Passive terminal locking device for railway vehicle door system

A technology for rail vehicles and locking devices, which is applied in door/window fittings, operating mechanisms of wing sashes, buildings, etc., can solve the problems of low reliability, difficult replacement of lead screws, and large installation space, and achieves safety and reliability. High performance, high safety and reliability, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

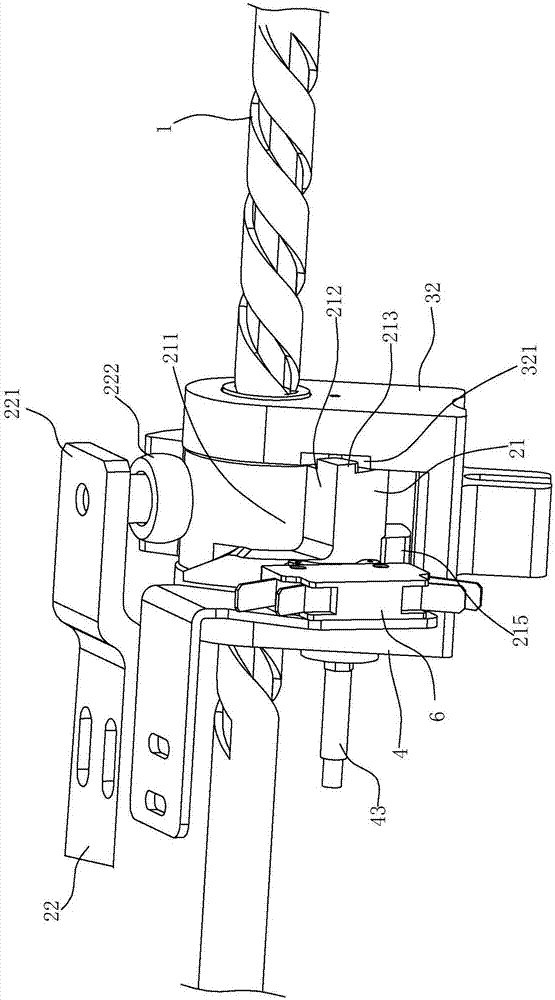

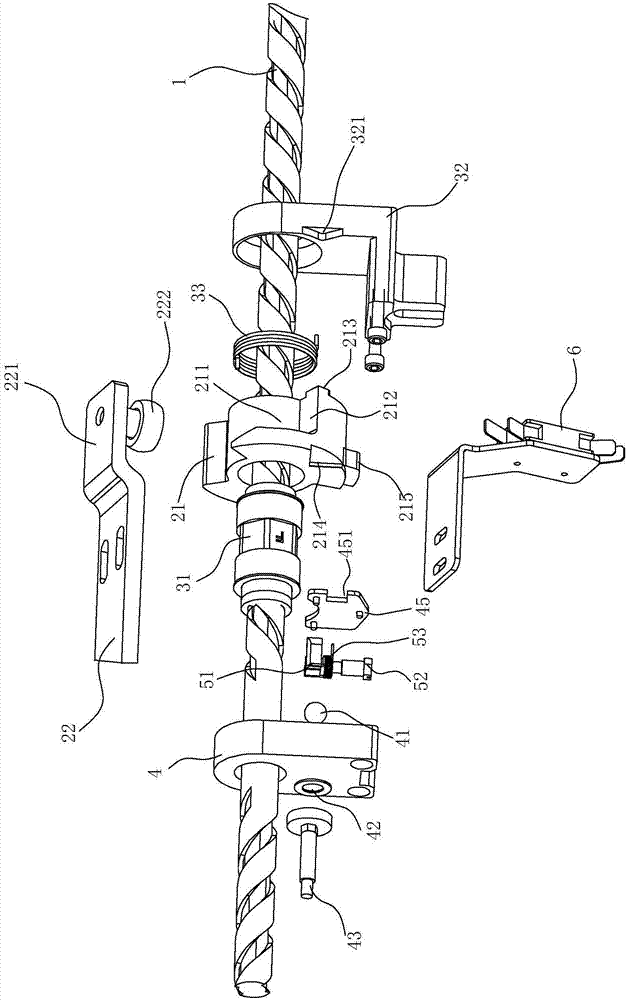

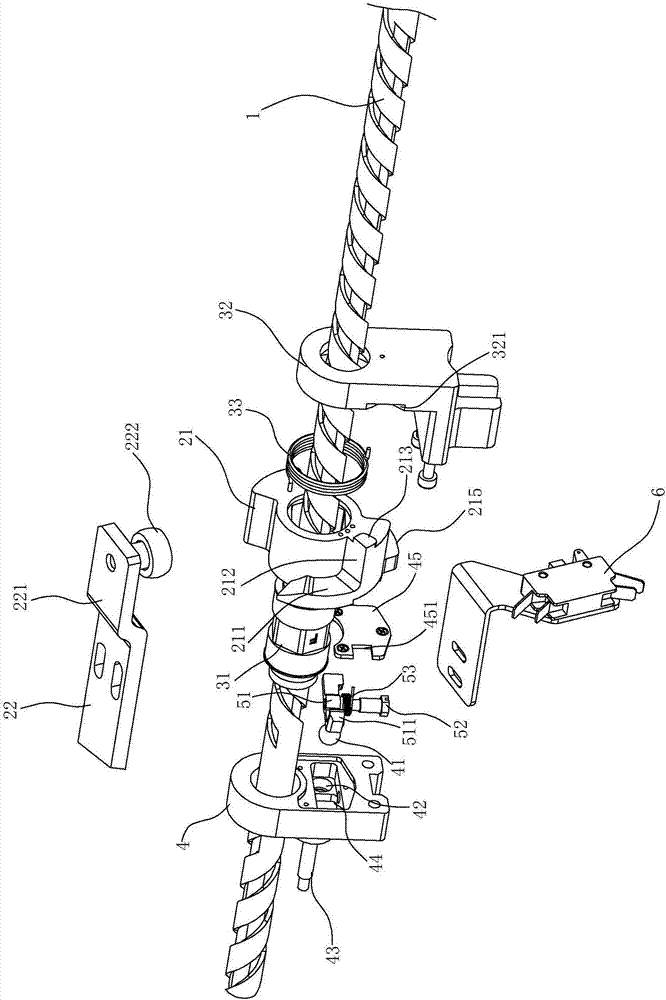

[0027] Such as Figure 1~6 Shown is a preferred embodiment of the present invention.

[0028] A passive terminal locking device for a rail vehicle door system includes a screw rod 1 and a locking mechanism. The locking mechanism includes a drive nut assembly, a locking assembly, a fixing assembly and a travel switch 6 .

[0029] The transmission nut assembly includes a nut pair 31 and a nut bracket 32 sleeved on the nut pair 31. The nut pair 31 is sleeved on the screw rod 1 and is driven with the screw rod 1. There is a lock between the nut pair 31 and the nut bracket 32. Close the torsion spring 33, and the nut support 32 can drive the seat so as to drive the door-carrying device to move to realize the opening and closing of the door leaf.

[0030] The locking assembly includes a locking nut 21 and a locking limit assembly 22. The locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com