Automatic recyclable garbage sorting and recycling device and method based on machine vision

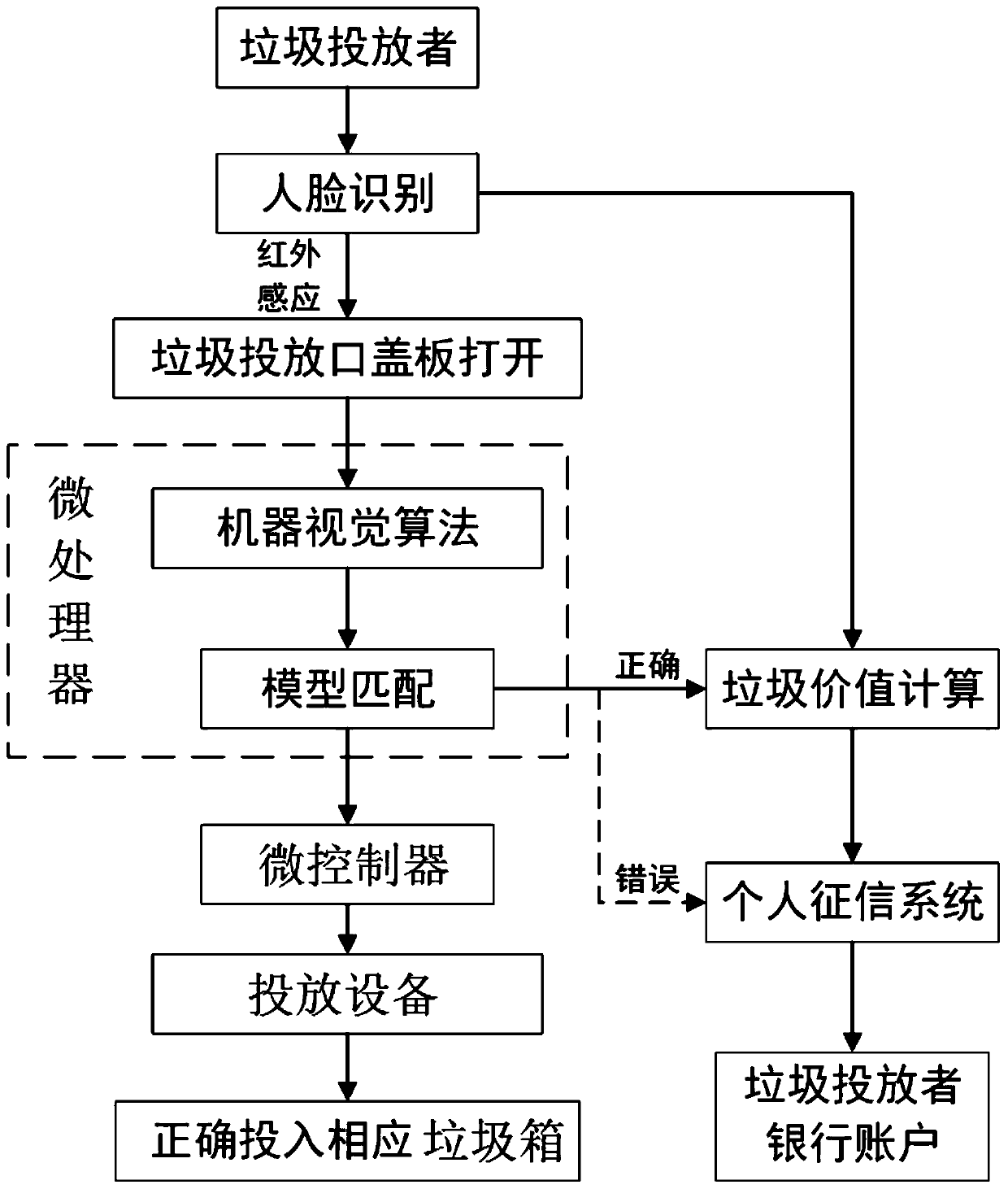

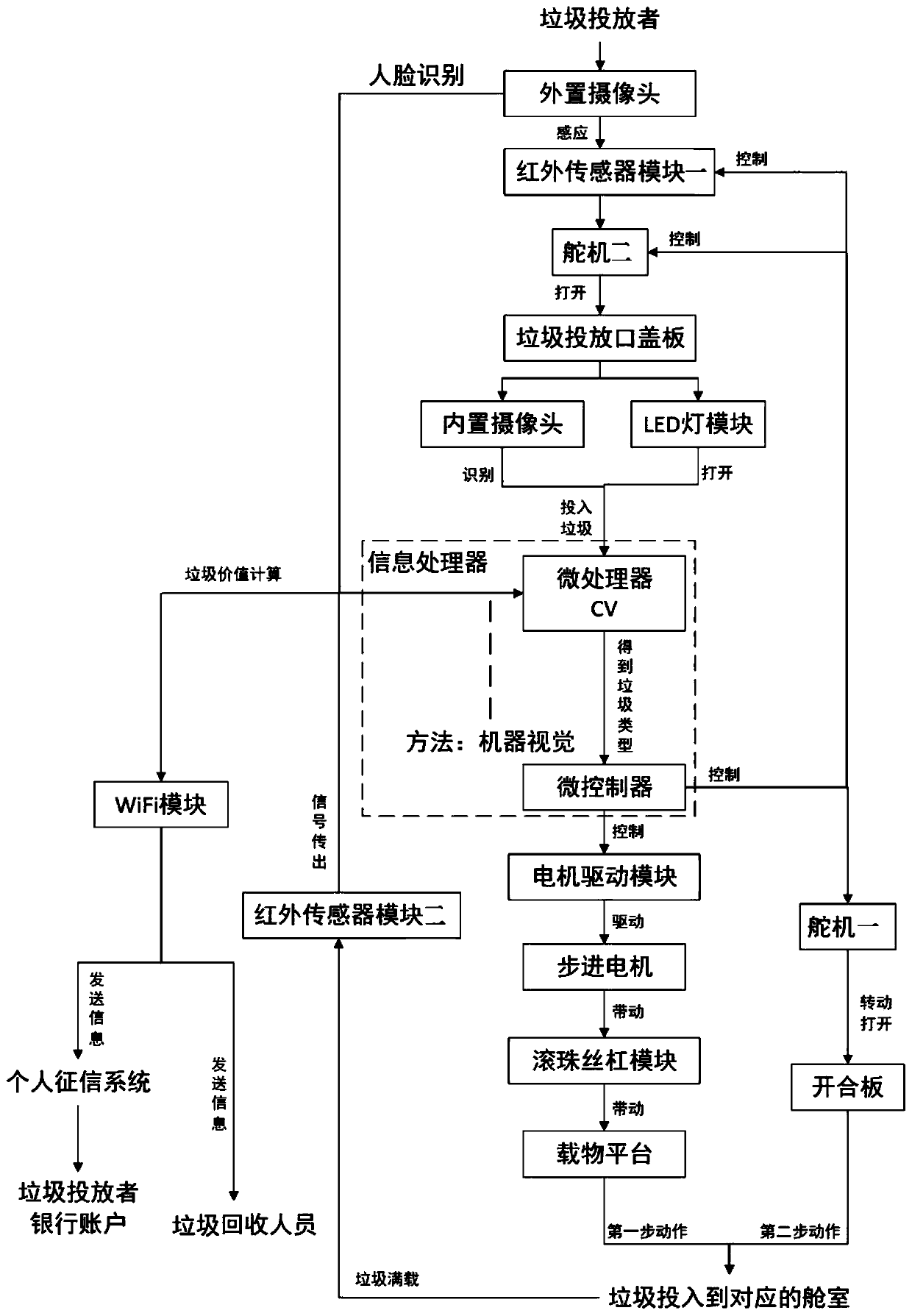

A technology of automatic classification and machine vision, applied in the direction of garbage collection, garbage bins, waste collection and transfer, etc., can solve the problem that the implementation and supervision of garbage classification policies are not in place, the personal credit information system cannot be implemented well, and the enthusiasm for recyclable garbage placement is not enough High-level problems, to achieve the effect of increasing the credit value of the personal credit system, increasing the enthusiasm for delivery, and speeding up the pace of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

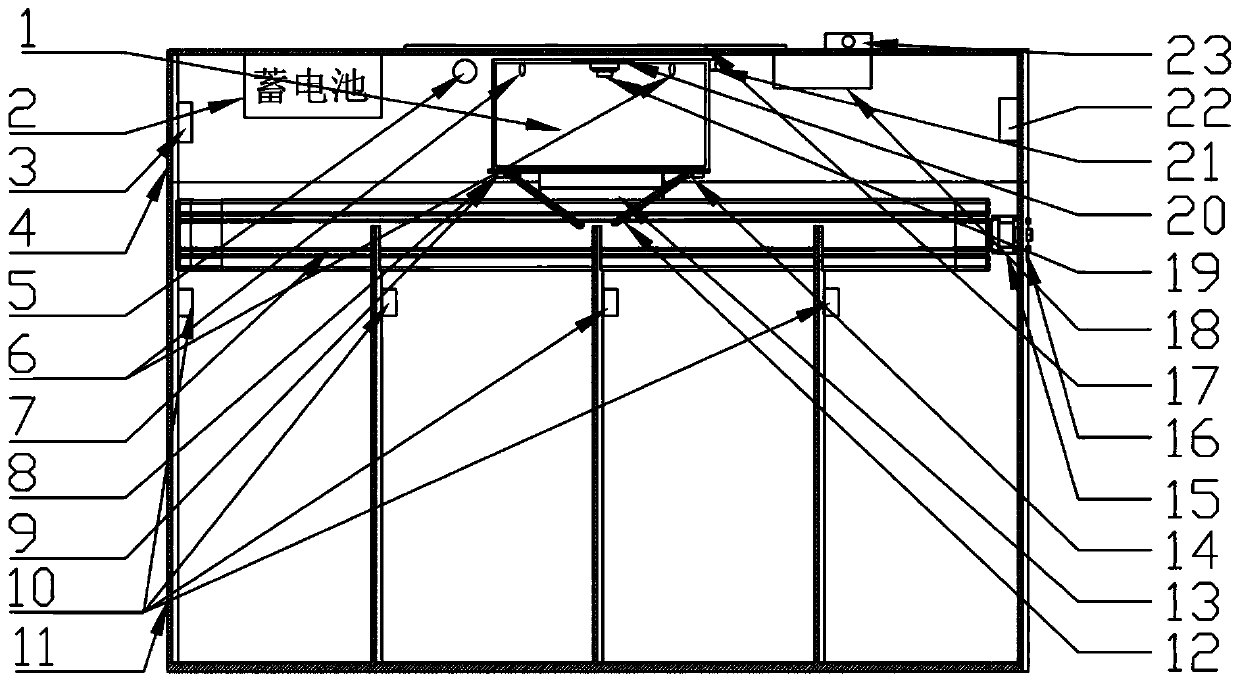

[0026] refer to figure 1 , image 3, the structure of the machine vision-based automatic sorting and recycling device for recyclable garbage in the present invention is to include an upper box body 4 and a lower box body 11, and the upper box body 4 and the lower box body 11 are interlocked up and down to form a whole garbage bin. The upper surface of the body 4 top plate is provided with a solar power generation mechanism 17, and a storage battery 2 is installed on the lower surface of the top plate of the upper box body 4. The solar power generation mechanism 17 is connected with the storage battery 2 to provide power to the storage battery 2; There is a garbage delivery port (these two garbage delivery outlets can be distributed symmetrically to the solar power generation mechanism 15), and an information processor 18 is installed next to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com