Preparation method of solvent-free sofa furniture microfiber synthetic leather

A solvent-free, synthetic leather technology, applied in furniture parts, household utensils, applications, etc., to achieve the effect of good hand feeling, moderate cost, strong sensuality and drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, dissolve 1 part of OFX-3238 wear-resistant additive, 0.3 part of wetting agent, 0.5 part of GE-UV antioxidant and 60 parts of ST-8030PC environment-friendly polyether polycarbon composite polyurethane resin into 60 parts of dimethyl carbonate In the ester solvent, add 6 parts of pigment paste, stir and mix evenly, then vacuumize, and then evenly smear on the front of the release paper as the surface layer and the middle layer, and the thickness of the surface layer slurry layer is 0.1mm , the coating thickness of the slurry layer of the middle layer is 0.15mm; it is air-dried at 130°C for 1min.

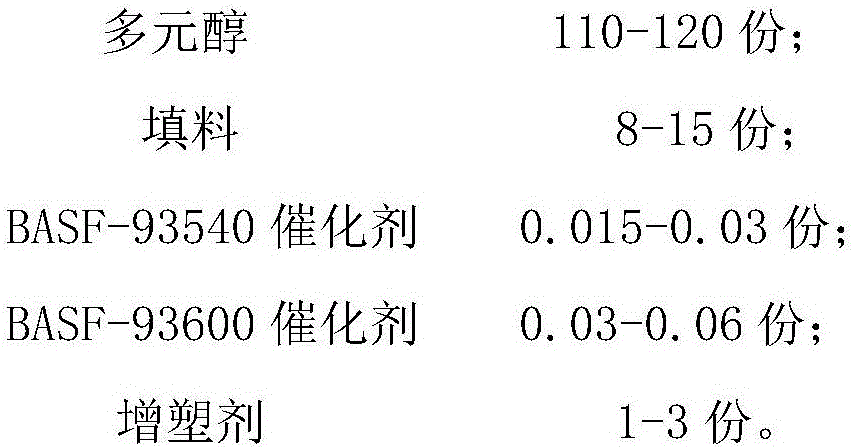

[0043] Secondly, 65 parts of diphenylmethane diisocyanate, 110 parts of polycaprolactone polyol, 0.015 parts of BASF-93540 catalyst, 0.03 part of BASF-93600 catalyst, 8 parts of light calcium carbonate filler, 3 parts of plasticizer TXIB, Add materials A and B respectively to the storage tanks corresponding to the production equipment, and adjust the metering pump to tra...

Embodiment 2

[0048] First, dissolve 1.5 parts of OFX-3238 wear-resistant additive, 0.5 parts of wetting agent, 0.5 parts of GE-UV antioxidant and 65 parts of ST-8030PC environment-friendly polyether polycarbon composite polyurethane resin in 70 parts of dimethyl carbonate In the ester solvent, add 6 parts of pigment paste, fully stir and mix evenly, then vacuumize, and then evenly smear on the front of the release paper as the surface layer and the middle layer, and the thickness of the surface layer slurry layer is 0.12mm , the coating thickness of the slurry layer of the middle layer is 0.15mm; it is air-dried at 130°C for 1min.

[0049] Next, 70 parts of hexadimethyl diisocyanate, 115 parts of polytetrahydrofuran ether polyol, 0.02 parts of BASF-93540 catalyst, 0.04 part of BASF-93600 catalyst, 10 parts of aluminum hydroxide filler, and 3 parts of plasticizer TXIB were added to the production In the A and B material storage tanks corresponding to the equipment, the uniformly stirred A a...

Embodiment 3

[0054] First, dissolve 1.5 parts of OFX-3238 wear-resistant additive, 0.6 parts of wetting agent, 0.6 parts of GE-UV antioxidant and 70 parts of ST-8030PC environment-friendly polyether polycarbon composite polyurethane resin in 70 parts of dimethyl carbonate In the ester solvent, add 6 parts of pigment paste, fully stir and mix evenly, then vacuumize, and then evenly smear on the front of the release paper as the surface layer and the middle layer, and the thickness of the surface layer slurry layer is 0.12mm , the coating thickness of the slurry layer of the middle layer is 0.15mm; it is air-dried at 130°C for 1min.

[0055] Next, add 70 parts of isophorone diisocyanate, 120 parts of polycarbonate polyol, 0.03 parts of BASF-93540 catalyst, 0.06 parts of catalytic BASF-93600 agent, 15 parts of diatomite filler, and 3 parts of plasticizer TXIB, respectively In the A and B material storage tanks corresponding to the production equipment, the uniformly stirred A and B materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com