Double-drum washing machine and support frame thereof

A technology for supporting a frame and a washing machine, applied in the field of washing machines, can solve the problems of large vibration of the upper drum, potential safety hazards, insufficient supporting strength, etc., and achieve the effects of stable frame, firm installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

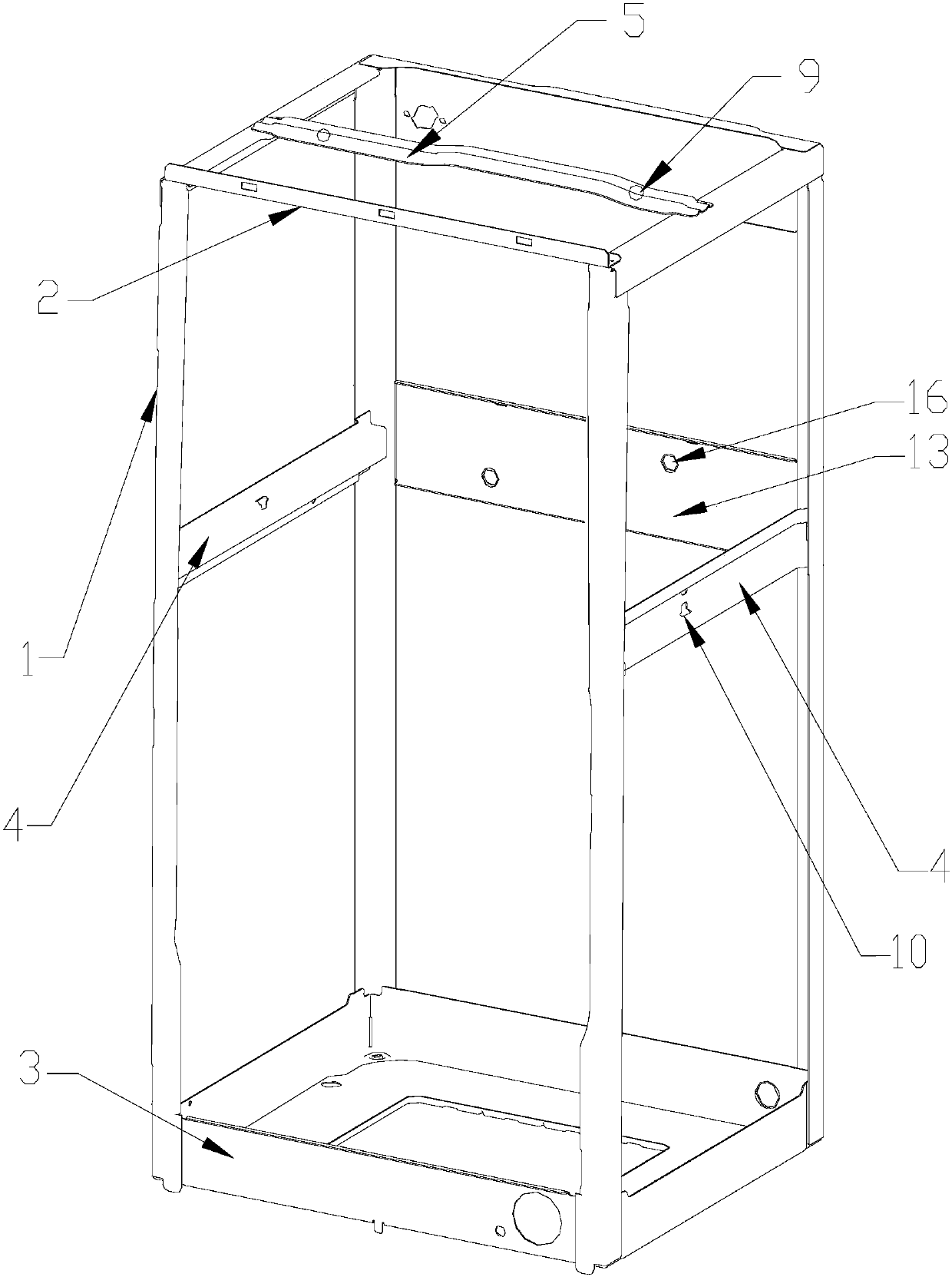

[0045] Such as figure 1 As shown, this embodiment introduces a support frame for a double-drum washing machine, including vertical beams 1 respectively installed at the four sides of the washing machine, upper reinforcement members 1 connected to the upper ends of adjacent vertical beams 1, and adjacent vertical beams 1. The lower ends of the beams 1 are connected to the base 3, the middle beams 4 are connected to the middle parts of the adjacent vertical beams 1, and the upper beams 5 are connected to the middle parts of the upper reinforcement members 2 on the left and right sides.

[0046] In this embodiment, the upper beam 5 is horizontally arranged on the upper end of the washing machine and between the upper reinforcement members 2 on the front and rear sides of the washing machine. The upper beam 5 is horizontally arranged in the middle of the upper reinforcements 2 on the left and right sides of the washing machine, and is perpendicular to the upper reinforcements 2 on...

Embodiment 2

[0051] Such as figure 1 As shown, this embodiment introduces a support frame for a double-drum washing machine, including vertical beams 1 respectively installed at the four sides of the washing machine, upper reinforcement members 1 connected to the upper ends of adjacent vertical beams 1, and adjacent vertical beams 1. The lower ends of the beams 1 are connected to the base 3, the middle beams 4 are connected to the middle parts of the adjacent vertical beams 1, and the upper beams 5 are connected to the middle parts of the upper reinforcement members 2 on the left and right sides.

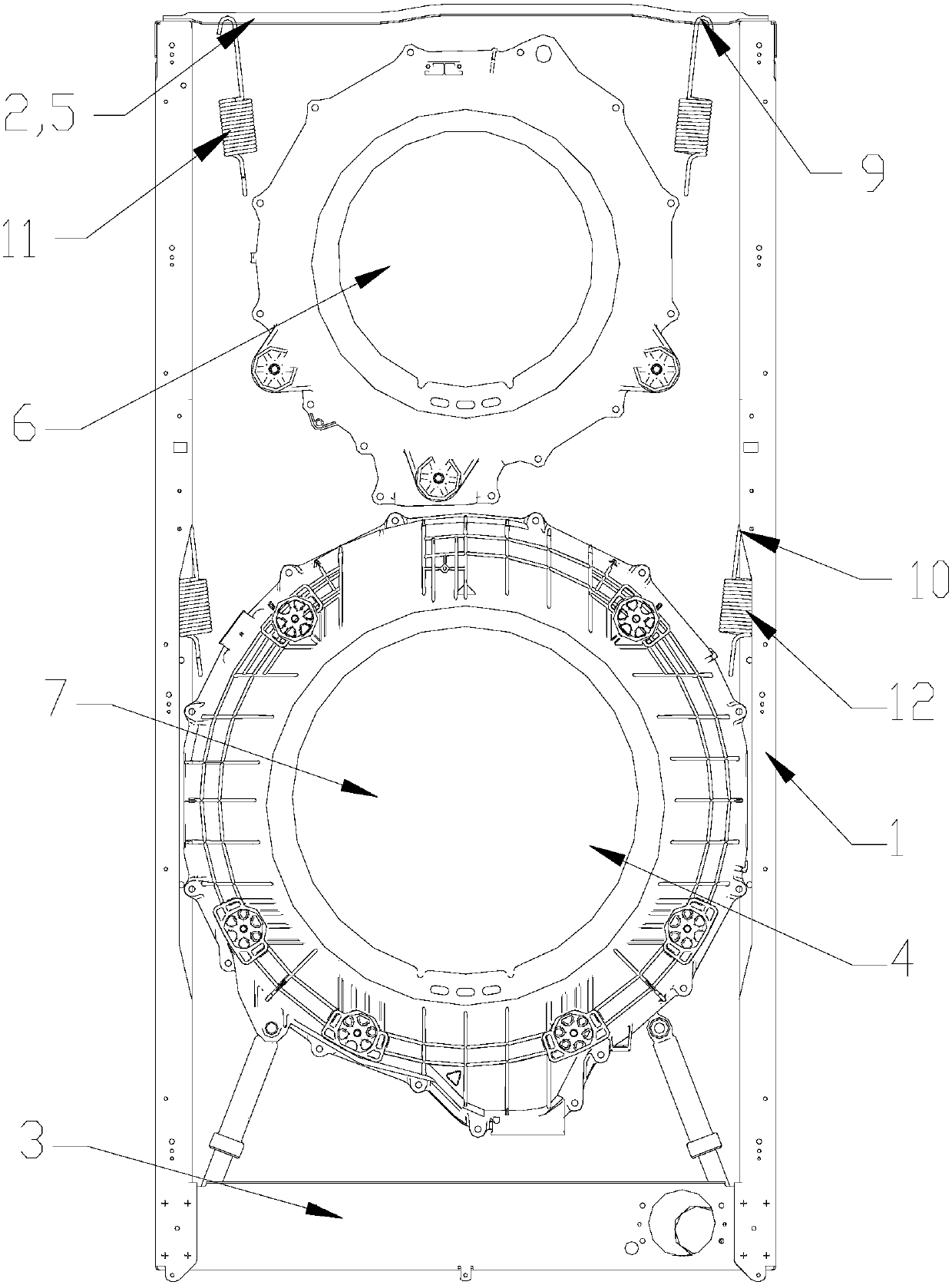

[0052] In this embodiment, the middle beam 4 is arranged on the left and right sides of the washing machine, and the middle beam 4 arranged on both sides of the washing machine is axially symmetrical with respect to the frame and installed horizontally between two vertical beams 1 respectively. A second installation hole 10 is arranged symmetrically on the middle beams 4 on the left and right si...

Embodiment 3

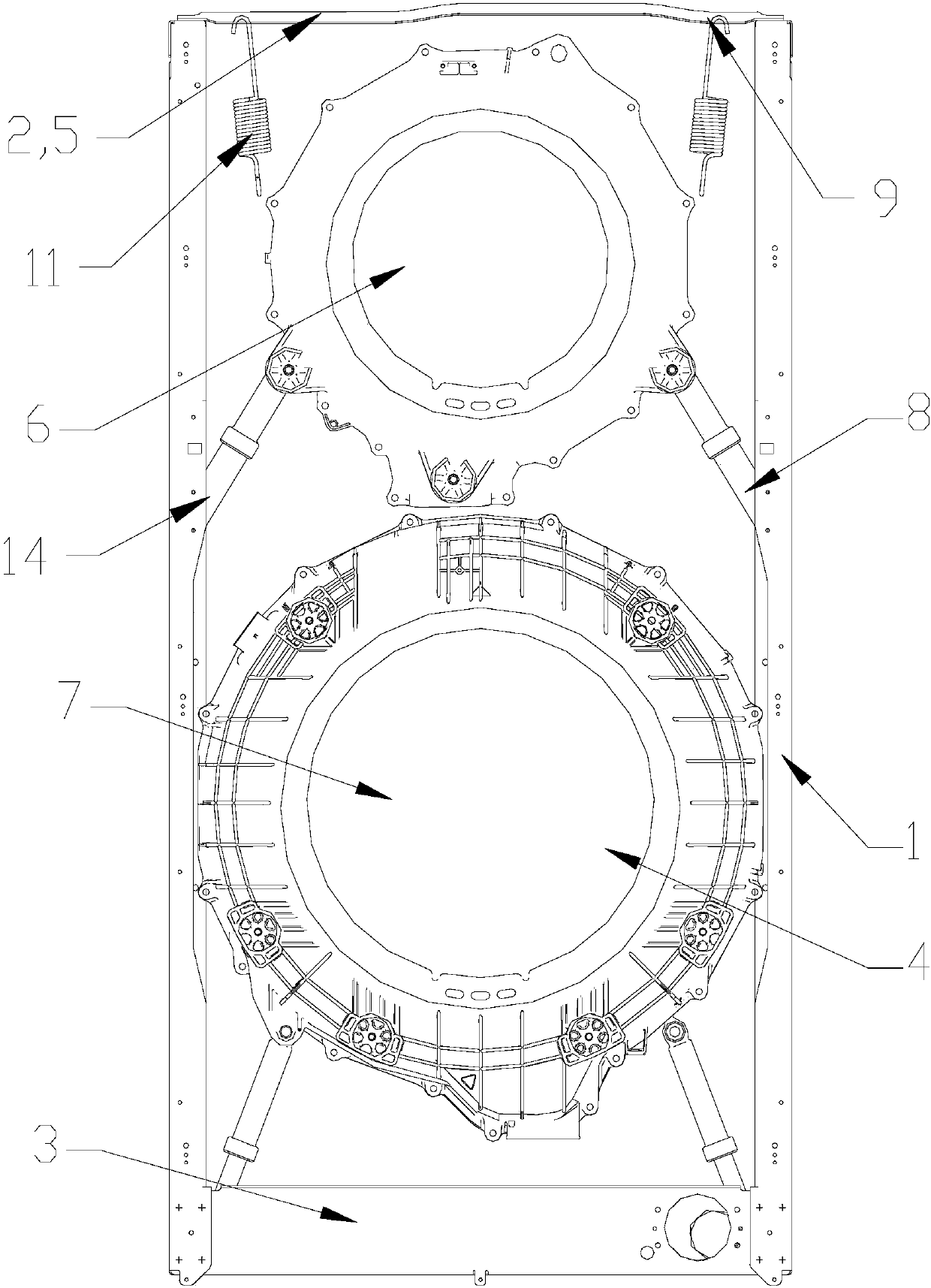

[0057] Such as Figure 4 As shown, this implementation introduces a support frame for a double-drum washing machine, including vertical beams 1 respectively installed at the four sides of the washing machine, upper reinforcements 2 connected to the upper ends of adjacent vertical beams 1, adjacent vertical beams The base 3 connected to the lower end of 1, at least one middle crossbeam 4 connected to the middle of adjacent vertical beams 1, and the upper crossbeam 5 connected to the middle of the upper reinforcement members 2 on the left and right sides.

[0058] In this embodiment, the middle beam 4 is arranged on the left and right sides of the washing machine. The left and right sides of the washing machine are respectively provided with two central beams 4 arranged in parallel. The middle crossbeams 4 arranged on both sides of the washing machine are axially symmetrical with respect to the frame and are installed horizontally between the two vertical beams 1 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com