Crossbeam press multi-hydraulic cushion synchronous control system

A technology of synchronous control and hydraulic cushion, which is applied in the field of forging machinery manufacturing, can solve the problems that it is difficult for multiple hydraulic cushions to jack up and retreat synchronously, the effect of synchronous jacking and retreat is not good, and the effect cannot reach users, etc., to improve The effect of pressing forming precision and qualified rate, avoiding core jamming and less control components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

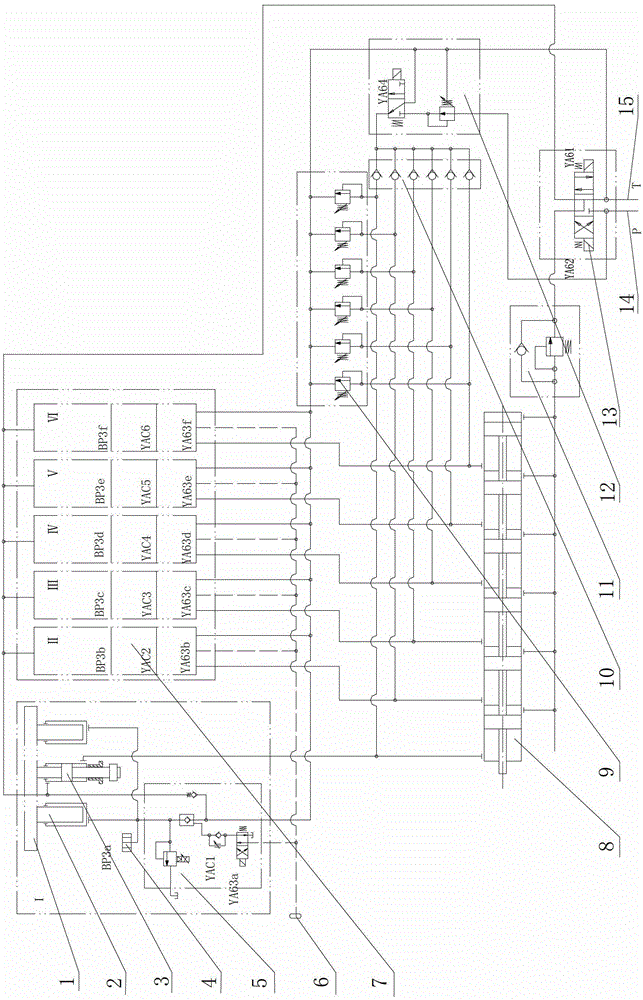

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] see figure 1 , a synchronous control system for multi-hydraulic pads of a girder press, including multiple groups of hydraulic pads 1, a hydraulic pad cylinder 2 that controls the hydraulic pads to produce technological actions, and an ejector cylinder 3 that controls the jacking up and retreat of the hydraulic pads. The hydraulic pads are fastened The parts are connected with the hydraulic cushion cylinder and the ejector cylinder. In this embodiment, the hydraulic cushion is connected with the hydraulic cushion cylinder and the ejector cylinder through bolts. The hydraulic pad cylinder is connected to the low-pressure oil return pipe 15 through the hydraulic pad control valve group 5, the hydraulic pad control valve group 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com