Patents

Literature

160results about How to "Small span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

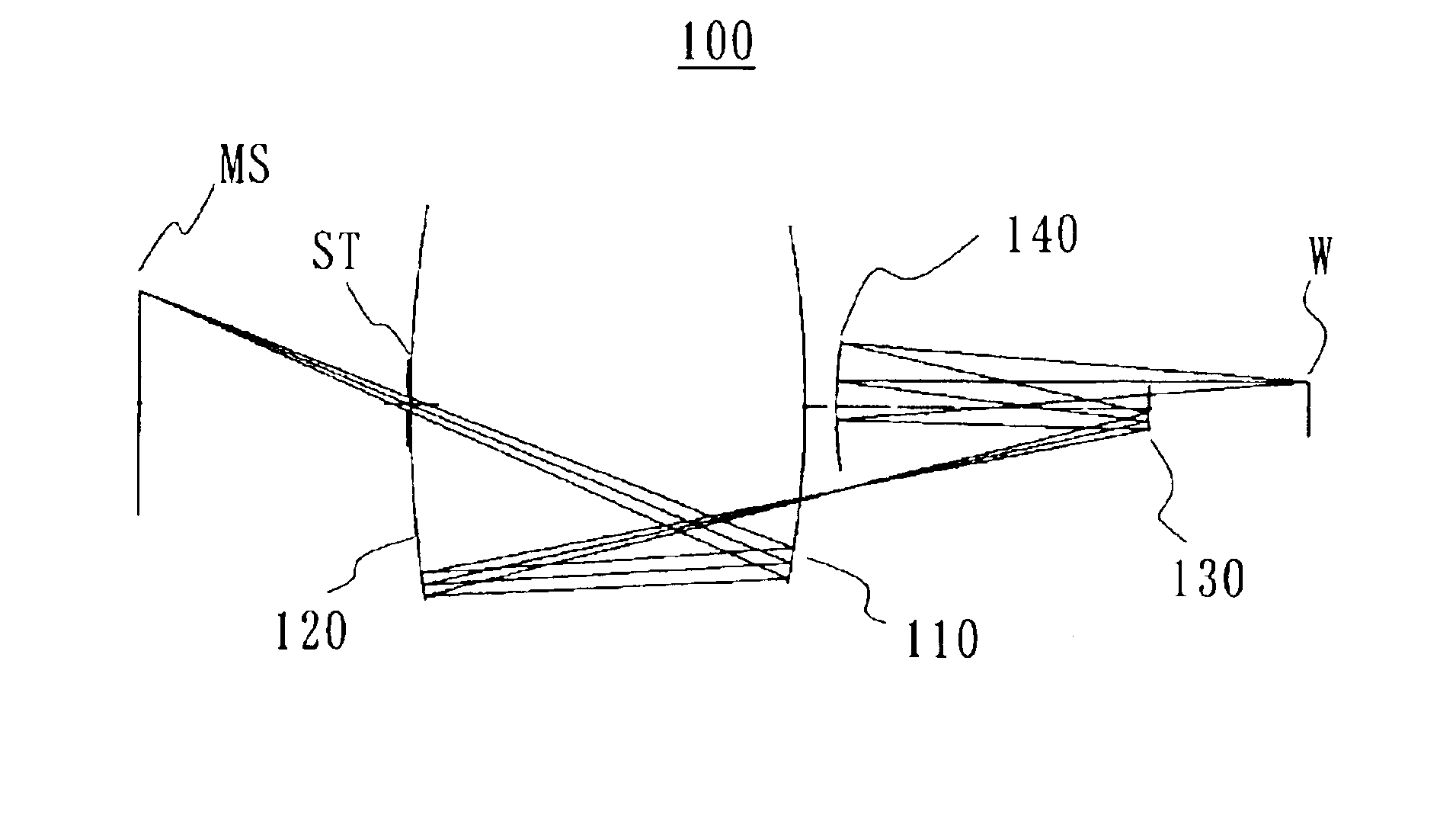

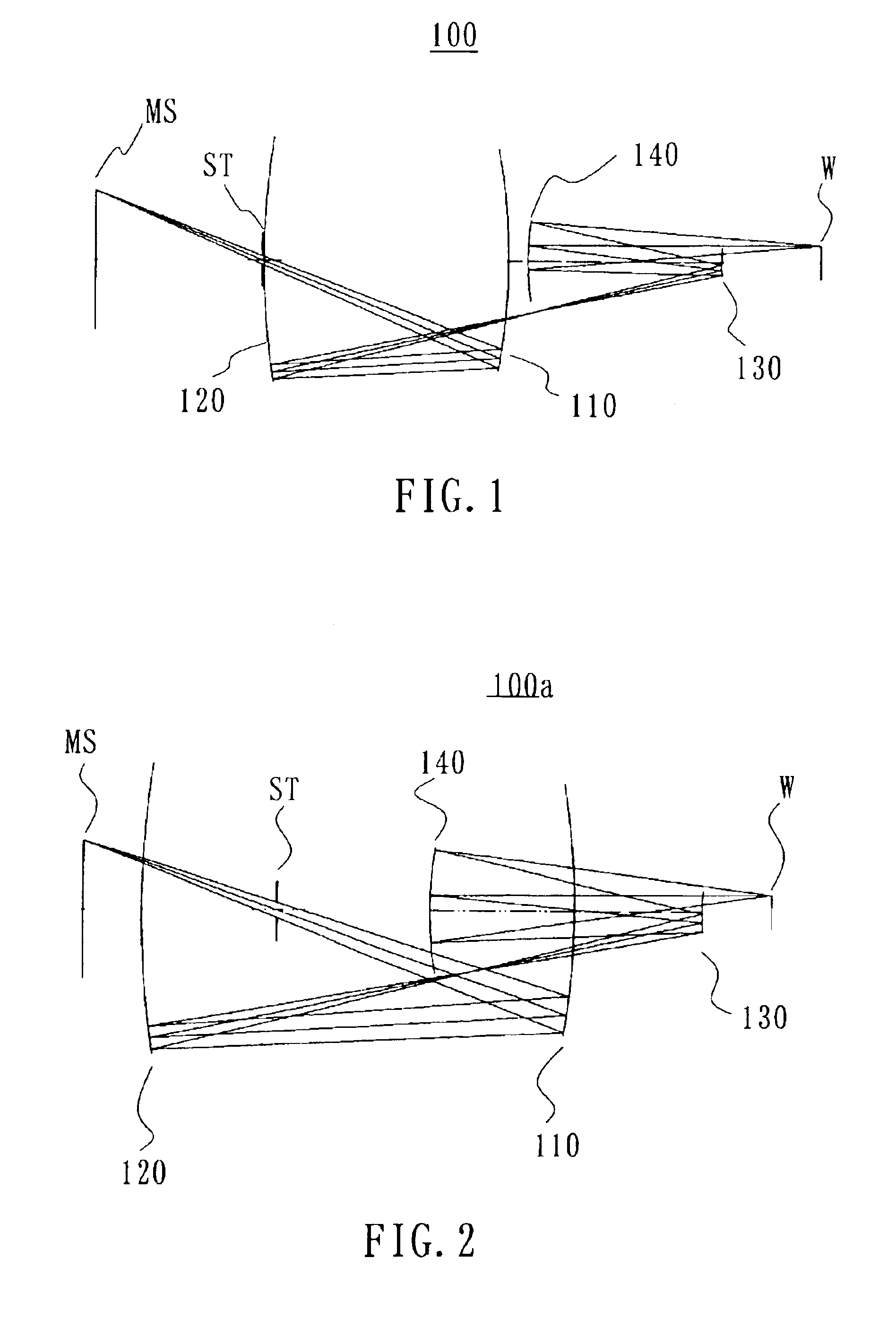

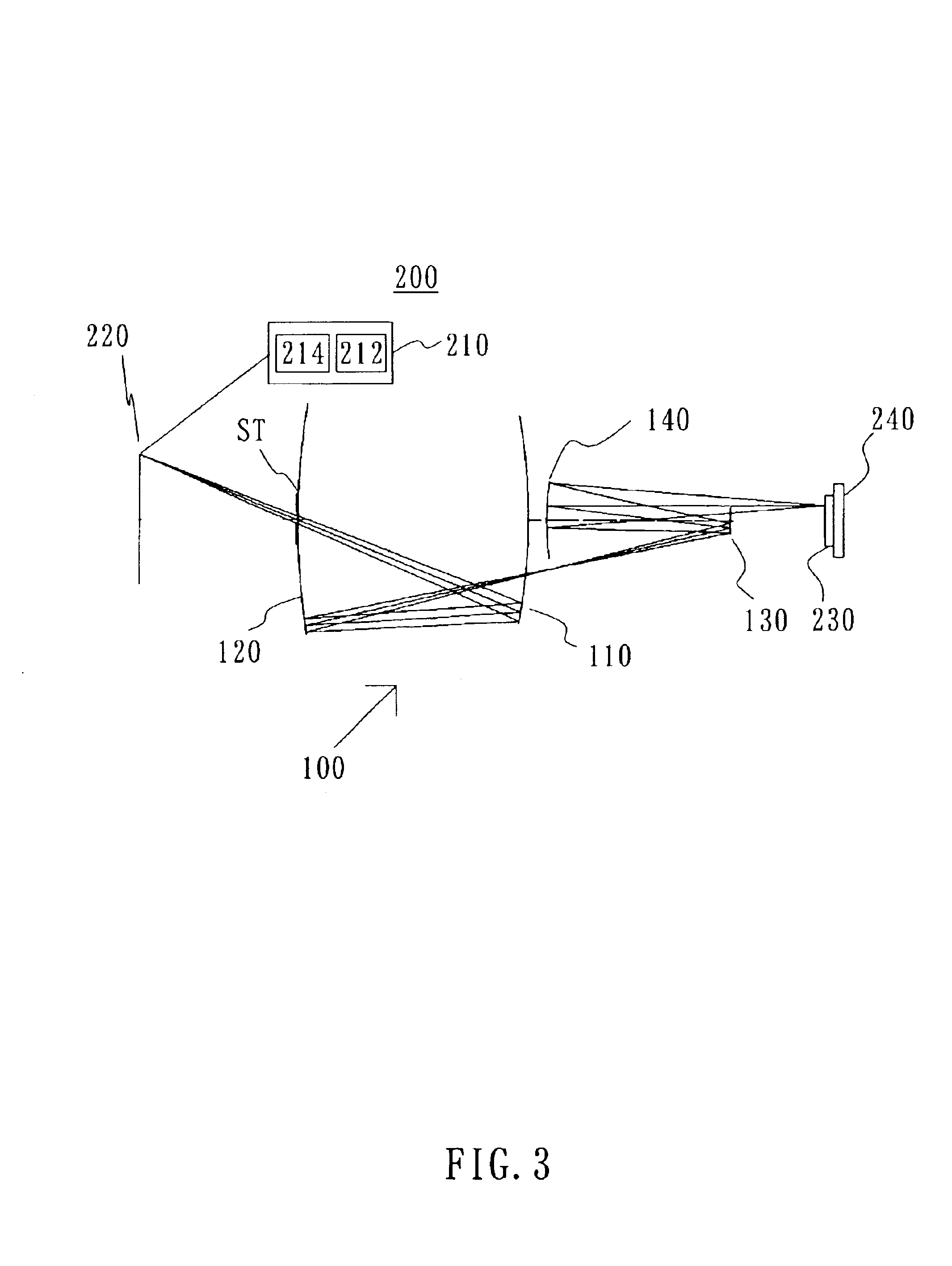

Catoptric projection optical system, exposure apparatus and device fabrication method using same

InactiveUS6947210B2Small spanImprove imaging effectMirrorsSemiconductor/solid-state device manufacturingIntermediate imageCatoptrics

A catoptric projection optical system for projecting a pattern on an object surface onto an image surface and for serving as an imaging system that forms an intermediate image includes first, second, third and fourth mirrors serving substantially as a coaxial system so as to sequentially reflect light from an object side to an image side, and being arranged so that light from the object surface to the first mirror may intersect light from the second mirror to the third mirror.

Owner:CANON KK

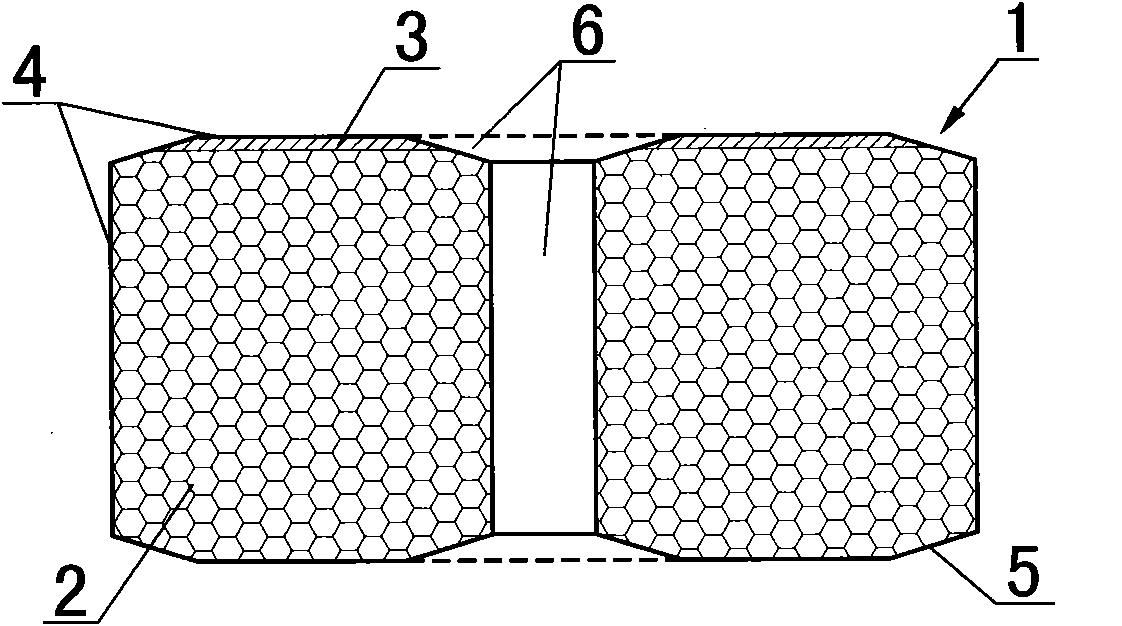

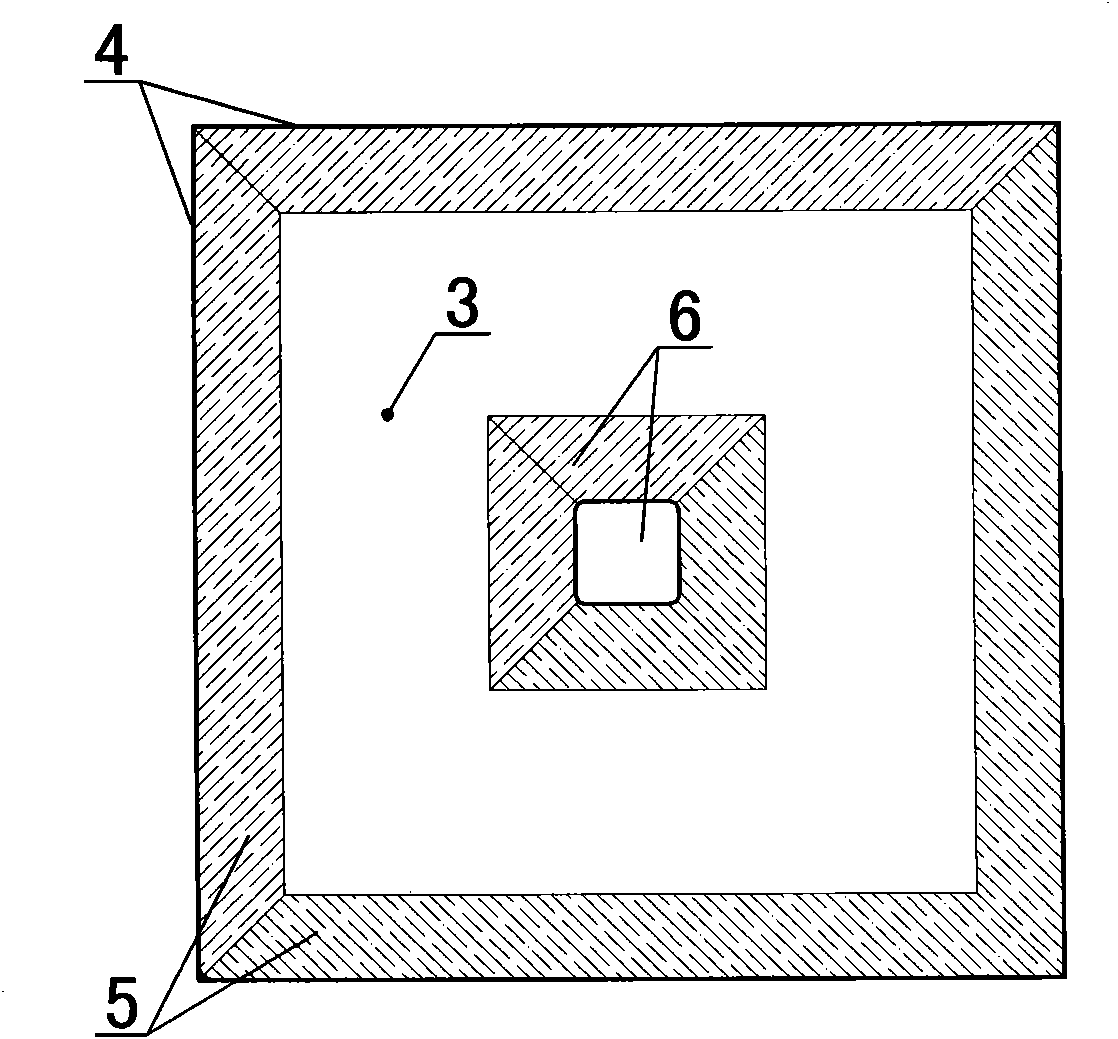

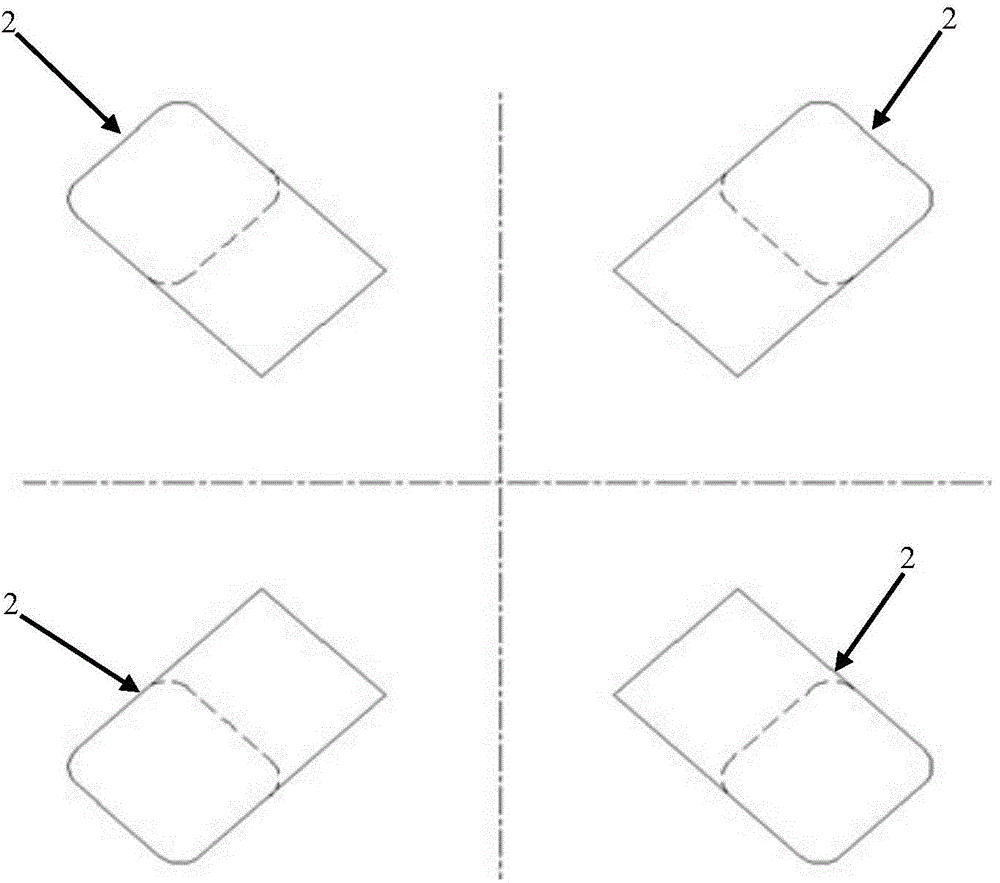

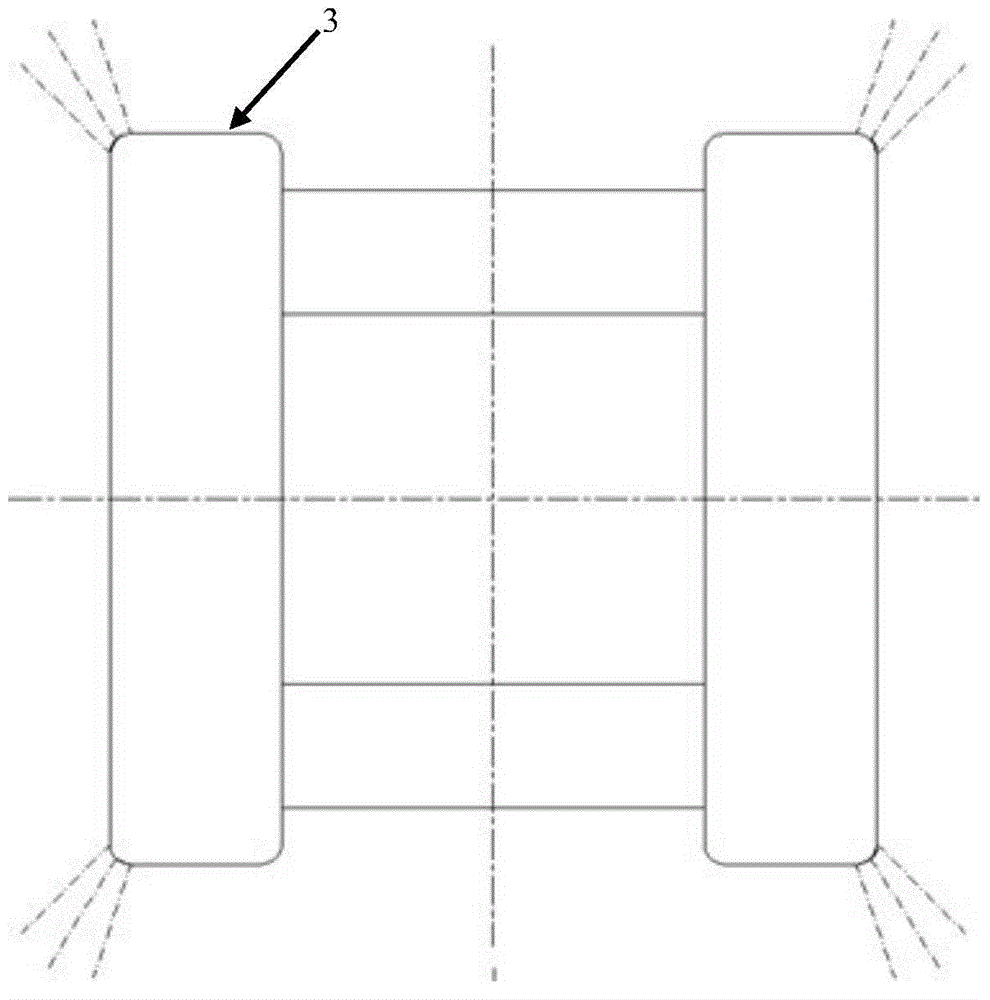

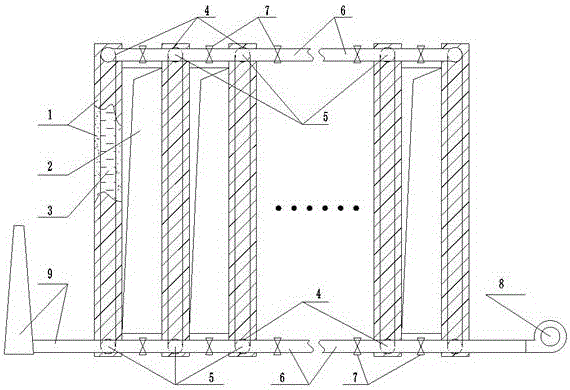

Foaming material filling box with reinforced layer and slurry leakage hole

ActiveCN102031870AEasy to pourEnsure safetyFloorsForms/shuttering/falseworksEngineeringShock resistance

The invention relates to a foaming material filling box with a reinforced layer and a slurry leakage hole and a manufacturing method thereof, belonging to the field of building construction. A main material of a body (2) of the filling box (1) is a light weight foaming material, the plane shape of the filling box (1) is rectangular, and the ratio of a long side to a short side is not more than 2;the upper surface of the body (2) is provided with the hard reinforced layer (3), the outer surface of the body is provided with an isolation layer (4); the hard reinforced layer (3) is located between the body (2) and the isolation layer (4); tangential angles or arc chamfers (5) are arranged at the peripheries of the upper surface and the lower surface of the filling box (1); and the middle part of the filling box (1) is provided with the vertical slurry leakage hole (6), the upper end of the slurry leakage hole (6) is in a big end up funnel shape, and the lower end of the slurry leakage hole (6) is in a big end down inverse funnel shape. In the invention, the sectional shape of the filling box meets the mechanical requirement, and the filling box is very convenient for production, transportation and installation, and has better structural reliability, shock resistance and crack resistance and favorable economical efficiency and applicability.

Owner:徐焱

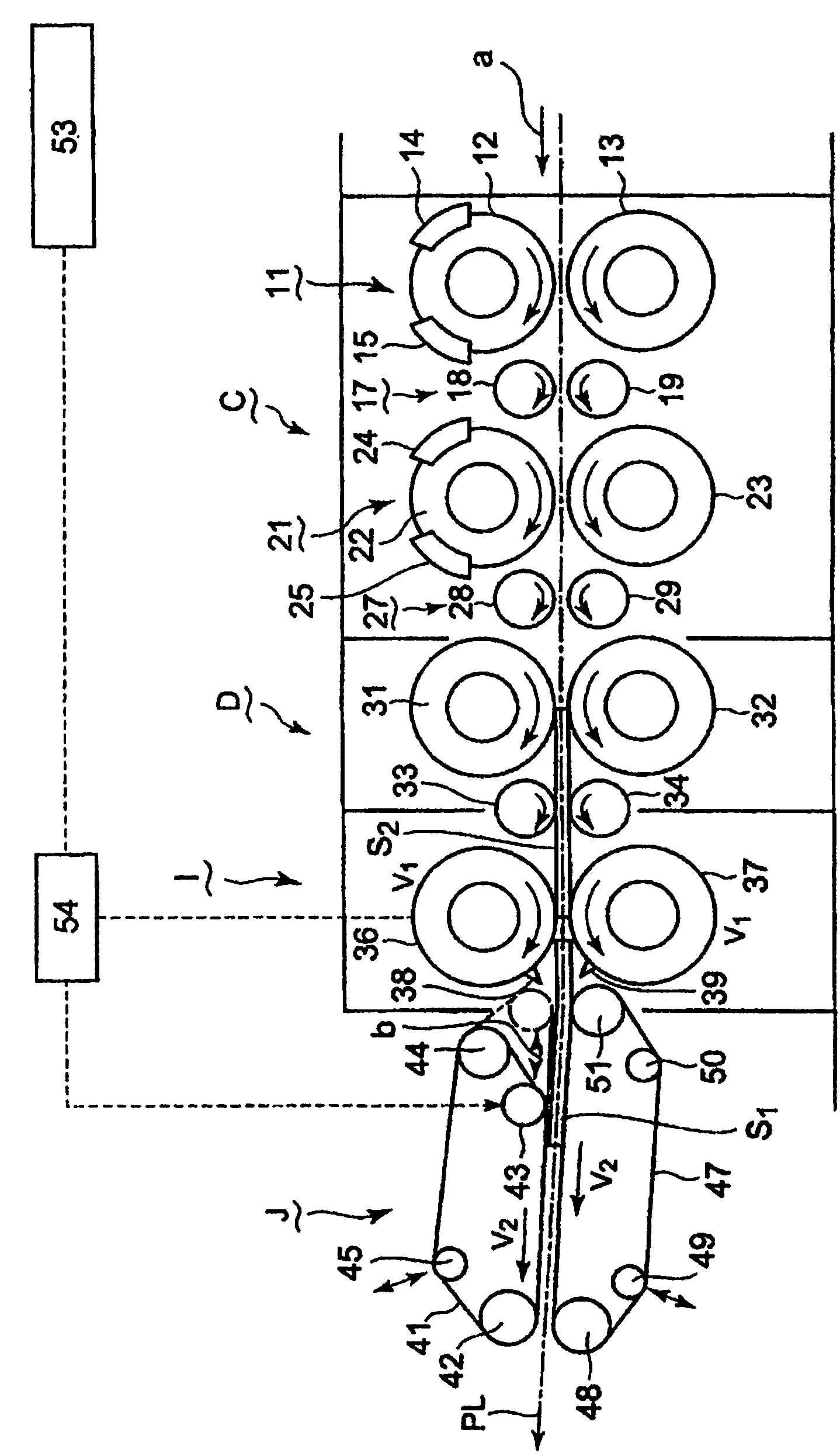

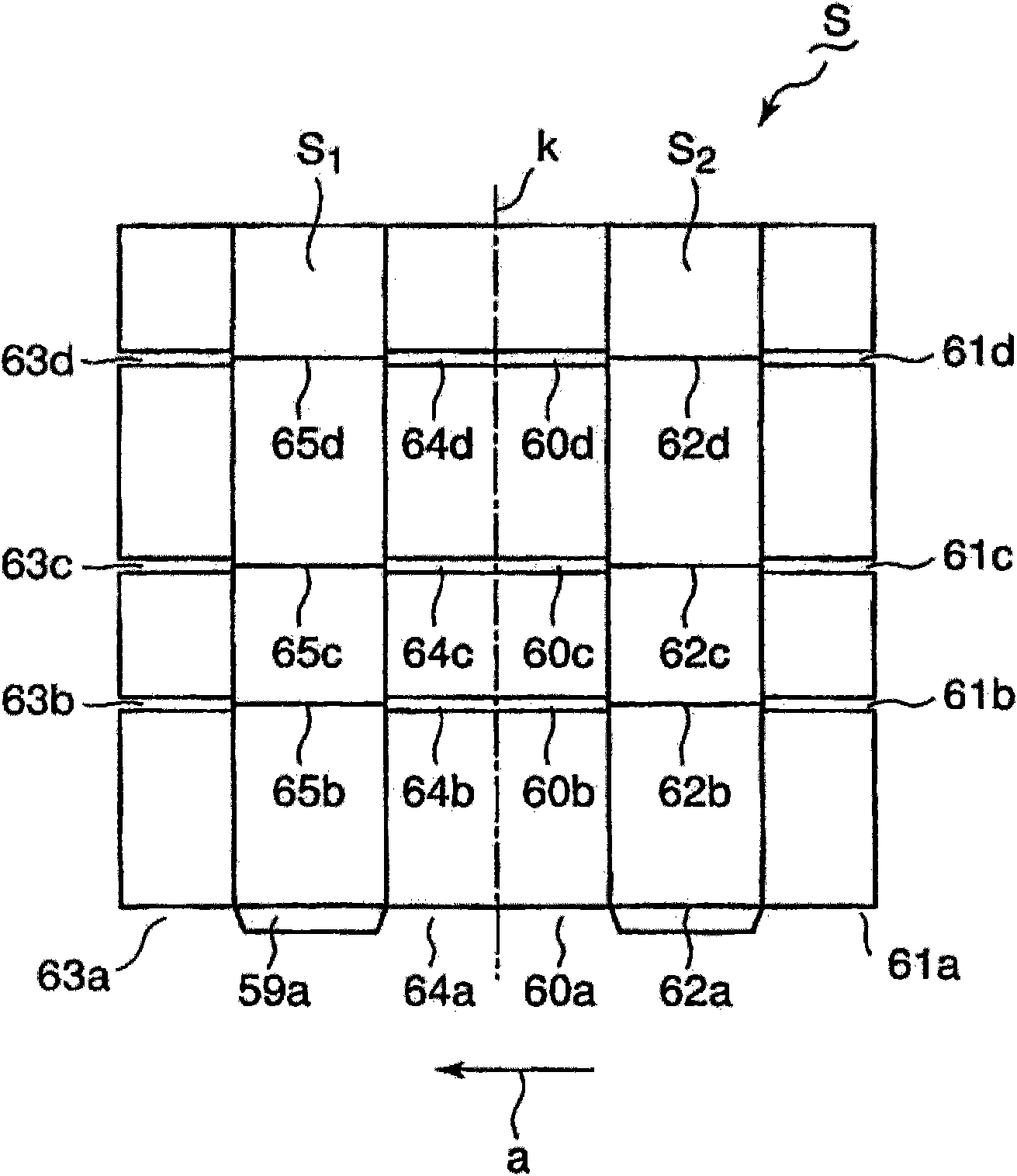

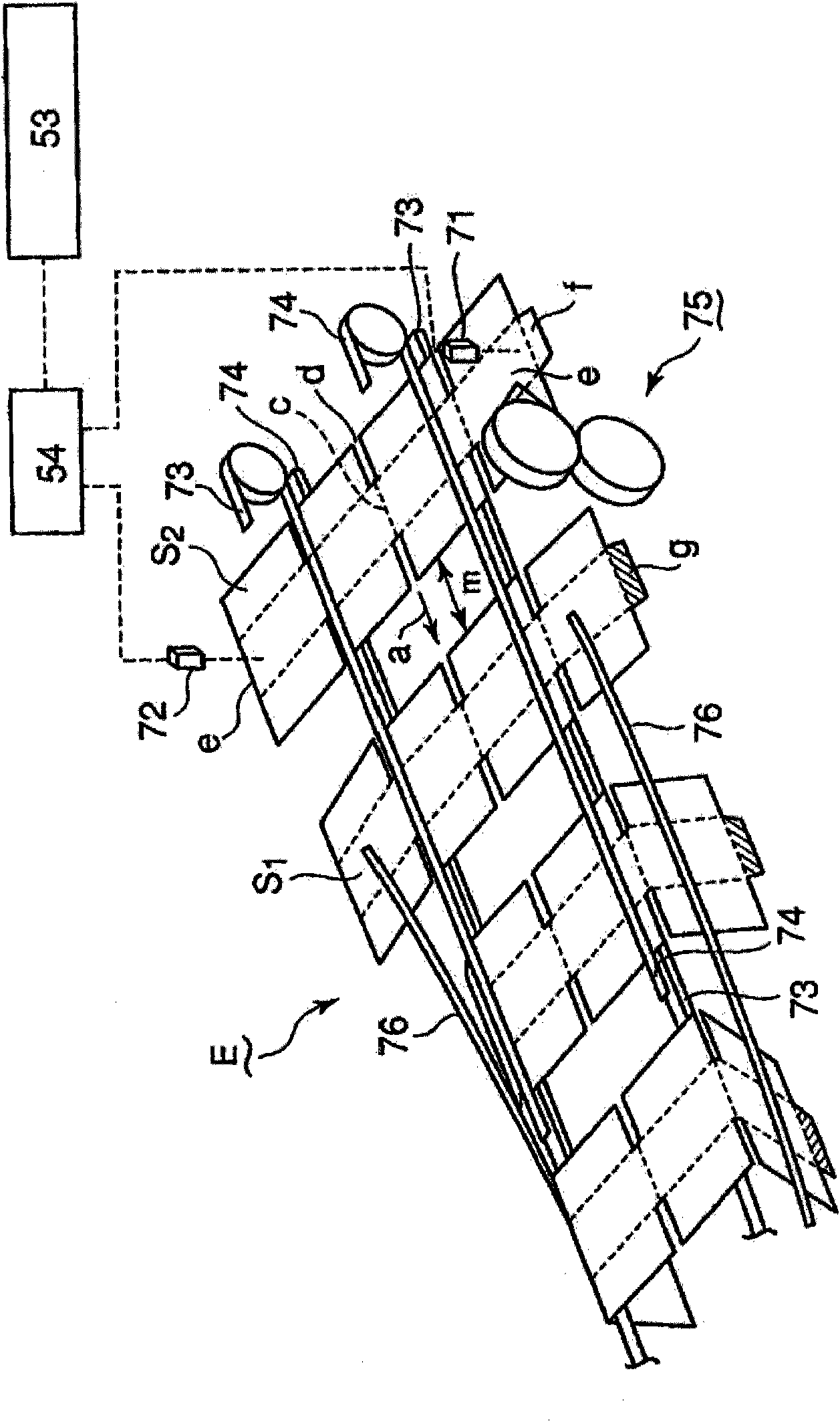

Method and device for making box of corrugated cardboard sheet

ActiveCN101873926ASmall spanEasy to handleBoxes/cartons making machineryPaper-makingCountermeasureCardboard box

Disclosed is a method for producing a cardboard box by performing a box-making process of a corrugated cardboard sheet which is formed to have dimensions of a plurality of cardboard boxes wherein the yield of the cardboard sheet and the production efficiency are enhanced and a countermeasure can be taken against paper powder. A method for making a box of a corrugated cardboard sheet by performinga box-making process of a cardboard sheet (S) which is formed to have dimensions of a plurality of cardboard boxes and then cutting the cardboard sheet (S) into dimensions of one cardboard box comprises a step (I) for cutting the cardboard sheet (S) into dimensions of one cardboard box by a cut line (k) in the direction intersecting the conveyance direction (a) along a box making line (PL) after a ruling and grooving step (C) and before a pasting and folding step (E), and a speed increase step (J) for spacing the cardboard sheets (S1) and (S2) thus cut by a set dimension following to the cutting step (I) by increasing the speed of the cardboard sheets (S1) and (S2) while conveying toward a subsequent step.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

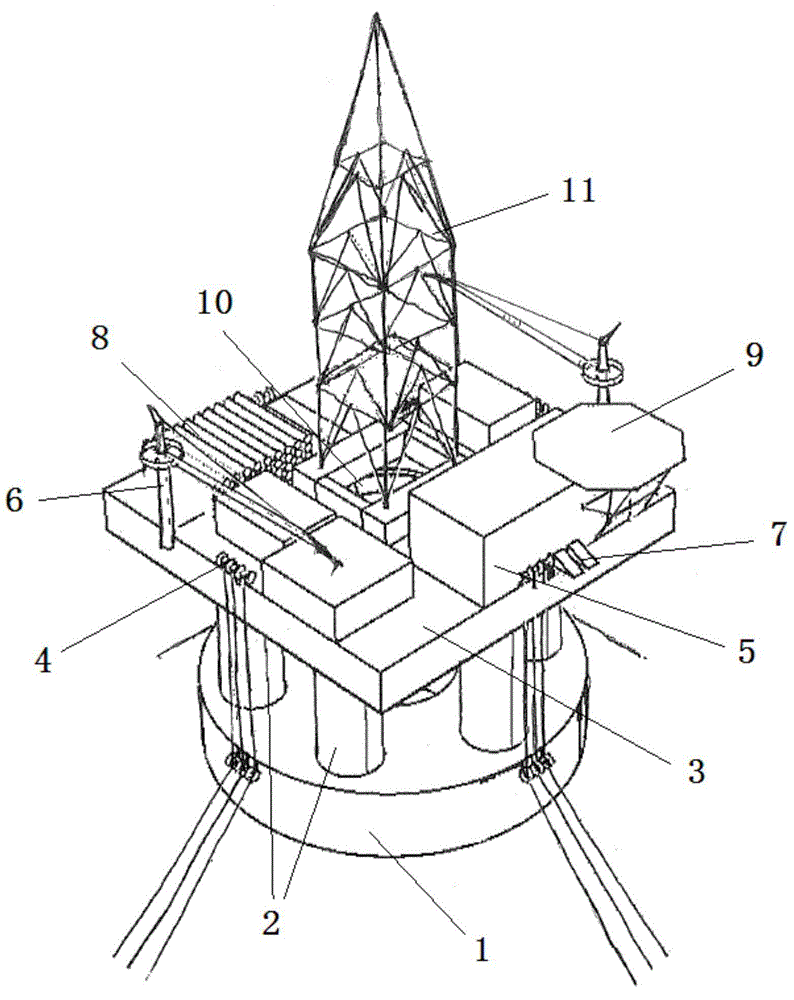

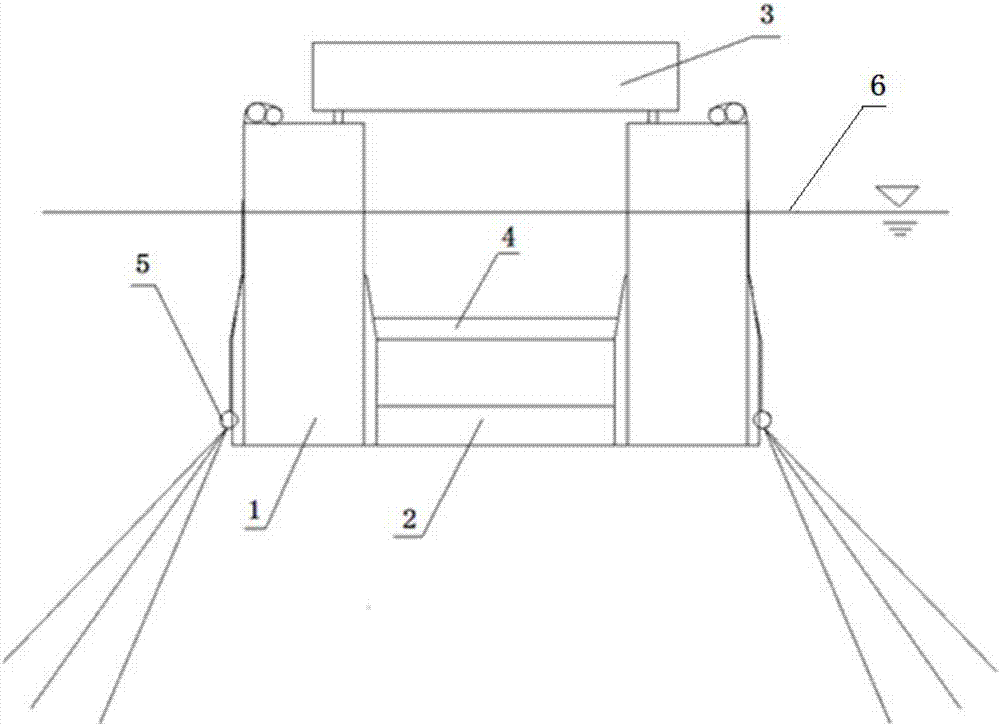

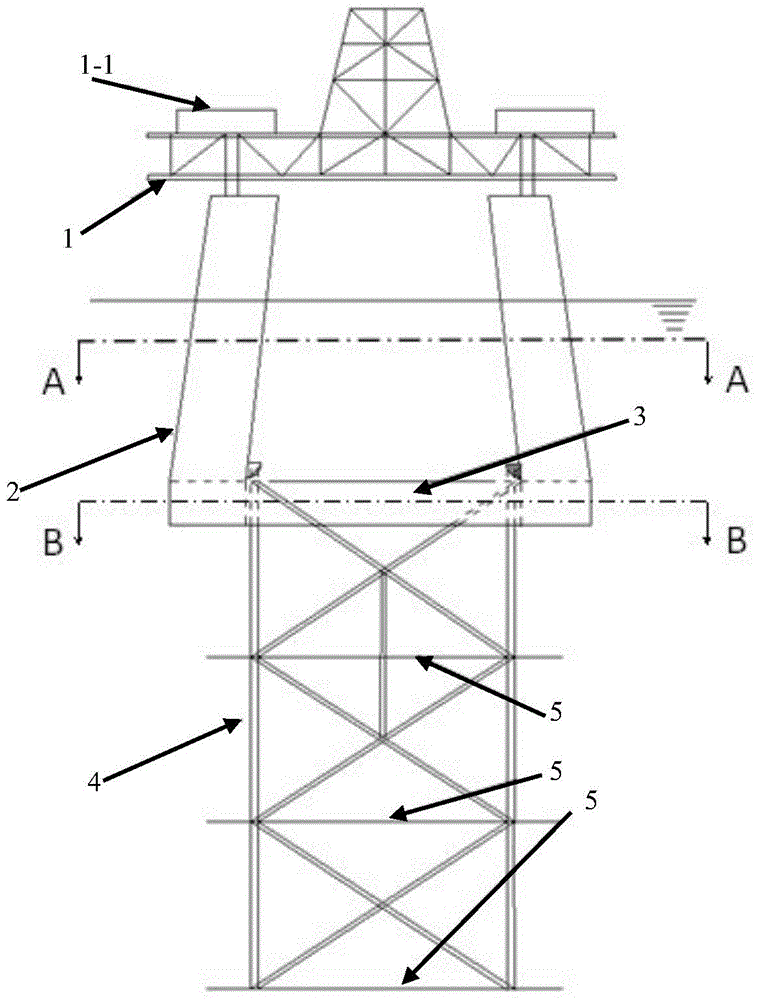

Multi-stand-column semi-submersible platform for cylindrical floating box

The invention relates to a multi-stand-column semi-submersible platform for a cylindrical floating box. The cylindrical floating box is arranged at the bottom of the semi-submersible platform. The inner portion of the cylindrical floating box is divided into a plurality of watertight cabins used for storing well drilling materials, consumables, anchor cables and ballast water. The circumference of the top of the cylindrical floating box is connected with the bottom of a platform deck through four or more stand columns. Branch cabins used for storing fresh water and drilling mud materials and elevator passageways penetrating the cylindrical floating box and the top of the platform deck are arranged in the stand columns. A generator set, an electrical equipment room and a drilling support device are arranged in the platform deck. A drilling or oil-gas production facility is arranged on the platform deck. The multi-stand-column semi-submersible platform is high in loading capacity adaptability, low in center of gravity, good in stability, small in movement range, high in overall strength, insensitive in environment direction, capable of changing the draft, capable of being towed by a tug or conducting self-propulsion through a propeller, simple in structure, convenient to construct and suitable for drilling and oil-gas production work of oil-gas fields in shallow sea and deepwater sea areas.

Owner:CHINA NAT OFFSHORE OIL CORP +1

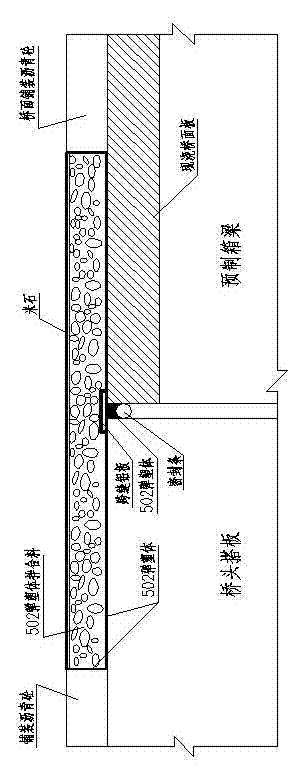

Construction method of bridge seamless type expansion joint

InactiveCN103088752APrevent fallingImprove adhesionBridge structural detailsExtensibilityGranolithic

The invention discloses a construction method of bridge seamless type expansion joint. The construction method of the bridge seamless type expansion joint includes the steps of embedding a sealing strip in the seam portion of the expansion joint, pouring melted 502 elastic-plastic bodies, placing a cross-seam aluminum sheet well, paving various high molecular polymers which fit in with the American society for testing material (ASTM) standard layer by layer, wherein the various high molecular polymers are mixed materials of the 502 elastic-plastic bodies and granite of a corresponding grade, finally using granitic plaster as a surface wearing layer, and the bridge seamless type expansion joint is achieved. The construction method of the bridge seamless type expansion joint has the advantages of satisfying stretch and displacement of an upper portion structure of the bridge, guaranteeing that cars run stably, improving riding comfort, and being strong in elastic restoring force, capable of resisting the high and low temperature, good in plasticity, extensibility, durability, waterproof performance and adhesion performance, long in service life, convenient to install, flexible in installation, rapid in traffic openness and the like. In addition, the construction method of the bridge seamless type expansion joint further has the advantage that the extensible displacement is from 20mm to 50 mm.

Owner:江西省城乡规划设计研究总院

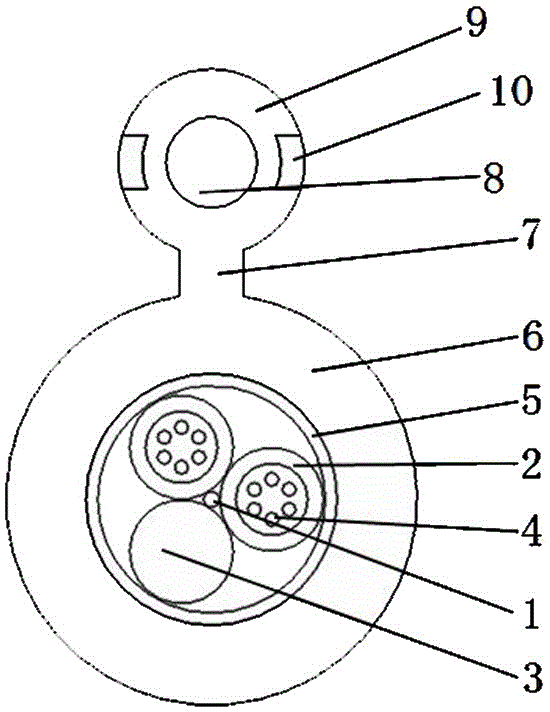

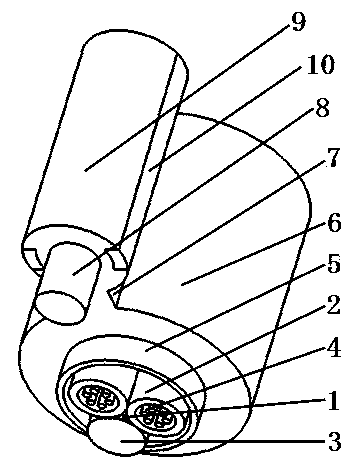

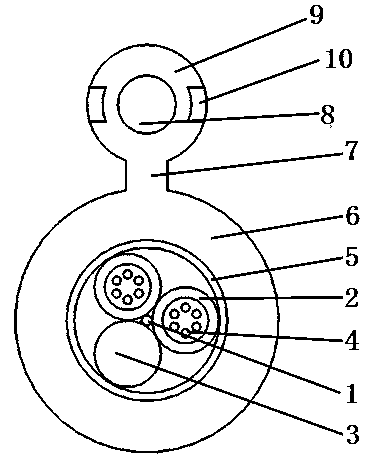

Self-supporting aerial optical cable capable of being identified through night vision

The invention relates to the technical field of cables and in particular relates to a self-supporting aerial optical cable capable of being identified through night vision. The self-supporting aerial optical cable comprises a cable core, an outer sheath, a reinforcing element, a suspension wire sheath and a rib, wherein the cable core is coated by the outer sheath; the reinforcing element is made of a single steel wire or glass fiber reinforced plastics and is coated by the suspension wire sheath; the rib is used for connecting the suspension wire sheath with the outer sheath; the cable core is formed by a central reinforcer, a plurality of loose tubes and a protective layer, wherein the loose tubes are arranged outside the central reinforcer and are coated by the protective layer; at least an optical fiber is arranged in each loose tube; two marking strips are symmetrically arranged on the suspension wire sheath; the suspension wire sheath, the outer sheath and the rib, which are made of the same materials, are formed integrally; and the marking strips are made of special materials. The self-supporting aerial optical cable has the main beneficial effects that the thickness of the suspension wire sheath is more convenient to control; the suspension wire sheath is smoother and round; the product production speed is higher and the percent of pass of the product is higher; the dead weight of the optical cable is lighter and the suitable span is longer; and the colors of the marking strips are more stable.

Owner:SUZHOU HIGH & SPECIALITY INFORMATION TECH CO LTD

Heavy-denier flat yarn continuous spinning process

InactiveCN102978722ASmall spanShort conveying distanceNew-spun product collectionFilament manufactureYarnSmall footprint

The invention discloses a heavy-denier flat yarn continuous spinning process. The process comprises the following steps of viscose metering molding, washing, baking and rolling, drawing molded yarns onto a small processing roll and a big processing roll through a yarn guide rod, sequentially performing regenerating, washing, desulfurizing, Ph value-adjusting, oiling and baking processes on the yarns on the small processing roll and the big processing roll, and rolling the baked yarns on a winding head under the action of a yarn guide wheel, wherein before the yarns are drawn to the small processing roll and the big processing roll, acid liquid on the yarns is scraped in a foam acid-scraping way. Continuous spinning can be finished on one set of spinning equipment, the breakage is low, the occupation area of the equipment is small, the acid bath loss is low, the continuity is higher, spindle positions are not mutually affected, and the produced heavy-denier flat yarns are high in quality, the rate of finished products and yield.

Owner:YIBIN HIEST FIBER +1

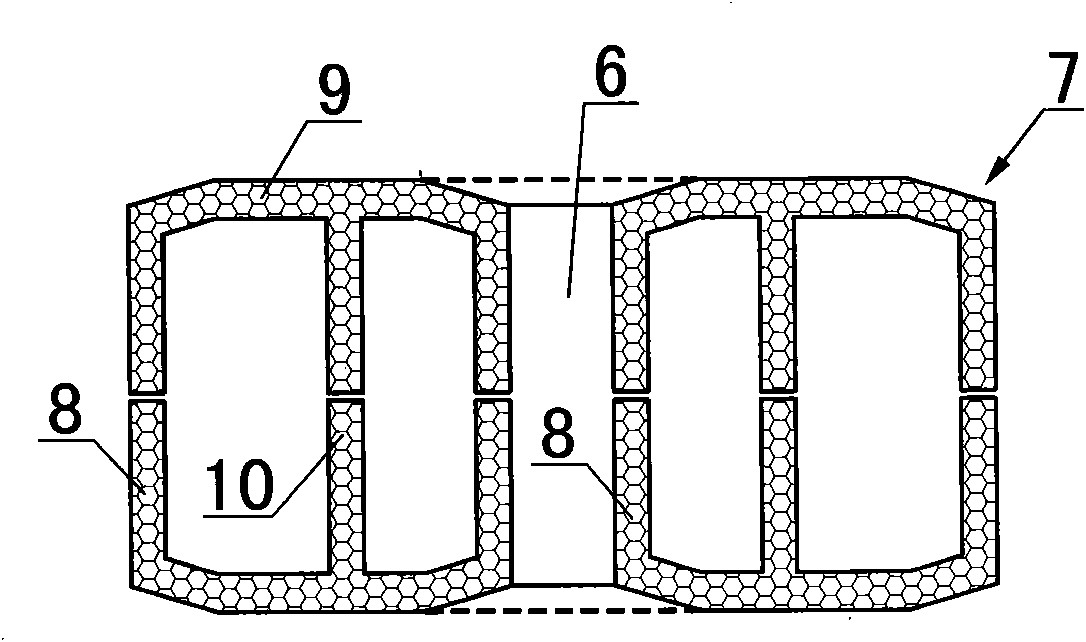

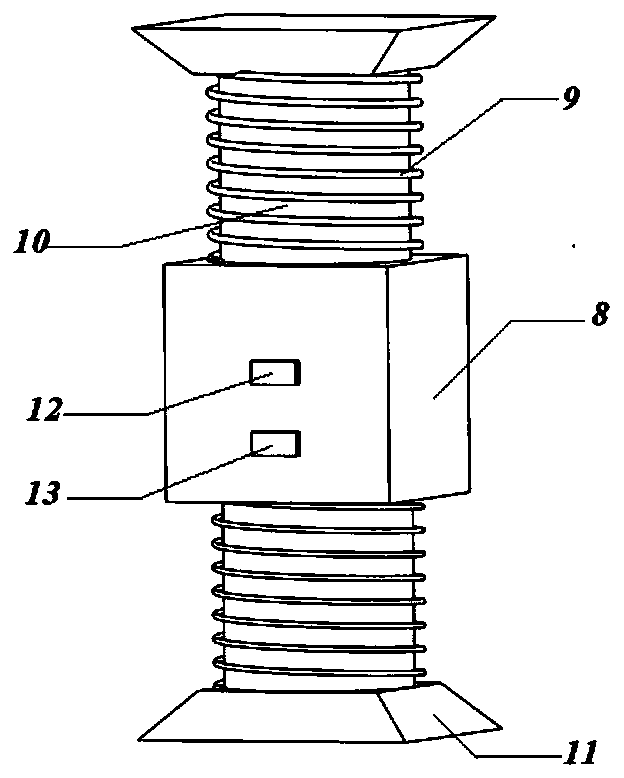

Series electromagnetic-elastic foil combined bearing

InactiveCN101799044AReduce voidsBig gapMagnetic bearingsSliding contact bearingsMagnetic bearingMagnetic poles

The invention discloses a series electromagnetic-elastic foil combined bearing integrated structure, which comprises a bearing base 17, wherein an electromagnetic bearing 1 is arranged in the bearing base 17; the electromagnetic bearing 1 is provided with a magnetic pole 6; the electromagnetic pole 6 is wound with a coil 7; the electromagnetic bearing 1 is axially provided with a left end cap 2 and a right end cap 3 which tightly press the electromagnetic pole 6; the left end cap 2 and the right end cap 3 are provided with grooves 12 along the circumferential direction; and a top elastic foil 13 and a bottom elastic foil 14 are arranged in the grooves 12. A rotor is suspended by the electromagnetic bearing 1, a lubricating gas film is arranged for supporting the rotor on the surfaces of the elastic foil 5 and a rotor shaft neck 4 when the rotor is accelerated to reach a takeoff speed, and when the electromagnetic bearing is in an idle state, the rotor can be independently supported by the elastic foil bearing 5. The series electromagnetic-elastic foil combined bearing structure has the characteristics of low power consumption, large bearing force, high precision and high stability.

Owner:XI AN JIAOTONG UNIV

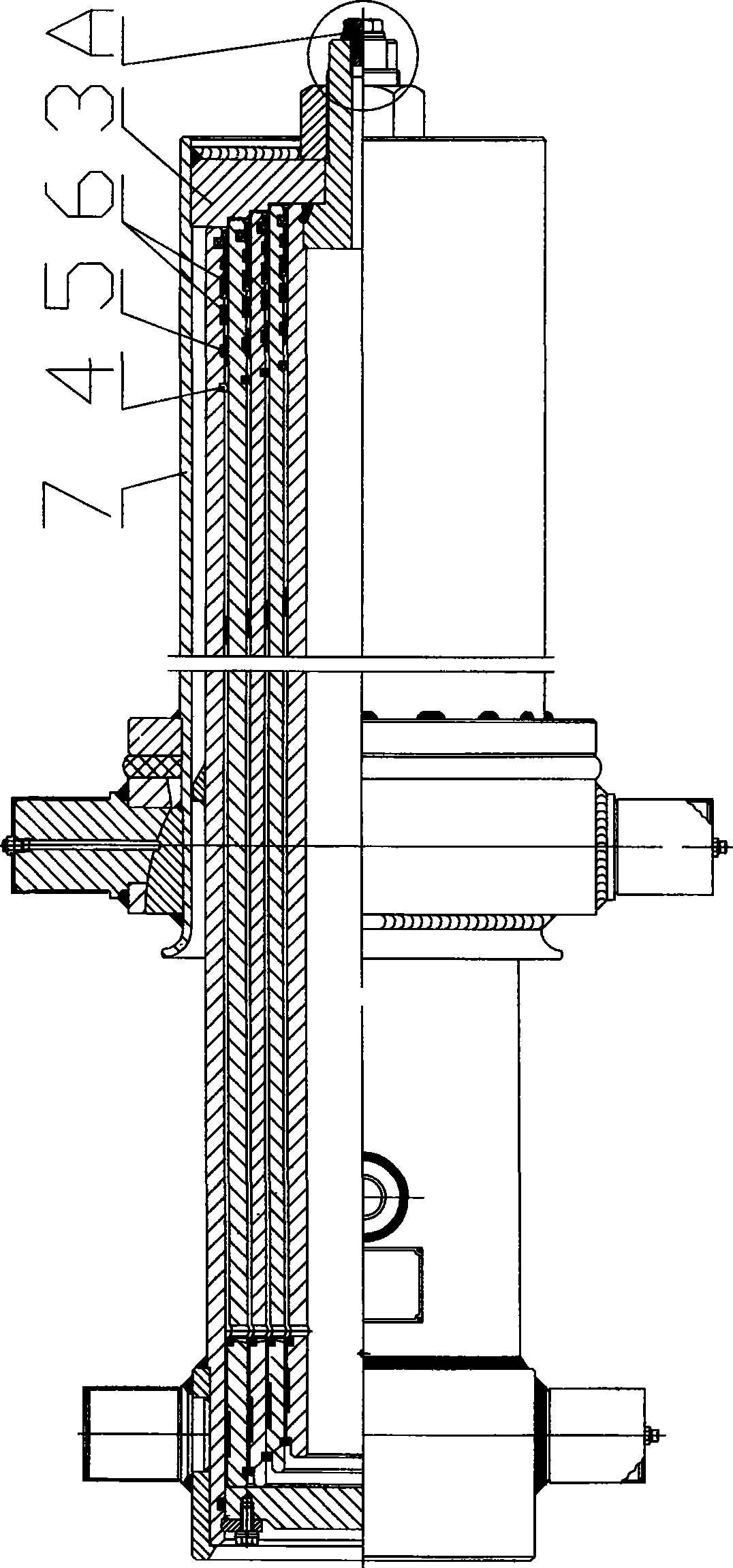

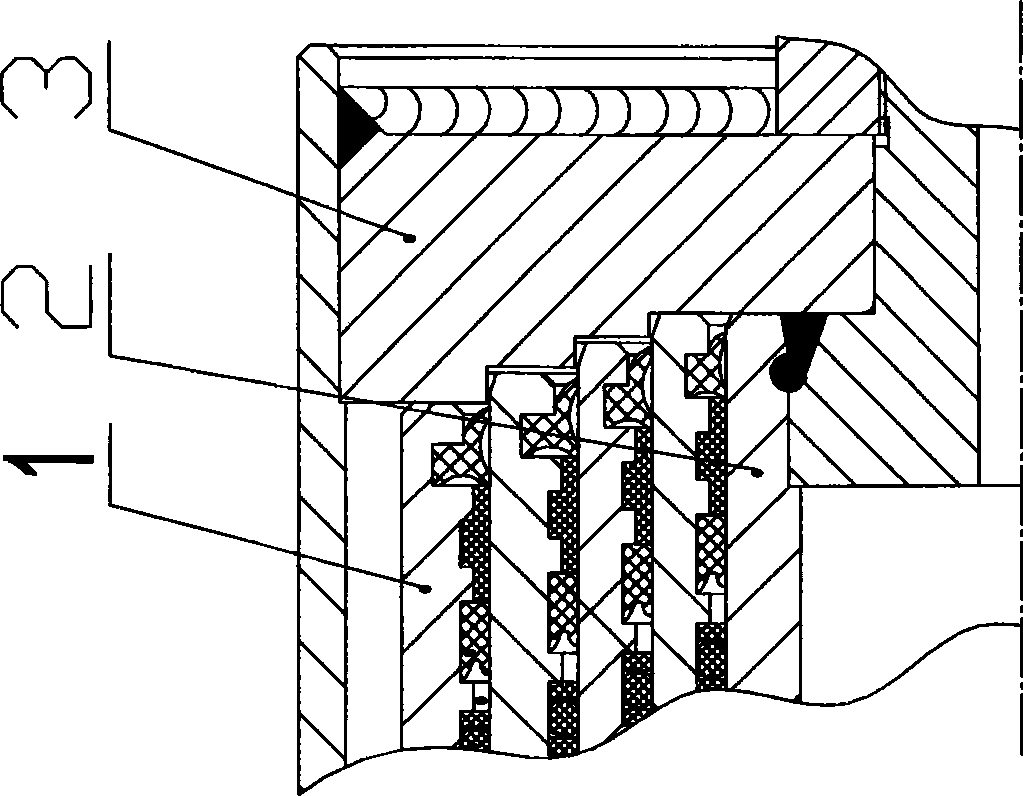

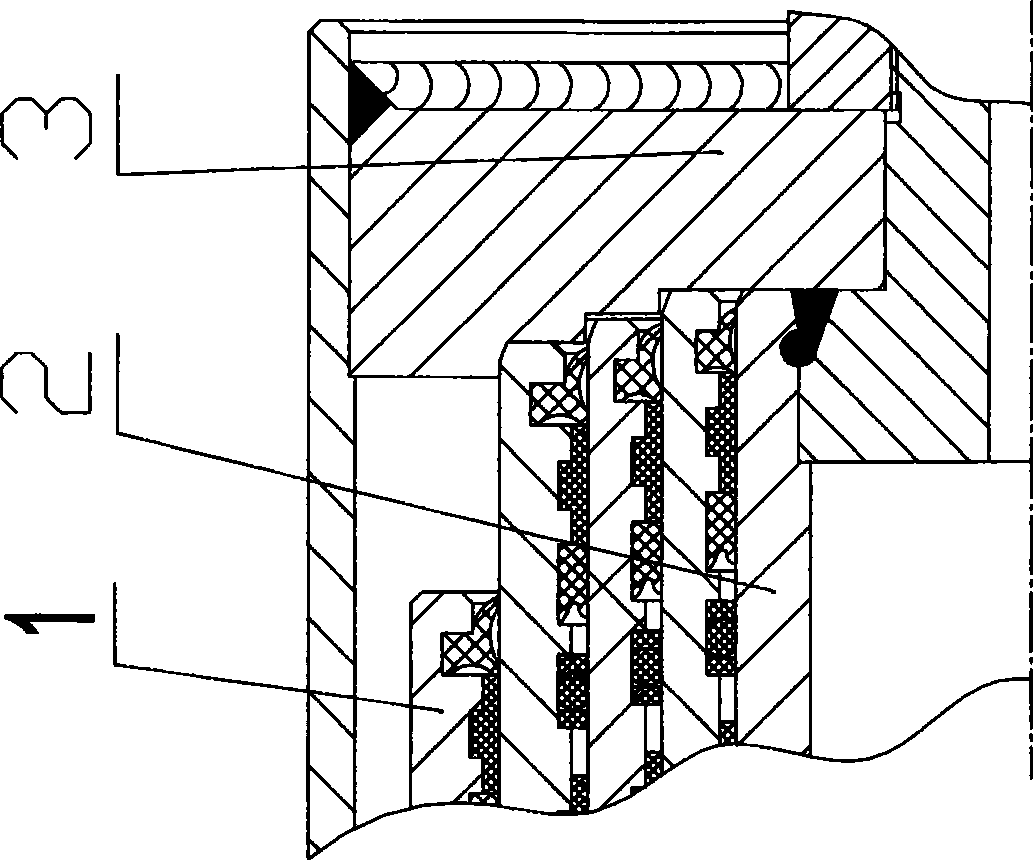

Improved single-action telescopic sleeve hydraulic cylinder

ActiveCN101532522AIncrease contact surfaceIncrease stiffnessFluid-pressure actuatorsHydraulic cylinderEngineering

The invention belongs to hydraulic cylinders, in particular to an improved single-action telescopic sleeve hydraulic cylinder. The improved single-action telescopic sleeve hydraulic cylinder comprises a multistage cylinder arranged in the cylinder body and matched by assembling, a lug arranged outside the top of the multistage cylinder and a spacing member, a guide member and a sealing member which are arranged among cylinders on each stage; a step-type ring-shaped convex edge adaptive to the end face outside the top of the multistage cylinder is arranged in a cavity of the lug; when the hydraulic cylinder is in a static state, end faces on the top of an outside cylinder and a final-stage cylinder are closely connected and fitted with the ring-shaped convex edge corresponding to the lug. The improved single-action telescopic sleeve hydraulic cylinder solves the problems of easily causing bending deflection of cylinders when the automobiles are overloaded or the traveling cranes incline in the process of lifting in the prior art, and the like and has the advantages of increasing rigidity of cylinders, solving the problem of leakage and overcoming creeping and random ignition, etc.

Owner:河北华春液压汽配有限公司

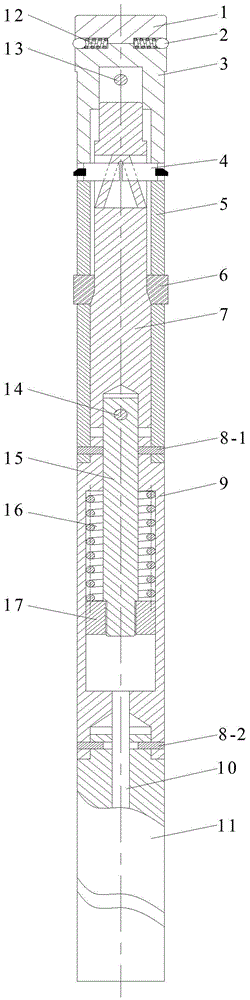

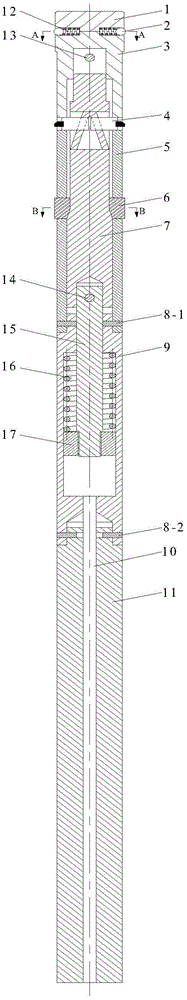

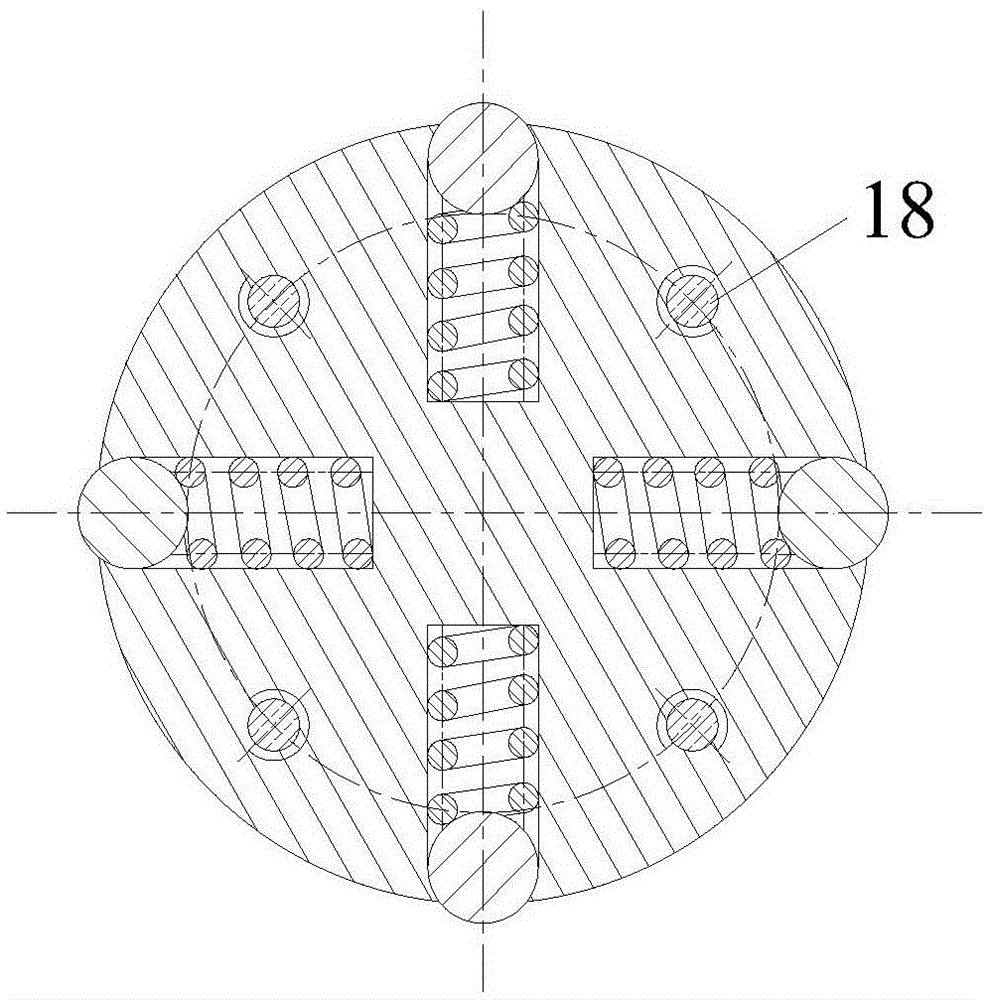

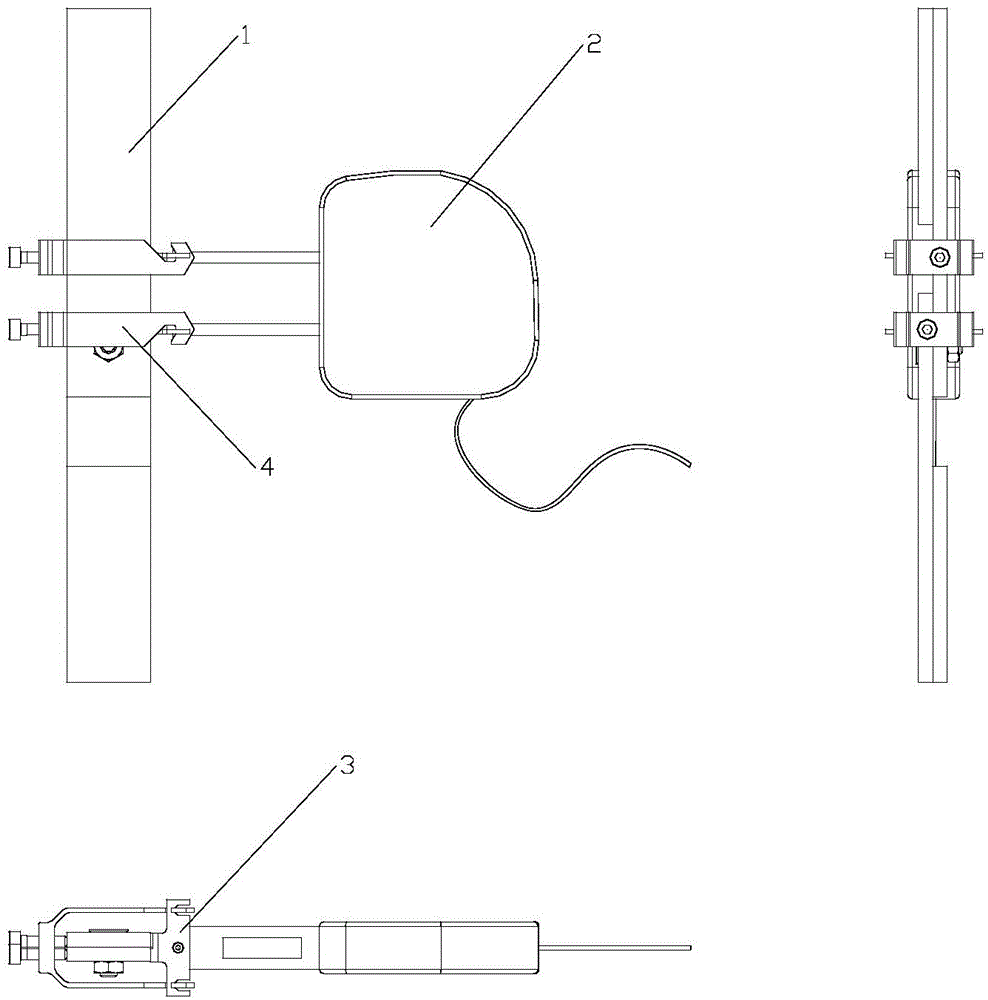

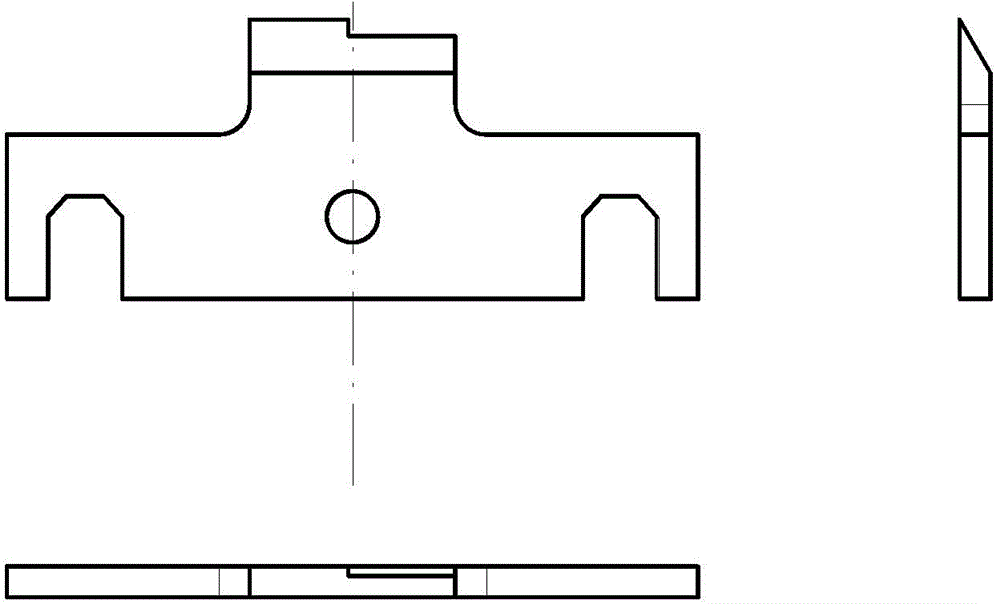

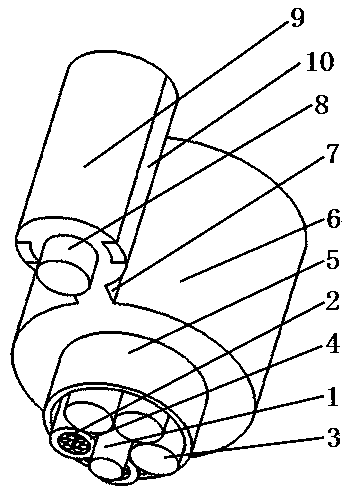

Boring bar special for machining deep hole and inner groove

InactiveCN105642929AIncrease stiffnessImprove local stiffnessBoring barsHydraulic cylinderTangential force

The invention discloses a segmented type boring bar with a guide support part and special for machining a deep and long hole and an inner groove. The boring bar comprises the guide support part, a tool bit part, a feeding and retracting mechanism, a rod body part and a hydraulic drive part. The guide support part comprises a guide head and an auxiliary support part. The guide head is divided into a front guide head body and a rear guide head body which are connected through a screw. The rear guide head body is connected with the front end of a sleeve through a pin, a hydraulic cylinder is connected with the rear end of the sleeve through a pin, and a cutter bar is connected with the bottom of the hydraulic cylinder through a pin. When the inner groove is bored, the guide support part has a supporting effect, and the local static rigidity of the tool bit part can be improved. By means of the feeding and retracting mechanism, the axial positioning and the feeding and retracting movement of the tool can be achieved. The segmented type special tool with the guide support part is suitable for machining the multi-layer inner groove and can also be used for boring the inner wall of the deep and long hole; a blade is symmetrically arranged, so radial force and tangential force counteract, the rigidity of the cutter bar is greatly improved, and machining conditions are remarkably improved.

Owner:NANJING UNIV OF SCI & TECH

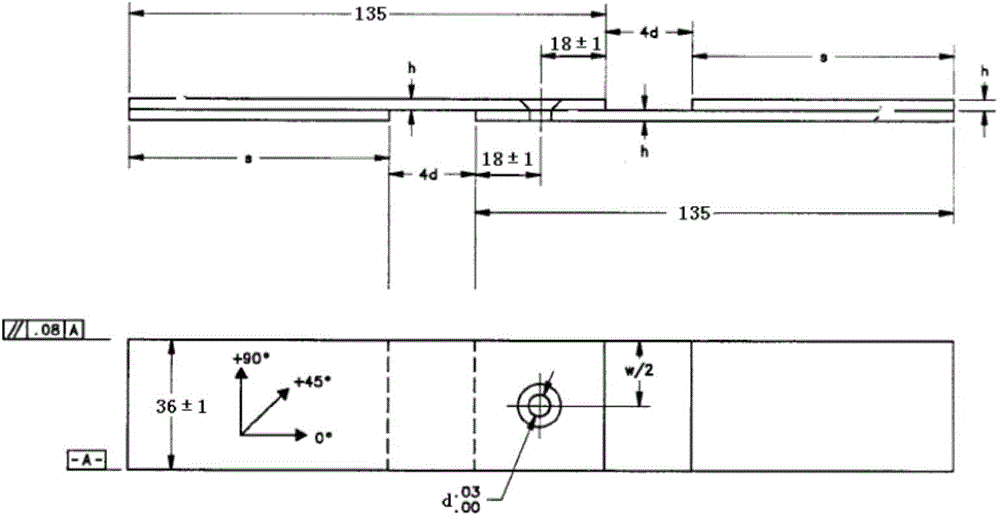

Device for measuring test hole compression deformation

ActiveCN105737790AThe installation process is simple and convenientImprove ergonomicsMaterial strength using tensile/compressive forcesEngineering

The invention belongs to the test technology of material performance test, in particular to a device for measuring the extrusion deformation of a mechanical connection test hole. The design of the connection part of the composite material structure is the key to the design of the aircraft structure, and the extrusion design value of the mechanical connection is based on the extrusion allowable value of the typical laminated single-nail-single-shear connection specimen. This is because the aircraft composite structure A single-lap mechanical connection is commonly used. The object of the present invention is to provide a device for measuring the extrusion deformation of a mechanical connection test hole. Compared with the existing measuring device, the device is easy to use, has high measurement accuracy, is safe and environmentally friendly, and can improve work efficiency.

Owner:CHINA AIRPLANT STRENGTH RES INST

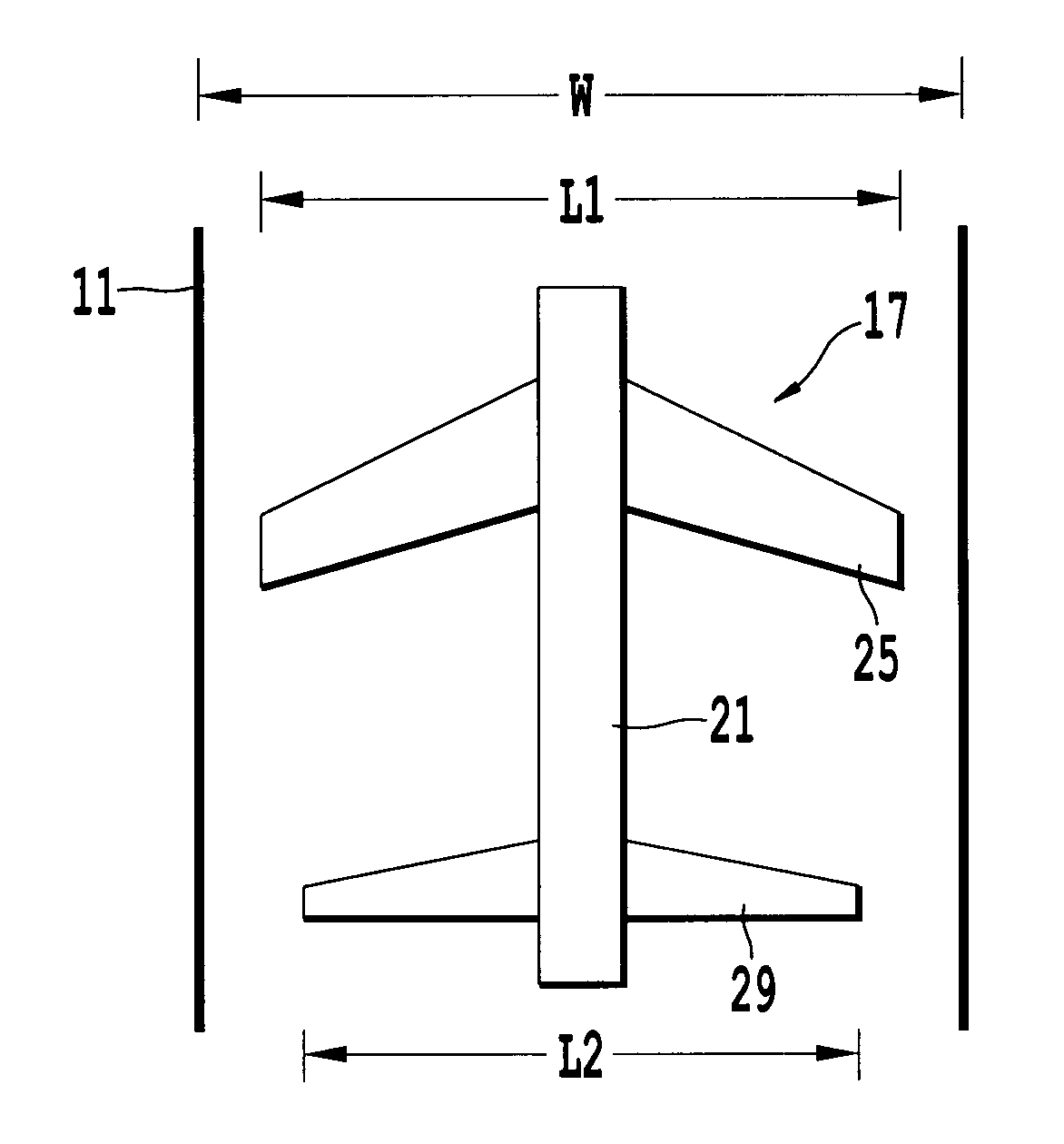

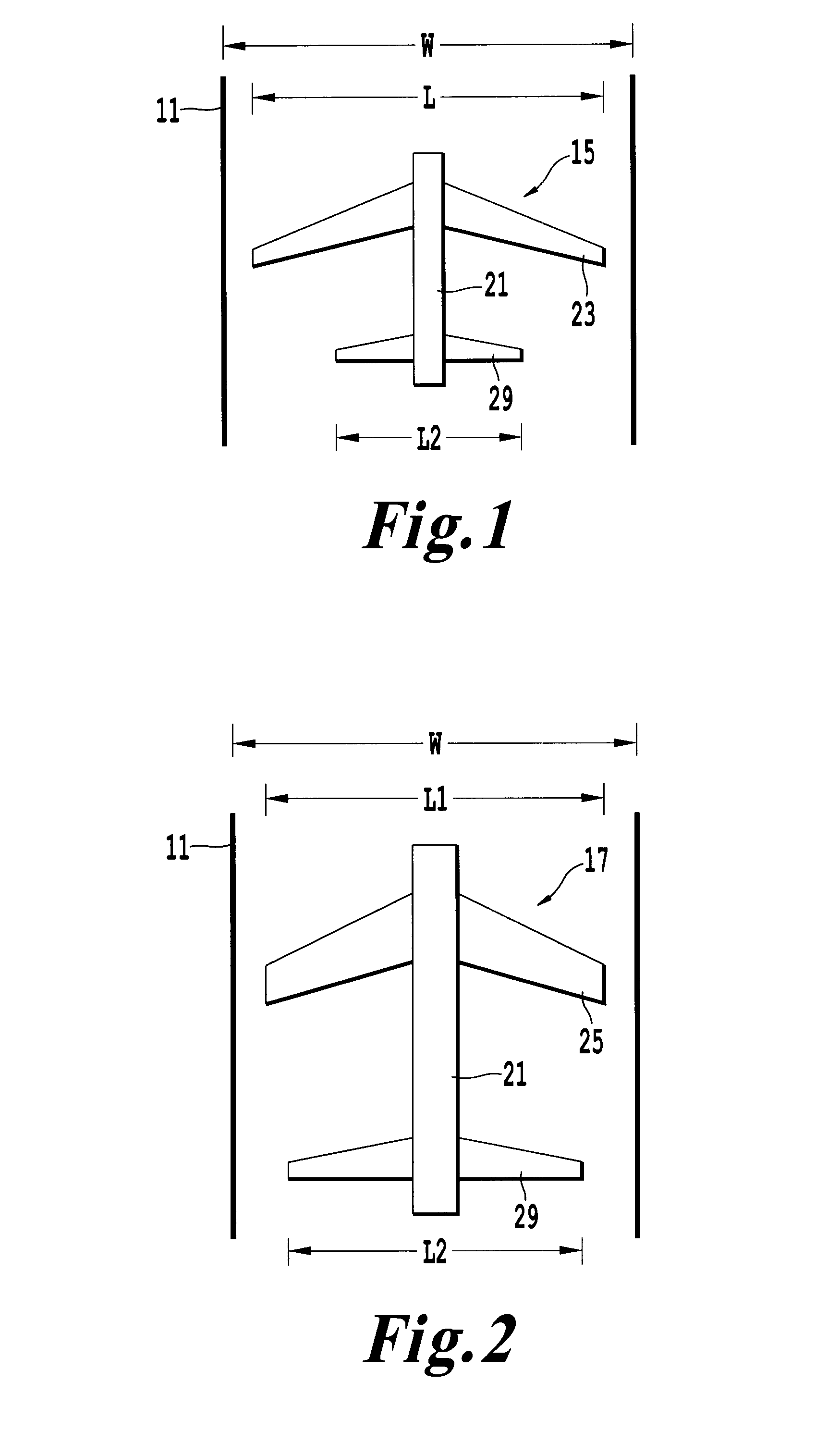

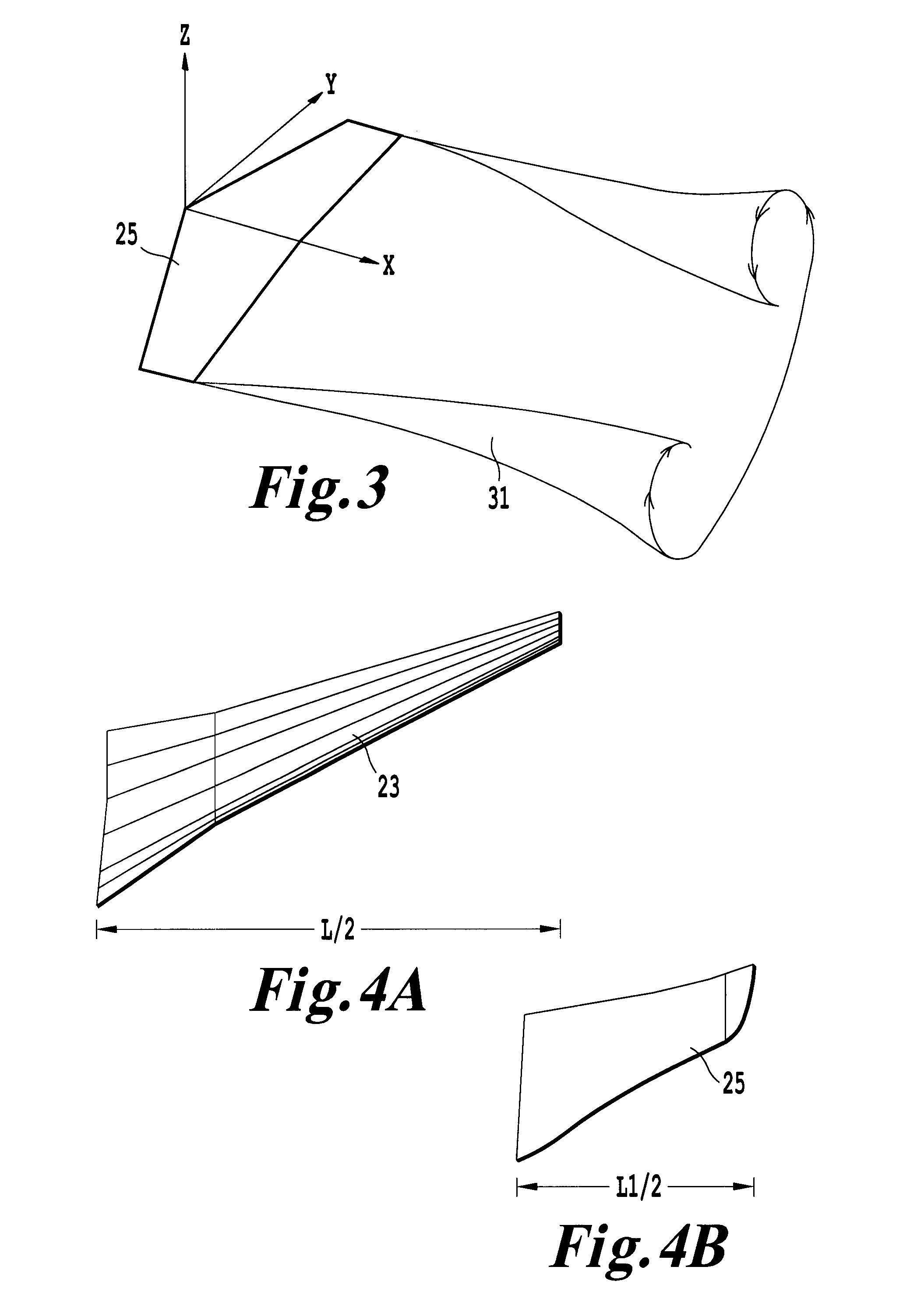

Wind tunnel aircraft model with truncated wing

InactiveUS20110106503A1Increase maximum scaleSmall spanAircraft stabilisationAerodynamic testingAirplaneTailplane

An aircraft model (17) for testing in a wind tunnel (11) of width W comprising a fuselage (21), a truncated wing (25) whose length L1 is lesser than the length L of a full scaled wing (23) and additional components in the rear aircraft as, in particular, an horizontal tail plane (29), that produces the same downwash arriving to said additional components than in a full scaled model. The shape of said truncated wing (25) may be designed for having a similar lift distribution (35) to the lift distribution (37) of a full scaled wing (23) along at least the maximum length L2 in the Y-axis of any component in the rear aircraft. The invention also relates to a method for designing said truncated wing (25).

Owner:AIRBUS OPERATIONS SL

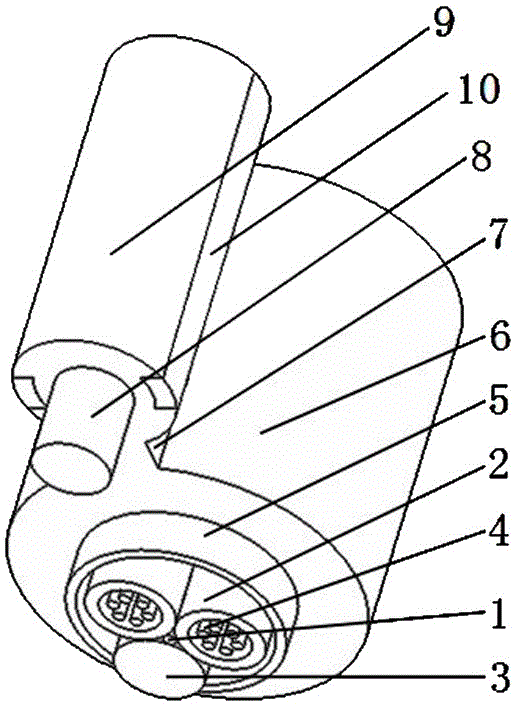

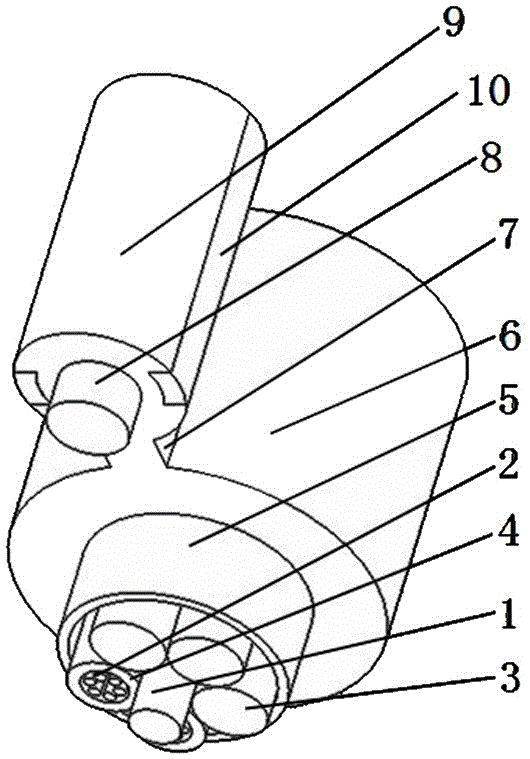

Self-supporting optical cable with marking strips

ActiveCN103777295ALight weightIncrease weightFibre mechanical structuresStructural engineeringProtection layer

The invention relates to the technical field of cables, in particular to a self-supporting optical cable with marking strips. The self-supporting optical cable with the marking strips is formed by a cable core, an outer protecting sleeve wrapping the cable core, a strengthening element, a suspension wire protecting layer wrapping the strengthening element and a rib enabling the suspension wire protecting layer and the outer protecting sleeve to be connected. The cable core is formed by a central strengthening piece located in the center, a plurality of loose sleeve pipes located outside the central strengthening piece and a protecting layer. Optical fibers are arranged in the loose sleeve pipes. The self-supporting optical cable with the marking strips is characterized in that the strengthening element is made of a steel wire or glass fiber strengthening plastic, the two marking strips are symmetrically arranged on the suspension wire protecting layer, and the suspension wire protecting layer, the outer protecting sleeve and the rib are formed integrally and are made of identical materials. The invention further discloses the components and proportions of the marking strips. The self-supporting optical cable with the marking strips has the advantages that the thickness of the suspension wire protecting layer is more convenient to control, more smooth and round, products can be produced faster and are higher in qualified rate, the optical fibers are lower in self-weight and longer in adaptive span, and the color of the marking strips is more stable.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD +1

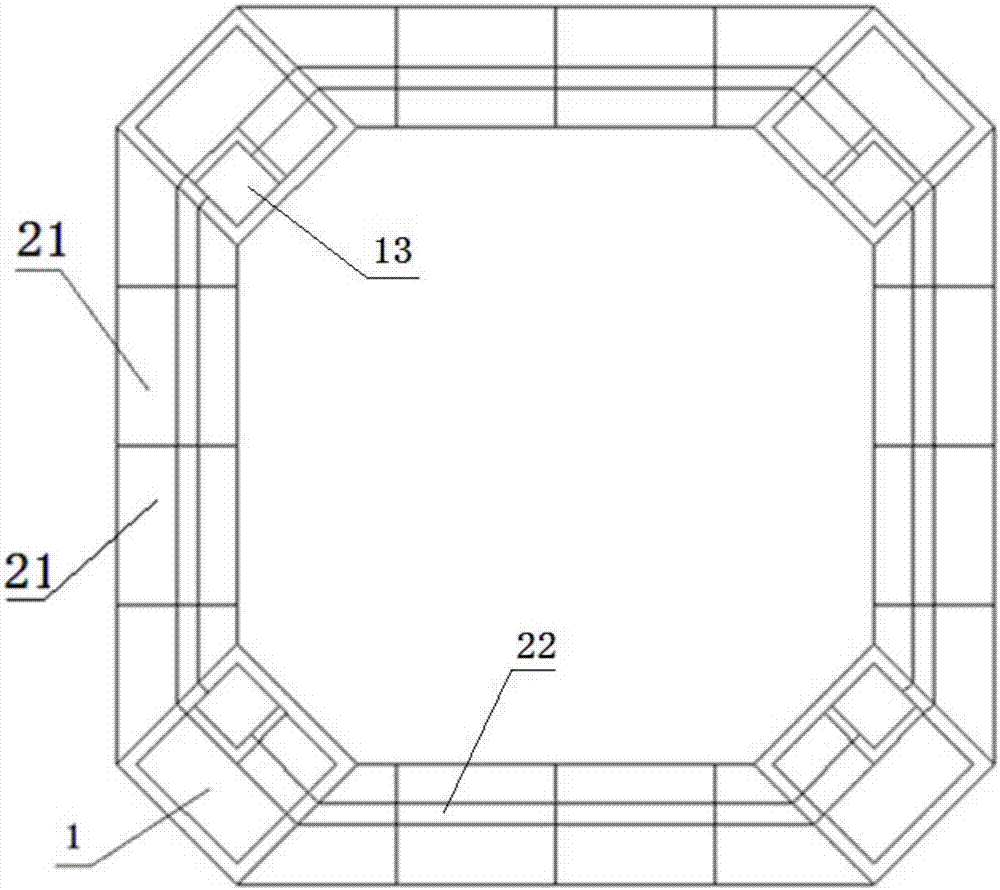

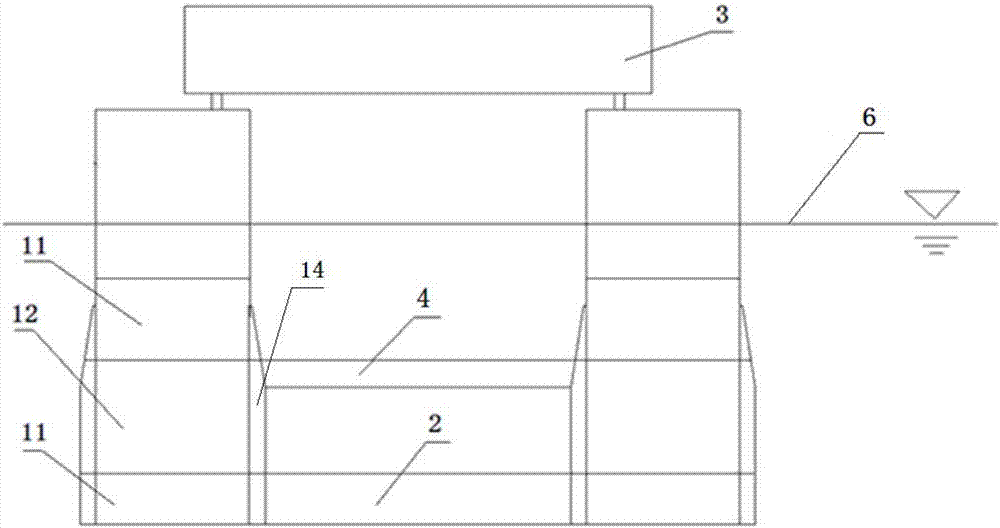

Deep draft dry-tree oil storage semisubmersible production platform

ActiveCN107140138ASmall range of motionSmall heave amplitudeFloating buildingsBallast tankBuoyancy function

The invention discloses a deep draft dry-tree oil storage semisubmersible production platform characterized by comprising columns, buoyancy tanks, and a topside module; the four buoyancy tanks are arranged on the bottom periphery of the semisubmersible production platform; the break angle between two adjacent buoyancy tanks is provided with the column; the top surfaces of the four columns support and are connected with the topside module; an oil tank is arranged in each column; a first ballast tank is respectively arranged on and below the oil tank in each column; the top of each column is provided with an equipment chamber; a void chamber is formed between the first ballast tank on the oil tank and the equipment chamber; a second ballast tank is arranged in each the buoyancy tank. The semisubmersible production platform uses the first ballast tanks to balance the oil tank crude oil amount changes, uses the second ballast tanks to ensure the whole production platform to have the draft depth at 50-60m, thus ensuring the whole platform to keep small moving amplitude and small heaving amplitude, satisfying SCR and dry-tree oil extraction requirements, and reducing engineering investments.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Inclined upright truss type semi-submersible oil production platform

InactiveCN105083485AIncrease heave cycleIncrease restoring torqueFloating buildingsMarine engineeringWhole body

The invention provides an inclined upright truss type semi-submersible oil production platform, which is used for offshore oil production. The platform is characterized by comprising a platform deck, at least three inclined uprights, an annual floating tank, a space truss structure and at least one heaving board. The platform deck is arranged above the waterline plane horizontally; the at least three inclined uprights are uniformly distributed below the platform deck, and are inclined towards the normal axis of the geometric center of the platform deck, the upper ends of the inclined uprights are fixedly connected to the platform deck and the lower ends of the inclined uprights extend to a position below the waterline plane; the annual floating tank is arranged below the waterline plane and fixedly connected to the lower ends of the inclined uprights; the upper ends of the space truss structure is fixedly connected with the annual floating tank to form a whole body; the at least one heaving board is horizontally arranged in the space truss structure.

Owner:SHANGHAI OCEAN UNIV

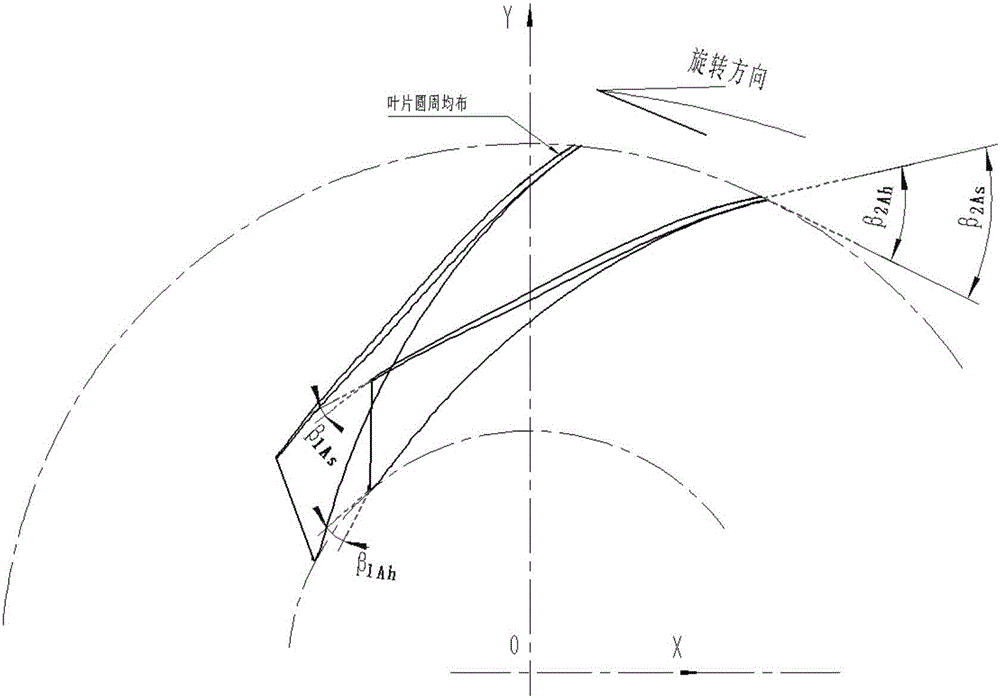

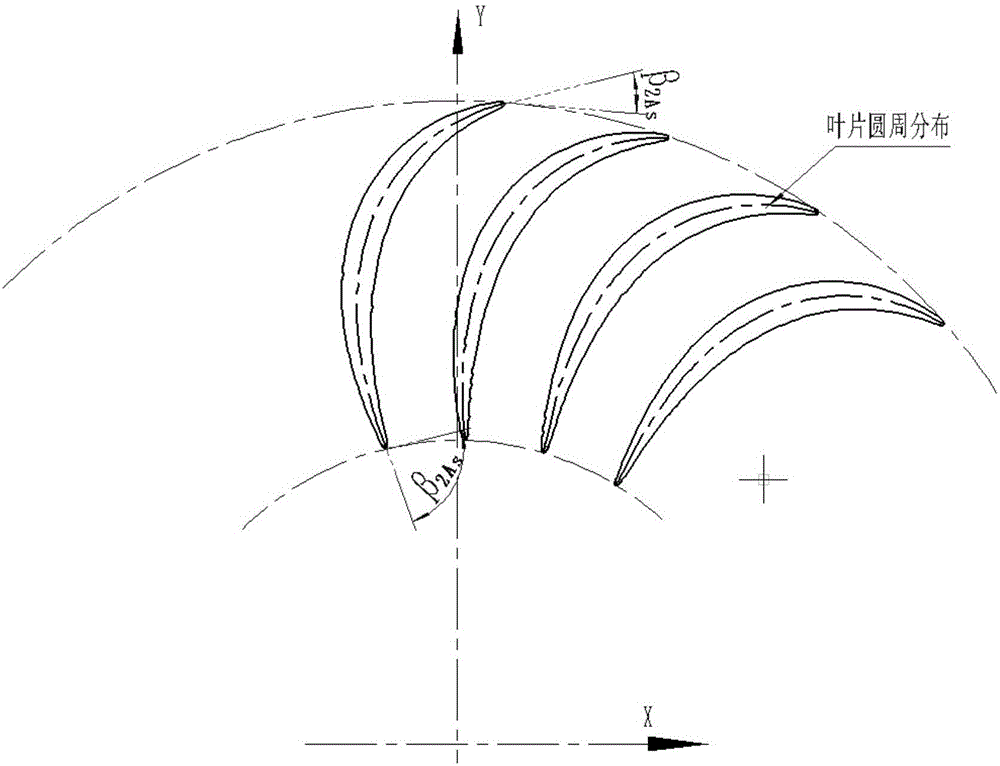

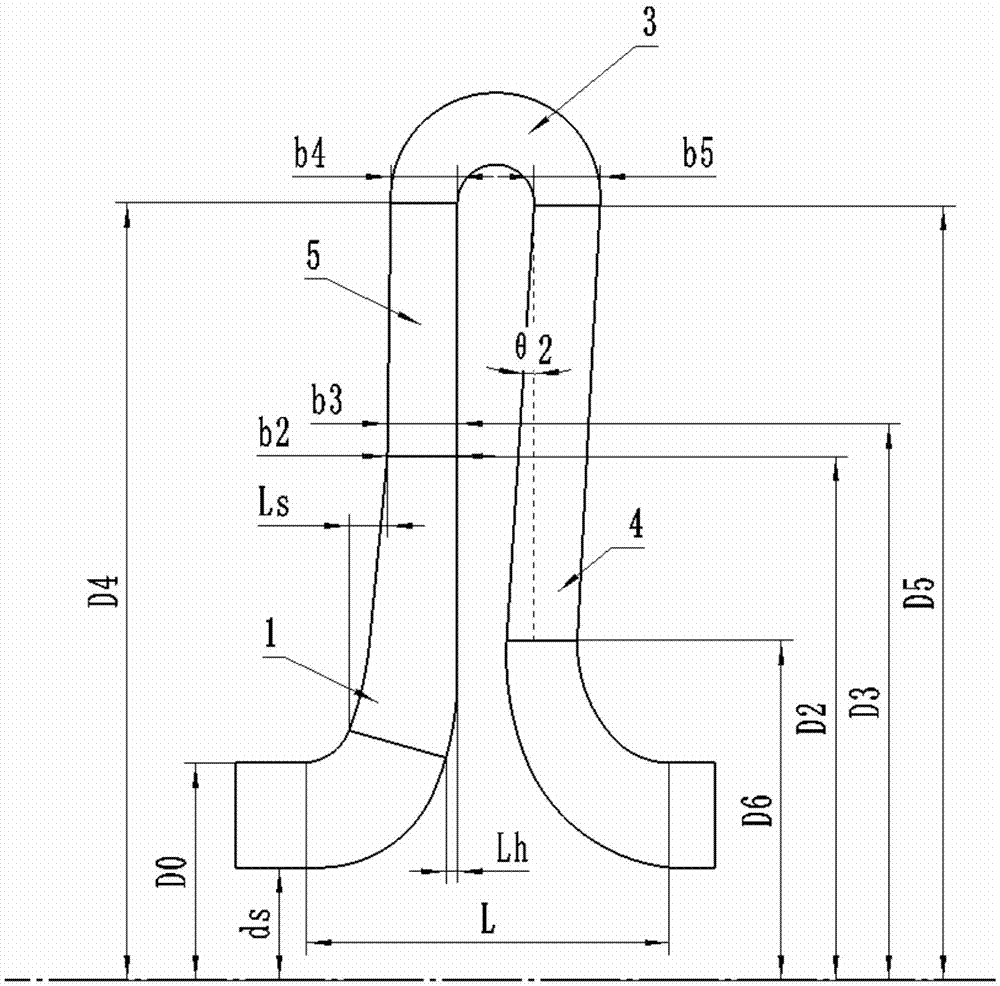

Pipeline compressor model stage with flow coefficient of 0.0495 and impeller design method

InactiveCN106762811AHigh head coefficientWheel hub ratioPump componentsDesign optimisation/simulationImpellerEngineering

Owner:SHENYANG TURBO MASCH CORP +1

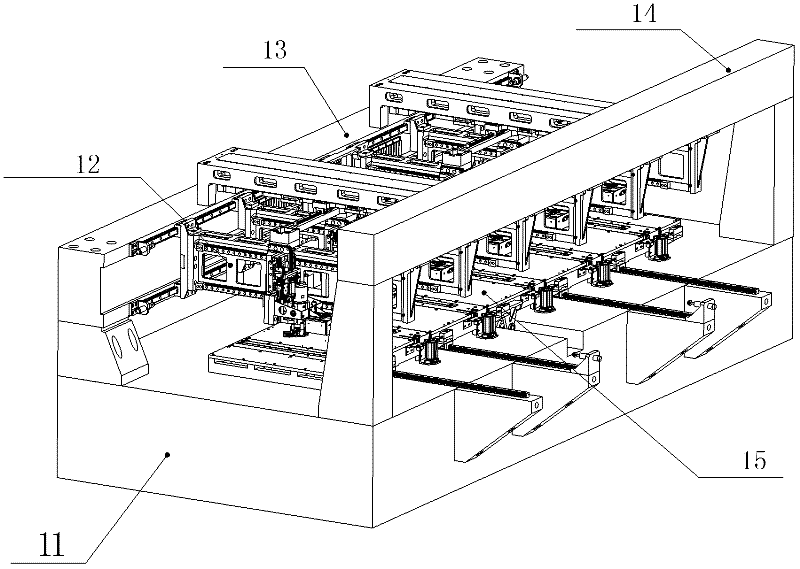

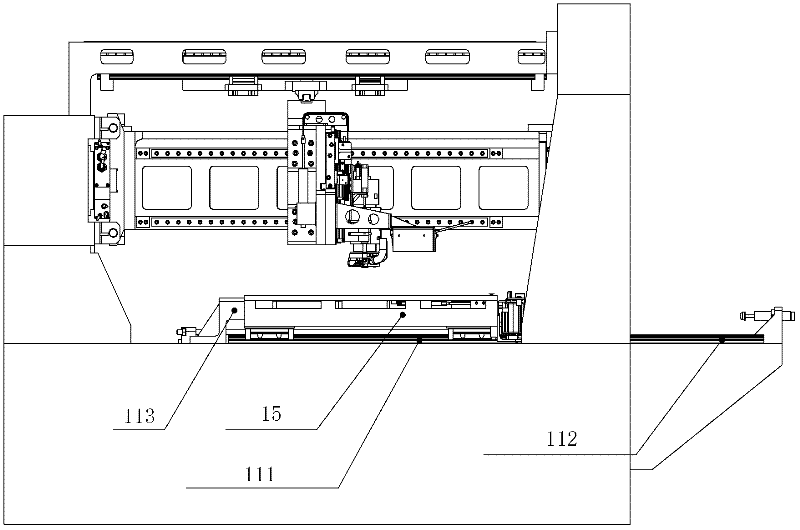

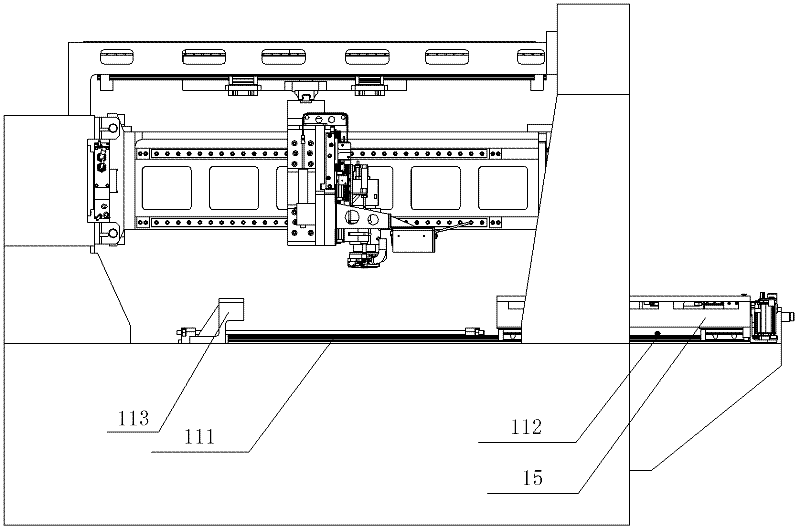

Multi-shaft cascaded mechanical drilling machine

ActiveCN102513574ASmall spanReduce distortionLarge fixed membersBoring/drilling componentsEngineeringDrilling machines

The invention relates to a multi-shaft cascaded mechanical drilling machine, comprising a machine body. A main beam and an auxiliary beam are mutually parallel and fixedly arranged on the machine body. At least three connection supporting points are arranged between the main beam and the machine body. An operating platform is further fixedly arranged on the machine body and is provided with a working component for assembling a circuit board. A three-coordinate axis movement component for driving the working component to move in an X direction, a Y direction and a Z direction is hung between the main beam and the auxiliary beam. The three-coordinate axis movement component comprises a working shaft group, an X coordinate driving component and a Y coordinate driving component, wherein the working shaft group consists of a plurality of working shafts and is used for driving the working component; the X coordinate driving component is used for controlling the working shaft group movement in the X direction; and the Y coordinate driving component is used for controlling the working shaft group movement in the Y direction. Each working shaft in the working shaft group is respectively provided with a Z coordinate driving device for driving the working component movement in the Z direction. The X coordinate driving component, the Y coordinate driving component and the working shaft group are connected in a framework manner.

Owner:HANS CNC SCI & TECH

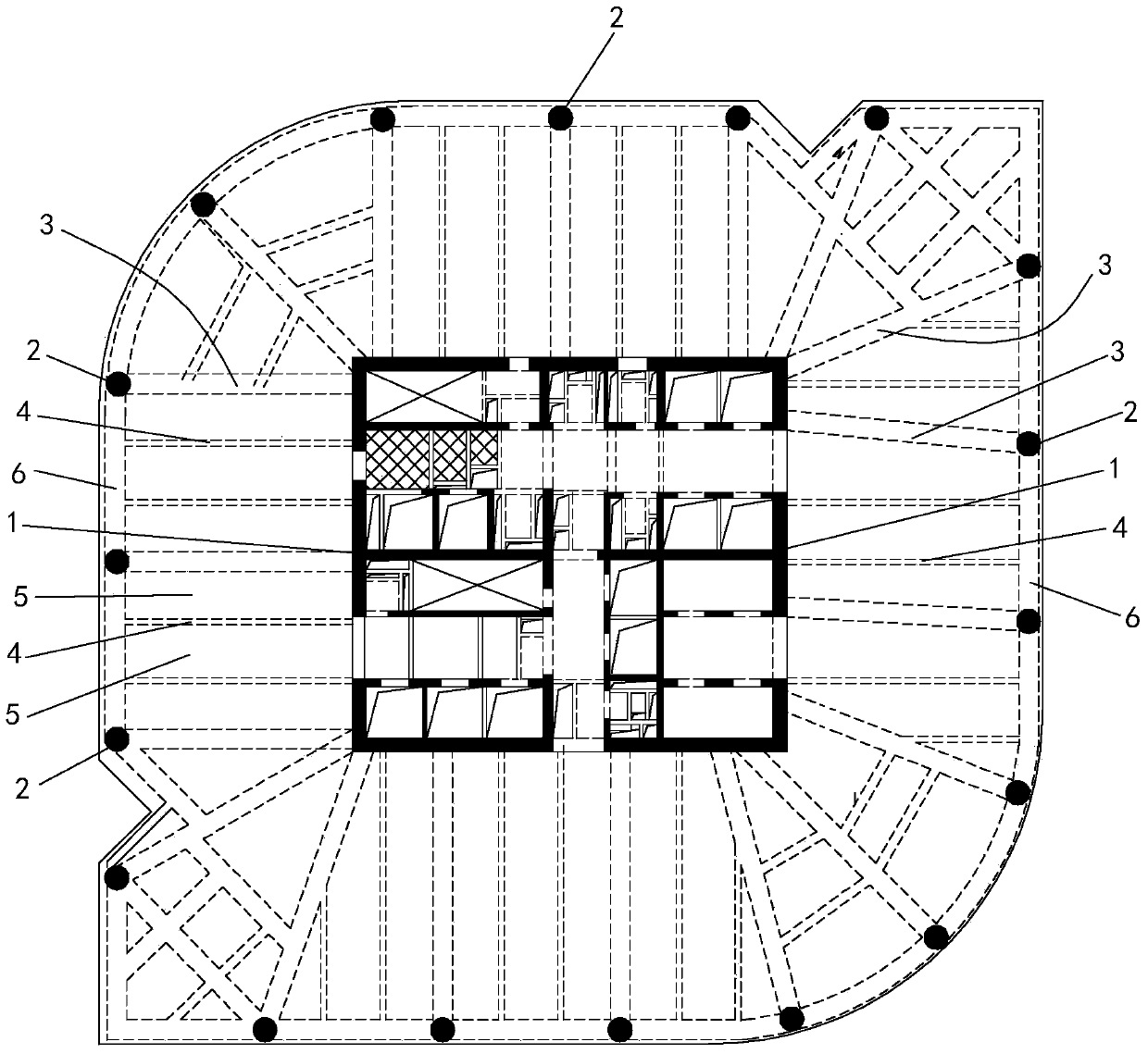

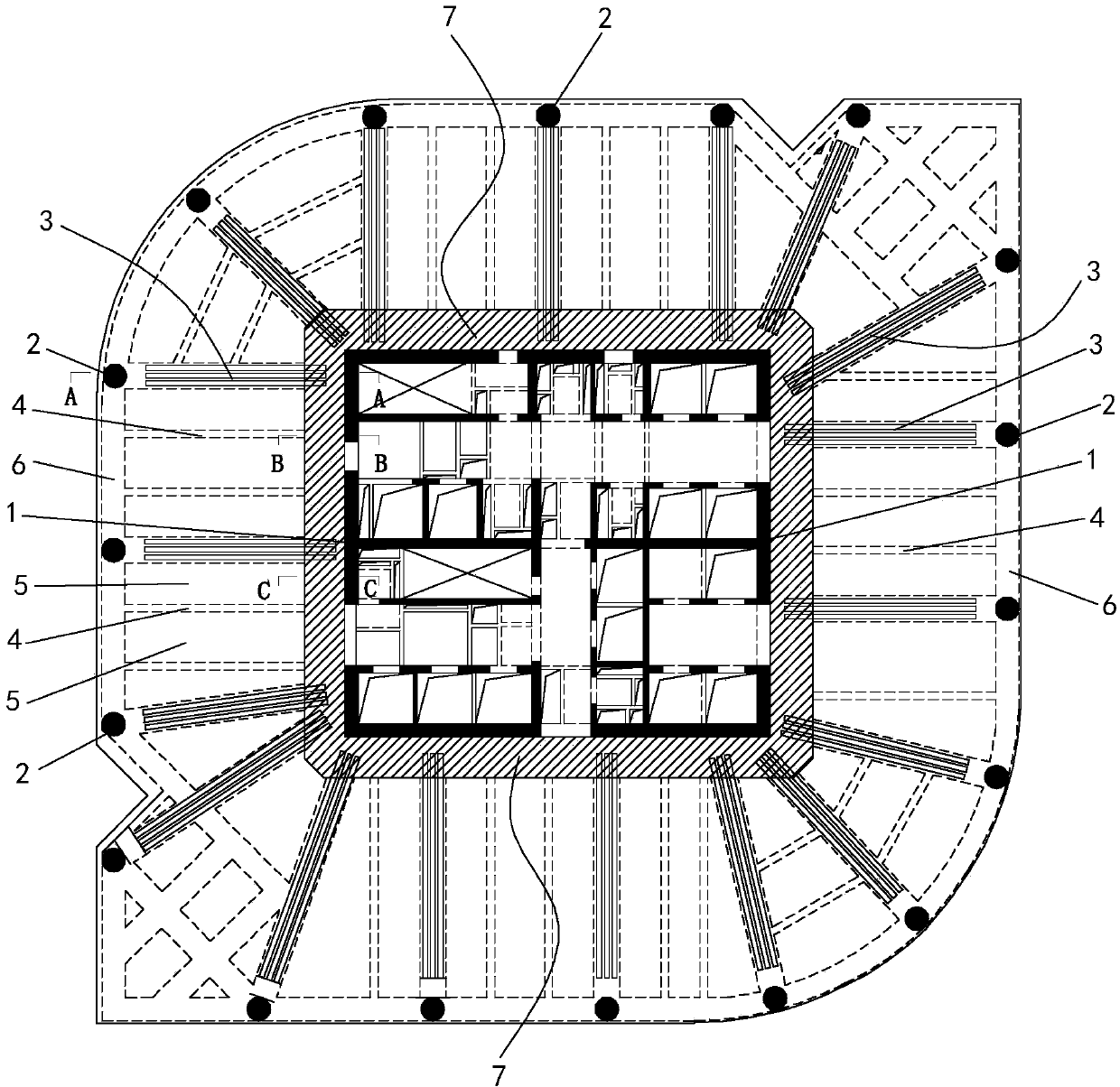

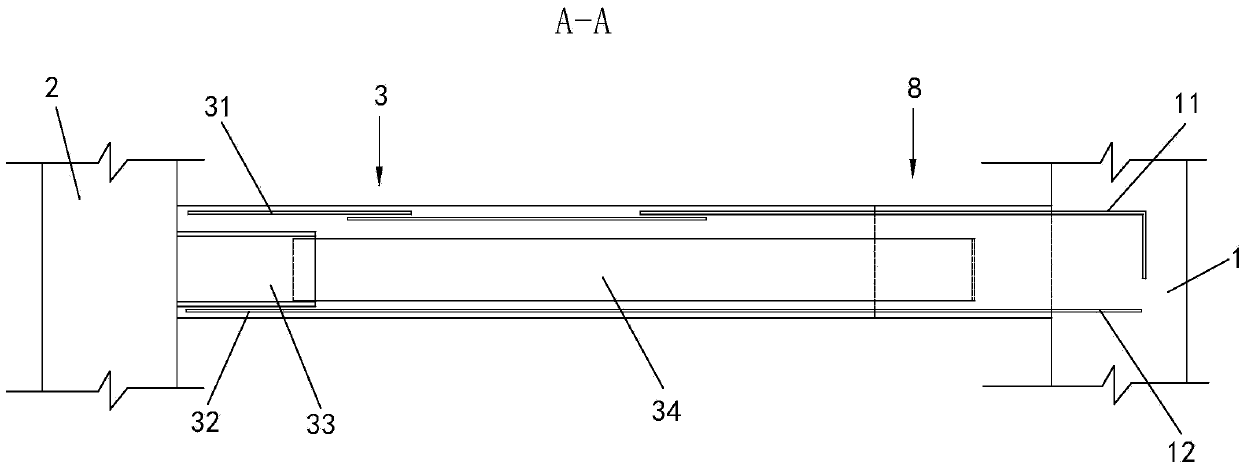

Overhanging wall cap building structure system for shear wall barrel of high-rise building

The invention discloses an overhanging wall cap building structure system for a shear wall barrel of a high-rise building. The building structure system consists of the shear wall barrel, frame beams, secondary beams, frame columns, outer-circle frame beams, floor slabs and wall caps, wherein the shear wall barrel is positioned at the central position of the high-rise building; the frame columns are positioned on the periphery of the shear wall barrel; the two ends of the frame beams are erected on the frame columns and the shear wall barrel respectively; the secondary beams are erected on the outer-circle frame beams and the shear wall barrel respectively; each wall cap is a closed annular cap edge-shaped structural body which is arranged on the outer wall of the corresponding layer of the shear wall barrel in an enclosing way and outwards and horizontally extends along the radial direction of the shear wall barrel; inner-end reinforcement bars of the wall caps are arranged in the shear wall barrel, and are connected and cast integrally with reinforcement bars of the shear wall barrel; the outer ends of the wall caps are shaped like cantilevers, and are fixedly connected with the corresponding frame beams or the corresponding secondary beams or the corresponding floor slabs. According to the building structure system, under the conditions of large beam span and limited sectional heights, the rigidity and the bearing capacity of the beams can be effectively improved, and the rigidity of a shear wall can be improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

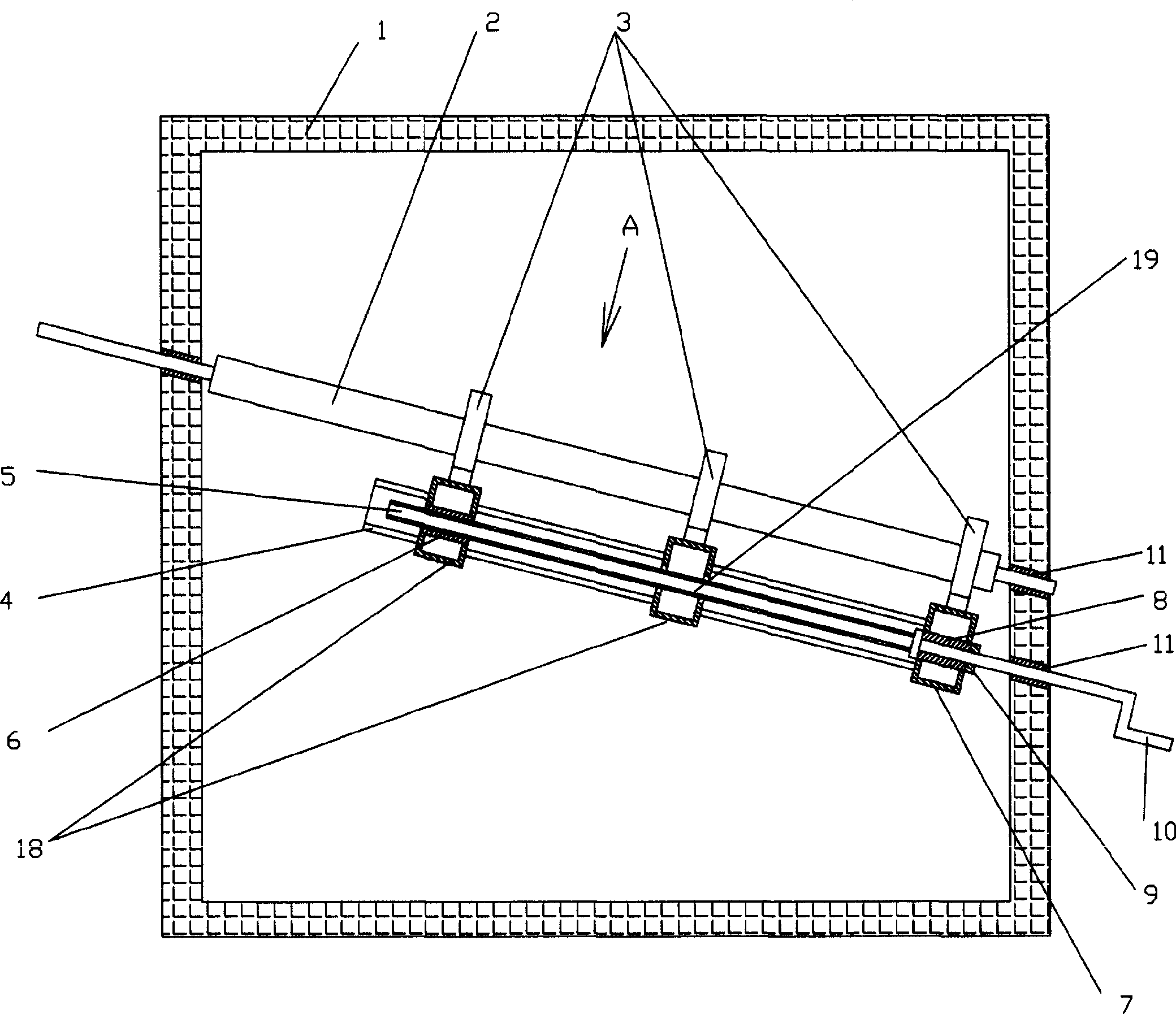

Energy-saving method and device of lengthwise graphitization furnace

InactiveCN105841500AReduce power consumptionSpeed up coolingEnergy inputWaste heat treatmentSmall footprintThermal energy

The invention discloses an energy-saving method and device of a lengthwise graphitization furnace. According to the method, air is used as a carrier, normal temperature air is blown into air channels through an air blower and is heated after passing through the air channels to take away a large amount of heat energy generated after the graphitization process is finished, thereby cooling materials which is already subjected to the graphitization process; and heated air which carries a large amount of heat energy is fed into furnace pit air channels of new materials needing to be graphitized and preheats the low-temperature materials needing to be heated, and power consumption needed by powering on and temperature rise of the low-temperature materials is reduced. By means of the device implementing the energy-saving method, waste heat energy is reused for the technological process, the cooling speed of the high-temperature materials is increased, therefore, the number of constructed furnace pits is reduced, and the initial temperature of the new materials can be rapidly raised. The energy-saving method and device of the lengthwise graphitization furnace have the advantages that the structure is simple; heating power consumption is reduced; the floor space is small; the equipment and civil engineering investment is reduced; cooling of the high-temperature materials and reutilization of heat of the lengthwise graphitization furnace are achieved; and energy is saved, and the production efficiency is improved.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

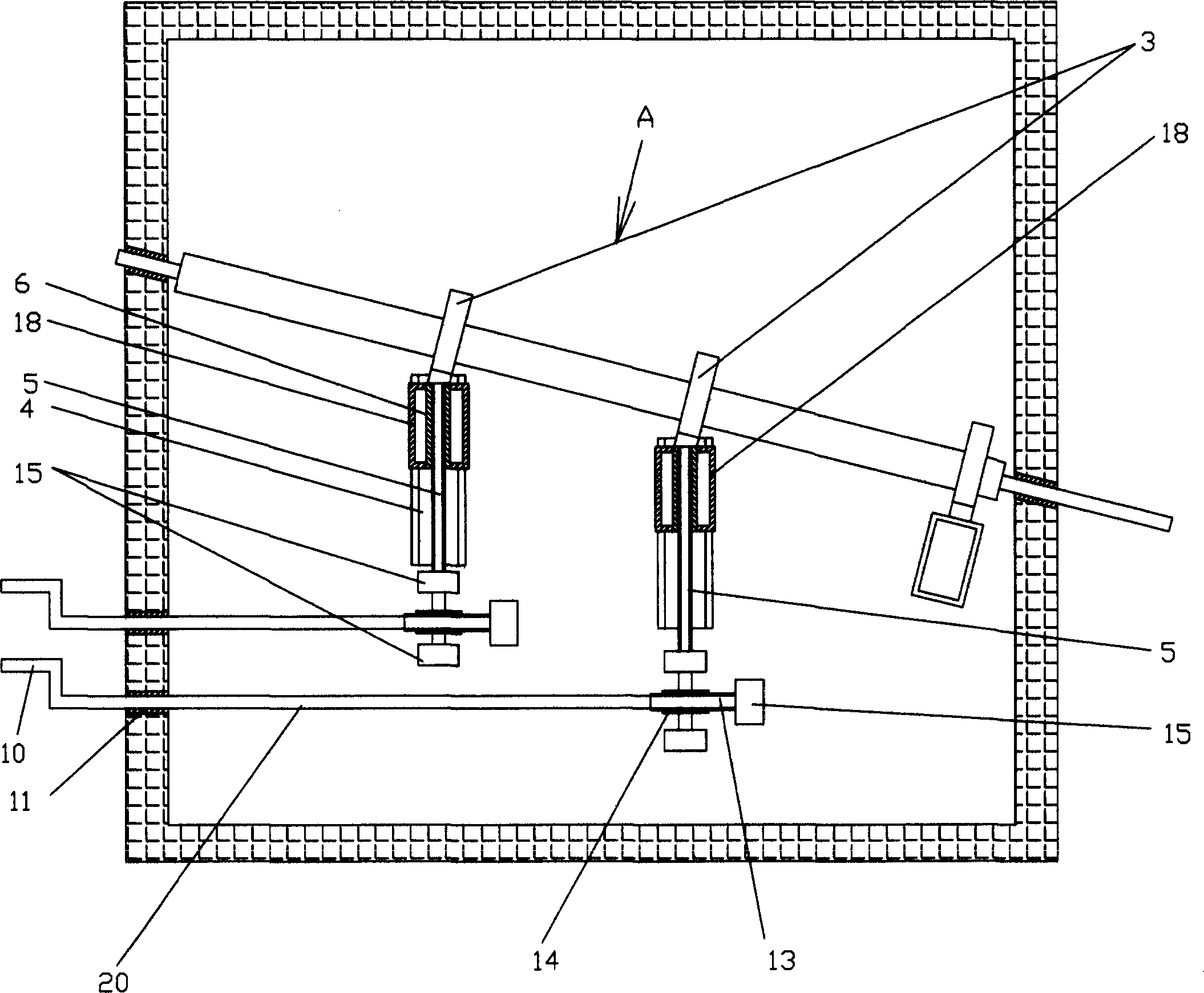

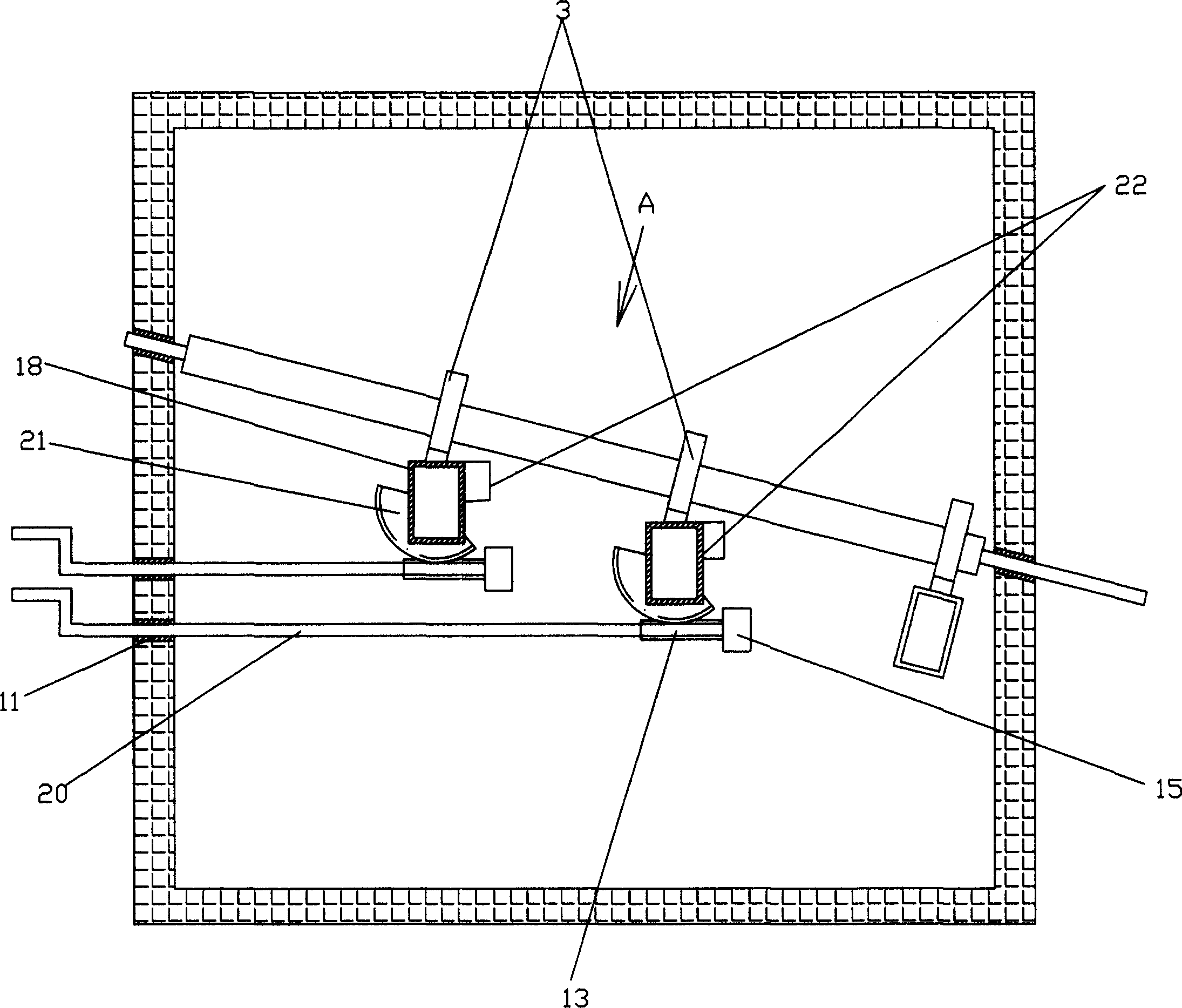

Inclined roller glass toughening furnace

The glass toughening furnace includes furnace body with intake door and discharge door, and ceramic roller ways supported via bearings on the furnace body. All the ceramic roller ways, the intake door and the discharge door are set obliquely. One group of supporting shafts are set in the lower end of the ceramic roller ways, each of the supporting shafts is set between two ceramic roller ways, the axes of the supporting shafts are perpendicular to the ceramic roller way plane. Each of the supporting shafts is provided with supporting guide sleeve. The present invention has small roller way diameter, low cost, long service life and high work efficiency.

Owner:江松伟

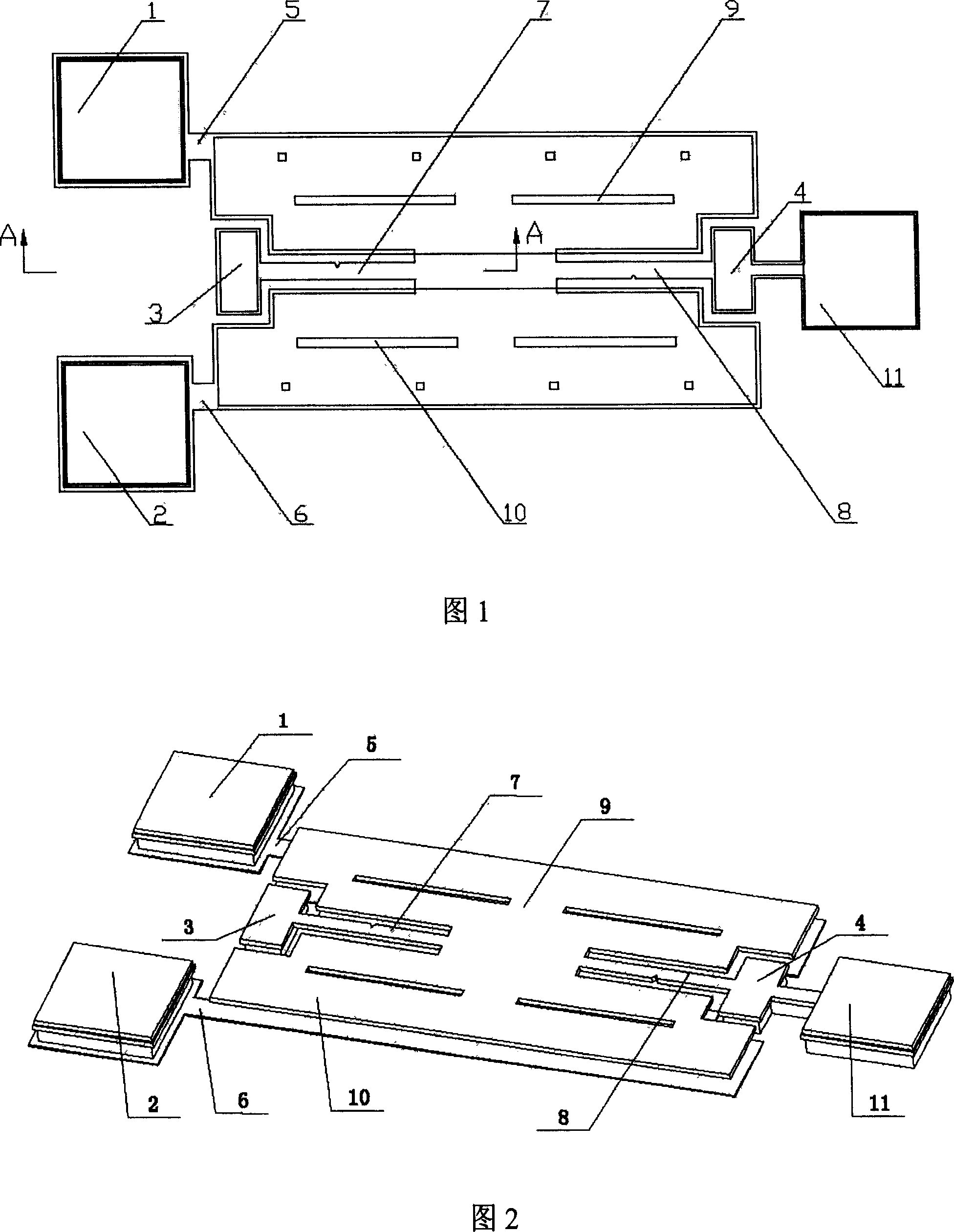

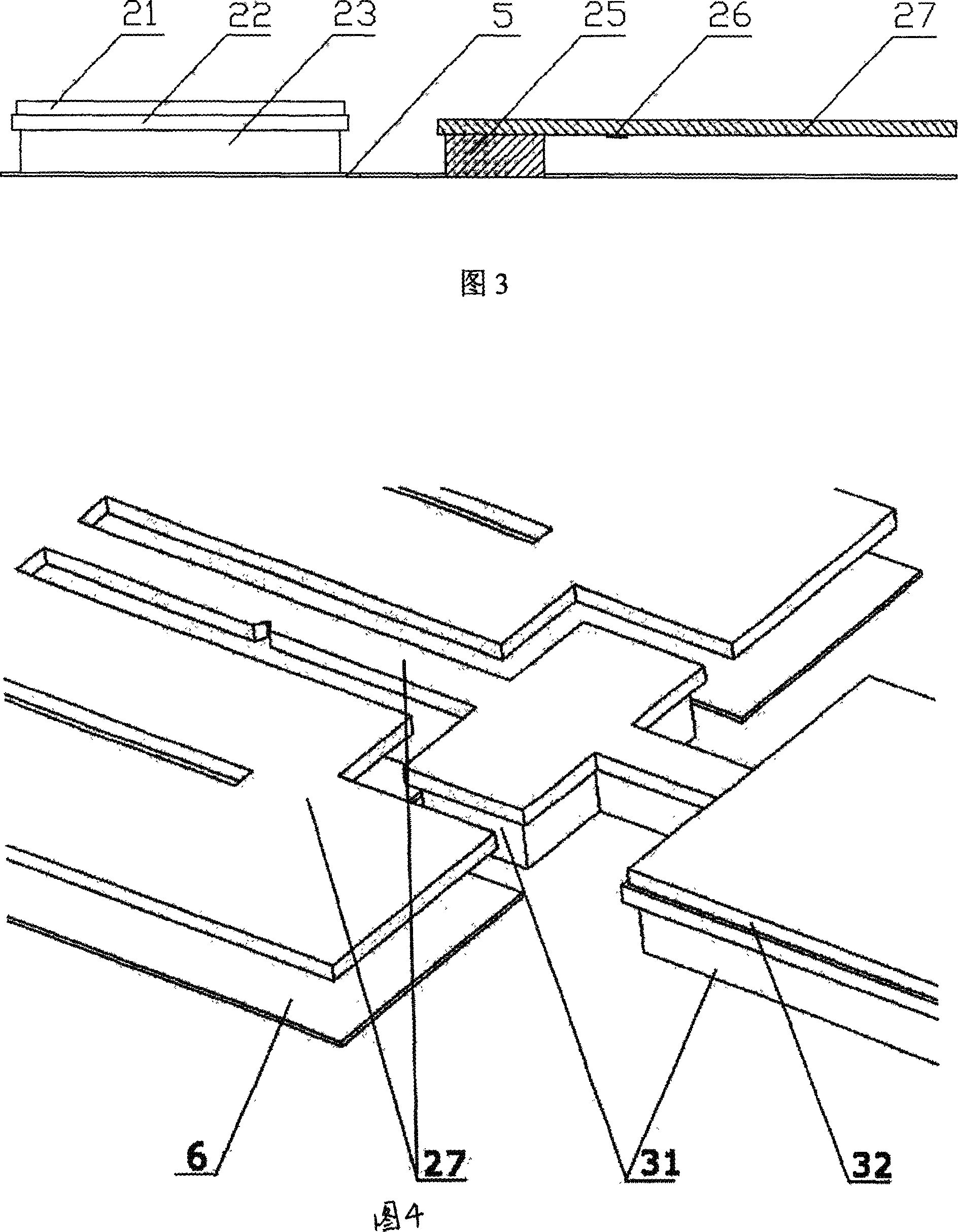

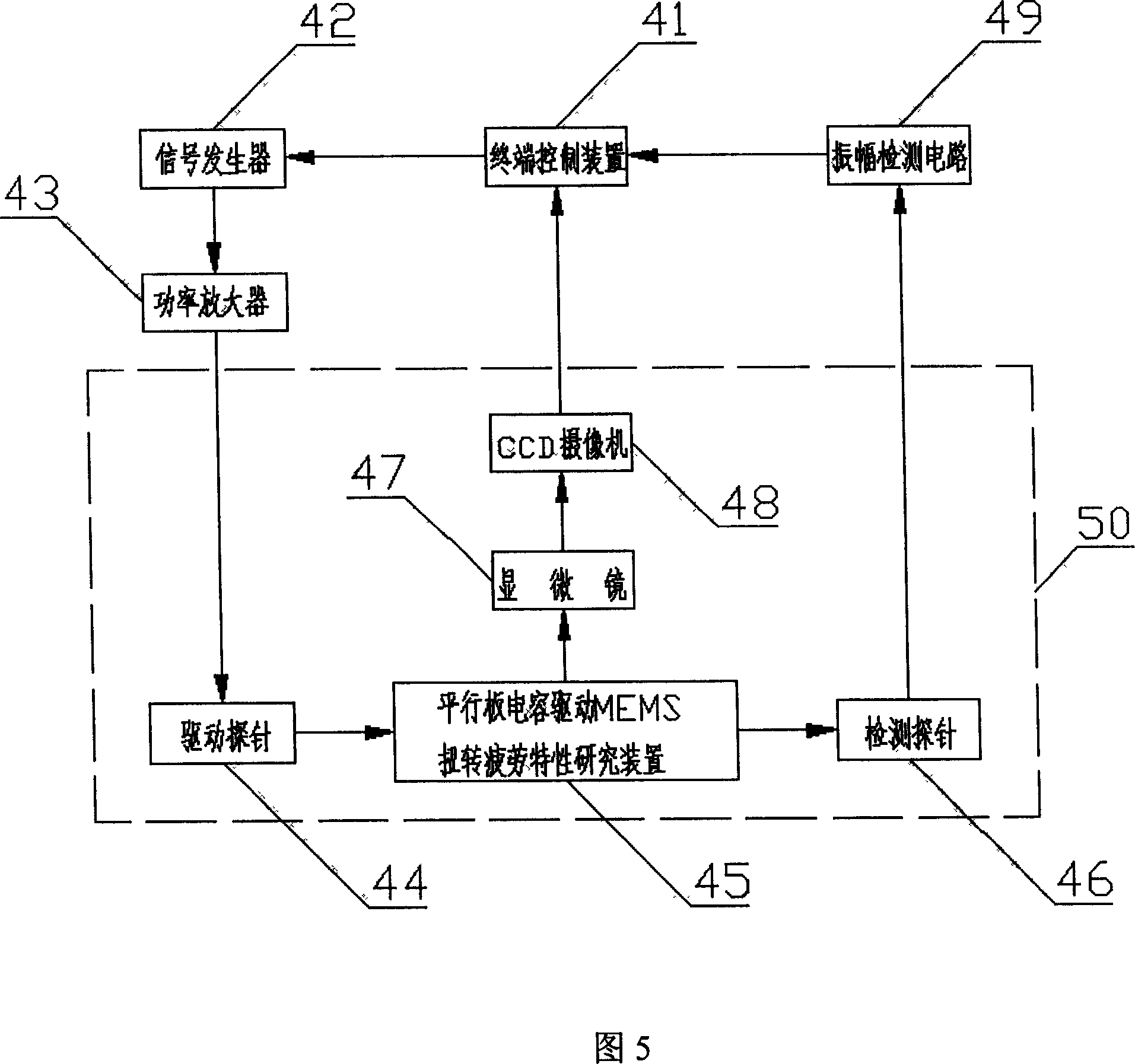

Endurance testing apparatus of micro-structure crankle driven by parallel plate capacitance

InactiveCN1963444ATo overcome the shortcomings of only horizontal driveOvercoming Vertical Electrostatic DriveStructural/machines measurementMaterial strength using steady torsional forcesMicro structureParallel plate

This invention relates to one parallel board capacitor drive micro structure fatigue test device, which comprises three electrodes, wherein, the drive one connected to alternating current to form parallel board drive tank through electrode bottom electrode layer and first hanging board to realize hanging board vertical drive; electrode bottom layer and second hanging parallel board form parallel capacitor sensor to get test distance changes between hanging board and bottom electrode; the third electrode is connected to earth.

Owner:BEIJING UNIV OF TECH

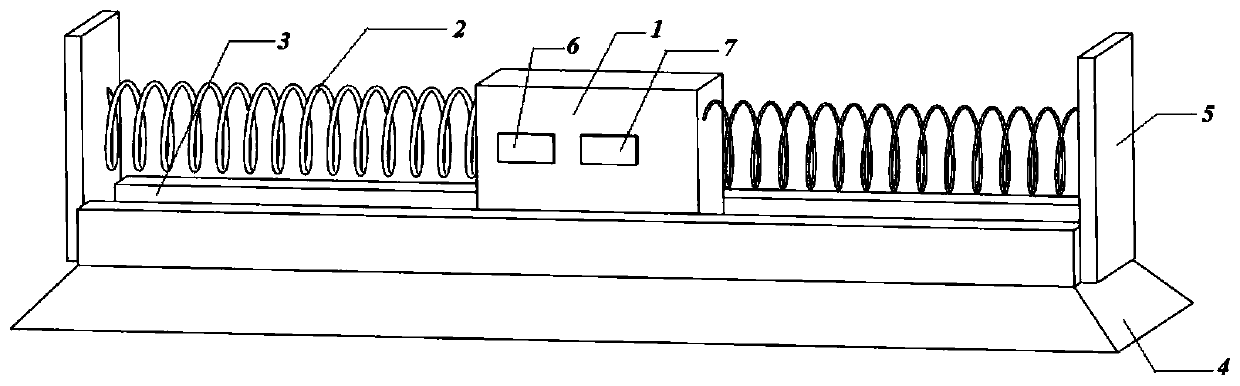

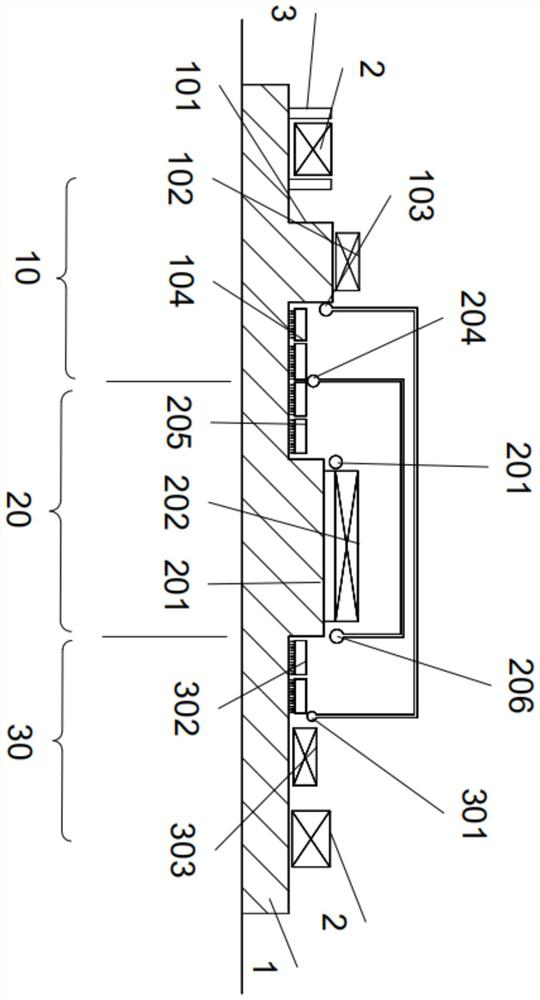

Single mass damper device for hull overall vibration control

PendingCN110422296AStable structureEasy to implementShip vibration reductionMovement controllersAntiresonanceInertia force

The invention relates to the field of mass damper devices, in particular to a single mass damper device for hull overall vibration control. The single mass damper device for hull overall vibration control comprises a single TMD device for controlling horizontal overall vibration of a hull and a single TMD device for controlling vertical overall vibration of the hull. During working, a first TMD mass block in the TMD device for controlling the horizontal overall vibration of the hull is pulled by a first spring to move to and fro between two baffles on a guide rail; a second TMD mass block in the TMD device for controlling the vertical overall vibration of the hull is pulled by a second spring to vertically move on an upright; and therefore, shock is absorbed by using inertia force resistance and antiresonance provided by assistant mass. The single mass damper device for hull overall vibration control is suitable for horizontal and vertical low frequency overall vibration control designof a large-sized surface ship, and has an obvious vibration control effect on the horizontal and vertical bending vibrations of the hull; and the overall response generated by the ship under the action of external load can be reduced, and the overall resistance of the ship to the horizontal and vertical bending vibrations is enhanced.

Owner:HARBIN ENG UNIV

Turbine rotor system

InactiveCN112253259AReduce air leakageShorten the lengthBlade accessoriesLeakage preventionEngineeringPhysics

The invention belongs to the technical field of turbine rotating machinery, and discloses a turbine rotor system which comprises a rotating shaft, and a first low-temperature area, a high-temperaturearea and a second low-temperature area are sequentially arranged in the axial direction of the rotating shaft; a balance disc is arranged in the first low-temperature area of the rotating shaft and sleeved with a first seal; a first air inlet is formed in the first low-temperature area of the rotating shaft and used for communicating with a cooling air source so as to cool the first seal; a turbine rotor is arranged in the high-temperature area of the rotating shaft, and blades are arranged on the periphery of the turbine rotor; and a second air inlet is formed in the high-temperature area ofthe rotating shaft and used for providing high-temperature air to drive the blades to drive the rotating shaft to rotate. According to the turbine rotor system, the air leakage amount of the balance disc can be reduced, the length of the balance disc is decreased, accordingly, the span of the rotating shaft is shortened, and the unit safety is improved.

Owner:SHANGHAI POWER EQUIP RES INST

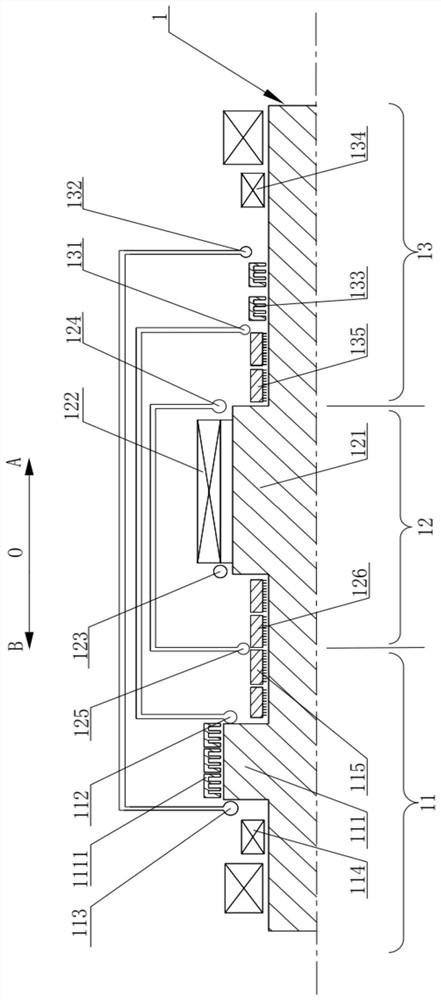

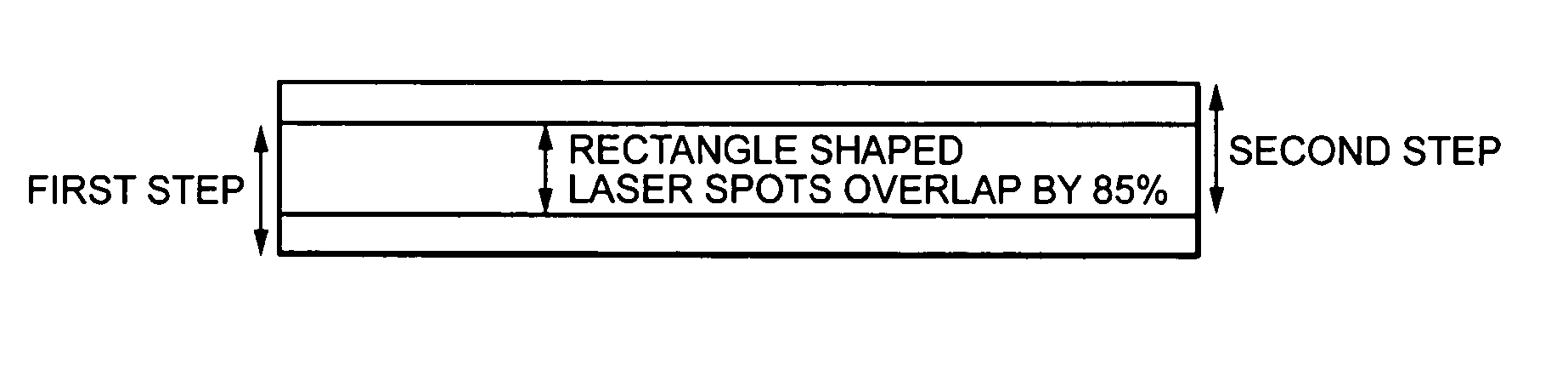

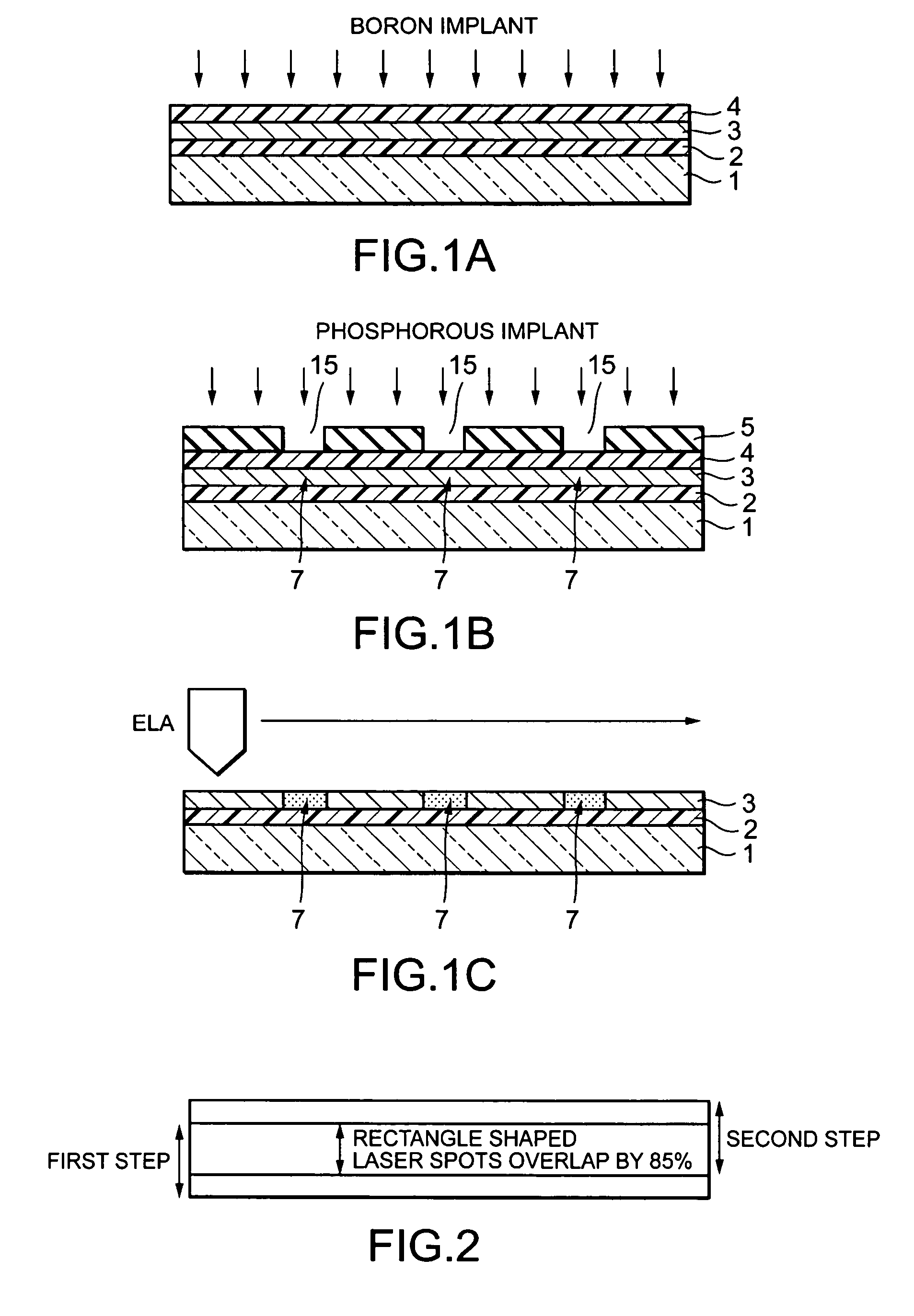

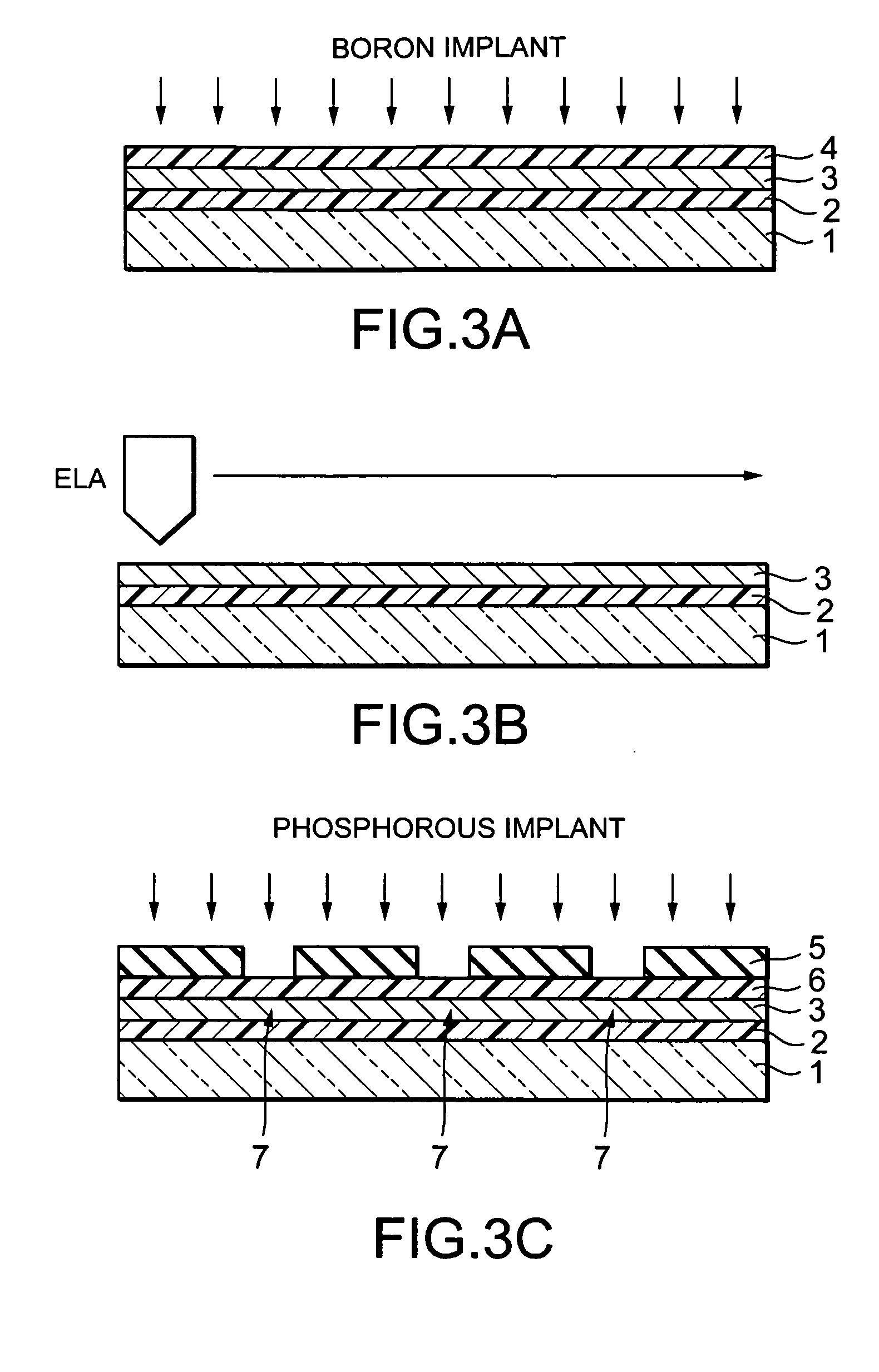

Method for manufacturing thin film transistor

Prior to converting a non-single crystal material of a semiconductor film into a single crystal material through the use of a laser beam, at least one dopant is introduced into whole of the semiconductor film. Then, the non-single crystal semiconductor film is irradiated with a laser beam to crystallize the semiconductor film. In this case, a ratio between quasi-fermi level of the single crystal material within one of transistor formation regions used to form transistors of different conductivity types and quasi-fermi level of the single crystal material within the other thereof is made to be between 0.5:1 and 2.0:1. Thus, transistors of different conductivity types are formed in the crystallized semiconductor film.

Owner:VISTA PEAK VENTURES LLC

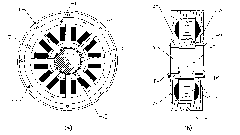

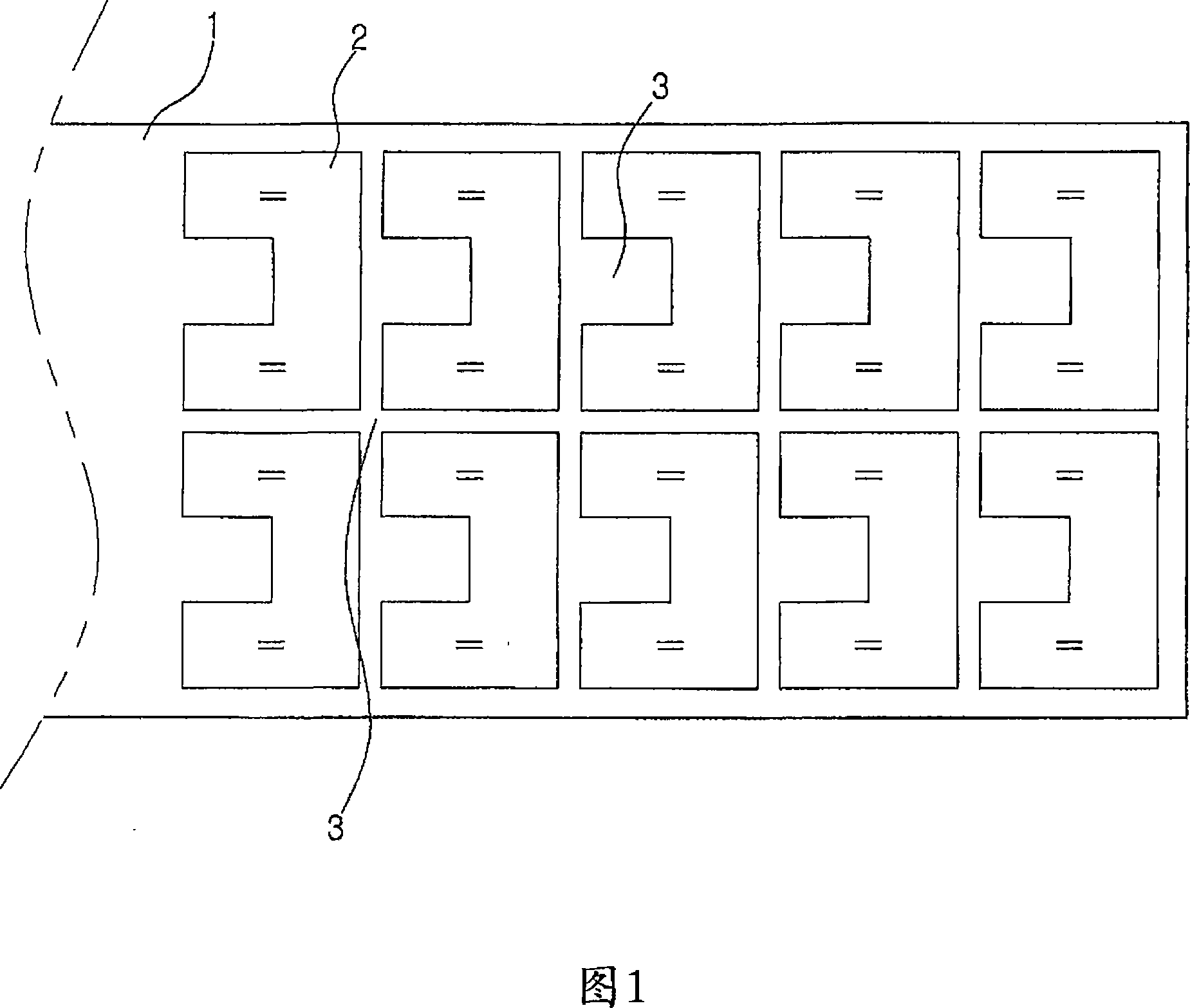

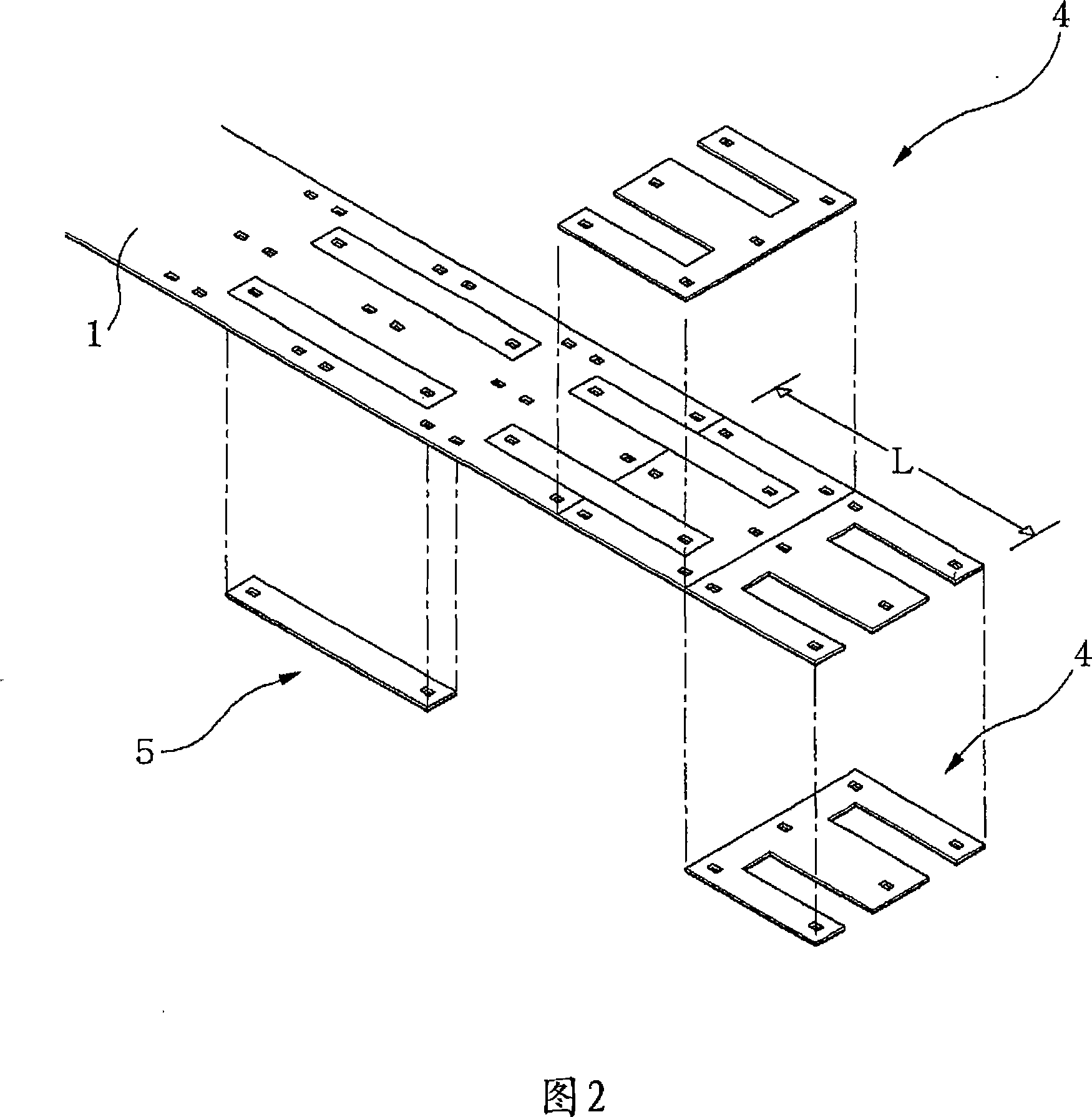

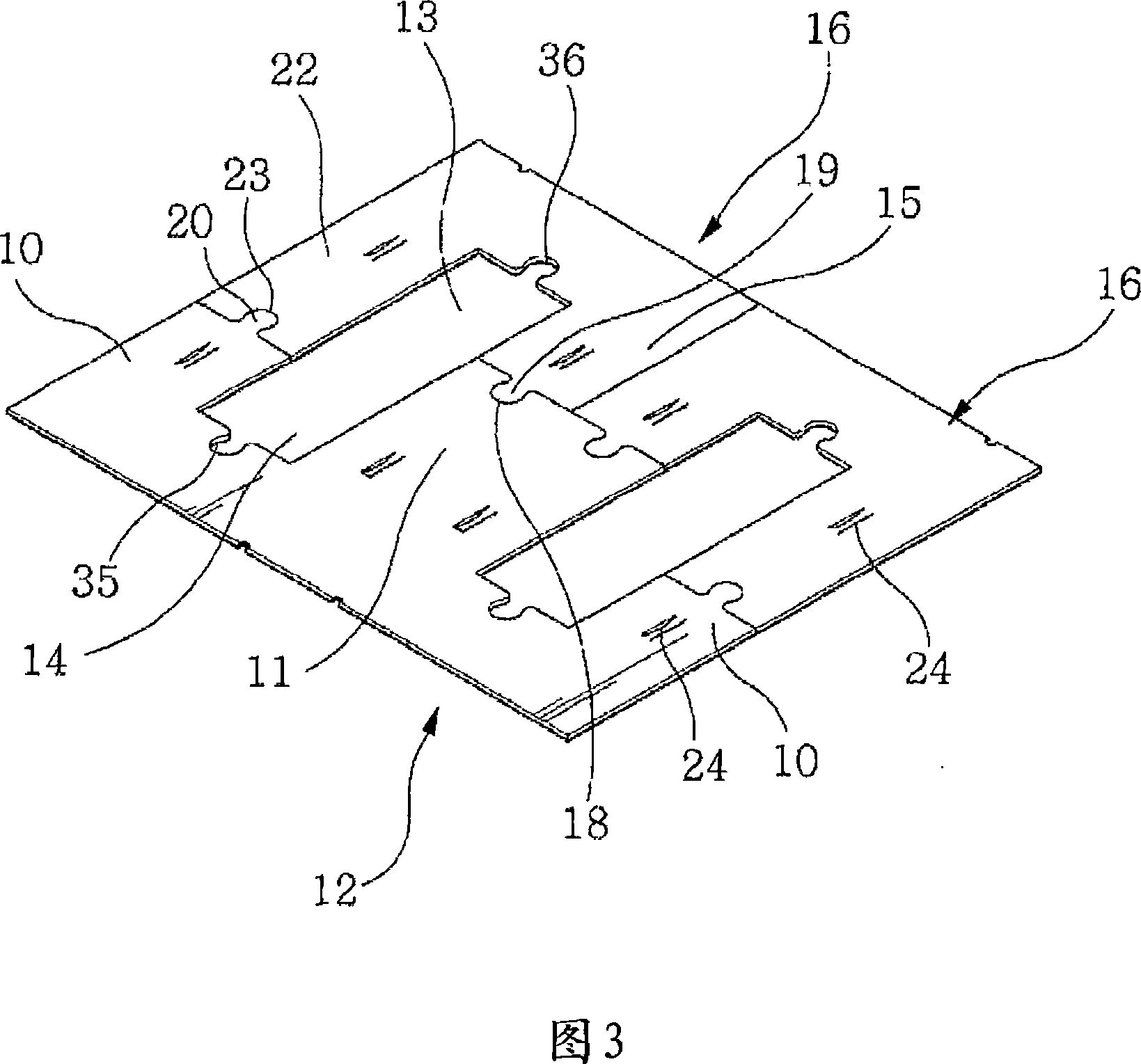

Iron core, mold and method of forming and laminating the same

An iron core built in a transformer, a rectifier, a stabilizer, a lamp, and others is disclosed. When the iron core is formed, an E-shaped iron core and a pair of c -shaped iron cores, which are arranged on both sides of the E-shaped iron core, are simultaneously stamped from a sheet of silicon steel. A predetermined number of E-shaped iron cores and pairs of c -shaped iron cores are assembled and laminated to form a laminated iron core. The iron core includes the E-shaped iron core having side legs symmetrically formed on both sides thereof and a center leg formed between the side legs and coupled to a bobbin around which a coil is wound, and the pair of C-shaped iron cores each having a long leg formed corresponding to the side leg of the E-shaped iron core and a short leg formed corresponding to the center leg of the E-shaped iron core.

Owner:金 明大 +2

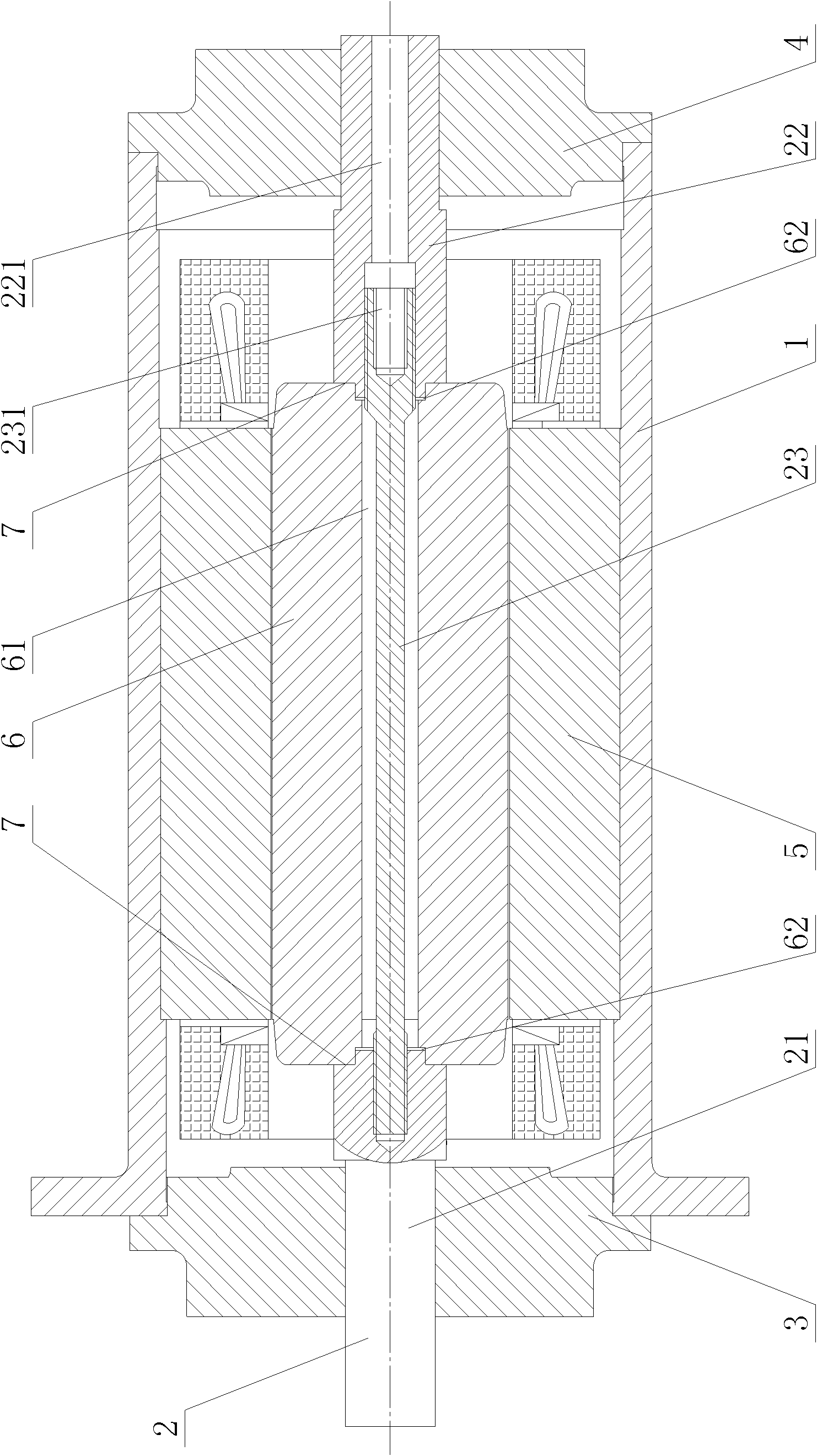

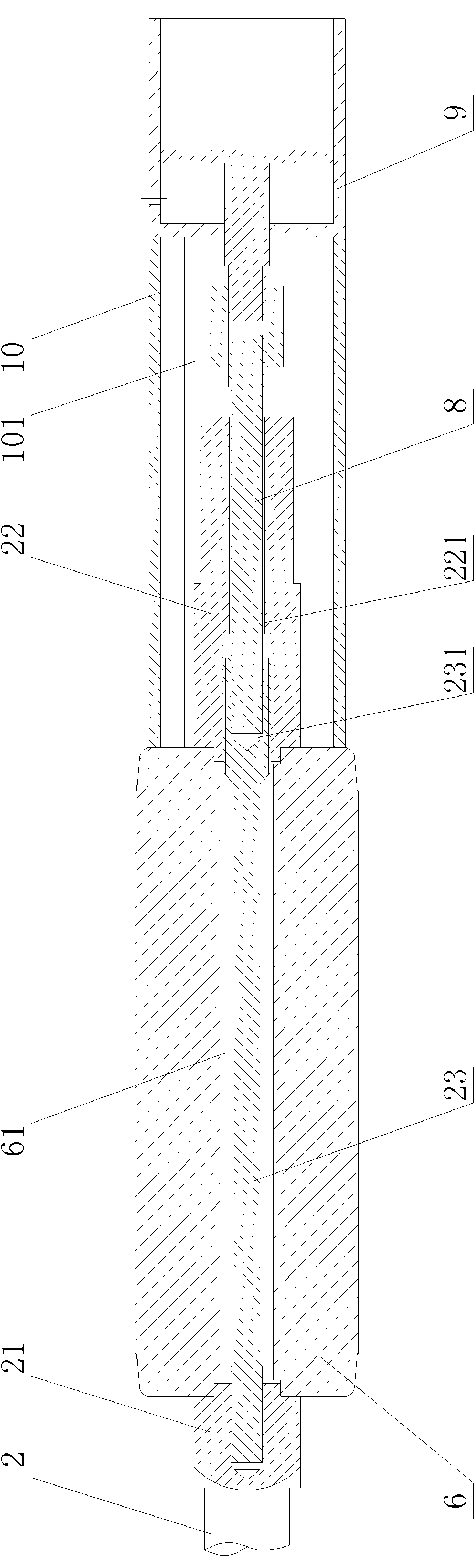

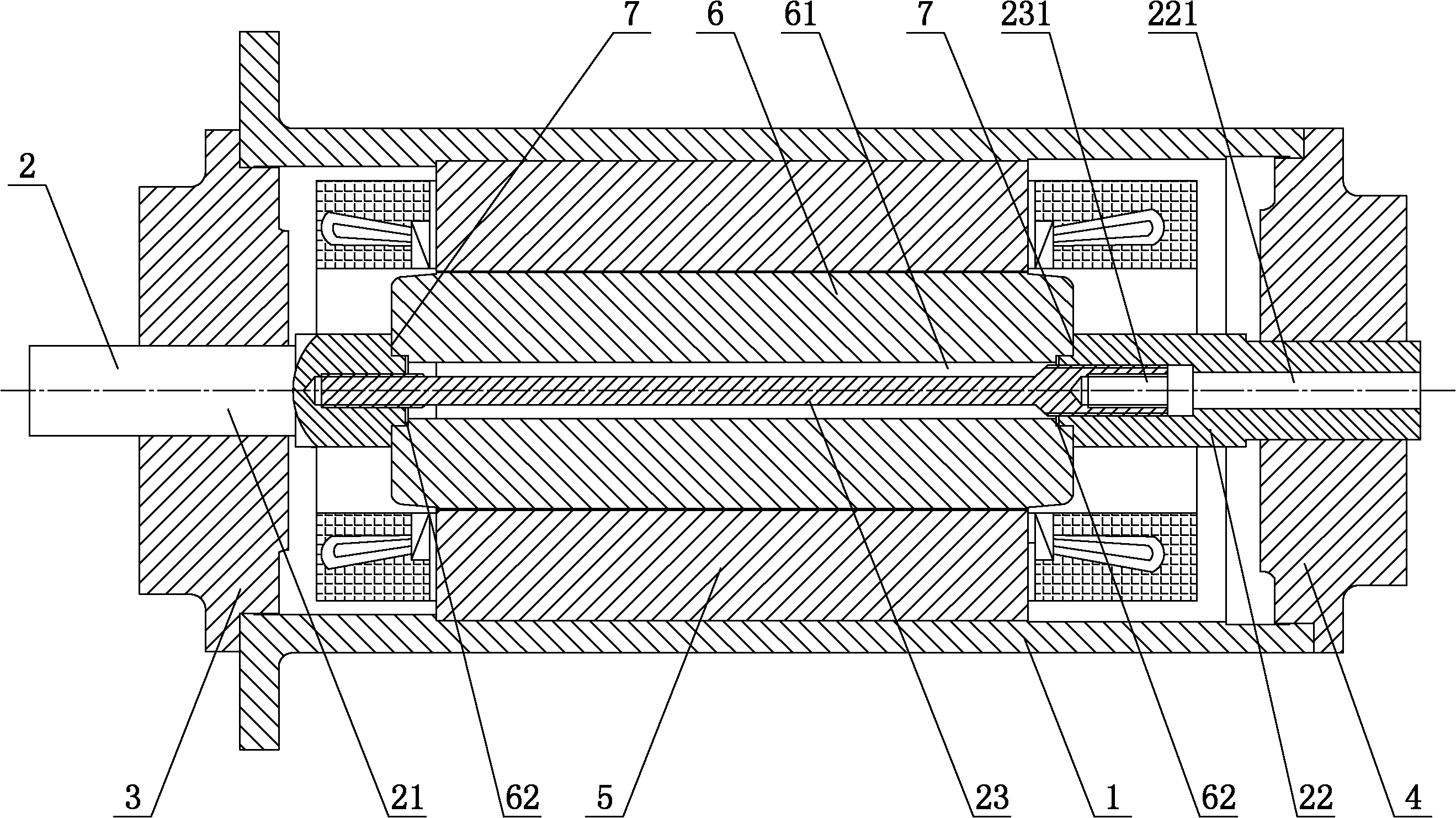

High-speed motor and assembly method thereof

ActiveCN101860117AHigh rotation accuracyImprove assembly accuracyManufacturing dynamo-electric machinesMechanical energy handlingEngineeringScrew thread

The invention discloses a high-speed motor, which comprises a motor casing, a motor main shaft, a motor stator and a motor rotor, wherein the motor stator is sleeved in the motor casing; the motor main shaft is arranged in the motor rotor and comprises a front half shaft, a rear half shaft and a pull rod; the pull rod is freely sleeved in an inner hole of the motor rotor; the front end of the pull rod is in threaded connection with the front half shaft; the rear end of the pull rod is in threaded connection with the rear half shaft; the front half shaft is tensioned with the rear half shaft by the pull rod; and the motor rotor is clamped between the front half shaft and the rear half shaft. The high-speed motor has the advantages of simple structure, convenient disassembly and assembly, convenient processing, large transmission torque and high critical rotation speed. The invention also discloses an assembly method of the high-speed motor.

Owner:FOSPOVA +1

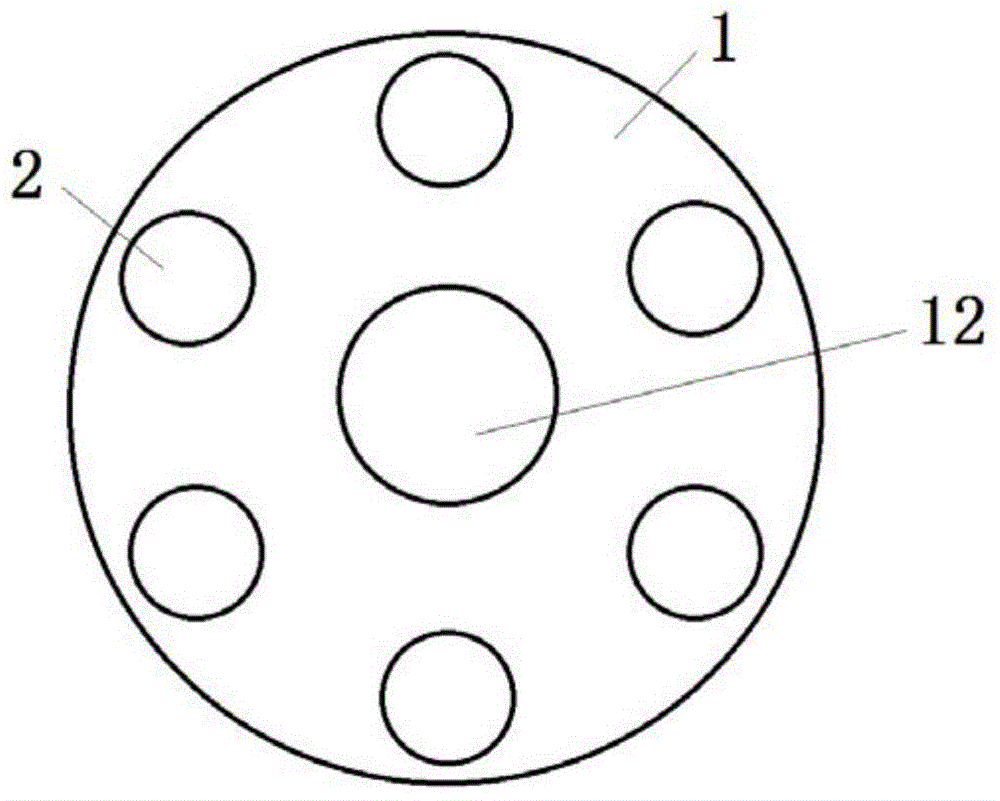

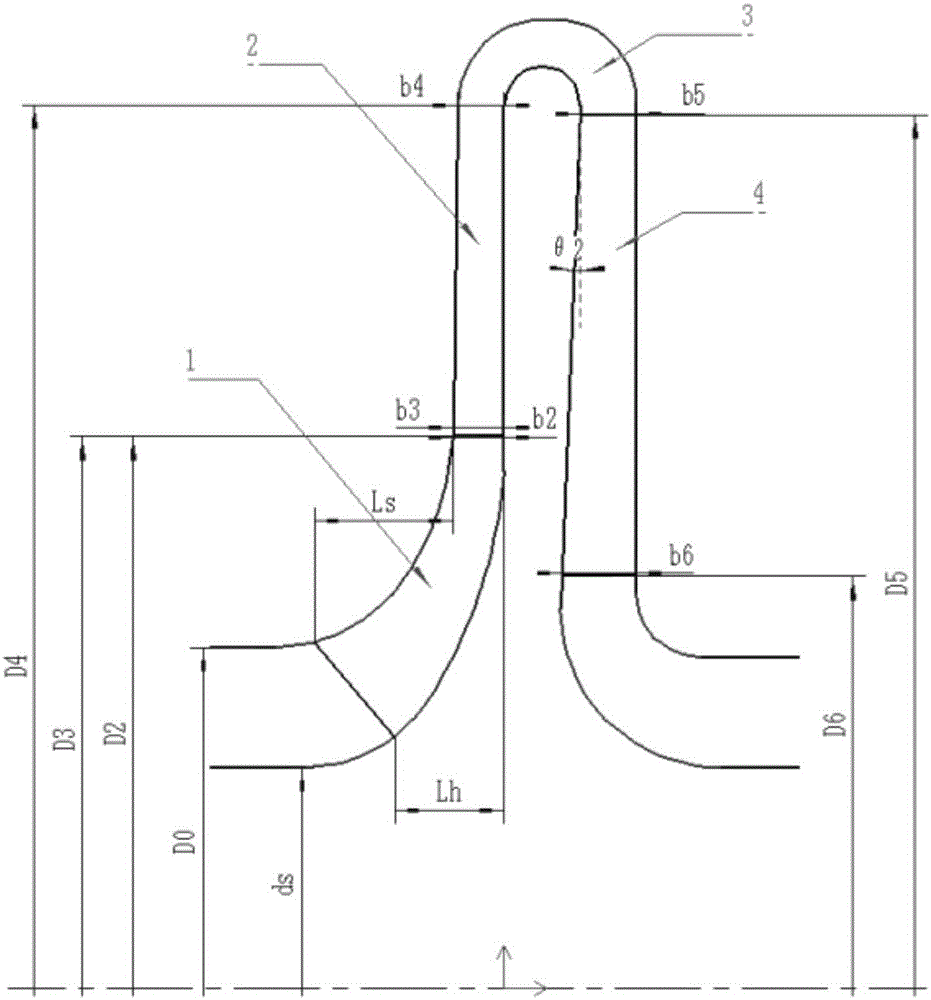

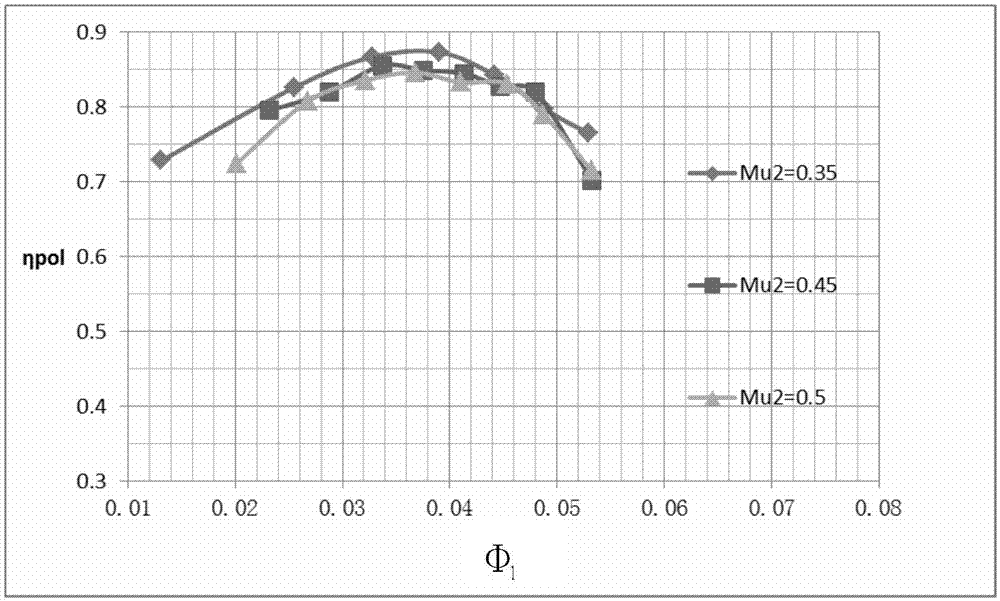

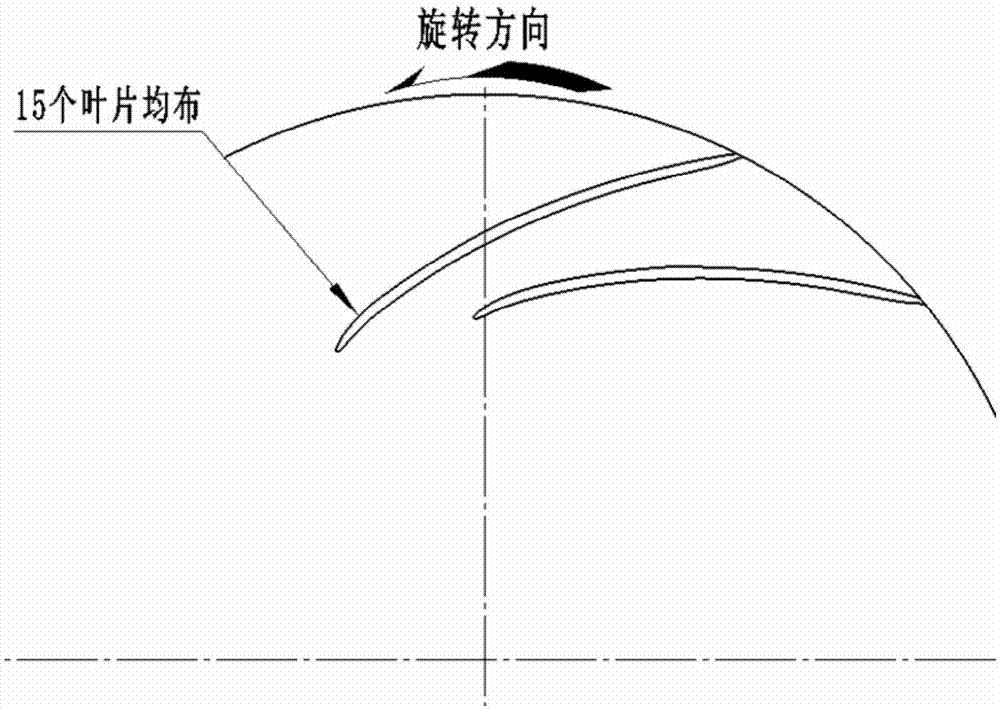

Model stage special for pipeline compressor

InactiveCN106870447AHigh variable efficiencyHigh head coefficientPump componentsPumpsCentrifugal compressorStreamflow

The invention belongs to a centrifugal compressor model stage, and particularly relates to a model stage special for a pipeline compressor. The model stage is suitable for modeling design of a pipeline compressor product. The model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the inlet position of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the outlet position of the model stage, and the vaneless diffuser is communicated with the backflow device through the bend; and the design machine mach number Mu2 of the model stage is 0.35 to 0.5, the flow coefficient phi1 is equal to 0.023 to 0.053, the energy head coefficient tau is equal to 0.47 to 0.71, the design condition point polytropic efficiency etapol under each mach number is equal to 0.846 to 0.873, the hub ratio ds / D2 of the model stage is equal to 0.4, and the ratio L / D2 of the span to the diameter is 0.292. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, the pipeline compressor can have the higher running efficiency and wider working condition scope; and meanwhile, the rotor working rotating speed can be decreased, the bearing span is shortened, and the rotor stability is improved.

Owner:SHENYANG BLOWER WORKS GROUP CORP

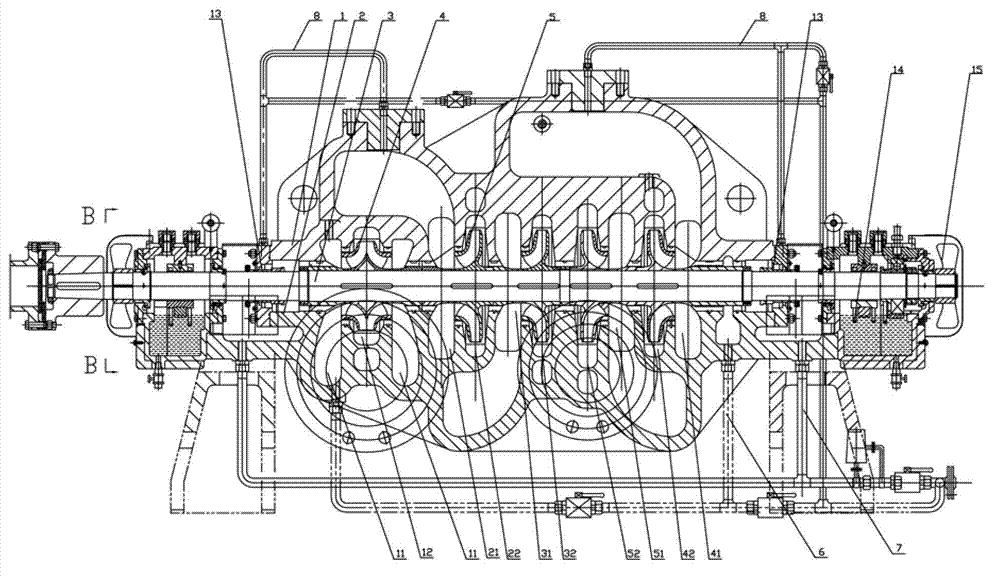

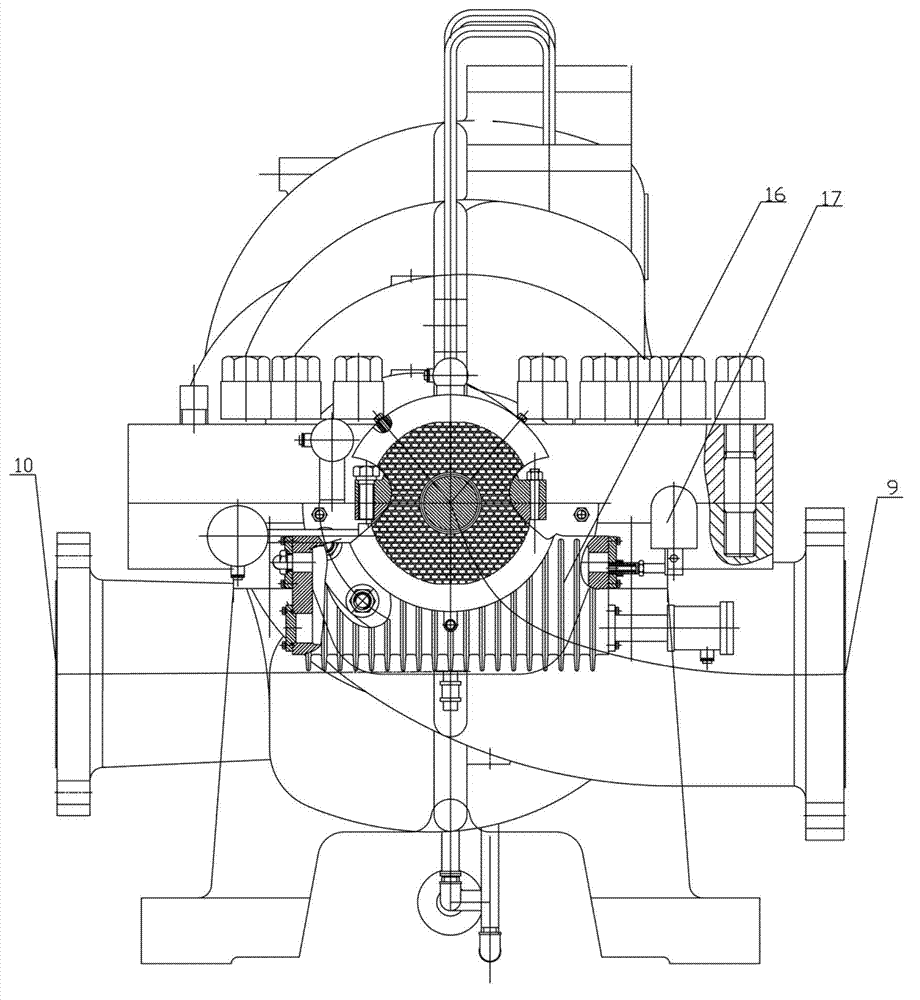

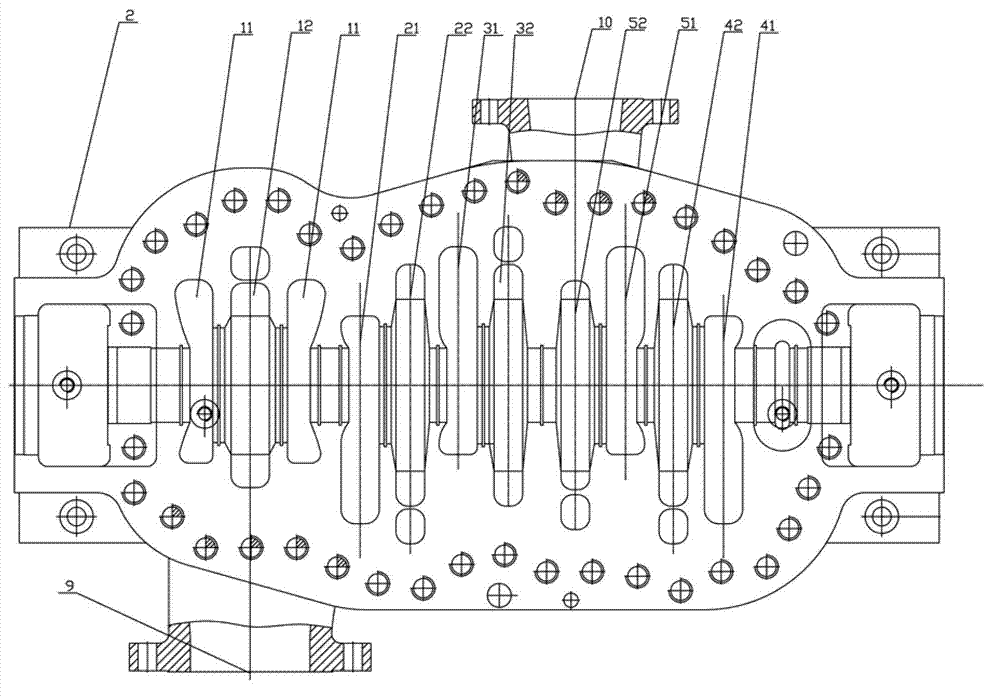

Double suction multistage horizontal split pump

ActiveCN102828960AImprove suction effectReduce vibrationPump componentsRadial flow pumpsImpellerEngineering

The invention relates to a double suction multistage horizontal split pump. The double suction multistage horizontal split pump mainly comprises a pump cover, a pump base and a pump shaft. The pump cover and the pump base are spliced up and down to form a pump shell pumping chamber. The pump shaft is provided with a primary impeller and more than one pairs of back-to-back secondary impellers from left to right. The primary impeller is communicated with a primary water suction chamber and a primary pumping chamber on a volute. The primary water suction chamber is communicated with an inlet. The secondary impellers are communicated with corresponding water suction chambers and pumping chambers. The pumping chamber communicated by the secondary impellers reversely arranged is communicated with an outlet. The double suction multistage horizontal split pump provided by the invention has the beneficial effects that the pump base provided by the invention is only provided with one inlet, the pipeline is convenient to install, and the primary impeller is a double suction impeller so that the suction performance of the pump is further enhanced; the secondary impellers are installed in a back-to-back way, so that the axial force is balanced; the pump has such a structure that the outlet is arranged in the middle of the pump so that the pressure of a sealed chamber is approximate to that of the inlet, therefore, the PV (Pressure of sealed fluid*average sliding Velocity at sealed end) value of mechanical seal is effectively reduced.

Owner:南方中金环境股份有限公司

Turbine rotor arrangement system

PendingCN113653539AShorten the overall spanConducive to the overall structure designBlade accessoriesLeakage preventionPhysicsRotary machine

The invention relates to the technical field of turbine rotating machinery, and discloses a turbine rotor arrangement system. The turbine rotor arrangement system comprises a turbine cylinder, a rotating shaft, a boss and a first air inlet, the rotating shaft is arranged in the turbine cylinder, and the rotating shaft is sequentially provided with a first low-temperature area, a high-temperature area and a second low-temperature area in the axial direction of the rotating shaft; the boss is arranged in the first low-temperature area of the rotating shaft, and the periphery of the boss is sleeved with a first dry gas seal; and the first air inlet is formed in the side, close to the high-temperature area, of the boss and used for communicating with a cooling air source. According to the turbine rotor arrangement system, a balance disc does not need to be arranged, through-flow and axial thrust generated by the sealing teeth are balanced through thrust generated by the differential pressure before and after the boss of the dry gas seal is installed, the overall operation efficiency of a unit is high, the overall span of the rotor is small, and the safety performance and the economic performance of the unit are good.

Owner:SHANGHAI POWER EQUIP RES INST

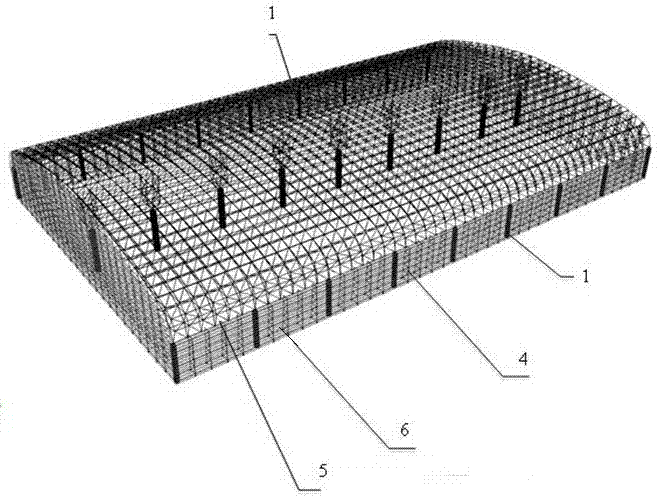

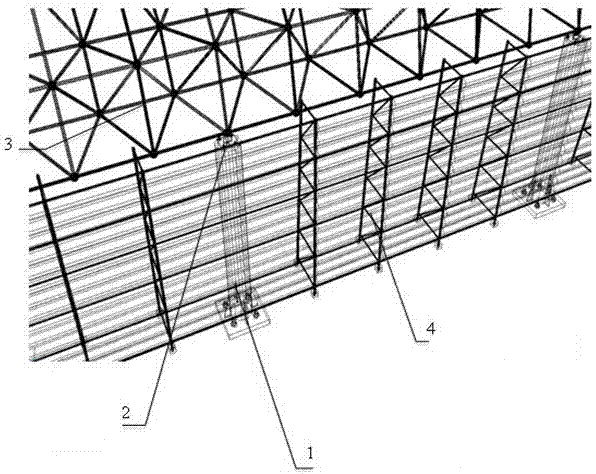

Totally-enclosed coal bunker formed by reconstructing wind shielding and dust suppression walls

ActiveCN107161587ALow costSimple structureConveyorsStorage devicesSupporting systemMining engineering

The invention discloses a totally-enclosed coal bunker formed by reconstructing wind shielding and dust suppression walls, and belongs to the field of environmental protection. The totally-enclosed coal bunker comprises roof supporting columns, a roof steel structure wire frame, the wind shielding and dust suppression walls, roof panels and wall panels. The totally-enclosed coal bunker is characterized in that one or several wind shielding and dust suppression wall steel structures of the wind shielding and dust suppression walls is or are dismounted, and the roof supporting columns are mounted in the positions where the wind shielding and dust suppression wall steel structures are dismounted; and the roof supporting columns form independent supporting systems and support the roof steel structure wire frame and the roof panels, and annular or band-shaped ventilation zones having ventilation functions are formed among the roof supporting columns by employing the wind shielding and dust suppression walls. The totally-enclosed coal bunker is simple in structure and good in dust prevention effect and is economical and practical, and the construction cost is lowered.

Owner:SHANXI SHANGFENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com