Patents

Literature

544results about How to "Realize heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

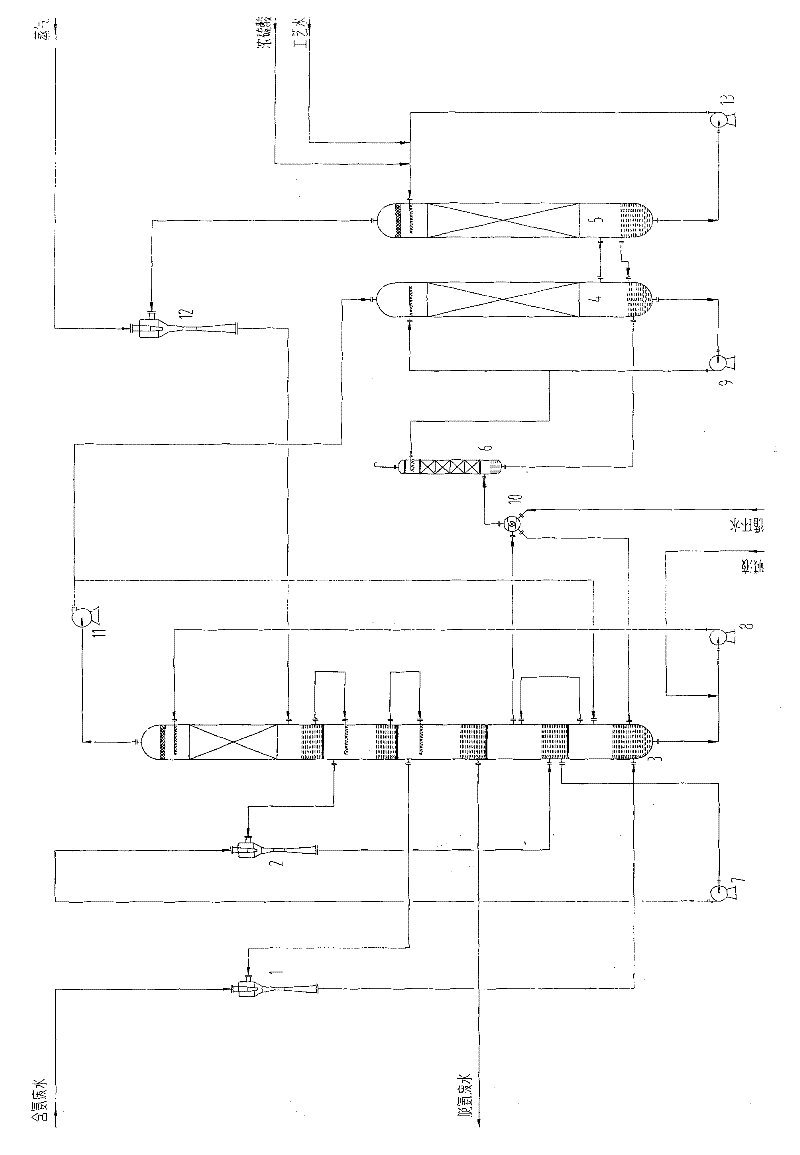

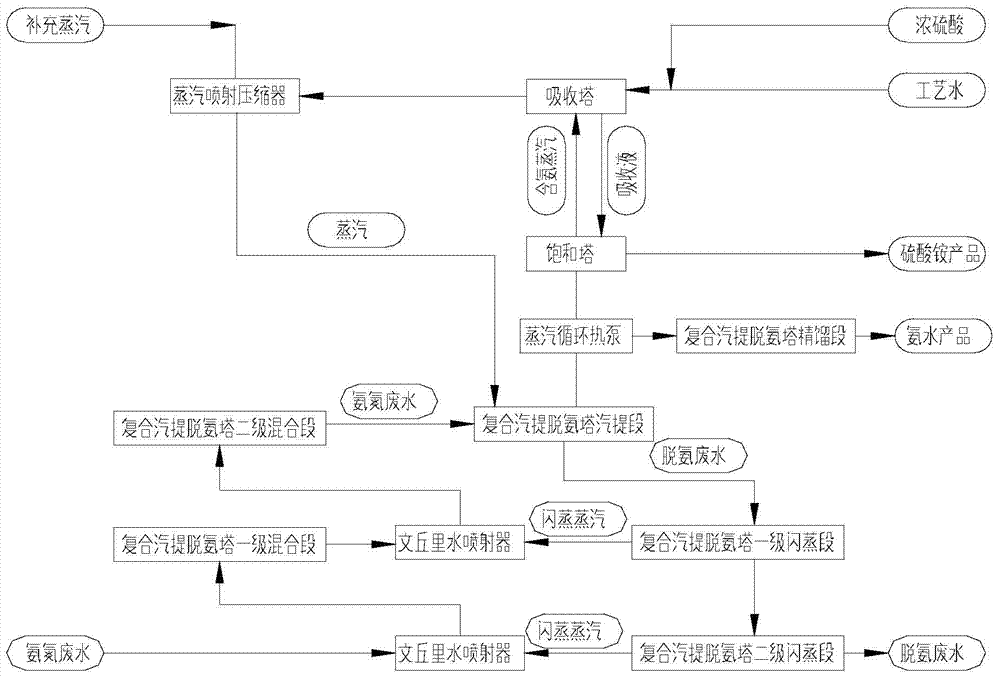

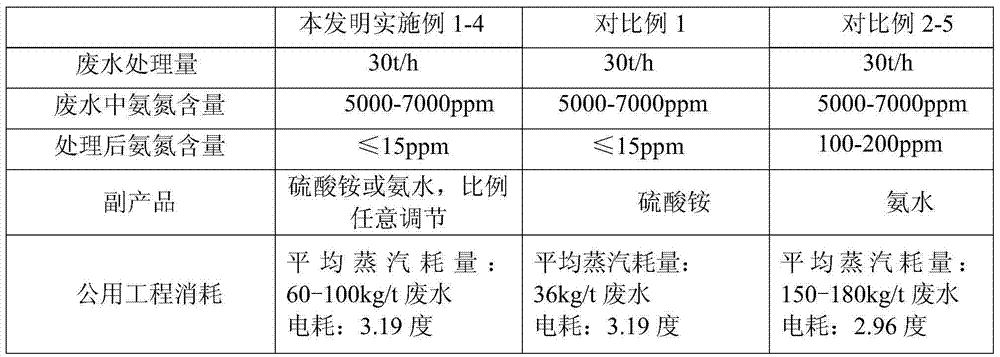

Stripping ammonia-removing method based on flash evaporation and heat pump technologies

ActiveCN102190341ARealize heat exchangeAvoid badWater contaminantsWater/sewage treatment by degassingAbsorption columnDirect heating

The invention relates to a stripping ammonia-removing method based on flash evaporation and heat pump technologies. The method comprises the following steps of: absorbing steam which is obtained after stripping ammonia removal and rich in ammonia nitrogen with an absorption column, pressurizing the purified steam with a heat pump set for recycling, carrying out flash evaporation on wastewater subjected to ammonia-removing process with a vacuum flash evaporation set composed of a Venturi and a liquid ring vacuum pump, and directly heating for pretreating wastewater with high ammonia nitrogen content. Compared with the traditional process with high ammonia-removing steam consumption and high operation cost, the method disclosed by the invention has prominent effects in energy saving and consumption reducing, and has broad market application prospect and high application potential in the treatment of wastewater containing ammonia nitrogen.

Owner:CHINA PETROLEUM & CHEM CORP +3

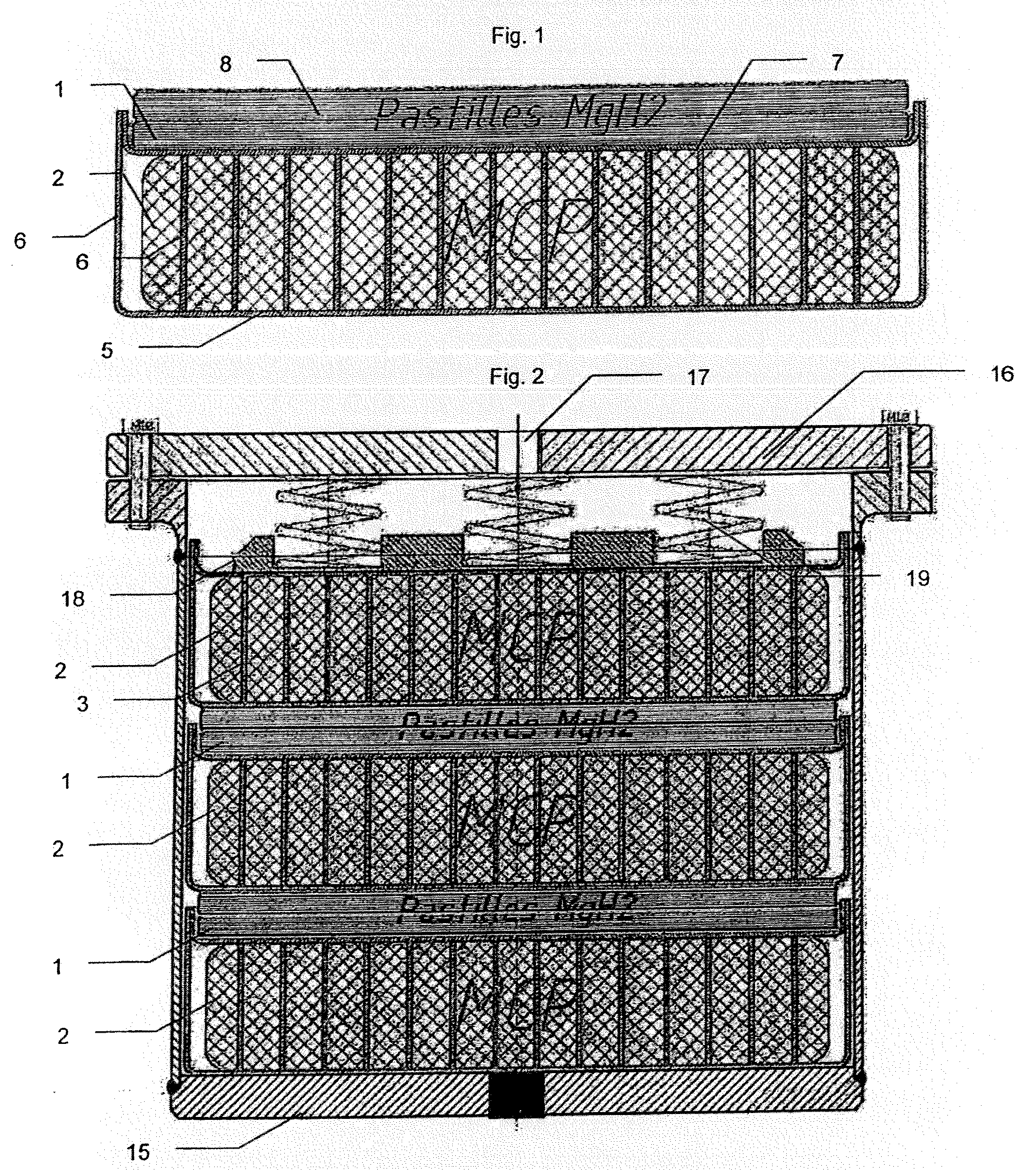

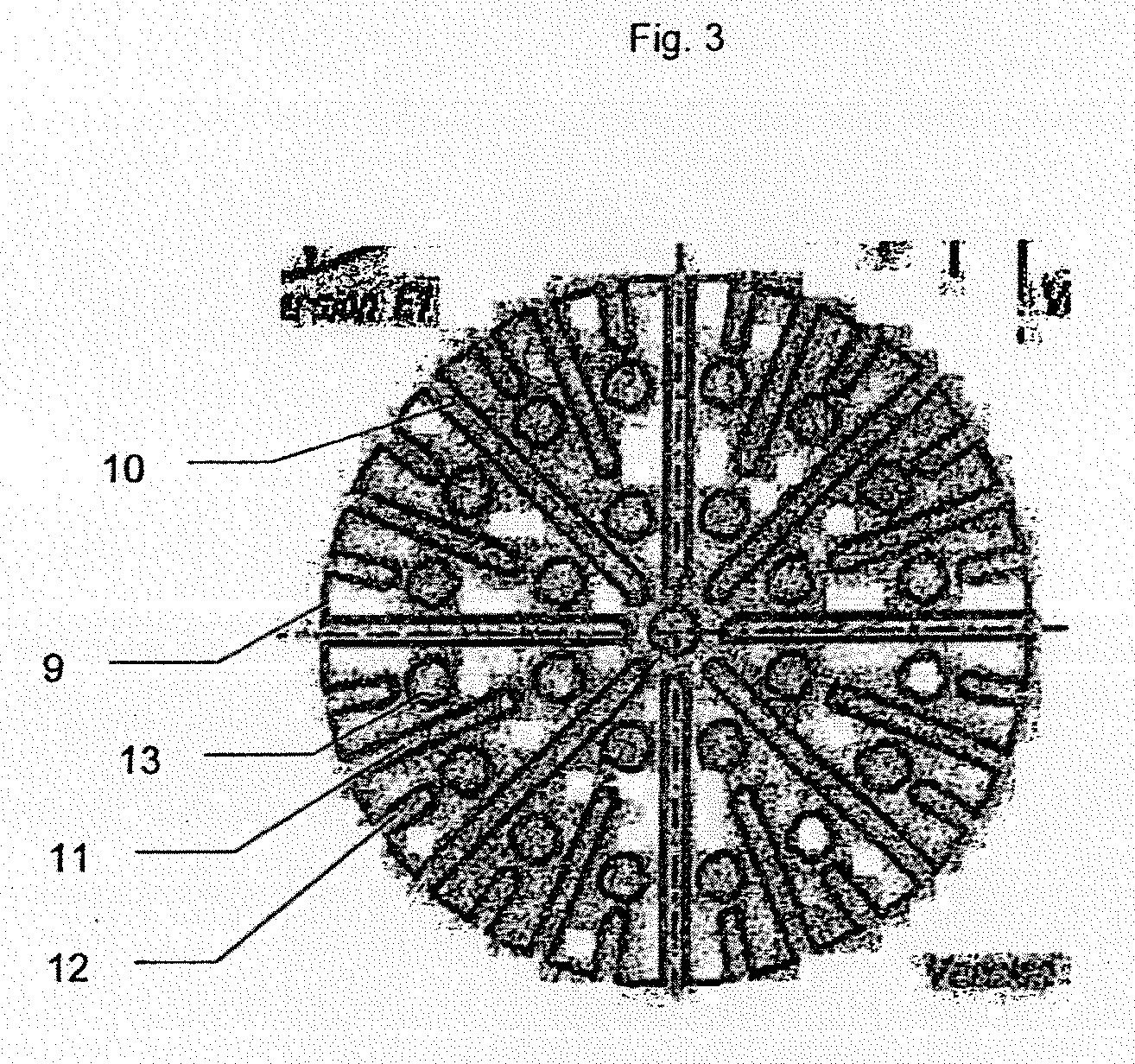

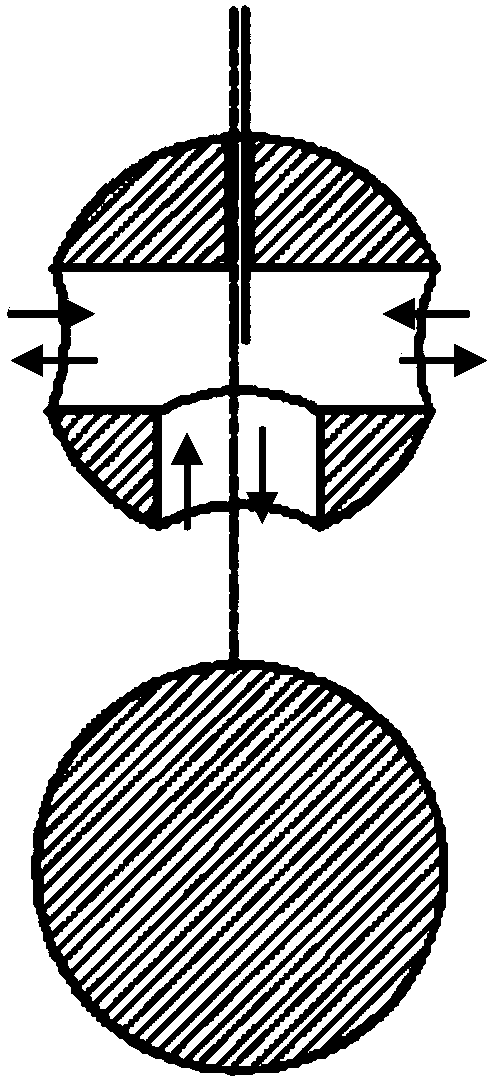

Tank for storing and withdrawing hydrogen and/or heat

InactiveUS20120201719A1Safe handlingSpeed up heat exchangeReversible hydrogen uptakeChemical/physical/physico-chemical stationary reactorsProcess engineeringGaseous hydrogen

The present invention relates to a tank for storing and withdrawing hydrogen by means of a reversible hydriding / dehydriding reaction, said tank consisting of a thermally insulated chamber that includes a plurality of elements (2) for storing hydrogen in the form of hydrides, each element having at least one surface for exchange with the gaseous hydrogen and at least one heat exchange surface, characterized in that it further comprises a plurality of heat storage elements (3) for preserving and releasing the heat that is associated with the reversible hydriding / dehydriding reaction.

Owner:MCPHY ENERGY +1

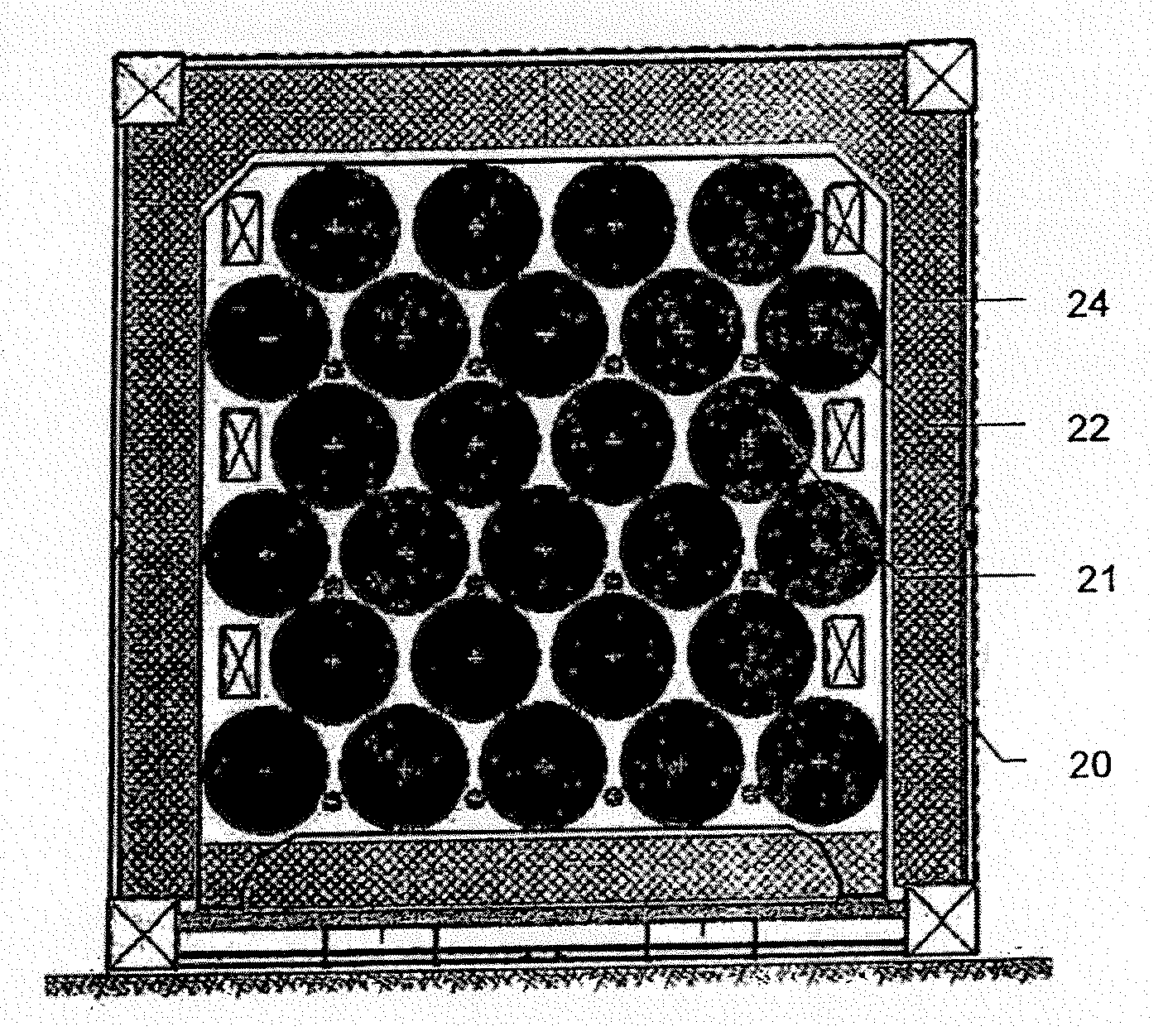

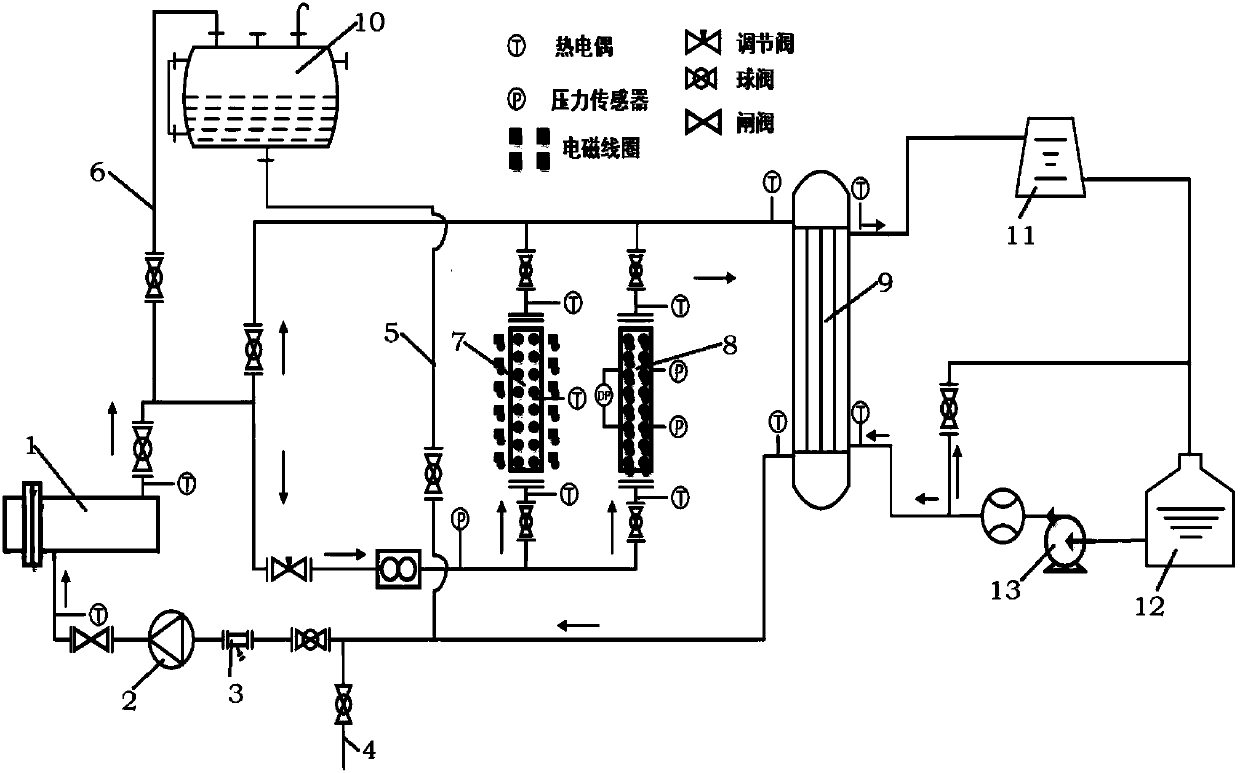

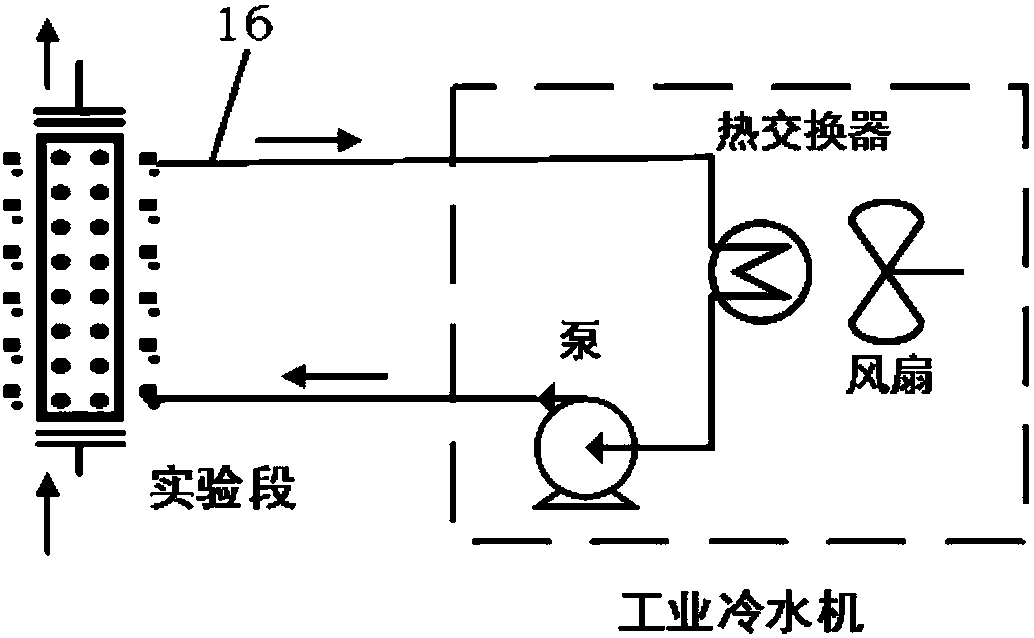

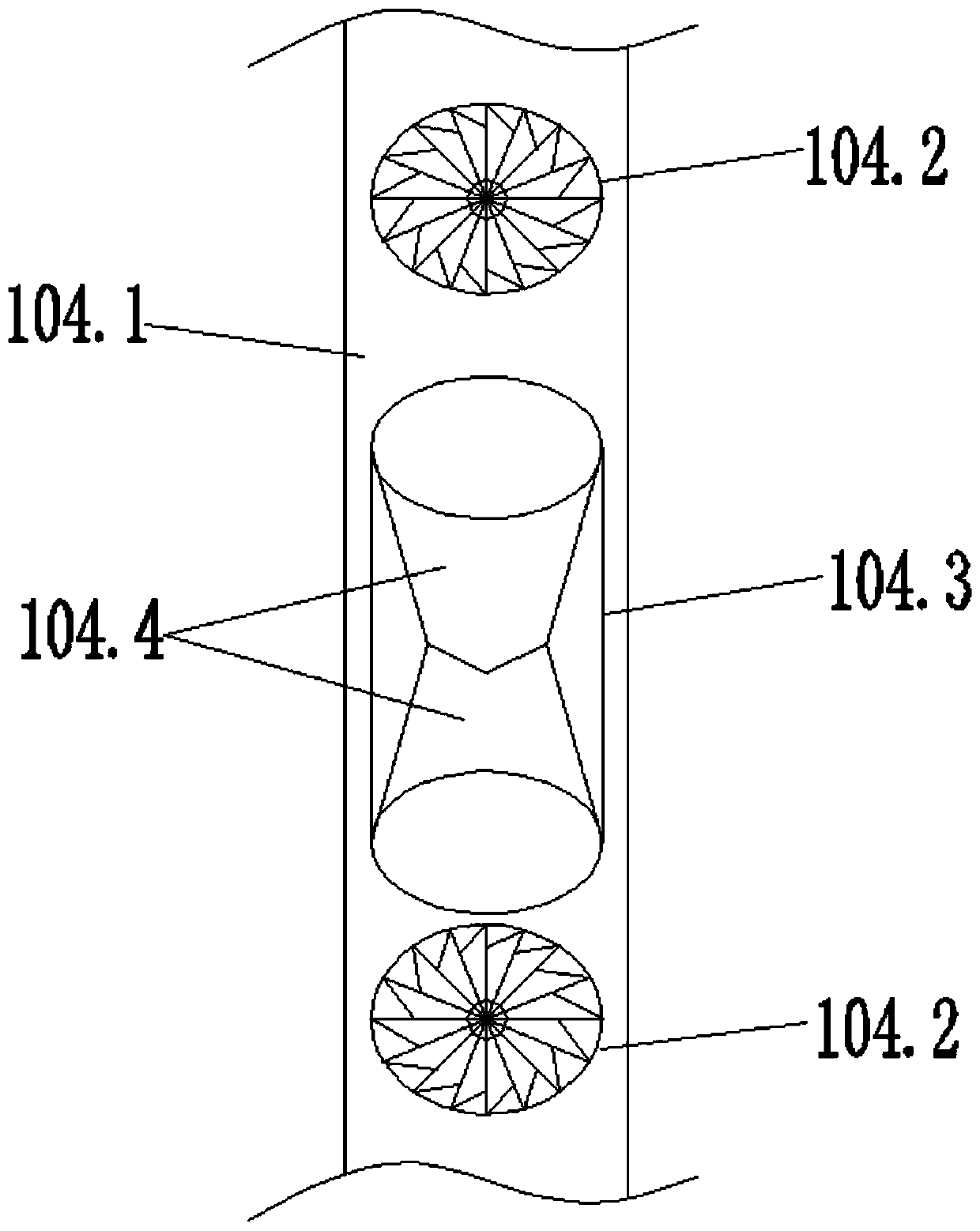

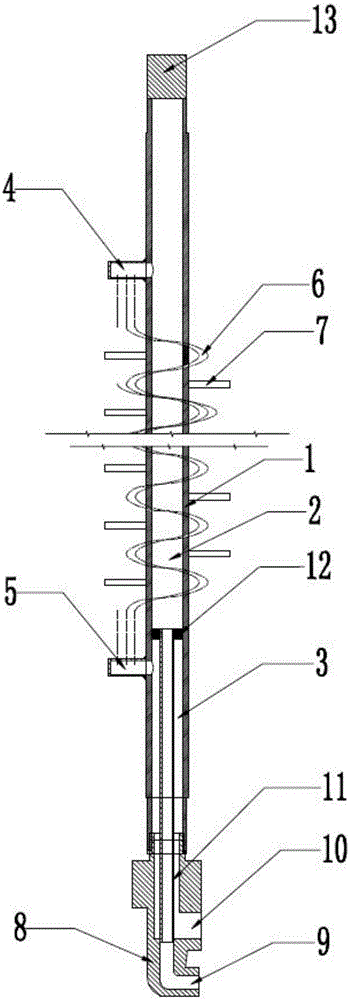

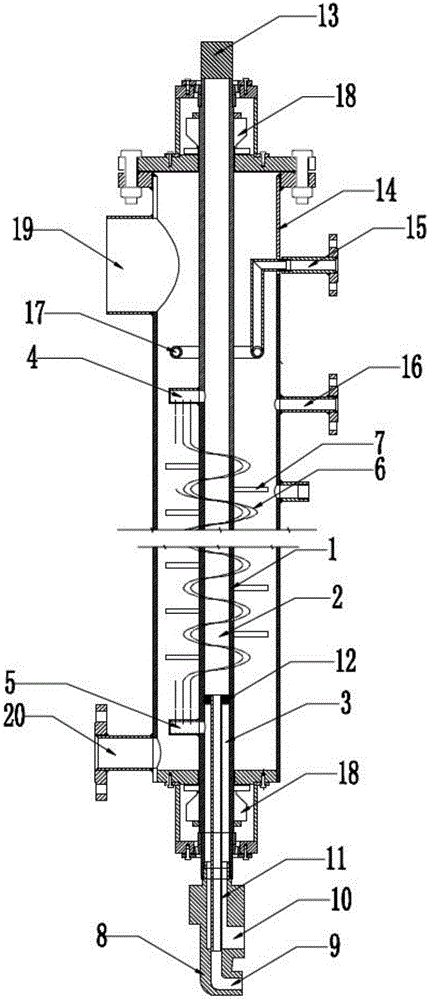

Villiaumite cooling ball bed high-temperature stack core flowing heat exchange simulating experiment system

ActiveCN108109708AReduce electricity loadThe experimental phenomenon is visibleNuclear energy generationNuclear monitoringPrandtl numberHeat conducting

The invention discloses a villiaumite cooling ball bed high-temperature stack core flowing heat exchange simulating experiment system. The system can perform two experiments of Dowtherm A heat-conducting oil flowing and heat exchange and can simulate the flowing heat exchange characteristic of high-temperature villiaumite under the working condition of low temperature. The experiment system can perform flowing experiment and heat transfer experiment on high Prandtl number heat-conducting oil in a bed ball channel and can realize flowing and heat exchange simulation of the villiaumite cooling ball bed high-temperature stack core FLiBe; and the experiment system has the advantages of high safety, high experiment data precision, low operating cost and the like.

Owner:XI AN JIAOTONG UNIV

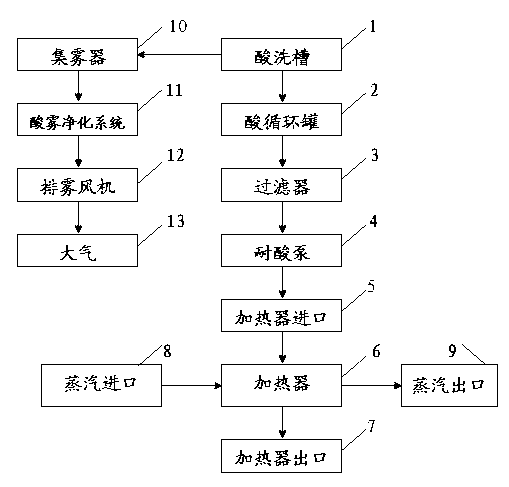

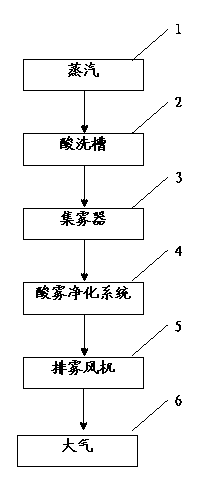

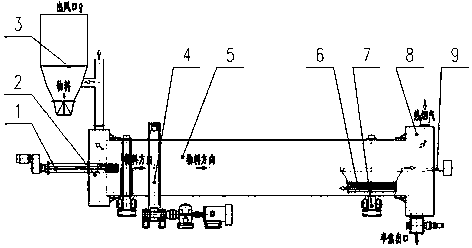

Method for heating acid washing solution

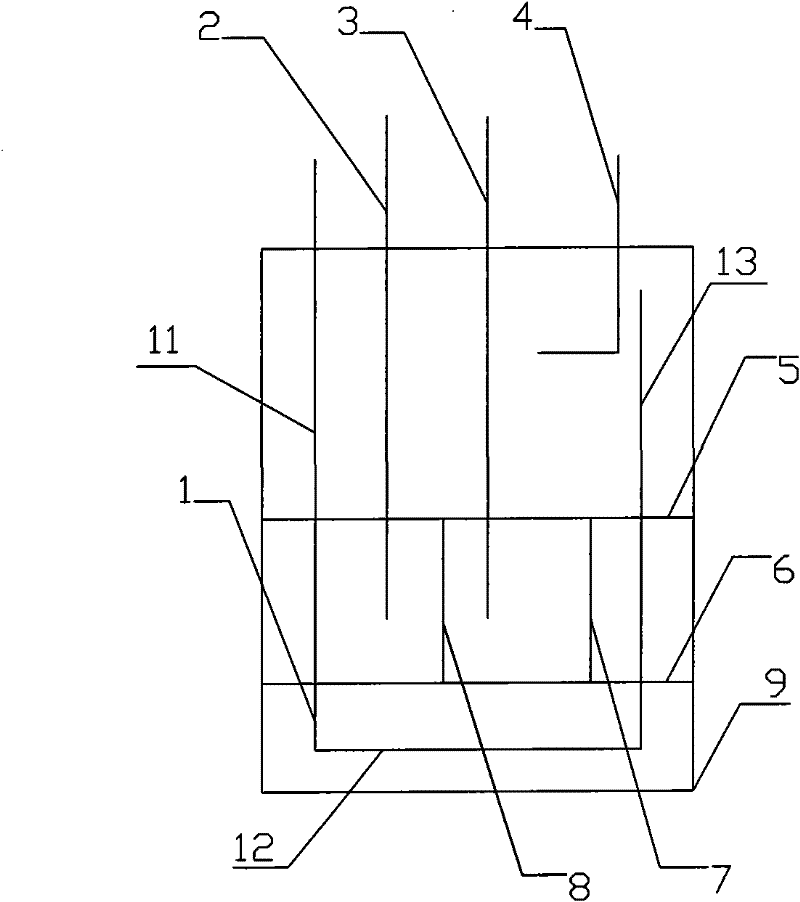

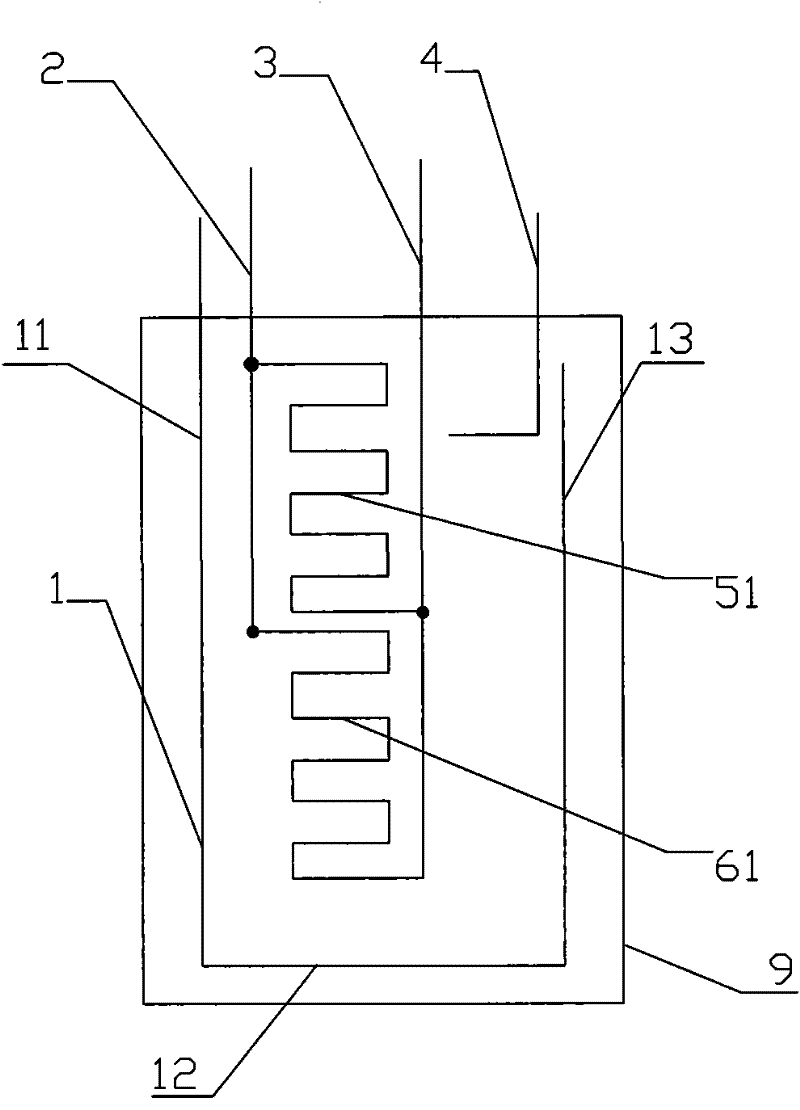

The invention discloses a method for heating acid washing solution. The method comprises: (1) the acid washing solution in an acid washing tank 1 flows back into an acid circulation tank 2, is filtered through a filter 3 and is pumped into a heater 6 by an acid-resistant pump 4 through an inlet 5 of the heater, the heated acid washing solution is pumped into the acid washing tank 1 through an outlet 7 of the heater to form circulation, and the circulation is repeated in the way; (2) heating steam enters through a steam inlet 8 and is discharged through a steam outlet 9, so that the acid washing solution is kept at normal technological temperature all the time; and (3) acid mist which is generated during the acid washing process is concentrated through a mist collector 10 under the action of a mist exhaust fan 12 and enters an acid mist purification system 11 to be purified, and the mist which meets the emission standards is discharged to the atmosphere 13 through the mist exhaust fan 12. By the method, heat exchange is indirectly realized, the acid washing solution cannot be diluted, excessive acid mist is not generated, the acid mist cannot be leaked during the heat exchange process, and the heating process of the acid washing solution and the temperature of the acid washing solution can be automatically controlled through adopting a heat exchanger.

Owner:TIANJIN YIBO STEEL MAKING

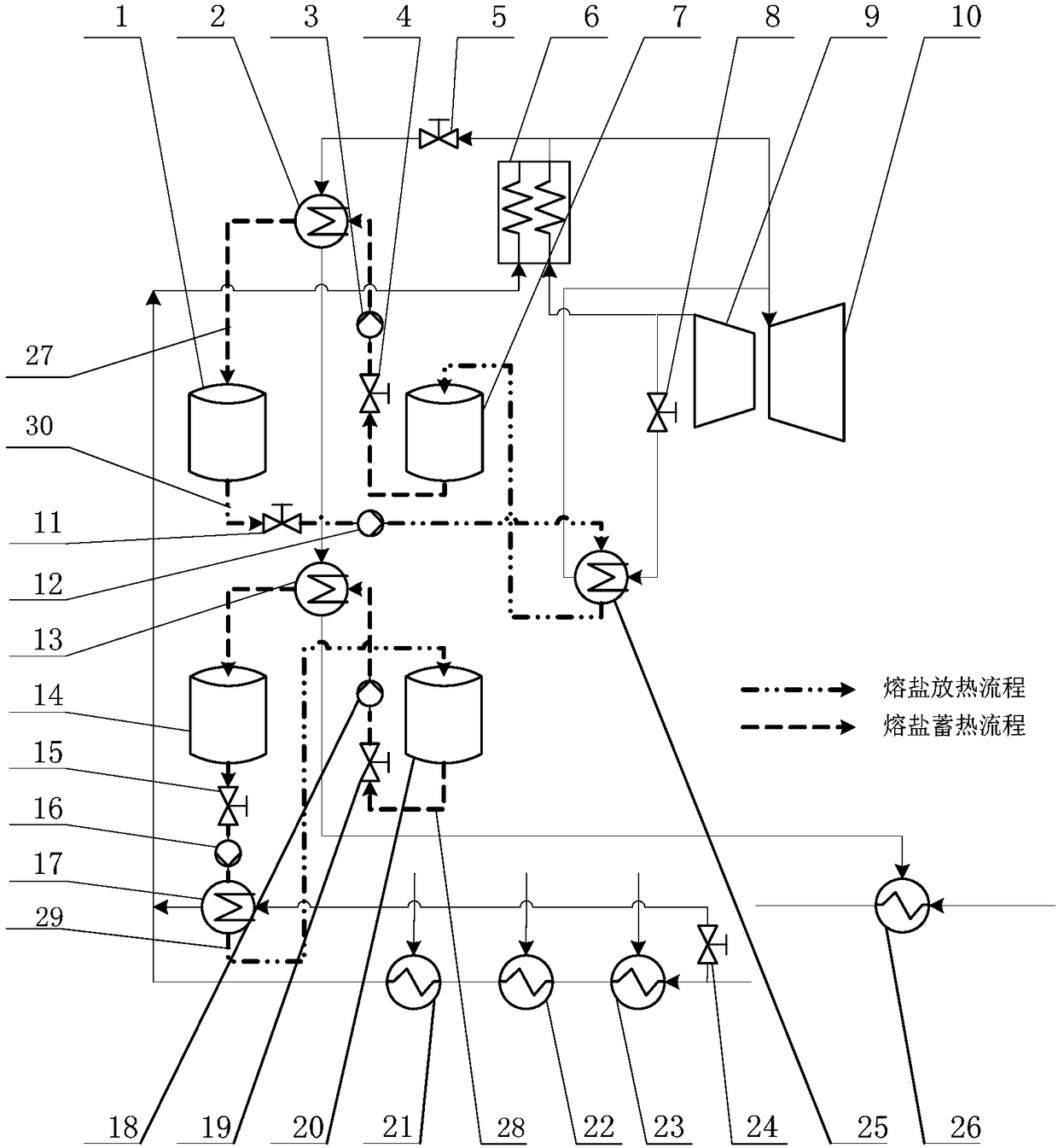

Fused salt heat storage and heat release peak load regulating system for thermal power generating unit

The invention discloses a fused salt heat storage and heat release peak load regulating system for a thermal power generating unit. According to the fused salt heat storage and heat release peak loadregulating system, a fused salt heat storage system, an I-stage fused salt low-temperature heat release system and a II-stage fused salt high-temperature heat release system are additionally arrangedon the basis of the original thermal power generating unit, and therefore peak load regulating of a power grid is realized through heat storage and heat release of fused salt; when the dispatching load of the power grid is decreased, part of high-temperature reheat steam is extracted from an outlet of a boiler reheater and exchanges heat with the fused salt in the fused salt heat storage system, and therefore consumption and utilization of the reheat steam in the electricity utilization off-peak season are completed; when the dispatching load of the power grid is increased, a part of high-pressure feedwater flowing to a high-pressure heater is divided into the I-stage fused salt low-temperature heat release system to exchange heat with the fused salt; and meanwhile, the steam discharge amount of a high-pressure cylinder is increased, part of increased exhaust steam of the high-pressure cylinder is fed into the II-stage fused salt high-temperature heat release system to exchange heat with the high-temperature fused salt, the heated steam enters an intermediate-pressure cylinder to apply work, the amount of the steam entering the intermediate-pressure cylinder and the output of a steam turbine can be increased, and the electric power of the thermal power generating unit can be rapidly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

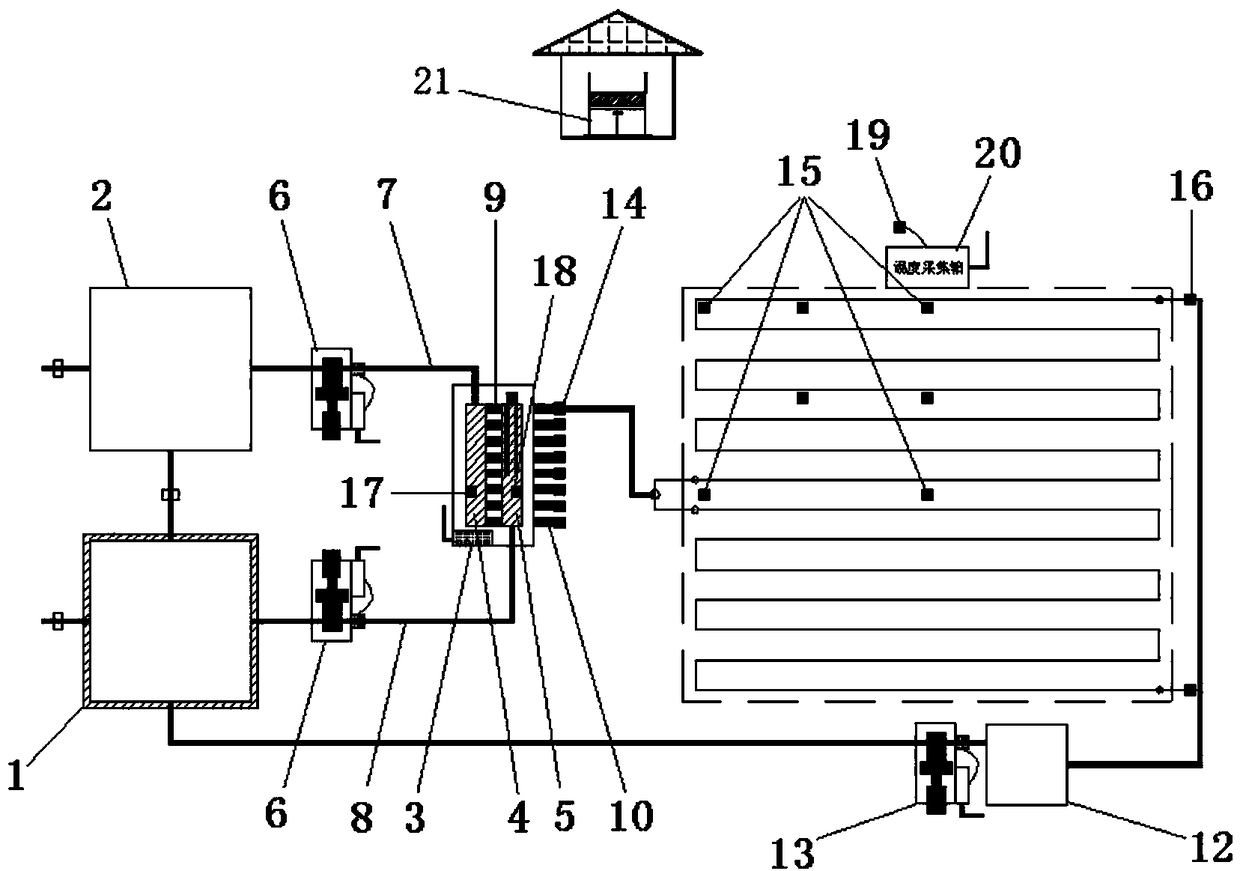

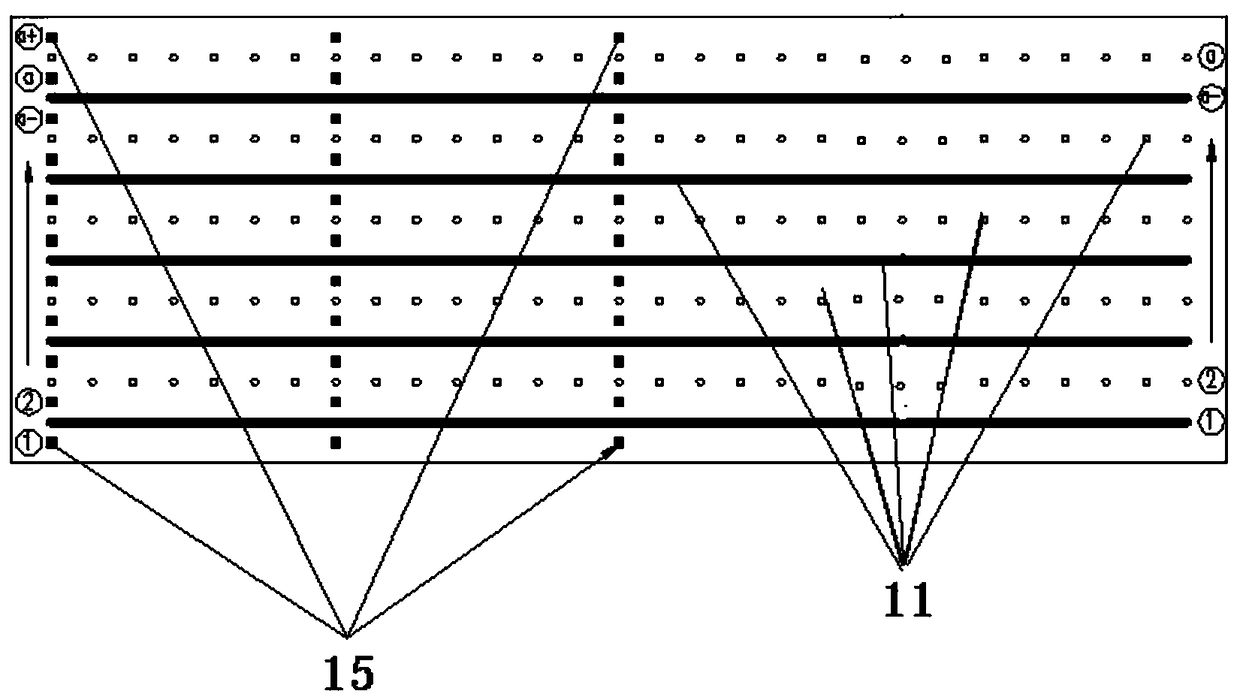

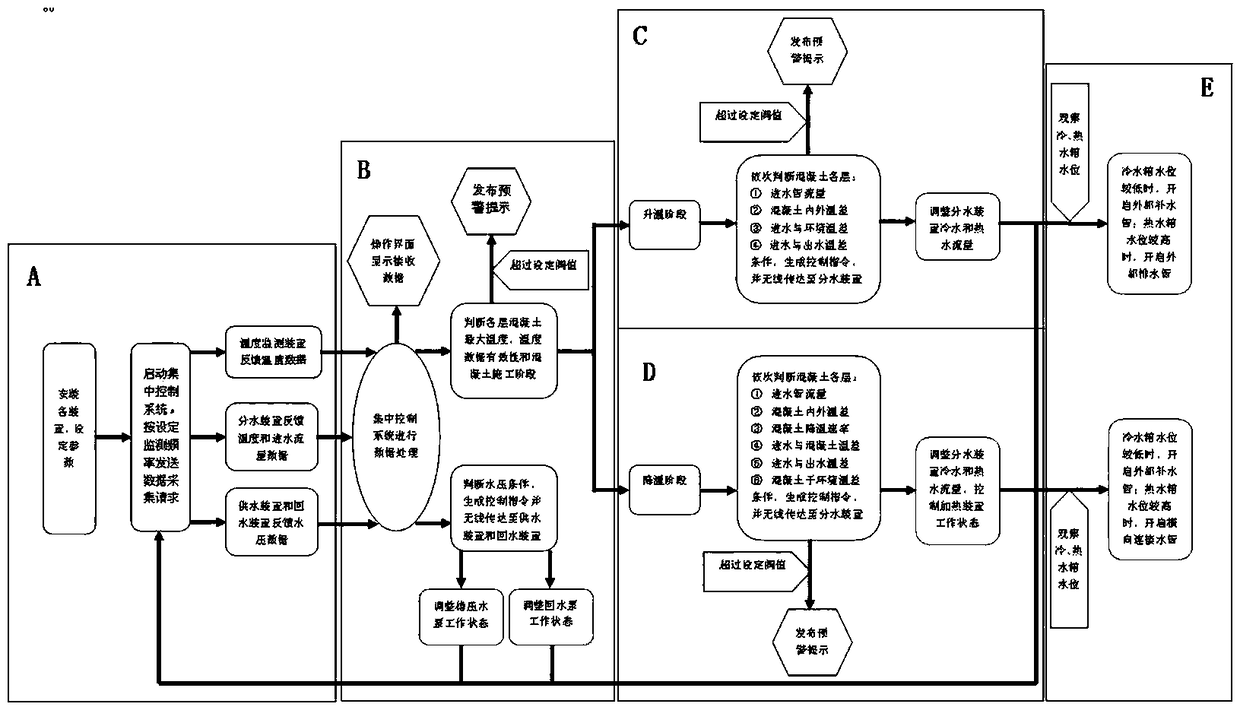

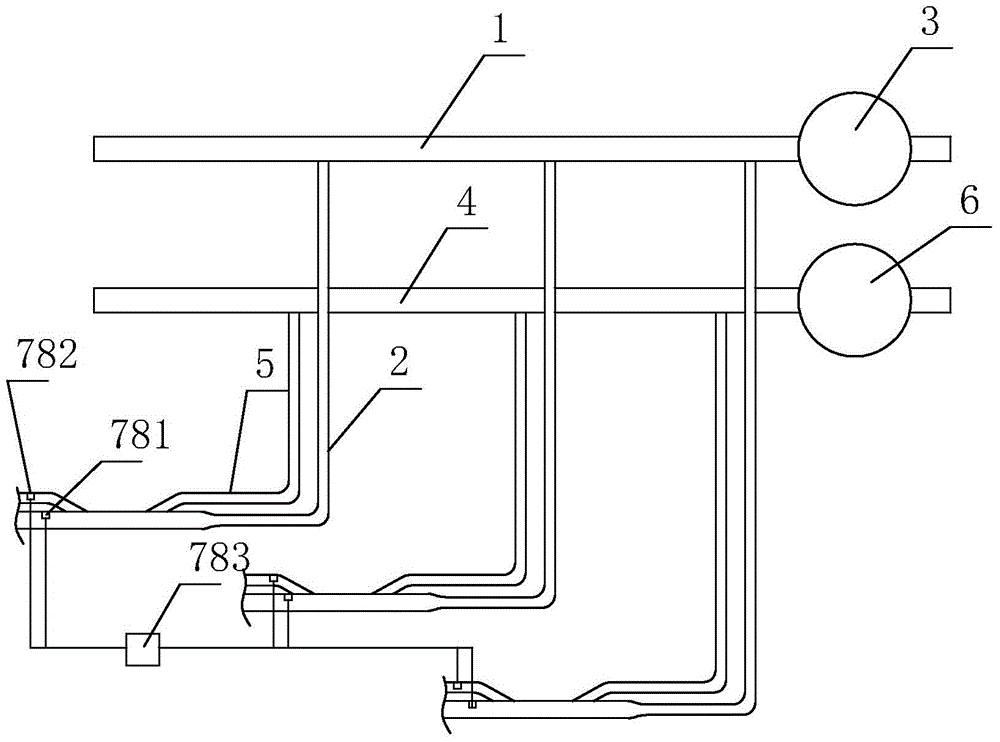

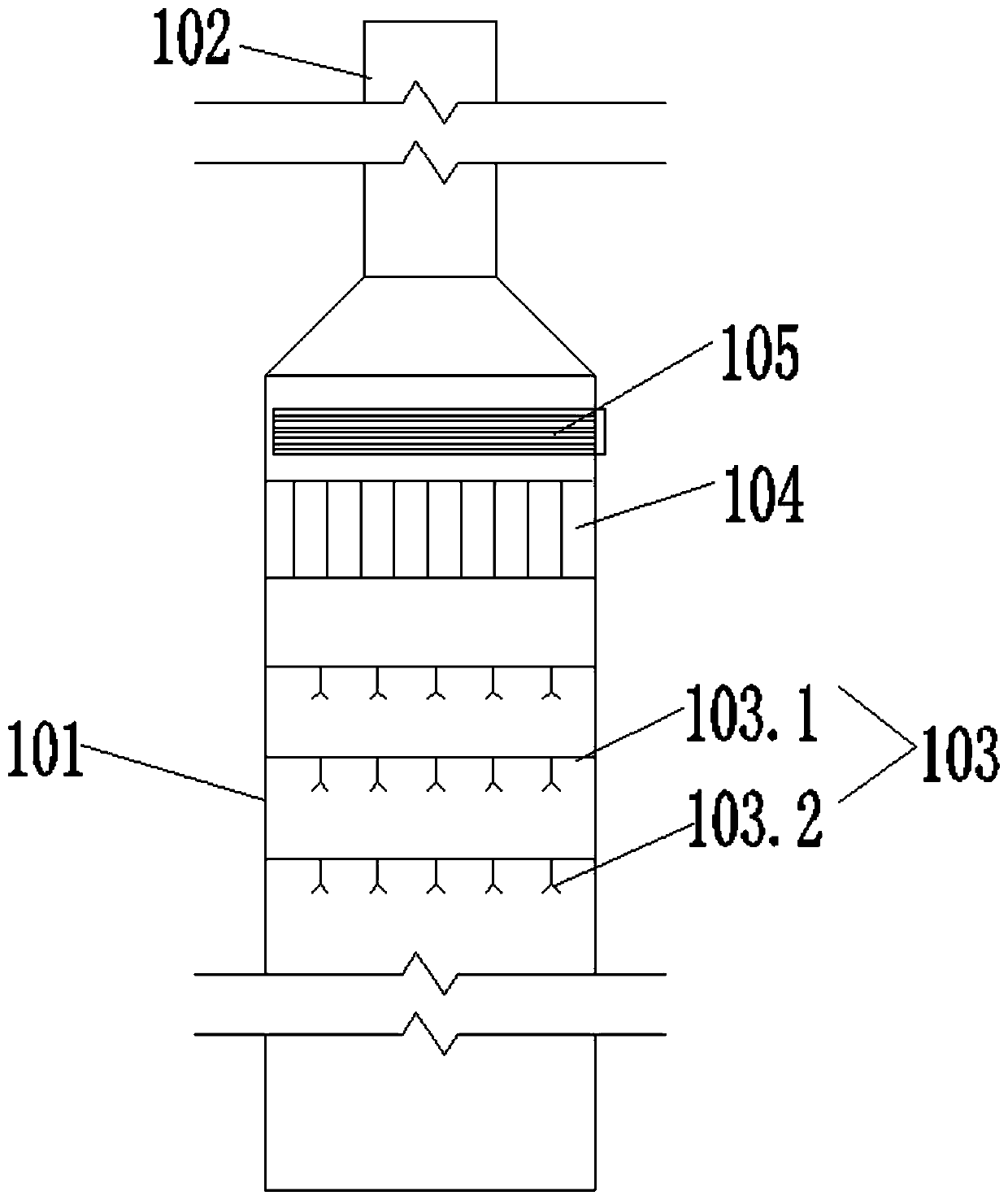

Mass concrete temperature intelligent monitoring and controlling device and method

InactiveCN109471468AControl the maximum temperatureControl cooling rateTemperatue controlPressure stabilizationData acquisition

The invention discloses a mass concrete temperature intelligent monitoring and controlling device, which comprises a circulating pipeline formed by sequentially connecting a water supply device, a water distribution device, a concrete cooling system and a water return device, wherein the concrete cooling system is internally provided with a temperature monitoring device; and a centralized controlsystem which is respectively connected with the water supply device, the water distribution device, the concrete cooling system and the water return device. The concrete cooling system comprises a cooling water pipe arranged in the concrete. Usage of the device comprises a concrete cooling system setting step, a monitoring device setting step, a water distribution device setting step, a water supply device setting step, a water return device setting step, a mass concrete construction preparation step, a data acquisition step, a water supply pressure stabilization step, an alarm step, a hot water tank drainage step and a cold water tank water replenishing step. By the adoption of the mass concrete temperature intelligent monitoring and controlling device, water supply pressure can be stabilized, different water inlet temperatures and flow rates of each layer can be dynamically adjusted, temperature field change in the mass concrete can be developed according to a target of temperature control, and an alarm function is equipped, so that the problems that a temperature difference of each region of the mass concrete is too large and cracks are easy to generate are solved.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

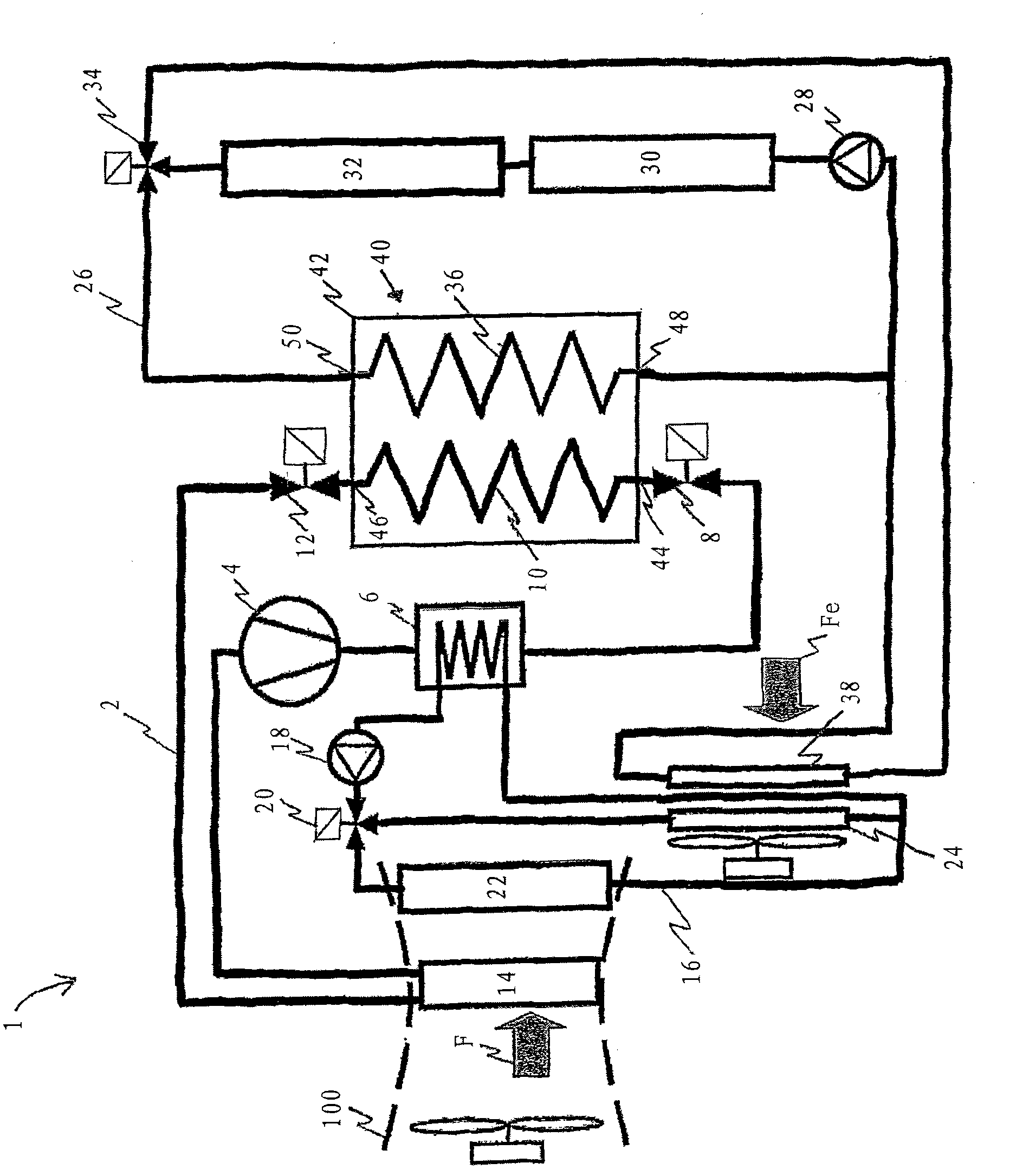

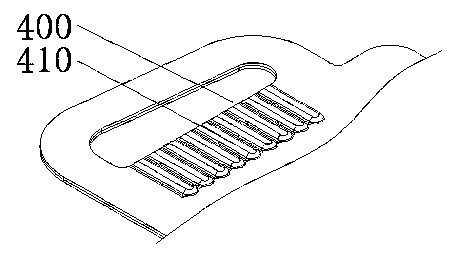

Heat exchange device and thermal management system

ActiveCN101949658ASolve frostingRealize heat exchangeAir-treating devicesHeat storage plantsThermal management systemEngineering

The invention relates to a heat exchange device and a thermal management system. The device (40) is equipped in a thermal management system and includes a first heat exchanger (10) allowing a cooling fluid to pass, a second heat exchanger (36) allowing carried hot fluid to pass. The device (40) includes a heat storing member (M) for heat exchange with first and second heat exchangers (10, 36). The thermal management system (1) includes such a heat exchange device (40).

Owner:VALEO SYST THERMIQUES

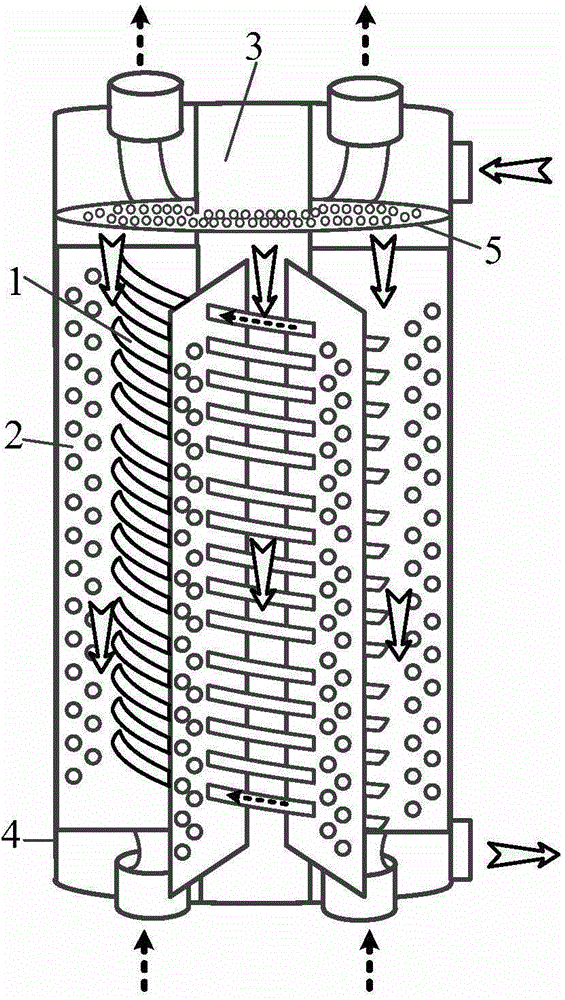

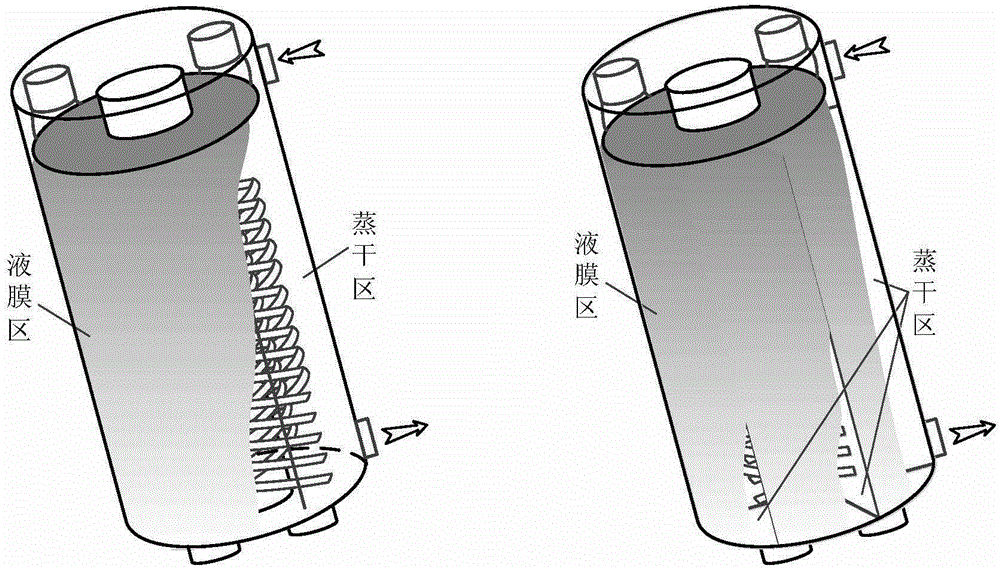

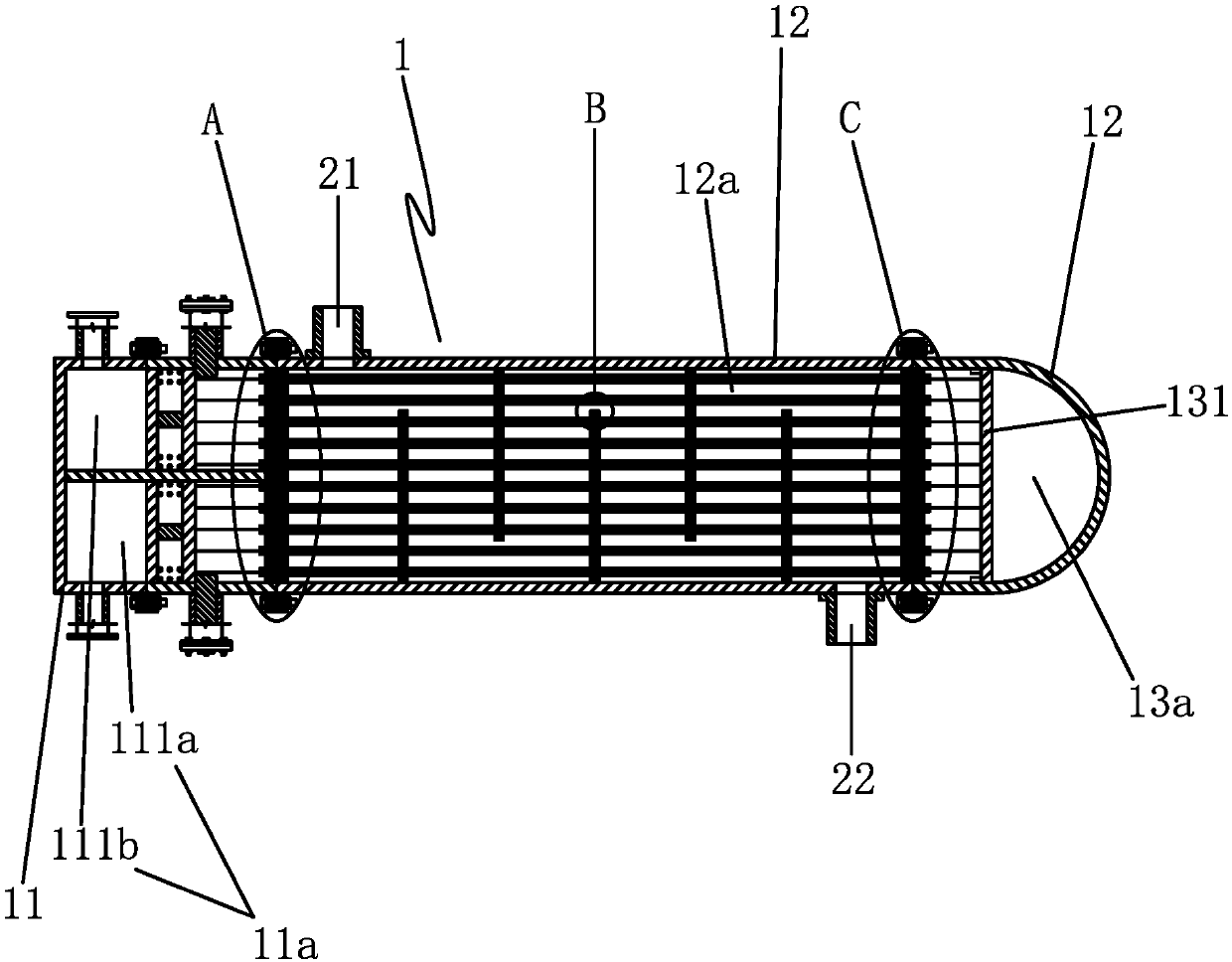

Winding tubular heat exchanger provided with vertical partition plate in cavity

InactiveCN104406430AIncrease the effective heat transfer areaIncrease coverageLiquefactionStationary tubular conduit assembliesRefrigerantMechanical engineering

The invention discloses a winding tubular heat exchanger provided with a vertical partition plate in a cavity. The winding tubular heat exchanger comprises a housing and a central barrel. The central barrel is arranged in the cavity of the housing to form an annular cavity. A plurality of winding tubes are winded in the annular cavity. A plurality of metal pore plates are arranged in the annular cavity and are vertically arranged in the annular cavity, and the winding tubes penetrate through the through holes formed in the metal pore plates. One end of each metal pore plate is connected to the inner wall of the housing, and the other end of each metal pore plate is connected to the outer wall of the central barrel. A gas-liquid even distributing device is arranged in the cavity between the metal pore plates and the top of the housing. The metal pore plates are vertically arranged in the cavity, so that one whole cavity is divided into a plurality of independent cavities, and refrigerants in the independent cavities do not flow into other cavities. Therefore, it can be ensured that liquid films of the housing-side refrigerants flowing into the independent cavities and an in-tube working medium inside the cavities perform full heat exchange, and the phenomenon that the refrigerants flow into other independent cavities due to hull inclination and then invalid heat exchange inside the original cavities is caused is avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

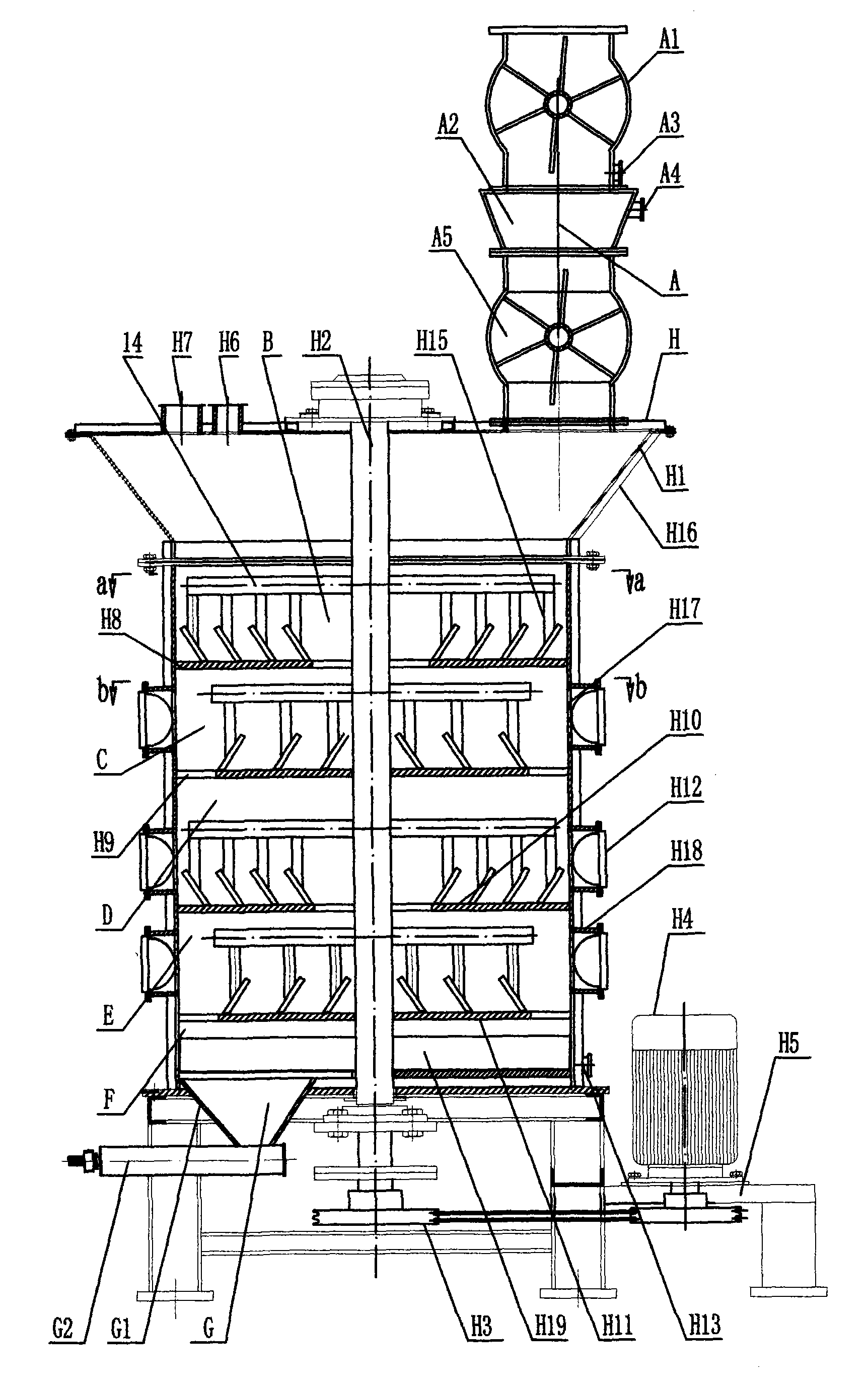

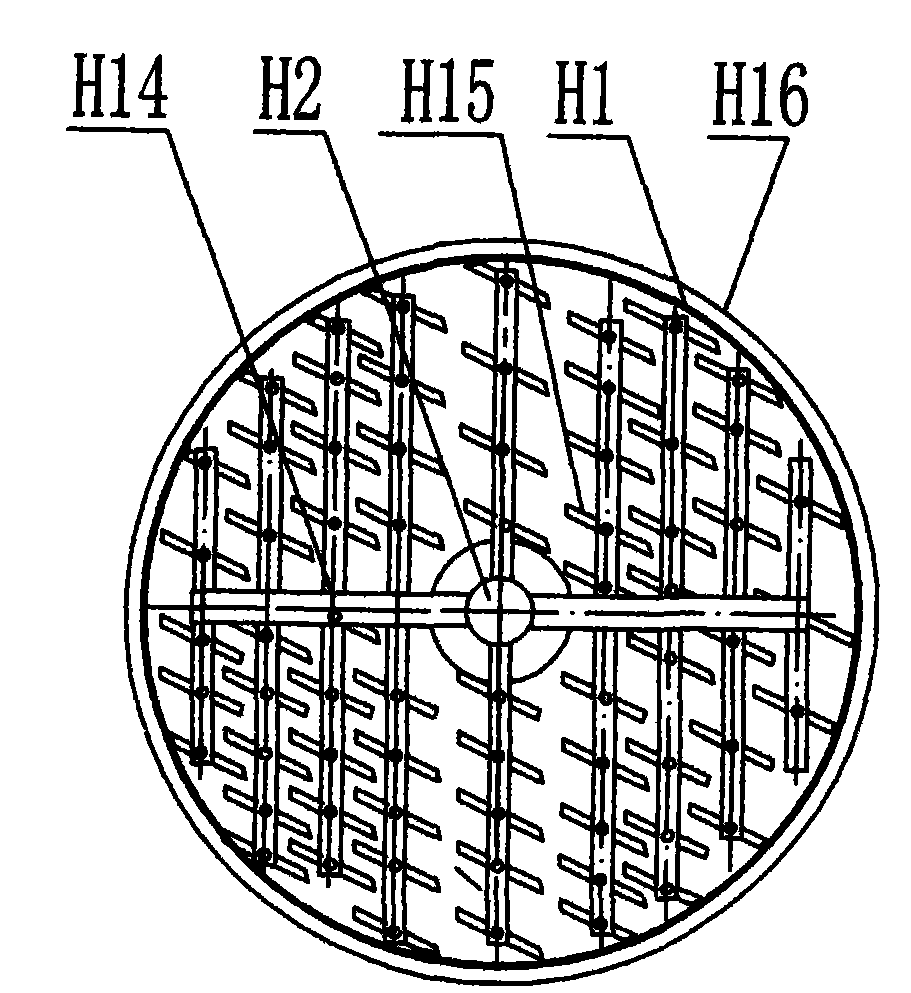

Vertical continuous microwave heating low-temperature cracking furnace for garbage

InactiveCN101811129AImprove continuityNovel and reasonable designSolid waste disposalSpecial form destructive distillationMicrowaveResource utilization

The invention provides a continuous reductive atmospheric microwave heating low-temperature cracking furnace structure for urban domestic garbage, which fulfills the purposes of improving the cracking efficiency, promoting the resource utilization level of garbage cracking reclamation substances, and realizing hazard-free treatment. The low-temperature cracking furnace consists of a feeding and garbage gas displacement mechanism arranged on a main body cylinder in a main body part, a garbage preheating and cracking vapor delivery chamber, a garbage water evaporation and heating chamber, a main garbage cracking chamber, a cracking material carbonization chamber, a carbonized material collecting chamber and a carbonized material collecting mechanism. The low-temperature cracking furnace has the advantages of continuously treating the garbage, consuming low energy, having minimum dust discharge amount, particularly avoiding the risks of generating NOx and dioxin, and basically reaching zero emission of the generated NOx and dioxin.

Owner:深圳市兖能环保科技有限公司

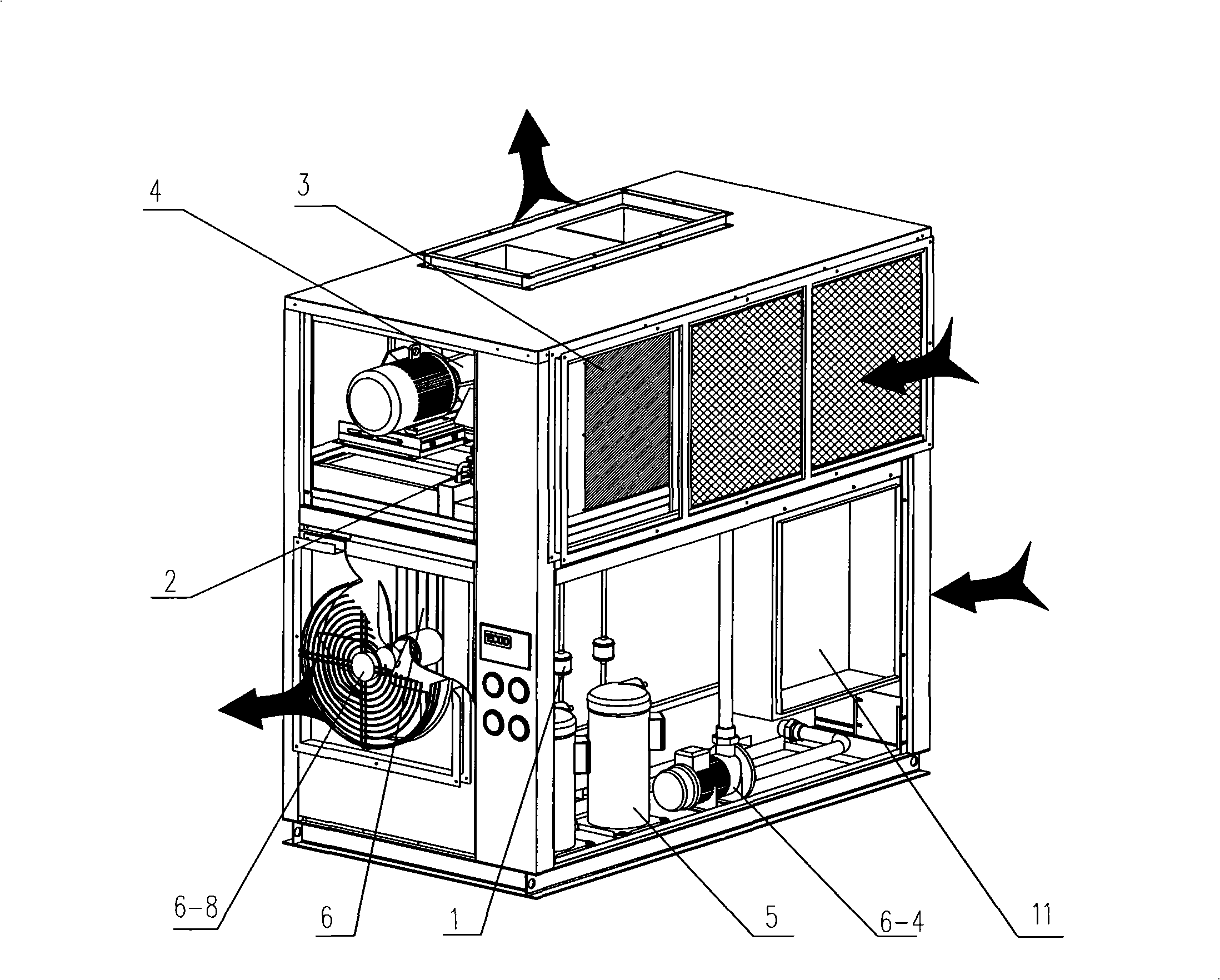

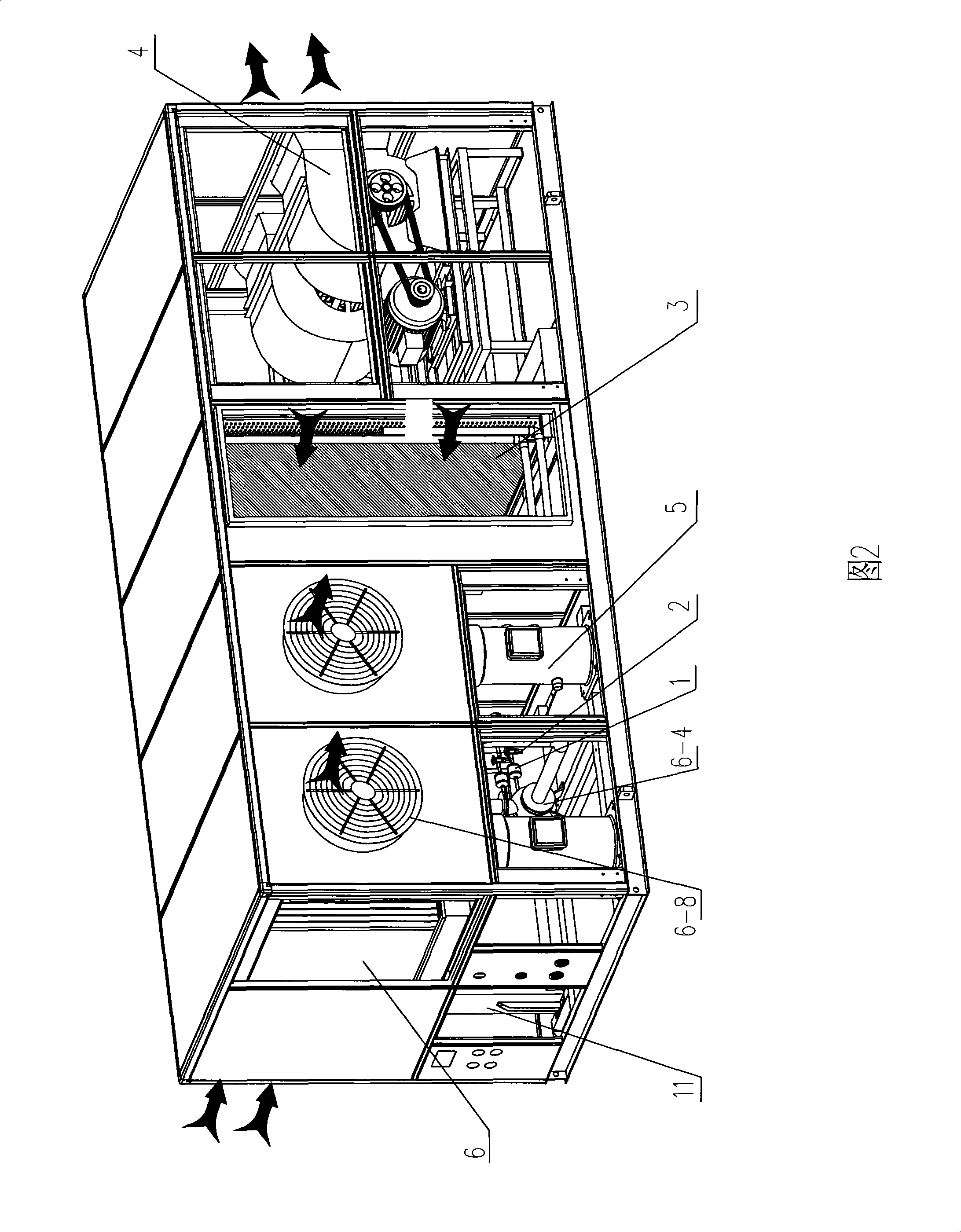

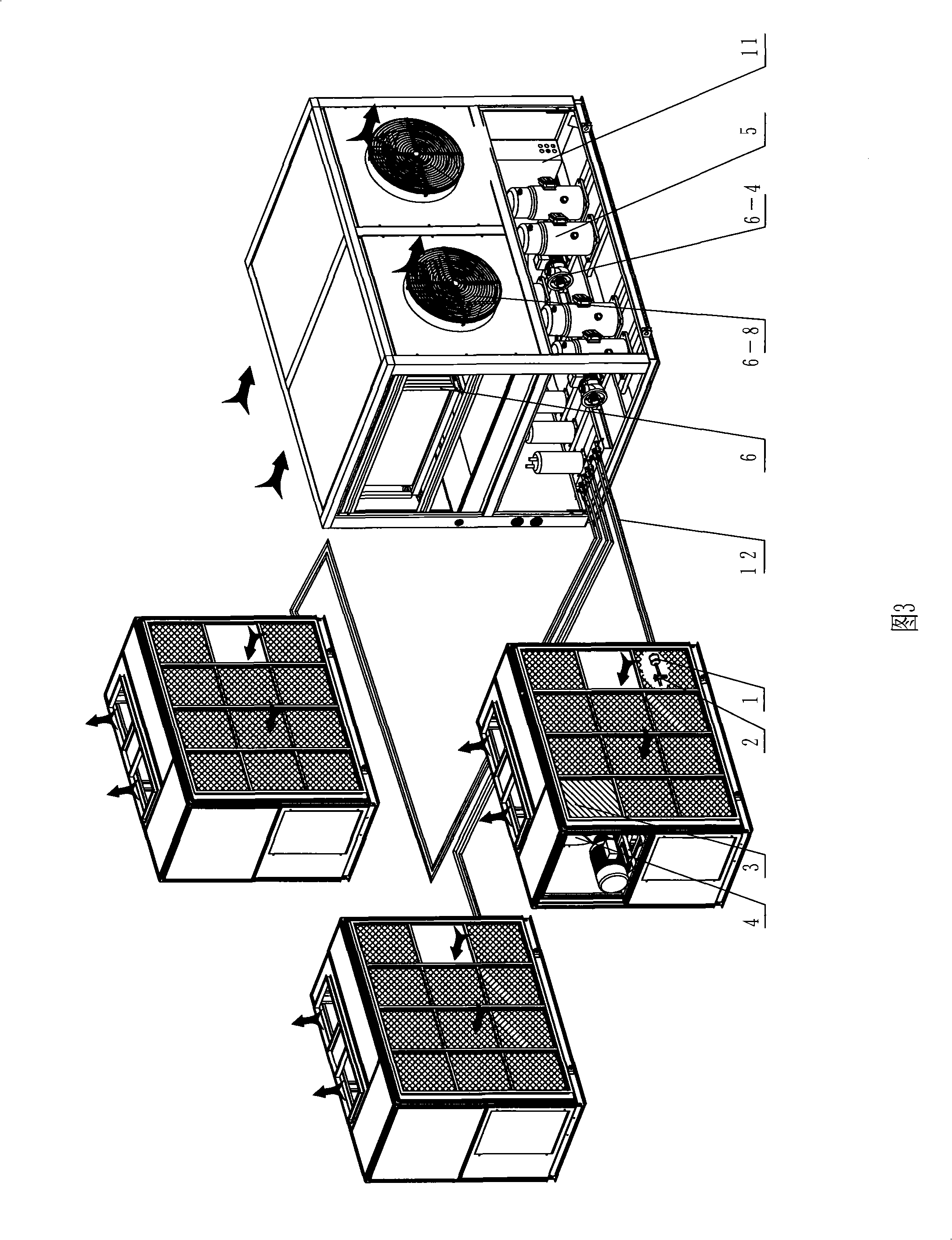

Tube-plate evaporative condensing air-conditioning unit with packing

ActiveCN101514829ARealize heat exchangeAchieve heat transfer performanceEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsFresh airEvaporation

The invention provides a tube-plate evaporative condensing air-conditioning unit with packing. The unit comprises an evaporation and air supply unit and a compression and condensing unit. The evaporation and air supply unit consists of a drying and filtering device, an expansion valve, an evaporator and a centrifugal fan which are sequentially connected, and the compression and condensing unit is formed by connecting a compressor and a condenser; the condenser is connected with the drying and filtering device, and the compressor is connected with the evaporator; the air-conditioning unit is provided with a condensate recovery system which is formed by connecting a condensate recovering collector of the evaporator with the condenser by a tube or a water pump; and an indoor air supply system of the evaporation and air supply unit consists of an outdoor fresh air inlet of the evaporator, a unit air supply outlet and the centrifugal fan, or consists of the outdoor fresh air inlet of the evaporator, a unit return air inlet, the unit air supply outlet and the centrifugal fan. The tube-plate evaporative condensing air-conditioning unit has high heat exchange efficiency, and can realize maximal energy recovery and reduction of energy consumption and water consumption, effectively solves increased energy consumption resulting from increased fresh air volume of an air-conditioning system and realizes double performance of saving energy and water and health care.

Owner:GUANGZHOU WIDE IND

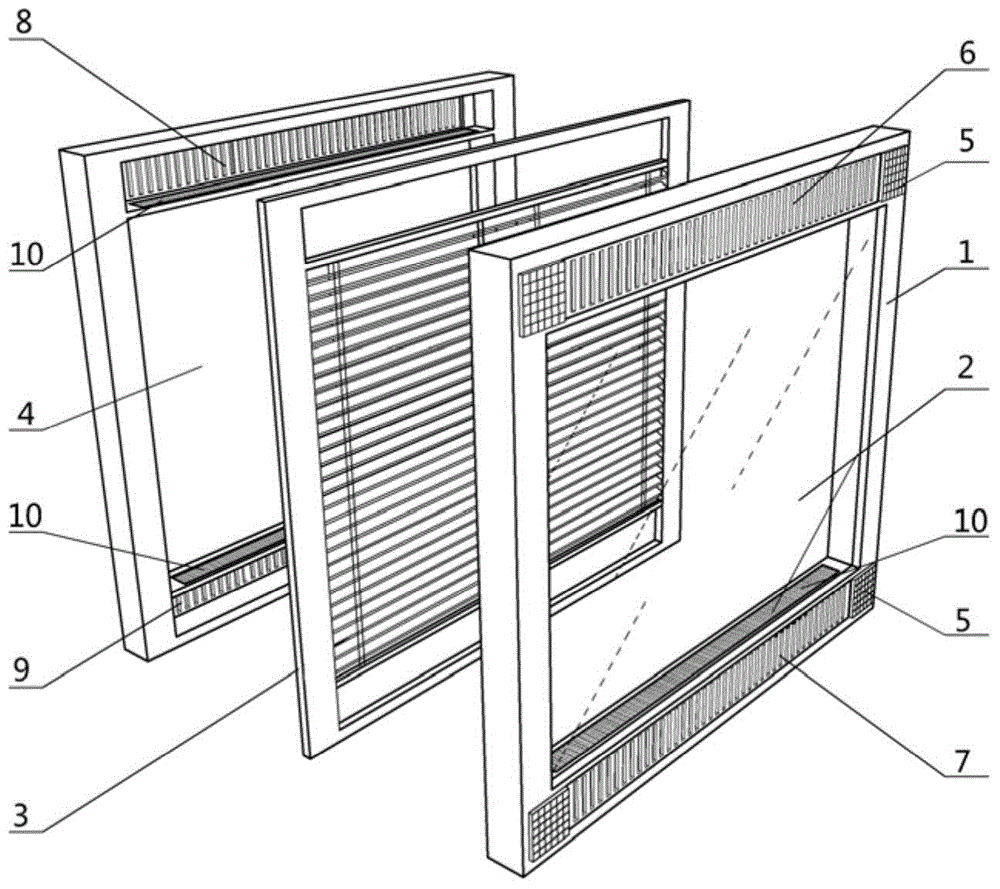

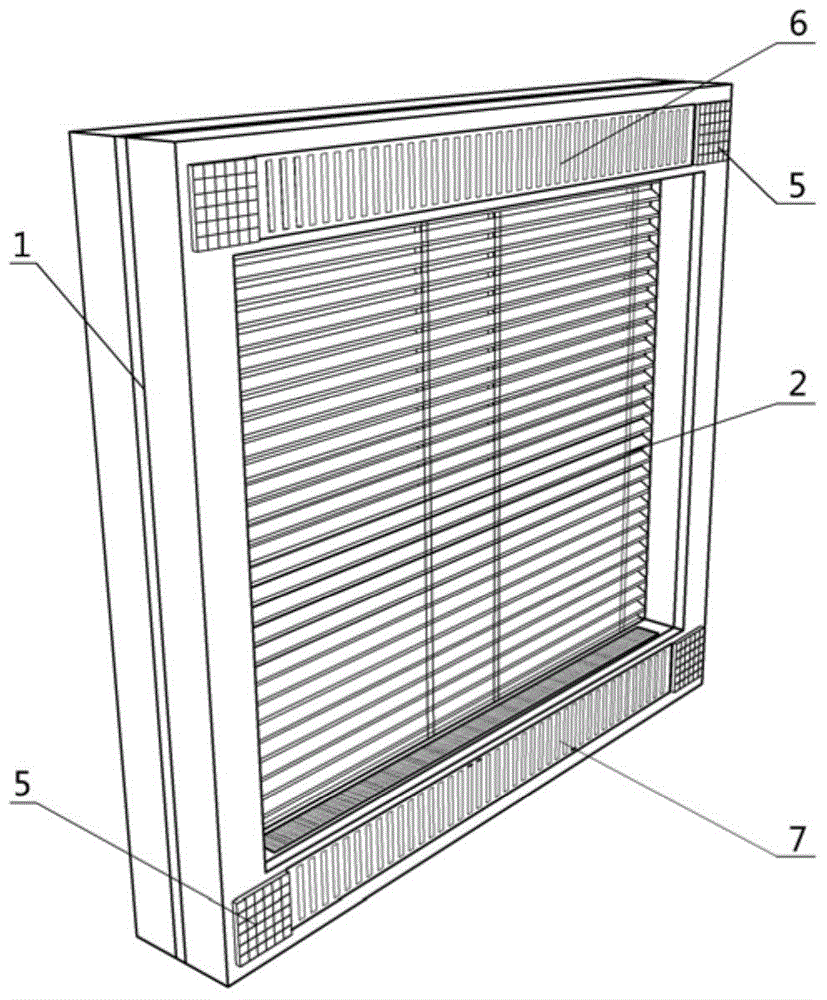

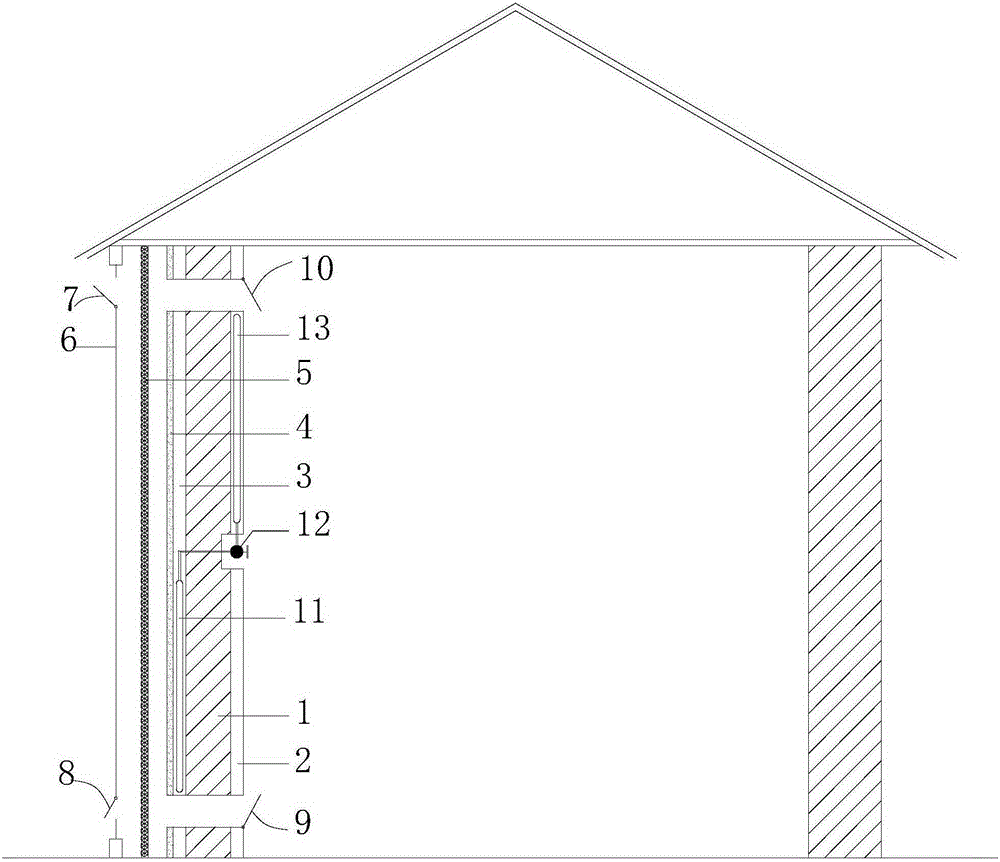

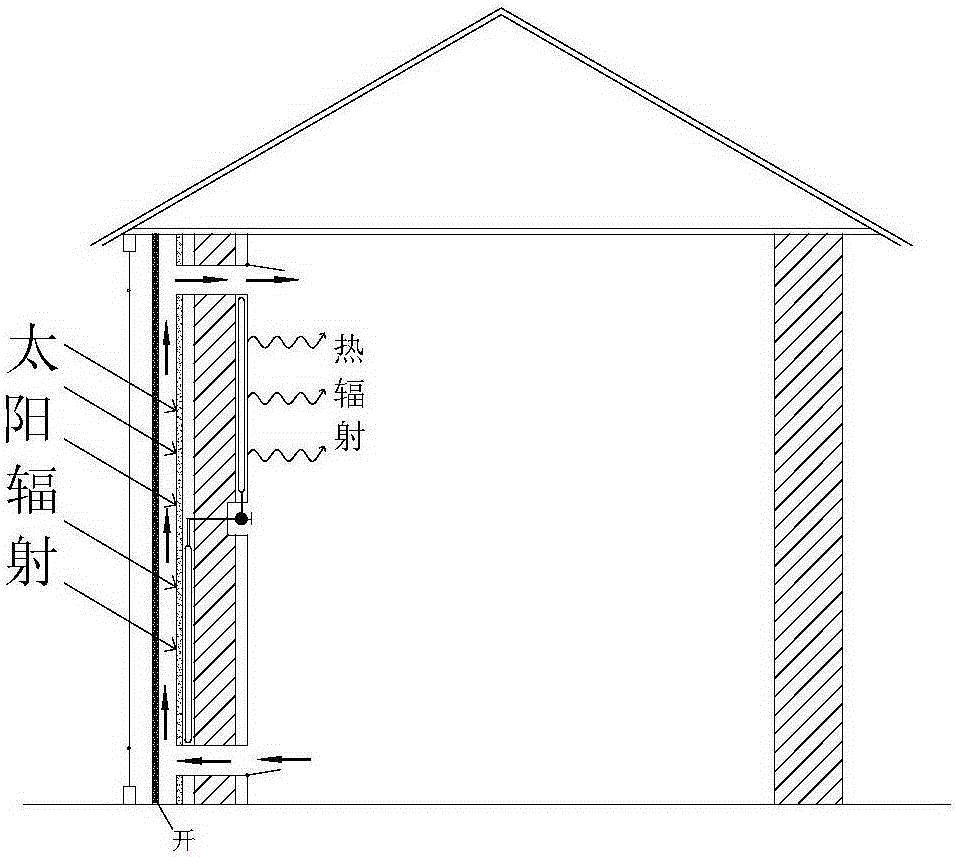

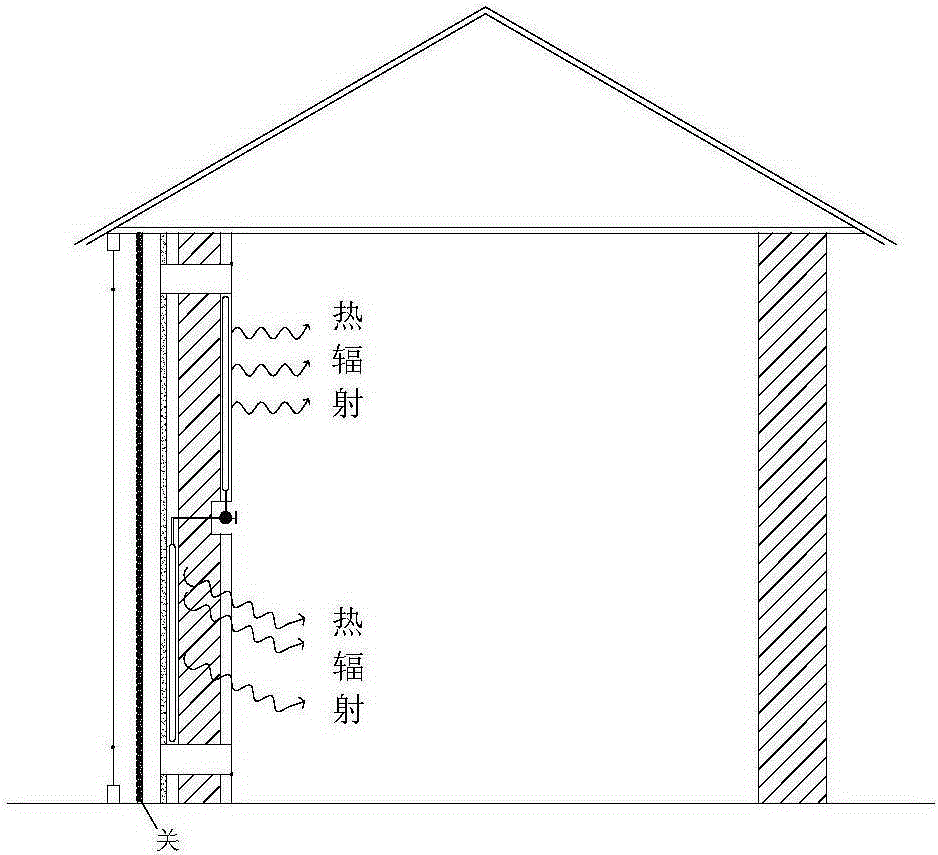

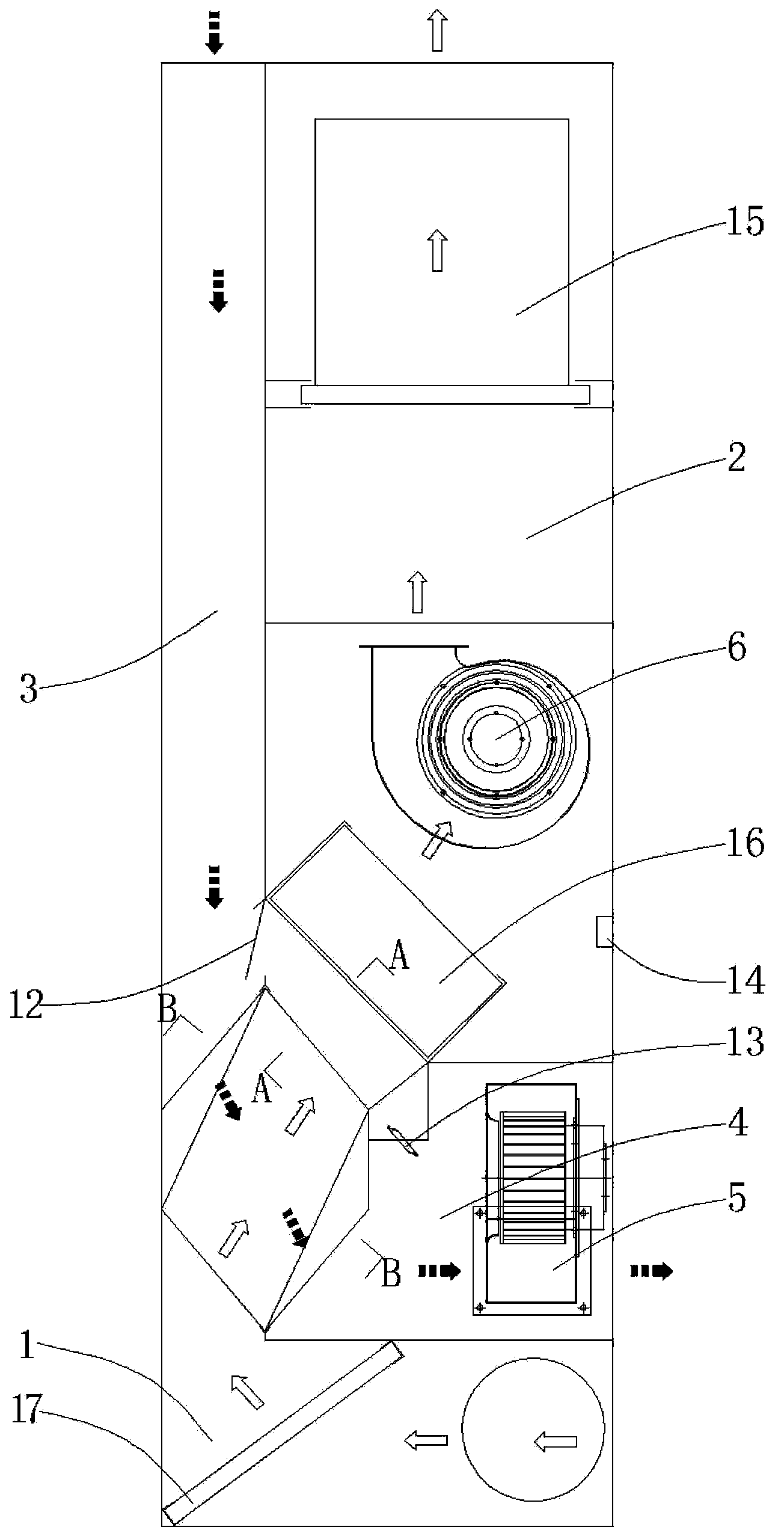

Passive heat collecting, sunshading and ventilation integrated window

ActiveCN104453601AAchieve ventilation effectRealize daylightingVentilation arrangementUnits with parallel planesNatural ventilationEngineering

The invention belongs to the technical field of natural resource using and discloses a passive heat collecting, sunshading and ventilation integrated window which is characterized in that on the basis of natural ventilation, the naturally-adjustingheating cooling technologies such as passive solar energy converting, air cycling heat collecting and dissipation and sunshading are used for achieving all-year-round indoor environment comfort. Multifunctional modules are divided into a heat collecting module, a sunshading module and a ventilation module. The window mainly comprises an inner glass layer, an outer glass layer, a solar photoelectric plate, a double-color sunshading louver, an outdoor ventilator, an indoor ventilator, a ventilator outer layer fixing louver, a ventilator inner layer movable adjusting louver and the like. The window has the advantages that during indoor environment adjusting, different module systems are matched for use so that a building can be adjusted naturally, and solar energy, wind energy and other natural energy are collected, converted and stored. Passive solar energy is widely used in buildings, and great significance in the technical field of building integrating is achieved.

Owner:DALIAN UNIV OF TECH

Passive solar energy wall

The invention relates to a passive solar energy wall, which comprises a concrete wall body with internal and external plastering layers. The passive solar energy wall is characterized in that the external plastering layer of the concrete wall body is in internally provided with a heat pipe evaporation section transistor gate and the internal plastering layer of the concrete wall body is in internally provided with a heat pipe condensation section transistor gate. The heat pipe evaporation section transistor gate and the heat pipe condensation section transistor gate are connected via an intelligent control valve to form a heat pipe-imbedded wall. The outer side of the concrete wall body is provided with an elevating louver cascade with a reflective coating layer. The outer side of the reflective coating layer-contained louver cascade is provided with a glass curtain wall. The heat pipe-imbedded wall and the glass curtain wall together form the entirely passive solar energy wall and the wall can be southward, eastward or westward. According to the technical scheme of the invention, the internal and external surfaces of the wall are provided with heat pipe transistor gates, the glass curtain wall and a ventilation structure. Therefore, the phase change-based heat absorbing and releasing property and the air heat convection property during the natural gravity cycling process are realized based on a working medium inside a heat pipe. As a result, the heat exchange between the indoor environment and the outdoor environment is realized.

Owner:TIANJIN CHENGJIAN UNIV

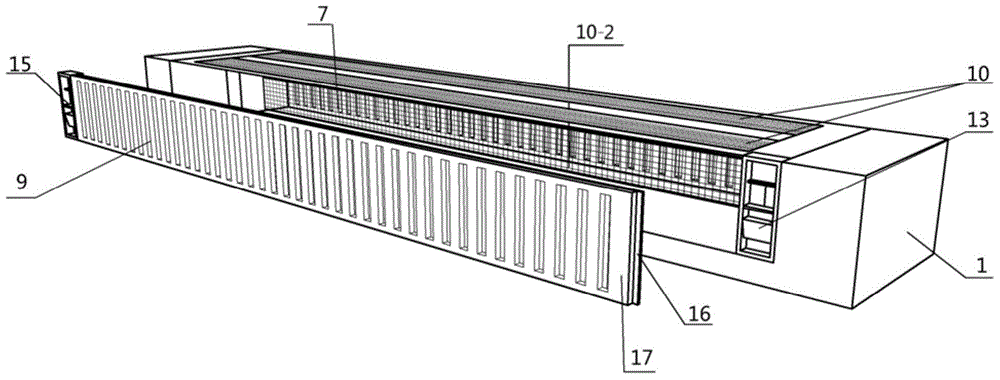

Clean fresh air system and air cleaning method

ActiveCN103398443ARealize heat exchangeImprove adaptabilityEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsAir cleaningReturn channel

The invention discloses a clean fresh air system which comprises a fresh air channel (1), an air feeding channel (2), an air returning channel (3), an air exhaust channel (4) and a bypass system. The fresh air channel (1) and the air exhaust channel (4) are respectively communicated with the outside of a room. The air returning channel (3) and the air feeding channel (2) are respectively communicated with the inside of the room, an exhaust fan (5) is arranged in the air exhaust channel (4), an air feeder (6) is arranged in the air feeding channel (2), and the collecting area of internal ports of the fresh air channel (1), the air feeding channel (2), the air returning channel (3) and the air exhaust channel (4) is provided with the bypass system. Due to the design of the bypass system and an air valve, heat exchange between fresh air and exhausted air and the backflow function of return air are achieved, high use flexibility and adaptability to environment are achieved, the energy-saving effect is good, and the capacity of filtering impurities is strong.

Owner:CHONGQING BLUEHORIZON ENERGY-SAVING TECH CO LTD

Integration device for refrigerant vapor-liquid separation and liquid storage and air-conditioning system using same

ActiveCN102242992ASave spaceRealize integrationFluid circulation arrangementLiquid storage tankEngineering

The invention provides an integration device for refrigerant vapor-liquid separation and liquid storage and an air-conditioning system using the same. In the invention, a vapor-liquid separator and liquid storage tank integral container is adopted, simultaneously the integration device is provided with the functions of the vapor-liquid separator and the liquid storage tank, the occupied space in a set is reduced, the refrigerant back heating can be carried out, and the refrigeration efficiency is improved. The integration device comprises a container-shaped shell; the refrigerant vapor-liquid separator and liquid storage tank integral device also comprises a liquid storage part and a vapor-liquid separation part, wherein the liquid storage part and the vapor-liquid separation part are evenly arranged in the inner cavity of the shell; the liquid storage part comprises a liquid inlet tube and a liquid outlet tube, and the liquid inlet tube and the liquid outlet tube are evenly extended out of the shell through the liquid storage part; and the vapor-liquid separation part comprises a refrigerant inlet tube and a refrigerant outlet tube, and the refrigerant inlet tube and the refrigerant outlet tube are evenly extended out of the shell through the vapor-liquid separation part. The air-conditioning system comprises the refrigerant vapor-liquid separation and liquid storage integral device, the liquid inlet tube of the liquid storage part of the refrigerant vapor-liquid separation and liquid storage integral device is connected with a throttling device, and the liquid outlet tube of the liquid storage part is connected with an indoor heat exchanger; and the refrigerant outlet tube of the vapor-liquid separation part of the refrigerant vapor-liquid separation and liquid storage integral device is connected with the suction end of a compressor.

Owner:GREE ELECTRIC APPLIANCES INC

Method for recovering waste heat of electrically fused magnesium fused weight

The invention relates to a method for breaking an electrically fused magnesium fused weight and simultaneously recovering waste heat by a dry quenching method, which belongs to the field of electrically fused magnesium smelting and provides an energy-saving technology for recycling the waste heat in the cooling process of the magnesium fused weight. The heat energy of the high-temperature magnesium fused weight is recovered by the dry quenching method in the cooling process of the magnesium fused weight, steam is generated through a heat exchanger by heat circulating gas which is obtained by adopting a direct countercurrent flow method of the air and the high-temperature magnesium fused weight, the steam is utilized for generating electricity, and the invention is used for the magnesite smelting process, achieves the purpose of energy saving, is beneficial to reducing the energy consumption level of electrically fused magnesium, achieves the coupling optimization of waste heat utilization and electrically fused magnesium quality improvement and has remarkable economic and social benefits.

Owner:PEKING UNIV

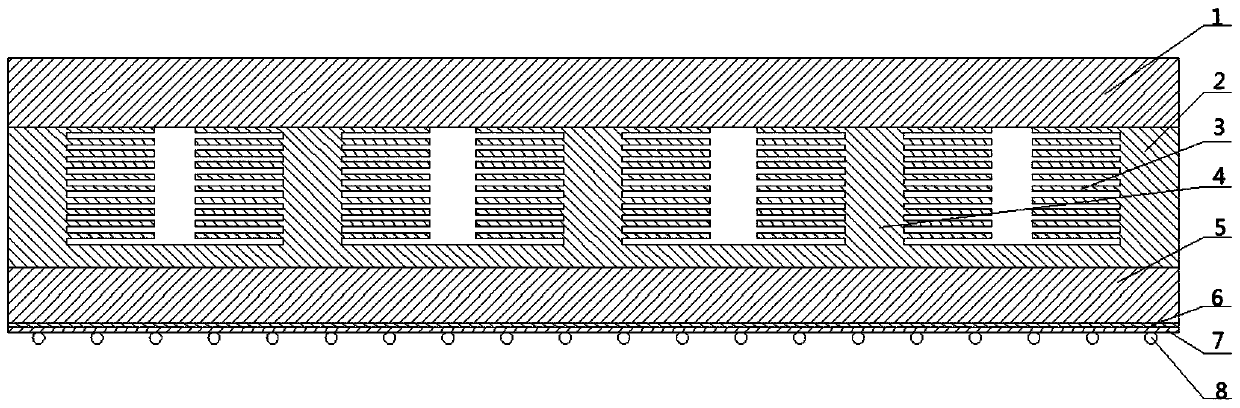

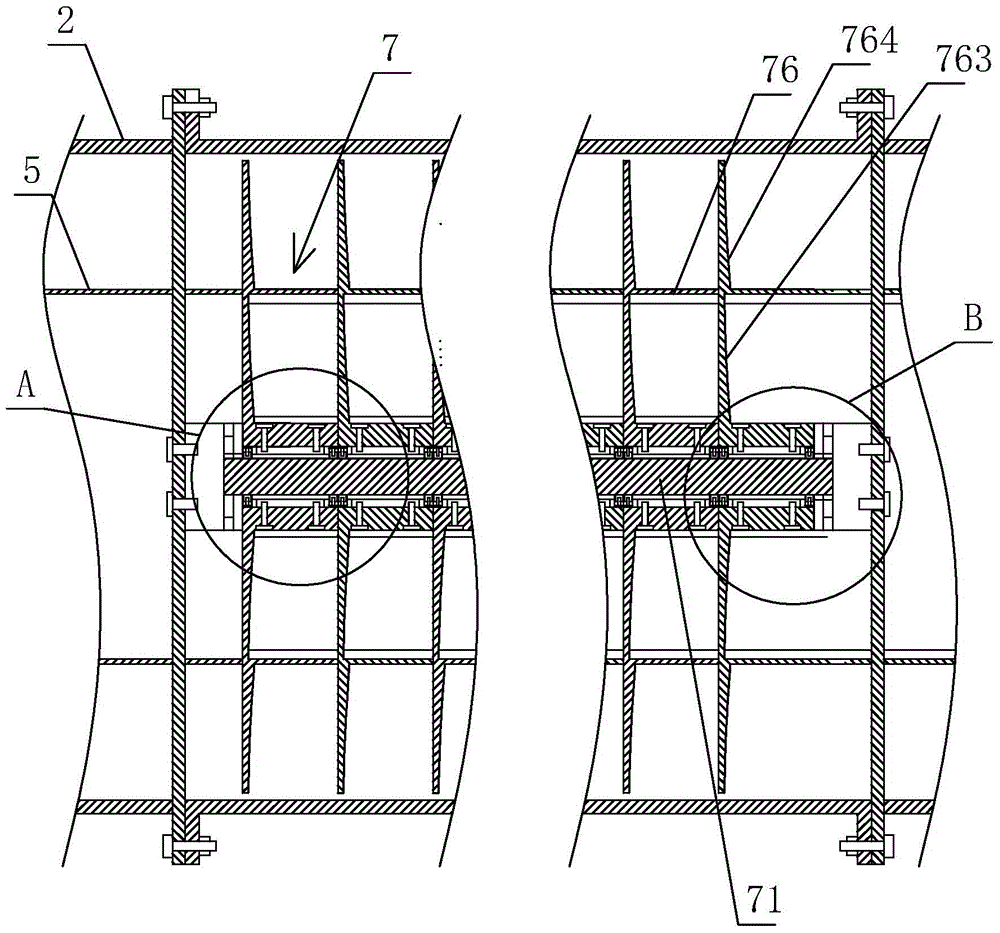

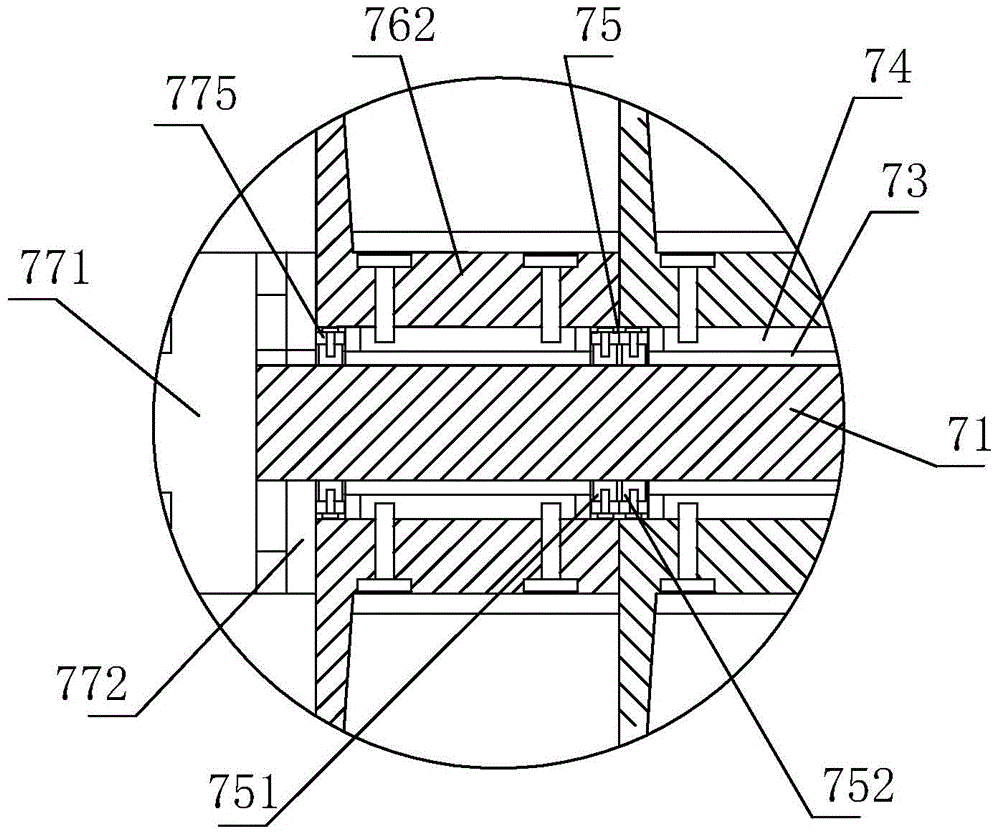

Integrated micro-channel heat dissipation structure, preparation method and wafer-level packaging structure

InactiveCN110255490AReduce thermal resistanceSolve the cooling problemDecorative surface effectsSemiconductor/solid-state device detailsMicrometerEngineering

The invention discloses an integrated micro-channel heat dissipation structure. The heat dissipation structure comprises a shell with a cavity, a plurality of first-stage fins which are arranged in parallel at intervals are arranged in the cavity, second-stage fins are arranged on the two sides of the first-stage fins and the inner side of the shell, the second-stage fins are formed by arranging a plurality of sheet-shaped cooling fins at intervals, and a liquid inlet for a cooling medium to enter and a liquid outlet for the cooling medium to flow out are formed in the top surface of the shell. The invention further discloses a preparation method of the integrated micro-channel heat dissipation structure and a wafer-level packaging structure adopting the integrated micro-channel heat dissipation structure. The heat dissipation structure has the advantages that the heat exchanger is provided with two stages of heat exchange fins, and the heat exchange area is dozens of times of the chip contact area; the heat dissipation structures are both made of silicon materials and are connected in a silicon-silicon bonding mode, due to the fact that only hundreds of micrometers of silicon materials exist between the refrigeration working medium and the heat source, the thermal resistance between the refrigeration working medium and the heat source can be reduced to the limit, the heat dissipation problem of the high-power chip is solved, and thermal mismatch of heterogeneous materials does not exist.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

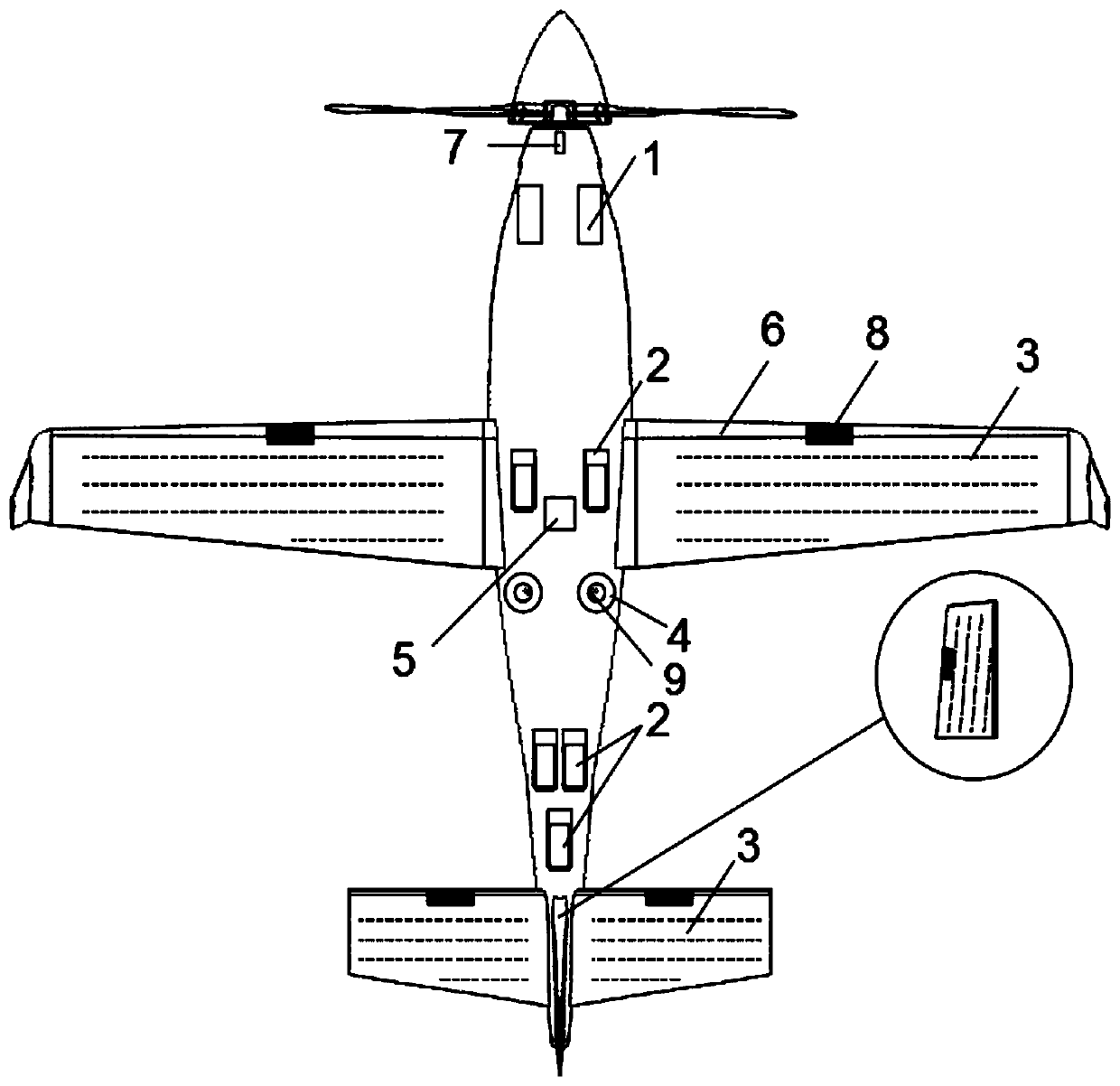

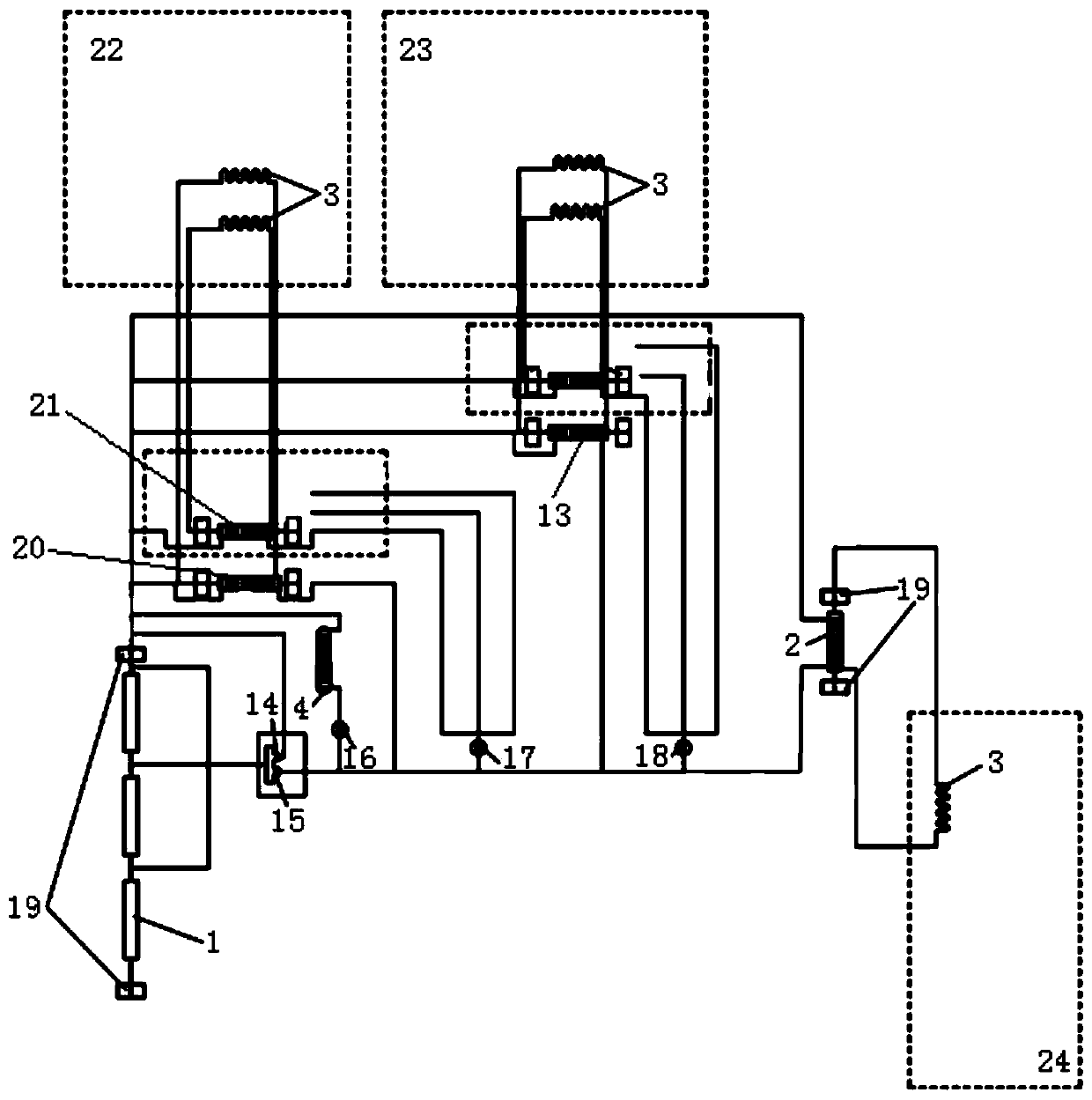

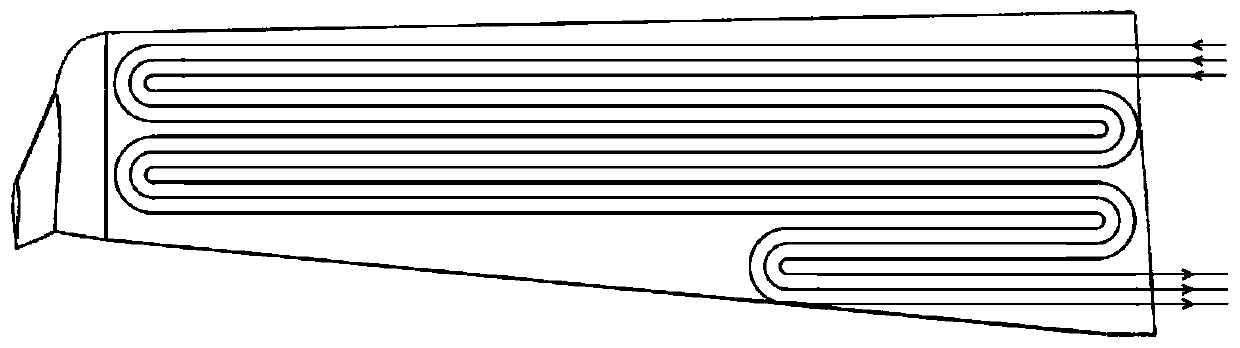

Anti-icing and deicing device and method for wings and emages of turbo-prop aircraft

The invention relates to an anti-icing and deicing device and method for wings and emages of a turbo-prop aircraft, the device comprises a system close loop, a TKS fluid reservoir heating loop, an anti-icing and deicing heat transfer loop heat pipe, a distributed loop heat pipe and a TKS deicing mechanism, wherein the system close loop, the TKS fluid reservoir heating loop and a heat transfer loopshare a set of heat transfer evaporator (1), in an anti-icing state, the TKS fluid reservoir heating loop, the anti-icing and deicing heat transfer loop heat pipe and the distributed loop heat pipe work; in a deicing state, the TKS deicing mechanism works. Compared with the prior art, the TKS system deicing efficiency is improved greatly, the icing phenomena of the wings and the emages are reduced, the flight stability of the aircraft is ensured, and the system safety is reliable; waste heat of an exhaust pipe is taken as a heat source, and the energy comprehensive utilization ratio of a single turbo-prop aircraft is improved.

Owner:SHANGHAI UNIV OF ENG SCI

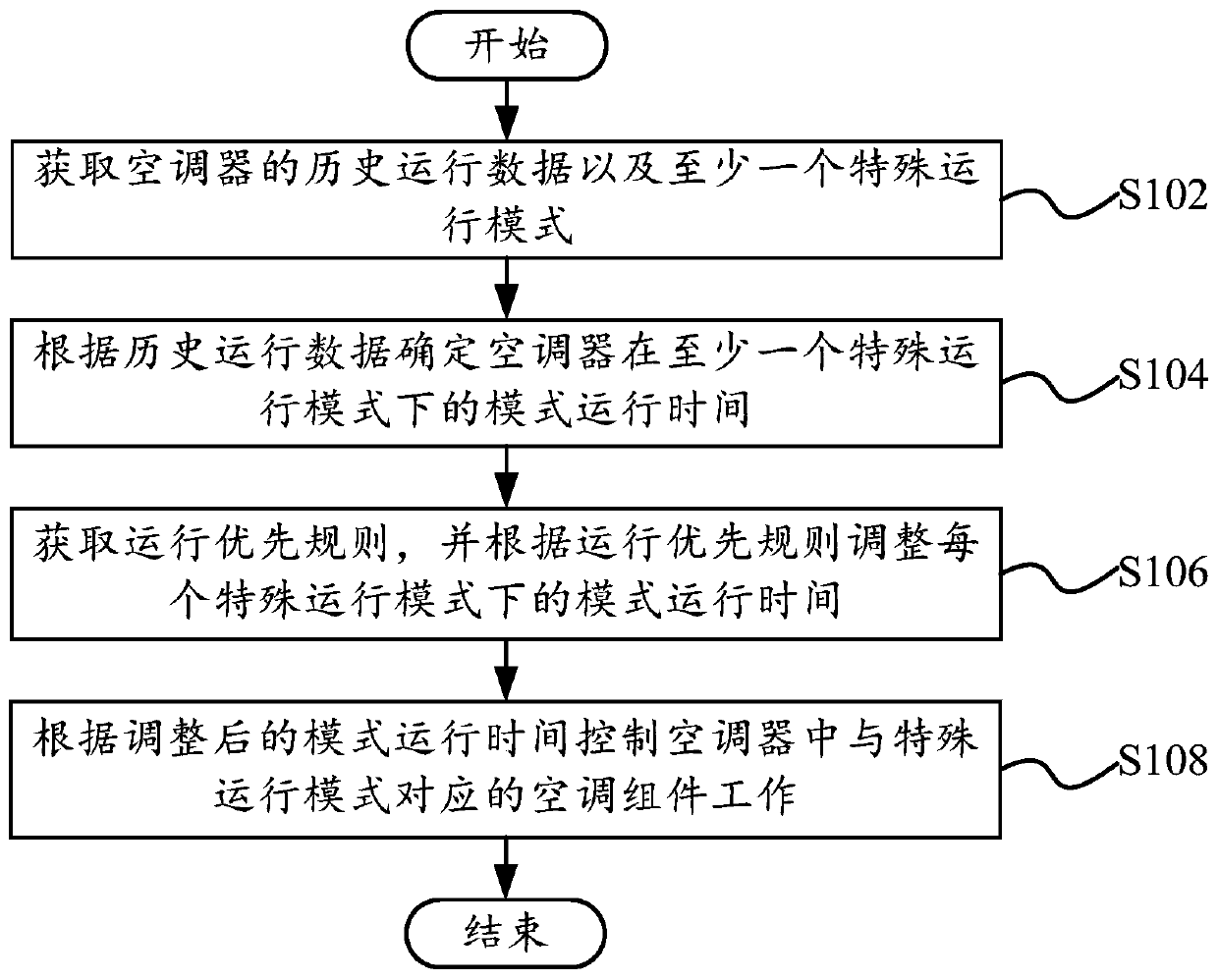

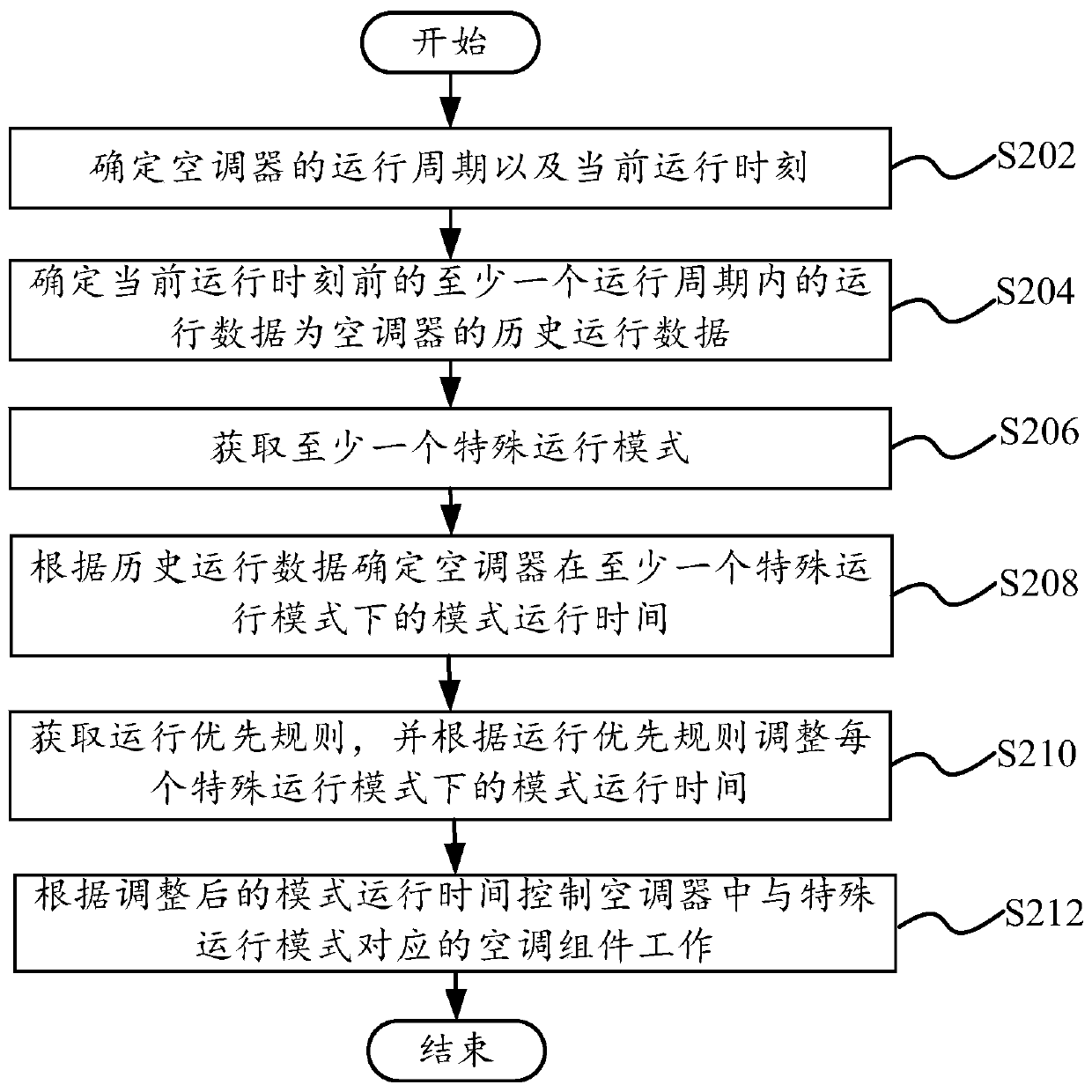

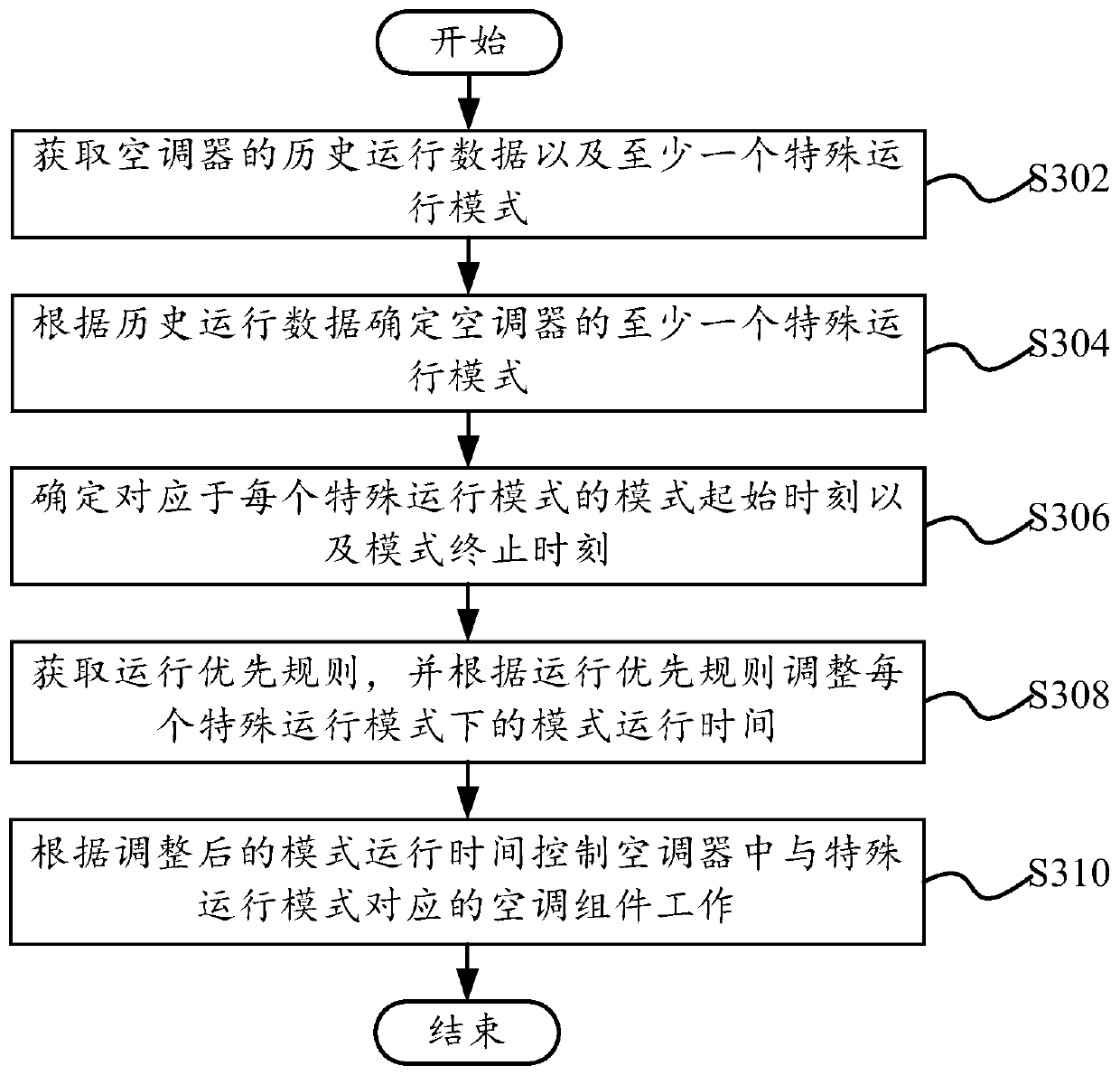

Control method, air conditioner and computer readable storage medium

The invention provides a control method, an air conditioner and a computer readable storage medium. The control method comprises the steps that historical running data and at least one special running mode of the air conditioner are acquired; the mode running time of the air conditioner in the at least one special running mode is determined according to the historical running data; a running priority rule is acquired, and the mode running time of the air conditioner in each special running mode is adjusted according to the running priority rule; and air conditioner assemblies corresponding to the special running modes in the air conditioner are controlled to work according to the adjusted mode running time. According to the technical scheme, the running time of the special running modes such as oil returning, defrosting and dehumidifying can be adjusted according to the running priority rule, on the one hand, reliable running of the air conditioner is guaranteed, on the other hand, influences of the special running modes such as oil returning, defrosting and dehumidifying on normal use of the air conditioner by a user are reduced, and the user experience is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

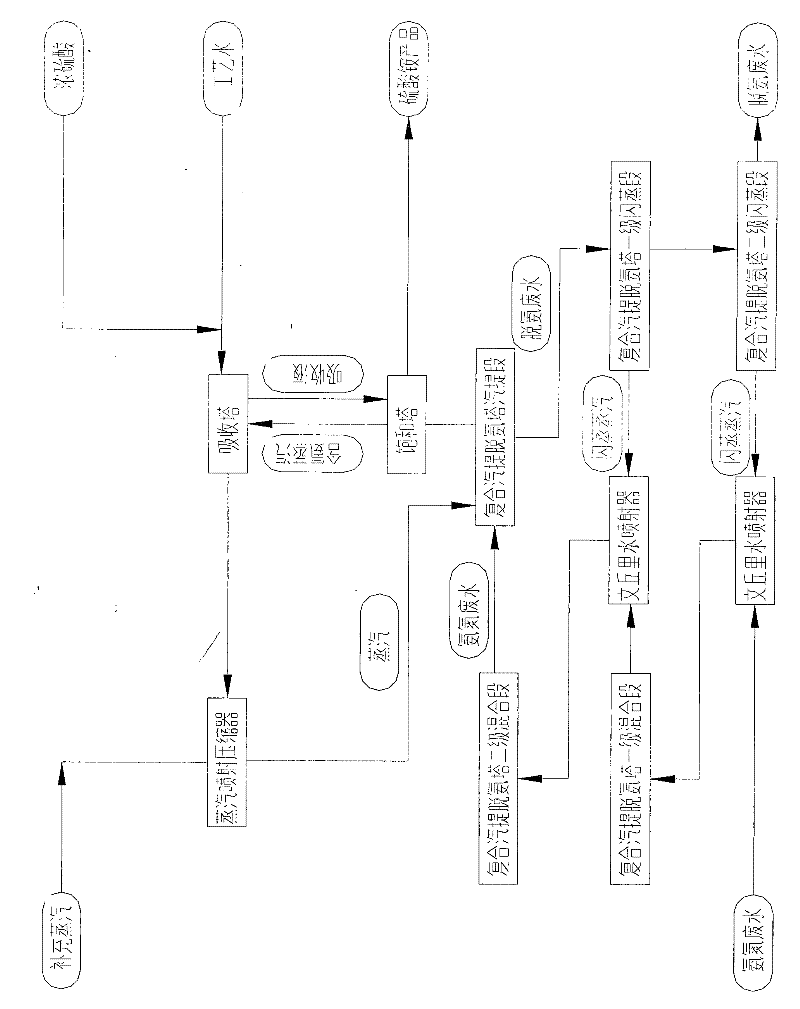

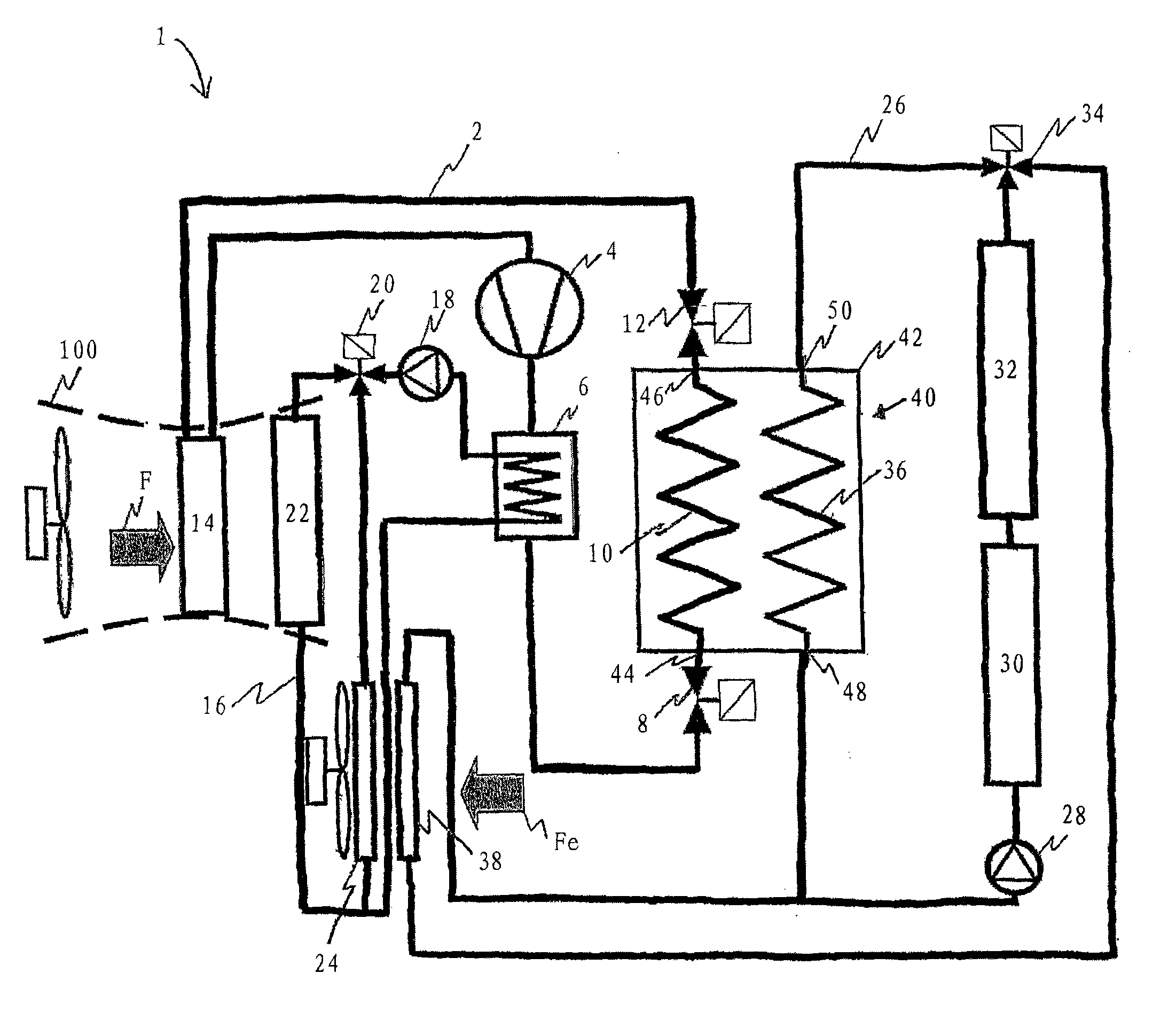

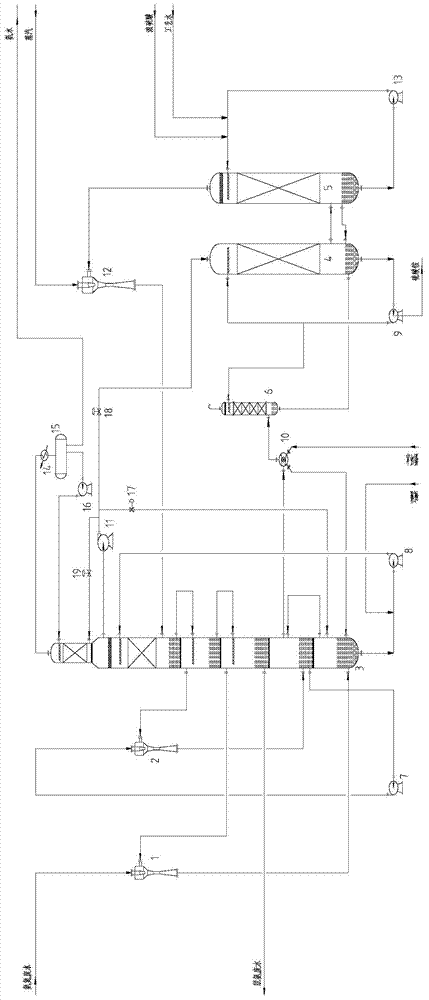

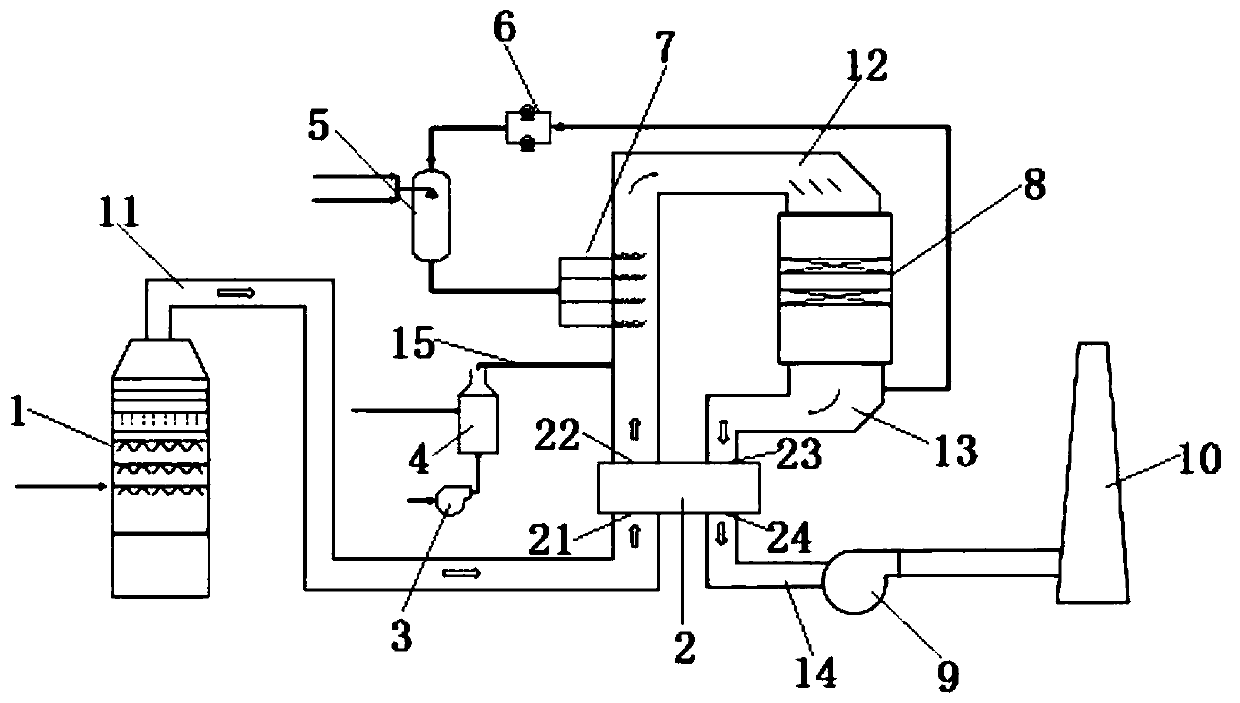

Method for combined production of ammonium sulfate and ammonia water through heat pump flash evaporation, stripping and deamination

ActiveCN104843816AReduce consumptionSolve the problem of easy fouling and blockage of equipmentWater contaminantsEnergy inputTowerAmmonia

The invention discloses a method for combined production of ammonium sulfate and ammonia through water heat pump flash evaporation, stripping and deamination. The method comprises the following steps: ammonia nitrogen steam discharged from the top of the stripping section of a composite stripping and deaminating tower (3) is pressurized through a steam circulating heat pump (11), and the pressurized ammonia nitrogen steam is divided into three parts; the first part of the ammonia nitrogen steam enters the two stage mixing section of the composite stripping and deaminating tower (3) to heat ammonia nitrogen wastewater; the second part of the ammonia nitrogen steam enters a saturation tower (4) and undergoes ammonia nitrogen preliminary absorption, and the absorbed ammonia nitrogen steam enters an absorption tower (5) and undergoes ammonia nitrogen purifying recovery; and the third part of the ammonia nitrogen stem enters the tower top rectifying section of the composite stripping and deaminating tower (3) to produce the ammonia water product. The method allows ammonium sulfate and ammonia water to be simultaneously produced, and a ratio of ammonium sulfate to ammonia water can be adjusted according to reuse requirements of a production device, so ammonia nitrogen recovered from the wastewater can be completely reused in the production device in order to realize good energy saving, consumption reduction and deamination effects.

Owner:CHINA PETROLEUM & CHEM CORP +3

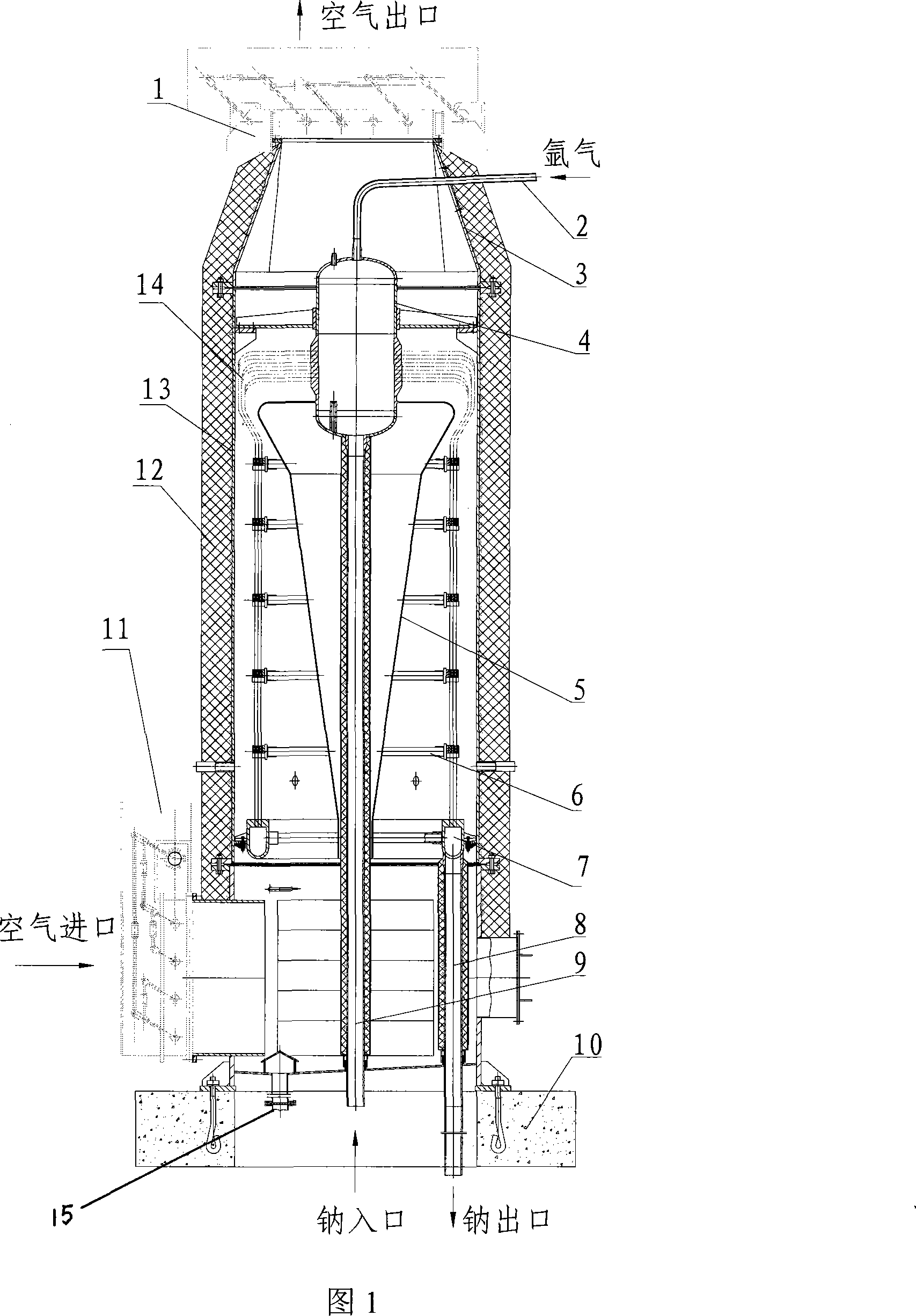

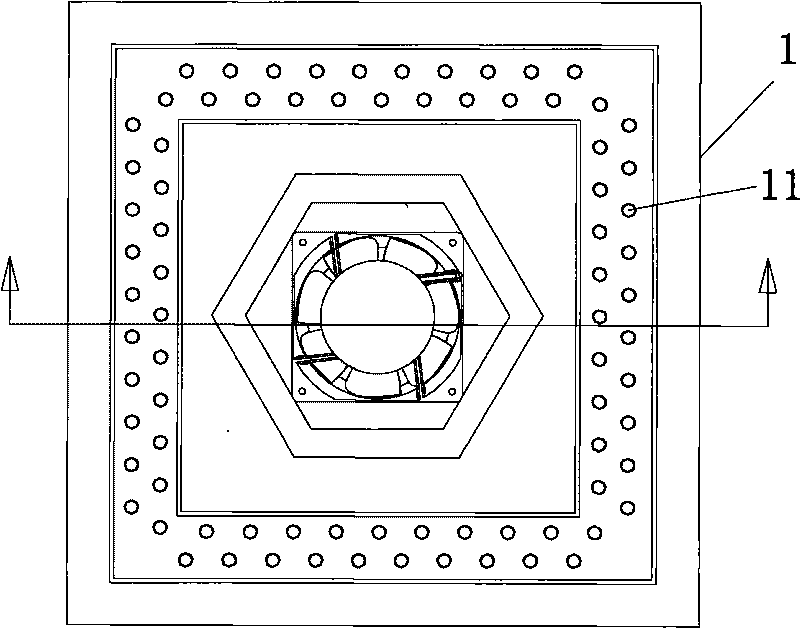

Sodium-air heat exchanger

ActiveCN101174482AAvoid chemical reactionsRealize heat exchangeNuclear energy generationStationary tubular conduit assembliesExpansion tankChemical reaction

The invention discloses a heat exchanger for heat exchange between liquid sodium metal and air, comprising a cylinder, wherein, an outlet air door is arranged at the top of the cylinder, and an inlet air door is arranged at the bottom. The invention is characterized in that an expansion tank is arranged at the upper part of an intracavity of the cylinder; an argon gas inlet connection is arranged at the top of the expansion tank, while the bottom is communicated with a sodium inlet pipe; the cylinder body is communicated with a heat exchange pipe bundle communicated with a sodium outlet pipe. The invention has the advantages that heat is taken away when air passes through the surface of heat exchange pipe bundle, enabling heat exchange between sodium and air; meanwhile, the chemical reaction between sodium and air is avoided due to inactivity.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

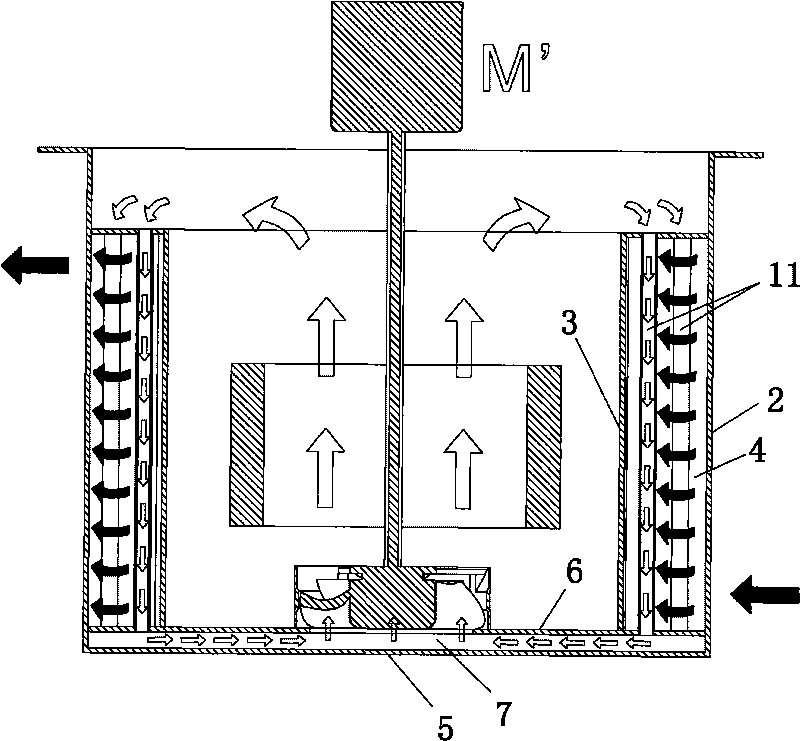

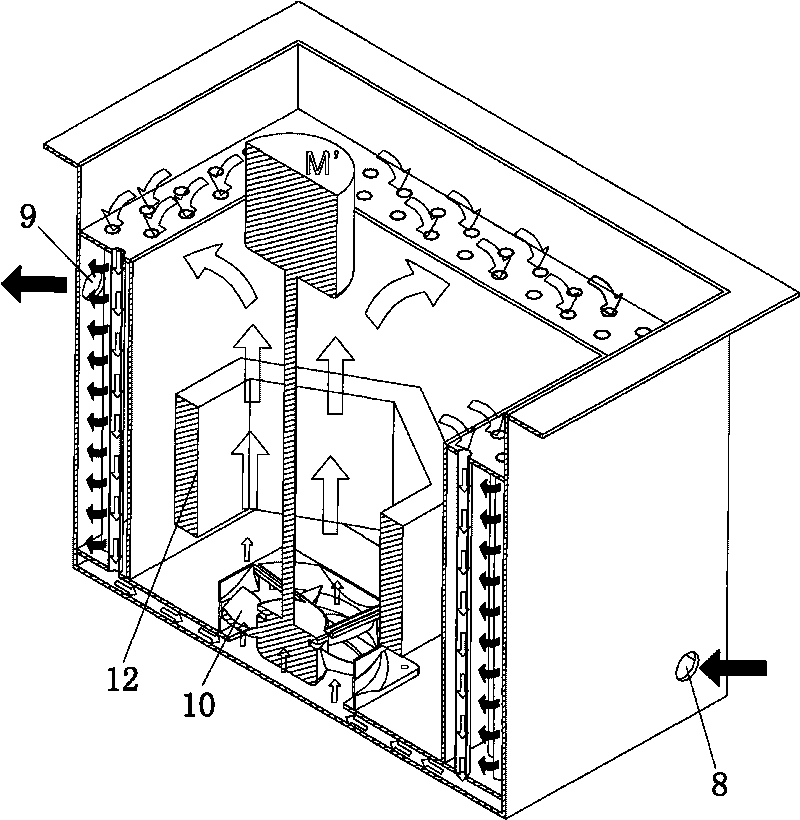

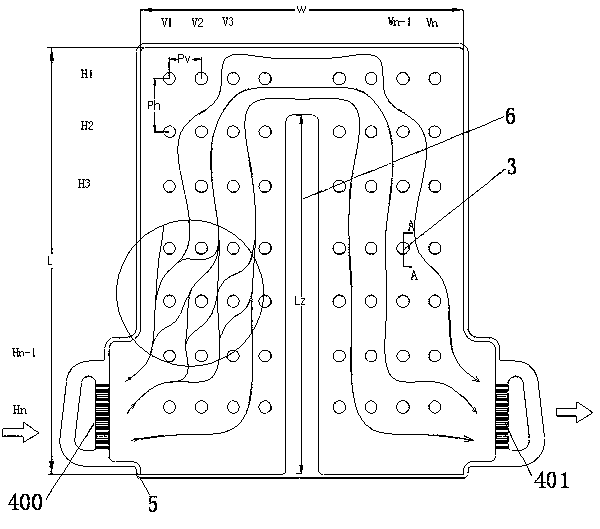

Forced oil circulation water-cooling radiator

InactiveCN101692384AAchieve coolingRealize heat exchangeTransformers/inductances coolingHeat transfer modificationTransformerWaste management

The invention discloses a forced oil circulation water-cooling radiator, which comprises a tank body and a cover body sealed on the tank body; a side cavity is formed between the outer wall and the inner wall on the side of the tank body; a bottom cavity is formed between the outer wall and the inner wall on the bottom of the tank body; the side cavity is not communicated with the bottom cavity; the side cavity is filled with water; the outer wall on the side of the tank body is provided with a water inlet and a water outlet; the tank body is filled with oil; the bottom cavity is provided with a stirrer; the side cavity is provided with an oil pipe; one end of the oil pipe is communicated with the inside of the tank body, while the other end is communicated with the bottom cavity; the oil in the tank body flows to and communicate with the bottom cavity through the oil pipe in the side cavity; the stirrer in the bottom cavity enables the oil to rise; and a transformer is immersed by the oil in the tank body. The forced oil circulation water-cooling radiator has good heat exchange effect and long service life.

Owner:彭伟简 +1

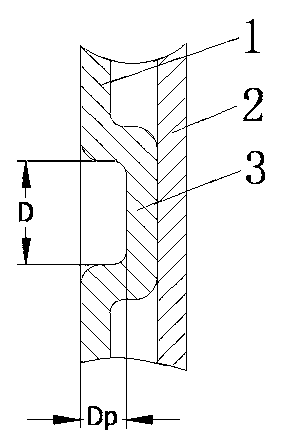

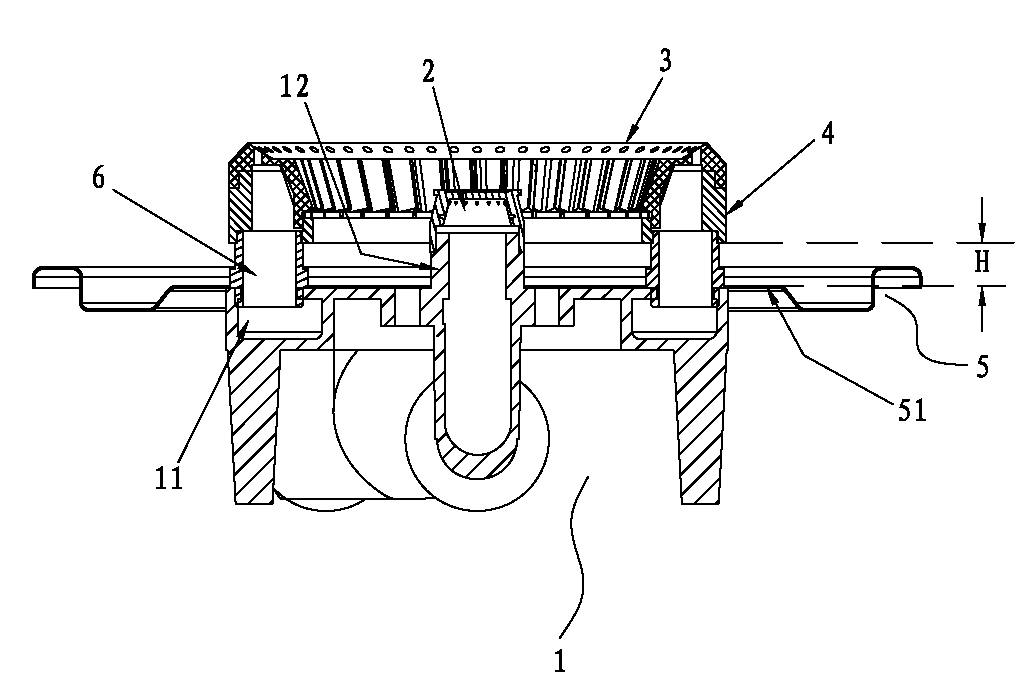

Power supply cooling unit

InactiveCN103296330AExtended flow timeIncrease flow resistanceSecondary cellsPropulsion coolingSurface patternCoolant flow

The invention relates to a power supply cooling unit which comprises at least two plates (a first plate (1) and a second plate (2)) which are arranged in a laminated mode, wherein the peripheries of the plates are fixedly connected in a hermetic mode; a coolant flow channel is arranged between every two plates; the central heat exchange region of at least one plate in every two adjacent plates is provided with a surface pattern and a barrier section (6); the length of the barrier section (6) is less than that of the plate; after the adjacent plates are fixedly connected in a hermetic mode, the barrier sections (6) of the adjacent plates mutually compact and contact, or the barrier section (6) on one plate and the other plate mutually compact and contact, so that the coolant flow channel is intercepted into a U-shaped route by the barrier section; and the surface pattern sinks to the inside of the coolant flow channel, and is arranged approximately along the U-shaped flow route of the coolant, thereby maximally prolonging the flow time of the coolant in the cooling unit.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Ventilation control system for laboratory

InactiveCN105115095AReduce temperature differenceRealize heat exchangeSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTorque motor

The invention discloses a ventilation control system for a laboratory. The system comprises a main air inflow pipe, an air inflow pipe branch, an air inflow device, a main exhaust pipe, an exhaust pipe branch and an exhaust device and is characterized in that an air adjusting heat exchange segment used for adjusting the air flow and heat exchange is arranged on the exhaust pipe branch and located in the air inflow pipe branch; the air adjusting heat exchange segment comprises a connecting shaft, a first torque motor, a rotating bearing, a gear sleeve, a transmission gear set and connecting cylinders, and the connecting cylinders are sequentially arranged from left to right. In the rotating process of a plurality of inner air adjusting heat exchange fins, a spiral channel can be formed, the size of the channel and the size of an opening of the channel change regularly, and therefore the air flow of the exhaust pipe branch can be adjusted, and in a similar way, the air inflow of the air inflow pipe branch can be adjusted; in the rotating process of the inner air adjusting heat exchange fins, the contact area of air in the channel and the inner air adjusting heat exchange fins is unceasingly increased, and therefore heat exchange between the exhaust pipe branch and the air inflow pipe branch can be achieved through the inner air adjusting heat exchange fins and outer air adjusting heat exchange fins, and the temperature difference of air in the exhaust pipe branch and air in the air inflow pipe branch is reduced.

Owner:LANZHOU UNIVERSITY

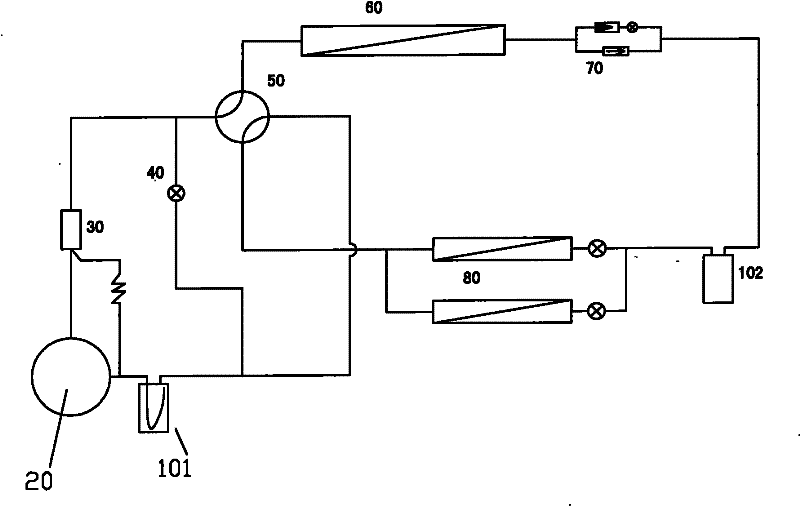

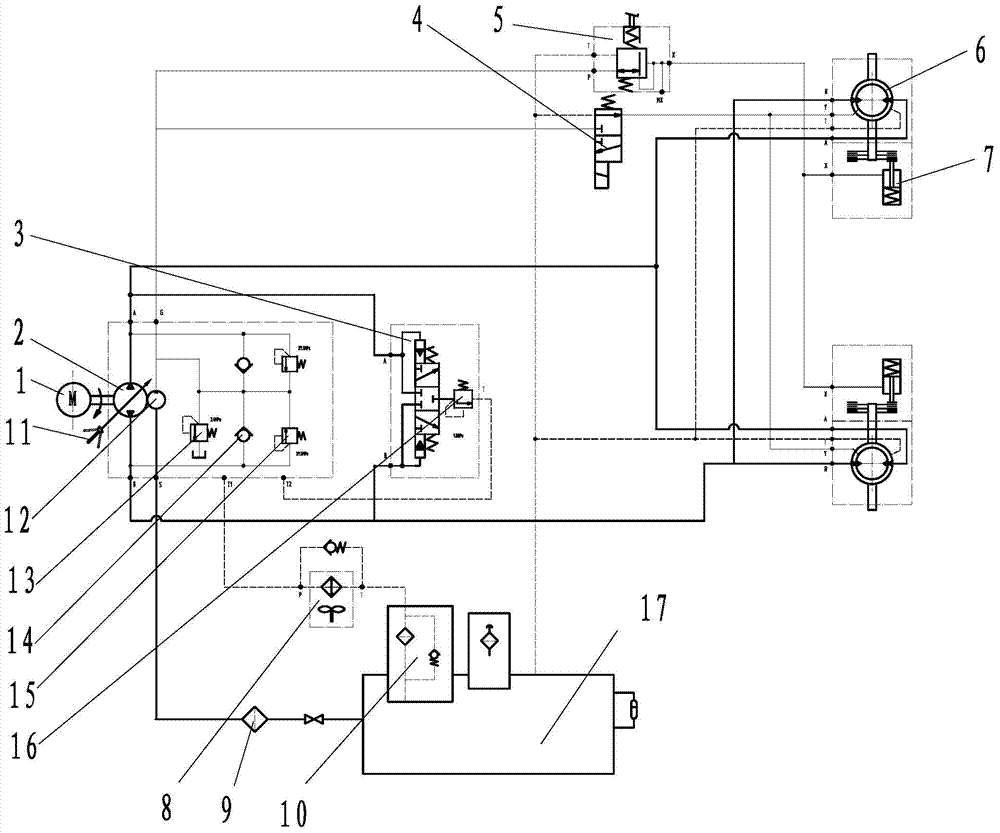

Autonomous-heat-exchange parallel-connection closed type forklift static-pressure drive system

ActiveCN103660928AImprove utilization efficiencyAvoid additional torque lossPropulsion coolingControl devicesDrive wheelEngineering

An autonomous-heat-exchange parallel-connection closed type forklift static-pressure drive system comprises an engine, a variable displacement piston pump, a heat exchange valve, a speed change valve, a parking control valve, a hydraulic motor, a parking hydraulic cylinder, an oil inlet filter net, an oil return heat dissipation device and an oil return filter. Power of the static-pressure drive system is provided by the engine, the engine is connected with the variable displacement piston pump through a transmission shaft, the variable displacement piston pump is in a double-outlet inclined disc type, input rotation speed through an adjusting pump and the position and angle of the inclined disc, output flow of the variable displacement piston pump is adjusted, and opening and closing of the variable displacement piston pump are achieved. Two pressure oil openings of the variable displacement piston pump are connected with the hydraulic motor and the heat exchange valve in parallel. The autonomous-heat-exchange parallel-connection closed type forklift static-pressure drive system has the advantages that a low-speed large-torque wheel motor is used for directly driving wheels, additional torque loss caused by mechanical speed reduction is avoided, the structure is simple, transmission efficiency is high, power loss is little, improvement of energy utilizing efficiency is facilitated, and the dynamic property is superior.

Owner:ANHUI XINGHUA FORKELEVATOR

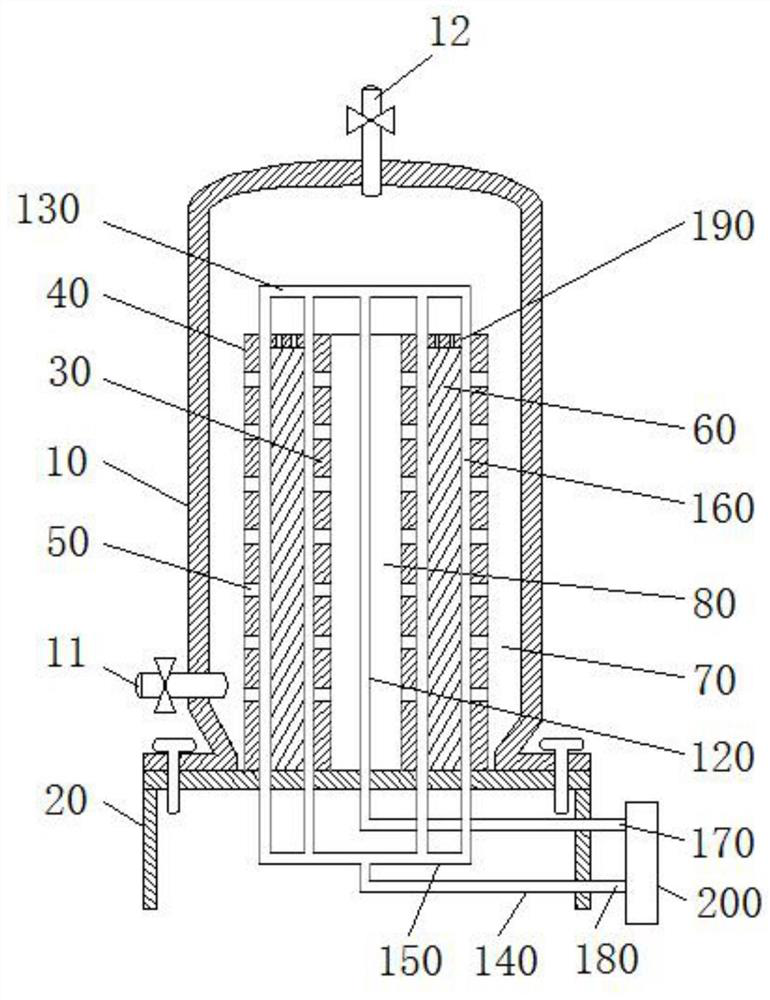

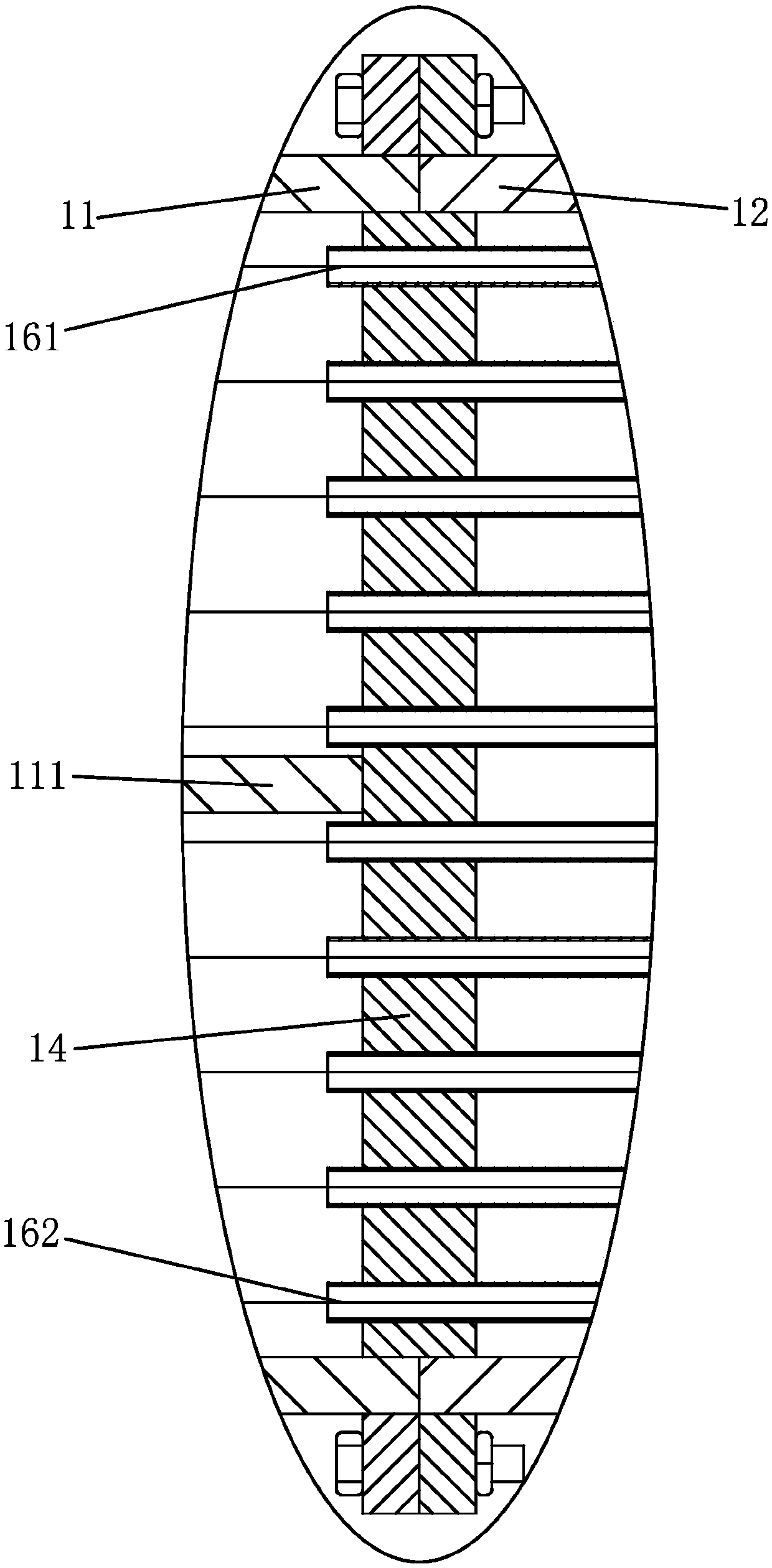

High-pressure composite metal hydride hydrogen storage tank and hydrogen storage method thereof

ActiveCN113375039AAbundant storageHigh mass density of hydrogen storageVessel geometry/arrangement/sizeContainer filling methodsMetallurgyGaseous hydrogen

The invention discloses a high-pressure composite metal hydride hydrogen storage tank and a hydrogen storage method thereof. The hydrogen storage tank comprises a base support and a hydrogen storage tank shell with an opening in the bottom, and the hydrogen storage tank shell is installed on the base support in a sealed and buckled mode. A hydrogen inlet and a hydrogen outlet are formed in the hydrogen storage tank shell. A hydrogen storage alloy storage space, a gaseous hydrogen storage gap and a circulating heat exchange system are arranged in the hydrogen storage tank shell. The hydrogen storage alloy storage space is filled with hydrogen storage alloy, and the circulating heat exchange system is used for absorbing heat when the hydrogen storage alloy absorbs hydrogen and heating the hydrogen storage alloy when the hydrogen storage alloy releases hydrogen. According to the high-pressure composite metal hydride hydrogen storage tank and the hydrogen storage method thereof, a gas hydrogen storage gap is formed in the hydrogen storage tank, the size of a reserved gap can be adjusted according to the requirement of hydrogen storage mass density, hydrogen storage of different mass densities is achieved, the advantages of high mass density of high-pressure gas hydrogen storage and high volume density of solid hydrogen storage are fully combined, and the volume of the solid hydrogen storage part is adjusted, the purpose of storing more hydrogen under equal pressure is achieved.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

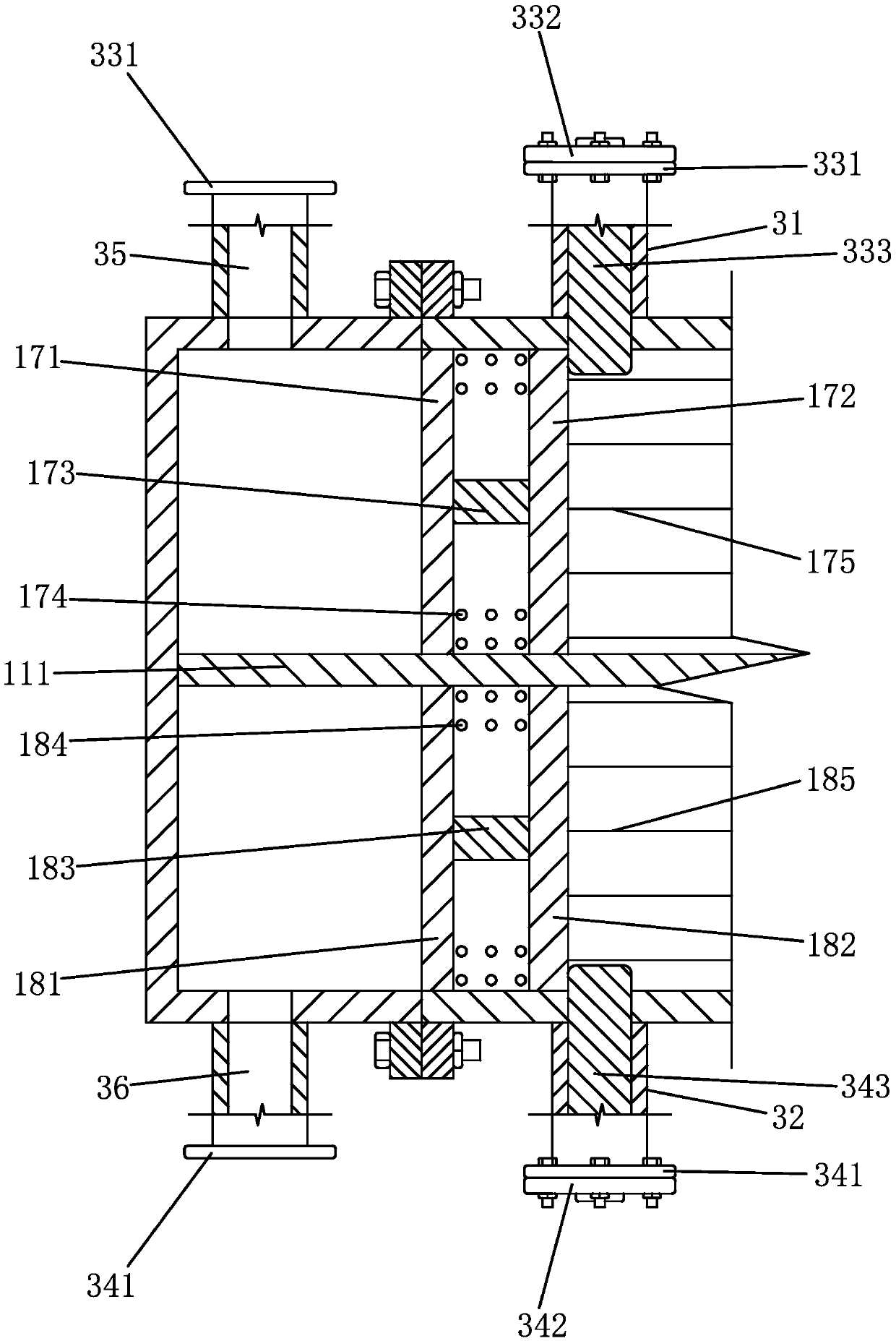

Chemical heat exchange device

ActiveCN109612310ARealize heat exchangeReasonable structureStationary tubular conduit assembliesRotary device cleaningCompound (substance)Engineering

The invention discloses a chemical heat exchange device. The chemical heat exchange device comprises a main shell body, an inner cavity liquid inlet pipe, an inner cavity liquid outlet pipe, an outercavity liquid inlet pipe and an outer cavity liquid outlet pipe, wherein the main shell body comprises a front shell head, a shell pipe and a rear shell head, and a front seat plate, a rear seat plate, a plurality of inner liquid inlet pipes and a plurality of inner liquid outlet pipes are arranged in front of the main shell body. An inlet self-dredging structure and an outlet self-dredging structure are arranged in front of the main shell body, wherein the inlet self-dredging structure comprises an inlet fixed plate, an inlet movable plate, a plurality of inlet springs and a plurality of inlet dredging inhaul cables, and the outlet self-dredging structure comprises an outlet fixed plate, an outlet moving plate, an outlet limiting block, a plurality of springs and a plurality of dredging inhaul cables. The chemical heat exchange device has the beneficial effects that the structure is reasonable, different liquid passages can be provided for the two liquids that need heat exchange, andtherefore heat exchange between the two liquids can be realized; and in the heat exchange process, the contact area is large, and the heat exchange effect is good. The chemical heat exchange device also has an automatic dredging structure to avoid the internal blockage problem.

Owner:江苏锐深化工机械科技有限公司

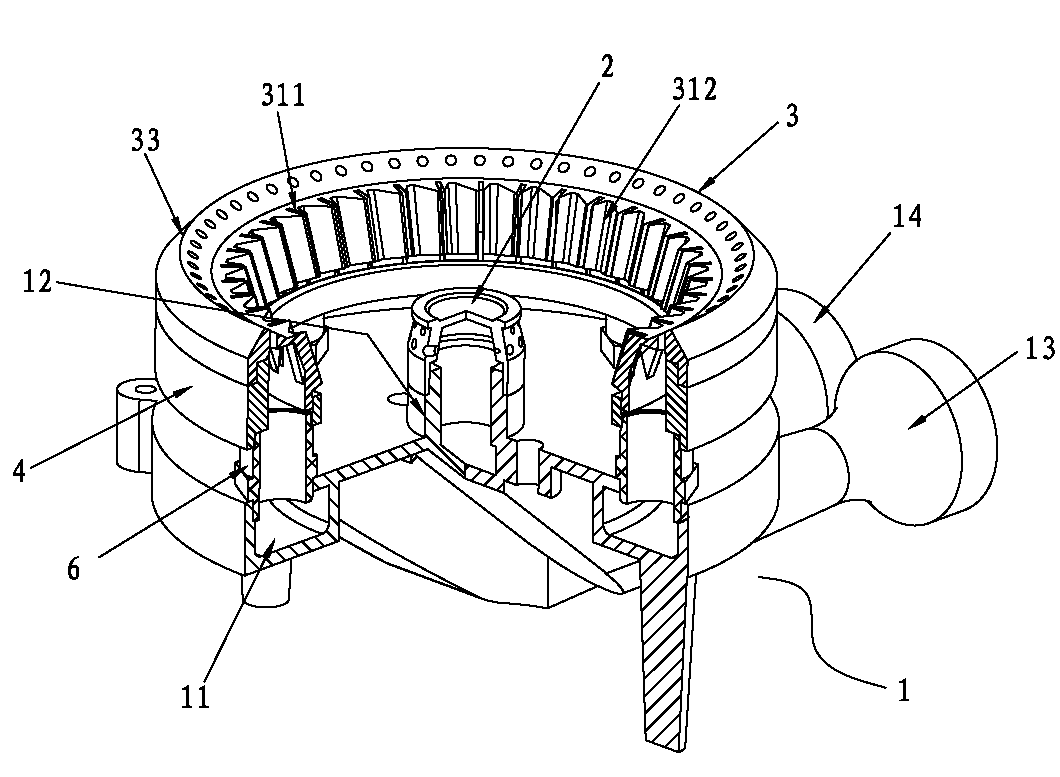

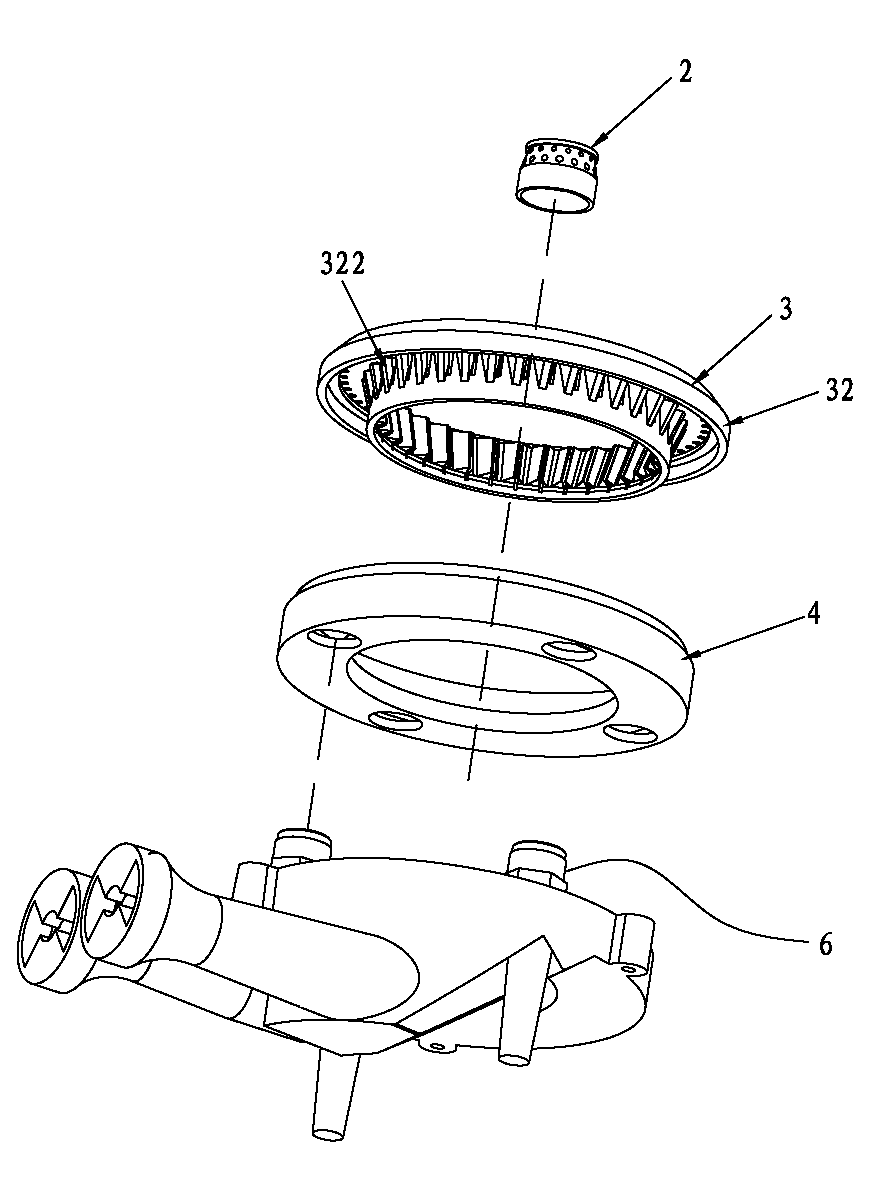

Gas cooker

InactiveCN103234226ARealize heat exchangeImprove ergonomicsDomestic stoves or rangesGaseous fuel burnerCombustorFlue gas

The invention relates to a gas cooker which comprises a liquid receiving disk, a furnace end, an inner fire cover, an outer fire cover and an outer ring distributor, wherein an extending hole of a burner is formed in a central boss of the liquid receiving disk; left-handed or right-handed inner fire grooves are formed in the inner ring wall of the outer fire cover; or the left-handed or right-handed inner fire grooves are formed in the inner ring wall of the outer fire cover, and outer fire holes are formed in the outer ring wall of the outer fire cover; and areas of the inner fire grooves in the outer fire cover account for 30%-100% of those of the outer fire holes. With the adoption of the structure, secondary air enters space between the inner fire cover and the outer fire cover via a gap between the outer ring distributor and the furnace end, and is contacted with gas sprayed by inner flame fire holes; the burning process is realized; another part of secondary air enters from the outside of the outer fire cover, and is contacted with the unburned gas of the inner flame fire holes and gas sprayed outward by the outer fire cover, thus complete burning is accomplished; and high-temperature flue gas formed after gas burning transmits heat to a heating kettle through convection and heat radiation, thus heat exchange is realized, the heating process is finished and the working efficiency is improved.

Owner:SUPERMAN ZHONGSHAN ELECTRIC APPLIANCES CO LTD

Sintering flue gas SCR denitration and vapor removal system and technology

The invention relates to a sintering flue gas SCR denitration and vapor removal system. The system comprises a flue gas condensation vapor-removal defogging dedusting tower, a heat exchange device, ahot-blast stove, an ammonium hydroxide evaporator, a dilution fan, an ammonia injection grid, an SCR denitration reaction device and a flue gas exhaust device. The heat exchange device is arranged between the flue gas condensation vapor-removal defogging dedusting tower and the SCR denitration reaction device. The heat exchange device is used for heat exchange on flue gas to be denitrated or denitrated flue gas to change the temperature, an original flue gas outlet of the heat exchange device is connected with a gas inlet of the SCR denitration reaction device through a second main flue, the hot-blast stove and the ammonia injection grid are arranged in sequence in the flowing direction of the flue gas in the second main flue, and the ammonium hydroxide evaporator and the dilution fan arearranged between the ammonia injection grid and a gas outlet of the SCR denitration reaction device. The sintering flue gas SCR denitration and vapor removal system can carry out SCR denitration on desulfurated sintering flue gas while carrying out vapor removal treatment, the effect of purifying sintering flue gas desulfurated with a wet method is improved, and environmental pollution is reduced.

Owner:江苏朗润环保科技有限公司

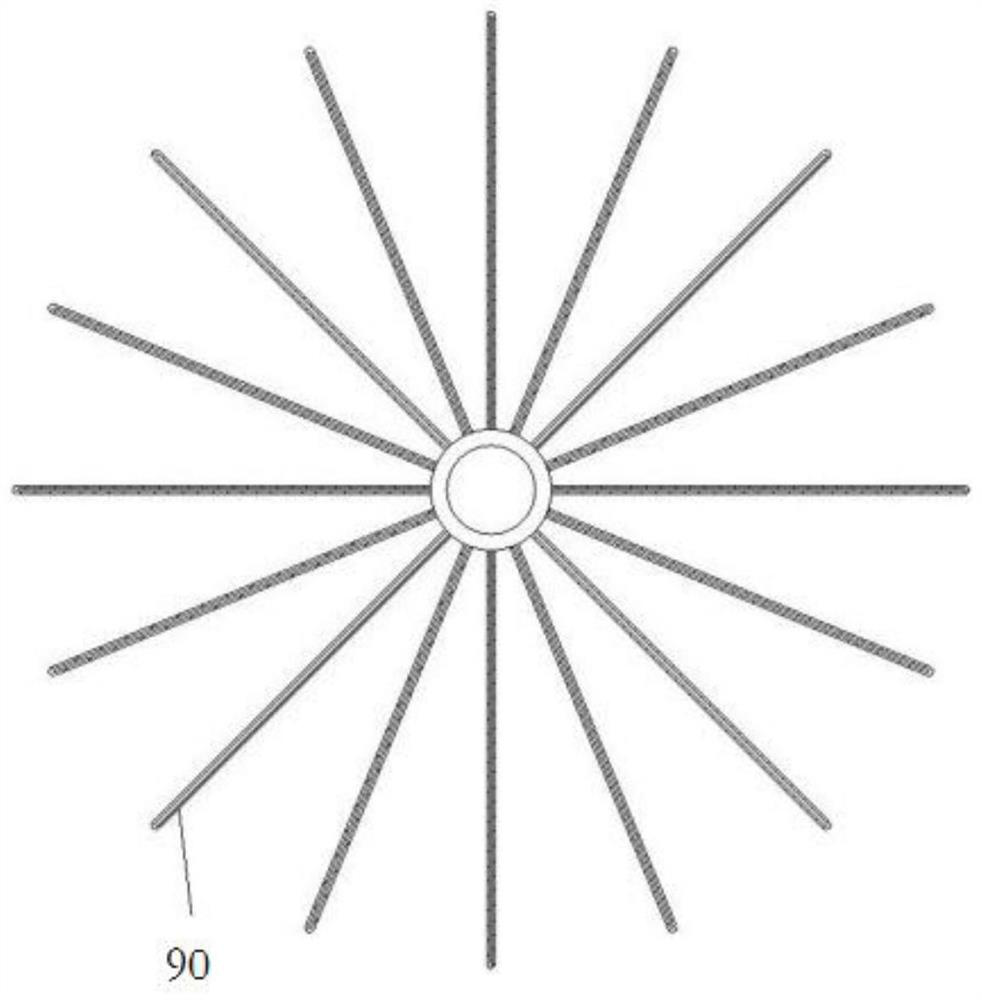

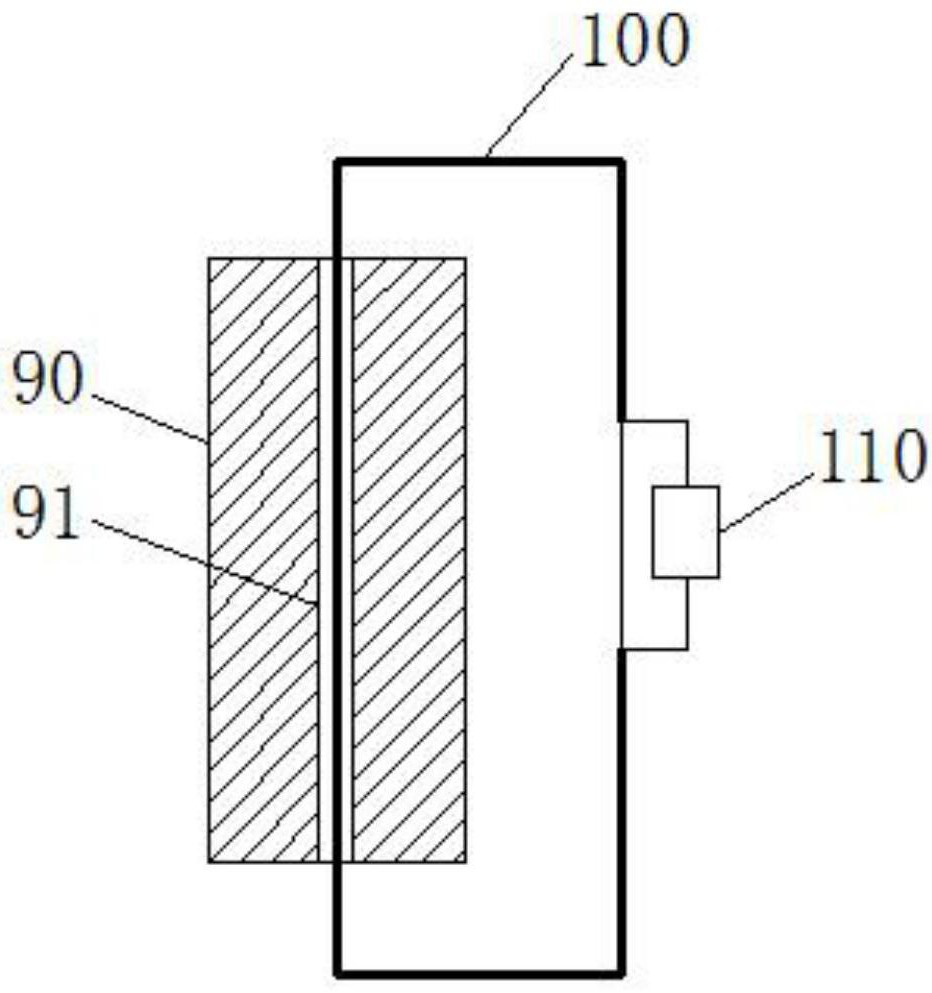

Novel heat exchange stirring shaft and tubular reactor

ActiveCN106179038ARealize the delivery functionStir wellRotary stirring mixersTransportation and packagingChemical reactionEngineering

The invention discloses a novel heat exchange stirring shaft, and belongs to the field of chemical reaction devices. The novel heat exchange stirring shaft comprises a main shaft, wherein a first chamber and a second chamber which are isolated from each other are formed in the main shaft; an opening is formed in each of the first and second chambers at one end of the main shaft; a first connecting pipe communicated with the first chamber is arranged on the main shaft; a second connecting pipe communicated with the second chamber is arranged on the main shaft; at least one spiral pipe for communication is arranged between the first and second connecting pipes. According to the novel heat exchange stirring shaft, a heat exchange medium is introduced into an inner communicated pipeline area to implement heat exchange in a reactor; by a structure formed by spirally winding the main shaft with the spiral pipe, a function of stirring a reaction raw material is realized, and meanwhile, the reaction raw material is driven to be delivered to one end of the axial direction of the main shaft; a heat exchange pipeline can be in contact with the reaction raw material more fully by the rotary movement of stirring columns, so that the heat exchange efficiency is greatly improved.

Owner:HIMILE MECHANICAL MFG

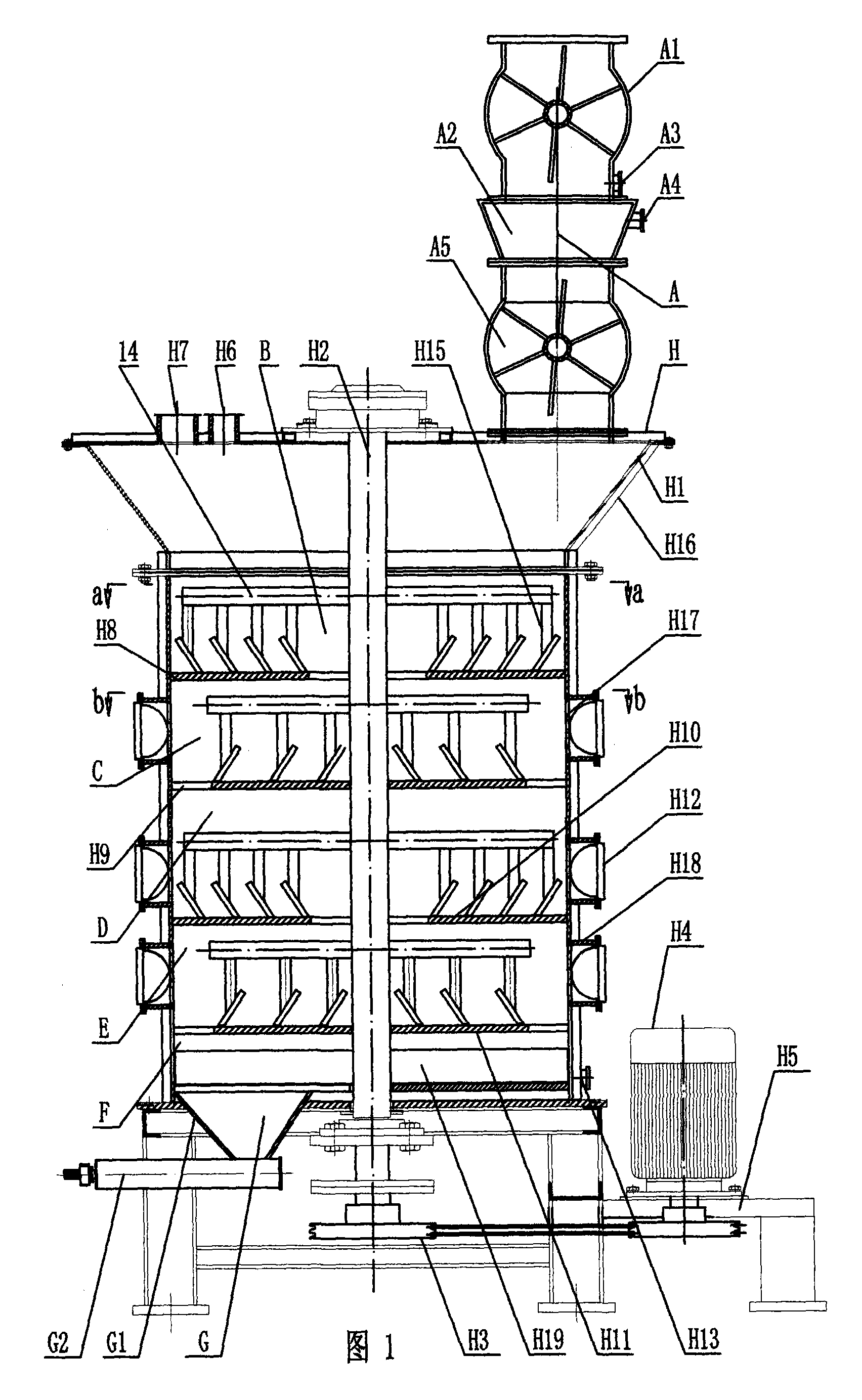

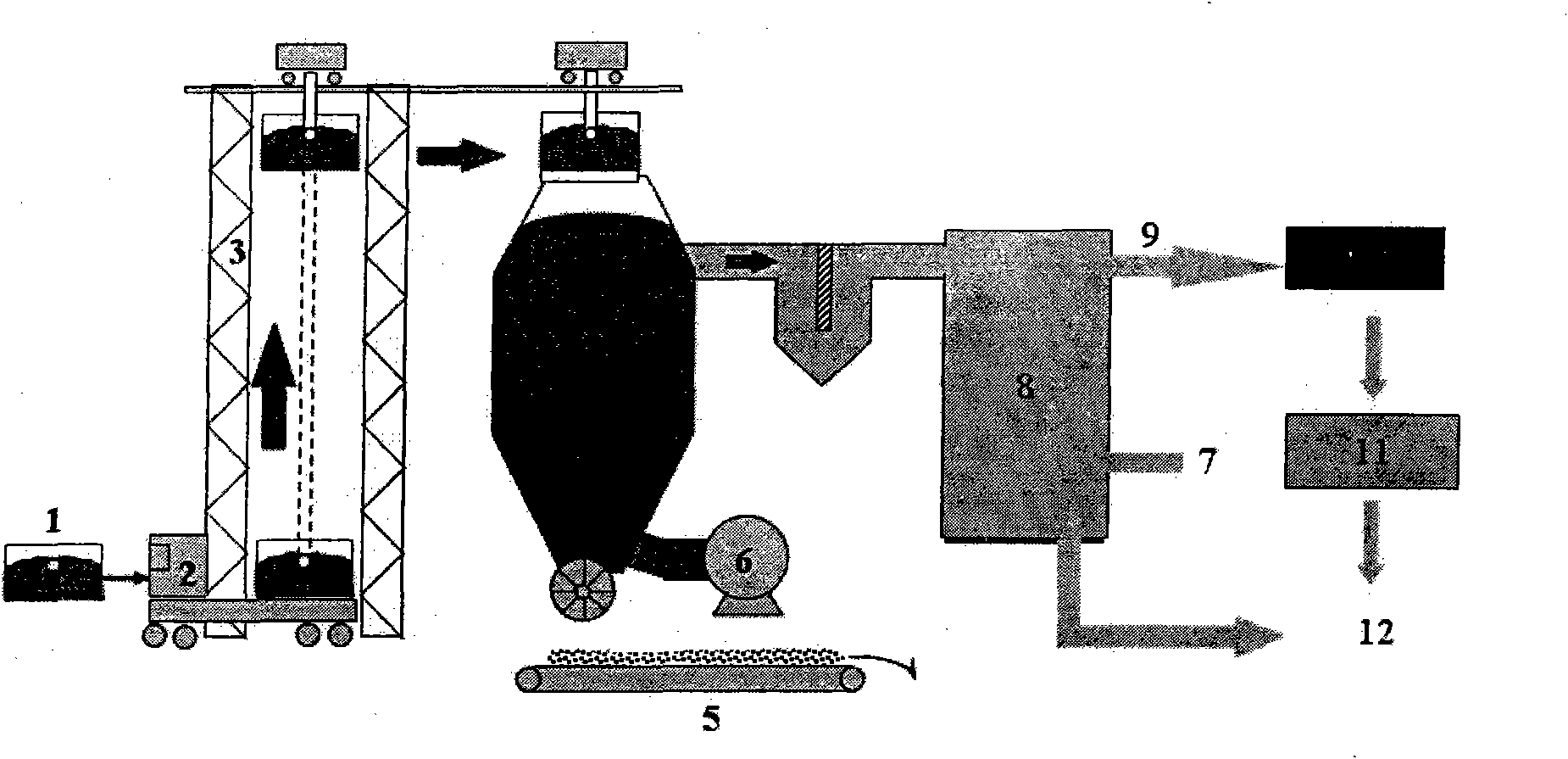

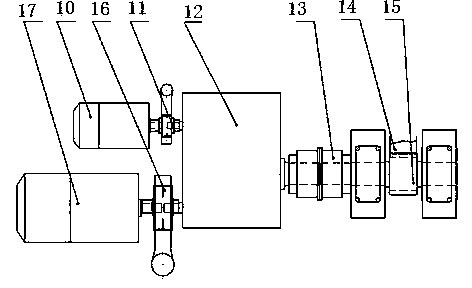

Multitube heating rotary pulverized coal pyrolysis system

InactiveCN104017592ARealize large-scale pyrolysisAchieve recyclingIndirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention discloses a multitube heating rotary pulverized coal pyrolysis system, including a feeder, an outlet gas gathering and distribution box, a preheater, a transmission mechanism, a rotating cylinder body, a heating pipe, a riding wheel device, an air inlet gas gathering and distribution box and a gas guiding device. The rotating cylinder body supports on the riding wheel device, and is driven by the transmission mechanism; a feed end of the rotating cylinder body is provided with the outlet gas gathering and distribution box, and a discharging end of the rotating cylinder body is provided with the inlet gas gathering and distribution box; The rotating cylinder body is provided with the heating pipe, both ends of the heating tube are respectively connected with the inlet gas gathering and distribution box and the outlet gas gathering and distribution box; the feeder is connected with the charging end of the rotating cylinder body through the gas gathering and distribution box; the gas guiding device is connected with the discharge end of the rotating cylinder through the gas inlet gathering and distribution box; and the feeder is installed on the upper part of the preheater, and is connected with the gas outlet gathering and distribution box. The invention realizes the scale pyrolysis of pulverized coal, and creates conditions for improving the comprehensive utilization and economic value of pulverized coal.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com