Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

A multi-physics field and in-situ testing technology, applied in the direction of measuring devices, analyzing materials, testing material hardness, etc., can solve problems such as inability to realize composite load loading, achieve novel structure, compact layout, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The detailed content and specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

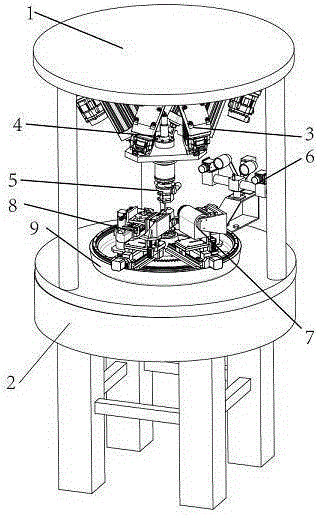

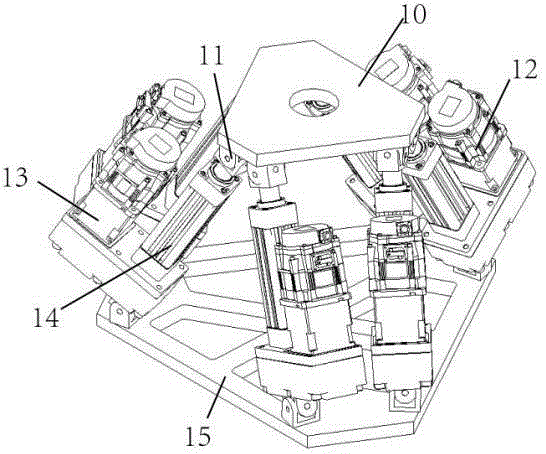

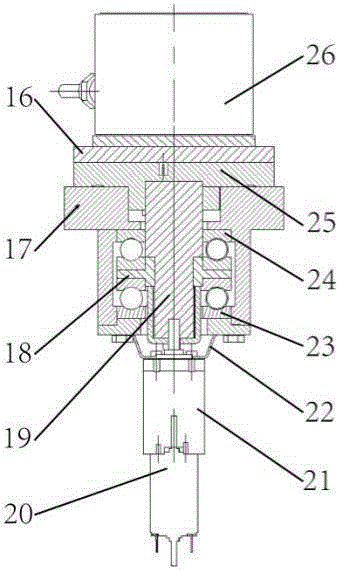

[0046] See Figure 1 to Figure 8 As shown, the material in-situ testing device under multi-load and multi-physics coupling service conditions of the present invention includes a supporting frame module 1, a seismic isolation platform 2, a precision six-degree-of-freedom composite load loading module 3, a precision torsion module 4, a fixture and an electric heater Coupling module 5, digital speckle strain measurement and infrared thermal imaging module 6, in-situ observation module 7, precision indentation module 8, circumferential positioning module 9. The present invention adopts a three-column vertical asymmetric arrangement as a whole. The precision six-degree-of-freedom composite load loading module 3 is connected to the supporting frame module 1 through its fixed platform 15, and the stretching of the device is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com