Porous metal-organic framework material, preparation method and adsorption and separation application of porous metal-organic framework material

A technology of organic framework and organic framework, which is applied in the field of adsorption and separation, and the preparation of two metal-organic frameworks, can solve the problems of increasing energy consumption and cost of the separation process, and achieve the advantages of promotion, high yield and stable framework Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

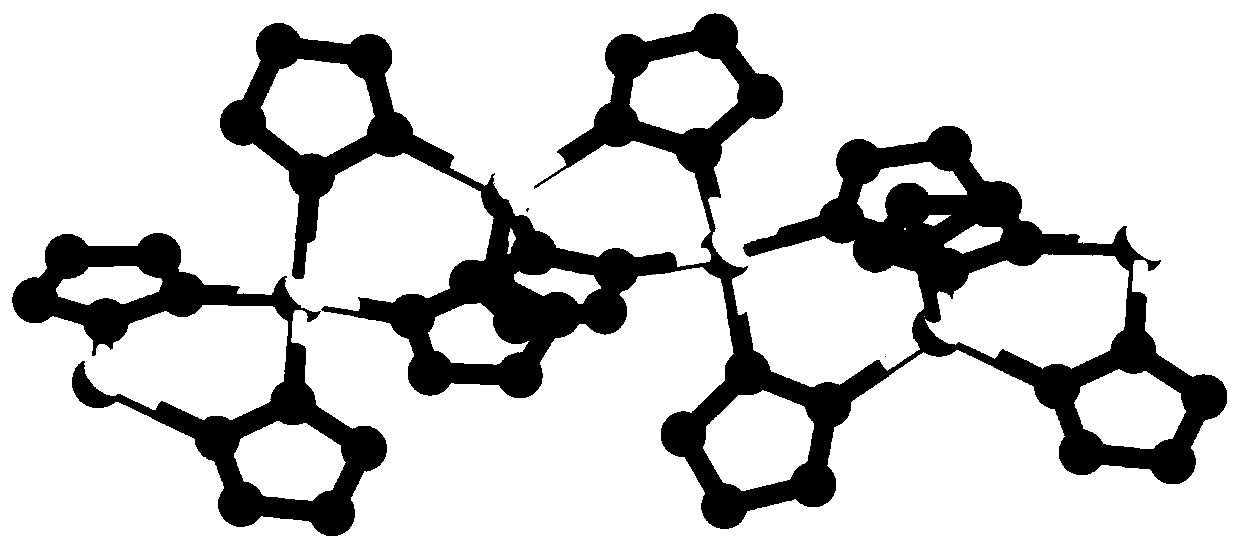

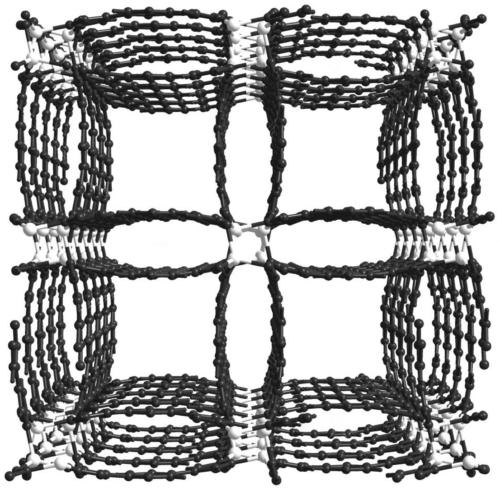

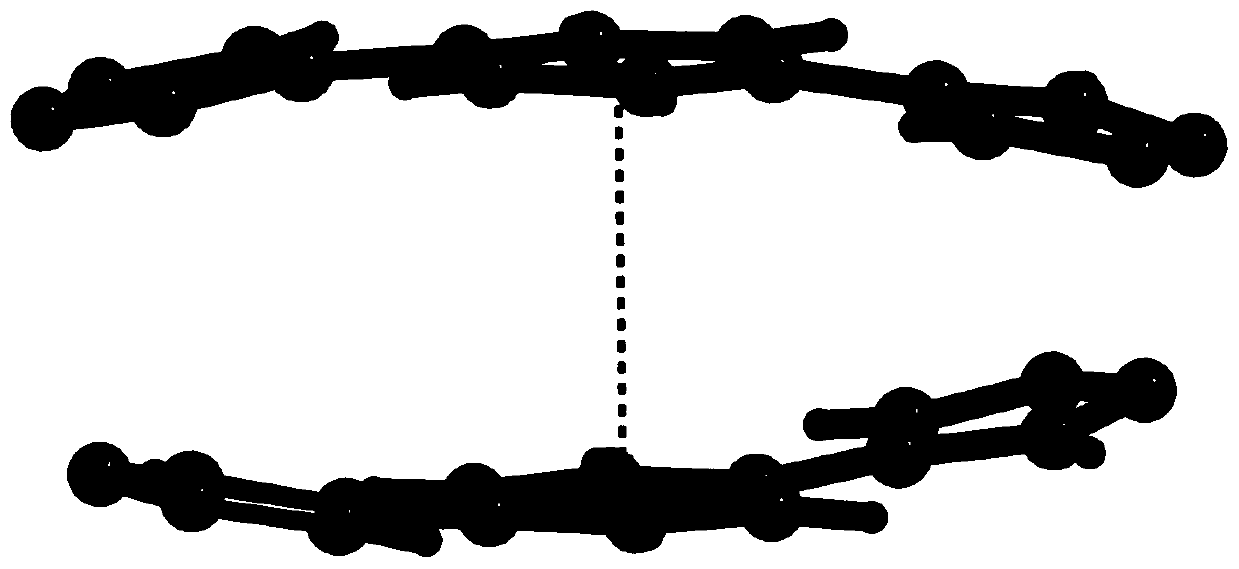

[0022] The organic ligand H 2 BDP (0.02 mmol) was ultrasonically dissolved in 1 ml of DMF, Co(NO 3 ) 2 ·6H 2 O or Zn(NO 3 ) 2 ·6H 2 O (0.05 mmol) was dissolved in 0.6 ml of deionized water, and after the two were mixed, 0.03 mmol of isophthalic acid and 0.5 ml of ethanol solution were added and sealed into the reaction kettle. Crystals of the metal-organic framework were obtained via thermal reaction at 130° C. for 48 hours.

Embodiment 2

[0024] The organic ligand H 2 BDP (0.02 mmol) and isophthalic acid (0.03 mmol) were dissolved in 1 ml of DMF, Co(NO 3 ) 2 ·6H 2 O or Zn(NO 3 ) 2 ·6H 2 O (0.05 mmol) was dissolved in 0.6 ml of deionized water, and after the two were mixed, 0.5 ml of ethanol solution was added and sealed into the reaction kettle. Crystals of the metal-organic framework were obtained via thermal reaction at 140° C. for 36 hours.

Embodiment 3

[0026] The organic ligand H 2 BDP (0.1 mmol) and 0.2 mmol isophthalic acid and sonication were dissolved in 5 mL of DMF solution, Co(NO 3 ) 2 ·6H 2 O or Zn(NO 3 ) 2 ·6H 2 O (0.3 mmol) was dissolved in 3 ml of deionized water, the two were mixed, 3 ml of ethanol solution was added, and sealed in a glass bottle. Crystals of the metal-organic framework were obtained via thermal reaction at 140° C. for 36 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com