Patents

Literature

246results about How to "Resistant to hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

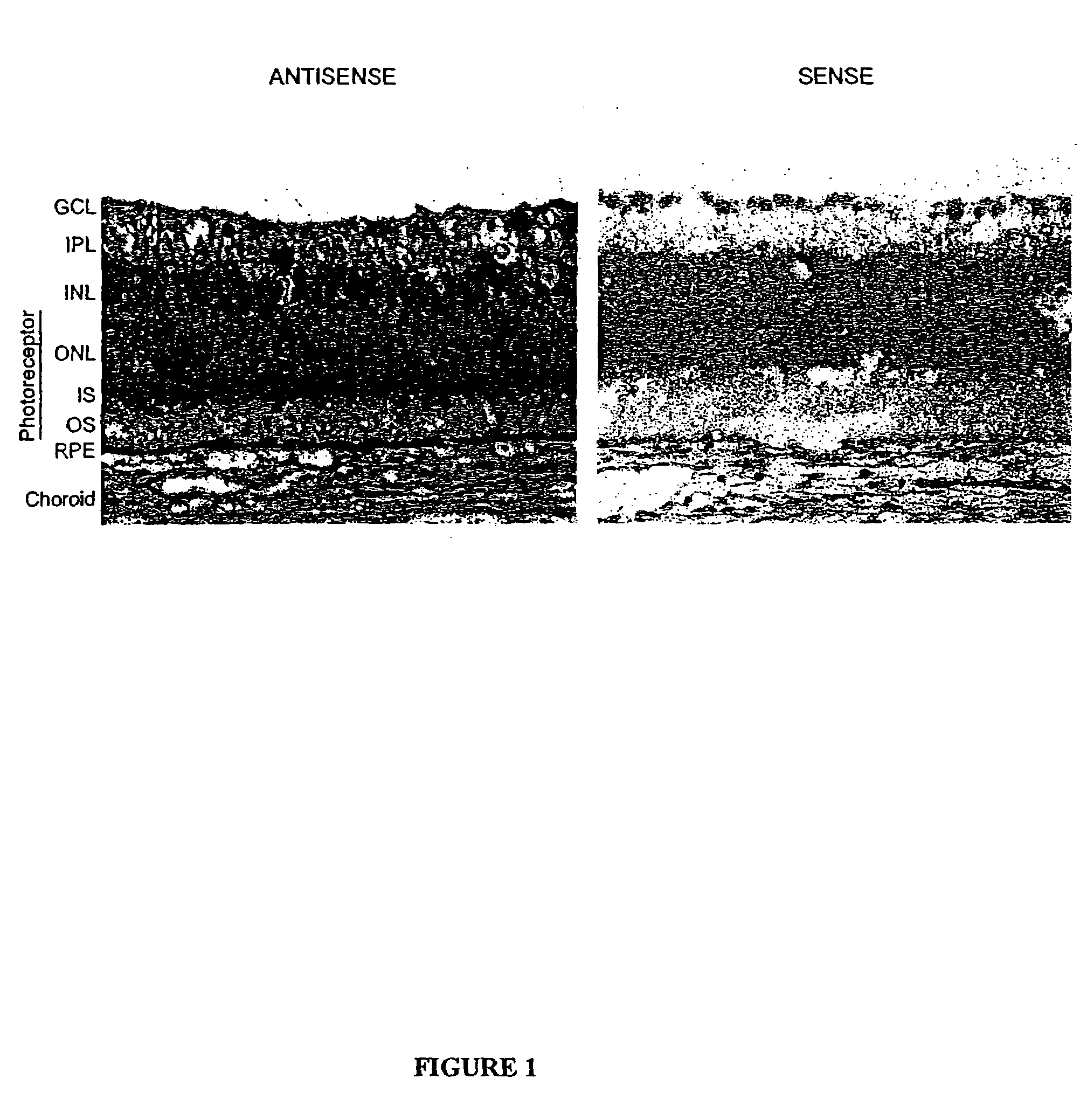

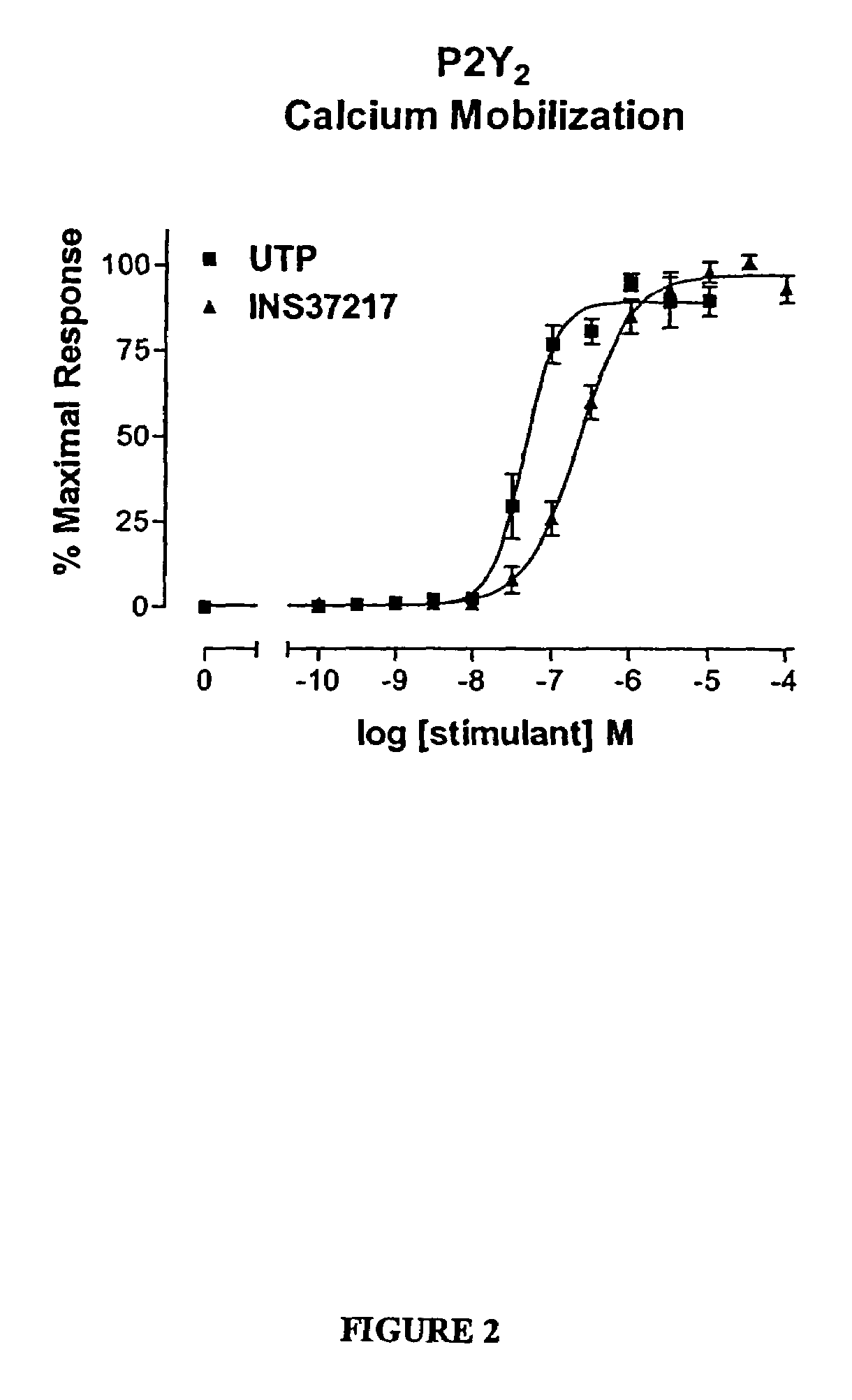

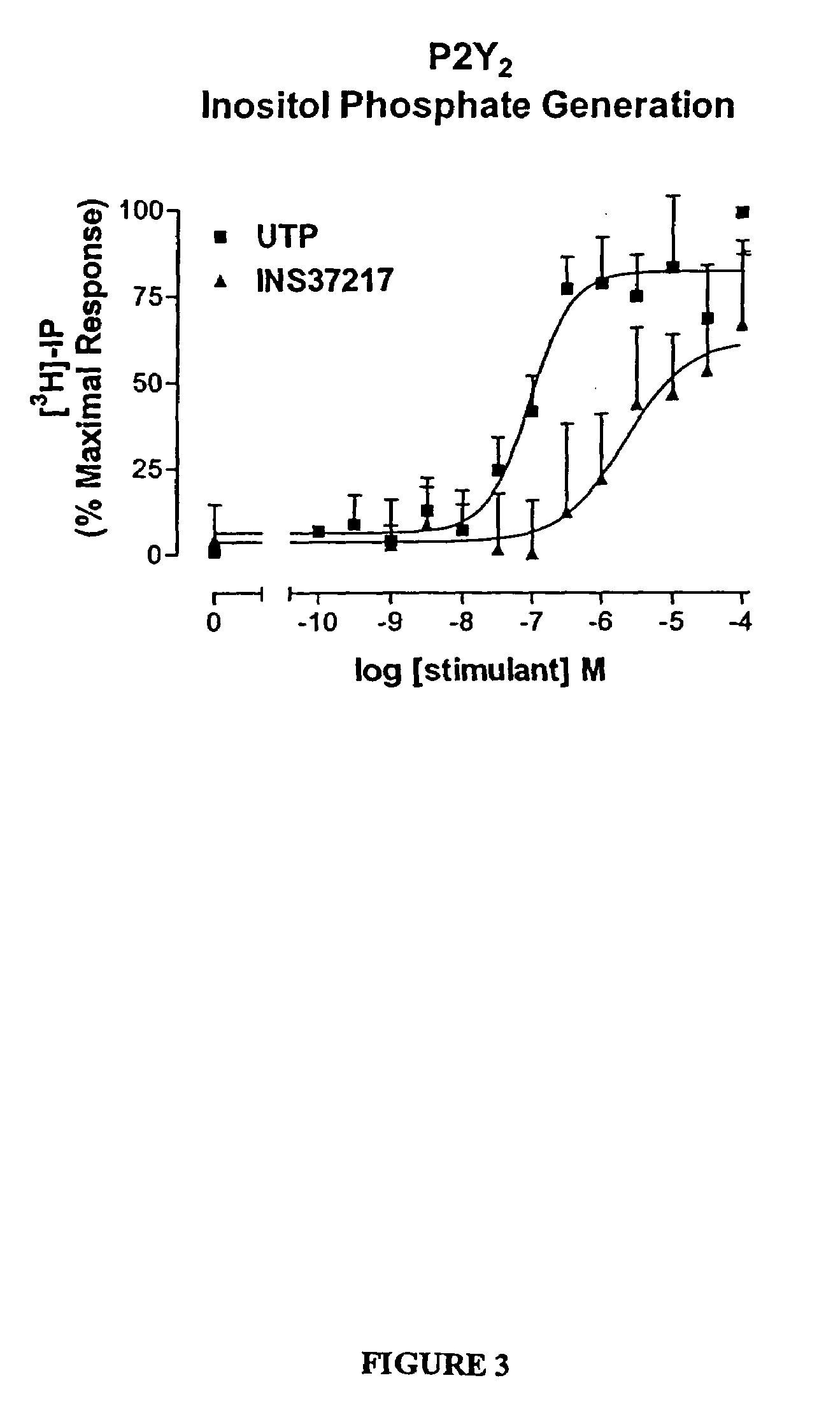

Pharmaceutical formulation comprising dinucleoside polyphosphates and salts thereof

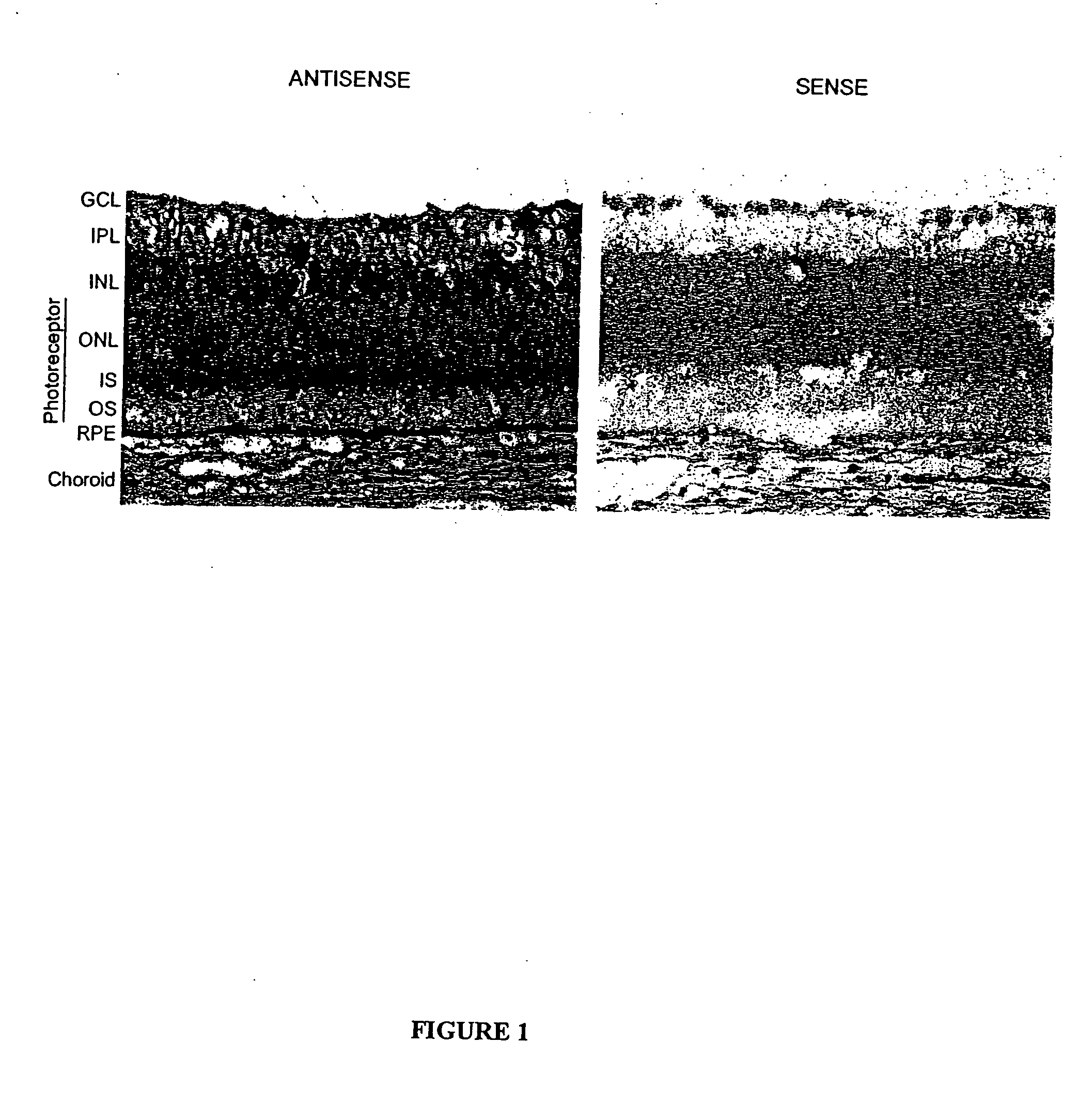

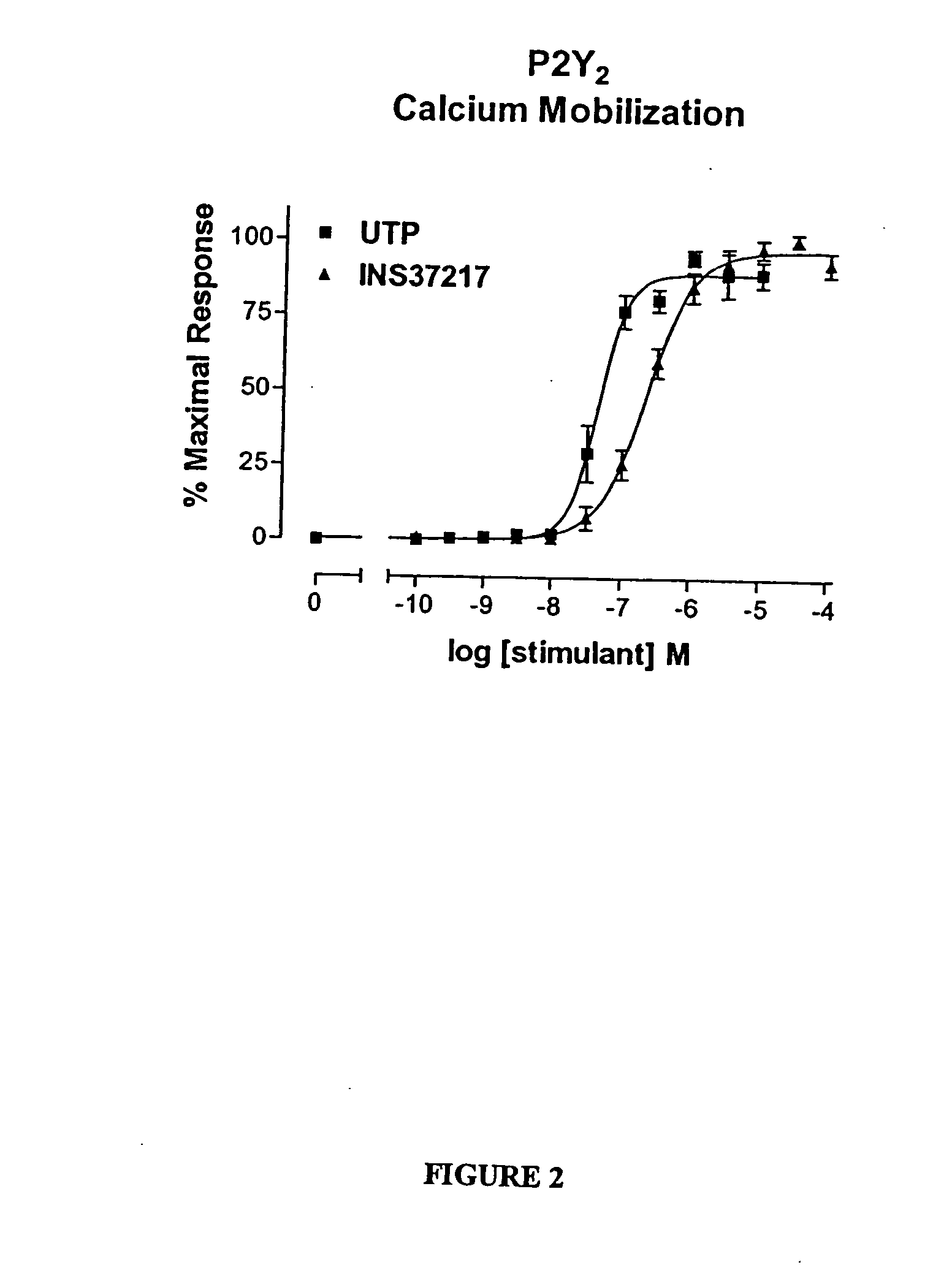

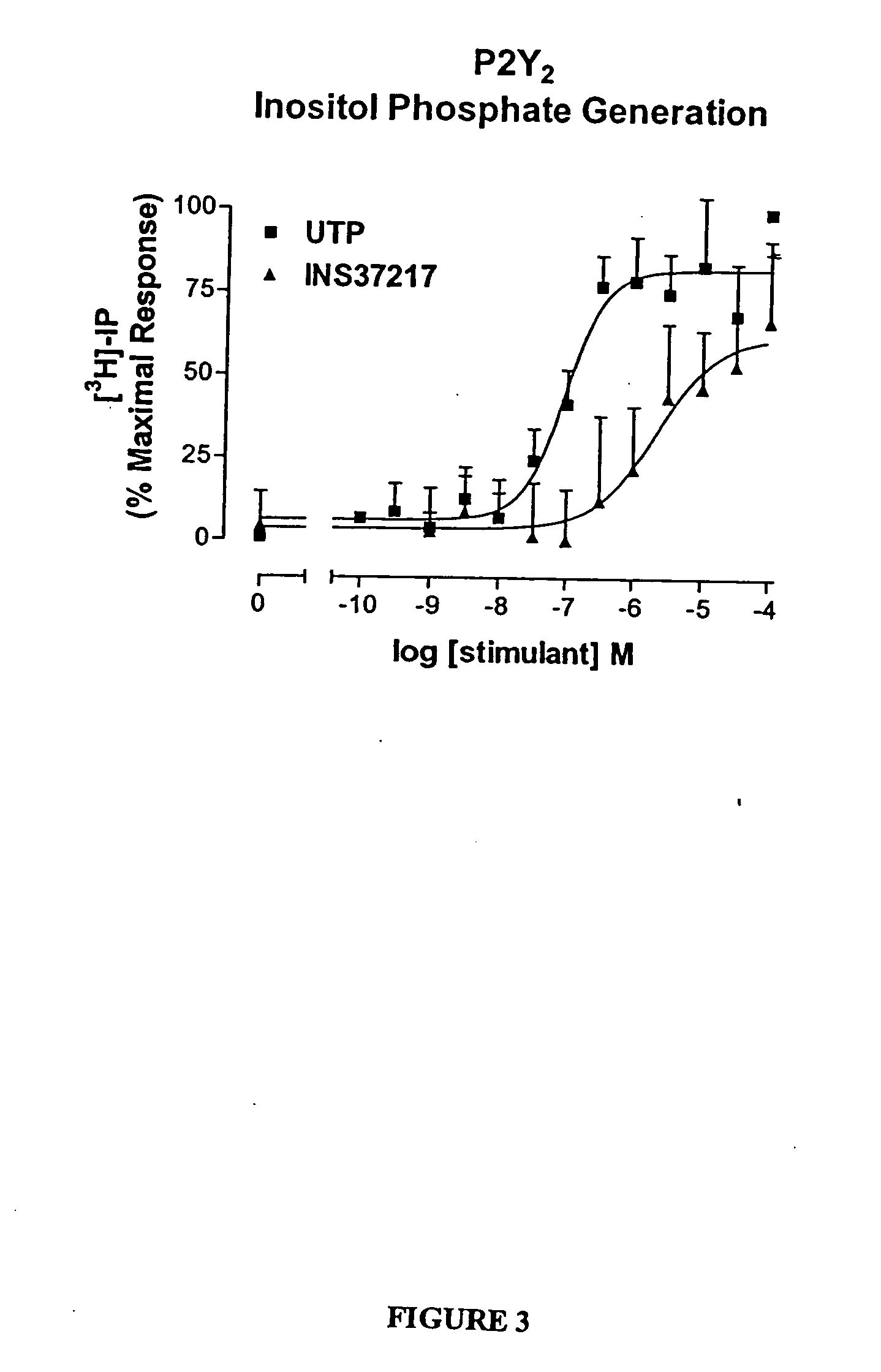

The present invention provides a method of treating edematous retinal disorders. The method comprises administration of a pharmaceutical formulation comprising a hydrolysis-resistant P2Y receptor agonist to stimulate the removal of pathological extraneous fluid from the subretinal and retinal spaces and thereby reduce the accumulation of said fluid associated with retinal detachment and retinal edema. The P2Y receptor agonist can be administered with therapeutic and adjuvant agents commonly used to treat edematous retinal disorders. The pharmaceutical formulation useful in this invention comprises a P2Y receptor agonist with enhanced resistance to extracellular hydrolysis, such as dinucleoside polyphosphate compounds, or hydrolysis-resistant mononucleoside triphosphate salts. The present invention also provides P1-(2′-deoxycytidine 5′-)P4-(uridine 5′-)tetraphosphate, tetra-(alkali metal) salts such as tetrasodium, tetralithium, tetrapotassium, and mixed (tetra-alkali metal) salts. The present further provides a pharmaceutical formulation comprising a P1-(2′-deoxycytidine 5′-)P4-(uridine 5′-)tetraphosphate, tetra-(alkali metal) salt, in a pharmaceutically acceptable carrier.

Owner:MERCK SHARP & DOHME LLC

Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

ActiveCN105350342AStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

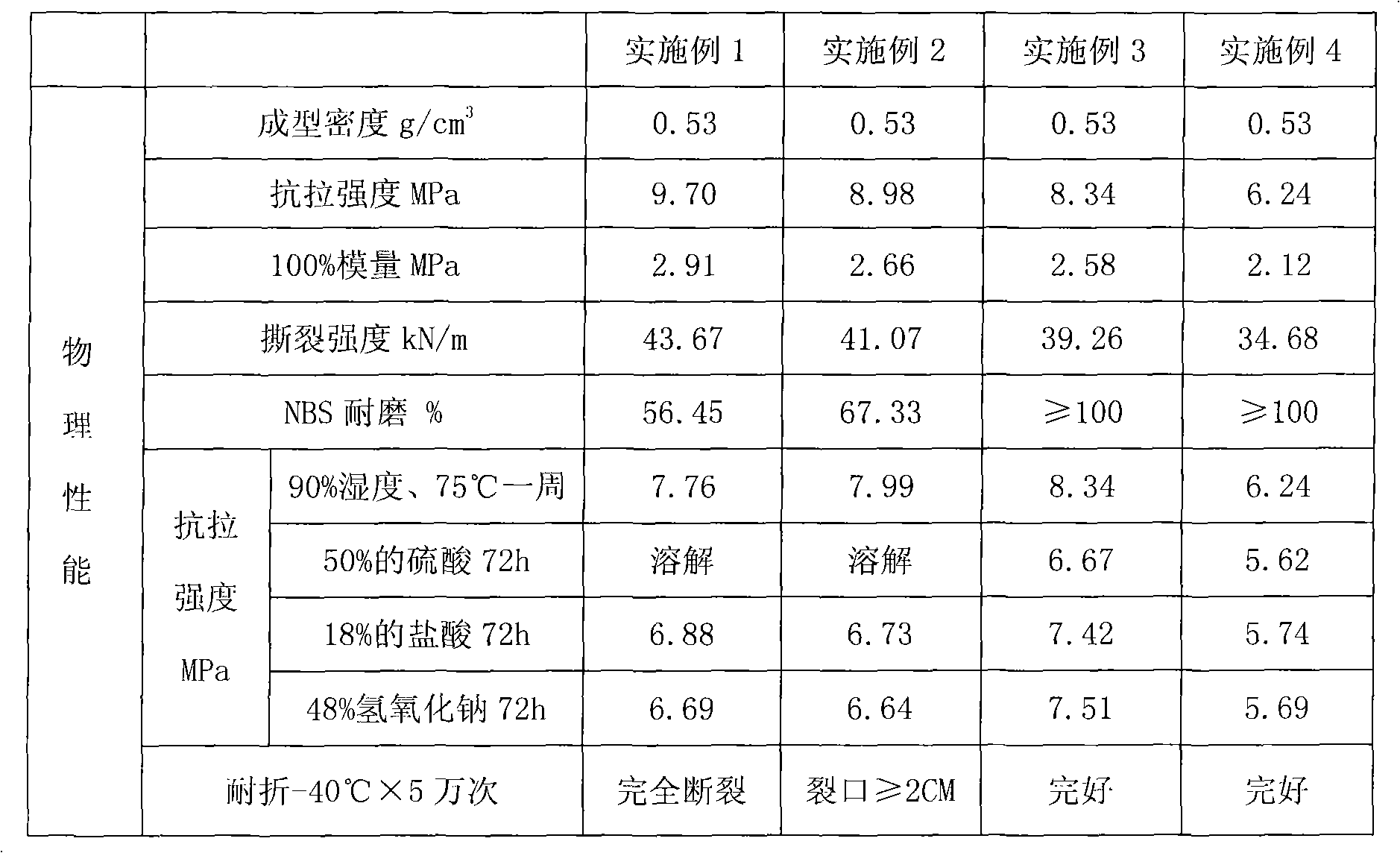

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

Method for producing emulational leather

ActiveCN101545211AHigh peel strengthHigh tear strengthLamination ancillary operationsPattern makingWoven fabricWork in process

The invention provides a method for producing emulational leather by cold pressing treatment to prepare high emulational synthetic leather, which comprises the following steps that: firstly, preparation of basic fabric: non-woven fabric passes through an impregnation groove containing PU resin, dimethylfomamide and a colorant, is subjected to pre-solidification treatment and coated with a layer of a coating material on the surface of the non-woven fabric; the nonwoven fabric passes through a coagulating tank and a rinsing bath to be subjected to solidification and water washing treatment and dried and shaped to manufacture the basic fabric; the surface of release paper is coated with a layer of a surface material containing the PU resin, dimethylfomamide and the colorant through a No.1 coating head; then a layer of a bottom material is coated on the surface material; the surface material and the bottom material are preheated and compounded with the basic fabric; the mixture is subjected to drying treatment to manufacture a semifinished product; the semifinished product is heated to the temperature of between 160 and 190 DEG C and subjected to embossing treatment through a pair of cold pressing rollers; and after the cold pressing treatment, the semifinished product is cooled and furled to manufacture a finished product.

Owner:福建兰峰制革有限公司

Preparation method of solvent-free sofa furniture microfiber synthetic leather

InactiveCN106381721AStrong leather effectResistant to hydrolysisFurniture partsPolyurea/polyurethane coatingsCarbon compositesSurface layer

The invention discloses a preparation method of solvent-free sofa furniture microfiber synthetic leather, and is characterized in that an environmental-protection type polyether polymeric carbon composite type polyurethane resin is selected as a dry surface layer and a middle layer, a solvent-free layer is a foaming adhesive layer, a microfiber cloth base cloth pasted by a whole dry process and having good hand feeling and high chemical properties is selected for preparing the environmental-protection type sofa furniture leather having the excellent properties of strong real leather effect feeling, three-dimensional and full pattern, abrasion resistance, scratch resistance, hydrolysis resistance and the like; the solvent-free foaming layer is two-liquid type double-compound polyurethane and is composed of an isocyanate A component and a polyether polyol B component. The prepared solvent-free environmental-protection type sofa furniture leather has the advantages of simple leather preparation process, high efficiency and environmental protection, also has the characteristics of strong real leather effect feeling, three-dimensional and full pattern, full and soft hand feeling, wear resistance (wyzenbeek 400 thousand times), scratch resistance, hydrolysis resistance (8 years) and other high physical properties.

Owner:ANHUI ANLI MATERIAL TECH

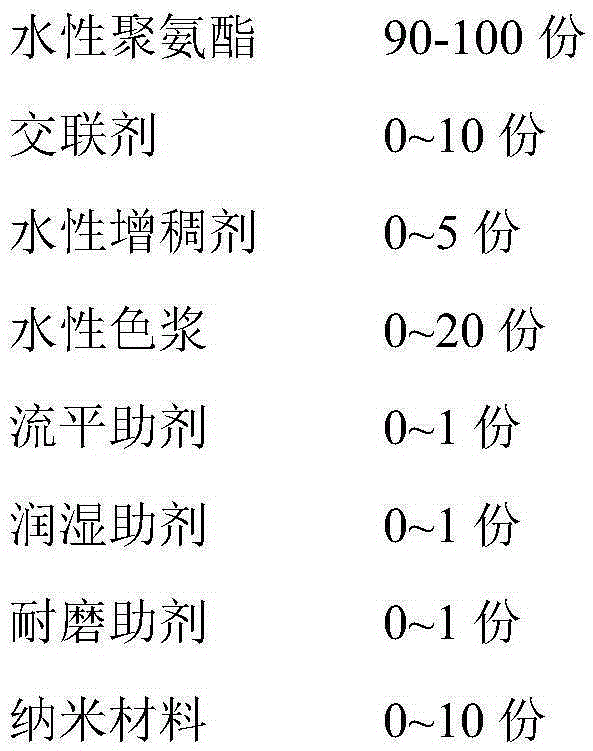

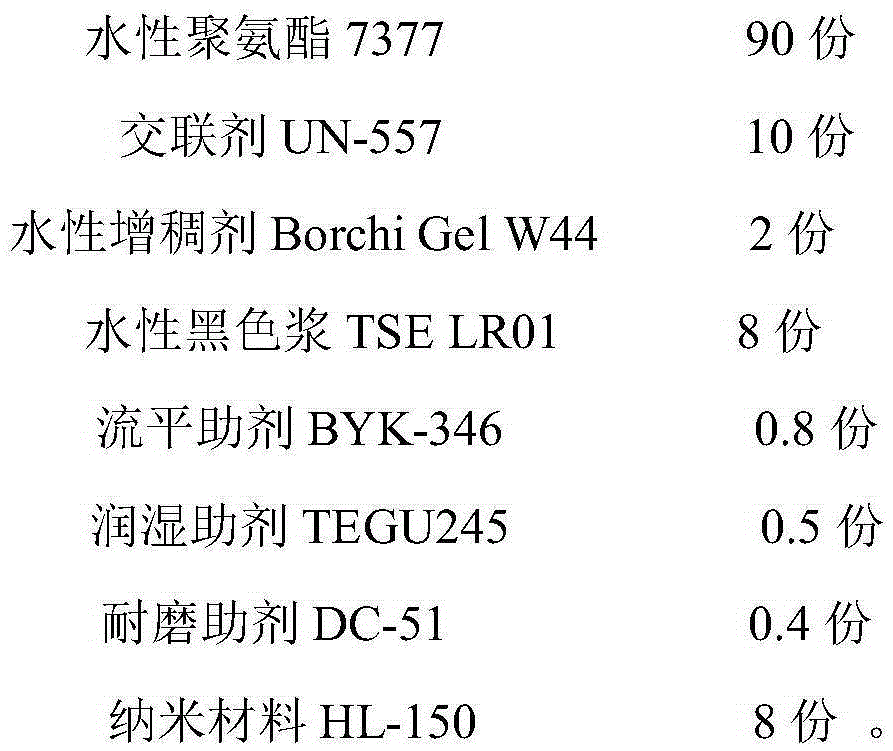

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

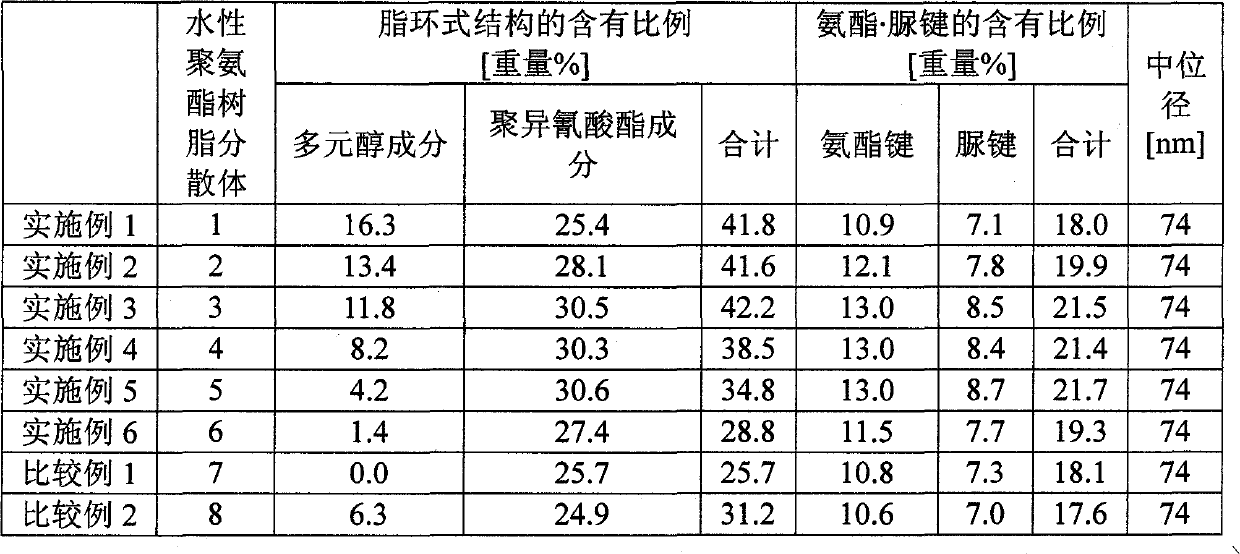

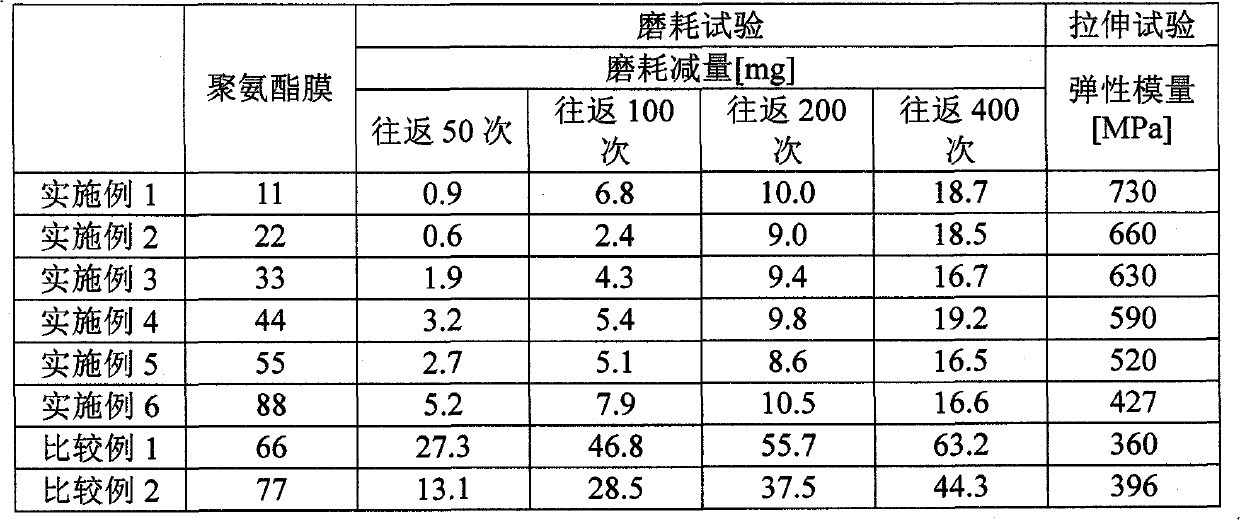

Aqueous polyurethane resin dispersion, manufacturing method for same, and paint composition containing same

ActiveCN102089342AExcellent film forming propertyImprove wear resistancePolyurea/polyurethane coatingsWater basedPolyurethane dispersion

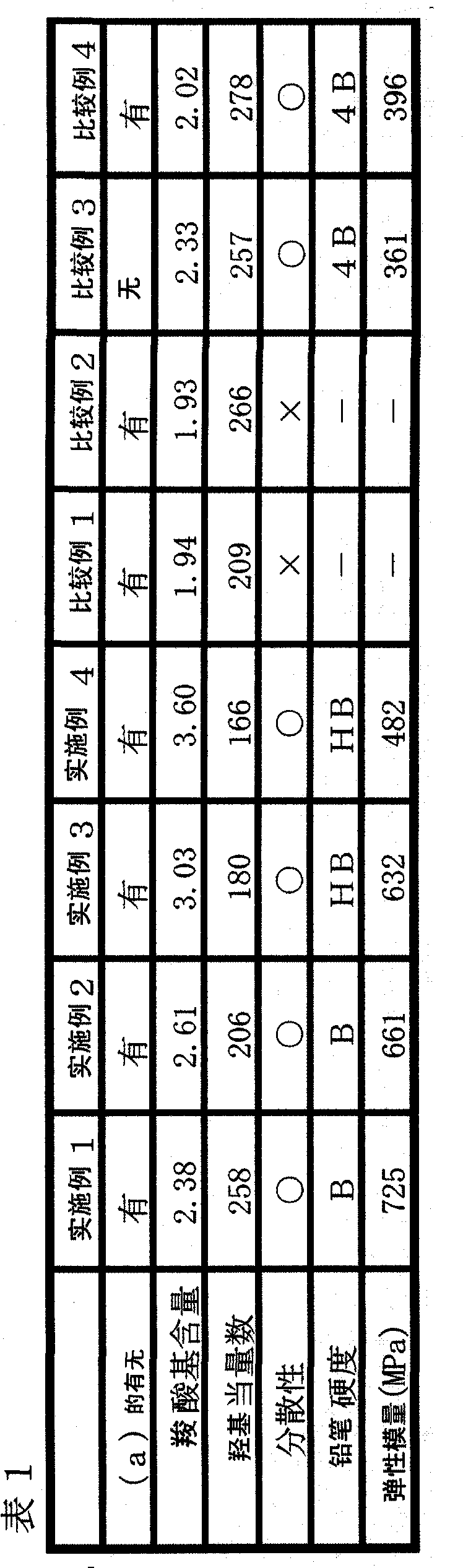

Disclosed is an aqueous polyurethane dispersion with superior wear resistance as a coating film. Provided is an aqueous polyurethane resin dispersion in which a polyurethane resin, which is obtained by reacting a polyurethane polymer (A)-which is obtained by reacting (a) a polyisocyanate compound, (b) a polyol compound containing a polycarbonate polyol with an alicyclic structure, and (c) an acidic-group-containing polyol compound-with a chain extender (B) that is reactive with the isocyanate group in the polyurethane polymer (A), is dispersed in a water-based vehicle, wherein the alicyclic structure content is 26.0 to 60.0% by weight based on the solids content, and the total of the urethane bond content and urea bond content is 17.7 to 30.0% by weight based on the solids content.

Owner:UBE IND LTD

Pharmaceutical formulation comprising dinucleoside polyphosphates and salts thereof

InactiveUS20050085439A1Easily manufactureResistant to hydrolysisBiocideEye implantsPharmaceutical formulationTetra

The present invention provides a method of treating edematous retinal disorders. The method comprises administration of a pharmaceutical formulation comprising a hydrolysis-resistant P2Y receptor agonist to stimulate the removal of pathological extraneous fluid from the subretinal and retinal spaces and thereby reduce the accumulation of said fluid associated with retinal detachment and retinal edema. The P2Y receptor agonist can be administered with therapeutic and adjuvant agents commonly used to treat edematous retinal disorders. The pharmaceutical formulation useful in this invention comprises a P2Y receptor agonist with enhanced resistance to extracellular hydrolysis, such as dinucleoside polyphosphate compounds, or hydrolysis-resistant mononucleoside triphosphate salts. The present invention also provides P1-(2′-deoxycytidine 5′-)P4-(uridine 5′-)tetraphosphate, tetra-(alkali metal) salts such as tetrasodium, tetralithium, tetrapotassium, and mixed (tetra-alkali metal) salts. The present further provides a pharmaceutical formulation comprising a P1-(2′-deoxycytidine 5′-)P4-(uridine 5′-)tetraphosphate, tetra-(alkali metal) salt, in a pharmaceutically acceptable carrier.

Owner:MERCK SHARP & DOHME LLC

Preparation method of antioxidant product with stable performance

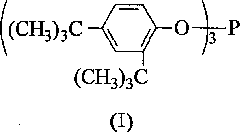

ActiveCN101798325ASimple production processHigh yieldGroup 5/15 element organic compoundsDistillationSolvent

The invention provides a preparation method of antioxidant product with stable performance. 2, 4-di-tert-butylphenol and phosphorus trichloride are taken as raw materials, organic amino compound is taken as catalyst, organic solvent is taken as reaction solvent, esterification is carried out to prepare tri(2,4-ditertrabutyl phenyl) phosphite ester crystal product, namely antioxidant crude product; after reaction is completed, the organic solvent is added into a kettle, so that the antioxidant crystal product is completely dissolved into the organic solvent, an amount of triethylamine is added to react with HCl remained in product mixture, so as to generate triethylamine hydrochloride crystal, filter aid is added to remove solids triethylamine hydrochloride and organic amine catalyst hydrochloride by heat filtering, reduced pressure distillation is carried out to remove the organic solvent, and crystal is washed by low carbon fatty alcohol, thus obtaining the antioxidant product with stable performance. The invention has the advantages of simple production technology, high product yield and good quality; and the obtained product has long time hydrolytic resistance, pyrolysis resistance and good oxidation resistance.

Owner:溧阳常大技术转移中心有限公司

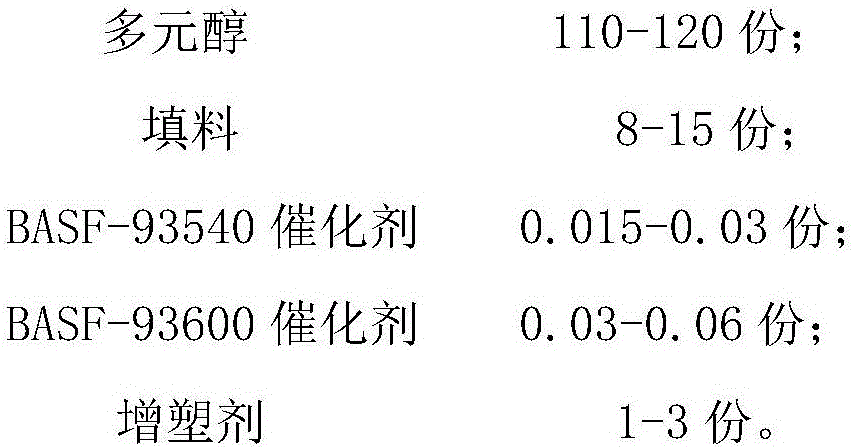

Novel shape memory spraying polyurethaneurea elastomer resin bathroom product and preparation method thereof

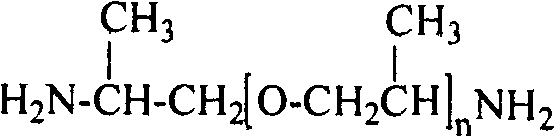

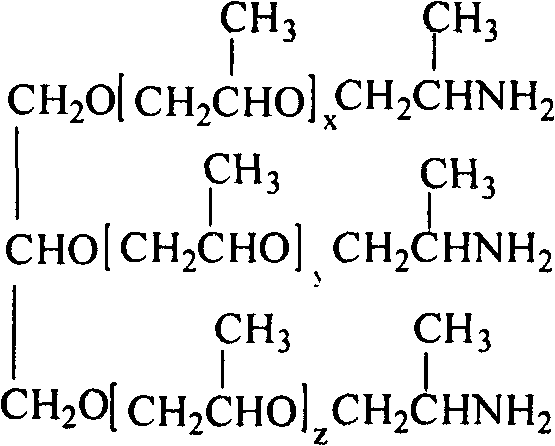

ActiveCN102504173ALow viscosityShort reaction timePretreated surfacesPolyurea/polyurethane coatingsPolyesterElastomer

The invention discloses a spraying elastomer raw material composition. The composition comprises an A component raw material and a B component raw material, wherein the A component raw material comprises one or more of polyester polyol having a number-average molecular weight of 400-3000, polyether polyol having a number-average molecular weight of 400-3000, vegetable oil polyol having a number-average molecular weight of 400-2000, amino-terminated polyether having a number-average molecular weight of 200-4000 and polyisocyanate; and the B component raw material comprises polyoxypropylene diamine having a number-average molecular weight of 200-4000, polyoxypropylene triamine having a number-average molecular weight of 400-5000, active aromatic diamine and aromatic diamine. The invention also discloses a prepolymer of a spraying elastomer, a raw material composition and a preparation method of the prepolymer as well as a bathroom product. The spraying elastomer disclosed by the invention is good in various comprehensive properties; and after pressed, the product can memory the original shape, thereby improving the whole comfortable sensation and broadening the use range of the spraying elastomer.

Owner:SHANGHAI MOERSHU CORP DEVING +1

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Aqueous decoration leather

ActiveCN103556487AIncrease speedLow costLamination ancillary operationsSynthetic resin layered productsSurface layerHazardous substance

The invention provides an aqueous decoration leather. A method for preparing the aqueous decoration leather comprises the following steps: 1, an aqueous wet process: pressing a base cloth, directly coating an aqueous polyurethane foam slurry, drying, reeling, and carrying out semi-finished product bass examination; and 2, an aqueous dry process: directly coating a polyurethane surface layer slurry on a release paper, drying, applying with a semi-finished product bass, drying, reeling, and carrying out finished product examination. The method substantially improves the workshop speed, reduces the cost and increases the output by utilizing the combination of the wet method bass and the dry method coating transfer process. The aqueous decoration leather has the advantages of flame retardation, yellowing resistance, hydrolysis resistance, mildew resistance, water resistance, and zero content of harmful substances comprising DMF, formaldehyde, o-benzene compounds and the like.

Owner:ZHEJIANG WUZHOU IND

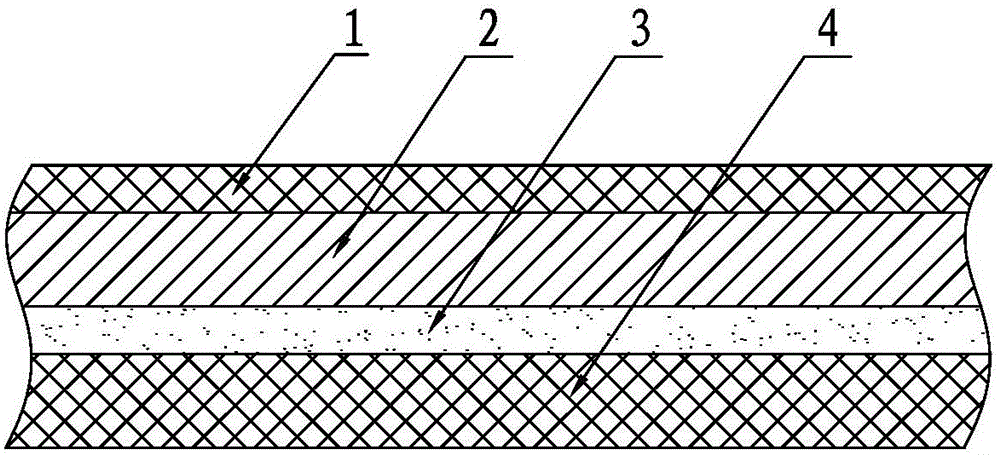

Environment-friendly breathable TPU (Thermoplastic polyurethanes) synthetic leather and preparation method thereof

InactiveCN105966027AReduce pollutionMethod route shortLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveAdditive ingredient

The invention discloses an environment-friendly breathable TPU synthetic leather and a preparation method thereof. The environment-friendly breathable TPU synthetic leather comprises a decorative surface layer, a TPU surface layer, an adhesive layer and a base cloth layer. The decorative surface layer is coated on The treatment agent on the upper surface of the TPU surface layer is generated, and the TPU surface layer is combined with the base cloth layer through the adhesive layer. The components and parts by weight of the TPU surface layer are: 30 to 95 parts by weight of TPU particles; 3 to 95 parts by weight of the flame retardant 25 parts by weight; 2-15 parts by weight of pigment; 0-5 parts by weight of light stabilizer; 0-5 parts by weight of anti-scratch agent; 0-20 parts by weight of filler. The adhesive is a water-based polyurethane adhesive; the surface treatment agent is a water-based polyurethane surface treatment agent. Adopting the preparation method of extrusion casting, shaping first, then compounding, and negative pressure embossing, the products are environmentally friendly, non-toxic, low-odor, low-VOC, clear in structure, soft in hand, scratch-resistant, wear-resistant, hydrolysis-resistant, genuine leather Strong features.

Owner:常州三聚塑胶科技有限公司

High-solid-content train leather production method

InactiveCN103031741AFireproofImprove scratch resistanceSynthetic resin layered productsTextiles and paperCross-linkSurface layer

The invention discloses a high-solid-content train leather production method, which comprises the following steps of: evenly agitating high-scratch-resistance polyurethane surface layer resin, dimethylformamide, butanone, flame retardant, assistants and toner to obtain dry-process surface materials; evenly agitating high-solid-content polyurethane resin, dimethylformamide, flame retardant, assistants, toner and cross-linking agent to obtain middle layer materials; evenly agitating polyurethane bonding resin, dimethylformamide, butanone, flame retardant, cross-linking agent and toner to obtain bonding agent; and evenly coating the dry-process surface materials on release paper, drying the release paper to obtain a surface layer dry film, evenly coating the middle layer materials on the surface layer dry film, drying the surface layer dry film to obtain a middle layer dry film, evenly coating the bonding agent on the middle layer dry film, bonding selected bottom fabrics on the surface of the bonding agent, then drying and cooling for formation and finally separating the release paper to obtain the finished product. The high-solid-content train leather production method has the advantages that the process is simple and the production operation is facilitated; and the synthetic leather produced by adopting the production method provided by the invention has the advantages of fire prevention, high scratch resistance, wear resistance and hydrolysis resistance, and can be used as train seat leather.

Owner:昆山协兴合成革有限公司

Water-soluble PU nubuck low-temperature foamex for synthetic leather

InactiveCN101666039ALow costThe ratio is scientific and reasonableFibre treatmentSolventWater soluble

The invention discloses water-soluble PU nubuck low-temperature foamex for synthetic leather, prepared by the following raw materials in percentage by weight: 30-40 percent of water-soluble polyurethane, 40-50 percent of water, 2-10 percent of low-temperature nubuck foam powder, 2-5 percent of organosilicon levelling agent, 2-5 percent of organosilicon antifoaming agent and 0.5-2 percent of water-soluble polyurethane thickener. The mixture ratio of each component of the water-soluble PU nubuck low-temperature foamex for synthetic leather is scientific and reasonable, and the components mutually coordinate and jointly act. The nubuck low-temperature foamex has the advantages of good film reforming property and firm adhesion, and coating is resistant to solvent, cold, hydrolysis and thermalageing. The original effect of the leather surface of a finished product prepared from the water-soluble PU nubuck low-temperature foamex can not be influenced; after the leather surface is treated bythe foamex, low-temperature foaming is carried out to produce nubuck leather, and therefore, the effect of the leather surface is unique; moreover, the synthetic leather has exquisite texture, good air permeability and excellent resultant effect of hand feeling, water proofing, adhesion and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Aqueous polyurethane resin dispersion, manufacturing method thereof, and paint composition containing the same

InactiveCN102046686AImprove dispersion stabilityResistant to hydrolysisPolyurea/polyurethane coatingsPolymer sciencePolyol

An aqueous polyurethane resin dispersion produced by dispersing, in an aqueous medium, a polyurethane resin that is obtained by causing a chain extender (B) to react with a polyurethane prepolymer (A) obtained by causing a polycarbonate polyol (a) having an alicyclic structure in the main chain thereof, to react with an acidic group-containing polyol compound (b), and, if necessary, a polyol (c) other than (a) and (b), and a polyisocyanate (d), wherein the content of carboxylic acid group in the polyurethane prepolymer (A) is 2.0 to 13.0 weight %, and the total hydroxyl group equivalent of the polycarbonate polyole (a) having the alicyclic structure in the main chain thereof, the acidic group-containing polyol compound (b), and, if necessary, the polyol (c) other than (a) and (b), is 70 to 270.

Owner:UBE IND LTD

Polyurethane microporous elastomer with characteristics of rubber and preparation method thereof

The invention discloses a polyurethane microporous elastomer with characteristics of rubber and a preparation method thereof. The preparation method comprises the following steps: heating and mixing polyester polyol A1, polyester polyol A2, polyester polyol A3, a chain extender, tertiary amine or organic metal catalyst, an organosilicon foam stabilizer and a foaming agent in a reaction kettle to obtain a component A; mixing diisocyanate, polyester polyol B1, polyester polyol B2, polyester polyol B3 and a side reaction inhibitor in a reaction kettle to react, thereby obtaining a component B; and thoroughly mixing the components A and B, and reacting to obtain the polyurethane microporous elastomer. The polyurethane microporous elastomer with characteristics of rubber is suitable to be used as a sole material, and has the advantages of excellent processability, mechanical properties, hydrolysis resistance and low-temperature resistance. The prepared sole is light and comfortable; and meanwhile, a double-component system and a cast molding technique which are used are simple and easy to control, thereby enhancing the competitive power of the traditional sole materials, such as polyurethane microporous elastomer materials, rubber and the like.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

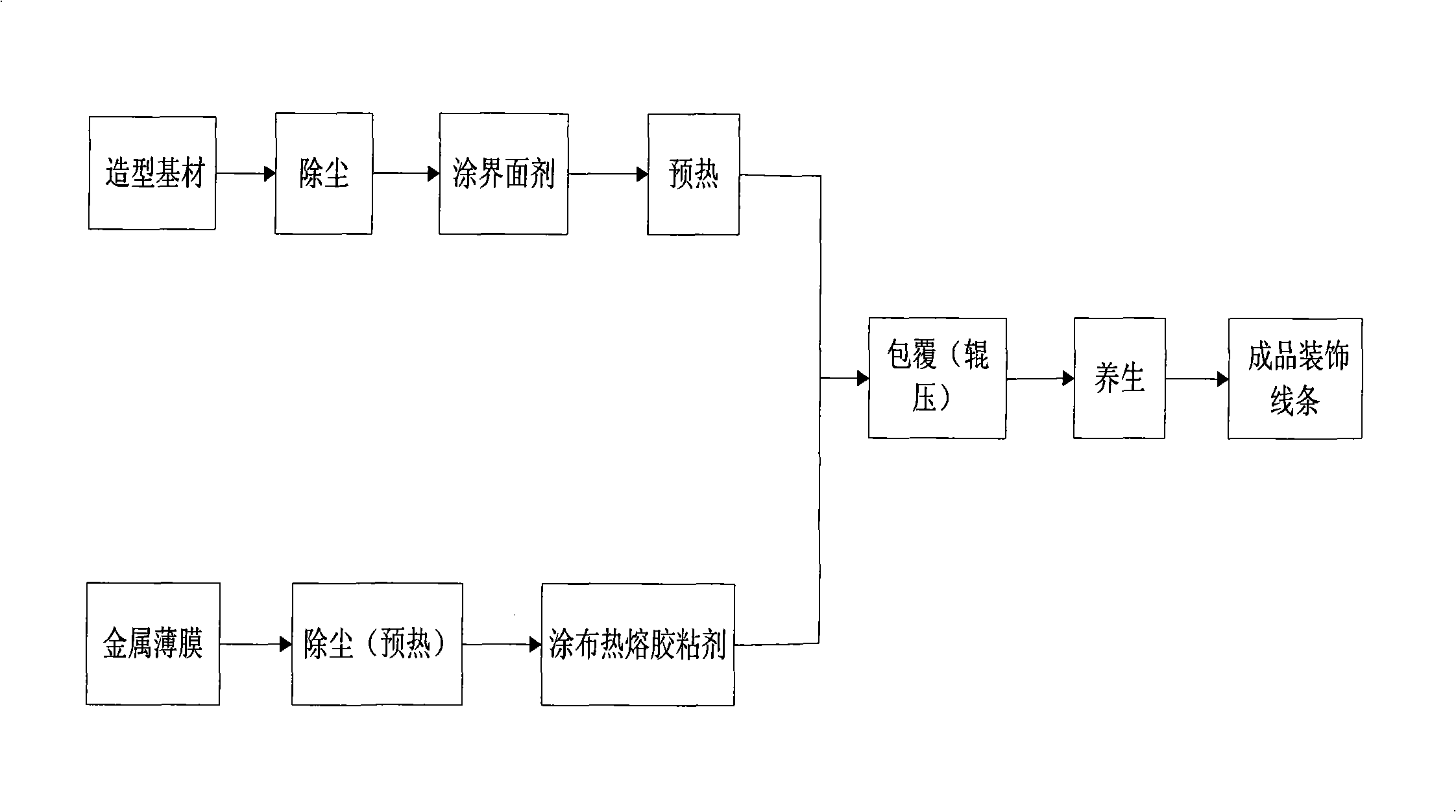

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Organic silicon wrapped fluorescent powder for light emitting coating and preparation method and application thereof

ActiveCN103436249AResistant to hydrolysisReduce loss of luminescent propertiesLuminescent paintsEmulsion paintsWater basedAlcohol

The invention relates to organic silicon wrapped fluorescent powder for a light emitting coating and a preparation method thereof, and further relates to an application of the organic silicon wrapped fluorescent powder in the light emitting coating. The organic silicon wrapped fluorescent powder is prepared by the following method: dissolving ethyl orthosilicate in mixed liquor of water and alcohol; first, adjusting the pH value to 1-2 by nitric acid, and then, adjusting the pH value to 5-7 by alkali to obtain a diluted liquid; adding fluorescent powder into the diluted liquid, and stirring and continuously adjusting the pH value to 7-8 by alkali to prepare the organic silicon wrapped fluorescent powder dispersed in the diluted liquid. The organic silicon wrapped fluorescent powder and the diluted liquid are added into the components of the light emitting coating, and a better embodiment is addition of a water-base resin film-forming material. According to the technical scheme provided by the invention, water-tolerant treatment and organic silicon wrapping are directly carried out in an aqueous phase, so that the fluorescent powder in a water-based medium has hydrolysis resistance and reduces the loss on light emitting property, the dispersibility of the fluorescent powder in the coating is improved to prevent coagulation by further improving the surface electrical property of the fluorescent powder.

Owner:武汉工大科技园发展有限公司

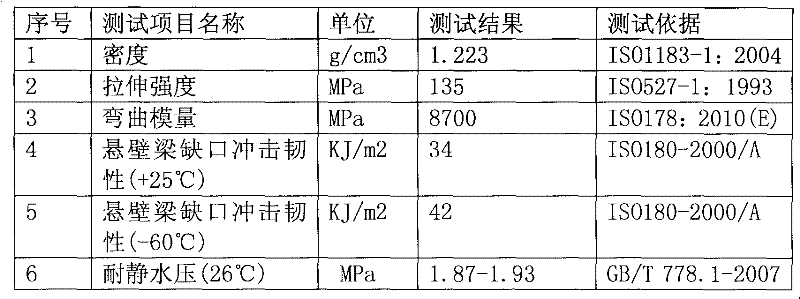

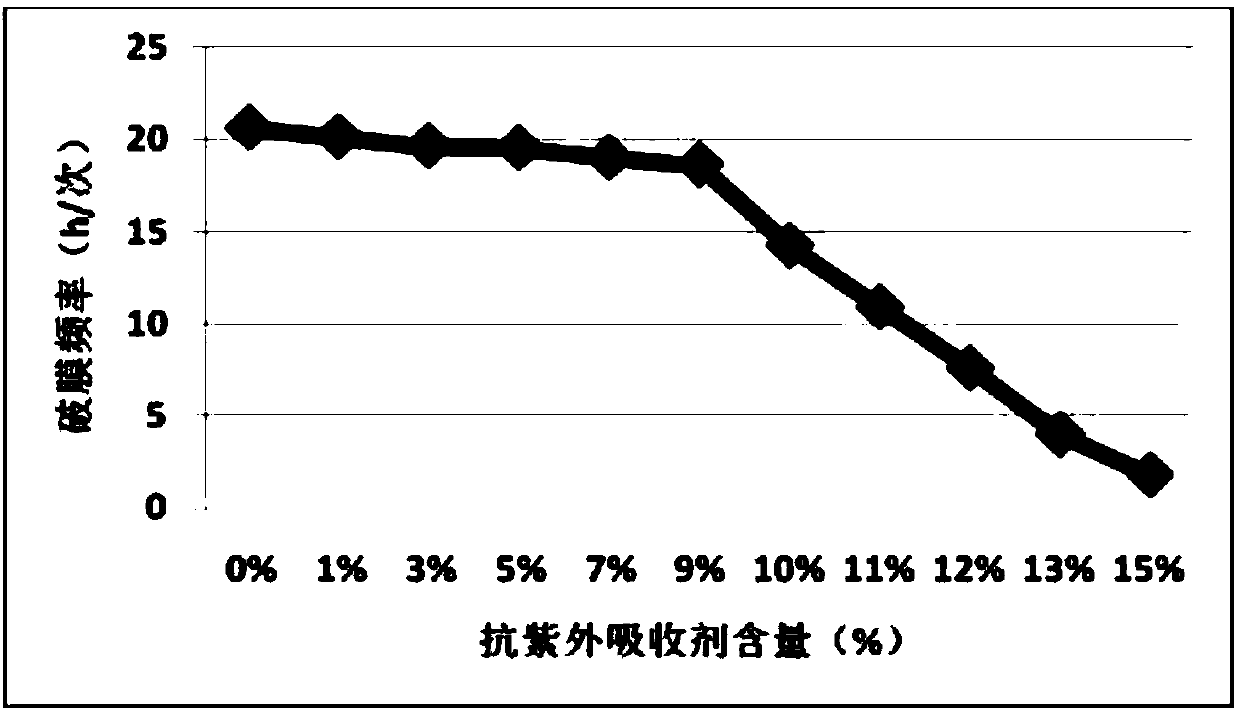

Long glass fiber enhanced polypropylene composite material water meter casing and manufacture method thereof

InactiveCN102504405AGood low temperature resistanceHigh low temperature impact resistanceVolume meteringHeavy metalsAntioxidant

The invention discloses a long glass fiber enhanced polypropylene composite material water meter casing and a manufacture method of the long glass fiber enhanced polypropylene composite material water meter casing. A thermal plastic composite material water meter casing comprises the following ingredients: blending alloy, auxiliary agents, color powder, antioxidants and ultraviolet absorbers, wherein the blending alloy consists of glass fiber, polypropylene and / or polypropylene modified materials. The thermal plastic composite material water meter casing made by adopting an injection molding forming process has the characteristics of high-temperature resistance, low-temperature resistance, impact resistance, creep deformation resistance, water pressure resistance, hydrolysis resistance, no heavy metal, long service life, low cost, environmental-friendly effect and the like, is easy to process and conforms to the industrial standard of the national plastic water meter casing material, so the thermal plastic composite material water meter casing is particularly suitable for large-scale industrial production and wide popularization and application.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

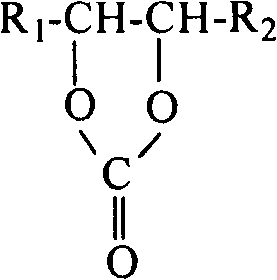

Polyurethane prepolymer

ActiveCN102167794AEasy to handleResistant to hydrolysisOther chemical processesInsolesPolypropylene glycolLiquid state

The invention provides a polyurethane prepolymer with moisture curing, which is in a liquid state at a normal temperature and will not soak towards the inner substrate. The polyurethane prepolymer has good elastic force and moisture permeability. Solvent-free polyurethane prepolymer is formed in a manner that polyether polyalcohol, polyester polyalcohol and polyisocyanates undergo a reaction with the equivalence ration of NCO / OH being 1.1-3.0 to contain amine curing catalyst of 0.01-5mass%. The mass ratio between the polyether polyalcohol and the polyester polyalcohol is arranged from 95 / 5 to 75 / 25. The main component of the polyether polyalcohol is polytetramethylene glycol-polyethylene glycol copolymer or polypropylene glycol.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

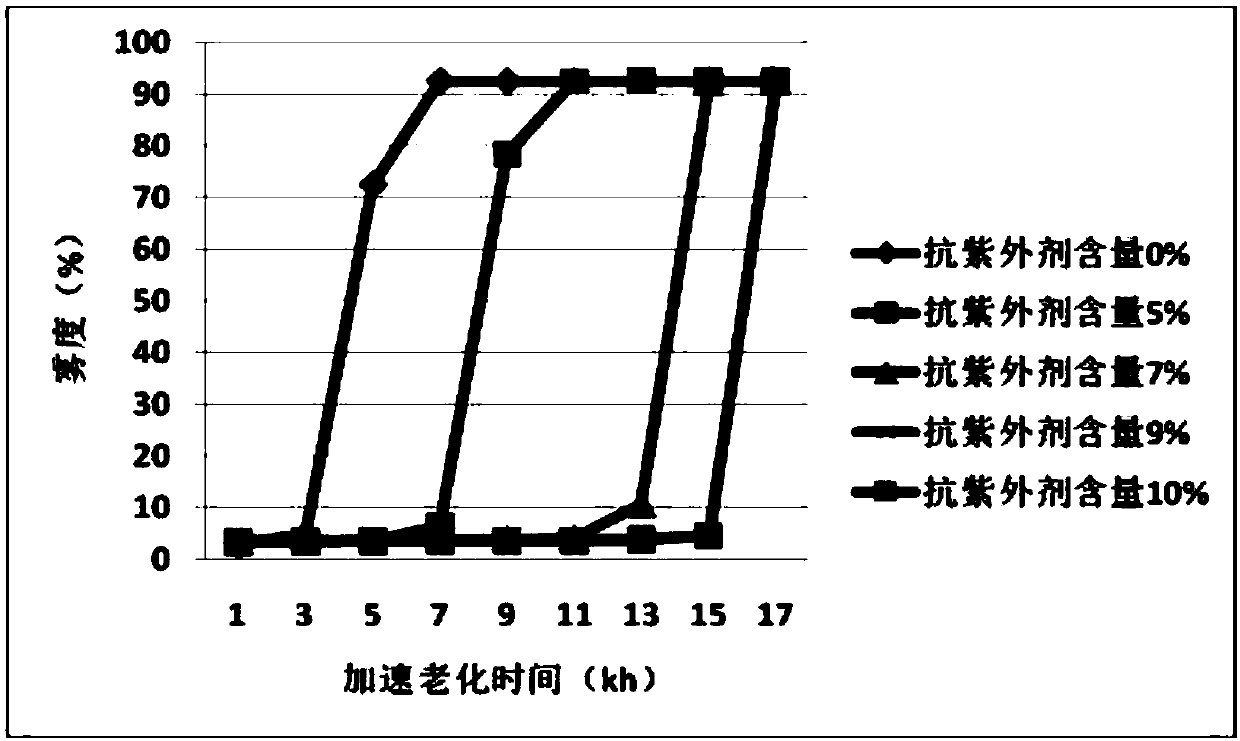

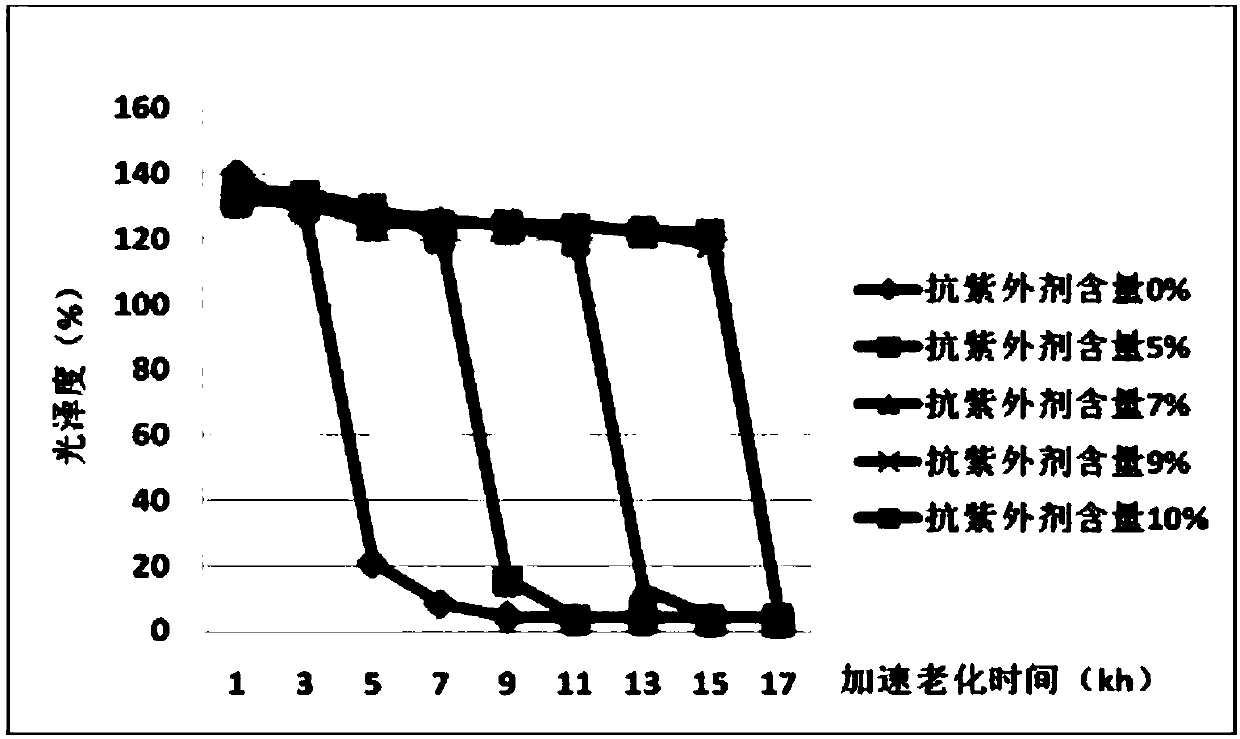

Anti-ultraviolet bidirectional stretching polyester film and preparation method thereof

InactiveCN107839323AImprove product performanceEnhanced anti-aging effectSynthetic resin layered productsFlat articlesPolyesterChemistry

The invention relates to an anti-ultraviolet bidirectional stretching polyester film and a preparation method thereof. The an anti-ultraviolet bidirectional stretching polyester film is composed of anupper surface layer, a core layer, and a lower surface layer. The core layer is composed of an anti-ultraviolet absorbent and polyethylene glycol terephthalate slice; the upper surface layer is composed of the anti-ultraviolet absorbent, an anti-adhesion agent, and the polyethylene glycol terephthalate slice; and the lower surface layer is composed of the anti-adhesion agent and the modified polyethylene glycol terephthalate slice. The product has the characteristics of UV resistance, heat sealing, high intensity, hydrolysis resistance, corrosion resistance, and high thermostability, can be widely used in the fields of outdoor product package and building, and belongs to the functional film, performance is outstanding, cost is low, and the method has a wide application prospect.

Owner:ANHUI GUOFENG PLASTIC

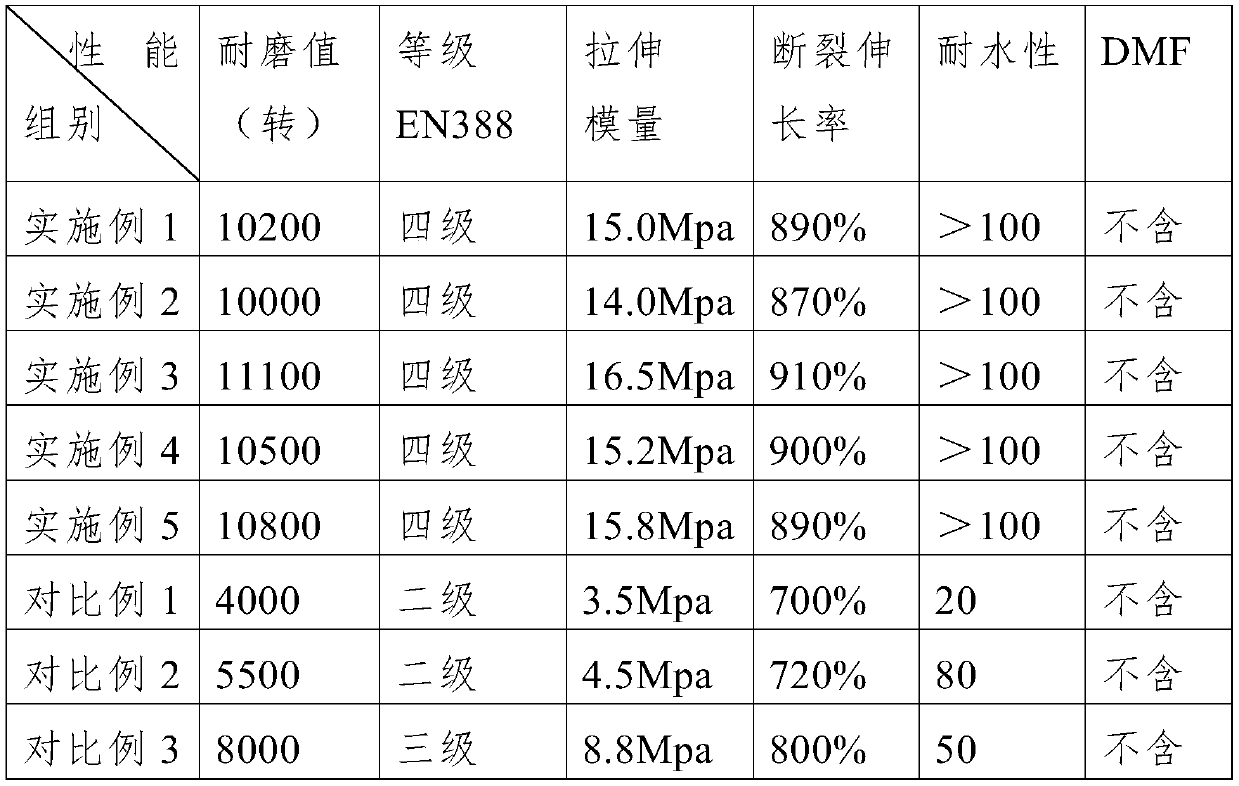

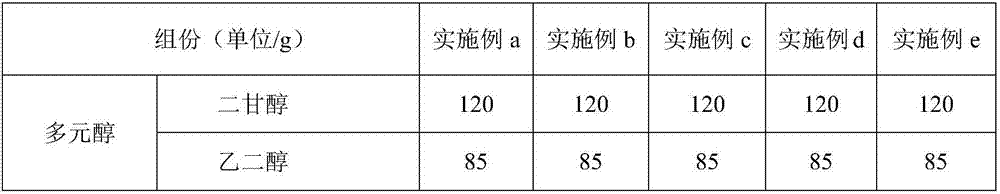

Waterborne polyurethane emulsion, preparation method and impregnated gloves

InactiveCN110452351AReduce pollutionReduce potential energyGlovesProtective garmentSolventSilicon nanoparticle

The present invention relates to a waterborne polyurethane emulsion. During preparation of the waterborne polyurethane emulsion, raw materials comprise an organosilicon polyol and modified silicon nanoparticles capable of reacting with hydrophilic groups in polyurethane molecular chains, so that the waterborne polyurethane molecular chains are introduced into reactive organosilicon and the modified silicon nanoparticles. The preparation method comprises the following steps: during preparation of a polyurethane prepolymer, taking an isocyanate and polyol as raw materials, and carrying out a reaction in the presence of a catalyst and a chain extender to obtain the polyurethane prepolymer, wherein the polyol contains at least one organosilicon polyol; and during preparation of the waterbornepolyurethane emulsion, mixing the polyurethane prepolymer with a water solution containing the modified silicon nanoparticles for emulsification to obtain the waterborne polyurethane emulsion. Compared with an existing mode of adding a filler by physical mixing to modify the waterborne polyurethane resin, the method provided by the invention has the advantages that water resistance / solvent resistance, low-temperature flexibility and wear resistance of the waterborne polyurethane resin can be improved, and retention timeliness of the excellent performance is longer.

Owner:SHANDONG XINGYU GLOVES

Nano silicon salt filler zinc-aluminum composite thermal-insulation coating and preparation method thereof

InactiveCN104673034ASelf-lubricatingWith wear resistanceFireproof paintsEpoxy resin coatingsEpoxyPowder talc

The invention discloses a nano silicon salt filler zinc-aluminum composite thermal-insulation coating. The coating comprises, in parts by mass, 18-24 parts of a silicone-acrylate emulsion, 12-14 parts of rutile type titanium dioxide, 2-4 parts of an aid, 55-60 parts of functional filler, 3-4 parts of propylene glycol, 10-15 parts of PPESK (poly(phthalazinone ether sulphone ketone)) modified resin, 15-25 parts of silicon carbide micro-powder, 15-20 parts of fluorinated graphite and 30-35 parts of a coupling agent, wherein the PPESK modified resin comprises, in parts by mass, 40-70 parts of epoxy resin and 20-35 parts of PPESK; the particle size of the silicon carbide micro-powder is 6 mu m; the particle size of the fluorinated graphite is in a range of 5-10 mu m; the functional filler comprises nano-montmorillonite type silicate and barrier type functional filler in the mass ratio of 1:1.5; the barrier type functional filler comprises, in parts by mass, 2-6 parts of hollow glass beads, 10-15 parts of graphite, 20-35 parts of black silicon carbide, 25-30 parts of fine-grained aluminum oxide, 5-10 parts of molybdenum disulfide, 1-5 parts of zinc oxide and 3-6 parts of talc powder. The invention further designs a preparation method of the nano silicon salt filler zinc-aluminum composite thermal-insulation coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

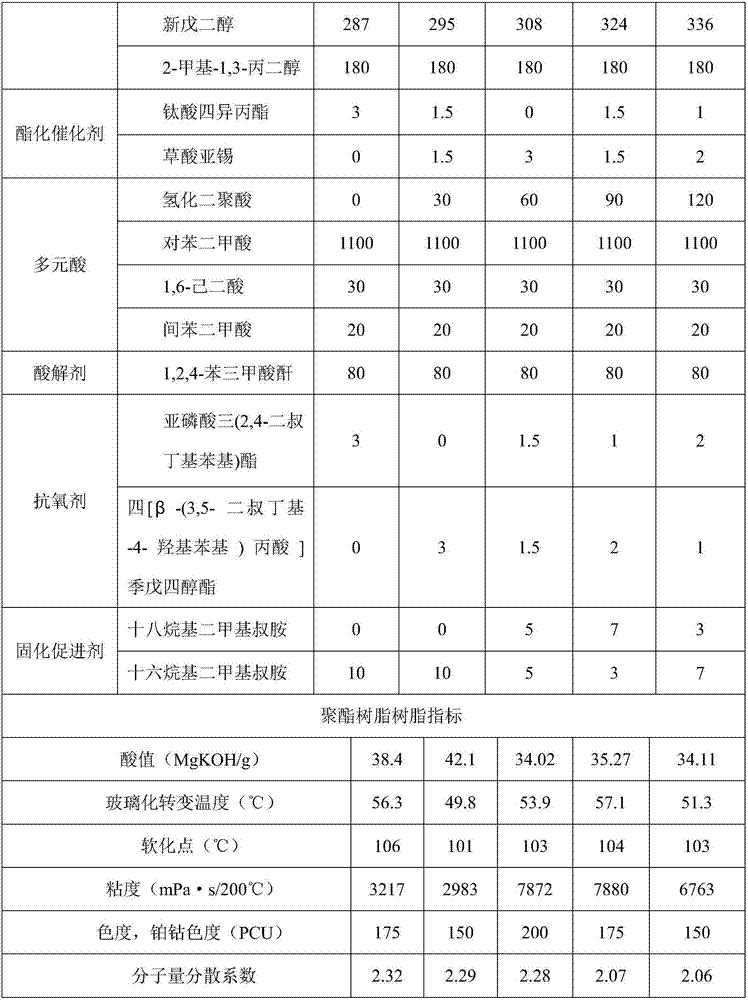

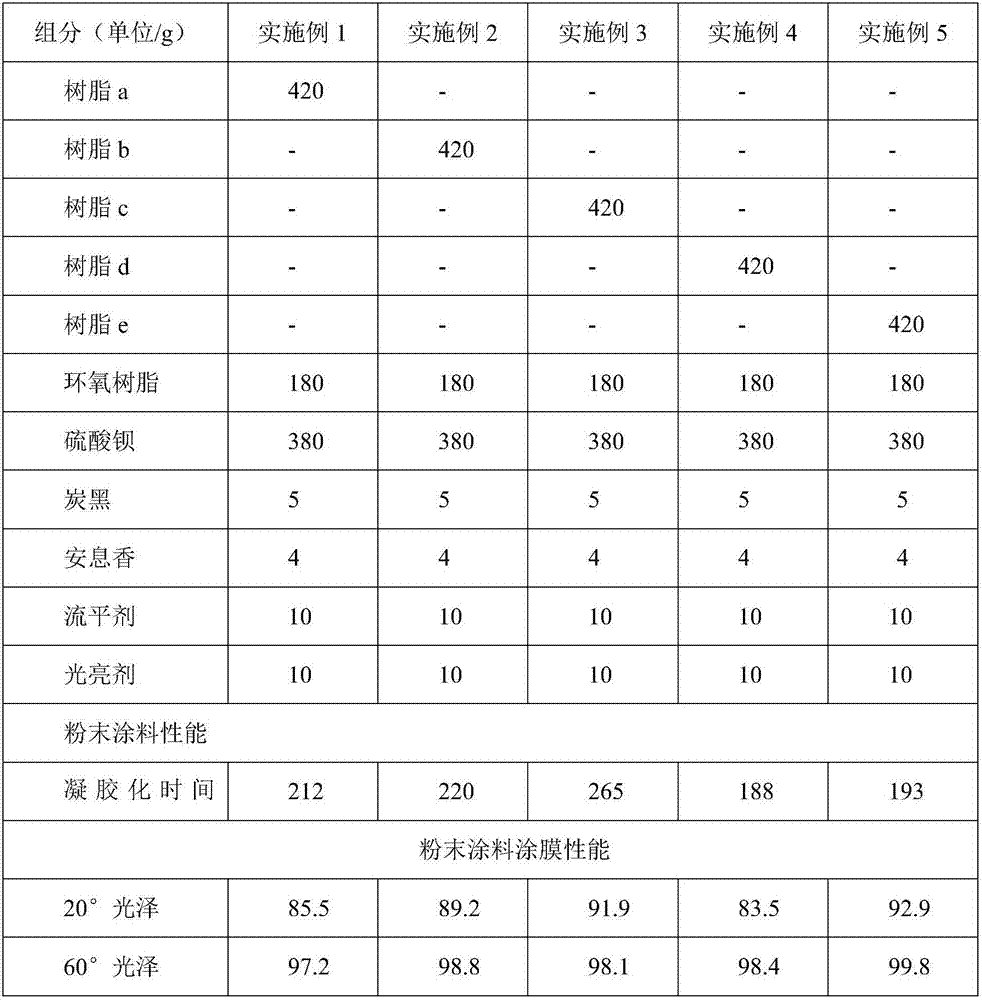

Epoxy cured polyester resin used for powdery paint having high surface decorative performance and high water resistance and preparation method thereof

ActiveCN107254240AThe temperature is 50.0~54.0℃, the rotational viscosity is highIncrease viscosityPowdery paintsPolyester coatingsEpoxyDistillation

The invention relates to epoxy cured polyester resin used for a powdery paint having high surface decorative performance and high water resistance and a preparation method thereof. The provided polyester resin has appropriate glass-transition temperature, a prepared powdery paint film has excellent dynamic mechanical properties, high surface decoration performance and high water resistance. The polyester resin is prepared by melt phase polycondensation of the raw materials of polyol, polyprotic acid, an acidulate agent, an esterification catalyst, an anti-oxidant and a curing accelerator. The method of the polyester resin comprises the following steps: 1) the polyol is delivered into a reaction kettle at a needed ratio, rapid heating esterification is carried out, water is generated, and is removed via distillation; 2) temperature is increased gradually, and an obtained material is maintained to be clear; 3) sample examination is carried out; 4) negative pressure polycondensation is carried out; and 5) cooling is carried out, the antioxidant and the curing accelerator are added, stirring dispersing is carried out, and an obtained product is cooled, and is collected.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

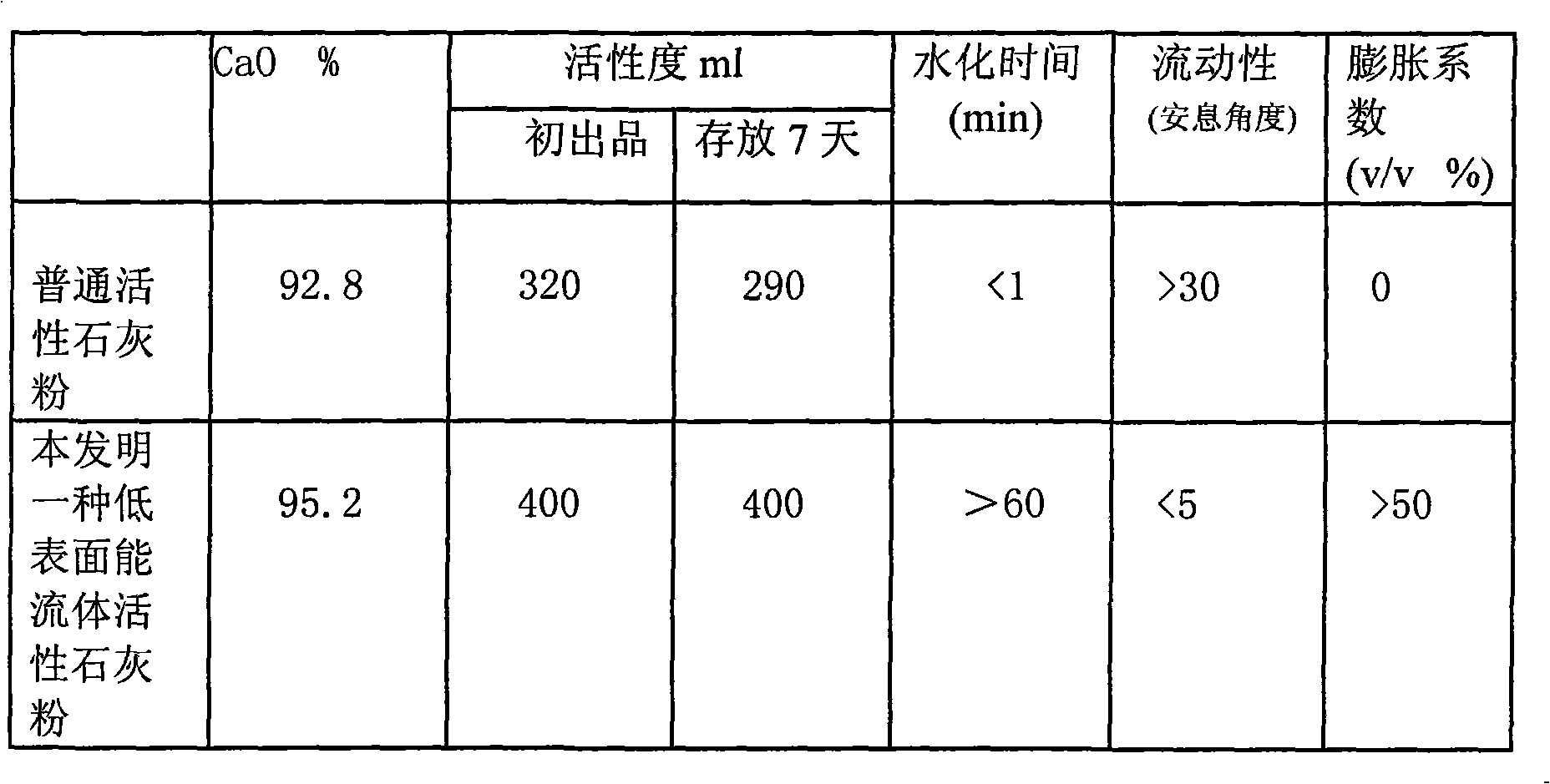

Fluid active lime powder with low surface energy and production method thereof

InactiveCN101643820AStrong moisture resistanceConducive to jet desulfurizationSurface energyIron production

The invention relates to fluid active lime powder, in particular to fluid active lime powder which has low surface energy, is used for desulfurizing molten steel and iron and comprises lime powder anda modifier in a weight ratio ranging 100:0.5 to 100:0.7. The modifier comprises the following components: a chromic compound, an ethanol solution, soap powder, alkali liquor, a vector and organic silicon oil. The production method of the fluid active lime powder with low surface energy comprises the following steps: sequentially selecting limestone; kilning; calcining; crushing; proportionally mixing the limestone in the modifier; and finally, grinding to obtain the active lime powder. The active lime powder has short calcination time, high activity, strong water resistance and higher fluidity, is suitable for desulphurization by an injection method and can improve the steel-iron production efficiency.

Owner:HUBEI HESHI CALCIUM IND DEV

Preparation method and use of rare earth coated titanium polyesterification catalyst

The invention provides a preparation method and use of a rare earth coated titanium polyesterification catalyst. The preparation method comprises: heating a solvent to a certain temperature; dissolving a titanate, a phosphate, a silicate ester and other metal compounds in the organic solvent, stirring, keeping the temperature, dripping a small amount of water to promote hydrolysis and obtaining ared precipitate; and repeatedly washing the obtained red precipitate with acetone, removing residual ethanediol, drying the precipitate at 70 DEG C under vacuum and obtaining red powdered catalyst. The polyester prepared by using the catalyst has good hue, other properties of the titanium catalyst are also improved, the catalyst does not contain toxic stibium compounds, and therefore the toxicityof the stibium compounds to the environment and human body is eliminated. The preparation method is mainly to solve the technical problem of the conventional polyesterification process and the yellowing problem of polyethylene glycol terephthalate (PET) and improve the quality of the polyester.

Owner:江西省铜鼓县二源化工有限责任公司 +1

Water-based PU matte surface finishing agent for synthetic leather

The invention discloses a water-based PU matte surface finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 45 to 55 parts of water, 4 to 10 parts of modified organic silicon polymer, 0.5 to 1.5 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 3 to 5 parts of modified organic silicon matting agent. For the water-based PU matte surface finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com