High-speed motor and assembly method thereof

A technology of high-speed motors and assembly methods, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of reduced interference between the motor rotor and the main shaft, reduced critical speed of the main shaft system, poor alignment, etc. problems, to avoid magnetic saturation, increase critical speed, improve assembly accuracy and assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

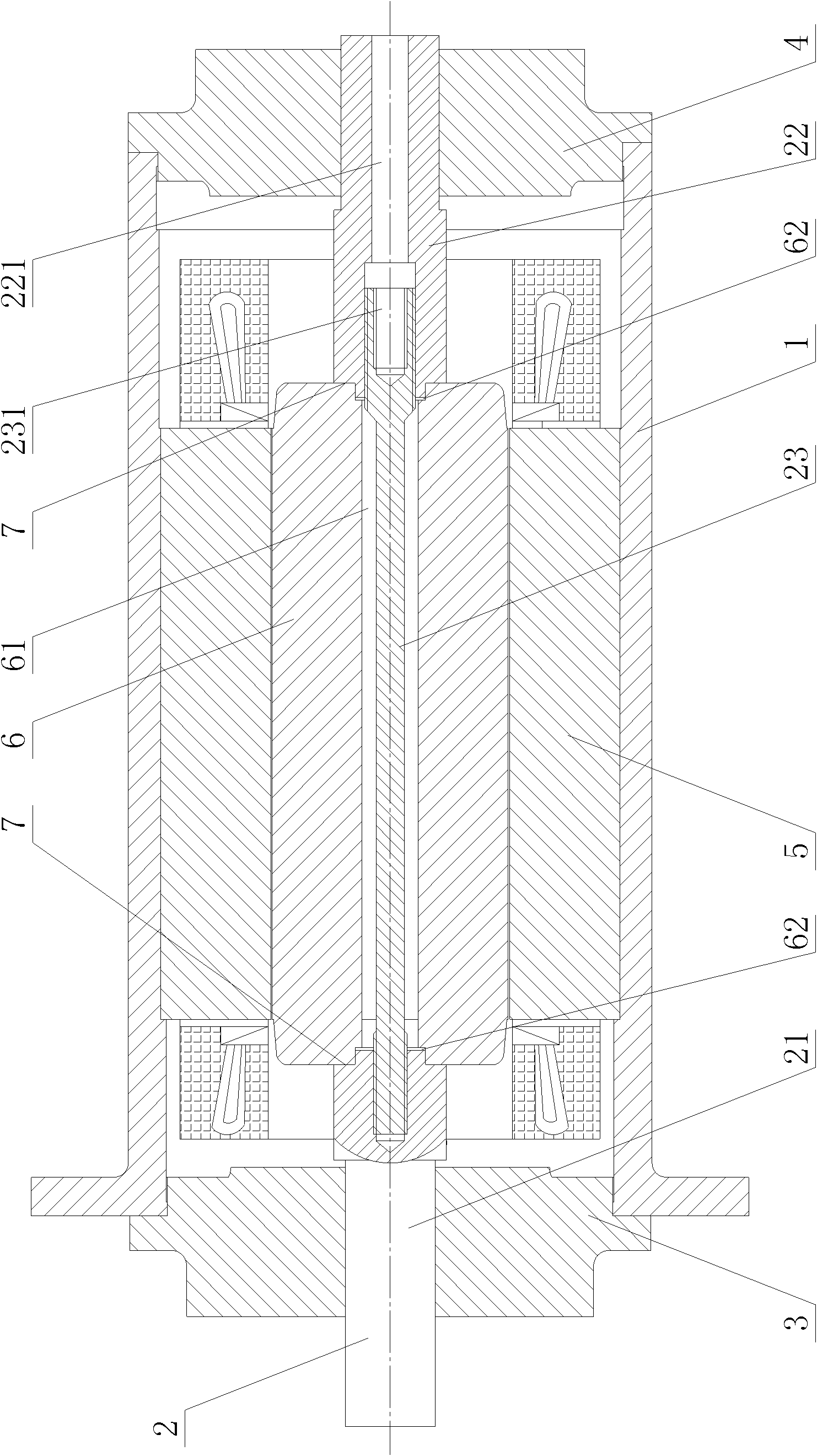

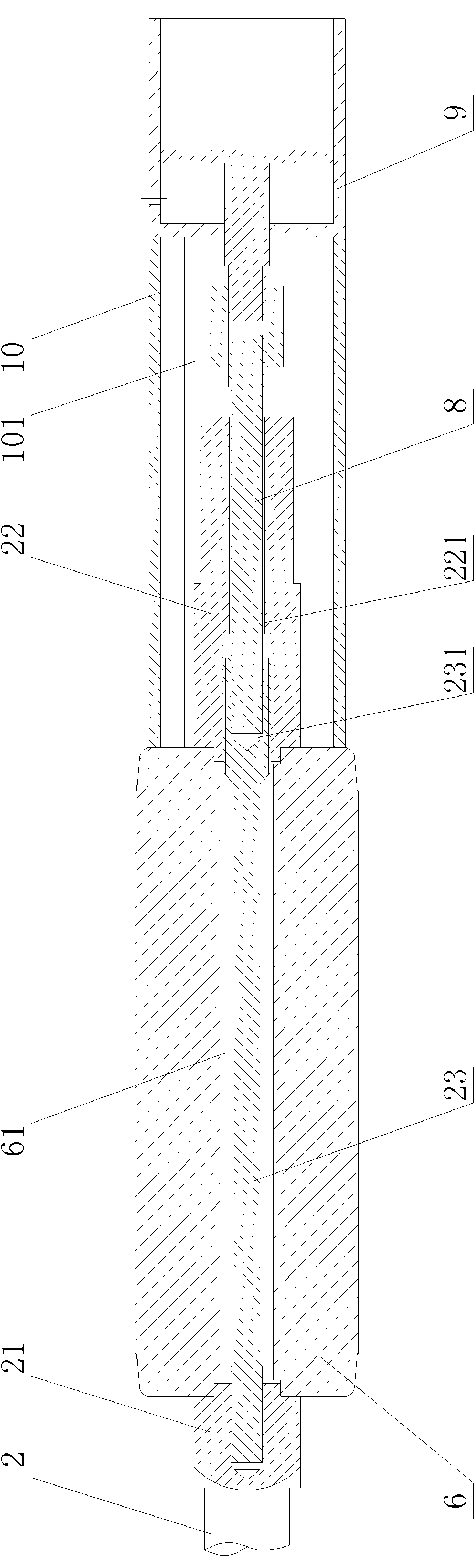

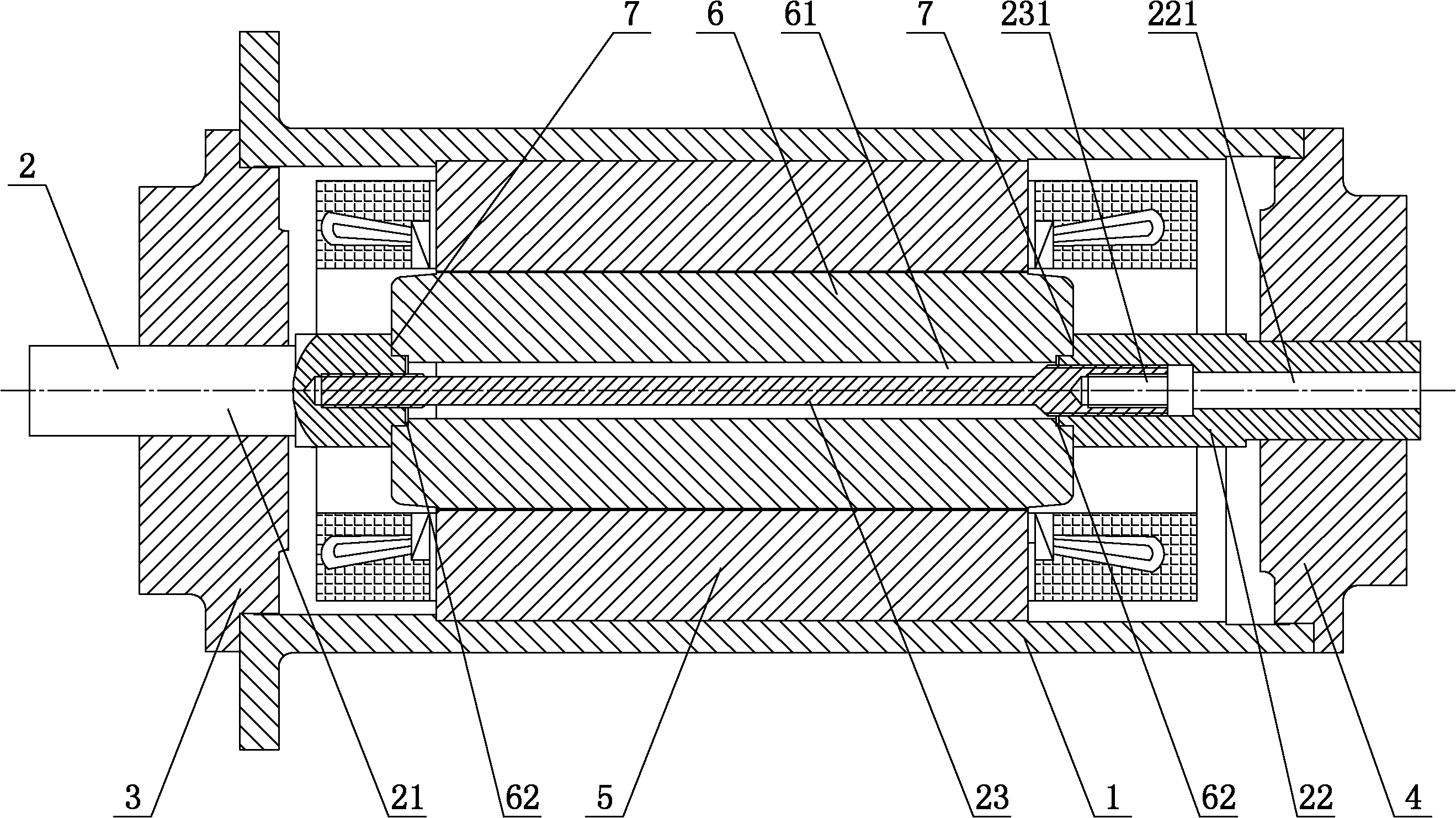

[0027] figure 1 A high-speed motor embodiment of the present invention is shown, the high-speed motor includes a motor housing 1, a motor shaft 2, a front flange assembly 3, a rear flange assembly 4, a motor stator 5 and a motor rotor 6, and the motor stator 5 Set in the motor housing 1, the motor main shaft 2 is placed in the motor stator 5, the motor main shaft 2 includes the front half shaft 21, the rear half shaft 22 and the tie rod 23, the tie rod 23 is sleeved in the inner hole 61 of the motor rotor 6, There is a gap between the pull rod 23 and the inner hole 61, the front end of the pull rod 23 is threaded with the front half shaft 21, the rear end of the pull rod 23 is threaded with the rear half shaft 22, and the front half shaft 21 and the rear half shaft 22 are tightened and clamped by the pull rod 23 It is held at both ends of the motor rotor 6, the front flange assembly 3 is installed on the front end of the motor housing 1, the front half shaft 21 is supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com