Patents

Literature

4083 results about "Mechanical drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

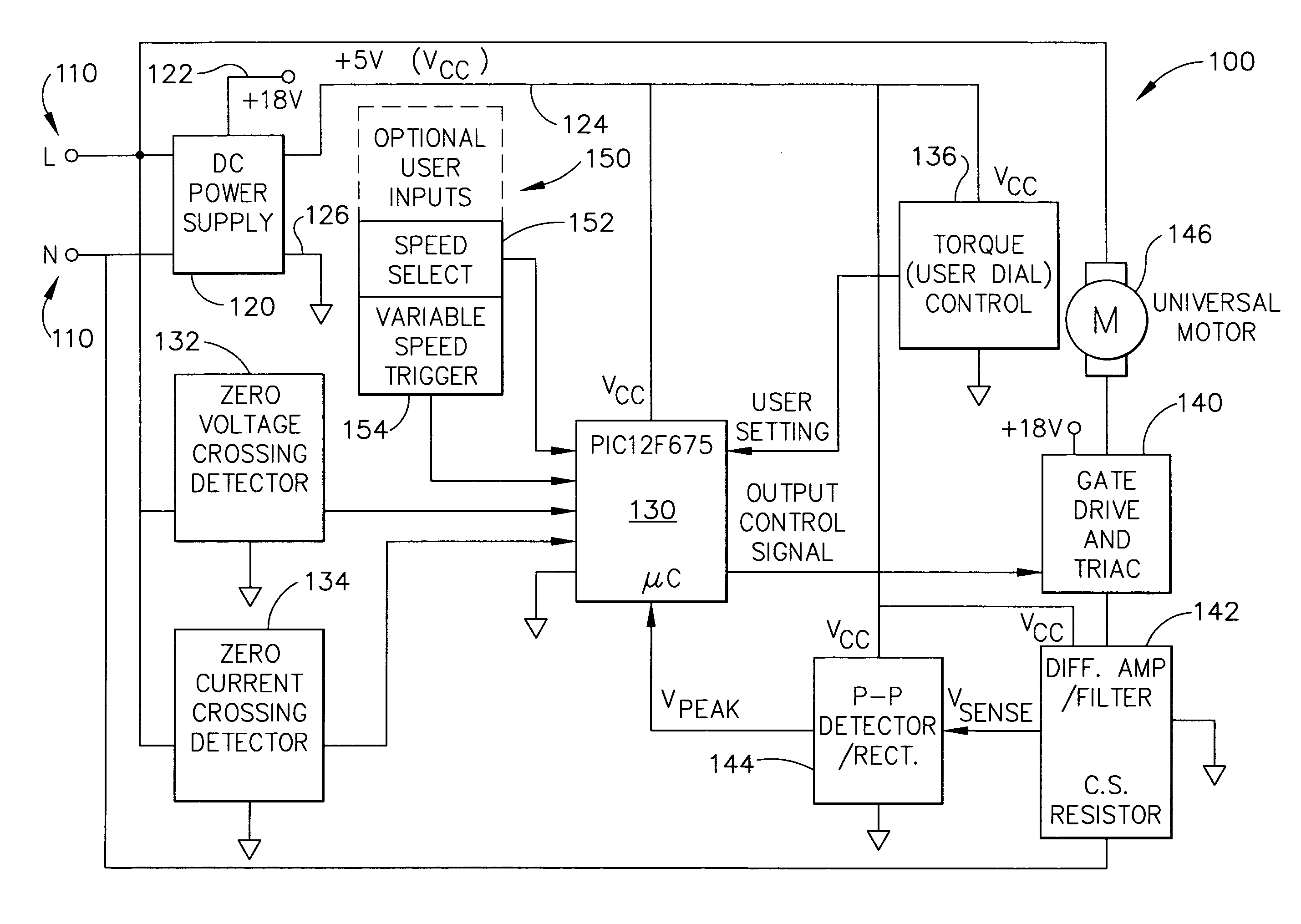

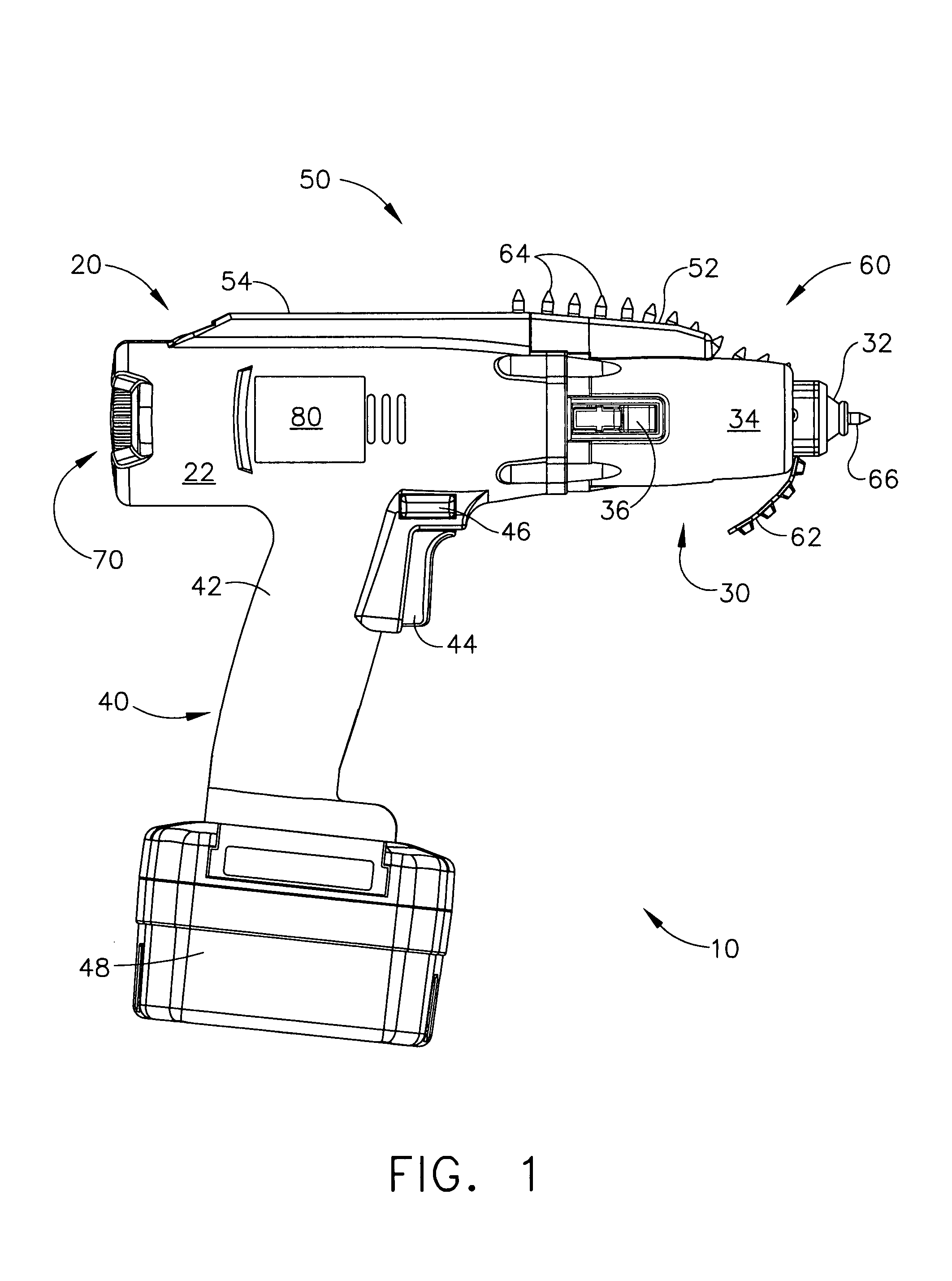

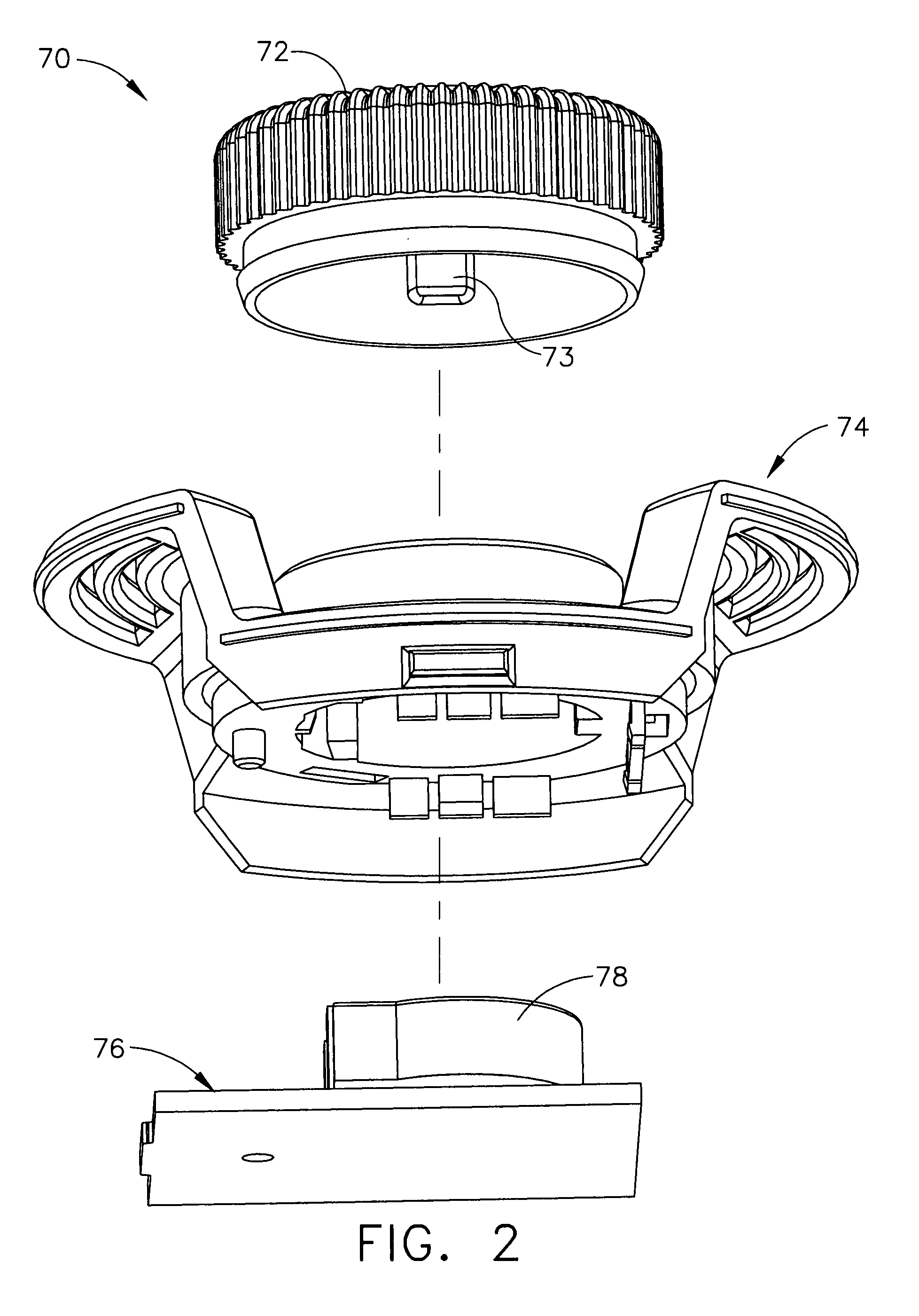

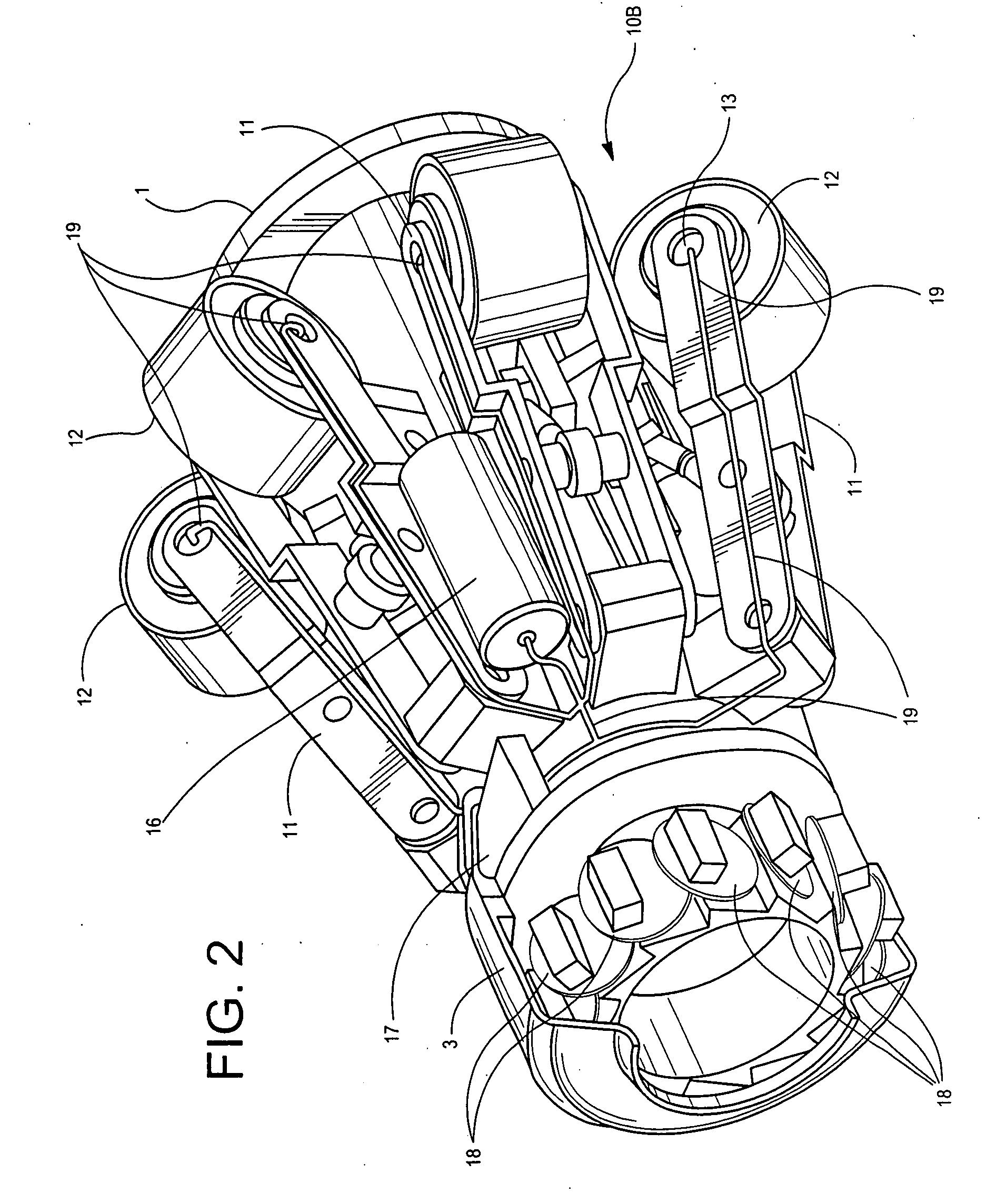

Apparatus for controlling a fastener driving tool, with user-adjustable torque limiting control

An improved hand-held fastener driving tool is provided with an adjustable torque limiting control. The tool is portable, and is electrically powered using either a battery pack or a power cord as a power source. The tool drives collated fasteners (e.g., screws) into solid objects. The motor current is measured to determine the amount of torque being applied to a screw by the motor and mechanical drive components. As the screw bottoms out, the motor torque increases to a point where it exceeds the user-adjusted torque limiting control. The motor is automatically turned off at that point, thereby preventing the screw from being stripped.

Owner:KYOCERA SENCO IND TOOLS INC

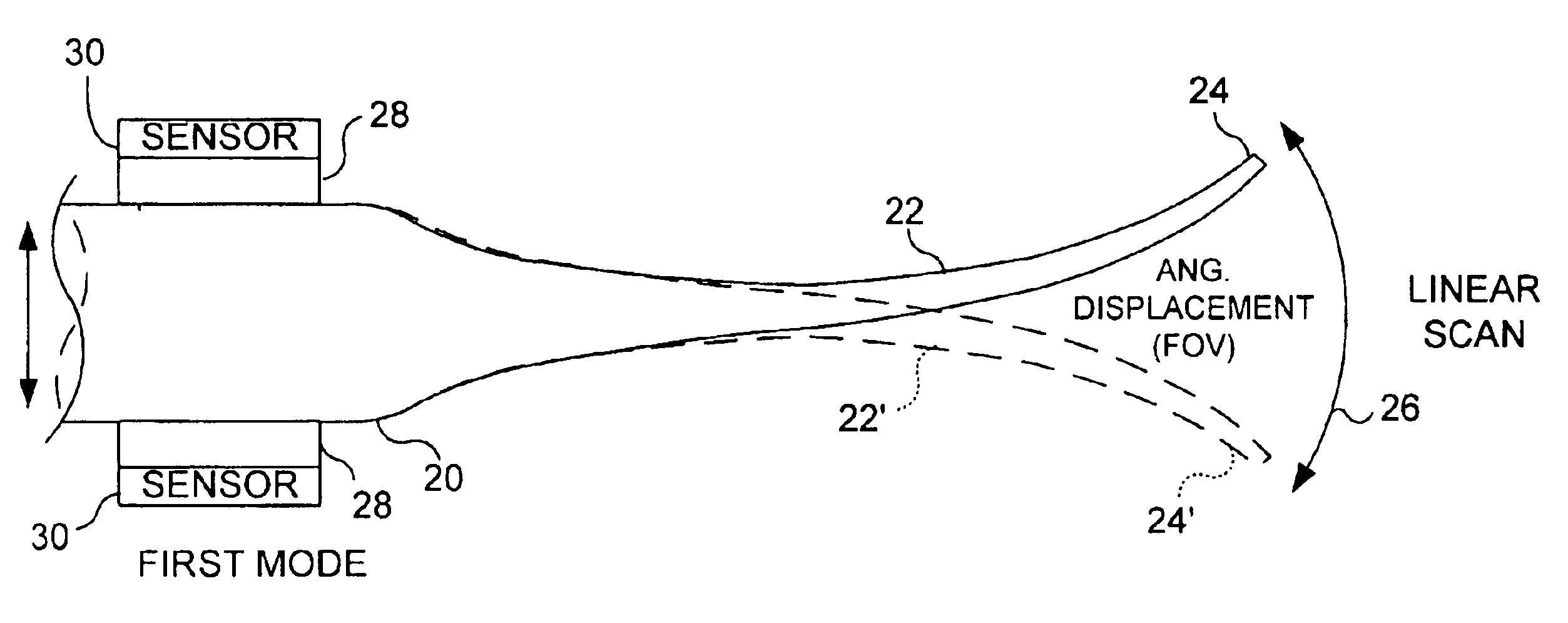

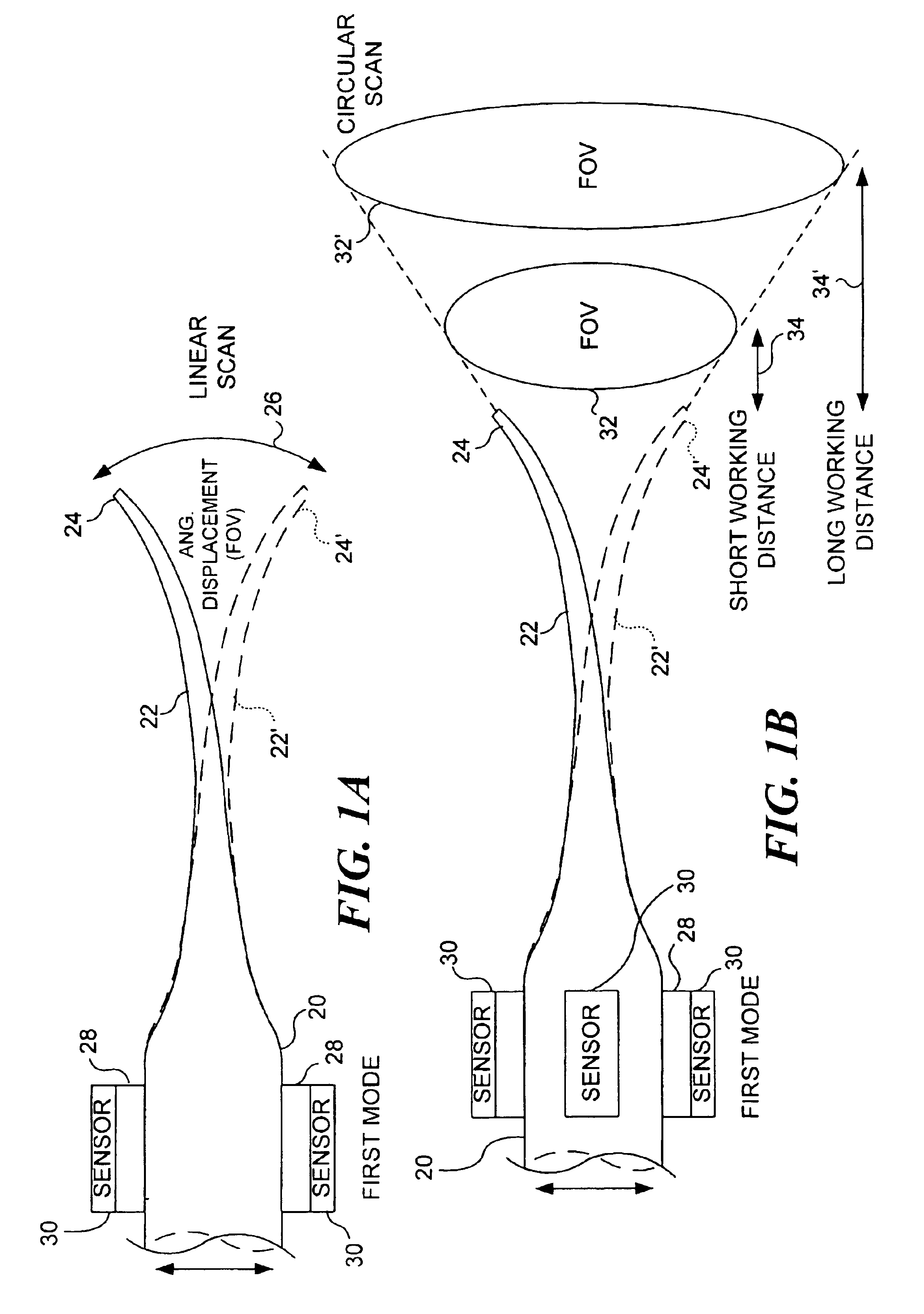

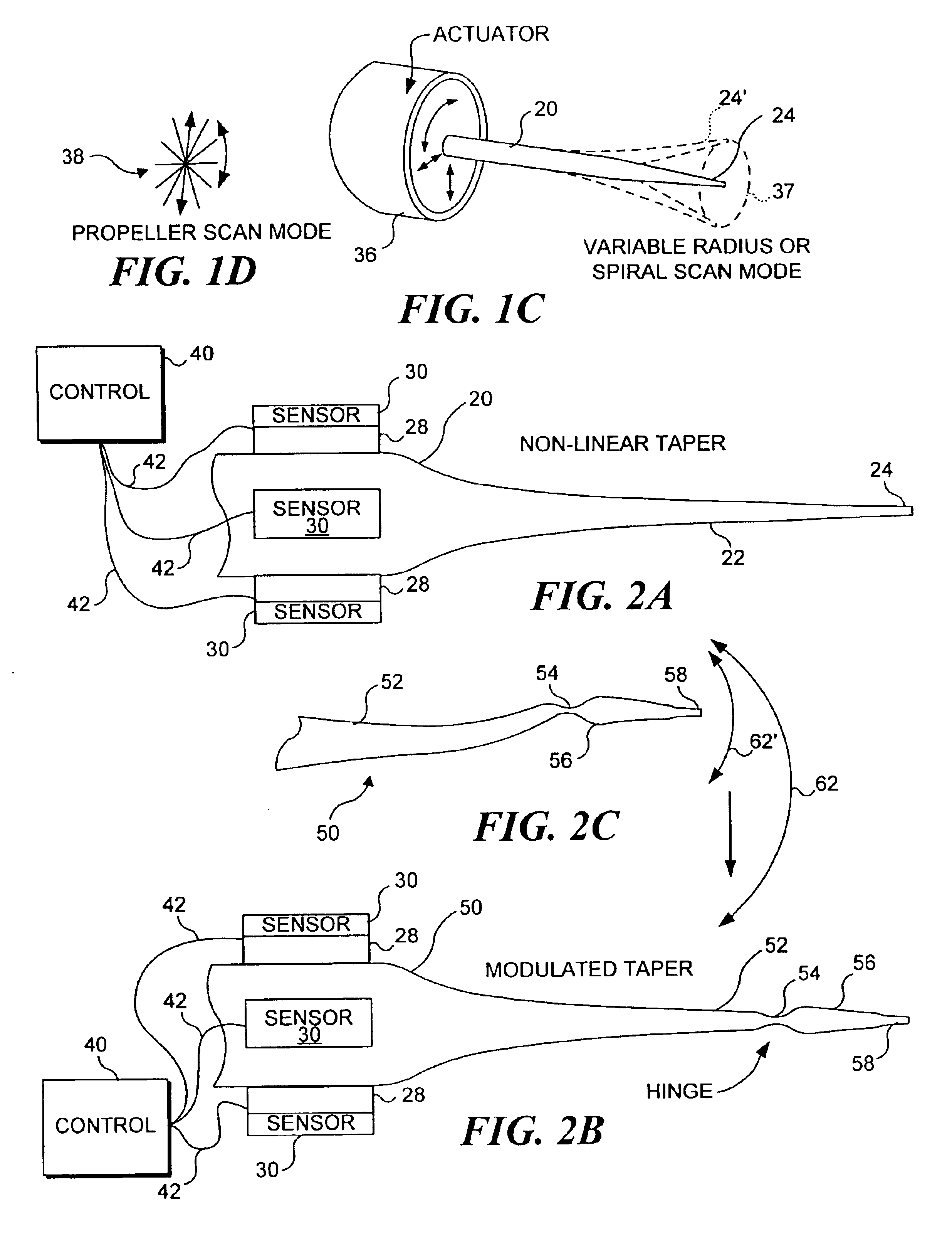

Micro-fabricated optical waveguide for use in scanning fiber displays and scanned fiber image acquisition

Small, rugged scanners micro-fabricated from commercial optical fibers to form waveguides or other structures. The scanning waveguide has a distal portion on which is formed a non-linear taper with a diameter that decreases toward a distal end. Optionally, a hinge portion having a reduced diameter can be formed in the distal portion, improving the scanning properties of the waveguide. A micro-lens can be integrally formed at the distal tip of the waveguide with either a droplet of an optical adhesive, or by using an energy beam to melt the material of the waveguide to form a droplet. The droplet is shaped with an externally applied force. When mechanically driven in vibratory resonance, the tip of the optical waveguides moves in linear or two-dimensional scan patterns of relatively high amplitude and frequency, and large field of view. The scanner can be used either for image acquisition or image display.

Owner:UNIV OF WASHINGTON +1

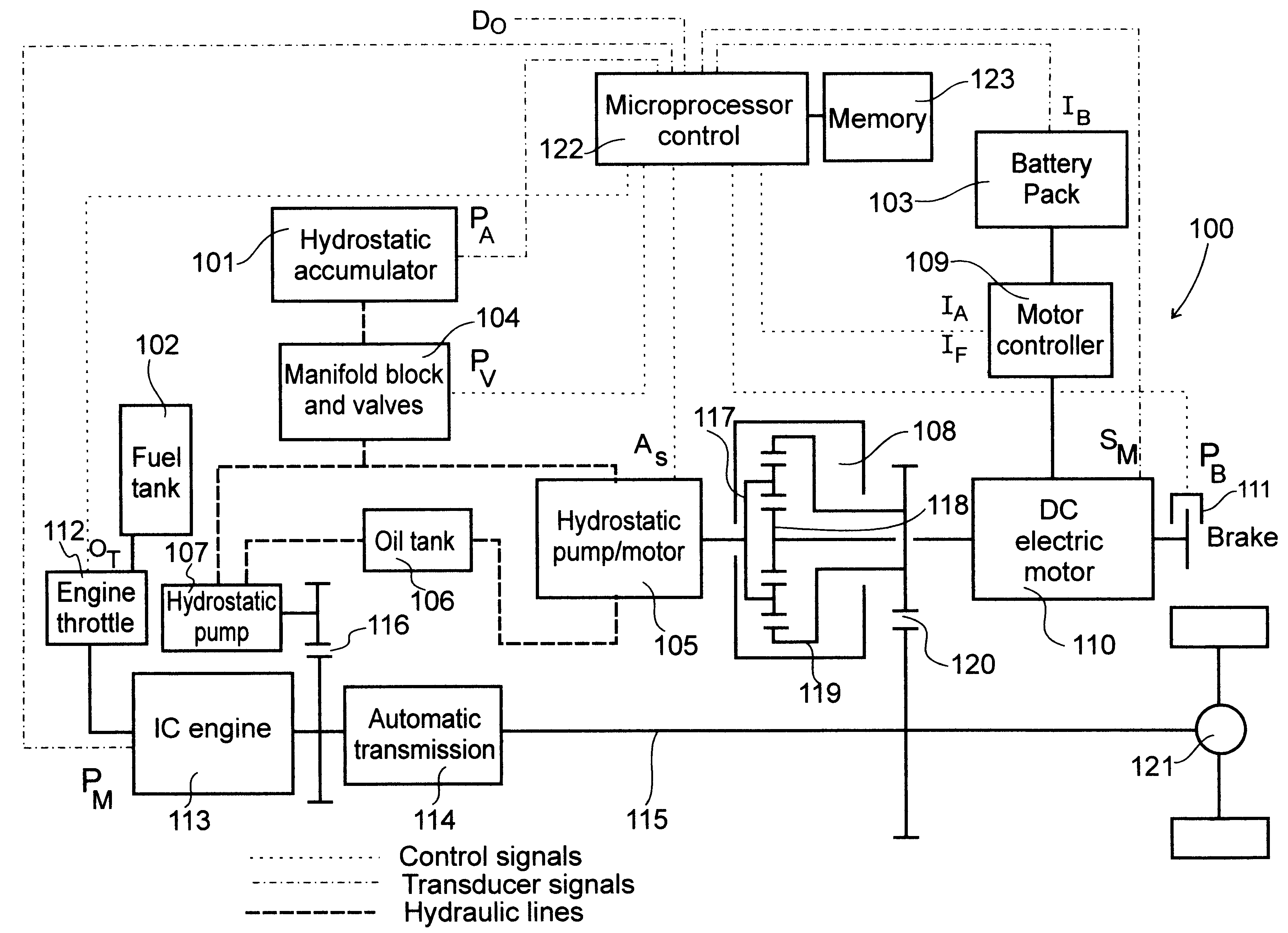

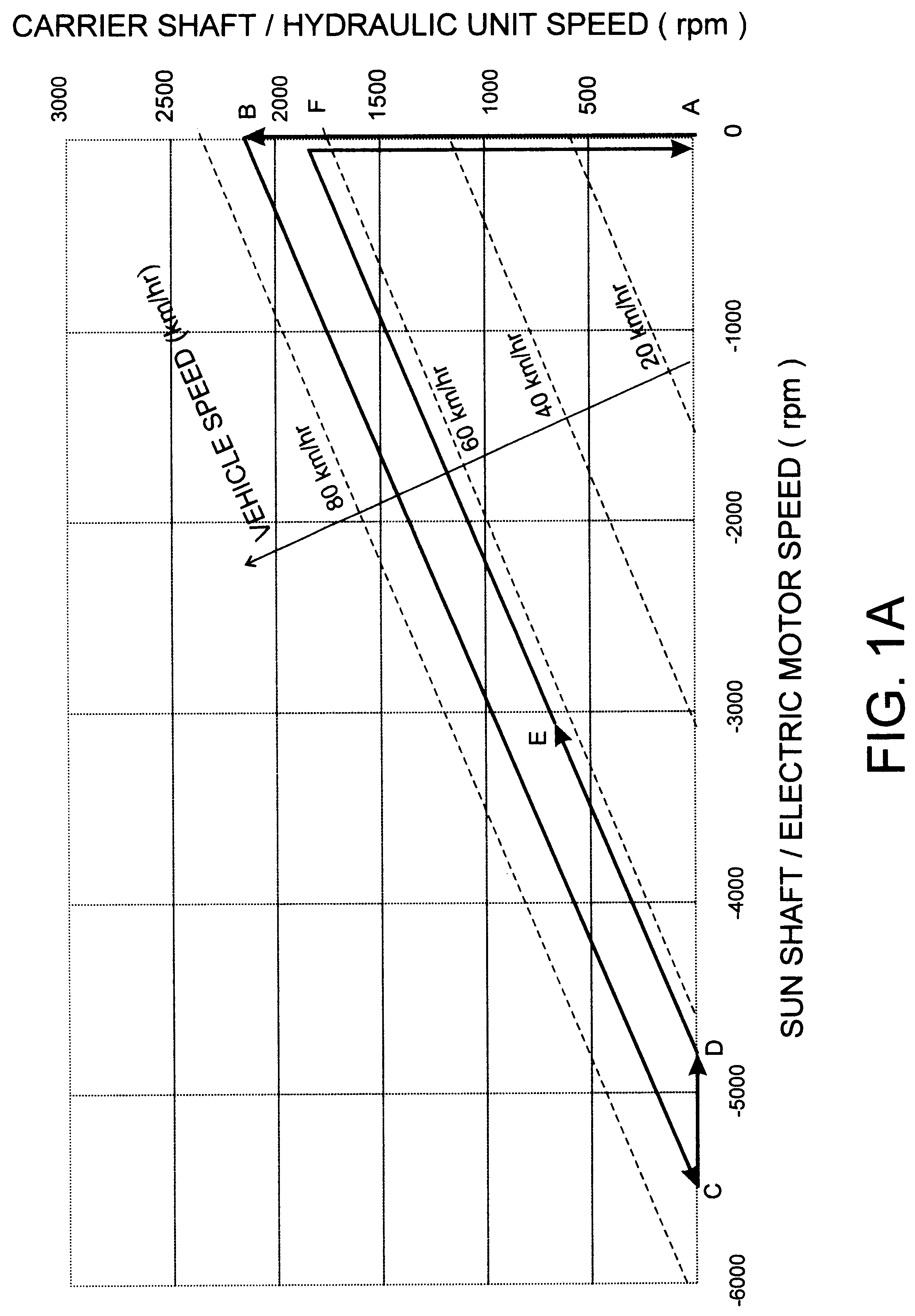

Hybrid propulsion system for road vehicles

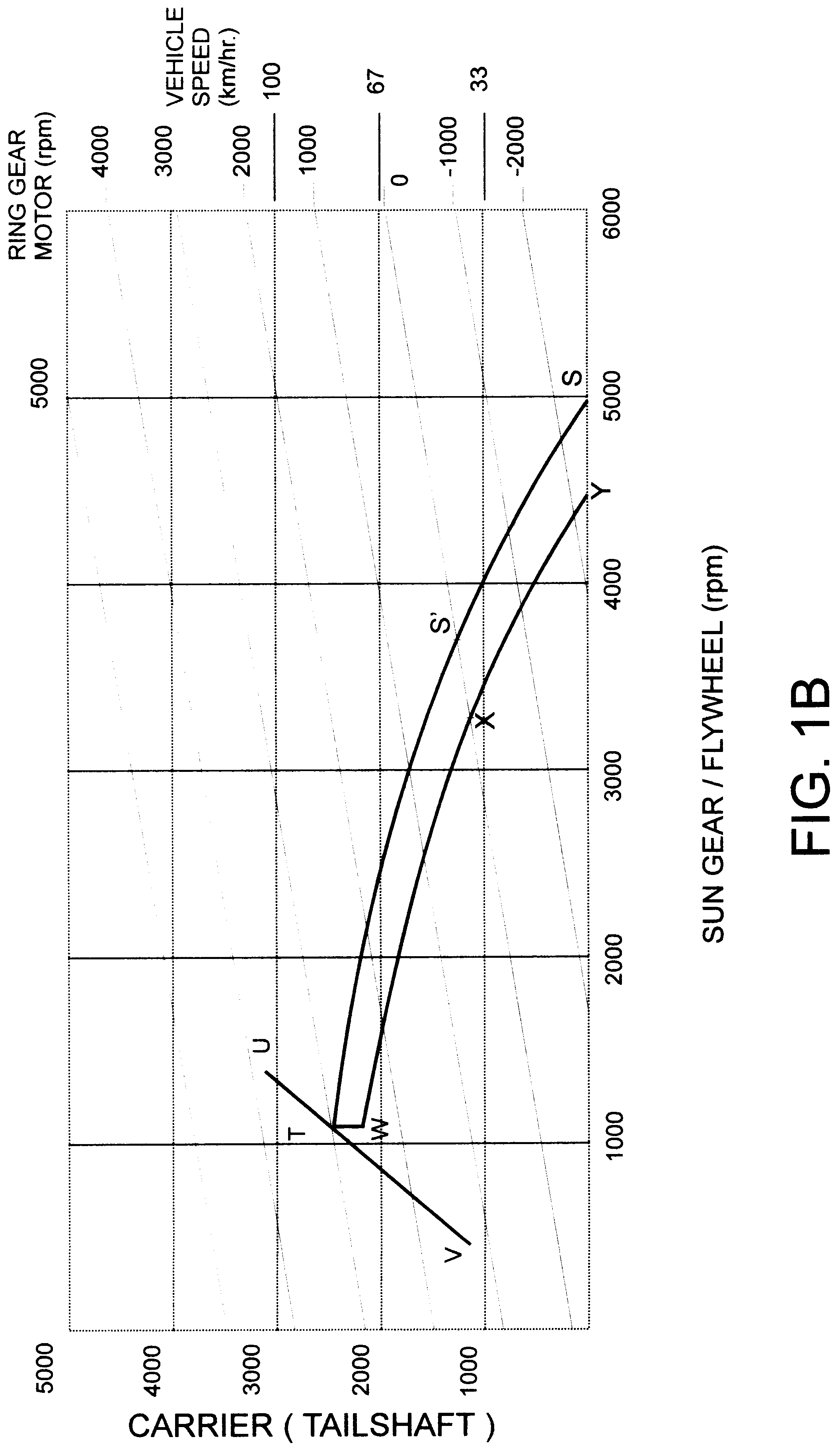

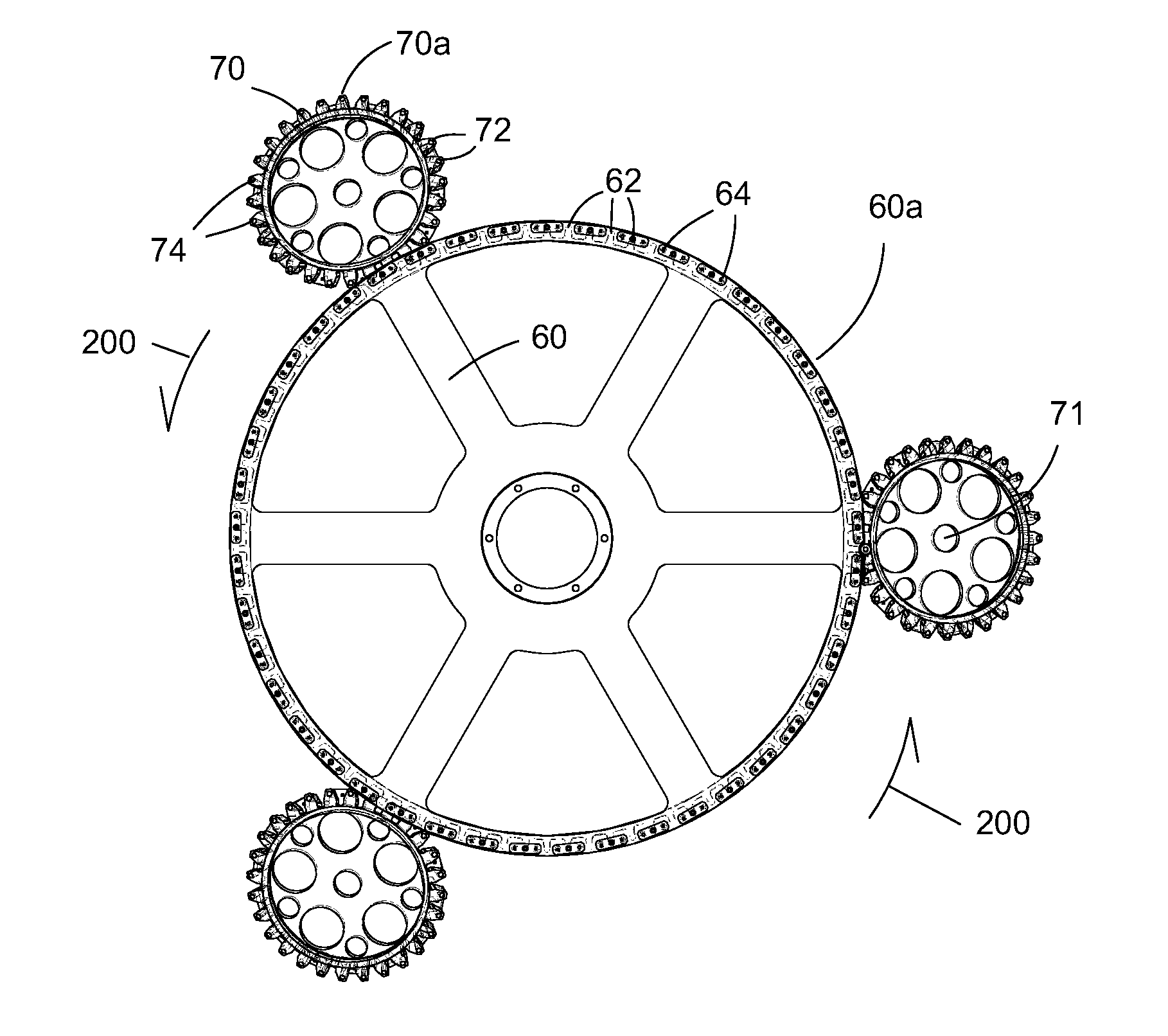

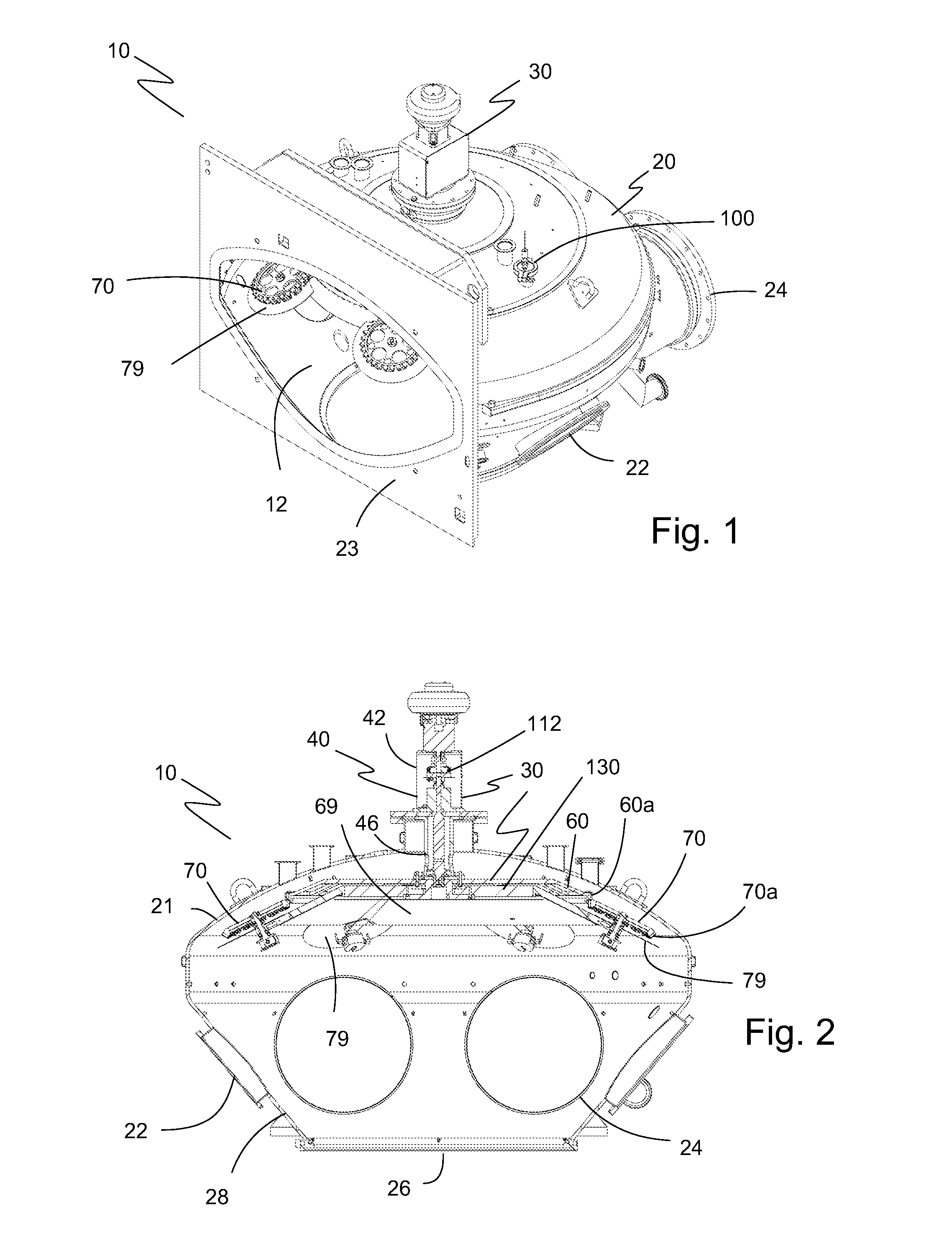

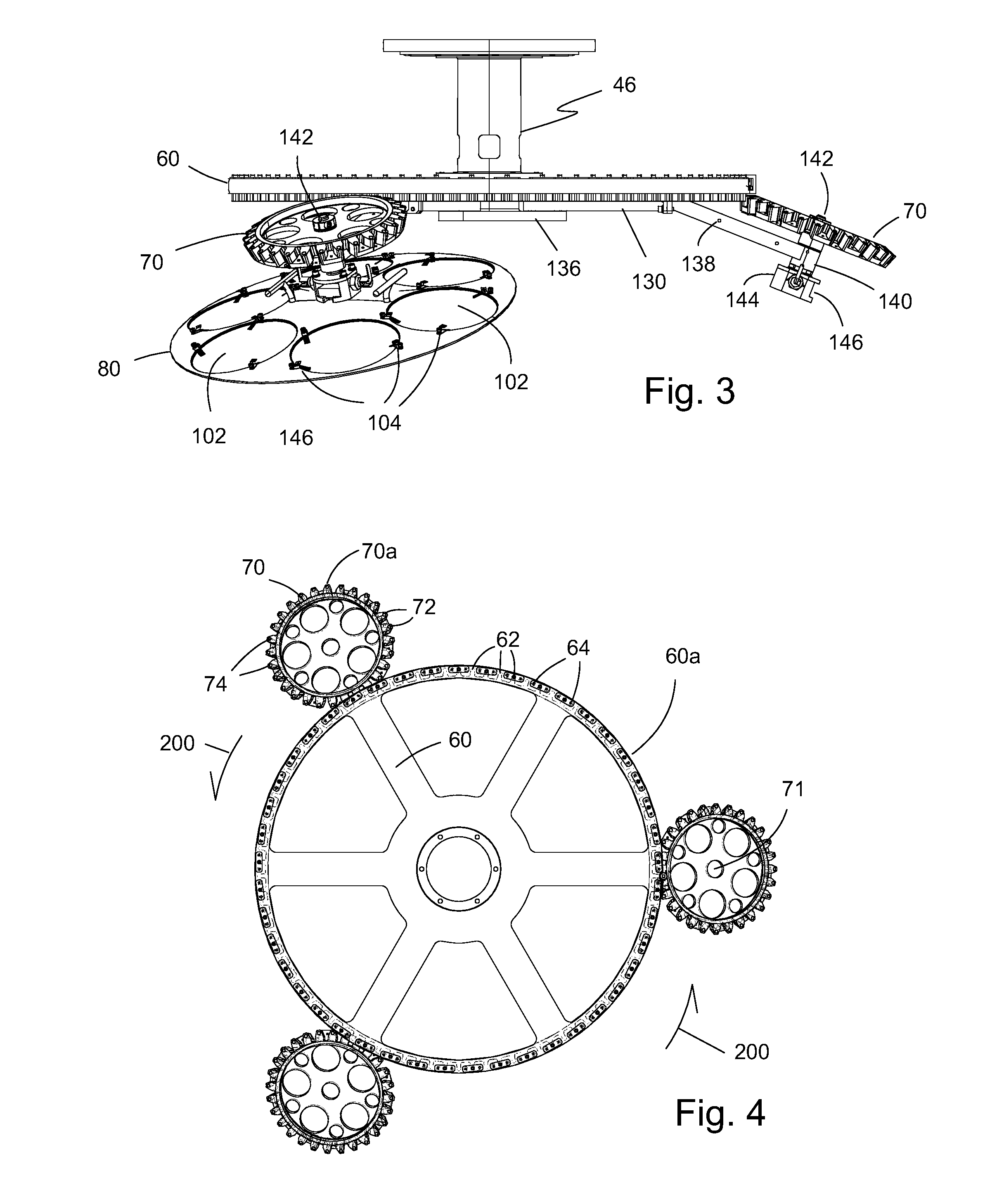

A hybrid propulsion system (100) for use in road vehicle operations, which propulsion system includes a power splitting mechanical transmission (108), suitably a three shaft epicyclic gearbox (117, 118, 119), for coupling to a tailshaft (115) of the vehicle; a first drive unit (105) arranged for regenerative operation and coupled to the power splitting mechanical transmission (108); a second drive unit (110) arranged for regenerative operation and coupled, independently of said first drive unit, to the power splitting mechanical transmission (108); a non-regenerative third drive unit (113) for coupling, in parallel to said power splitting mechanical transmission, to the tailshaft; and a propulsion control system (122) for coordinating operation of the drive units in accordance with a plurality of predetermined modes corresponding to a drive cycle of the vehicle. Two forms of the invention are disclosed, being suited to non-transit and transit operations, respectively. Methods for the optimal control of the hybrid propulsion system of each form of the invention are also disclosed.

Owner:TRANSPORT ENERGY SYST

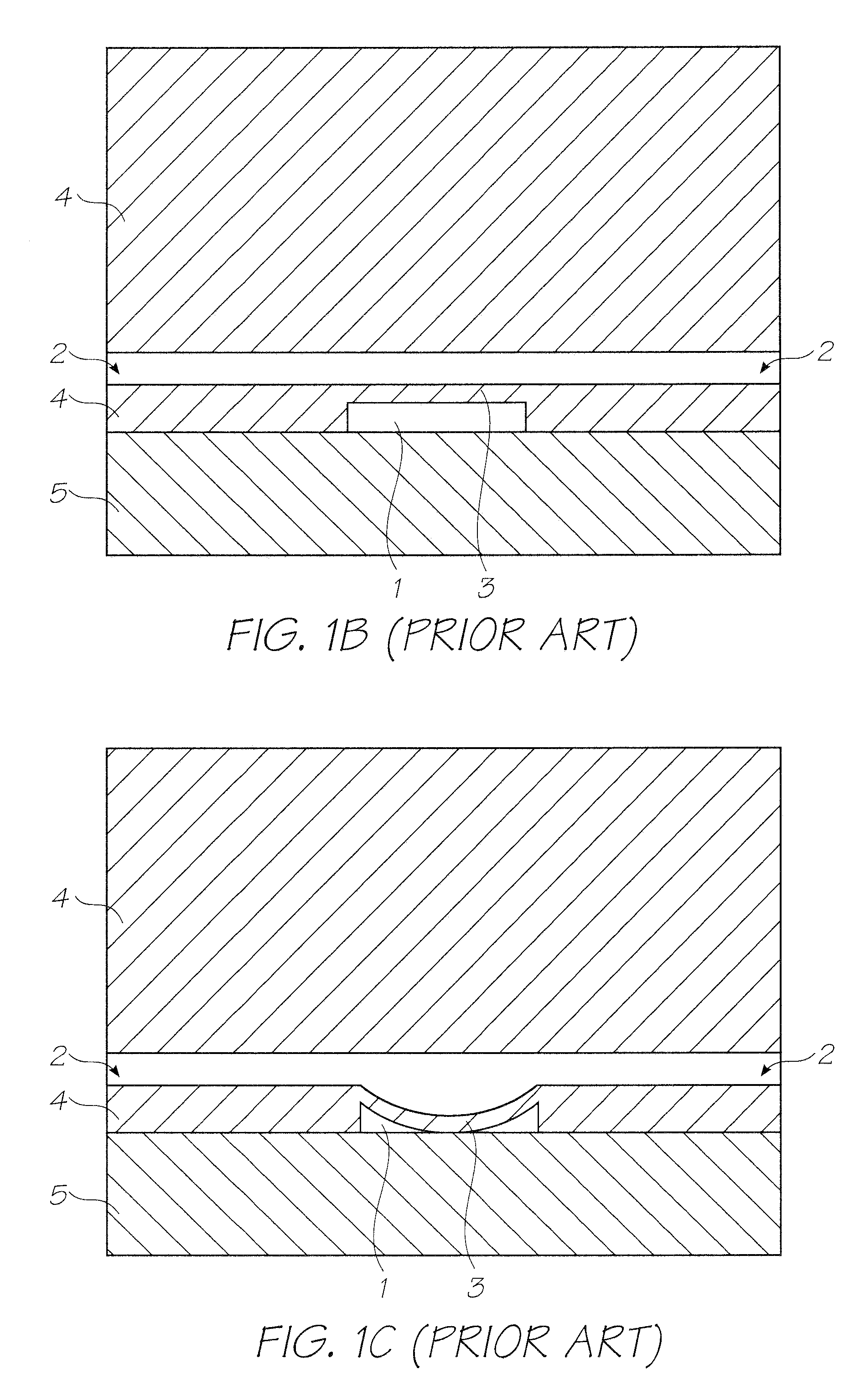

Non-contact magnetic drive assembly with mechanical stop elements

ActiveUS20130095973A1Improve throughputMinimizing particulate contaminationVacuum evaporation coatingSemiconductor/solid-state device manufacturingMechanical driveVacuum deposition

A non-contact magnetic drive assembly with mechanical stop elements for a vacuum deposition system employing a lift-off process having a HULA configuration featuring a plurality of magnets coupled in an annular orientation to a central ring and an orbital ring, each magnet of the orbital ring becomes superposed with a magnet of the central ring as the orbital ring rotates, and a central drive component driving either the central ring, the orbital ring around the central ring or both simultaneously, the central drive component provides a rotational speed allowing non-contact, magnetic drive rotation of the orbital ring around the central ring until a difference between a magnetic drive torque of the superposed magnets and the rotational speed of the central drive component causes the superposed magnets to decouple enabling mechanical drive rotation by interactive contact between a plurality of central ring teeth and a plurality of orbital ring.

Owner:FERROTEC USA CORP

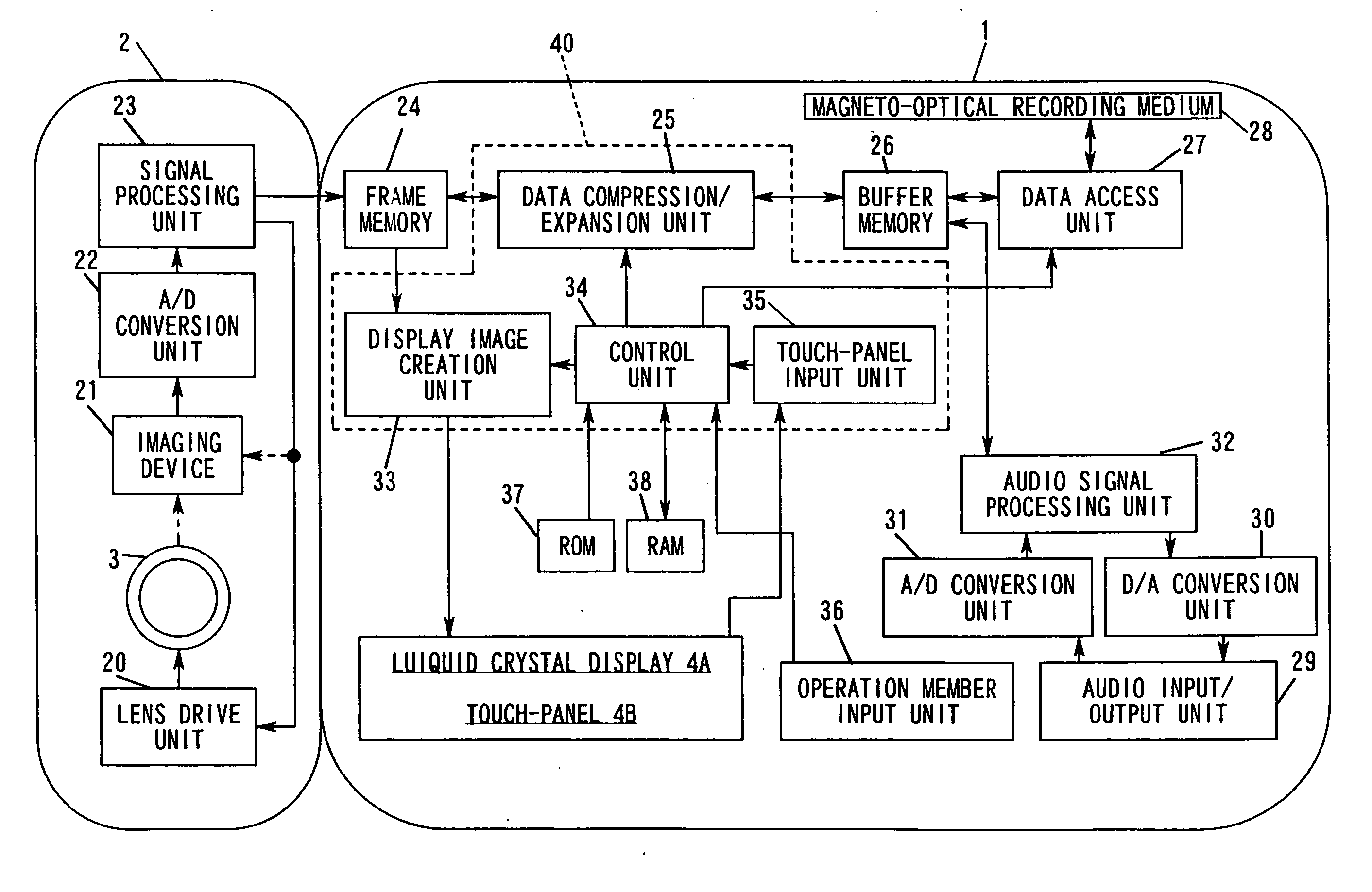

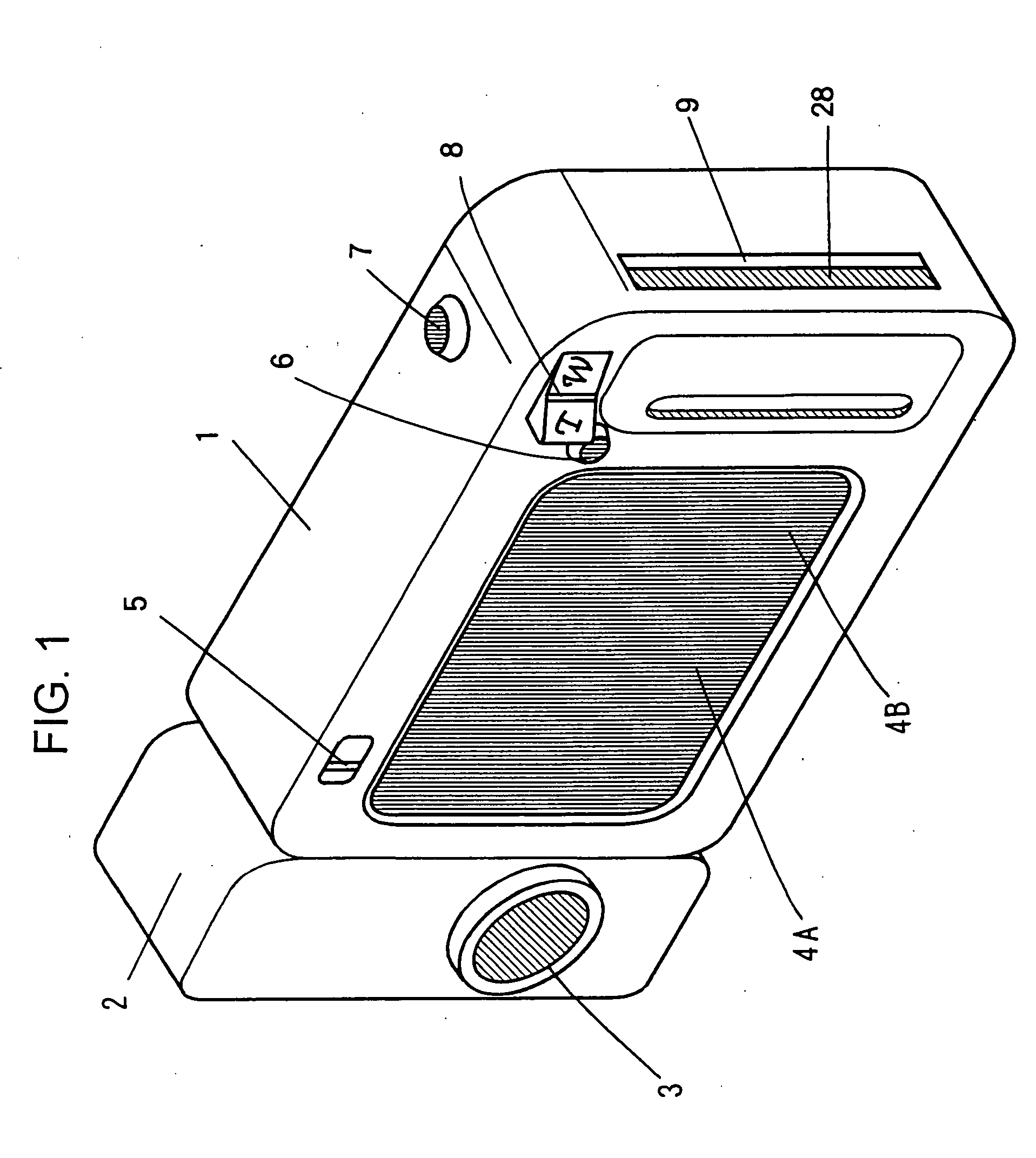

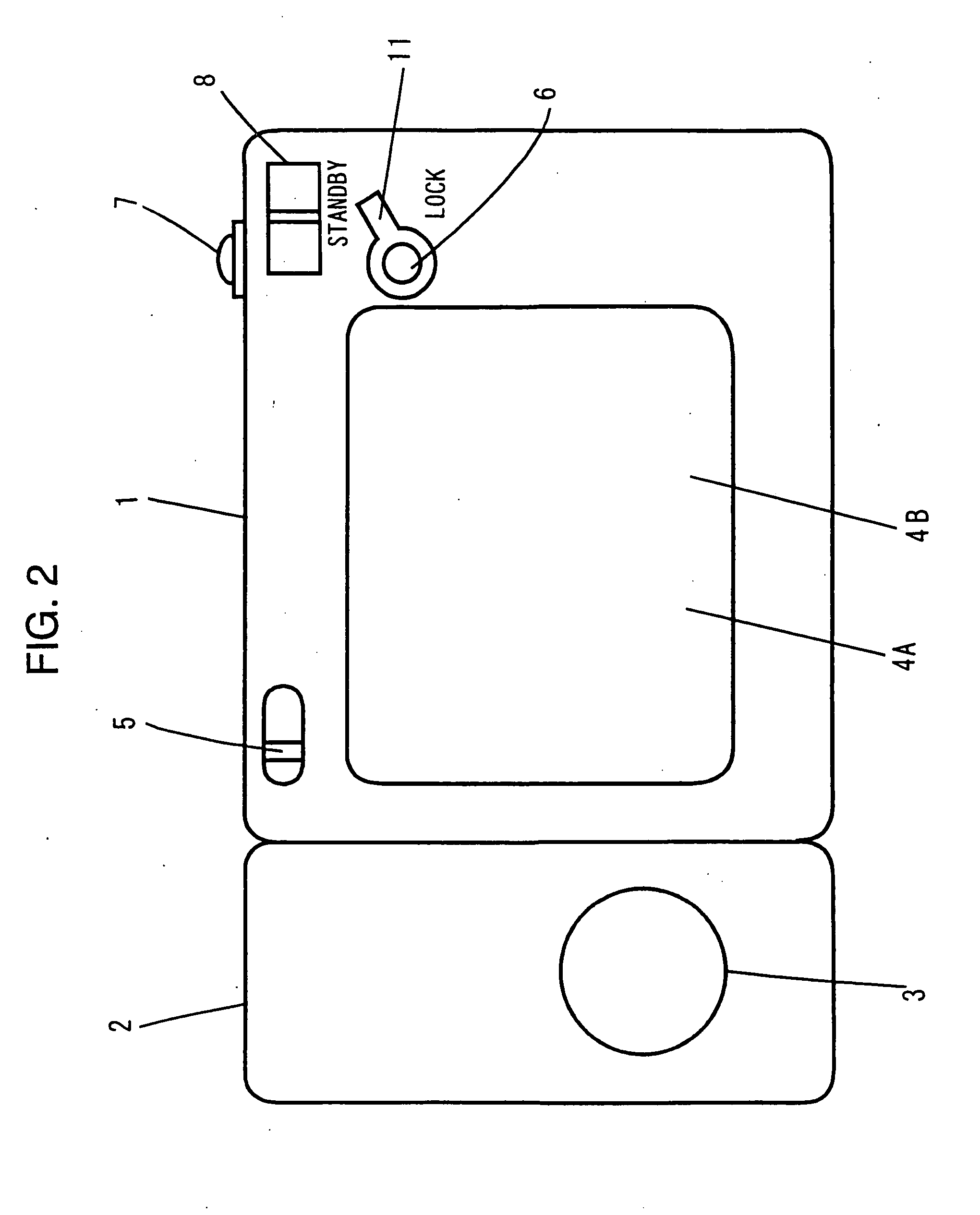

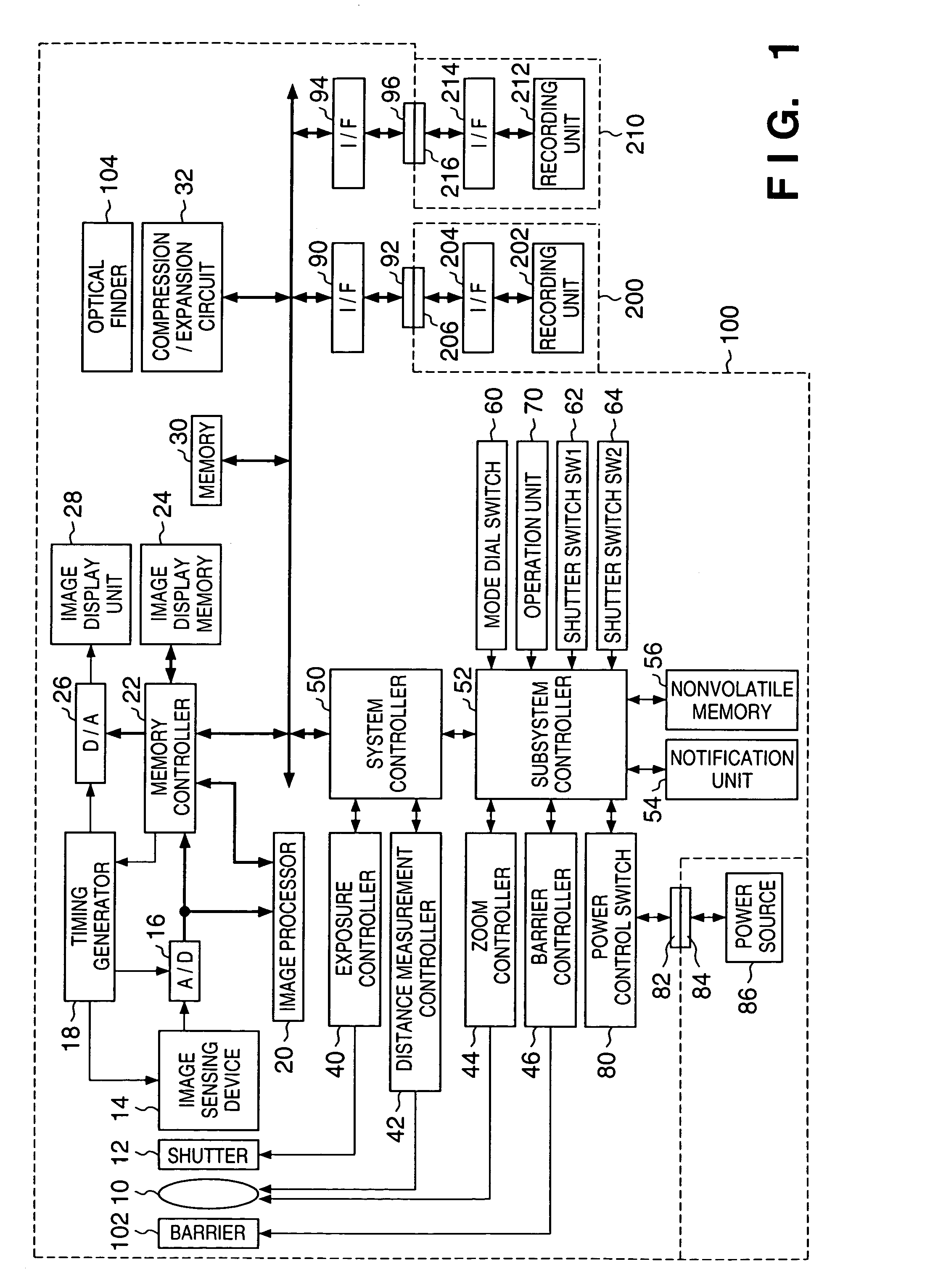

Image signal recording/reproduction apparatus, method employed therein, and image signal recording apparatus

InactiveUS20080025701A1Television system detailsColor television signals processingComputer hardwareLiquid-crystal display

A dynamic image recording button and a still image recording button are provided at the main unit of a movie camera. A magneto-optical recording medium is loaded in a slot. If the dynamic image recording button or the still image recording button is operated during a reproduction operation, the reproduction operation is interrupted in a state in which the mechanical drive (rotation) of the magneto-optical recording medium is sustained. At this point, a dynamic image signal or a still image signal obtained through a photographing operation performed at the camera unit is temporarily recorded in a buffer memory, and is written in the magneto-optical recording medium when a write in the magneto-optical recording medium becomes enabled. Instructions to record dynamic images and to record still images can be issued to the movie camera through a touch-panel provided on the screen of a liquid crystal display unit. Even when operation cannot be performed through the touch-panel, the instructions can be issued through the dynamic image recording button or the still image recording button.

Owner:NIKON CORP

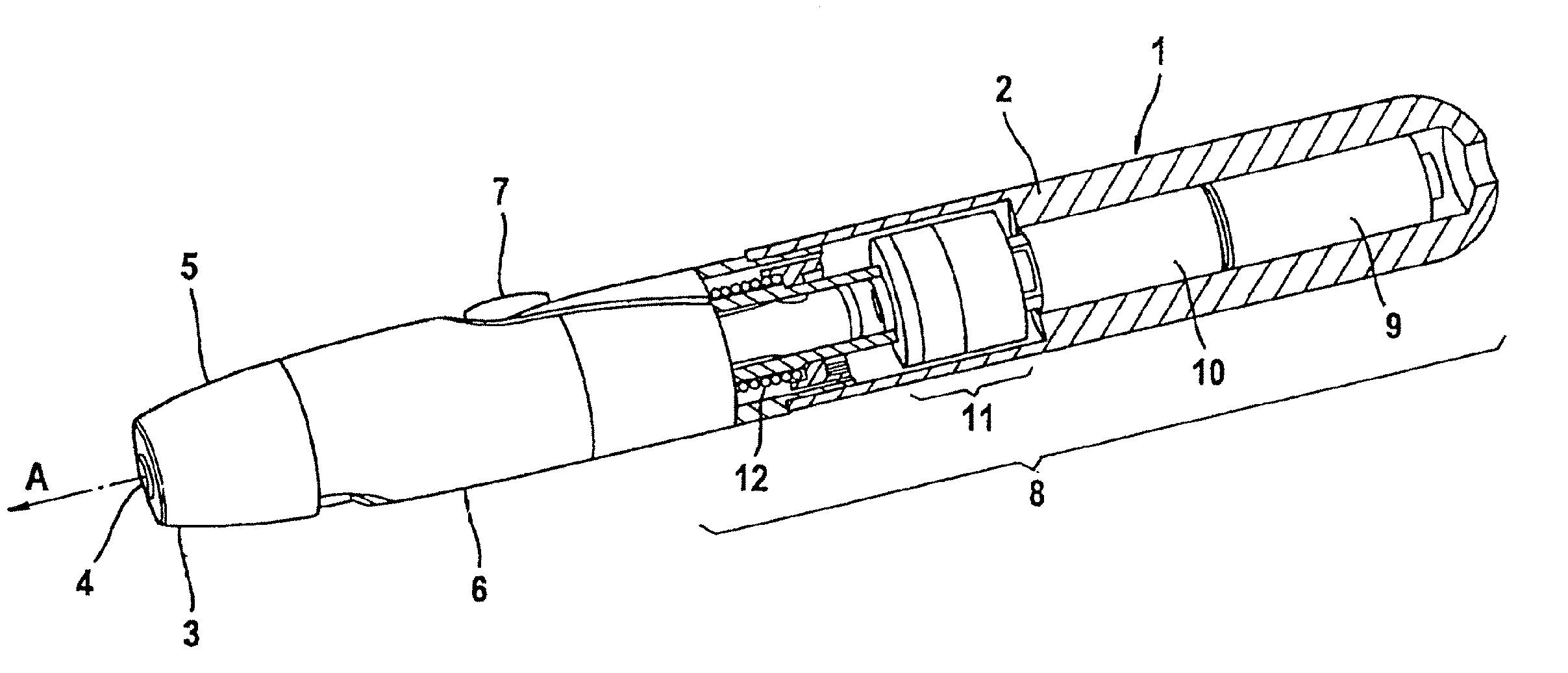

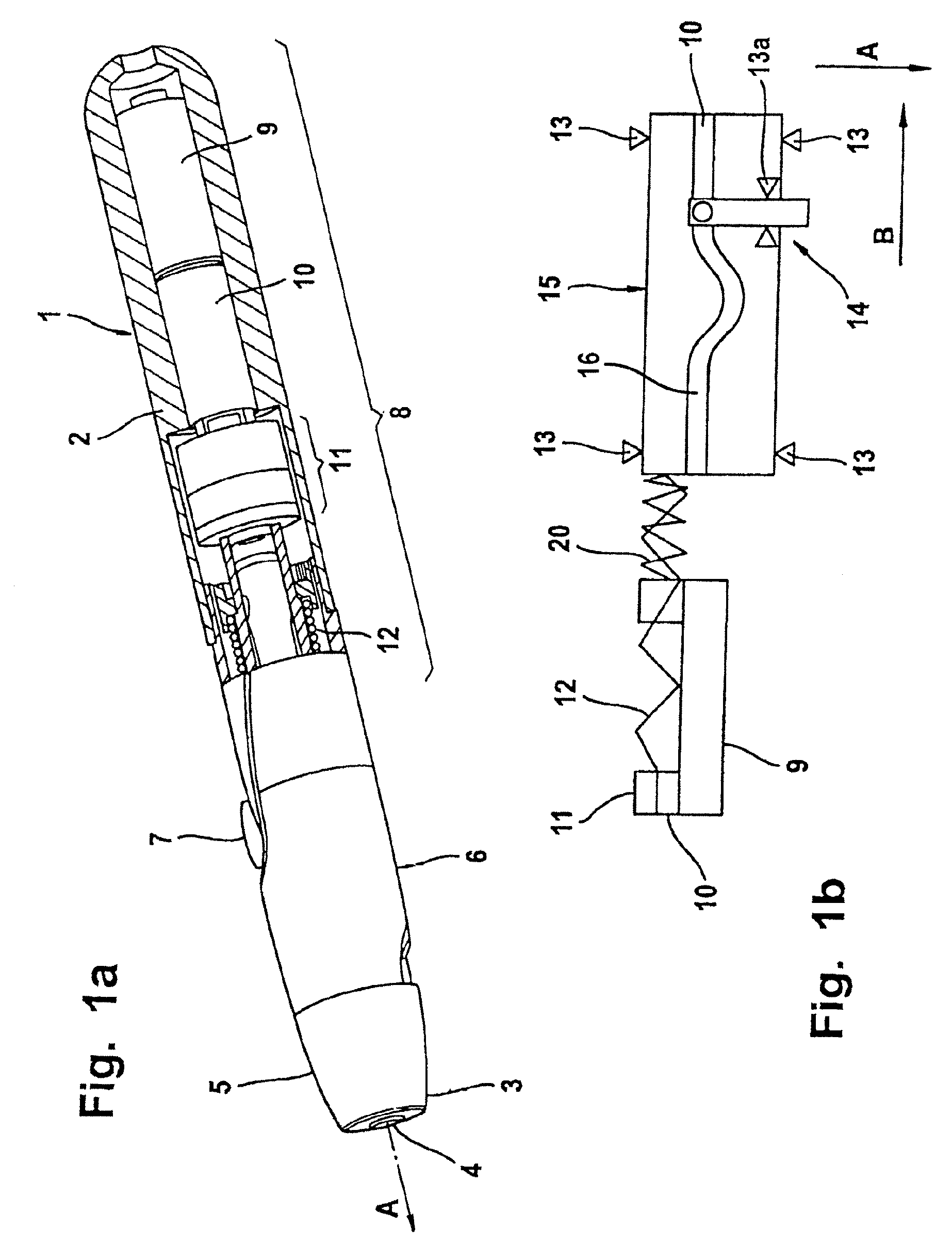

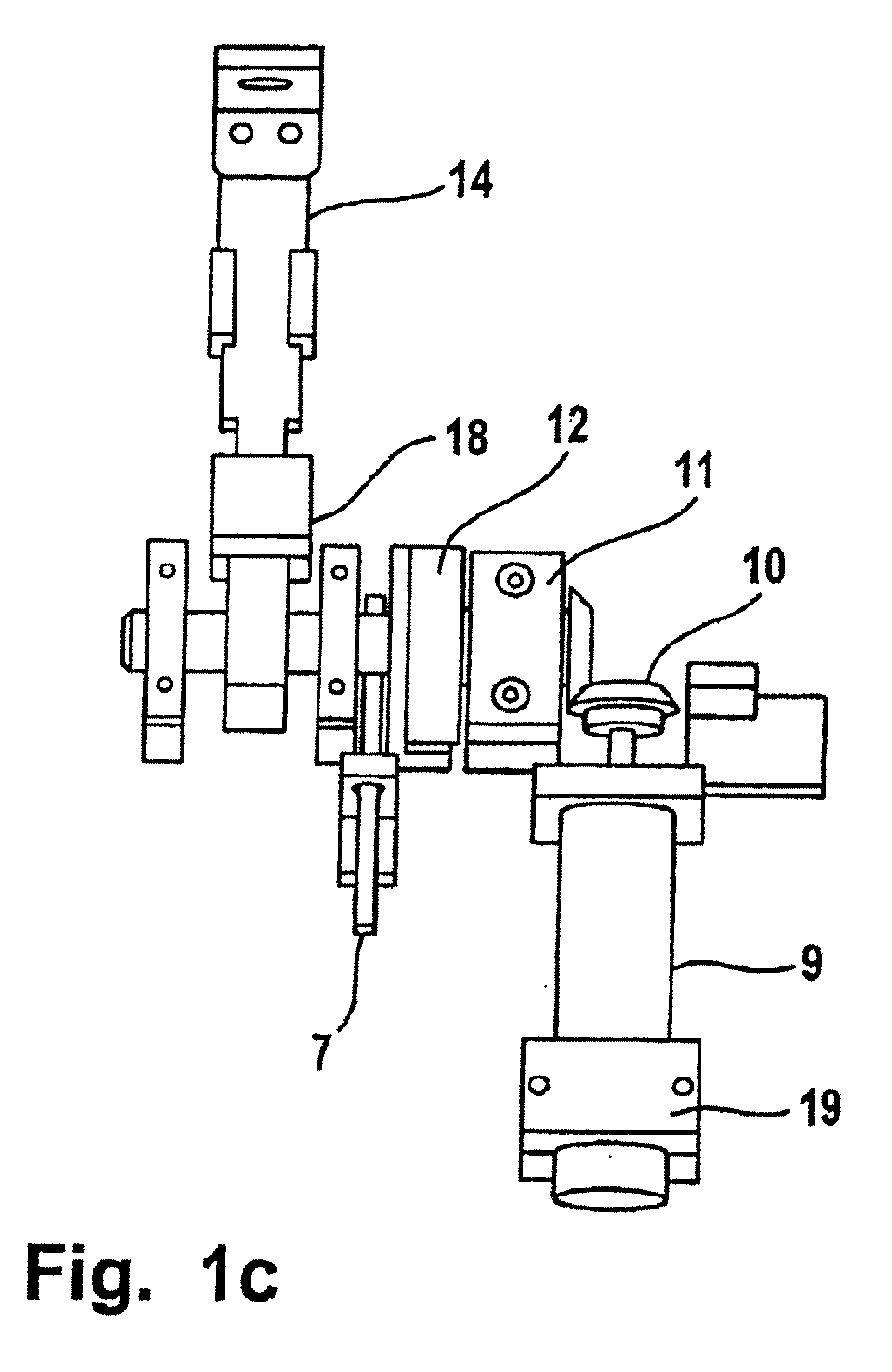

Integrated device for diagnostic purposes

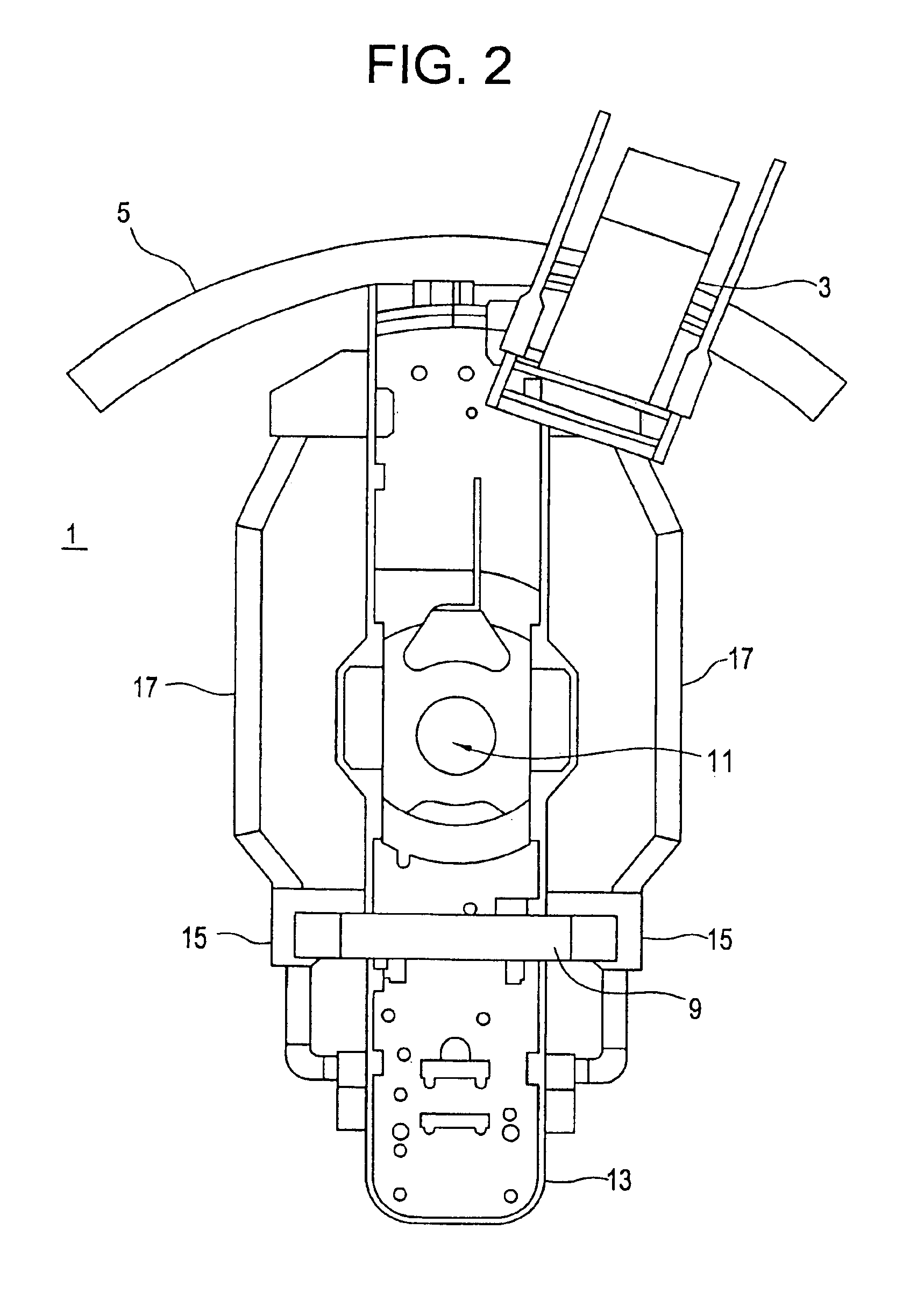

The present invention provides an integrated measuring device that includes a blood collection system for collecting blood for diagnostic purposes. The blood collection system comprises an electric motor which provides energy for propelling a lancet. The blood collection system comprises a mechanical energy store in which the electric energy that is converted by the motor is stored in the form of mechanical energy. The use of a mechanical energy store allows the use of known mechanical drive elements. The blood collection system can also be electrically activated and is thus easy to use for the operator. The motor can also be coupled to another system component, such as a test strip or lancet drum, to operate it.

Owner:ROCHE DIABETES CARE INC

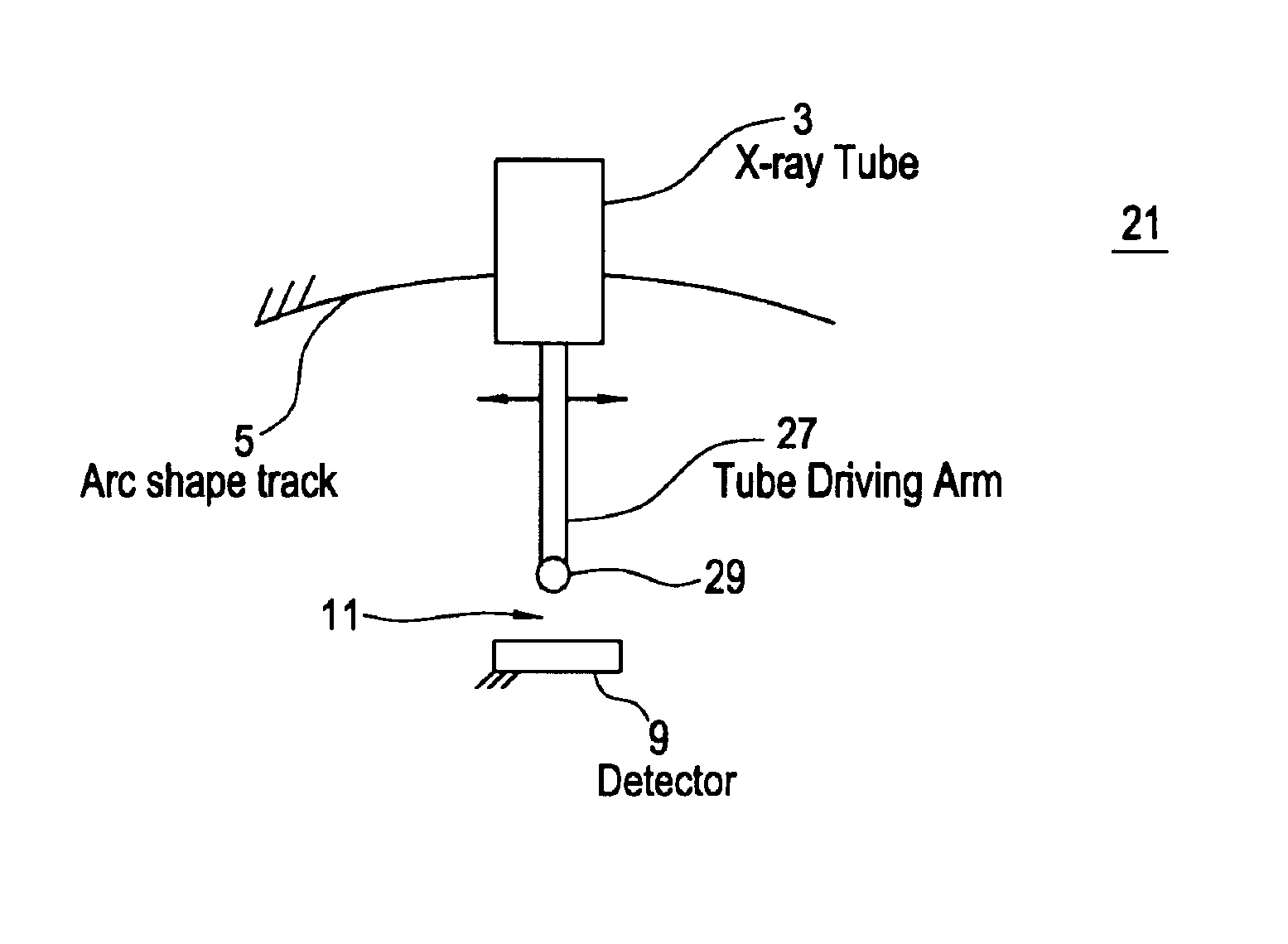

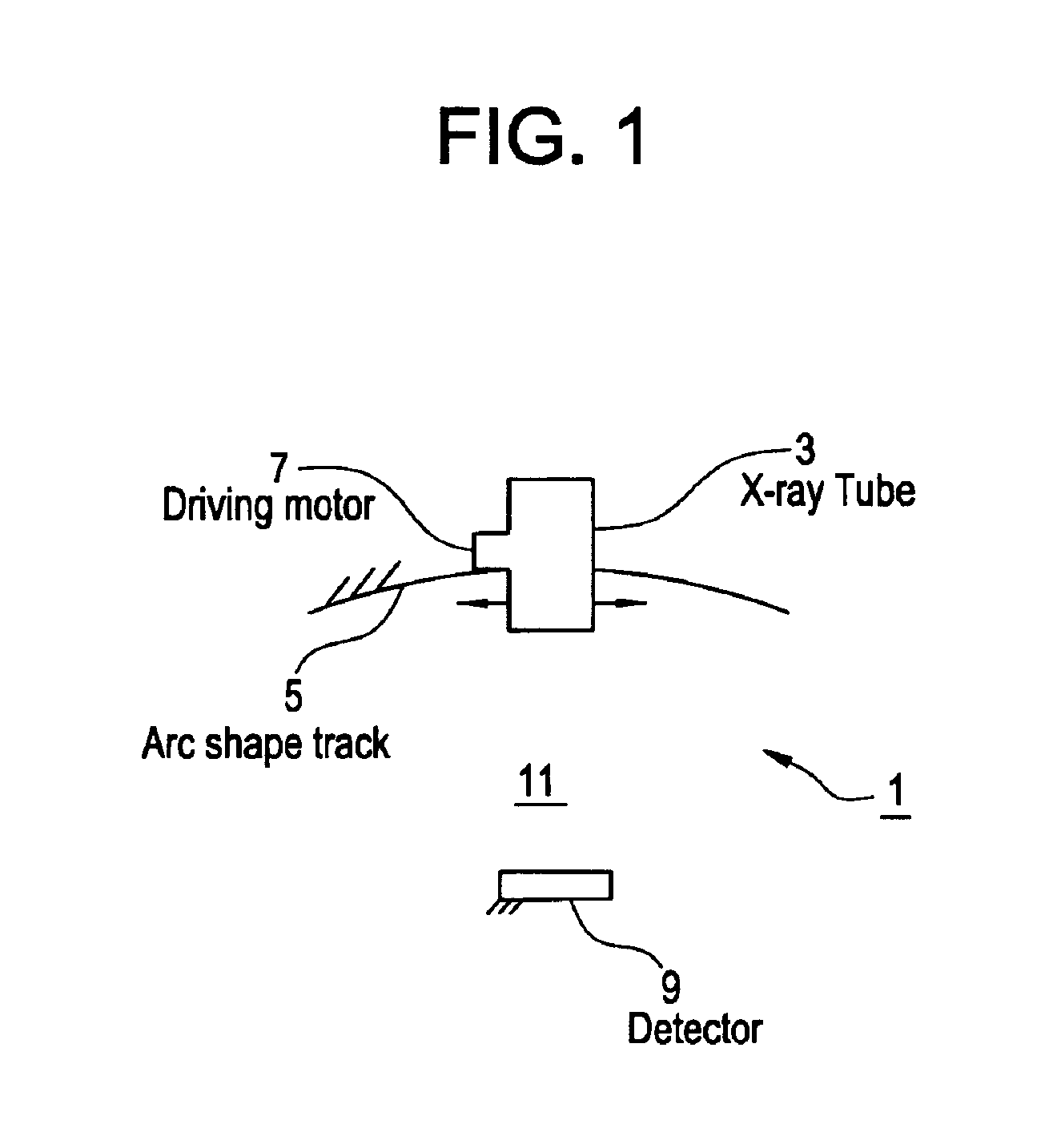

Tomosynthesis X-ray mammogram system and method with automatic drive system

InactiveUS6882700B2Radiation diagnosis data transmissionMaterial analysis using wave/particle radiationTomosynthesisX-ray

An imaging system includes an X-ray source adapted to move in an arc shaped path and a stationary electronic X-ray detector. The system also includes a track and a mechanical driving mechanism which is adapted to move the X-ray source in the arc shaped path. A tomosynthesis X-ray imaging method includes mechanically moving an X-ray source in a stepped motion on an arc shaped path around an object using a track and irradiating the object with an X-ray dose from the X-ray source located at a plurality of steps along the arc shaped path. The method also includes detecting the X-rays transmitted through the object with an electronic X-ray detector, and constructing a three dimensional image of the object from a signal output by the electronic X-ray detector.

Owner:GENERAL ELECTRIC CO

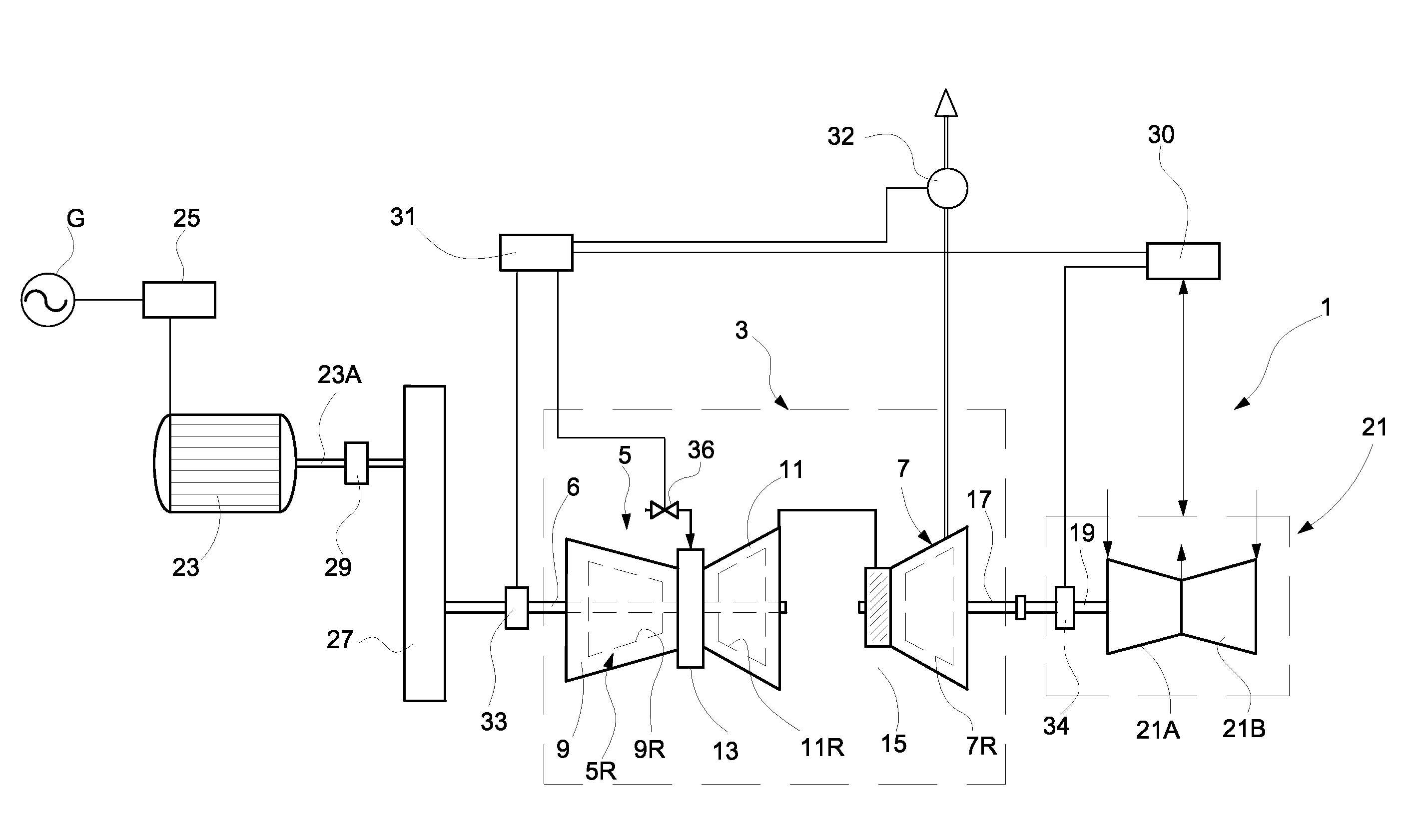

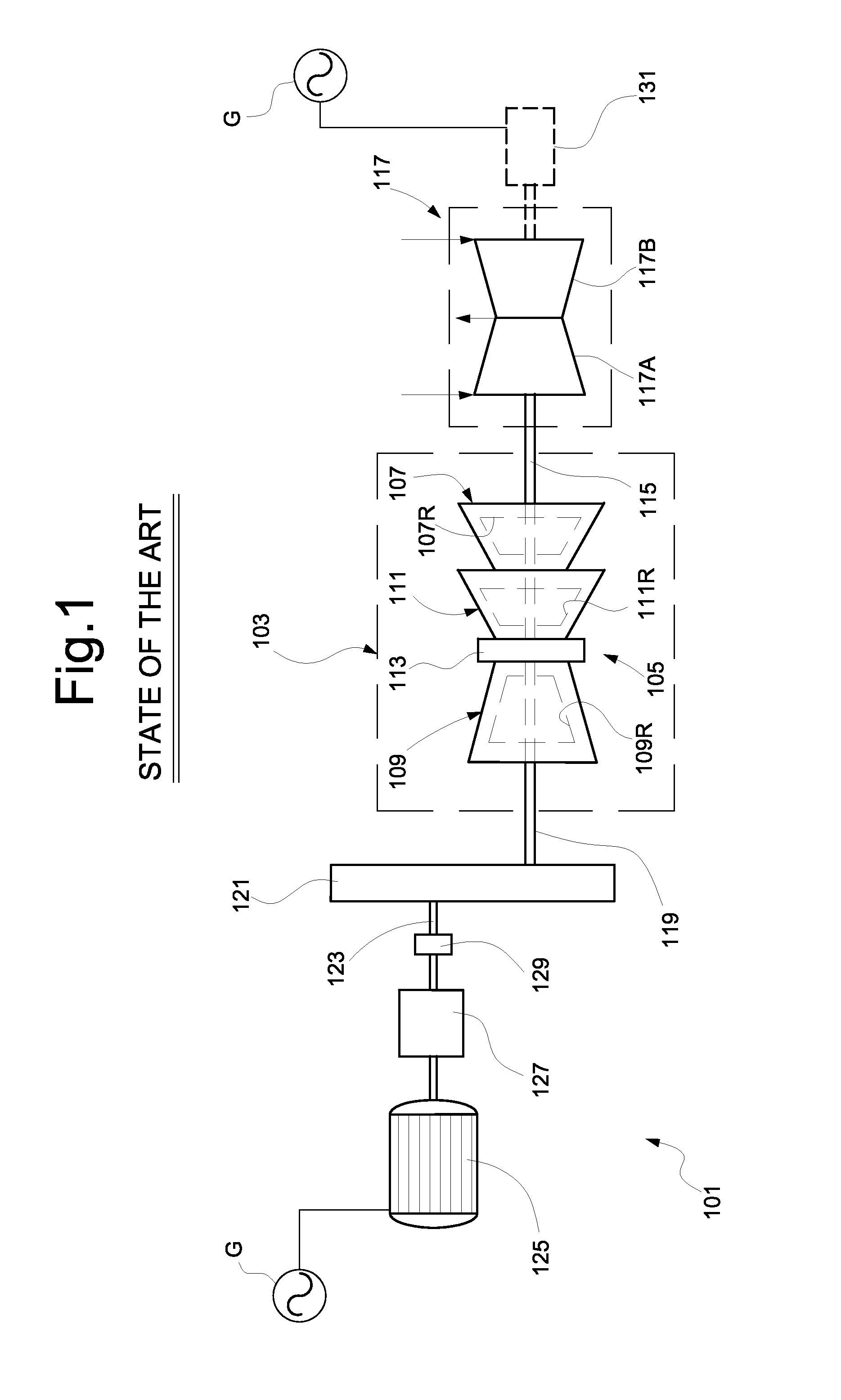

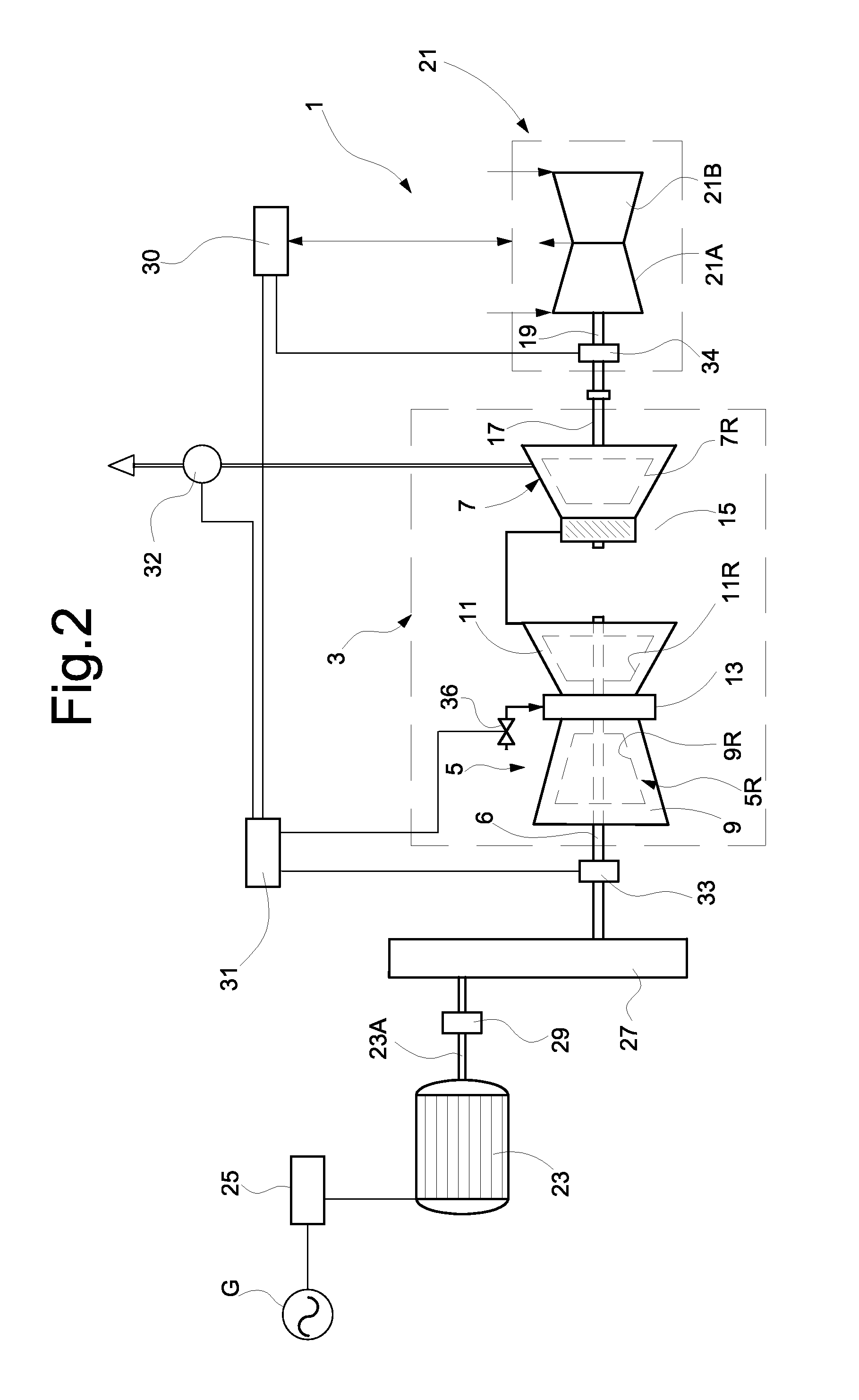

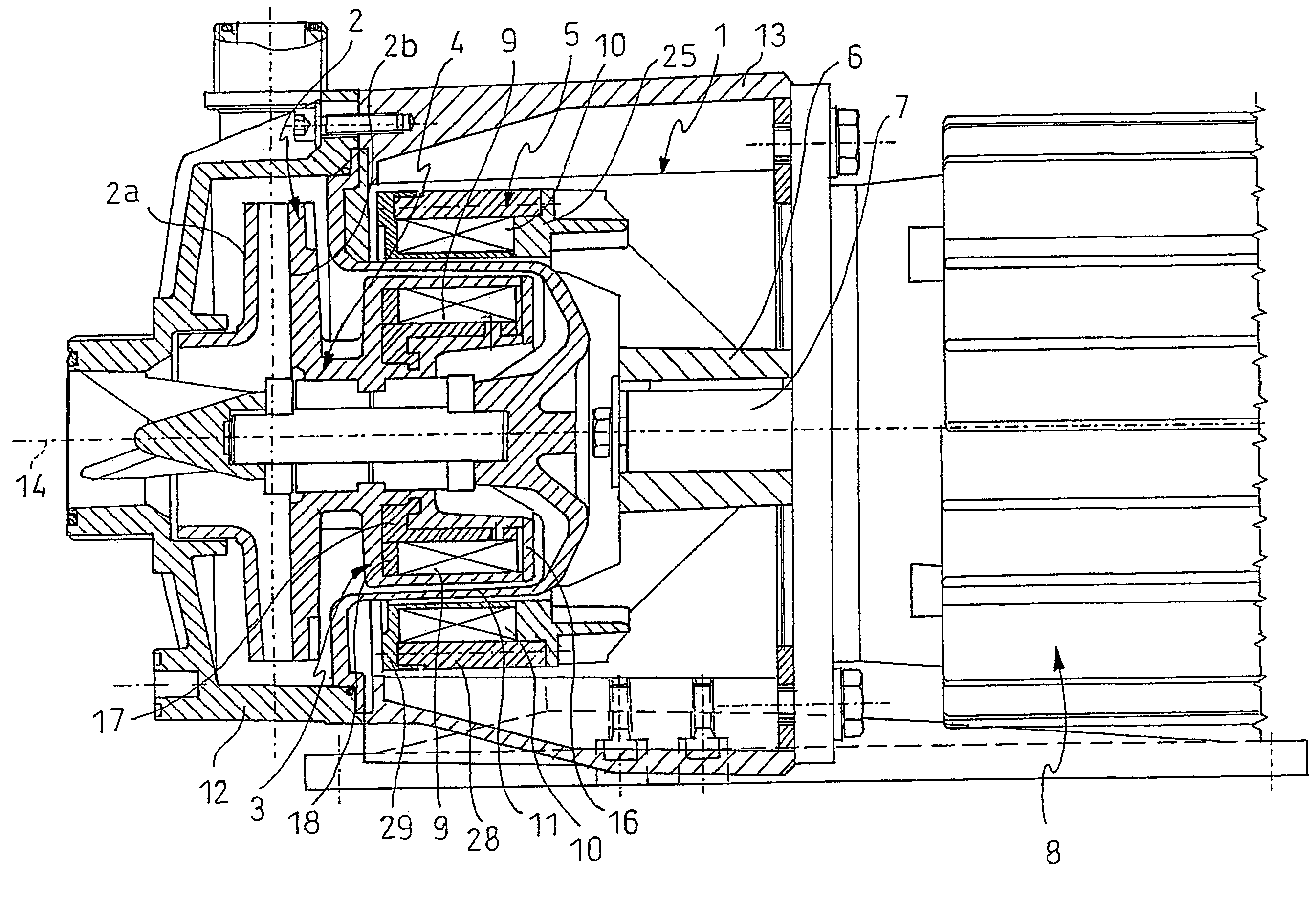

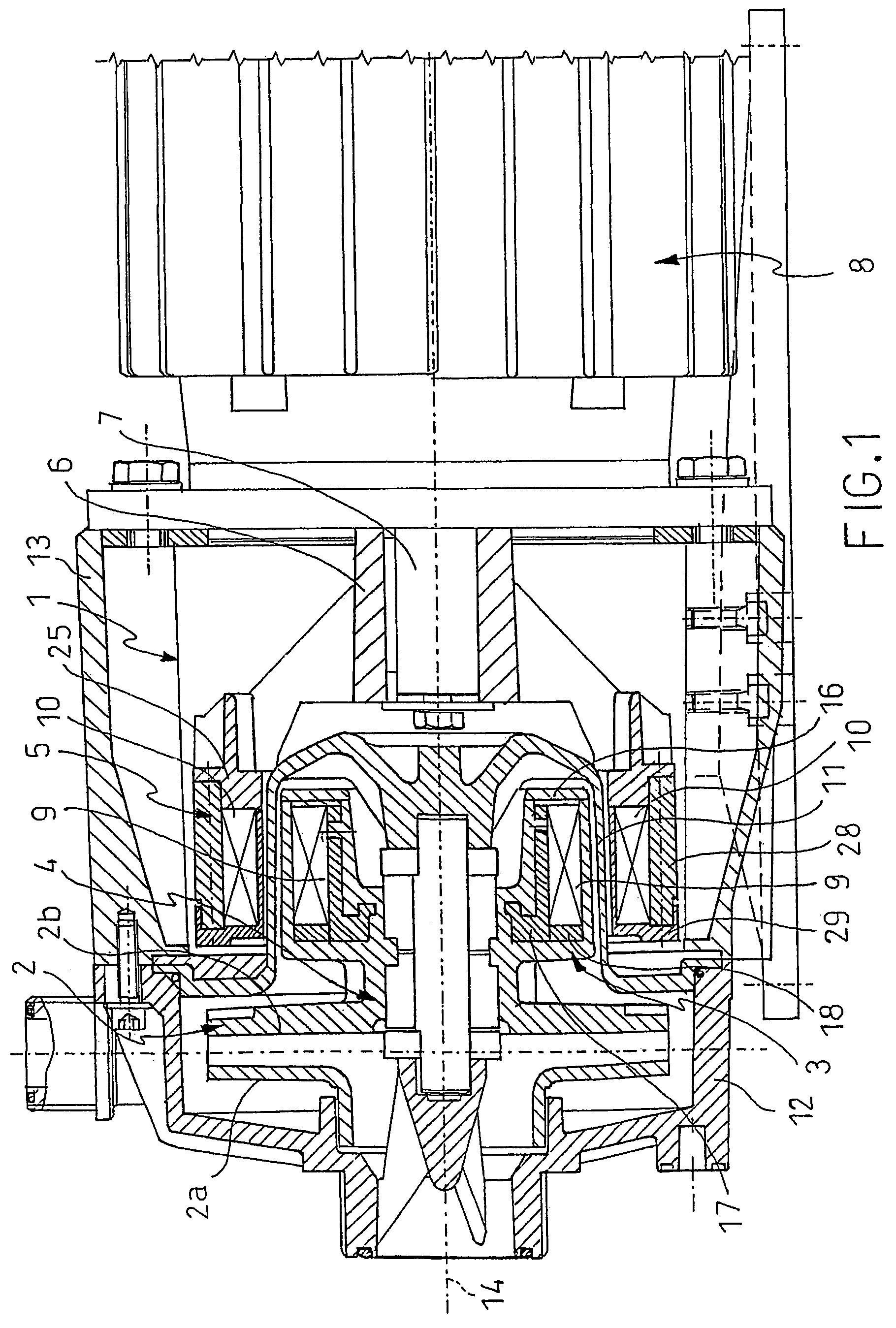

Gas turbines in mechanical drive applications and operating methods

A drive system for driving a load by a gas turbine. The gas turbine comprises a gas generator having a gas-generator rotor and comprising at least one gas-generator compressor and one high-pressure turbine driving the gas-generator compressor. The gas turbine further comprises a power turbine having a power-turbine rotor, which is torsionally independent of the gas-generator rotor. The load is connected to the power-turbine rotor. The system further comprises an electric motor / generator mechanically connected to the gas-generator rotor and electrically connected to an electric power grid. The electric motor / generator is adapted to function alternatively: as a generator for converting mechanical power from the gas turbine into electrical power; and as a motor for supplementing driving power to the load. A set of movable nozzle guide vanes is arranged at the inlet of the power turbine.

Owner:NUOVO PIGNONE SPA

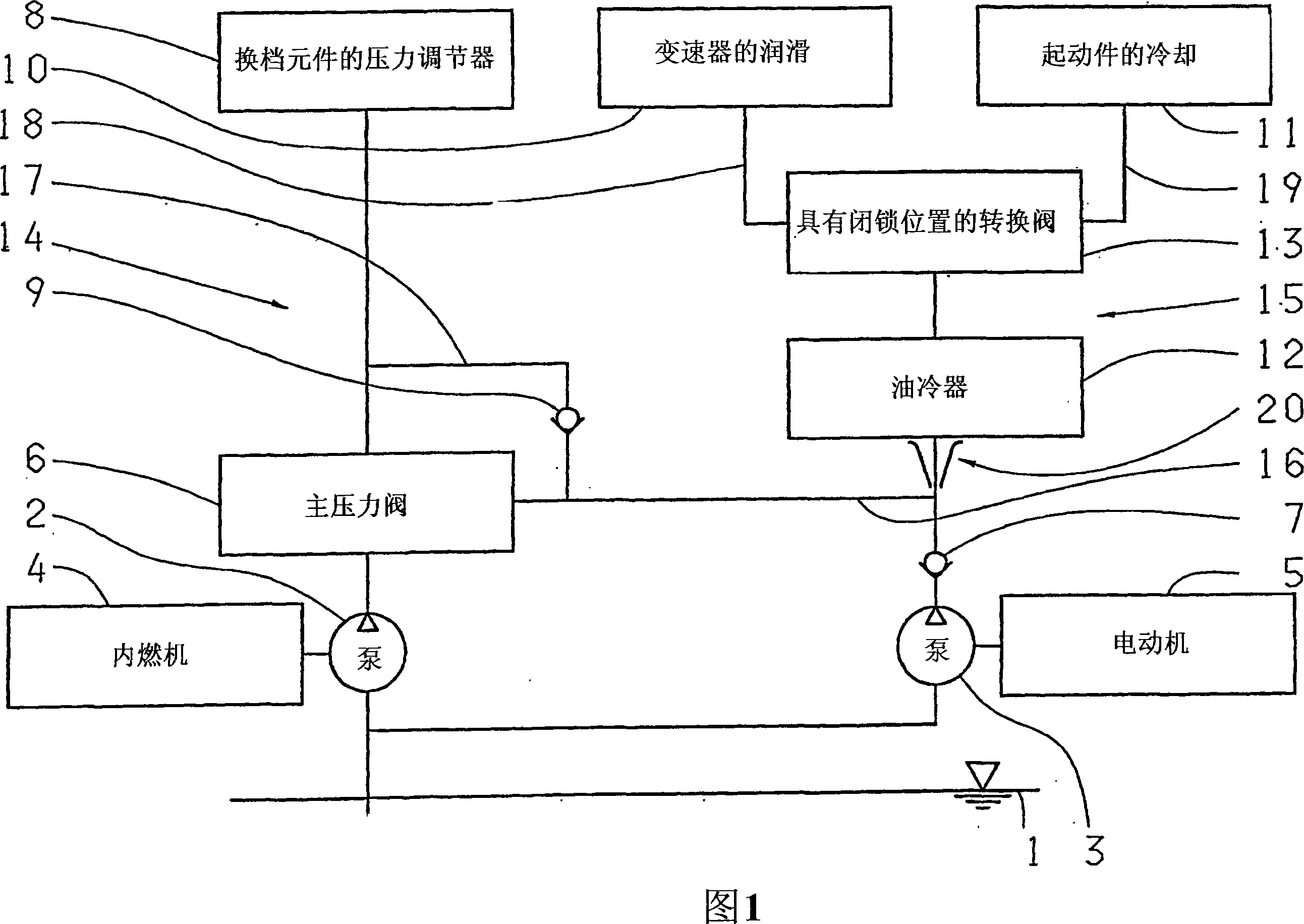

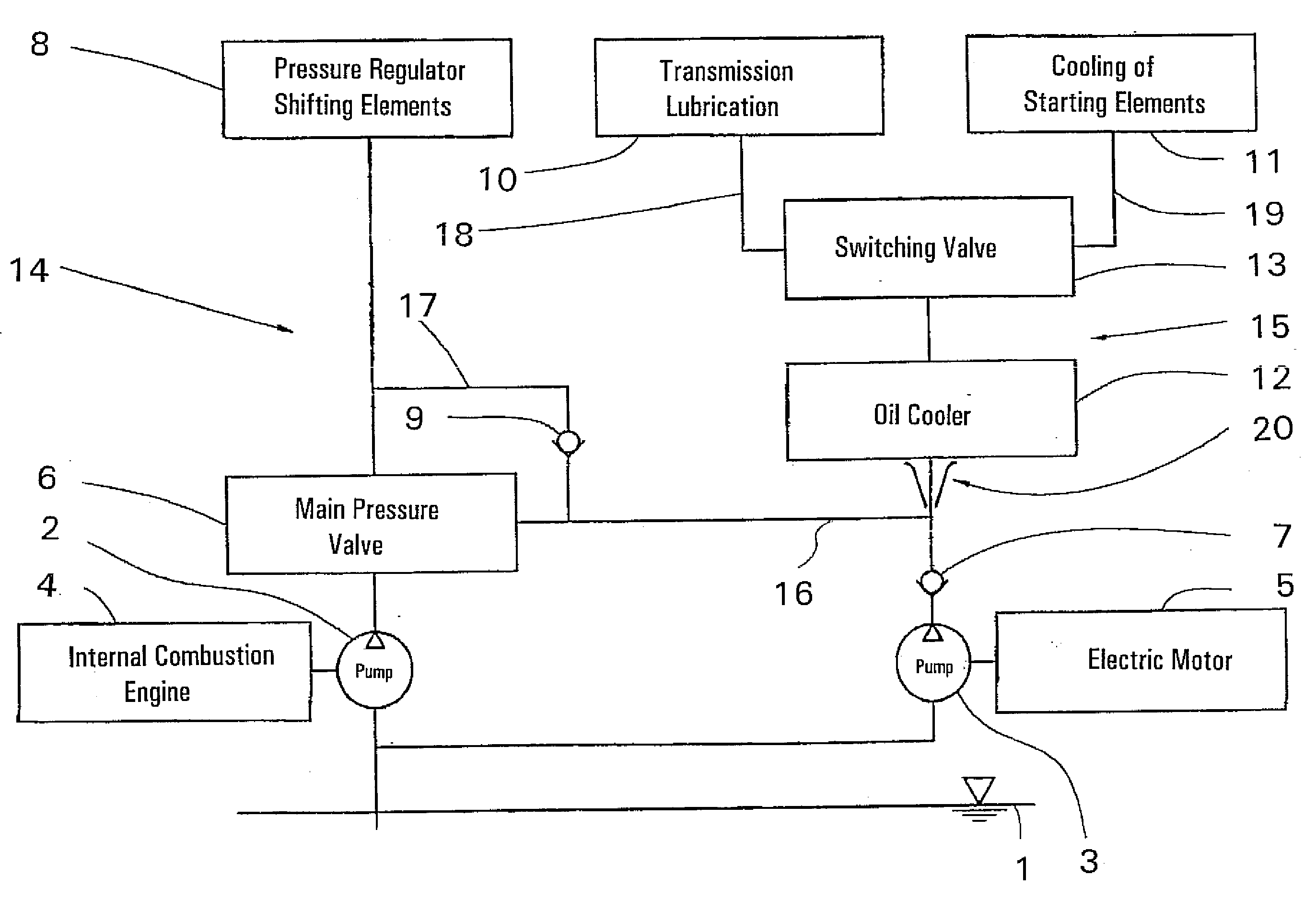

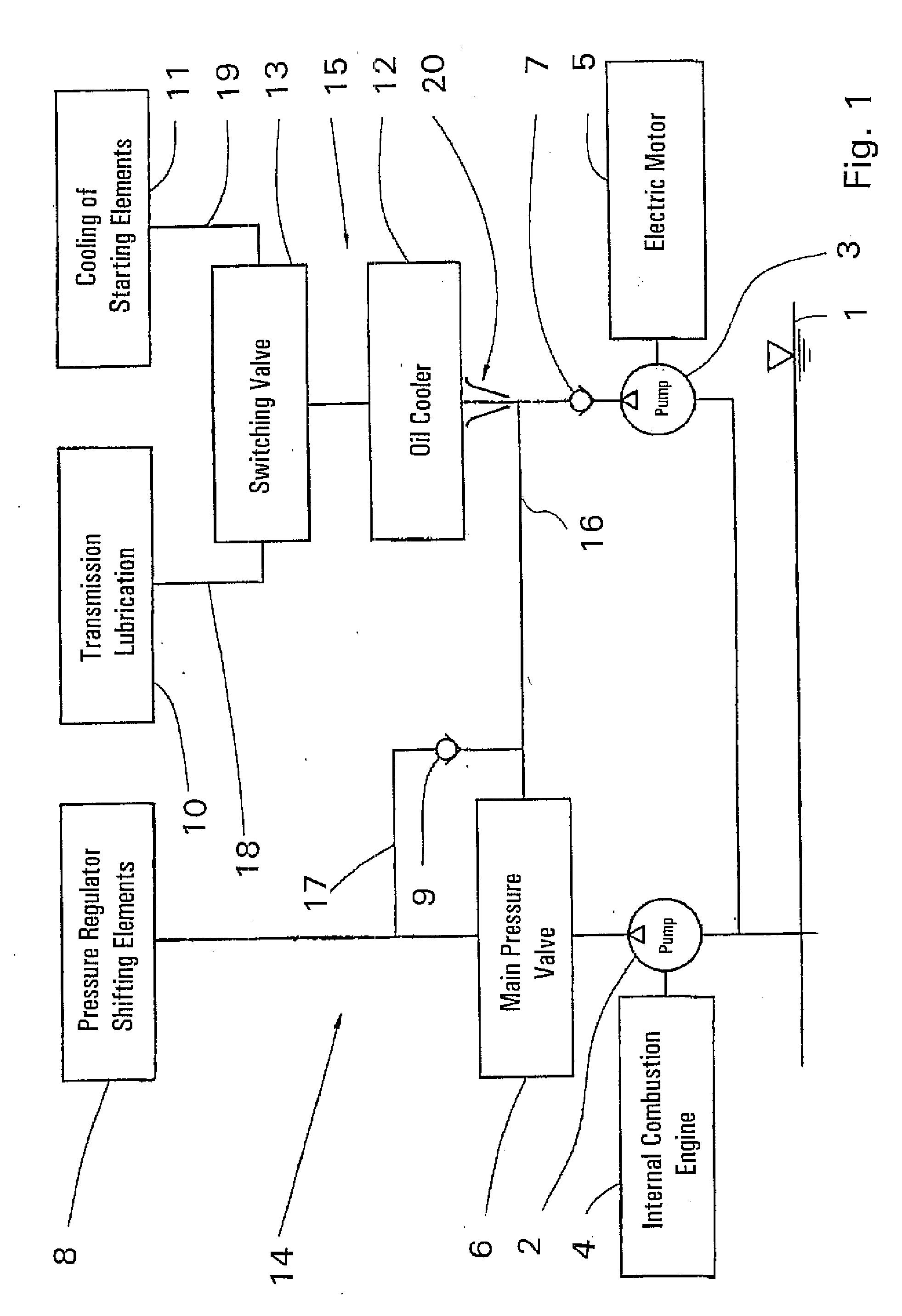

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveCN101147014AAvoid emissionsSave fuelGear lubrication/coolingGearing controlHydraulic control unitAutomatic transmission

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

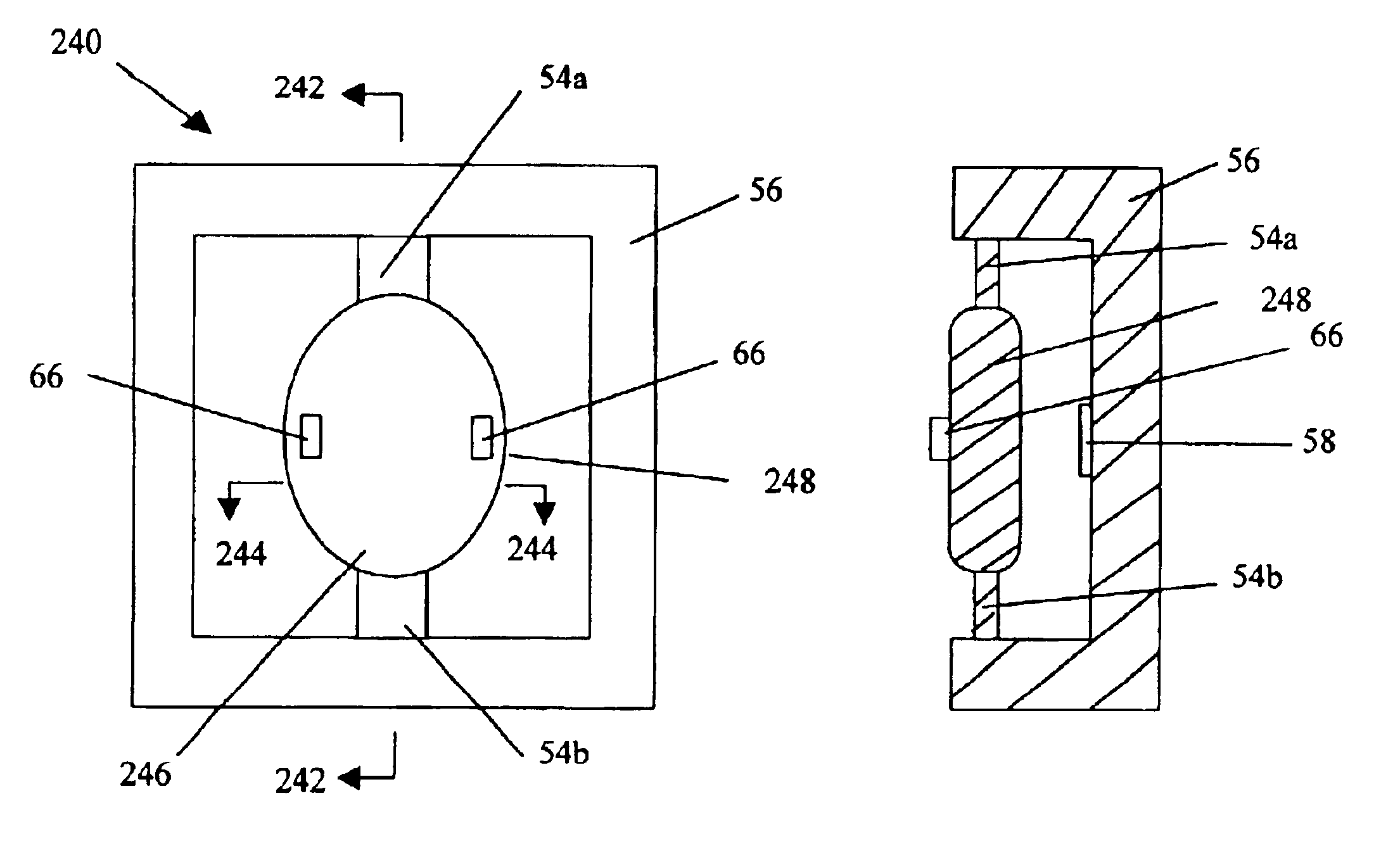

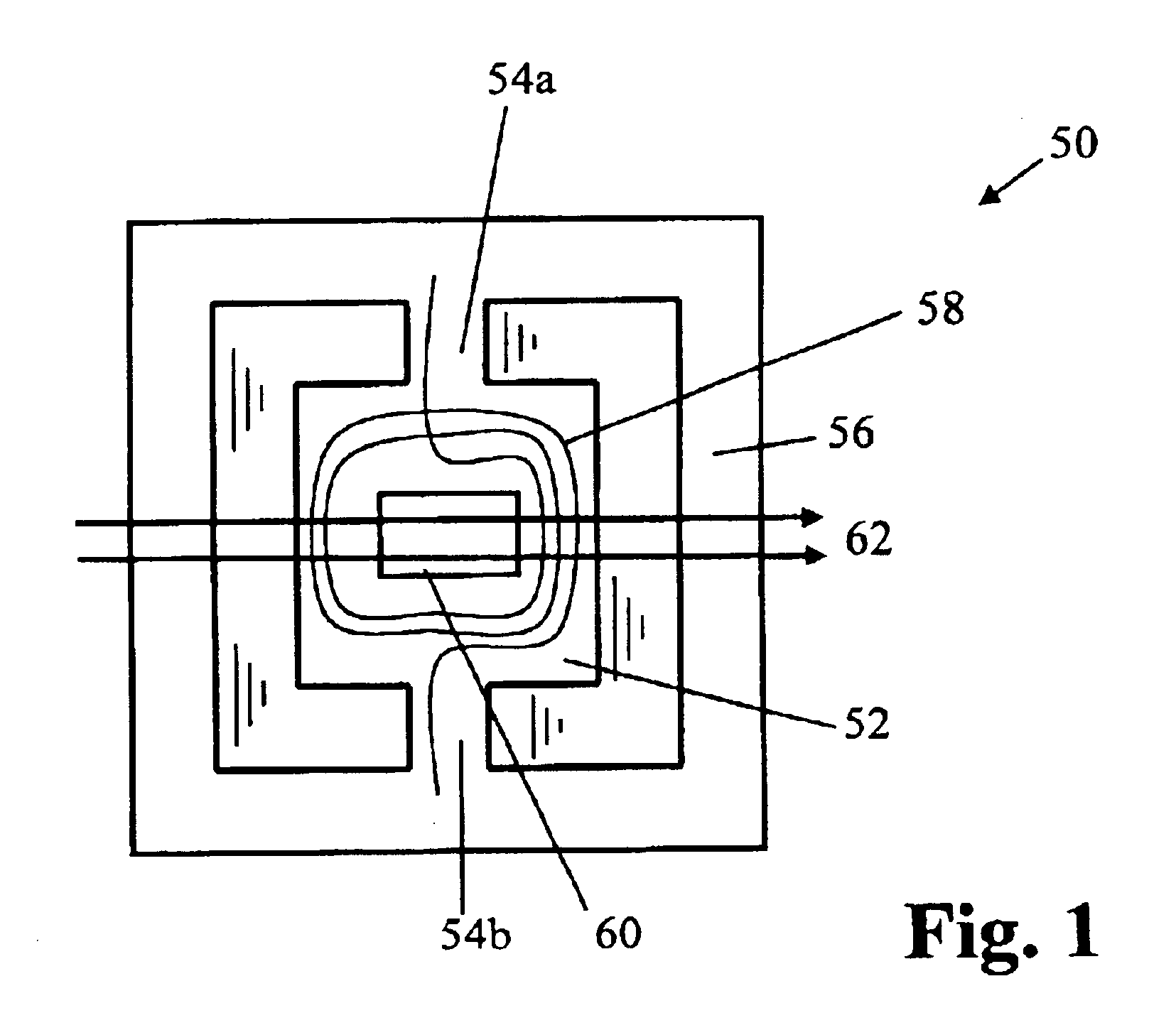

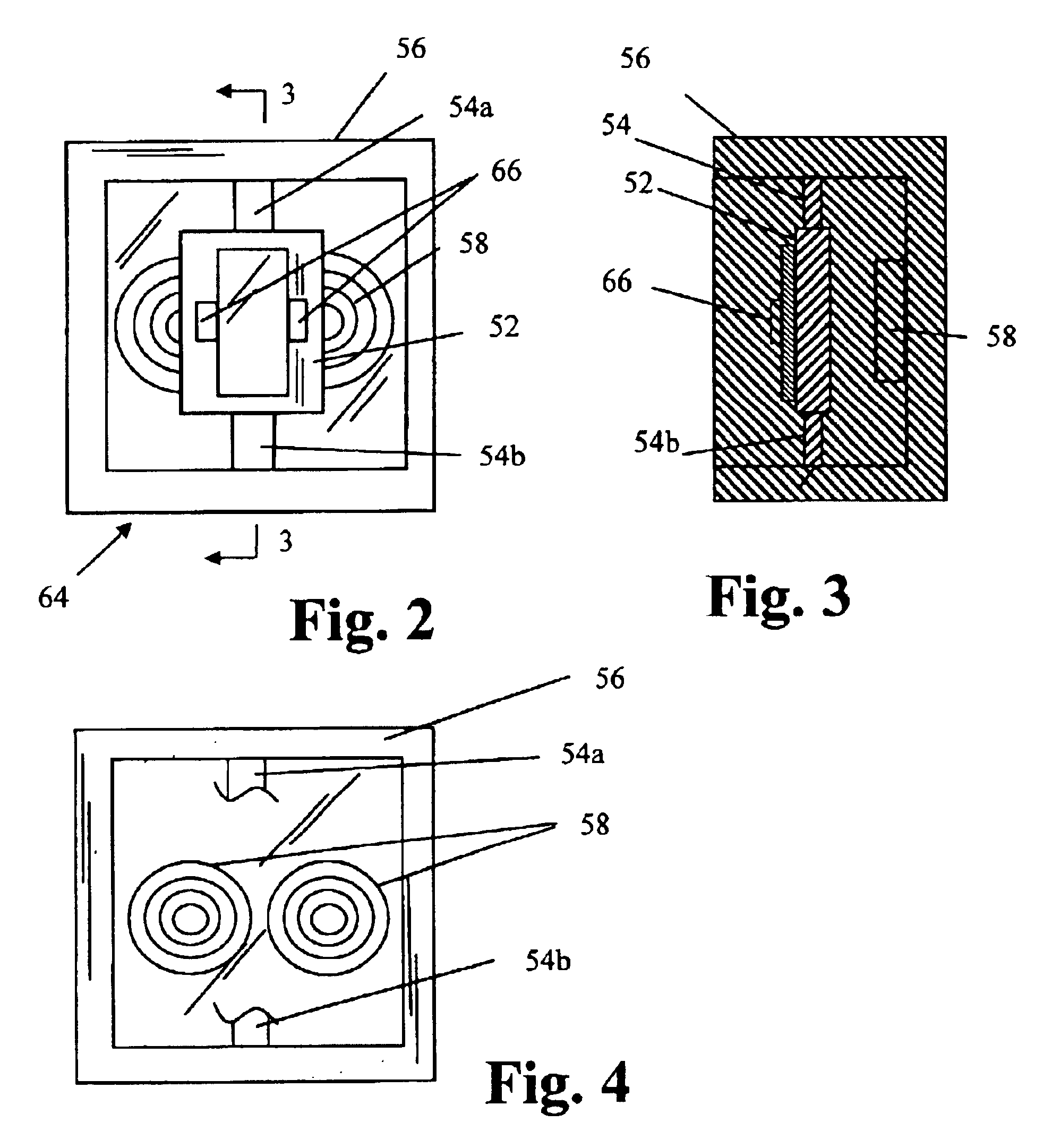

Stationary coil oscillator scanning system

InactiveUS6844951B2Small sizeLack of expenseInking apparatusOptical elementsControl systemLight beam

An image scanning apparatus and a torsion oscillator are capable of operating across a dynamic range of possible operating frequencies. The image scanning apparatus uses a light source to produce a light bean, and the oscillator scans the light beam through a scanning pattern. The oscillator includes a plate member having a non-rectangular shape. At least one magnet is disposed on the plate. A surface of the plate member includes a reflective surface for reflecting a light beam. A frame is disposed in a spaced apart relation to a lower surface of the plate member. The fame includes at least one coil configured to induce an electromagnetic force on the at least one magnet to thereby oscillate the reflective surface to a rotational angle of oscillation at an oscillation frequency. The system also includes an imaging surface disposed in the path of the scanning pattern so that the light beam scans across the imaging surface, and a mechanical drive to move the imaging surface. A control system controls electric current provided to the at least one coil to achieve the oscillation.

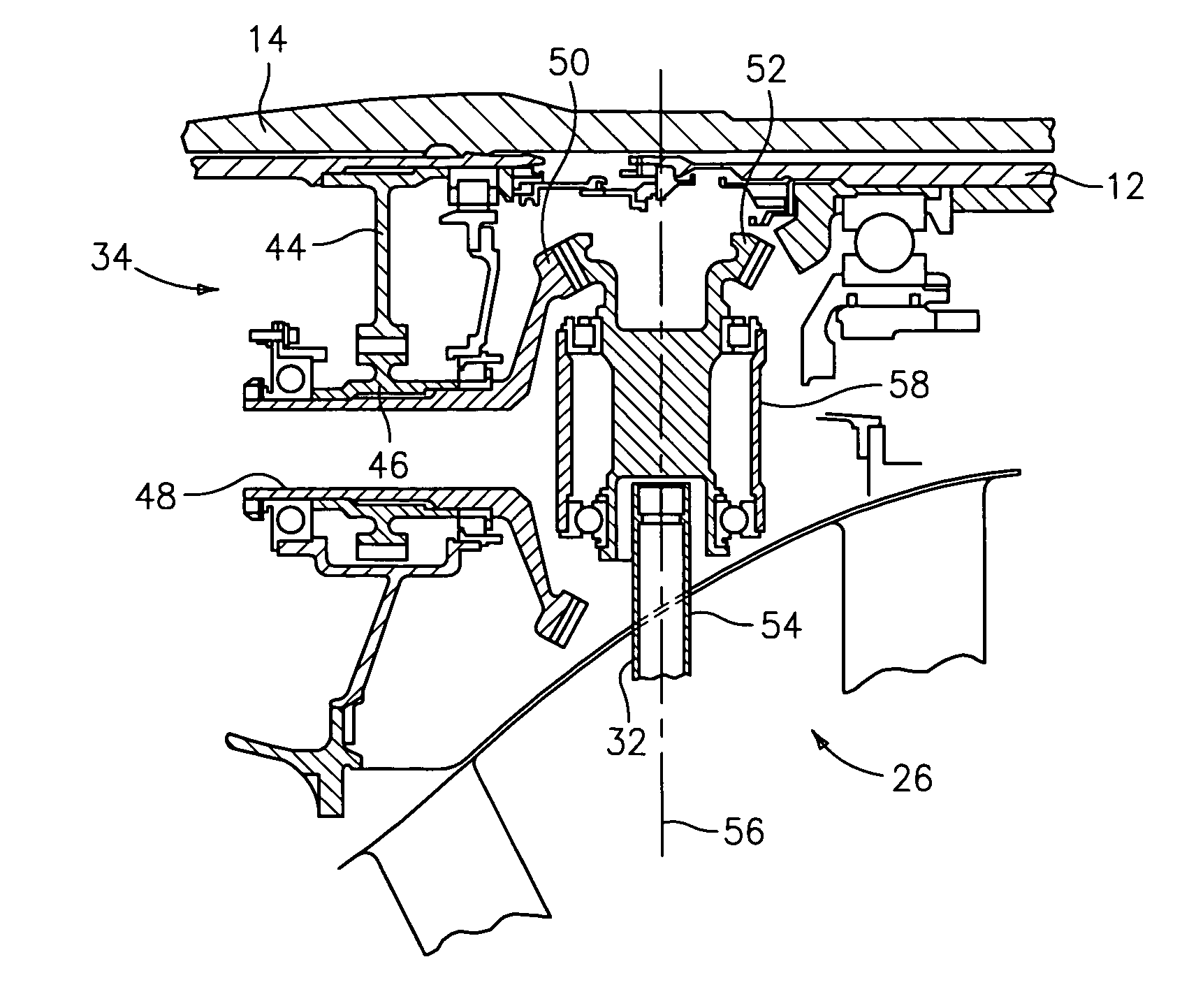

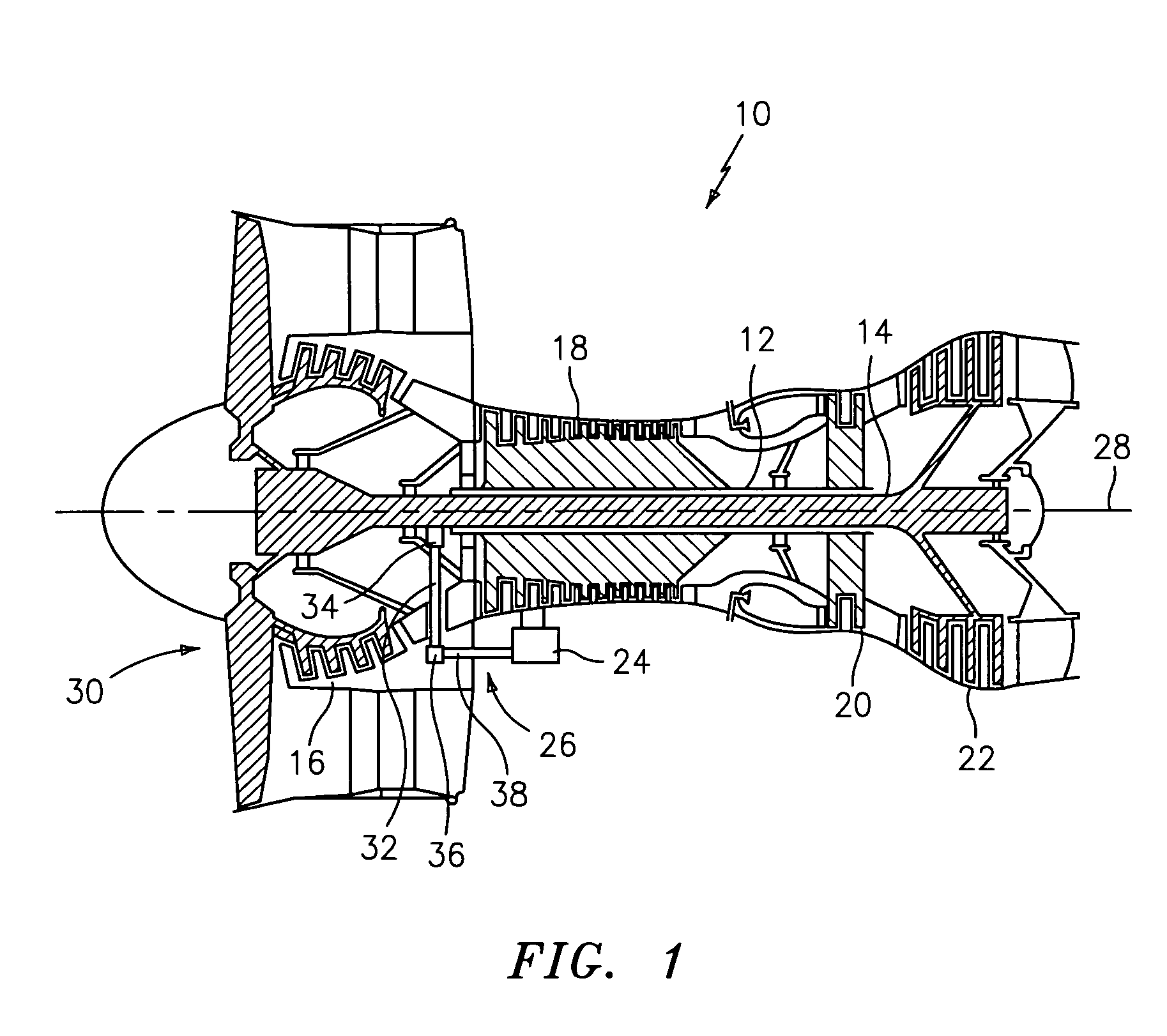

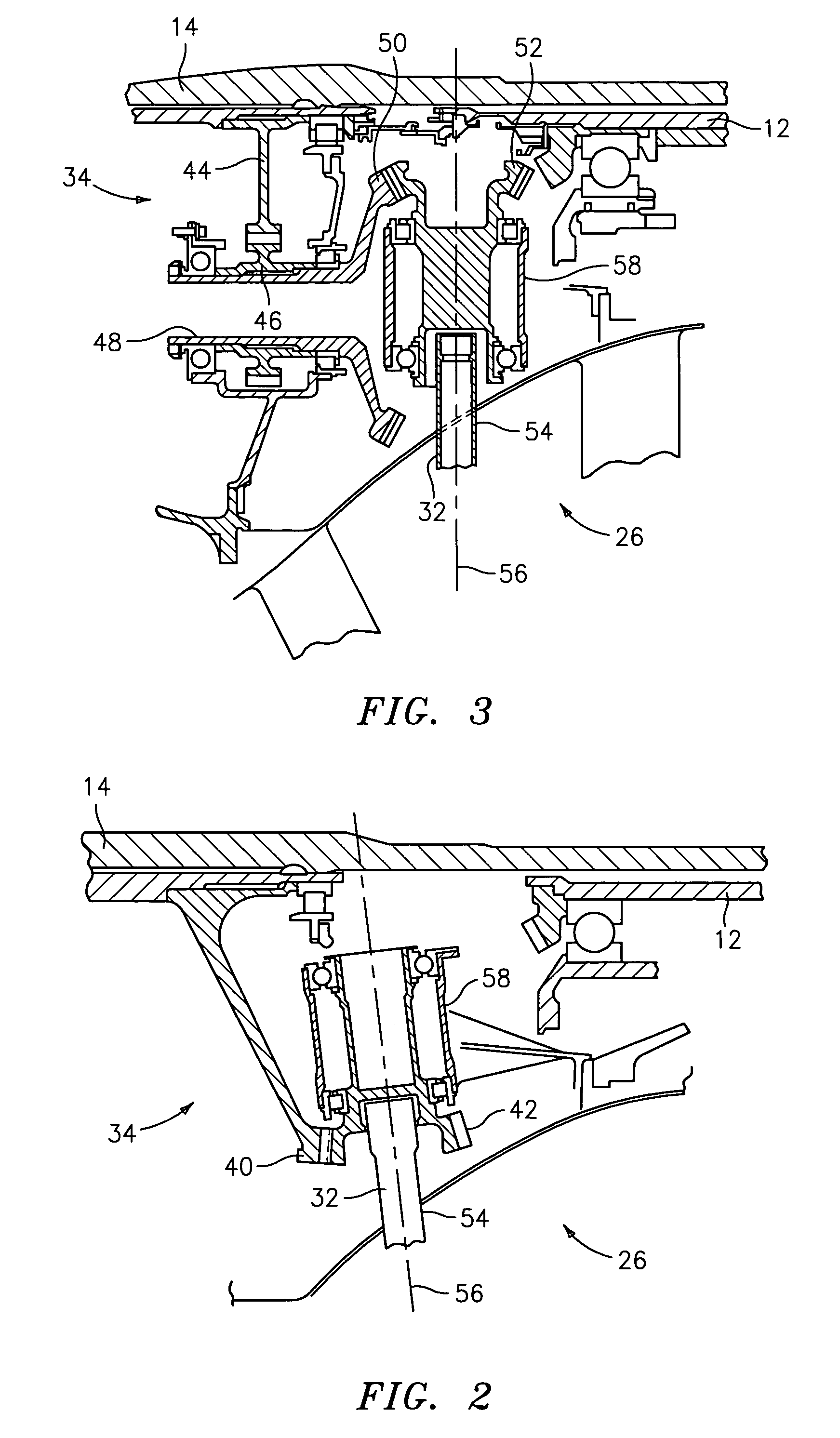

Apparatus for driving an accessory gearbox in a gas turbine engine

InactiveUS7055330B2Increased versatility and capabilityEngine fuctionsToothed gearingsPressure.driveDrive shaft

Owner:UNITED TECH CORP

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveUS20090232673A1Avoiding substantial energy lossIncrease productionLiquid coolingGear lubrication/coolingHydraulic control unitElectricity

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

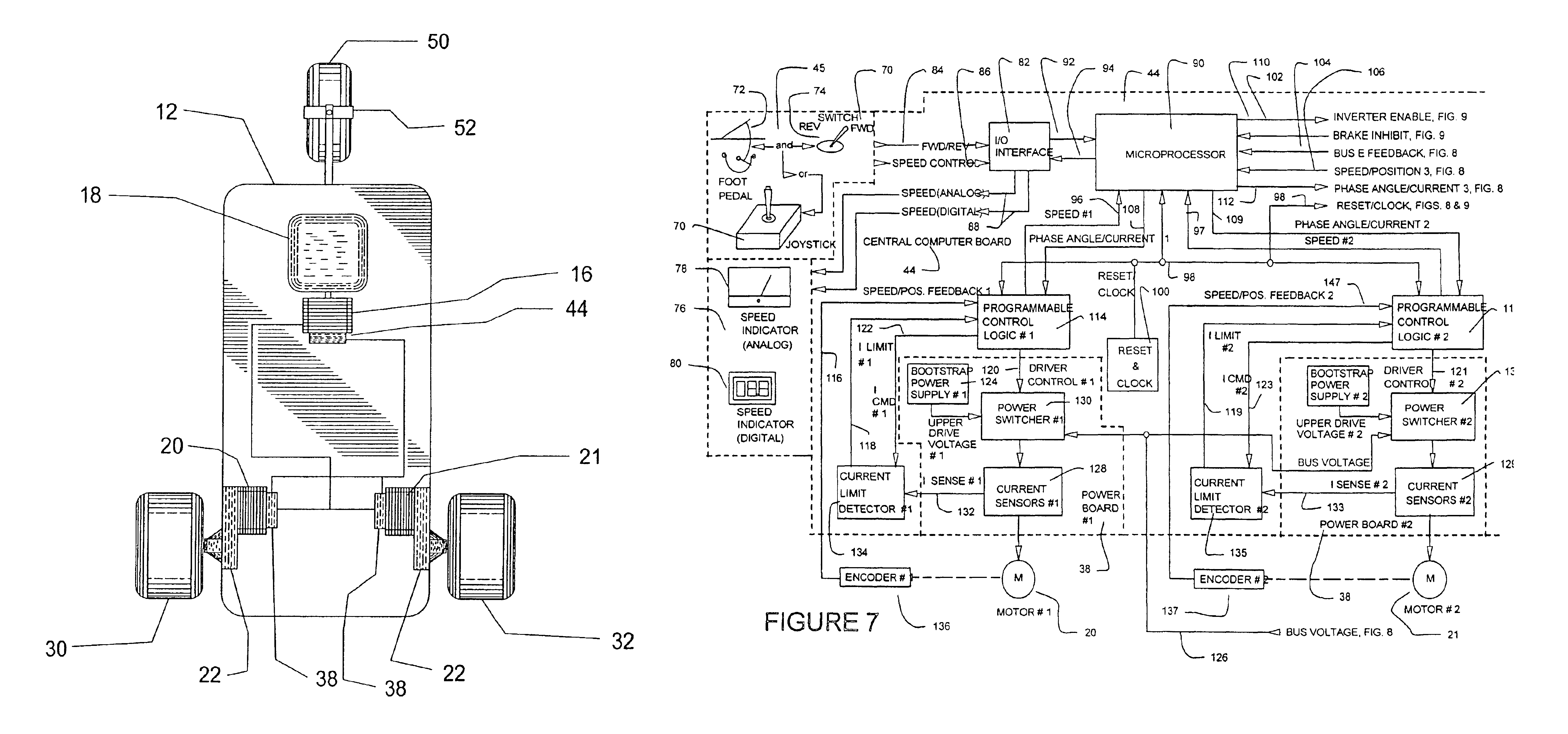

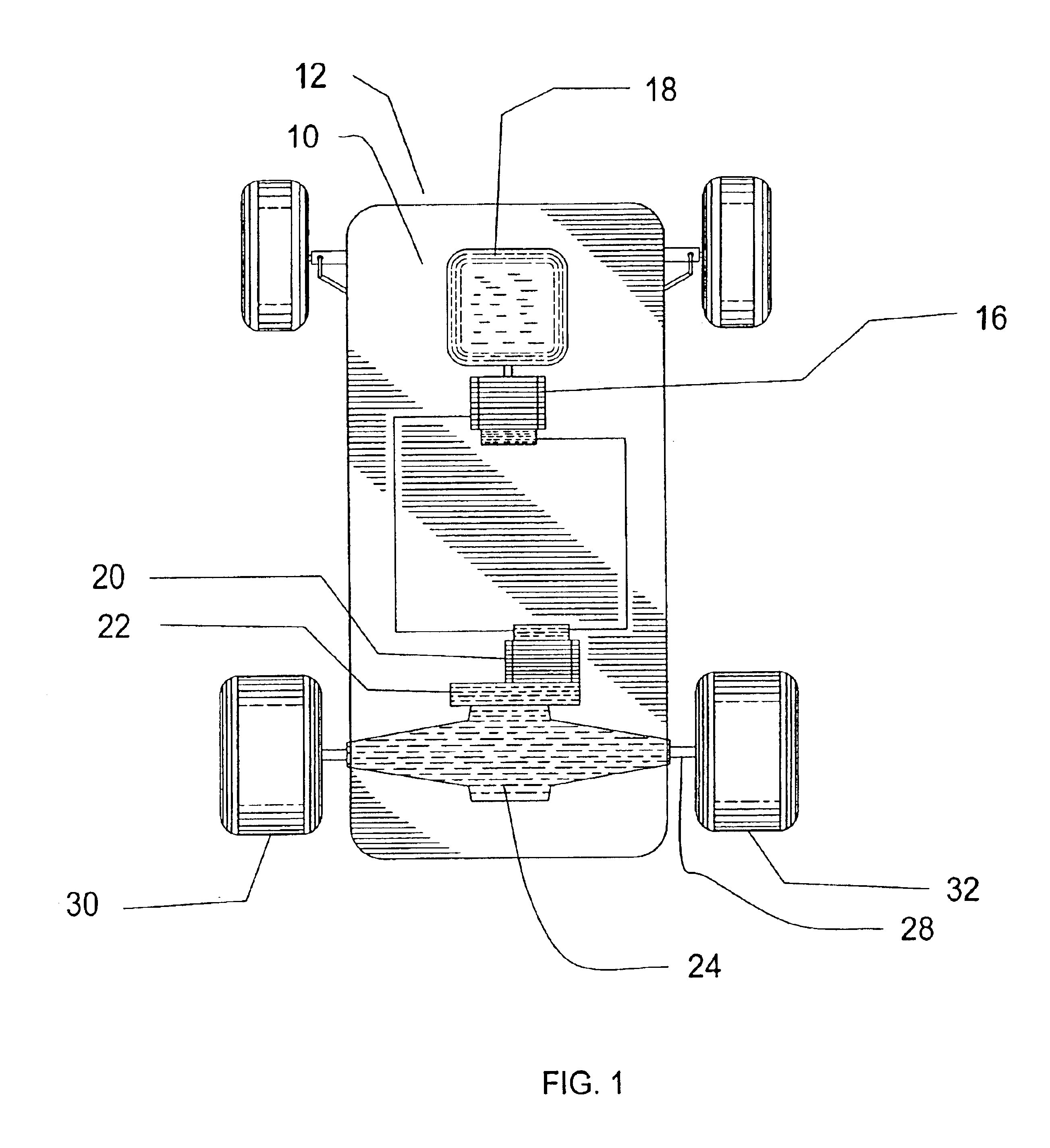

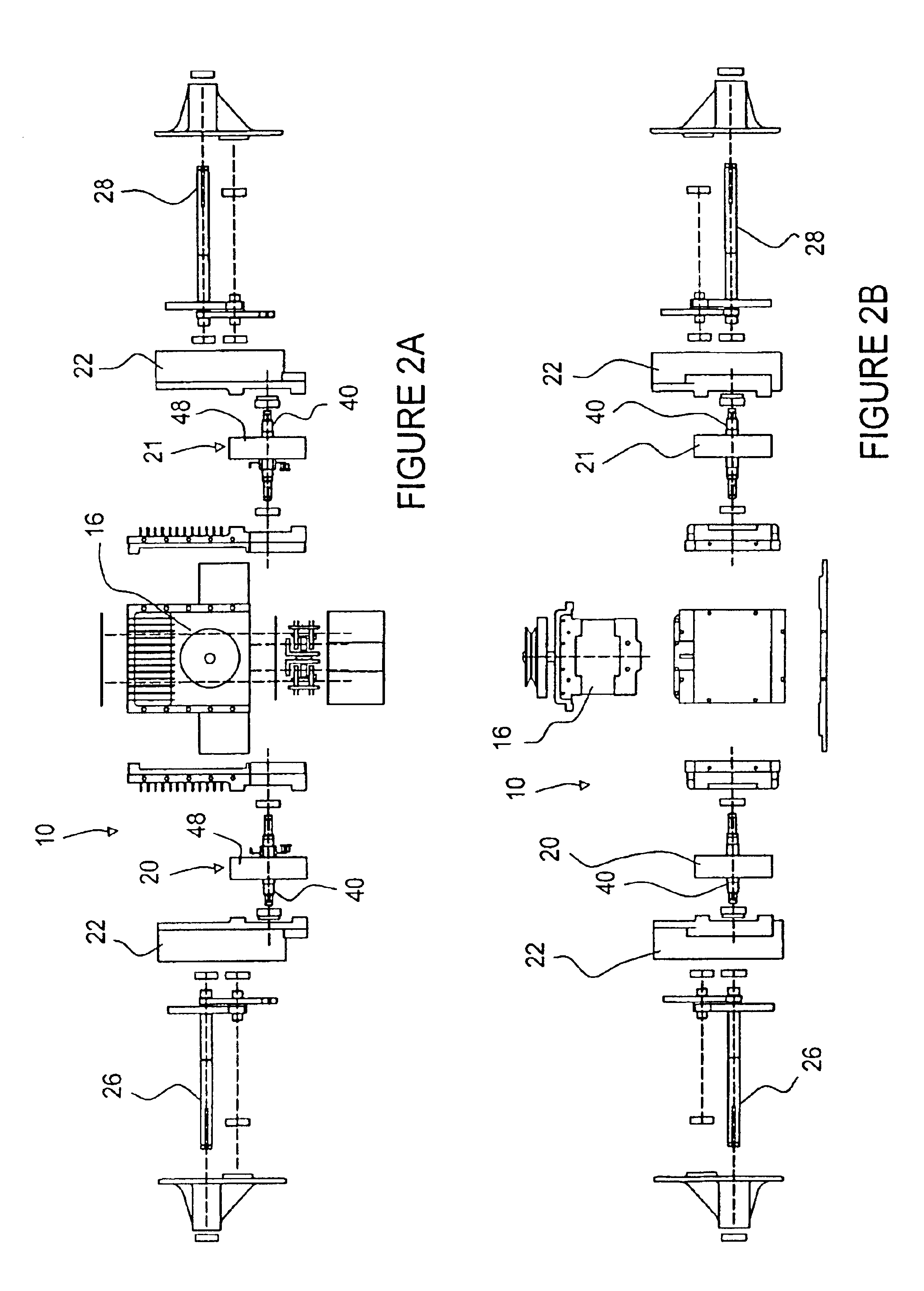

Electric generator and motor drive system

A drive system which integrates an electric generator, one or more electric motors and an electronic control module is configured as a variable speed drive in either single, dual or four wheeled traction drive configurations for a mower. The generator is mechanically driven by the output shaft of an internal combustion engine to generate the electrical power for energizing the electric motors. A central computer in the electronic control module controls the output voltage of the generator and the speed and torque of each of the motors in the drive system. The speed input signal for the motors can be analog signals that come from sources such as a joystick, a potentiometer mounted on a steering wheel, control panel, foot pedal or remote location or digital signals from a digital device. Position / speed detectors on each motor and the generator send signals back to the central computer for closed-loop control of the generator and of the motors. The generator supplies the DC voltage to the power control board for each motor as commanded by the central computer. The rotor of each motor is connected to a gearbox for speed reduction and increased torque that is applied to the wheel mounted on the output shaft of the gearbox. When the motors are not being driven, the generator may optionally supply DC power to the input of an inverter that has an output to standard electric utility AC outlets that can be used to power auxiliary equipment.

Owner:BRANDON DENNIS +1

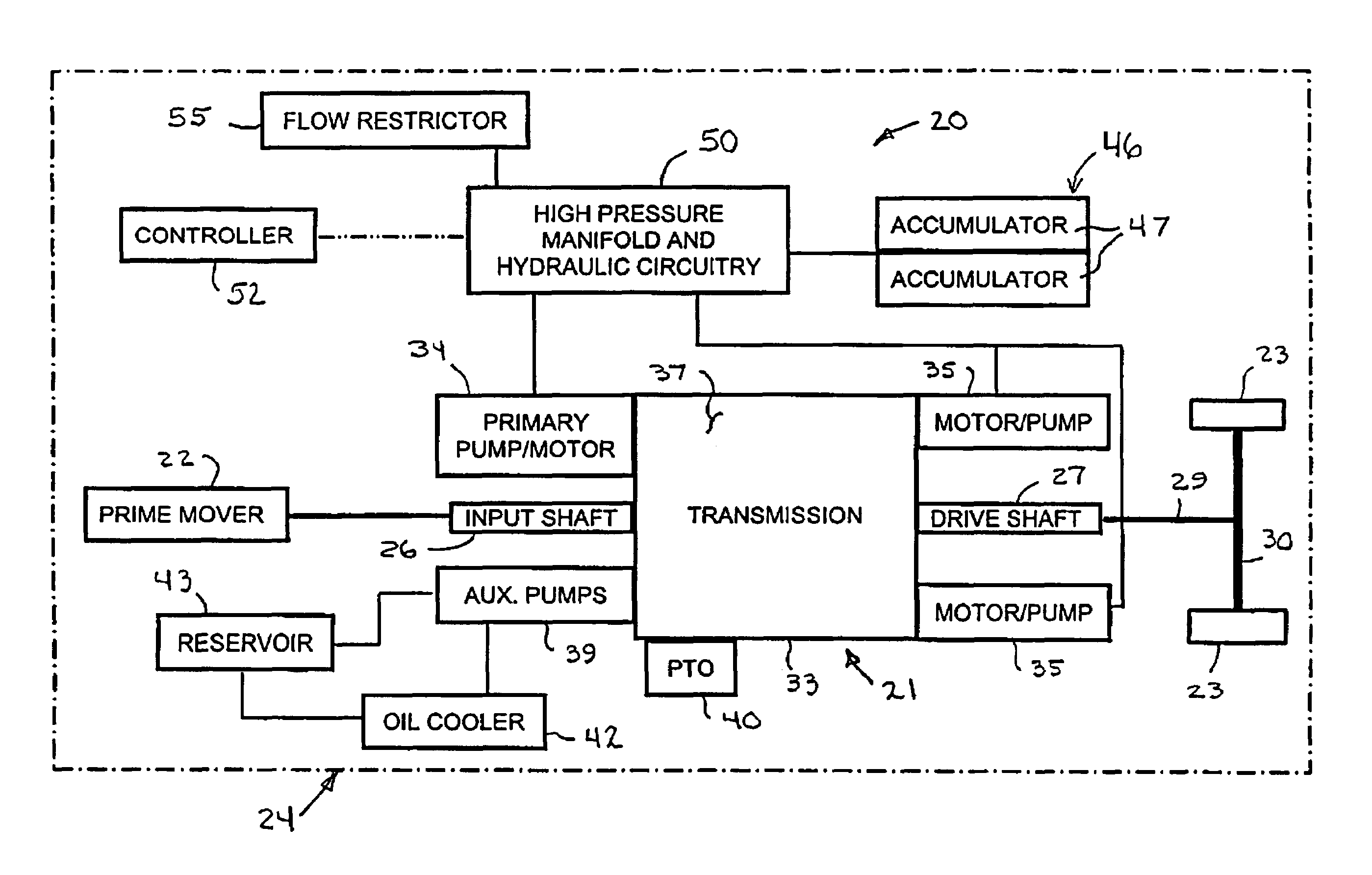

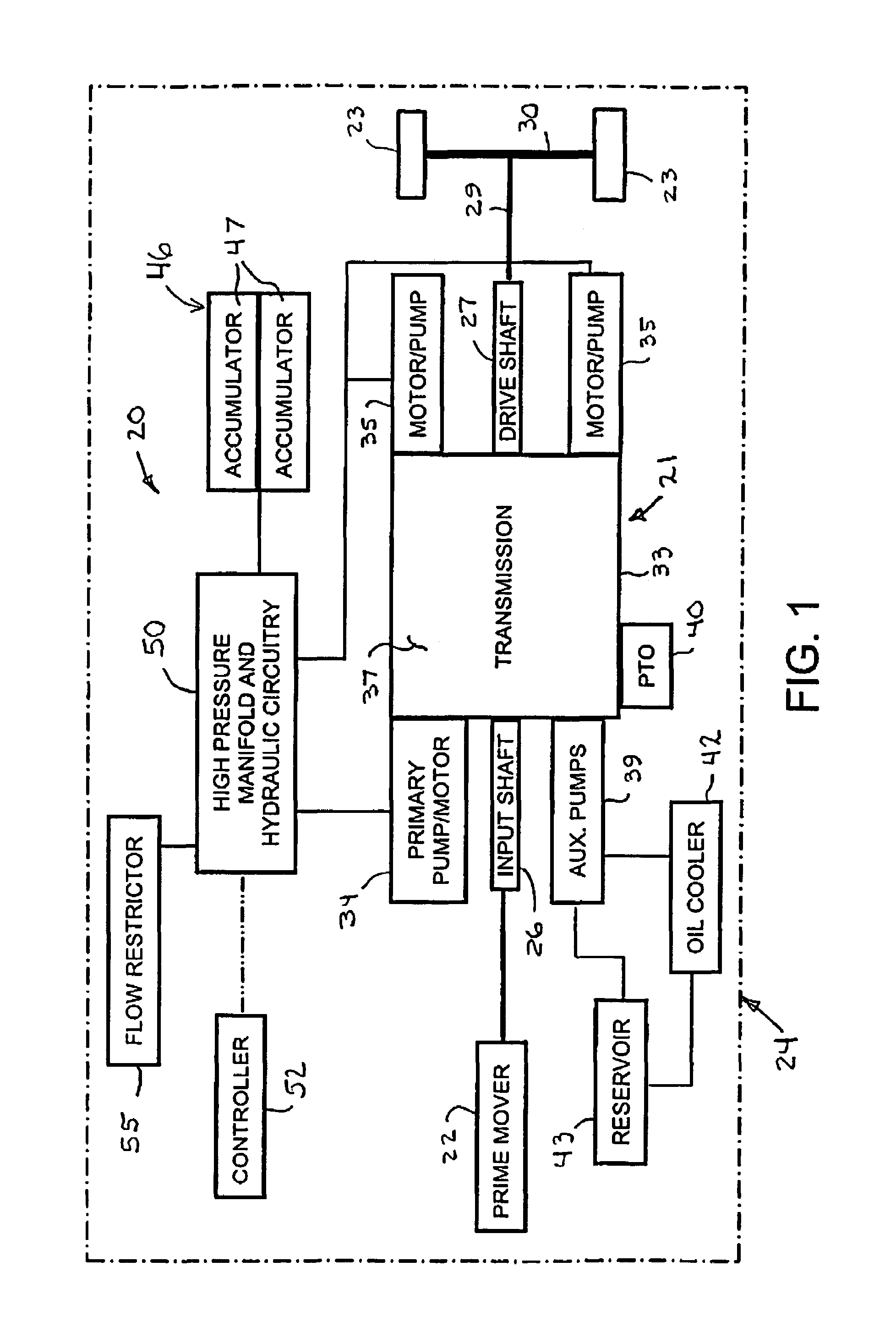

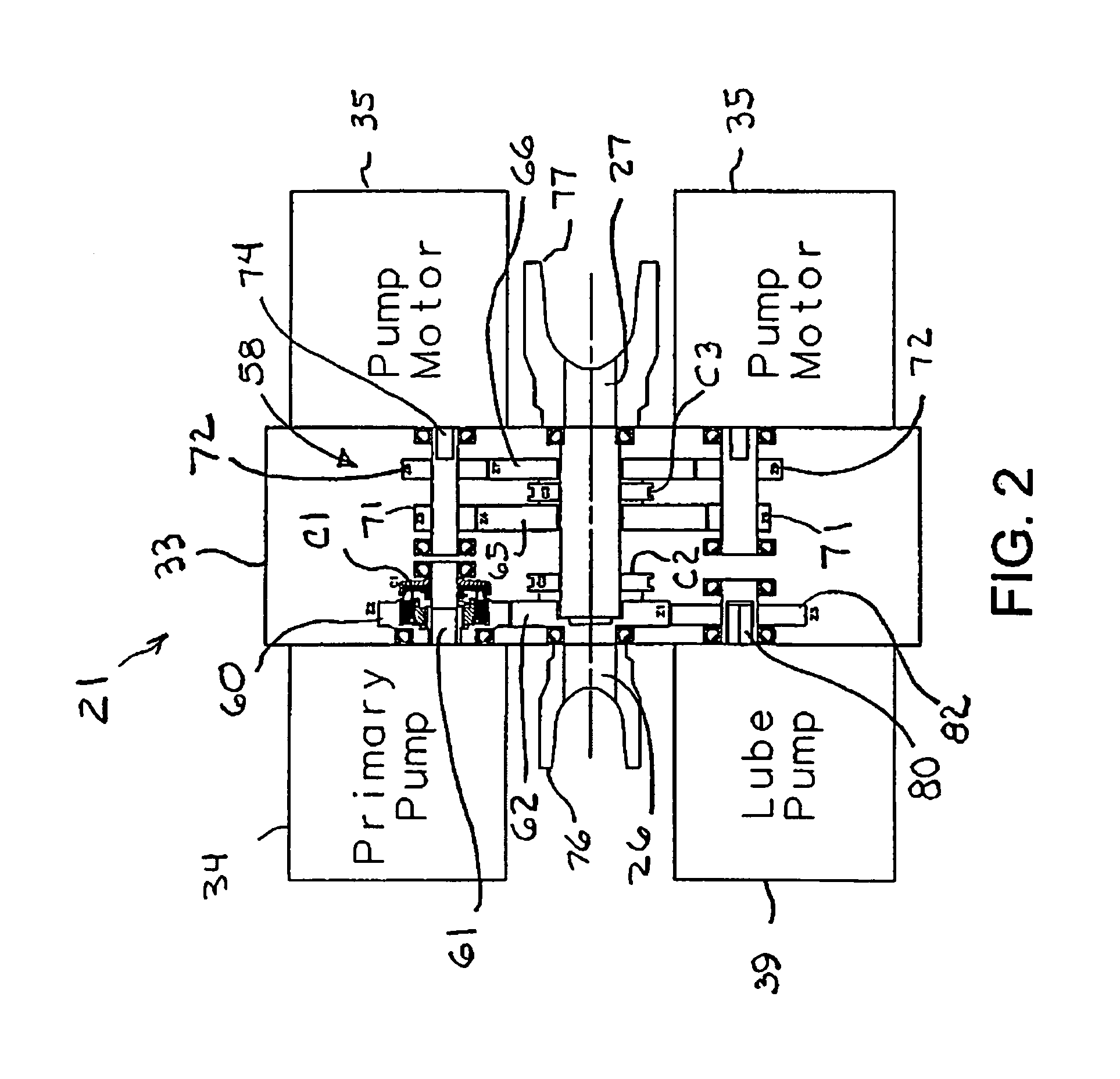

Gear box for hydraulic energy recovery

A hydraulic energy recovery and a mechanical drive system in one unit that also provides integral mounting of hydraulic pump / motors for primary drive, secondary drive, and pumps for cooling, lubrication, and low pressure systems along with a mounting position for a power take-off device.

Owner:PARKER HANNIFIN CORP

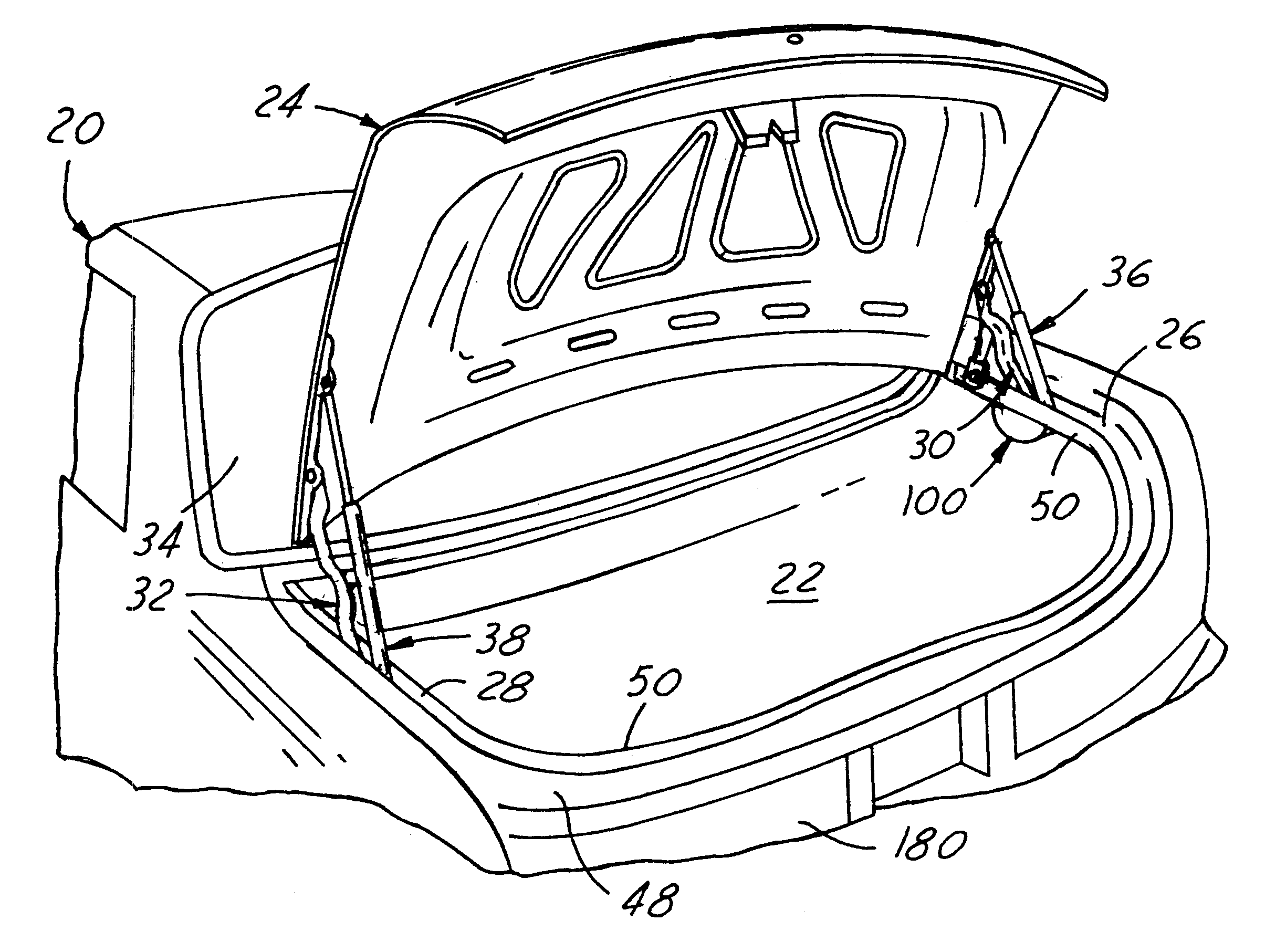

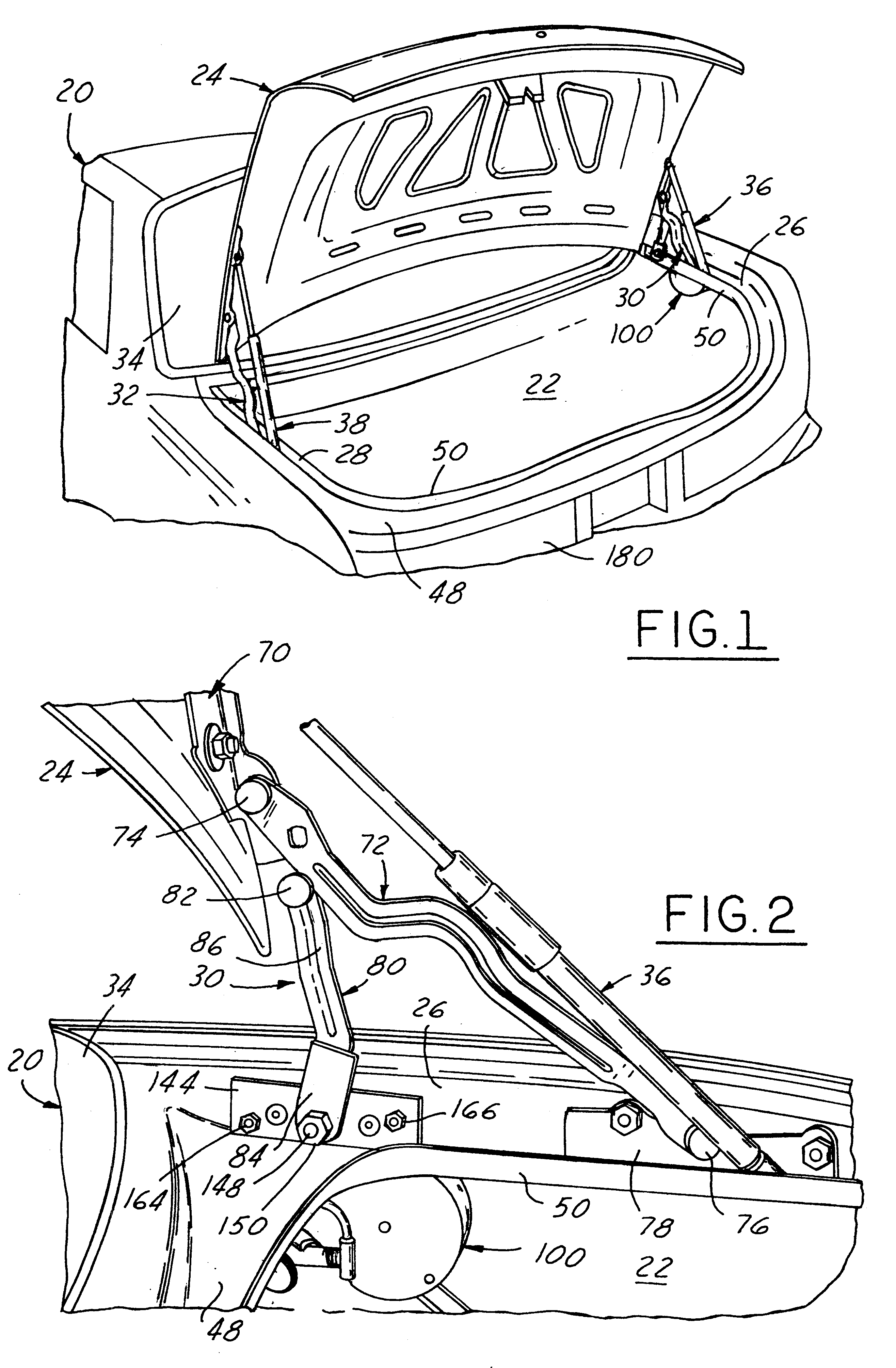

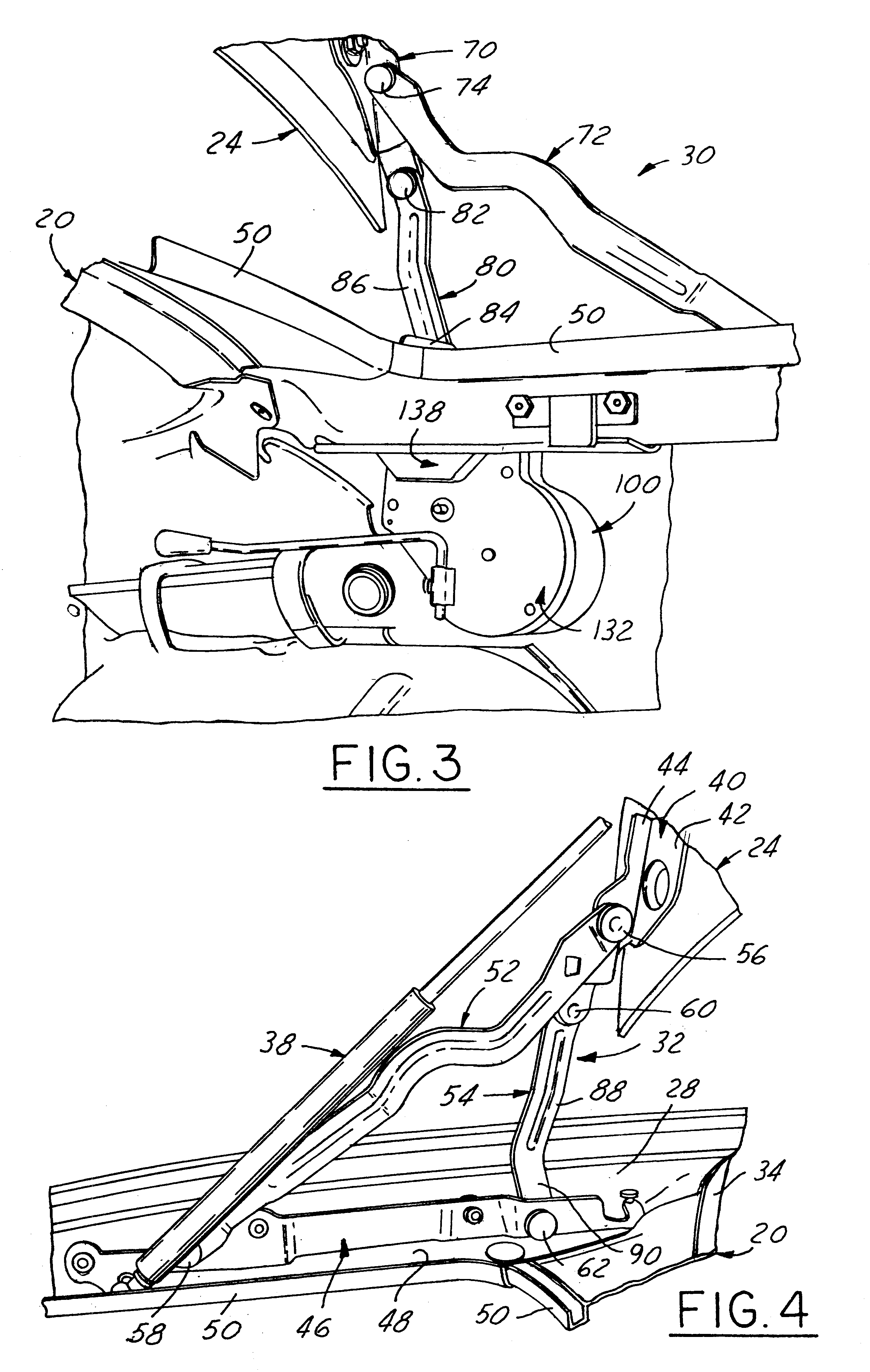

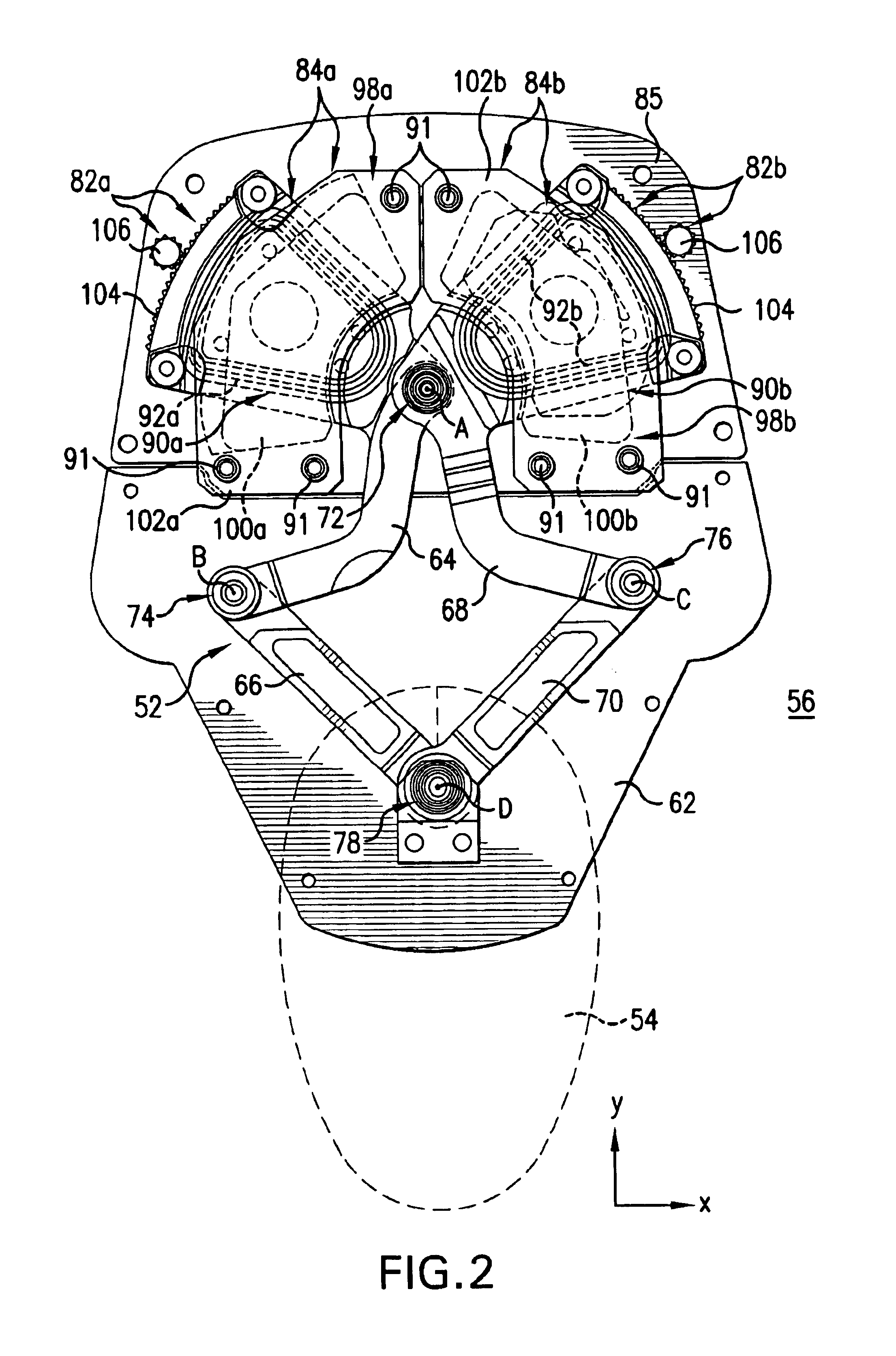

Power actuating system for four-bar hinge articulated vehicle closure element field of the invention

InactiveUS6520557B2Compact and economical in constructionCompact and economical in and installationPower-operated mechanismSuperstructure subunitsTrunk compartmentDrive shaft

An improved four-bar hinge assembly for attaching a trunk deck lid to a vehicle body in which the control link of the four-bar linkage has its usual vehicle-mounted pivot pin replaced by the rotatably driven output drive shaft of a power drive mechanism that is rigidly and directly coupled to the control link to swing to the same and thereby power actuate the four-bar linkage in order to pivot the deck lid between open and closed positions. The hinge elements are located on the weather side of the vehicle body components and the drive shaft extends through the vehicle sheet metal into the weather sealed trunk compartment so that the electro-mechanical drive components are mounted within the weather sealed trunk.

Owner:STRATTEC POWER ACCESS

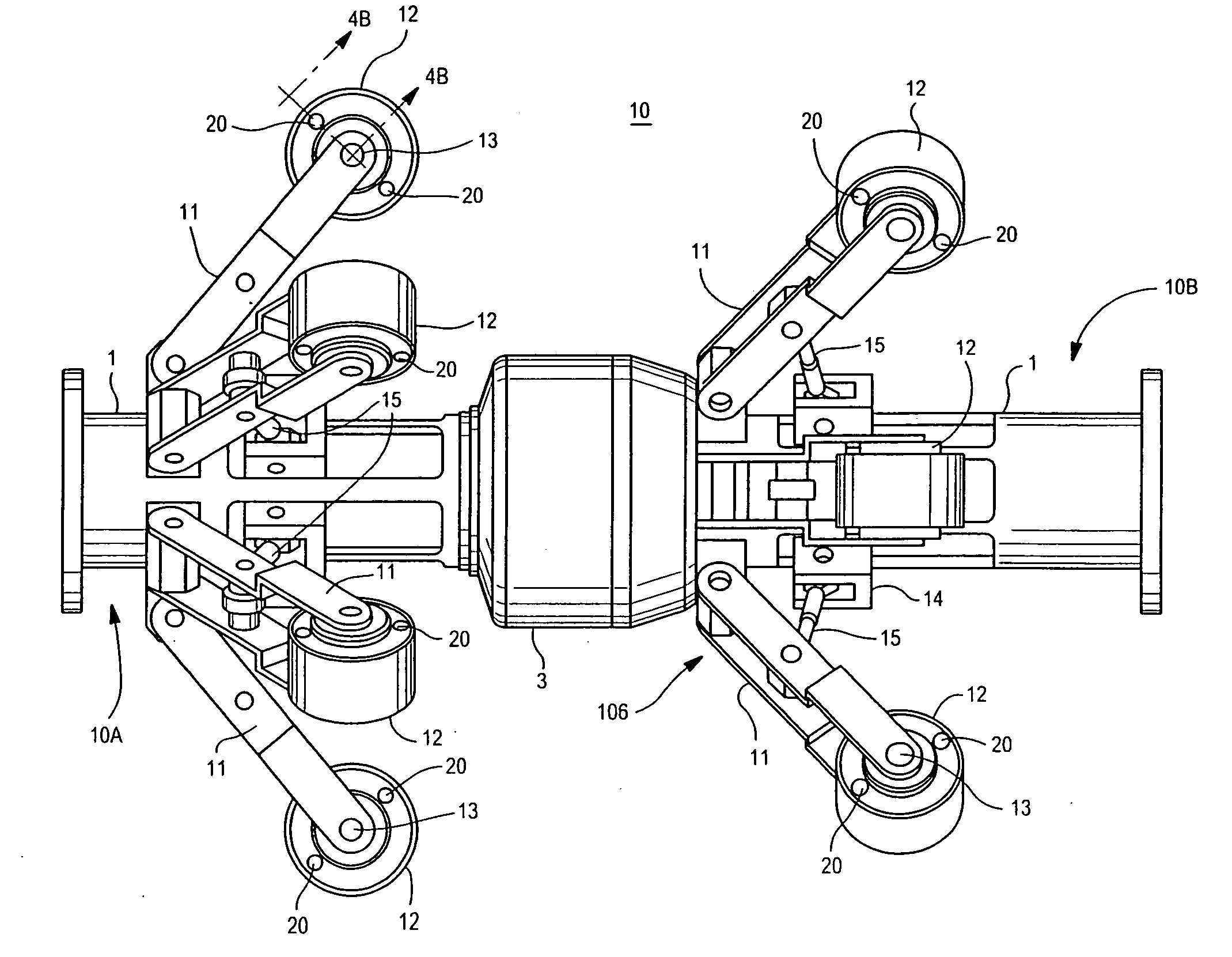

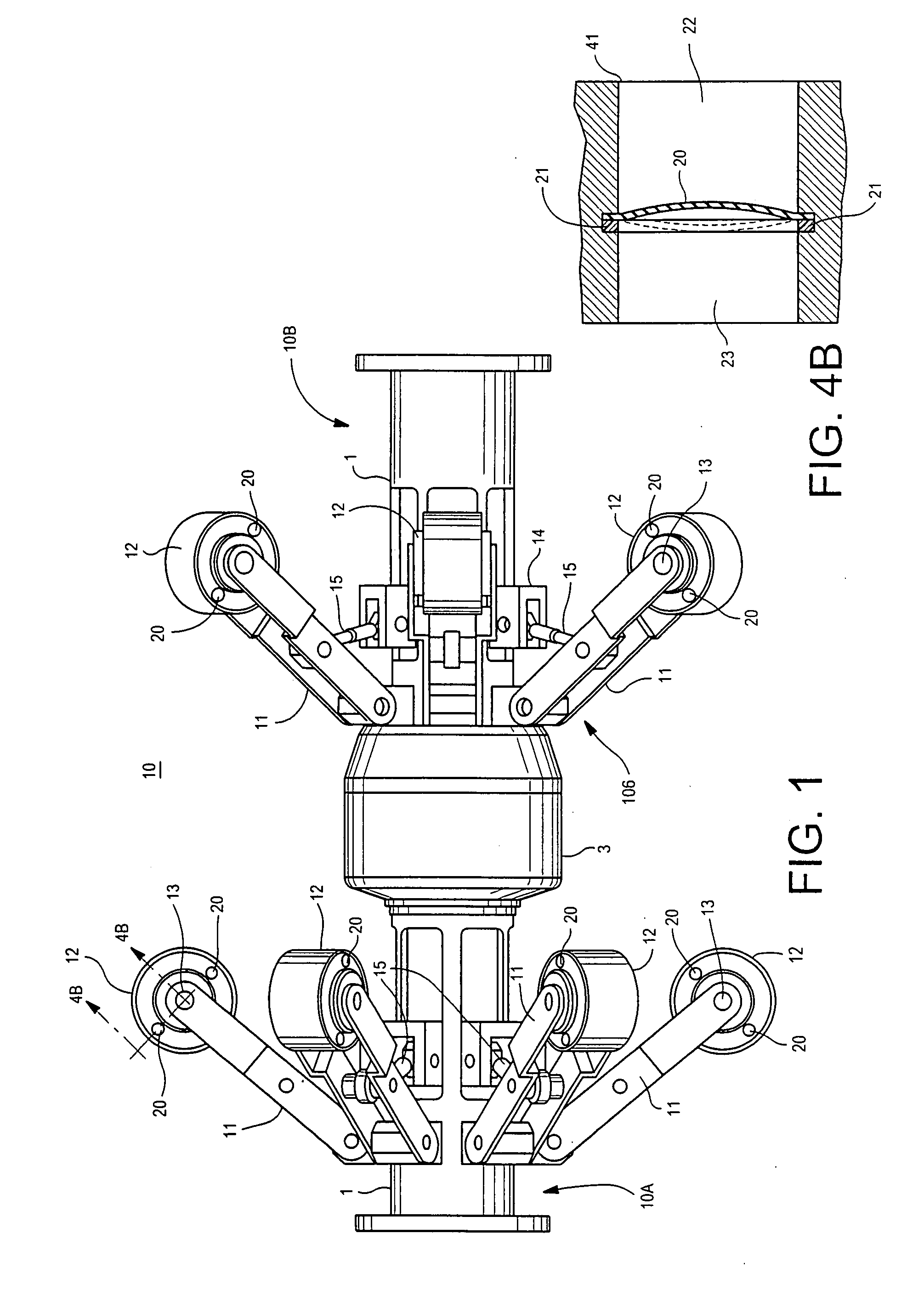

Pressure-balanced electric motor wheel drive for a pipeline tractor

InactiveUS20080245258A1Avoid lostReduce sensitivityRailway tunnelsRailway componentsMotor driveAmbient pressure

A self-propelled crawler / tractor apparatus is disclosed for traveling through a tubular pipeline while conducting pipeline wall inspection operations and / or towing gear for cleaning, maintenance and the like. The crawler / tractor apparatus is propelled by a plurality of radially positioned motorized traction wheels. Each motorized traction wheel includes a brushless DC electric motor along with clutch, gearbox and other mechanical drive components integrated into a compact self-contained motorized wheel assembly which is sealed and filled with an electrically non-conductive lubricating / cooling oil. The seal integrity at each wheel assembly is maintained against oil leakage and debris ingress by a pressure-balancing mechanism which matches internal oil pressure to the exterior ambient pressure present in the pipeline. The electric motor drive for each traction wheel is individually controlled via an onboard computer to provide a wide range of torque and wheel speeds.

Owner:GENERAL ELECTRIC CO

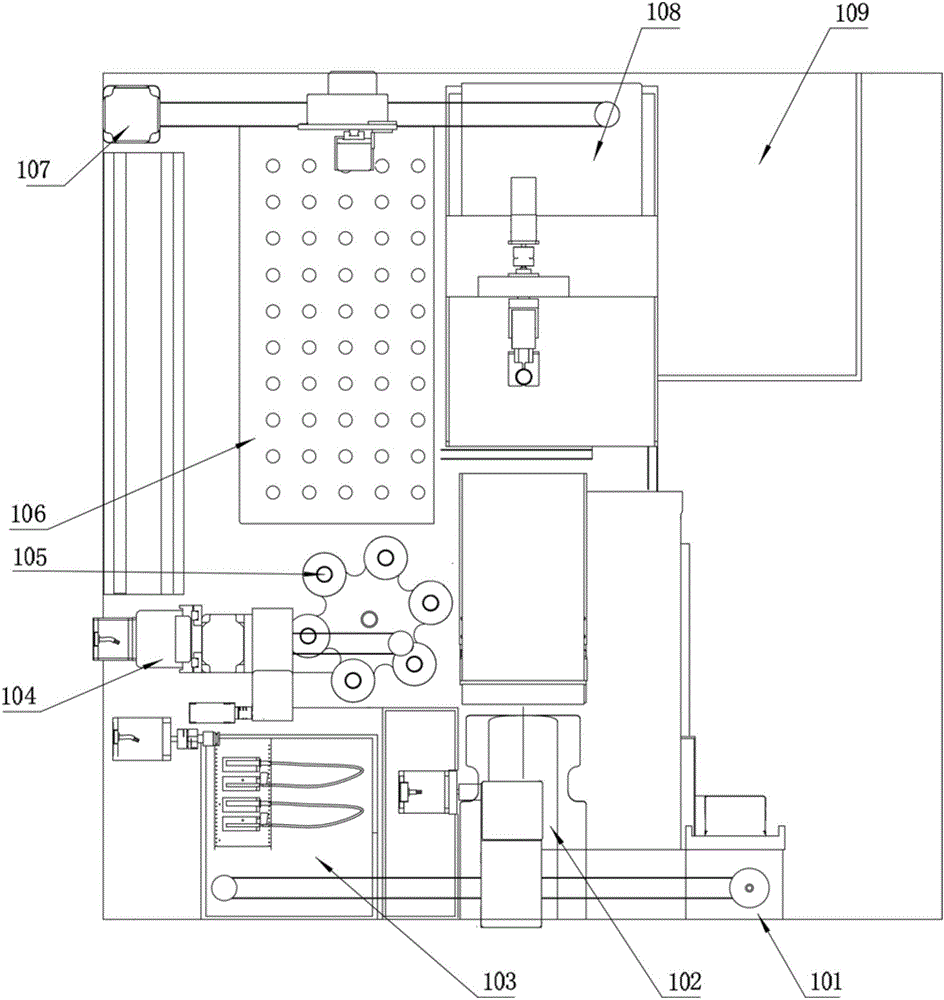

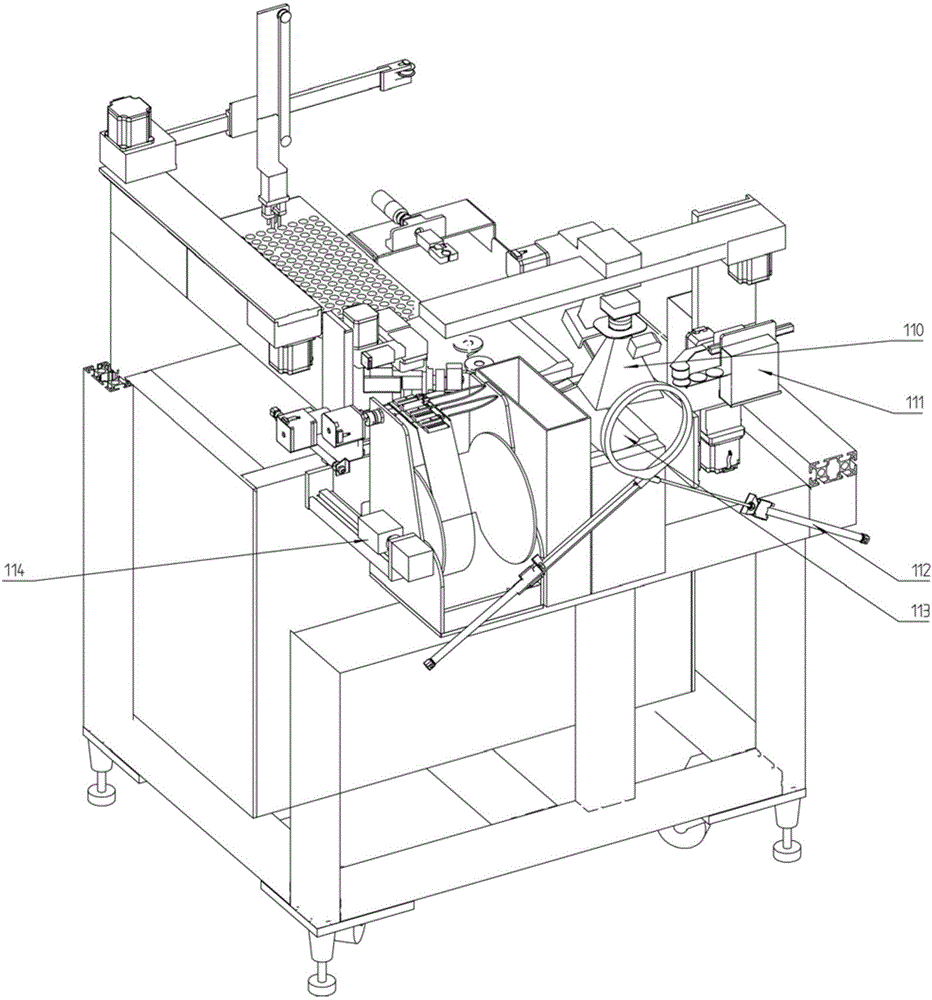

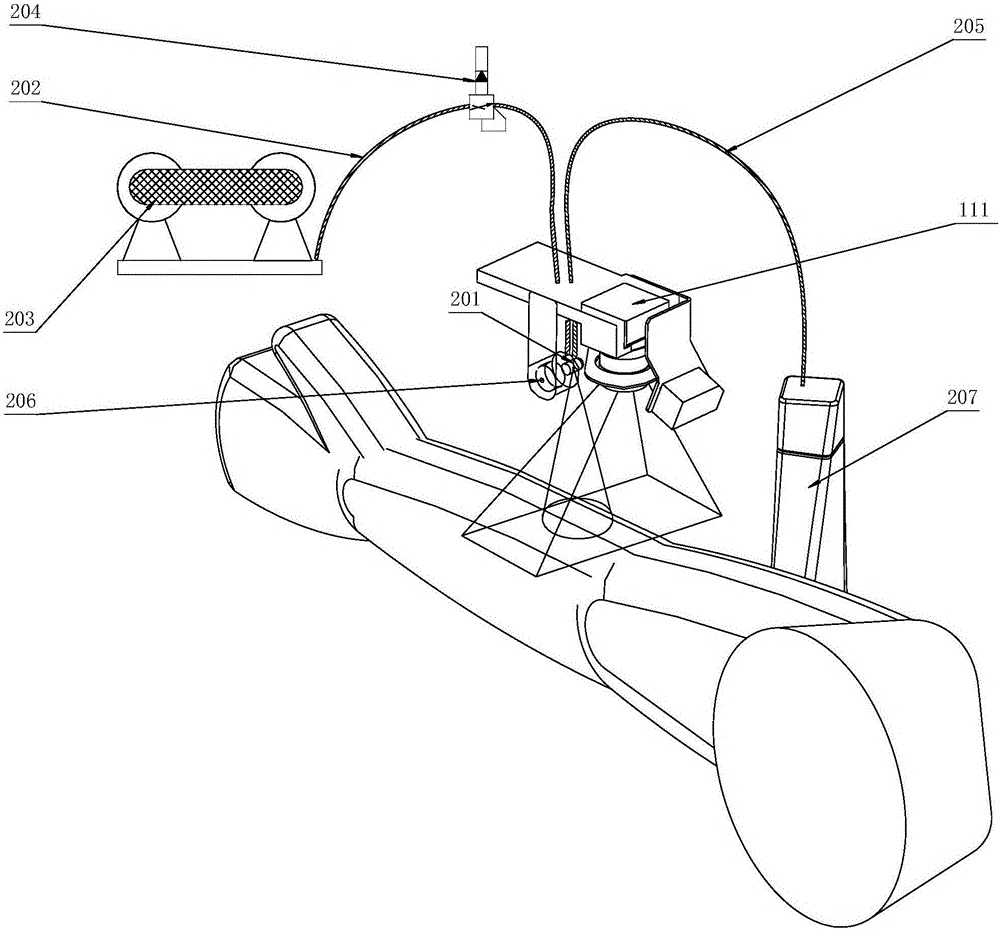

Venous blood collection robot and venous blood collection method employing same

ActiveCN106580344AHigh positioning accuracyRelieve painDiagnostic recording/measuringSensorsVeinBlood collection

The invention relates to a venous blood collection robot, comprising an arm rest; a full-automatic recognition positioning device and a mechanical drive mechanism connected with a clamping device that clamps a blood collection needle are arranged above the arm reset, the lateral side of the arm rest is provided with an intelligent navigation vessel-recognizing device, and the front of the arm rest is provided with an automatic vein presser. The venous blood collection robot is capable of preventing operational errors due to manual operation, reducing blood collection difficulty and relieving the pain of a person under blood collection.

Owner:BEIJING MAGICNURSE SURGICAL ROBOT TECH CO LTD

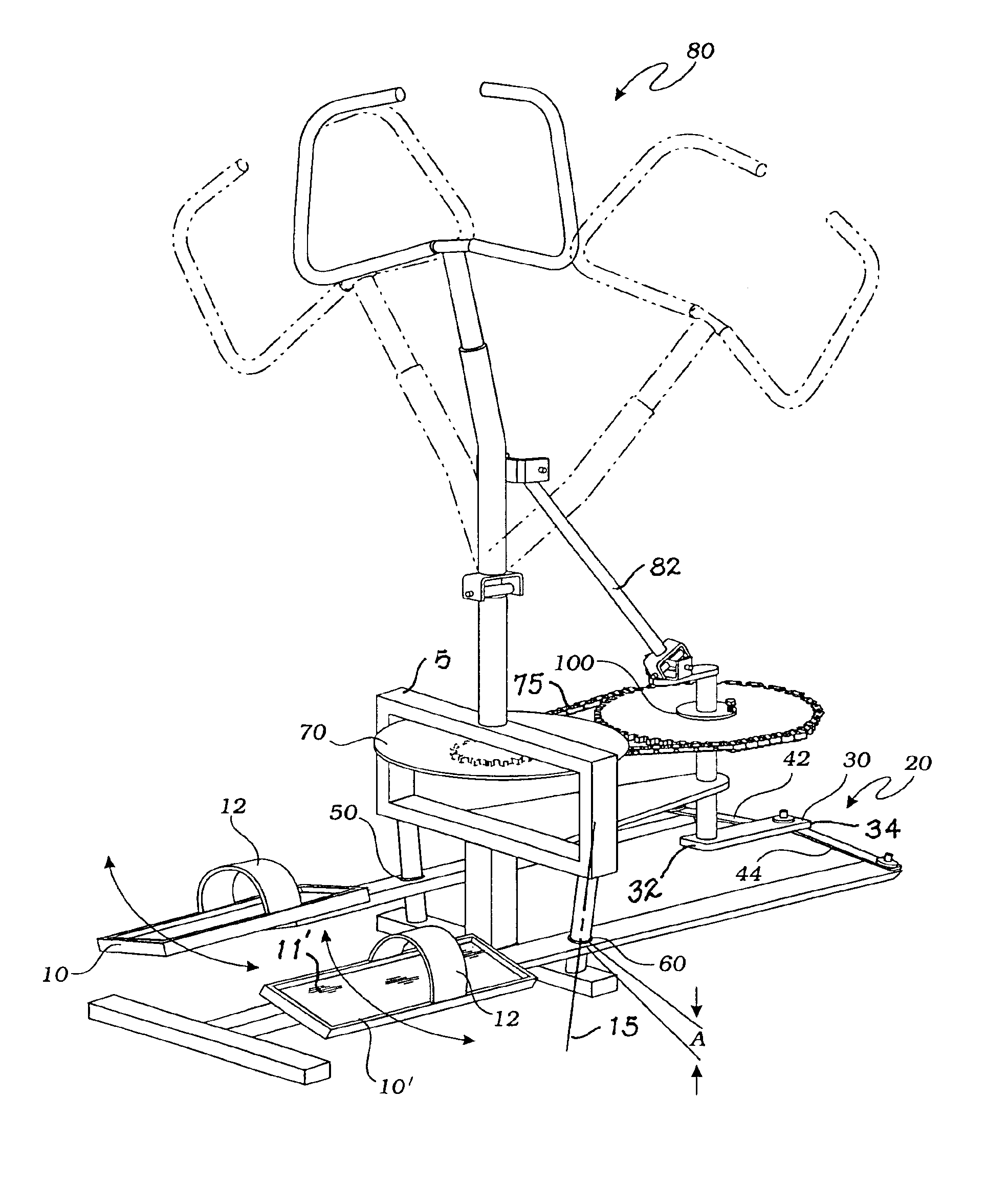

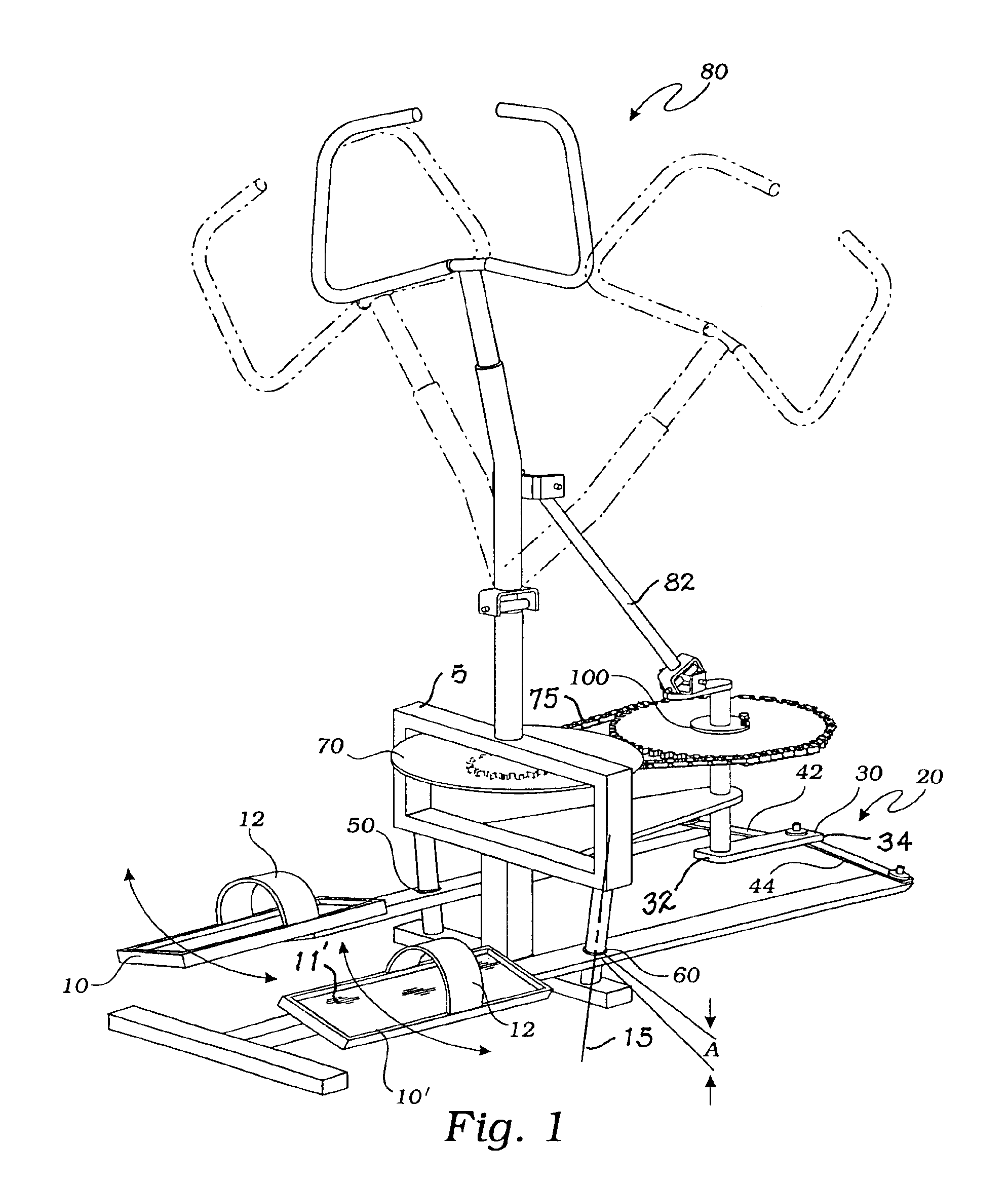

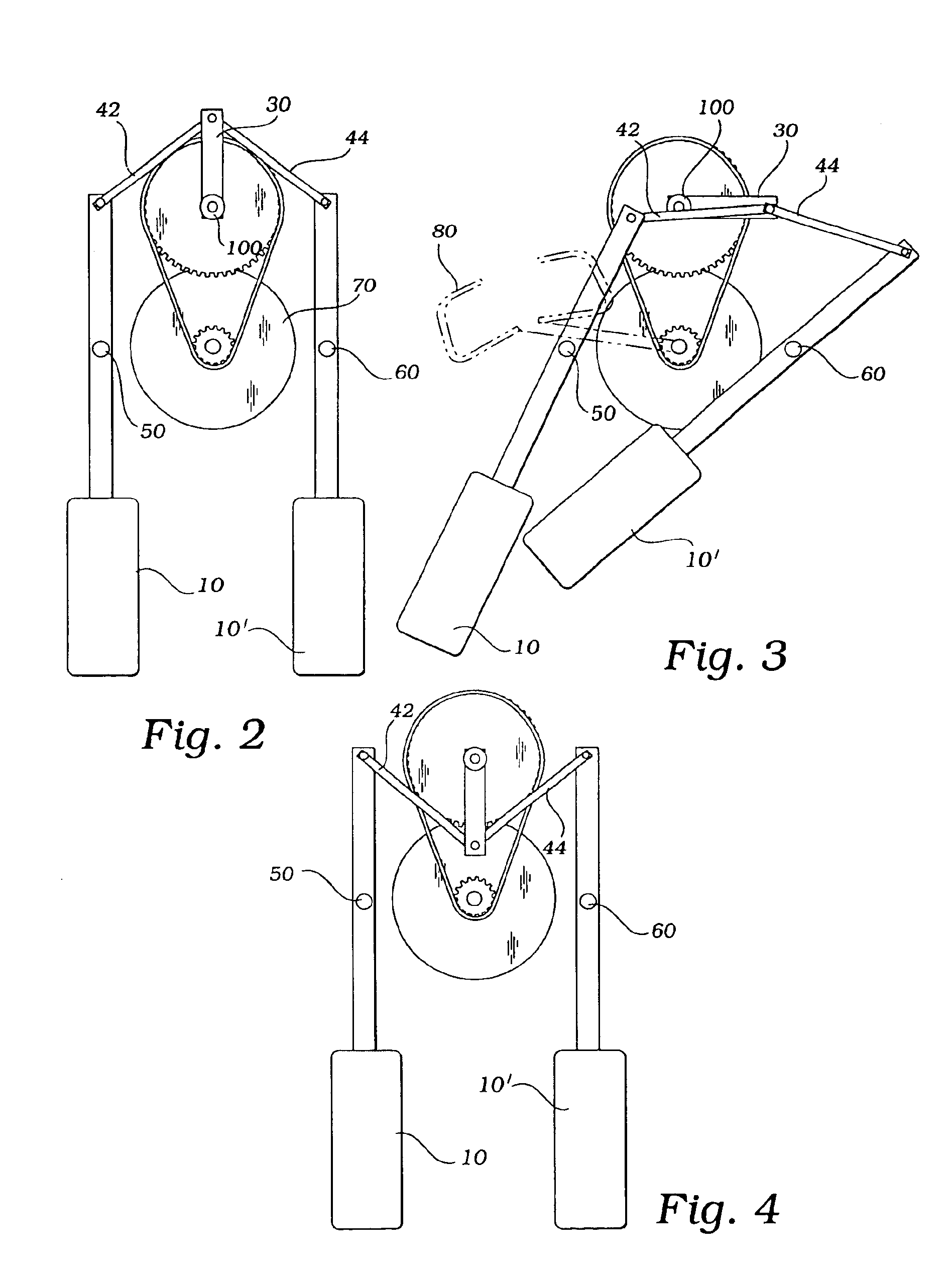

Exercise apparatus simulating skating motions

InactiveUS6849032B2Maintain balanceReduce manufacturing costMuscle exercising devicesMovement coordination devicesFreewheelFoot supports

A pair of a skater foot supports are joined with a skating motion director including, a simple crank interconnected with the foot supports by a pivotal linkage, such that as the crank rotates in a circle, one of the foot supports is pulled and the other pushed during a first one-half of the circle rotation, while, the reverse occurs during the second one-half of the circle rotation. The crank is rotationally engaged with a flywheel through a mechanical drive train, enabling the flywheel to rotate at a speed greater than that of the crank whereby the foot supports move with a skating motion for exercising a skater.

Owner:FITNESS BOTICS

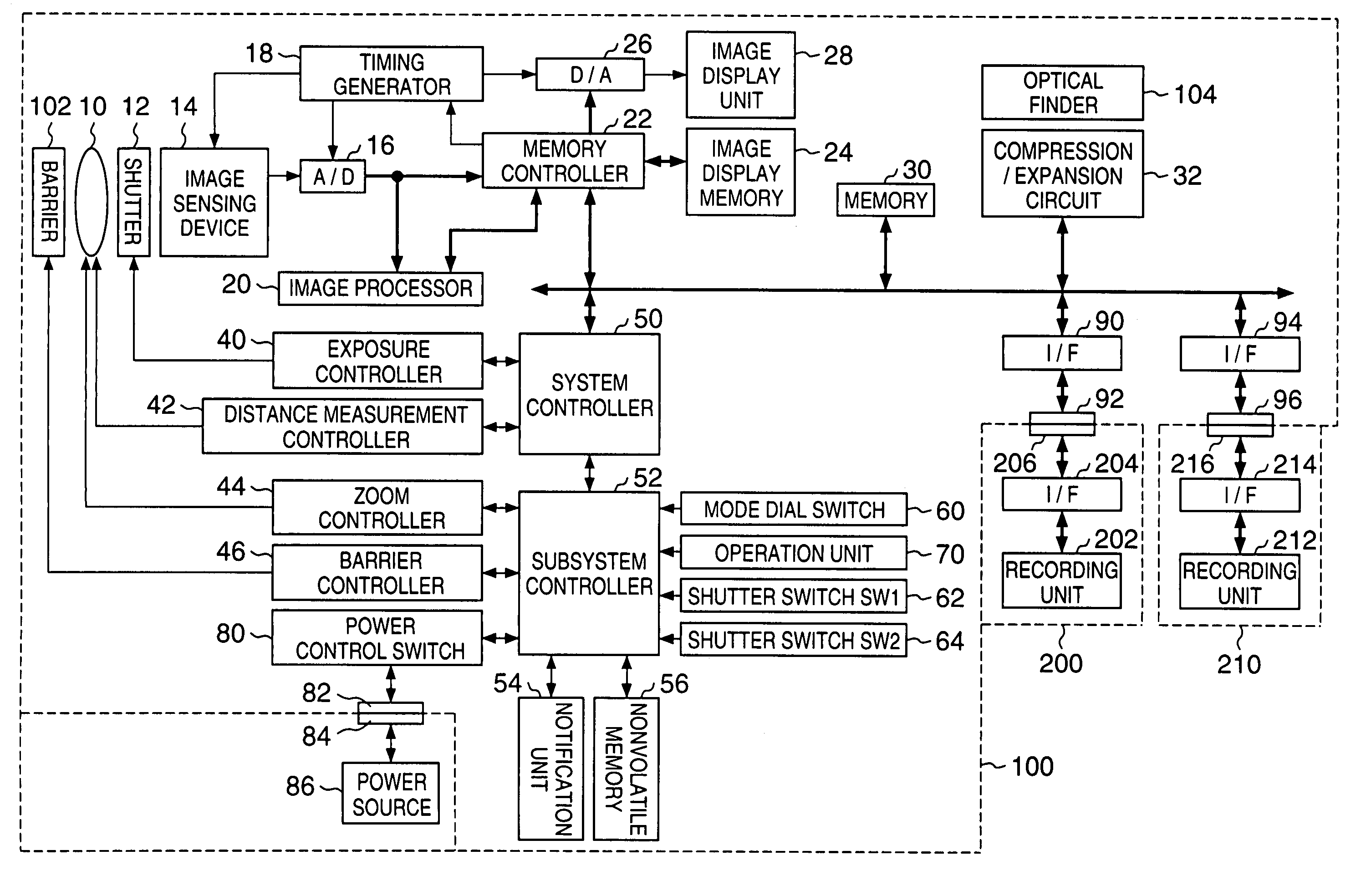

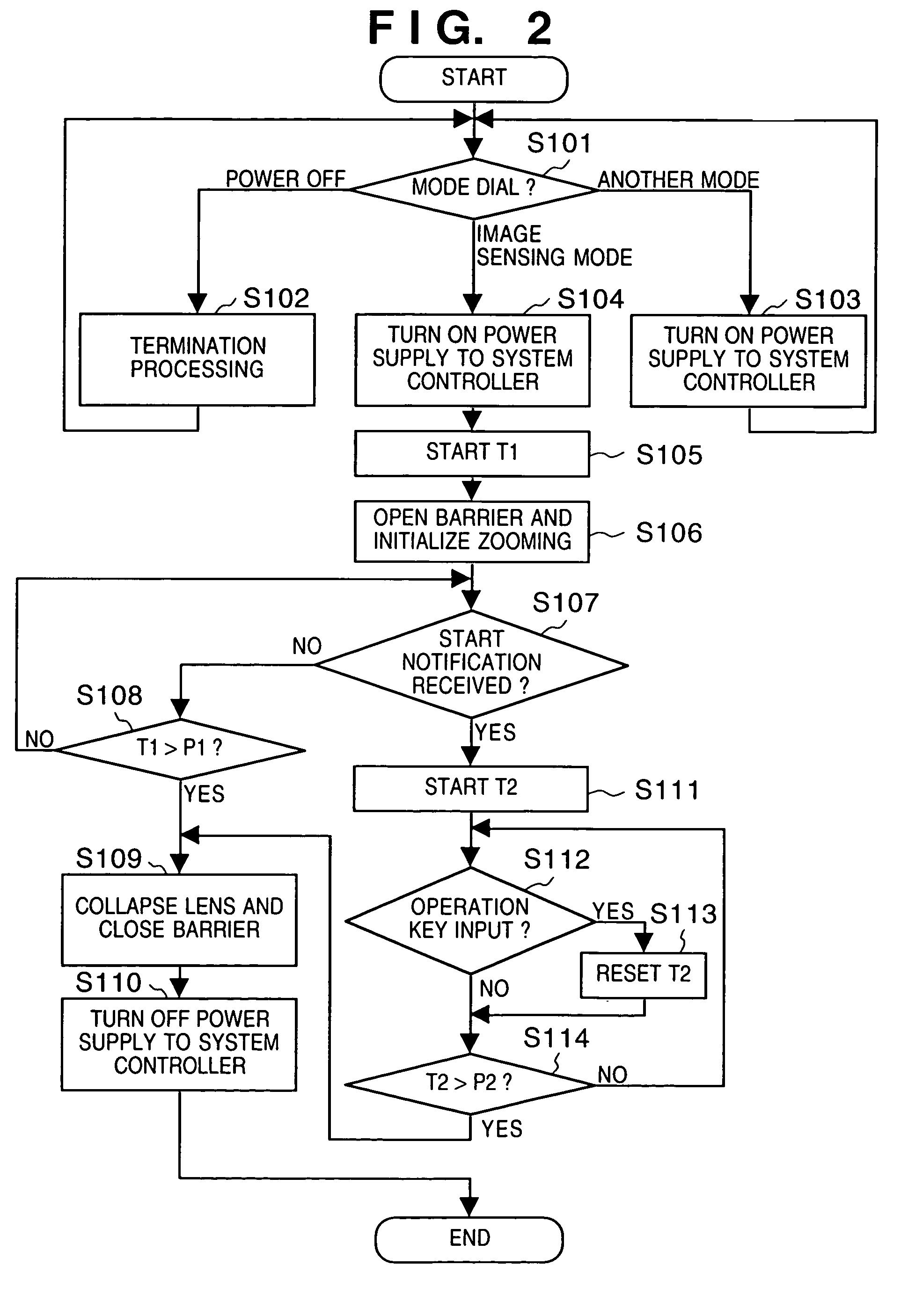

Electronic device using operating system for overall apparatus control including mechanical operation

InactiveUS7129984B1Television system detailsPicture signal generatorsOperational systemMechanical drive

A control method for an electronic device such as a digital camera, having a mechanical driving member comprising a collapsible barrel, a lens barrier and the like, which performs mechanical operations, and a system controller which controls the overall device including the mechanical driving member is provided. In accordance with turning on of power supply to the system controller, the mechanical driving member is driven until the device enters a main-operation stand-by status, in parallel to start of an OS by the system controller.

Owner:CANON KK

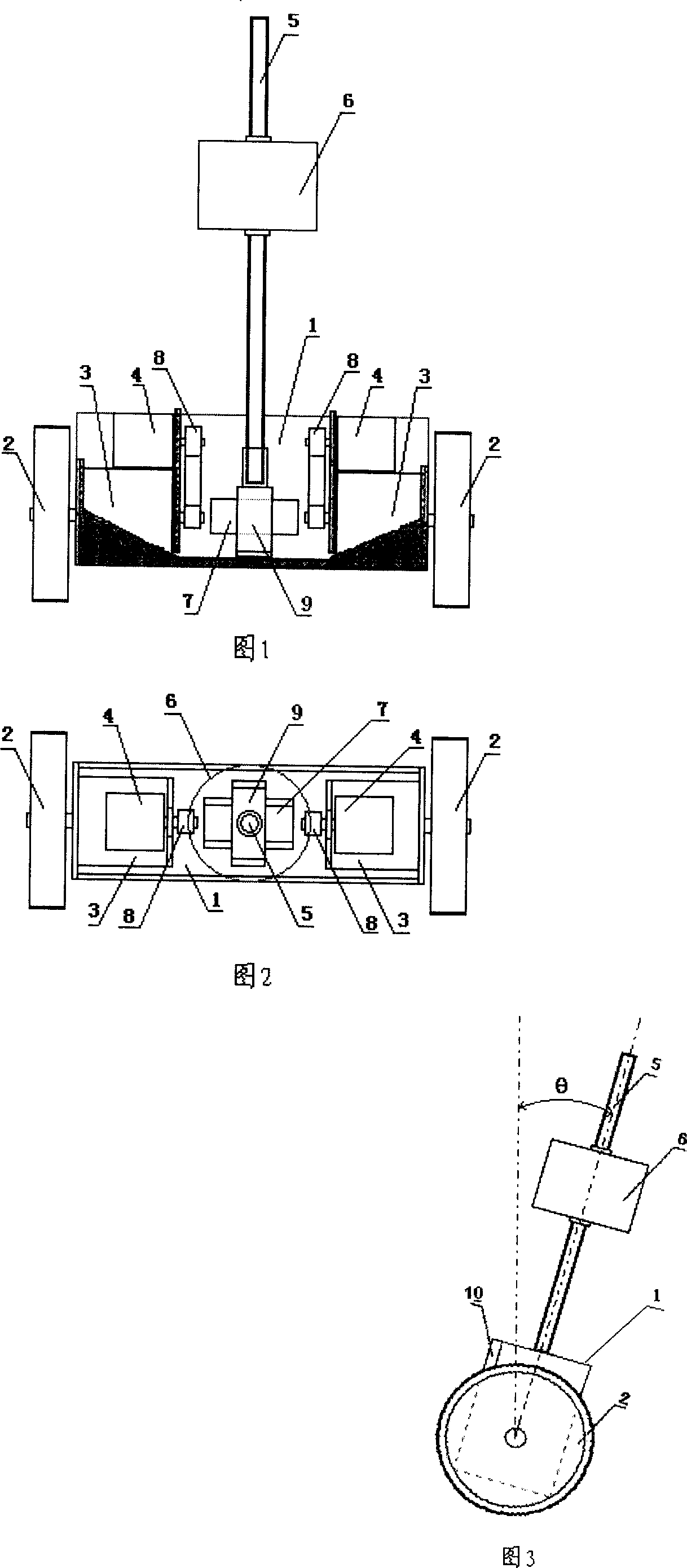

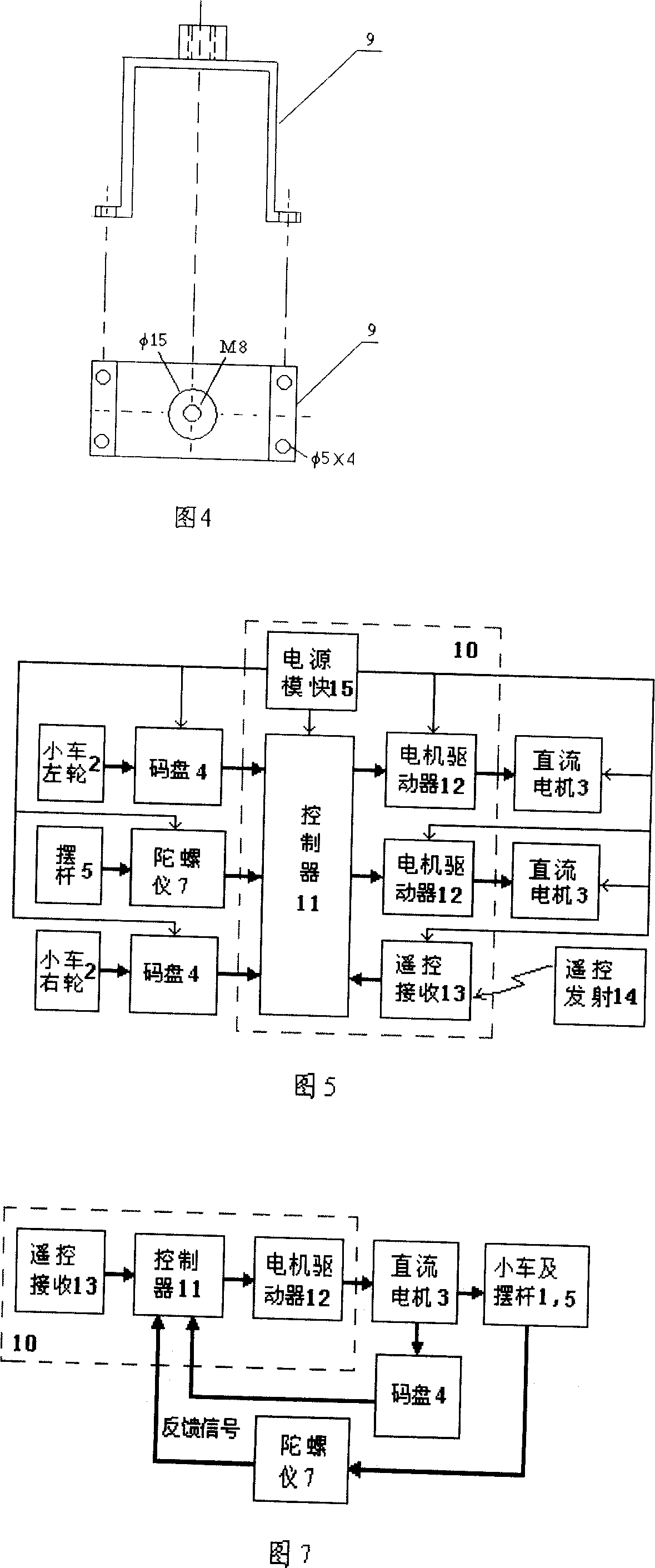

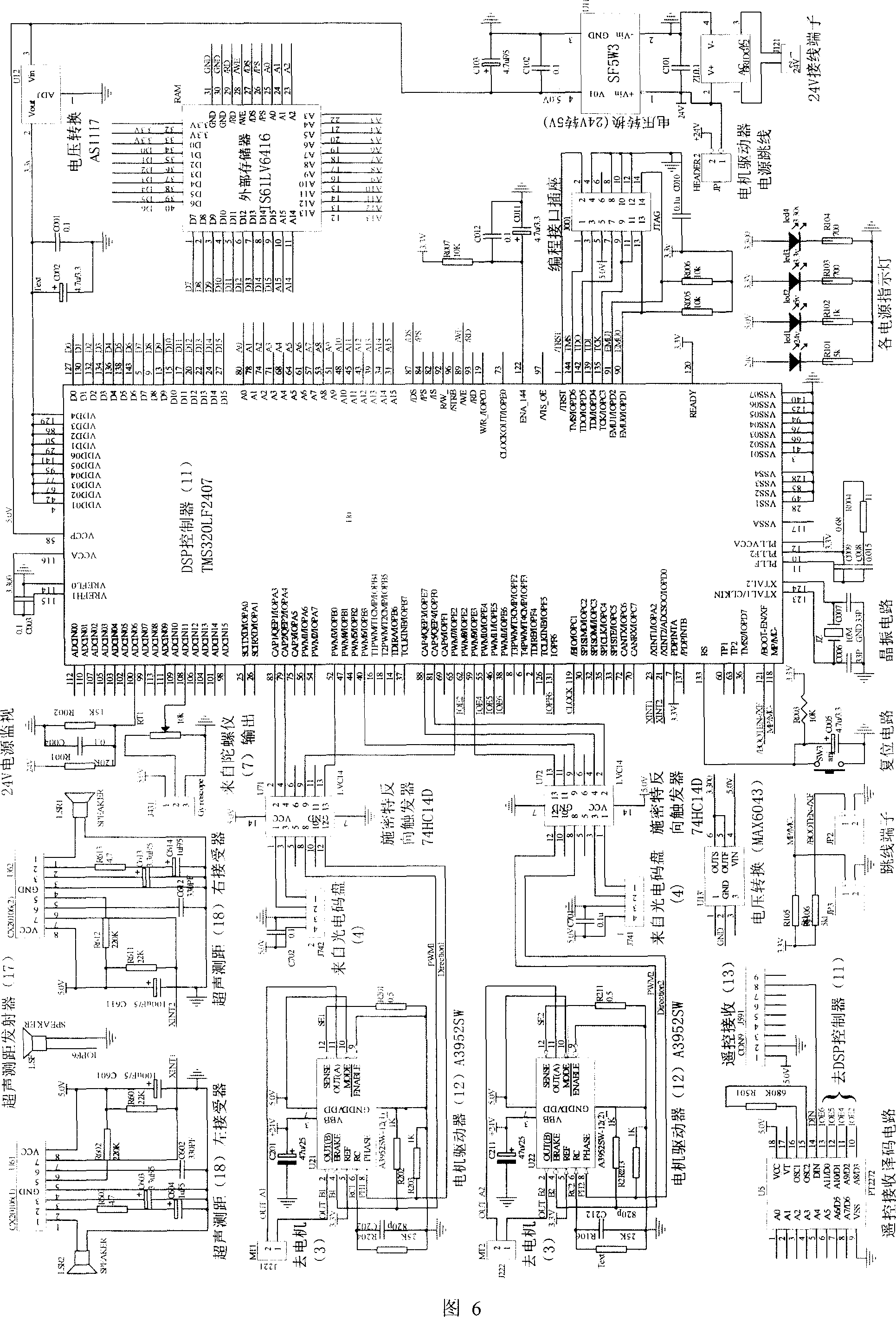

Inverted pendulum of remote car with two wheels and balance control method thereof

InactiveCN1952996ADifficult to controlRich control meansComputer controlControl using feedbackGyroscopeElectric machine

This invention relates to two remote trolley swing and its balance control method, which is characterized by the following: fixing the two direct motors onto car with one end of motor axis connected to wheel and with other end connected to code disc axis; the two axis middle position is fixed with gyroscope with swing bar, controller, remote receiver, power conversion module and motor driver welded on circuit board; the circuit board and direct power are fixed on car. The balance control method comprises automatically parts voltage judging, float correcting and noise measuring for filtering.

Owner:UNIV OF SCI & TECH OF CHINA

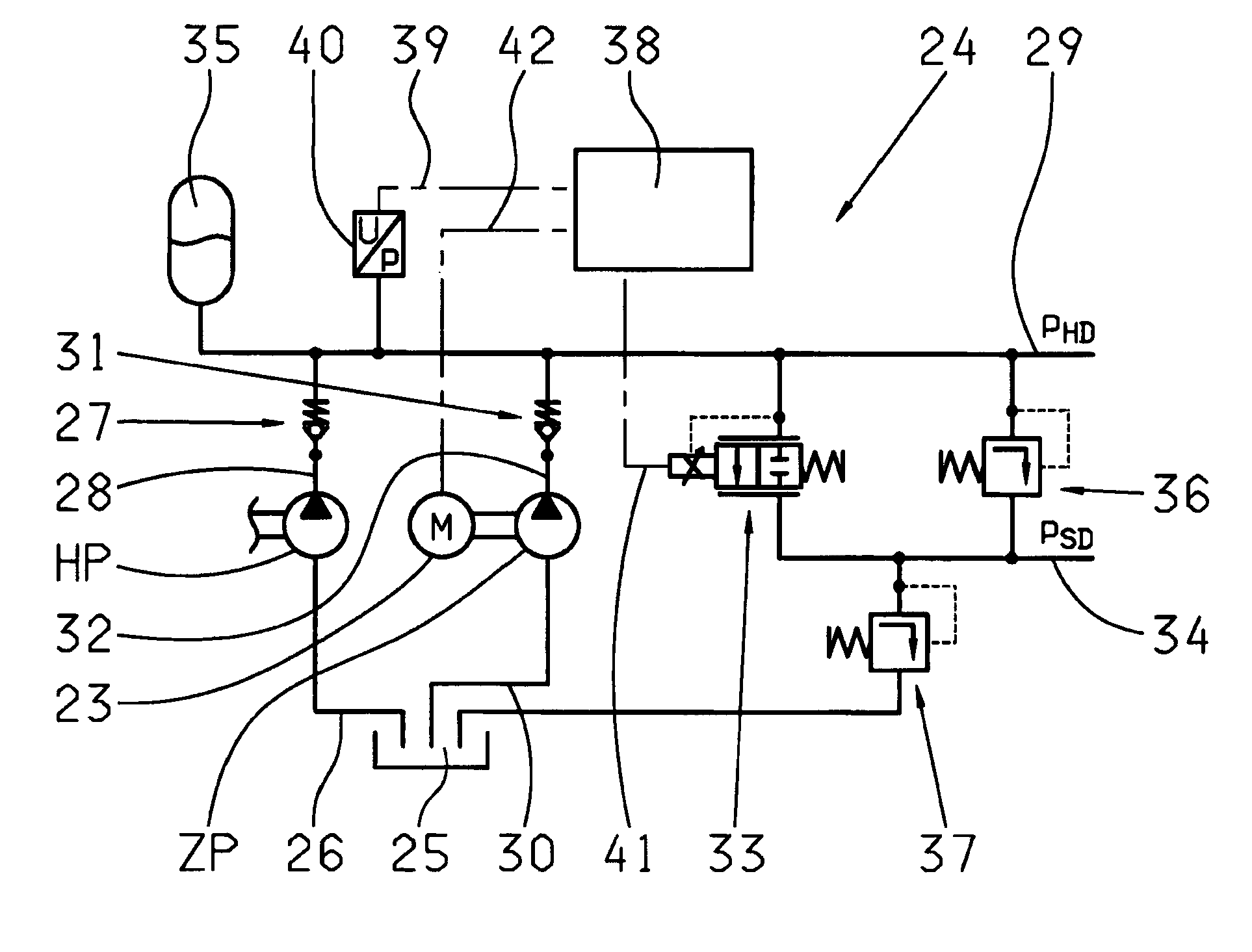

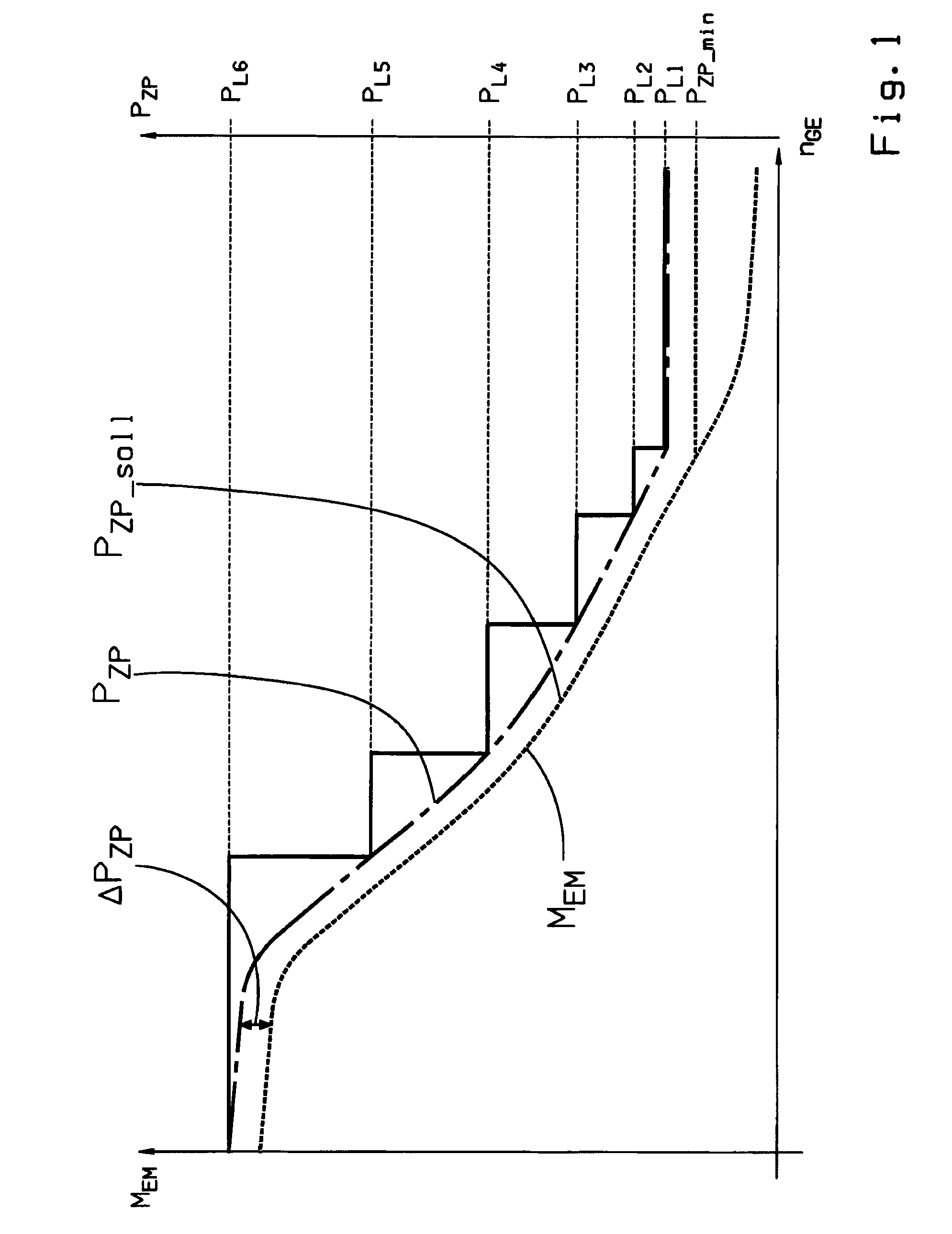

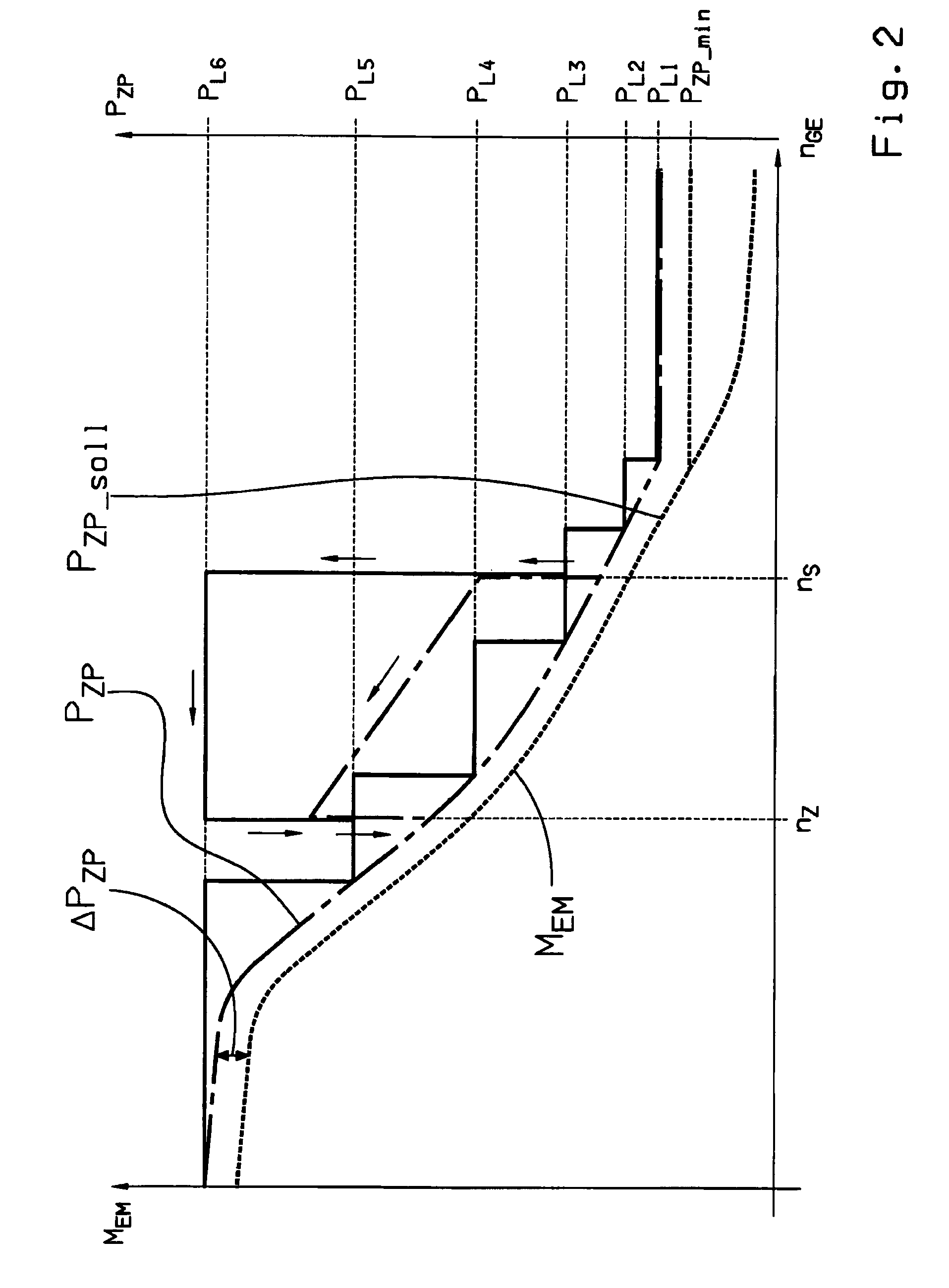

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS20100018808A1Improve accessibilityIncrease installation spaceElectric propulsion mountingGear lubrication/coolingEngineeringInternal combustion engine

The invention relates to a method for controlling the oil supply device of an automatic planetary transmission, comprising a main oil pump (HP), which is mechanically drivably connected to the drive shaft of an internal combustion engine (VM), and an auxiliary oil pump (ZP) that may be driven via a controllable electric motor, the automatic transmission (ATG) being part of a parallel hybrid powertrain of a motor vehicle having an input shaft (5), which may be connected via a separating clutch (K) to the drive shaft (2) of the internal combustion engine (VM) and is permanently drivably connected to the rotor (4) of an electric machine (EM).In order to achieve an oil supply to the automatic transmission (ATG) as and when needed, it is provided that the current oil requirement (PHD<sub2>—< / sub2>soll) of the automatic transmission is determined as a function of at least one currently captured operating parameter, and that the delivery rate (PZP) of the auxiliary oil pump (ZP) is set, by a correspondingly actuation of the associated electric motor, in the combustion and combined driving mode below a minimum input speed of the main oil pump (HP) and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum input speed of the main oil pump (HP) is set to at least the residual oil requirement exceeding the delivery rate (PHP) of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

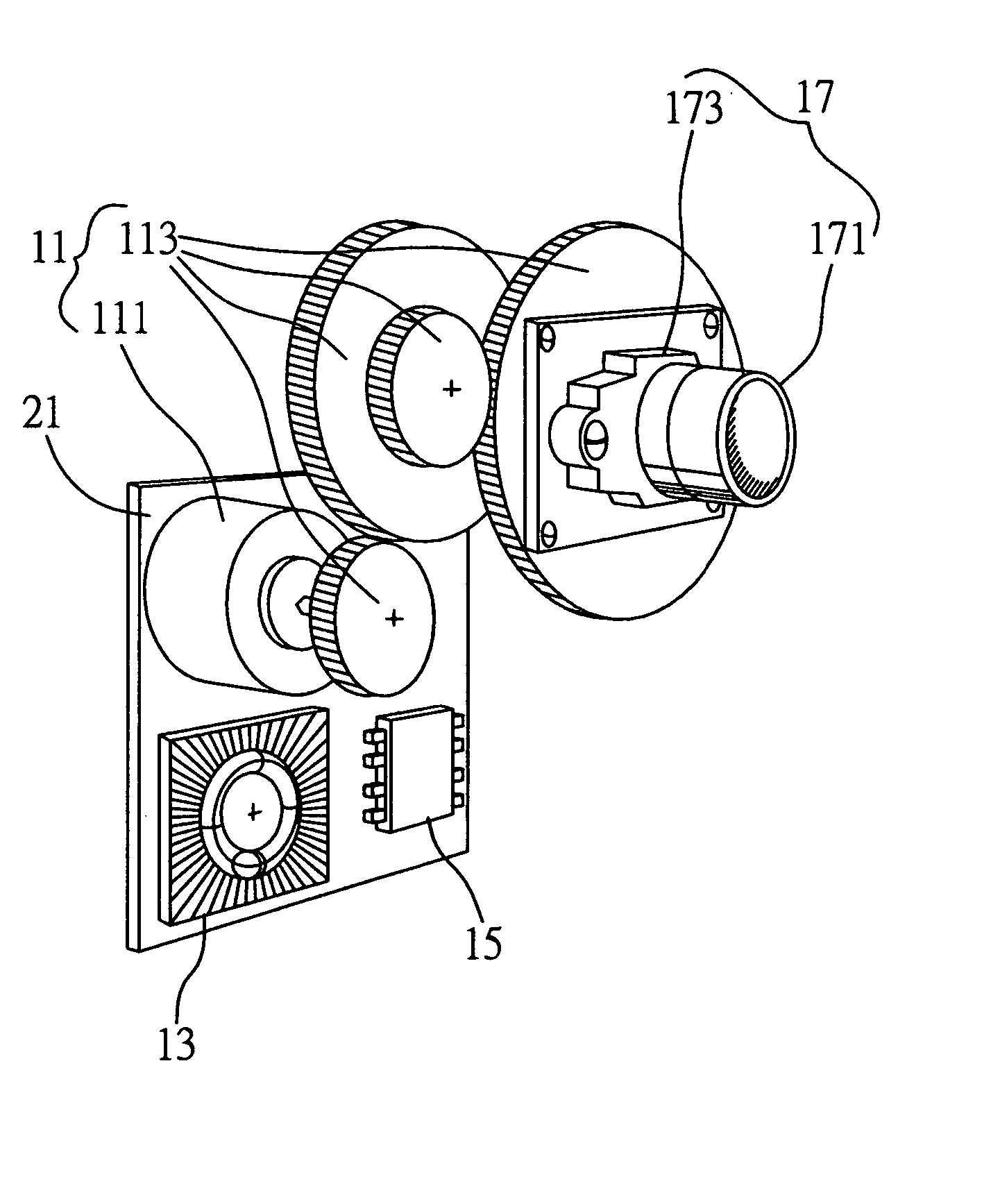

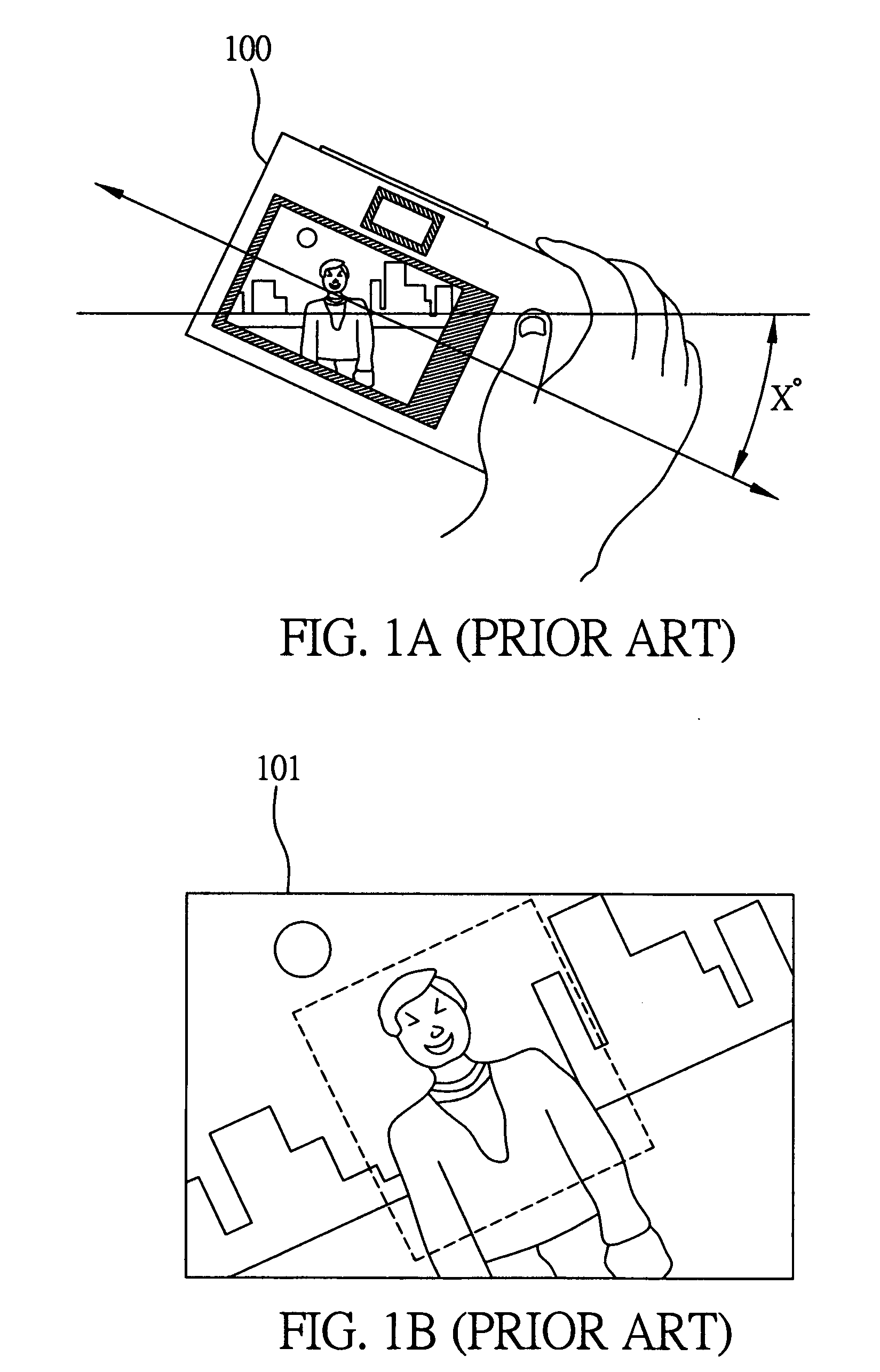

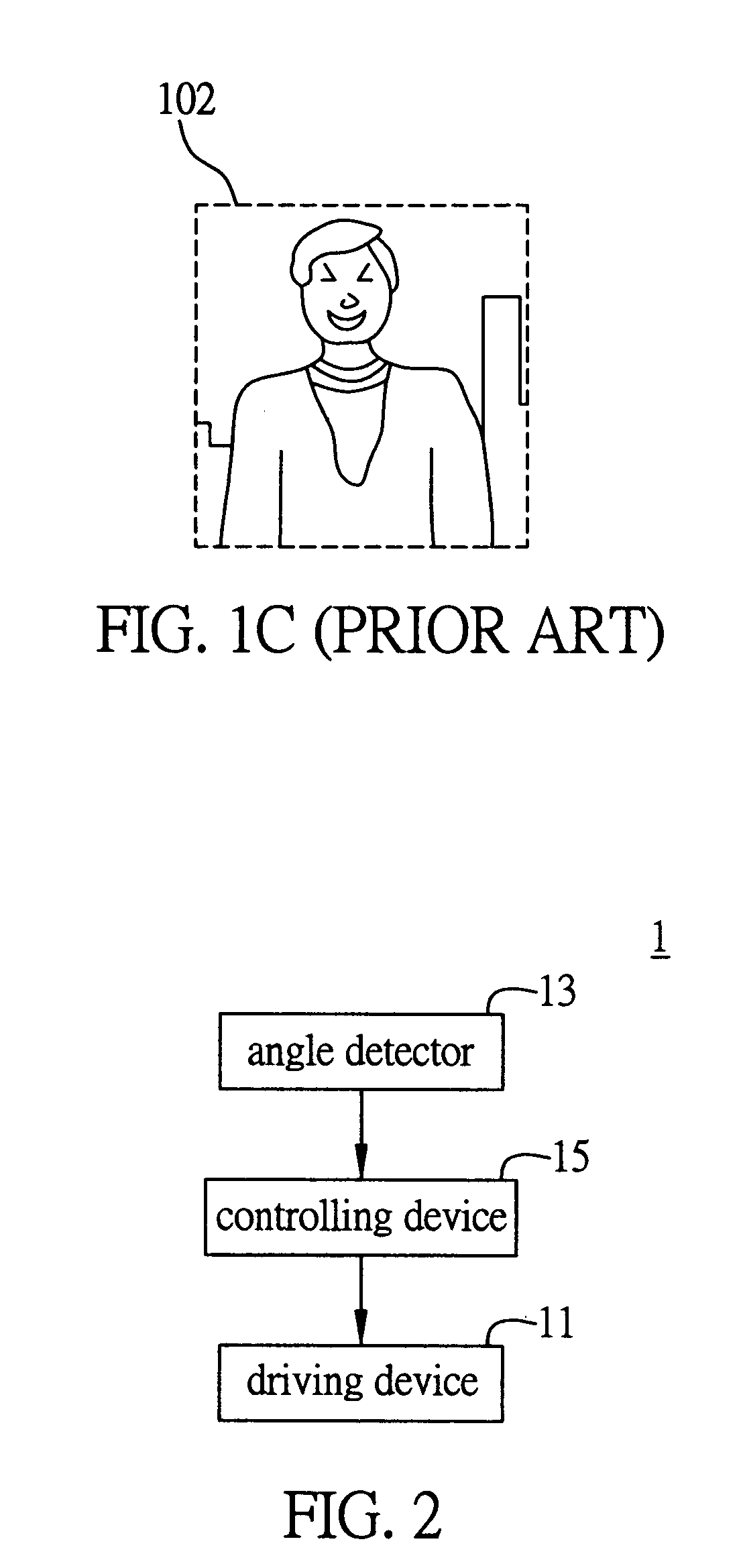

Automatic angle adjusting system

InactiveUS20050206736A1Intact main bodyIntact background preservedTelevision system detailsColor television detailsComputer hardwareMechanical drive

An automatic angle adjusting system for an image capturing device is provided, the image capturing device having an image capturing unit. The automatic angle adjusting system includes a driving device, an angle detector and a controlling device. The angle detector detects the location of the image capturing unit. The controlling device calculates an angle of the location of the image capturing unit deviating from a preset angle, and transmits a signal to the driving device that generates a mechanical driving force to rotate and resume the image capturing unit to the preset angle.

Owner:INVENTEC MULTIMEDIA & TELECOM

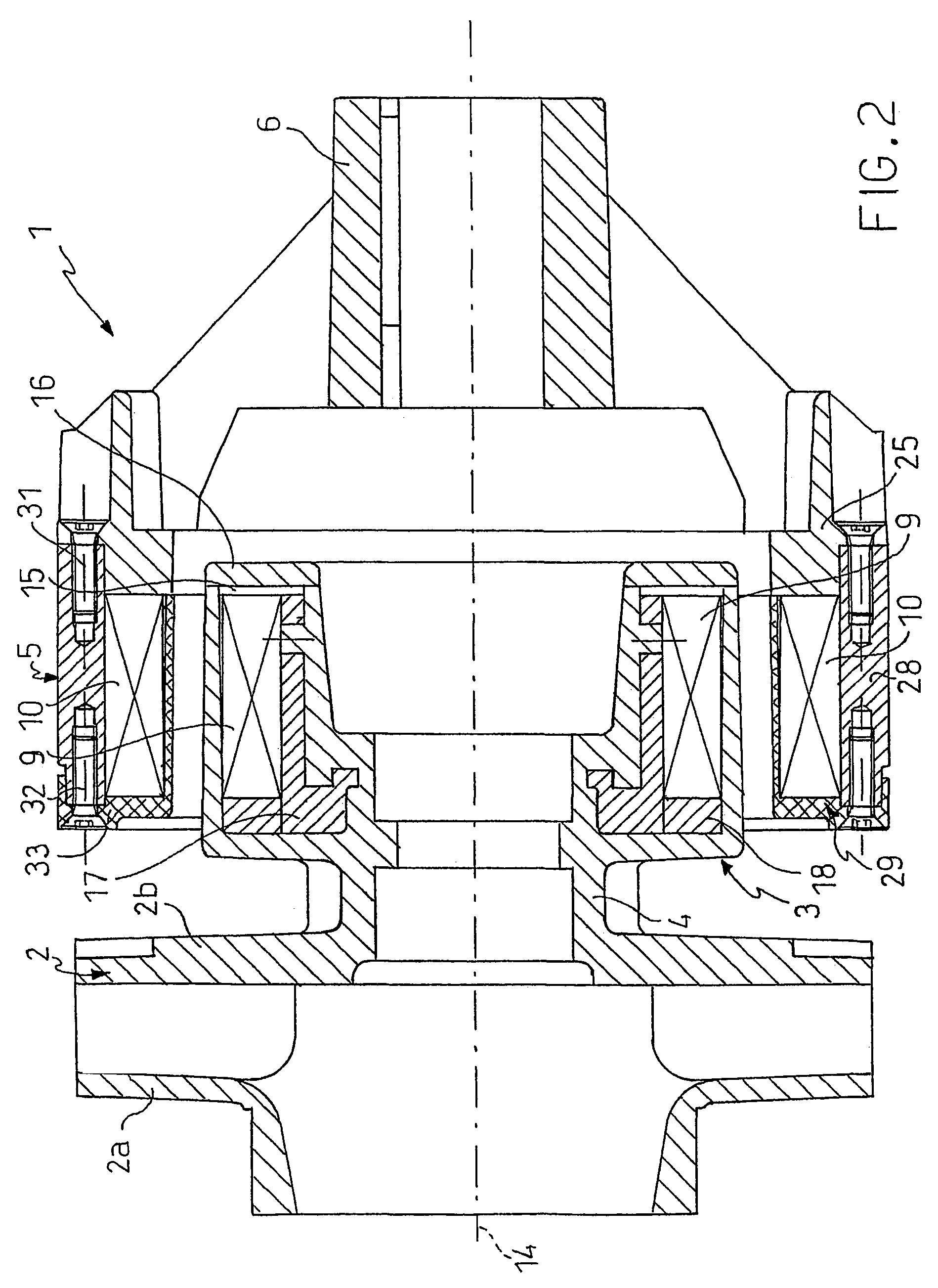

Mechanical drive system operating by magnetic force

InactiveUS7057320B2Magnetic circuit rotating partsMagnetically actuated clutchesMagnetic tension forceDrive shaft

A mechanical drive system operating by magnetic force, to be fitted on a pump, comprises a basic structure on which a drive shaft, which extends along a longitudinal axis, is supported rotatably. A driving element operatively connected to the drive shaft is provided with driving magnets arranged in a ring. A driven element provided with driven magnets arranged in a ring is also mounted on the basic structure. A bell is inserted between the driving element and the driven element and isolates the environment containing the driven element. The driving element and the driven element comprise respective cages each having seats for housing the respective driving magnets or driven magnets.

Owner:C D R POMPE

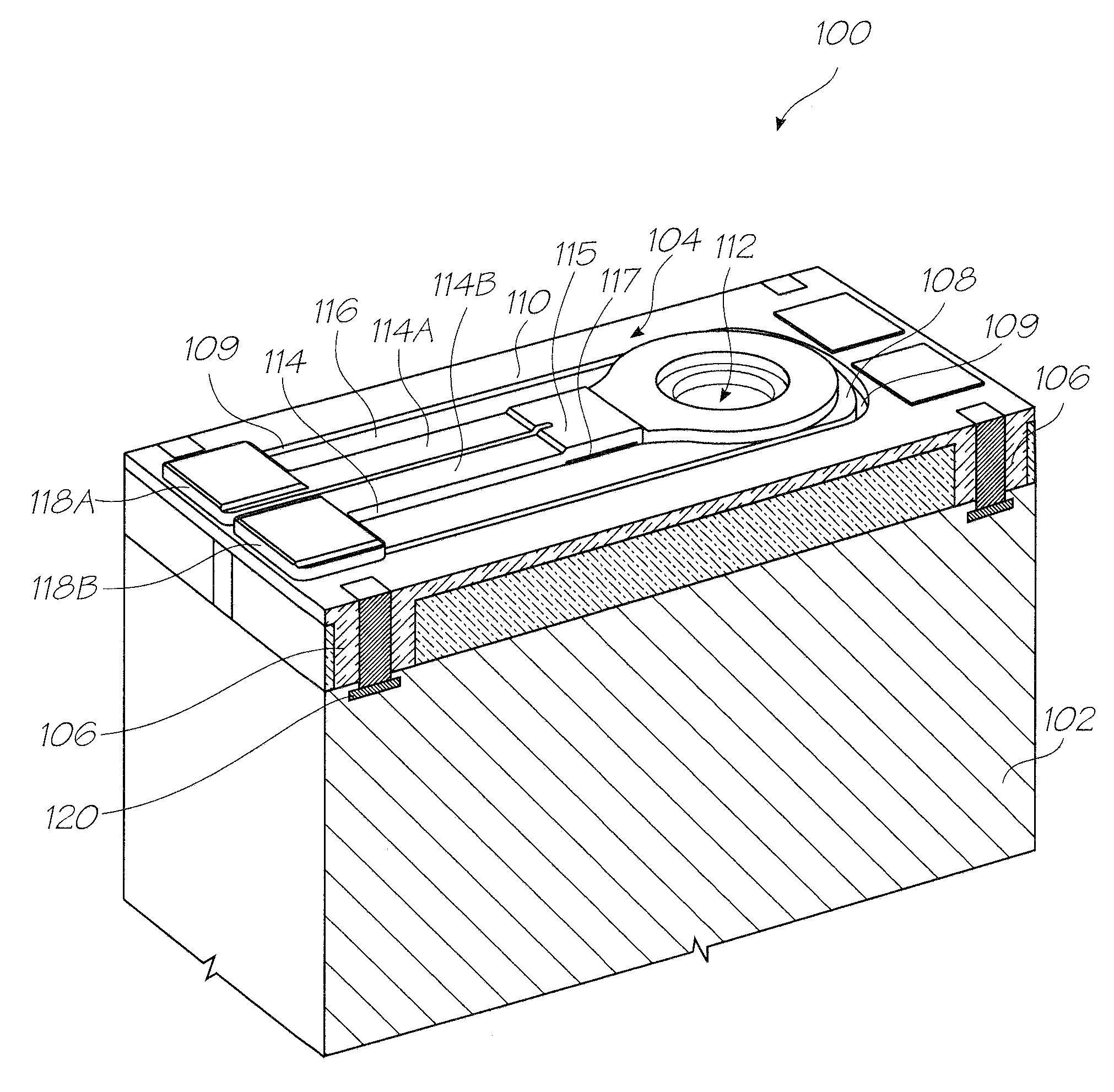

Mechanically-Actuated Microfluidic Pinch Valve

A microfluidic pinch valve. The valve comprises a microfluidic channel defined in a compliant body; a valve sleeve defined by a section of the microfluidic channel, the valve sleeve having a membrane wall defining part of an outer surface of the body; a compression member for pinching the membrane wall against an opposed wall of the valve sleeve; and a thermal bend actuator for moving the compression member between a closed position in which the membrane wall is sealingly pinched against the opposed wall, and an open position in which the membrane wall is disengaged from the opposed wall.

Owner:SILVERBROOK RES PTY LTD

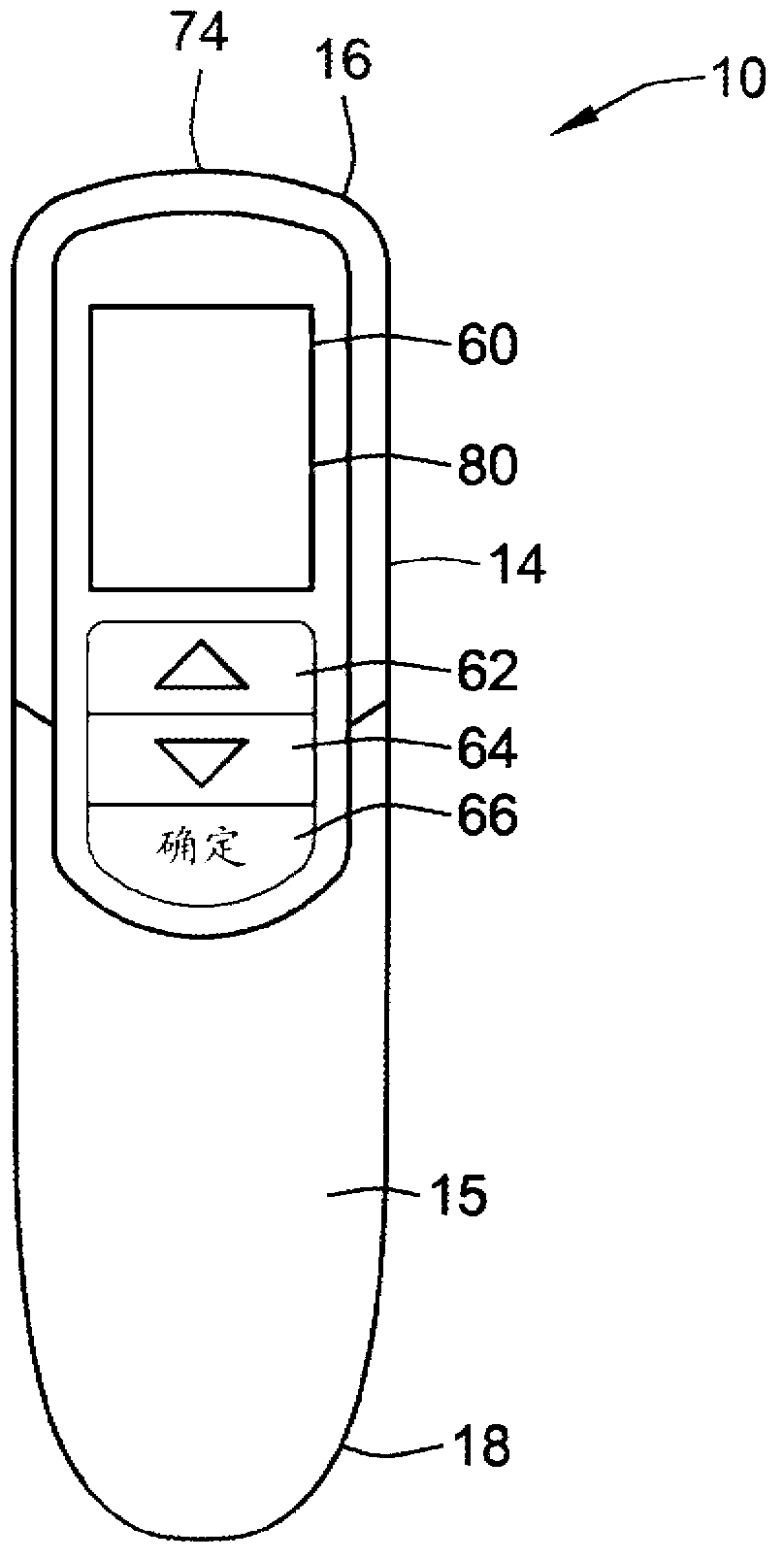

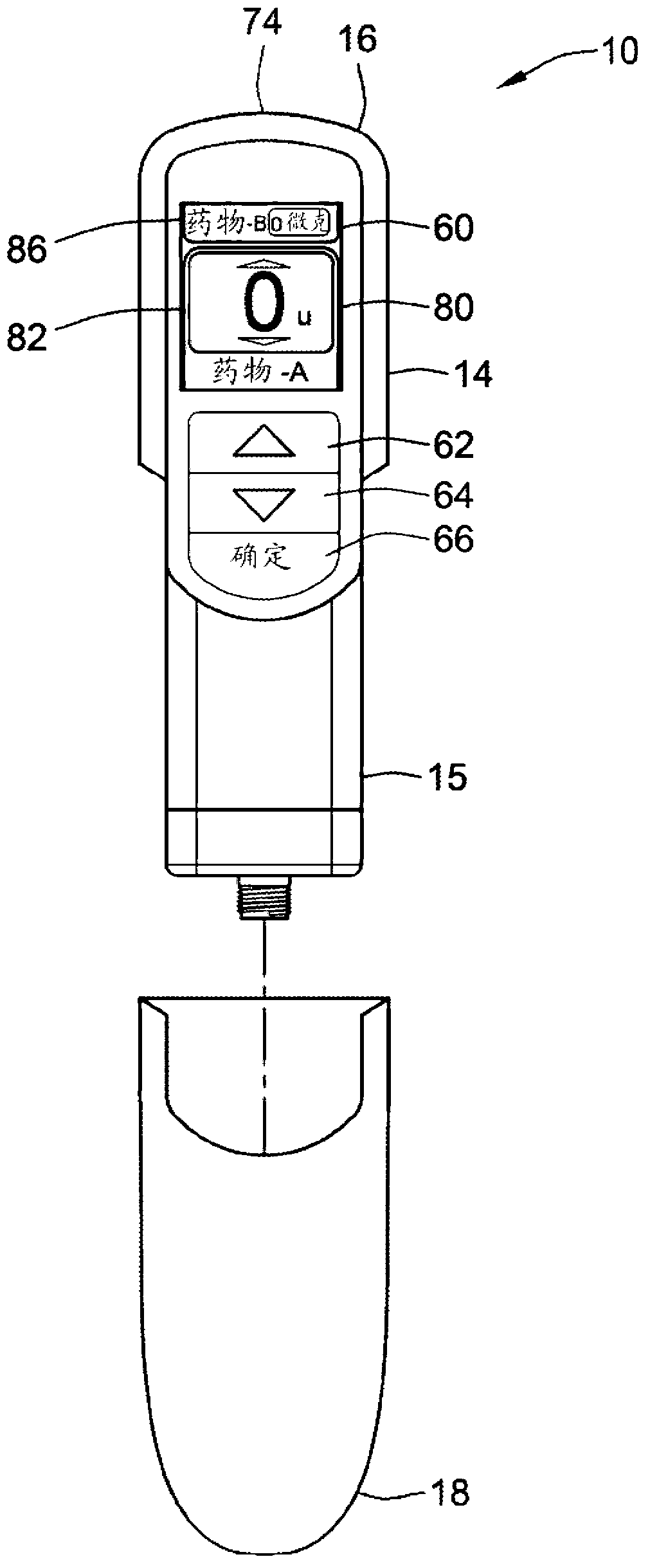

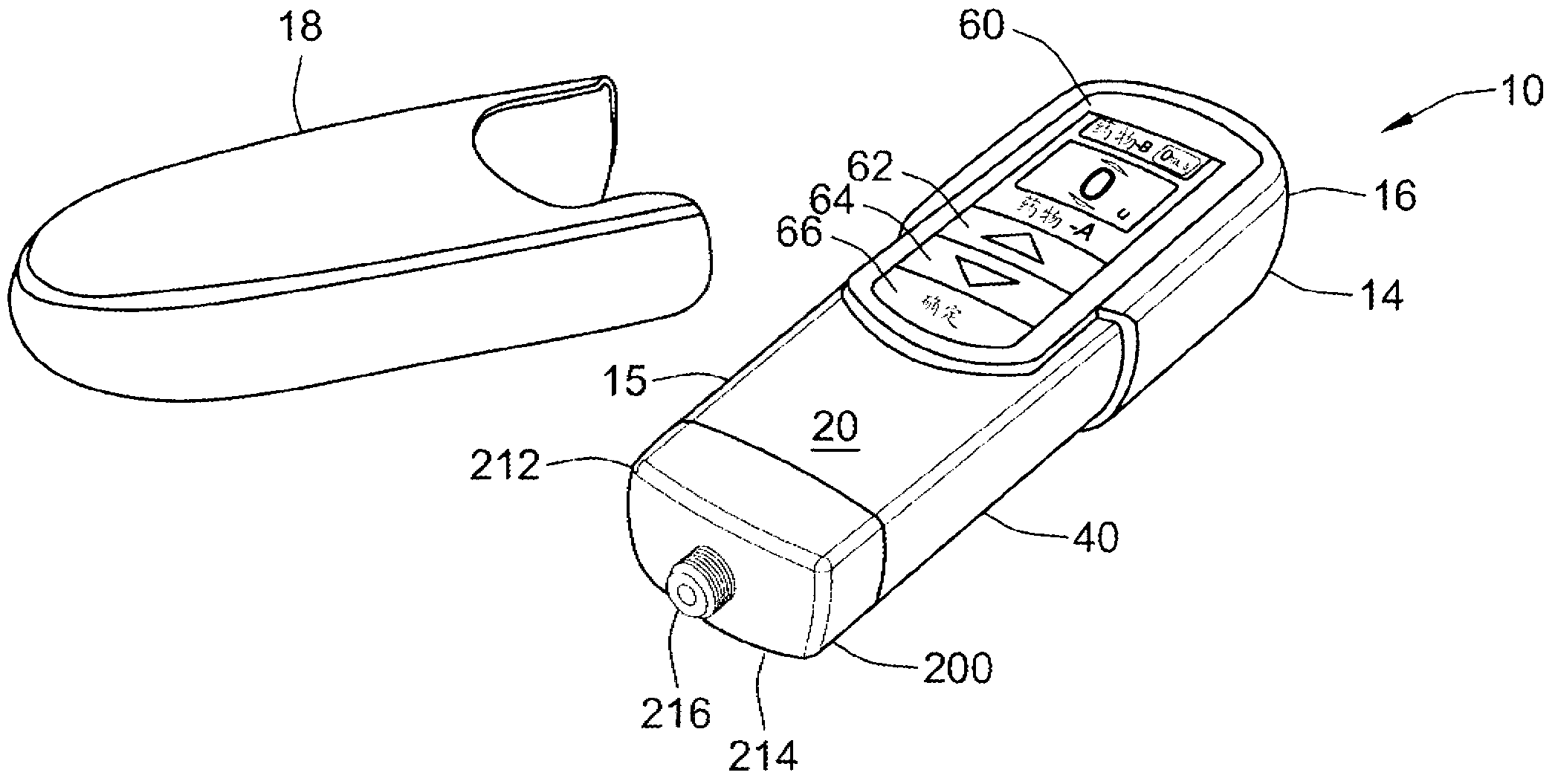

Device and method for delivery of two or more drug agents

ActiveCN102740907AEasy dose settingEase of dosingAmpoule syringesAutomatic syringesDose profileMechanical drive

A computerized electro-mechanical drug delivery device (10) configured to deliver at least one dose of two or more medicaments. The device comprises a control unit (300). An electro-mechanical drive unit (500, 600) is operably coupled to the control unit and a primary reservoir (90) for a first medicament and a secondary reservoir (100) for a fluid agent, e.g. a second medicament. An operator interface (60) is in communication with the control unit (300). A single dispense assembly (200) is configured for fluid communication with the primary (90) and the secondary (100) reservoir. Activation of the operator panel sets a first dose from the primary reservoir and based on the first dose and a therapeutic dose profile (860), the control unit (300) is configured to determine a dose or range of the fluid agent. Alternatively, the control unit determines or calculates a dose or range of a third medicament.

Owner:SANOFI AVENTIS DEUT GMBH

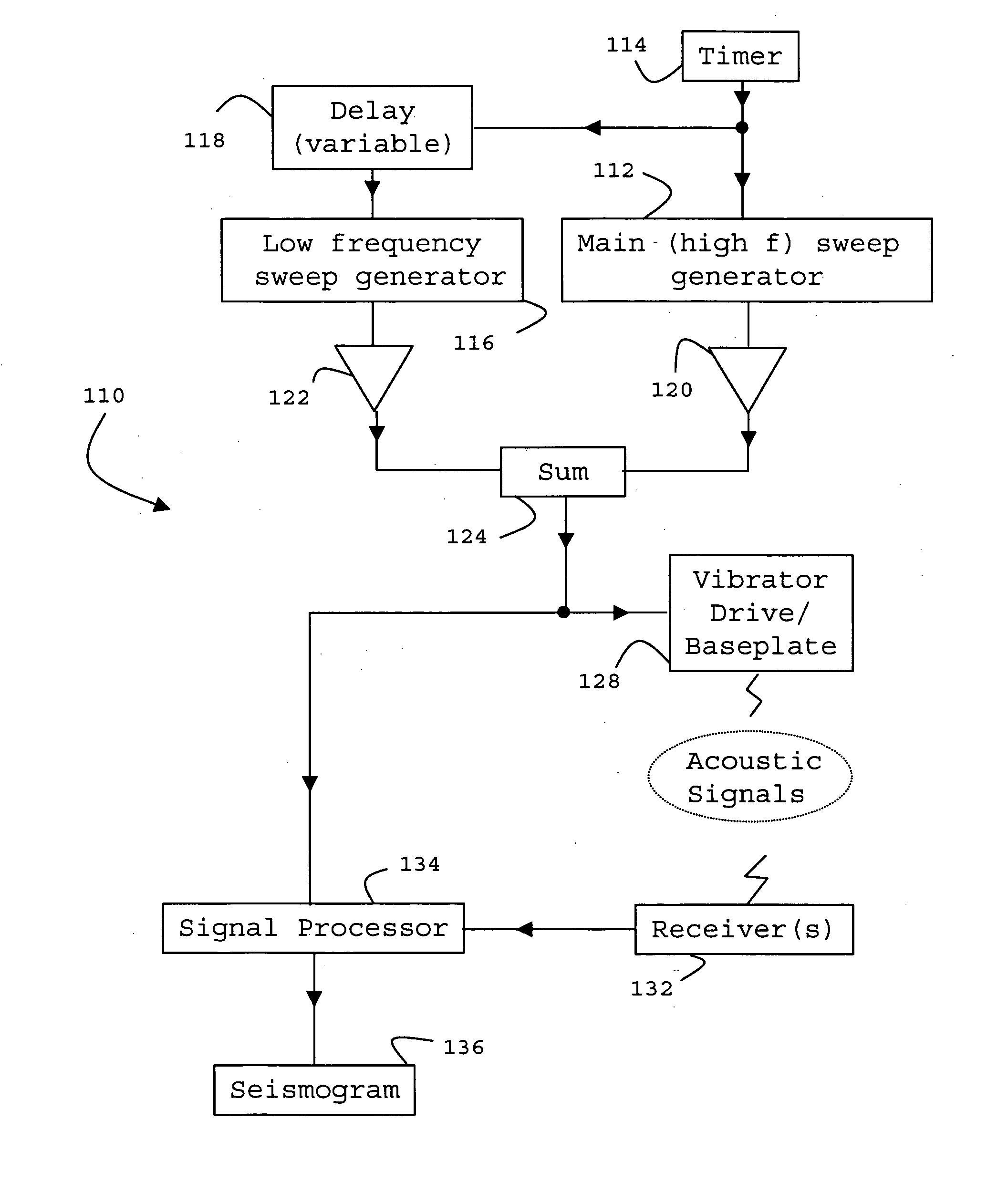

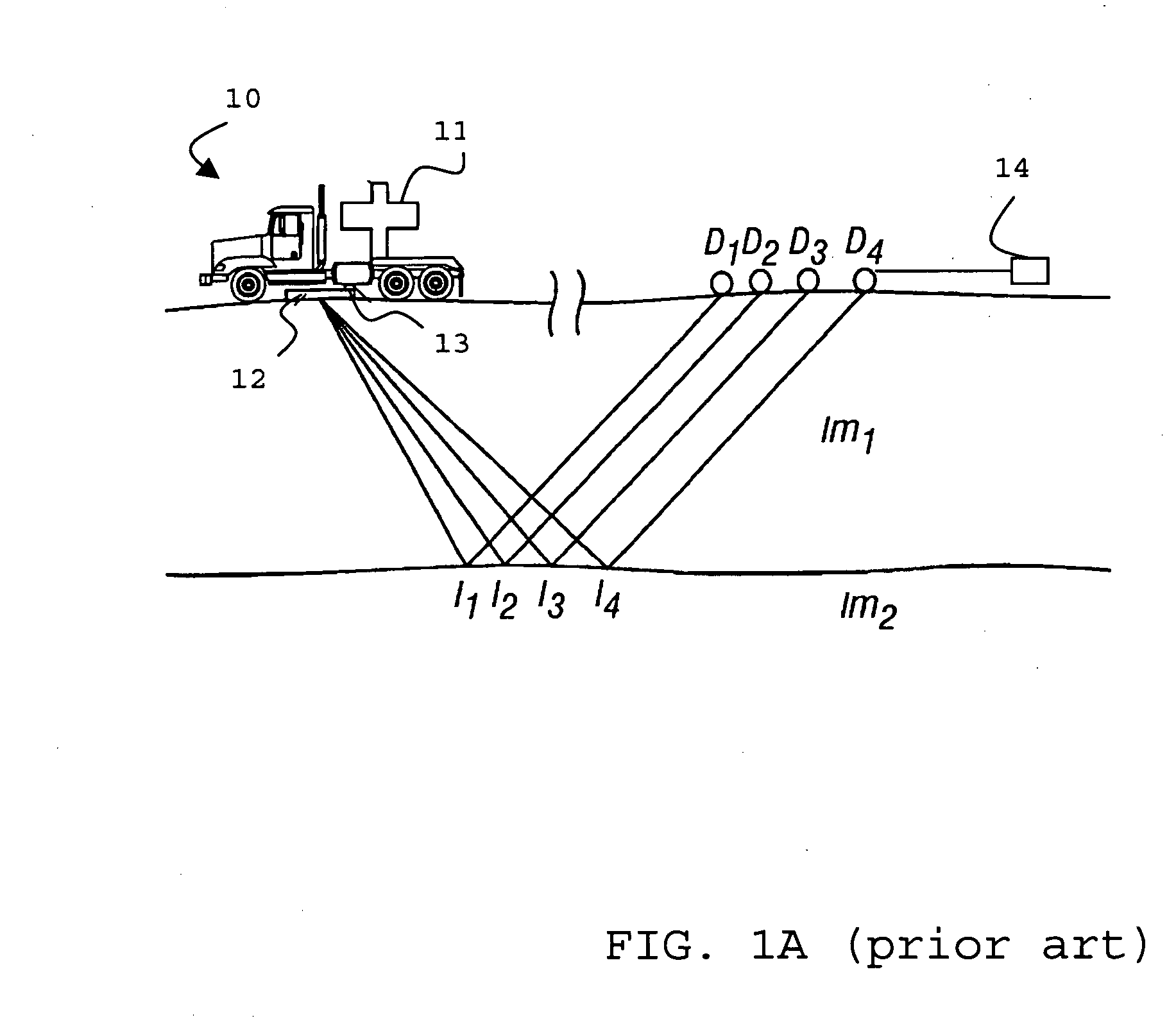

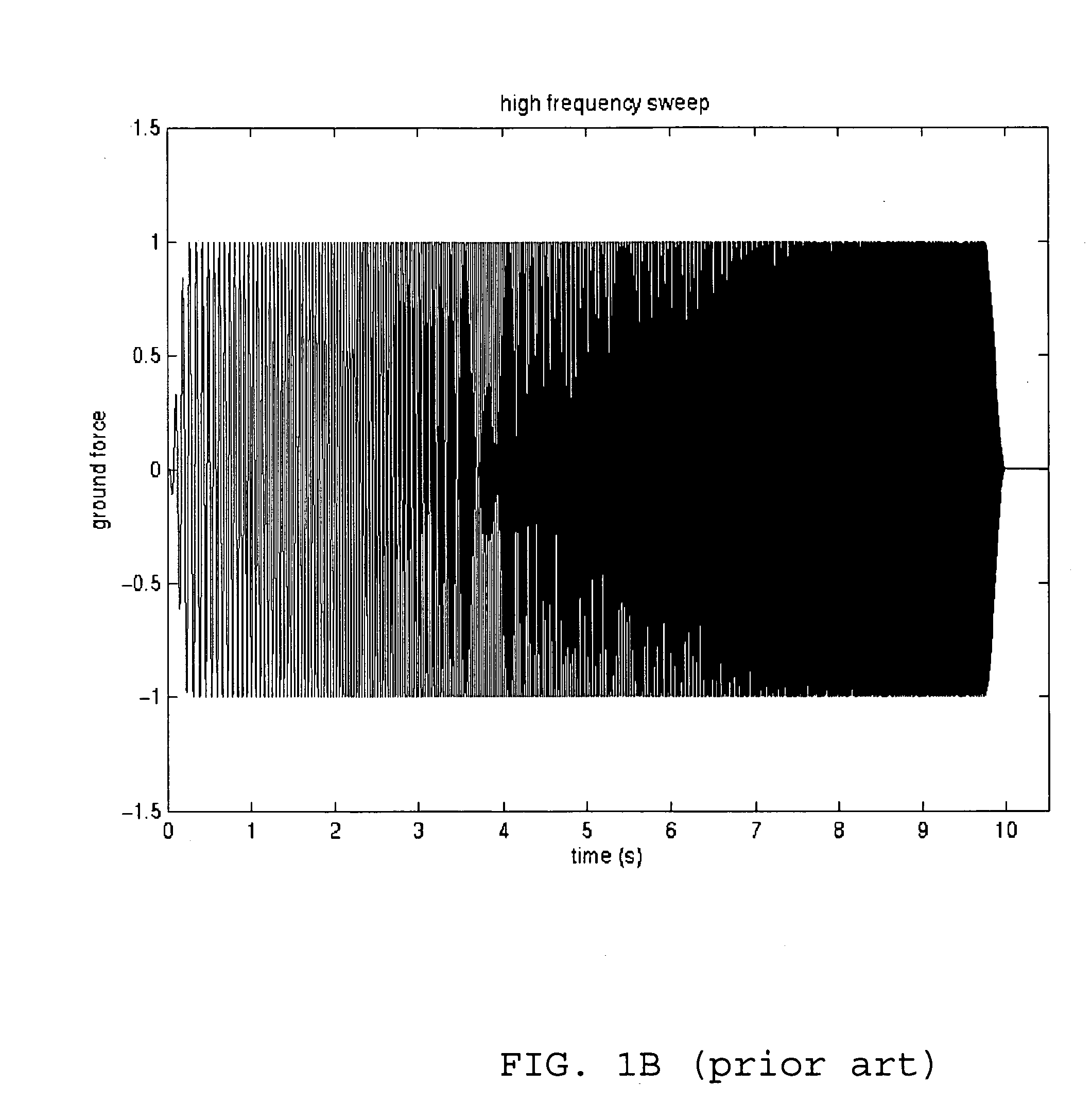

Seismic vibratory acquisition method and apparatus

InactiveUS20060018192A1Increase profitSeismic data acquisitionSeismic energy generationSeismic surveyLow frequency band

A method and related apparatus are described for generating acoustic signals for use in a vibratory seismic survey, including the step of combining into a drive signal a high frequency sweep signal, which sweeps upwardly through a high frequency band during a first time interval, and a low frequency sweep signal which is of lower amplitude than the high frequency sweep signal and which sweeps upwardly through a low frequency band during a second time interval, wherein the second time interval starts during the first time interval but after the beginning thereof; and applying the drive signal to a mechanical drive system for a vibratable element. The method improves the utilization of a single vibratory source.

Owner:WESTERNGECO LLC

Off road vehicle

InactiveUS20050217906A1Maximises manoeuvrabilitySteering linkagesHand leversDrive wheelDriver/operator

Owner:SPARK IAN JAMES

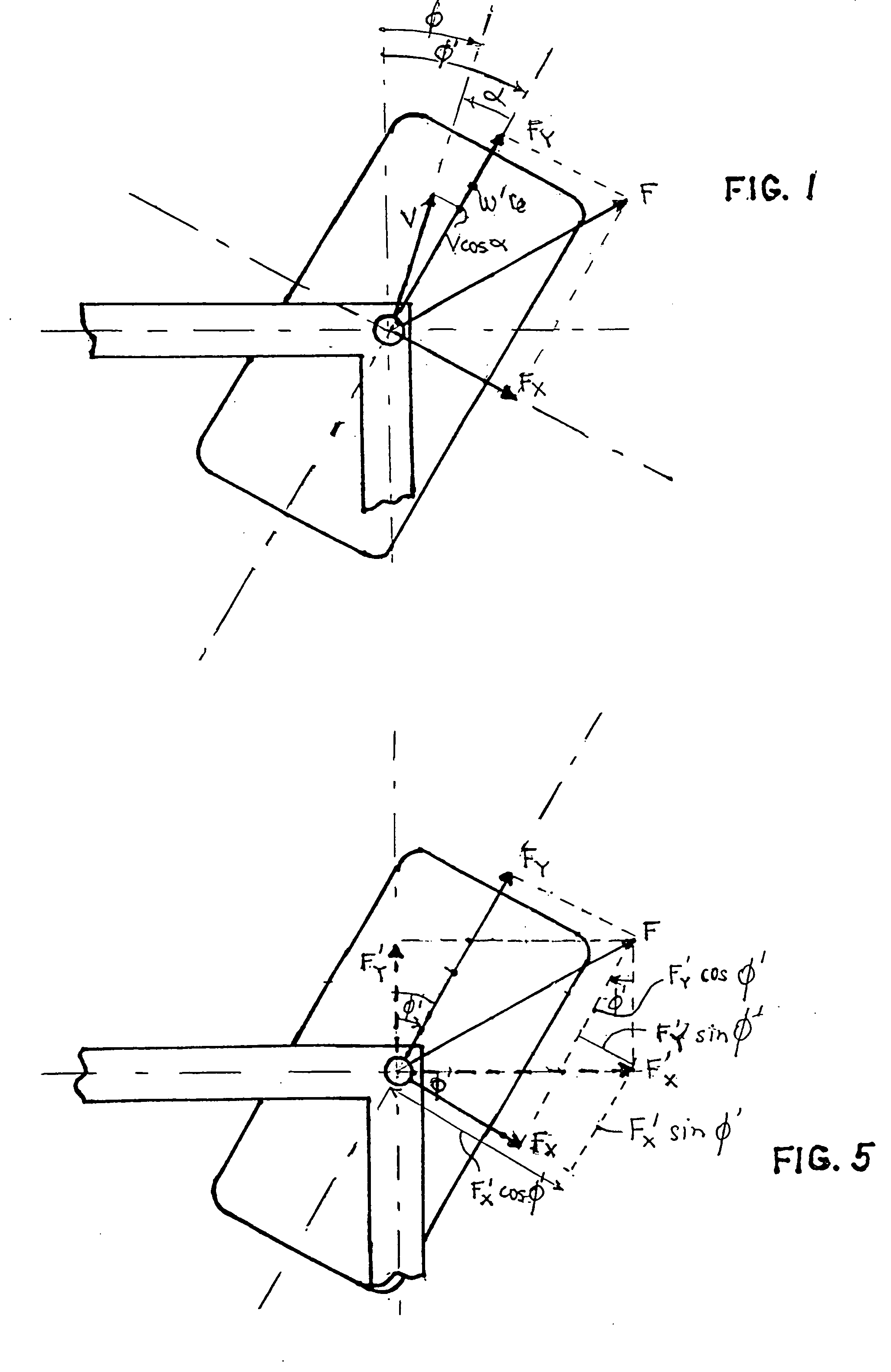

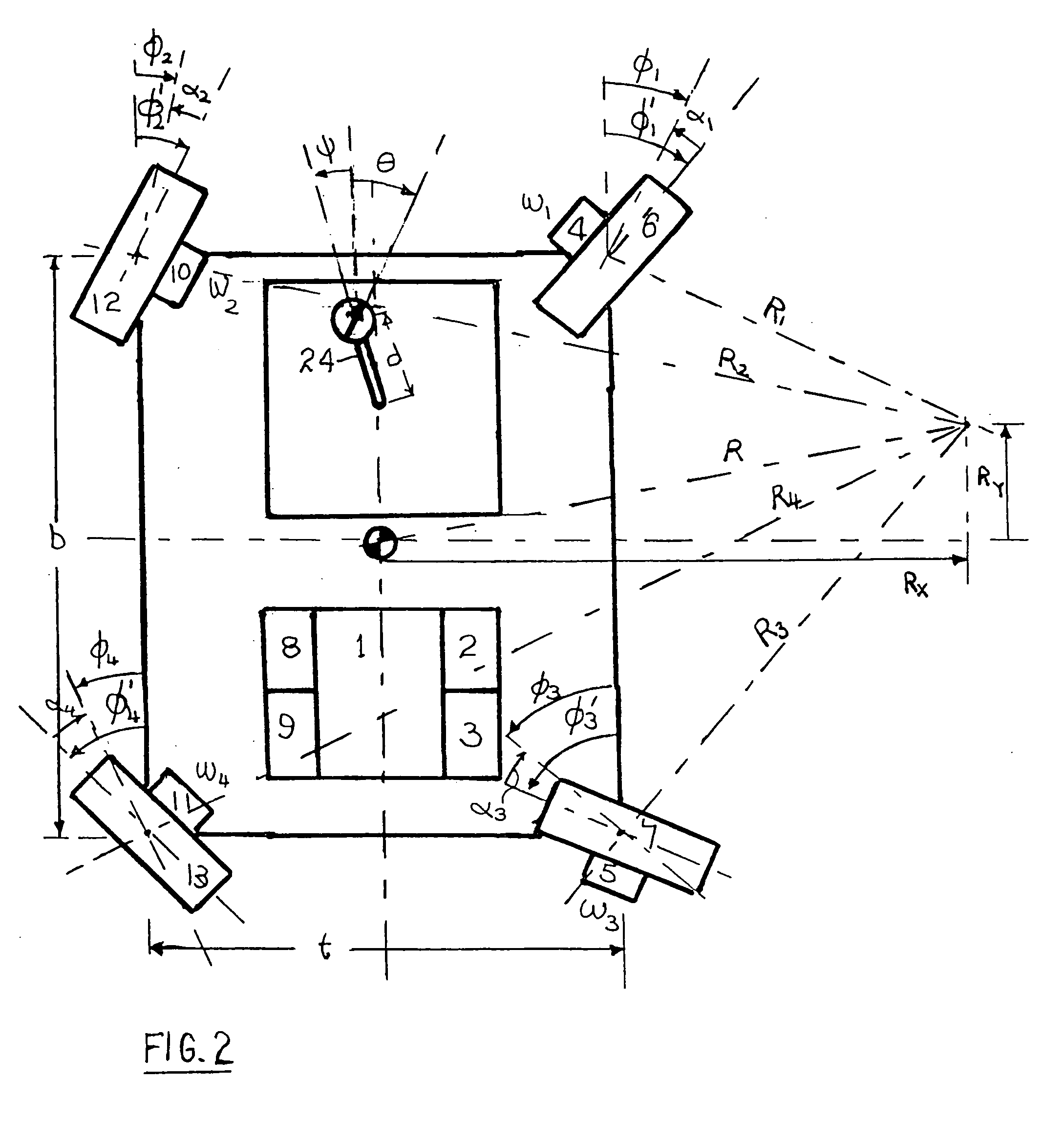

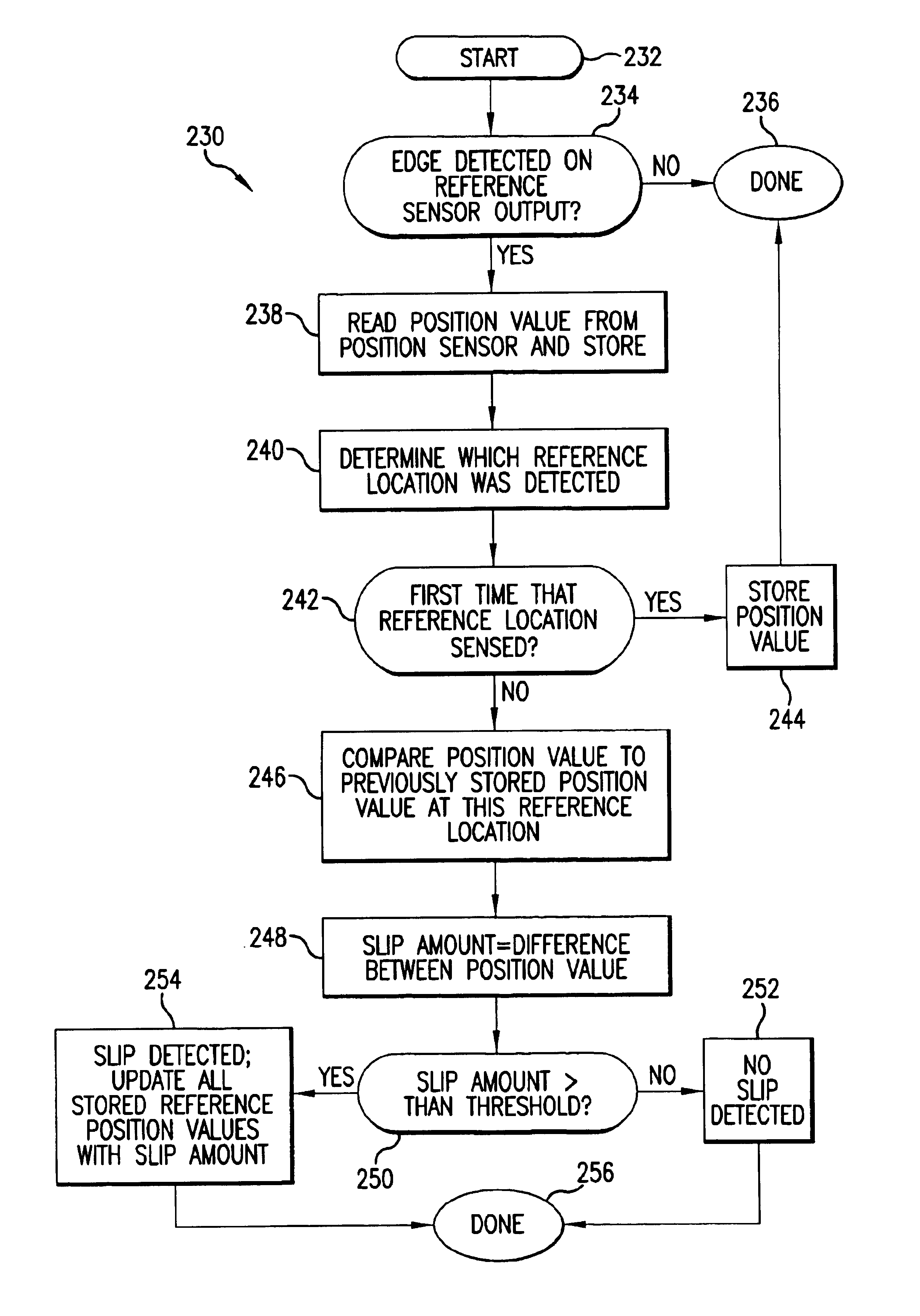

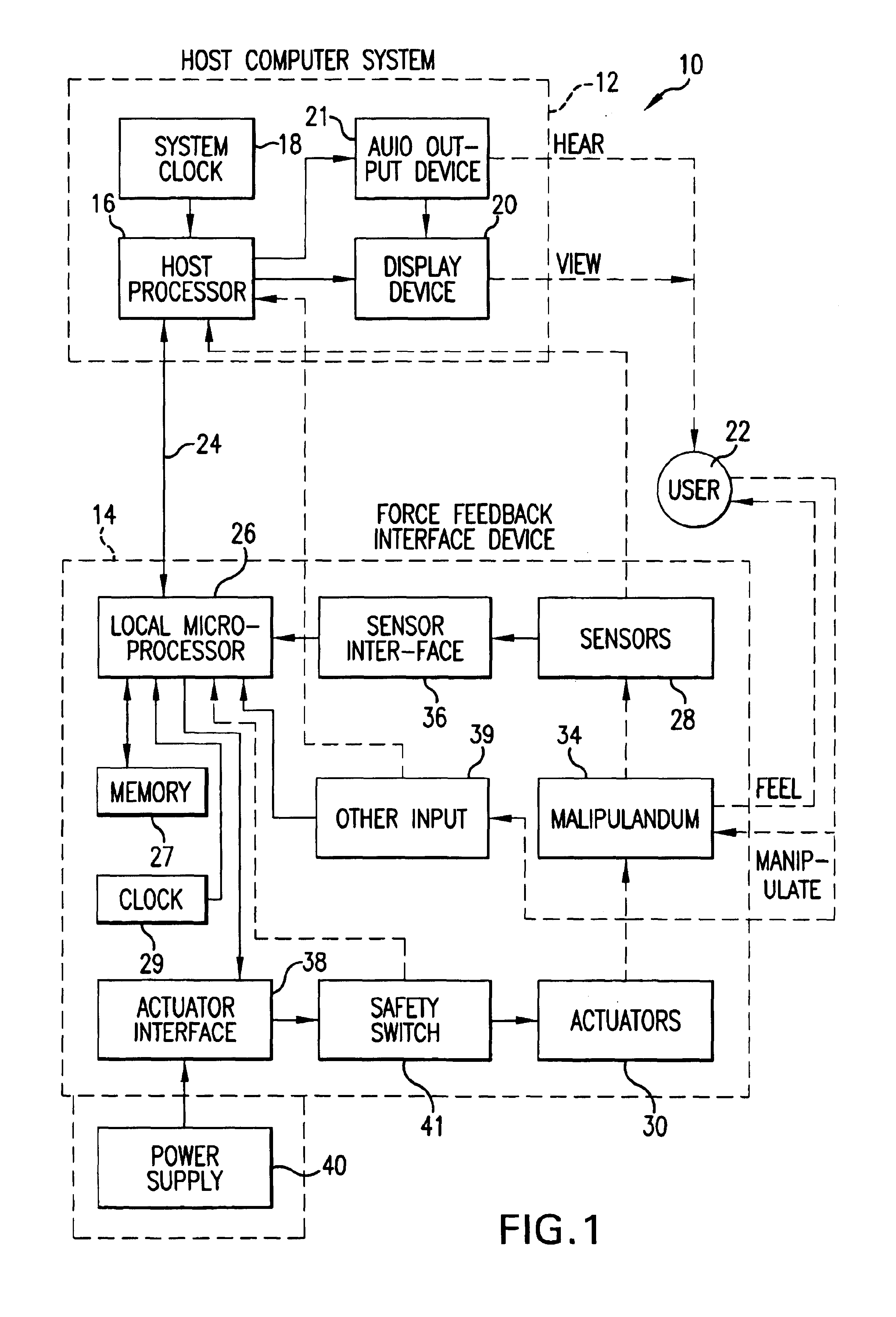

Method and apparatus for compensating for position slip in interface devices

InactiveUS6903721B2Accurate inductionSmooth displayInput/output for user-computer interactionIndoor gamesEmbedded systemObject control

Method and apparatus for compensating for position slip in interface devices that may occur between a manipulandum and a sensor of the device due to a mechanical transmission. A device position delta is determined from a sensed position of a manipulandum of an interface device. It is determined if position slip has occurred caused by a change in position of the manipulandum that was not sensed by a sensor of the interface device, typically caused by a mechanical transmission between sensor and manipulandum. If position slip has occurred, an error in the sensed position caused by the position slip is corrected by adjusting the sensed position to take into account the position slip. The adjusted position delta is used as the position of the manipulandum and the display of objects controlled by the interface device are accordingly compensated.

Owner:IMMERSION CORPORATION

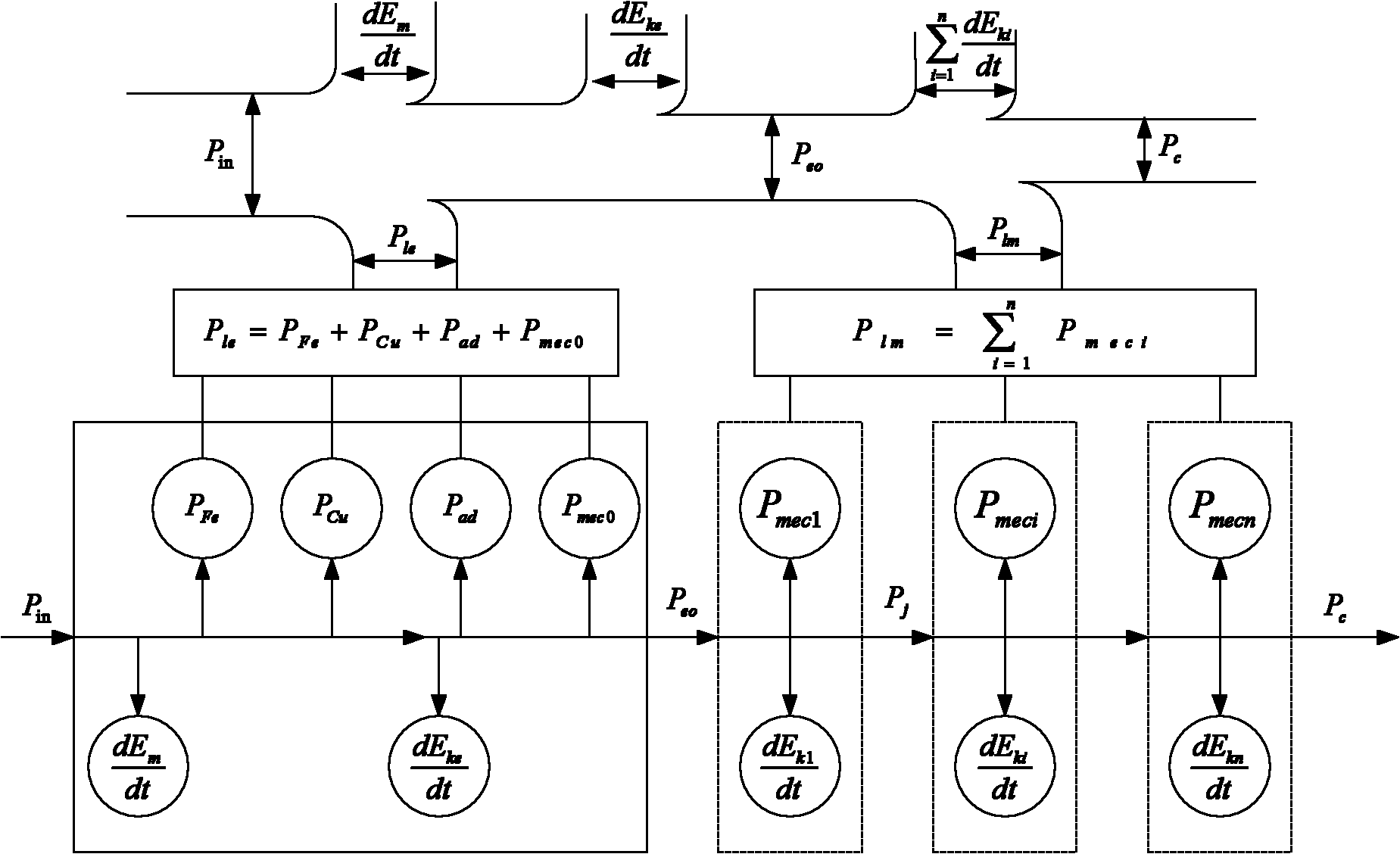

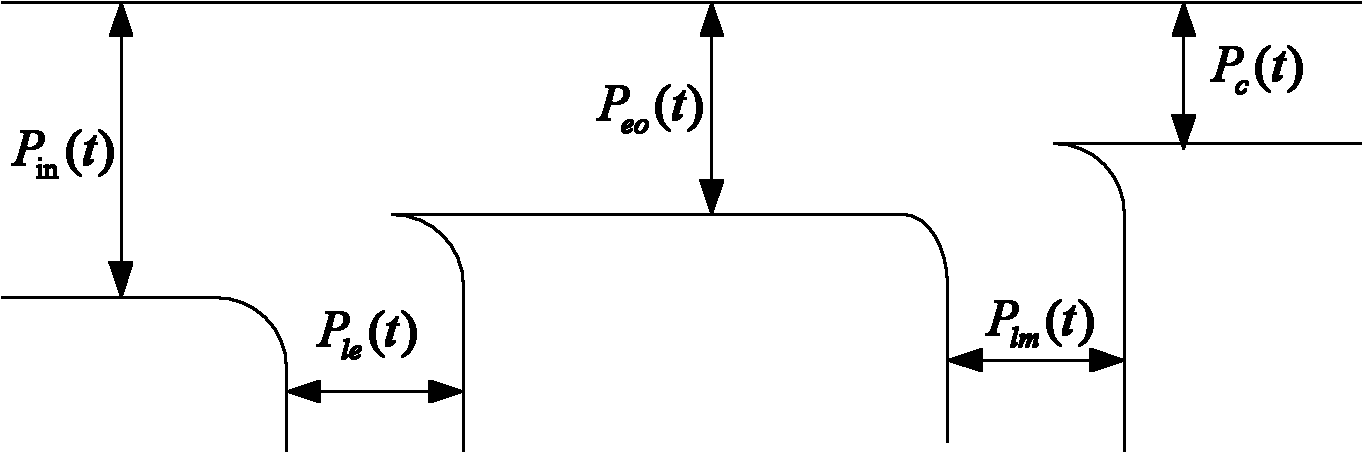

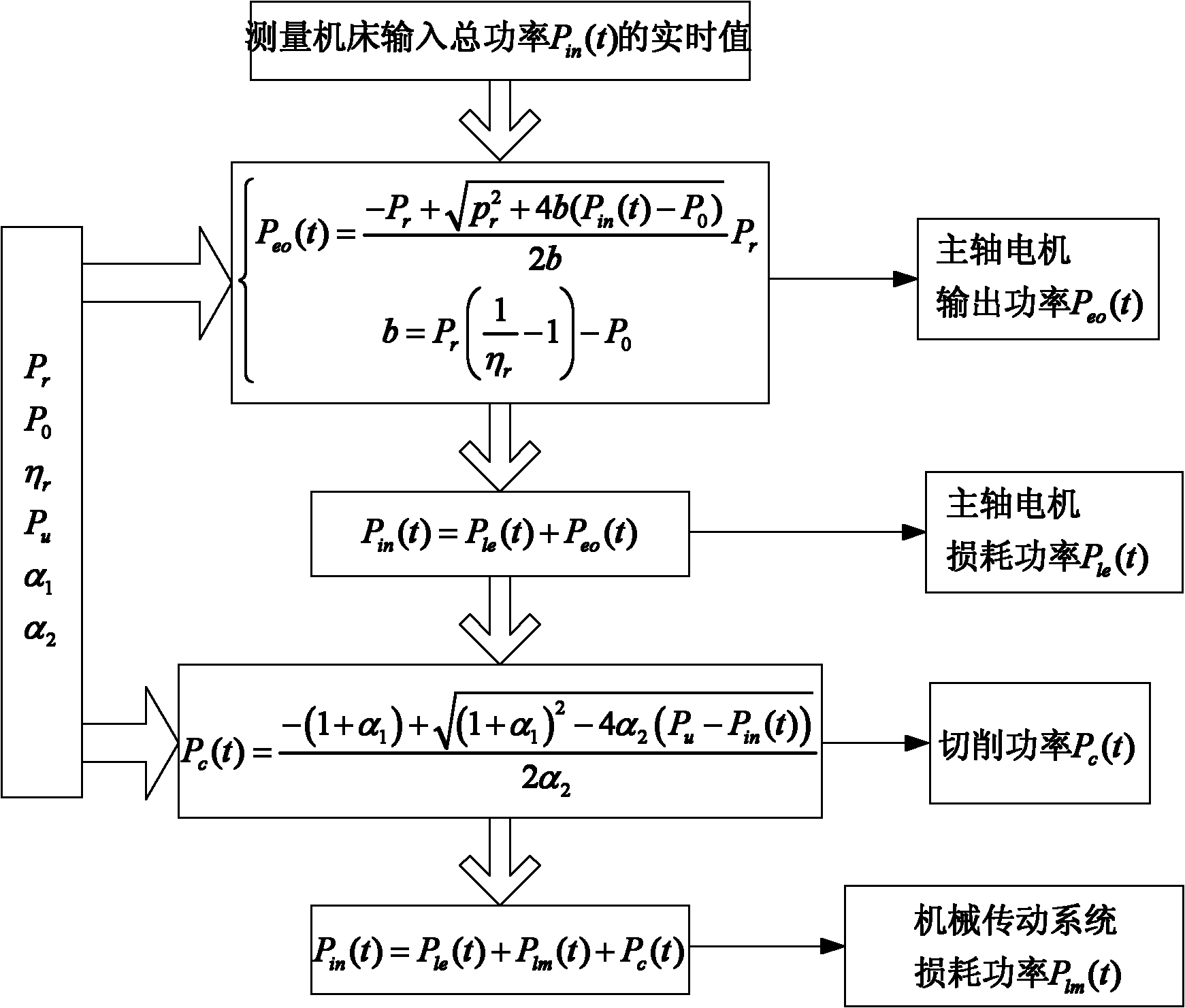

Online detection method of energy consumption information in machining process of main drive system of machine tool

InactiveCN102179727AThe online detection process is simpleEasy to operateMeasurement/indication equipmentsReal-time dataElectric machine

The invention provides an online detection method of energy consumption information in a machining process of a main drive system of a machine tool. According to the method, real-time data, such as loss power of a mainshaft motor, output power of the mainshaft motor, loss power of a mechanical drive system, cutting power, and the like of energy consumption information of the main drive system of the machine tool can be solved just by measuring the total input power of the machine tool in the production site in the machining process, according to established mathematical models of energy flowsand main energy consumption information of the main drive system in the machining process of the machine tool, and base data, such as no-load power and additional load loss coefficient of the machinetool, which are obtained in advance when a mainshaft is in a machining rotation speed, rated power of the mainshaft motor, rated efficiency of the mainshaft motor, no-load power of the mainshaft motor, and the like. The online detection method can be directly applied to researches, such as acquisition of energy efficiency of the machine tool, efficiency estimation of the machining process, energyconsumption monitoring, energy management and energy saving technologies and has wider application prospect.

Owner:CHONGQING UNIV

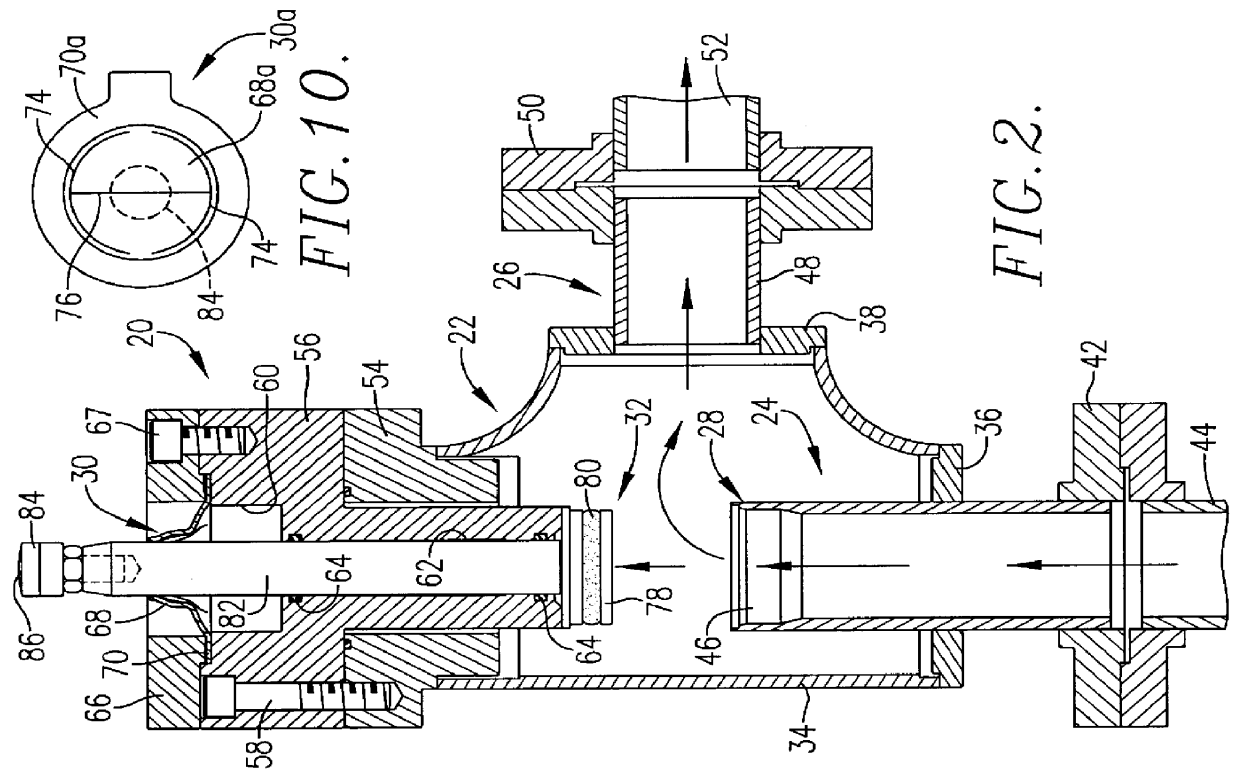

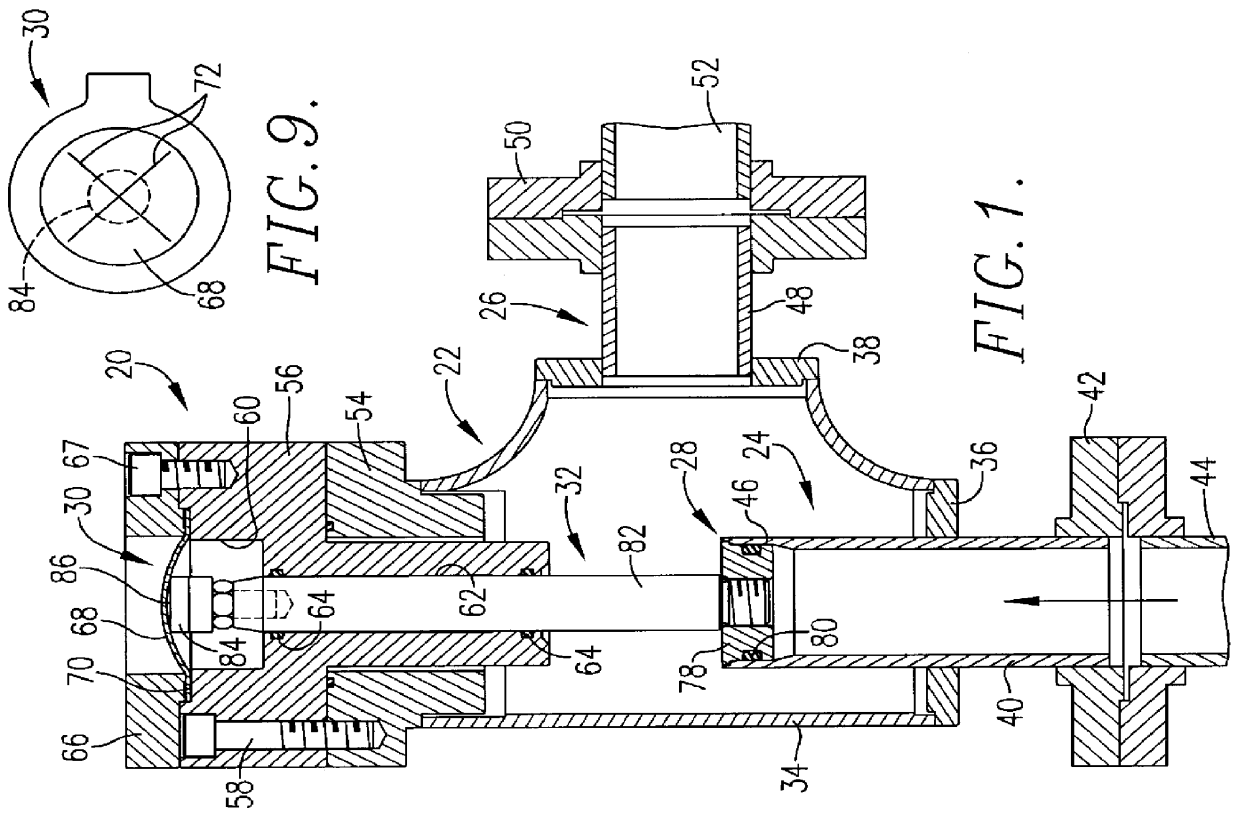

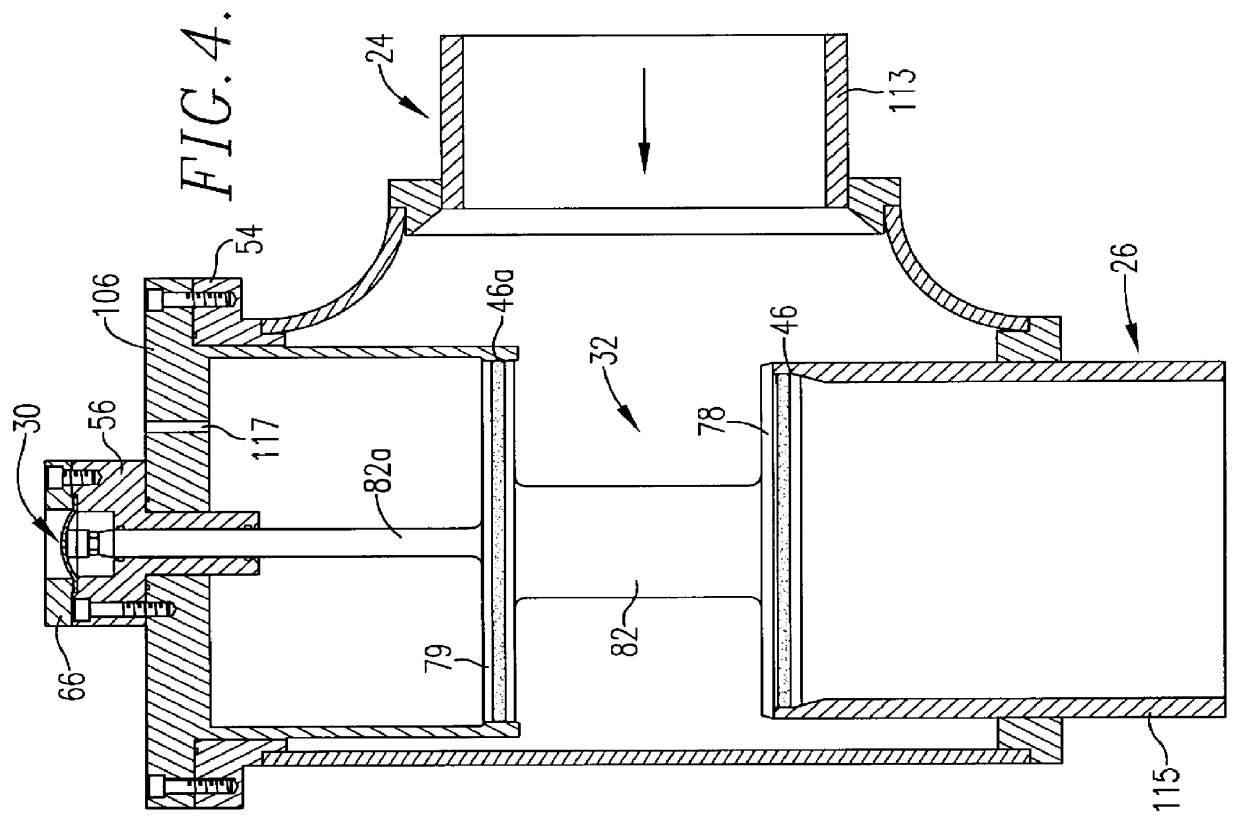

Rupture disk controlled mechanically actuated pressure relief valve assembly

Improved burst disk-type pressure responsive valve assemblies (20, 184) of the pressure relief and shutdown variety are provided which utilize frangible burst disks (30, 204) which largely determine the set point pressures for the valves. The assemblies (20, 184) include a housing (22, 186) having an inlet (24, 188), an outlet (26, 190) with a valve seat (28, 192) therein. The housing (22, 186) also supports a frangible burst disk (30, 204). An actuating unit (32, 210) within the housing (22, 186) includes a shiftable, pressure responsive piston (78, 212) supporting a valve stem actuator rod (82, 214); the rod (82, 214) is operatively coupled with a disk actuating element (84, 216) located adjacent a face of the rupture disk (30, 204). When an overpressure is sensed at the inlet (24, 188), the actuating unit (32, 210) serves to burst the disk (30, 204), allowing the piston (78, 212) to move relative to the valve seat (28, 192) to establish or close communication between the inlet (24, 188) and outlet (26, 190). The valve assemblies (20, 184) can be easily repaired or retrofitted in the field, without the need for extensive dismantling of conduits or the like. Use of disks (30, 204) which rupture during valve operation affords a visual indication of valve operation and permits fabrication of high capacity, long stroke length valves.

Owner:FIKE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com