Optical adhesive film, apparatus including the same, and optical adhesive composition

A technology of optical adhesives and compositions, applied in the direction of adhesive types, polyurea/polyurethane adhesives, film/sheet adhesives, etc., can solve the problem that materials can no longer be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

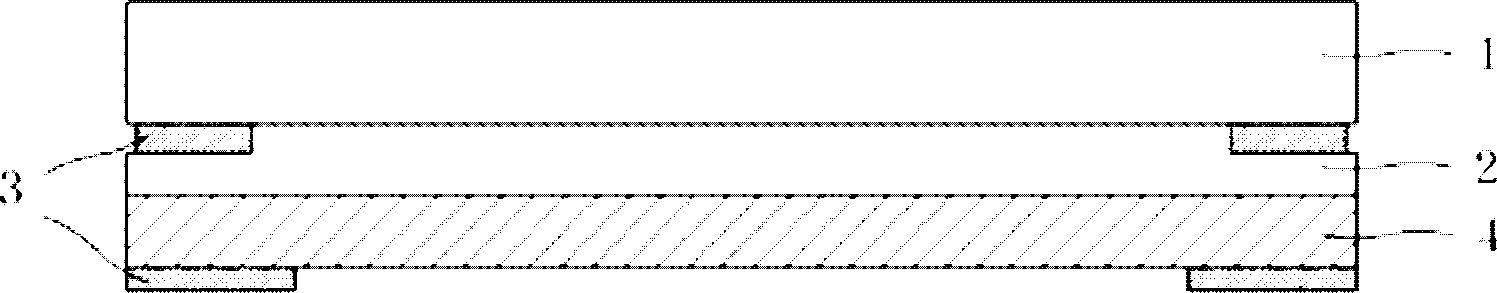

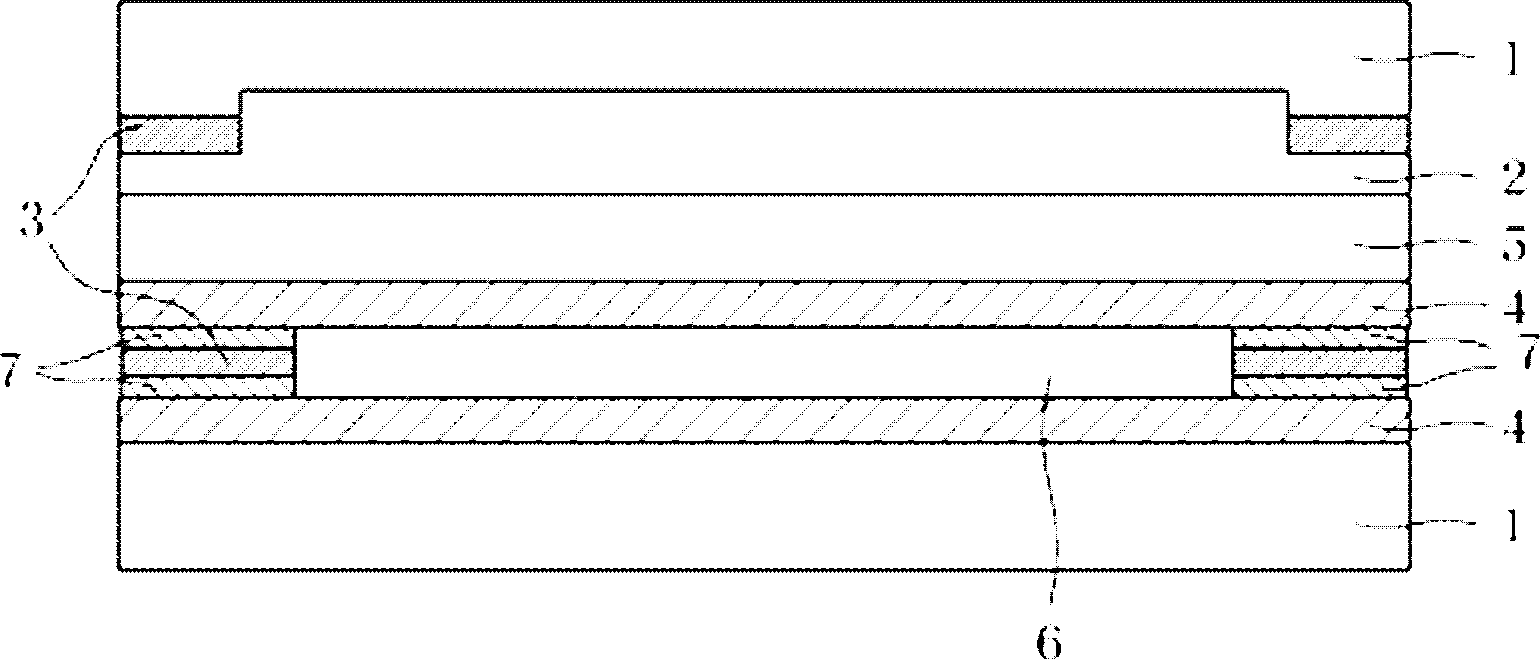

Image

Examples

preparation example 1

[0073] Preparation Example 1: Preparation of Polyurethane (meth)acrylate Copolymer

[0074] 80 g of polypropylene glycol and 10 g of 1,4-butanediol were placed in a 2L four-necked flask, which was equipped with a reflux cooling system on one side, a thermometer on the other side, and a dropping funnel on the third side. The solution in the flask was heated to 60° C., and 1.3 g of dibutyltin dilaurate (DBTDL) dissolved in toluene at a concentration of 10% was added thereto. 6 g of isophorone diisocyanate and 0.7 g of hexamethylene diisocyanate cyclic trimer (HDI trimer, DESMODUR N-330, Bayer) were sequentially added to the flask, and reacted at 75°C. After the disappearance of the residual isocyanate was confirmed by IR, the flask was cooled to 50° C., and 1 g of 2-methacryloyloxyethyl isocyanate (MOI) was added thereto. The flask was kept at 50° C. for 2 hours, and then the disappearance of the residual isocyanate was confirmed by IR, whereby a urethane (meth)acrylate copolym...

preparation example 2

[0075] Preparation example 2: the preparation of polyurethane (meth)acrylate copolymer

[0076] 89.45g of polypropylene glycol was placed in a 2L four-neck flask, one side of the flask was equipped with a reflux cooling system, the other side was equipped with a thermometer, and the third side was equipped with a dropping funnel. The solution in the flask was heated to 60° C., and 1.3 g of dibutyltin dilaurate (DBTDL) dissolved in toluene at a concentration of 10% was added thereto. 9.15 g of isophorone diisocyanate and 0.7 g of hexamethylene diisocyanate cyclic trimer (HDI trimer, DESMODUR N-330, Bayer) were sequentially added to the flask, and reacted at 75°C. When the theoretical NCO% was reached after 3 hours of reaction, the flask was cooled to 60° C., and 3.37 g of 2-hydroxyethyl acrylate was added thereto. The flask was kept at 60° C. for 2 hours, and then the disappearance of the residual isocyanate was confirmed by IR, whereby a urethane (meth)acrylate copolymer was ...

Embodiment 1 to 3

[0083] Examples 1 to 3: Preparation of Optical Adhesive Compositions

[0084] Optical adhesive compositions were prepared by mixing the components according to the composition listed in Table 1 and stirring the mixture for 1 hour or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com