Patents

Literature

46results about How to "Simple and reliable action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

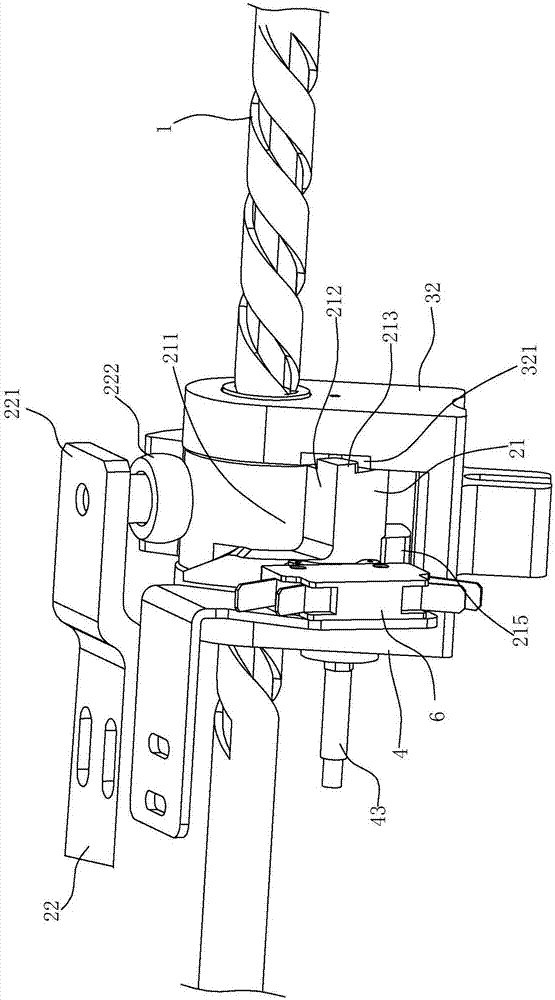

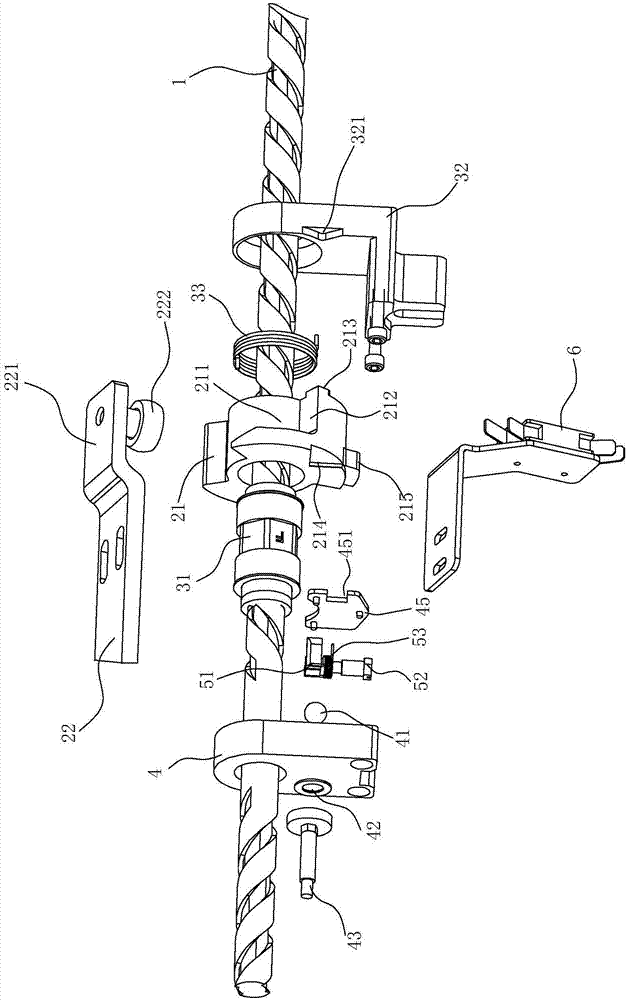

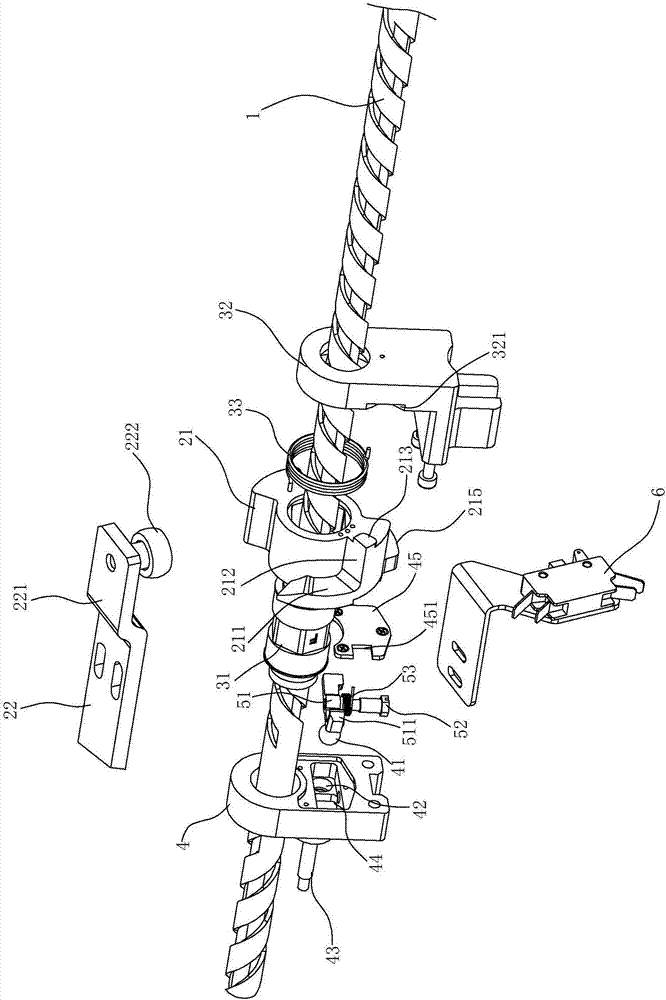

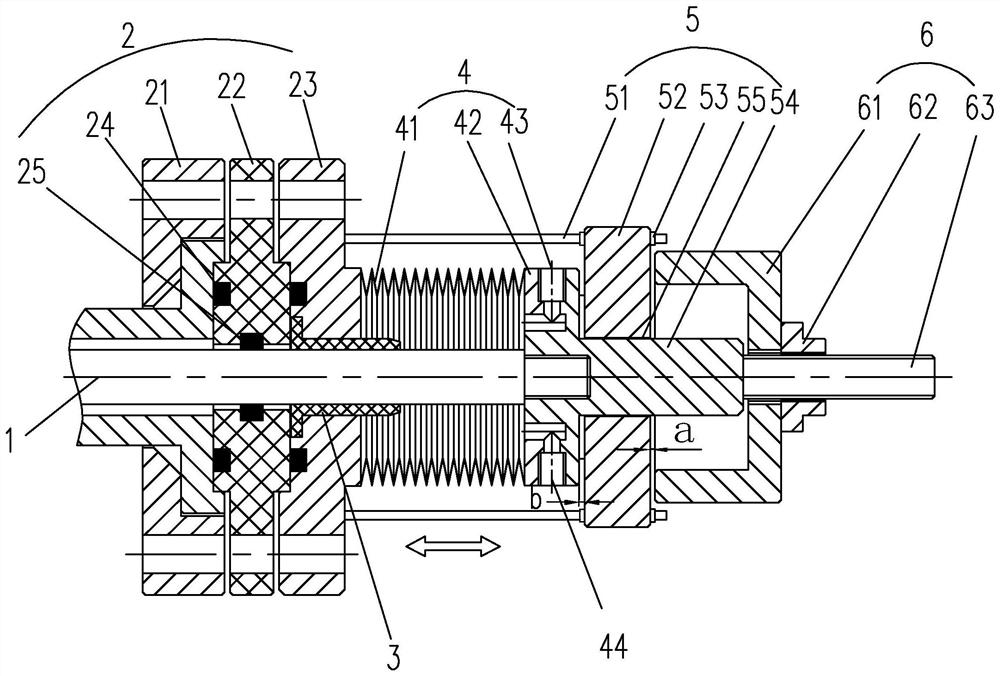

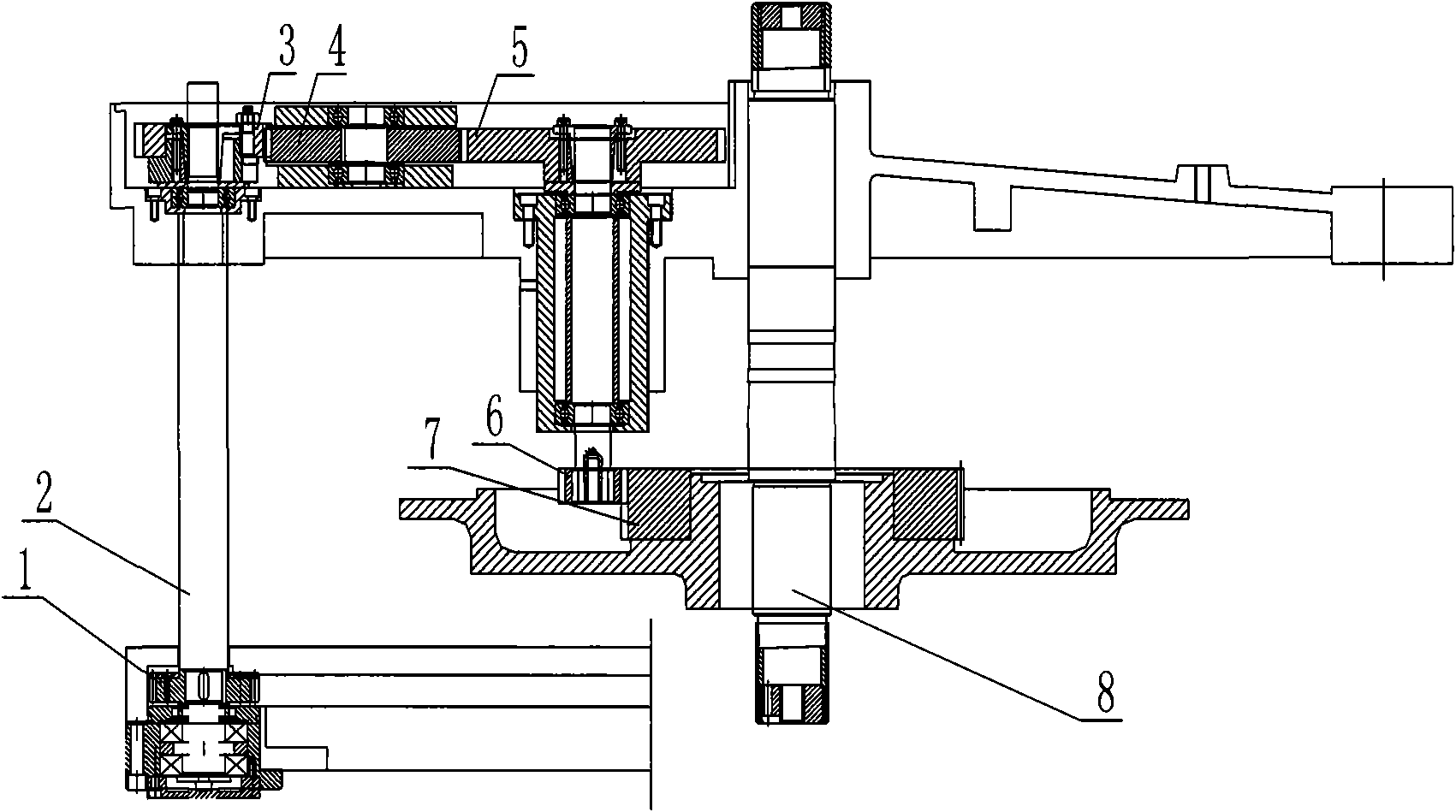

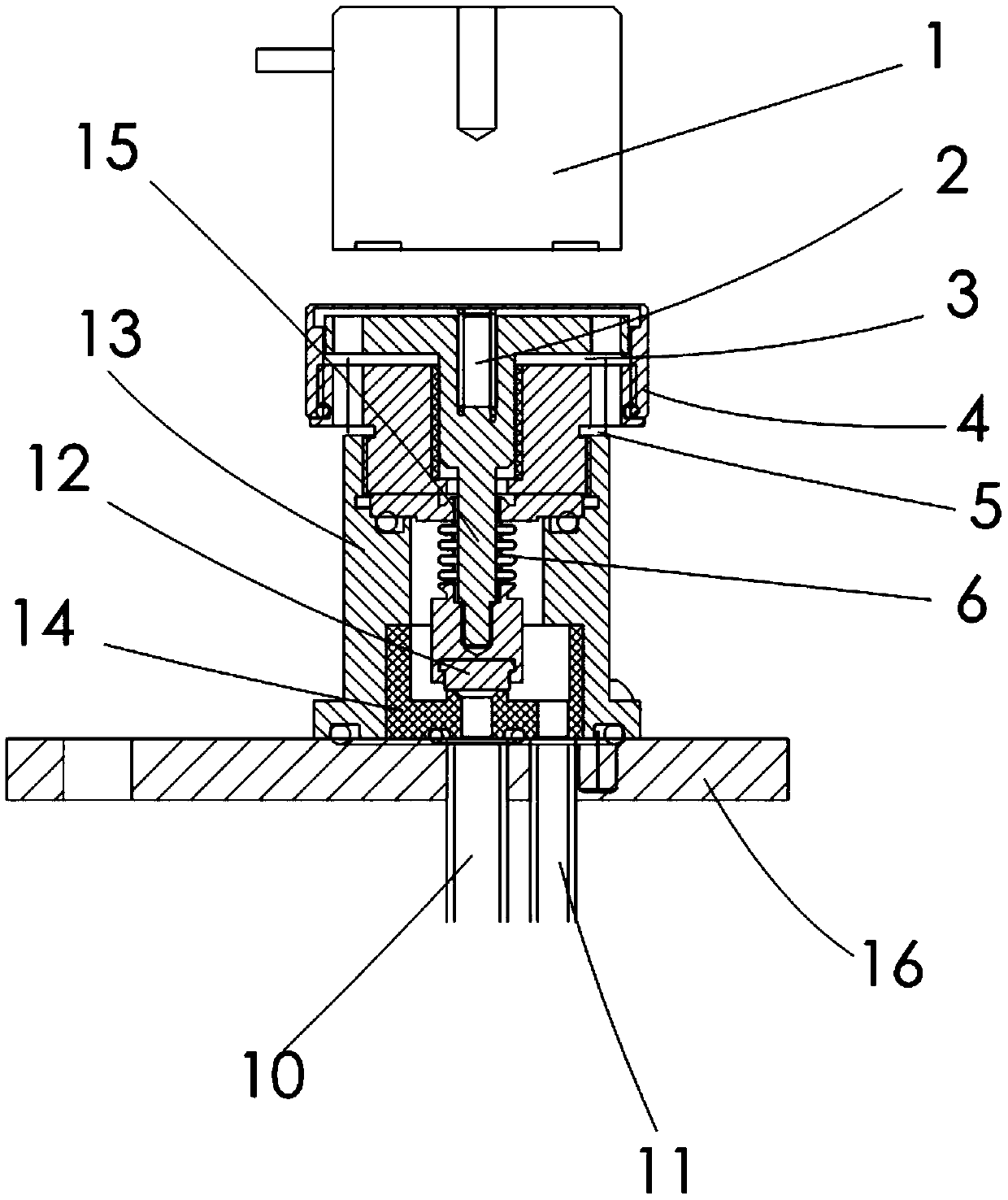

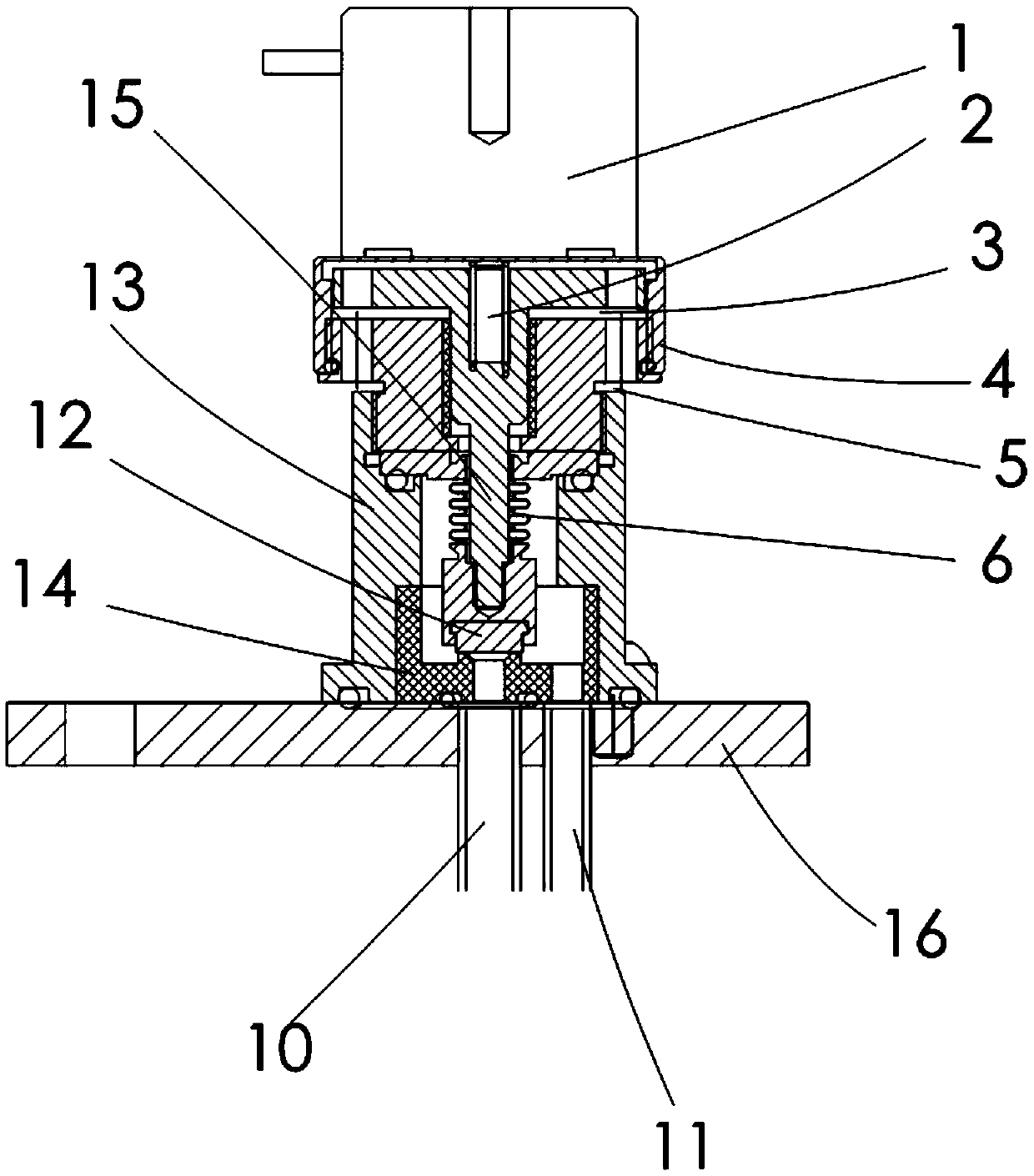

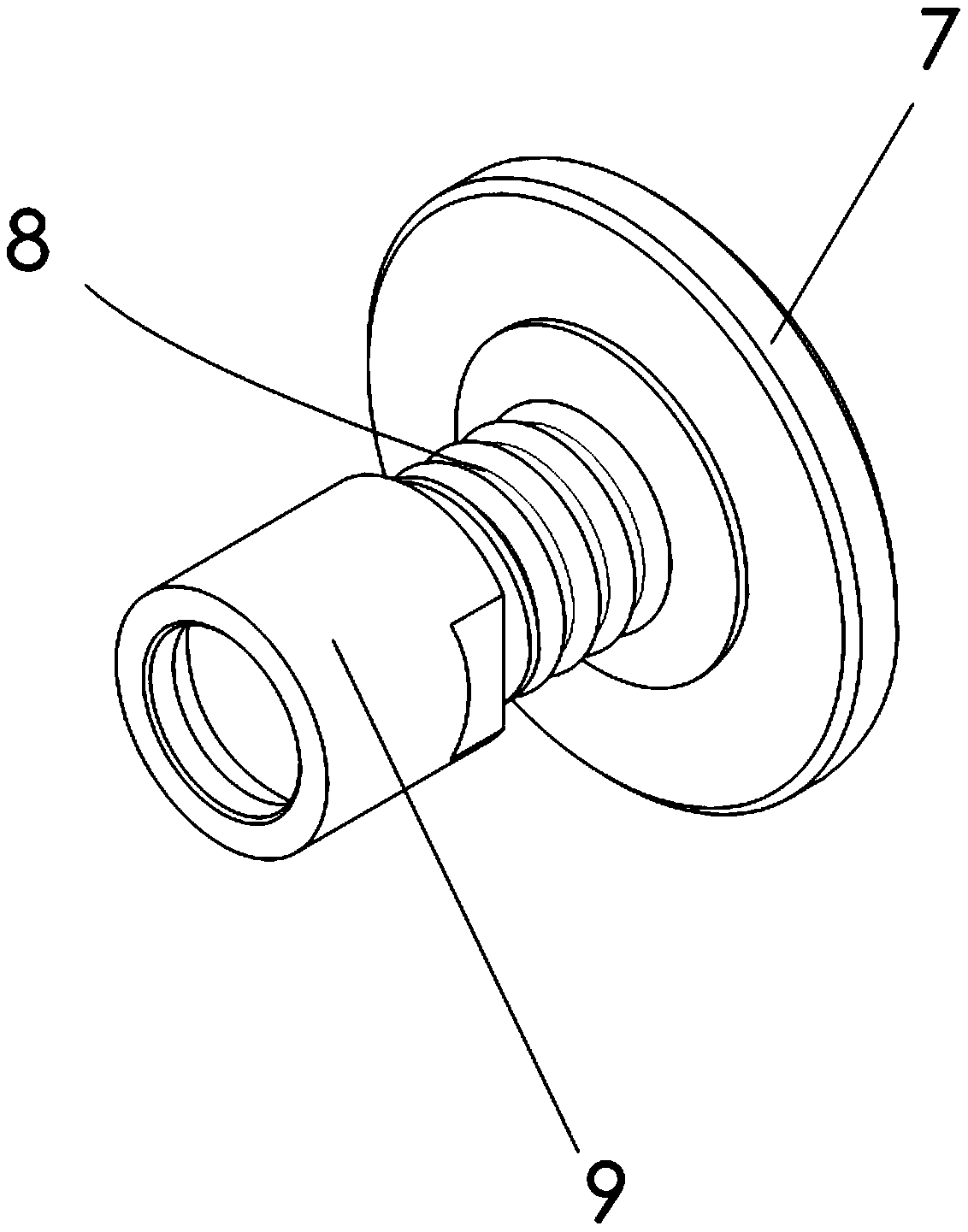

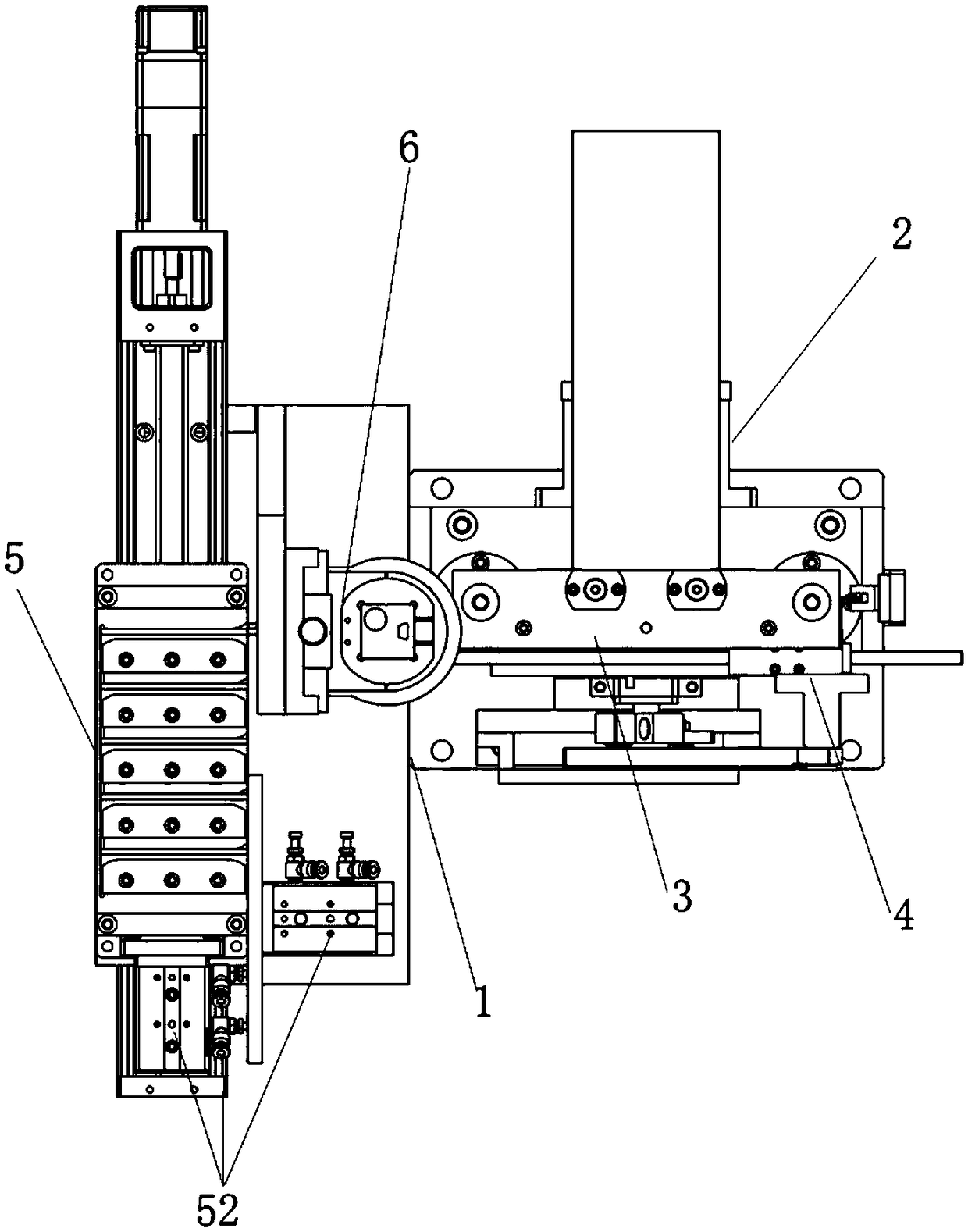

Passive terminal locking device for railway vehicle door system

ActiveCN107339045AAchieve lockingReduce in quantityPower-operated mechanismLocking mechanismEngineering

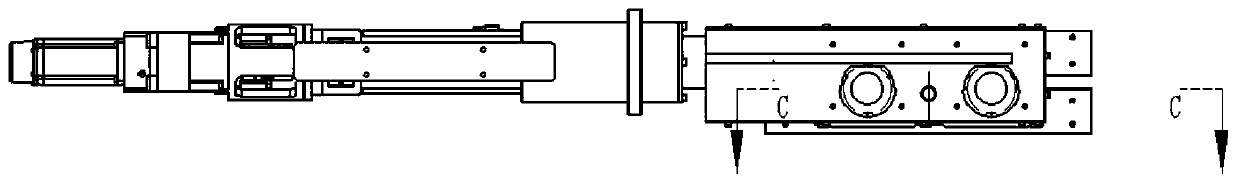

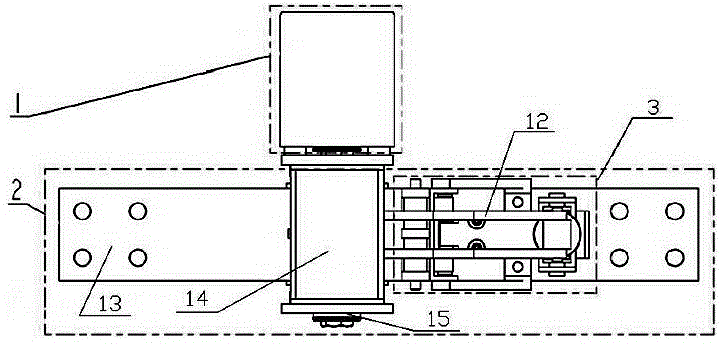

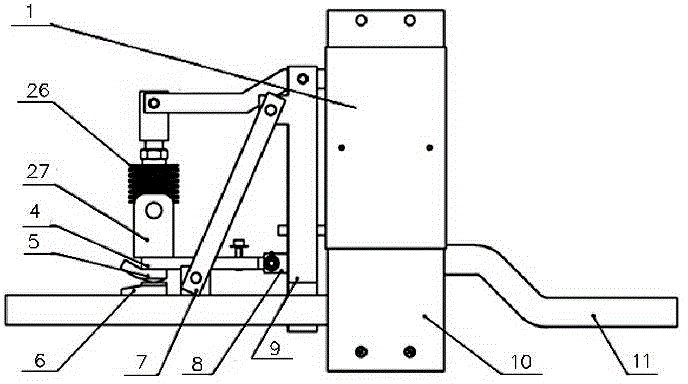

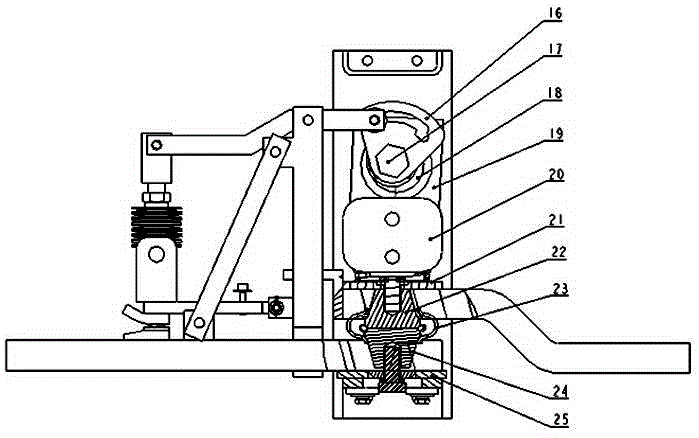

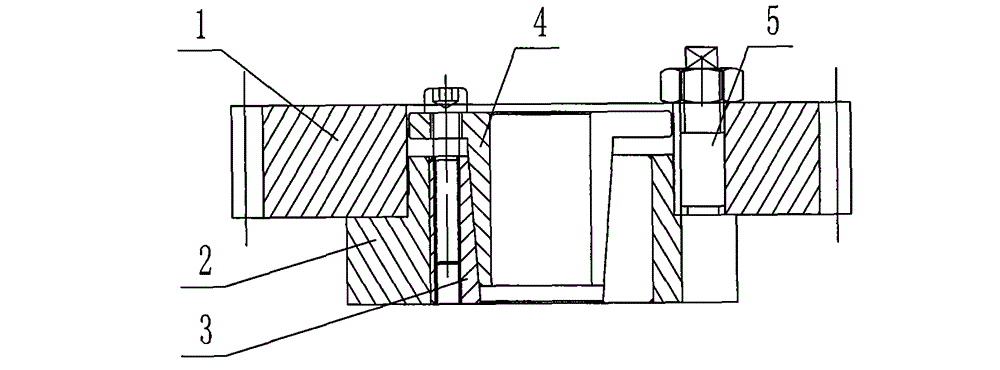

The invention relates to a passive terminal locking device for a railway vehicle door system. The passive terminal locking device comprises a lead screw and a locking mechanism. The locking mechanism comprises a transmission nut assembly and a locking assembly, wherein the transmission nut assembly is arranged on the lead screw in a sleeving manner and achieves transmission with the lead screw; the locking assembly comprises a locking nut and a locking limitation assembly; the locking nut is arranged on the transmission nut assembly in a sleeving manner, the locking limiting assembly is fixed to the upper portion of the locking nut, the locking nut is driven by the transmission nut assembly to rotate in the circumferential direction of the lead screw, the locking nut is located when rotating to the position abutting against the locking limitation assembly, and therefore the transmission nut assembly is also locked; and when the locking nut rotates to disengage from the locking limitation assembly, unlocking of the locking nut is achieved. According to the passive terminal locking device, by arranging the locking nut and the locking limitation assembly, locking of a door leaf is achieved, the structure is simple, concise and compact, the number of components is small, machining is easy, the dead load is small, and too large installation space is not needed; and moreover actions are easy and reliable, the components cannot be damaged, and the safety and the reliability are high.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

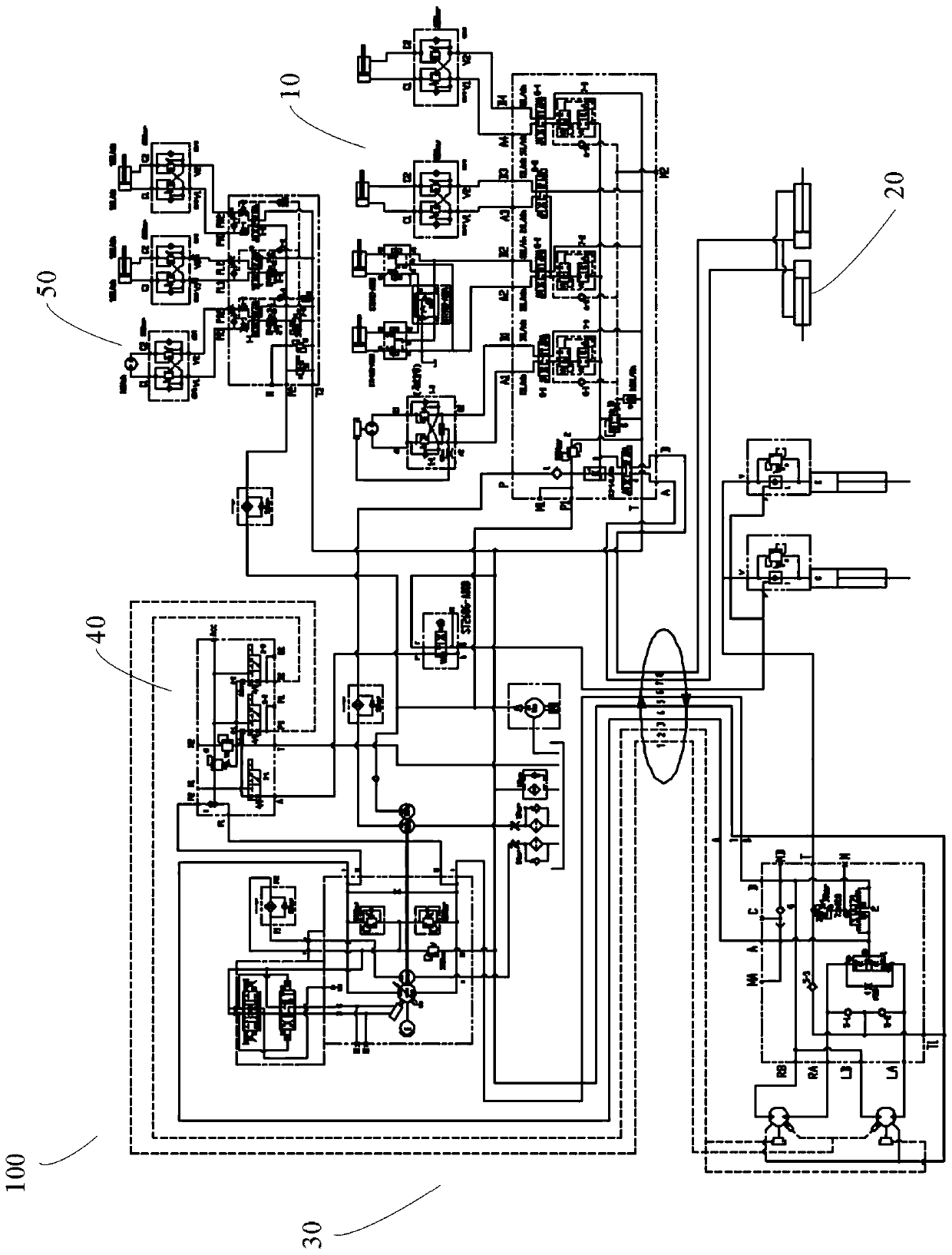

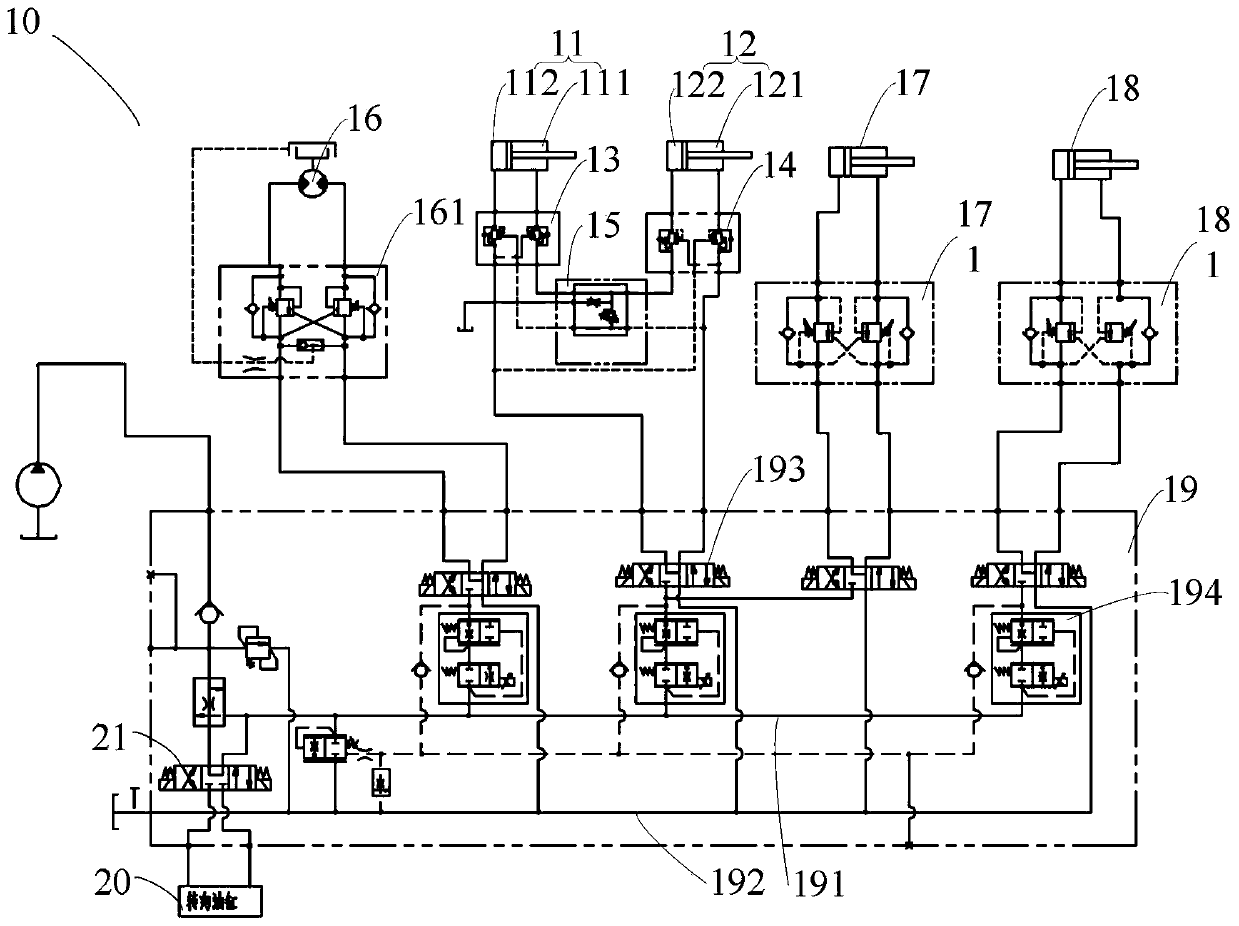

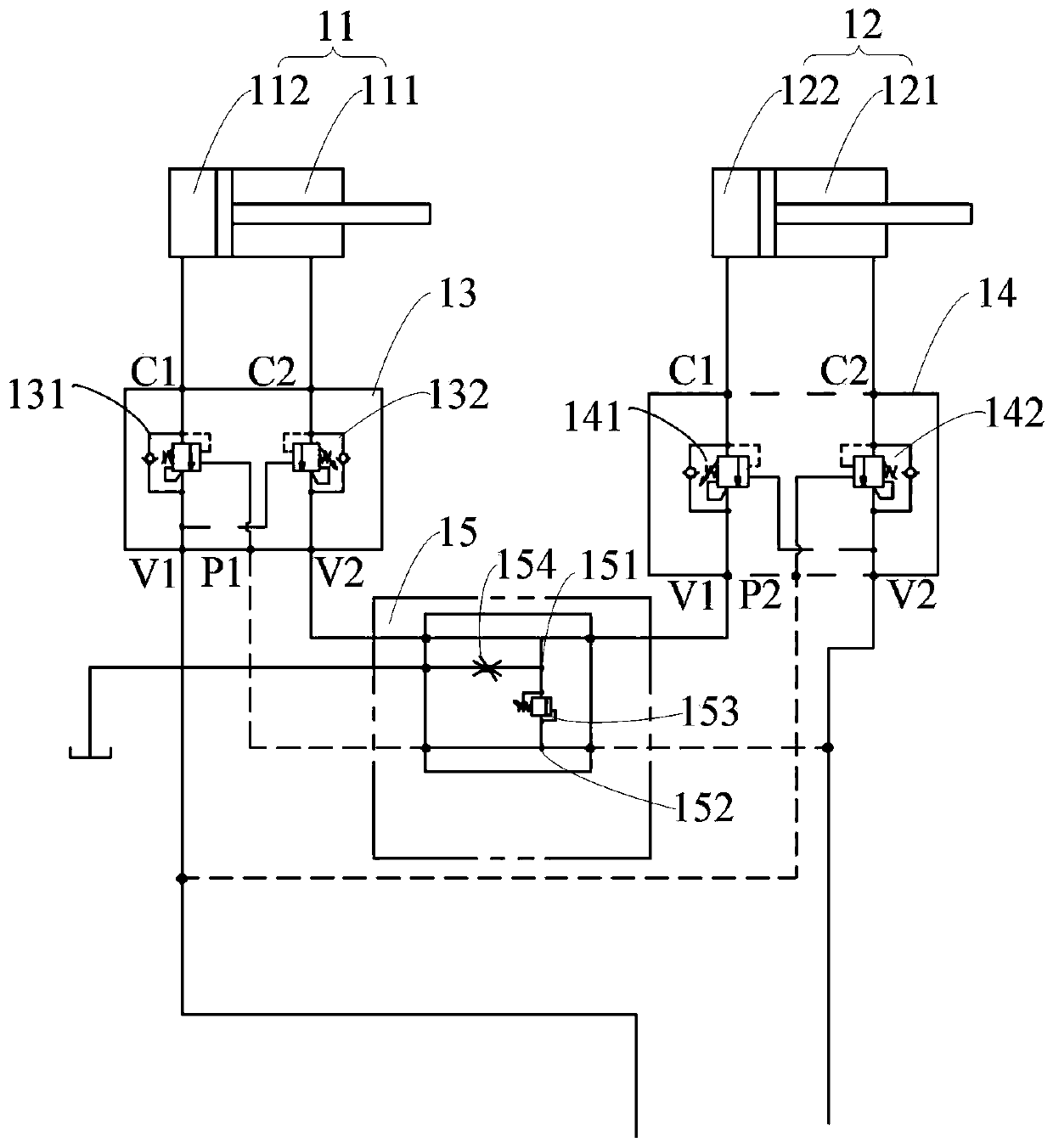

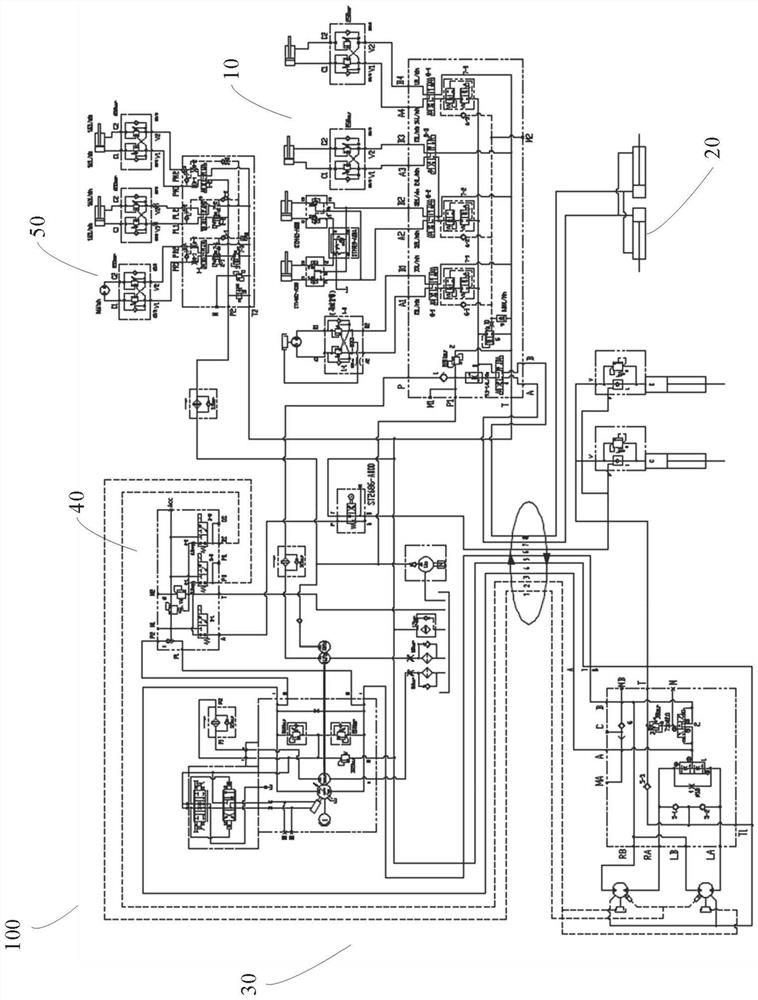

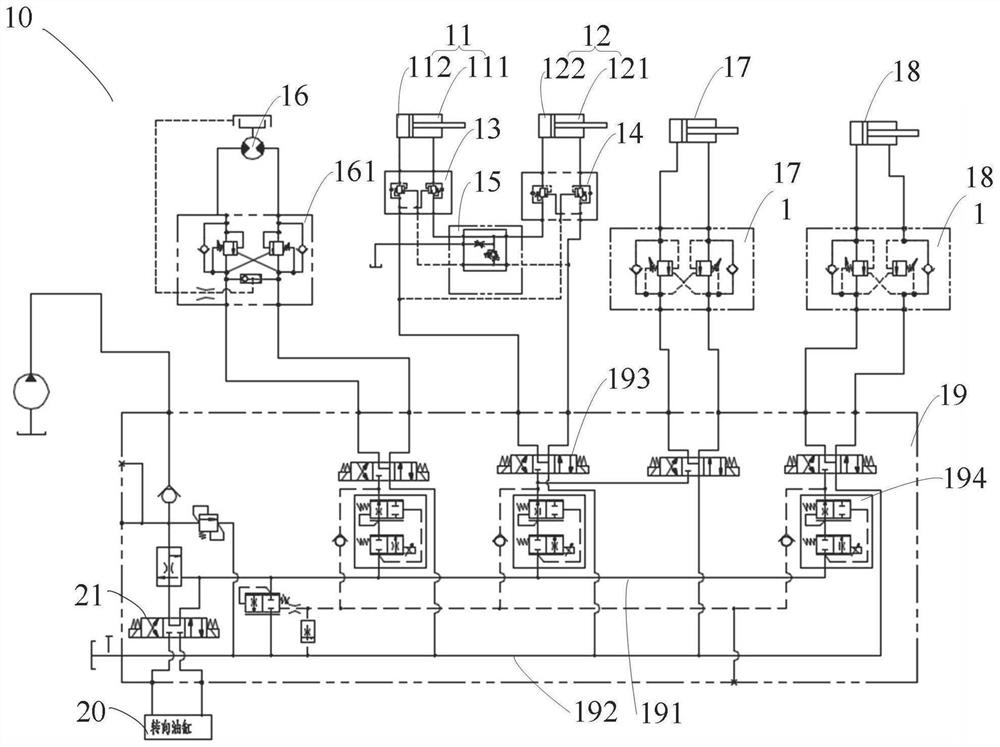

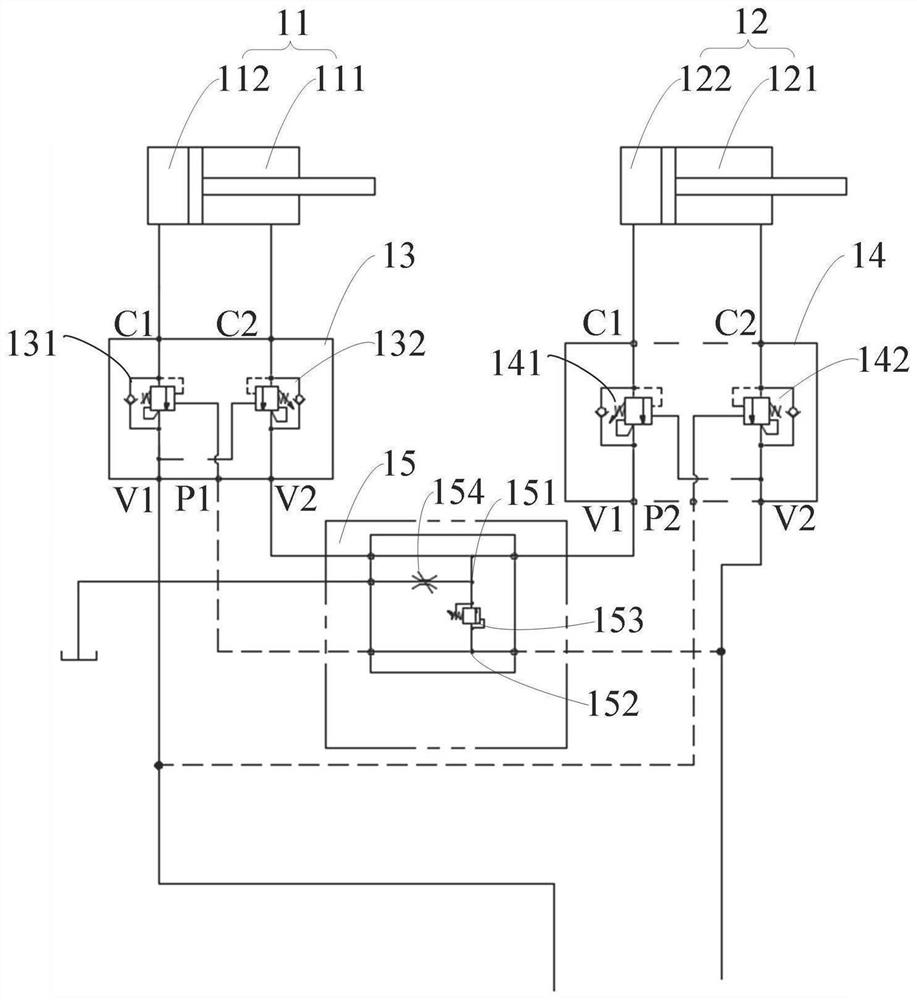

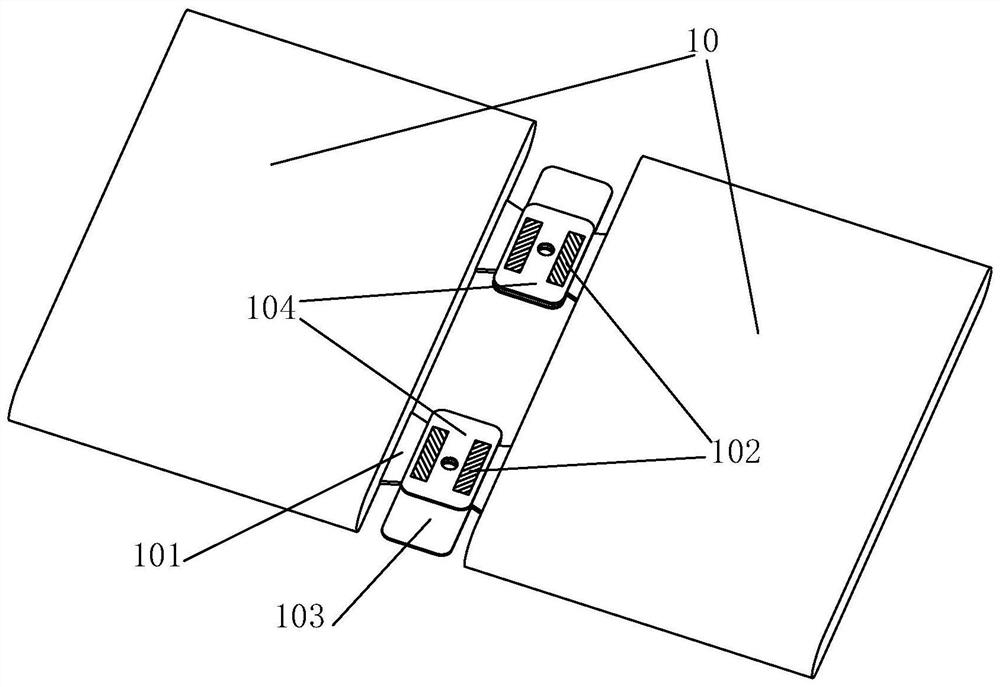

Crank arm type aerial work vehicle hydraulic system

The invention relates to a crank arm type aerial work vehicle hydraulic system. A rod cavity of a lower amplitude-variable oil cylinder of the crank arm type aerial work vehicle hydraulic system communicates with a rodless cavity of a medium amplitude-variable oil cylinder through a first two-way balance valve and a second two-way balance valve, and a communication oil path of the first two-way balance valve and the second two-way balance valve communicates with an oil inlet of an auxiliary synchronization valve; a first oil control port of the first two-way balance valve communicates with a rod cavity of the medium amplitude-variable oil cylinder through the second two-way balance valve, and a communication oil path of the first oil control port and the second two-way balance valve communicates with an oil outlet of the auxiliary synchronization valve; a second oil control port of the second two-way balance valve communicates with a rodless cavity of a lower amplitude-variable oil cylinder through the first two-way balance valve; and the auxiliary synchronization valve includes an overflow valve and a throttle valve which are connected in parallel. According to the crank arm typeaerial work vehicle hydraulic system, the auxiliary synchronization valve enables the lower amplitude-variable oil cylinder and the medium amplitude-variable oil cylinder to move at the same time, sothat the crank arm type aerial work vehicle hydraulic system is compact in layout and easy to maintain.

Owner:HUAIHUA UNIV

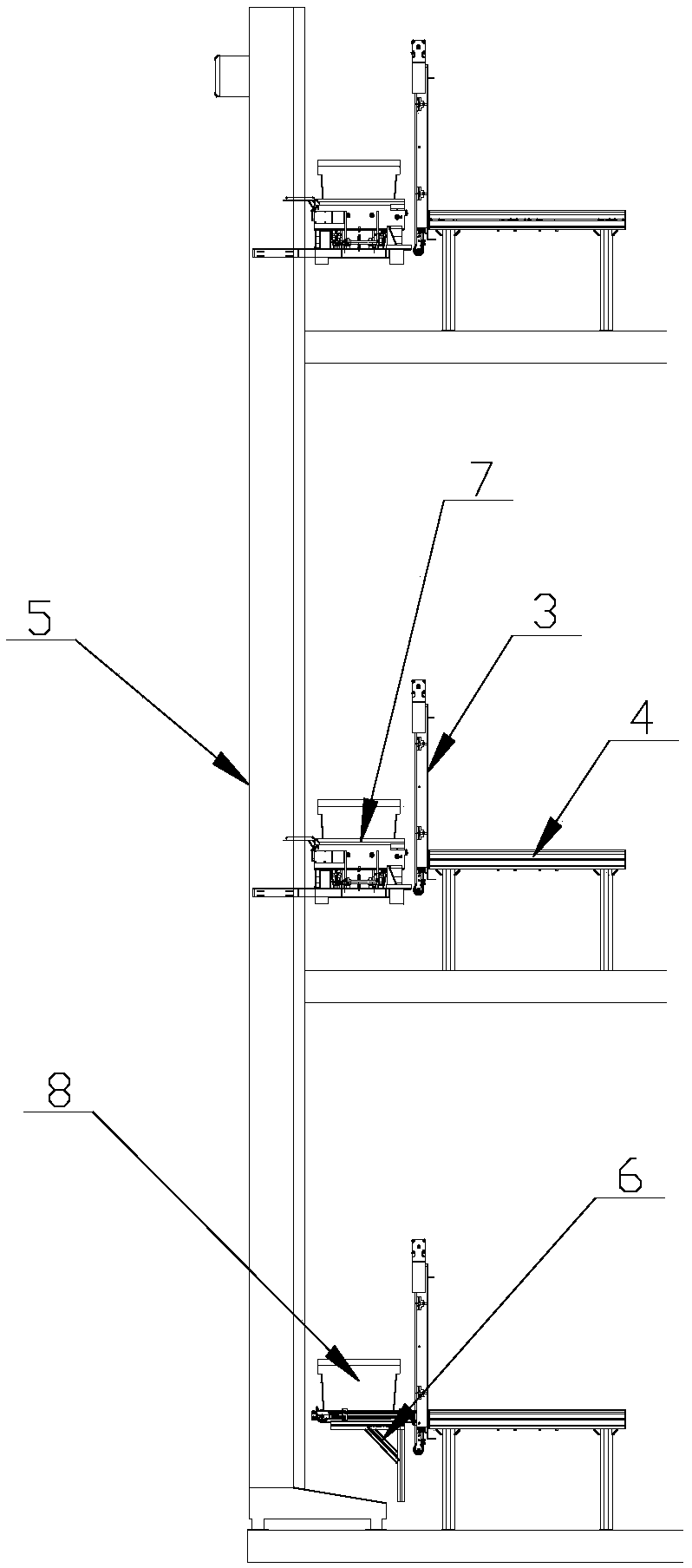

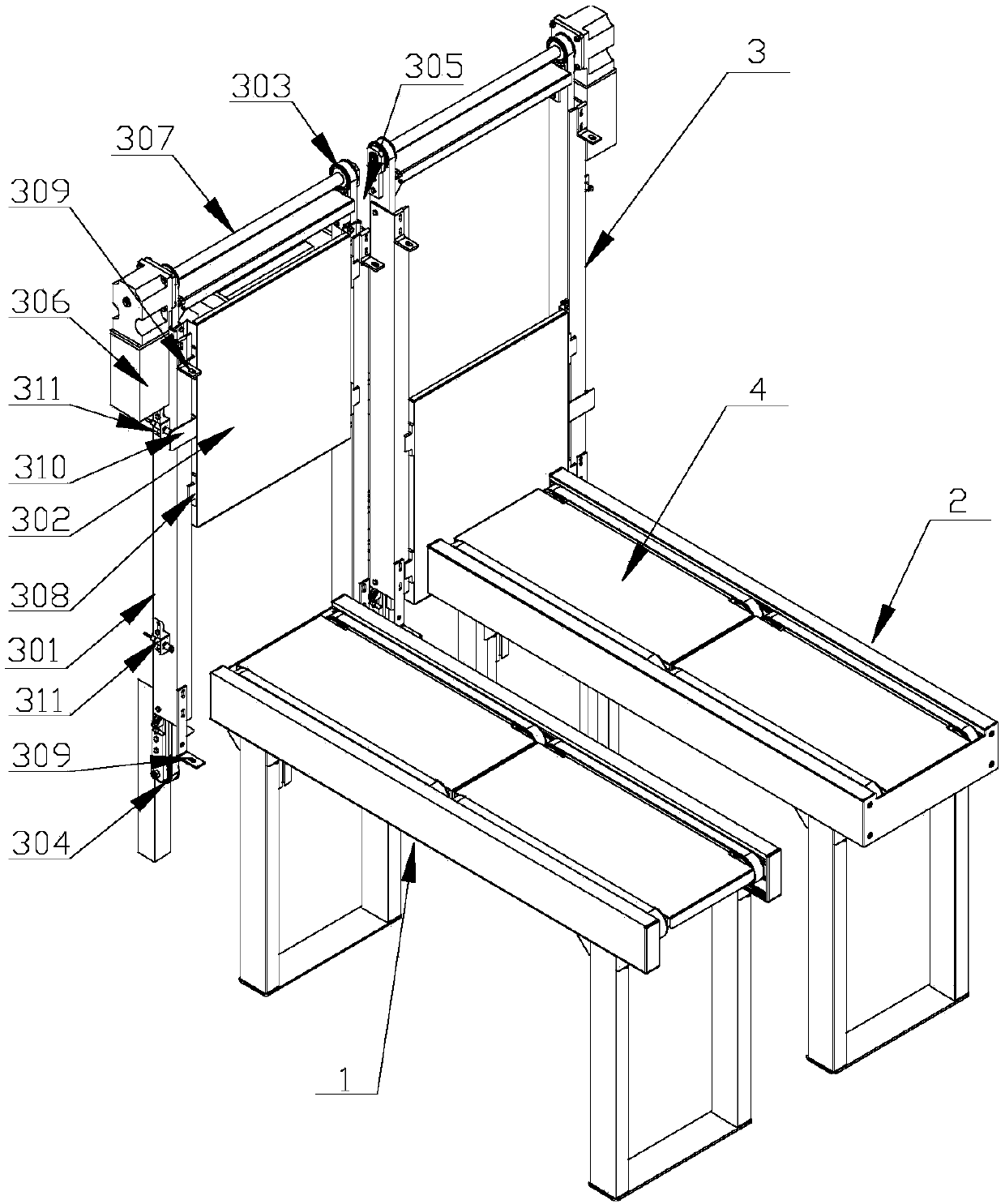

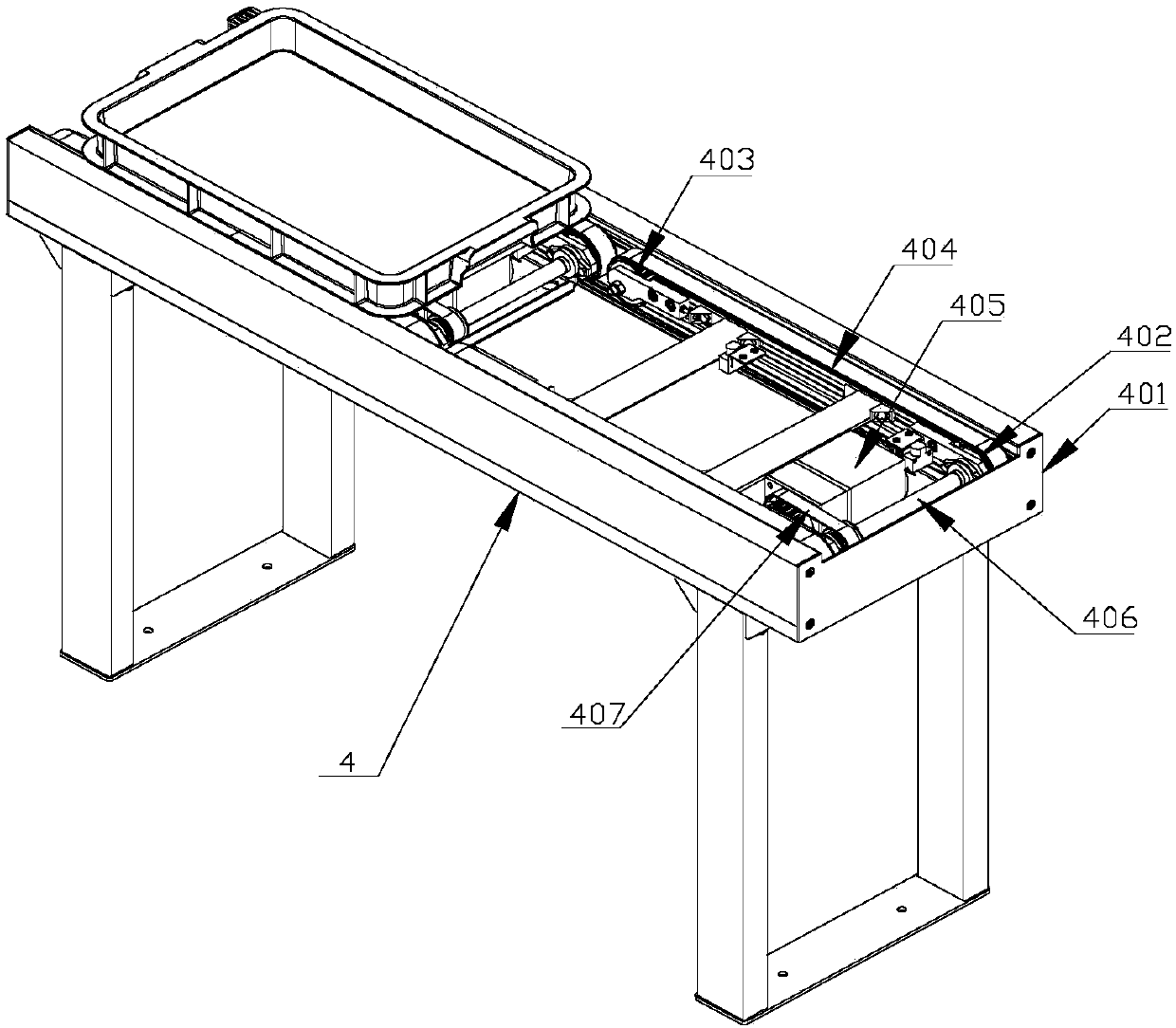

Hospital logistics conveying system

ActiveCN107555078AEfficient deliveryHigh degree of intelligenceConveyorsConveyor partsLogistics managementConstruction engineering

The invention relates to a hospital logistics conveying system. The system comprises conveying workstations which are respectively arranged in every floor in a building and used for conveying or outputting turnover boxes, a circulating ladder mechanism which is vertically arranged in the building and used for conveying the turnover boxes to the conveying workstations in corresponding floors and move-in / out conveying mechanisms which are respectively arranged between the conveying workstations and the circulating ladder mechanism and used for conveying the turnover boxes on the conveying workstations to the circulating ladder mechanism or conveying the turnover boxes on the circulating ladder mechanism to the conveying workstations, wherein the move-in / out conveying mechanism at the bottommost floor of the building is a fixed move-in / out conveying mechanism and the move-in / out conveying mechanisms at other floors are turnover move-in / out conveying mechanisms. Through the system disclosed by the invention, the efficient transportation of hospital materials is realized; and the system is high in intelligent degree.

Owner:蓓安科仪(北京)技术有限公司

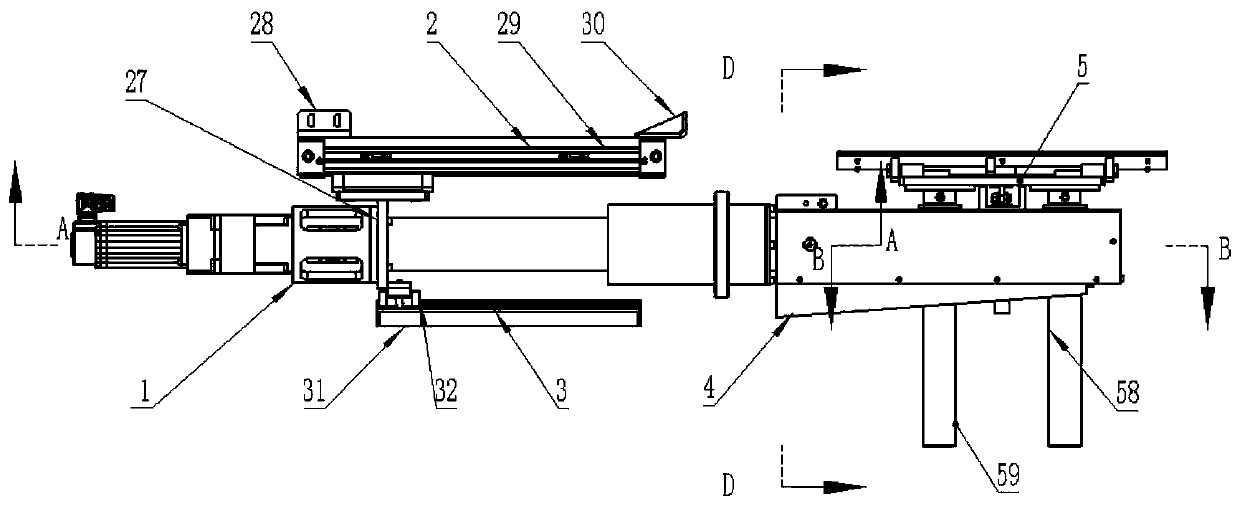

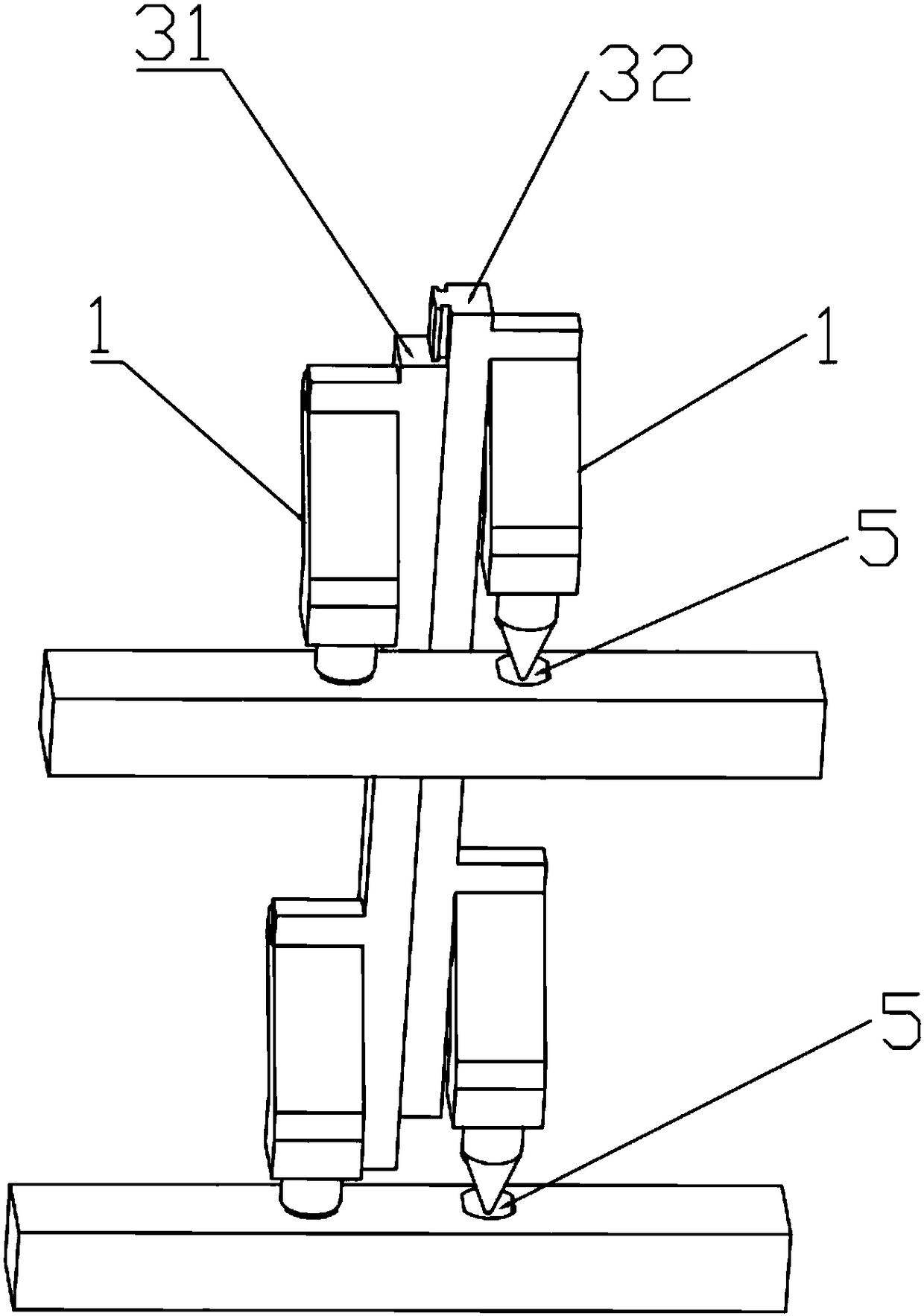

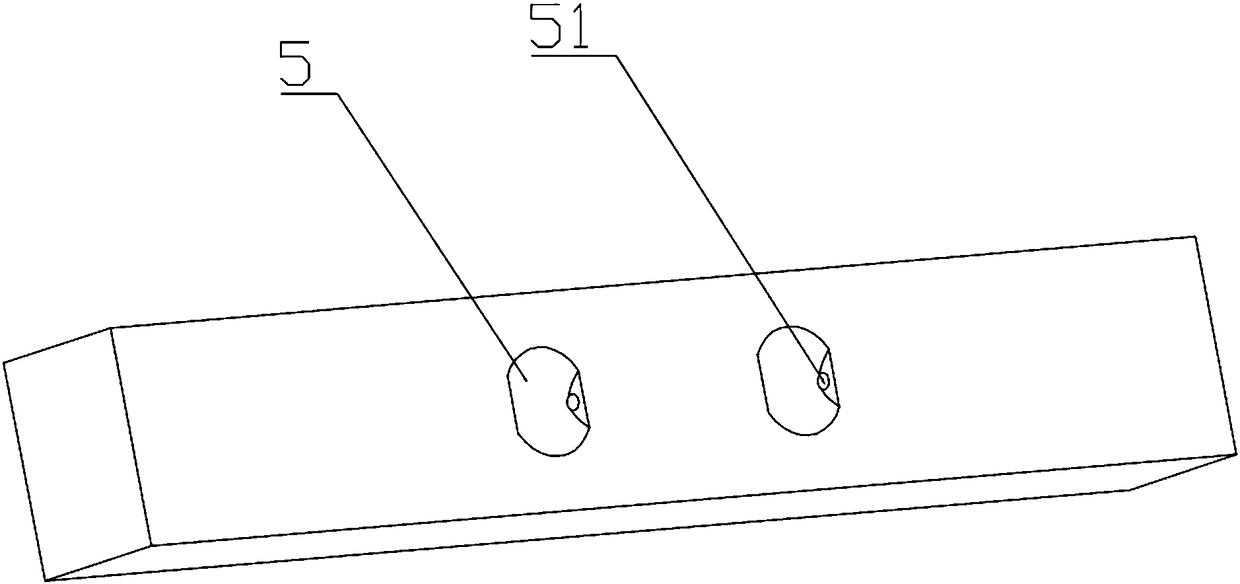

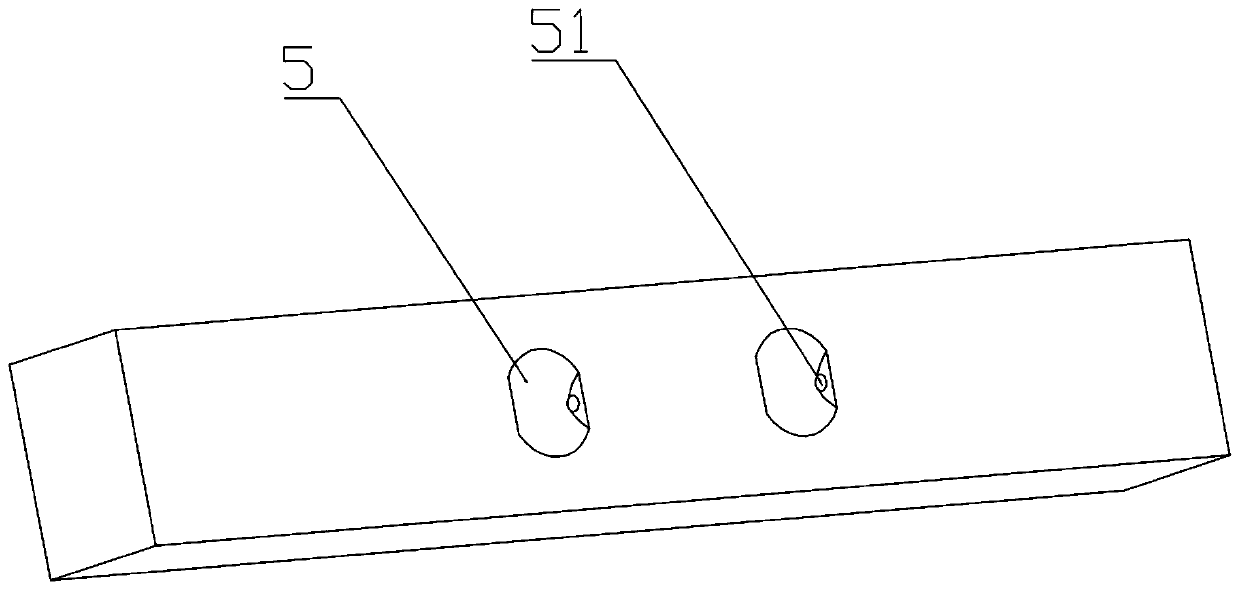

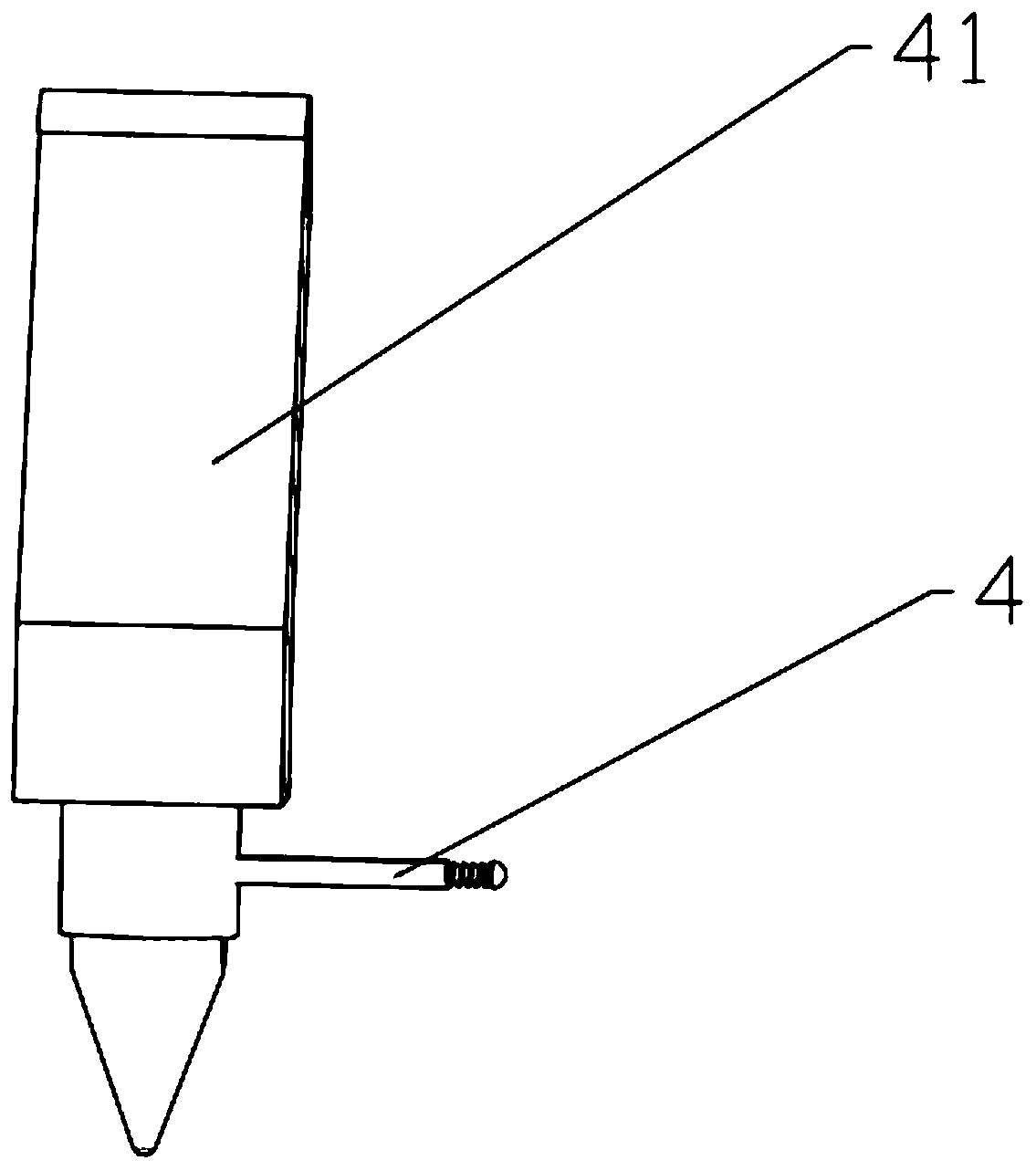

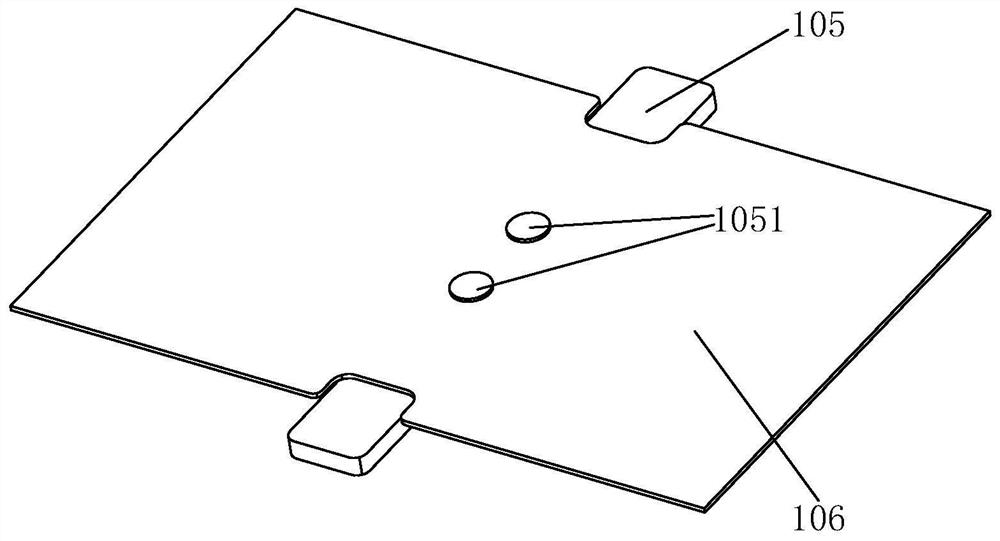

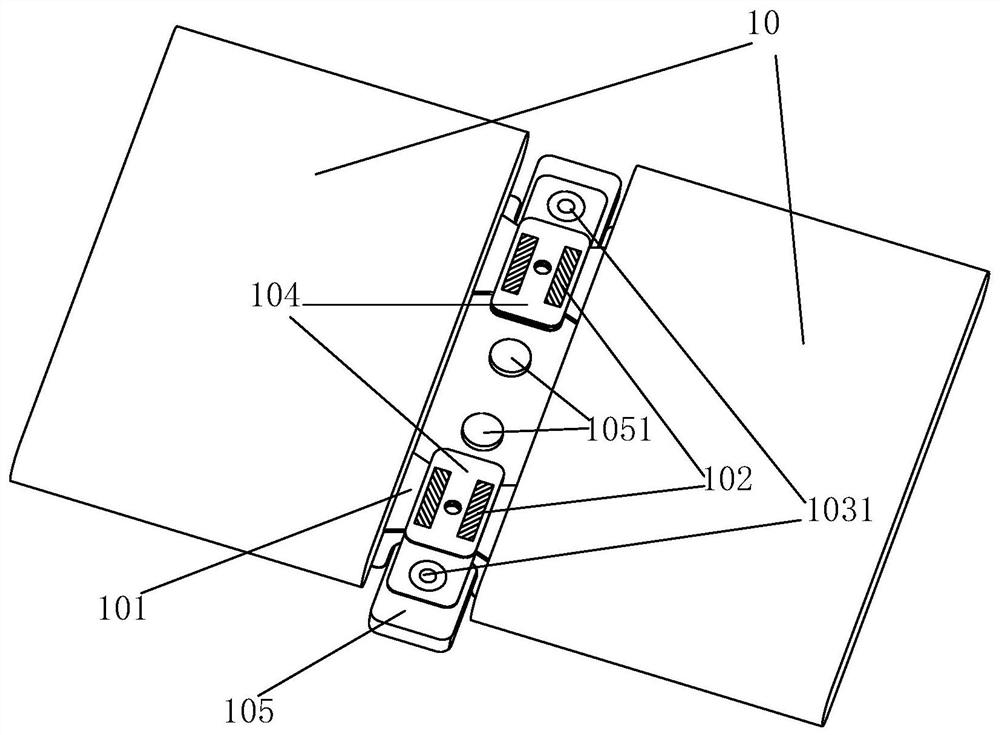

Driving method of ejector pin rod and negative pressure jacking type photovoltaic module laminating machine

ActiveCN113062896AImprove consistencyImprove efficiencyFlexible wall reciprocating enginesFinal product manufactureEngineeringMaterial resources

The invention provides a driving method of an ejector pin rod and a negative pressure jacking type photovoltaic module laminating machine to overcome the defects that when an air cylinder is adopted to drive the ejector pin rod in the prior art, the consistency of the ejection speed and time of the ejector pin rod is poor, battery assemblies are prone to being damaged and deviated, the ejection distance of the ejector pin rod is not prone to being detected, and defective products are prone to being generated. The laminating machine comprises a heating plate and an ejector pin system, the ejector pin system comprises a plurality of ejector pin rods and an ejector pin rod driving mechanism, a through hole for the ejector pin rods to pass through is formed in the heating plate, and the method comprises the steps that a telescopic pipe stretches out and draws back in the axial direction of the telescopic pipe by inflating and exhausting air in the telescopic pipe so as to drive the ejector pin rods fixedly connected with the telescopic pipe to reciprocate to drive the ejector pin rods to rise and fall. According to the driving method of the ejector pin rod and the negative pressure jacking type photovoltaic module laminating machine, additional debugging operation is not needed, manpower and material resources are saved, installation and debugging are easy, the debugging time is shortened, the production efficiency is improved, the problem of positioning failure is avoided, and the action is simple, reliable and easy to control.

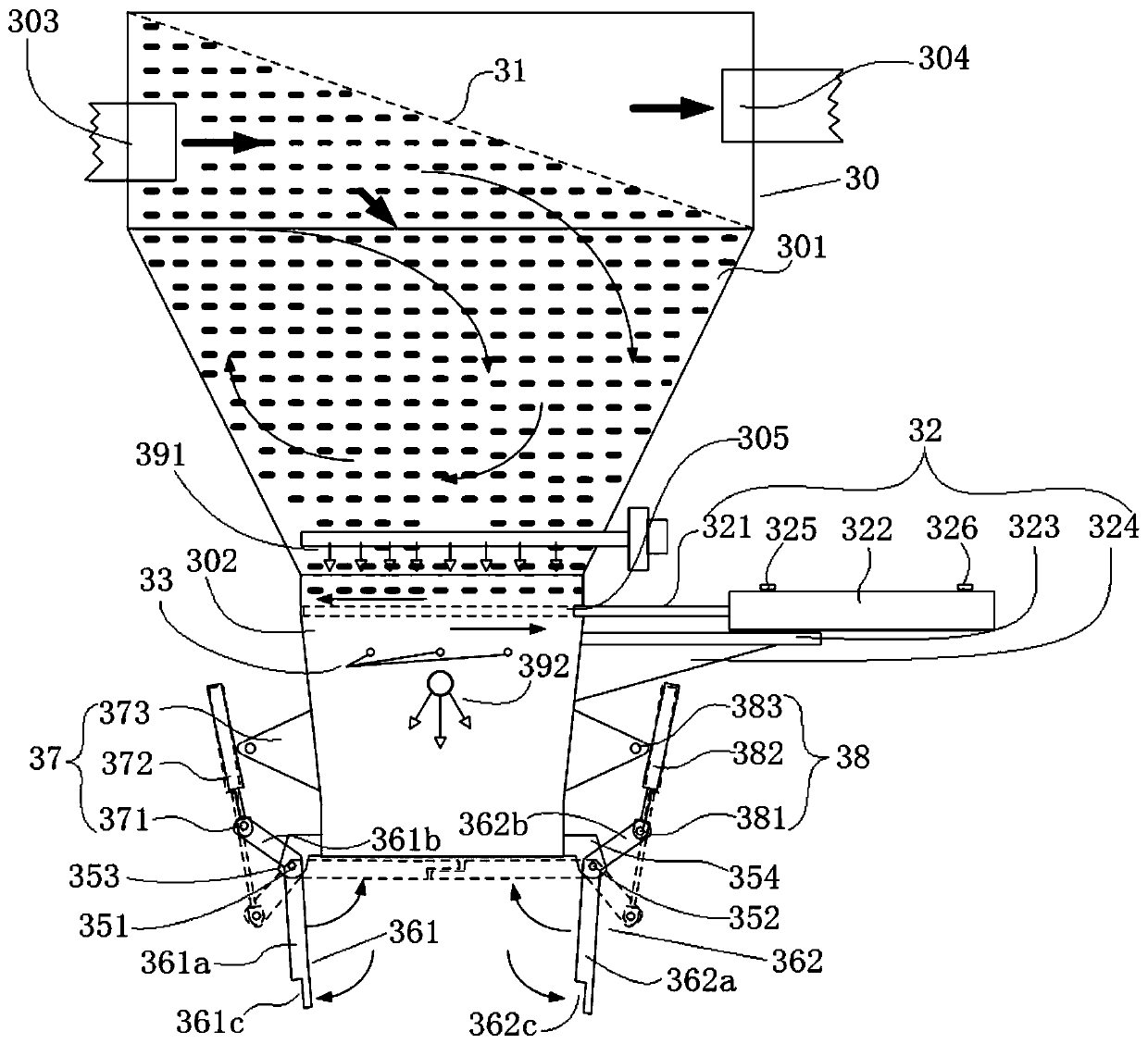

Automatic yarn unloading device of glass fiber drawing machine

PendingCN110698054ACompact structureSimple structureGlass making apparatusGlass productionGlass fiberYarn

The invention relates to an automatic yarn unloading device of a glass fiber drawing machine, which comprises a rack and a cylinder pushing mechanism arranged on the rack, an air cylinder mechanism isarranged at the upper part of the cylinder pushing mechanism, a linear slide rail mechanism is arranged at the lower part of the cylinder pushing mechanism, and a lifting mechanism is arranged at oneside of the cylinder pushing mechanism and is driven by the cylinder pushing mechanism; a tray mechanism is installed on the upper portion of the lifting mechanism, the cylinder pushing mechanism andthe air cylinder mechanism are connected into a control box, and the linear slide rail mechanism, the lifting mechanism and the tray mechanism act under the assistance of the cylinder pushing mechanism and the air cylinder mechanism. The production efficiency is high, the labor intensity can be effectively reduced, glass fiber production automation can be achieved, the service life is long, and obvious technical advantages are achieved in domestic and overseas glass fiber traction equipment. The automation degree of enterprises can be improved, the production efficiency is improved, the production cost is reduced, and the market prospect is wide.

Owner:泰安佳成机电科技有限公司

Press fit device and method for narrow and small space of automobile covering parts

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

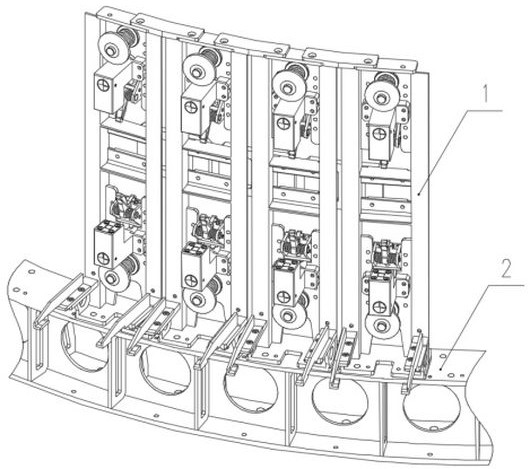

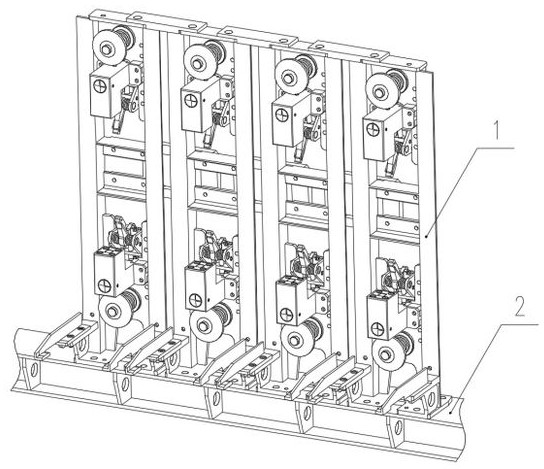

Load switch for magnesium electrolysis

InactiveCN104064393AExtended service lifeThe overall structure is simple and reliableHigh-tension/heavy-dress switchesAir-break switchesElectricityElectrolysis

The invention discloses a load switch used for a rated voltage of 30VDC and a rated current of 6KA, and used for cell shut-down and start-up for magnesium electrolysis (called as load switch for short below), which belongs to the technical field of direct-current switching devices. The load switch is composed of the parts of a main switch, a drive motor, an air-type arc extinguishing system and the like. The switch adopts a structure with a single-pole hard-bar and soft connection, the single-pole hard-bar is used for mechanical fixed installation, and the soft connection is used for installation tolerance adjustment; the main touch system of the main switch adopts a conical structure, thus facilitating a bearing current to reduce a voltage drop; the operation mechanism of the main switch is used for driving a cam rotation mechanism by virtue of a hexagonal shaft, thus greatly simplifying the operation mechanism; the air-type arc extinguishing system is designed and installed on the hard copper bar of the main switch, and a certain time sequence of the main switch is ensured by virtue of an eccentric wheel installed on the hexagonal shaft, thus greatly prolonging the service life of the switch. According to the load switch, the cell shut-down and start-up working for magnesium electrolysis in case of no power-off is solved, and the effects of saving energy and reducing consumption, and improving product quality are remarkable.

Owner:东莞市大展机械自动化科技有限公司

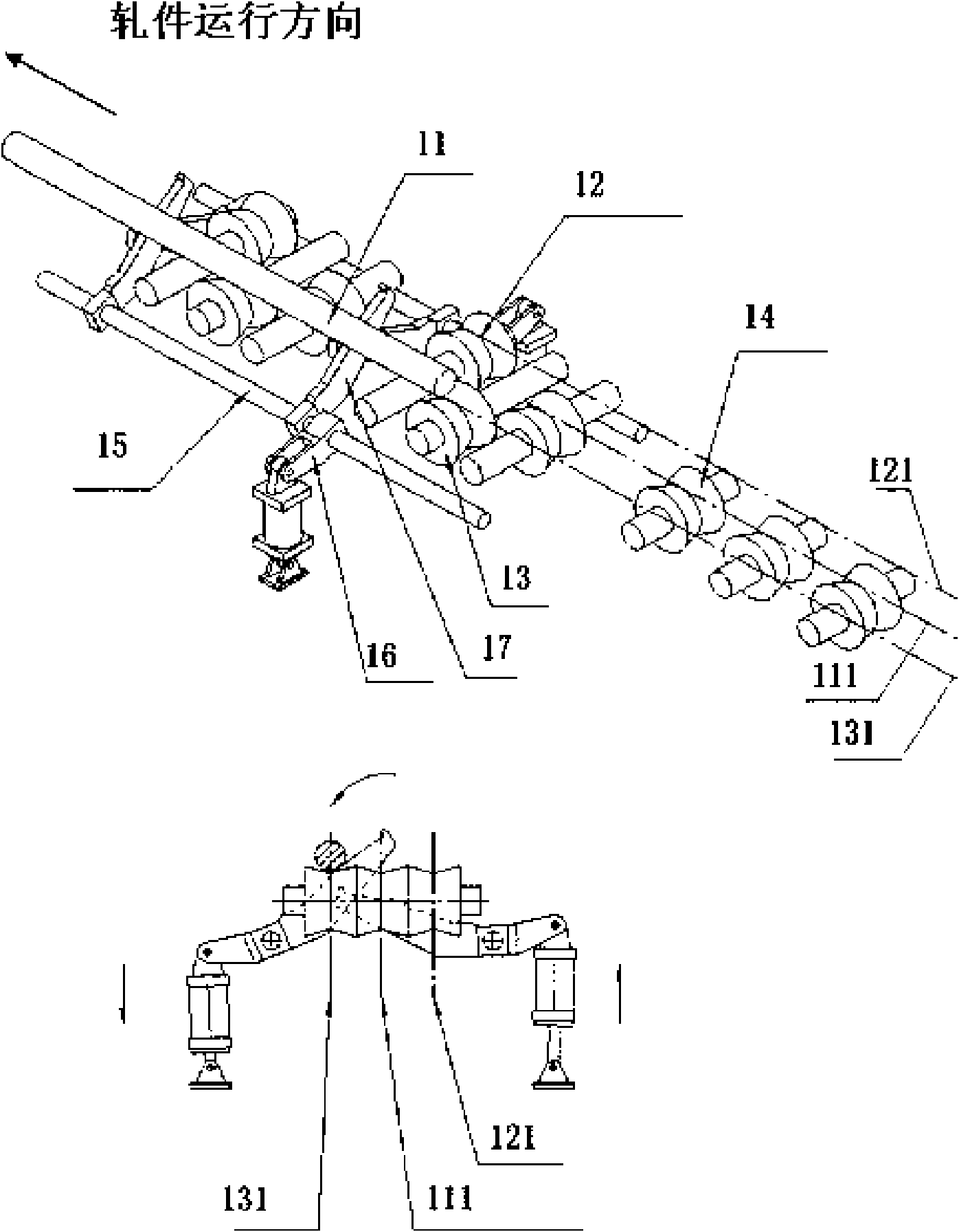

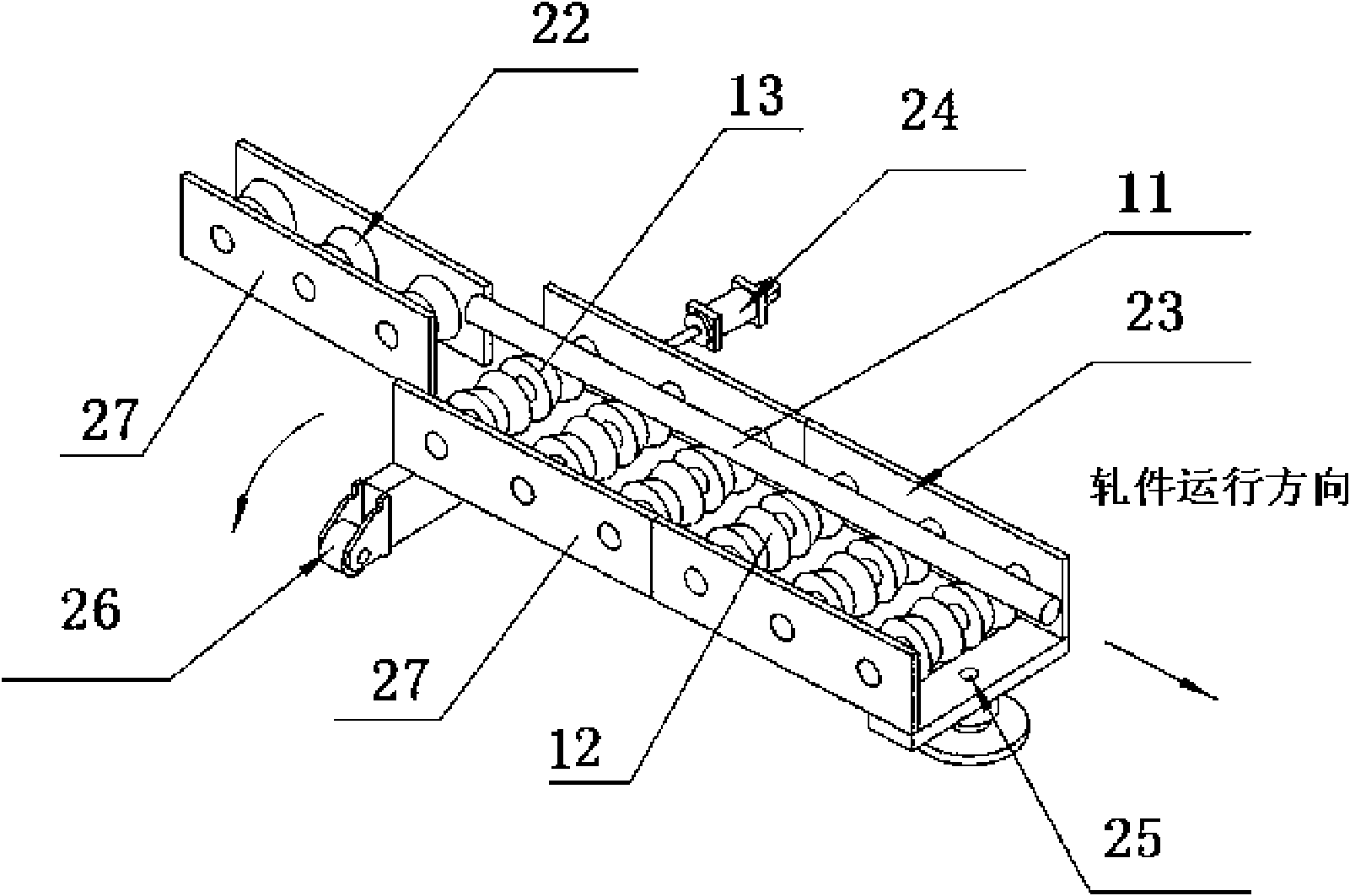

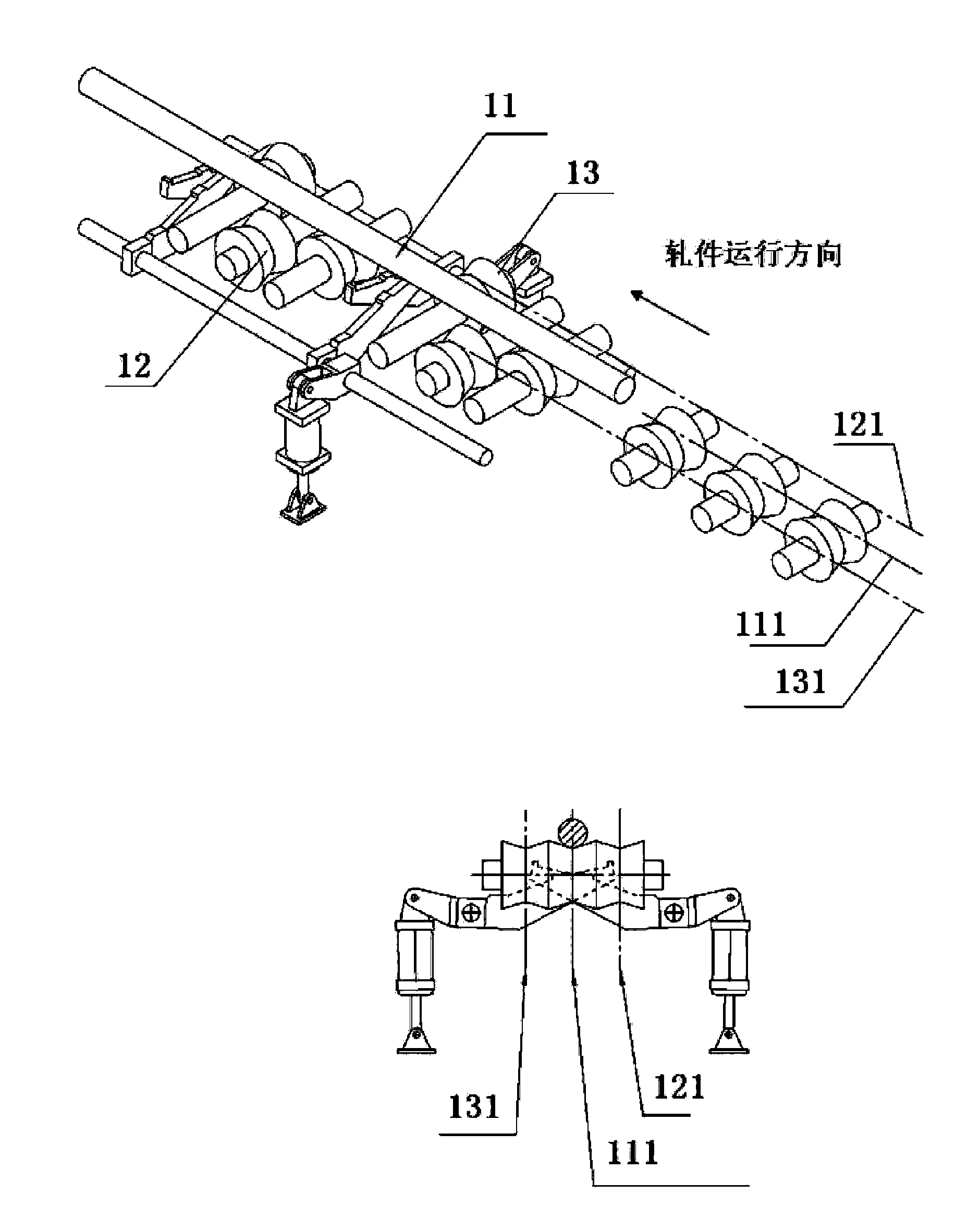

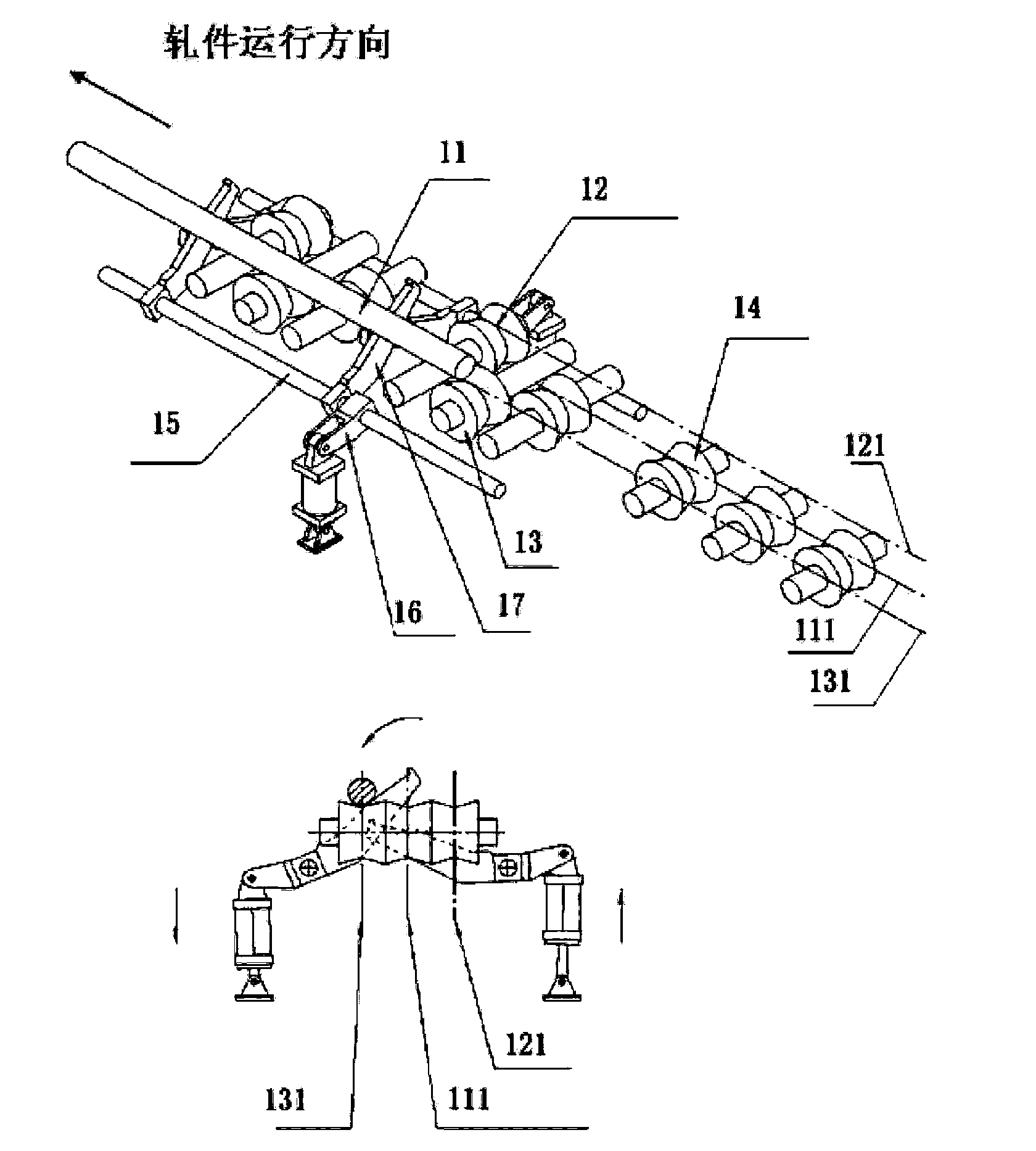

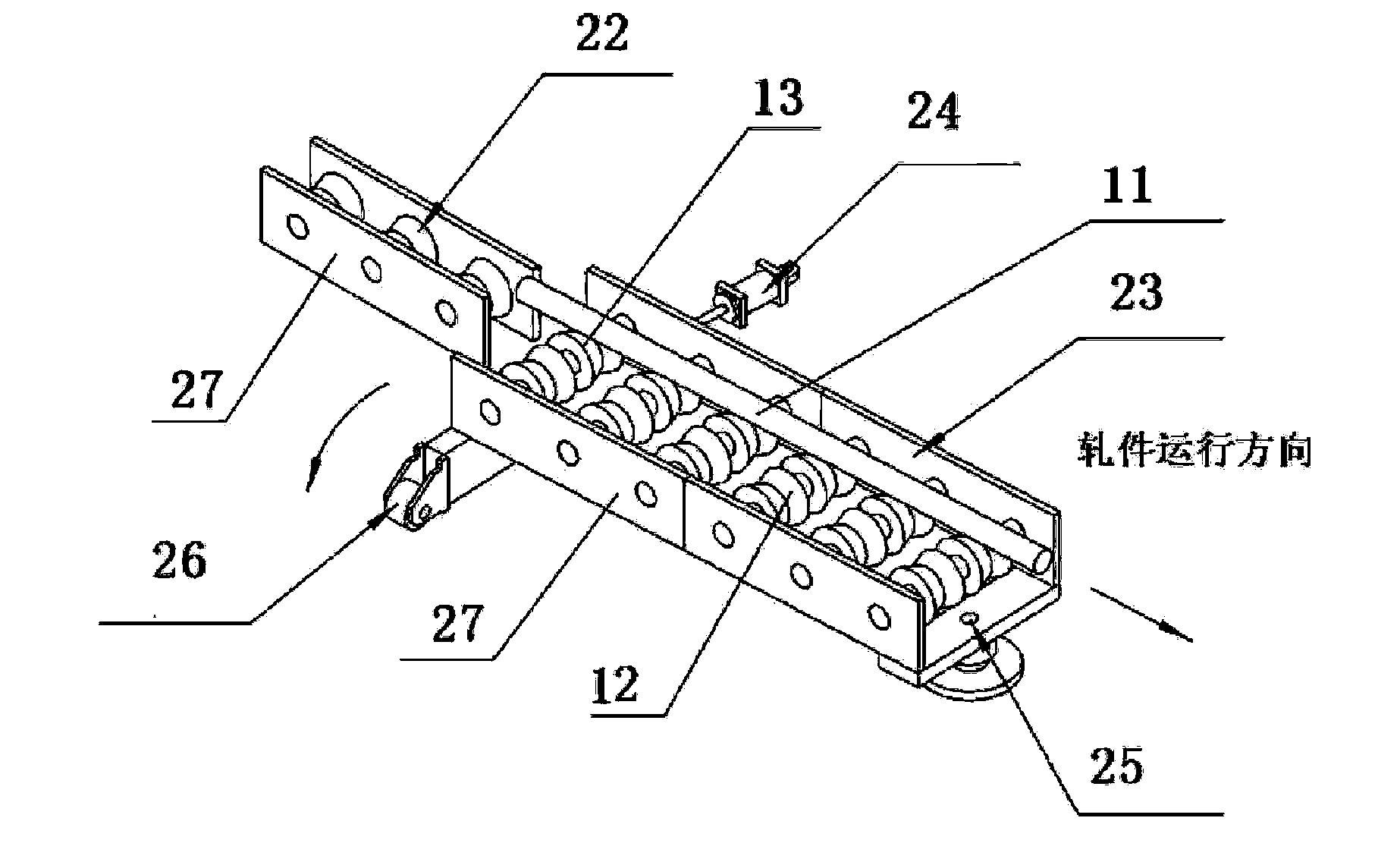

High-speed wire double production line swinging wire separation device

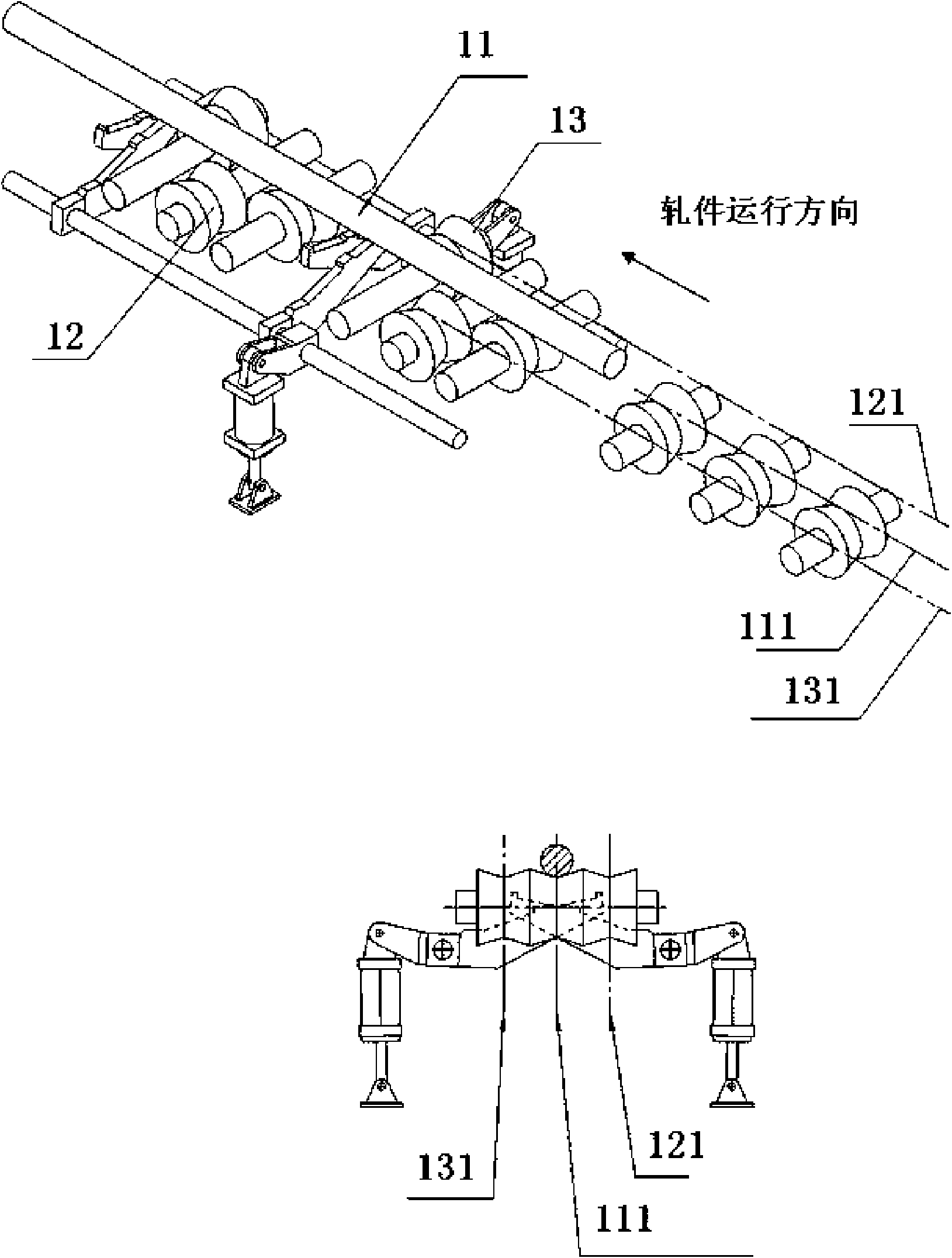

InactiveCN101653787AEasy to operateShort cycleGuiding/positioning/aligning arrangementsMetal rolling arrangementsWire rodProduction line

The invention discloses a high-speed wire double production line swinging wire separation device, comprising a single-wire output roller table and a double-wire input roller table. The double-wire input roller at least comprises an A line roller table and a B line roller table and provided with a roller table swinging device at the input end thereof for butting the entrances of two roller tables therein with the exit of the single-wire output roller table in a swinging way and reciprocating in cycle to achieve the wire separation, i.e. a single production line is divided into double production lines. The device changes the fixed heat-preservation roller table structure into the swinging heat-preservation roller table structure through the heat-preservation roller table frequently used in high-speed wire production line, thereby omitting special wire separation roller tables, greatly optimizing the production process and reducing the investment cost of equipment; and the high-speed wire double production line swinging wire separation device has the characteristics of simple and reliable operation and structure and low failure rate, and the advantages of continuous rolling, short wire renewing period, greatly improved production efficiency and no increase of space when used for renewing the old equipment, and the like.

Owner:武钢集团有限公司

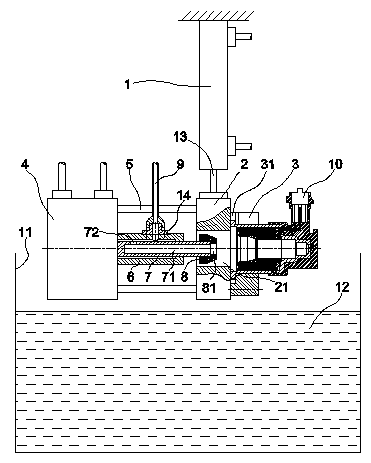

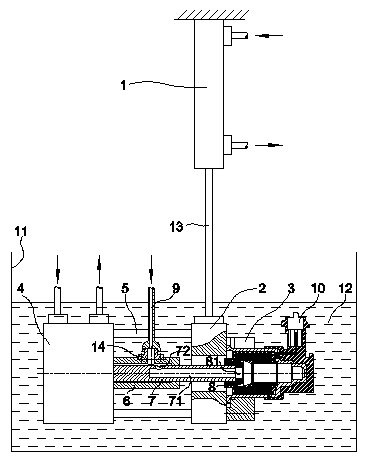

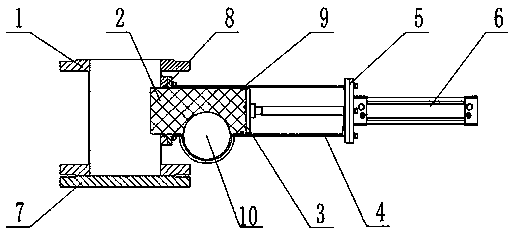

Electromagnetic valve air tightness test device

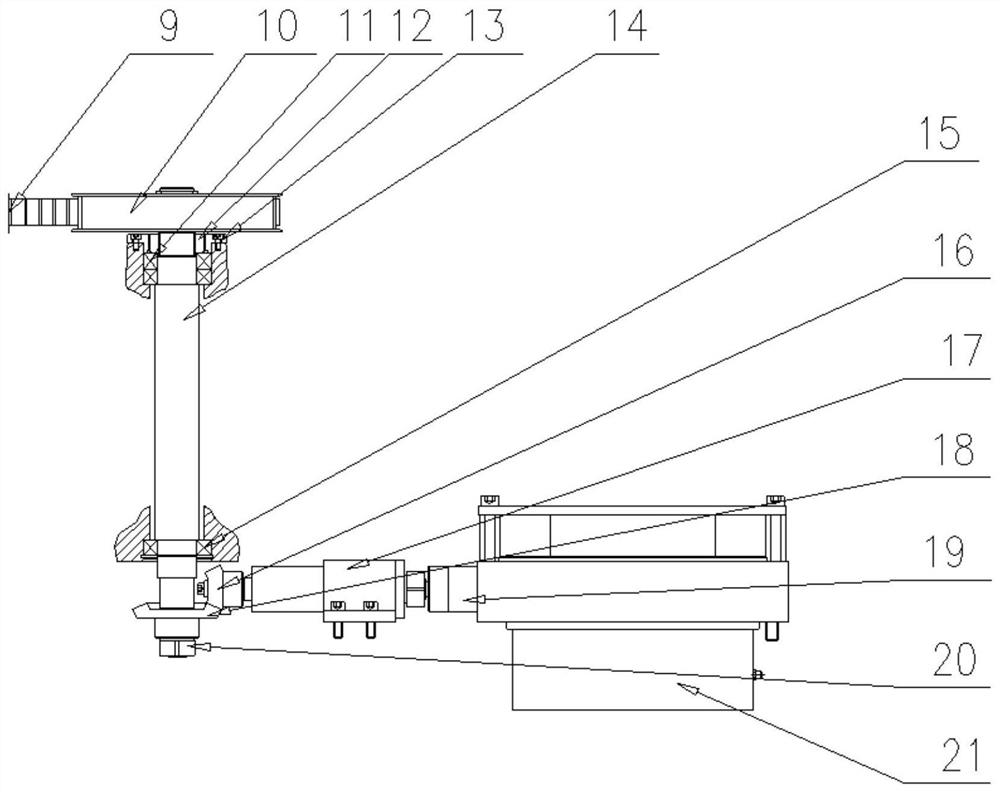

PendingCN108680309ASimple and reliable actionAir tightness test works reliablyDetection of fluid at leakage pointTest efficiencyEngineering

The invention discloses an electromagnetic valve air tightness test device. The electromagnetic valve air tightness test device comprises a first cylinder, a first piston rod, a support, an electromagnetic valve fixing seat, a second cylinder, a connection rod, a ventilation sleeve, a second piston rod, a buffer head, an air inlet pipe, an oil tank and oil, wherein the first cylinder is fixed above the oil tank, the first piston rod stretches out from a lower side of the first cylinder, a lower end of the first piston rod is fixedly connected with the support, the support is provided with a transverse through hole, a right end of the support is fixedly provided with the electromagnetic valve fixing seat at the transverse through hole, a left end of the support is fixedly connected with thesecond cylinder through the connection rod, the second piston rod of the second cylinder stretches out rightwards and extends into the transverse through hole, and the second piston rod is internallyprovided with a center hole opened at a right end. The electromagnetic valve air tightness test device is advantaged in that the compressed air and the oil are employed to test air tightness of an electromagnetic valve, and compact structure, low cost, reliable action and high test efficiency are further realized.

Owner:无锡正大轴承机械制造股份有限公司

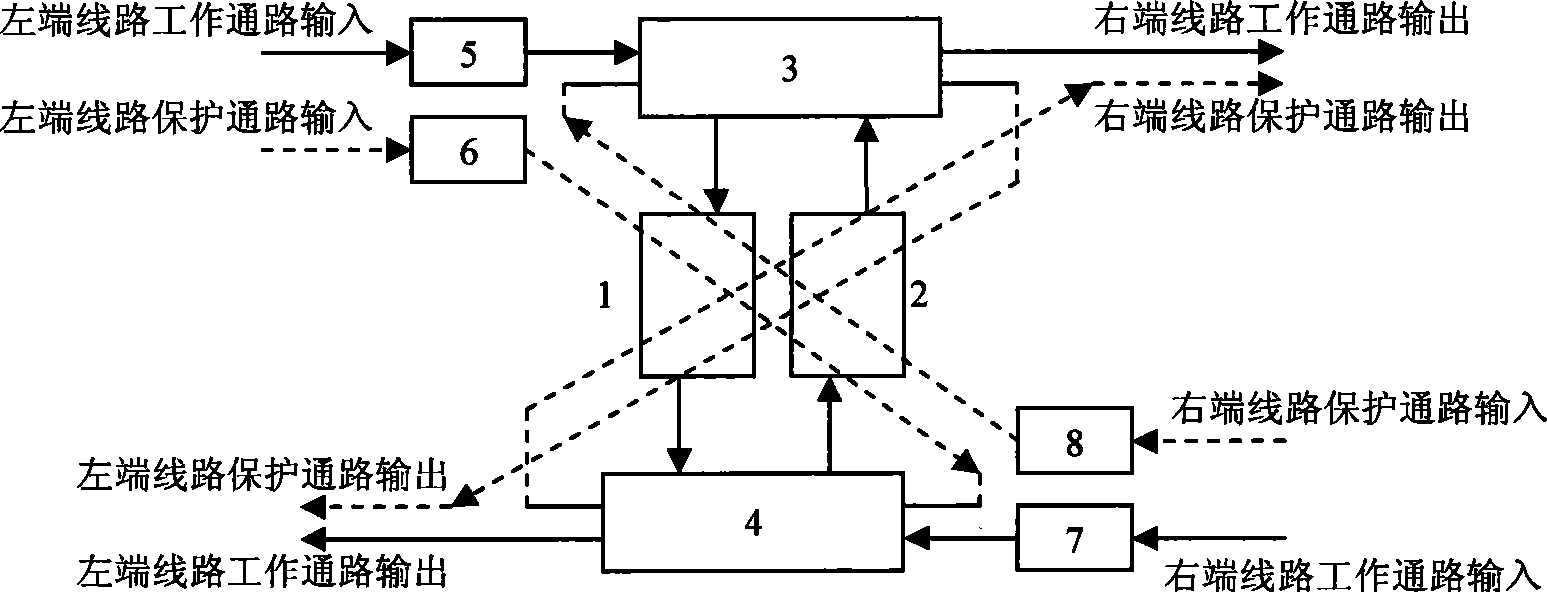

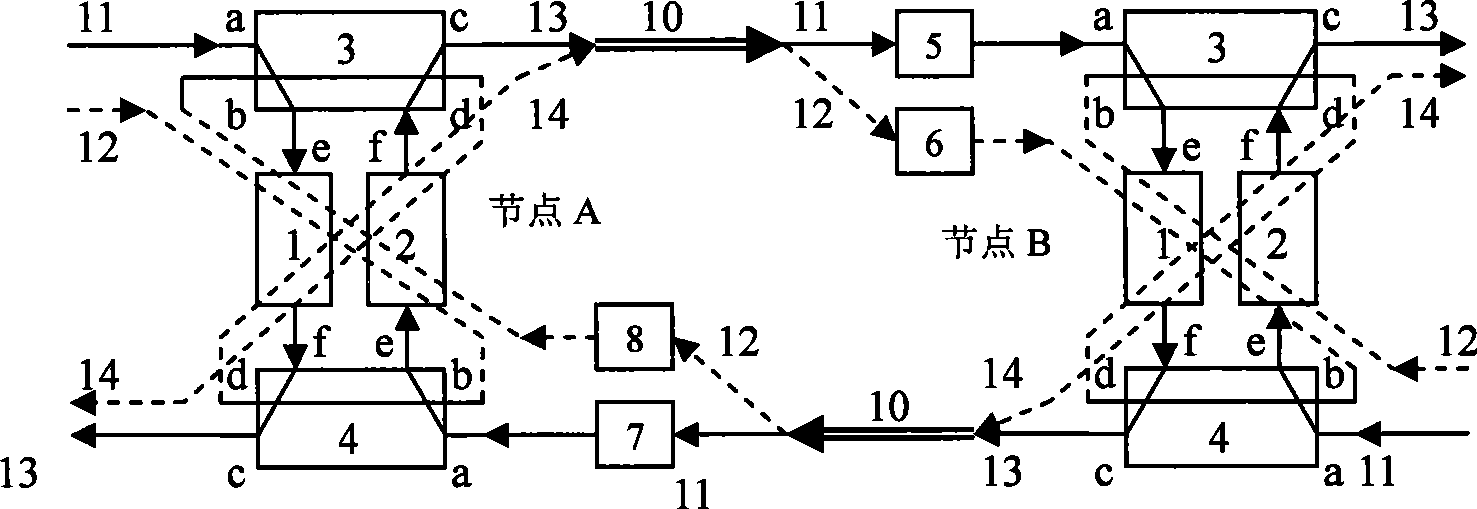

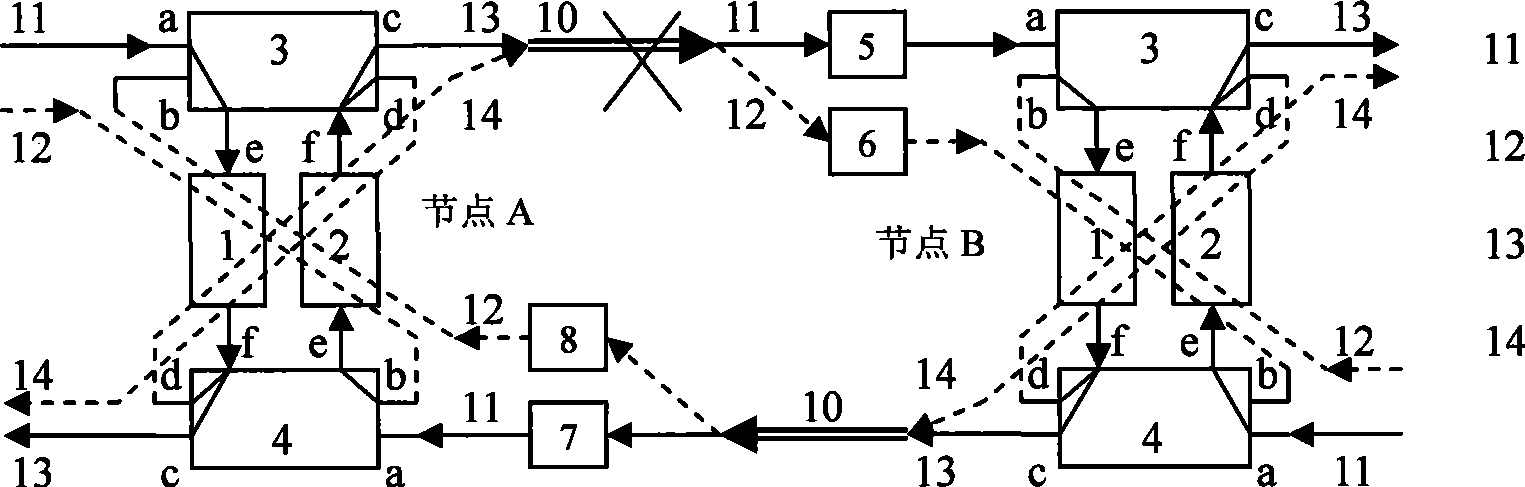

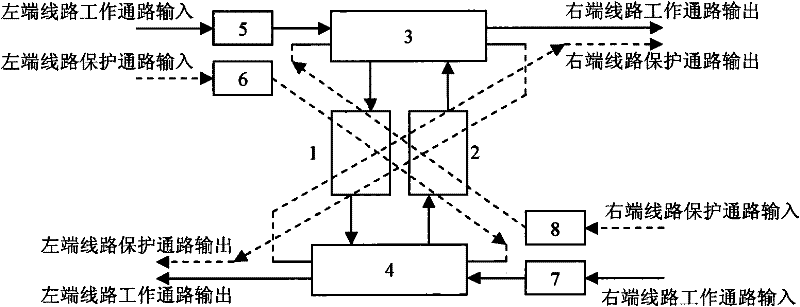

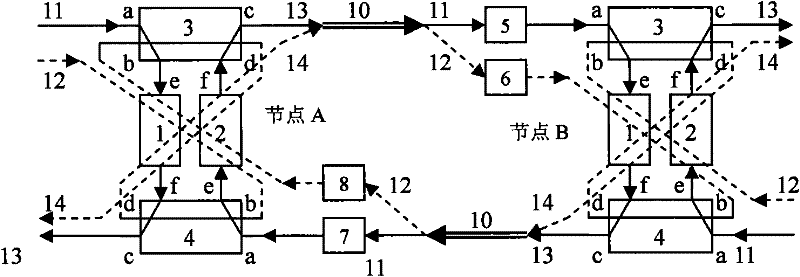

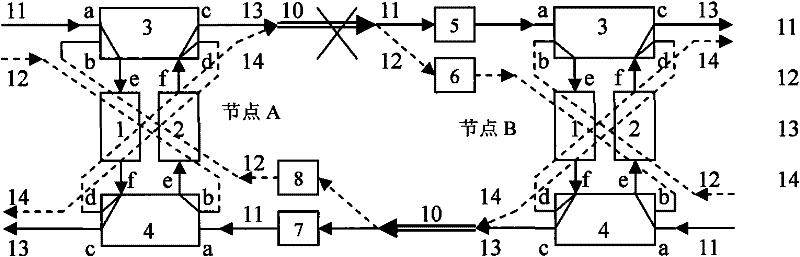

Optical path sharing protection method in DWDM optical transmission system

InactiveCN101478706ASimple structureStrong scalabilityMultiplex system selection arrangementsTime-division multiplexOptical pathTransmission system

The present invention discloses an optical pass sharing protecting method in DWDM optical transmission system. On two optical transmission units which requires to provide protecting node in the transmission system, two sharing protecting units with same structure and four input optical signal monitoring units which also have same structure form a protecting device. The invention has the advantage that the operation between nodes is totally harmonized by the on-off state of signal. The coding / decoding and signal analysis are not required similarly to protection to switching protocol by APS. The protecting device of the invention has the advantages of simple structure, no effect to the service structure of existing OADM looped network, and no change to the structure of network device. The purpose of service protection can be realized through directly adding a sharing passage protecting chassis. Furthermore the automatic protection switching and recovering can be realized without protocol software management. The restriction of loop node number does not exist. The time for switching and recovering is irrelevant to the length of loop and node number. The protecting device of the invention also has the characteristics of strong extendibility, convenient upgrading and reconstruction of network, simple and reliable action, multi-point failure protection, etc.

Owner:宁波春天通信工业有限公司

Gear synchronous driving mechanism

InactiveCN101608681AReliable actionImprove assembly precision and transmission precisionLoomsToothed gearingsEngineeringDrive shaft

The invention relates to a gear synchronous driving mechanism which comprises a central main shaft, wherein a needle cover gear is arranged on the central main shaft and connected with an upper driving pinion, the upper driving pinion and an upper driving gearwheel are driven coaxially, the upper driving gearwheel is meshed with an adjusting gear through an intermediate gear, the adjusting gear is connected with a driving gear through a driving shaft, and the driving gear is connected with external power. The gear synchronous driving mechanism has the beneficial effects: the fine tuning of the driving gear can be realized, the action is simple and reliable, the adjustment is free and not limited by shaft shoulders, the assembling precision and the driving precision of the driving gear are improved, and the service life of the driving gear is prolonged.

Owner:无锡市金龙人造毛皮机械有限公司

Electromagnetic drive switching valve

PendingCN110748657ASimple structureLow costSpindle sealingsOperating means/releasing devices for valvesAutomatic controlEngineering

The invention provides an electromagnetic drive switching valve. The electromagnetic drive switching valve can be used for feeding and discharging in the product preparation process adopting the automatic control mode. The electromagnetic drive switching valve is simple in structure, low in cost and convenient to mount. Through the energization and power-off of an electromagnet, the turning-on andturning-off of the electromagnetic drive switching valve are realized; the dosing action of a metering valve is completed; the whole action is simple and reliable; the practicability is high; the defects that an existing drive switching valve is high in cost and large in mounting workload are overcome; and through the use of an integrally formed corrugated pipe sealing device, the reliability ofvalve sealing is further improved, manufacturing and mounting are easier and more convenient, and the electromagnetic drive switching valve is suitable for popularization.

Owner:BAOYING RENHENG IND

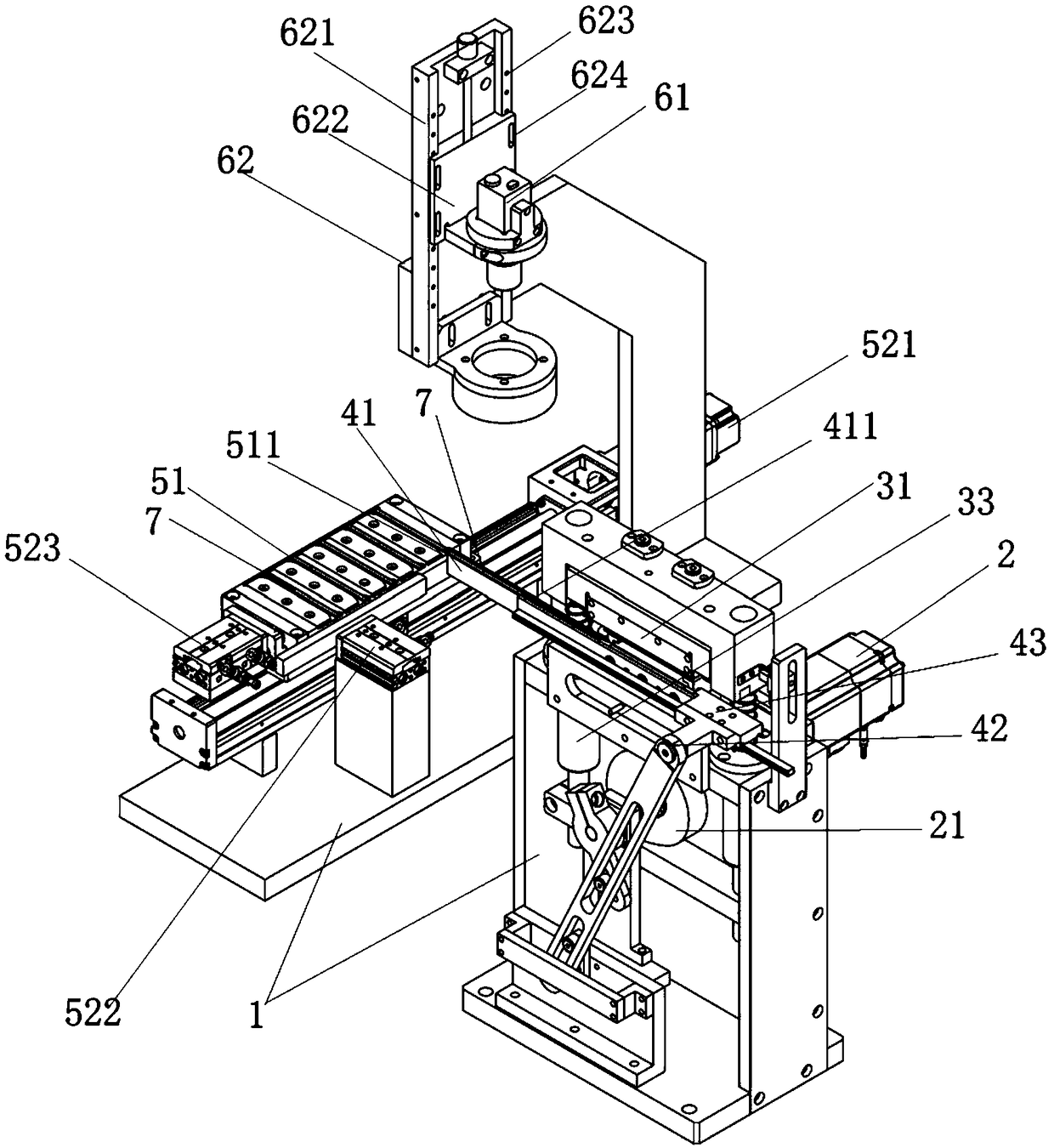

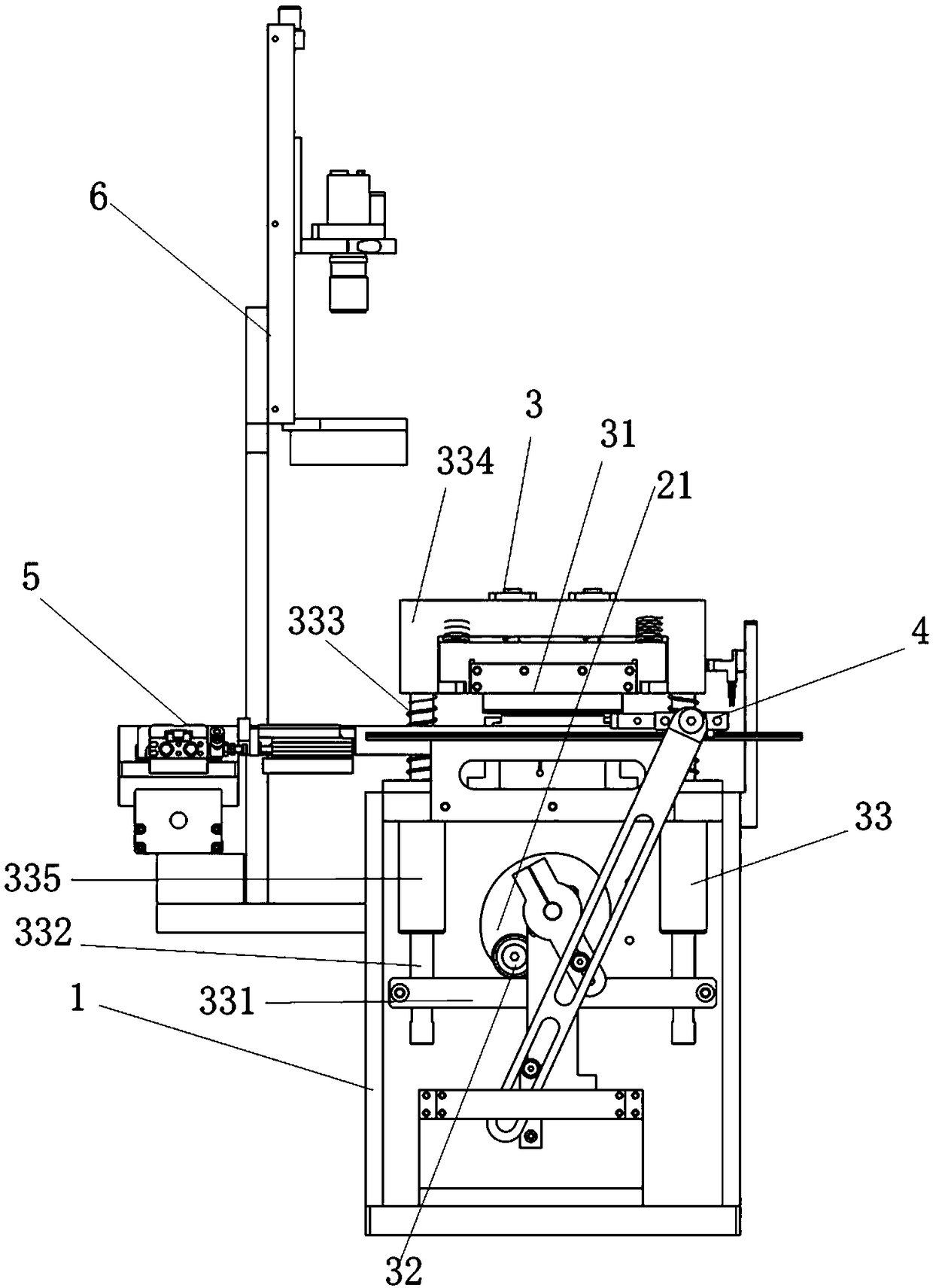

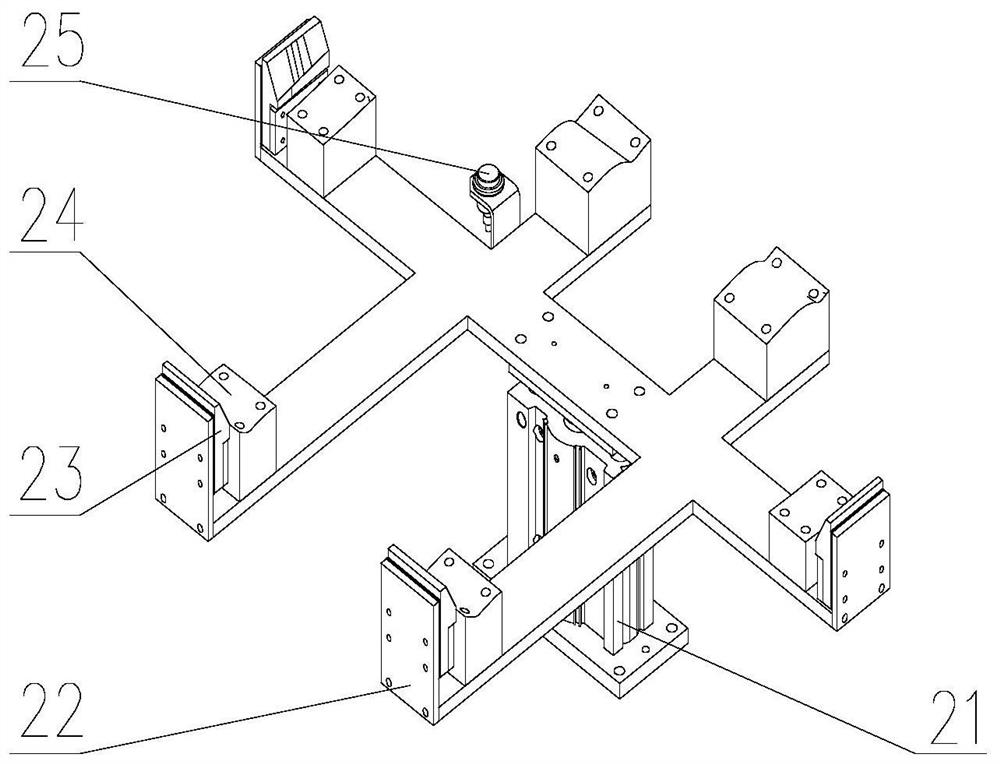

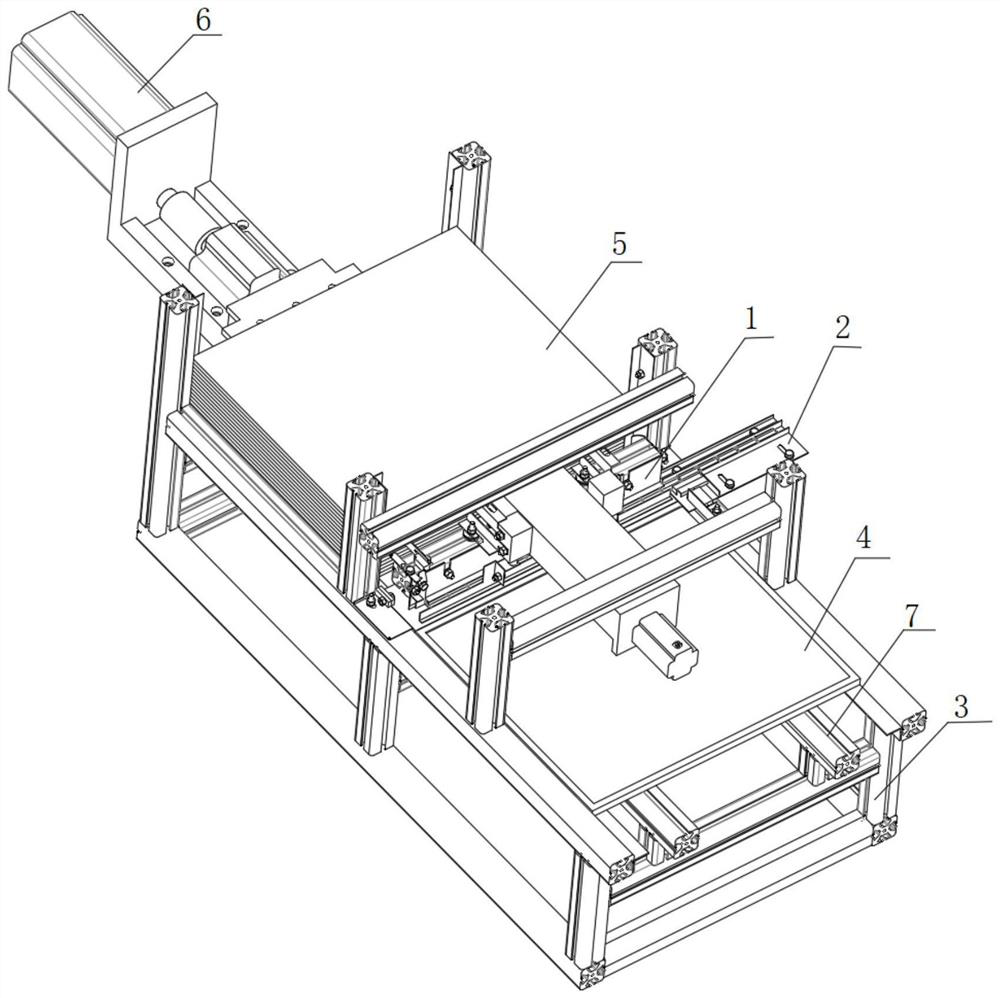

Automatic cropping, sorting and ranking device for test paper

PendingCN109291094APrecise positioningReliable actionSortingMetal working apparatusCcd cameraSynchronism

The invention discloses an automatic cropping, sorting and ranking device for test paper. The automatic cropping, sorting and ranking device comprises a rack and further comprises a drive motor, a cropping mechanism, a ranking mechanism, a positioning tool and a sorting mechanism, all of which are arranged on the rack. The drive motor drives the cropping mechanism and the ranking mechanism througha cam. The cropping mechanism comprises a cutter, a cropping connecting rod and a cropping transmission assembly. The ranking mechanism comprises a track, a ranking connecting rod and a side pushingblock. The positioning tool comprises a positioning carrier and a positioning drive set, and the positioning drive set drives a positioning cavity in the positioning carrier to be in butt joint with the tail end of the track. The sorting mechanism comprises a CCD camera and a camera assembly arranged on the rack. The CCD camera is arranged on the camera assembly. By means of the automatic cropping, sorting and ranking device, cut-off products can be directly ranked, positioning is accurate and tidy, the automatic cropping, sorting and ranking device can be directly guided into an automatic production line to be applied without manual intervention, actions are simple and reliable, synchronism is good, the speed is high, and OK products and NG products can be sorted.

Owner:苏州元控自动化设备有限公司

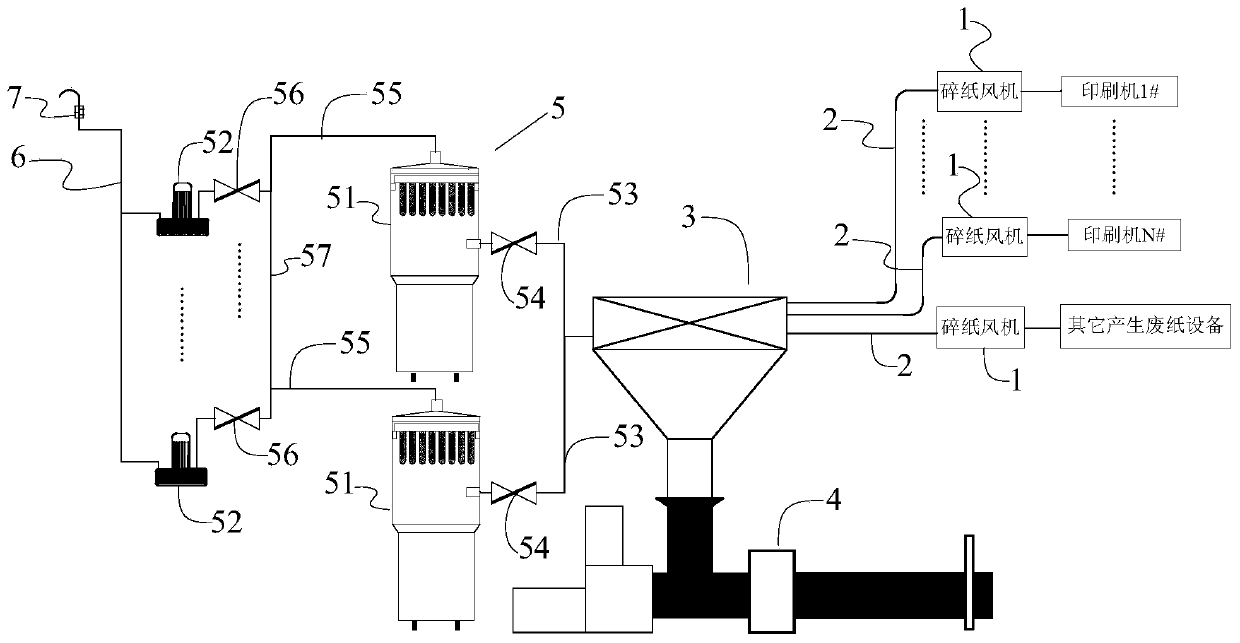

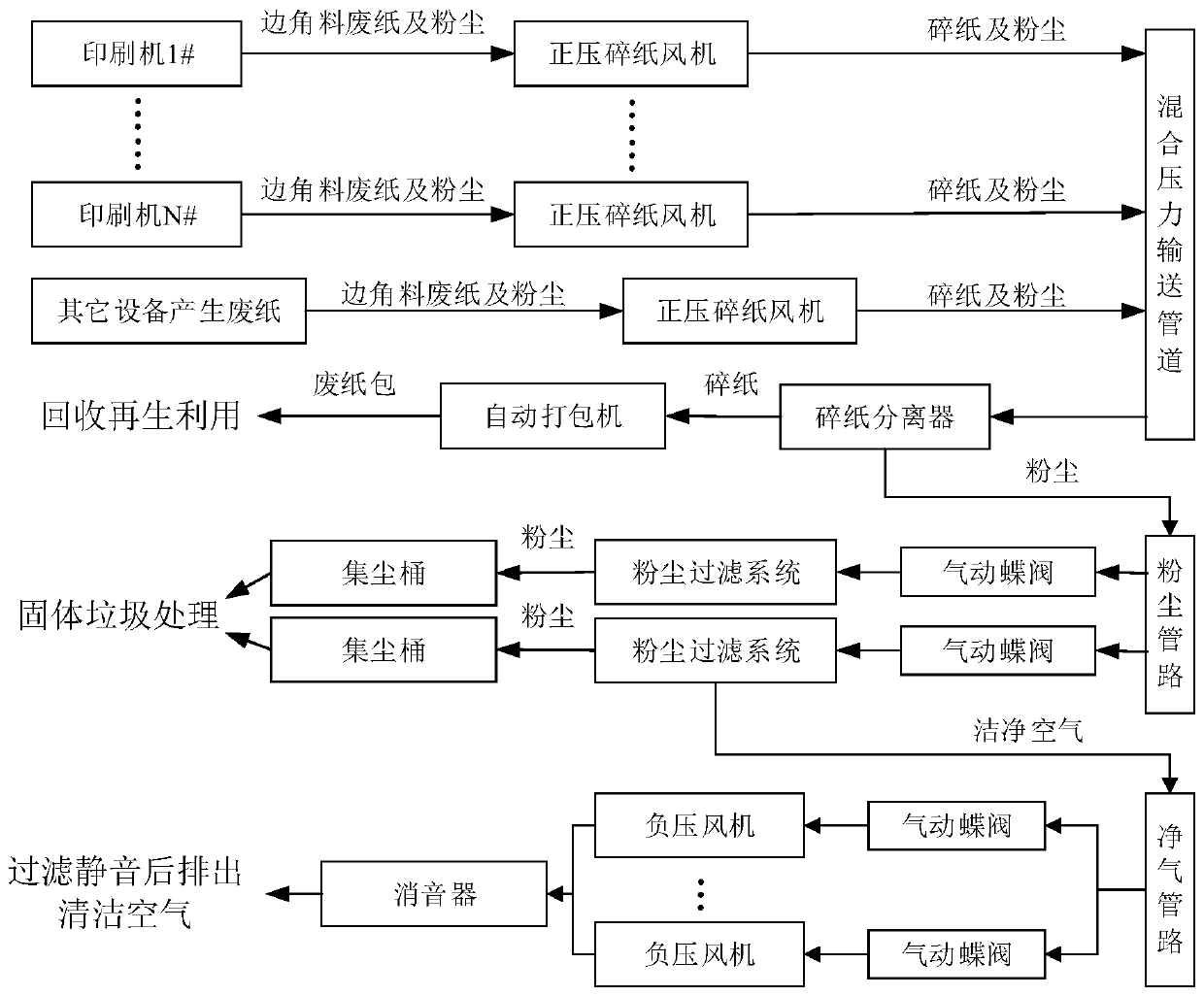

Shredded paper separator and shredded paper separation method thereof

PendingCN110341230ASolve the separation problemSave energyGas current separationPressesCollection systemPulp and paper industry

The invention discloses a shredded paper separator. The shredded paper separator comprises a shredded paper separation bin, a filter net, a bin fullness detection unit, an upper and lower bin divisionand combination mechanism, a bin door and a bin door driving device, wherein the shredded paper separation bin comprises an upper bin and a lower bin; the filter net is arranged on the upper end of the shredded paper separation bin; the bin fullness detection unit is arranged at the upper end of the lower bin; the upper and lower bin division and combination mechanism is movably inserted in the interior of the shredded paper separation bin; the bin door is arranged at a lower bin opening of the shredded paper separation bin; the bin door driving device is used for driving the bin door to openand close; the bin fullness detection unit, the upper and lower bin division and combination mechanism and the bin door driving device are electrically connected to a waste paper collecting control device of a waste paper collecting system; a shredded paper input end communicating with a shredded paper output end of a shredded paper draught fan of the waste paper collecting system is arranged onthe upper end of the shredded paper separation bin and is located at a position below the filter net; and a dust output end communicating with a dust input end of a negative pressure moisture-proof system of the waste paper collection system is arranged on the upper end of the shredded paper separation bin and is located at a position above the filter net.

Owner:深圳市东鹏科技发展有限公司

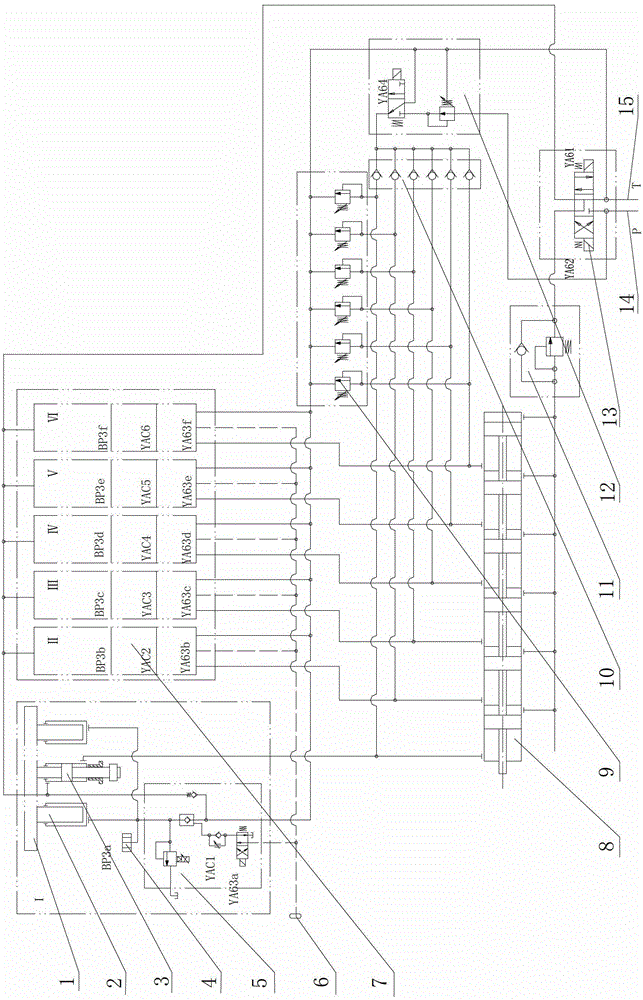

Crossbeam press multi-hydraulic cushion synchronous control system

ActiveCN102758806BAvoid getting stuckHigh precisionServomotorsForging press drivesHydraulic cylinderSynchronous control

The invention relates to a crossbeam press multi-hydraulic cushion synchronous control system which comprises a plurality of groups of hydraulic cushions, a hydraulic cushion cylinder and an ejector cylinder, wherein the hydraulic cushions are connected with the hydraulic cushion cylinder and the ejector cylinder, the hydraulic cushion cylinder is connected onto a low-pressure return oil pipe by a hydraulic cushion control valve group which is connected with a control oil pipe, a retreat cavity oil inlet of the ejector cylinder is connected with the hydraulic cushion control valve group and a J-shaped electromagnetic directional valve, an ejector cavity oil way of the ejector cylinder is connected with the low-pressure return oil pipe by a safety overflowing valve, and the crossbeam press multi-hydraulic cushion synchronous control system is characterized in that the ejector cavity oil way of the ejector cylinder is further connected with a one-way valve and a synchronous cylinder which controls the hydraulic cushions to be synchronously ejected and retreated. The crossbeam press multi-hydraulic cushion synchronous control system has the advantages of being capable of ensuring that the multiple hydraulic cushions can be synchronously ejected and retreated, controlling a mold core in a mold to stably work, avoiding blocking of the mold core, improving the press forming precision and pass percent of a car crossbeam, and being convenient to debug and simple to maintain.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Optical path sharing protection method in DWDM optical transmission system

InactiveCN101478706BSimple structureDoes not affect business structureTime-division multiplexElectromagnetic transmissionExtensibilityAutomatic protection switching

Owner:宁波春天通信工业有限公司

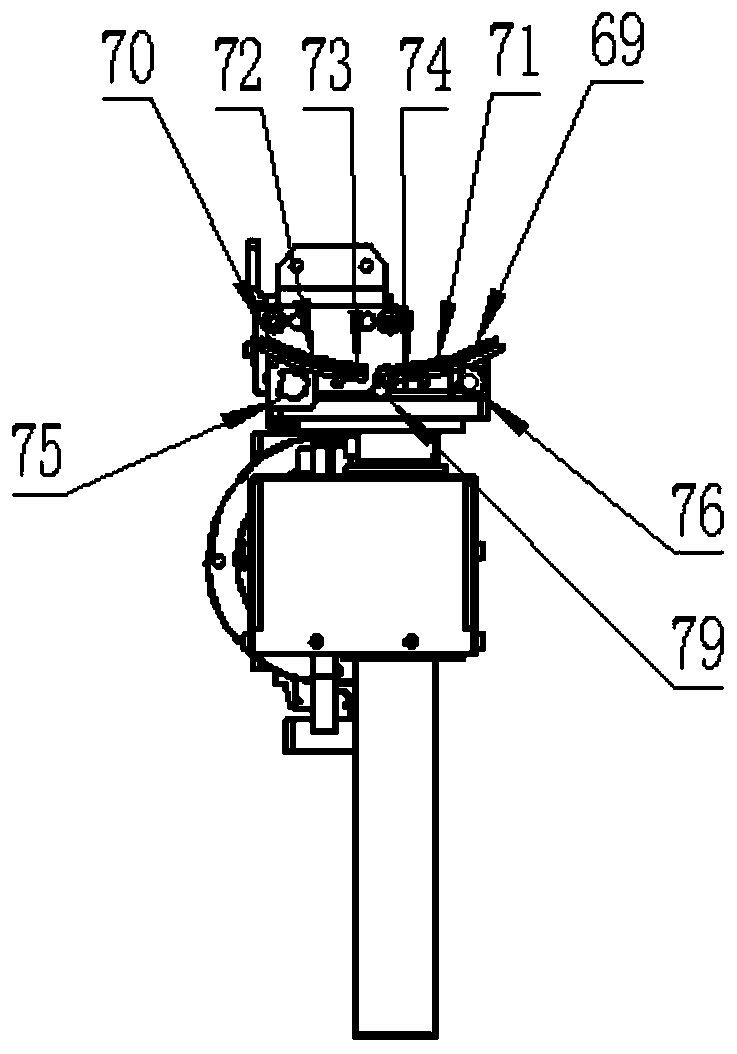

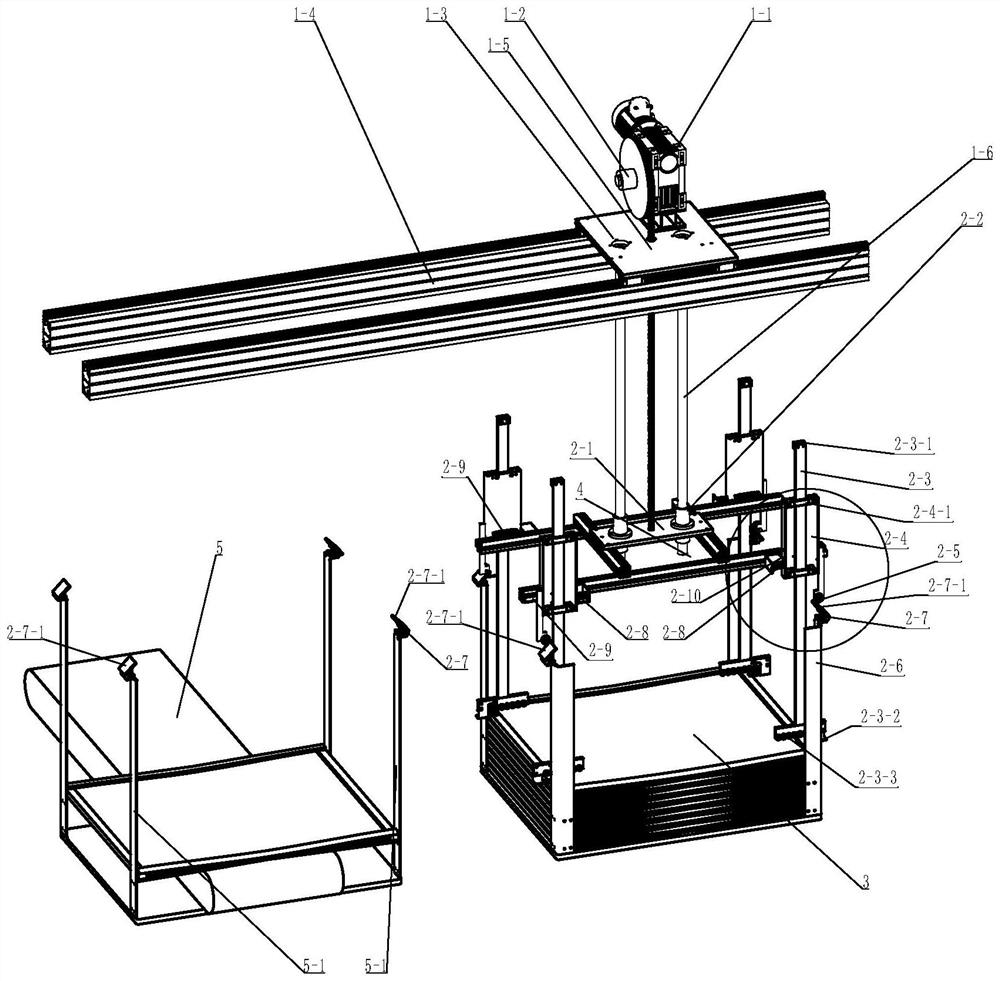

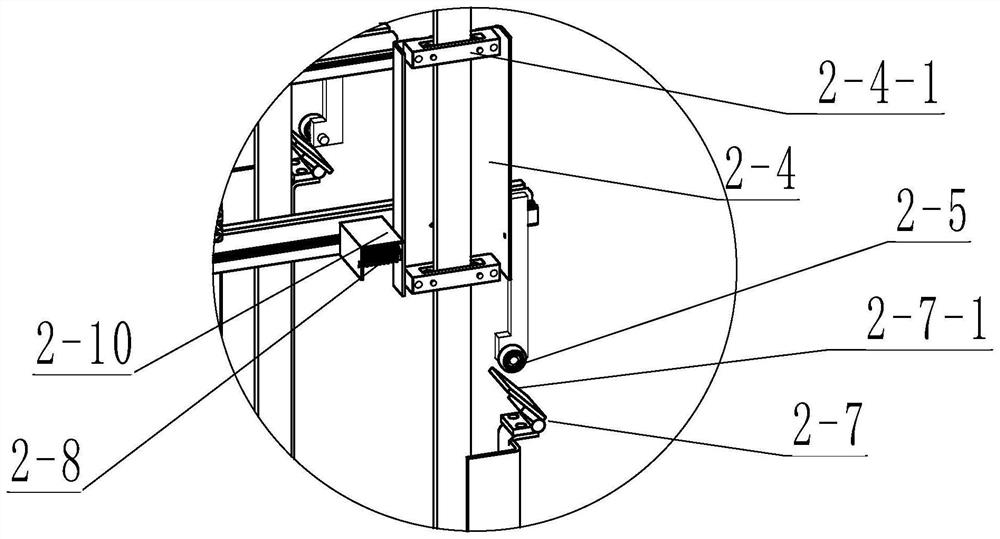

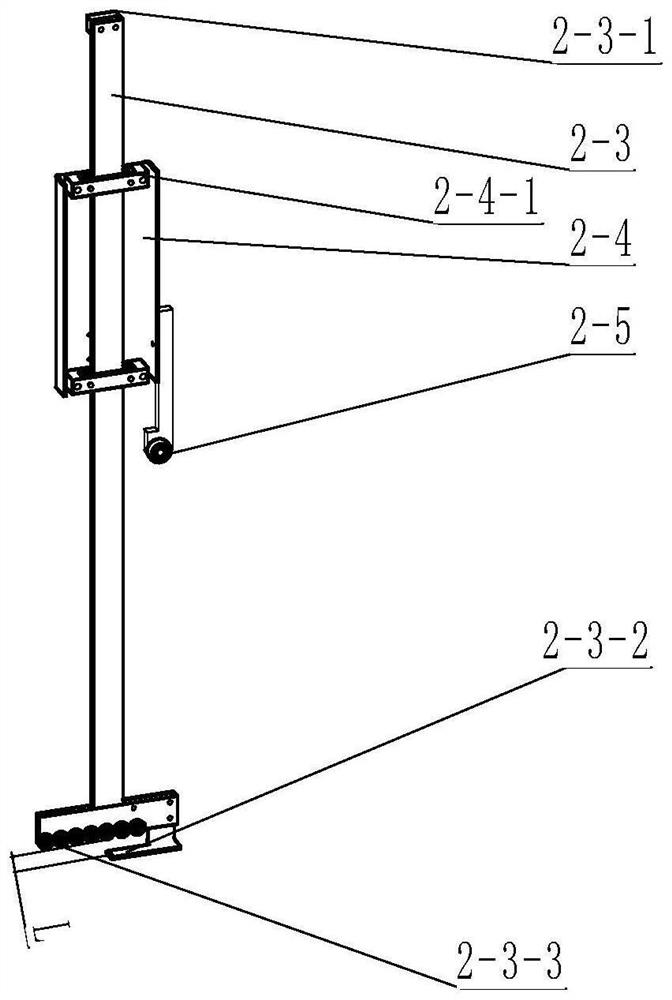

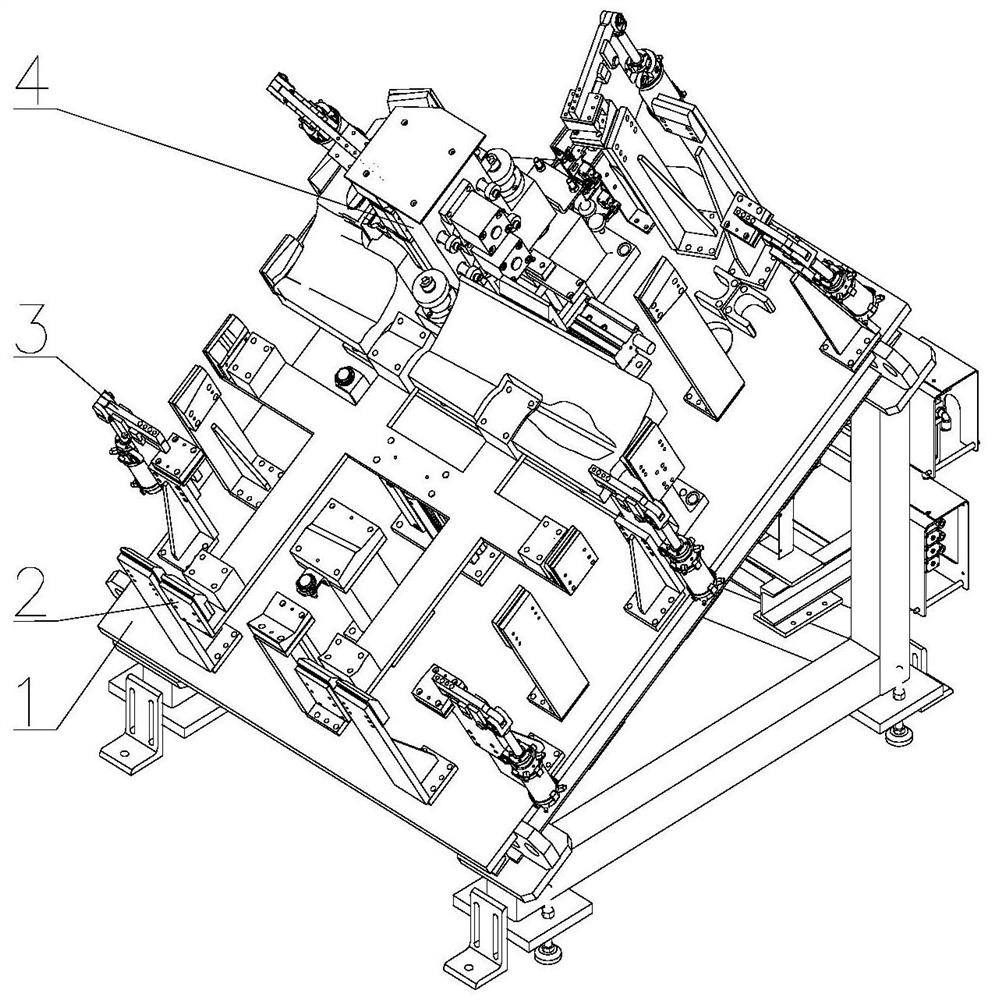

Automatic grabbing and transferring machine for spatial curved-surface thin plaque

PendingCN114524262ASimple and reliable actionRealize automatic feeding processBio-packagingStacking articlesReciprocating motionClassical mechanics

The invention discloses an automatic grabbing and transferring machine for a spatial curved-surface thin plaque, a rail of the transferring machine is arranged above a limiting feeding frame, a driving device is provided with a sliding block type fixing piece, the sliding block type fixing piece slides on the rail, and the sliding block type fixing piece is arranged on the limiting feeding frame. The self-adaptive grabbing device comprises a plurality of self-adaptive grabbing mechanisms used for grabbing the thin plaques, a lifting device used for driving the self-adaptive grabbing mechanisms to do lifting motion and a horizontal moving device enabling the self-adaptive grabbing mechanisms to do horizontal reciprocating motion, and the horizontal moving device is arranged on the lifting device. The self-adaptive grabbing mechanism is installed on the horizontal moving device, the limiting feeding frame is located below the self-adaptive grabbing mechanism, and the limiting feeding frame is used for stacking thin plaques.

Owner:FUJIAN PROV AGRI MACHANIZATION INST

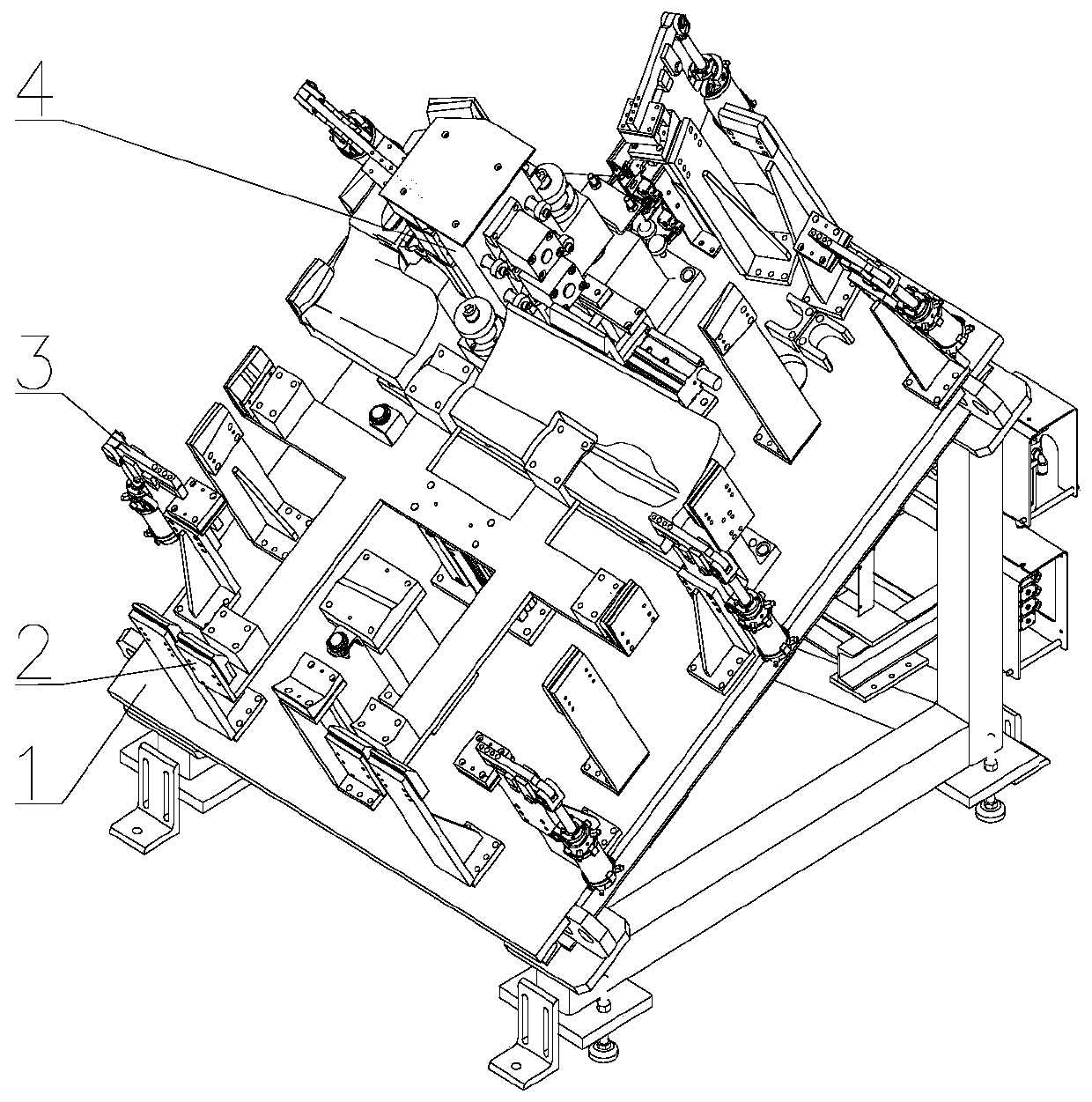

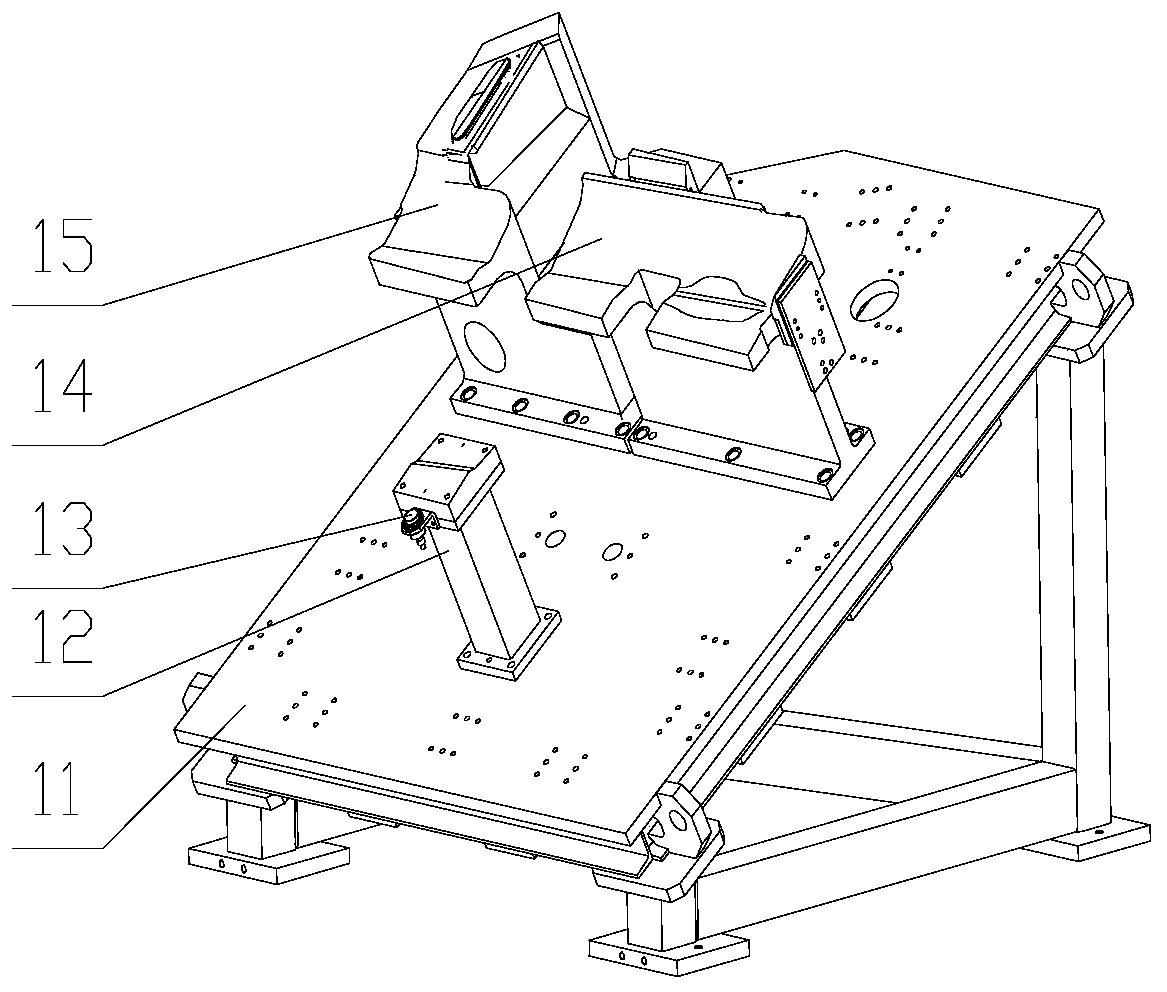

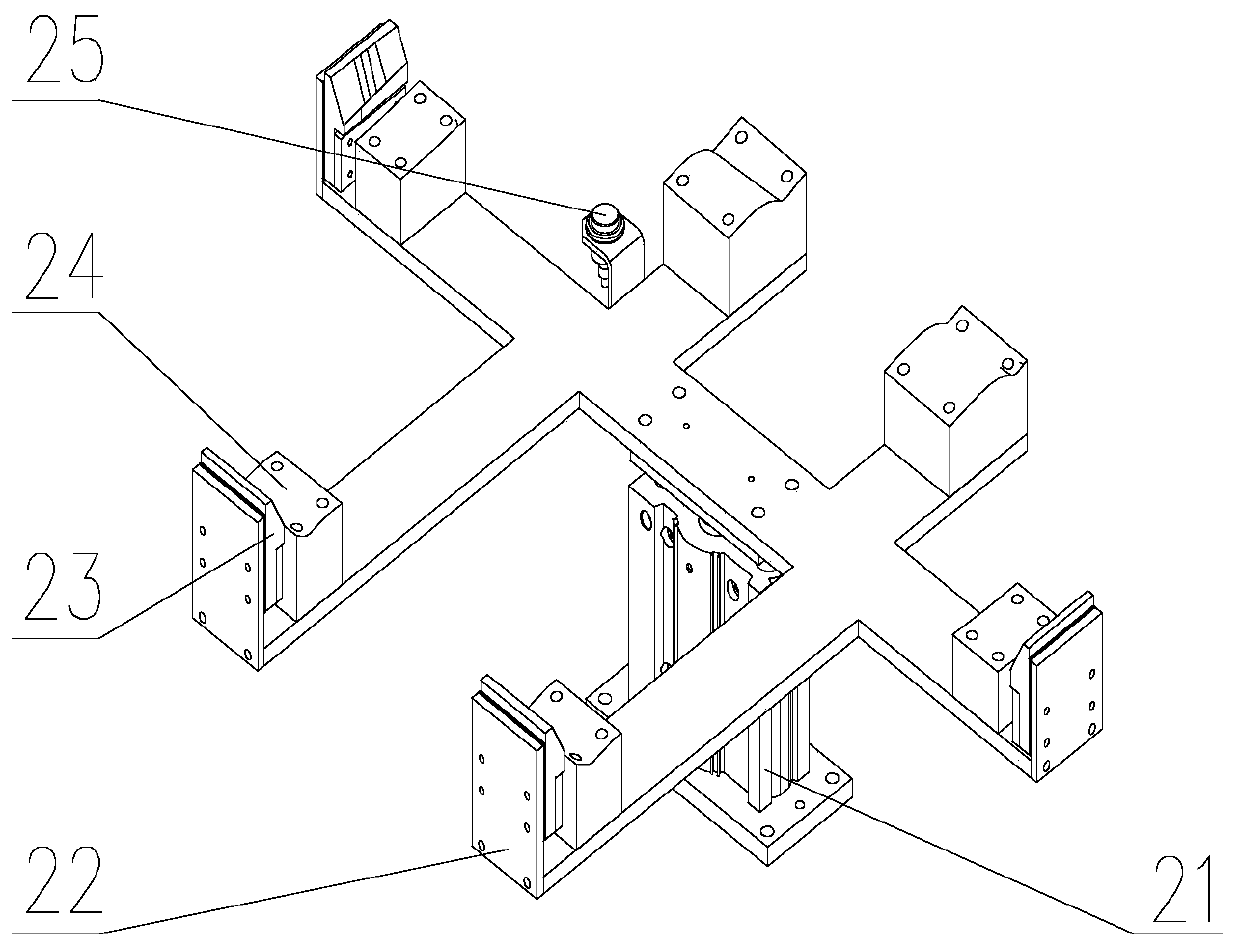

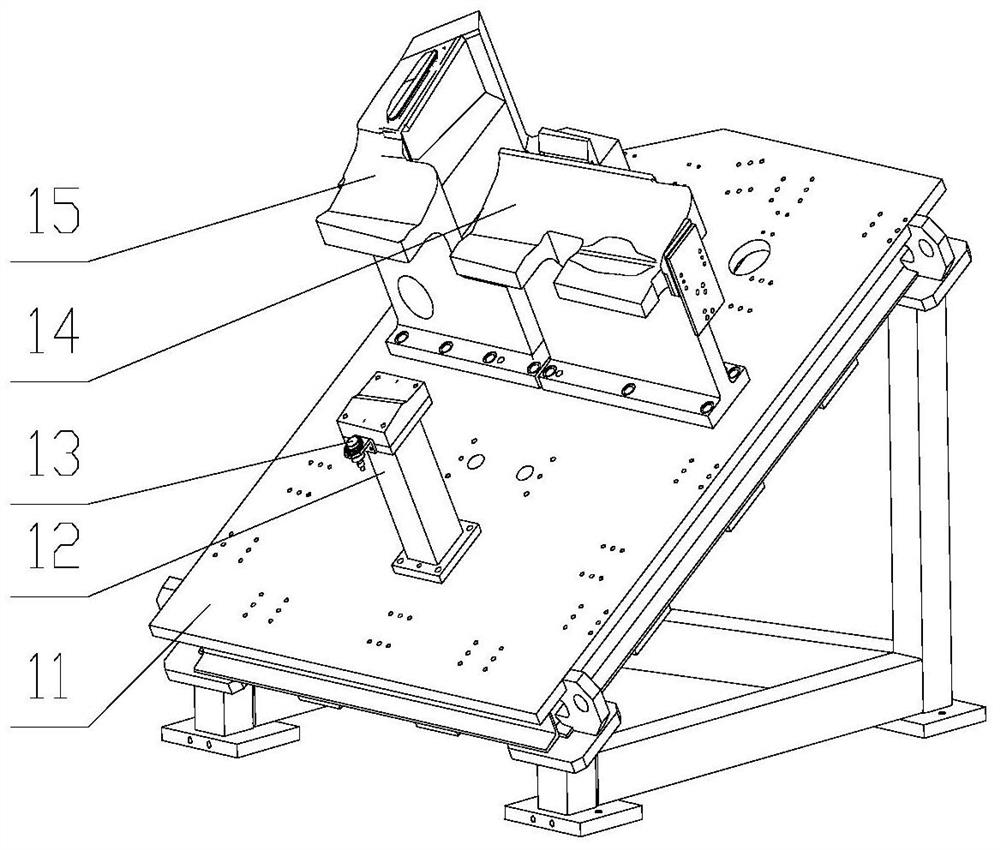

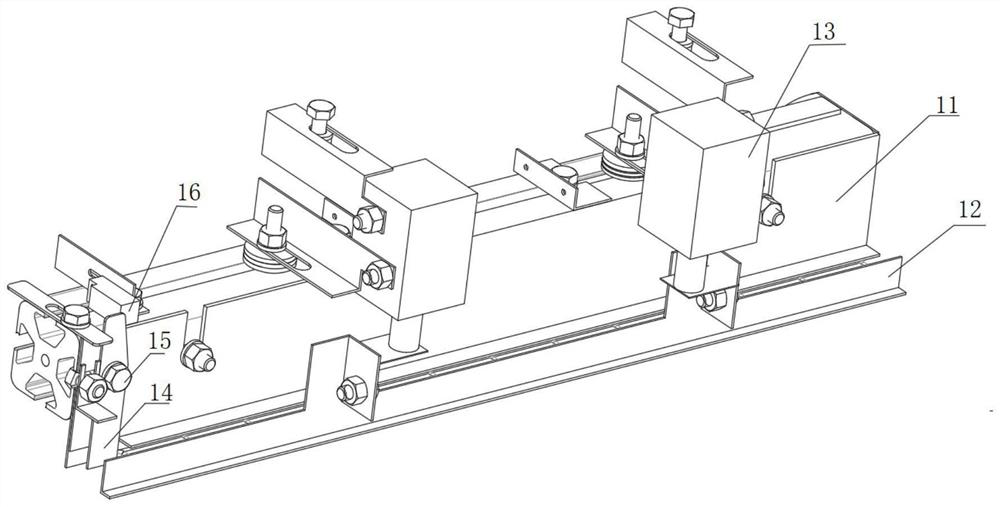

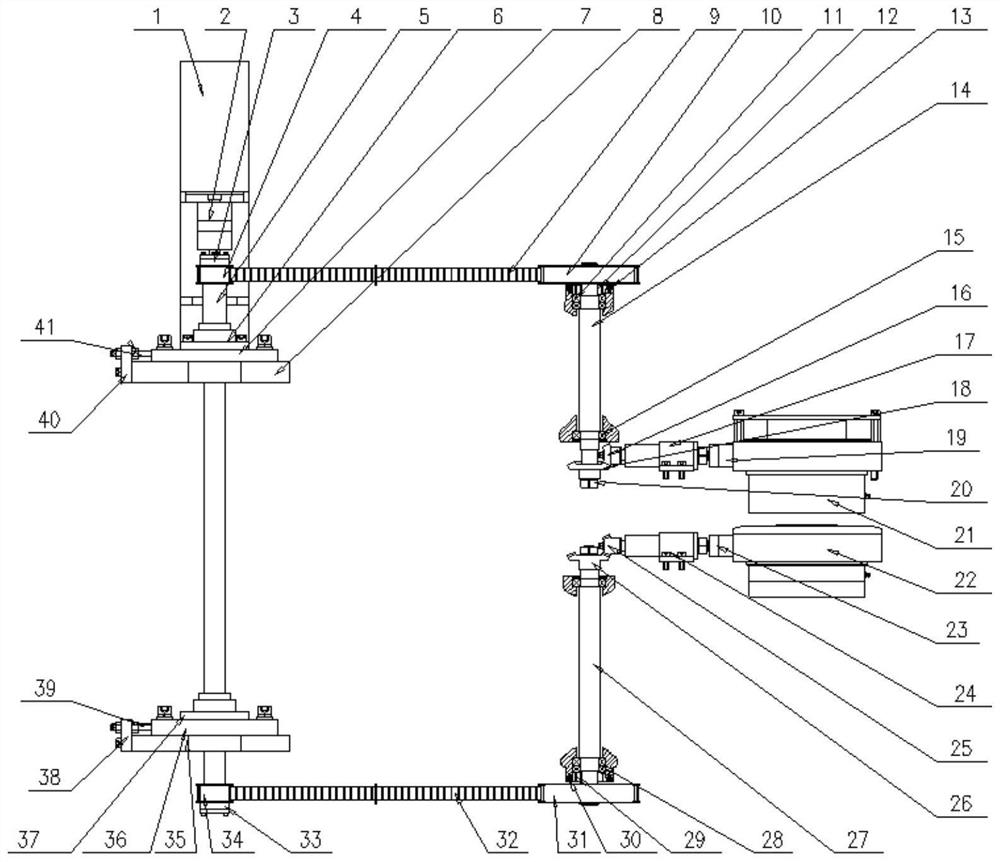

A device and method for hemming in a narrow space of an automobile panel

The invention discloses a hemming device for a narrow space of an automobile cover, which comprises a base, a jacking mechanism, a positioning and clamping mechanism, and a hemming mechanism. The hemming mechanism includes a limit cylinder bracket, a jacking cylinder, a limit Position cylinder, limit mechanism, telescopic guide column, pre-wrapping cylinder, wrapping cylinder, wrapping lifting seat, position sensor, module mounting plate, wrapping module, pre-packing module, travel switch block, travel switch, travel The switch bracket, the wrapping base; the pre-wrapping cylinder drives the pre-wrapping module forward, the jacking cylinder drives the wrapping seat down, the pre-wrapping module descends, the wrapping seat rises, the pre-wrapping module rises and retreats to complete the pre-wrapping. After the hemming seat descends to a certain height, the hemming oil cylinder drives the hemming module forward, and after the hemming seat drives the hemming module down again, the hemming seat starts to rise. After the hemming action is realized, the hemming module moves backward to complete the hemming process .

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

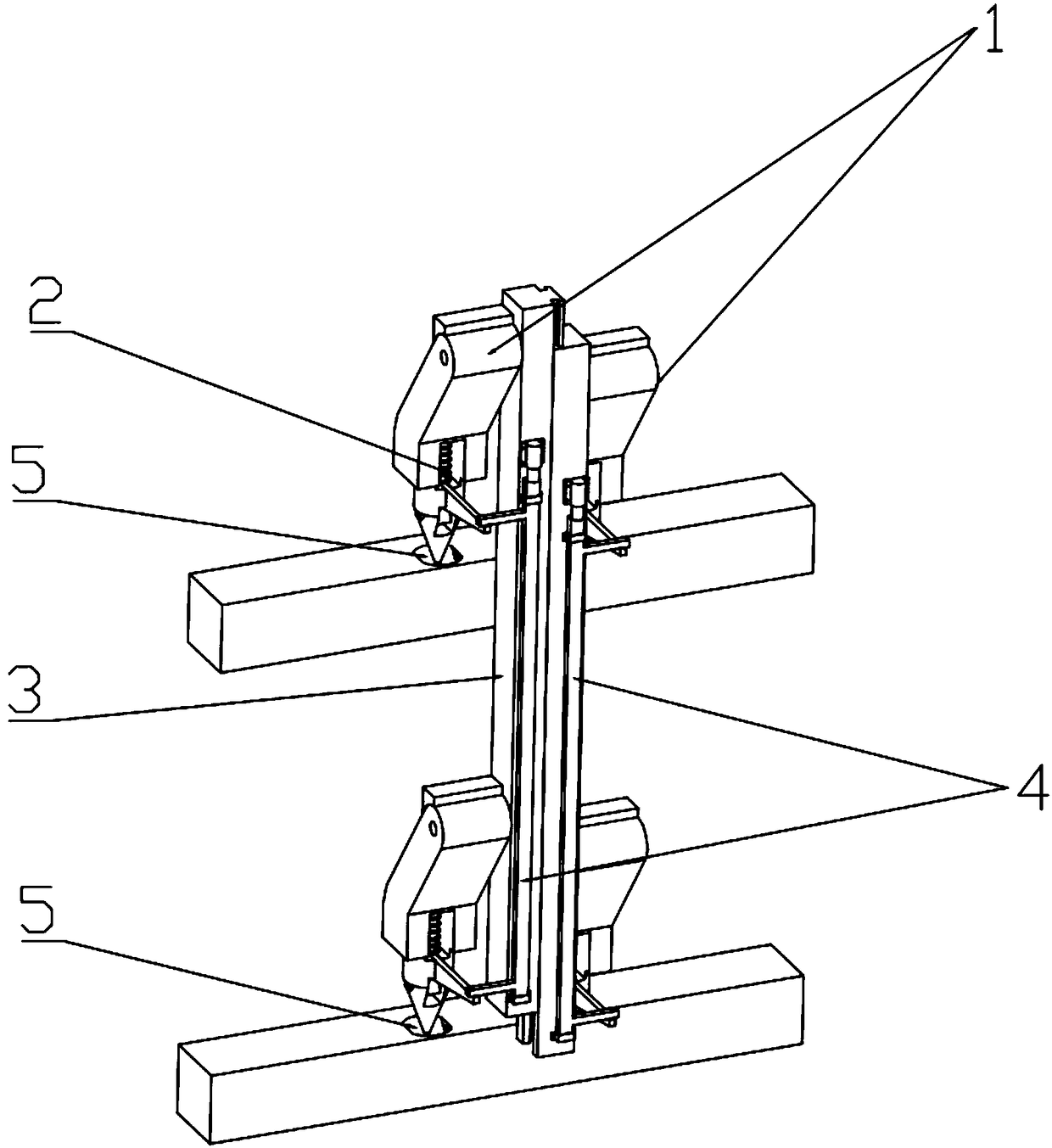

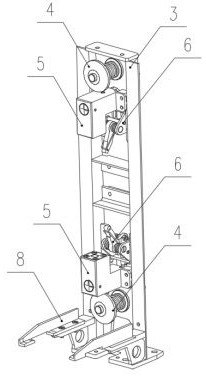

Mechanical arm mechanical lock and climbing device using mechanical arm mechanical lock

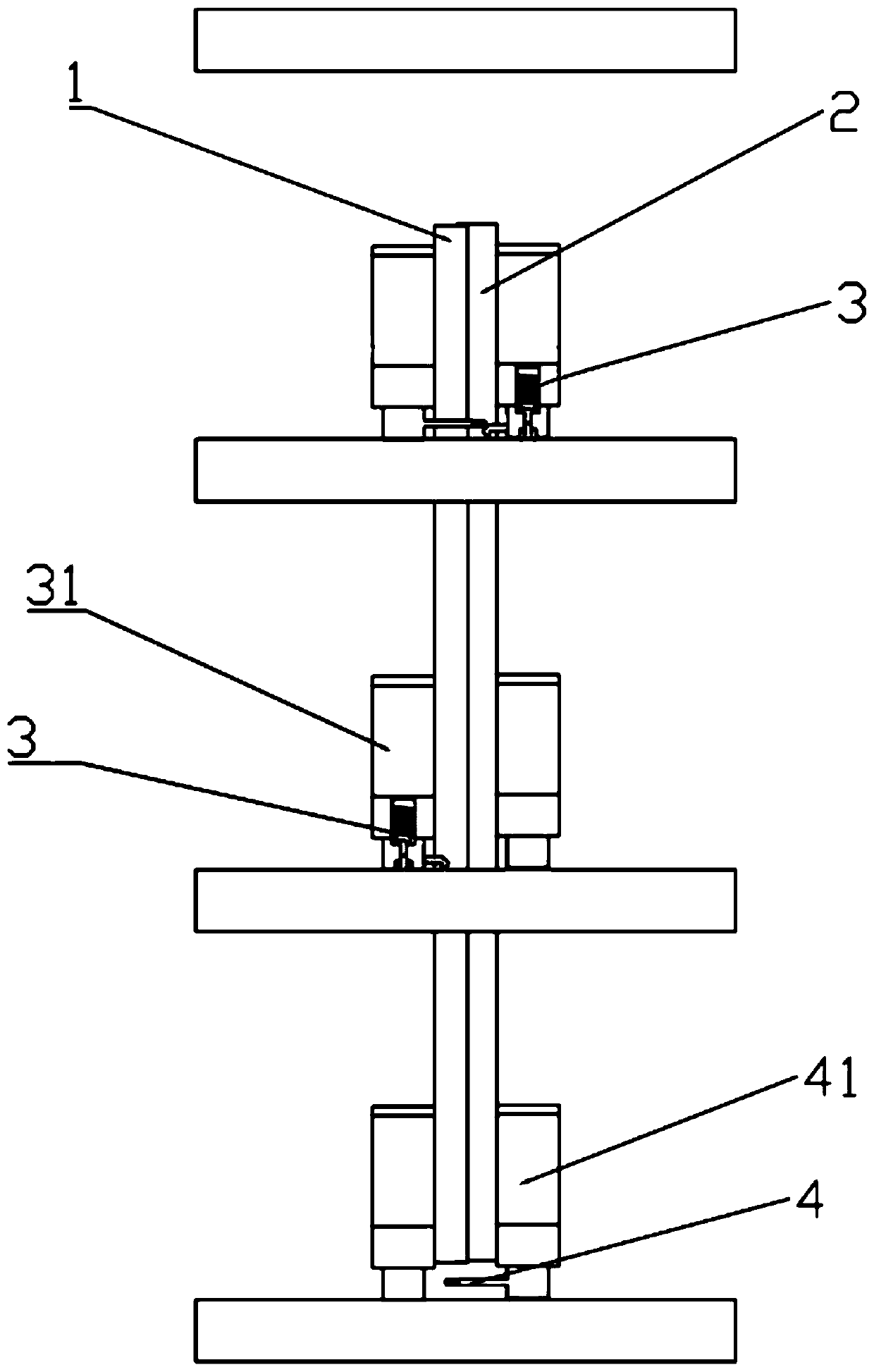

ActiveCN108100963ASimple actionSimple and reliable actionLifting devicesMechanical engineeringControl system

The invention relates to a mechanical arm mechanical lock structure and a climbing device using the mechanical arm mechanical lock structure. The mechanical arm mechanical lock structure comprises a mechanical arm body mounted on the climbing device, a locking structure arranged on the mechanical arm body and an unlocking structure arranged on the climbing device; the locking structure can be locked in the upper portion of a building, and the mechanical arm body can be locked; the unlocking structure can unlock the locking structure from the building, the mechanical arm body can be unlocked. The mechanical arm mechanical lock structure and the climbing device have the automatic locking and unlocking functions, the mechanical program type locking manner is adopted, the action is simple andreliable, the number of links is small, the manufacturing cost of a control system is greatly reduced, the structure is simple, use is convenient, full-automatic operation is achieved, labor intensityof workers is reduced, construction efficiency is greatly improved, and labor cost is saved.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

Magnetic shoe moving device and conveying system

InactiveCN112678240AArranged in a compact structureCompact structureShock-sensitive articlesStacking articlesControl engineeringStructural engineering

The invention discloses a magnetic shoe moving device and a conveying system, and belongs to the technical field of magnetic shoe packaging. Aiming at solving the problems of low moving efficiency and high cost of existing column-shaped magnetic shoes, the invention provides the magnetic shoe moving device which comprises a moving plate and a lifting plate arranged opposite to the bottom of the moving plate; the lifting plate is connected with a lifting mechanism, and the moving plate is connected with a driving mechanism; a magnetic shoe arrangement channel is formed between the lifting plate and the moving plate, a limiting plate is arranged at the end, away from a conveying mechanism, of the magnetic shoe arrangement channel and hinged to the moving plate, a sensor is further arranged at the end, provided with the limiting plate, of the moving plate, and the sensor, the lifting mechanism and the driving mechanism are electrically connected with a controller. The whole magnetic shoe moving device is simple and reliable in action, and production cost is saved; and manual participation in arrangement of the magnetic shoes is not needed, the working efficiency is greatly improved, and the labor cost is reduced. According to the magnetic shoe conveying system, all components do not interfere with one another, and maintenance and replacement are convenient.

Owner:SINOSTEEL TIANYUAN MAANSHAN TONGLI MAGNETIC MATERIAL

High-speed wire double production line swinging wire separation device

InactiveCN101653787BEasy to operateShort cycleGuiding/positioning/aligning arrangementsMetal rolling arrangementsProduction lineFailure rate

The invention discloses a high-speed wire double production line swinging wire separation device, comprising a single-wire output roller table and a double-wire input roller table. The double-wire input roller at least comprises an A line roller table and a B line roller table and provided with a roller table swinging device at the input end thereof for butting the entrances of two roller tables therein with the exit of the single-wire output roller table in a swinging way and reciprocating in cycle to achieve the wire separation, i.e. a single production line is divided into double production lines. The device changes the fixed heat-preservation roller table structure into the swinging heat-preservation roller table structure through the heat-preservation roller table frequently used in high-speed wire production line, thereby omitting special wire separation roller tables, greatly optimizing the production process and reducing the investment cost of equipment; and the high-speed wire double production line swinging wire separation device has the characteristics of simple and reliable operation and structure and low failure rate, and the advantages of continuous rolling, short wire renewing period, greatly improved production efficiency and no increase of space when used for renewing the old equipment, and the like.

Owner:武钢集团有限公司

Transmission structure of rotating mold

PendingCN111618168AReduce the difficulty of assemblyLow failure rateShaping toolsPerforating toolsDrive shaftGear wheel

The invention discloses a transmission structure of a rotating mold. The transmission structure comprises a servo motor, a long transmission shaft coupling and a long transmission shaft. The servo motor drives the long transmission shaft through the long transmission shaft coupling. A first transmission mechanism and a second transmission mechanism are connected to the long transmission shaft. Thefirst transmission mechanism comprises a first tensioning sleeve, a first small synchronous belt wheel, a first large synchronous belt wheel and a first large bevel gear. The first small synchronousbelt wheel is fixed to the long transmission shaft through the first tensioning sleeve, the first large synchronous belt wheel is connected with the first small synchronous belt wheel through a firstsynchronous belt, the first large synchronous belt wheel is fixed to a first short transmission shaft, and the first large bevel gear is fixed to the first short transmission shaft. According to the transmission structure, the servo motor drives two rotating mold assemblies to achieve synchronous transmission through a transmission system, after punching is finished, the structure does not need toreturn to the zero point, action is simple and reliable, work efficiency is improved, a plug mechanism and a locking mechanism are omitted, and mechanical failures are reduced.

Owner:爱克(苏州)机械有限公司

A mechanical arm device with automatic locking and mutual unlocking

ActiveCN107720638BReduce manufacturing costReduce labor intensityLifting devicesLocking mechanismEngineering

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

Hydraulic system of articulating arm type aerial work vehicle

The invention relates to a hydraulic system of an articulating arm type aerial work vehicle. The rod chamber of the lower luffing cylinder of the hydraulic system of the crank arm type aerial work vehicle communicates with the middle luffing rodless chamber through the first two-way balance valve and the second two-way balance valve, wherein the first two-way balance valve and the second two-way balance The communication oil passage between the valves communicates with the oil inlet port of the auxiliary synchronous valve; the first oil control port of the first two-way balance valve communicates with the rod chamber of the middle luffing through the second two-way balance valve, wherein the first oil control port communicates with the The communication oil passage between the second two-way balance valves communicates with the oil outlet of the auxiliary synchronous valve; the second oil control port of the second two-way balance valve communicates with the rodless chamber of the lower amplitude through the first two-way balance valve; wherein, the auxiliary The synchronous valve consists of a relief valve and a throttle valve connected in parallel. The hydraulic system of the crank arm type aerial work vehicle provided by the present invention uses the auxiliary synchronous valve to make the lower luffing oil cylinder and the middle luffing oil cylinder move simultaneously, so that the hydraulic system of the articulating arm type aerial work vehicle has a compact layout and is easy to maintain.

Owner:HUAIHUA UNIV

A Lithium battery combined core film driving device

ActiveCN109755629BAutomatically realize the film catch actionSimple and reliable actionFinal product manufactureSecondary cells manufactureEngineeringStructural engineering

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Multi-mechanism linkage type storage box device

PendingCN114873123ASimple and reliable storageEasy to expandStorage devicesEngineeringLever pressing

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

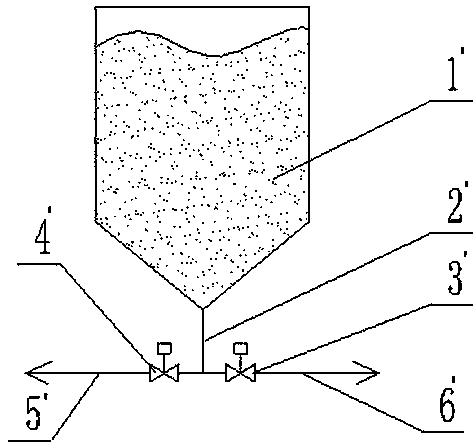

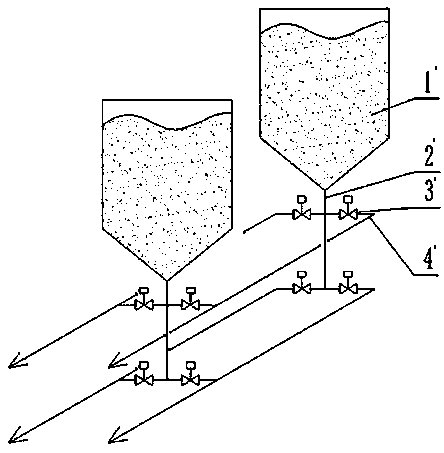

A negative pressure conveying bin bottom retrieving device

ActiveCN105736724BDoes not cause cross section changesIncrease the number ofSlide valveLoading/unloadingMechanical engineeringModular structure

The invention provides a negative-pressure conveying bin bottom material fetching device. The negative-pressure conveying bin bottom material fetching device comprises a material fetching device main body connection pipe, a bulk material bin, a valve body and an execution cylinder, wherein the material fetching device main body connection pipe is directly connected to the bottom of the bulk material bin; the side surface of the material fetching device main body connection pipe is connected with the valve body; a material fetching passage is formed in the valve body and vertically communicates with a material conveying pipe below the valve body; a valve element is arranged in the valve body; the rear end of the valve element is provided with a notch and is connected with the execution cylinder through a connection plate; the execution cylinder is connected with the valve body through an assembly plate; the part, connected with the material fetching device main body connection pipe, of the valve body is fixedly provided with a first sealing ring; when the valve element is at a closing state, sealing is maintained; and the rear end of the valve element is provided with a second sealing ring, and the second sealing ring moves along with the valve element, so that the interval between the valve element and the inner wall of the valve body is in a sealing state all the time. The negative-pressure conveying bin bottom material fetching device has the beneficial effects that a modular structure is adopted, so that movement is simple and reliable; and the assembly is rapid; space is saved; and no connection bend is needed.

Owner:广州创特技术有限公司

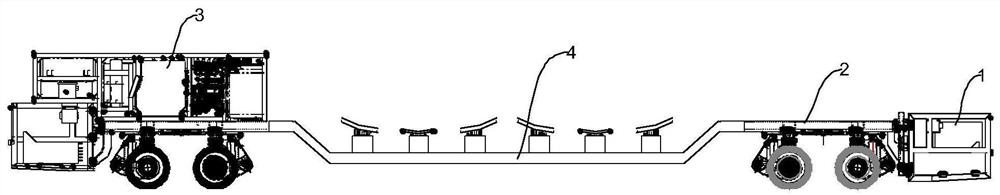

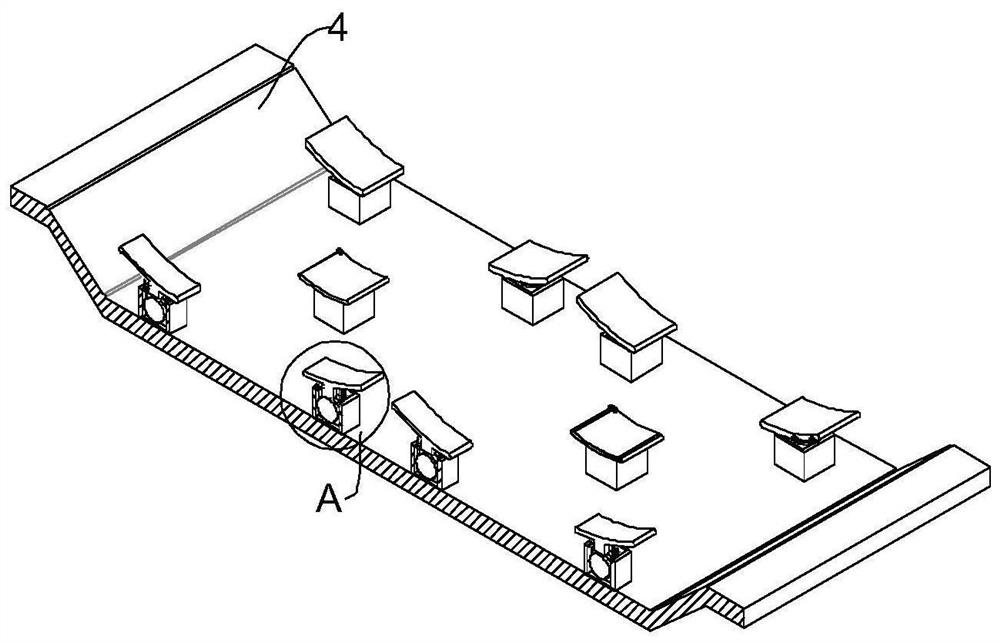

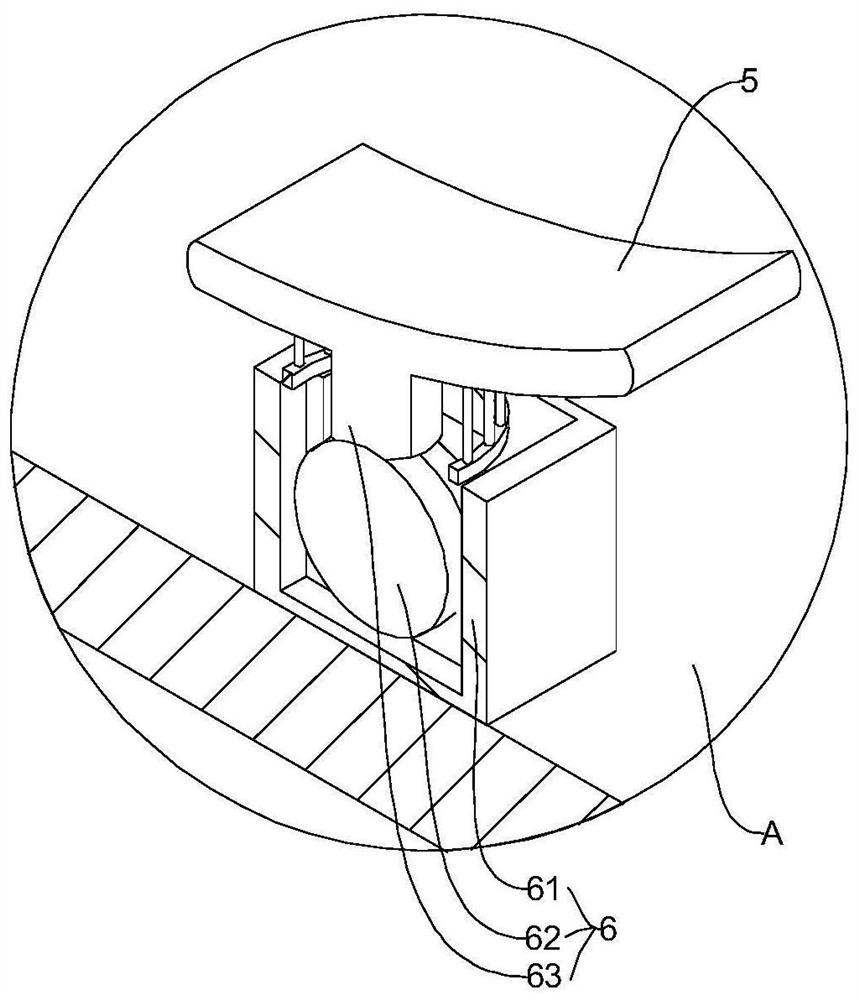

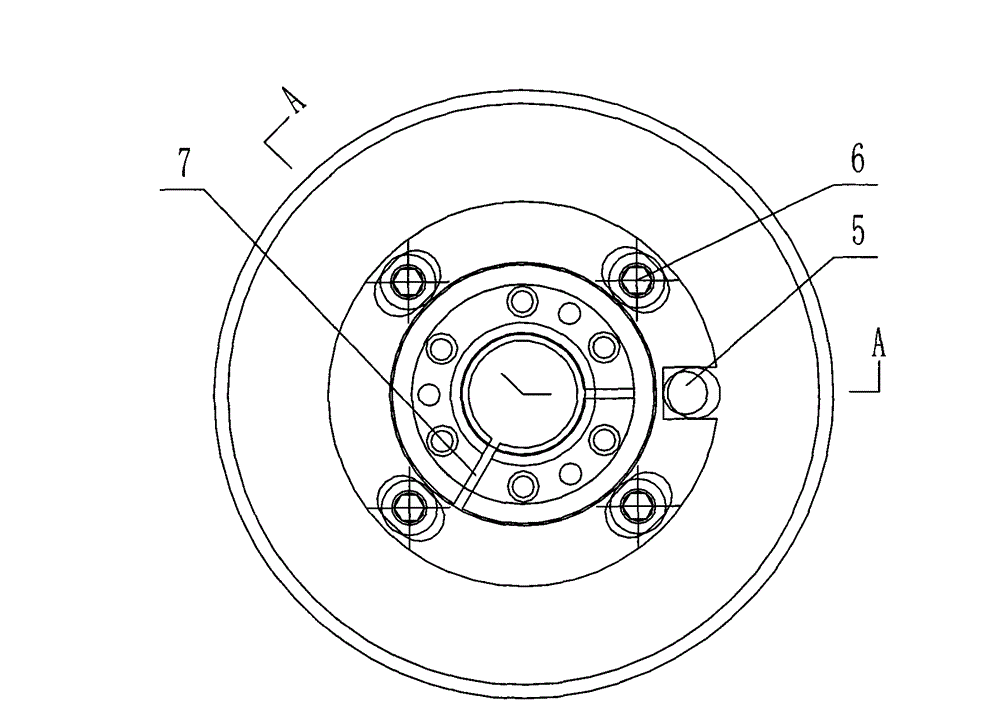

Explosion-proof trackless rubber-tyred vehicle with inverted arch block stable supporting function

PendingCN114851944AAchieve angle adjustmentSmooth rotationLoad securingItem transportation vehiclesClassical mechanicsEngineering

Owner:CHINA COAL NO 3 CONSTR GRP +4

Driving shaft fine-tuning connecting taper sleeve

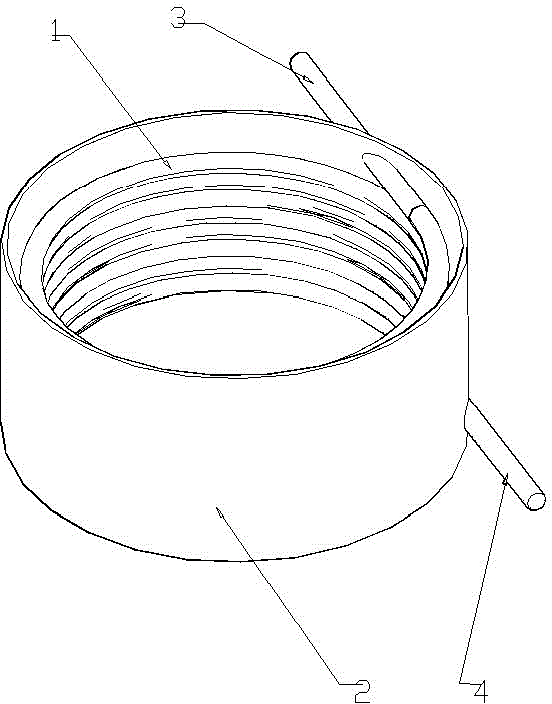

InactiveCN101608671BAchieve fine-tuningImprove assembly accuracyCouplings for rigid shaftsDrive shaftEngineering

The invention relates to a driving shaft fine-tuning connecting taper sleeve which is arranged on a gear shaft and comprises a driving gear adjusting seat, a circular driving shaft fixed taper seat assembled inside the driving gear adjusting seat, and a driving shaft fixed taper sleeve arranged inside the driving shaft fixed taper seat, wherein the driving gear adjusting seat is connected with a driving gear through an eccentric shaft, the driving shaft fixed taper seat and the driving shaft fixed taper sleeve are matched by a tapered surface and fixedly connected by bolts, and the driving shaft fixed taper seat and the driving shaft fixed taper sleeve are both provided with opening seams along the vertical direction. The driving shaft fine-tuning connecting taper sleeve has the beneficial effects: the fine tuning of the driving gear can be realized, the action is simple and reliable, the adjustment is free and not limited by shaft shoulders, the assembling precision and the driving precision of the driving gear are improved, and the service life of the driving gear is prolonged.

Owner:无锡市金龙人造毛皮机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com