Concrete-filled steel tube connector and construction method thereof

A technology of steel pipe concrete and connectors, which is applied in the direction of construction, building structure, and building material processing, etc., to achieve the effects of firm overall connection, good practical effect, and good axial force performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with embodiment.

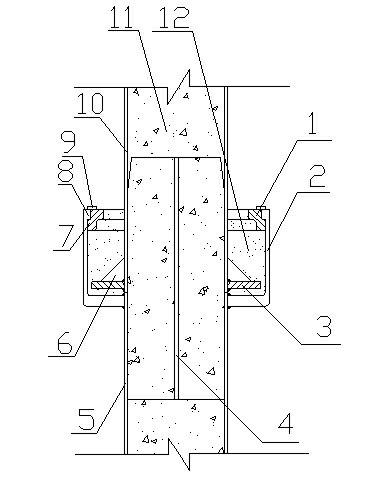

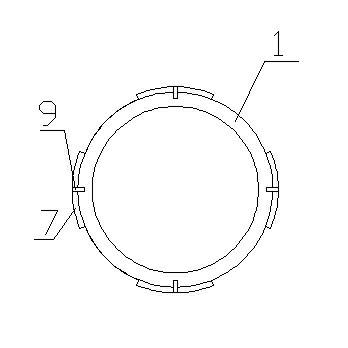

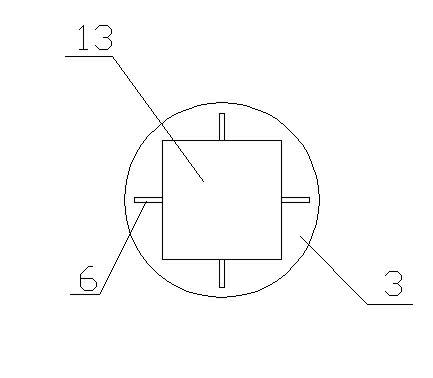

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , The concrete-filled steel pipe connector is composed of three separate components: a cover plate 1, a chuck 2, and a sleeve 3. The cover plate 1 is a ring-shaped body with a circular outer edge, four stop blocks 9 are fixed on its upper edge by quartering, and four arc-shaped cover plate convex teeth 7 are fixed on the outside of its lower edge by quartering. , the four cover plate convex teeth 7 correspond to the positions of the four limit blocks 9; there is a chuck pocket 13 in the middle of the chuck 2, and the diameter of the chuck pocket 13 is the same as that of the connected upper steel pipe 10 and the lower steel pipe 5. diameter and equal size (square mouth), the edge of the chuck sleeve 13 presses down the position of the cross-guiding shear plate 4 welded on the inner wall of the steel pipe 5, and four stiffening r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com