Electron injection enhanced high voltage IGBT and manufacturing method thereof

A technology of electron injection and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of reduced current capacity, high process cost, and prone to latch-up, etc., to reduce saturation voltage and meet application requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

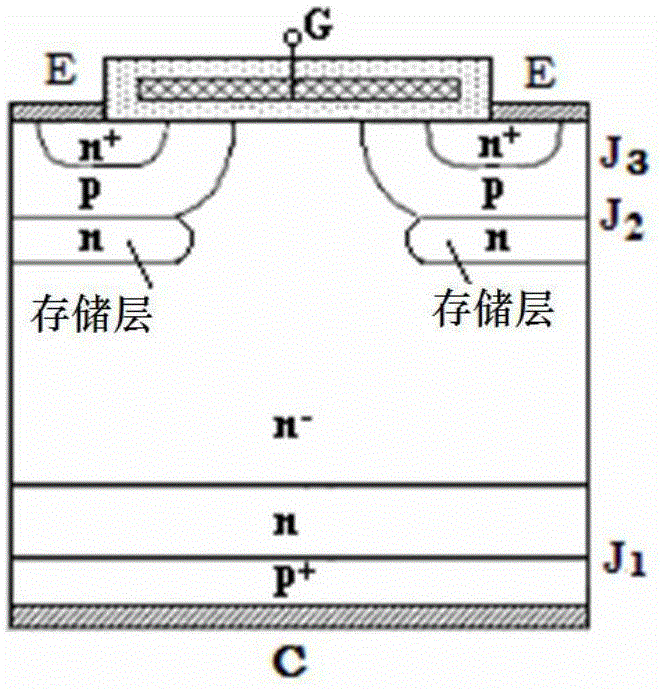

[0037] refer to figure 1 , the conductive channel of the existing CS-IGBT structure is on the surface, and its length is determined by the p base region and n + The difference in lateral junction depth of the emitter diffusion is determined. In addition, below the p base region there is a slightly higher concentration than the n - n-carrier storage layer in the drift region.

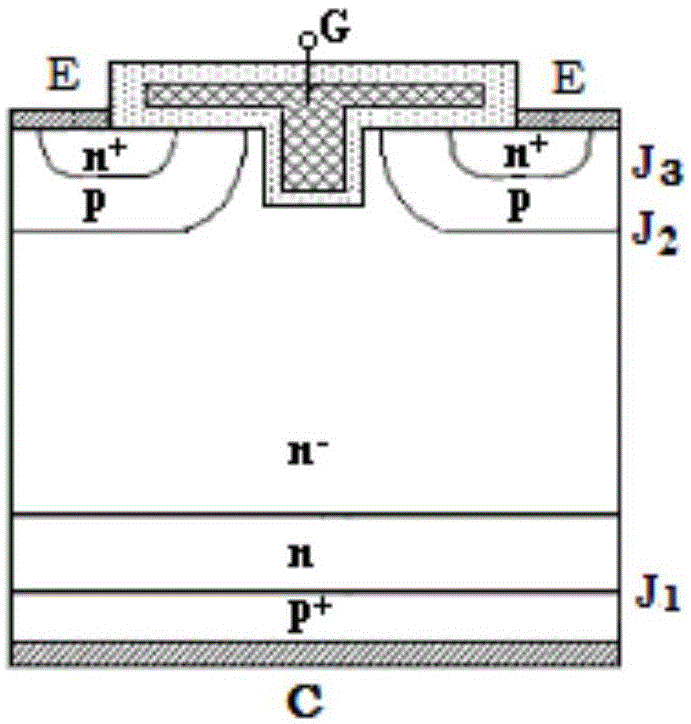

[0038] refer to figure 2 , the conductive channel of the existing TP-IGBT structure is also on the surface, only the n between the two p-base regions - A shallow groove is set above the drift region, and the depth of the groove is smaller than that of the p-base region, and the width of the groove is smaller than the distance between the p-base regions on both sides.

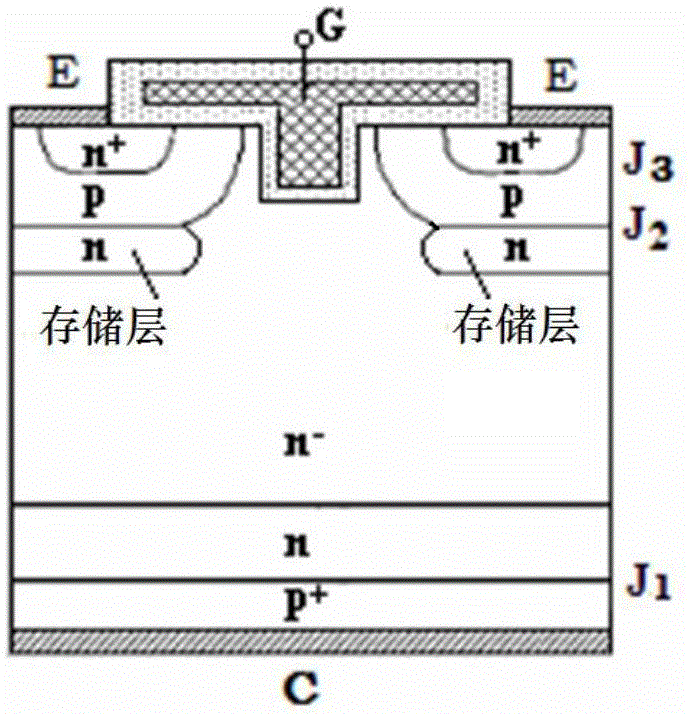

[0039] refer to image 3 , the electron injection enhanced high voltage IGBT structure of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com