Patents

Literature

176 results about "Optical bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical bonding refers to a protective glass that is glued in front of a display to enhance its readability where installed in high humidity outdoor environments. When a normal display is used in an outdoor environment, there are some factors that affect its readability. The most common one is “fog”, or condensation, which forms on the inner surface of display's vandal shield. Another factor is the reflection of sunlight, which causes a mirror-image on the display. Both phenomena can be solved by using optical bonding.

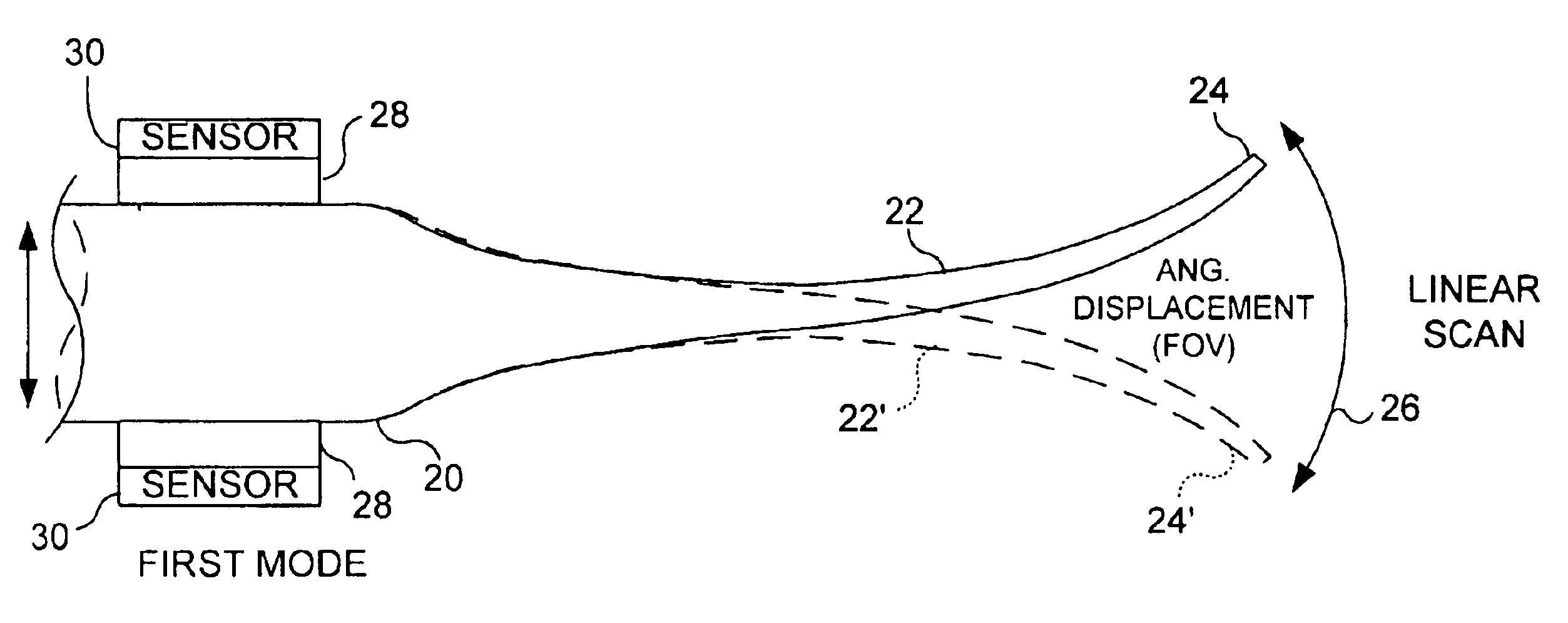

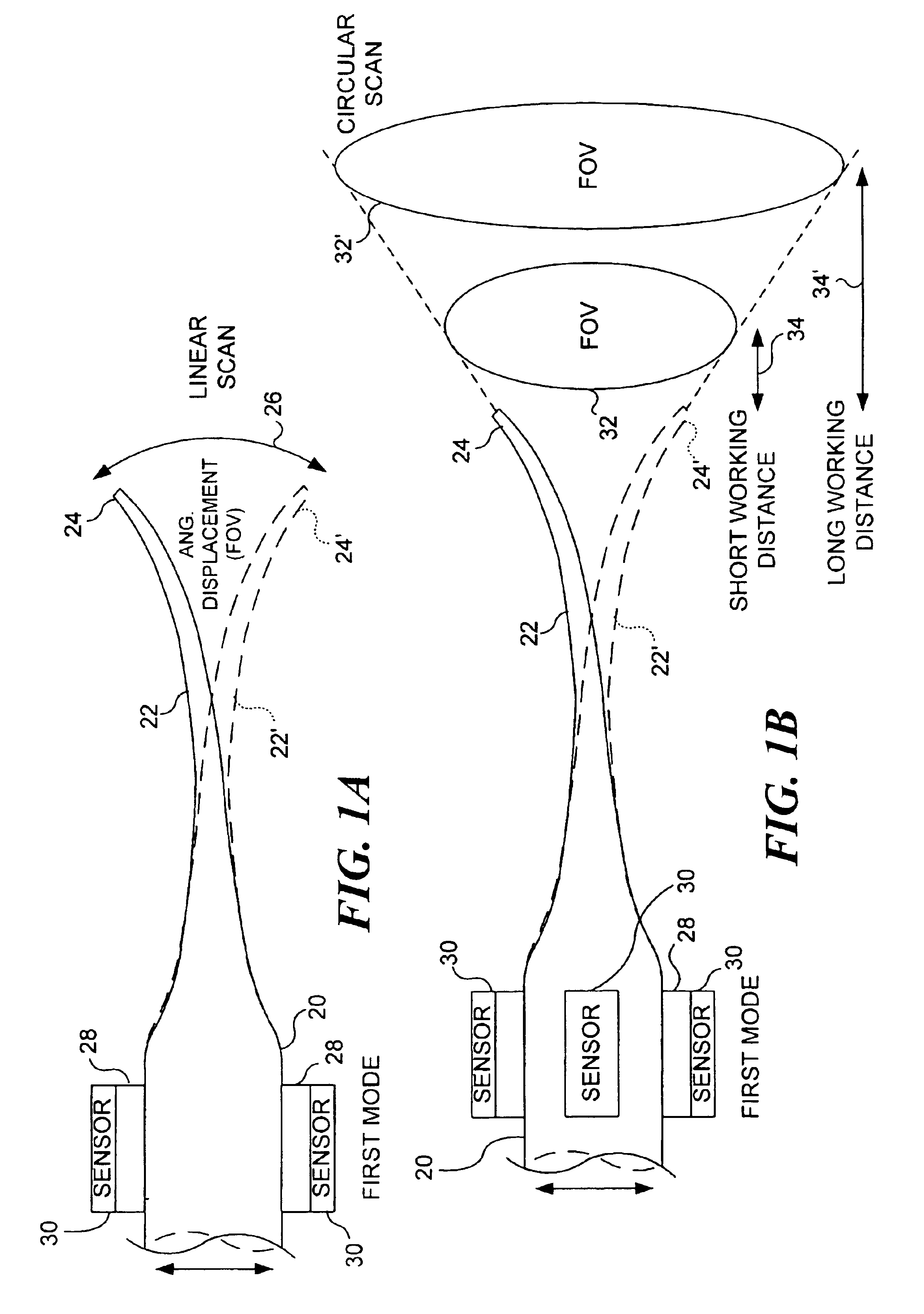

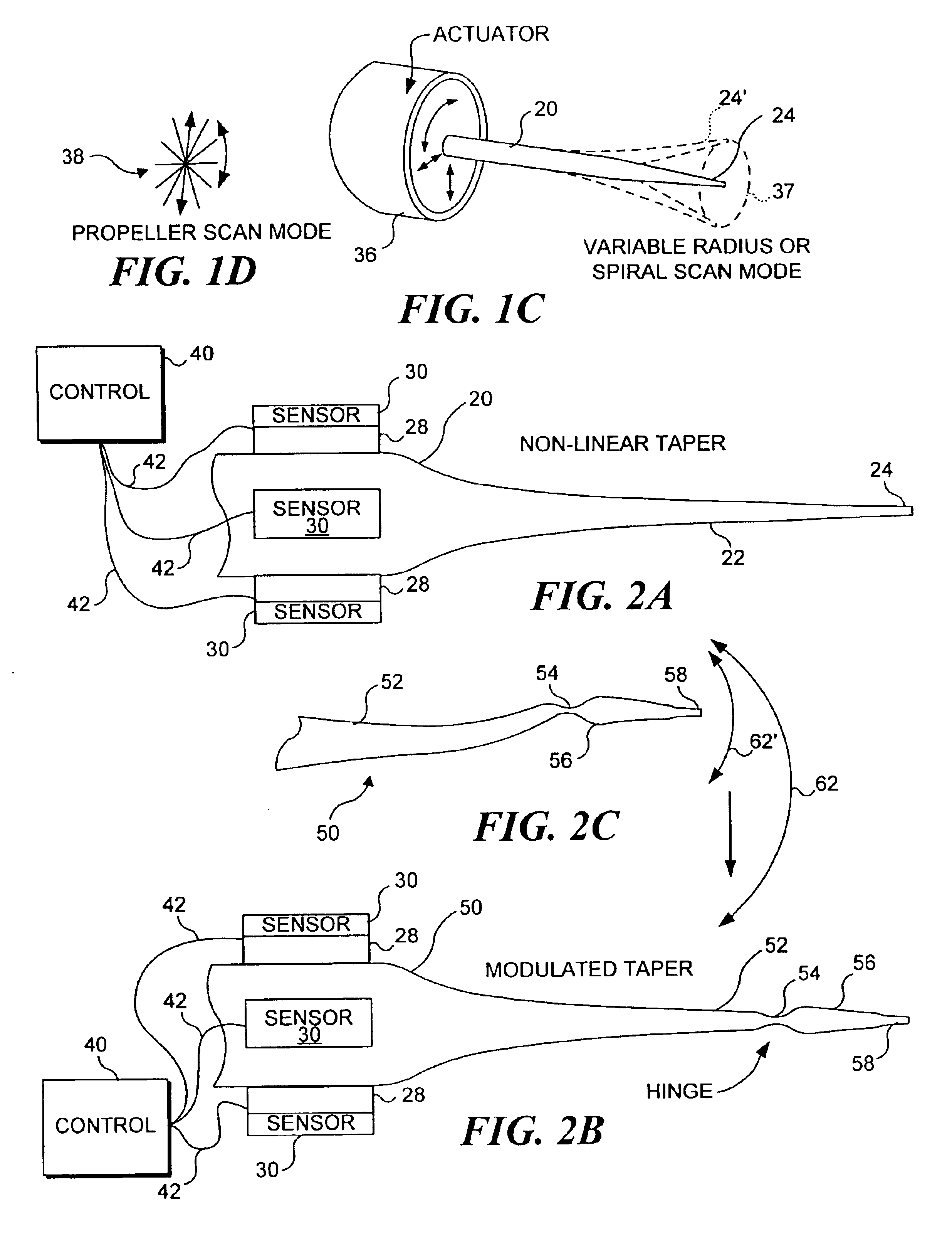

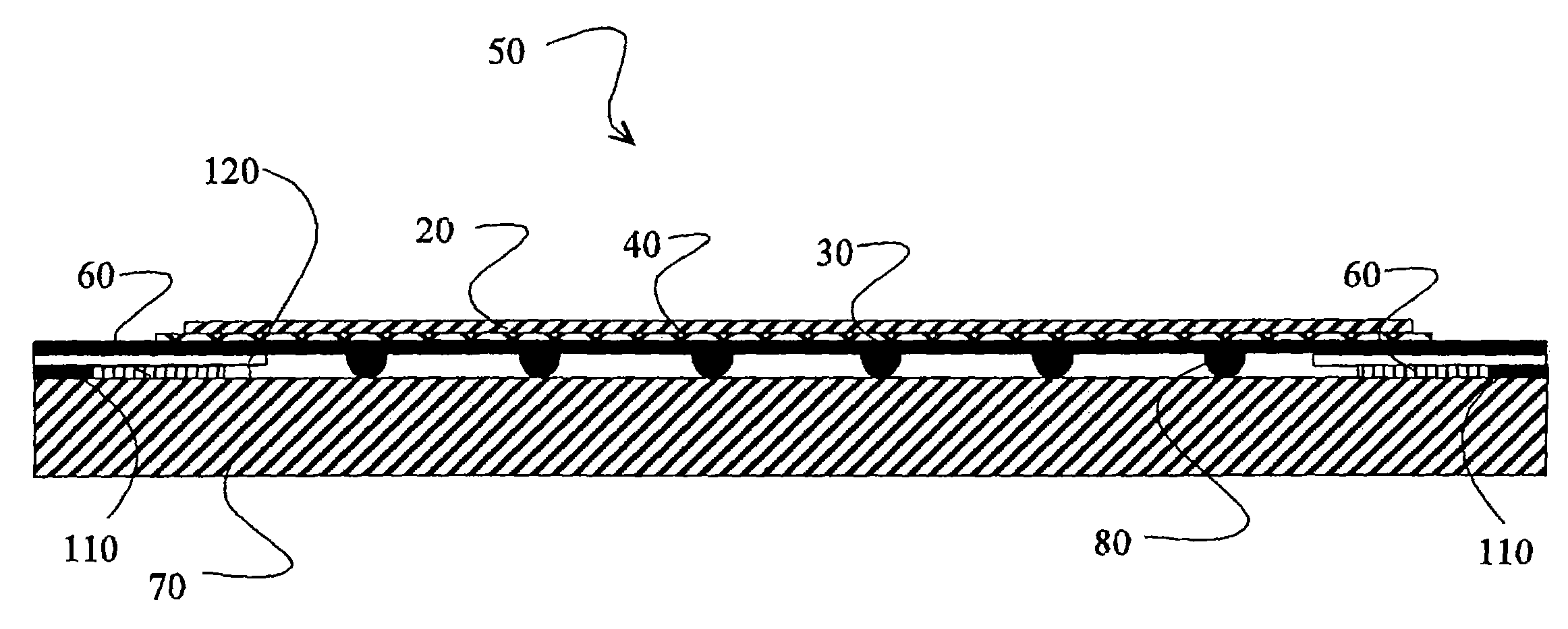

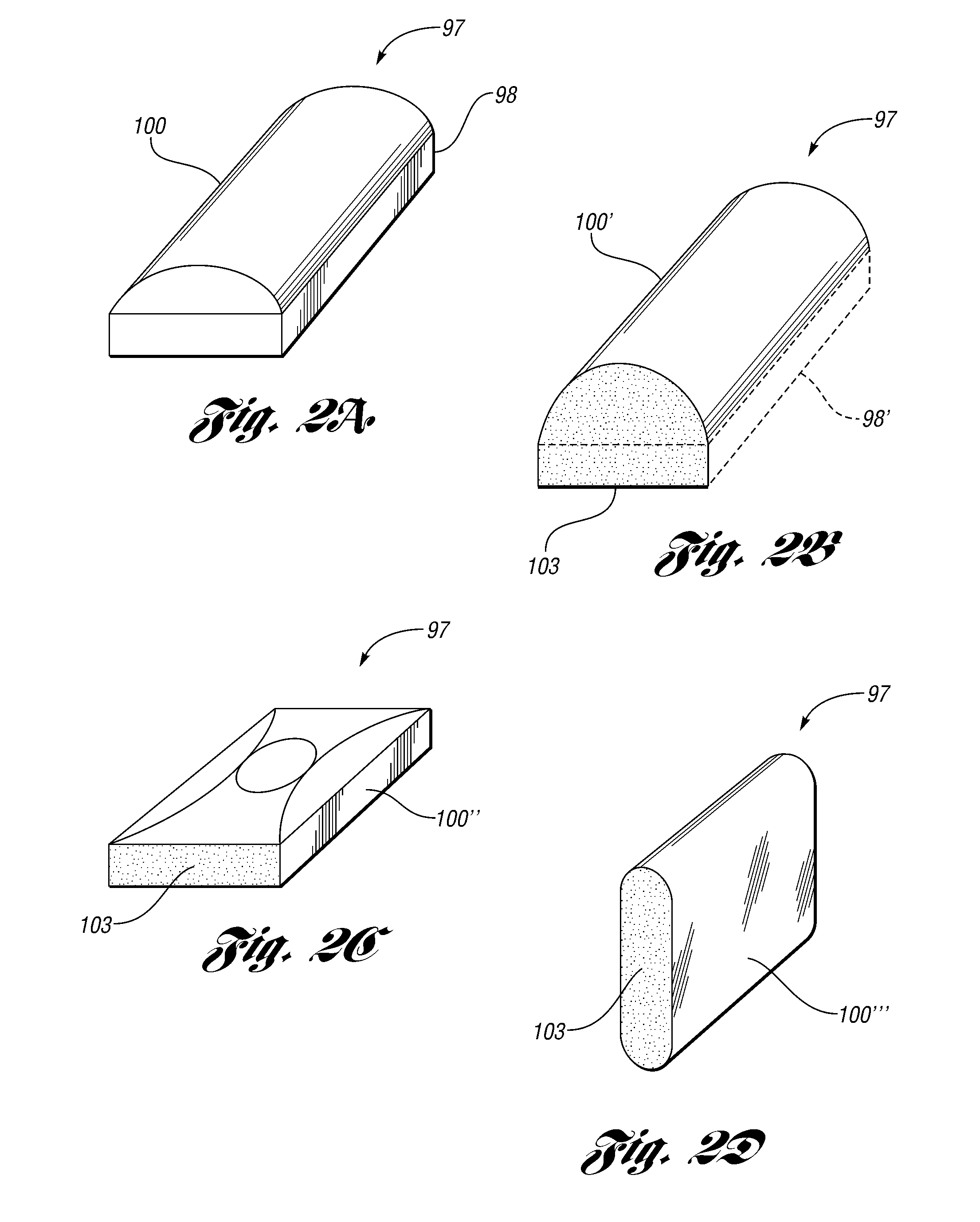

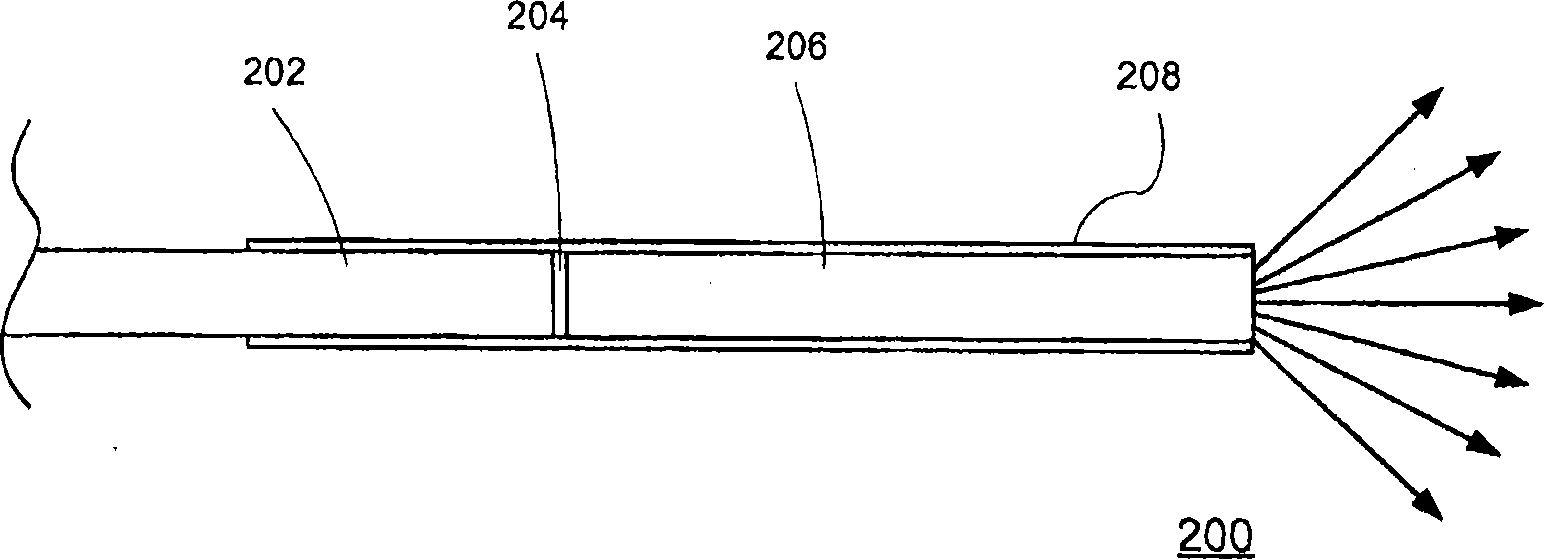

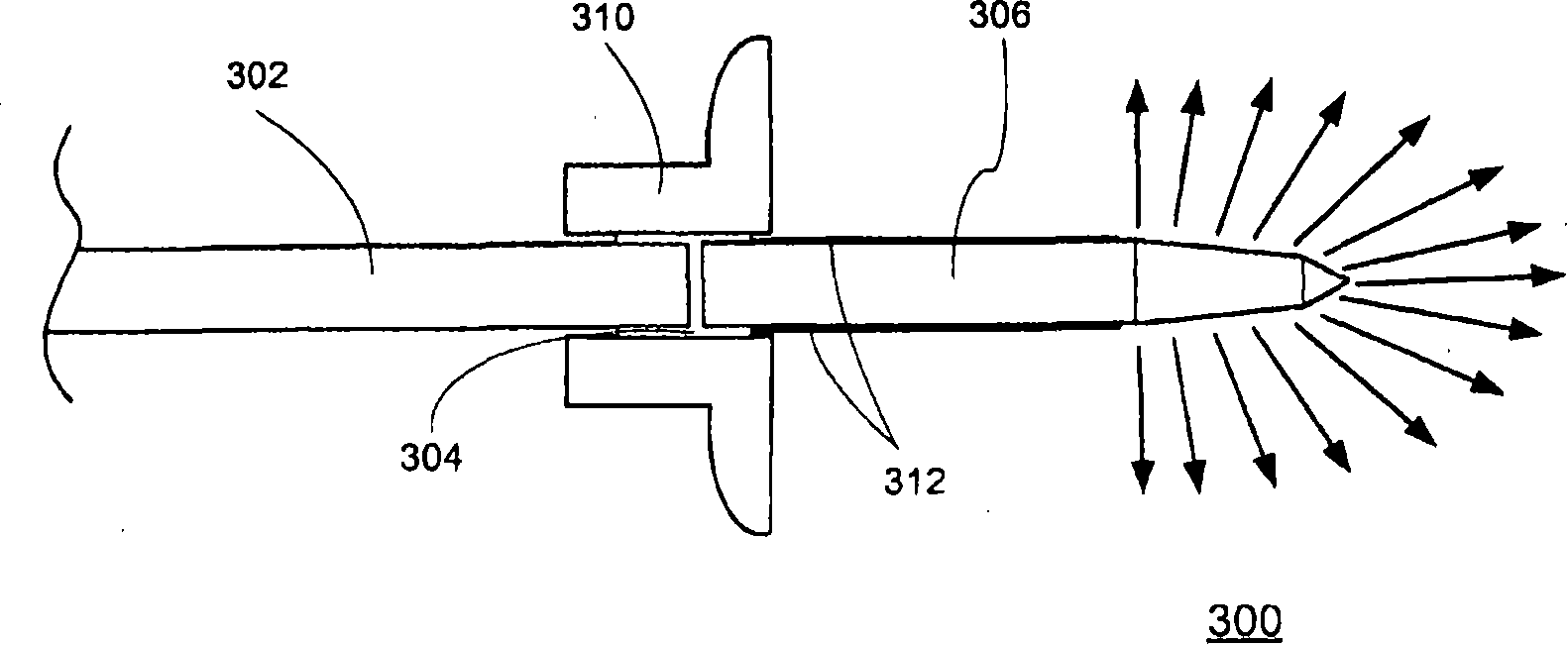

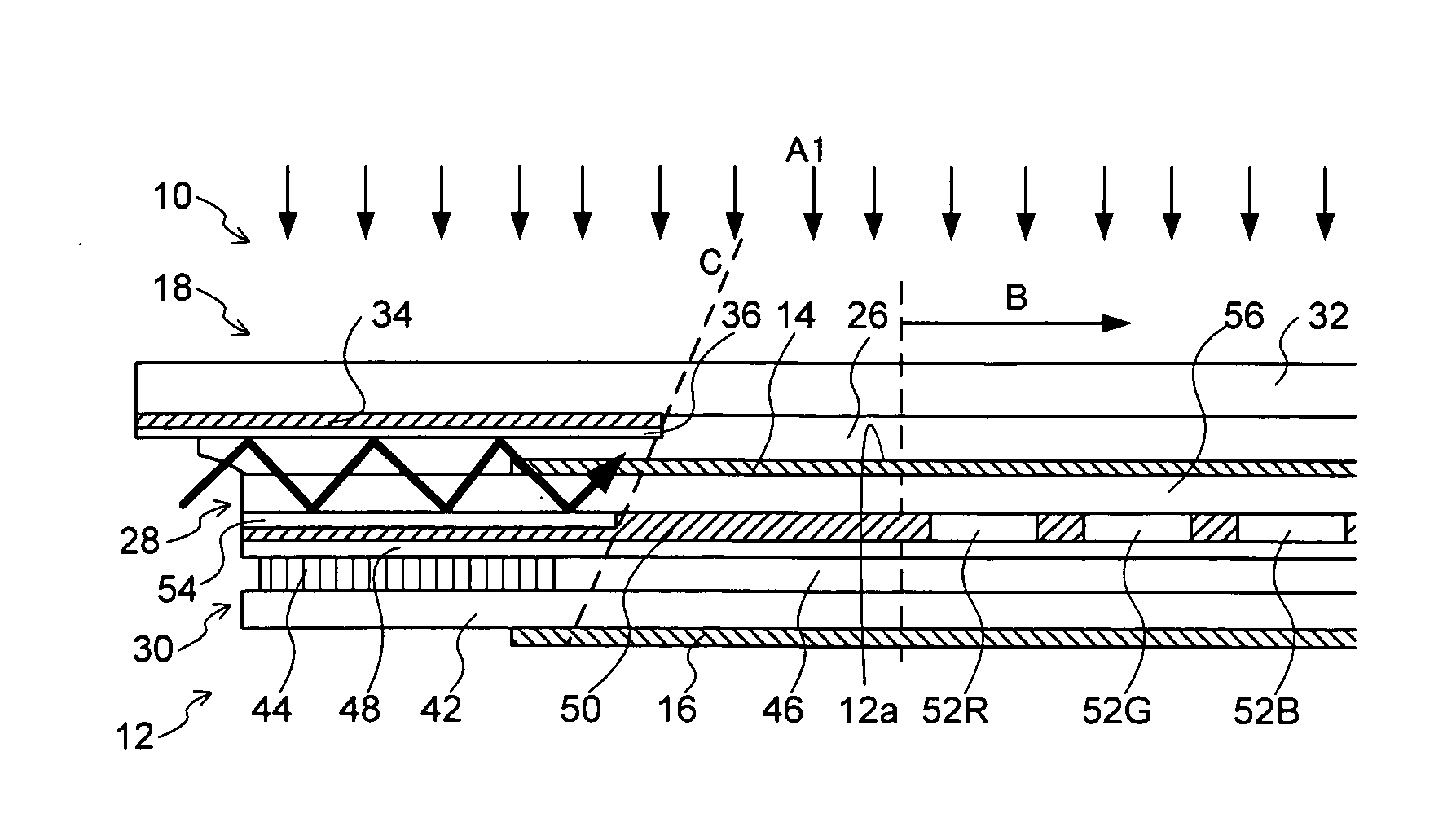

Micro-fabricated optical waveguide for use in scanning fiber displays and scanned fiber image acquisition

Small, rugged scanners micro-fabricated from commercial optical fibers to form waveguides or other structures. The scanning waveguide has a distal portion on which is formed a non-linear taper with a diameter that decreases toward a distal end. Optionally, a hinge portion having a reduced diameter can be formed in the distal portion, improving the scanning properties of the waveguide. A micro-lens can be integrally formed at the distal tip of the waveguide with either a droplet of an optical adhesive, or by using an energy beam to melt the material of the waveguide to form a droplet. The droplet is shaped with an externally applied force. When mechanically driven in vibratory resonance, the tip of the optical waveguides moves in linear or two-dimensional scan patterns of relatively high amplitude and frequency, and large field of view. The scanner can be used either for image acquisition or image display.

Owner:UNIV OF WASHINGTON +1

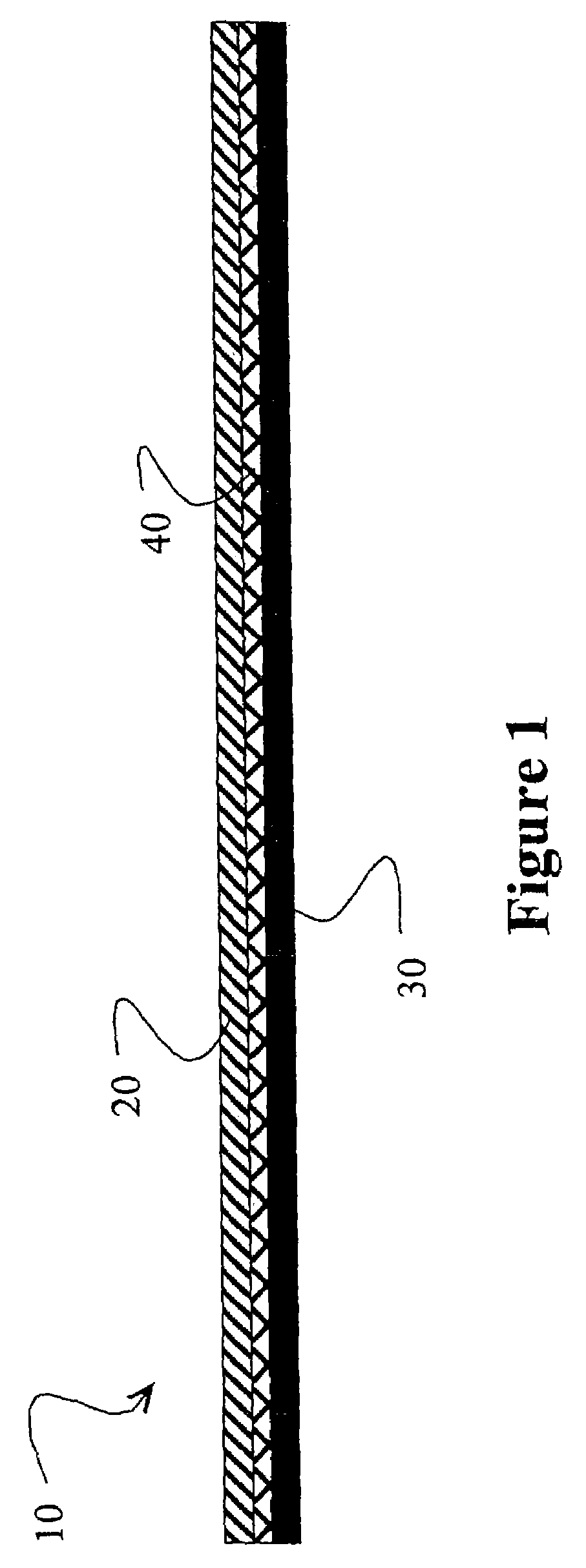

Laminated touch screen

ActiveUS7345680B2Difficult to vandalizeOvercomes shortcomingTransmission systemsElectrical equipmentOptical bondingEngineering

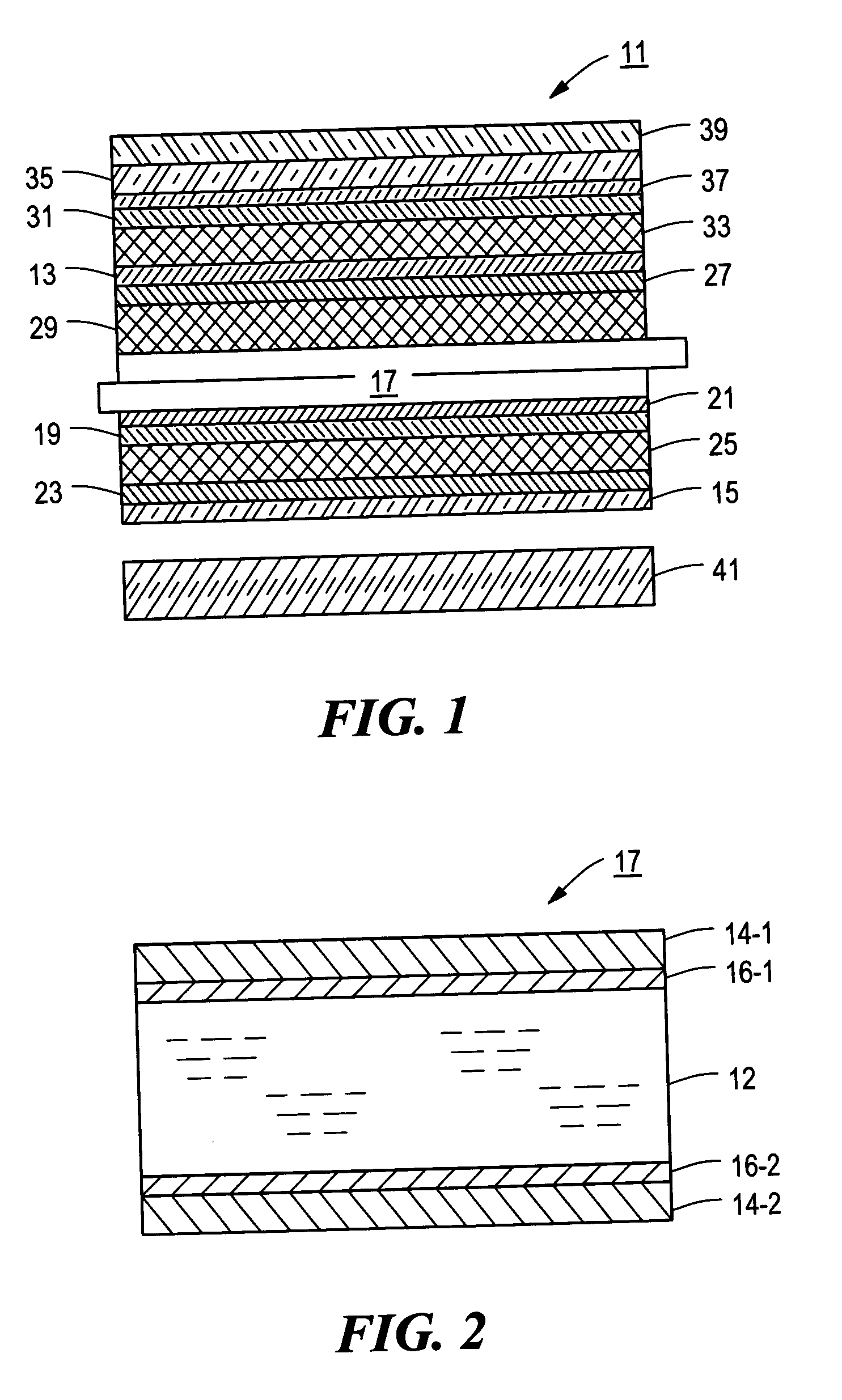

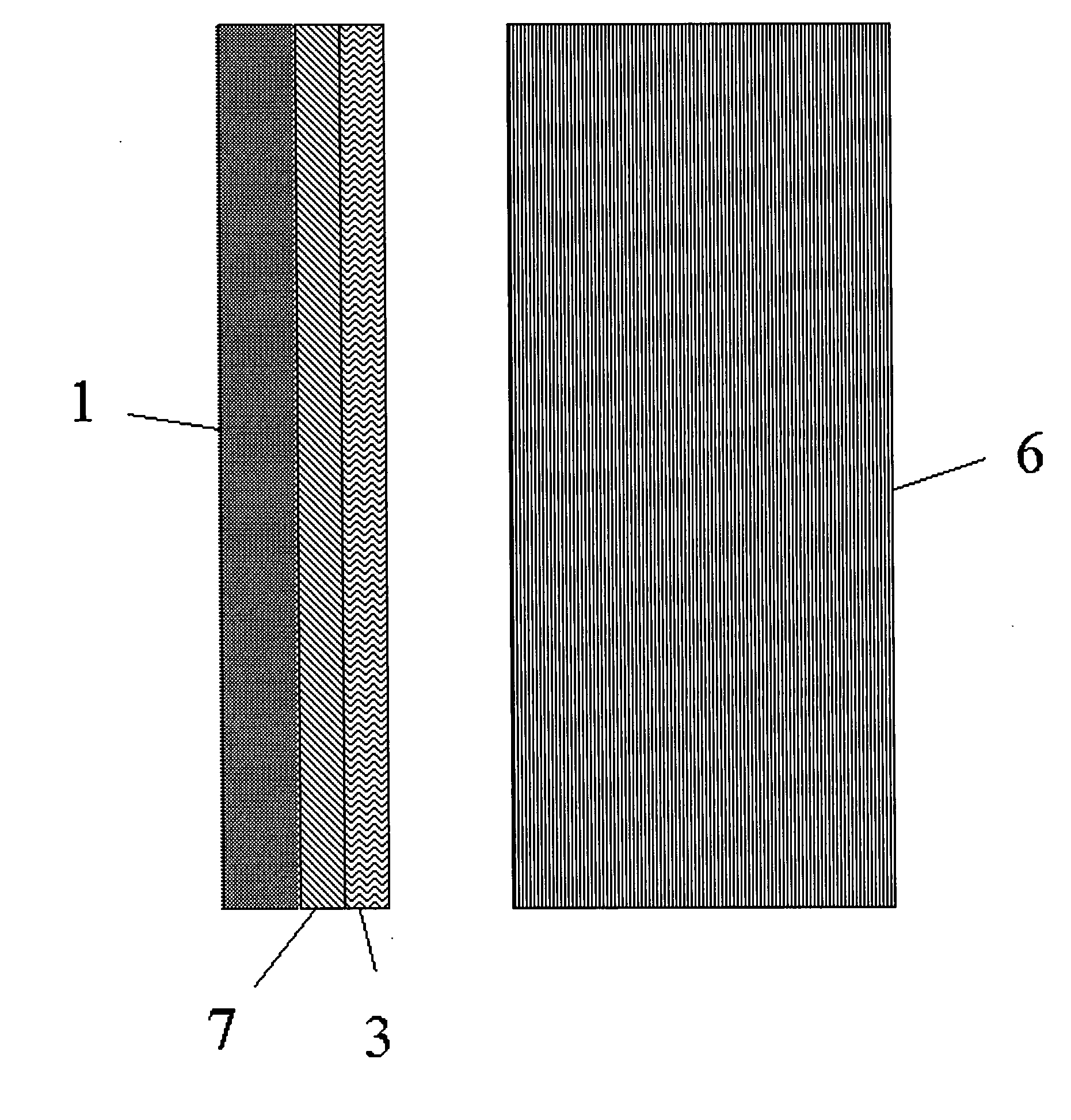

In a touch screen having a flexible outer membrane with a first conducting surface, a backing surface with a second conductive surface, and sensors to detect contact between the first conducting surface and the second conducting surface, the improvement comprising the flexible outer membrane, wherein the flexible outer layer consists of an ultra-thin glass layer, a polymer layer; and an optical adhesive between the ultra-thin glass layer and the polymer layer, the optical adhesive holding the ultra-thin glass layer to the polymer layer.

Owner:DAVID ALBERT M

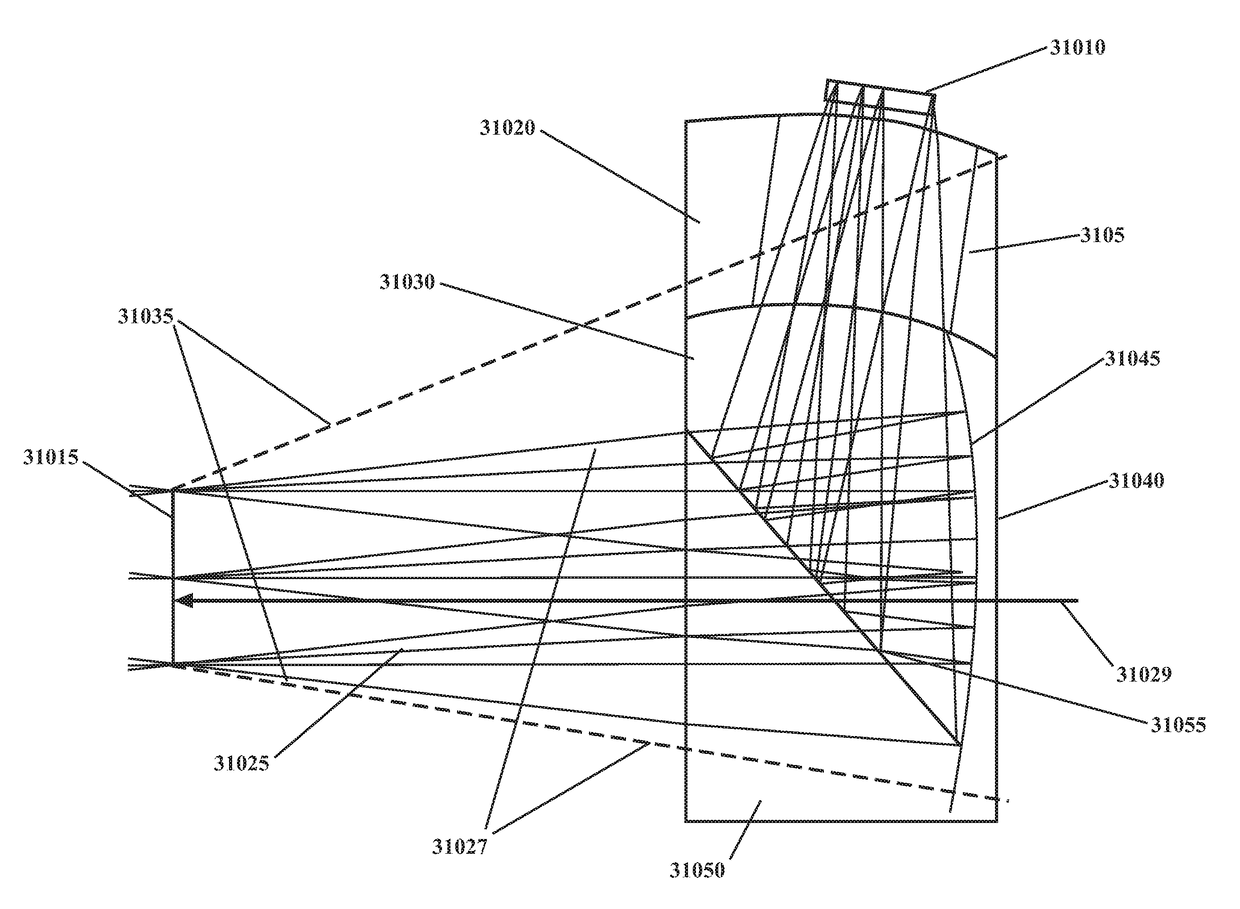

Robust optics for a head-worn display

InactiveUS20170343822A1Spectales/gogglesAuxillary optical partsPartially reflective surfaceOptical bonding

Aspects of the present disclosure relate to solid optical systems and methods for use in head-worn computing systems. An optical assembly may include multiple elements that are aligned relative to one another and then adhesively bonded together to preserve the alignment in an adhesively bonded optic, wherein the adhesively bonded optic includes at least one internal refractive surface and two or more internal reflective surfaces, and wherein the internal partially reflective surfaces comprise partially reflective surfaces that are protected by other elements in the adhesively bonded optic

Owner:MENTOR ACQUISITION ONE LLC

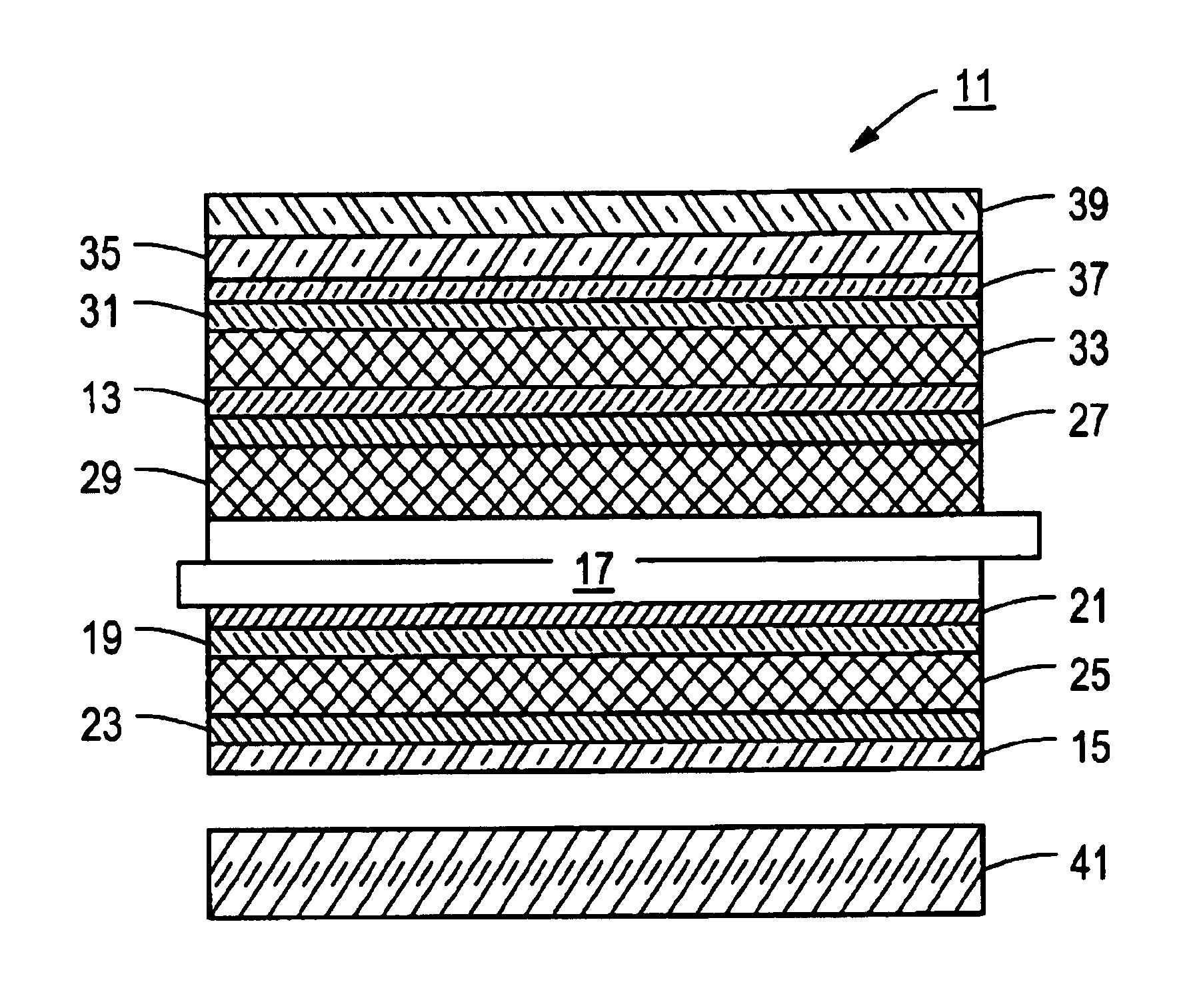

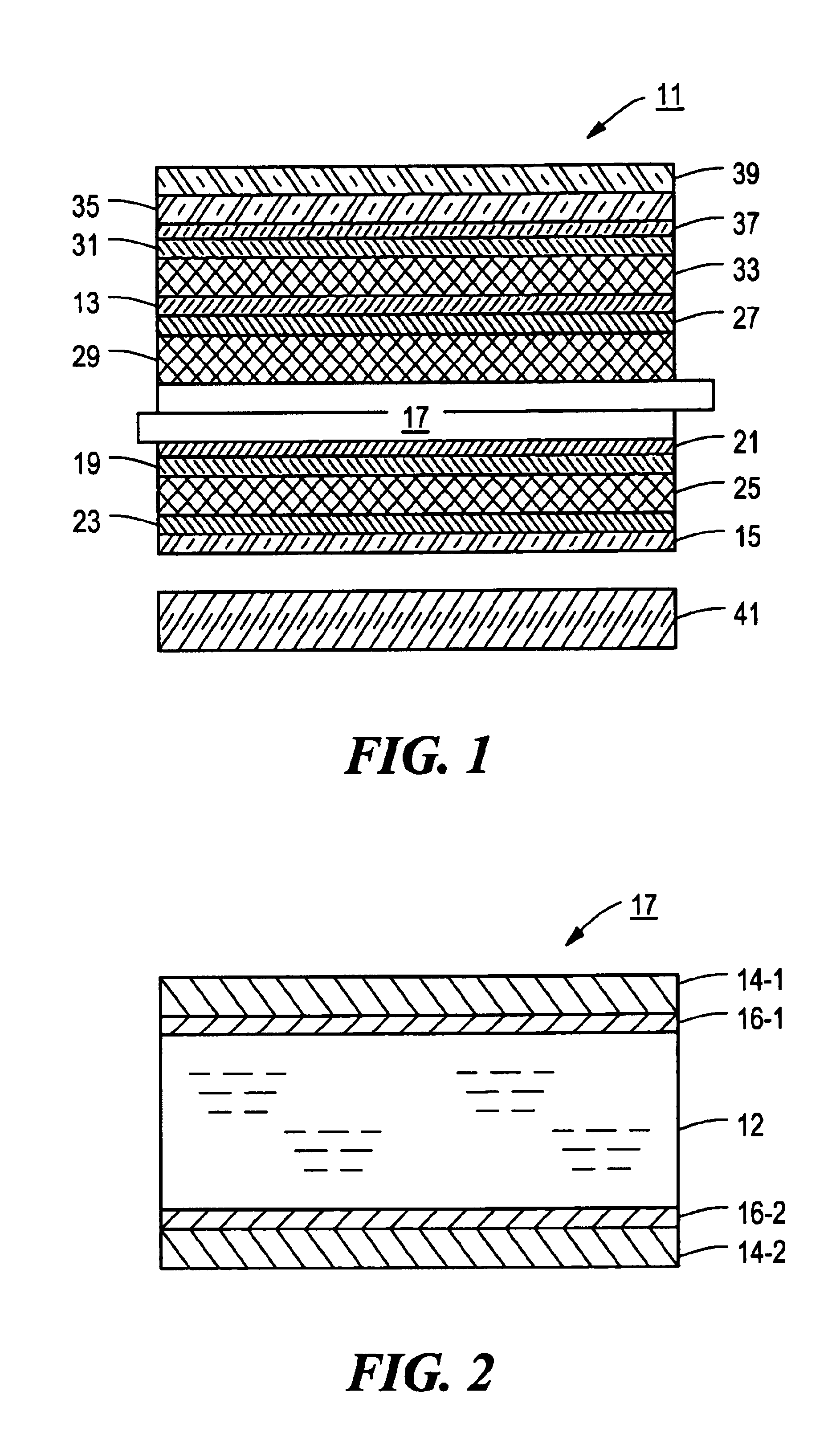

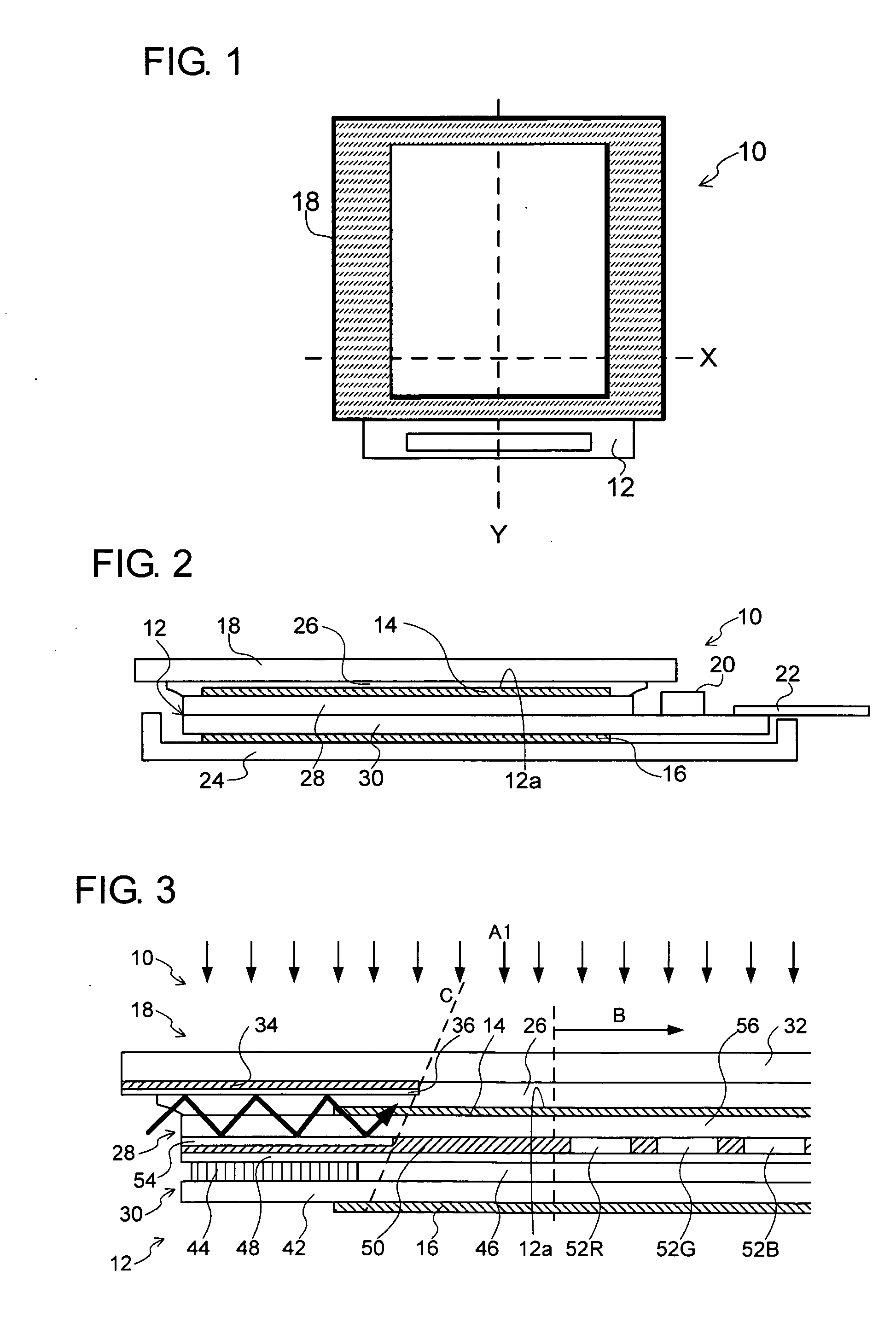

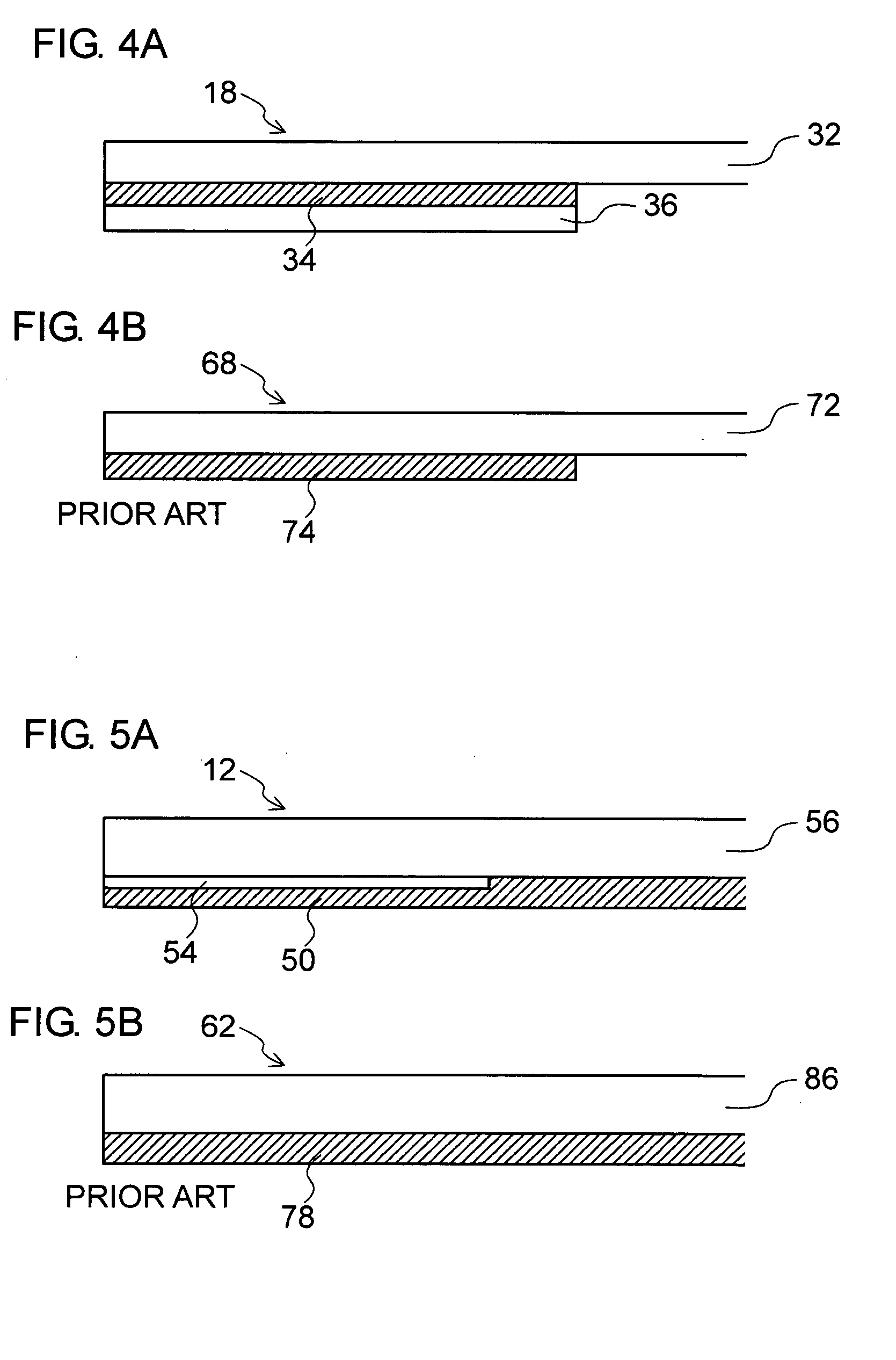

Super bright low reflectance liquid crystal display

InactiveUS6933991B2Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingPolarizer

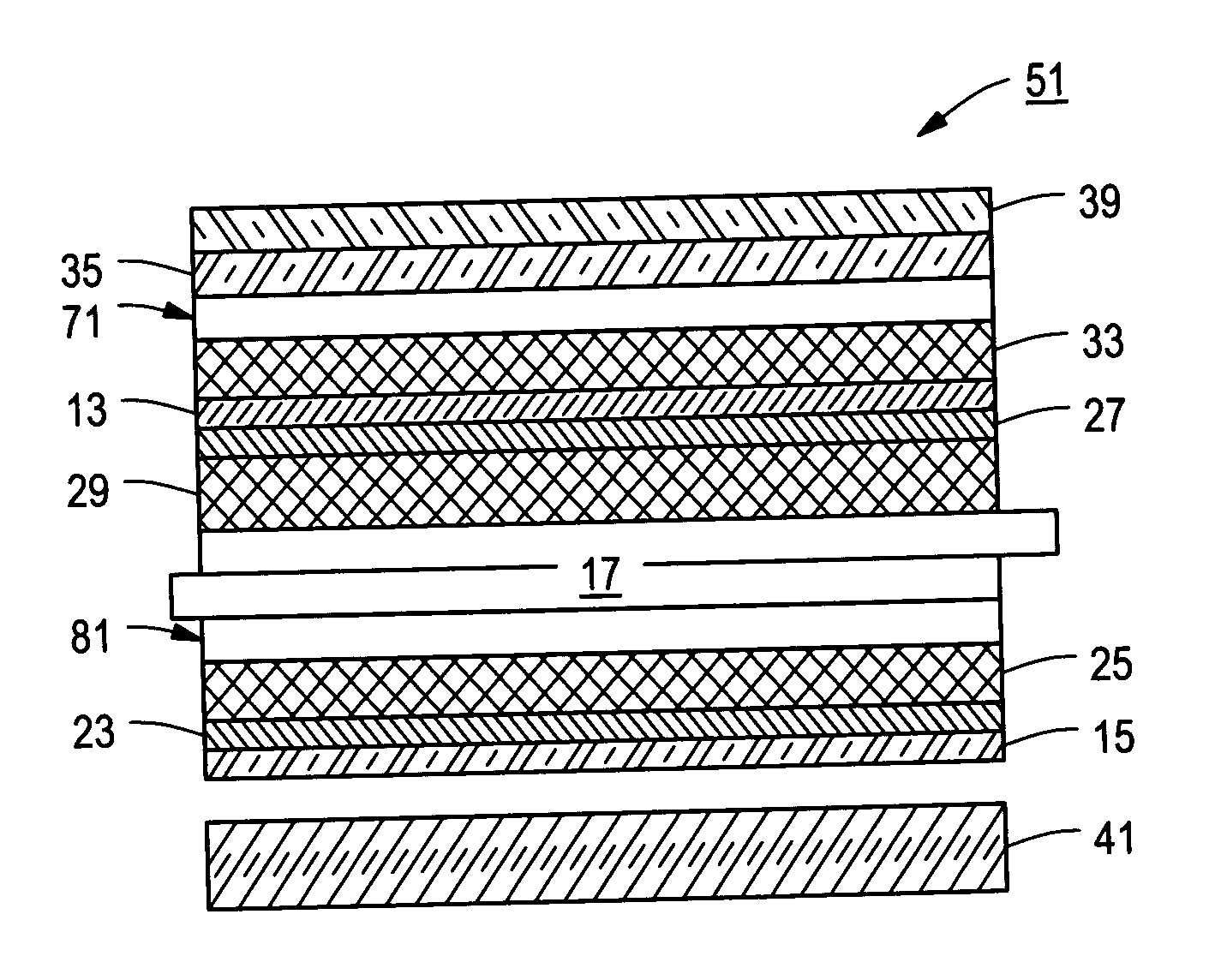

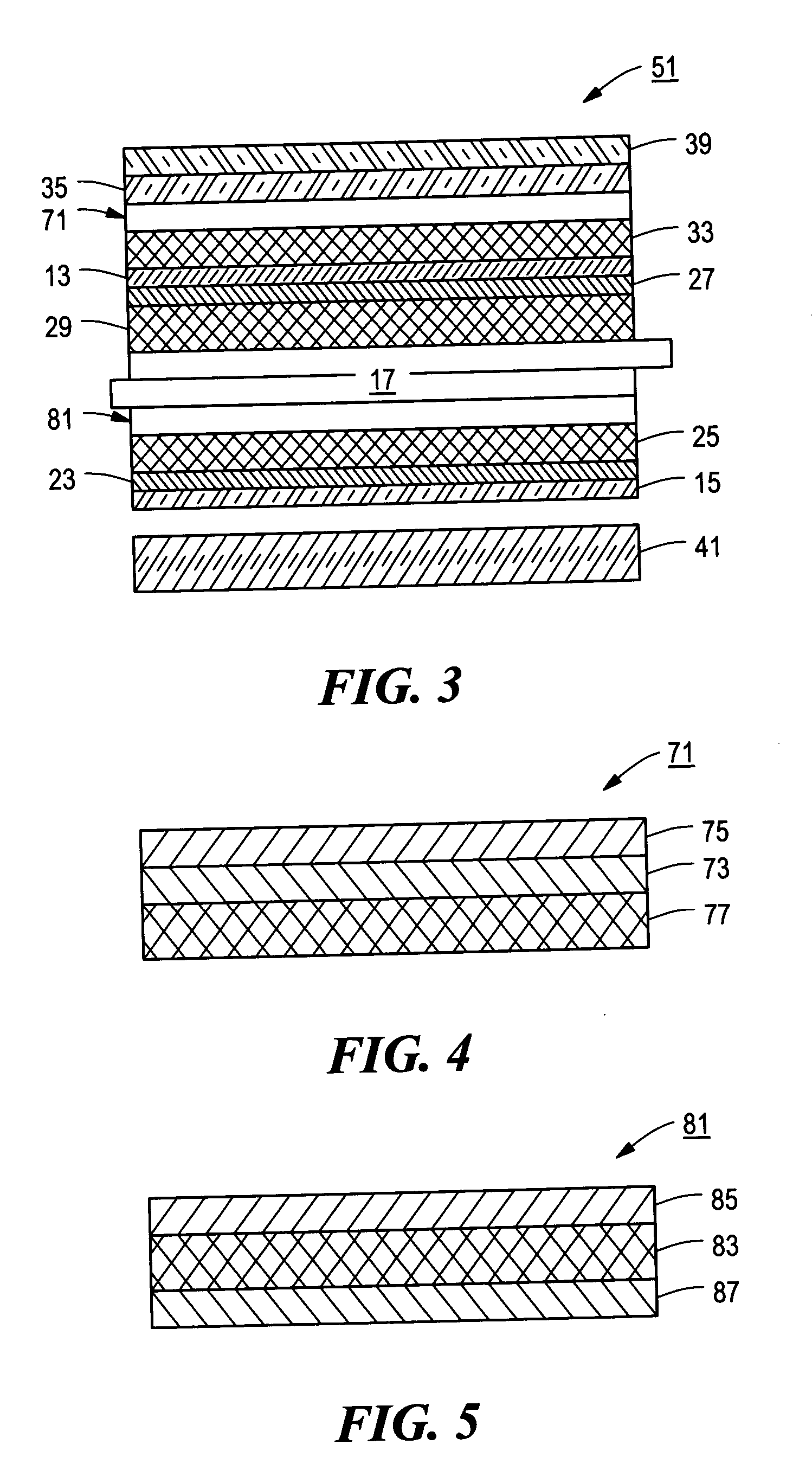

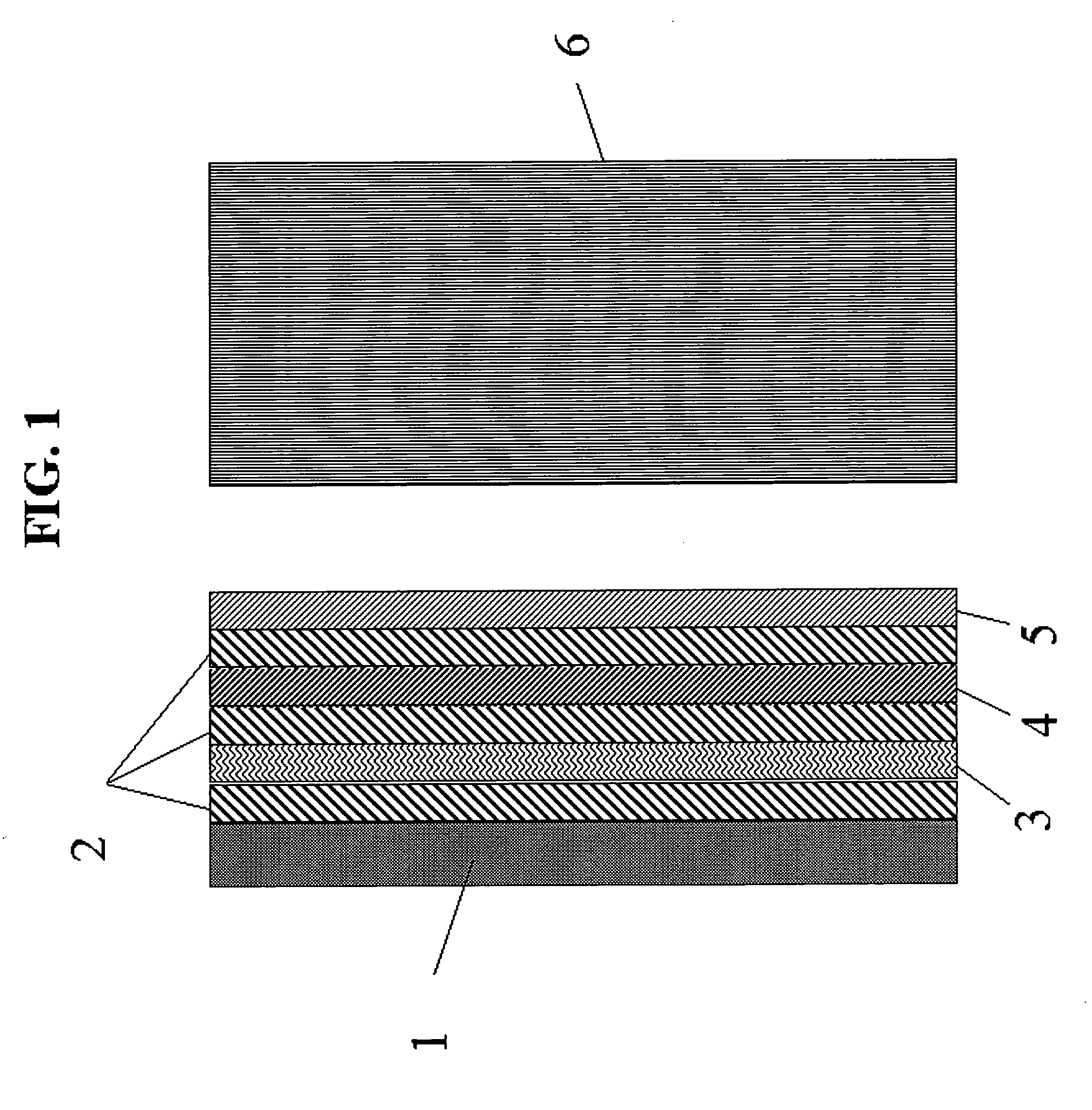

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS

Super bright low reflectance liquid crystal display

InactiveUS20060001800A1Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingAnti-reflective coating

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS GMBH

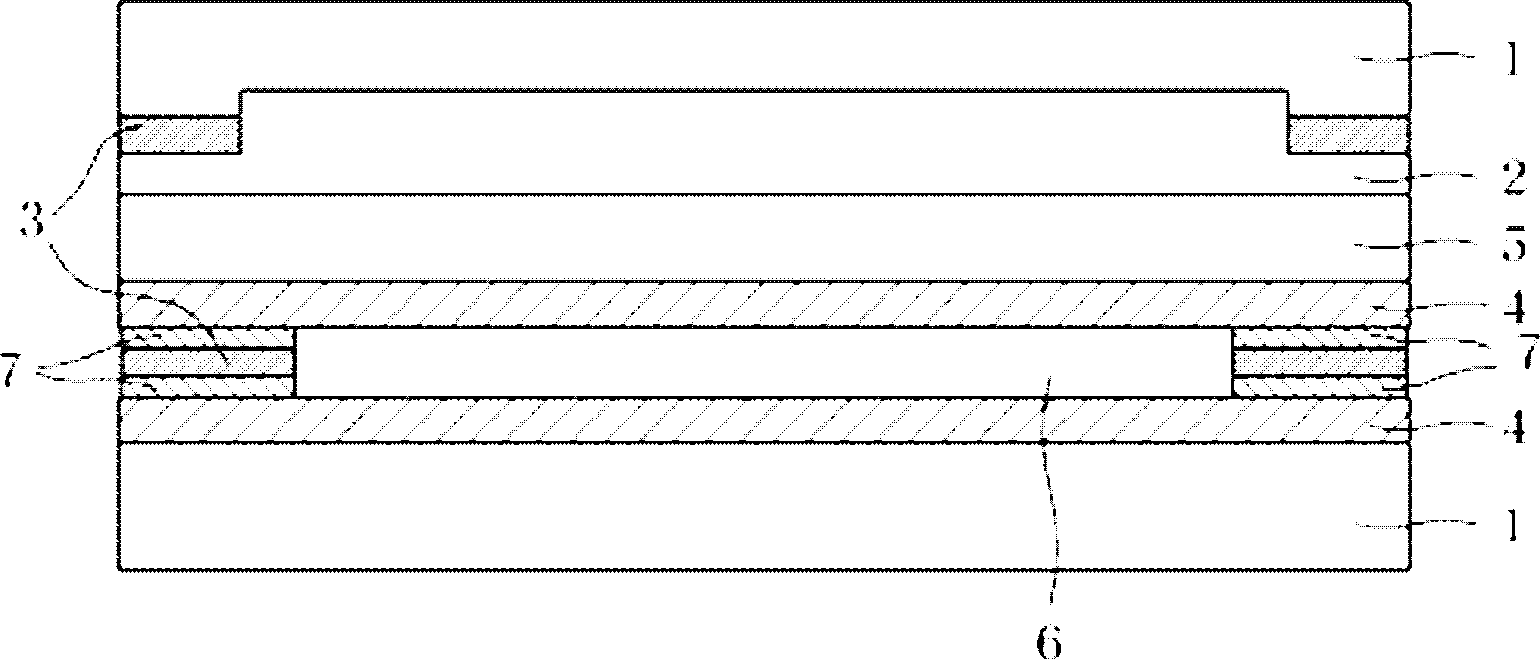

High-strength optical bonding method using optical silicone as a bonding medium and pressure sensitive adhesive as an intermediate layer

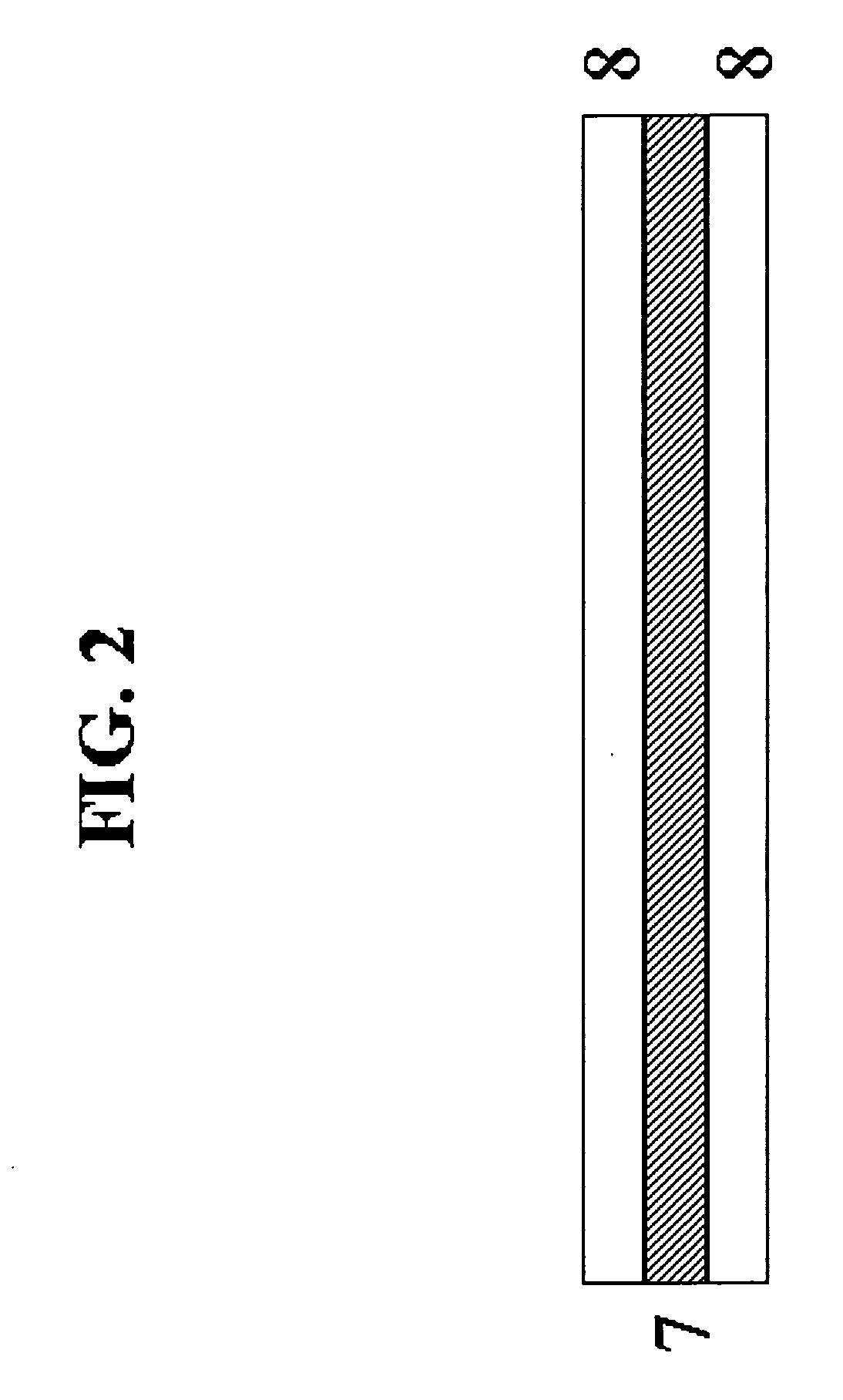

InactiveUS20060159867A1High strengthImprove adhesionLiquid crystal compositionsLaminationOptical bondingInter layer

A method of bonding an optical cover panel to an information display device through the use of intermediate layers of optical pressure-sensitive adhesive film which adheres to both optical silicone bonding medium and polymer plastic, and structures formed thereby.

Owner:ODONNELL STEPHEN DERBY

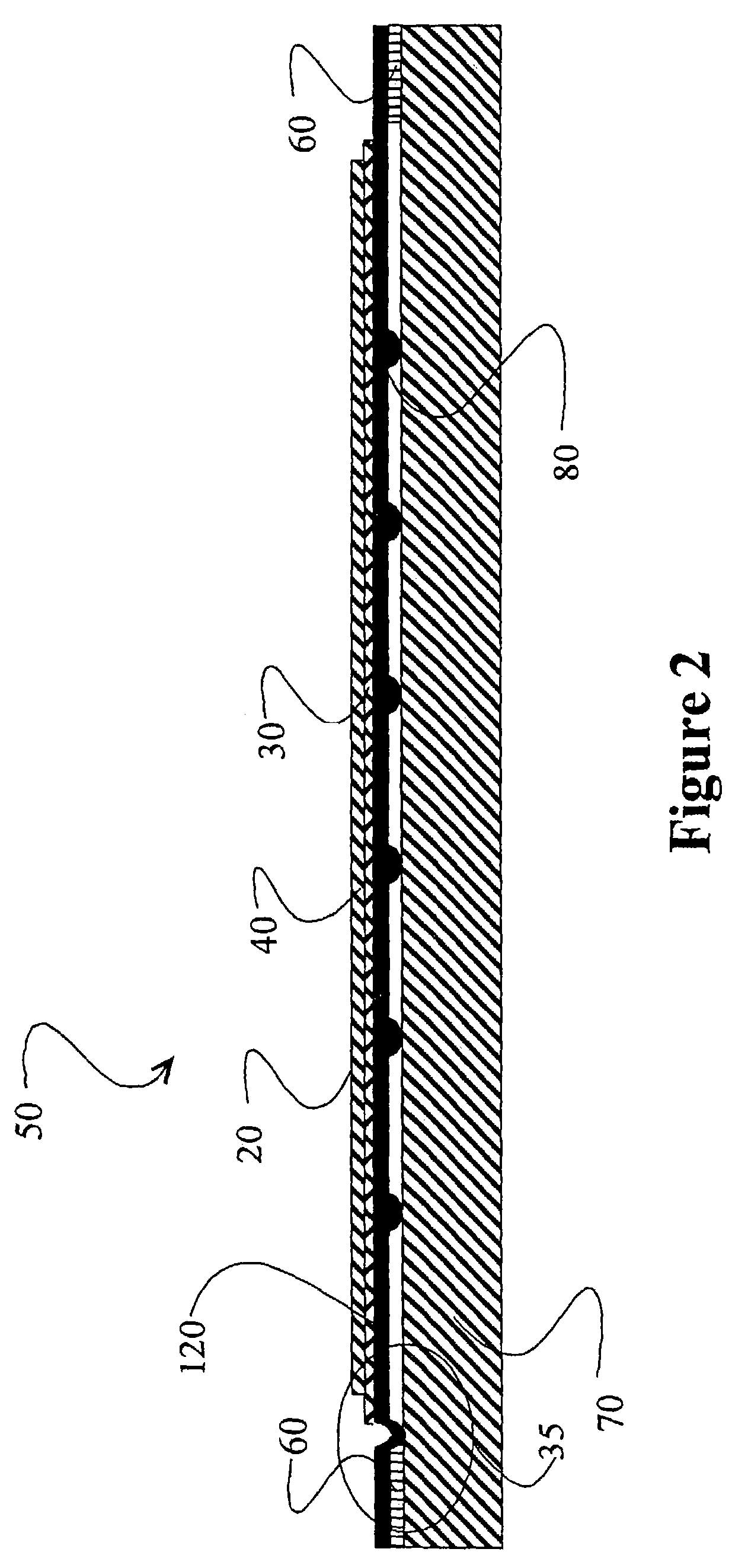

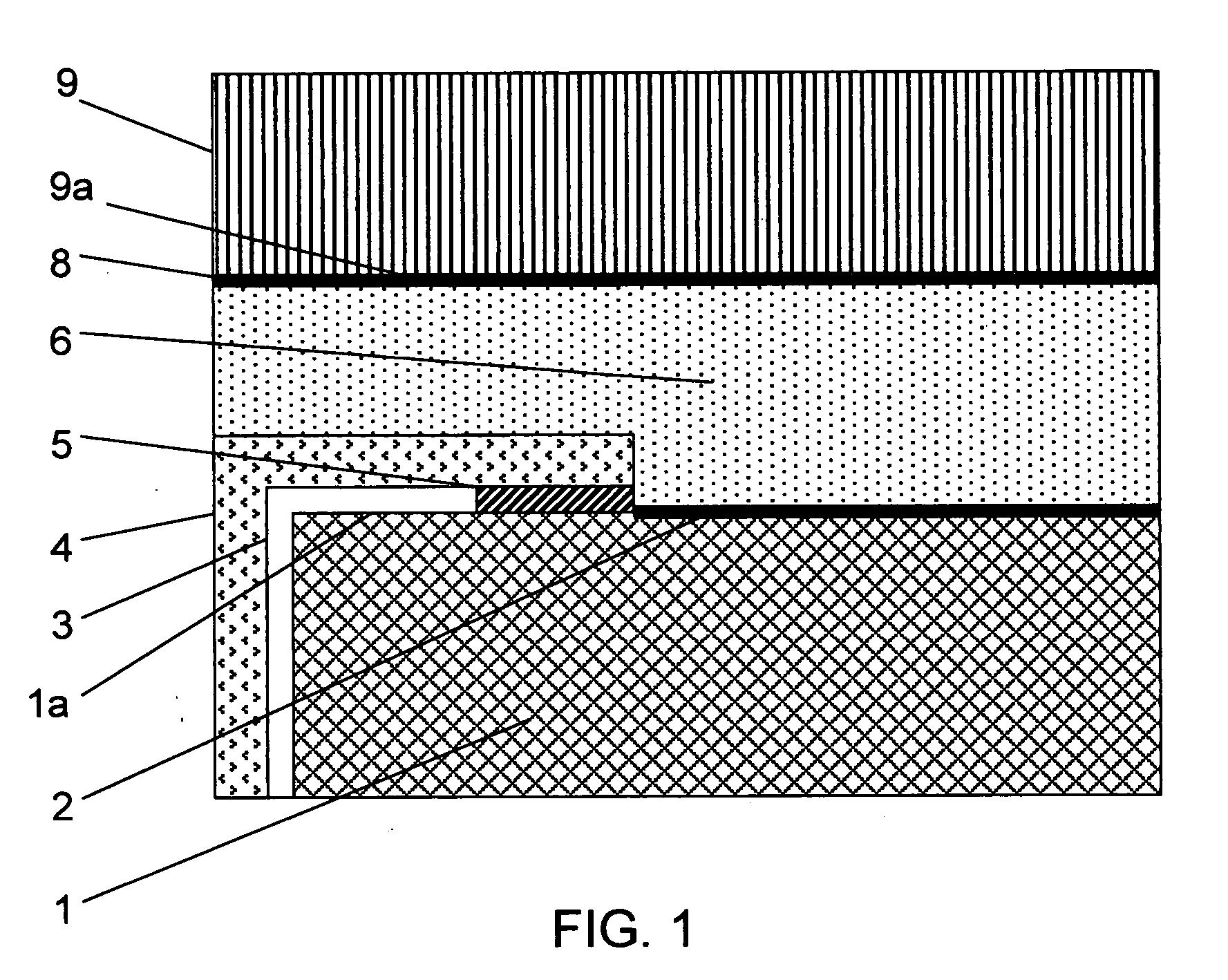

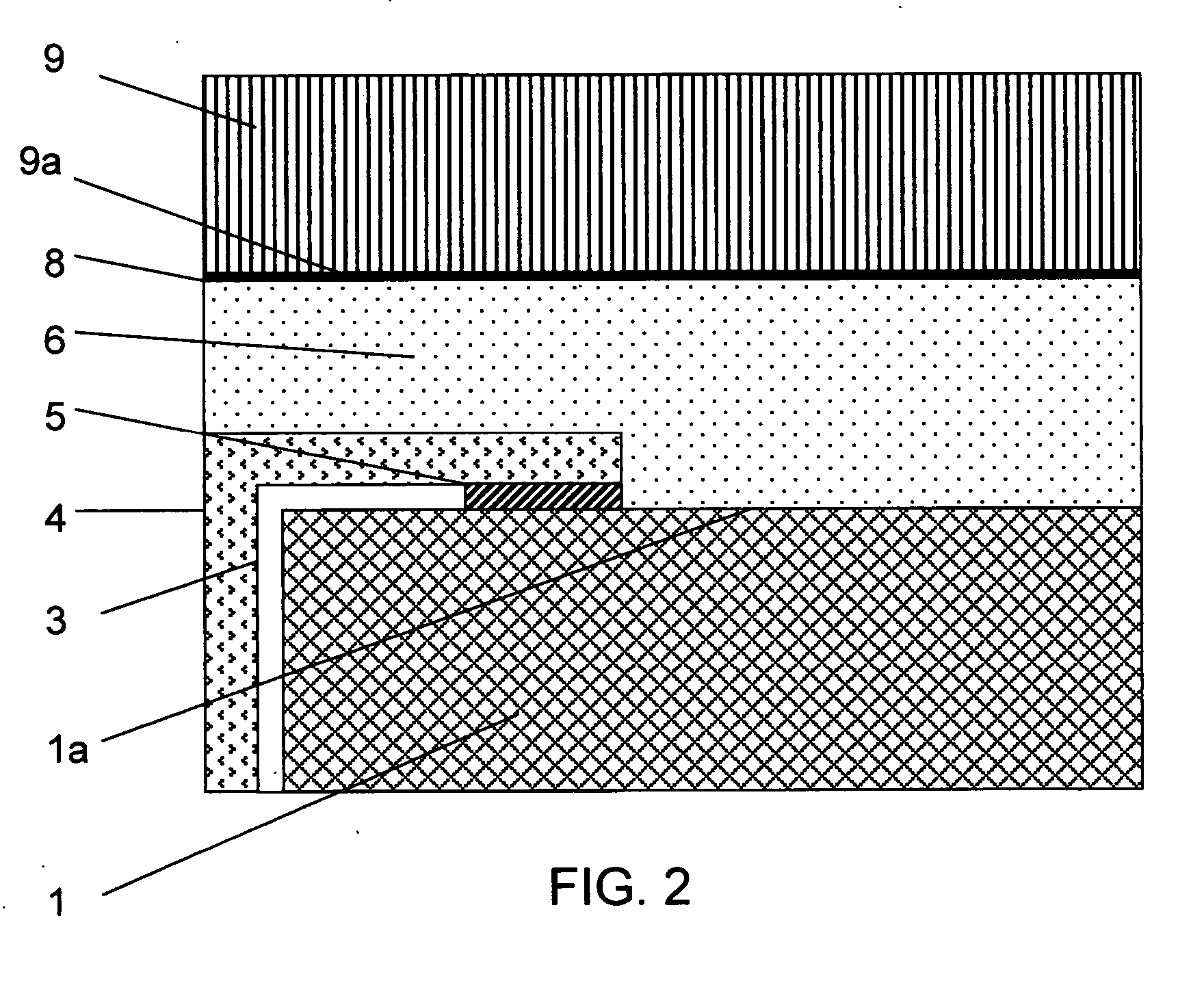

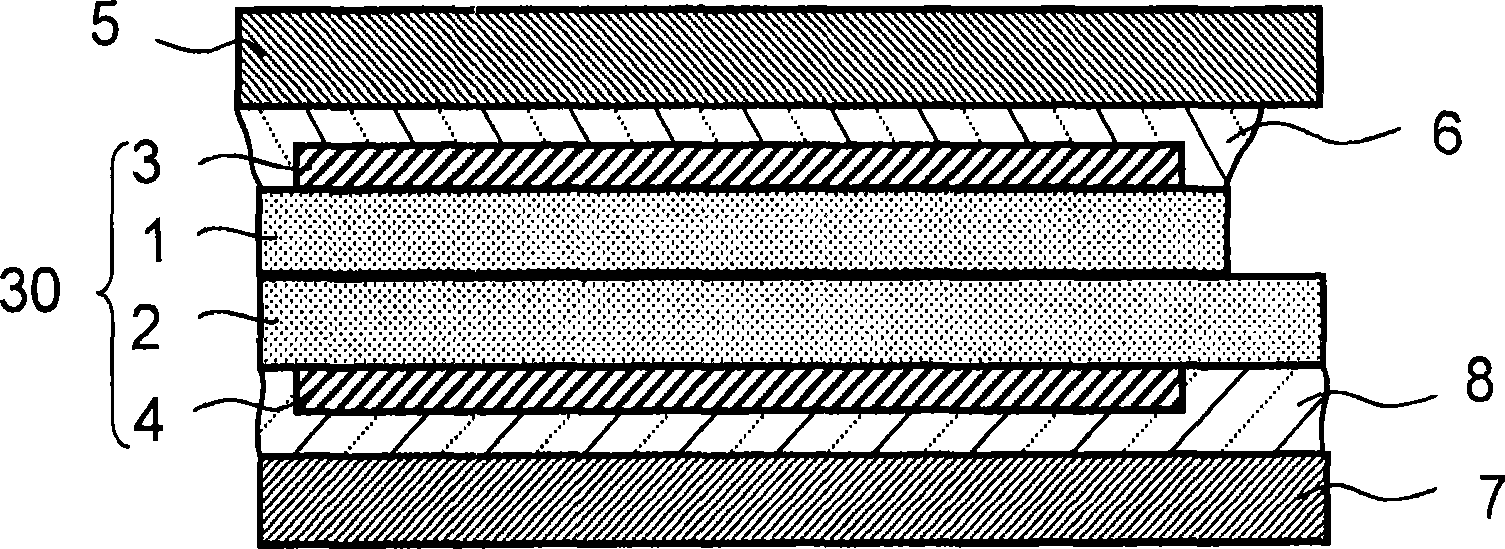

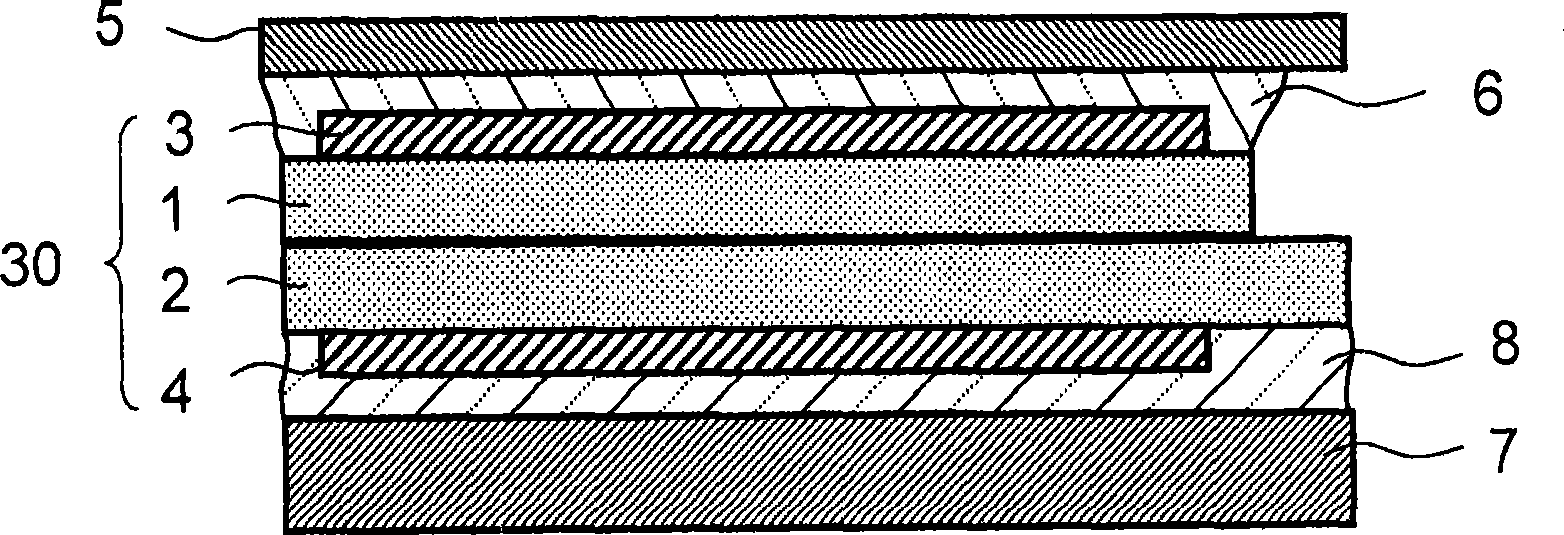

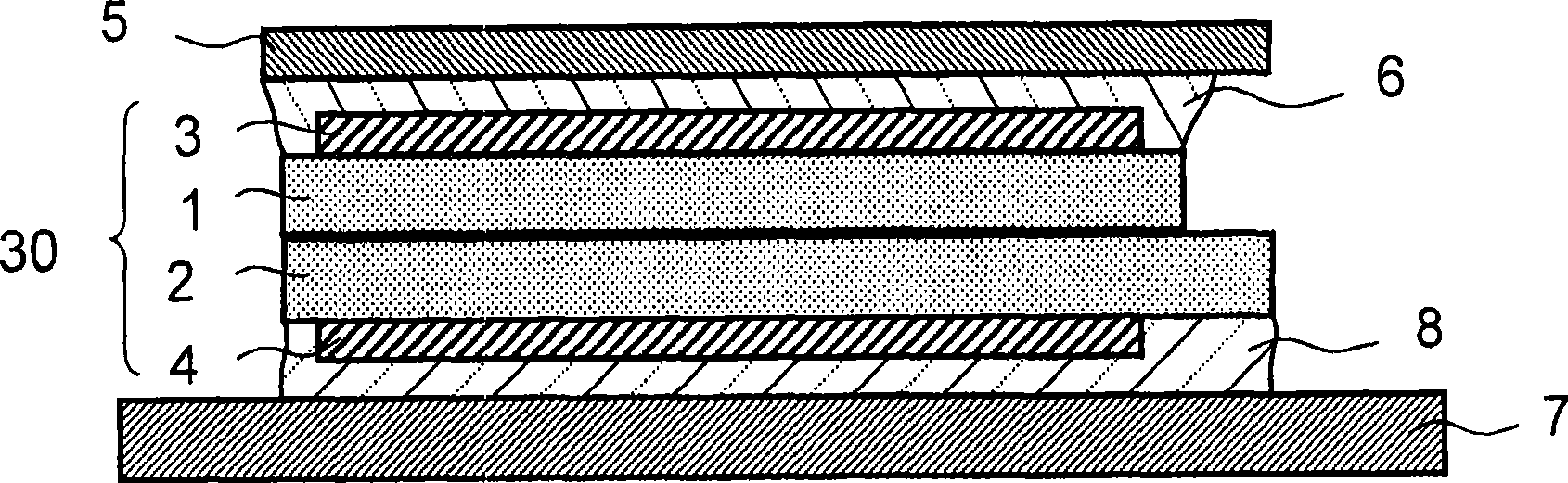

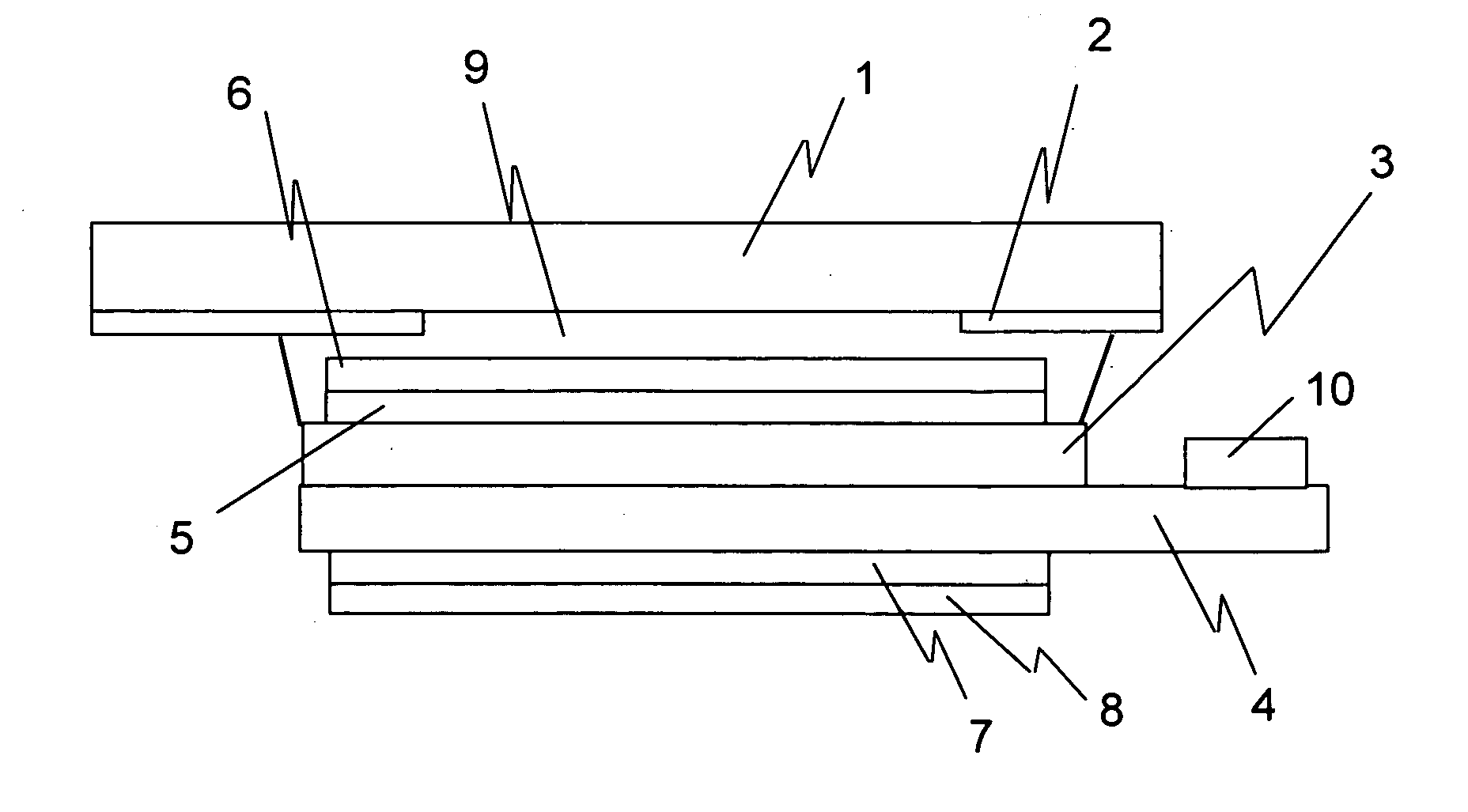

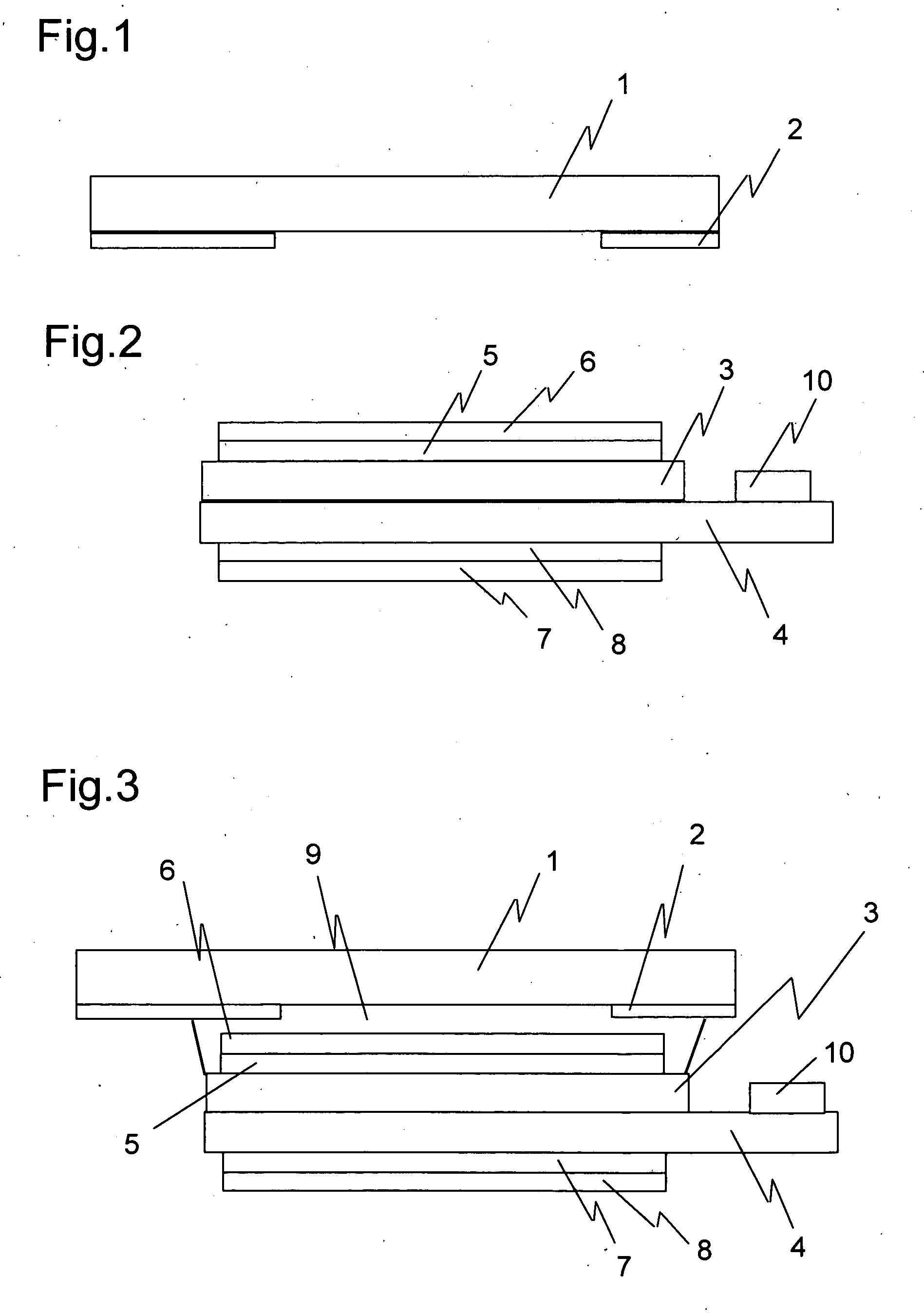

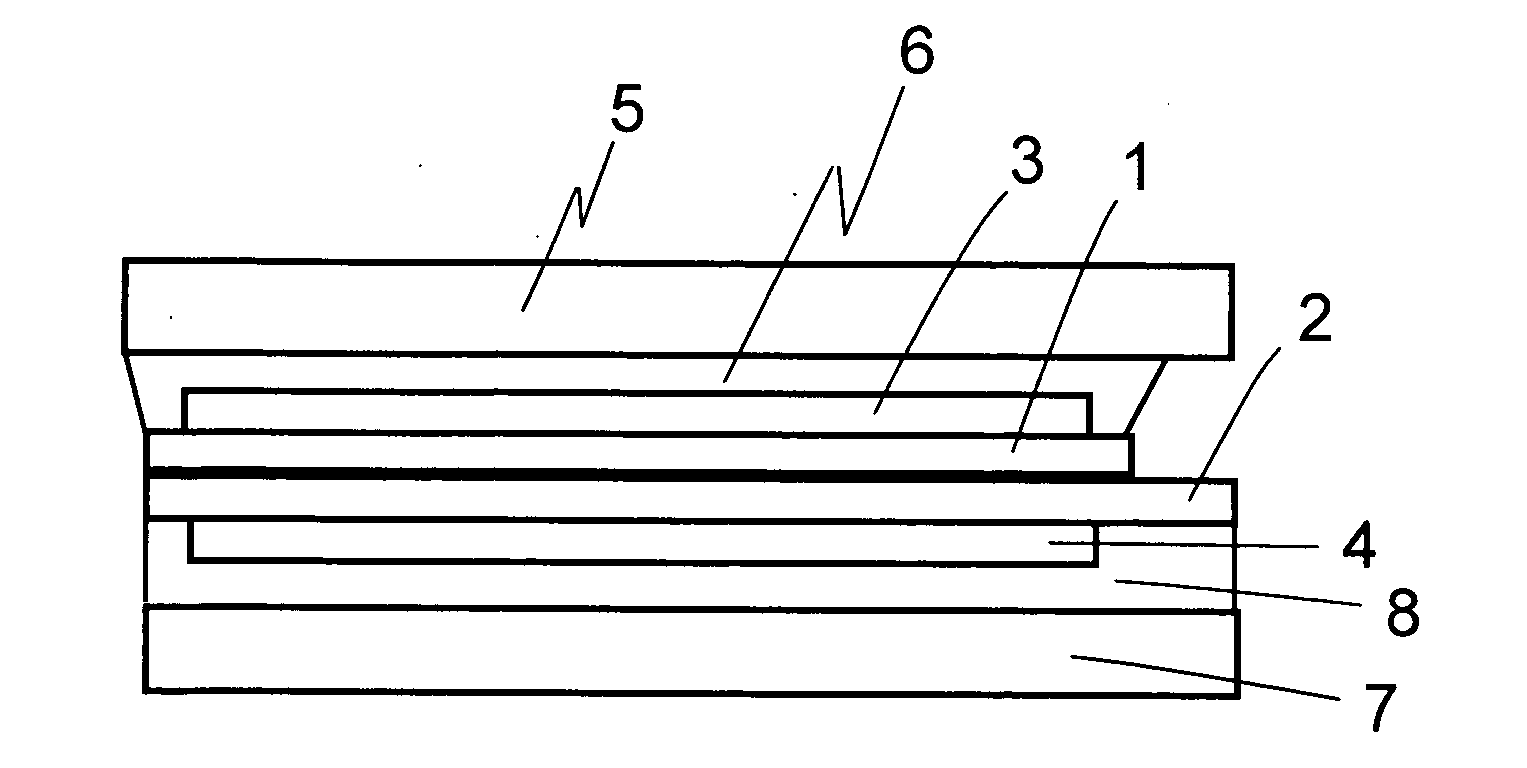

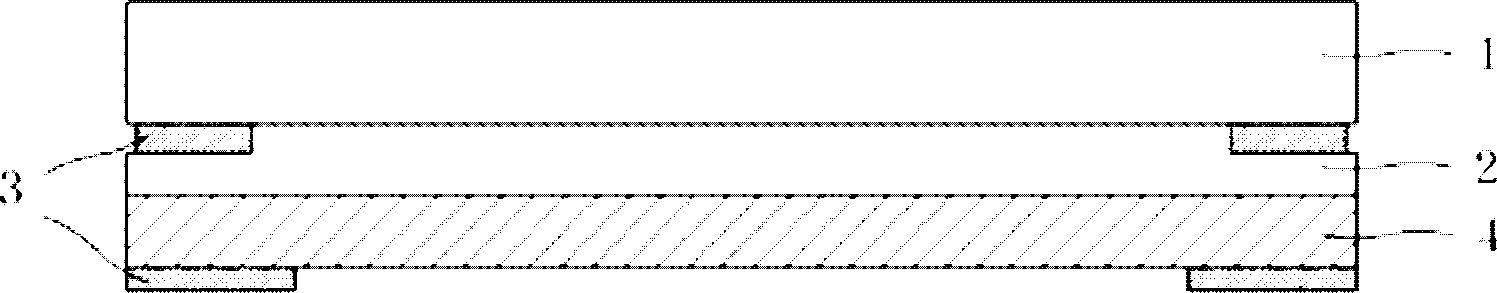

Display device

InactiveCN101523275APrevent prominenceNon-linear opticsIdentification meansOptical bondingLiquid-crystal display

An enforcing glass plate is attached to the entire display region of the display side and the opposite side of a liquid crystal panel (30) so as to improve the applied weight resistance against an external shock or pressure, which enables reduction of the thickness of the liquid crystal panel (30). That is, a display device includes: a liquid crystal panel (30) which sandwich liquid crystal inside two transparent substrates and having an optical film arranged on at least one of the external surfaces of the transparent substrates; a first glass plate bonded to the display surface side of the liquid crystal panel (30) via a first adhesive formed by an optical adhesive or a transparent adhesive sheet; and a second glass bonded to the rear surface side of the liquid crystal panel (30) via a second adhesive formed by an optical adhesive or a transparent adhesive sheet.

Owner:SEIKO INSTR INC

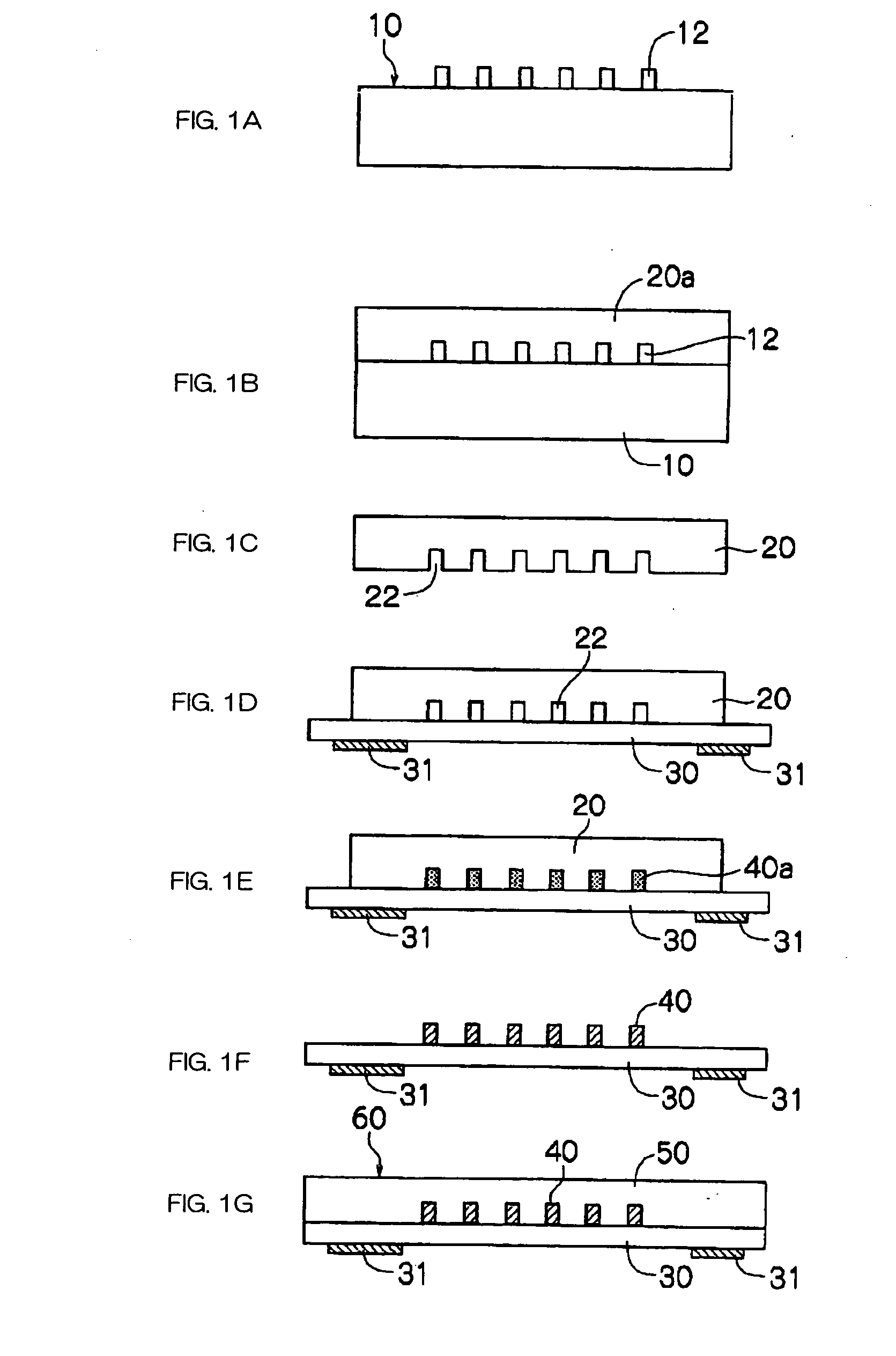

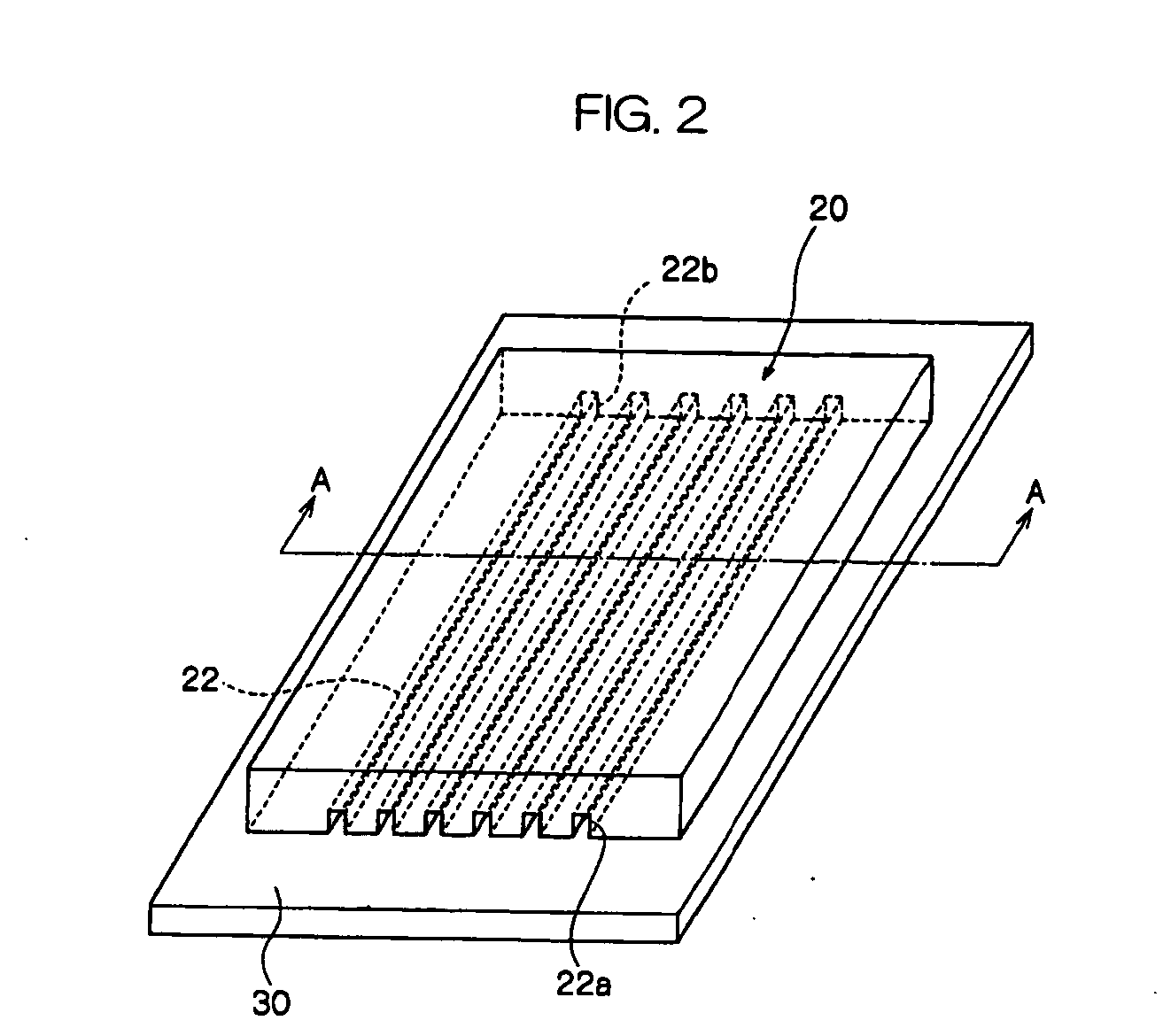

Display Apparatus and Method of Manufacturing a Display Apparatus

InactiveUS20090162645A1Less unevenness in displayed imageNo peelingLamination ancillary operationsLaminationOptical bondingLiquid-crystal display

A display apparatus is provided in which a transparent cover plate or a touch panel is bonded to a liquid crystal display device in a full-surface contact manner and which is free from unevenness in displayed colors and peeling. The transparent cover plate or touch panel and the liquid crystal display device are bonded with an optical adhesive, which is set to a Shore A hardness of 1 or more to 30 or less. The thickness of the adhesive layer is set to 30 to 200 μm.

Owner:SEIKO INSTR INC

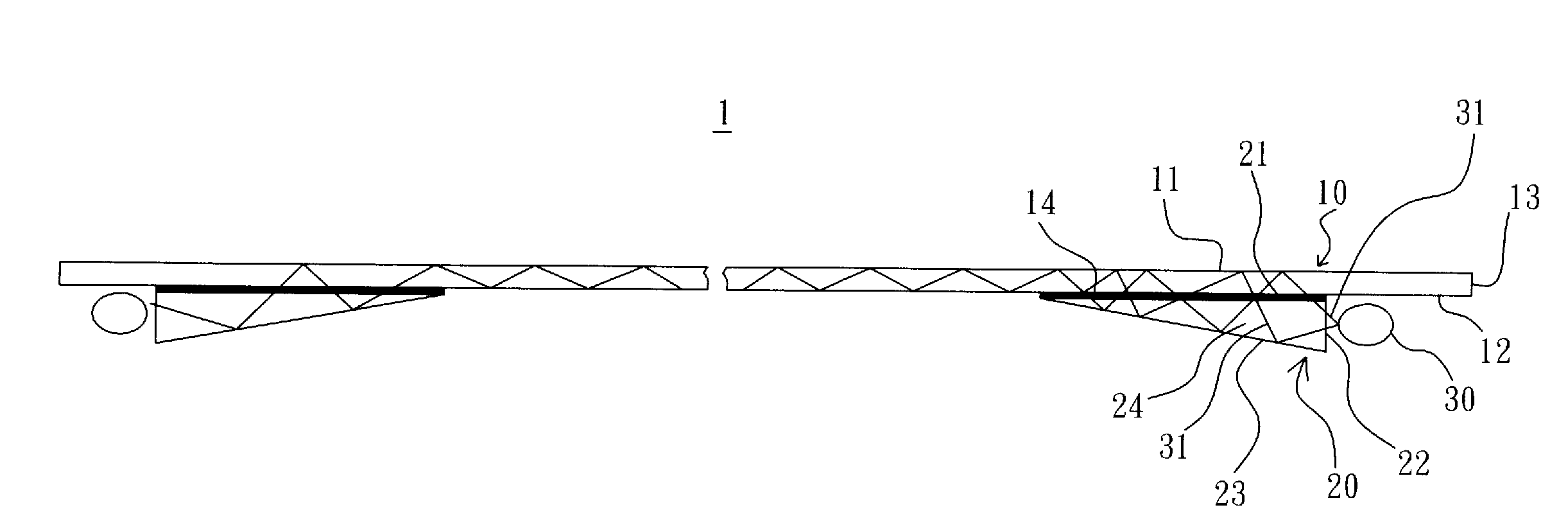

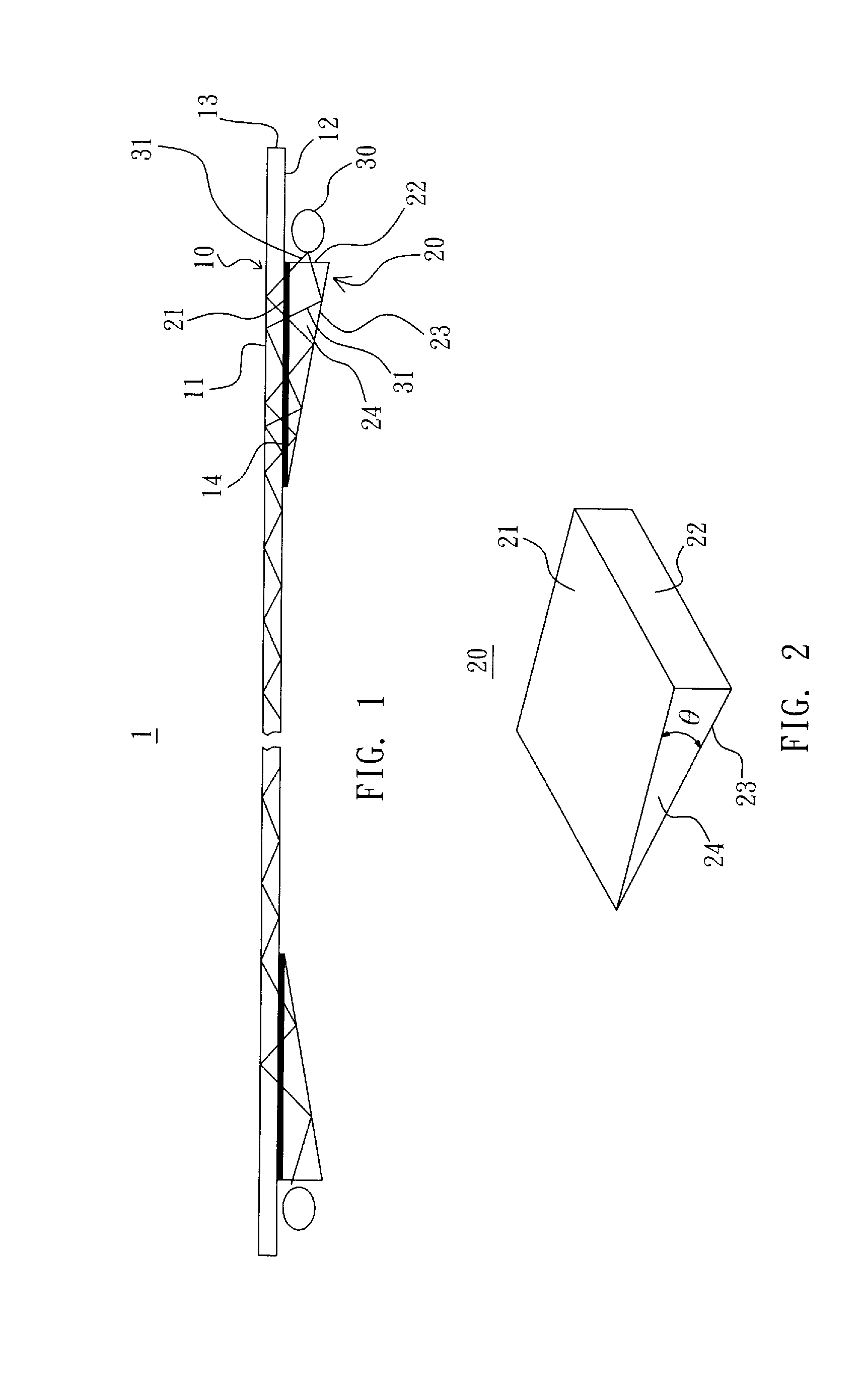

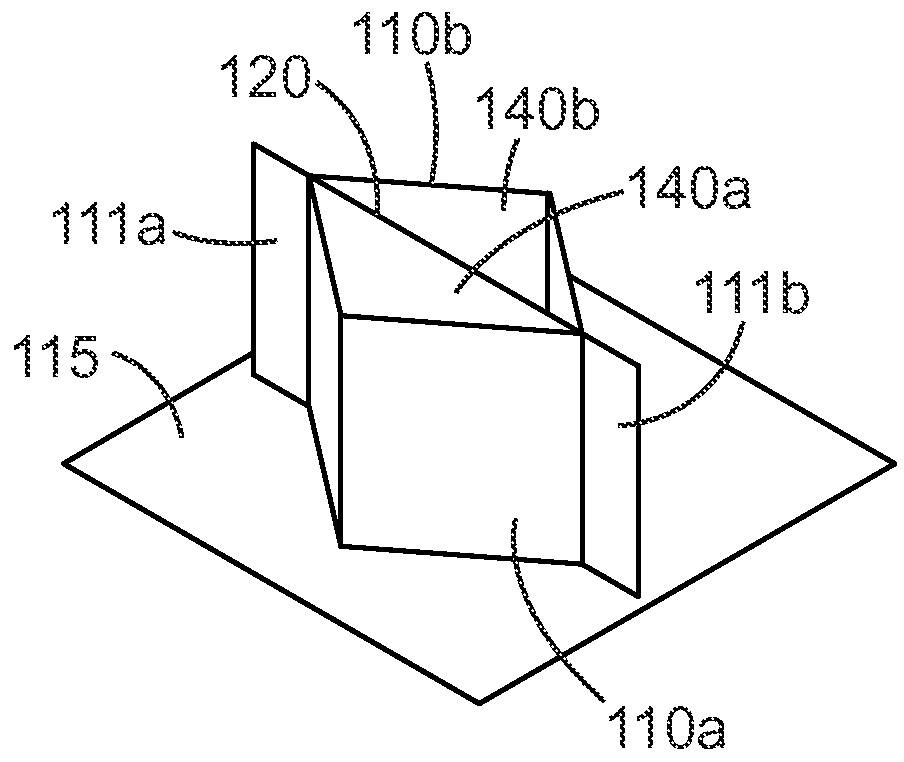

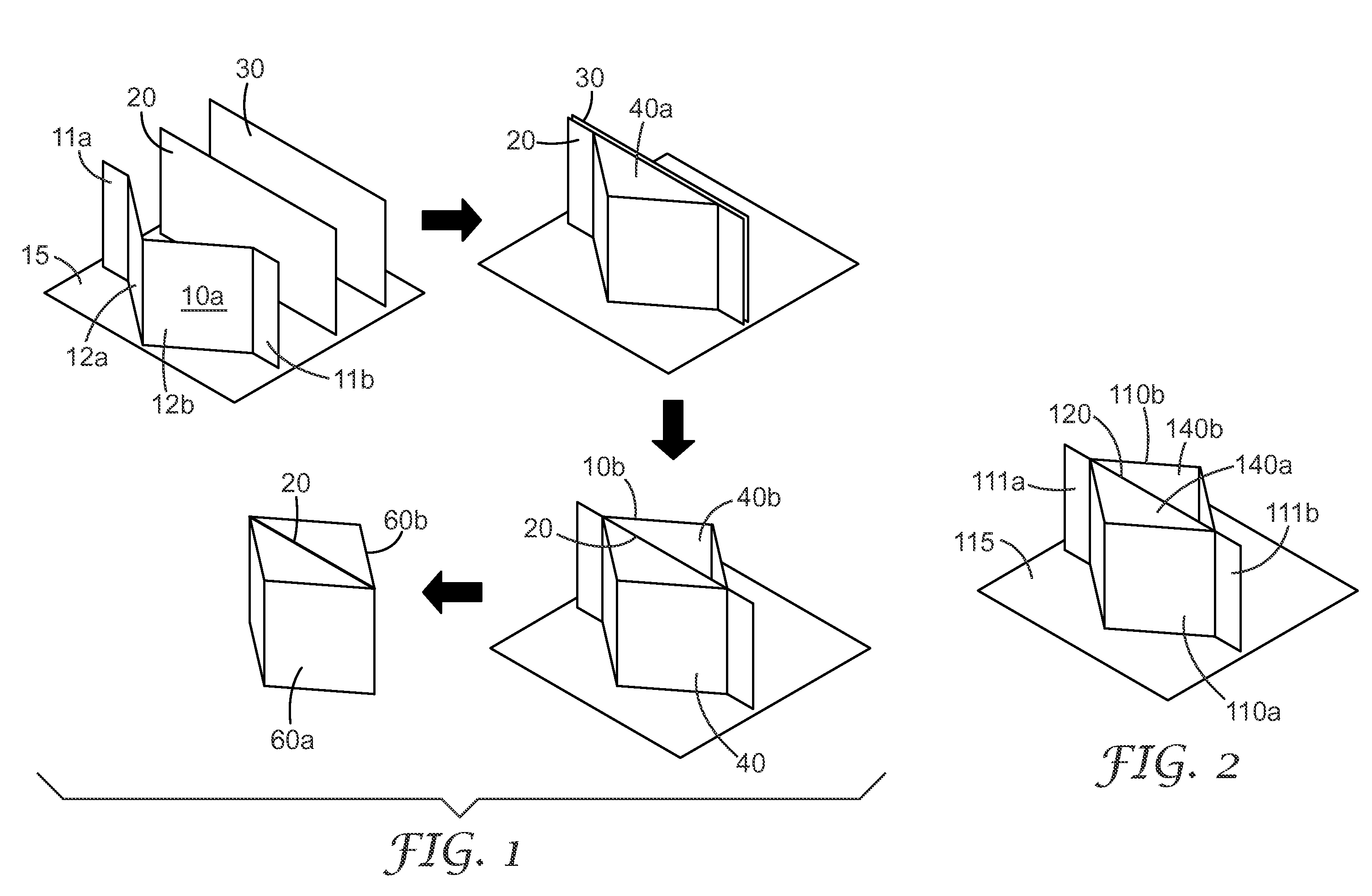

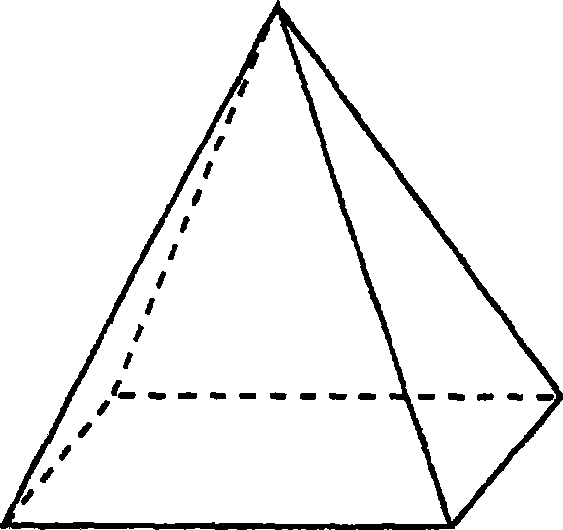

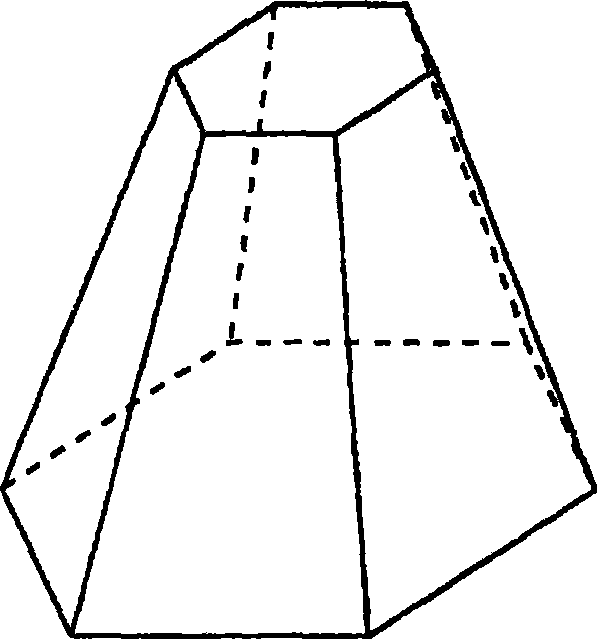

Structure for guiding light into guide light plate to conduct total internal reflection

InactiveUS20150009687A1Low efficiencyReduce thicknessMechanical apparatusLighting device detailsOptical bondingTotal internal reflection

A structure for guiding light into a light guide plate to conduct total internal reflection comprises a guide light plate and a prism; the prism is integrated with the guide light plate or joined to the guide light plate with an optical adhesive layer; the horizontal surface of the prism is parallel to the upper and lower surfaces of the guide light plate; the maximum angle between the horizontal surface and the slant surface of the prism is only 20 degrees to reduce the thickness of the prism greatly to meet requirements of lightness, thinness, shortness, and smallness for the electronic product; due to a special configuration of the prism and a special arrangement between the guide light plate and the prism, the most part of the light shot to the prism by the light source with any projecting angle is guided into the guide light plate to propagate the total internal reflection such that the light has an intensity capable of being sensed.

Owner:ERA OPTOELECTRONICS

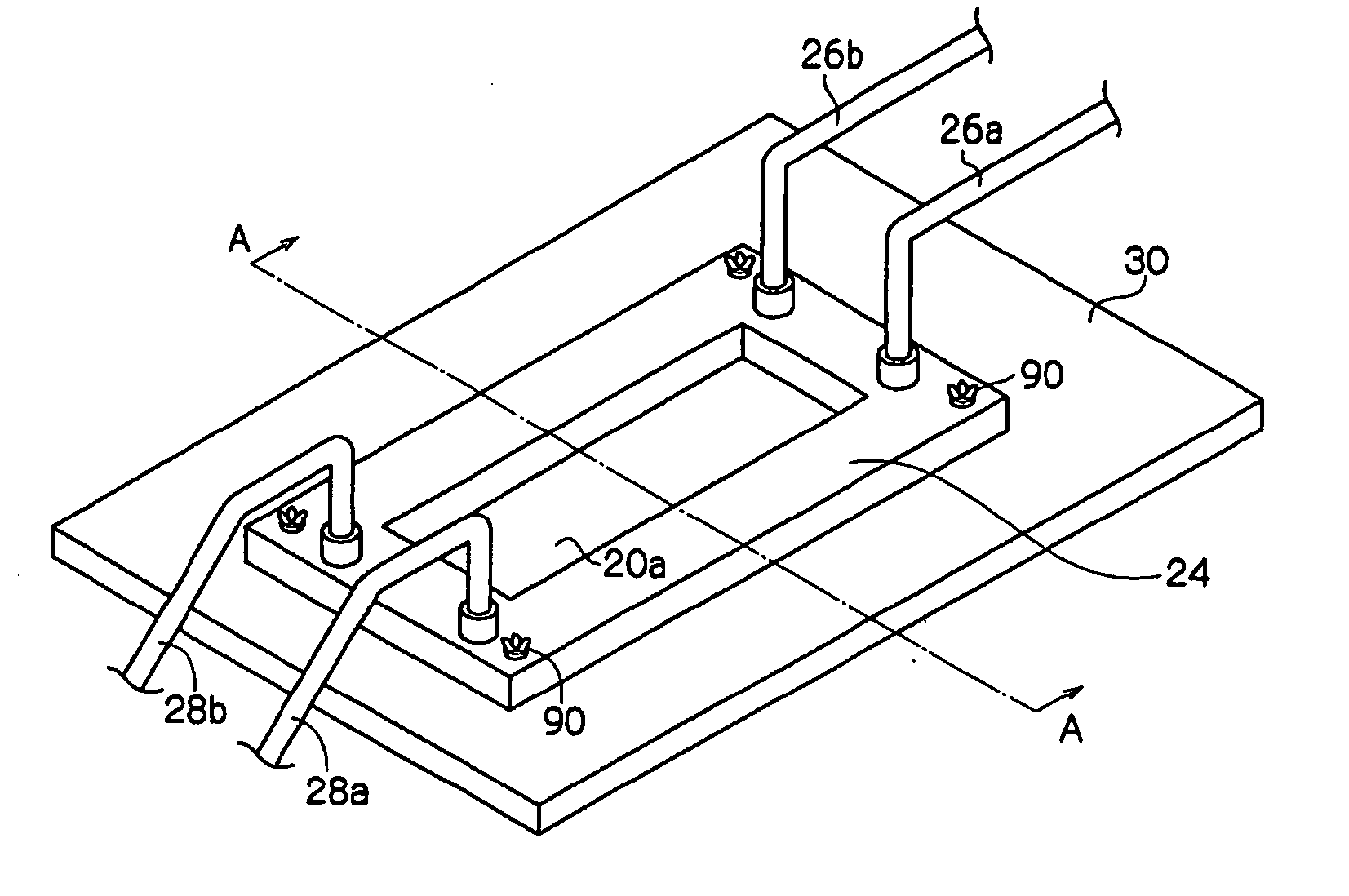

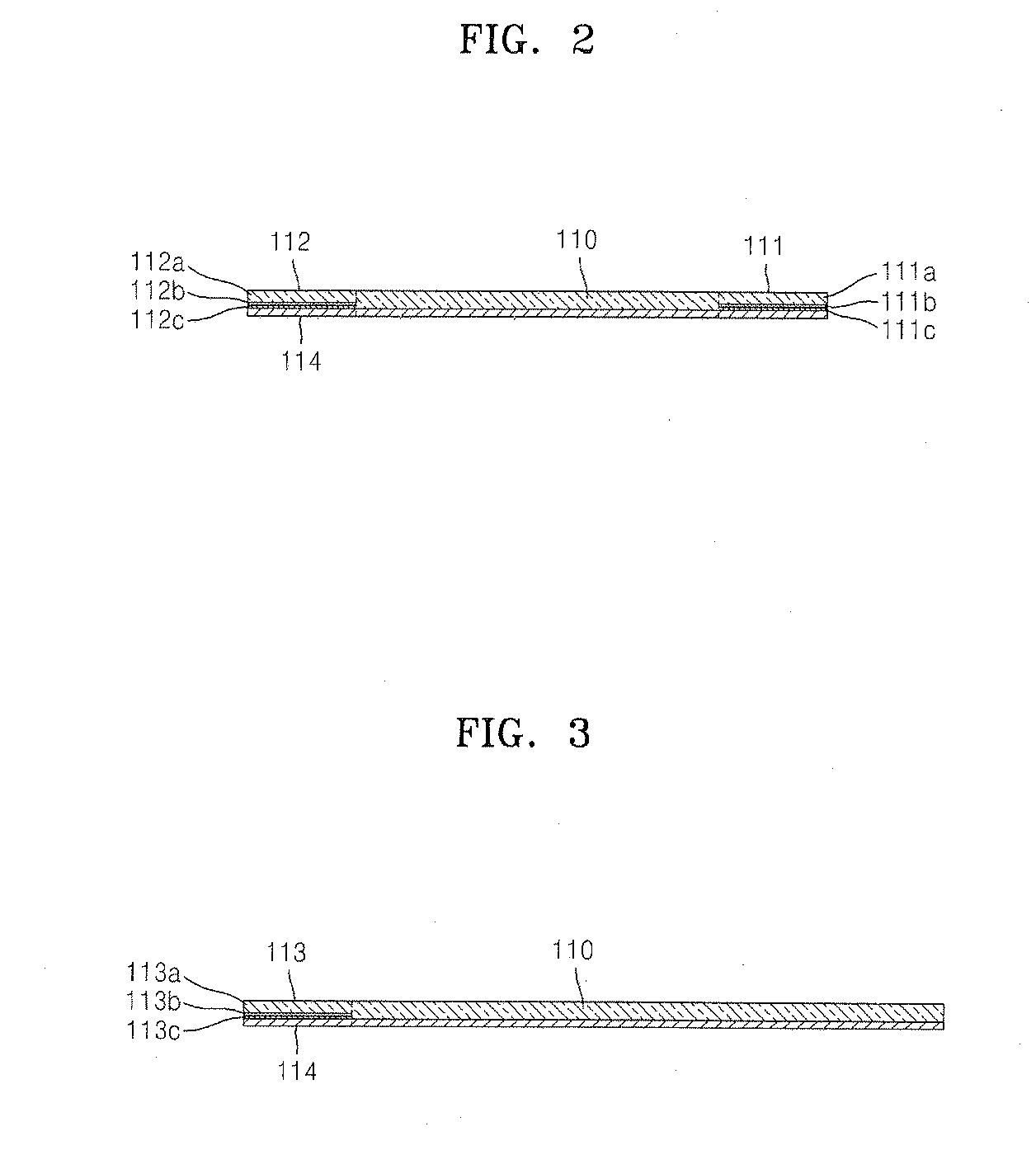

Method for fabricating polymer optical waveguide device

InactiveUS20060091571A1Easy to manufactureReduce light lossOptical articlesOptical waveguide light guideOptical bondingPolymer optical waveguide

The present invention provides a method for fabricating a polymer optical waveguide device, the method at least includes: preparing a mold including a cured resin layer of a mold forming curing resin and having a concave portion correspondent to a core portion of an optical waveguide formed therein; attaching the mold to a cladding base material; filling the concave portion of the mold with a core forming curing resin; hardening the core forming curing resin to form a cured core portion; forming a space or a groove for placing an optical device in a middle part in the waveguide direction of the core portion such that the optical device cuts across the core portion; inserting and positioning the optical device in a predetermined position of the space or groove; and conducting an optical bonding between an optical pathway portion of the optical device and the core portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

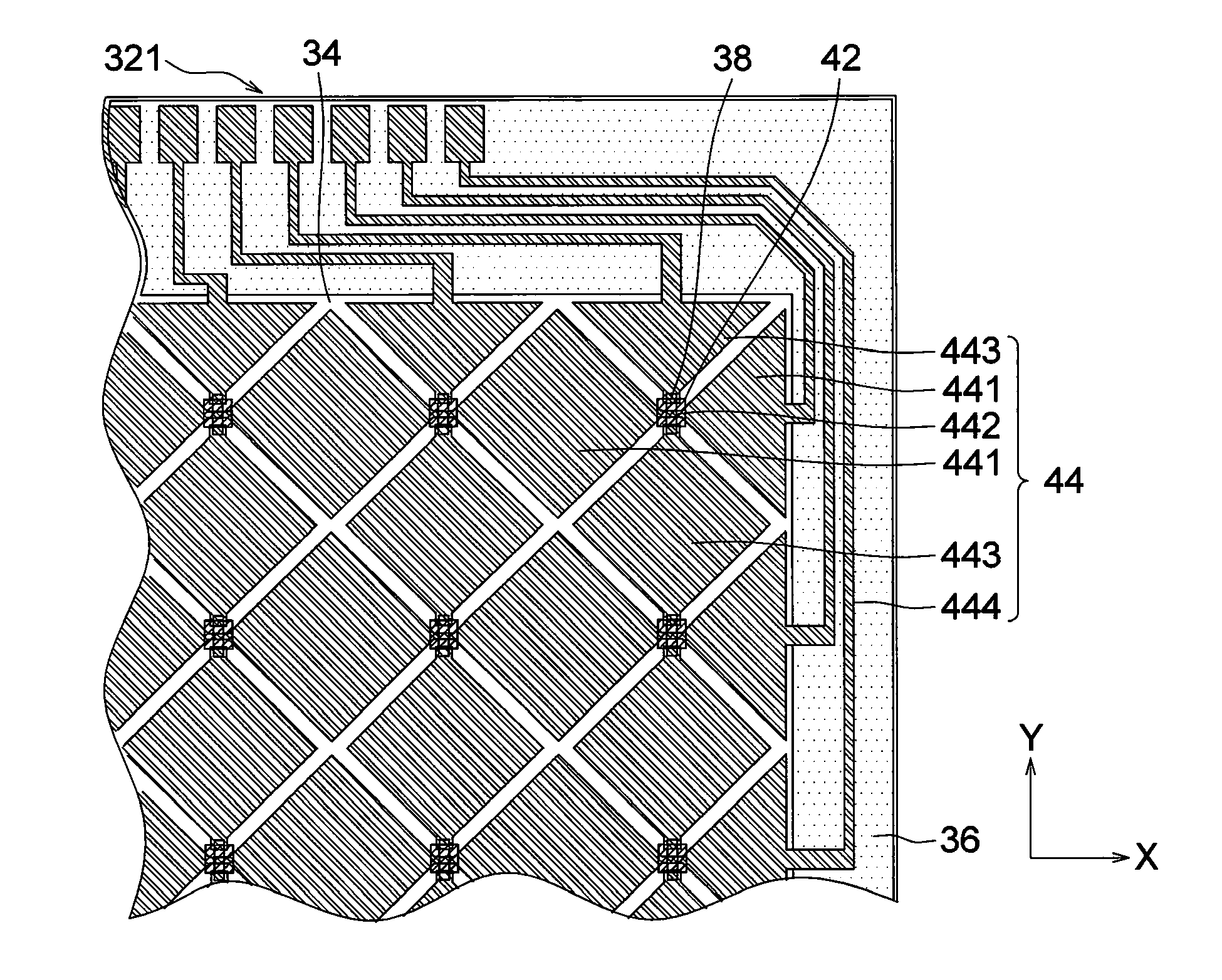

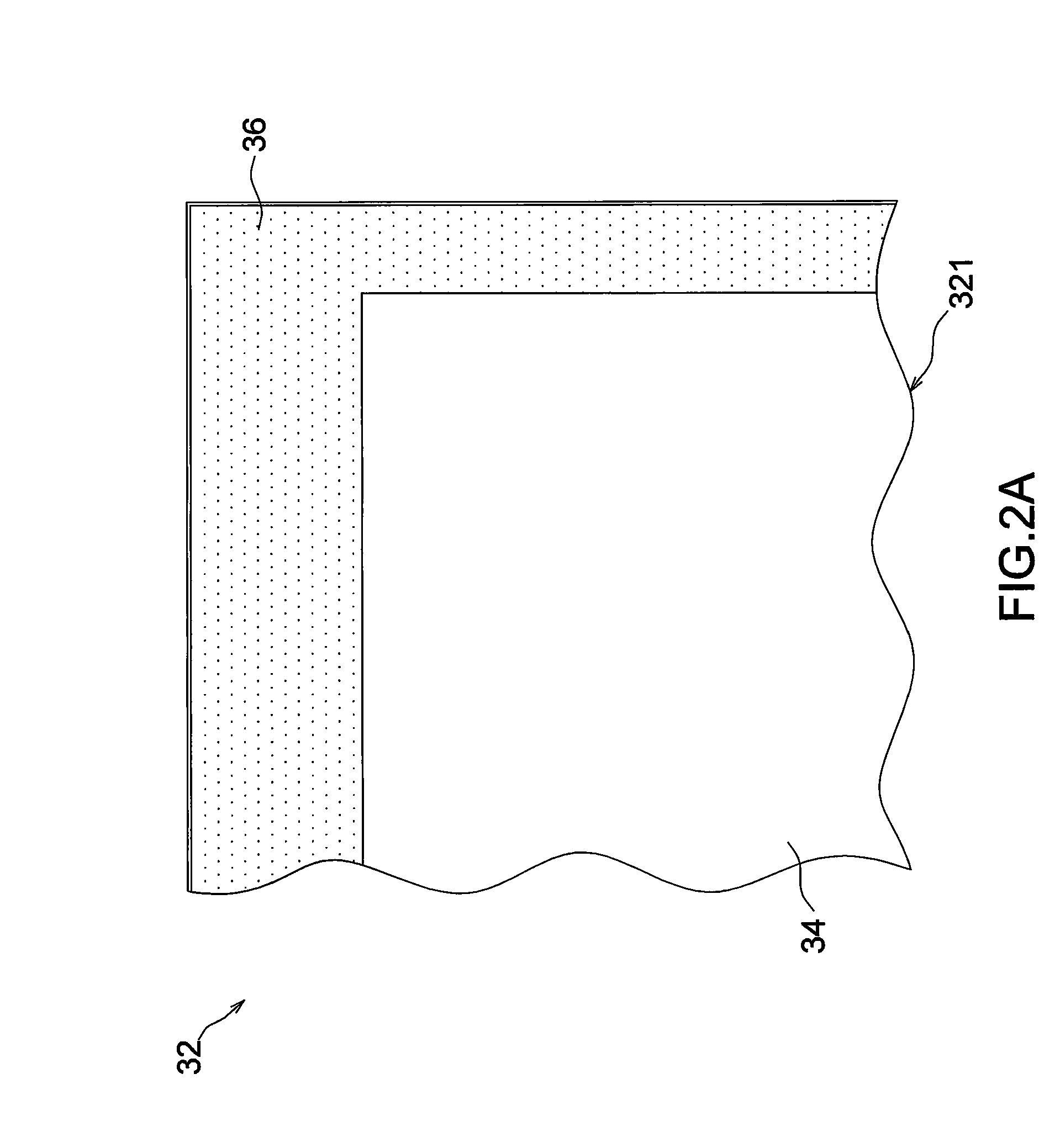

Thin touch panel

ActiveUS20110007005A1Reduce material consumptionHigh transparencyNon-linear opticsInput/output processes for data processingManufacturing cost reductionOptical bonding

A thin touch panel includes a transparent substrate with a black bordering around the inner surface of the transparent substrate. A plurality of metal connecting structures, metal guiding lines, transparent insulating structures and a transparent sensing layer are formed on the inner surface, so that the transparent substrate not only provides a touch surface, but also has the touch sensing ability, to decrease the manufacture material and increase the transmittance of the touch panel. Besides, the manufacture of the thin touch panel may not use any optical adhesive to decrease the manufacture cost and improve the yield. Further, the thin touch panel may satisfy the trend of thin design.

Owner:BUWON PRECISION SCI

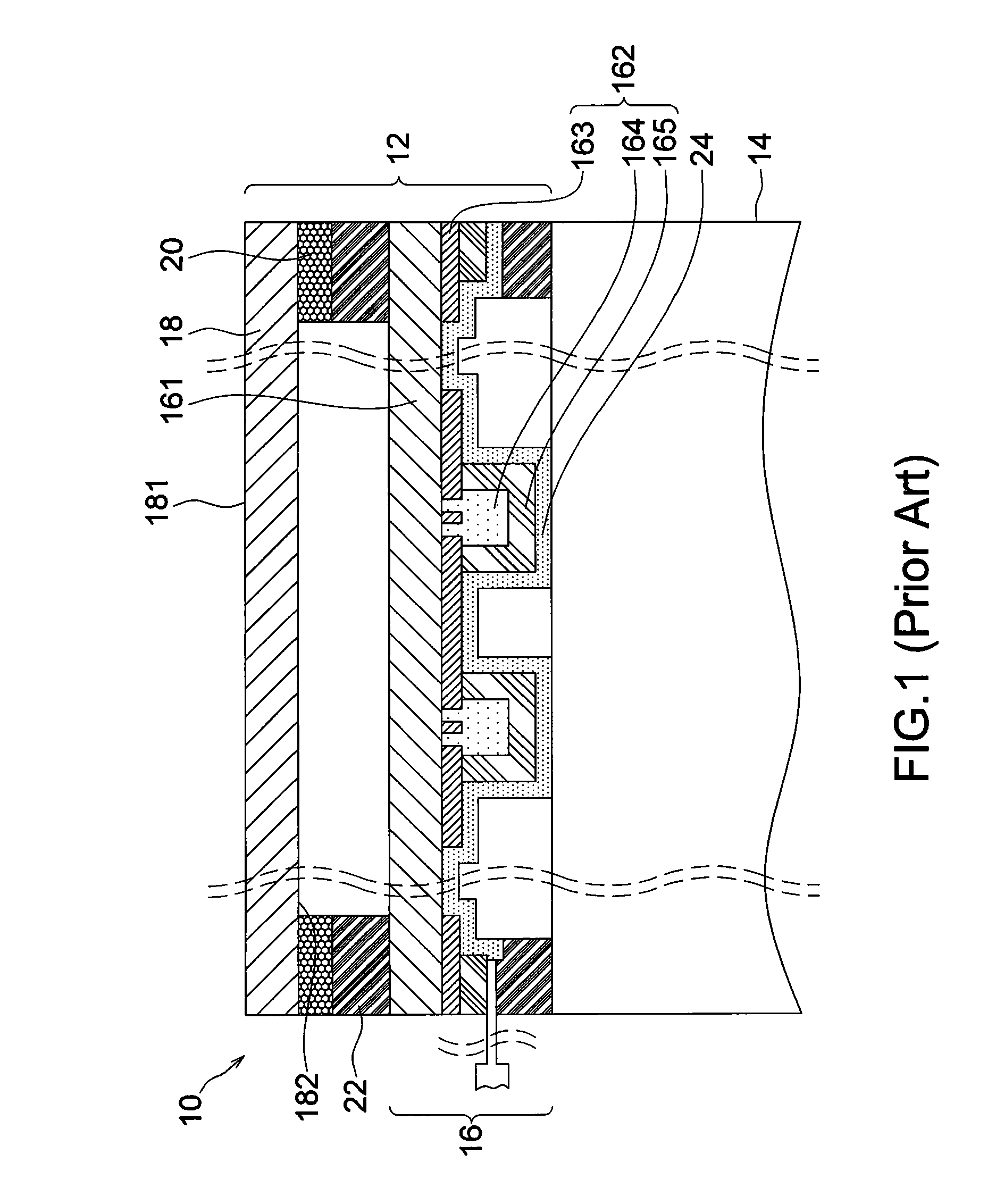

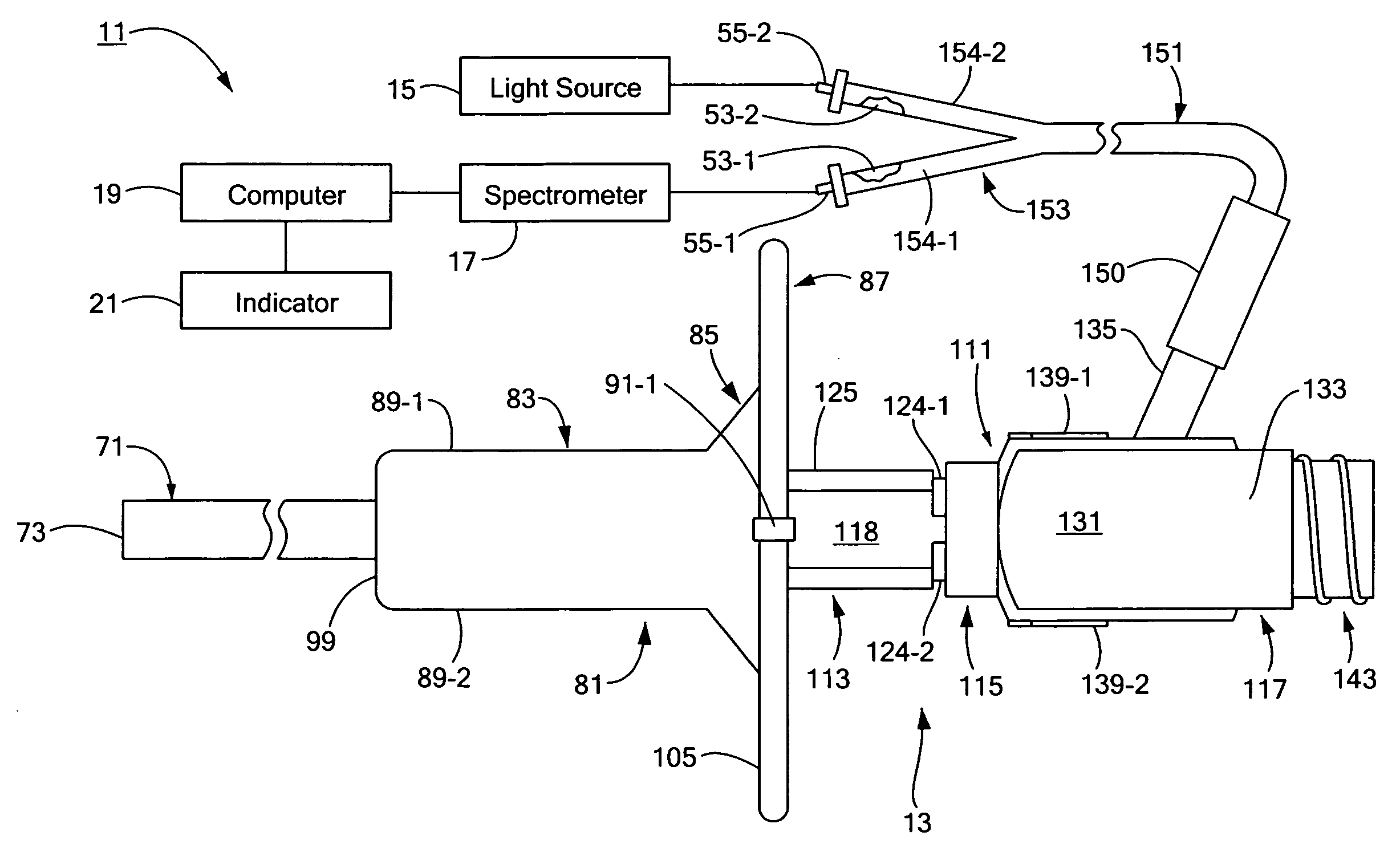

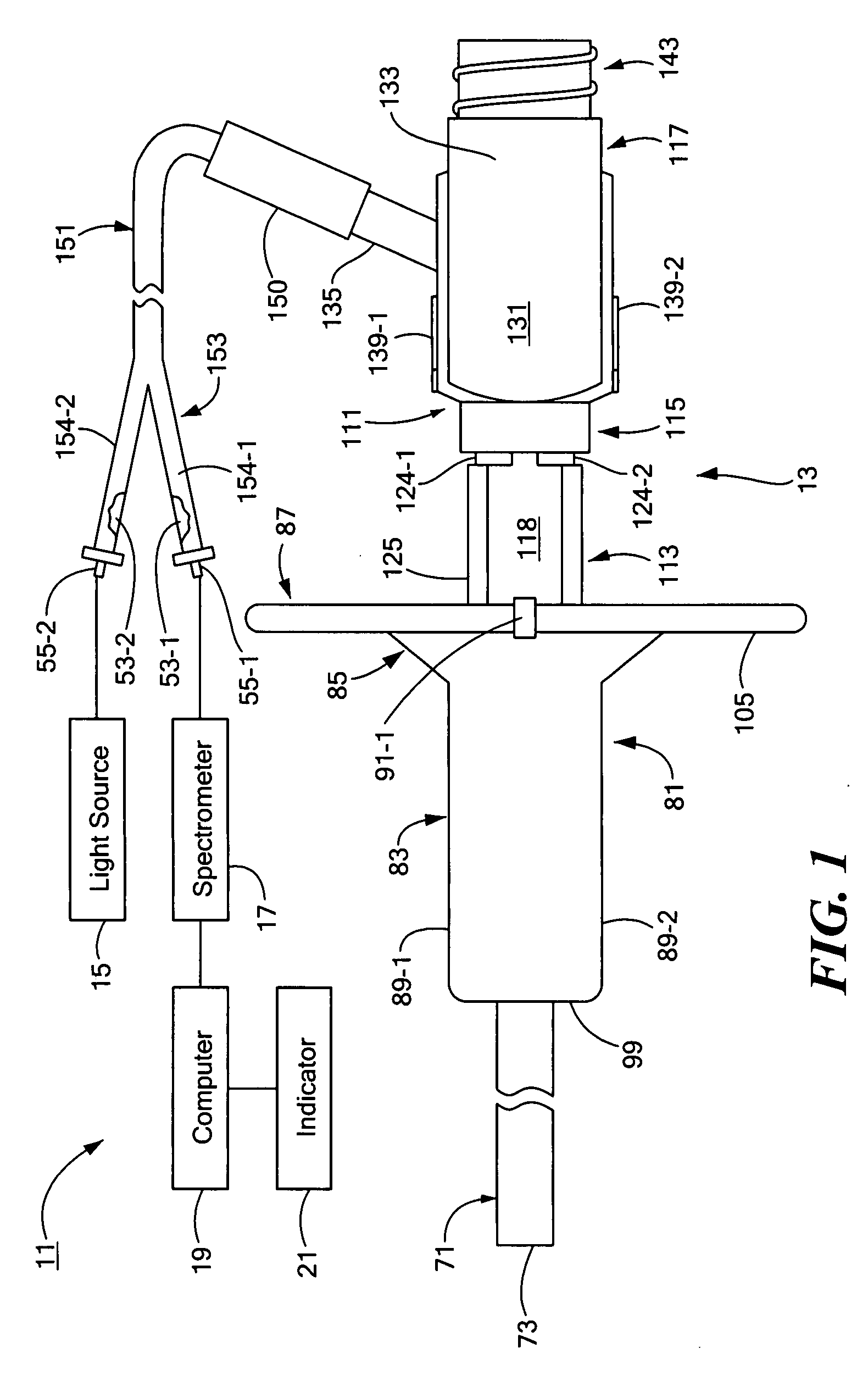

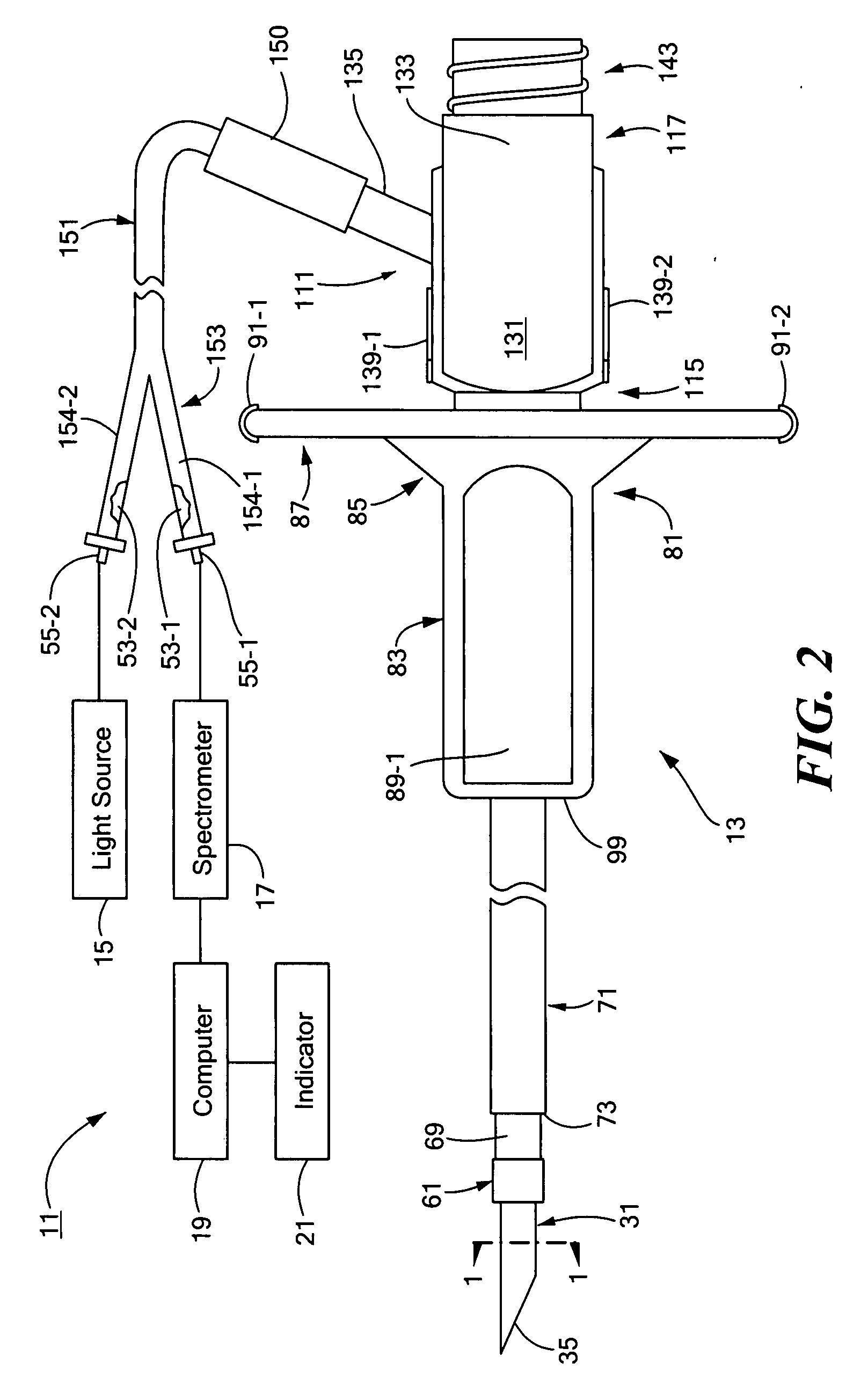

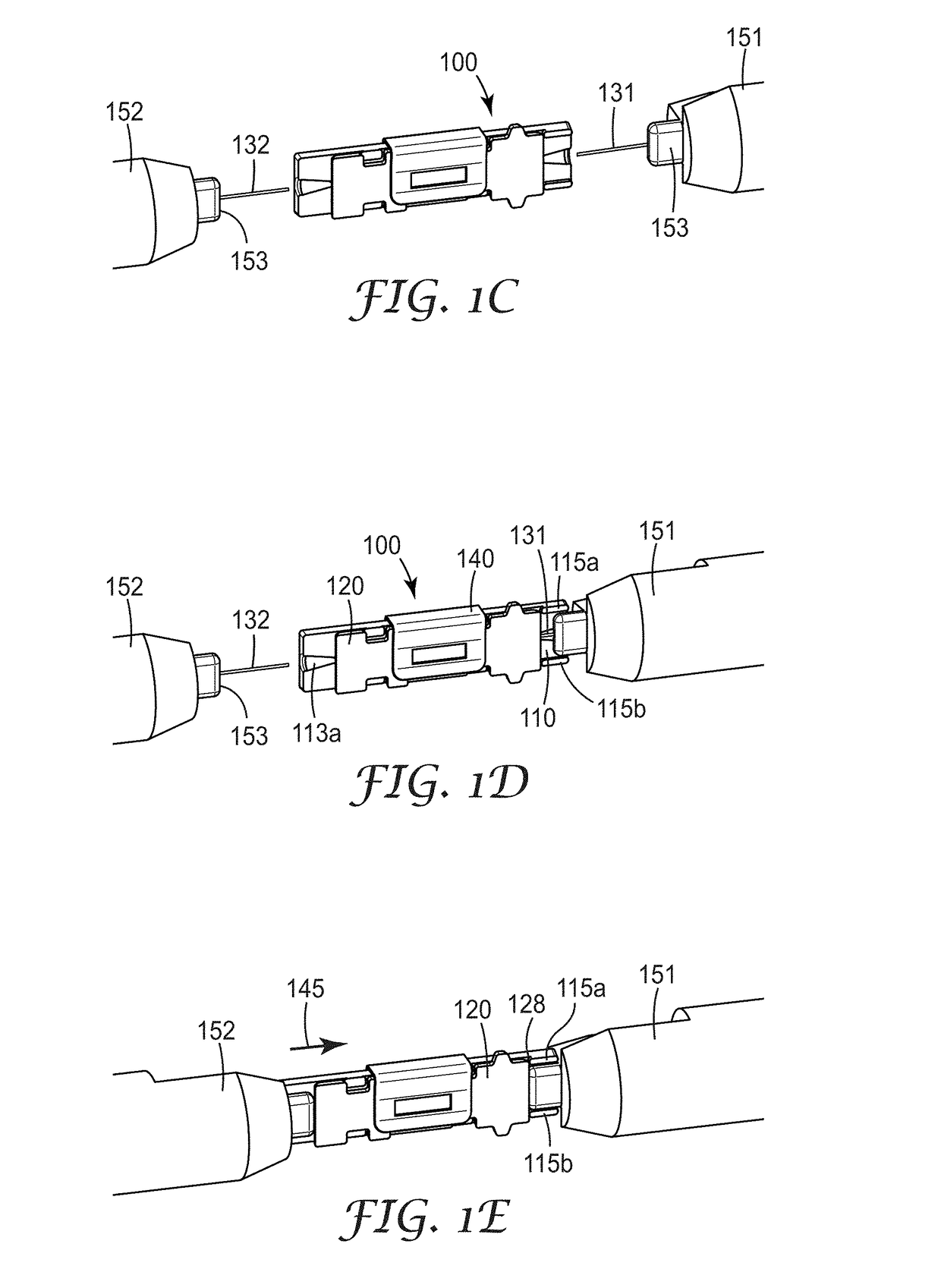

Optical spectroscopic injection needle

An optical spectroscopic injection needle assembly. According to one embodiment, the assembly may include an injection needle, a light source, a spectrometer, a computer and an indicator. The injection needle, in turn, may include a hollow outer needle, a hollow inner needle, a pair of optical fibers, an inner catheter, an outer catheter, an inner hub and an outer hub. The proximal end of the outer needle may be fixedly mounted within the distal end of the inner catheter. The distal end of the inner hub may be fixedly mounted on the proximal end of the inner catheter, the proximal end of the inner hub being suited for connection to a syringe. The inner needle, as well as the distal ends of the optical fibers, may be positioned within the outer needle and may be held in place by an optical bonding material. The proximal ends of the optical fibers may extend from a side arm of the inner hub, one fiber may be coupled to the light source, the other fiber may be coupled to the spectrometer. The inner catheter and the outer needle may be slidably mounted within the outer catheter to permit the outer needle to be selectively extended or retracted from the distal end of the outer catheter. The outer hub may be fixedly mounted on the proximal end of the outer catheter. In use, as the outer needle may be inserted into a tissue, the tissue may be illuminated and the reflected light may be detected and compared to standards for various tissue types. The results of the comparison may then be indicated.

Owner:BOSTON SCI SCIMED INC

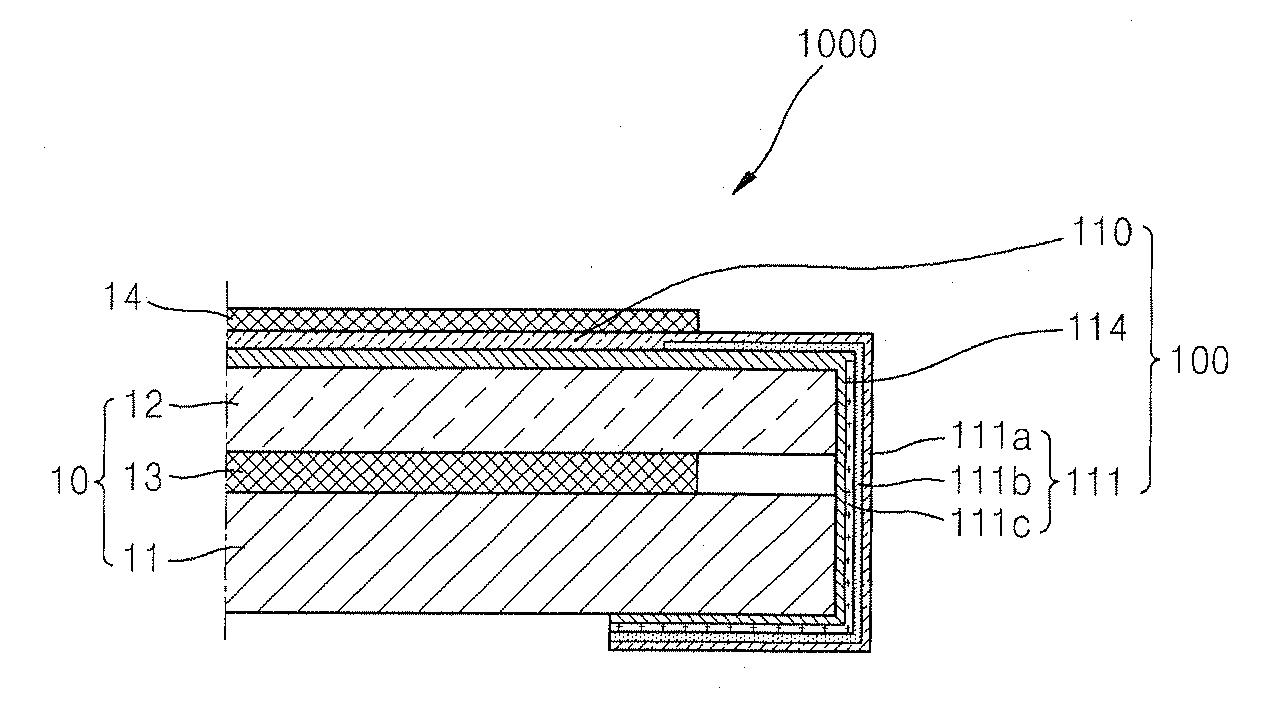

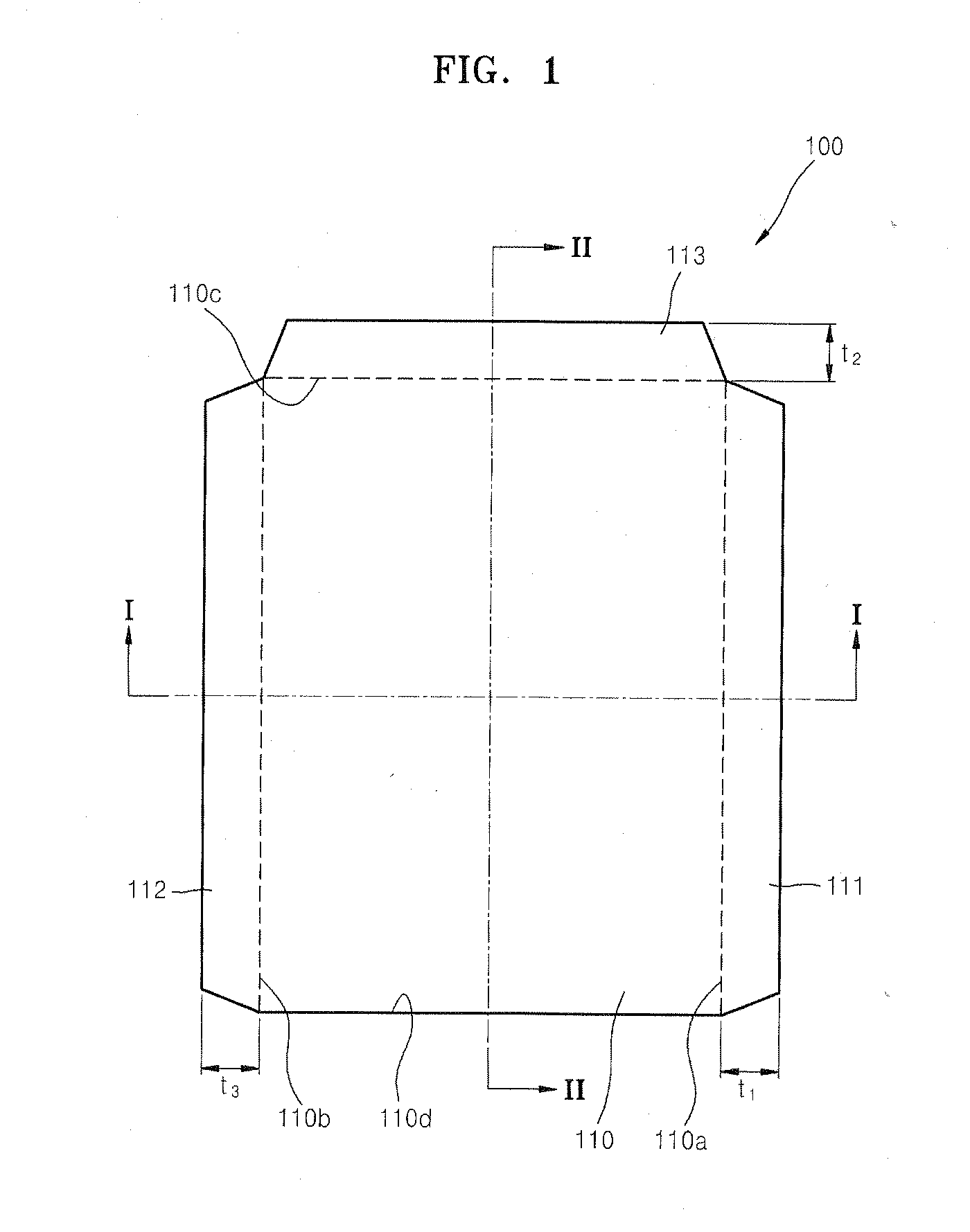

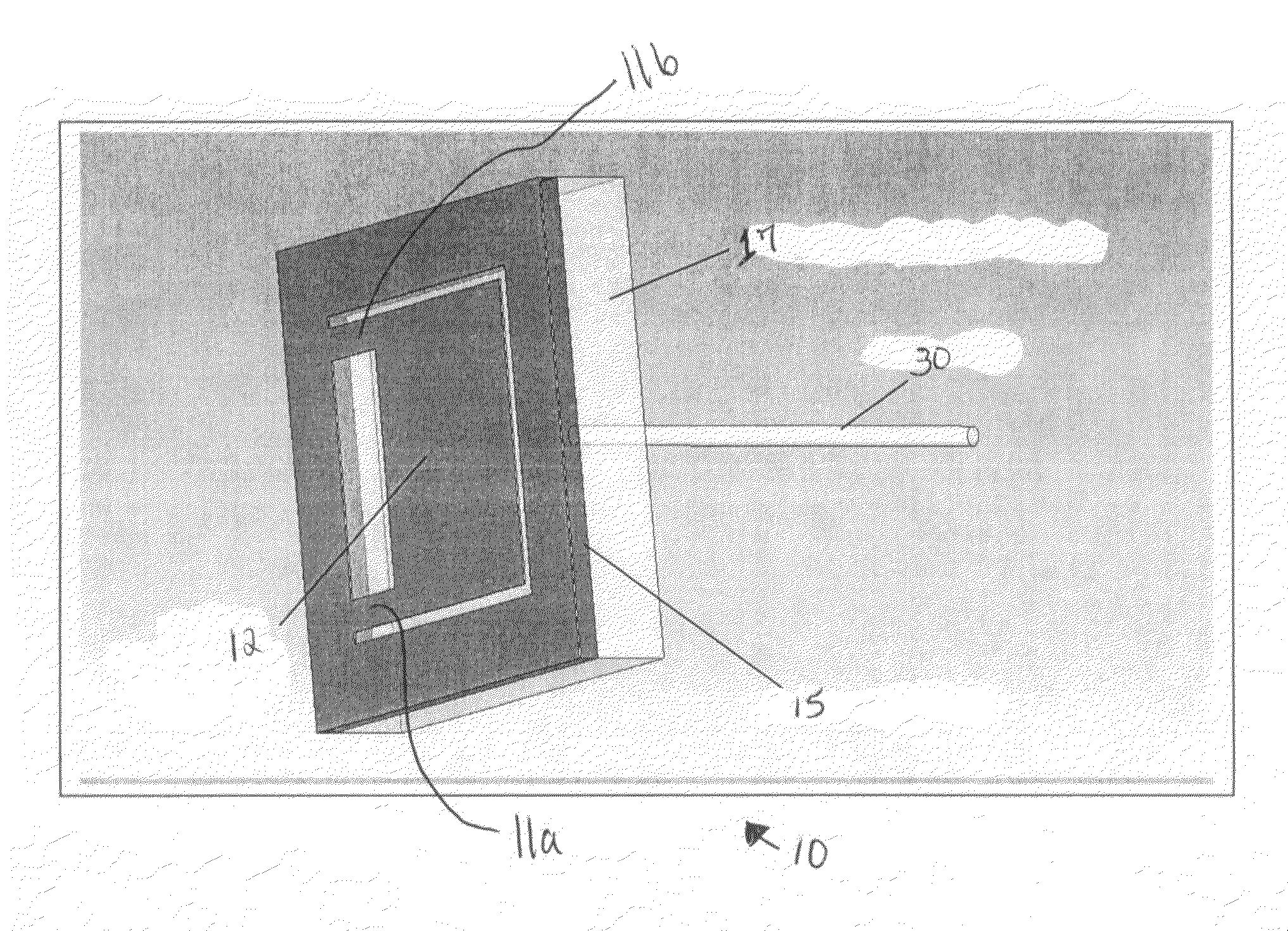

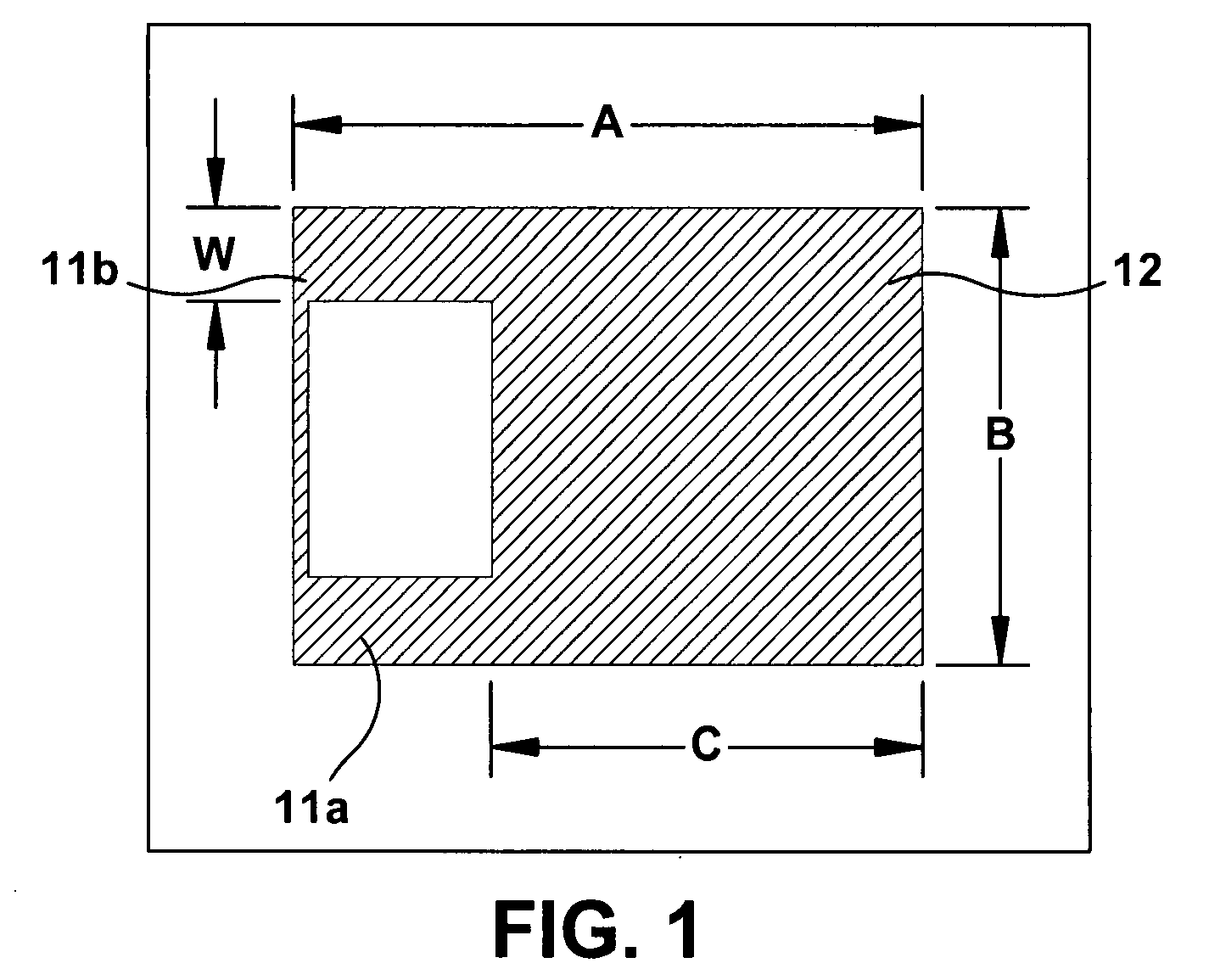

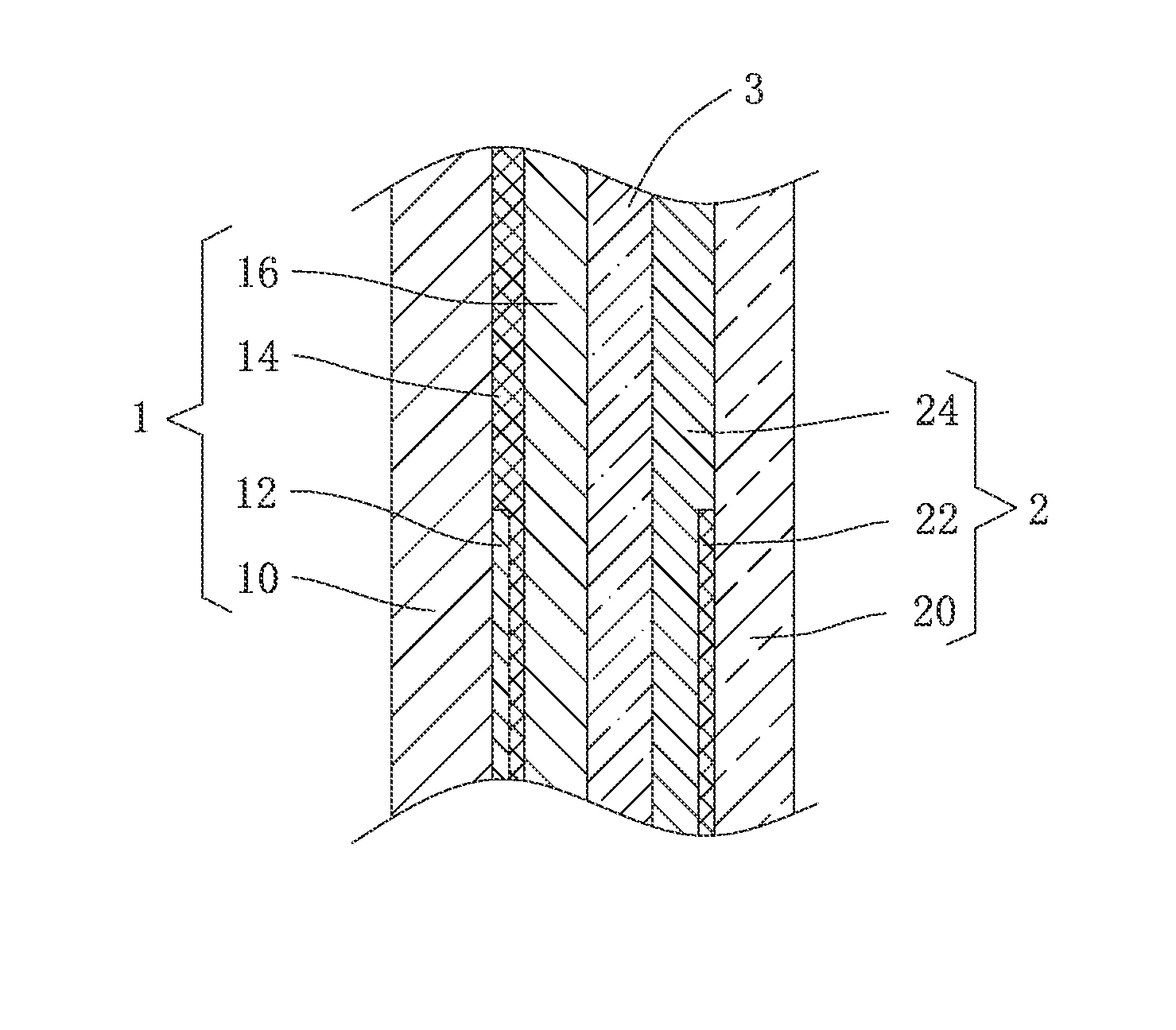

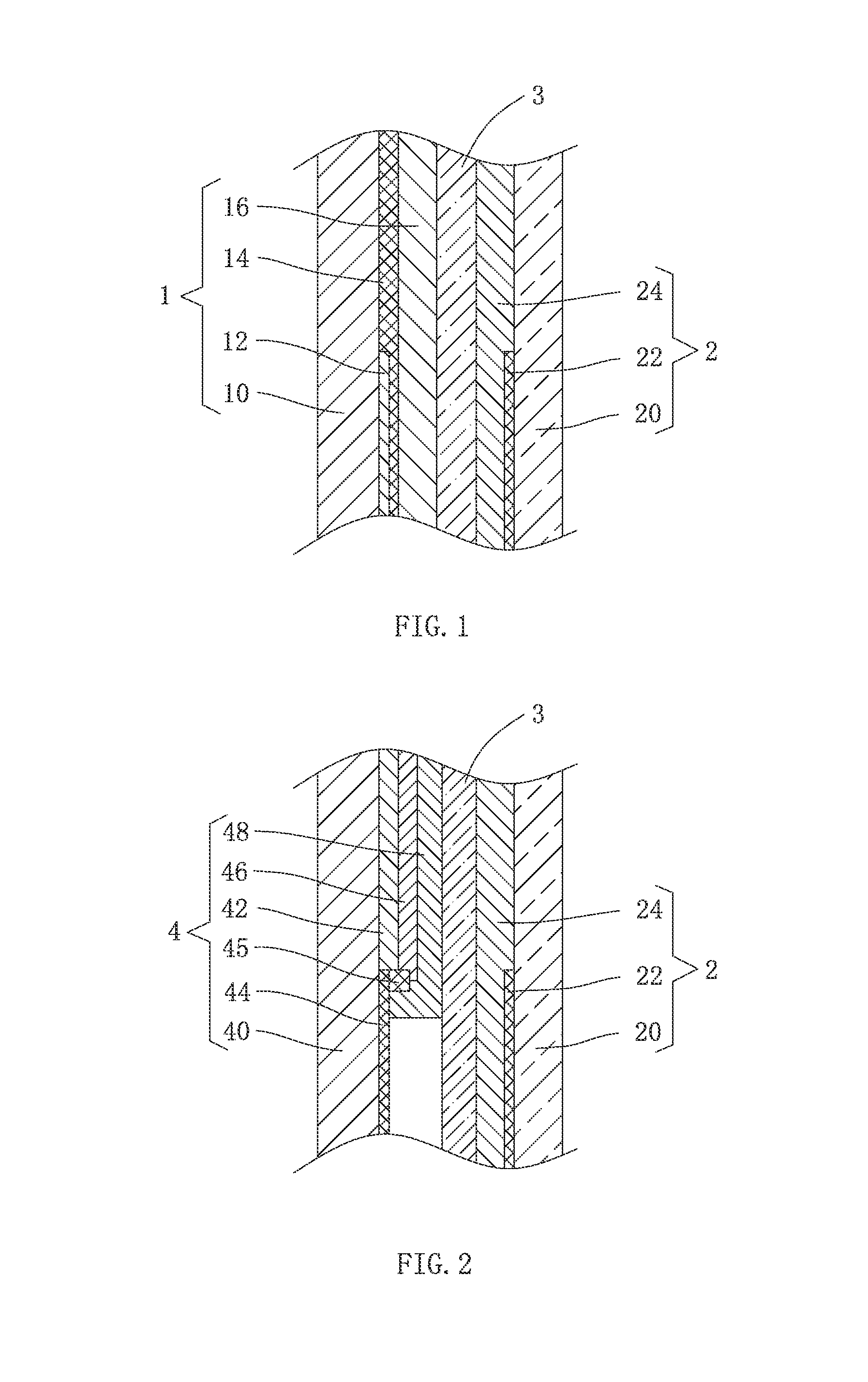

Optical adhesive film and flat panel display device having the same

ActiveUS20120113369A1High bonding strengthPrevent leakageStampsLayered productsOptical bondingEngineering

An optical adhesive film for improving the adhesive strength between constitutional elements of a flat panel display device, and a flat panel display device having the same. According to an aspect of the present invention, there is provided an optical adhesive film for use in a flat panel display module that displays an image, the optical adhesive film including a transmission unit disposed on the flat panel display module and allowing the image to transmit through the transmission unit; a wing member extending from at least one side surface of the transmission unit, and covering side surfaces and a portion of a rear surface of the flat panel display module; and an adhesive member disposed covering all surfaces of the transmission unit and the wing member.

Owner:SAMSUNG DISPLAY CO LTD

Fiber optic seismic sensor based on MEMS cantilever

A dual cantilevered beam structure is attached to a silicon frame. An optical fiber extends from a borosilicate wafer bonded to the bottom of the frame. A second borosilicate wafer is bonded to the top of the frame. The bottom borosilicate wafer is bonded to the optical fiber with a bonding agent having an index of refraction between the refractive index of the fused silica optical fiber and the refractive index of the borosilicate wafer. In an embodiment, the bonding agent has a refractive index substantially similar to optical cement. Light is reflected into the optical fiber from the beam structure for measuring seismic changes.

Owner:HALLIBURTON ENERGY SERVICES INC

Display device

ActiveUS20100014034A1High strengthReduce thicknessSubstation equipmentNon-linear opticsOptical bondingElectrical resistance and conductance

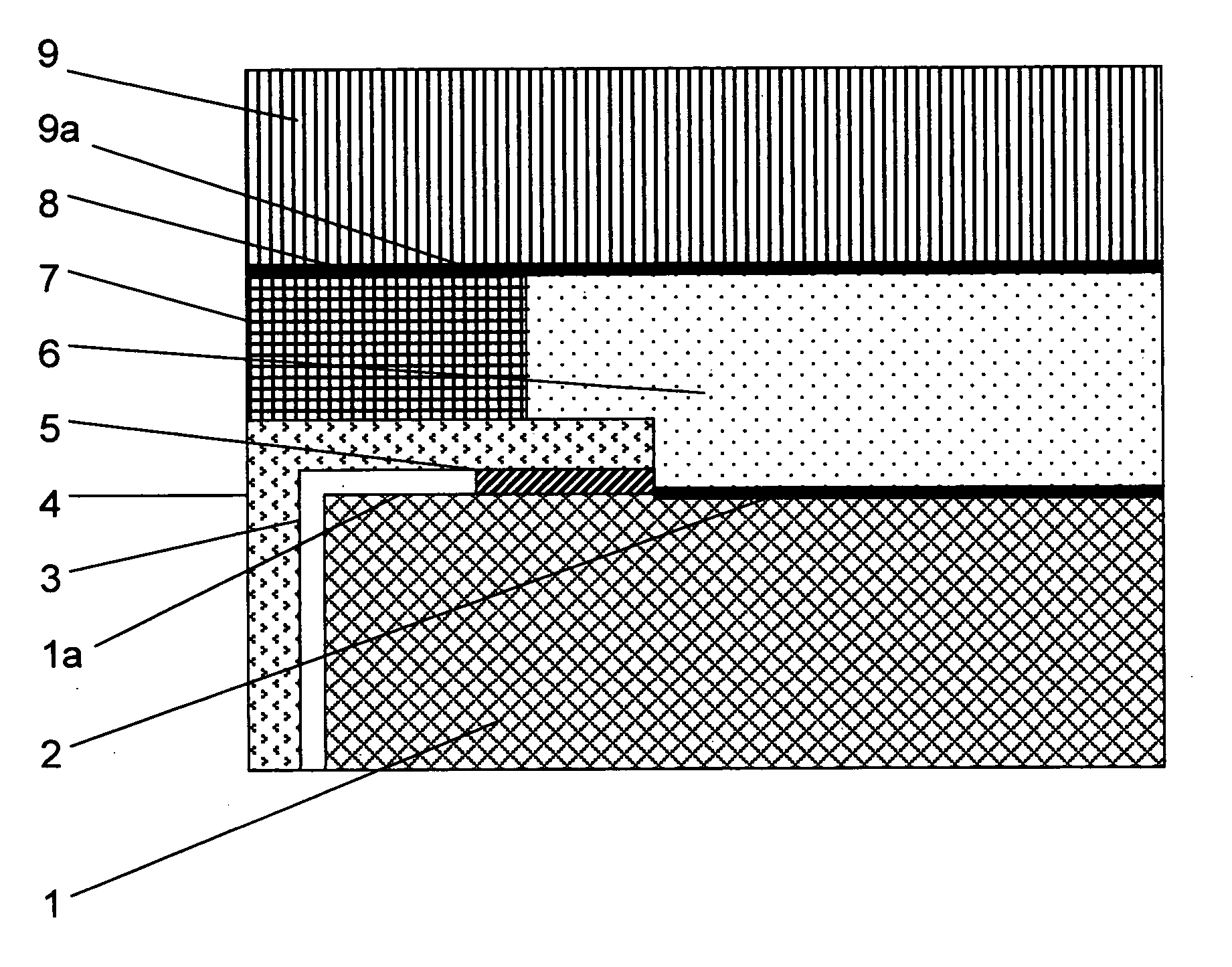

To prevent a reduction in load resistance of a liquid crystal panel which is caused along with a reduction in thickness thereof, tempered glass is entirely bonded to both of front and back surfaces or one of the surfaces of the liquid crystal panel using an optical adhesive, and an amount of warp by which the liquid crystal panel alone is broken due to a pressure is set equal to or larger than that in a case of the tempered glass.

Owner:DAWNCREST IP LLC

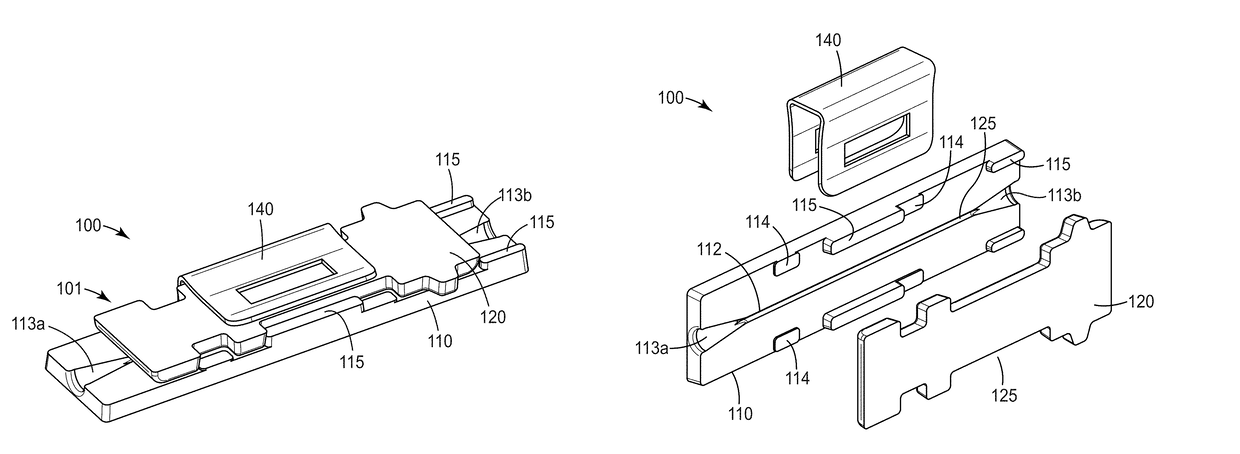

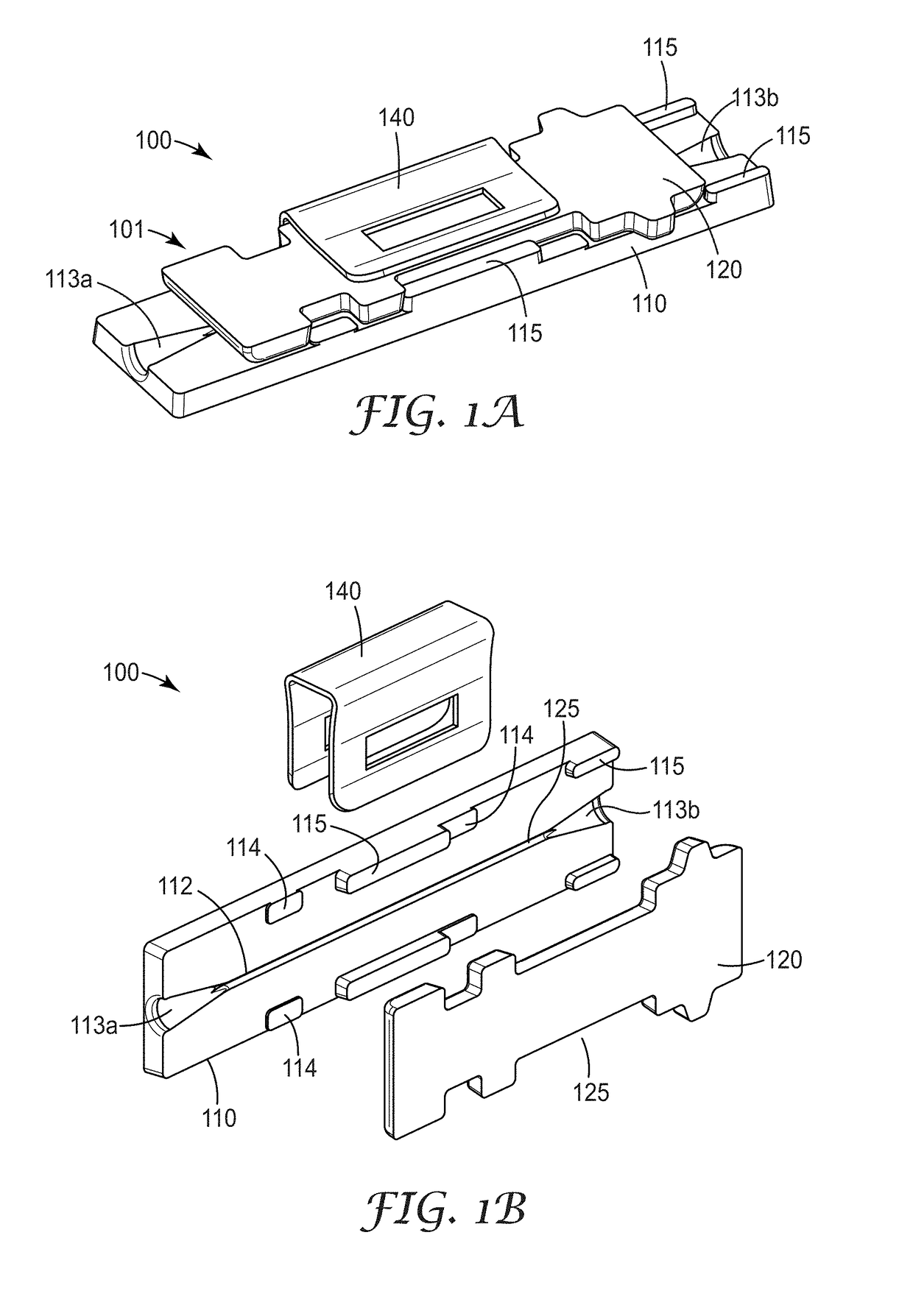

Optical fiber splice element

InactiveUS20180067262A1Physical/chemical process catalystsNon-macromolecular adhesive additivesOptical bondingEngineering

A splice element for splicing a first and a second optical fiber comprises an alignment mechanism having a base plate and a clamp plate. At least one of the base plate and clamp plate is formed from a silica material and at least one of the base plate and clamp plate includes an alignment groove configured to receive the first and second optical fibers in an end-to-end manner. The splice element also comprises an optical adhesive disposed in at least a portion of the alignment groove, wherein the optical adhesive is curable via actinic radiation.

Owner:3M INNOVATIVE PROPERTIES CO

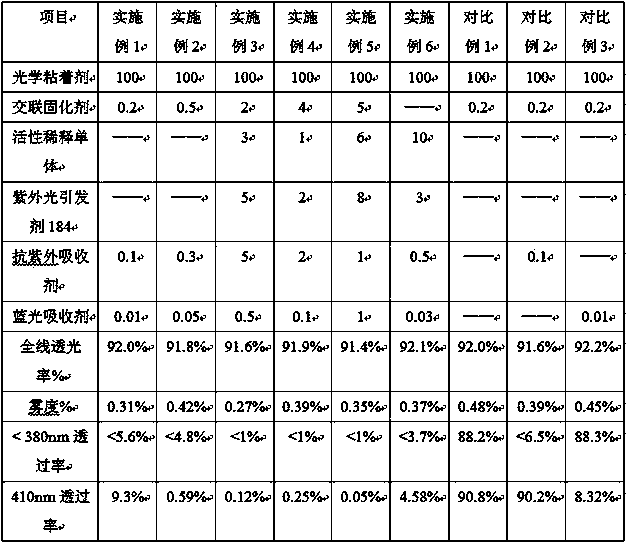

Ultraviolet-resistant blue-light-absorbable optical bonding agent composition and optical bonding piece

ActiveCN104403612AHigh light transmittanceLow hazeNon-macromolecular adhesive additivesFilm/foil adhesivesOptical bondingUv absorbance

The invention discloses an ultraviolet-resistant blue-light-absorbable optical bonding agent composition and an optical bonding piece with the bonding agent layer. The optical bonding agent composition comprises 100 parts of optical bonding agent, 1-10 parts of crosslinking curing agent, 0.01-5 parts of ultraviolet-resistant absorbent and 0.001-1 part of blue light absorbent. The ultraviolet-resistant blue-light-absorbable optical bonding agent composition and bonding piece have high light transmittance, low haze and favorable ultraviolet (with the wavelength of 300-380nm or so) shielding capacity, can absorb harmful blue light (400-470nm) to the human body in the visible portion, can be widely used as a current screen display device lamination body or intelligent screen protective film or other products capable of resisting ultraviolet and blue light (such as sunglasses, polaroids and the like), and greatly lower the injuries of ultraviolet and blue light to the skin and eyes of the human body.

Owner:PANYU NANSHA YAN TIN CHEM

Capacitive Touch Screen

InactiveUS20140176481A1Simple structureImprove production efficiencyInput/output processes for data processingOptical bondingProduction rate

This invention discloses a capacitive touch screen comprising an Indium Tin Oxide (ITO) tempered glass and an ITO film both of which are adhesively laminated integrally together via an optical adhesive. The ITO tempered glass comprises a glass substrate comprising a viewing window area and a non-viewing window area, a black ink layer disposed on a first lateral surface of the glass substrate and printed in a corresponding area thereof to the non-viewing window area, an ITO circuit plating layer covering the black ink layer and the viewing window area. The present invention utilizes the optical adhesive to directly adhesively laminate the ITO tempered glass and the ITO film, and as a result, its lamination structure is able to simplify. Furthermore, the present invention not only effectively reduces its integral thickness thereof, but also has simple production techniques, a low cost of manufacturing, and a high yield rate of production.

Owner:GAN ZHOU DPT TECH

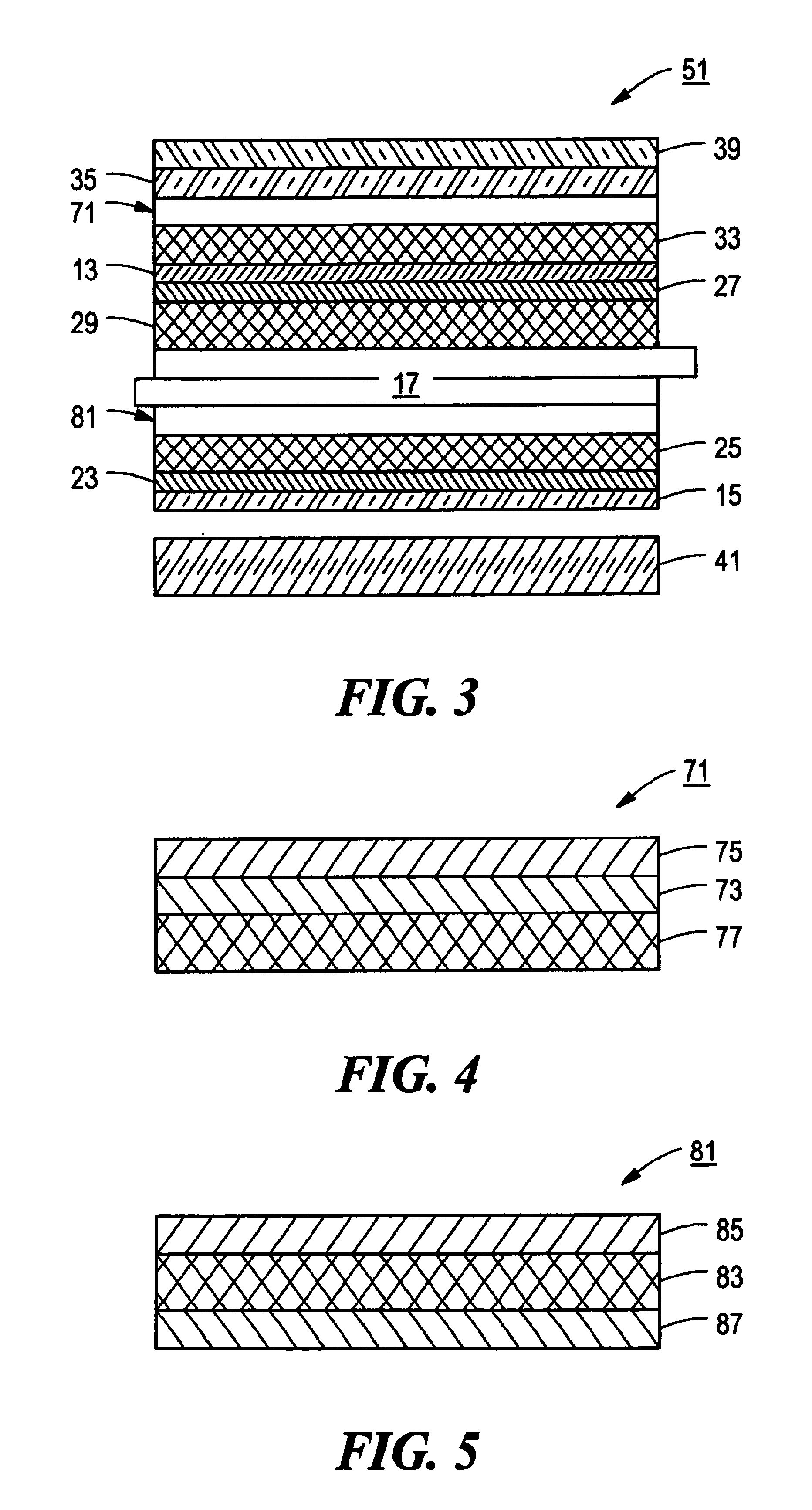

Orange and NIR-absorbing optical adhesives for plasma displays

InactiveUS20050280342A1Improve performanceImprove manufacturabilityIncadescent screens/filtersAlternating current plasma display panelsOptical bondingPorphyrin structure

The present invention is a tinted, optical adhesive for use in making plasma display filters comprising a substantially acid free, pressure-sensitive adhesive (PSA) containing a narrow-band, visible spectrum dye (e.g. less than 30 nm bandwidth) and a broader-band, near infra-red spectrum dye (e.g. greater than 200 nm), the second dye providing enhanced thermal stability as well as near infra-red (NIR) blocking. Further, acid-free adhesives offer improved stability of light control dyes. In the present invention, porphyrin-based dyes combined with acrylate-based, pressure-sensitive optical adhesives are preferred. Invention offers reduced number of functional layers in an optical filter structure as well as reduced number of manufacturing (lamination) steps in the optical filter / plasma display assembly process.

Owner:WENZ ROBERT P

System and Method for Autostereoscopic Imaging

InactiveUS20110032587A1High resolutionHigh color fidelityHolographic light sources/light beam propertiesPhotomechanical apparatusOptical bondingDisplay device

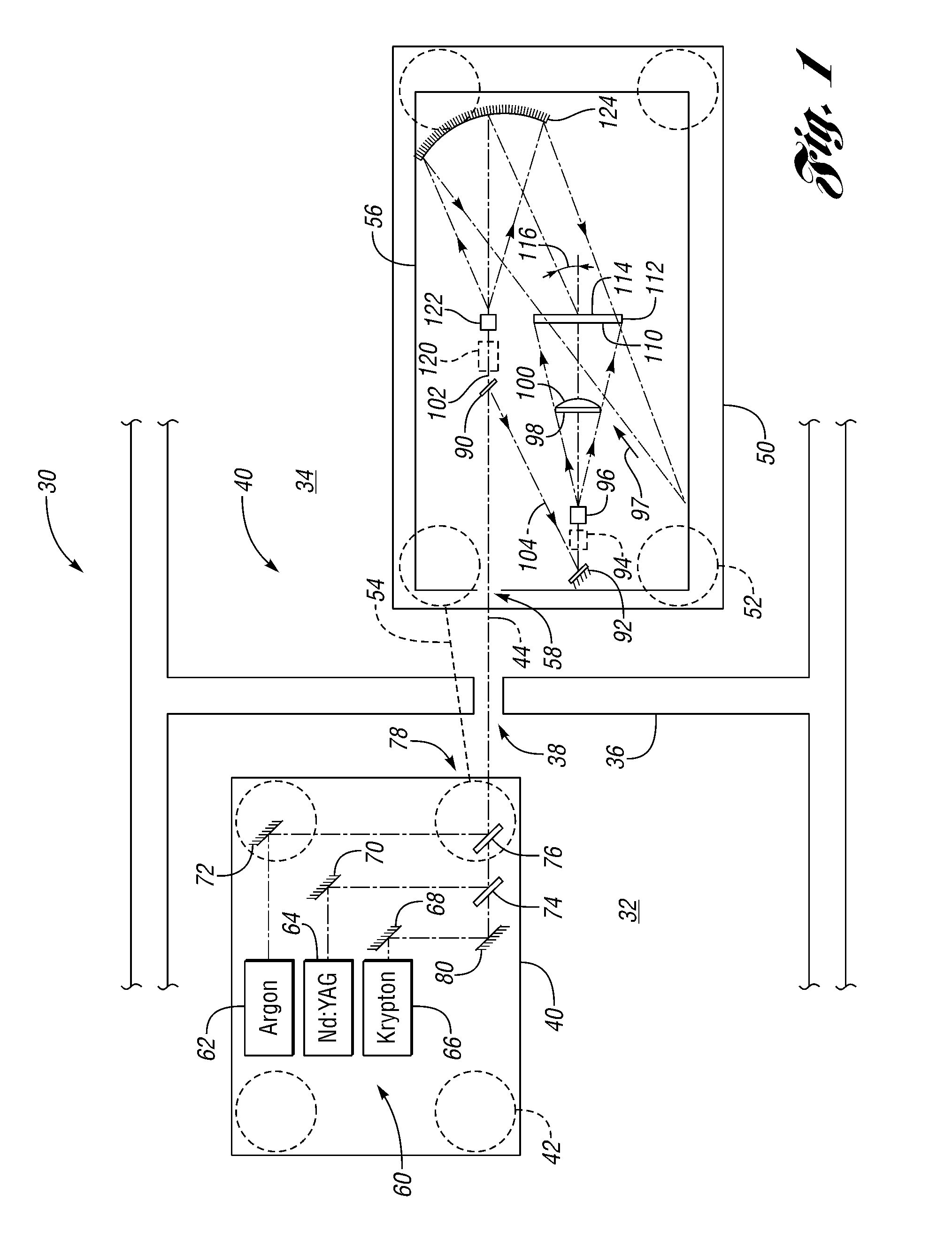

Systems and methods for autostereoscopic display of three-dimensional images include a holographic optical element made by preparing a silver halide gelatin emulsion, coating one side of a glass substrate with the emulsion, holographically recording an eyebox on the coated glass substrate using at least three wavelengths of coherent light combined in a source beam that is divided into a reference beam and object beam with at least one of the reference and object beam passing through a beam shaping device to substantially uniformly illuminate the glass substrate from opposite sides, processing the coated glass substrate, and sealing the coated glass substrate by covering the coated side of the glass substrate with an optical cement and securing to a black glass plate. The element may be mounted in a display and illuminated with at least one projector having optical keystone correction with source wavelengths aligned or matched with the recording wavelengths.

Owner:KUGHN ABSOLUTE HLDG

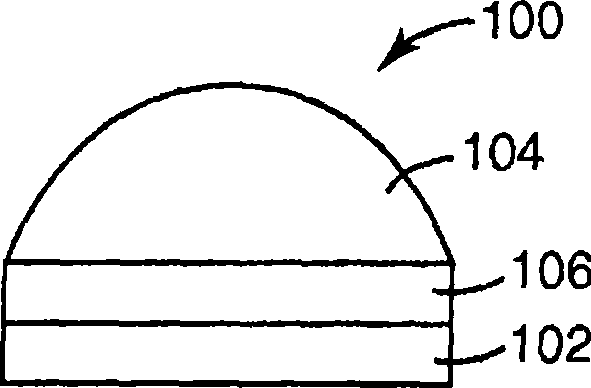

Display device

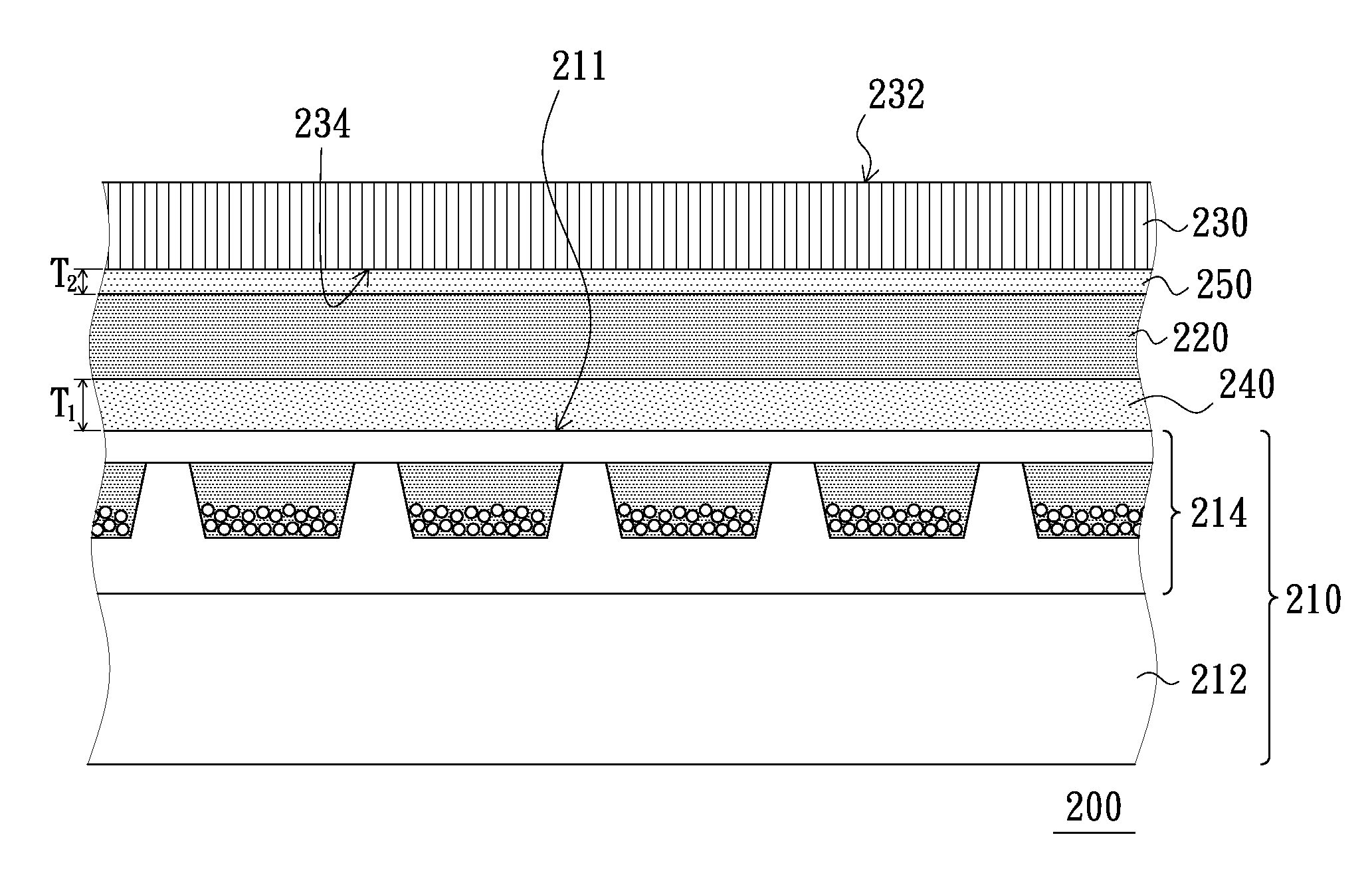

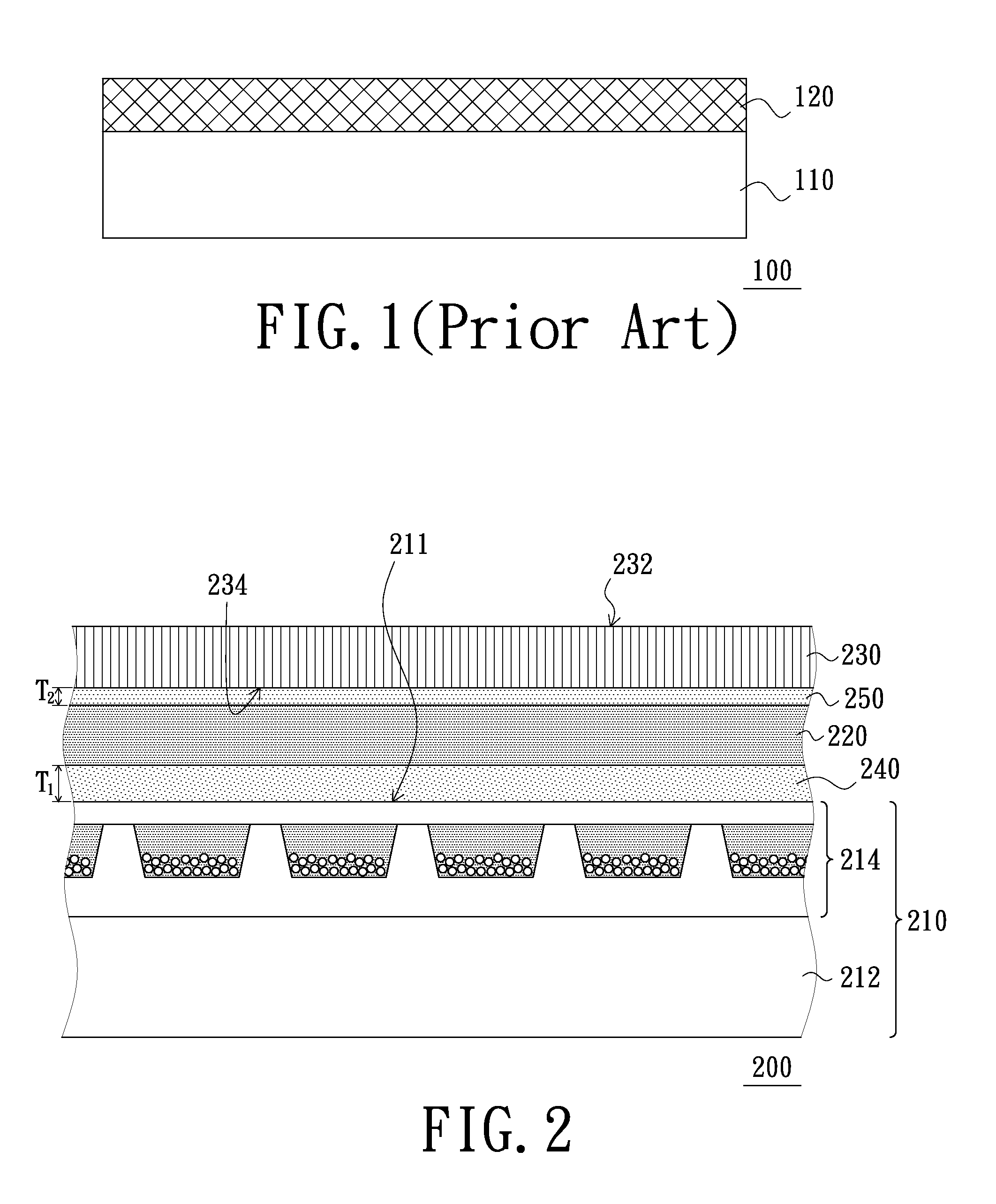

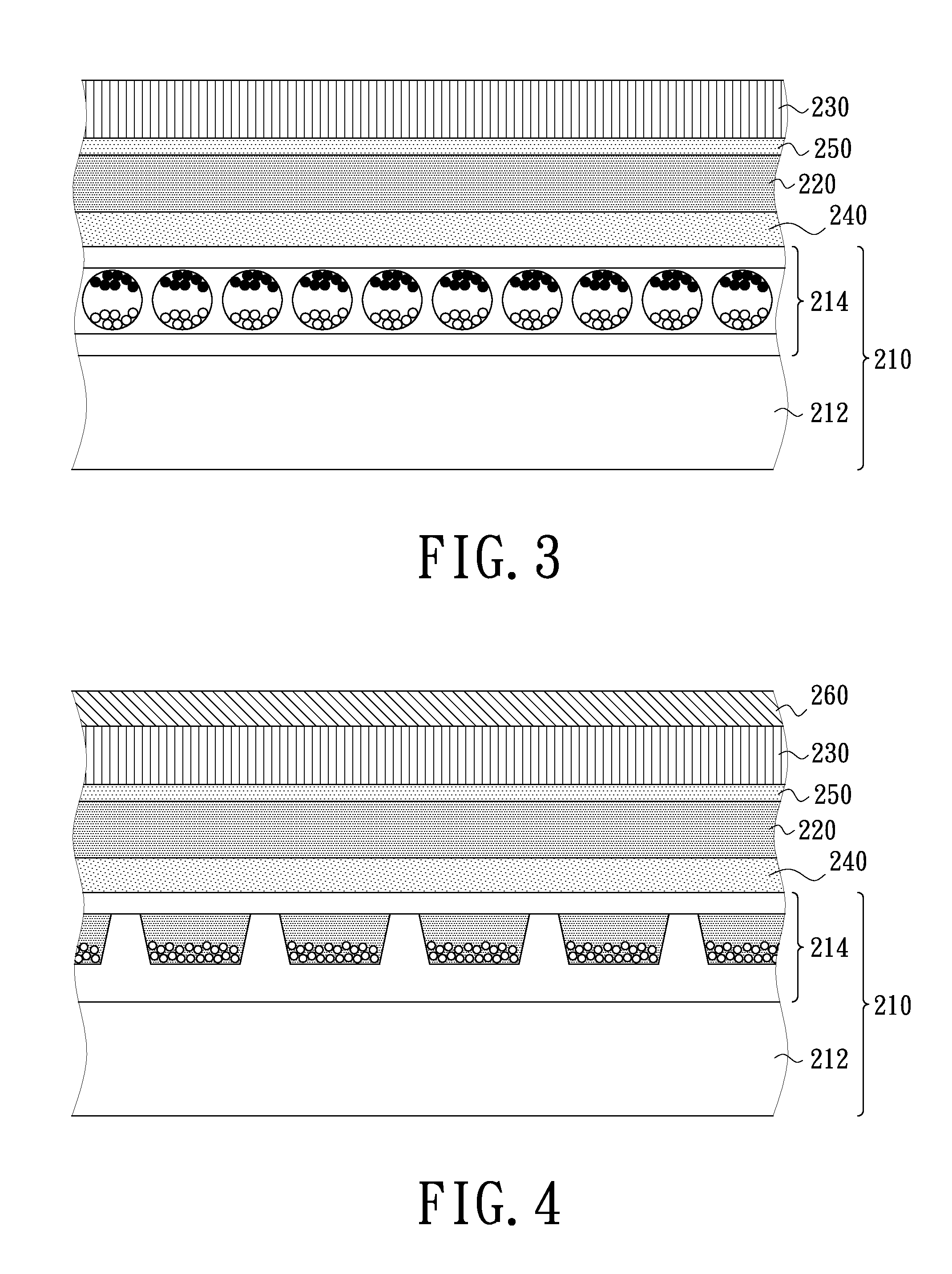

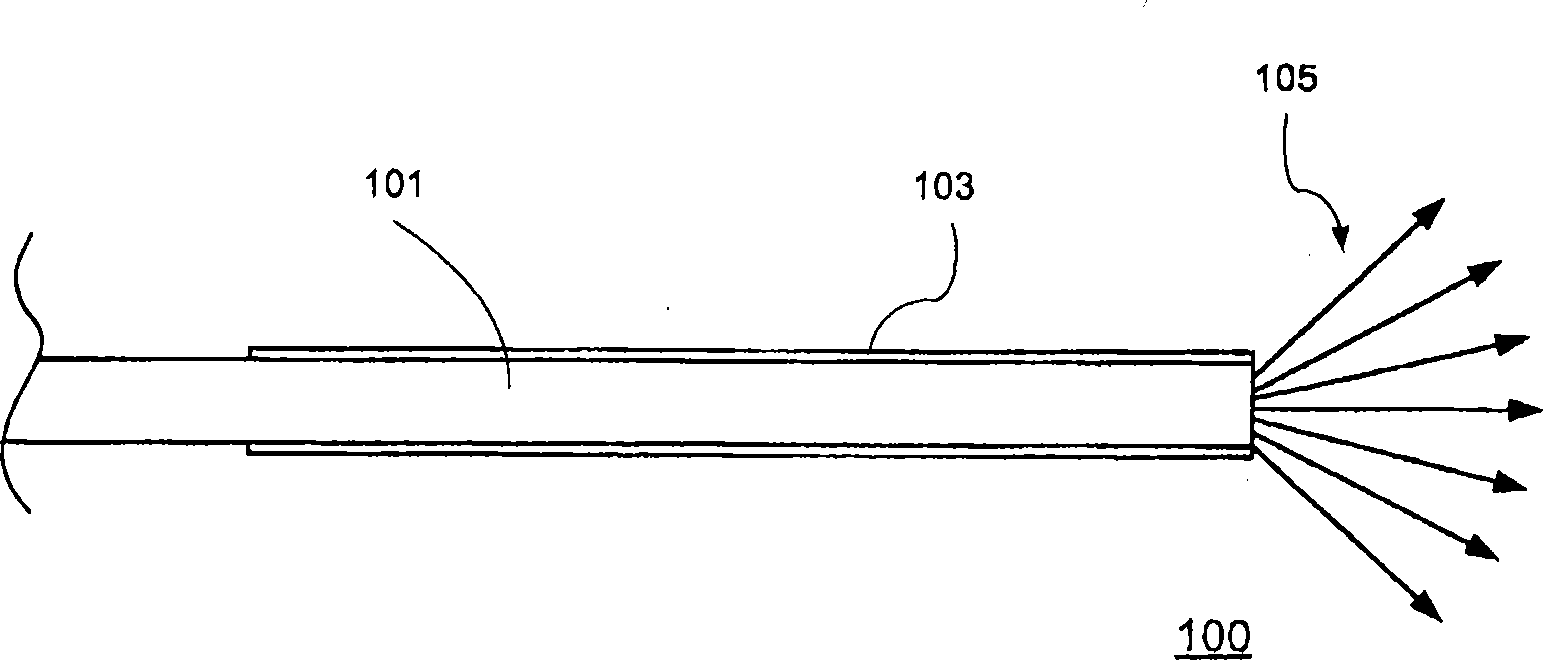

ActiveUS20110273760A1High impact strengthHigh strengthNon-linear opticsOptical elementsOptical bondingDisplay device

A display device includes a display panel, a barrier layer, a protective layer, a first optical adhesive layer and a second optical adhesive layer. The barrier layer is disposed above the display panel. The protective layer is disposed above the barrier layer. The first optical adhesive layer with a first thickness is disposed between the display panel and the barrier layer. The second optical adhesive layer with a second thickness is disposed between the protective layer and the barrier layer. The first thickness is larger than the second thickness.

Owner:AU OPTRONICS CORP

Thermally robust illuminator probe tip

In embodiments of the invention, a plastic optical fiber is bonded to a high temperature distal part to form a thermally robust illumination probe. The distal part is short in length, is made of a high temperature material(s), has a proper shape for guiding light in a desired application, and may be coated with a reflective coating to ensure that the light rays trapped within the part do not escape when the side of the part is in contact with high refractive index or absorptive materials. The distal part may be made of high temperature material(s) such as high temperature plastic rods, glass optical fibers, and so on. The distal end may be tapered or sculpted to a desired configuration. The plastic optical fiber and the high temperature distal part may be joined, using an optical adhesive, inside a steel cannula, a plastic hub, an optical connector, etc.

Owner:ALCON INC

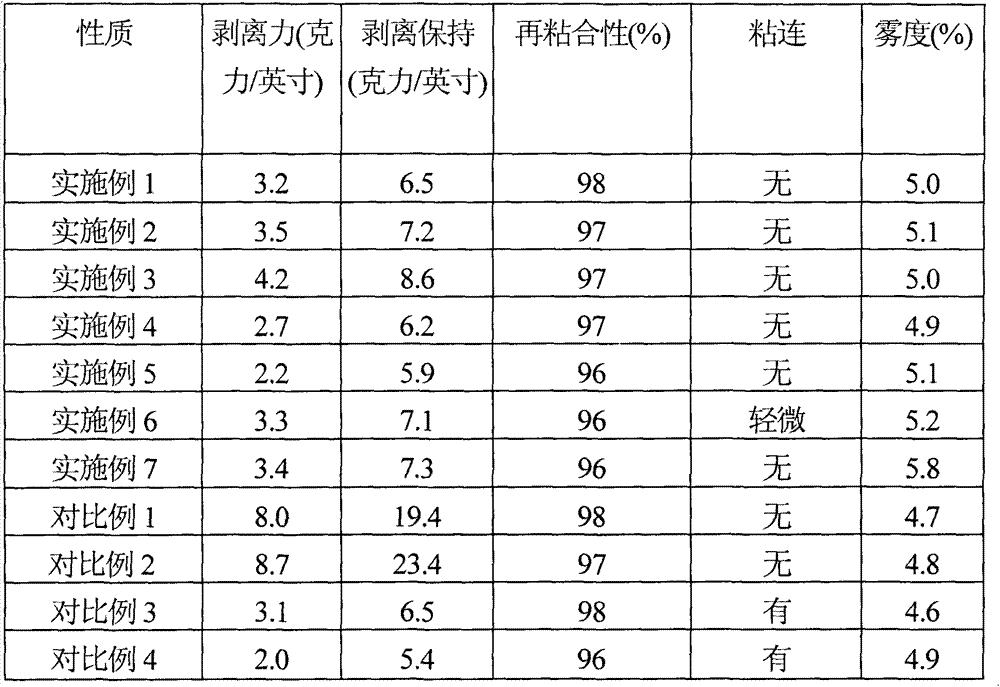

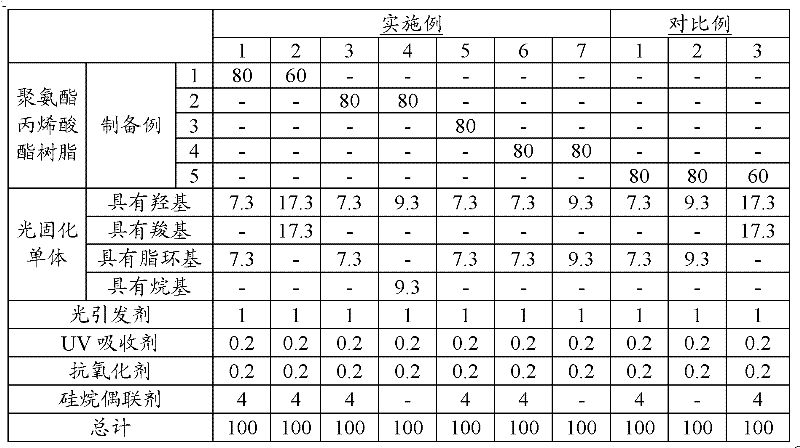

Optical adhesive film, apparatus including the same, and optical adhesive composition

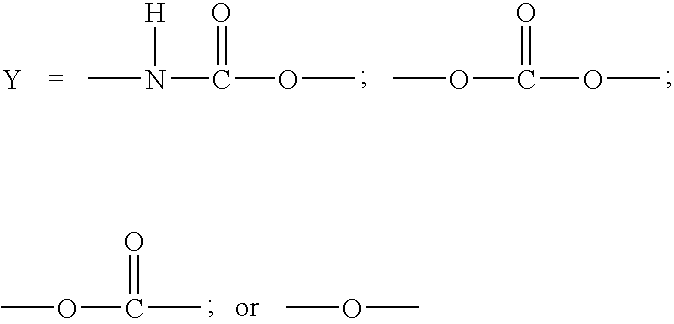

ActiveCN102585712APolyureas/polyurethane adhesivesFilm/foil adhesives without carriersOptical bondingAcrylate copolymer

The invention provides an optical adhesive film for an OCA film, an optical adhesive composition for the adhesive film and apparatus including the same. In the concrete, The invention provides an optical adhesive film for an OCA film and an optical adhesive composition for the adhesive. The optical adhesive film includes a urethane (meth)acrylate copolymer to improve retreatment and solve bubble generation and increasing cost of manufacture.

Owner:CHEIL IND INC

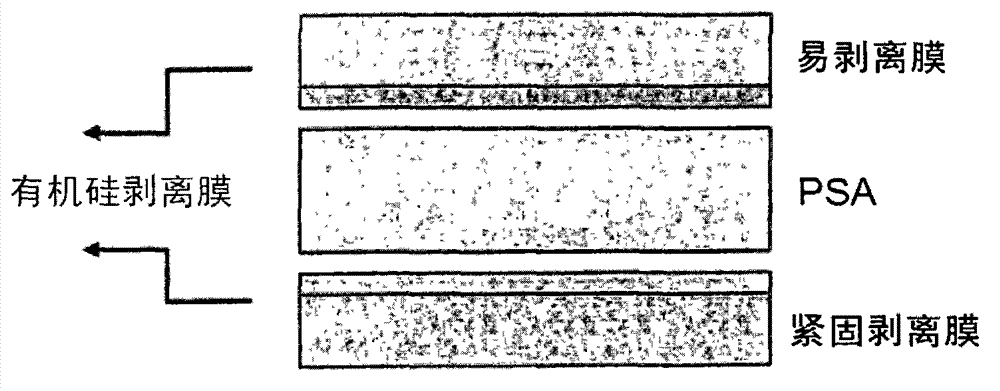

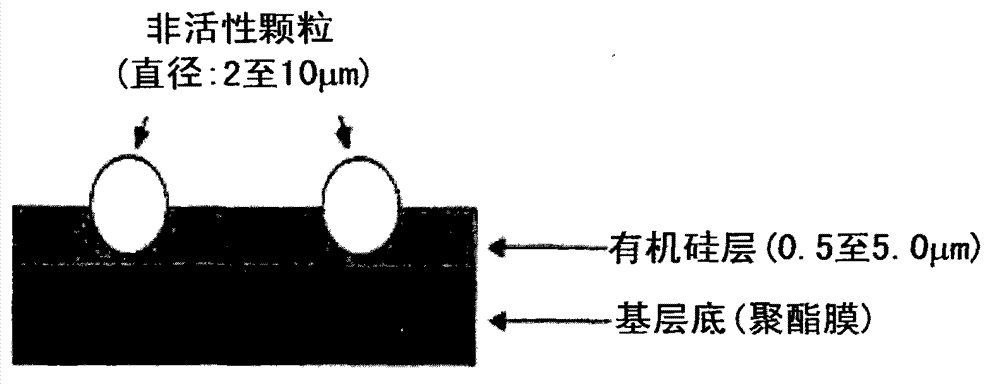

Silicone release film with improved release performance and anti-adhesion performance

InactiveCN103242548AHigh hazeFilm/foil adhesivesSynthetic resin layered productsOptical bondingDisplay device

The present invention relates to a silicone release film which protects a binding layer in a preparing process of an optical binding film, and a method for preparing the release film. The optical binding film is used for display devices such as touch screen panel (TSP), LCD and PDP. Particularly, the invention provides a method for preparing the release film, wherein compared with the traditional film, the release film has the following advantages: high release performance (easy release), high rebinding performance, stable release keeping performance in storage, improved anti-adhesion performance, excellent machining performance, andn slightly increased haze caused by forming a coarse surface on a coating layer. The release film prepared according to the method is particularly useful for an optical bound film.

Owner:SKC HAAS DISPLAY FILMS CO LTD

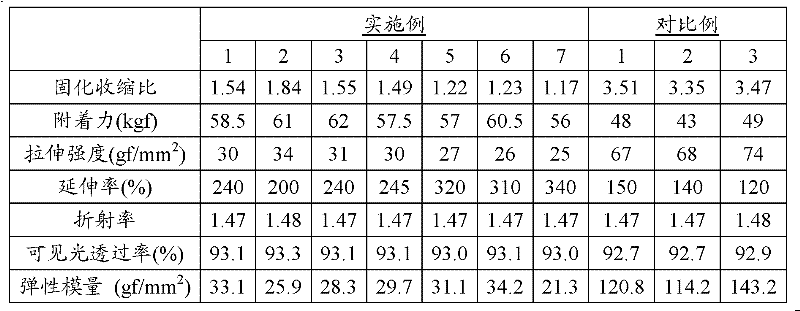

Optical adhesive composition and display panel including the same

The invention relates to an optical adhesive composition and a display panel including the same. Concretely, the invention relates to an optical adhesive composition and a display panel including the same, the optical adhesive composition includes a urethane(meth)acrylate resin having at least one hydroxyl group and at least one vinyl group so as to improve curing contraction ration, adhesion force, extension rate, and outdoor visibility, and no bubbles are generated when the optical adhesive composition is attached on a film or glass.

Owner:CHEIL IND INC

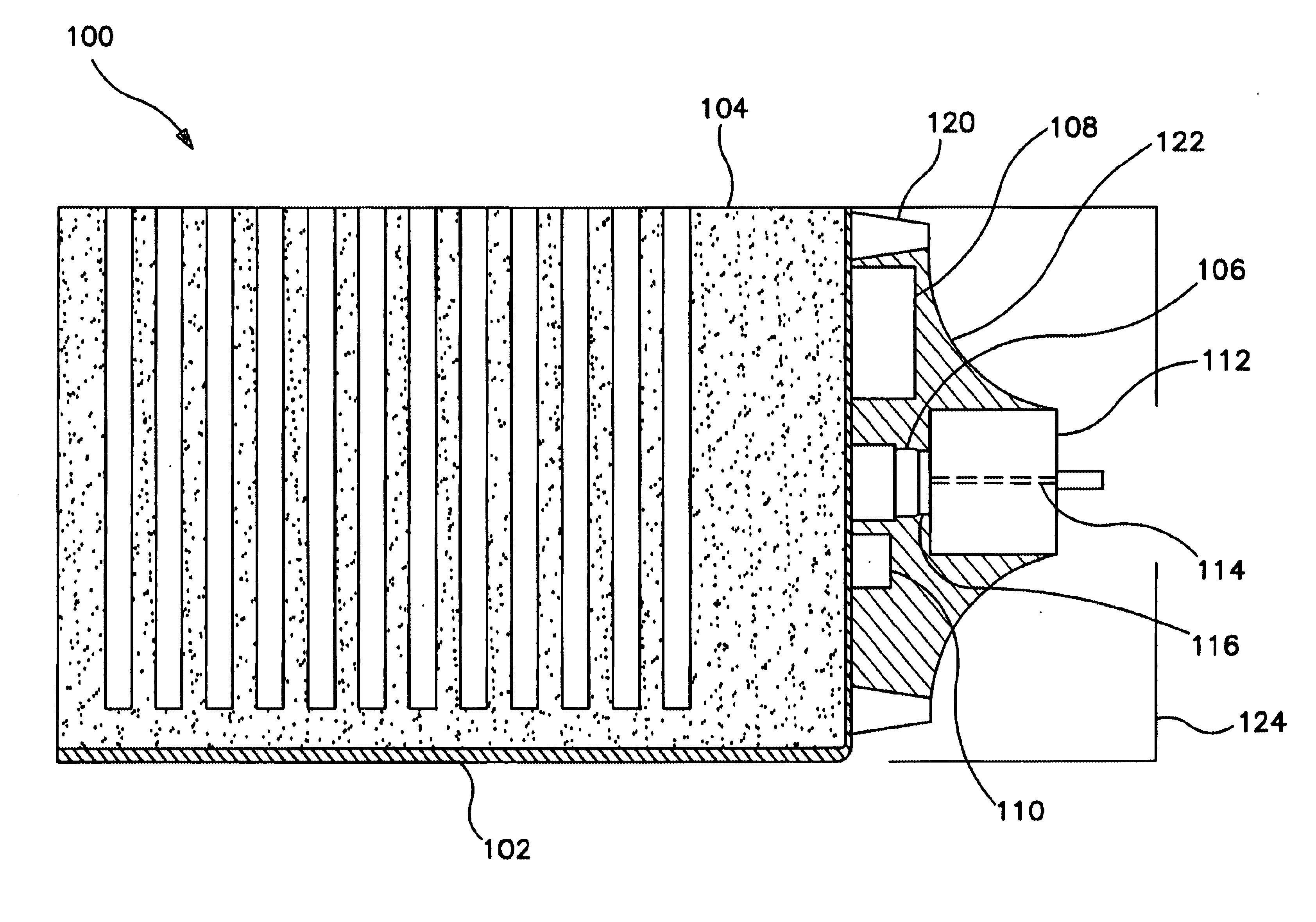

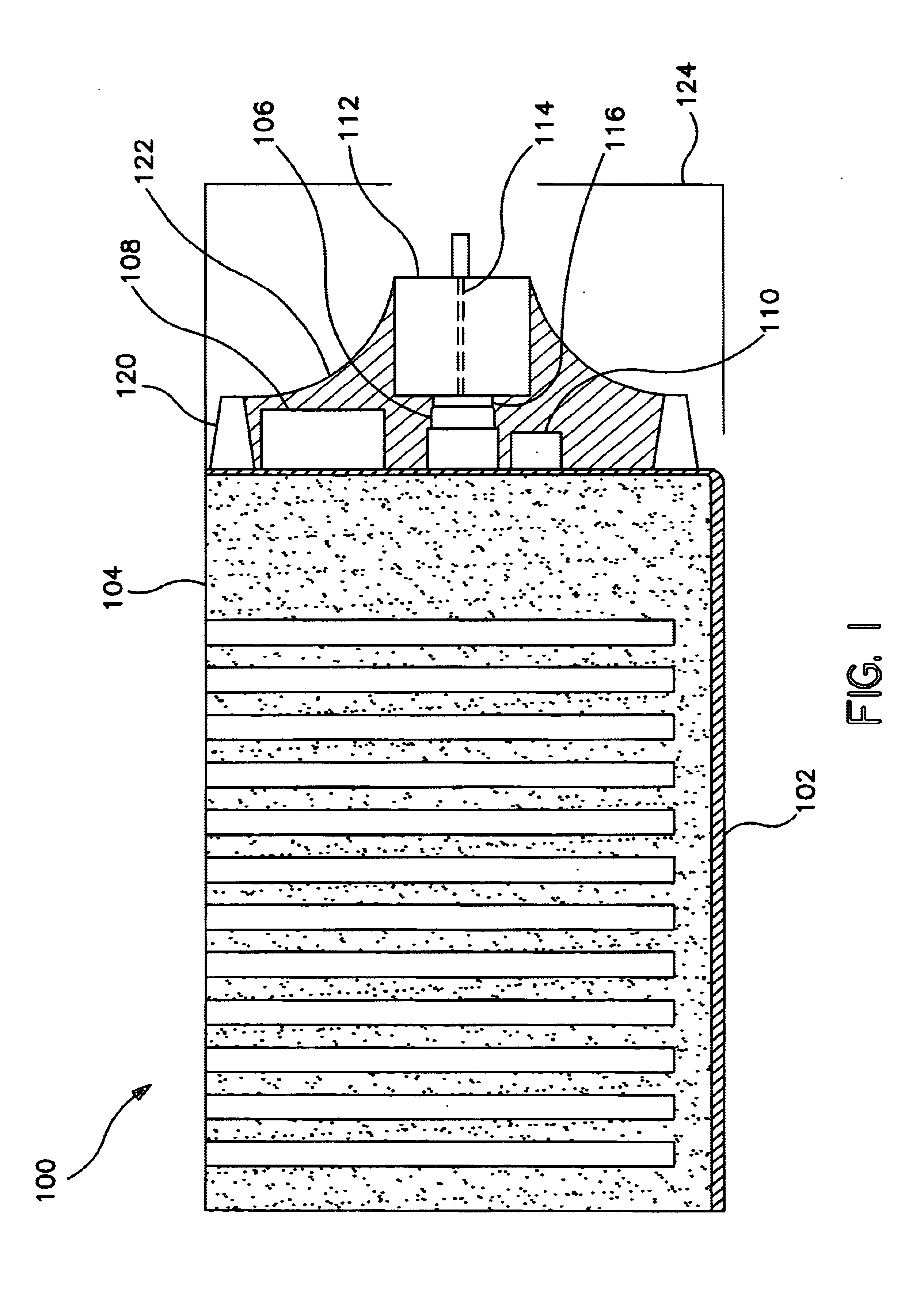

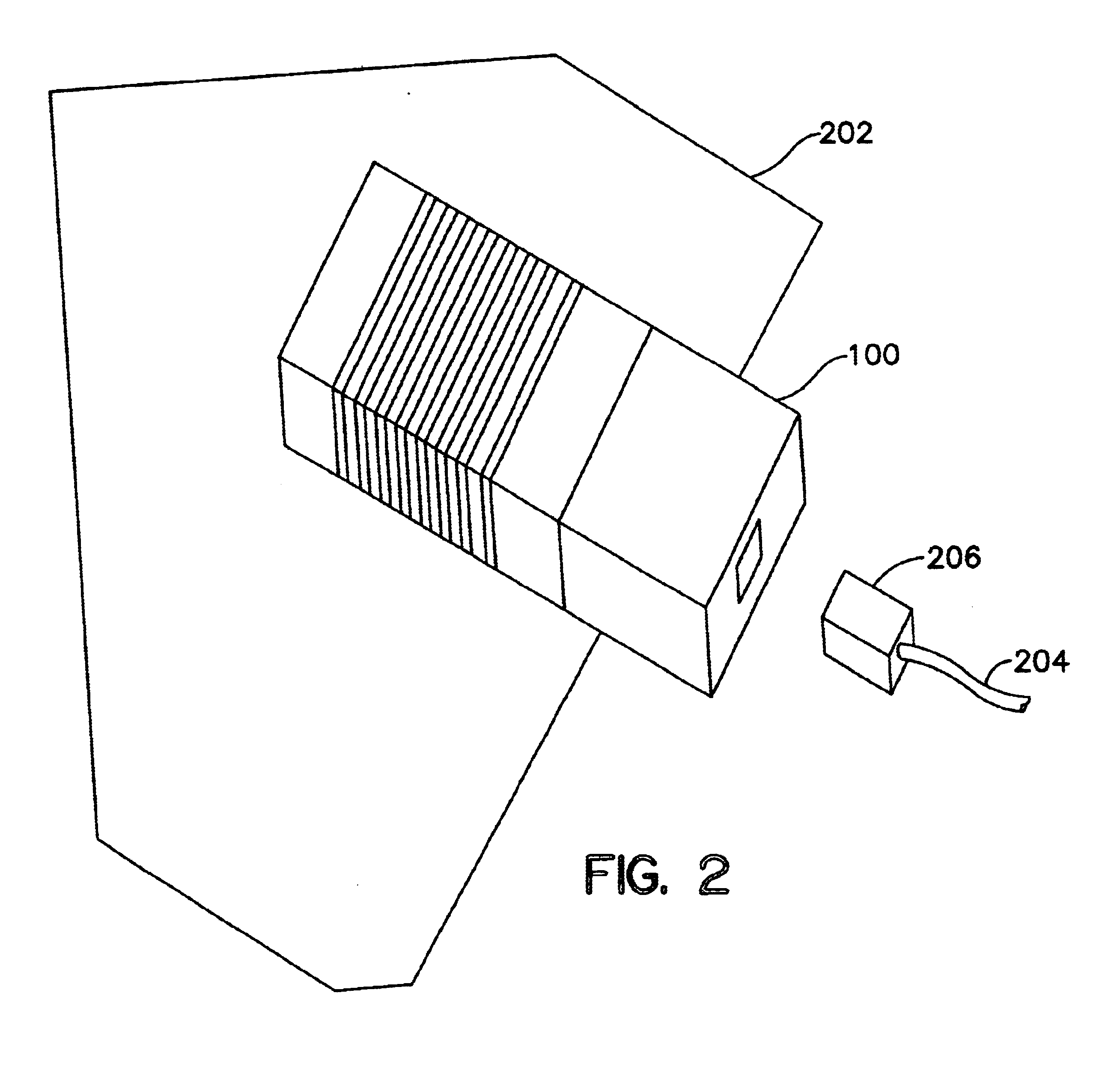

Method and apparatus for coupling optical elements to optoelectronic devices for manufacturing optical transceiver modules

InactiveUS6905260B2Absorbs stressHighly precise machinery and adhesiveCoupling light guidesVertical-cavity surface-emitting laserTransceiver

A process is provided for aligning and connecting at least one optical fiber to at least one optoelectronic device so as to couple light between at least one optical fiber and at least one optoelectronic device. One embodiment of this process comprises the following steps: (1) holding at least one optical element close to at least one optoelectronic device, at least one optical element having at least a first end; (2) aligning at least one optical element with at least one optoelectronic device; (3) depositing a first non-opaque material on a first end of at least one optoelectronic device; and (4) bringing the first end of at least one optical element proximate to the first end of at least one optoelectronic device in such a manner that the first non-opaque material contacts the first end of at least one optoelectronic device and the first end of at least one optical element. The optical element may be an optical fiber, and the optoelectronic device may be a vertical cavity surface emitting laser. The first non-opaque material may be a UV optical adhesive that provides an optical path and mechanical stability. In another embodiment of the alignment process, the first end of at least one optical element is brought proximate to the first end of at least one optoelectronic device in such a manner that an interstitial space exists between the first end of at least one optoelectronic device and the first end of at least one optical element.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS U S A

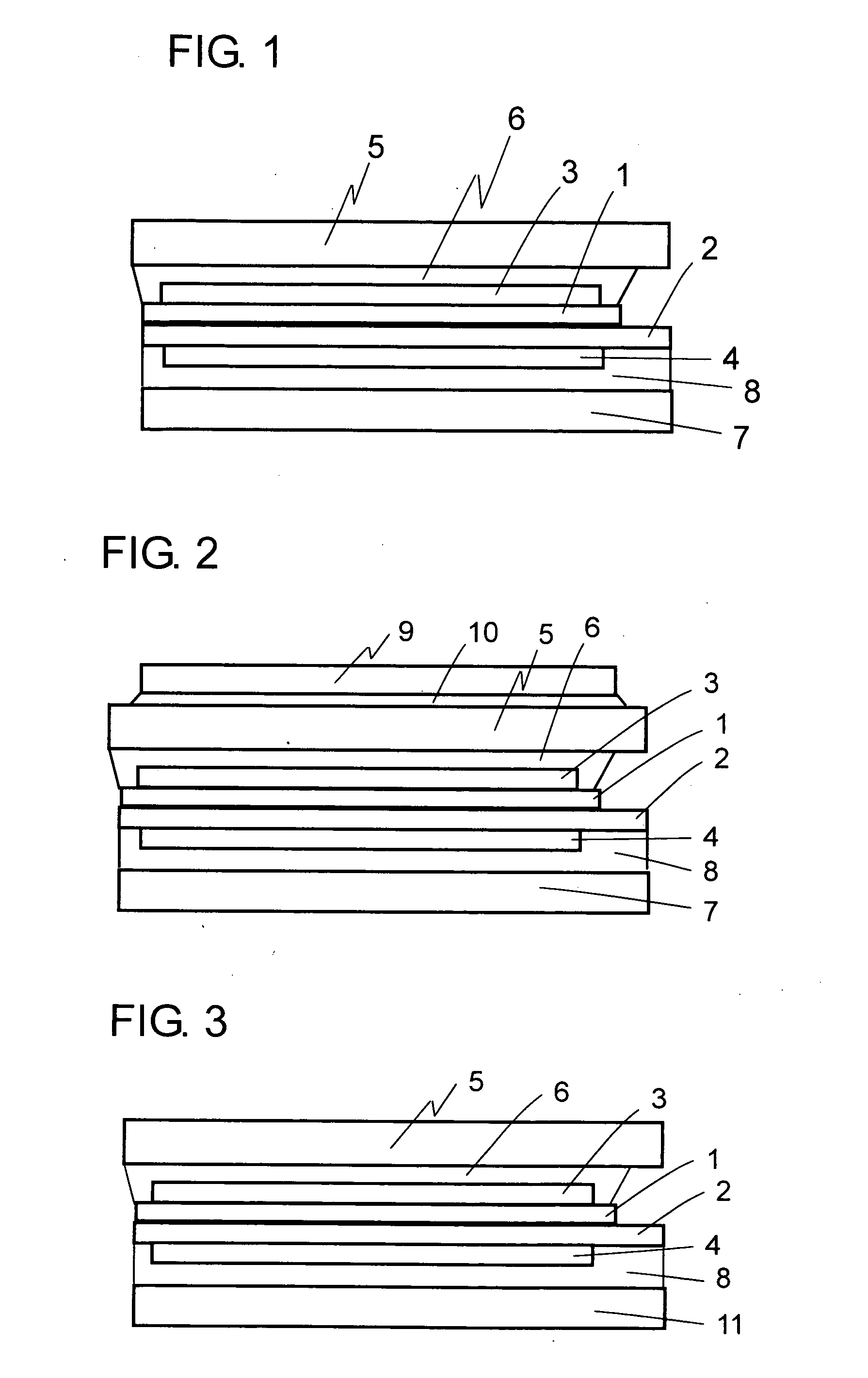

Display device

ActiveUS20090207350A1Improve mechanical bond strengthDeterioration of image qualityNon-linear opticsOptical bondingLiquid-crystal display

In a case of curing and bonding a liquid crystal display panel (LCD) and a translucent substrate by using an optical adhesive, in order to reduce bonding fluctuations occurring in the vicinity of a light shielding portion provided on a periphery of the translucent substrate, enhance mechanical bonding strength, and prevent deterioration of image quality, which arises from curing variations of the optical adhesive, there is provided a display device including: a display panel including a display surface; a translucent substrate opposed to the display surface; a light shielding portion provided on a periphery of a display surface side of the translucent substrate, for shielding light; and a light reflecting portion provided on a display surface side of the light shielding portion.

Owner:DAWNCREST IP LLC

Optical articles from curable compositions

ActiveUS7463417B2Low viscosityLow shrinkagePolarising elementsOptical light guidesOptical bondingPolymer science

A curable composition is provided which includes an oligomer having a plurality of pendent and / or terminal ethylenically unsaturated, free-radically polymerizable functional groups, a free-radically polymerizable crosslinking agent, and / or a diluent monomer, and a photoinitiator. The composition, when cured, is non-yellowing, exhibits low shrinkage and low birefringence making it suitable for many optical applications such as optical lenses, optical fibers, prisms, light guides, optical adhesives, and optical films.

Owner:3M INNOVATIVE PROPERTIES CO

Optical bonding composition for led light source

The present invention discloses an optical bonding composition and LED light source comprising the composition, as well as a method of making the LED light source. The LED light source may comprise: an LED die; an optical element optically coupled to the LED die; and a bonding layer comprising an amorphous organopolysiloxane network, the organopolysiloxane network comprising a silsesquioxane portion derived from (RSiO1.5)n wherein R is an organic group and n is an integer of at least 10; the bonding layer bonding the LED die and the optical element together. Efficiency of the LED light source may be increased when using an optical extractor as the optical element.

Owner:3M INNOVATIVE PROPERTIES CO

Optical adhesive and preparation method thereof

ActiveCN101591517AGood light transmissionImprove adhesion strengthNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneOptical bonding

The invention relates to an optical adhesive and a preparation method thereof. The optical adhesive comprises the components of a methacrylic acid C4-12 alkyl ester polymer and a crosslinking curing agent, wherein the crosslinking curing agent is a tripolycyanamide compound, an isocyanate compound or an epoxy compound, and the molecular weight of the ester polymer is between 600,000 and 800,000. The preparation method of the adhesive comprises the following steps: precisely weighing the components of the methacrylic acid C4-12 alkyl ester polymer and the crosslinking curing agent in proportion, and mixing the components; defoaming the mixture and coating the mixture on an anti-mucous release film; and drying the anti-mucous release film in a drying oven, and then using another anti-mucous release film to compound with the anti-mucous release film. The adhesive prepared by the method has the advantages of high transparency, excellent weathering resistance and the like, has no xanthochromia with the passage of time, and simultaneously has high adhesive strength, and can be widely applied to adhering and fixing liquid crystal flat panel display and protective films and the like in the optical field.

Owner:PANYU NANSHA YAN TIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com