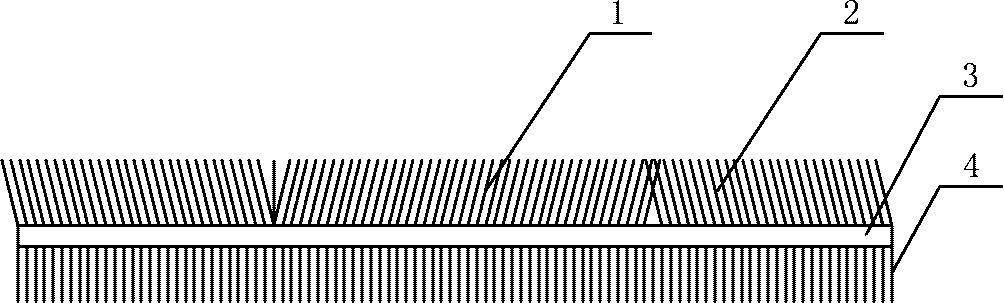

Single-layer and double-face velveting and weaving method thereof

A velvet, double-sided technology, applied in the field of single-layer double-sided velvet fabrics and single-layer double-sided velvet, can solve the problems of failure to form large-scale production, affecting the comfort of suede, and covering a large area, and achieve manufacturing costs. Low, soft gloss effect with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

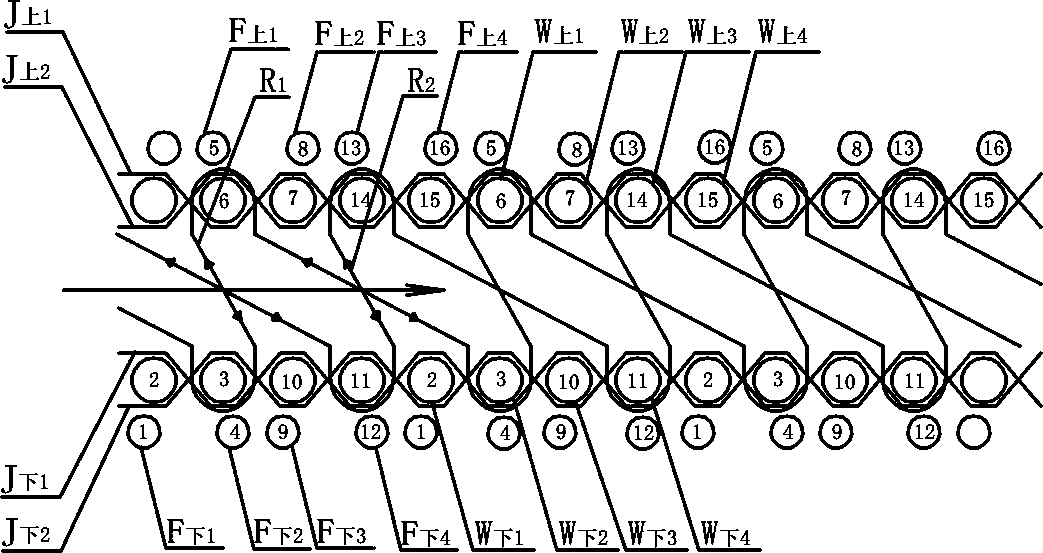

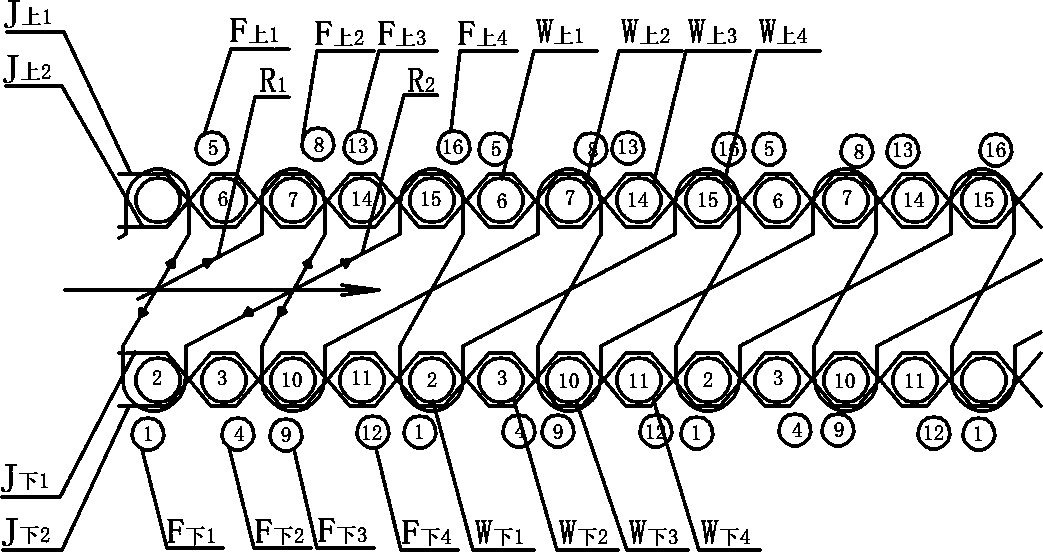

[0029] figure 2 It shows the structure when the pattern pile is consolidated with the ground weft V-shaped structure in the single-layer double-sided velvet fabric of the present invention, the back pile is consolidated with the ground weft U-shaped structure, and the pile of the upper base cloth is tilted forward, and the specific weaving See the first reed tooth part in Table 1 for the method.

[0030] image 3 Shown in the single-layer double-faced velvet fabric of the present invention is that the pattern pile is consolidated with the V-shaped structure of the ground weft, the back pile is consolidated with the U-shaped structure of the ground weft, and the structure when the pile of the upper base fabric is tilted backward, the specific weaving The method is shown in the first reed tooth part in Table 2.

[0031] Figure 4 It shows that in the single-layer double-faced velvet fabric of the present invention, the pattern pile is consolidated with the V-shaped structure...

Embodiment 2

[0108] Figure 7 It shows the pile head of the pattern pile and the back pile pile are consolidated on the weft yarn of the base fabric in a W-shaped structure, and the structure when the pile head of the upper base fabric is tilted forward. For the specific weaving method, see the first reed tooth in Table 5. part.

[0109] Figure 8 It shows the pile head of the patterned pile and the pile of the back pile are consolidated on the weft yarn of the base fabric in a W-shaped structure, and the structure when the pile of the upper base fabric is reclined. For the specific weaving method, see the first reed tooth in Table 6. part.

[0110] Figure 9 It shows the pile head of the pattern pile and the pile pile of the back pile are consolidated on the weft yarn of the base fabric in a W-shaped structure, and the structure of the pile head of the upper base fabric is converted from forward to backward. The specific weaving method is shown in Table 7. The middle part of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com