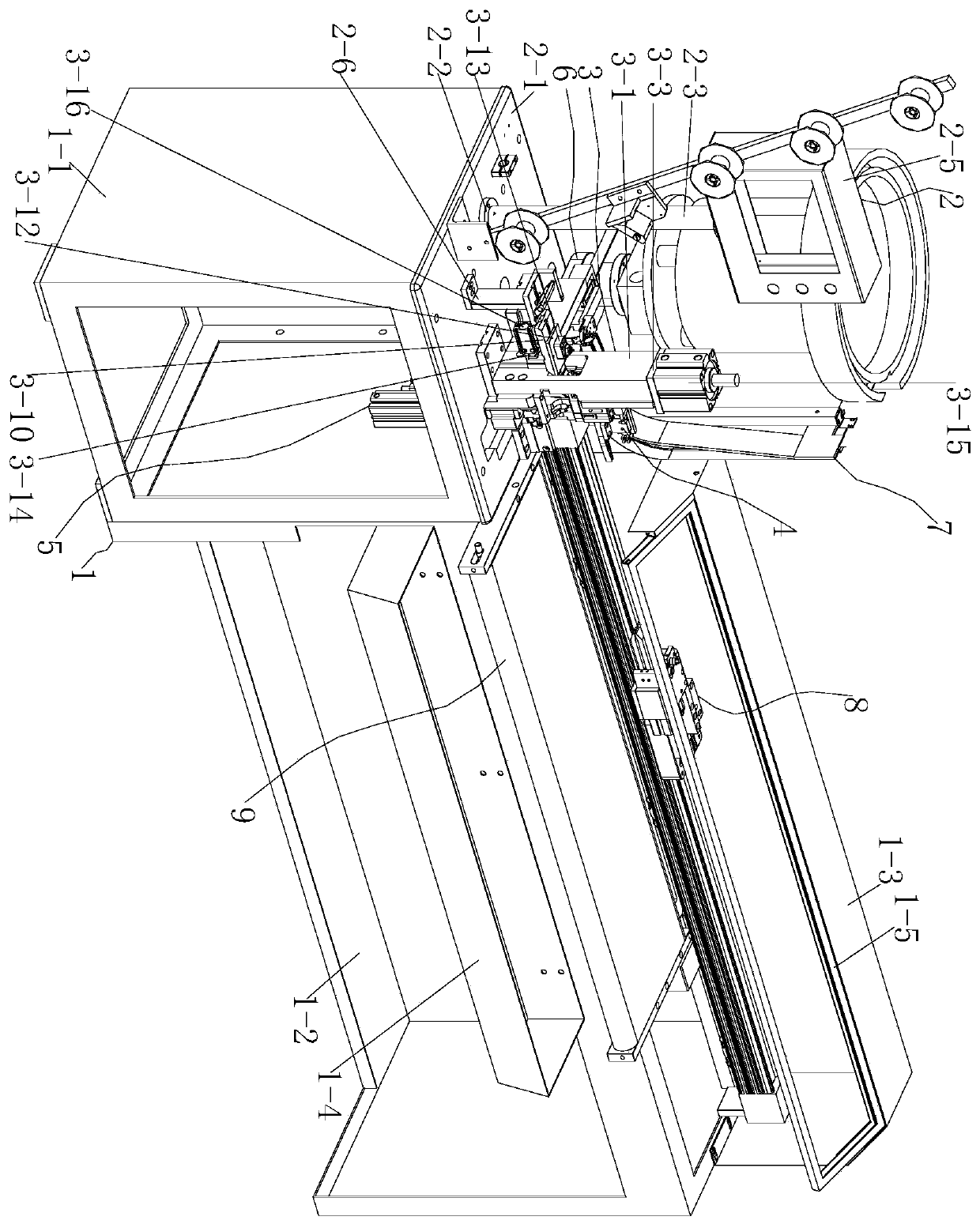

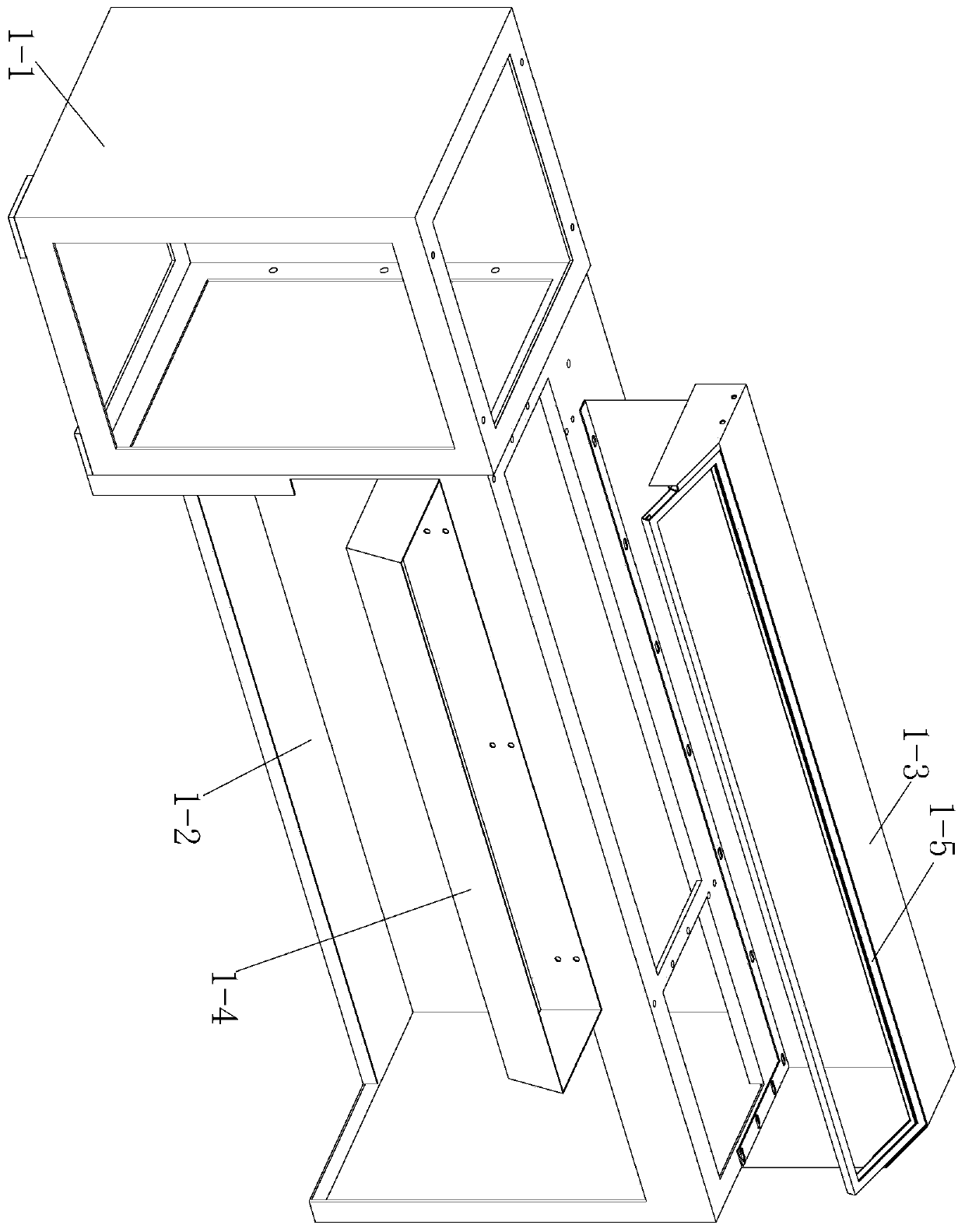

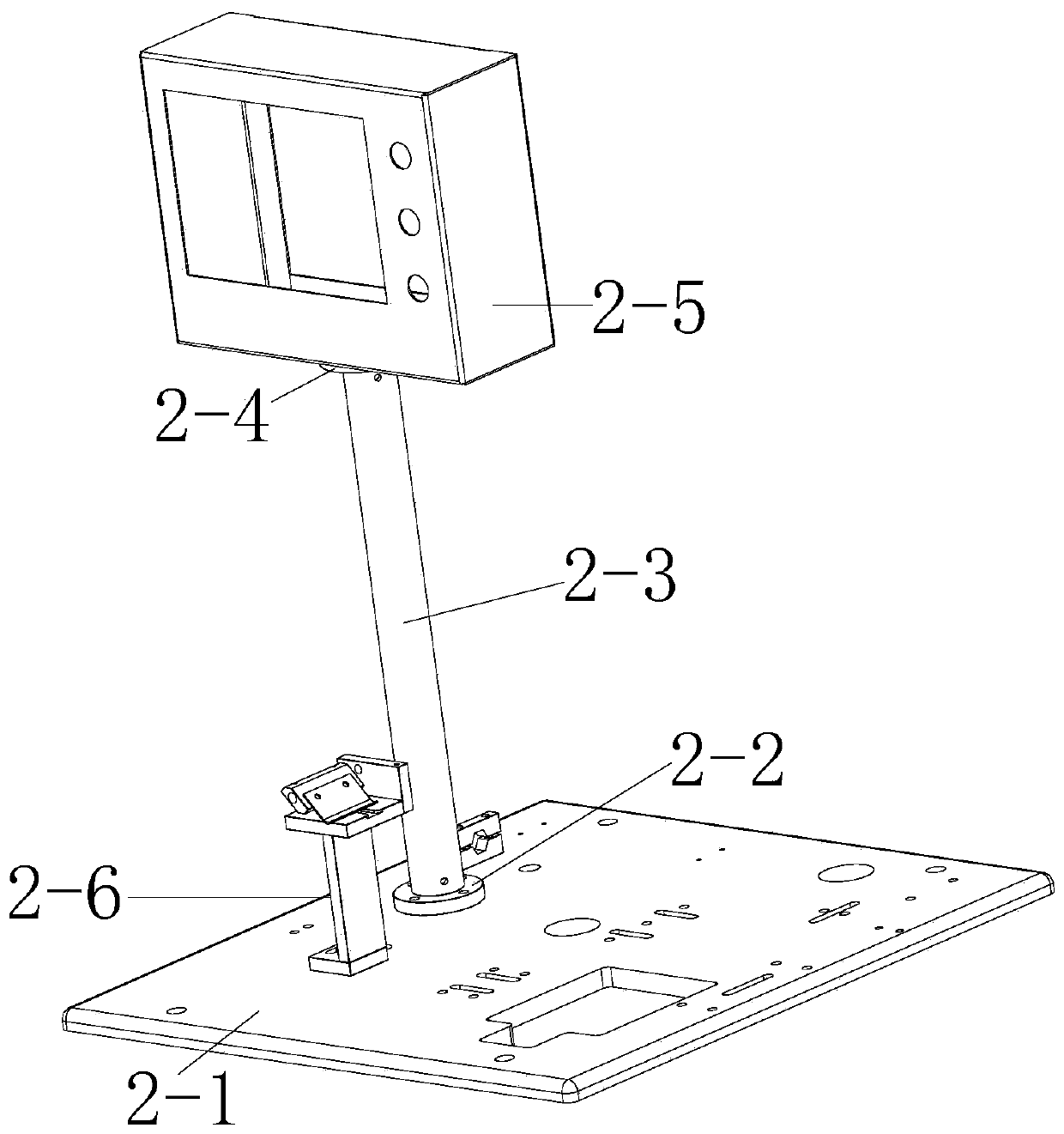

Automatic production all-in-one machine for penetrating pulling head into zipper

A technology of wearing and pulling a head and an integrated machine, which is applied in the directions of sliding fastener components, applications, fasteners, etc., can solve the problems of low assembly efficiency, high rejection rate, error-prone, etc., and achieve the effect of high operation efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Start the cut-off function first, and cut off the piston rod of the cylinder 3-15 to move downwards, because the cut-off cylinder connection block 3-4 is connected with the piston rod end of the cut-off cylinder 3-15, and the cut-off cylinder connection block 3-4 is connected with the piston rod end of the cut-off cylinder 3-15. The upper end of the cutting slider 3-5 is clamped, the upper cutting knife 3-6 is tightly connected to the lower end of the cutting slider 3-5, and the lower cutting knife 3-7 is tightly connected to the lower end of the large sliding box 3-1, Therefore, the piston rod of the cut-off cylinder 3-15 moves down together with the cut-off cylinder connection block 3-4, the cut-off slider 3-5 and the cut-off upper knife 3-6, and then the zipper cloth is cut off by the upper knife 3-6, and then Cut off the piston rod of the cylinder 3-15 and move upwards to reset, this step operation has guaranteed the flatness of the cut surface of the zipper cloth. ...

Embodiment 2

[0058] The induction seat 4-5 is provided with a contact sensor, and the piston rod of the large cylinder 5-11-1 is pushed up, because the main seat 5-1 of the lower mold is provided with a guide rail 5-1-1, The guide rail one 5-1-1 slides and is provided with a slider one 5-1-2, and the movable block 5-2 of the lower mold is tightly connected with the slider one 5-1-2, and the slider mold A5 -3 is tightly connected to the middle of the side of the lower mold movable block 5-2, the slider mold B5-4 is tightly connected to the middle of the upper end of the lower mold movable block 5-2, and the connecting block 5-5 is fastened to the Between the slider mold A5-3 and the slider mold B5-4, the link plate 5-6 is tightly connected to the upper end of the side of the slider mold A5-3, and the slider baffle plate 5-7 is connected to the slider mold The center of the upper end of A5-3 is tightly connected, so the movable block 5-2 of the lower die moves upward along the guide rail 1 5...

Embodiment 3

[0063] The piston rod of the large cylinder 5-11-1 is pushed up, and the lower mold movable block 5-2 moves upward along the guide rail 1 5-1-1 with the parts connected with the lower mold movable block 5-2. When the corresponding contact sensor on the induction pin 4-9 turns off the light, it proves that there is no slider on the lower membrane assembly 5, and then the piston rod of the large cylinder 5-11-1 shrinks and resets, and at the same time pushes the cylinder 7-14-1 The piston rod shrinks, because the push rod 7-9 is slidingly connected with the push rod slide box 7-10, and the slider limit block 7-14 and the connecting block 7-13 are tightened on the push rod 7-9 At the end, the "I" buckle 7-15 is clamped with the slider limit block 7-14, and the upper end of the push rod sliding box 7-10 is fastened with a push cylinder 7-14-1. The pushing card 7-11 is tightly connected with the end of the pushing rod 7-9, and the pushing plate baffle 7-12 is tightly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com