Patents

Literature

39results about How to "Realize closed-loop feedback control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

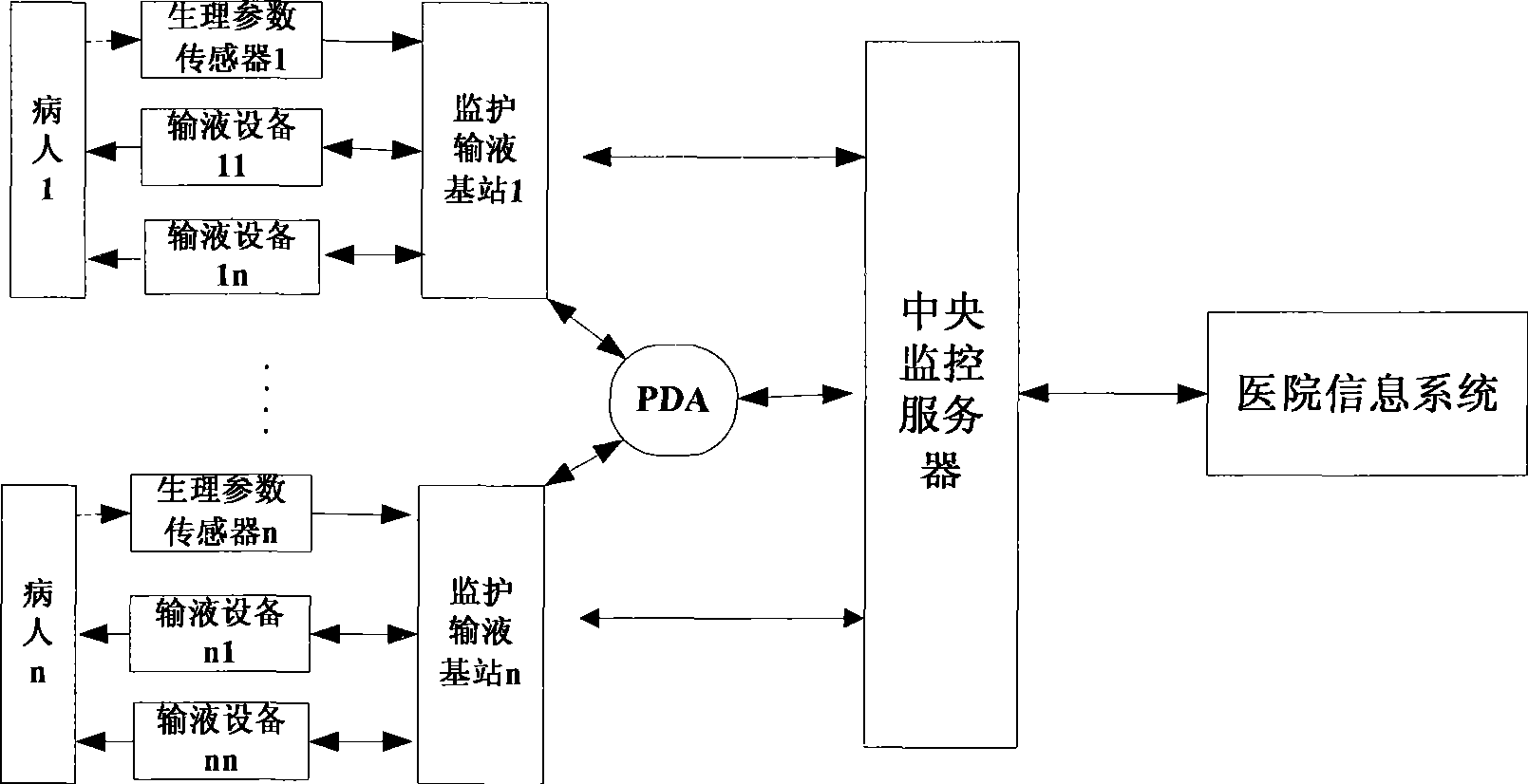

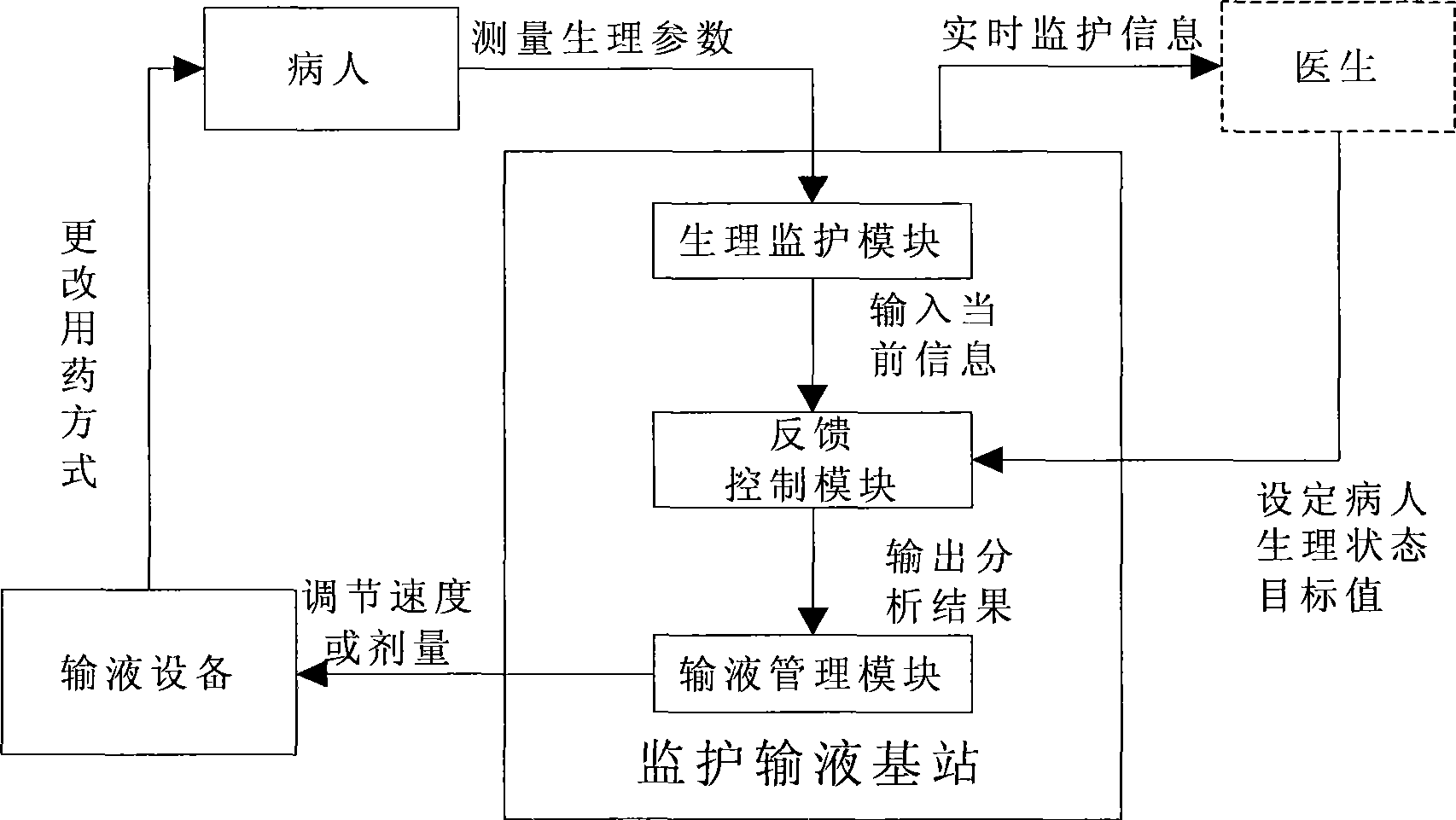

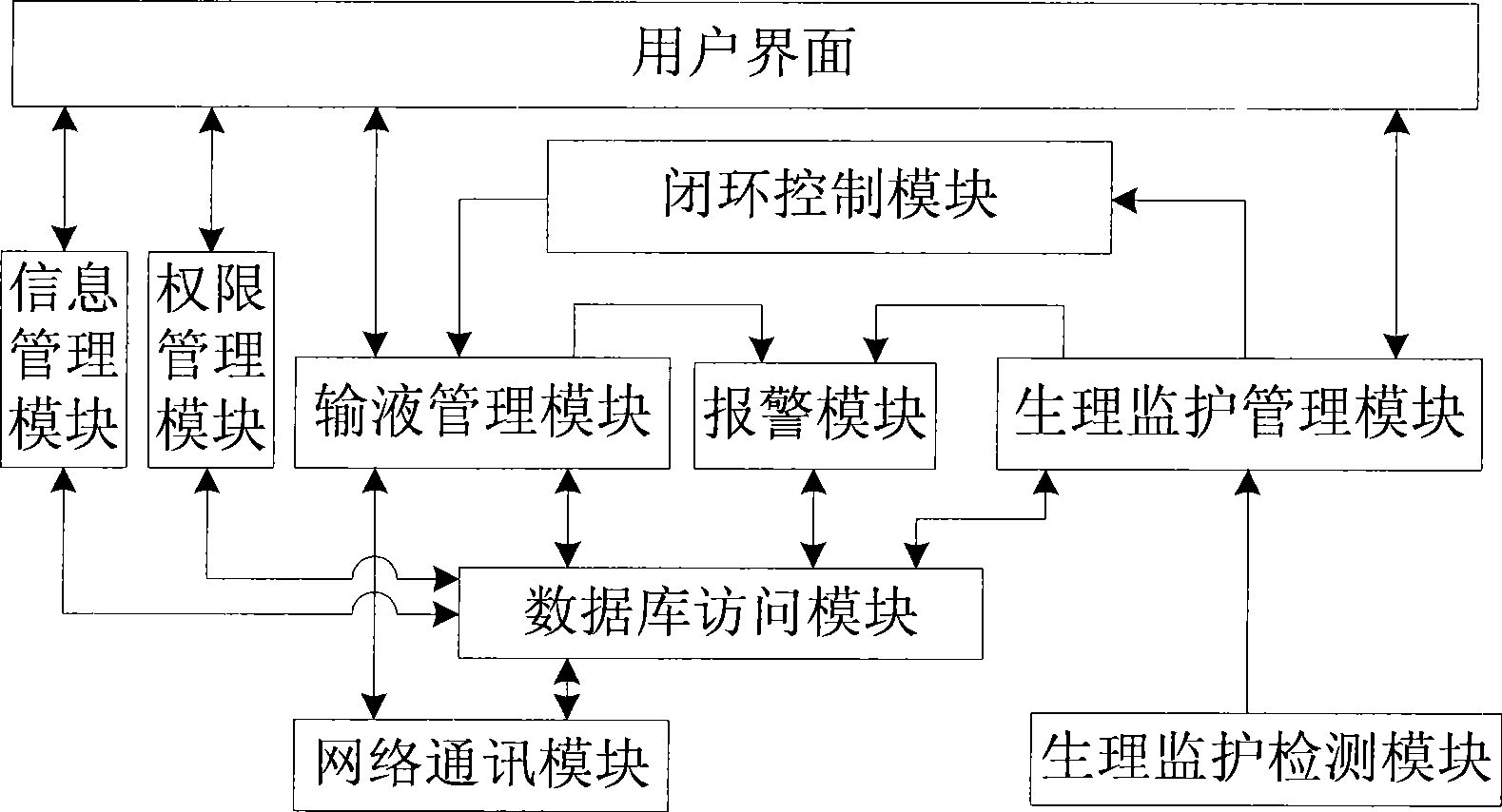

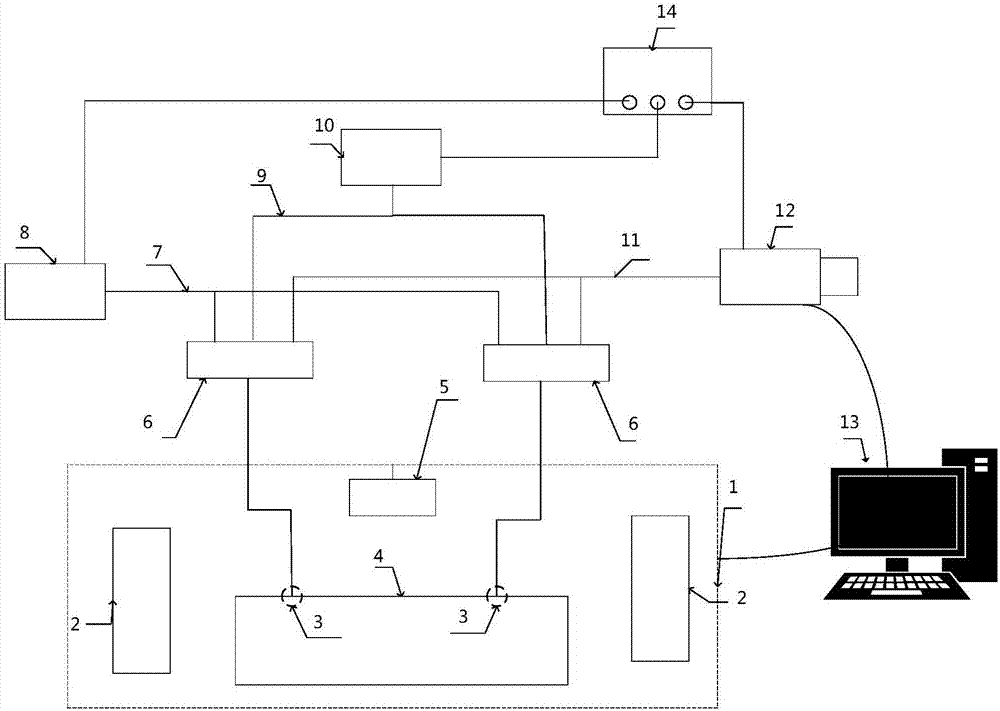

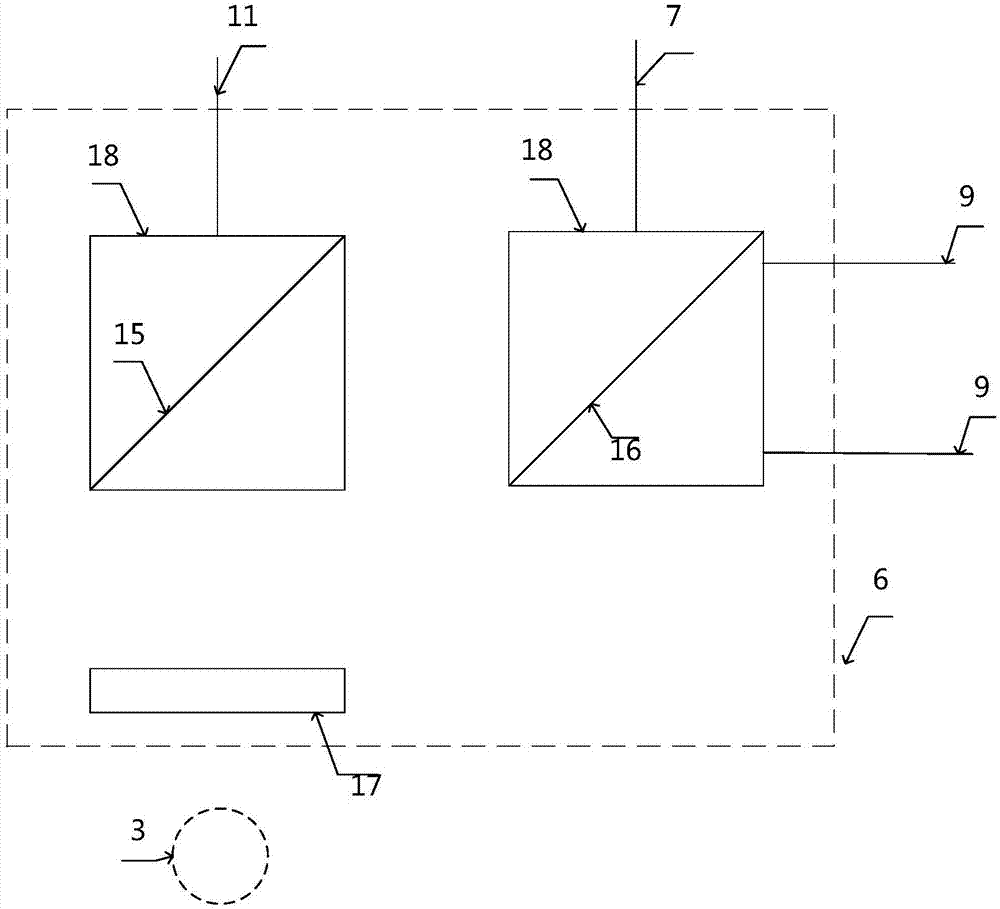

Critical illness monitoring, infusion controlling, diagnosis and treatment integrated system and control method thereof

InactiveCN101496923ARealize closed-loop feedback controlCatheterFlow monitorsLoop controlCritical illness

The invention discloses a critical care, transfusion control, and diagnosis and treatment integrated system and a control method thereof. The system comprises a transfusion device, a transfusion care base station, a central monitoring server and a medical PDA, wherein the transfusion care base station forms a transfusion scheme and performs open-loop control on the transfusion device by a wireless or wire mode, or adjusts transfusion parameters according to a corresponding closed-loop algorithm by monitoring and analyzing physiological parameters of patients during the transfusion execution, and performs closed-loop control on the transfusion device by the wireless or wire mode; the central monitoring server is connected with the transfusion care base station by the wireless or wire mode and monitors the operating state of the transfusion care base station; and the medical PDA is connected with the transfusion care base station and / or the central monitoring server by the wireless mode and is used for displaying transfusion condition and managing transfusion process. The system organically combines a treatment means (venous transfusion) and the effect of the treatment means (the monitoring of the physiological parameters) into one system, thereby realizing the closed-loop control of one or more transfusion devices, and improving medical quality and work efficiency of medical personnel.

Owner:SUN YAT SEN UNIV +1

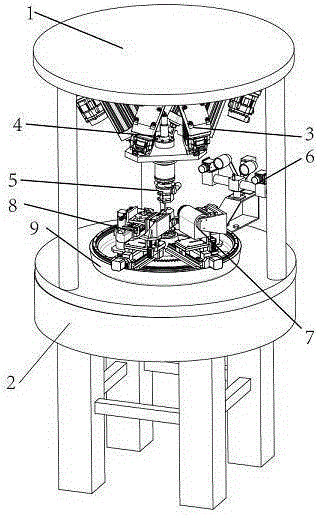

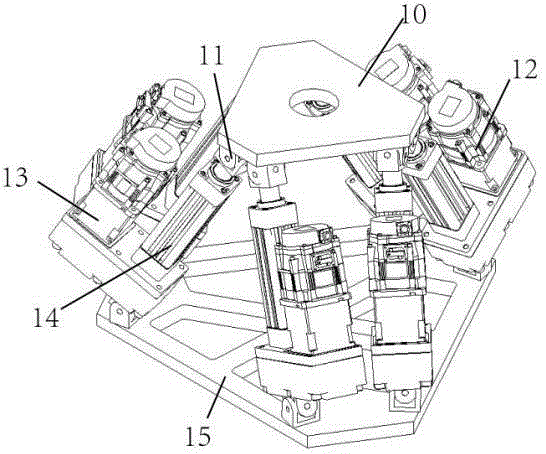

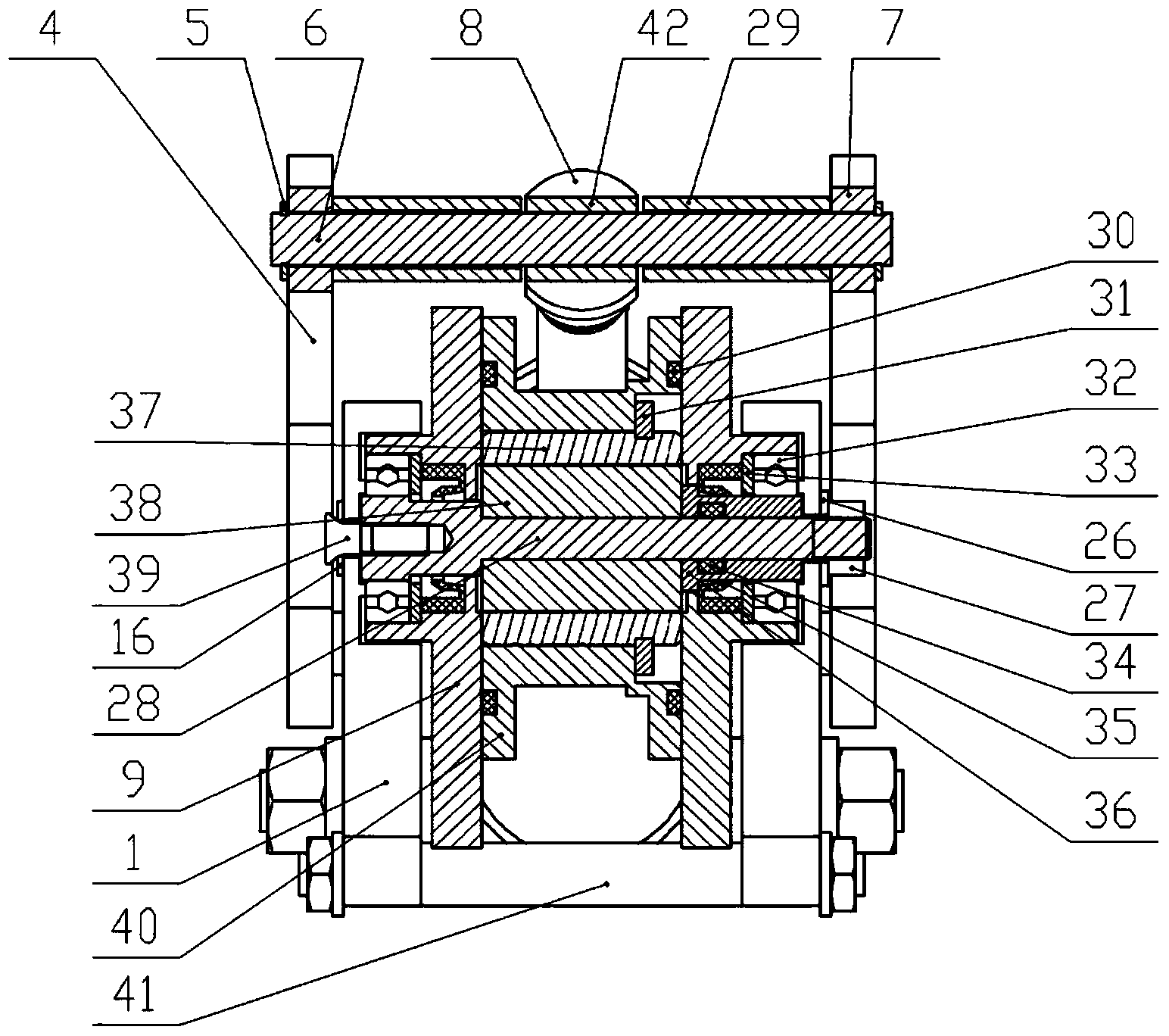

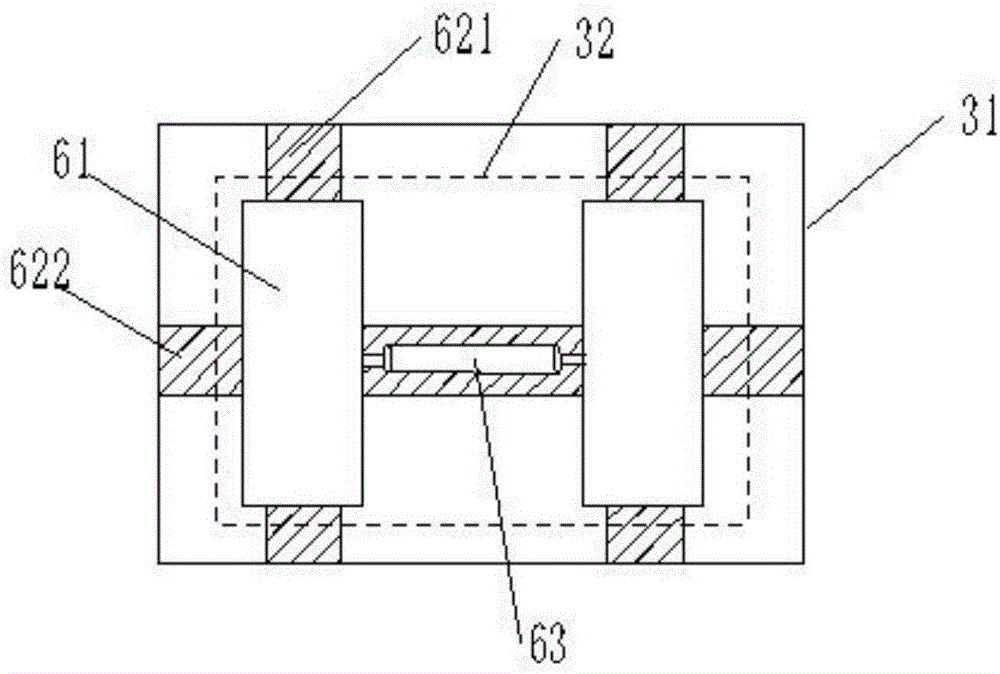

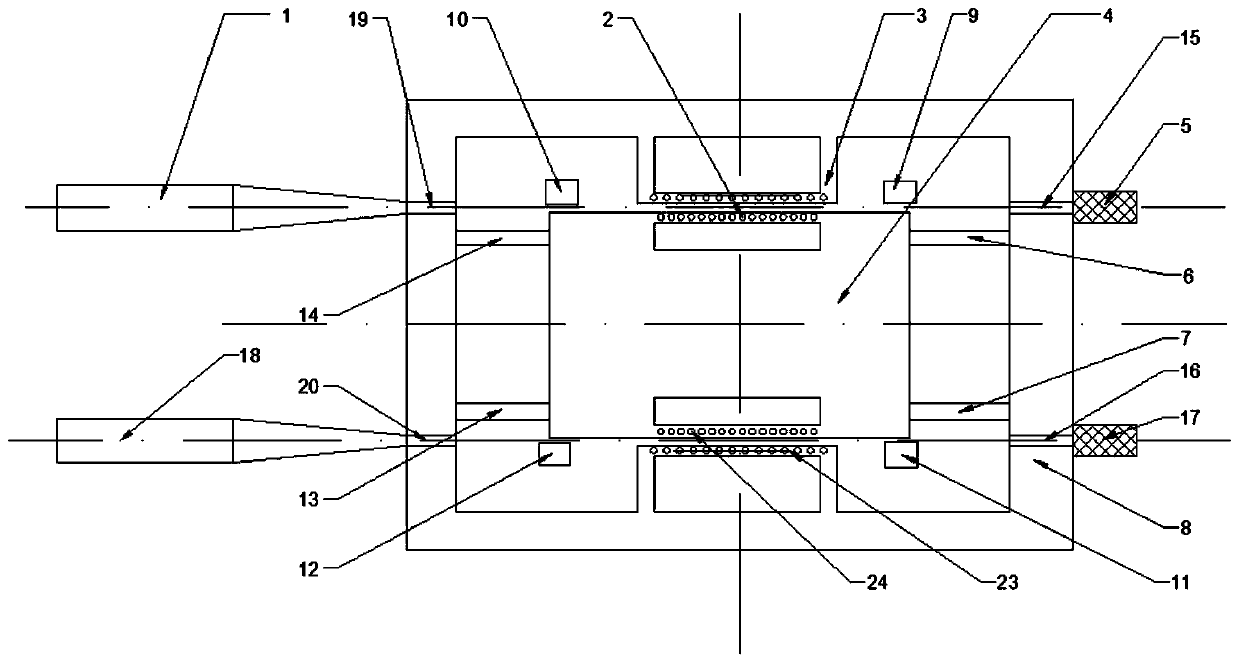

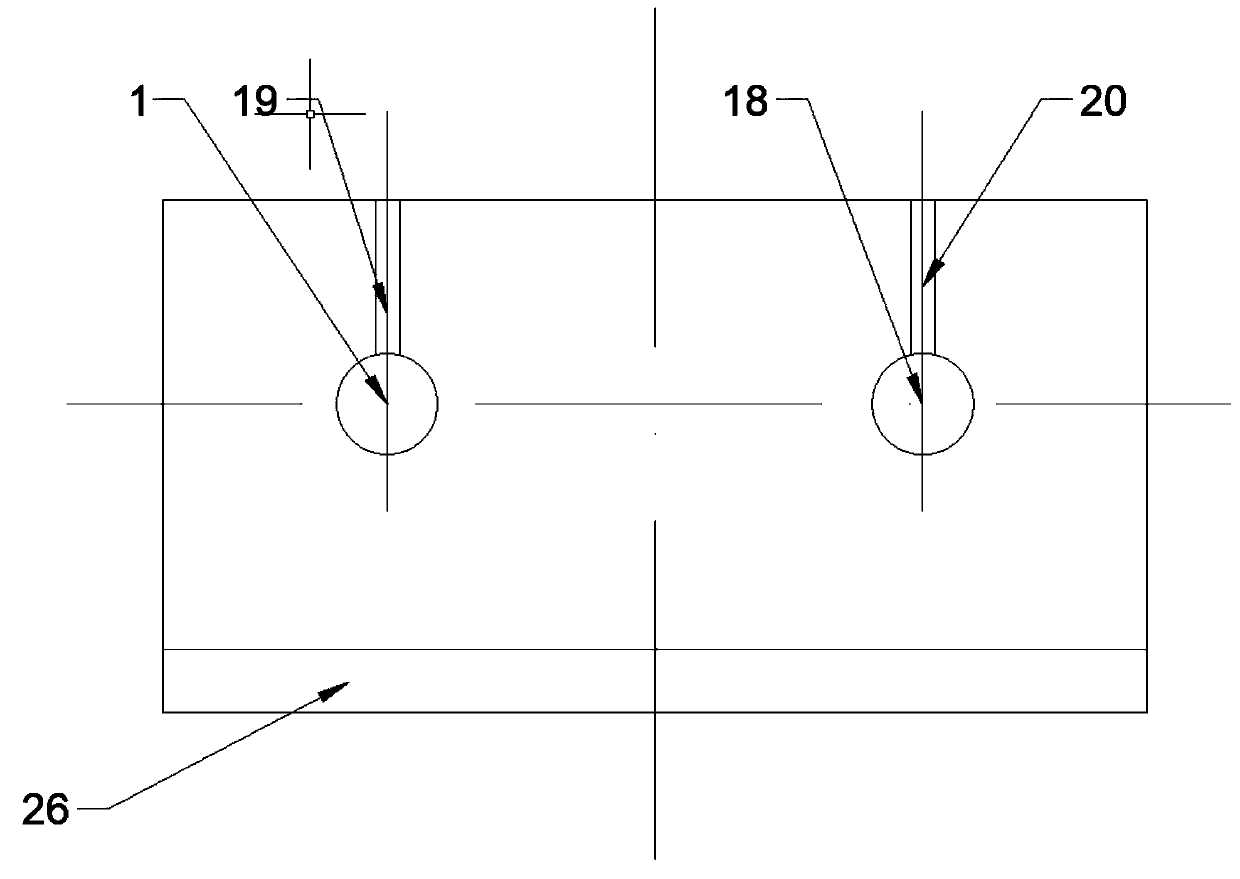

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

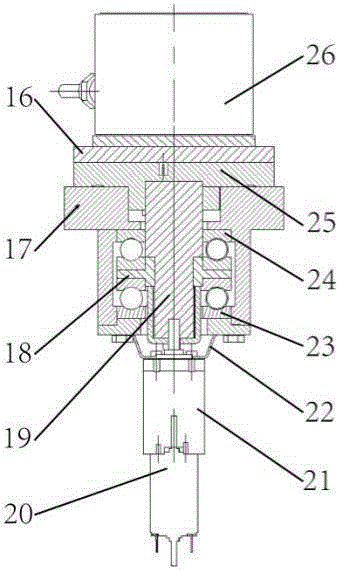

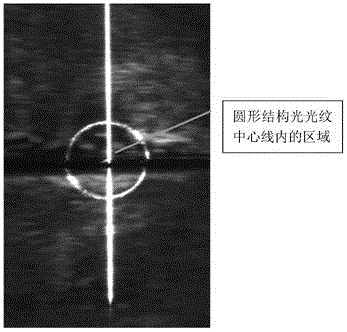

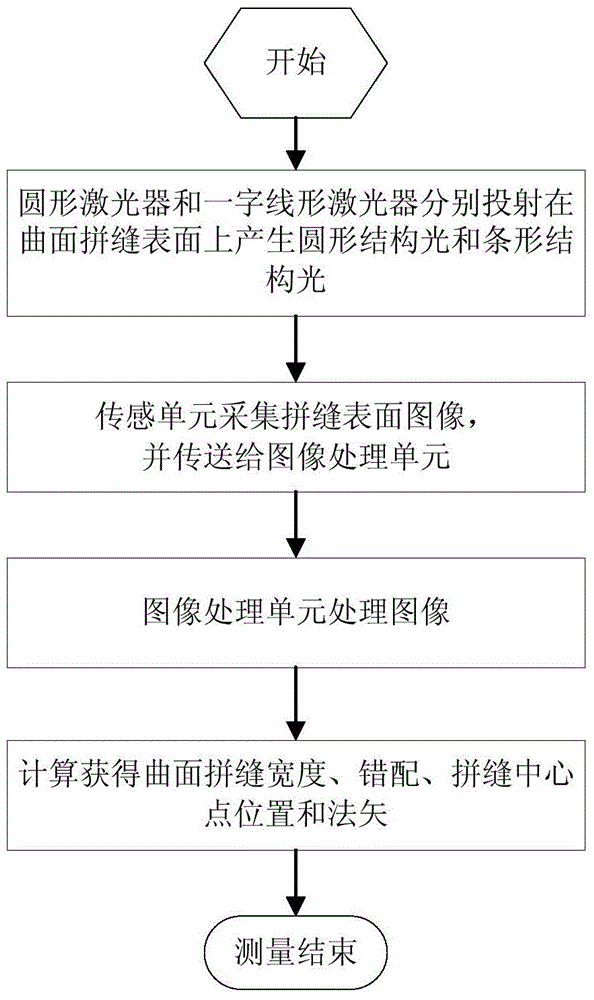

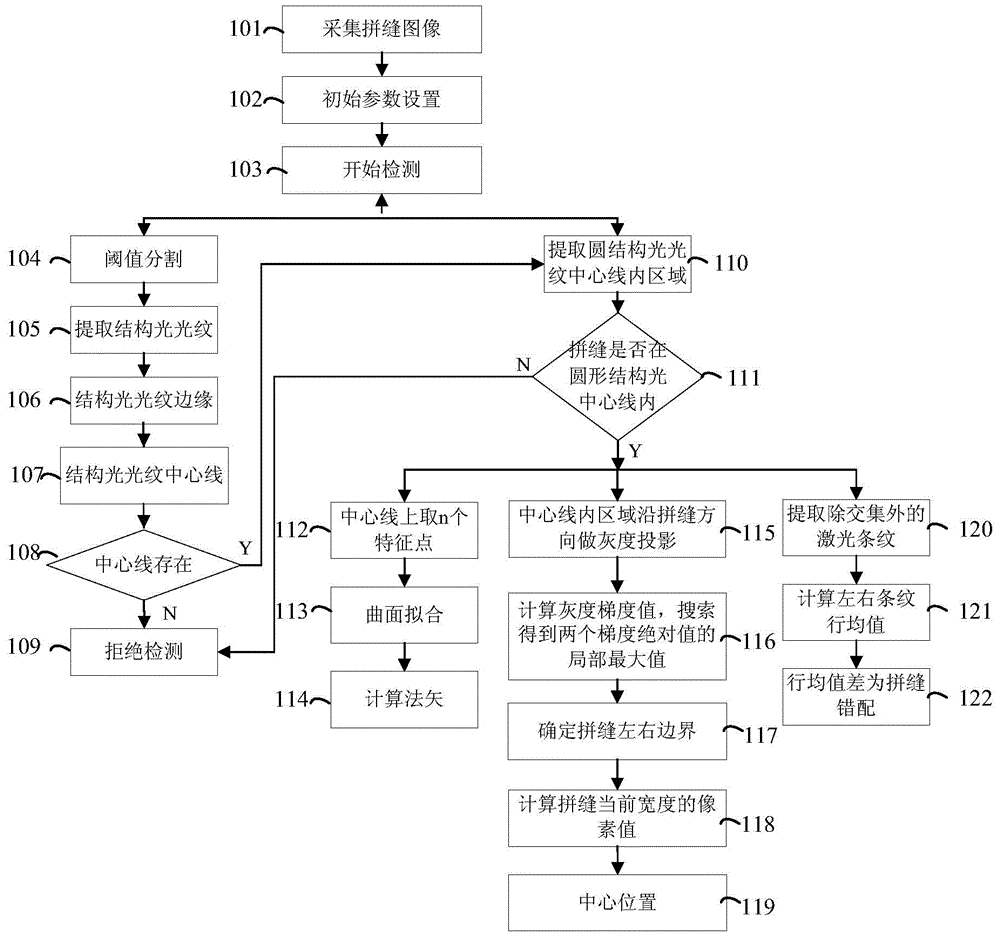

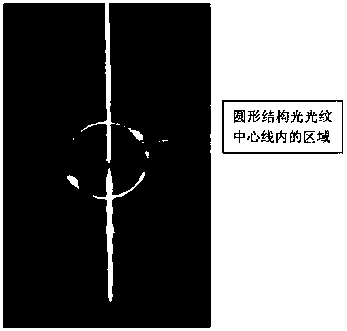

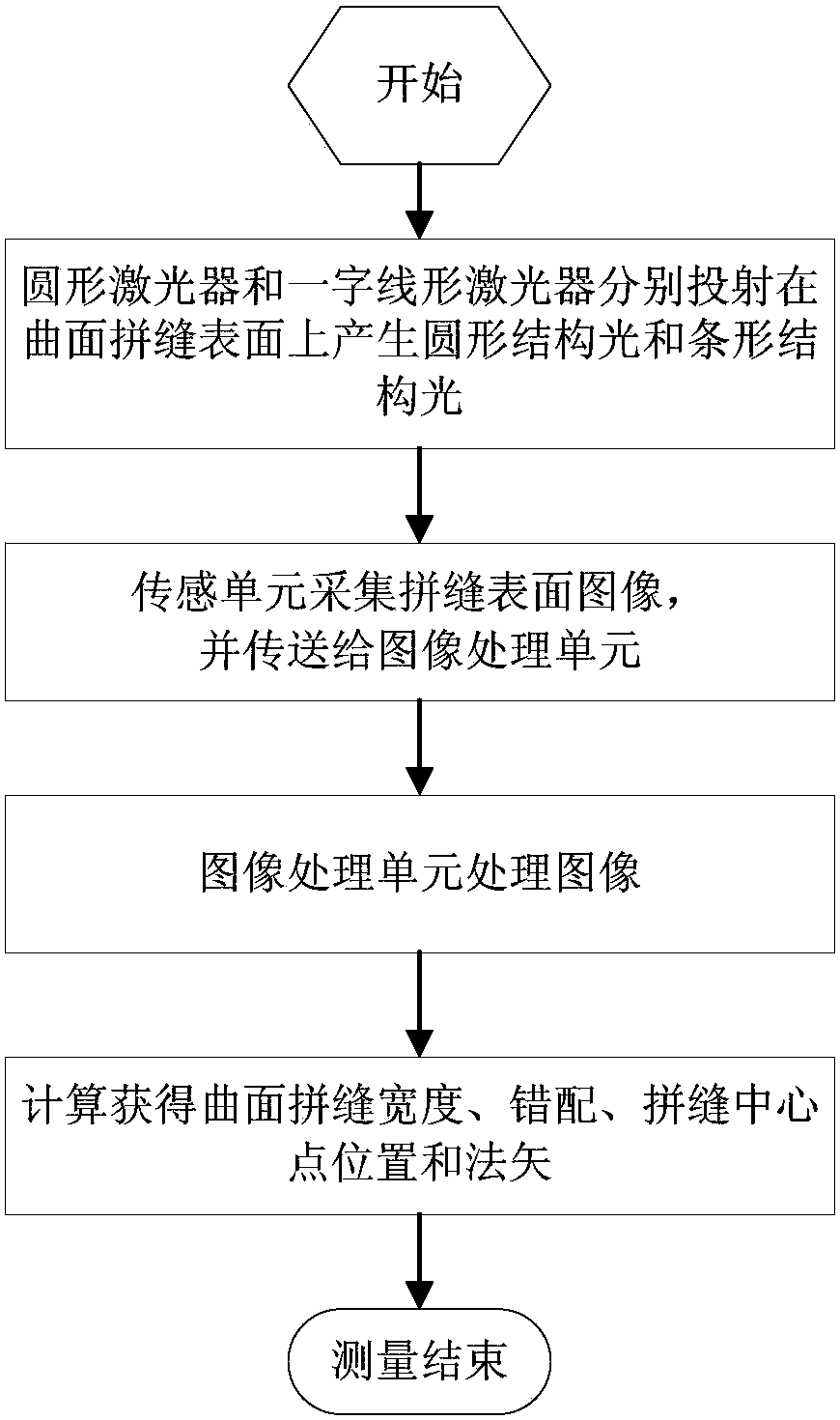

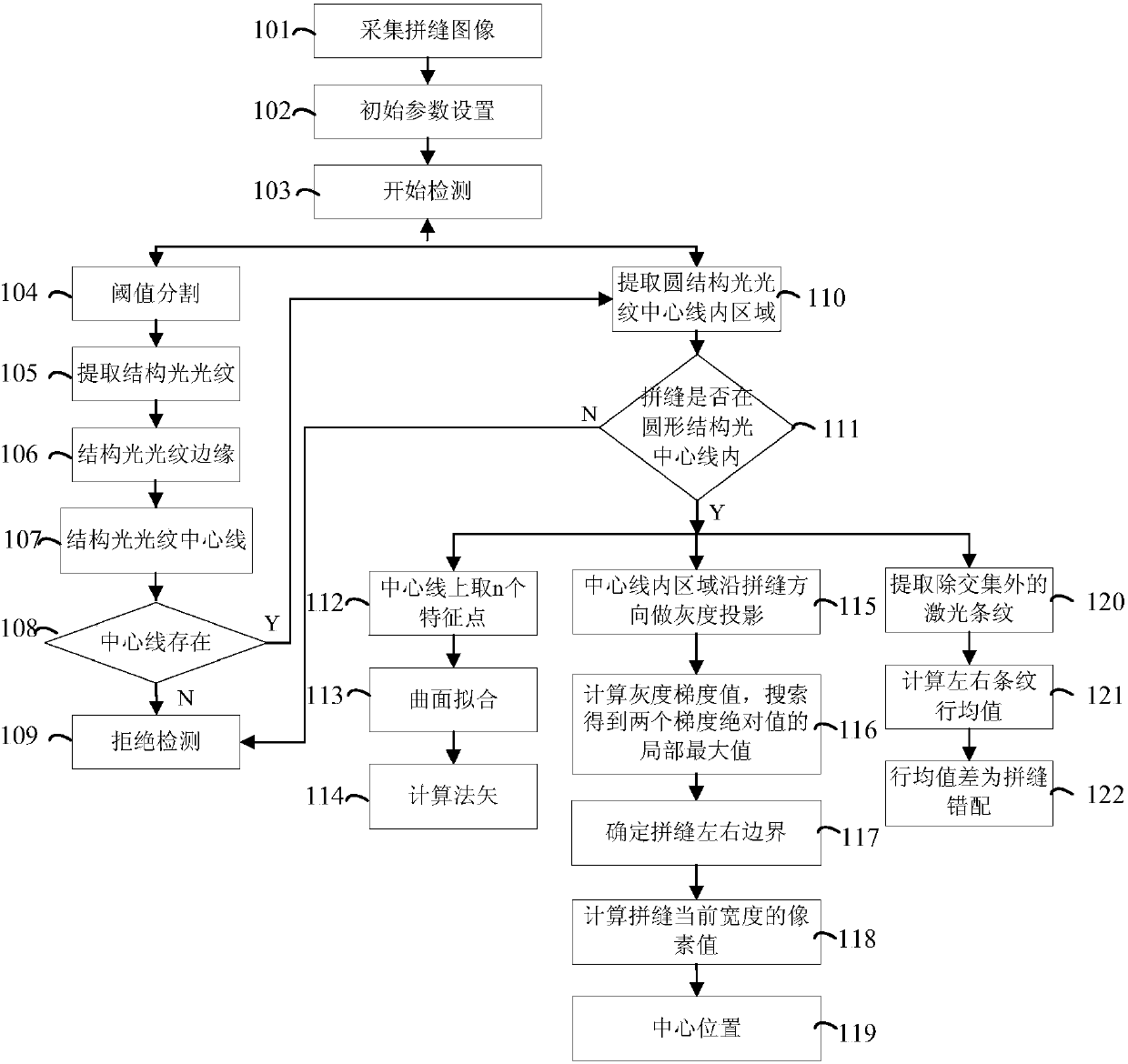

Laser tailored welding curved surface abutted seam measuring method and realization device thereof

InactiveCN105300296AAvoid measurement errorsImprove detection accuracyUsing optical meansImaging processingOptoelectronics

The invention relates to a laser tailored welding curved surface abutted seam measuring method and a realization device thereof. The method comprises the following steps: generating circular structured light by utilizing a circular laser, and generating horizontal-I linear structured light by utilizing a horizontal-I linear laser, wherein the circular structured light and the horizontal-I linear structured light are projected to the surface of a curved surface abutted seam and intersected; collecting and obtaining an abutted seam surface gray level image comprising the horizontal-I linear structured light and the circular structured light through a sensing unit, and transmitting the collected image to an image processing unit; and carrying out processing by the image processing unit on the collected image to obtain three-dimensional position and normal vector of the curved surface abutted seam center and abutted seam width and mismatching values. The device comprises the sensing unit for collecting the laser tailored welding curved surface abutted seam image and transmitting the image to the processing unit; the image processing unit for carrying out processing on the collected abutted seam image; and a parameter setting and control unit for setting parameters and in communication connection with the sensing unit, the image processing unit and an upper computer. The laser tailored welding curved surface abutted seam measurement precision is improved, online tracking adjustment of the pose of a welding torch for curved surface laser tailored welding is realized favorably, welding quality is ensured.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

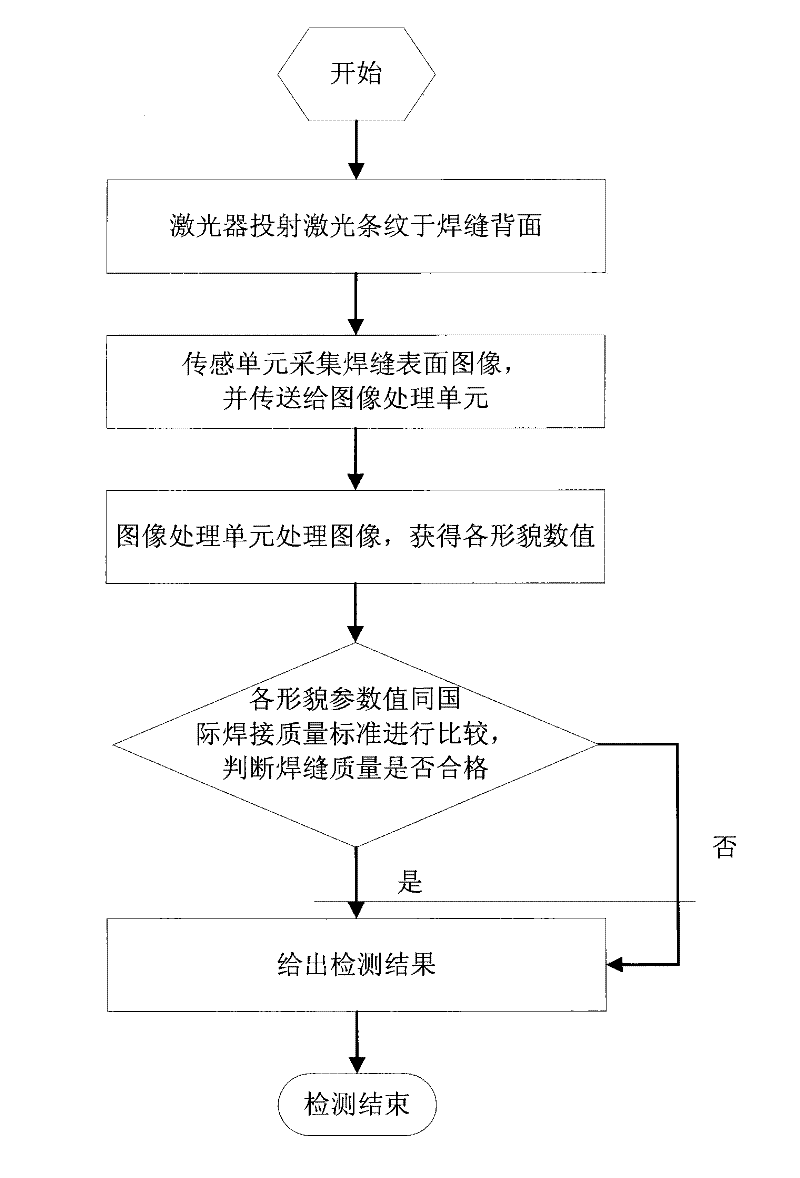

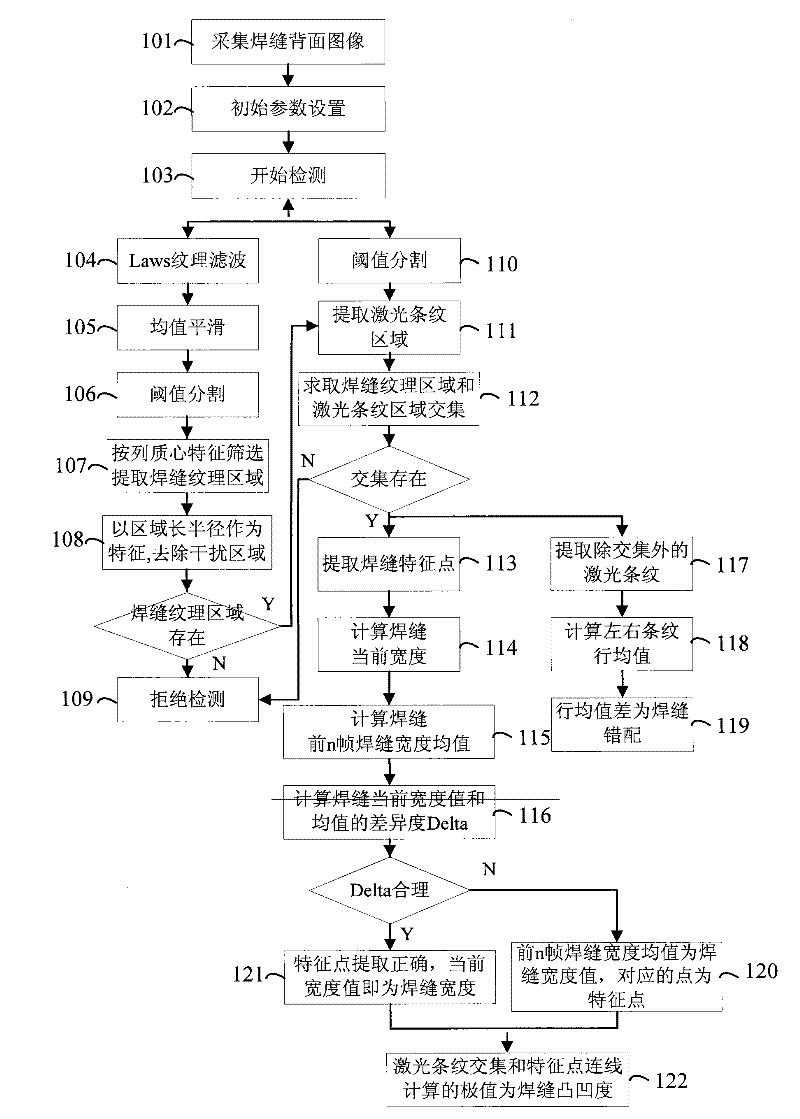

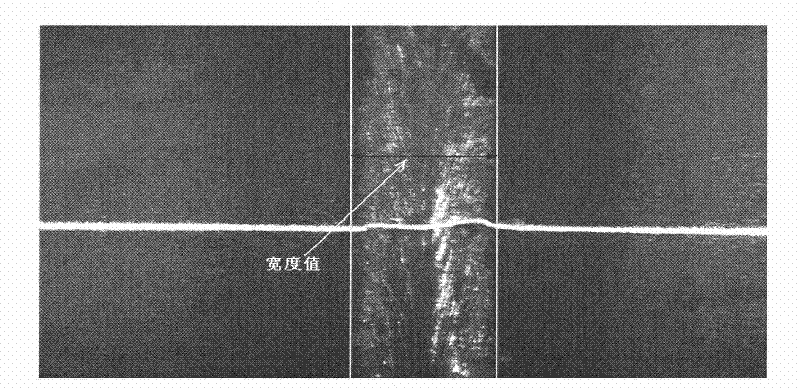

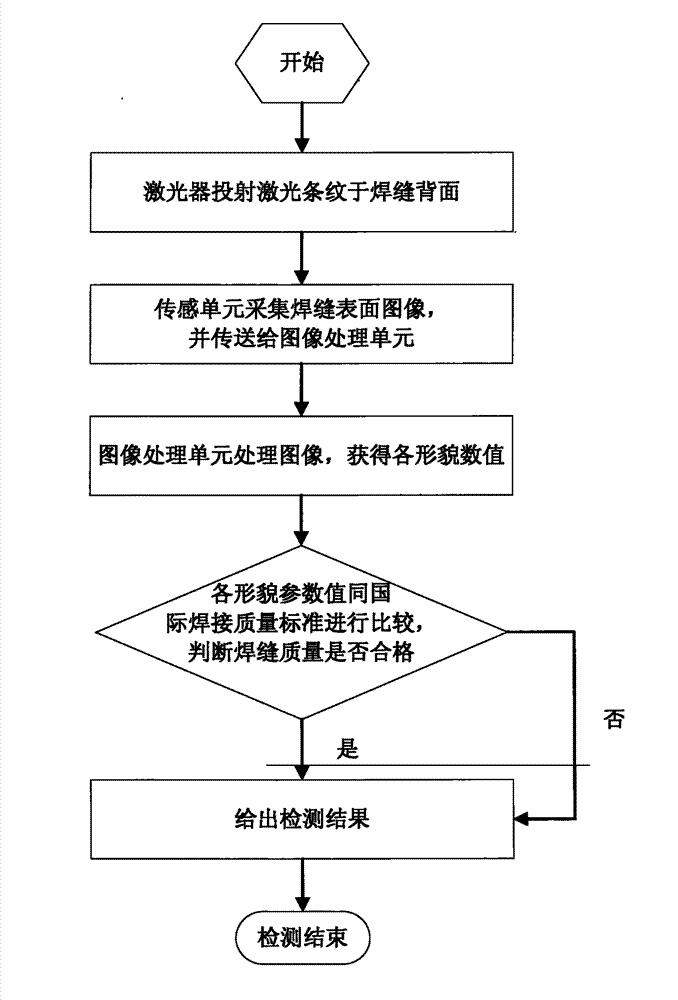

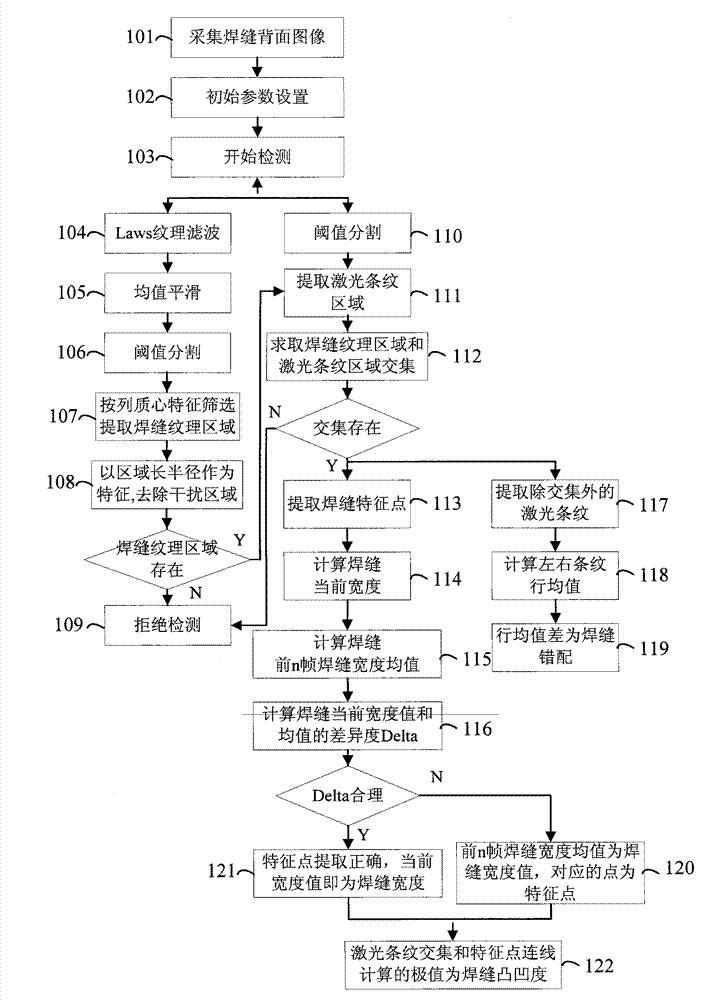

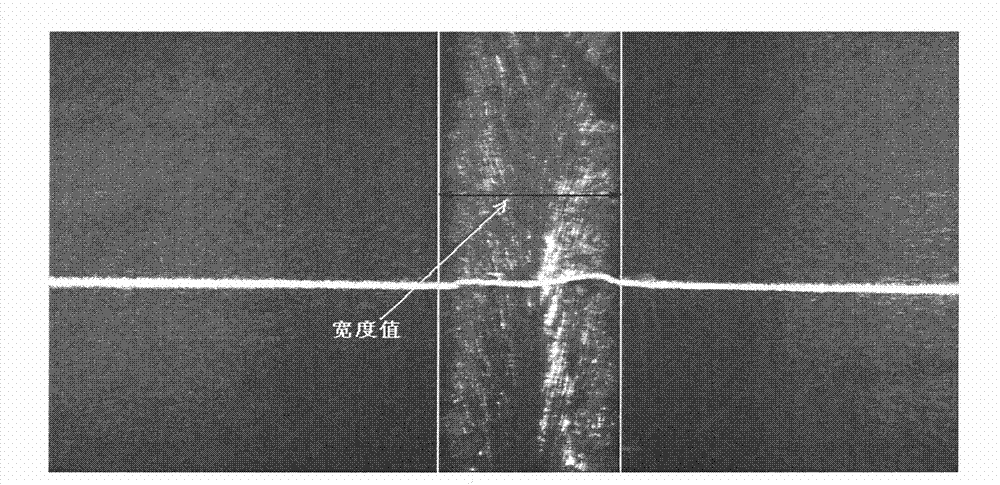

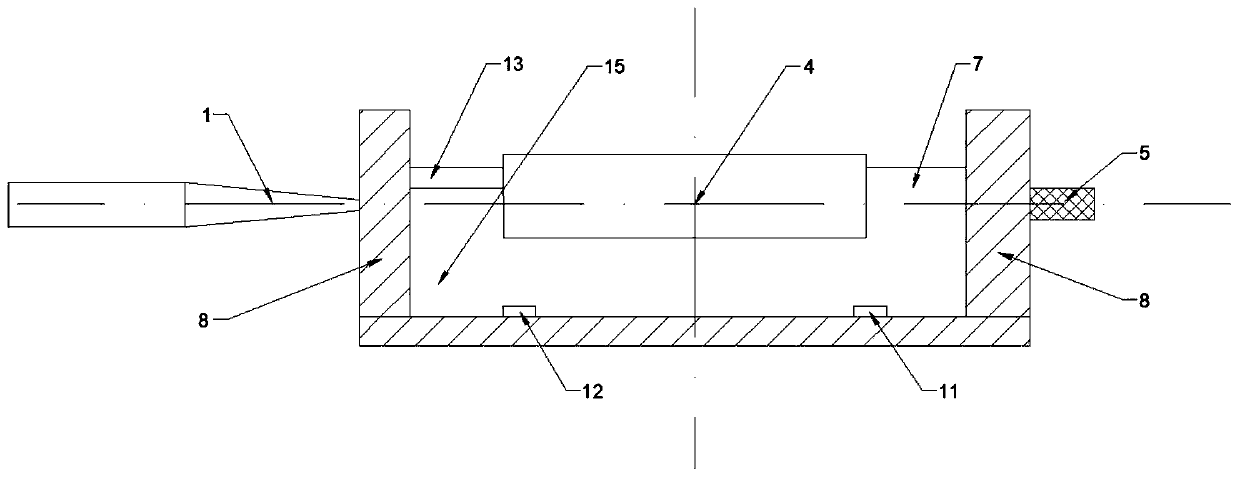

Method for detecting geometric shape of back of tailor-welding weld and implementing device thereof

InactiveCN102455171AGuaranteed validityAvoid detection errorsUsing optical meansImaging processingInterference factor

The invention relates to a method for detecting the geometric shape of the back of a tailor-welding weld and an implementing device thereof. The method comprises the following steps that: a linear laser is used for projecting laser on the back of a tailor-welding weld so as to generate a plurality of laser streaks on the surface of the tailor-welding weld; a sensing unit acquires and obtains a weld surface gray level image including the laser streaks and transmits the acquired image to an image processing unit; the image processing unit processes the acquired weld image to obtain all shape parameters; and the weld quality is judged and thus the detection on the geometric shape of the back of the weld is finished. The implementing device of the method comprises a sensing unit, an image processing unit and a parameter setting and control unit, wherein the sensing unit is used for acquiring the image of a tailor-welding weld and transmitting the image to the image processing unit, the image processing unit is used for processing the acquired weld image, the parameter setting and control unit is used for setting all parameters and is respectively in communication with the sensing unit, the image processing unit and an upper computer. According to the invention, detection error caused by interference factors such as dust on the back of the weld, welding splatter, board scratch and the like in the welding process can be avoided, and the detection accuracy is improved greatly.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

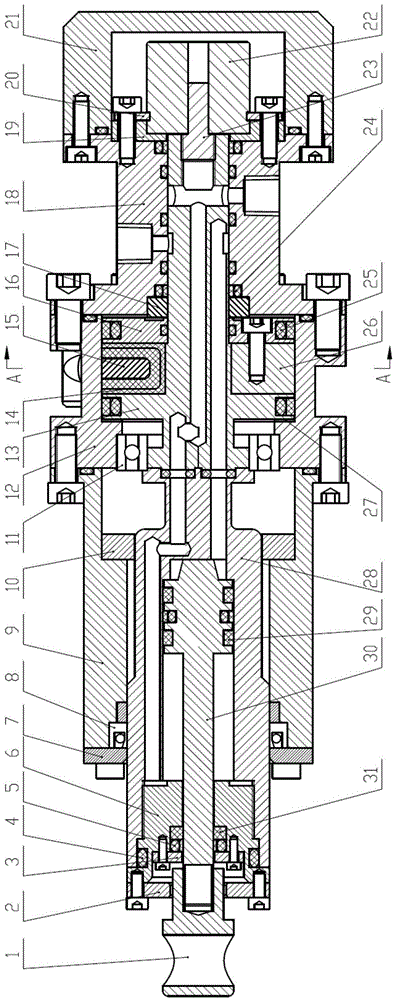

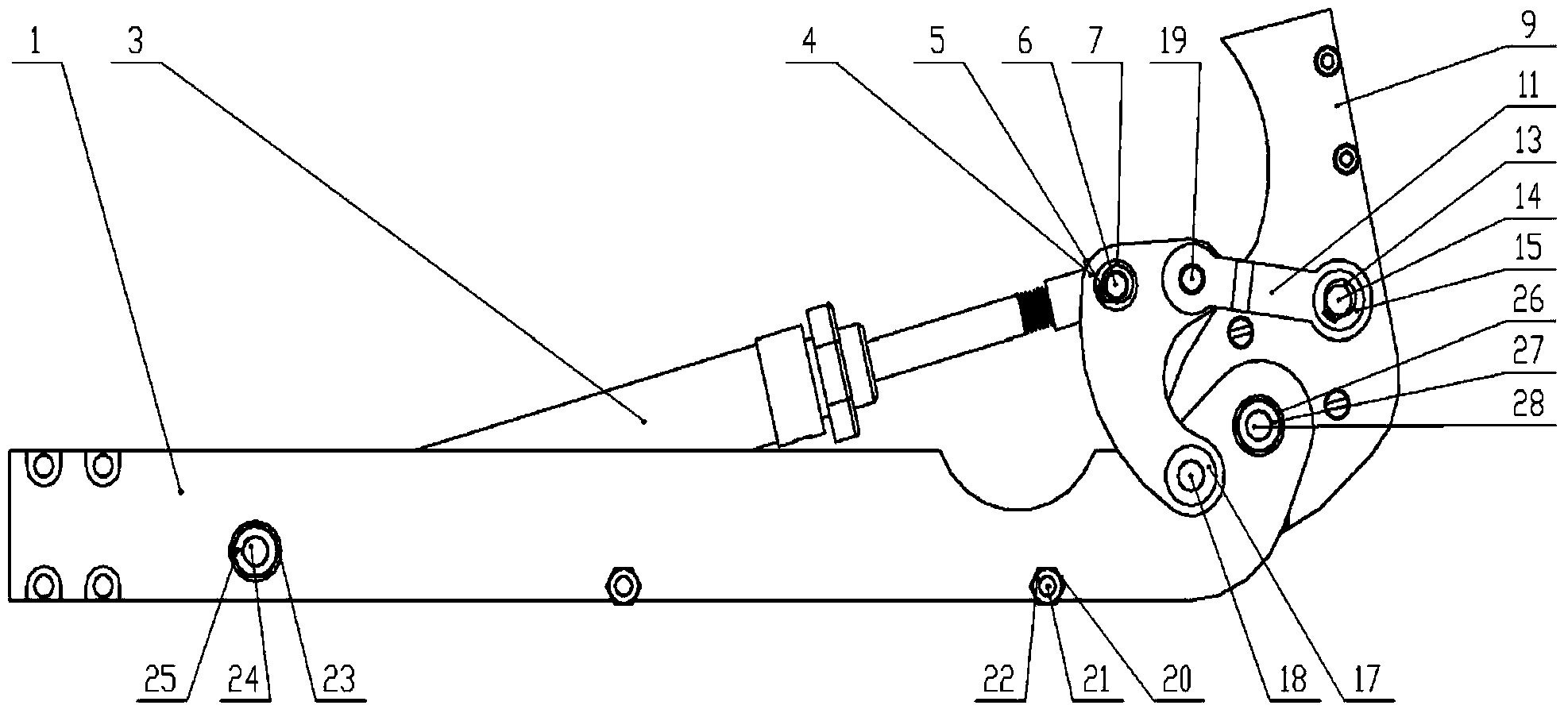

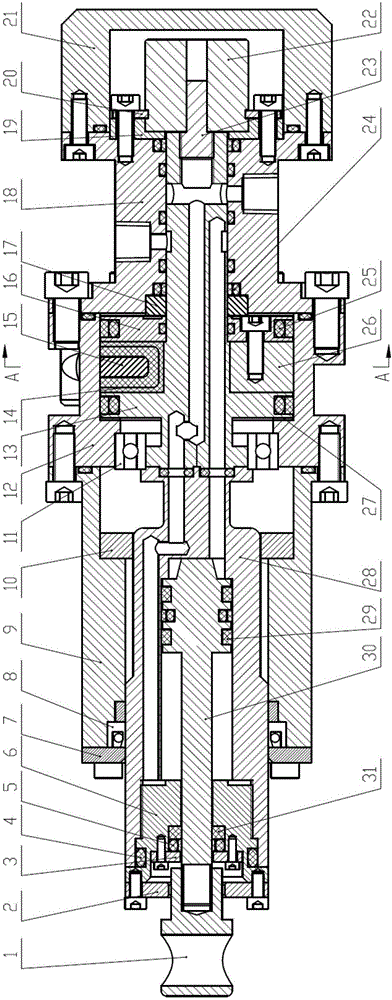

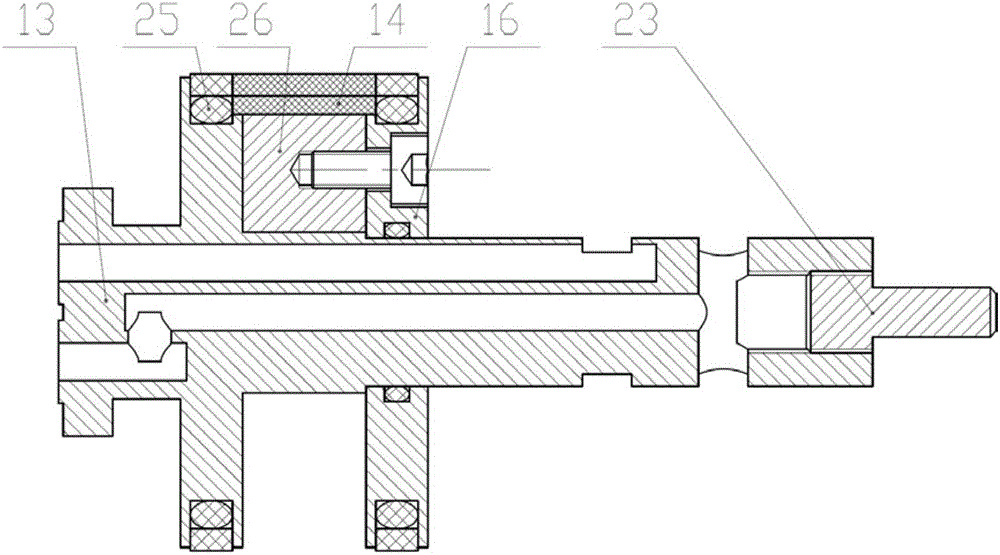

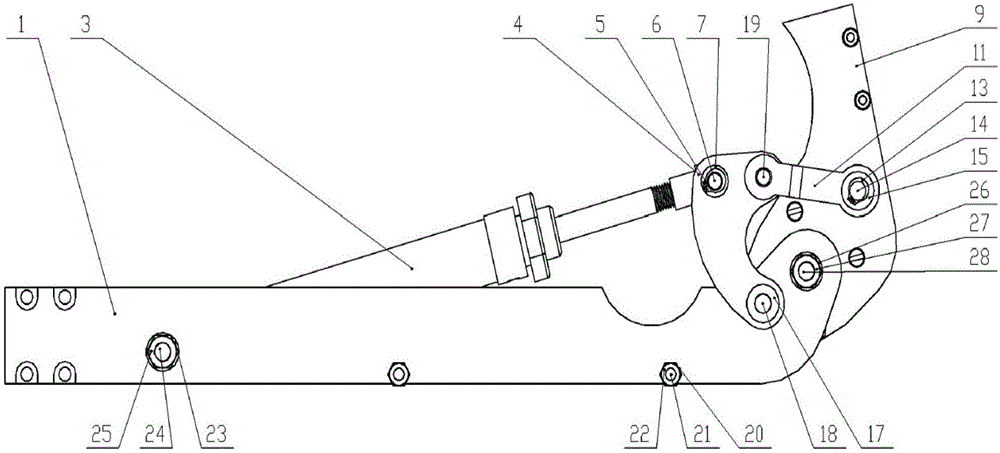

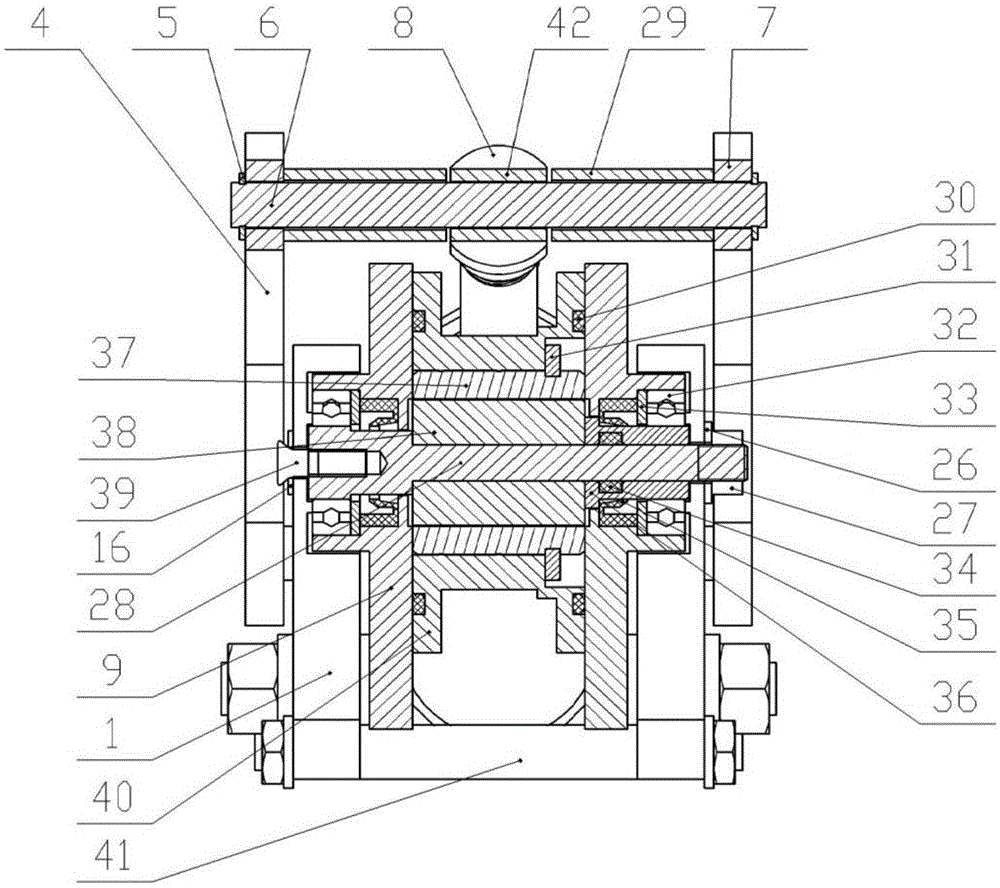

Small underwater hydraulic mechanical arm two-stage drive joint

The invention aims at providing a small underwater hydraulic mechanical arm two-stage drive joint. The small underwater hydraulic mechanical arm two-stage drive joint comprises a gripper drive hydraulic cylinder assembly for the first-stage linear movement, a second-stage joint rotation assembly and a position detection assembly, wherein the rear end of the first-stage hydraulic cylinder assembly is connected with the front end of a second-stage wrist joint through screws, an oil way inside the first-stage hydraulic cylinder assembly is sealed through an O-shaped seal ring, and the position detection assembly is in interference fit with the rear end of the second-stage wrist joint through a supporting shaft. The wrist joint is driven by hydraulic oil at the oil inlet / outlet in the middle of a second-stage joint mechanism to rotate, and the first-stage gripper hydraulic cylinder assembly is driven to rotate together with the second-stage joint mechanism, a first-stage gripper hydraulic cylinder is driven by hydraulic oil at the oil inlet / outlet in the tail portion of the second-stage joint through the oil way in the first-stage gripper hydraulic cylinder assembly to do linear movement, and the drive torque is provided for a gripper. By means of the small underwater hydraulic mechanical arm two-stage drive joint, the interference of hydraulic connectors connected with the oil inlets and the oil outlets to an outer cylinder is avoided when a first-stage hydraulic cylinder rotates together with the wrist joint in the traditional hydraulic cylinder front and back oil inlet and outlet form.

Owner:HARBIN ENG UNIV

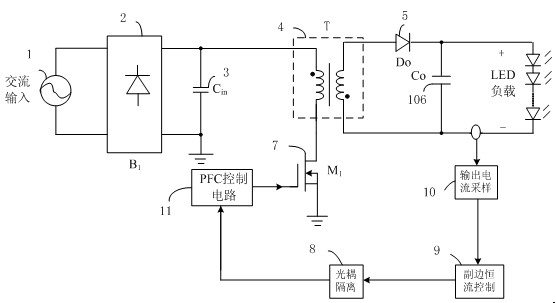

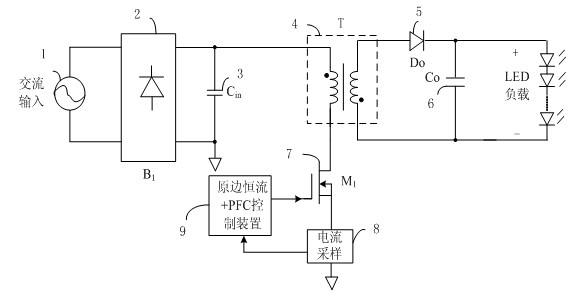

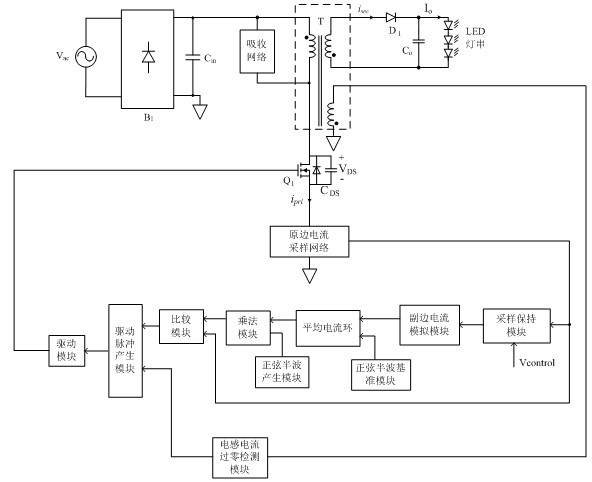

Primary edge current reference generating circuit and method for high power factor constant-current switch power supply

InactiveCN102186292ARealize closed-loop feedback controlHigh precision constant currentEfficient power electronics conversionElectric light circuit arrangementPower factorSwitching power

The invention relates to a primary edge current reference generating circuit and a primary edge current reference generating method for a high power factor constant-current switch power supply. The conventional primary edge current reference generating circuit is complicated. An input end of a first multiplier is used as an input end of the primary edge current reference generating circuit; an input end of a conduction angle detection circuit is used as another input end of the primary edge current reference generating circuit, and the output end of the conduction angle detection circuit is connected with another input end of the first multiplier; the output end of the first multiplier is used as an input end of a current loop; another input end of the current loop is used as the other input end of the primary edge current reference generating circuit; the output end of the current loop is connected with an input end of a second multiplier; another input end of the second multiplier is connected with the input end of the conduction angle detection circuit; and the output end of the second multiplier is used as the output end of the primary edge current reference generating circuit. Sampling hold is not required, so that the error caused by sample hold is eliminated, and the constant-current precision of the output current is improved.

Owner:同码信息科技(常州)有限公司

Laser-induced breakdown spectroscopy (LIBS)-based selective laser melting (SLM) formation process on-line detection equipment

ActiveCN107402193ASimple processing technologyAbundant spectral informationColor/spectral properties measurementsSelective laser meltingSelective laser sintering

The invention discloses laser-induced breakdown spectroscopy (LIBS)-based selective laser melting (SLM) formation process on-line detection equipment, which is used for realizing the on-line monitoring of the physical mechanism and component change of an SLM formation process and solving the technical problem that the component information of metal additive manufacturing materials is very difficult to detect in an on-line way. The LIBS-based SLM formation process on-line detection equipment comprises a pulse laser, an indicating laser, a spectrophotometer and a matched detector thereof, an optical transmission system and a computer. The LIBS-based SLM formation process on-line detection equipment can be matched with SLM formation equipment for use, and can be used for detecting the components of a forming platform in the SLM formation process in real time and analyzing the physical mechanism of a machining process by means of the component change; furthermore, the LIBS-based SLM formation process on-line detection equipment realizes on-line detection of multiple points and selected points by using one-division multichannel energy transmission optical fibers, and reduces detection cost under the premise of realizing the full-scale detection of the forming platform.

Owner:HUAZHONG UNIV OF SCI & TECH

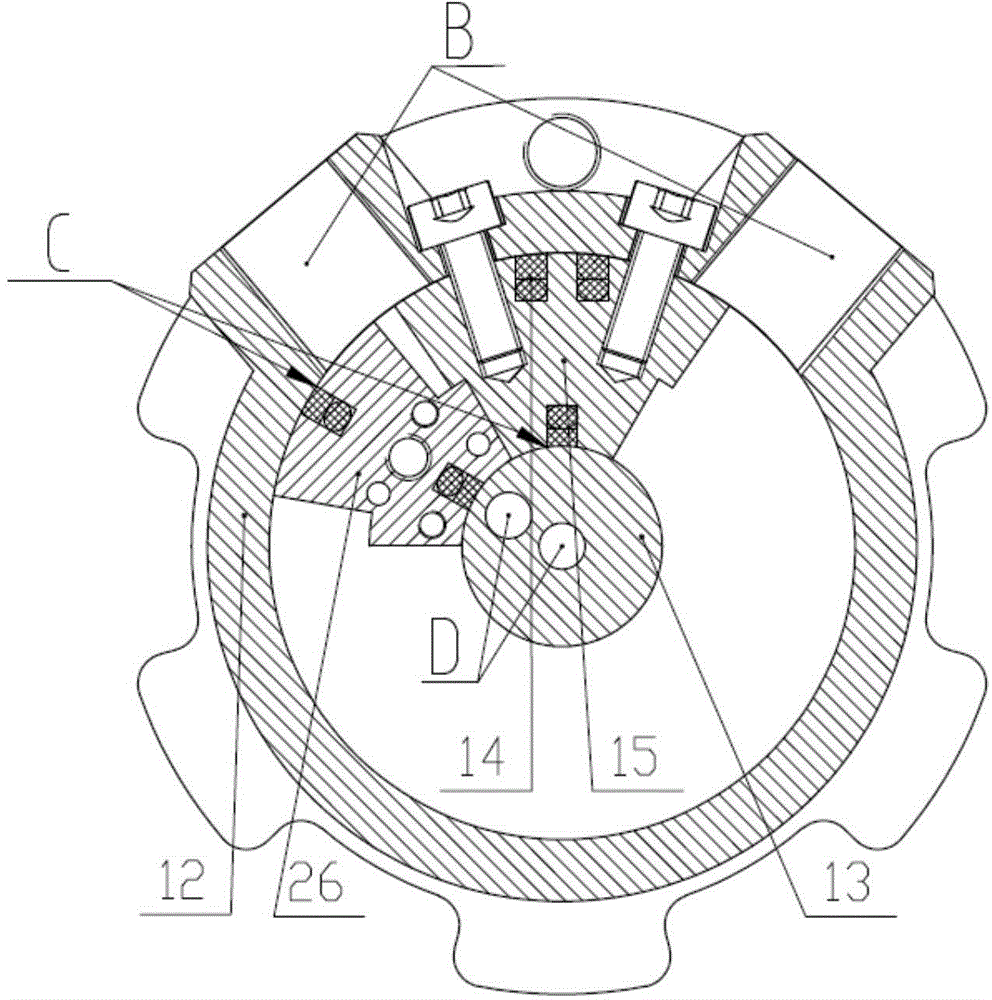

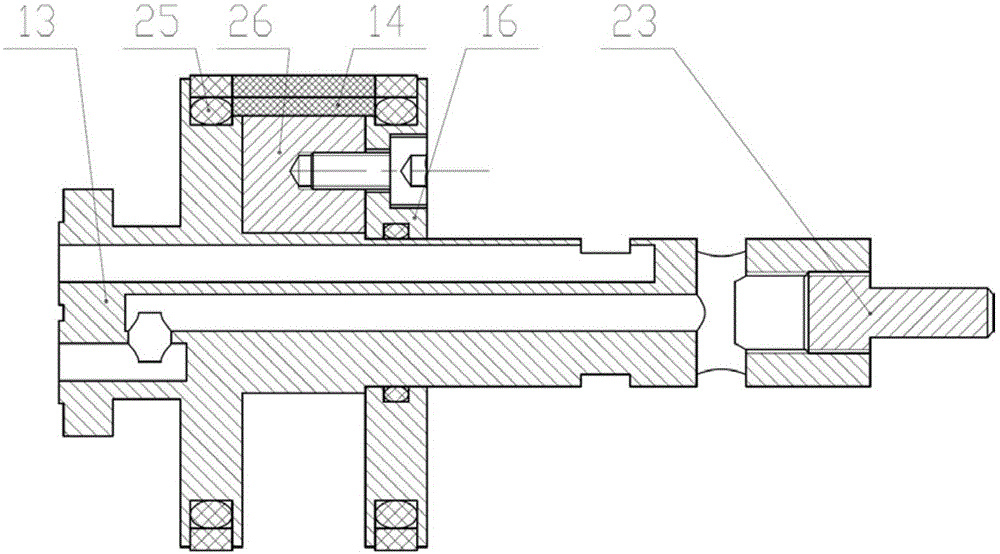

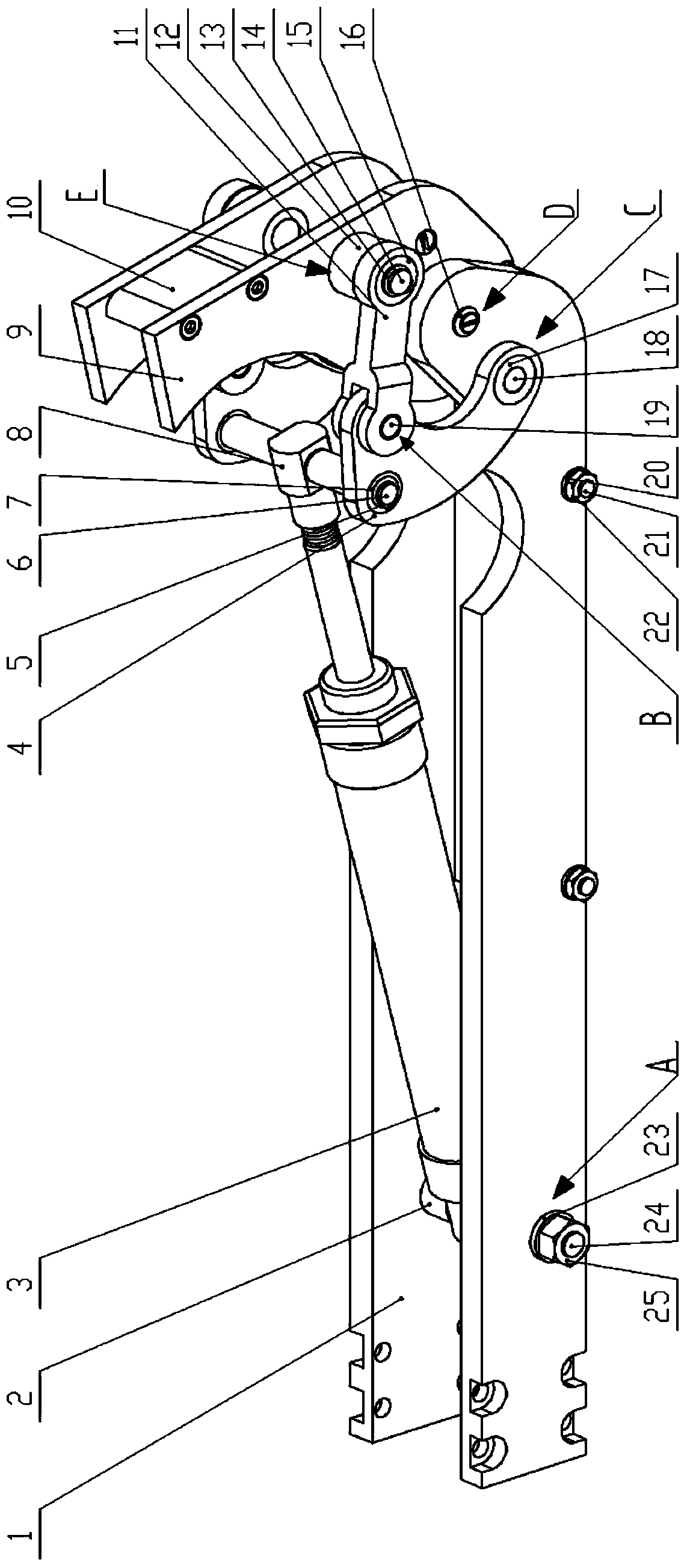

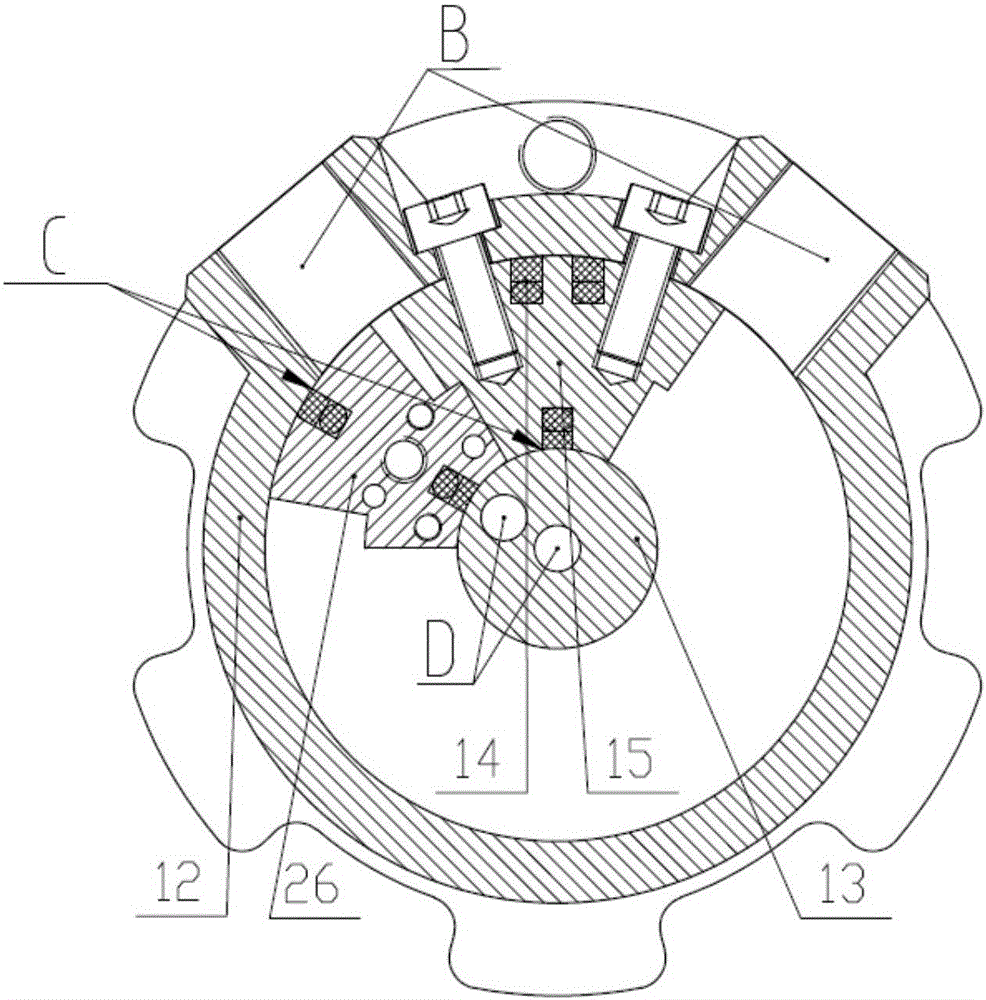

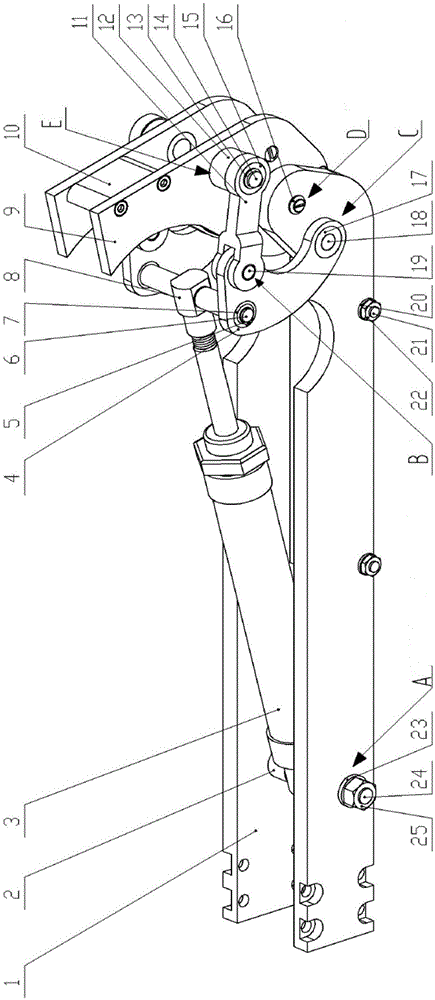

Arm joint structure of small underwater hydraulic manipulator

The invention relates to an arm joint structure of a small underwater hydraulic manipulator, which comprises a first mechanical arm, a second mechanical arm and a drive mechanism, wherein the front end of the first mechanical arm is connected with the rear end of the second mechanical arm via a rotation shaft; the drive mechanism is arranged between the first mechanical arm and the second mechanical arm and comprises a hydraulic cylinder, a C-shaped plate and a straight plate; a cylinder body of the hydraulic cylinder is articulated with the first mechanical arm; a cylinder rod is articulated with the middle of the C-shaped plate; one end of the C-shaped plate is articulated with the first mechanical arm; the other end of the C-shaped plate is articulated with one end of the straight plate; and the other end of the straight plate is articulated with the second mechanical arm. The arm joint structure has the advantages of compact structure, small size, convenience in mounting, flexible joint driving and strong driving power, can achieve 180-degree rotation of a manipulator joint, and is applicable to driving the small underwater hydraulic manipulator joint.

Owner:HARBIN ENG UNIV

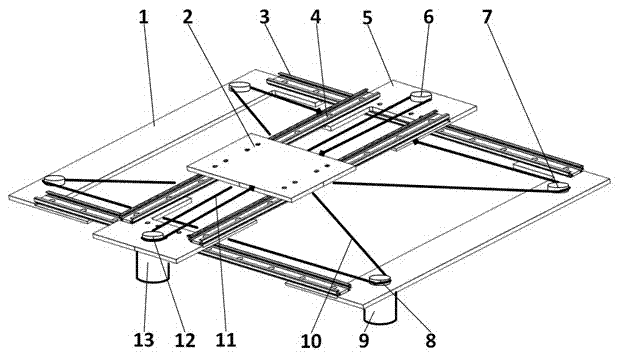

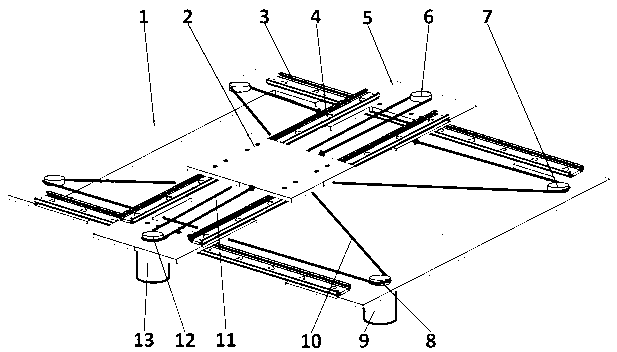

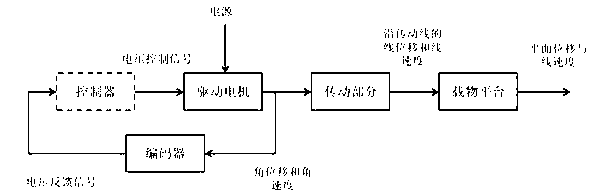

Rapid plane movement platform

Owner:HANGZHOU DIANZI UNIV

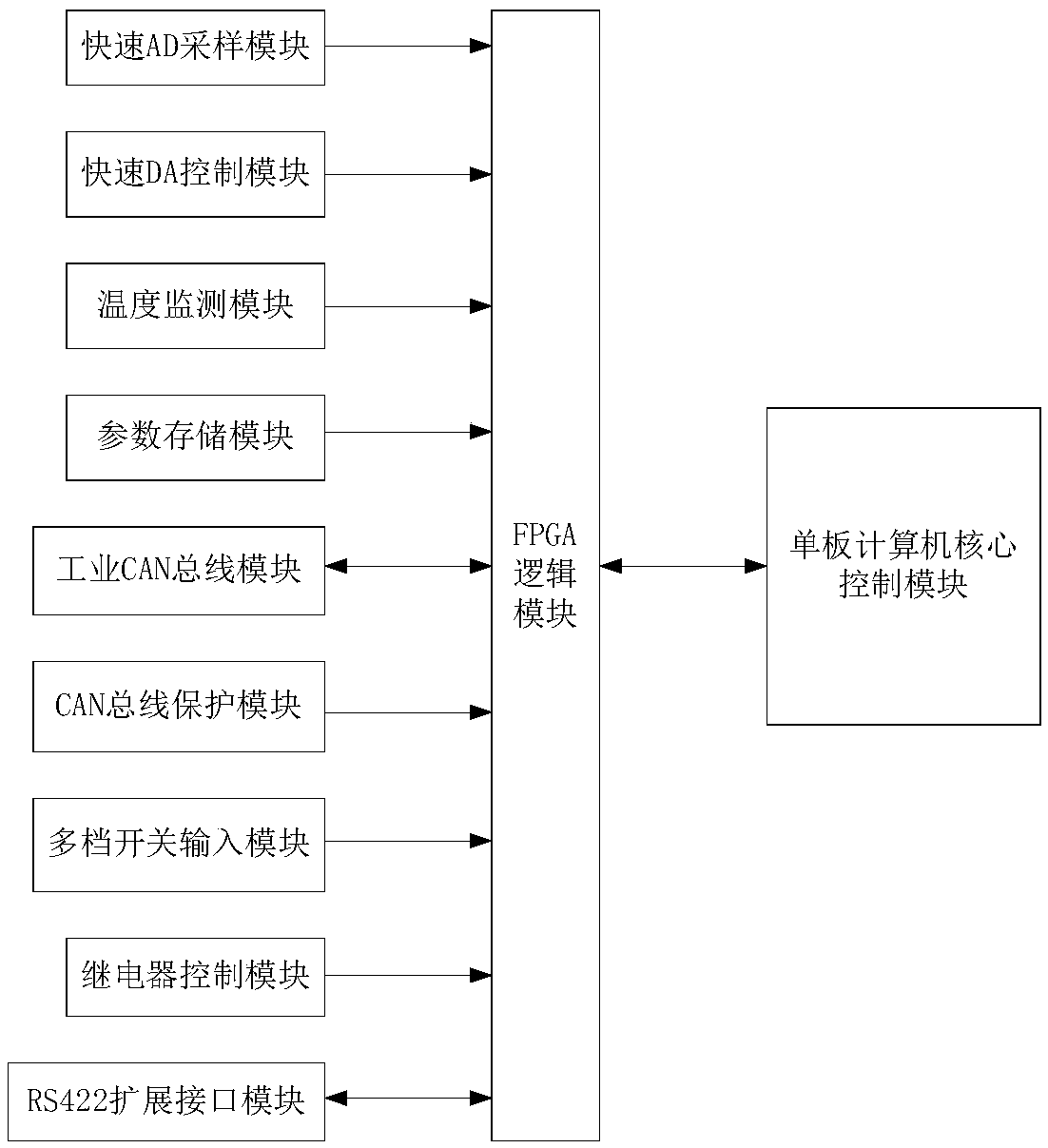

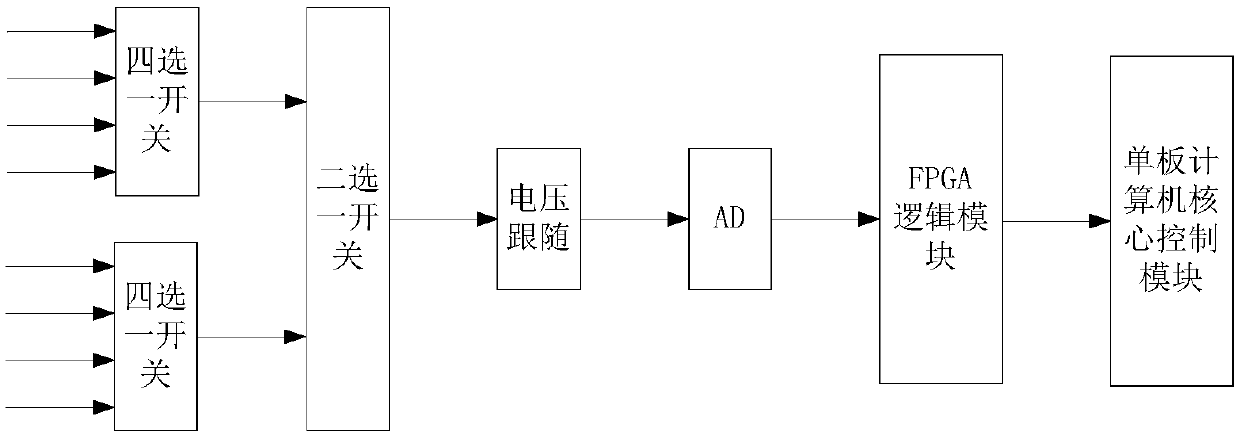

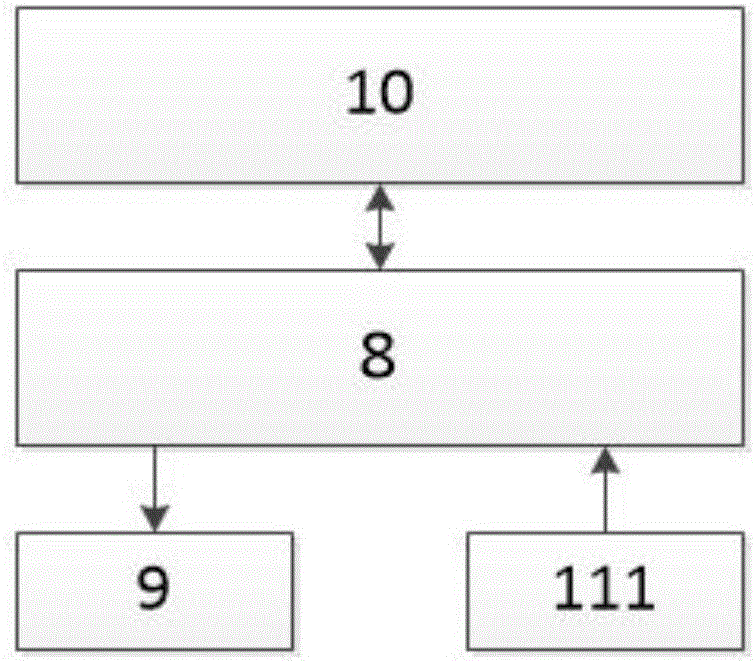

Control device, system and method for unmanned vehicle

InactiveCN109582001AReal-time monitoring status informationMeet the needs of equipment combat effectiveness inspectionElectric testing/monitoringRadarRemote control

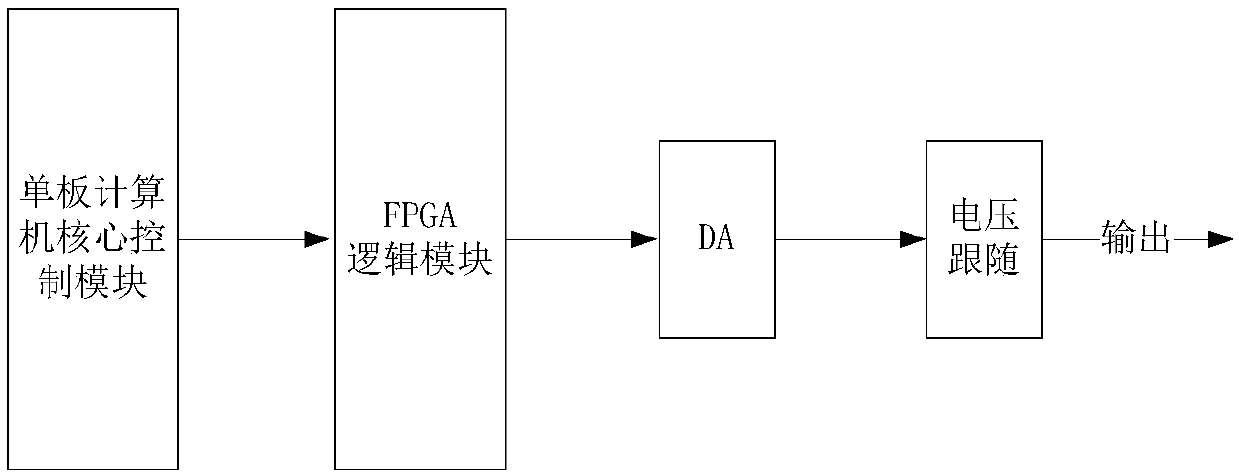

The invention discloses a control device, system and method for an unmanned vehicle. The device comprises an FPGA logic module that is communicated with a single board computer core control module viaa cPCI bus; a fast AD sampling module collects analog data of a throttle sensor, a brake sensor and an electric appliance proportional valve, and converts the analog data into a digital quantity to be conveyed to the FPGA logic module; a fast DA control module achieves electric proportional valve control; a multi-gear switch input module achieves selection and switching of driving control modes,and the driving control modes comprise a remote control driving mode, a manned driving mode and an unmanned driving mode; and the device also comprises an industrial CAN bus module and a CAN bus protection module. The device is provided with the three driving control modes, can control the vehicles driving in the Gobi deserts and serve for troop tests, and meets the requirement that military equipment simulates the radiation property, scattering property and interference property of the enemy radar; the requirement of full process combat training of the troop is met; and the requirement of checking the operational effectiveness of missile weapon and equipment is met.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

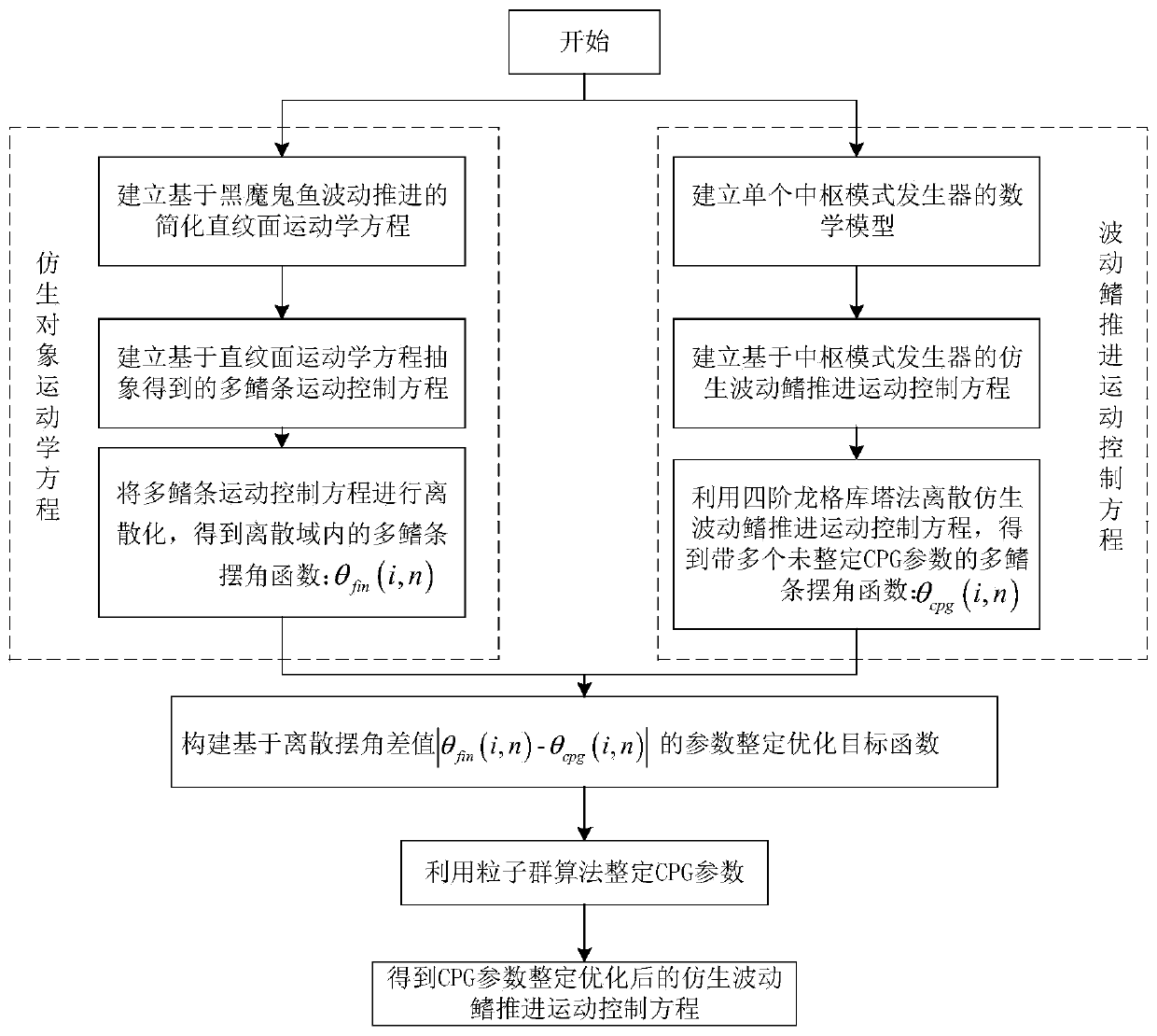

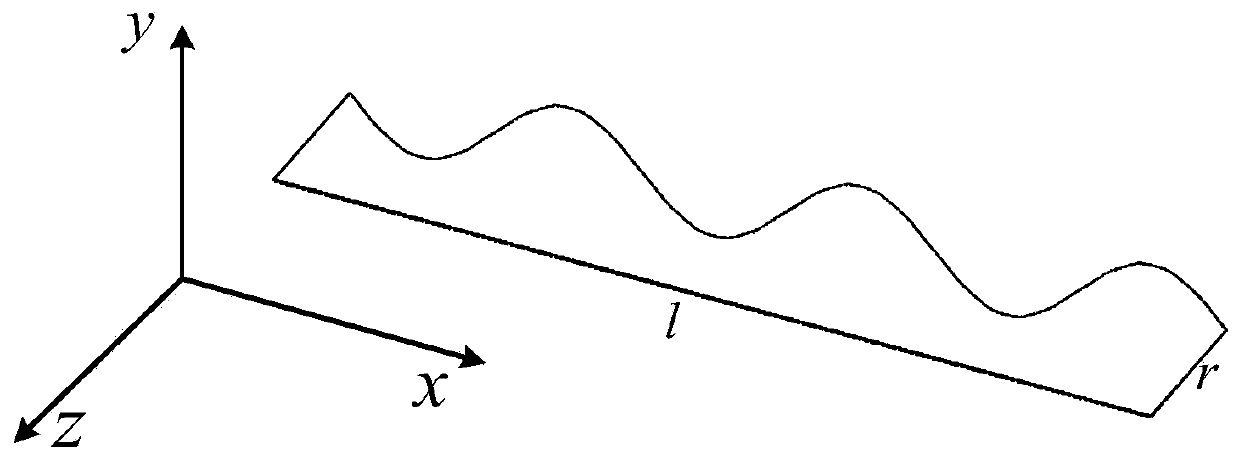

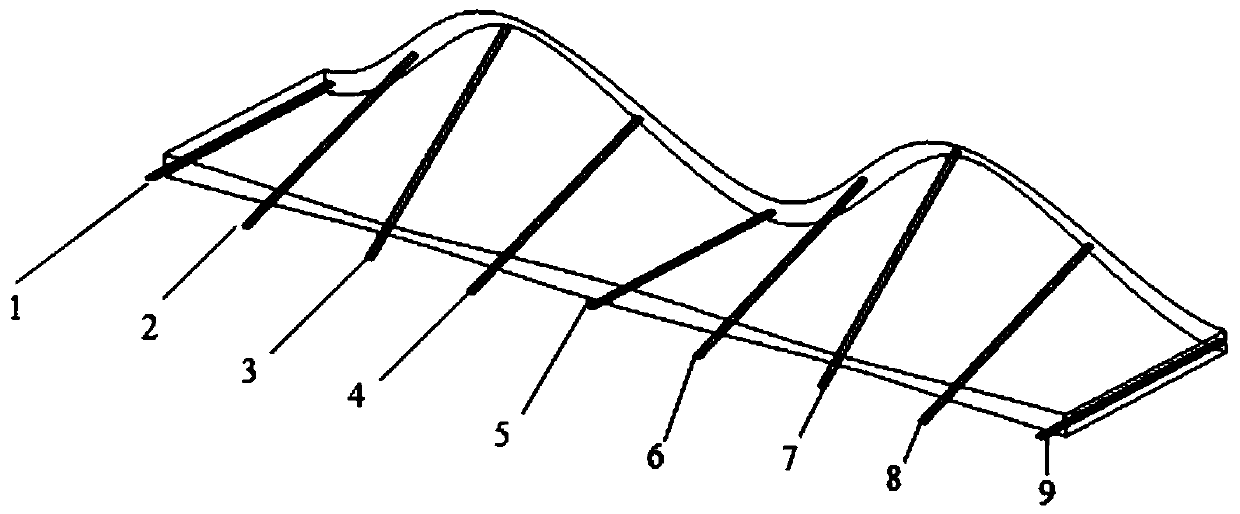

Construction of propulsion motion control equation of bionic undulatory fin and parameter setting optimization method thereof

ActiveCN111443605ARealize closed-loop feedback controlAdjustable speedAdaptive controlKinematics equationsSimulation

The invention discloses construction of a propulsion motion control equation of a bionic undulatory fin and a parameter setting optimization method thereof, wherein an improved particle swarm algorithm is used for setting and optimizing parameters of the propulsion motion control equation of the bionic undulatory fin based on a central pattern generator. The motion control equation based on the central pattern generator can generate various rhythm signals with variable phase difference, frequency and amplitude, can resist the influence of sudden change of control parameters on the continuity of output signals, and can realize flexible transition of a bionic undulatory fin underwater robot under the switching of different swimming modes; and a method of CPG parameter setting optimization based on the improved particle swarm algorithm by taking a kinematic equation of a simplified ruled surface of a wave motion of a bionic object black ghost fish as a reference is proposed,. An inertia factor of the particle swarm algorithm is improved, and decreases linearly with the iteration of the algorithm, the accuracy of CPG parameter setting optimization is improved, and the performance of the bionic undulatory fin underwater robot is improved from a control algorithm level.

Owner:XI AN JIAOTONG UNIV

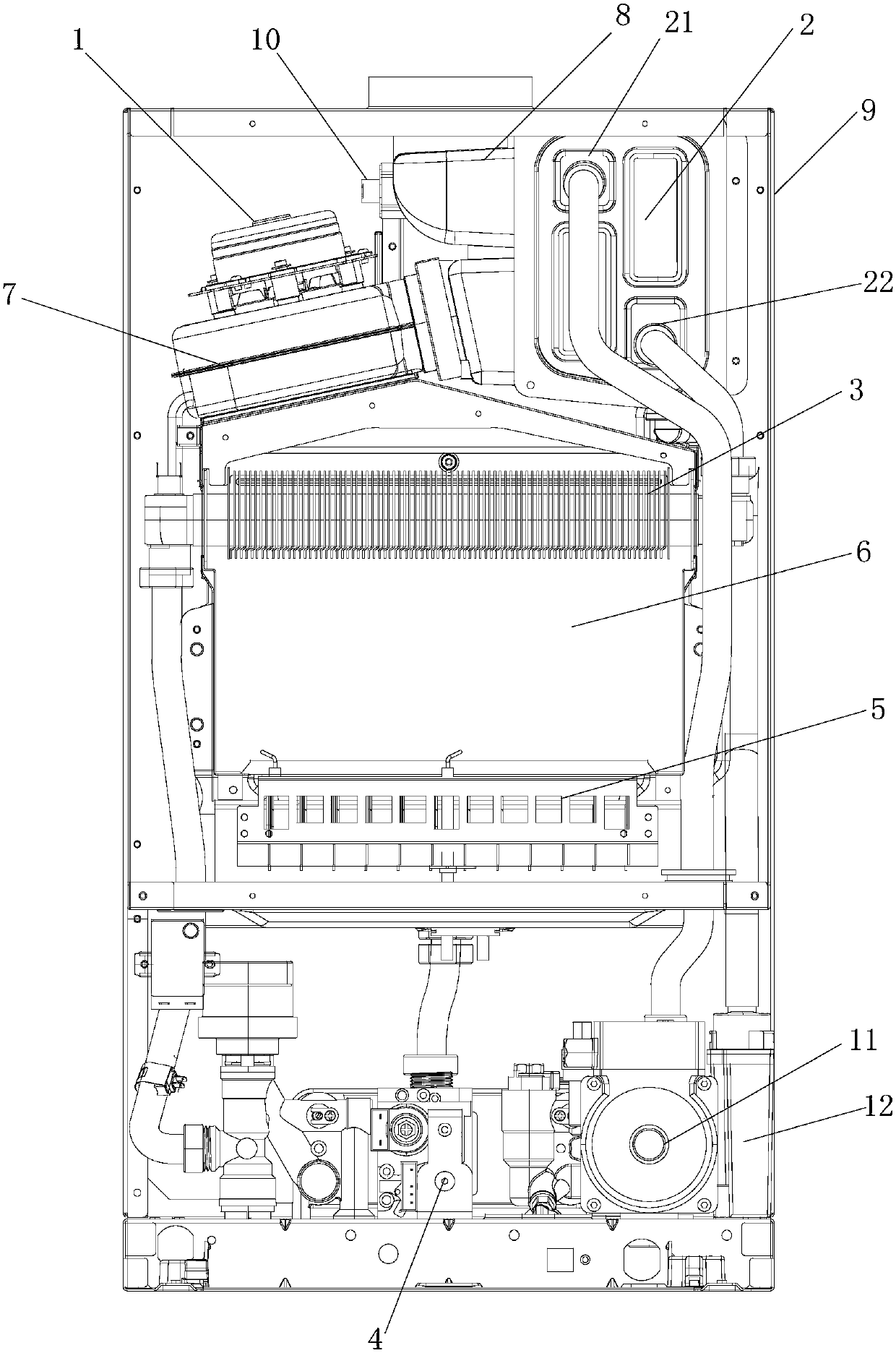

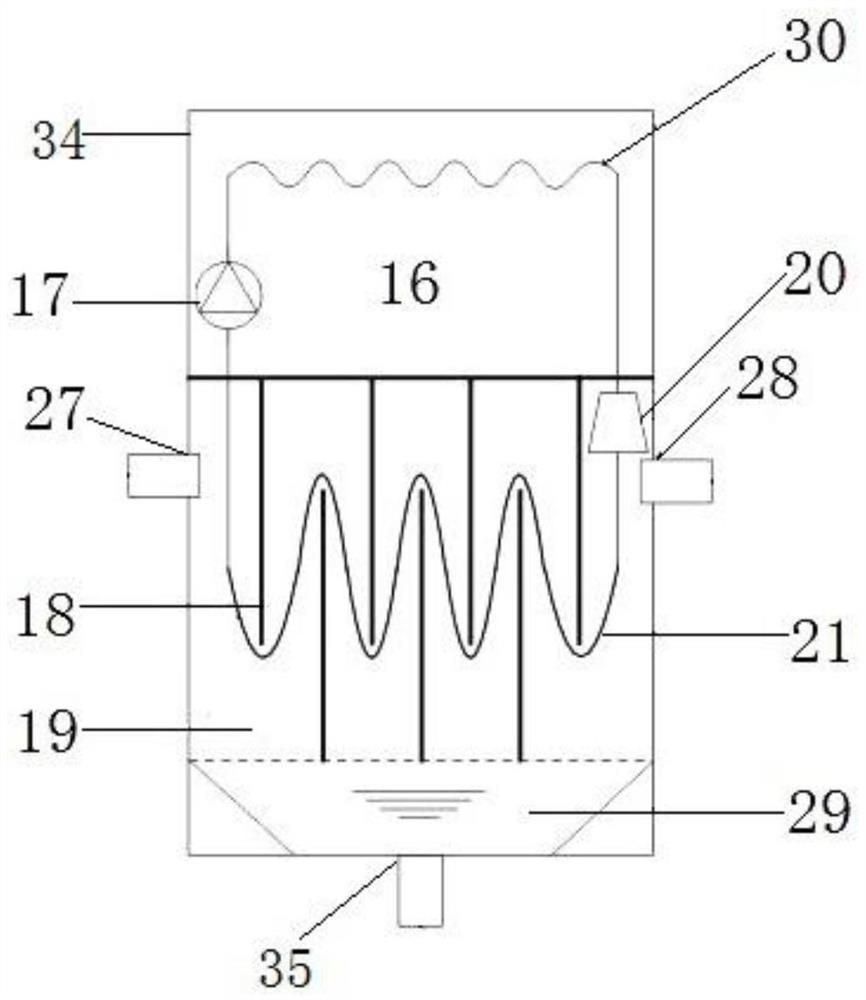

Condensation type fuel gas heating stove

InactiveCN107869846AWide speed rangeRealize closed-loop feedback controlAir heatersSustainable buildingsFlueAir–fuel ratio

The invention discloses a condensation type fuel gas heating stove. The condensation type fuel gas heating stove comprises a main heat exchanger, a gas valve, a combustor, a combustion cavity, a smokecollecting hood, a flue, a shell and a circulating water pump and further comprises a direct-current draught fan and a waste heat recycling device; the direct-current draught fan is a noninductive brushless direct-current draught fan and comprises a draught fan electric control plate and a draught fan body, the draught fan body is separated from the draught fan electric control plate, and is mounted between the main heat exchanger and the waste heat recycling device, the draught fan electric control plate adjusts the rotating speed of the draught fan body in real time along with changes of combustion power of the heating stove, and controls the air-fuel ratio in the combustion process to be kept unchangeable, the noninductive brushless direct-current draught fan is adopted in the heatingstove, no induction elements exist in the draught fan body, the draught fan body and the draught fan electric control plate are separated, and the draught fan body can be applied to the severe environment; meanwhile, the wind speed of the direct-current draught fan is precisely adjustable, the air-fuel ratio in the combustion cavity is kept as definite value under different types of combustion power, meanwhile, the heating stove is combined with the waste heat recycling device to promote the condensation effect, work efficiency is improved, and energy is saved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

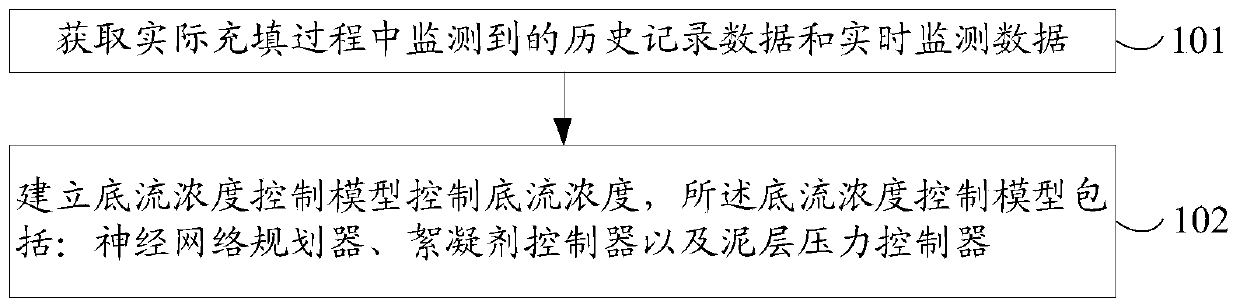

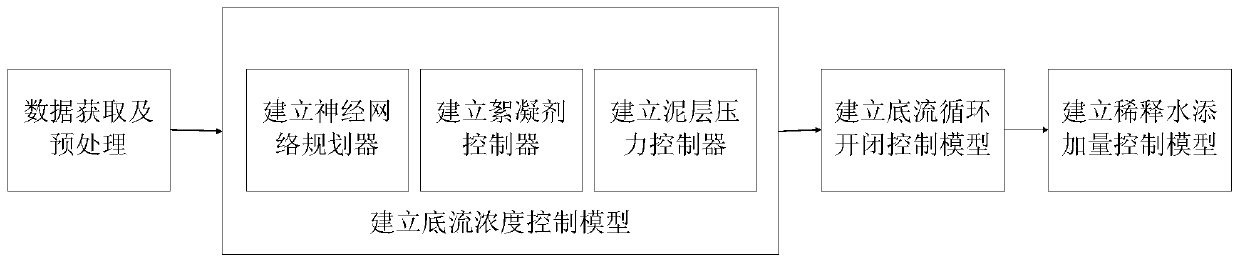

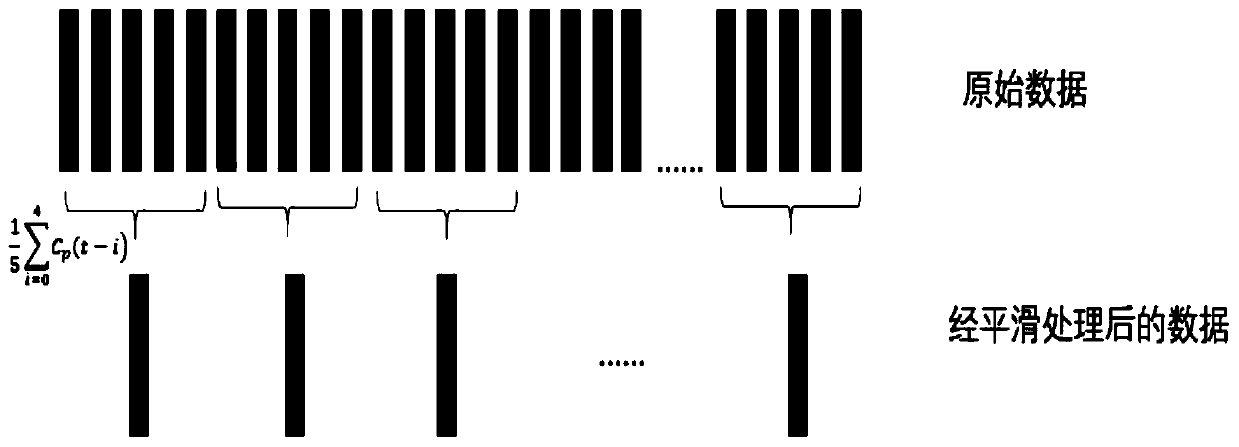

Intelligent control method of deep cone thickener under filling scene

ActiveCN110090478AHigh control precisionImprove stabilitySedimentation separationWet separationModel controlOnline learning

The invention provides an intelligent control method of a deep cone thickener under a filling scene, and the intelligent control method can improve the control precision of underflow concentration. The method comprises the following steps of: establishing an underflow concentration control model to control the underflow concentration, offline training a neural network planner through historical record data, and outputting an optimal rake frame rotation speed setting value, an optimal flocculant addition ratio and an optimal mud layer pressure setting value; dynamically adjusting a flocculant addition flow setting value according to real-time monitoring data and the optimal flocculant addition ratio by a flocculant controller; adjusting an underflow flow setting value by a mud layer pressure controller to enable a deep cone thickener mud layer pressure monitoring value tracks the optimal mud layer pressure set value; and applying the obtained optimal rake rotation speed setting value, flocculant addition setting value and underflow flow setting value to the actual filling process in real time, and transmitting monitoring data generated in real time to the underflow concentration control model in real time for online learning and training of the underflow concentration control model. The invention relates to the field of mine tailings disposal.

Owner:UNIV OF SCI & TECH BEIJING

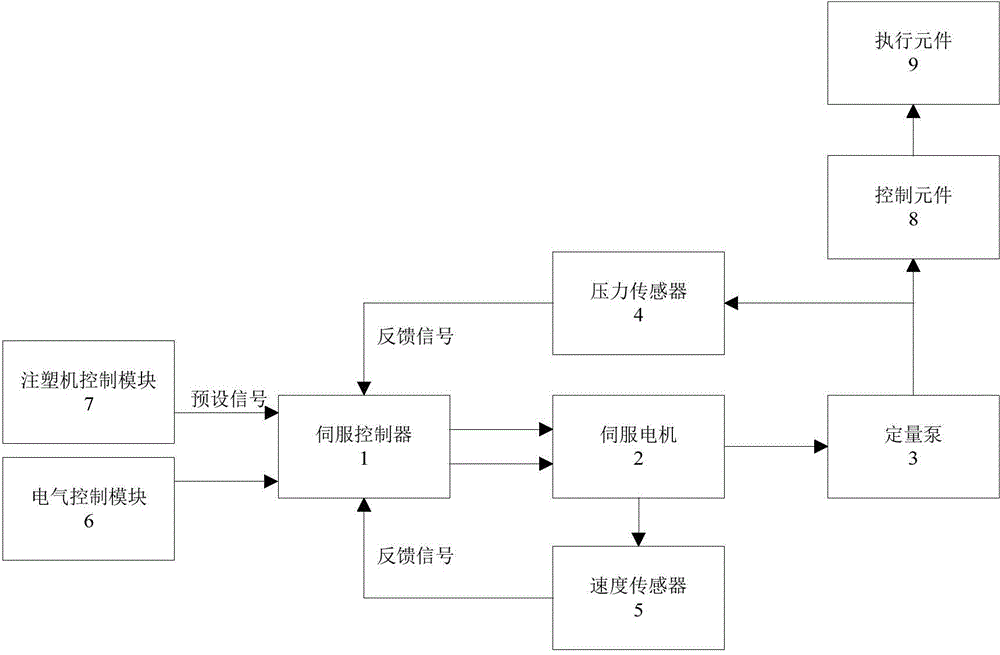

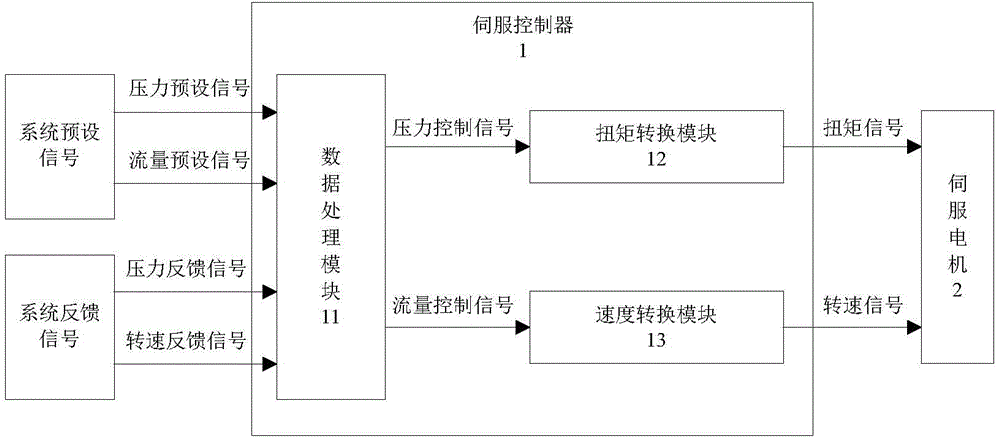

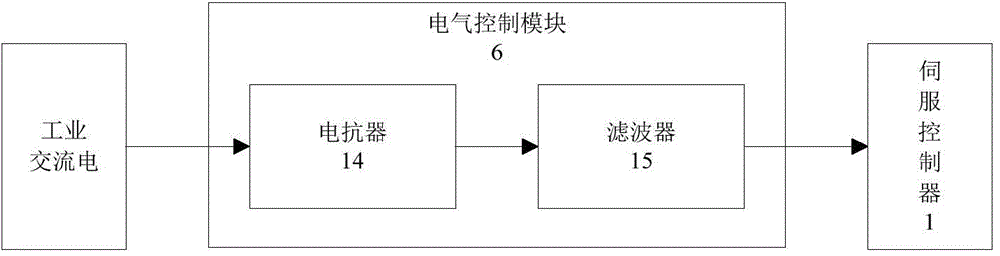

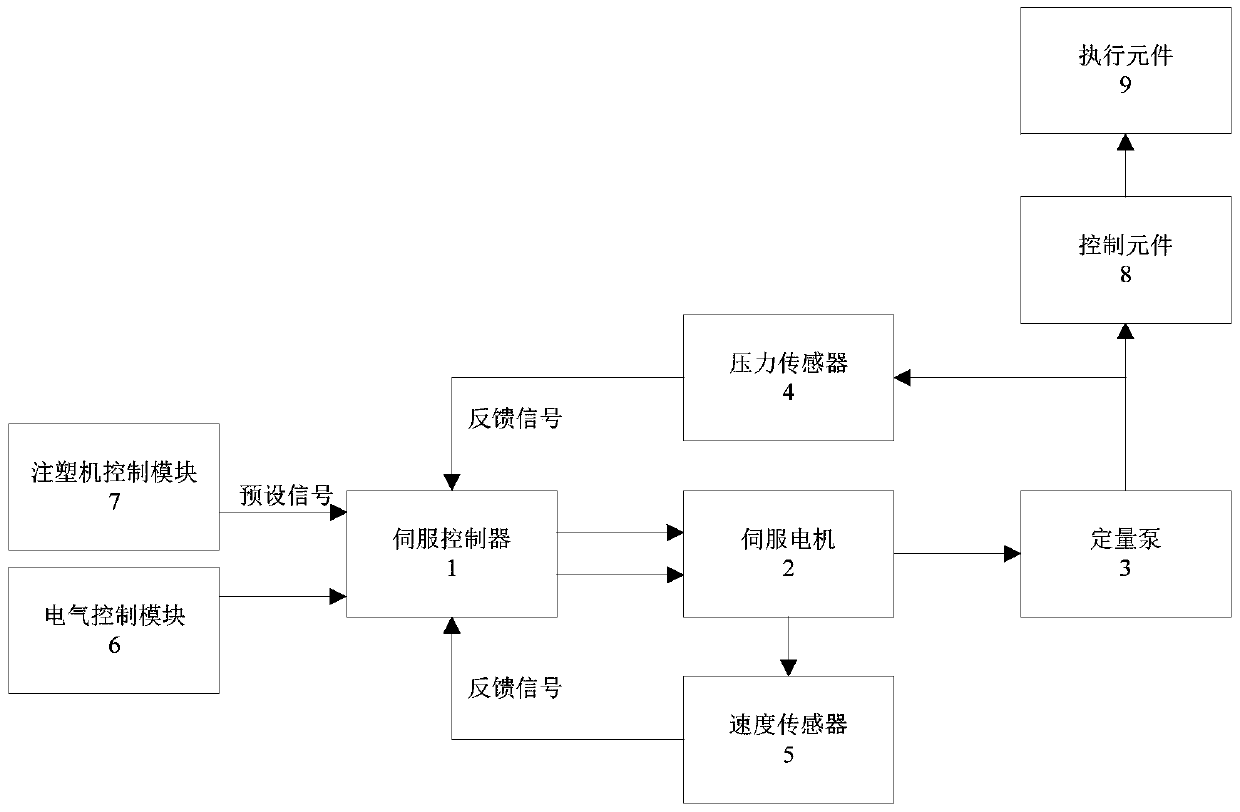

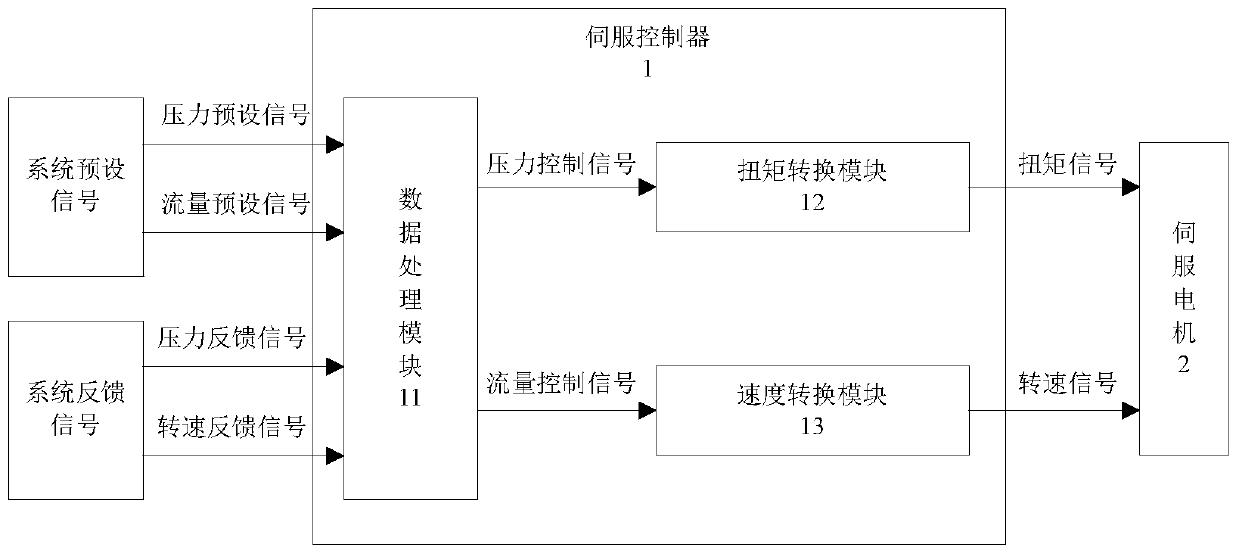

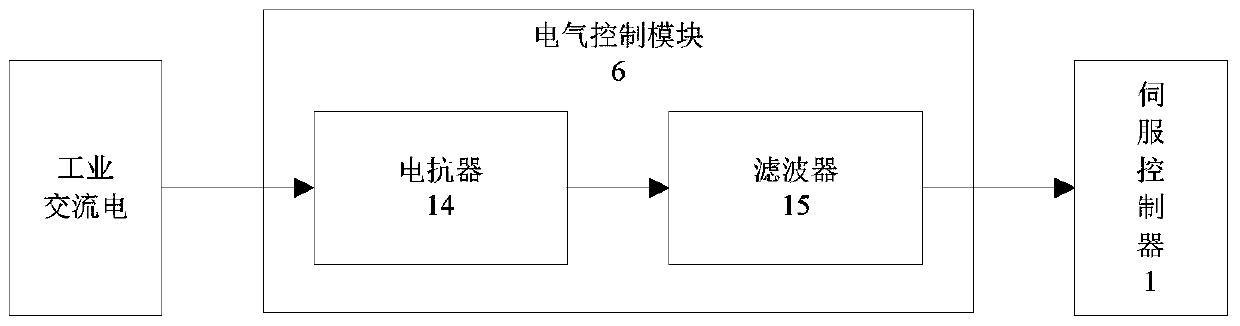

Energy-saving servo control system for injection molding machine

The invention relates to an energy-saving servo control system for an injection molding machine. The energy-saving servo control system comprises a control module of the injection molding machine, a servo motor, a constant displacement pump, a control element and a performing element, and further comprises a servo controller, a pressure sensor and a speed sensor, wherein the servo controller comprises a data processing module, a torque conversion module and a speed conversion module; the control module of the injection molding machine comprises a data processing module which is respectively connected to the pressure sensor, the speed sensor, the torque conversion module and the speed conversion module; the torque conversion module and the speed conversion module are respectively connected to the servo motor; the pressure sensor is arranged on an oil outlet pipeline of the constant displacement pump; the speed sensor is arranged on the output shaft of the servo motor; and the servo motor is used for receiving a torque signal and a rotation speed signal which are independent from one another. Compared with the prior art, a purpose of regulating the control system by double closed-loop feedback of a pressure flow rate and rotation speed is realized, so that the working performance of the operation of the injection molding machine is relatively stable, and the energy utilization efficiency of the injection molding machine is improved.

Owner:SHANGHAI UNIV OF ENG SCI

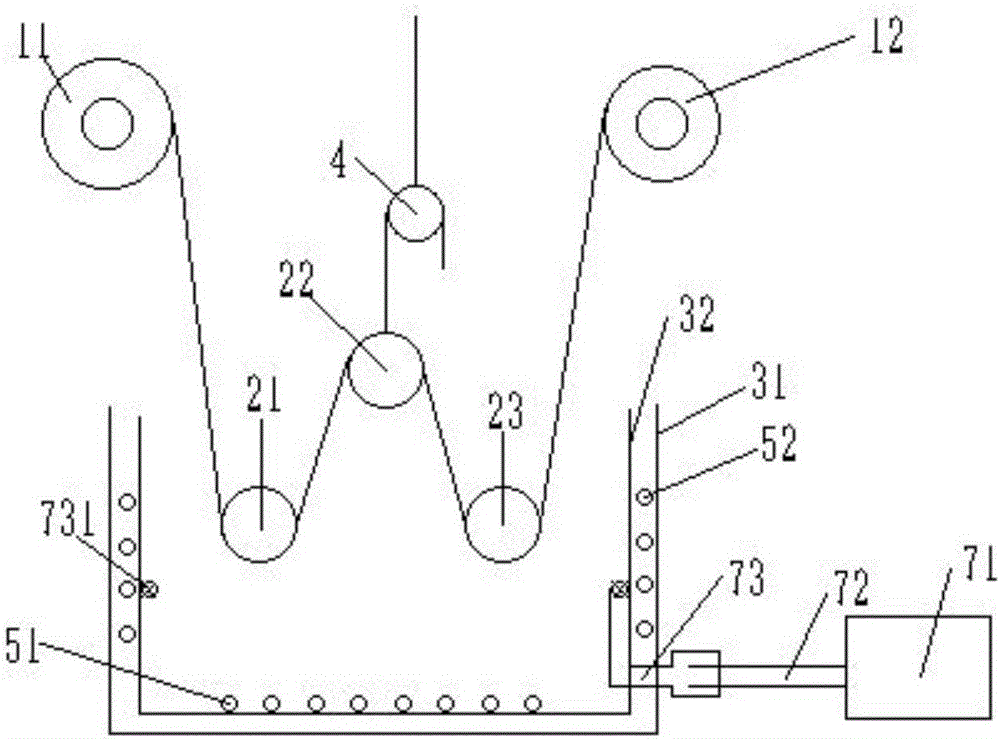

Horizontal door opening type jig dyeing machine and control system thereof

ActiveCN106048935AImprove dyeing effectEven by forceLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor treatment machines driving mechanismsControl systemPulp and paper industry

The invention provides a horizontal door opening type jig dyeing machine and a control system thereof. The horizontal door opening type jig dyeing machine comprises winding rollers, cloth guide rollers, a dyeing vat combination, a controller and a heating system. The cloth guide rollers include a cloth guide roller a, a cloth guide roller b and a cloth guide roller c which are arranged above the dyeing vat combination in an inverted 'V' shape, and a tension detecting roller is arranged at the upper end of the cloth guide roller b. The winding rollers include a winding roller A and a winding roller B which are arranged at the front and back ends of the dyeing vat combination respectively. The heating system is arranged in the dyeing vat combination. The invention further provides a control system of the horizontal door opening type jig dyeing machine. The dyeing vat combination comprises a first dyeing vat and a second dyeing vat, and heating tubes are arranged between the first dyeing vat and the second dyeing vat, so that evenness in heating of dye liquor in the second dyeing vat without sharp falling of the temperature is guaranteed. Additionally, the dye liquor can be evener by the aid of a swing mechanism arranged below the second dyeing vat, and accordingly jig dyeing quality is improved greatly.

Owner:海安苏博机器人科技有限公司

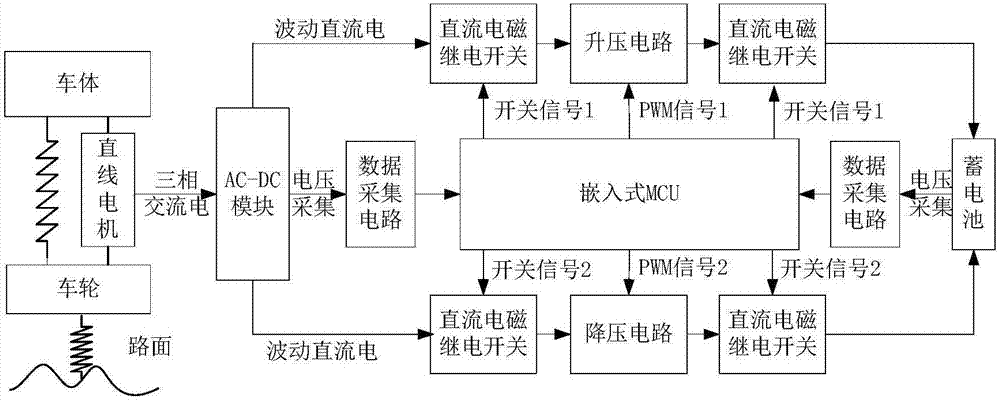

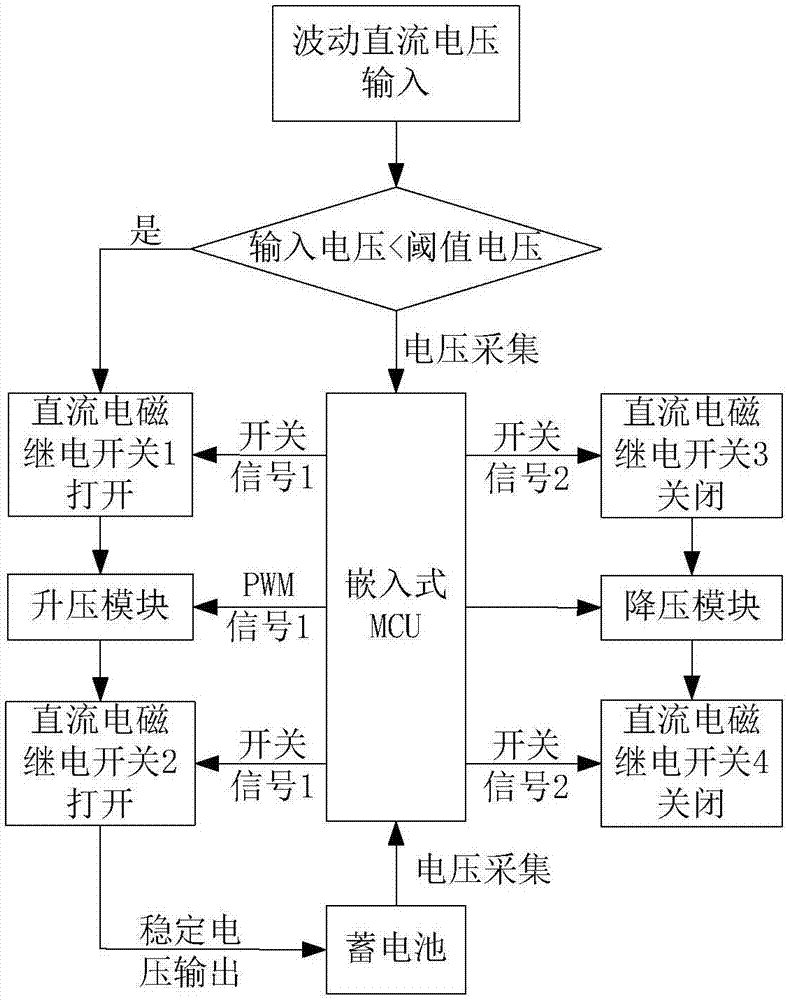

Vehicle suspension system vibration energy recovery device

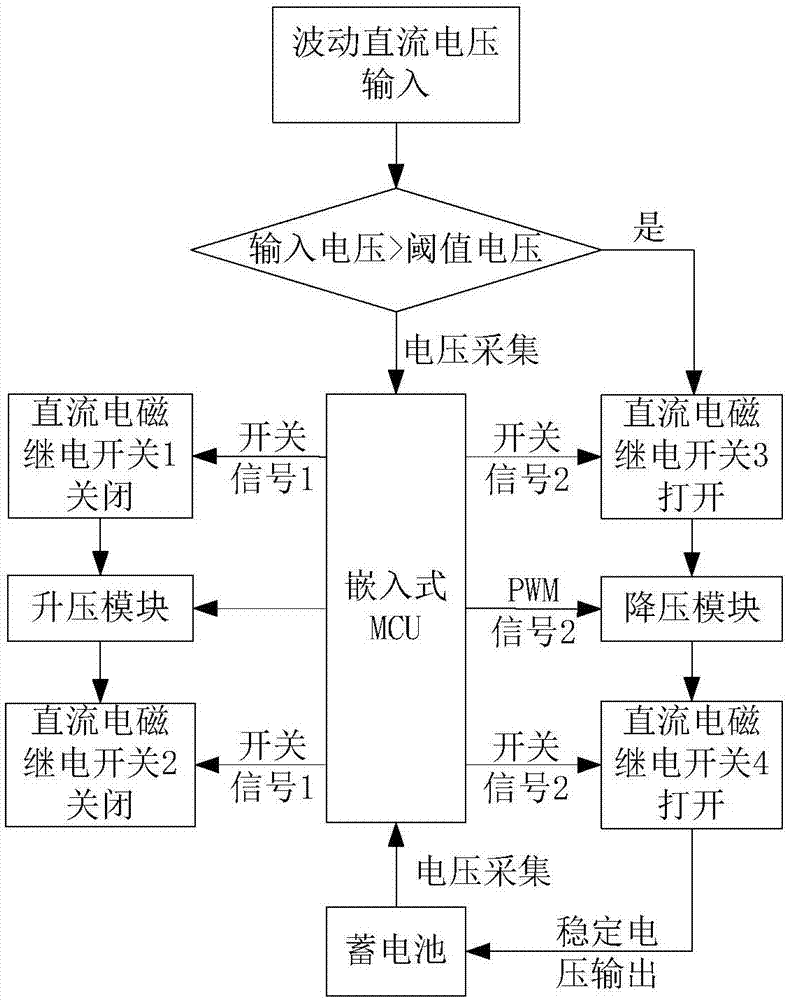

InactiveCN107069919ASolve the problem that cannot be effectively recycled and storedWide range of recyclingBatteries circuit arrangementsElectric powerVoltage amplitudeClosed loop feedback

The invention provides a vehicle suspension system vibration energy recovery device. Classical rectifier circuits and buck-boost circuits are taken as design basis, the voltage at the input end and the voltage at the output end are constantly collected, the error between an output voltage actual value and an output voltage target value is calculated, and the duty ratio of a PWM signal is amended, so that closed-loop feedback control for voltage regulation is realized, three-phase alternating current with constantly changing voltage amplitude can be converted into stable direct current capable of charging a storage battery, and the operation is stable and reliable.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

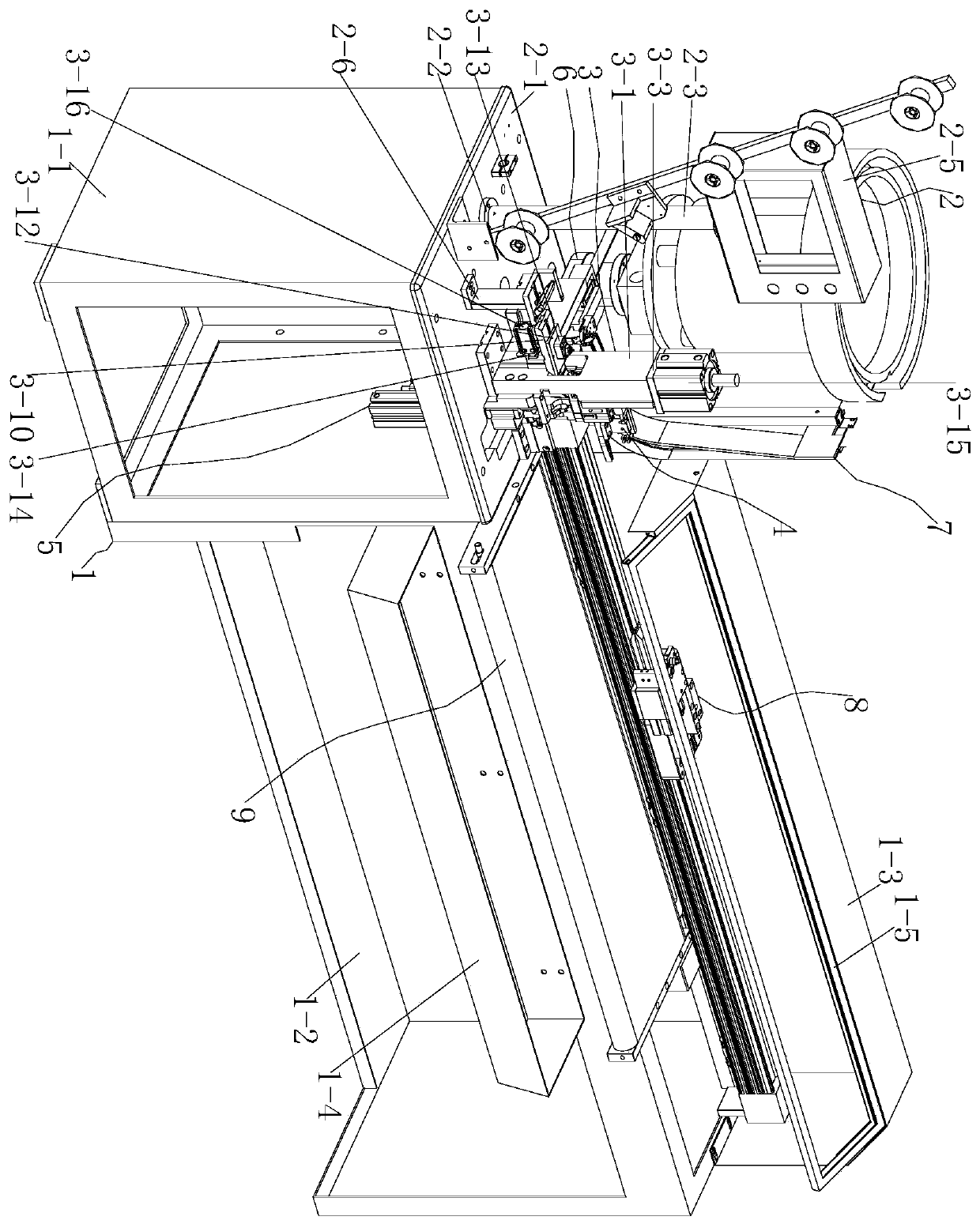

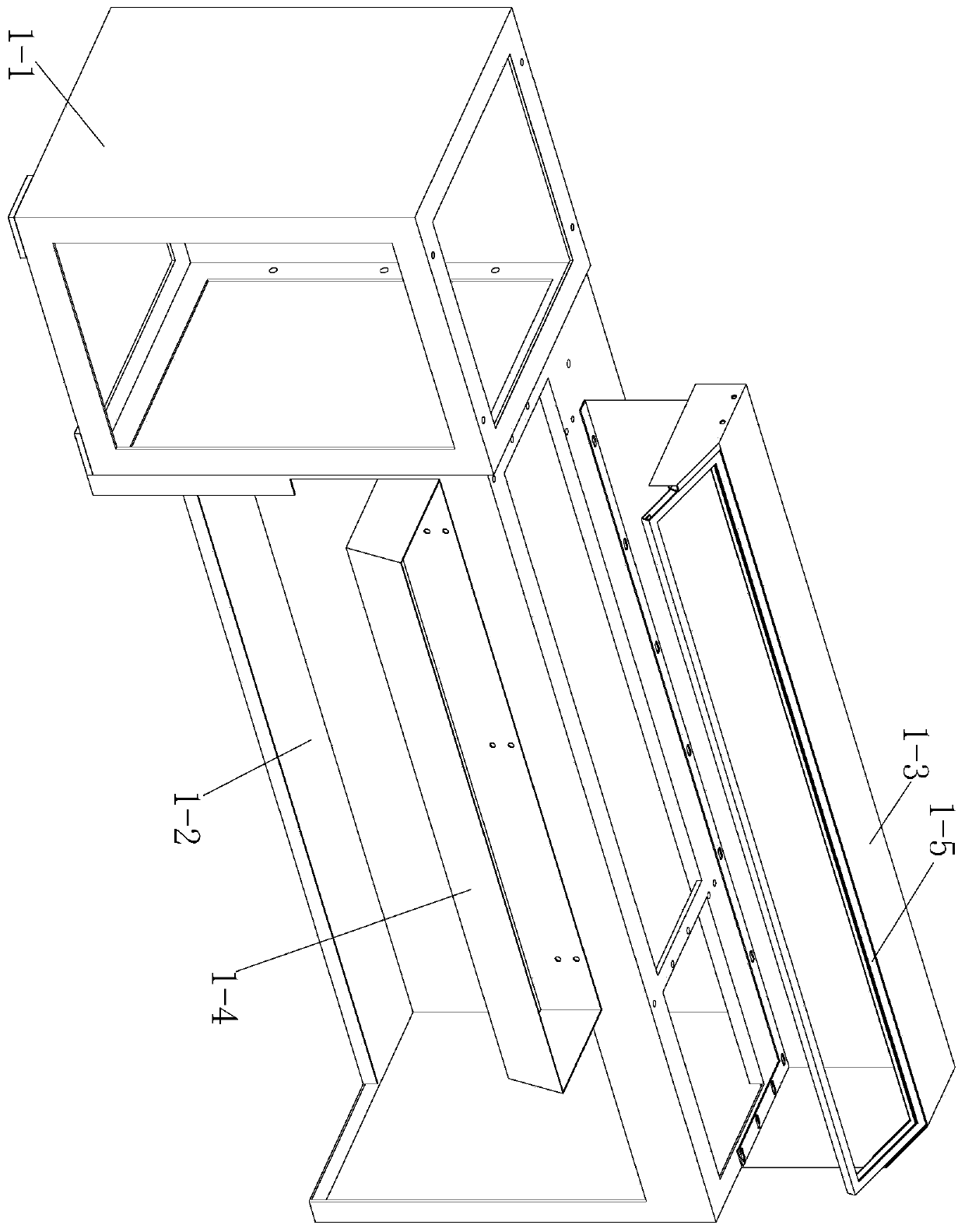

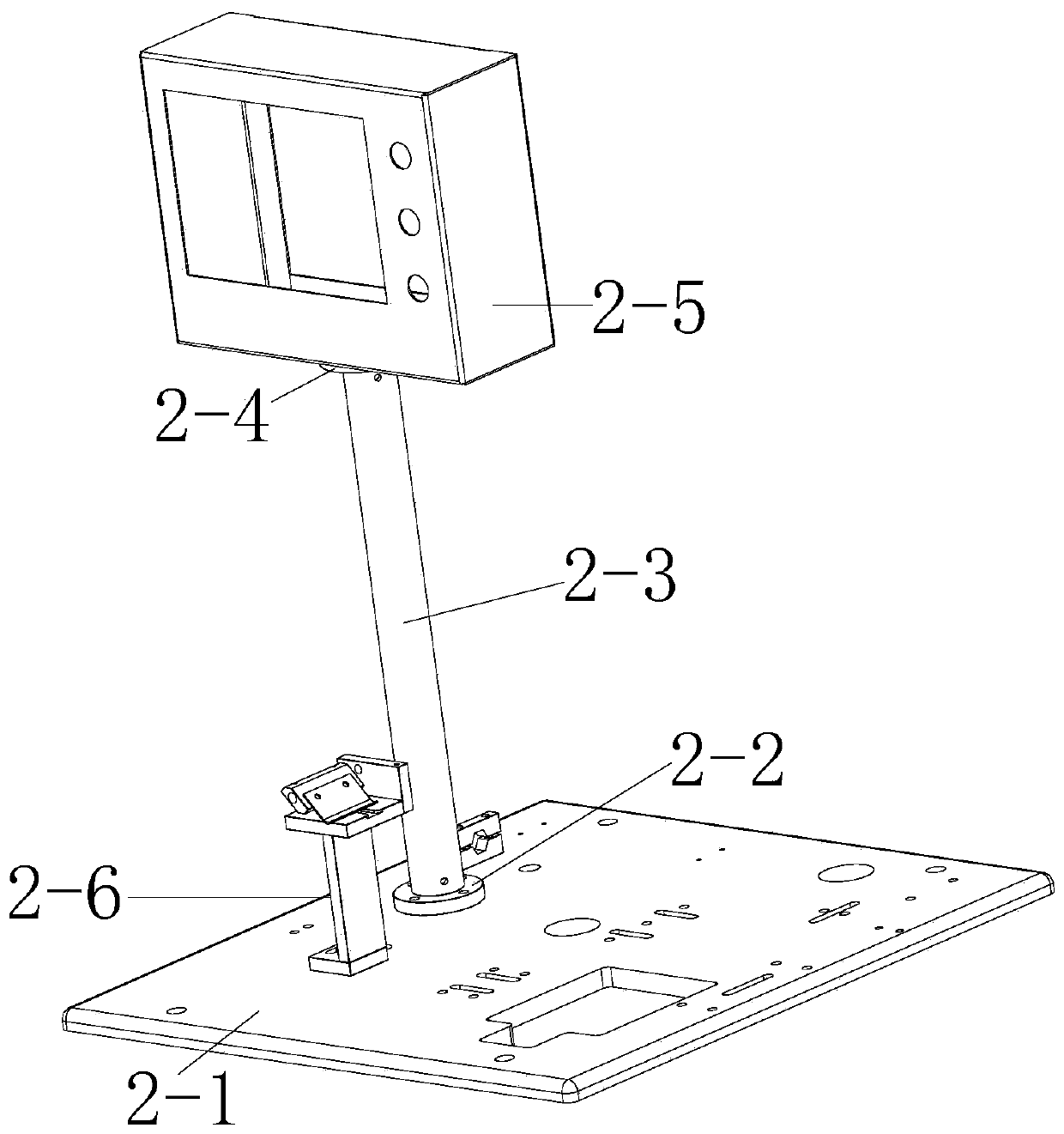

Automatic production all-in-one machine for penetrating pulling head into zipper

The invention discloses an automatic production all-in-one machine for penetrating a pulling head into a zipper. The all-in-one machine comprises a machine case assembly, a panel assembly, a cut-off assembly, an upper mold assembly, a lower mold assembly, a feeding assembly, a pull head track assembly, a clamp assembly, a conveying belt assembly, a vibration disc assembly, a chain guiding frame assembly and an outer rail assembly, wherein the cut-off assembly is in tight connection with the panel assembly, the upper mold assembly is in tight connection with the cut-off assembly, the lower moldassembly is in tight connection with the cut-off assembly, the feeding assembly is in tight connection with the panel assembly, the pull head track assembly is in tight connection with the panel assembly and is connected with the vibration disc assembly, the clamp assembly is in sliding connection with the outer rail assembly, the conveying belt assembly is in tight connection with the machine case assembly, the vibration disc is in tight connection with the panel assembly, and the chain guiding frame assembly is in tight connection with the upper end of the panel assembly. According to the automatic production all-in-one machine, the automatic penetrating operation of the zipper head is realized and is convenient, the efficiency is high, the manual operation is not required, a waste product is not produced in the assembling process of zipper cloth and the zipper head, and the rejection rate is decreased.

Owner:池州美利达智能装备科技有限公司

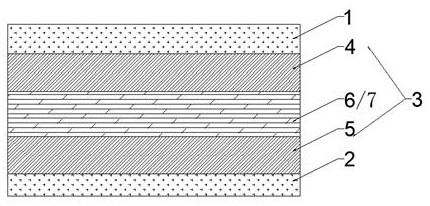

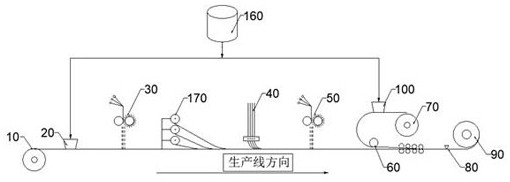

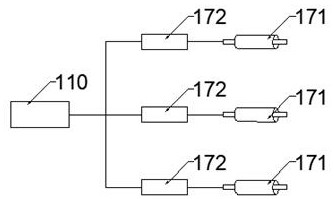

Sandwich type SMC sheet and automatic production line thereof

PendingCN114074433AHigh mechanical strengthImprove bearing capacitySynthetic resin layered productsYarnProduction line

The invention discloses a sandwich type SMC sheet and an automatic production line thereof. The sheet comprises a core material impregnated with a resin paste material, the core material comprises two short fiber layers and a continuous layer positioned between the two short fiber layers; the automatic production line comprises a first yarn cutting device, a continuous layer laying device, a second yarn cutting device and a winding roller which are sequentially arranged in the direction of the production line. The first yarn cutting device, the continuous layer laying device and the second yarn cutting device are all in signal connection with a first program controller. According to the SMC sheet, the continuous layers are added to serve as transmission units of force between fibers, the continuous layers and the short fiber yarn layers on the upper side and the lower side form a sandwich type structure, and the mechanical strength and the force bearing performance of the whole SMC sheet are effectively improved; by means of the improved design of the production line, the regulation and control over the content of SMC fibers, closed-loop feedback control over the glue content in SMC sheets and real-time monitoring over the weight of the SMC sheets are achieved, and the production efficiency and the product quality are effectively improved.

Owner:亨弗劳恩(江苏)复合材料研发有限公司

An energy-saving servo control system for an injection molding machine

The invention relates to an energy-saving servo control system for an injection molding machine. The energy-saving servo control system comprises a control module of the injection molding machine, a servo motor, a constant displacement pump, a control element and a performing element, and further comprises a servo controller, a pressure sensor and a speed sensor, wherein the servo controller comprises a data processing module, a torque conversion module and a speed conversion module; the control module of the injection molding machine comprises a data processing module which is respectively connected to the pressure sensor, the speed sensor, the torque conversion module and the speed conversion module; the torque conversion module and the speed conversion module are respectively connected to the servo motor; the pressure sensor is arranged on an oil outlet pipeline of the constant displacement pump; the speed sensor is arranged on the output shaft of the servo motor; and the servo motor is used for receiving a torque signal and a rotation speed signal which are independent from one another. Compared with the prior art, a purpose of regulating the control system by double closed-loop feedback of a pressure flow rate and rotation speed is realized, so that the working performance of the operation of the injection molding machine is relatively stable, and the energy utilization efficiency of the injection molding machine is improved.

Owner:SHANGHAI UNIV OF ENG SCI

Secondary drive joint of small underwater hydraulic manipulator

The invention aims at providing a small underwater hydraulic mechanical arm two-stage drive joint. The small underwater hydraulic mechanical arm two-stage drive joint comprises a gripper drive hydraulic cylinder assembly for the first-stage linear movement, a second-stage joint rotation assembly and a position detection assembly, wherein the rear end of the first-stage hydraulic cylinder assembly is connected with the front end of a second-stage wrist joint through screws, an oil way inside the first-stage hydraulic cylinder assembly is sealed through an O-shaped seal ring, and the position detection assembly is in interference fit with the rear end of the second-stage wrist joint through a supporting shaft. The wrist joint is driven by hydraulic oil at the oil inlet / outlet in the middle of a second-stage joint mechanism to rotate, and the first-stage gripper hydraulic cylinder assembly is driven to rotate together with the second-stage joint mechanism, a first-stage gripper hydraulic cylinder is driven by hydraulic oil at the oil inlet / outlet in the tail portion of the second-stage joint through the oil way in the first-stage gripper hydraulic cylinder assembly to do linear movement, and the drive torque is provided for a gripper. By means of the small underwater hydraulic mechanical arm two-stage drive joint, the interference of hydraulic connectors connected with the oil inlets and the oil outlets to an outer cylinder is avoided when a first-stage hydraulic cylinder rotates together with the wrist joint in the traditional hydraulic cylinder front and back oil inlet and outlet form.

Owner:HARBIN ENG UNIV

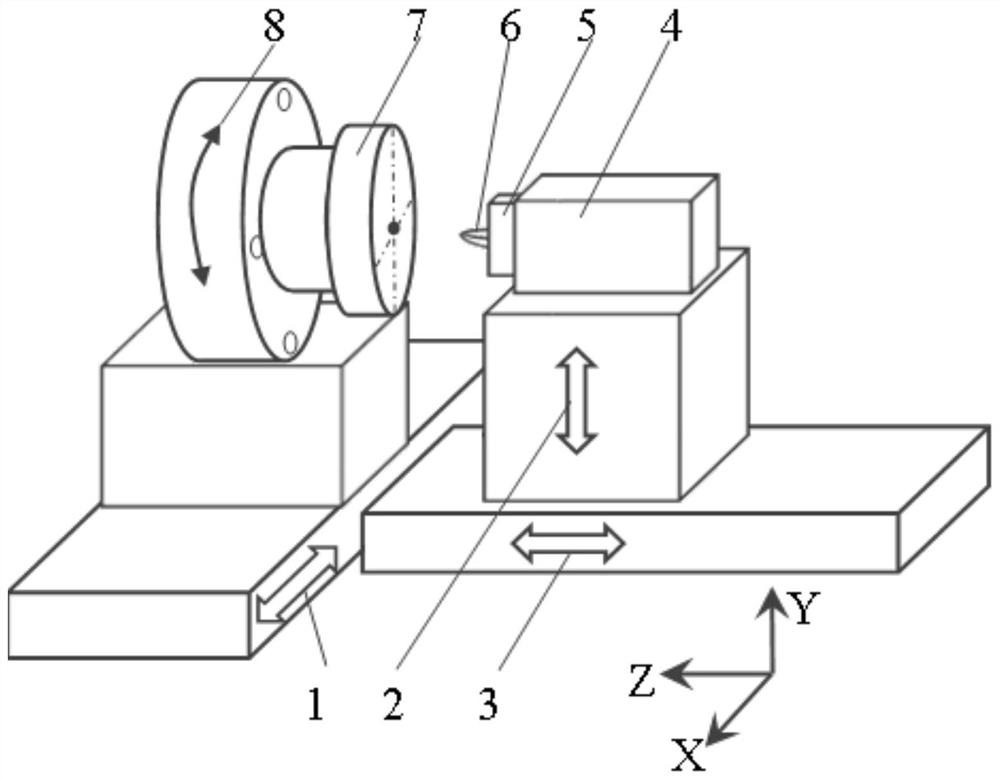

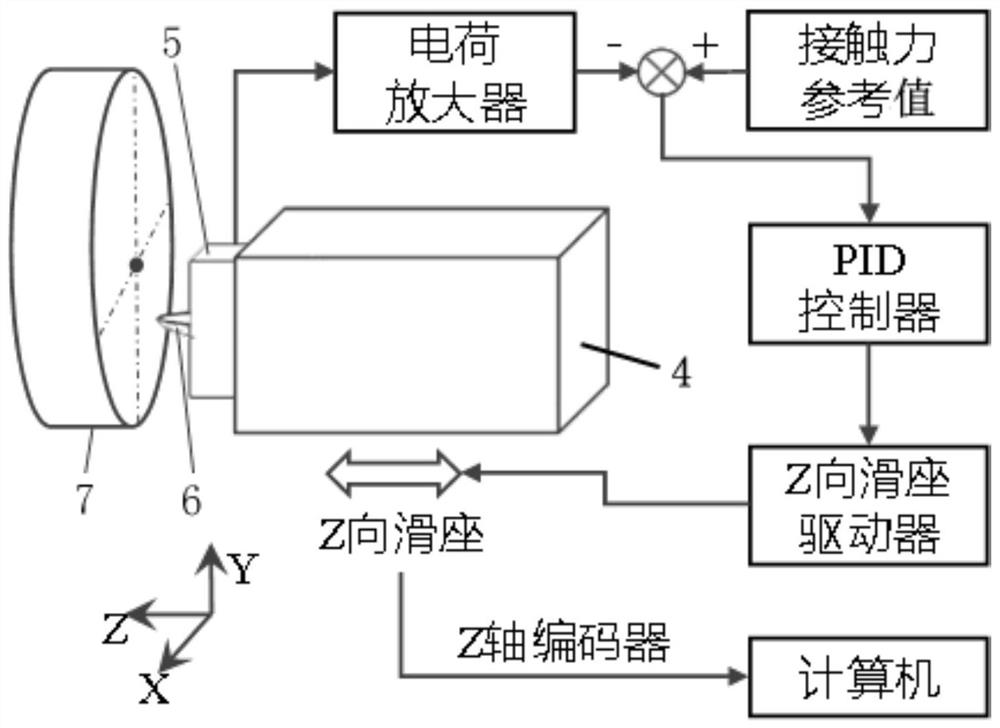

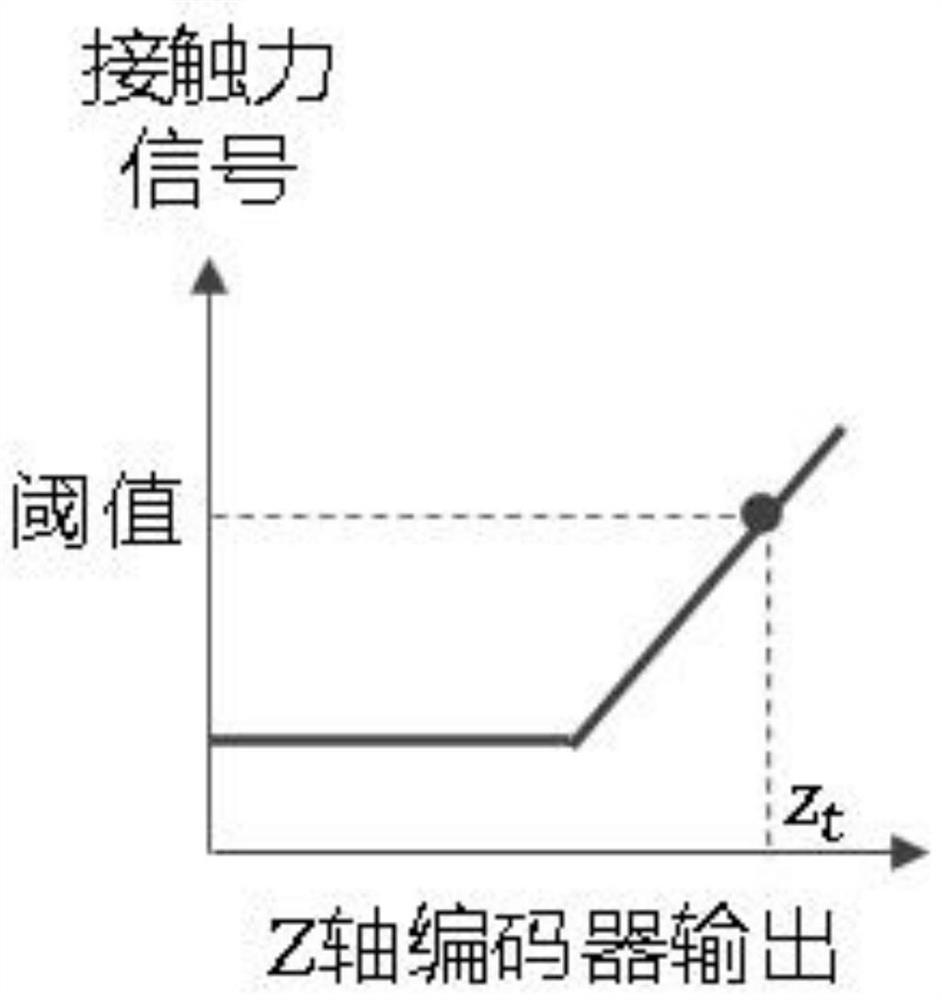

Machining equipment integrated with force sensor and ultra-precision cutting tool setting method

PendingCN113245625AReal-time sensing of contact force/cutting forceRealize closed-loop feedback controlAutomatic control devicesFeeding apparatusControl systemEngineering

The invention belongs to the technical field of precision manufacturing equipment, and particularly relates to machining equipment integrated with a force sensor and an ultra-precision cutting tool setting method. The machining equipment comprises a main shaft, a tool, a three-axis driving device, a position transmission device and a tool setting control system. The tool setting control system comprises the force sensor and a PID controller. The force sensor is arranged on the tool and used for detecting contact force between the tool and a workpiece. The PID controller controls a Z-direction driving mechanism to work according to the magnitude of the contact force. According to the machining equipment integrated with force sensor and the ultra-precision cutting tool setting method, the contact force / cutting force closed-loop feedback control function and the scanning measurement function are achieved, the ultra-precision cutting tool setting method is researched and developed based on the above functions, ultra-precision tool setting can be achieved, other instruments are not needed, the tool setting requirement under the condition that the machining range space is limited, and other tool setting instruments are difficult to install is met, and universality is achieved. Meanwhile, the operation process of tool setting is simplified, and the automation degree of tool setting and the tool setting precision are greatly improved.

Owner:ZHEJIANG UNIV

Method for detecting geometric shape of back of tailor-welding weld and implementing device thereof

InactiveCN102455171BGuaranteed validityAvoid detection errorsUsing optical meansImaging processingInterference factor

The invention relates to a method for detecting the geometric shape of the back of a tailor-welding weld and an implementing device thereof. The method comprises the following steps that: a linear laser is used for projecting laser on the back of a tailor-welding weld so as to generate a plurality of laser streaks on the surface of the tailor-welding weld; a sensing unit acquires and obtains a weld surface gray level image including the laser streaks and transmits the acquired image to an image processing unit; the image processing unit processes the acquired weld image to obtain all shape parameters; and the weld quality is judged and thus the detection on the geometric shape of the back of the weld is finished. The implementing device of the method comprises a sensing unit, an image processing unit and a parameter setting and control unit, wherein the sensing unit is used for acquiring the image of a tailor-welding weld and transmitting the image to the image processing unit, the image processing unit is used for processing the acquired weld image, the parameter setting and control unit is used for setting all parameters and is respectively in communication with the sensing unit, the image processing unit and an upper computer. According to the invention, detection error caused by interference factors such as dust on the back of the weld, welding splatter, board scratch and the like in the welding process can be avoided, and the detection accuracy is improved greatly.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A high-precision optical accelerometer based on zipper-type photonic crystal micro-nano cavity

ActiveCN109946480BIncrease detection limit capabilityHigh sensitivityTelevision system detailsImpedence networksAccelerometerEngineering

The invention discloses a high-precision photodynamic accelerometer based on a zipper type photonic crystal micro-nano cavity. The accelerometer comprises a laser input and reception structure arranged in the left and right sides of the accelerometer structure, a silicon micro mechanical structure arranged in the middle portion of the accelerometer, and a glass substrate structure positioned in the bottom of the silicon micro mechanical structure and provided with electrodes. A laser incident structure is arranged in an input groove in the left side of a main silicon microstructure, a reception structure is arranged in an output groove in the right side of the main silicon microstructure. An optical signal serves as a measurement signal of the micro accelerometer, the sensitivity is high,the uncertainty is low, the detection limit of the micro accelerometer is improved, and the detection sensitivity is improved greatly. The zipper type photonic crystal micro-nano cavity is used, the performance is more stable and the optical precision is higher compared with a common planar parallel resonance micro-nano cavity at present, and higher acceleration sensitivity is achieved.

Owner:SOUTHEAST UNIV

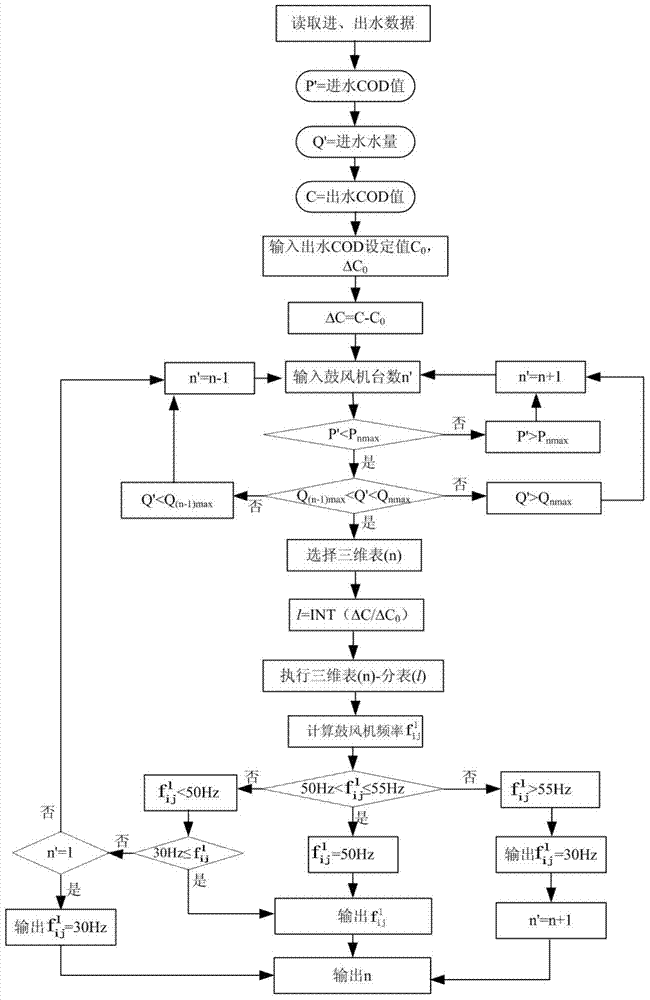

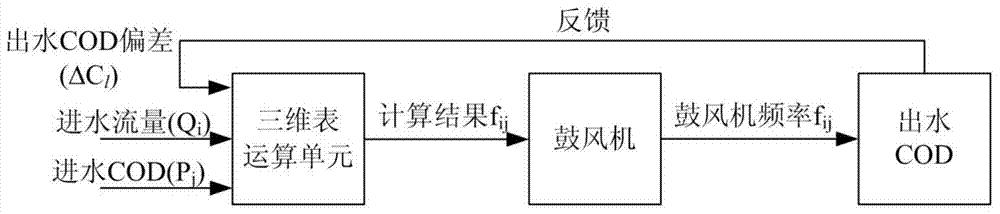

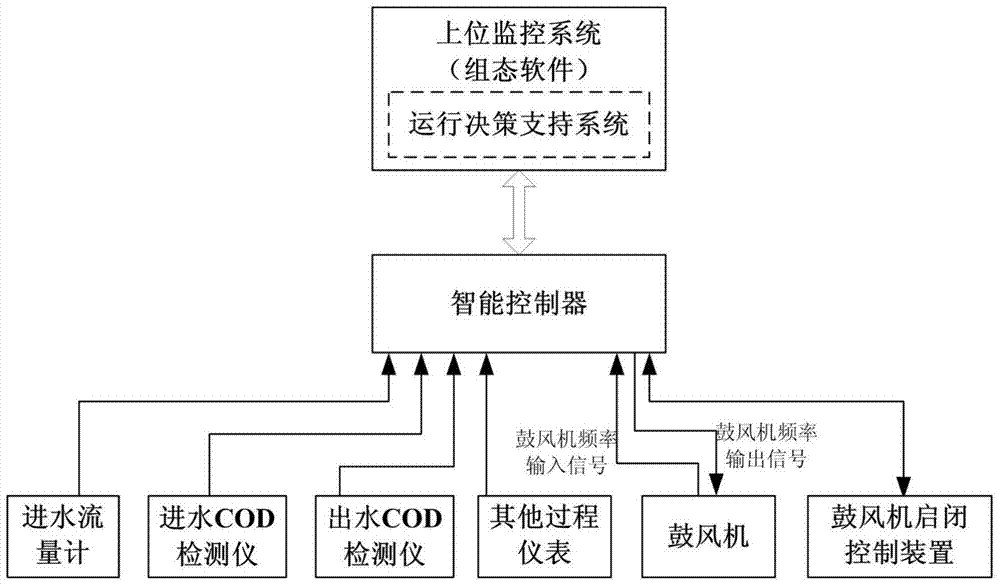

Sewage treatment energy-saving control method based on three-variable three-dimensional table

ActiveCN104731060ARealize closed-loop feedback controlGuarantee water qualityTotal factory controlProgramme total factory controlEngineeringSewage

The invention discloses a sewage treatment energy-saving control method based on a three-variable three-dimensional table. According to the sewage treatment energy-saving control method based on the three-variable three-dimensional table, the output frequency of air blowers is adjusted according to the change of the sewage inflow rate, the water inflow chemical oxygen demand and the water effluent chemical oxygen demand deviation. The sewage treatment energy-saving control method based on the three-variable three-dimensional table comprises the steps that the three-dimensional table with the gradually increasing sewage inflow rate Q, the gradually increasing water inflow chemical oxygen demand P and the gradually increasing water effluent chemical oxygen demand deviation delta C used as the three variables, and the corresponding theoretical number n of working air blowers and the theoretical output frequency values (please see the specification for the symbol) of the air blowers are increased or decreased along with the increasing or decreasing of the gradually increasing sewage inflow rate Q, the gradually increasing water inflow chemical oxygen demand P and the gradually increasing water effluent chemical oxygen demand deviation delta C; the current water inflow rate Q', the current water inflow chemical oxygen demand P' and the current water effluent chemical oxygen demand C are obtained regularly; the water effluent chemical oxygen demand deviation delta C is calculated according to the current water effluent chemical oxygen demand deviation C and a water chemical oxygen demand discharging standard value; the current theoretical number n of working air blowers and the current theoretical output frequency values (please see the specification for the symbol) of the air blowers are obtained by positioning the current water inflow rate Q', the current water inflow chemical oxygen demand P' and the water effluent chemical oxygen demand deviation delta C in the three-dimensional table, and then the number n' of actually-working air blowers and the actual output frequency of the air blowers are adjusted in real time. According to the sewage treatment energy-saving control method based on the three-variable three-dimensional table, the frequency and the number of the air blowers can be adjusted intelligently, and thus the situation that the sewage treatment capacity is not high enough due to the fact that the frequency of the air blowers is too low or waste is caused due to the fact that frequency of the air blowers is too high is avoided.

Owner:BEIJING JINKONG DATA TECH

A miniaturized underwater hydraulic manipulator arm joint structure

The invention relates to an arm joint structure of a small underwater hydraulic manipulator, which comprises a first mechanical arm, a second mechanical arm and a drive mechanism, wherein the front end of the first mechanical arm is connected with the rear end of the second mechanical arm via a rotation shaft; the drive mechanism is arranged between the first mechanical arm and the second mechanical arm and comprises a hydraulic cylinder, a C-shaped plate and a straight plate; a cylinder body of the hydraulic cylinder is articulated with the first mechanical arm; a cylinder rod is articulated with the middle of the C-shaped plate; one end of the C-shaped plate is articulated with the first mechanical arm; the other end of the C-shaped plate is articulated with one end of the straight plate; and the other end of the straight plate is articulated with the second mechanical arm. The arm joint structure has the advantages of compact structure, small size, convenience in mounting, flexible joint driving and strong driving power, can achieve 180-degree rotation of a manipulator joint, and is applicable to driving the small underwater hydraulic manipulator joint.

Owner:HARBIN ENG UNIV

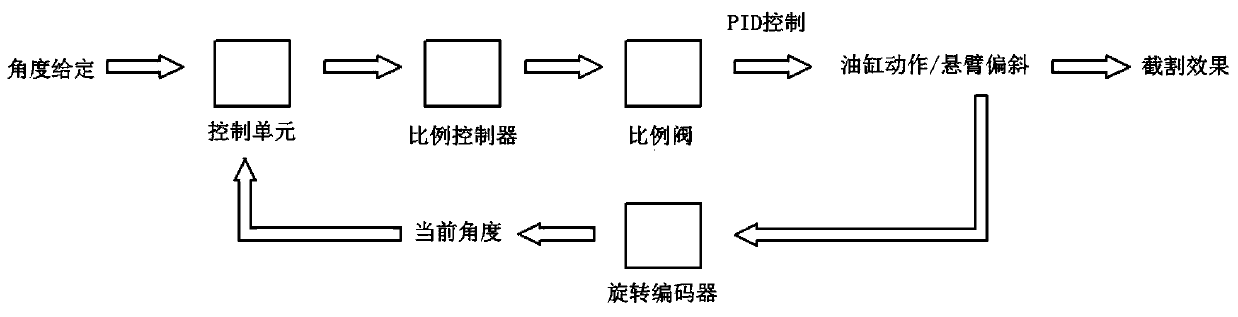

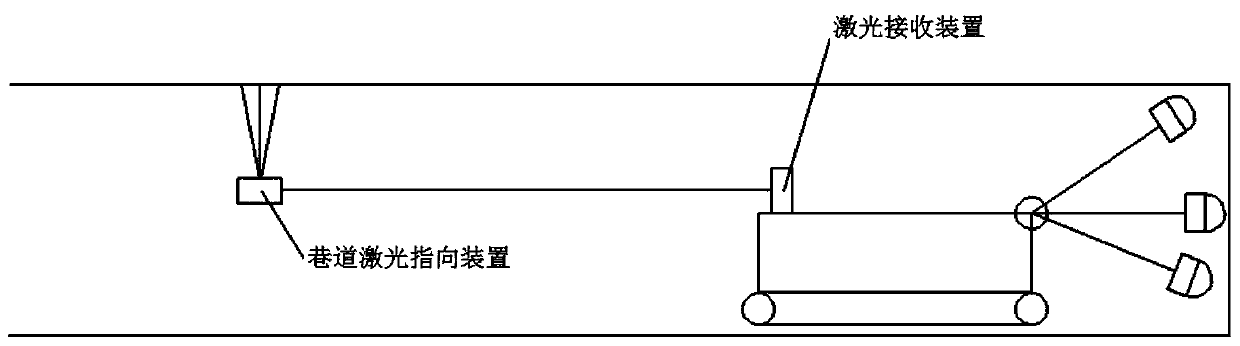

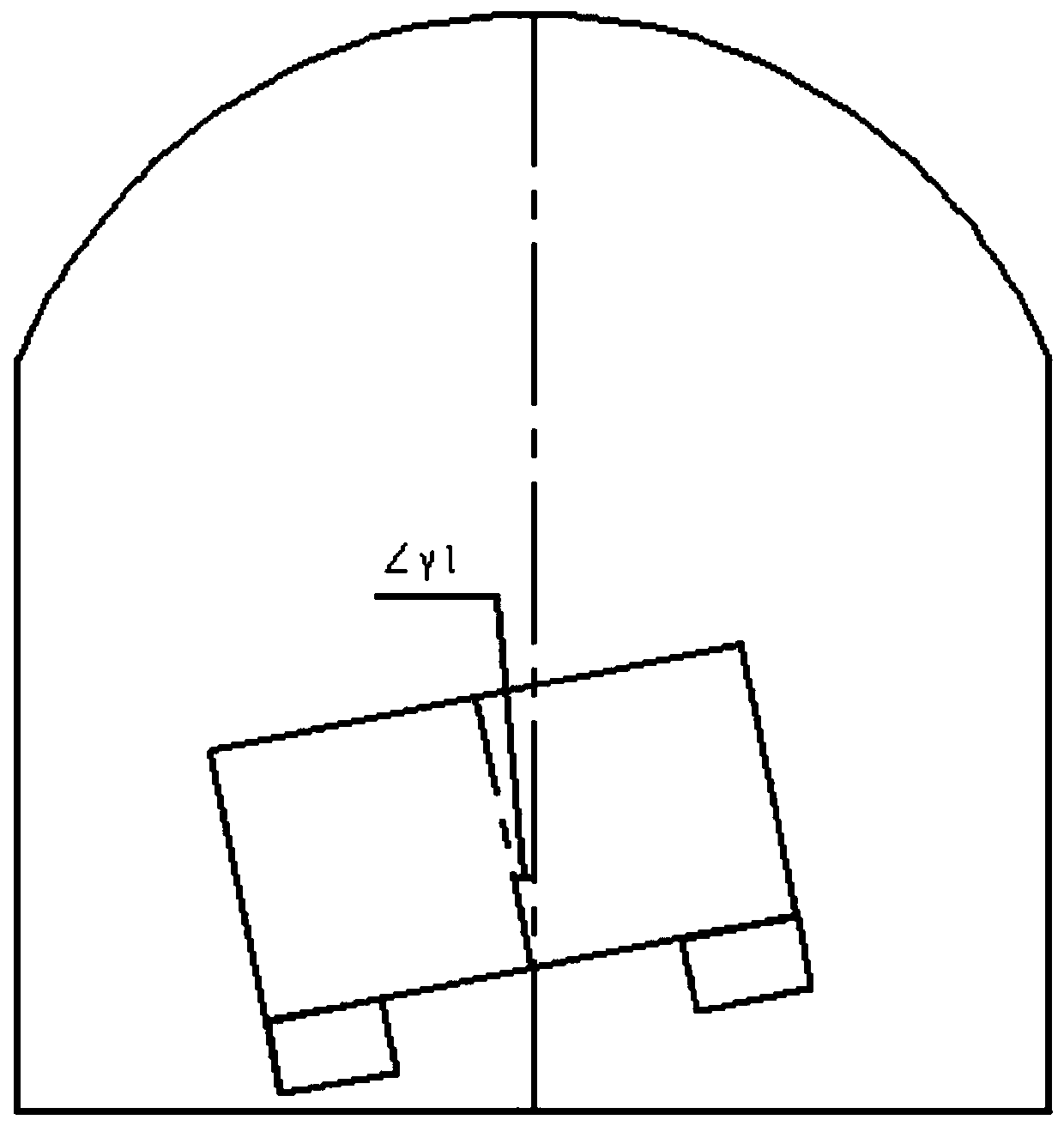

Cantilever tunneling machine and tunneling control method thereof

InactiveCN111425198ARealize regulationRealize closed-loop feedback controlDriving meansCutting machinesAutomatic controlControl cell

The invention discloses a cantilever tunneling machine and a tunneling control method thereof. The cantilever tunneling machine comprises a horizontal adjusting oil cylinder, a vertical adjusting oilcylinder and a control unit, wherein the horizontal adjusting oil cylinder and the vertical adjusting oil cylinder are used for adjusting an angle of a cantilever and connected with the control unit through proportional valves; a transverse rotary encoder and a longitudinal rotary encoder are arranged on the cantilever and used for detecting a horizontal angle and a vertical angle of the cantilever respectively and sending the horizontal angle and the vertical angle to the control unit; and the control unit is used for controlling the horizontal adjusting oil cylinder and the vertical adjusting oil cylinder to act through the proportional valves. According to the cantilever tunneling machine and the tunneling control method thereof, the oil cylinders are controlled by the proportional valves to act and the rotary encoders are arranged and used for measuring angle information, so that automatic adjustment and closed loop feedback control for the angle of the cantilever are realized, theposition accuracy of the angle of the cantilever is relatively high, and the forming quality of a tunneling roadway is improved. Besides, manual operation is replaced with automatic control, the labor intensity is reduced, and the safety performance is improved.

Owner:TZ COAL MINE MACHINERY

A laser tailor welding curved surface seam measurement method and its realization device

InactiveCN105300296BAvoid measurement errorsImprove detection accuracyUsing optical meansImaging processingEngineering

The invention relates to a laser tailored welding curved surface abutted seam measuring method and a realization device thereof. The method comprises the following steps: generating circular structured light by utilizing a circular laser, and generating horizontal-I linear structured light by utilizing a horizontal-I linear laser, wherein the circular structured light and the horizontal-I linear structured light are projected to the surface of a curved surface abutted seam and intersected; collecting and obtaining an abutted seam surface gray level image comprising the horizontal-I linear structured light and the circular structured light through a sensing unit, and transmitting the collected image to an image processing unit; and carrying out processing by the image processing unit on the collected image to obtain three-dimensional position and normal vector of the curved surface abutted seam center and abutted seam width and mismatching values. The device comprises the sensing unit for collecting the laser tailored welding curved surface abutted seam image and transmitting the image to the processing unit; the image processing unit for carrying out processing on the collected abutted seam image; and a parameter setting and control unit for setting parameters and in communication connection with the sensing unit, the image processing unit and an upper computer. The laser tailored welding curved surface abutted seam measurement precision is improved, online tracking adjustment of the pose of a welding torch for curved surface laser tailored welding is realized favorably, welding quality is ensured.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

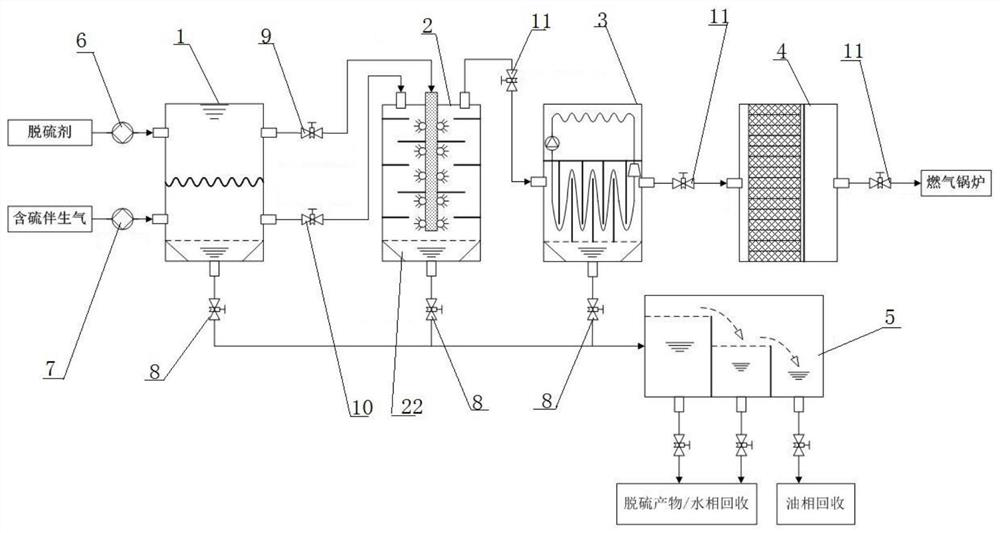

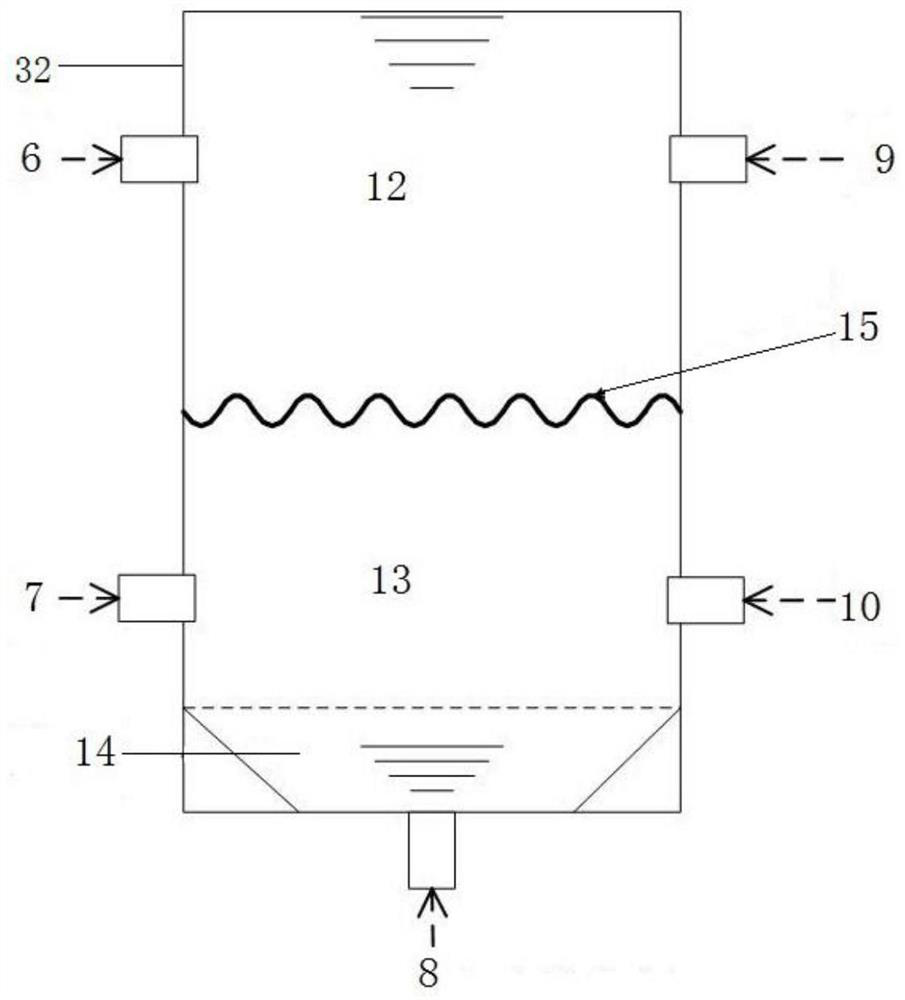

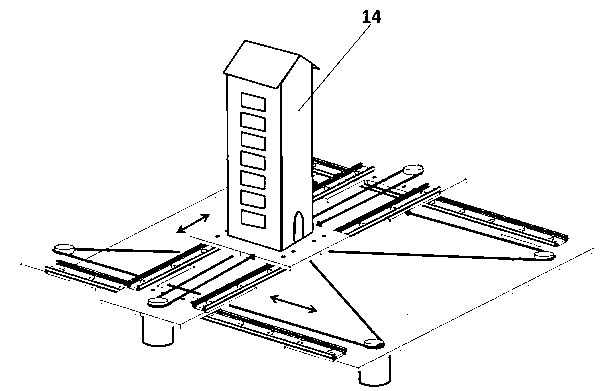

An in-situ purification treatment system and method for directly supplying gas-fired boilers with low-sulfur oilfield associated gas

ActiveCN111205898BRealize closed-loop feedback controlRealize resource utilizationGaseous fuelsAtmospheric pollutionTreatment system

The invention belongs to the technical field of resource utilization of associated gas in oilfields, and in particular relates to an in-situ purification treatment system and method for directly supplying gas-fired boilers with associated gas in low-sulfur oilfields. The invention is composed of an energy storage and voltage stabilizing device, an atomization and trapping device, a refrigerant liquid removal device, a dry filter device and the liquid phase recovery device. In the drying and filtering device of the present invention, the pressure of the associated gas is raised and lowered and the operation of the energy storage and pressure stabilizing device, the atomization and trapping device, and the liquid level control device at the bottom of the refrigerant removal device solves the problem of dispersion It is difficult to centrally collect sulfur-containing associated gas with a small amount of gas in oil wells, and it is easy to cause air pollution and poisoning of surrounding personnel when venting and burning. Compared with traditional natural gas desulfurization tower processing devices, it is no longer limited by large natural gas volume and continuous operation conditions. It ensures the resource utilization of sulfur-containing associated gas, and ensures that there is no hydrogen sulfide in the gas source, no hazards in combustion products, and no condensate in the gas supply pipeline when directly supplying gas-fired boilers.

Owner:PETROCHINA CO LTD

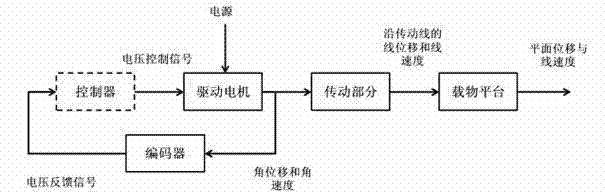

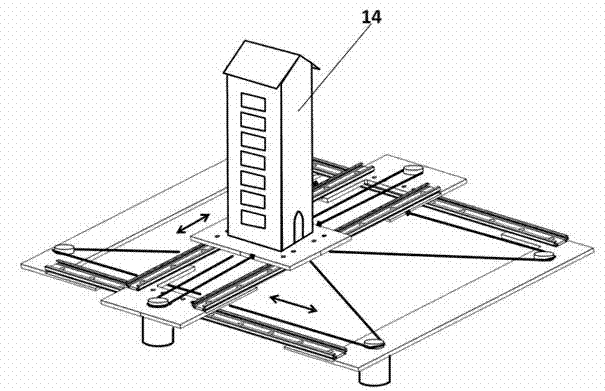

Rapid plane movement platform

ActiveCN102394024BHigh precisionRealize closed-loop feedback controlEducational modelsEngineeringMechanical engineering

Owner:HANGZHOU DIANZI UNIV

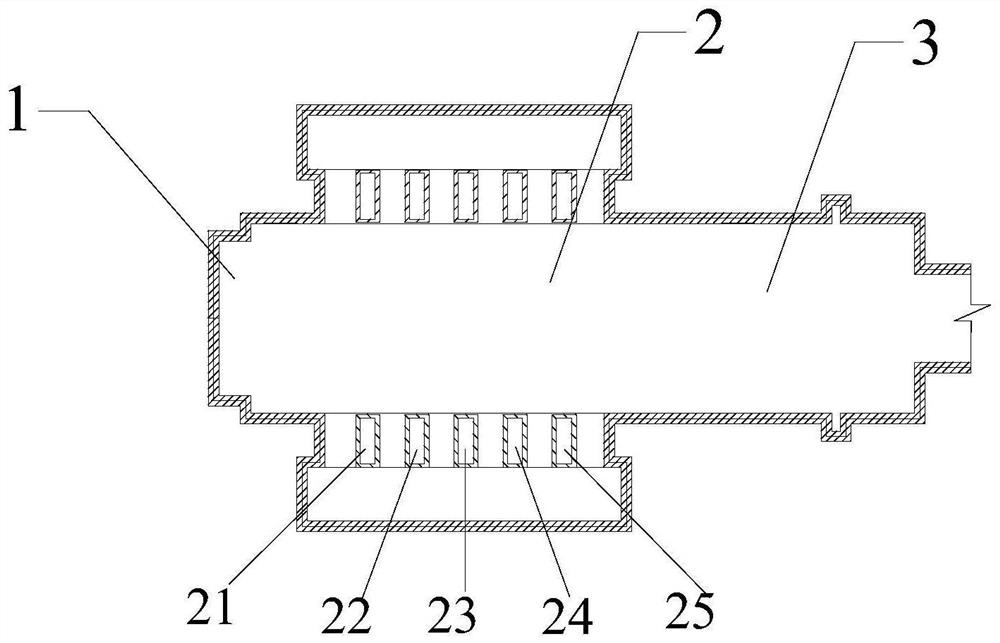

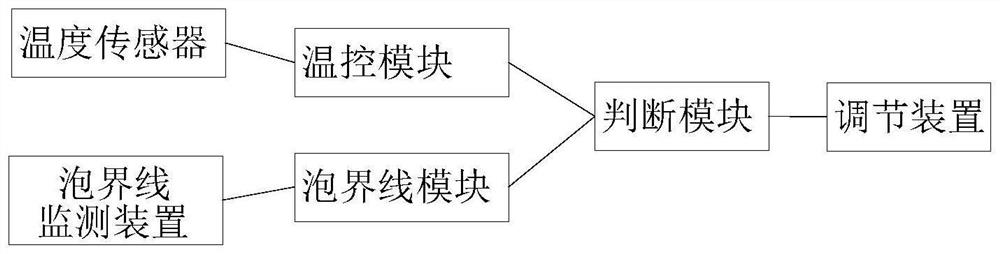

Method for intelligently controlling melting temperature field of glass melting furnace

ActiveCN114671592ASmall fluctuationRealize closed-loop feedback controlGlass furnace apparatusThermodynamicsEngineering

The invention relates to the technical field of float glass production and manufacturing, in particular to a method for intelligently controlling a melting temperature field of a glass melting furnace. Comprising the following steps that S1, by controlling the total amount of fuel, the fuel amount of each small furnace is adjusted at the same time; adjusting the fuel proportion distribution of each small furnace until the melting temperature field of the glass melting furnace is stable; s2, acquiring the hot-spot temperature change of the glass melting furnace, and adjusting the total amount of fuel according to the hot-spot temperature change; when the hot spot temperature is reduced, the total fuel amount is increased; when the hot spot temperature rises, the total fuel amount is reduced; s3, the moving direction of the bubble boundary is obtained, and the total fuel amount is adjusted according to the hot spot temperature change and the bubble boundary moving direction; when the temperature of the hot spot drops, the bubble boundary line moves towards the feeding port to reduce the total amount of fuel; when the hot-spot temperature rises, the bubble boundary line moves towards the clarification area, and the total fuel amount is increased.

Owner:成都南玻玻璃有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com