Patents

Literature

67results about How to "Realize the noise reduction function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-adaptive denoising method and system based on sub-band noise analysis

ActiveCN103871421ASignificant Gain DifferenceImprove signal-to-noise ratioSpeech analysisTarget signalAdaptive denoising

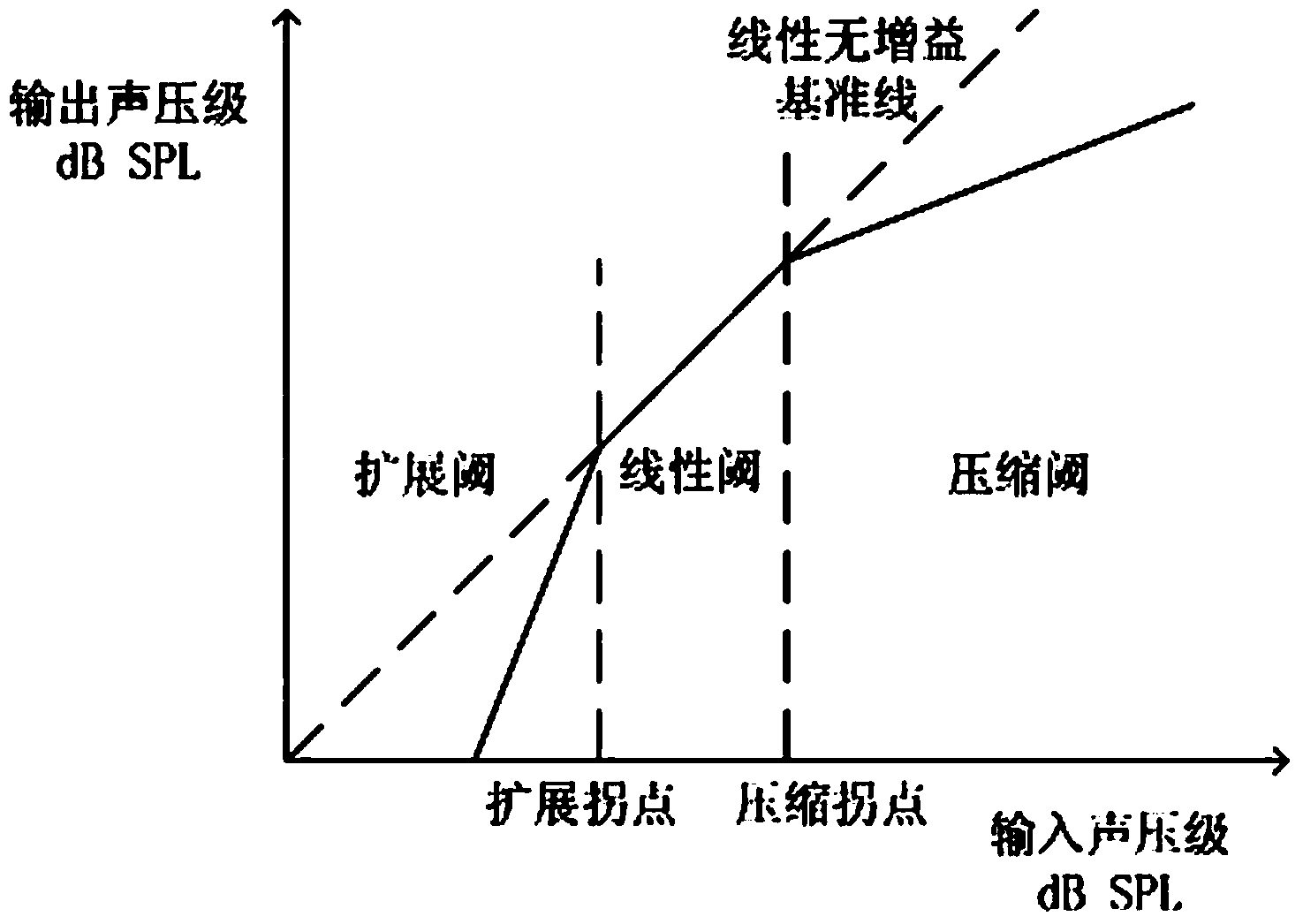

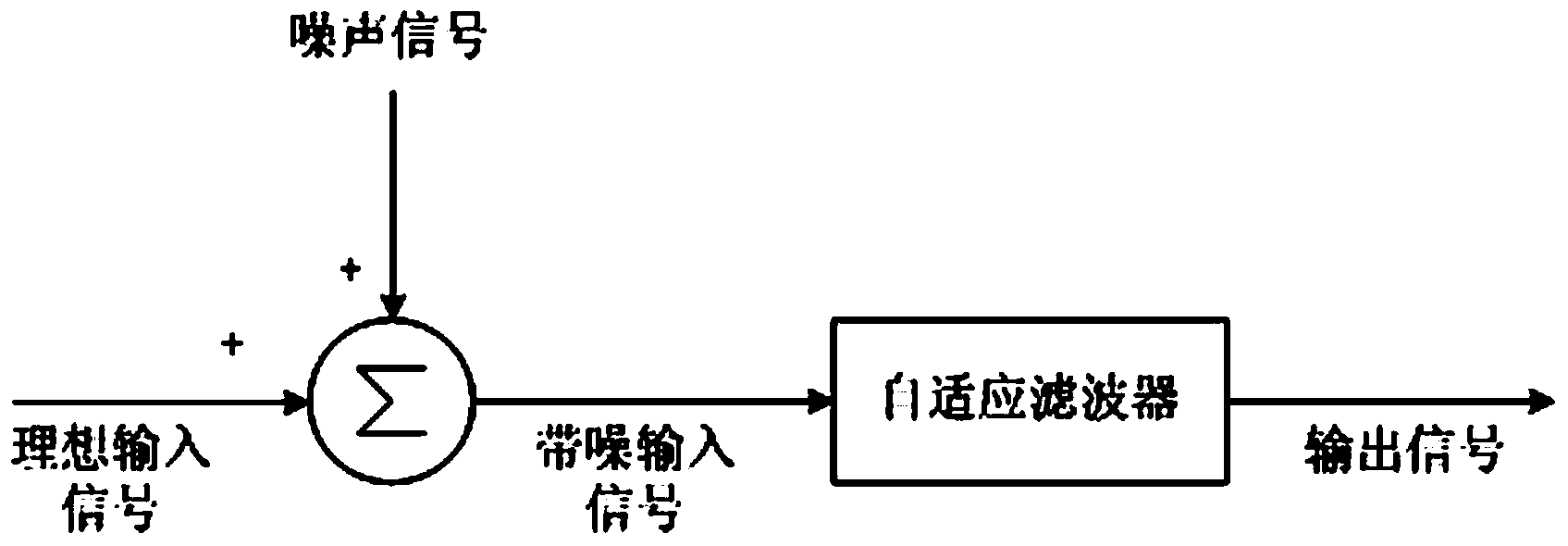

The invention relates to the field of voice technologies, in particular to a self-adaptive denoising method based on sub-band noise analysis. The method includes the steps that firstly, framing and short time frequency domain transformation are conducted on input time domain audio signals with noise, and then frequency domain audio signals with noise are generated; secondly, a noise energy spectrum of the frequency domain audio signals with noise is estimated through a minimum value tracking method; thirdly, the posterior signal to noise ratio and the prior signal to noise ratio of the noise energy spectrum are calculated; fourthly, through a nonlinear gain extension method, denoising gains of all time frequency units are calculated through the posterior signal to noise ratio and the prior signal to noise ratio; fifthly, smoothing filtering is conducted on the denoising gains of all the time frequency units to reduce tone quality distortion; sixthly, the denoising gains act on all the time frequency units of the audio signals with noise in the first step, and then denoised frequency domain audio signals are acquired; seventhly, short time frequency domain inverse transformation is conducted, and then the final denoised time frequency audio signals are acquired and output. According to the method and system, stable noise in target signals can be greatly lowered.

Owner:厦门莱亚特医疗器械有限公司

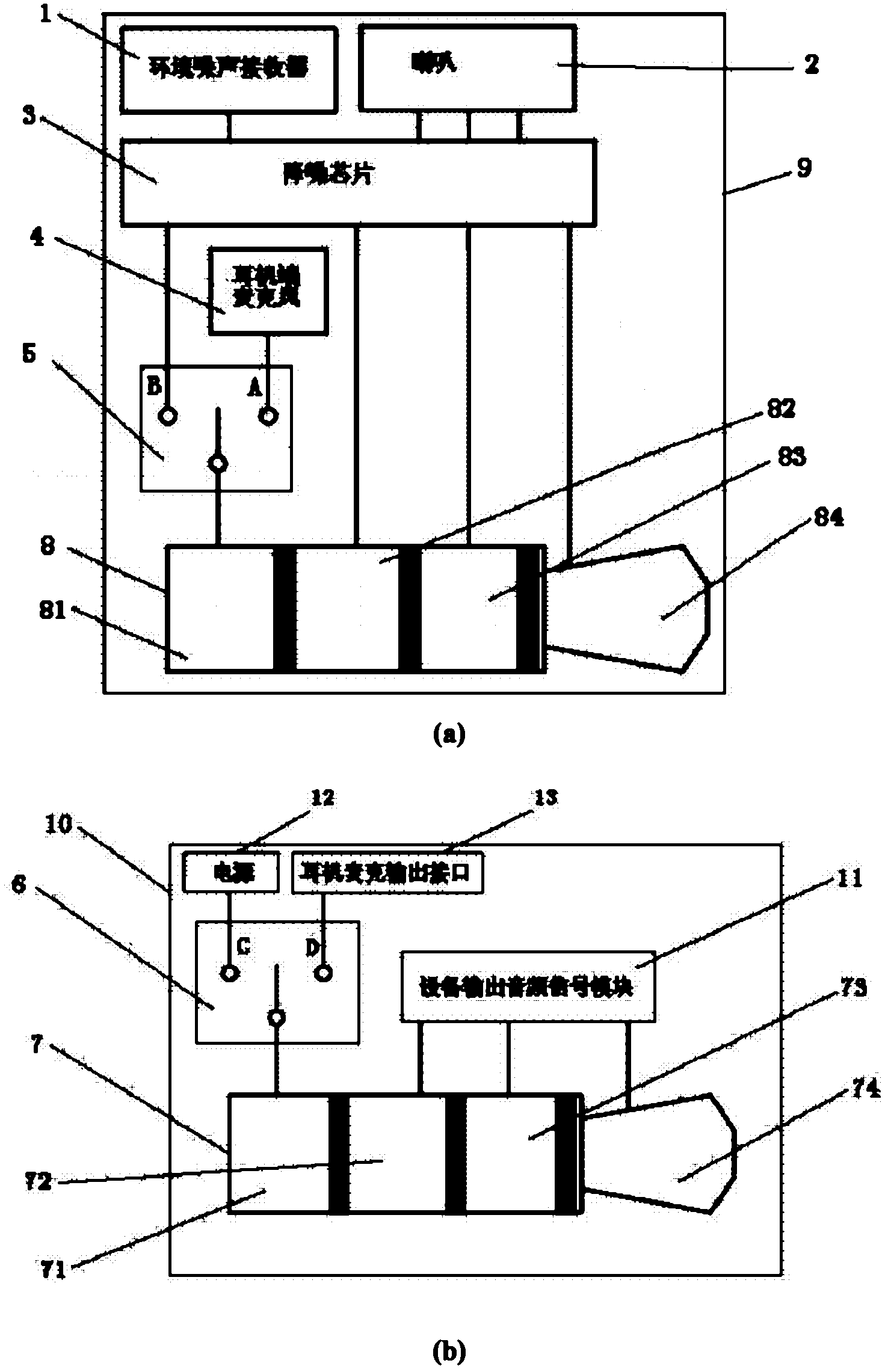

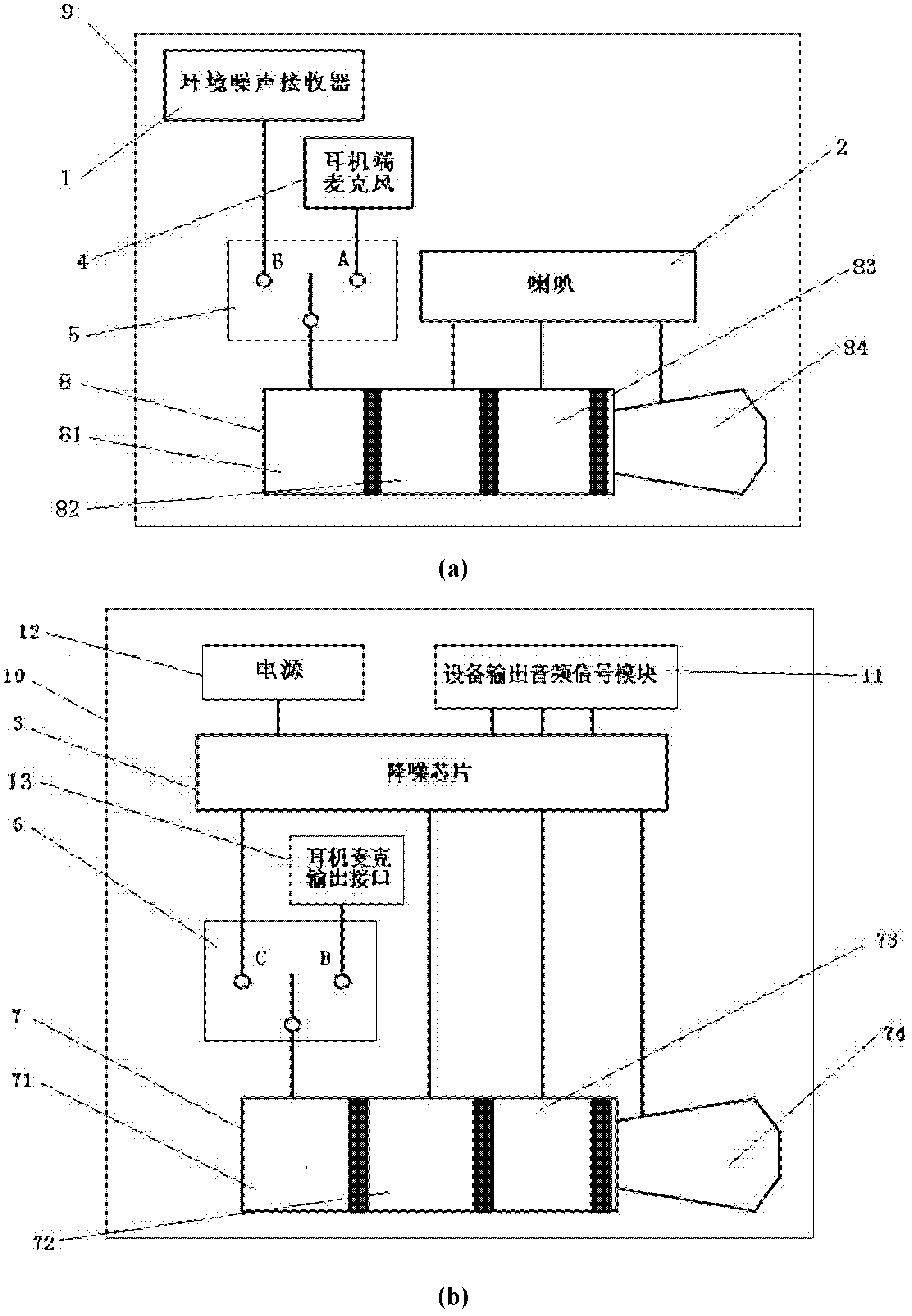

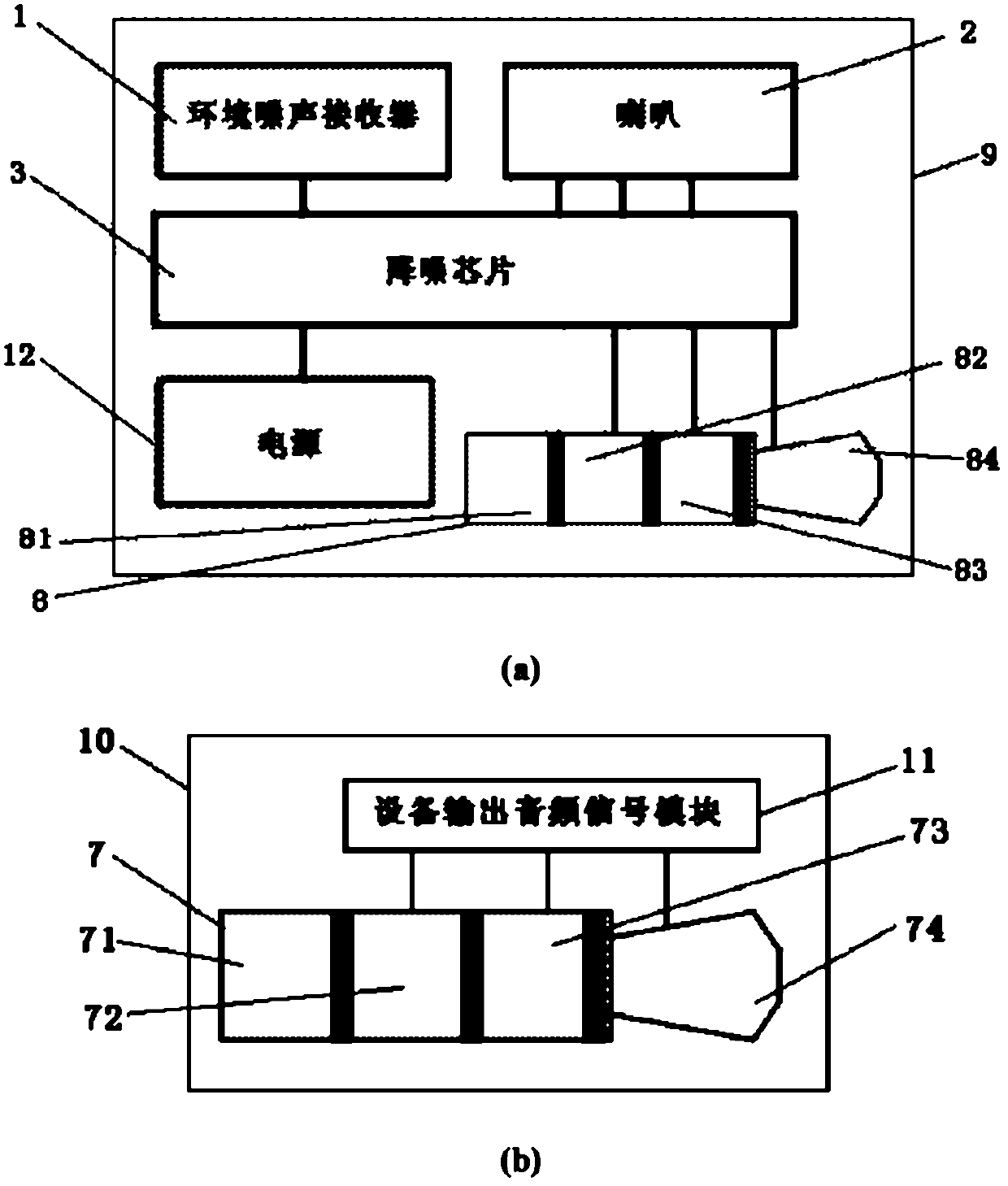

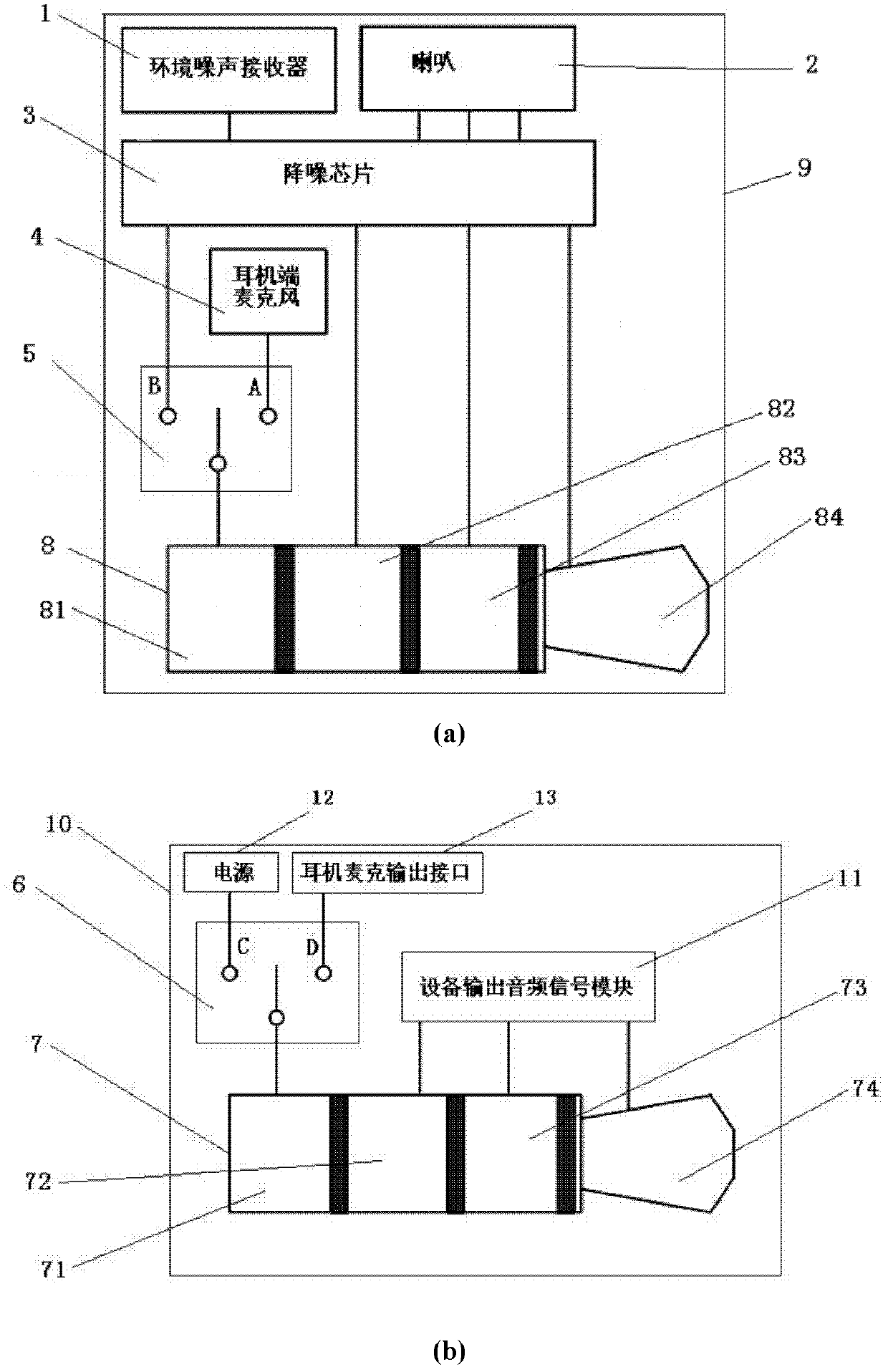

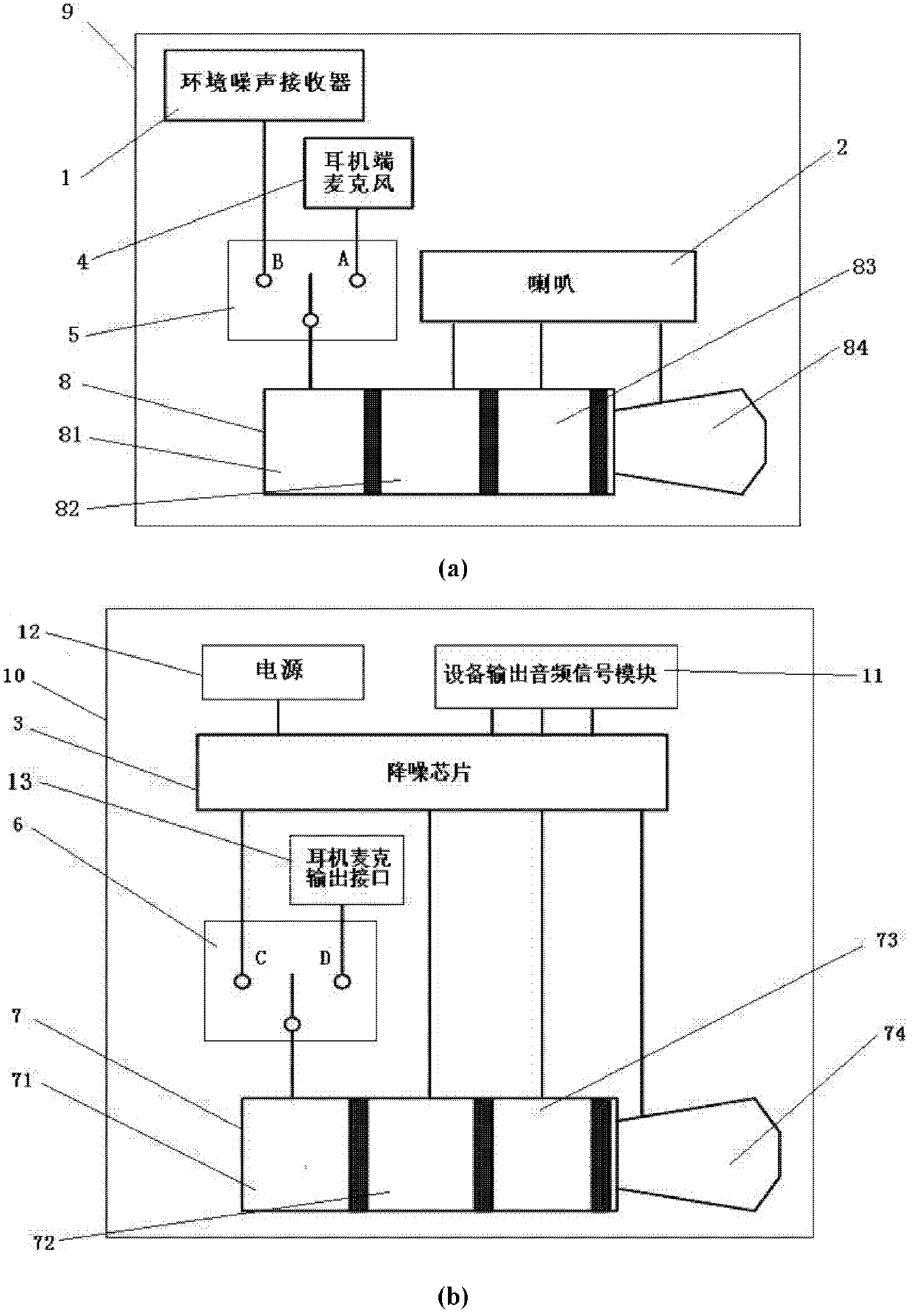

Noise Canceling Headphone Interface Architecture

ActiveCN102291643ARealize the noise reduction functionEarpiece/earphone attachmentsEngineeringHeadphones

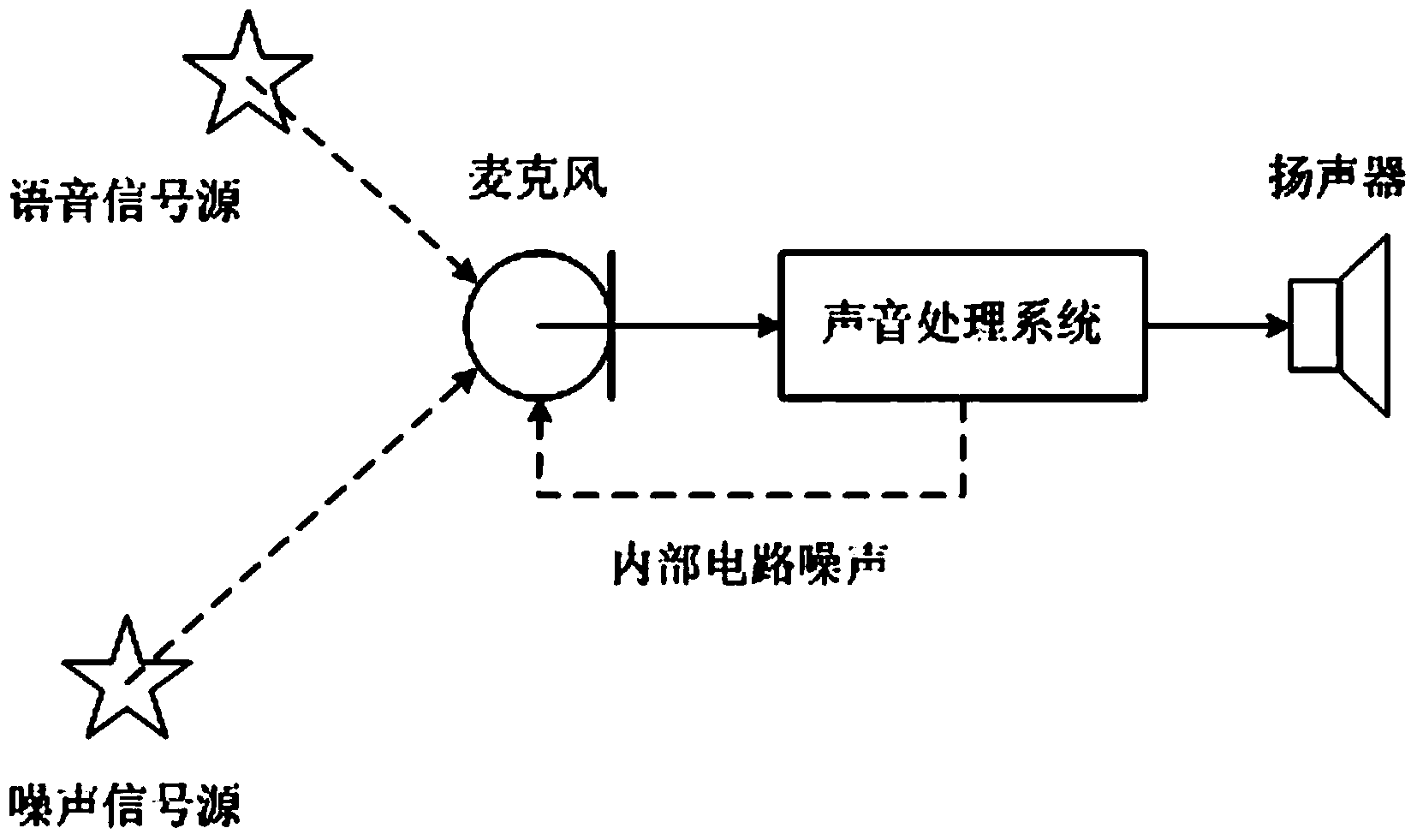

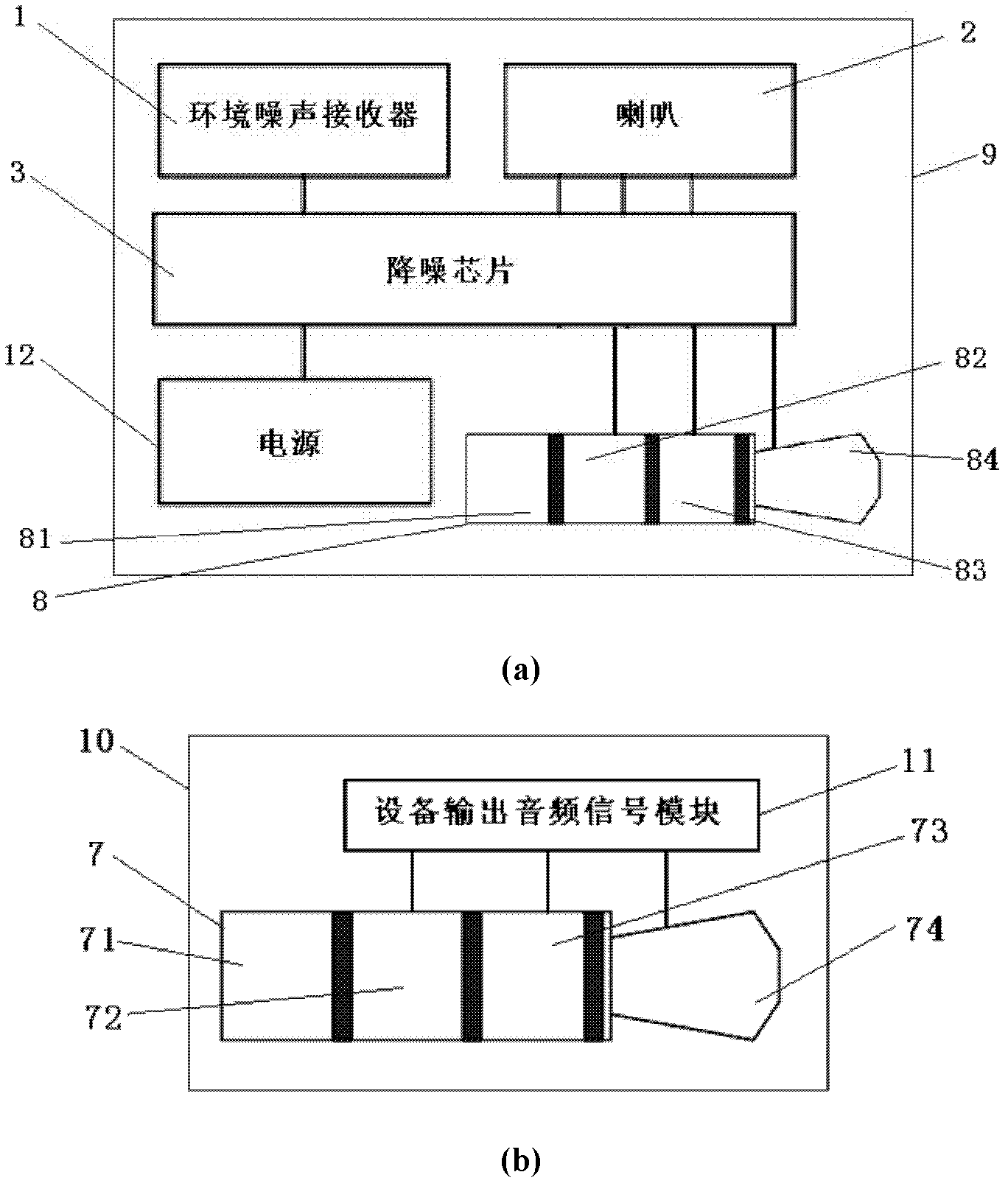

The invention relates to a noise reduction earphone interface structure in the technical field of equipment noise reduction. The noise reduction earphone interface structure comprises a noise reduction chip, a loudspeaker, an earphone-side microphone, a device-side control switch, a device-side audio interface and an earphone-side audio interface. The noise reduction earphone interface structure solves the problems of large earphone volume, heavy weight and limited endurance caused by an external power supply of a noise reduction earphone.

Owner:CHIPHOMER TECH SHANGHAI

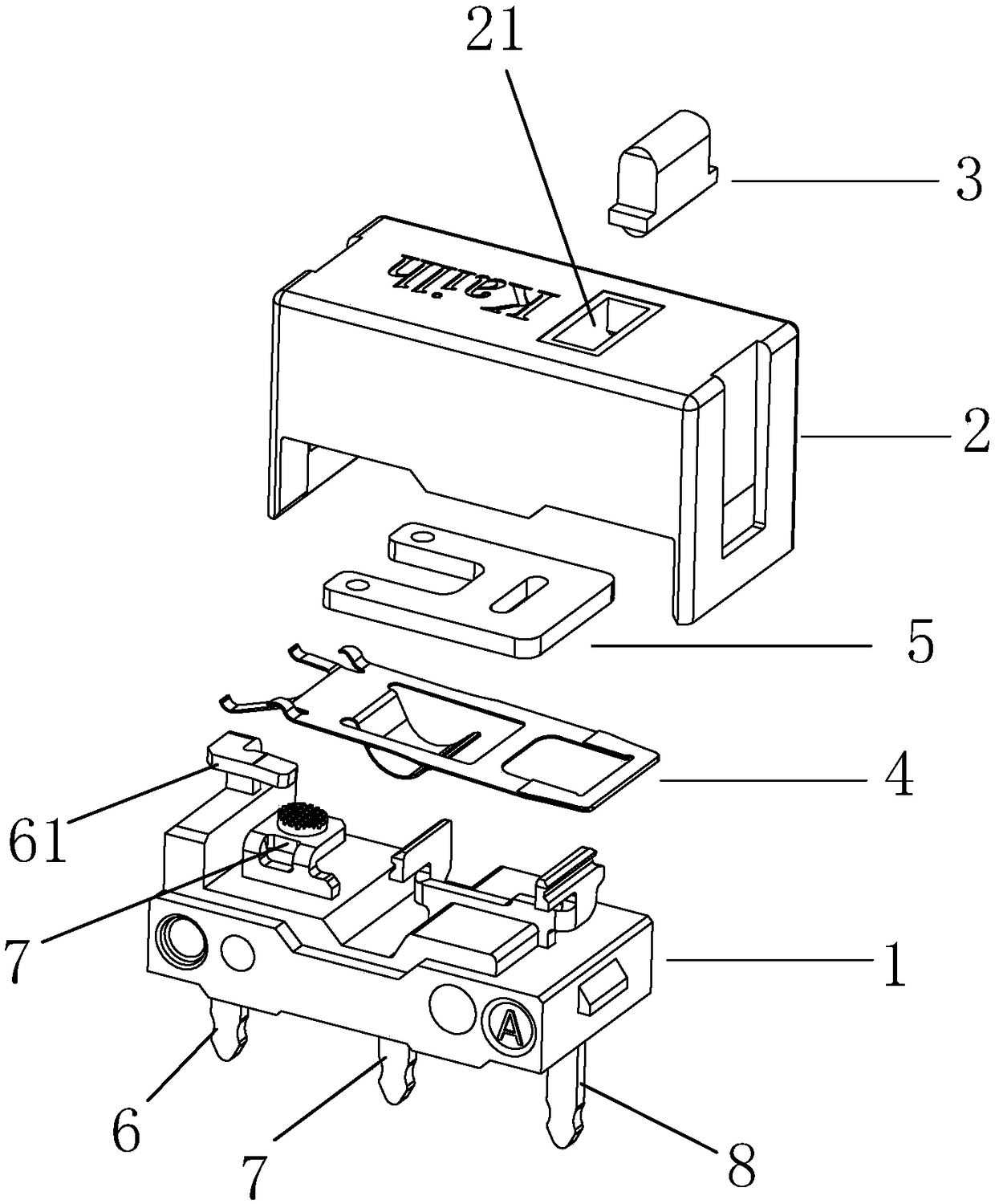

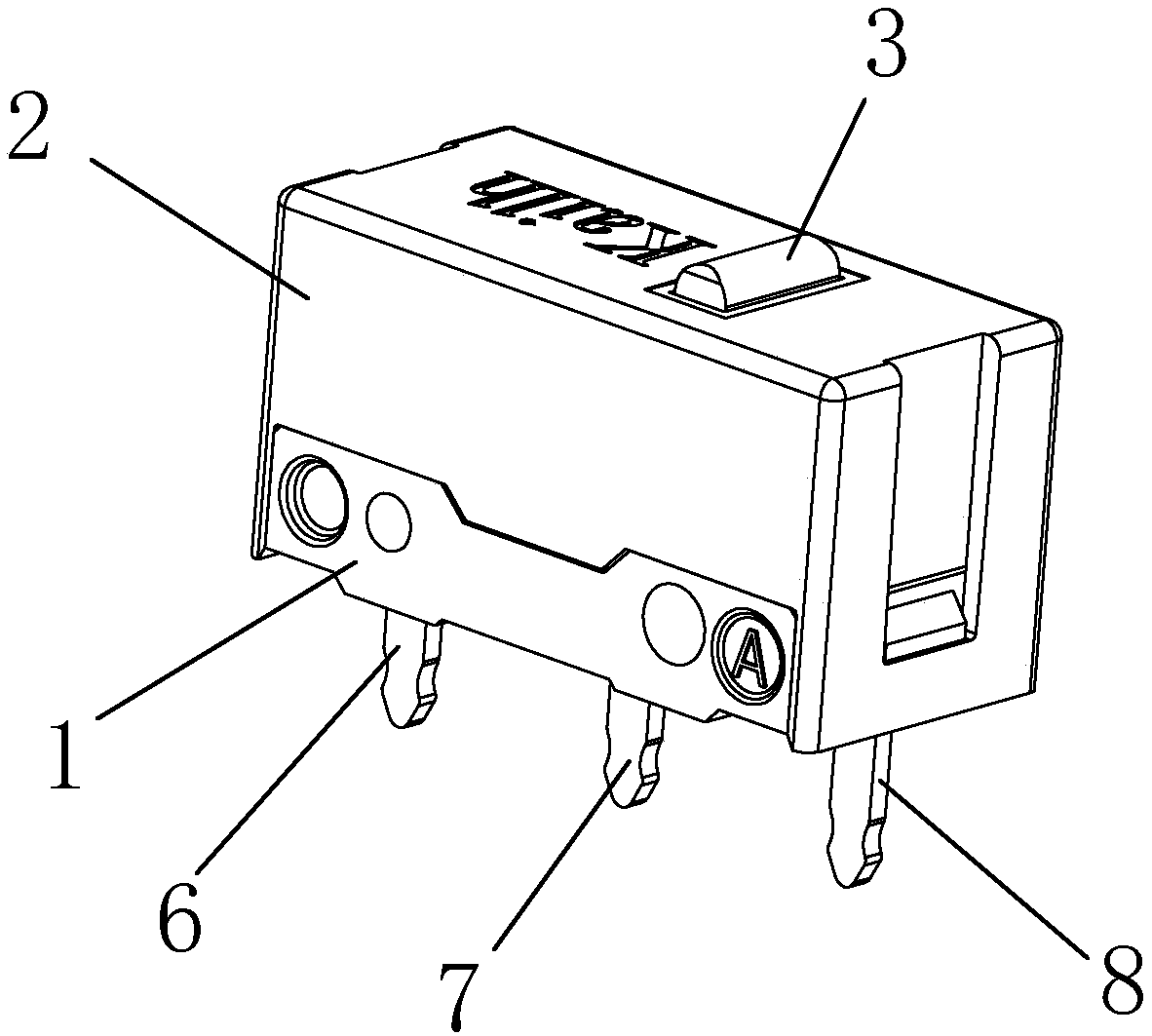

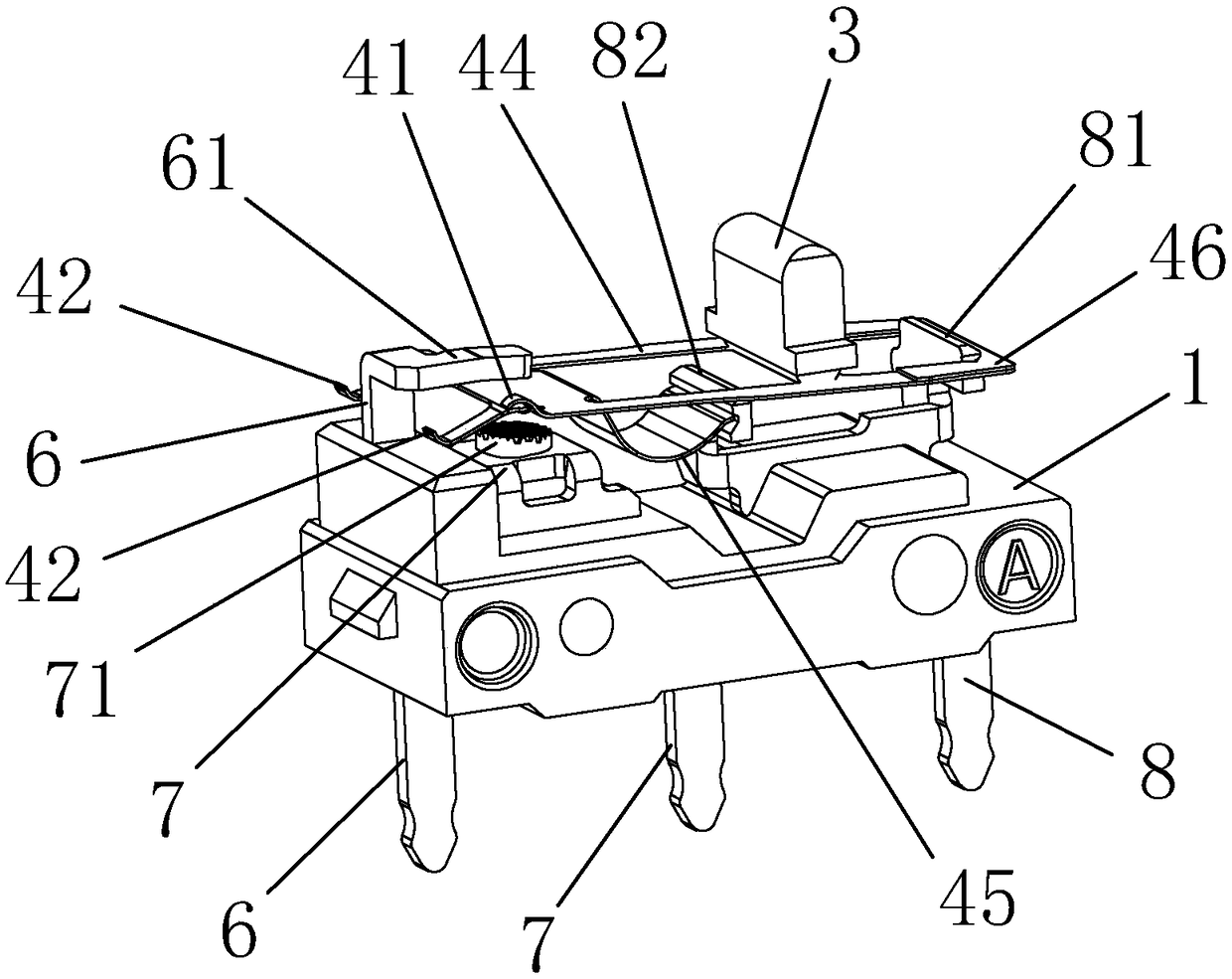

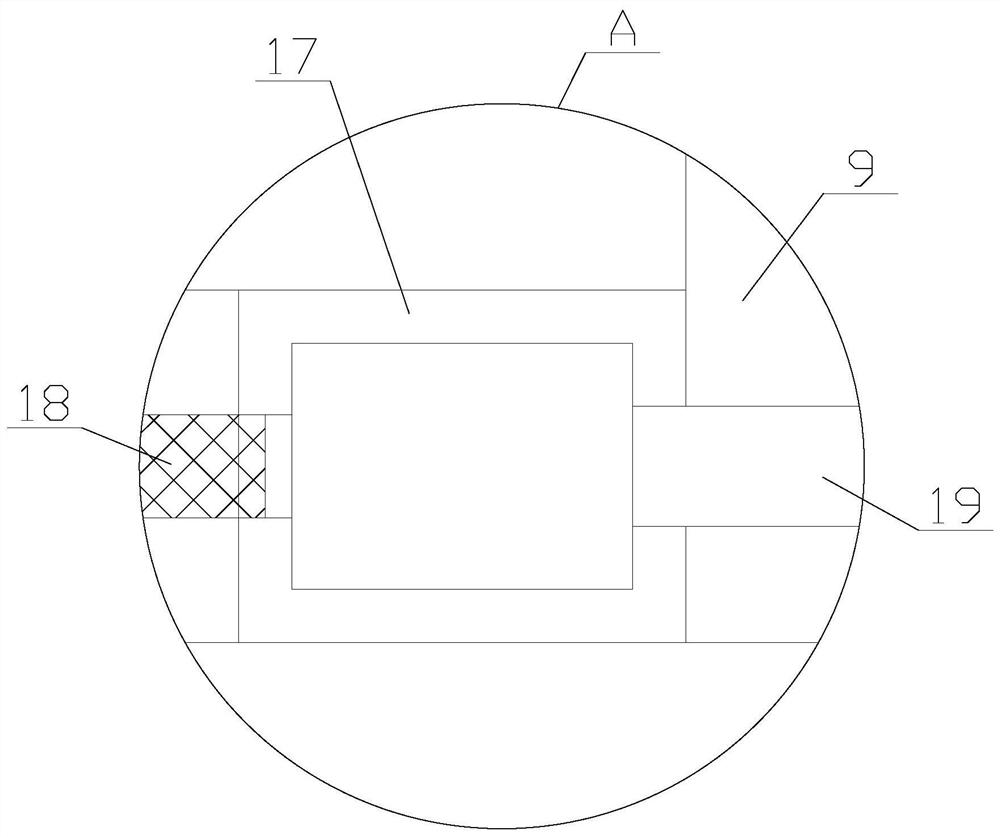

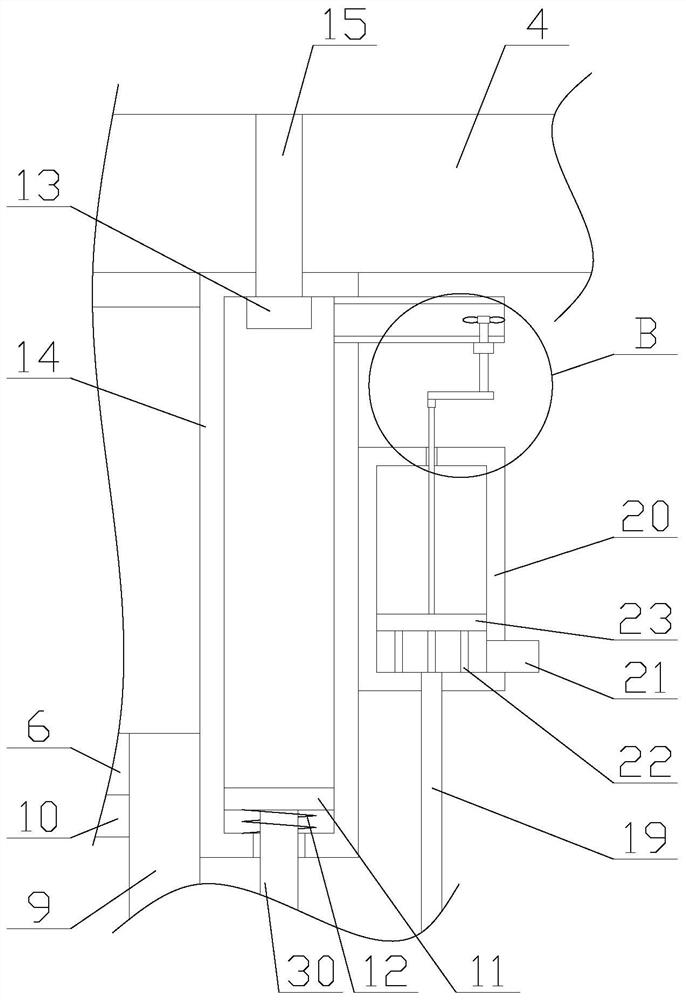

High-life mute micro-switch

PendingCN108281314AReduce impactRealize the noise reduction functionElectric switchesElastomerEngineering

The invention discloses a high-life mute micro-switch, which comprises a base, a cover covering the base, an elastic body and a flexible body, wherein the cover covers the base to form an accommodating cavity; a guide core is arranged in the accommodating cavity; an upper opening through which the upper end of the guide core passes is formed in the cover; the elastic body is arranged in the accommodating cavity and is located at the lower part of the guide core; the flexible body is arranged on the lower end surface of the cover and is located at the upper part of one end of the elastic body;a plurality of upper elastic strips are arranged at one end of the elastic body in a manner of extending upwards; the plurality of upper elastic strips are located below the flexible body; and when pressing on the guide core is released, the elastic body rebounds due to deformation recovery, and the upper elastic strips are prompted to touch the flexible body and flexibly deform, so that the impact force is reduced through generated buffer force to achieve the muting effect. The micro-switch disclosed by the invention has the muting function, a good muting effect is achieved, and meanwhile, the whole life is prolonged and reaches 80,000,000 times.

Owner:DONGGUAN CITY KAIHUA ELECTRONICS

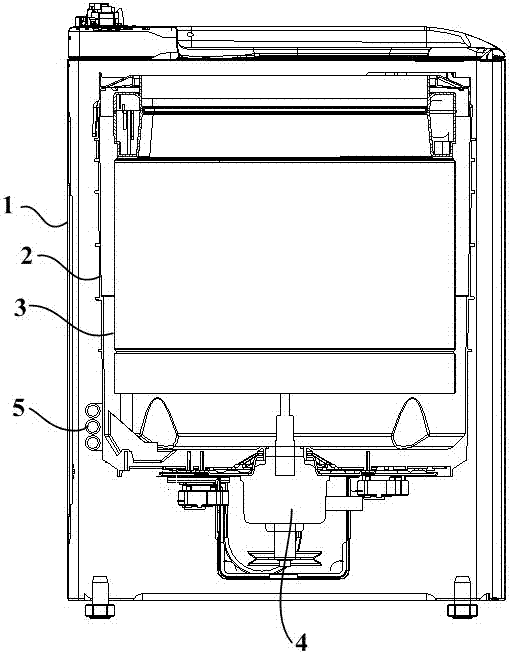

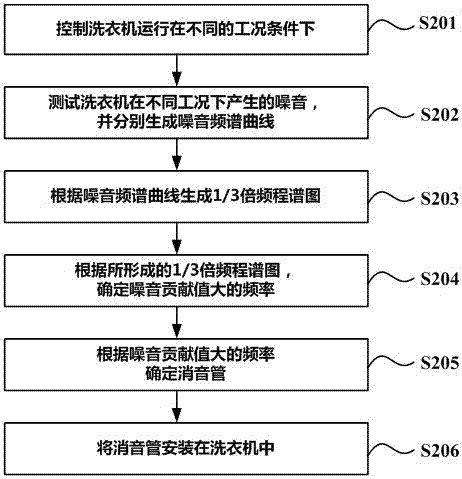

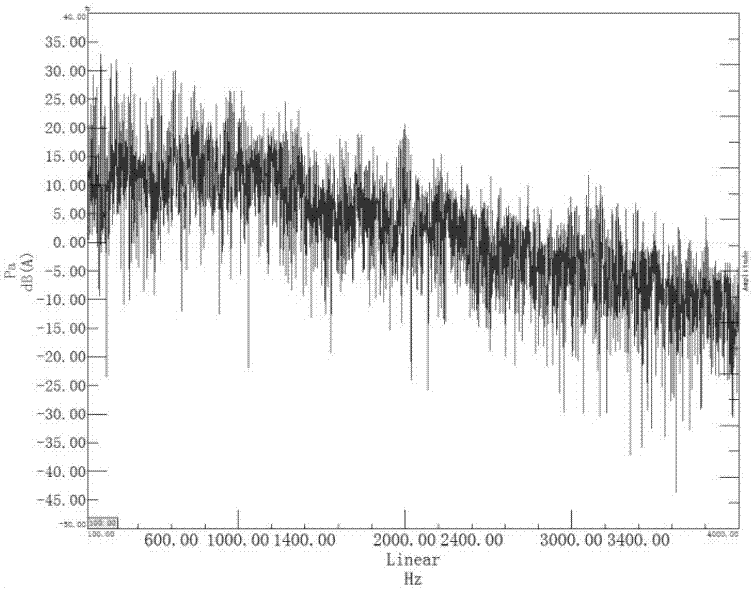

Washing machine silencing method and washing machine

InactiveCN106868796AReduce machine noiseImprove user experienceOther washing machinesTextiles and paperEngineeringLaundry washing machine

The invention discloses a washing machine silencing method and a washing machine. The method includes the steps that noise generated in the work process of the washing machine is tested, and a noise frequency spectrum curve is generated; according to the noise frequency spectrum curve, the frequency large in noise contribution value is determined; according to the frequency large in noise contribution value, a silencing tube is determined; the silencing tube is installed in the washing machine to absorb the noise at the frequency. The silencing tube is added into the washing machine, the noise of the whole washing machine is lowered in the mode that the silencing tube absorbs part of system noise generated during operation of the washing machine, and the use experience of a user is improved. Compared with the design scheme that vibration of the washing machine is inhibited to lower the noise of the whole machine, the structure is simpler, the practicality is higher, an existing structure of the washing machine does not need to be changed, the existing washing machine can be conveniently improved, and the noise reduction function of the washing machine is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

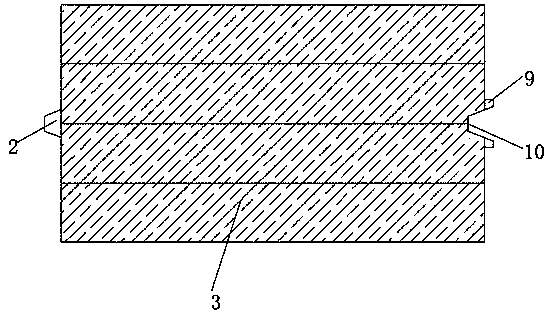

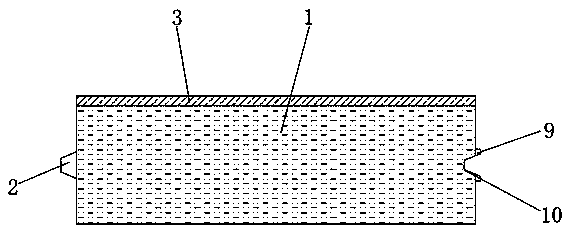

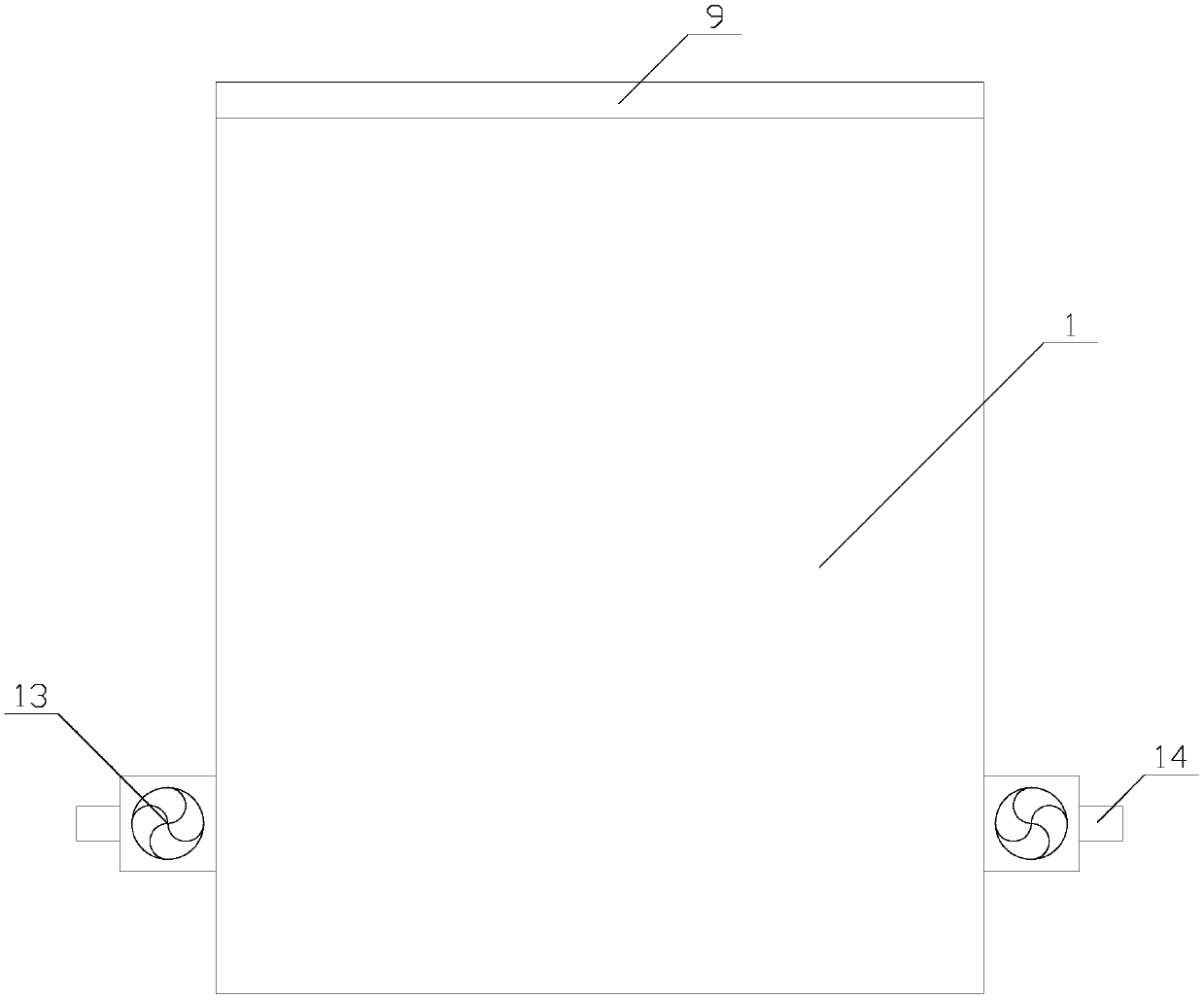

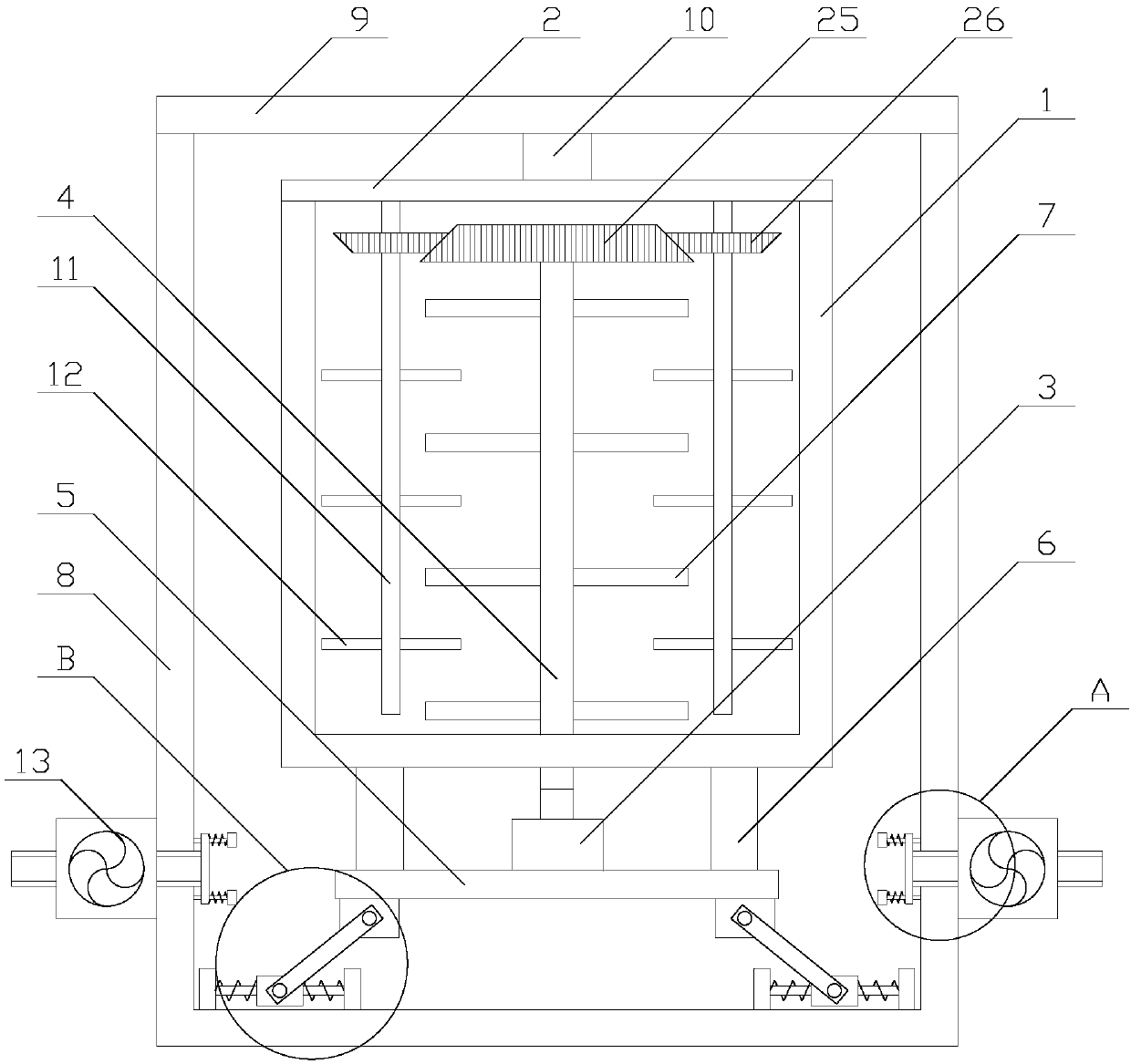

Bottom support device special for automobile battery box

ActiveCN110233219ARealize heat exchangeImprove cooling effectNon-rotating vibration suppressionElectric propulsion mountingVibration amplitudeAutomotive battery

The invention provides a bottom support device special for an automobile battery box. The bottom support device comprises a cooling mechanism and a shockproof mechanism, wherein the shockproof mechanism is arranged in the cooling mechanism, the cooling mechanism comprises an outer shell, an installation frame, a dustproof network, cooling fins, comb teeth, a cooling plate and a coiled pipe, and the shockproof mechanism comprises an inner shell, a connection rod, a piston, a shockproof spring and a noise reduction cylinder. Compared with the prior art, the bottom support device has the following beneficial effects that the replacement of the cooling fins is achieved, and the cooling effect is improved; moreover, the cooling efficiency is improved by cycle flowing of cooling water in the coiled pipe, an elastic force is generated by the shockproof spring, the horizontal vibration amplitude is effectively reduced, the shockproof effect is improved, and the stability is high; and meanwhile, the guide function is achieved during the process of the piston horizontally moving along an inner wall of the noise reduction cylinder, the vibration amplitude in other directions is effectively reduced, the shockproof effect is further improved, and the noise reduction function is achieved by design of the piston and the noise reduction cylinder.

Owner:ZHEJIANG SHANQI TIANYING VEHICLE IND CO LTD

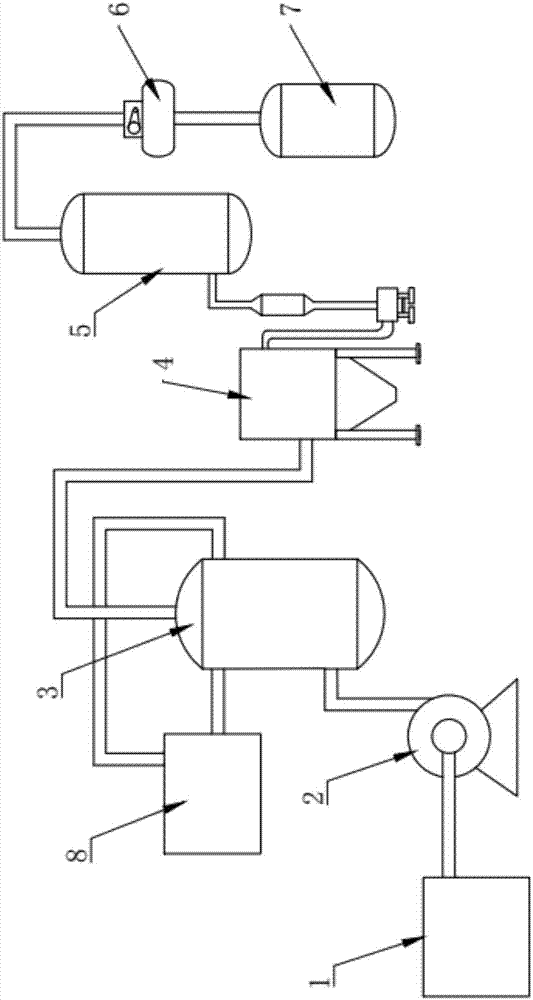

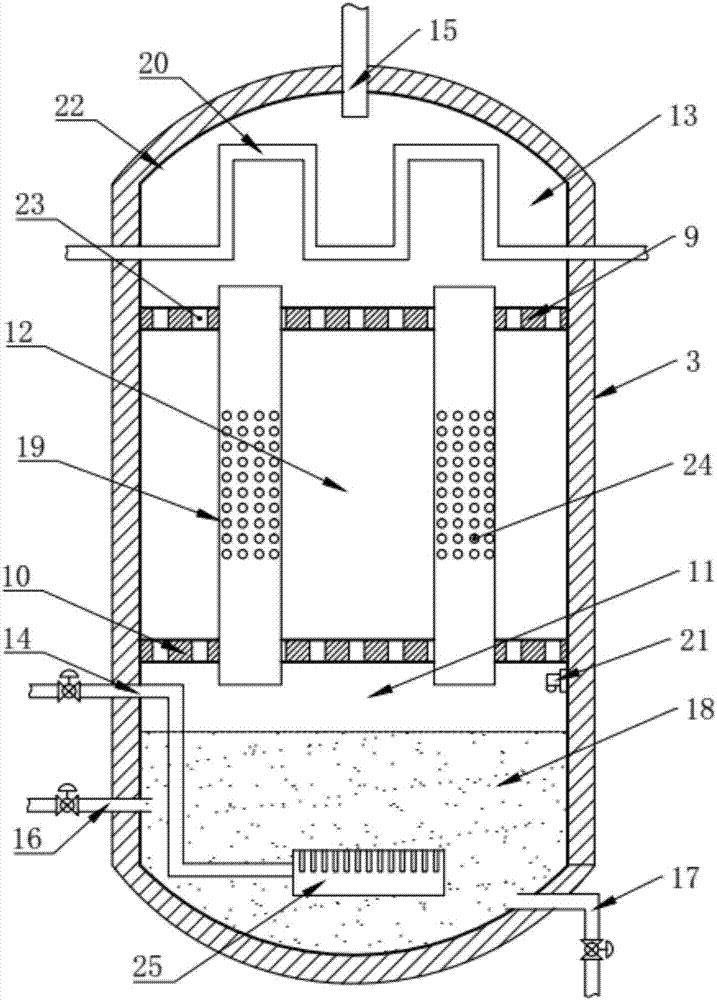

Calcium carbide furnace tail gas recycling device

InactiveCN107174940AReduce dust contentReduce the temperatureHuman health protectionCombination devicesSodium bicarbonateGas compressor

The invention belongs to the technical field of chemical environmental protection and provides a calcium carbide furnace tail gas recycling device. A tail gas outlet of a calcium carbide furnace is sequentially communicated with an induced draft fan, a silencing type environment-friendly canister, a cyclone separator, a spray washing tower, a gas compressor and a synthetic reactor; an upper partition board and a lower partition board which divide the inside cavity of the silencing type environment-friendly canister into an absorbing chamber, a noise reduction chamber and a cooling chamber are arranged in the silencing type environment-friendly canister, a plurality of first silencing holes are formed in the upper partition board and the lower partition board, an absorbing liquid is accommodated in the absorbing chamber, at least two silencing pipes communicated with the absorbing chamber and the cooling chamber are arranged in the noise reduction chamber, a heat exchange pipe is arranged in the cooling chamber, a gas inlet communicated with the absorbing chamber is formed in the bottom of the silencing type environment-friendly canister, and a gas outlet communicated with the cooling chamber is formed in the top of the silencing type environment-friendly canister; a sodium bicarbonate water solution is accommodated in the synthetic reactor. Recycling of calcium carbide furnace tail gas is realized, resource waste is avoided, pollution to the environment is avoided, and damage to body health is avoided.

Owner:HENGYANG YISHUN CHEM CO LTD

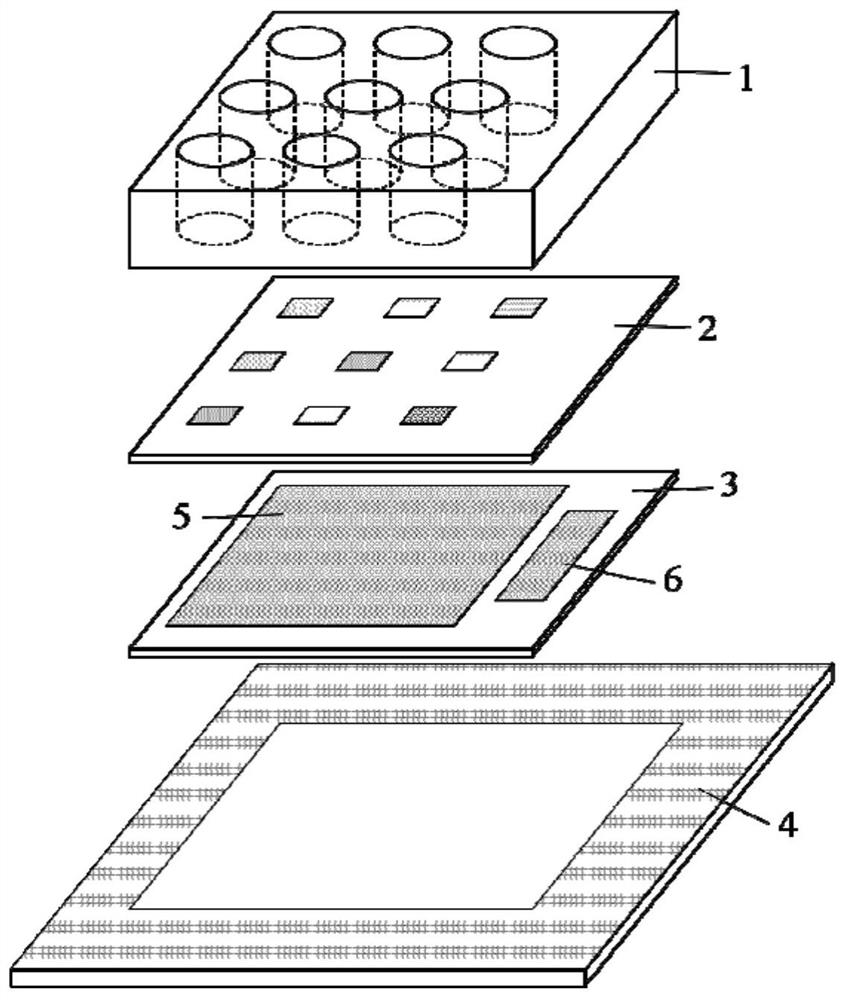

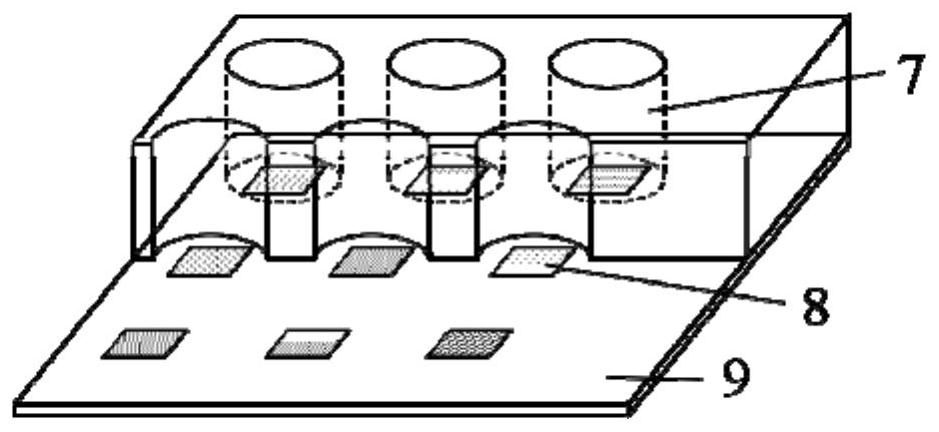

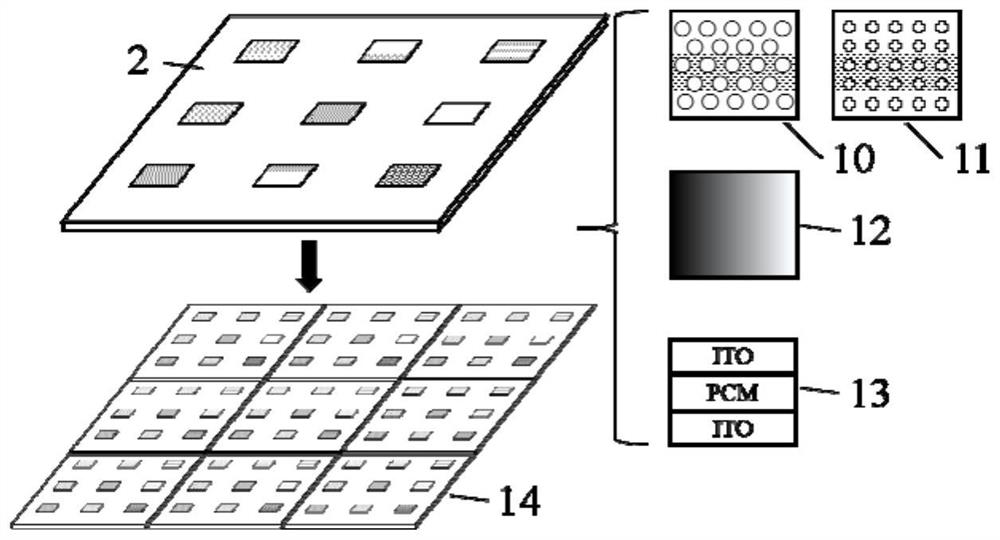

Miniature snapshot spectrometer

PendingCN113588085AEarthquake resistance and poor reliabilityReduce the difficulty of matching each otherRadiation pyrometrySpectrum investigationOptical spectrometerWave band

The invention discloses a miniature snapshot spectrometer. The spectrometer comprises an angle filter, a spectrum selection layer, a photosensitive surface and a reading circuit which are sequentially arranged from top to bottom. According to the invention, a wide-spectrum-angle filtering function is realized by using the high-aspect-ratio diaphragm array, and a micro-nano structure or band gap and refractive index adjustable thin film is constructed to realize specific spectrum transmission in the same plane. The light-sensitive surface is used for converting transmitted light of different spectrum selection layers into light current signals, and the light current signals collected by the light-sensitive surface are processed and output through a reading circuit or an external processing circuit. According to the invention, an ultra-small-size snapshot spectrograph can be realized, so that high-precision and large-spectral-range spectral analysis is realized, and the device can be suitable for various wavebands, so that different spectral analysis requirements are met.

Owner:杭州纳境科技有限公司

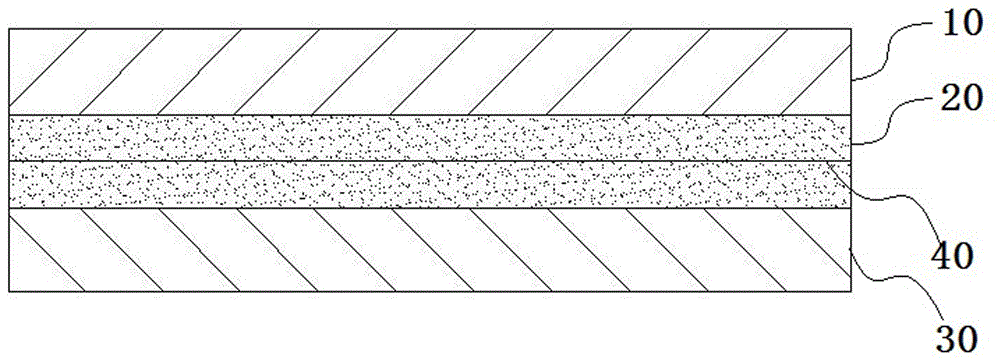

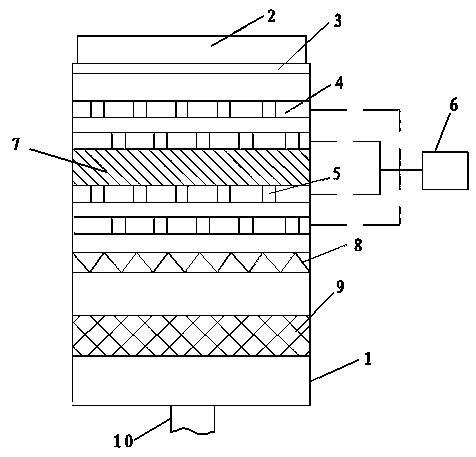

Damping composite material, damping pressing machine bottom plate structure and refrigerator

ActiveCN106633640AImprove damping performanceHigh mechanical strengthLighting and heating apparatusDomestic refrigeratorsEpoxyAdhesive

The invention discloses a damping composite material, a damping pressing machine bottom plate structure and a refrigerator. The damping composite material comprises a base material, filler and an aid, wherein the base material comprises 40 to 50 parts of epoxy resin; the filler comprises 20 to 25 parts of polyurethane polymers, 20 to 40 parts of glass fibers, 5 to 15 parts of barium sulfate, 10 to 20 parts of mica sheet, 3 to 8 parts of talcum powder, 5 to 10 parts of graphite, 5 to 20 parts of nano silicon dioxide, 5 to 10 parts of zinc oxide crystal whisker, and 5 to 10 parts of adhesives; and the content of the aid is 5 to 10 parts by weight. The damping pressing machine bottom plate structure comprises an upper metal plate, a middle damping layer and a lower metal plate, wherein the middle damping layer is made of the damping composite material. The damping pressing machine bottom plate structure is used as a compressor supporting plate to be applied to a refrigerator, so that the overall noise of the refrigerator is obviously reduced, and the overall silence effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

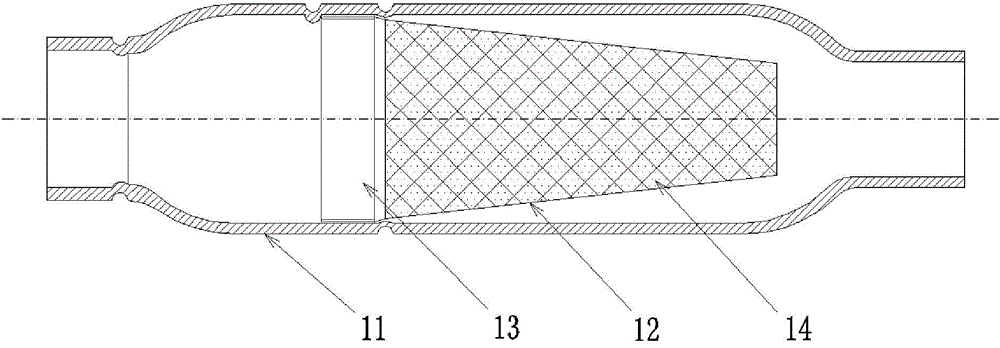

Noise reducing filter and air conditioner

InactiveCN105020876ASmall pulsationReduce flow noiseLighting and heating apparatusNoise suppressionEngineeringAir conditioning

The invention discloses a noise reducing filter and an air conditioner and relates to the technical field of air conditioning system pipeline filtering and noise reducing. The filter can achieve a noise reducing function, and the circulation amount of fluid in the filter cannot be reduced. The noise reducing filter comprises a pipe and a filter screen located in the pipe. A spiral noise reducing device is arranged in the filter screen, and the length direction of the spiral noise reducing device is consistent with the main flowing direction of the fluid in the pipe. The noise reducing filter can be applied to air conditioning systems.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

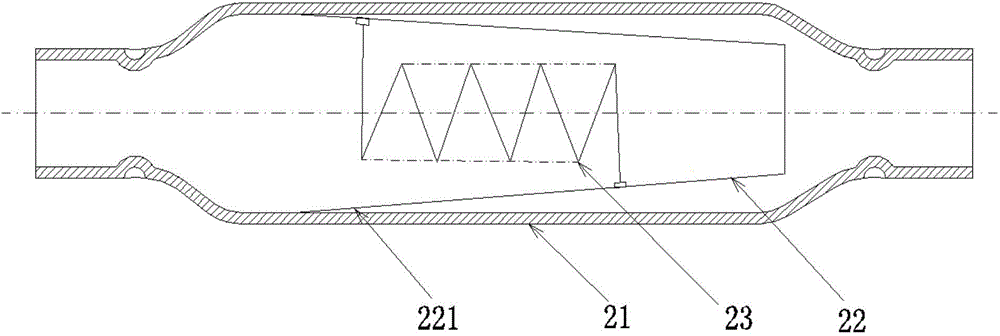

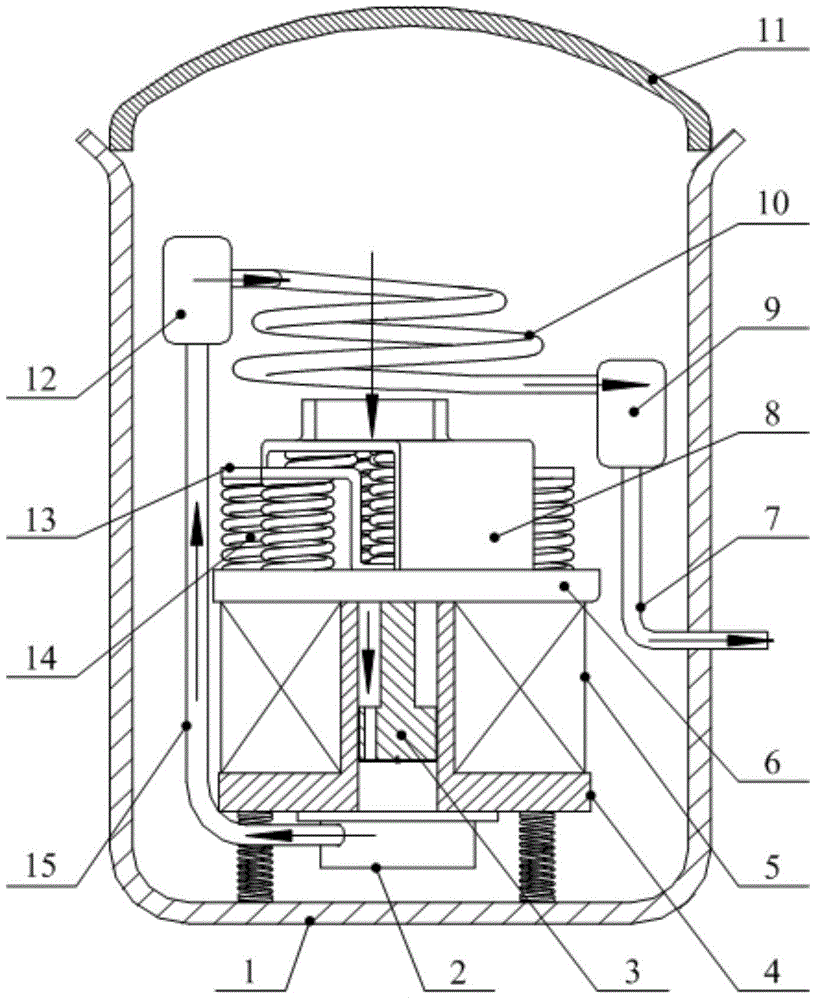

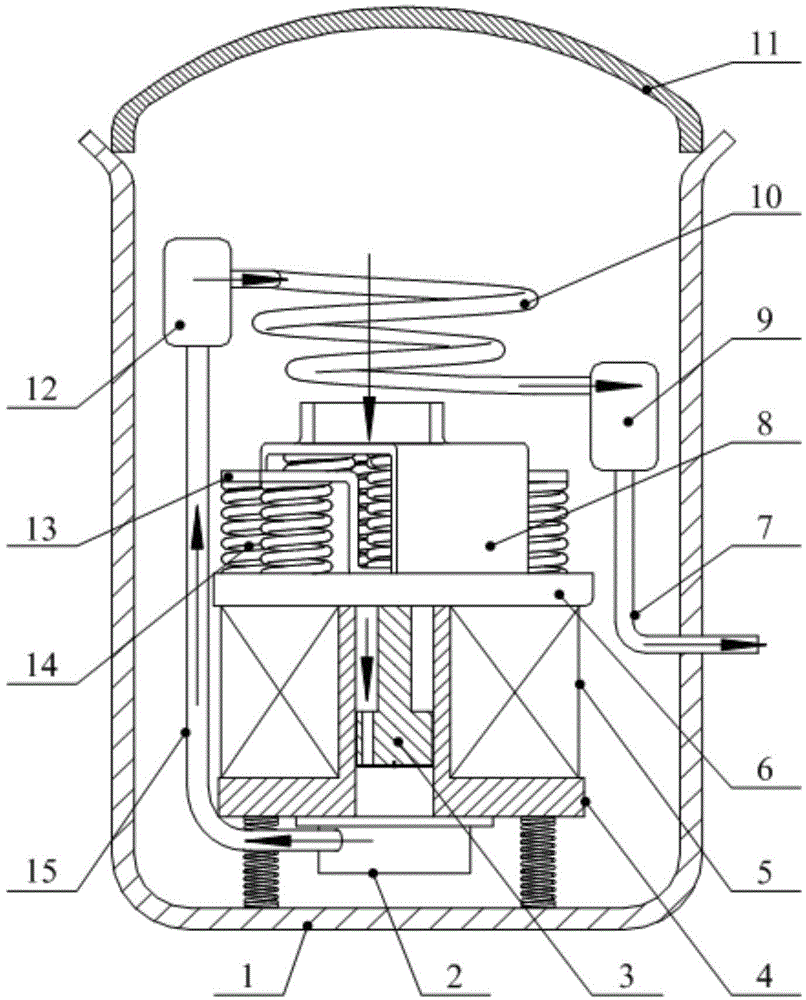

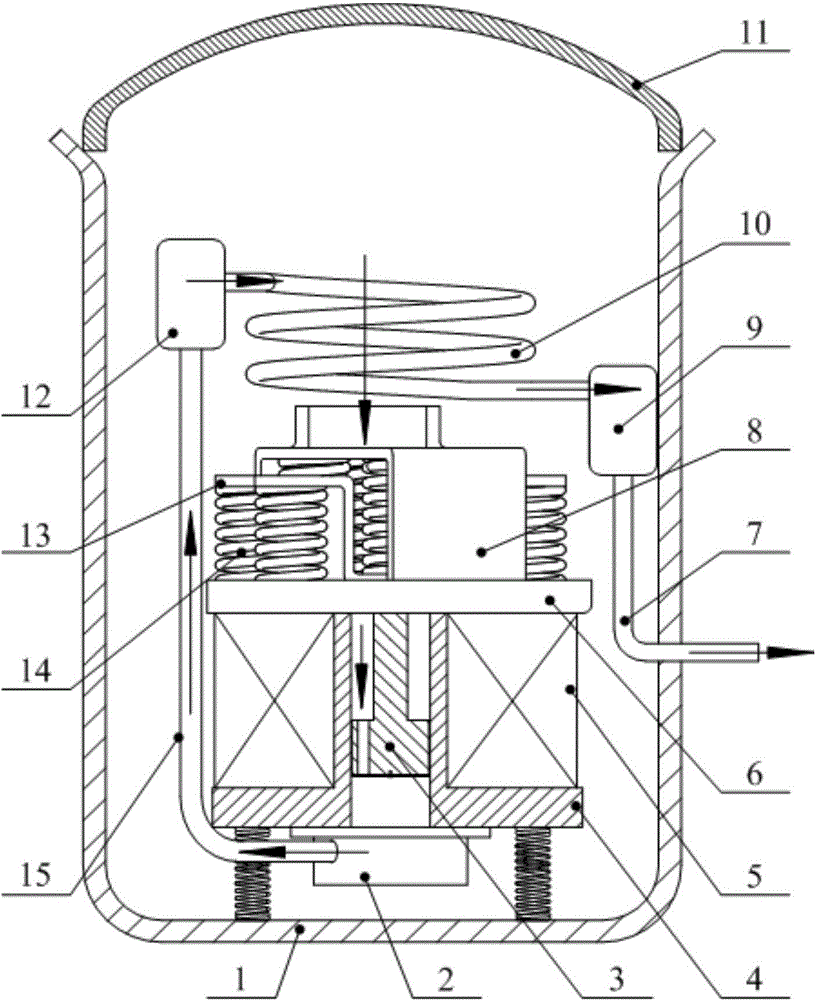

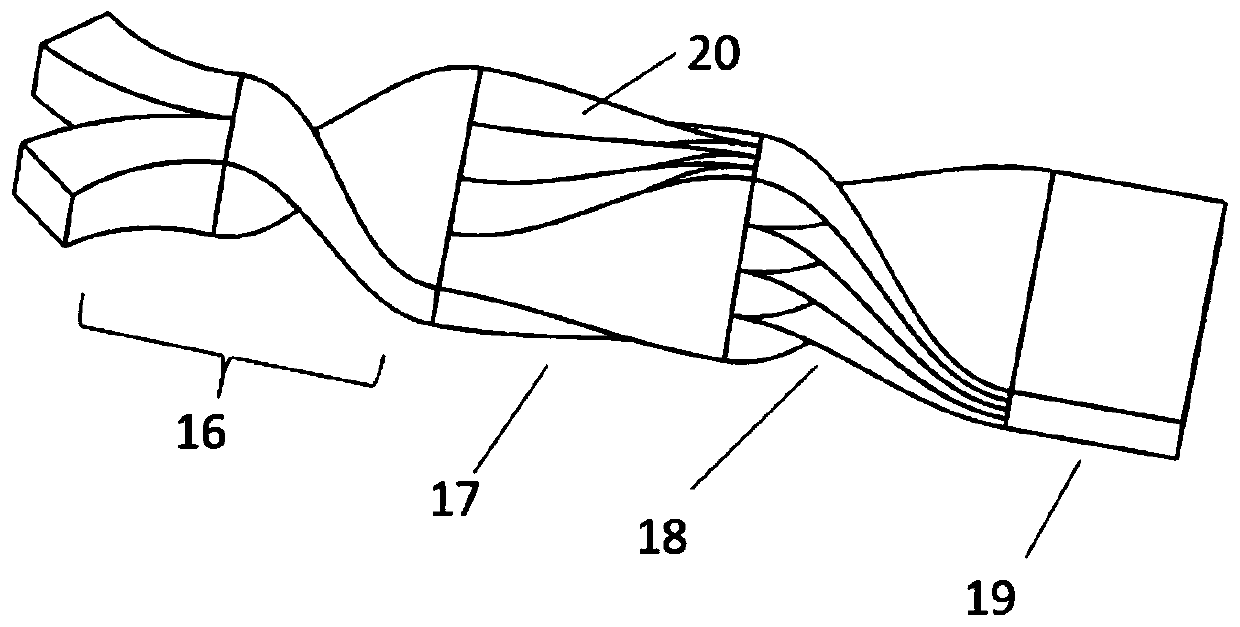

Reciprocating linear compressor and inner exhaust tube set thereof

InactiveCN105298798AReduce work impactReduce vibrationPositive displacement pump componentsPositive-displacement liquid enginesLinear compressorEngineering

The invention provides a reciprocating linear compressor and an inner exhaust tube set thereof. The inner exhaust tube set of the reciprocating linear compressor comprises a first tube section and a second tube section communicated with the first tube section through a first buffer. The second tube section is a spiral coil and extends in the axial direction. According to the inner exhaust tube set of the reciprocating linear compressor, the spiral coil has a buffering effect, so that vibration of the inner exhaust tube set is reduced, the probability that the inner exhaust tube set is broken due to vibration of a machine body is lowered, and influences on normal work of the reciprocating linear compressor are reduced. Meanwhile, the first tube section and the second tube section are communicated through the first buffer, the stress of a pipeline at the joint of the first tube section and the second tube section is effectively reduced, and the probability that the inner exhaust tube set is broken is lowered. Airflow pulses are also reduced, vibration of the inner exhaust tube set is reduced, flowing noise of air flow is also lowered, and the silencing function is achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

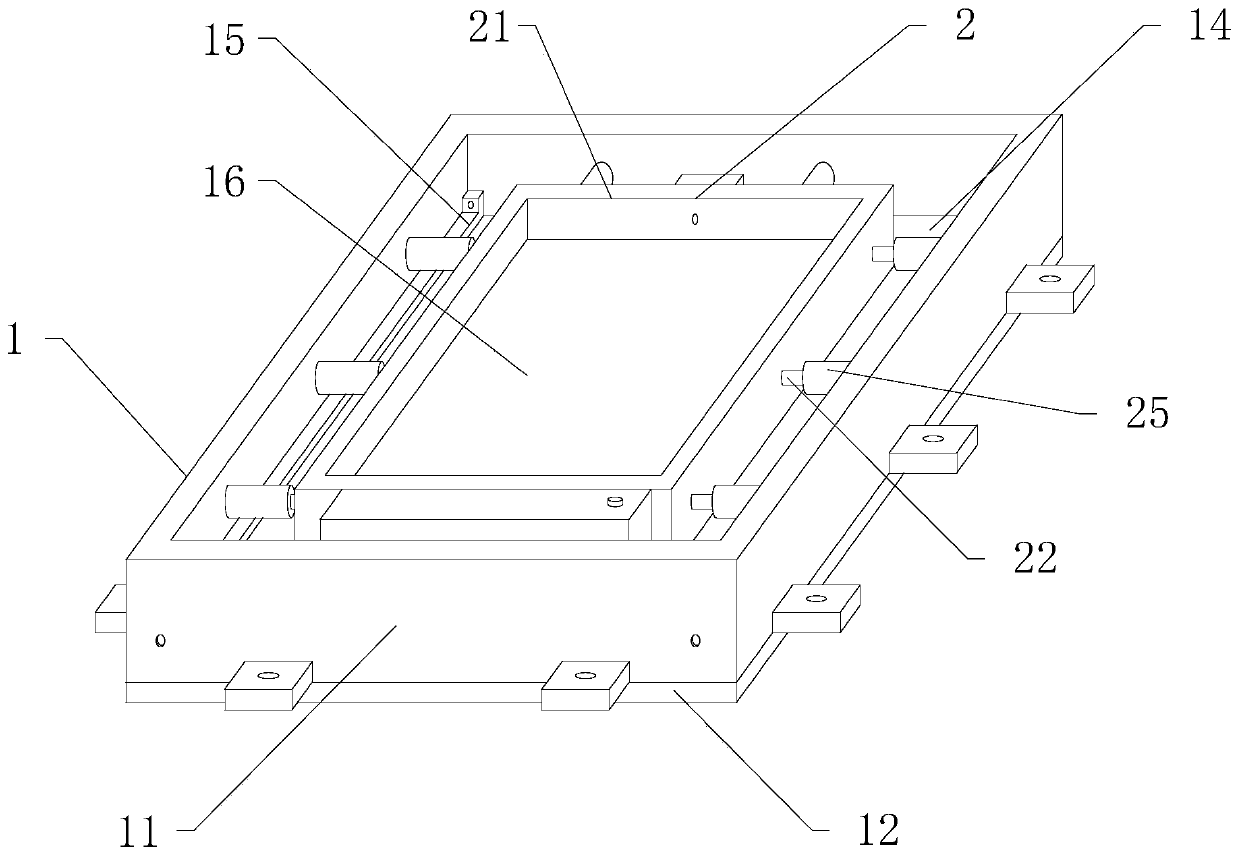

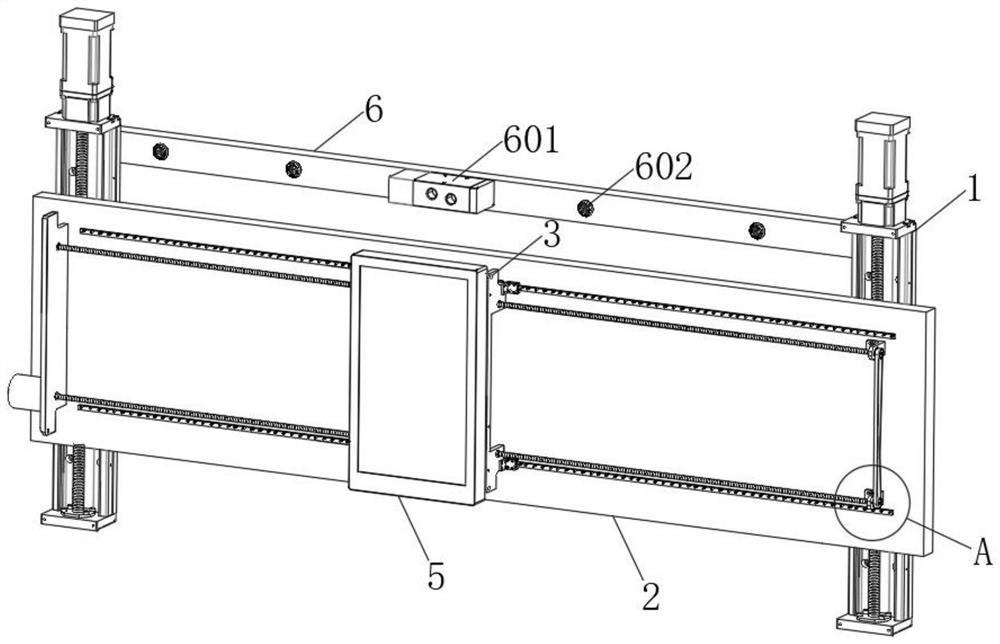

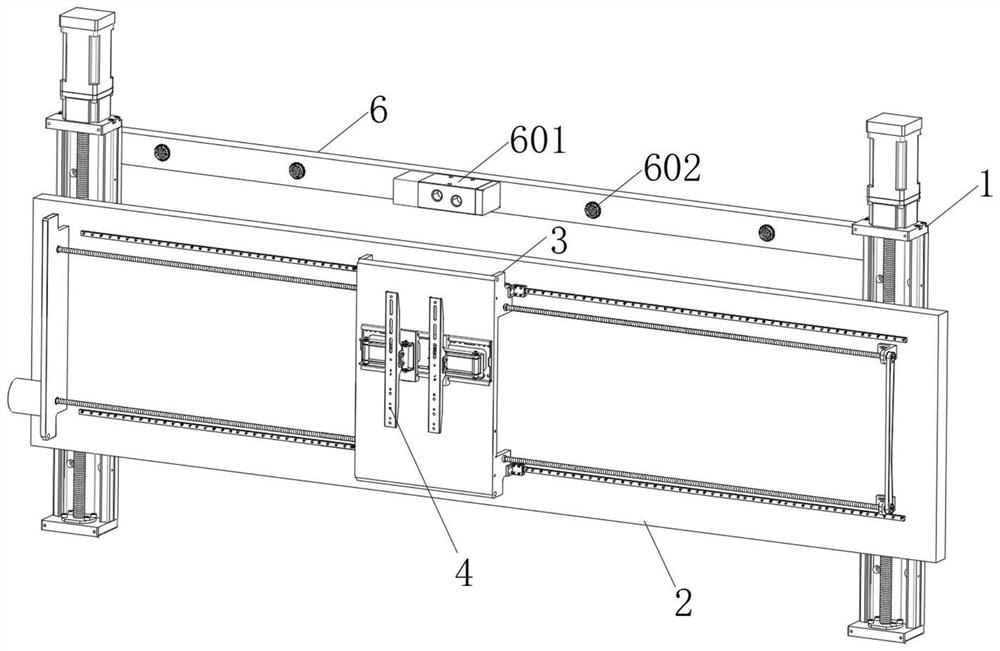

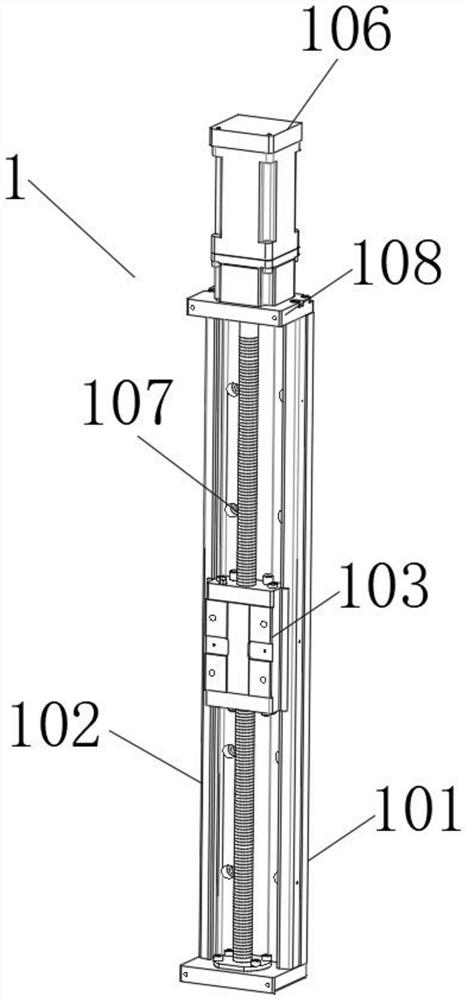

Intelligent sliding rail screen based on voice control

PendingCN113739018AEasy to operateImprove convenienceStands/trestlesSpeech recognitionSpeech controlSpeech sound

The invention relates to the technical field of intelligent sliding rail screens, in particular to an intelligent sliding rail screen based on voice control. The intelligent sliding rail screen comprises a lifting assembly, a back plate, a moving assembly, a mounting frame and a connecting plate. The intelligent sliding rail screen is characterized in that the display range of a display screen is larger by adjusting the position of the display screen left and right, so that the display effect of the sliding rail screen is further improved; the display screen slides and is matched with the back plate, so that the dynamic and static combination effect is achieved, and the demonstration effect of the sliding rail screen is further improved; a second sliding block is used for being in sliding fit with a second sliding rail, so that sliding of the display screen is smoother; a transmission lead screw and a driven lead screw are used, so that the display screen can move more accurately and slide more stably, and the accuracy of control management of the sliding rail screen is improved; and the display screen can be pulled out by pulling the mounting frame, and convenience is provided for replacement and maintenance of the display screen.

Owner:苏州拓凡互动科技有限公司

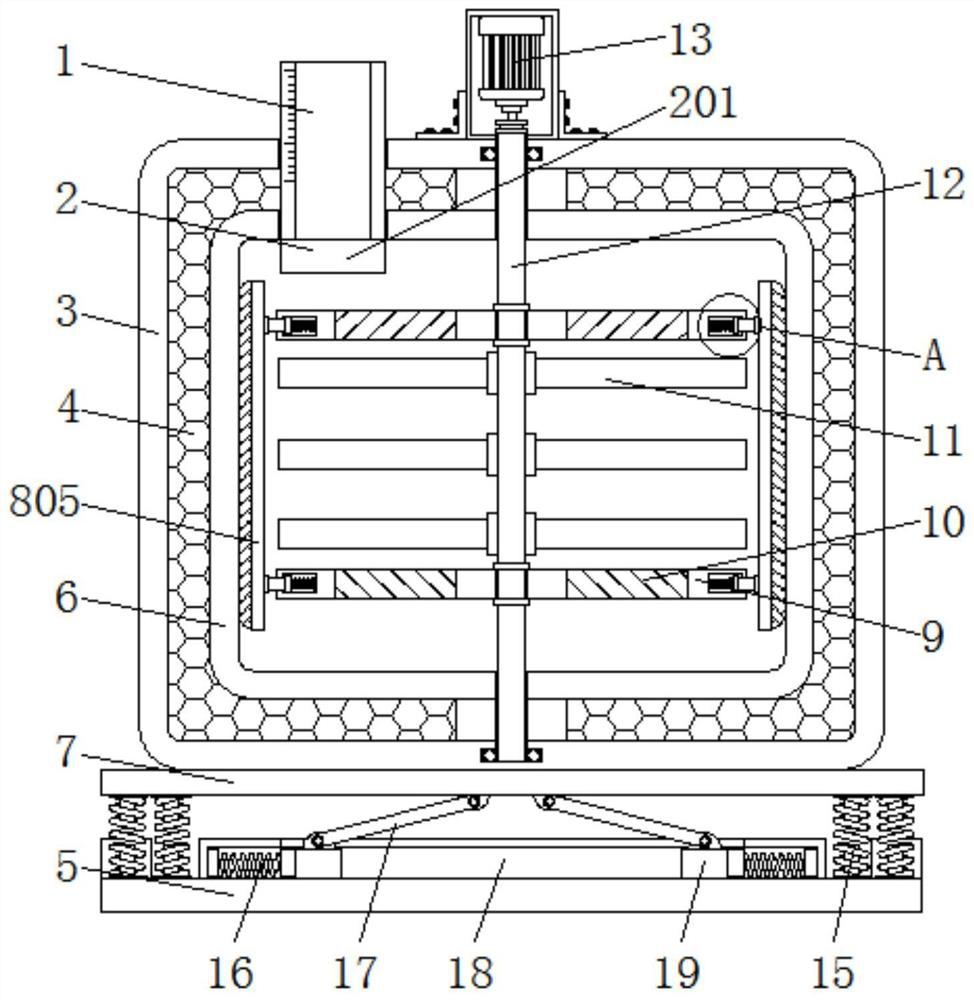

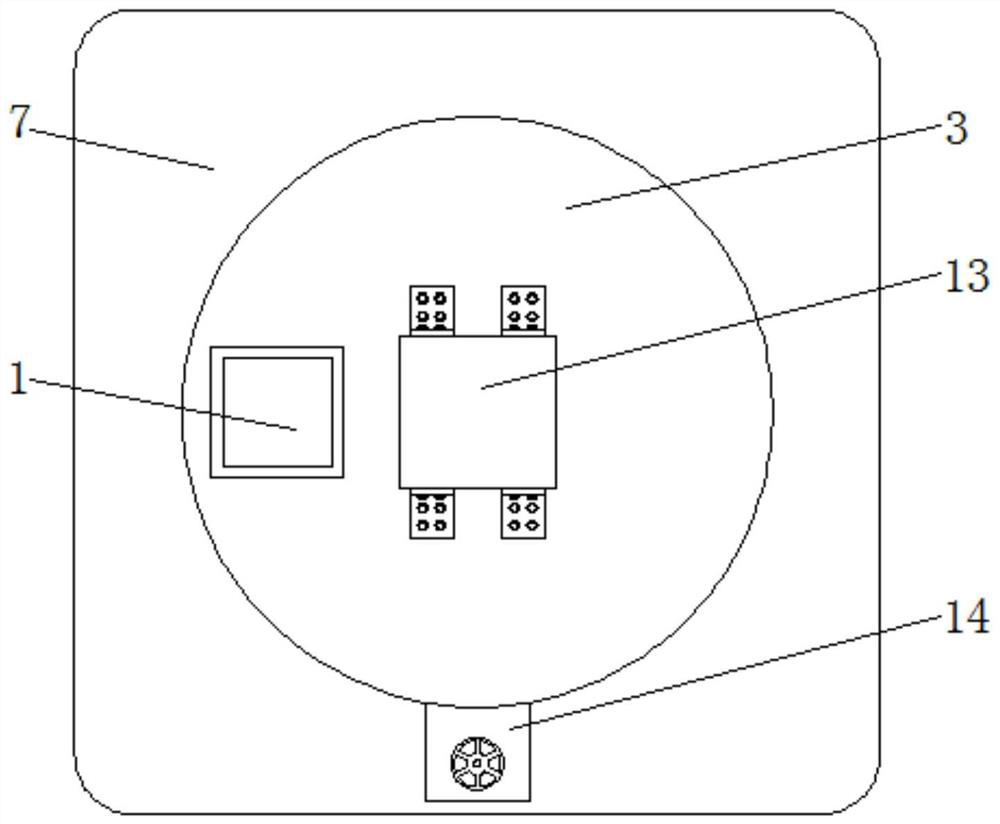

Noise reduction type stirring system

PendingCN112156686AReduce vibrationSmall volumnRotary stirring mixersTransportation and packagingEngineeringNoise reduction

The invention discloses a noise reduction type stirring system which comprises a feeding port, a base and stirring blades, limiting boxes are evenly installed at the top end of the base, two buffer springs are installed on each of the two sides of the interior of each limiting box, a moving block is installed on one side of each buffer spring, and damping springs are installed on the two sides ofeach limiting box; a bottom plate is installed at the top ends of the damping springs, transmission rods are evenly hinged to the bottom end of the bottom plate, the bottom ends of the transmission rods are hinged to the top end of a moving block, a shell is welded to the top end of the bottom plate, and a working cavity is formed in the shell. Sound insulation cotton can block sound generated bycollision vibration in the internal stirring process, vibration of the whole device can be reduced through damping springs, movement of a bottom plate pushes a moving block to be further buffered by extruding a transmission rod, and therefore vibration of the device is reduced, the sound is reduced as much as possible, and the noise reduction function of the device is achieved.

Owner:REED XINXIANG ROAD INC

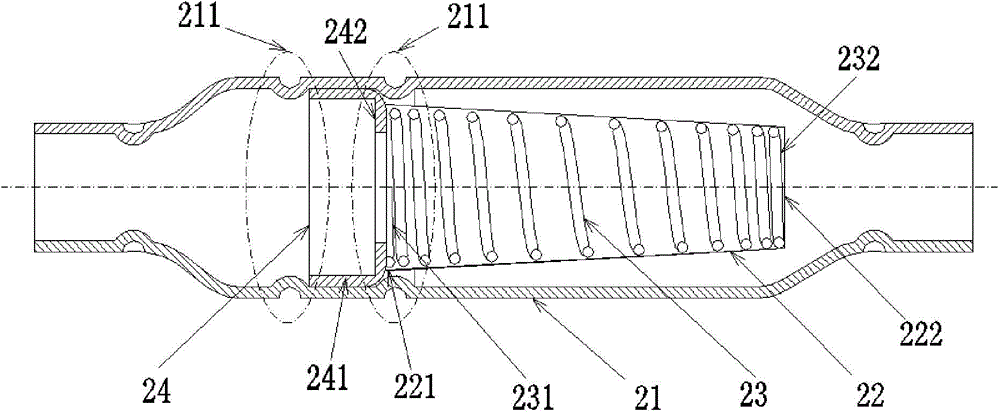

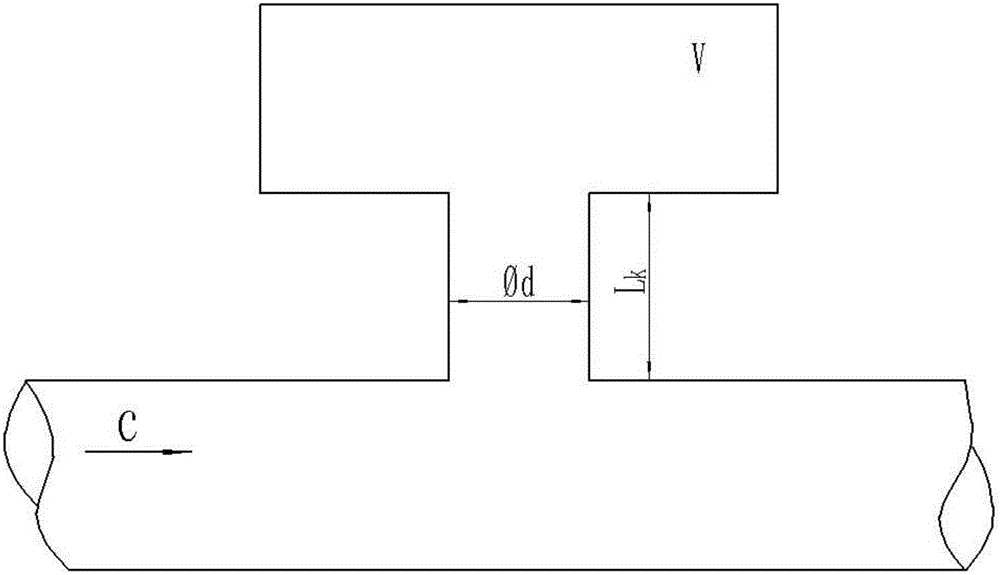

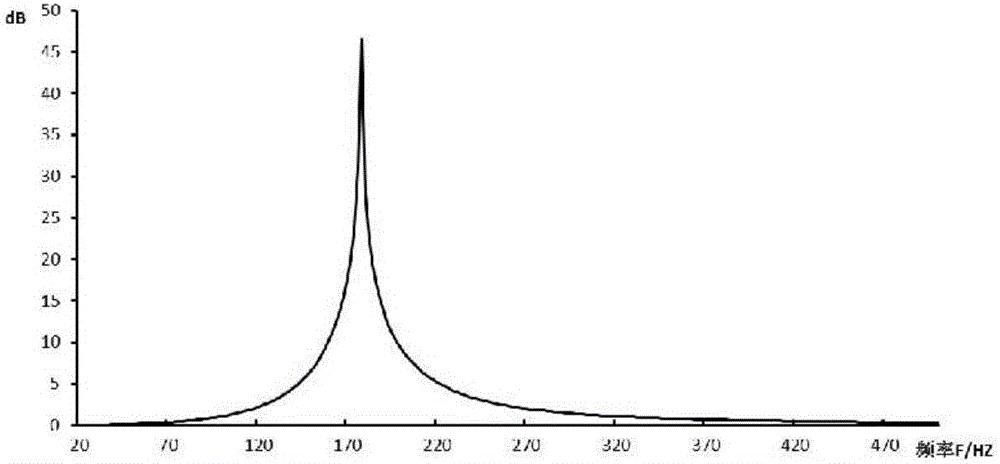

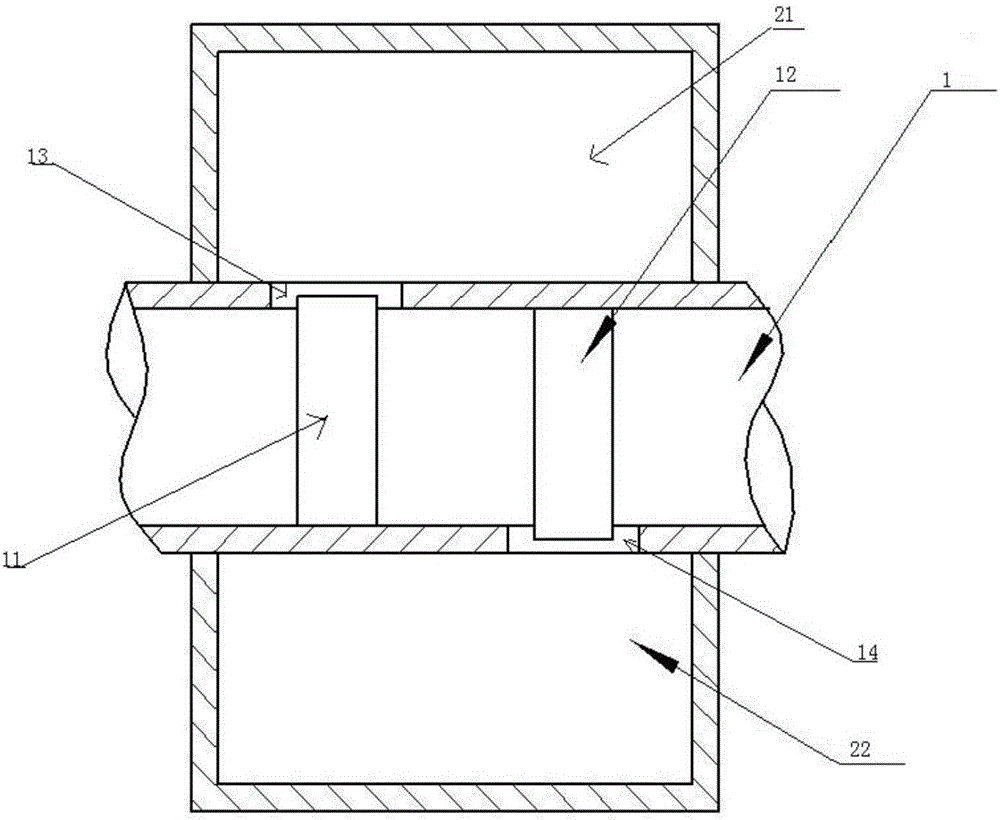

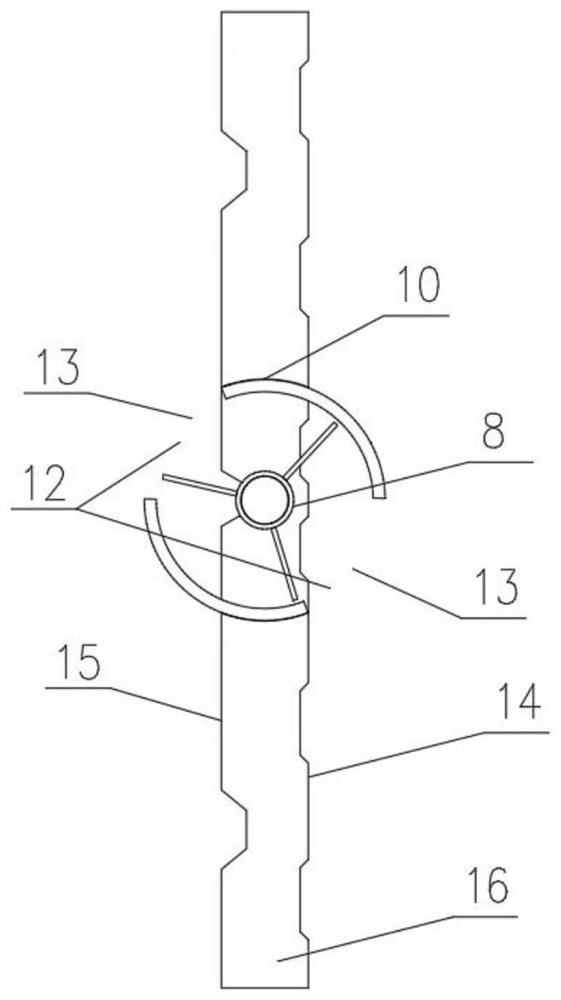

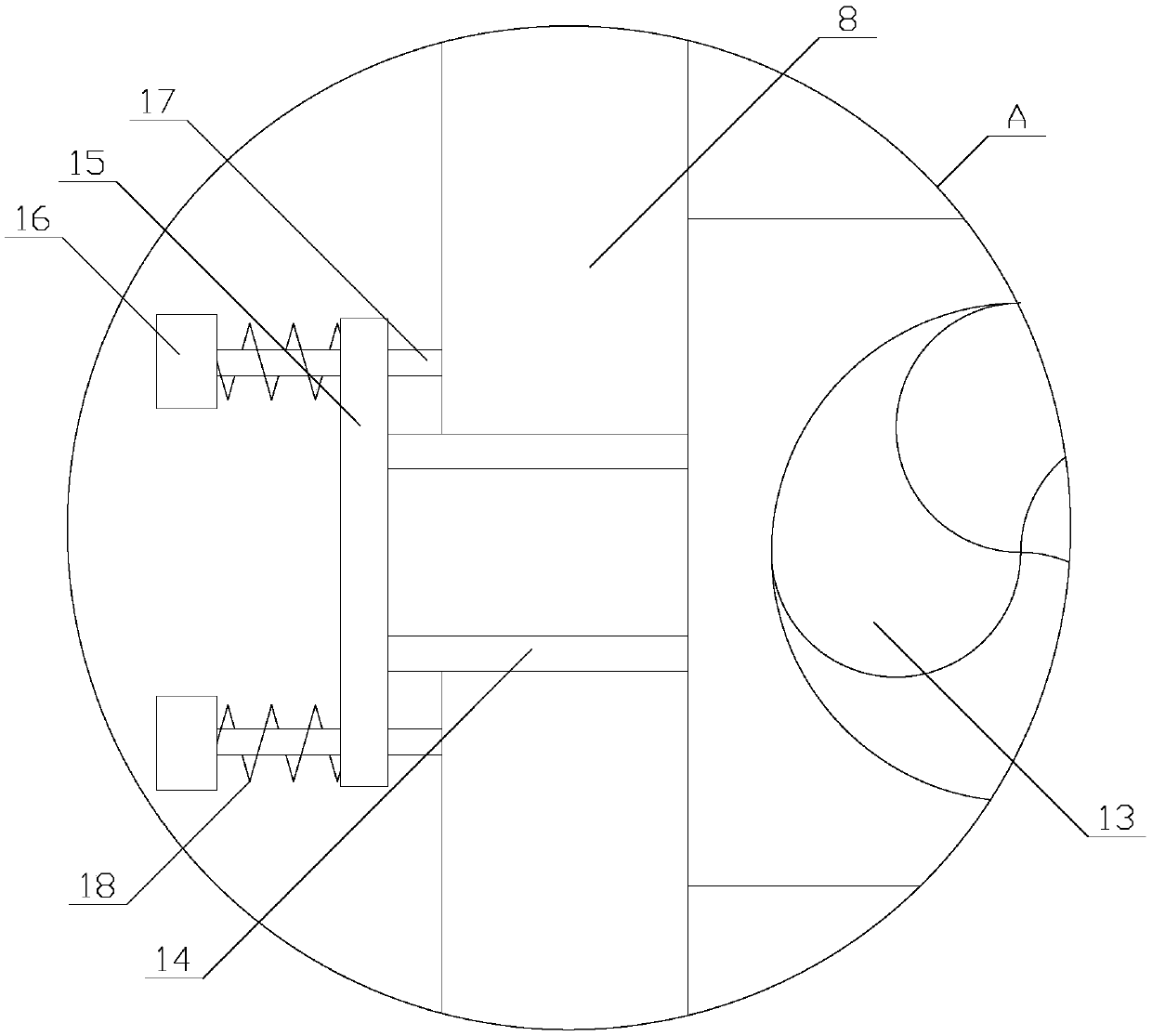

Internal combustion engine exhaust silencer capable of automatically following two working conditions

ActiveCN106523071ASolve the problem of good noise reduction effectRealize the noise reduction function of automatic follow-upSilencing apparatusMachines/enginesResonant cavityEngineering

An internal combustion engine exhaust silencer capable of automatically following two working conditions comprises a pipe 1 and a sealed first resonant cavity 21 outside the pipe 1, and is characterized in that a first round hole 13 is formed in a wall surface of the pipe 1, and communicates with a cavity of the pipe 1 and the first resonant cavity 21; a first cylinder 11 is arranged on the inner wall, which is opposite to the first round hole 13, of the pipe 1, and extends into the first round hole 13; and the expansion coefficient of the material of the first cylinder 11 is smaller than the expansion coefficient of the materials of the pipe 1 and the first resonant cavity 21.

Owner:ZHEJIANG UNIV OF TECH

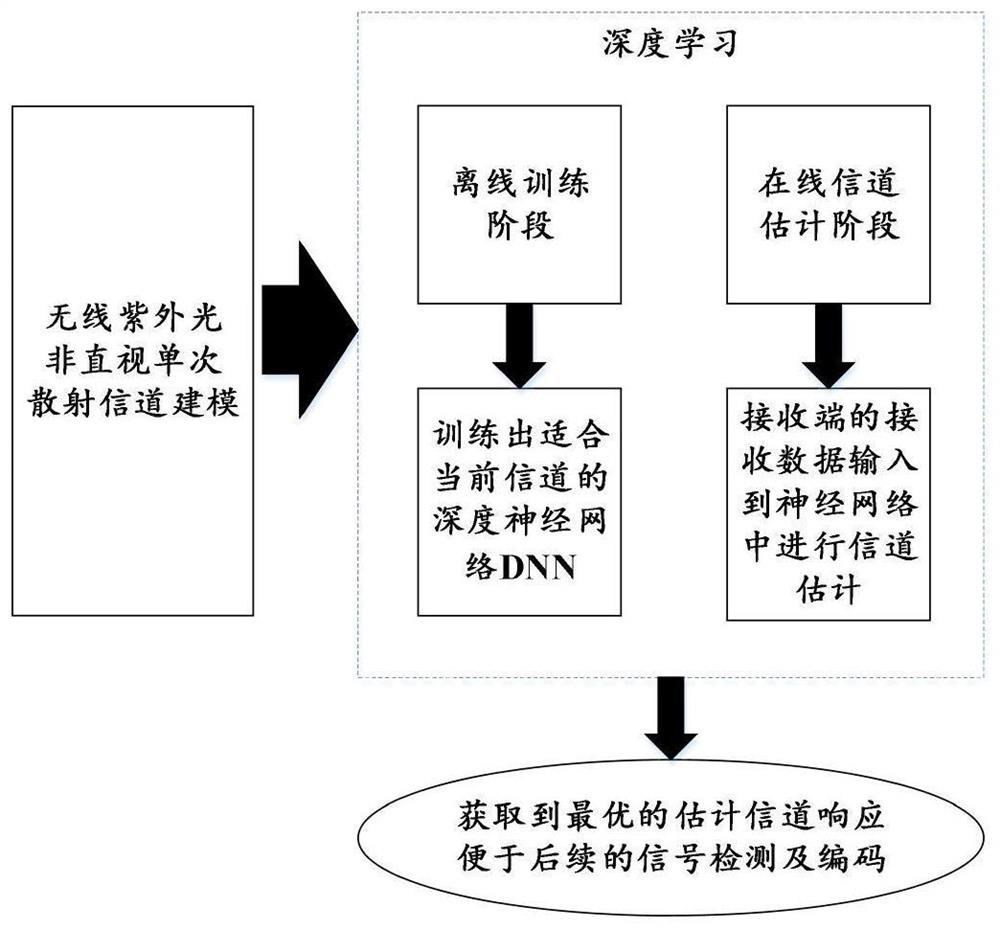

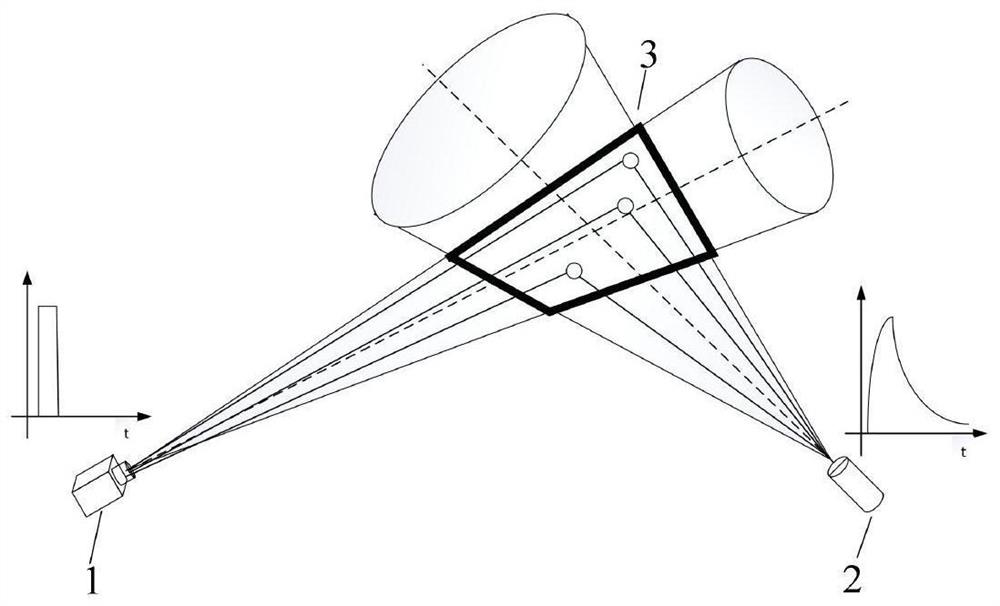

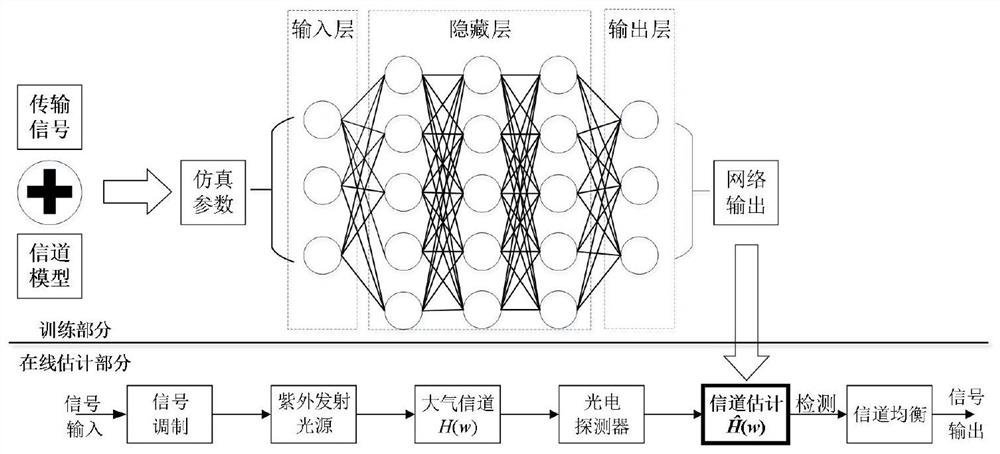

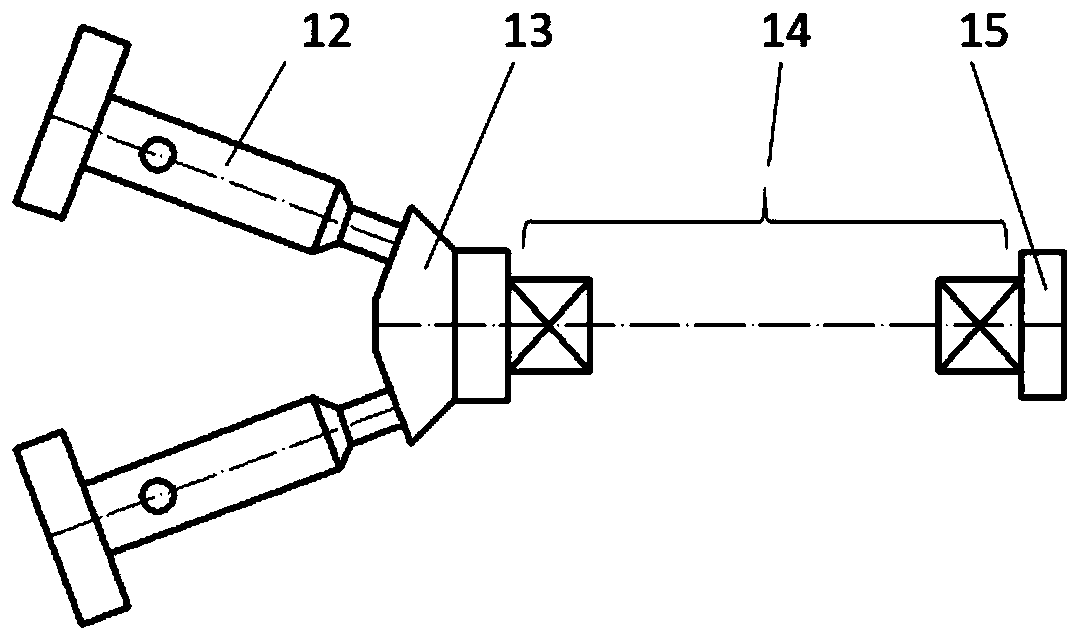

Wireless ultraviolet light scattering channel estimation method based on deep learning

ActiveCN112468230AIntersymbol Interference SuppressionSuppression of multipath fading problemsBaseband system detailsFree-space transmissionCommunications systemChannel parameter

The invention discloses a wireless ultraviolet light scattering channel estimation method based on deep learning, and the method comprises the specific steps: firstly carrying out the modeling of a wireless ultraviolet light non-direct-view single scattering channel, calculating the related channel parameters of channel response and the like, and then carrying out the offline deep neural network training through a large amount of offline channel training data, calculating a mapping relationship between the received data and the channel response according to a training result, finally performing channel estimation by using the trained deep neural network, sending the trained channel parameters to a receiving end, inputting the received data into the deep neural network, and outputting the optimal channel response, thereby realizing channel estimation. According to the method, the problems of high bit error rate, poor robustness, requirement on prior channel characteristics and the likein a traditional channel estimation algorithm are solved, deep learning and wireless ultraviolet light communication are combined, the transceiving accuracy and reliability of a communication system are improved, and a theoretical basis is provided for further application of deep learning to optical communication.

Owner:西安华企众信科技发展有限公司

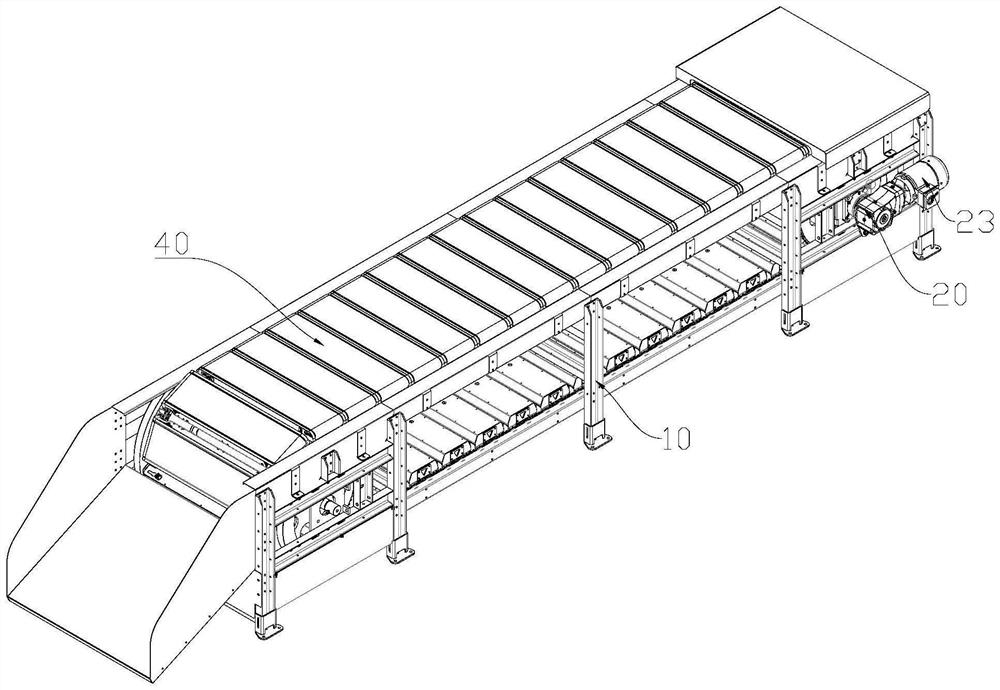

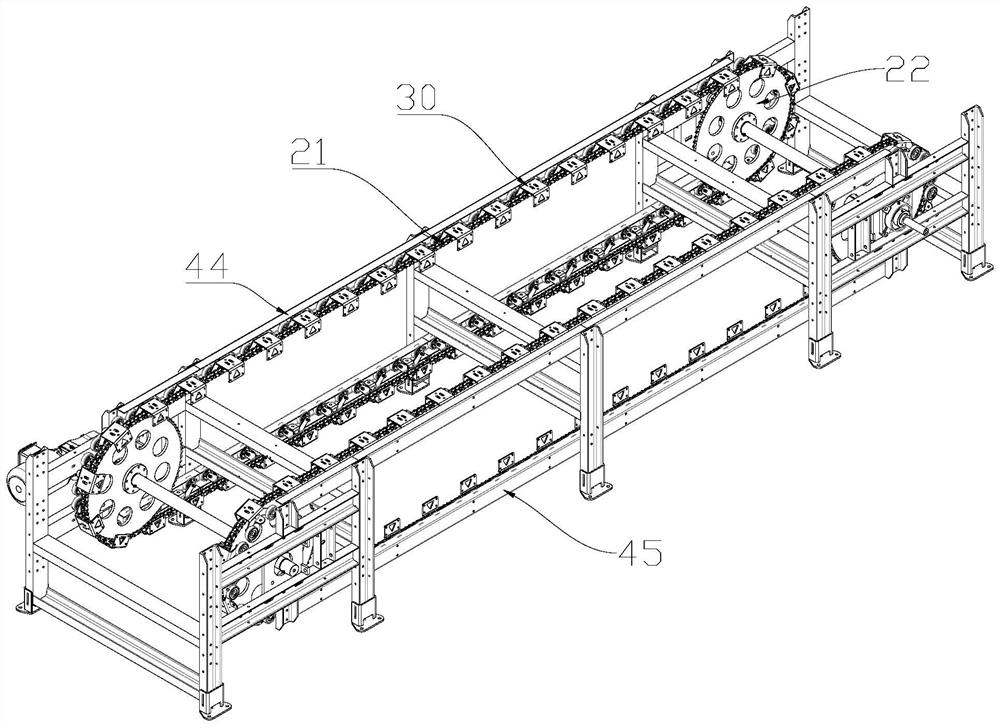

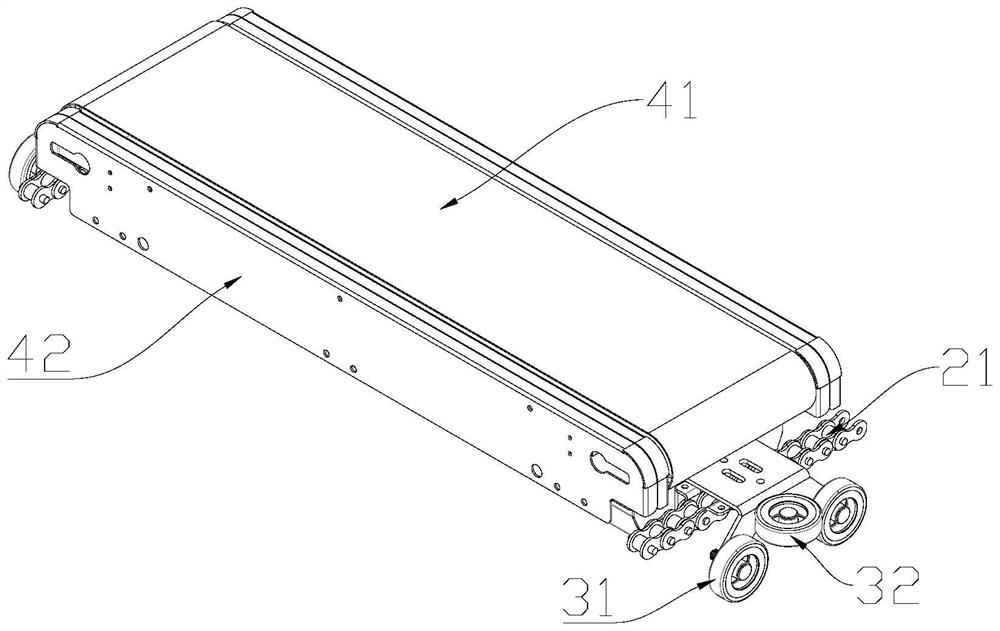

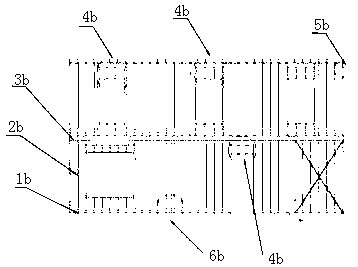

Narrow vehicle linear sorting machine and sorting method

The invention discloses a narrow vehicle linear sorting machine which comprises a rack, a driving mechanism, a bearing assembly, a conveying trolley and a detection coding assembly, the bearing assembly is slidably installed on the rack, the driving mechanism is arranged on the conveying trolley, the conveying trolley is installed on the bearing assembly, the driving mechanism comprises a chain, and the chain is arranged on the conveying trolley. The bearing assembly is connected to the chain, the bearing assembly comprises a walking wheel, a guide wheel and a wheel carrier, the wheel carrier is connected to the chain, the guide wheel is installed on the wheel carrier in a rolling mode, the walking wheel is also arranged on the wheel carrier, and the detecting and coding assembly is arranged above the conveying trolley. According to the narrow vehicle linear sorting machine, double chains are adopted for synchronous driving, the abrasion degree of the chains is reduced, and therefore the noise reduction function is achieved; the operation method of the narrow vehicle linear sorting machine is suitable for sorting parcels of different specifications, long and large parcels can also be sorted, the applicability of equipment is enhanced, and the use cost of the equipment is reduced.

Owner:苏州紫宏智能物流装备系统有限公司

Noise reduction earphone interface structure

ActiveCN102291643BRealize the noise reduction functionEarpiece/earphone attachmentsEngineeringNoise reduction

The invention relates to a noise reduction earphone interface structure in the technical field of equipment noise reduction. The noise reduction earphone interface structure comprises a noise reduction chip, a loudspeaker, an earphone-side microphone, a device-side control switch, a device-side audio interface and an earphone-side audio interface. The noise reduction earphone interface structure solves the problems of large earphone volume, heavy weight and limited endurance caused by an external power supply of a noise reduction earphone.

Owner:CHIPHOMER TECH SHANGHAI

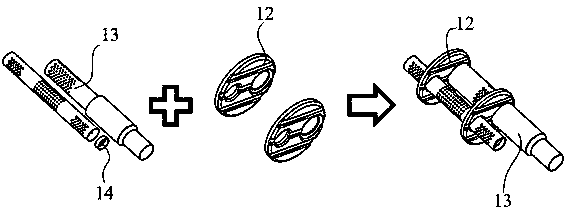

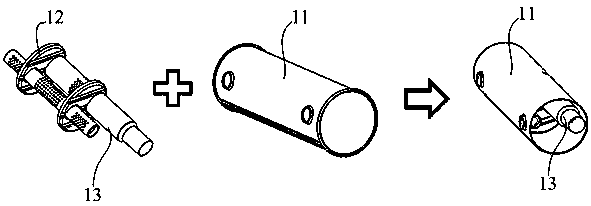

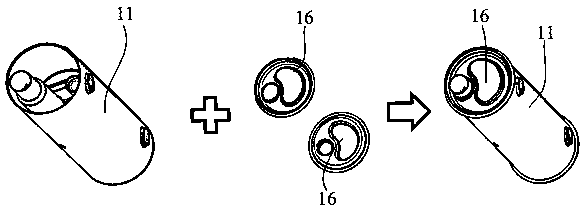

Silencer manufacturing method and silencer

InactiveCN108942092ARealization of noise reduction functionImprove qualitySilencing apparatusMachines/enginesBarrel ShapedEngineering

The invention relates to the technical field of silencers, in particular to a silencer manufacturing method and the silencer. The manufacturing method comprises the steps that a barrel-shaped silencershell body with an opening at one end is pulled out through a deep drawing and stretching integrated forming mode, wherein the shell body is provided with a cover part and a side part which are integrally formed, the cover part is located at one end of the shell body, and the side part is located on the circumferential side of the shell body; and one end, with the opening, of the shell body is arranged towards an inner audio assembly in the silencer, the shell body is correspondingly assembled at the two ends of the inner audio assembly. Therefore, compared with an original method in which the silencer is manufactured by carrying out welding and seam locking on a metal plate after the metal plate undergoes edge rolling, and then an edge cover is installed, the noise reduction function ofthe silencer is guaranteed, meanwhile, machining and mounting steps of the original part edge cover are reduced, and then the complex repetition of the part and the waste of materials are reduced; andmeanwhile, the barrel-shaped silencer shell body with the opening at one end is manufactured through the deep drawing and forming mode, so that the uniformity of the size of the part of the silenceris better, and the stability of the quality of the silencer is guaranteed.

Owner:ENGINEERED EXHAUST SYST B T INC

Energy-saved and environment-friendly vehicle exhaust pipe purifier device

InactiveCN105507986AQuick clearEfficient removalExhaust apparatusSilencing apparatusActivated carbonIn vehicle

The invention discloses an energy-saved and environment-friendly vehicle exhaust pipe purifier device. The device comprises a device body, an exhaust pipe connecting pipe, a silencer, a control protector and an exhaust pipe; the exhaust pipe connecting pipe for connecting with the exhaust pipe is arranged at the upper end of the device body; the silencer is arranged between the exhaust pipe connecting pipe and the device body; and two sets of electrostatic particle absorption electric conducting plates, an ultrafine HEPA filter screen layer and an active carbon purification layer are arranged in the device body. The device is simple in structure and reasonable in technology; the electrostatic particle absorption electric conducting plates, the ultrafine HEPA filter screen layer and the active carbon purification layer are arranged in the device body for filtering and purifying gas; in addition, the silencer is provided for realizing a silencing function; and the device is convenient for installation, wide in application range and capable of quickly and effectively removing most harmful substances in vehicle tail gas, and has the effects of energy conservation and environmental protection.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

Protection hood, control method of protection hood and air conditioner

ActiveCN104595992AGuaranteed Energy ConversionSimple structureSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringNoise reduction

The invention provides a protection hood, a control method of the protection hood and an air conditioner. The protection hood comprises a hood body and a noise blocking assembly, wherein the hood body is provided with an opening; the noise blocking assembly is arranged at the opening of the hood body and comprises a drive structure and a plurality of angle-adjustable noise blocking pieces used for blocking noise, and the drive structure drives the noise blocking pieces to rotate to the preset angle so as to reduce noise. According to the protection hood, the control method of the protection hood and the air conditioner, a user can control the noise blocking pieces to work at different angles according to the using characteristics of the user and the motion load of the air conditioner, and the corresponding noise reduction function is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

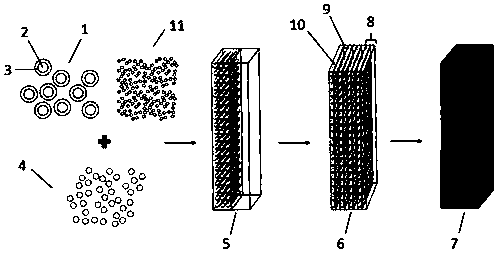

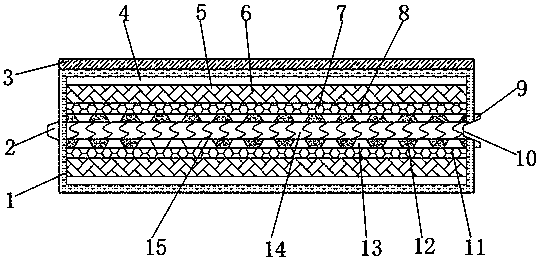

Polyurethane elastomer phononic crystal noise-reducing film and preparation method thereof

InactiveCN110014709AGood barrier effectSimple manufacturing processSynthetic resin layered productsConstructions elementsChemistryPhonon

The invention relates to a polyurethane elastomer phononic crystal noise-reducing film and a preparation method thereof. The noise reducing film comprises at least four periodic components, each periodic component is composed of one polyurethane layer and one vibrator layer, wherein each vibrator layer is formed by coating a large amount of microbead vibrators by a polymer, and each microbead vibrator is formed by coating each metal microbead by a layer of soft elastomer; and the preparation method comprises the following steps: the microbead vibrators formed by coating the metal microbeads bythe soft elastomers and polymer pellets are uniformly mixed, the mixed material is subjected to melt extrusion by one extrusion unit, the polyurethane raw material is subjected to melt extrusion by another extrusion unit, the extrudate enters a confluence unit, the confluent material sequentially passes through m lamination units, partition, torsion and lamination are performed for n times in n torsion flow channels in each lamination unit to form the phononic crystals in which the vibrator layers and the polyurethane layers are alternately arranged. The preparation process of the noise reducing film provided by the invention is very simple, the production efficiency is high, large-scale production is easy to realize, and the noise reducing film has strong applicability, and can cover thesurface of a large target to realize a noise reducing function.

Owner:BEIJING UNIV OF CHEM TECH +1

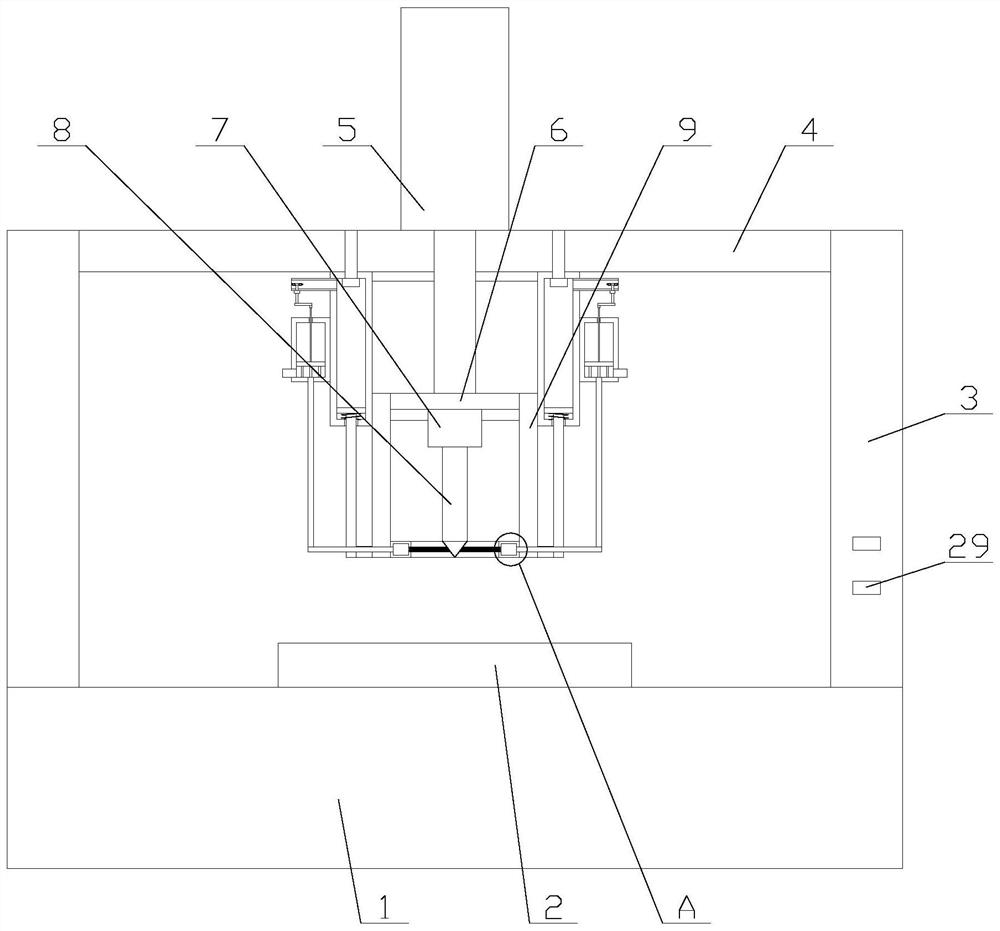

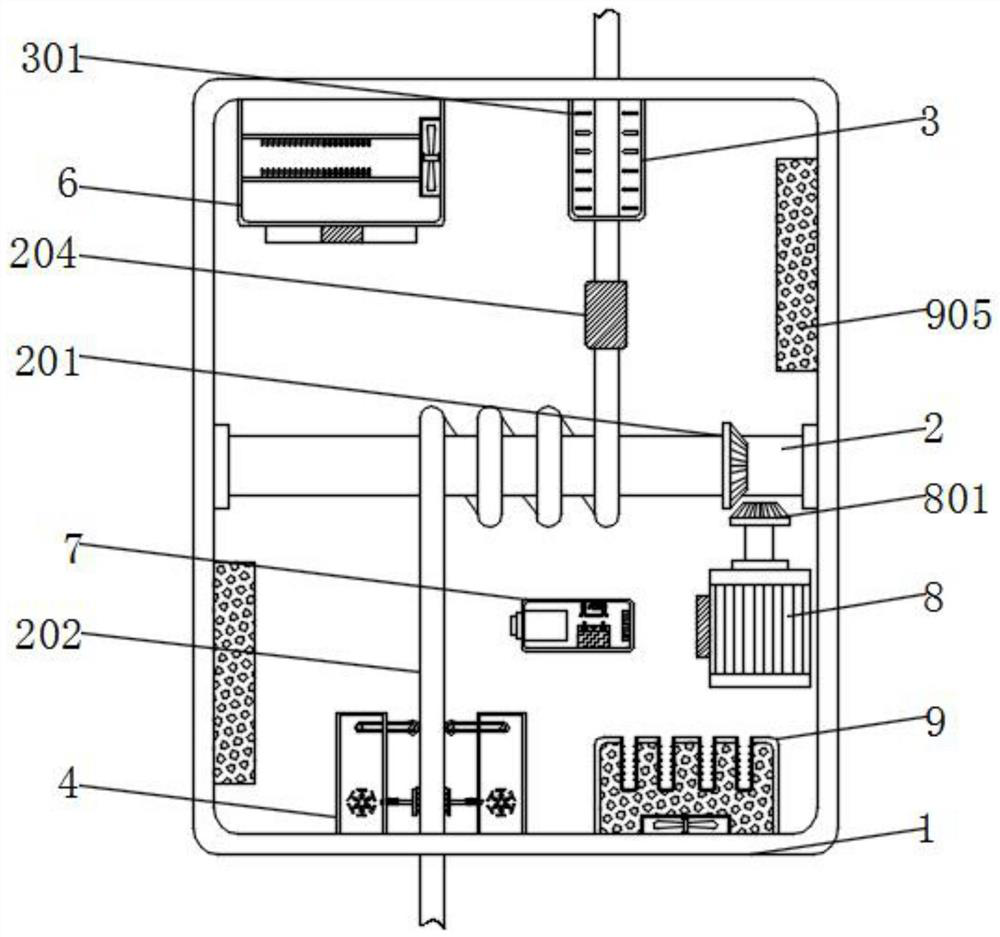

Aluminum product machining center with noise reduction function

InactiveCN112517958AHearing Health HazardsAffect circulationMaintainance and safety accessoriesBoring/drilling machinesElectric machineryEngineering

The invention relates to an aluminum product machining center with a noise reduction function. The aluminum product machining center comprises a workbench, a base, a top plate, an air cylinder, a supporting plate, a motor, a drilling rod, two supporting rods, a cleaning mechanism and a noise reduction mechanism, wherein the noise reduction mechanism comprises a noise absorption plate, a baffle andtwo driving assemblies; each driving assembly comprises a fixing rod, a driving box, an air inlet pipe, an air outlet pipe, an electromagnet, a driving plate, a spring and a driving rod; the cleaningmechanism comprises a fixing box, a filter screen and two air inflation assemblies; each air inflation assembly comprises an air inflator, a piston, a power unit, a first connecting pipe, a second connecting pipe and a plurality of elastic ropes; and each power unit comprises a blade, a rotating shaft, a rotating disc, a first bearing, a protruding point and a pulling rope. According to the aluminum product machining center with the noise reduction function, the purpose of reducing the noise is achieved through the noise reduction mechanism; the harm to the hearing health of the user caused by excessive noise is avoided; the function of cleaning the drilling rod is achieved through the cleaning mechanism; and the situation that chippings adhere to the drilling rod and cause influence on the machining work is avoided.

Owner:吴树发

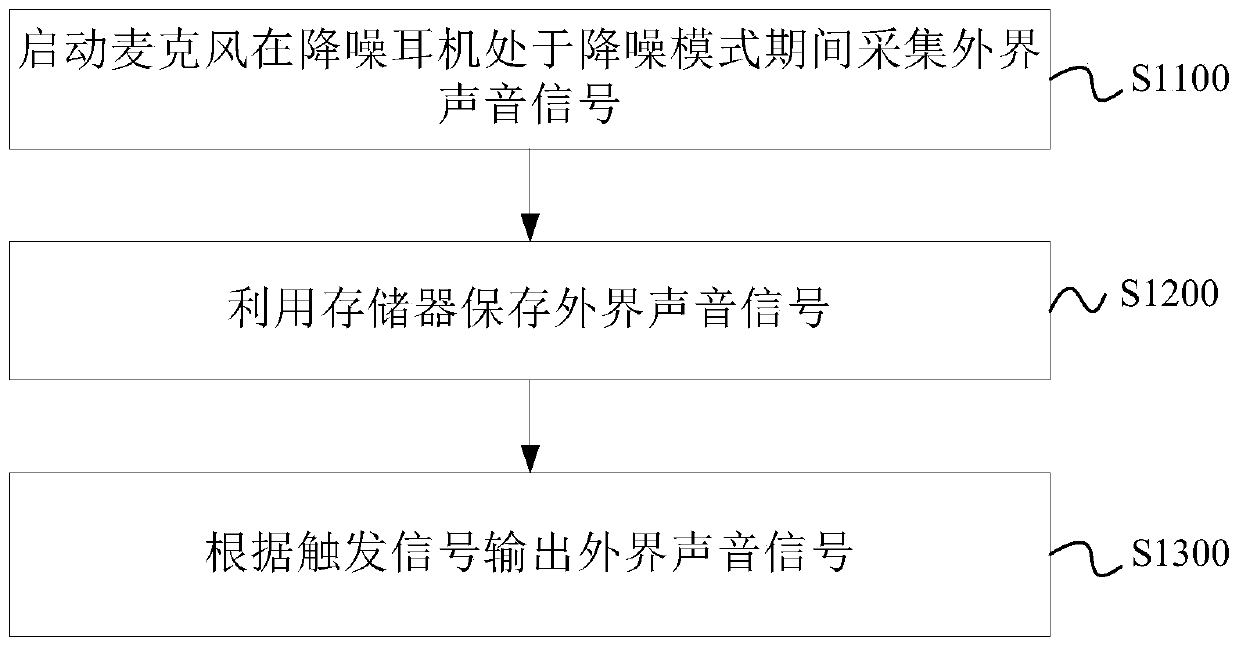

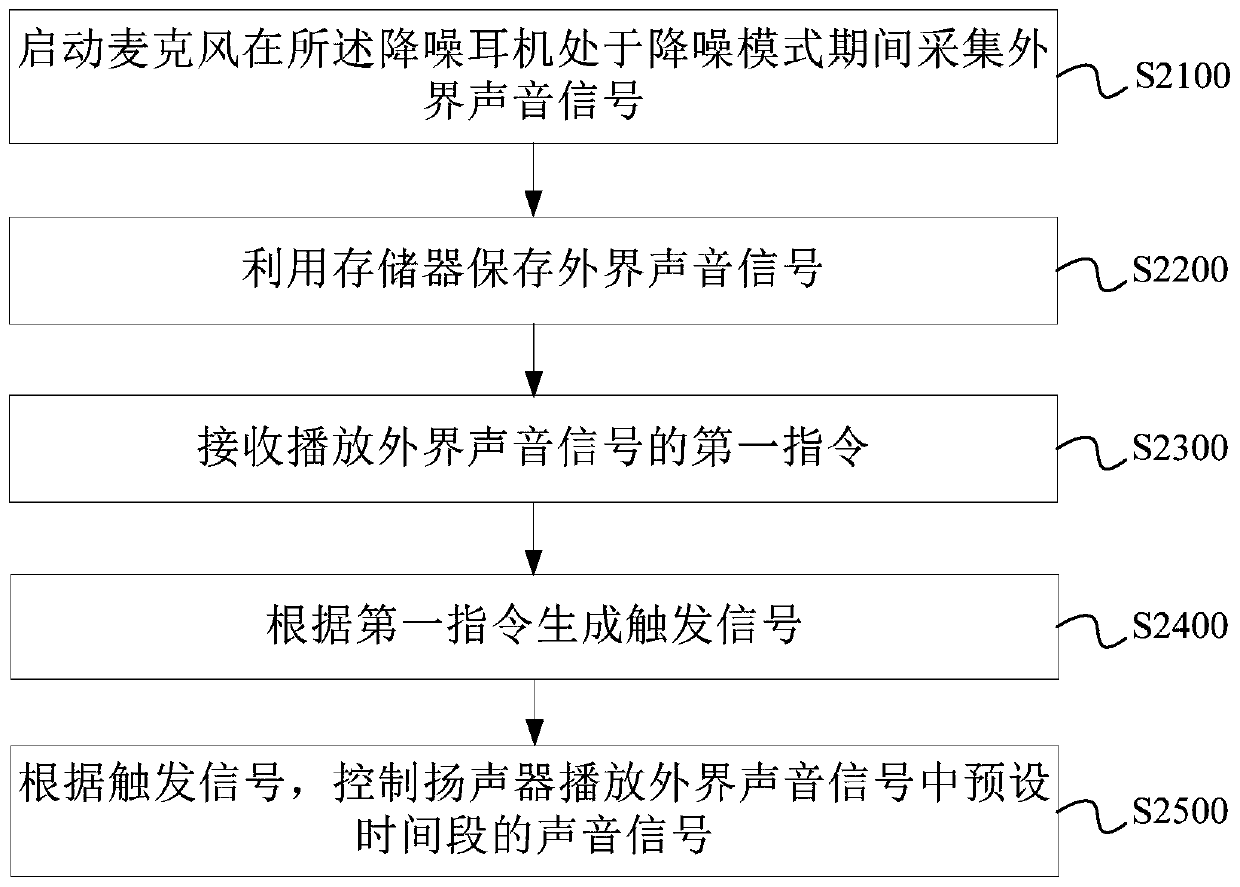

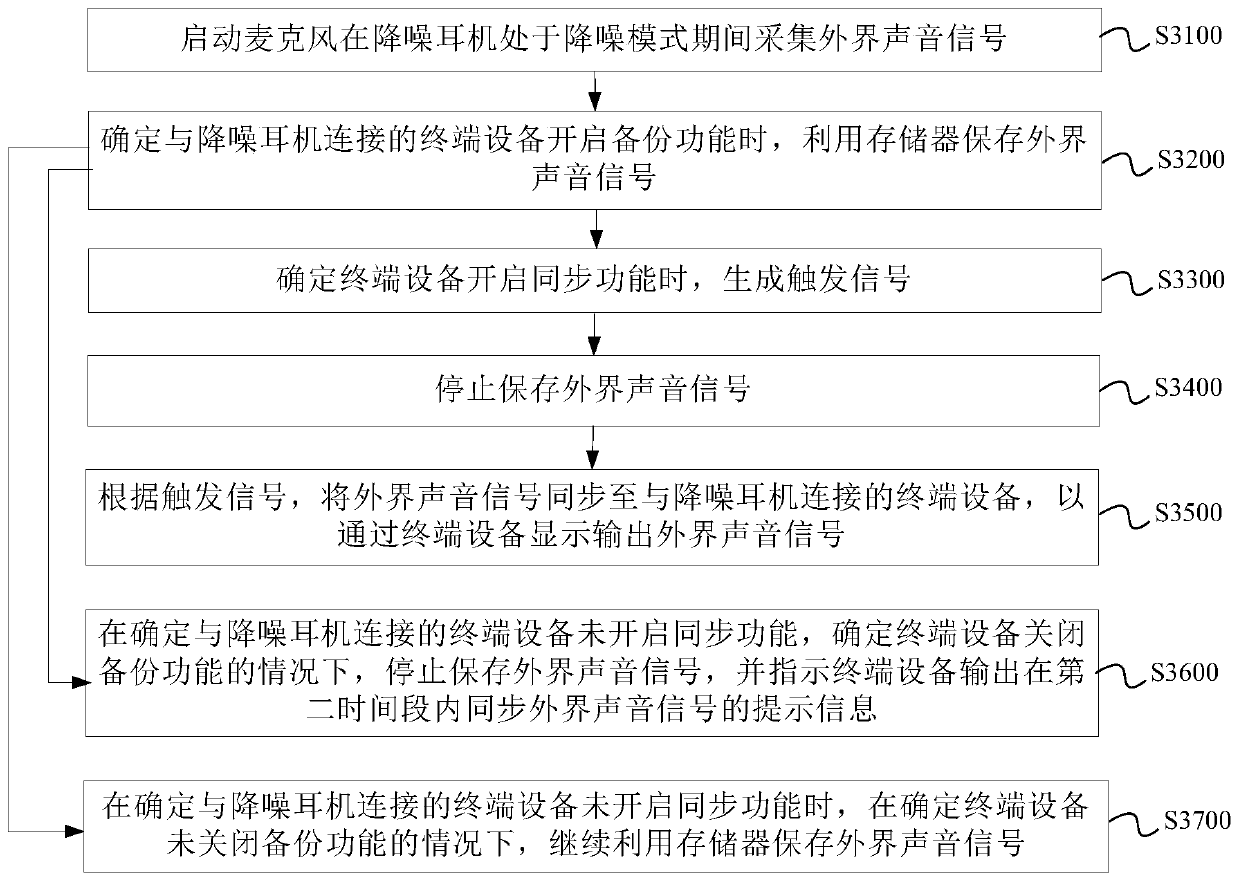

Sound signal processing method and device of noise reduction earphone, equipment and storage medium

InactiveCN110753285ARealize the noise reduction functionMicrophonesHearing device active noise cancellationHeadphonesNoise reduction

The invention discloses a sound signal processing method, device and equipment of a noise reduction earphone and a storage medium, the noise reduction earphone comprises a microphone and a memory. Themethod comprises the following steps: starting the microphone to collect an external sound signal when the noise reduction earphone is in a noise reduction mode; storing the external sound signal byusing the memory; and outputting the external sound signal according to a trigger signal.

Owner:GOERTEK INC

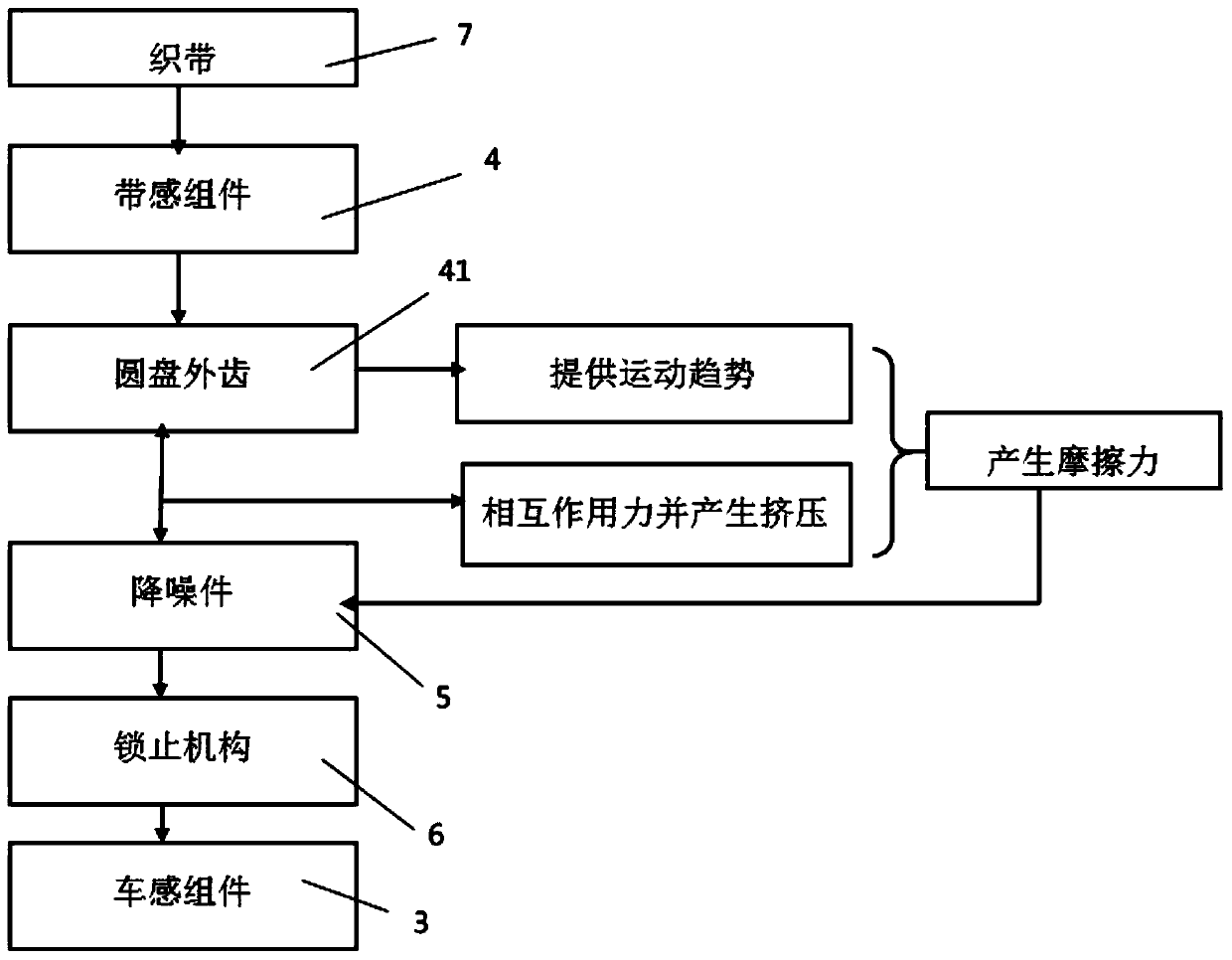

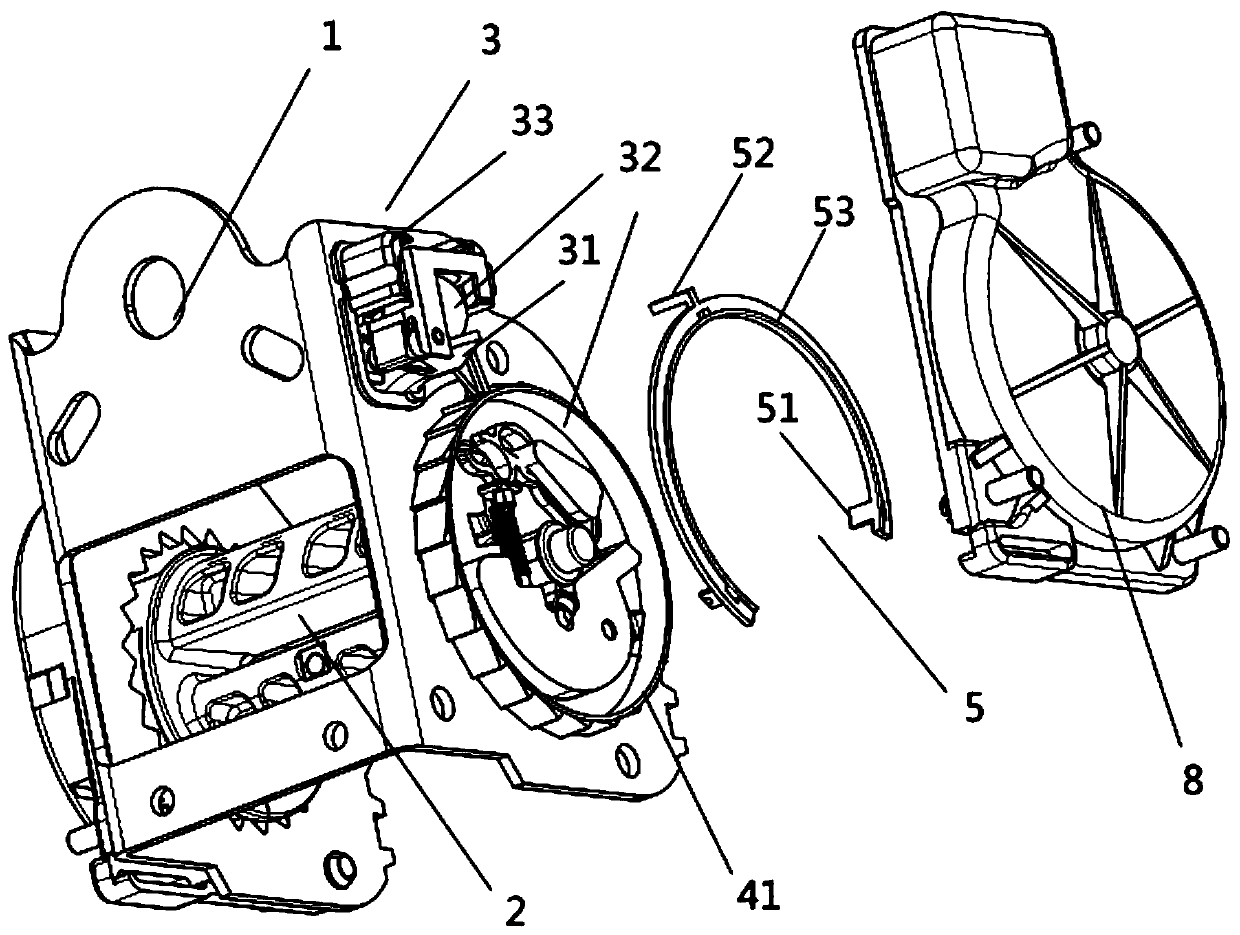

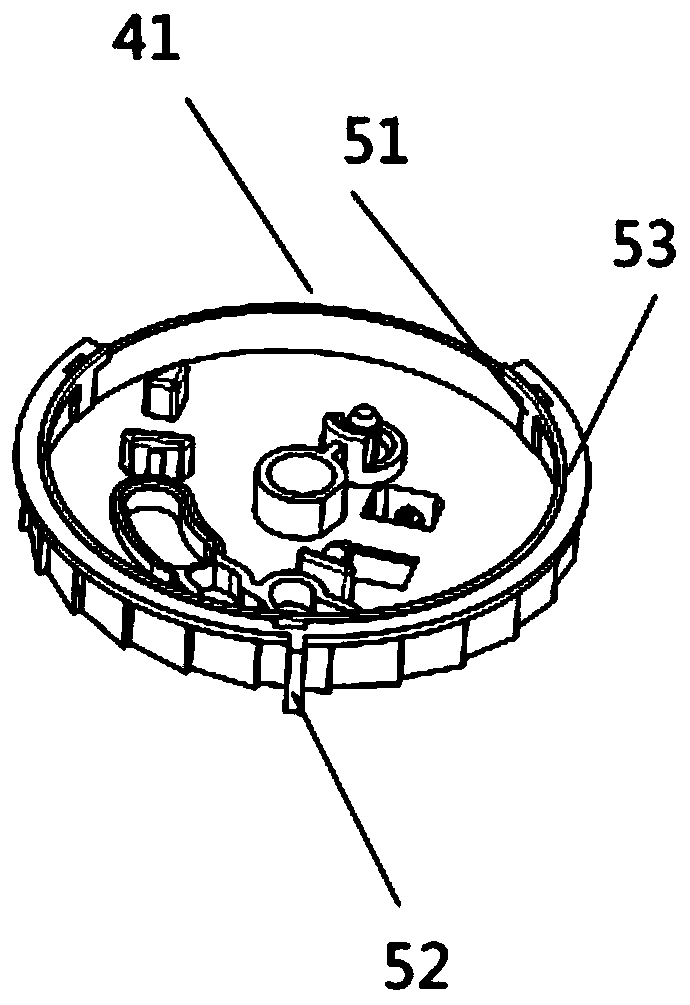

Emergency locking retractor for noise reduction on vehicle sensing assembly

ActiveCN109823303ACancel soundRestoration of locking functionBelt retractorsLocking mechanismSteel ball

The invention relates to an emergency locking retractor for noise reduction on a vehicle sensing assembly. The emergency locking retractor comprises a belt sensing assembly, a noise reduction piece and the vehicle sensing assembly; the belt sensing assembly is provided with a disc outer tooth, the noise reduction piece is arranged on the disc outer tooth, the interaction force exists and the extrusion is generated between the noise reduction piece and the disc outer tooth, and the disc outer tooth performs circular motion under the trigger of a ribbon and provides a movement trend for the noise reduction piece to generate friction force; when the ribbon is unreeled, the noise reduction piece rotates and squeezes a vehicle sensing arm of the vehicle sensing assembly from the front face or side face through a locking mechanism of the noise reduction piece, thereby limiting moving space of a steel ball of the vehicle sensing assembly; when the ribbon is pulled out, the noise reduction piece rotates reversely, and the noise reduction piece breaks away from the vehicle sensing arm of the vehicle sensing assembly. The emergency locking retractor for the noise reduction at the vehicle sensing assembly has the advantages that the steel ball state of the vehicle sensing assembly can be limited, so that after a passenger does not wear or wears a safety belt, the steel ball is in a specified position and cannot move due to vehicle running, thereby eliminating the sound made by the vehicle sensing assembly.

Owner:CHONGQING GUANGDA IND

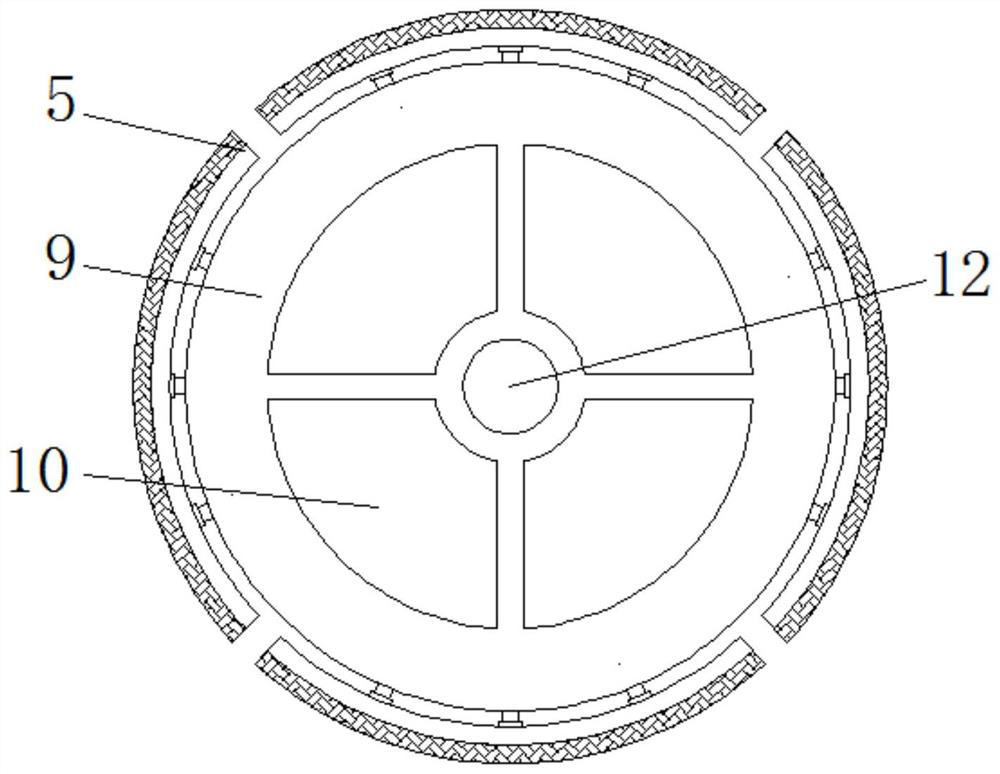

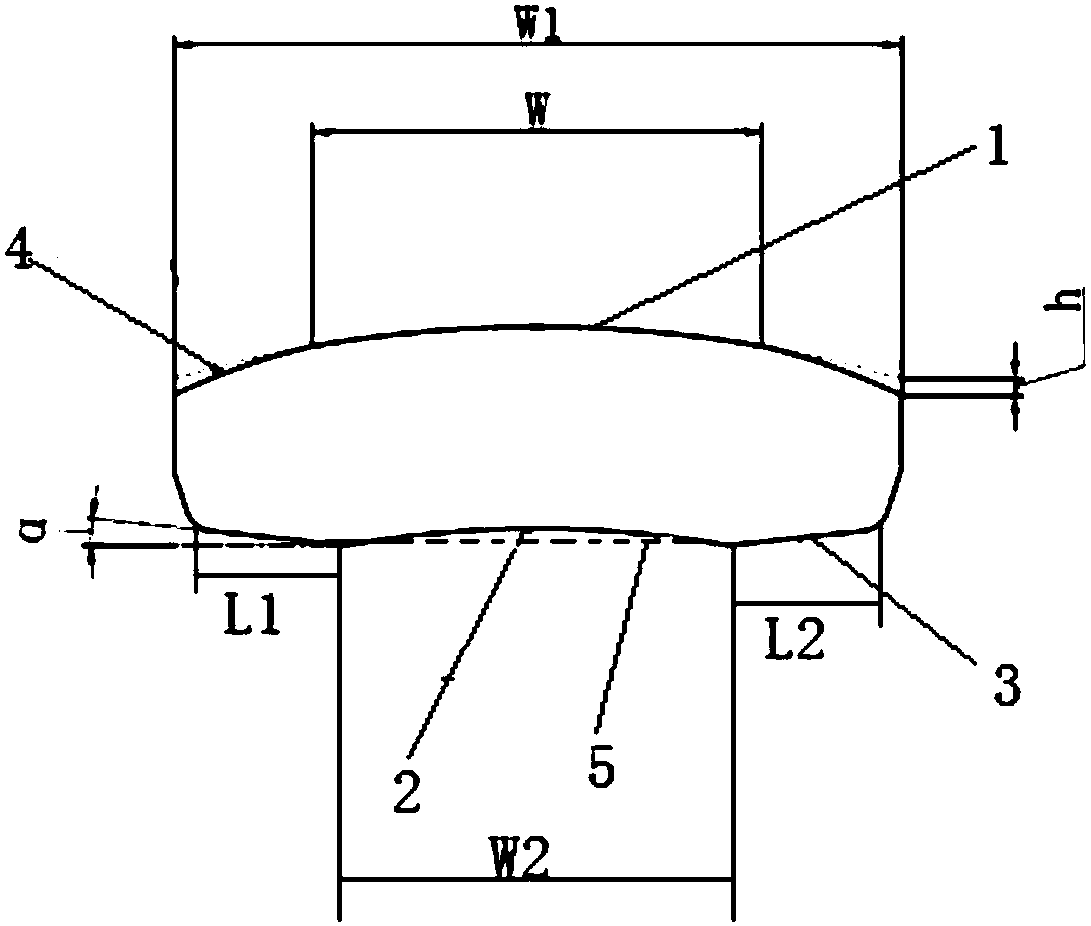

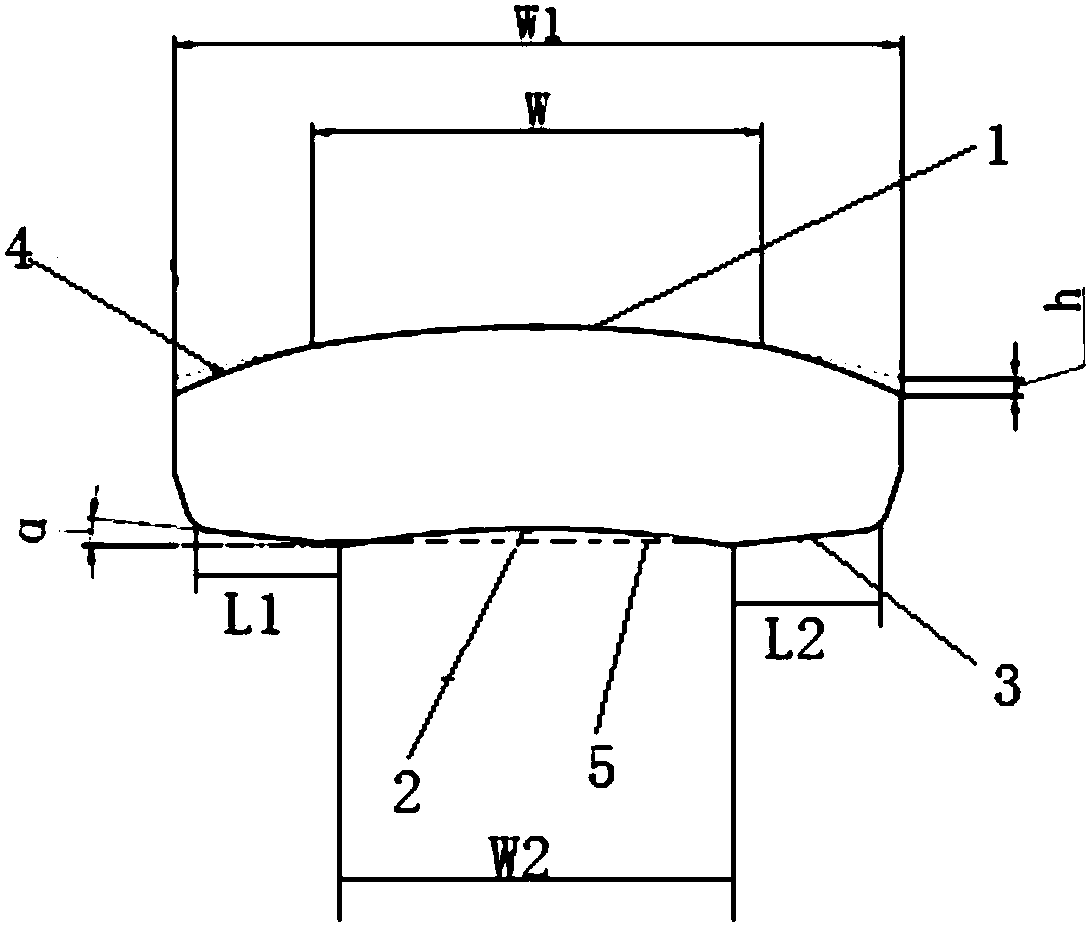

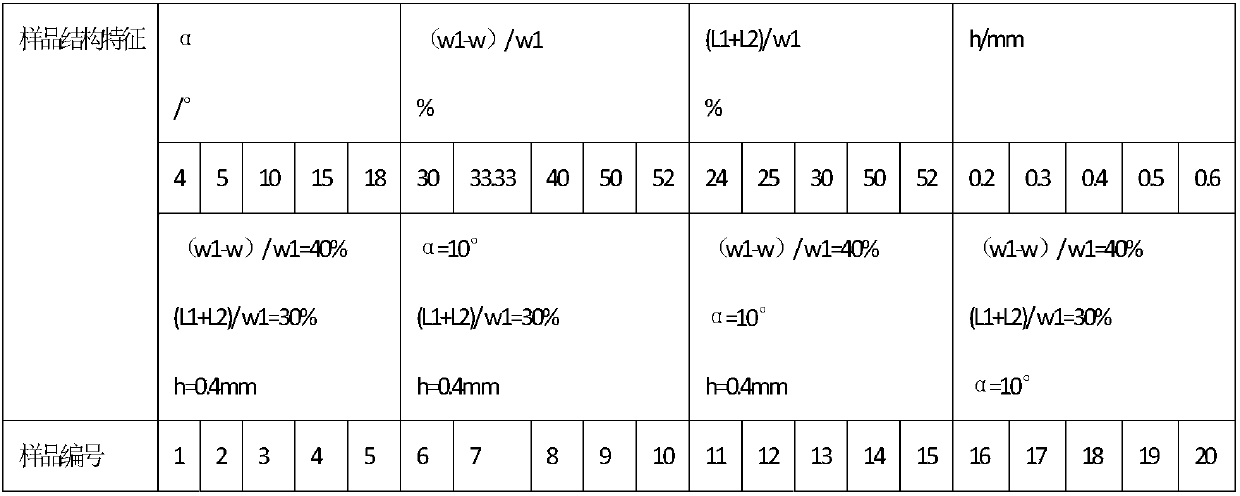

Motor magnetic steel

PendingCN109962540AReduce motor torque rippleGuaranteed uptimeMagnetic circuit stationary partsMagnetic energyMagnet

Disclosed is motor magnetic steel. The motor magnetic steel is characterized in that the two ends of an outer arc surface of a magnet steel main body are provided with arc surfaces which transit withthe outer arc surface in an arc manner, gaps exist between the arc surfaces and extending lines of the outer arc surface, the gaps are air gaps, the arc surfaces are air gap transition arcs, the totalwidth of the air gaps is 1 / 3-1 / 2 of the total width of the magnetic steel, the vertical distance between an outer arc extending surface of the main body and the outer end of each air gap transition arc is 0.3-0.5 mm, the two ends of an inner arc surface of the magnetic steel main body are provided with platforms, the total projection length of the platforms is 1 / 4-1 / 2 of the total width of the magnetic steel, and angles between the platforms and inner arc chords form platform air gap angles which are 5 degrees to 15 degrees. The motor magnetic steel reduces the motor noise and improves the magnetic energy utilization rate.

Owner:自贡市江阳磁材有限责任公司 +1

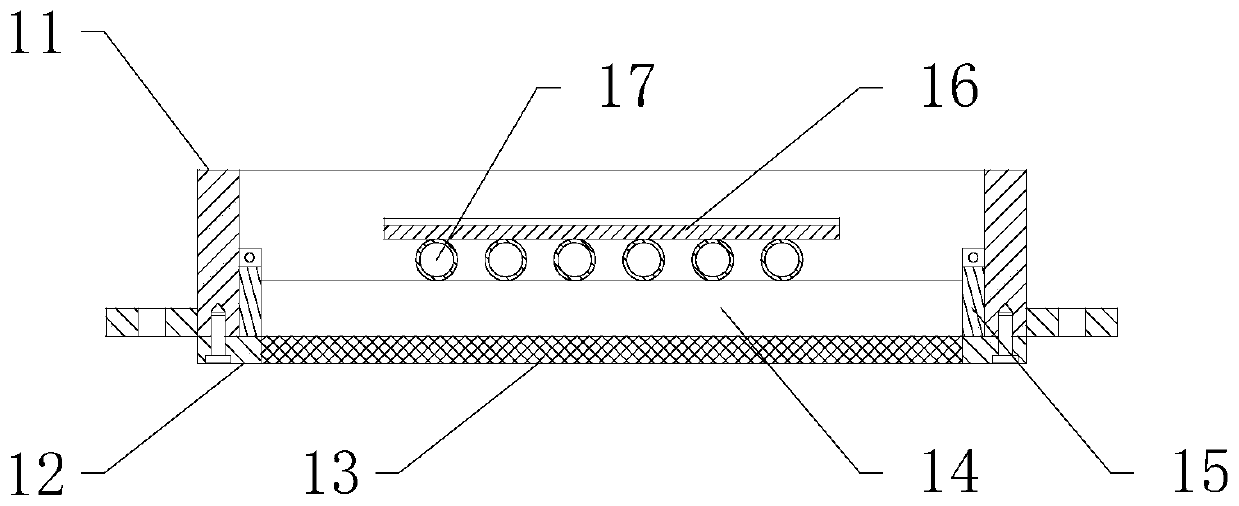

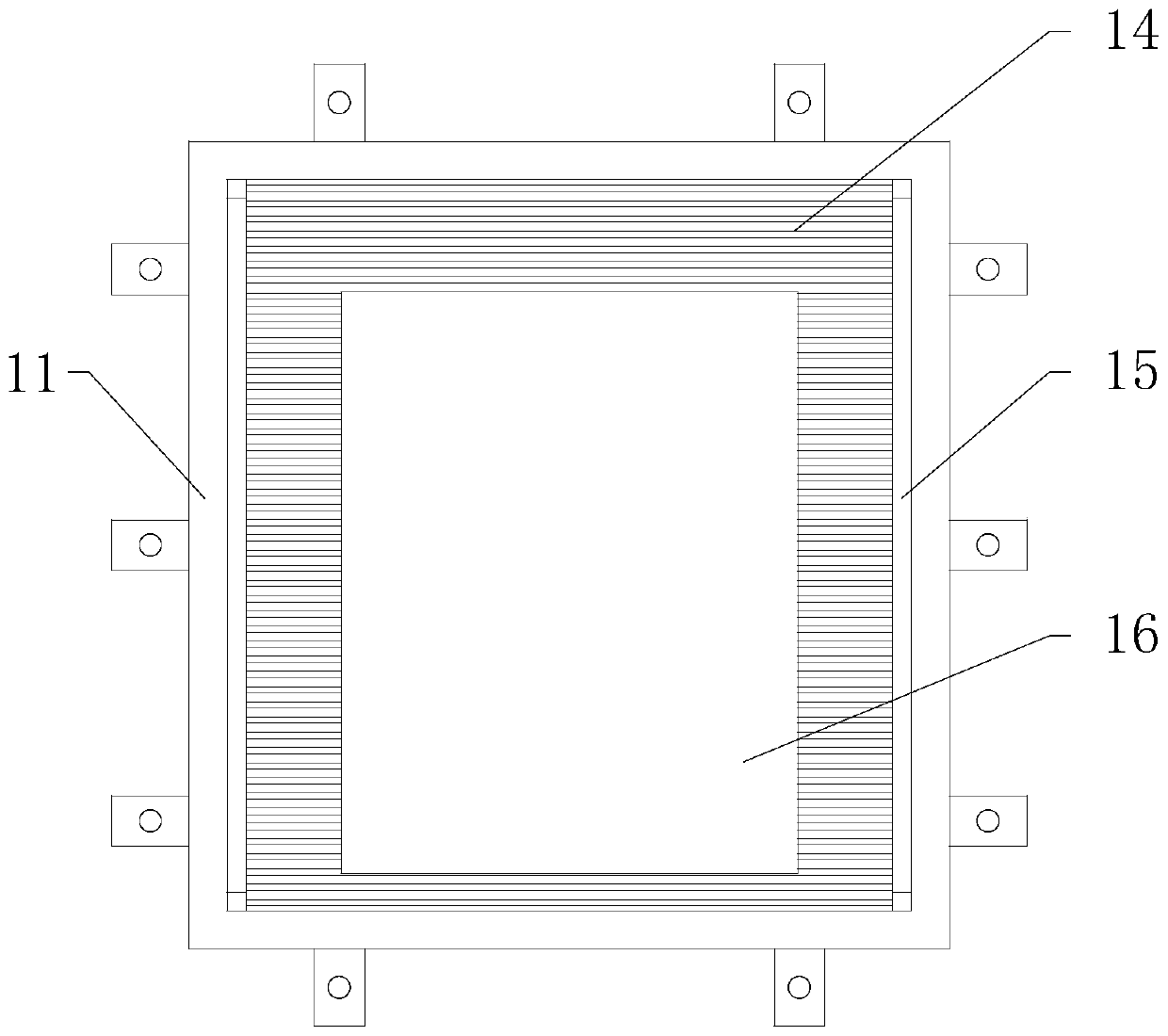

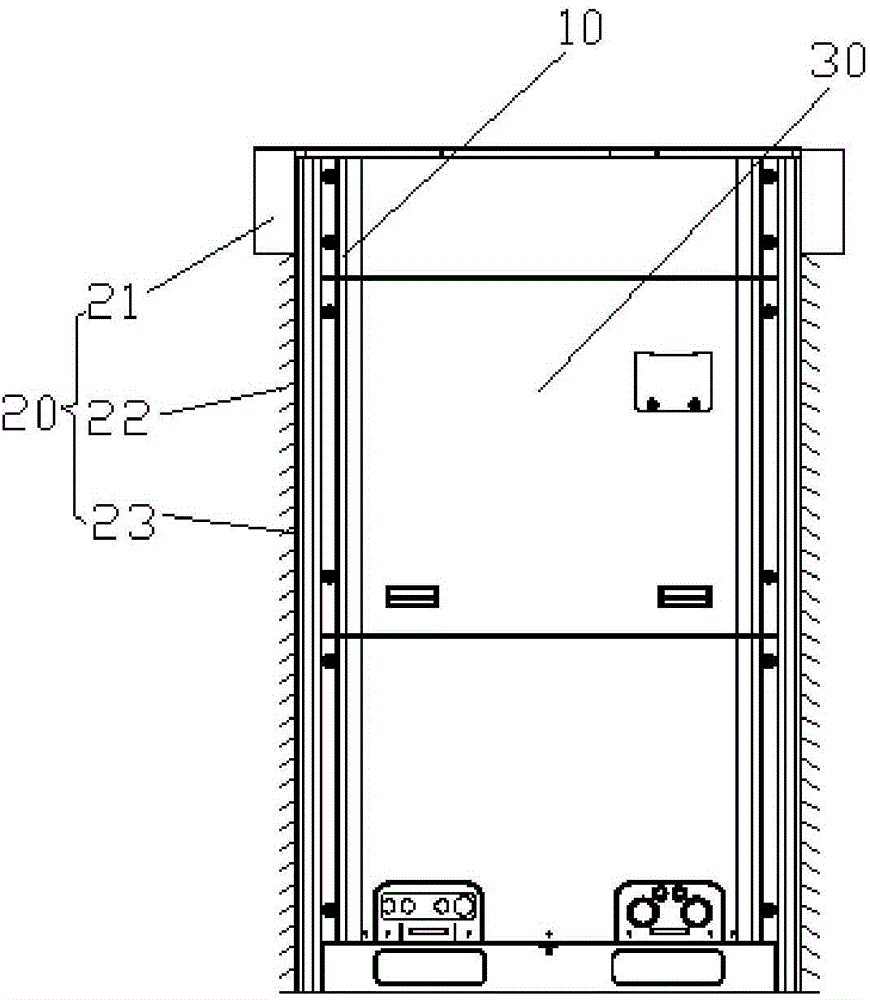

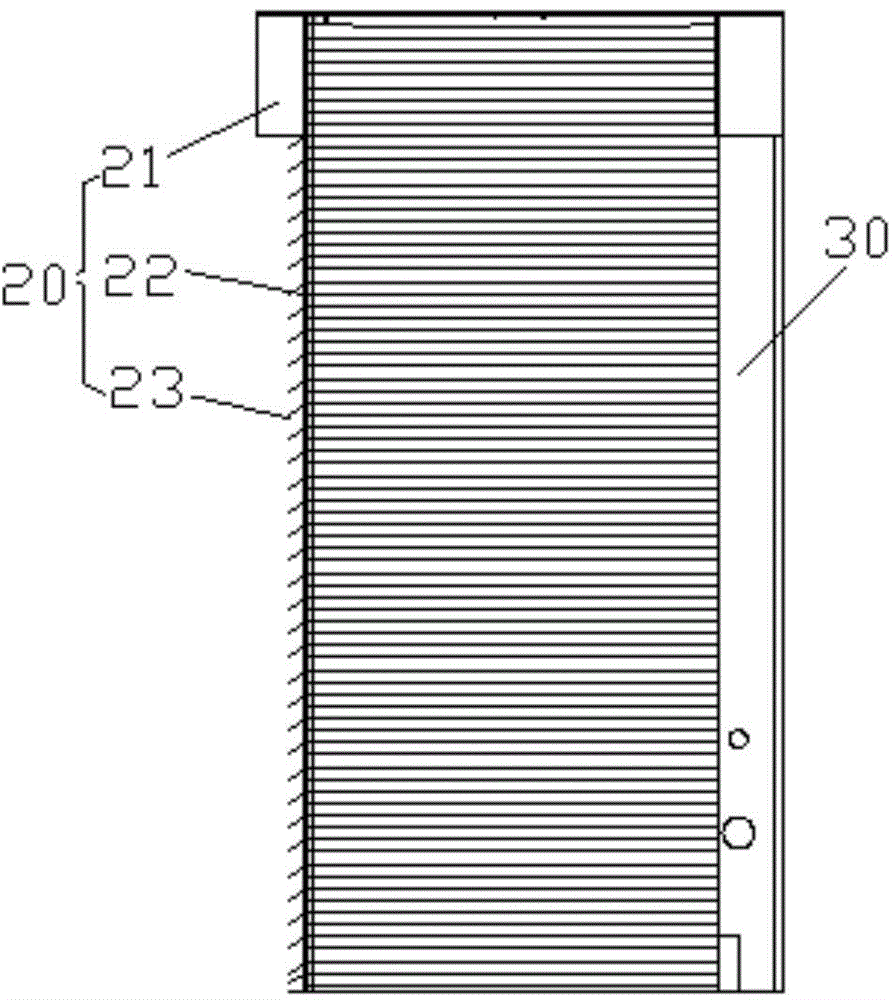

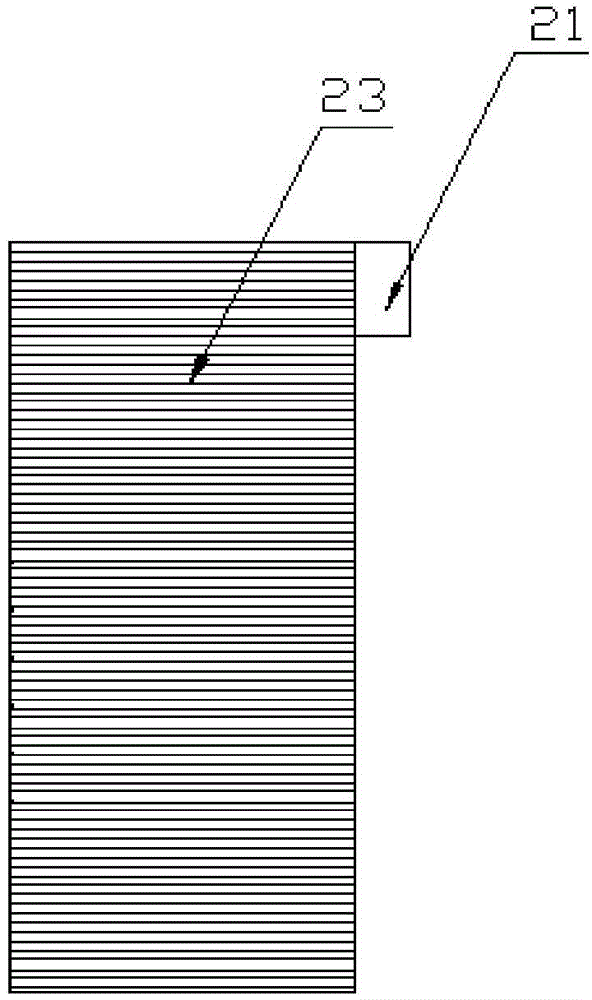

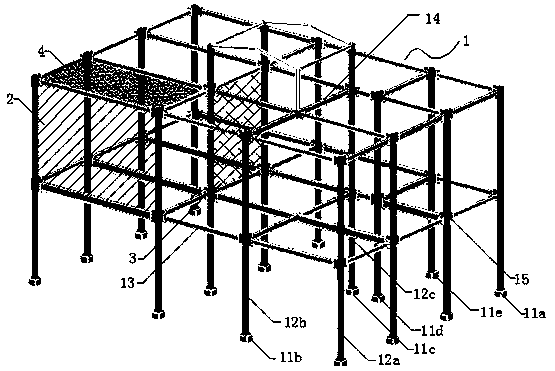

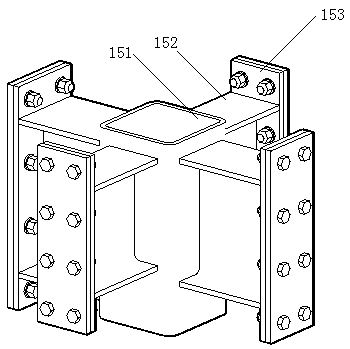

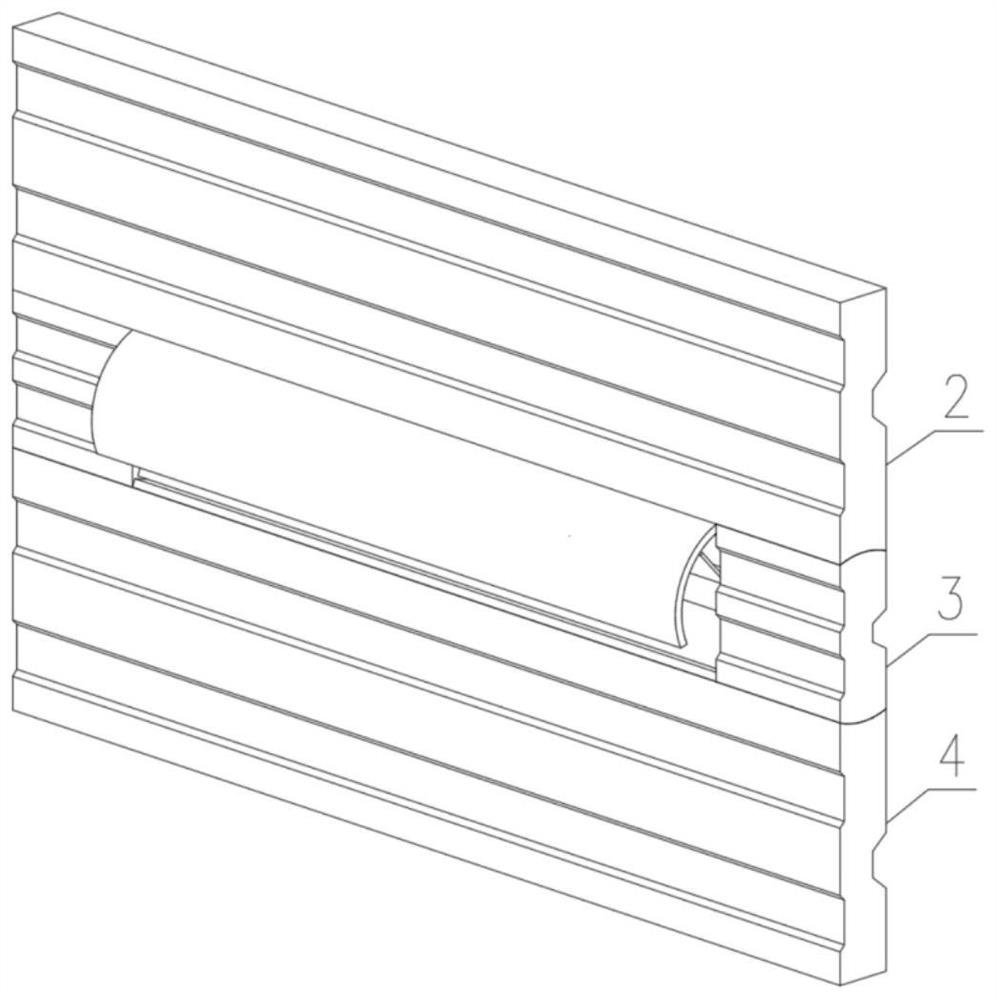

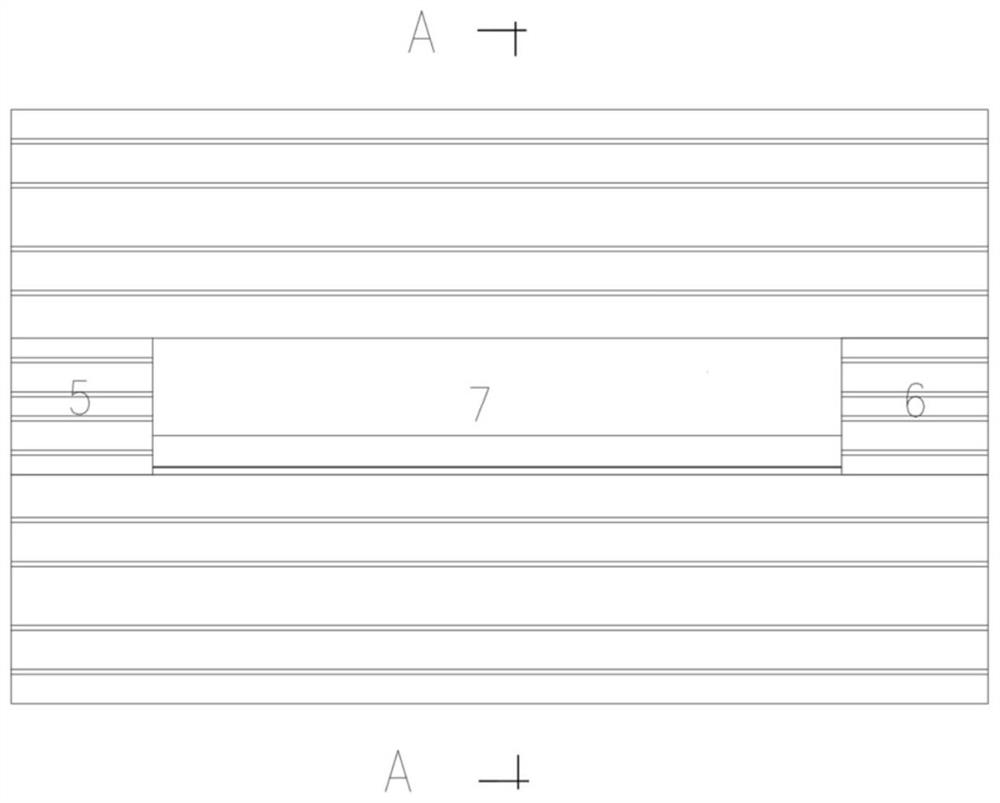

A light steel structure house and its construction method

ActiveCN106948472BFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

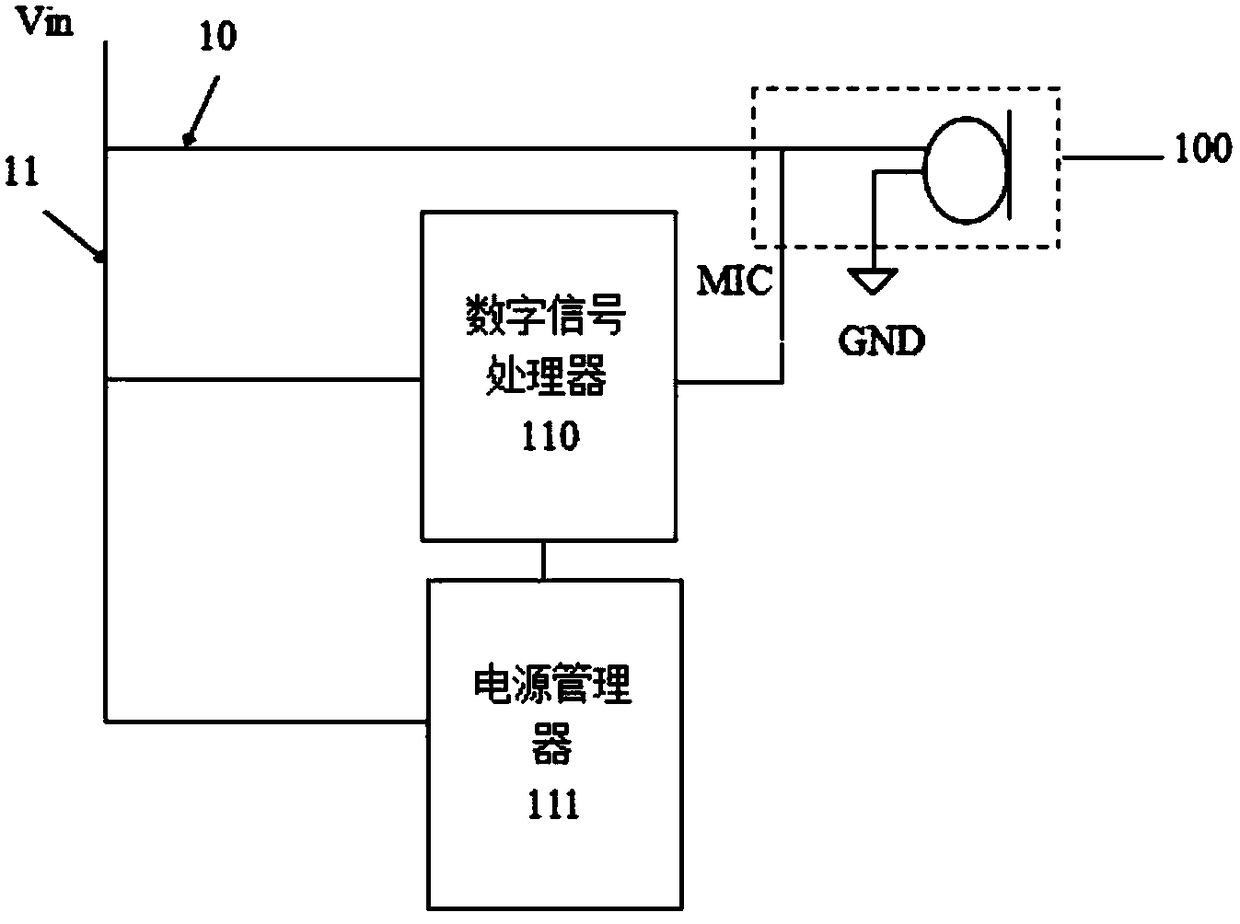

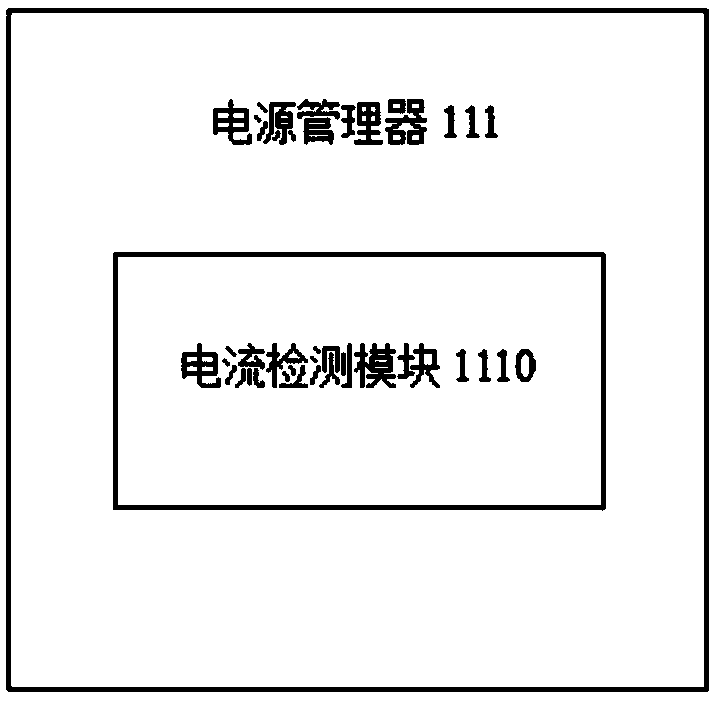

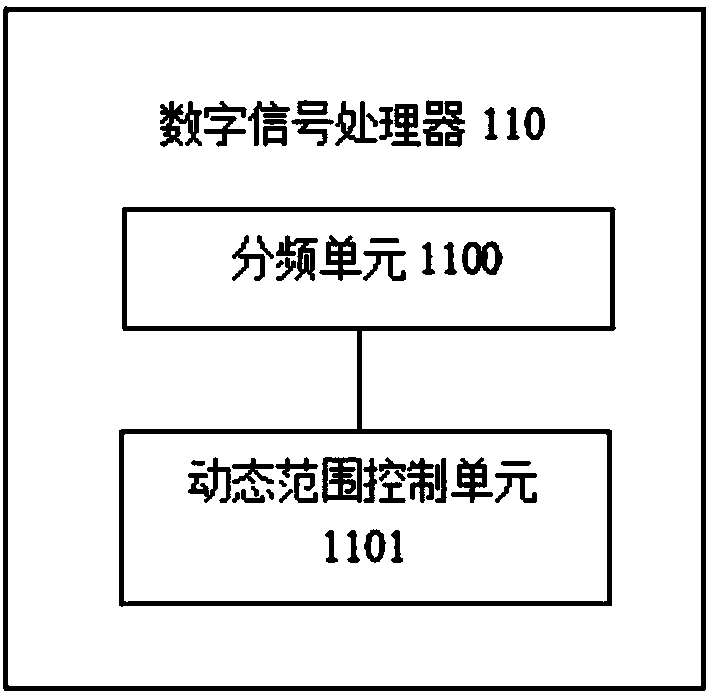

Microphone circuit and earphone with noise reduction function

PendingCN108235173AThe total current remains constantRealize the noise reduction functionMicrophonesLoudspeakersPower managerVIT signals

The invention discloses a microphone circuit and an earphone with a noise reduction function. The microphone circuit comprises: a microphone branch, connected to a microphone transducer which is connected to an input voltage terminal and a ground terminal; a fixed current branch, connected in parallel to the microphone branch, comprising a digital signal processor which is connected to a signal output end of the microphone transducer; and a power manager, connected to the input voltage terminal and the digital signal processor, further comprising a current monitoring module for compensating the total current of the fixed current branch to be stable. The microphone circuit has the advantages: output signals of the microphone transducer are processed by adopting the digital signal processor,and the signals within a set band range are strengthened to suppress the signals of other bands, thereby realizing the noise reduction function; and the power manager reduces the input voltage for providing constant current for the digital signal processor, and is provided with the current monitoring module for compensating the current difference in real time to keep the total current stable.

Owner:ZILLTEK TECH SHANGHAI +1

Load shedding sound barrier unit and sound barrier thereof

PendingCN114753275AEasy to achieve seamless fixationAvoid affecting the sound insulation performanceNoise reduction constructionPhysicsImpeller

The invention provides a load shedding sound barrier unit and a sound barrier thereof. The load shedding sound absorption screen body comprises at least one load shedding unit structure arranged in the vertical direction, and an upper screen body and a lower screen body which are adjacent to the load shedding unit structure. The load shedding unit structure comprises a left screen body, a right screen body and a load shedding structure located between the left screen body and the right screen body. The load shedding structure comprises a rotating wheel and an outer cylinder. The rotating wheel comprises a rotating shaft and at least three impellers, the two ends of the rotating shaft are connected with the left screen body and the right screen body respectively and can rotate freely, and the impellers are evenly arranged on the rotating shaft in a surrounding mode. The outer cylinder is fixed to the upper screen body and the lower screen body which are adjacent to the outer cylinder, each screen body is provided with an arc-shaped attaching face matched with the outer cylinder, and the gap between the outer end of the impeller and the inner side of the outer cylinder is not larger than 2 mm. The connecting surfaces of the upper and lower adjacent screen bodies are bent arc-shaped binding surfaces; the diameter of the outer cylinder is at least 200 mm, and the outer cylinder is provided with an end air opening and a surface air opening. After wind pressure acts on the two-end tuyeres and the surface tuyeres, the impeller is pushed to rotate around the rotating shaft, the pressure is converted, and the wind load is effectively reduced.

Owner:CHINA SHIPPING ENVIRONMENT SCI & TECH SHANGHAI CO LTD

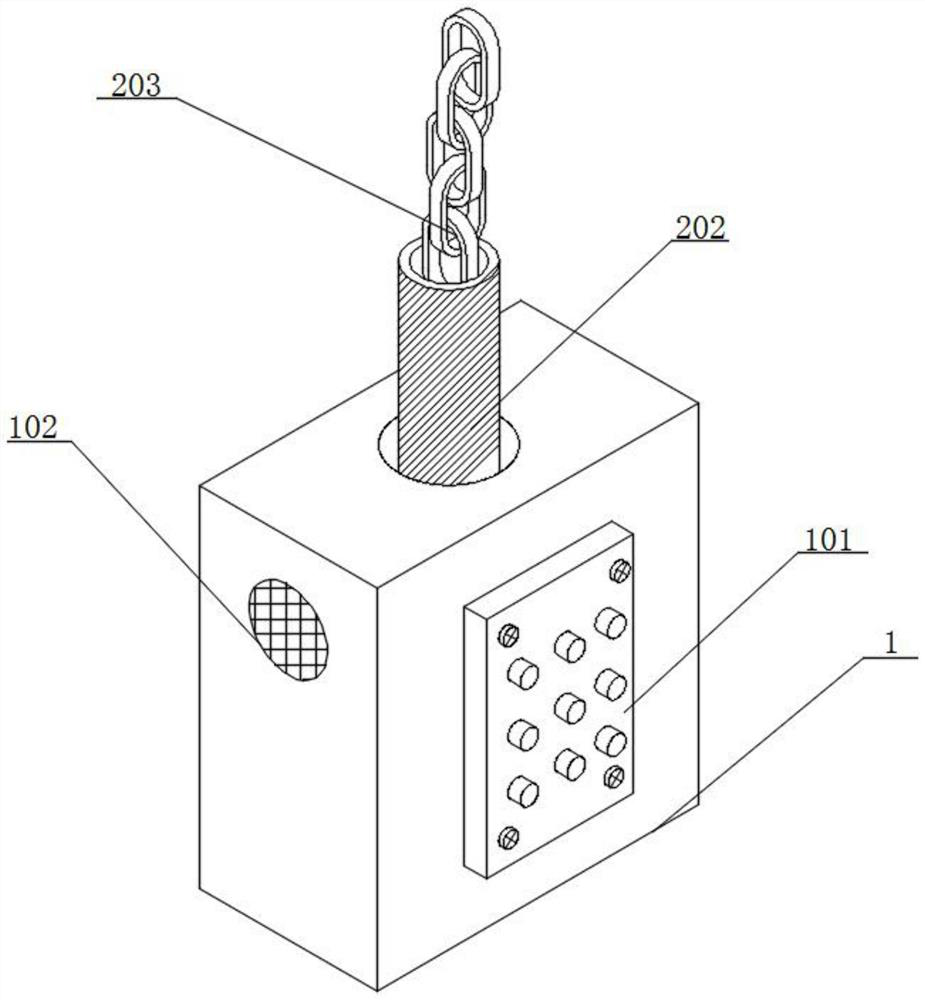

Elevator compensation chain with chain breakage protection function

ActiveCN114538236APrevent fallingPrevent rustDrying gas arrangementsElevatorsControl engineeringElectric machinery

The elevator compensation chain with the chain breakage protection function comprises a box body, a stopper, a dryer, a detector and a noise reduction box, the stopper is installed on the inner bottom wall of the box body, a dehumidifier is installed on the inner top wall of the box body, the dryer is installed on the inner top wall of the box body, the dryer is located on one side of the dehumidifier, and the detector is located on the other side of the dehumidifier. A detector is installed on the rear wall of the interior of the box body, a noise reduction box is installed on the bottom wall of the interior of the box body, a motor is installed on the inner wall of the box body, and a rotating shaft is installed on the inner wall of the box body. By installing a stopper and a moving rod, falling of the compensation chain caused by breakage of the compensation chain can be effectively prevented, when the compensation chain is broken, a supporting shaft rotates to drive a telescopic cylinder and a supporting rod to rotate, when the rotating speed is large, the supporting rod extends outwards, then an impact block impacts the moving rod, and the moving rod extends to drive a reset spring to extend; the moving rod drives the blocking plate to be tightly attached to the rubber sleeve, and the wedge-shaped block hooks the rubber sleeve to prevent the compensation chain from falling down.

Owner:南通中力科技有限公司

Bamboo floor convenient to splice

InactiveCN108797947ARealize the shock absorption effectImprove comfortCovering/liningsFlooring insulationsEngineeringBamboo floor

The invention discloses a bamboo floor convenient to splice. The bamboo floor convenient to splice includes bamboo foundation plates, muting effect layers, a PVC sound-proof block, a damping layer anda damping small spring. The damping layer is installed at the central position of the inner portion of the bamboo foundation plates. The muting effect layers are arranged in the bamboo foundation plates of the two ends of the damping layer. Damp proof and anti-bacteria layers are fixedly arranged on one ends, far from the damping layer, of the muting effect layers. The insect-proofing layers arefixedly arranged in the bamboo foundation plates far from one end of the damp proof and anti-bacteria layers. Sealing bamboo plates are arranged at the top end of the bamboo foundation plates, far away one side of the damp proof and anti-bacteria layers, of the insect-proofing layers. A splicing groove is formed in the central position, far from the outside wall of a splicing bump, of the bamboo foundation plates, bamboo stop blocks are fixedly arranged on the outside wall of the bamboo foundation plates of the two ends of the splicing groove. The bamboo floor convenient to splice not only improves the using comfort of the bamboo floor, and avoids the noise pollution, but also prolongs the service life of the bamboo floor.

Owner:安吉远峰竹木有限公司

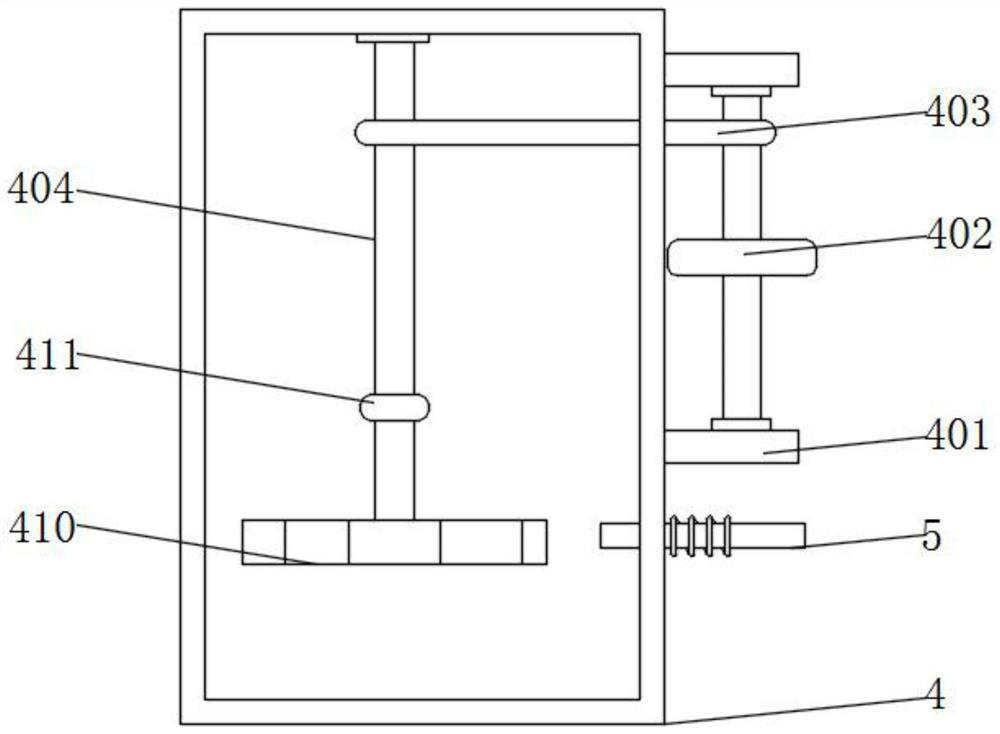

Stirring equipment with noise reduction function for coal chemical industry

PendingCN109647251AImprove noise reductionSimple structureRotary stirring mixersTransportation and packagingDrive shaftEngineering

The invention relates to stirring equipment with a noise reduction function for a coal chemical industry. The equipment comprises a body, a connecting cover, a driving motor, a transmission shaft, a bottom plate, two fixing blocks and at least one first stirring rods, the bottom plate is horizontally arranged under the body, the driving motor is fixed to the top of the bottom plate, the transmission shaft is vertically arranged, the driving motor is in transmission connection with the bottom of the transmission shaft, the bottom of the body sleeves the transmission shaft, two fixing blocks arearranged on both sides of the driving motor respectively, the top of the bottom plate is fixedly connected with the bottom of the body through the fixing blocks, the first stirring rods are uniformlyfixed to the two sides of the transmission shaft from top to bottom, the connecting cover horizontally covers the top of the body, the bottom plate is provided with a noise reduction mechanism, and an auxiliary mechanism is arranged in the body. The equipment has the advantages that the function of noise reduction is achieved through the noise reduction mechanism, the stirring effect is improvedthrough the auxiliary mechanism.

Owner:刘彦杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com