Thermally robust illuminator probe tip

A probe, heat-resistant technology, applied in the field of lighting probes, can solve problems such as deformation of the end of the lighting probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

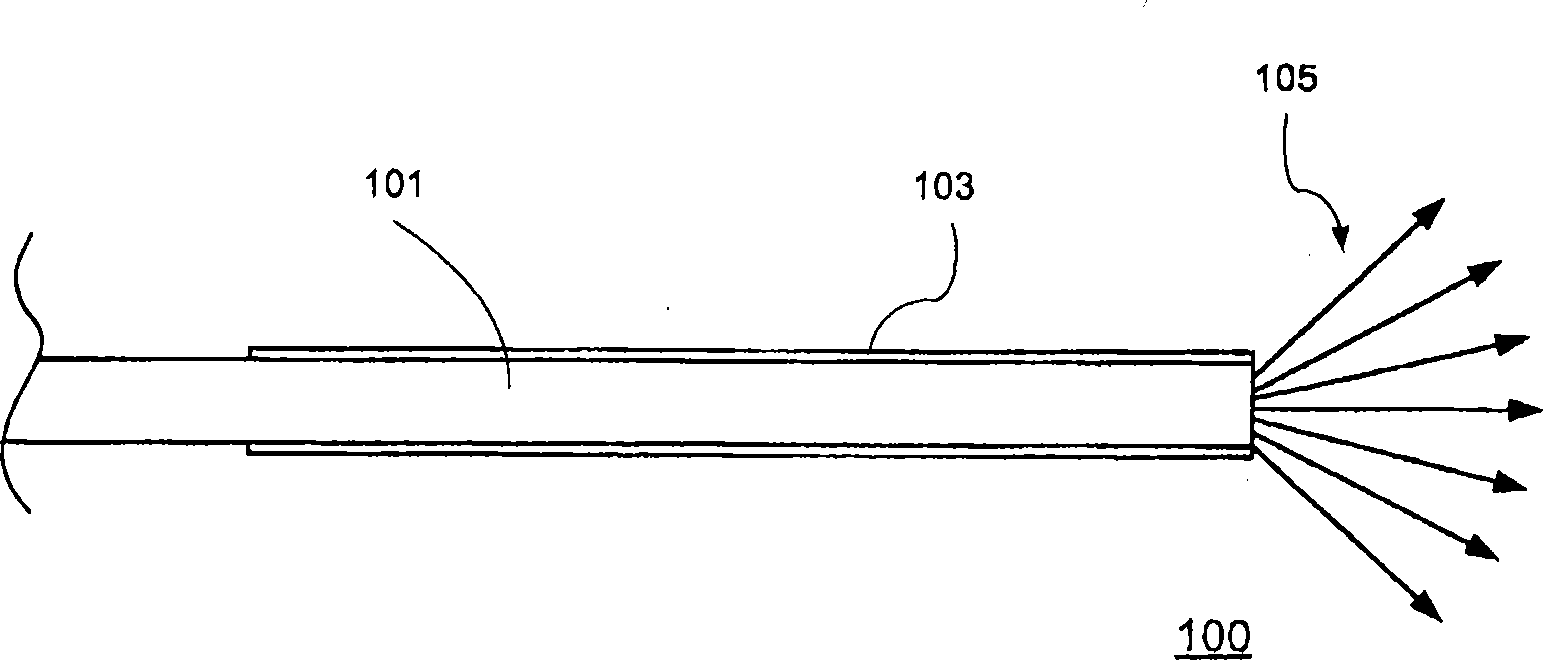

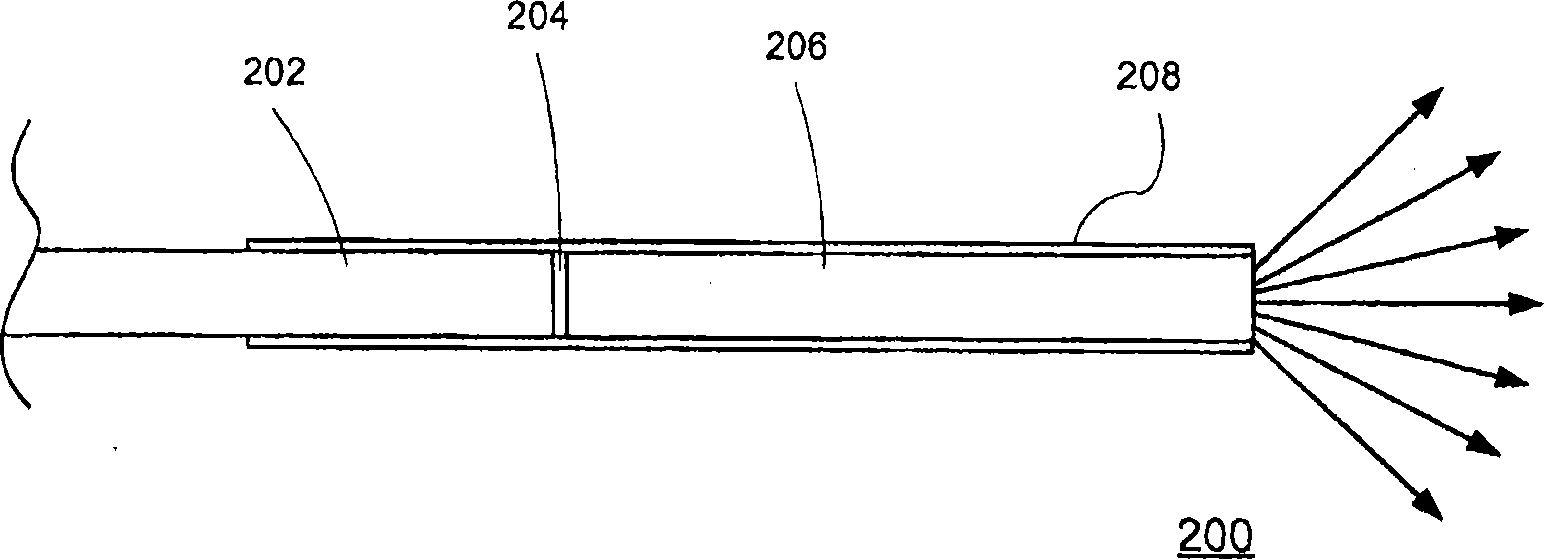

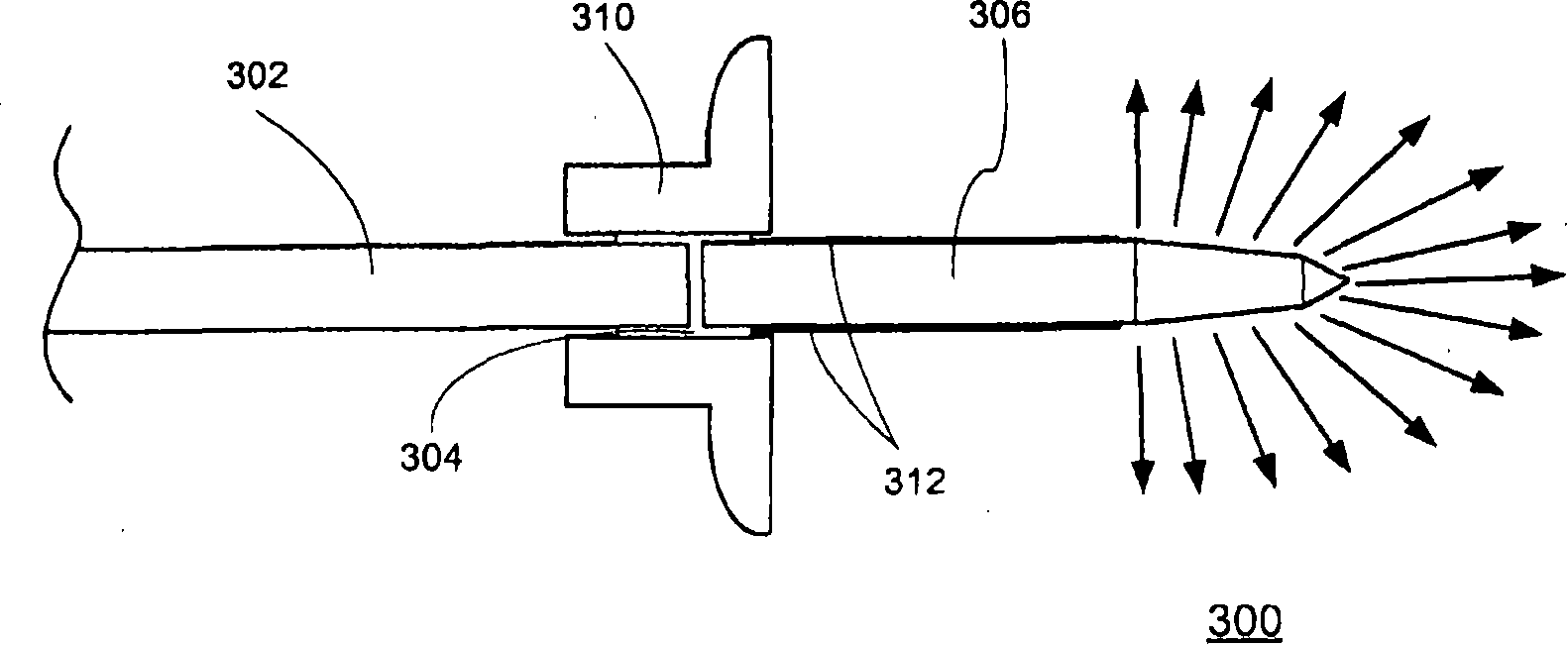

[0032] The drawings illustrate a preferred embodiment of the invention, and like numerals in different drawings represent like and corresponding parts.

[0033] Various embodiments of the present invention provide illumination probes with heat-resistant terminated plastic optical fibers. The embodiments of the present invention are applicable to plastic optical fibers of all specifications (such as 20, 23, 25, etc.). There is now a trend towards gauge 25 and especially gauge 23 - smaller diameter indications which allow sutureless wounding of the sclera. Heat-resistant lighting probes are part of surgical systems such as ophthalmic lighting and are useful in many medical procedures such as vitreoretinal / posterior segment surgery. A typical ophthalmic illuminator may include a manual component that transmits a relatively incoherent light beam from a light source (eg, xenon light source, halogen light source, etc.) to the surgical field through an optical fiber. The heat resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com