Patents

Literature

52results about How to "Frame stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

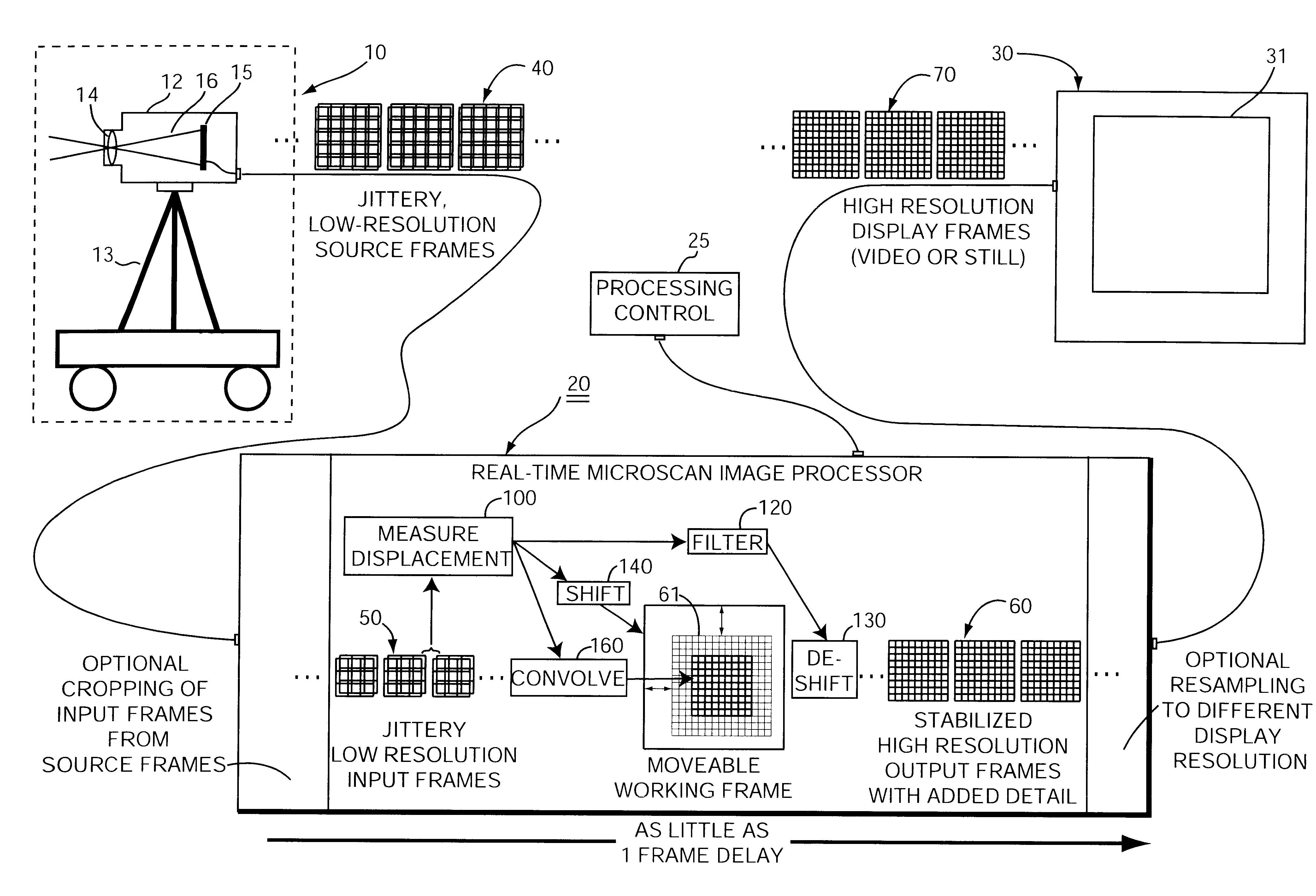

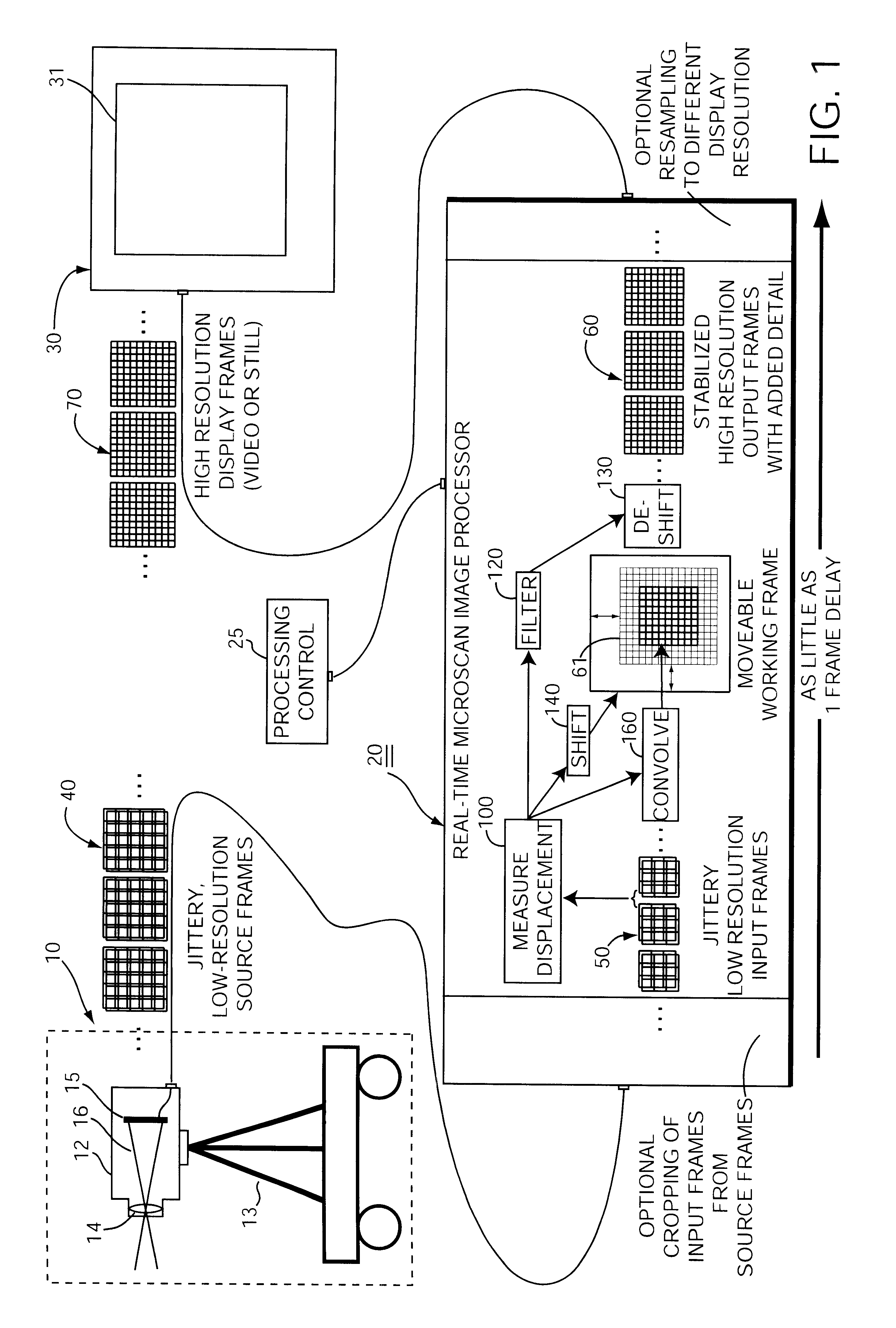

Method of producing a high quality, high resolution image from a sequence of low quality, low resolution images that are undersampled and subject to jitter

InactiveUS6650704B1Increase the number of pixelsQuality improvementTelevision system detailsGeometric image transformationFrame basedImage resolution

A method of processing low resolution input frames containing undersampled views of an optically imaged scene to produce a higher quality, higher resolution output frame. This method operates by obtaining a sequence of low resolution input frames containing different undersampled views of an optically imaged scene. With regard to each new low resolution input frame, the method involves the further steps of measuring a displacement between a previous low resolution input frame and a new low resolution input frame to sub-pixel precision to produce a measured displacement; coarsely registering a high resolution working frame with the new low resolution input frame based on the measured displacement; finely registering the new low resolution input frame with the high resolution working frame by expanding the new low resolution input frame into a new high resolution input frame based on the measured displacement; and merging the new high resolution input frame into the high resolution working frame to produce an output frame.

Owner:NYTELL SOFTWARE LLC

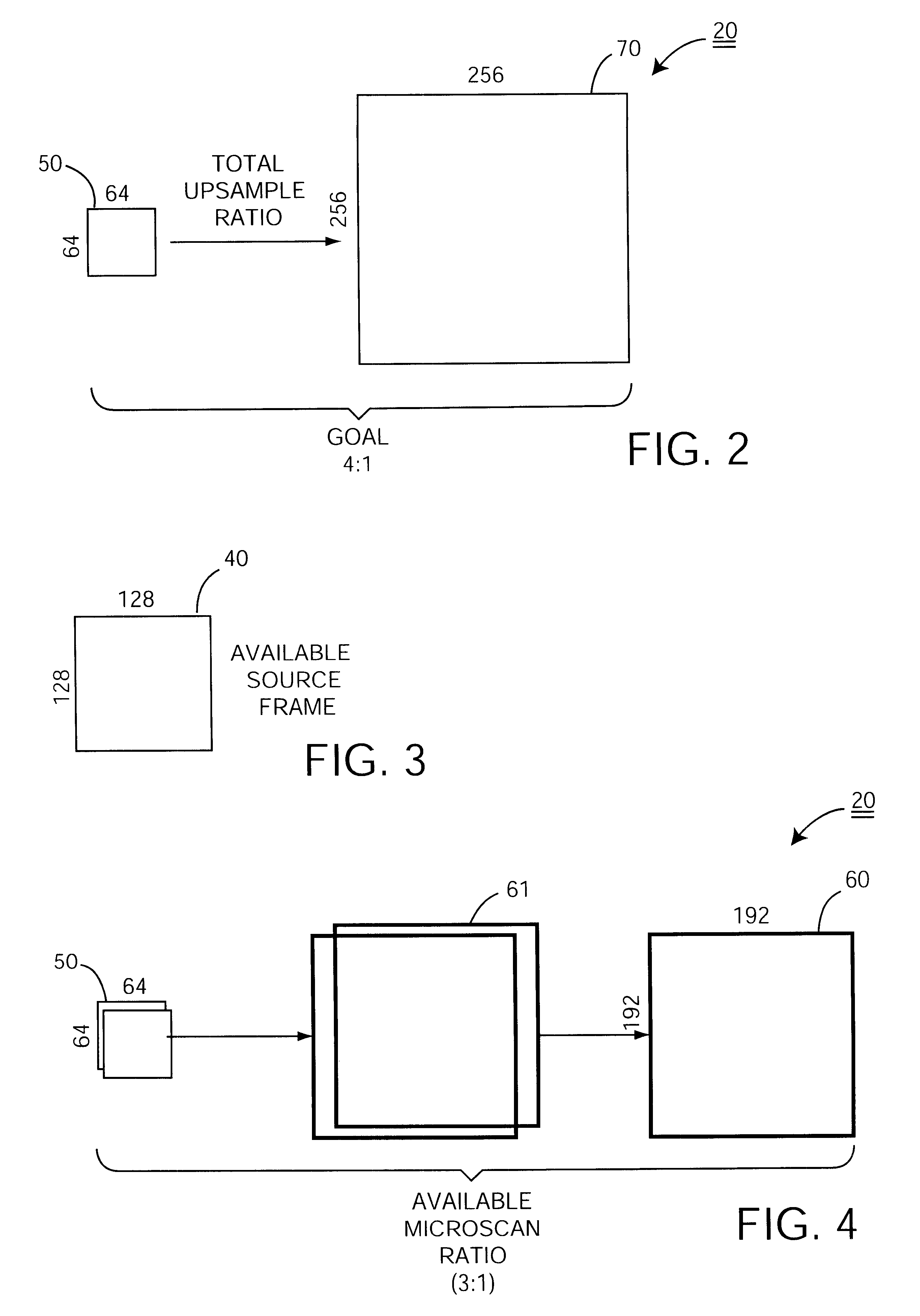

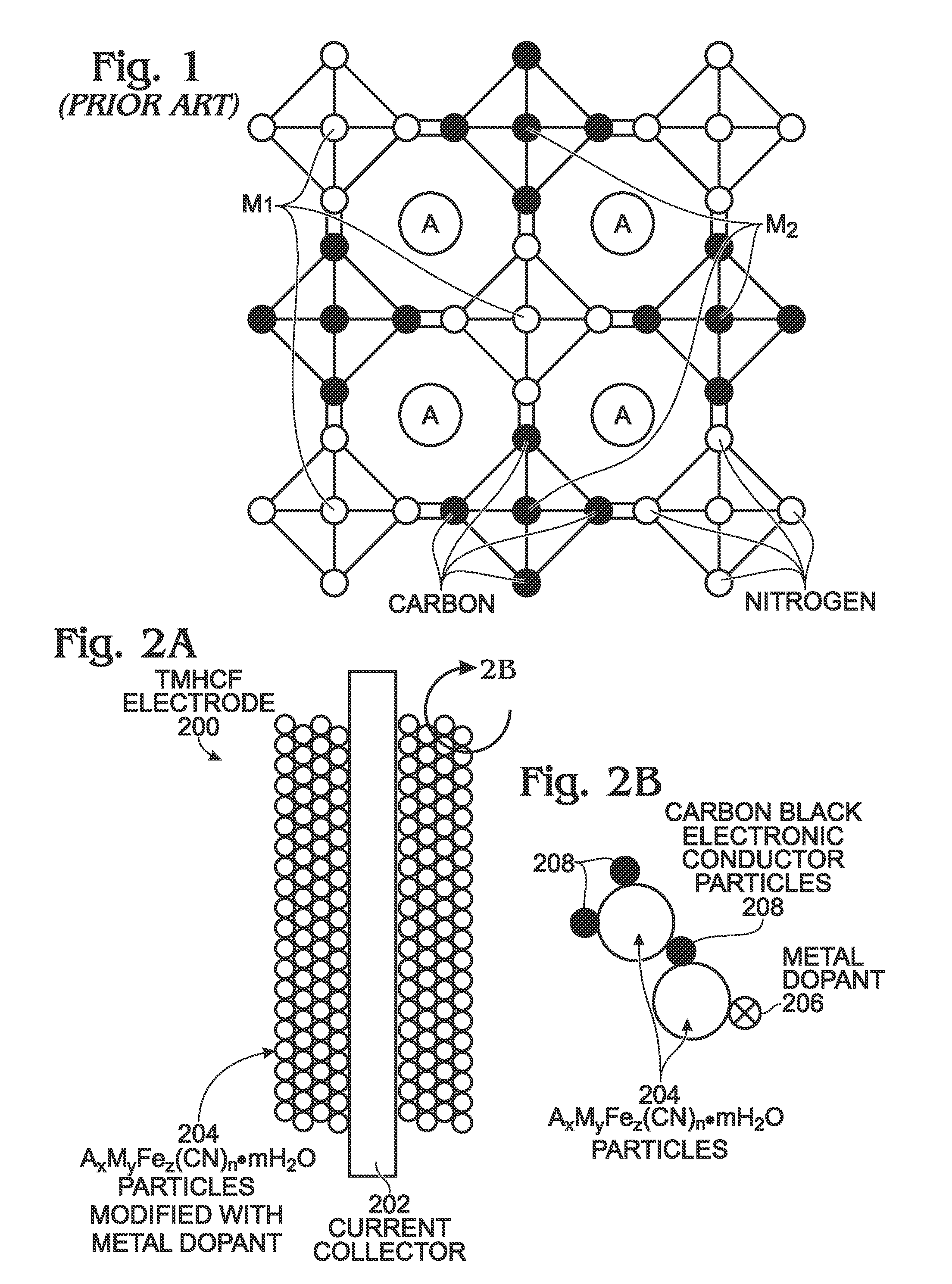

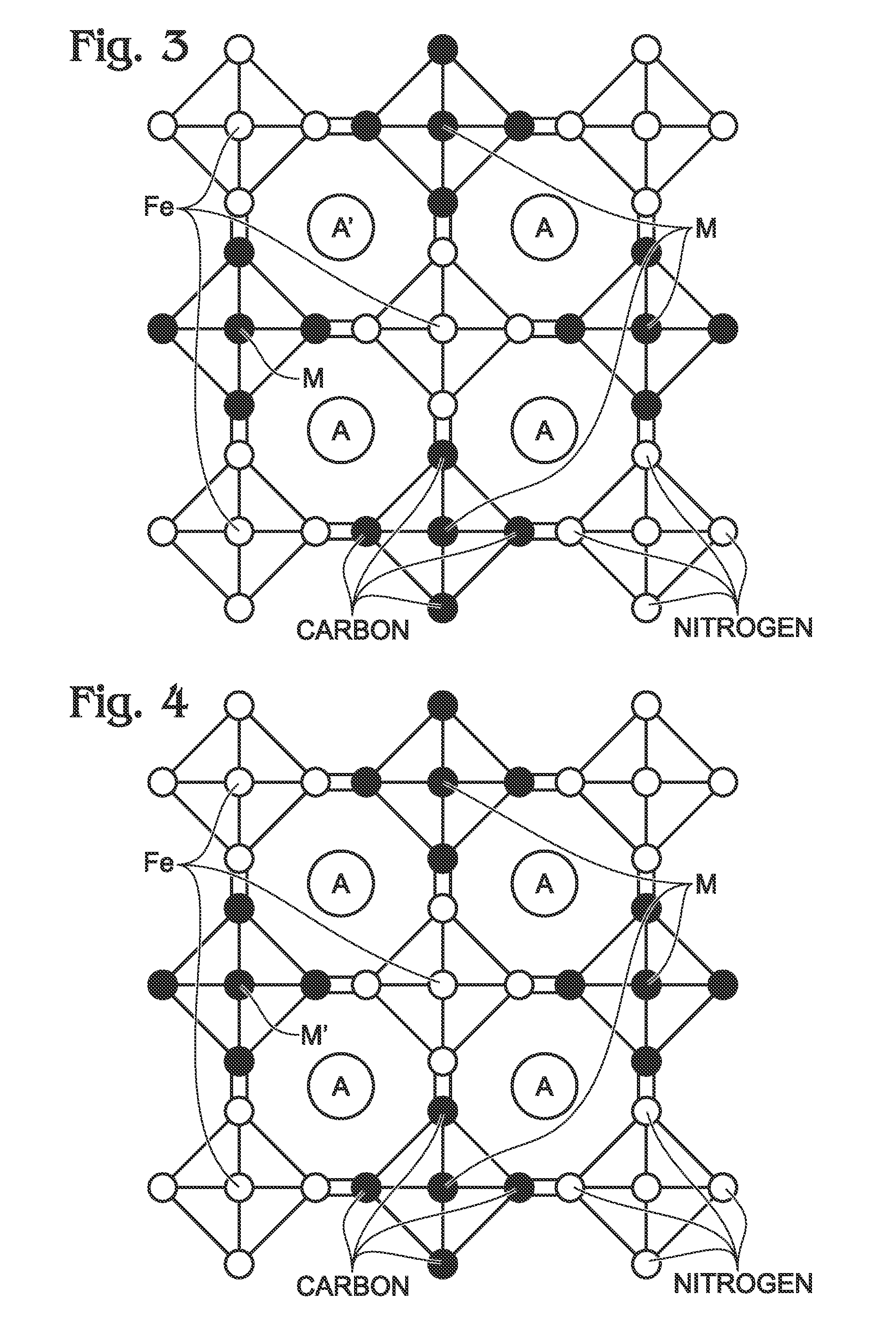

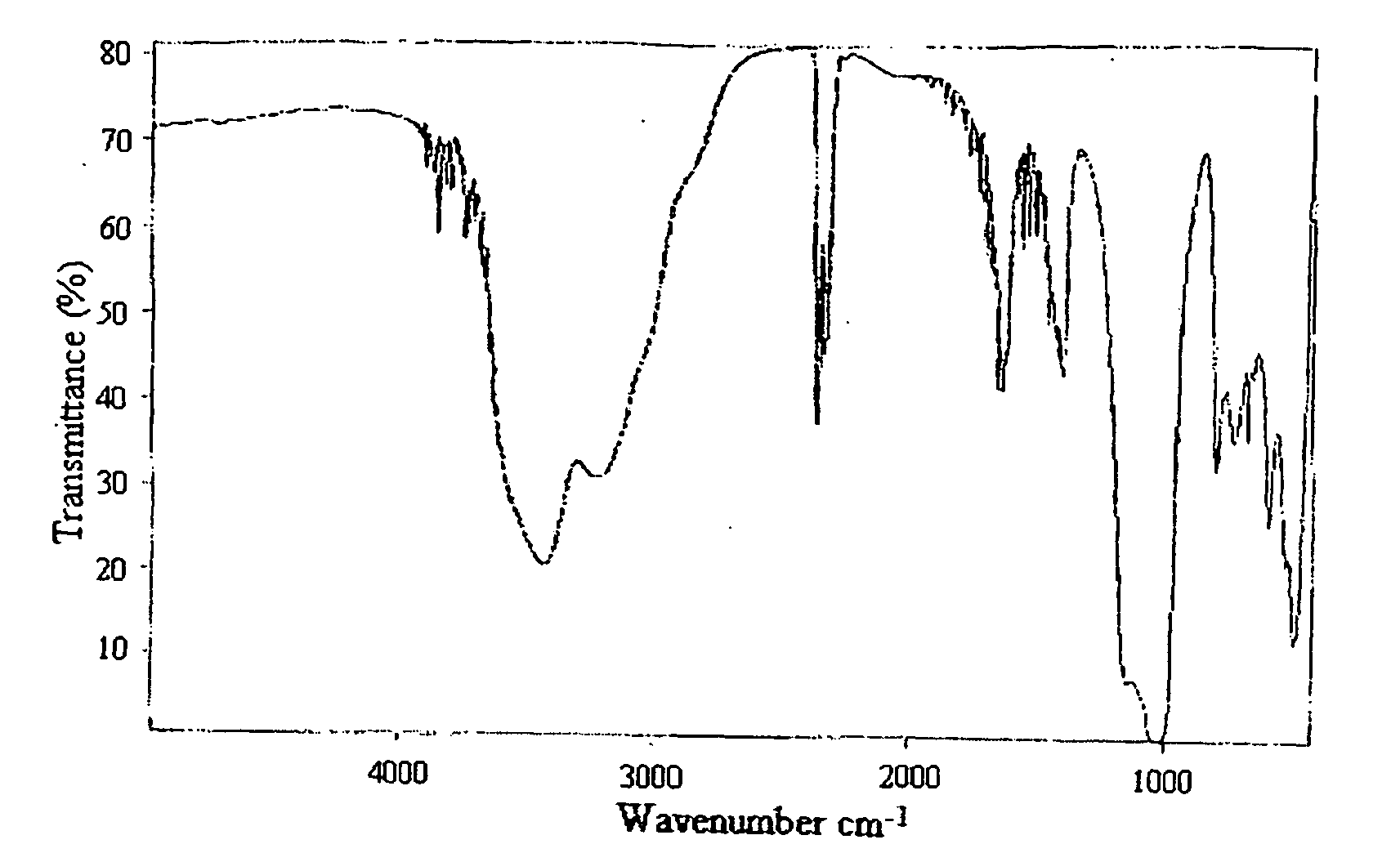

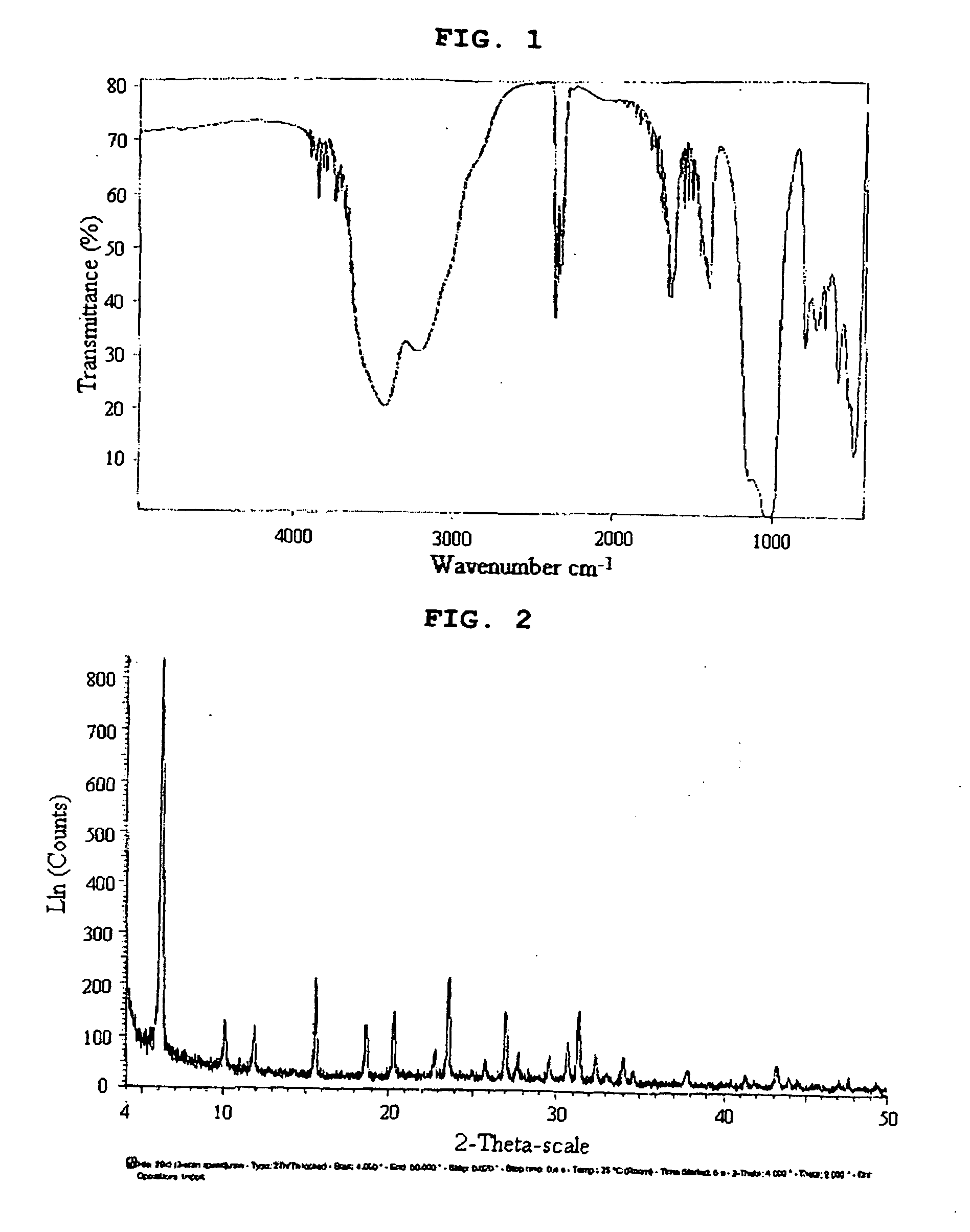

Metal-Doped Transition Metal Hexacyanoferrate (TMHCF) Battery Electrode

ActiveUS20130266861A1Improve performanceFrame stabilityConductive materialActive material electrodesDopantAlkaline earth metal

A method is provided for synthesizing a metal-doped transition metal hexacyanoferrate (TMHCF) battery electrode. The method prepares a first solution of AxFe(CN)6 and Fe(CN)6, where A cations may be alkali or alkaline-earth cations. The method adds the first solution to a second solution containing M-ions and M′-ions. M is a transition metal, and M′ is a metal dopant. Subsequent to stirring, the mixture is precipitated to form AxMcM′dFez(CN)n.mH2O particles. The AxMcM′dFez(CN)n.mH2O particles have a framework and interstitial spaces in the framework, where M and M′ occupy positions in the framework. Alternatively, the method prepares AaA′bMyFez(CN)n.mH2O particles. A and A′ occupy interstitial spaces in the AaA′bMyFez(CN)n.mH2O particle framework. A metal-doped TMHCF electrode is also provided.

Owner:SHARP KK

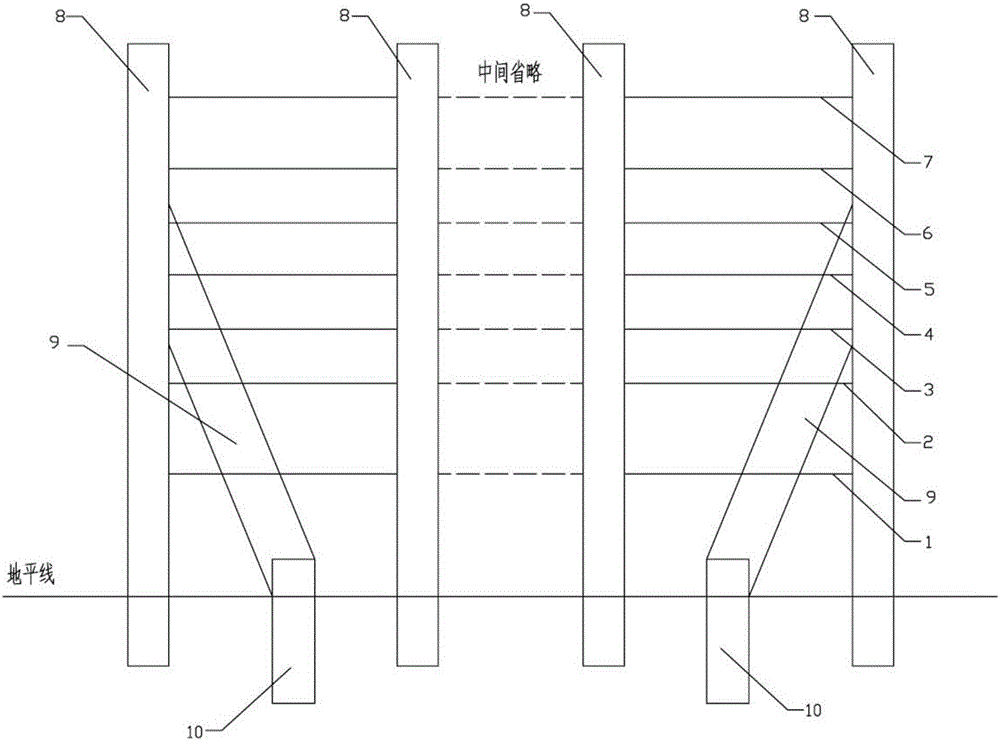

Method for cultivating lycium barbarum in fence wall mode

ActiveCN105900770ATimely and efficient control of pests and diseasesFrame stabilityCultivating equipmentsFertilizerPesticide

The invention discloses a method for cultivating lycium barbarum in a fence wall mode. The method for cultivating lycium barbarum in the fence wall mode has the advantages of bringing convenience to production and management of lycium barbarum planting, saving time and labor and being efficient. A fence wall type frame body is stable and firm and can effectively lift or erect various sprinkler irrigation facilities such as drip irrigation belts and mist-spray sprinkler irrigation pipes, the problems of integration of water, fertilizer and pesticide in soil and integration of foliage pesticide spray and top dressing of micro-element fertilizer are solved, damage, caused by planting measures such as weeding and soil loosening, to the drip irrigation belts can be eliminated, and work of top dressing of foliage micro-element fertilizer and unified prevention and control of diseases and insect pests can be conducted conveniently and efficiently in time. Therefore, by means of the brand-new cultivating mode of combining fence walls with agricultural measures such as water-saving irrigation, electrostatic mist spray and pruning, field mechanization management is promoted and is more convenient and rapid, the purposes of saving the labor and achieving high-efficiency production are achieved, and a powerful guarantee is provided for producing high-quality and high-yield lycium barbarum.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

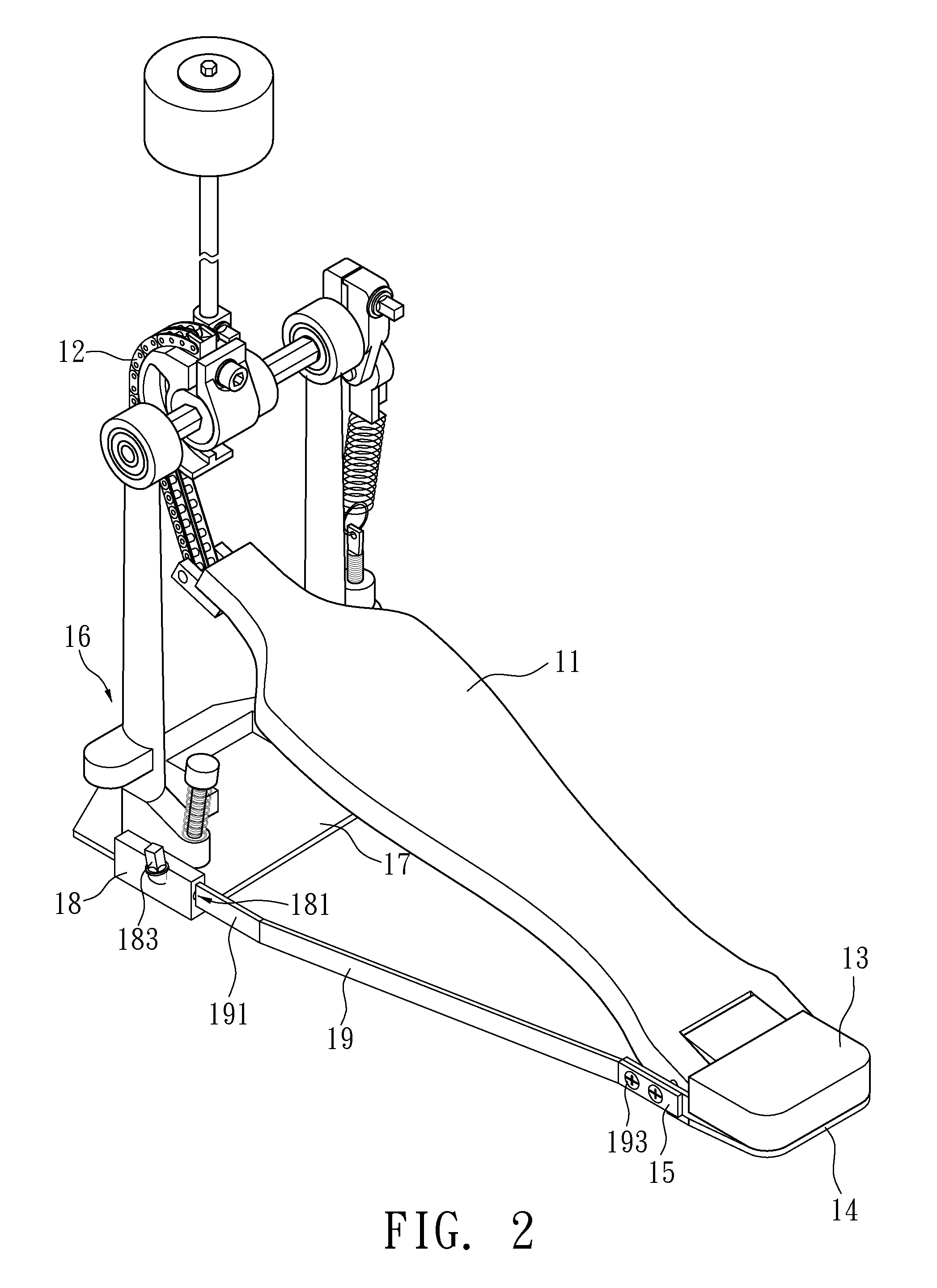

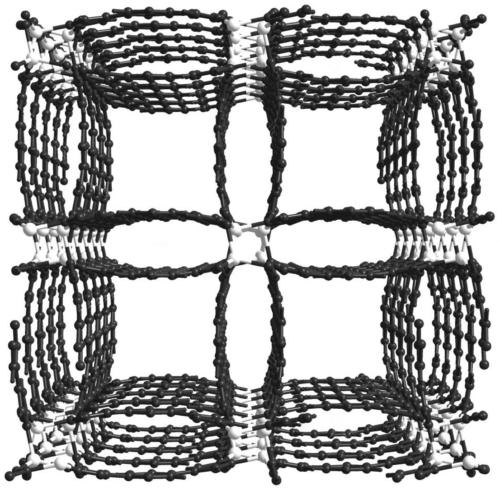

Chiral inorganic-organic composite porous material and method for preparing the same

InactiveUS20090018334A1Improve physiological activityHigh selectivitySolid sorbent liquid separationGlass/slag layered productsChiral selectivityIon exchange

The present invention provides a chiral inorganic-organic composite porous material in which cationic chiral organic molecules are present as charge-balancing cations in a porous material containing charge-balancing cations, as well as a method for preparing the same by an ion exchange process. The chiral inorganic-organic composite porous material according to the present invention is excellent in stability, selectivity and durability, and thus, will be useful as a chiral-selective catalyst or a material of separating an isomeric mixture.

Owner:CHIROLITE INC

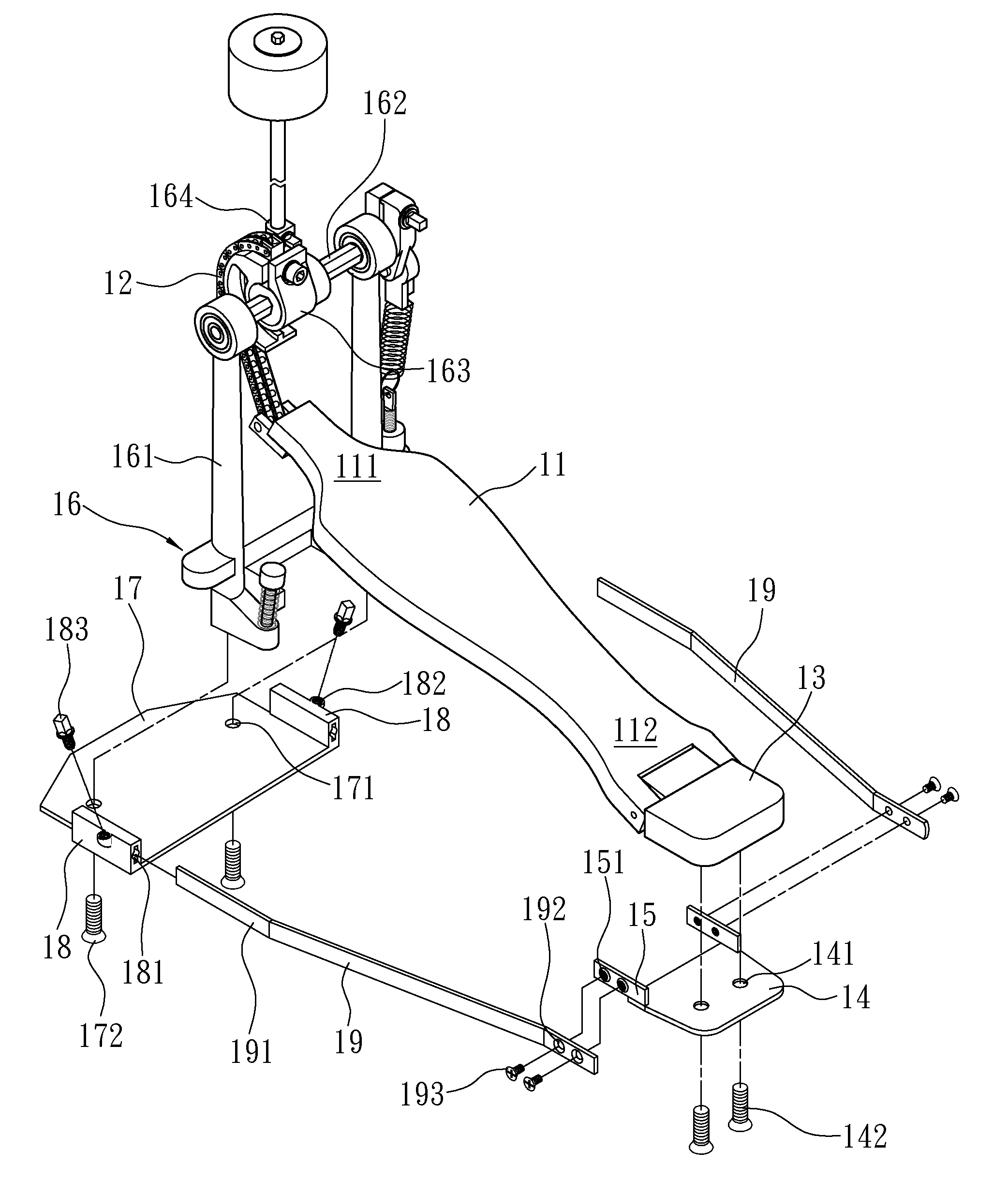

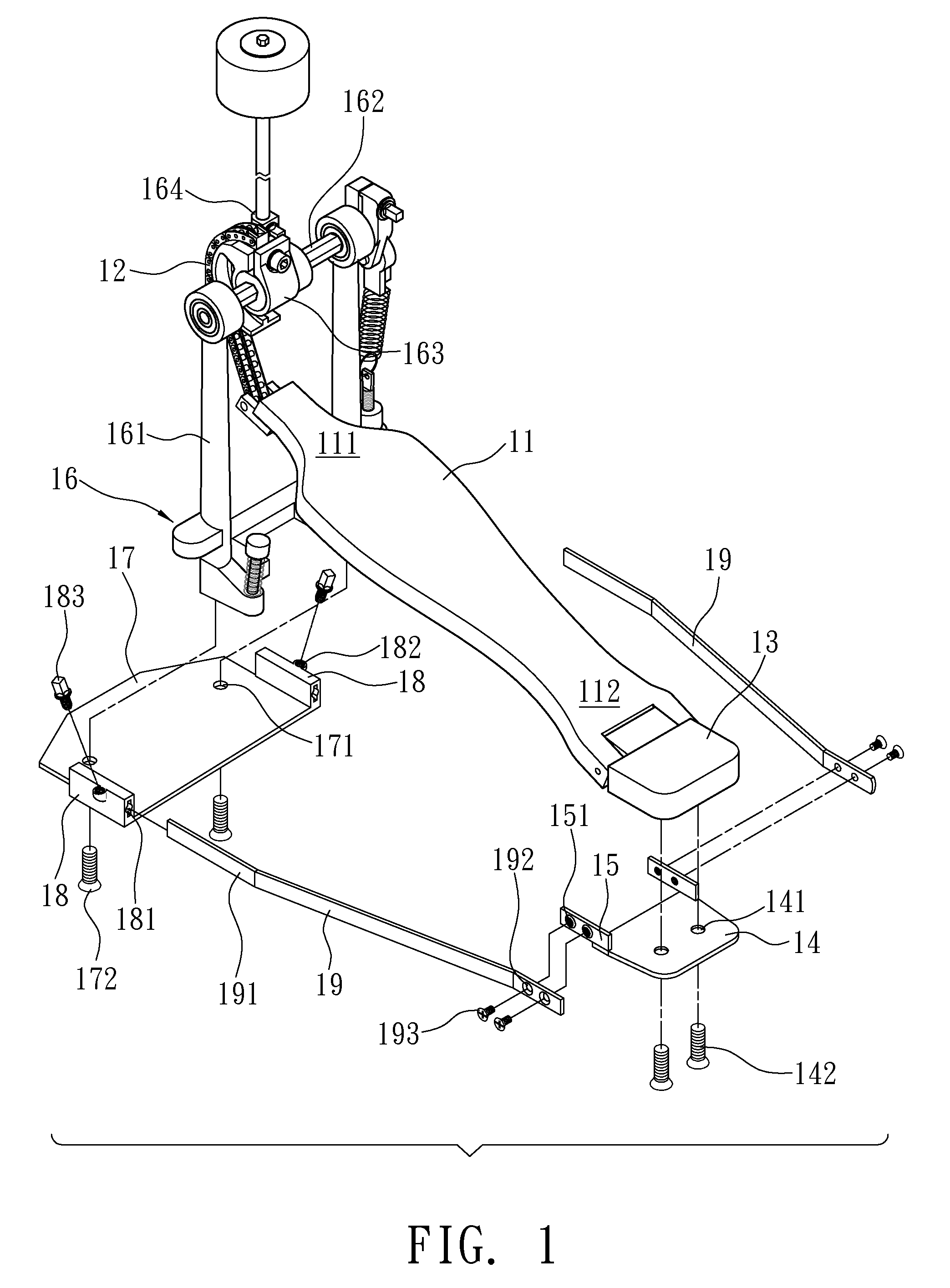

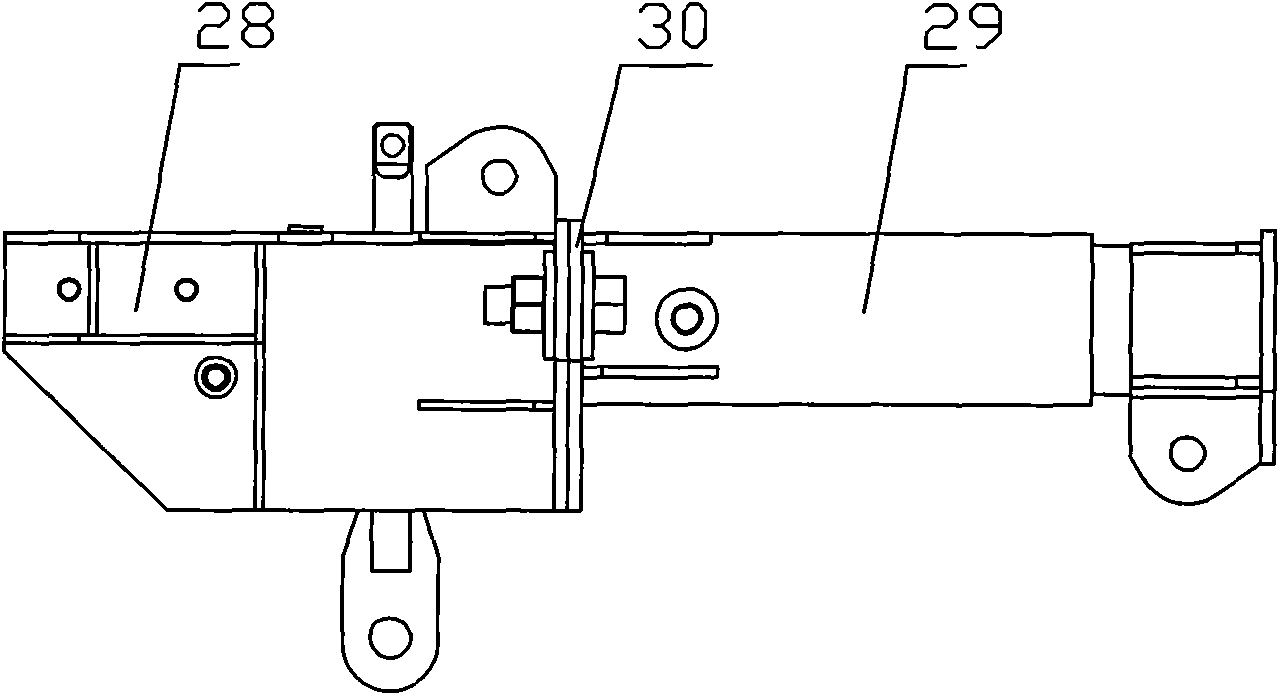

Pedal assembly for percussion instrument

InactiveUS7629525B1Easily assemble and disassemble and carryLow costPercussion musical instrumentsEngineeringTreadle

A pedal assembly includes a pedal, a base and two frames, a chain is connected between the front end of the pedal and a locking member on the shaft of the base. The rear end of the pedal is pivotably connected to the heel plate so that the pedal is pivotable along the stepping direction. The heel plate and the base are positioned by the respective frames which are fixed to the base and the heel plate by screws. By using the screws, the pedal assembly is stable and made at less material. The frames can be adjusted back and forth to meet different users' needs such that the different sizes of the feet of the users can operate the pedal assembly efficiently.

Owner:LIN HSI TAN

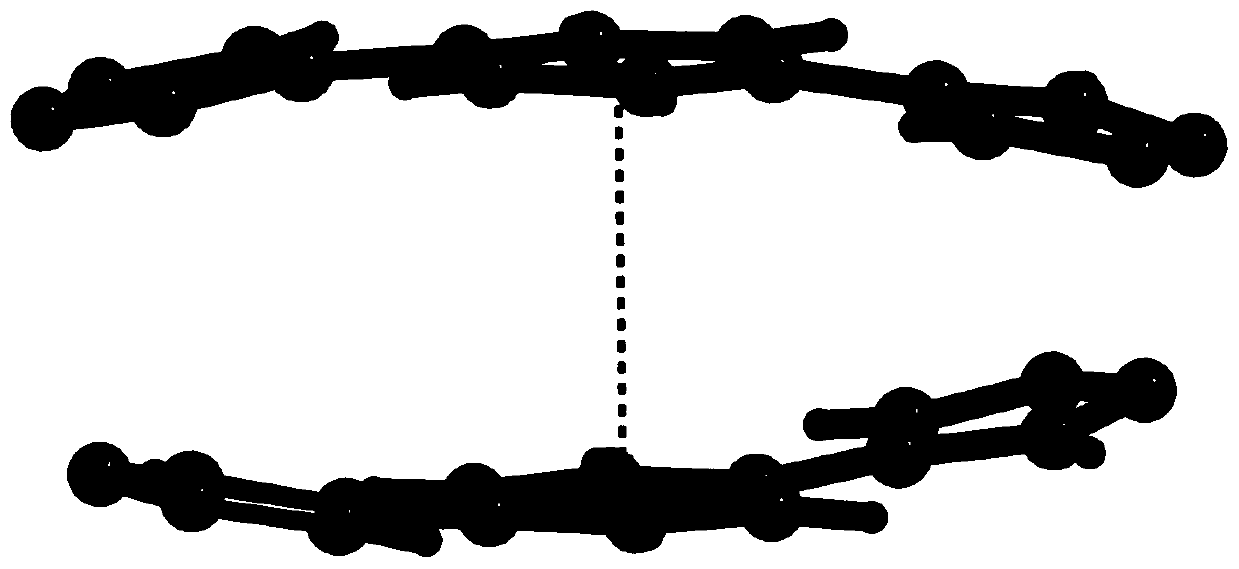

Porous metal-organic framework material, preparation method and adsorption and separation application of porous metal-organic framework material

ActiveCN110016145ANovel structureFrame stabilityGas treatmentOther chemical processesN dimethylformamideMetal-organic framework

The invention discloses a porous metal-organic framework material, a preparation method and an adsorption and separation application of the porous metal-organic framework material, and belongs to thetechnical field of crystalline materials. The chemical formula is [M (BDP)], wherein M is Zn or Co and the organic ligand is 1, 4-bis (lH-pyrazol-4-yl) benzene (H2BDP). Under the sealing condition, the organic ligand H2BDP, isophthalic acid and cobalt nitrate hexahydrate or zinc nitrate hexahydrate are subjected to thermal reaction in a mixed solution of N, N-dimethylformamide, ethanol and water to obtain crystals of the metal-organic framework. In the structure of the metal-organic framework, benzene rings of the ligand have 'face-to-face' pi-pi action, and the ligand is arched. The materialhas a large specific surface area and a permanent pore structure, and can be used as a material for separating ethane-ethylene mixed gas from propane-propylene mixed gas.

Owner:BEIJING UNIV OF TECH

Attached support structure

InactiveCN101672103AReduce installation stressFrame stabilityScaffold accessoriesEngineeringScrew thread

Owner:CHONGQING DONGCHEN BUILDING MACHINERY INSTALLATION ENG CO LTD

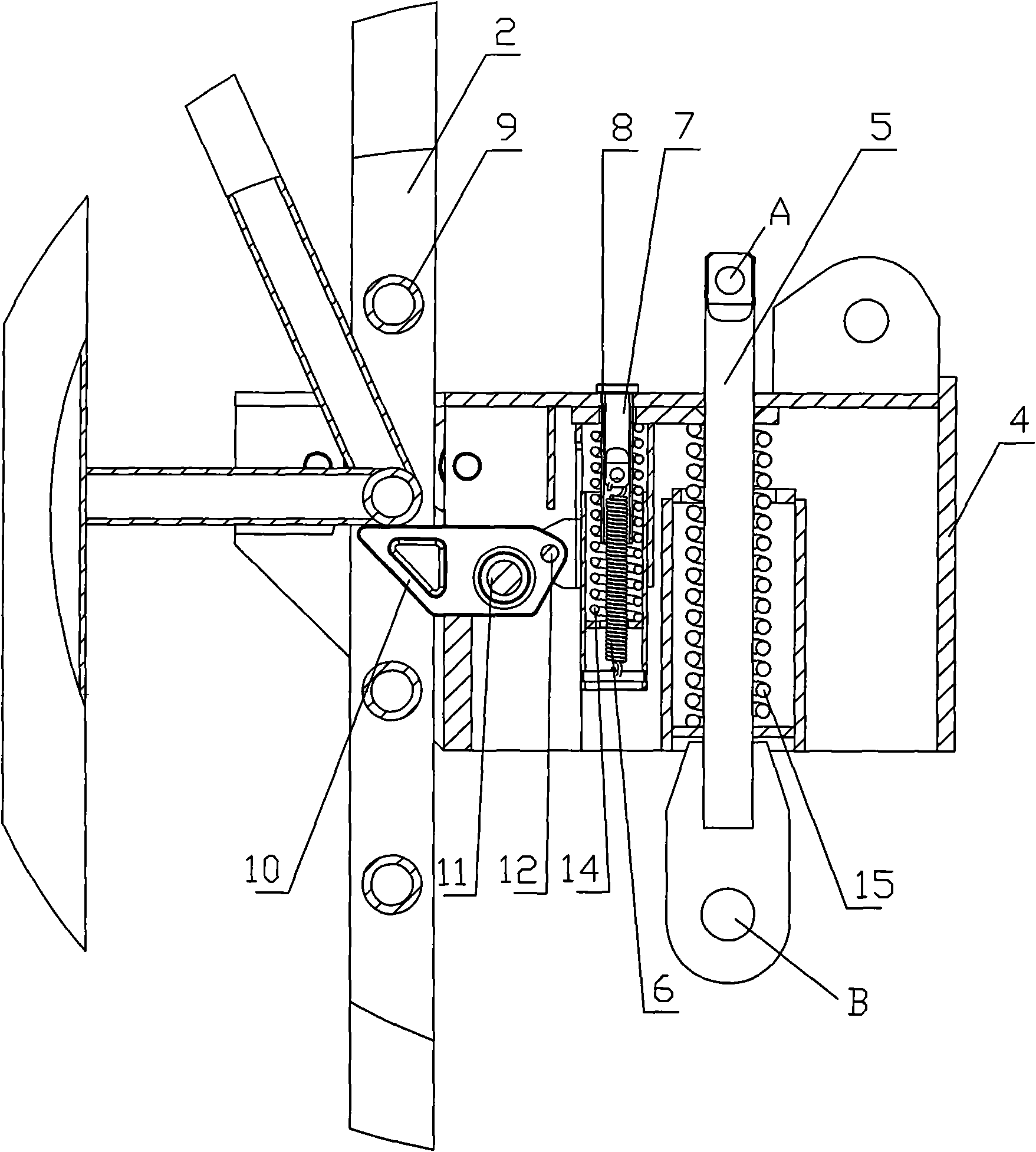

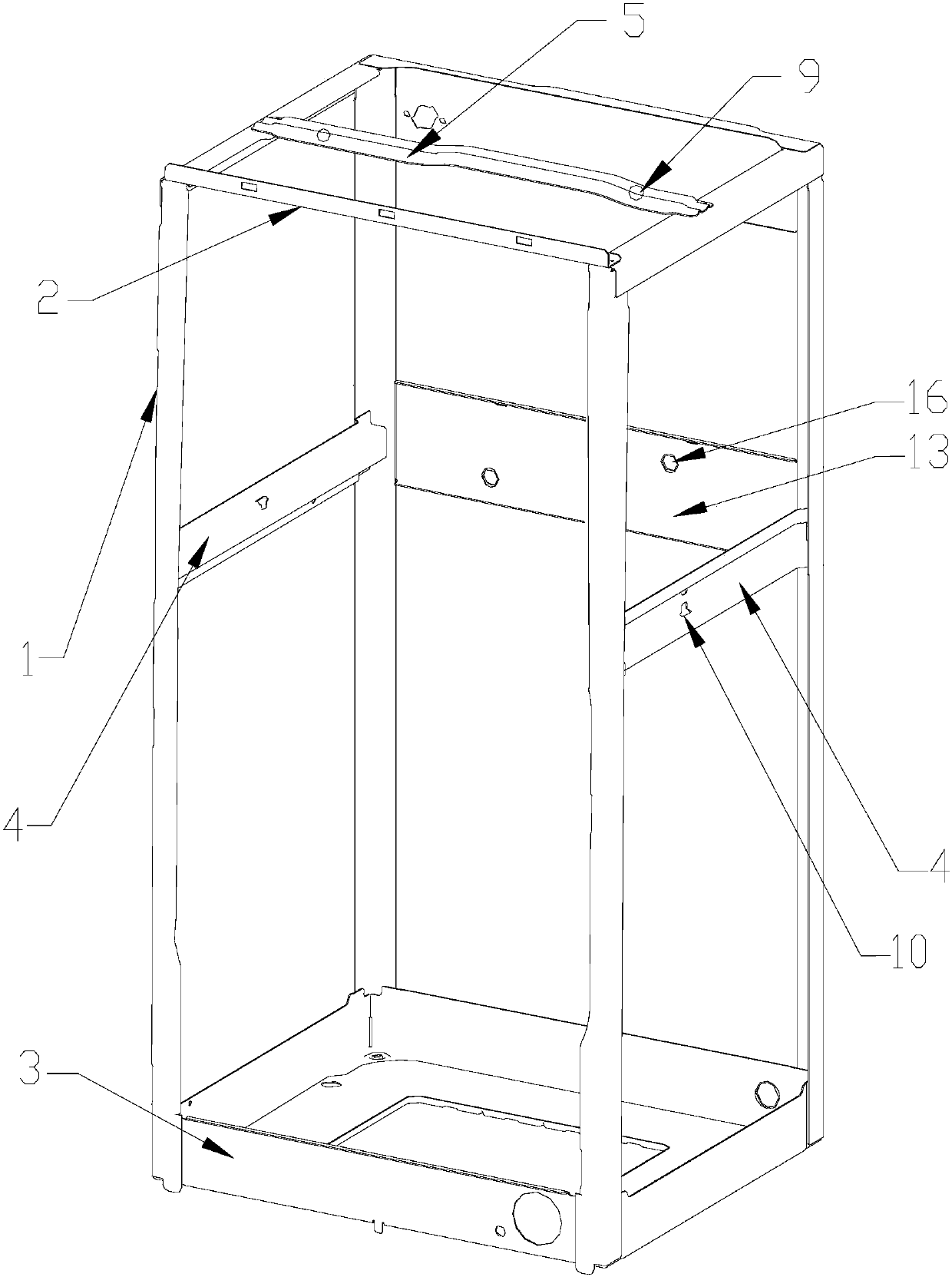

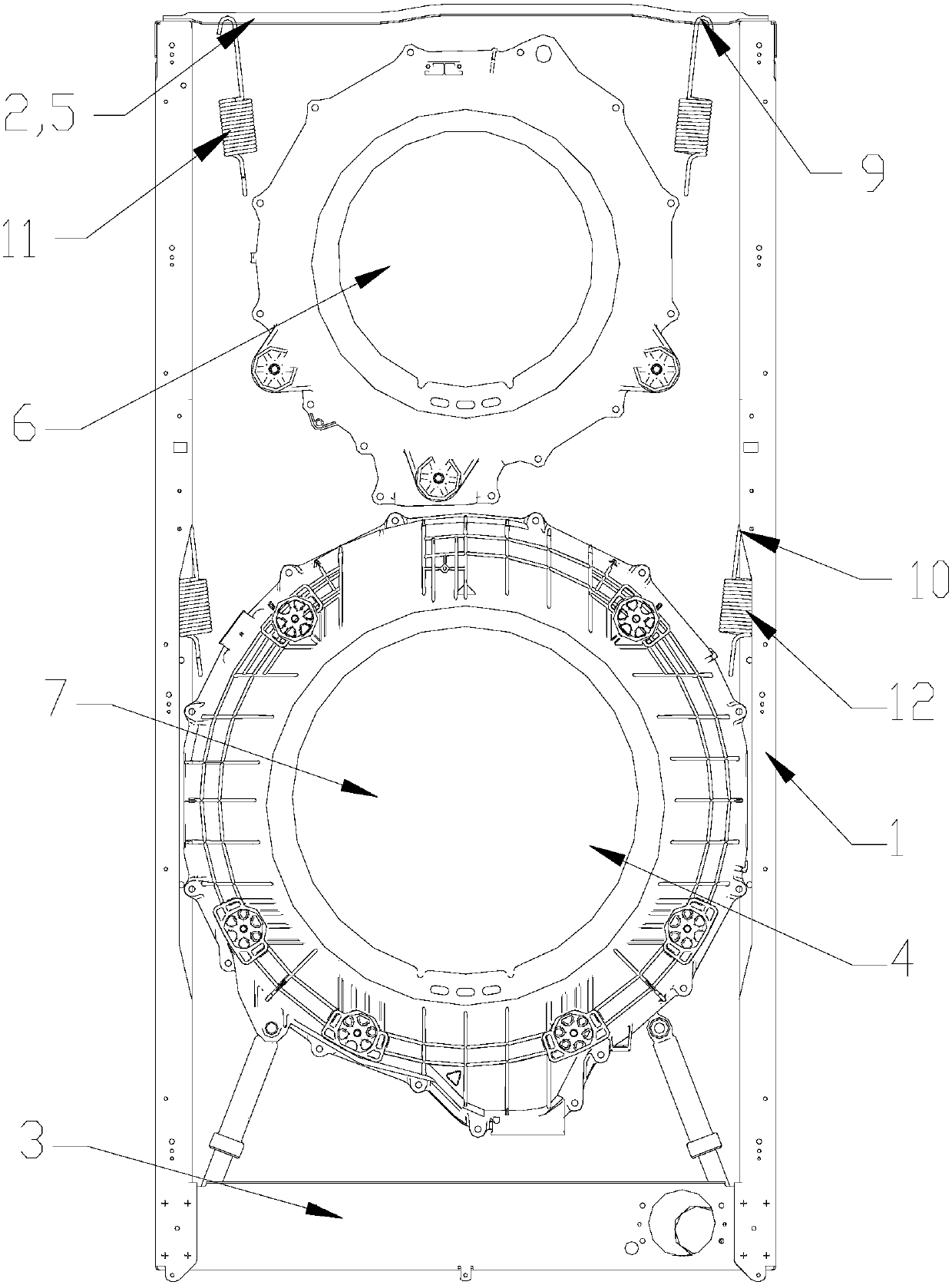

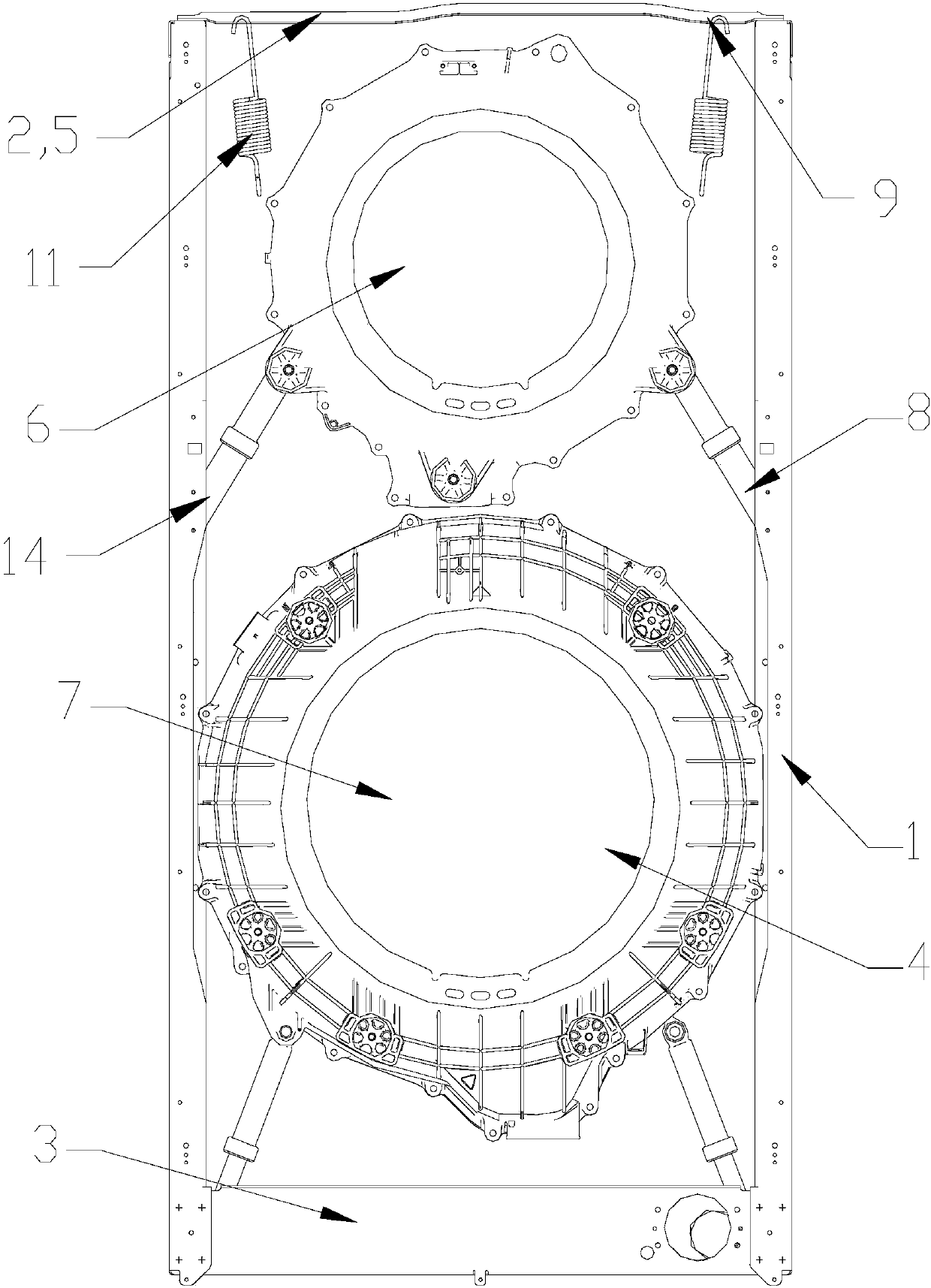

Double-drum washing machine and support frame thereof

PendingCN110219132AEasy to installFrame stabilityOther washing machinesTextiles and paperArchitectural engineeringSupport point

The invention discloses a support frame of a double-drum washing machine. The support frame comprises four vertical beams, upper reinforcement members and a base to form a square frame structure. Theupper ends of the adjacent vertical beams are connected with the upper reinforcement members, and the lower ends of the vertical beams are connected with the base. The left and right upper reinforcement members of the washing machine are connected through an upper cross beam. The middle portions of the left and right upper reinforcement members of the washing machine are connected through the upper cross beam to stabilize the top of the frame, and accordingly, the washing machine is mounted firmly. Particularly, a first mounting hole is formed in the upper cross beam, a support point is provided for mounting an upper drum and / or a lower drum, and the upper drum and / or the lower drum can be mounted on the upper cross beam through hanging springs, so that the damping effect is greatly improved. The support frame is simple in structure, has a remarkable effect and is suitable for popularization and use.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

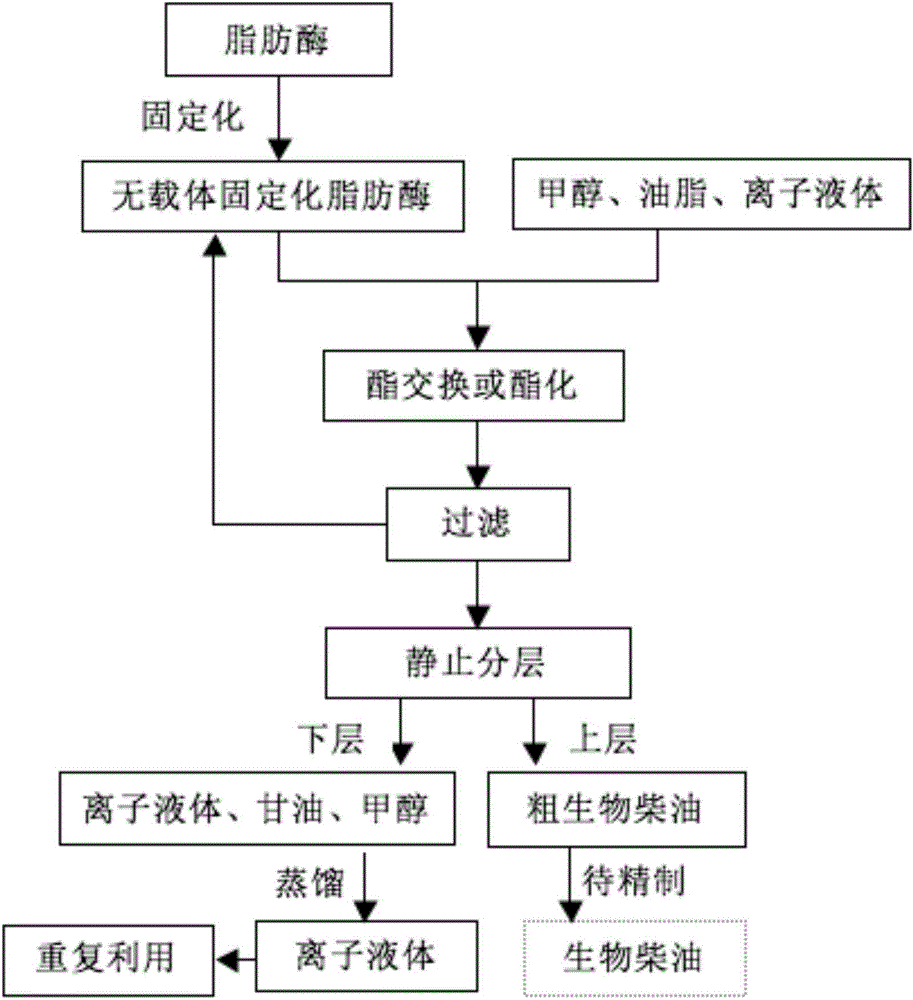

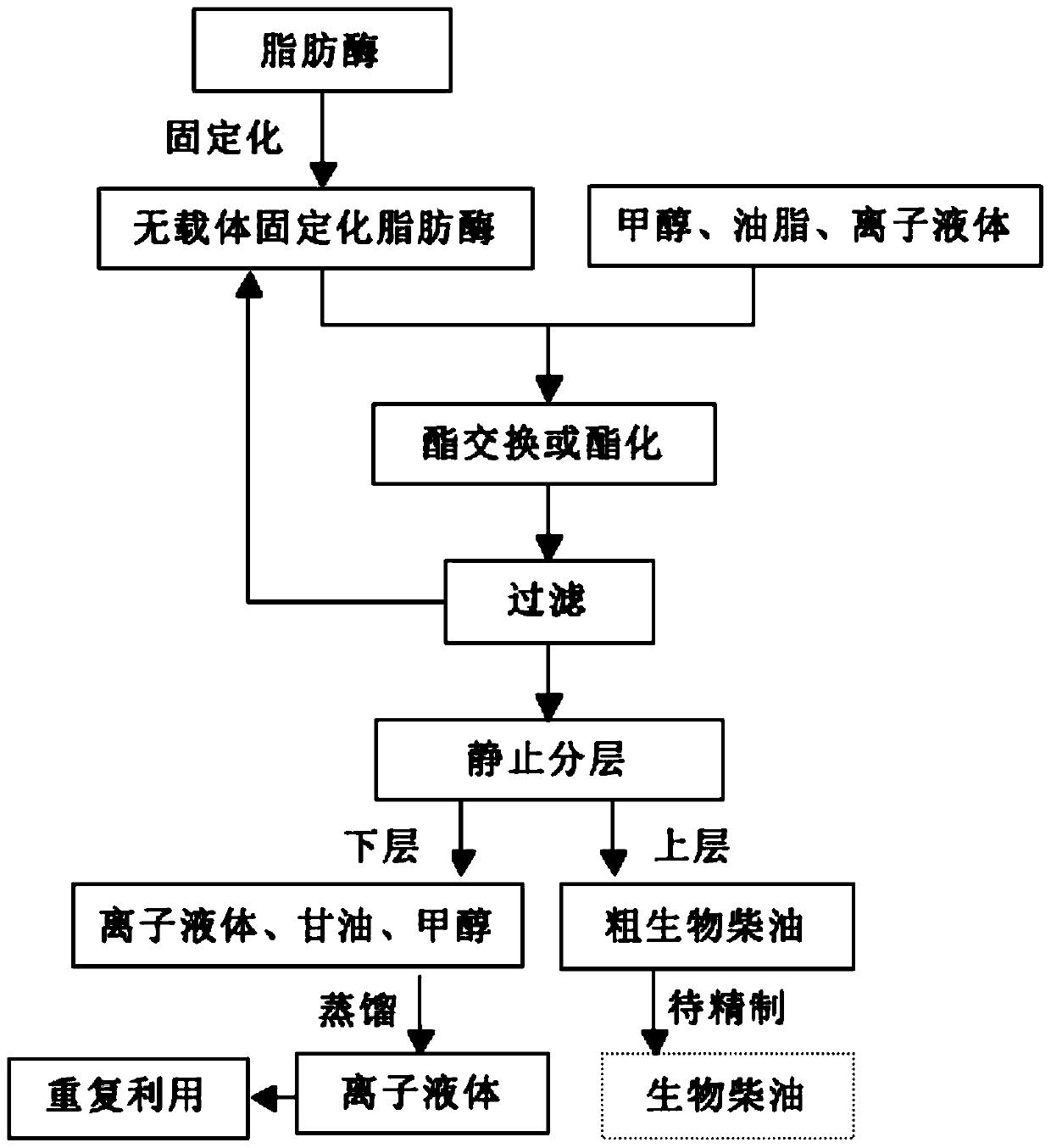

Method for preparing biodiesel by catalyzing vector-free immobilized lipase in ionic liquid system

InactiveCN104911222AWill not destroy the three-dimensional structureIncrease loadHydrolasesBiofuelsBiodieselAlcohol

The invention discloses a method for preparing biodiesel by catalyzing vector-free immobilized lipase in an ionic liquid system. The method comprises the following two steps: (1) preparing vector-free immobilized lipase; and (2) preparing the biodiesel by catalyzing the prepared vector-free immobilized lipase in the ionic liquid system. The prepared vector-free immobilized lipase is high in activity and free of high-cost vectors; an ionic liquid medium is used as an immobilized enzyme for preparing the biodiesel; the stability and the stereoselectivity of substrates of the enzyme can be obviously improved; the problem of the enzyme poisoning caused by methyl alcohol and glycerol can also be avoided; the efficient catalysis of the enzyme is ensured; the yield of the biodiesel is greatly increased; the immobilized enzyme and the ionic liquid used in the method can be recycled and reused; the waste of resources is avoided; the production cost is reduced; the method has a good industrial application prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

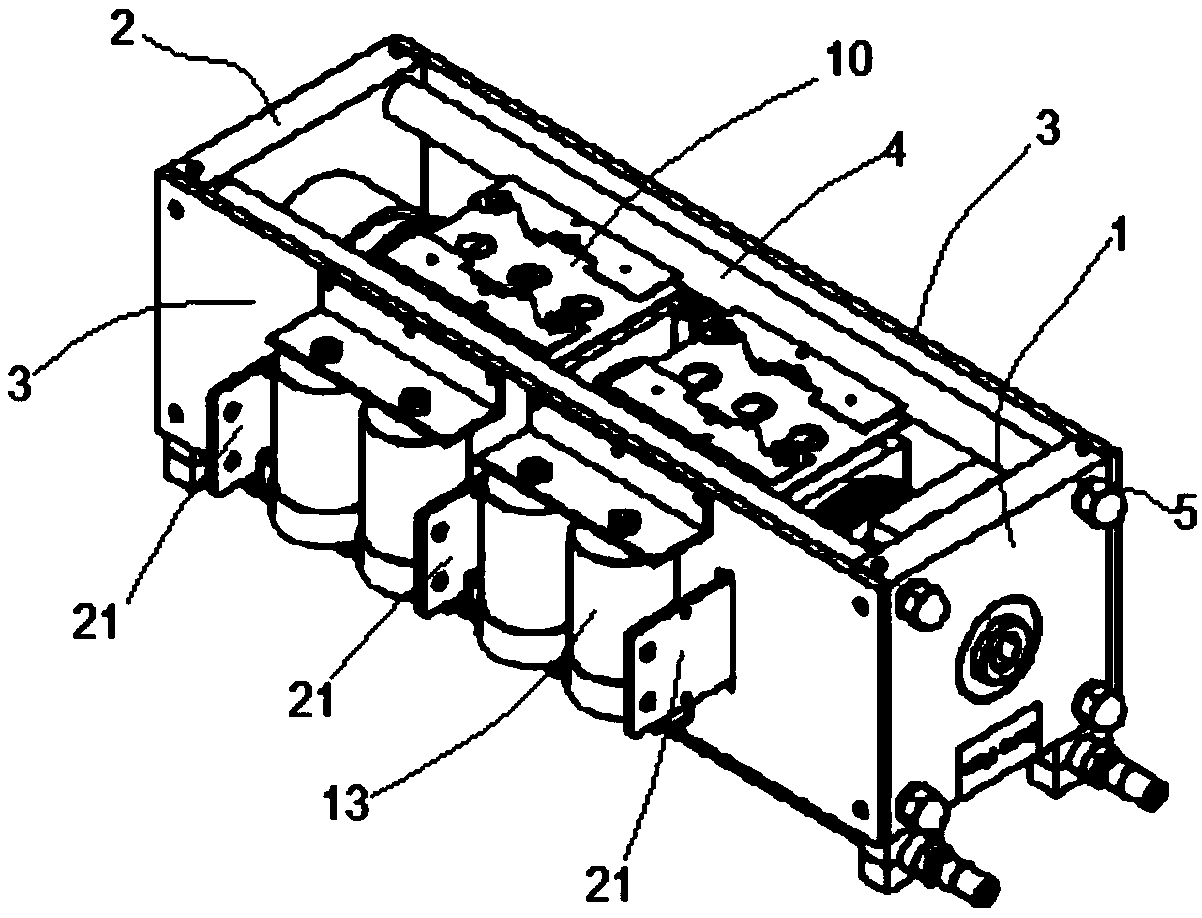

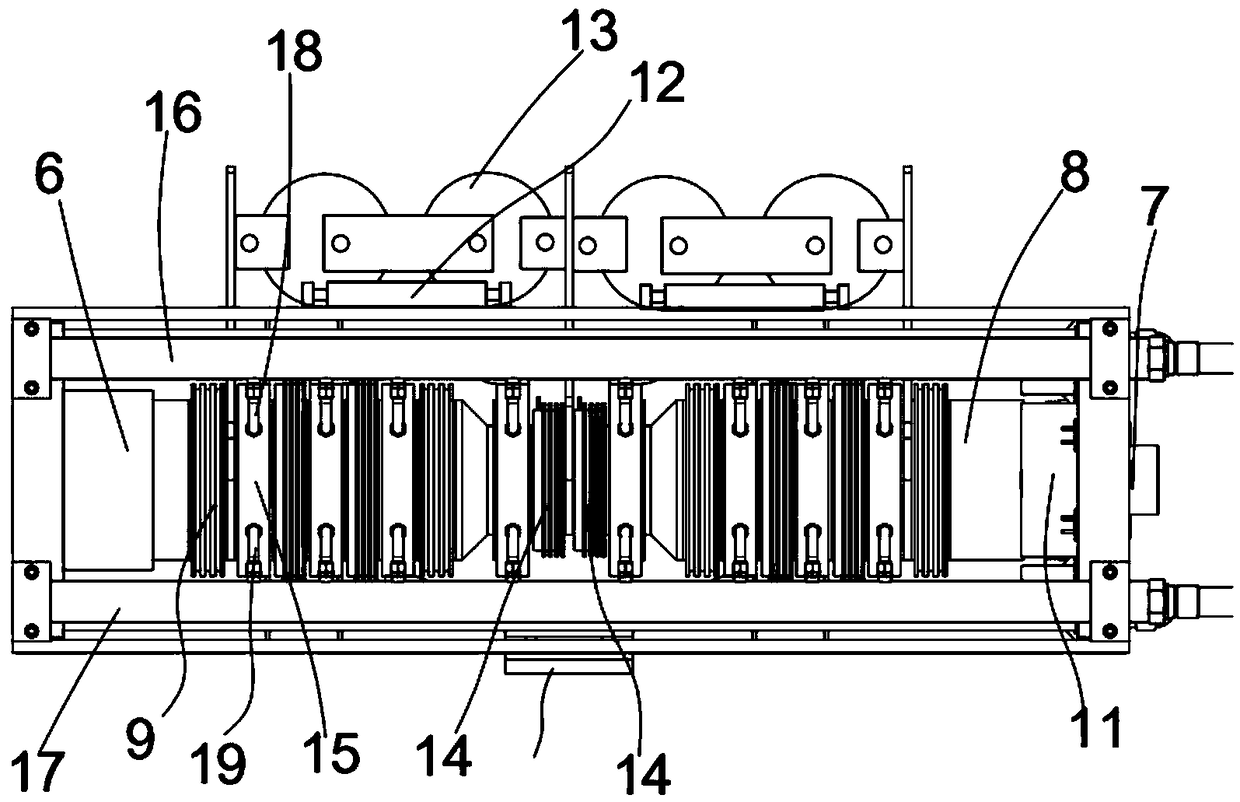

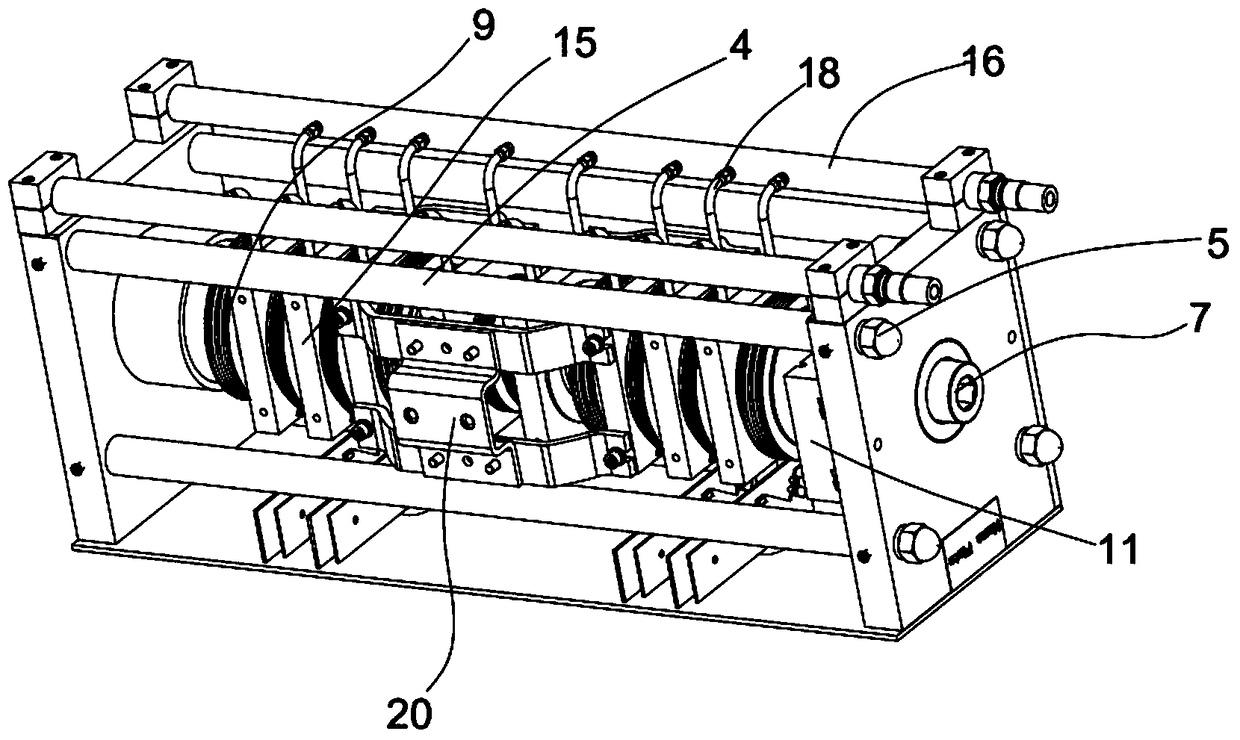

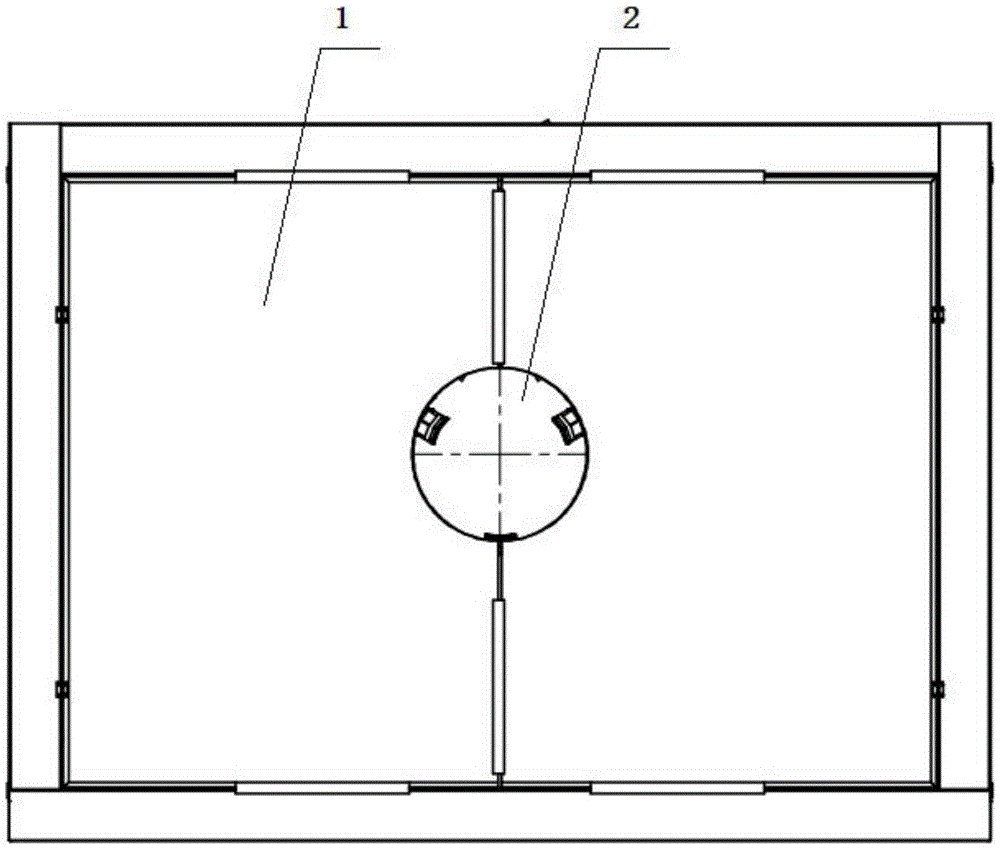

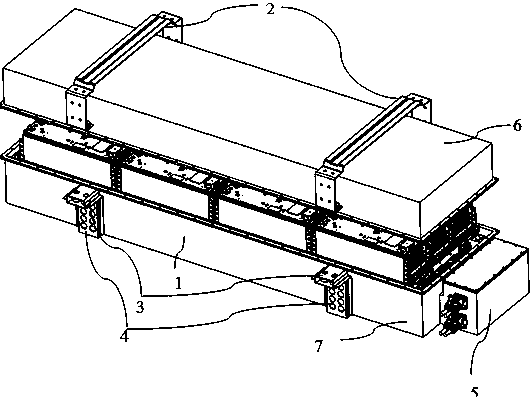

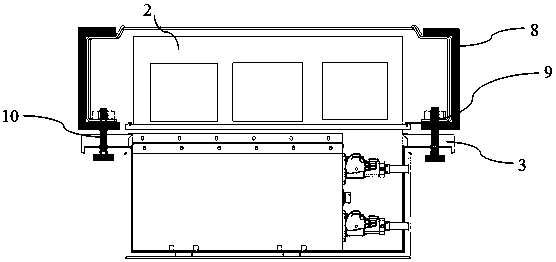

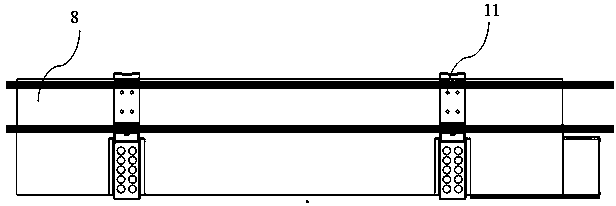

Three-level large-capacity water-cooled converter assembly based on crimping type IEGT

PendingCN108809119AGuaranteed parallelismFrame stabilityConversion constructional detailsThree levelCarrying capacity

The invention provides a three-level large-capacity water-cooled converter assembly based on a pressure-bonded IEGT, comprising a valve body frame assembly, wherein the valve body frame assembly is internally provided with a power device, and a compression adjustment mechanism for applying pressure to the power device is arranged between the two ends of the power device and the valve body frame assembly; and the side wall of the valve body frame assembly is provided with an AC connection terminal, the AC connection terminal is connected to the power device, the valve body frame assembly is provided with an inlet pipe and an outlet pipe, and the inlet pipe and the outlet pipe are in communication with the power device. The IEGT package form adopted by the assembly is in the form of crimping, and has the following advantages that: there is no binding wire inside, the reliability is higher, double-sided heat dissipation is achieved, the current carrying capacity is better, and the crimping-type package is adopted to achieve greater explosion-proof and moisture-proof capabilities.

Owner:上海旭择电子零件有限公司

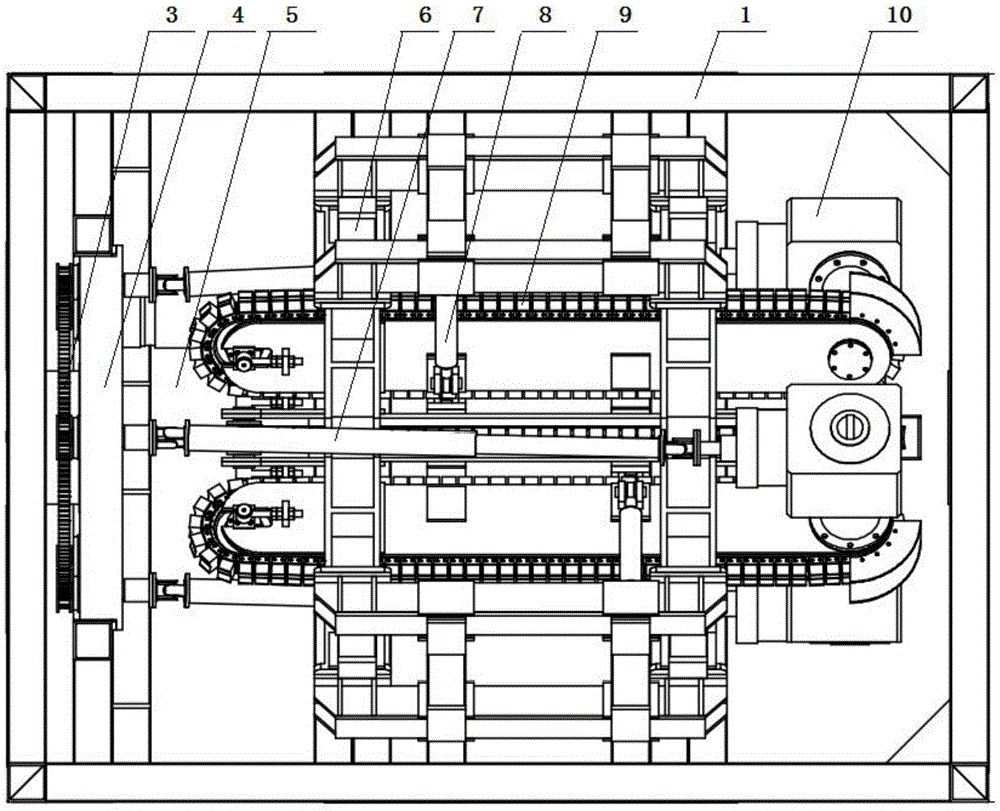

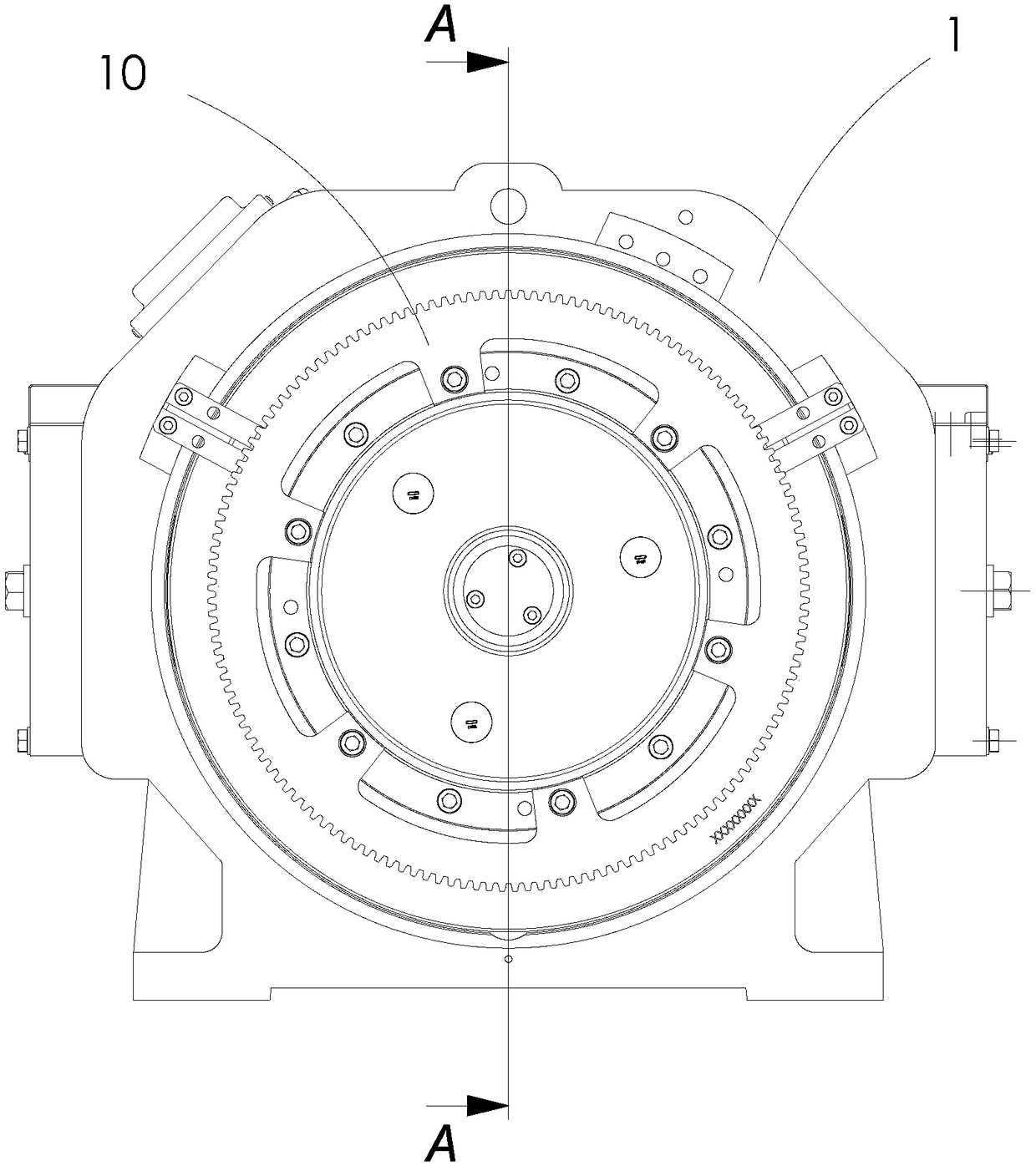

Three-crawler-type intelligent flexible automatic tractor for large-size flexible pipe

The invention relates to a three-crawler-type intelligent flexible automatic tractor for a large-size flexible pipe. Crawlers are longitudinally and fixedly installed in a structural steel box body through structural steel frames. The number of the crawlers is three and the crawlers are uniformly distributed at a centripetal angle of 120 degrees. Flexible pipe inlet through holes and flexible pipe outlet through holes are coaxially formed in the two sides, corresponding to centripetal shaft parts of the crawlers, of the structural steel box body. A transmission device is longitudinally and fixedly installed in the position, on one sides of the flexible pipe outlet through holes, of the interior of the structural steel box body through a fixing plate. Universal transmission shafts are driven through a main motor by the transmission device in an engaged mode and drive reducers in an engaged mode. The output shaft end of each reducer drives the corresponding crawler to rotate. Hydraulic synchronous clamping devices are fixedly installed on the radial structural steel frames of the crawlers. According to the three-crawler-type intelligent flexible automatic tractor for the large-size flexible pipe, the tractor is transmitted through the three crawlers, the operating speed of the tractor is determined under the condition that a servo motor drives the reducers to drive an outer gear ring, and torque is transmitted into the final-stage reducer through the corresponding transmission shaft by three pairs of gears of the outer gear ring; the stability of the transmission operation mode is improved a lot compared with that of a chain driving mode, and more importantly, the operating speed synchronism of the three crawlers is greatly improved.

Owner:陈德言

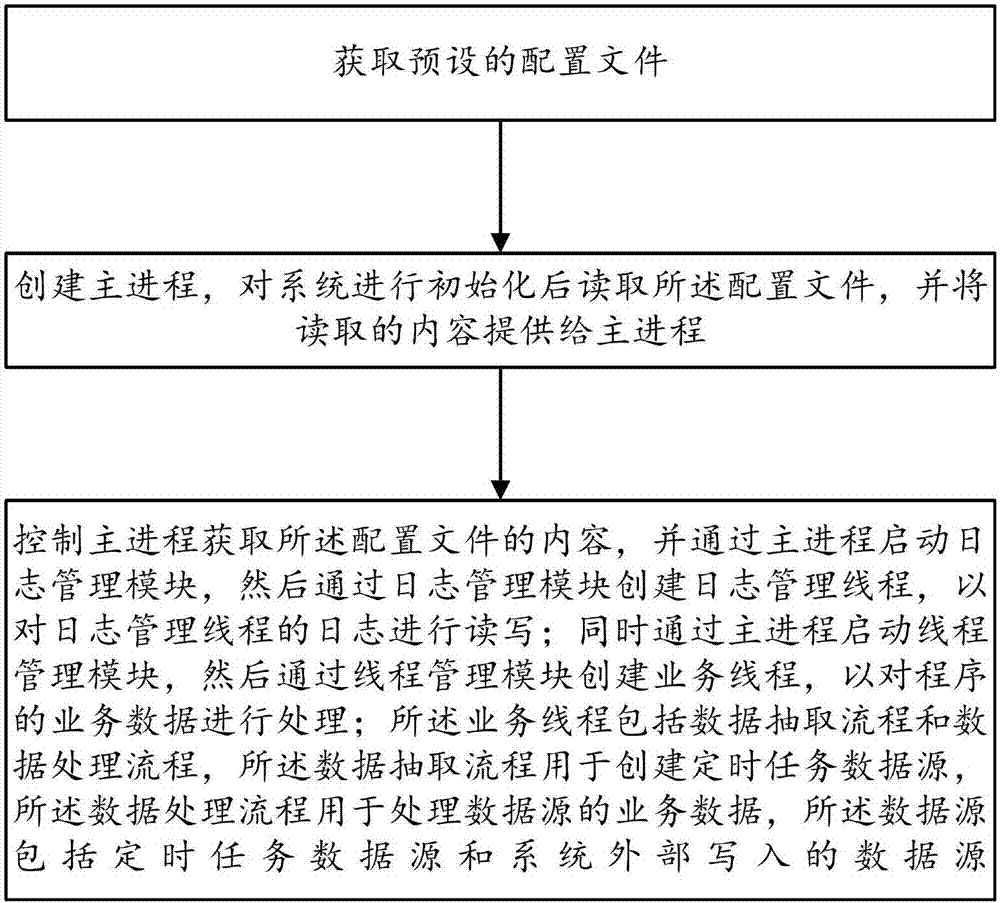

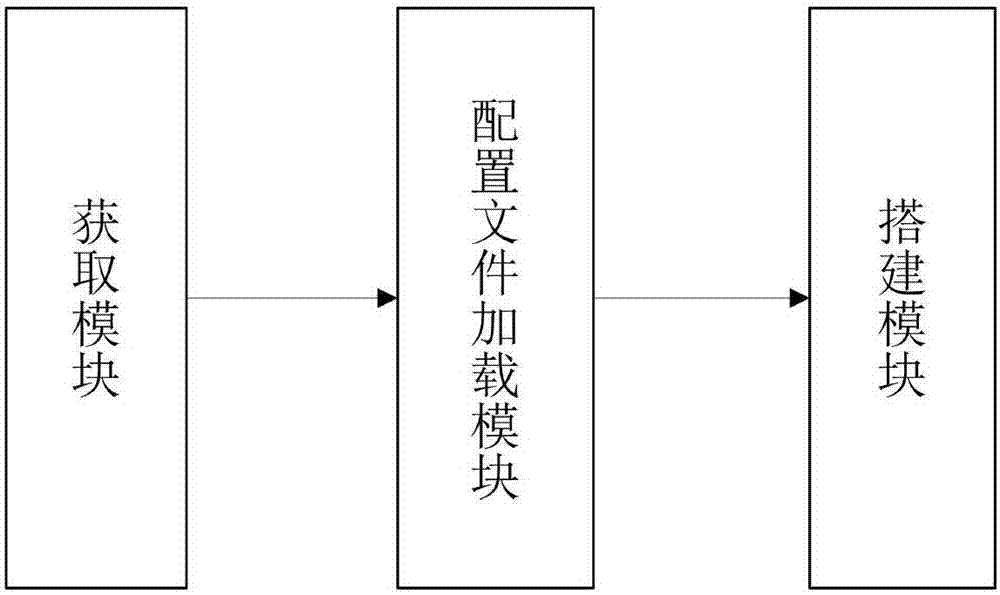

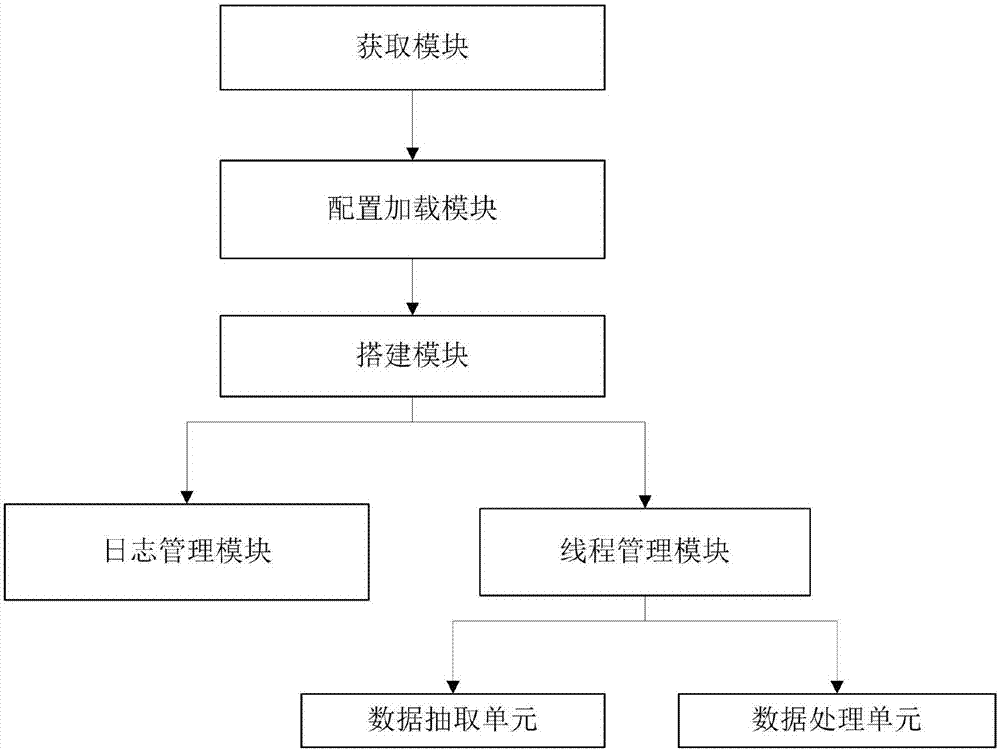

Background business processing framework establishment method and system

InactiveCN107291493AImprove efficiencySystem framework is stableProgram initiation/switchingResource allocationBatch processingSoftware engineering

The invention particularly relates to a background business processing framework establishment method and system. The method comprises the steps of obtaining a preset configuration file; after a system is initialized, reading contents of the configuration file, and providing the read contents for a main process; after the main process obtains the contents of the configuration file, starting a log management module, and creating a log management thread through the log management module to perform reading / writing on logs of a program; and starting a thread management module through a main thread, and creating a business thread through the thread management module to process businesses of the program, wherein the business thread comprises a data extraction process and a data processing process, the data extraction process is used for creating a timed task data source, and the data processing process is used for processing business data. By solidifying a common part of a batch processing application in a background, the efficiency of developers is greatly improved, the system framework is more stable, and the problem troubleshooting is more direct and effective.

Owner:北京思特奇信息技术股份有限公司

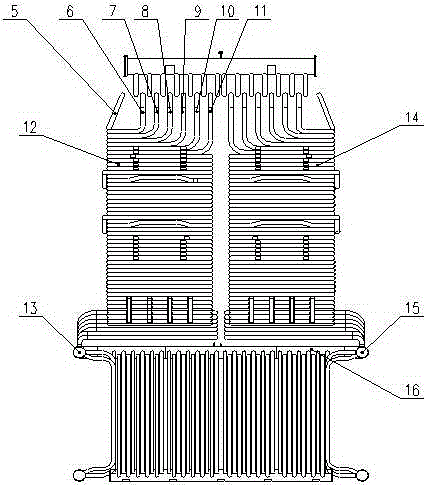

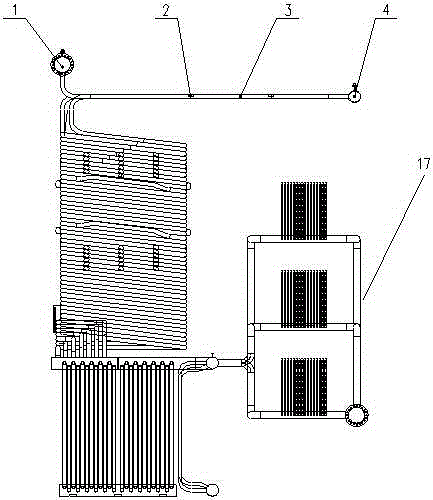

Coal powder burning organic heat carrier boiler

The invention provides a coal powder burning organic heat carrier boiler which comprises a lower hearth, an upper hearth, a convection region and a waste heat boiler. The coal powder burning organic heat carrier boiler is characterized in that the length of the lower hearth is smaller than the length of flame of a burning region, one side of the lower hearth is provided with an air feeding device, the flame of the burning region is bent to be in an L shape, the cross section of a heat exchange region of the lower hearth is in a U shape, a double-rectangular-coil structure is adopted for the upper hearth, the upper hearth is provided with two rectangular coil assemblies of the same shape and size, the convection region is formed by connecting three sets of coils in parallel, the upper portion of the waste heat boiler is provided with a flue gas collection region, and the cross section of the flue gas collection region is circular and gradually increased from top to bottom.

Owner:ZHEJIANG TUFF BOILER

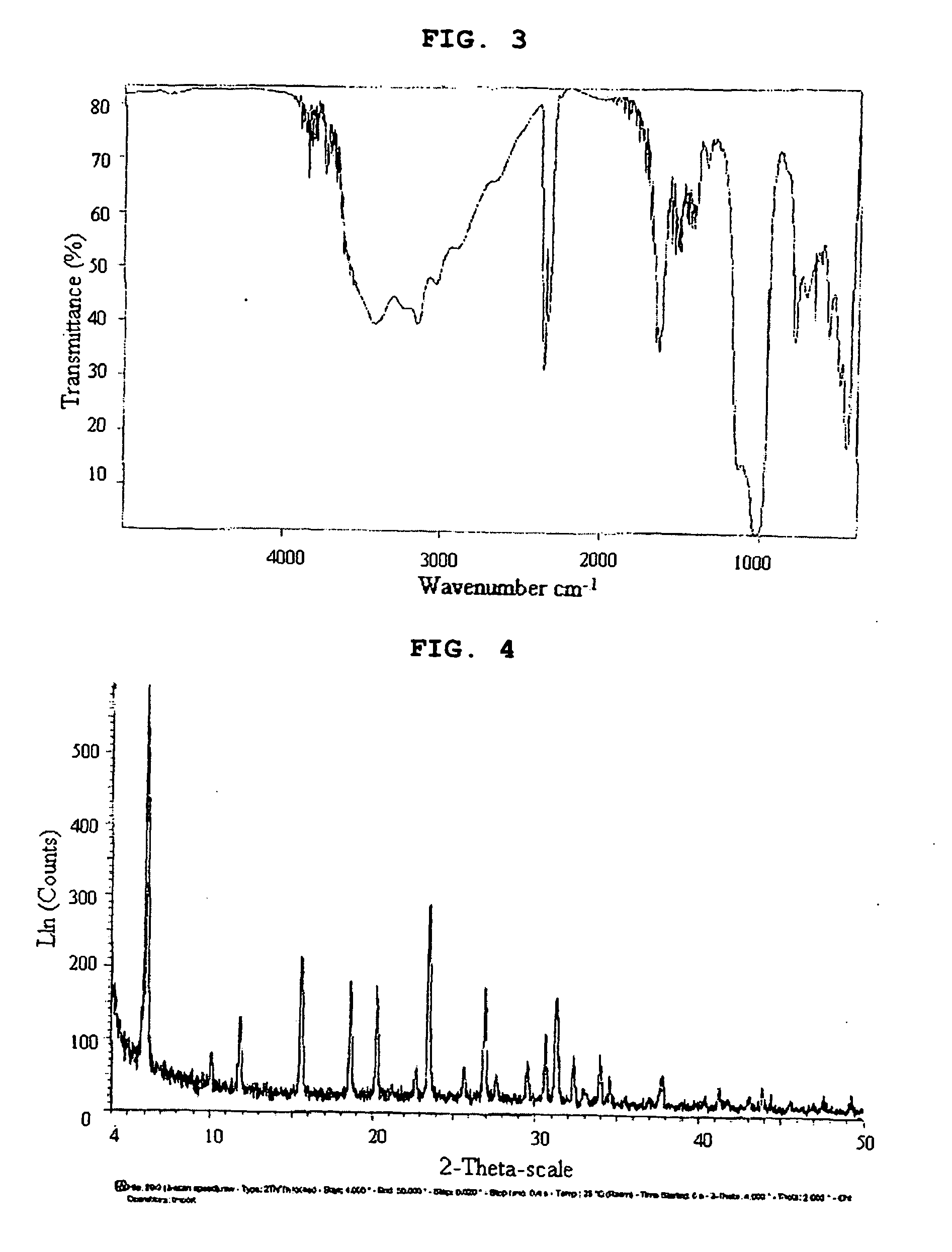

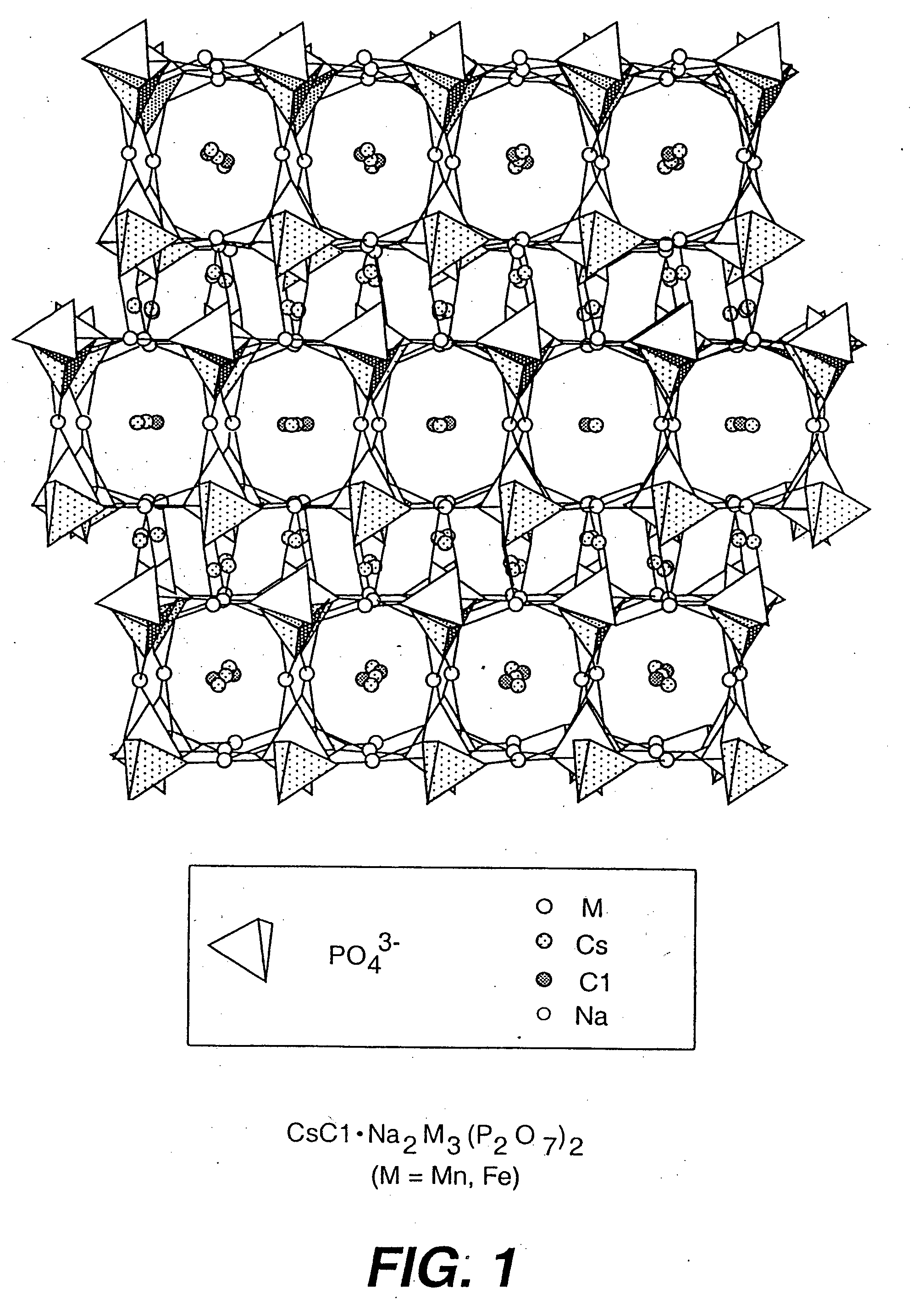

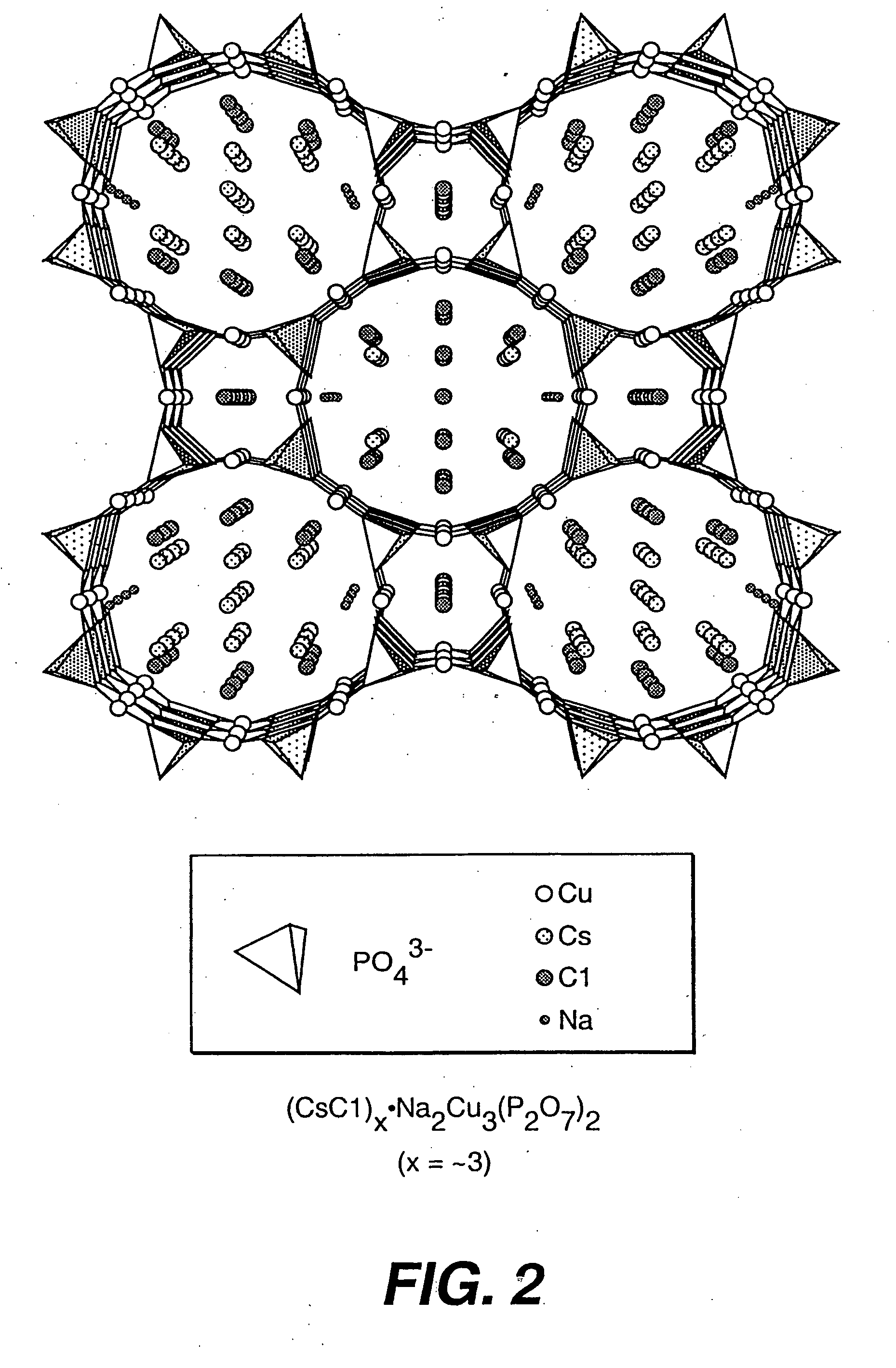

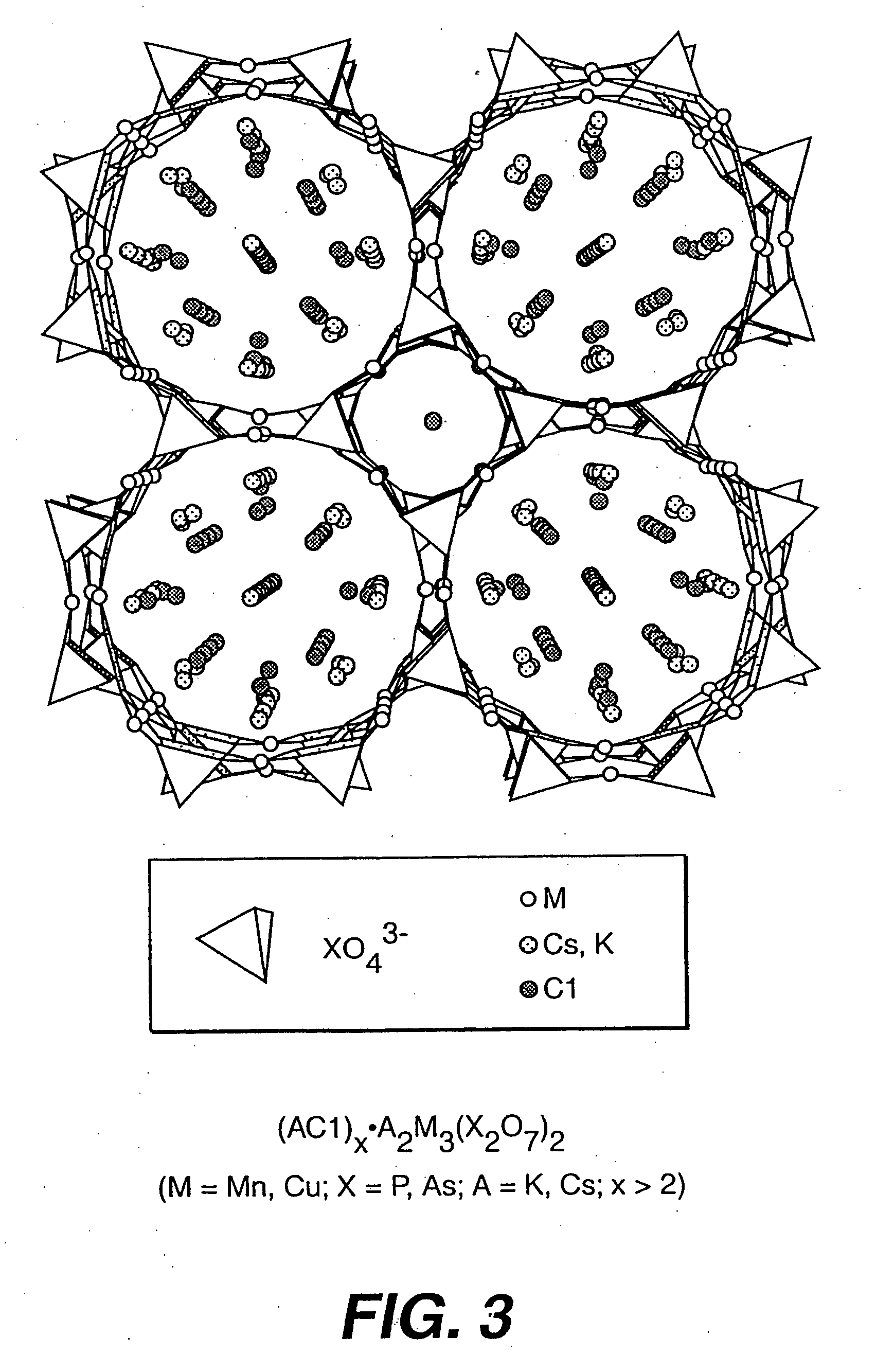

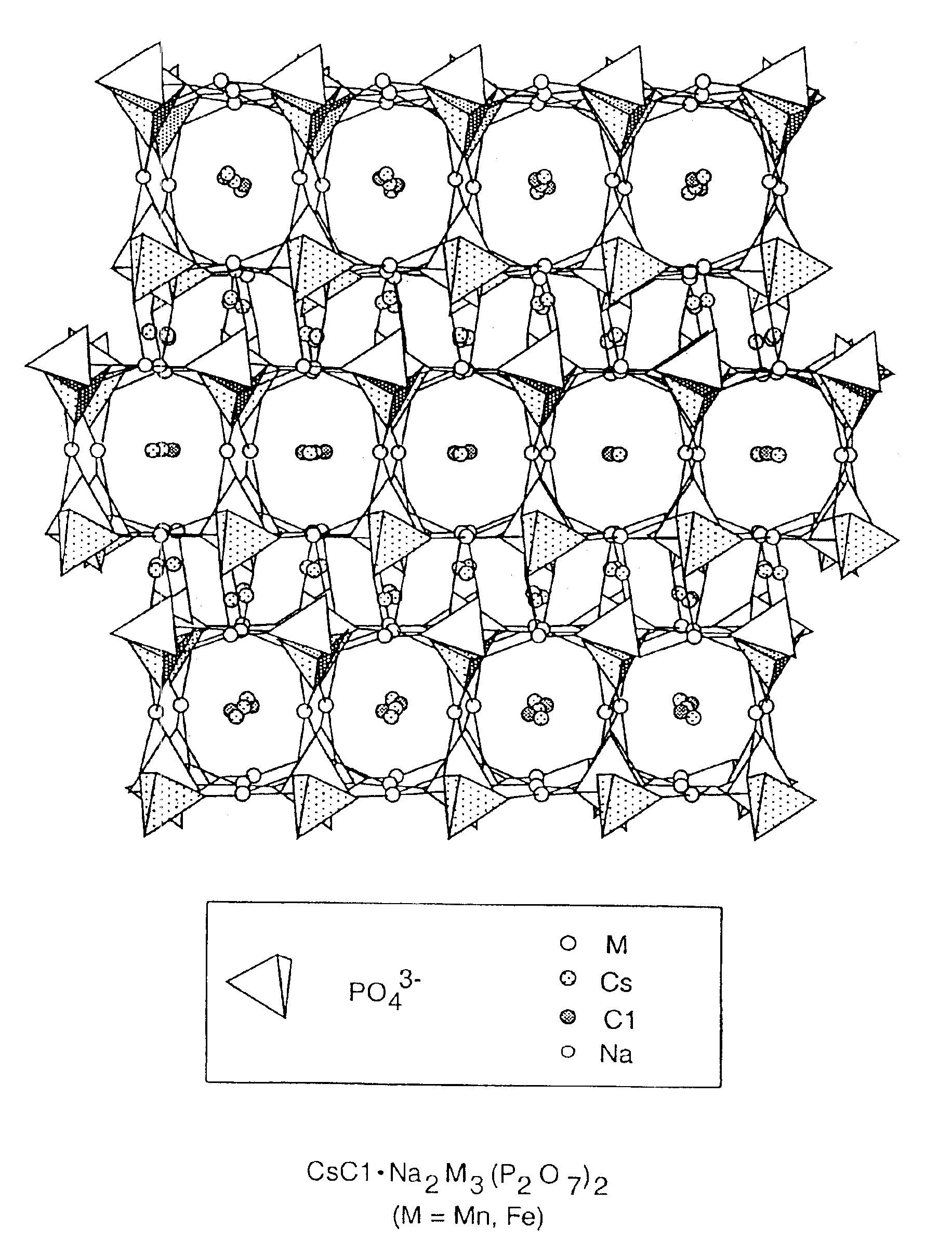

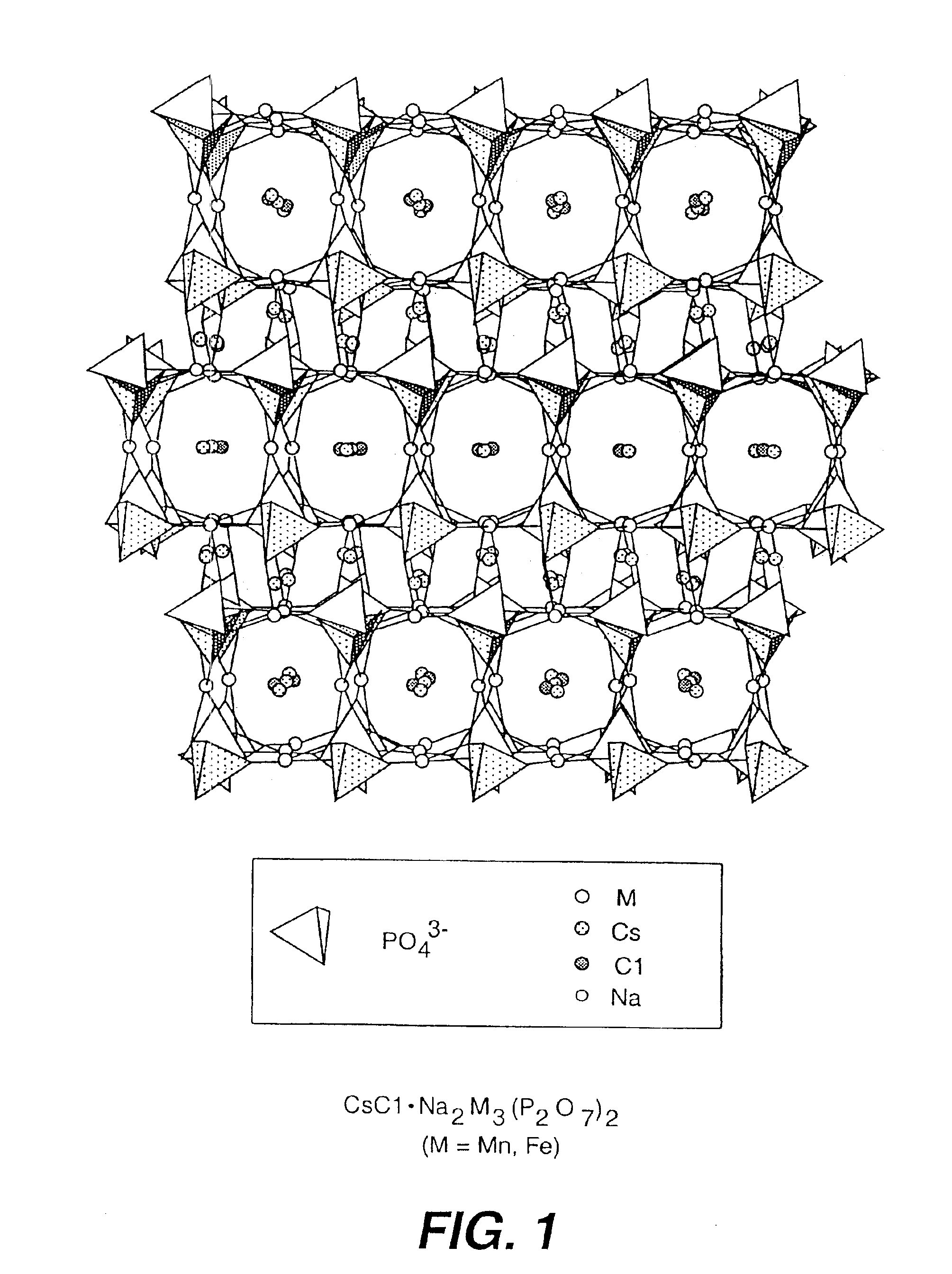

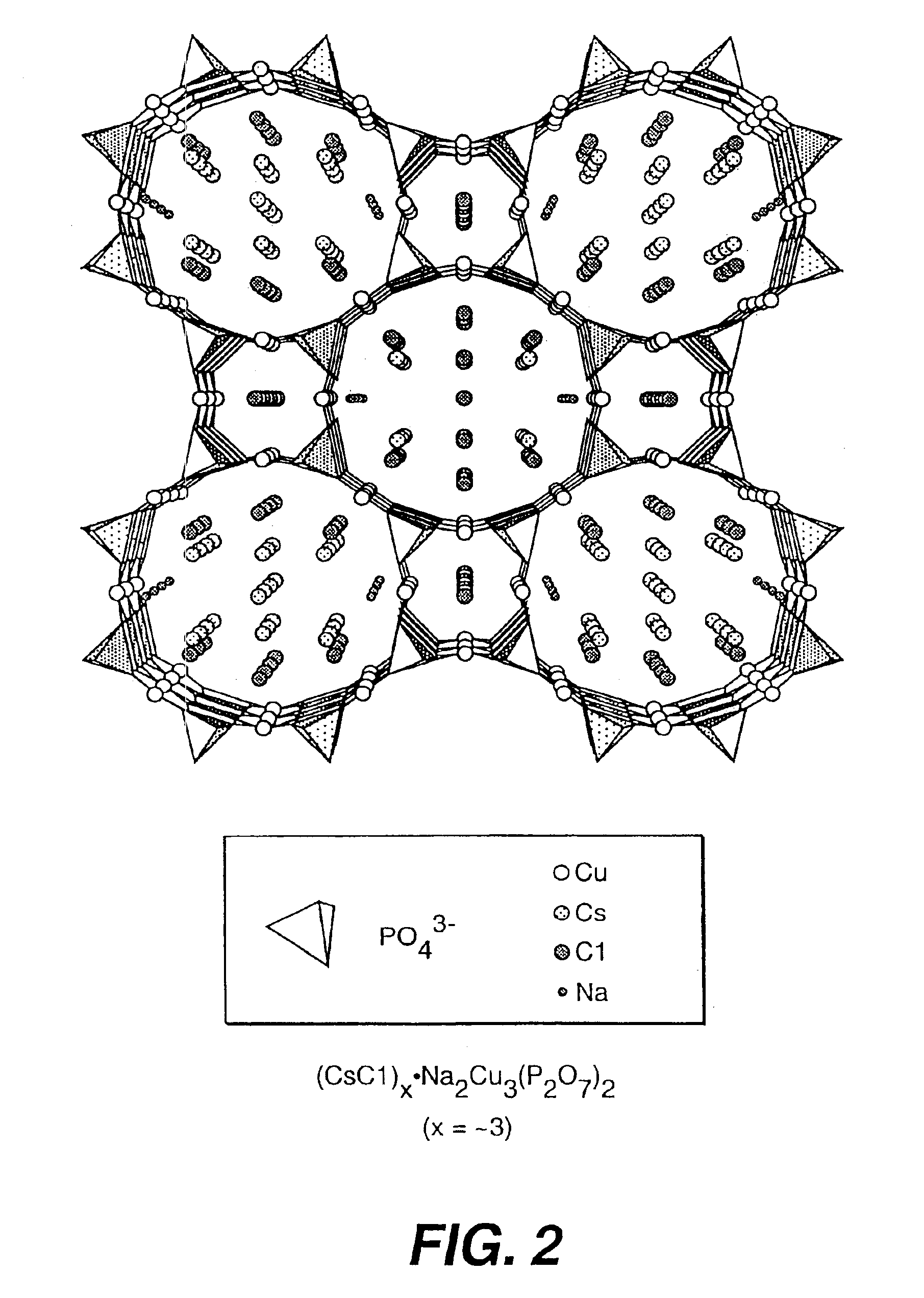

Salt-templated microporous solids

InactiveUS20050008556A1Frame stabilityAttractive chemical propertyArsenites/arsenatesNitrogen compoundsGreek letter betaSpace group

The present invention is directed to open-framework and microporous solids particularly well suited for use in catalysis and ion exchange. The microporous solids are constructed by using a salt template which can be readily removed without destroying the framework of the micropore. Various microporous solids can be formed having different geometric structures depending upon the templating salt used and the concentration. Examples of two compounds include Na2Cs[Mn3(P2O7)2]Cl(1) and K2.02Cs2.90[Cu3(P2O7)2]C12.92(2). Compound 1 crystallizes in the space group C2 / c with a=21.210(8), b=5.272(2), c=13.924(2)Å, beta=119.04(2), and Z=4. Compound 2 crystallizes in the space group 14 / mcm with a=b=18.001(3), c=13.530(4)Å, and Z=8. Both compounds have 3-D (Mn, Cu)-P-O frameworks. For 1, two MnO4, two MnO5 polyhedra and four PO4 tetrahedra form small tunnels where Cs+ and Cl− ions reside. For 2, CuO4 and P2O7 groups form two different tunnels, one is similar to that in 1 (ca. 5.3 Å in diameter) while the other formed by eight CuO4 polyhedra and eight PO4 tetrahedra has an approximate diameter of 12 Å.

Owner:CLEMSON UNIV RES FOUND

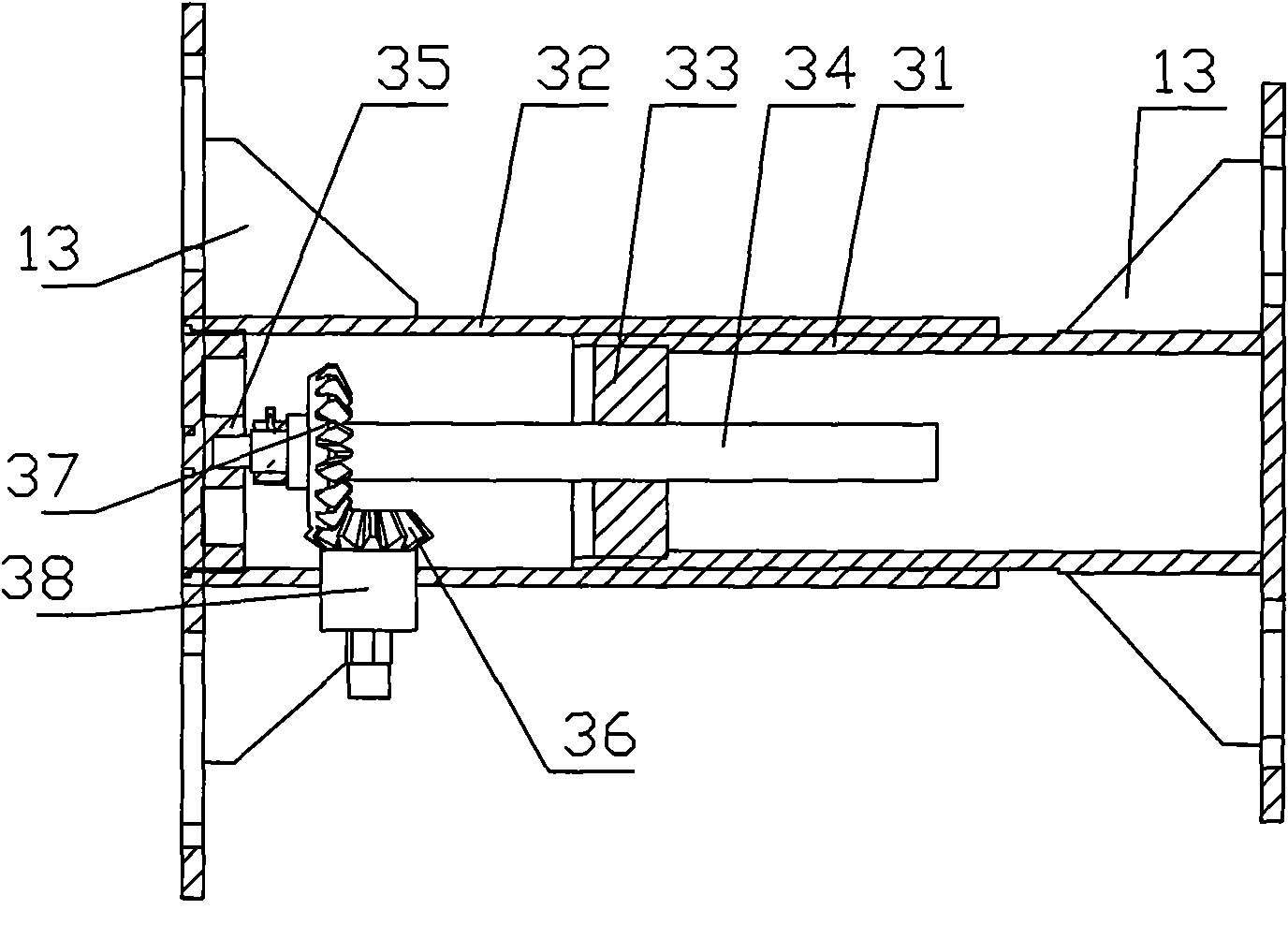

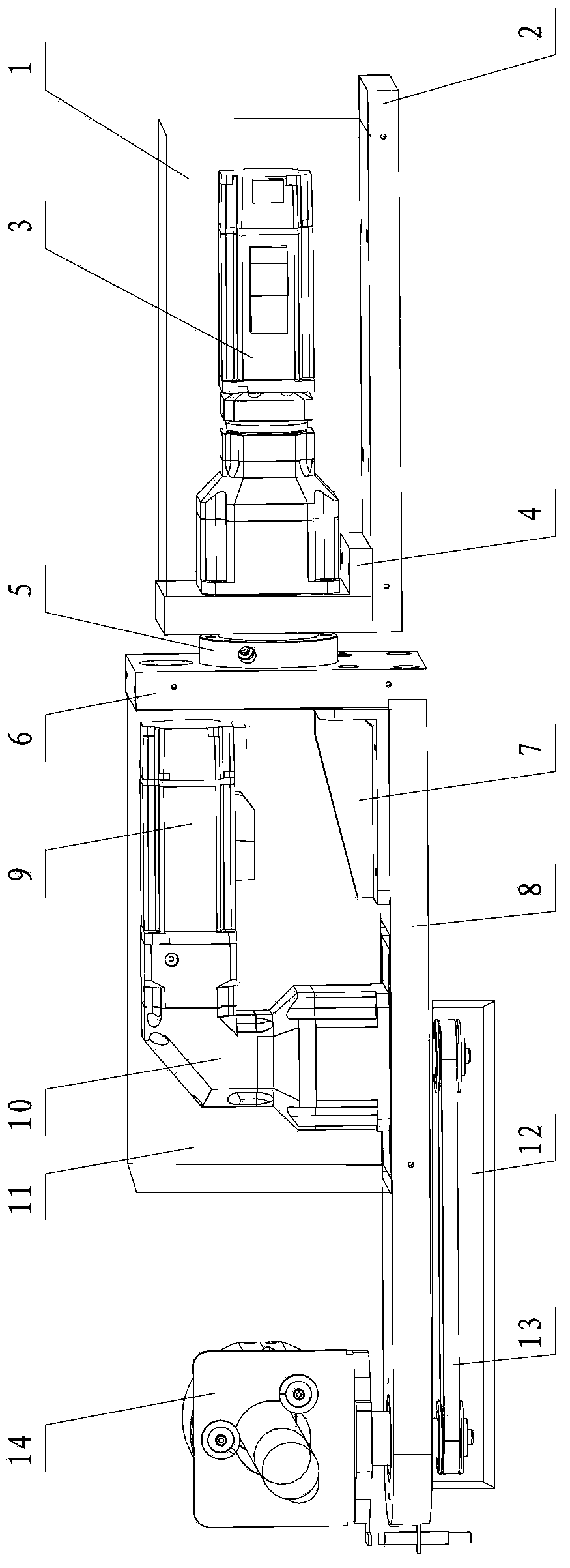

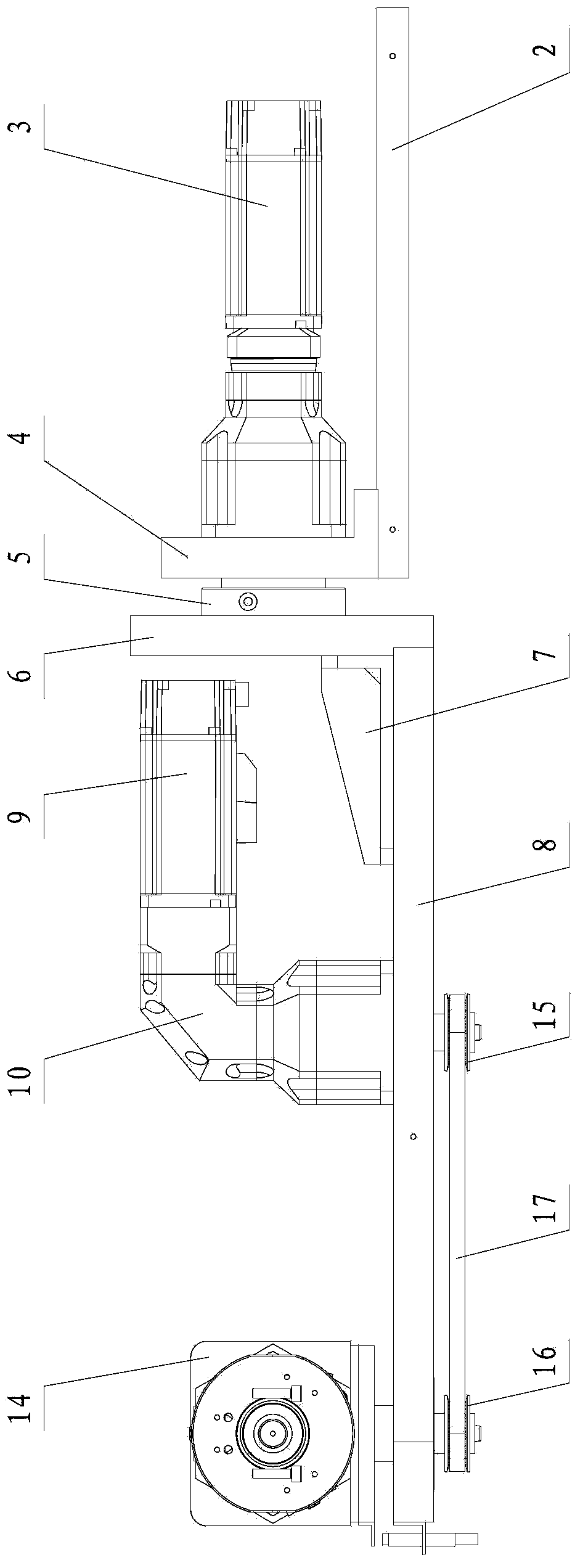

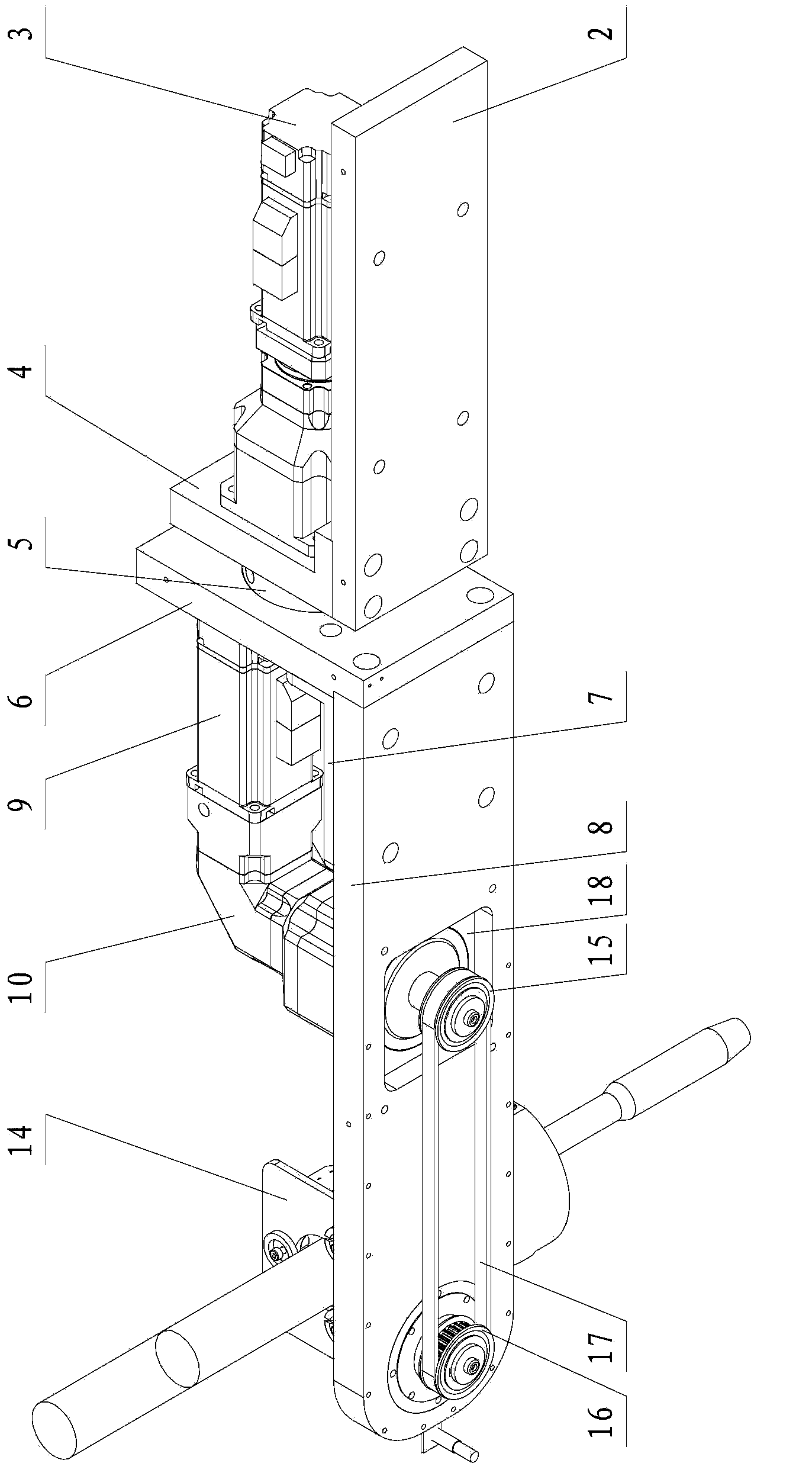

Robot wrist for precise laser machining

InactiveCN104117990ACompact structureWide applicabilityProgramme-controlled manipulatorJointsActuatorControl theory

The invention relates to a laser micropore machining device, in particular to a robot wrist for precise laser machining. The robot wrist comprises an A shaft part achieving rotation of a Y shaft and a B shaft part achieving rotation of a Z shaft, the A shaft part comprises an A shaft frame, a first speed reducer motor and an outer connection shaft, the A shaft frame is connected with a robot arm, the first speed reducer motor is arranged on the A shaft frame, and a main shaft of the first speed reducer motor is connected with the B shaft part through the outer connection shaft and drives the B shaft part to achieve rotation of the Y shaft. The B shaft part comprises a B shaft frame, a second speed reducer motor, a bevel gear steering mechanism and a belt wheel transmission mechanism, wherein the second speed reducer motor, the bevel gear steering mechanism and the belt wheel transmission mechanism are arranged on the B shaft frame, the B shaft frame is connected with the outer connection shaft, the second speed reducer motor is linked with one end of the belt wheel transmission mechanism through the bevel gear steering mechanism, and the other end of the belt wheel transmission mechanism is connected with an actuator and drives the actuator to achieve rotation of the Z shaft. The device is compact in structure, wide in application range, and capable of achieving the state that a laser machining head swings at will at a fixed point.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Salt-templated microporous solids

InactiveUS6890500B2Superior structural and chemical and physical propertyEasy to separateArsenites/arsenatesPhosphatesOpen frameworkIon exchange

The invention is directed to open-framework and microporous solids well suited for use in catalysis and ion exchange. The microporous solids are constructed by using a salt template which can be readily removed without destroying the framework of the micropore. Various microporous solids can be formed having different geometric structures depending upon the templating salt used and the concentration. Examples of two compounds include Na2Cs[Mn3(P2O7)2]Cl and K2.02Cs2.90[Cu3(P2O7)2]Cl2.92. Both compounds have 3-D (Mn, Cu)—P—O frameworks.

Owner:CLEMSON UNIV RES FOUND

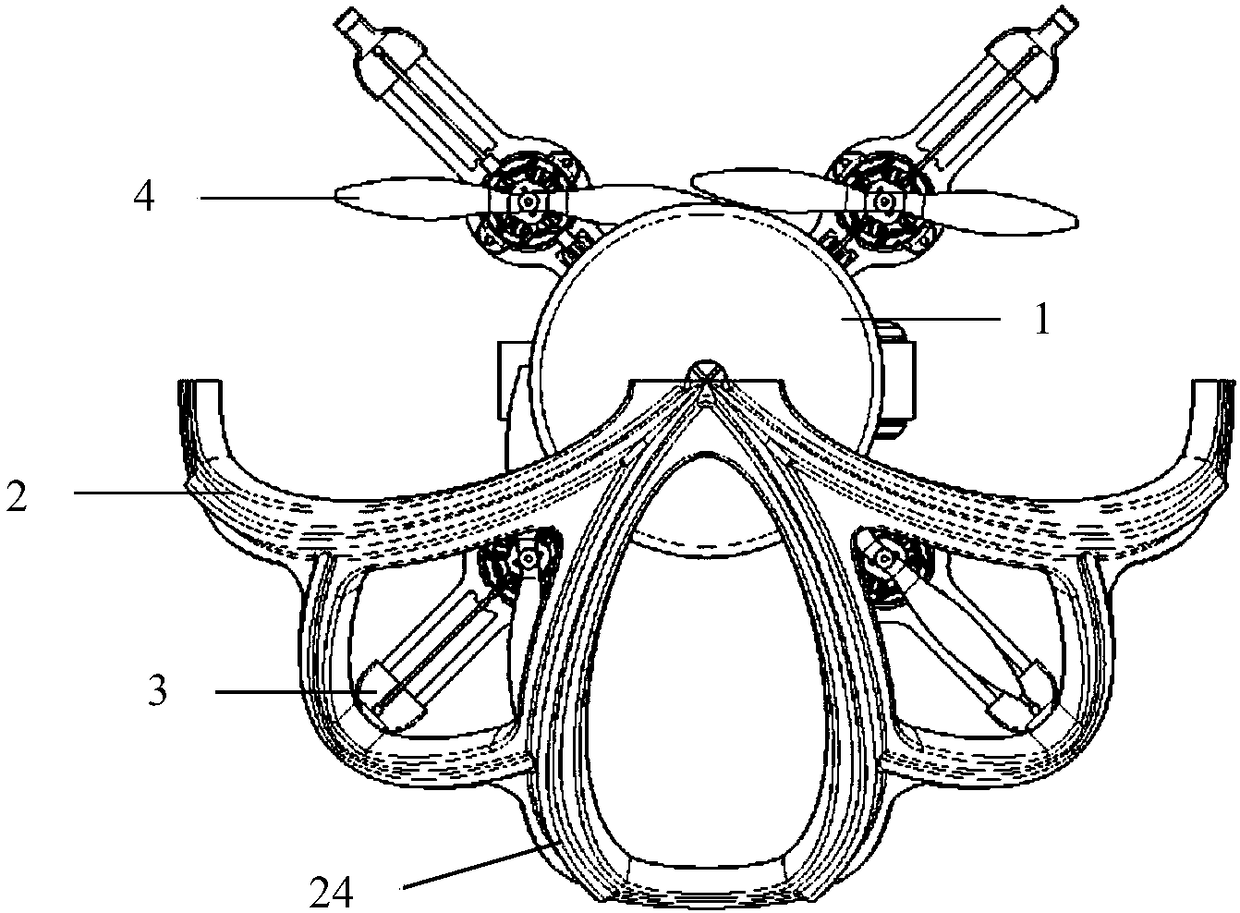

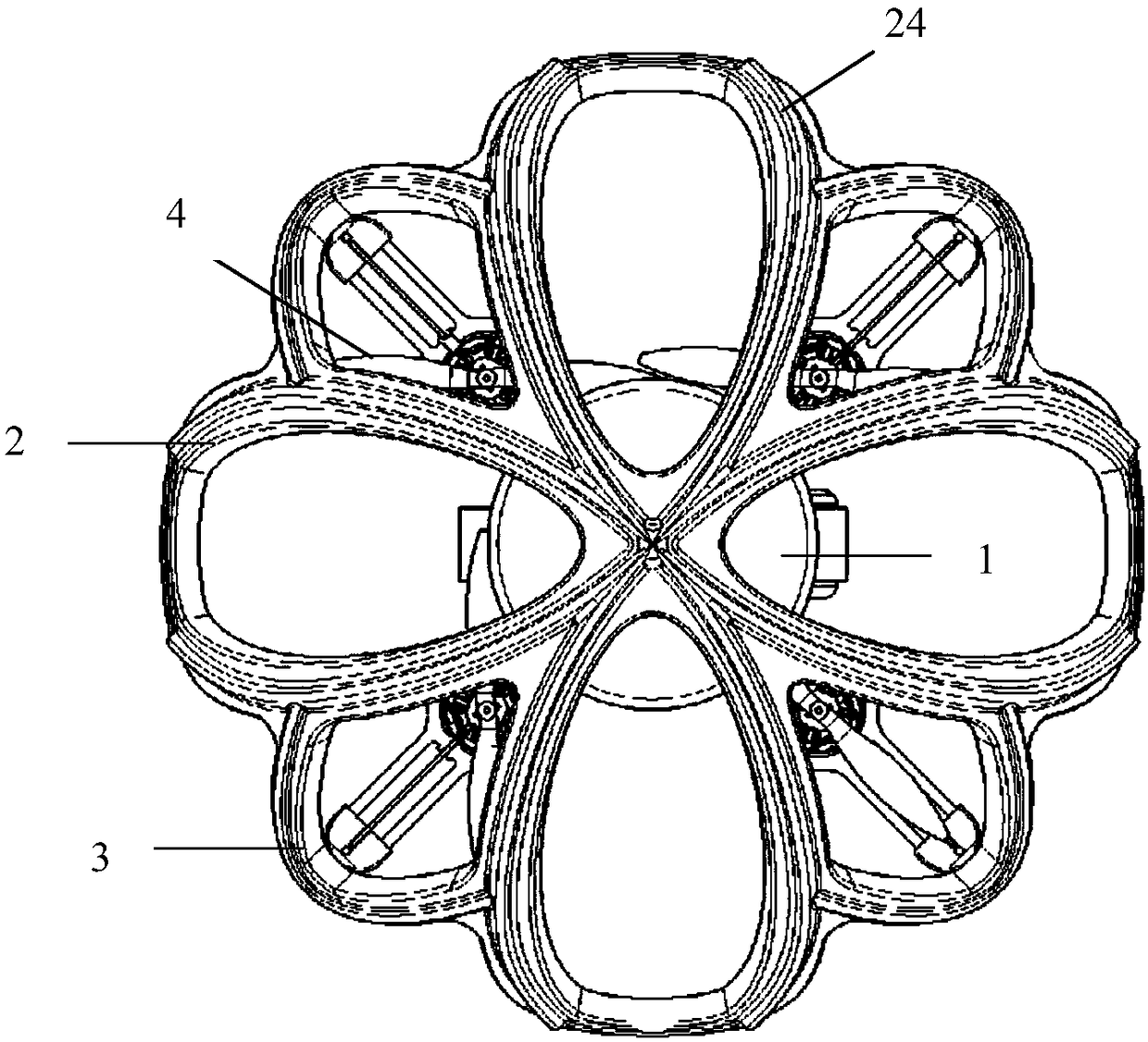

Unmanned aerial vehicle

PendingCN108082506AImprove structural strengthImproved steering responseFuselagesRotocraftPropellerFlight vehicle

The invention provides an unmanned aerial vehicle. The unmanned aerial vehicle comprises a body, a cage-like frame embracing the body, at least two connecting beams and propellers. One ends of the connecting beams are connected with the body, and the other ends of the connecting beams are connected with the cage-like frame. The propellers are arranged on the connecting beams correspondingly or parts of the connecting beams and provided with blades located on one sides of the connecting beams, and the adjacent blades rotate in different planes. According to the unmanned aerial vehicle, the adjacent blades rotate in the different planes, the overlap ratio of the blades is 0-3 cm, and the blades can be half overlapped under the extreme condition so that through the arrangement, the size of the whole aerial vehicle can be decreased as much as possible, and the aerial vehicle is downsized and thus is more suitable for flying in the indoor space or entering narrow spaces such as pipelines.

Owner:深圳锐合飞航智能设备有限公司

Anchoring strength testing device

ActiveCN107014632AFrame stabilitySafe and stable removalStructural/machines measurementEngineeringUltimate tensile strength

The invention discloses an anchoring strength testing device including a base, two parallelly arranged bearing seats are arranged on the base, the opposite sides of the two bearing seats are provided with a jack and a load sensor respectively, a protection net is arranged between the two bearing seats, the sides where the jack and the load sensor are arranged are slidably provided with protection devices, each of the protection devices includes a slide seat axially slipping along the jack, the slide seat is provided with a swing mechanism and a cover body connected with the swing mechanism, one end of the cover body is opened, the cover body forms a protection state or a discharging state through the swing of the swing mechanism, when in the protection state, the opening of the cover body abuts against the end face of the jack or the end face of the load sensor to form a protection bin, and when in the discharging state, the opening of the cover body faces upwards, and the inner side wall of the cover body is provided with an inclined surface for guiding the dropped anchoring component to slip to the bottom of the cover body when in the protection state. The anchoring strength testing device improves the safety in the testing process.

Owner:WENZHOU XINDA TRAFFIC ENG TEST DETECTION

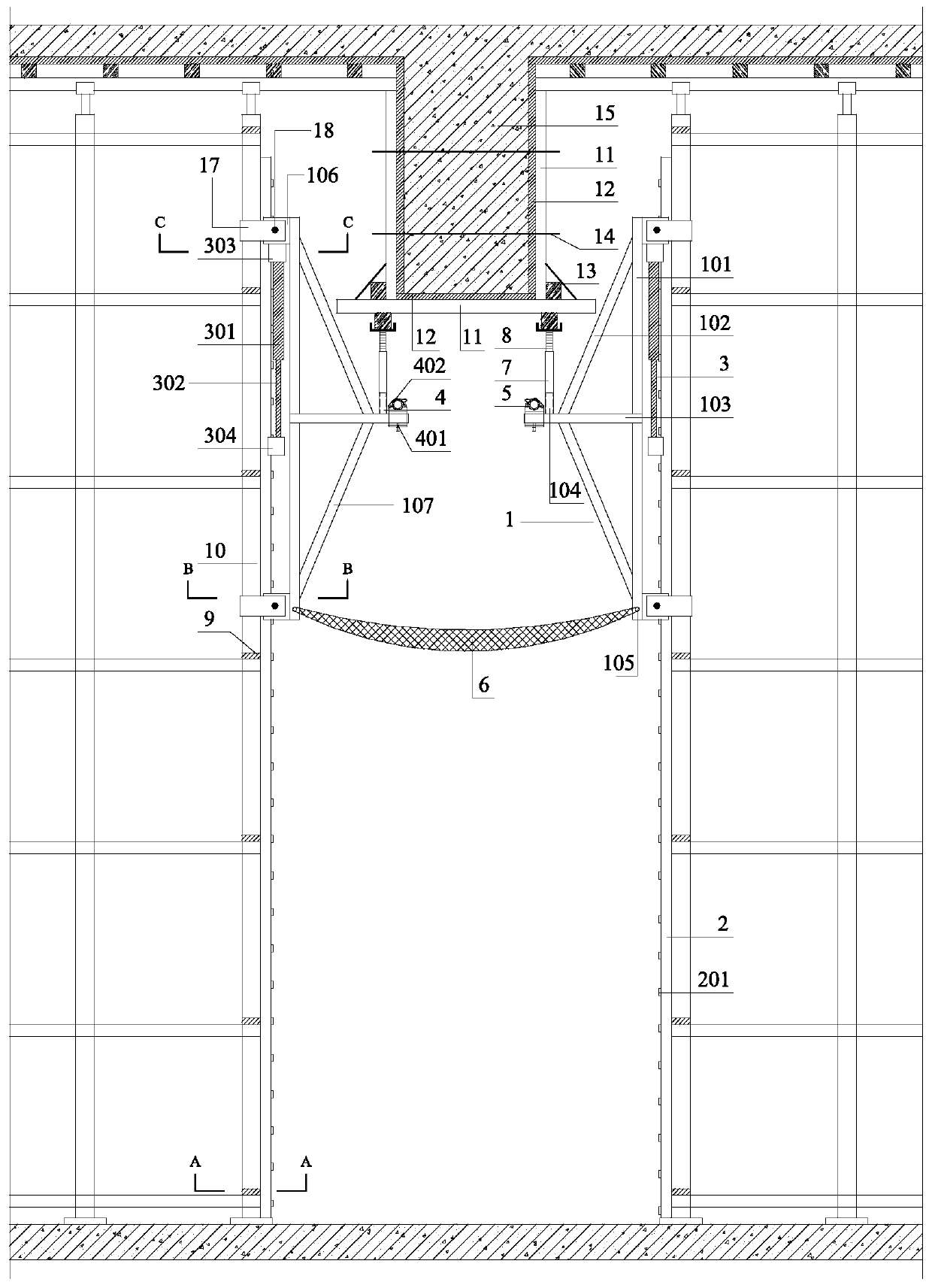

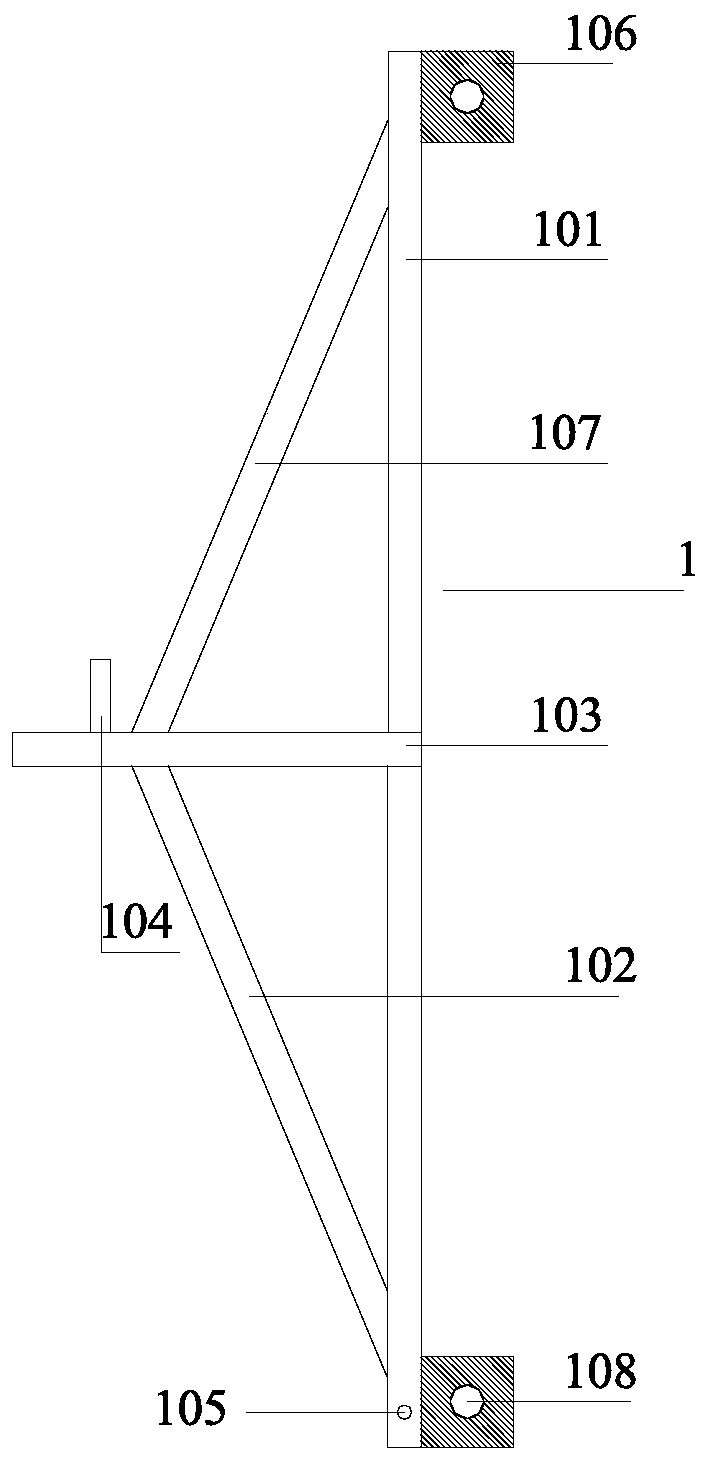

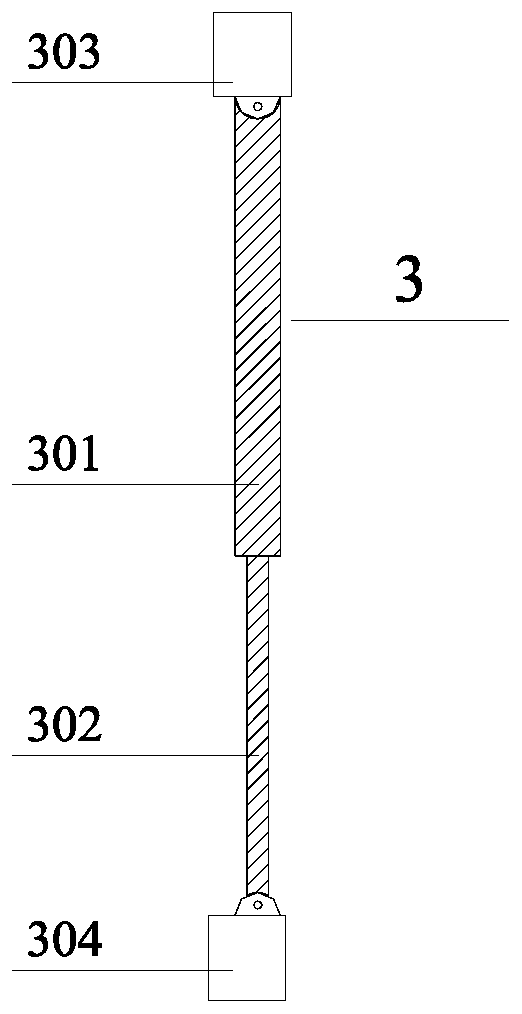

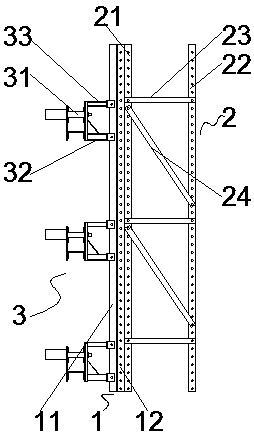

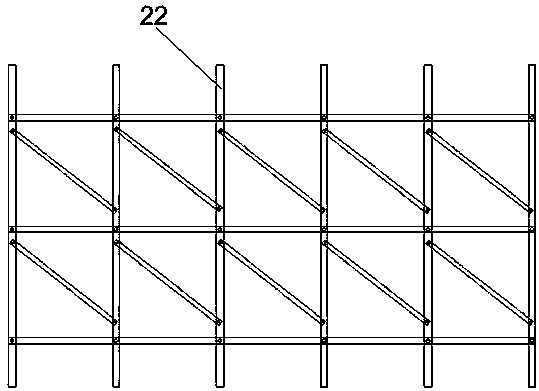

Construction method of tall formwork symmetrical suspension climbing triangular truss support system

InactiveCN109797967AReduce dosageSet up fastAuxillary members of forms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention relates to a construction method of a tall formwork symmetrical suspension climbing triangular truss support system. The main construction steps include vertical slideway installation, triangular truss assembly, triangular truss installation, triangular truss climbing, and beam formwork and support installation. An under beam scaffold in the traditional formwork support system is substituted by a tripod which is symmetrically suspended and combined with pulling and bracing, a plurality of tripods are pulled and combined to form a triangular truss, and a hydraulic climber is further applied to realize an automatic lifting of the triangular truss. The operation space beside and under the beam is large, the construction safety is high, the consumption of steel pipes and fasteners is less, the operation is convenient and the recycling rate of components is high, thereby overcoming the problems such as large supporting and disassembling workload, small operation space, long construction period and unsafe security in the construction of the traditional formwork support system, and the economic and technical benefit is remarkable.

Owner:杭州昂创科技有限公司

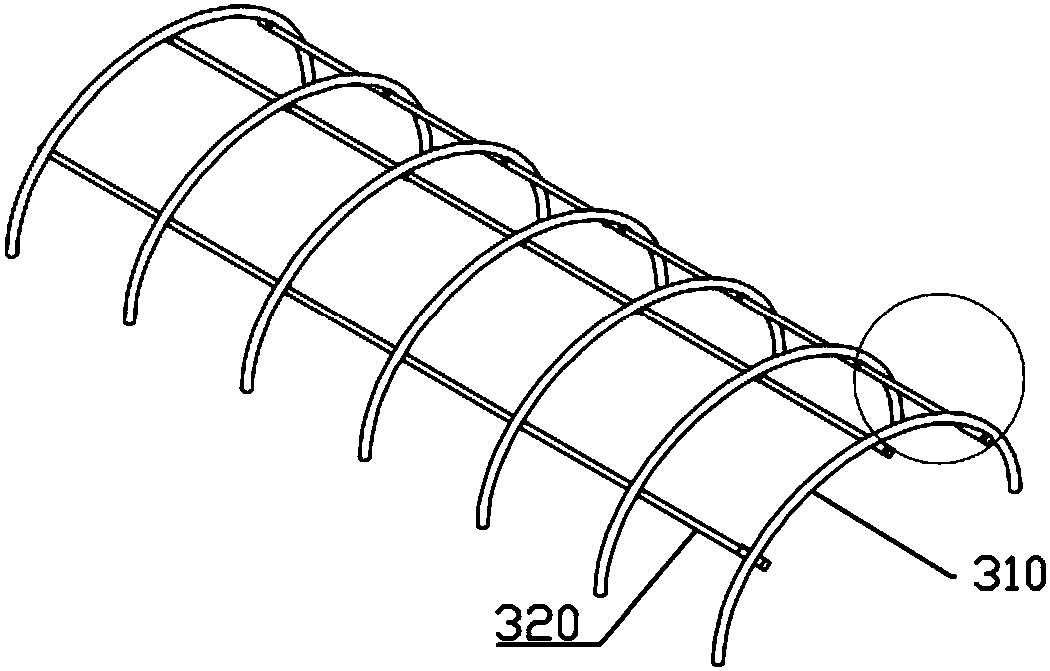

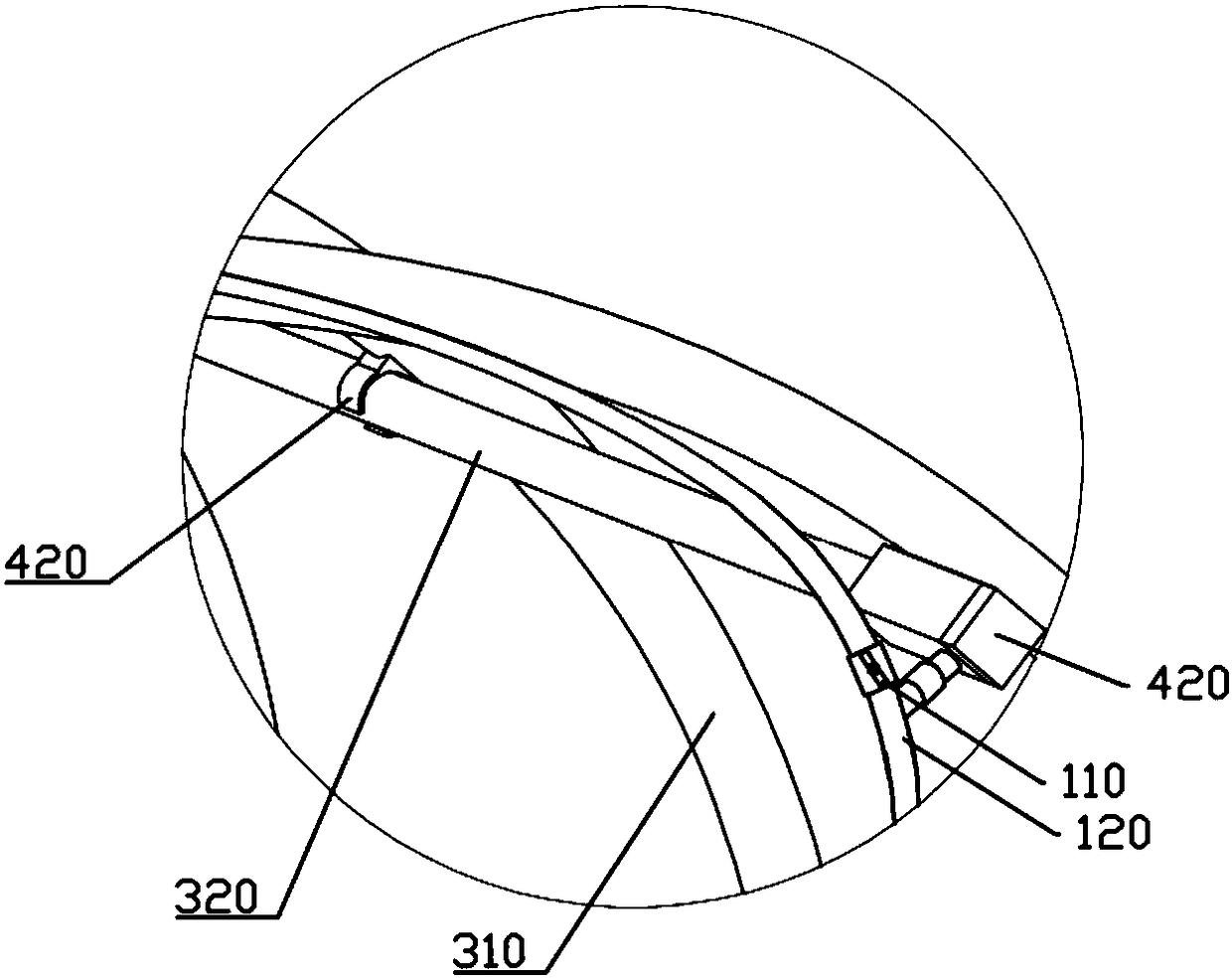

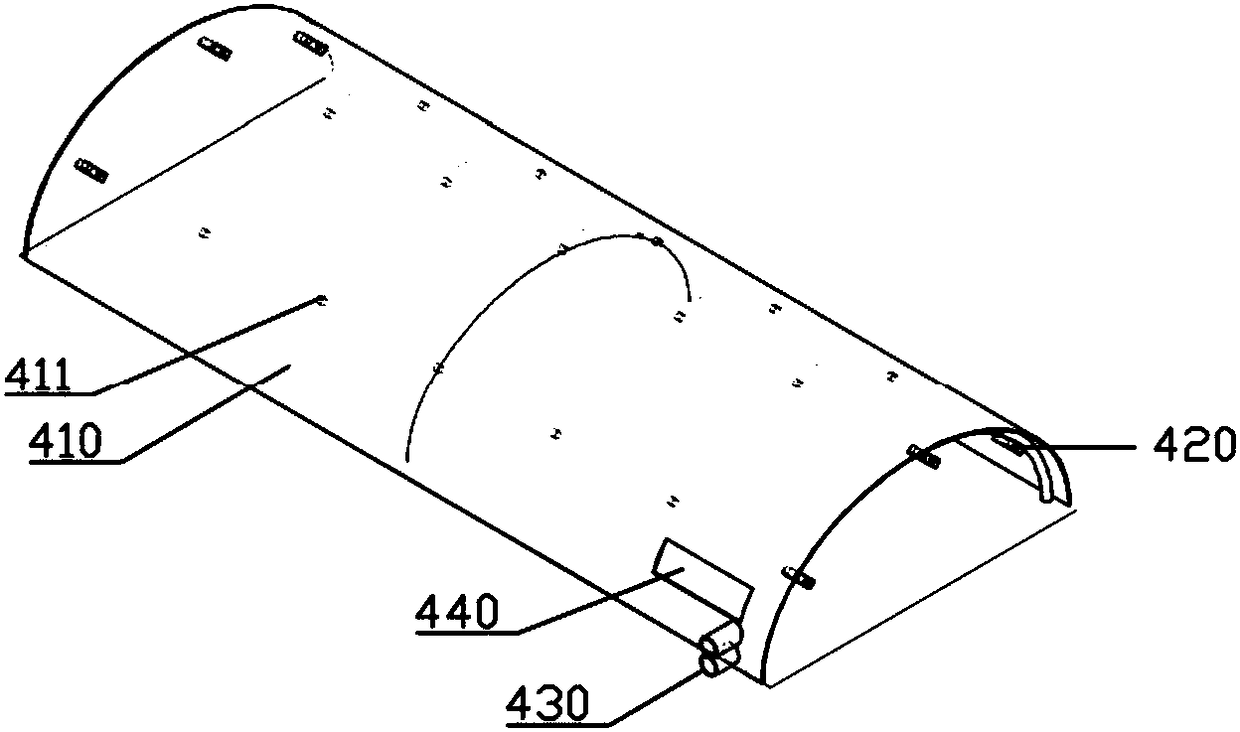

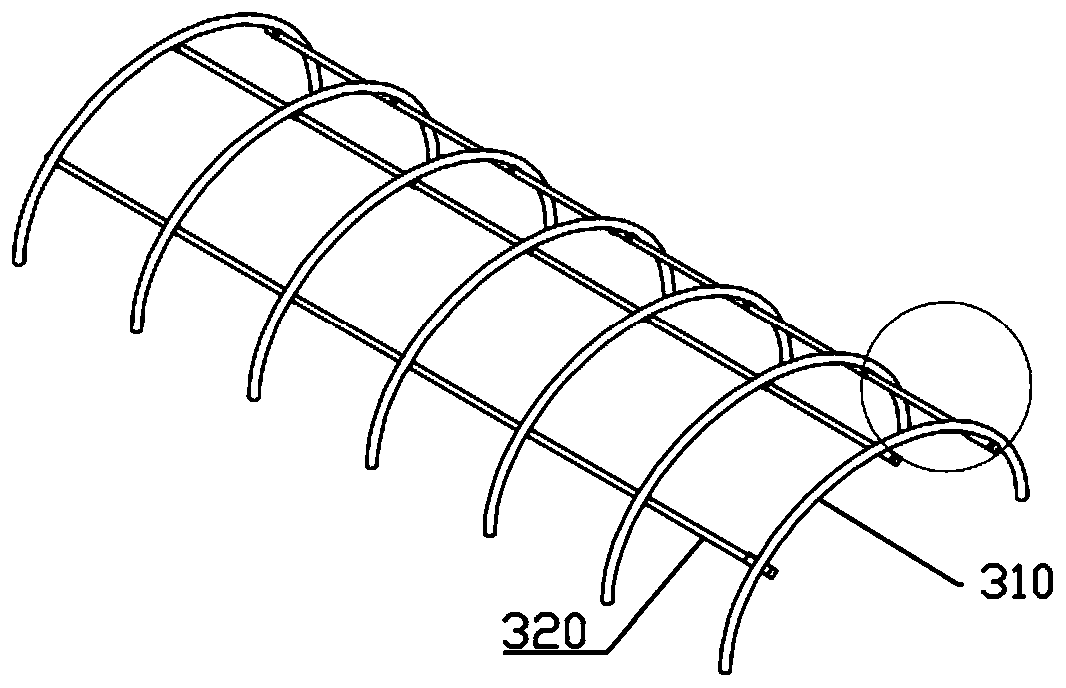

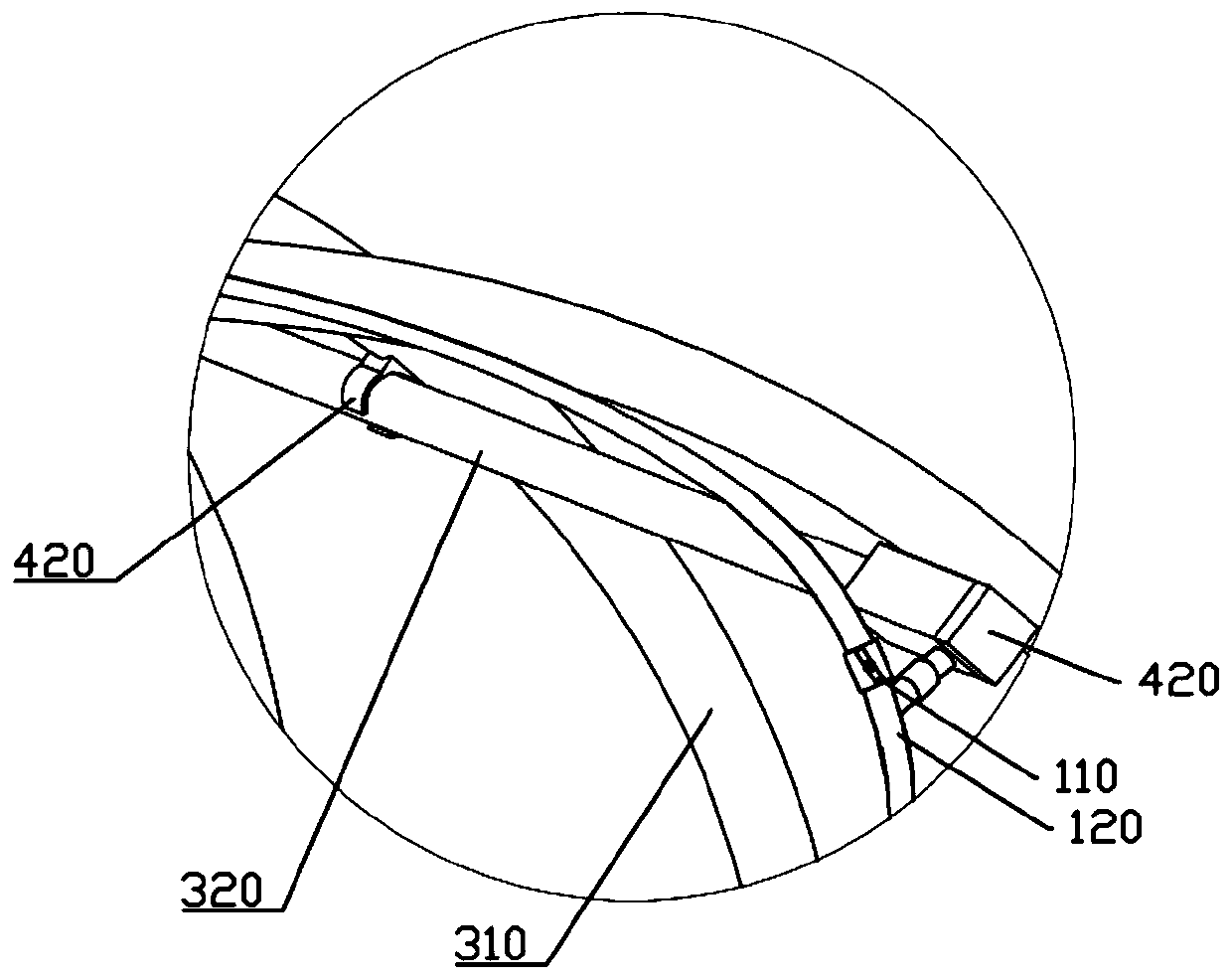

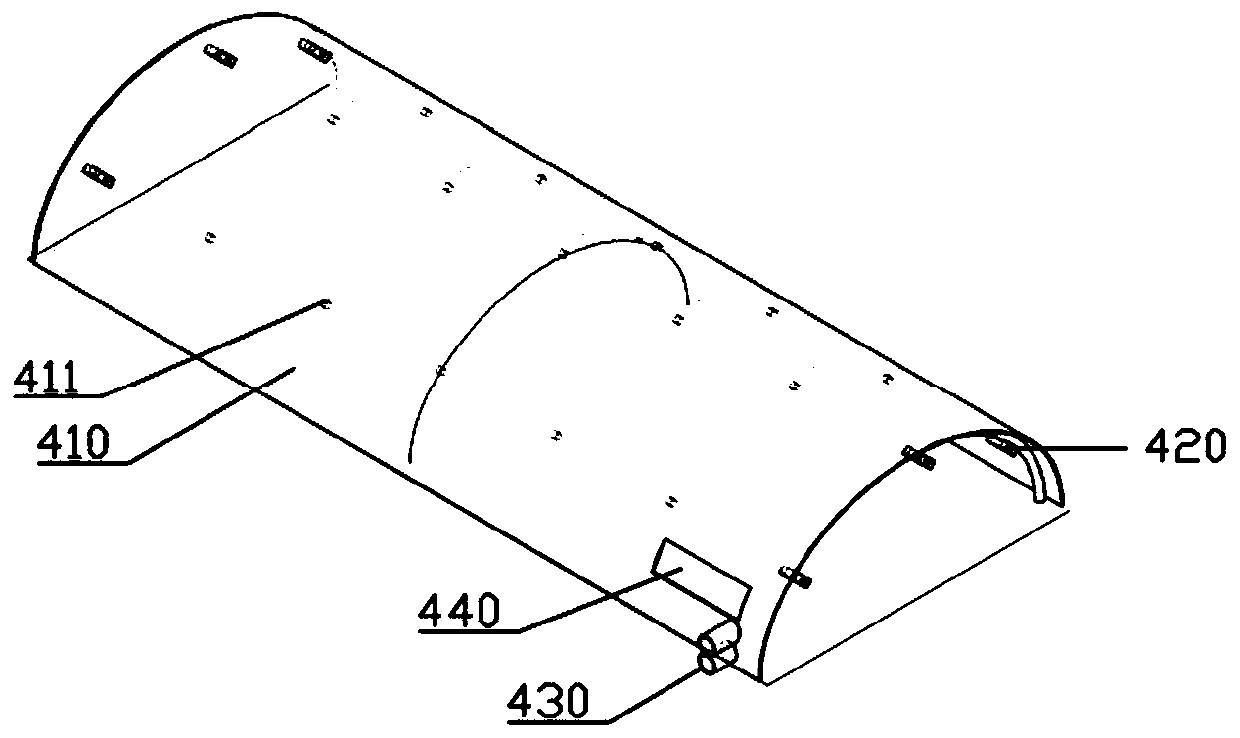

Gas pillar supporting system for high-pressure tent

The invention relates to a supporting system for a tent for field rescue, in particular to a gas pillar supporting system for a high-pressure tent. The gas pillar support system comprises at least onestrip-shaped inflating longitudinal beam and a plurality of parallel and arched inflating cross beams. The air pressure in the inflating cross beams and the inflating longitudinal beams is 0.61-0.85Mpa. The inner sides of the inflating cross beams are provided with mounting seats. The mounting seats are arranged longitudinally and linearly, and the inflating longitudinal beams are detachably connected to the mounting seats. The invention provides a gas pillar supporting system with higher strength in order to solve the problem that a supporting system of an existing high-pressure tent is insufficient in strength.

Owner:CHONGQING DONGDENG TECH

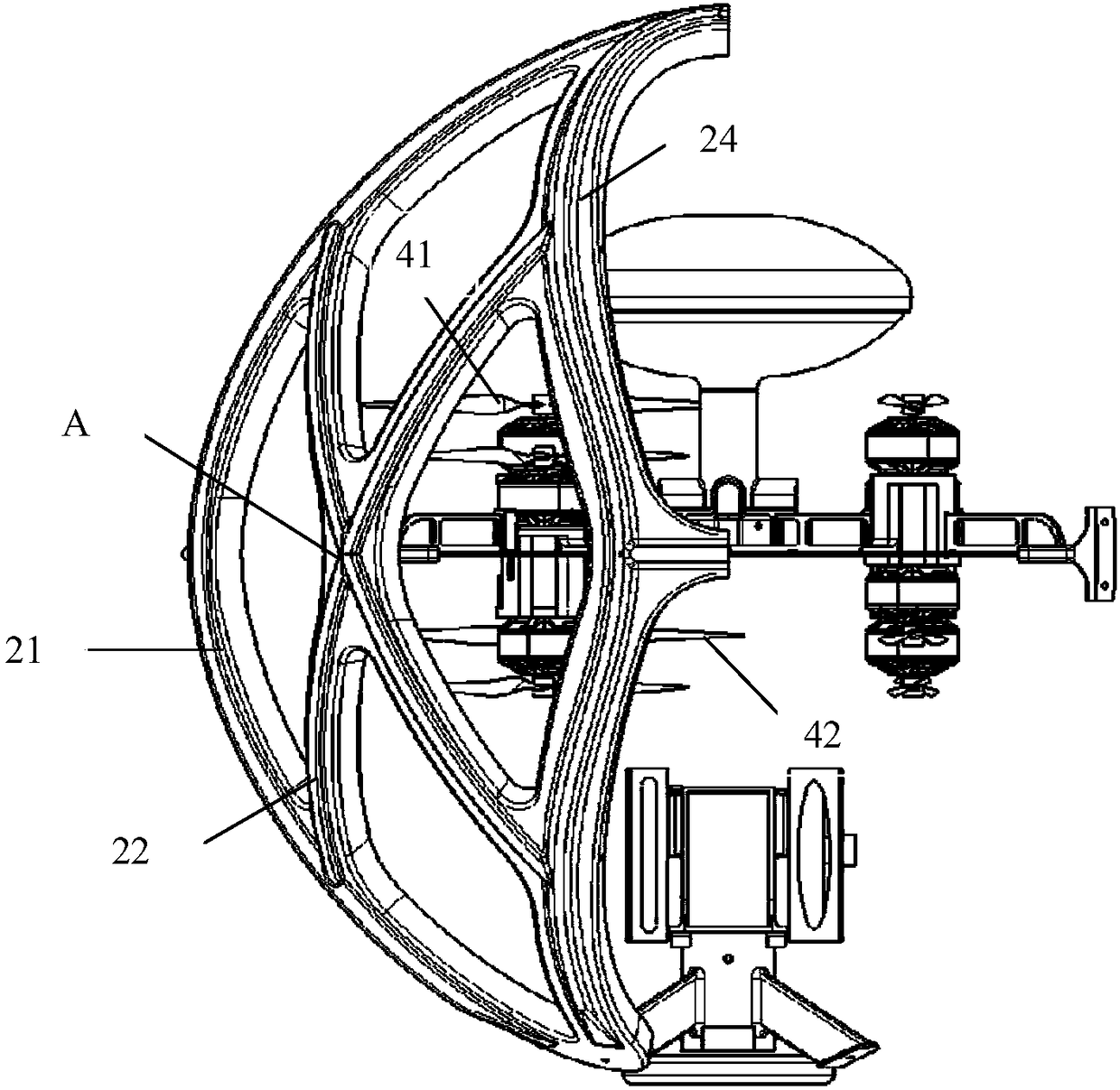

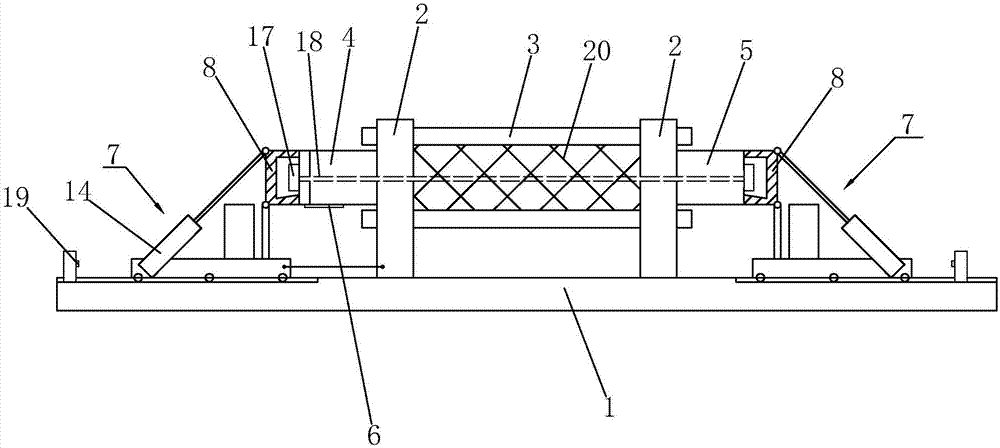

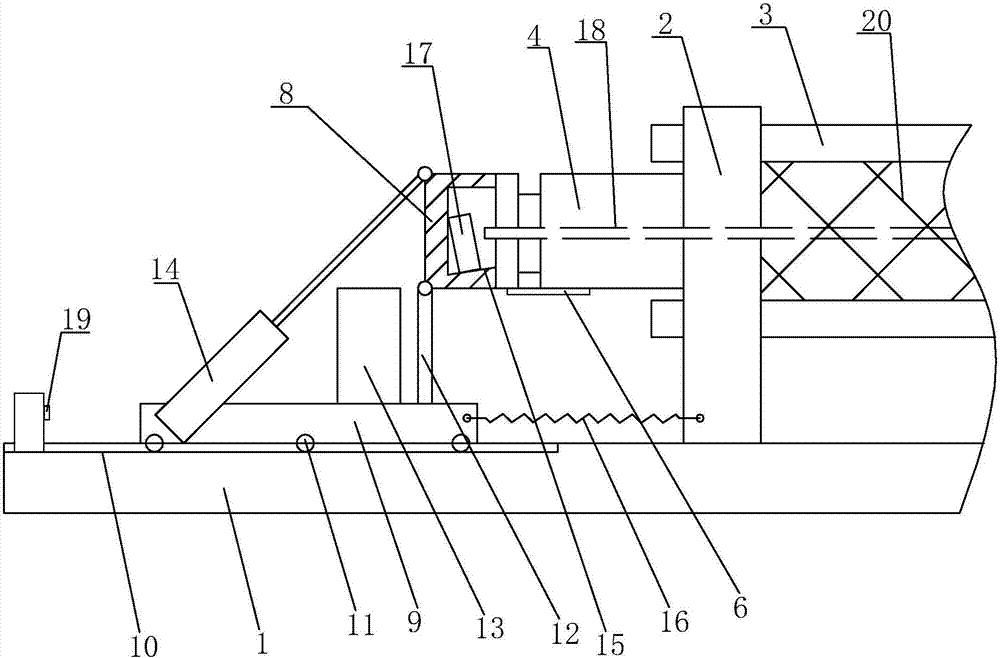

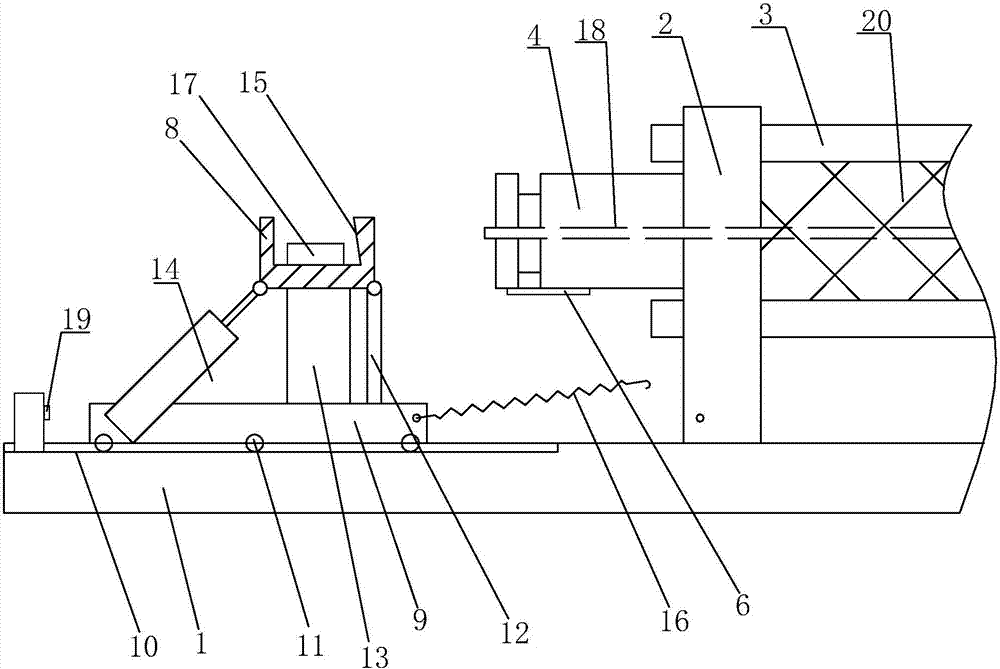

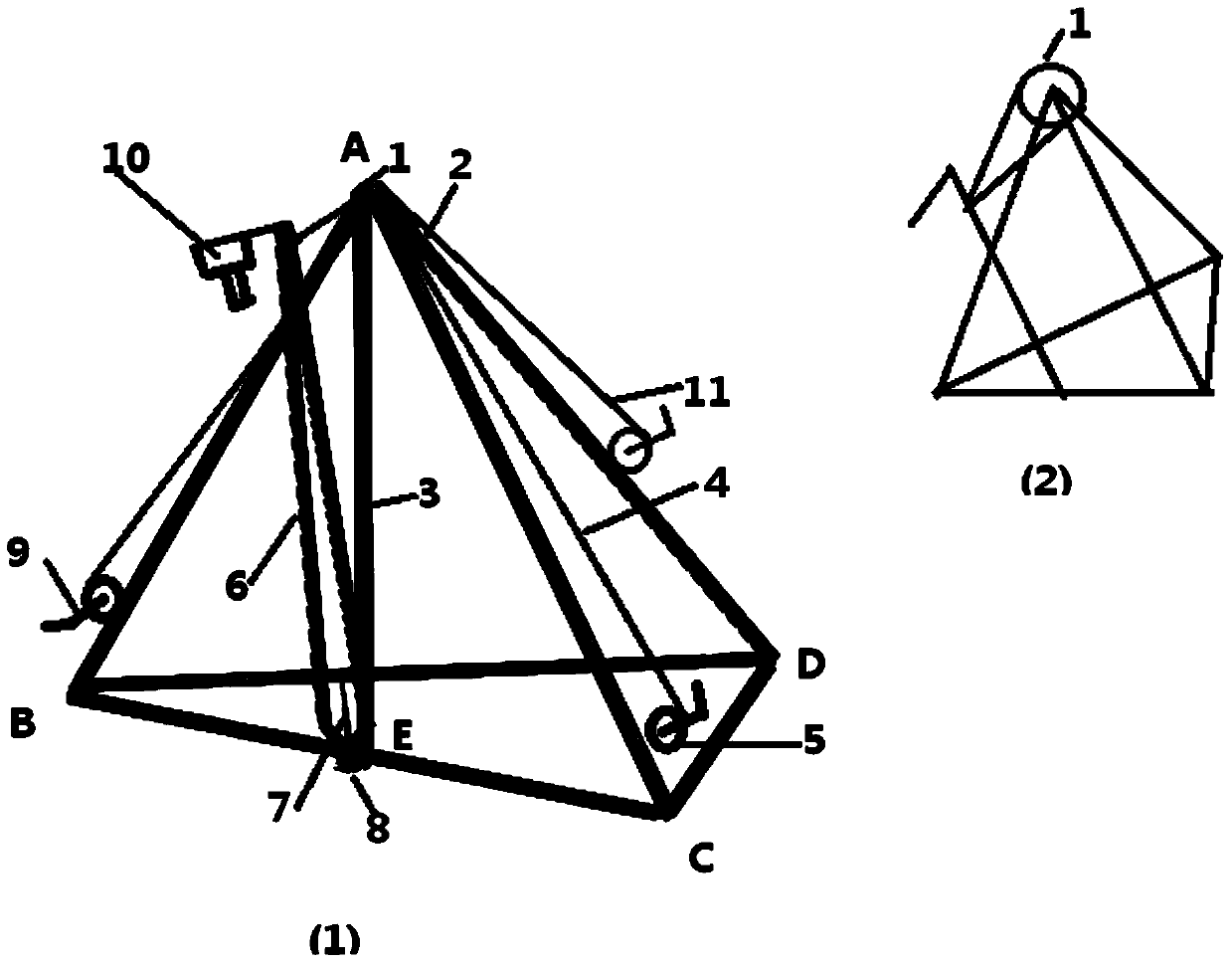

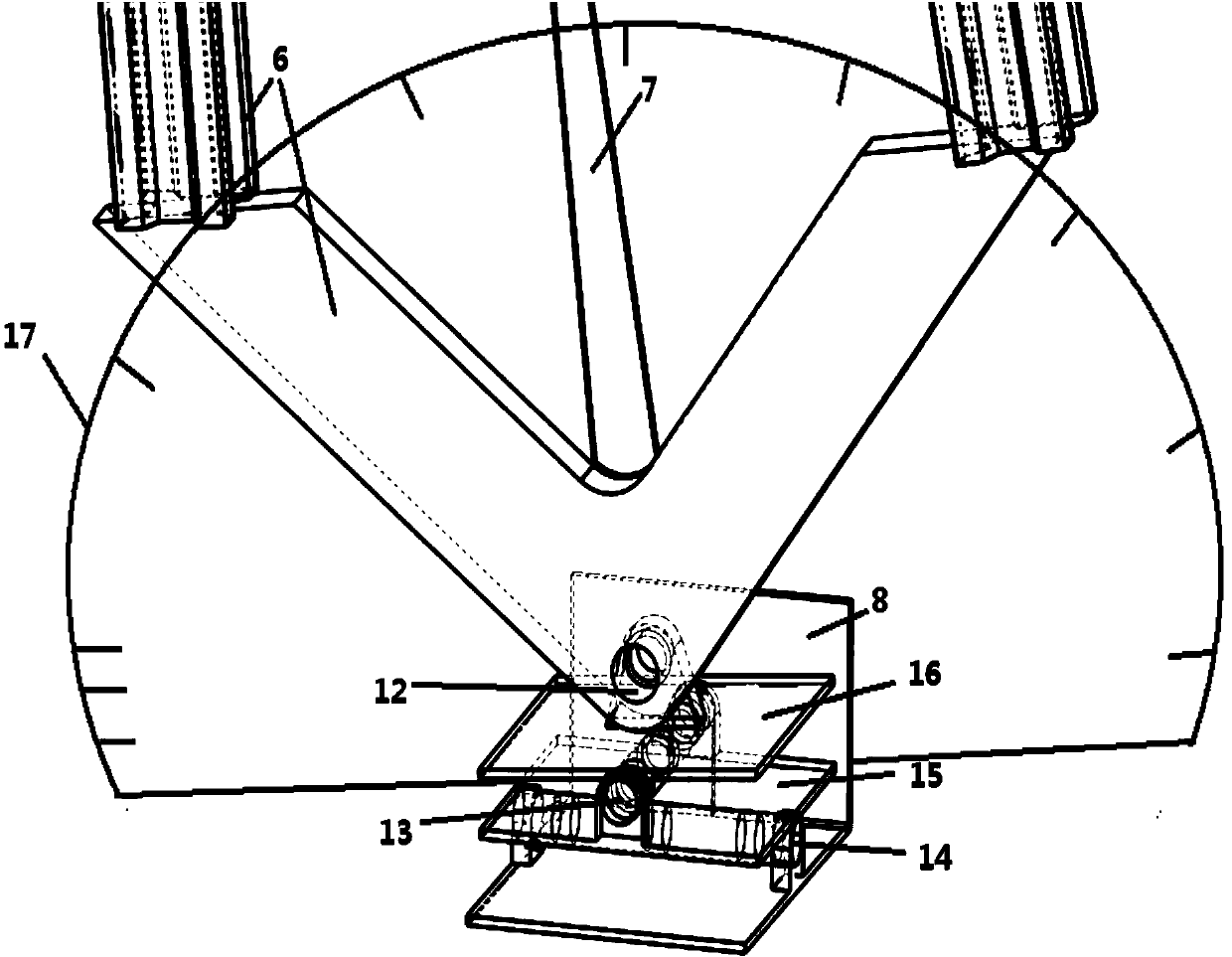

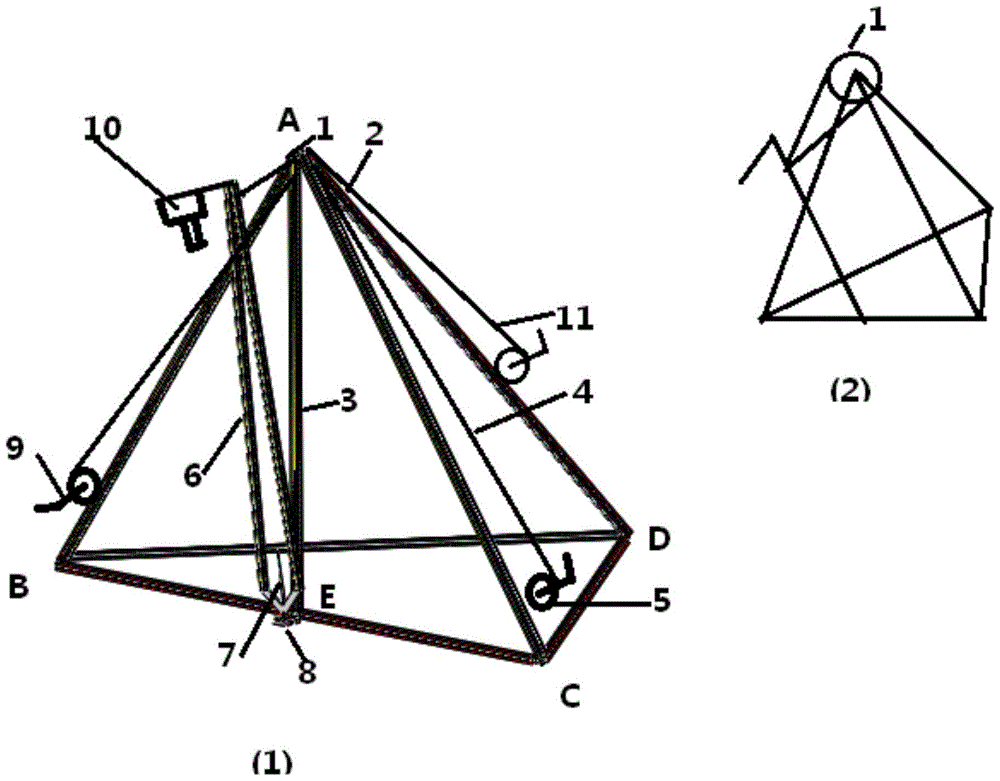

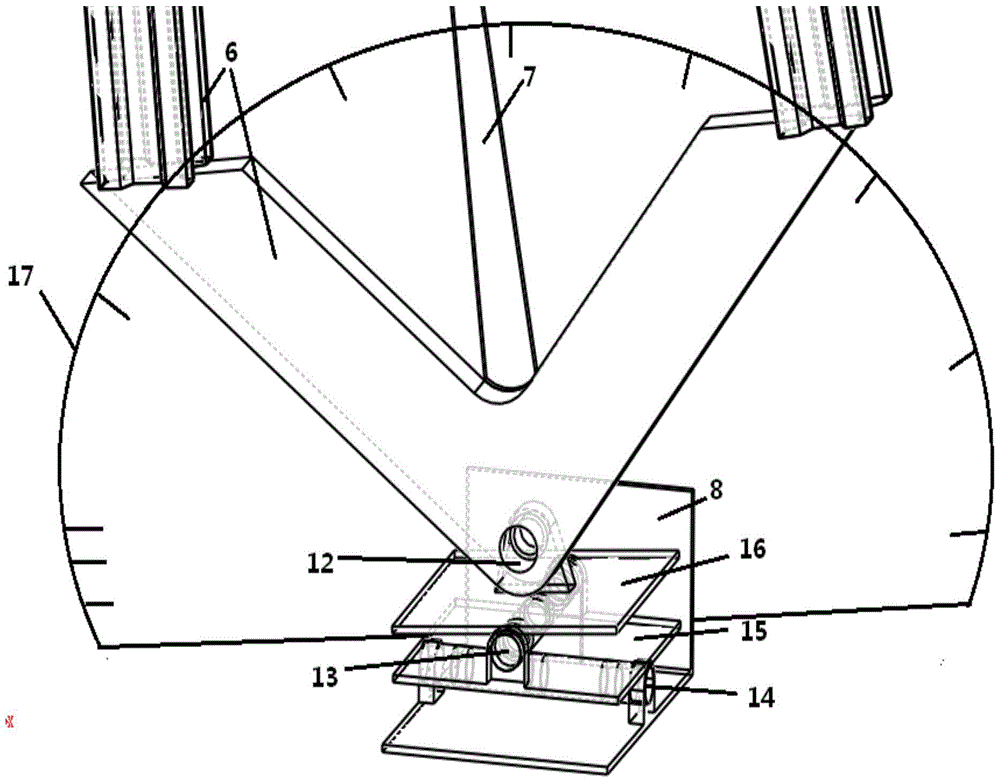

Remote sensing ground simulation test frame

The invention discloses a remote sensing ground simulation test frame and relates to the field of erection and simulation of positions and motion states of ground imaging sensors. The remote sensing ground simulation test frame is characterized by comprising a triangular-pyramid-shaped truss body structure, a center pillar of a triangular-pyramid-shaped truss body perpendicular vertical face ABC, an inverted-L-shaped swing rod, a swing rod traction angle indicating needle, a swing rod initial position adjusting base plate and an imaging sensor, wherein a pulley is arranged on the top of the truss body, the position and angle of the inverted-L-shaped swing rod are controlled through a steel wire traction rope, one end of the steel wire rope is connected to the position lower than the top end of the inverted-L-shaped swing rod, the steel wire rope surrounds the pulley to be twisted to a hand-cranking traction rope winch which is used for winding and unwinding the traction rope, the swing rod traction angel indicating needle is matched with the angle indicating base plate and reads the angle of the swing rod, the imaging sensor is installed on the cross rod of the inverted-L-shaped swing rod, and the inverted-L-shaped swing rod can swing leftwards and rightwards around a rotary middle shaft of the adjusting base plate. According to the remote sensing ground simulation test frame, the truss body is stable, the angle of the swing rod is readable and adjustable, and the angle of the swing rod is safely controlled in a labor-saving mode.

Owner:徐州新南湖科技有限公司

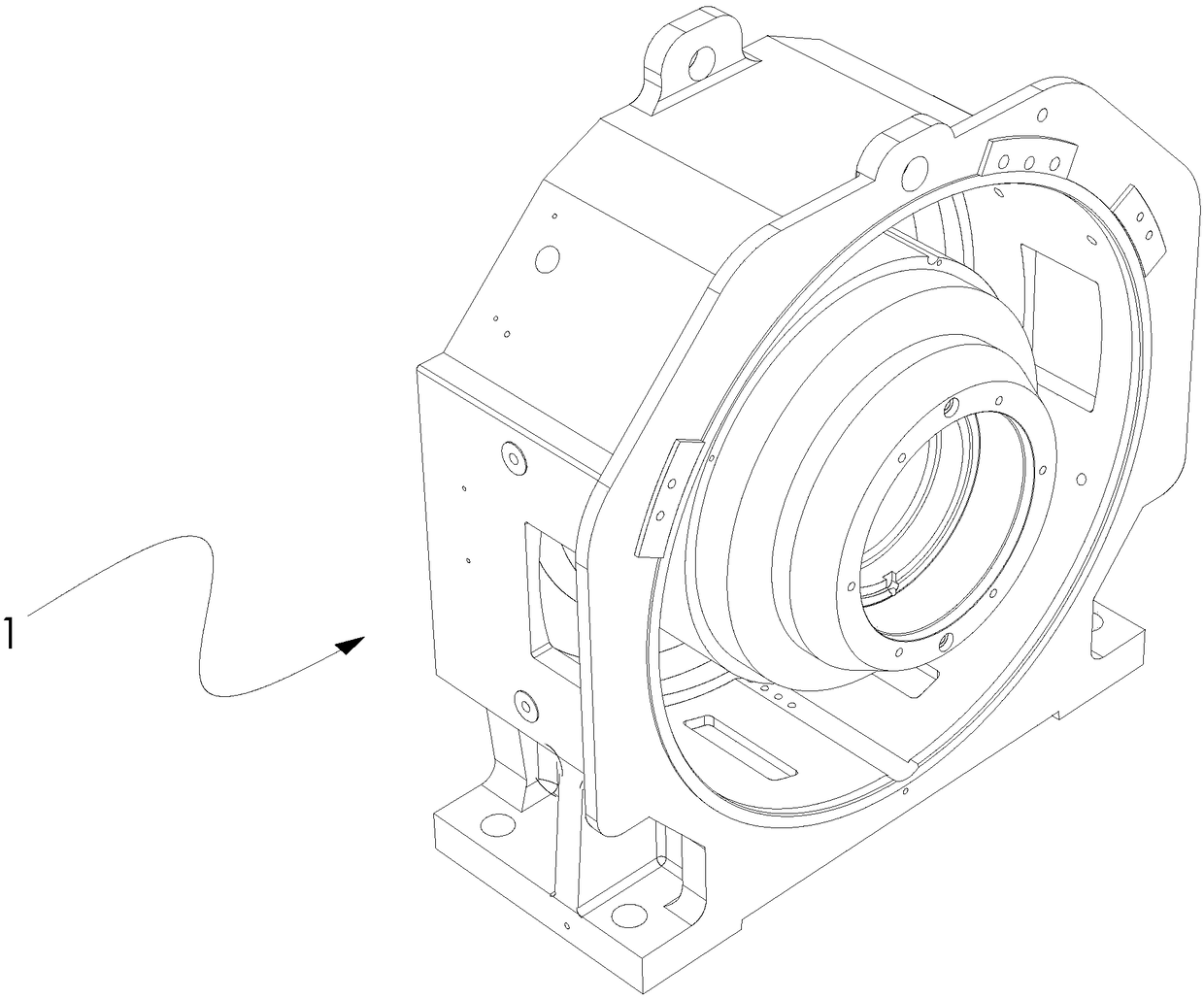

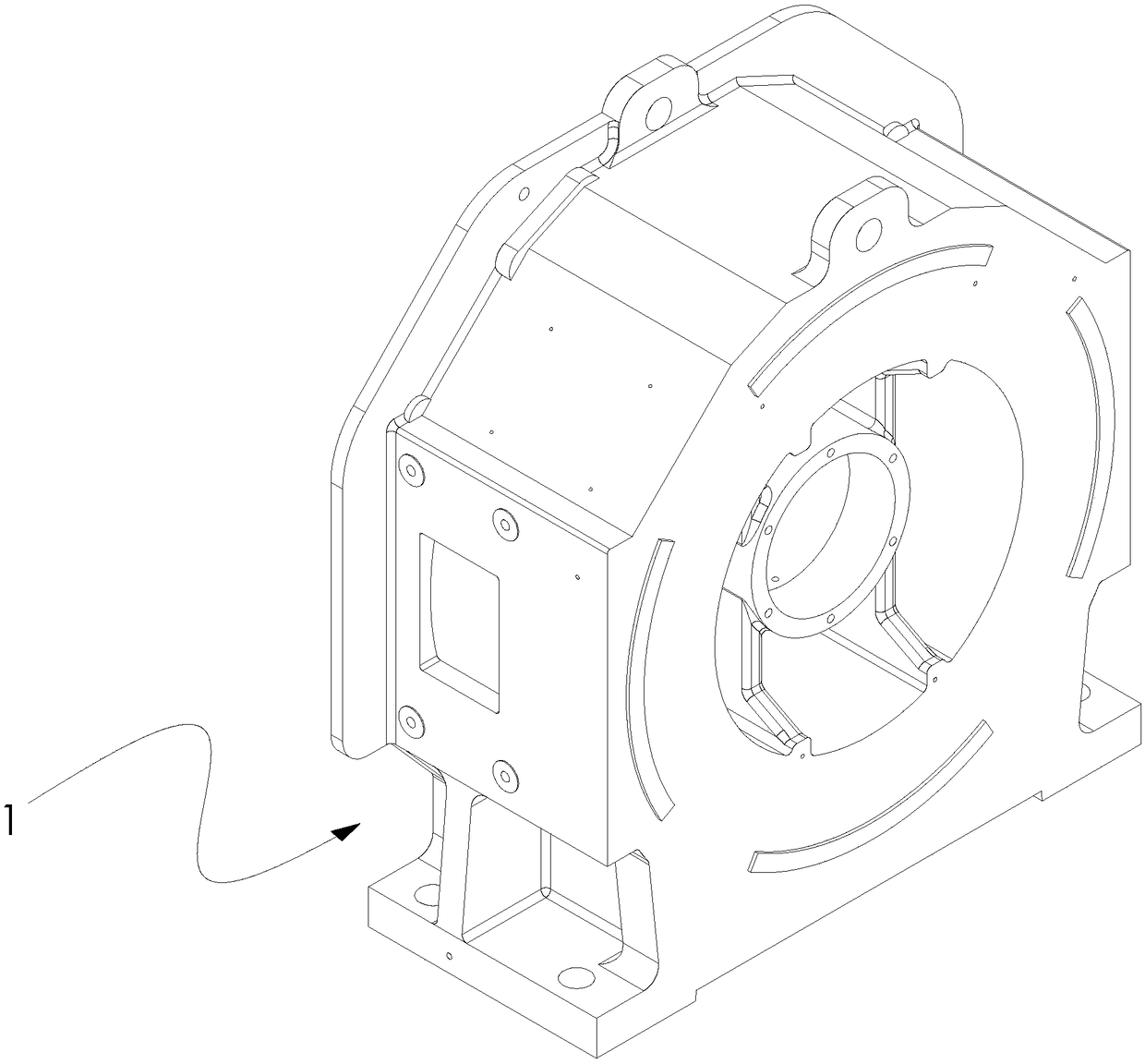

Permanent magnet synchronization traction machine

PendingCN108134482AEasy to shapeGood design workmanshipStructural associationMechanical energy handlingEngineeringSupport point

The present invention discloses a permanent magnet synchronization traction machine. The permanent magnet synchronization traction machine comprises a machine base, a stator module, a rotor module cooperated with the stator module, a traction wheel and a shafting module. The machine base comprises a base plate located at the bottom portion, side plates located at two sides of the base plate and asupport plate connected with the side plate, and the support plate is provided with a pipeline; the shafting module comprises a rotating shaft, the rotating shaft is arranged in the pipeline in a penetrating mode, one end of the rotating shaft is connected with the rotor module, and the other end of the rotating shaft is connected with the traction wheel. The permanent magnet synchronization traction machine is reasonable in structure design, and can be suitable for welding and casting of the machine base; the machine based of the permanent magnet synchronization traction machine is simple inshape, has no a periphery and a cavity with complex shapes, and is convenient to measure; a force bearing point is close to a support point in the structure design of the traction machine, and the internal portion shafting and the rotor structure are simple and reliable; and the installation structure of the traction machine coder is reasonable in design, stable in whole frame and low in cost.

Owner:WITTUR ELEVATOR COMPONENTS SUZHOU

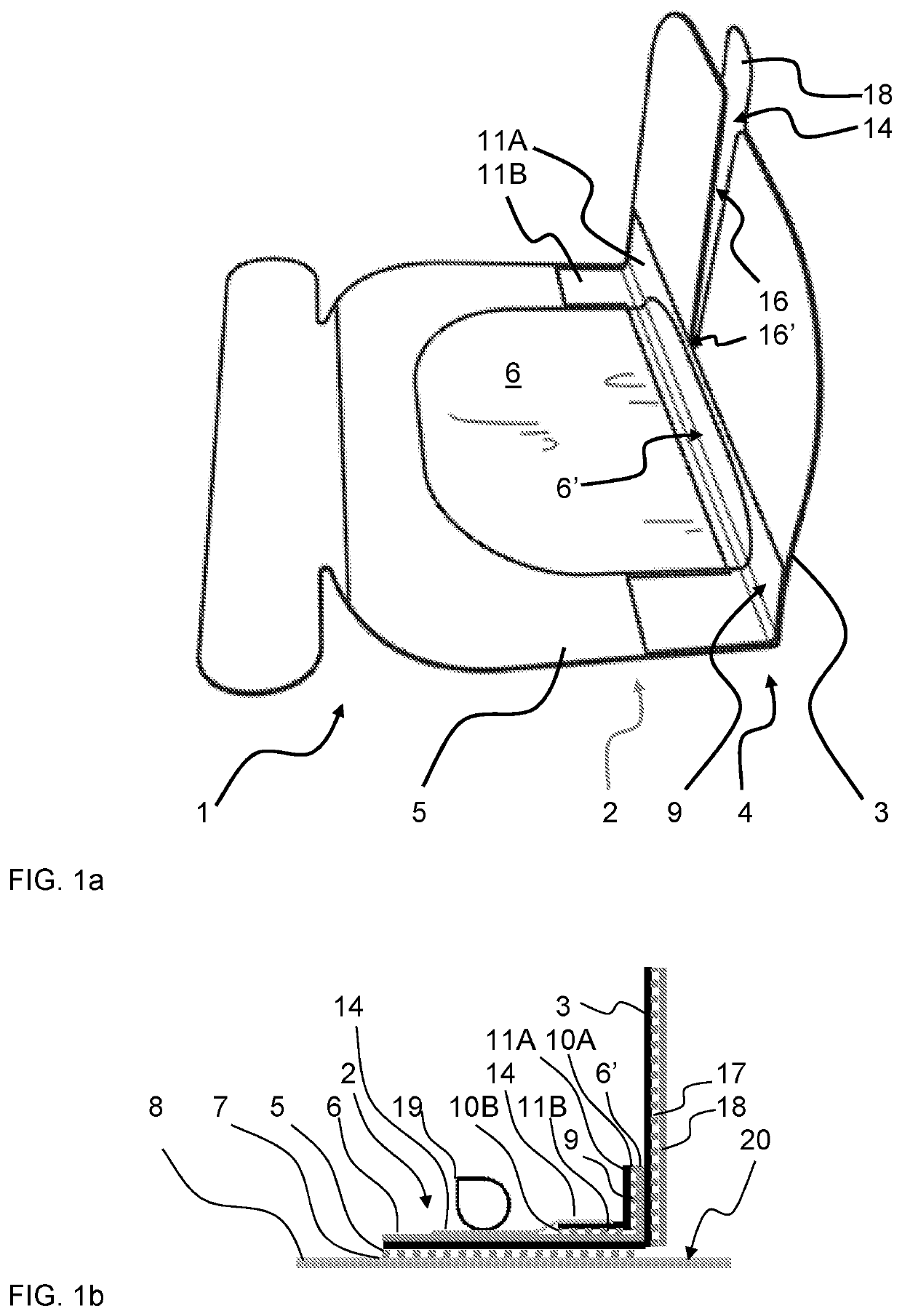

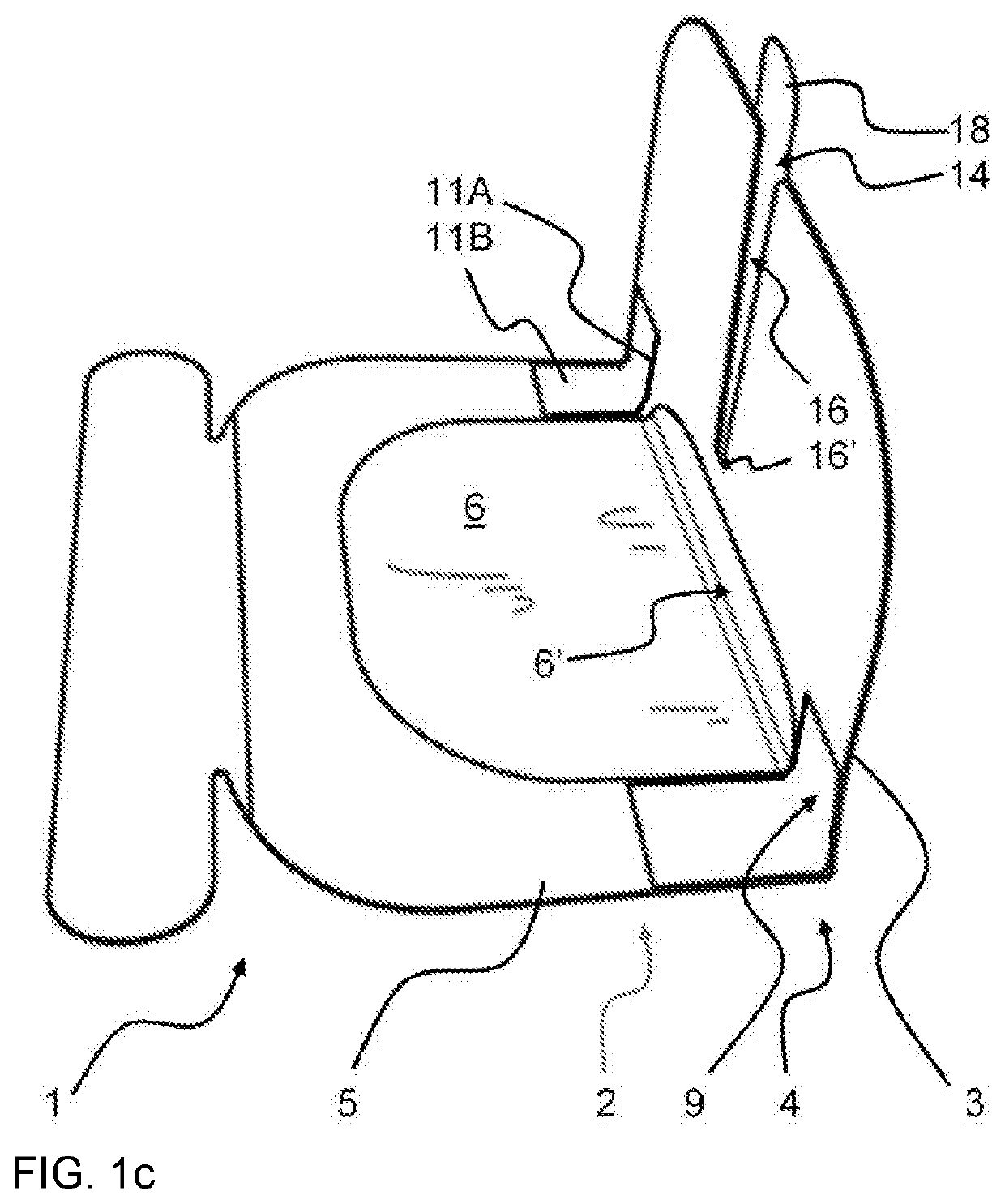

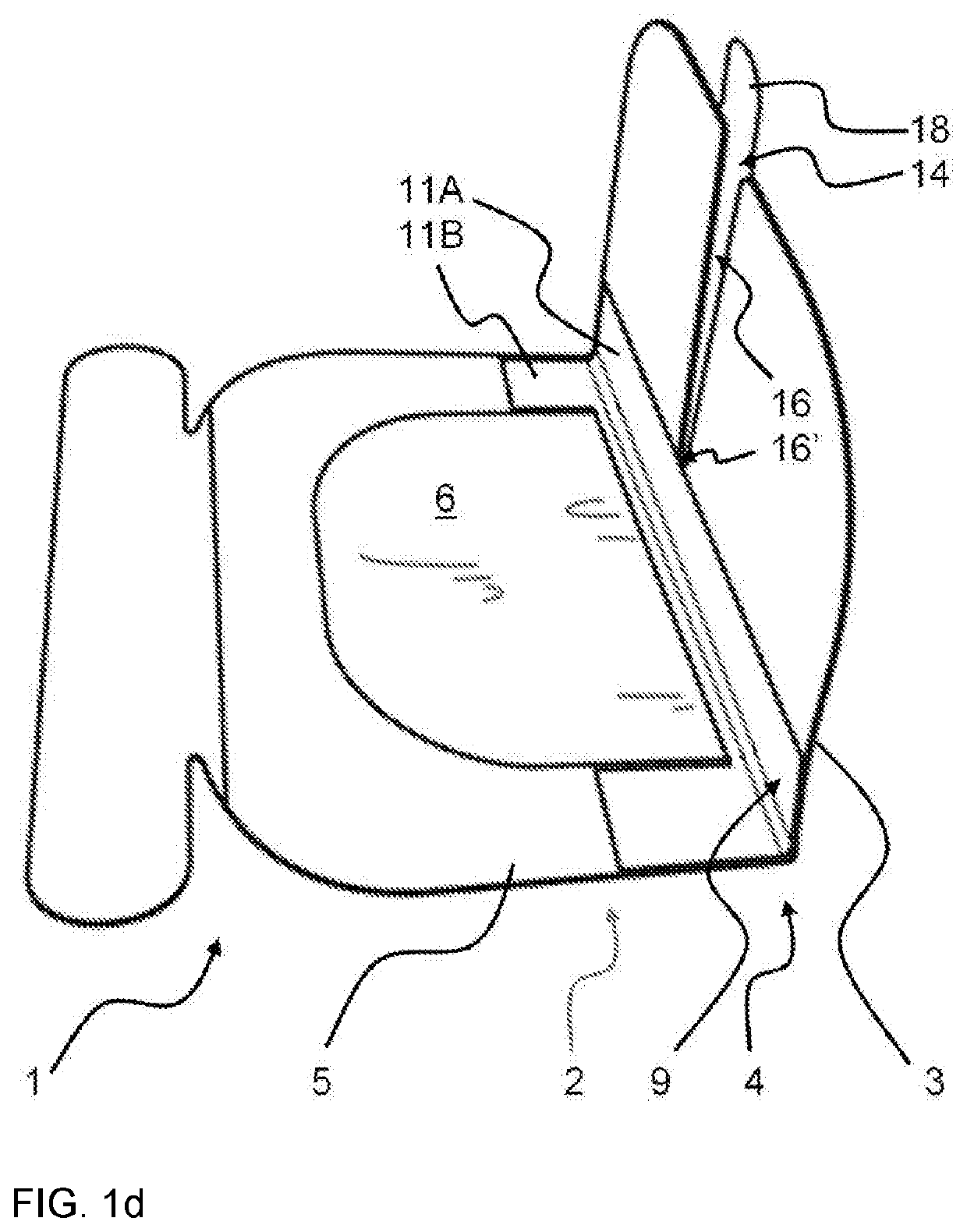

A method for Preparing an Insertion Site for a Cannula on a Skin of a Patient, a Skin Cover Unit Therefore and Its Use

PendingUS20210038249A1Good skin contactGood adhesionOrgan movement/changes detectionSurgical needlesUltrasound sonographyEngineering

An insertion site for a cannula (23) on a skin (8) of a patient is prepared by applying a skin cover unit (1) of the type comprising a window (2) and a wall (3) in extension of the window (2) and connected to the window (2) by a bending region (4) for bending the wall (3) into an angled orientation relatively to the window (2); wherein the win-dow (2) comprises a stabilizing frame (5) and an ultrasonic-transparent flexible sheet (6) within the frame (5). The flexible sheet (6) is glued onto the skin (8) of the patient for ultrasonic investigation of the insertion site through the flexible sheet (6). By bending the bending region (4), the angular orientation of the wall (3) is adjusted into an approximately perpendicular orientation relatively to the window (2) for separating the insertion site from the flexible sheet (6) by the wall (3). The cover unit (1) in or at the bending region (4) comprises a stabilizer (9) that is configured for maintaining the angled orientation between the wall (3) and the window (2) by a stabilizing action of the stabilizer (9).

Owner:US ENOVACOR APS

Remote sensing ground simulation test stand

ActiveCN103900630BEffort controlSafe and reliable controlMeasurement apparatus componentsEngineeringWinch

The invention discloses a remote sensing ground simulation test frame and relates to the field of erection and simulation of positions and motion states of ground imaging sensors. The remote sensing ground simulation test frame is characterized by comprising a triangular-pyramid-shaped truss body structure, a center pillar of a triangular-pyramid-shaped truss body perpendicular vertical face ABC, an inverted-L-shaped swing rod, a swing rod traction angle indicating needle, a swing rod initial position adjusting base plate and an imaging sensor, wherein a pulley is arranged on the top of the truss body, the position and angle of the inverted-L-shaped swing rod are controlled through a steel wire traction rope, one end of the steel wire rope is connected to the position lower than the top end of the inverted-L-shaped swing rod, the steel wire rope surrounds the pulley to be twisted to a hand-cranking traction rope winch which is used for winding and unwinding the traction rope, the swing rod traction angel indicating needle is matched with the angle indicating base plate and reads the angle of the swing rod, the imaging sensor is installed on the cross rod of the inverted-L-shaped swing rod, and the inverted-L-shaped swing rod can swing leftwards and rightwards around a rotary middle shaft of the adjusting base plate. According to the remote sensing ground simulation test frame, the truss body is stable, the angle of the swing rod is readable and adjustable, and the angle of the swing rod is safely controlled in a labor-saving mode.

Owner:徐州新南湖科技有限公司

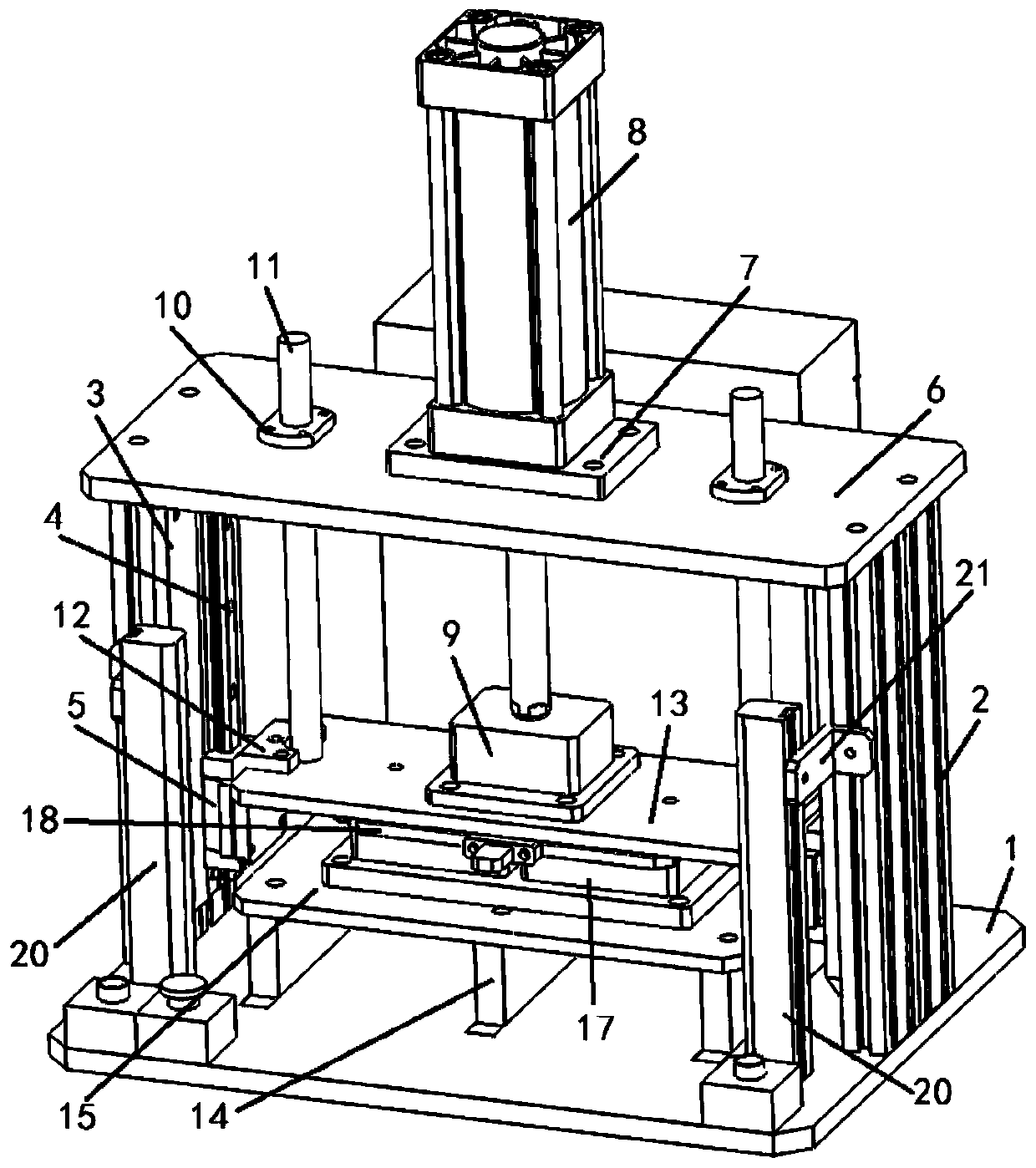

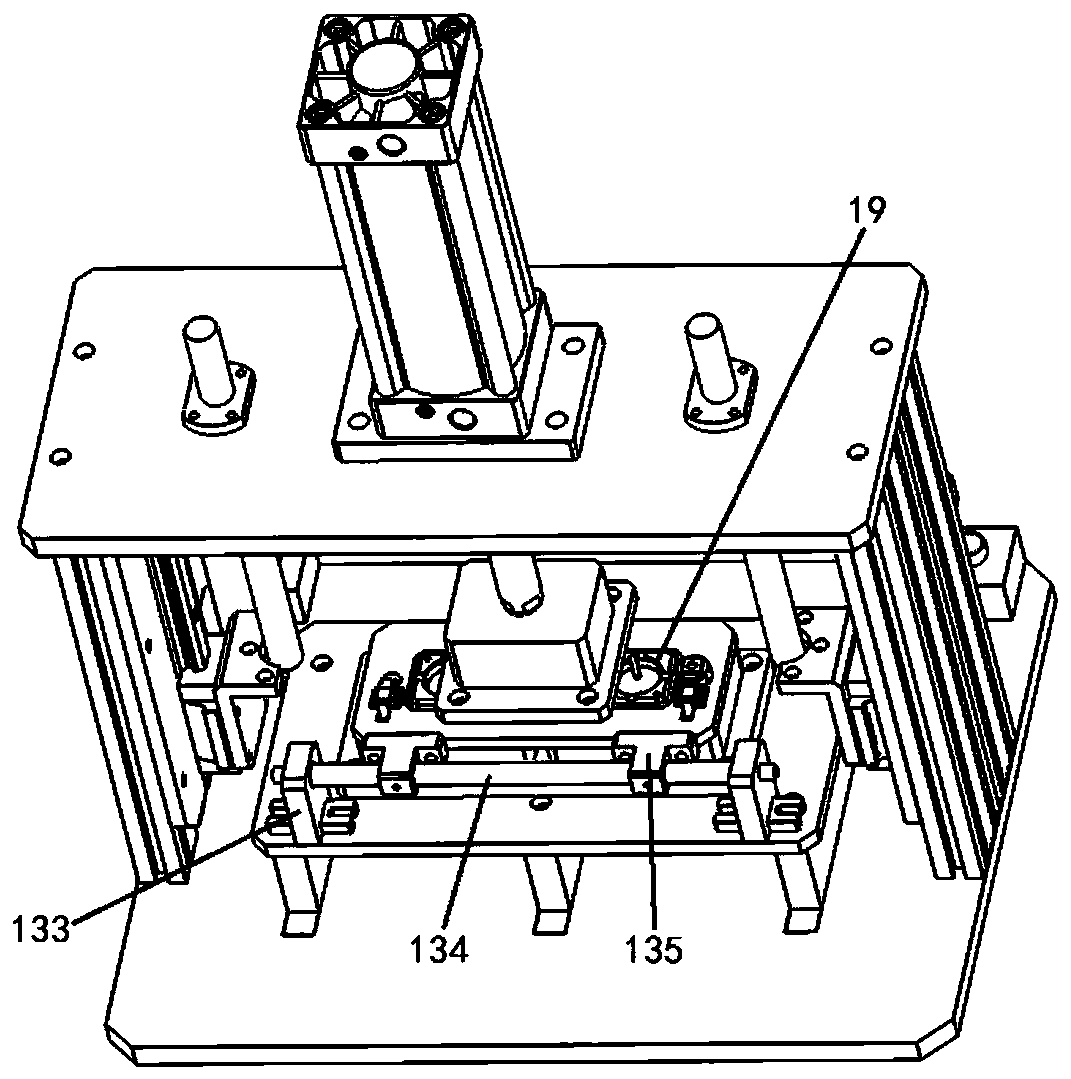

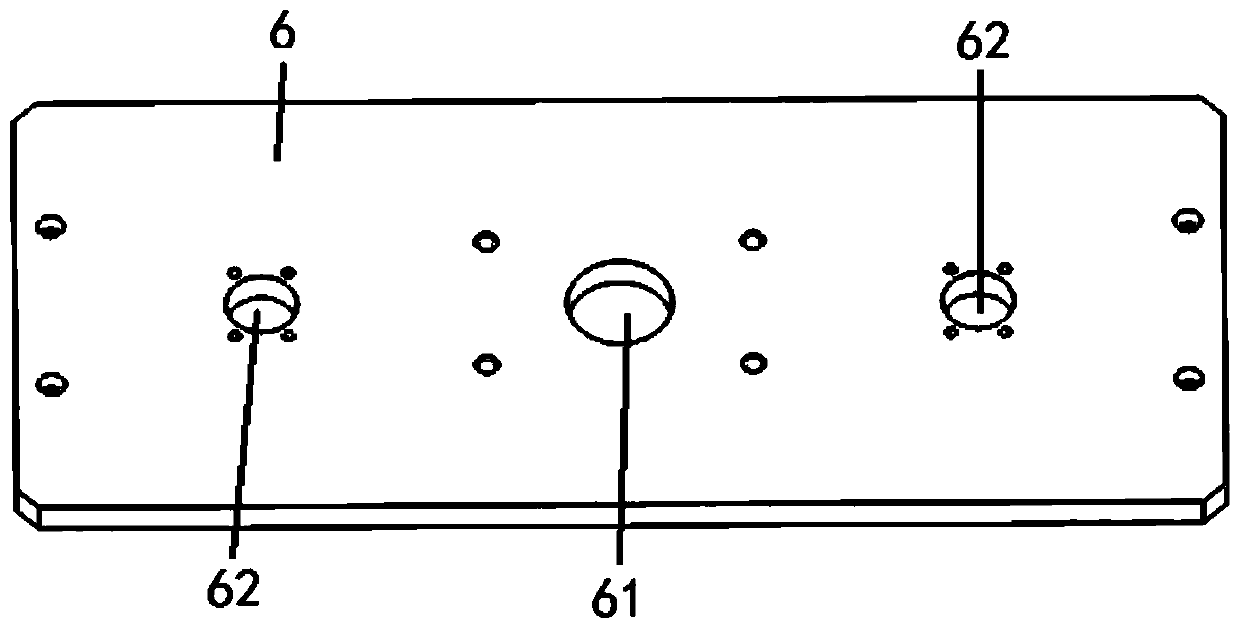

A ring fastener pressing device

Owner:嘉善卡勒机车零部件有限公司

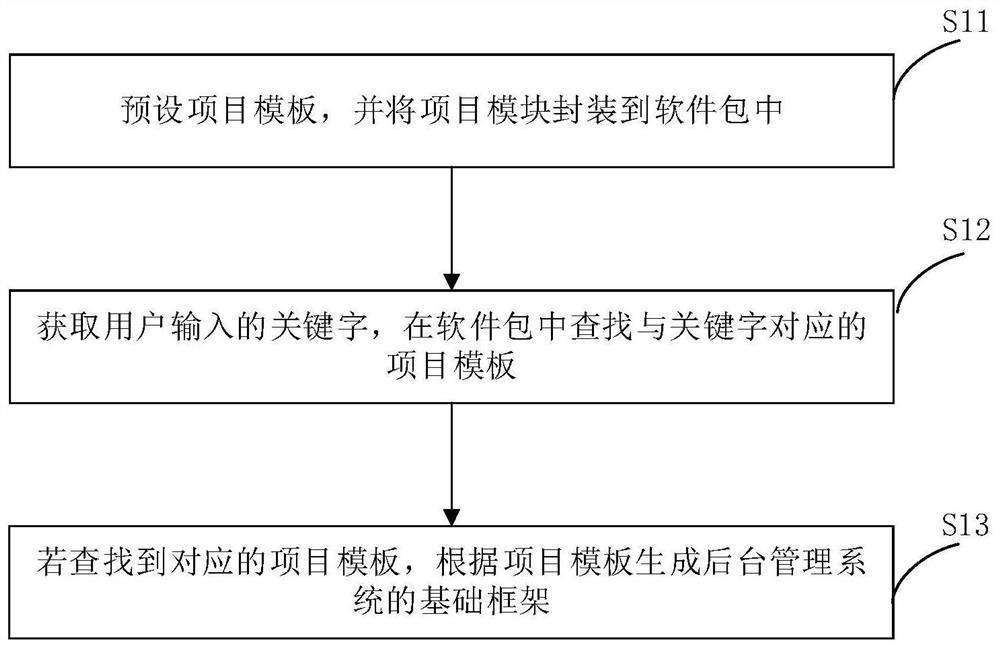

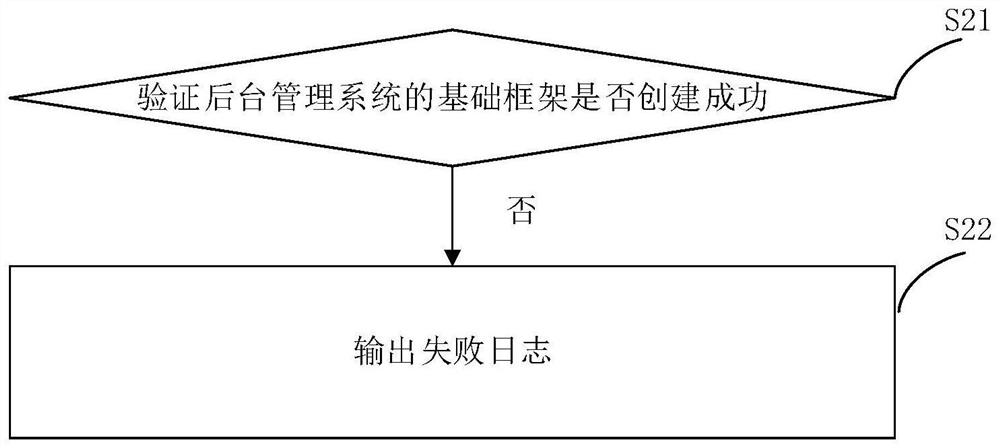

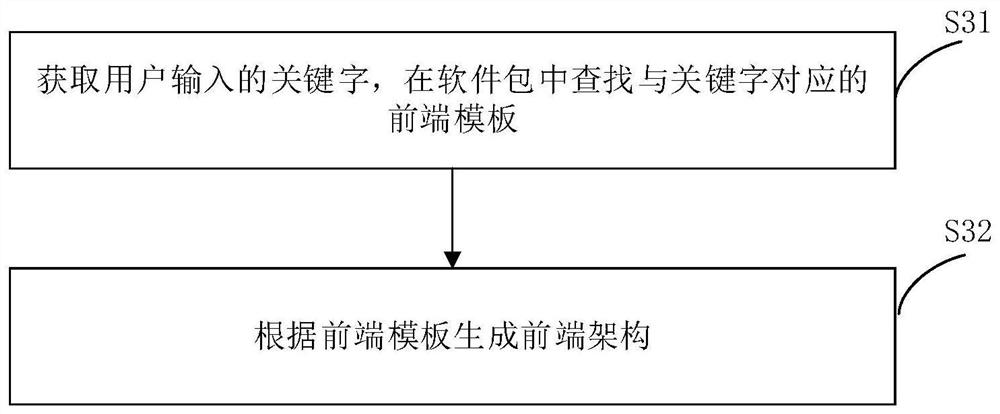

Background management system creation method and apparatus, and electronic device

PendingCN112015375AReduce error rateImprove efficiencySoftware designModel driven codeSoftware engineeringSoftware package

The invention relates to a background management system creation method and device and electronic equipment. The method comprises the steps: presetting a project template, and packaging a project module into a software package; obtaining a keyword input by a user, and searching a project template corresponding to the keyword in the software package; If the corresponding project template is found,generating a basic framework of the background management system according to the project template. According to the method, the efficiency of developers can be greatly improved, the system frameworkis more stable, and the error rate of creating the background management system is reduced.

Owner:GUANGZHOU HUANWANG TECH

A method for preparing biodiesel catalyzed by carrier-free immobilized lipase under ionic liquid system

InactiveCN104911222BWill not destroy the three-dimensional structureIncrease loadHydrolasesBiofuelsBiodieselAlcohol

The invention discloses a method for preparing biodiesel by catalyzing vector-free immobilized lipase in an ionic liquid system. The method comprises the following two steps: (1) preparing vector-free immobilized lipase; and (2) preparing the biodiesel by catalyzing the prepared vector-free immobilized lipase in the ionic liquid system. The prepared vector-free immobilized lipase is high in activity and free of high-cost vectors; an ionic liquid medium is used as an immobilized enzyme for preparing the biodiesel; the stability and the stereoselectivity of substrates of the enzyme can be obviously improved; the problem of the enzyme poisoning caused by methyl alcohol and glycerol can also be avoided; the efficient catalysis of the enzyme is ensured; the yield of the biodiesel is greatly increased; the immobilized enzyme and the ionic liquid used in the method can be recycled and reused; the waste of resources is avoided; the production cost is reduced; the method has a good industrial application prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

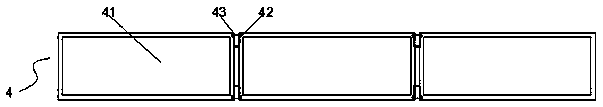

Intelligent all-steel modular attaching type lifting scaffold

PendingCN109138400AFirmly connectedIncrease production capacityScaffold connectionsBuilding support scaffoldsFalseworkEngineering

The invention belongs to the technical field of building engineering, and provides an intelligent all-steel modular attaching type lifting scaffold. The intelligent all-steel modular attaching type lifting scaffold comprises a plurality of groups of sliding rail assemblies, a plurality of groups of scaffold assemblies, a wall-attached assembly and a scaffold plate assembly. The scaffold assembliesare fixedly connected with the sliding rail assemblies, and the scaffold assemblies are located on the front surfaces of the sliding rail assemblies. Through arrangement of mesh piece feet and mesh pieces, the two mesh piece feet and mesh pieces are fixed by welding, the two adjacent scaffold plates are fixed through the mesh piece feet and the mesh pieces, and zero gap between the mesh piece feet and the mesh pieces is achieved. According to the intelligent all-steel modular attaching type lifting scaffold, a single-chip connecting part has simple structure, low manufacturing cost, convenient production and transportation, thus connection of the scaffold plates is more firm, assembly and disassembly are convenient, the scaffold body is more stable, the ability to resist wind is greatly improved, sealing of skirting plates is not required, and the zero gap between the mesh pieces and the scaffold plates is achieved.

Owner:佛山市构业宝安防科技有限公司

For high pressure tent air column support system

The invention relates to a supporting system for a tent for field rescue, in particular to a gas pillar supporting system for a high-pressure tent. The gas pillar support system comprises at least onestrip-shaped inflating longitudinal beam and a plurality of parallel and arched inflating cross beams. The air pressure in the inflating cross beams and the inflating longitudinal beams is 0.61-0.85Mpa. The inner sides of the inflating cross beams are provided with mounting seats. The mounting seats are arranged longitudinally and linearly, and the inflating longitudinal beams are detachably connected to the mounting seats. The invention provides a gas pillar supporting system with higher strength in order to solve the problem that a supporting system of an existing high-pressure tent is insufficient in strength.

Owner:CHONGQING DONGDENG TECH

Battery system structure with chassis cross beam running through battery pack

InactiveCN109421503AClear frameworkFrame stabilityElectric propulsion mountingElectrical and Electronics engineeringBattery system

The invention discloses a battery system structure capable of realizing integration of a battery system and an automobile chassis. The battery system structure capable of realizing integration of thebattery system and the automobile chassis comprises a battery pack body, an upper cross beam, a through cross beam, an adapter bracket, a bottom inverted omega-shaped bracket and an external electricappliance box which are mounted between chassis longitudinal beams. The battery pack body consists of an upper box body and a lower box body; the upper cross beam strides over the upper box body to befixed on longitudinal beams on the two sides by being attached to the longitudinal beam profiles; the bottom inverted omega-shaped bracket and the battery pack body are fixed to the through cross beam; the external electric appliance box is fixed to the lower box body; and the through cross beam with the battery pack body and the bottom inverted omega-shaped bracket are fixed to the longitudinalbeams or the adapter bracket. According to the battery system structure capable of realizing integration of the battery system and the automobile chassis, the structure is reasonable; the battery packframework is firm; and as the through cross beam running through the lower box body and the external electric appliance box are arranged, the integration of the chassis and the battery pack is realized.

Owner:北京华田汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com