Patents

Literature

350results about How to "Improve assembly speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

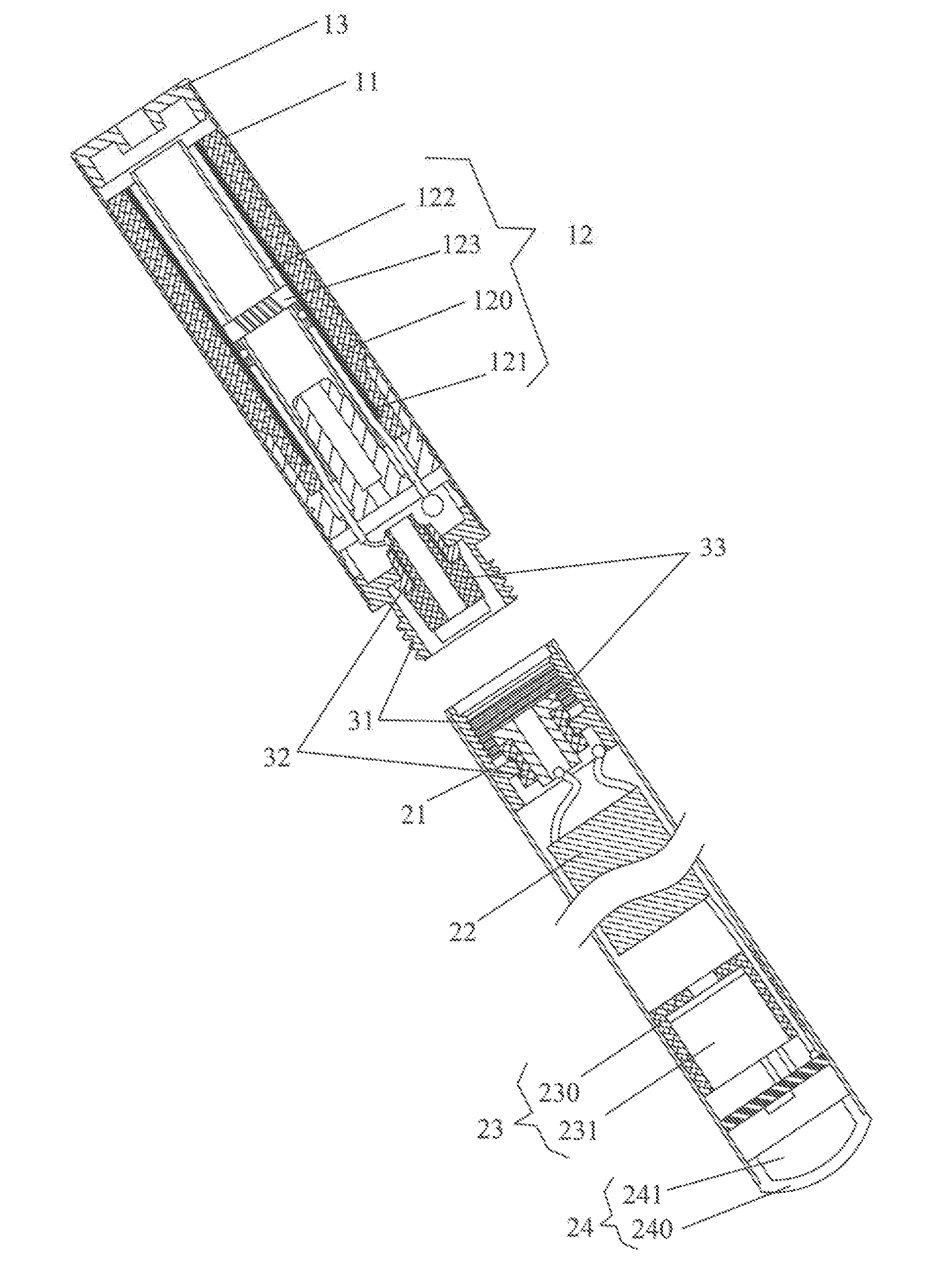

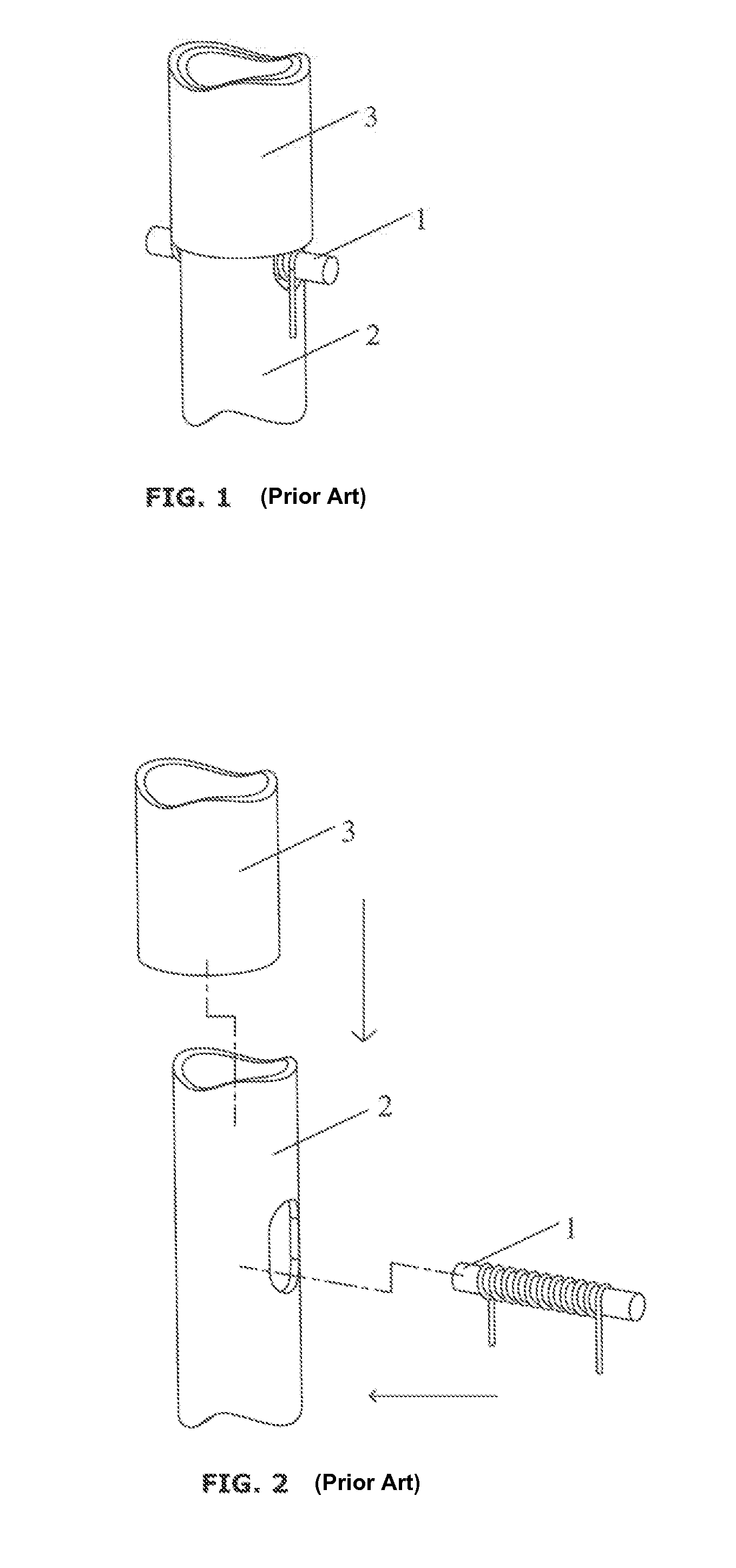

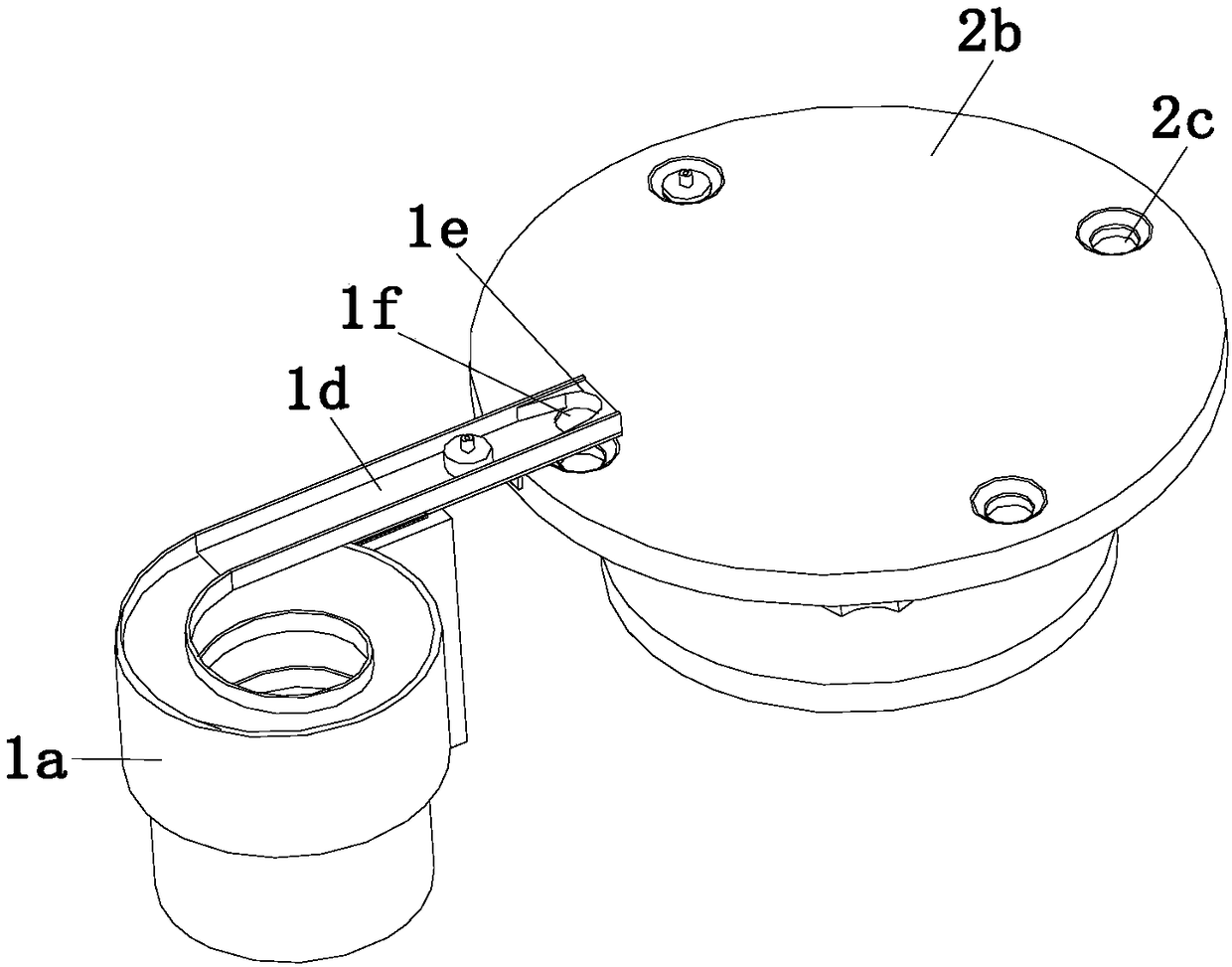

Electronic cigarette and assembly method of atomizer thereof

InactiveUS20150196056A1Simple assemblyHigh efficiencyElectric heatingTobacco pipesCost savingsEngineering

An electronic cigarette and a method for assembling an atomizer thereof. The electronic cigarette comprises a suction rod (10) and a power supply rod (20). The suction rod (10) comprises a suction tube (11) and an atomizer (12) disposed in the suction tube (11) and used for generating smoke. The atomizer (12) comprises an air pipe (122) and a heating assembly (123). The air pipe (122) is provided with a through hole (100) along a radial direction used for accommodating and fixing the heating assembly (123). The air pipe (122) is also provided with a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly. By disposing a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly (123) on the air pipe (122), technical effects of simple assembly, high efficiency, stable quality and cost saving are achieved.

Owner:KIMREE HI TECH

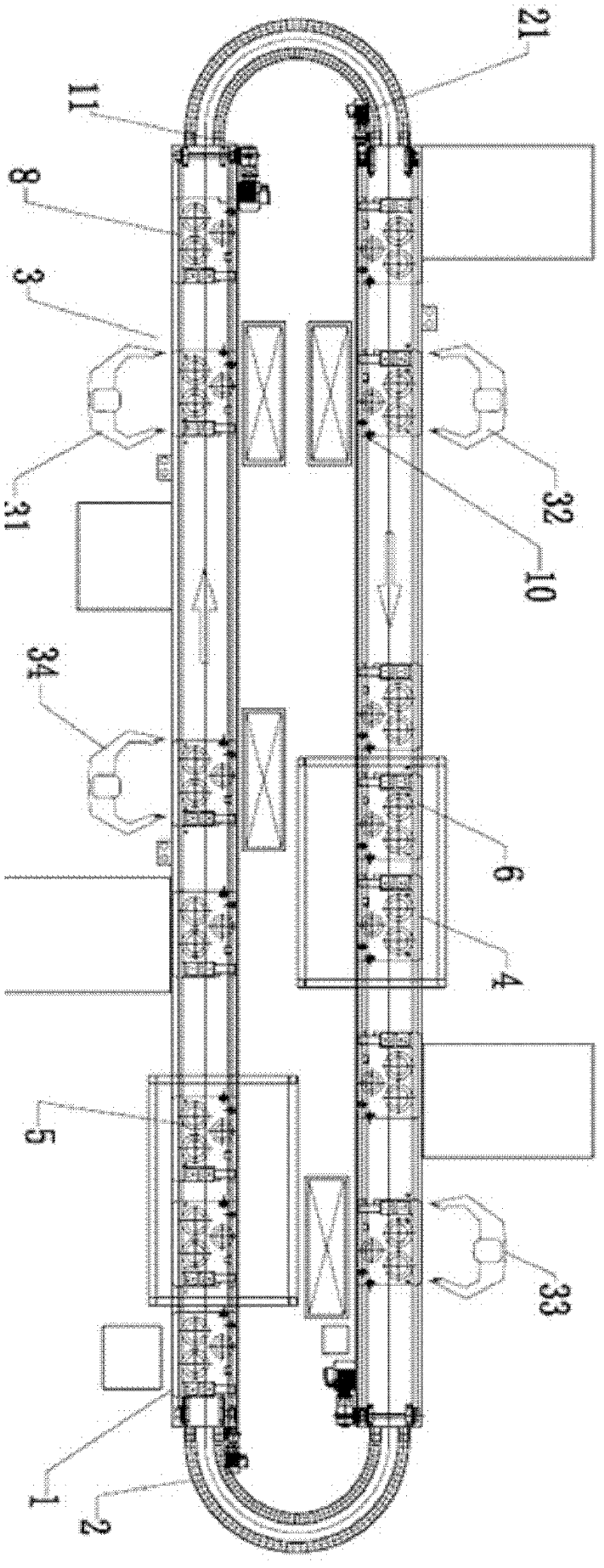

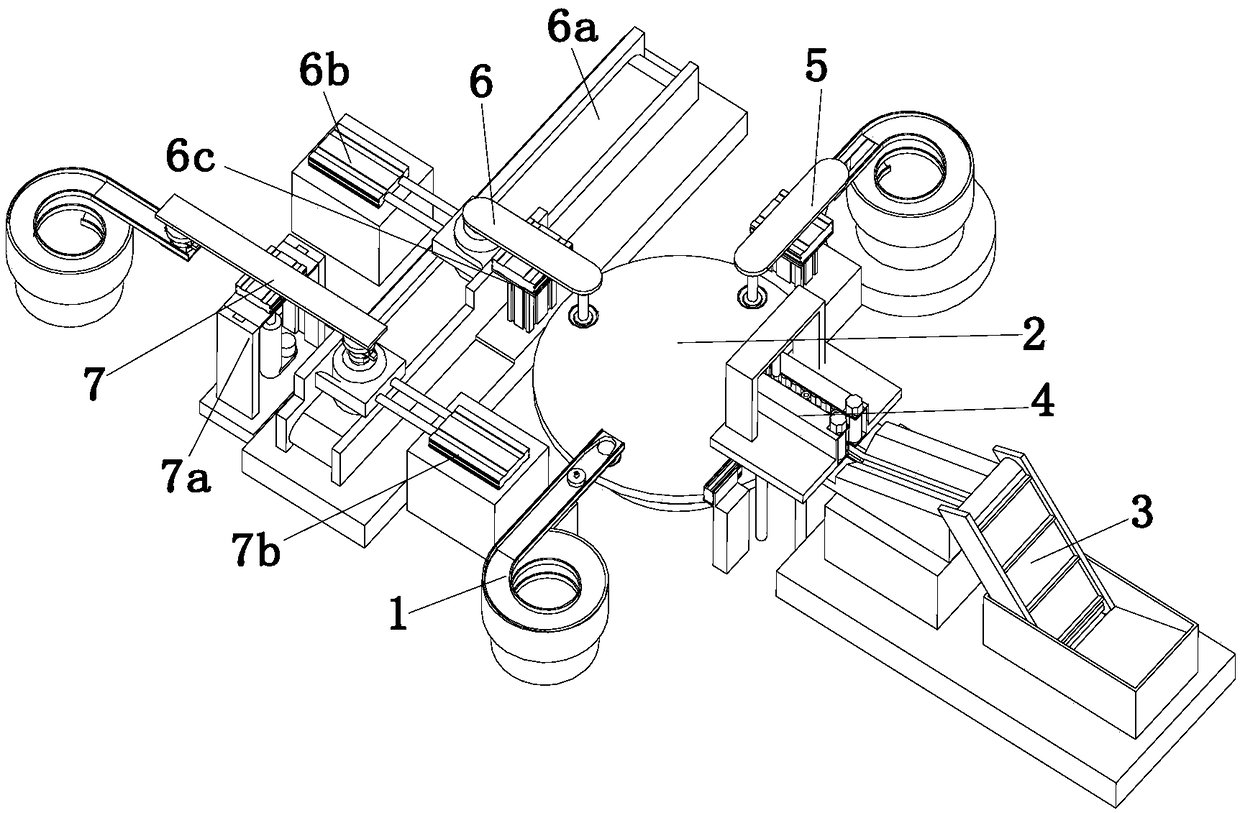

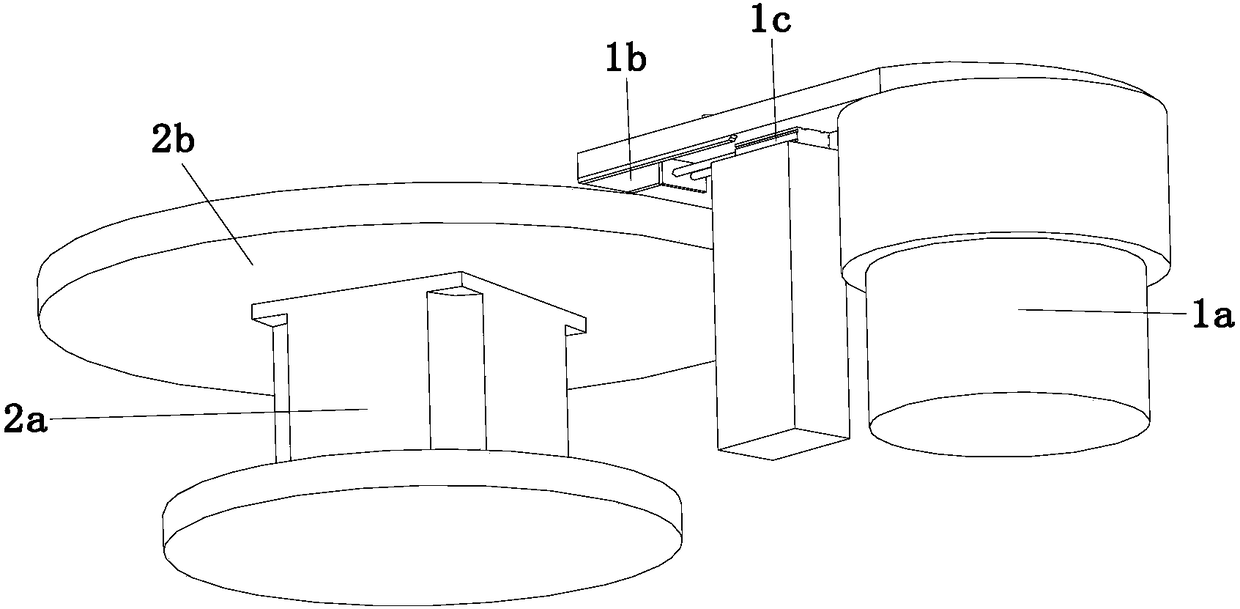

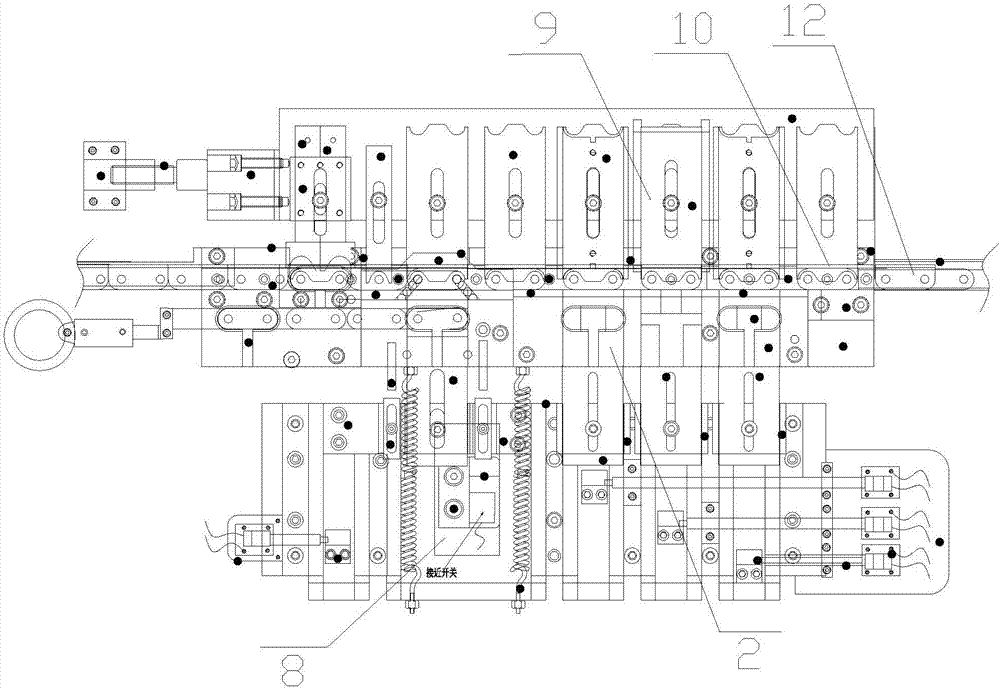

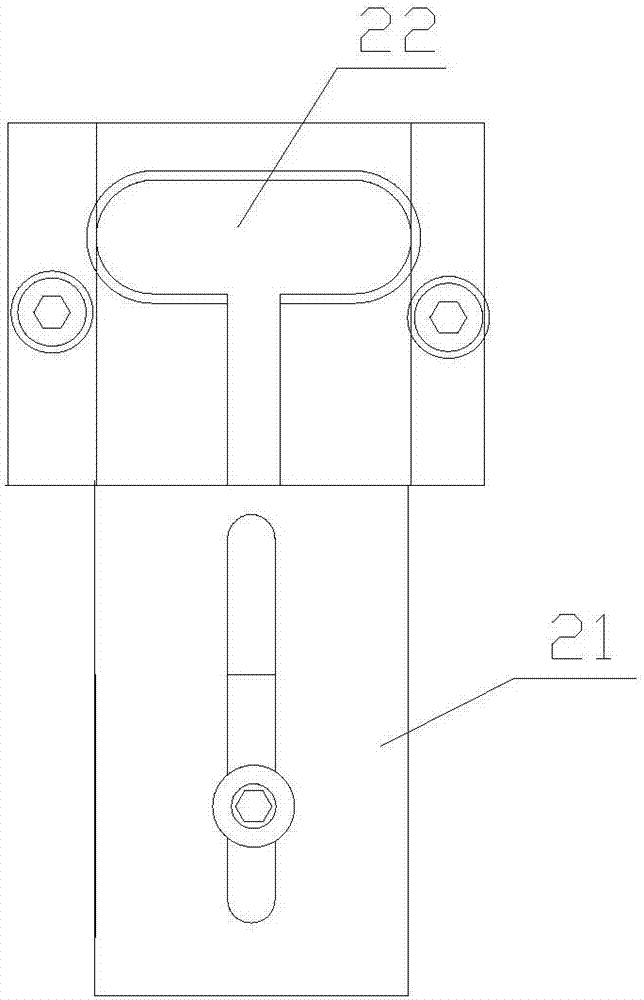

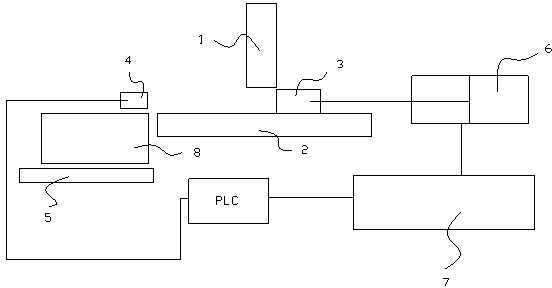

Water pump automatic circulation assembly line

ActiveCN102284860AAccurate detectionOptimizationPump testingAssembly machinesDifferential lineEngineering

The invention discloses an automatic flow assembly line for a water pump. The automatic flow assembly line comprises a circulated flow line mainly consisting of a differential chain line and an arc flat chain line and is characterized in that the circulated flow line is provided with an automatic water pump comprehensive testing platform, an air tightness testing unit, a main sealing automatic pressing table and more than two manual placement stations. The circulated flow line is also provided with circularly delivered tool plates. The automatic water pump comprehensive testing platform, the air tightness testing unit, the main sealing automatic pressing table and the manual placement stations are respectively provided with a tool plate jacking unit and a positioning stopper. In the automatic flow assembly line for the water pump, a part to be assembled can be conveniently placed on the tool plate for corresponding installation during assembly, and different automatic tests can be performed on different stations, so the labor intensity is reduced, and the production efficiency is improved.

Owner:JUNHE PUMPS HLDG

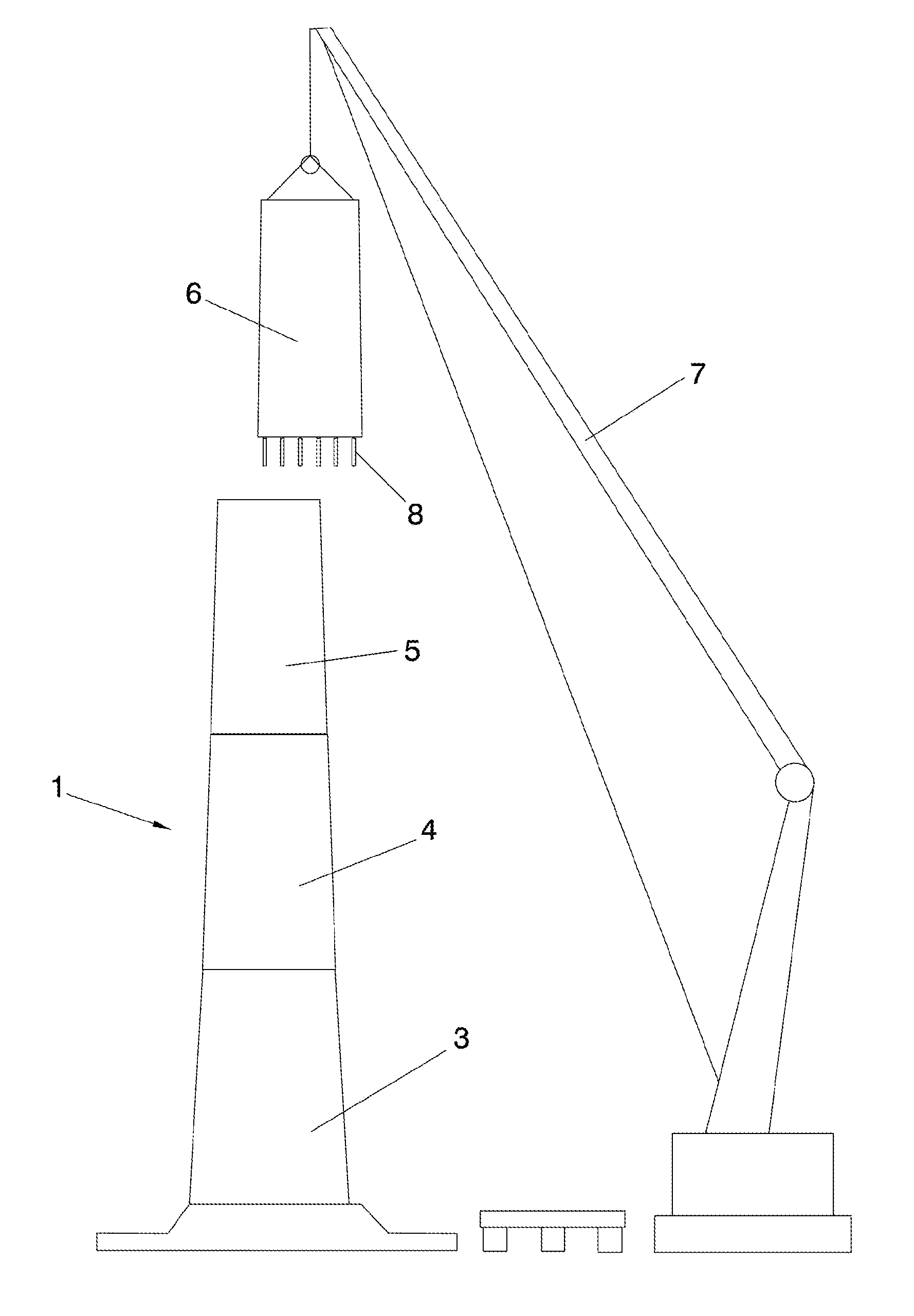

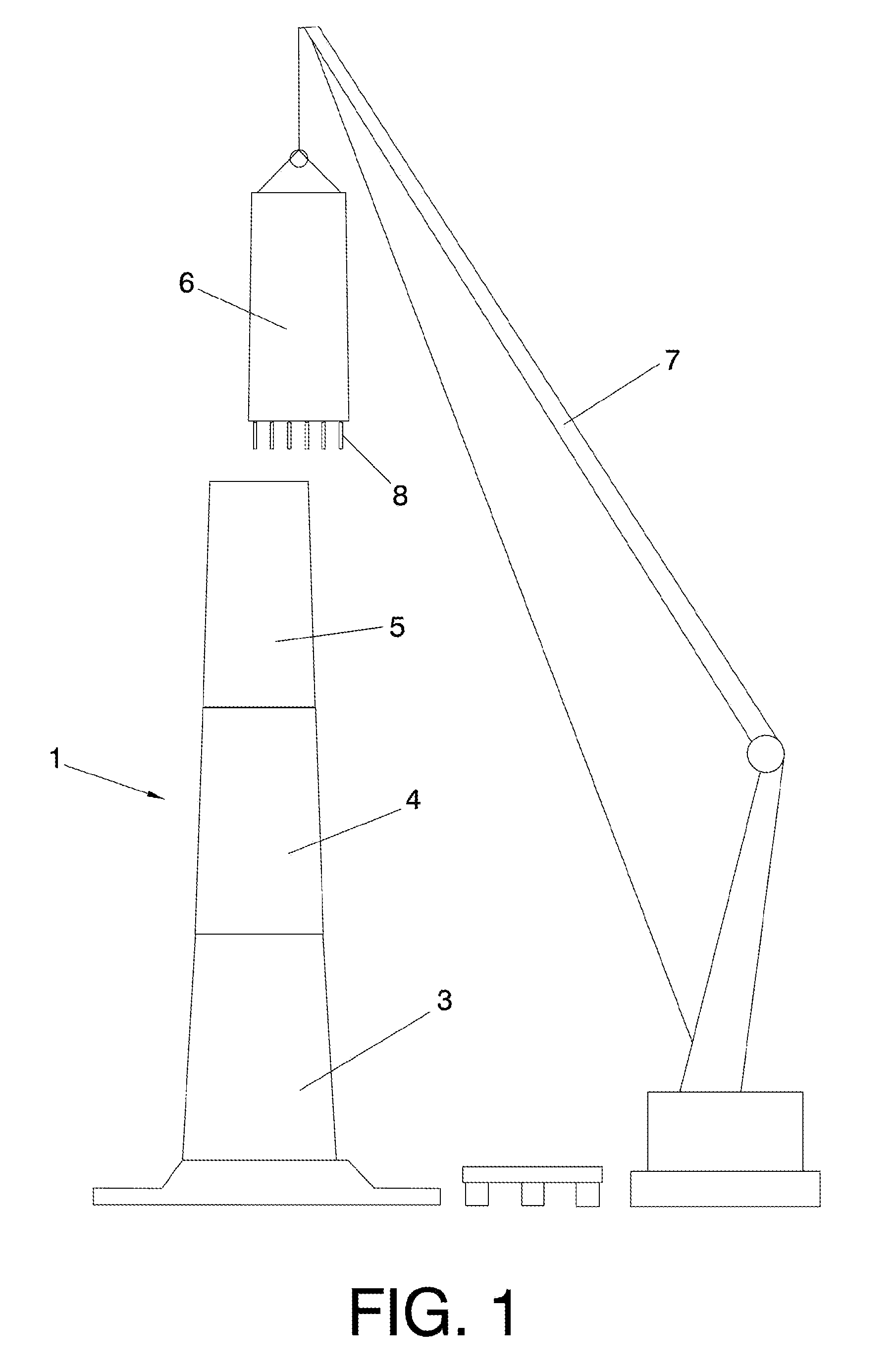

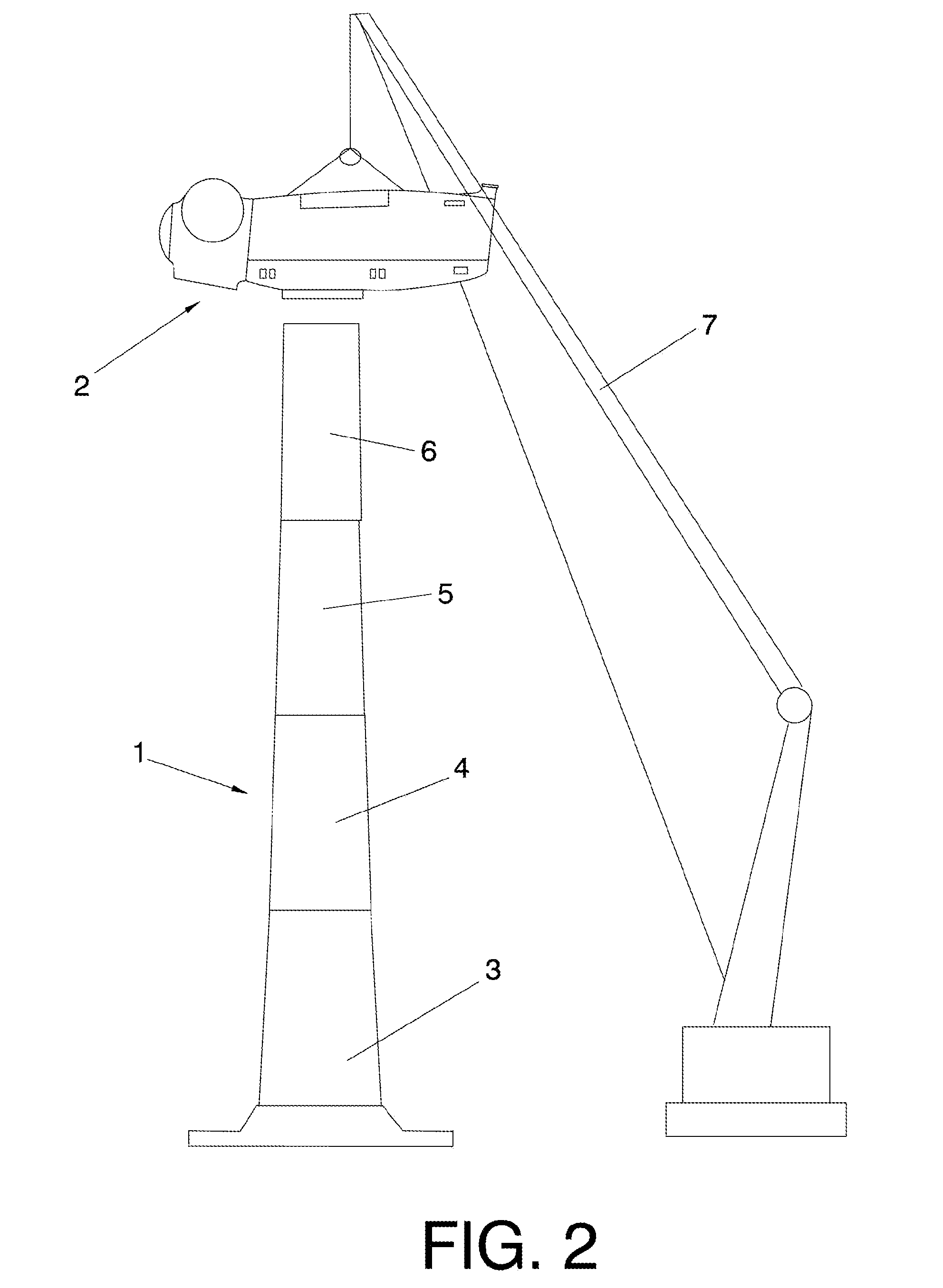

Wind turbine assembling method and wind turbine assembled according to said method

ActiveUS20130001954A1Increase speedImprove assembly speedEngine manufactureEngine fuctionsNacelleTower

The method allows higher speed in assembling a wind turbine a tower, a nacelle and a rotor, the tower comprising at least two stackable annular sections made of concrete, the method comprising the steps of a) stacking the annular sections by using lifting and positioning means; b) stacking the nacelle onto the upper annular section by using lifting and positioning means; and c) connecting the annular sections to each other, as well as the upper annular section to the nacelle, through main connecting means adapted to withstand loads induced by the wind turbine rotor, wherein the step c) is performed after stacking the nacelle onto the upper annular section.

Owner:NORDEX ENERGY SPAIN SA

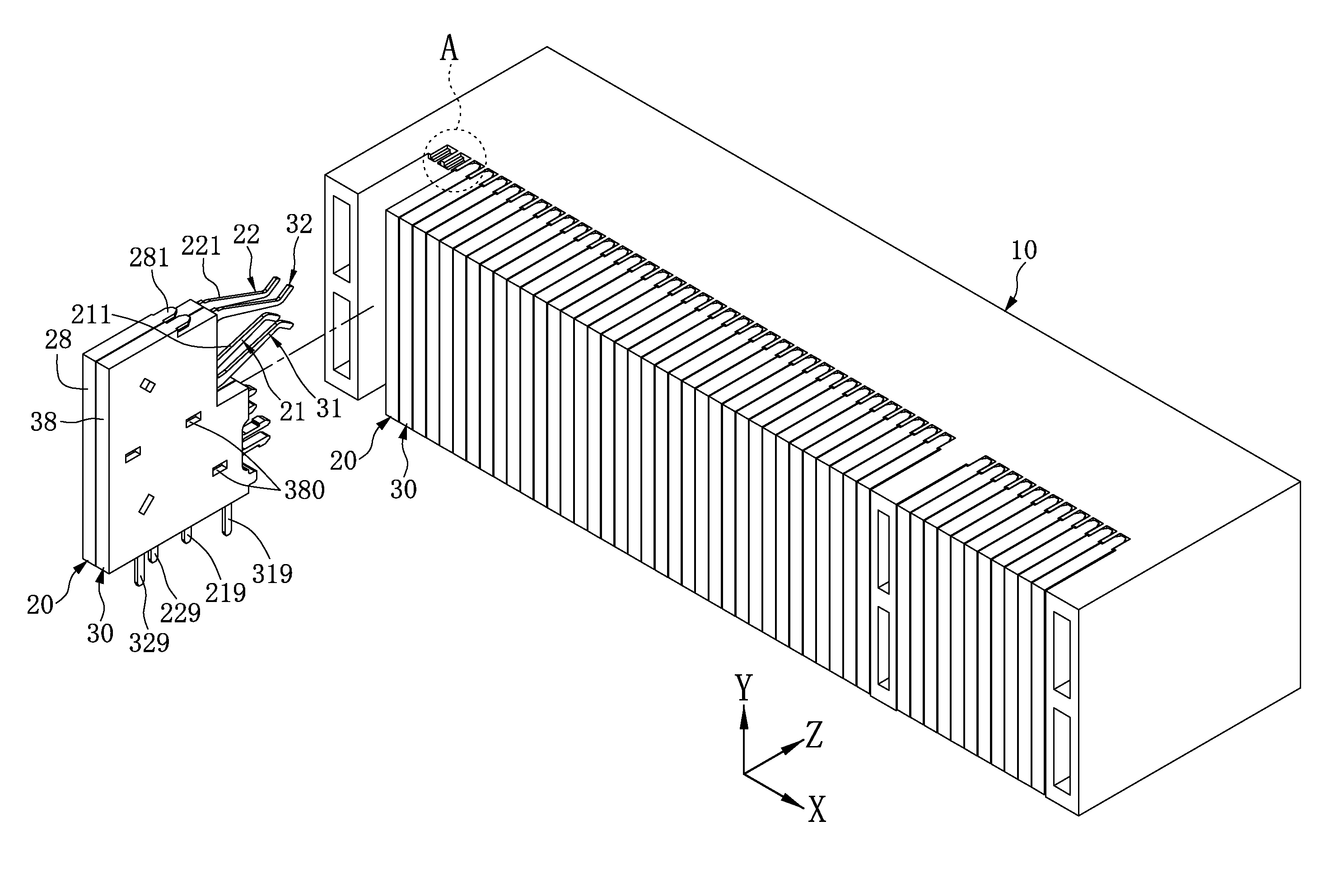

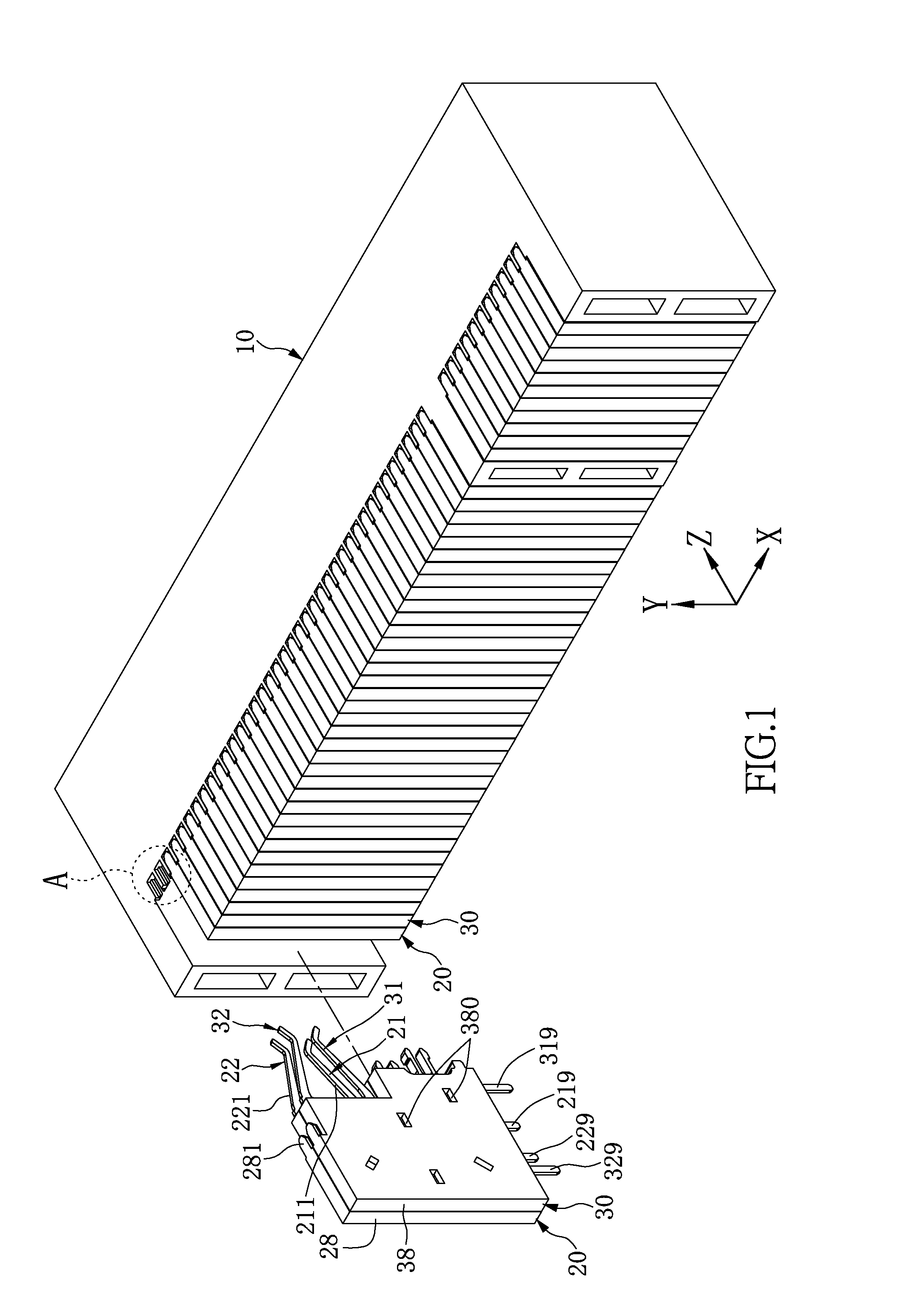

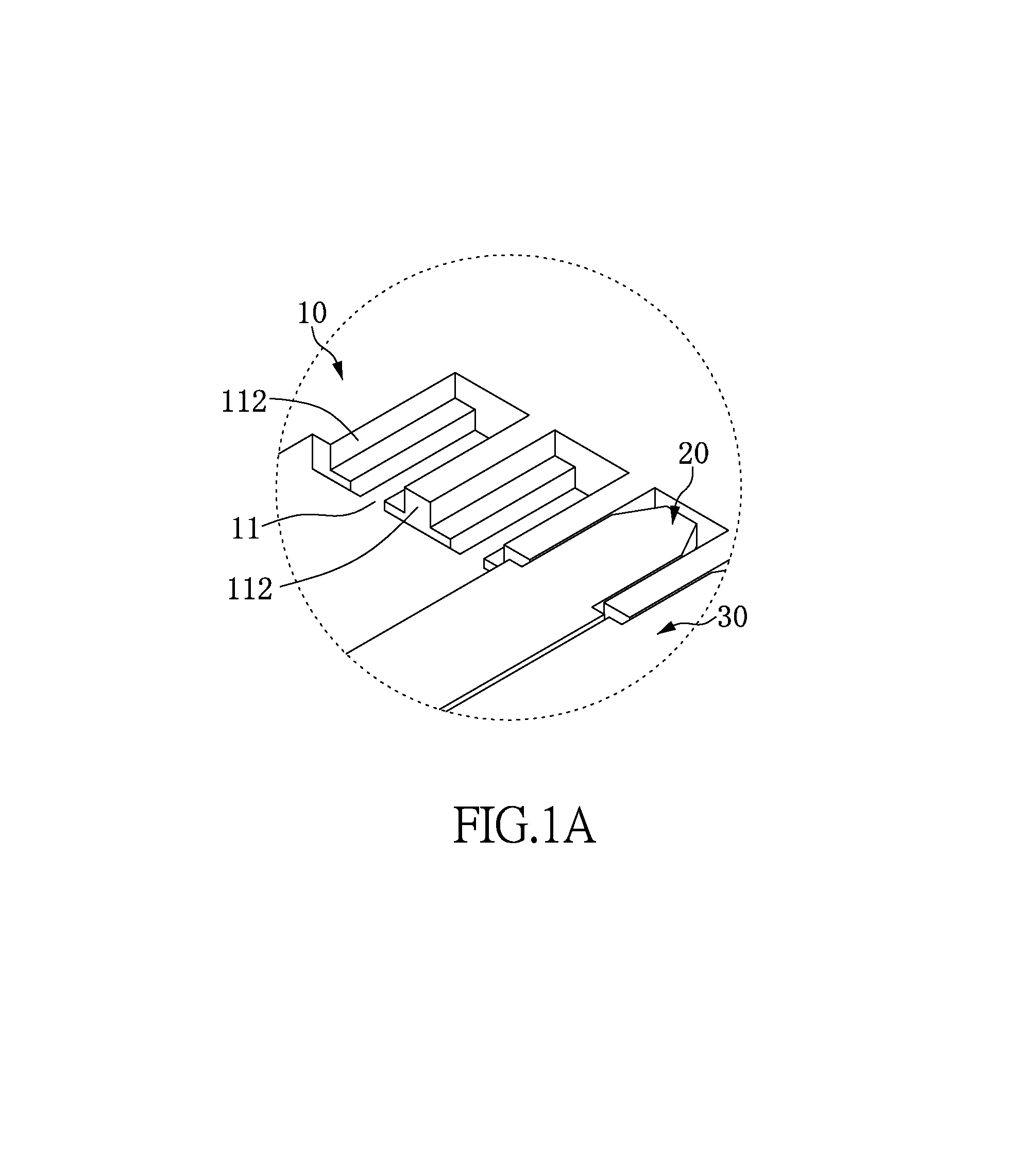

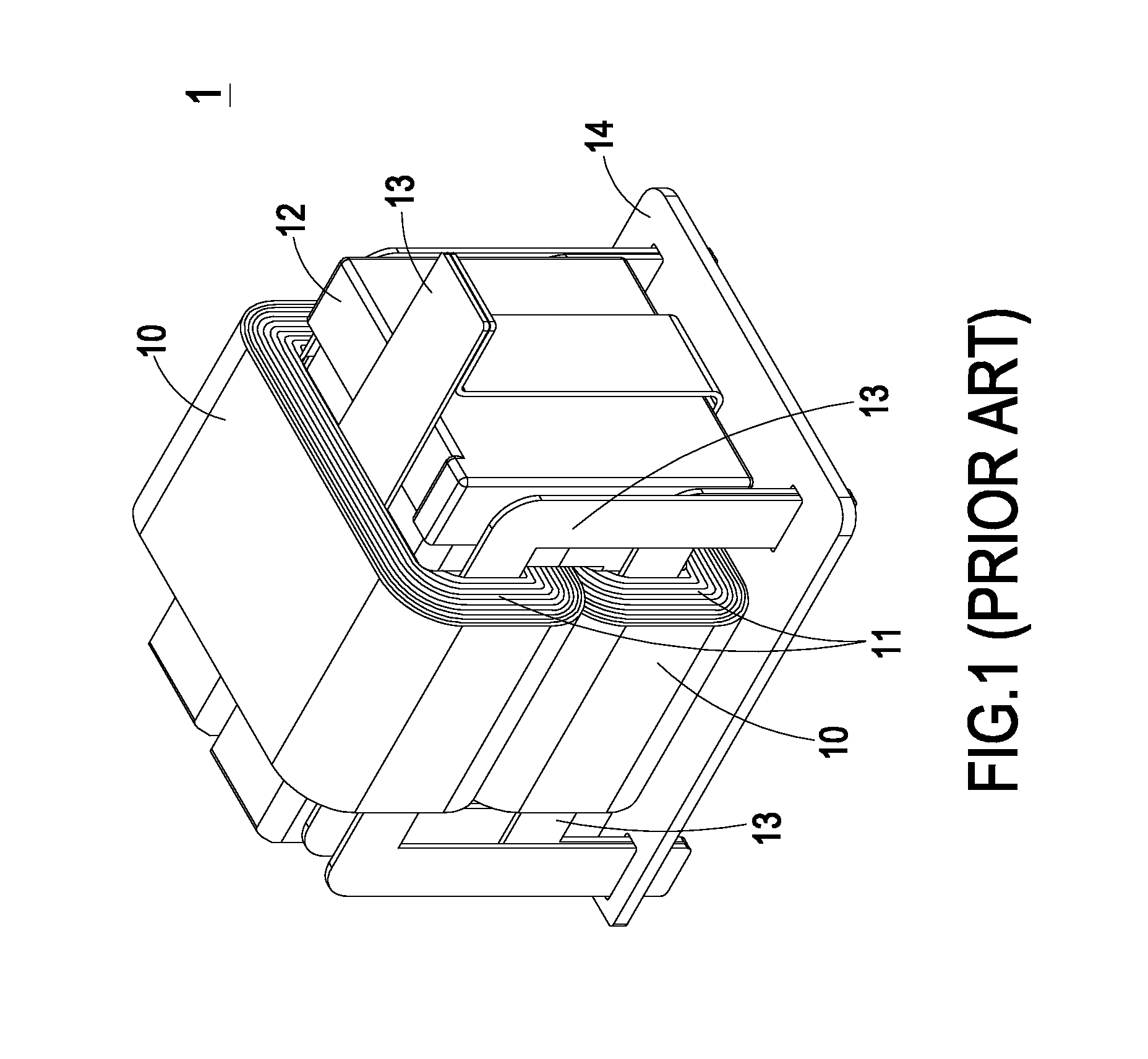

Electrical connector having terminals embedded in a packaging body

ActiveUS9543688B2Prevent terminals from being deformedStable structureCoupling device detailsSoldered/welded conductive connectionsElectricityEngineering

An electrical connector includes a housing and a plurality of terminal wafers. The housing is formed with a plurality of terminal slots along a traverse direction. The terminal wafers are contiguous to each other and retained in the housing. Each terminal wafer has a first terminal, a second terminal and a packaging body. The first terminal has a first contacting section, a first soldering portion and a first embedded section. The second terminal has a second contacting section, a second soldering portion and a second embedded section. The first and second contacting sections are extended along a plugging direction into one corresponding terminal slot. The packaging body wraps the first and second embedded sections. A curve contour of the first embedded section is corresponded to a curve contour of the second embedded section, so that an attachment relationship is configured with substantial identical distance therebetween.

Owner:CHIEF LAND ELECTRONICS CO LTD

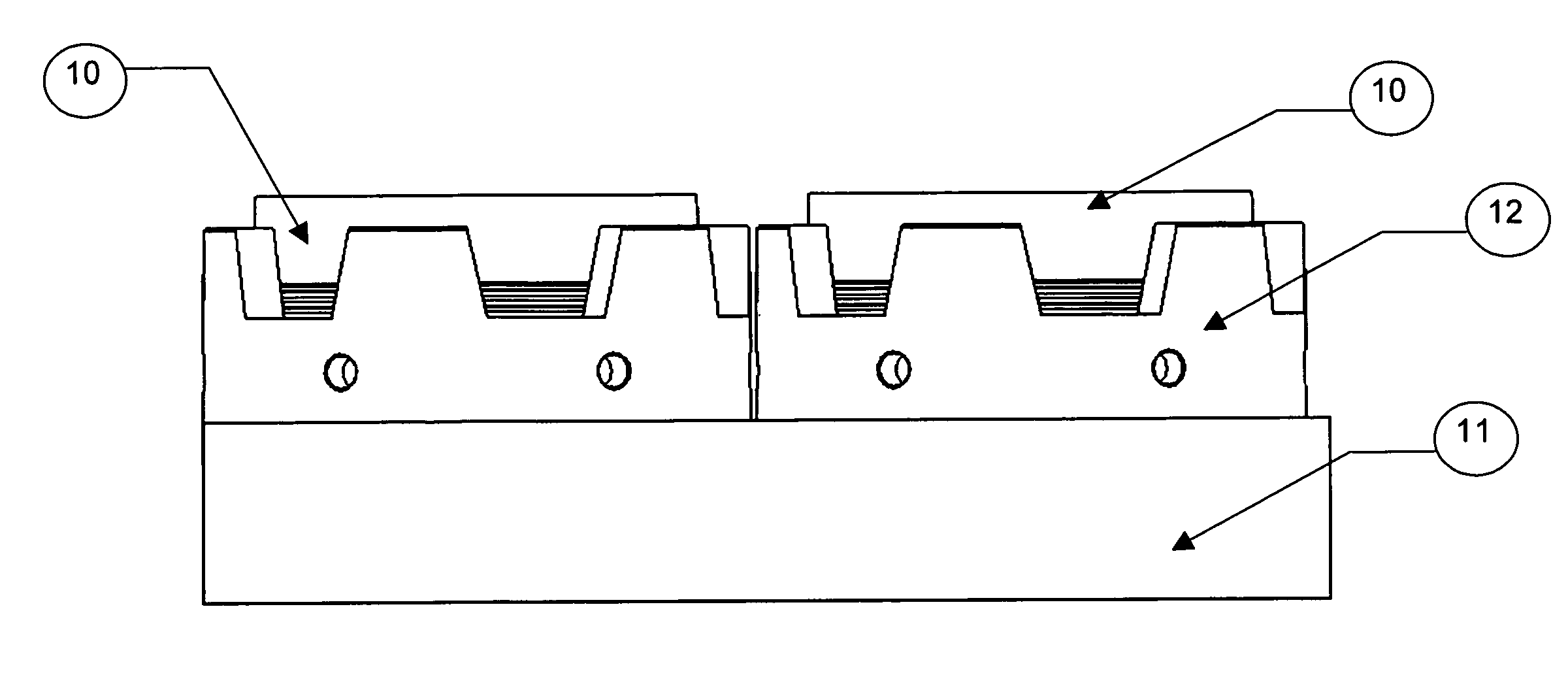

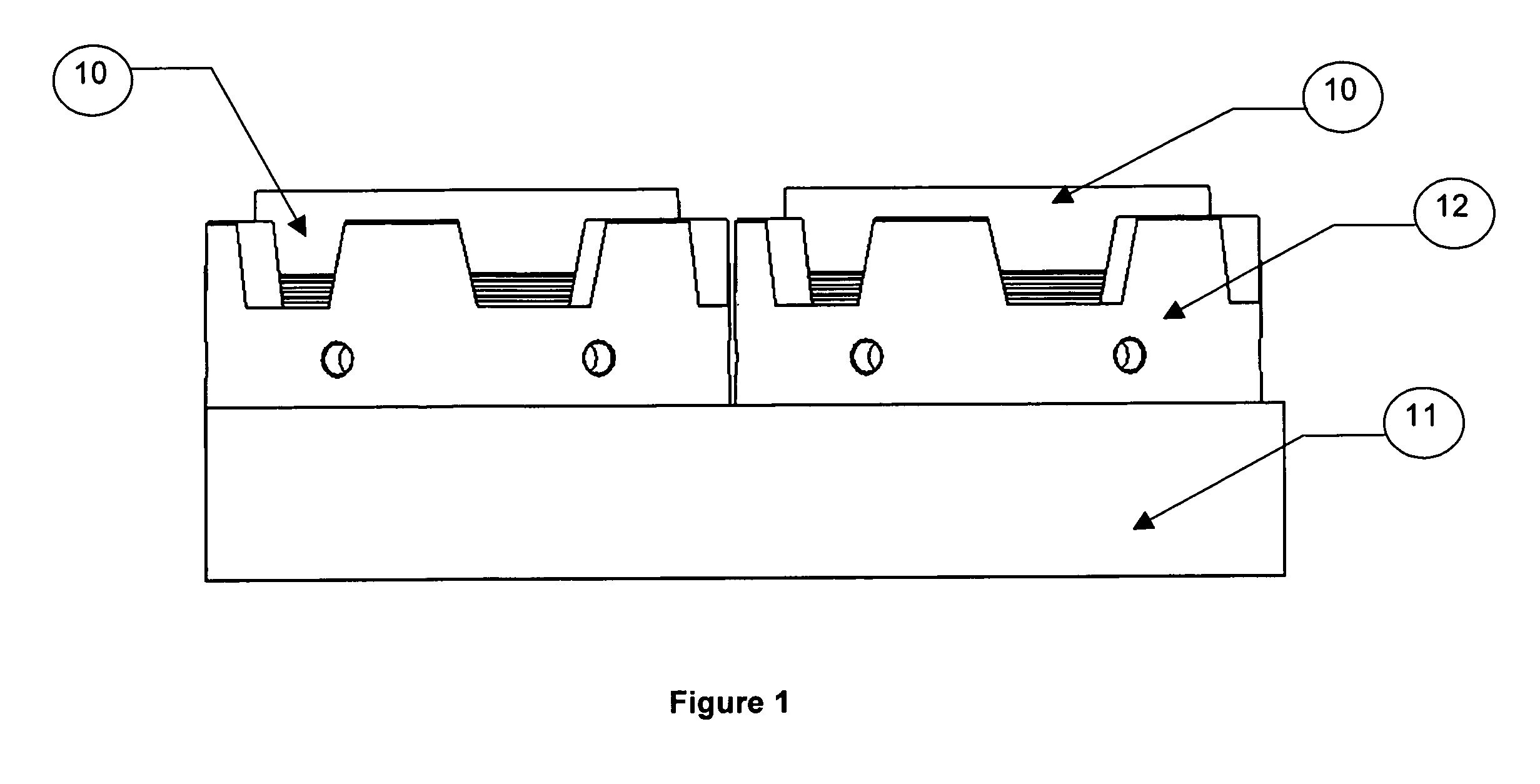

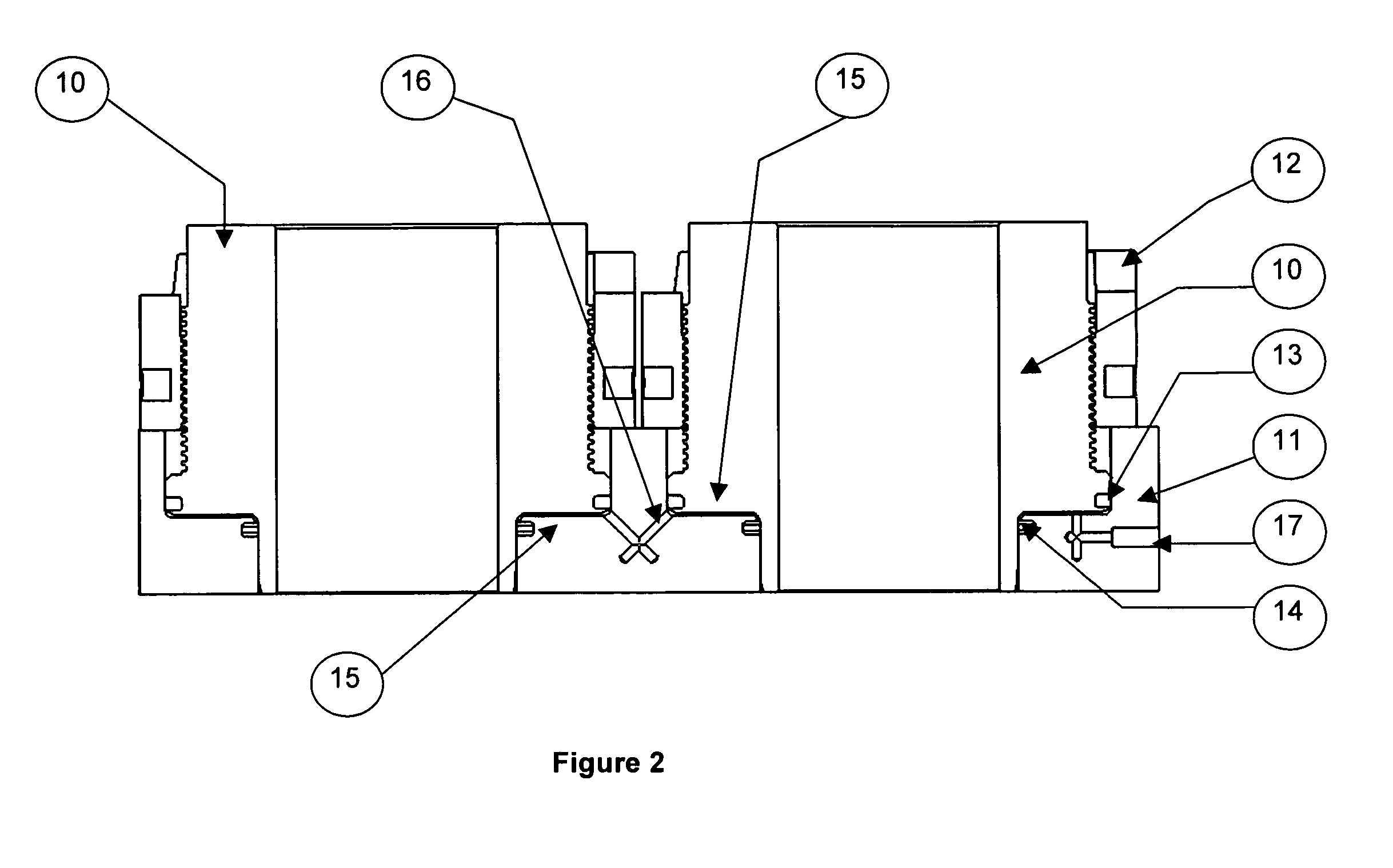

Fuel cell unit structure and electric pile assembly

ActiveCN101083335AReduce in quantityReduce typesFuel cells groupingFinal product manufactureThermodynamicsFuel cells

The invention relates to the combination cell structural design which is sealed by the fuel cell metal pole plate and the membrane electrode module, concretely is a fuel cell cellular structure and its pile assembly, which includes the mold pressing metal pole plate which has two pieces flow field and the membrane electrode module (MEA). The fuel cell pole plate seals MEA and the seal structure in together and combines the orientation slot and the inspect slot to form the fuel cell unit. The structure formed the only unit module of the generate electric element when groups the pile, reduced the component quantity of the pile assembly, enhanced the assembly speed and the size stability of the pile, and reduced the replacement damage of MEA when assembles, is advantageous in enhances battery's performance, suits the mechanized production of the pole plate and the pile assembly.

Owner:SUNRISE POWER CO LTD

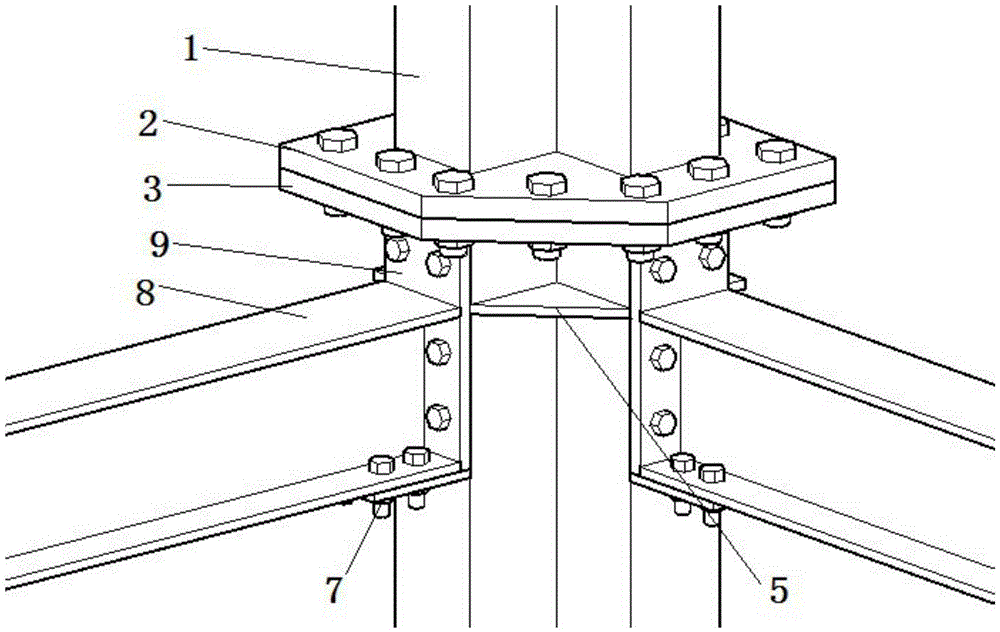

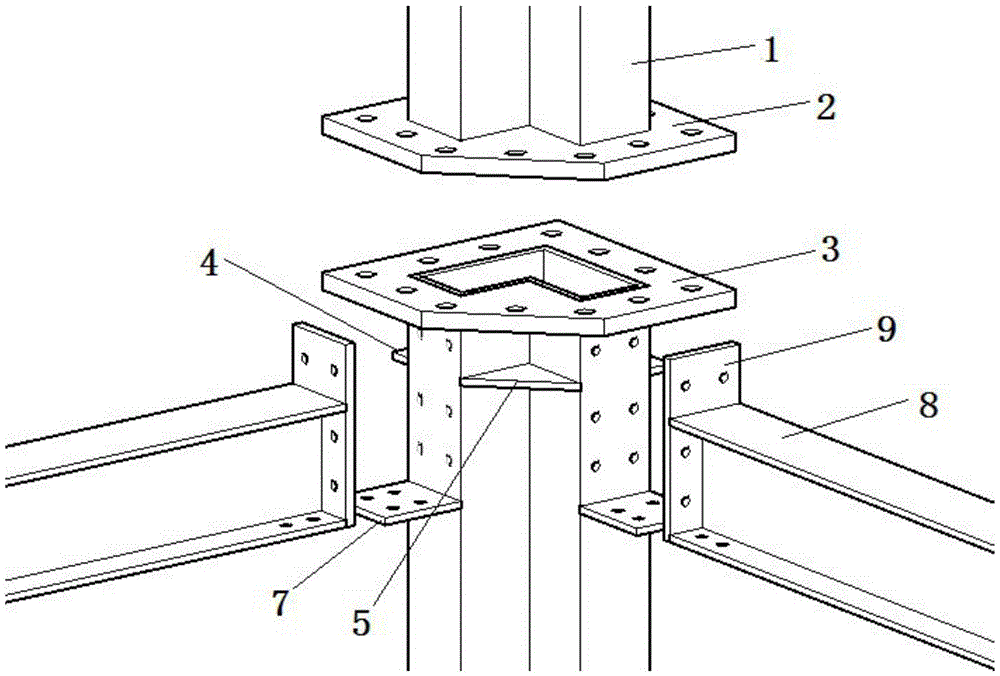

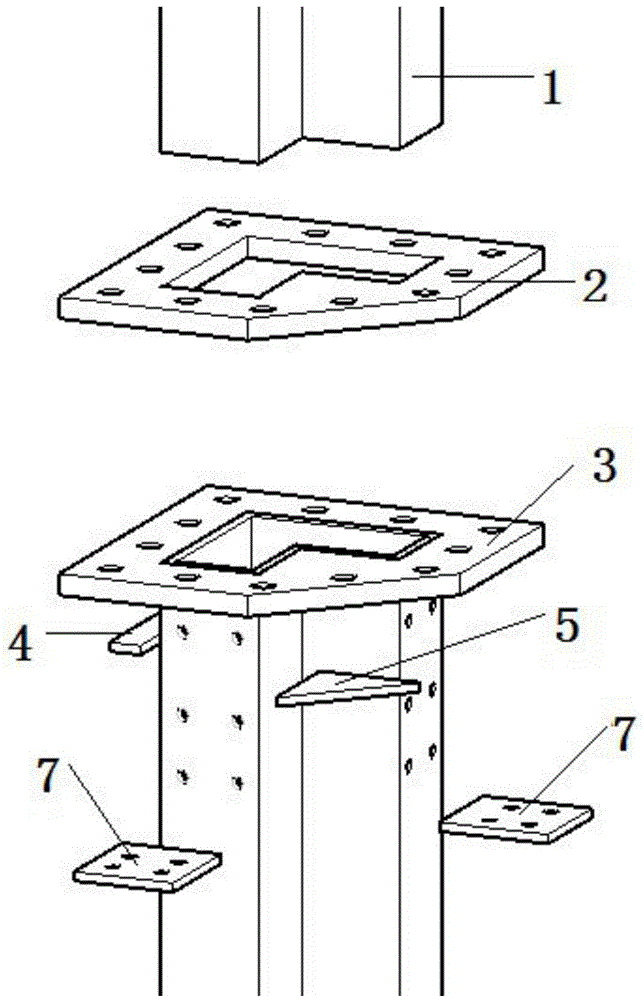

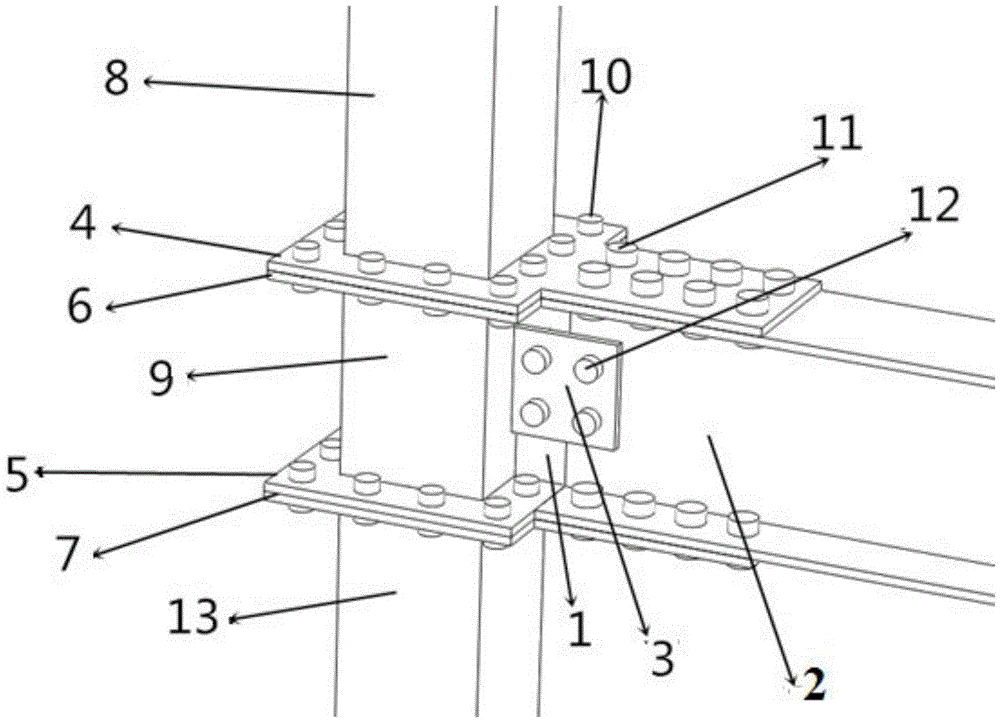

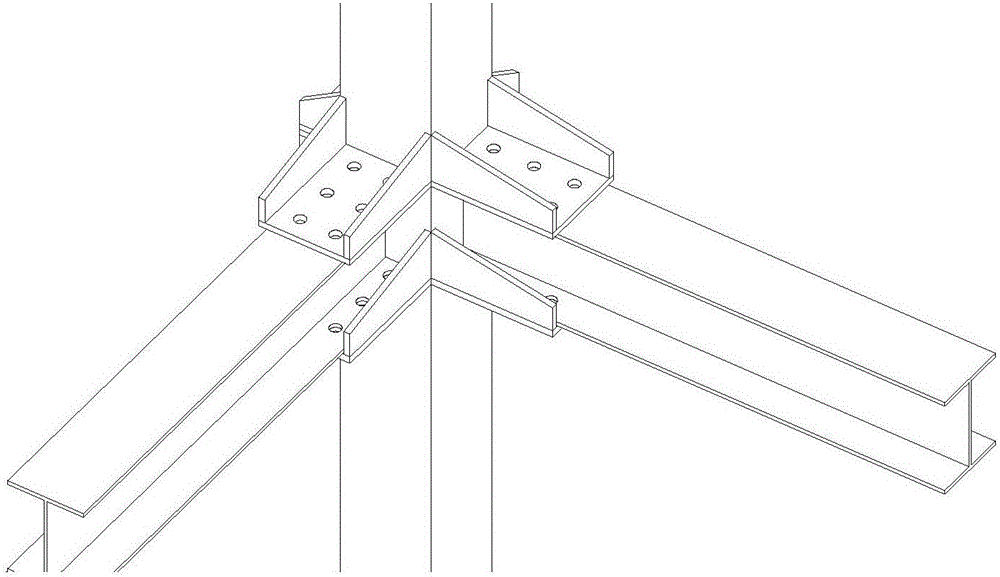

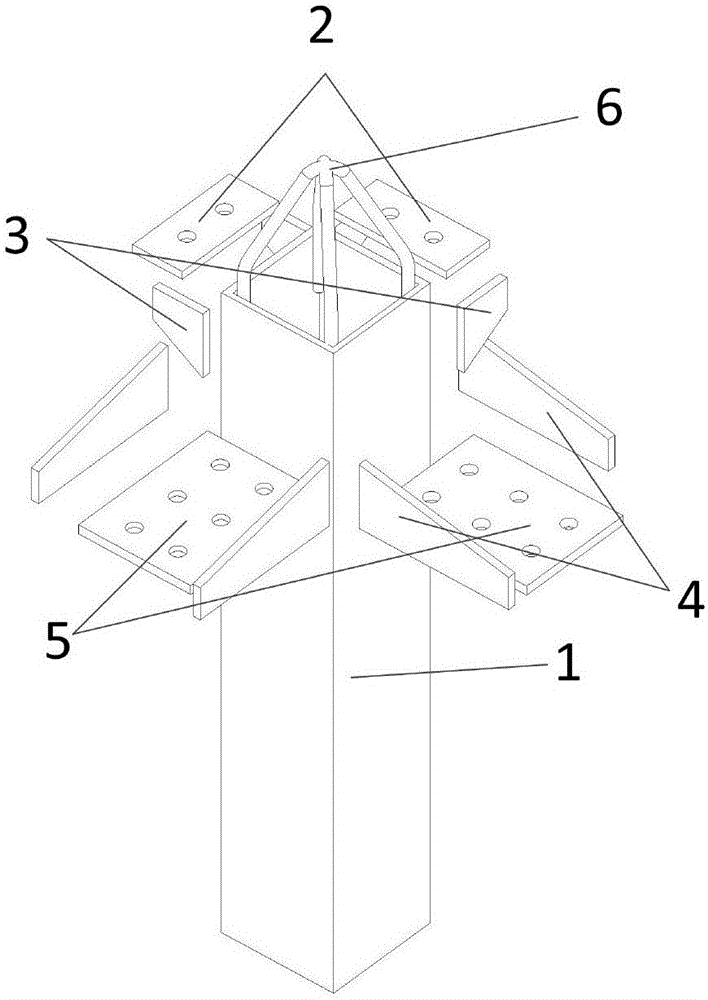

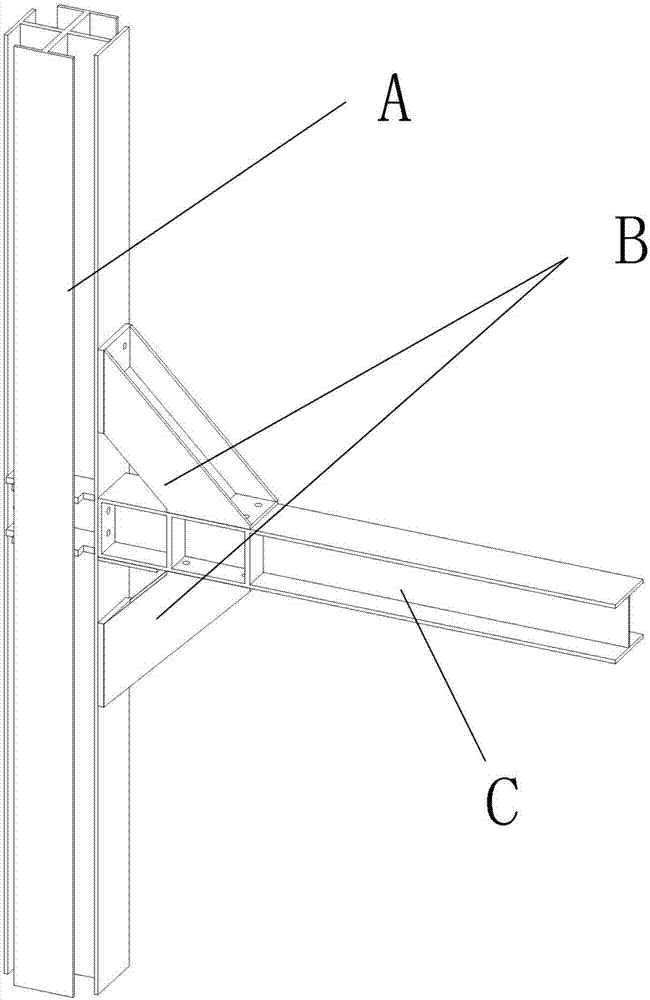

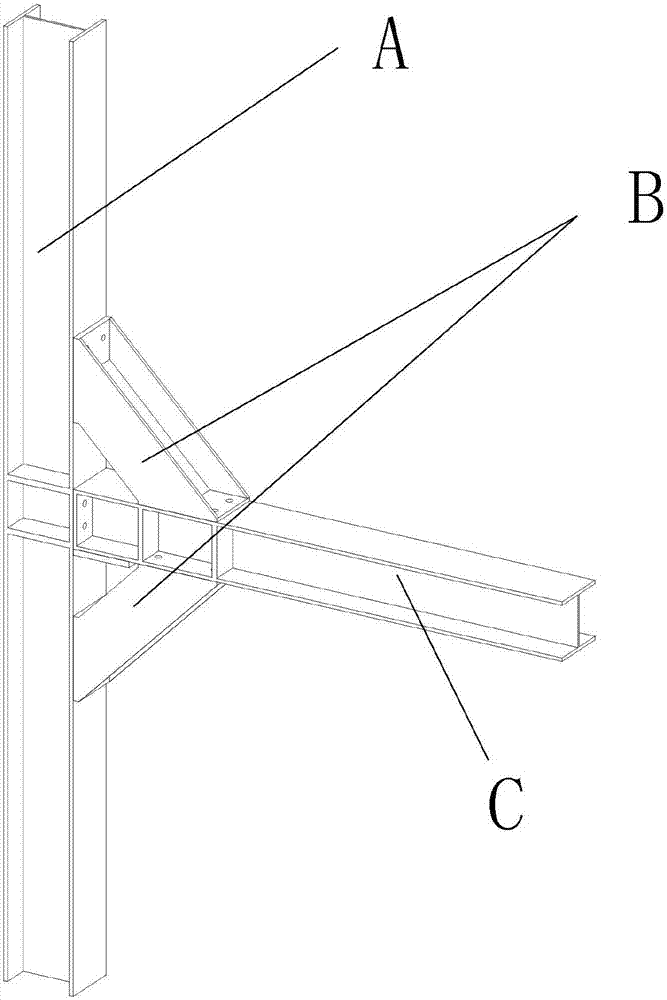

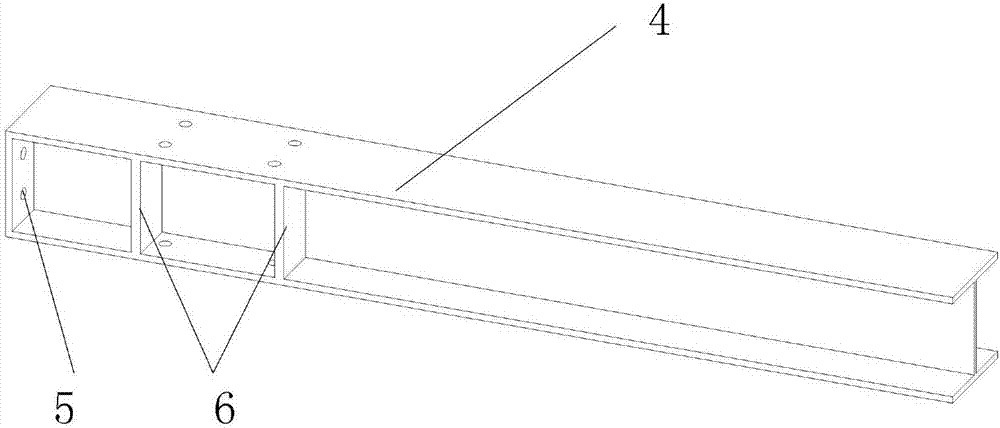

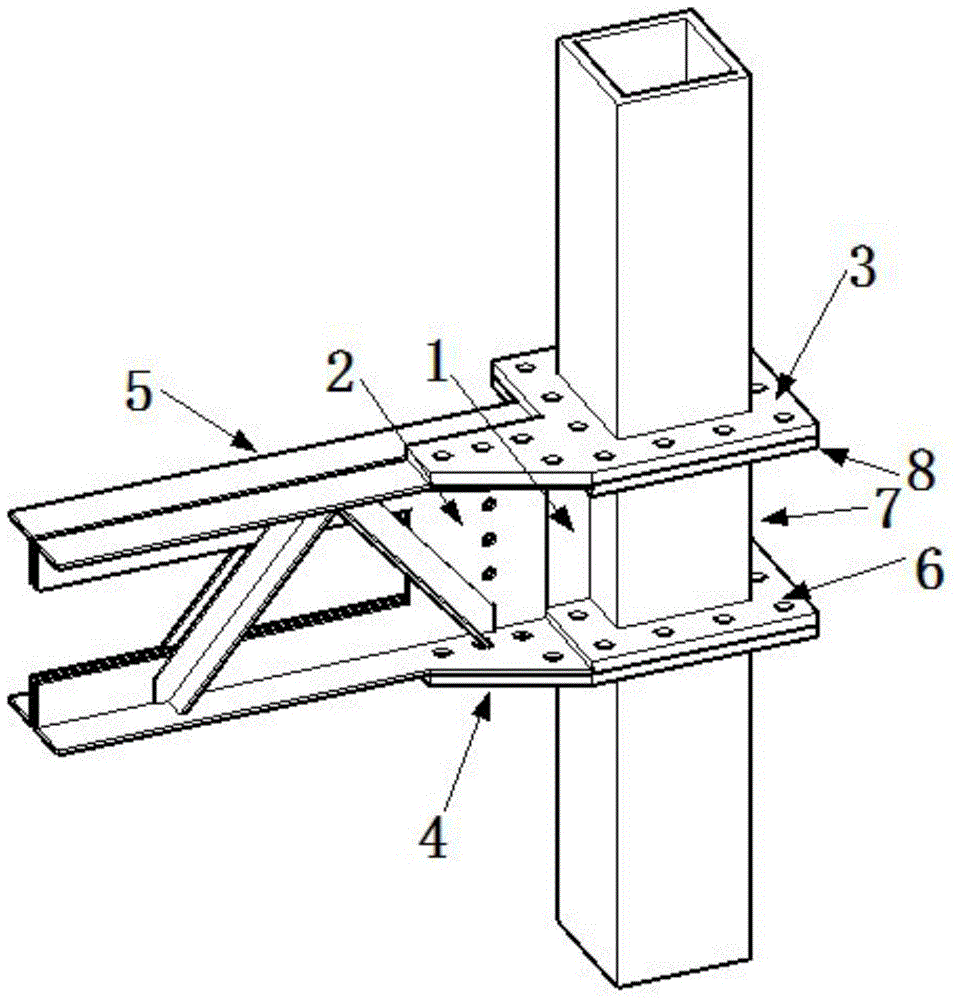

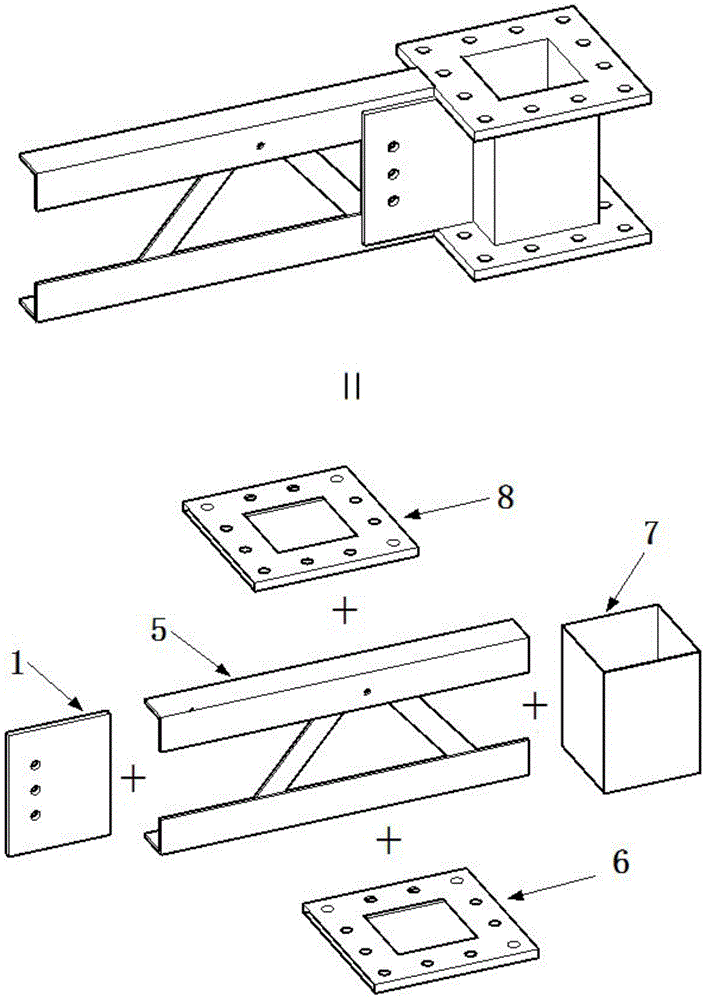

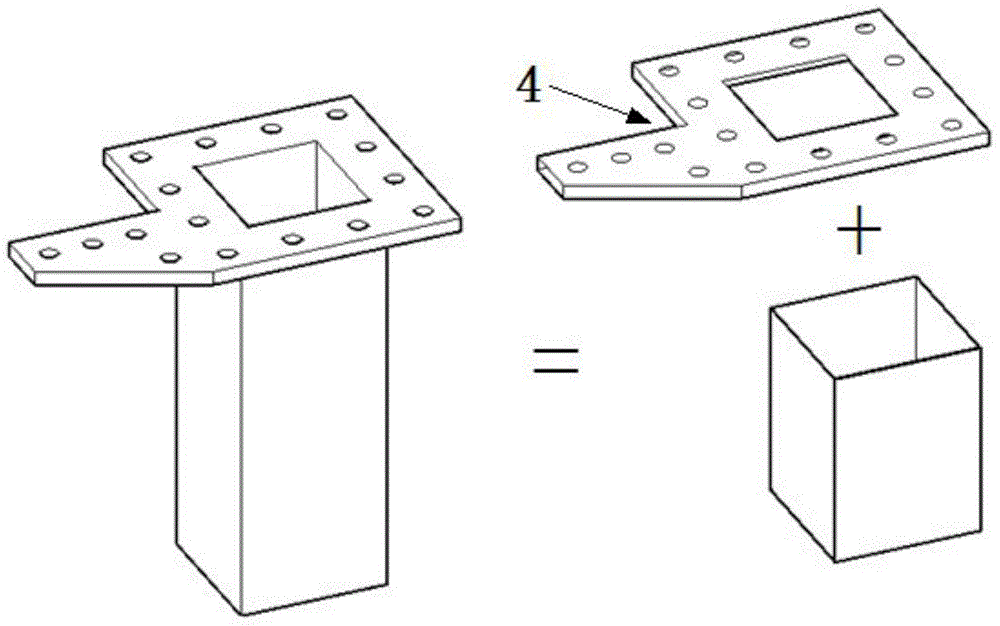

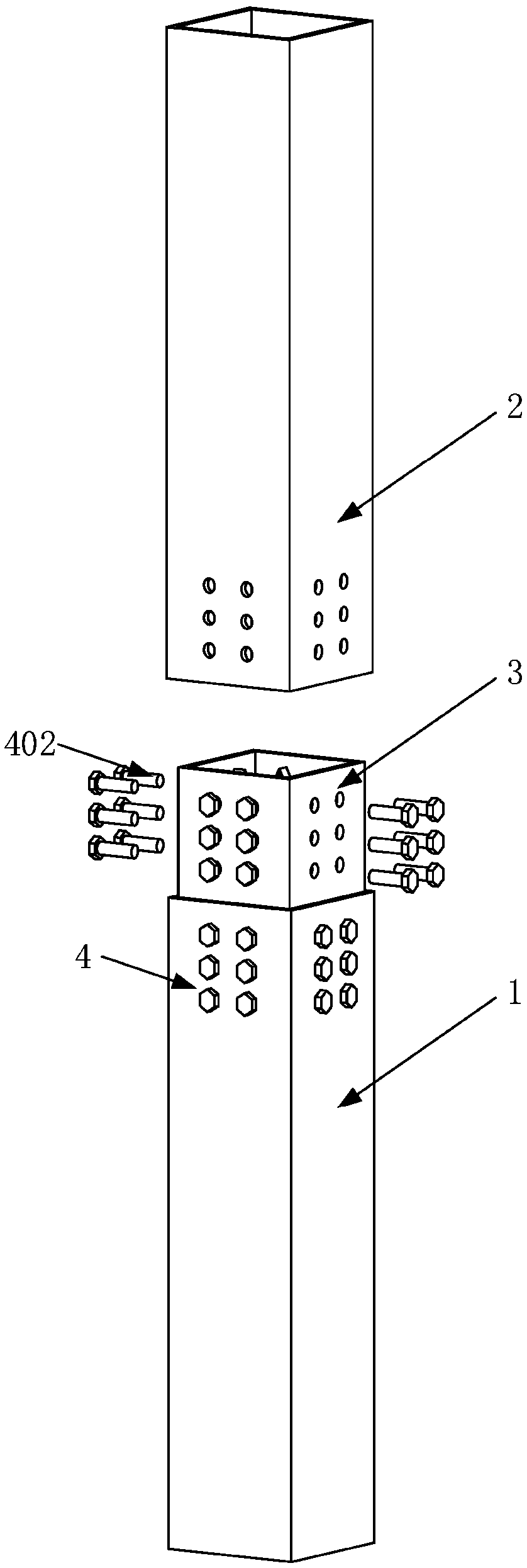

Beam-column node connecting device for assembled steelwork

InactiveCN105604187AEasy to operateImprove assembly speedBuilding constructionsArchitectural engineeringBeam column

The invention relates to a beam-column node connecting device for assembled steelwork and belongs to the technical field of structural engineering. The beam-column node connecting device comprises an upper column, a lower column and beams. Each of the upper and lower columns is manufactured in a factory through welding an L-shaped square tubular column, a column top ring flange, a column bottom ring flange, an external fin I, an external fin II, an internal fin and supporting plates, and each beam is manufactured in a factory through welding an H-shaped steel beam and an end plate; the form of the column is not limited to L-shaped square tubular columns, and other irregular columns or box-shaped columns can be selected. According to the beam-column node connecting device for the assembled steelwork, welding work is completely completed in the factories, assembling is carried out on site by adopting bolts, the work of bolt fastening is convenient and fast, and the speed and quality of construction are greatly improved, so that factory production and on-site rapid assembling are achieved.

Owner:迁安市金东顺防腐工程有限公司

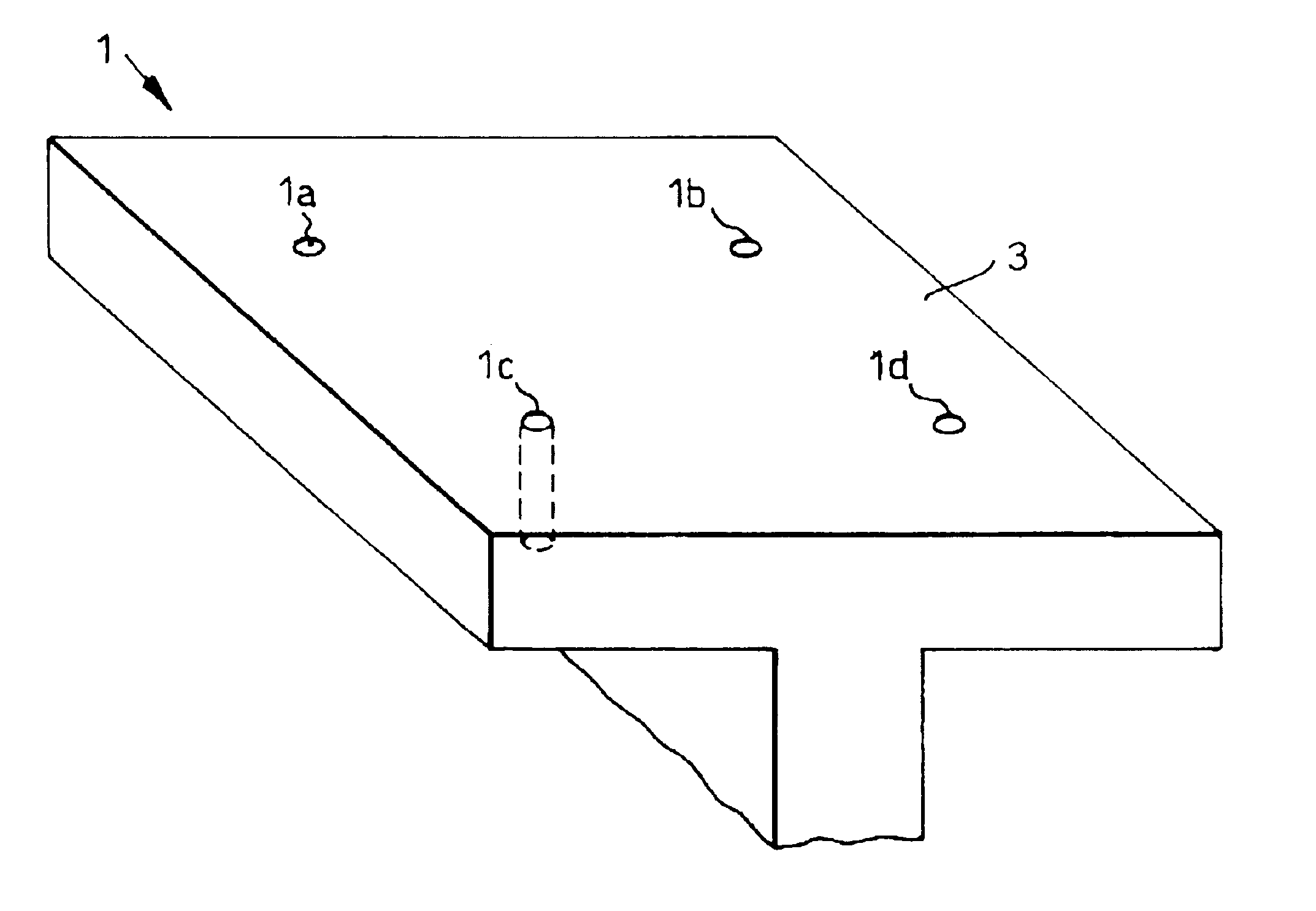

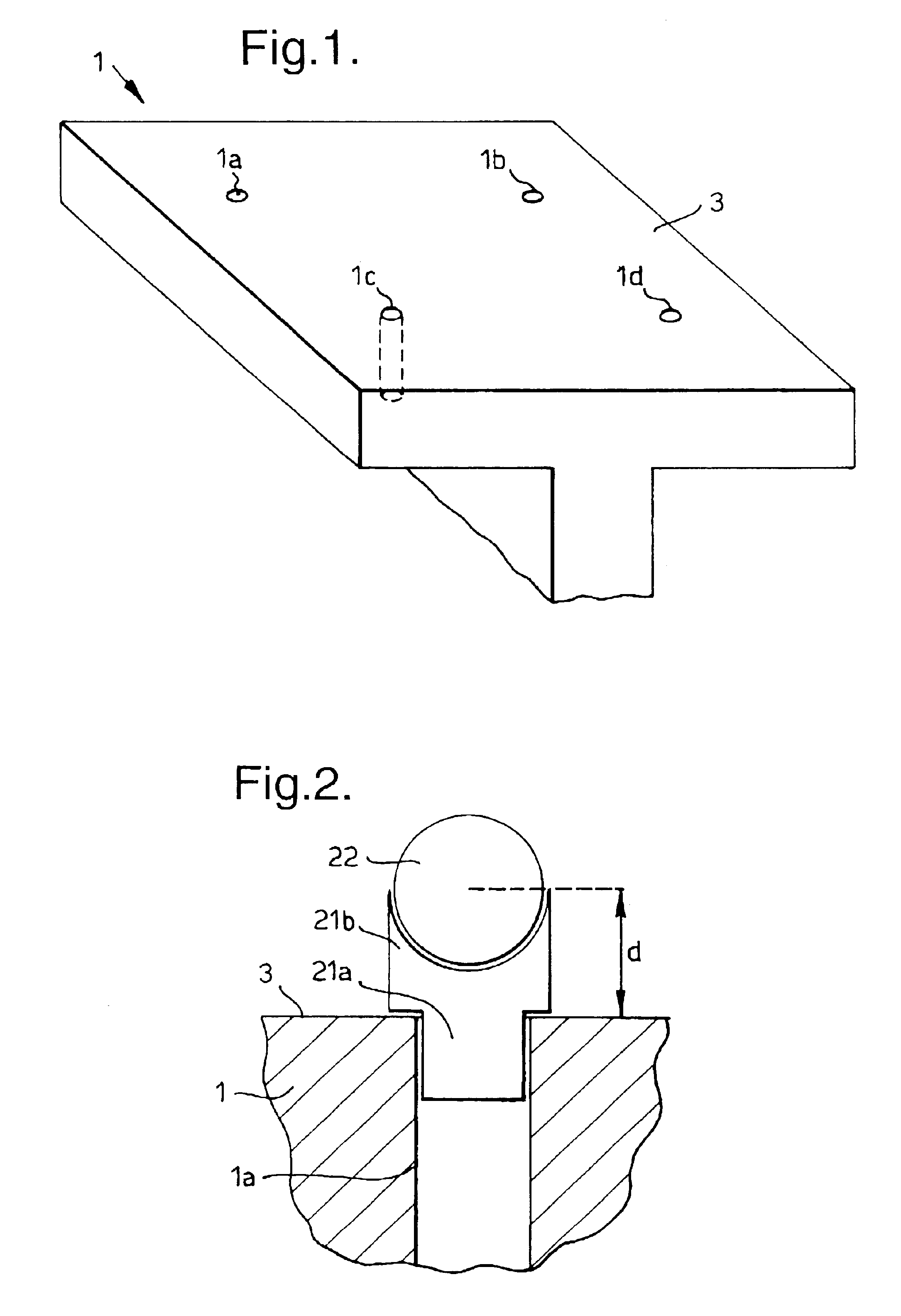

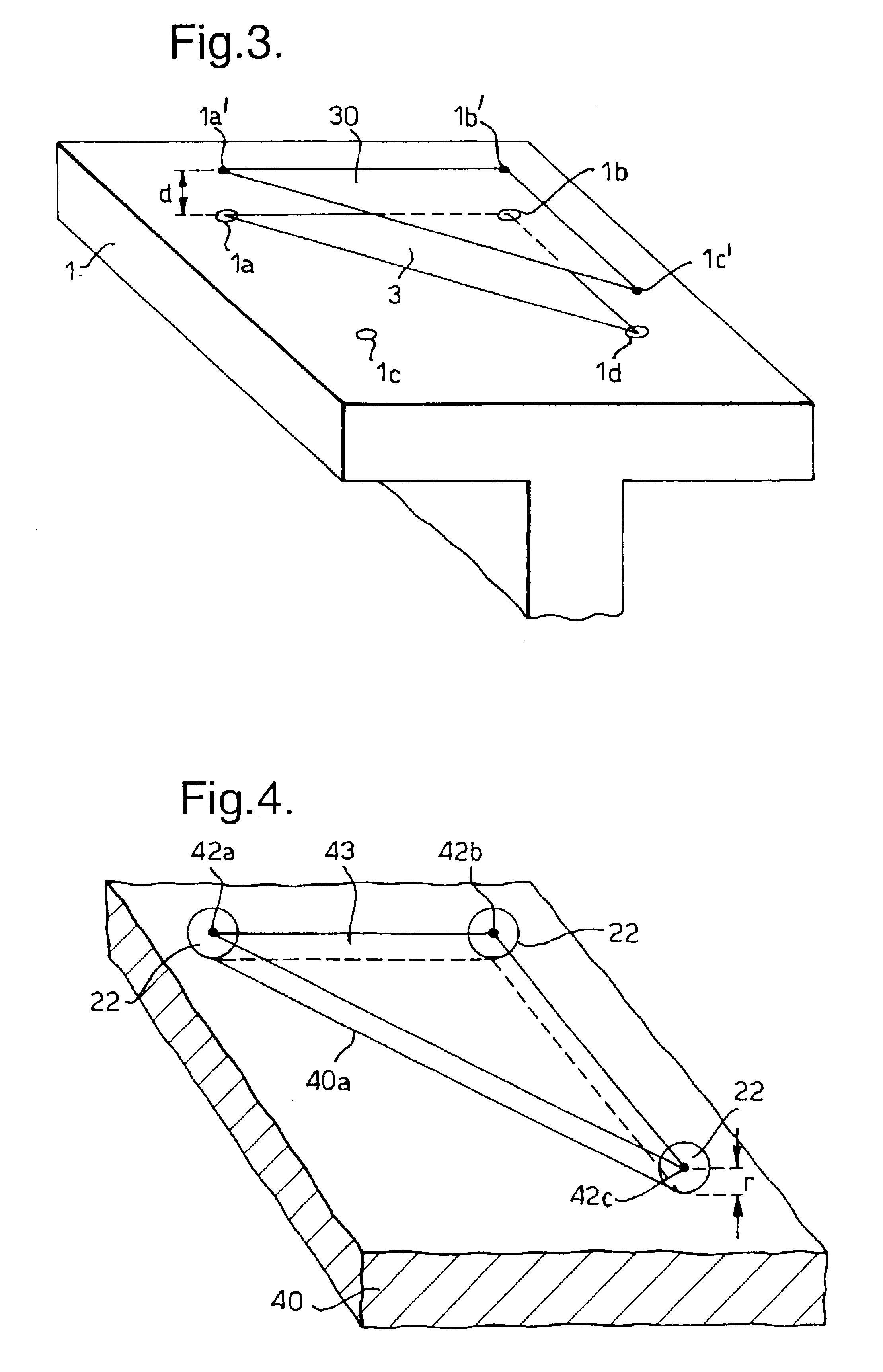

Assembly method

InactiveUS6892160B2Accurate identificationEfficient methodDrilling/boring measurement devicesDigital computer detailsEngineeringAssembly line

A method of locating an assembly point (P) on a first part (40), at which assembly point the first part is to be joined to a second part (1), the method comprising the steps of: determining an assembly location (1a, 1b, 1c, 1d) in respect of the second part; measuring a portion (42a, 42b, 42c) of a surface (43) of the first part, the surface being spaced away from the second part, so as to define the position and orientation of the surface; and, calculating the assembly point on the surface of the first part, where the surface of the first part is intersected by a vector (N) passing between the determined assembly location and the surface of the first part.

Owner:BAE SYSTEMS PLC

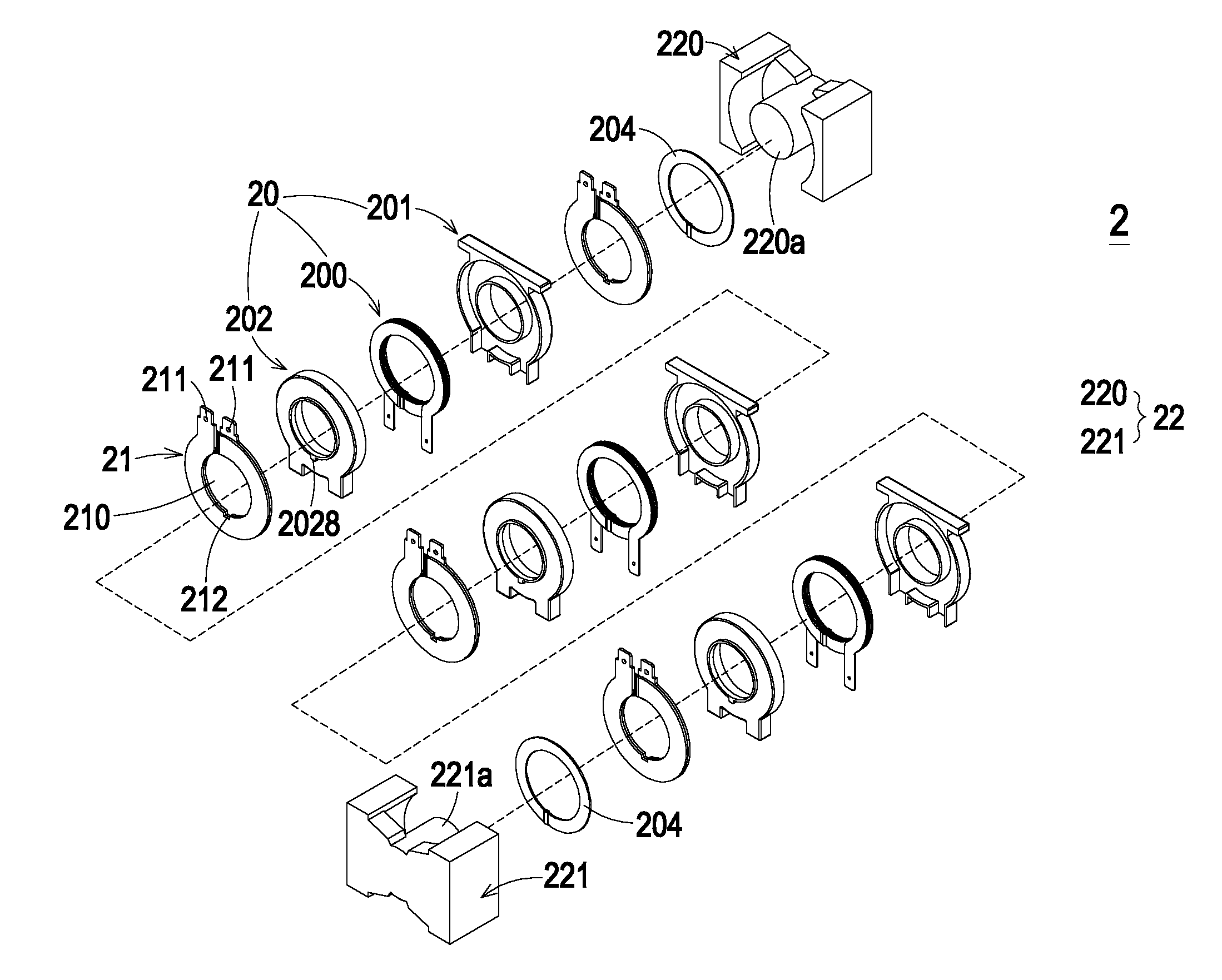

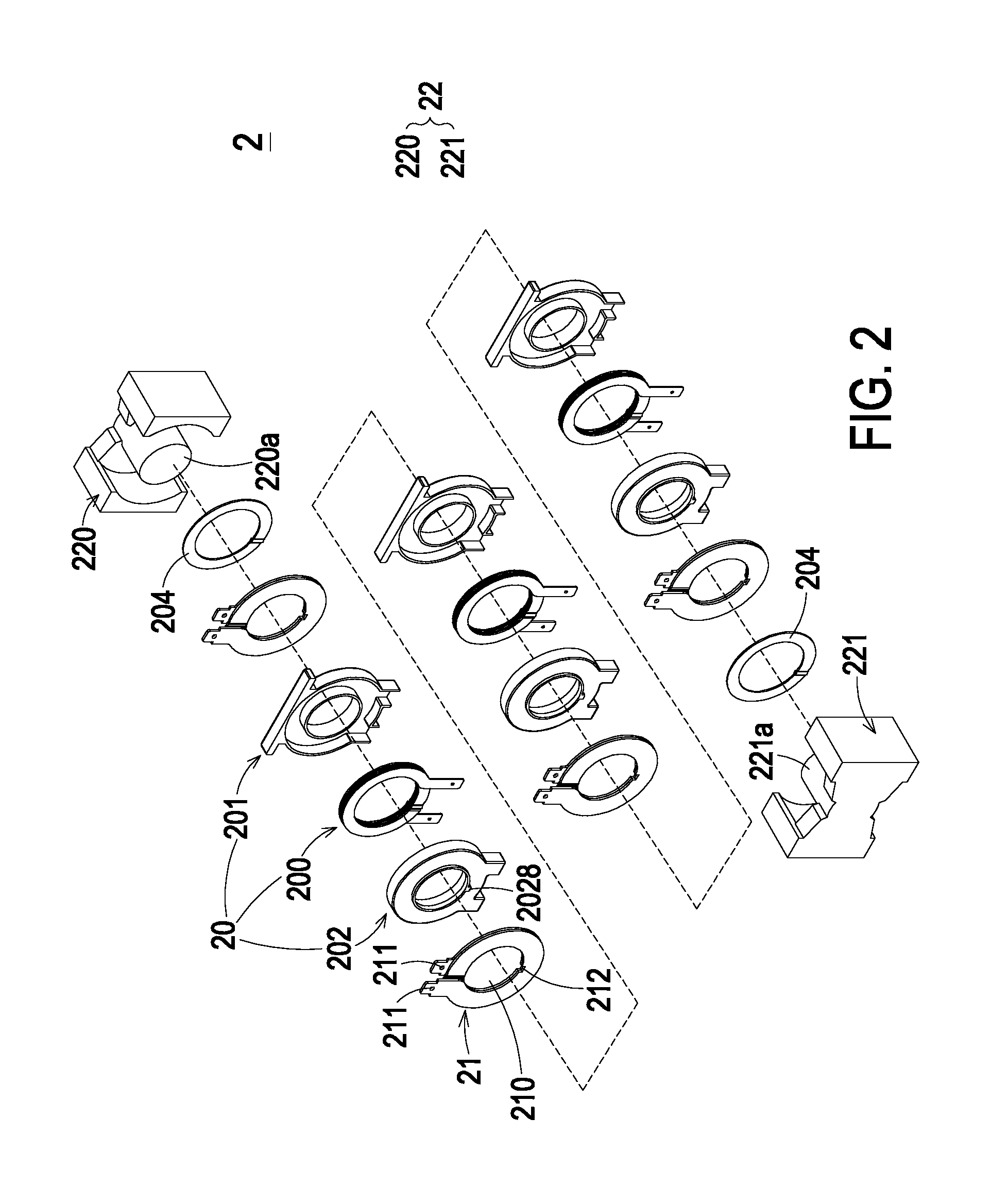

Primary side module and transformer with same

ActiveUS20140327511A1Improve universal usabilityImprove assembly speedTransformers/inductances coils/windings/connectionsTransformerStructural engineering

A transformer includes a primary side module, a secondary winding structure, and a magnetic core assembly. The primary side module includes a primary winding structure, a first covering structure and a second covering structure. The primary winding structure has a first opening. The first covering structure includes a second opening corresponding to the first opening and a first receiving recess for accommodating the primary winding structure. The first receiving recess is covered and sealed by the second covering structure. The second covering structure includes a third opening corresponding to the first opening. The first opening, the second opening and the third opening are in communication with each other to be defined as a channel. The secondary winding structure includes a fourth opening, which is in communication with the channel. The magnetic core assembly is partially embedded within the channel and the fourth opening.

Owner:DELTA ELECTRONICS INC

Unibody hydraulic nut

ActiveUS7673849B2Easy to useTime savings during flange assembly and disassemblyLoad modified fastenersSecuring devicesEngineeringScrew thread

Owner:INTEGRA TECHNOLOGIES LTD

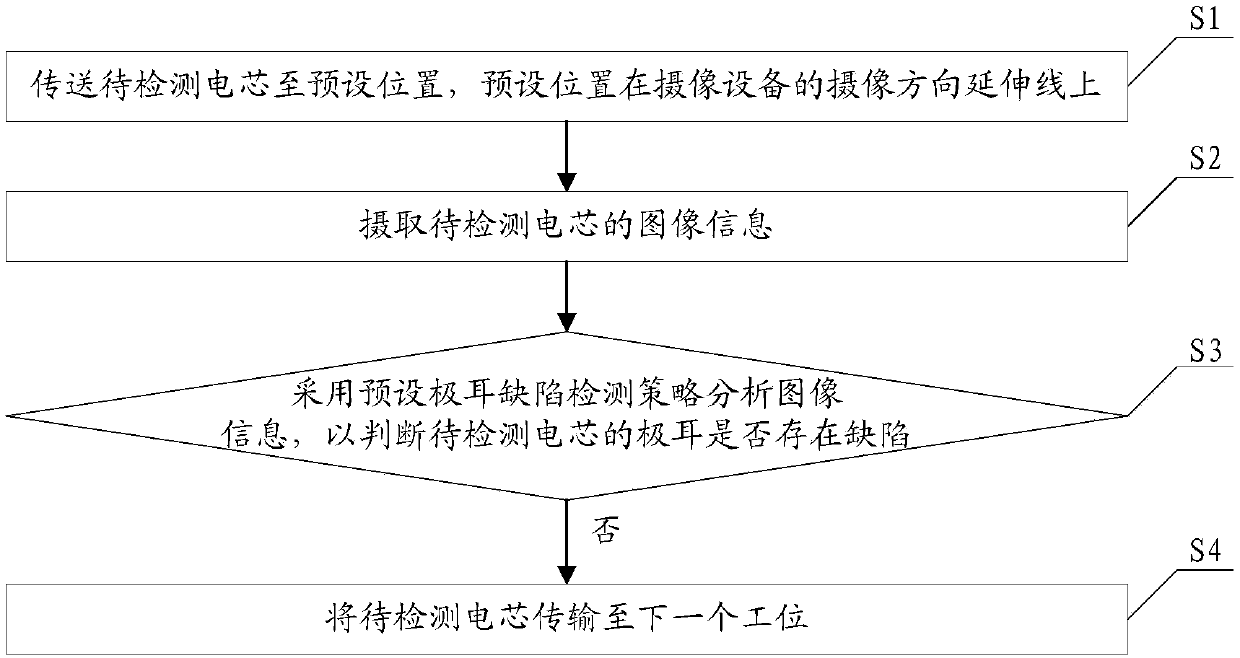

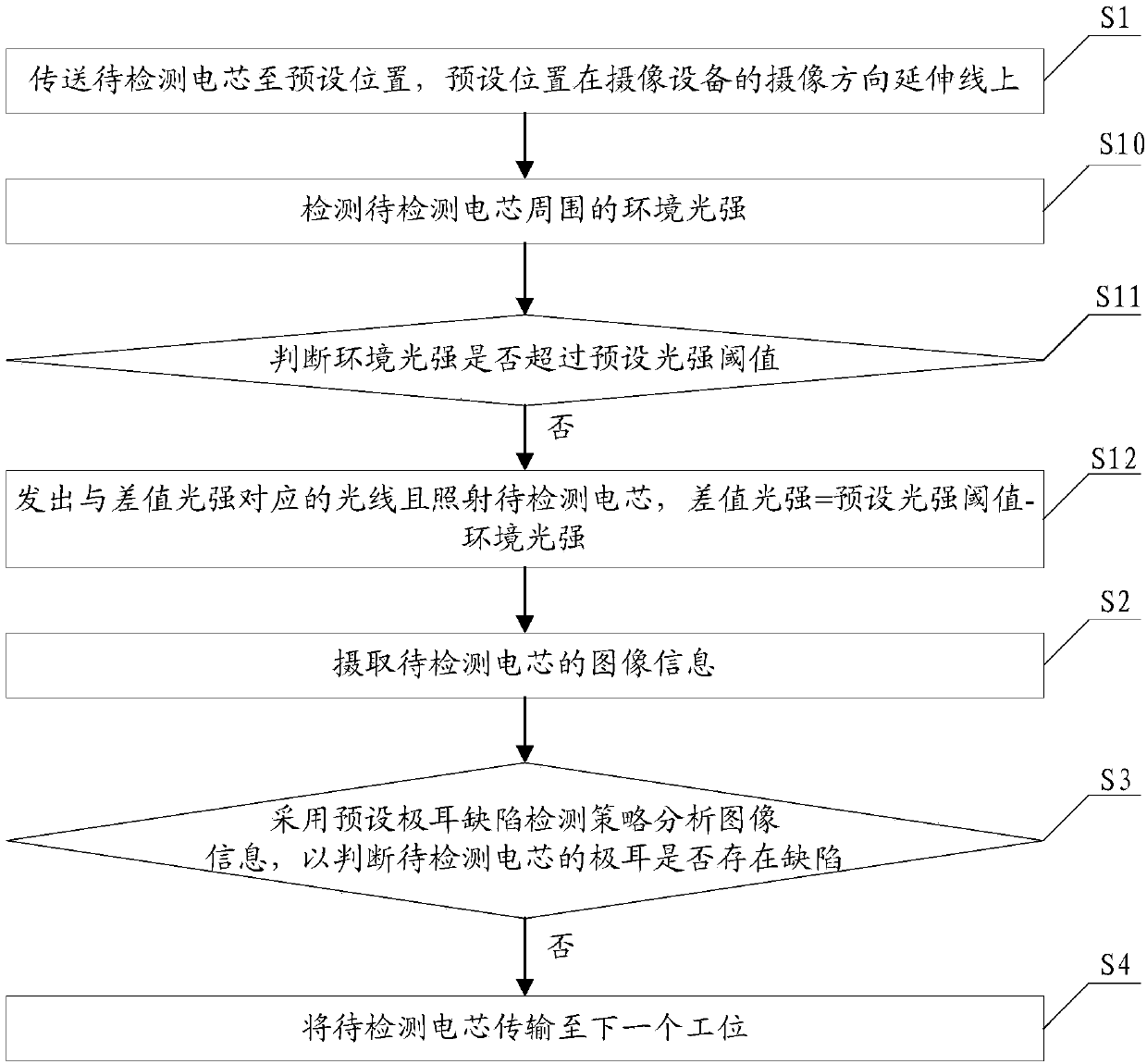

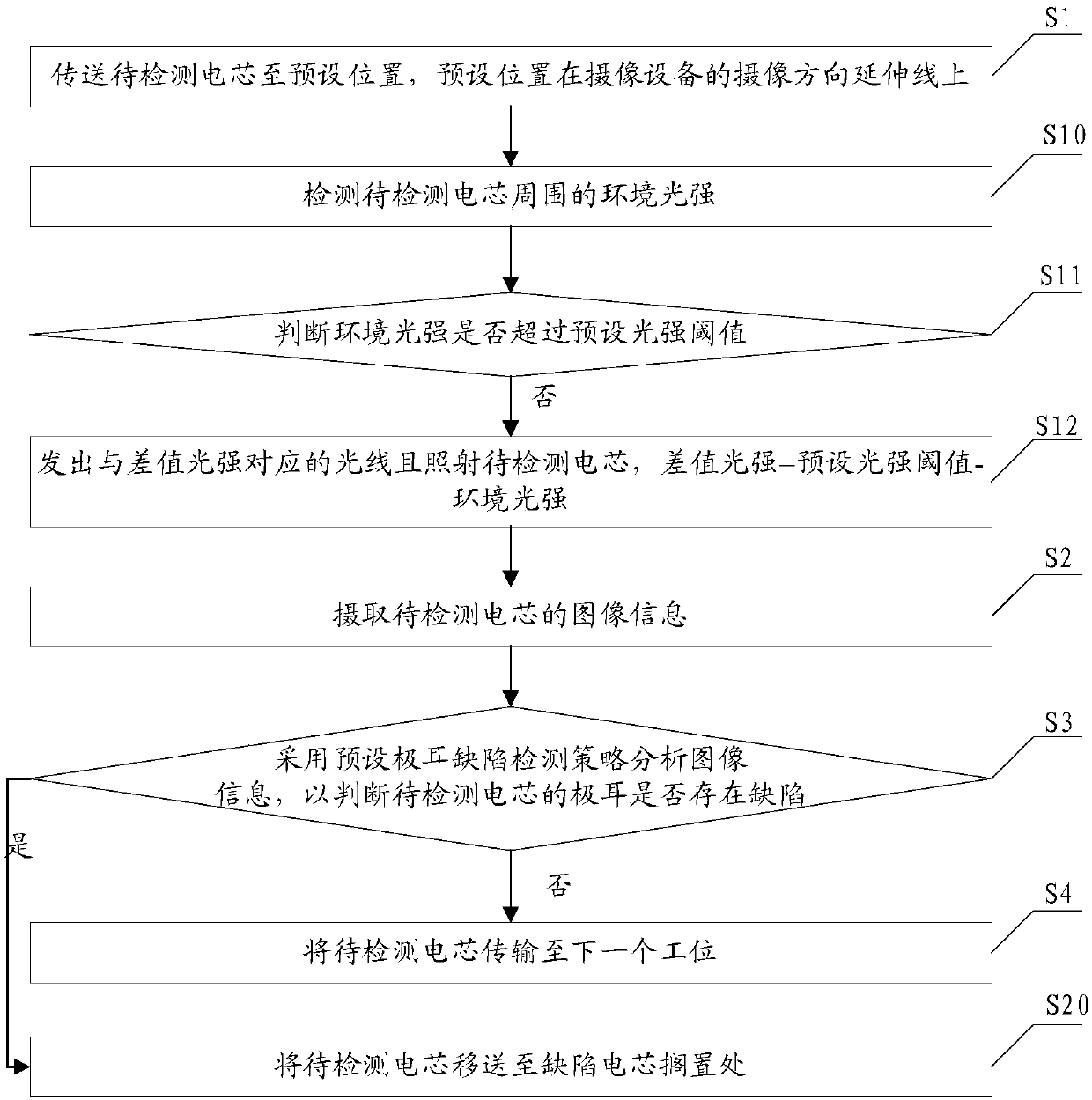

Automatic detection method and automatic detection device for cell tab defects

ActiveCN108037130AQuality improvementImprove assembly speedOptically investigating flaws/contaminationUsing optical meansComputer scienceStrategy analysis

The invention discloses an automatic detection method and an automatic detection device for cell tab defects. The method includes the steps: conveying a cell to be detected to a preset position in anextending line of a camera shooting direction of a camera shooting device; acquiring image information of the cell to be detected; judging whether a tab of the cell to be detected has the defects or not by the aid of preset tab defect detection strategy analysis image information; conveying the cell to be detected to next station if the cell to be detected does not have defects. The automatic detection method automatically analyzes whether the tab of the cell has shortcomings or not according to the image information acquired by the camera shooting device, labor cost is saved, judgment accuracy rate of the tab defects is increased, so that the quality of a battery module is improved, and the assembly rate of the battery module is increased.

Owner:SHENZHEN CLOU ELECTRONICS

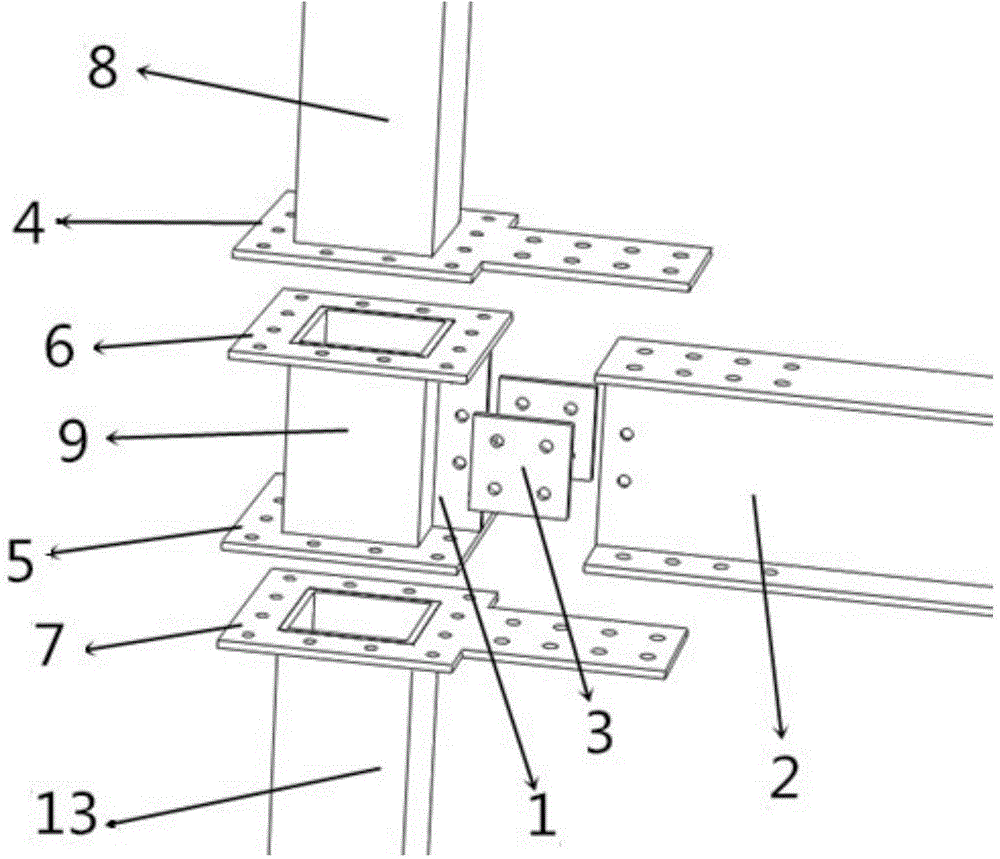

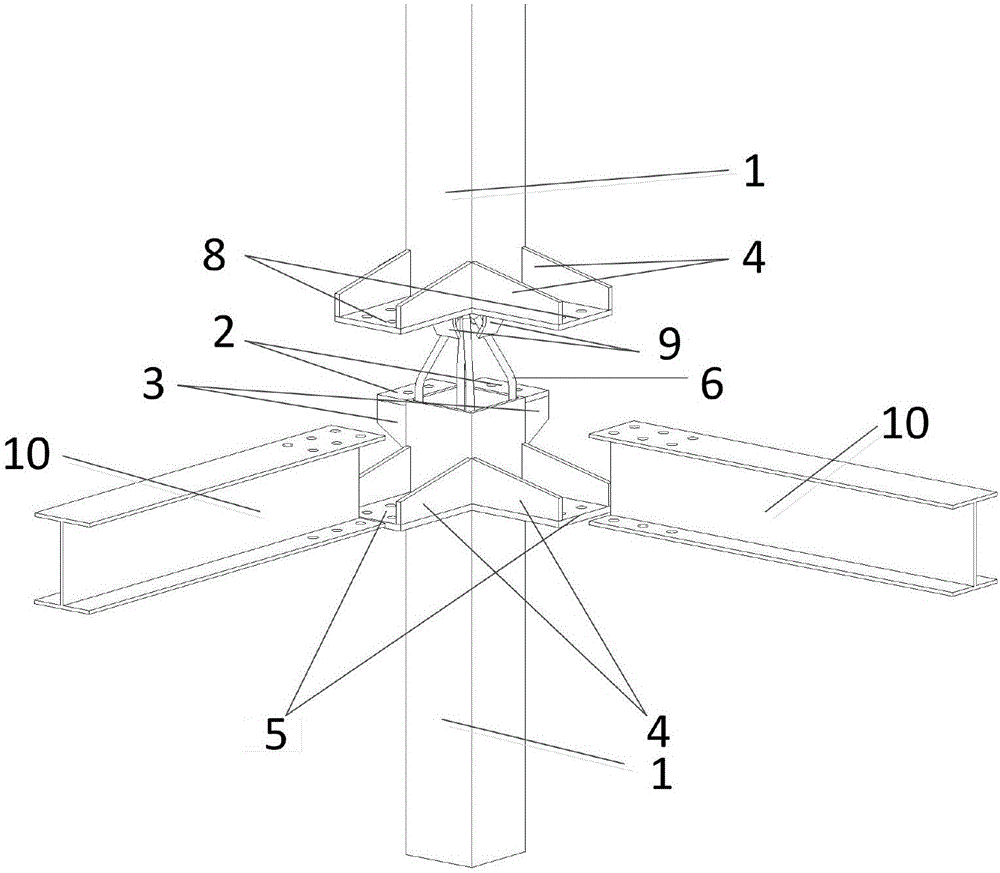

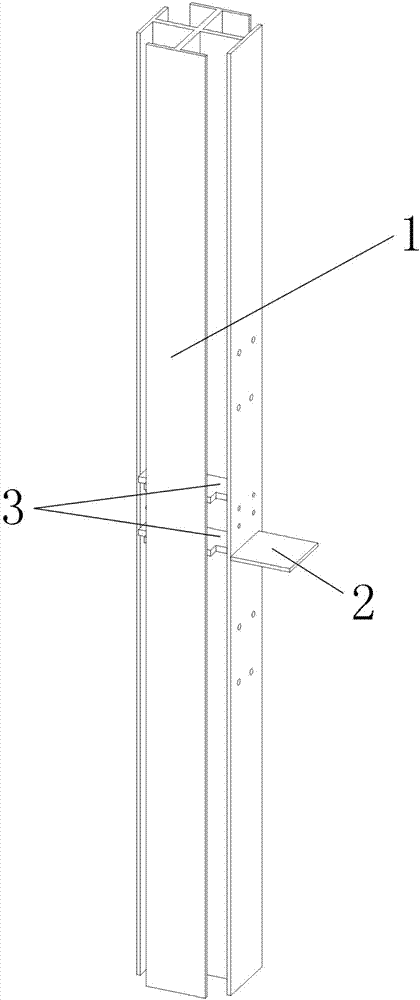

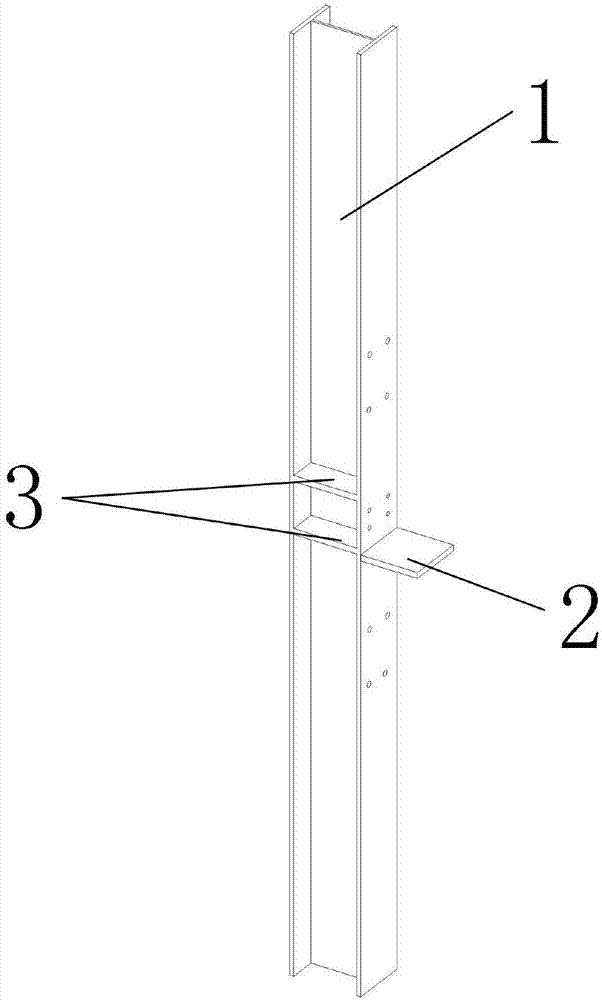

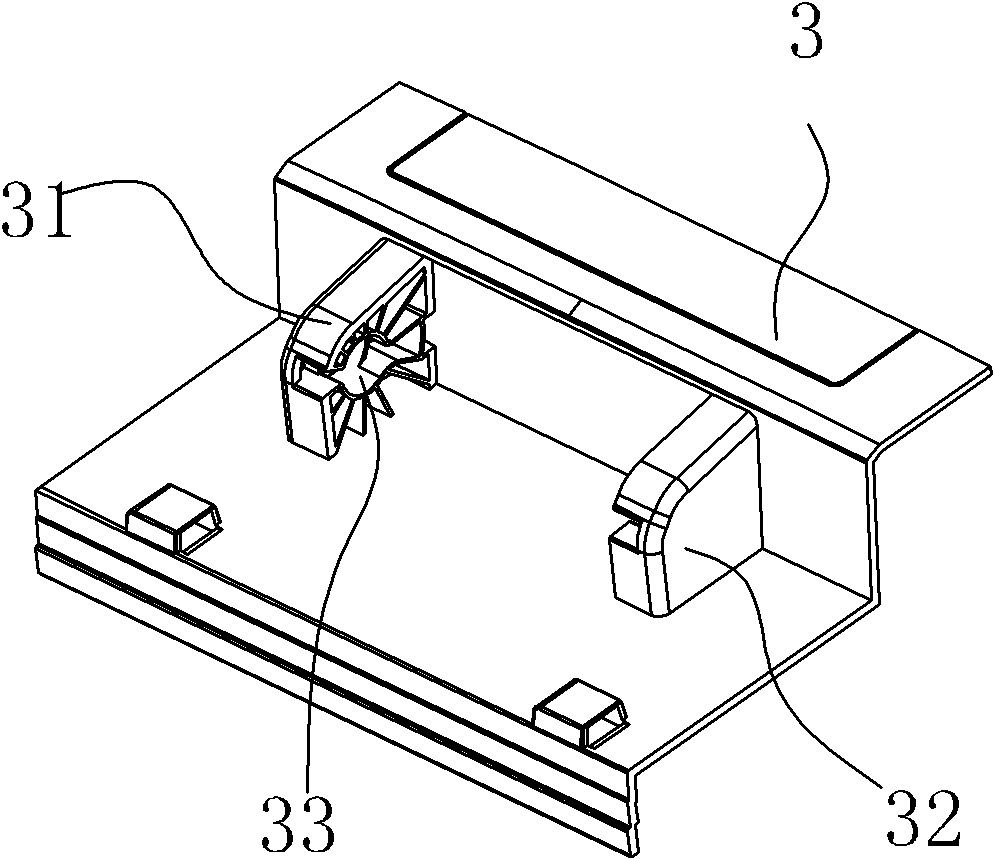

Beam-column joint connection device of assembly type steel structure system

InactiveCN104652615AImprove speed and quality of assemblyGuard nodeBuilding constructionsLoad carryingDuctility

The invention relates to a beam-column joint connection device of an assembly type steel structure system and belongs to the technical field of structural engineering. According to the beam-column joint connection device, a column base connecting plate, a joint short column, a joint short column upper end flange and a joint short column lower end flange are welded into one body in the factory; an upper column flange and an upper column are welded into one body in the factory; a lower column flange and a lower column are welded into one body in the factory; connection is carried out by only using bolts during field assembly. According to the joint connection device, welded portions can be completed in the factory, the field assembly is carried out by adopting the bolts, the work of fastening of the bolts is convenient and fast, and the speed and quality of construction are greatly improved, so that the beam-column joint connection device is applicable to the development of assembly type steel structures; meanwhile, joints of the joint connection device are rigid joints and are good in ductility and strong in load-carrying ability.

Owner:BEIJING UNIV OF TECH

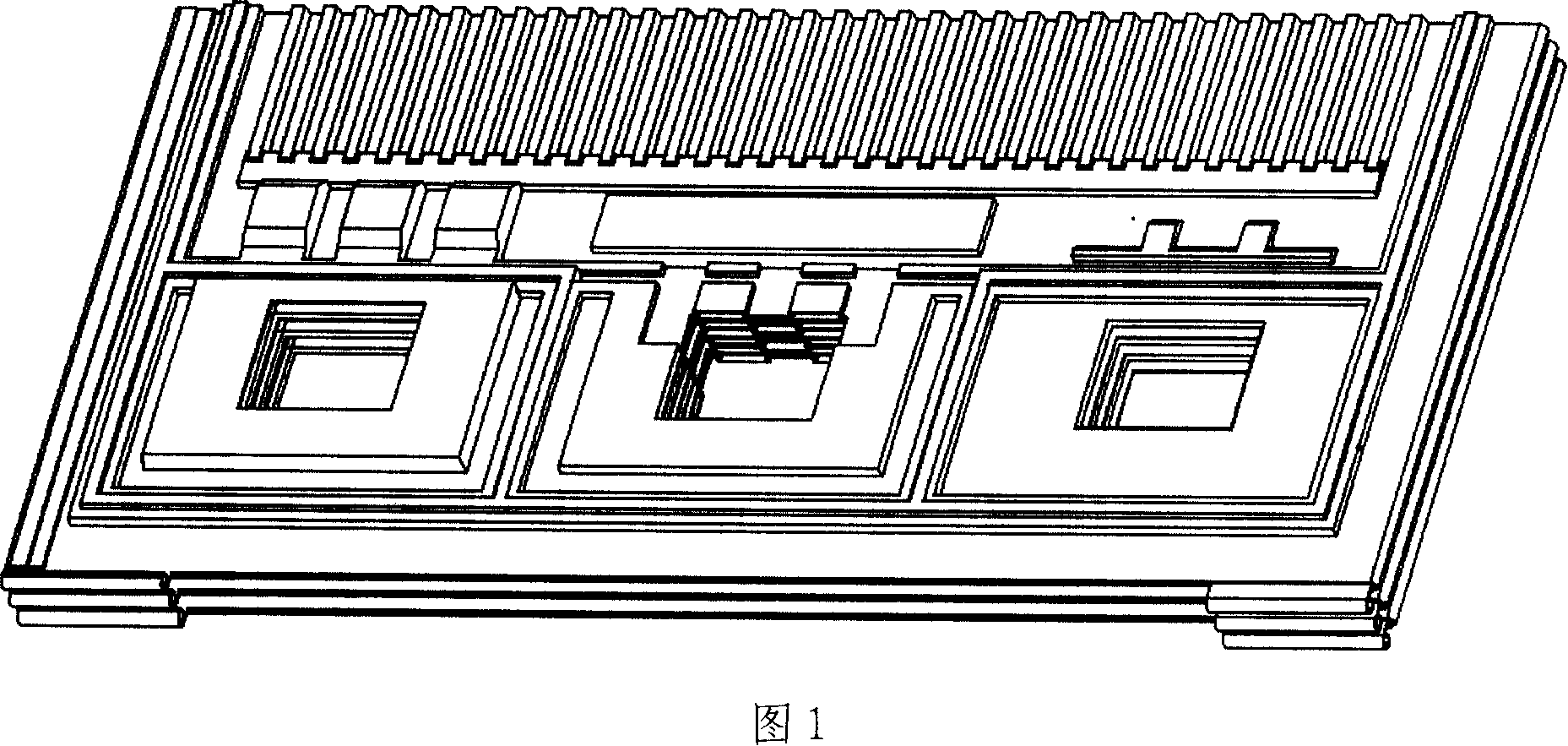

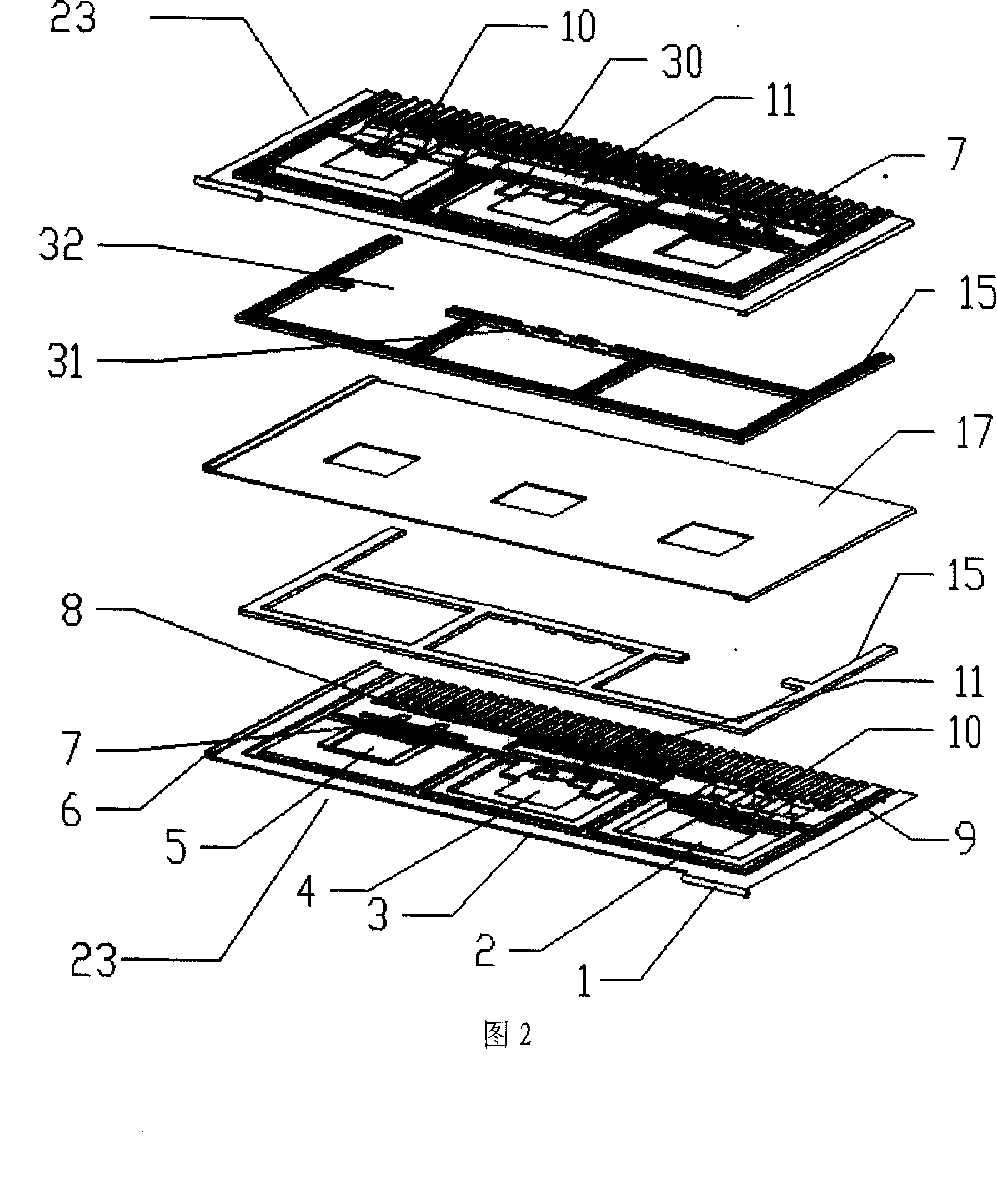

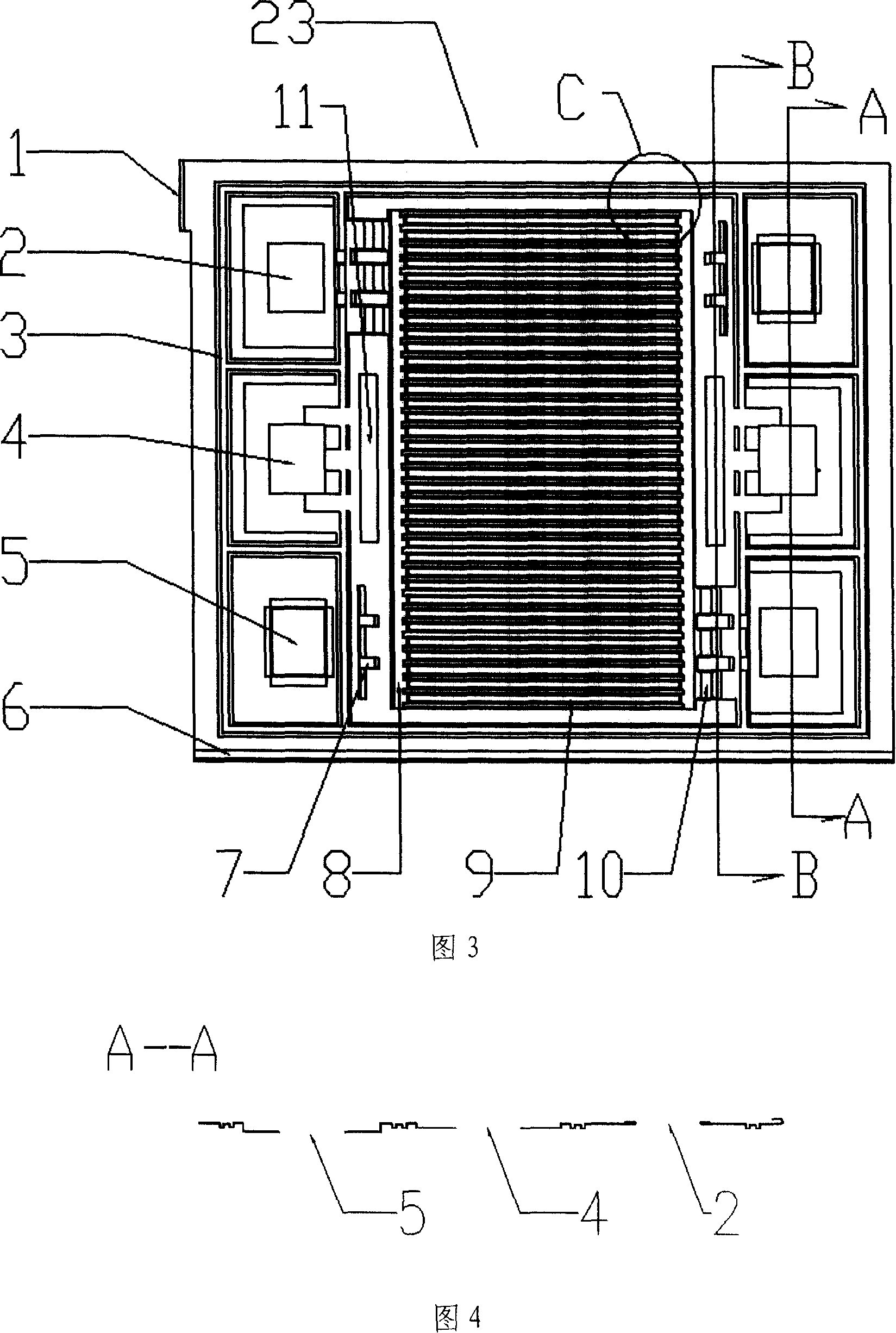

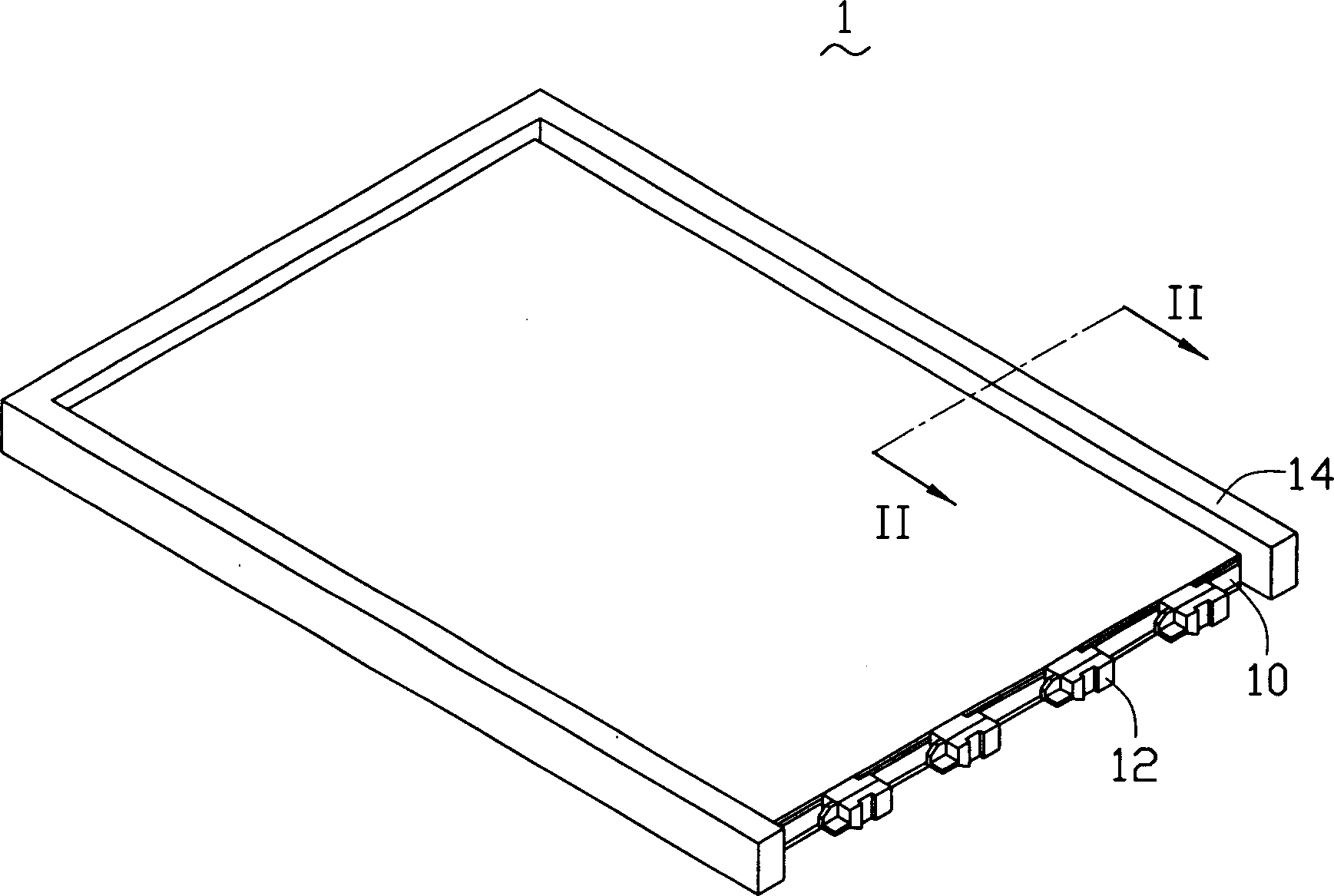

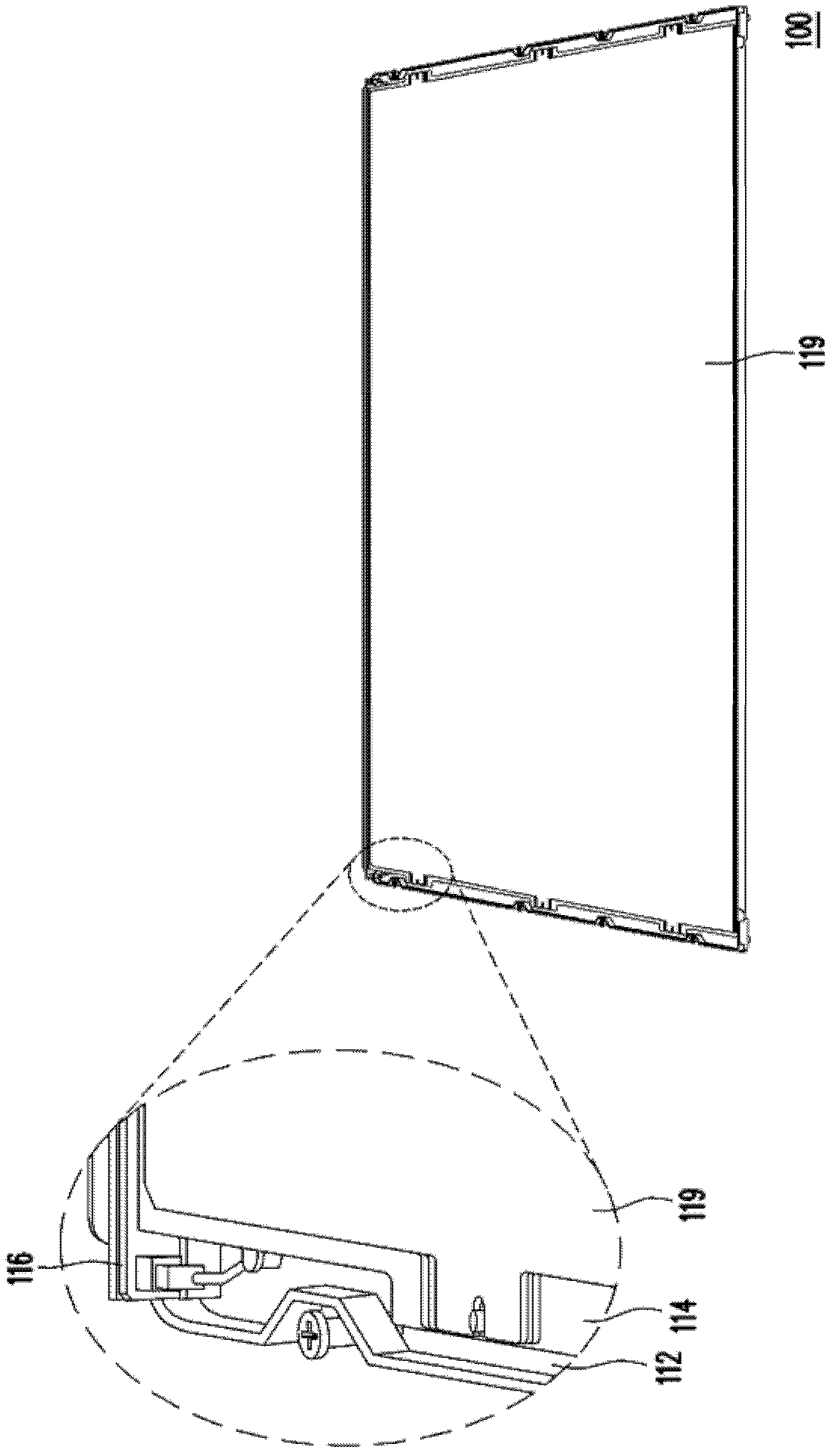

Light element and preparation method, and its backlight mould set

InactiveCN1869738AEliminate gapsReduce lossDiffusing elementsOptical light guidesLight guideLight energy

The invention relates to a light guide component and the preparing method thereof as well as a backlight module using it. And it comprises a light guide plate and a frame, where the light guide plate comprises an incident face, an outgoing face connected with the incident face, a reflecting face corresponding to the outgoing surface and three side faces beside the incident face, and the frame is integrated with the above three sides. And it is formed by double-color injection moulding technique, able to eliminate gap between light guide plate and frame, and thus reducing light energy losses and improving its boundary optical phenomenon. And the invention also provides a background module using it, which has advantages of low material costs, high assembling speed and high mechanical intensity.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

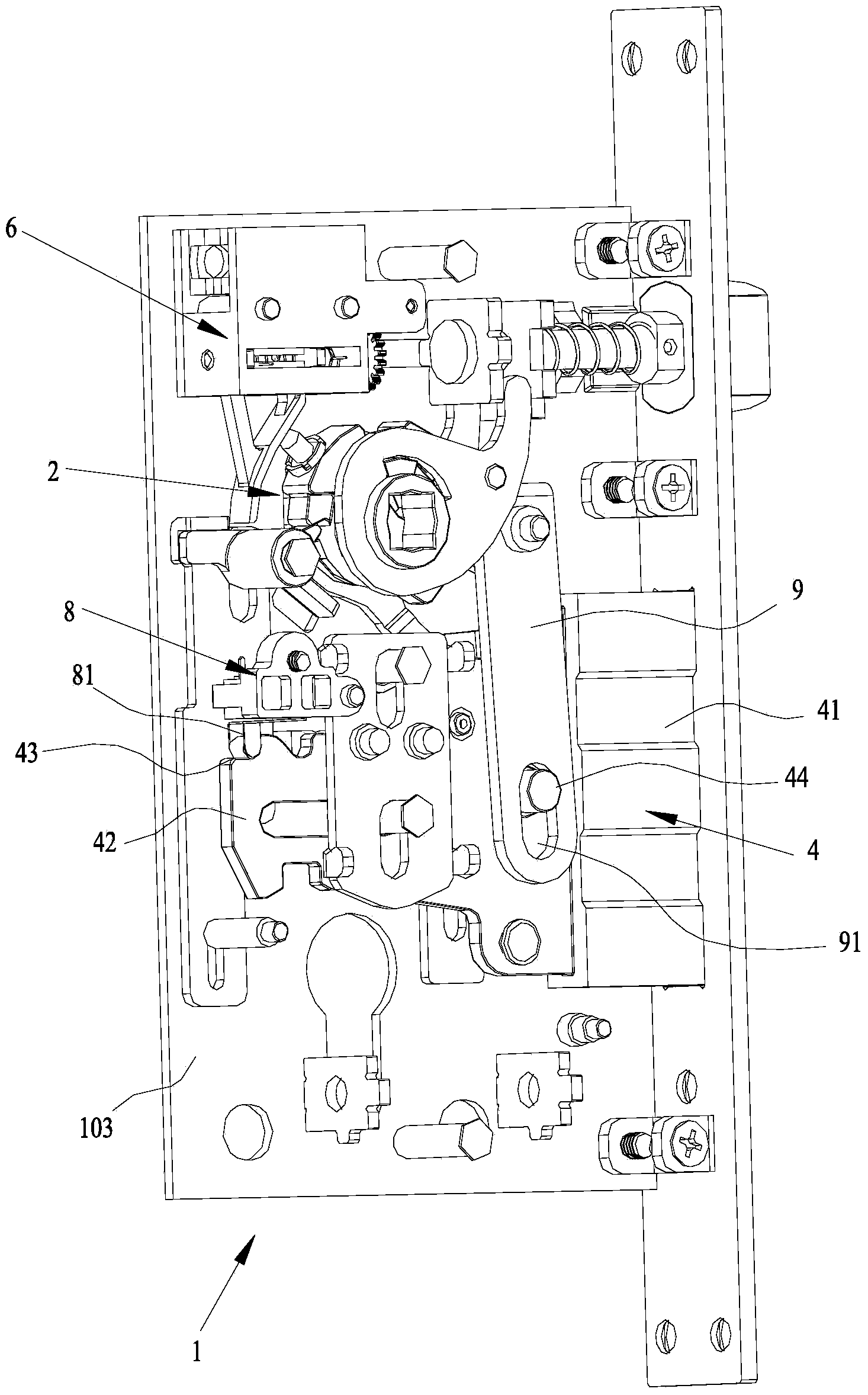

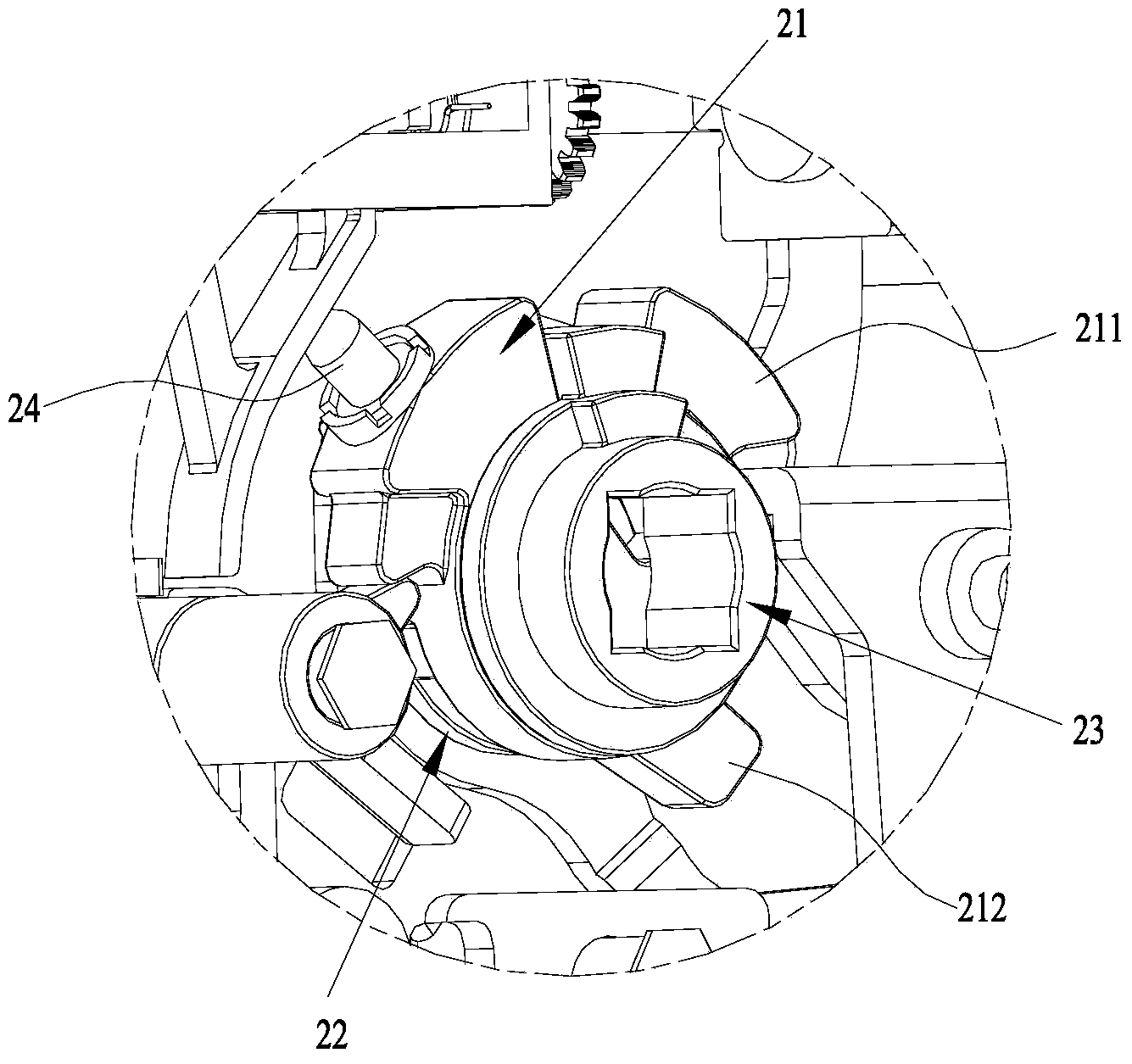

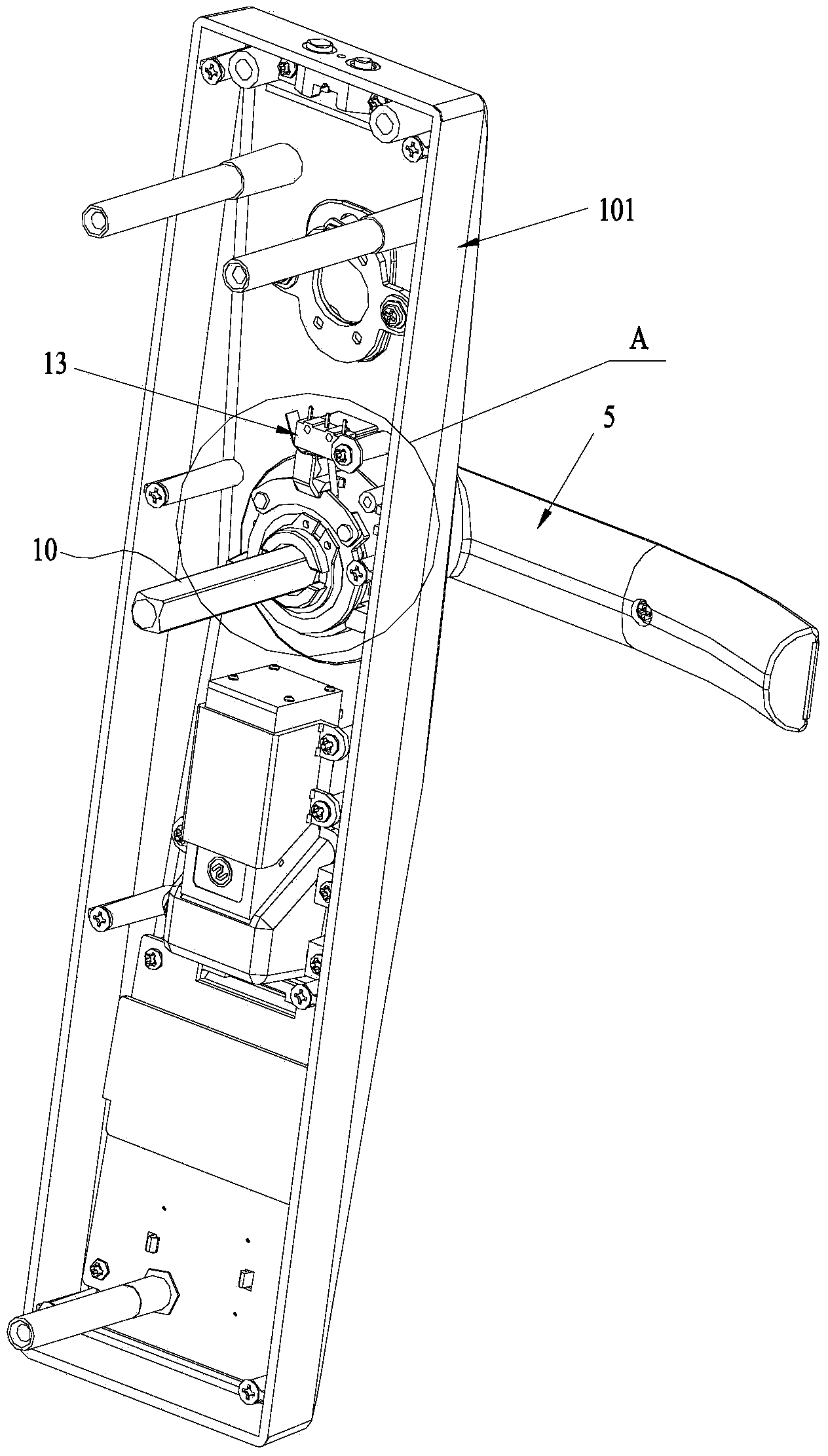

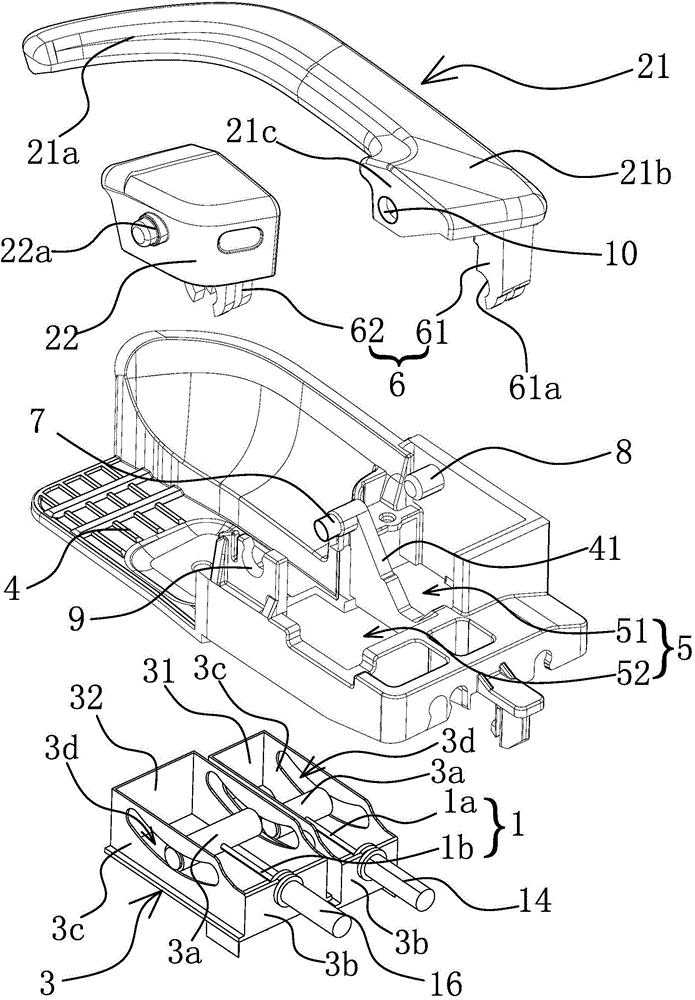

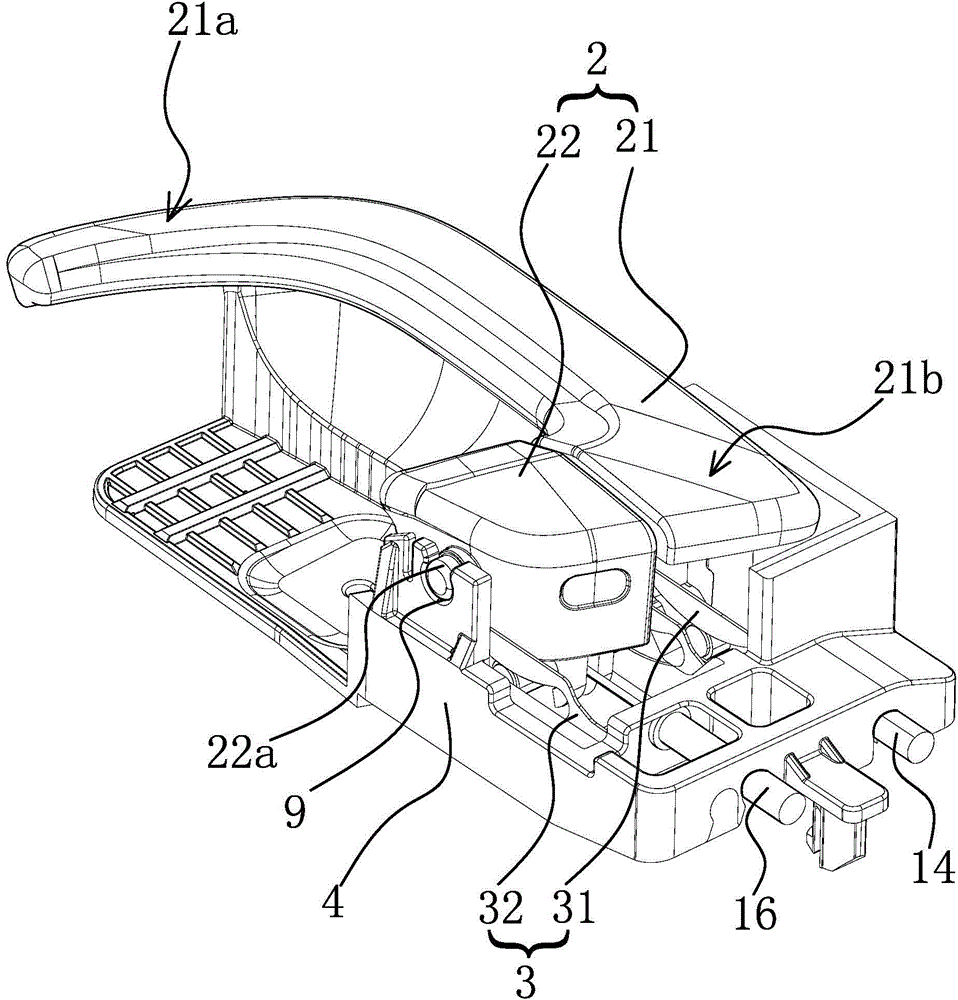

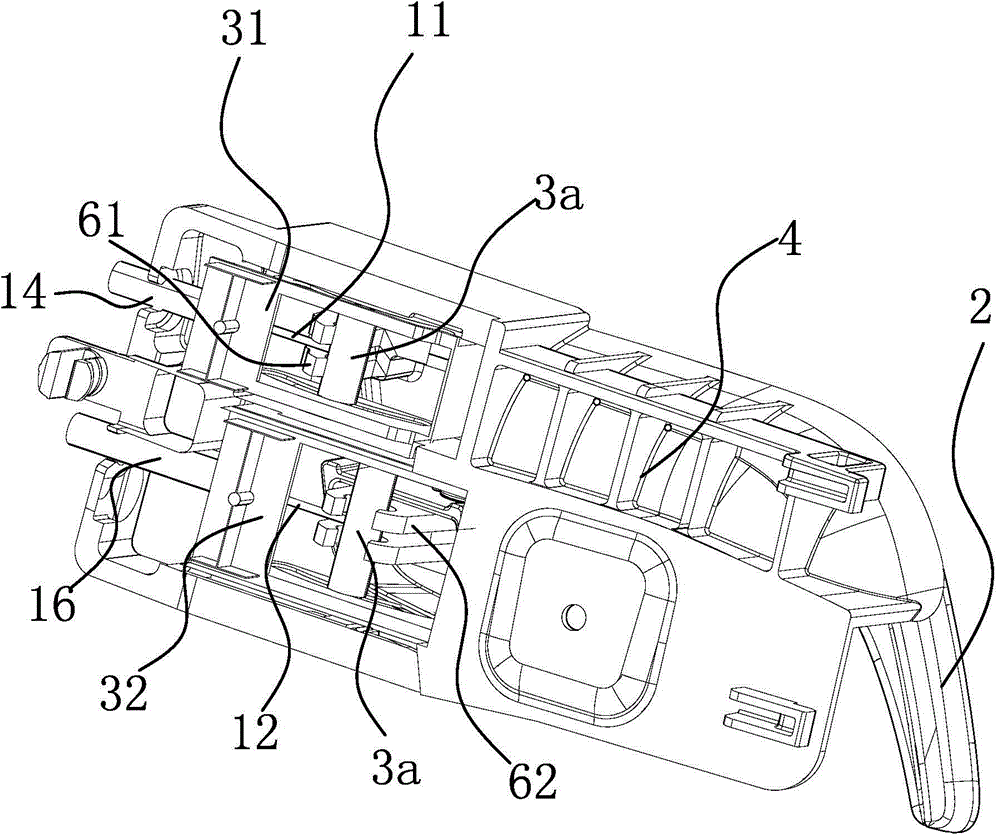

Intelligent door lock capable of being locked outside door and double locked inside door conveniently

ActiveCN103924845AReduce manufacturing costImprove assembly speedElectric permutation locksHandle fastenersControl engineeringClutch

The invention discloses an intelligent door lock capable of being locked outside a door and double locked inside the door conveniently. The intelligent door lock comprises a lock body, a clutch, a main transmission mechanism, a main locking dog, a control module, a first sensor, a second sensor and a driving mechanism, the clutch, the main transmission mechanism, the main locking dog, the control module, the first sensor, the second sensor and the driving mechanism are all arranged in the lock body, a handle inside the door is arranged on the inner side of the lock body, a handle outside the door is arranged on the outer side of the lock body, the handle inside the door is in transmission connection with the main locking dog through the main transmission mechanism, and the handle outside the door is in transmission connection with the main locking dog through the clutch and the main transmission mechanism in sequence. The first sensor is arranged on one side of the main locking dog, the second sensor is arranged on the side, arranged at the mounting position of the lock body, of the handle outside the door, and the driving mechanism, the first sensor and the second sensor are respectively and electrically connected with the control module. The intelligent door lock can be locked outside the door and double locked inside the door easily and conveniently.

Owner:AP TENON INFORMATION IDENTIFICATION TECH GUANGZHOU

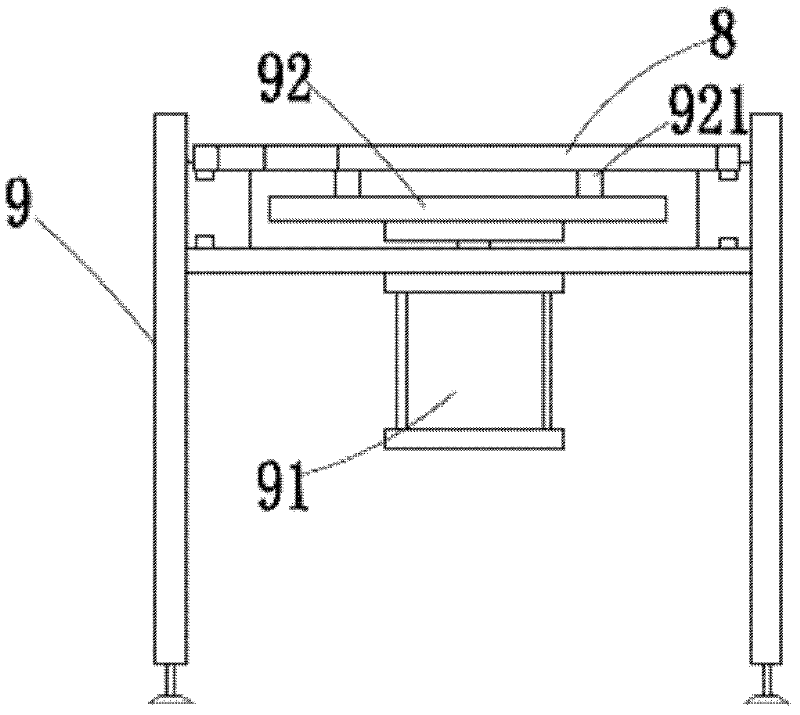

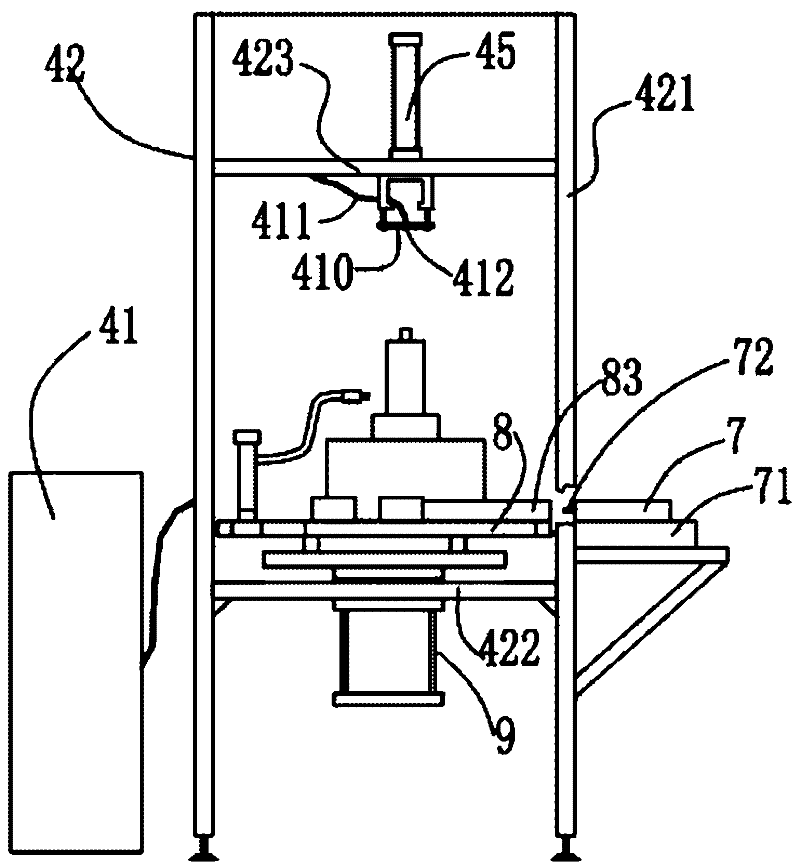

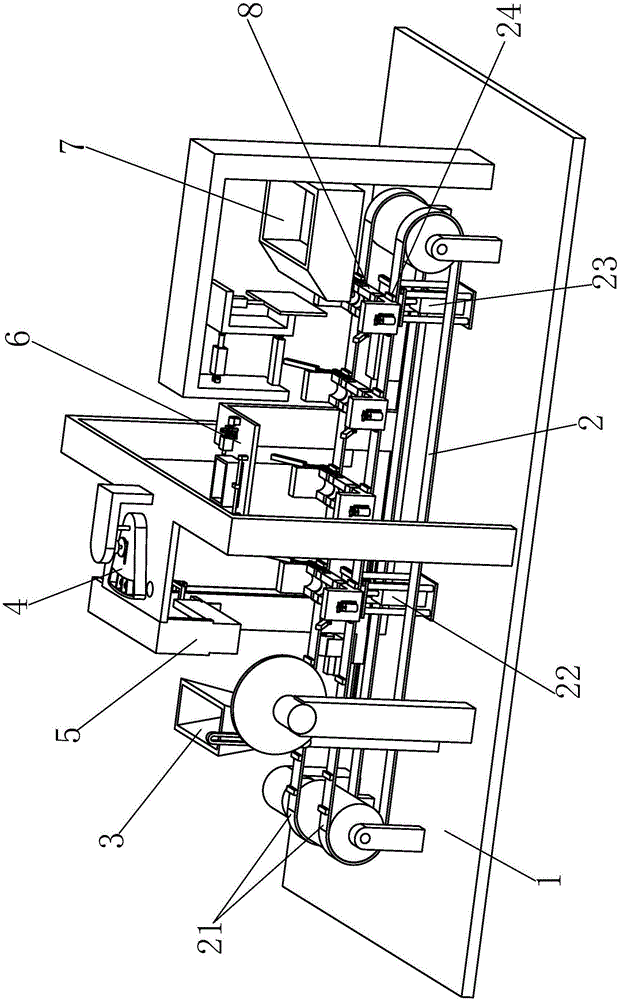

Working method of assembling device for medical one-off oxygen humidification bottle

The invention provides a working method of an assembling device for a medical one-off oxygen humidification bottle. The assembling device comprises a humidifying plug charging device, a transferring device, a ventilating pipe charging device, a ventilating pipe assembling device, a first assembling device, a second assembling device and a third assembling device, wherein the ventilating pipe charging device comprises a material box, a first conveyor belt, a charging block and an aligning assembly; the bottom part of the material box is obliquely arranged; a plurality of charging strips are arranged on the first conveyor belt; charging grooves are obliquely formed in the middle part of the charging block; the aligning assembly comprises an aligning motor, an aligning block and four aligningstrips; the cross section of the aligning block is of a rectangular structure, and four aligning grooves which are circumferentially distributed are formed in the aligning block; and the four aligning strips are fixedly connected to the aligning block. The method has the beneficial effects that a humidifying plug, a ventilating pipe, a connecting plug, a bottle body and a bottle cap can be automatically assembled, so that the product production cost is decreased; and the difficulty in production of the one-off oxygen humidification bottle can be increased.

Owner:王槐照

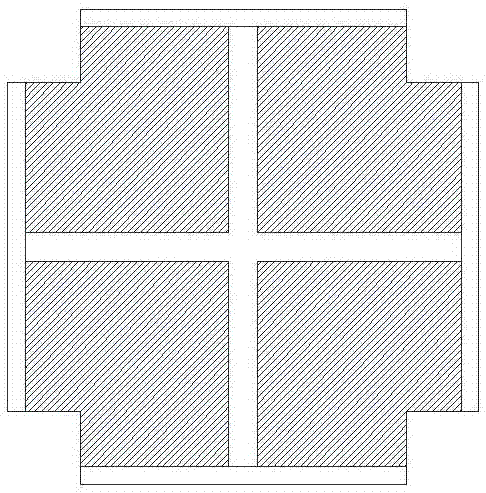

Node connection device of assembly-type steel structure beam pillar

InactiveCN106812214AIncrease rigid connectionPlay an anchoring roleBuilding constructionsFriction forceBolt connection

A node connection device of an assembly-type steel structure beam pillar belongs to the technical field of structure engineering. An upper pillar and a lower pillar are manufactured through welding of square tube pillars, pillar top flange plates, pillar bottom flange plates, long ribs, short ribs, supporting plates, cover plates, hanging hooks and bending plates at a plant, and beams are welded by H-shaped steel beams at the plant; and the form of pillars is not limited to corner pillars, and can also be applied to lateral pillars and middle pillars. According to the invention, all the welding work is completed at the plant, the hanging hooks and bending plates play a role in insertion and guidance during hoisting of the upper pillars and lower pillars, so the hanging difficulty of the upper and lower pillars is reduced, and accuracy corresponding to bolt holes is increased; and when concrete pouring in the pillars is needed, the hanging hooks and bending plates also play a role in anchoring, so rigid connection of nodes could be enhanced. Due to existence of the cover plate, supporting plate and reinforced rib of the pillar, the supporting plate and the cover plate could have very strong building-in effects toward beam ends, so bolt connection will bear pull force and friction force; the bolt utilization rate is increased; and consumption of bolts is reduced under the same bearing force.

Owner:BEIJING UNIV OF TECH

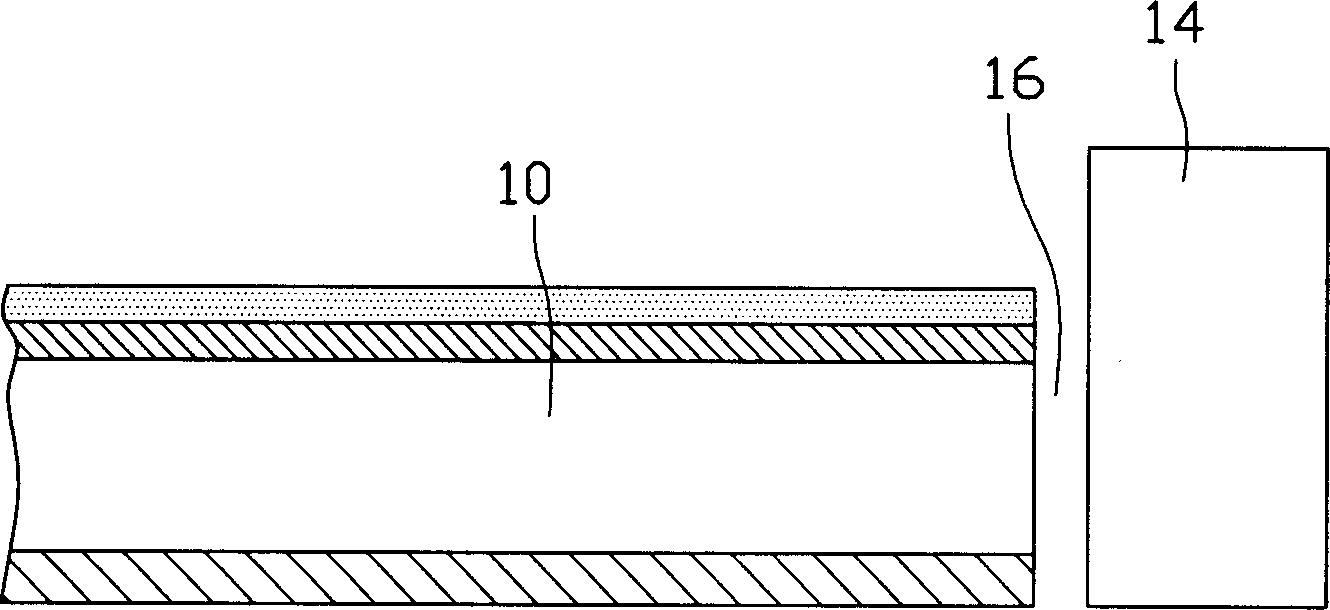

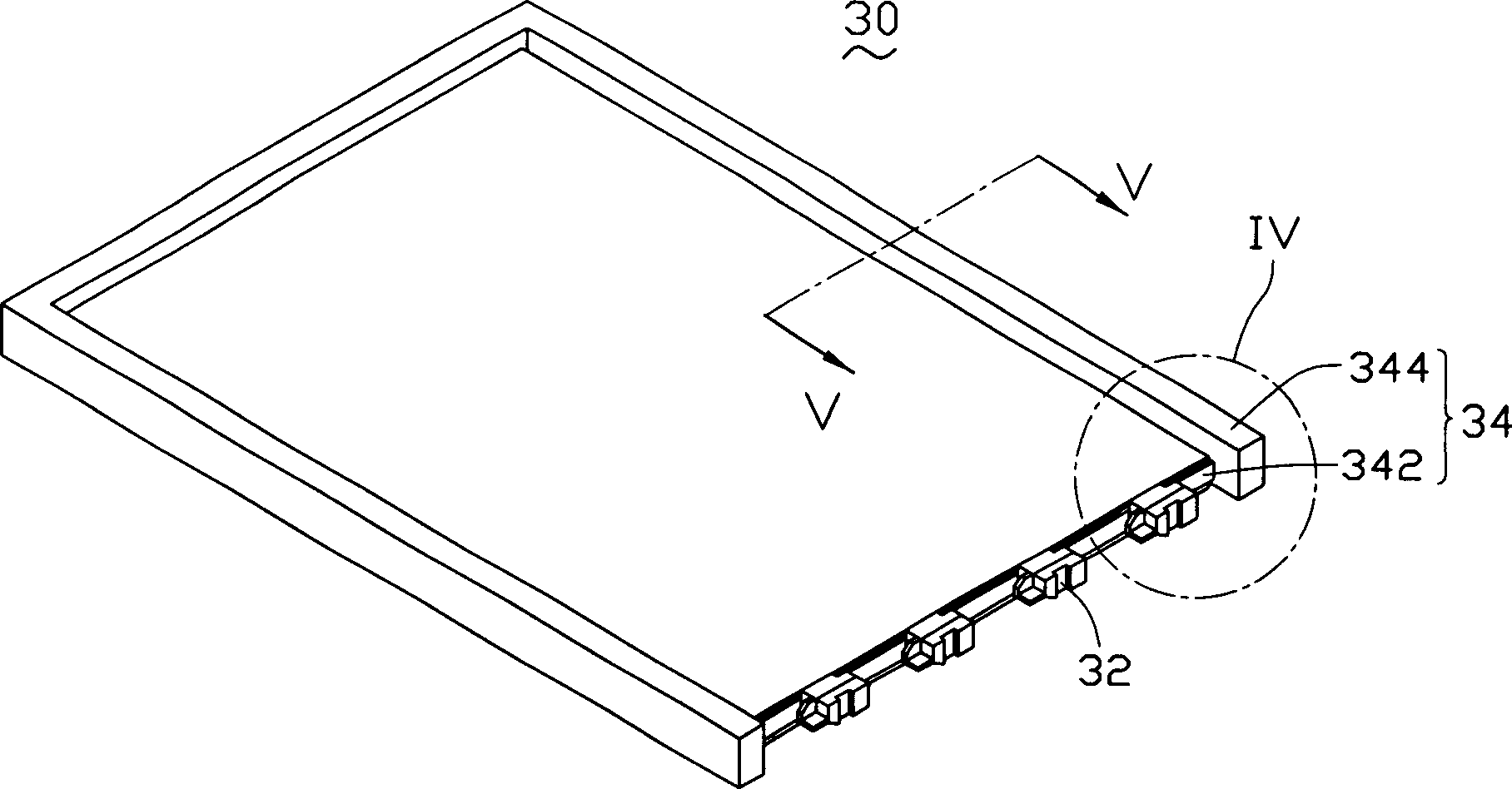

Backlight module and display module

InactiveCN102506358ASimplify internal structureReduce manufacturing costNon-linear opticsLight fasteningsLight guideComputer science

The invention discloses a display module and a backlight module. The display module includes the backlight module and a display panel arranged on the backlight module. The backlight module includes a base plate, a light guide plate, a support frame, a buffer material and a baffle. The light guide plate is arranged on the base plate and includes the top face, the bottom face and a plurality of side faces connecting between the top face and the bottom face. The support frame surrounds the light guide plate. The buffer material is arranged on at least one side of the light guide plate and includes the top wall, the bottom wall and the side wall. The top wall is arranged on the outer periphery of the top face of the light guide plate. The bottom wall leans between the base plate and the bottom face of the light guide plate. The side wall connects with the top wall and the bottom wall and wraps at least one side face of the light guide plate. The baffle is arranged on the base plate vertically and is disposed on at least one side of the light guide plate. The side wall of the buffer material leans between the baffle and at least one side face of the guide plate.

Owner:AU OPTRONICS CORP

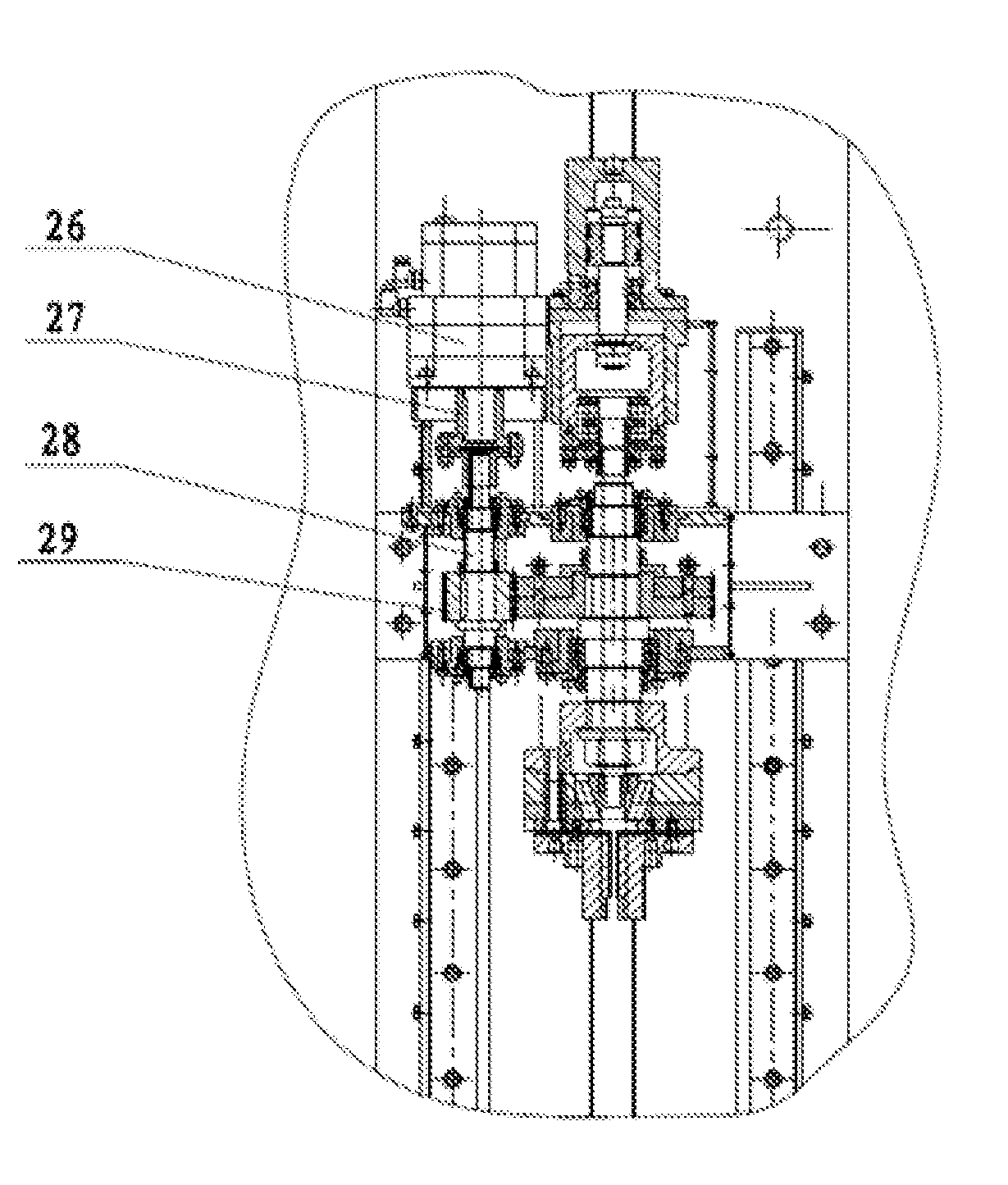

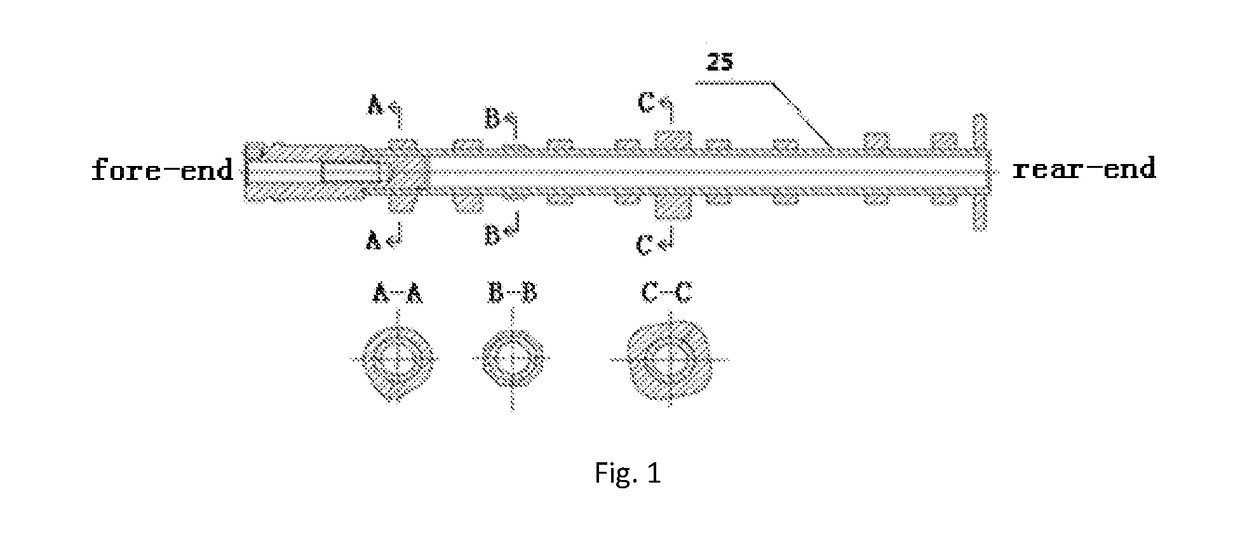

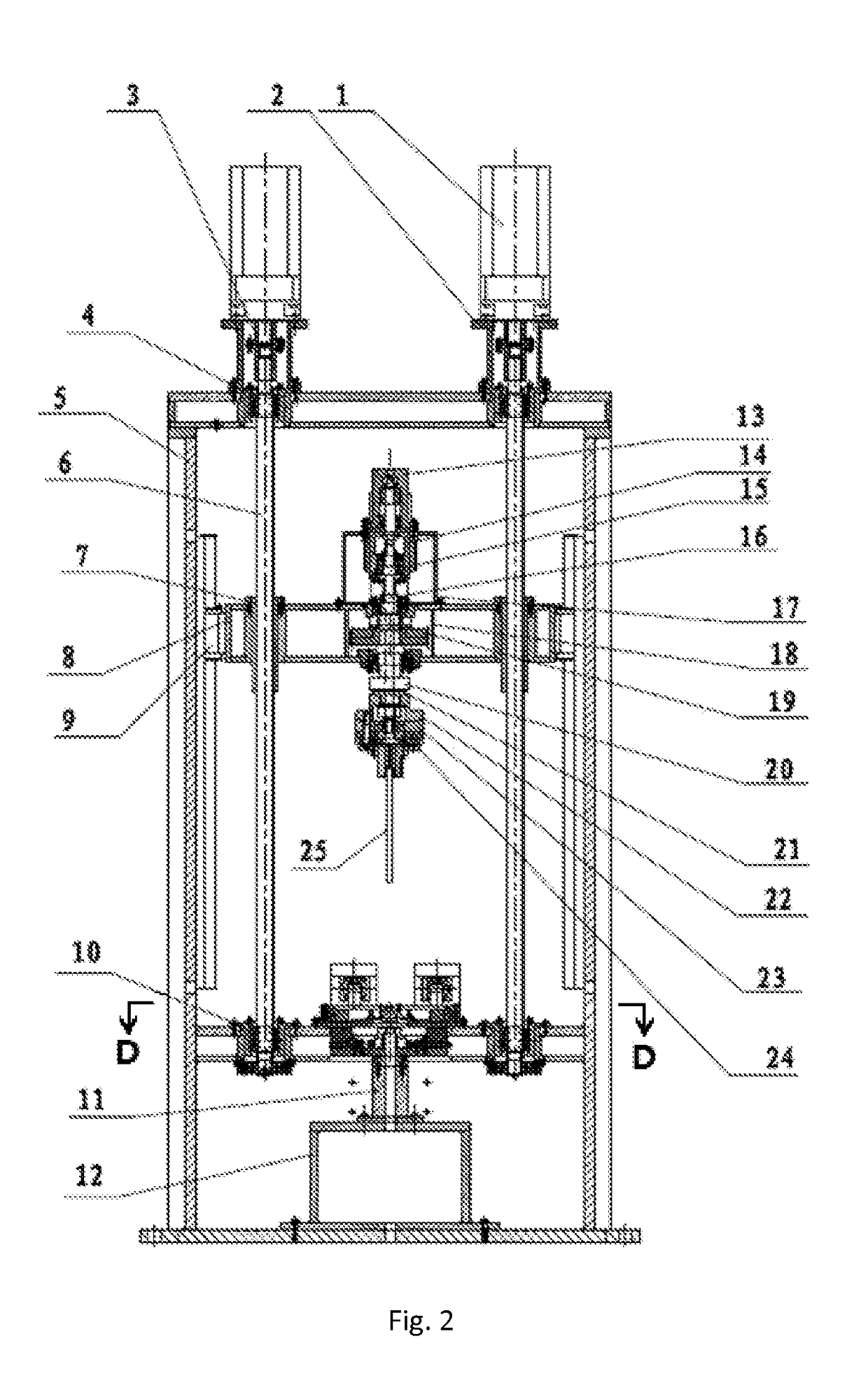

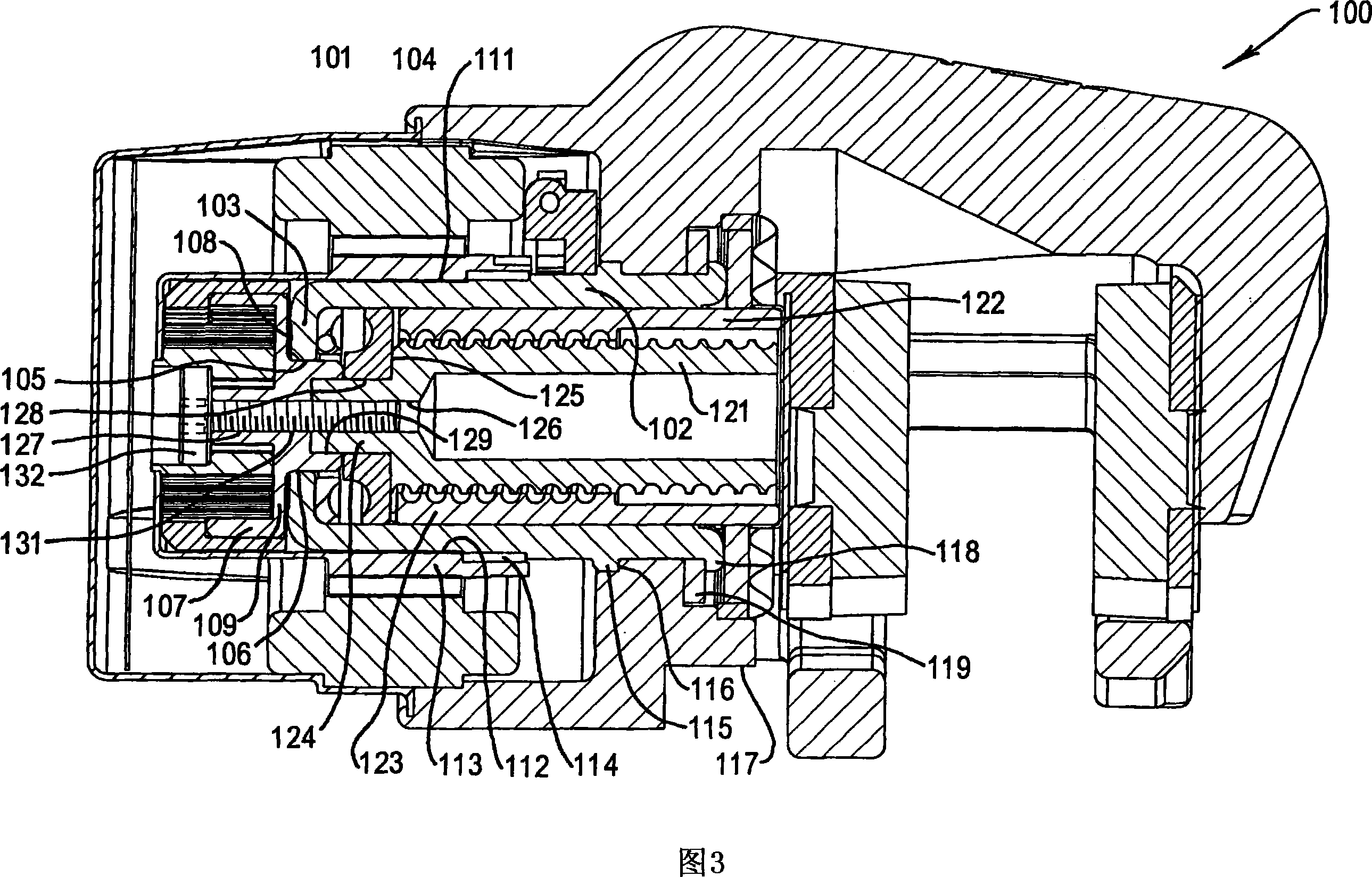

Slider Driving Mechanism on a CNC Assembly Machine for Assembled Camshaft

InactiveUS20170146103A1Improve assembly speedImprove manufacturing precision and product qualityCamsGearingGear systemEngineering

The present invention relates to a slider driving mechanism on a CNC assembly machine for assembled camshaft. The mechanism includes a servo motor (1), the host frame (5), ball screw (6), linear guides (9) and the slider body (8), wherein, the servo motor (1), ball screw (6) and linear guides (9) are mounted vertically on the host frame (5). The servo motor (1) connects with the ball screw. The slider body (8) connects with both the ball screw (6) and the linear guides (9). It is driven by a ball screw (6) and moves along a linear guides (9) in the vertical direction. The present invention is novel. It not only can greatly improve the assembly speed of cam, hexahedron on assembled camshaft and improve productivity, but also can eliminate complex gear system. It makes the manufacturing and processing more simple. The installation is also more convenient. It can further improve product quality and manufacturing precision of assembled camshaft.

Owner:CHANGCHUN JIYANGHUAXIN SCI & TECH +1

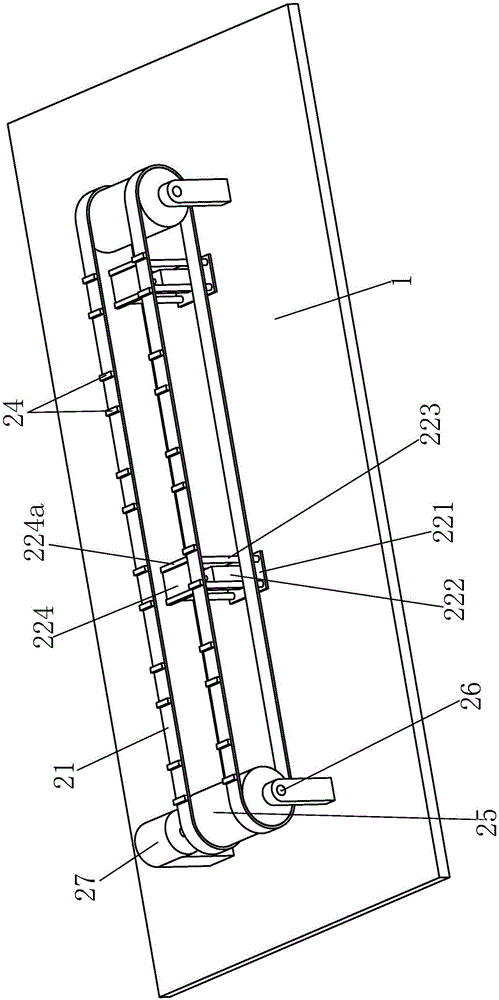

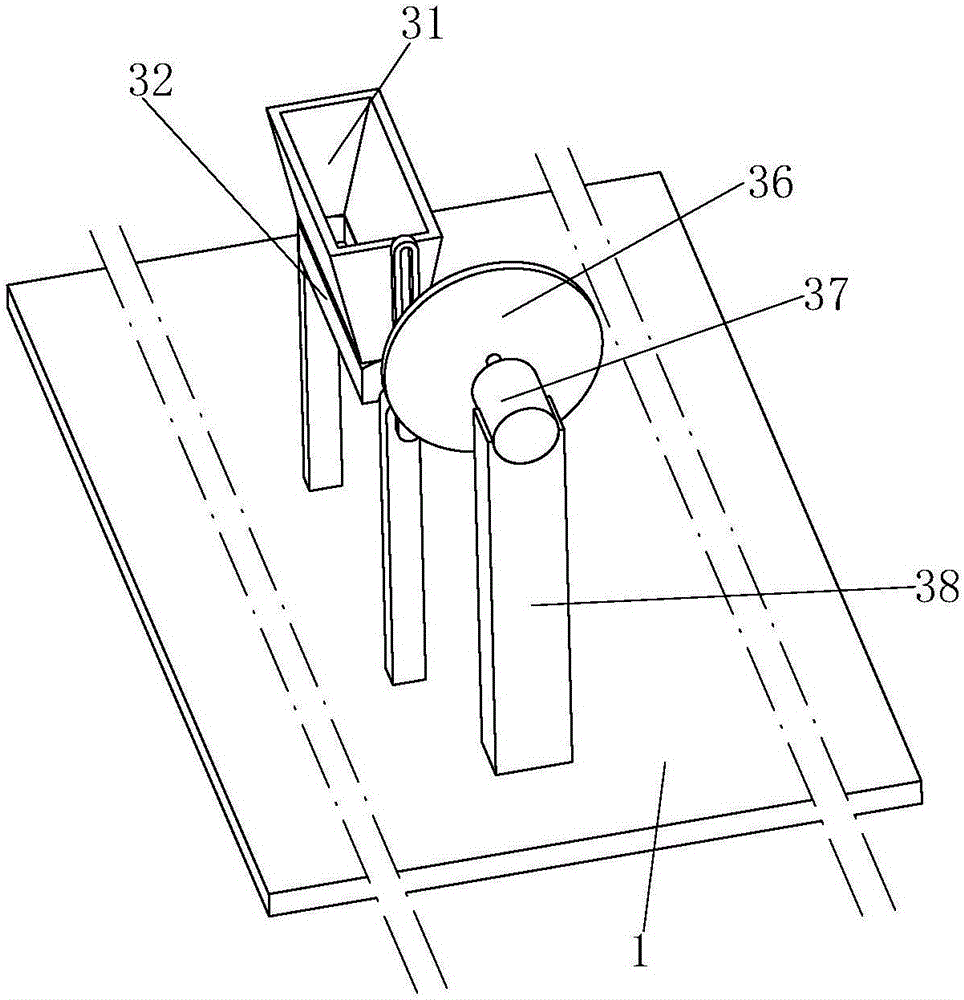

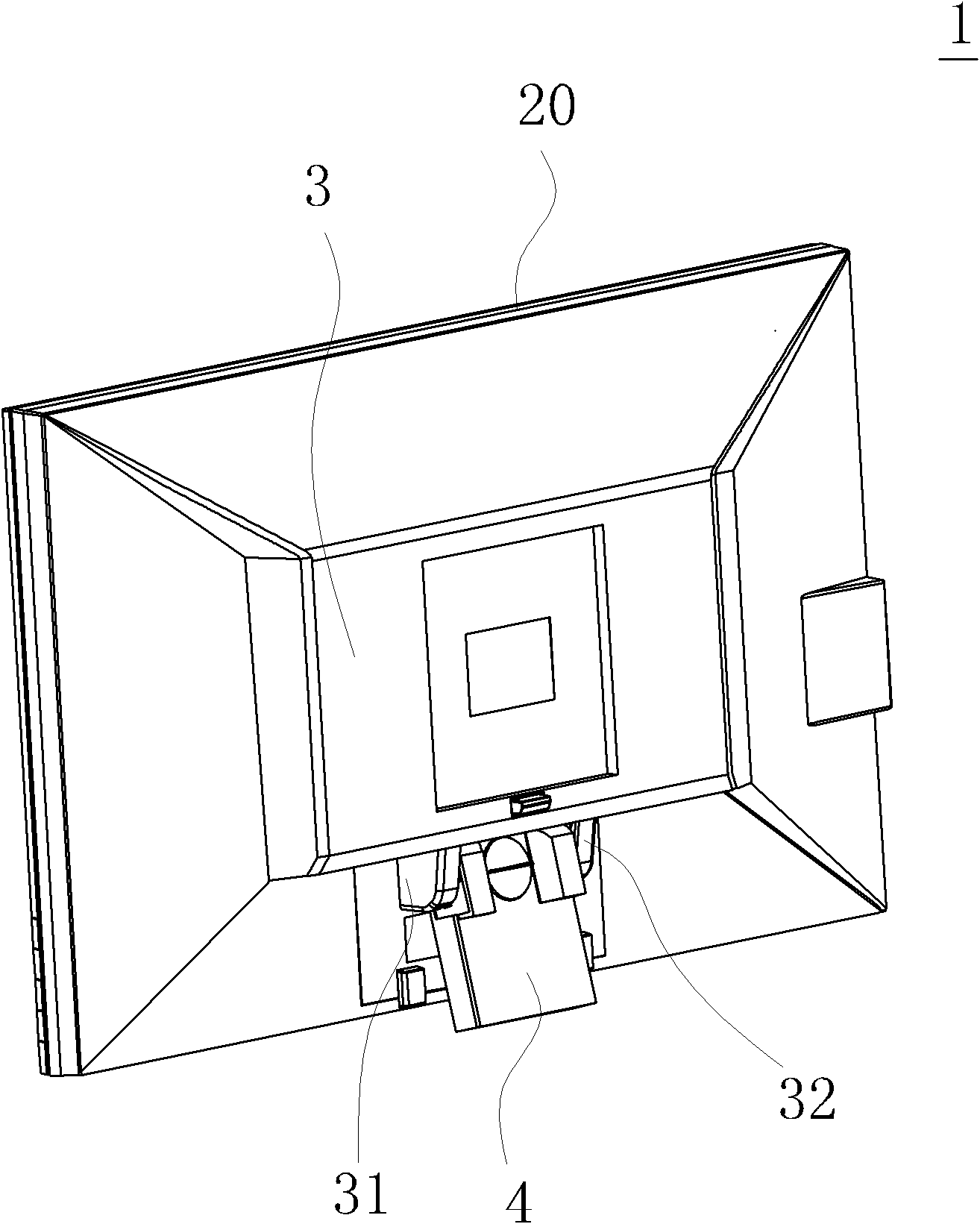

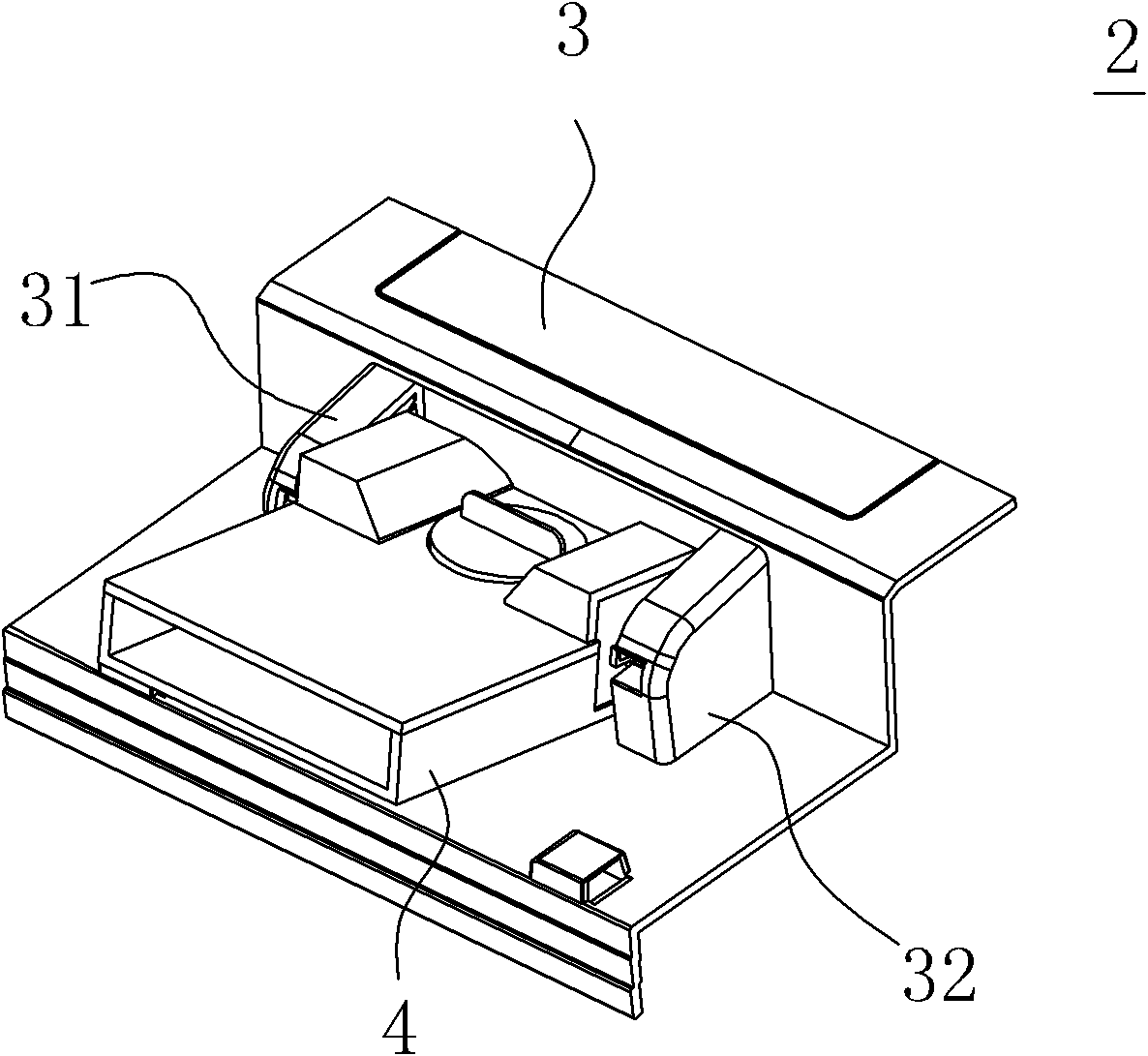

Intelligent assembler with K-shaped accessory chain

InactiveCN107344224AEasy to operateHigh degree of automationMetal chainsAutomatic controlEngineering

The invention discloses an intelligent assembly machine with a K-type accessory chain, relates to the technical field of chain assembly, and solves the problem of low assembly efficiency of existing chains. Including the machine tool workbench and PLC automatic control terminal, the machine tool workbench is equipped with a positioning clip for fixing chain pieces and K-shaped accessories, one side of the positioning clip is equipped with an automatic assembly mold, and the outside of the positioning clip is equipped with a The horizontal feeding mechanism of the chain mold, the outer side of the automatic assembly mold is equipped with a parts blanking mechanism that cooperates with the automatic assembly mold, the upstream section of the automatic assembly mold is connected with a single-section feeding mechanism, and the single-section feeding mechanism is connected with a single-section vibration plate, A bracket is arranged on the machine tool table, and a chain press-fit assembly mechanism is arranged on the bracket, and the chain press-fit assembly mechanism is located directly above the automatic assembly mold. The intelligent chain assembling machine of the present invention has high degree of automation, good chain assembling quality, fast chain assembling speed, stable performance and low failure rate.

Owner:HANGZHOU DONGHUA CHAIN GRP

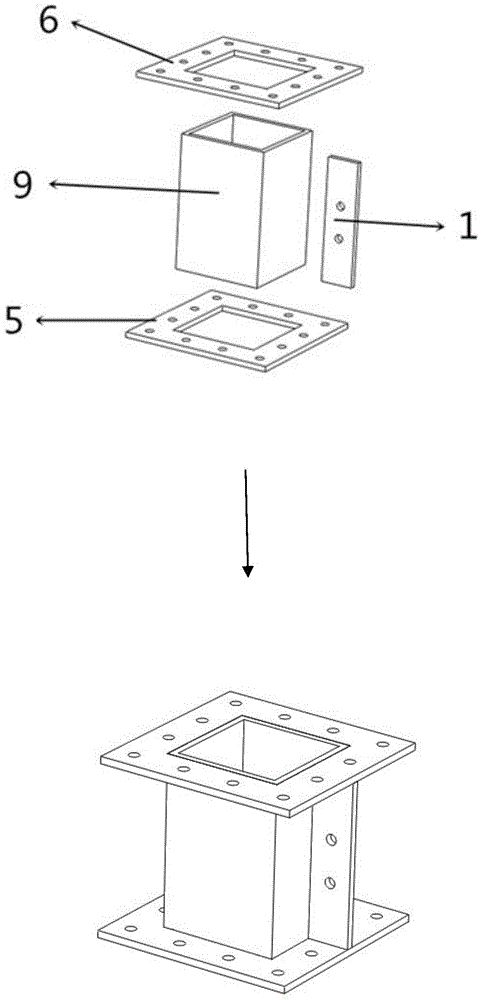

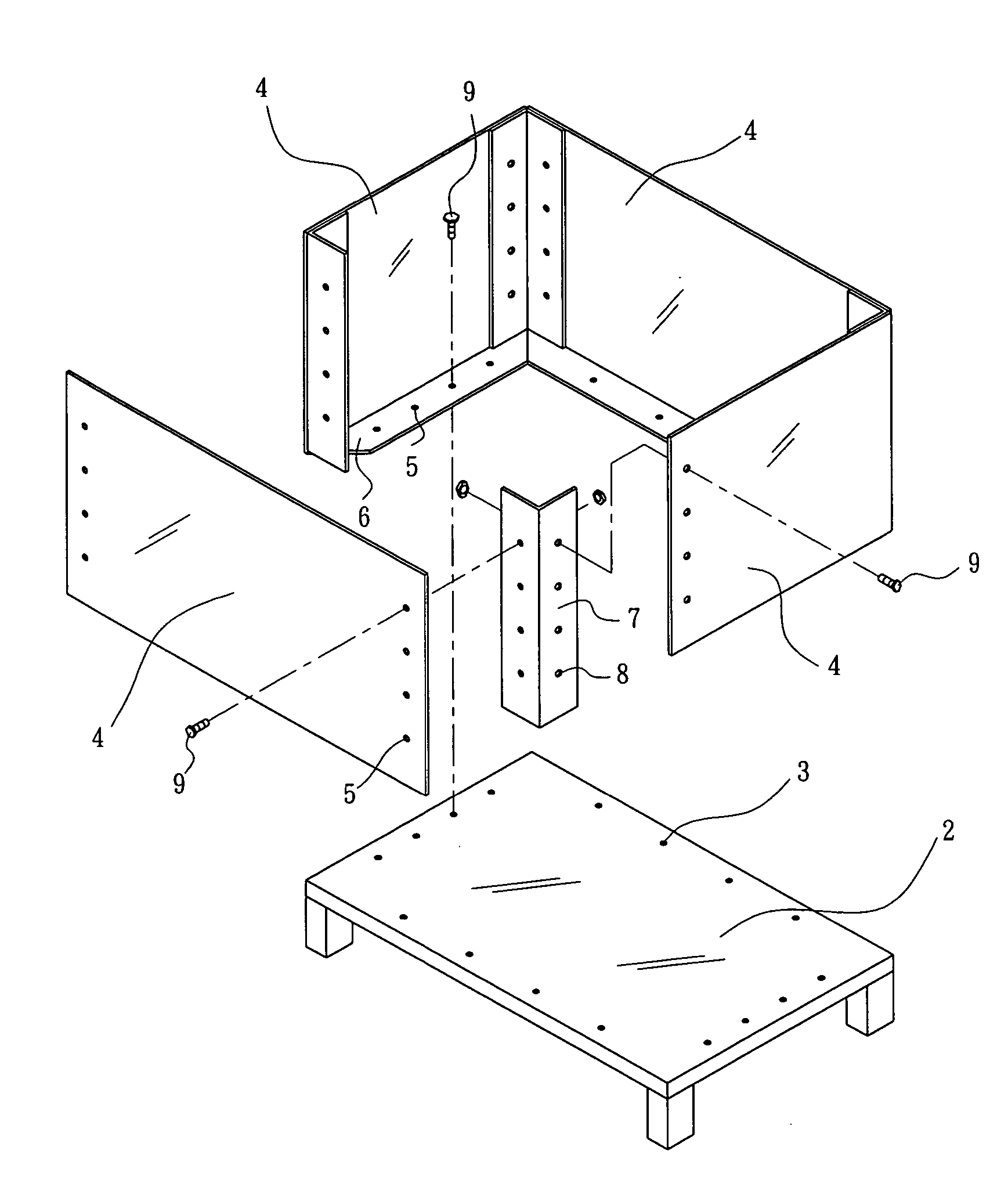

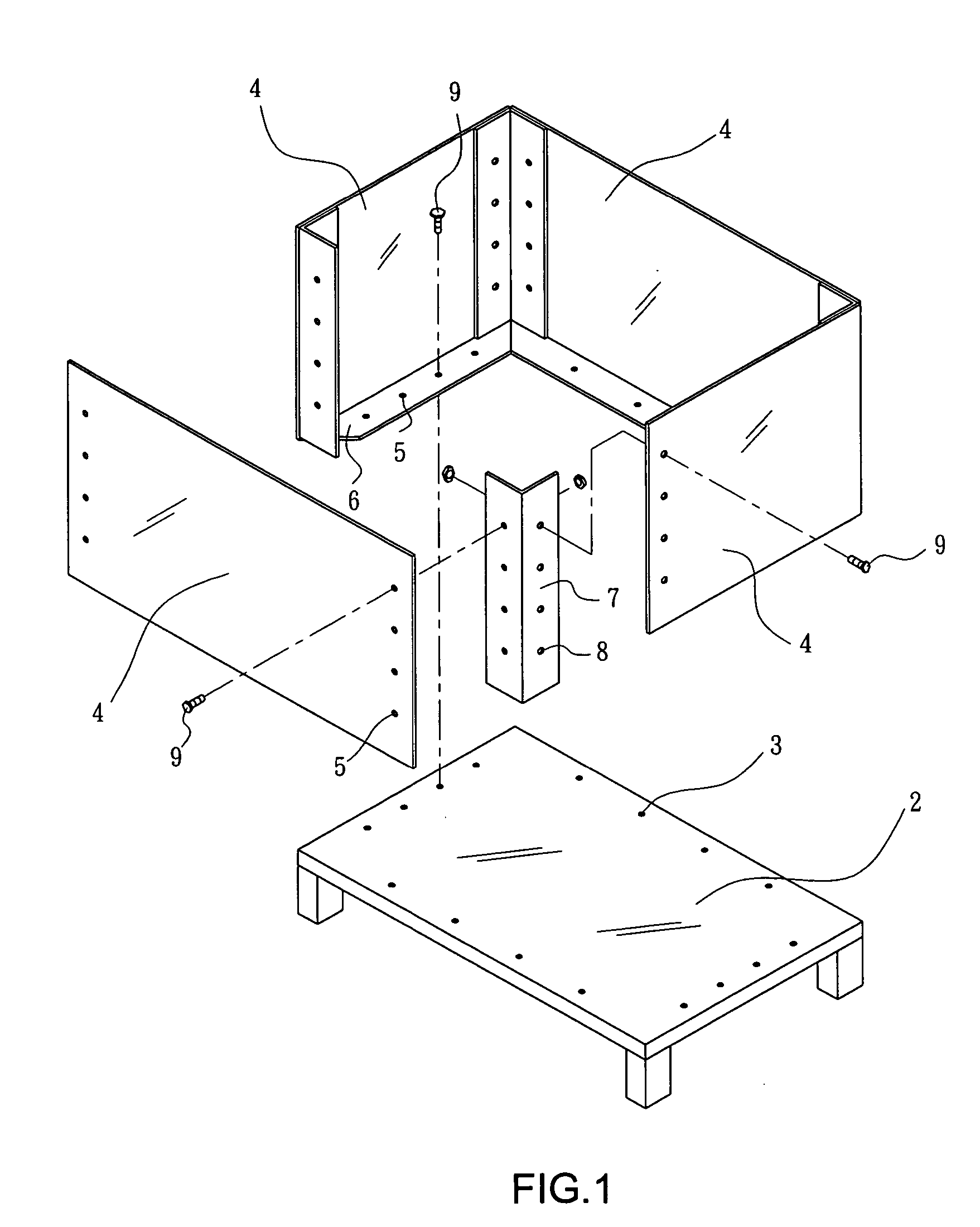

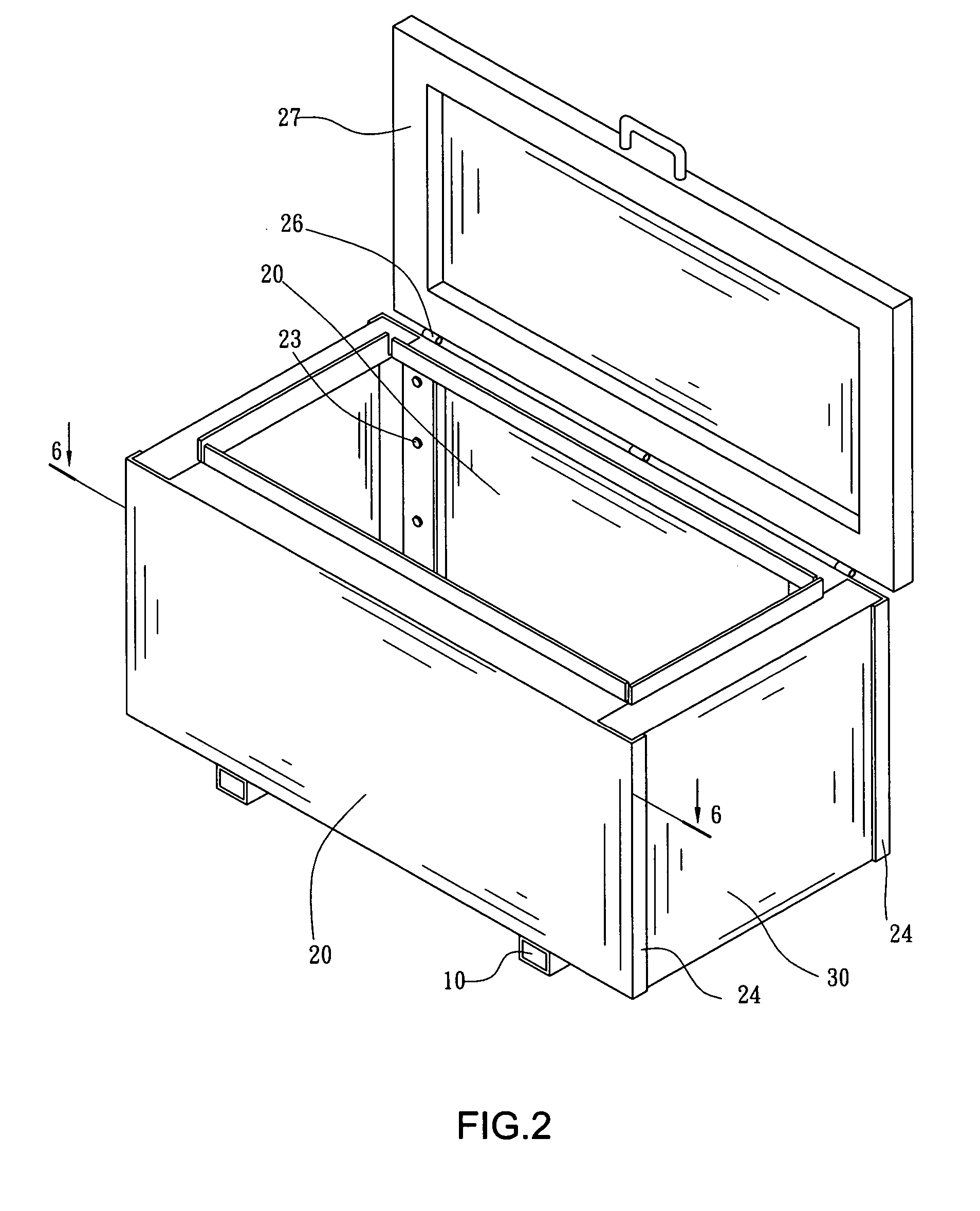

Built-up container

A built-up container includes a base, a front and rear side plates, a right and left side plates and a lifted upper cover. The base provides threaded holes and the side plates provide through holes and threaded holes so that the container can be built up with bolts engaging with the threaded holes. It is characterized in that no holes and no bolts expose outside the container with reinforced strength such that integrity and smoothness of the container can be obtained and the fasteners inside the container are free from water and unable to hurt foreign objects. In addition, the container is capable of being set up fast easily to enhance facility of assembling job.

Owner:E MAKE

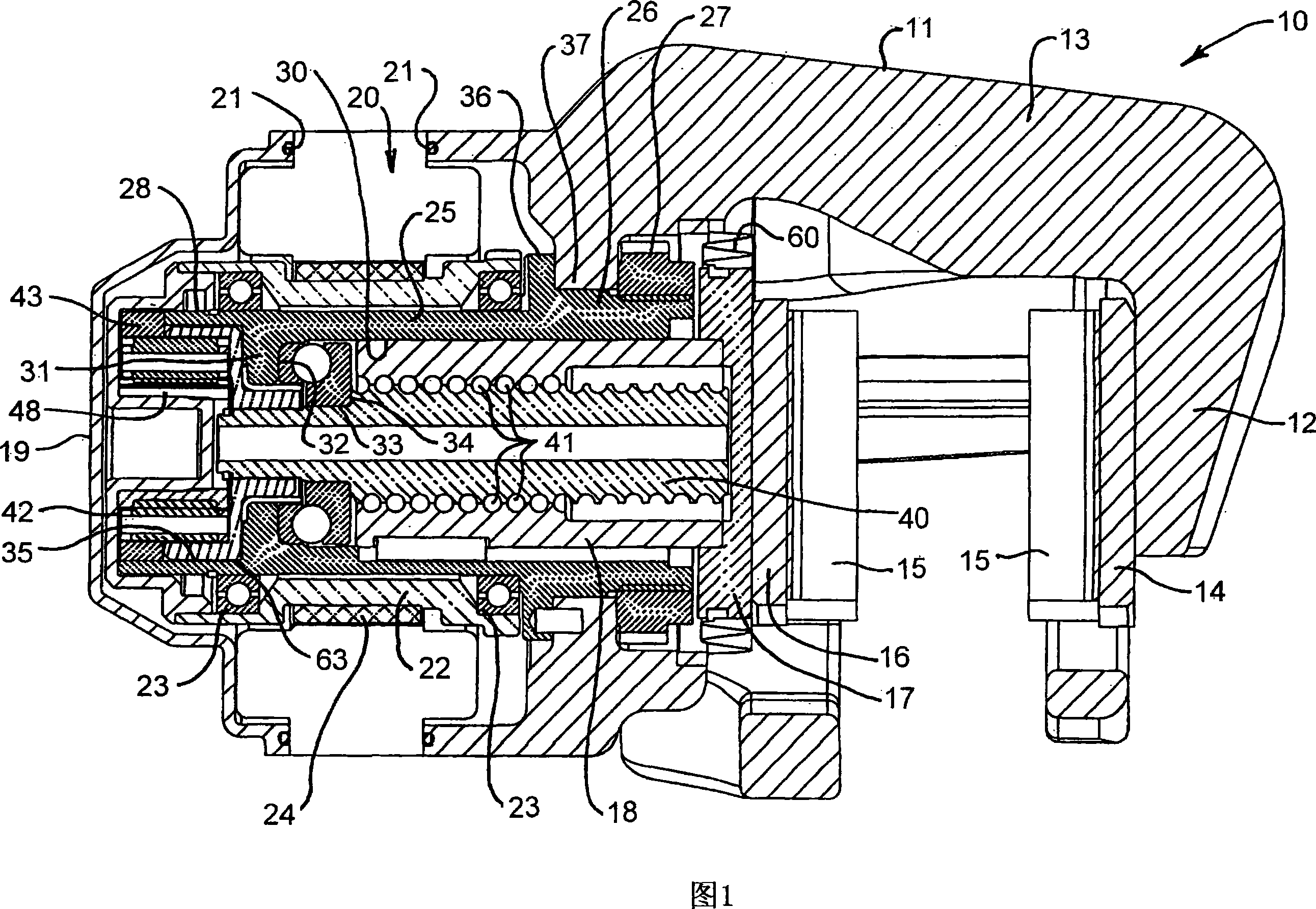

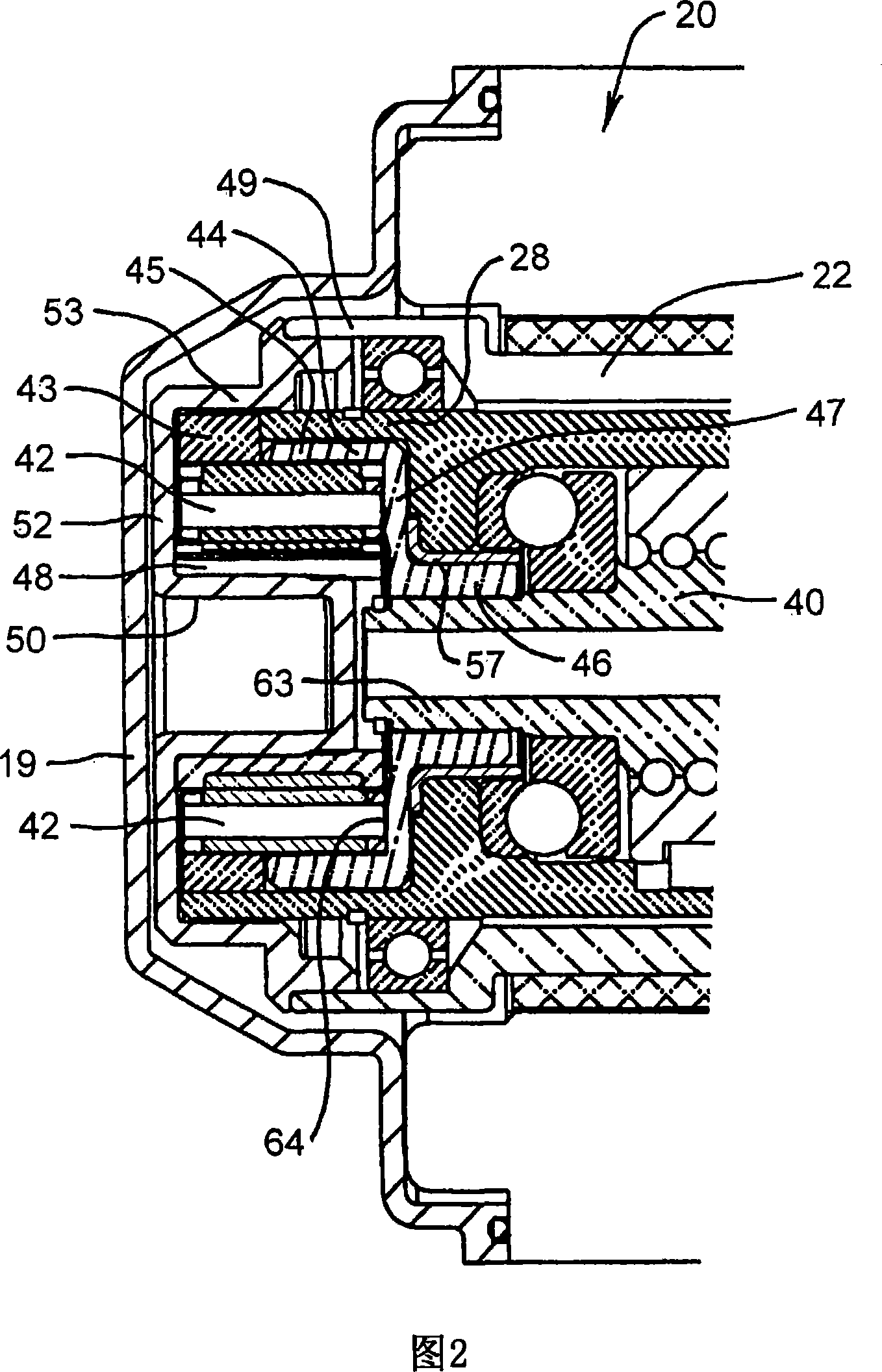

Actuating mechanism and brake assembly

InactiveCN1981142ADoes not affect operationGuaranteed efficacyBrake actuating mechanismsActuatorsAbutmentAxial thrust

An actuating mechanism, particularly for a disc brake caliper, including a screw actuator having a screw (40) and a nut (18) threadably coupled together, an electric drive for driving one of the screw (40) and the nut (18) axially relative to the other and including a stator (20) and a rotor (22), a sleeve assembly including a generally cylindrical sleeve (25) interposed between the rotor (22) and the nut (18) and supporting the rotor (22) for rotation relative to the sleeve (25). The rotor (22) is connected to one of the screw (40) or the nut (18) for rotating the screw (40) or the nut (18). The screw actuator being at least partly mounted within the sleeve (25) and being arranged to bear against a portion of the sleeve assembly to transmit axial thrust to the sleeve assembly, and the sleeve assembly cooperating with an abutment to transmit the axial thrust to the abutment.

Owner:PBR AUSTRALIA PTY LTD

Beam-column joint connecting device with inclined strut for fabricated steel structure special-shaped column

InactiveCN107366362AIncreased bearing capacity and stiffnessReduce dosageBuilding constructionsAbnormal shapedBeam column

The invention discloses a beam-column joint connecting device with an inclined strut for a fabricated steel structure special-shaped column, belonging to the technical field of structural engineering. The beam-column joint connecting device comprises a column, beams and the inclined strut, wherein the column is produced by welding a cross-shaped special-shaped column, a support plate and reinforcing ribs I in a factory; and the beams are produced by welding an H-shaped steel beam, an end plate and reinforcing ribs II in the factory. All welding operations of the beam-column joint connecting device are finished in the factory; by arranging the inclined strut, the rigidity and bearing force of joints can be substantially enhanced, the use amount of bolts is reduced, the external transfer of a plastic hinge is effectively realized, damaged positions of the joints are located on the beam outside the inclined strut, and the joints are protected; by arranging the support plate, the beam can be accurately located, and meanwhile, the stability of the joints is improved; by distributing the bolts, the operation of workers is easy, the fabricating speed is greatly increased, and the fabricating quality is greatly improved; and by utilizing an onsite bolt fabricating manner, the bolts can be conveniently and rapidly fastened, the construction speed is greatly increased, the construction quality is greatly improved, the industrialized production is realized, and the onsite rapid fabricating is realized.

Owner:BEIJING UNIV OF TECH

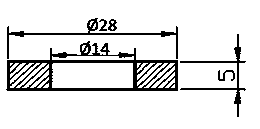

Quantitative pushing device for air valve spring gaskets on engine cylinder cover

InactiveCN103447793AImprove assembly qualityImprove assembly speedMetal working apparatusElectrical and Electronics engineeringGasket

The invention provides a quantitative pushing device for air valve spring gaskets on an engine cylinder cover, which can be used for quantitatively pushing spring gaskets needed during assembling of an engine cylinder cover assembly. The device comprises a charging barrel which is arranged vertically, wherein the diameter of the charging barrel is matched with the diameters of the spring gaskets; a substrate is arranged below the charging barrel; a material pushing block is arranged between the lower end of the charging barrel and the substrate; the height of the pushing block is larger than a thickness which is (N-1) times larger than the thickness of each spring gasket and is smaller than a thickness which is N times larger than the thickness of each spring gasket; N refers to the fixed quantity of the spring gaskets pushed each time; the distance between the lower end of the charging barrel and the substrate is larger than a thickness which is N times larger than the thickness of each spring gasket and is smaller than a thickness which is (N+1) times larger than the thickness of each spring gasket; the material pushing block can move between the charging barrel and the substrate along a horizontal direction in an reciprocating way. During working, the spring gaskets fall onto the substrate freely in the charging barrel; when an operator needs spring gaskets, the material pushing block is used for pushing spring gaskets of a certain height out of the charging barrel along the substrate and away from the charging barrel, the material pushing block returns after the needed spring gaskets are put in place, and the spring gaskets in the charging barrel fall freely to fill the blanks.

Owner:CHERY AUTOMOBILE CO LTD

Mounting structure for automobile door lock

ActiveCN104631972ASimplify the installation processImprove assembly speed and accuracyVehicle locksCar doorDoor handle

The invention provides a mounting structure for an automobile door lock, and belongs to the technical field of automobiles. The mounting structure solves the problems that a door handle and door lock pull wires of an automobile cannot be assembled easily and time and labor are consumed in the prior art. The mounting structure for the automobile door lock comprises door lock pull wires, a door handle, a fixed base and a door guard board which is mounted on an automobile body. The door guard board is provided with a mounting cavity, the door handle is located on one side of the door guard board and hinged to the door guard board, and the other side, facing the door guard board, of the mounting cavity is opened. The fixed base is arranged in the mounting cavity, and the fixed base is provided with sliding columns in a sliding mode. The door handle is fixedly connected with a shifting piece which can drive the sliding columns to slide on the fixed base when the door handle is pulled, and one end of each door lock pull wire is connected to the corresponding sliding column. The mounting structure for the automobile door lock has the advantage of being convenient and fast to mount.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Fabricated steel structure H-shaped steel column and beam column joint connecting device with diagonal braces

InactiveCN107489197AIncrease stiffnessImprove bearing capacityBuilding constructionsEngineeringSteel columns

The invention discloses a fabricated steel structure H-shaped steel column and beam column joint connecting device with diagonal braces, and belongs to the technical field of structural engineering. The fabricated steel structure H-shaped steel column and beam column joint connecting device comprises columns, beams and the diagonal braces. The columns are formed by welding cross-shaped special-shaped columns, supporting plates and stiffened ribs I in a factory, and the beams are formed by welding H-shaped steel beams, end plates and stiffened ribs II in the factory. The forms of the diagonal braces are not limited to H-shaped steels, and the types of channel steel and T-shaped steels can also be used. According to the fabricated steel structure H-shaped steel column and beam column joint connecting device with the diagonal braces, all welding work is completed in the factory; the diagonal braces are arranged, the rigidity and the bearing capacity of joints can be greatly improved, the using amount of bolts is reduced, out-shifting of plastic hinges is realized effectively, so that the broken location of the joints is located on the beams besides the diagonal braces, the role of protecting the joints is achieved; the bolts are arranged, operation for workers is also easy, the assembly speed and quality are greatly improved; bolt assembling is adopted on site, the fastening work of the bolts is convenient and quick, the construction speed and quality are greatly improved, industrialized production is realized, and on-site assembling is quick.

Owner:BEIJING UNIV OF TECH

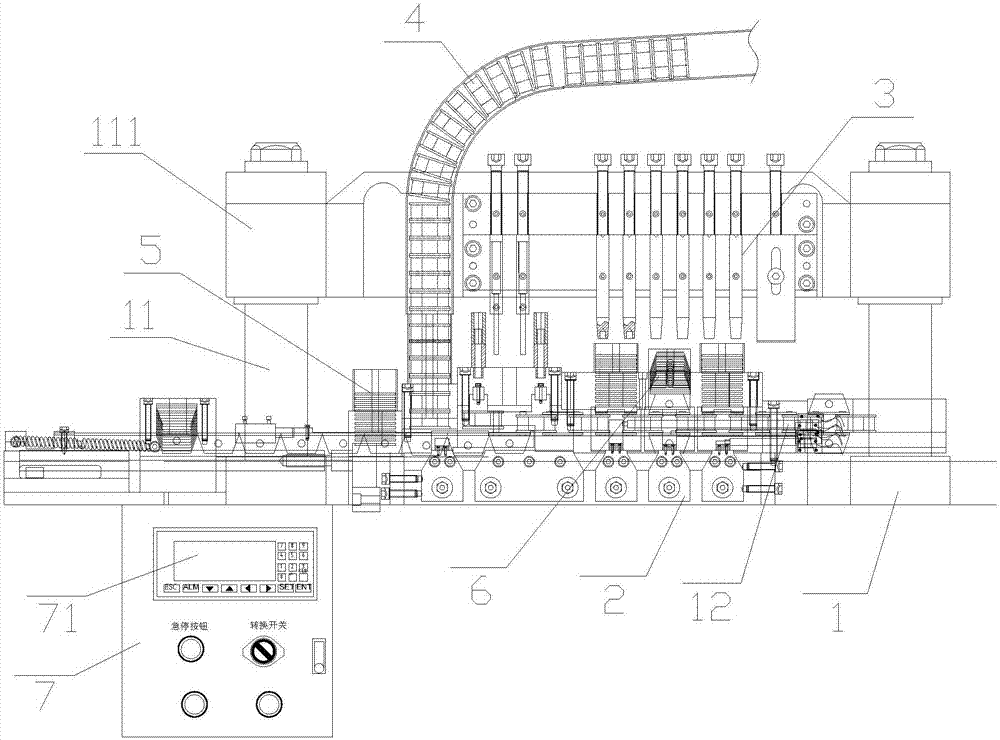

Electric-heating aluminum tube automatic assembling machine

ActiveCN106736510ATo achieve the effect of automatic fixationFast assemblyAssembly machinesMetal working apparatusProduction lineMaterial supply

The invention relates to an electric-heating aluminum tube automatic assembling machine which comprises a base, wherein a chain transmission mechanism for assembling is arranged on the base. The chain transmission mechanism for the assembling comprises two parallel transmission chains, wherein hollow aluminum tube feeding devices are arranged above the left portions of the two transmission chains, a first hoisting mechanism and a second hoisting mechanism are sequentially arranged on the middle portion and the right portion between the two transmission chains, an opening sealing material supplying device is arranged right above the first hoisting mechanism, an electric heating wire installation device and an insulation filler adding device are correspondingly arranged on the left side and the right side of the opening sealing material supplying device, an unloading device is arranged above the second hoisting mechanism, paired limit transportation plates are evenly distributed at the upper ends of the two transmission chains in the horizontal direction, and an assembling carrier is arranged between each pair of limit transportation plates. The electric-heating aluminum tube automatic assembling machine has the characteristics of high automation and convenience in control and use, can assemble and mould electric-heating aluminum tubes step by step in a production line mode and effectively improves assembling speed and assembling efficiency.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

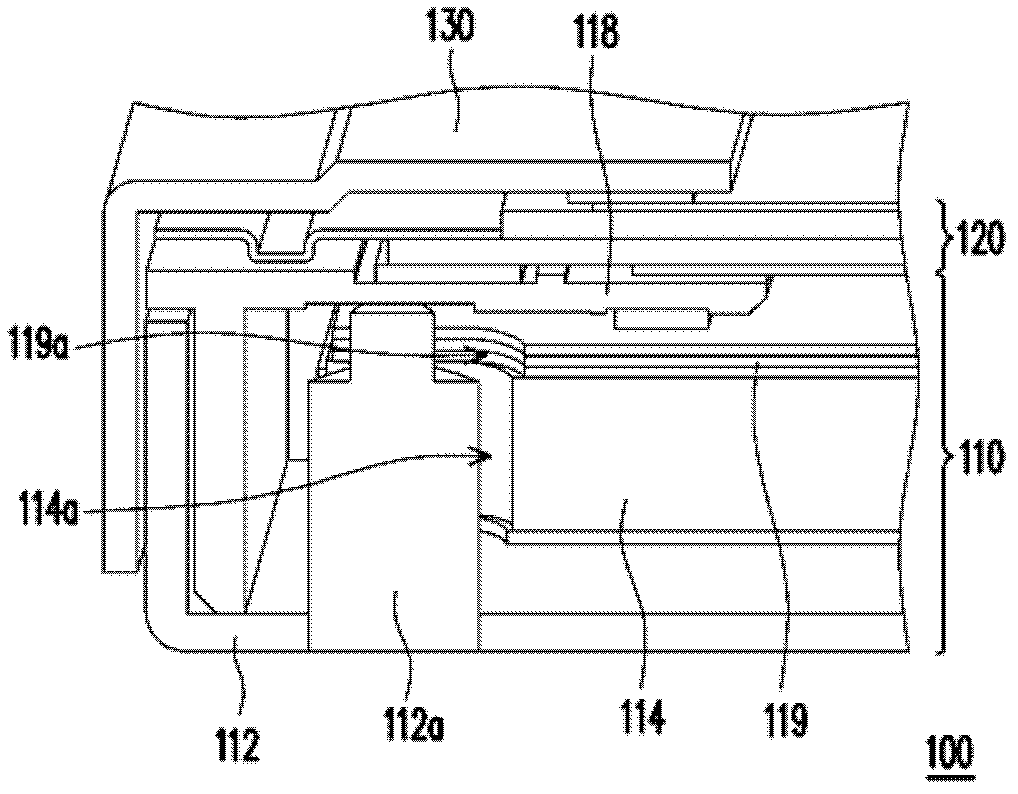

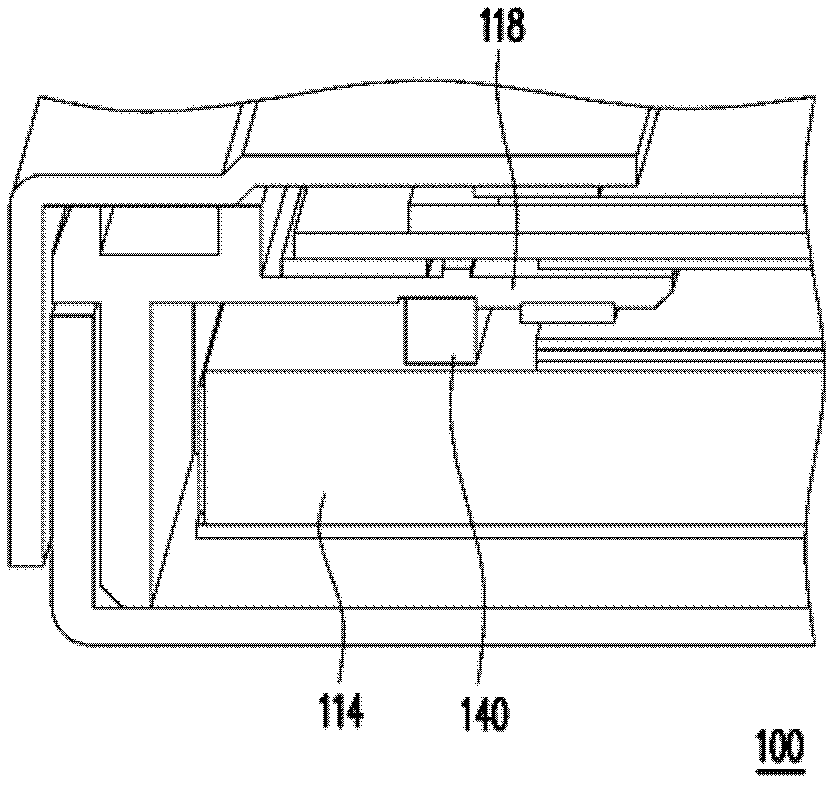

Support device

InactiveCN102088832AReduce manufacturing costImprove assembly speedLighting support devicesCasings/cabinets/drawers detailsElastomerFriction force

The invention discloses a support device which comprises a pivoting body and a support seat, wherein, the pivoting body is provided with a first pivoting part. The support seat comprises a support seat body, a first chute, a first sliding rod and a first elastomer, wherein, a first side of the support seat body is equipped with a first through hole; the first chute is arranged in the support seatbody; the first sliding rod enters the support seat body via the first through hole to be matched with the first chute and can slide along the first chute so that a first end part of the first sliding rod is exposed outside the first through hole to be rotatably connected with the first pivoting part; the first elastomer is sheathed at the first end part; and when the first end part is rotatably connected with the first pivoting part, the first elastomer is positioned between the first pivoting part and the first end part so as to provide friction force for fixing the support seat at arbitrary angle relative to the pivoting body. In the invention, the support seat of the support device can be assembled at the pivoting body in a screw-free joint manner, which can lower the manufacturing cost of fixed components and effectively improve the assembly or disassembly speed between the support seat and the pivoting body.

Owner:QISDA SUZHOU +1

Half-welding half-bolt beam-column joint connection device of assembly type steel structure system

InactiveCN104652616AEasy to operateImprove assembly speedBuilding constructionsBolt connectionBeam column

The invention relates to a half-welding half-bolt beam-column joint connection device of an assembly type steel structure system and belongs to the technical field of structural engineering. According to the half-welding half-bolt beam-column joint connection device, a column base connecting plate, a joint short column, a joint short column upper end flange, a joint short column lower end flange and a truss beam of one side can be welded into one body in the factory; a beam end connecting plate and a truss beam end upper and lower chord rod of the other side are welded into one body in the factory; the beam end connecting plate and the column base connecting plate are connected through bolts. According to the joint connection device, welded portions can be completed in the factory, field assembly is carried out by adopting the bolts, the work of fastening of the bolts is convenient and fast, and the speed and quality of construction are greatly improved, so that the half-welding half-bolt beam-column joint connection device is applicable to the development of assembly type steel structures; meanwhile, joints of the joint connection device are rigid joints and are good in ductility and strong in load-carrying ability.

Owner:BEIJING UNIV OF TECH

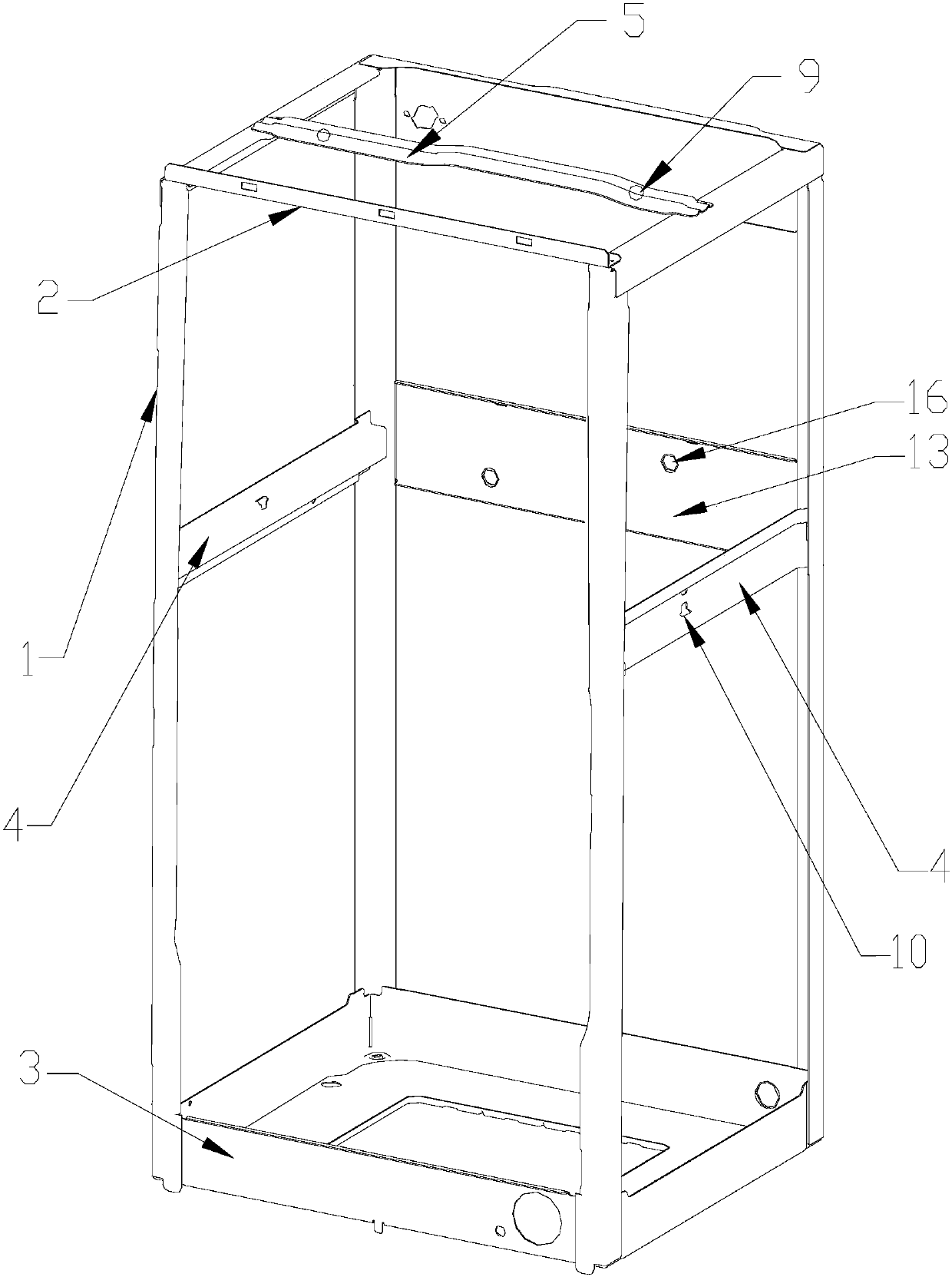

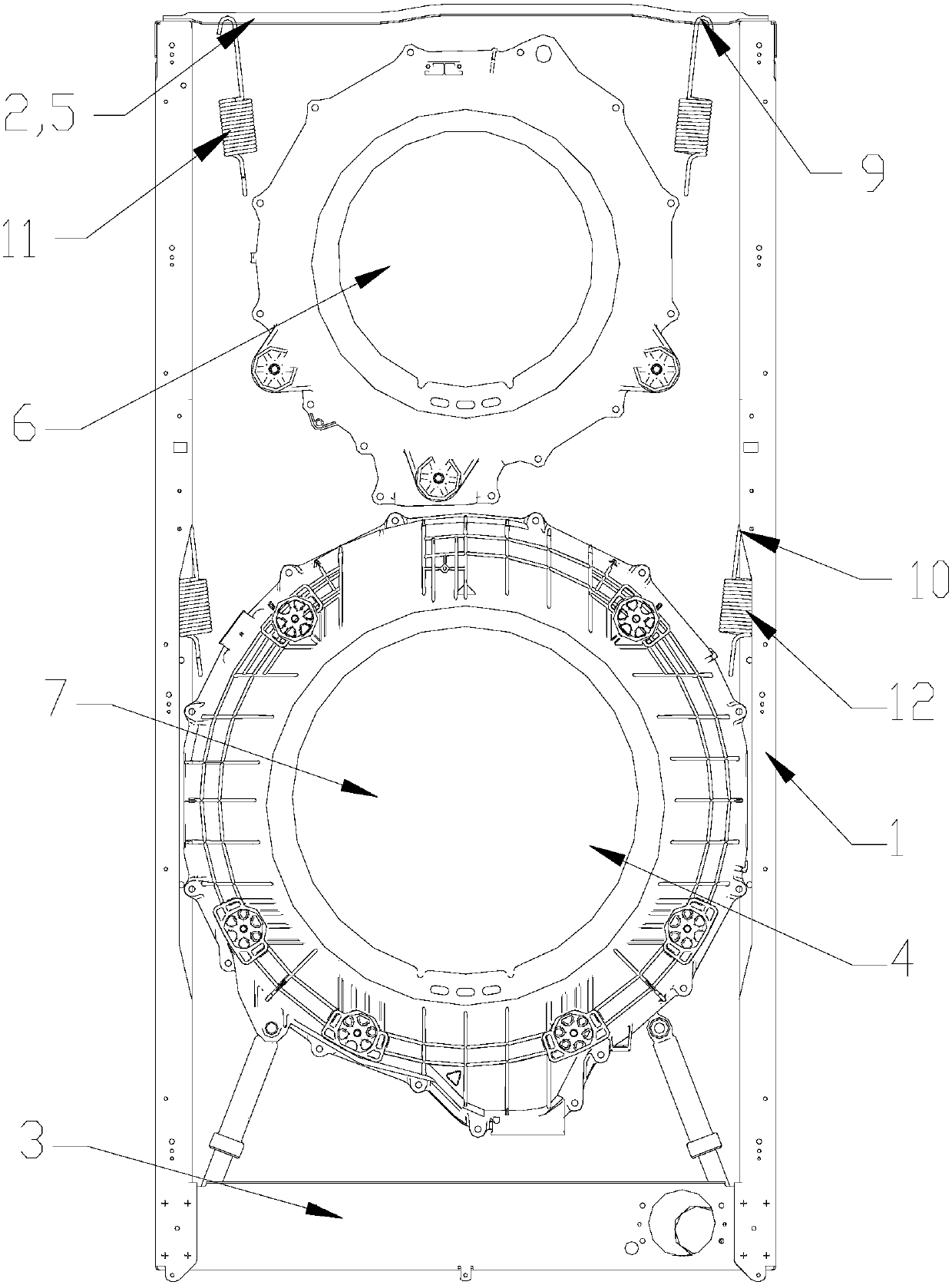

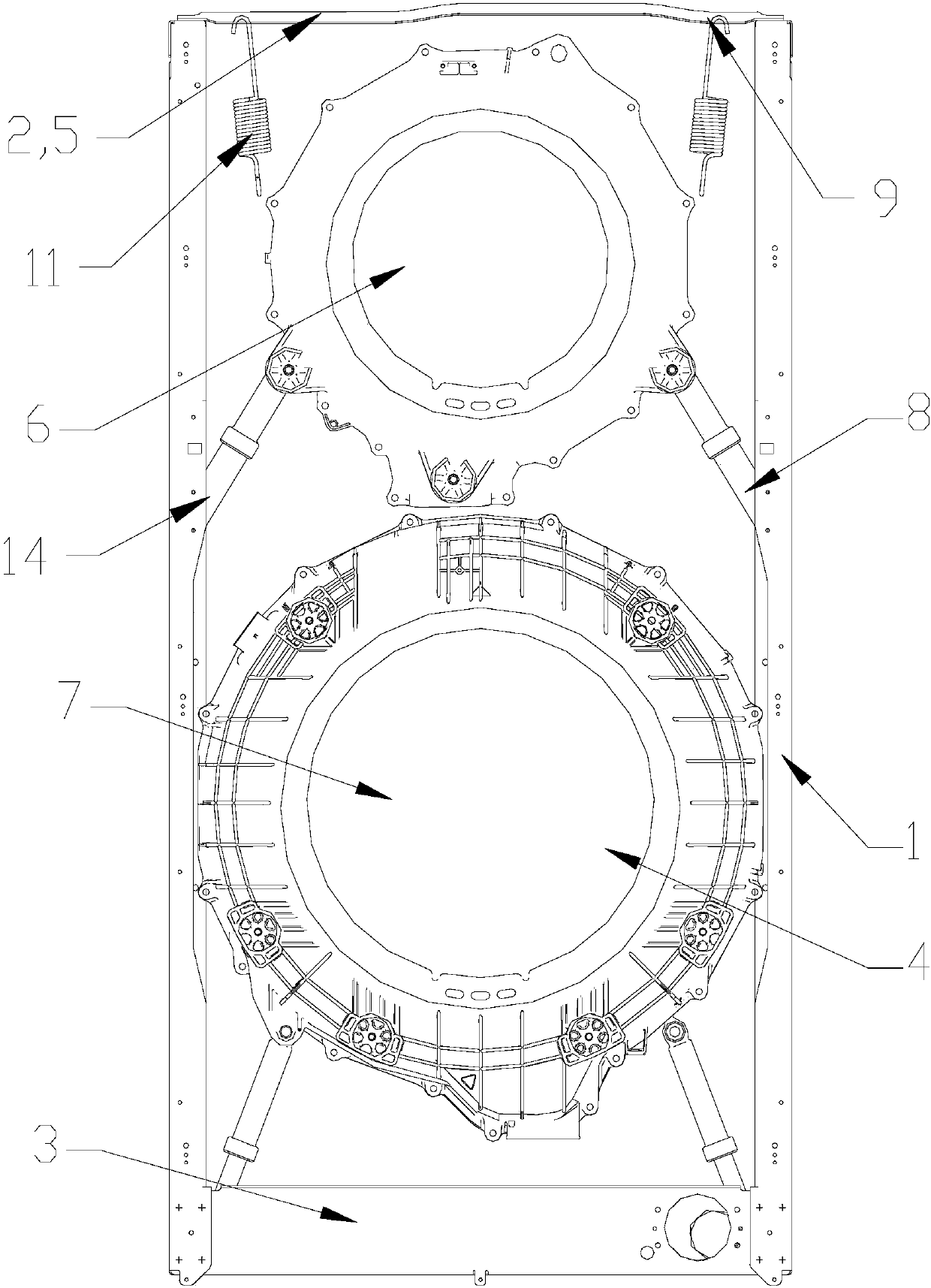

Double-drum washing machine and support frame thereof

PendingCN110219132AEasy to installFrame stabilityOther washing machinesTextiles and paperArchitectural engineeringSupport point

The invention discloses a support frame of a double-drum washing machine. The support frame comprises four vertical beams, upper reinforcement members and a base to form a square frame structure. Theupper ends of the adjacent vertical beams are connected with the upper reinforcement members, and the lower ends of the vertical beams are connected with the base. The left and right upper reinforcement members of the washing machine are connected through an upper cross beam. The middle portions of the left and right upper reinforcement members of the washing machine are connected through the upper cross beam to stabilize the top of the frame, and accordingly, the washing machine is mounted firmly. Particularly, a first mounting hole is formed in the upper cross beam, a support point is provided for mounting an upper drum and / or a lower drum, and the upper drum and / or the lower drum can be mounted on the upper cross beam through hanging springs, so that the damping effect is greatly improved. The support frame is simple in structure, has a remarkable effect and is suitable for popularization and use.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

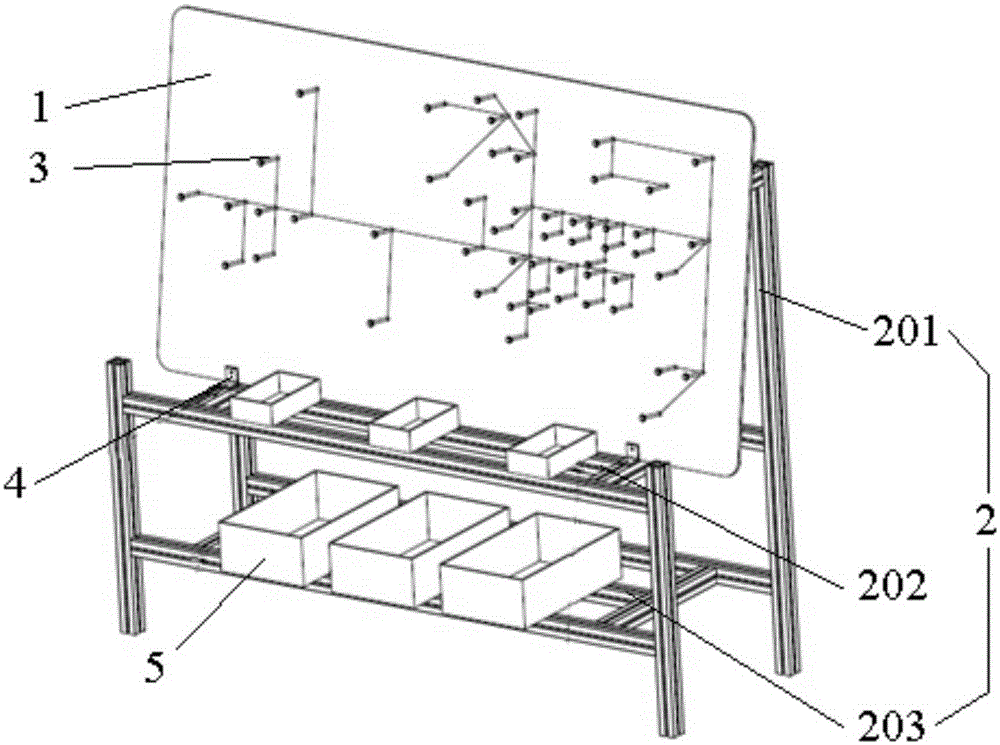

Assembling workbench for engine harnesses

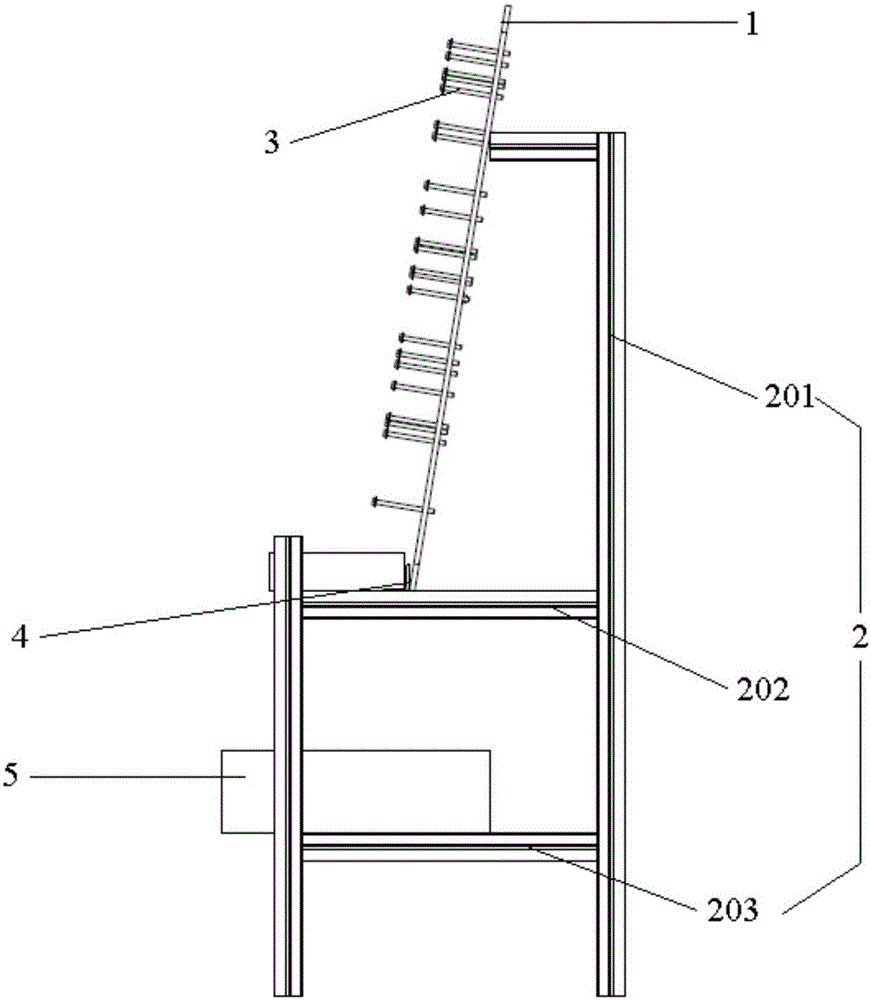

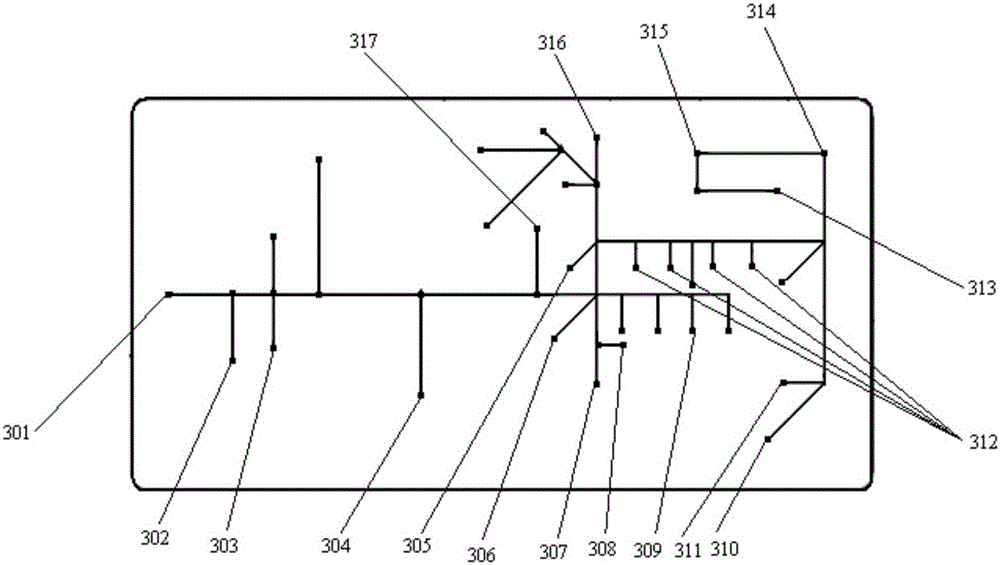

InactiveCN105171703AImprove assembly speed and accuracyImprove assembly speedWork benchesEngineeringSurface plate

The invention discloses an assembling workbench for engine harnesses and belongs to the technical field of automobile engine harnesses. The assembling workbench for the engine harness comprises an assembling panel (1) and an assembling panel support (2). The assembling panel support (2) comprises a vertical support body (201) and a first horizontal support body (202). One end of the assembling panel (1) abuts against the vertical support body (201), and the other end of the assembling panel (1) is fixed to the first horizontal support body (202) through fixing parts (4). The included angle between the assembling panel (1) and the horizontal plane is smaller than 90 degrees. The assembling panel (1) is provided with wire fixing parts (3). When the assembling workbench for the engine harnesses is used for harness assembling, all wires are clear at glance, the assembling speed is effectively increased, and the assembling accuracy is effectively improved; and the assembling workbench is suitable for small-batch manual assembling of the engine harnesses at the automobile engine development stage.

Owner:CHERY AUTOMOBILE CO LTD

Detachable fabricated steel structure closed section column-column connecting node

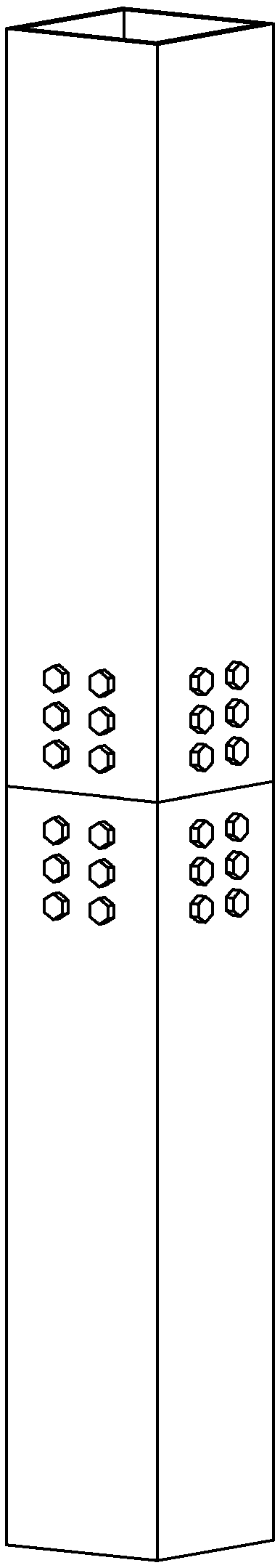

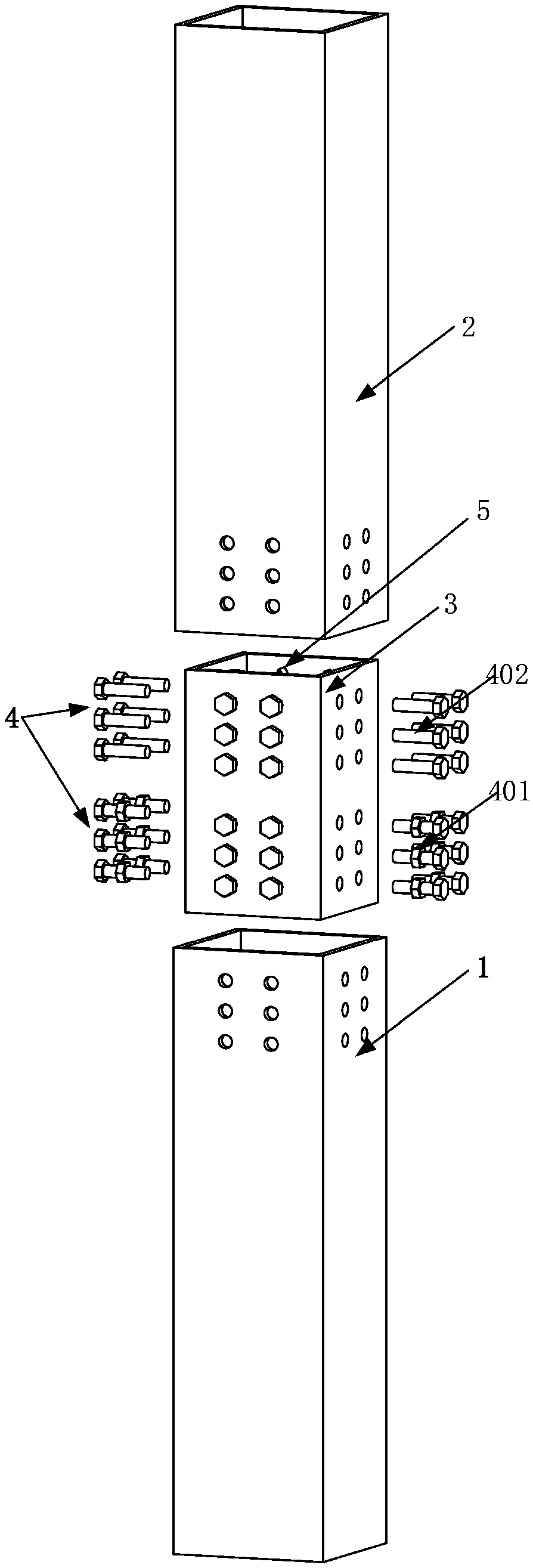

InactiveCN109025061ANo welding workImprove assembly speedStrutsPillarsArchitectural engineeringSteel columns

The invention relates to a detachable fabricated steel structure closed section column-column connecting node. The column-column connecting node comprises a lower column, an upper column, a sleeve andhigh-strength bolts. Bolt holes are reserved in the sleeve and the steel columns, and a nut is fixed by a special fixing device at the bolt hole reserved at the inner side of one end of the sleeve. When the connecting node is assembled, the sleeve and the lower column are connected and fixed by the traditional high-strength bolts, then the upper column sleeves the upper part of the sleeve, the reserved bolt holes of the sleeve are aligned with the reserved bolt holes of the upper column, then bolt rods traverse the reserved bolt holes from the outer side of the column, and the nuts pre-arranged in the inner side of the sleeve are unilaterally screwed in to realize the fastening of the upper column and the sleeve. When the service life expires and the connecting node is dismounted, the bolt rods are screwed off to separate the upper column and the sleeve. The steel structure closed section column-column connecting node has the advantages of high rigidity, insignificant increase of thesection area of a node area, simplicity in assembling and constructing, convenience in restoration after earthquake and replacement of damaged members, and convenience in dismounting of the structureafter the expiry of the service life.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com