Patents

Literature

204results about How to "Prevent circumferential rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

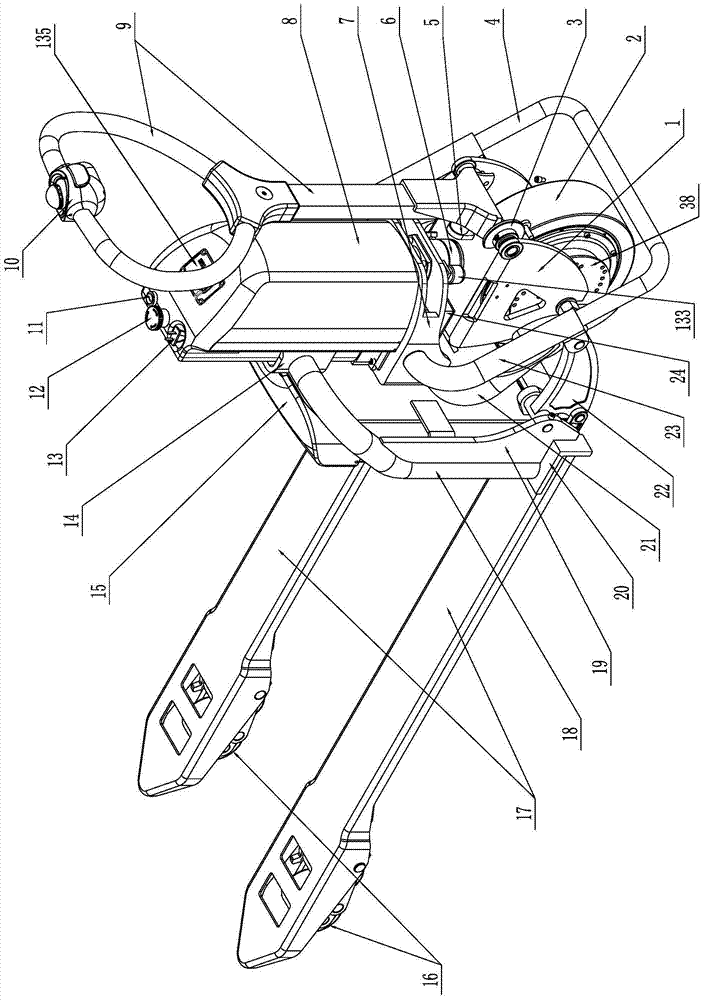

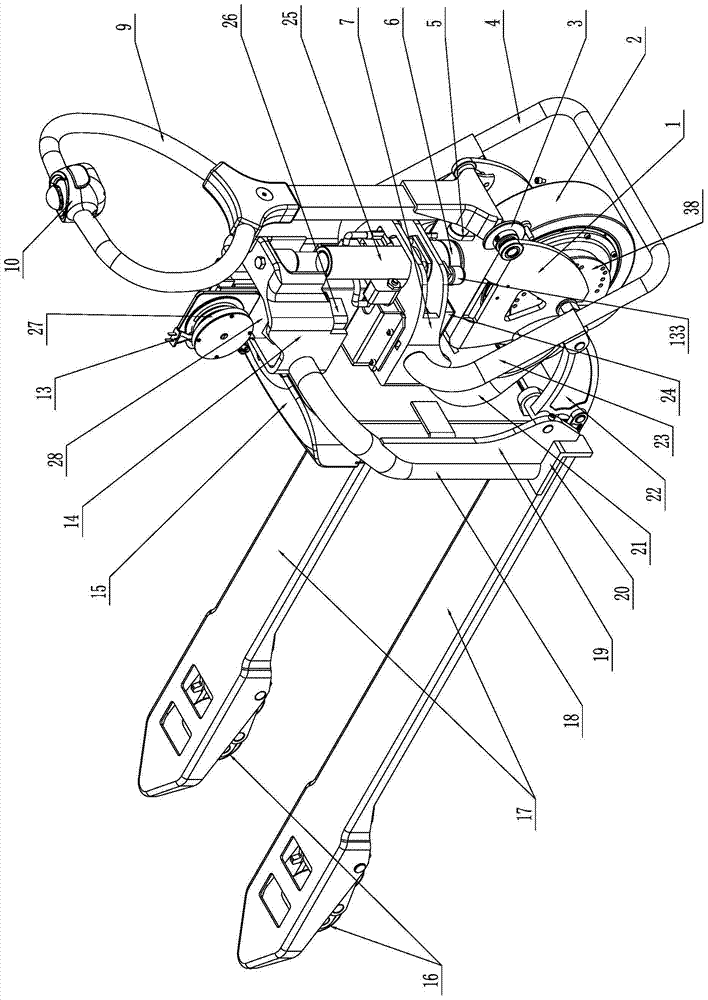

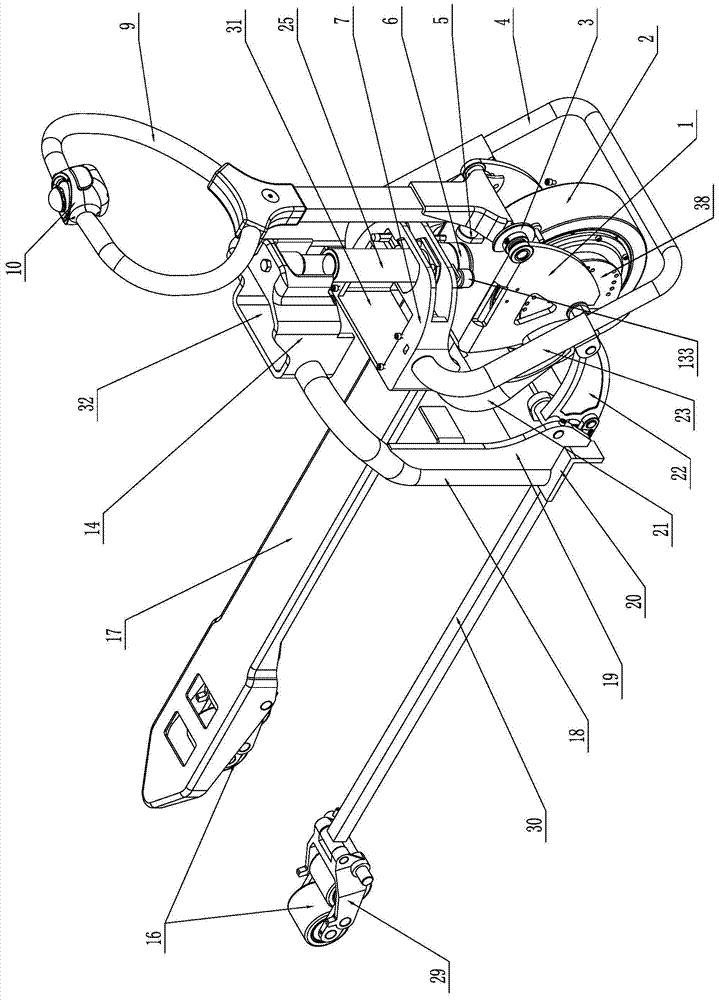

Mini electric carrier

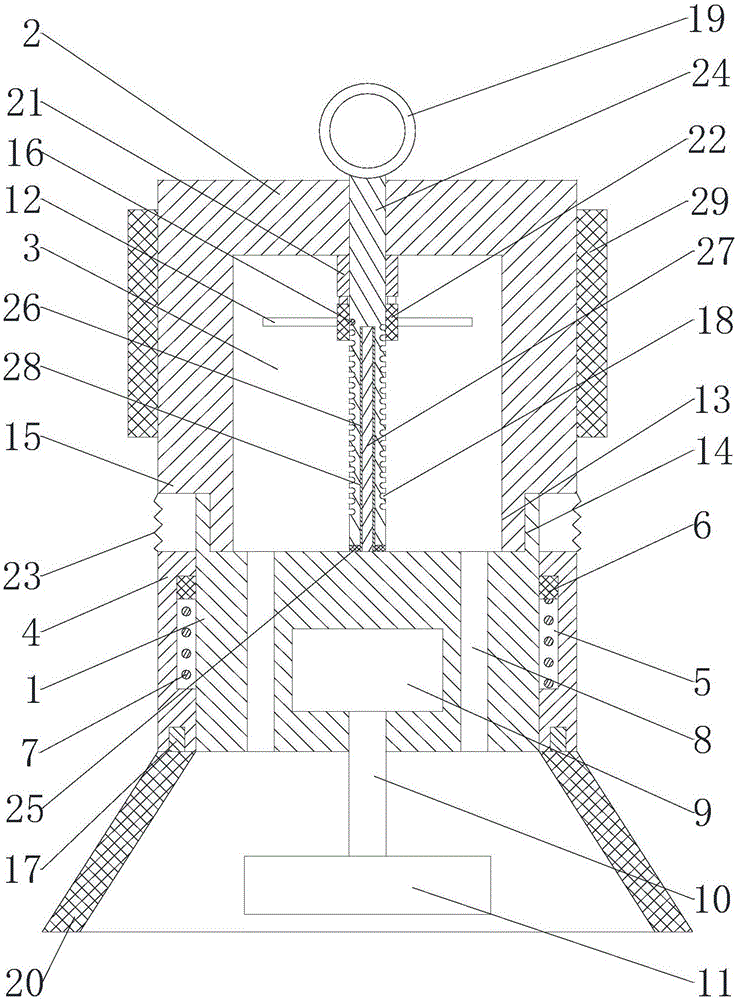

The invention discloses a mini electric carrier and belongs to a carrier. The mini electric carrier comprises a supporting seat plate, a wheel frame, a drive wheel, a handle, a lifting frame, an ejection plate, a storage battery box with storage batteries, two forks, a main controller, an oil cylinder and a hydraulic pump station system. The handle is provided with a handle controller. The front of each fork is provided with a front wheel. The hydraulic pump station system comprises a strong magnetism motor, a valve plate, an oil tank and an oil pump located in the oil tank. The lifting frame comprises a stand column welding plate, tubular main stand columns and a stand column reinforcing plate. The tubular main stand columns are respectively of a hollow pipe structure, and the storage battery box is installed between the two tubular main stand columns. Supporting base protection pipes and protection pipe reinforcing pipes are arranged on the two sides of the supporting seat plate and are respectively of a hollow pipe structure. The ejection plate is provided with a first through cavity, the supporting seat plate is provided with a second through cavity, the oil tank is located in the second through cavity, the upper portion of the strong magnetism motor is located in the first through cavity, and the main controller is located in the first through cavity. The mini electric carrier is small in size, light in weight, flexible in motion and capable of entering narrow and small aisles for work or leaving the narrow and small aisles.

Owner:NINGBO HAOMAI MACHINERY

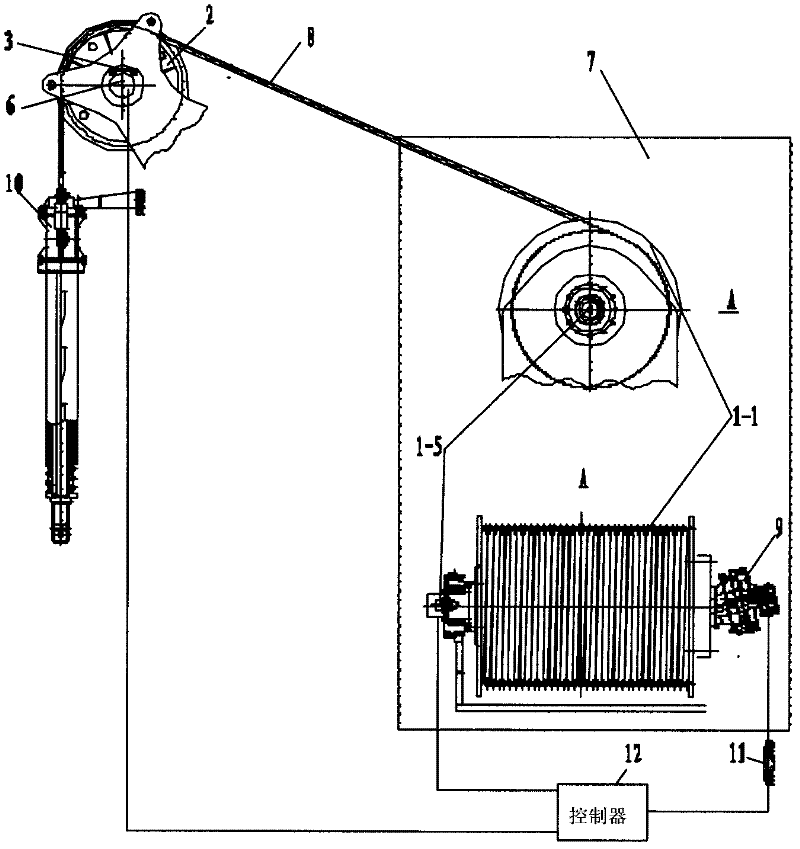

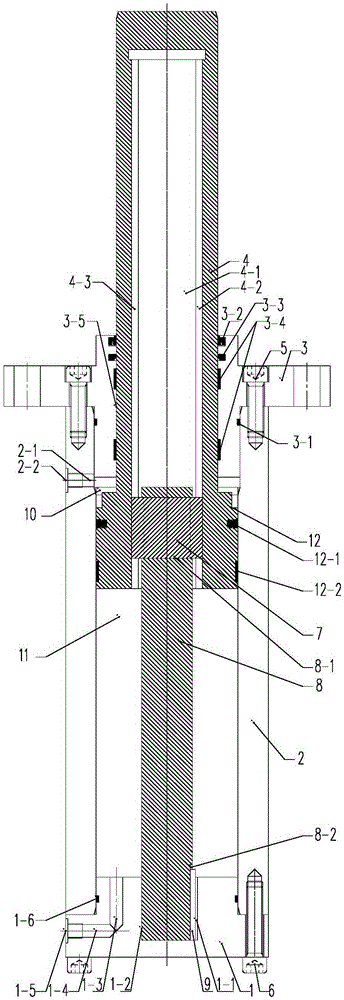

Rod carrying monitoring system for drill rod of rotary drilling machine

InactiveCN102359366AEffective monitoringTroubleshoot severe damageAutomatic control for drillingSolenoid valveMonitoring system

The invention relates to a rod carrying monitoring system for a drill rod of a rotary drilling machine, belonging to monitoring systems of engineering machinery. The monitoring system comprises a pin shaft sensor, a sounding coder, a controller, a pilot solenoid valve and a main winding system, wherein the pin shaft sensor is connected to the center of the main winding pulley, the sounding coder is connected with a rotating shaft at one side of a main winding drum, the output ends of the pin shaft sensor and the sounding coder are both connected with the input end of the controller, the output end of the controller is connected with the pilot solenoid valve, the pilot solenoid valve is connected with a main winding motor of the main winding system, the controller is arranged in an electric control box, the pilot solenoid valve is installed on the drilling machine car body, the main winding system and the main winding motor are connected with the winding drum, the main winding drum is connected with the drill rod through a steel wire rope, the steel wire rope pass through a main winding pulley groove, a main winding pulley is installed on a main winding pulley bracket. The rod carrying monitoring system has the advantages of simple structure, capability of effectively monitoring the rod carrying condition of the drill rod and judging whether the rod carrying of the drill rod happens or not without depending on the experience of operators, and good reliability and practical applicability.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

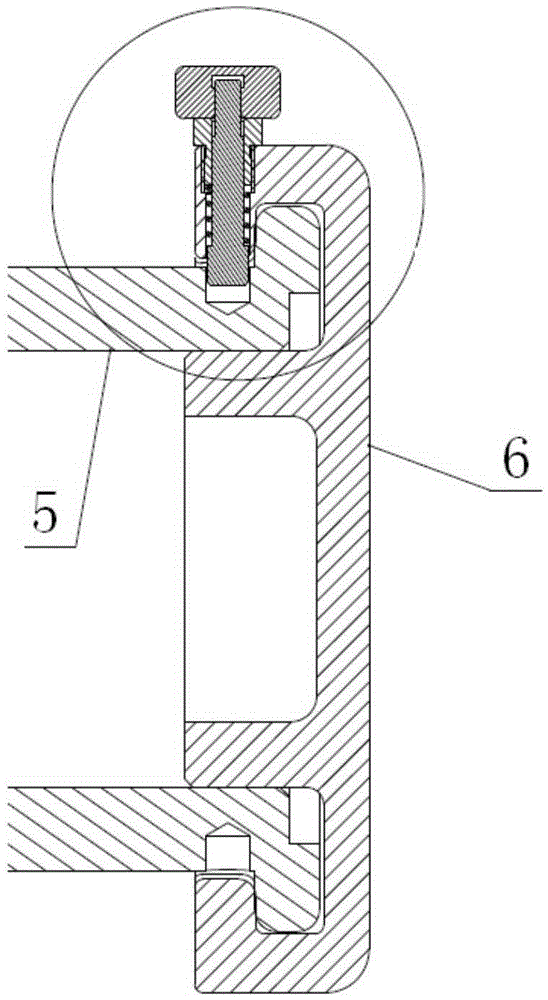

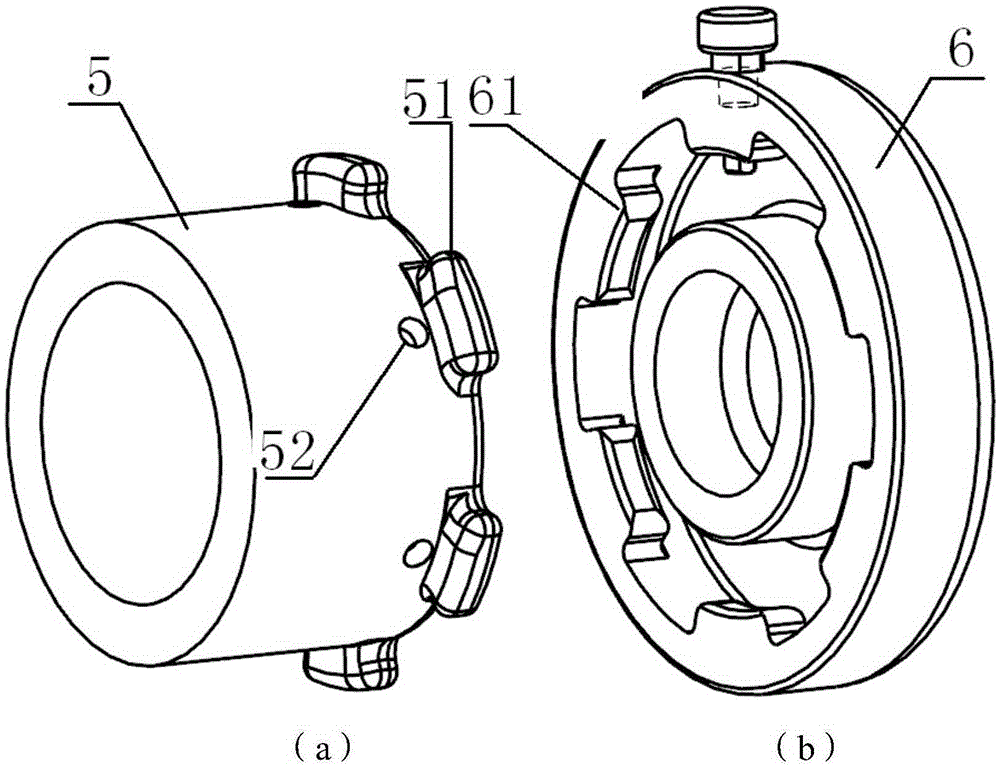

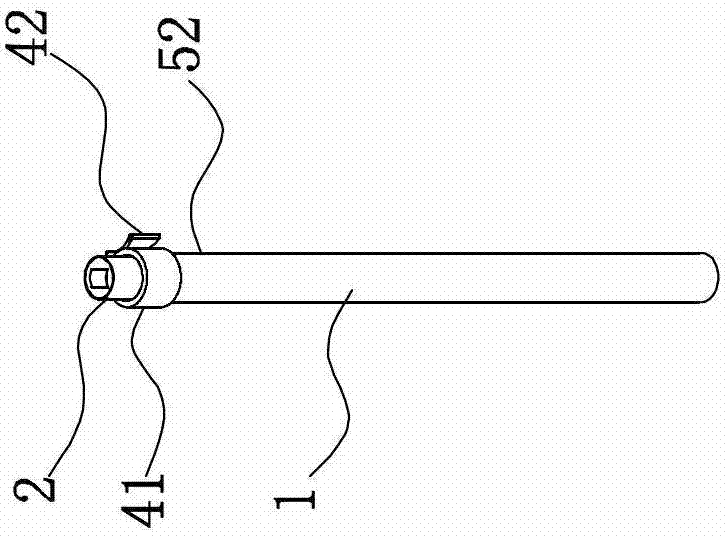

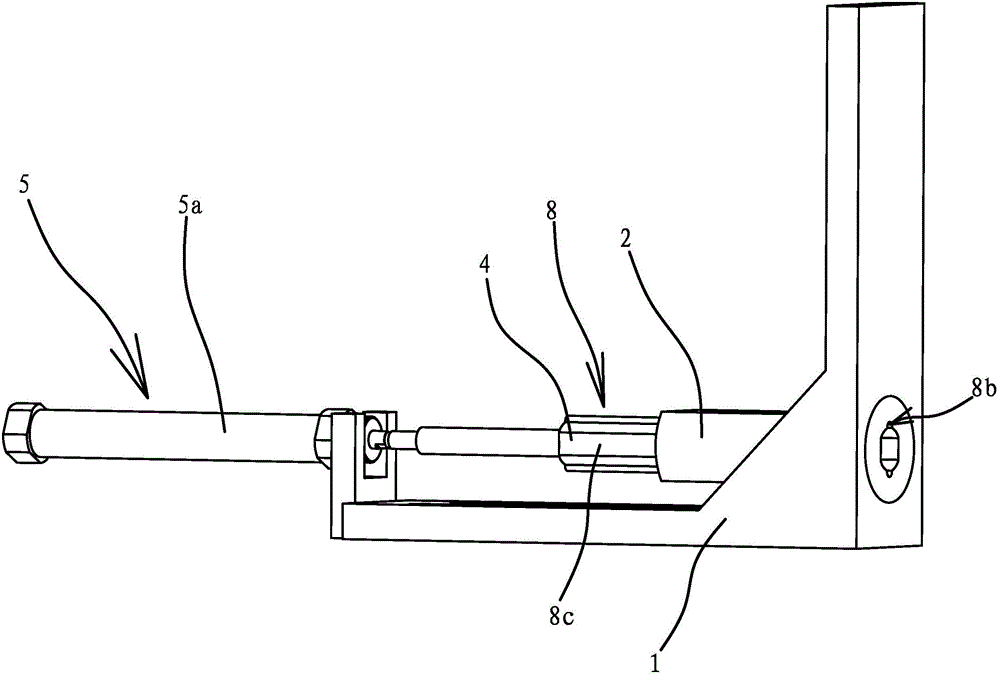

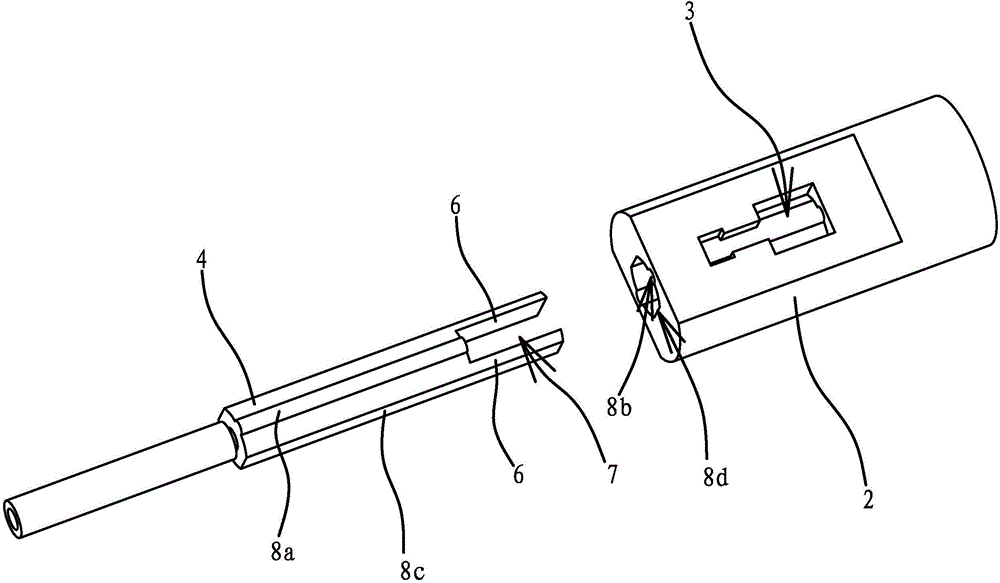

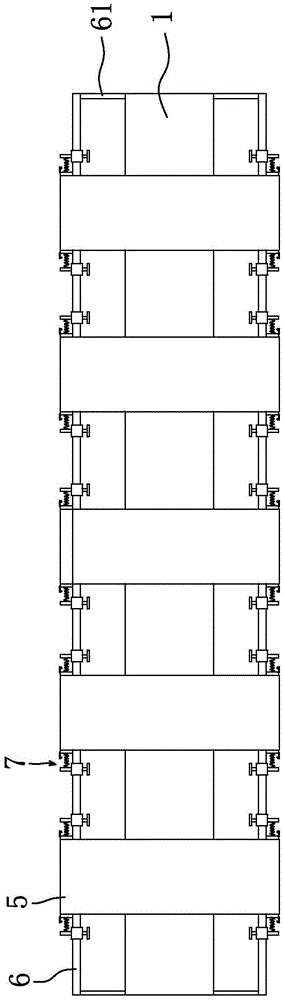

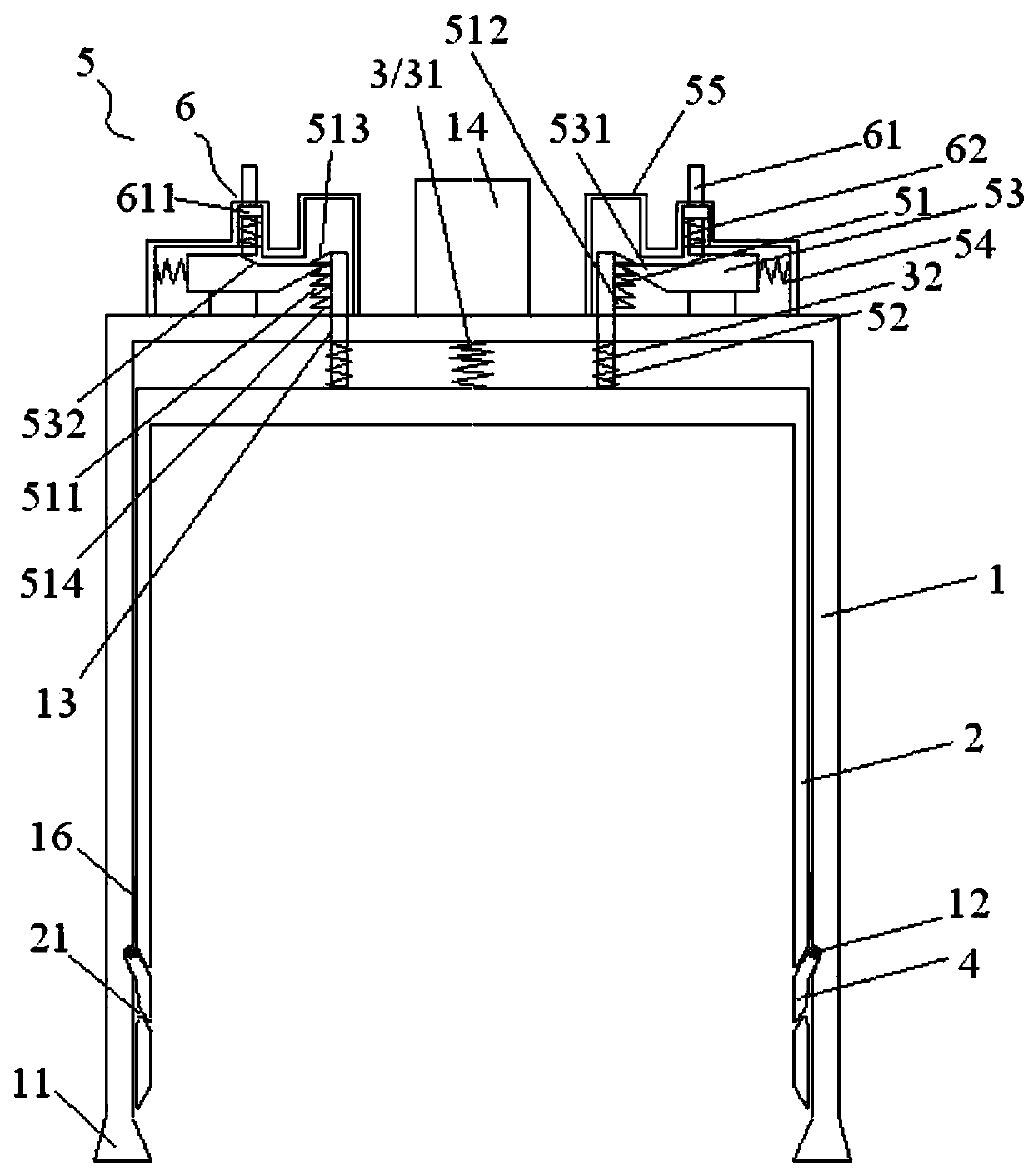

Fast clamping locking device

The invention provides a fast clamping locking device which comprises nuts (1), thread sleeves (2), springs (3), locking pins (4), first clamping supporting rims (61) and second clamping supporting rims (51). One end of each locking pin (4) is fixedly connected with the corresponding nut (1), and the other end of each locking pin (4) is inserted in a locking blind hole (52). Each locking pin (4) is sleeved with the corresponding thread sleeve (2). Each thread sleeve (2) is mounted in a mounting hole of an end cover (6). Each locking pin (4) is sleeved with the corresponding spring (3). One end of each spring (3) is connected with the corresponding thread sleeve (2), and the other end of each spring (3) is connected with the end, inserted in the corresponding locking blind hole (52), of the corresponding locking pin (4). The nuts (1) are pulled out or loosened, the springs (3) are driven to stretch out and draw back, the locking pins (4) are made to move in the mounting holes of the end cover (6), and therefore mounting, dismounting and locking of the end cover (6) and a shell (5) are achieved. Through the fast clamping locking device, high-precision and high-reliability connection between structures is achieved in a narrow space; the fast clamping locking device is compact in structure, easy to operate, capable of being dismounted and mounted repeatedly and good in maintainability.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

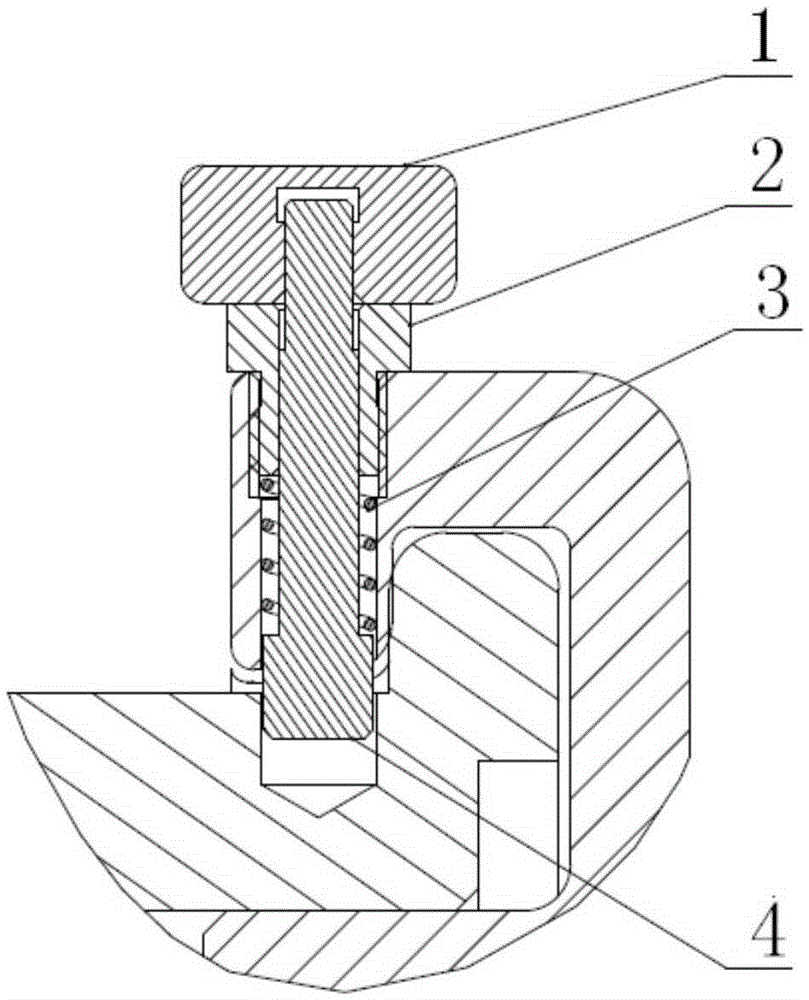

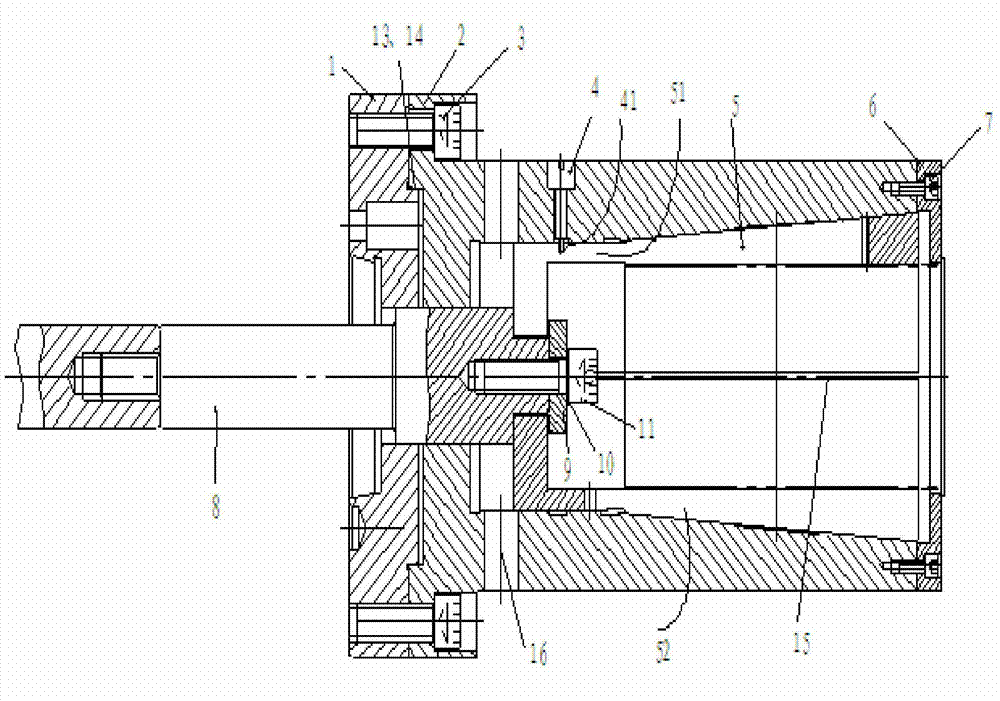

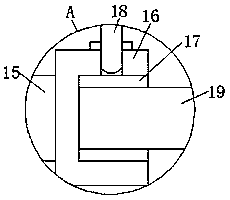

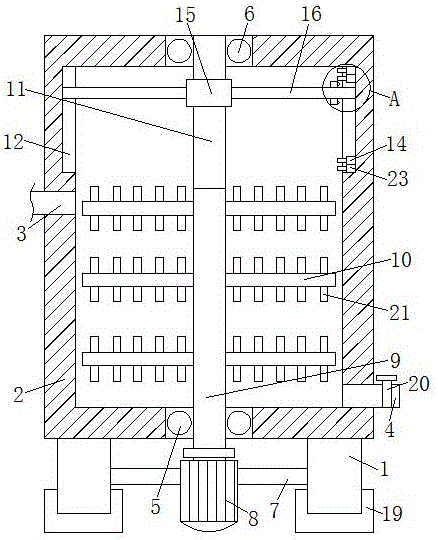

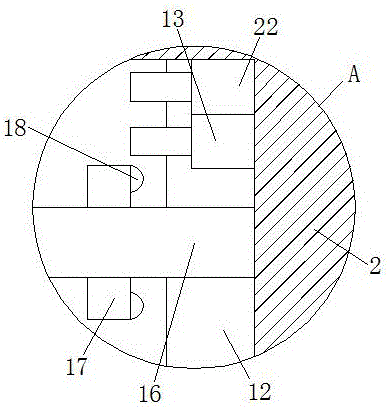

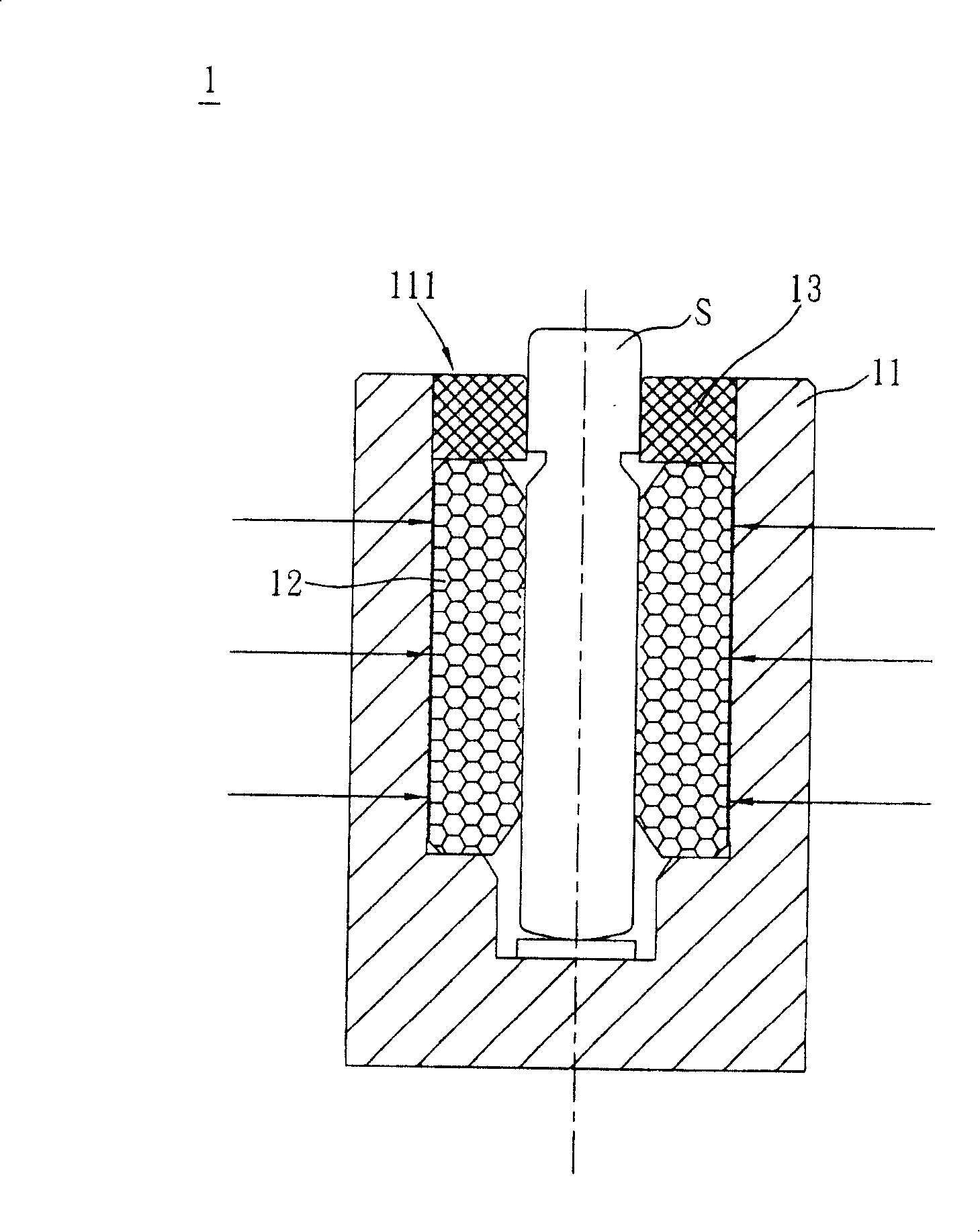

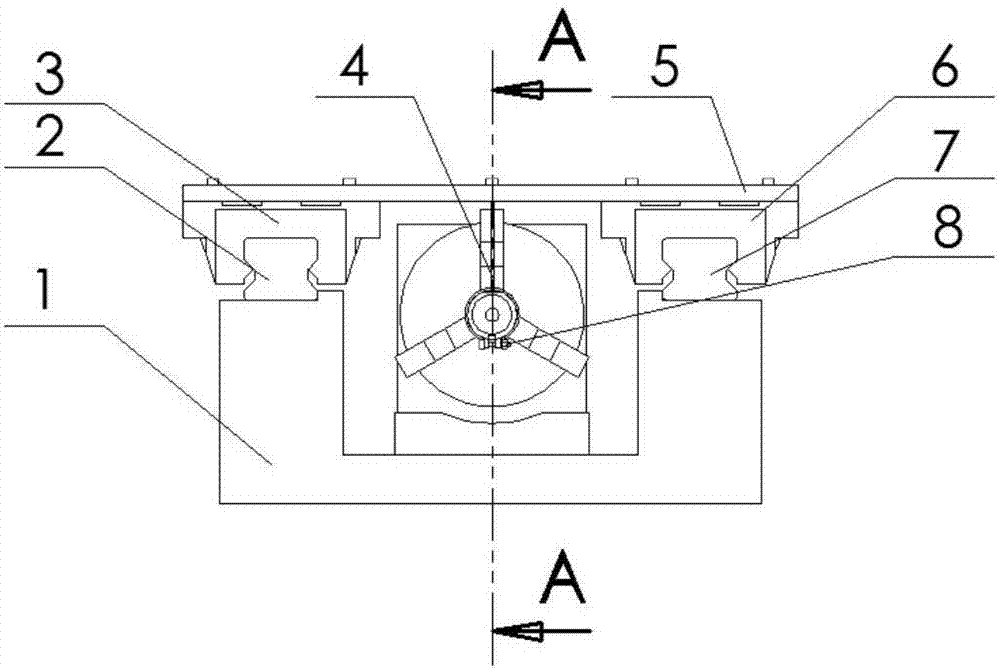

Special tooling for turning high-precision thin-wall cylinder liner bores

InactiveCN104493600AReliable positioning and clampingUniform clamping forcePositioning apparatusMetal-working holdersCircular coneEngineering

The invention discloses a special tooling for turning high-precision thin-wall cylinder liner bores, which comprises an internal taper sleeve, an elastic clamp and an axial positioning disk, the left end of the internal taper sleeve is connected with a spindle flange, the right end of the internal taper sleeve is connected with the axial positioning disk, the right side of the internal taper sleeve is provided with a taper hole, the taper hole is connected with a cylindrical hole of the left side, the sidewall of one side of the cylindrical hole is provided with a guide hole, a vent hole is formed in the left side of the guide hole, the elastic clamp comprises an internal cylindrical hole and an external conical surface, the external conical surface is connected with an external cylindrical surface, a pull rod holder is arranged on the external cylindrical surface, the pull rod holder is provided with a pull rod-fixing hole, a washer is arranged at the right side of the pull rod-fixing hole, the outer diameter of the washer is greater than the inner diameter of the pull rod-fixing hole, the excircle of the end of an oil cylinder pull rod is matched with the pull rod-fixing hole, the end of the oil cylinder pull rod is provided with a threaded hole, and the oil cylinder pull rod is connected with the washer. The structural precision of the special tooling is high, a thin-wall cylinder liner can be positioned and clamped reliably, clamping stress is uniform, the deformation of the thin-wall cylinder liner caused by clamping force is reduced, and the precision requirement of workpieces is met.

Owner:JINAN FIRST MACHINE TOOL GROUP

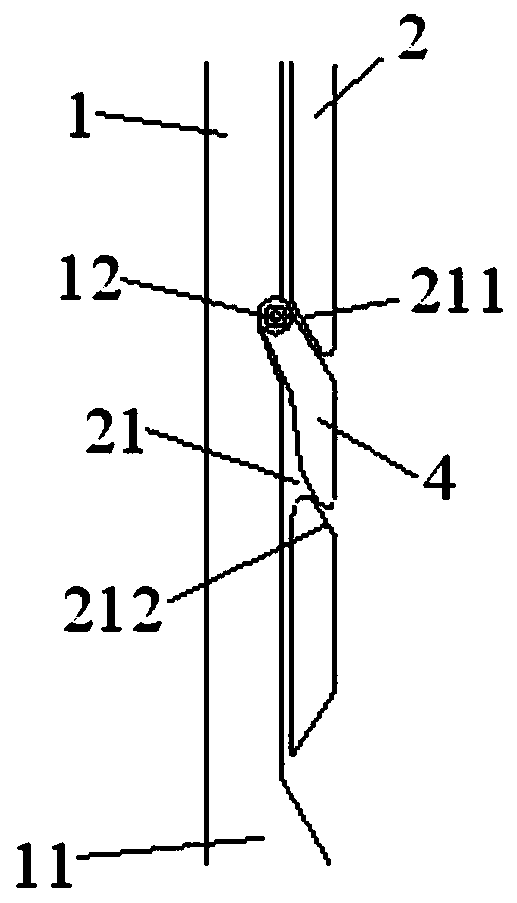

Expansion pole

InactiveCN102966647AGuaranteed StrengthPrevent circumferential rotationRod connectionsTextiles and paperEngineeringMechanical engineering

Owner:胡杰波

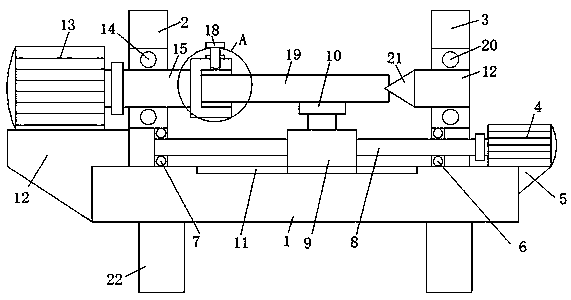

Pressing rivet stud surface polishing device

InactiveCN107838755APrevent circumferential rotationSolve the errorRevolution surface grinding machinesGrinding drivesCouplingArchitectural engineering

The invention relates to the technical field of mechanical parts, and discloses a pressing rivet stud surface polishing device. The pressing rivet stud surface polishing device comprises a working table and a stud main body. A first vertical column and a second vertical column are fixedly connected with the two sides of the top of the working table correspondingly, a first motor is fixedly connected with the position, on one side of the second vertical column, of the top of the working table, and an output shaft of the first motor is fixedly connected with a threaded rod through a coupler; anda first bearing is fixedly connected with one side of the second vertical column, a second bearing is fixedly connected with one side of the first vertical column, and one end of the threaded rod penetrates through the first bearing and is fixedly connected to the axis of the second bearing in an inserted mode. According to the pressing rivet stud surface polishing device, the threaded rod can conduct positive and negative rotation through arrangement of automatic positive and negative rotation of the first motor, finally a polishing machine is driven to move to polish the stud main body through a threaded pipe, so that the problems that a polishing error is prone to being generated, and the polishing efficiency is reduced when polishing is conducted manually are effectively solved, and using is convenient for people.

Owner:无锡华利达金属制品有限公司

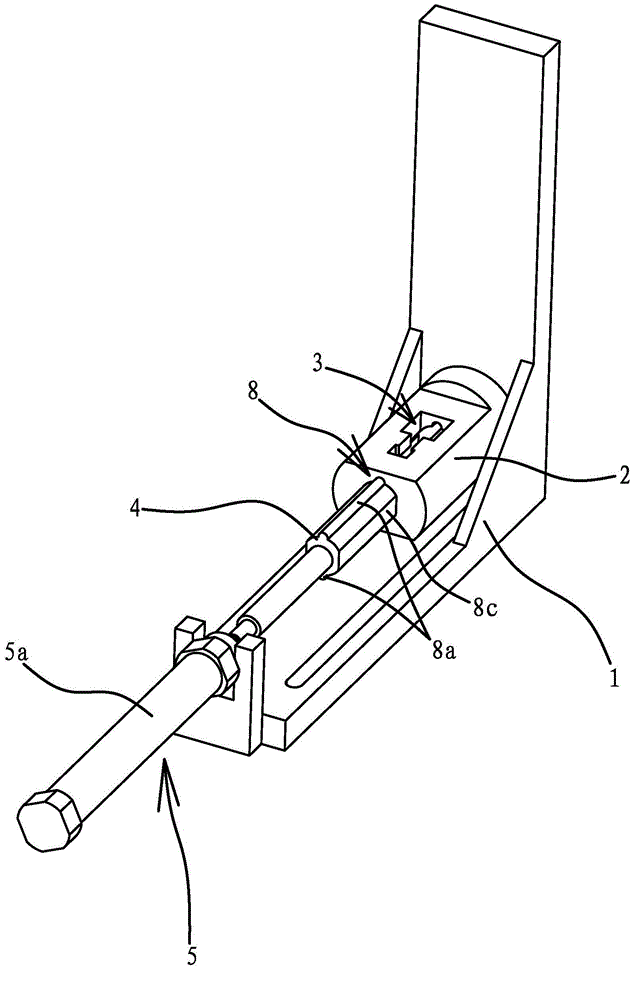

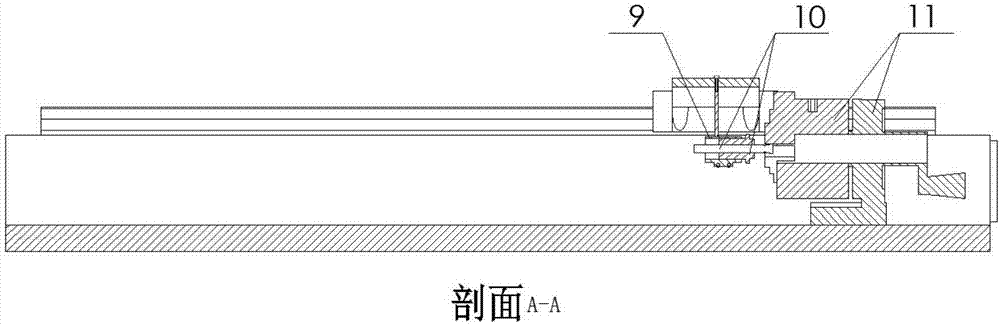

Pushing mechanism of feeding device

ActiveCN103978400AWork reliablyGood positioning effectMetal working apparatusGastric tube feedingFeeding tube

The invention provides a pushing mechanism of a feeding device, belongs to the technical field of machine components, and solves the problem of incapability of pushing smoothly of the existing feeding device. The pushing mechanism of the feeding device comprises a support and a feeding tube arranged on the support, wherein one side of the feeding tube is provided with a feed port I which is communicated with a cavity of the feeding tube; a pushing rod is arranged in the feeding tube; the support is further provided with a driving mechanism I capable of driving the pushing rod to do reciprocating movements; a pushing part which is protruded out of the end face of the pushing rod and is in a shape of a column is arranged on the inner end face of the pushing rod. The pushing mechanism of the feeding device has the advantages of reliable operation and smooth feeding of workpieces.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Automatic anti-sedimentation device for textile assistant

InactiveCN106669502AAvoid centrifugationReduce the possibility of stirring dead endsRotary stirring mixersTransportation and packagingEngineeringTextile

The invention discloses an automatic anti-sedimentation device for a textile assistant. The device comprises a support leg and a stirring motor, wherein a stirring box is fixedly connected with the upper surface of the support leg; a feeding hole and a discharging hole are respectively formed in the surface of the stirring box; a first bearing and a second bearing are respectively fixed on the inner bottom wall and the inner top wall of the stirring box; a supporting plate is fixedly connected with the middle part of the support leg; the stirring motor is fixedly arranged in the middle of the supporting plate; an output shaft of the stirring motor is fixedly connected with a rotating shaft through a coupler. The automatic anti-sedimentation device for the textile assistant can achieve the effect of positively and negatively turning the stirring motor, and meanwhile, the effect of the stirring motor capable of automatically positive and negative turning also can be achieved, the effect of positively and negatively stirring the textile assistant in the stirring box can be achieved, the problem of centrifugal separation of the matters in the textile assistant can be effectively avoided, a contact block connected with the surface of a contact rod can ascend and descend, and an upper travel switch, a lower travel switch, an upper limiting switch and a lower limiting switch can be conveniently touched.

Owner:佘峰

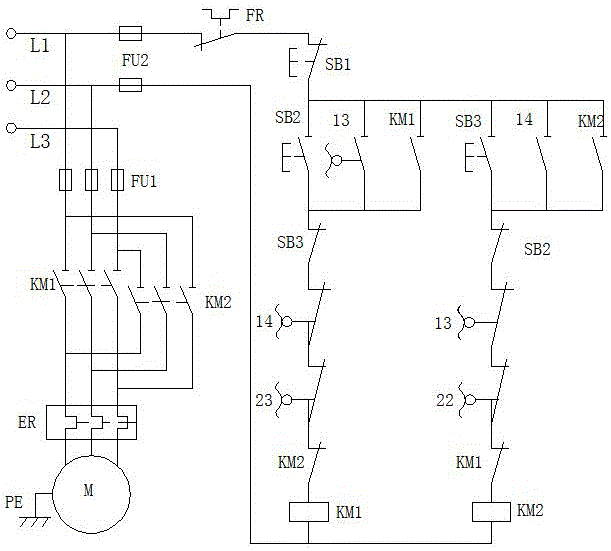

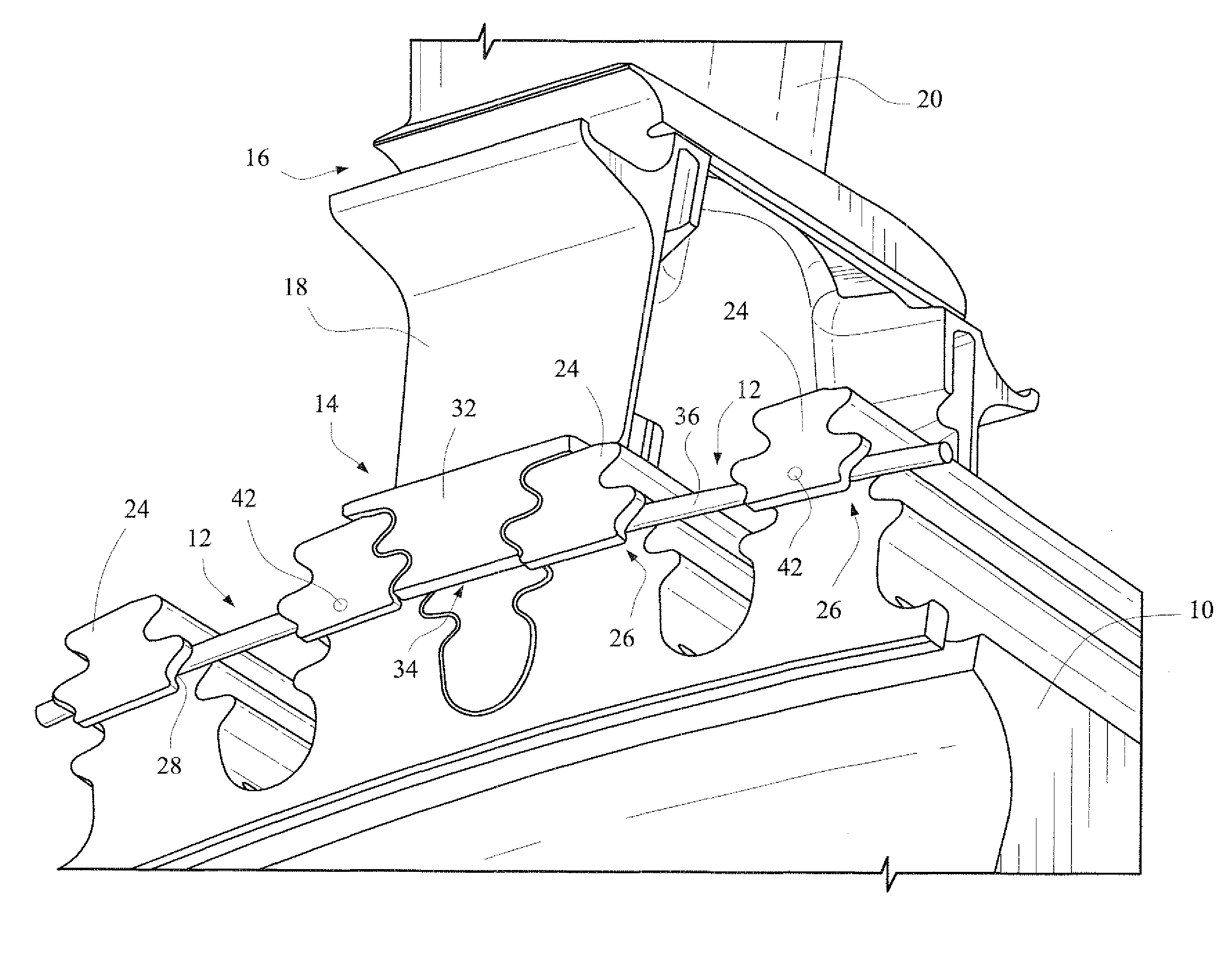

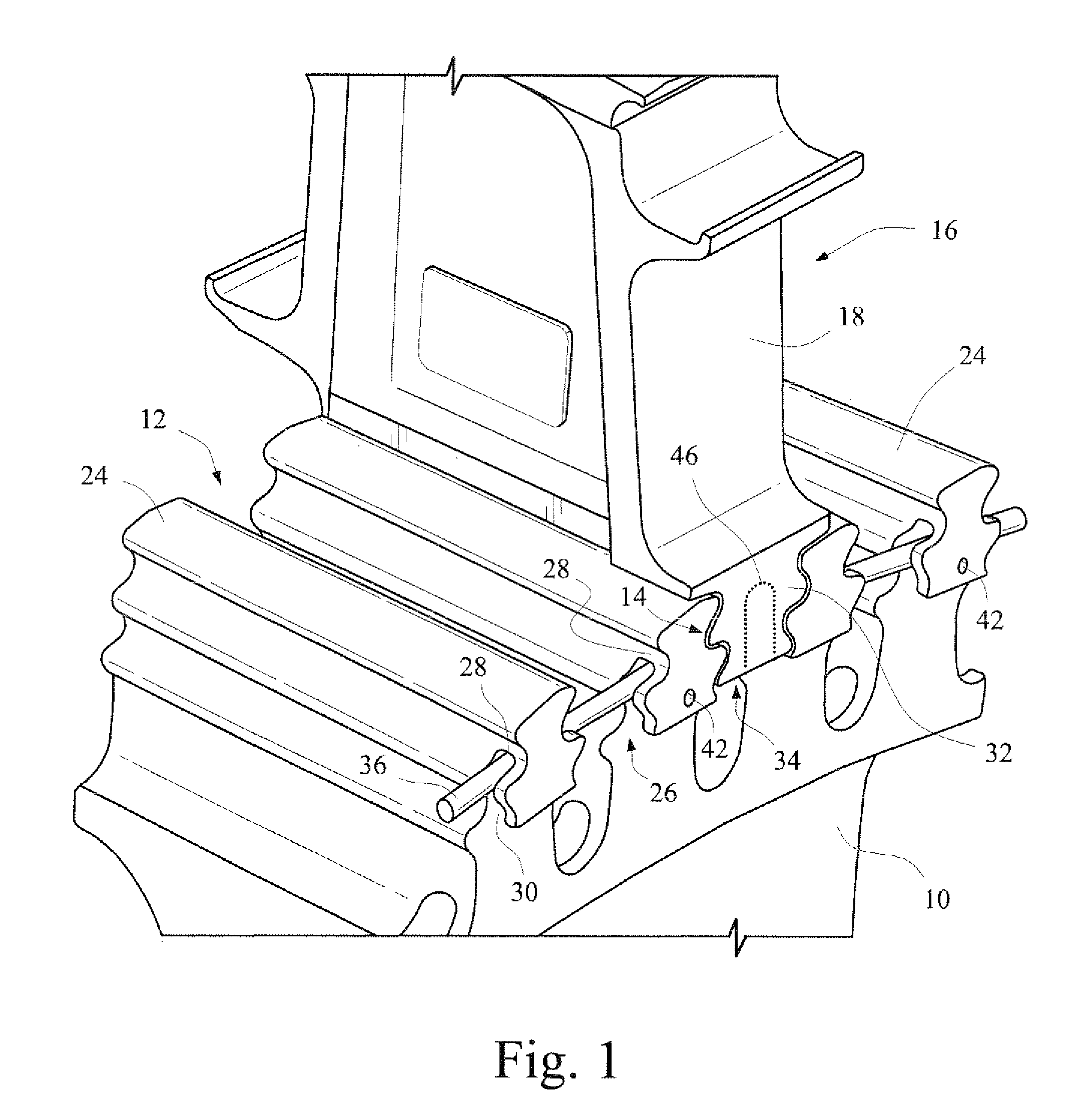

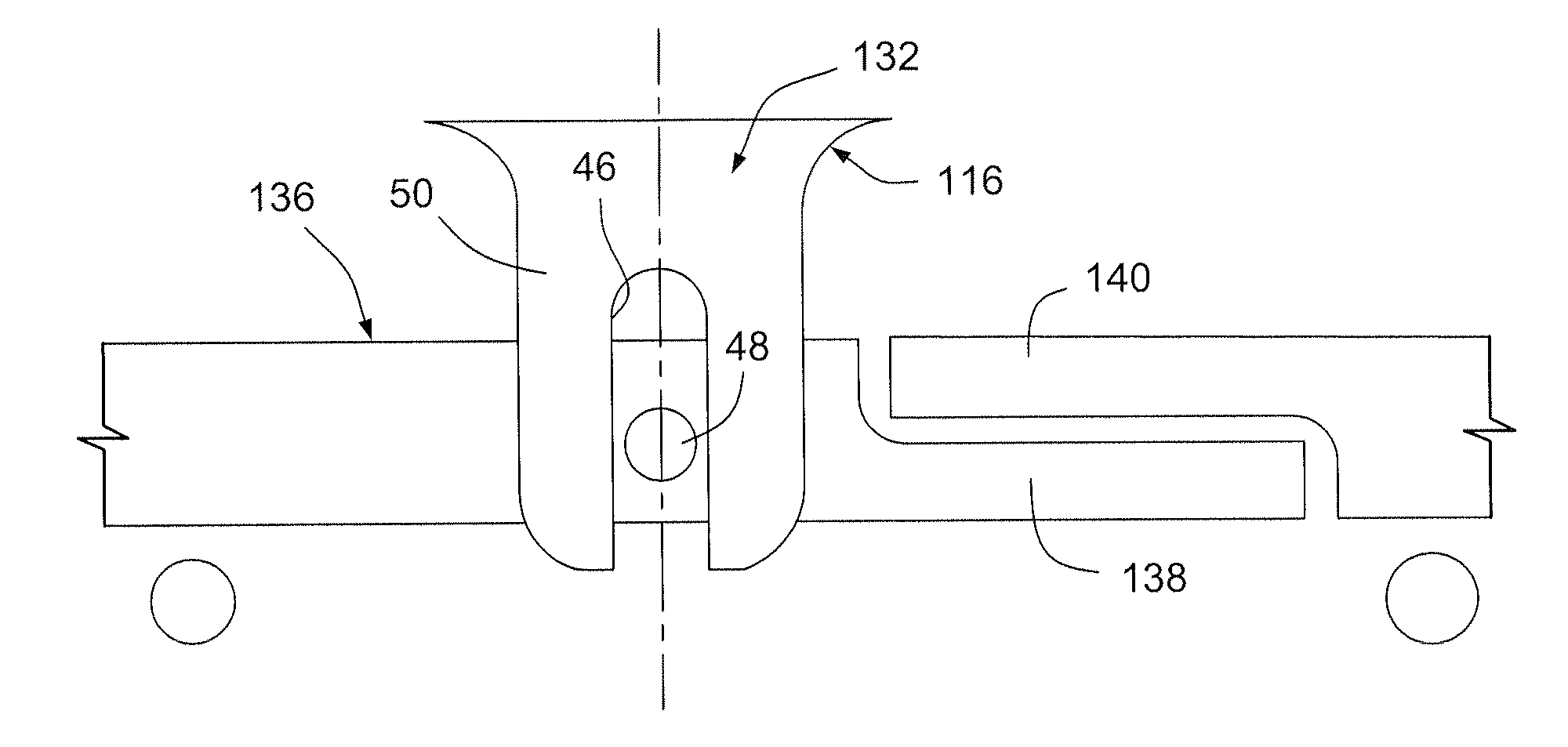

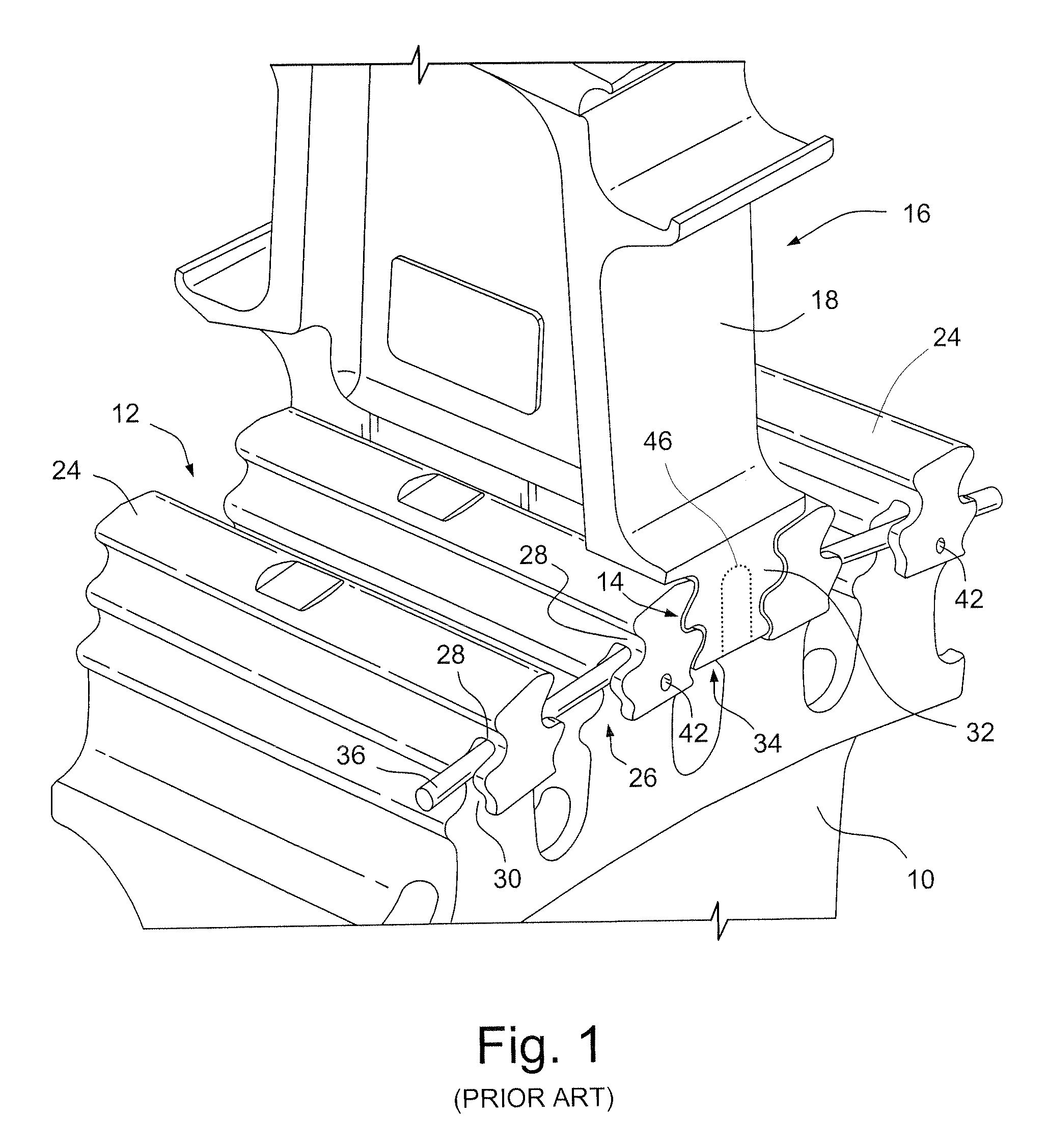

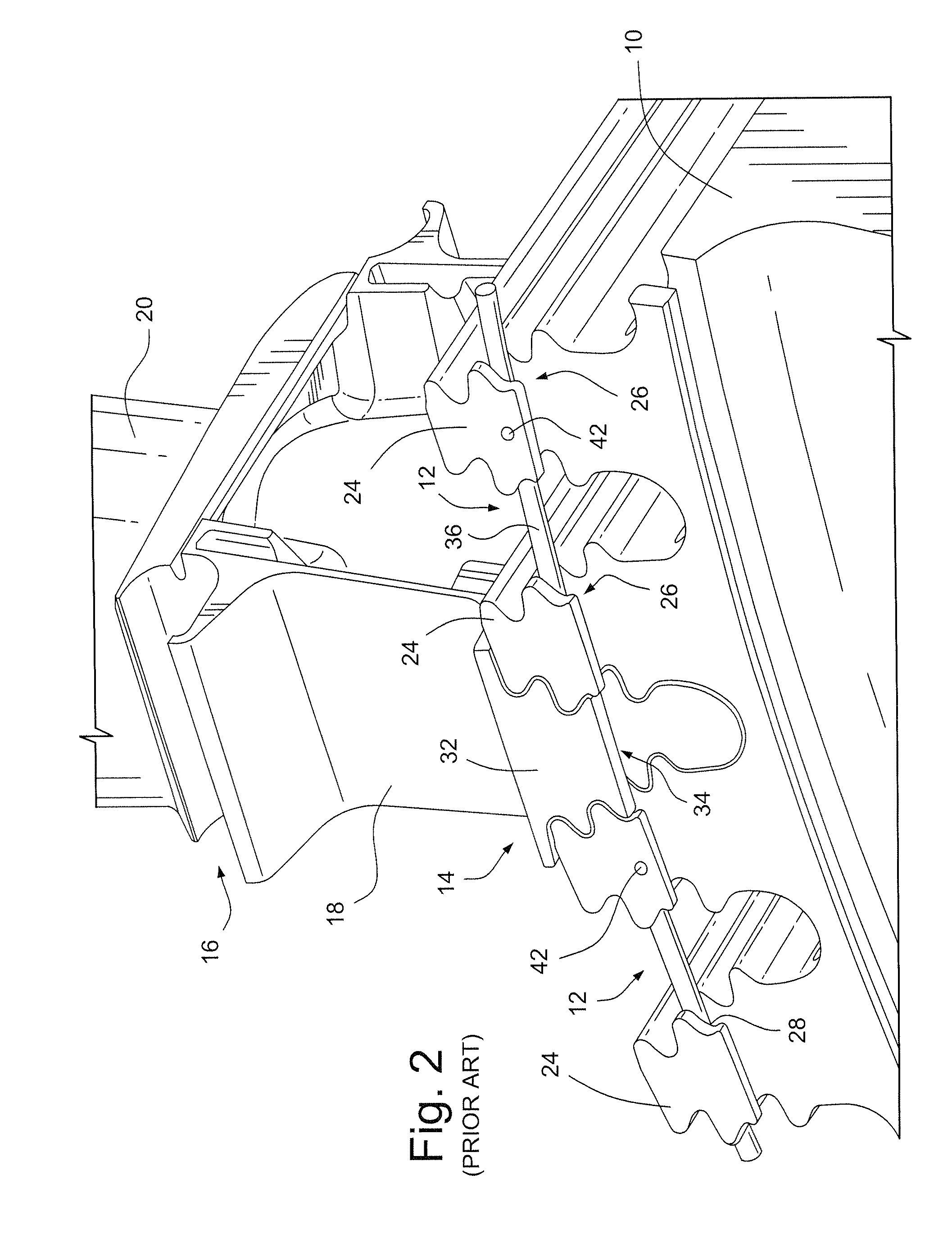

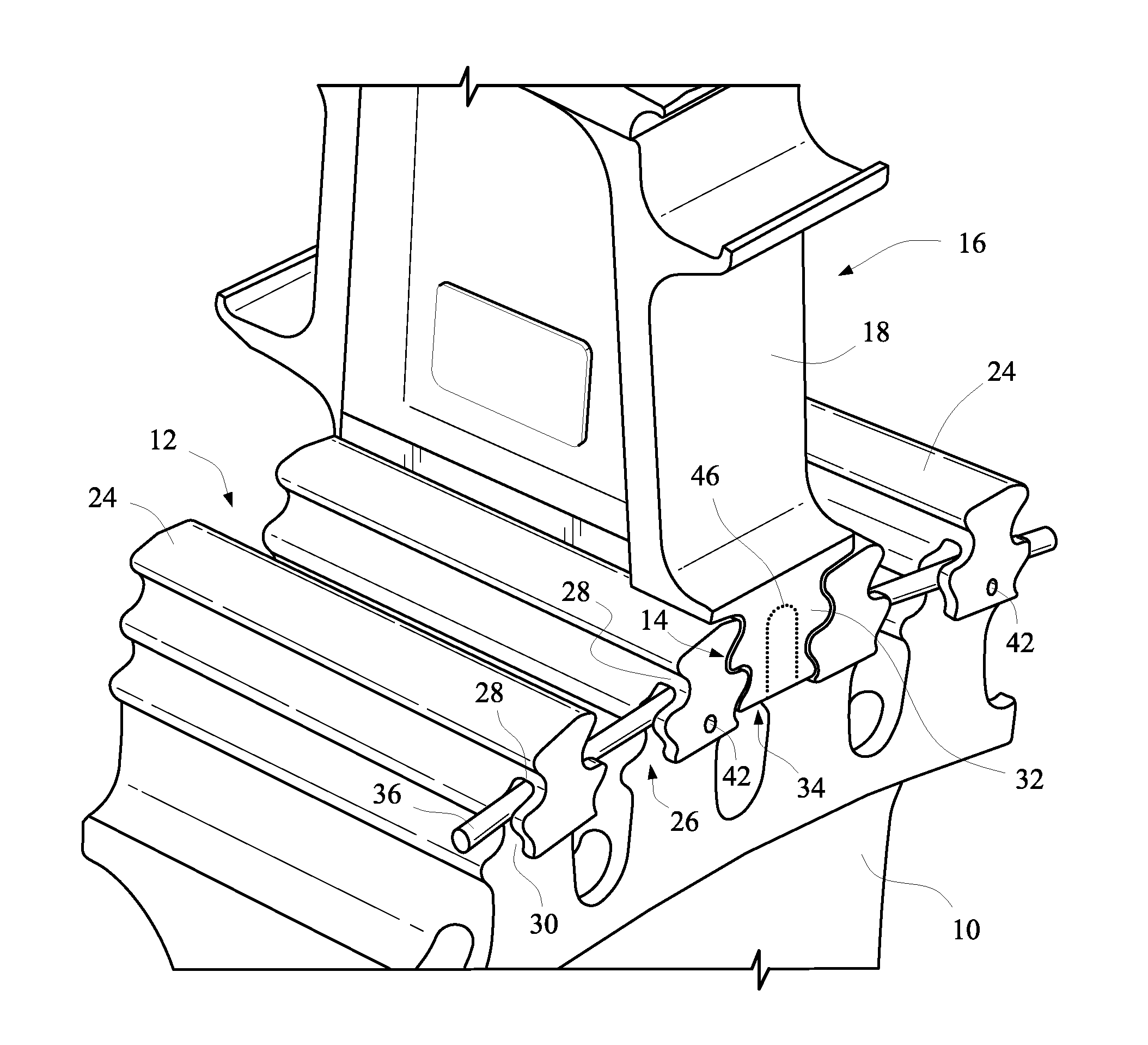

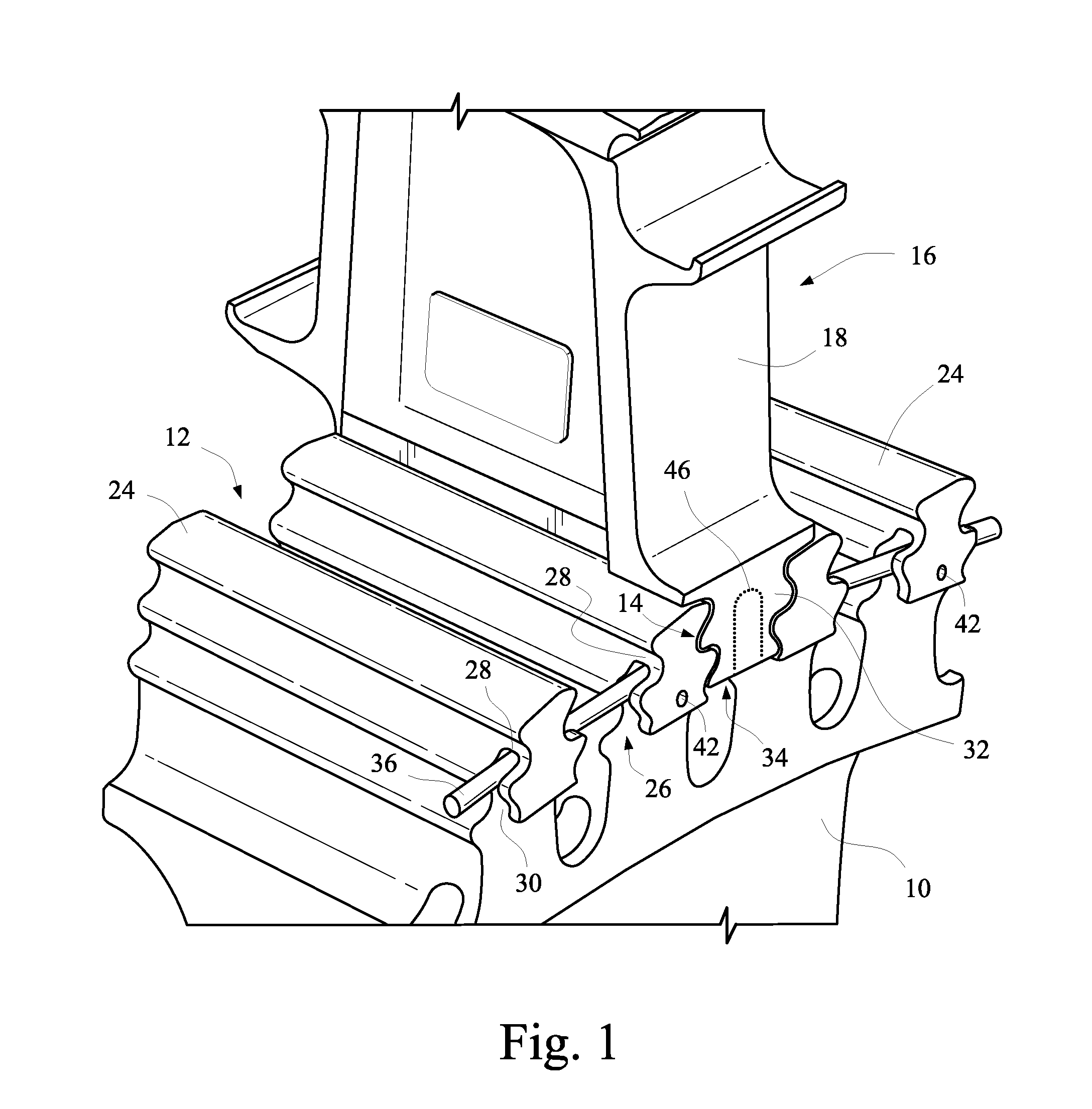

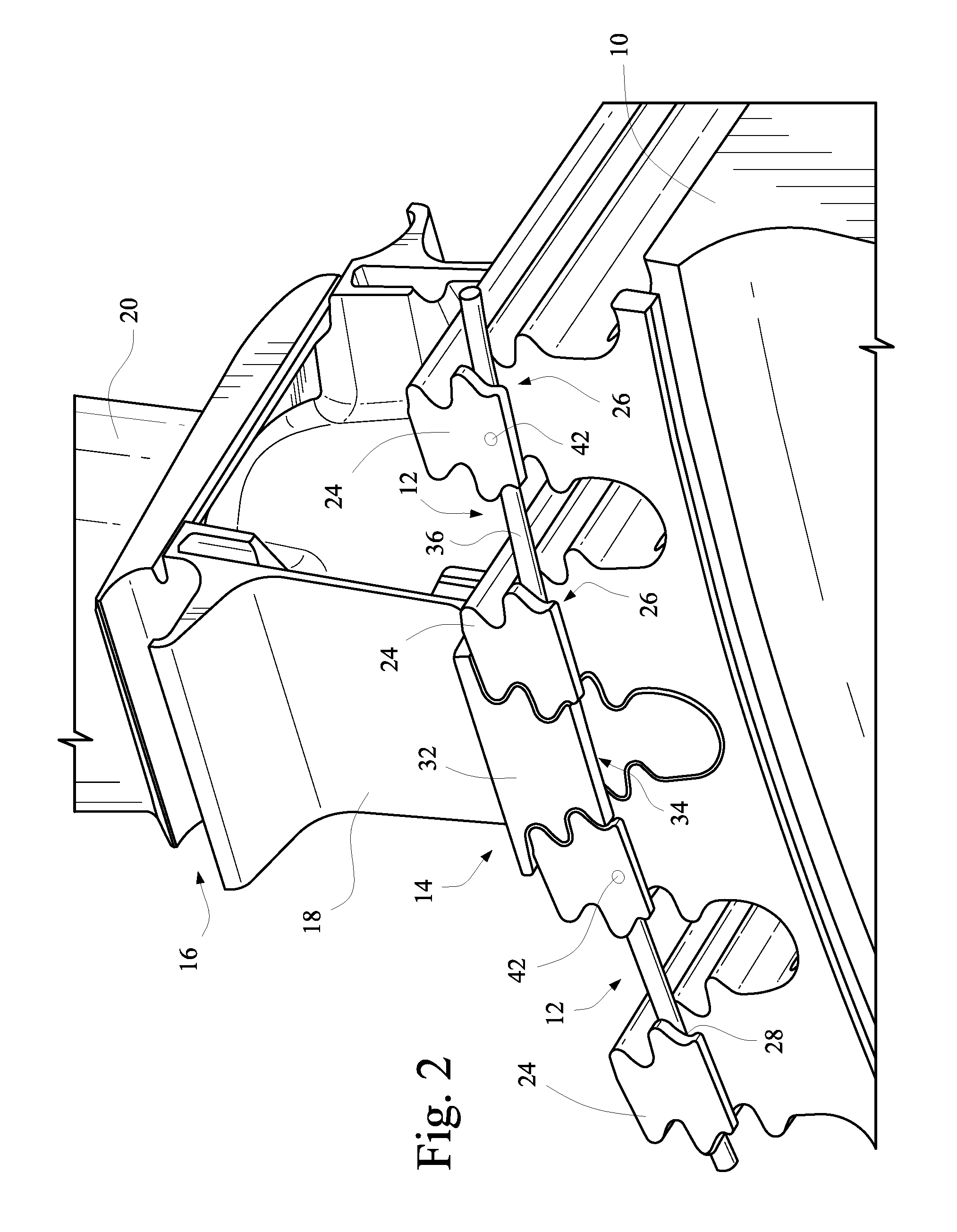

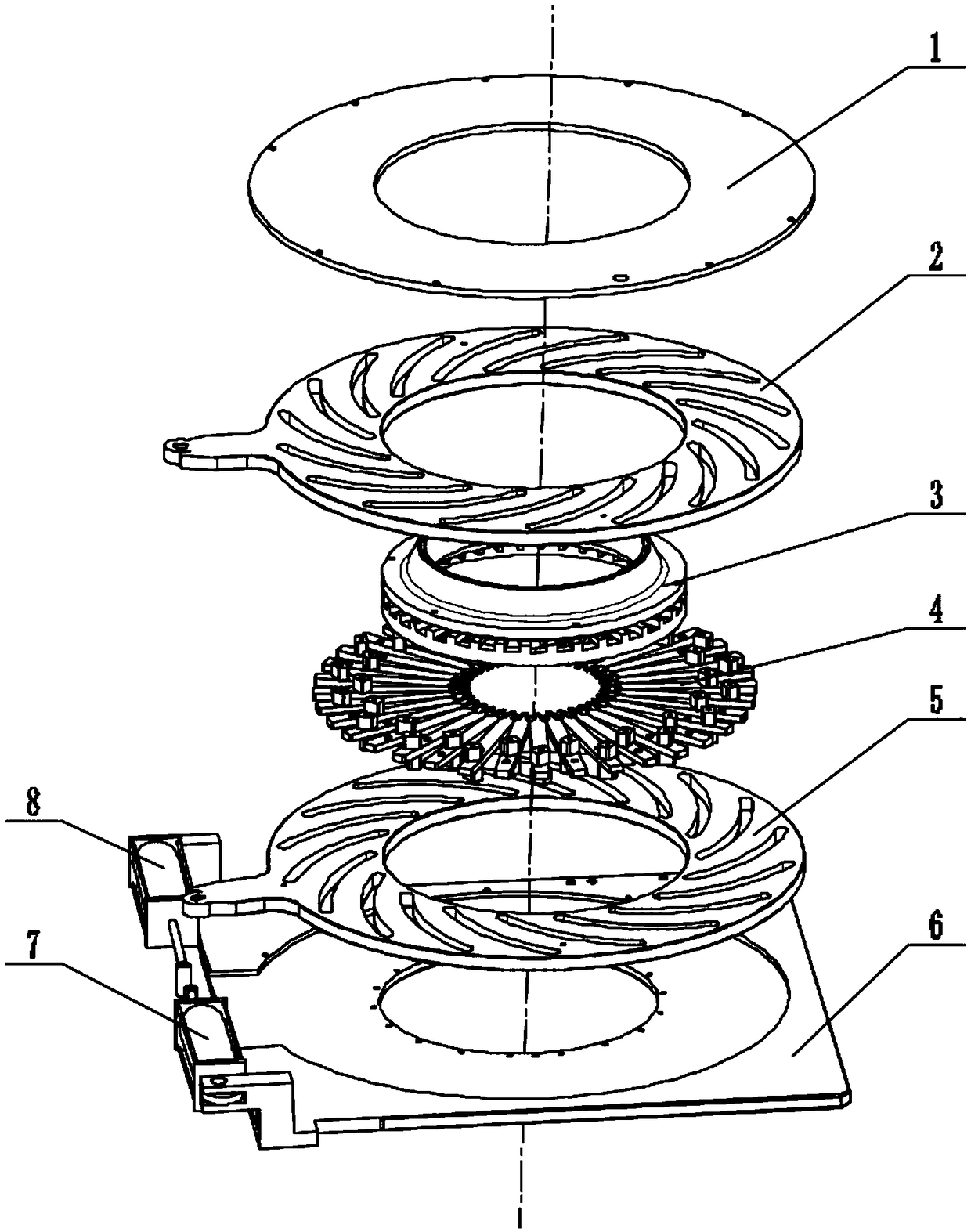

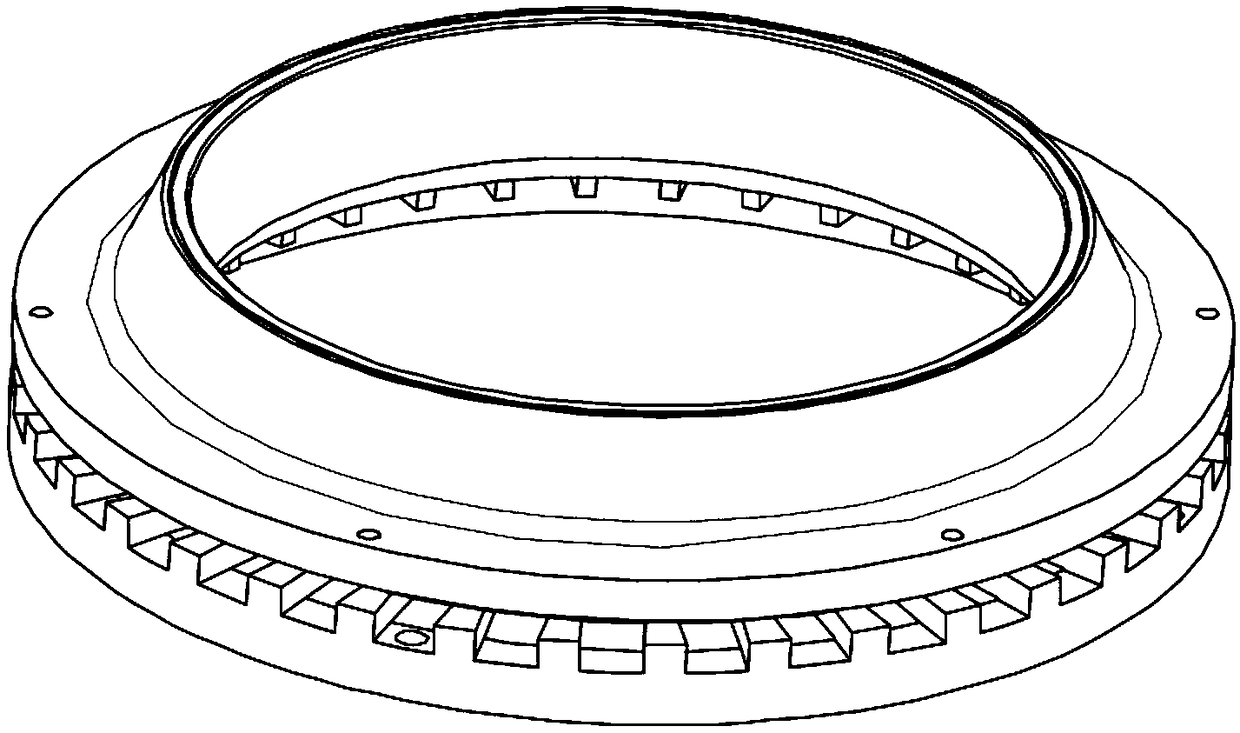

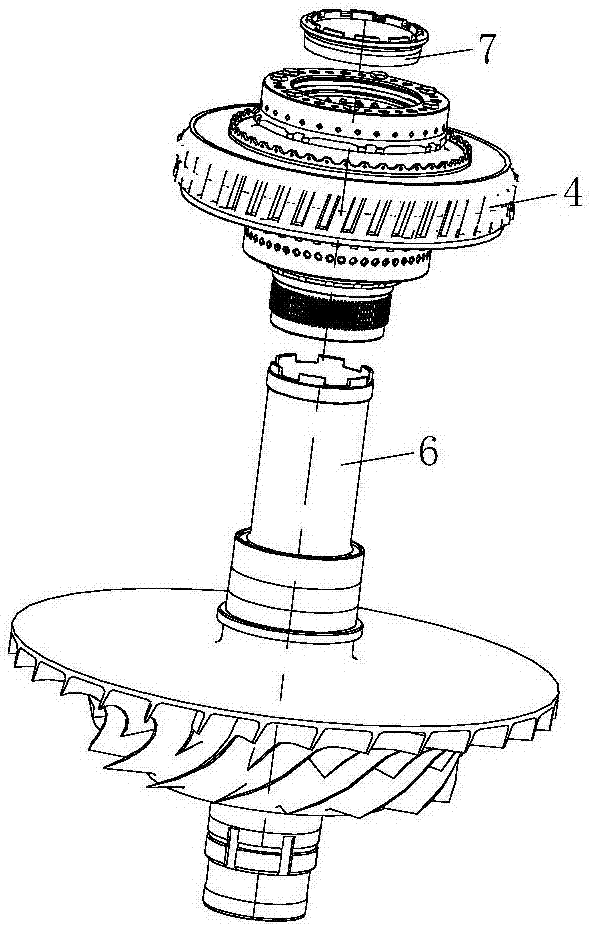

Turbine bucket lockwire rotation prevention

ActiveUS20120087798A1Prevent circumferential rotationPropellersRotary propellersImpellerTurbine rotor

A retention system for a plurality of turbine buckets located in respective mating slots in a turbine rotor wheel includes a plurality of first circumferentially-oriented retention slots formed in outer peripheral portions of the turbine wheel; a plurality of second circumferentially-oriented retention slots formed in wheel mounting portions of said buckets, the first and second circumferentially-oriented retention slots aligned to form an annular lockwire retention slot; and a lockwire located within the annular lockwire retention slot. A first surface feature on one or both of the turbine rotor wheel and one or more of said plurality of turbine buckets is adapted to engage a second surface feature on the lockwire for preventing rotation of the lockwire beyond predetermined limits.

Owner:GENERAL ELECTRIC CO

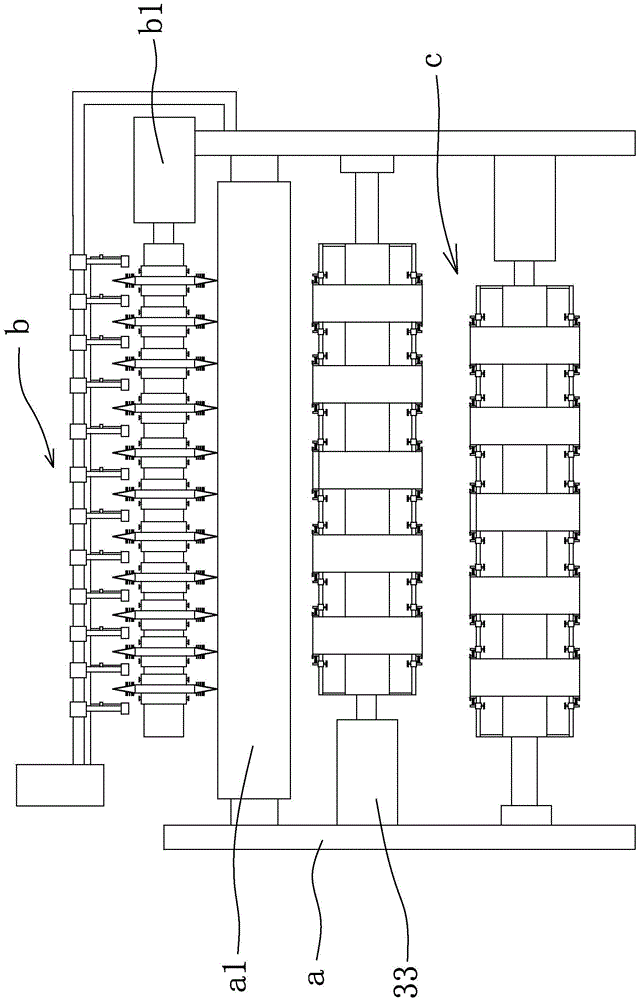

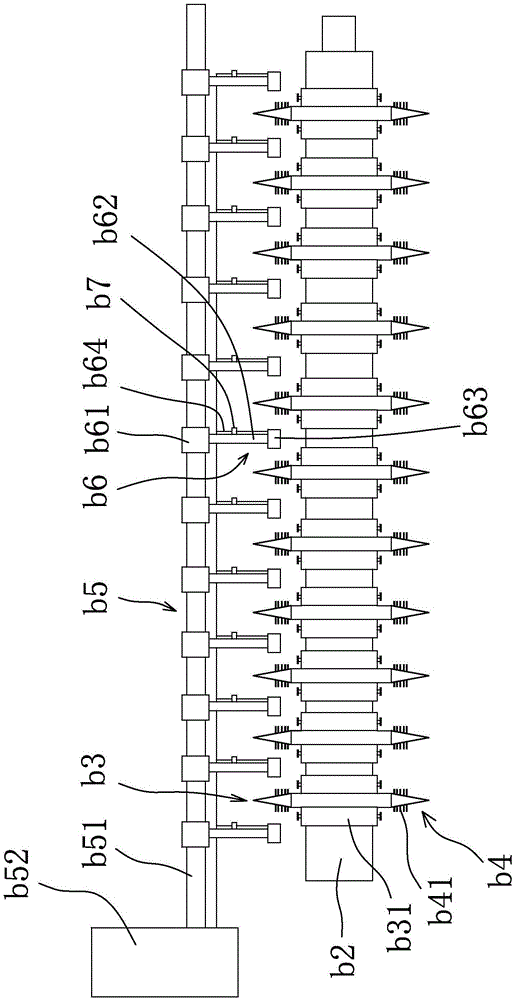

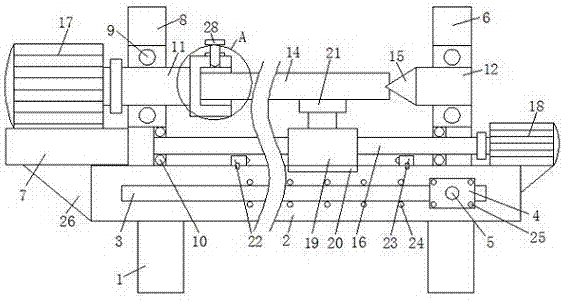

Efficient thin film slitting machine

InactiveCN105600565AQuality improvementGuaranteed stabilityArticle deliveryWebs handlingEngineeringLocking mechanism

The invention provides an efficient thin film slitting machine. The efficient thin film slitting machine comprises a rack, wherein a feeding roller is arranged on the rack; a slitting blade mechanism for slitting a thin film wound on the feeding roller is arranged above the feeding roller; the thin film, which is slit by the slitting blade mechanism, is wound on a winding mechanism; the winding mechanism comprises at least two rollers which are connected with a first driving mechanism; the two rollers are provided with tensioning mechanisms which are arranged in sequence in a staggered manner; each tensioning mechanism comprises at least one tensioning assembly; each tensioning assembly is connected with a tensioning part which sleeves a winding barrel; an elastic sealing assembly is arranged between each tensioning part and the corresponding roller; each tensioning part is provided with fastening devices which are located at the two sides of the corresponding winding barrel and can be used for tightly clamping the winding barrel; the position between the two fastening devices can be adjusted; locking mechanisms are arranged on the fastening devices. The efficient thin film slitting machine has the advantage of good slitting effect.

Owner:ZHEJIANG OUTE ELECTRONICS TECH CO LTD

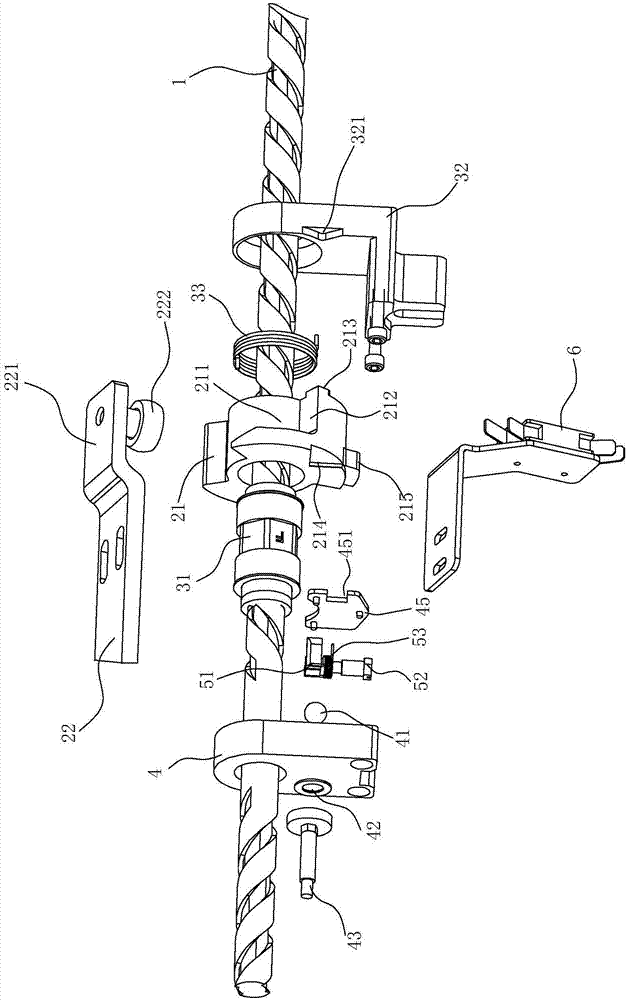

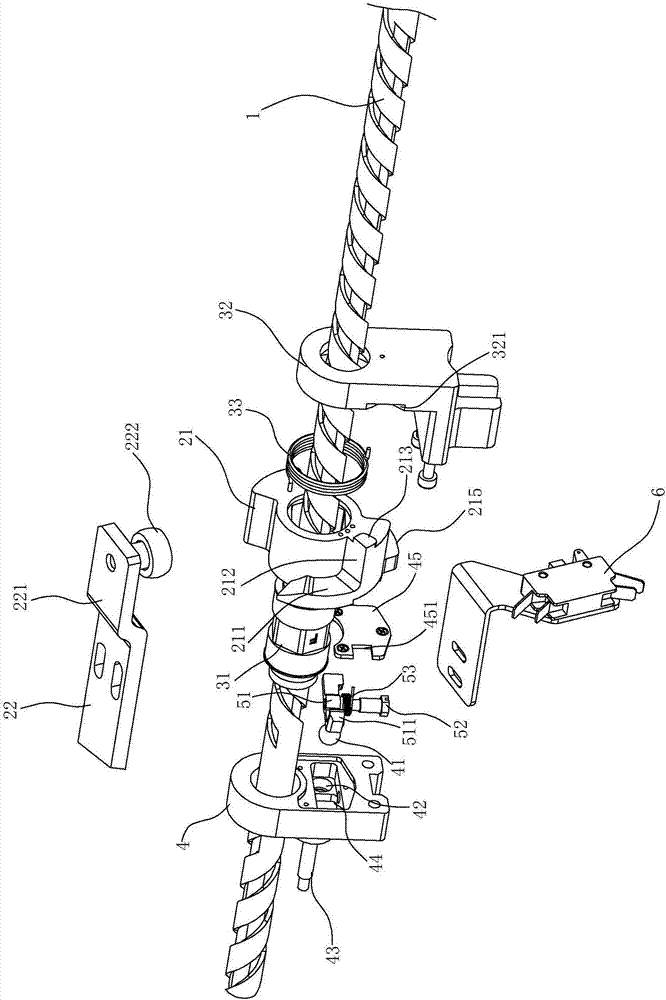

Passive terminal locking device for railway vehicle door system

ActiveCN107339045AAchieve lockingReduce in quantityPower-operated mechanismLocking mechanismEngineering

The invention relates to a passive terminal locking device for a railway vehicle door system. The passive terminal locking device comprises a lead screw and a locking mechanism. The locking mechanism comprises a transmission nut assembly and a locking assembly, wherein the transmission nut assembly is arranged on the lead screw in a sleeving manner and achieves transmission with the lead screw; the locking assembly comprises a locking nut and a locking limitation assembly; the locking nut is arranged on the transmission nut assembly in a sleeving manner, the locking limiting assembly is fixed to the upper portion of the locking nut, the locking nut is driven by the transmission nut assembly to rotate in the circumferential direction of the lead screw, the locking nut is located when rotating to the position abutting against the locking limitation assembly, and therefore the transmission nut assembly is also locked; and when the locking nut rotates to disengage from the locking limitation assembly, unlocking of the locking nut is achieved. According to the passive terminal locking device, by arranging the locking nut and the locking limitation assembly, locking of a door leaf is achieved, the structure is simple, concise and compact, the number of components is small, machining is easy, the dead load is small, and too large installation space is not needed; and moreover actions are easy and reliable, the components cannot be damaged, and the safety and the reliability are high.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

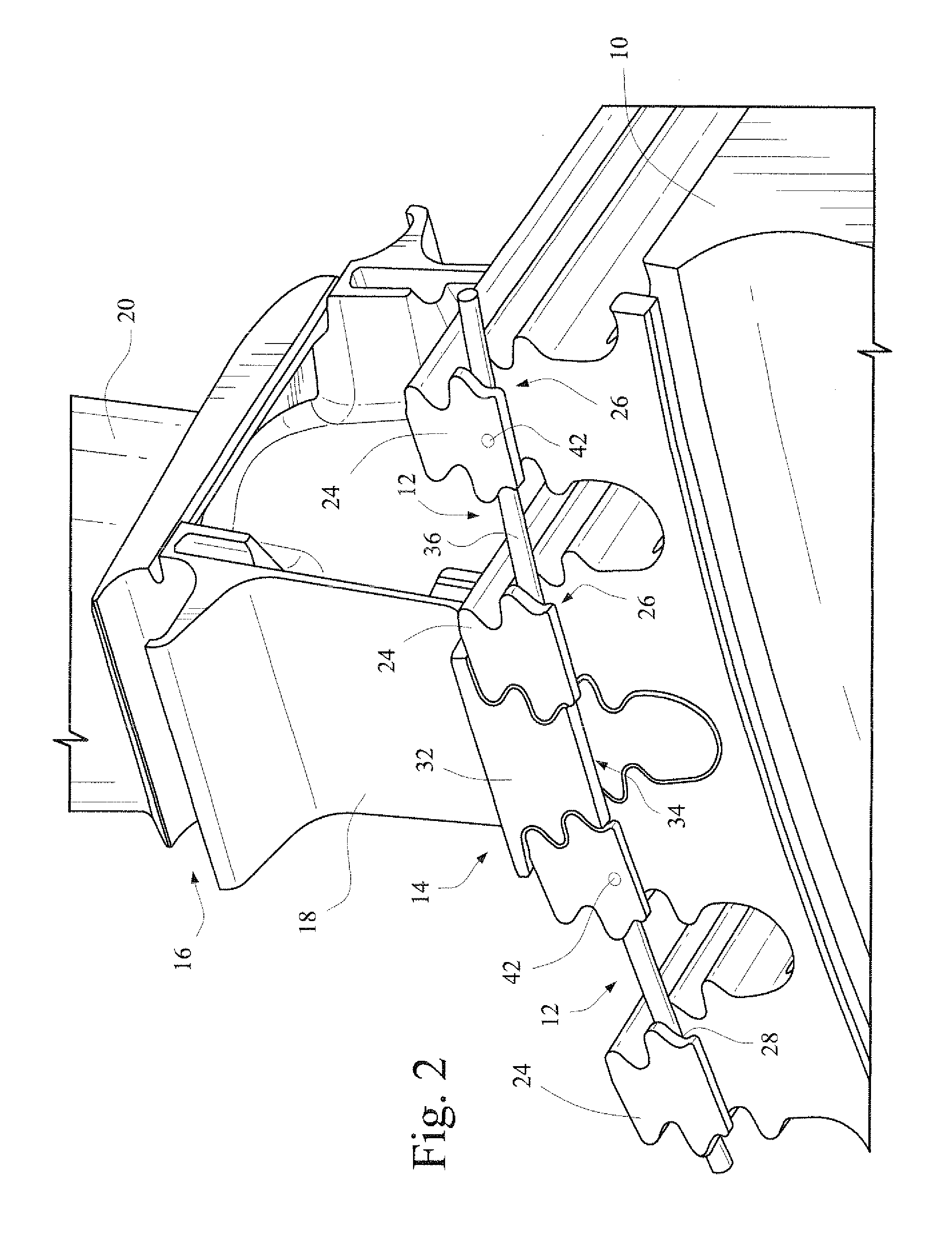

Turbine bucket lockwire rotation prevention

A retention system for a plurality of turbine buckets located in respective mating slots in a turbine rotor wheel includes a plurality of first retention slots formed in outer peripheral portions of the turbine wheel, and a plurality of second retention slots formed in wheel mounting portions of the buckets. The first and second retention slots are aligned to form an annular retention slot extending about a peripheral portion of the rotor wheel. A lockwire is located within the annular retention slot, the lockwire having engaged free ends. A plurality of axially-oriented retaining pins are fixed in the rotor wheel to hold the lockwire in the annular retention slot, and various techniques are employed for at least limiting or substantially preventing circumferential rotation of the lockwire within the annular slot.

Owner:GE INFRASTRUCTURE TECH INT LLC

Turbine bucket lockwire rotation prevention

A retention system for a plurality of turbine buckets located in respective mating slots in a turbine rotor wheel includes a plurality of first circumferentially-oriented retention slots formed in outer peripheral portions of the turbine wheel; a plurality of second circumferentially-oriented retention slots formed in wheel mounting portions of said buckets, the first and second circumferentially-oriented retention slots aligned to form an annular lockwire retention slot; and a lockwire located within the annular lockwire retention slot. A first surface feature on one or both of the turbine rotor wheel and one or more of said plurality of turbine buckets is adapted to engage a second surface feature on the lockwire for preventing rotation of the lockwire beyond predetermined limits.

Owner:GE INFRASTRUCTURE TECH INT LLC

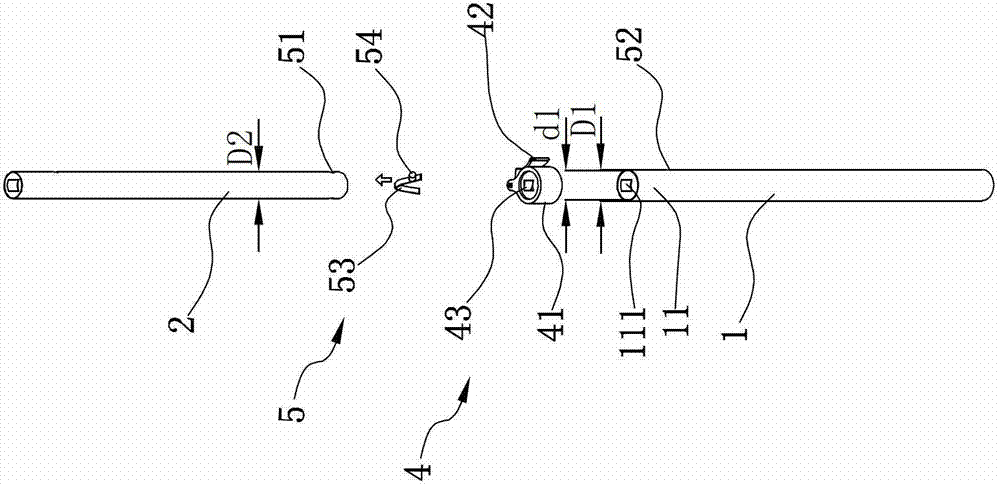

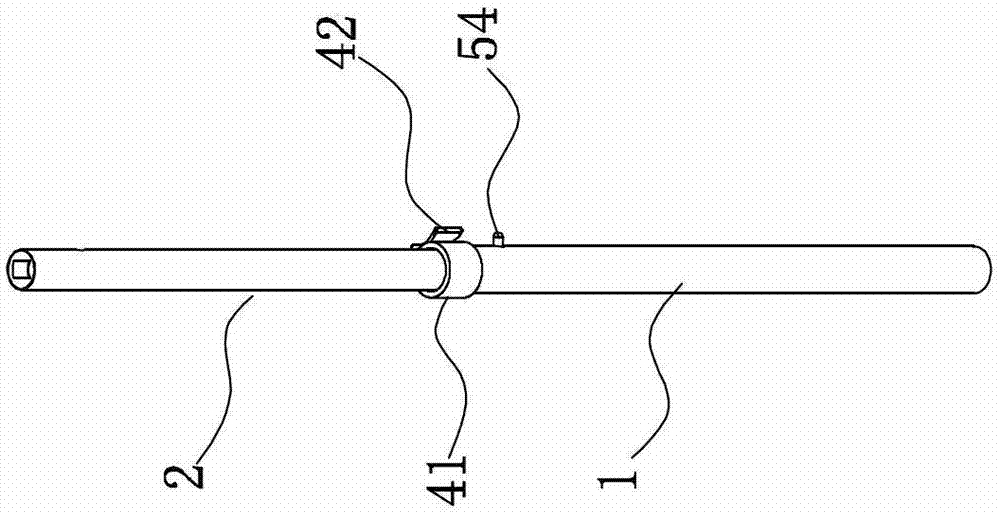

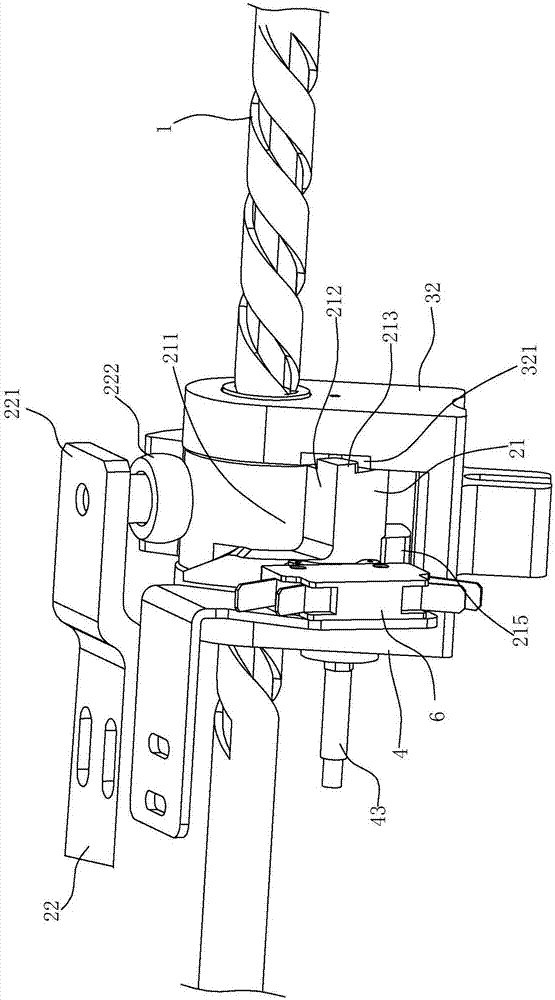

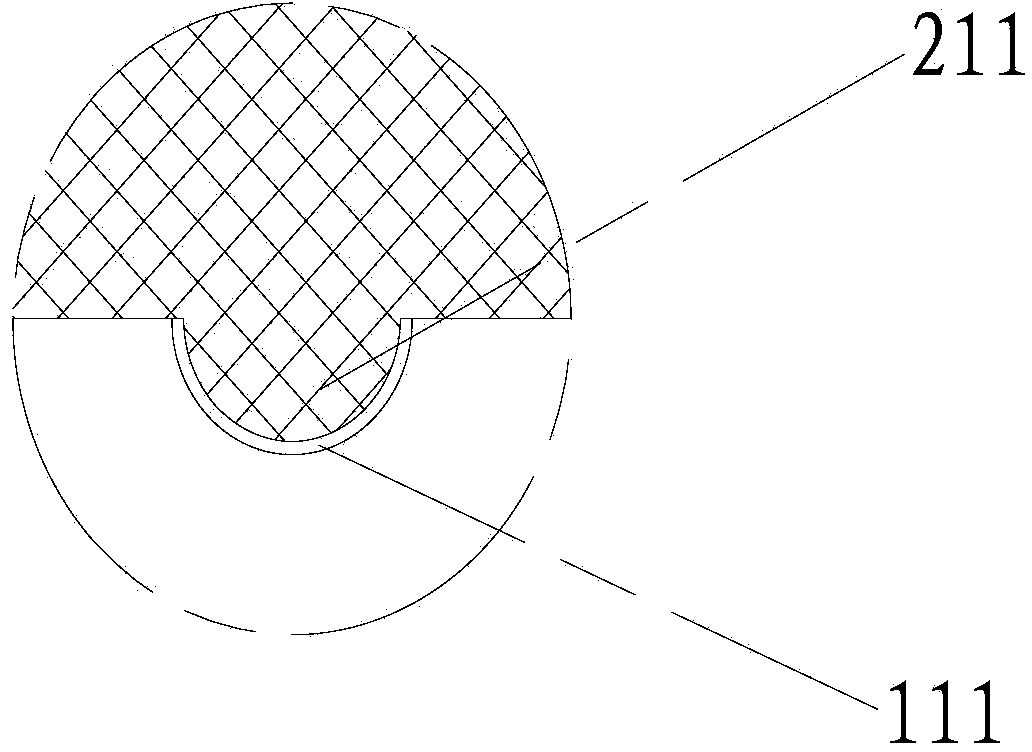

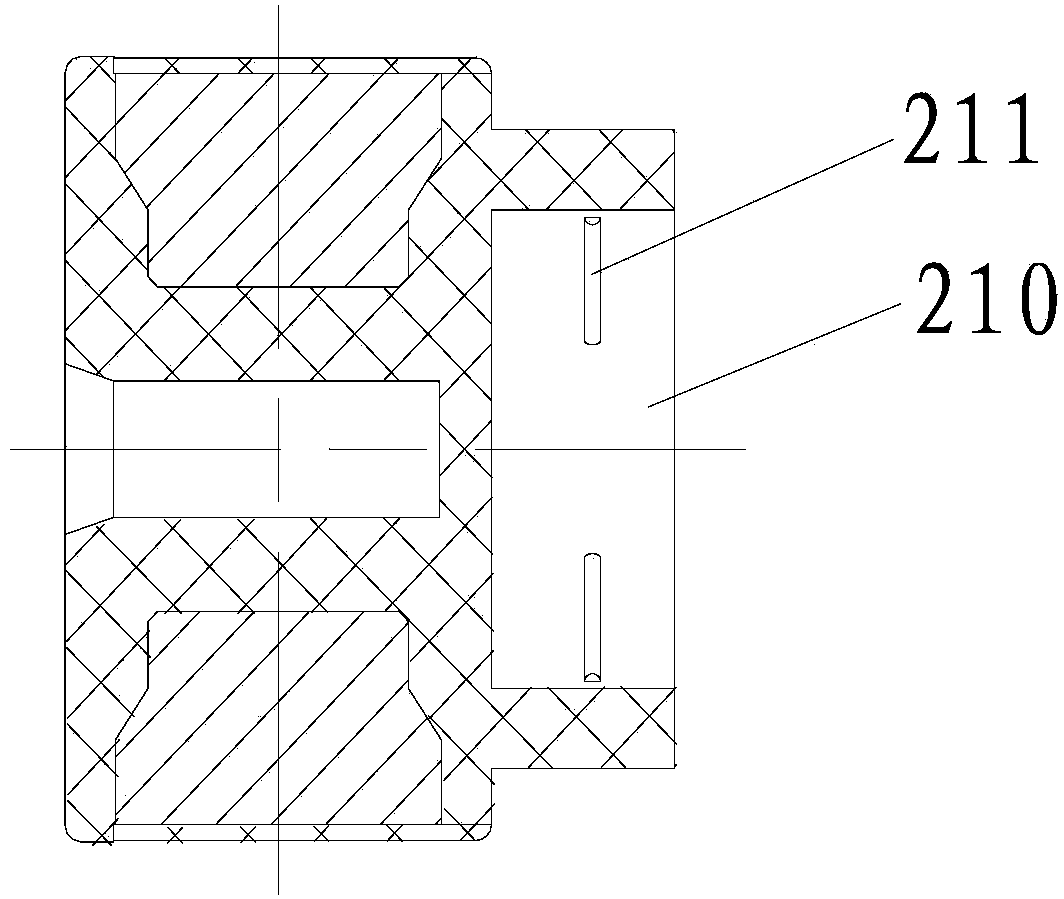

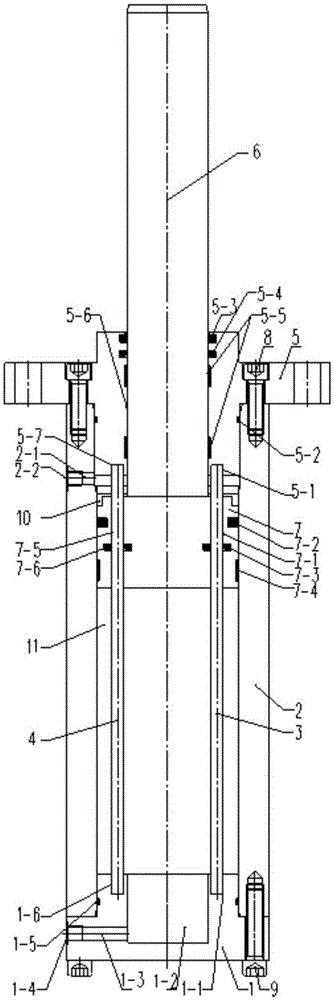

Motor speed detection and feedback device and motor with motor speed detection and feedback device

ActiveCN104022589APrevent circumferential rotationFirmly connectedMagnetic circuit rotating partsMotor speedStructural reliability

The invention is suitable for the technical field of motors and discloses a motor speed detection and feedback device and a motor with the motor speed detection and feedback device. The motor speed detection and feedback device comprises a rotor shaft and a magnet assembly. The magnet assembly comprises a bracket and a magnet. The bracket sleeves the rotor shaft. An axial spacing structure and a radial spacing structure are arranged between the bracket and the rotor shaft. The axial spacing structure contains a clamping part arranged on the bracket and an annular groove disposed in the rotor shaft. The radial spacing structure contains a raised part disposed on the bracket and a vertical groove arranged in the rotor shaft. The motor has the above motor speed detection and feedback device. According to the motor speed detection and feedback device and the motor with the motor speed detection and feedback device provided by the invention, relative circumferential rotation between the magnet assembly and the rotor shaft can be effectively prevented by the arrangement of the axial spacing structure and the radial spacing structure.

Owner:FOSHAN WEILING WASHER MOTOR MFG

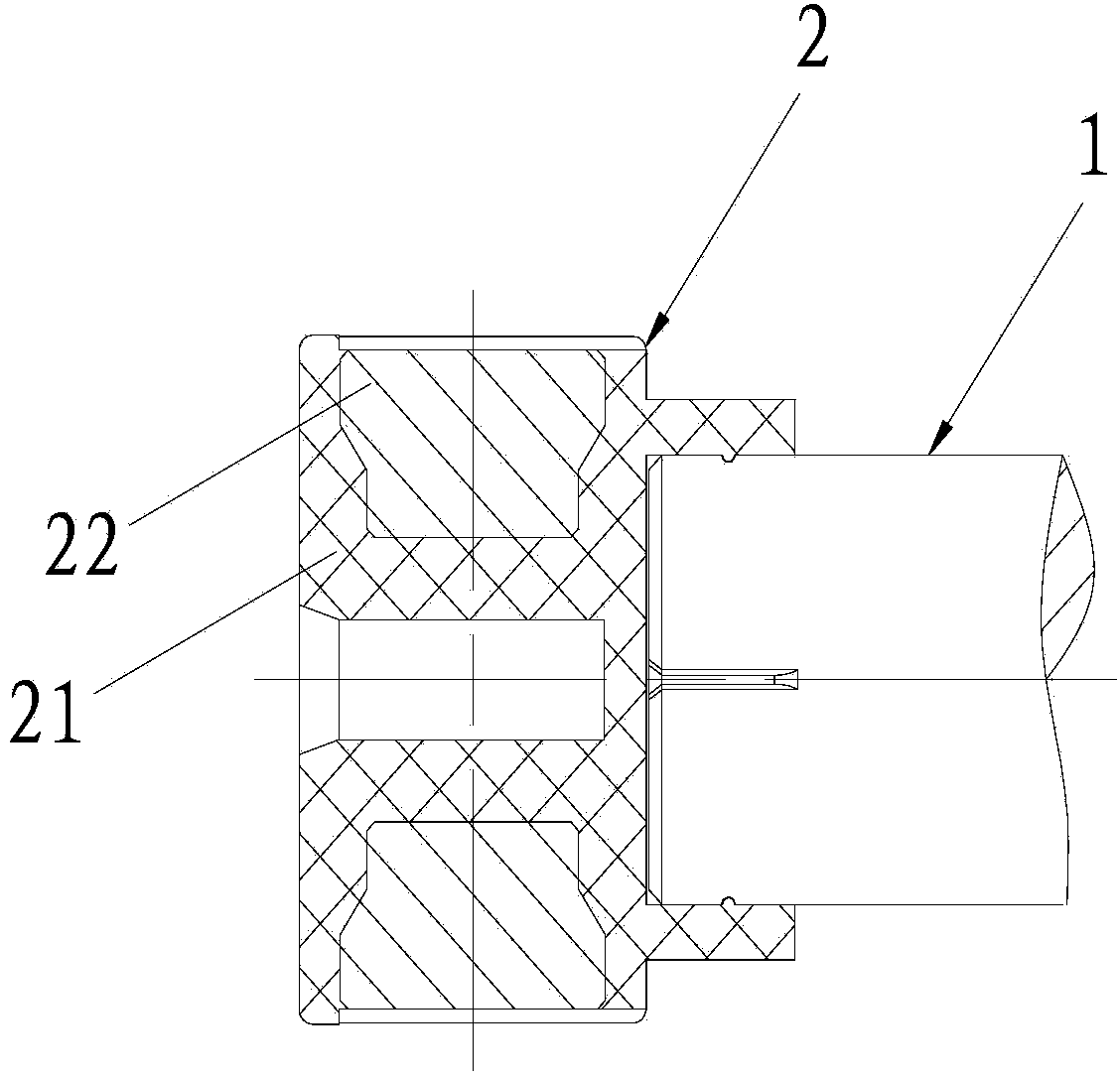

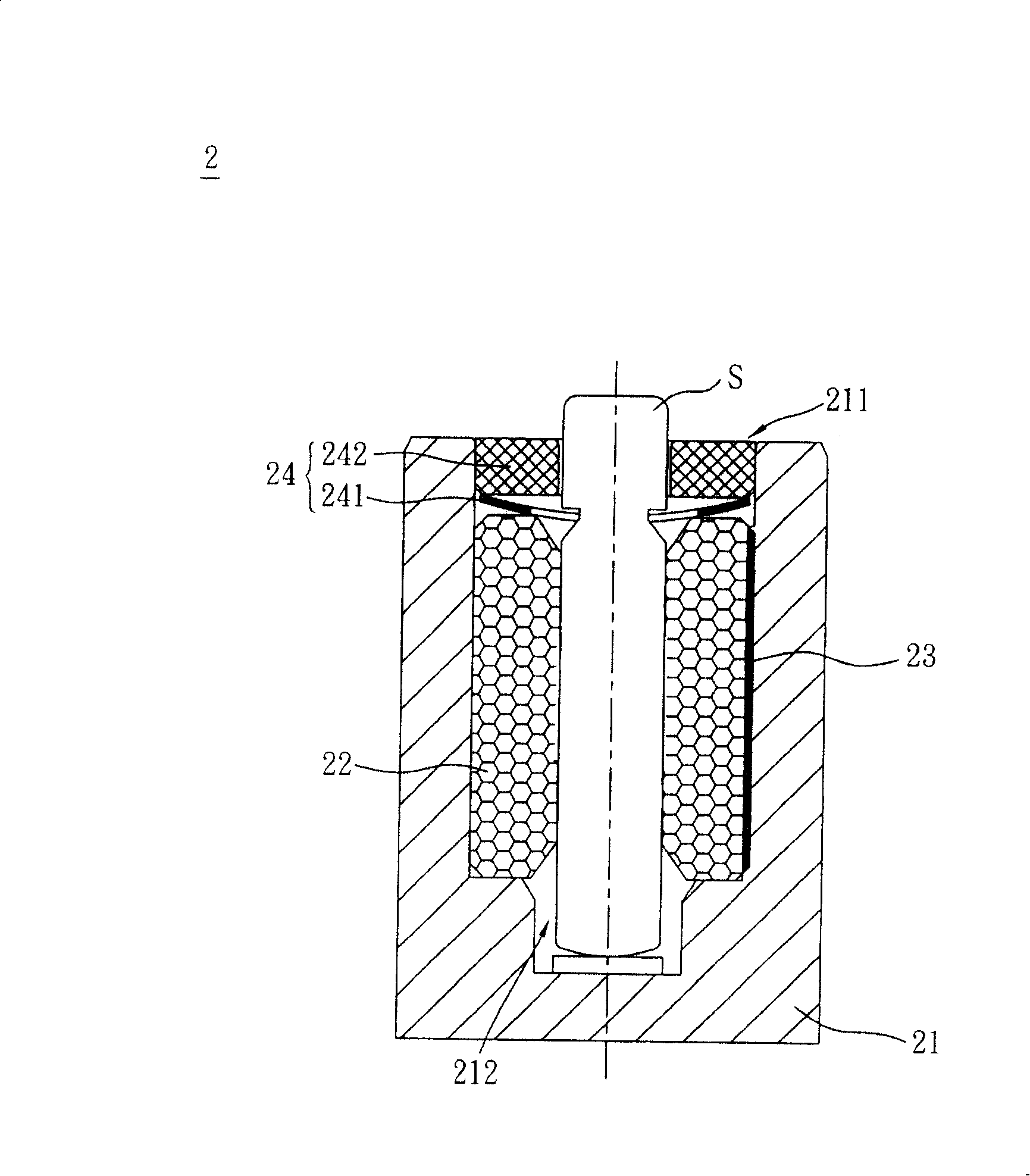

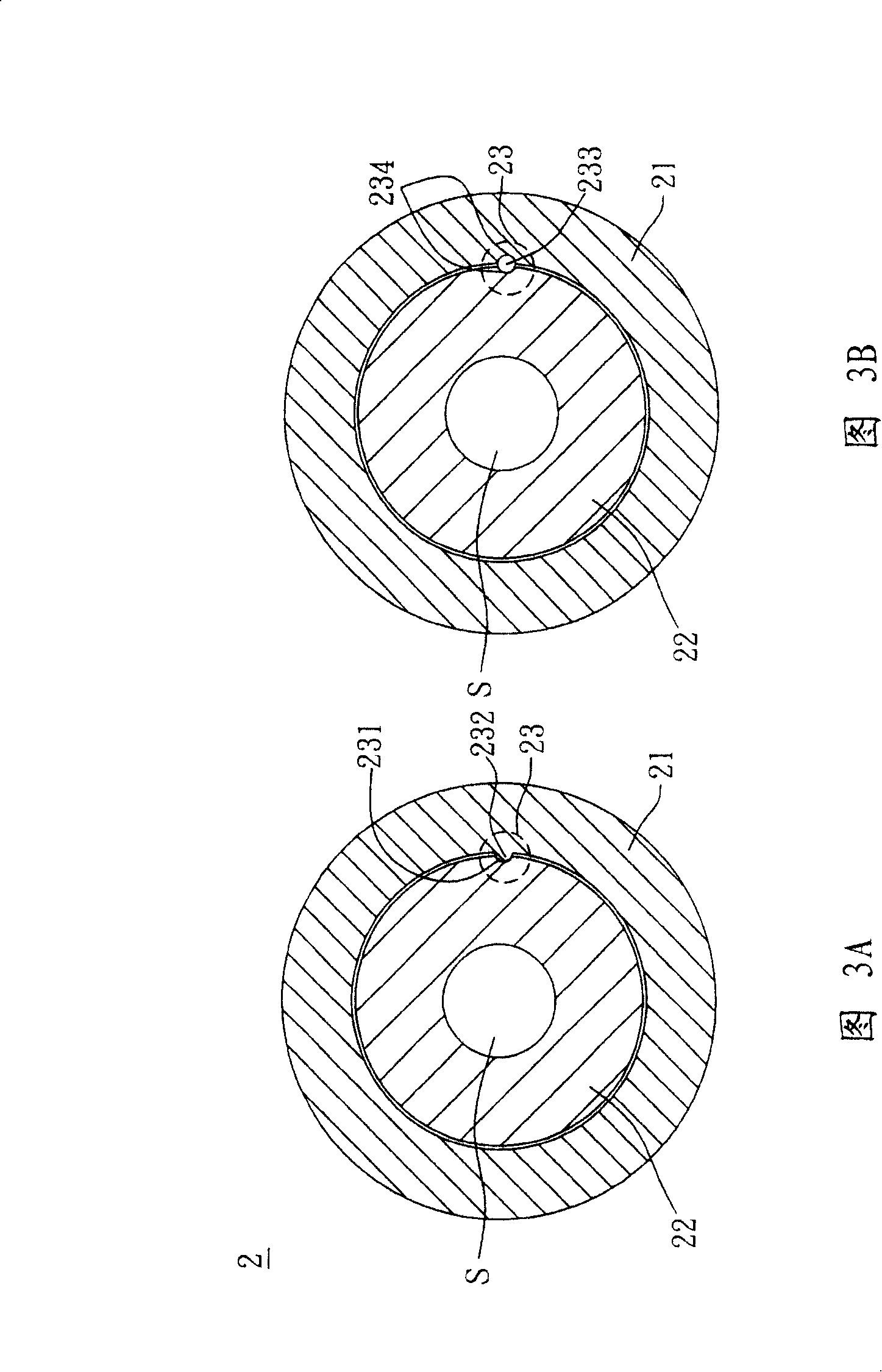

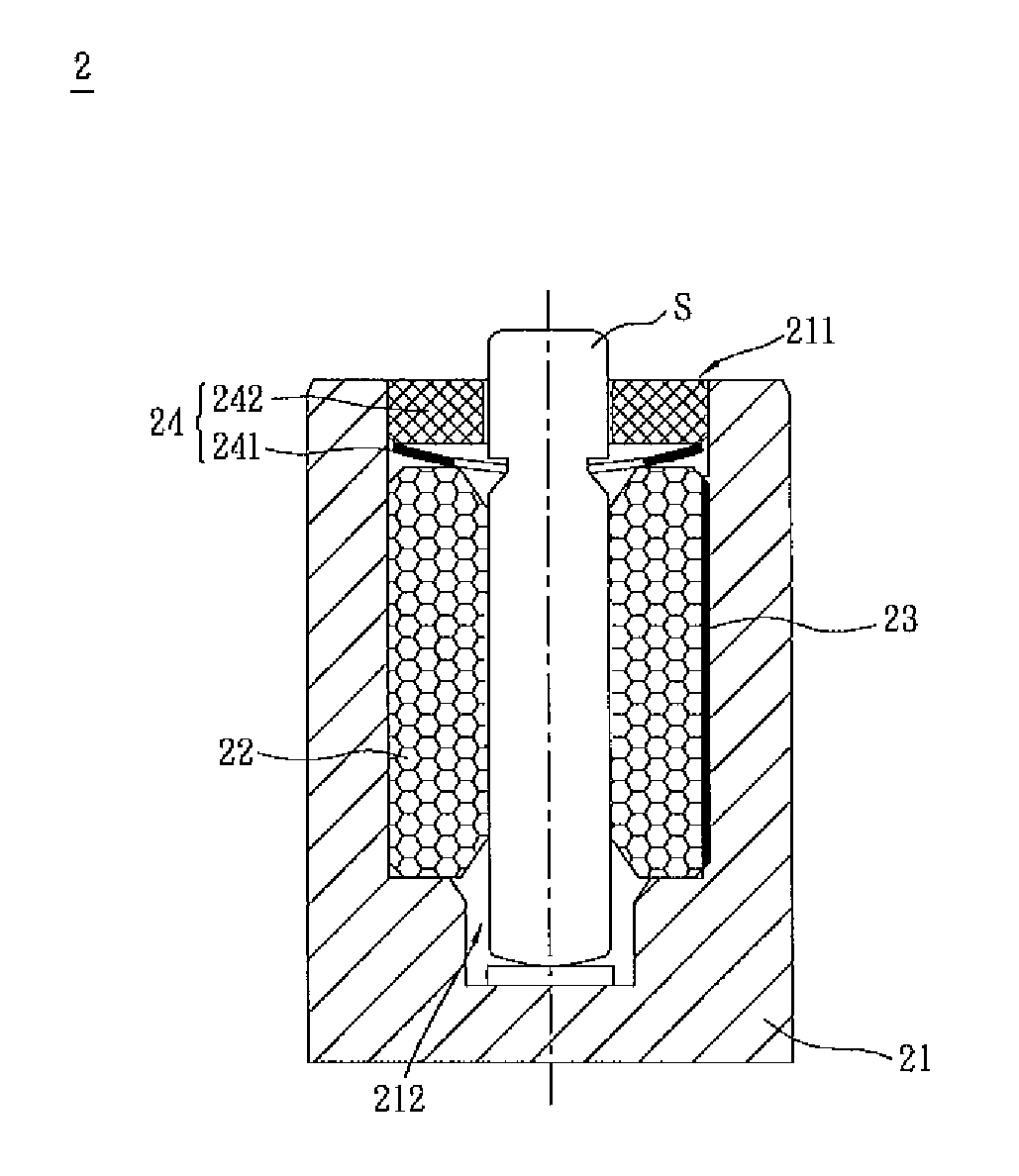

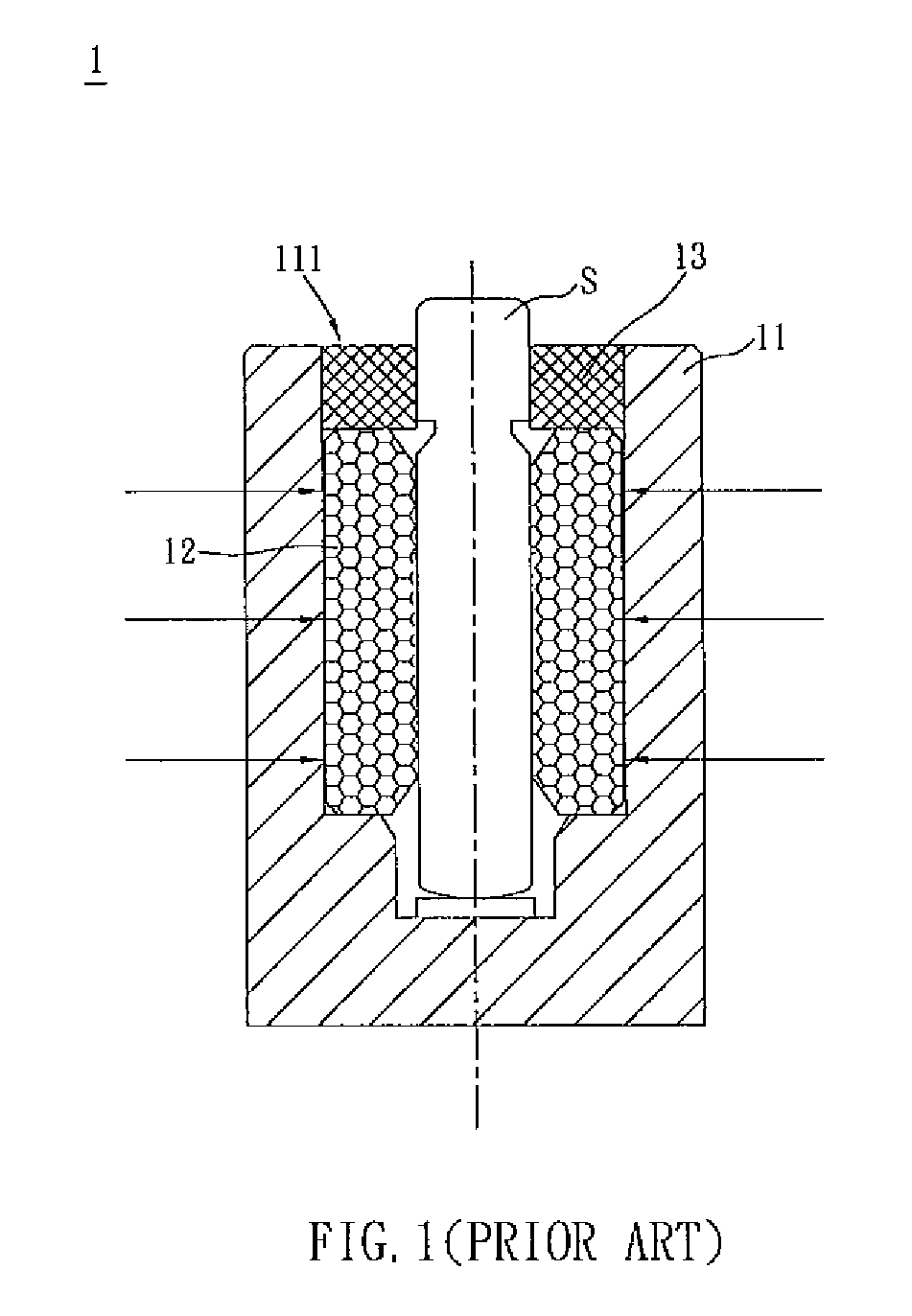

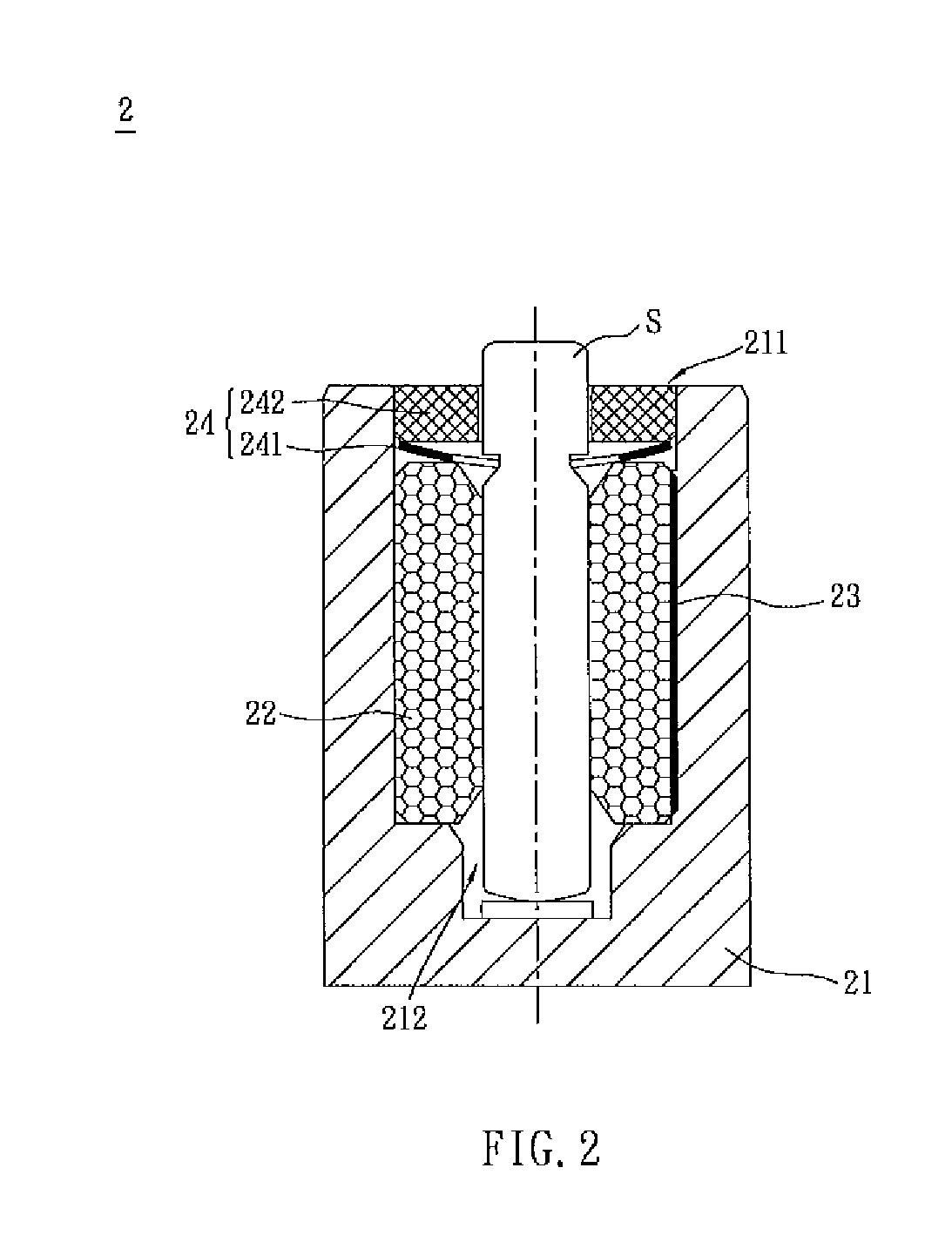

Motor and bearing supporting structure

ActiveCN101242121APrevent circumferential rotationPrevent axial movementStructural associationSupports/enclosures/casingsEngineeringMechanical engineering

Provided is a motor and bearing support structure thereof to support a shaft. The bearing support structure includes a bushing that has an opening and a placing space, a bearing being positioned in the placing space and supporting at least part of the shaft, and at least one first restriction component being disposed where the bearing is connected with the bushing.

Owner:DELTA ELECTRONICS INC

Clamping device for thin-walled pipes

PendingCN109500638APrevent circumferential rotationEven by forceWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:JIANGXI FG NEW ENERGY TRANSMISSION TECH CO LTD

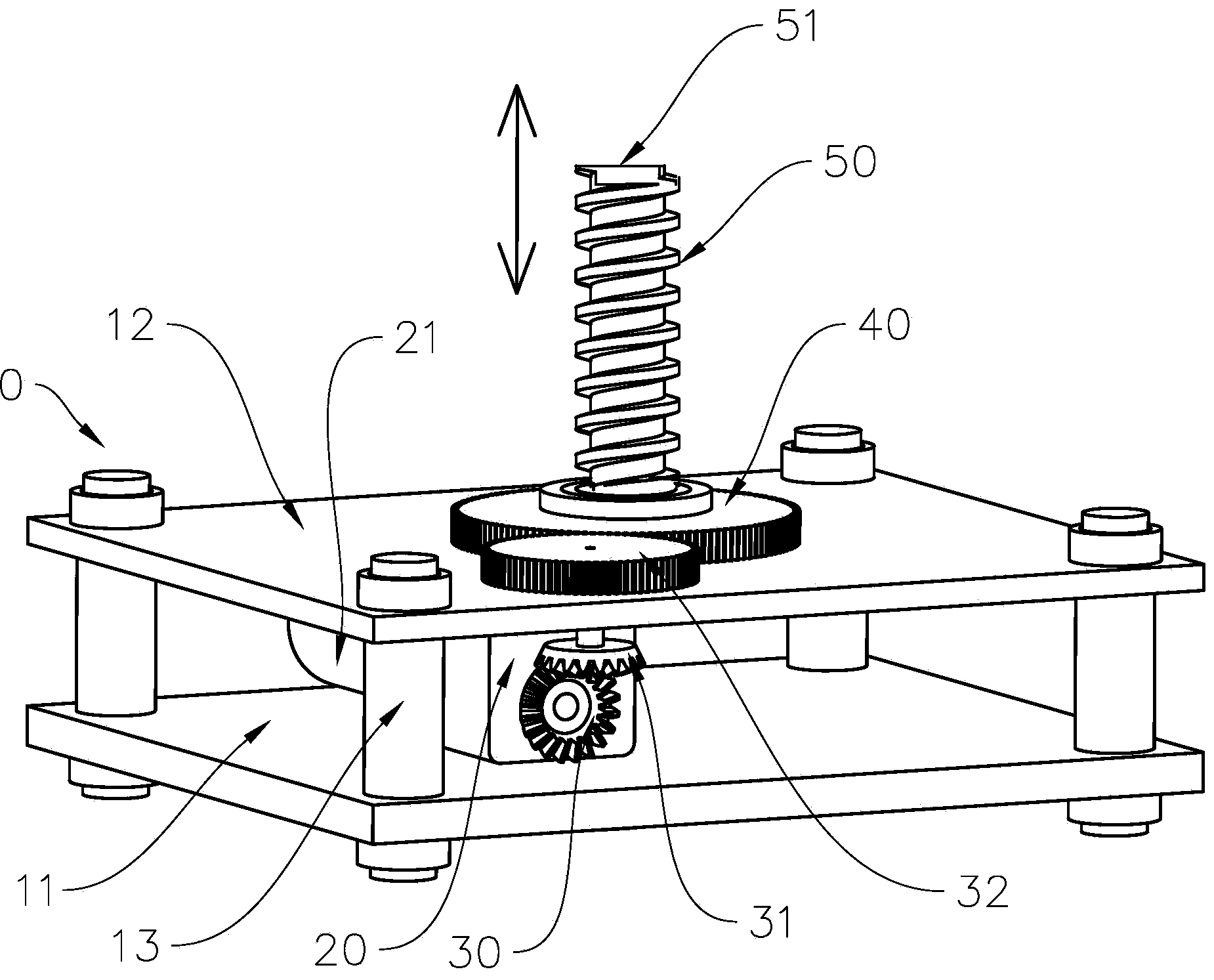

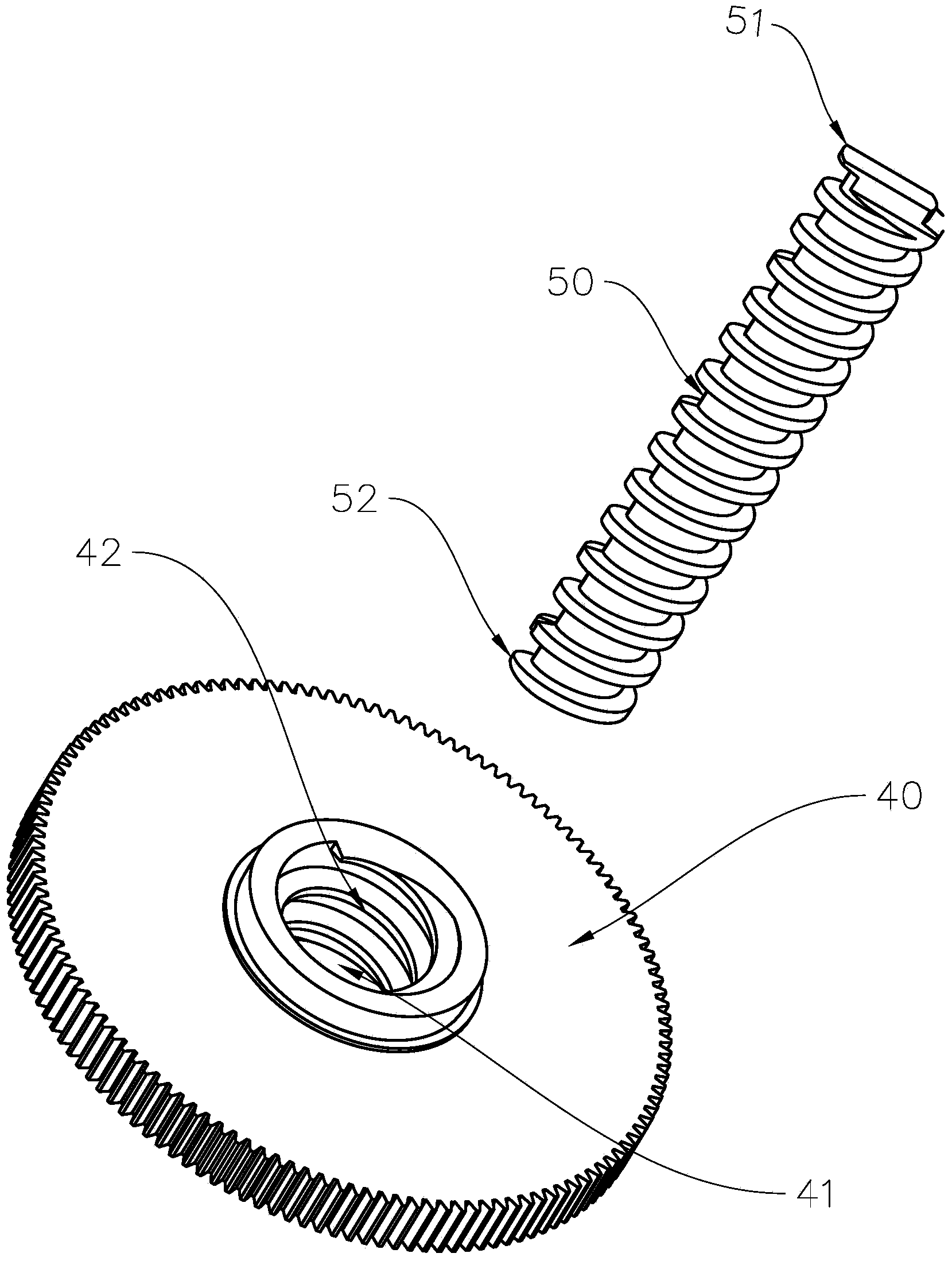

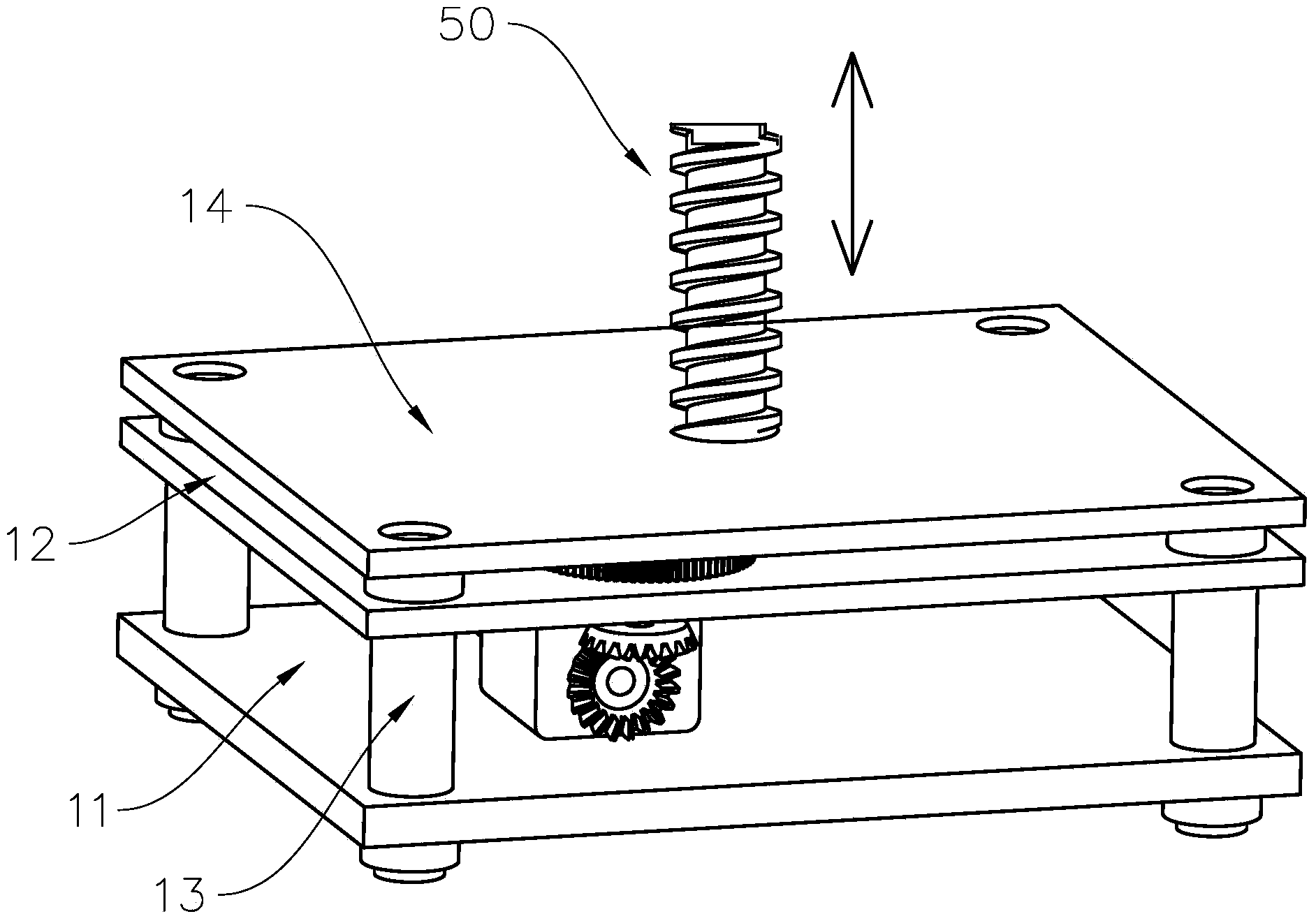

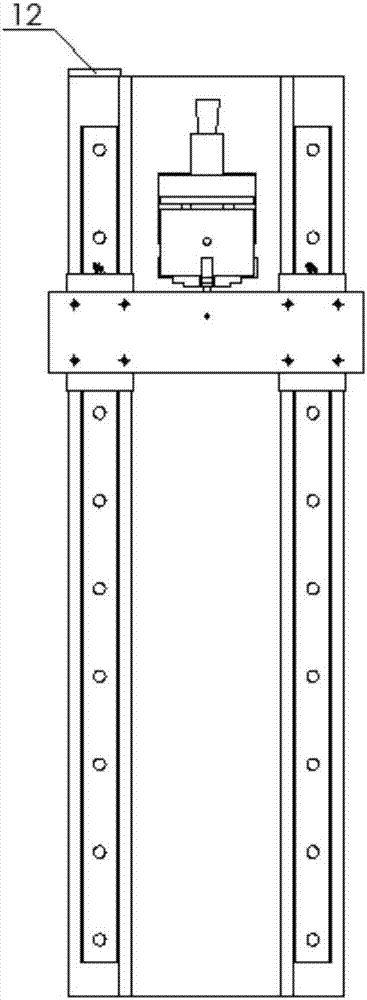

Vehicle-mounted electric hoist

InactiveCN104261301APrevent circumferential rotationStable center of gravityLifting devicesDrive wheelTransmitted power

The invention provides a vehicle-mounted electric hoist which comprises a framework. The framework comprises a first platform, a second platform, a first power part, a first driven wheel and a first screw. The first platform and the second platform are parallel to each other and connected through columns. The first power part is arranged on the first platform. The first driven wheel is connected with the first power part and supported on the second platform through a bearing. A first opening is formed at the center of the first driven wheel, and inner threads are formed on the first opening in the circumferential direction. The first screw penetrates through the first opening of the first driven wheel, and outer threads of the first screw are meshed with the inner threads. A driving head of a first motor transmits power to the first driven wheel, the first driven wheel drives the first screw to ascend or descend in the vertical direction, and therefore a vehicle-mounted chassis is lifted. The vehicle-mounted electric hoist is simple in structure and convenient to operate and saves physical power.

Owner:罗新涛

Metal part grinding machine

InactiveCN106425780AAvoid flying aroundKeep healthyPortable grinding machinesGrinding/polishing safety devicesDrive motorPulp and paper industry

The invention discloses a metal part grinding machine. The metal part grinding machine comprises a fixing body, a connecting cylinder and a collecting cylinder, wherein the collecting cylinder comprises a collecting chamber; a driving motor is mounted inside the fixing body; an output end of the driving motor is connected with a rotating shaft; the lower end of the rotating shaft is connected with a grinding wheel; the connecting cylinder sleeves the outer surface of the fixing body; a protective cover is arranged at the bottom end of the connecting cylinder; a supporting cylinder is mounted at the top of the inner wall of the collecting cylinder; a movable cylinder is rotationally arranged at the lower end of the supporting cylinder; a guide column is vertically arranged at the upper end face of the fixing body; a positioning protruding bar is arranged on the sidewall of the guide column; an adjusting rod is also vertically arranged inside the collecting chamber; the inner wall surface of the adjusting rod is provided with a positioning groove; the outer wall surface of the adjusting rod is provided with a helical groove; the inner wall of the movable cylinder protrudes outwards to form a transmission column. By coordination between the adjusting rod and the movable cylinder, the metal part grinding machine disclosed by the invention is capable of realizing forward rotation or reverse rotation of a plurality of blades so as to realize collection and emission of iron scraps and dust.

Owner:重庆新缔欧机械制造有限公司

Motor and its bearing supporting structure

InactiveUS20080181547A1Improve efficiencyImprove product reliabilityAssociation with control/drive circuitsMagnetic circuitEngineeringElectric motor

A motor and its bearing supporting structure are disclosed. The bearing supporting structure supporting a shaft includes a bushing, a bearing and at least one first limiting assembly. The bushing has an opening and an accommodating space. The bearing supports at least a portion of the shaft and is disposed in the accommodating space. The first limiting assembly is disposed at a connection of the bearing and the bushing.

Owner:DELTA ELECTRONICS INC

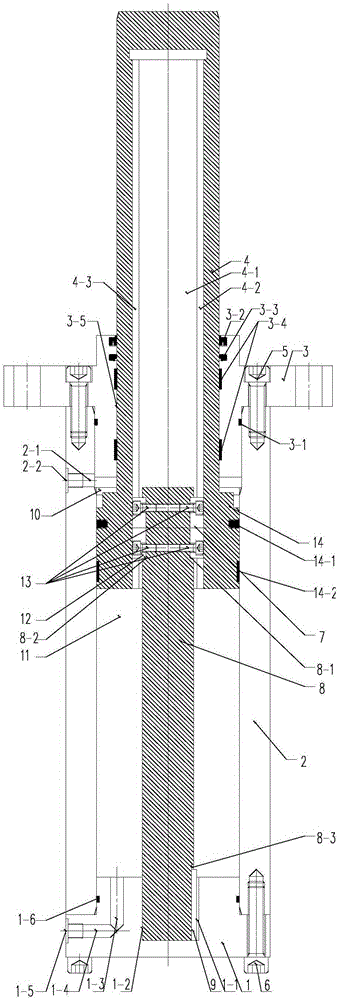

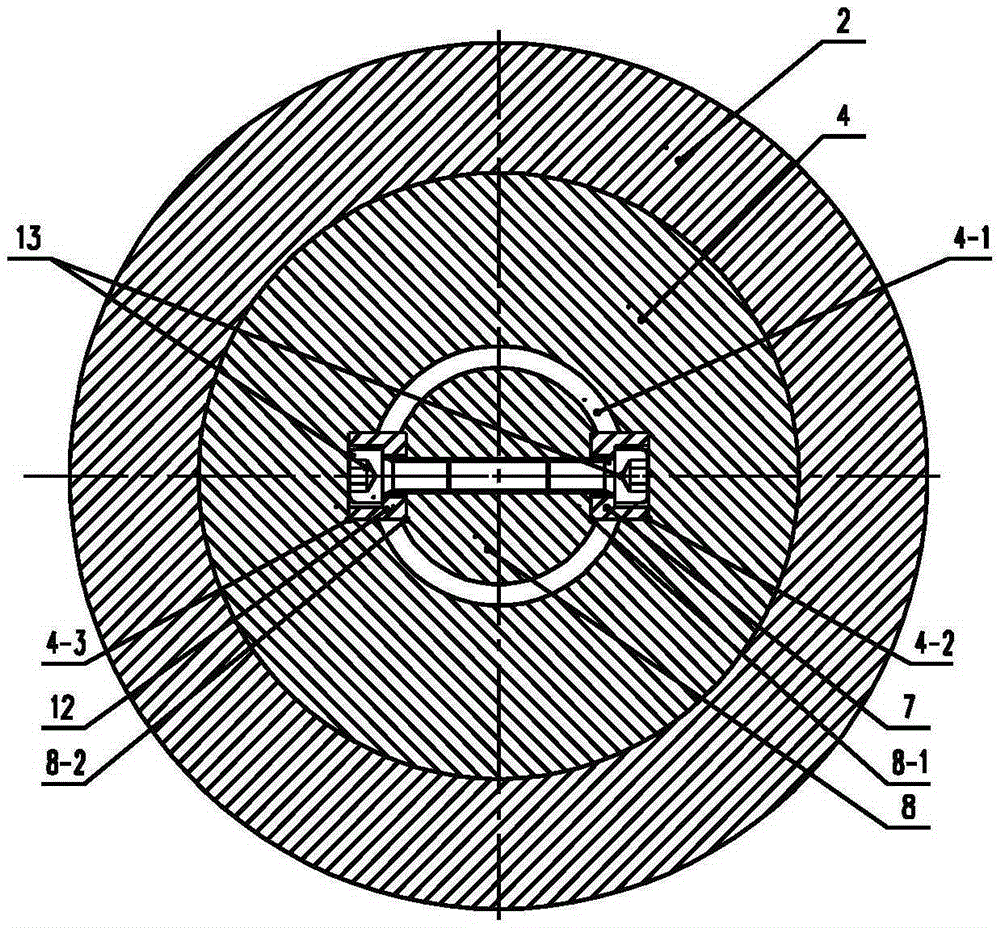

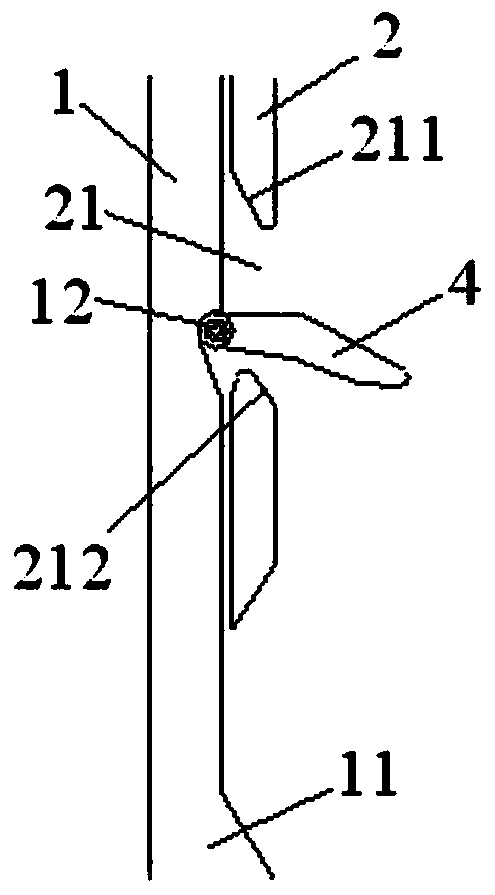

Built-in guiding oil cylinder

ActiveCN105402193AEnhanced radial guidanceReliable circumferential guidanceFluid-pressure actuatorsPiston rodPetroleum engineering

The invention discloses a built-in guiding oil cylinder which comprises a lower end cap, a cylinder barrel, an upper end cap, a piston, a piston rod, upper screws, a lower screw, a guiding rod, a guiding block and a key. According to the invention, the guiding device is mounted in the oil cylinder, which enhances the radial guiding function of the oil cylinder on one hand, and limits the rotation of the oil cylinder and reliably realizes the circumferential guiding of the oil cylinder on the other hand during the operating process of the oil cylinder. The built-in guiding oil cylinder is simple in structure, works reliably, solves the problem that the mounting space and condition of an external accessory guiding device of an oil cylinder are limited, can be applied to the occasion of limiting circumferential rotation during an oil cylinder operating process, and has a wide application prospect.

Owner:SHANGHAI SSOEC MARINE ENG CO LTD

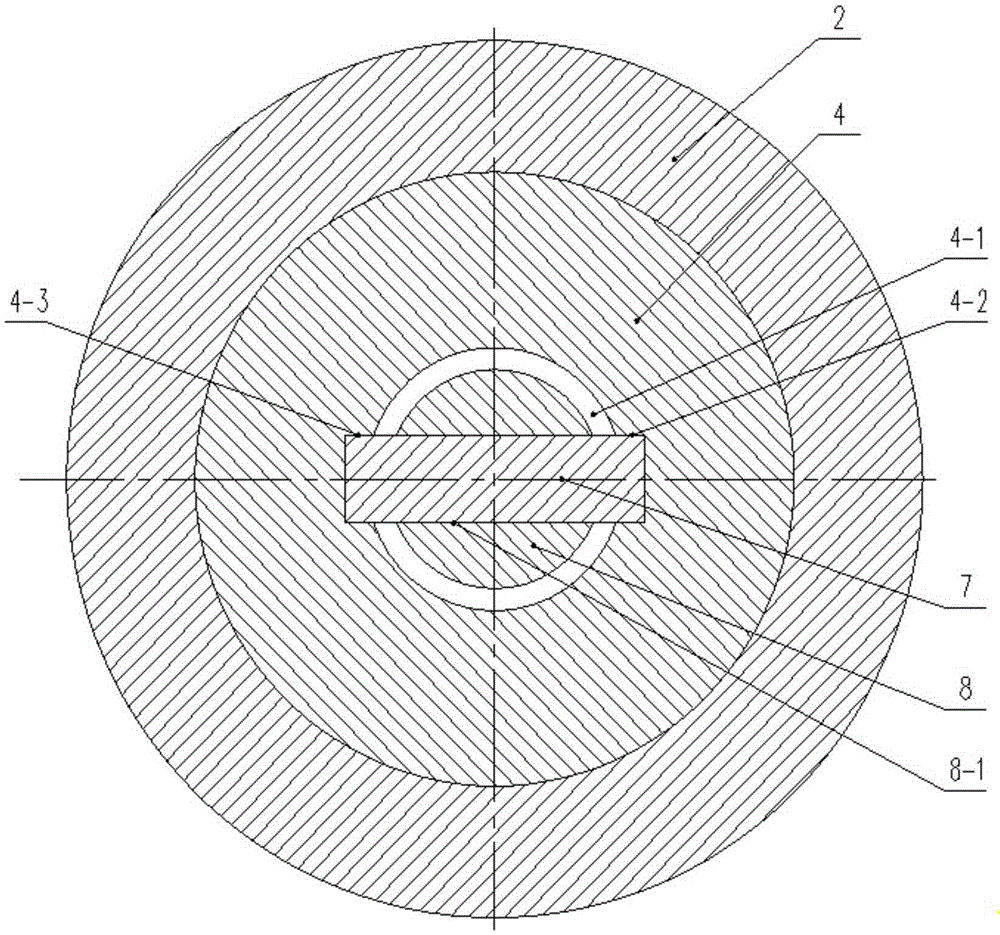

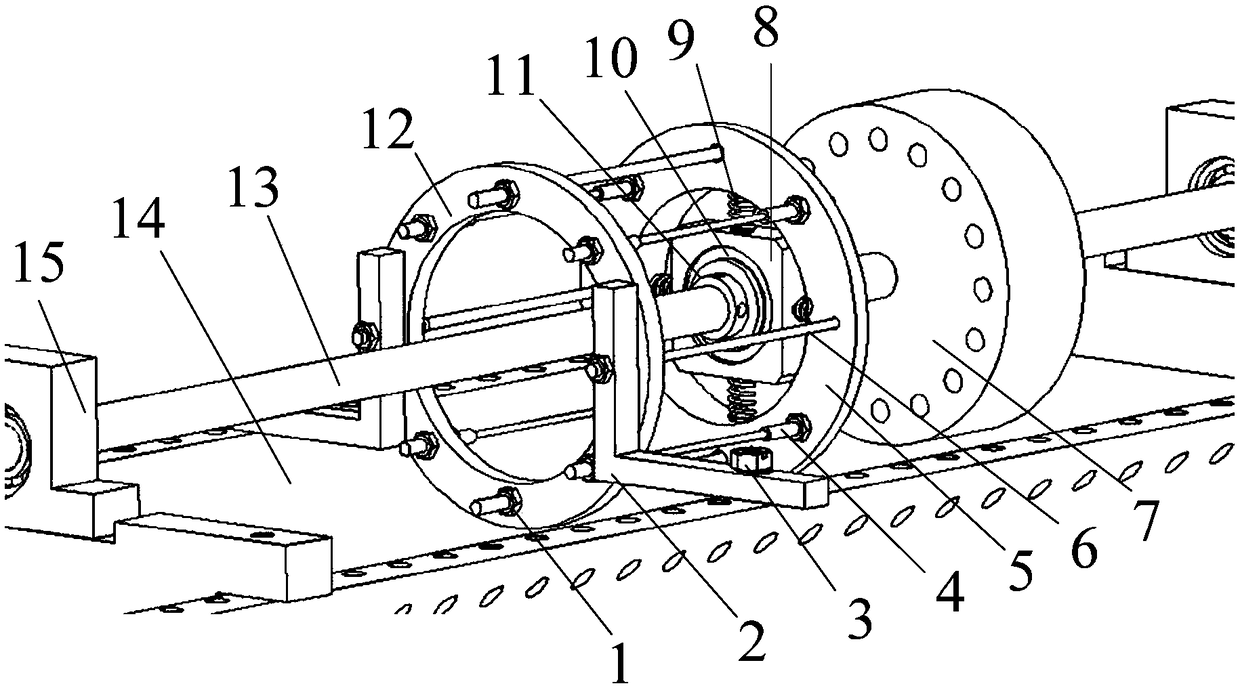

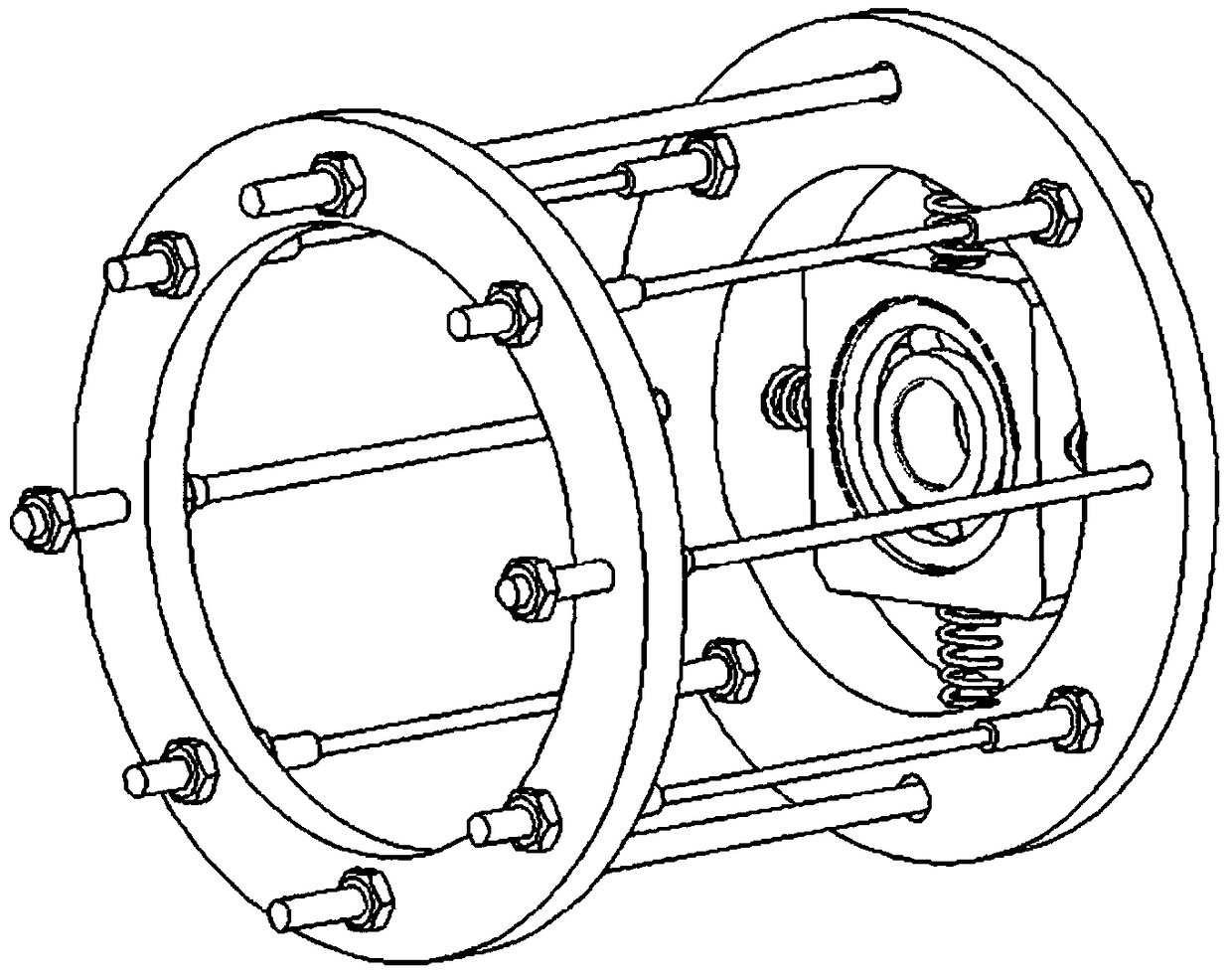

Grounding type nonlinear energy trap for restraining rotator system vibration

ActiveCN108825718AEfficient vibration energy absorption capacityEnhanced inhibitory effectRotating vibration suppressionNoise controlExternal energy

The invention discloses a grounding type nonlinear energy trap for restraining rotator system vibration. The grounding type nonlinear energy trap comprises a grounding type nonlinear energy trap bodyand a fixed frame, wherein the grounding type nonlinear energy trap body comprises a fixed ring, a connection component, an oscillator mass absorption block, a weak-rigidity spring and a bearing component; the bearing component is matched with a shaft and comprises a shaft sleeve, a bearing and a bearing sleeve; the weak-rigidity spring is matched with the bearing component and the oscillator massabsorption block; the connection component is matched with the fixed ring and the oscillator mass absorption block and comprises segmented linear rigidity rods; clearance holes with different diameters are formed on a same circumference of the oscillator mass absorption block and are in clearance fit with the segmented linear rigidity rods to form segmented linear rigidities and fit nonlinear cubic rigidities; and the fixed frame is fixed on a rack to embody the grounding performance of the grounding type nonlinear energy trap. The grounding type nonlinear energy trap is capable of effectively restricting the vibration of wide bands of rotor systems and belongs to the field of vibration noise control. The grounding type nonlinear energy trap is simple and compact in overall structure, small in additional mass, high in reliability, convenient to use and free of external energy sources.

Owner:NORTHEASTERN UNIV

Automatic reciprocating type polishing device for automobile shafts

ActiveCN107139065APrevent circumferential rotationWon't shakePolishing machinesGrinding drivesThreaded pipeEngineering

The invention discloses an automatic reciprocating type polishing device for automobile shafts. The automatic reciprocating type polishing device for the automobile shafts comprises supporting legs. The top ends of the supporting legs are fixedly connected with a supporting plate. The surface of the supporting plate is provided with an adjusting groove. The inner wall of the adjusting groove is connected with an adjusting plate in a sliding manner. The middle portion of the adjusting plate is fixedly connected with a bearing column. The surface of the bearing column is fixedly connected with a first supporting column. The upper surface of the supporting plate is fixedly connected with a base and a second supporting column. According to the automatic reciprocating type polishing device for the automobile shafts, automatic frontward and backward rotation control over a second motor is conducted, so that a threaded rod is controlled to rotate forwards or backwards, finally a polishing machine is driven by a threaded pipe to automatically conduct reciprocating movement to polish the shaft to be polished, the problem that the threaded rod conduct circumferential movement can be effectively avoided, the base cannot be shaken, the problem that a clamping bolt and a sleeve scratch the shaft to be polished can be effectively avoided, and therefore the problems that a manually controlled polishing device is prone to generating polishing errors and lowers the polishing efficiency are effectively solved.

Owner:上海伟奕传动轴配件有限公司

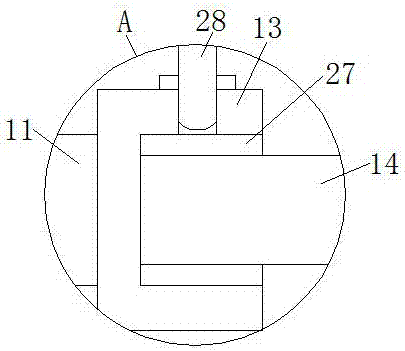

Multi-type high-precision planetary roller lead screw pair precision detection device

InactiveCN106885518ARealization errorAchieve precisionMachine gearing/transmission testingUsing optical meansGratingRoller screw

The invention provides a multi-type high-precision planetary roller lead screw pair precision detection device which comprises a grating ruler, a reading head, a slider, a linear guide rail, a nut sleeve, a punch molding device, a display screen and the like. The two-way positioning handle of the punch molding device is connected with a three-jaw chuck through a rotating shaft, and the three-jaw chuck clamps a lead screw for synchronous rotary motion. One end of a nut sleeve guide rod is fixedly connected with a connection plate, and the other end is fixedly connected with the nut sleeve. Both ends of the connection plate are fixedly connected with the slider and the reading head. The reading head horizontally slides on the grating ruler. The slider slides horizontally on the linear guide rail. The nut position information acquired by the reading head is displayed on the display screen during the straight nut movement. The device provided by the invention can test the return error, the two-way lead precision and the like of a planetary roller lead screw pair, has the advantages of high test precision and simple operation, and is suitable for the test of multiple types of planetary roller lead screw pairs. A reliable method is provided for the precision test of the planetary roller lead screw pair.

Owner:BEIHANG UNIV

Built-in guide oil cylinder

InactiveCN105387019AOriented to Reliable ImplementationReduce radial shakeFluid-pressure actuatorsPiston rodPetroleum engineering

The invention discloses a built-in guide oil cylinder which comprises a lower end cover, a cylinder barrel, an upper end cover, a piston, a piston rod, upper screws, lower screws, a guide rod, a right guide block, a left guide block, a key and guide block installing screws. According to the built-in guide oil cylinder, a guide device is installed in the oil cylinder, in the movement process of the oil cylinder, on one hand, the radial guiding action of the oil cylinder is enhanced, and on the other hand, rotation of the oil cylinder is limited, and circumferential guiding of the oil cylinder is reliably achieved. The built-in guide oil cylinder is simple in structure and reliable in work, solves the problem that the installing space and condition of the external accessory guide device of the oil cylinder are limited, can be applied to the occasions where circumferential rotating in the movement process of the oil cylinder is limited and has the wide application prospect.

Owner:HOHAI UNIV CHANGZHOU

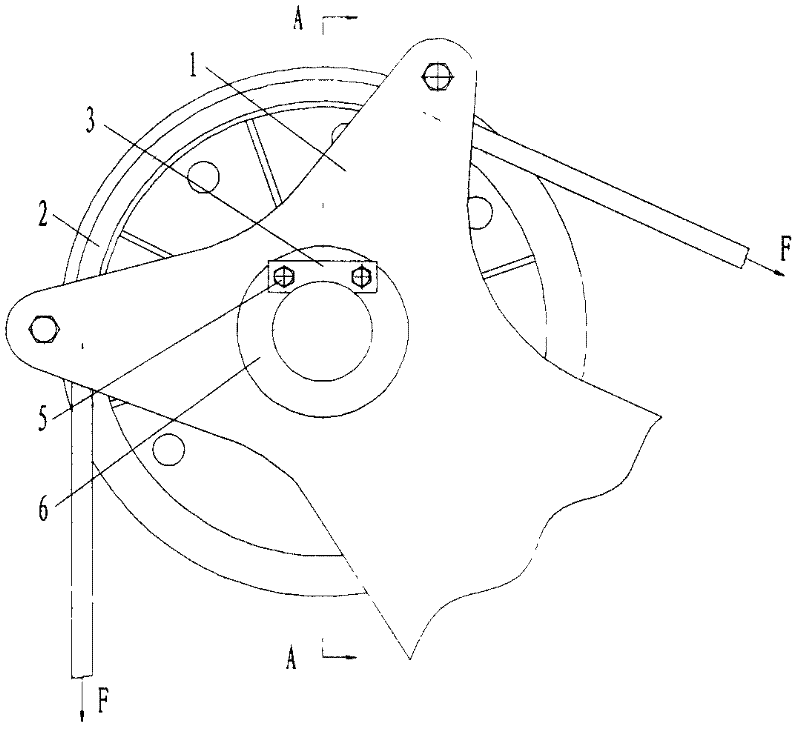

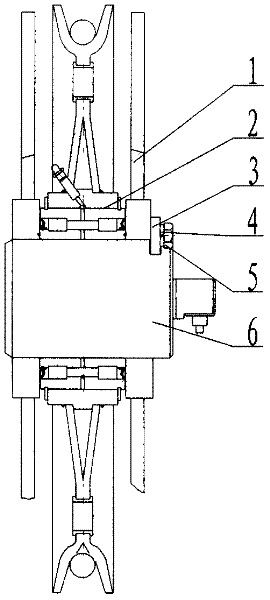

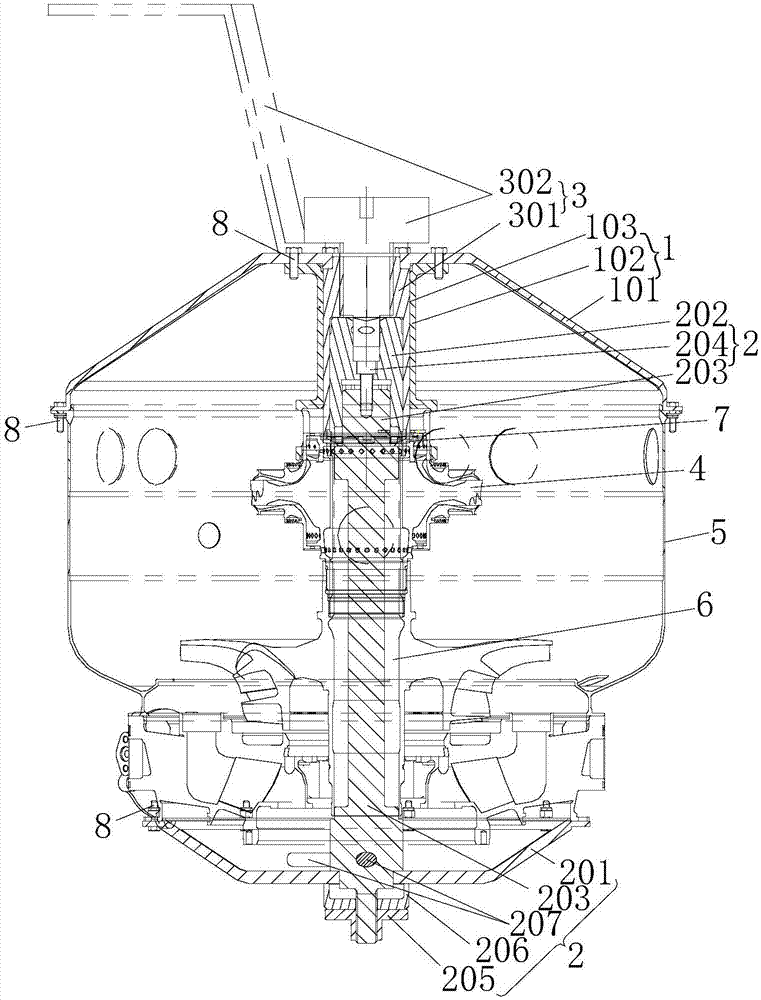

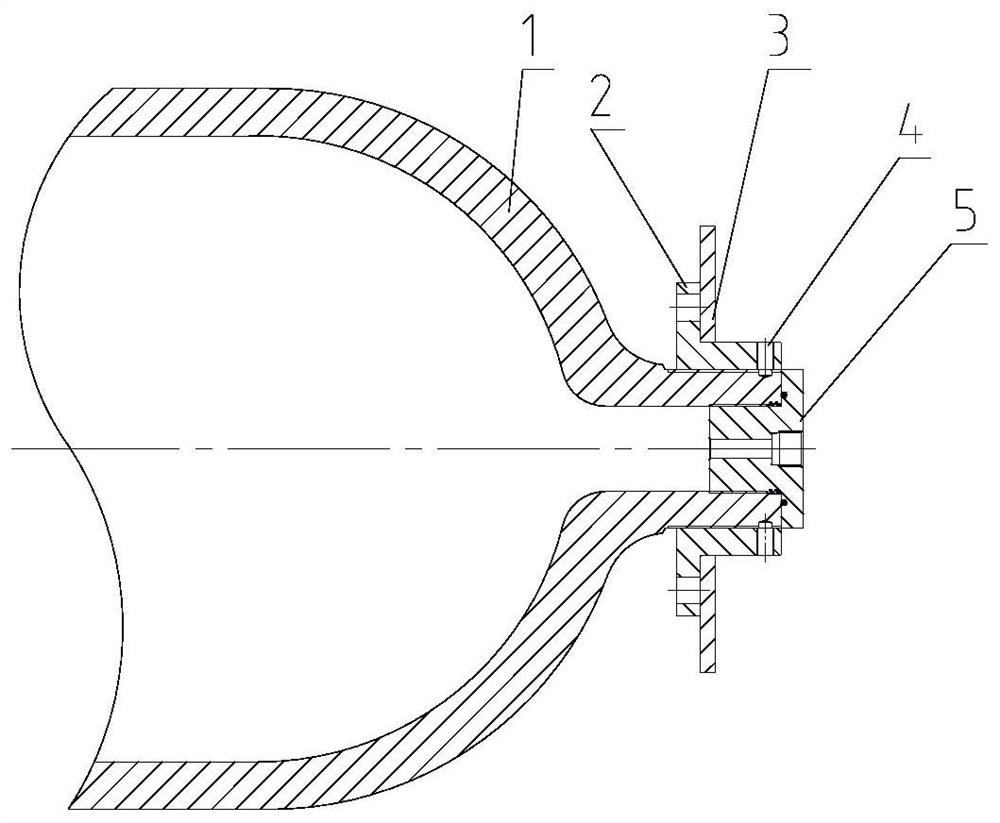

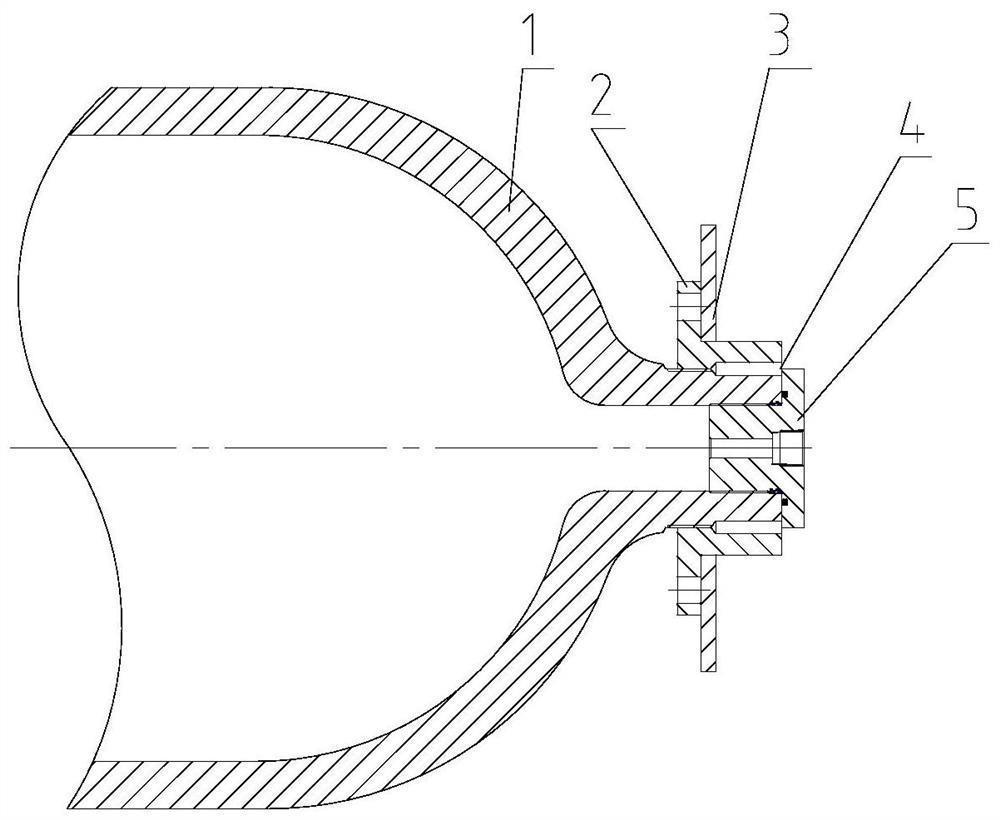

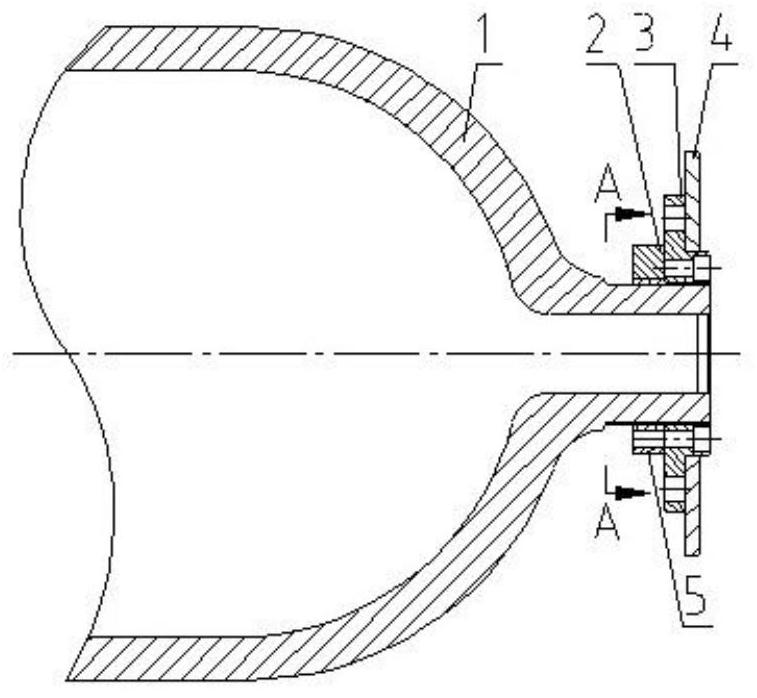

Dismounting device for aero-engine high-pressure combined rotor

ActiveCN107363779AMeet assembly process requirementsPrevent circumferential rotationMetal-working hand toolsHigh pressureAero engine

The invention discloses a dismounting device for an aero-engine high-pressure combined rotor. The dismounting device comprises a first fixing mechanism, a second fixing mechanism and a force applying mechanism, wherein the first fixing mechanism is used for fixing a high-pressure turbine rotor component of a high-pressure combined rotor on a first end face of an engine cast; the second fixing mechanism is used for fixing a high-pressure shaft of the high-pressure combined rotor on a second end face of the engine cast; the force applying mechanism is used for penetrating through the first fixing mechanism along an axial direction of the high-pressure combined rotor and is connected with a gland nut of the high-pressure combined rotor so as to dismount the gland nut in the manner of twisting; the first fixing mechanism is used for fixing the structure of the high-pressure turbine rotor component, so as to prevent the high-pressure turbine rotor component from being influenced by the dismounting of the gland nut and rotating along circumferential direction; the second fixing mechanism is used for fixing the structure of a high-pressure shaft, so as to prevent the high-pressure shaft from being influenced by the dismounting of the gland nut and rotating along circumferential direction; the condition that the aero-engine high-pressure combined rotor meets the assembling technical requirement without influence on the surrounding part structures can be guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

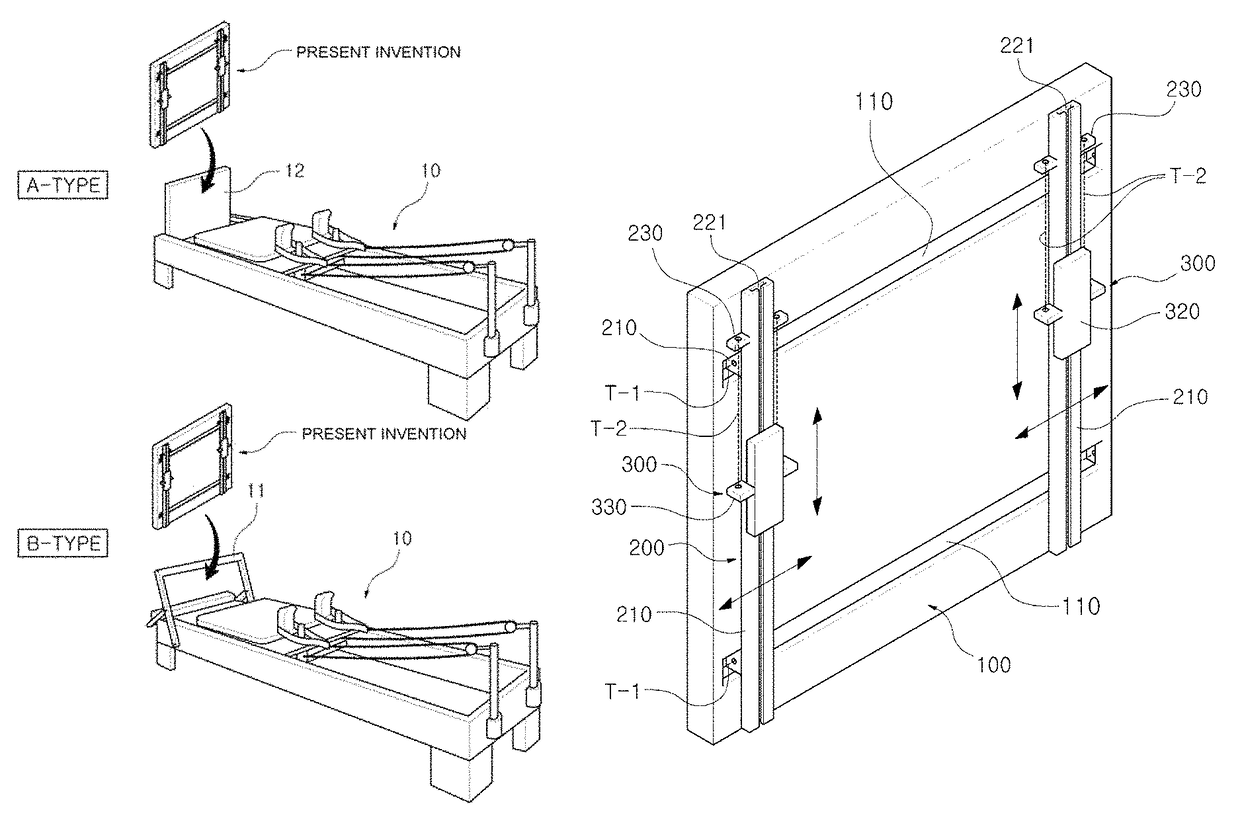

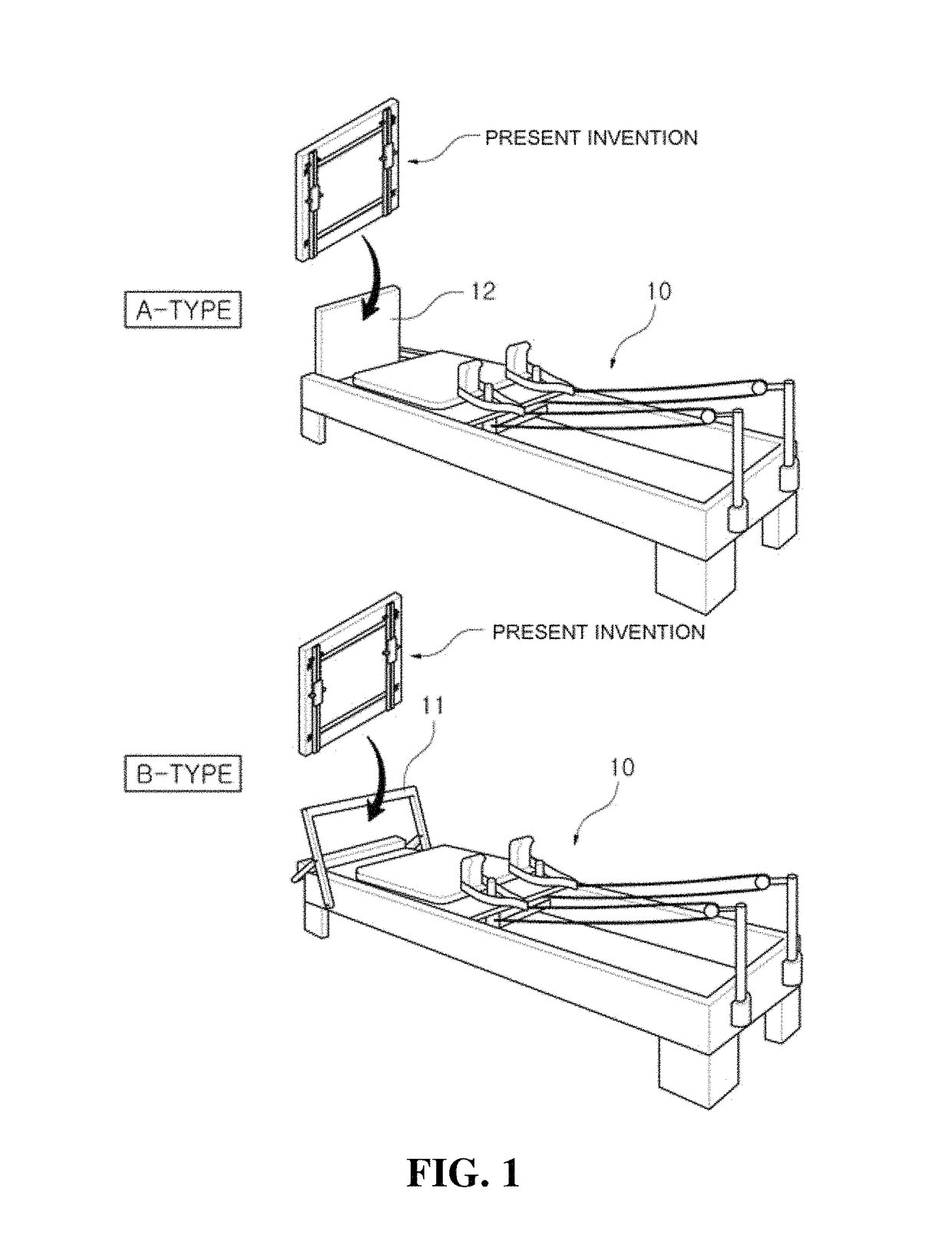

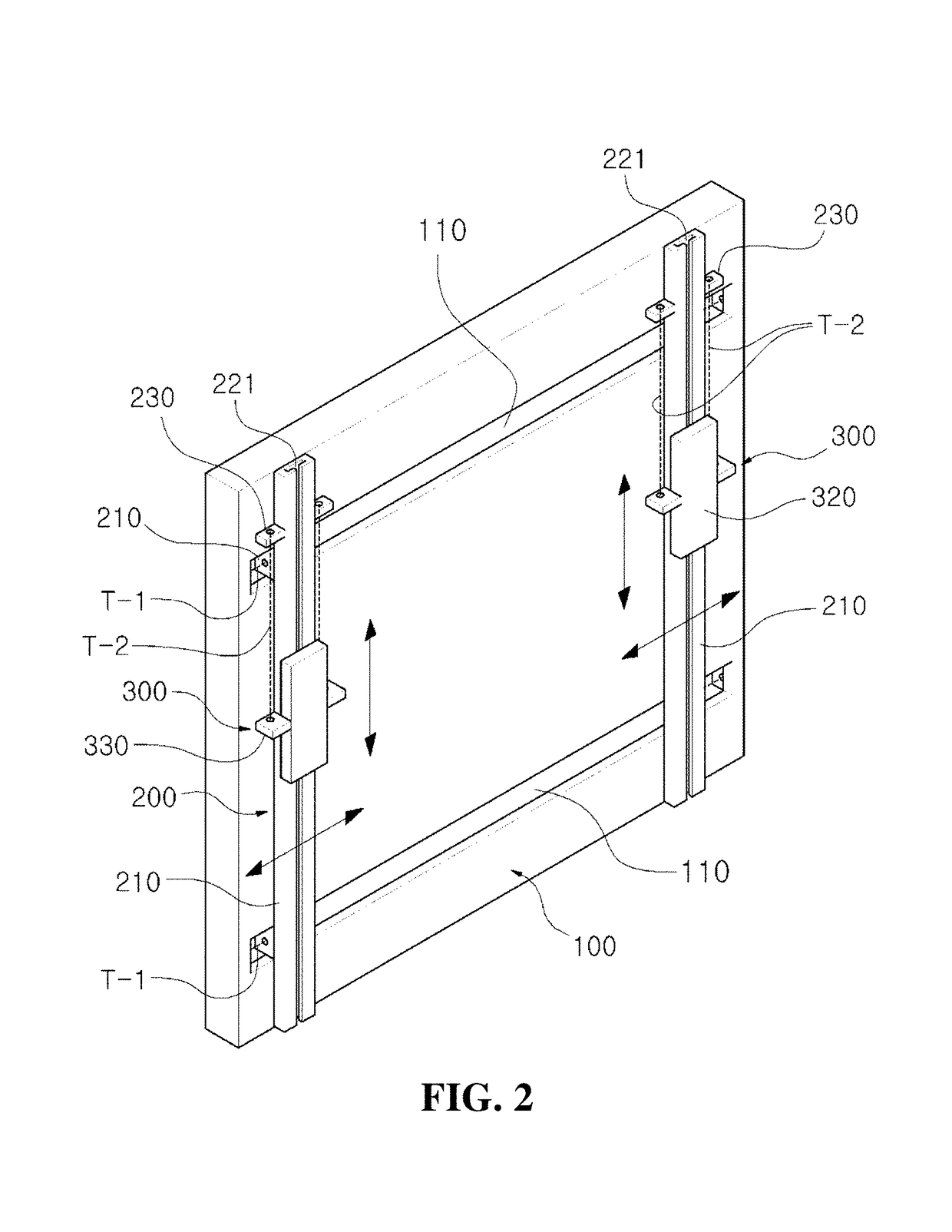

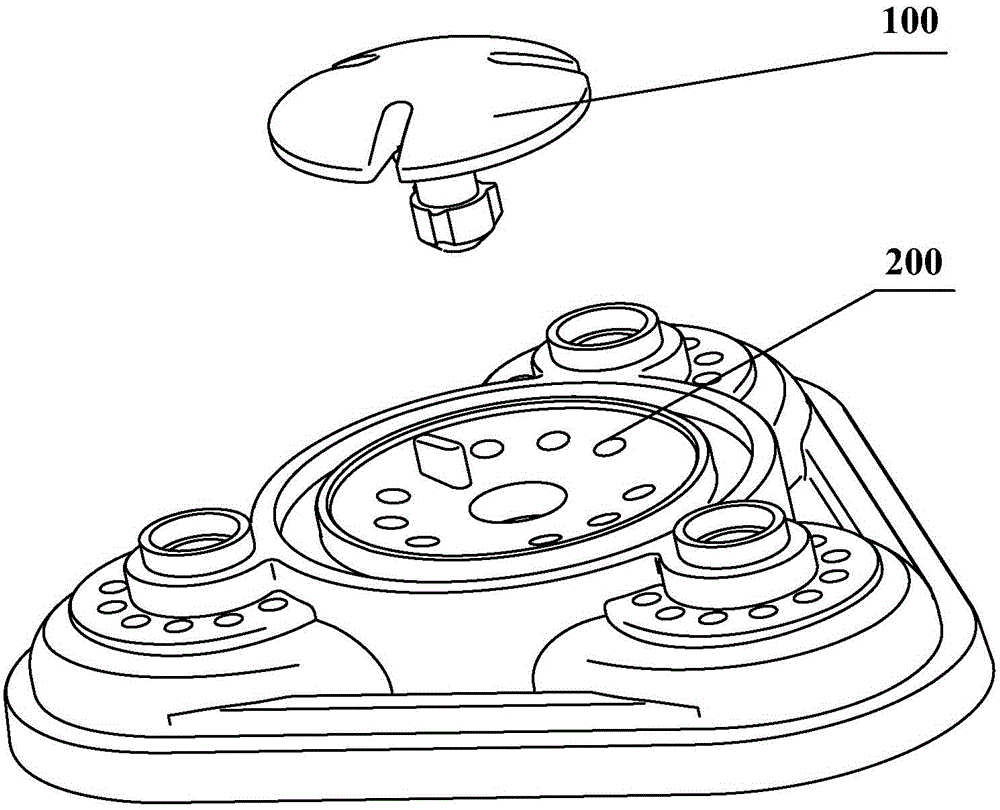

Detachable kinetic chain energy movement board for posture when using pilates reformer

InactiveUS9919181B1Prevent circumferential rotationOptimizationMuscle exercising devicesMovement coordination devicesRange of motionEngineering

Provided is a detachable kinetic chain energy movement (KEM) board for posture when using a Pilates reformer. The KEM board is configured to be detachably mounted to a foot bar or a footstool board of the Pilates reformer in order to provide flexion and extension, which are not conventionally possible, wherein the KEM board is configured to be easily and conveniently mounted to and detached from all kinds of Pilates reformers, is configured to derive much better muscle exercise effects during reformer exercises through the motion of the ankle and the hip joint within a full range of motion (ROM) and elastic resistance, and is configured to enable various kinds of exercises to be performed.

Owner:LEE SANG GON

Anti-rotation device of thin-wall storage and transportation gas cylinder

PendingCN111911804AReduce weightPrevent circumferential rotationVessel mounting detailsVessel geometry/arrangement/sizeGas cylinderEngineering

The invention discloses an anti-rotation device of a high-pressure thin-wall storage and transportation gas cylinder. The anti-rotation device comprises a flange connected with a frame, and further comprises a storage and transportation gas cylinder and a pressing block, the pressing block is arranged at the periphery of a bottleneck of the storage and transportation gas cylinder, and the pressingblock is connected with the flange, wherein the pressing block comprises an upper pressing block body and a lower pressing block body, the lower pressing block body is provided with a cavity, and theupper pressing block body is embedded into the lower pressing block body. According to the anti-rotation device, circumferential rotation and axial movement of the high-pressure thin-wall storage andtransportation gas cylinder in the transportation process are prevented, the phenomena of rotation and movement of the storage and transportation gas cylinder are avoided, and therefore it is guaranteed that the high-pressure thin-wall storage and transportation gas cylinder can be safely transported while the transportation gas cylinder is light in self-weight and the capacity is large.

Owner:ZHEJIANG REIN GAS EQUIP

Double-cylinder loose blade clamping and taking type self-locking cutting tooth core drill cylinder

PendingCN110872936ALow drilling resistanceSimple structureBorehole/well accessoriesStructural engineeringMechanics

The invention provides a double-cylinder loose blade clamping and taking type self-locking cutting tooth core drill cylinder which comprises an outer cylinder, an inner cylinder, a first reset spring,multiple rotating loose blades, multiple sets of self-locking mechanisms and unlocking devices corresponding to the sets of self-locking mechanisms. When the cylinder is filled with rocks and the inner cylinder overcomes pressure of the first reset spring to move upwards relative to the outer cylinder, the tail ends of the rotating loose blades at the bottom of the outer cylinder can be opened gradually, the self-locking mechanism can lock the positions of the inner cylinder and the rotating loose blades, the rocks in the inner cylinder are blocked, and the rocks are prevented from falling from the inner cylinder. Unlocking rods of the unlocking devices are pressed, locking of the position of the inner cylinder and the angles of the rotating loose blades can be released, and rock unloading is completed. The double-cylinder loose blade clamping and taking type self-locking cutting tooth core drill cylinder is simple in structure, convenient to operate and high in efficiency; the rotating loose blade does not affect the rotary excavation drilling work of the outer cylinder, the drilling resistance of the drill cylinder is small, and the drilling work efficiency is high. A guide barand a guide groove which are matched in a sliding manner are arranged between the inner cylinder and the outer cylinder, a guiding effect is achieved on moving of the inner cylinder, and the inner cylinder can be prevented from rotating in the circumferential direction relative to the outer cylinder.

Owner:湖南基础工程有限公司

Built-in guide oil cylinder

InactiveCN105387021ALimited rotationReliable circumferential guidanceFluid-pressure actuatorsPiston rodPiston

The invention discloses a built-in guide oil cylinder which comprises a lower end cover, a cylinder barrel, a right guide rod, a left guide rod, an upper end cover, a piston rod, a piston, an upper oil cavity, a lower oil cavity, upper screws and lower screws. According to the built-in guide oil cylinder, a guide device is installed in the oil cylinder, in the movement process of the oil cylinder, on one hand, the radial guiding action of the oil cylinder is enhanced, and on the other hand, rotation of the oil cylinder is limited, and circumferential guiding of the oil cylinder is reliably achieved. The built-in guide oil cylinder is simple in structure and reliable in work, solves the problem that the installing space and condition of the external accessory guide device of the oil cylinder are limited, can be applied to the occasions where circumferential rotating in the movement process of the oil cylinder is limited and has the wide application prospect.

Owner:HOHAI UNIV CHANGZHOU

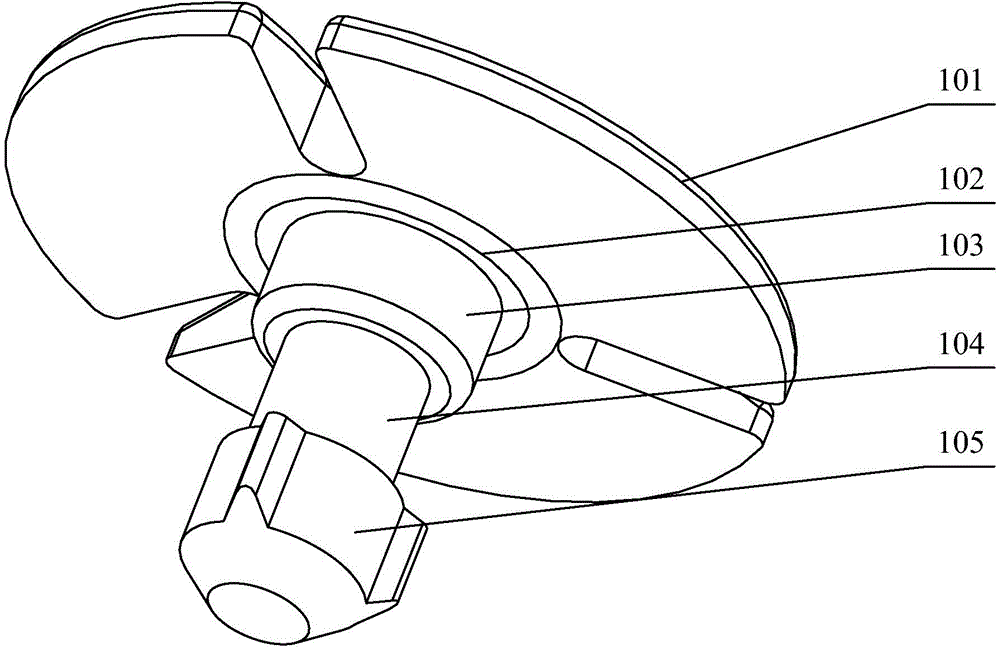

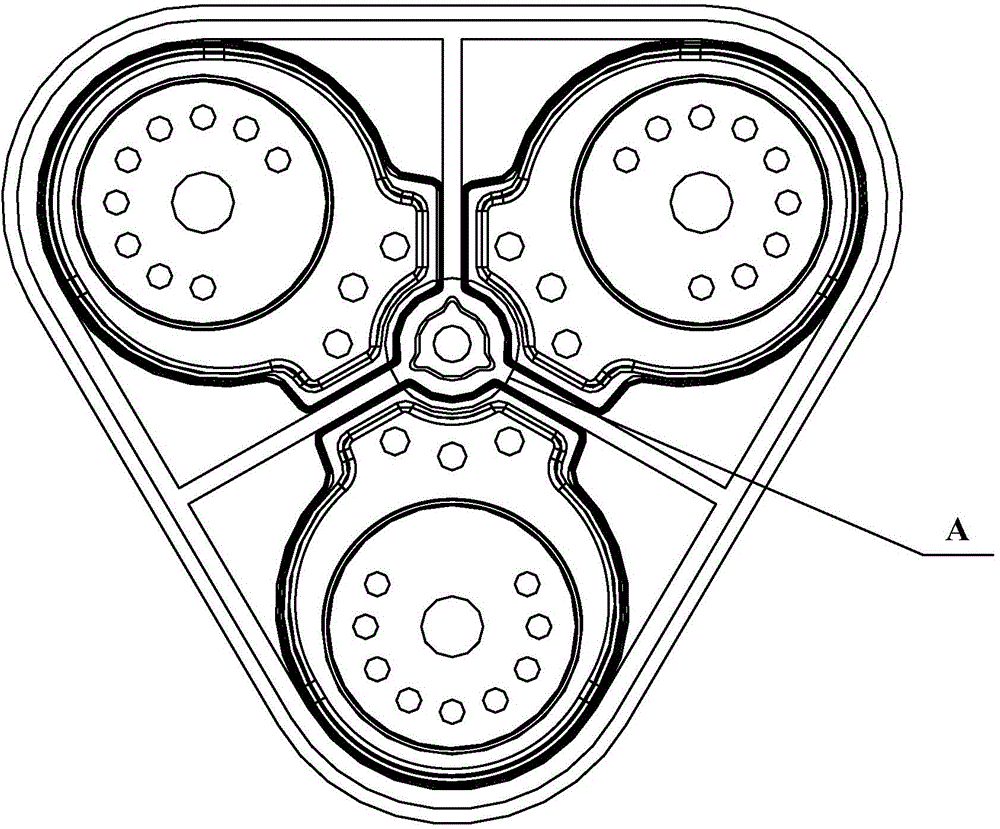

Valve plate and one-way valve

InactiveCN104832422APrevent backflowReduce contact areaPositive displacement pump componentsLiquid fuel engine componentsHigh-pressure areaLow-pressure area

The present invention discloses a valve plate comprising valve clacks and mounting pillars connected to the valve clacks, wherein a plurality of valve clacks are distributed radially; a partition groove is formed between two adjacent valve clacks; the mounting pillars are arranged at the junction of each valve clack; an annular convex rib is arranged on the lower surface of each valve clack; the annular convex ribs are arranged between the partition grooves and the mounting pillars and are collinear with axes of the mounting pillars. By virtue of the annular convex rib structure, the useless contact area between the valve clacks and valve seat water pressing grooves can be reduced; the returning elastic force used for sealing a connection hole is correspondingly increased; the valve clacks are accurately clung to the periphery of the connection hole, thereby achieving the better effect of sealing the connection hole. During long-term operation, the material of the valve plate is aged, fatigued and shrunk, so the elasticity is reduced; the elastic returning force is capable of ensuring the sealing effect all the time, thereby preventing the water in a low-pressure area from reversely flowing or leaking the water to a high-pressure area. The invention also discloses a one-way valve comprising the valve plate.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com