Nerve conduit material having topological structure and modified by CNT/conducting polymer composite coating and preparation method of nerve conduit material

A technology of conductive polymers and nerve guides, applied in coatings, medical science, prostheses, etc., can solve problems such as poor functional recovery, poor conductivity, and non-conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

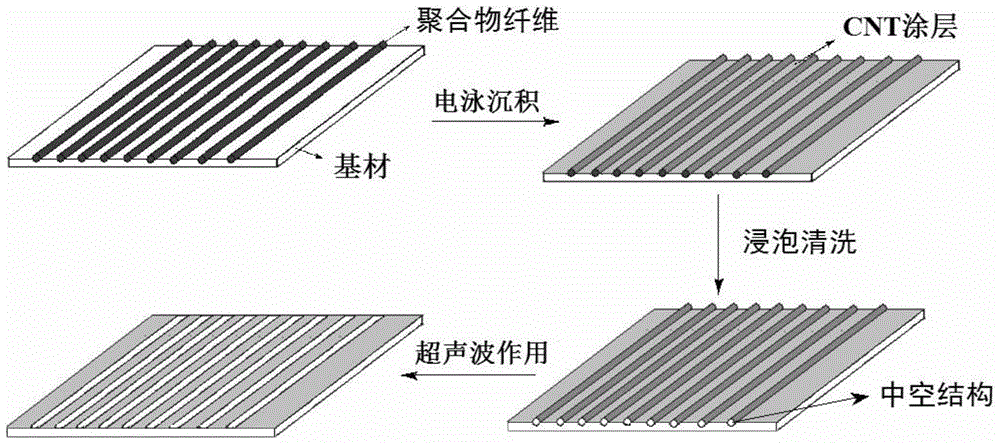

Method used

Image

Examples

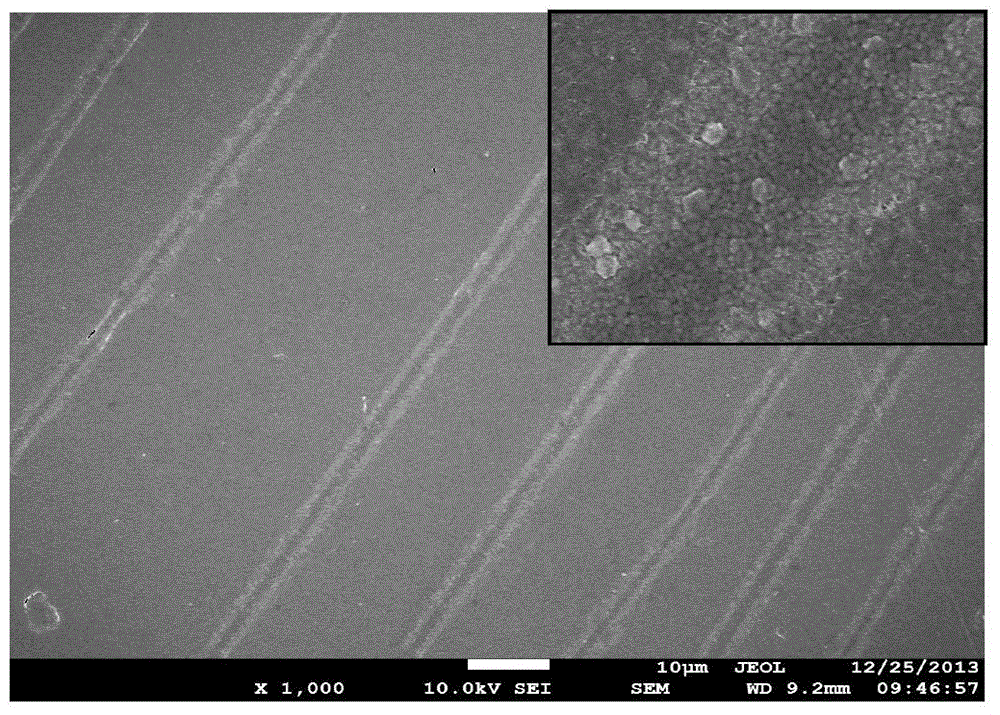

Embodiment 1

[0031] Oriented polylactic acid (PLLA) fibers are achieved by electrospinning technology. 0.36g of PLLA was dissolved in 2.65g of a mixture of chloroform and ethanol (volume ratio: 3:1), and stirred for 0.5h to obtain a uniform PLLA solution for spinning. The electrospinning voltage was set at 6.5kV, and the distance from the receiver to the needle tube was 7.5cm, so that the fiber diameter was between 1-2μm, and then the PLLA spinning fibers were collected on the catheter substrate through static parallel electrodes, and placed Bake in an oven at 60°C for 0.5h, take it out and set aside.

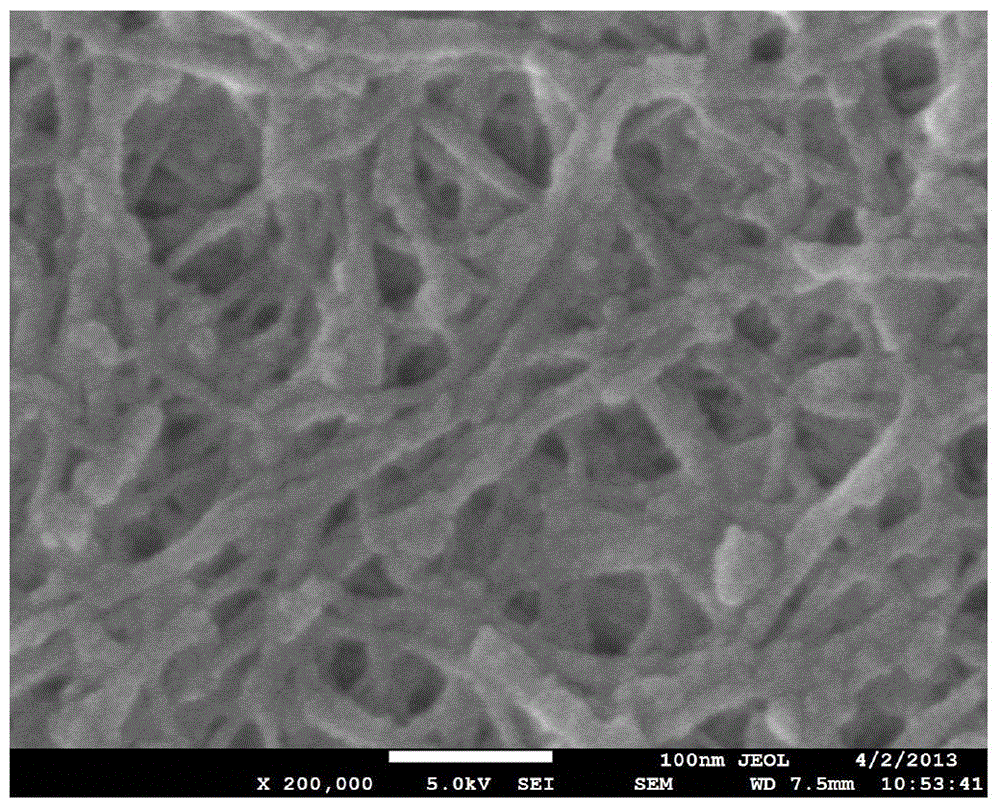

[0032] Measure 75 μL of 0.1M Al(NO 3 ) 3 / ethanol solution was added to a glass bottle containing 19.5mL of absolute ethanol, and then 0.5mL of mixed acid-treated single-walled CNT / ethanol dispersion (dispersion concentration: 0.5mg / mL) was added to the glass bottle, under the condition of 40kHz After ultrasonication for 5min, it was used for electrophoretic deposition. In this embodime...

Embodiment 2

[0038] A CNT-coated modified catheter material with an oriented groove structure was prepared in the same manner as in Example 1. The electrospinning voltage was set at 8 kV, and the electrophoretic deposition time was set at 10 min. The modified catheter prepared above was used as a working electrode, and in a mixed aqueous solution of 0.1M sodium p-toluenesulfonate and 0.01M 3,4-ethylenedioxythiophene, electrochemical pulse polymerization was used to deposit a conductive electrode on the surface of the CNT bundle. polymer. Electrochemical deposition was carried out in an electrochemical workstation, using a three-electrode system, Ag / Ag + The electrode served as a reference electrode, and the Pt sheet served as a counter electrode. Polymerization potential 1.0V, deposition time (T d ) is 5s, sleep time (T r ) for 600s, repeated 12 cycles during the polymerization deposition process, and obtained a CNT / conductive polymer composite coating with a directional groove structur...

Embodiment 3

[0043] A CNT-coated modified catheter material with an oriented groove structure was prepared in the same manner as in Example 1. The electrospinning voltage was set at 8 kV, and the electrophoretic deposition time was set at 10 min. The modified electrode prepared above was used as a working electrode, and a conductive polymer was deposited on the surface of the CNT bundle by electrochemical pulse polymerization in a mixed aqueous solution of 0.1M lithium perchlorate and 0.02M aniline. Electrochemical deposition was carried out in an electrochemical workstation, using a three-electrode system, Ag / Ag + The electrode served as a reference electrode, and the Pt sheet served as a counter electrode. Polymerization potential 1.0V, deposition time (T d ) is 5s, sleep time (T r ) for 600s, repeated 4 cycles during the polymerization deposition process, and obtained the CNT / conductive polymer composite coating modified nerve conduit material with directional groove structure, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com