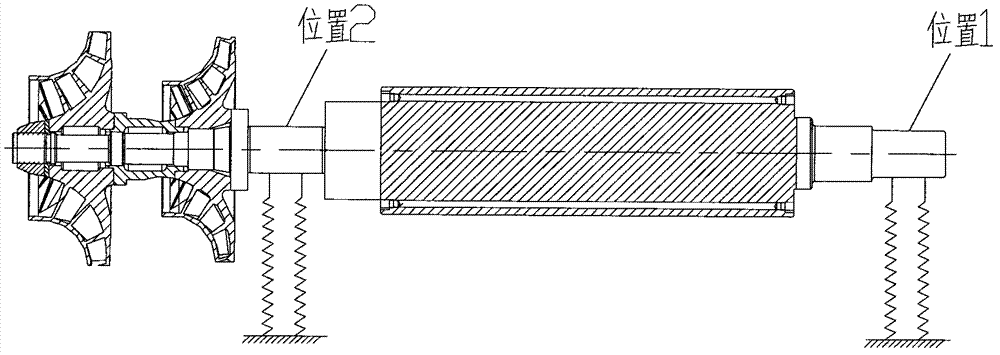

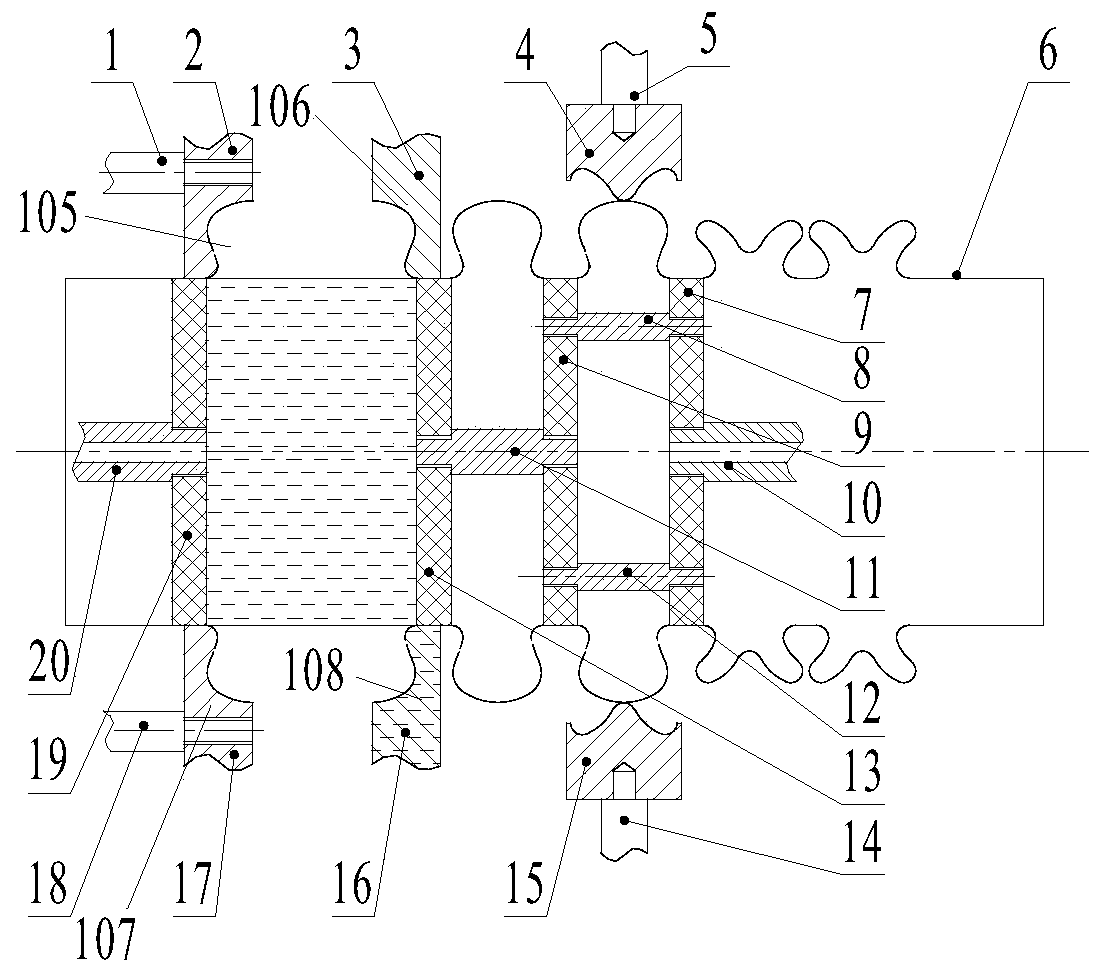

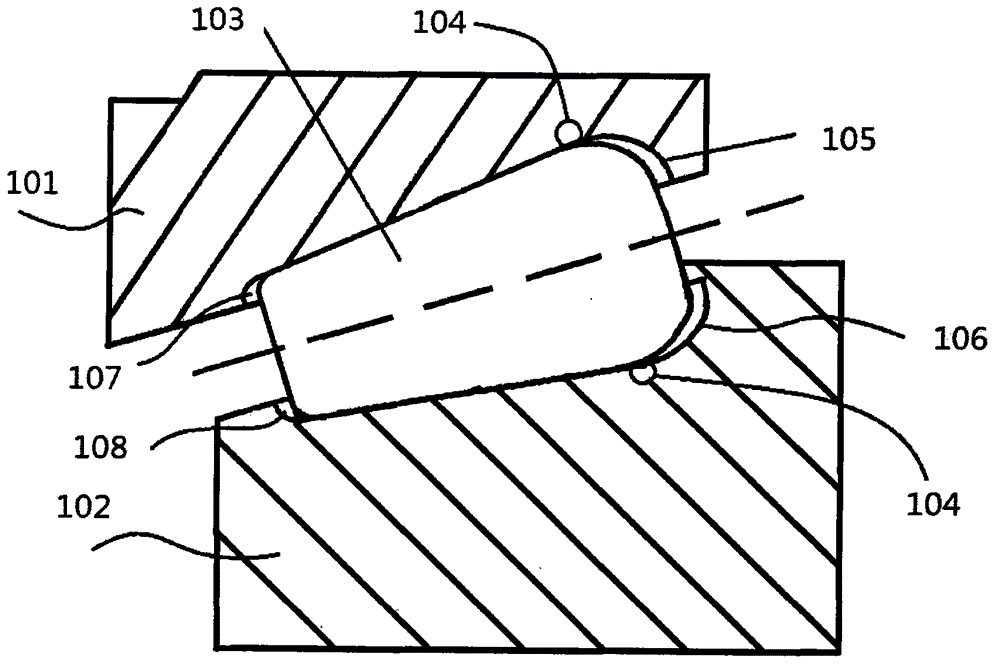

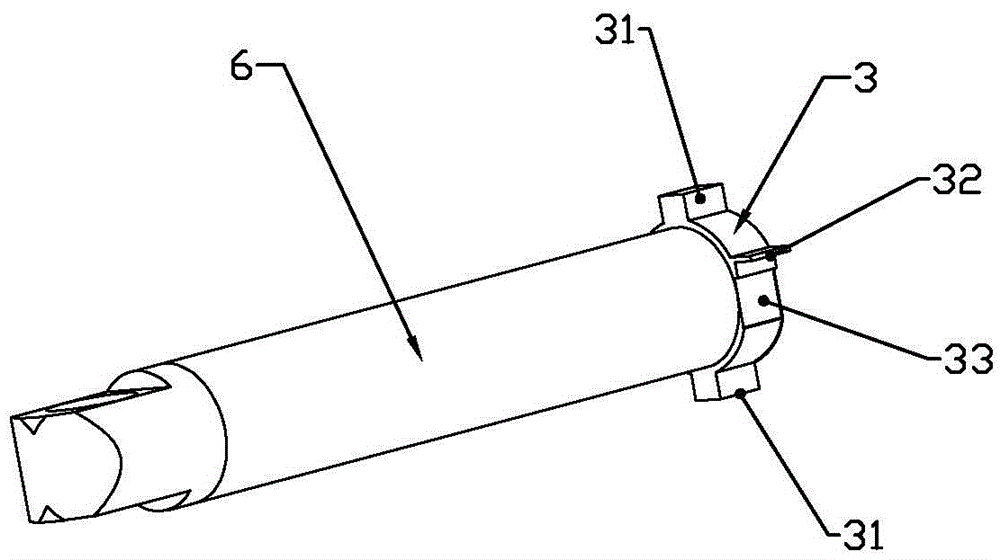

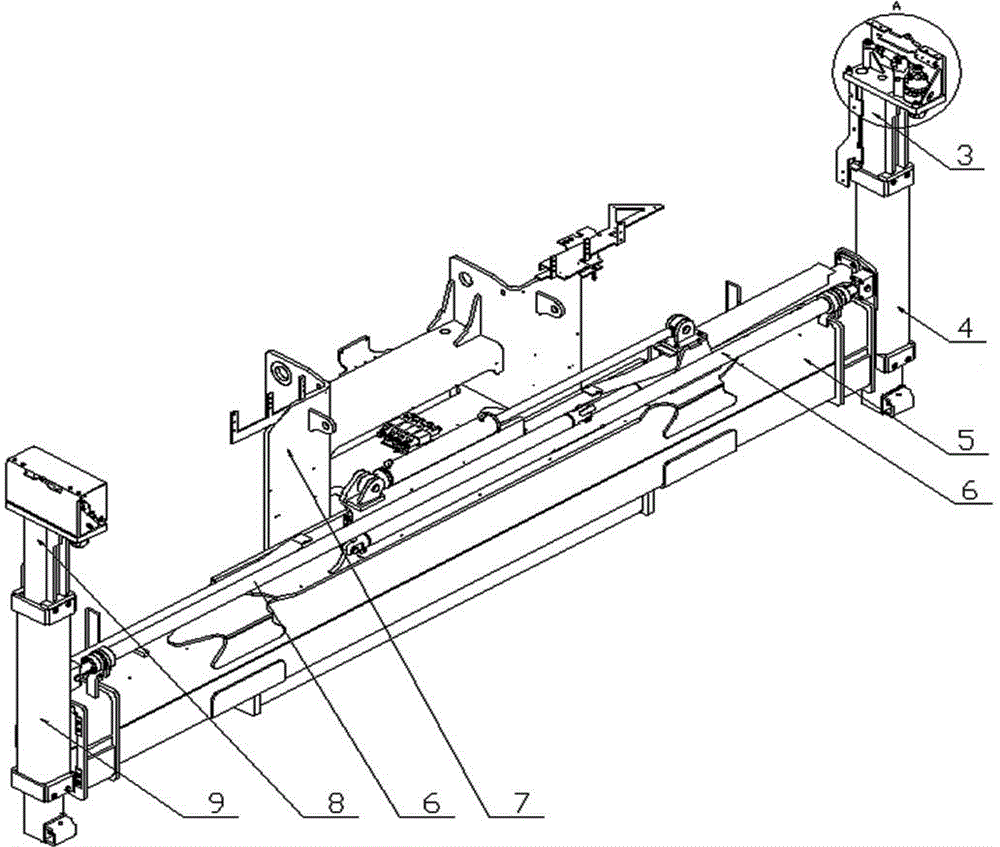

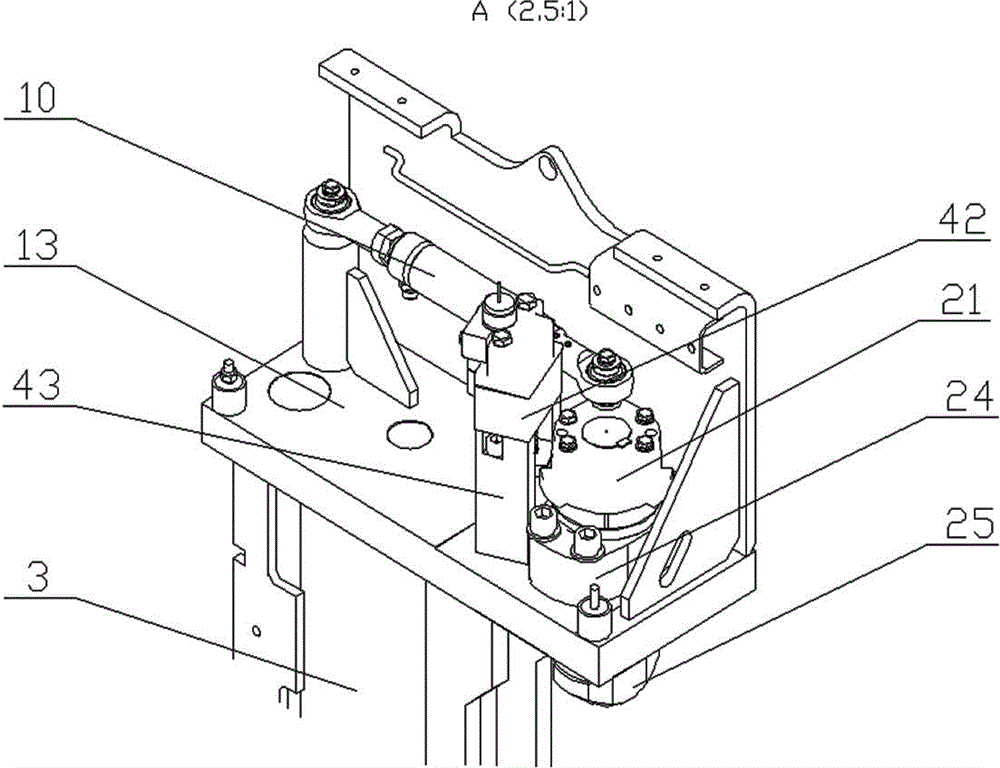

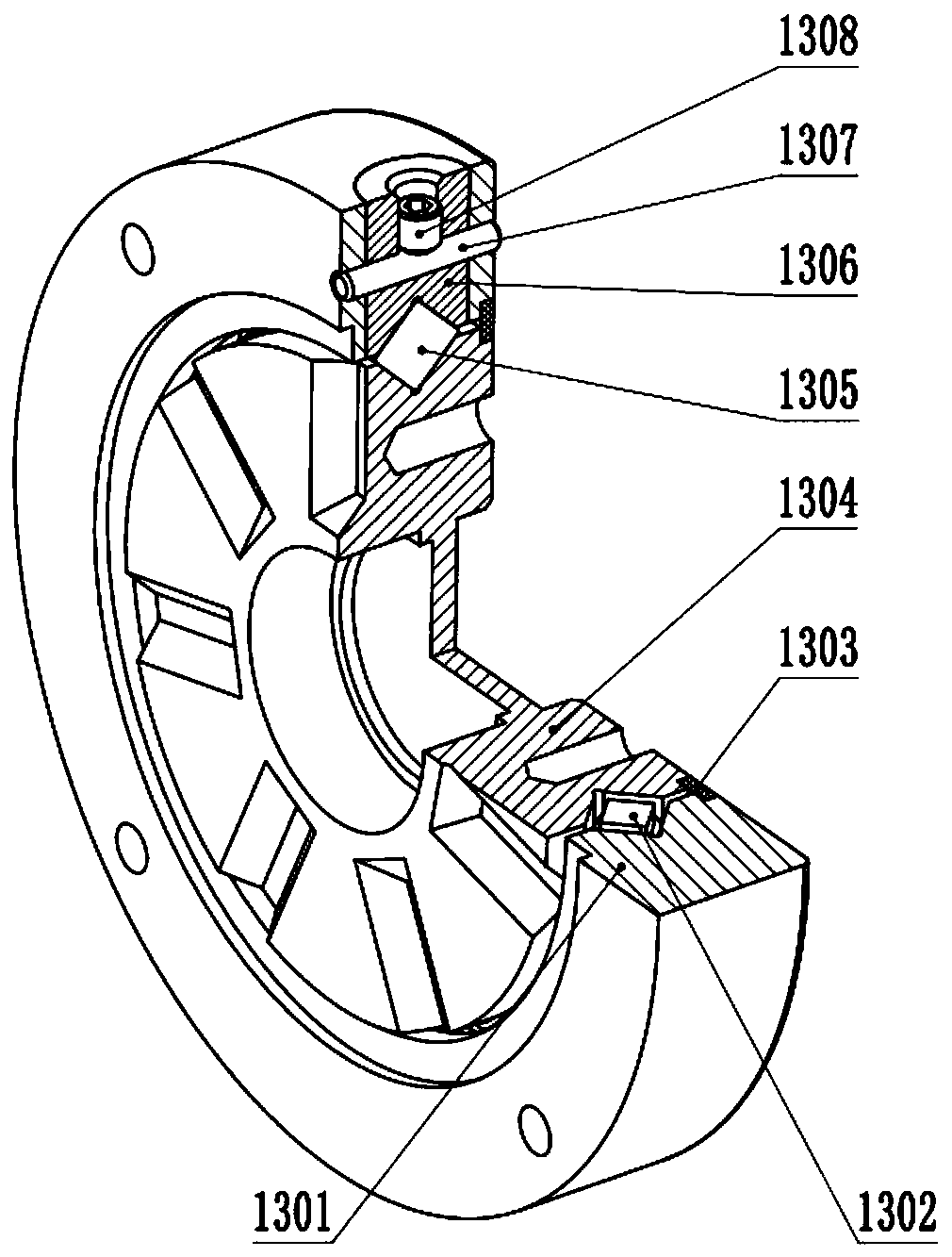

PDM (positive displacement motor) drilling tool for well drilling

InactiveCN104675324AImprove axial load capacityHighly corrosiveMagnetic circuit stationary partsBearing componentsDrive shaftWell drilling

The invention relates to a PDM (positive displacement motor) drilling tool for well drilling, comprising a bypass valve assembly, a motor assembly, a universal shaft assembly and a driving shaft assembly, wherein the driving shaft assembly comprises a driving shaft shell, a driving shaft and a whole floating type thrust bearing; the whole floating type thrust bearing comprises a bearing shell, a plurality of bearing moving rings and a plurality of bearing static rings; a shaft sleeve is arranged between every two bearing moving rings; the bearing moving rings and the bearing static rings are all fastened and sleeve the driving shaft; two bearing static rings sleeve each shaft sleeve at intervals; an annular flange is formed on the inner wall of the bearing shell positioned between every two bearing static rings; a shock-absorption energy storage body is respectively arranged between the annular flange and every two bearing static rings; a plurality of long slots are formed in the lateral wall of each bearing static ring along the axial direction of the bearing shell; a bolt is connected with the position, corresponding to each long slot, of the bearing shell; the end part of each bolt extends into the corresponding long slot; each bearing static ring is matched with the corresponding bearing moving ring through two diamond compacts; one diamond compact is arranged on the corresponding bearing static ring; the other diamond compact is arranged on the corresponding bearing moving ring.

Owner:CHINA NAT OFFSHORE OIL CORP +1

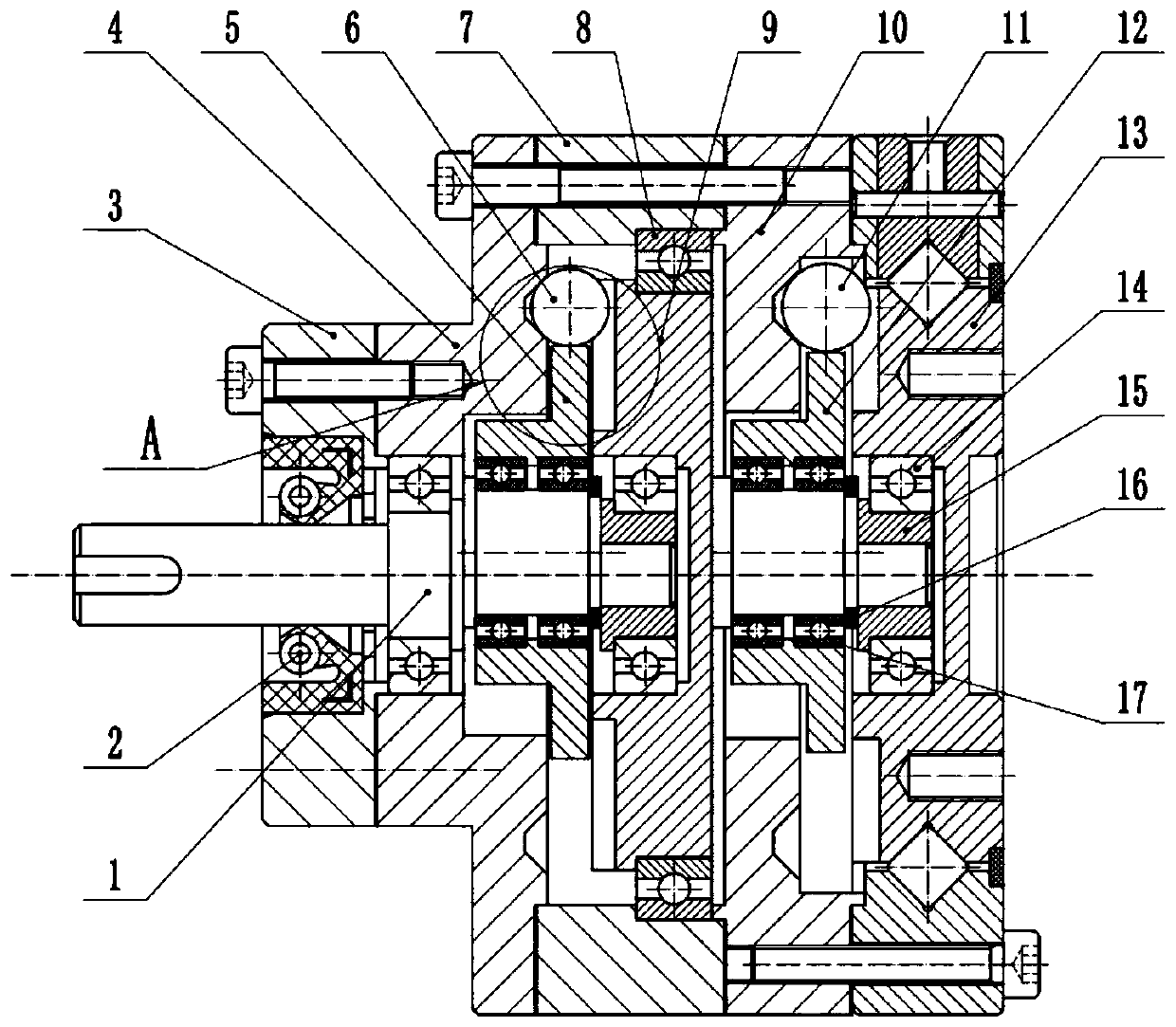

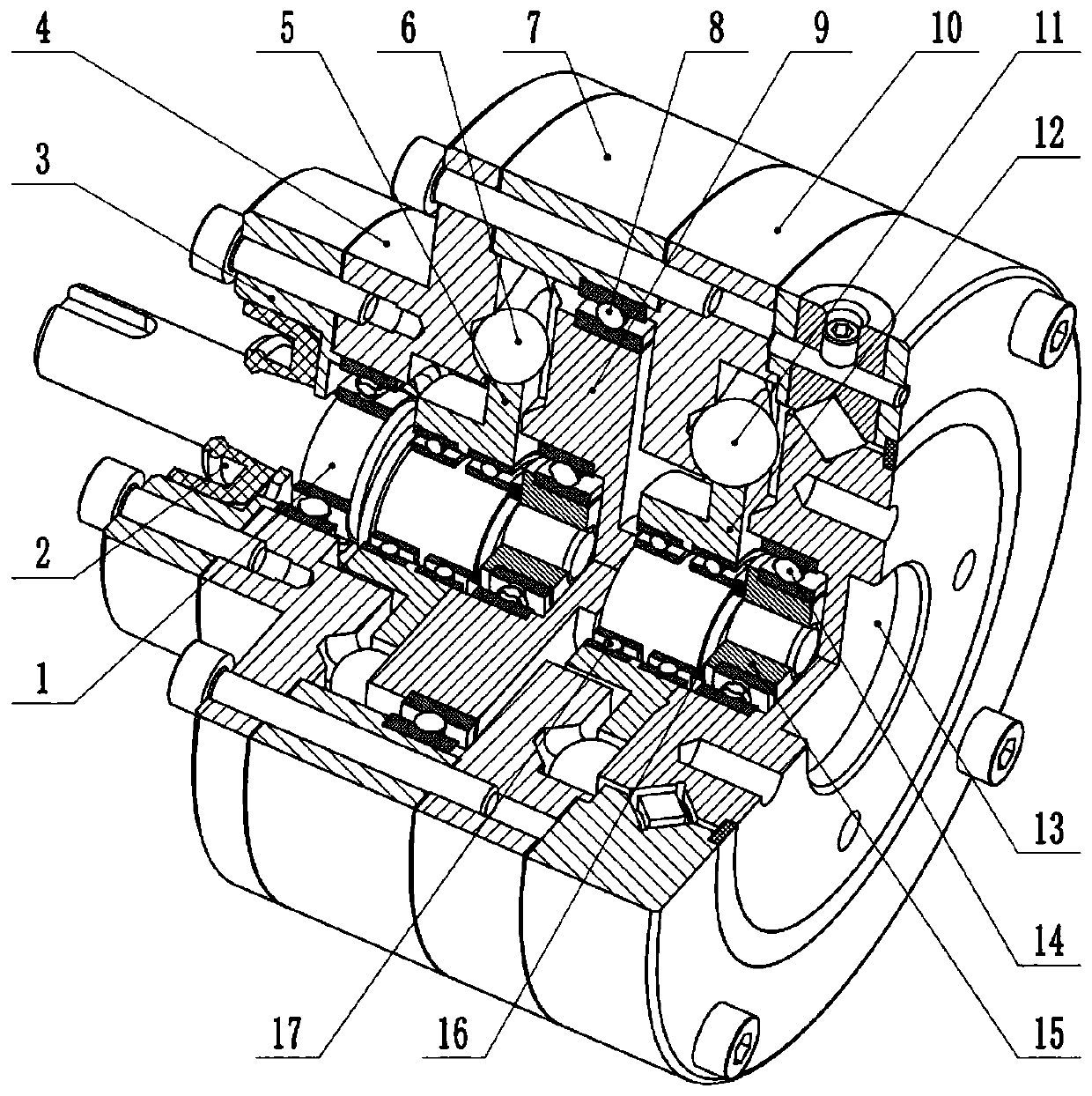

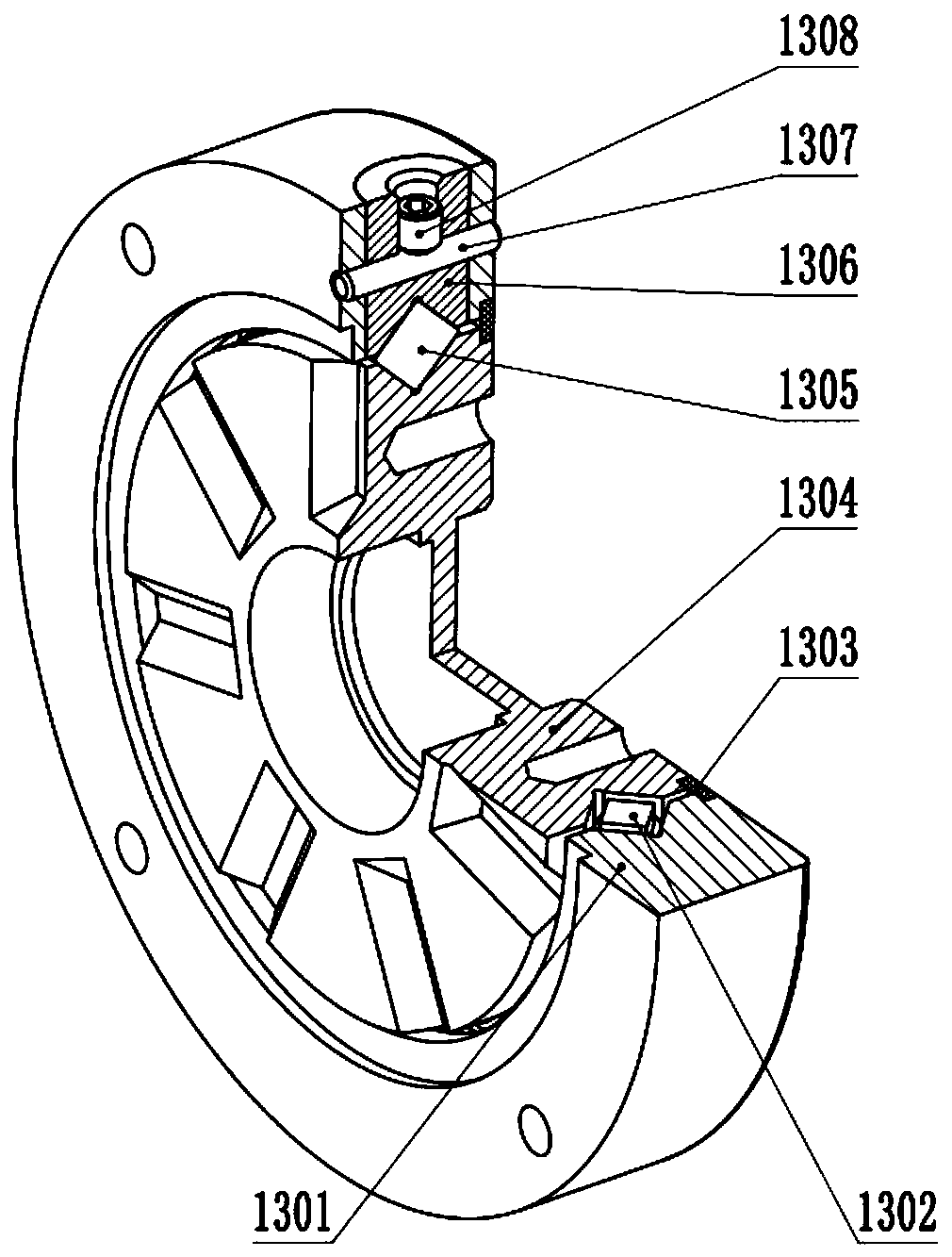

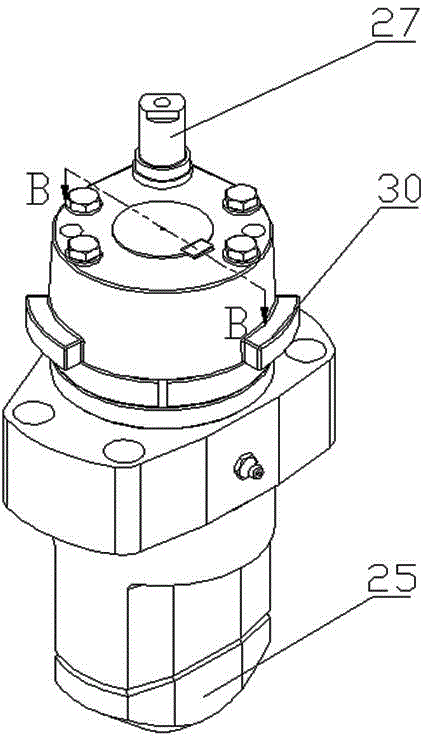

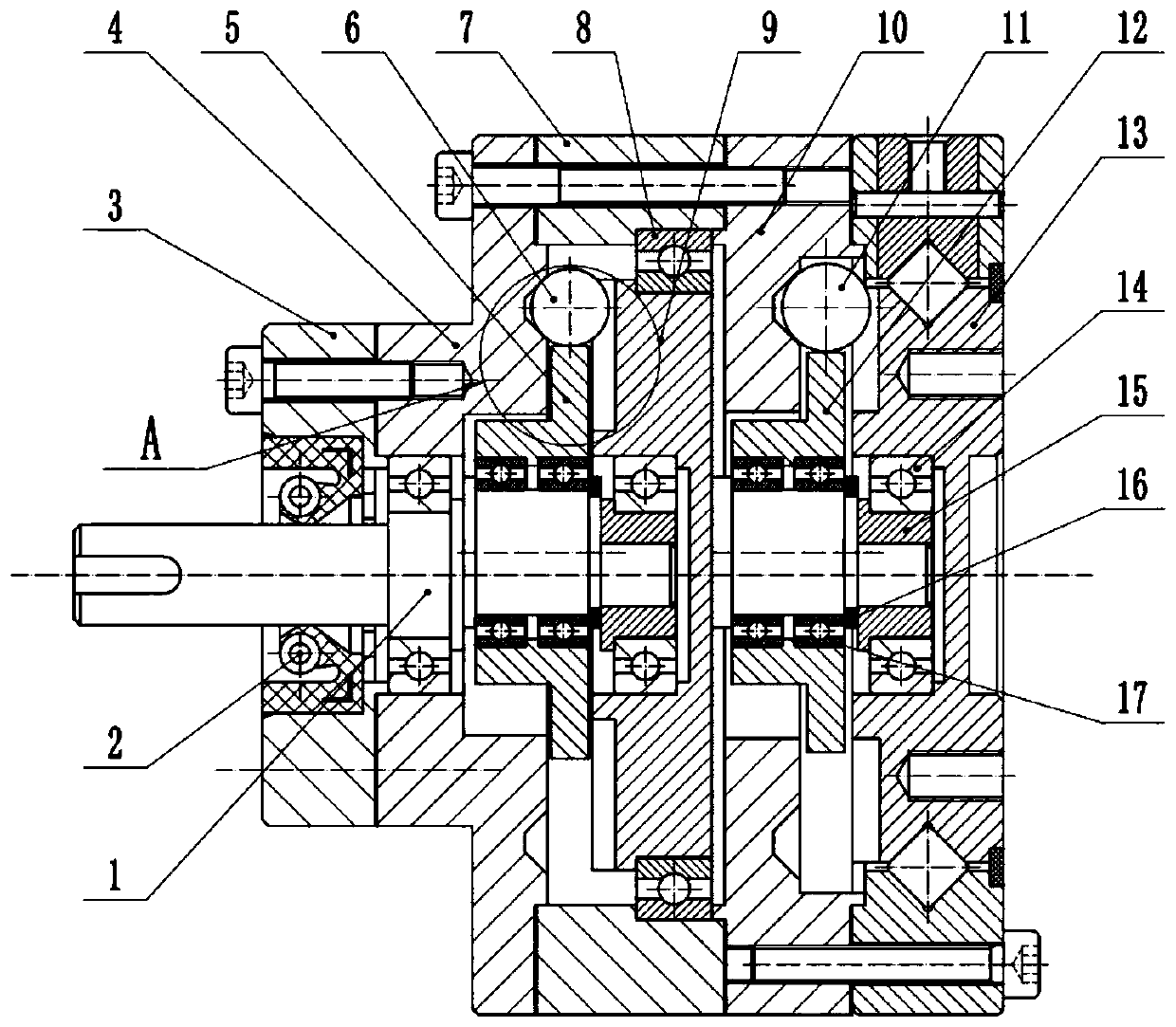

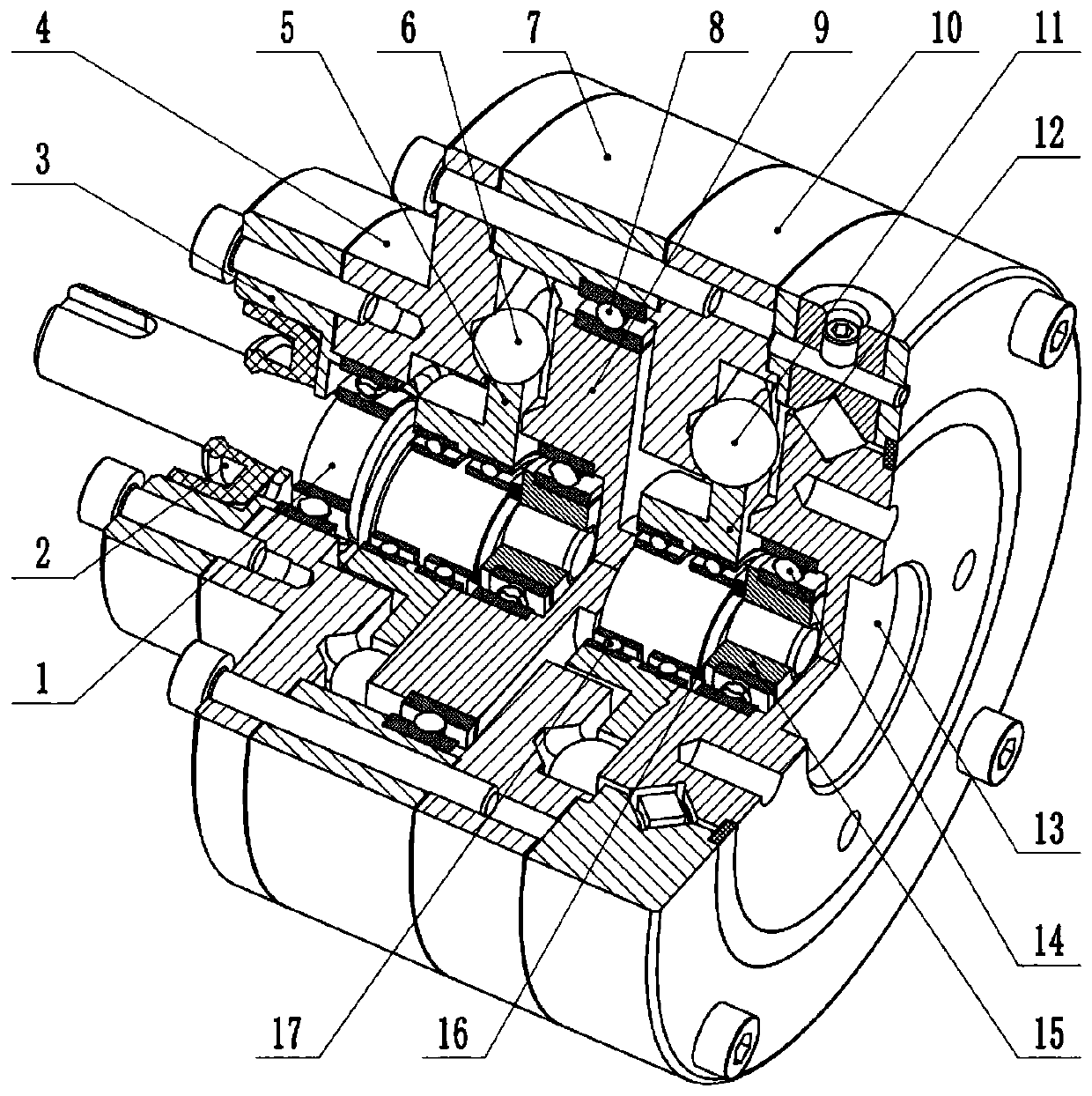

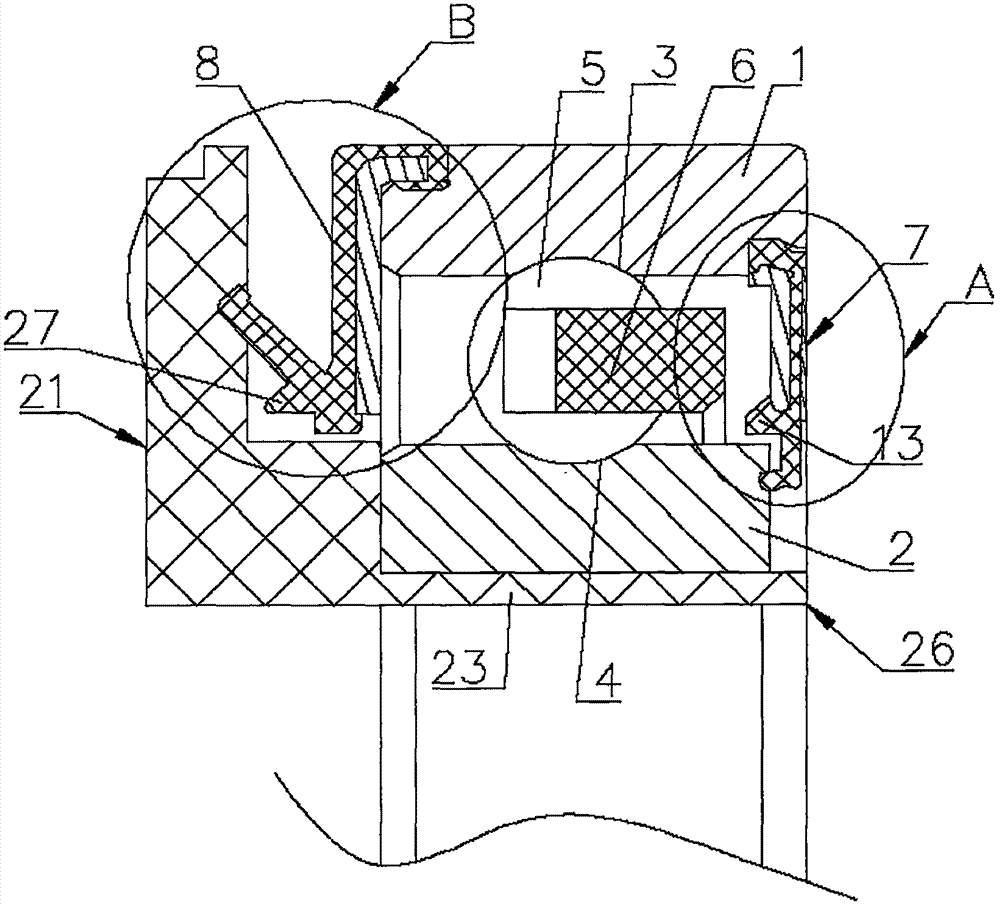

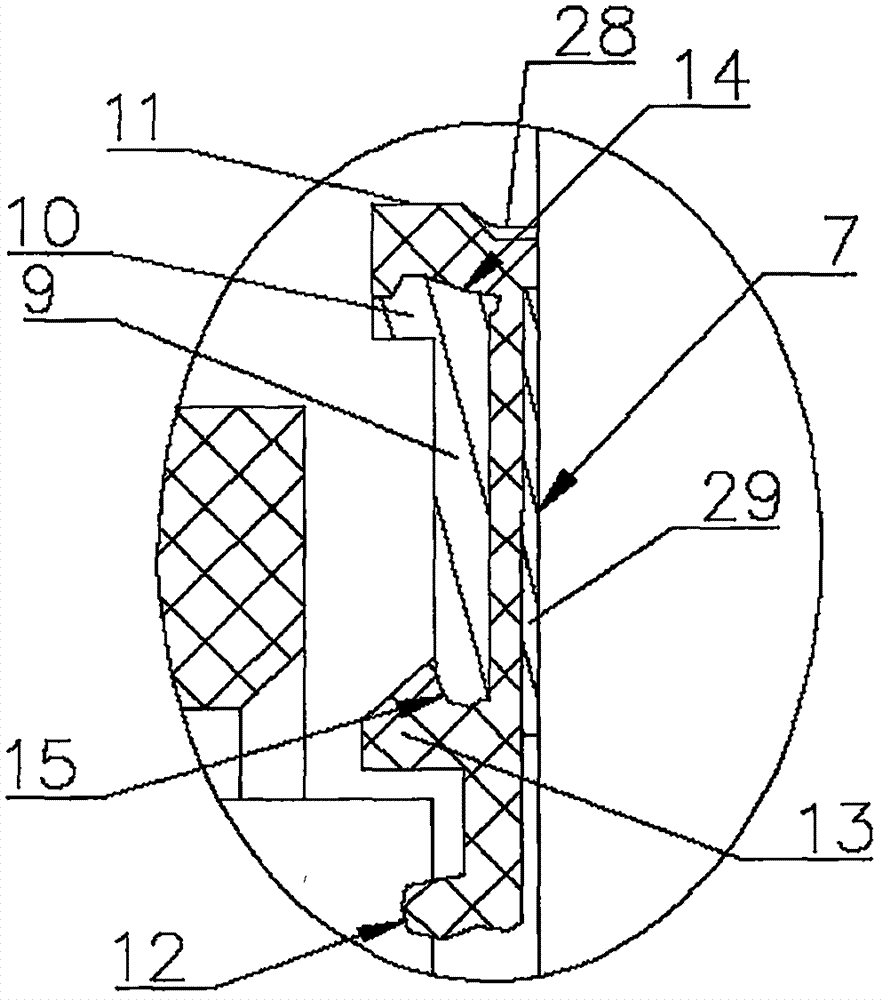

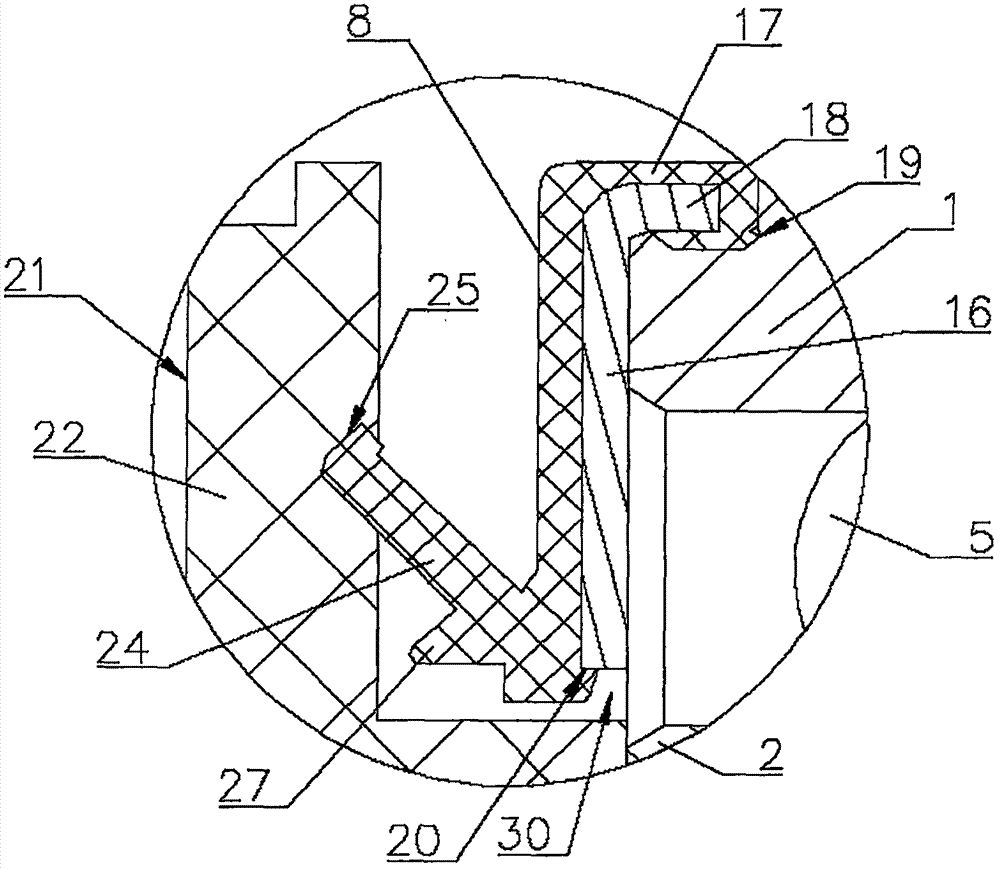

Cam shock wave type two-stage planar steel ball reducer

The invention provides a cam shock wave type double-stage planar steel ball reducer. The cam shock wave type double-stage planar steel ball reducer comprises an input shaft, a lip type sealing ring, aleft end cover, a first-stage center wheel, a first-stage shock wave cam, a first-stage steel ball, a shell, a first thin-wall bearing, a first-stage guide frame, a second-stage center wheel, a second-stage steel ball, a second-stage shock wave cam, a cross roller bearing, a deep groove ball bearing, a sleeve cup, a check ring and a second thin-wall bearing. The first-stage shock wave cam and thesecond-stage shock wave cam are hinged to the corresponding shaft section through the second thin-wall bearing, the right side of the second thin-wall bearing is limited through the check ring, the left end cover is connected to the left end of the first-stage center wheel through screws, the right end of the first-stage center wheel and the shell are fixedly arranged at the left end of the second-stage center wheel through screws, and the cross roller bearing and the right end of the second-stage center wheel are fixedly connected. The cam shock wave type double-stage planar steel ball reducer has the advantages of being simple and compact in structure, high in transmission efficiency, wide in transmission ratio range, large in bearing capacity and the like, can be subjected to parameterization and serialized design and is suitable for wide application.

Owner:YANSHAN UNIV

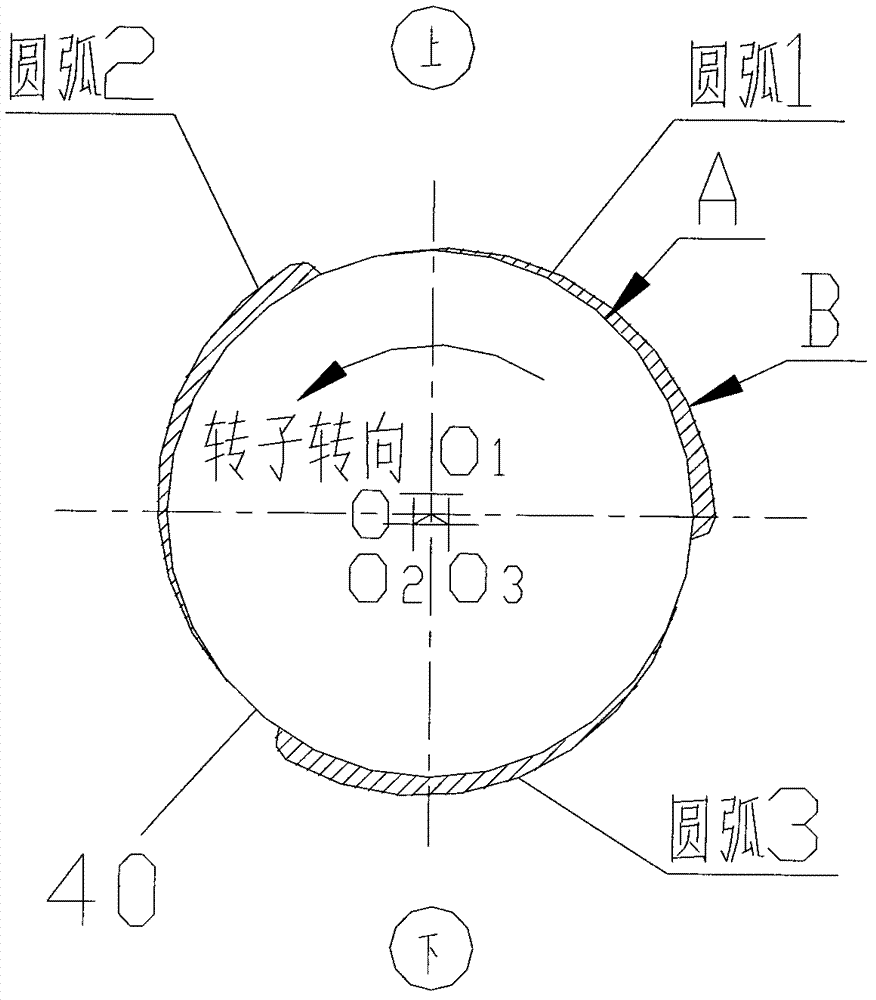

Dynamic pressure bearing, high-speed fluid power machinery and high-speed centrifugal compressor

InactiveCN103362949AImprove rigidityImprove stabilityPump componentsBearing componentsCarrying capacityEngineering

The invention discloses a centrifugal compressor. A rotating shaft of a motor stretches into a closed cavity of the compressor from a box body to be directly connected with an impeller, and a rotating shaft of the compressor is located in a shell through dual radial bearings. The dual radial bearings enable the rotating shaft to have the advantages of large rigidity, high carrying capacity, less deformation after carrying, stability in operation and the like. The dual radial bearings also adopt three special oil wedge slots to support the rotating shaft, so that the rotating shaft can operate stably in a high-speed rotating process.

Owner:GREE ELECTRIC APPLIANCES INC

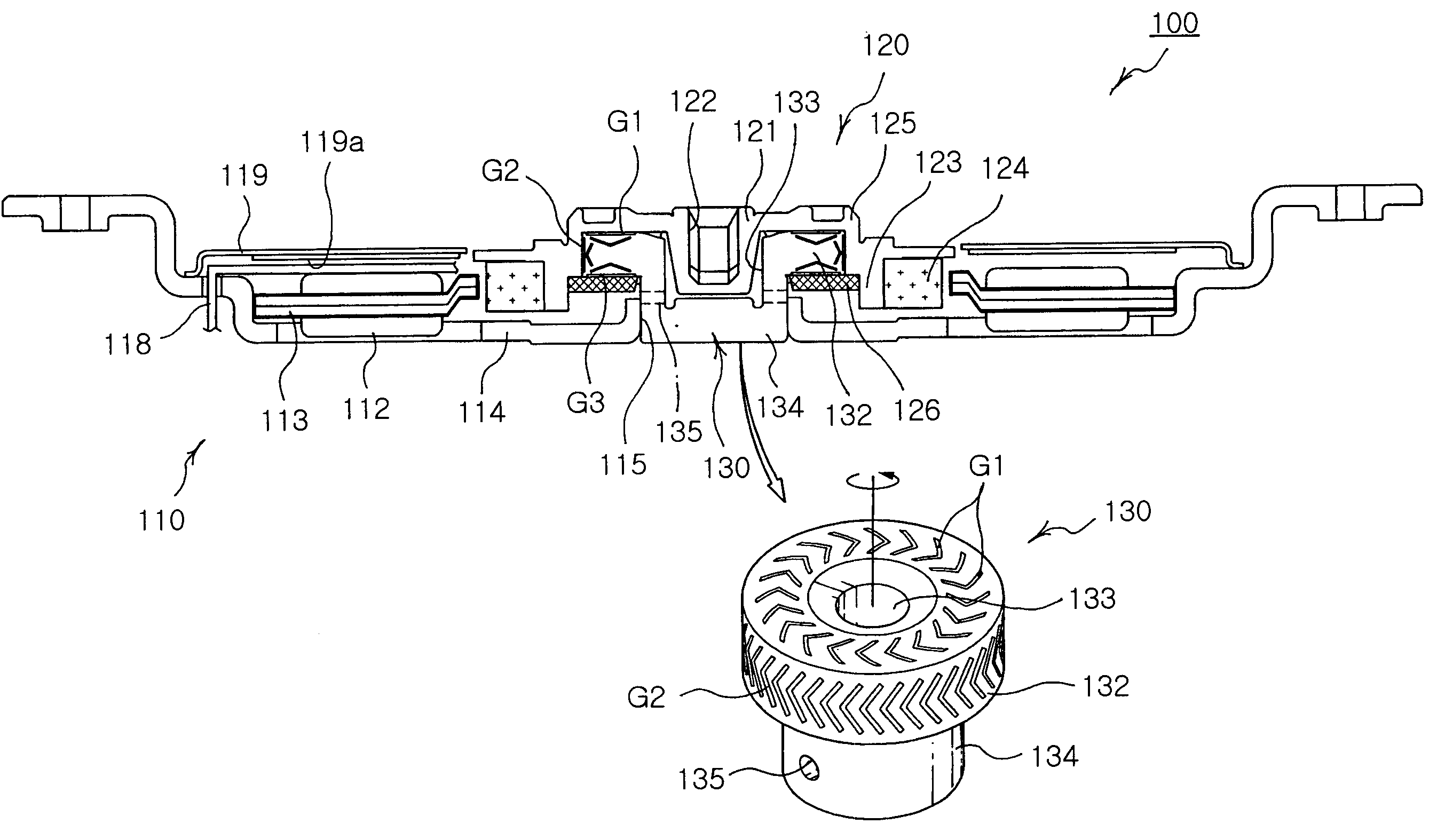

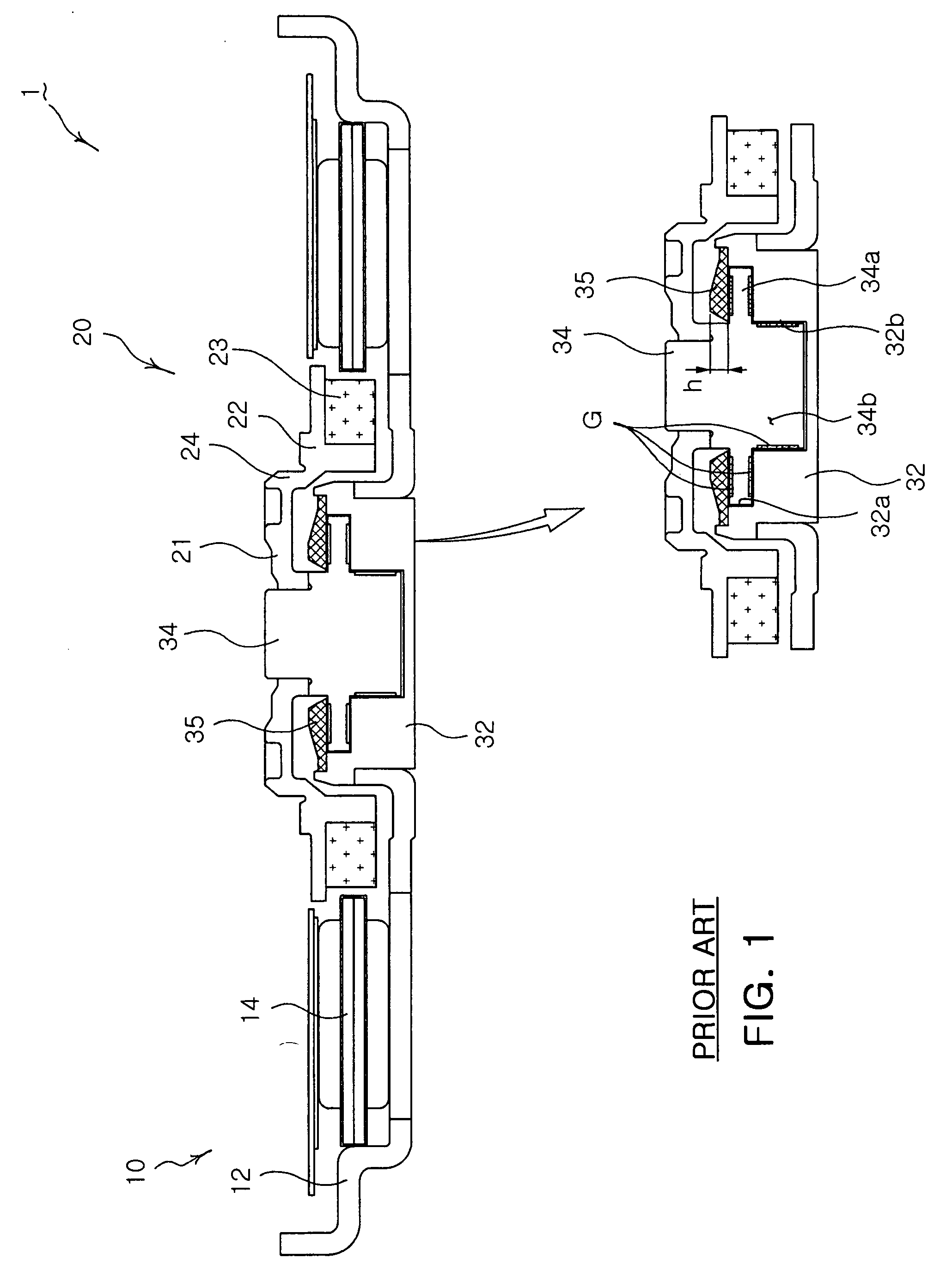

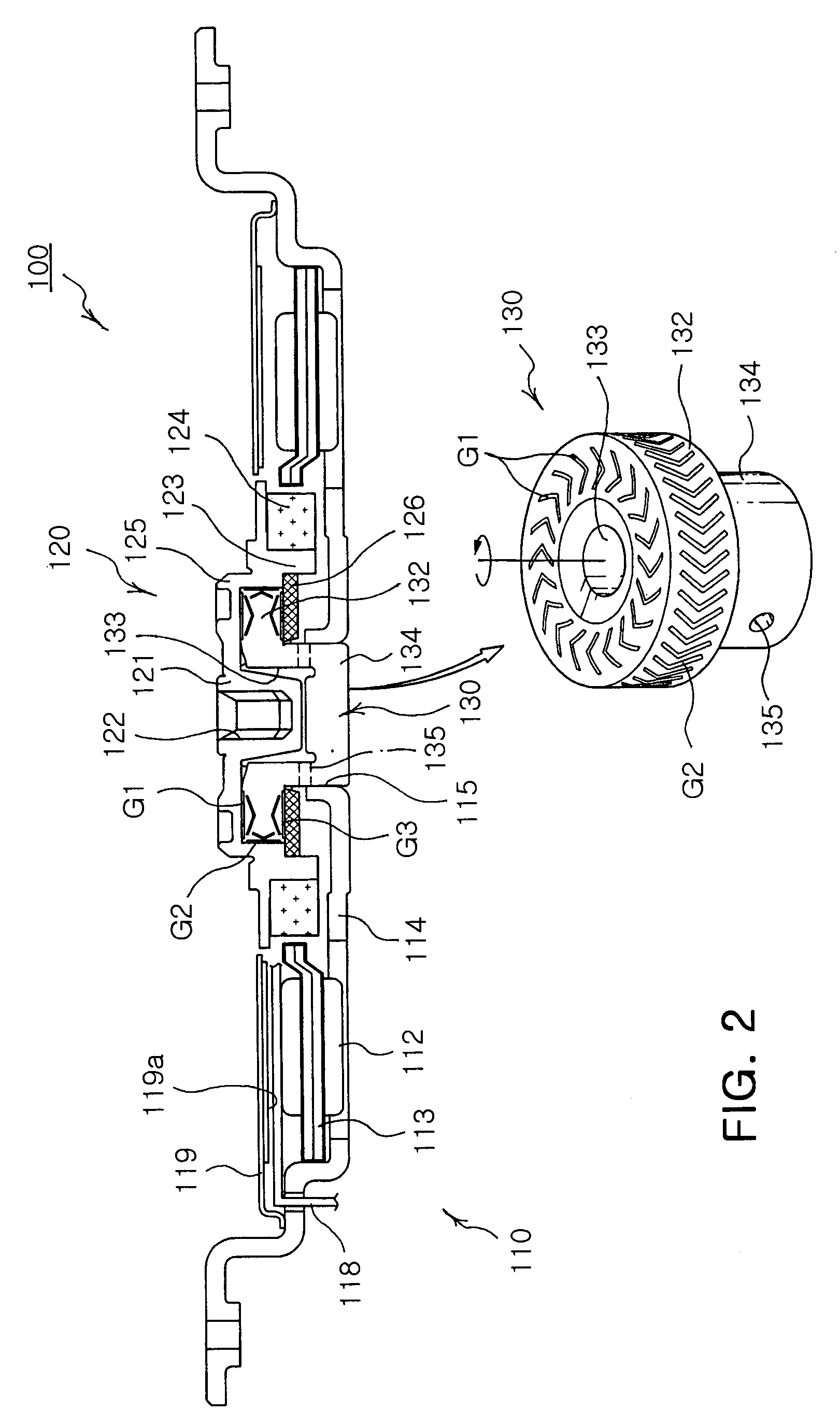

Hydrodynamic pressure bearing spindle motor

InactiveUS20060043808A1Improve axial load capacityReducing axial lossDriving/moving recording headsShaftsEngineeringDynamic pressure

A spindle motor, having a hydrodynamic pressure bearing, including: a stator including a core, on which at least one winding coil is wound, and a base provided with a central hole formed through the central area of the main body thereof so that the core is placed on the upper surface thereof; a rotor including a hub having a magnet formed on the outer circumference thereof to correspond to the winding coil leaving a designated interval with the winding coil, and a stop ring installed on the inner circumference of the hub; and a sleeve, for supporting the rotation of the rotor, including at least one dynamic pressure generating groove formed on the outer surface thereof correspondingly contacting the inner circumference of the hub and the stop ring, and a hub receiving hole formed through the central area of the main body thereof assembled with the central hole of the base.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

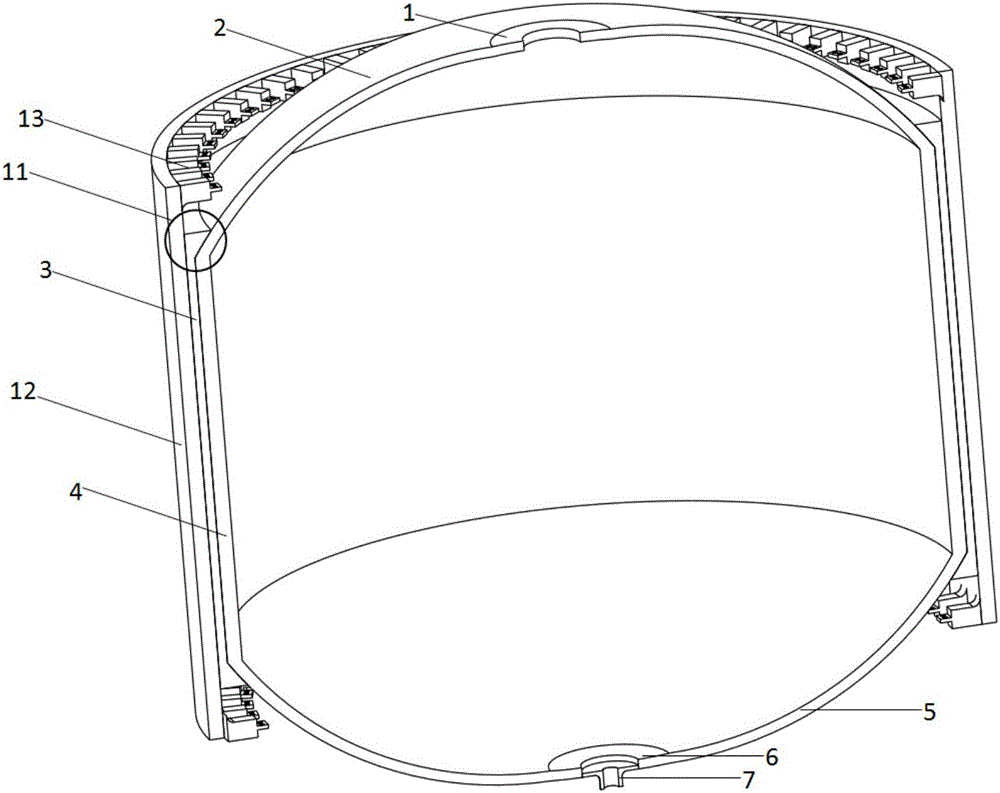

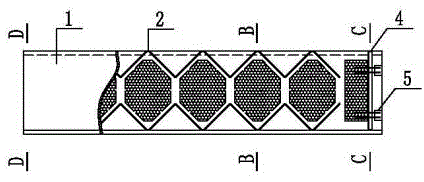

Carrier rocket composite storage tank provided with honeycomb sandwich walls and machining method thereof

ActiveCN106542123AIncreased shear strengthImprove sealingCosmonautic vehiclesCosmonautic propulsion system apparatusHoneycombRocket

The invention provides a carrier rocket composite storage tank provided with honeycomb sandwich walls. The carrier rocket composite storage tank comprises a front bottom cover, a front end socket, a tank cylinder section inner wall, a tank cylinder section outer wall, a back end socket, a back bottom cover and a back bottom pool shell. The front bottom cover is connected with the front end socket. The back end socket is connected with the back bottom cover. The front end socket and the back end socket are fixed to the upper end and the lower end of the tank cylinder section correspondingly through adhesive layers. The back bottom cover is in bolt connection with the back bottom pool shell. The carrier rocket composite storage tank is characterized in that the tank cylinder section outer wall is connected with the front end socket, the back end socket and the tank cylinder section inner wall in a honeycomb manner. The invention further discloses a machining method of the carrier rocket composite storage tank provided with the honeycomb sandwich walls. According to the machining method of the carrier rocket composite storage tank provided with the honeycomb sandwich walls, the integral forming technology comprising filament winding forming, filament placement forming and cementing co-curing is adopted. According to the carrier rocket composite storage tank provided with the honeycomb sandwich walls, because the honeycomb sandwich structure is additionally arranged at the connection portions between the storage tank end socket section, the tank cylinder section inner wall and the tank cylinder section outer wall, so that the shearing strength of the carrier rocket composite storage tank provided with the honeycomb sandwich walls is improved, and the overall axle load bearing capacity of the storage tank structure is improved; and the carrier rocket composite storage tank provided with the honeycomb sandwich walls is manufactured through the forming technology comprising winding, placement and cementing co-curing, and the effects of improving the seal performance, resisting seepage, lowering the structure assembly complexity, improving the production efficiency and the like are achieved.

Owner:DALIAN UNIV OF TECH

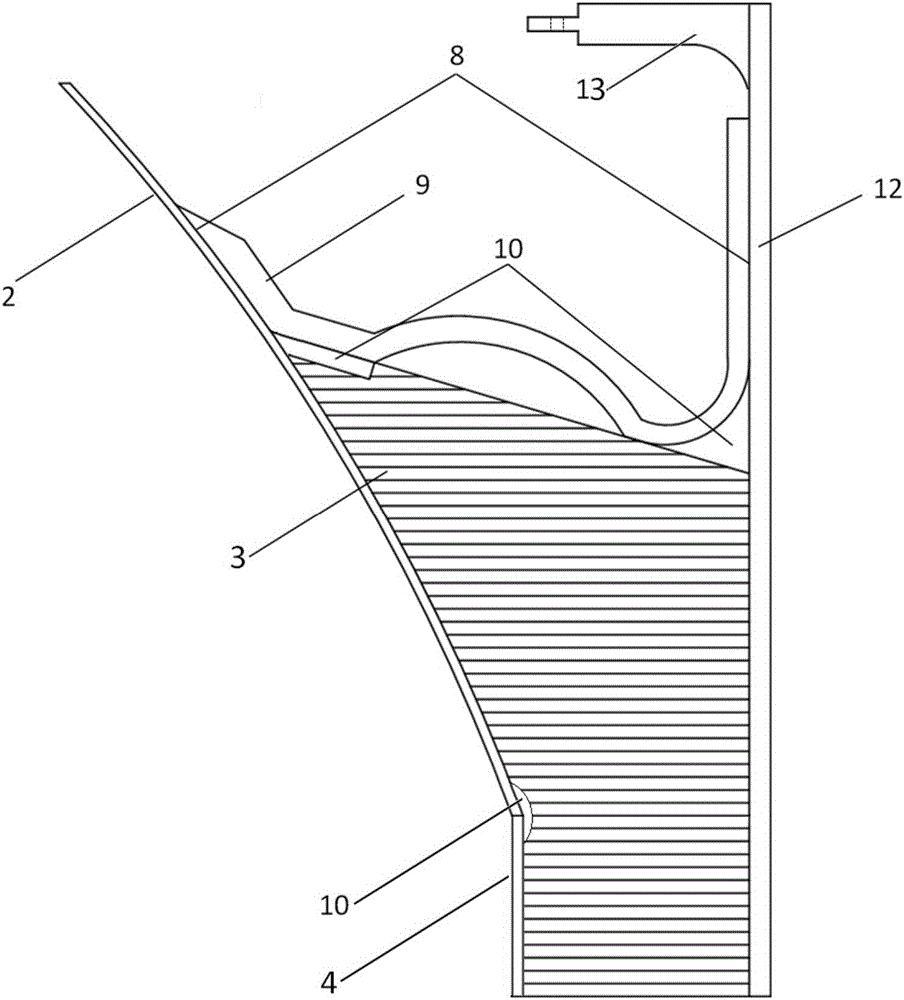

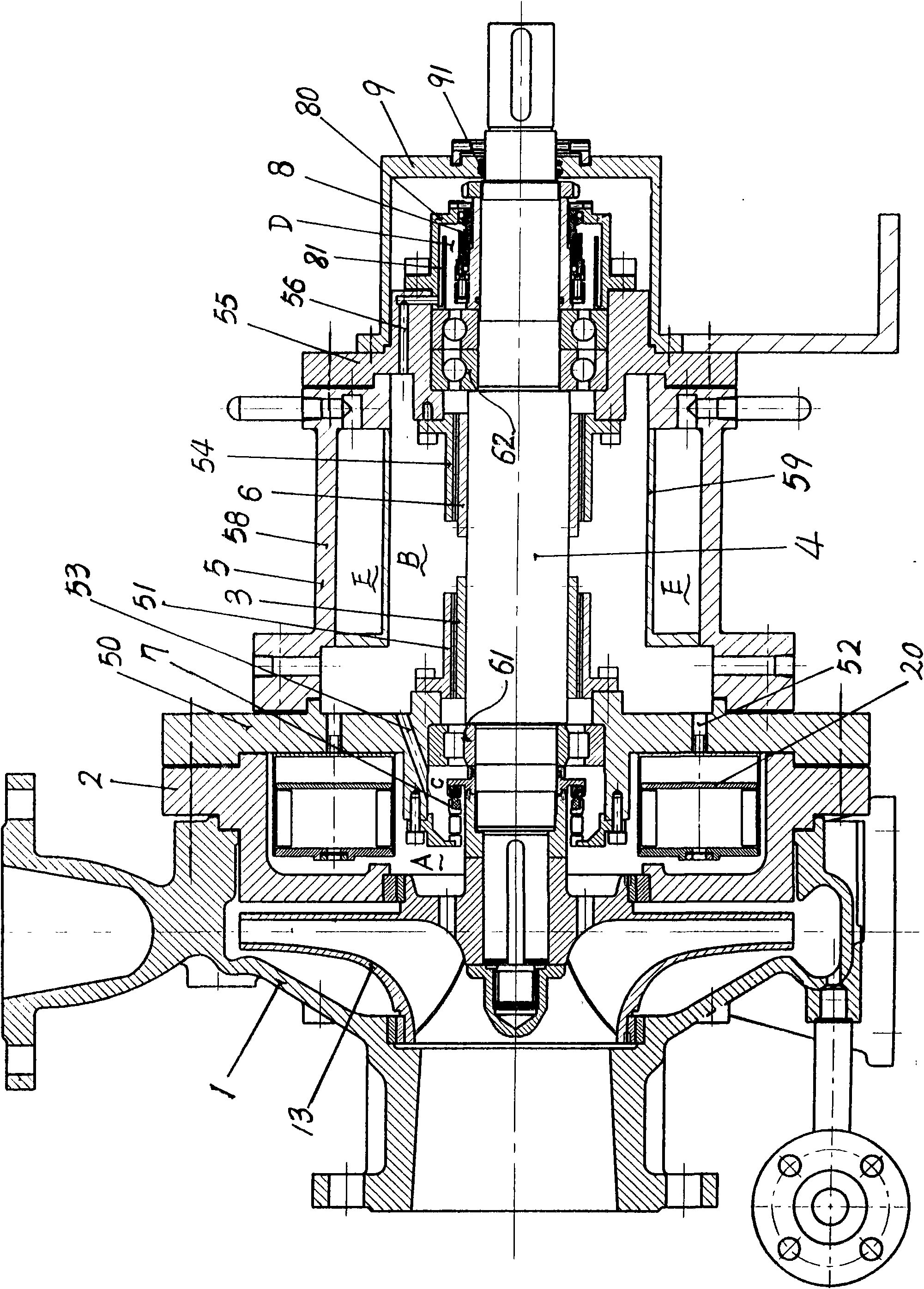

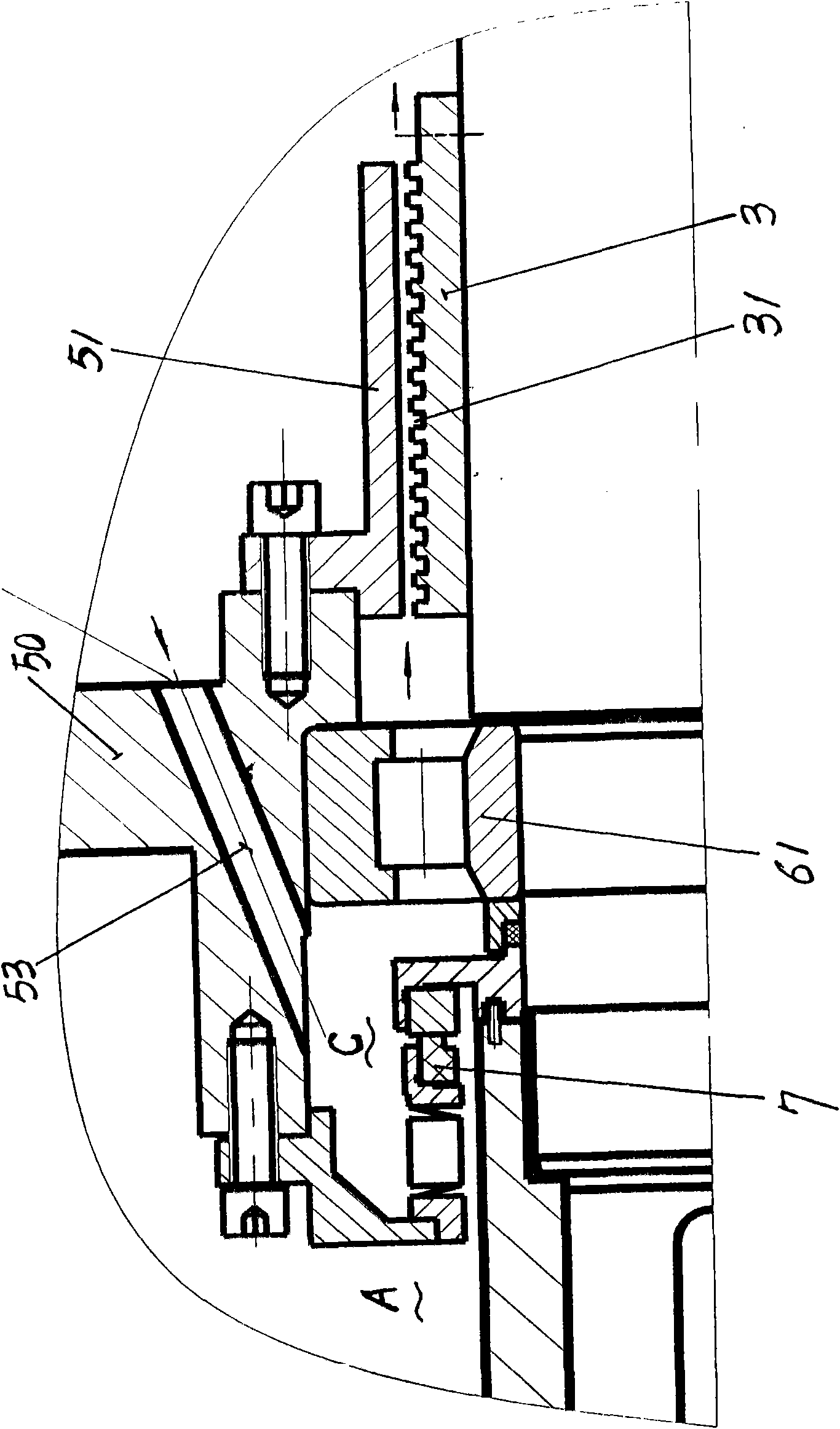

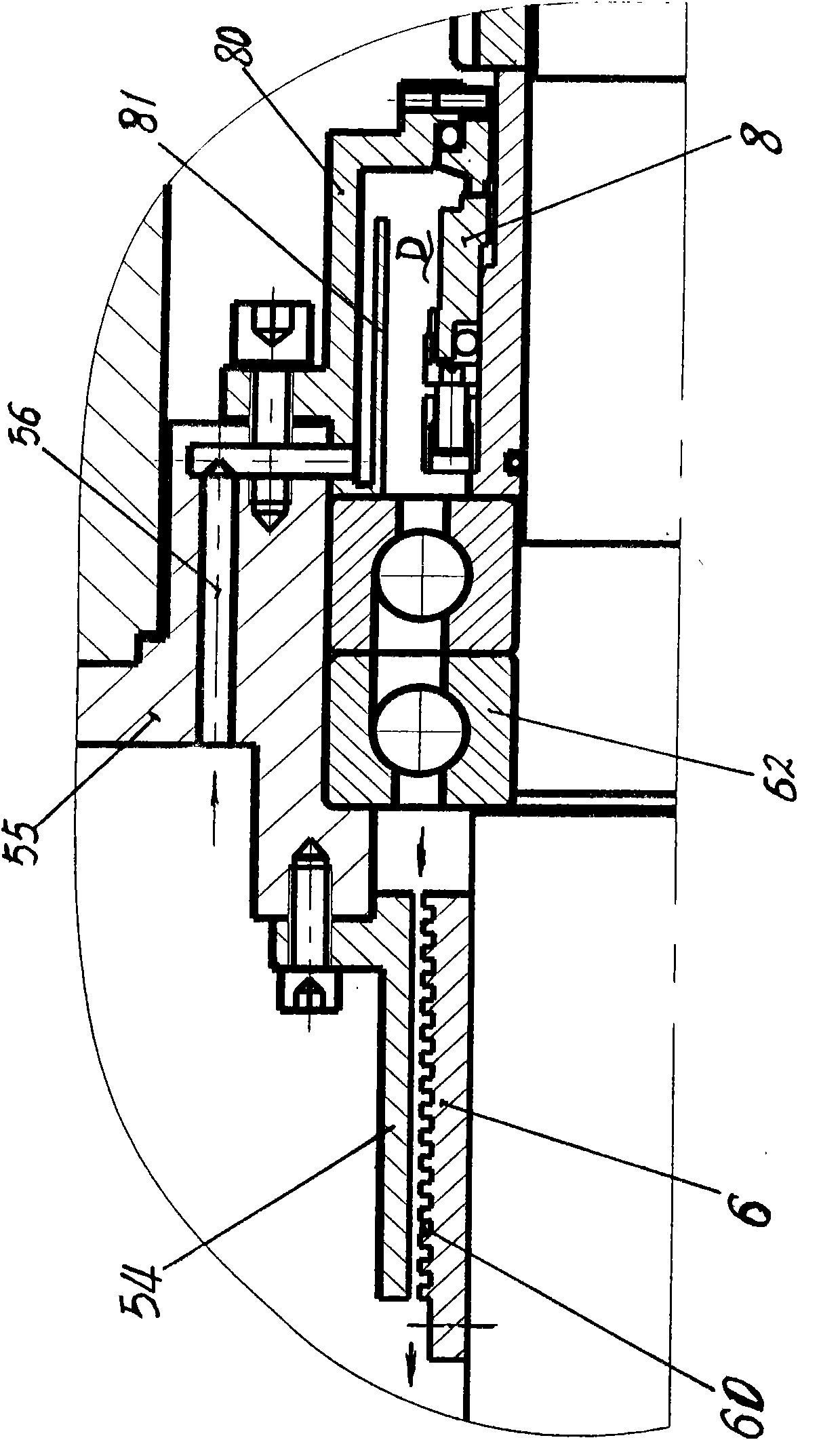

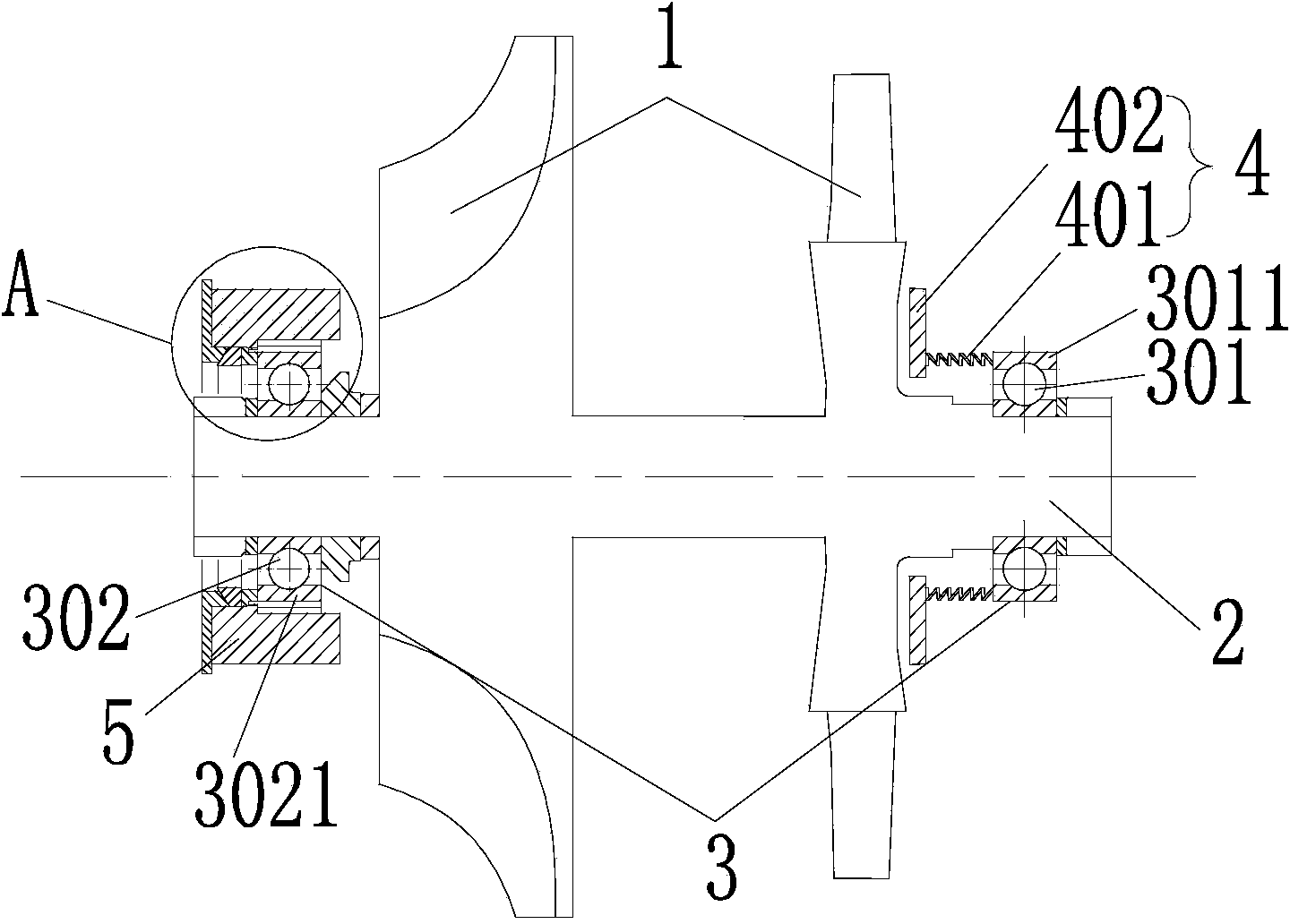

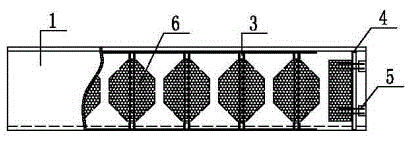

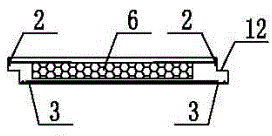

High performance mechanical canned motor pump

ActiveCN101566158AExtended service lifeImprove axial load capacityPump componentsRadial flow pumpsImpellerWorking pressure

The invention provides a high performance mechanical canned motor pump, which comprises a pump body (1), a pump cover (2), an impeller (13), a pump shaft (4), and a bearing box (5), and is characterized in that: a mechanical sealing device (7) is arranged between the front end of the bearing box (5) and an impeller hub or the pump shaft; a mechanical sealing device (8) is arranged between the rear end of the bearing box (5) and the pump shaft (4); a front end plate (50) of the bearing box (5) is provided with a pressure equalizer (20) to make the pressure of an inner cavity (B) of the bearing box and the inner cavity (A) of the pump cover (2) balanced; and screw pumping rings (3 and 6) and circumfluence holes (53 and 56) are arranged corresponding to the front and back mechanical sealing devices to fully cool and radiate the mechanical sealing devices and a rolling bearing. The high performance mechanical canned motor pump has the advantages of good leakproofness, long service life, safe and reliable use, good functionality and strong adaptive capacity, can be applicable to various working pressures, and fully meets the use requirement on places under working conditions such as high-pressure, toxic, flammable and explosive medium and the like.

Owner:DANDONG COLOSSUS GROUP

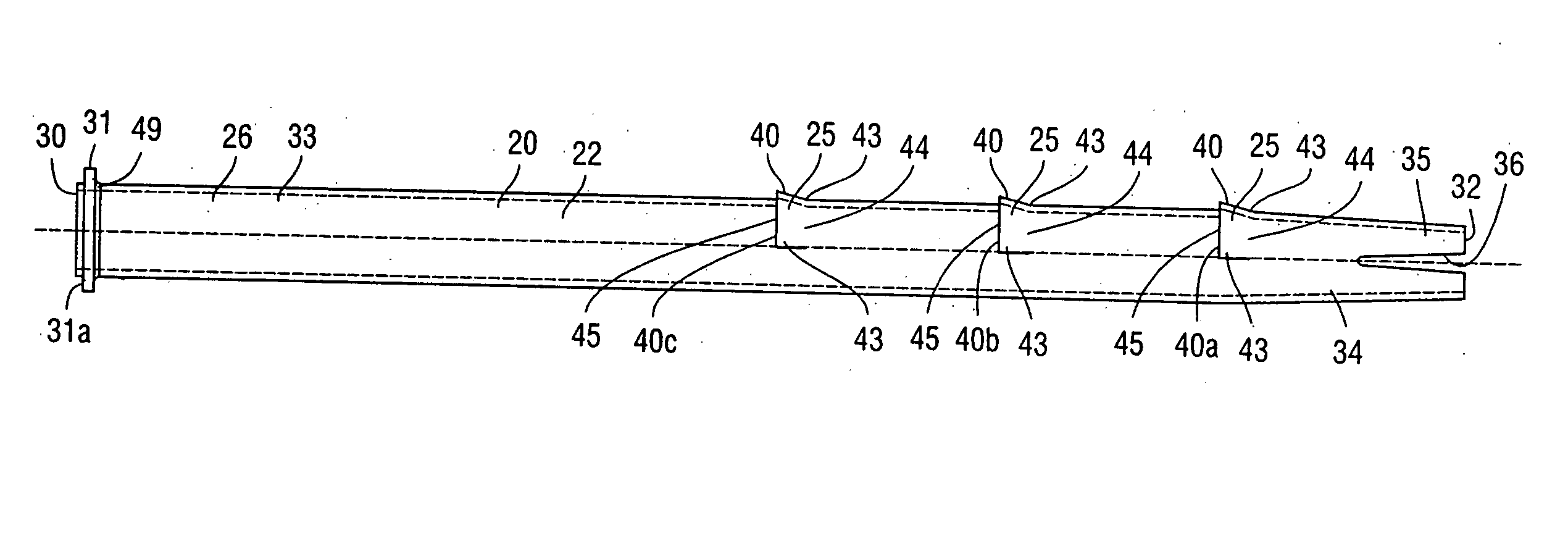

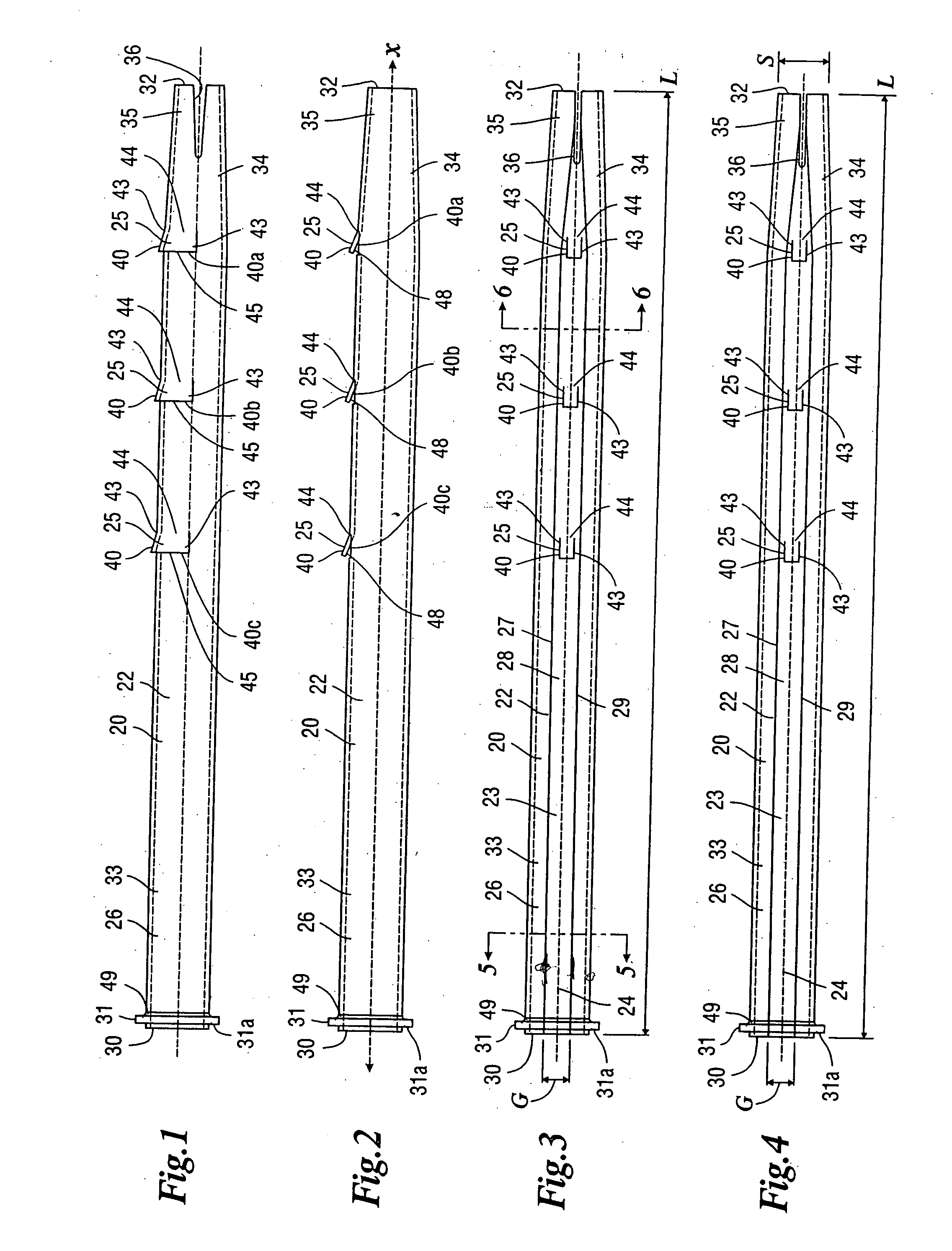

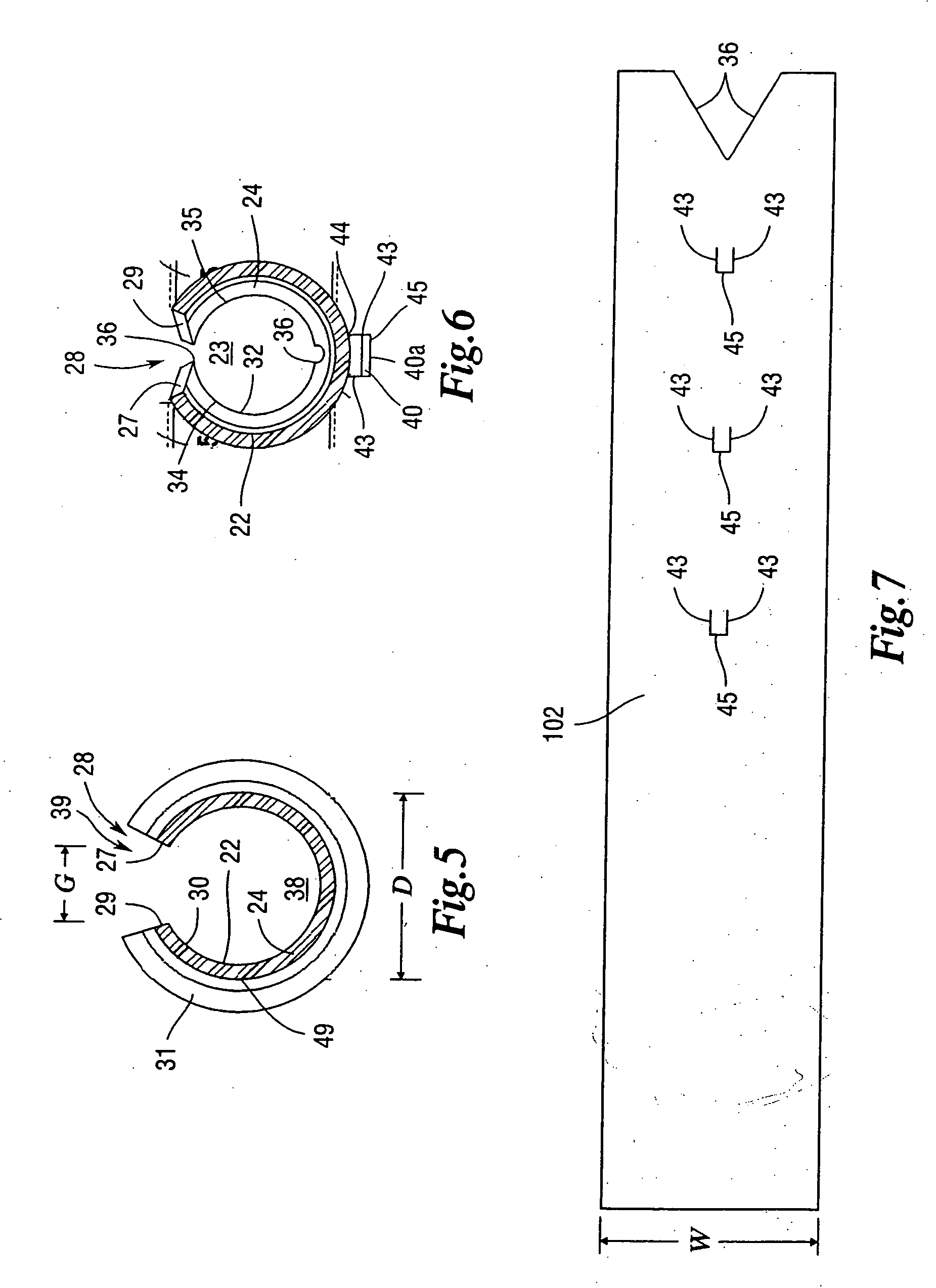

Friction stabilizer with tabs

InactiveUS20070196183A1Difficult to removeDecrease spaced distanceAnchoring boltsEngineeringSheet material

Owner:VALGORA GEORGE G

Structure-optimized long-life tapered roller bearings

ActiveCN102287450AImprove fatigue lifeImprove stress distributionRolling contact bearingsShaftsStress distributionEngineering

The invention relates to a structure-optimized long-life tapered roller bearing which comprises an outer ring, an inner ring, a roller and a cage. The structure-optimized long-life tapered roller bearing is characterized in that an inner ring roller path bus, an outer ring roller path bus and a roller bus are in the shape of mutually matched logarithmic curve convexity. According to the invention, the stress distribution between the roller and the contact surface formed by the inner ring roller path and the outer ring roller path can be improved, so that edge stress can be eliminated and fatigue life of the bearing can be improved. Besides, the large flange root width of the inner ring and the bearing contact angle can be increased, thus the axial bearing capacity can be improved and the problem that the bearing can be damaged in the high torque and high axial load working conditions can be solved, furthermore, the bearing provided by the invention can be applied to meet the requirement of the main teeth of a main reducing gear of an eight-ton truck drive axle.

Owner:FUJIAN YONGAN BEARING

Process for processing space ring of double-section drive axle for automobile

InactiveCN101700613AImprove machining accuracyExtended service lifeSolid state diffusion coatingFurnace typesEngineeringCorrosion resistant

The invention relates to a process for processing a space ring of a double-section drive axle for an automobile, comprising the following steps: the end surface and the excircle of a blank are roughly lathed with a lathe, and the end surface, the inner hole and the excircle of the blank are finely lathed; the processed work piece is quenched under high frequency, and the quenched work piece is loaded in a furnace so that the quenched work piece is glowed and compact and uniform corrosion-resistant white bright layer is formed on the surface of the glowed work piece; the excircle of the glowed work piece is firstly roughly ground and then finely ground with a grinder with the roughness of the work piece being controlled between Ra 0.3 and Ra 0.5 until the space ring is produced. The process can improve the processing precision of the space ring and the assembling precision of the space ring and an oil seal, further save the energy, enhance the work efficiency and facilitate the operation and is particularly suitable for deep hole and slit nitridation.

Owner:青岛元通汽车法兰有限公司

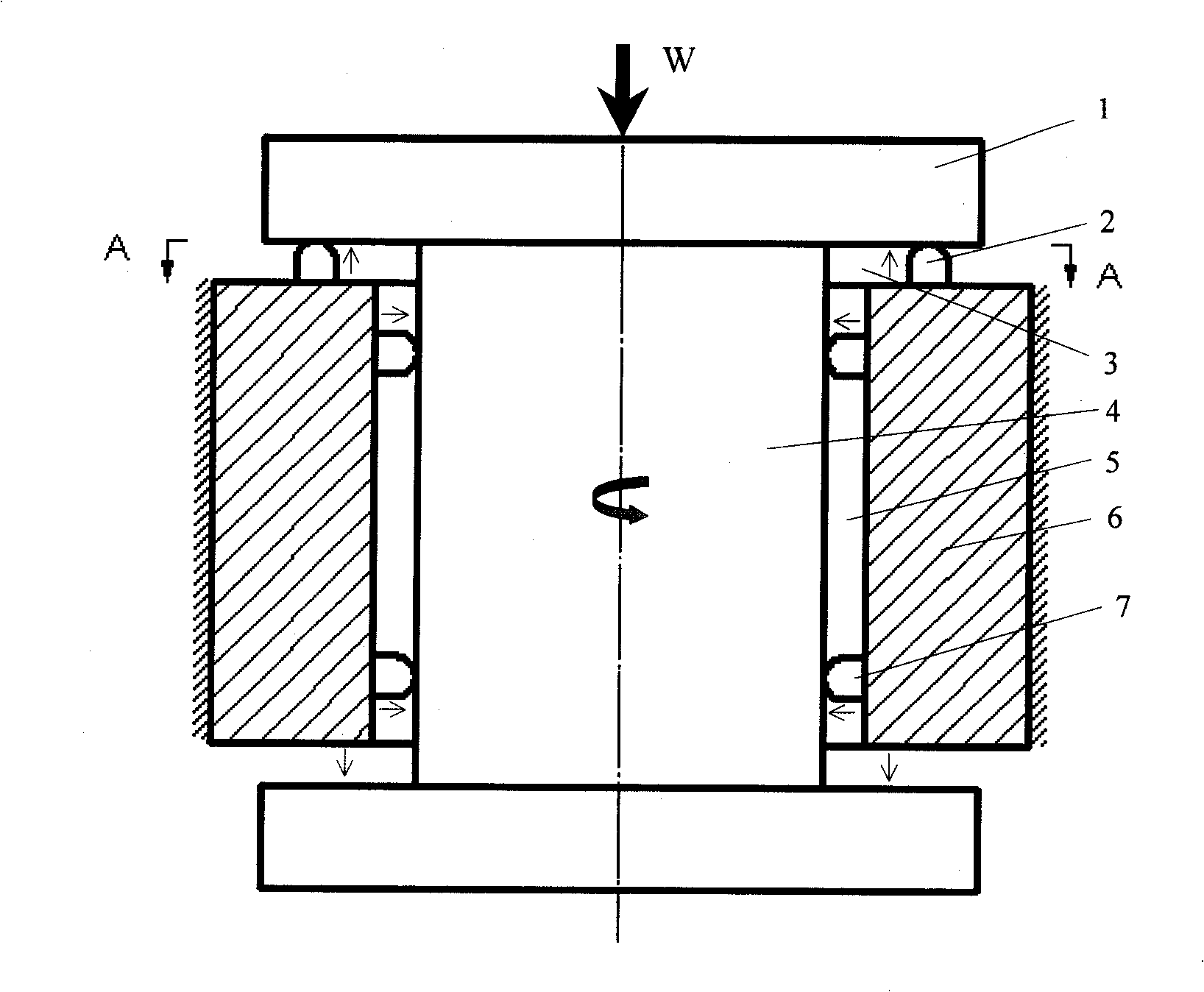

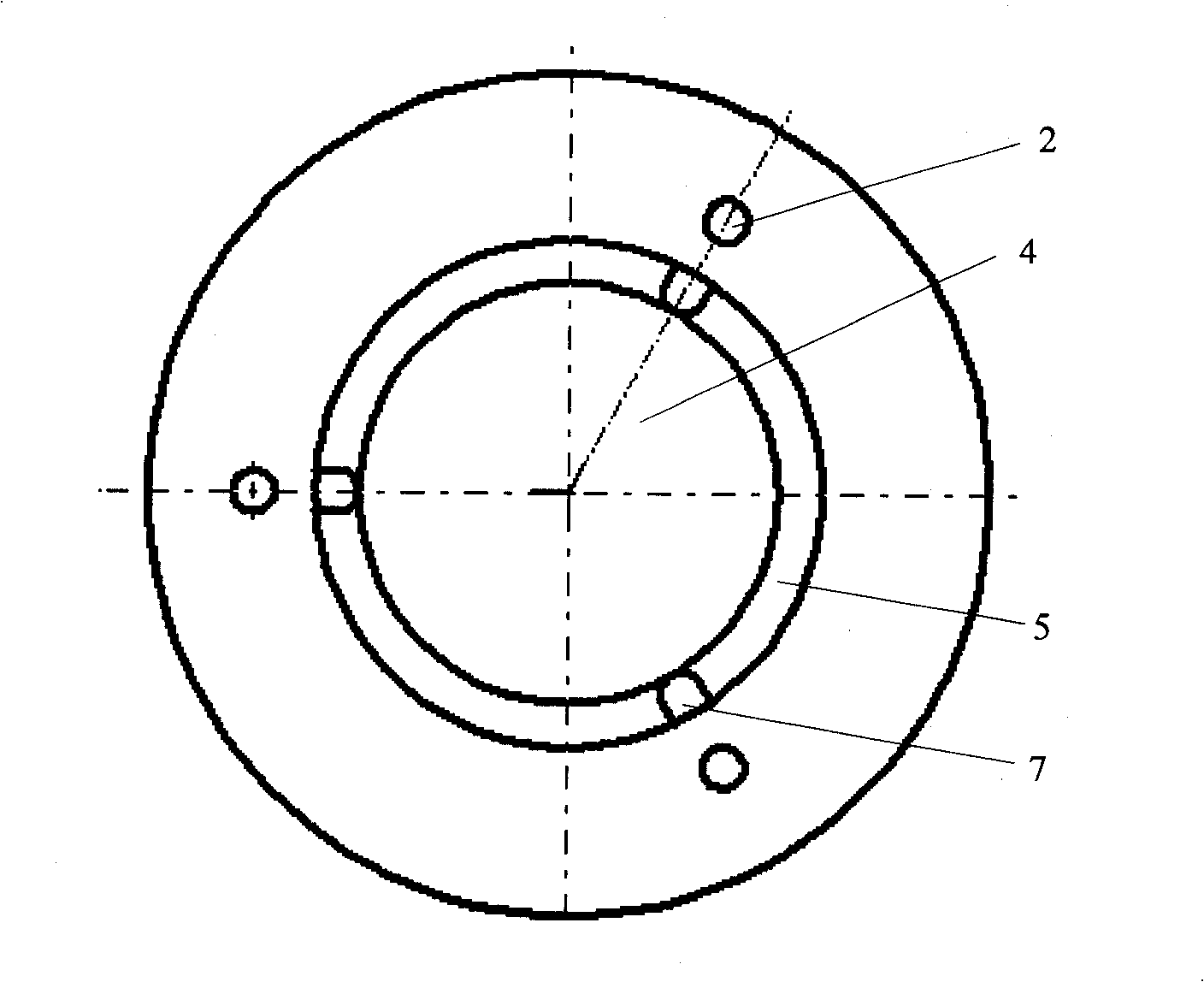

Gas/ solid two-phase composite gyration basic method and device

InactiveCN101338790AOvercome the shortcomings of not being able to take care of these features at the same timeImprove carrying capacityBearingsGas lubricationGas phase

The present invention relates to a gas phase / solid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas lubricating and error averaging technology and the solid supporting and damping technology, the method applies axial solid support in the axial anti-thrust gaseous film of a gas-floated shafting to form a composite supporting mode with the primary solid support and the subsidiary gas support or the primary gas support and the subsidiary solid support or the gas support and the solid support which are the equivalent in order to notably enhance the axial rigidity and bearing capacity of the gas-floated shafting. Applying radial solid support in the radial gaseous film of the gas-floated shafting, the method utilizes the slight elastic deformation of elastic elements to dissipate the medium / high-frequency micro-vibration energy of a mainshaft and the stored deformation energy and static friction characteristic of the elastic elements to enhance positioning damp in order to increase positioning precision. In the device, the solid elastic elements are respectively assembled in the axial anti-thrust gaseous film and the radial gaseous film. The method can establish a gyration benchmark which also takes high precision, high rigidity, high support, low vibration and high displacement sensitivity into consideration.

Owner:HARBIN INST OF TECH

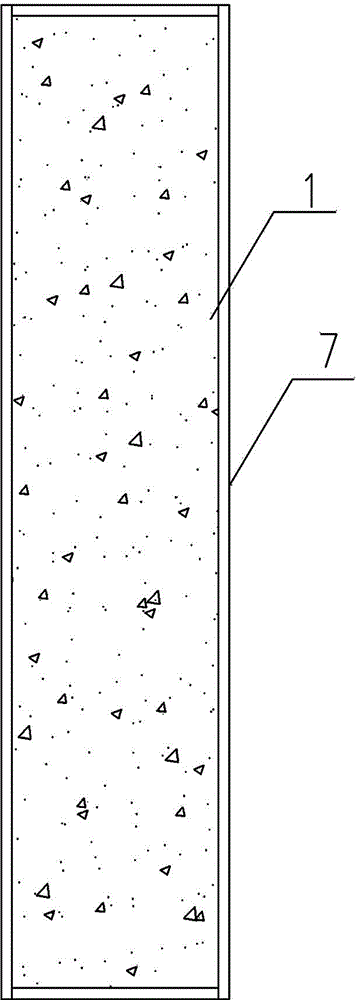

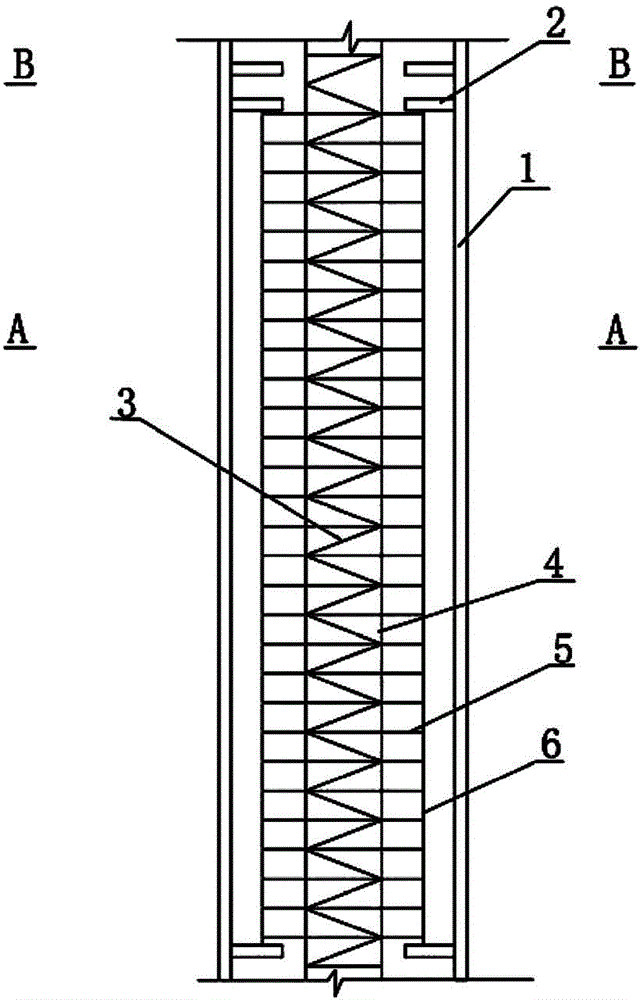

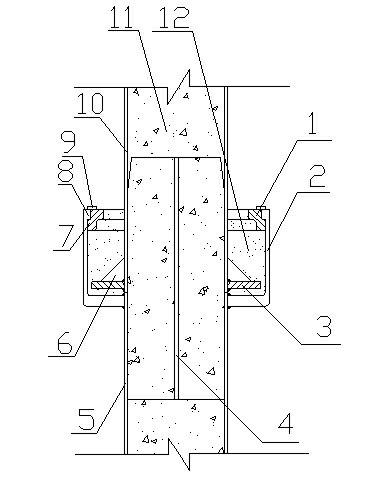

Multi-cavity concrete-filled steel tubular wall with internal pre-machined semi-continuous reinforcement cage and construction method

ActiveCN104674986AHigh compressive strengthIncreased shear strengthWallsSteel frameCompressive strength

The invention relates to a multi-cavity concrete-filled steel tubular wall with internal pre-machined semi-continuous reinforcement cages and a construction method. The multi-cavity concrete-filled steel tubular wall comprises a steel frame and a continuous reinforcement cage; discontinuous reinforcement cages are prefabricated in the steel frame; the length-to-width ratio of the steel frame is more than or equal to 3; the steel frame in which the discontinuous reinforcement cages are prefabricated is a whole consisting of the discontinuous reinforcement cages, a giant steel frame and tying parts; the giant steel frame is internally divided into a plurality of cavities by transverse vertical partition plates; transverse partition plates are arranged at intervals along the height direction in each cavity; the discontinuous reinforcement cages are positioned between the adjacent transverse partition plates, and are integrally connected with the inner wall of the giant steel frame through the tying parts; the continuous reinforcement cage is arranged in a full-length manner along the lengths of the cavities; holes through which the continuous reinforcement cage penetrate are formed in the middle parts of the transverse partition plates. According to the multi-cavity concrete-filled steel tubular wall and the construction method, the technical problems of weak compressive strength and shear strength and poor fire resistance of an ultra-long giant steel plate wall structure are solved, and the multi-cavity concrete-filled steel tubular wall and the construction method can be widely applied to a super high-rise large-span structure.

Owner:姚攀峰

Launch vehicle low-temperature composite storage tank with triangular sandwich wall and processing method of tank

ActiveCN106586035AImprove axial load capacityIncreased shear strengthCosmonautic vehiclesCosmonautic propulsion system apparatusCarrying capacityEngineering

The invention provides a launch vehicle low-temperature composite storage tank with a triangular sandwich wall. The storage tank comprises a front bottom cover, a front sealing head, a tank cylinder section inner wall, a tank cylinder section outer wall, a rear sealing head, a rear bottom cover and a rear bottom tank housing and is characterized in that a triangular sandwich wall structure comprising reinforcing ribs is arranged between the tank cylinder section outer wall and the tank cylinder section inner wall; and Y ring triangular sandwich wall connecting structures are formed at connecting parts between the front sealing head and the tank cylinder section inner wall, between the front sealing head and the tank cylinder section outer wall, between the rear sealing head and the tank cylinder section inner wall and between the rear sealing head and the tank cylinder section outer wall. The invention further discloses a processing method of the storage tank, which employs an integral co-bonding forming technology of fiber winding forming combined with fiber laying forming. According to the storage tank, the triangular sandwich wall structures are arranged at the high shear stress connecting parts between the sealing heads and a tank cylinder section; the shear strength of the connecting parts is improved; and the storage tank has the effects that the axial carrying capacity of the storage tank is improved, the structure assembly complexity is reduced, and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

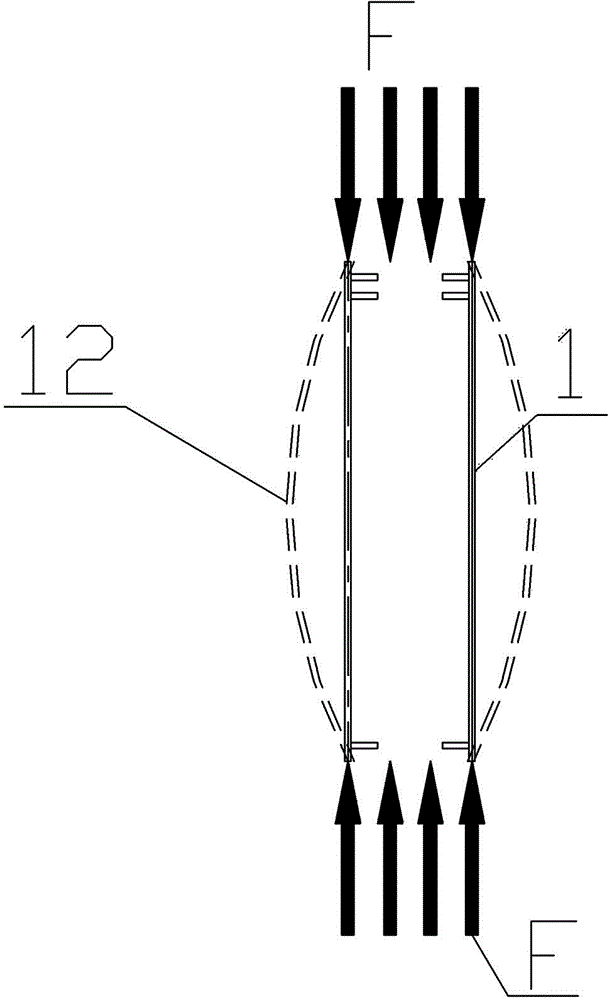

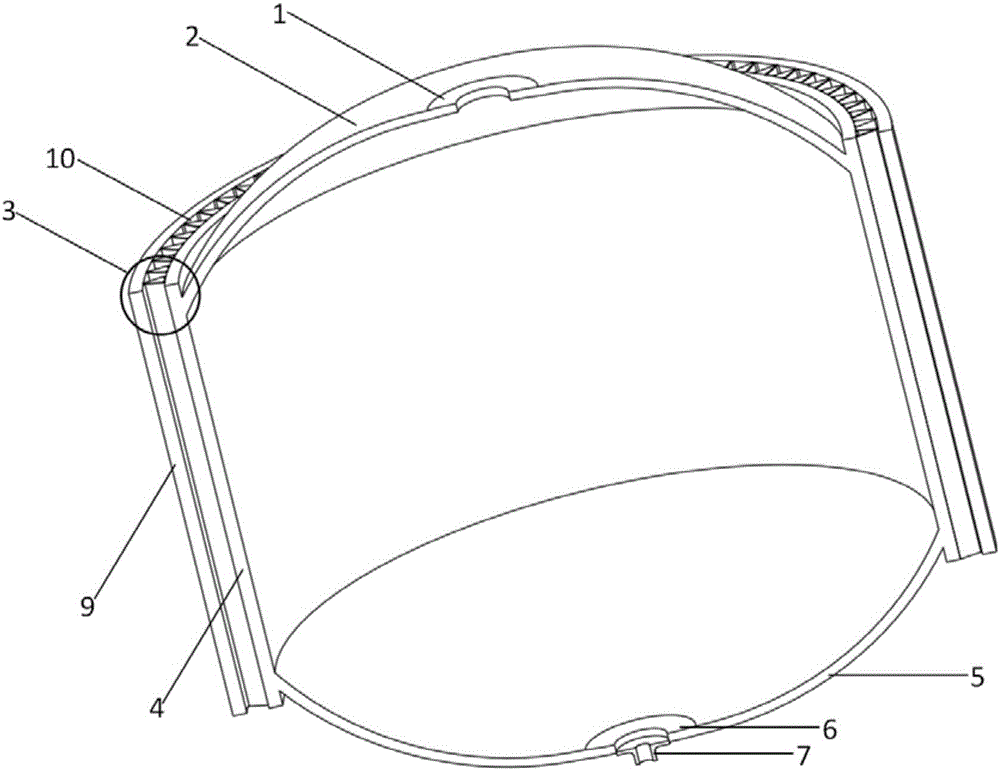

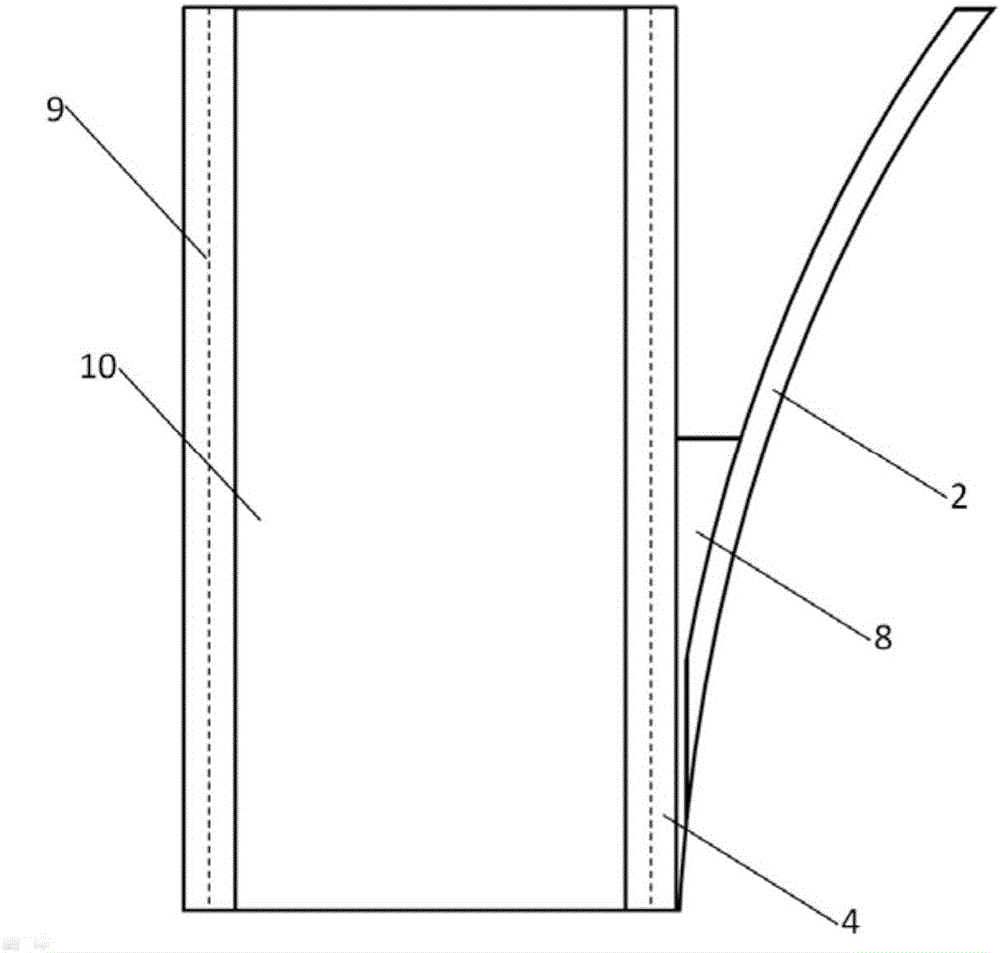

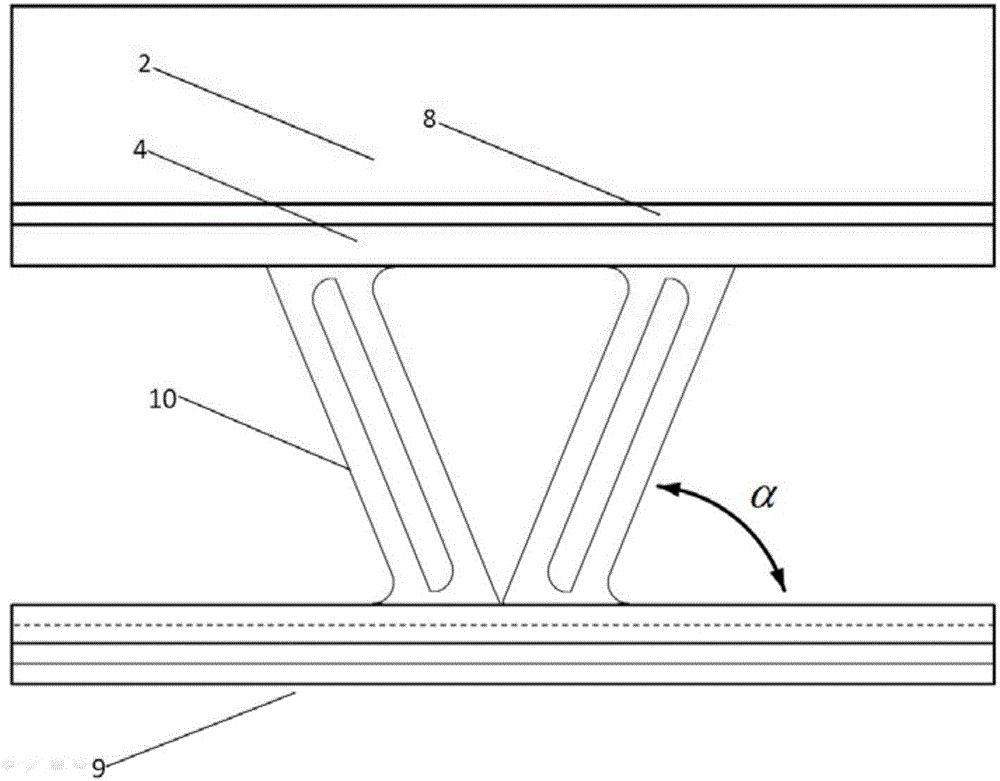

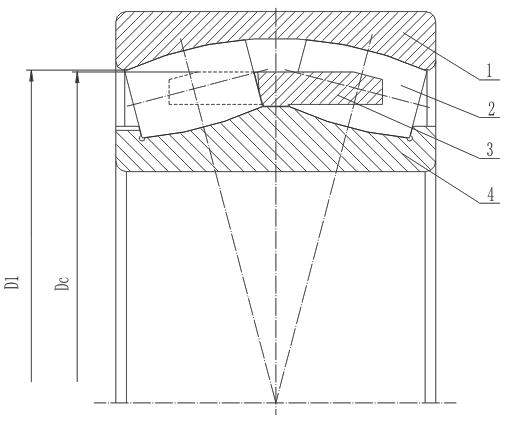

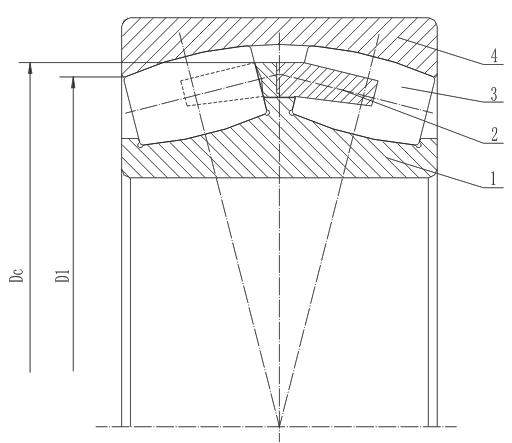

Self-aligning roller bearing split-type retainer and design method thereof

InactiveCN102506075AImprove running stabilityImprove axial load capacityRolling contact bearingsBearing componentsCarrying capacityLeft half

The invention discloses a self-aligning roller bearing split-type retainer and a design method thereof. The outer diameter of the retainer is increased based on a current double-claw integral solid retainer, so that the outer diameter dimension Dc of the retainer is bigger than the inner diameter dimension of an outer ring; the middle part of the retainer is split into a left half part and a right half part from the middle part, and then split into two halves from the centre of a pocket hole along the axial direction of the left half part and the right half part of the retainer; the right half part of the retainer is rotated by 90 degrees clockwise or clockwise to stagger the axial split part, so that the centre of a beam on the right half part of the retainer is aligned to the centre of the pocket hole on the right half part of the retainer, and drilled with a connecting hole in a matched manner; four parts respectively formed in the radial direction and the axial direction of the retainer are placed between the inner ring and the outer ring of the bearing, and then rotate out with the inner ring from an outer ring roller, and finally are connected together by a plurality of inner hexagonal bolts and spring pins to form an integer. The retainer has high strength and high reliability, so that the bearing has high carrying capacity in the axial direction and the radial direction, and operating stability.

Owner:洛阳瑞成轴承有限责任公司

Gas turbine rotor supporting mechanism and gas turbine with same

ActiveCN104005797AImprove axial load capacityEliminate light load skiddingMachines/enginesTurbine/propulsion lubricationStructural stabilityGas turbines

The invention discloses a gas turbine rotor supporting mechanism and a gas turbine with the same. The gas turbine rotor supporting mechanism comprises ball bearings arranged on two sides of a gas turbine rotor wheel disc to be used for supporting a gas turbine rotor, the ball bearings comprise a first ball bearing arranged on a rotor shaft on a first side of the gas turbine rotor wheel disc and a second ball bearing arranged on a rotor shaft on a second side of the rotor wheel disc, the first ball bearing comprises a first outer ring, the first outer ring is provided with an elastic mechanism used for exerting axial force on the gas turbine rotor and buffering the gas turbine rotor axial force, and the second ball bearing is arranged into a thrust bearing for bearing the axial force of the gas turbine rotor. The gas turbine rotor supporting mechanism can improve axial bearing capability of the gas turbine, the problem of light load slippage is solved, and structural stability of the whole supporting mechanism in a high-speed running state is good.

Owner:CHINA AVIATION POWER MACHINE INST

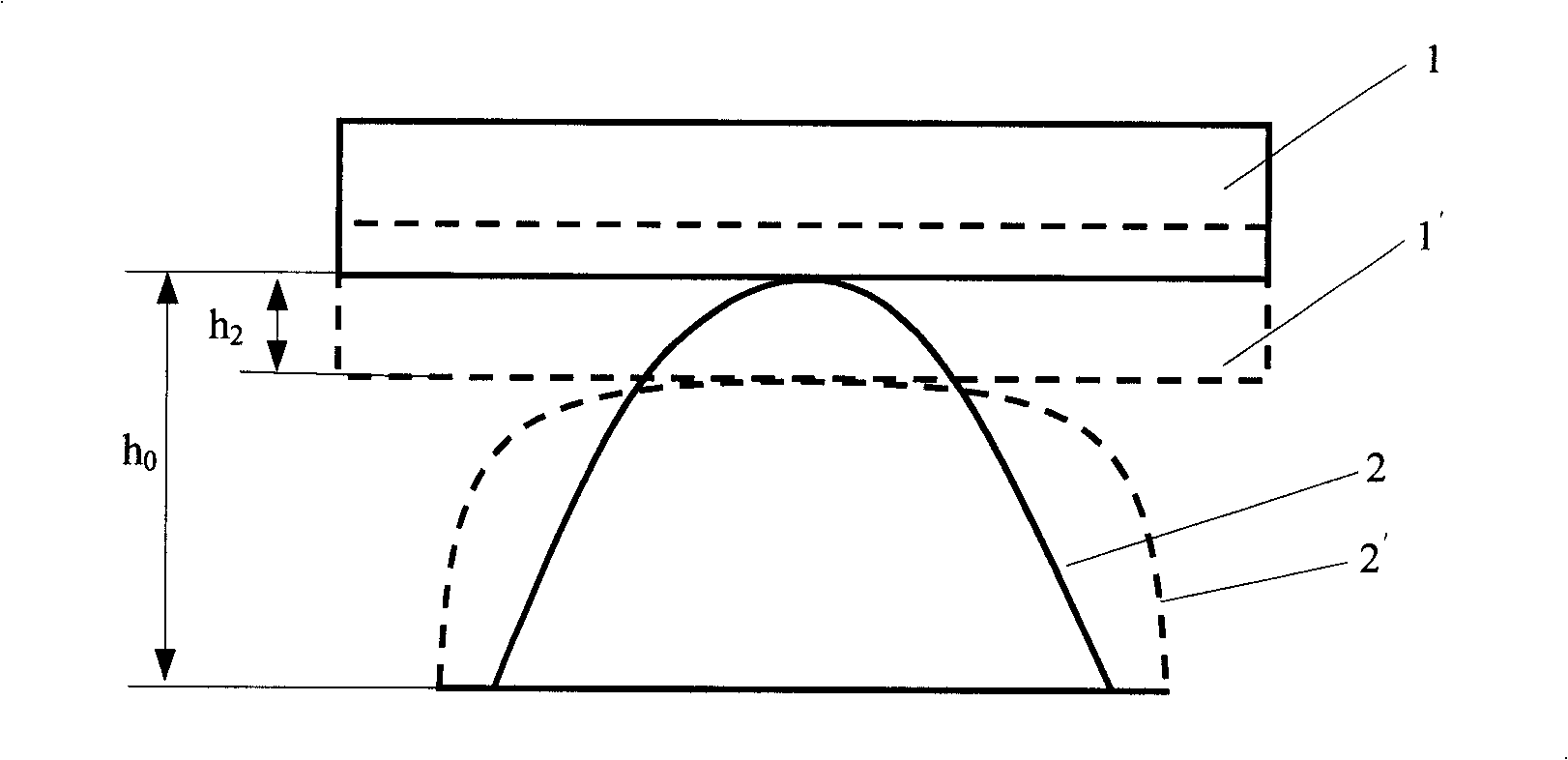

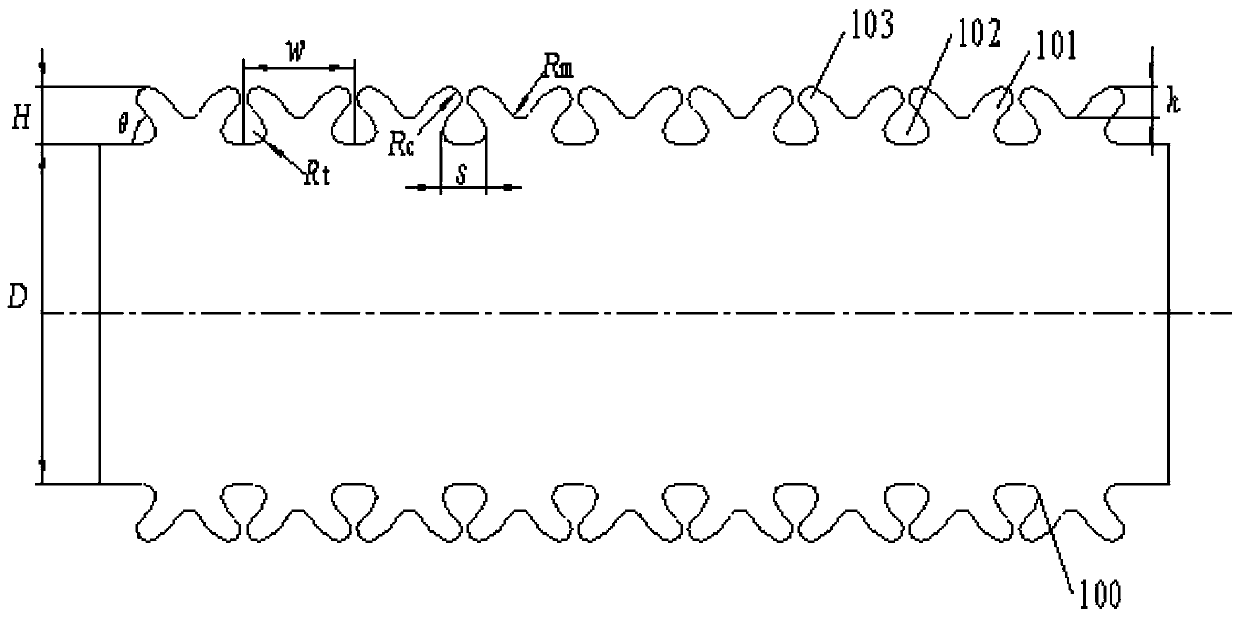

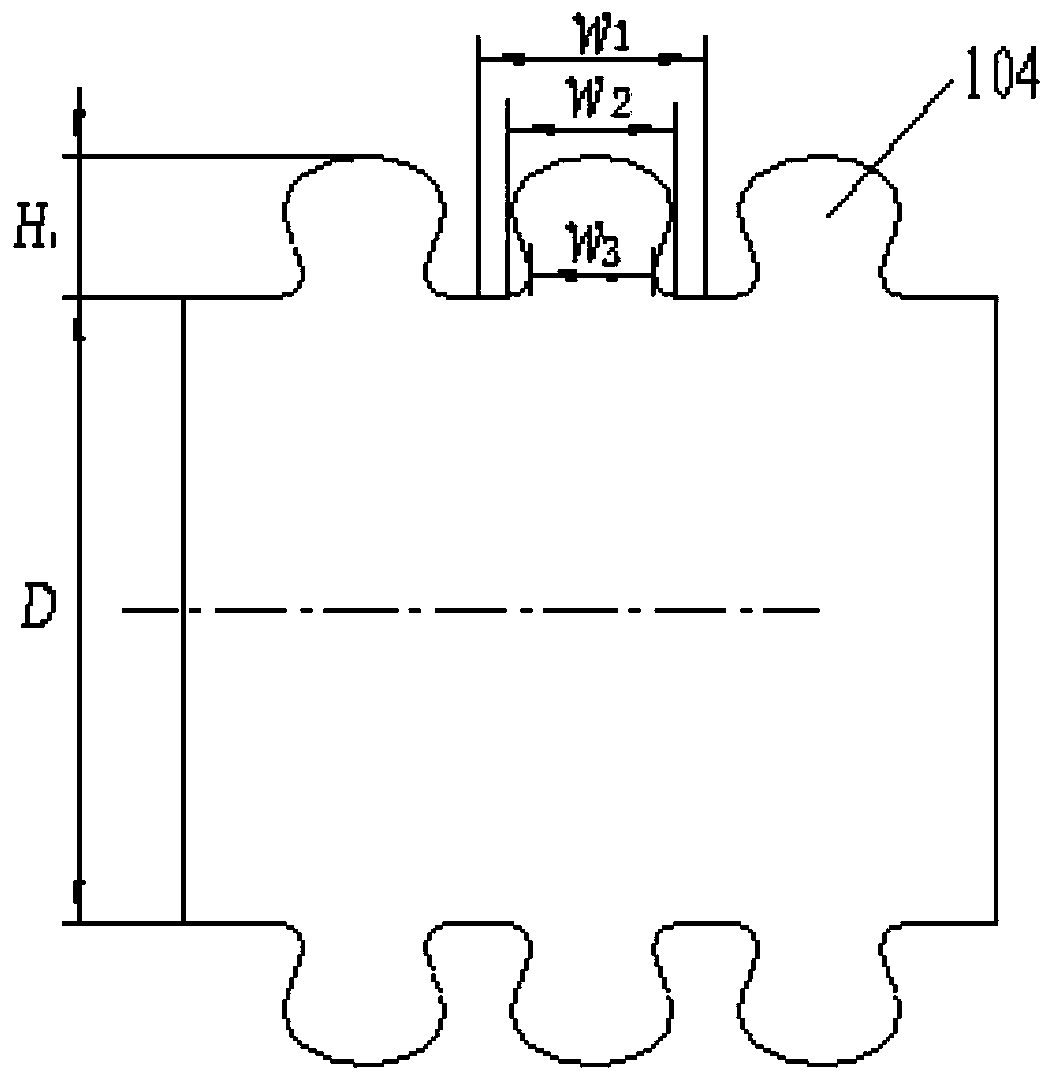

Y-shaped corrugated pipe with one-way elongation compensation, forming device and forming method

ActiveCN110523833AGood axial elongation compensation abilityImprove axial load capacityPipeline expansion-compensationWave shapeWave form

The invention provides a Y-shaped corrugated pipe with unidirectional elongation compensation, wherein the edge part of the corrugated pipe comprises a plurality of adjacently arranged waveform structures, each waveform structure comprises a wave crest of a Y-shaped structure and a groove of a drop-shaped structure, the wave crest of the Y-shaped structure comprises two U-shaped waves, and the twoU-shaped waves form two branches of the Y-shaped structure. Meanwhile, the invention further provides a forming device and a forming method of the Y-shaped corrugated pipe with the one-way extensioncompensation function. The Y-shaped corrugated pipe has good axial elongation compensation capacity and higher axial bearing capacity, the corrugated pipe can meet axial elongation displacement compensation under the high-temperature condition, and the service life of the corrugated pipe is prolonged. According to the method, a two-step forming process can be adopted, the die design and machiningcost is reduced, and meanwhile the production efficiency of the corrugated pipe is improved.

Owner:YANSHAN UNIV

Fully-dry connection precast concrete plate, floor and method for improving seismic performance of floor

InactiveCN104878871AImprove bearing capacityIncrease lateral stiffnessConstruction materialFloorsFloor slabRebar

The invention discloses a fully-dry connection precast concrete plate, a floor and a method for improving seismic performance of the floor. The concrete plate comprises a precast concrete plate, wherein plate top embedded parts are embedded in two sides of the top of the precast concrete plate; plate bottom embedded parts are arranged at the bottom of the precast concrete plate; each plate top embedded part comprises a plate top anchor slab; each plate top anchor slab is connected with an exposed plate top anchor bar; each plate bottom embedded part comprises horizontal plate bottom steel bars; the horizontal plate bottom steel bars are connected with embedded metal plates; longitudinal plate bottom steel bars are arranged among the embedded metal plates; the metal plates are exposed on the plate bottom surface of the precast concrete plate. The floor comprises a floor body spliced by the fully-dry connection precast concrete plates; the periphery of the floor is connected with a beam. By virtue of the method for improving the seismic performance of the floor, the node connection deformation capability of the floor spliced by the fully-dry connection precast concrete plates can be regulated by welding the adjacent plate bottom embedded parts with corresponding positions in the fully-dry connection precast concrete plates, so that the deformation capability of the plate bottom embedded parts is superior to that of the plate top embedded parts.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Roller bearing for supporting main shaft of wind driven generator

ActiveCN102748382AAvoid the problems of obvious stress concentration and high heat generationImprove enduranceRoller bearingsWind drivenHigh intensity

The invention discloses a roller bearing for supporting a main shaft of a wind driven generator. The roller bearing for supporting a main shaft of a wind driven generator is prepared from a high-strength alloy steel material, has a single-row tapered roller bearing structure, and comprises an outer ring, an inner ring, a tapered roller, an upper groove which is used for receiving the tapered roller and is located at the outer ring, a lower groove which is used for receiving the tapered roller and is located at the inner ring, a keeper which is used for keeping the tapered roller, an upper lubricant groove which is located at the outer ring and provides lubricant to the tapered roller, and a lower lubricant groove which is located at the inner ring and provides lubricant to the tapered roller, wherein four corners of the tapered roller have arc shapes; the upper groove which is used for receiving the tapered roller and is located at the outer ring and the lower groove which is used for receiving the tapered roller and is located at the inner ring compose a tapered roller receiving groove; and four corners of the tapered roller receiving groove have arc shapes.

Owner:JIANGSU JINYUAN FORGE

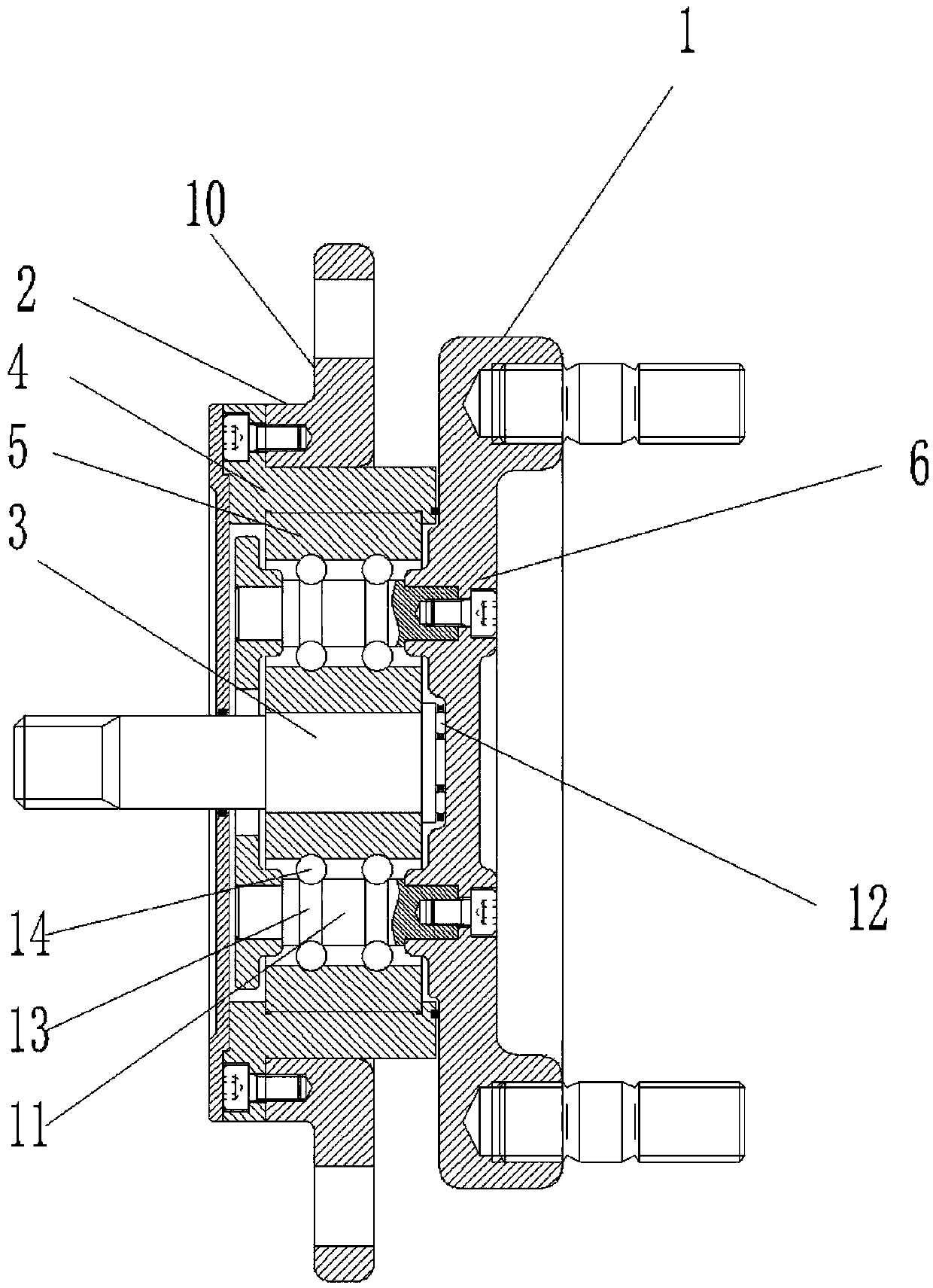

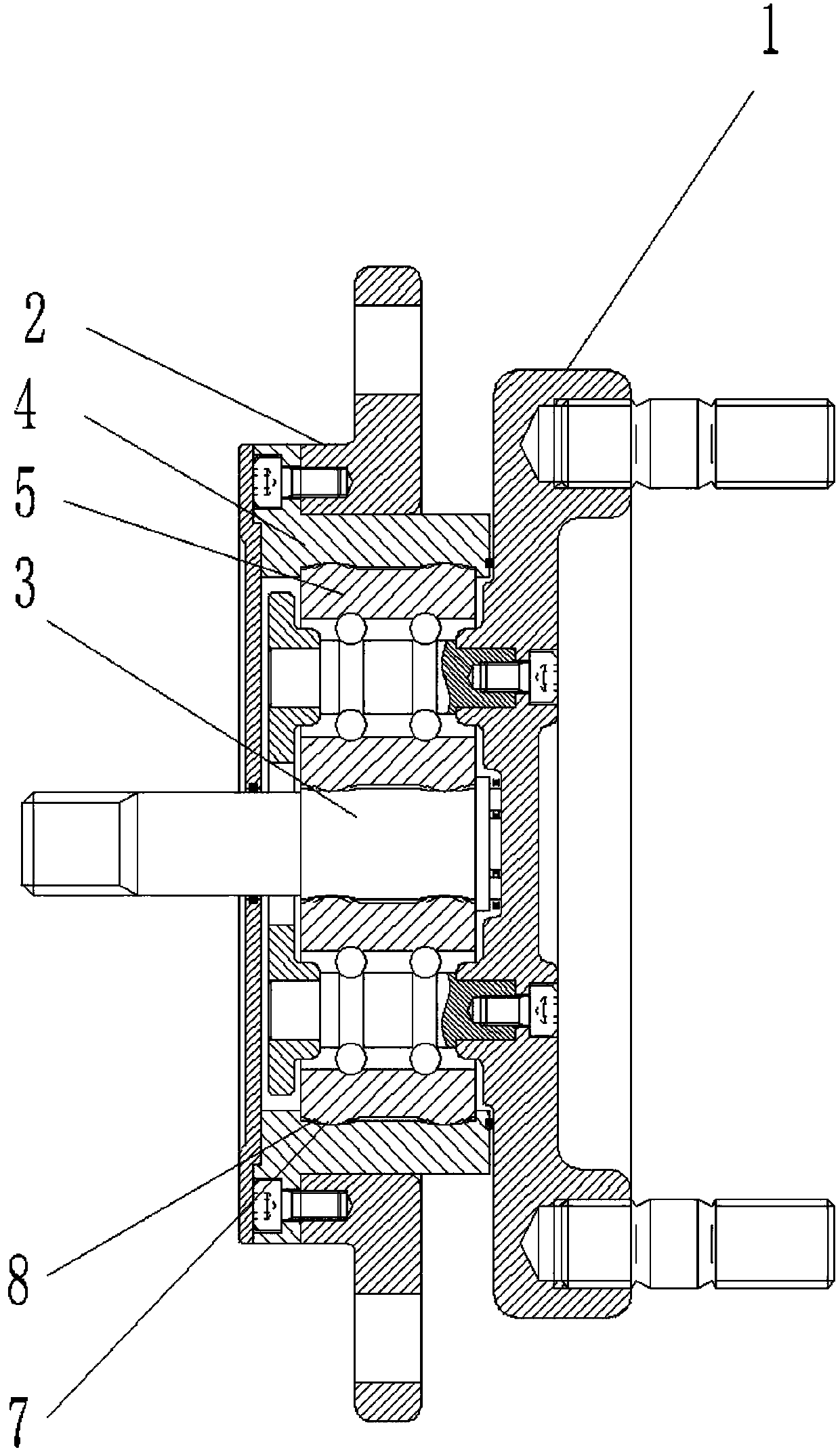

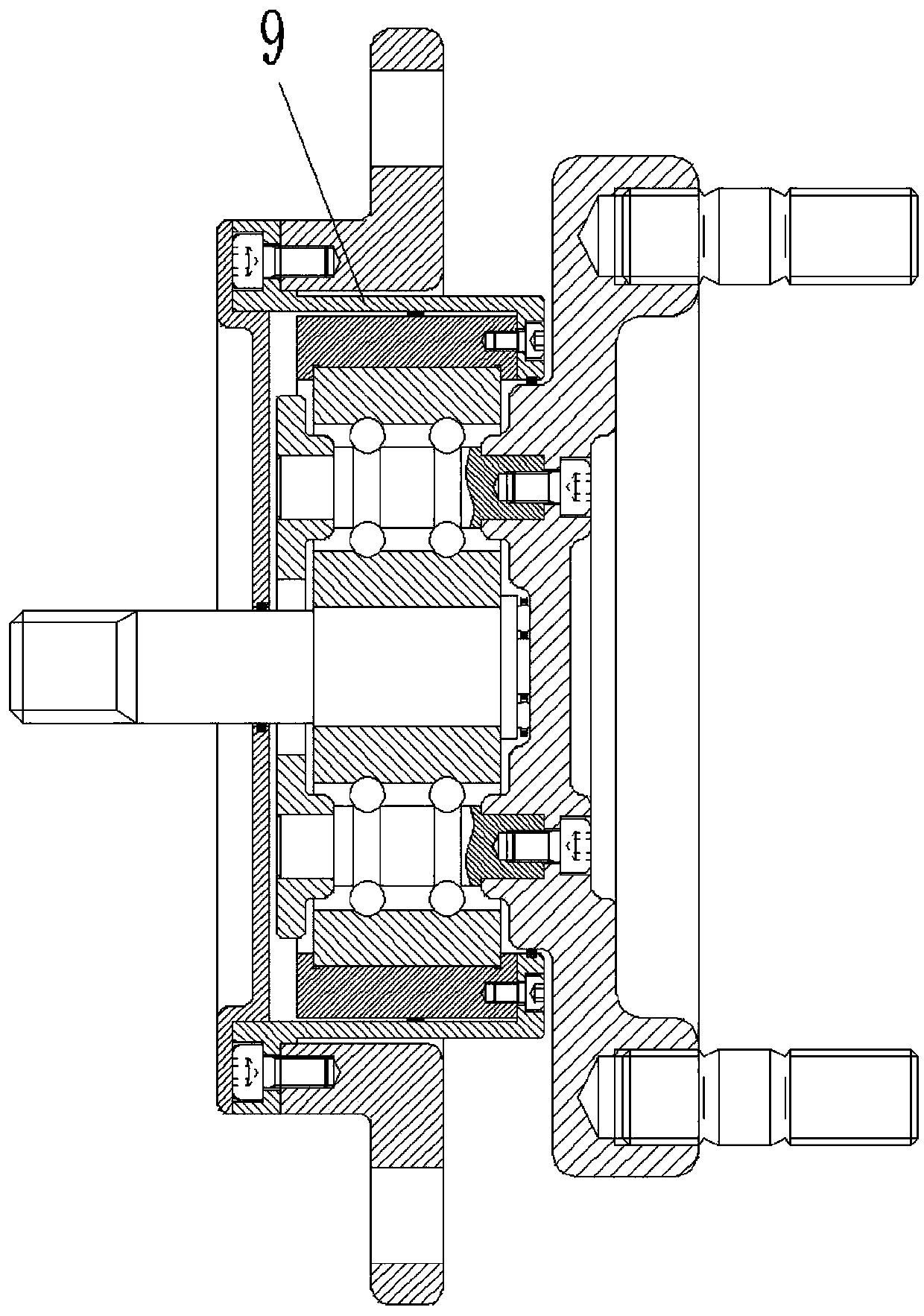

Planetary traction drive bearing type integral reduction hub

InactiveCN109538704AReduce axial sizeImprove compactnessToothed gearingsBearing componentsReduction driveReducer

The invention discloses a planetary traction drive bearing type integral reduction hub which comprises a hub body and a planetary traction drive bearing type reducer; the planetary traction drive bearing type reducer comprises a planetary traction drive gear train collectively formed by a reducer drive inner shaft, a reducer outer ring, a planetary rolling body and a planetary carrier; the planetary rolling body is matched with the reducer drive inner shaft and the reducer outer ring in a friction drive manner; and the power output end of the planetary traction drive gear train is in drive connection to the hub body. The planetary traction drive bearing type integral reduction hub simplifies combination of a wheel-side reducer and a hub bearing, enables the hub bearing to be organically integrated to a planetary traction reduction drive structure, integrates functions of speed reduction and a bearing as well as is simple and compact in structure, small in size and low in processing size.

Owner:CHONGQING UNIV

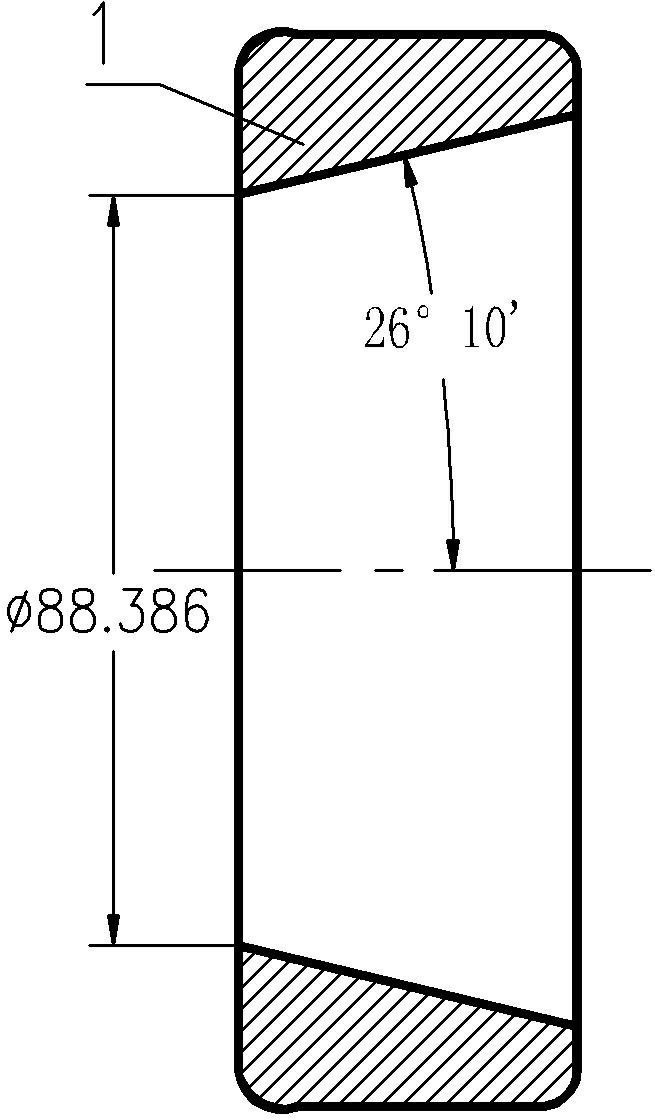

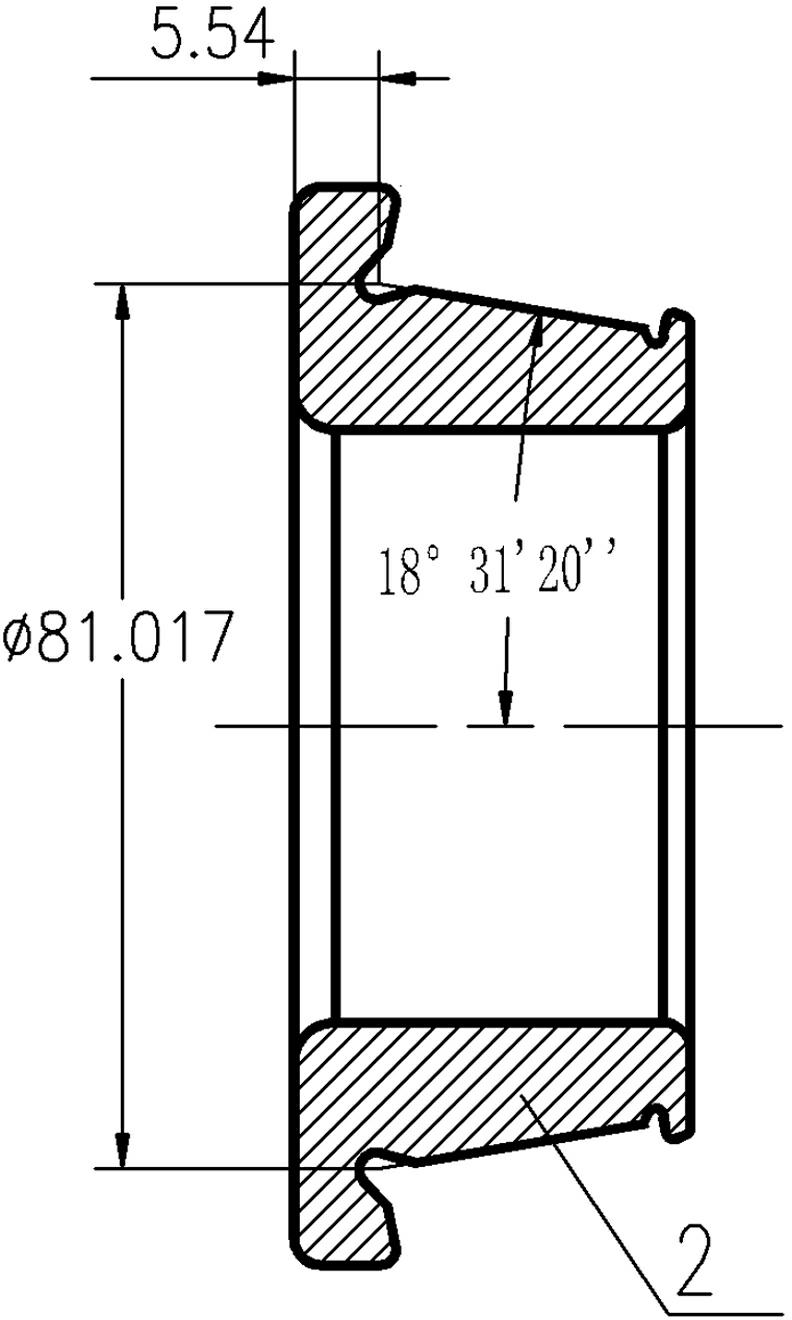

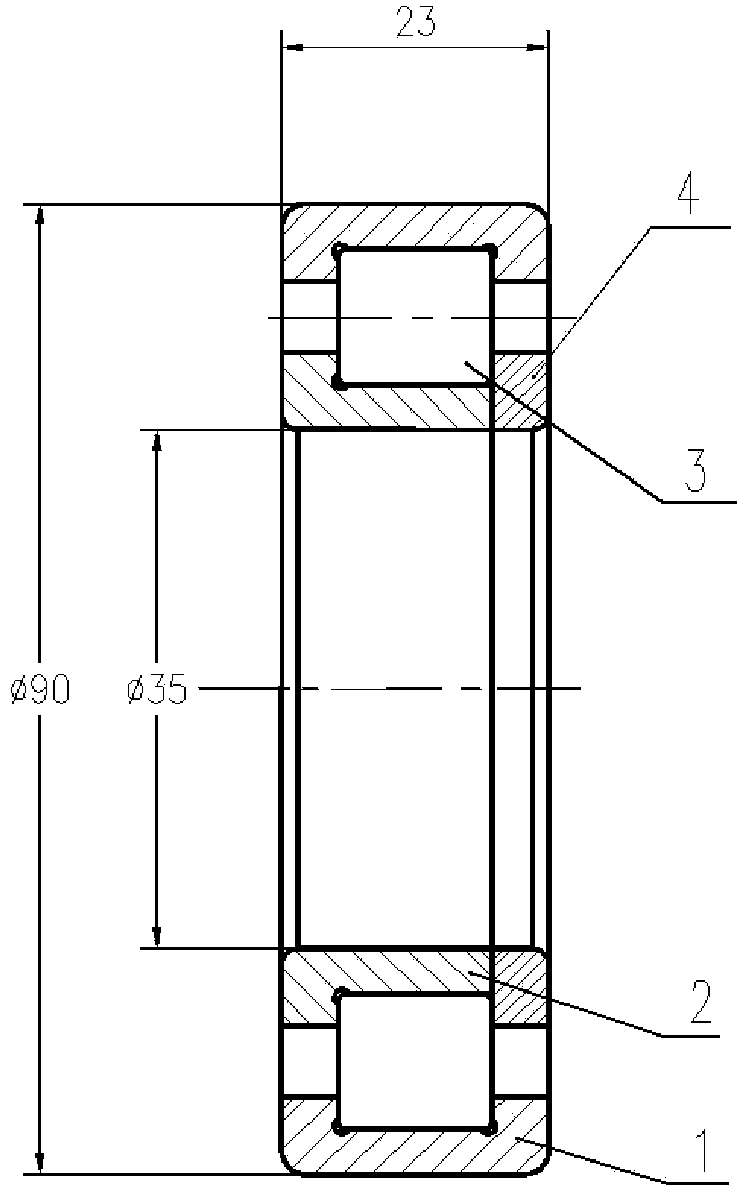

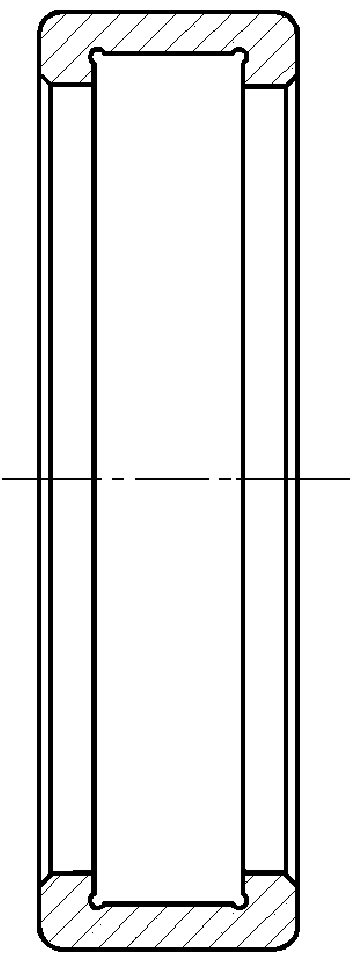

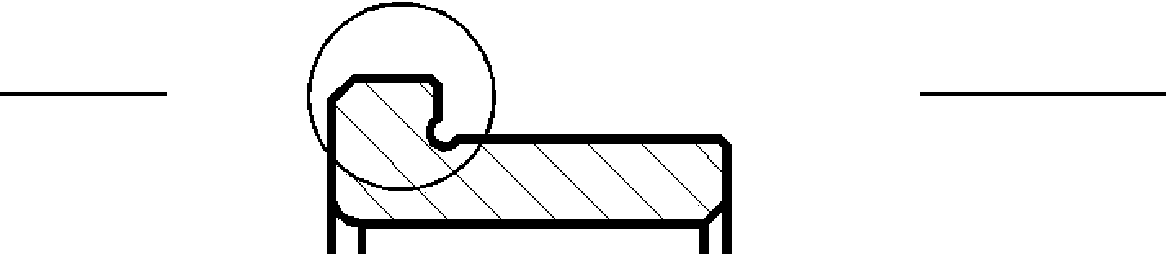

Cylindrical roller bearing with high axial bearing capacity

ActiveCN103967930AAvoid breakingImprove the lubrication effectRoller bearingsBearing componentsFailure rateReducer

The invention relates to the technical field of rolling bearings, in particular to a cylindrical roller bearing with high axial bearing capacity, which is used for a main cone guiding support of a main reducer of a drive axle of a truck. The cylindrical roller bearing comprises an outer ring, an inner ring, a full complement cylindrical roller clamped between the outer ring and the inner ring, and a flat check ring arranged on one side of the inner ring and one side of the cylindrical roller. Through the improvement of the strength of the retaining sides and the change of the shape of the retaining side at the contact part of the inner ring of the bearing and the end surface of the roller, the shape of the retaining side at the contact part of the outer ring of the bearing and the end surface of the roller, and the shape of the contacted end surface of the roller, the lubricating condition of the contact area of the retaining side of the inner ring of the bearing and the end surface of the roller and the lubricating condition of the contact area of the retaining side of the outer ring of the bearing and the end surface of the roller are improved to form better elastic dynaflow lubricating, so that the axial bearing capacity can be improved greatly, the breakage of the retaining side of the inner ring can be effectively prevented, and the use failure rate of the product can be reduced.

Owner:FUJIAN YONGAN BEARING

Concrete-filled steel tube connector and construction method thereof

InactiveCN102561528AIncreased ultimate strength and deformationEasy to installBuilding material handlingSteel tubeGrout

The invention relates to connection of concrete-filled steel tube structures, in particular to a concrete-filled steel tube connector and a construction method thereof. The concrete-filled steel tube connector comprises a cover plate, a clamping disk and a sleeve, and the parts are designed and manufactured in a factory according to the requirements of a steel tube to be connected on size and connection strength. The parts are respectively connected with the end of the steel tube during mounting, and are clamped and temporarily secured according to construction process requirements, fiber doped high-strength expansion grout is filled into the steel tube, and the temporary support is removed and the steel tube is filled with concrete when the design strength is reached. The loaded high-strength expansion grout is strained in three directions by the steel tube and the sleeve, so that smooth load transfer is guaranteed, and connection rigidity and strength are also improved. By means of the concrete-filled steel tube connector, a joint has high axial load bearing capacity, high bending resistance and high fatigue resistance and has the advantages of fastness and convenience in constructional operation, and the shortages of traditional flange connection, welding and casing connection can be avoided.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

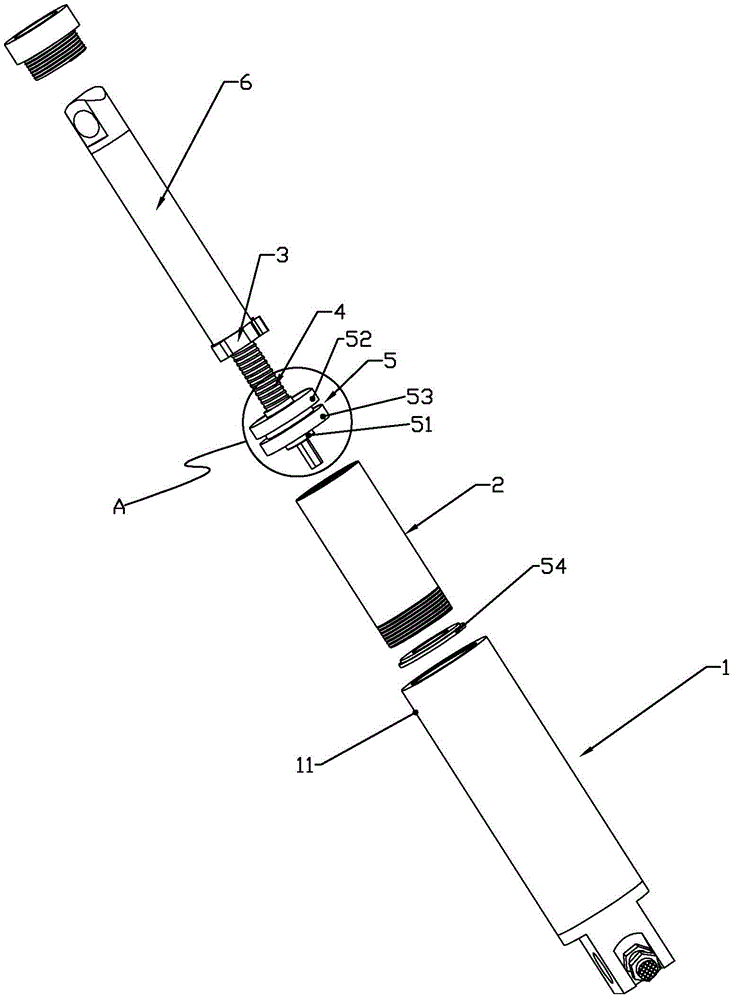

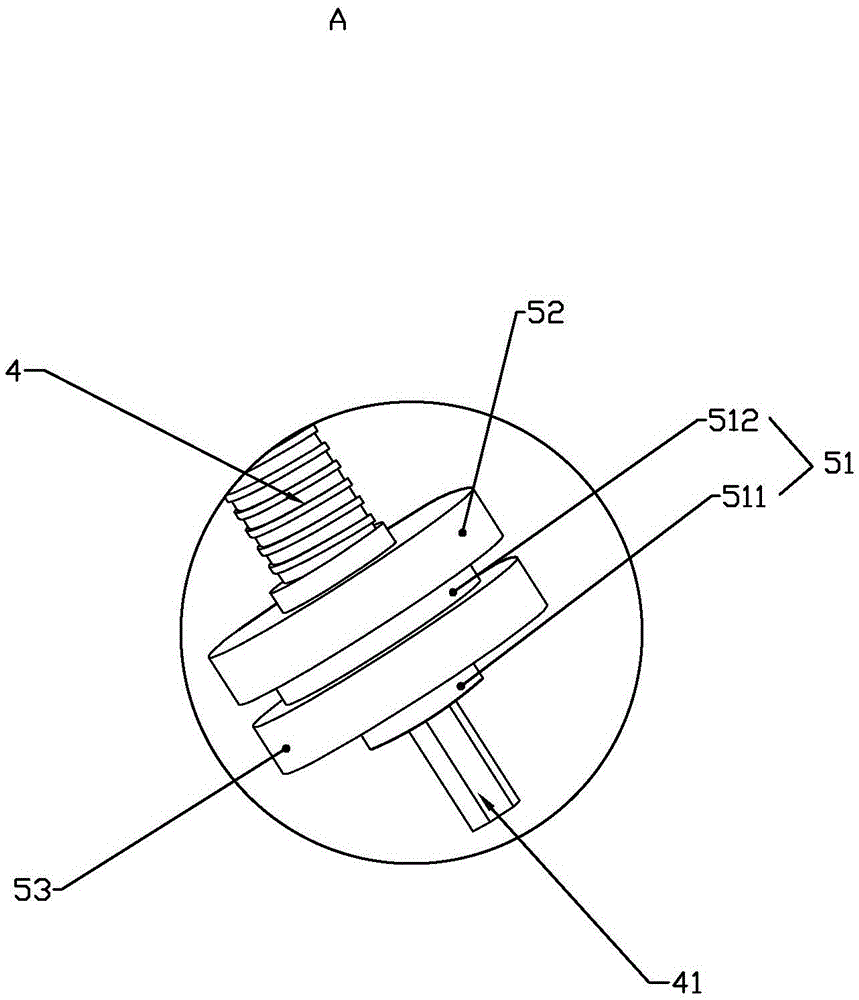

High thrust linear electric push rod

ActiveCN105529866AReasonable designImprove axial load capacityMechanical energy handlingSupports/enclosures/casingsReduction driveReducer

The invention relates to a high thrust linear electric push rod, comprising a power device, an electronic control device, a transmission mechanism and a flexible push rod. The power device comprises a motor outer sleeve, and a motor and a gear reducer arranged in the motor outer sleeve; the transmission mechanism comprises a travel bushing, a nut, a screw and a bearing assembly; the nut is screwed on the screw through threads; the nut and the flexible push rod are fixedly connected; the nut dynamically matches in the travel bushing in an axial reciprocating slide mode; the flexible push rod stretches into or retreats from the travel bushing along with the moving of the nut; the power input end of the screw is in transmission connection with the power output end of the gear reducer; the power input end of the screw is born in the motor outer sleeve through the bearing assembly; the bearing assembly comprises a bearing base fixed on the screw; a pair of conical roller bearings is mounted on the bearing base; and the large ends of the pair of conical roller bearings are arranged oppositely. The high thrust linear electric push rod is advantaged by stable and reliable screw bearing, great axial bearing capability and great thrust.

Owner:WENZHOU GEMING TRANSMISSION EQUIP CO LTD

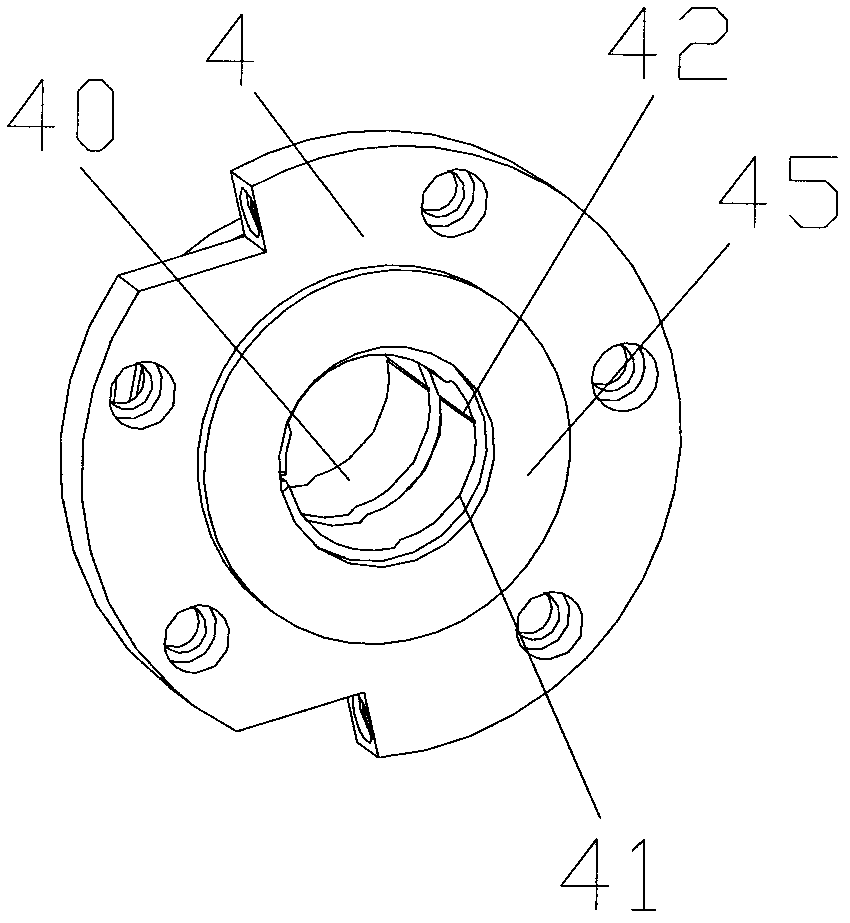

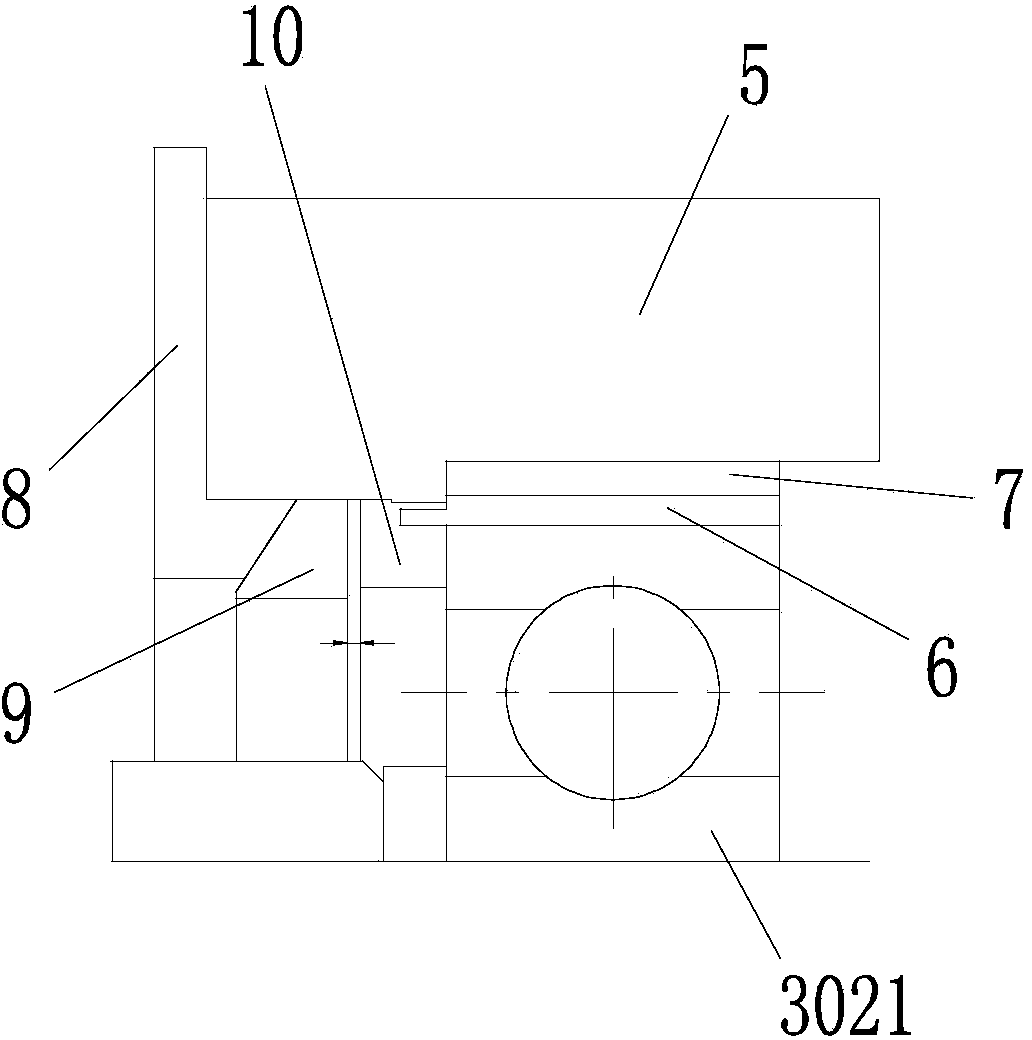

Bearing fixing device

InactiveCN103603876AImprove axial load capacityNo axial slippageBearing unit rigid supportEngineeringMechanical engineering

The invention is suitable for the field of mechanical structure design, and relates to a bearing fixing device. The bearing fixing device is characterized in that: the bearing fixing device comprises pins, a bearing pedestal, an outer lining, an inner lining, and a bearing; the bearing pedestal is a single-lug bearing pedestal; the outer lining and the inner lining are provided with shoulders at one side; through holes are disposed at the outside of a bearing hole of the bearing pedestal; the outer lining and the inner lining are respectively provided with through holes; the bearing is pressed in the inner lining, a side of the bearing is contacted with the shoulder of the inner lining and then the inner lining is installed in the outer lining; the bearing is contacted with the shoulder of the outer lining; the shoulder of the inner lining and the shoulder of the outer lining are respectively disposed at each side of the bearing; the outer lining is pressed in the bearing pedestal; and the pins are inserted into the through holes of the outer lining, the through holes of the inner lining and the through holes of the bearing pedestal. The bearing fixing device is advantageous in that axial bearing capability of the bearing is largely enhanced on a premise of not influencing radial bearing capability of the bearing; cases of axial sliding and shedding will not occur when the bearing bears frequent axial load; the axial shedding load of the bearing can be calibrated accurately by utilization of that the pins have designability; and the convertibility of the bearing is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Transmission shaft support unit

InactiveCN104141697AImprove integrityEasy to installSwivelsBearing unit rigid supportBall bearingDrive shaft

The invention discloses a transmission shaft support unit, belongs to the technical field of bearing production, and mainly solves the problem of damage of the transmission shaft support unit caused by easy release of a support bearing and function loss of a rubber pad in the prior art. The transmission shaft support unit is characterized by comprising a support base, a rubber shock pad, a support bearing and a sealing ring, wherein two snap spring grooves and a large inner snap spring are arranged in an inner hole of the support base; honeycomb blind hole grooves are formed in two peripheral end surfaces of the rubber shock pad; two snap spring grooves, a small inner snap spring and a waveform spring are arranged in an inner hole of a metal ring; the support bearing adopts an inner-outer ring integrated four-point contact ball bearing; an outer lip of the sealing ring is fixed in the inner hole of the metal ring; and the inner diameter of a sealing lip is lightly contacted with and fits the outer diameter of the inner race of the support bearing. The transmission shaft support unit has the characteristics of improving the axial bearing capacity of the bearing, reducing the axial impact load, improving the torque resistance and preventing the release of the support bearing to prolong the service life of the bearing, and is mainly applied to an automotive transmission shaft support unit.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

Lifting appliance for lifting and carrying container

ActiveCN104085772AImprove axial load capacityImprove fatigue lifeSafety gearProtection mechanismEngineering

Provided is a lifting appliance for lifting and carrying a container. The invention relates to the empty container lifting appliance having high-performance tapered end mechanisms. The lifting appliance includes a carriage, a fixing arm, a left telescopic arm, a left floating arm, a right telescopic arm, a right floating arm and telescopic oil cylinders; each floating arm includes an oil cylinder, a tapered end, an address recognizing piece, a box-landing signal switch and the like, wherein one side of the tapered end is provided with a security protection mechanism, the security protection mechanism includes a guide seat, and the guide seat is internally provided with an upright movable lifting pin, one side of the top of the lifting pin is provided with a protruding-outward positioning block, the top of the lifting pin is provided with a blind hole, the blind hole is internally insertedly provided with a guide rod, and the guide rod is sleevedly provided with a spring. With adopting of the lock catch type fixing tapered ends and the security protection devices, on one hand, the shear-bearing capacity of lock catches is utilized to replace the screw thread pair bending resistant capacity, on the other hand, precision positioning of vice springs is utilized and the guide structure is optimized, so that the strength of the tapered end mechanisms is increased, and the security of the tapered end mechanisms is greatly improved.

Owner:ANHUI HELI CO LTD

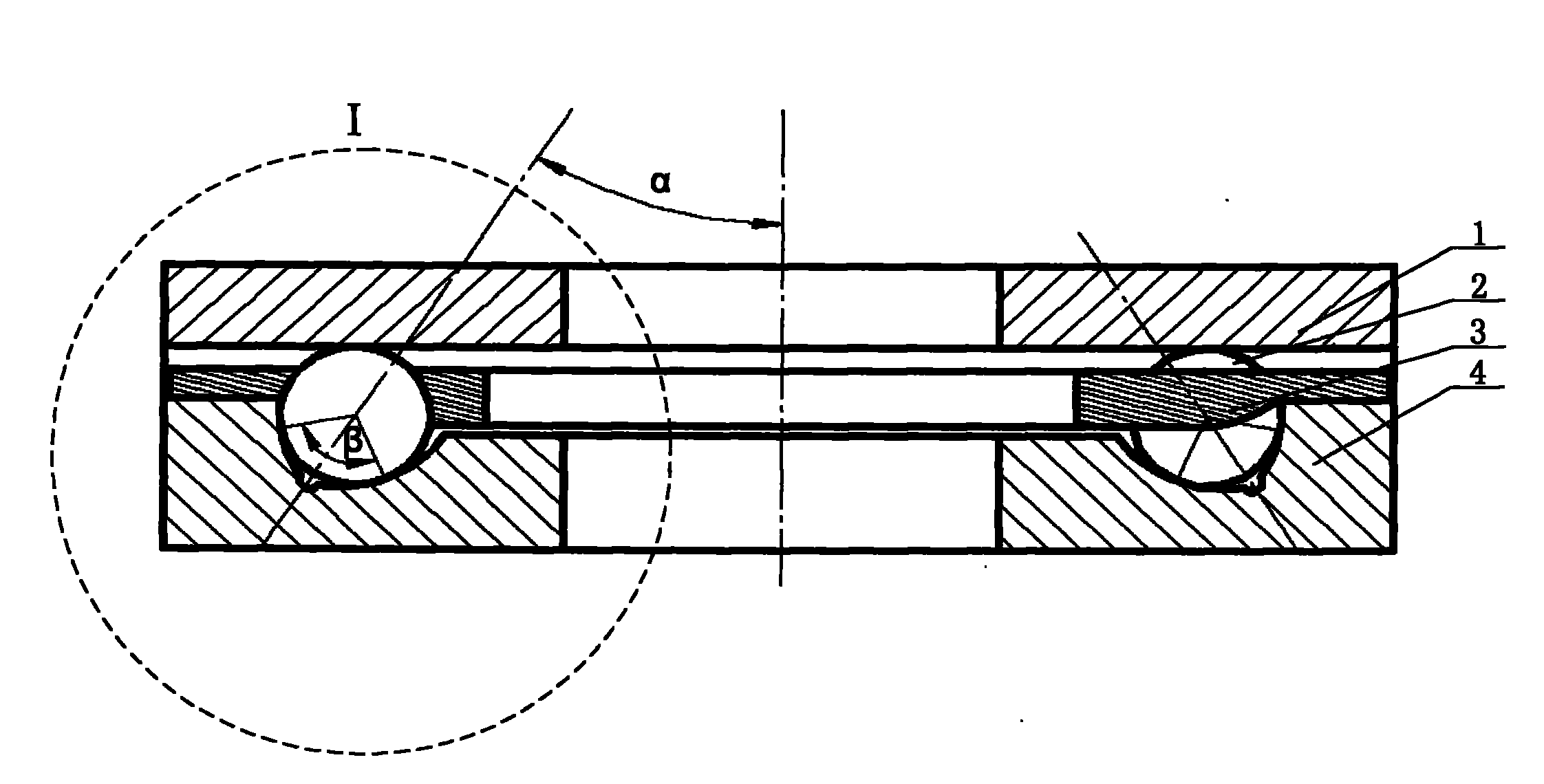

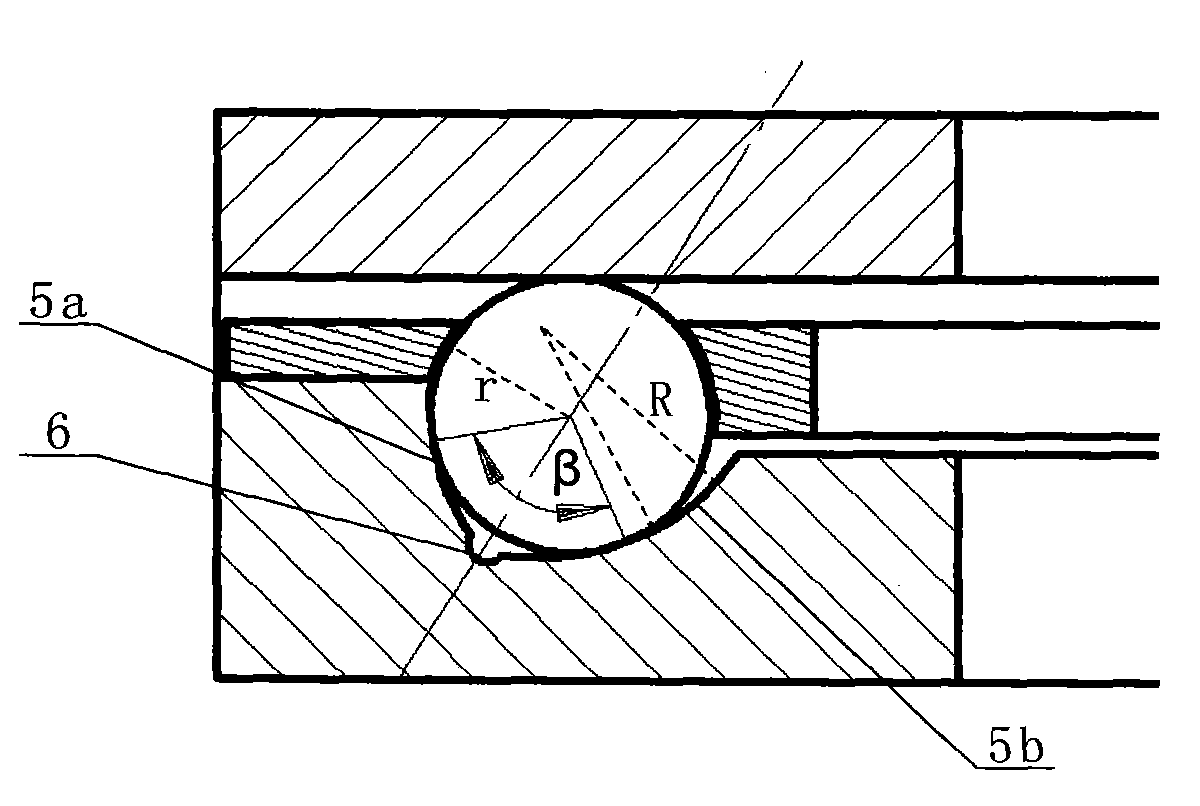

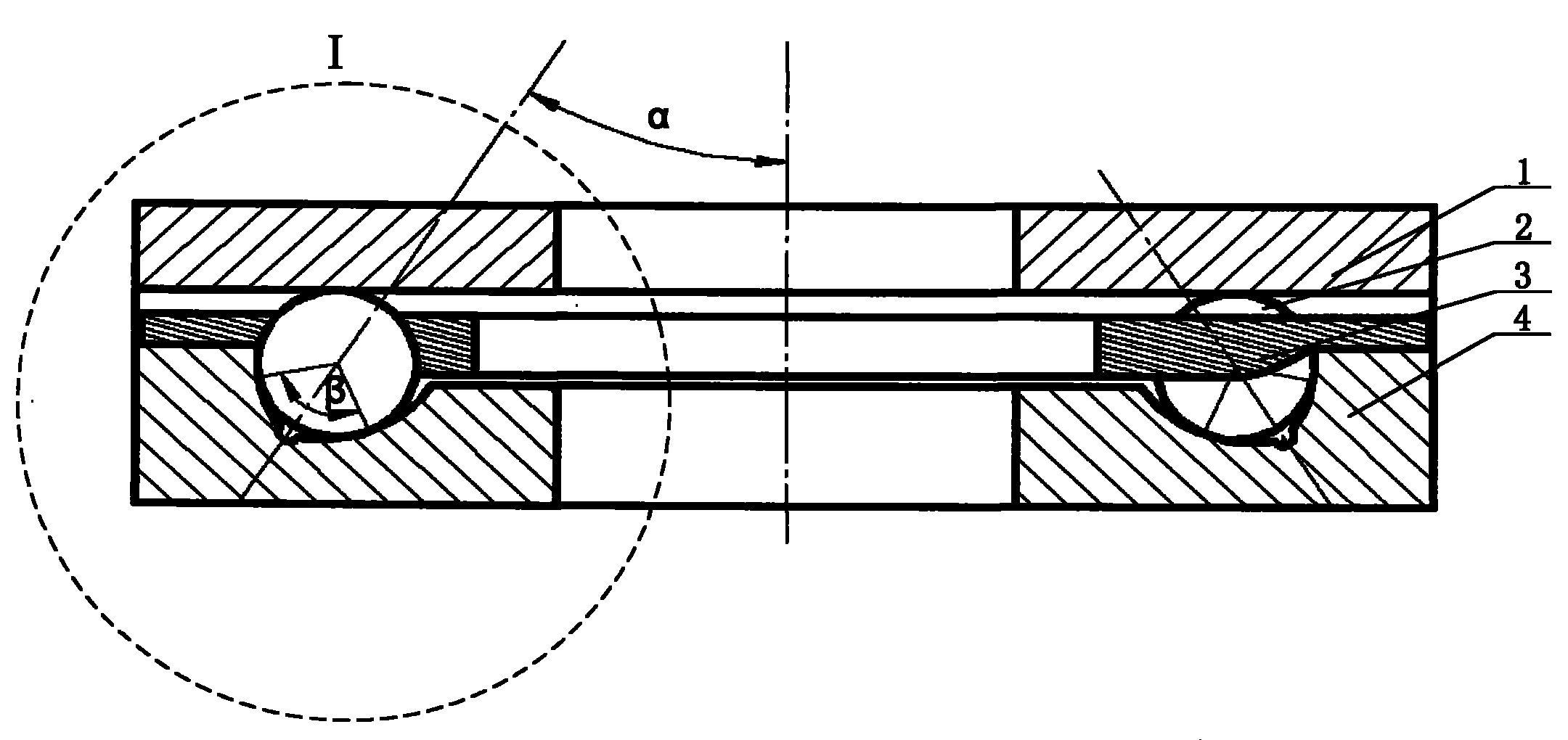

Three-point contact thrust ball bearing and design method

InactiveCN101776121AReasonable structural designIngenious ideaBall bearingsBearing componentsThrust bearingEngineering

The invention belongs to the technical field of thrust bearings and discloses a three-point contact thrust ball bearing and a design method. The three-point contact thrust ball bearing consists of a shaft washer, a housing washer, a steel ball and a retainer, wherein the housing washer is provided with an annular channel, the longitudinal section of the channel is an arc curve consisting of two segments of arcs, the steel ball and the annular channel on the housing washer are in two-point contact, the two arcs are symmetrical relative to the spinning rotary central line of the steel ball, an included angle alpha is formed between the central line and the central line of the bearing, and an included angle beta is formed between the connection lines of two contact points of the steel ball and the annular channel and the steel ball core; and the shaft washer is not provided with a channel, and the steel ball and the shaft washer is in one-point contact. The invention makes the steel ball, the shaft washer and the housing washer have three contact points, so the axial bearing capacity is increased, the bearing capacity is about 4 / 3 times of that of a two-point contact thrust ball bearing, and radial load can also be borne so as to prolong the service life of the bearing.

Owner:HENAN SANWEI HEAVY IND

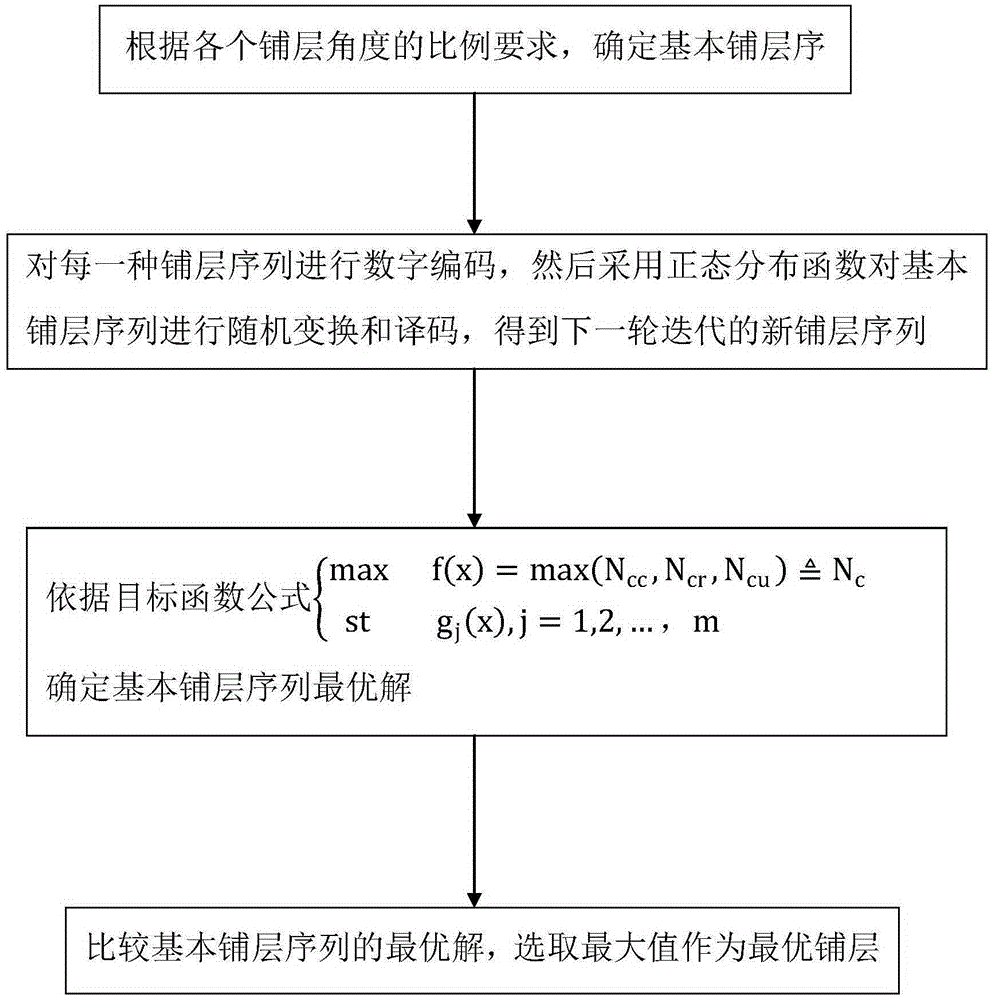

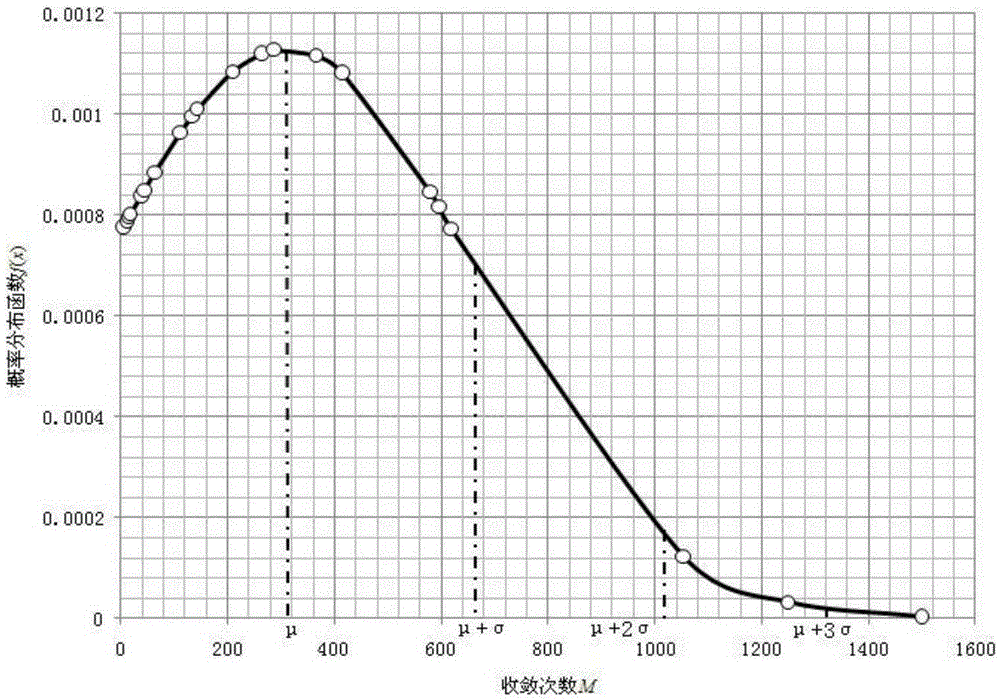

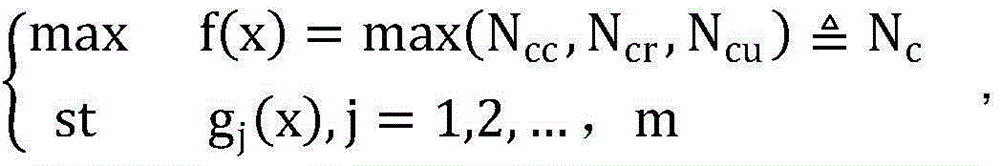

Random normal distribution based composite laminate stacking layer optimization method

InactiveCN105404732AGood axial load capacityReduced Structural Weight RatioGeometric CADDesign optimisation/simulationSkew normal distributionAxial compression

The invention discloses a random normal distribution based composite laminate stacking layer optimization method, and relates to the technical field of machinery. The random normal distribution based composite laminate stacking layer optimization method comprises the following steps of: step 1: according to a ratio requirement of each stacking layer angle, determining a basic stacking layer sequence; step 2: performing digital coding on each stacking layer sequence, and then performing random transformation and decoding on the basic stacking layer sequence by adopting a normal distribution function to obtain a new stacking layer sequence in a next round of iteration; step 3: according to a target function formula defined in the specification, determining an optimal solution of the basic stacking layer sequence; and step 4: comparing optimal solutions of basic stacking layer sequences, and selecting a maximum value as an optimal stacking layer. The method has the beneficial effects that the basic stacking layer sequence is reconstructed by utilizing the random normal distribution function, an optimal axial compression bearing capacity of a flange of a composite laminate can be obtained, a structural weight ratio is reduced, the confidence degree is high, and the convergence is quick.

Owner:CHINA HELICOPTER RES & DEV INST

Cam shock wave double-stage planar steel ball reducer

ActiveCN110397711BReduce axial sizeSmall aspect ratioGearingGearing detailsBall bearingReduction drive

Owner:YANSHAN UNIV

Sealing waterproof structure of deep groove ball bearing

ActiveCN107165941AImprove axial load capacityImprove radial load capacityBearing componentsBall bearingWater vapor

The invention relates to a sealing waterproof structure of a deep groove ball bearing. The sealing waterproof structure of the deep groove ball bearing comprises an inner ring, an outer ring, a steel ball, a retainer and a sealing device. An inner groove and an outer groove which are used for accommodating the steel ball and allowing the steel ball to slide therein are formed in the inner ring and the outer ring correspondingly. The inner groove and the outer groove are each a combined groove which is composed of two arcs, wherein the curvatures of the arcs are larger than the curvature of the steel ball, and the two sides of each arc are symmetrical. The sealing device comprises a first sealing ring and a second sealing ring, wherein the first sealing ring is arranged on one sides of the inner ring and the outer ring, and the second sealing ring is arranged on the other sides of the inner ring and the outer ring. A vacuum airtight environment is formed through the inner ring and the outer ring, dust and water vapor are prevented from entering the bearing, and thus the sealing effect of the deep groove ball bearing is effectively ensured.

Owner:NINGBO WANFENG BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com