Patents

Literature

41results about How to "Excellent chemical corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free anti-flaming polycarbonate/thermoplastic polyester resin composition

InactiveCN101104731AExcellent chemical corrosion resistanceImprove liquidityPolyethylene terephthalateAntioxidant

The invention discloses a halogen-free flame retardant polycarbonate / thermoplastic polyester resin composition, whose components and proportions are as follow: polycarbonate 50 percent to 85 percent, thermoplastic polyethylene terephthalate resin 5 percent to 30 percent, core-shell graft coplolymer 2 percent to 15 percent, phosphorus-containing flame retardant 5 percent to 15 percent, super fine talc powder 0 to 20 percent and phosphite antioxidant 0 to 0.05 percent, the above contents are all in weight percentage. The product of the invention has the advantages that no large amount of harmful gas is released when the product is burned with environmental protection and safety.

Owner:SHANGHAI PRET COMPOSITES

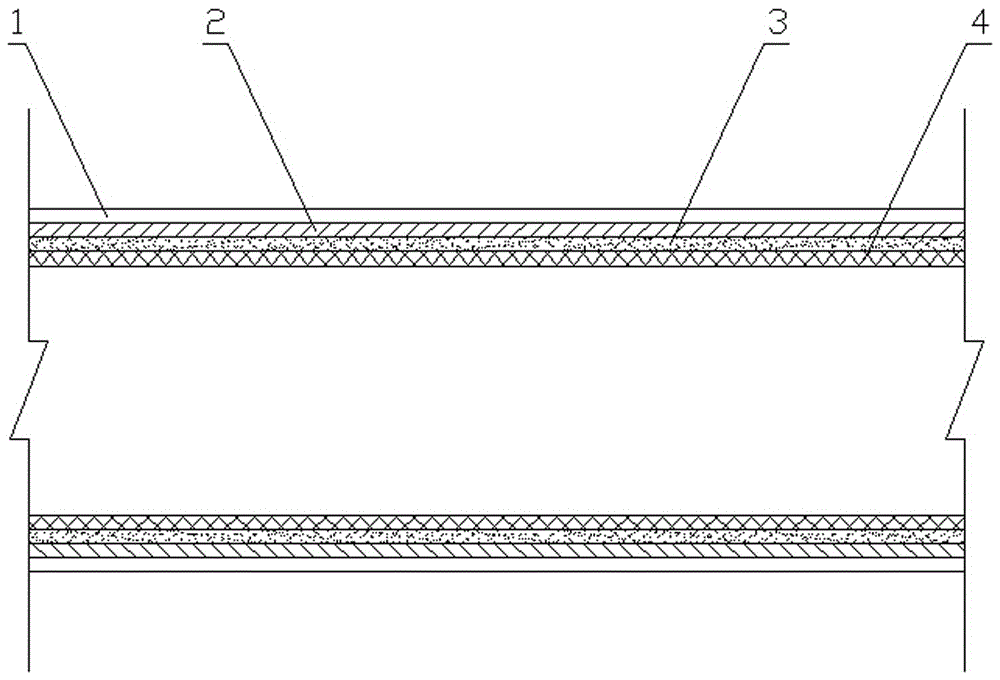

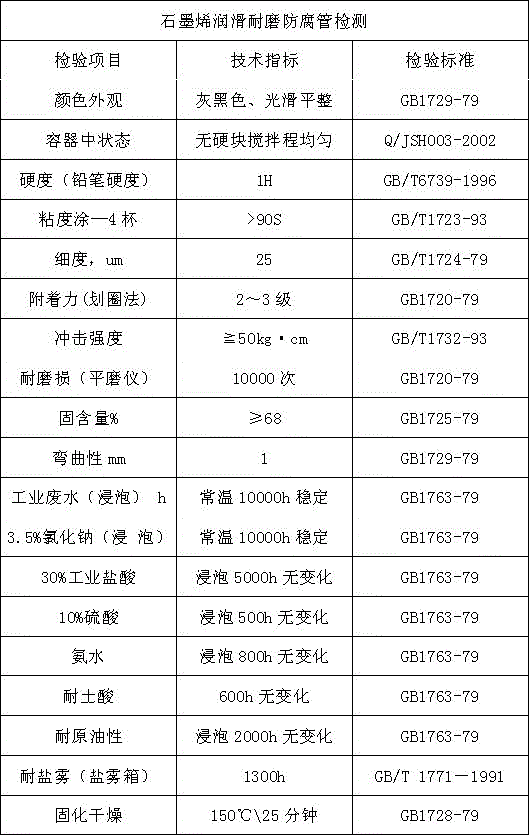

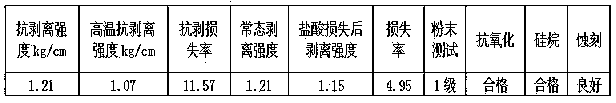

Lubricant, wear-resistant and anti-corrosion graphene pipe and preparation process thereof

InactiveCN106337977AExcellent chemical corrosion resistanceStrong adhesionPretreated surfacesSpecial surfacesAdhesive cementGraphene

The invention provides a lubricant, wear-resistant and anti-corrosion graphene pipe and a preparation process thereof and relates to the technical field of petroleum equipment. The pipe comprises an oil pipe, a lubricant, wear-resistant and anti-corrosion layer, an adhesive layer and a protecting layer, wherein the oil pipe is in a hollow cylindrical structure, the inner wall of the oil pipe is sprayed with the lubricant, wear-resistant and anti-corrosion layer, the adhesive layer and the protecting layer from outside to inside sequentially by a high-pressure gas-free spraying system in a hot-air curing manner. The lubricant, wear-resistant and anti-corrosion layer is made of lubricant, wear-resistant and anti-corrosion powder, and the thickness of the lubricant, wear-resistant and anti-corrosion layer is larger than 100um; the adhesive layer consists of an adhesive, and the thickness of adhesive layer is 120-260 mum; the protecting layer consists of graphene, and the thickness of the protecting layer is 0. 5-3.7 mum. The graphene lubricant, anti-wear and anti-corrosion pipe reduces conveying resistance to the oil pipe, and when the pipe is applied as a gas field well pipe is used to improve gas well productivity, reduce corrosion of inner wall of gas field pipeline, reduce the number of pigging and prolong service life of gas field pipeline.

Owner:大庆市盛日石油技术开发有限公司

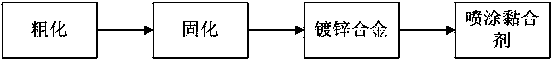

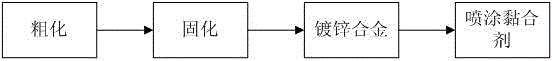

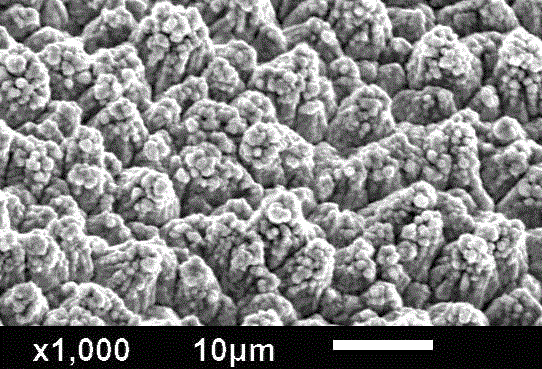

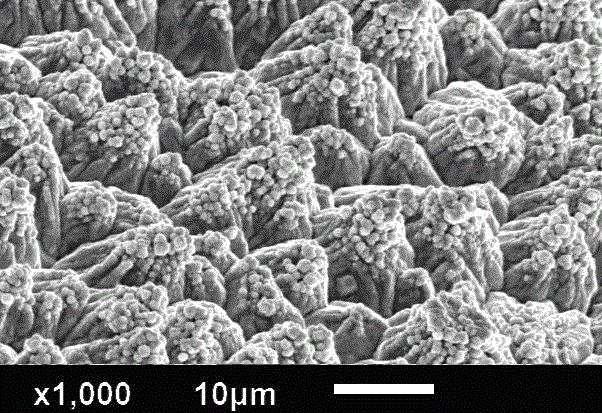

Process method for carrying out surface treatment on electrolysis copper foil, and cooper foil treated by using the same

ActiveCN103469267AExcellent chemical corrosion resistanceExcellent room temperature oxidation resistanceElectrolysisAdhesive

The present invention discloses a one-time surface treatment method for electrolysis copper foil. The process method comprises: 1, coursing solution preparation: carrying out mixing dissolving on cathode cooper, sulfuric acid and soft water to produce a copper sulfate solution, adding an additive A to the copper sulfate solution, completely mixing, and adding the obtained mixture to a coursing tank to be subjected to electroplating; 2, curing solution preparation: carrying out mixing dissolving on cathode cooper, sulfuric acid and soft water to produce a copper sulfate solution, and adding the copper sulfate solution to a curing tank to be subjected to electroplating; 3, zinc plating alloy solution preparation and a passivation treatment: respectively dissolving zinc sulfate, chromic anhydride and phosphoric acid, adding the zinc sulfate solution to a chromic acid and phosphoric acid mixed solution, adding an additive D solution to the obtained mixing solution in a dropwise manner while adjusting the pH value by using sodium hydroxide, completely mixing, and then adding the obtained mixture to a zinc plating alloy tank to be subjected to electroplating; and 4, spray coating of an adhesive: dissolving an adhesive in water, and carrying out cycle spray coating of the adhesive on the surface of copper foil. According to the present invention, the process is simple, the steps are less, passivation solution components are stable, and the treated electrolysis copper foil has excellent physical properties.

Owner:江西省江铜铜箔科技股份有限公司

Preparation method for anti-high-temperature oxidative damage ZrB2-SiC-ZrC-W multiphase ceramic

The invention belongs to the technical field of engineering material preparing, and specifically relates to a preparation method for anti-high-temperature oxidative damage ZrB2-SiC-ZrC-W multiphase ceramic. The preparation method aims at solving the problem that when the temperature is over 1600 DEG C, the stability of an existing ZrB2 base ceramic material is poor. The preparation method comprises the steps that 1, raw materials are prepared; 2, mixing and ball milling are conducted, and sizing agents are obtained; 3, drying and grinding are carried out, and mixed powder materials are obtained; and 4, hot pressed sintering is conducted, and the ZrB2-SiC-ZrC-W multiphase ceramic is obtained. The anti-high-temperature oxidative damage ZrB2-SiC-ZrC-W multiphase ceramic has the advantages that 1, the consistency is greater than 99%; 2, compared with the existing ZrB2 base ceramic material, the anti-high-temperature oxidative damage performance is more prominent. The method is mainly used for preparing the anti-high-temperature oxidative damage ZrB2-SiC-ZrC-W multiphase ceramic.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

Epoxy floor coating

InactiveCN103305091AExcellent chemical corrosion resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses an epoxy floor coating, which is characterized by comprising a host and a curing agent, wherein the mixing ratio of the host to the curing agent is 2: 1, and wherein the host comprises the following components in parts by weight: 22-50 parts of epoxy resin, 10-30 parts of filler, 1-8 parts of thickener, 4-7 parts of auxiliaries, 18-35 parts of pigment or color cream and 6-20 parts of plasticizer, and wherein the curing agent is fatty amine and / or polyamide. The epoxy floor coating provided by the invention has excellent chemical corrosion resistance, high hardness, and excellent physical characteristics such as impact resistance, scrub resistance, abrasive resistance and the like; the epoxy floor coating is simple to prepare and convenient for construction; the epoxy floor coating is prepared from environment-friendly, solvent-free good-quality epoxy resin; the epoxy floor coating is wearproof and insulating, and hard and fine in surface; the epoxy floor coating is excellent in resistance to acid, to alkali, to salt, to oil, to esters, and to drugs; the epoxy floor coating is waterproof and non-absorbent, easy to flush, and simple and easy to clean and maintain; besides, the epoxy floor coating is bright and comfortable, smooth and beautiful in appearance with mirror face effect.

Owner:杭州宝力物资再生利用有限公司

Fluorine-containing heavy-duty anticorrosive coating and its application

InactiveCN102732124AStrong adhesionGood chemical corrosion resistanceAnti-corrosive paintsChemistryFluorocarbon

The invention relates to a fluorine-containing heavy-duty anticorrosive coating and its application. The coating comprises an epoxy vinyl resin, hexafluorobutyl methacrylate, methacrylate, a diluent and an initiator, wherein the mass ratio of the epoxy vinyl resin to the hexafluorobutyl methacrylate to the methacrylate is 4:0.5-6:0-0.4; the mass of styrene accounts for 20-65% of the mass of the epoxy vinyl resin; and the amount of he initiator accounts for 0.1-1% of the total mass of the coating. The fluorine-containing heavy-duty anticorrosive coating of the invention combines the excellent adhesion of epoxy resin coats and good chemical anticorrosive characteristics of fluorocarbon coats, coat products of the coating have already have the chemical anticorrosive capability under extreme environments through continuous technical innovation and improvement, and simultaneously the coating products have excellent weatherability same as that of the fluorocarbon coats, excellent adhesion same as that the epoxy resin coats, and a use temperature which is near 100DEG C higher than that of the epoxy resin coats and the fluorocarbon coats averagely.

Owner:SHANGHAI UNIV

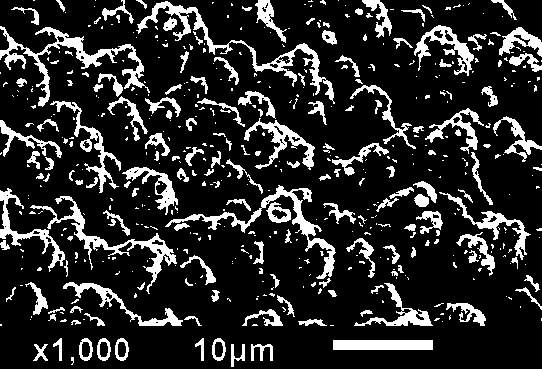

Preparation method of oil-water separation membrane

The invention discloses a preparation method of an oil-water separation membrane, and belongs to the technical field of chemical engineering and macromolecule functional materials. The preparation method includes the steps that an aluminum net is subjected to ultrasonic cleaning in an ultrasonic cleaner for 15-25 minutes through acetone and absolute ethyl alcohol, washed through deionized water to remove oil stains on the surface and dried through nitrogen; the aluminum net is soaked into an HCL water solution for 5-15 minutes, washed through deionized water and dried through nitrogen; PVC is dissolved into deionized water of 90 DEG C to be prepared into a solution, the mass concentration of the solution is 14%, nanometer SiO2 particles are ultrasonically dispersed into a PVA solution according to the proportion of 3-4 mg / ml, and a PVA / SiO2 compound is obtained after generated suspension is dried in a drying box of 60-80 DEG C; the compound is ground into powder and ultrasonically dispersed into absolute ethyl alcohol according to the proportion of 10-15 mg / ml; the aluminum net obtained in the step 2 is soaked into a PVA / SiO2 ethanol solution for about 30 minutes and dried for 1-2 hours at room temperature, and after ethyl alcohol volatilizes completely, the operation of soaking-drying is repeated 4-5 times to obtain the super-hydrophilic super-oleophobic net membrane.

Owner:SHANGHAI YUGONG MACHINERY SCI & TECH

Polyaniline-containing polyaspartate polyurea anti-corrosive paint and preparation method thereof

InactiveCN108559375AEmission reductionHigh solid contentAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceUv absorber

The invention provides polyaniline-containing polyaspartate polyurea anti-corrosive paint and a preparation method thereof and belongs to the technical field of anti-corrosive paint. The paint is prepared from a component A and a component B, wherein the component A is prepared from polyaspartate resin, a solvent, eigenstate polyaniline, pigment, functional filler, a thixotropic agent, an ultraviolet absorbent and additives; and the component B is a curing agent. The preparation method comprises the following steps: preparing the component A; weighing the component B; respectively packaging the component A and the component B; and uniformly mixing the component A with the component B before use under the condition that the molar ratio of the hydroxyl group-OH of the component A to the isocyanate group-NCO of the component B is (1.0-1.2):1.0 so as to obtain the paint provided by the invention. The paint has excellent weather resistance, adhesive force and chemical corrosion resistance,the solid content reaches 90% or above, zero VOC emission or ultra-low VOC emission is realized, the required film thickness can be obtained by construction once, the construction frequency is reduced, the working efficiency is improved, the construction period is shortened, and the cost is greatly reduceed.

Owner:BEIHUA UNIV

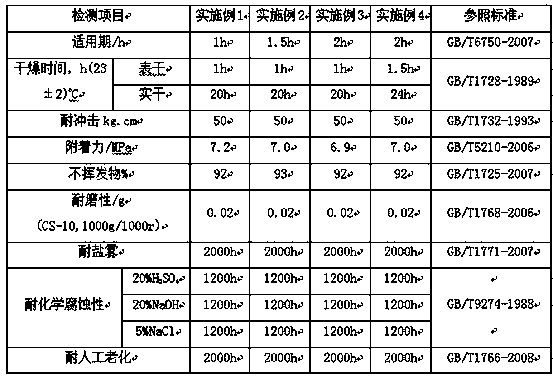

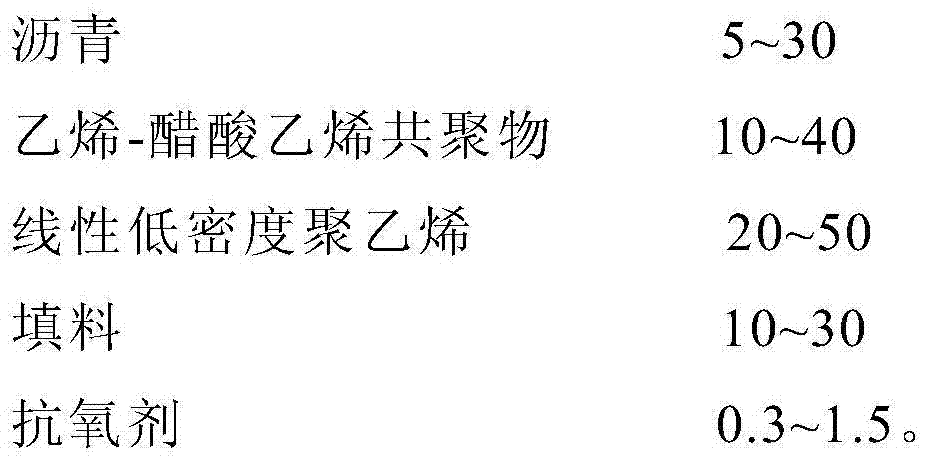

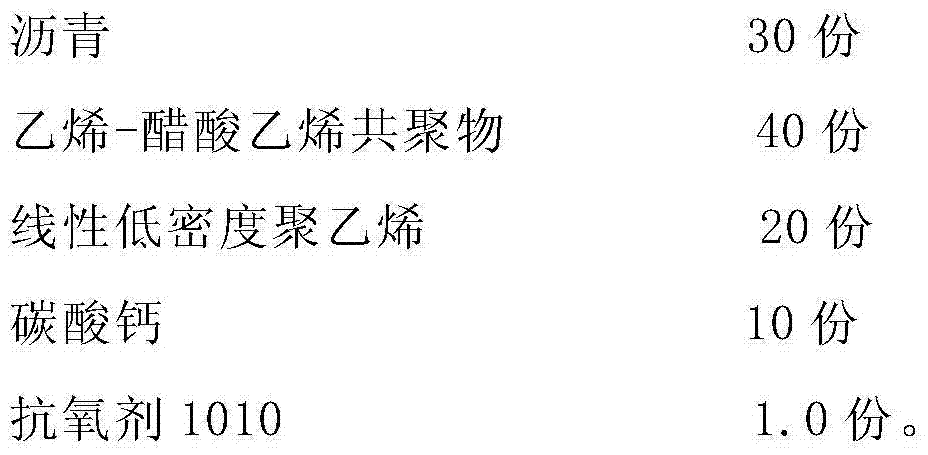

Plastic waterproof plate and preparation method therefor

InactiveCN104844886AImprove mechanical propertiesExcellent hot melt welding performanceBuilding insulationsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic waterproof plate and a preparation method therefor. The plastic waterproof plate is prepared from raw materials comprising an ethylene-vinyl acetate copolymer, linear low density polyethylene, asphalt, filler and an antioxidant. The plastic waterproof plate disclosed by the invention has excellent aging resistance and chemical medium corrosion resistance of the asphalt, excellent flexibility, tensile strength and wear resistance of the linear low density polyethylene and excellent low-temperature flexibility and sweat soldering performance of the ethylene-vinyl acetate copolymer. The composition of the product is environmentally friendly and the product can be widely suitable for waterproofness and seepage resistance of civil engineering such as a plurality of tunnels, underground civil engineering, city subways, water conservancy, artificial lakes, refuse landfills, waste residue treatment fields of petroleum plants, sewage adjusting pools and the like.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Preparation method of polyethylene nucleating agent

InactiveCN109232323AHigh crystallinityRaise the crystallization temperatureUrea derivatives preparationOrganic compound preparationPolymer scienceEvaporation

The invention discloses a preparation method of a polyethylene nucleating agent. The preparation method comprises the steps as follows: firstly, 1,3-propanediamine and phenylurea are mixed, dioxane isadded, the mixture is subjected to a reflux reaction at 100-120 DEG C for 15-20 h under the protection of nitrogen, after the reaction, a product is cooled to the room temperature; ethyl acetate is added to dissolve reactants which do not react completely; a reaction solution is washed with acid; an organic layer obtained after standing layering is dried by anhydrous sodium sulfate, rotary evaporation is performed, a solid product obtained after rotary evaporation is recrystallized by methanol, and a final product is obtained. The product obtained through a polymerization reaction of 1,3-propanediamine and phenylurea has a better crystallization promotion function on a polyethylene material, the spherocrystal size of polyethylene can be significantly reduced, and the mechanical performance of the material can be remarkably improved.

Owner:HEFEI GENIUS NEW MATERIALS

Solvent-free epoxy self-leveling heavy anticorrosive terrace coating

InactiveCN105623459AGood chemical corrosion resistanceSolve the smellAnti-corrosive paintsEpoxy resin coatingsSolvent freeCashew nut

The invention discloses a solvent-free epoxy self-leveling heavy anticorrosive terrace coating, which is composed of the following raw materials (by weight): 40-50% of epoxy resin, 5-10% of a diluent, 30-40% of a filling material, 5-10% of pigment, 3-10% of a curing agent and 1-2% of an auxiliary agent. Total percentage of the above components is 100%. According to the invention, modified liquid epoxy resin, a nonactive epoxy diluent and a cashew nut shell oil modified amine epoxy resin solvent-free curing agent are used as raw materials to obtain the terrace coating. The coating has good resistance to chemical corrosion, and the problem that existing solvent-free epoxy terrace coatings have strong smell and are poisonous is solved.

Owner:西安优信机电工程有限公司

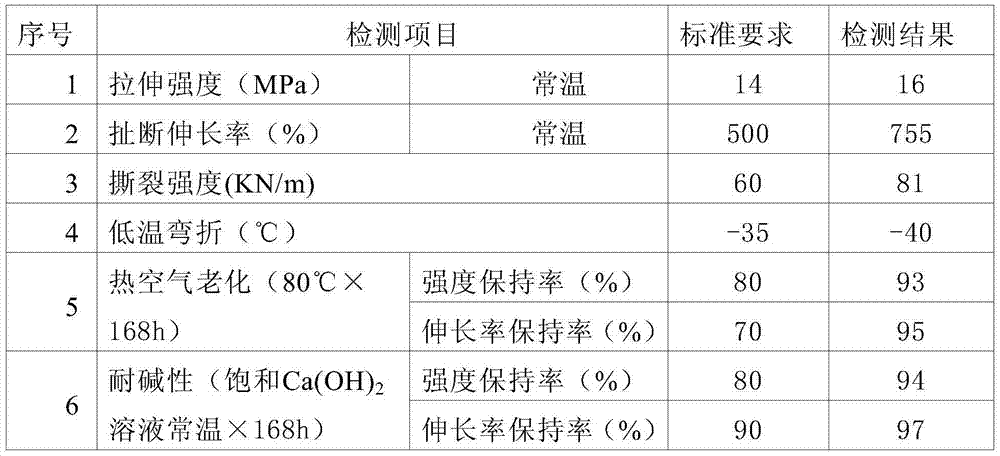

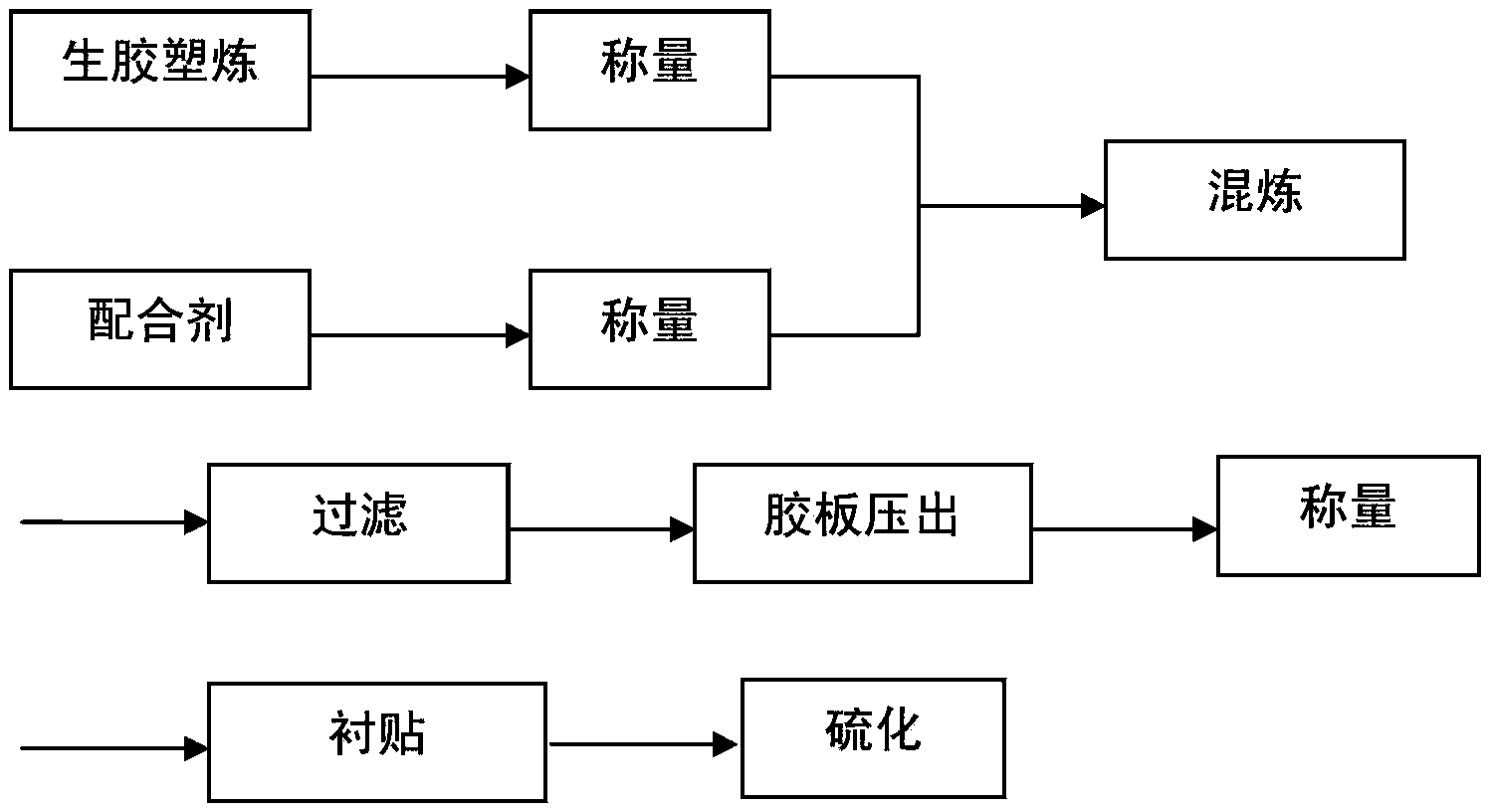

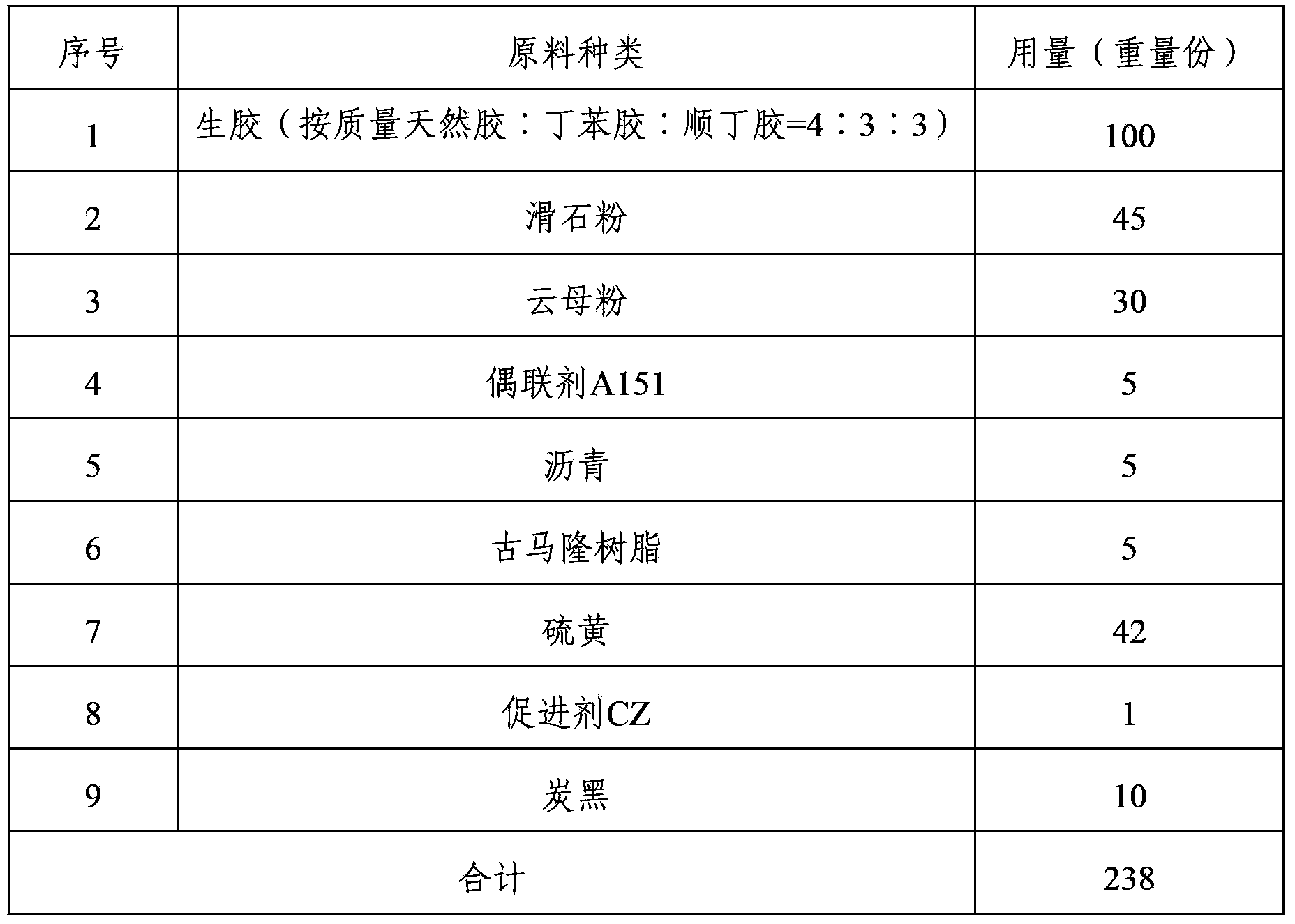

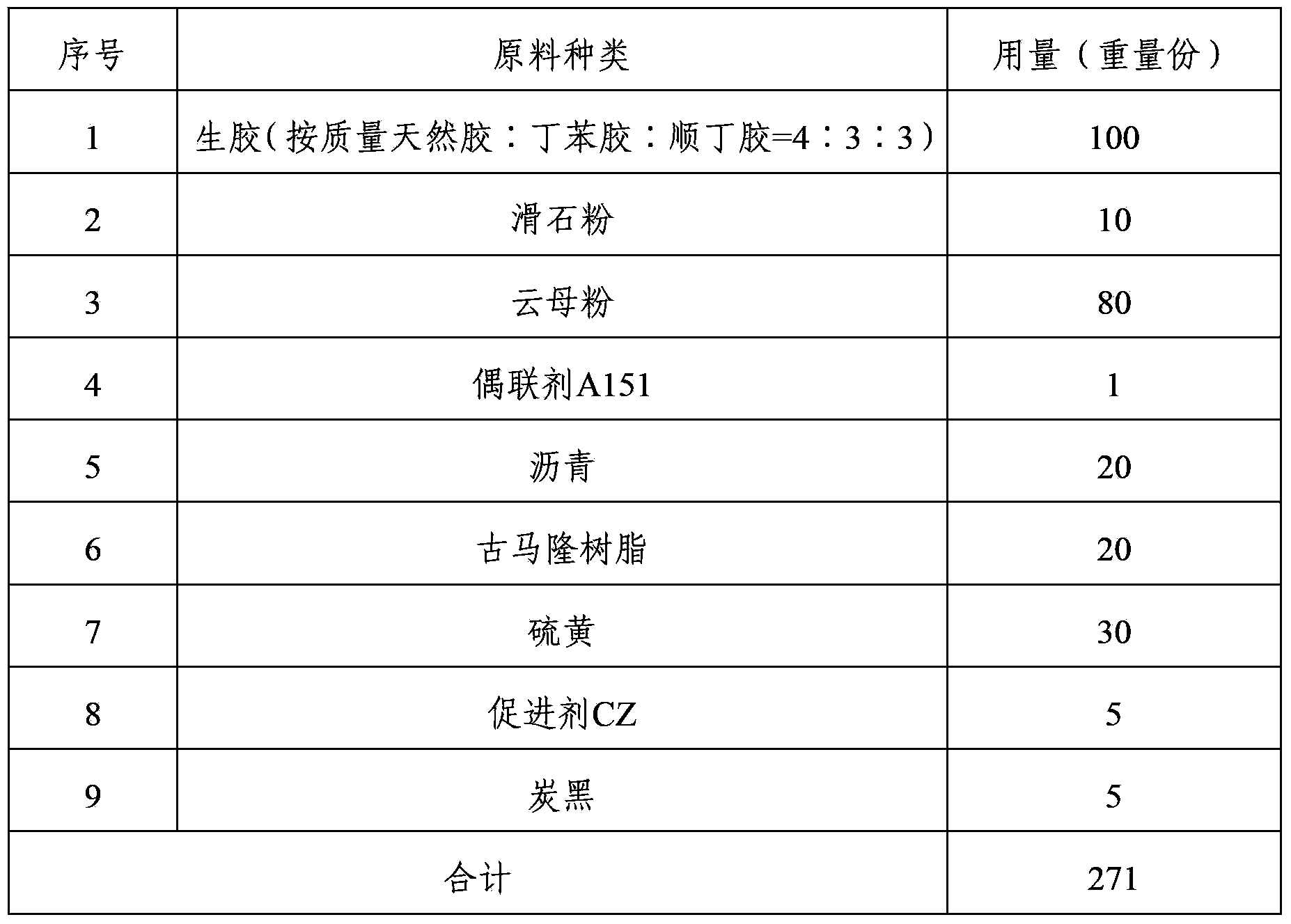

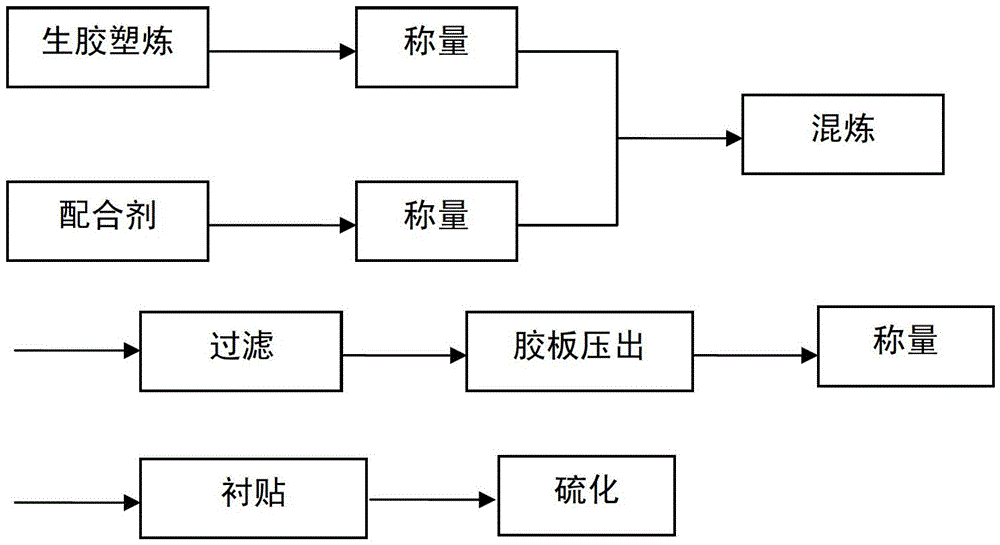

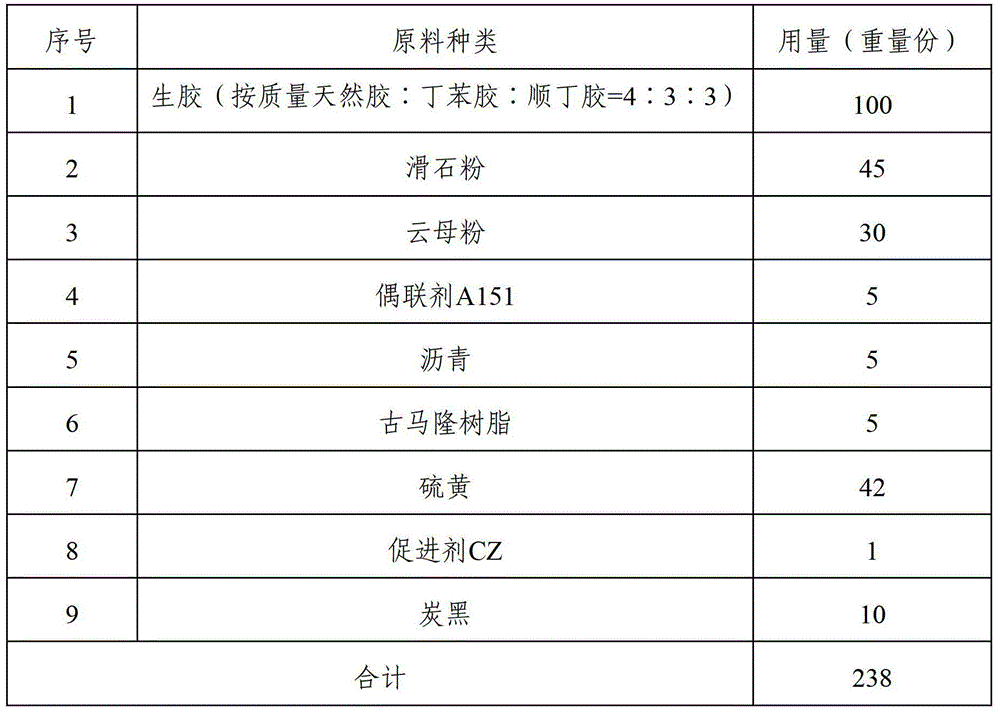

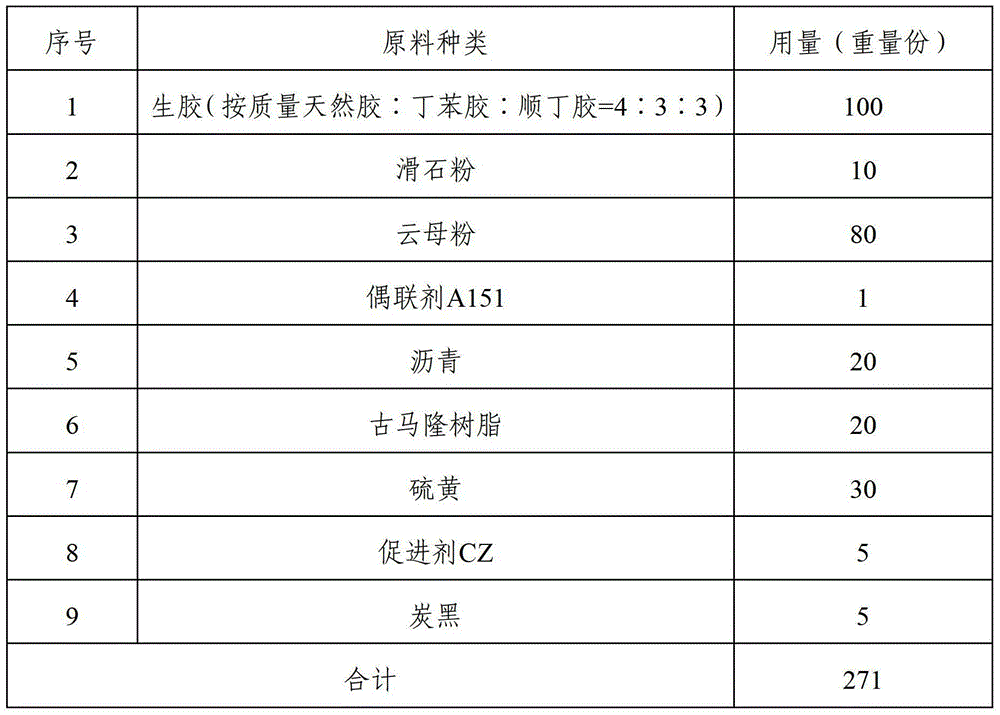

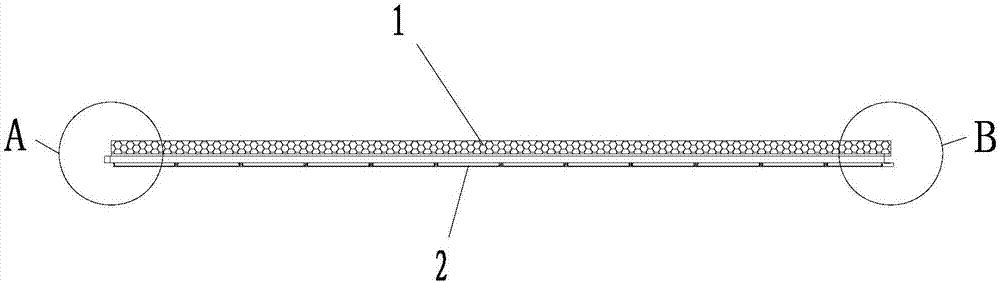

Anti-corrosion rubber composition and anti-corrosion rubber lining

The invention relates to an anti-corrosion rubber composition. The anti-corrosion rubber composition comprises the components of, by weight, 100 parts of raw rubber, 20-80 parts of talcum powder, 10-60 parts of mica powder, 0.5-10 parts of coupling agent, 0.5-15 parts of pitch, 1-20 parts of coumarone resin, 30-60 parts of sulphur, 0.1-5 parts of accelerant and 1-20 parts of dyeing agent. The invention also relates to an anti-corrosion rubber lining. The rubber lining produced through the anti-corrosion rubber composition provided in the invention can bear a working temperature of 130 DEG C under a high vacuum degree, is acid and alkali resistant at high temperatures and is applicable to a 11-stage flash device of an adhesive production line.

Owner:XIANYANG SAIFU ANTICORROSION EQUIP

Silicon carbide ceramic cylinder sleeve for well-drilling slurry pump and preparation method of silicon carbide ceramic cylinder sleeve

InactiveCN104761262AExcellent chemical corrosion resistanceLow corrosion rateCarbide siliconSlurry pump

The invention relates to a silicon carbide ceramic cylinder sleeve for a well-drilling slurry pump. The silicon carbide ceramic cylinder sleeve is composed of micron silicon carbide, submicron boron carbide powder, nanometer carbon black, and an organic binder, the amount ratios of which are, per one hundred grams of dried submicron boron carbide powder, 0.2-4.8% of submicron boron carbide powder, 12-25% of nanometer carbon black, and 6-25% of the organic binder. According to the invention, silicon carbide is taken as a raw material, and the silicon carbide ceramic cylinder sleeve is obtained via iso-static cool pressing and pressureless sintering. The hardness of the resultant silicon carbide ceramic cylinder sleeve can reach more than 26GPa, and is good in abrasive resistance, excellent in chemical resistance, and uniform and dense in inner organization structure. After the silicon carbide ceramic cylinder sleeve is subjected to fine machining, the internal surface smoothness can reach Ra0.2, and the service life can reach 4500 hours. The silicon carbide ceramic cylinder sleeve in the invention can work in mediums, such as well-drilling slurry or other liquid with high corrosivity.

Owner:NINGXIA MACHINERY RES INST

Solvent-free epoxy terrace paint

InactiveCN107353780AExcellent chemical corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsOrganic solventPlasticizer

The invention discloses solvent-free epoxy terrace paint. A component A is prepared from phenolic aldehyde epoxy resin, a plasticizer, low molecular weight epoxy resin, an active diluting agent, pigments and fillers, a dispersant, an anti-settling agent and a flatting agent and is faint yellow; a component B is prepared from cashew nut shell modified phenolic aldehyde amine, a modified alicyclic amine compound curing agent and pigments and fillers and is reddish brown; the solvent-free epoxy terrace paint does not contain an organic solvent; solvent-free epoxy rustproof paint is prepared from the component A and the component B according to the weight ratio of 6 to 1. The solvent-free epoxy terrace paint disclosed by the invention has the advantages that the paint has good chemical corrosion prevention performance and the problems of existing solvent-free epoxy terrace paint which the odor is heavy, the viscosity is great and the toxicity is caused are solved.

Owner:启东维度化工科技有限公司

Preparation method of multifunctional rubber synthesized on basis of nitrile rubber

The invention discloses a preparation method of a multifunctional rubber synthesized based on nitrile rubber, which is made of the following raw materials in parts by mass: nitrile rubber 25-40, chlorohydrin rubber 60-70, modified chloroprene rubber 20‑50, carbon black 10‑20, decabromodiphenylethane 4‑5, magnesium oxide 12‑18, vulcanizing agent 1‑1.5, stearic acid 4‑6, zinc oxide 5‑8, antioxidant 7‑10 , flame retardant 8‑15, 2‑dihydroquinoline polymer 1‑2. It can be made of temperature and cold resistance through a simple preparation method. Not only the cost of rubber is low, the effect of chemical corrosion resistance is good, but also the preparation process is simple, easy to industrialize, and it has excellent flame retardancy, stability, heat resistance, and no rubber. It is non-toxic and environmentally friendly, can effectively reduce environmental pollution, and has a long service life.

Owner:成都米利得科技有限公司

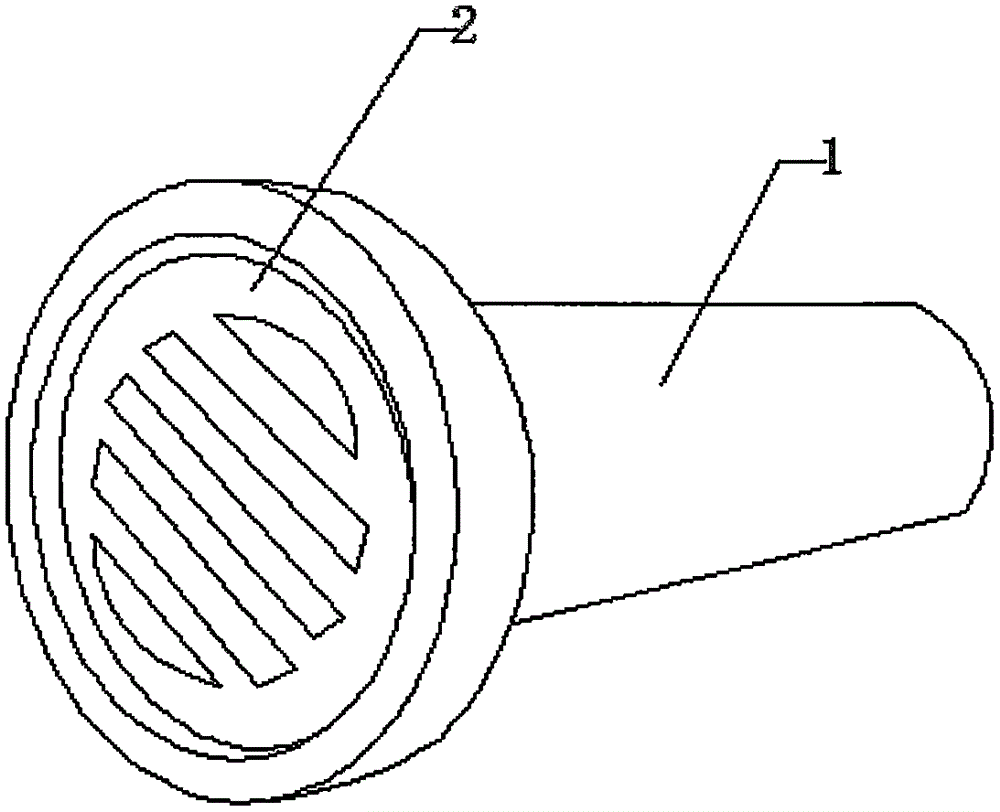

SMC drain pipe and preparation material and preparation method thereof

The invention discloses an SMC drain pipe and a preparation material and a preparation method thereof; the SMC drain pipe comprises a water inlet pipe and an anti-blocking cover, wherein the water inlet pipe is prepared from the SMC drain pipe preparation material; the anti-blocking cover is embedded in the upper part of the water inlet pipe; the SMC drain pipe preparation material is composed of the following materials by the weight fraction: 20%-28% of unsaturated polyester resin, 5%-8% of short thick glass fibers, 20%-32% of medium-alkali glass fiber cloth, 25%-38% of a filler, 8%-15% of industrial waste residues, 10%-20% of glass powder, 0.5%-2.0% of an internal demolding agent, 1%-2.8% of a low-shrinkage additive, 0.5%-2.5% of a chemical thickening agent, 0.2%-1.0% of an initiator, and 0.5%-4.5% of a coloring agent. The preparation method comprises calcining, foaming, annealing and cooling, raw material mixing, impregnation, sheet preparation and finished product obtaining. According to the SMC drain pipe and the preparation material and the preparation method thereof, with foam glass and the SMC material structure, the drain pipe has the advantages of both the foam glass and the SMC material, and has the advantages of low production costs, long service life, and excellent electrical insulation performance, mechanical properties, thermal stability, and resistance to chemical corrosion.

Owner:衡水润通公铁路桥器材有限公司

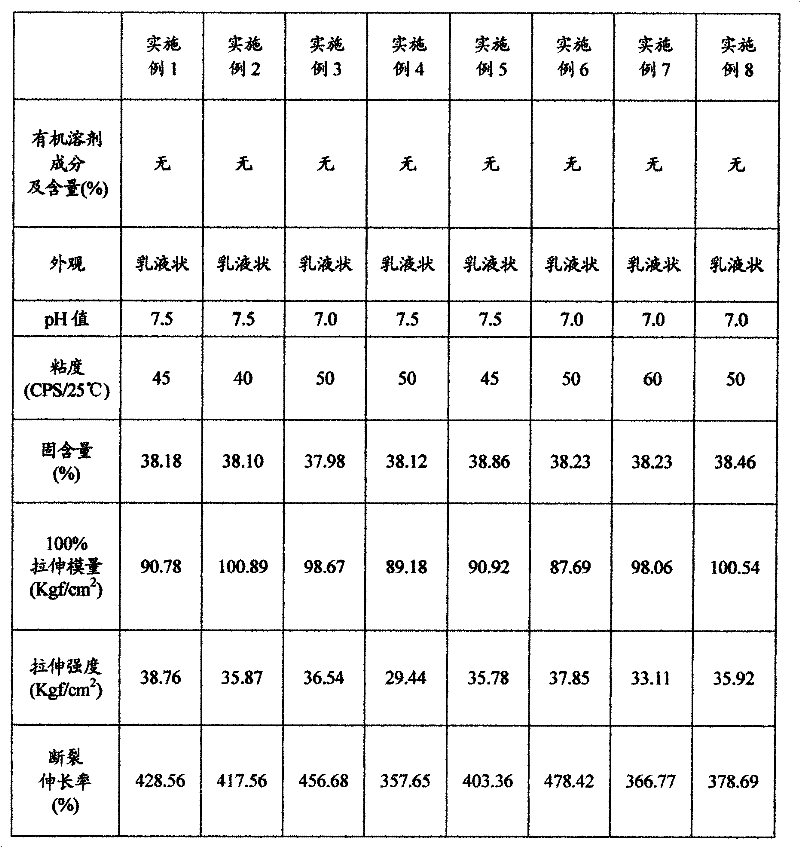

Preparation method of aqueous polyurethane butyronitrile resin

A preparation method of aqueous polyurethane butyronitrile resin comprises the following steps: firstly, preparing polyurethane prepolymer by macromolecular polyalcohol, isocyanate monomers, a hydrophilic group compound, a chain extender, a solvent and hydroxyl acrylic ester; secondly, adding a neutralizing agent, water emulsion, a water-based chain extender into the polyurethane prepolymer to prepare aqueous polyurethane emulsion; thirdly, conducting the steps of preparing a hydrocarbon phase and a water phase, polymerizing, degassing and the like, synthetizing the aqueous polyurethane emulsion, butadiene and acrylonitrile to obtain the aqueous polyurethane butyronitrile resin. As the aqueous polyurethane resin and nitrile rubber are grafted, the performance of the resin is improved, andthe prepared aqueous polyurethane butyronitrile resin has the advantages of hydrolysis resistance, weather resistance and good environmental performance, the coating prepared by the aqueous polyurethane butyronitrile resin has good chemical corrosion resistance, abrasion resistance and durability. The aqueous polyurethane butyronitrile resin can completely meet the requirement on outdoor road rubber.

Owner:JIAXING HEXIN CHEM IND

Preparation method of high-temperature-resistant and corrosion-resistant environment-friendly rubber

The invention discloses a preparation method of high-temperature-resistant and corrosion-resistant environment-friendly rubber. The high-temperature-resistant and corrosion-resistant environment-friendly rubber is prepared from the following raw materials in parts by mass: 85-95 of natural rubber, 15-20 of stabilizer, 10-20 of acrylonitrile-butadiene rubber, 30-45 of modified chloroprene rubber, 20-26 of carbon black, 7-16 of polystyrene, 0.5-1.5 of sulfurizing agent, 2-4 of stearic acid, 2-8 of zinc oxide, 12-18 of magnesium oxide, 9-16 of anti-aging agent, 15-25 of flame retardant, 20-30 ofparaffin and 4-5 of accelerant. The temperature-resistant and corrosion-resistant environment-friendly rubber prepared by using the simple preparation method is not only low in rubber cost and good inchemical corrosion resistance effect, but also simple in preparation process and easy to realize industrialization; in addition, the high-temperature-resistant and corrosion-resistant environment-friendly rubber has excellent stability and heat resistance and is nontoxic, environment-friendly, capable of effectively reducing environment pollution and long in service life.

Owner:成都米利得科技有限公司

High-temperature-resistant and corrosion-resistant environmental protection rubber

The invention discloses a high-temperature-resistant and corrosion-resistant environment-friendly rubber, which is made of the following raw materials in parts by mass: 80-100 natural rubber, 8-15 stabilizer, 25-40 nitrile rubber, and modified chloroprene rubber 20‑50, carbon black 15‑30, polystyrene 8‑12, vulcanizing agent 1‑1.5, stearic acid 2‑4, zinc oxide 5‑10, magnesium oxide 12‑18, antioxidant 10‑14, flame retardant Agent 15‑25, paraffin wax 20‑30, accelerator 4‑5. The temperature-resistant and corrosion-resistant environmentally friendly rubber is prepared by a simple preparation method. Not only the rubber cost is low, the chemical corrosion resistance is good, but also the preparation process is simple, easy to industrialize, and has excellent stability, heat resistance, and non-toxic , Environmental protection, can effectively reduce environmental pollution, long service life.

Owner:成都米利得科技有限公司

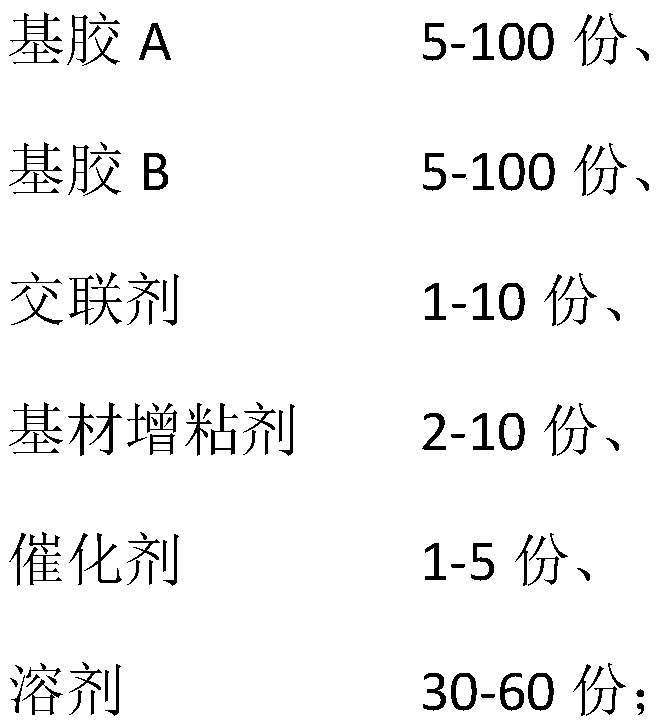

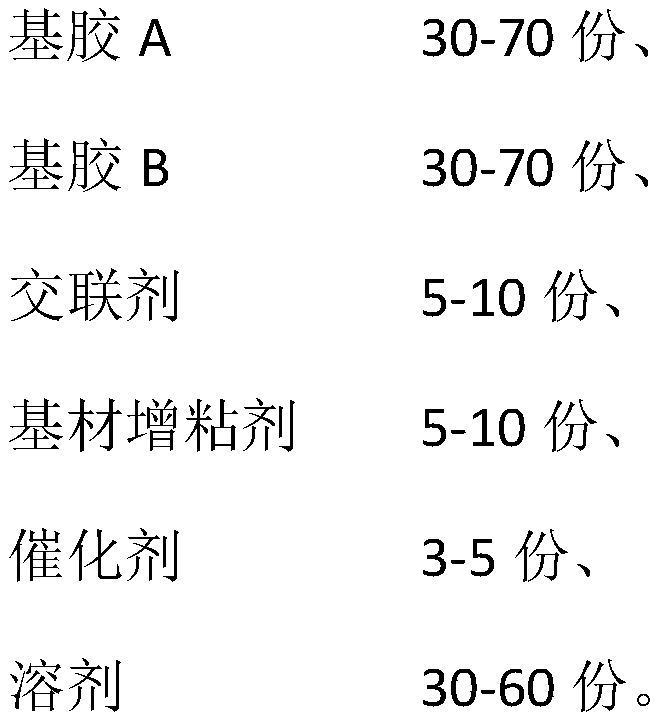

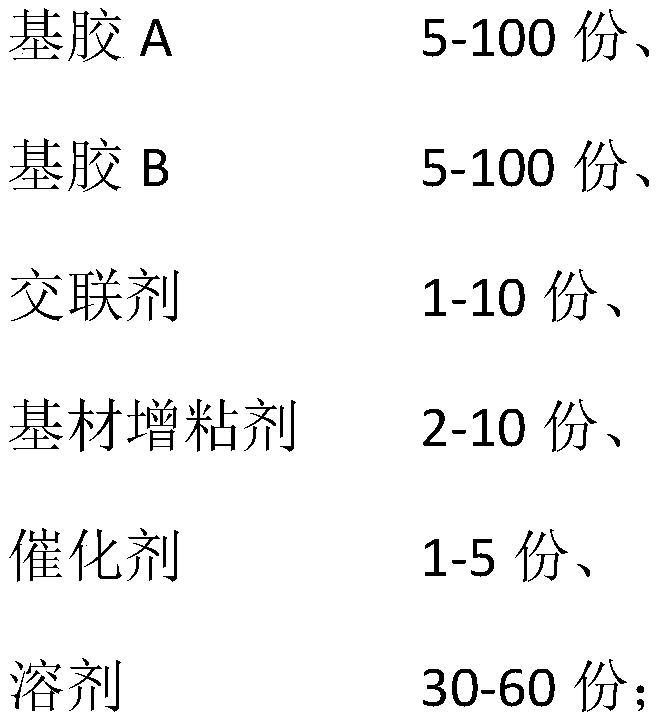

Fluorine-containing organic silicon coating adhesive and preparation method thereof

ActiveCN110698981ACuring speed can be adjustedGood chemical resistanceAdhesive processes with surface pretreatmentAnti-corrosive paintsPtru catalystMeth-

The invention relates to fluorine-containing organic silicon coating adhesive and a preparation method thereof. The fluorine-containing organic silicon coating adhesive is prepared from the followingraw materials in parts by weight: 5 to 100 parts of base adhesive A, 5 to 100 parts of base adhesive B, 1 to 10 parts of crosslinking agent, 2 to 10 parts of base material tackifier, 1 to 5 parts of catalyst and 30 to 60 parts of solvent, wherein the base adhesive A is hydroxyl terminated methyl-3,3,3-trifluoropropyl(siloxane and polysiloxane); and the base adhesive B is hydrogen-containing fluorosilicon oil. The fluorine-containing organic silicon coating adhesive is adjustable in curing speed and is oil-resistant and salt-spray resistant; the chemical corrosion resistance is greatly enhancedand the adhesive property is excellent; and the fluorine-containing organic silicon coating adhesive has three-prevention effect and excellent performance.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD +2

A process method for surface treatment of electrolytic copper foil and the treated copper foil

ActiveCN103469267BExcellent chemical corrosion resistanceExcellent room temperature oxidation resistanceElectrolysisAdhesive

The present invention discloses a one-time surface treatment method for electrolysis copper foil. The process method comprises: 1, coursing solution preparation: carrying out mixing dissolving on cathode cooper, sulfuric acid and soft water to produce a copper sulfate solution, adding an additive A to the copper sulfate solution, completely mixing, and adding the obtained mixture to a coursing tank to be subjected to electroplating; 2, curing solution preparation: carrying out mixing dissolving on cathode cooper, sulfuric acid and soft water to produce a copper sulfate solution, and adding the copper sulfate solution to a curing tank to be subjected to electroplating; 3, zinc plating alloy solution preparation and a passivation treatment: respectively dissolving zinc sulfate, chromic anhydride and phosphoric acid, adding the zinc sulfate solution to a chromic acid and phosphoric acid mixed solution, adding an additive D solution to the obtained mixing solution in a dropwise manner while adjusting the pH value by using sodium hydroxide, completely mixing, and then adding the obtained mixture to a zinc plating alloy tank to be subjected to electroplating; and 4, spray coating of an adhesive: dissolving an adhesive in water, and carrying out cycle spray coating of the adhesive on the surface of copper foil. According to the present invention, the process is simple, the steps are less, passivation solution components are stable, and the treated electrolysis copper foil has excellent physical properties.

Owner:江西省江铜铜箔科技股份有限公司

Composite silicate fire partition

InactiveCN103628596ANot easily deformedHigh strengthCovering/liningsWallsThermal conductivityCorrosion

The invention discloses a composite silicate fire partition. The composite silicate fire partition comprises a metal net frame formed by welding metal rods which are crisscross. The front side and the reverse side of the frame are respectively bound with a composite silicate hard heat insulation plate through a binding agent, and wood veneers are arranged on the sides, away from the frame, of the composite silicate hard heat insulation plates. The metal net frame which is wholly formed by welding the metal rods which are crisscross is used as a support, and therefore the composite silicate fire partition is not prone to deforming and collapsing and high in strength; the composite silicate hard heat insulation plates are good in heat insulation and fireproof performance, and a glass fiber cloth layer is good in forming, small in volume density, low in heat conductivity, good in heat insulation and sound absorption performance, stable in chemical performance, and capable of resisting corrosion; the wood veneers have the certain decorative effect, and the composite silicate fire partition is simple in structure and low in cost.

Owner:CHENGDU ZHILIDA TECH

Low-cost low-temperature plastic dipping PVC glove forming process method

InactiveCN111592725ALow costHigh hardnessDomestic articlesCoatingsPolymer scienceIn situ polymerization

The invention belongs to the field of high polymer materials, and especially relates to a low-cost low-temperature plastic dipping PVC glove forming process method. The low-temperature plastic dippingPVC glove forming process method uses chloro-ether resin and allyl resin monomers, low-temperature plastic dipping of PVC gloves is realized through in-situ polymerization and synchronous crosslinking, the preparation cost is low, a hand mold does not need to be preheated, high temperature production environment is not needed, energy consumption is low, the production working environment and conditions are improved, the prepared PVC gloves are more durable, good in sealing performance, free of peculiar smell, large in elasticity, resistant to acids and alkalis, convenient and comfortable to wear, integrally formed, non-sticky, convenient and safe, free of natural latex allergic protein and free of anaphylactic reaction, and the strength, the corrosion resistance and the hygienic propertyare improved.

Owner:安徽攀望科技有限公司

Environment-friendly high solid content polyaniline epoxy anticorrosive coating and preparation method thereof

InactiveCN108485459AEasy to operateExcellent chemical corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses an environment-friendly high solid content polyaniline epoxy anticorrosive coating and a preparation method thereof, and belongs to the technical field of anticorrosive coatings. The coating is prepared from a component A coating body and a component B coating body, wherein the component A coating body is prepared from eigenstate polyaniline, epoxy resin, a thixotropic agent, pigment, functional filler, a mixed solvent and aids; the component B coating body is prepared from a curing agent and a diluent. The preparation method comprises the following steps: weighing allraw materials of the component A coating body and uniformly stirring, adding glass beads for sanding and filtering to obtain the component A coating body; uniformly mixing the raw materials of the component B coating body to obtain the component B coating body; respectively packaging the component A coating body and the component B coating body; sufficiently mixing according to the mass ratio anduniformly stirring before use, thus obtaining the environment-friendly high solid content polyaniline epoxy anticorrosive coating disclosed by the invention. The product can be used after being stoodand cured and the solid mass content reaches 85 percent or above; the use of organic solvents is reduced while the anti-corrosion properties of the coating are ensured, so that the problems of environmental pollution and waste of chemical raw materials caused by organic solvent volatilization are solved.

Owner:BEIHUA UNIV

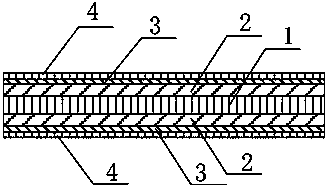

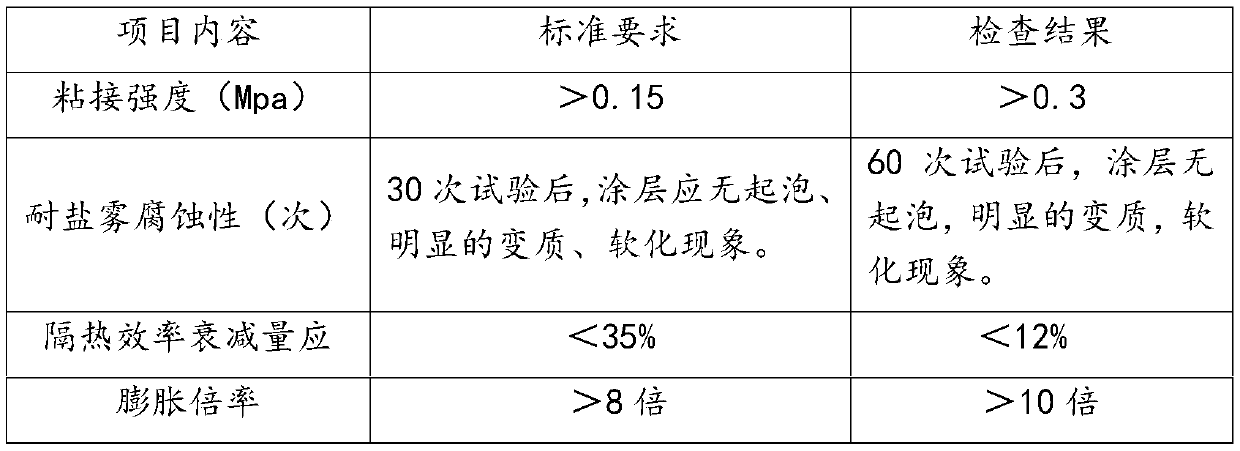

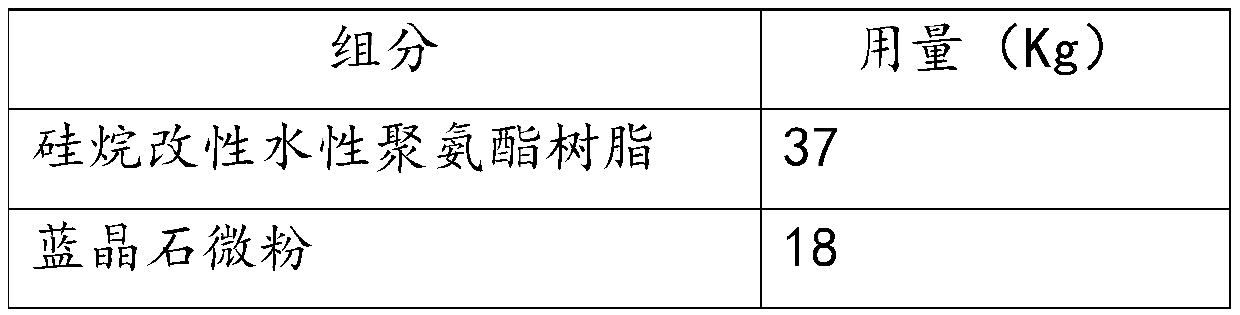

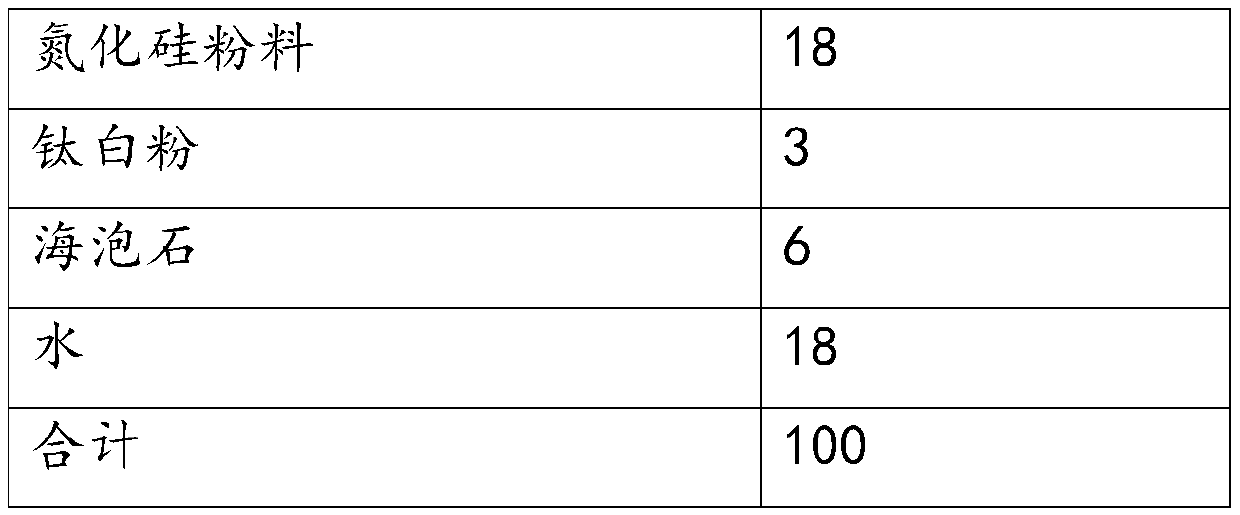

Novel high-temperature resistant environment-friendly steel structure fireproof coating and preparation method thereof

ActiveCN110128928AImprove fire resistanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsWater basedSilanes

The invention provides a novel high-temperature resistant environment-friendly steel structure fireproof coating which comprises the following raw materials: 35-40 parts of silane modified water-basedpolyurethane resin, 18-20 parts of kyanite micropowder, 18-20 parts of silicon nitride, 2-3 parts of titanium dioxide, 3-6 parts of sepiolite and 13-23 parts of water. The preparation method of the fireproof coating comprises the following steps: in the first step, polyol, polyisocyanate, a chain extender and a crosslinking agent are put into a reaction kettle for heating reaction, triethylamine,a coupling agent and a film forming additive are added, and high-speed dispersion is carried out to prepare silane modified water-based polyurethane resin; and in the second step, kyanite micropowder, the silicon nitride, the titanium dioxide, the sepiolite and the water are added in proportion and stirred and mixed evenly to obtain the finished product. The steel structure fireproof coating caneffectively play a role in fire prevention and heat insulation, the expansion ratio can reach more than 10 times, and the fire resistance limit can reach 60-180 minutes. When a fire occurs, the novelhigh-temperature resistant environment-friendly steel structure fireproof coating can rapidly expand to form a fire-resistant and heat-insulating protective layer, thus improving the fire resistance limit of steel structures.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Chemical corrosion resistant additive for improving plastic products

InactiveCN108892808AExcellent chemical corrosion resistanceStrong chemical corrosion resistanceGlycerolAluminum silicate

The invention provides a chemical corrosion resistant additive for improving plastic products. The additive is prepared from the following materials in parts by weight: 28-38 parts of calcium carbonate, 6-12 parts of polycarbonate resin, 4-11 parts of aluminum silicate, 12-20 parts of hydroxypropyl methyl cellulose, 8-17 parts of spraying carbon black, 5-16 parts of calcium hydroxide, 1-6 parts ofresorcinol, 11-20 parts of a vulcanizing agent, 7-15 parts of lignin, 5-13 parts of stearic acid, 7-18 parts of zinc oxide, 3-9 parts of magnesium sulfate, 15-26 parts of disodium hydrogen phosphateand 8-17 parts of a lubricating agent, wherein the lubricating agent is one or more of octadecanamide, oleamide, erucyl amide and glycerol tristearate. The chemical corrosion resistant additive has the beneficial effect of reasonable formula, and can be added into production of plastic products due to interaction among materials to improve the chemical corrosion resistance.

Owner:佛山市高明区生产力促进中心

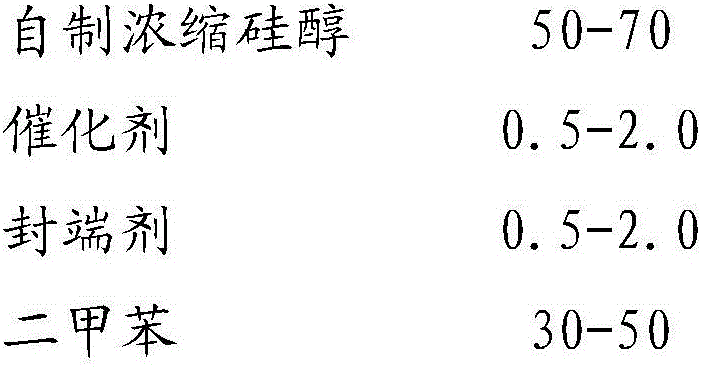

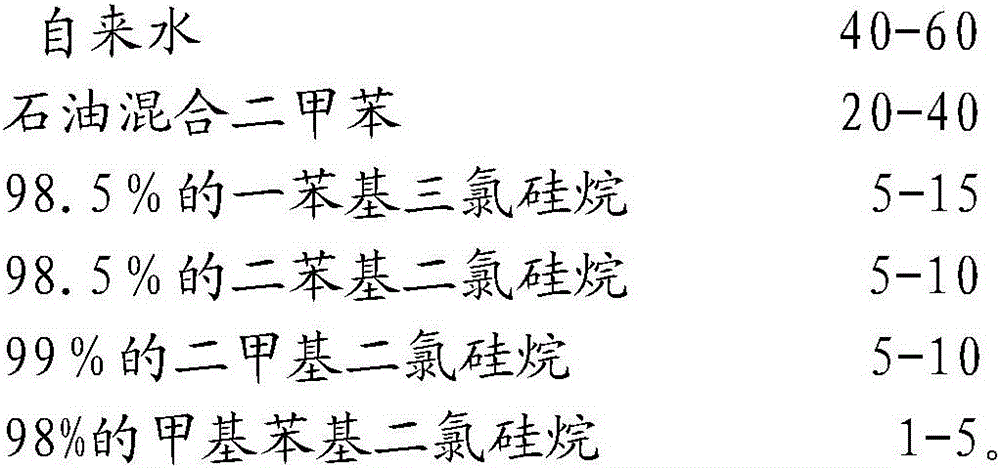

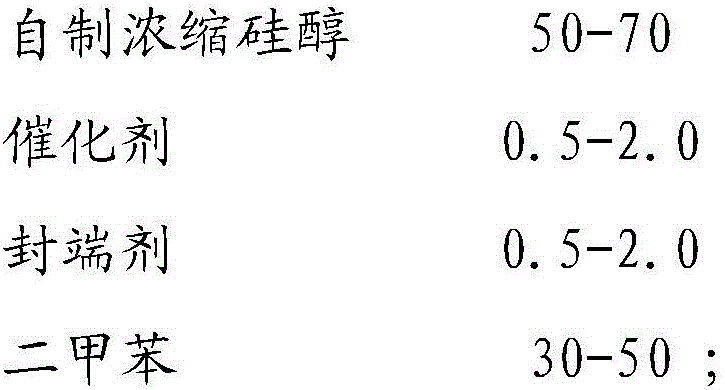

Organosilicon drying insulating varnish and preparation method thereof

The invention relates to an organic silicon drying insulating varnish, which comprises the following components, in parts by weight, self-made concentrated silanol 50-70, catalyst 0.5-2.0, end-capping agent 0.5-2.0, and xylene 30-50; Describe the components of self-made concentrated silanols: tap water 40-60, petroleum mixed xylene 20-40, 98.5% diphenyltrichlorosilane 5-15, 98.5% diphenyldichlorosilane 5-10, 99% Dimethyldichlorosilane 5‑10, 98% methylphenyldichlorosilane 1‑5. Preparation method Add the concentrated silanol to the reaction kettle, stir and add the catalyst, mix evenly and heat up to evaporate the solvent, the gelation time is 60-90 seconds / 200°C, add xylene, end-capping agent and catalyst, stir and filter. Beneficial effect: it has excellent performances of heat resistance, insulation, chemical corrosion resistance, electric arc resistance, salt spray resistance, moisture resistance and mildew resistance, and belongs to H-class insulation material.

Owner:天津灯塔涂料工业发展有限公司

Anti-corrosion rubber composition and anti-corrosion rubber lining

ActiveCN103382270BResilience balanceImprove penetration resistancePolymer scienceWorking temperature

The invention relates to an anti-corrosion rubber composition. The anti-corrosion rubber composition comprises the components of, by weight, 100 parts of raw rubber, 20-80 parts of talcum powder, 10-60 parts of mica powder, 0.5-10 parts of coupling agent, 0.5-15 parts of pitch, 1-20 parts of coumarone resin, 30-60 parts of sulphur, 0.1-5 parts of accelerant and 1-20 parts of dyeing agent. The invention also relates to an anti-corrosion rubber lining. The rubber lining produced through the anti-corrosion rubber composition provided in the invention can bear a working temperature of 130 DEG C under a high vacuum degree, is acid and alkali resistant at high temperatures and is applicable to a 11-stage flash device of an adhesive production line.

Owner:XIANYANG SAIFU ANTICORROSION EQUIP

Epoxy floor coating

InactiveCN111234647AExcellent chemical corrosion resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePlasticizer

The invention provides an epoxy floor coating which is characterized by comprising a main agent and a curing agent in a mixing ratio of 2: 1, wherein the main agent comprises the following componentsin parts by weight: 22-50 parts of epoxy resin; 10 to 30 parts of a filler; 1-8 parts of a thickening agent; 4-7 parts of an auxiliary agent; 18 to 35 parts of a pigment or color paste and 6-20 partsof a plasticizer, wherein the curing agent is selected from aliphatic amine and / or polyamide. The epoxy floor coating disclosed by the invention has excellent chemical corrosion resistance, relativelyhigh hardness and excellent physical properties such as stamping resistance, scrub resistance and wear resistance, and is simple to prepare and convenient to construct; the paint is prepared from environment-friendly solvent-free high-quality epoxy resin; the surface is hard and fine; acid, alkali, salt, oil, esters and chemical resistance are excellent; water is impermeable, water absorption isavoided, flushing is easy, and cleaning and maintenance are simple and easy; the appearance is bright, comfortable, smooth and attractive, and the mirror surface effect is achieved.

Owner:卢列定

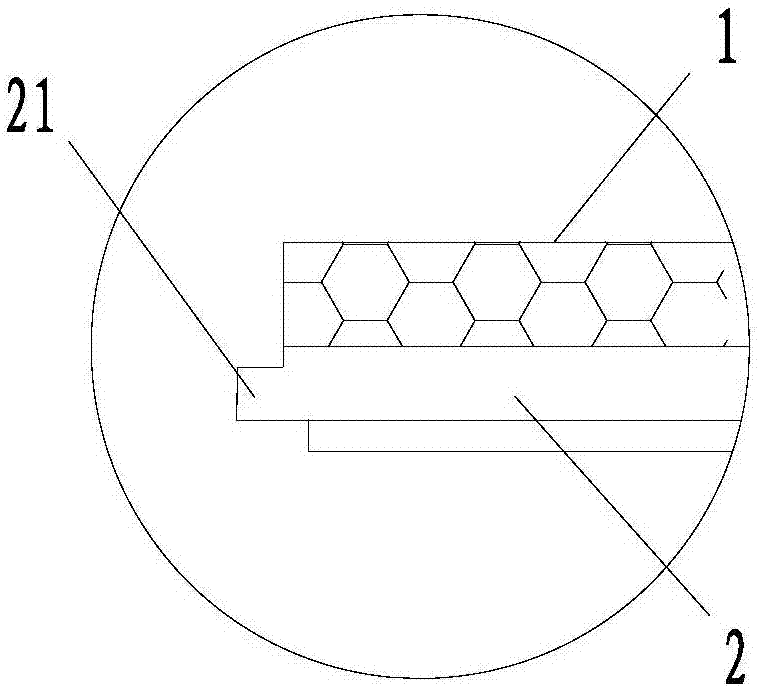

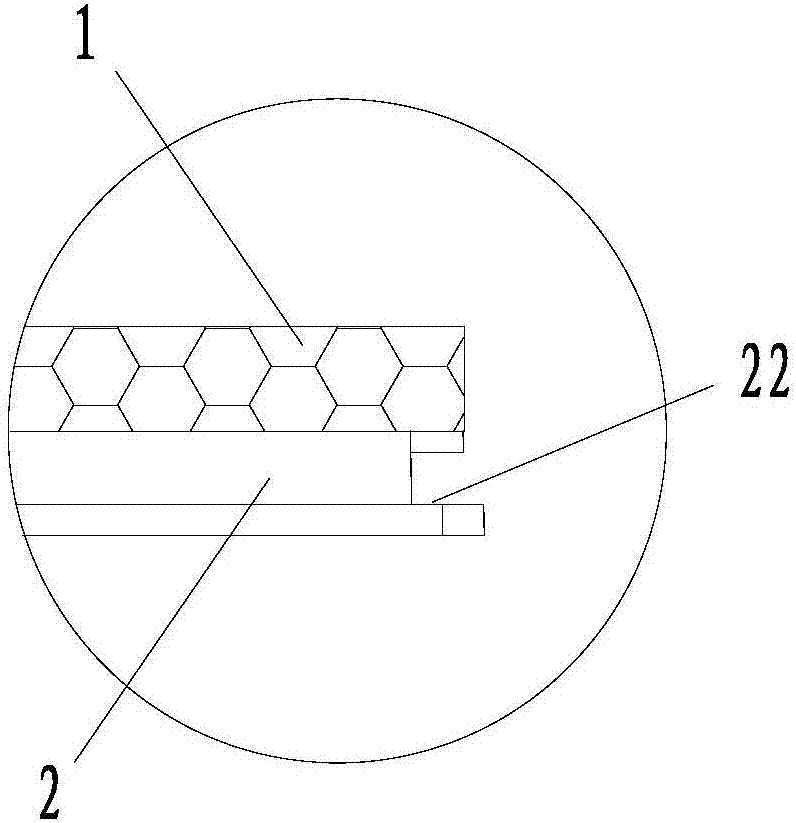

A kind of ceramic tile veneer composite board

ActiveCN104712121BStay acid resistantKeep Alkali ResistantCovering/liningsSynthetic resin layered productsAdhesiveEngineering

Owner:科逸装配科技(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com