Working medium contact type cooling system for high-power electric power device

A cooling system, high-power technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of high-power heat accumulation, high junction temperature of electronic devices, and deterioration of device performance. Effects of reduced contact thermal resistance, high heat flux density, improved operating life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

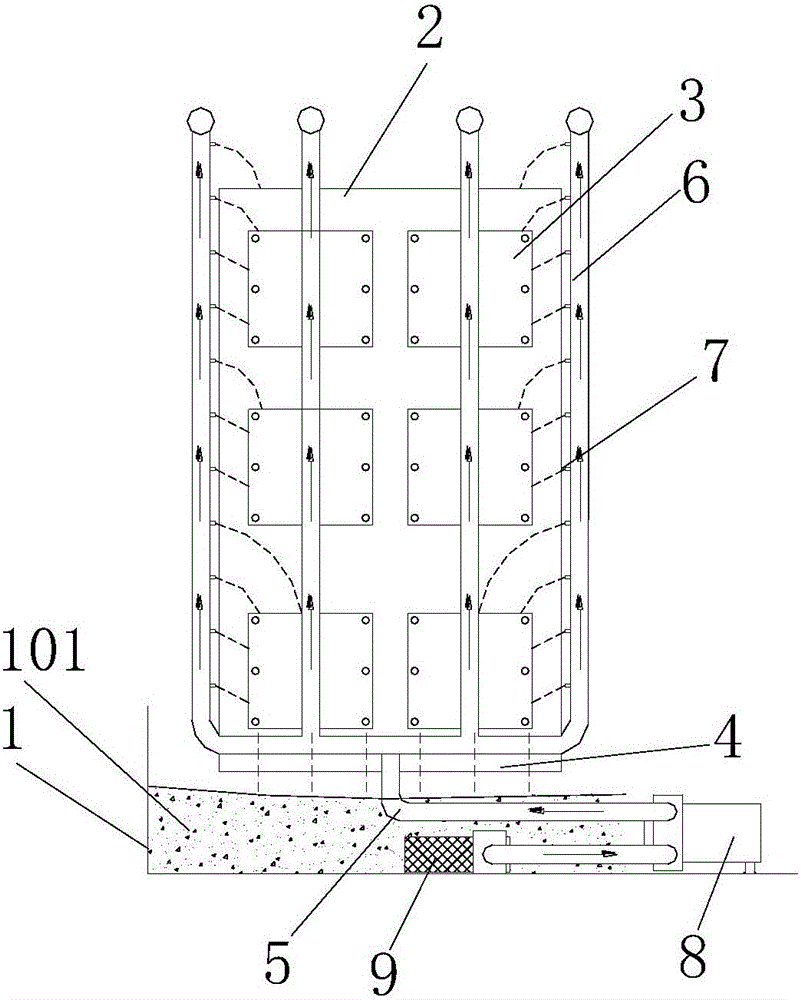

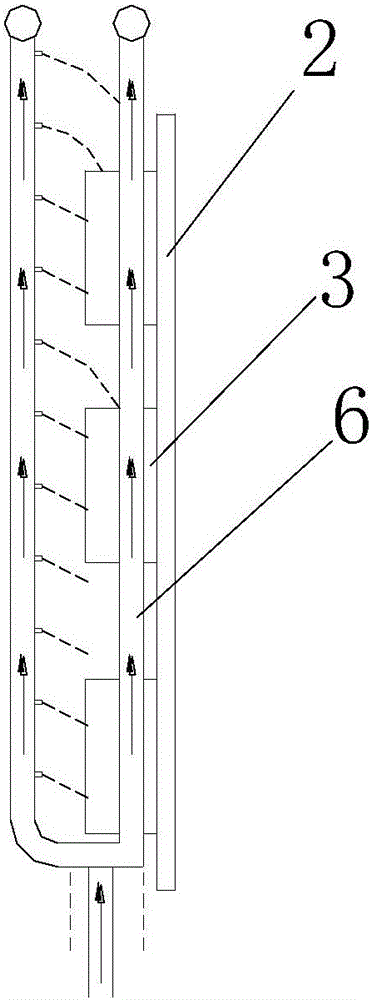

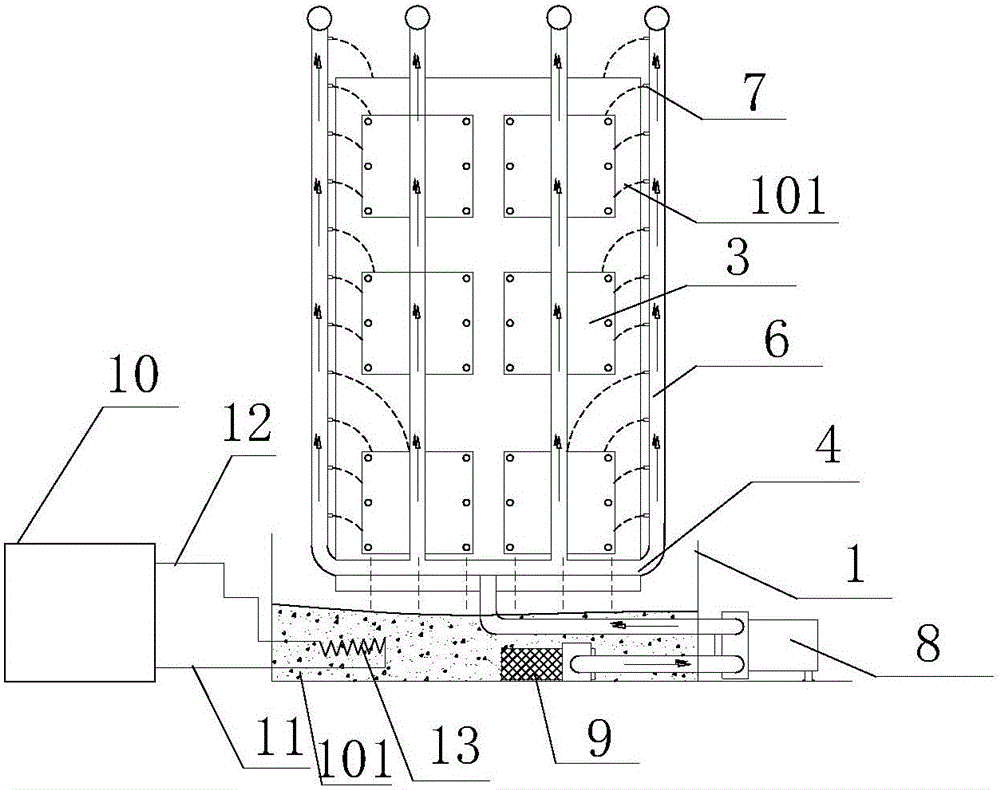

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0043] Such as Figures 1 to 6 As shown, a working medium contact cooling system for high-power electric devices includes a liquid working medium tank 1 equipped with insulating and heat-conducting liquid working medium 101; multiple mounting plates 2, and multiple mounting plates 2 are vertical and parallel Arrangement; high-power electric device 3, described high-power electric device 3 is installed on one side and / or two sides of described installation board 2; Main pipe liquid distributor 4, described main pipe liquid distributor 4 communicates with described Liquid working medium box 1; a plurality of liquid working medium spray pipes 6, a plurality of liquid working medium spray pipes 6 are evenly arranged wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com