Winding tubular heat exchanger provided with vertical partition plate in cavity

A winding tube type, vertical baffle technology, applied in heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem of uneven distribution of gas and liquid, and achieve improved heat exchange performance and high strength stress. , the effect of increasing the effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

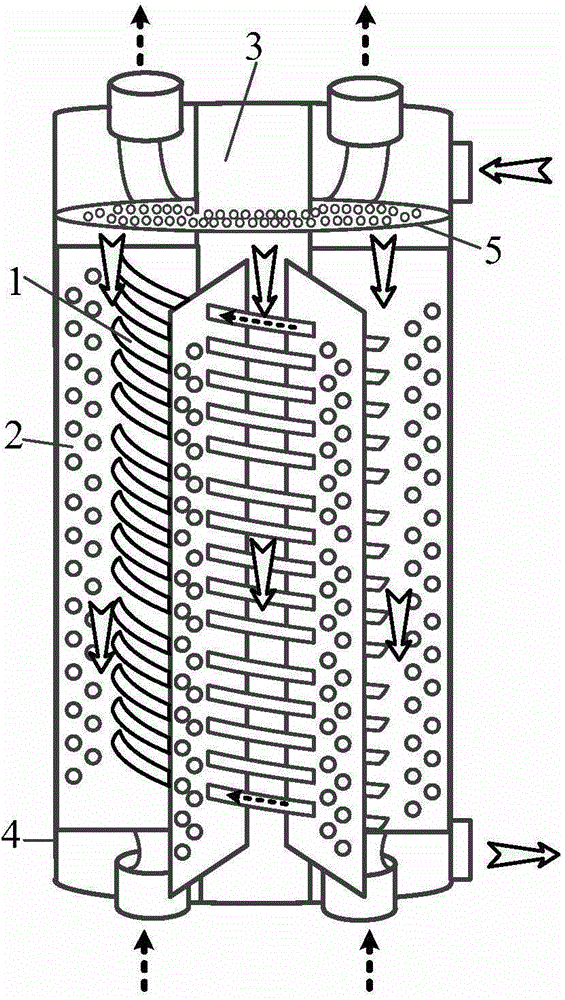

[0019] Such as figure 1 As shown, it is a wound tube heat exchanger with a vertical partition in the cavity of the present invention, which includes a shell 1 and a central cylinder 3, wherein the central cylinder 3 is arranged in the cavity of the shell 1 to form an annular cavity . A plurality of winding tubes 1 are wound in the annular cavity for passing in fluid. There are a plurality of metal orifice plates 2 in the ring cavity, which are vertically arranged in the ring cavity and arranged symmetrically along the circumference of the central cylinder 3, and each layer of winding pipe 1 passes through the through holes on each metal orifice plate 2 to fix. One end of the metal orifice plate 2 is welded on the inner wall of the housing 4, and the other end is welded on the outer wall of the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com