Patents

Literature

371 results about "Saturation voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saturation voltage, collector-emitter (VCE(sat)) The voltage between the collector and emitter terminals under conditions of base current or base-emitter voltage beyond which the collector current remains essentially constant as the base current or voltage is increased. (Ref. IEC 747‑7.)

Method and system to differentially enhance sensor dynamic range using enhanced common mode reset

ActiveUS7176438B2Extend effective differential dynamic range of differentialInhibitionTelevision system detailsTelevision system scanning detailsAudio power amplifierPhotodetector

Owner:MICROSOFT TECH LICENSING LLC

Method and system to differentially enhance sensor dynamic range using enhanced common mode reset

ActiveUS20060027730A1Extend effective differential dynamic range of differentialInhibition effectTelevision system detailsTelevision system scanning detailsAudio power amplifierPhotovoltaic detectors

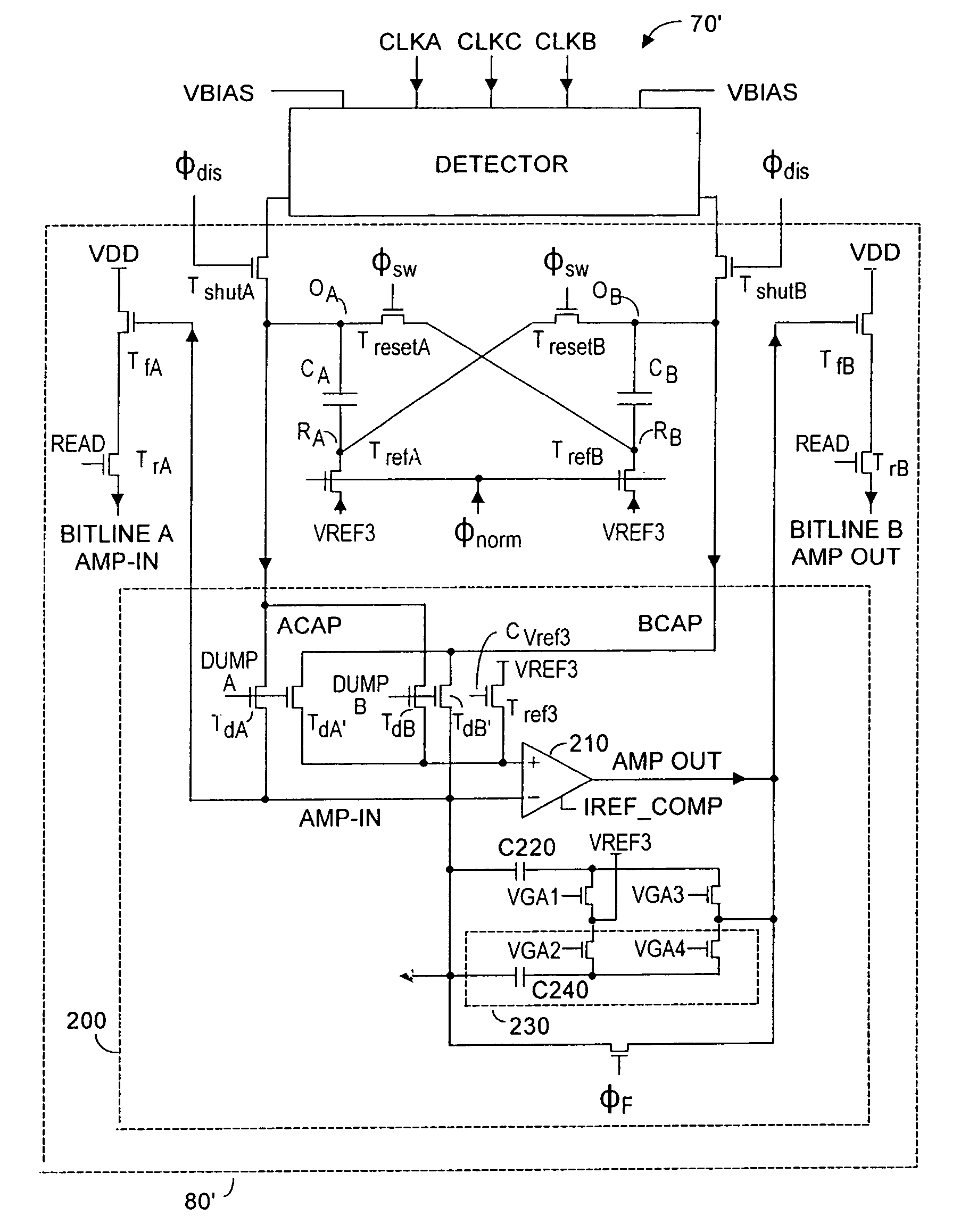

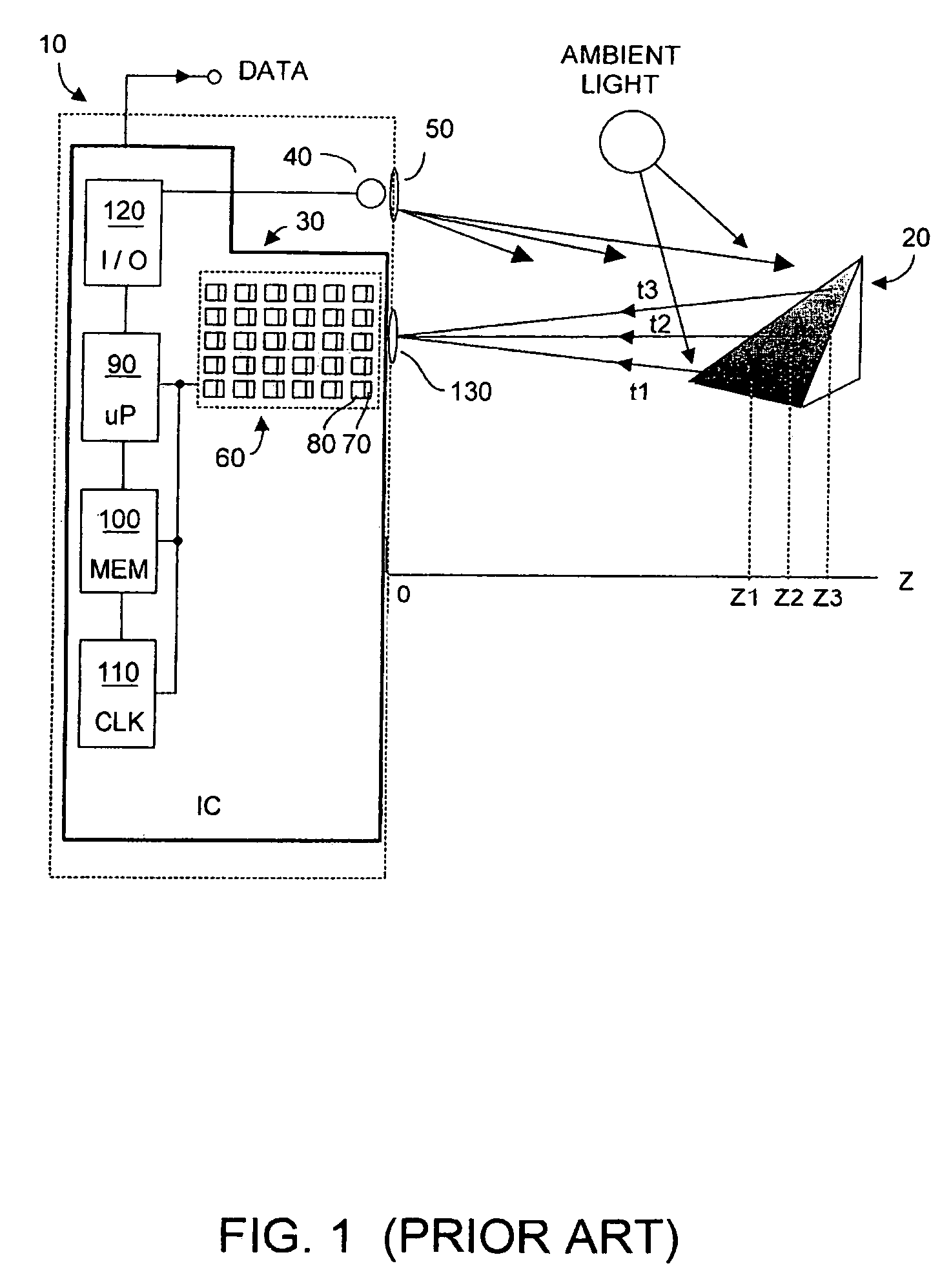

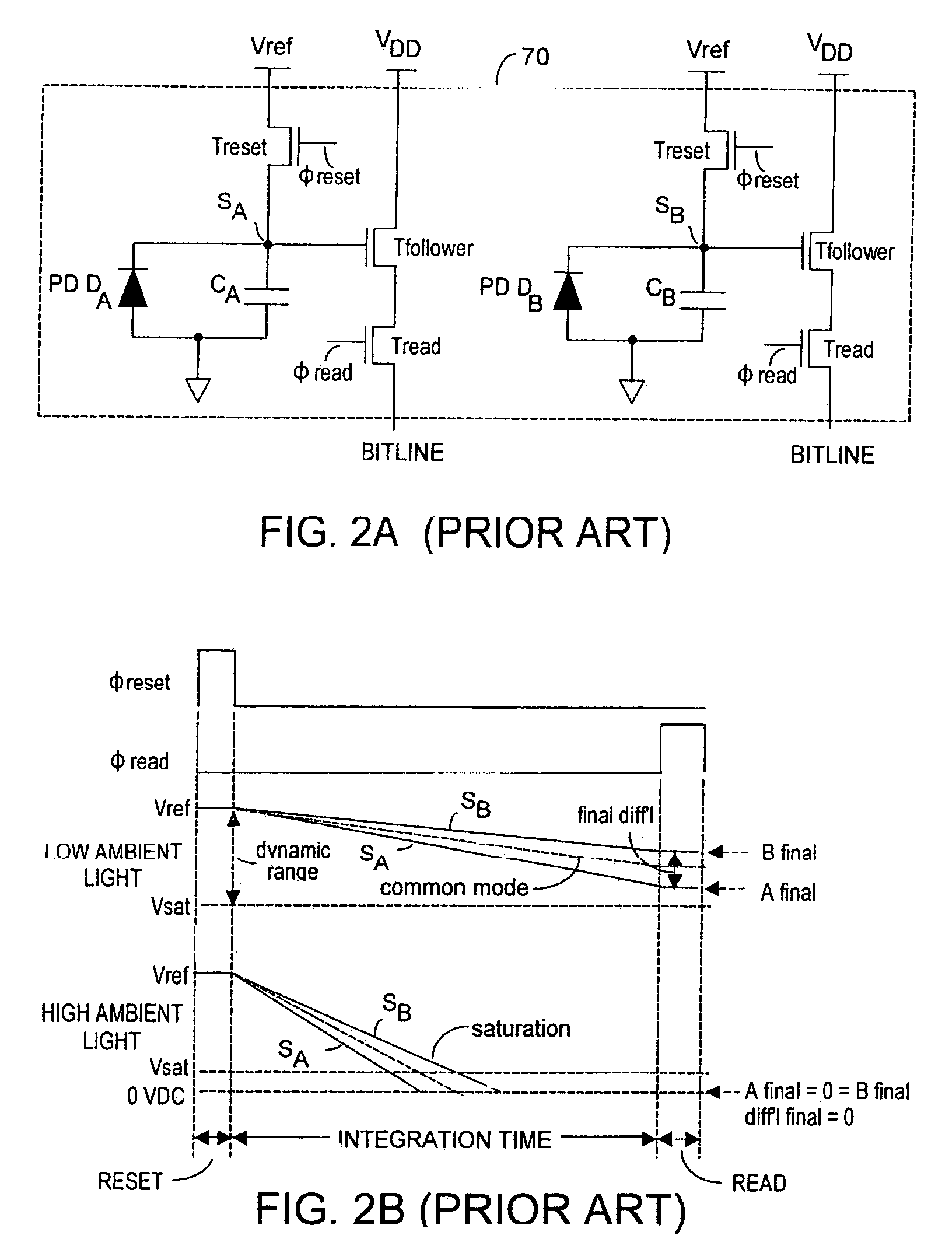

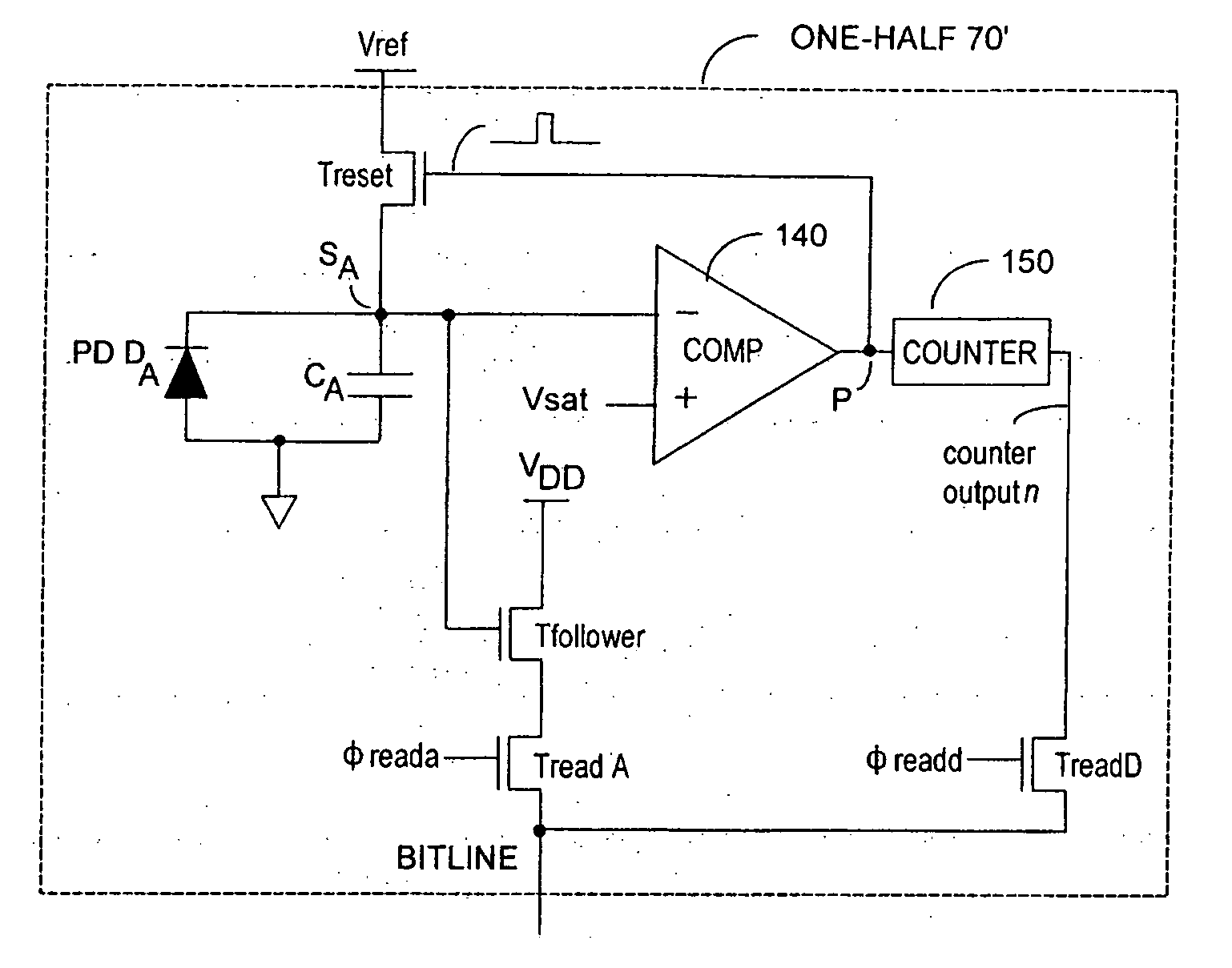

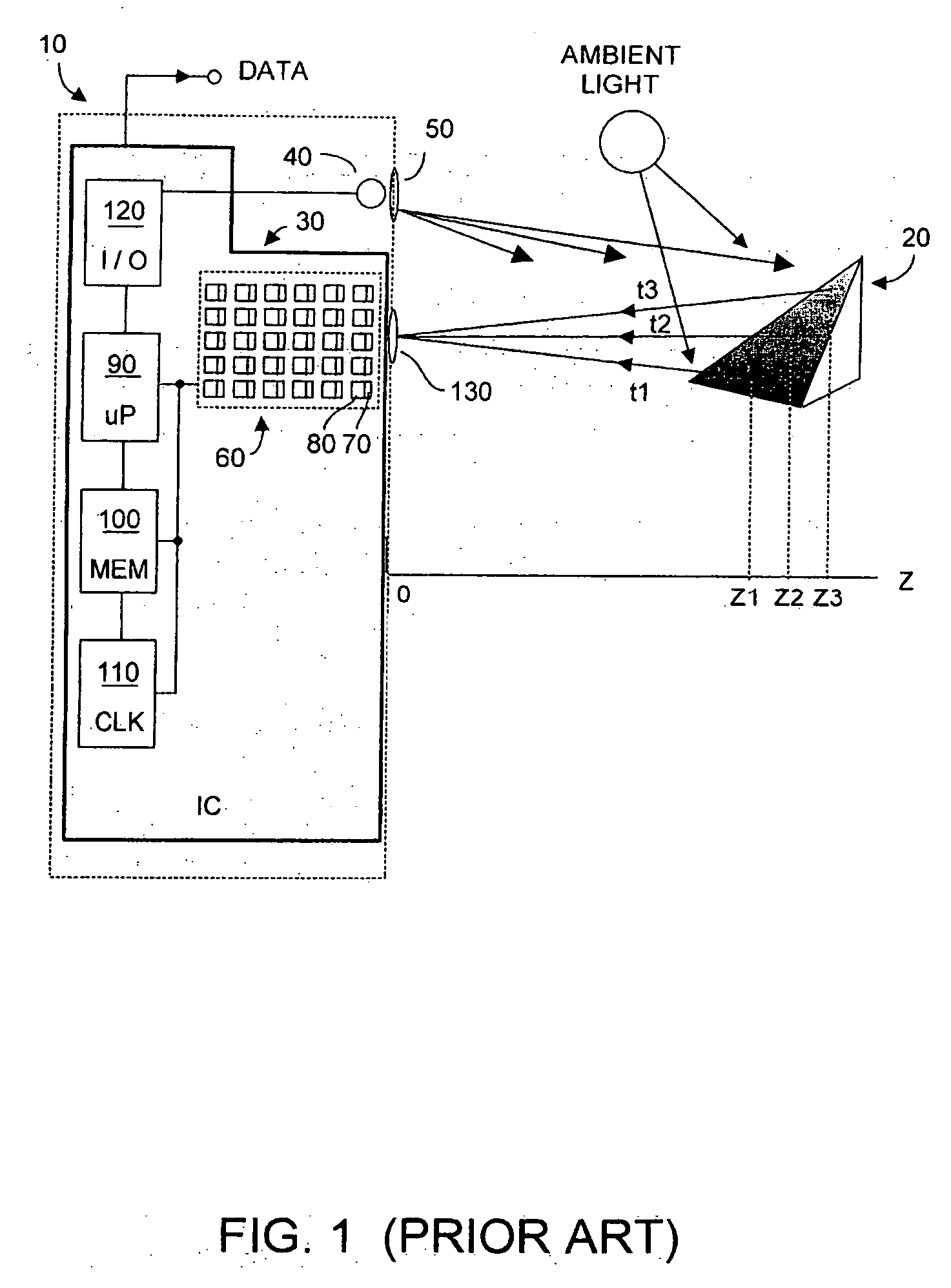

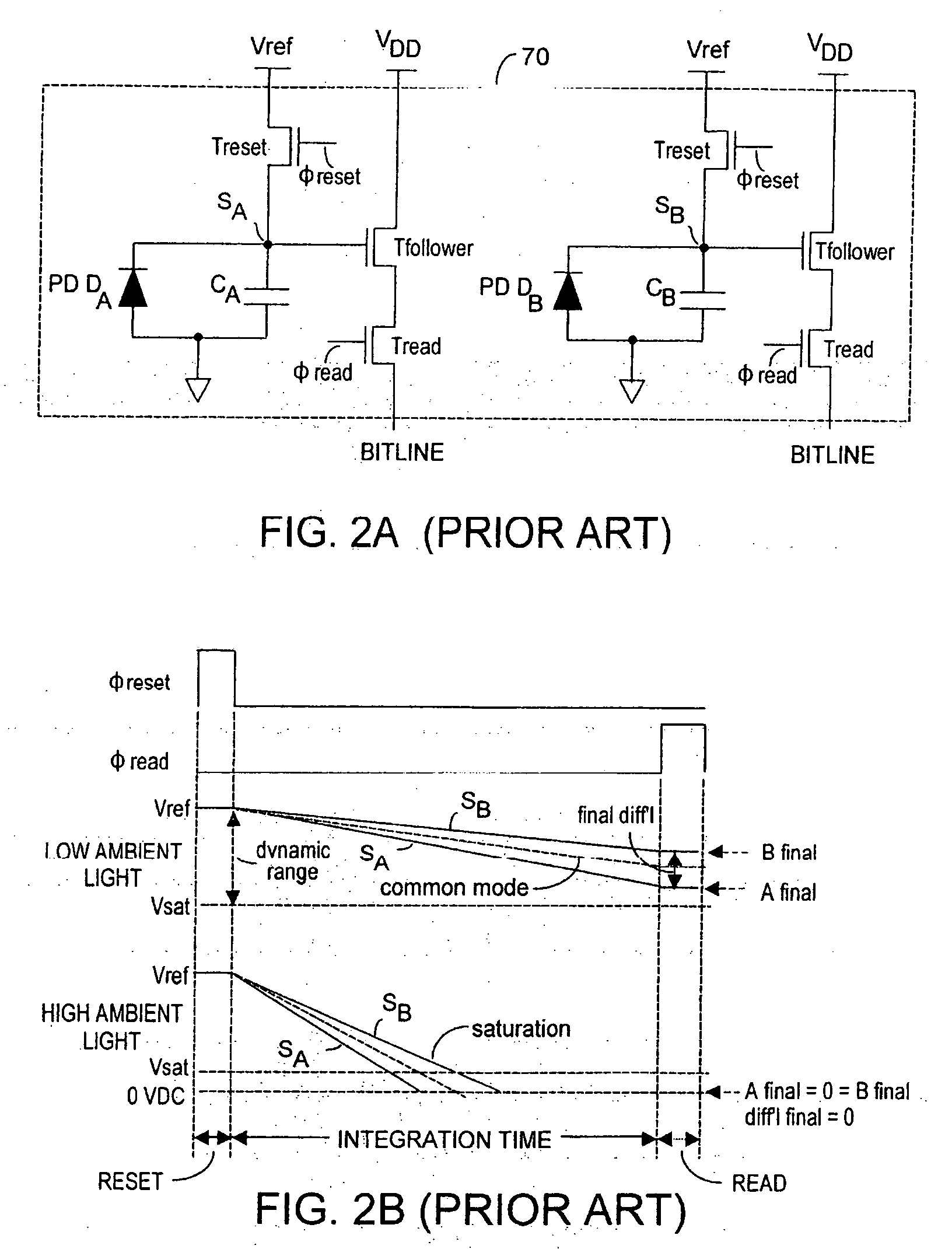

Effective differential dynamic range and common mode rejection in a differential pixel detector are enhanced by capturing and isolating differential detector charge output before using common mode reset to avoid detector saturation due to common mode components of optical energy to be detected. Differential charge is stored into an integration capacitor associated with an operational amplifier coupled to receive as input the differential detector outputs. Common mode reset is achieved by resetting storage capacitors coupled to the outputs of the differential detector at least once within an integration time T before storage potential exceeds a saturation voltage Vsat for the photodetector.

Owner:MICROSOFT TECH LICENSING LLC

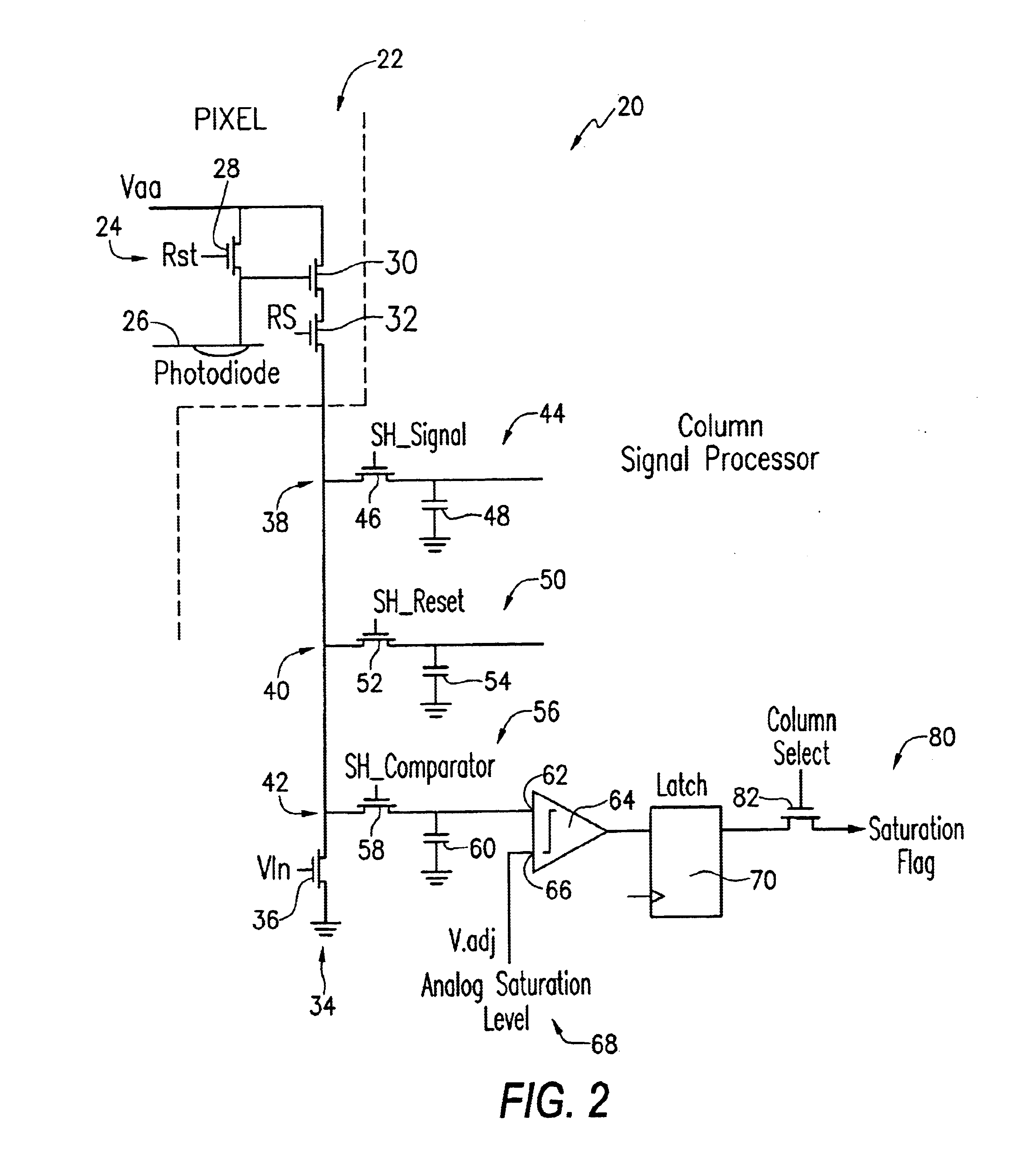

Technique for flagging oversaturated pixels

InactiveUS6873363B1Television system detailsTelevision system scanning detailsCMOS sensorPattern recognition

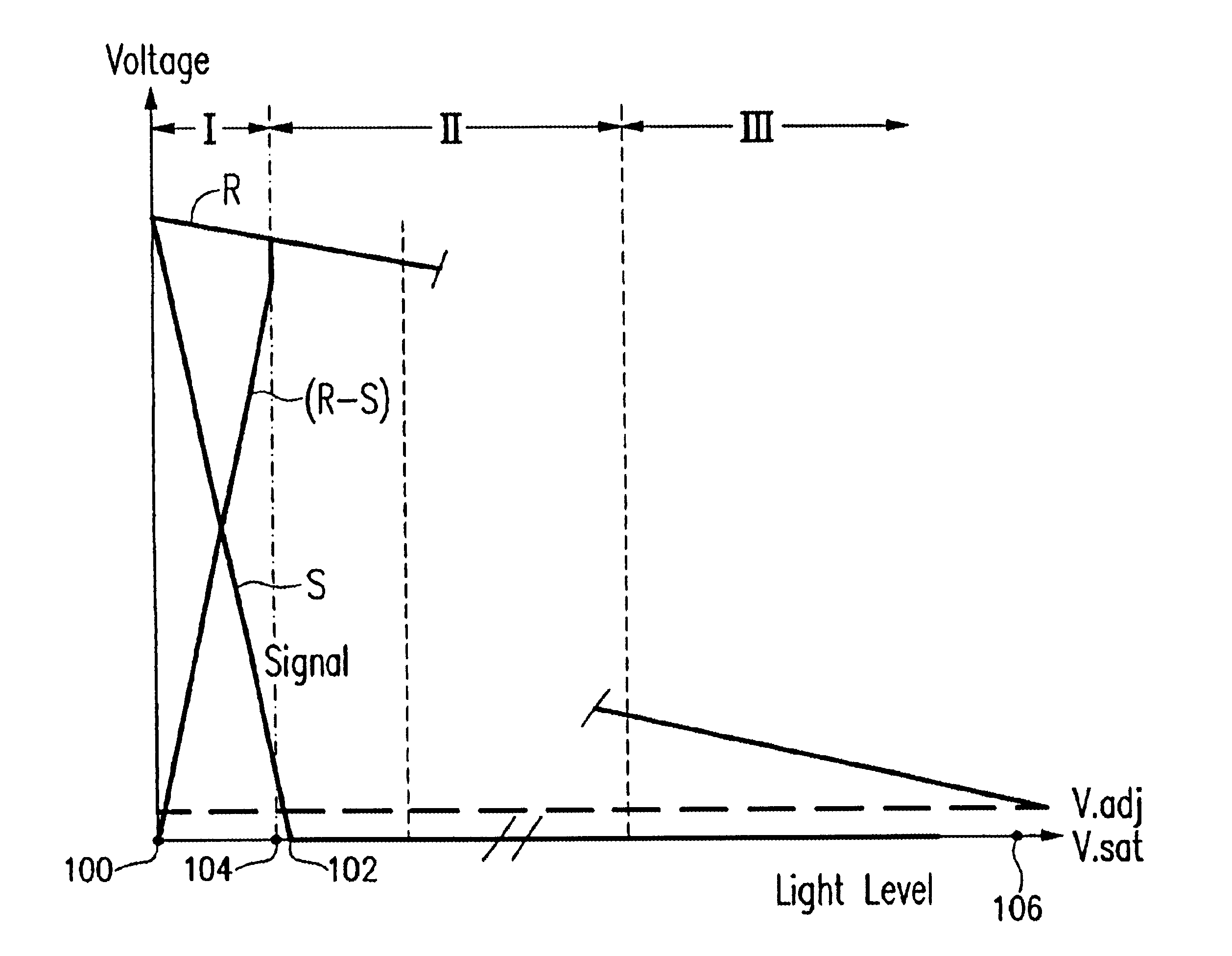

An active pixel sensor (APS) that includes circuitry to eliminate artifacts in digital images. The APS includes a comparator for comparing a signal level from a pixel to an adjusted saturation voltage to determine if the pixel is saturated. If the pixel is saturated, an associated saturation flag is stored and used to replace the signal from the pixel with a maximum value corresponding to a brightest pixel in the image.

Owner:APTINA IMAGING CORP

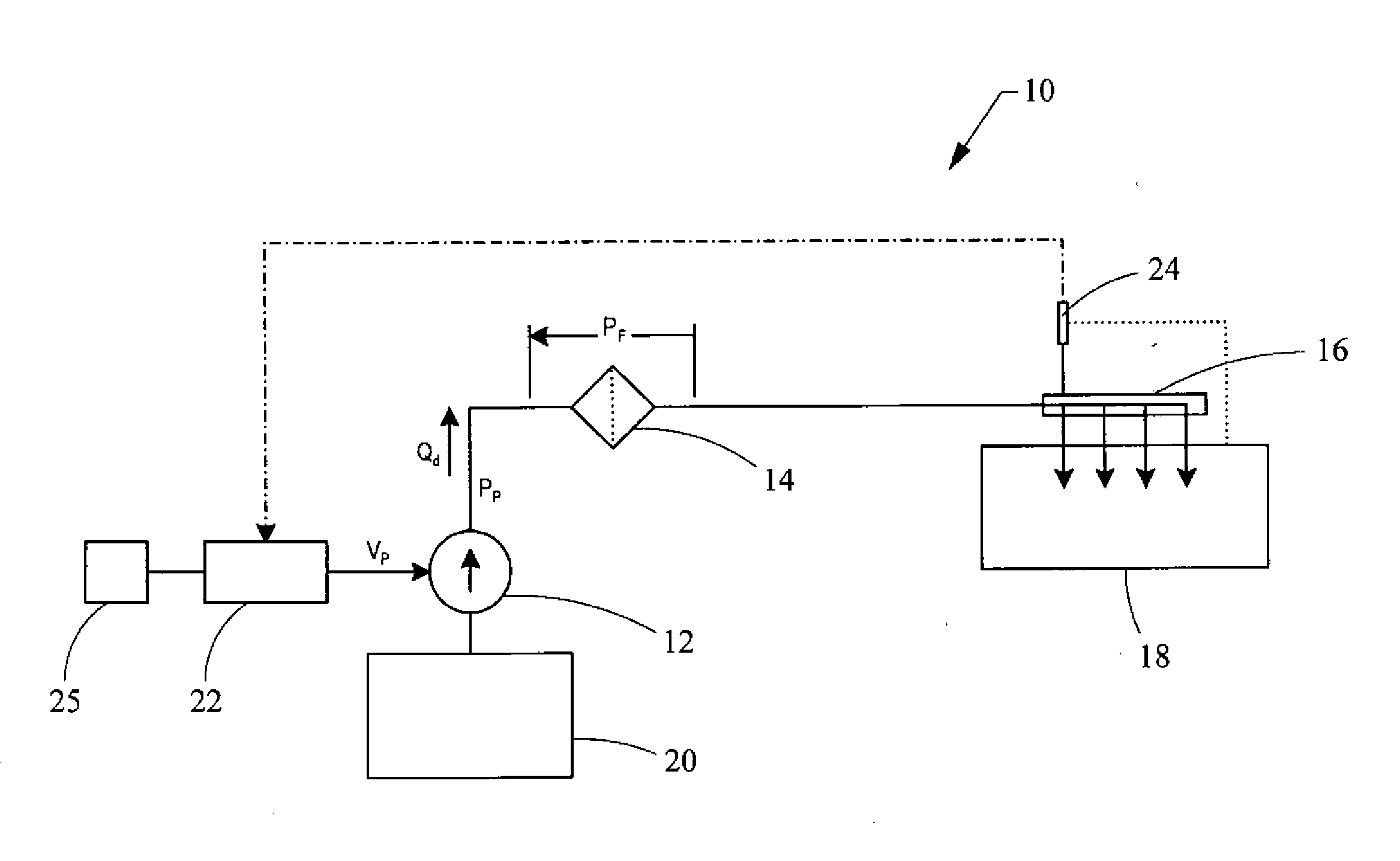

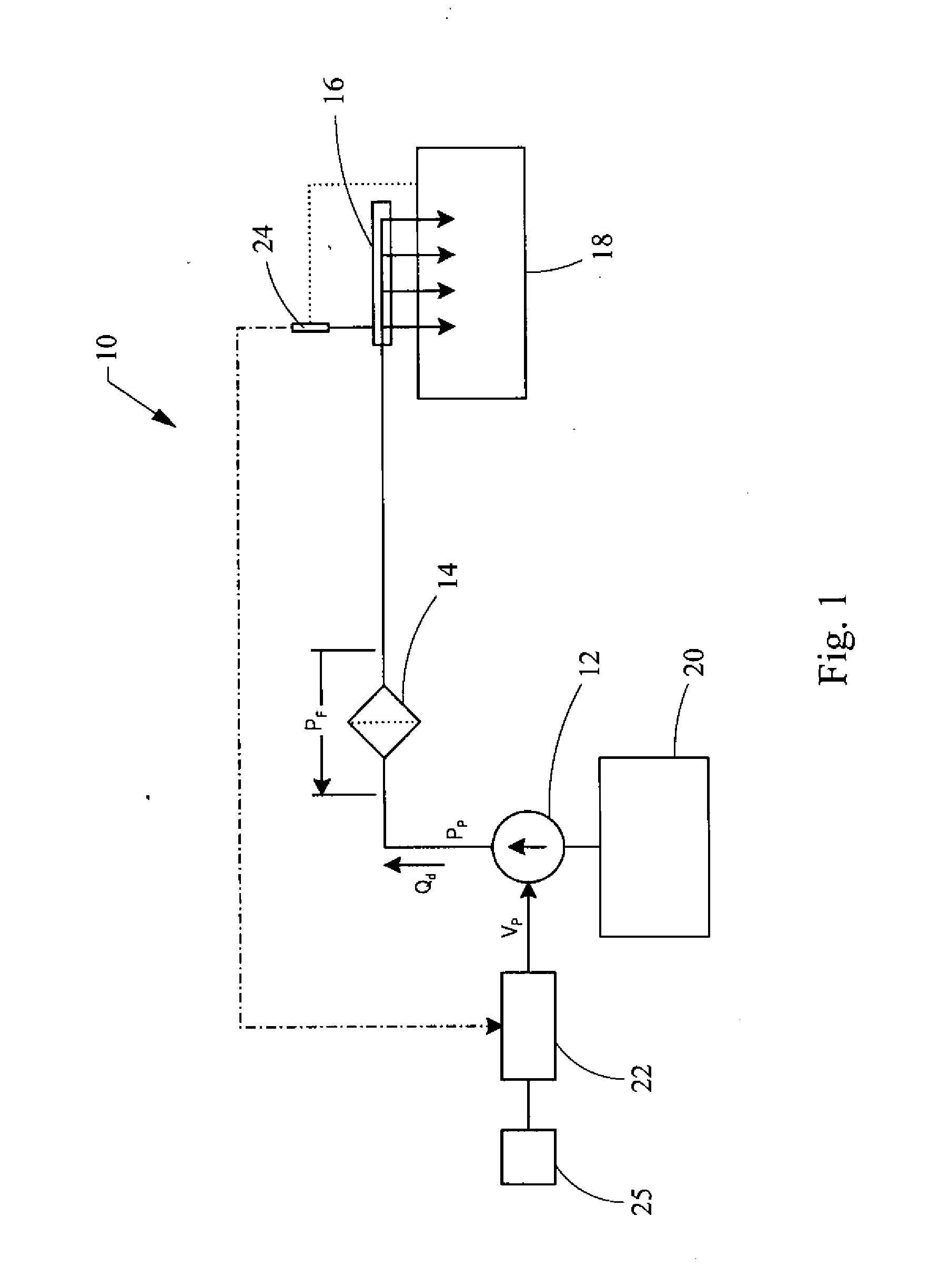

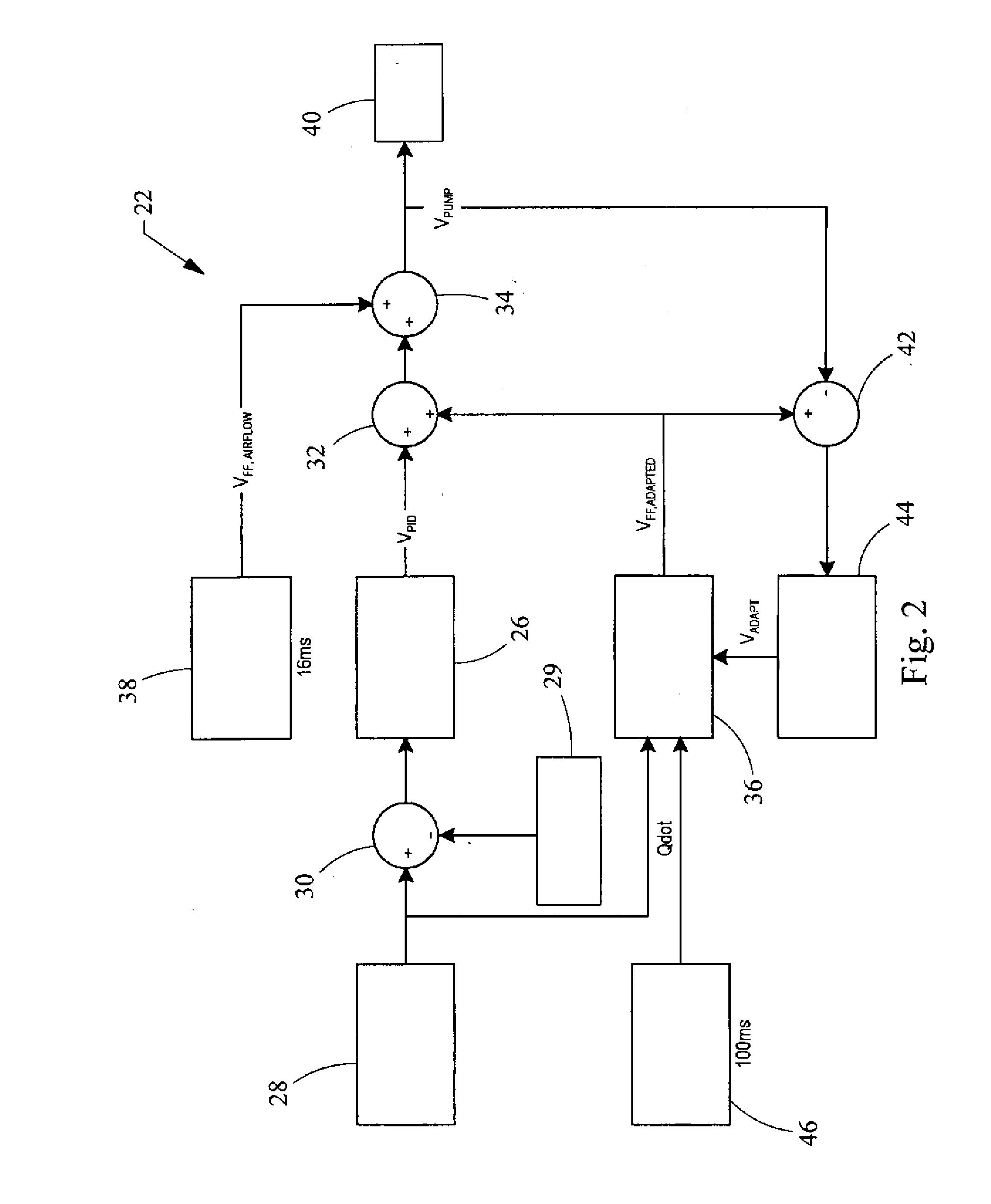

Detection of fuel system problems

A method for detecting failures in a fuel system of a motor vehicle including monitoring a feed-forward table of a fuel pump controller that is electrically connected to a fuel pump of the fuel system. The fuel pump controller is electrically connected to a rail pressure sensor, which is coupled to the fuel injector rail. The actual fuel injector rail pressure measured by the rail pressure sensor is compared to a desired fuel injector rail pressure associated with the feed-forward table. The feed-forward table is adjusted if the actual fuel injector rail pressure is less than the desired fuel injector rail pressure. A fuel system error is signaled if an adjusted feed-forward table differs from an initial feed-forward table. A fuel system failure is signaled of the adjusted feed-forward table requires a saturation voltage of the controller.

Owner:MICHIGAN MOTOR TECH LLC

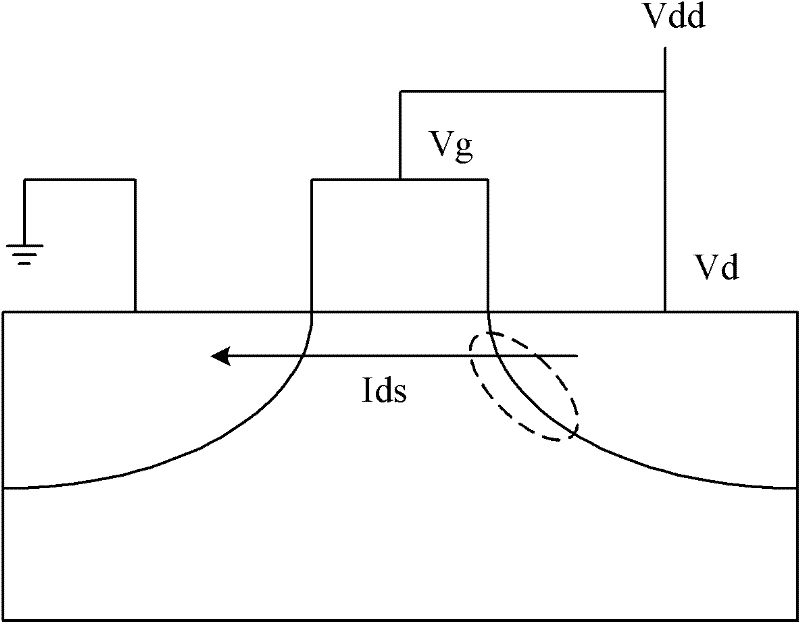

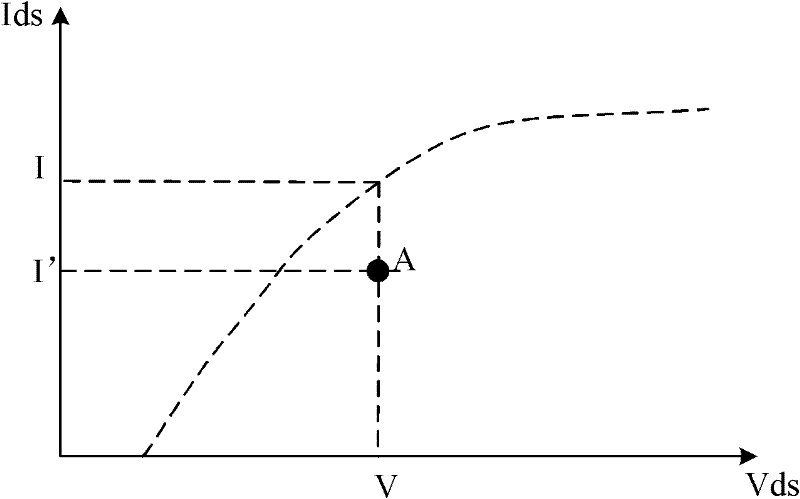

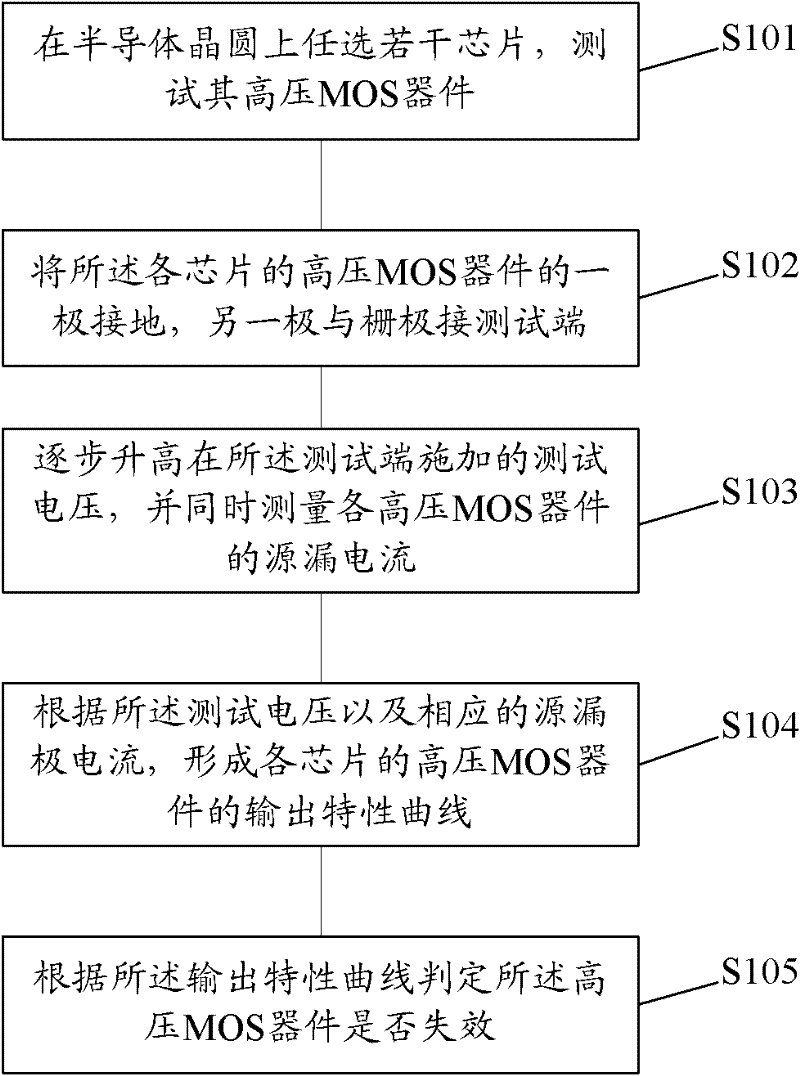

Method for testing high-voltage MOS device

InactiveCN102385029AAvoiding the Problem of MisjudgmentSemiconductor/solid-state device testing/measurementIndividual semiconductor device testingEngineeringDrain current

The utility model provides a method for testing a high-voltage MOS (Metal Oxide Semiconductor) device. The method is used for testing whether the high-voltage MOS device of each chip on a semiconductor wafer becomes invalid, and comprises the following steps of: optionally selecting a plurality of chips on the semiconductor wafer and testing the high-voltage MOS devices thereof; grounding one pole of the high-voltage MOS device of each chip and connecting the other pole and the gate thereof to a test end; gradually increasing a test voltage applied to the test end, and simultaneously measuring the corresponding source-drain current of each high-voltage MOS device, wherein the initial value of the test voltage is lower than the saturation voltage of the high-voltage MOS device; forming the output characteristic curve of the high-voltage MOS device of each chip according to the test voltage and the corresponding source-drain current; and determining whether the high-voltage MOS device becomes invalid according to the output characteristic curve. Compared with the prior art, the method is to test the source-drain currents by gradually increasing and adjusting the test voltage, so that the problem of wrong determination due to low source-drain currents caused by the parasitic effect can be avoided.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

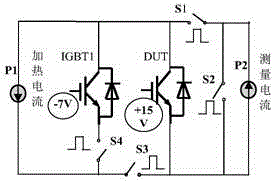

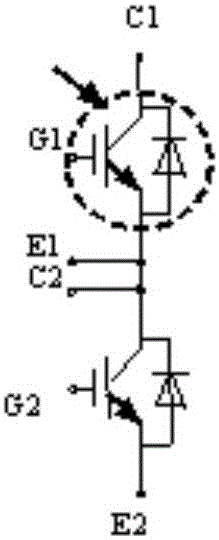

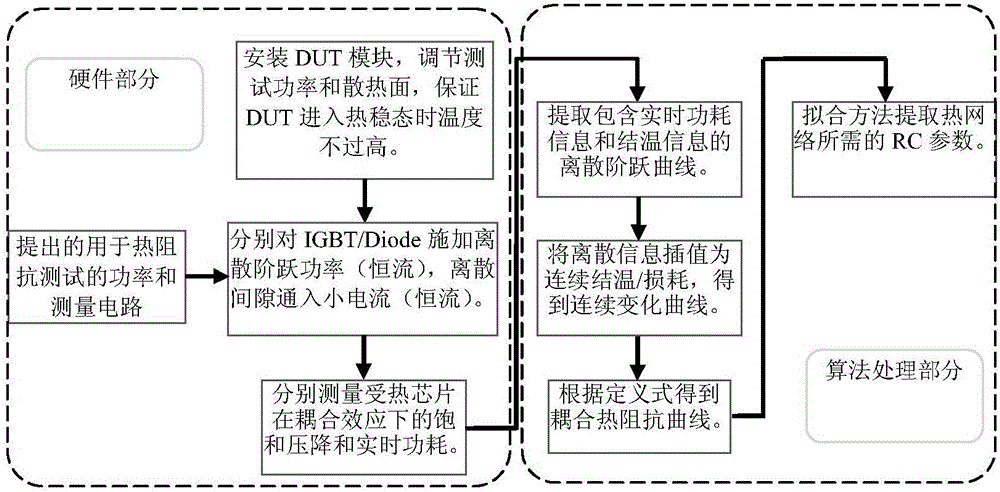

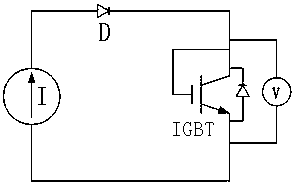

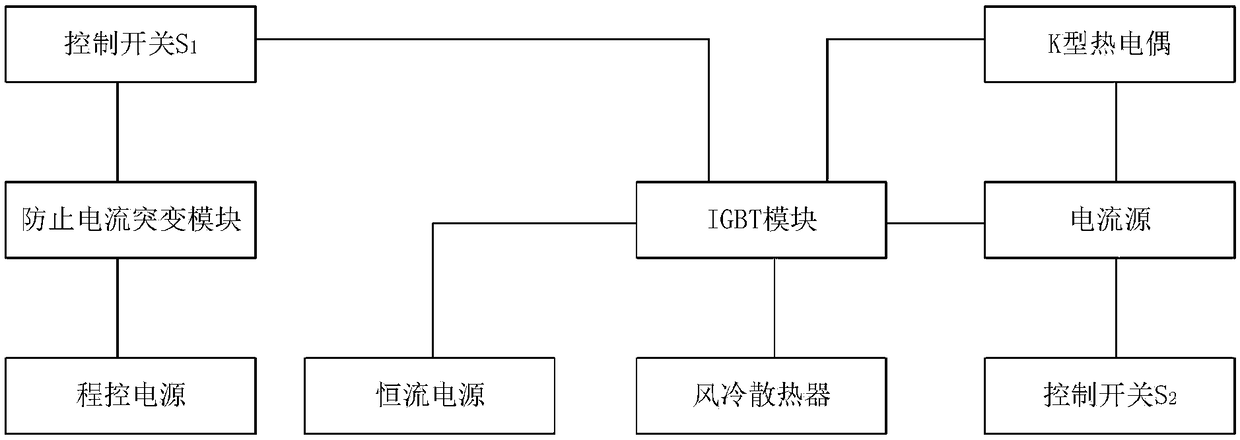

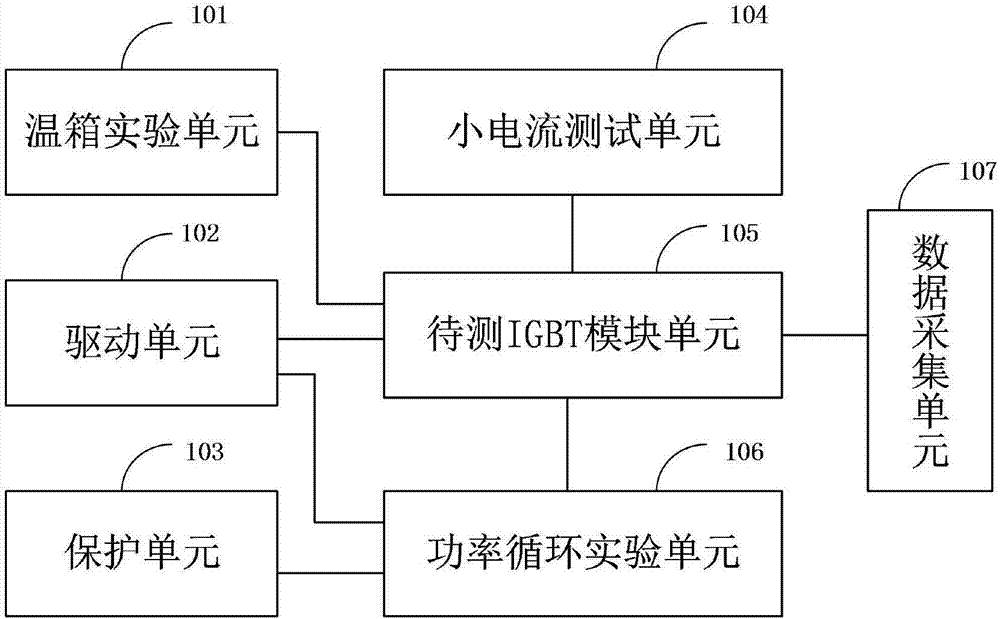

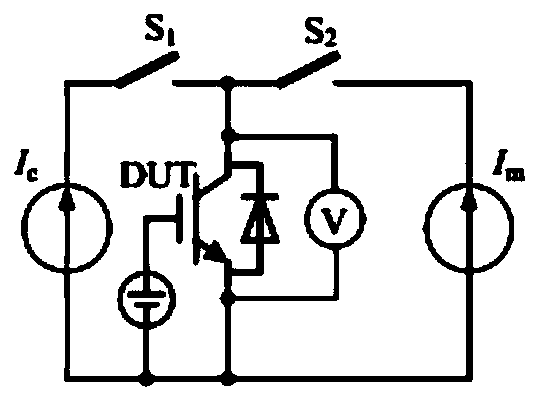

Discretized square wave extraction method and apparatus for IGBT coupling thermal impedance

ActiveCN105699775ARealize measurementAccurate measurementResistance/reactance/impedenceSquare waveformJunction temperature

The invention provides a discretized square wave extraction method for an IGBT coupling thermal impedance. The method comprises: an IGBT is heated a conductive voltage drop of an FWD under a small current density is measured; the FWD is heated and a saturation voltage drop of the IGBT under the small current density is measured; according to the conductive voltage drop of the FWD and the saturation voltage drop of the IGBT under the small current density, junction temperature changing curves of the IGBT and the FWD are obtained indirectly and calculation is carried out to obtain a continuously-changing coupling thermal impedance curve; and fitting is carried out on the coupling thermal impedance curve to obtain coupling thermal impedance information of the IGBT and the FWD is obtained. According to the invention, with a simple method, the coupling thermal impedance of the IGBT module is extracted by measuring an end electrical feature quantity and then a perfect IGBT integrated thermal network model is established. The IGBT module is viewed as a black box and the internal packaging structure is ignored; under the circumstance that module packaging is not damaged, measurement of the coupling thermal impedance is realized based on discretized square wave measurement according to a principle of measuring thermal impedance by using an existing thermal sensitive parameter method. Moreover, the method has advantages of simpleness, effectiveness, fast response, and accurate measurement.

Owner:CHONGQING UNIV

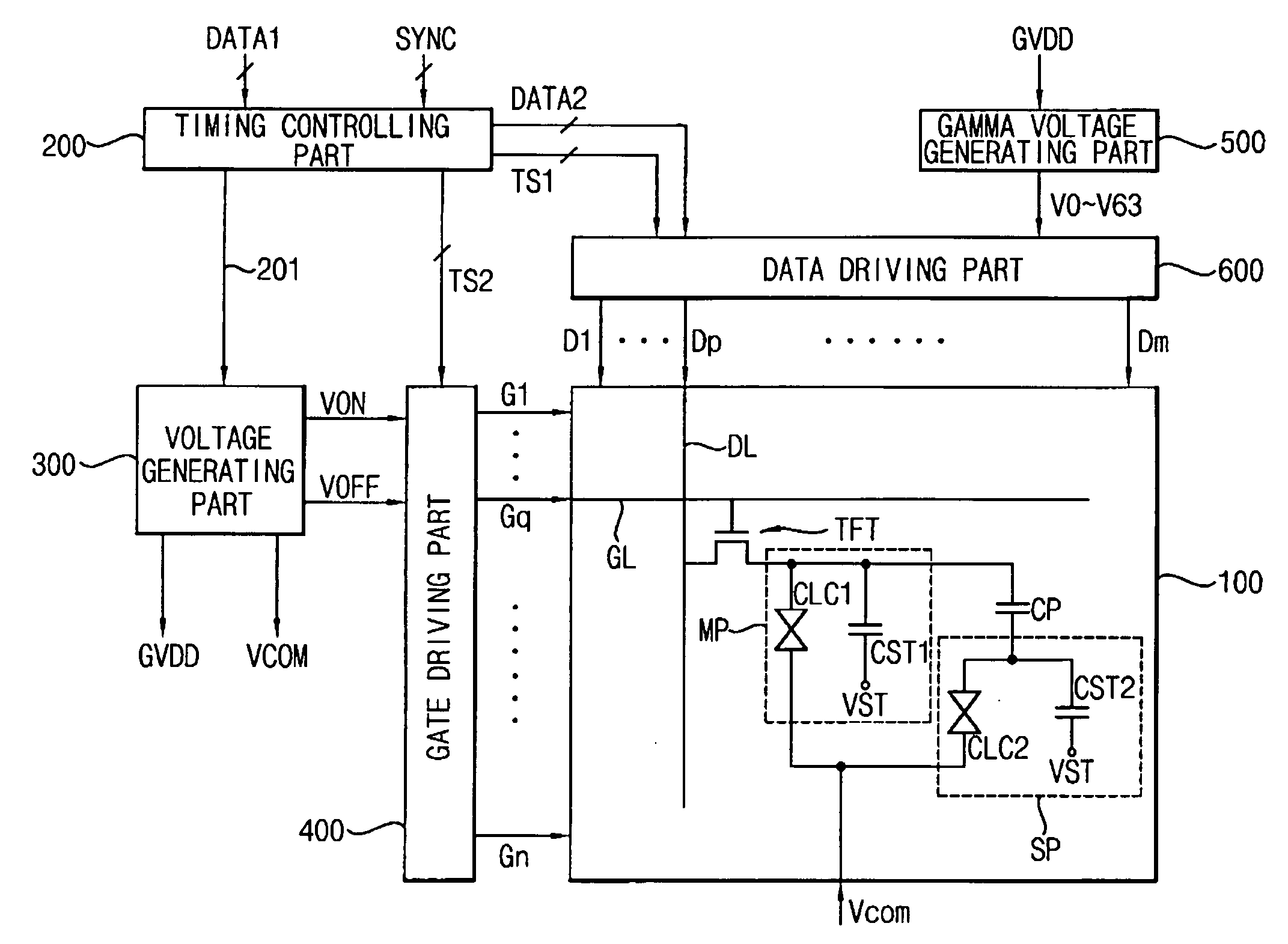

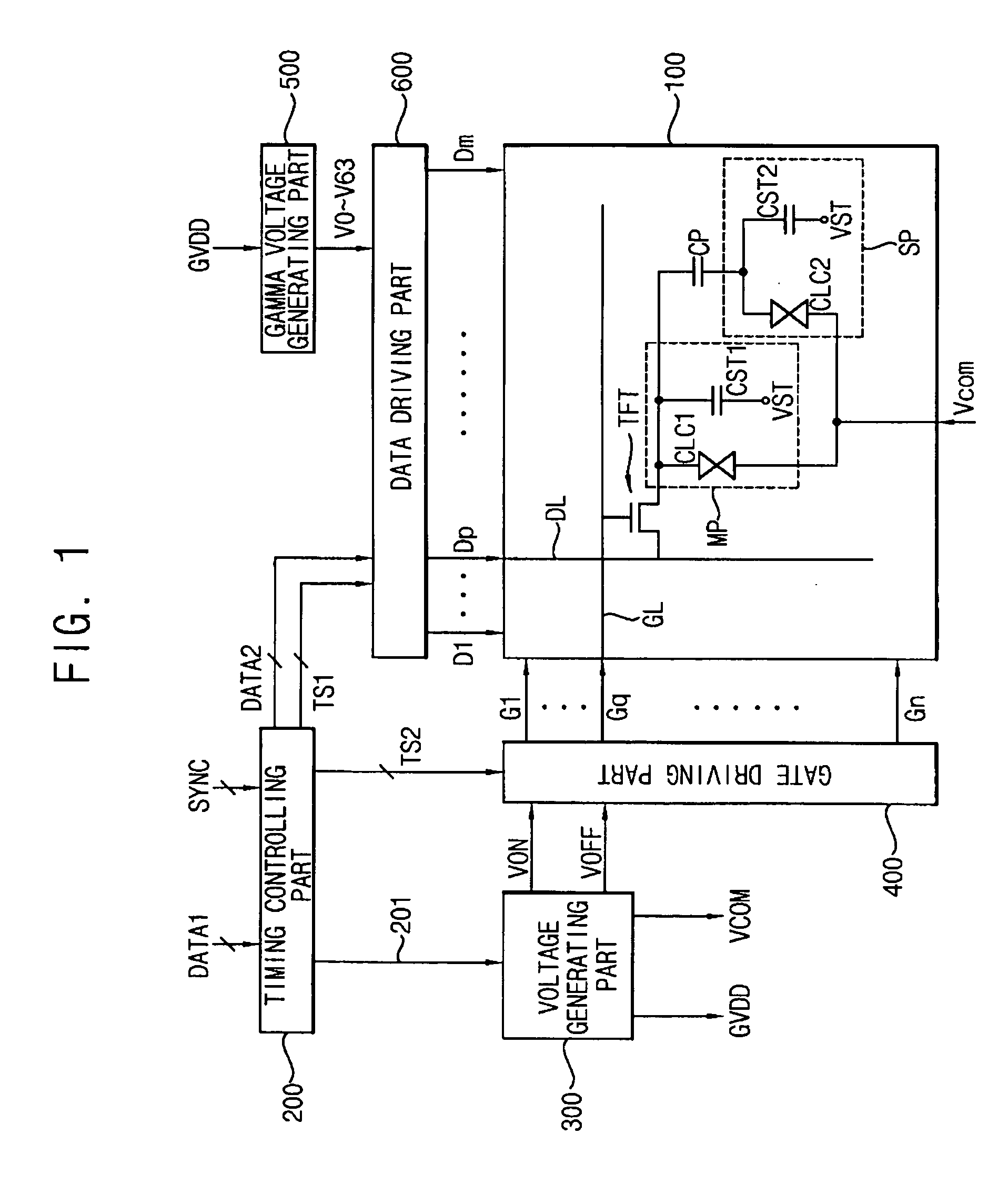

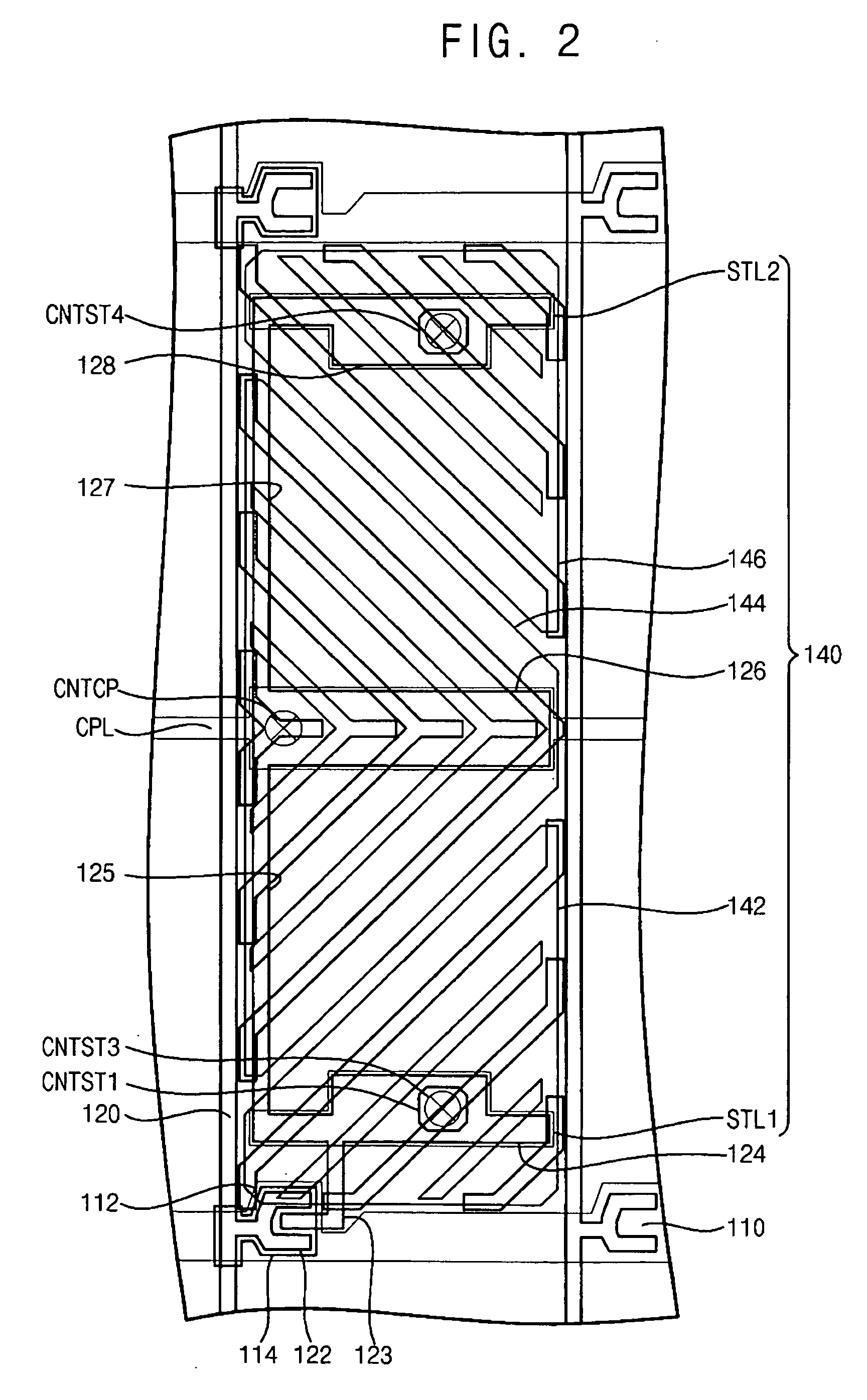

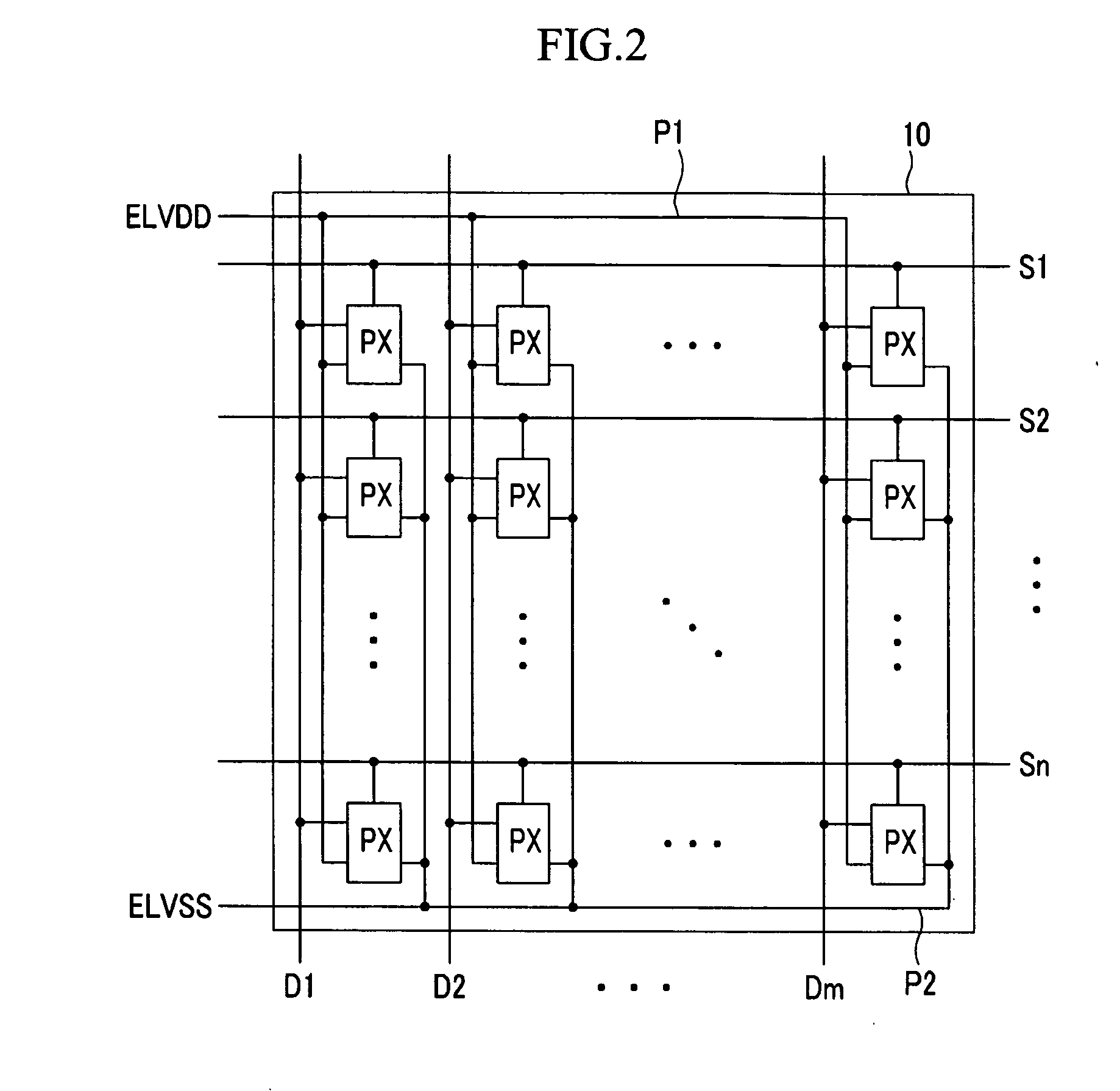

Display device and apparatus for driving the same

InactiveUS20060164354A1Improve viewing angleImprove luminanceStatic indicating devicesSynthetic resin layered productsCapacitanceElectricity

A display device includes a display panel and a voltage generating part. The display panel includes a switching element, a main pixel section, a coupling capacitor and a sub pixel section. The main pixel section is electrically connected to the switching element. The coupling capacitor has a first end electrically connected to the switching element. The sub pixel section is electrically connected to a second end of the coupling capacitor. The voltage generating part controls data voltages corresponding to a gray-scale in a range from a low gray-scale to a high gray-scale that corresponds to a saturation voltage of the sub pixel section for displaying an image. The data voltages are applied to the display panel. Therefore, the viewing angle and the luminance are improved.

Owner:SAMSUNG ELECTRONICS CO LTD

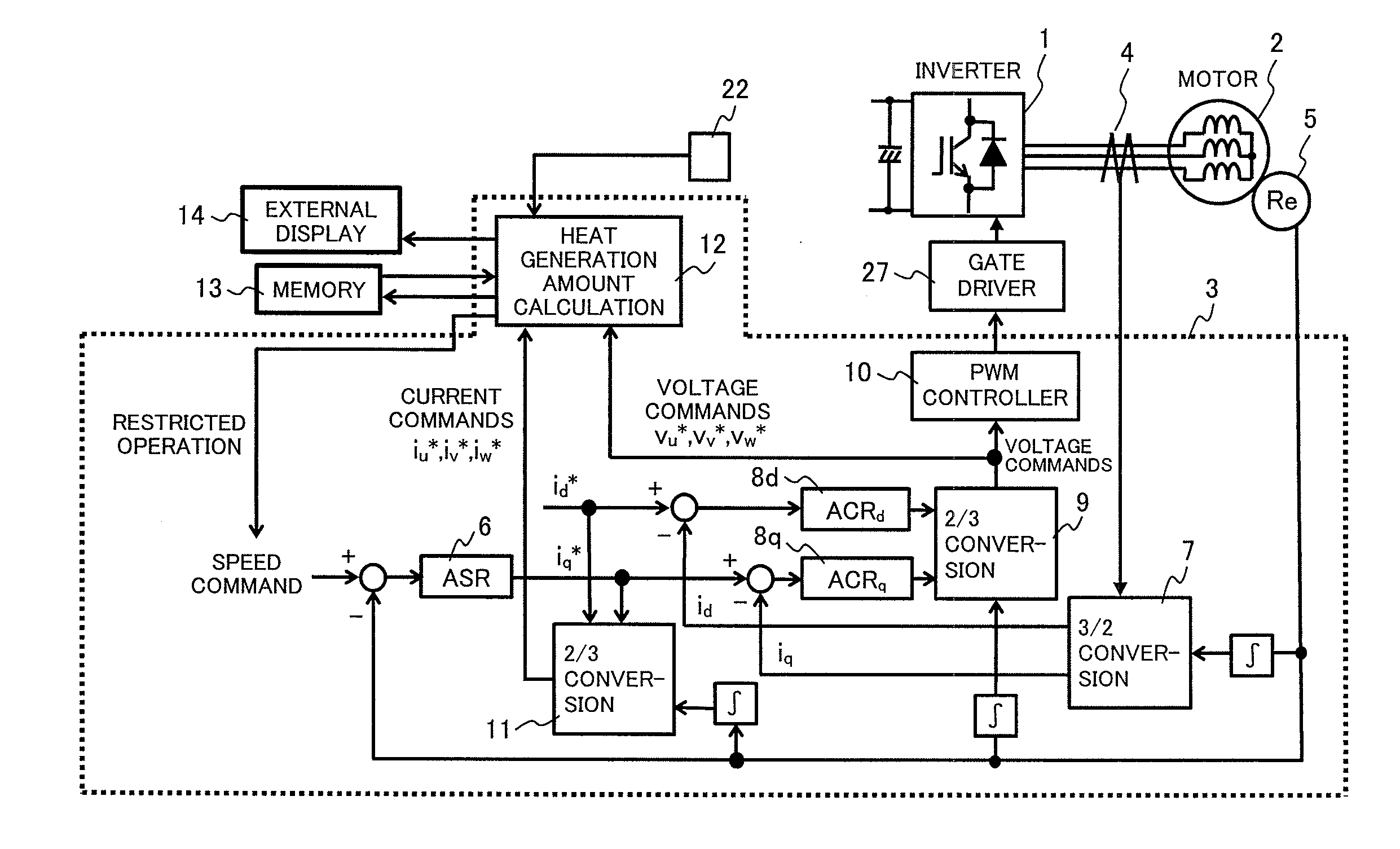

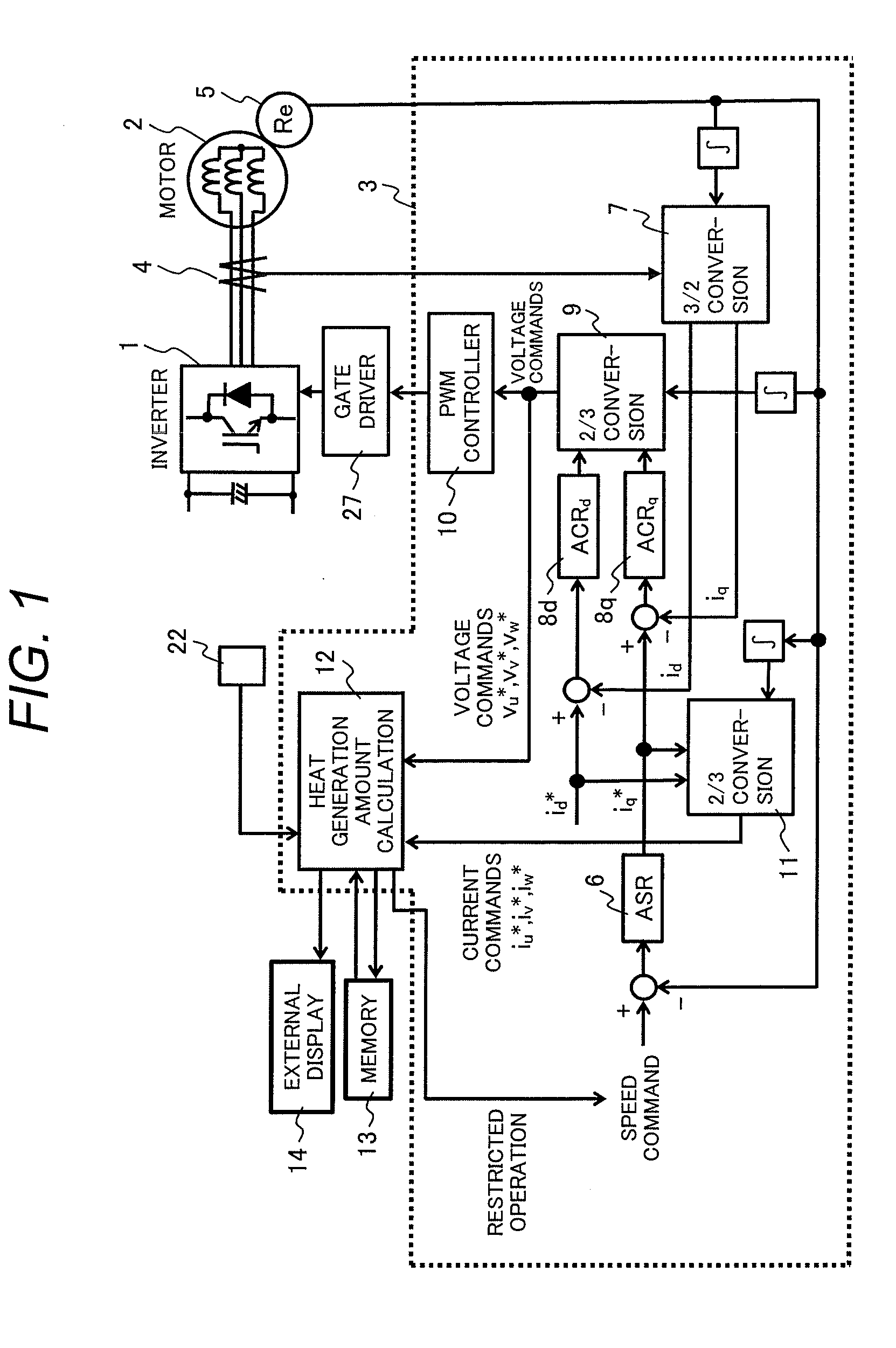

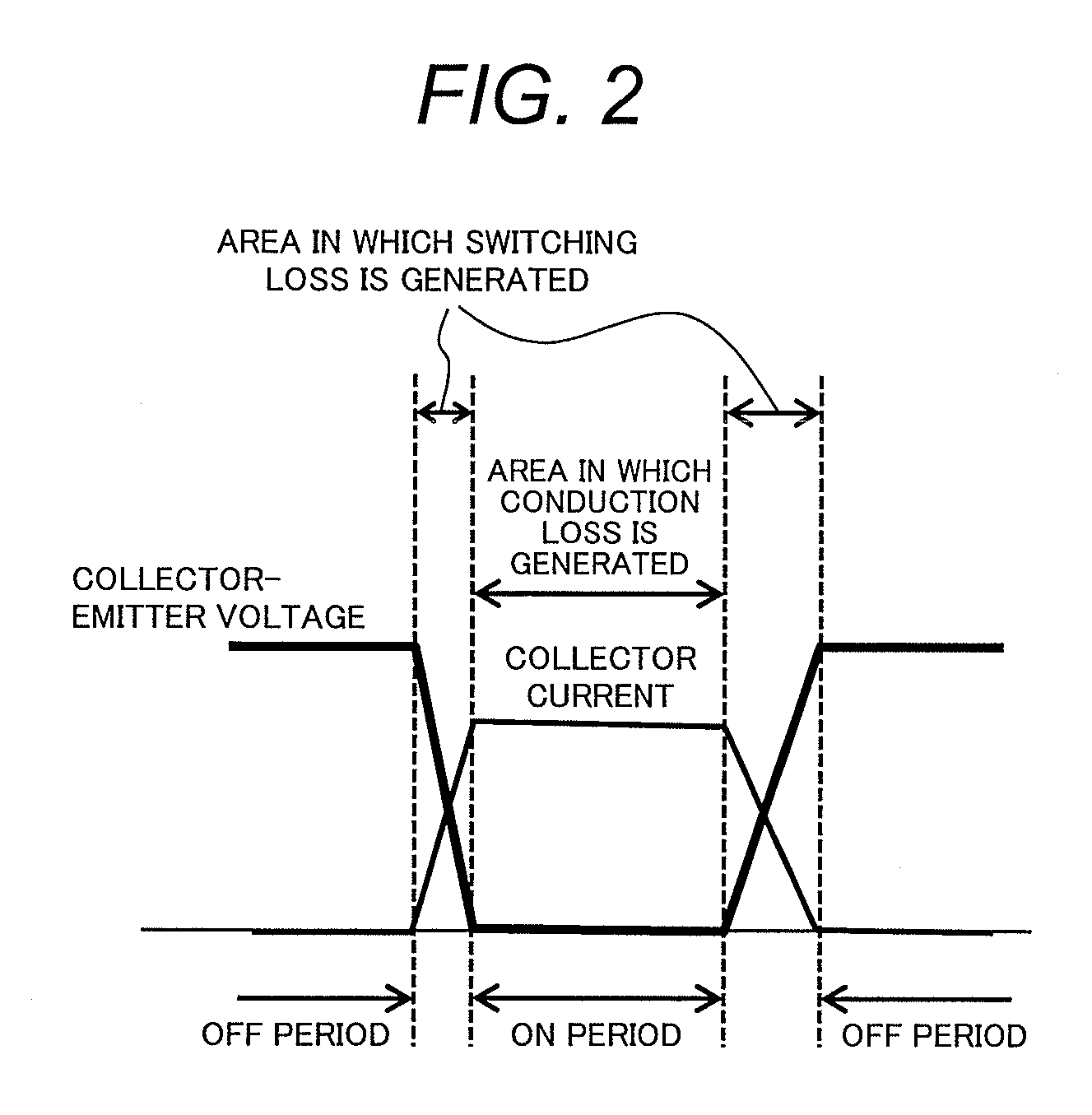

Power Conversion Device and Temperature Rise Calculation Method Thereof

InactiveUS20130119912A1Simple calculationSimple methodDC motor speed/torque controlVector control systemsEngineeringConduction loss

A temperature rise of a semiconductor switching element, which is part of a power conversion device such as an inverter, is estimated by an extremely simple method to assess the degradation and remaining lifetime of the semiconductor switching element.In a heat generation amount calculation unit 12 in a calculation processor 3, current command values Id* and Iq* and voltage command values vu*, vv* and vw* are used to calculate a chip loss. First, current values iu*, iv* and iw* of all output phases are estimated from the current command values. The ON / OFF loss of the chip is represented by a function of an estimated value for a current flowing in each output phase, and the loss can be derived by integration with a PWM carrier frequency f. In addition, with respect to a conduction loss, it is necessary to integrate a conduction time with the estimated current value and a saturation voltage, which is a function of the estimated current value. In this case, the conduction time is calculated from a relationship between a carrier amplitude and the voltage command value in each control cycle fsw of the switching element. In addition, an ambient temperature sensor is added to calculate an absolute temperature.

Owner:HITACHI LTD

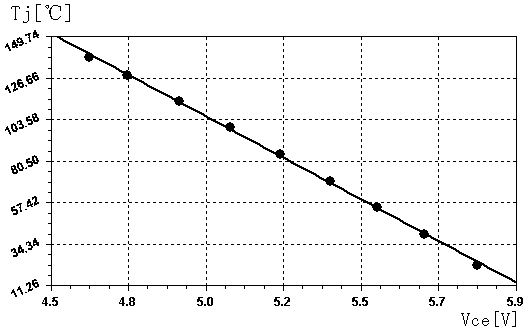

A method for estimating the junction temperature of a power element IGBT in a motor controller

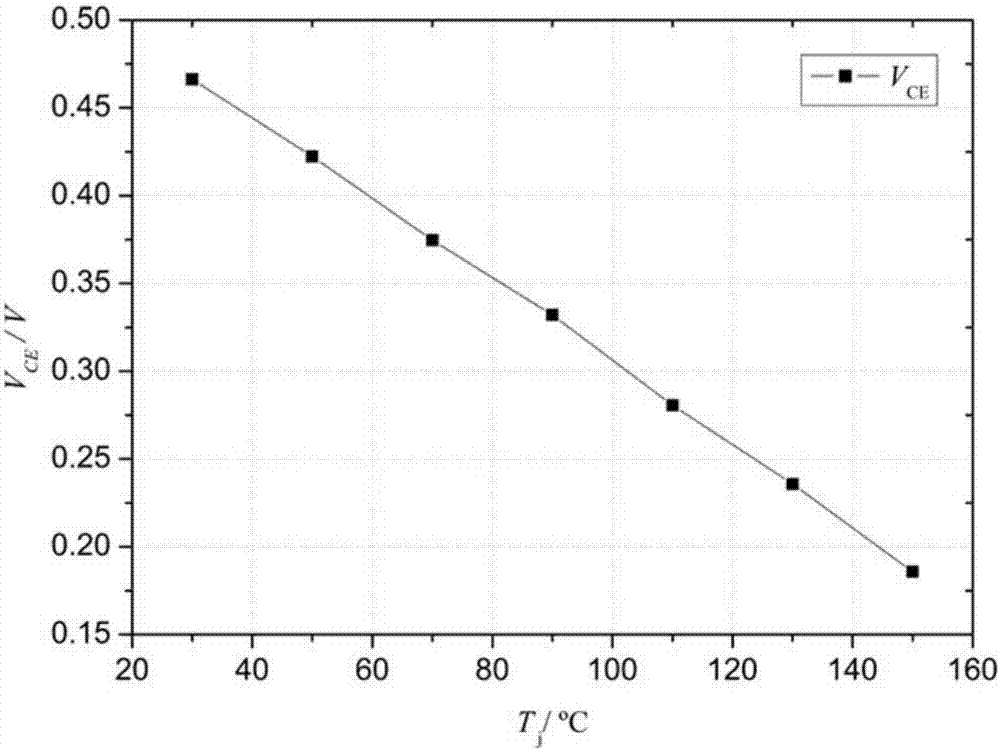

ActiveCN109597966AImprove the maximum output capacityImprove securityMaterial heat developmentThermometers using electric/magnetic elementsMathematical modelJunction temperature

The invention discloses a method for estimating the junction temperature of a power element IGBT in a motor controller. The method comprises the following steps: within a certain temperature range, the saturation voltage drop and the junction temperature of the IGBT have a relationship which can be approximately considered to be linear; the junction temperature is indirectly obtained by utilizingthe relationship between the saturated pressure drop and the temperature; Therefore, a transient thermal impedance curve from the IGBT substrate to the IGBT chip is obtained according to the corresponding relation between the junction temperature and the temperature measured by the thermistor, then an IGBT transient thermal impedance mathematical model is obtained through curve fitting, and the transient junction temperature of the IGBT is calculated through the model. According to the method, the defect of traditional IGBT junction temperature estimation is overcome, the transient thermal resistance model of the IGBT is established according to actual test data, the precision of model parameters is improved, the junction temperature estimation is simple, the implementation is convenient,the calculated amount is small, the component cost is reduced, the estimation error is small, and the maximum output capability and safety of the motor controller are improved.

Owner:SHANGHAI DAJUN TECH

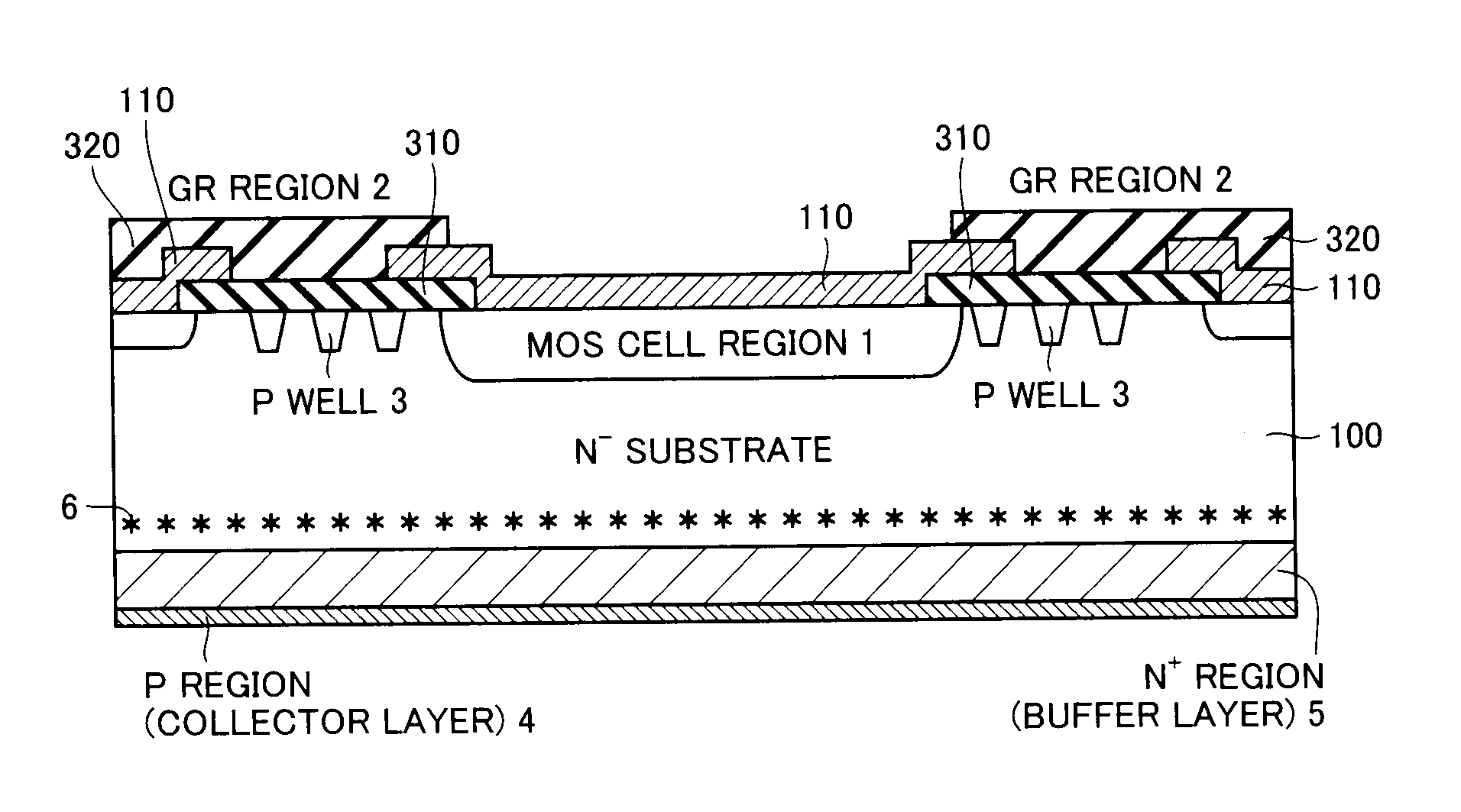

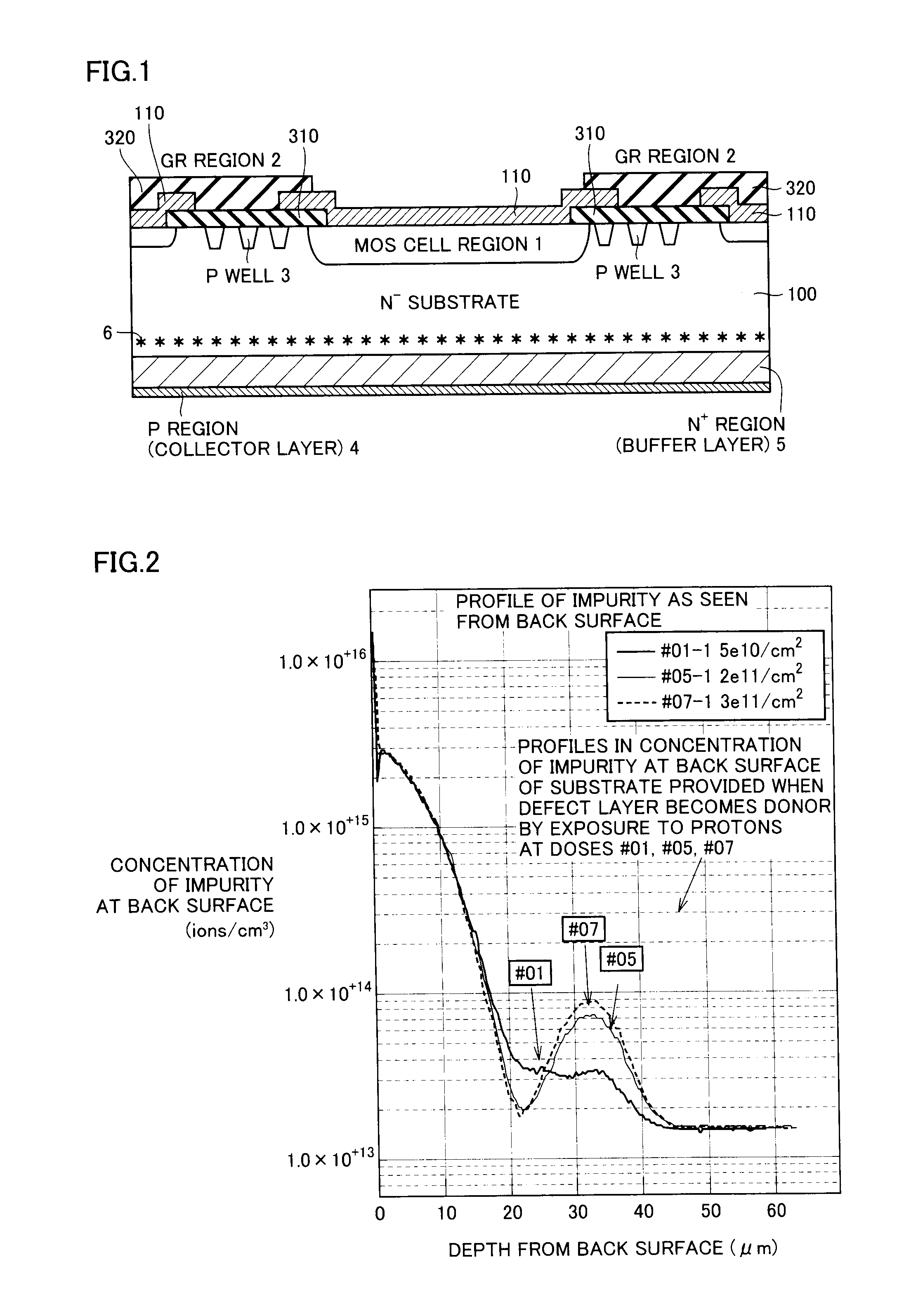

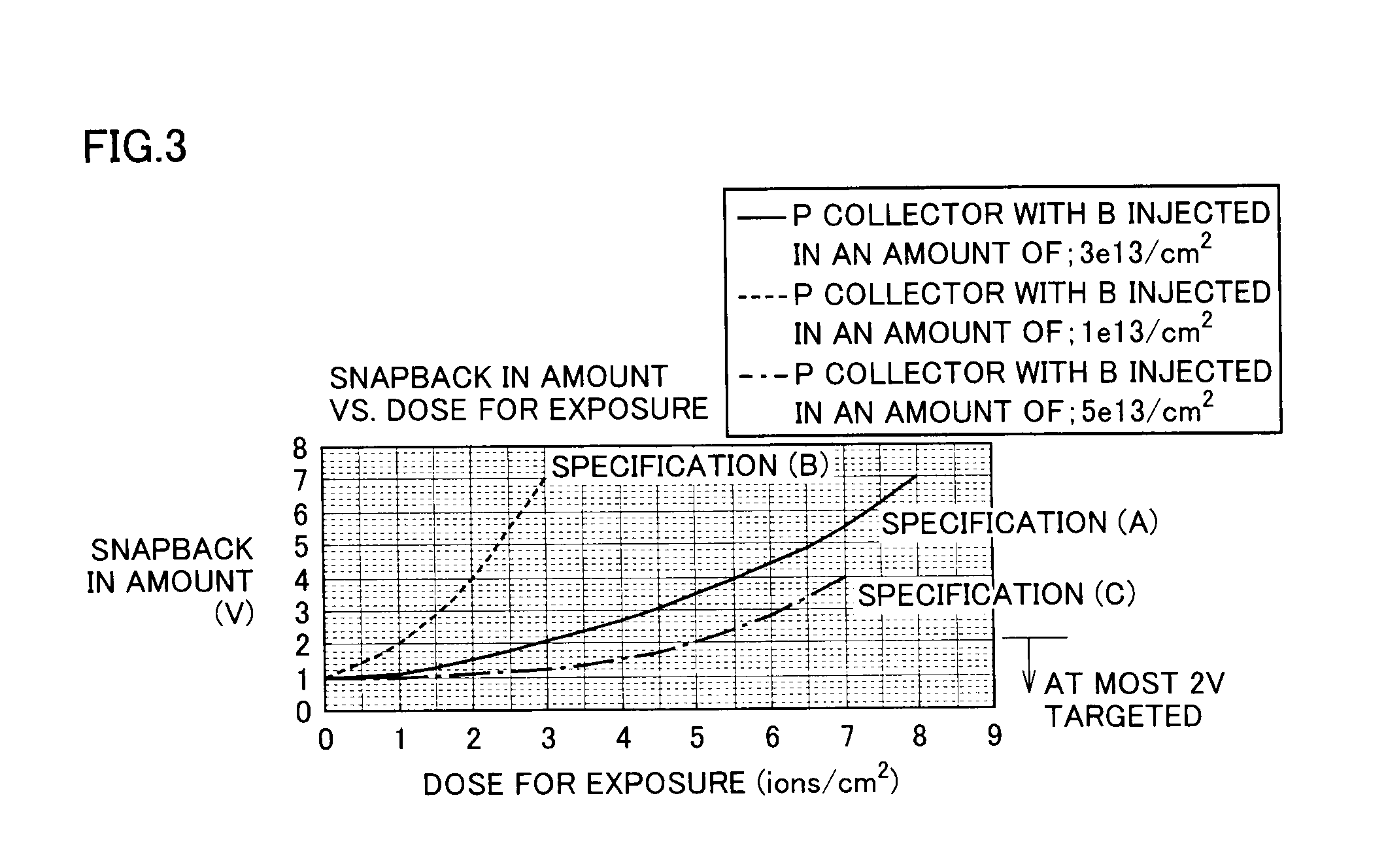

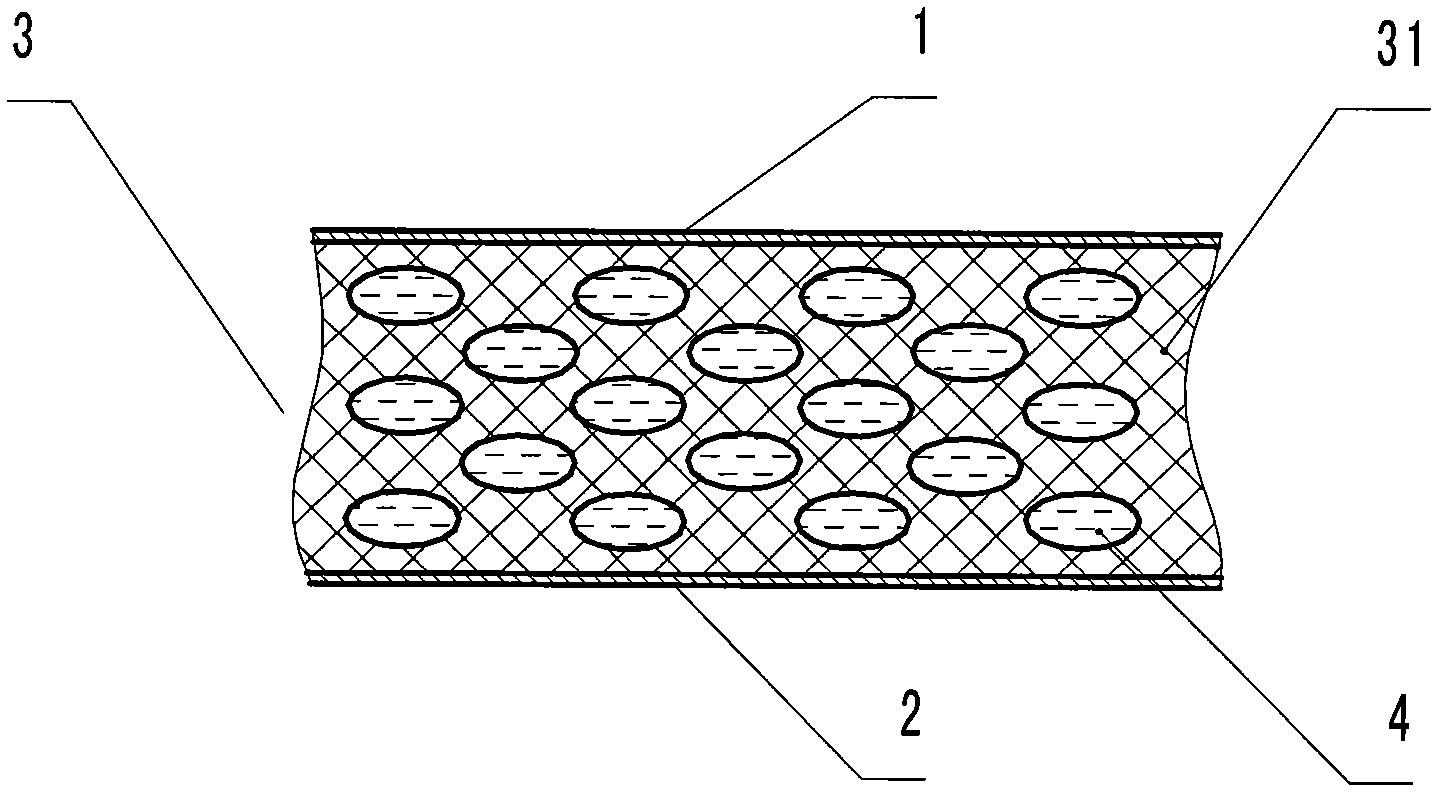

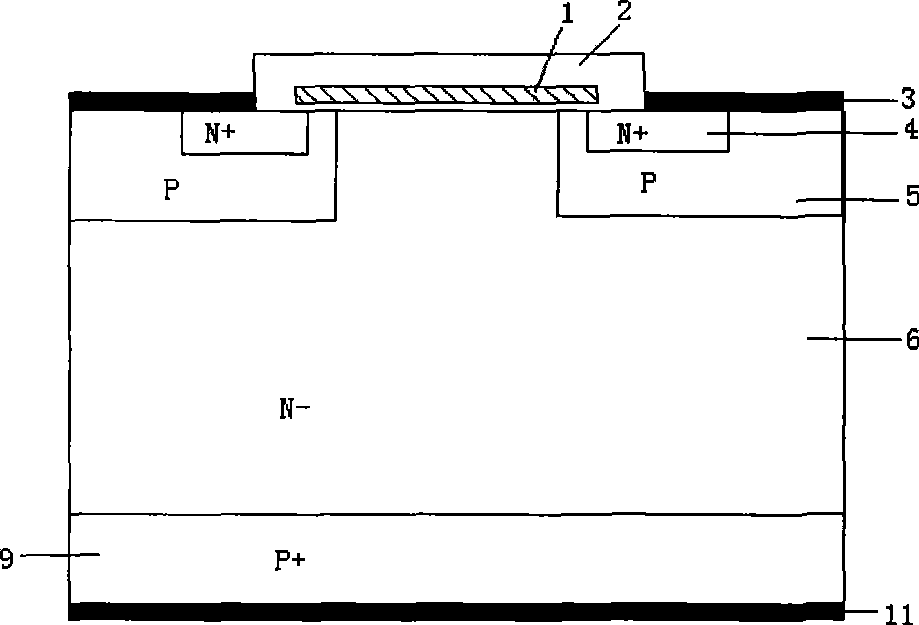

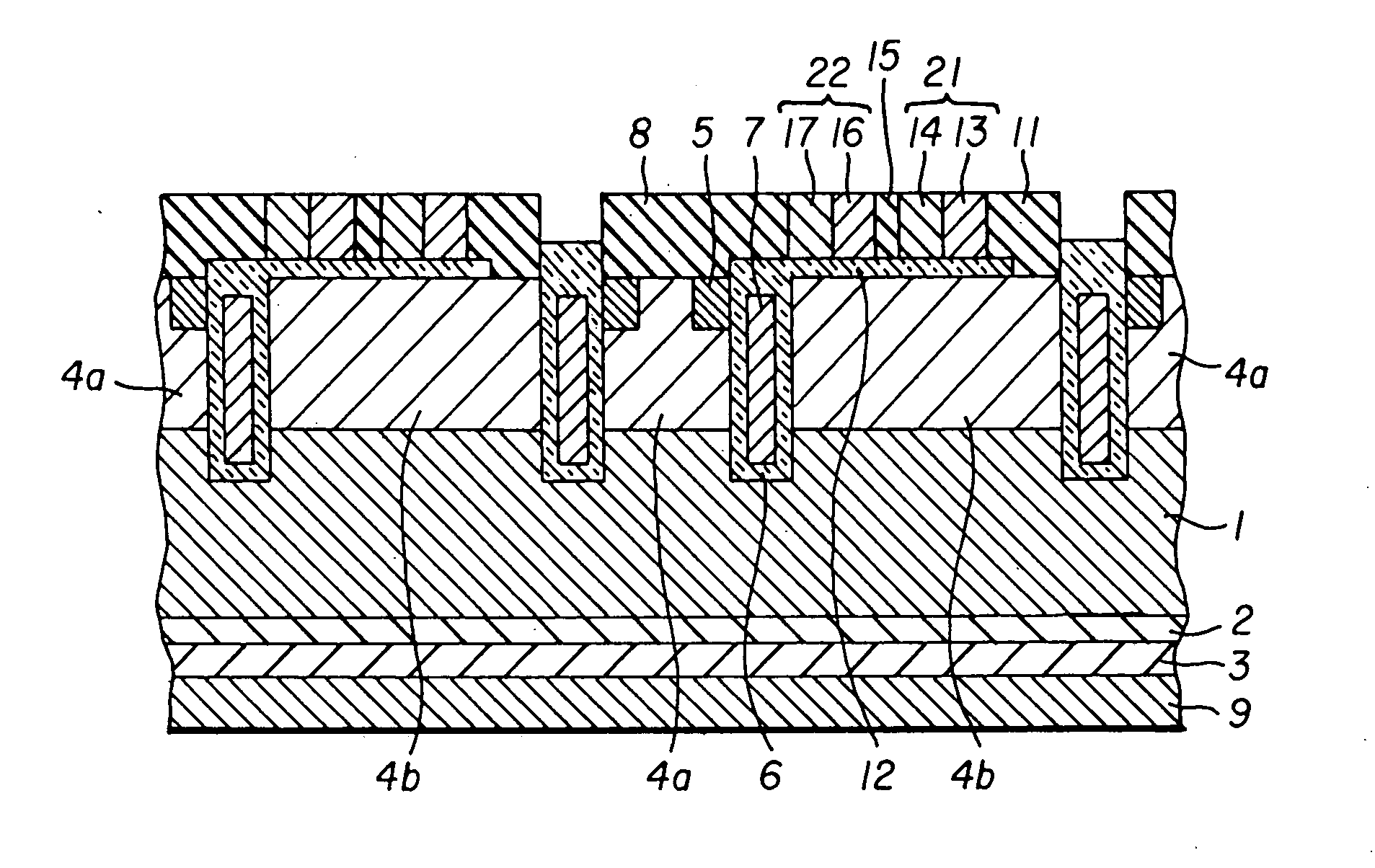

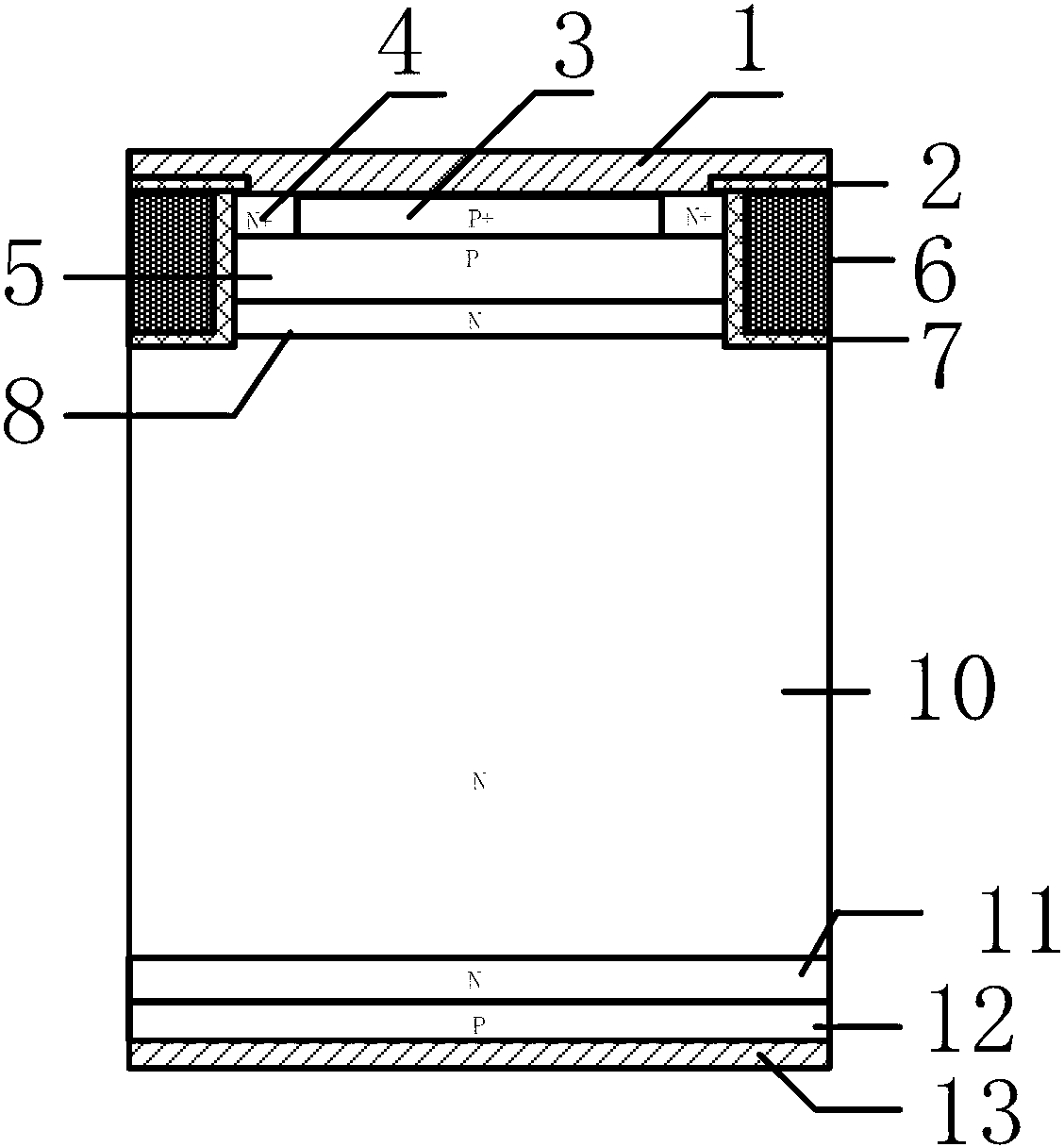

Semiconductor device

A semiconductor device having the present high withstand voltage power device IGBT has at a back surface a p collector layer with boron injected in an amount of approximately 3×1013 / cm2 with an energy of approximately 50 KeV to a depth of approximately 0.5 μm, and an n+ buffer layer with phosphorus injected in an amount of approximately 3×1012 / cm2 with an energy of 120 KeV to a depth of approximately 20 μm. To control lifetime, a semiconductor substrate is exposed to protons at the back surface. Optimally, it is exposed to protons at a dose of approximately 1×1011 / cm2 to a depth of approximately 32 μm as measured from the back surface. Thus snapback phenomenon can be eliminated and an improved low saturation voltage (Vce (sat))-offset voltage (Eoff) tradeoff can be achieved.

Owner:MITSUBISHI ELECTRIC CORP

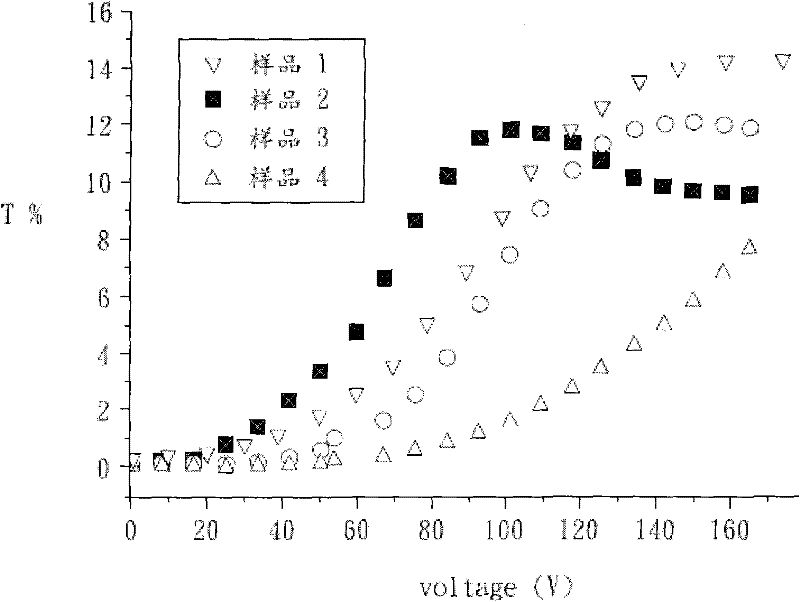

Plastic liquid crystal film and making method thereof

InactiveCN102385188AHigh scatterTo achieve grayscale adjustmentLiquid crystal compositionsNon-linear opticsMicrosphereGray level

The invention relates to a plastic liquid crystal film which comprises a liquid crystal-plastic core layer and two transparent conductive films, wherein the transparent conductive films are parallel and are arranged symmetrically, the liquid crystal-plastic core layer is clamped between the two transparent conductive films and comprises a high molecular polymer substrate, micro balls made of a liquid crystal material are uniformly distributed in the high molecular polymer substrate, the refractive index of the high molecular polymer substrate is matched with the refractive index of ordinary light of the liquid crystal material, liquid crystal molecule directors in the micro balls made of the liquid crystal material are approximately parallel to the two transparent conductive films, and electrodes are arranged on the transparent conductive films. The plastic liquid crystal film has the characteristic of high scattering degree during power off, and the gray level of the plastic liquid crystal film can be adjusted when the voltage of an external electric field is between a threshold voltage and a saturation voltage.

Owner:江苏同辉新材料有限公司

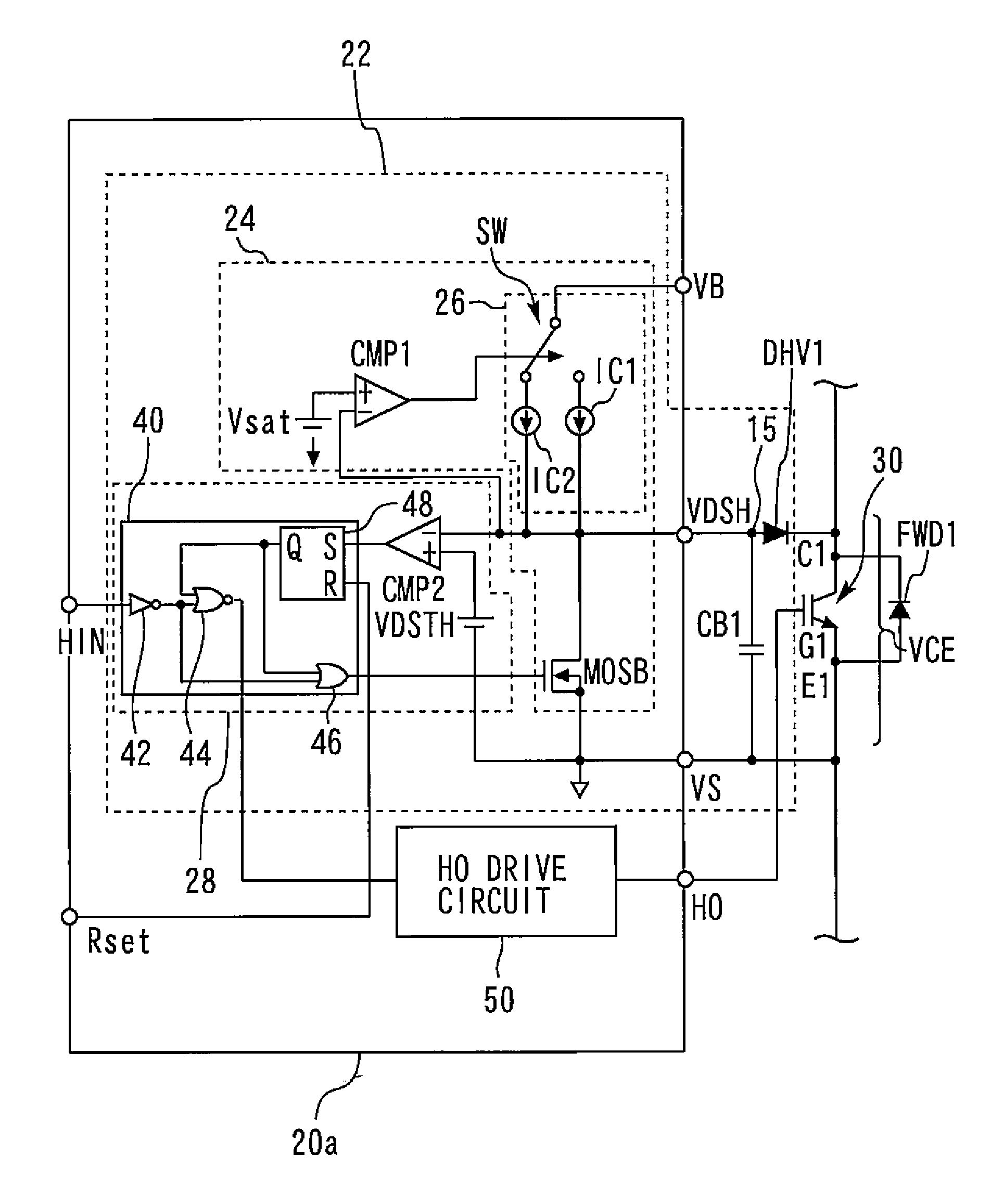

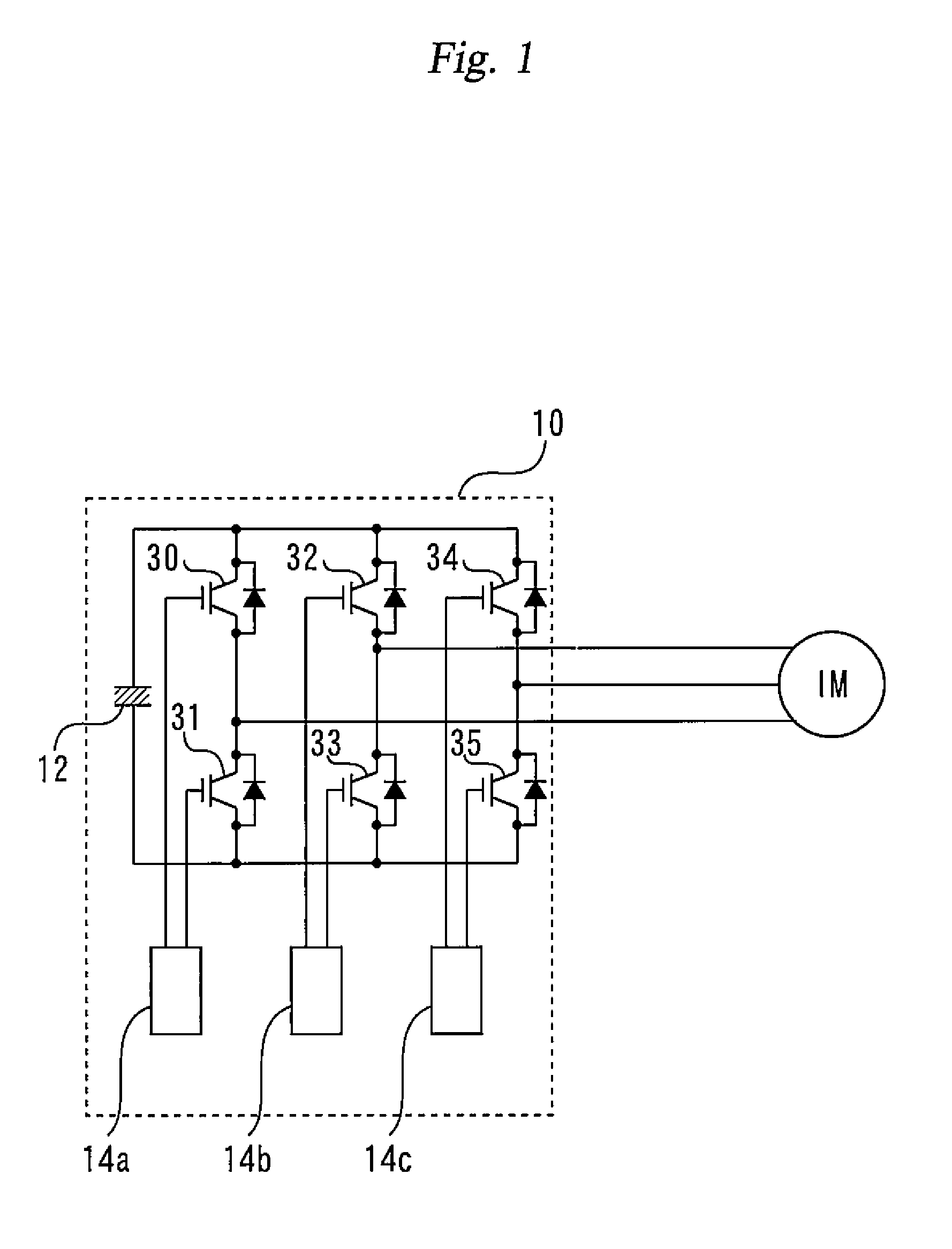

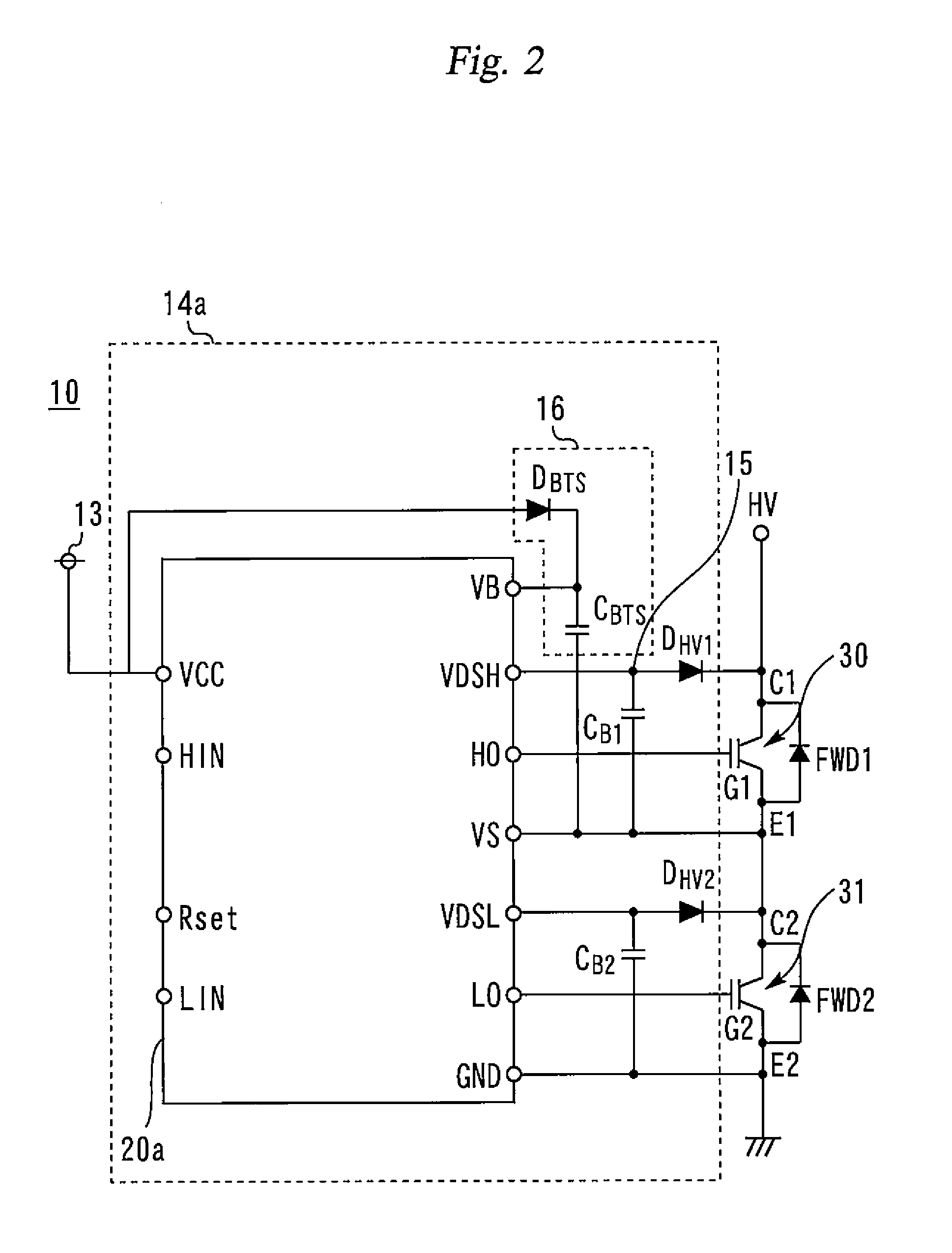

Driving device for semiconductor elements, and semiconductor device

ActiveUS20160028219A1Fast chargingTransistorAmplifier with semiconductor-devices/discharge-tubesCapacitanceDriver circuit

The device for driving the semiconductor element is provided with a drive circuit section, a charging circuit section and a shutting circuit section. The charging circuit section is electrically connected to an external circuit provided with a diode and a capacitive element. The semiconductor element has a first electrode, a second electrode and a control terminal. The cathode of the diode is connected to the first electrode. One of two terminals of the capacitive element is connected to the cathode of the diode, and the other terminal is connected to the second electrode. The charging circuit section enables the capacitive element to be charged at a higher rate after a timed point at which the voltage on the capacitive element becomes equal to a saturation voltage in a case where the input signal is an on-signal.

Owner:MITSUBISHI ELECTRIC CORP

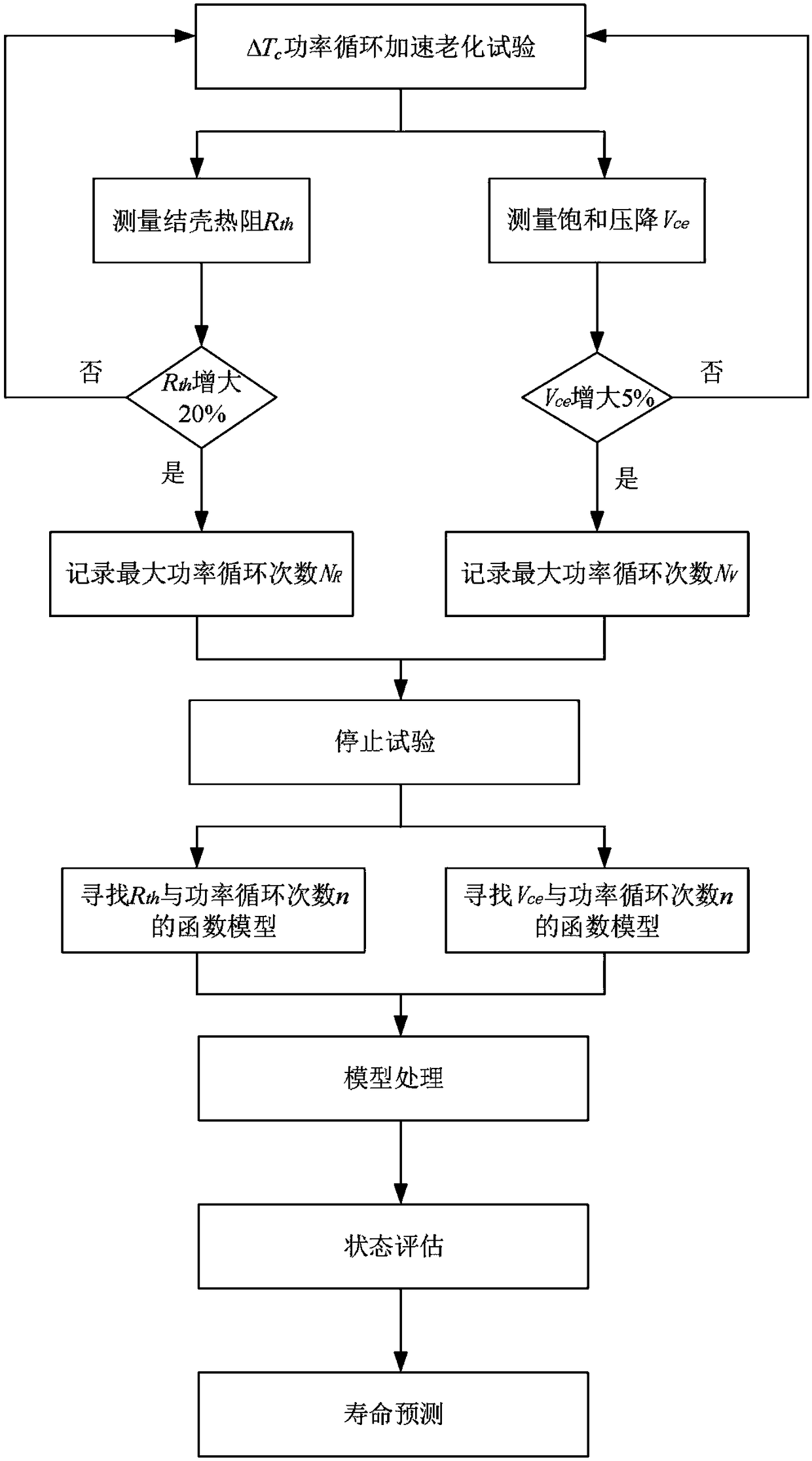

Method for constructing state evaluation and remaining life prediction model of IGBT module

ActiveCN109188232AAccurately get aging statusGet aging stateBipolar transistor testingPower cycleMathematical model

The invention relates to a method for constructing a state evaluation and remaining life prediction model of an IGBT module. The method comprises the following steps: measuring electric heating parameters of the IGBT module under different aging degrees through testing; establishing a functional model of average crust thermal resistance change rate-average power cycle index and a functional modelof average saturation pressure drop change rate-average power cycle index of test samples of the IGBT module; evaluating the aging state of the IGBT module according to the above functional models, and expressing the aging state of the IGBT by a real number on the interval [0, 1] to obtain a state evaluation result; and establishing a calculation model of the remaining life of the IGBT module according to the state evaluation result. The method provided by the invention establishes mathematical models of electrical parameters, thermal parameters and power cycle indexes according to a power cycle accelerated aging test, and the models comprehensively consider the influence of electrical parameters and thermal parameters on the evaluation results to make up for the deficiency of single parameter evaluation, thereby accurately obtaining the aging state of the IGBT module under the condition of thermal resistance and saturation voltage drop of a certain crust.

Owner:HEBEI UNIV OF TECH

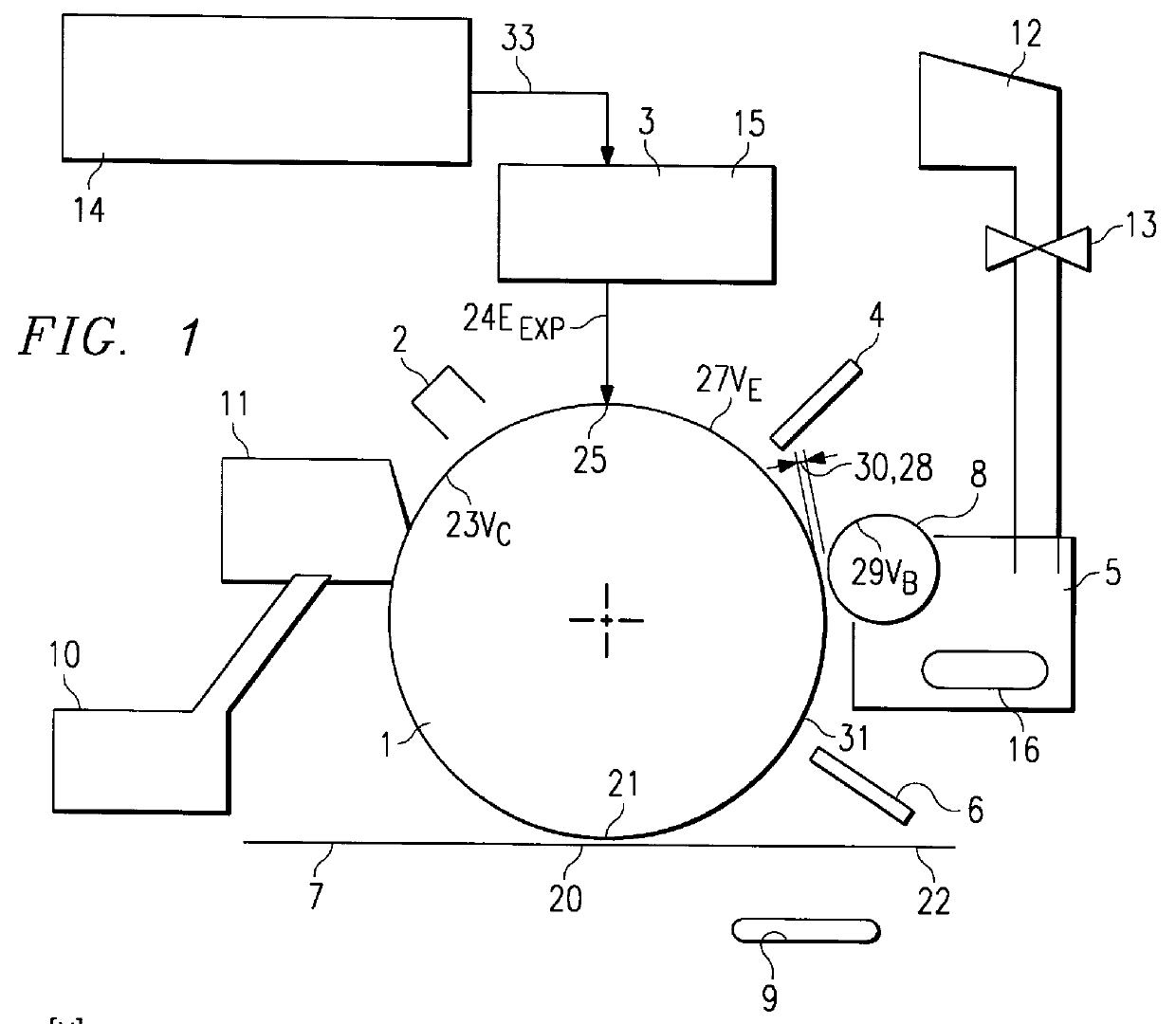

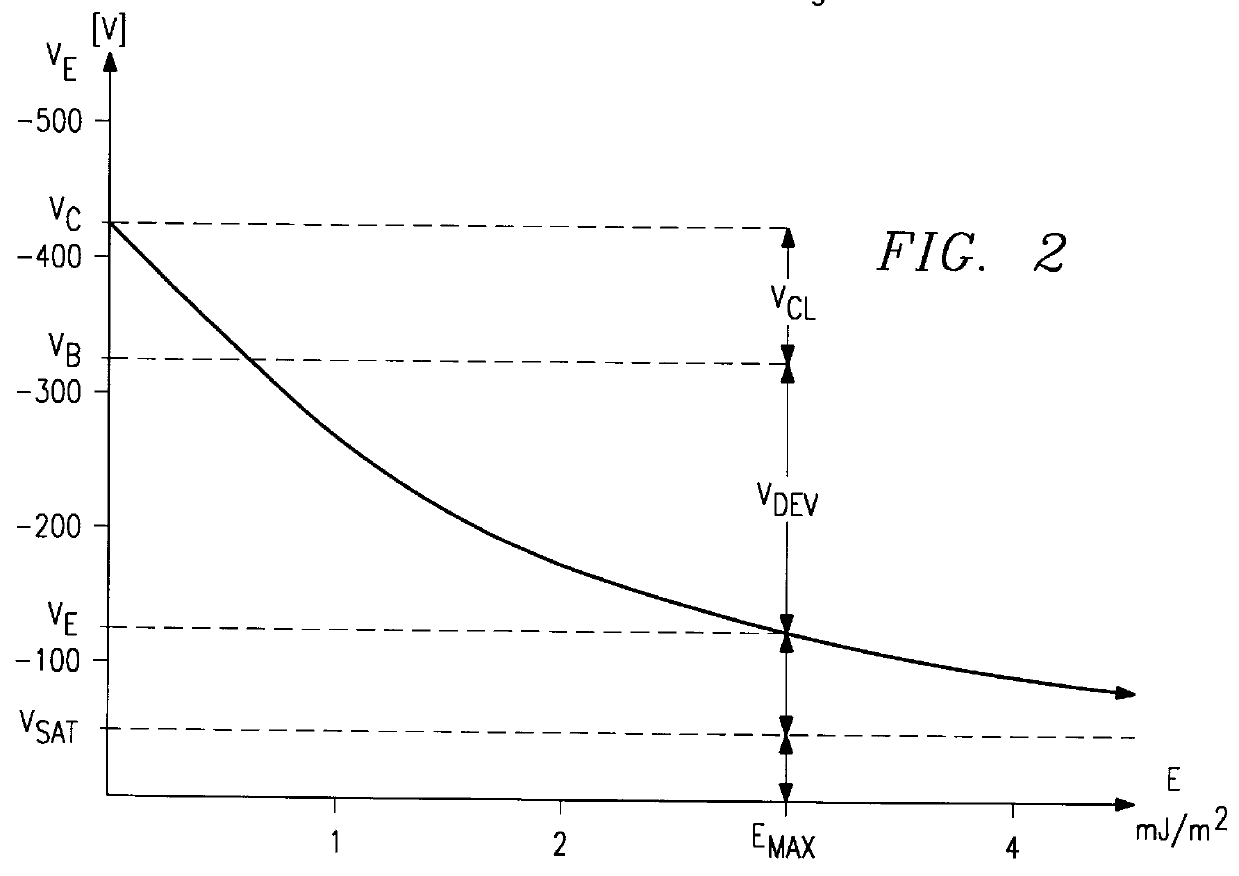

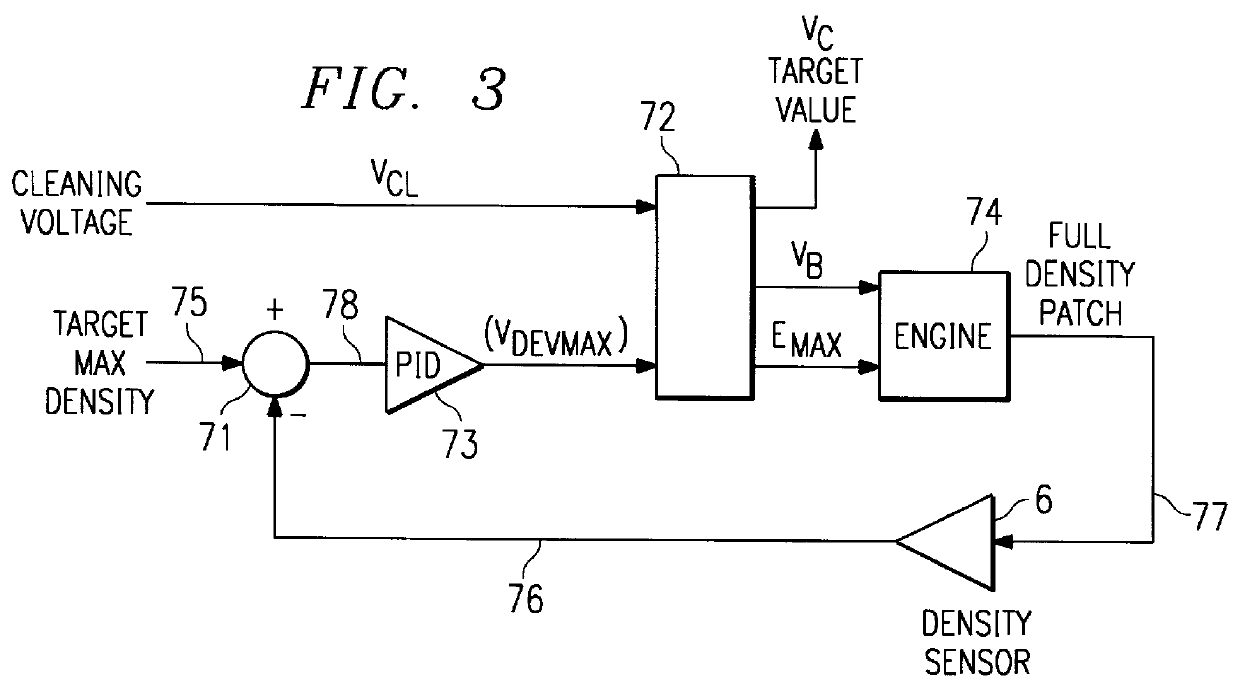

Process control of electrophotographic device

InactiveUS6034703AImproved tone scale linearityScale upElectrographic process apparatusElectrographic processes using charge patternVolumetric Mass DensityMaximum density

A method is described to control the maximum density and the pixel profile of microdots produced by a binary or multilevel electrophotographic device. In various embodiments, from the maximum development potential. The working point of the device is established by imposing a relation between charge level, discharge level and saturation voltage level of the photosensitive element. This allows to achieve consistent output densities, irrespective of the environmental parameters, such as relative humidity and temperature.

Owner:TEXAS INSTR INC +1

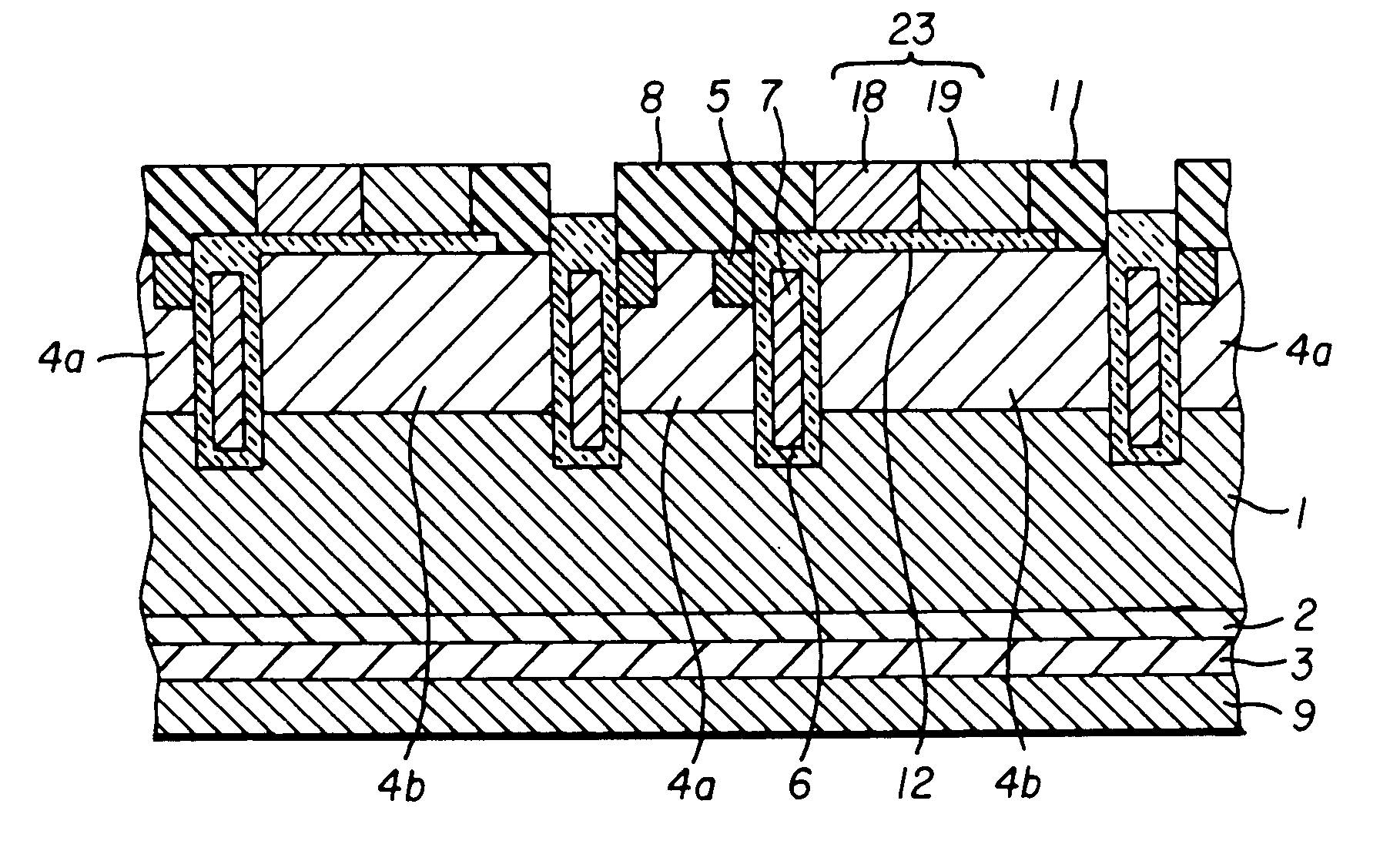

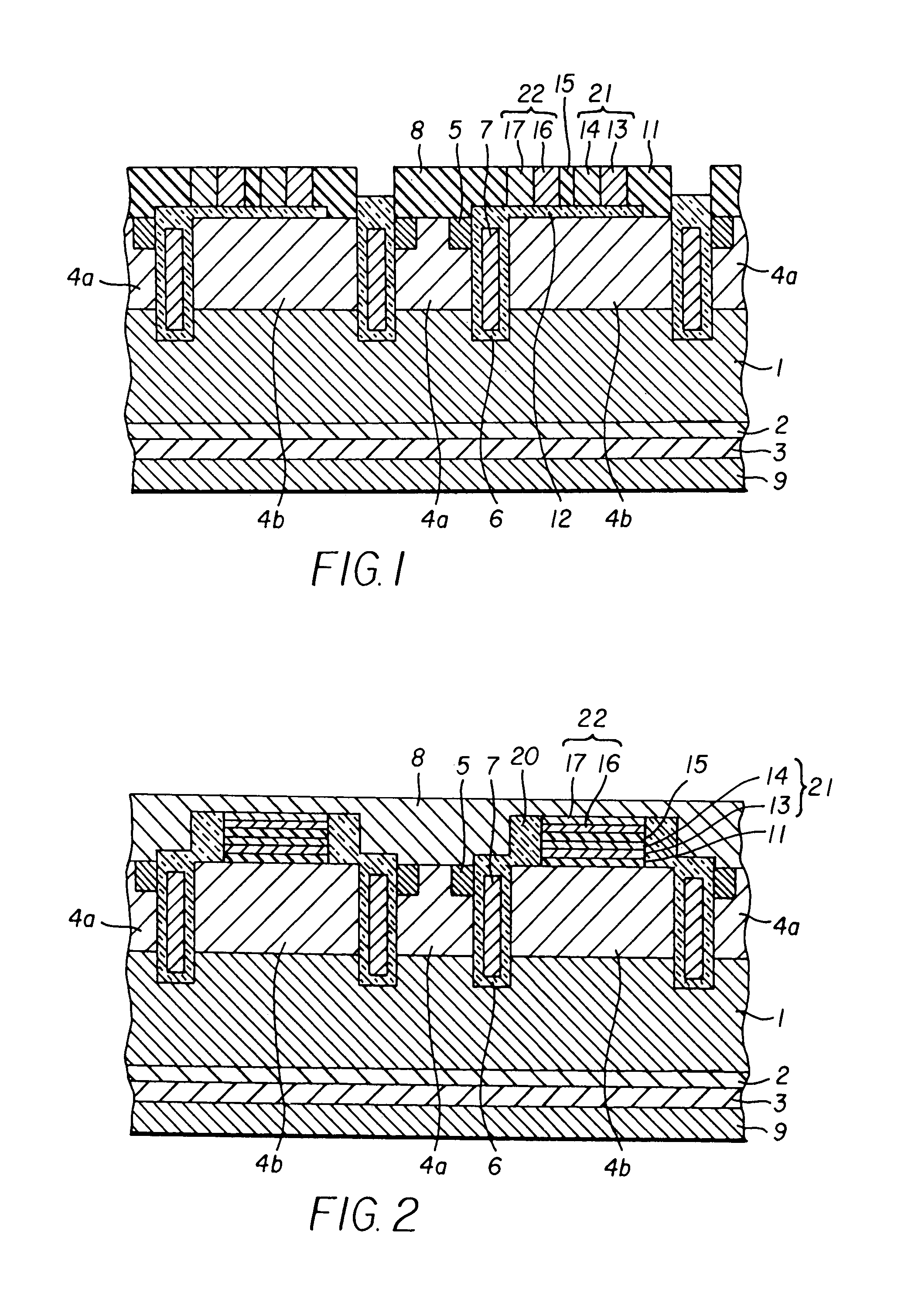

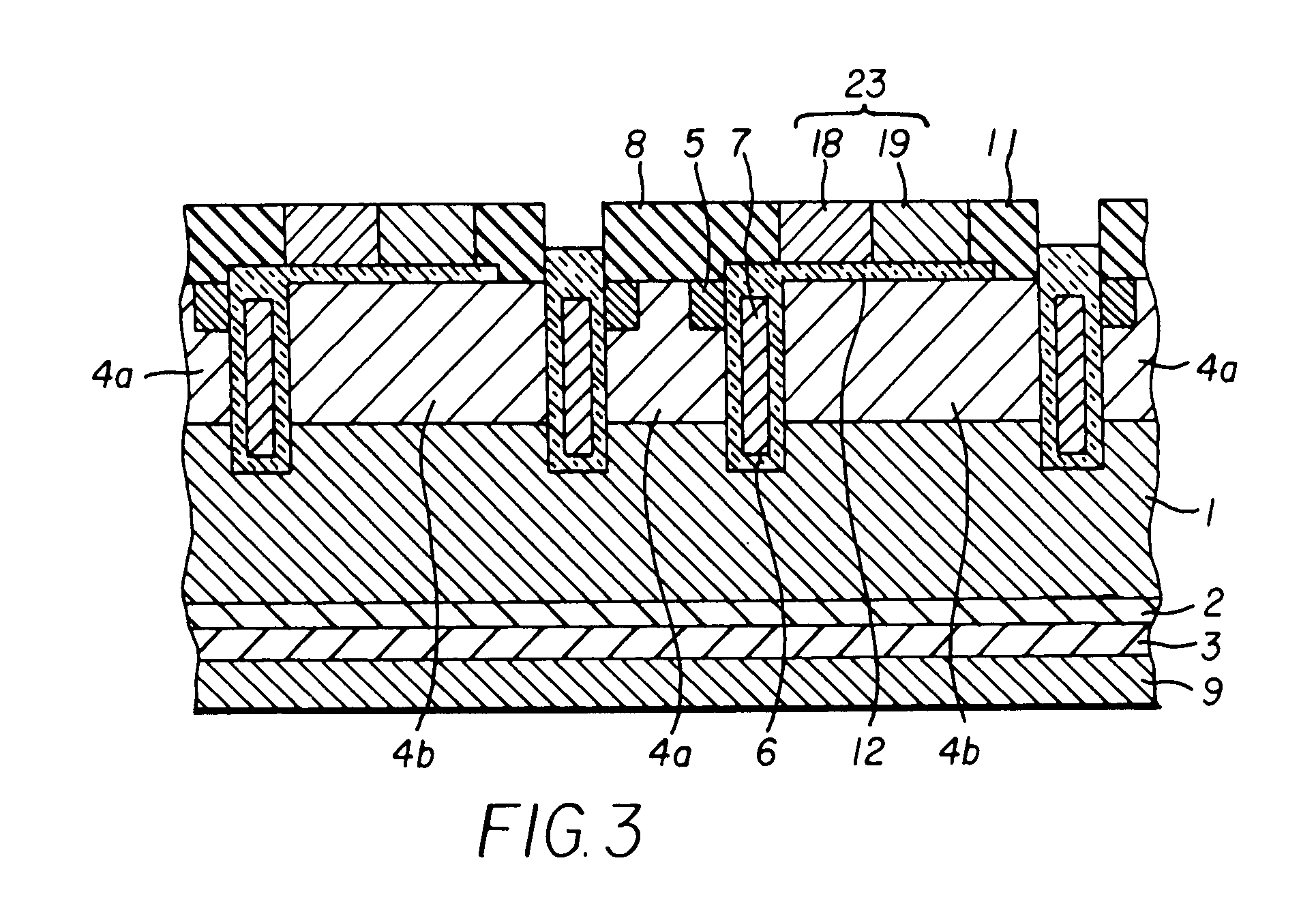

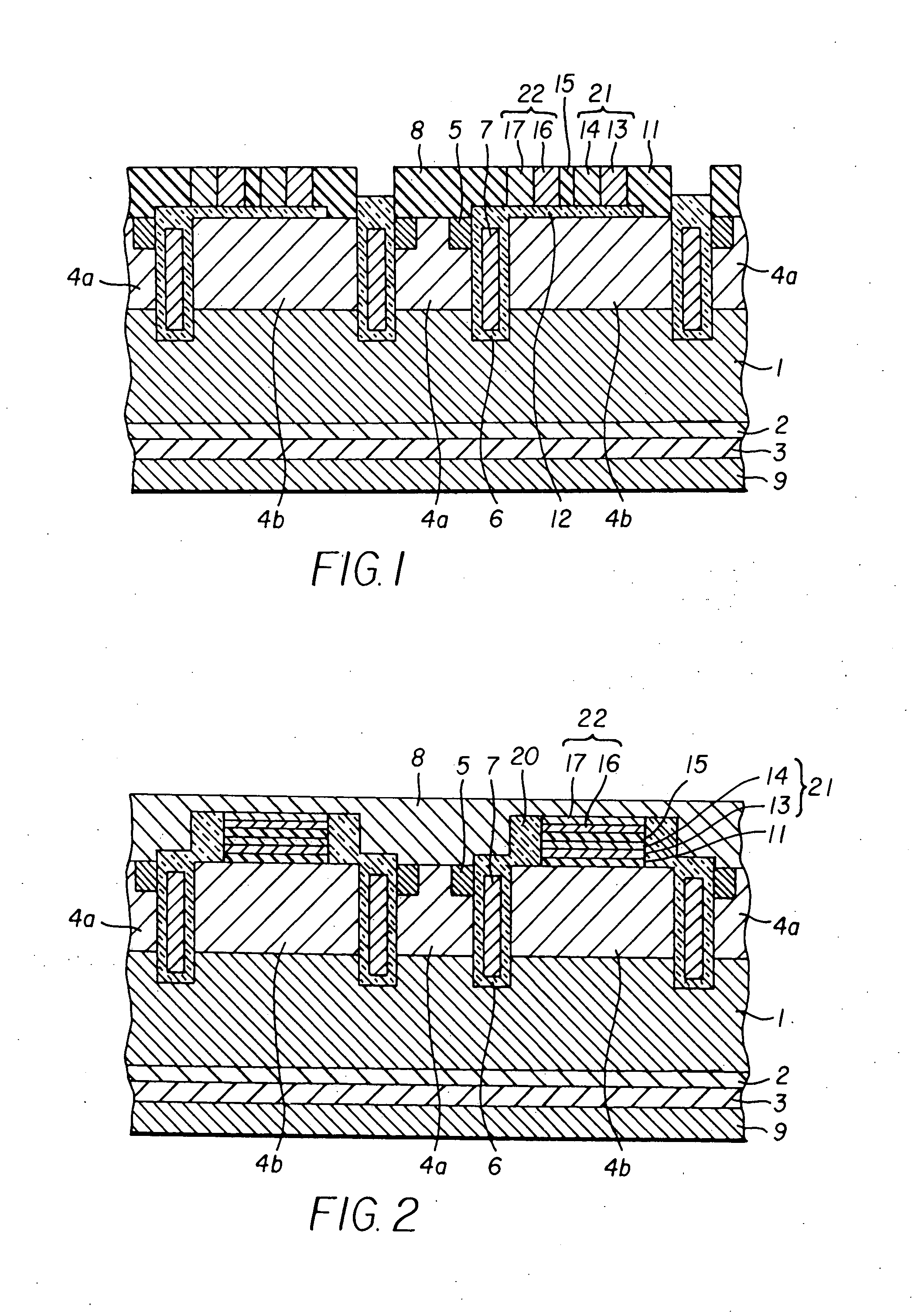

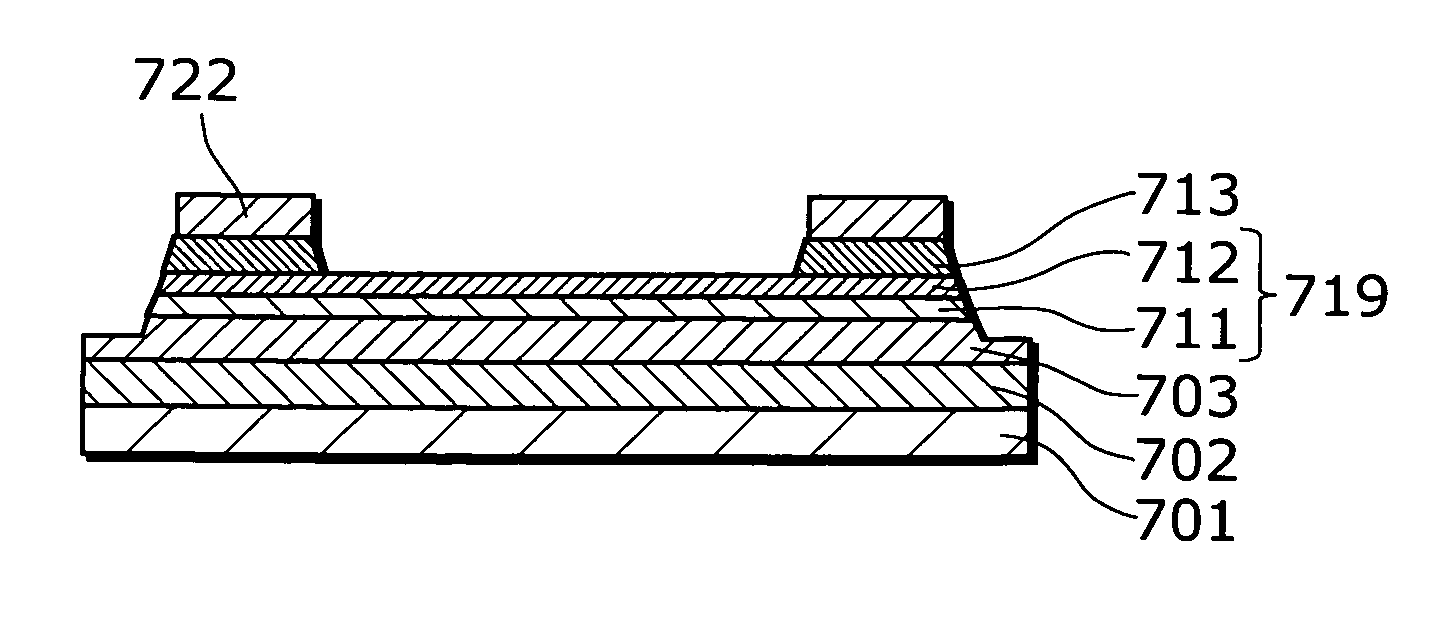

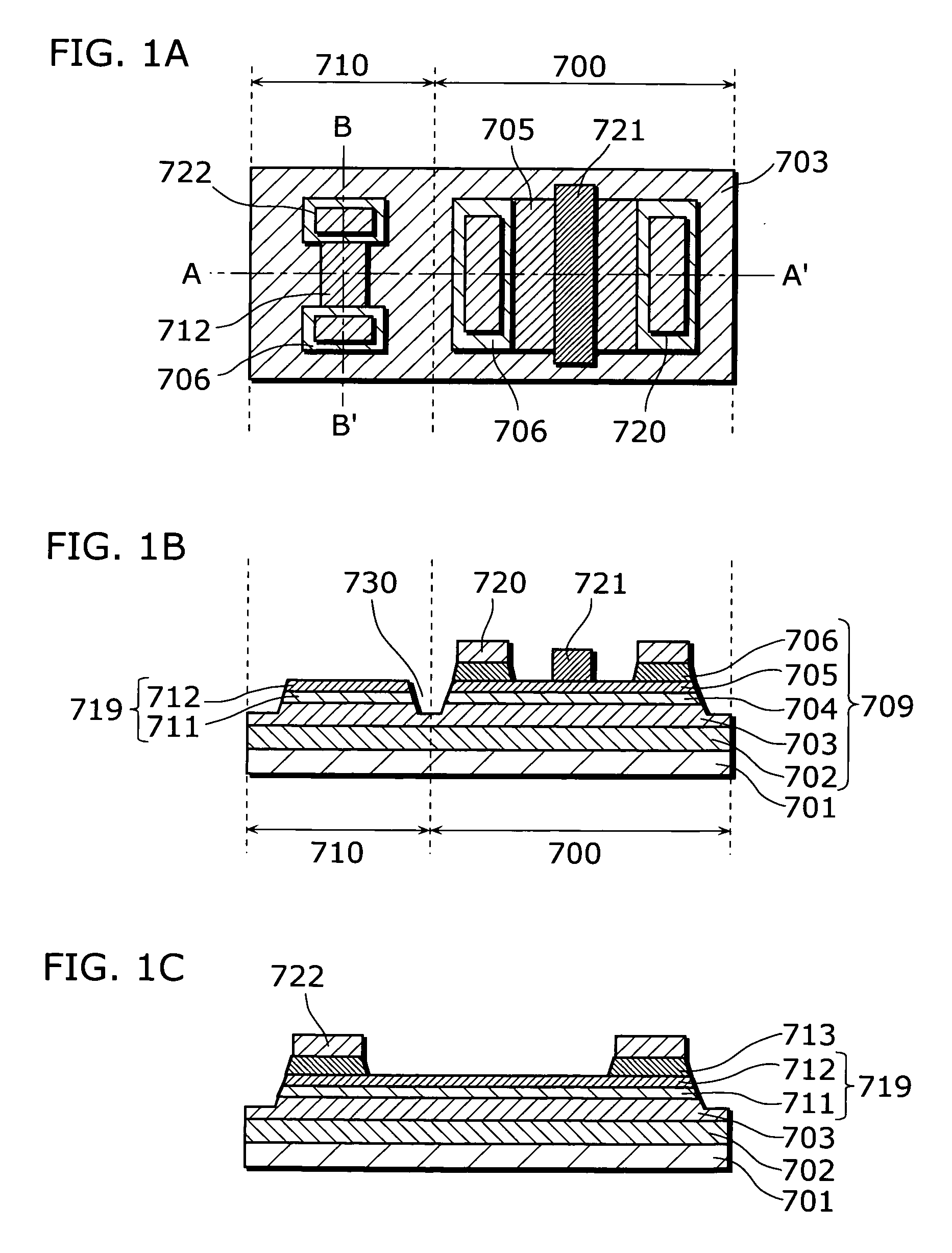

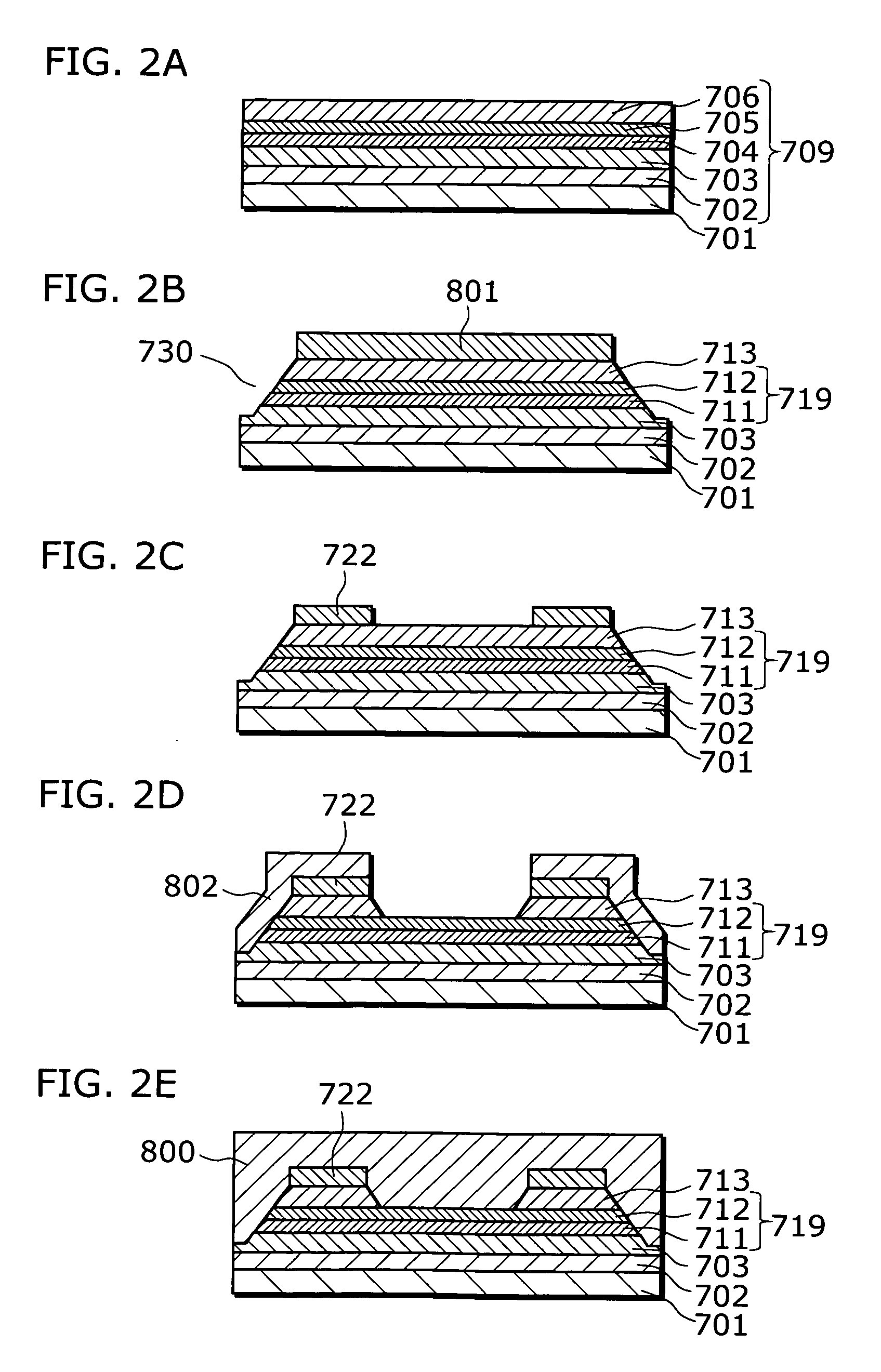

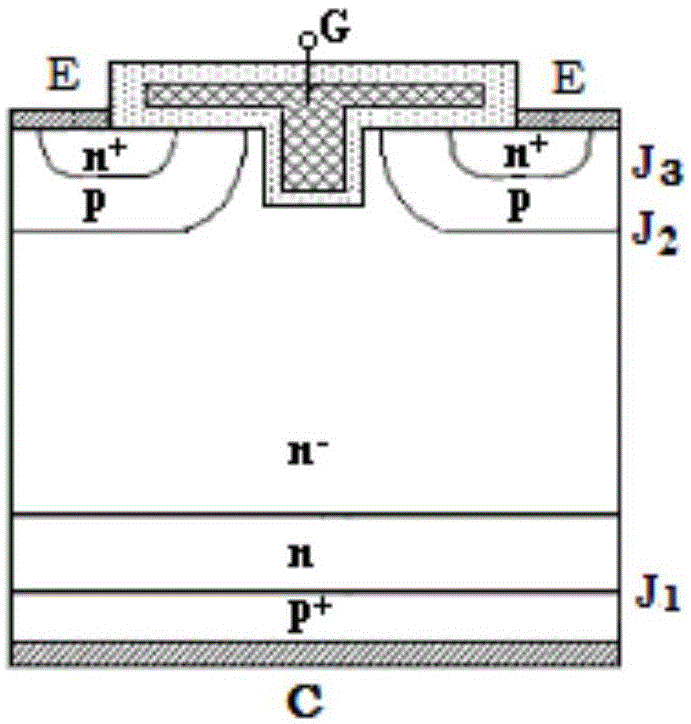

Insulated gate bipolar transistor

InactiveUS7098488B2Excellent trade-off characteristicShorten speedTransistorSemiconductor/solid-state device detailsCapacitanceEngineering

An IGBT having a trench gate structure is disclosed which generates decreased noise at switching and displays superiority in saturation voltage to turn-off loss characteristics (trade-off characteristics). In a part of a region on an emitter side surface interposed between trench gates, a sub well region is provided, which is connected to an emitter electrode through diodes. When the IGBT is in a turned-on state, the diodes are brought into a non-conduction state to isolate the sub well region from the emitter electrode, by which carriers are accumulated. When the IGBT is in a turned-off state, the diodes are brought into a conduction state to electrically connect the sub well region to the emitter electrode, by which carriers are discharged at a high speed. In an early stage of turning-on of the IGBT, capacitance of a portion of the gate facing the sub well region is converted to gate-emitter capacitance to thereby reduce gate-collector capacitance, by which electromagnetic noise at switching is reduced.

Owner:FUJI ELECTRIC HLDG CO LTD

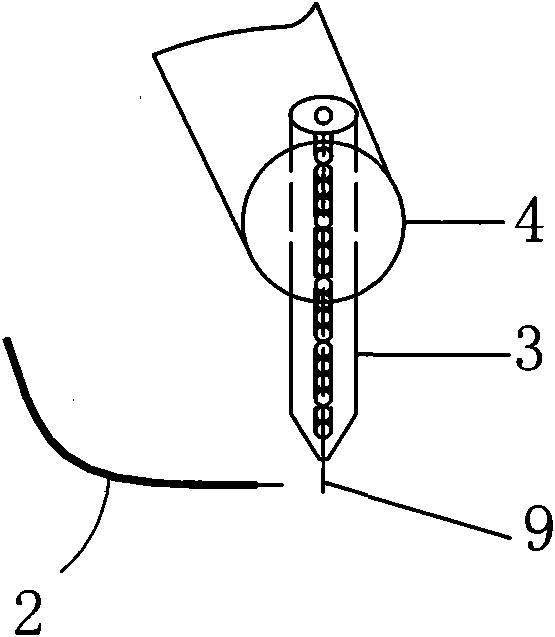

Method for bonding copper wire of power device

InactiveCN101862897AImprove conductivityLow costSolid-state devicesSemiconductor/solid-state device manufacturingCopper wireUltrasonic welding

The invention provides a method for bonding a copper wire of a power device, in particular to a method for bonding the copper wire (91) with the welding joints of a chip (511). The method comprises the following steps: burning the lower end (9) of the copper wire into a spherical shape; applying the pre-pressure on the spherical end of the copper wire, i.e., flattening the spherical end of the copper wire to increase the contact area of the spherical end of the copper wire and the chip; and welding the spherical end of the copper wire to the bonding area of the chip on an ultrasonic-welding basis, wherein the pre-pressure is preferably 80g to 120g, and the time for applying the pre-pressure is preferably 80ms to 150ms. By increasing the contact area, the invention can improve the stability and reliability in welding the copper wire and the chip; the bonding production can be smooth without breaking the copper wire, breaking the welding joints or shutting down; the chip cannot be damaged by bonding; and the bonding strength of the copper wire, the chip and the pin is high. By substituting the copper wire for the gold wire for bonding, the invention can reduce the cost for the bonding metal wire by about 84%, reduce the overall cost for the product by 5.7% to 8.6%, reduce the saturation voltage drop parameter of the product and improve the reliability of the product; and compared with the gold wire, the conductivity of the copper wire is increased by about 20%, thus improving the reliability of the product.

Owner:深圳市贵鸿达电子有限公司

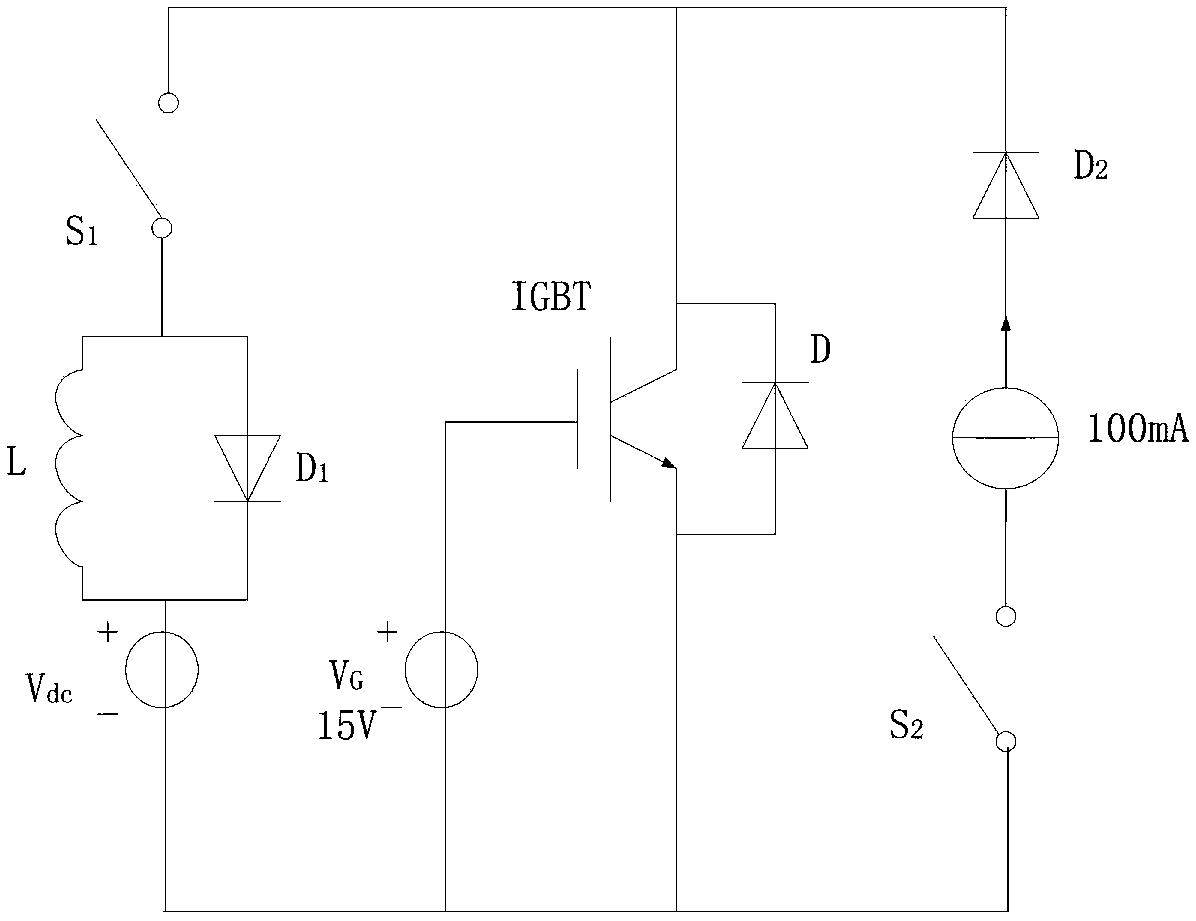

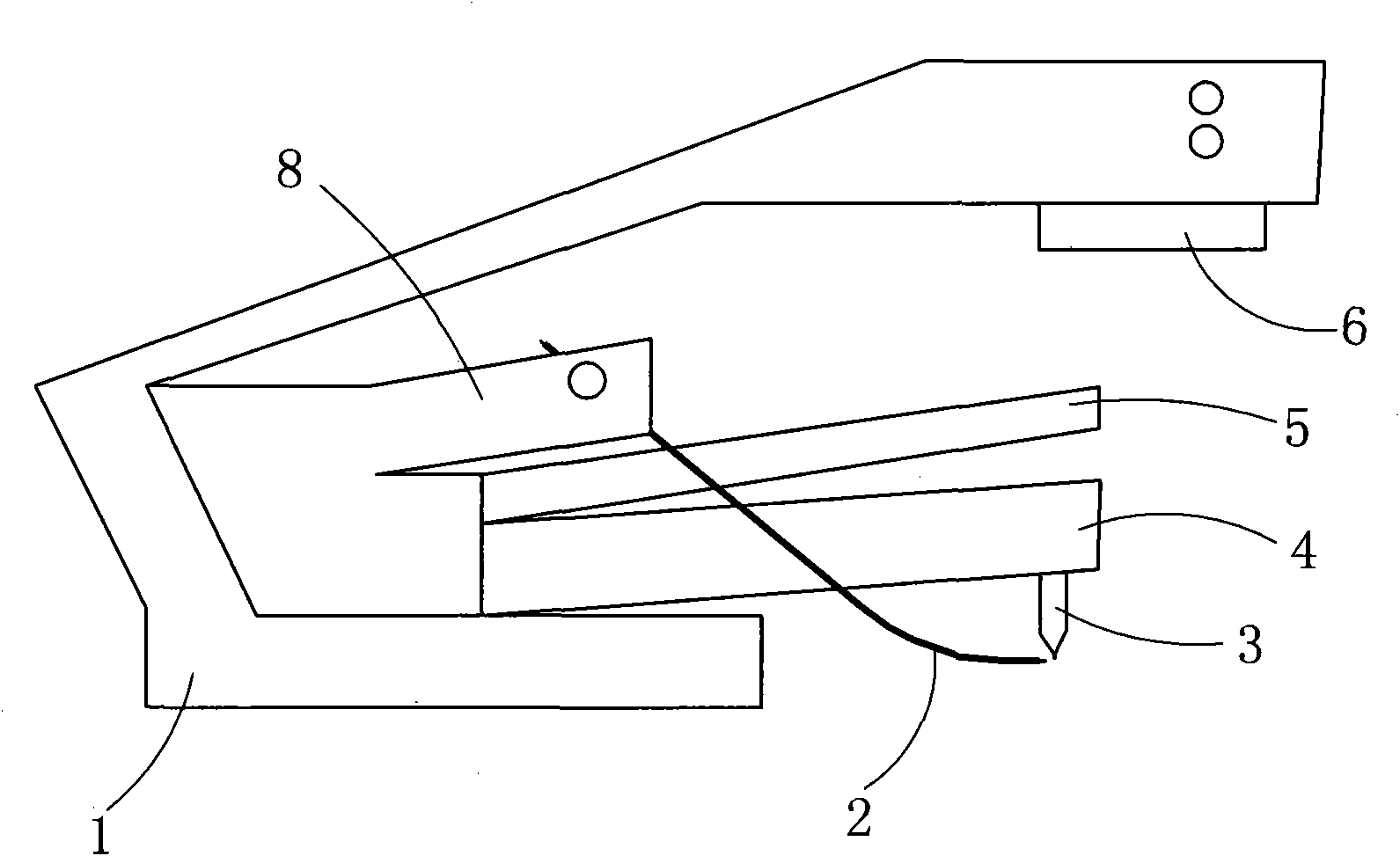

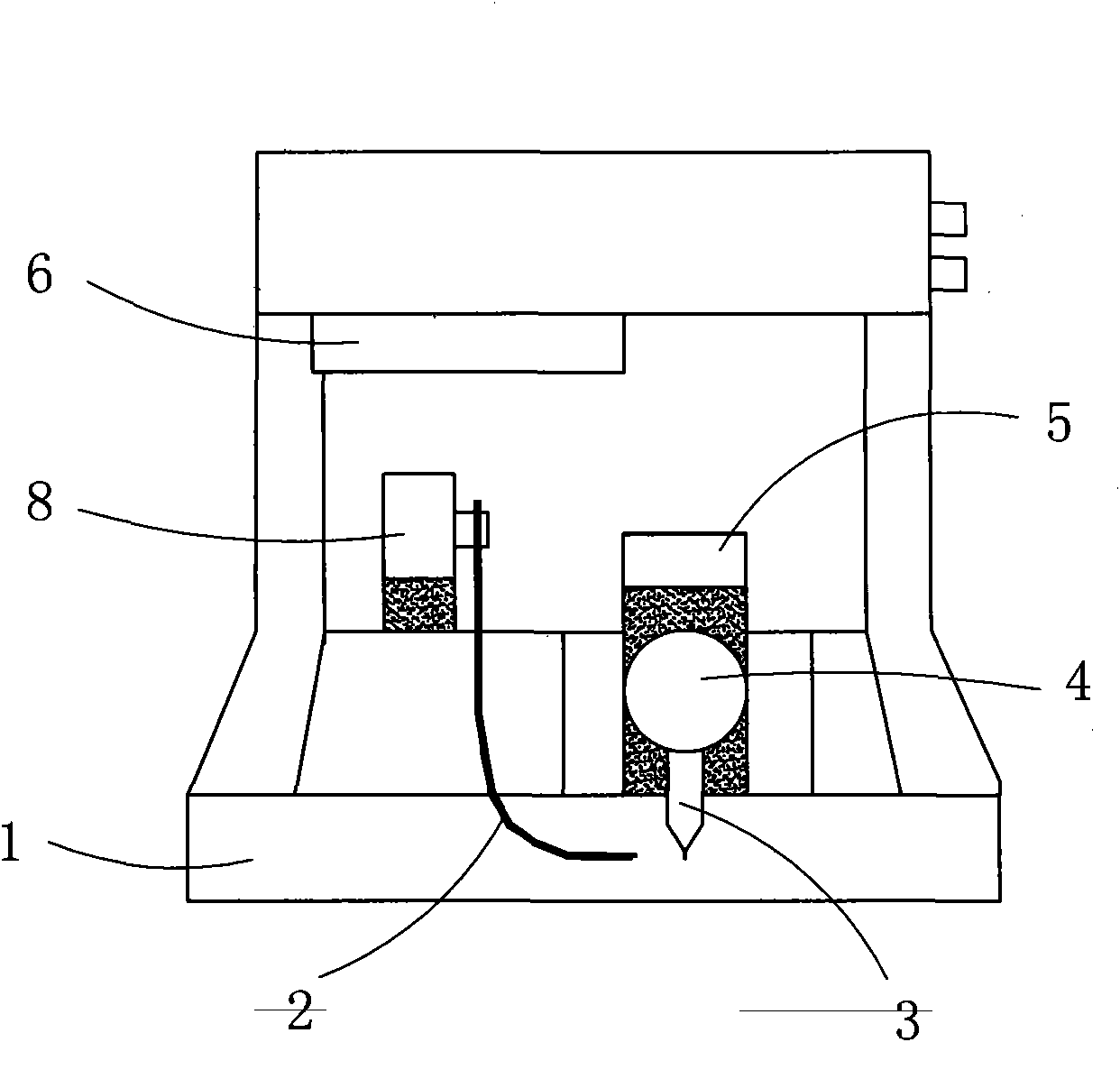

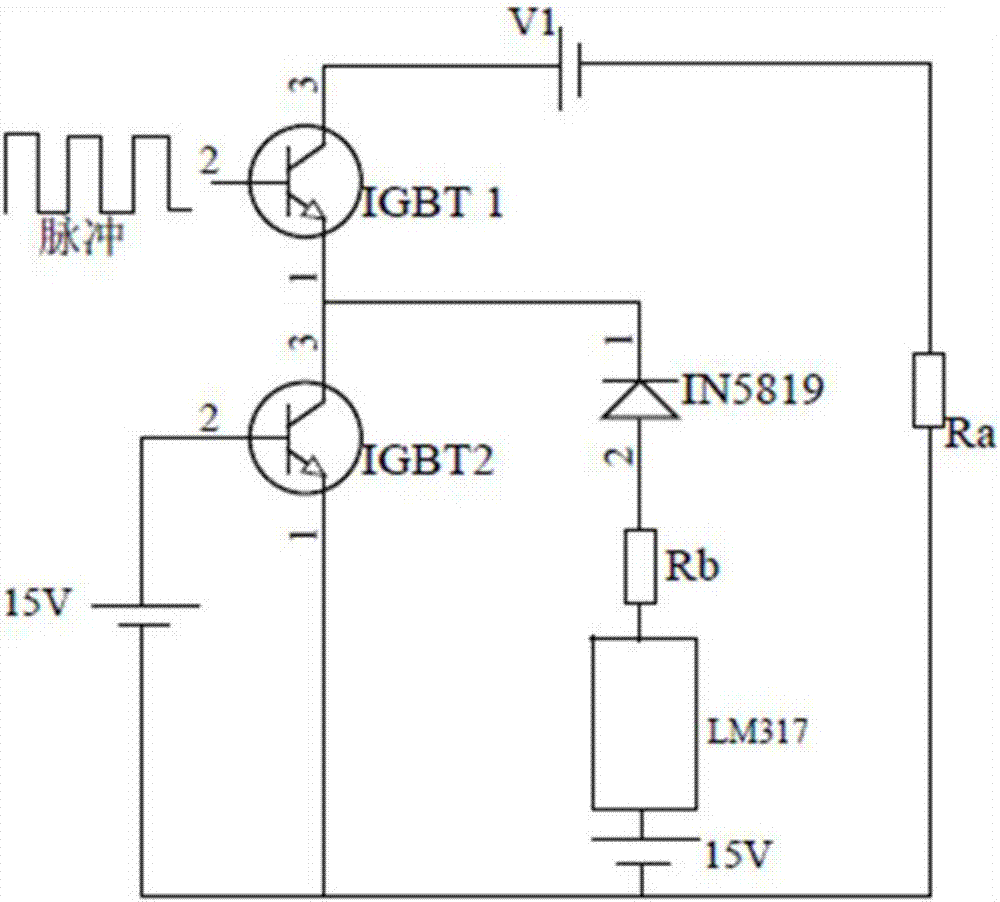

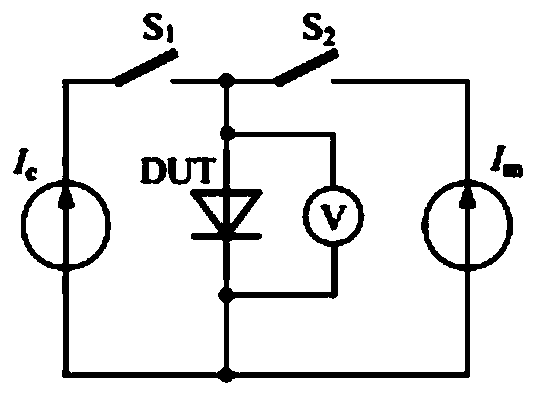

On-line detection device for measuring junction temperature of IGBT power module based on saturation voltage drop

ActiveCN106969851AThermometers using electric/magnetic elementsUsing electrical meansElectricityJunction temperature

The present invention provides an on-line detection device for measuring the junction temperature of an IGBT power module based on saturation voltage drop. According to the device, the voltages VCE of a collector and an emitter under small current are selected as temperature sensitive parameters. The detection device comprises a temperature box experimental unit. A function relationship between saturation voltage drop VCE and junction temperature Tj under the small current is determined; the switching off of high current is controlled through a switch IGBT module under a power cyclic condition; the change of the VCE at the moment when an IGBT to be detected is switched off is monitored; and the change of the VCE is introduced into the function relationship which is obtained in advance, and the change process of the junction temperature Tj can be obtained. With the device adopted, the junction temperature of the IGBT can be detected in real time. According to the device, an overcurrent unit and an overtemperature unit are additionally adopted, and therefore, the IGBT device can be protected in real time through an automatic power-off means, and therefore, the device of the present invention can obtain the junction temperature of the IGBT more simply and quickly than devices which obtain junction temperature through opening covers or changing circuit structures.

Owner:BEIJING UNIV OF TECH

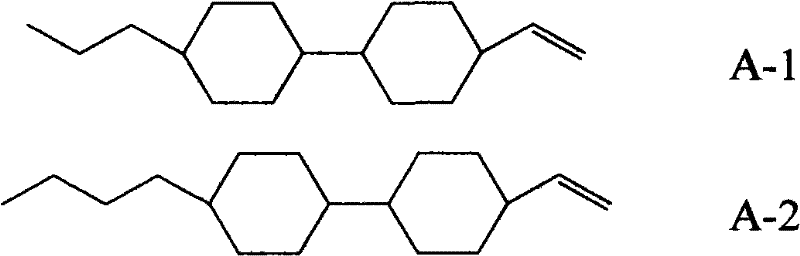

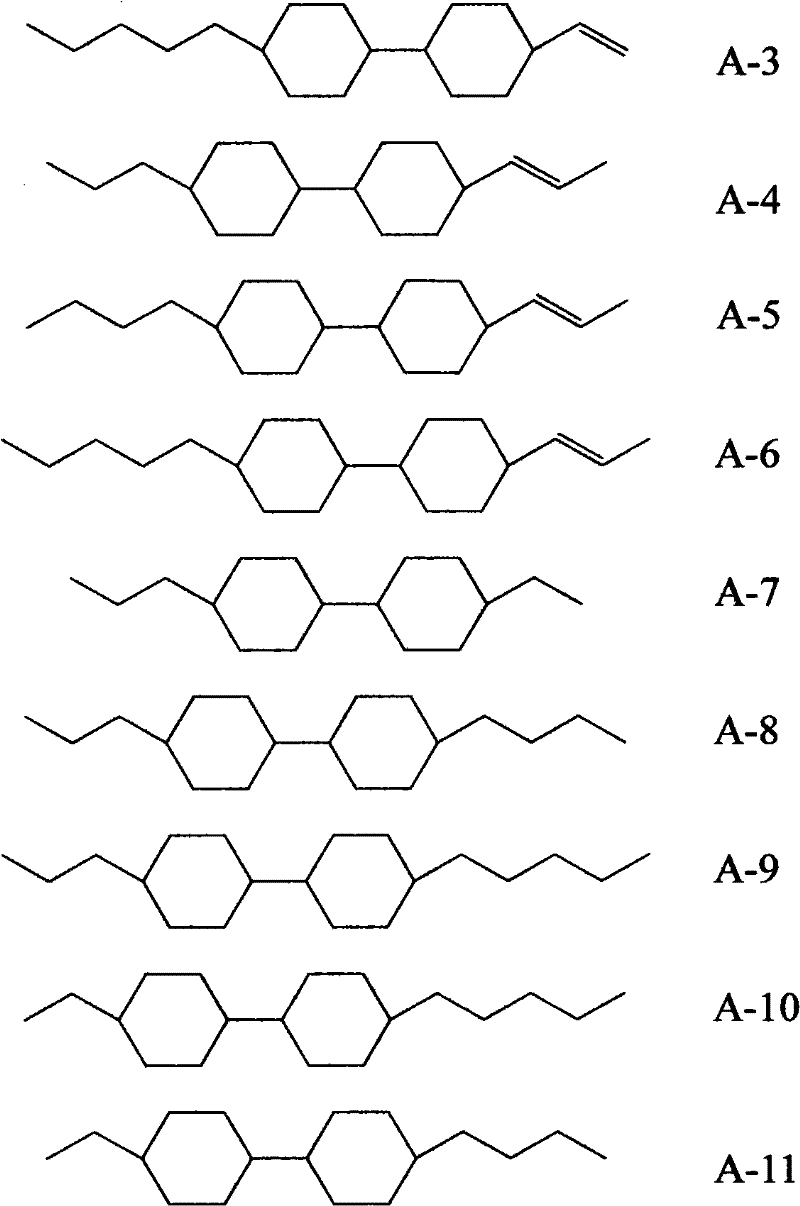

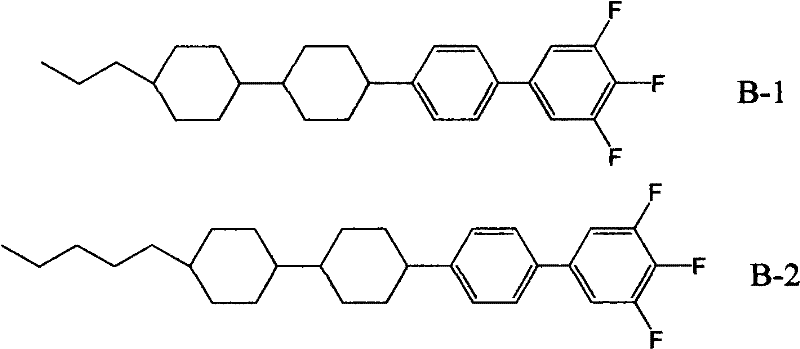

Wide nematic phase mixed liquid crystal material with low threshold value

The invention provides a wide nematic phase mixed liquid crystal material with a low threshold value. Four compounds are adopted; a component A has a bicyclohexane structure and the lowest viscosity, and contributes to improving the response speed of the mixed liquid crystal material in a display device; a component B is a compound having a framework that cyclohexane is directly connected with a benzene ring and containing a fluorine substituent, and is used for forming the nematic phase of liquid crystal and inhibiting a smectic phase of the mixed liquid crystal material; a component C has a polyfluorophenyl structure, is connected with the cyclohexane through an intermediate bridge bond, can provide certain dielectric anisotropy and has wide temperature width of the nematic phase; and a component D has a polyfluorobiphenyl structure and has the effect of greatly reducing the threshold voltage of the mixed liquid crystal material. The liquid crystal material prepared has a wide nematic phase of which the temperature width is higher than 140DEG C, has low threshold voltage and saturation voltage, and high response speed, and is suitable for liquid crystal display devices with positive dielectric anisotropy.

Owner:XIAN CAIJING OPTO ELECTRICAL SCI & TECH

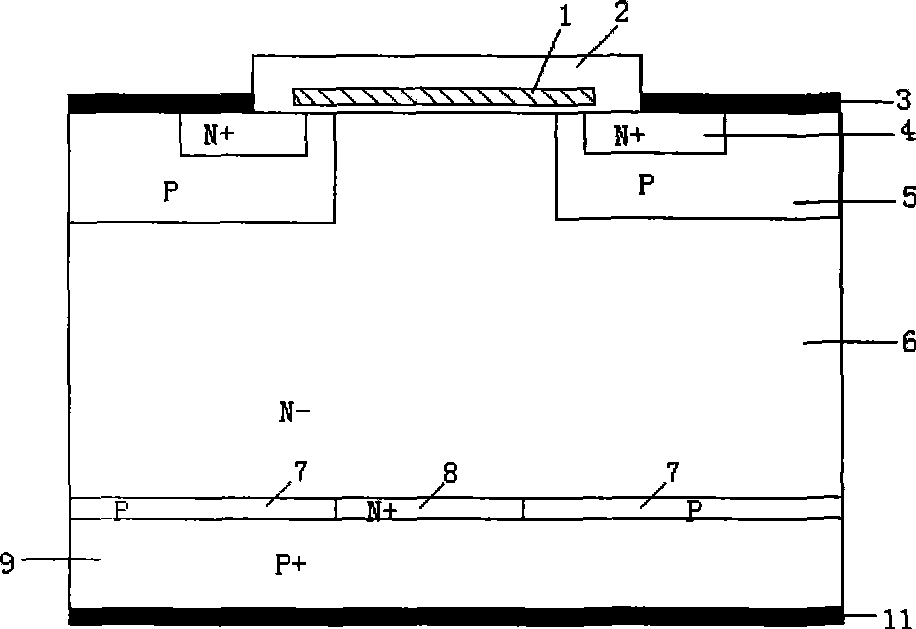

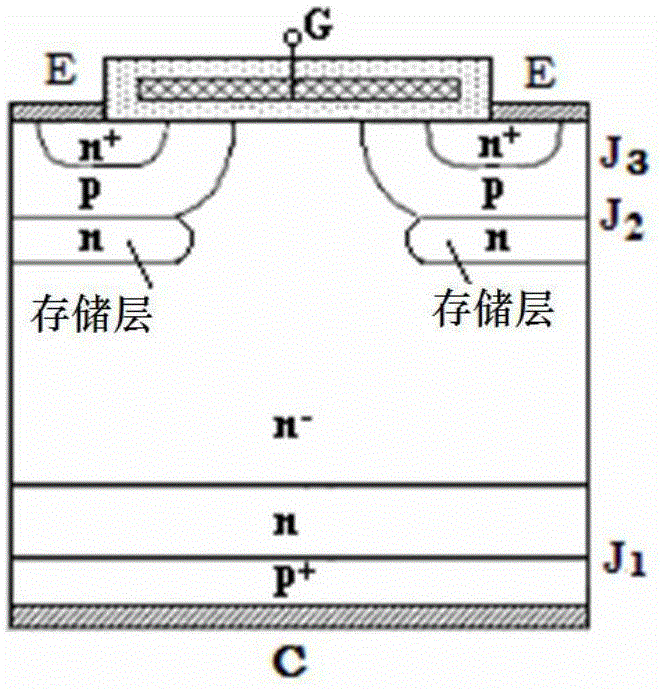

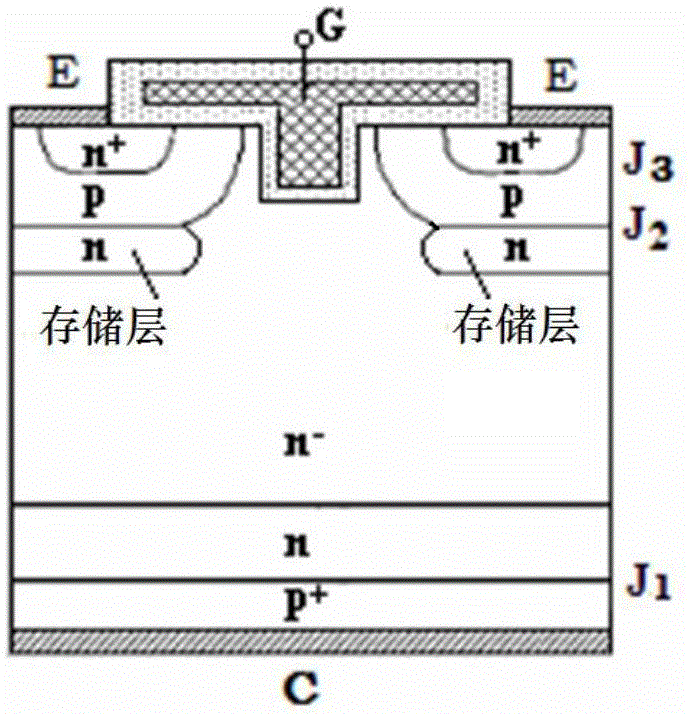

Tunnel IGBT with anode in short circuit

InactiveCN101393928AImprove conduction characteristicsShorten off timeSemiconductor devicesVoltage dropEngineering

An anode-short tunnel pump IGBT belongs to the technical field of semiconductor power devices. With an anode-short structure and a tunnel pump structure simultaneously introduced into a traditional IGBT, or a tunnel pump structure into an anode-short IGBT, or an anode-short structure into a tunnel pump IGBT, the invention gives the advantages of both the anode-short IGBT and the tunnel pump IGBT to the anode-short tunnel pump IGBT so as to improve the turn-off characteristic of the device and lower the conductive voltage drop of the device. The invention can better reconcile the positive saturation voltage drop with the turn-off time, and optimize the conductive characteristic of the device, so that the invention is suitable in particular for application environments characterized by high voltage, heavy current and high frequency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

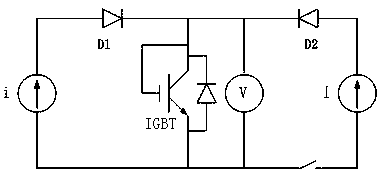

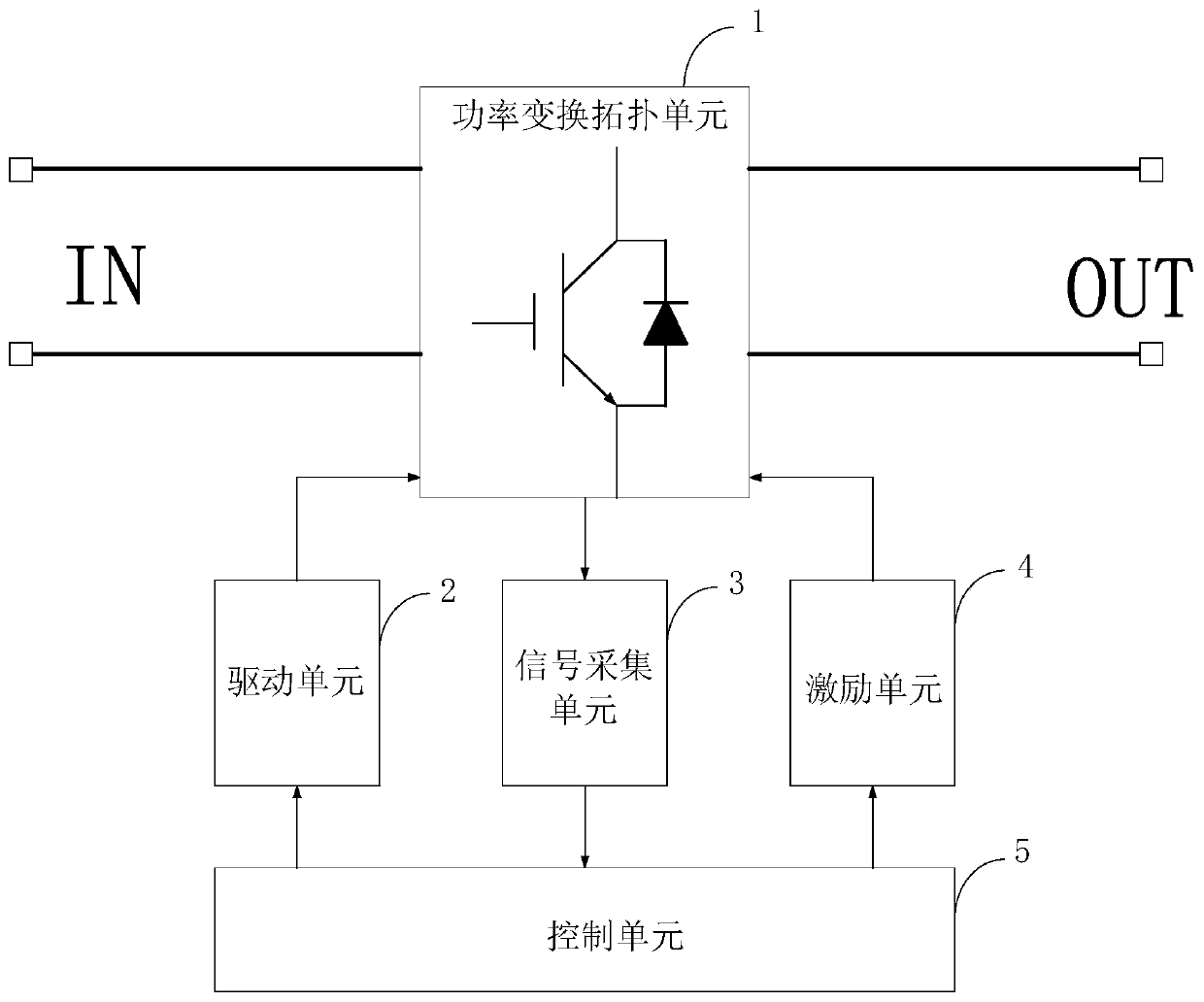

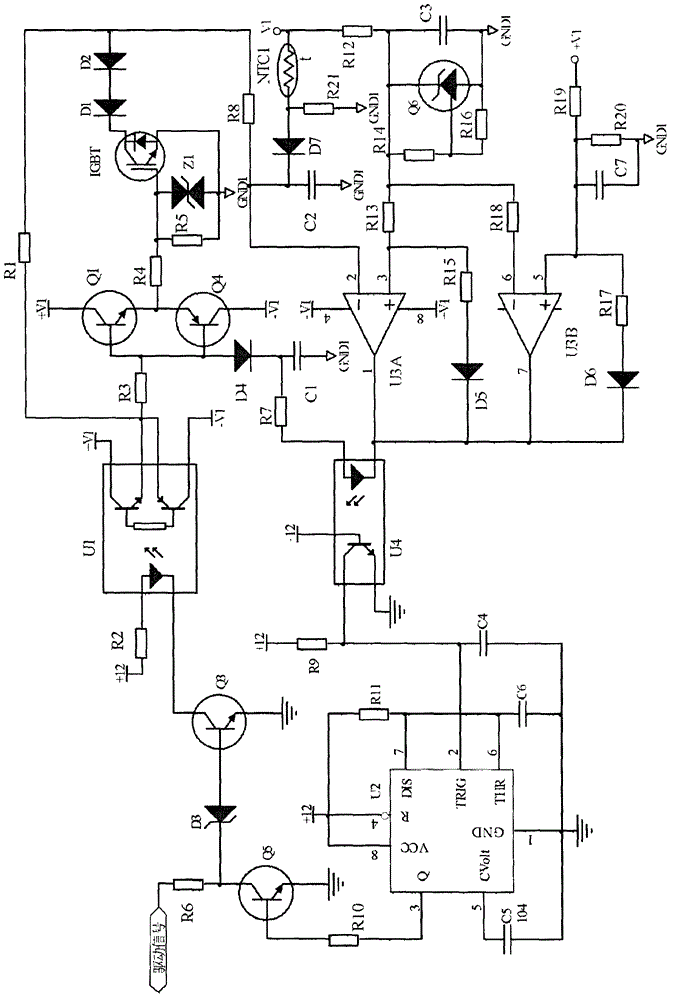

Online detection system and method for IGBT (Insulated Gate Bipolar Translator) module working junction temperature

ActiveCN110108999ARealize the function of online detection of junction temperatureIndividual semiconductor device testingFreewheelExcitation current

The invention provides an online detection system and method for an IGBT (Insulated Gate Bipolar Translator) module working junction temperature. The system comprises a power conversion topological unit, a driving unit, a signal collection unit, an excitation unit and a control unit, wherein the signal collection unit collects the target parameter of the power conversion topological unit; the control unit determines the switching state of an IGBT module to be detected on the basis of the target parameter; when main power current does not flow through the IGBT module to be detected, saturationvoltage drop which flows through a freewheel diode and is collected by the signal collection unit is obtained; and on the basis of the saturation voltage drop, the working junction temperature of theIGBT module to be detected is determined. Obviously, by use of the online detection system for the IGBT module working junction temperature, when the main power current does not flow through the IGBTmodule to be detected, the excitation unit is controlled to output excitation current, the saturation voltage drop which flows through the freewheel diode and is collected by the signal collection unit is obtained, the working junction temperature of the IGBT module to be detected is determined on the basis of the saturation voltage drop, and a function of online junction temperature detection isrealized.

Owner:SUNGROW POWER SUPPLY CO LTD

Insulated gate bipolar transistor

InactiveUS20050045945A1Excellent trade-off characteristicShorten speedSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

An IGBT having a trench gate structure is disclosed which generates decreased noise at switching and displays superiority in saturation voltage to turn-off loss characteristics (trade-off characteristics). In a part of a region on an emitter side surface interposed between trench gates, a sub well region is provided, which is connected to an emitter electrode through diodes. When the IGBT is in a turned-on state, the diodes are brought into a non-conduction state to isolate the sub well region from the emitter electrode, by which carriers are accumulated. When the IGBT is in a turned-off state, the diodes are brought into a conduction state to electrically connect the sub well region to the emitter electrode, by which carriers are discharged at a high speed. In an early stage of turning-on of the IGBT, capacitance of a portion of the gate facing the sub well region is converted to gate-emitter capacitance to thereby reduce gate-collector capacitance, by which electromagnetic noise at switching is reduced.

Owner:FUJI ELECTRIC HLDG CO LTD

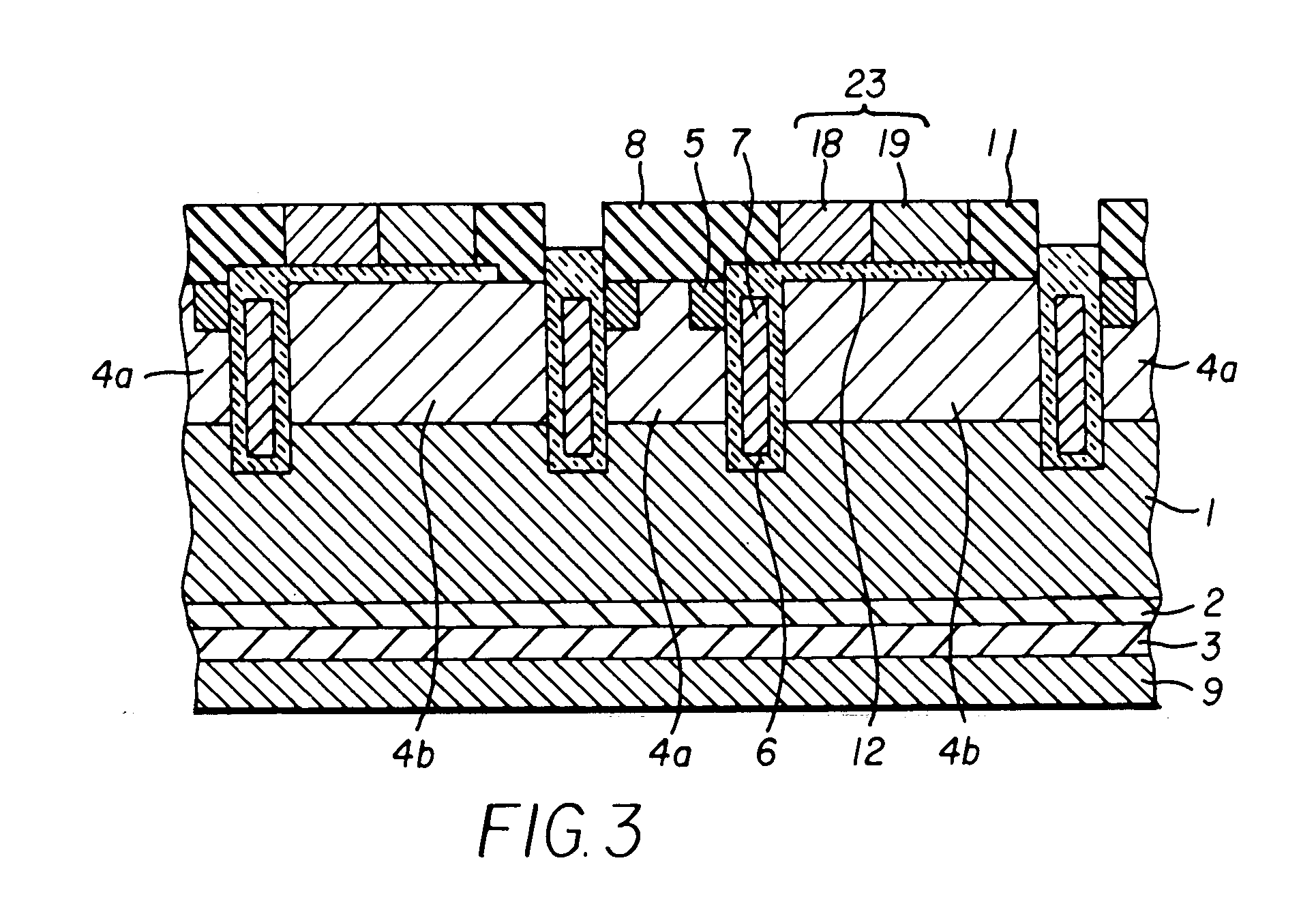

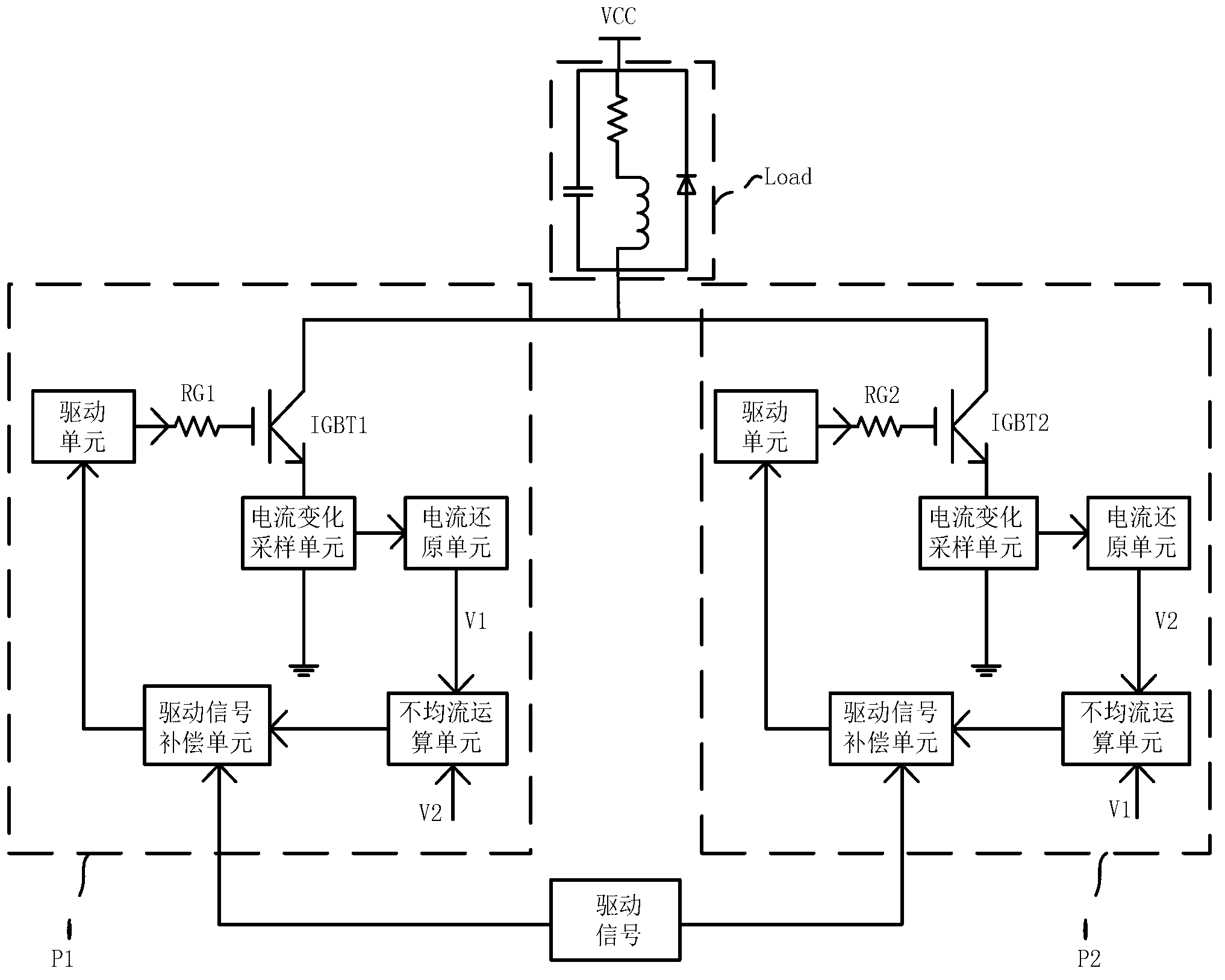

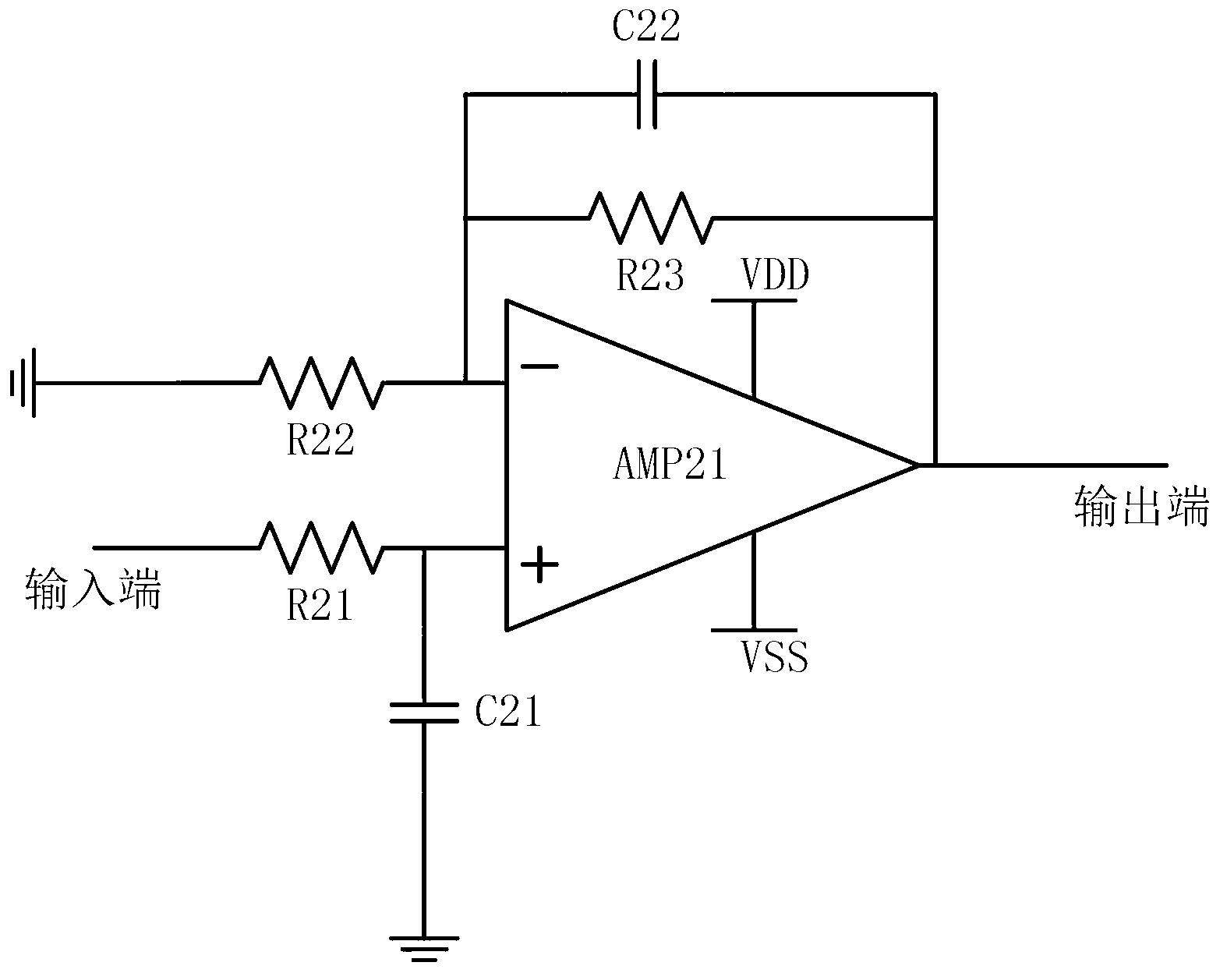

Equalized current output circuit of insulated gate bipolar transistor

InactiveCN103199679ASimple structureStable structurePower conversion systemsComputer moduleEngineering

The invention relates to a parallel equalized current circuit of an IGBT (insulated gate bipolar transistor), and in particular relates to an equalized current output circuit of an insulated gate bipolar transistor to solve the problem of uneven current caused by inconsistent electrical characteristics particularly saturation voltage drop parameters of the IGBT. The technical scheme of the invention is as follows: the equalized current output circuit of the insulated gate bipolar transistor consists of N modules connected in parallel, wherein N is an integer and is more than or equal to 2; and each module comprises a current change sampling unit, a current reduction unit, an uneven current arithmetic unit, a driving signal compensation unit, a driving unit and an IGBT. The equalized current output circuit of the insulated gate bipolar transistor can be used for performing dynamic current equalization and static current equalization parallelly on IGBTs with different electrical characteristics, and is particularly suitable for performing parallel current equalization on the IGBTs of which the electrical characteristics are greatly different, therefore, the equalized current output circuit has universality.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

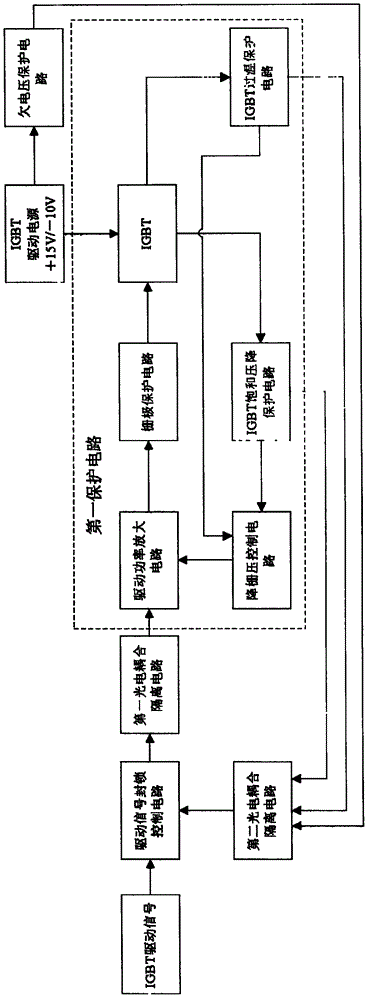

IGBT (Insulated Gate Bipolar Translator) driving protection circuit

ActiveCN102751970AProtection worksSimple structureElectronic switchingControl circuitSaturation voltage

The invention discloses an IGBT (Insulated Gate Bipolar Translator) driving protection circuit which comprises a driving signal locking control circuit, a first protection circuit and an undervoltage protection circuit, wherein the first protection circuit comprises a driving power amplifying circuit, a grid protection circuit, an IGBT over-temperature protection circuit, an IGBT saturation voltage drop protection circuit and a grid voltage drop soft turn-off control circuit; an output end of a first photoelectric coupling isolating circuit passes by the driving power amplifying circuit and the grid protection circuit in turn and then is connected with a grid of an IGBT; a collector of the IGBT passes by the IGBT over-temperature protection circuit and the grid voltage drop soft turn-off control circuit in turn and then is connected with a corresponding input end of the driving power amplifying circuit; and the collector of the IGBT passes by the IGBT saturation voltage drop protection circuit and the grid voltage drop soft turn-off control circuit in turn and then is connected with the corresponding input end of the driving power amplifying circuit. The IGBT driving protection circuit provided by the invention has the advantages of simple structure, reliable work and low cost.

Owner:FOSHAN BAYKEE NEW ENERGY TECH INC

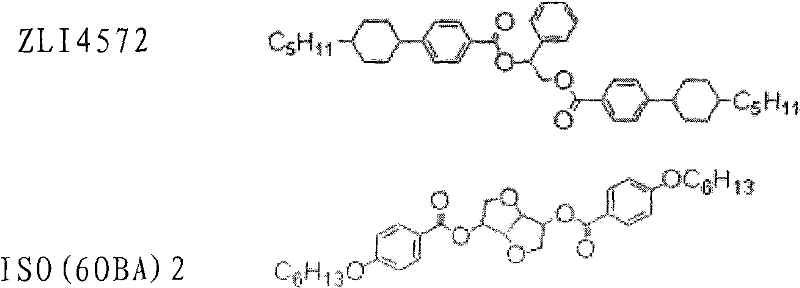

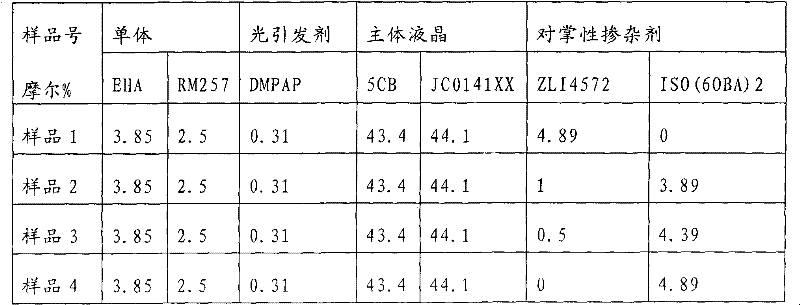

Blue-phase liquid crystal formula

InactiveCN102220143ALower saturation voltageExtended service lifeLiquid crystal compositionsNon-linear opticsDopantCrystallography

The invention provides a blue-phase liquid crystal formula, which is characterized by comprising Component A and Component B, wherein the Component A simultaneously contains two chiral dopants, namely ZLI 4572 and ISO(60BA)2 with the mole concentration ratio of ZLI 4572 to ISO(60BA)2 being 5:95-95:5; and the Component B contains a main liquid crystal, two reactive monomers and a light starting agent. By the mixed chiral dopants of different rate, the blue-phase liquid crystal formula can be utilized to effectively reduce the saturation voltage of the blue-phase liquid crystal so as to minimize energy consumption.

Owner:AU OPTRONICS CORP

Insulated-gate bipolar transistor with embedded island structure

InactiveCN102842612AImprove the withstand voltage levelIncrease the doping concentrationSemiconductor devicesIon implantationElectric field

An insulated-gate bipolar transistor with an embedded island structure belongs to the technical field of power semiconductor devices, and adopts a structure that a P-type embedded island and an N-type carrier storage layer structure are respectively introduced below the surface of an MOS (Metal Oxide Semiconductor) structure of a device. During forward blocking, the charge and the auxiliary electric field which are introduced by the P-type embedded island can weaken the peak electric field below the MOS structure so as to improve the voltage resistance of the device. During backward blocking, owing to high doping concentration or large thickness of the N-type carrier storage layer, the potential barrier of a cavity is lifted, the concentration of carriers near the emitting electrode is enhanced, accordingly, better carrier distribution is acquired, the forward saturation voltage drop of the device is reduced, better forward conduction voltage drop and turn-off loss compromise are obtained. The introduced P-type embedded island and N-type carrier storage layer are formed through ion implantation, epitaxy and other processes before the formation of a P-type base region. The insulated-gate bipolar transistor is suitable for the field of semiconductor power devices and power integrated circuits from low power to high power.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

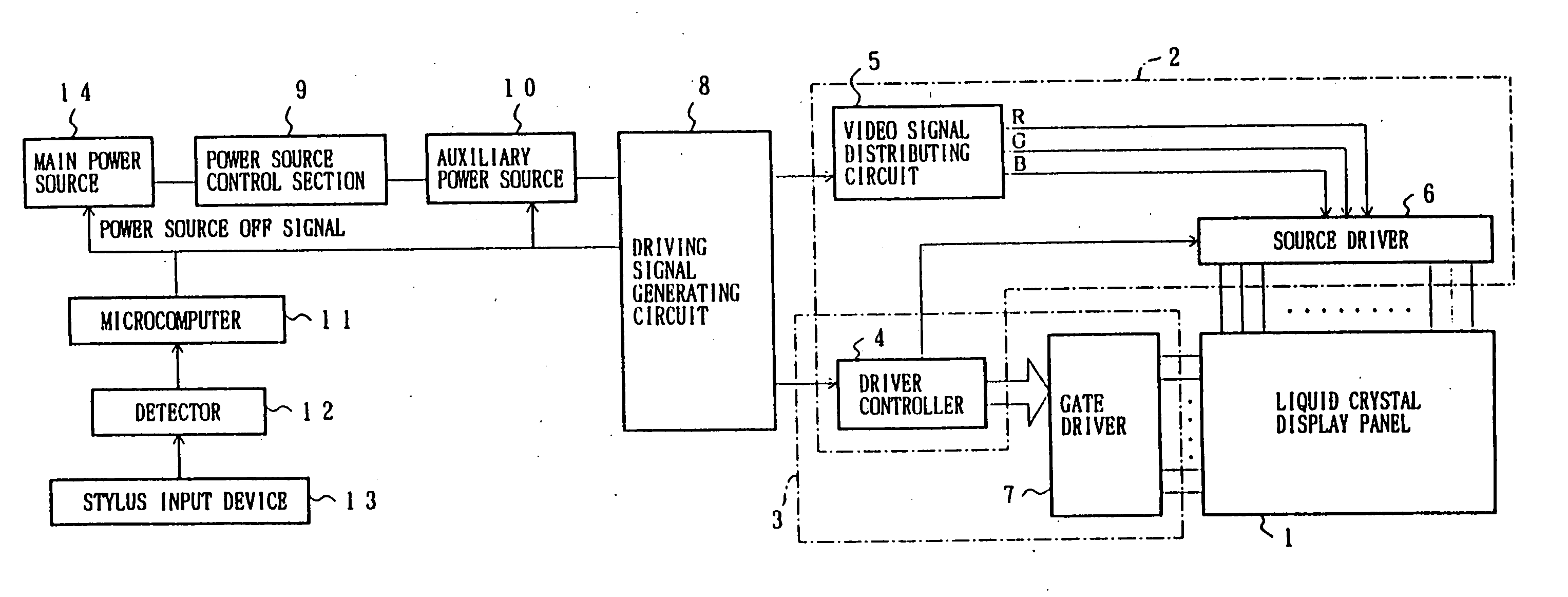

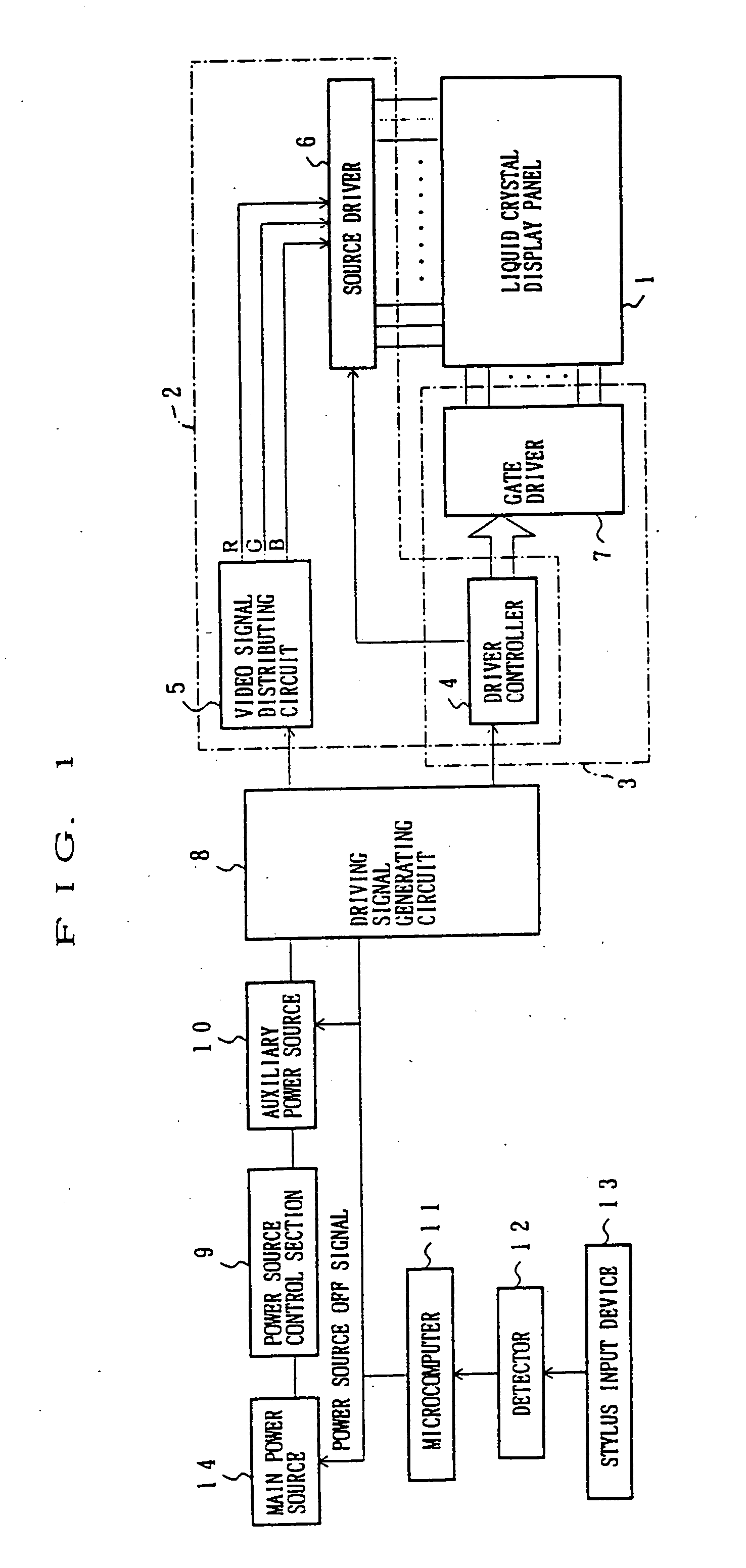

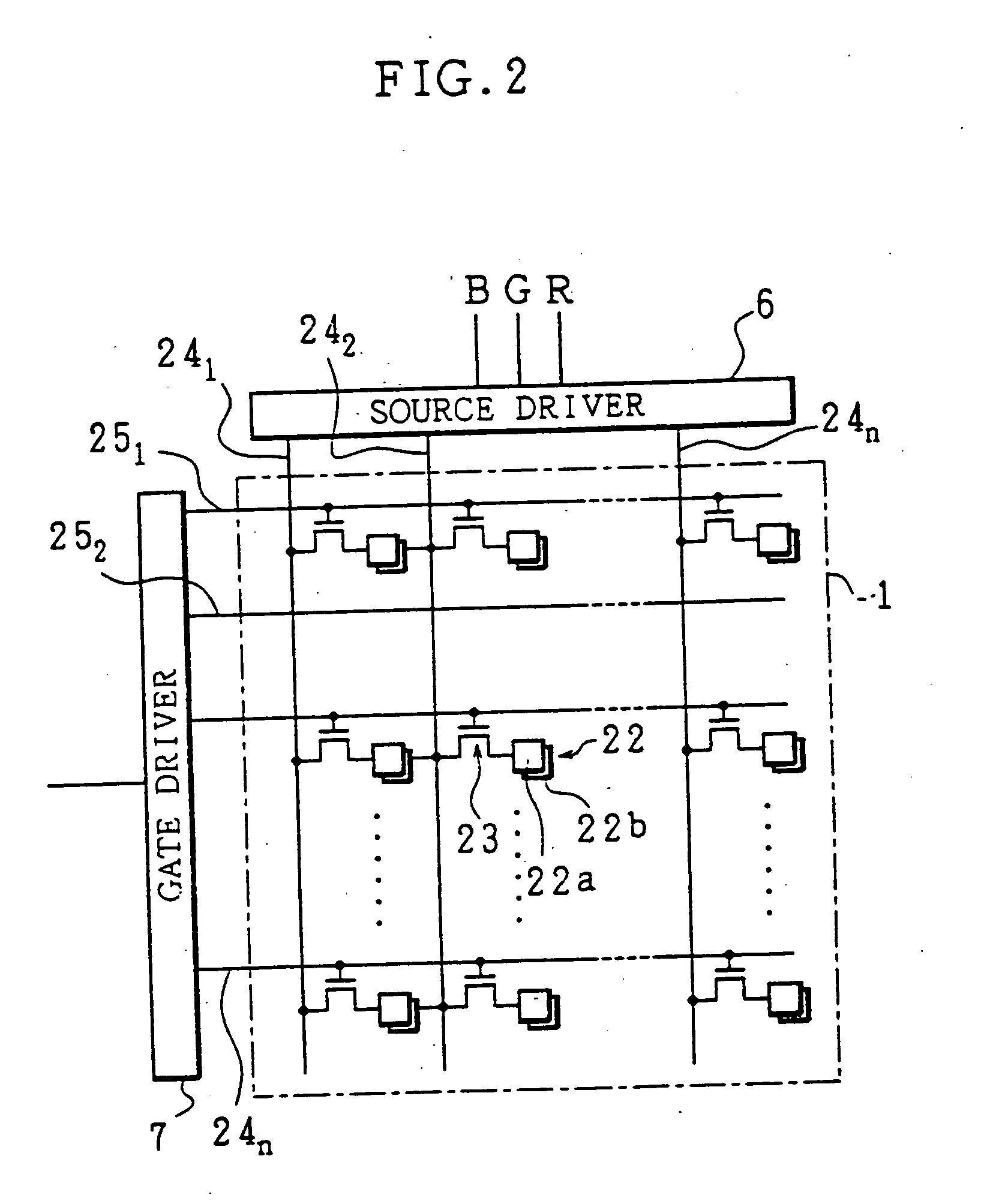

Erasing device for liquid crystal display image and liquid crystal display device including the same

InactiveUS20060007217A1Inhibit deteriorationErase an afterimage quicklyCathode-ray tube indicatorsInput/output processes for data processingActive-matrix liquid-crystal displayLiquid-crystal display

An erasing device for a liquid crystal display image of the present invention is furnished with an auxiliary power source for continuously supplying power source to a liquid crystal display panel for a certain period after the main power source of the main body of the liquid crystal display device is turned OFF. Upon input of a power source OFF signal directing to turn OFF the main power source, a driving signal generating circuit and a driver controller light up the liquid crystal display panel entirely on a saturation voltage of the liquid crystal and subsequently shut off the same entirely using the power supply from the auxiliary power source. Consequently, it has become possible to erase an afterimage quickly on an active matrix liquid crystal display panel with a memory maintaining function of a liquid crystal display device, thereby not only upgrading the display quality, but also preventing deterioration of the liquid crystal caused by an application of an abnormal voltage associated with the occurrence of an afterimage.

Owner:SHARP KK

Semiconductor resistor and method for manufacturing the same

InactiveUS20060076585A1Good saturation voltage characteristicImprovement in saturation voltage characteristicTransistorSolid-state devicesSaturation voltageEngineering

An object of the present invention is to provide a semiconductor resistor that allows improvement in saturation voltage characteristics and a method for manufacturing the same. The semiconductor resistor of the present invention is formed on the substrate on which a GaAs FET is formed. The GaAs FET includes: a channel layer; a Schottky layer formed on the channel layer and made of undoped InGaP; and a contact layer formed on the Schottky layer. The semiconductor resistor includes: a contact layer including a part of the contact layer isolated from the GaAs FET; an active region including a part of the Schottky layer and a part of the channel layer, both of which are isolated from the GaAs FET; and two ohmic electrodes formed on the contact layer, and the Schottky layer isolated from the GaAs FET is exposed in an area between the two ohmic electrodes.

Owner:PANASONIC CORP

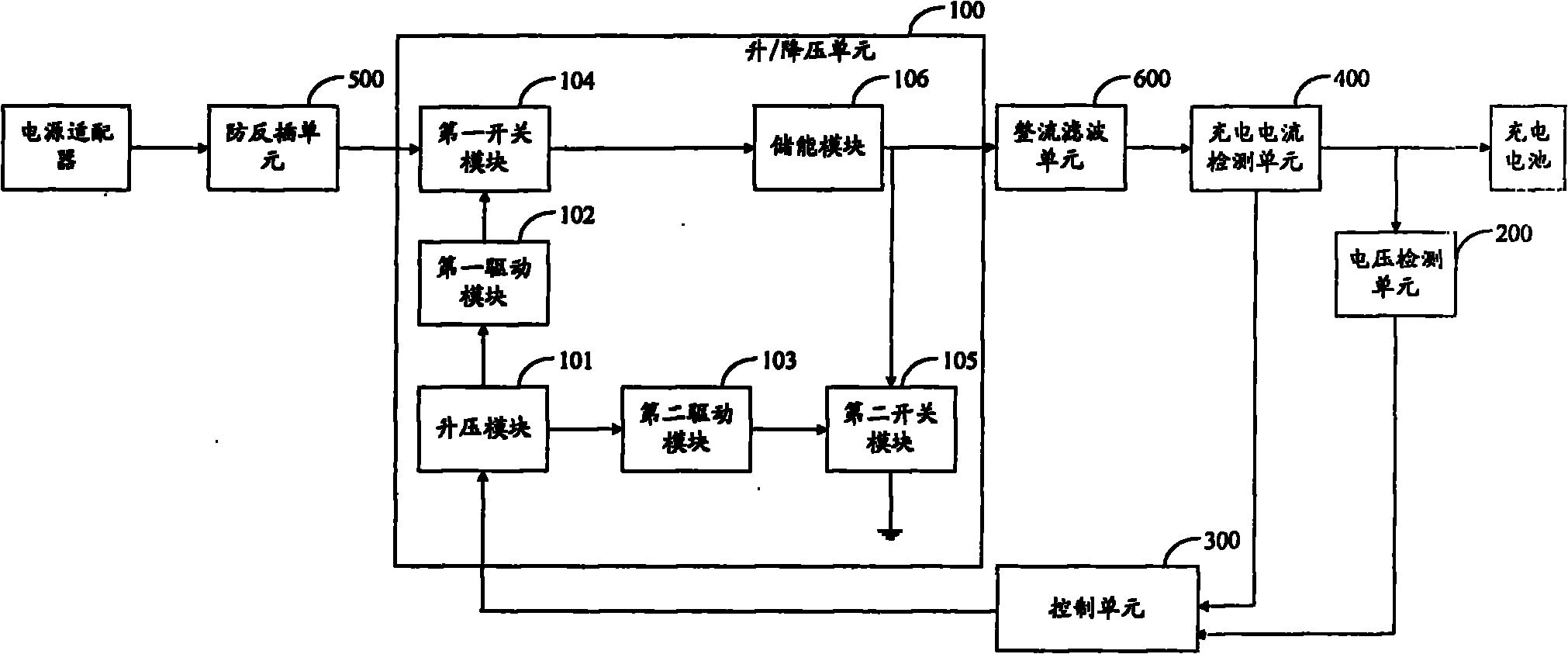

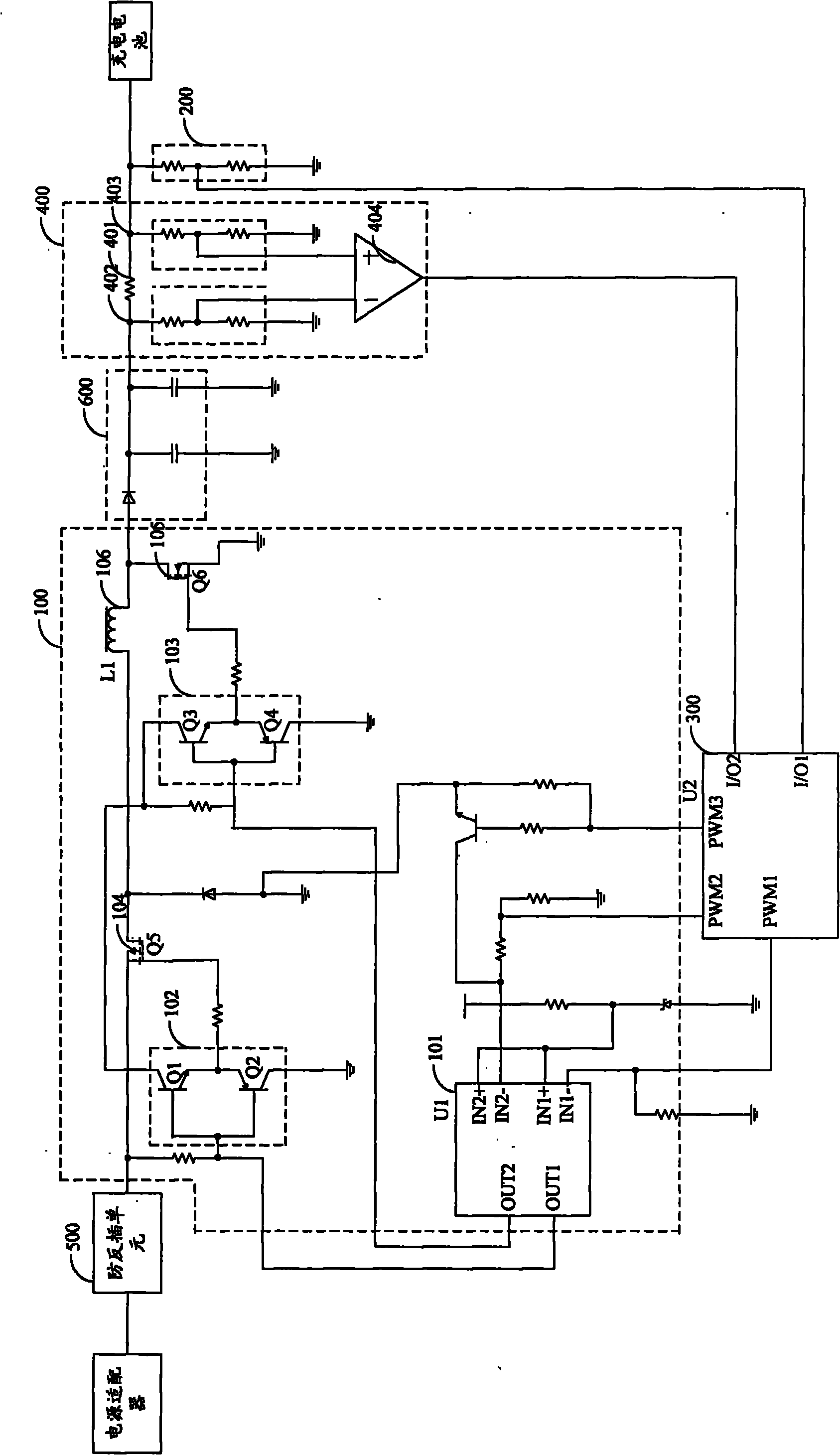

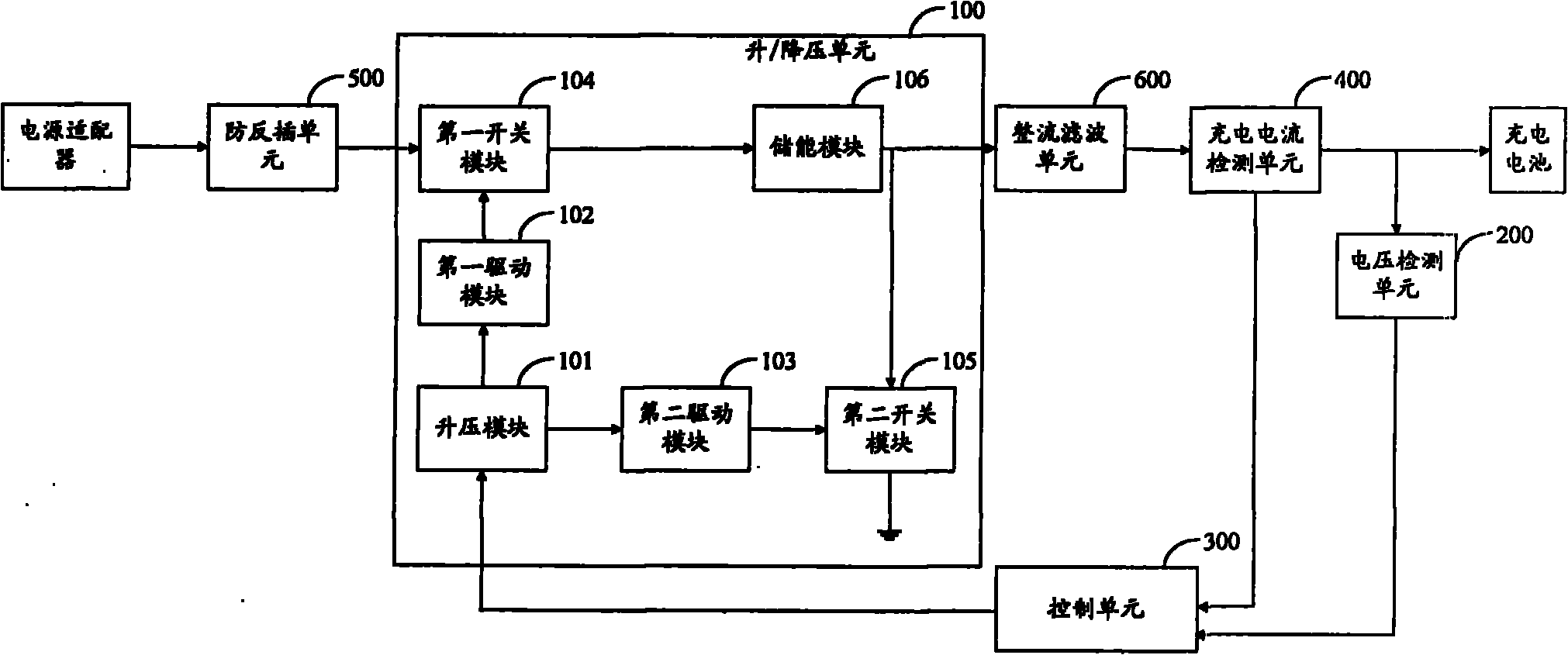

Charging management circuit and power supply adapting device

ActiveCN101807805AEffective expansionBatteries circuit arrangementsElectric powerEngineeringSaturation voltage

The invention is applicable to the battery power supply equipment technical filed and provides a charging management circuit and a power supply adapting device; wherein the charging management circuit comprises a boosting / reducing unit, a voltage detection unit and a control unit. In the invention, the charging management circuit regulates the charging voltage output by the power supply adapter to be voltage matched with saturation voltage of rechargeable battery, thus the charging voltage output by the power supply adapter is effectively expanded, and the power supply adaptor can cause the battery to be full of power even the charging voltage output by the power supply adapter is less than the saturation voltage of rechargeable battery.

Owner:SHENZHEN CERTAINN TECH CO LTD

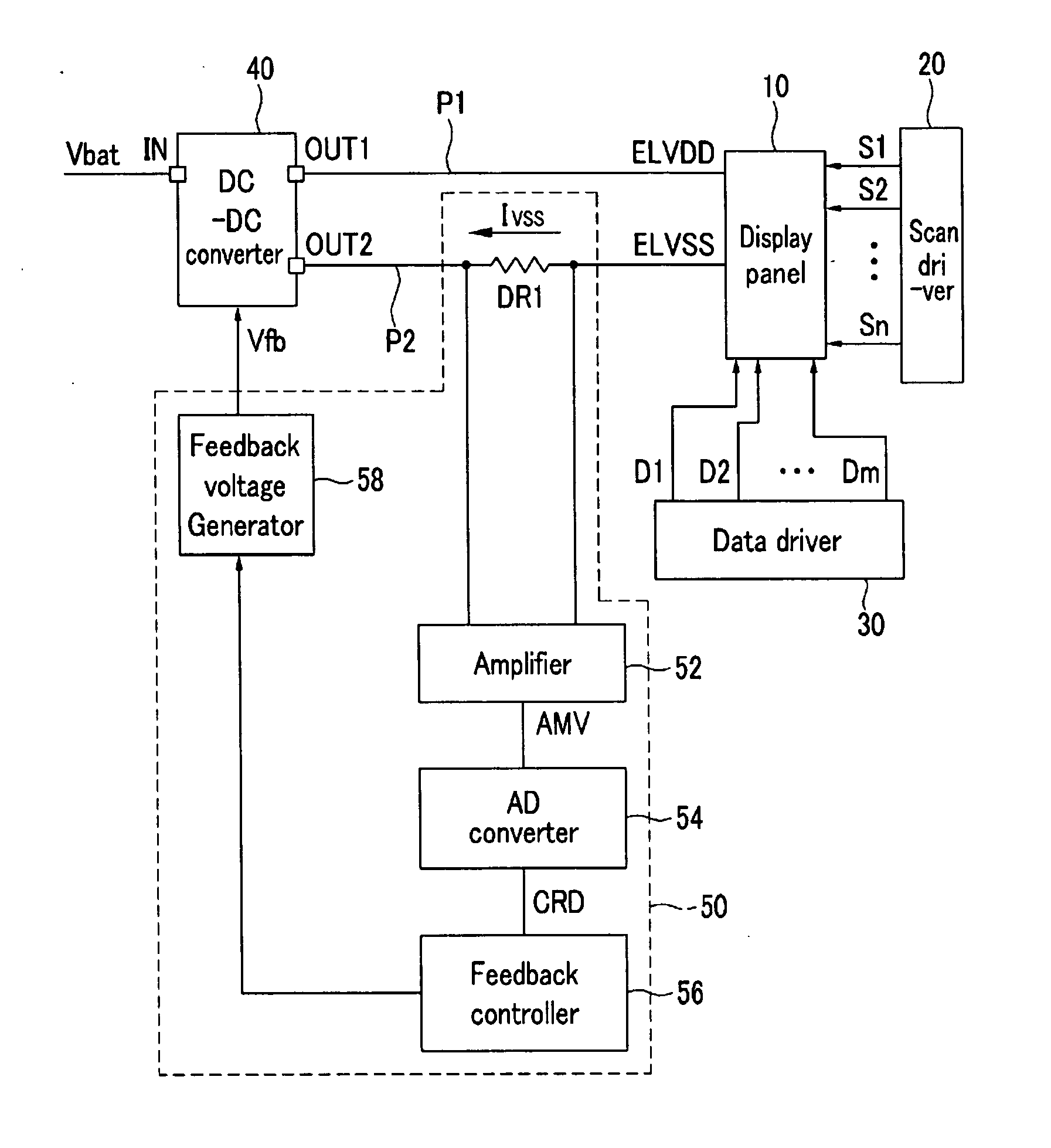

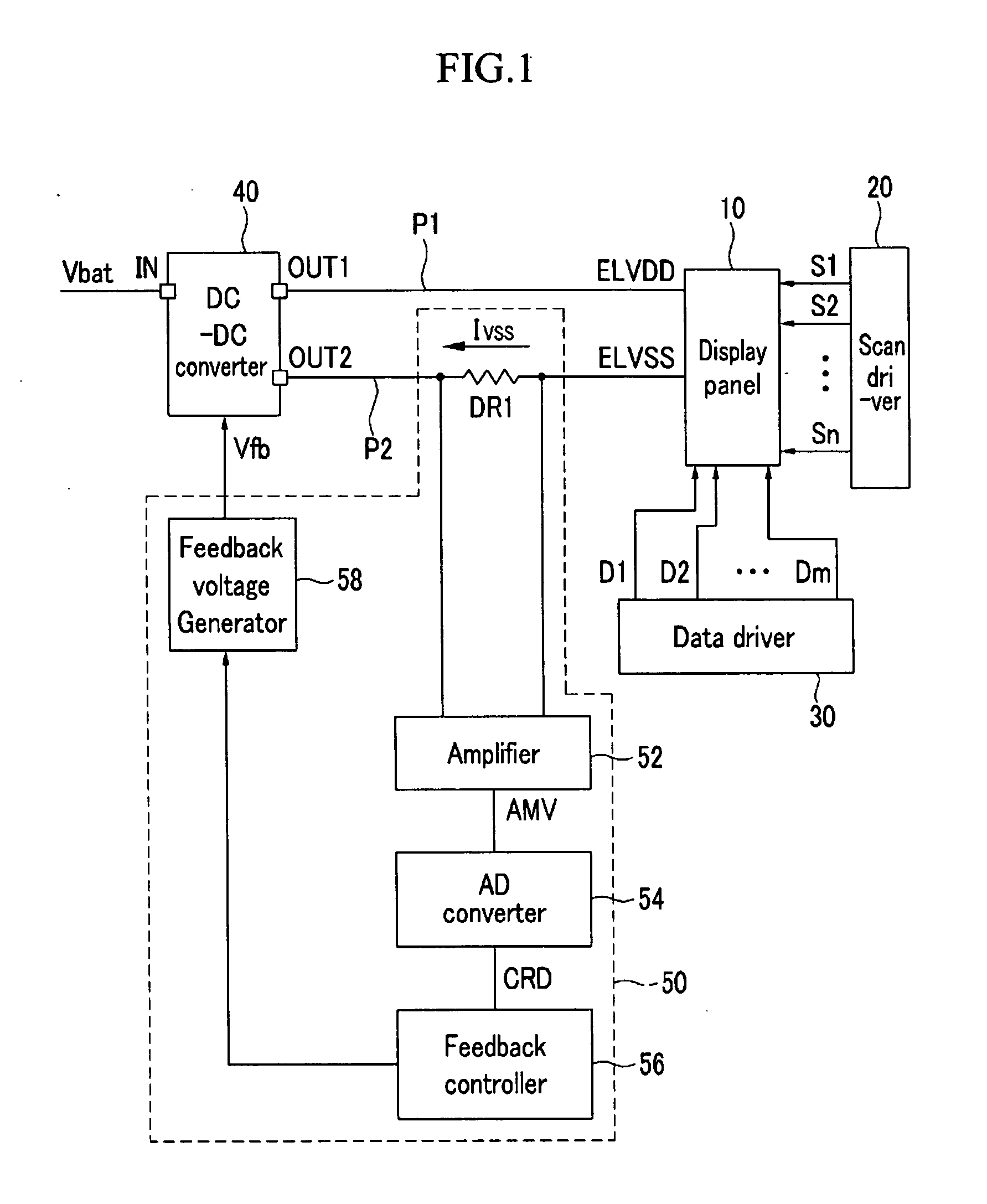

Display device and driving method thereof

ActiveUS20110050669A1Cathode-ray tube indicatorsInput/output processes for data processingControl powerDisplay device

A driving method of a display device that includes a display panel including a plurality of light emitting elements, is supplied with a power source voltage, and includes a saturation region and a non-saturation region according to variation of a panel current flowing to the display panel is provided. The driving method includes sensing the panel current, determining the power source voltage and the panel current, controlling a feedback voltage to drive the power source voltage to be equal to a saturation voltage corresponding to a saturation point at a boundary between the saturation region and the non-saturation region based on the determined power source voltage and the determined panel current, and controlling the power source voltage according to the feedback voltage to supply the controlled power source voltage to each of the plurality of light emitting elements.

Owner:SAMSUNG DISPLAY CO LTD

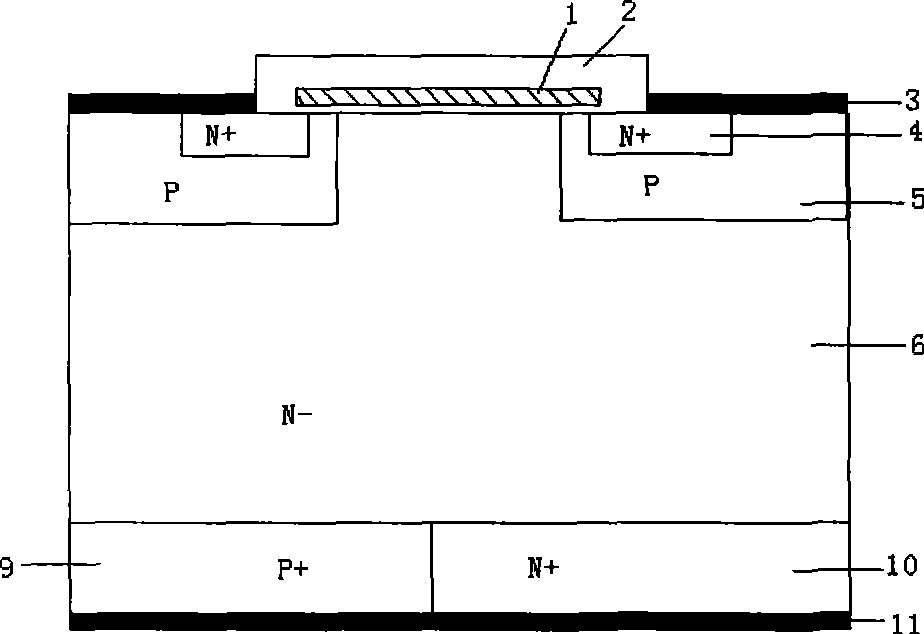

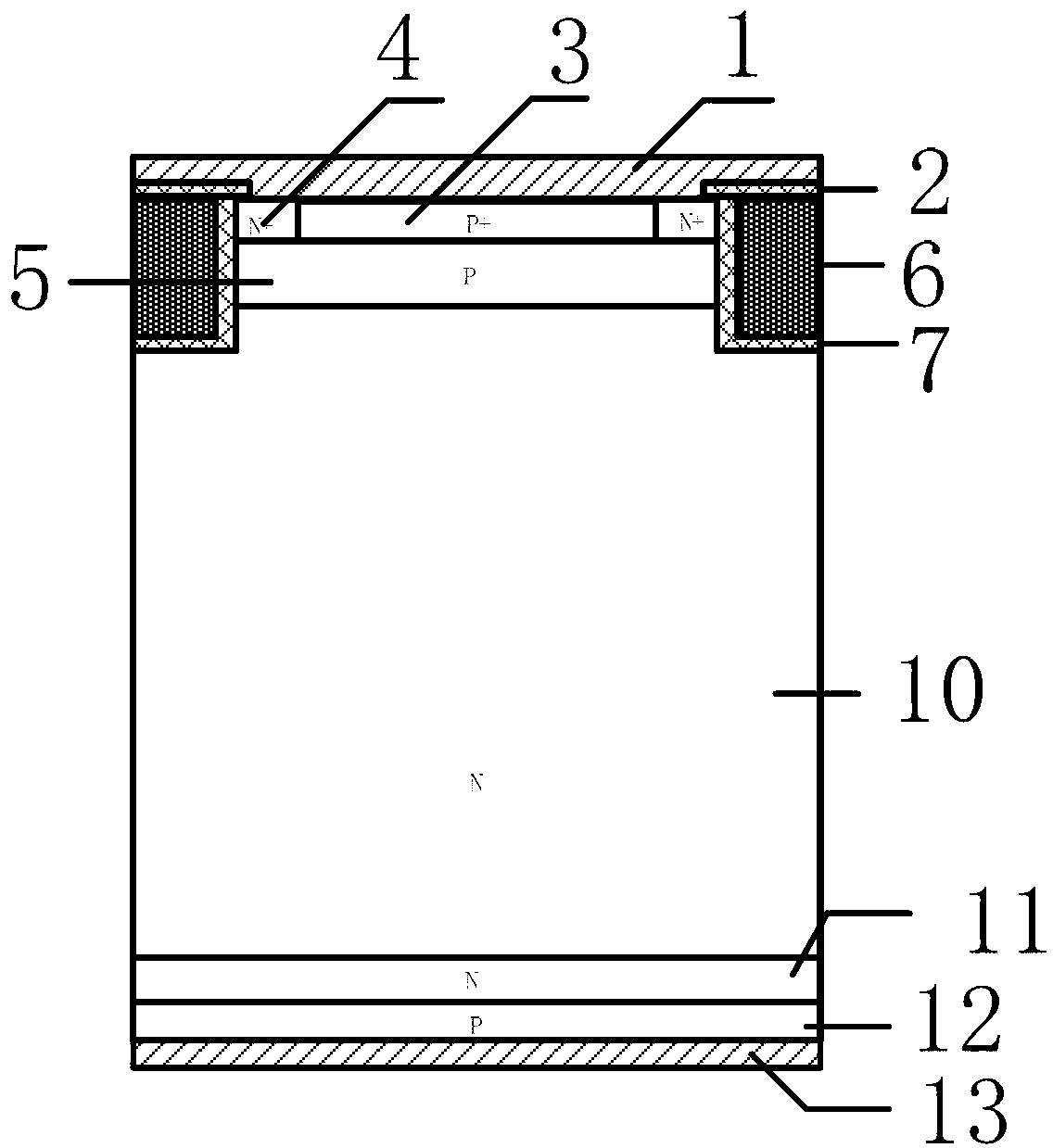

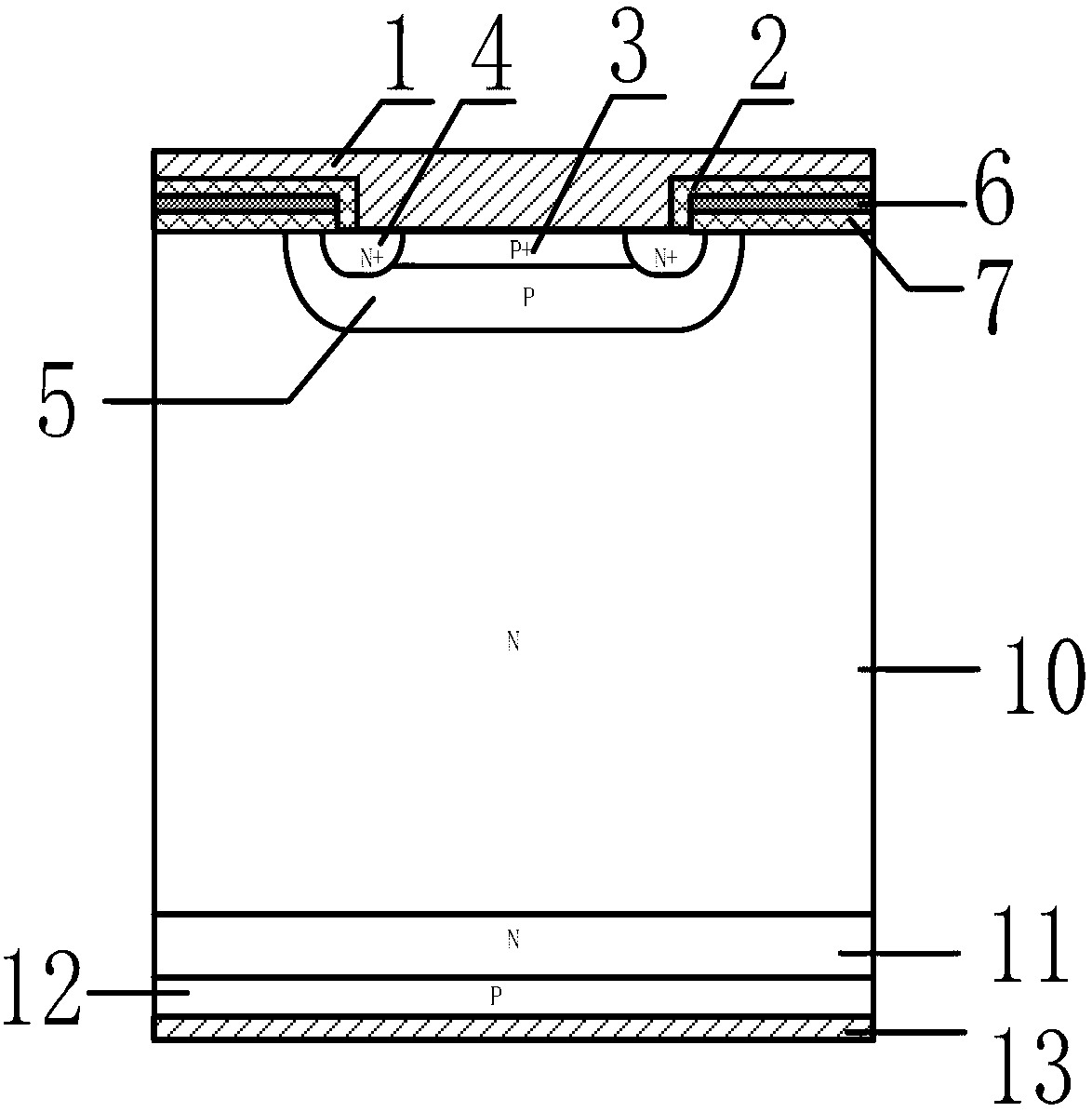

Electron injection enhanced high voltage IGBT and manufacturing method thereof

ActiveCN105047705AMeet application requirementsLower saturation voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHigh voltage igbtElectron injection

The invention discloses an electron injection enhanced high voltage IGBT. Gate oxide layers are arranged in a trench in a middle part on an n- silicon substrate and flat surface parts at two sides, and a polycrystalline silicon layer is arranged on the gate oxide layers, which is called a trench-planar gate G; two sides of the trench-planar gate G are each provided with a p base region on the n- silicon substrate, the p base regions are isolated from the trench-planar gate G through the gate oxides, and in each p base region an upper surface of an n+ emitter region and the p base region are short-circuited to form an emitting electrode E; joints of the upper side of an n- drift region and bottoms of the p base regions at the two sides are provided with discrete n carrier storage layers; and an n field stop layer, a p+ collector region and a collector electrode C are arranged in sequence under the n- drift region. The high voltage IGBT structure provided by the invention remarkably improves saturation voltage when a device is turned on, blocking voltage is high, on-state loss is low, and latch current density is relatively high.

Owner:XIAN SEMIPOWER ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com