Patents

Literature

282results about How to "Add equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

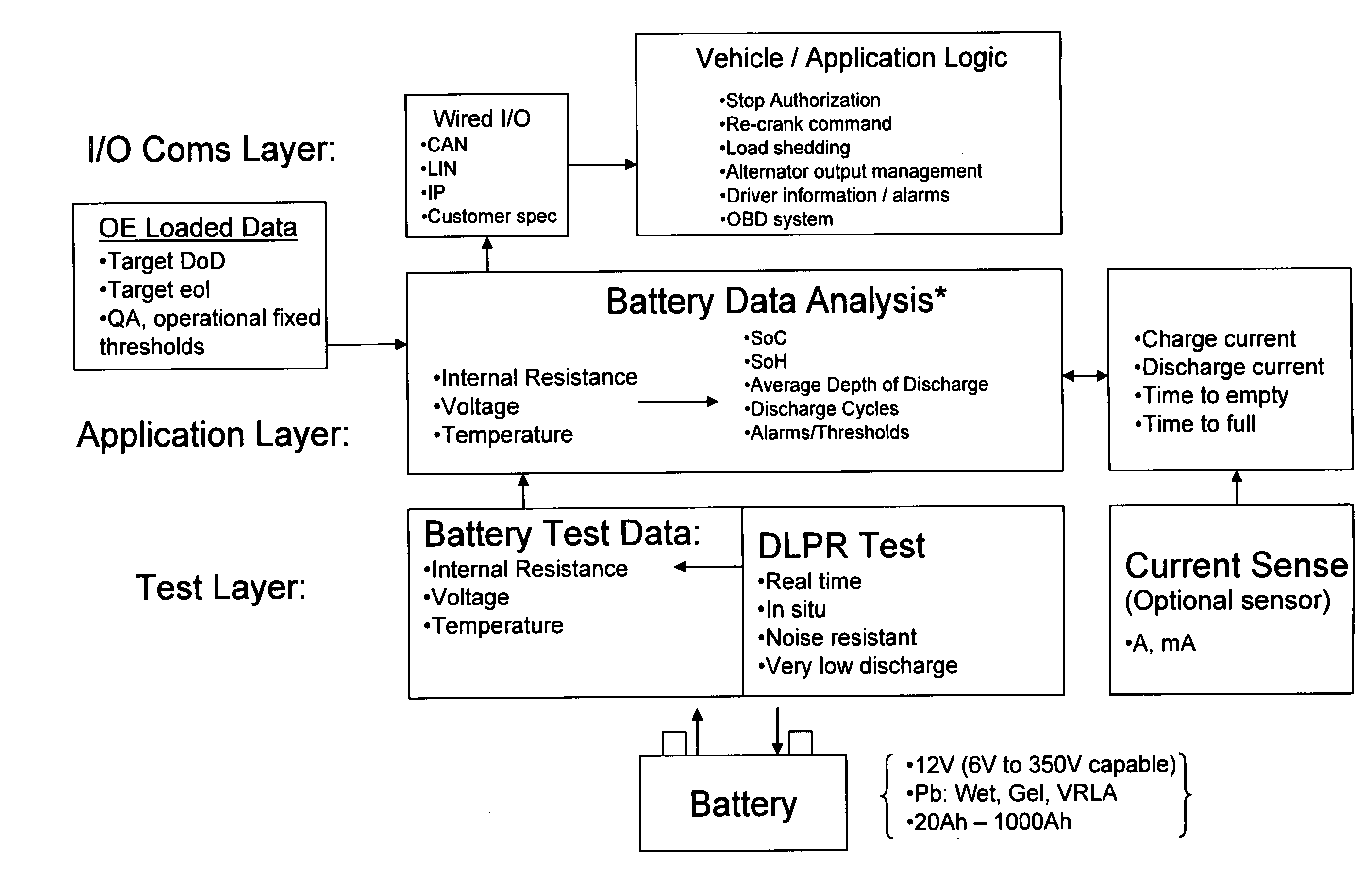

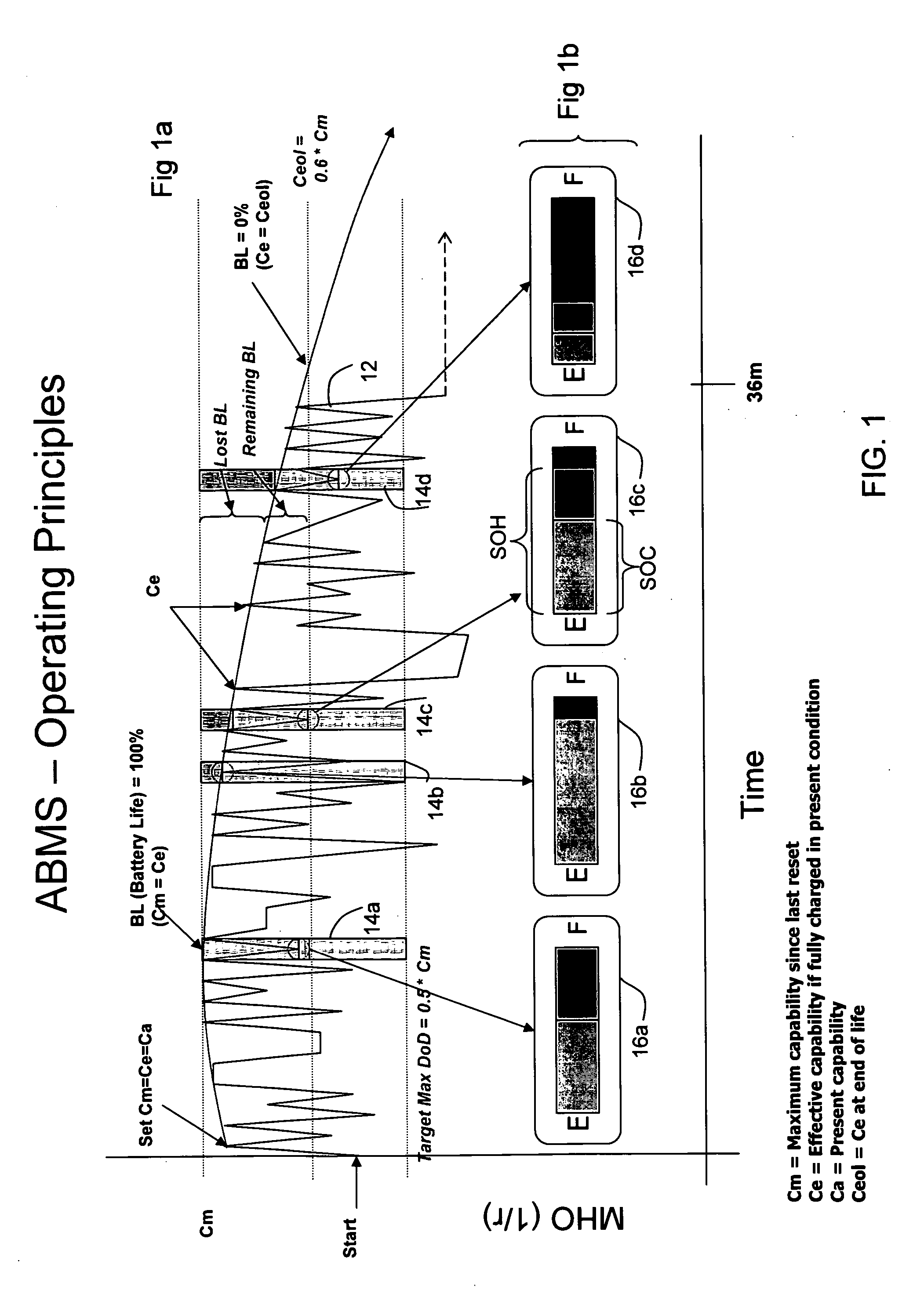

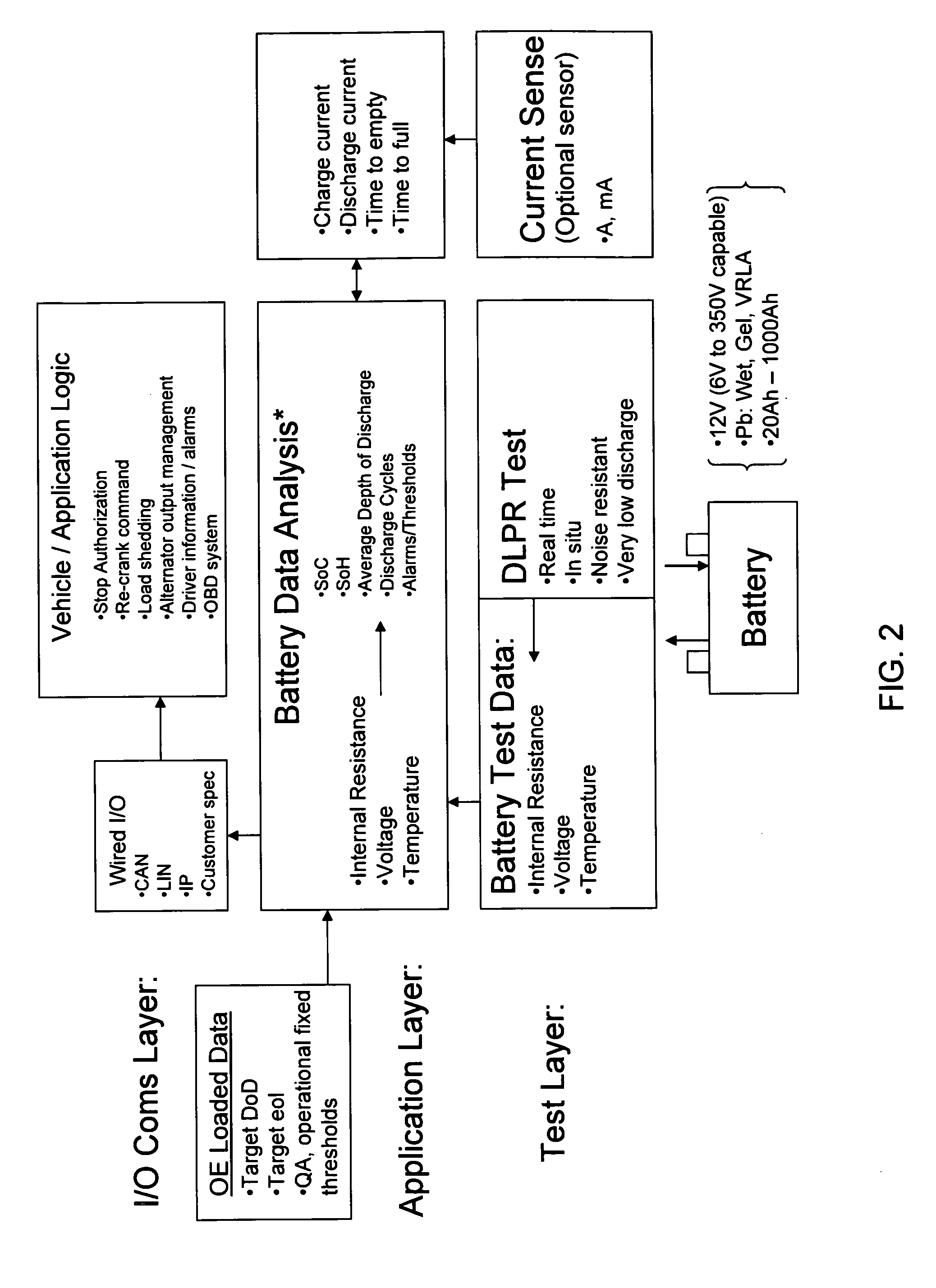

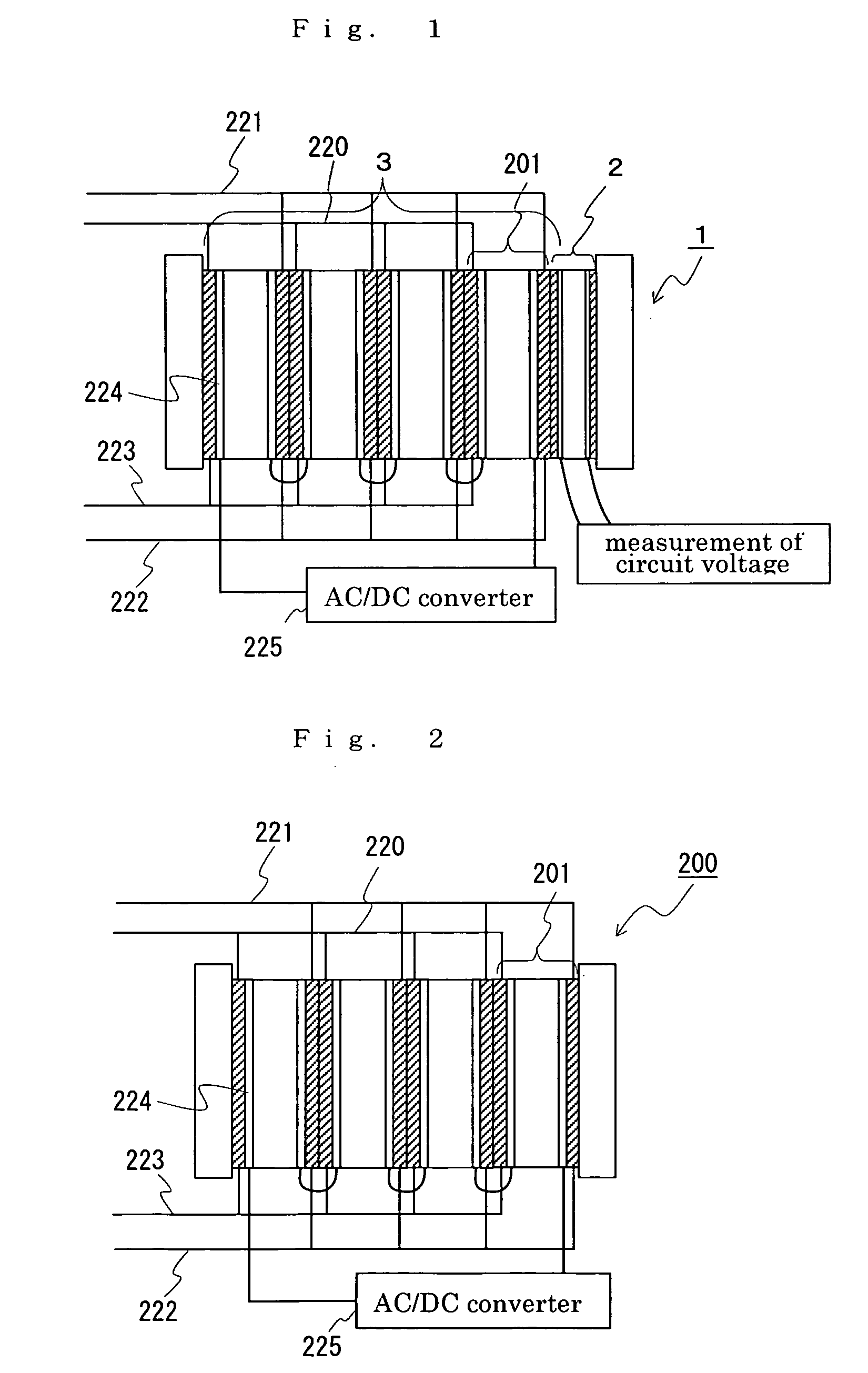

Battery performance monitor

ActiveUS20090027056A1Add equipmentEasy to modifyBatteries circuit arrangementsOperating modesOperational systemInternal resistance

Improvements both in the methods whereby existing techniques for determining the condition of a battery are communicated to a user (for example, to the owner of a private vehicle, or to the service manager of a fleet of vehicles), or the vehicle's operating system, and in the methods for evaluating the condition of the battery are disclosed. It has been discovered by the inventors that the difference in internal resistance of a fully charged battery as measured during charging and as measured after charging is greater for a battery in poor condition than for a new battery. The invention relates in part to instruments and corresponding methods for evaluating the condition of a battery utilizing this discovery.

Owner:BATTERY TECH HLDG

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

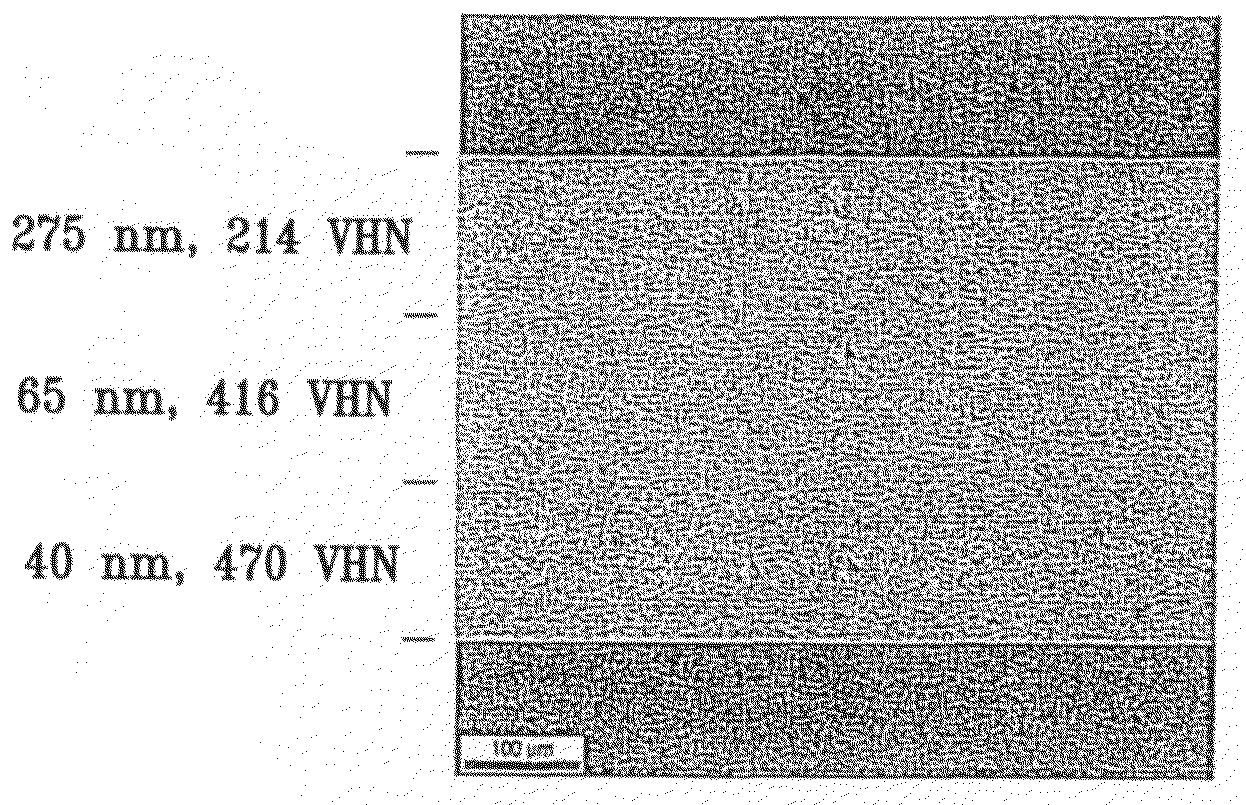

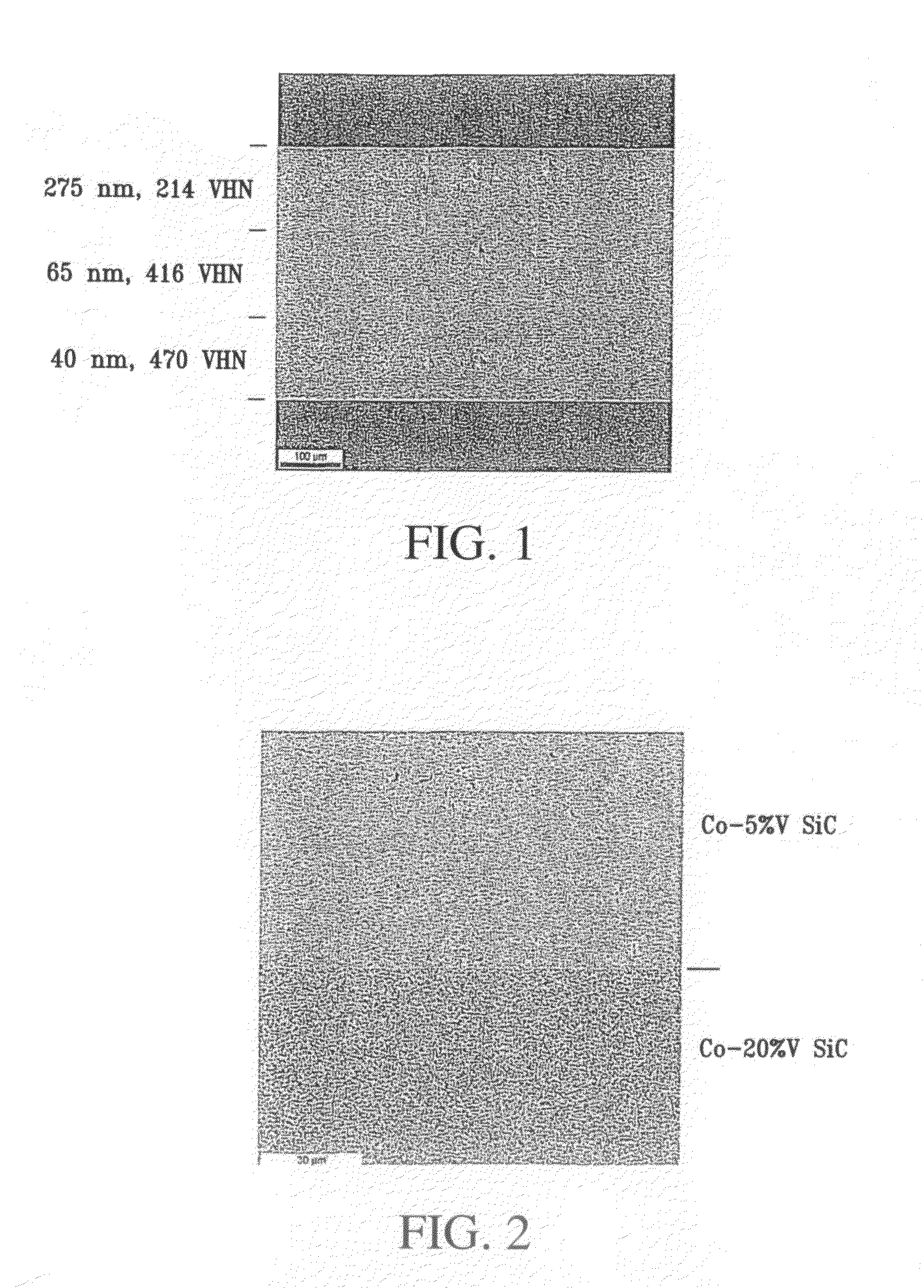

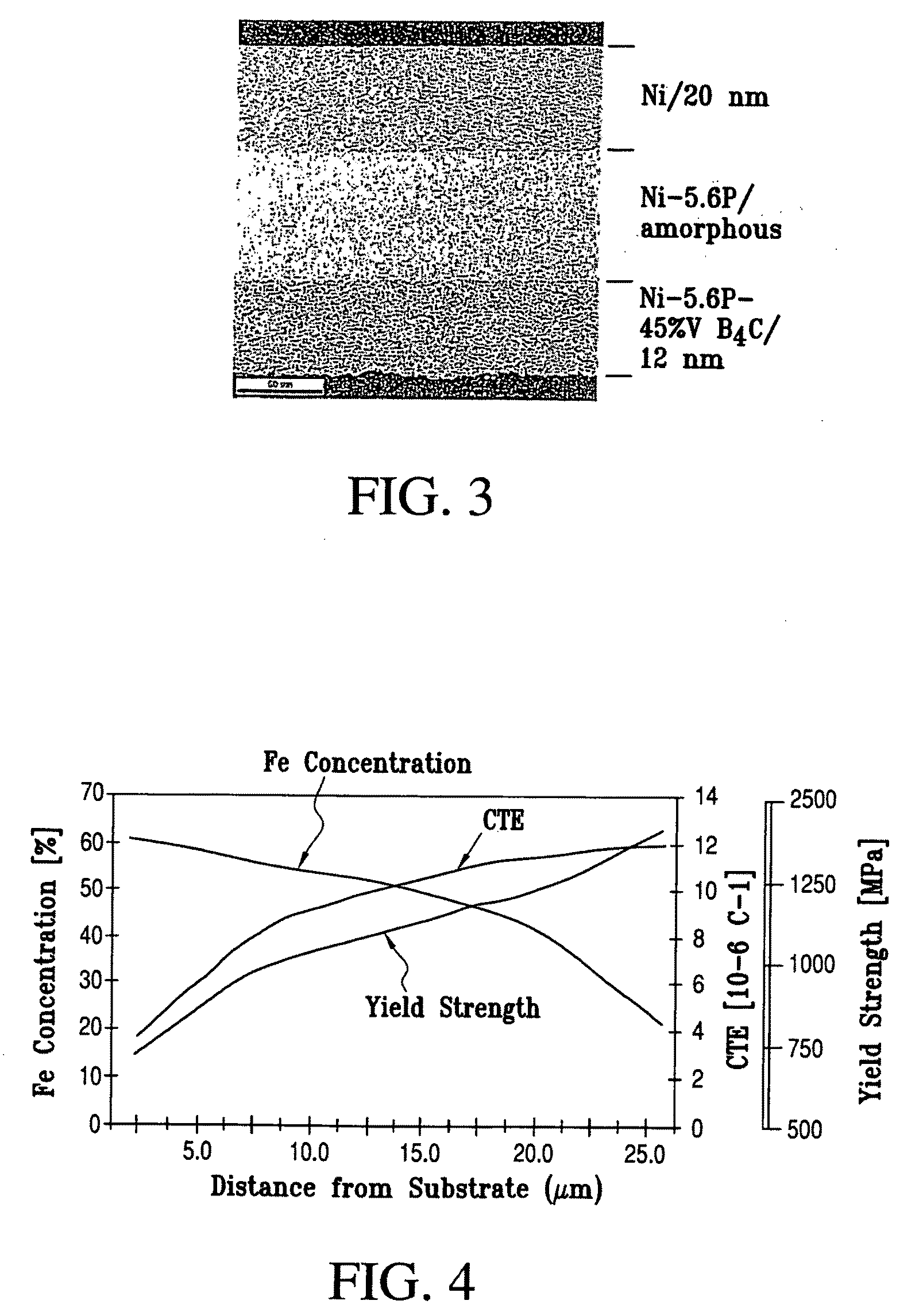

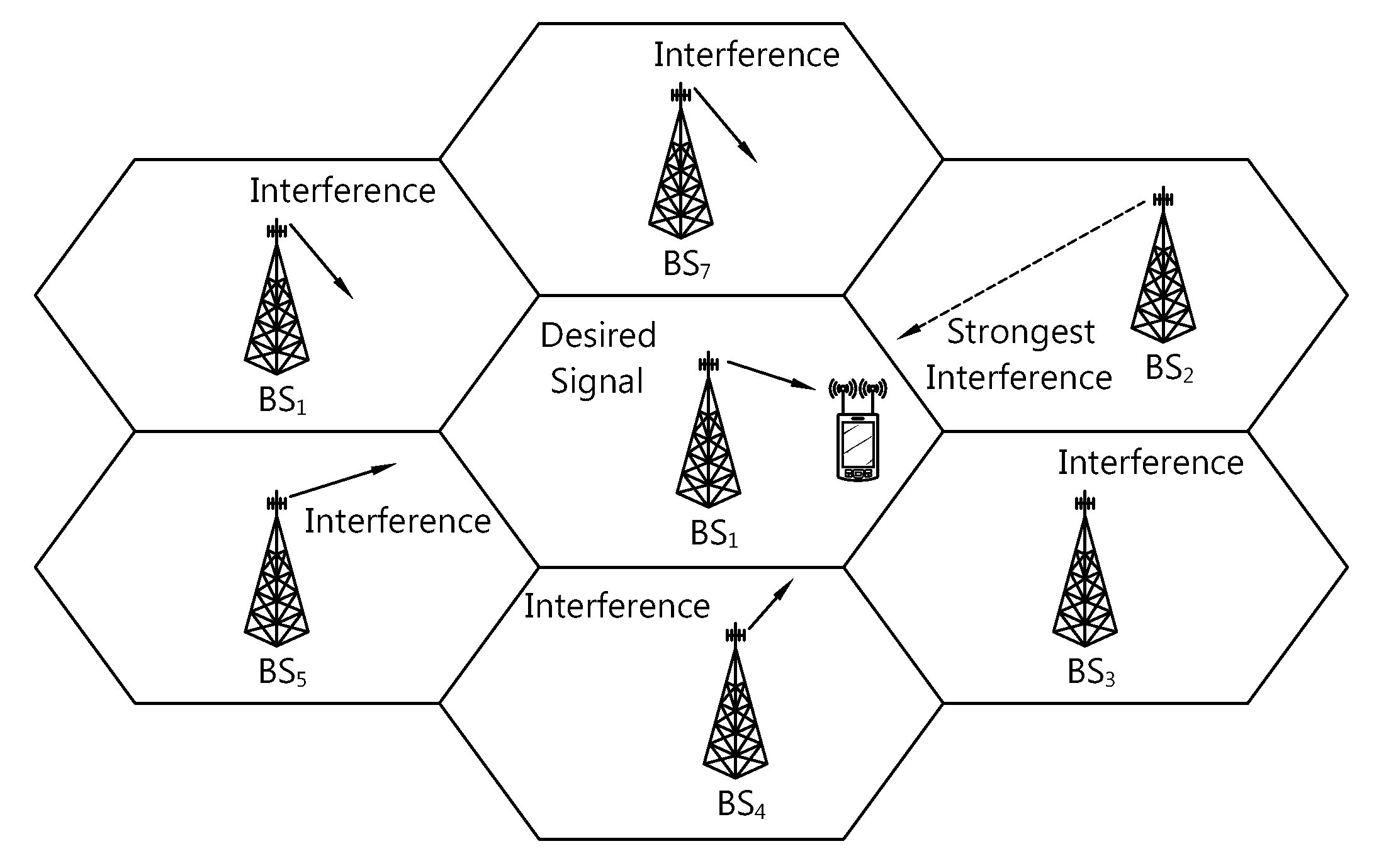

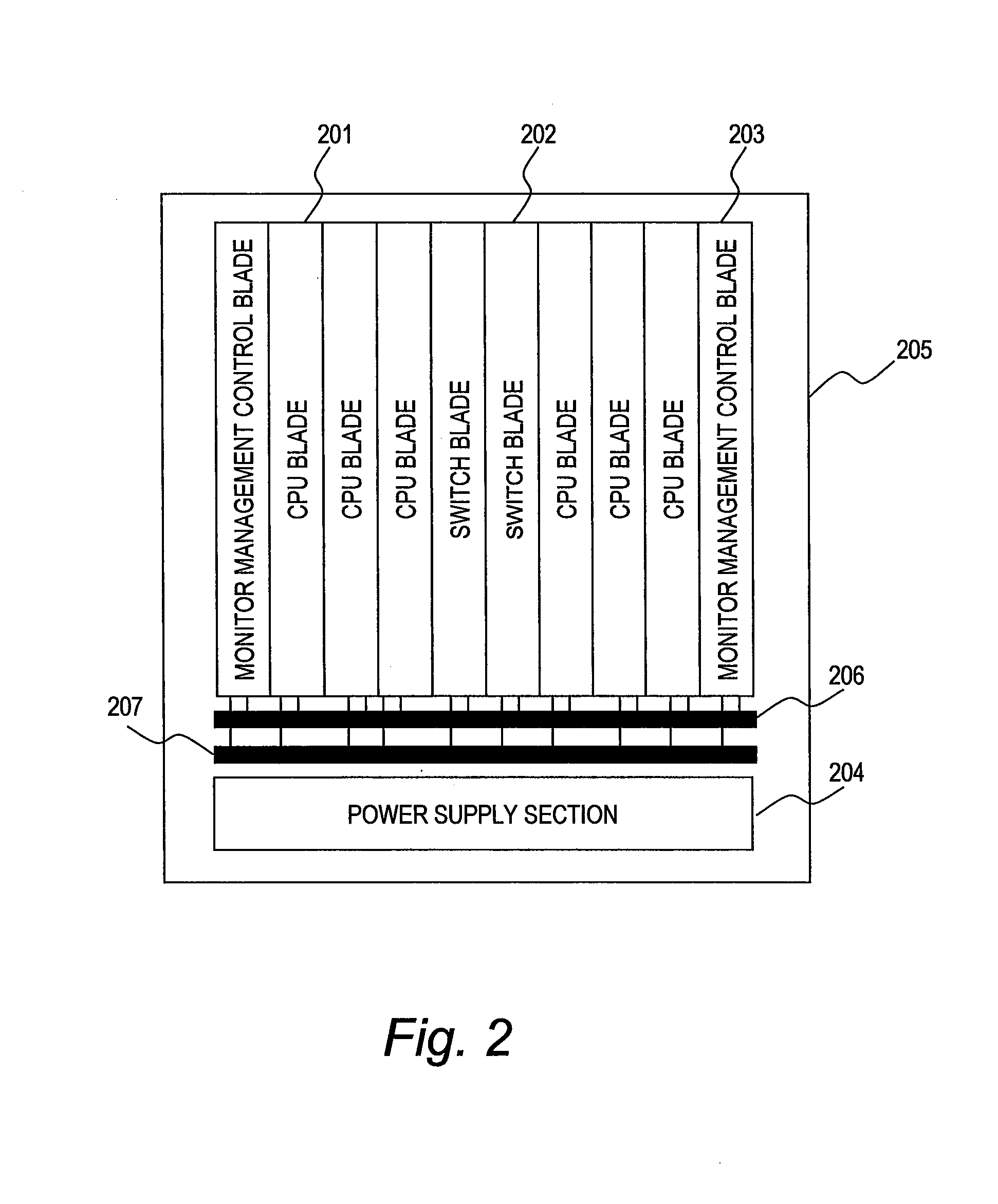

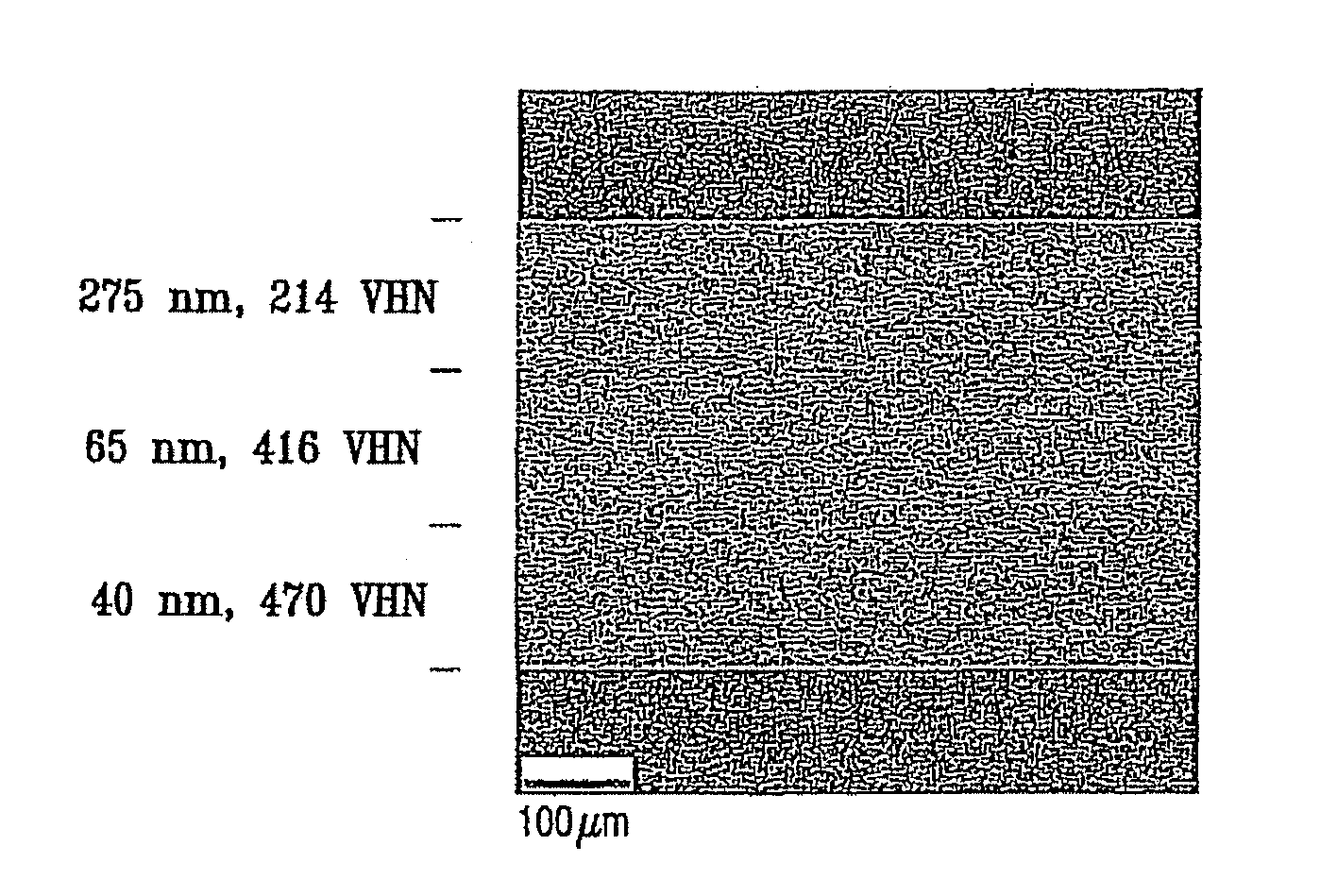

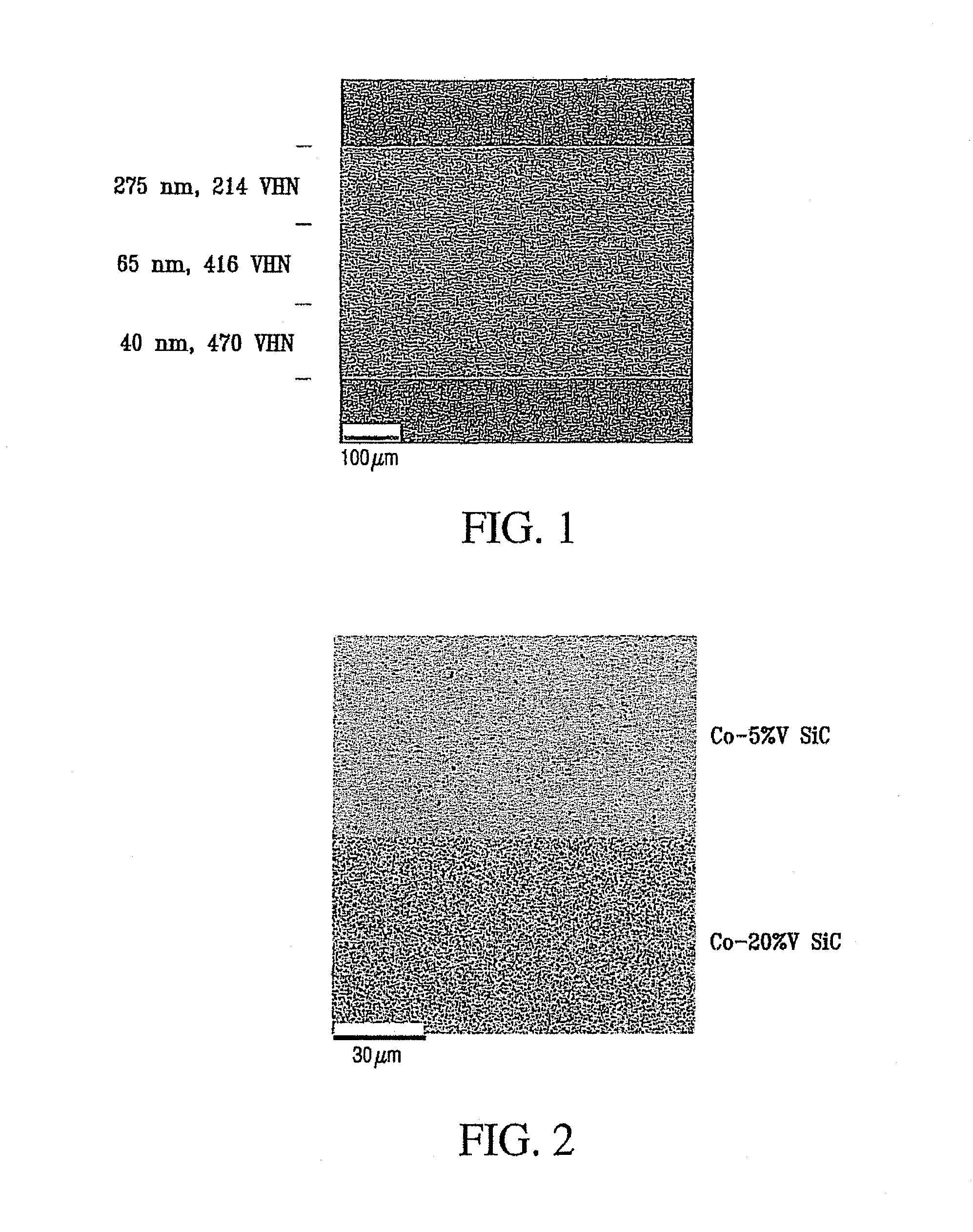

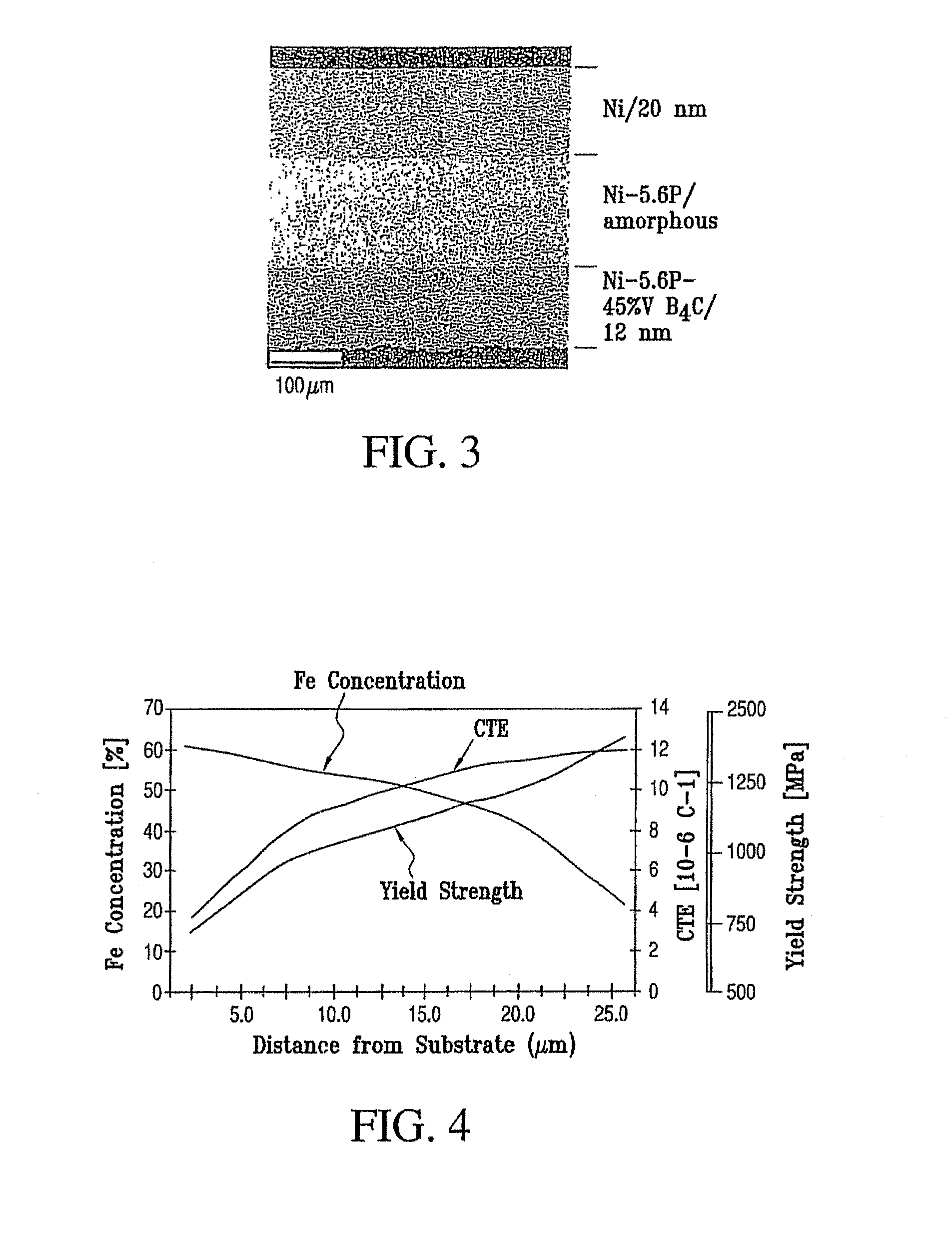

Variable property electrodepositing of metallic structures

ActiveUS20090159451A1Increase floor spaceAdd equipmentCellsElectrolytic coatingsParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: 2 nm-5 micron), entirely coarse-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

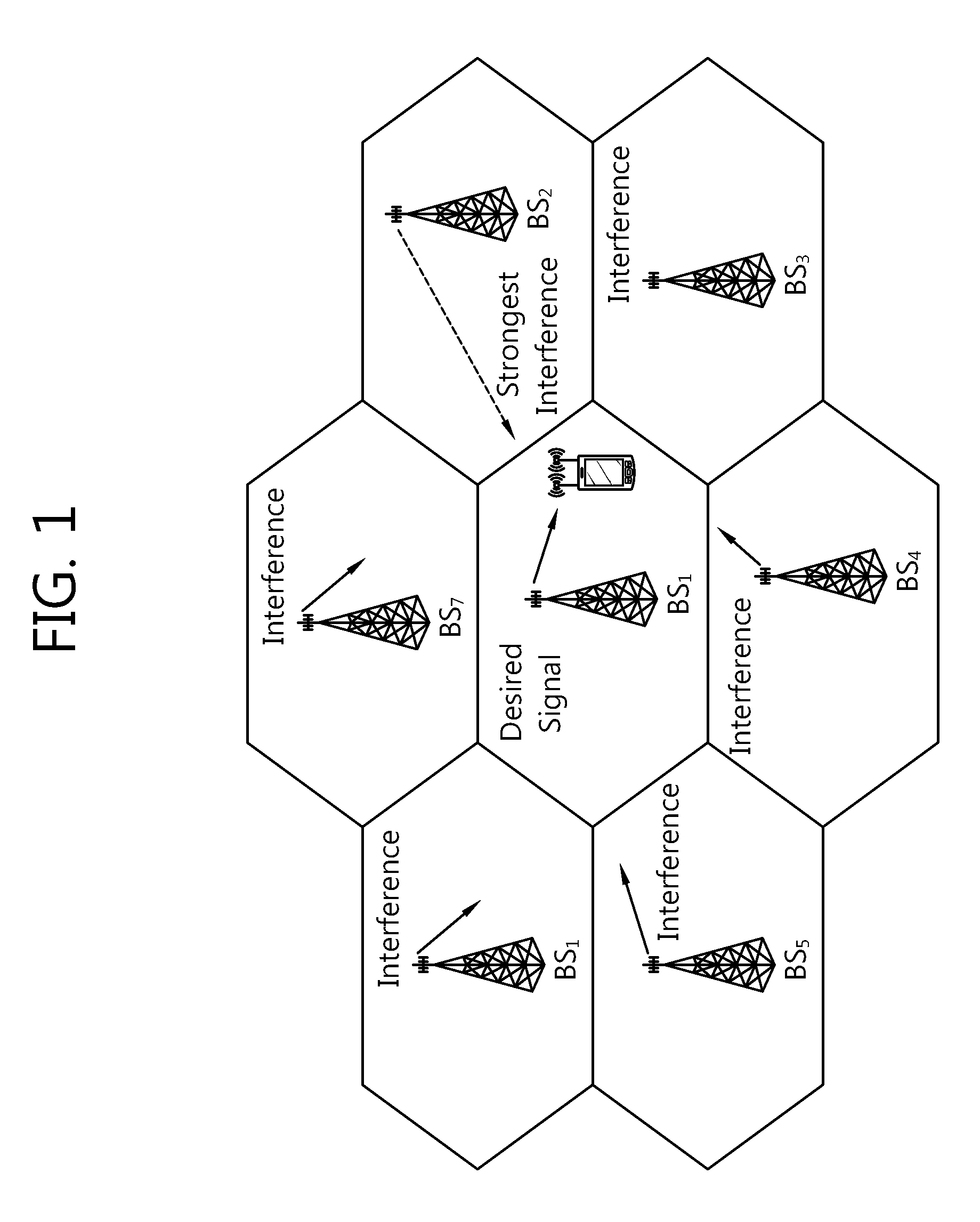

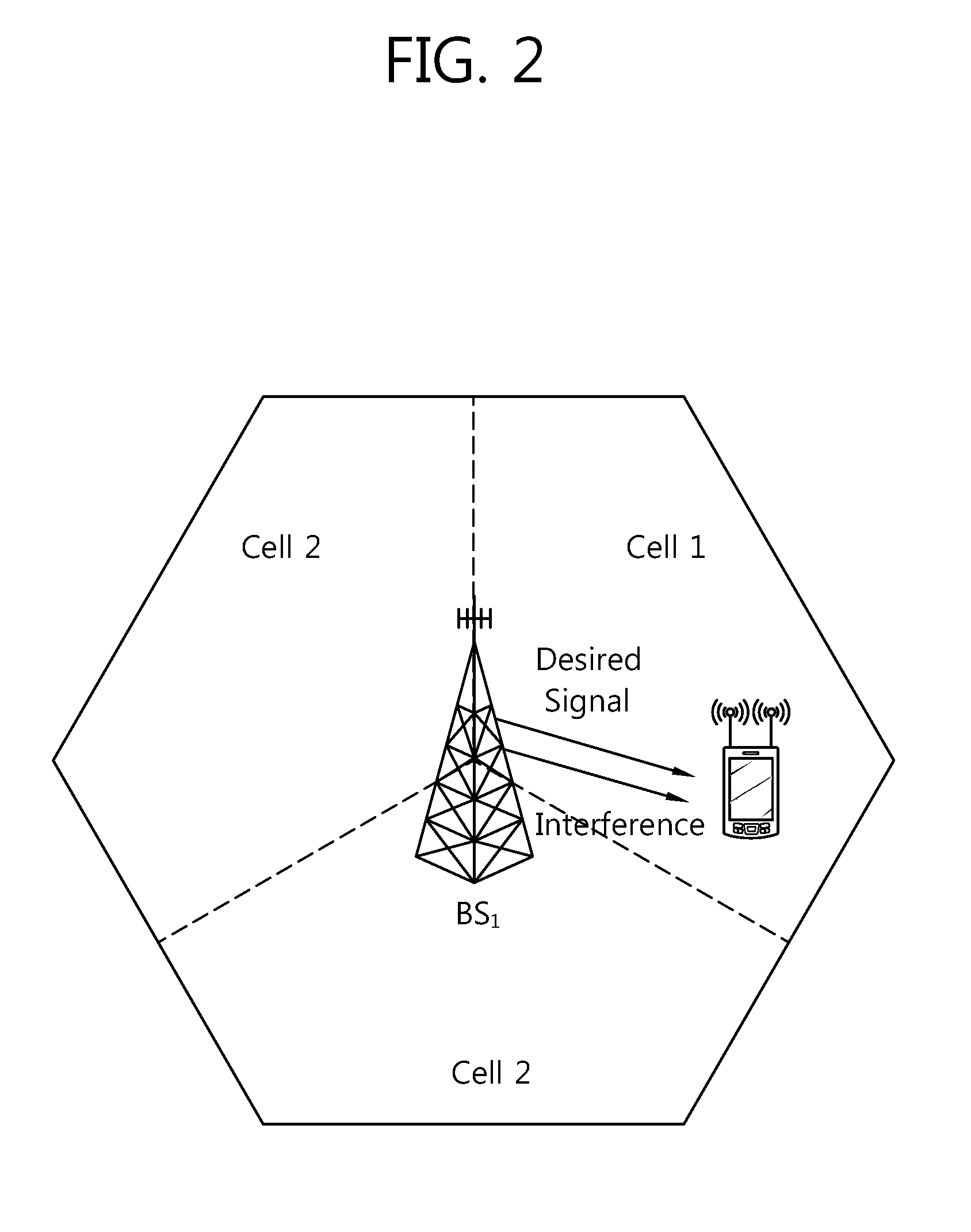

Method and apparatus for transmitting a reference signal in a wireless communication system

InactiveUS20120002740A1Add equipmentImprove performanceSecret communicationRadio transmissionCommunications systemResource element

A method and an apparatus for transmitting a reference signal in a wireless communication system are provided. A first base station maps a first reference signal to a resource region and transmits the first reference signal to a user equipment. A second base station maps a second reference signal to said resource region and transmits the second reference signal to said user equipment. The resource elements, to which the first reference signal and the second reference signal are mapped in the resource region, are determined in accordance with the index on a Latin square matrix occupied by two different elements, respectively, from among N elements constituting the Latin square matrix with a size of N×N.

Owner:LG ELECTRONICS INC

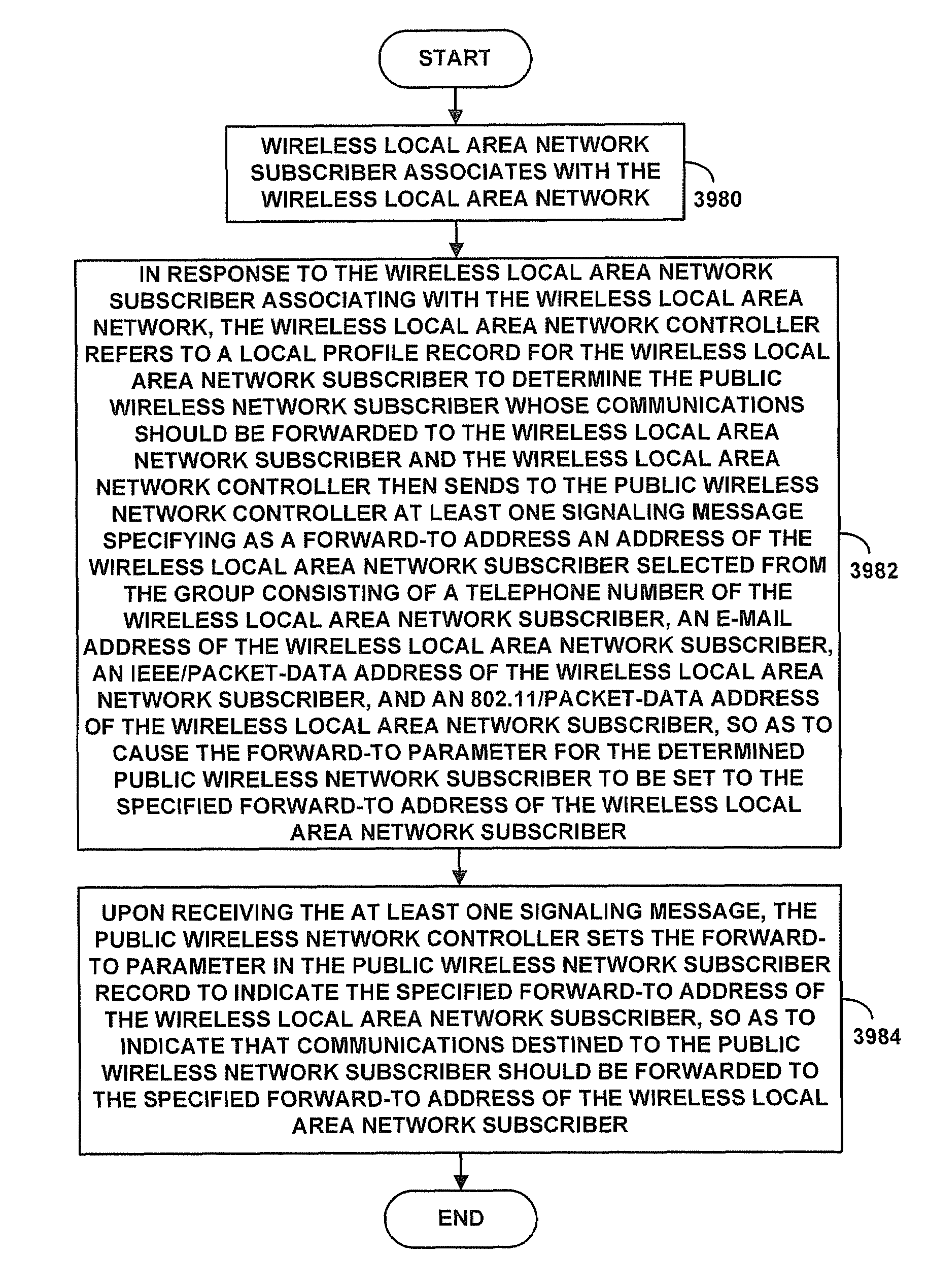

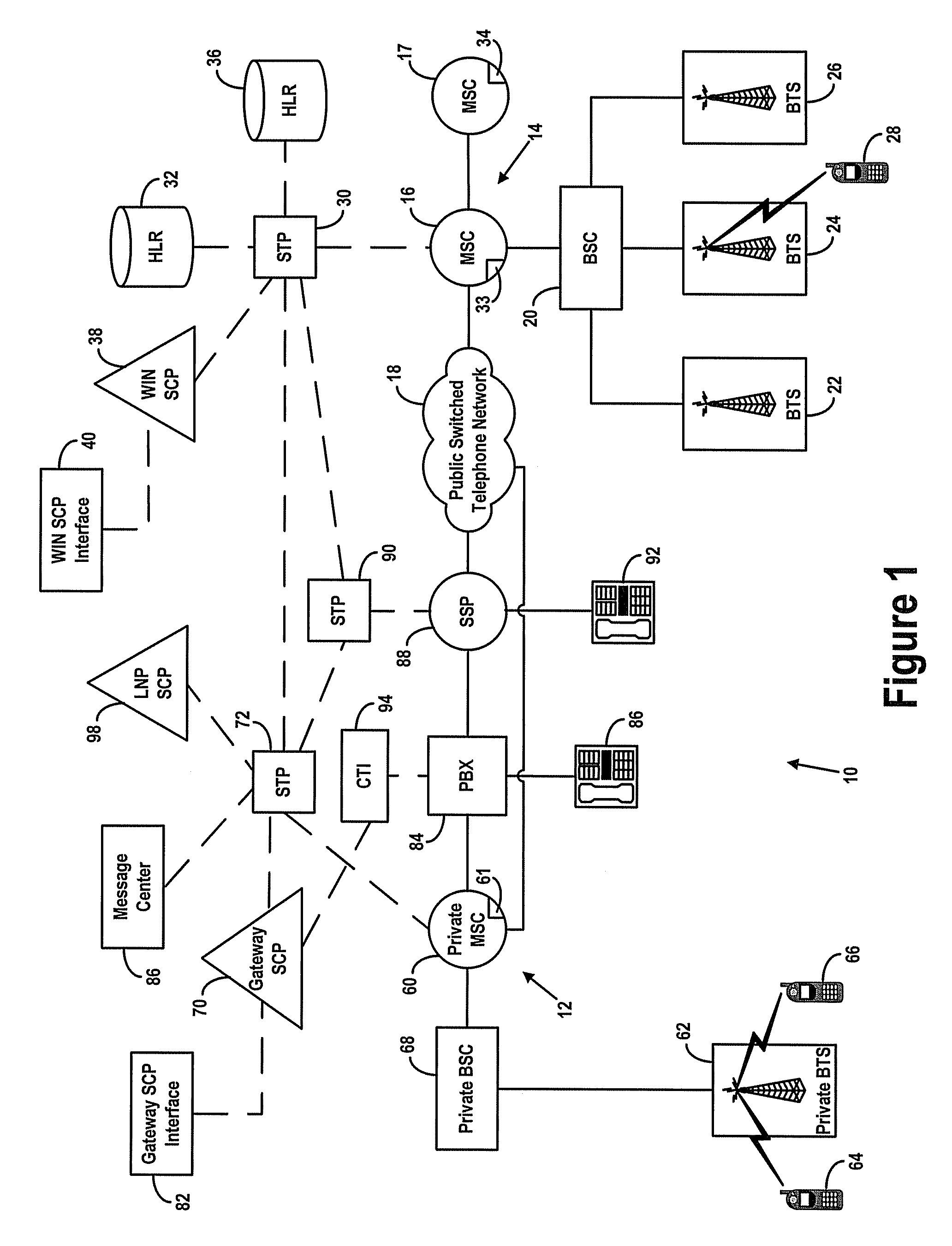

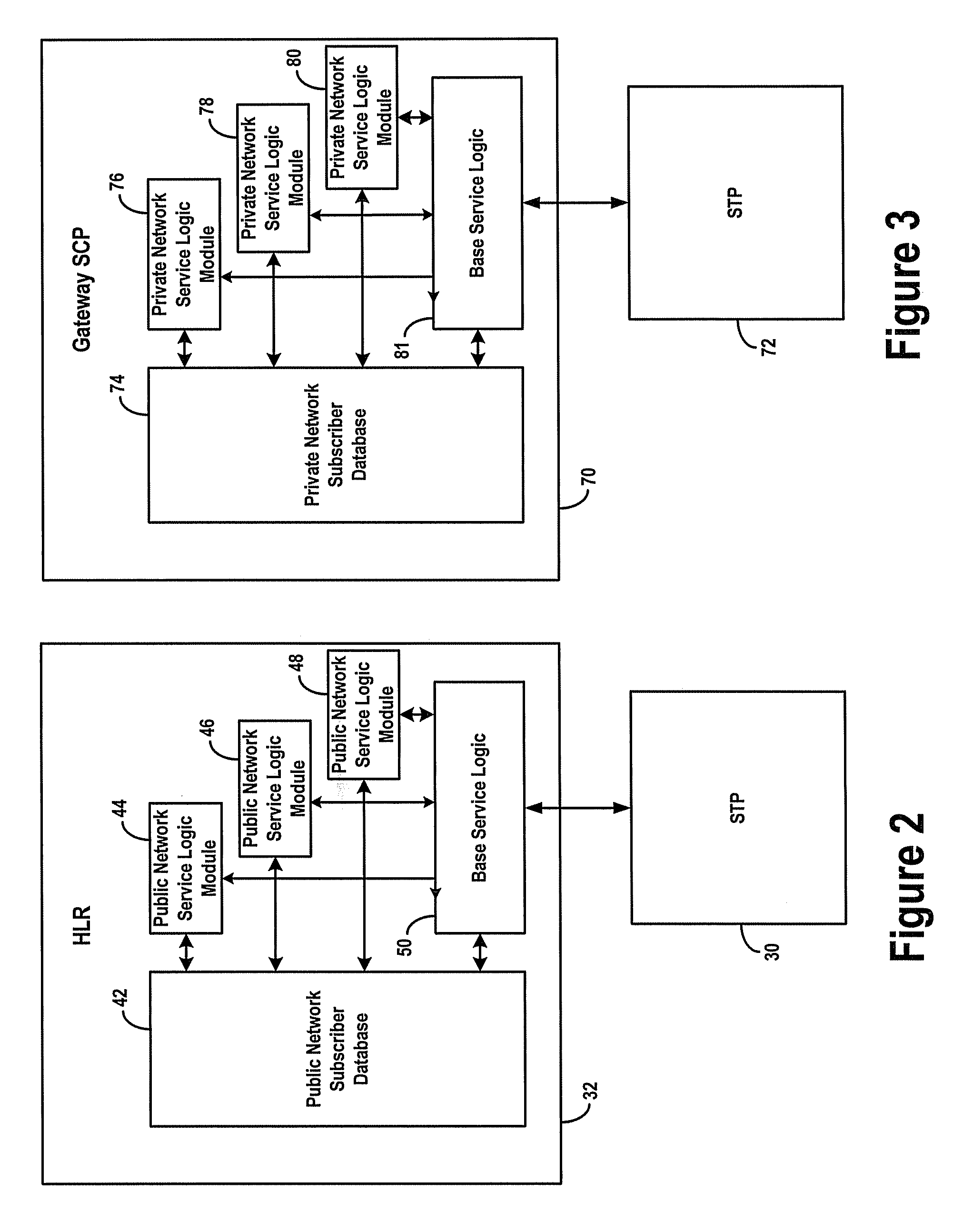

Method and system for diverting wireless network communications

InactiveUS7356001B1Increase data rateSuperior building coverageMultiplex system selection arrangementsNetwork topologiesService profilePrivate network

A private wireless network is able to provide wireless telecommunication services to subscriber mobile stations that also subscribe to a public wireless network. The private wireless network includes a private base transceiver station (BTS), a private mobile switching center (MSC), and a gateway service control point (SCP). The private BTS provides a private network wireless coverage area within which the mobile station can communicate with the base transceiver station over an air interface. The gateway SCP has a private network database containing private network data records for subscribing mobile stations. A private network data record includes a private network service profile and a private network locator address. The public wireless network has a home location register (HLR) with a public network database containing public network data records for subscribing mobile stations. A public network data record includes a public network service profile and a public network locator address. When a subscriber mobile station is active on the private wireless network, the private network locator address identifies the private MSC, and the public network locator address identifies the gateway SCP. By providing the private network wireless coverage area so that it overlaps the public network's wireless coverage area, the subscriber mobile station may be handed off between the private and public wireless networks.

Owner:SPRINT SPECTRUM LLC

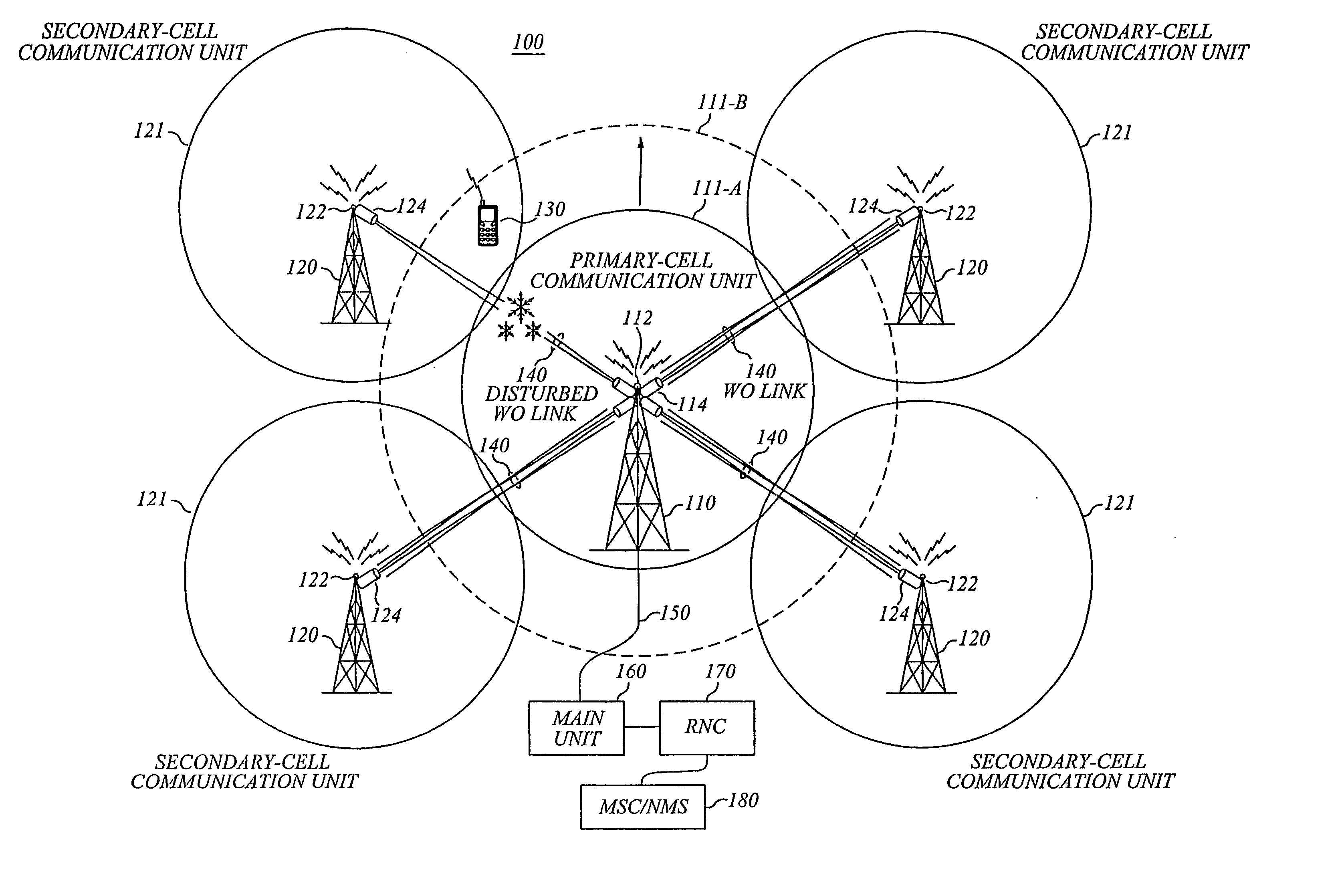

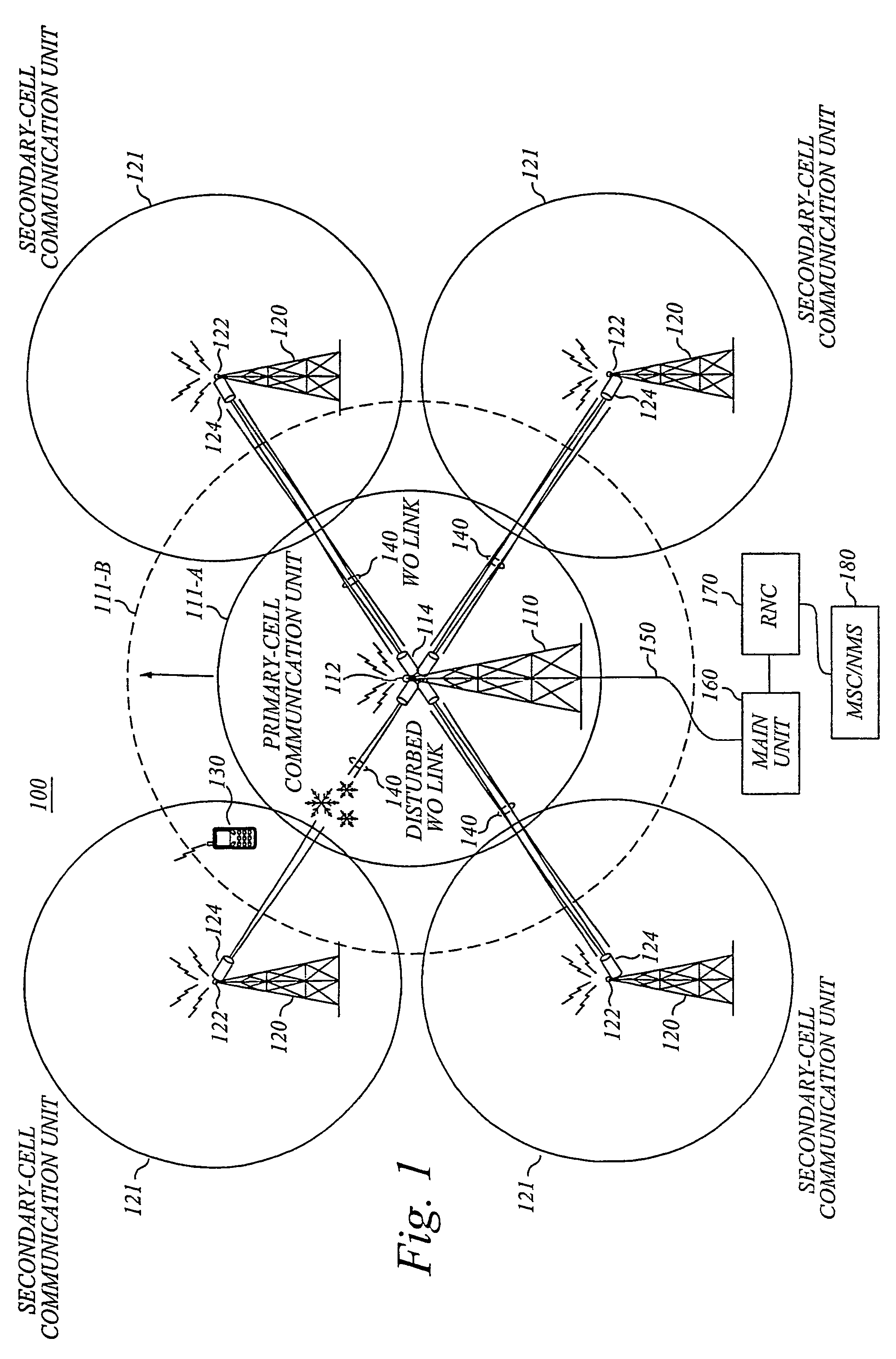

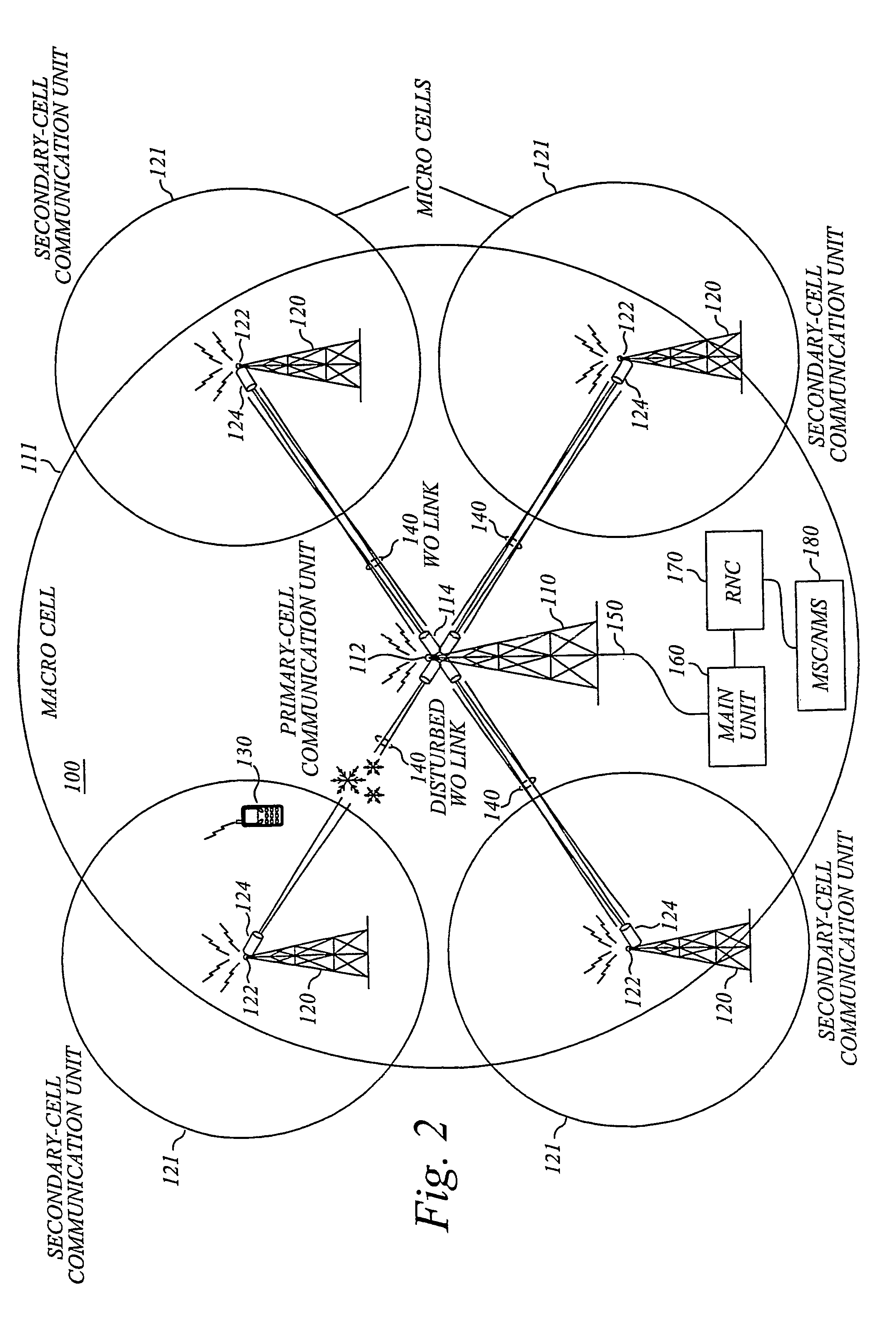

Cellular communications system employing wireless optical links

InactiveUS7343164B2Without discriminating reliabilityCost-effectiveLine-of-sight transmissionRadio/inductive link selection arrangementsRadio coverageCommunications system

The invention relates to a cellular communication system based on a central main unit, a primary-cell communication unit connected to the central main unit, and a number of secondary-cell communication units. Each secondary-cell unit is connected to the primary-cell unit via a respective wireless optical link. The secondary-cell communication units are preferably remote radio units in a distributed radio base system, where each remote radio unit forms a distributed radio base station together with the central main unit. The wireless optical link quality is measured to detect reduced link availability. The invention compensates for insufficient link availability by providing adequate radio coverage from another communication unit within the cellular system and re-directing the radio traffic to that communication unit. Adequate radio coverage from another communication unit within the cellular system and re-directing the radio traffic to that communication unit. Adequate radio coverage is accomplished either by dynamically increasing the radio coverage or using a micro-macro cell architecture.

Owner:TELEFON AB LM ERICSSON (PUBL)

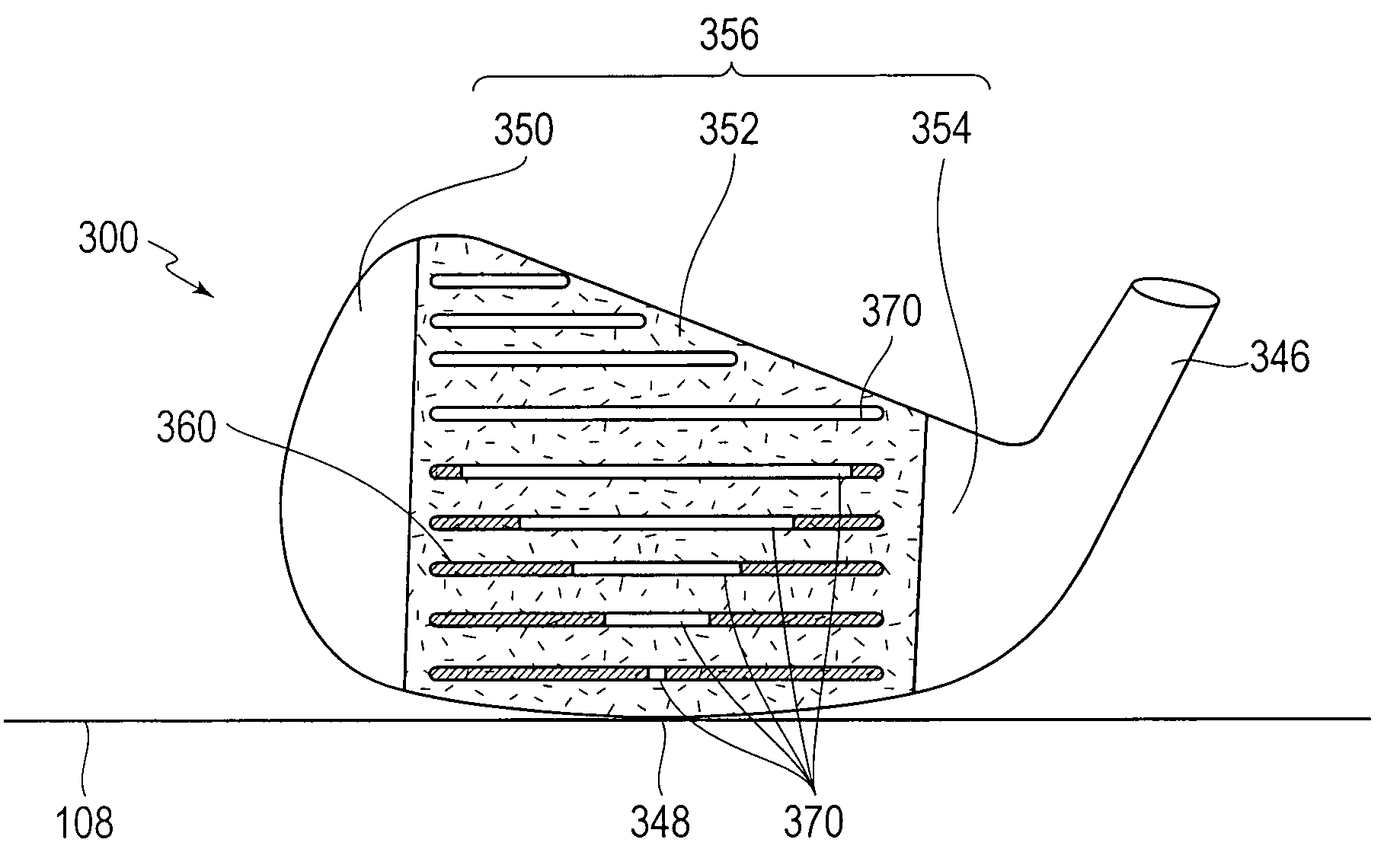

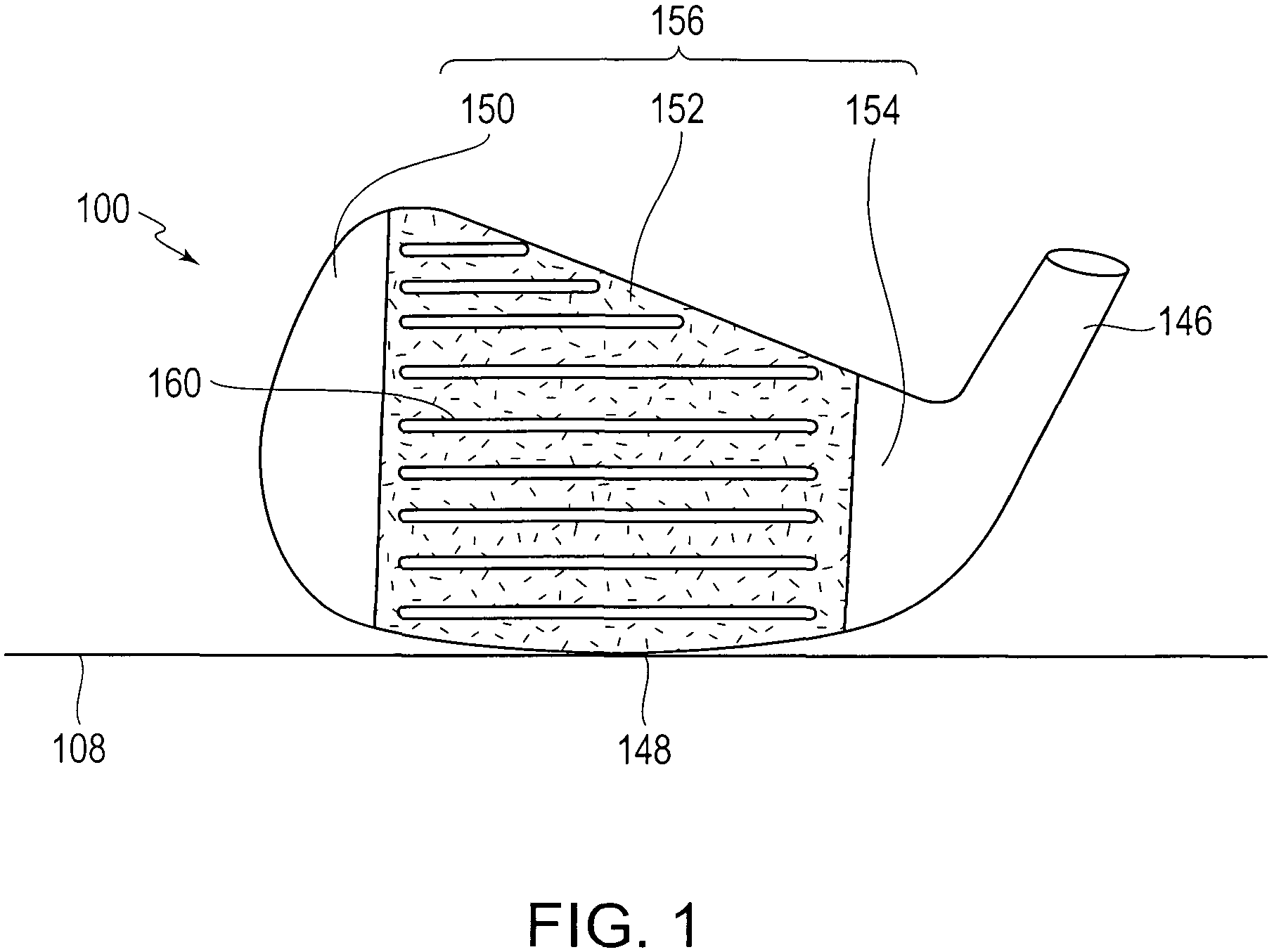

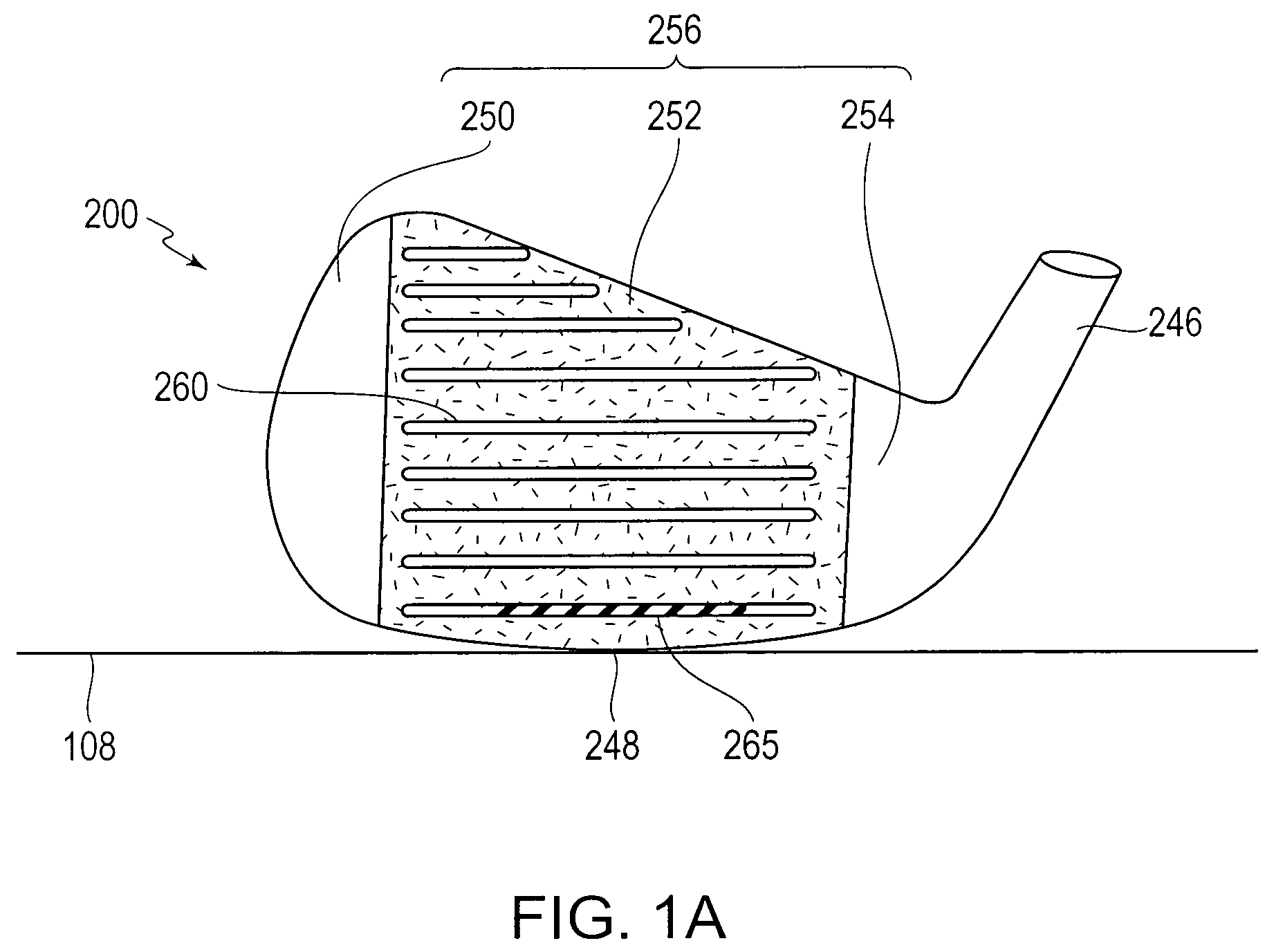

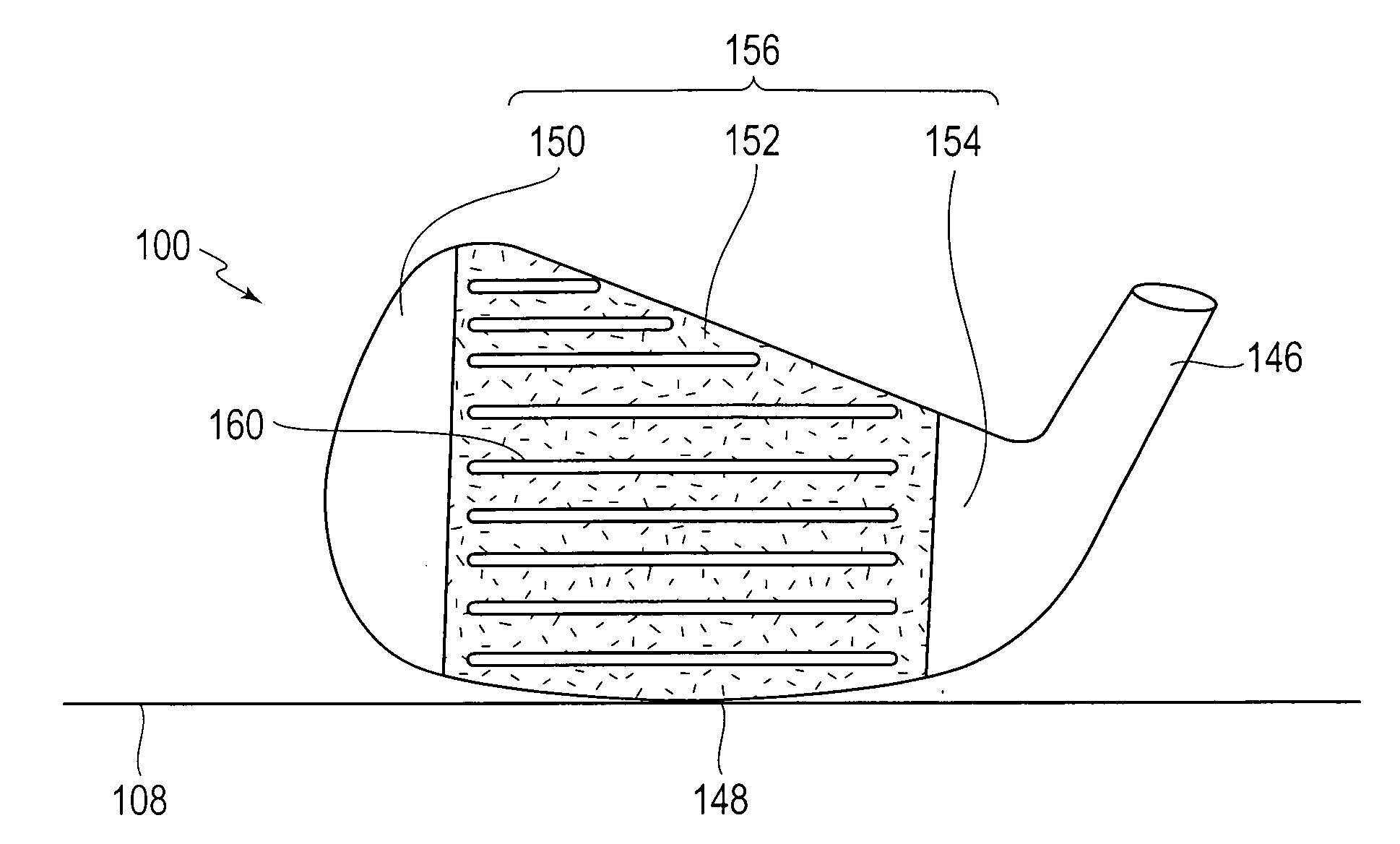

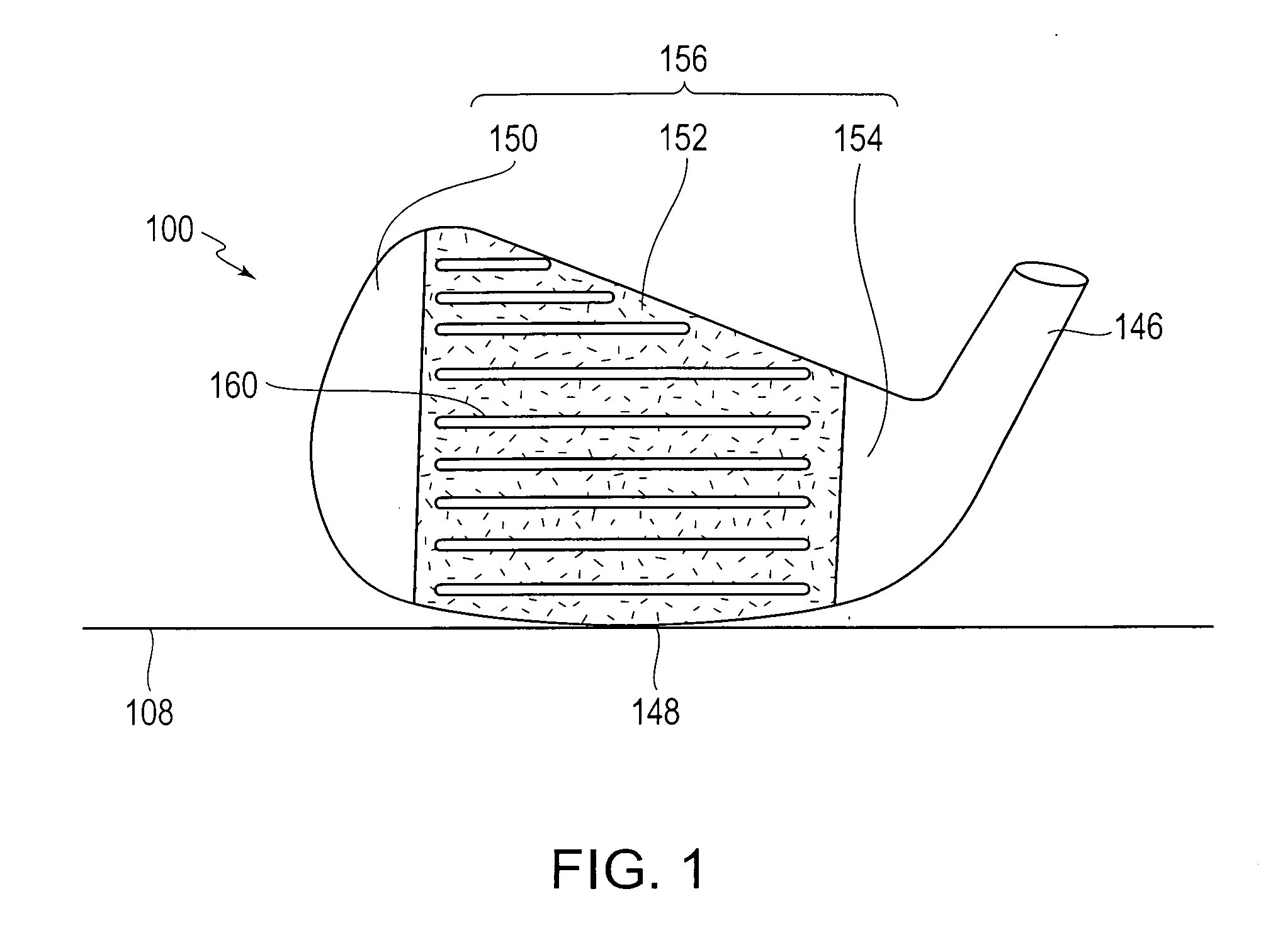

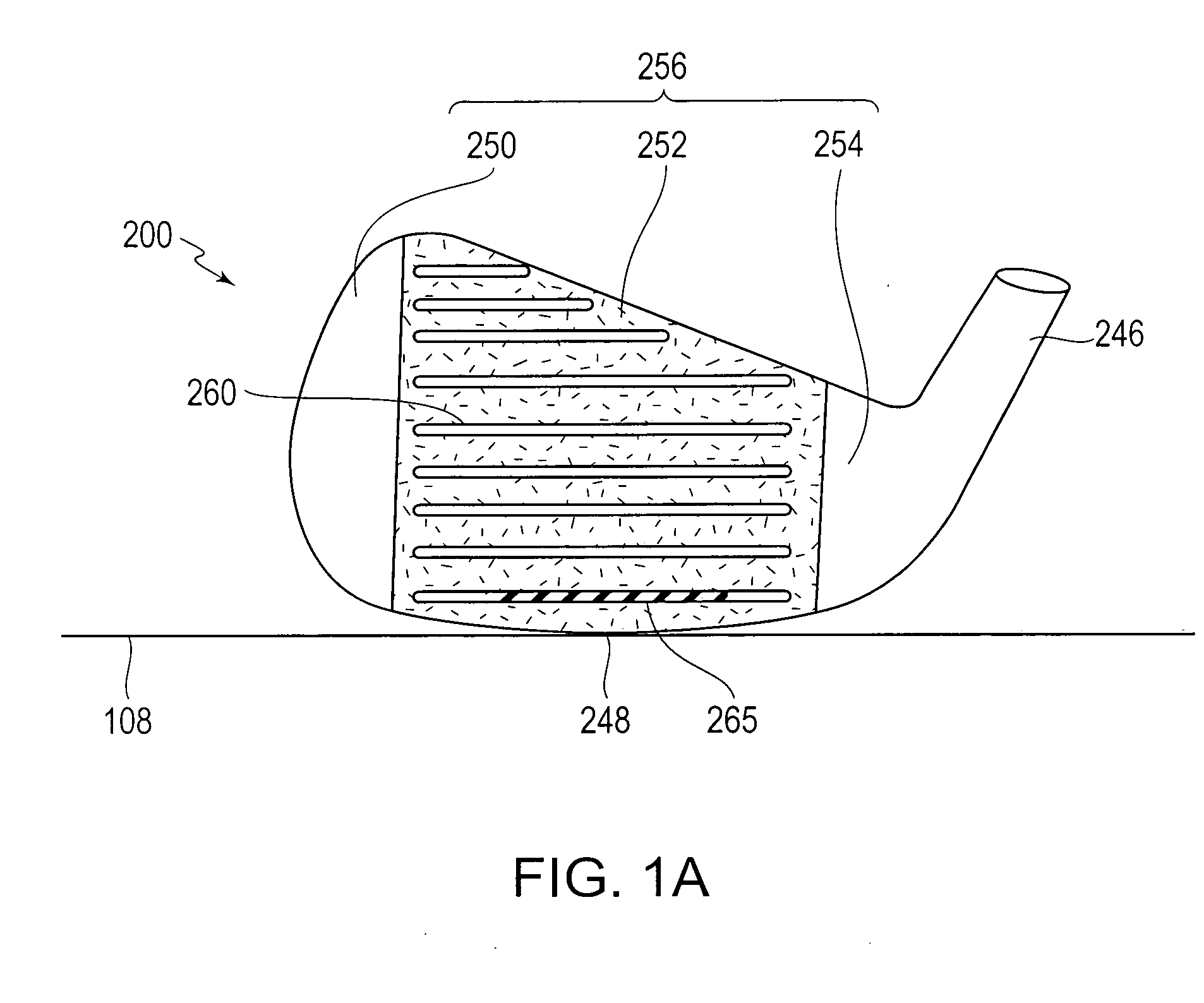

Golf club head

ActiveUS7780549B2Improved spin characteristicEasy to cleanMetal rolling stand detailsMetal working apparatusSurface roughnessEngineering

A golf club head comprising a strike face having a heel portion, a toe portion, and an intermediate portion. The intermediate portion includes one or more score lines. At least a portion of one or more score lines include a different average surface roughness and associated surface reflectance than at least the intermediate portion. A method for producing such a club head is also provided.

Owner:SUMITOMO RUBBER IND LTD

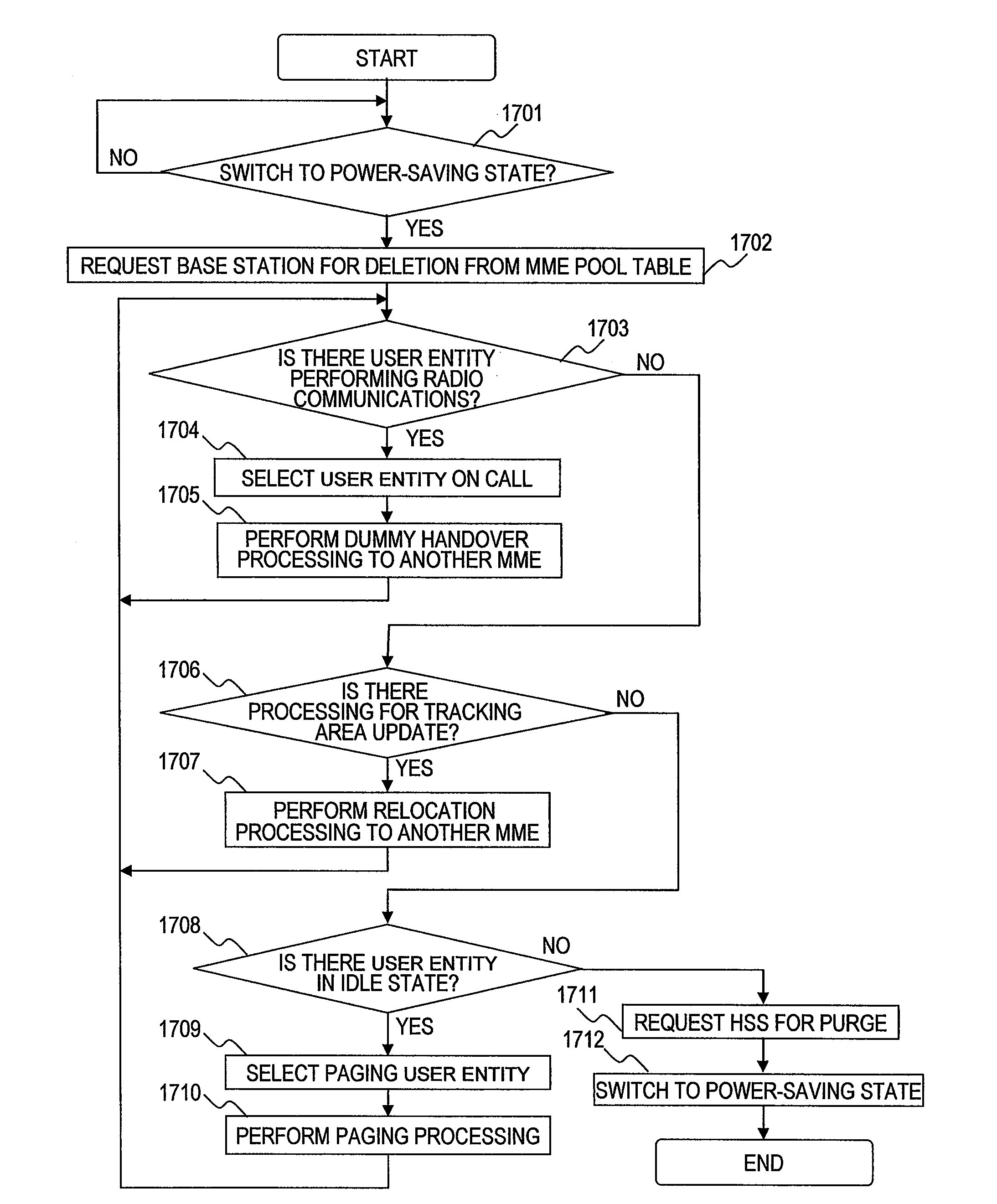

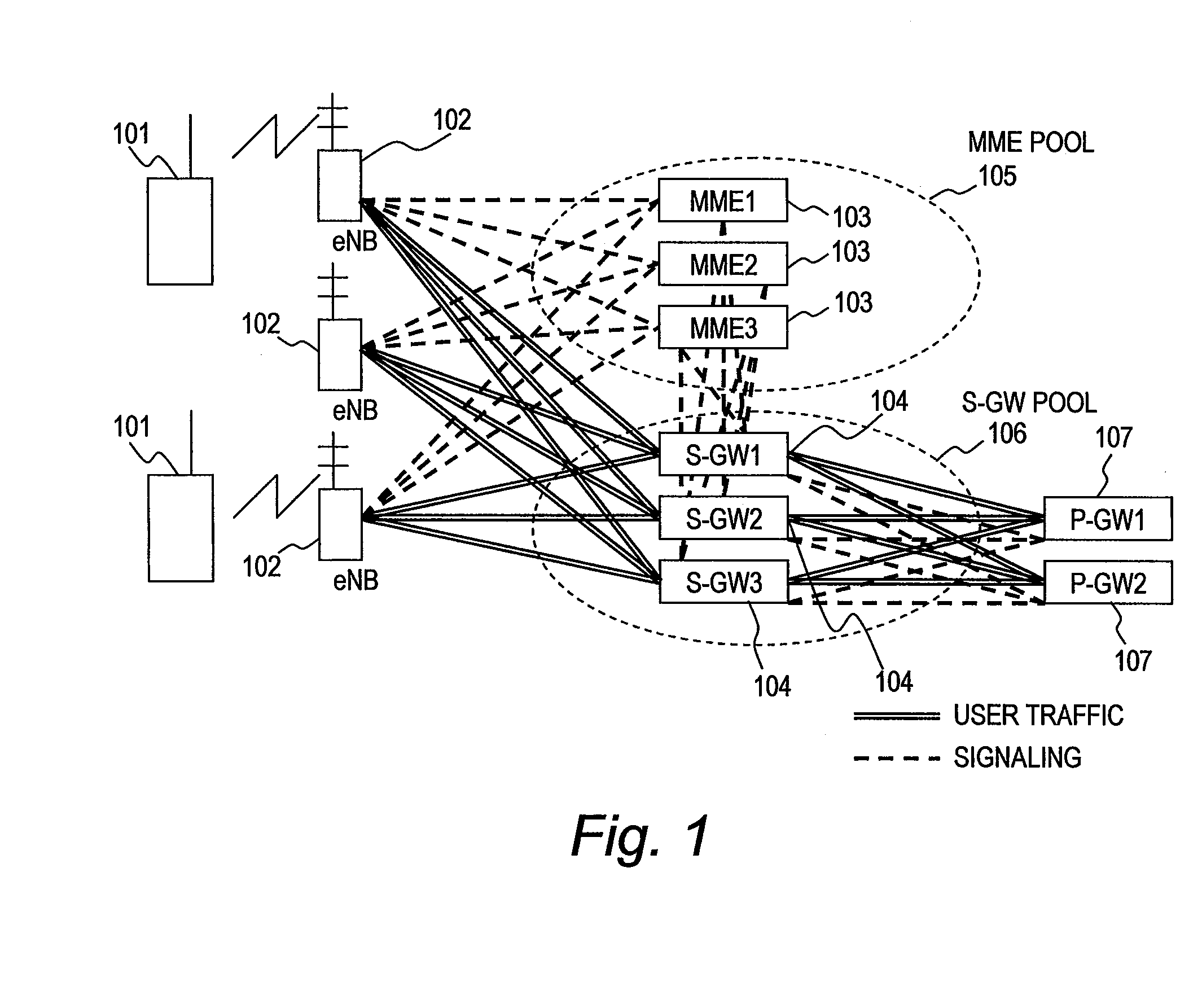

Mobile communication system for low power consumption, call control server and access gateway

InactiveUS20100184432A1Reduce power consumptionImprove performanceUnauthorised/fraudulent call preventionEavesdropping prevention circuitsControl signalComputer terminal

It is provided a mobile communication system comprising base stations, call control servers and access gateways. The call control servers cause a mobile terminal accommodated in one of the control server to transmit the location registration request so that the mobile terminal accommodates in another control server according to a processing amount of control signals. The base station selects a second call control server into which the one of the mobile terminals is to be newly accommodated. The one of the call control server switches to a power-saving state after the mobile terminal is accommodated into the another call control server.

Owner:HITACHI LTD

Metallic Structures with Variable Properties

InactiveUS20110256356A1Increased durabilityIncrease floor spaceVacuum evaporation coatingSputtering coatingParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

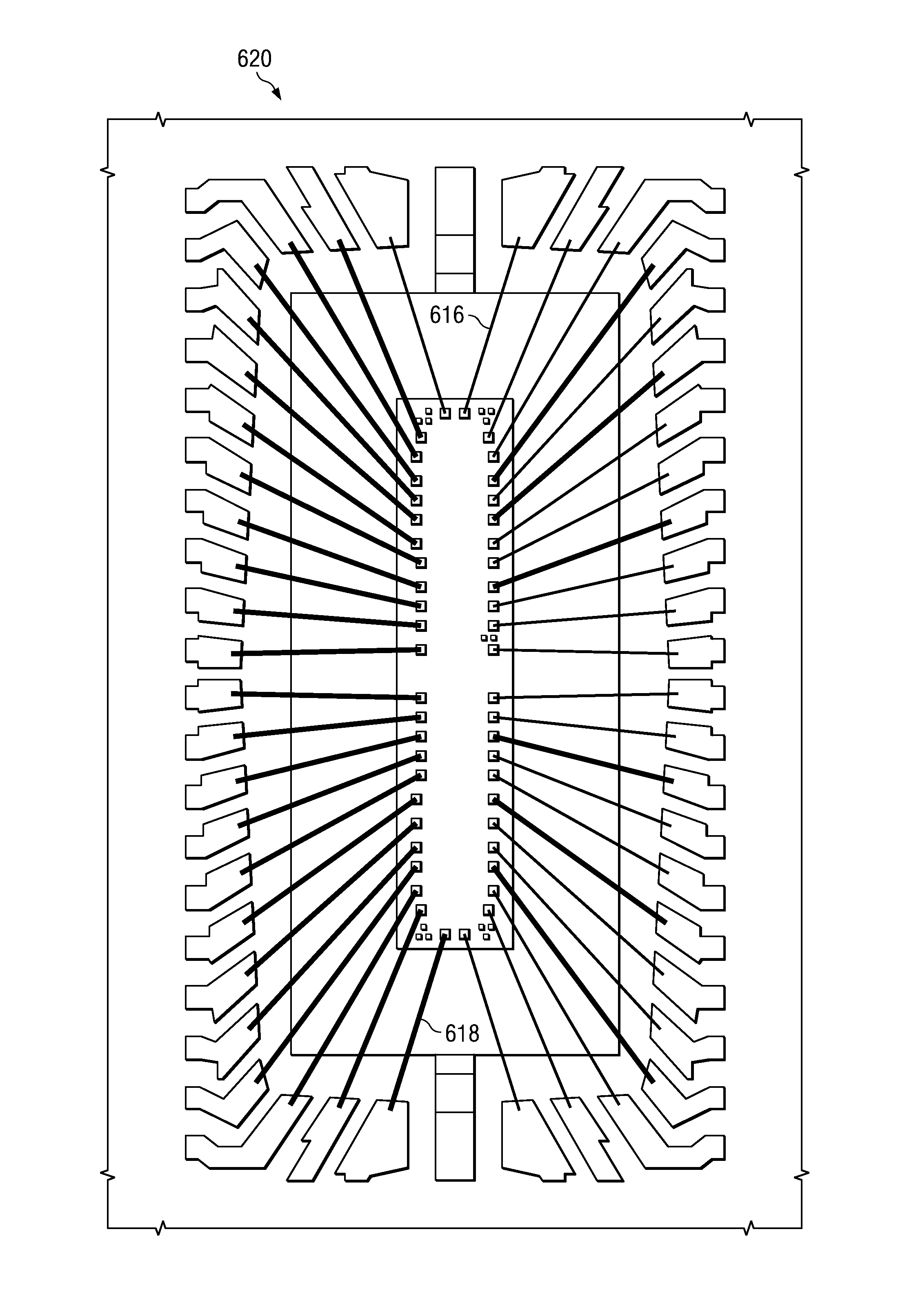

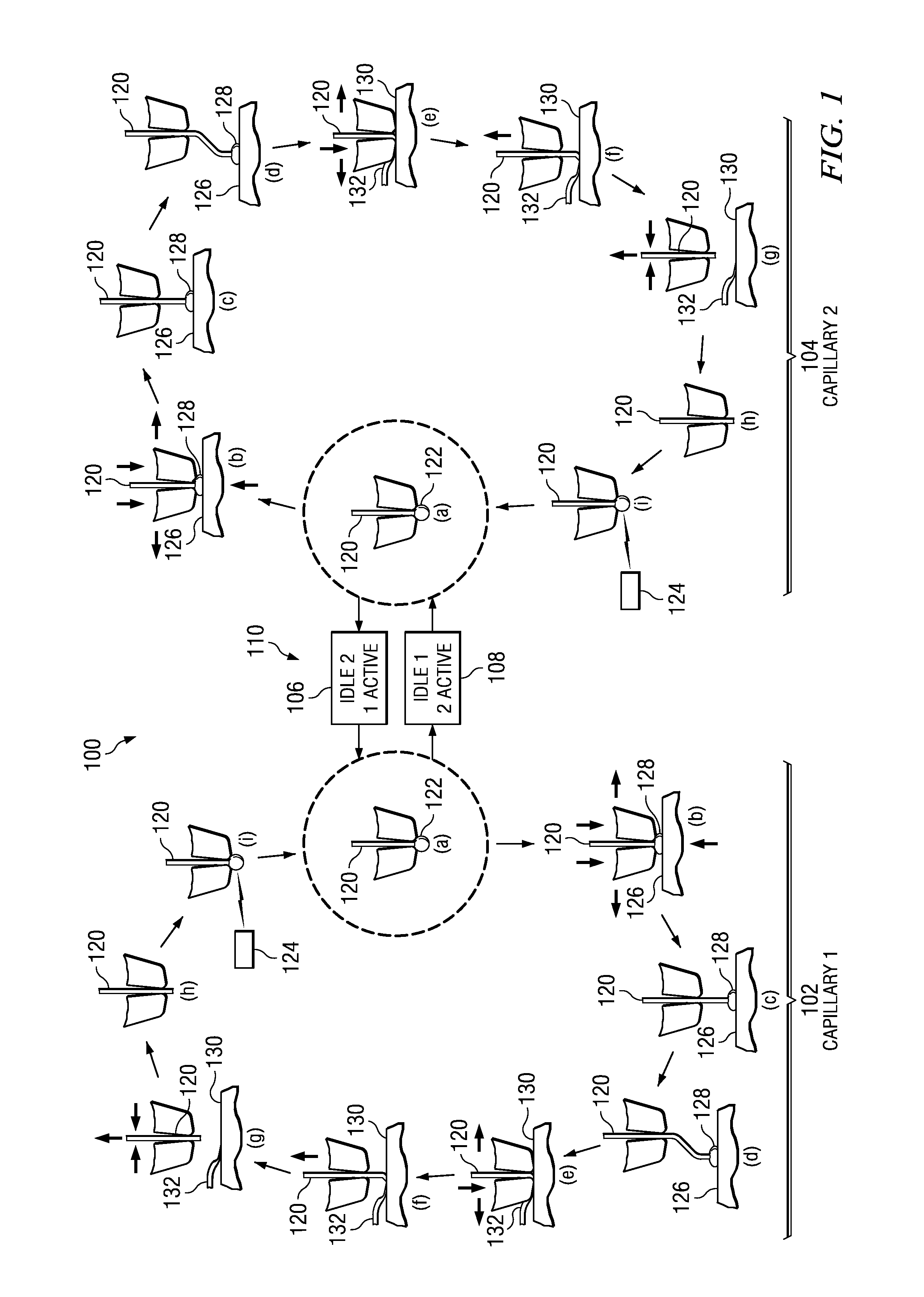

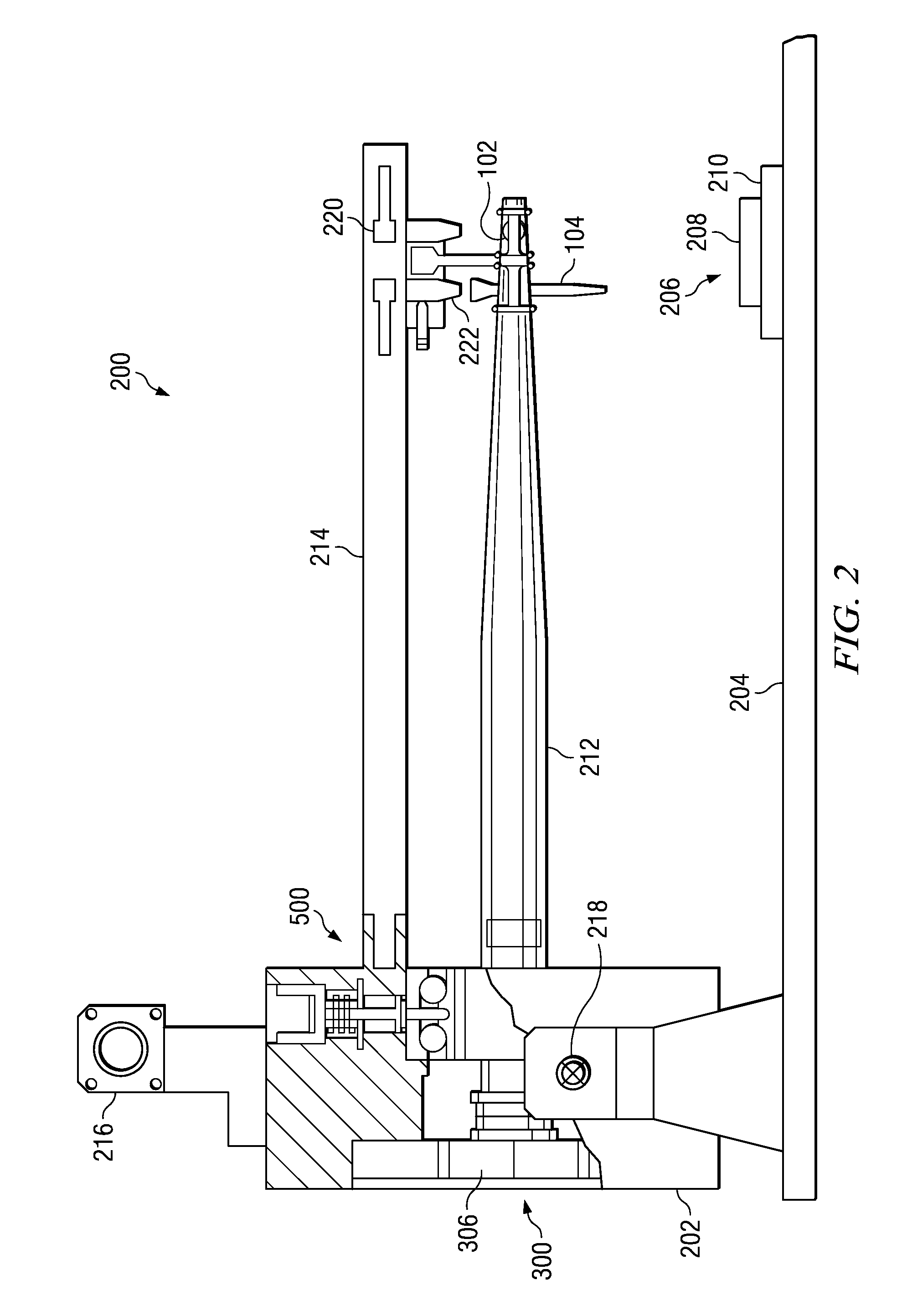

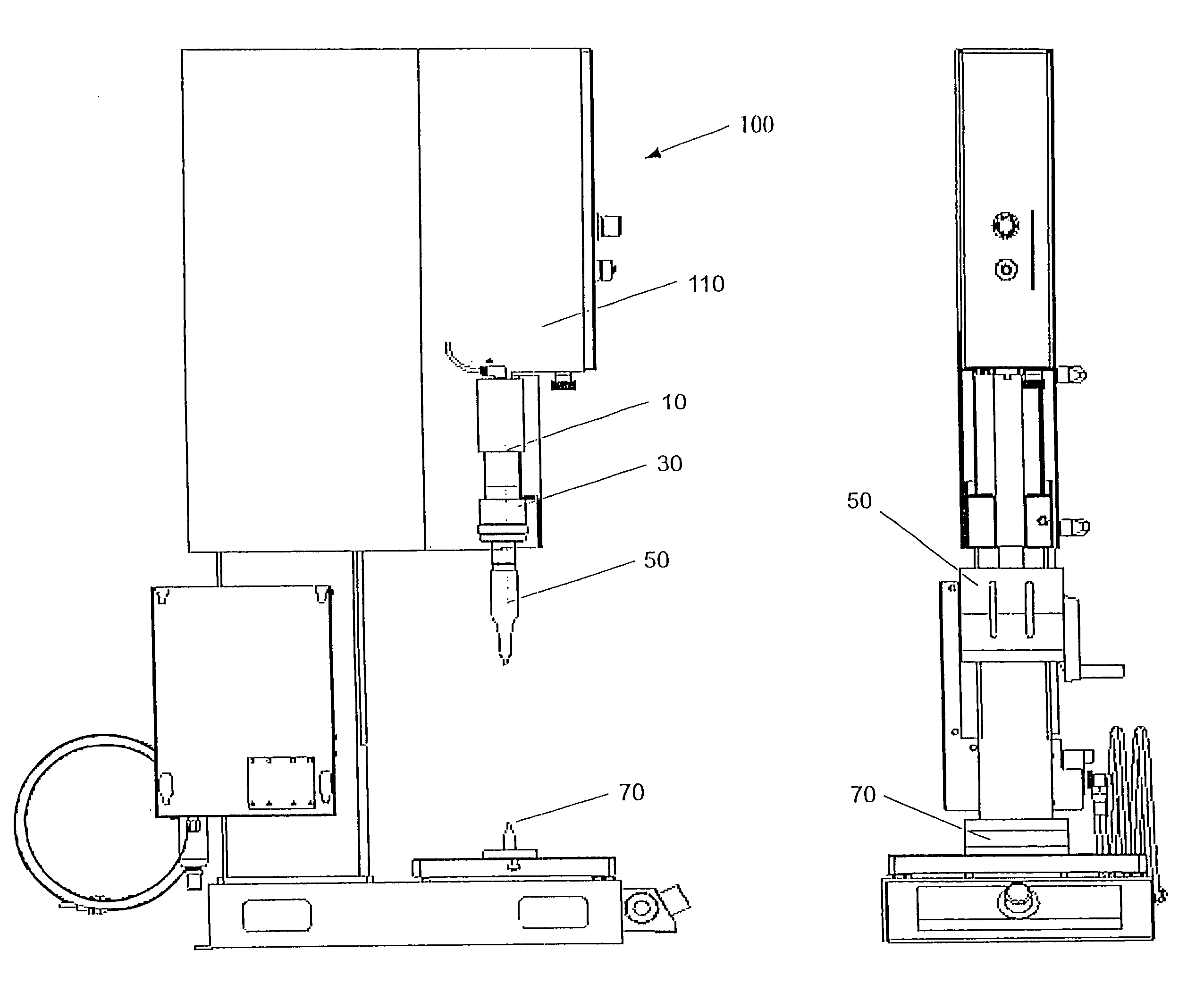

Dual Capillary IC Wirebonding

ActiveUS20110272449A1Add equipmentImprove processing throughputSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

The invention discloses apparatus and methods for the formation of bond wires in integrated circuit assemblies by attaching two separate wires using a dual capillary bond head. The separate wires are preferably non-identical, for example, being of different gauges and / or material composition. According to a preferred embodiment of the invention, dual capillary bond head apparatus includes a rotatable ultrasonic horn with a pair of capillaries for selectably dispensing separate strands of bond wire and for forming bonds on bond targets. According to another aspect of the invention, a method is provided for dual capillary IC wirebonding including steps for using two dual capillary bond heads for contemporaneously attaching non-identical bond wires to selected bond targets on one or more IC package assemblies.

Owner:TEXAS INSTR INC

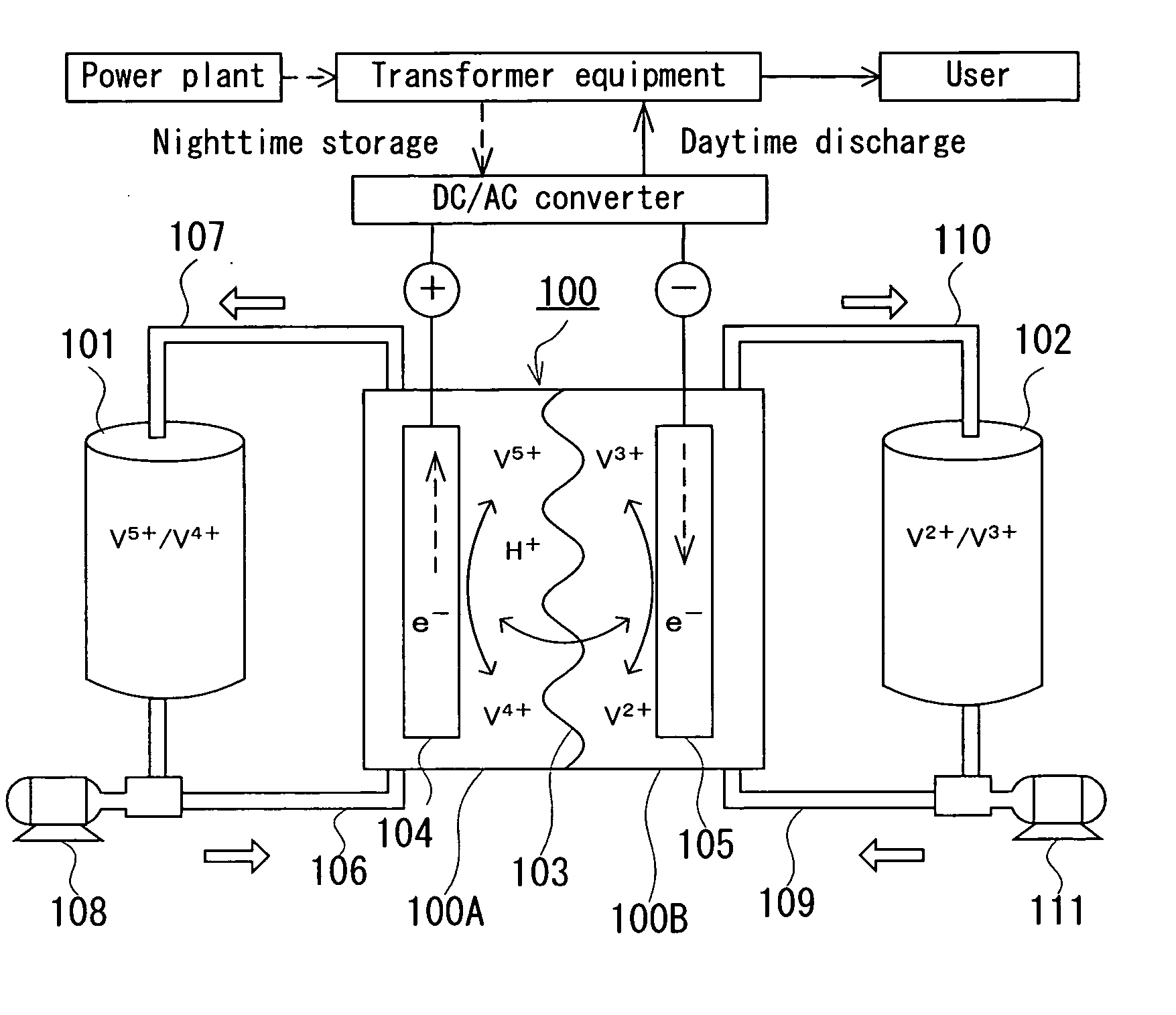

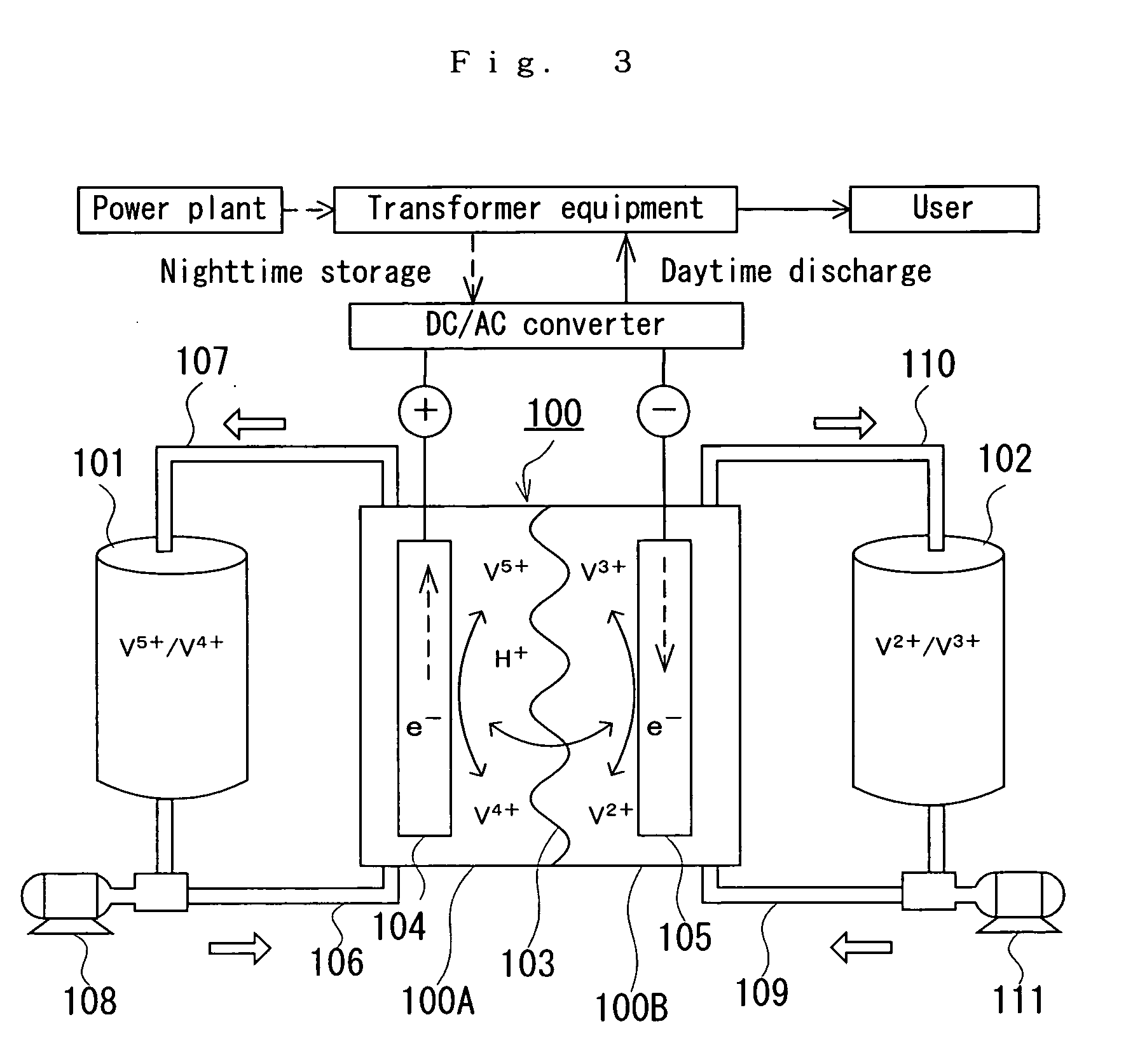

Method for operating redox flow battery and redox flow battery cell stack

InactiveUS20050164075A1Cost reductionImprove output performanceFuel cell combinationsFuel cells groupingAuxiliary cellEngineering

Owner:KUMAMOTO TAKAHIRO +1

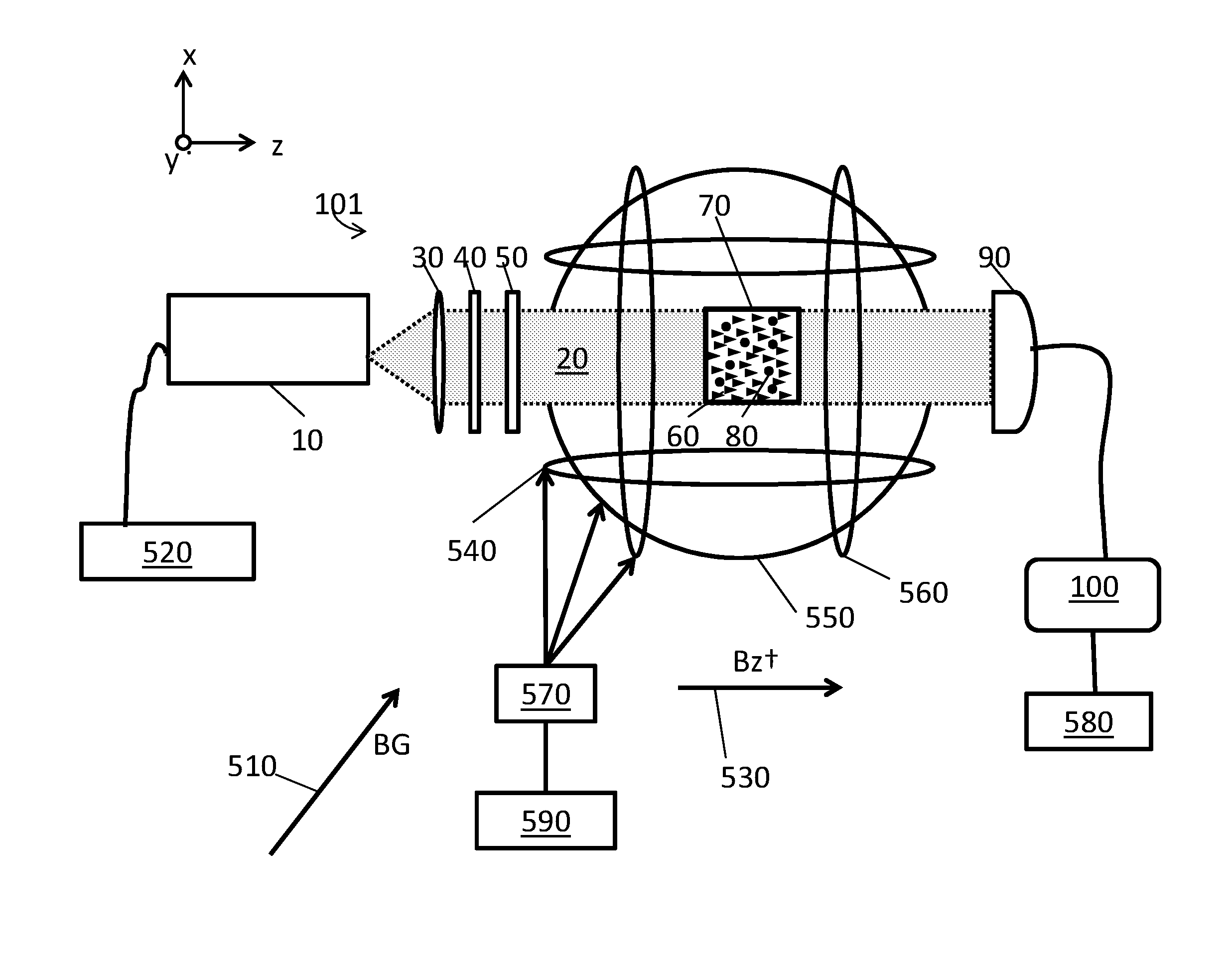

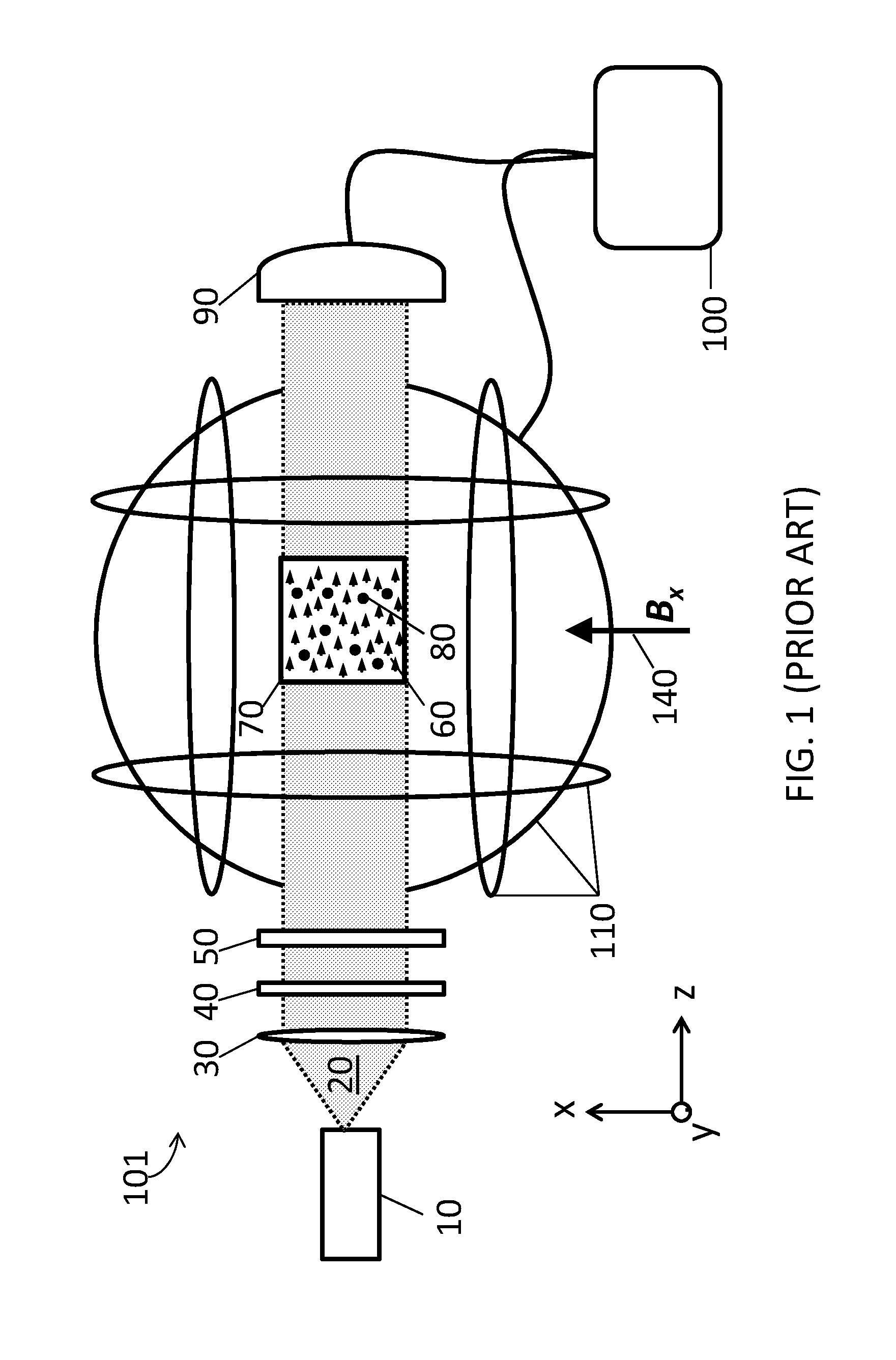

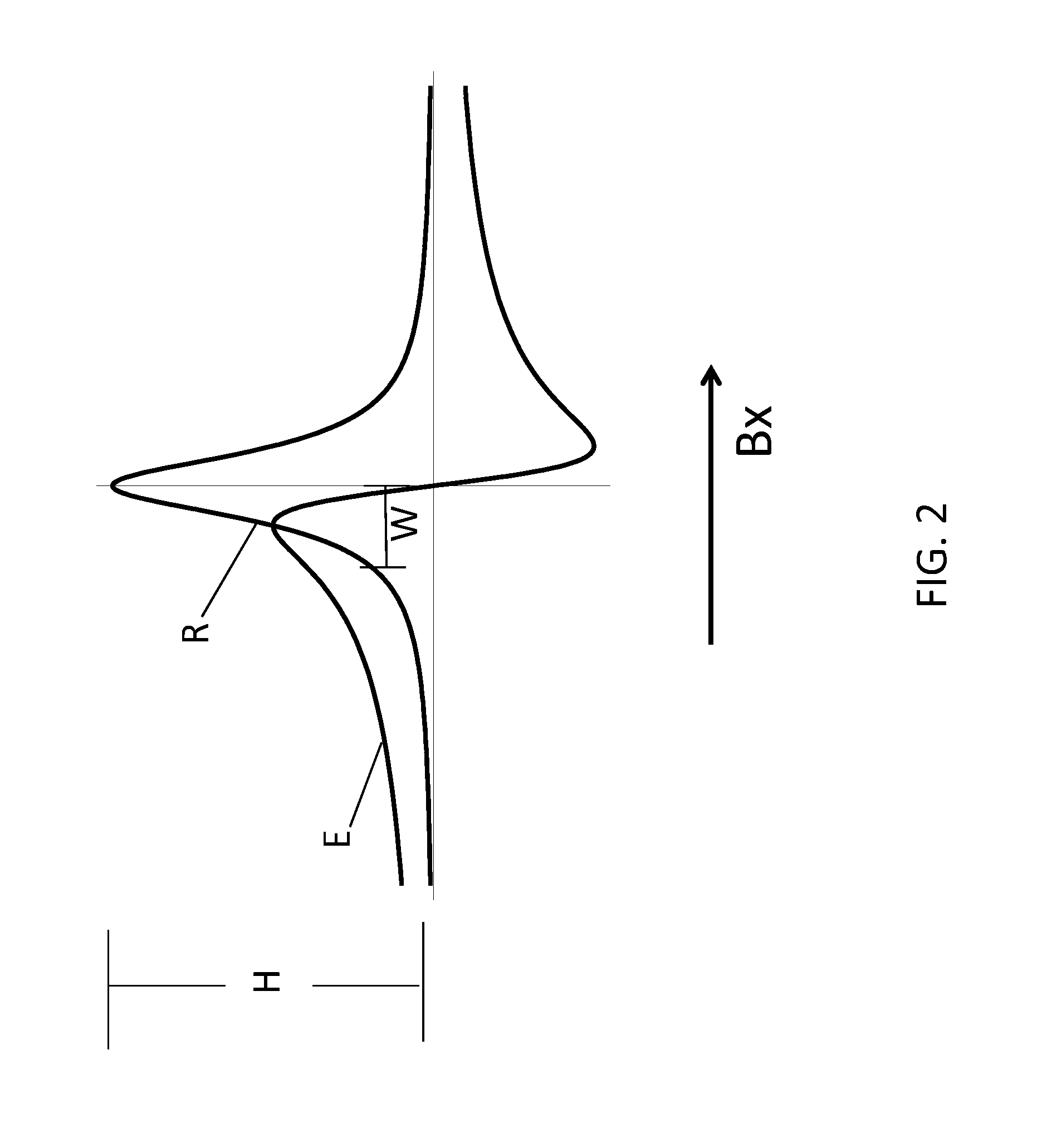

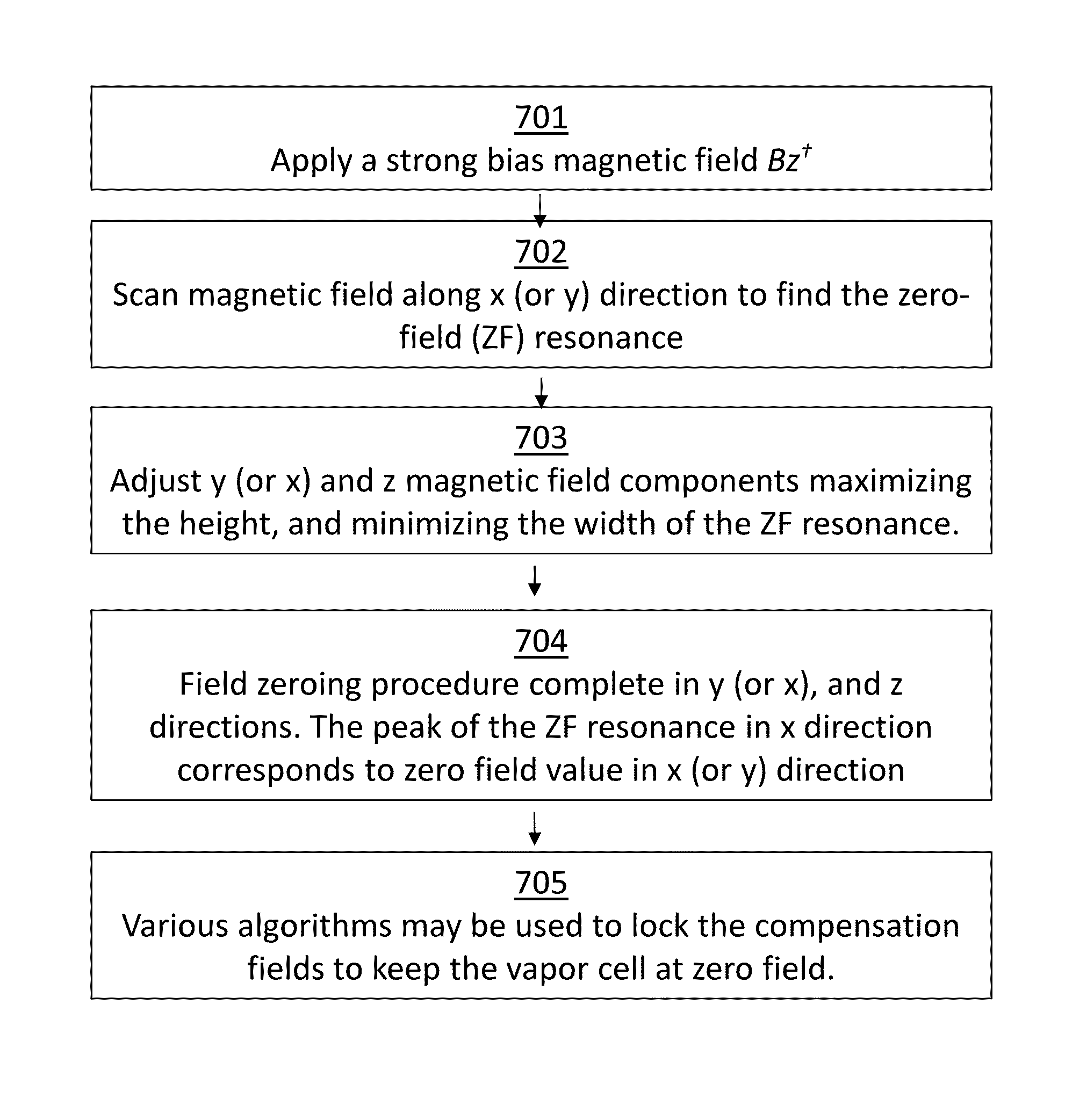

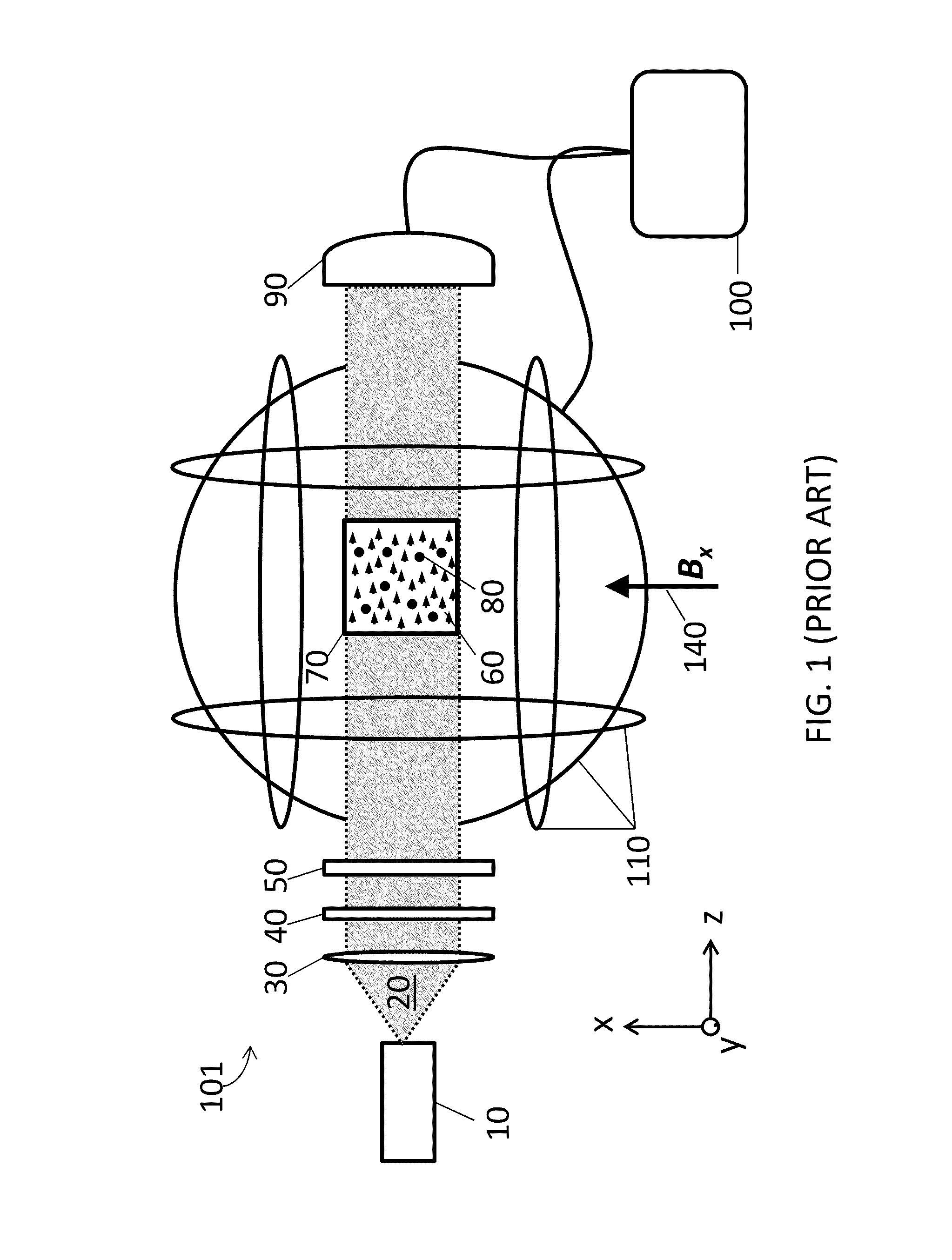

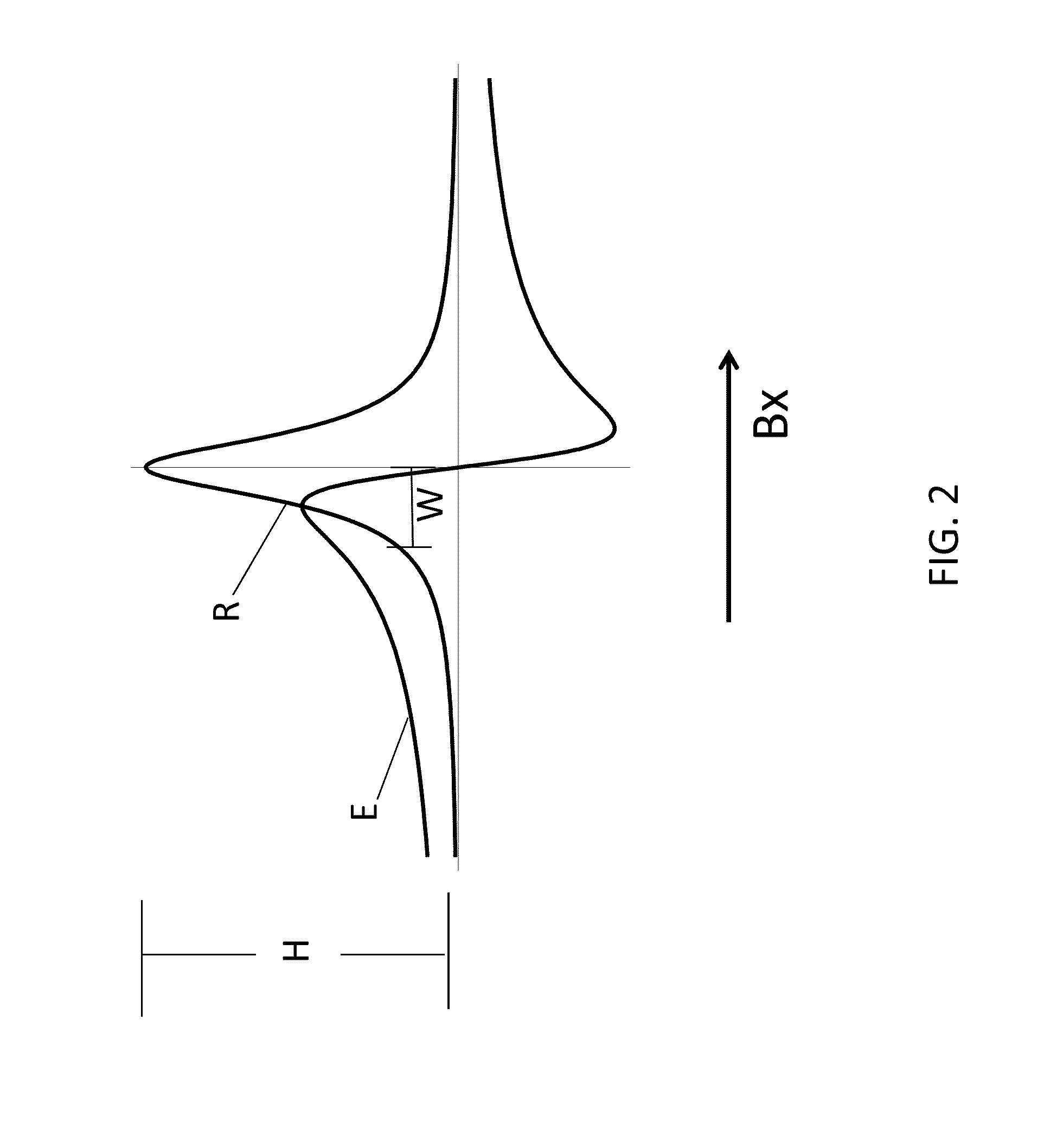

System for detecting zero-field resonance

ActiveUS20160223627A1Width minimizedImprove maximizationAnalysis using optical pumpingAnalysis using electron paramagnetic resonanaceResonanceBias field

A zero-field paramagnetic resonance magnetometer (ZF-PRM) system and method for quickly and efficiently finding and optimizing the zero-field (ZF) resonance is described. In this system and method a magnetic coil is used to apply a magnetic bias field in the direction of the pump beam to artificially broaden the width and maximize the strength of the ZF resonance. By making the ZF resonance easy to detect, the ZF resonance may be found quickly found without the use of additional components and complex algorithms. Once the ZF resonance is found, a compensating magnetic field can be applied to null the magnetic field in the vicinity of the vapor cell in the ZF-PRM, thereby initializing it for operation.

Owner:QUSPIN

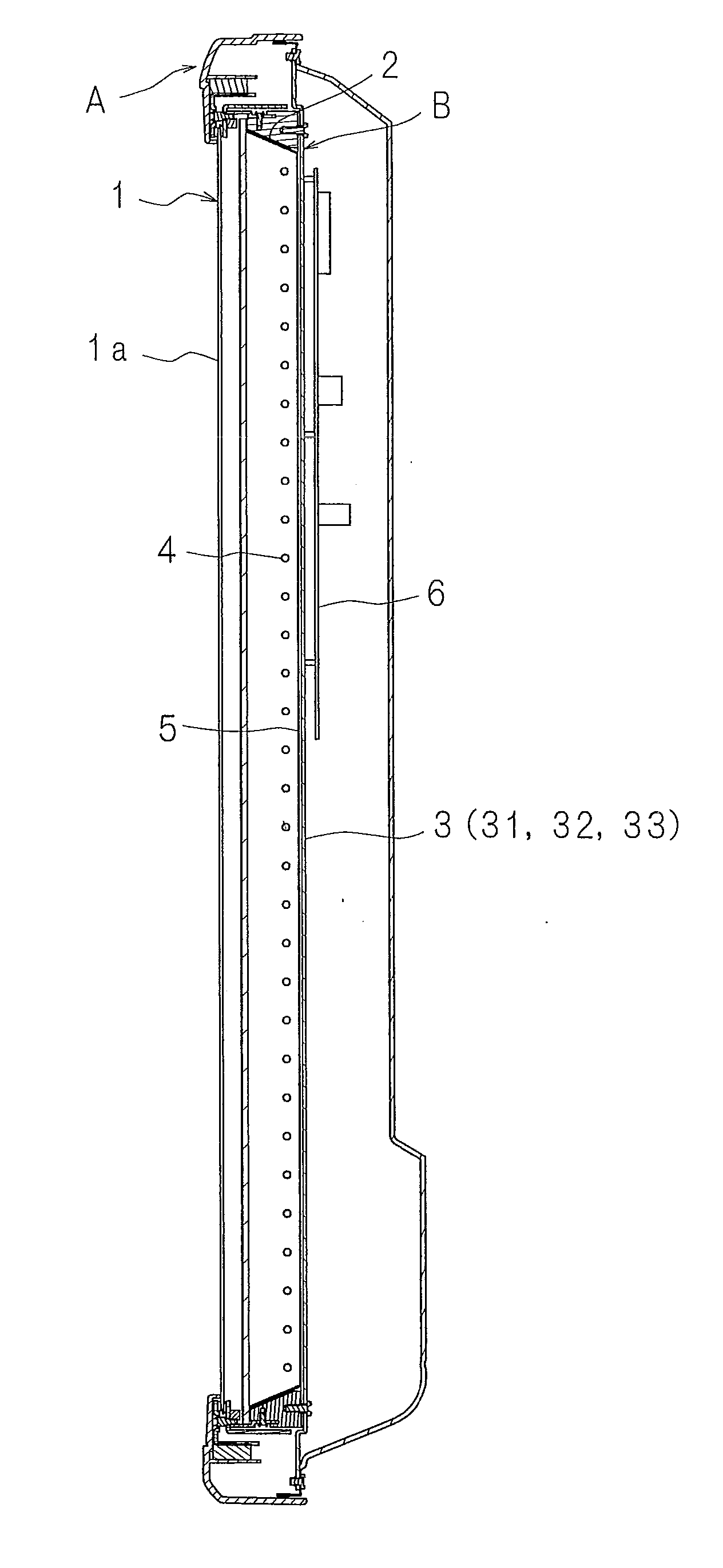

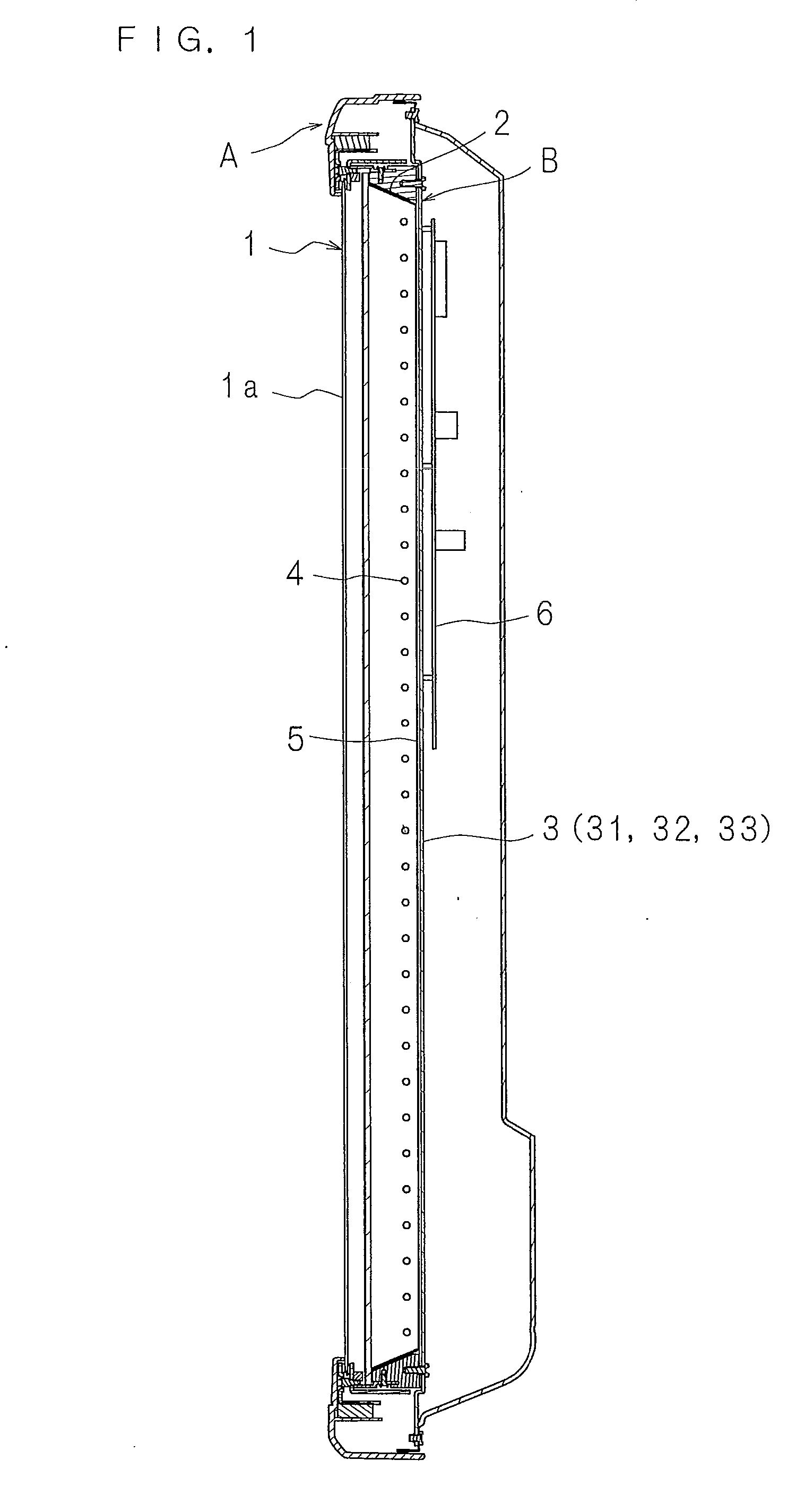

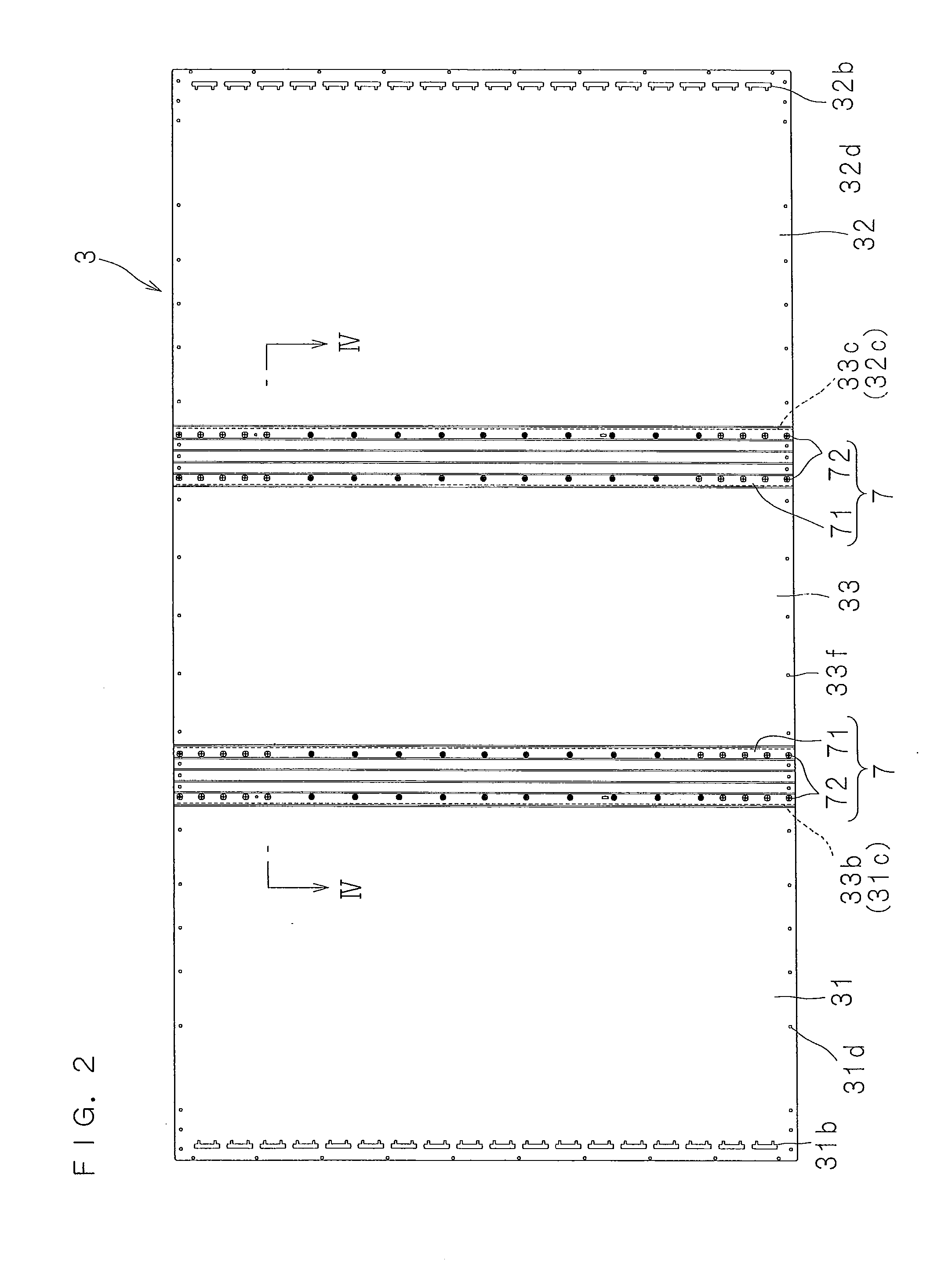

Illuminant device

InactiveUS20100172154A1Simple structureImprove workabilityLighting support devicesIlluminated signsLight emitting deviceChassis

In a chassis which has a lid plate closing an opening portion of a frame part and in which a plurality of lamps are juxtaposed, the lid plate includes a plurality of plate bodies juxtaposed with their end parts superposed on each other and a connecting unit connects the superposed end parts of the plate bodies and the superposed end parts of the plate bodies, respectively.

Owner:SHARP KK

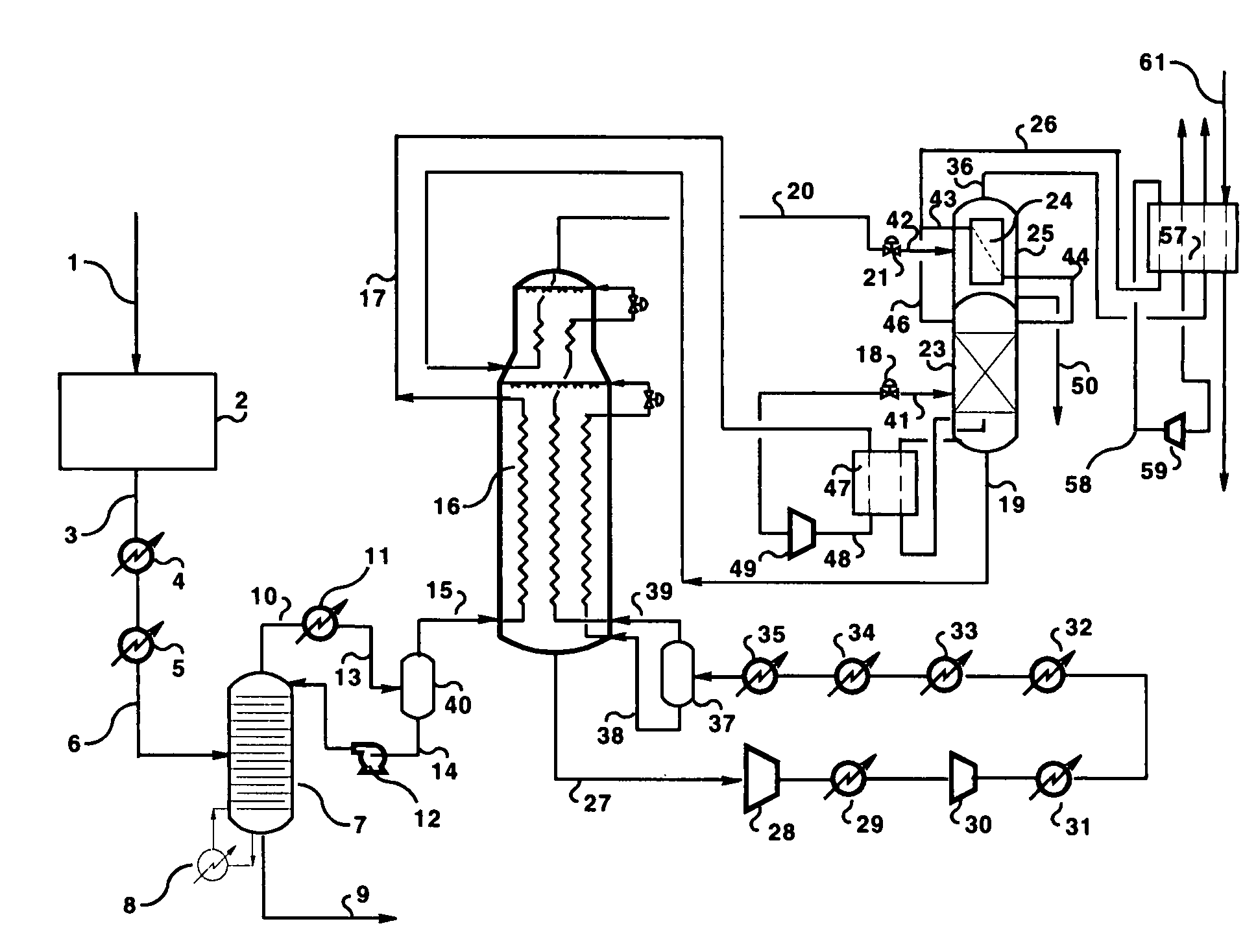

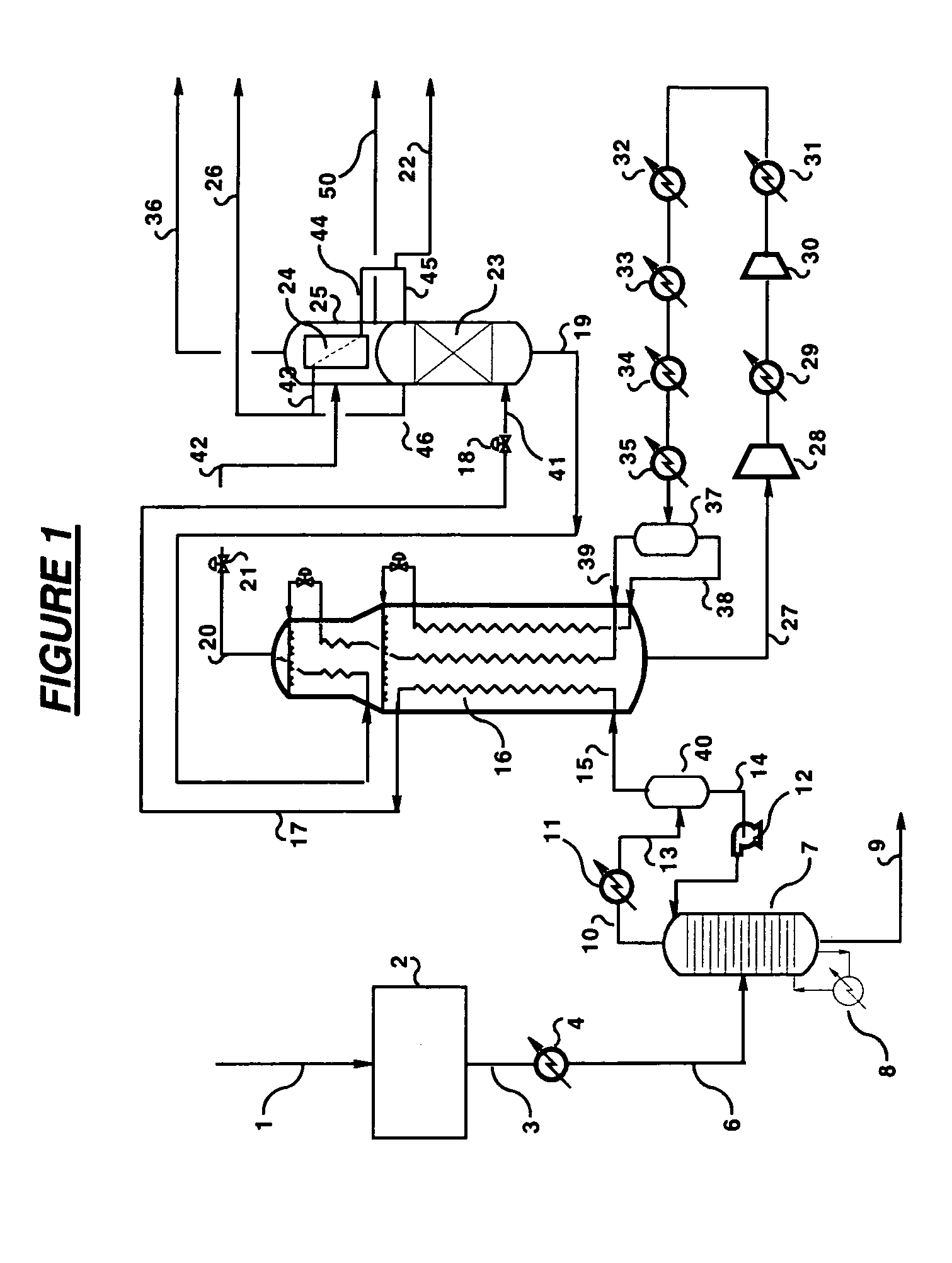

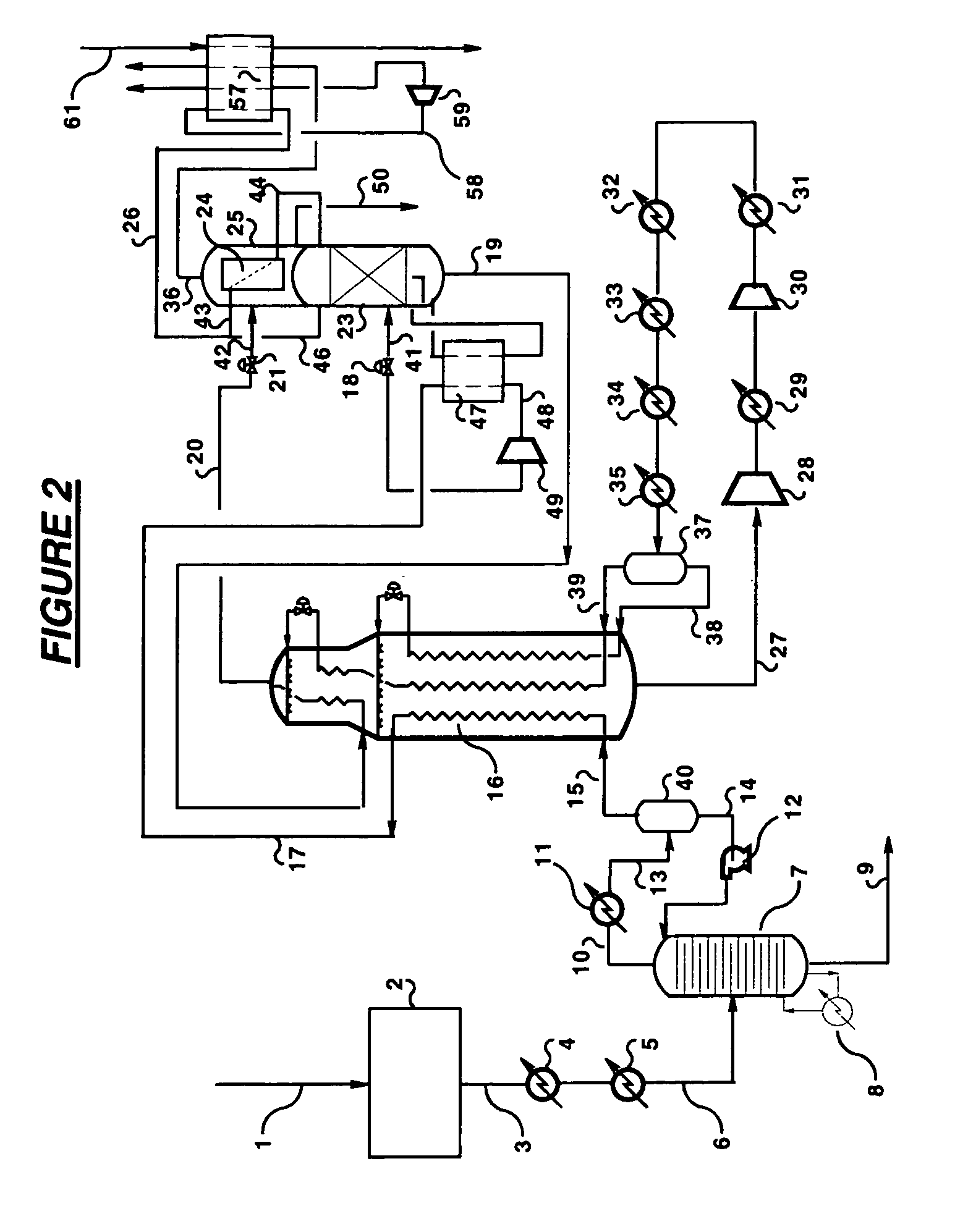

Dual stage nitrogen rejection from liquefied natural gas

Nitrogen is removed from a liquefied natural gas feed (41) by a two stage separation in which the liquefied natural gas (41) is first fractionated (23) to provide a first nitrogen-enriched overhead vapour stream (46) and a nitrogen-containing bottoms liquid stream (19) and then at least a portion of said bottoms liquid stream (19) is fractionated (25) to provide a second nitrogen-enriched overhead vapour stream (36) that is of lower purity than said first overhead vapour stream (46) and a purified liquefied natural gas stream (50). The first fractionation is conducted in a distillation column (23) refluxed (45) with nitrogen overhead (43) condensed in a condenser (24) located in a flash drum (25) in which the second fractionation is conducted. The second nitrogen-enriched overhead vapour stream (36) provides fuel gas for use in the natural gas liquefaction plant.

Owner:AIR PROD & CHEM INC

Method for detecting zero-field resonance

ActiveUS9116201B2Width minimizedImprove maximizationAnalysis using optical pumpingAnalysis using electron paramagnetic resonanaceResonanceBias field

A zero-field paramagnetic resonance magnetometer (ZF-PRM) system and method for quickly and efficiently finding and optimizing the zero-field (ZF) resonance is described. In this system and method a magnetic coil is used to apply a magnetic bias field in the direction of the pump beam to artificially broaden the width and maximize the strength of the ZF resonance. By making the ZF resonance easy to detect, the ZF resonance may be found quickly found without the use of additional components and complex algorithms. Once the ZF resonance is found, a compensating magnetic field can be applied to null the magnetic field in the vicinity of the vapor cell in the ZF-PRM, thereby initializing it for operation.

Owner:QUSPIN

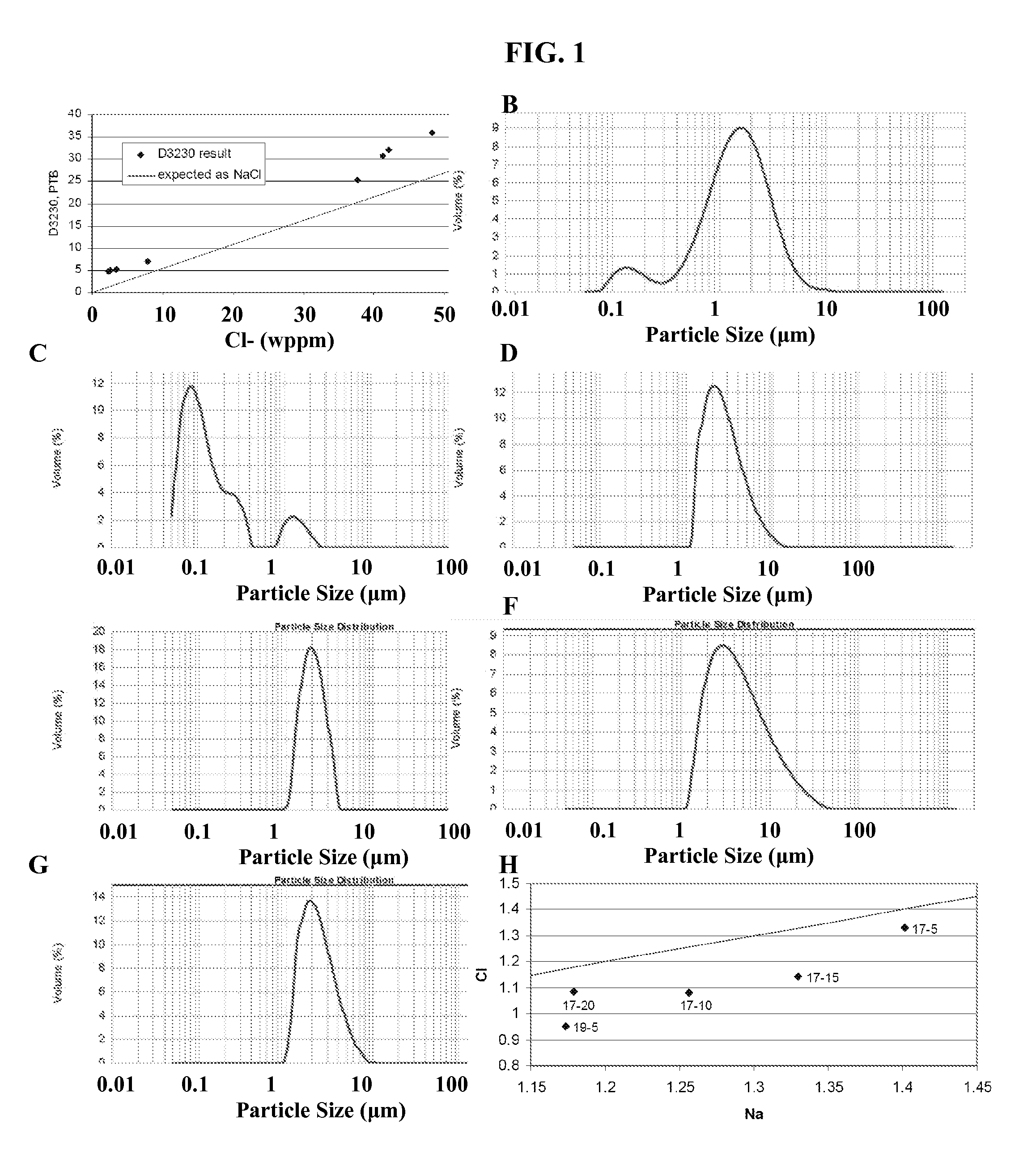

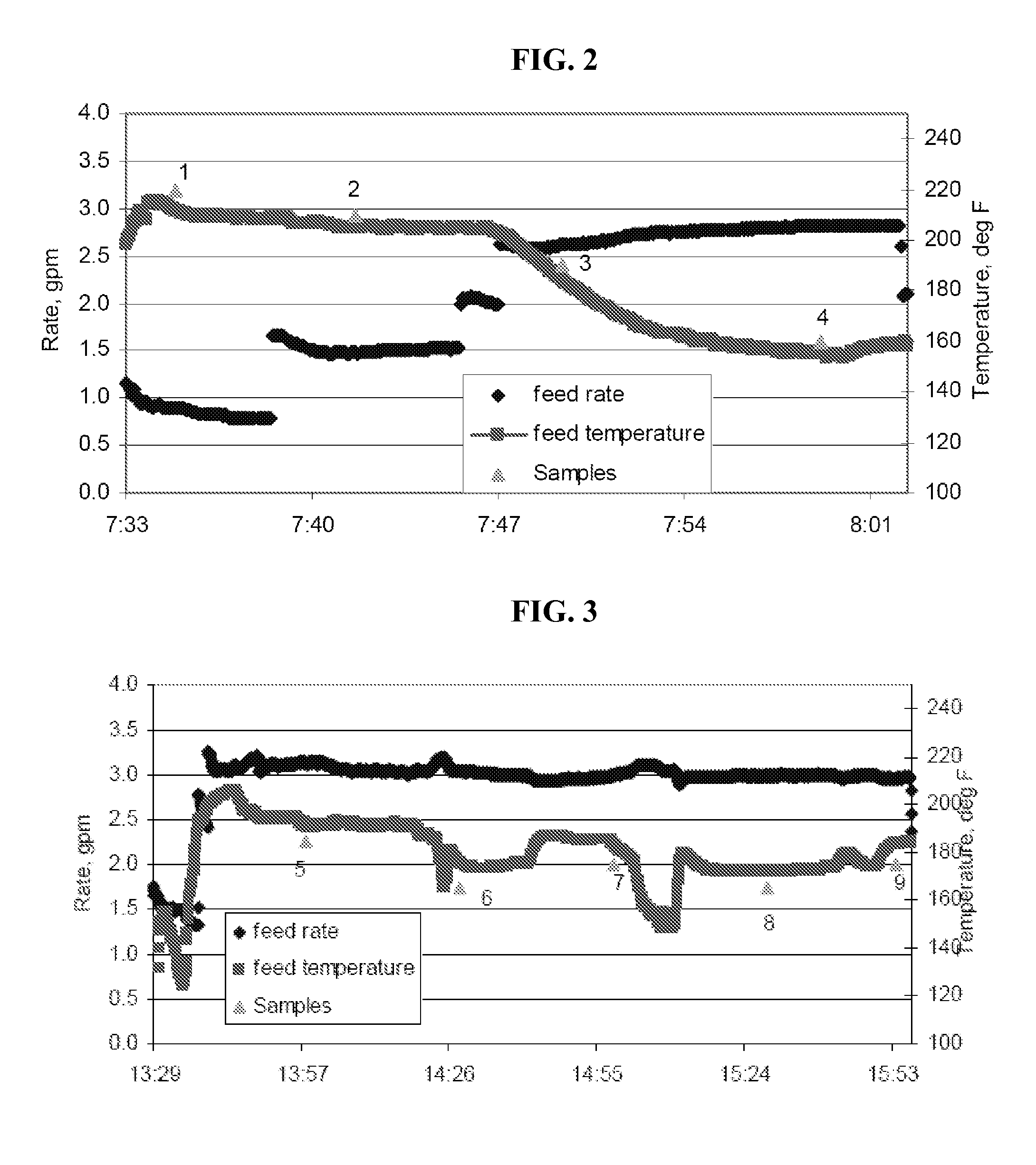

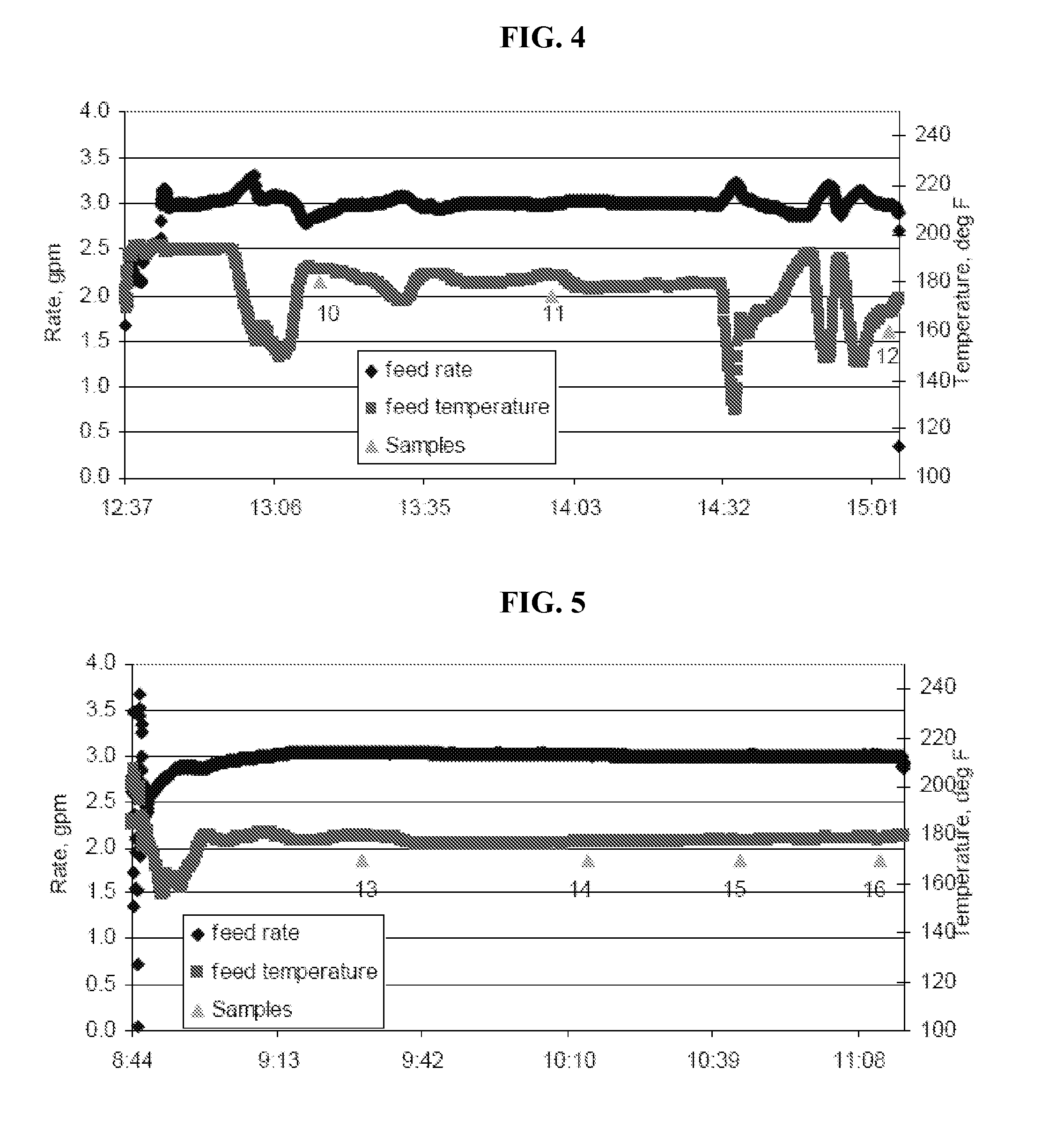

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

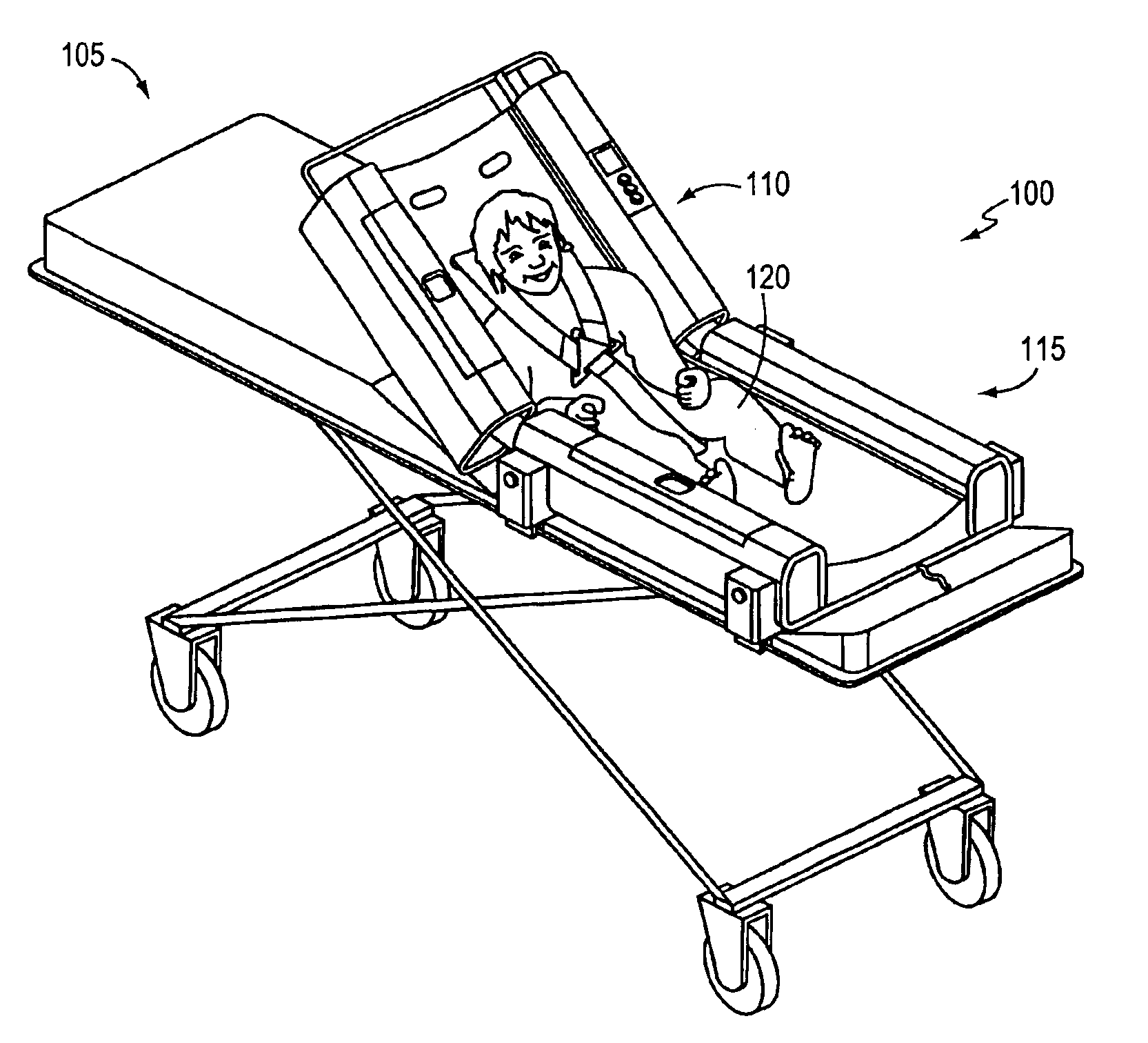

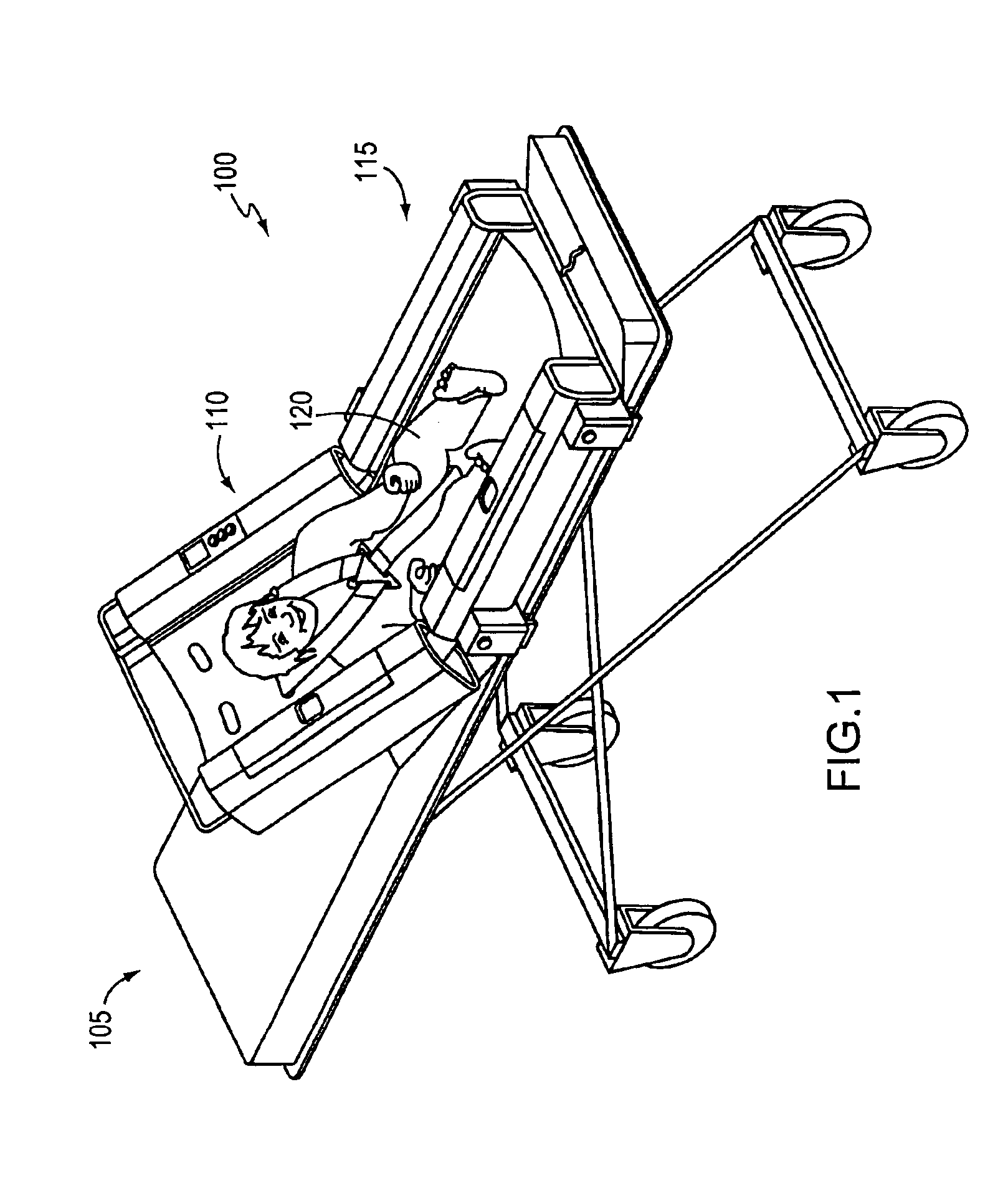

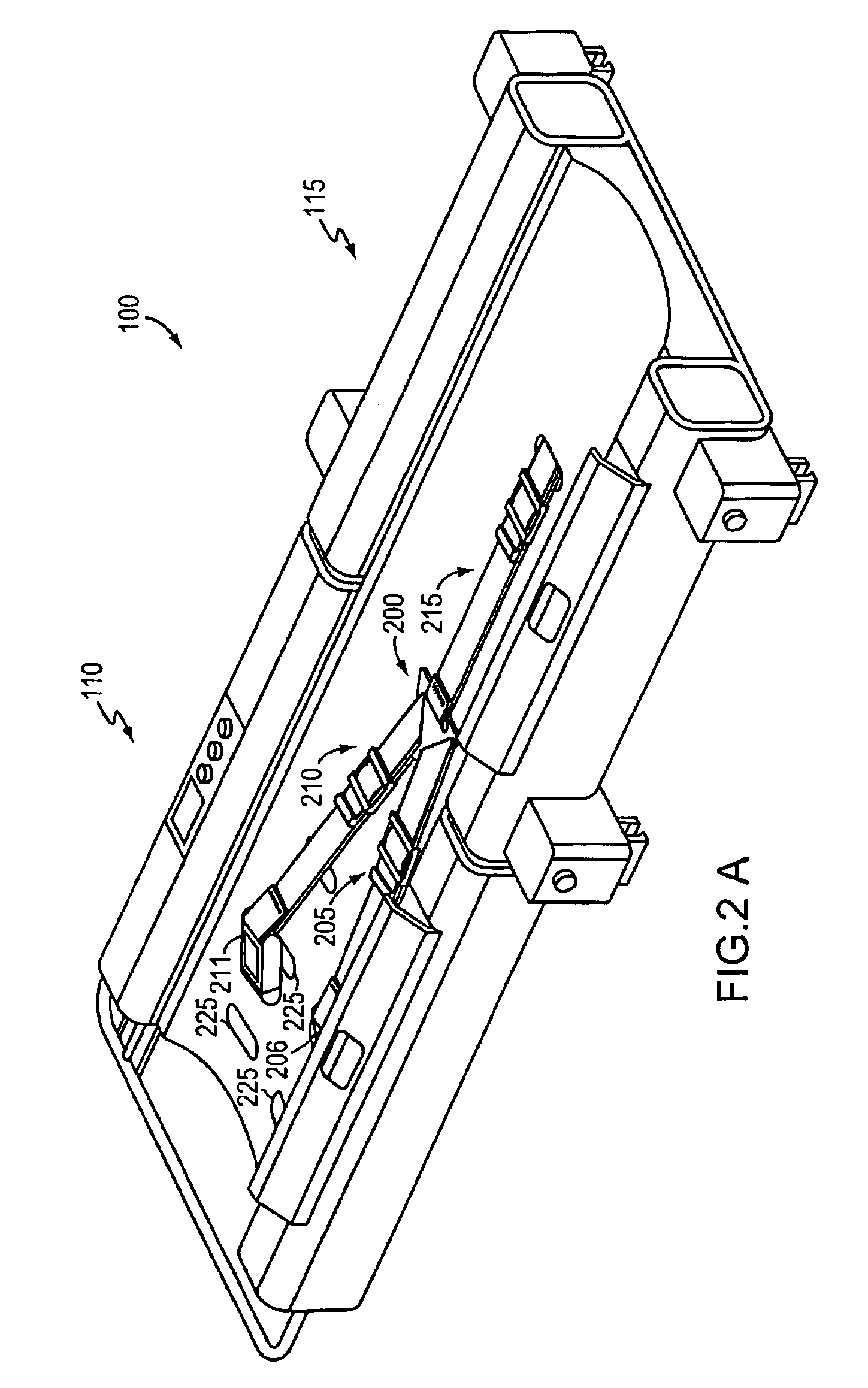

Device for emergency transport of pediatric patients

InactiveUS6898811B2Effectively aid in administration of medical procedureAdd equipmentStretcherSofasPediatric patientDevices fixation

A device for emergency transport of pediatric patients that safely and efficiently transports a pediatric patient to a medical facility. To confine the patient to the device frame, it includes a child restraint in the form of a restraining belt assembly. The device accommodates children of varying size using the restraining belt assembly. The device also includes a hinge assembly that controls the relative rotation of portions of the frame. A clamp that can releasably attach to an object with a rail, such as a medical transport device is also described. To increase efficiency, the clamp includes a width accommodation feature and a universality feature. These features enable it to secure the device to objects of varying shapes and widths.

Owner:SCHNEE SANDY +1

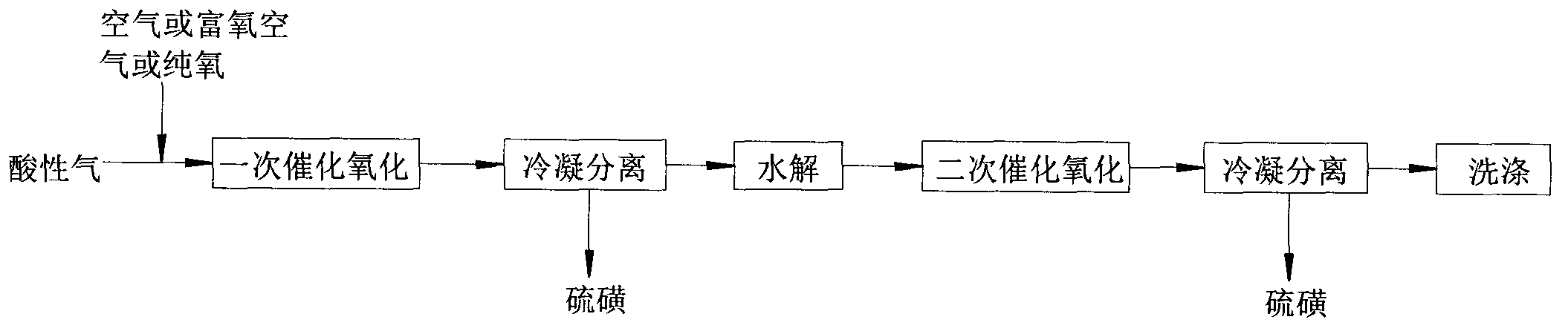

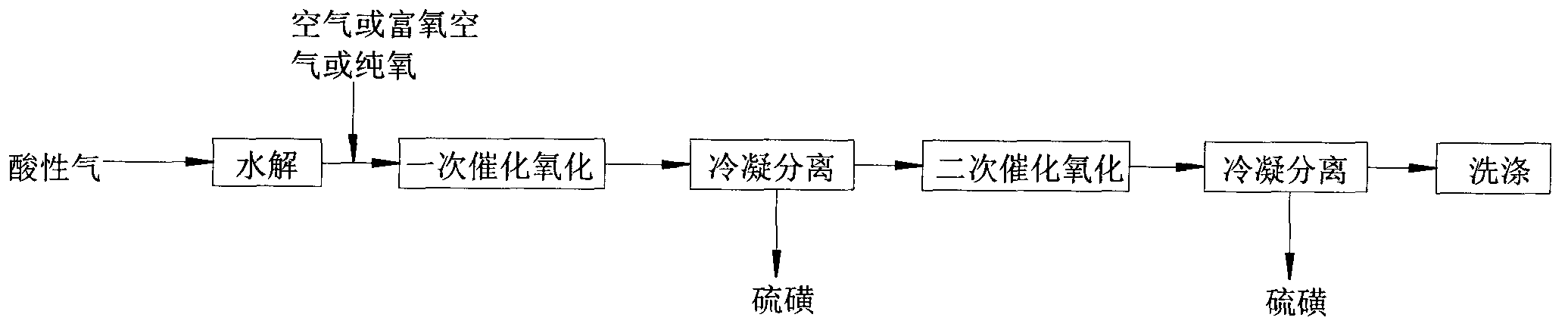

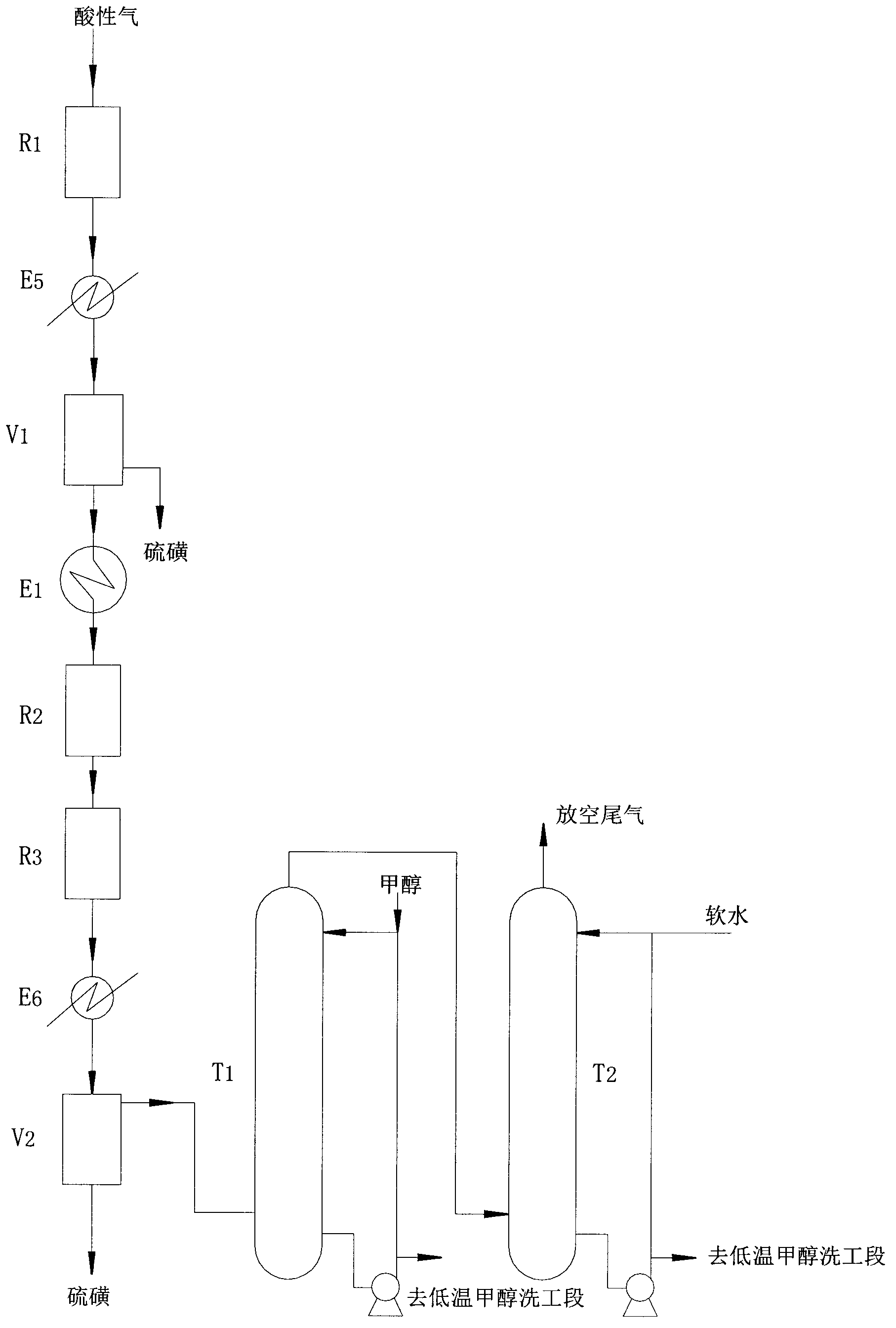

Method, device and reactor for recovery of sulfur from acidic gas

InactiveCN104138713AAffect conversion performanceImpact protectionDispersed particle separationSulfur preparation/purificationAlcoholSulfur

The invention discloses a method, device and reactor for recovery of sulfur from acidic gas. An inorganic sulfide in the acidic gas is catalyzed and oxidized into sulfur by catalytic oxidation reaction, then the organic sulfur in the acidic gas is hydrogenated and hydrolyzed into an inorganic sulfide through catalytic hydrolysis reaction, finally the residual inorganic sulfur in the reaction gas is oxidized into sulfur through secondary catalytic oxidation reaction, and the tail gas is washed by a methanol lotion and / or water, thus realizing complete recovery of sulfur. The invention also discloses the device and reactor for realizing the method. The method and device provided by the invention are suitable for sulfur recovery of low H2S content acidic gas. An alcohol-containing solution is utilized for washing treatment of desulfurized tail gas according to the low temperature methanol washing process, the content of sulfide in the tail gas is reduced, and the environment is protected. At the same time, the reactor involved in the invention has a simple and reasonable structure, saves land occupation of equipment, and lowers the project investment.

Owner:杭州林达化工技术工程有限公司

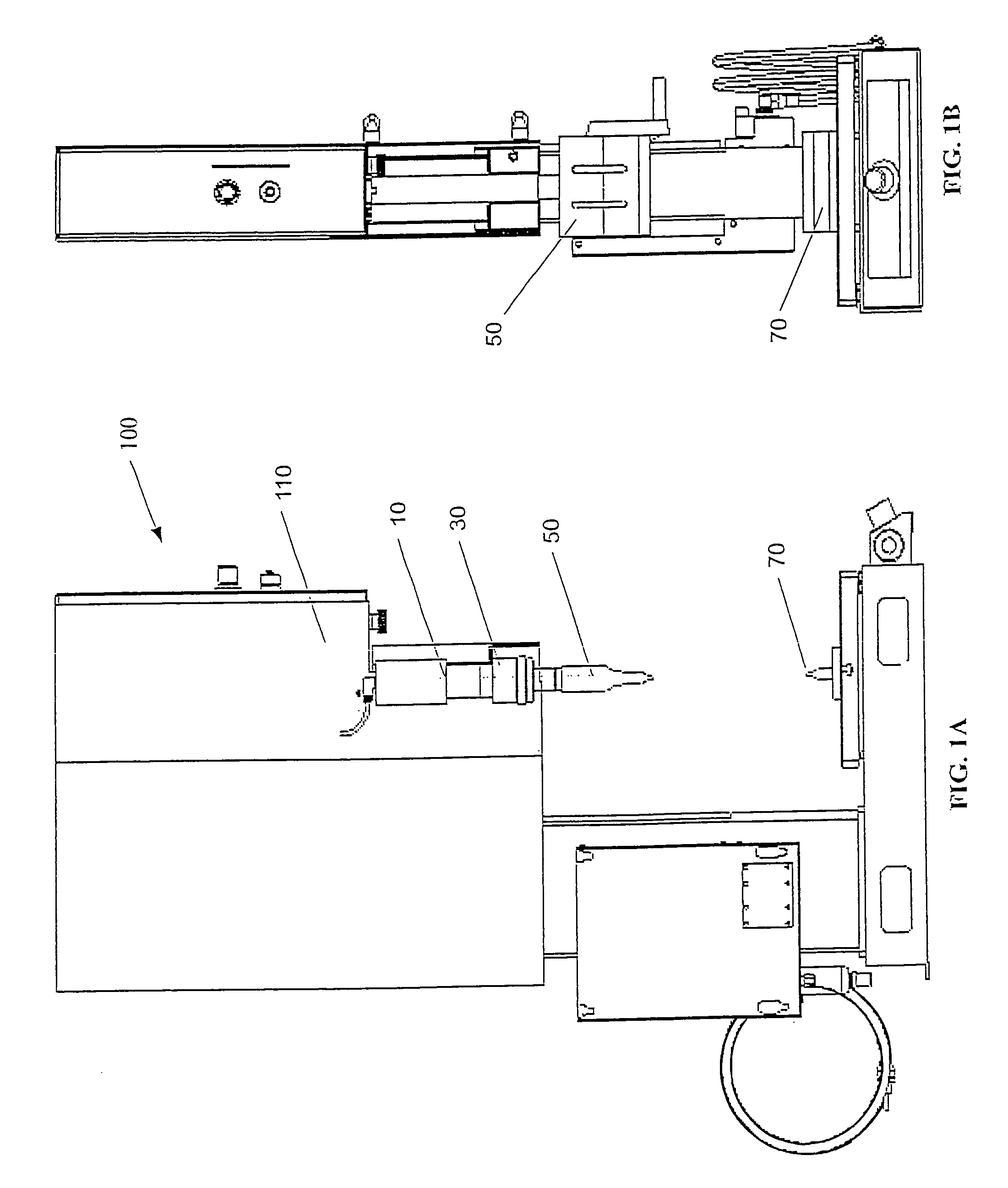

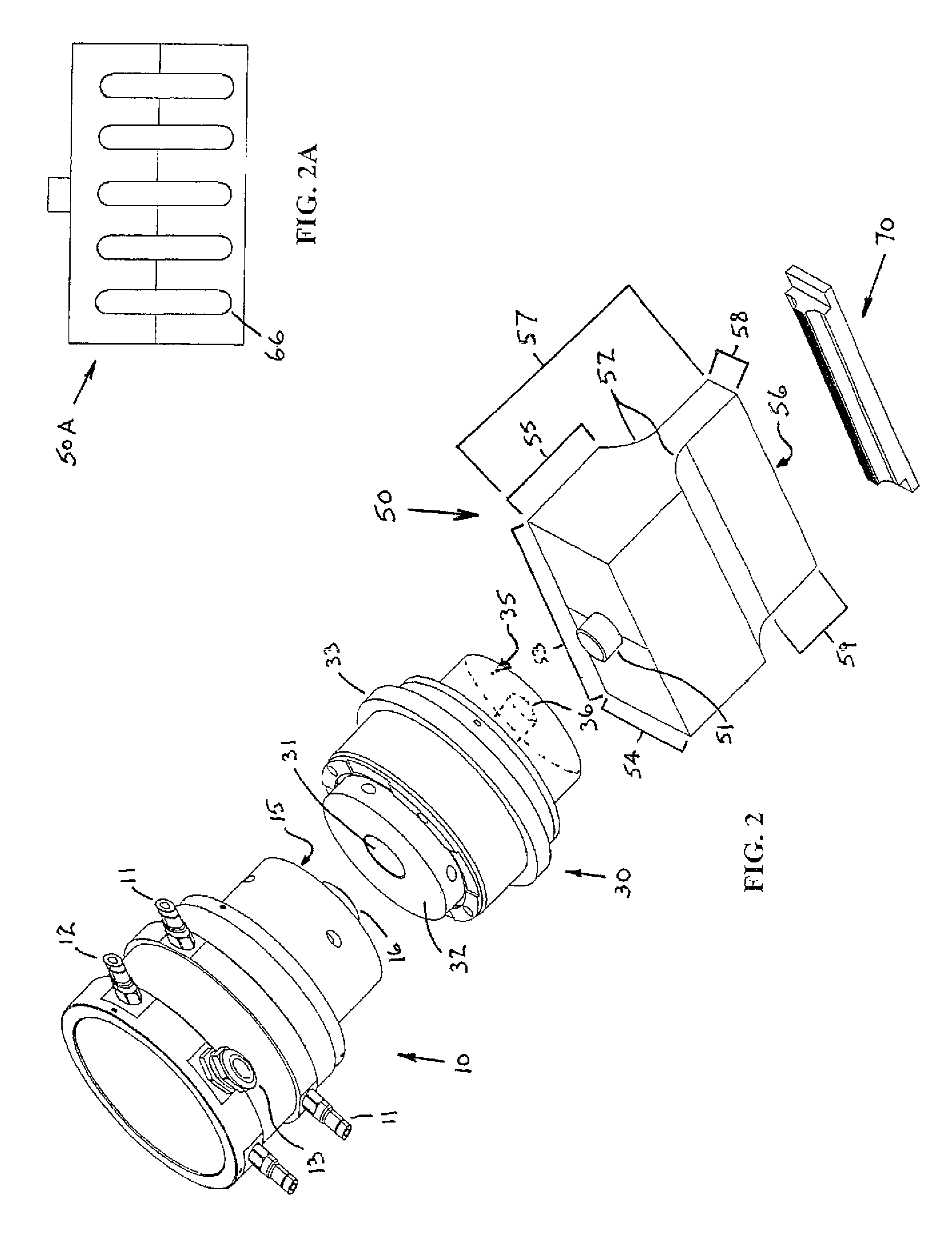

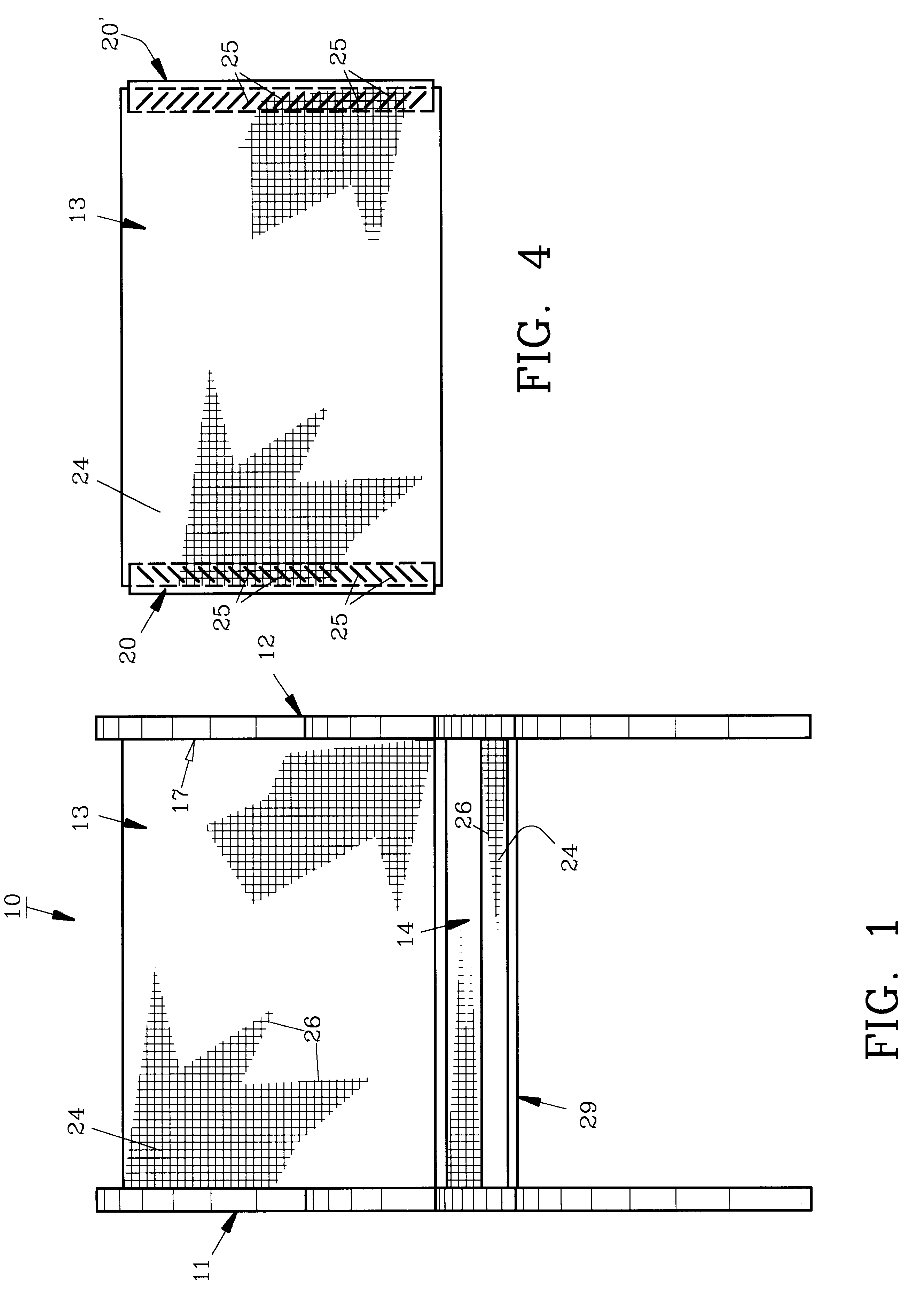

Sonotrode and anvil energy director grids for narrow/complex ultrasonic welds of improved durability

InactiveUS9278481B2Reduce material costsAdd equipmentLaminationLamination apparatusGrid patternEnergy control

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

Golf club head

ActiveUS20080108453A1Improved spin characteristicEasy to cleanMetal rolling stand detailsMetal working apparatusSurface roughnessEngineering

A golf club head comprising a strike face having a heel portion, a toe portion, and an intermediate portion. The intermediate portion includes one or more score lines. At least a portion of one or more score lines include a different average surface roughness and associated surface reflectance than at least the intermediate portion. A method for producing such a club head is also provided.

Owner:SUMITOMO RUBBER IND LTD

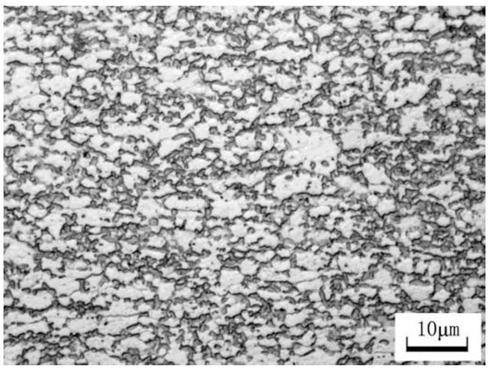

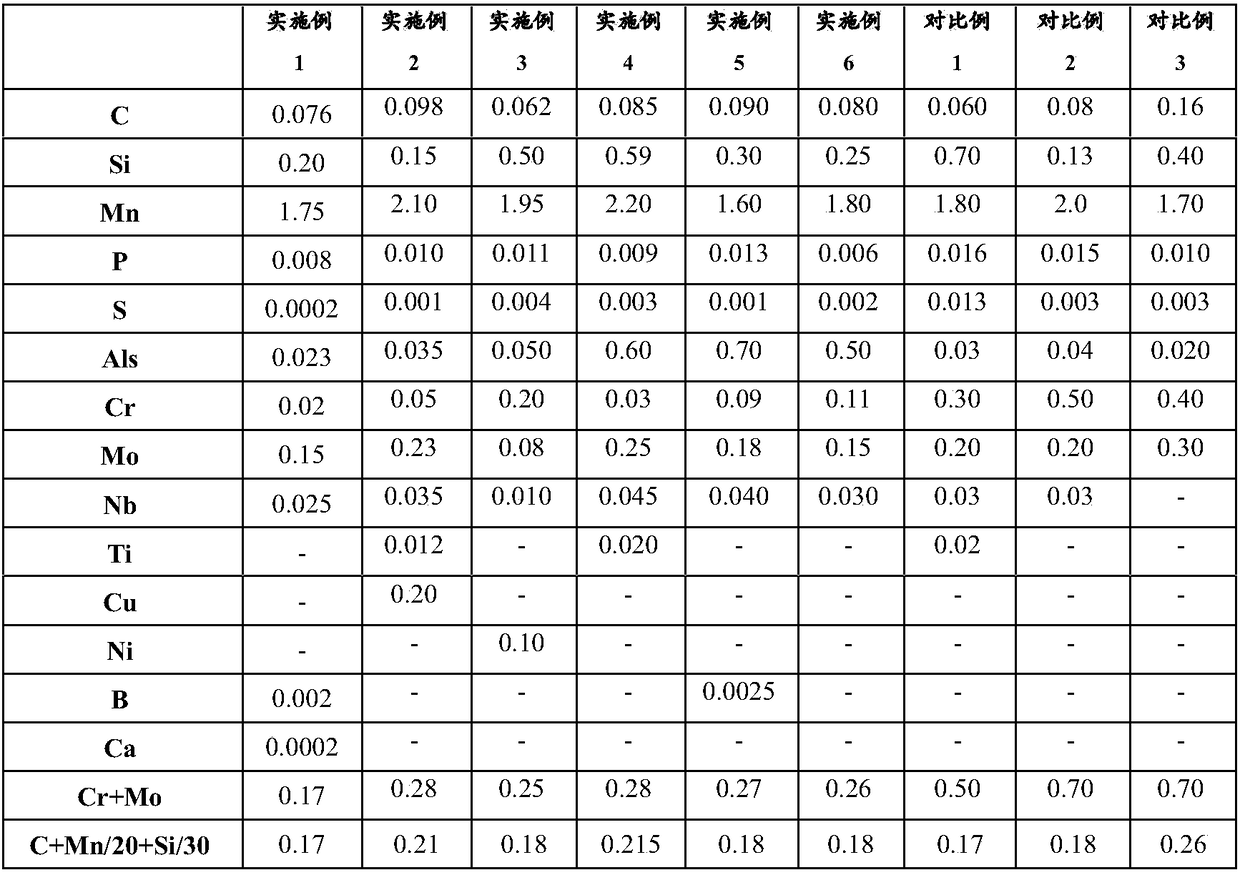

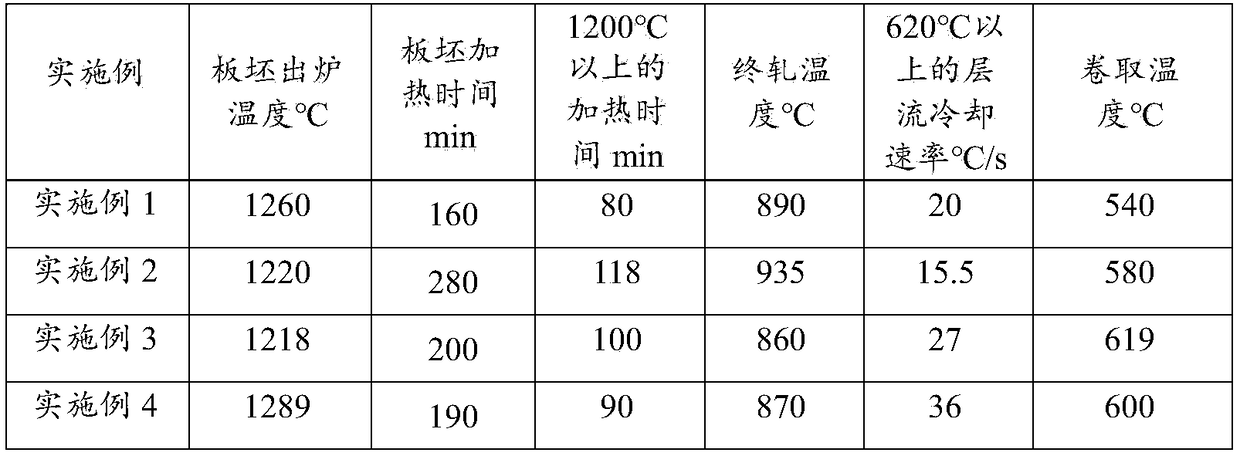

800MPa-grade cold-rolled hot-galvanizing dual-phase steel and production method thereof

The invention discloses 800MPa-grade cold-rolled hot-galvanizing dual-phase steel. The 800MPa-grade cold-rolled hot-galvanizing dual-phase steel comprises the following raw materials taken as chemicalcomponents in percentage by mass (%): 0.05% to 0.10% of C, 1.60% to 2.30% of Mn, 0.010 to 1.0% of Als, 0.10% to 0.60% of Si, 0.010 to 0.050% of Nb, 0.05 to 0.30% of Cr, 0.05 to 0.30% of Mo, P not smaller than 0.015%, S not greater than 0.010%, N not greater than 0.008%, and the balance of Fe and inevitable impurities, and noble metal elements Cr and Mo satisfy the relation that Cr+Mo is not smaller than 0.05 and not greater than 0.30, and C+Si / 30+Mn / 20 is not greater than 0.22. The production method for the hot-galvanizing steel for an automobile wheel cover comprises the steps of smelting, continuous casting, heating, hot rolling, cooling, coiling, pickling, cold rolling, annealing and coat-plating. According to the invention, the obtained cold-rolled hot-galvanizing dual-phase steel hasless precious alloying elements, so that the product has good mechanical properties, surface quality, formability and welding performances. Furthermore, the 800MPa-grade cold-rolled hot-galvanizing dual-phase steel disclosed by the invention can be produced on the existing conventional production line without additional equipments.

Owner:武汉钢铁有限公司

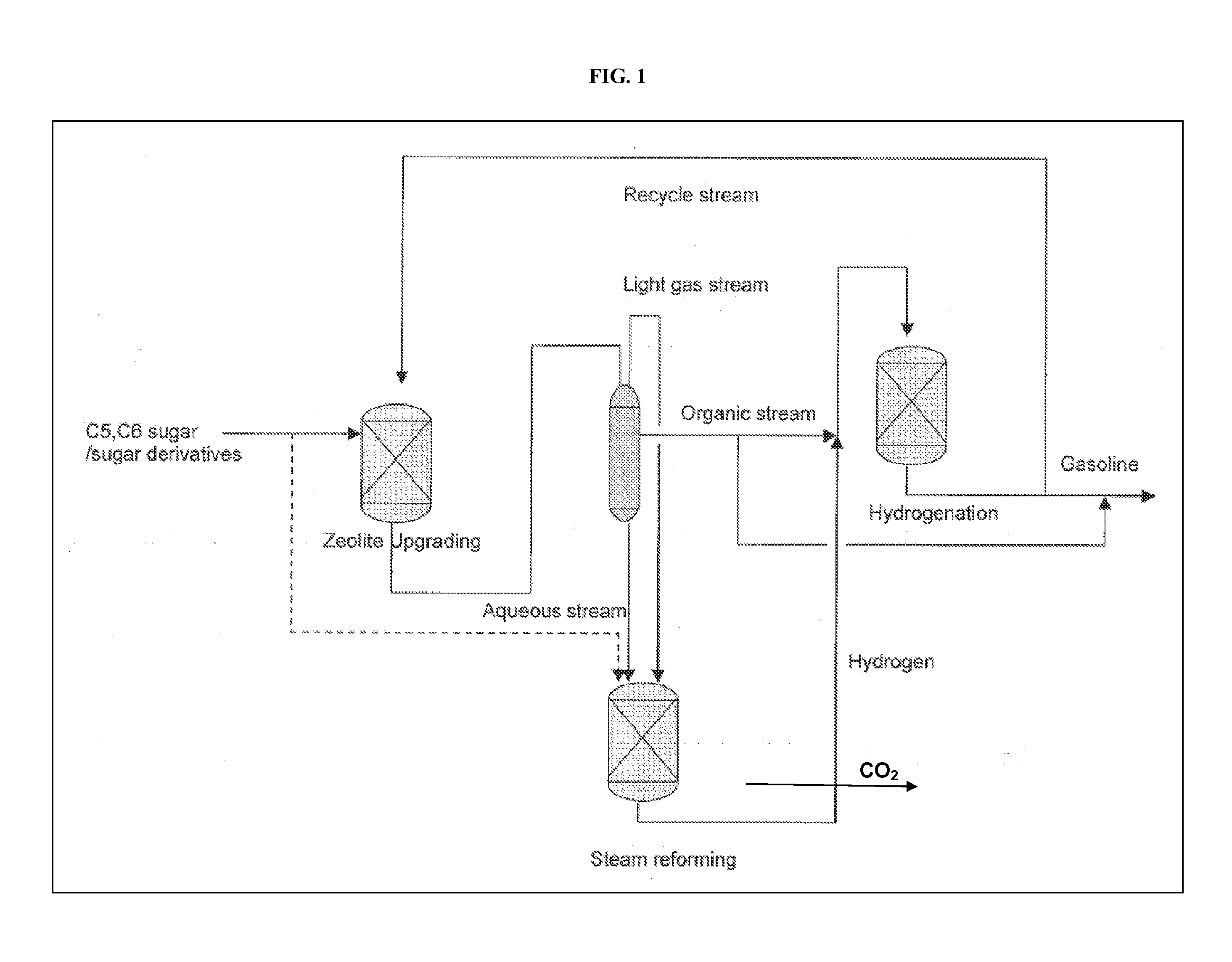

Carbohydrates upgrading and hydrotreating to hydrocarbons

ActiveUS20110263916A1Easy to convertReduced liquid yieldHydrogenBiofuelsCarbon footprintLiquid hydrocarbons

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A process was designed to reduce the coke by co-feeding sugars / sugar derivatives with a saturated recycle stream containing hydrogenated products.

Owner:PHILLIPS 66 CO

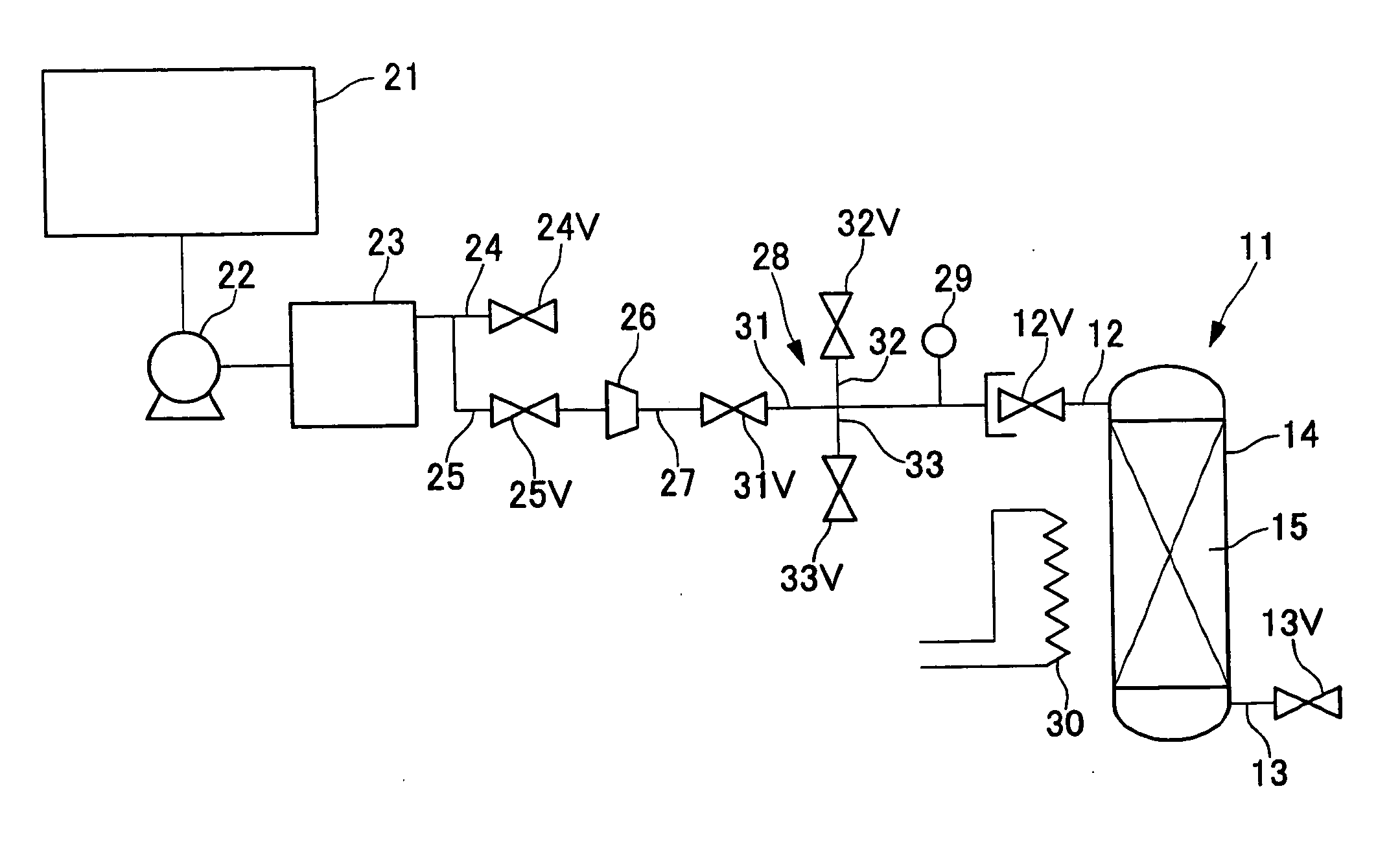

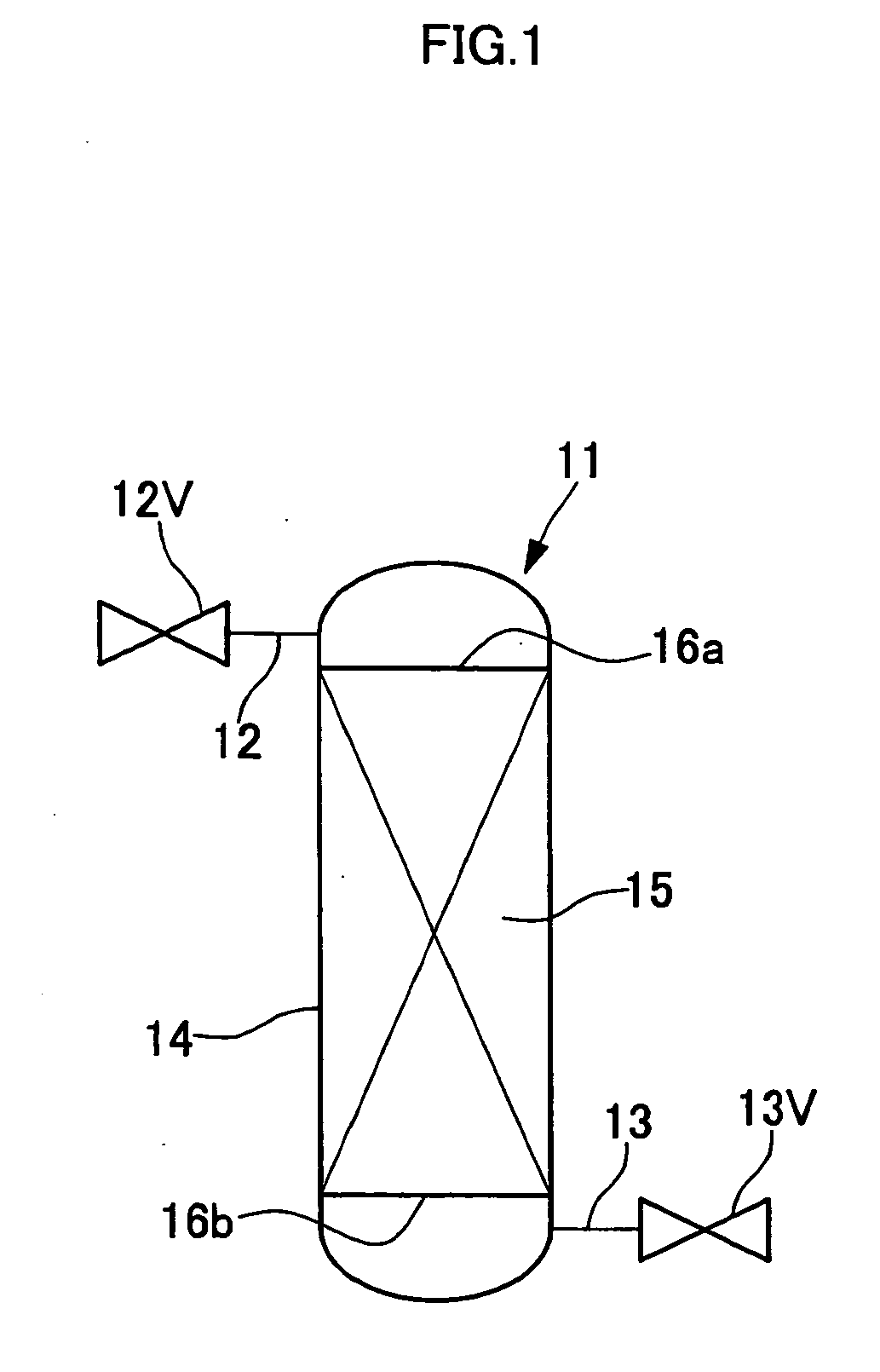

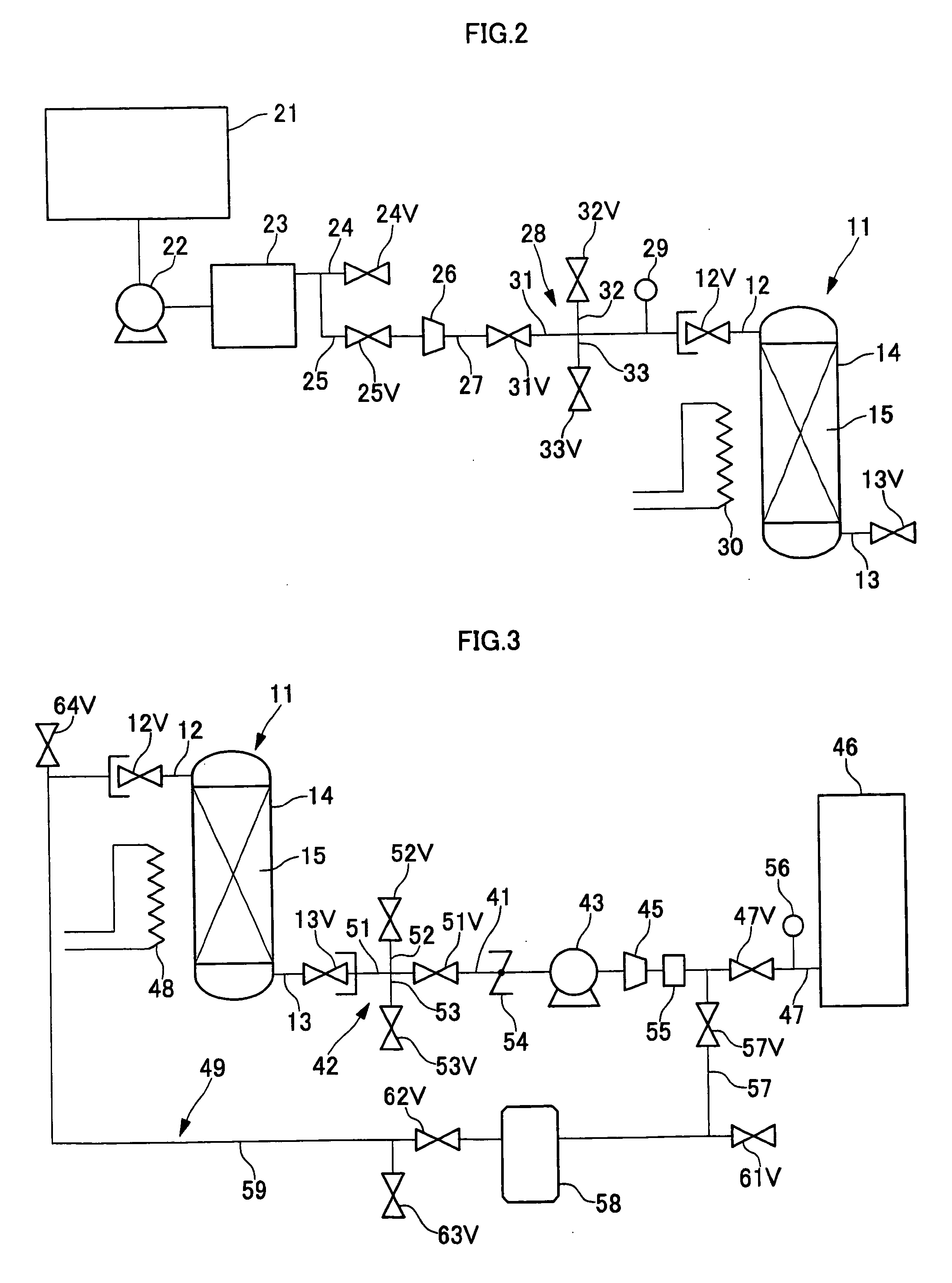

Process for recovering rare gases using gas-recovering container

ActiveUS20050235828A1Improve processing efficiencyAdd equipmentGas treatmentIsotope separationExhaust gasChemistry

A process comprises the steps of recovering exhaust gas containing krypton or xenon which are used as an atmospheric gas for semiconductor product preparation apparatuses; introducing the exhaust gas to separating and purifying equipment and thereby separating and purifying krypton or xenon from the exhaust gas, wherein the former step of recovering a rare gas-containing exhaust gas discharged from an equipment using a rare gas comprises removing one or more interfering gases which lower(s) the adsorption ability of activated carbon capable of adsorbing rare gases; and thereafter pressure filling the rare gas-containing exhaust gas obtained after said one or more interfering gases removal treatment into a gas-recovering container, which comprises a air-tight container having a joint section capable of connecting a gas duct through an on-off valve and containing therein the activated carbon capable of adsorbing rare gases; and thereby recovering the rare gas containing exhaust gas; and the latter step of introducing the recovered rare gas-containing exhaust gas in the gas-recovering container to rare gas separating and purifying equipment comprises desorbing the rare gas adsorbed on the above activated carbon by reducing the pressure of the inside of the above gas-recovering container; and discharging the rare gases desorbed from the gas-recovering container and introducing to the above rare gas separation and purifying equipment.

Owner:TAIYO NIPPON SANSO CORP

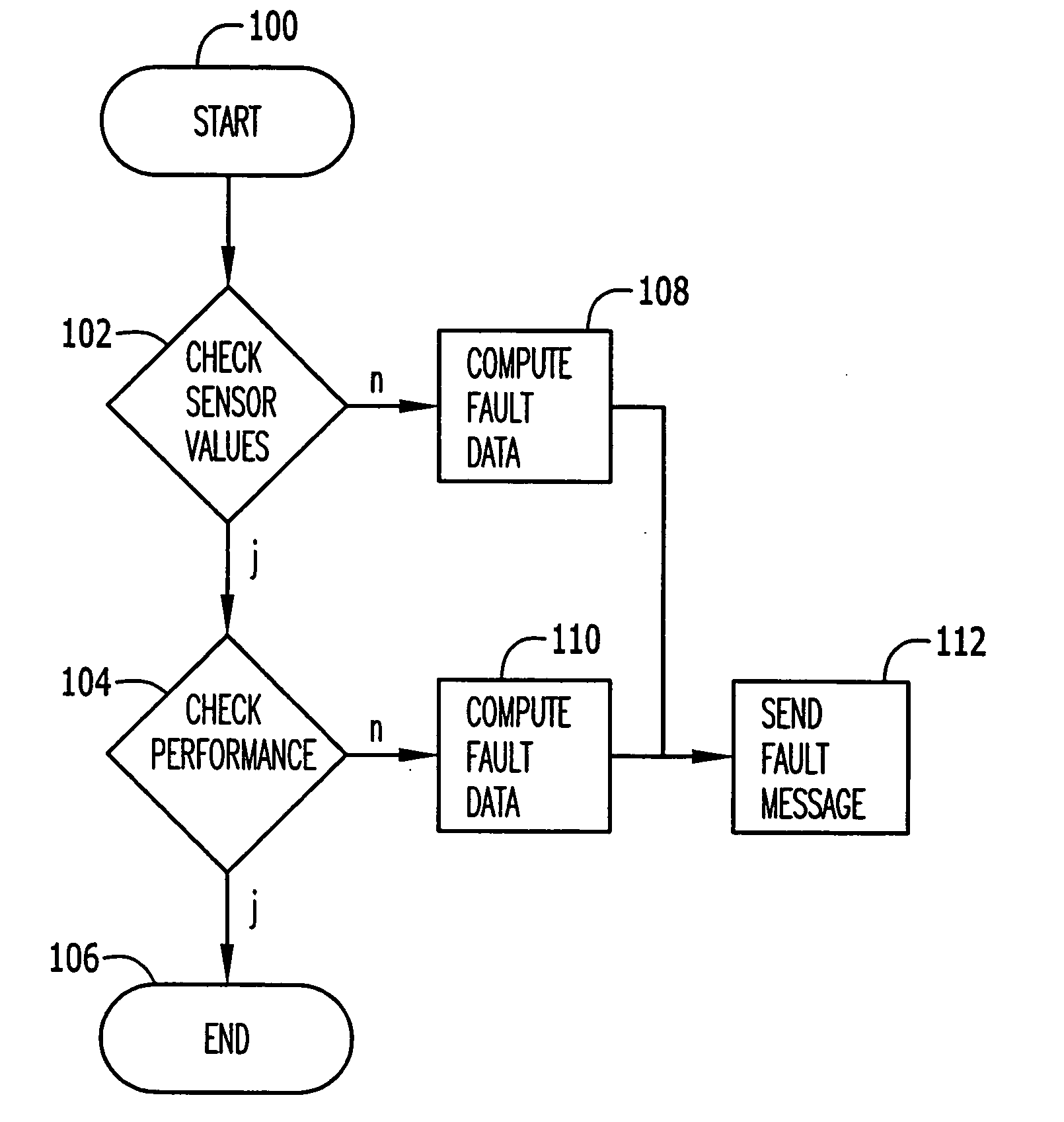

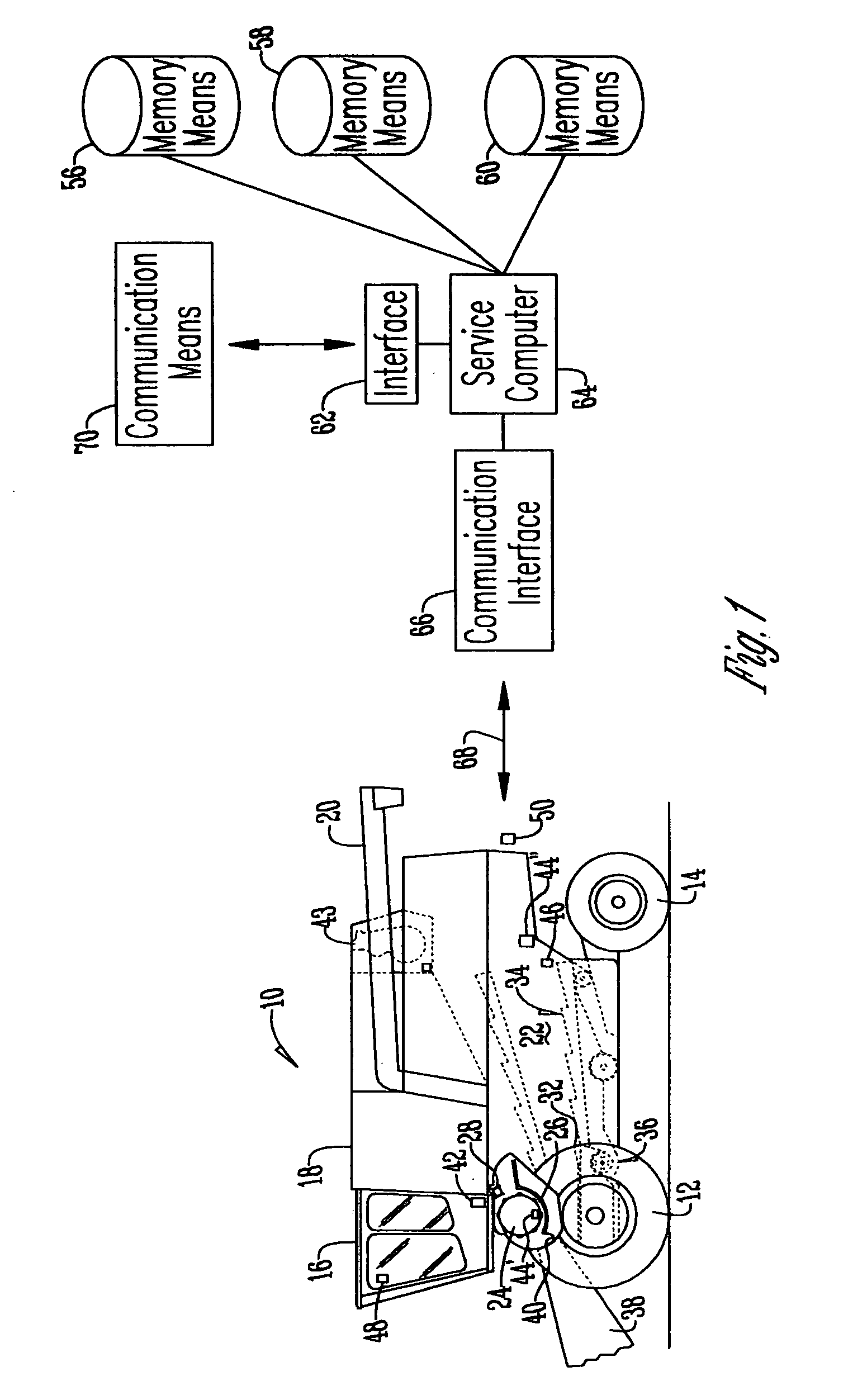

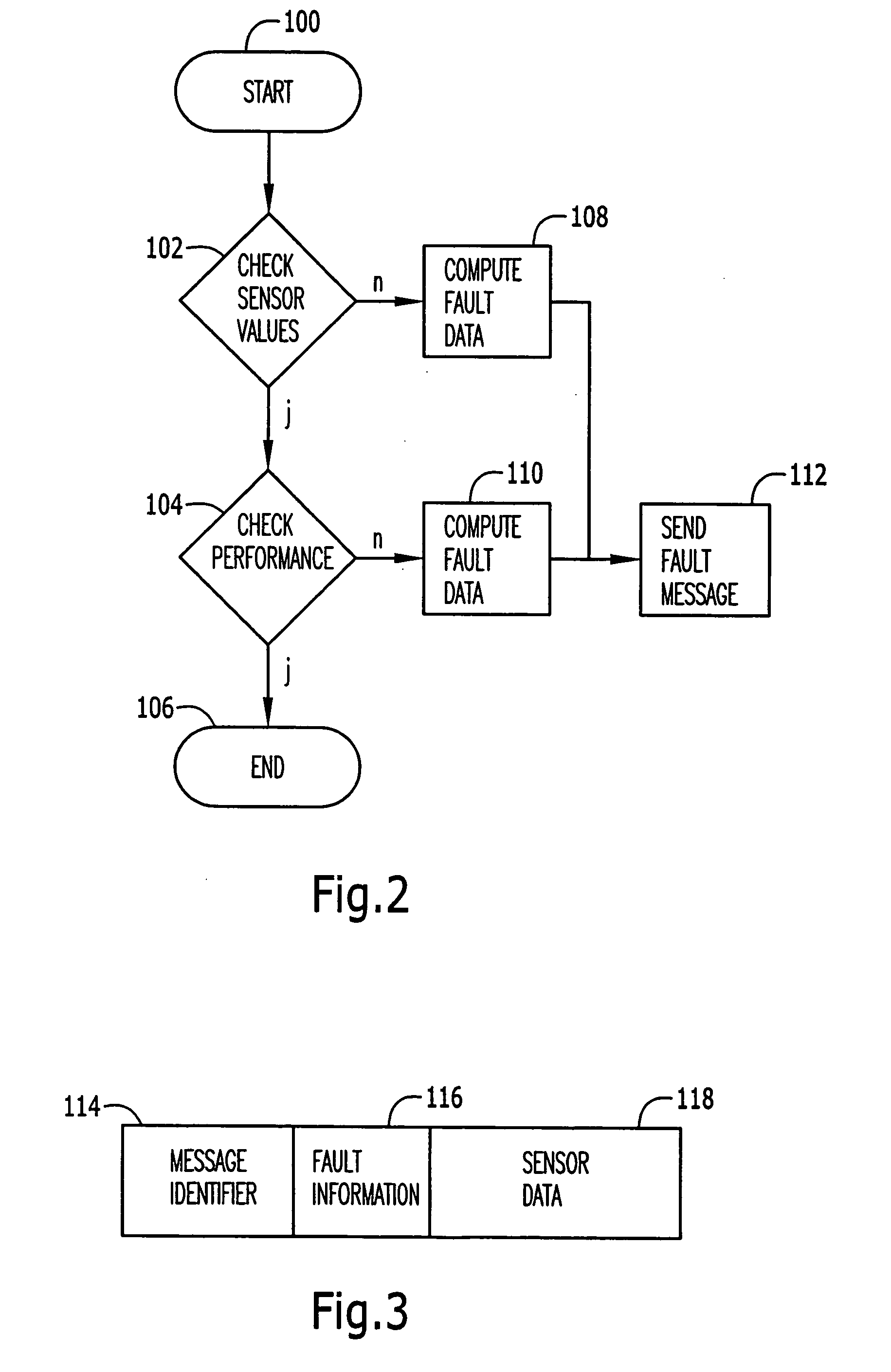

Method of monitoring equipment of an agricultural machine

InactiveUS20050096810A1Quick identificationAdd equipmentVehicle testingAgricultural machinesCommunication interfaceMonitor equipment

A method of monitoring equipment of an agricultural machine includes taking a process computer and connecting the same to at least one sensor measuring an operational characteristic of the agricultural machine. The process computer evaluates the data received from the sensor and checks whether they indicate a fault of the agricultural machine. In this case, the data may be below and / or above a predetermined threshold. When such as fault or error occurs, the process computer submits a fault message to a remote station using a communications interface. The fault message contains a fault information identifying a type of the fault.

Owner:DEERE & CO

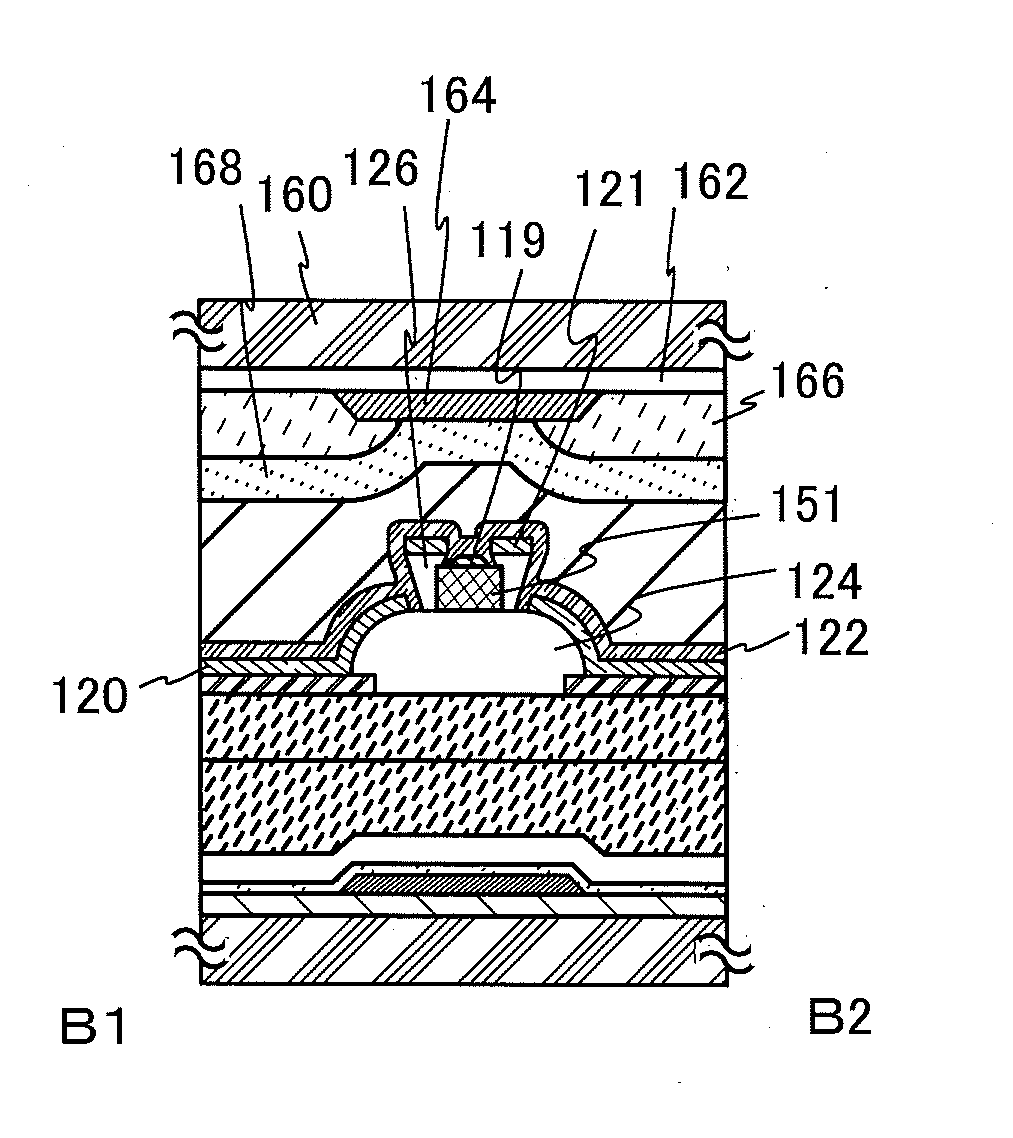

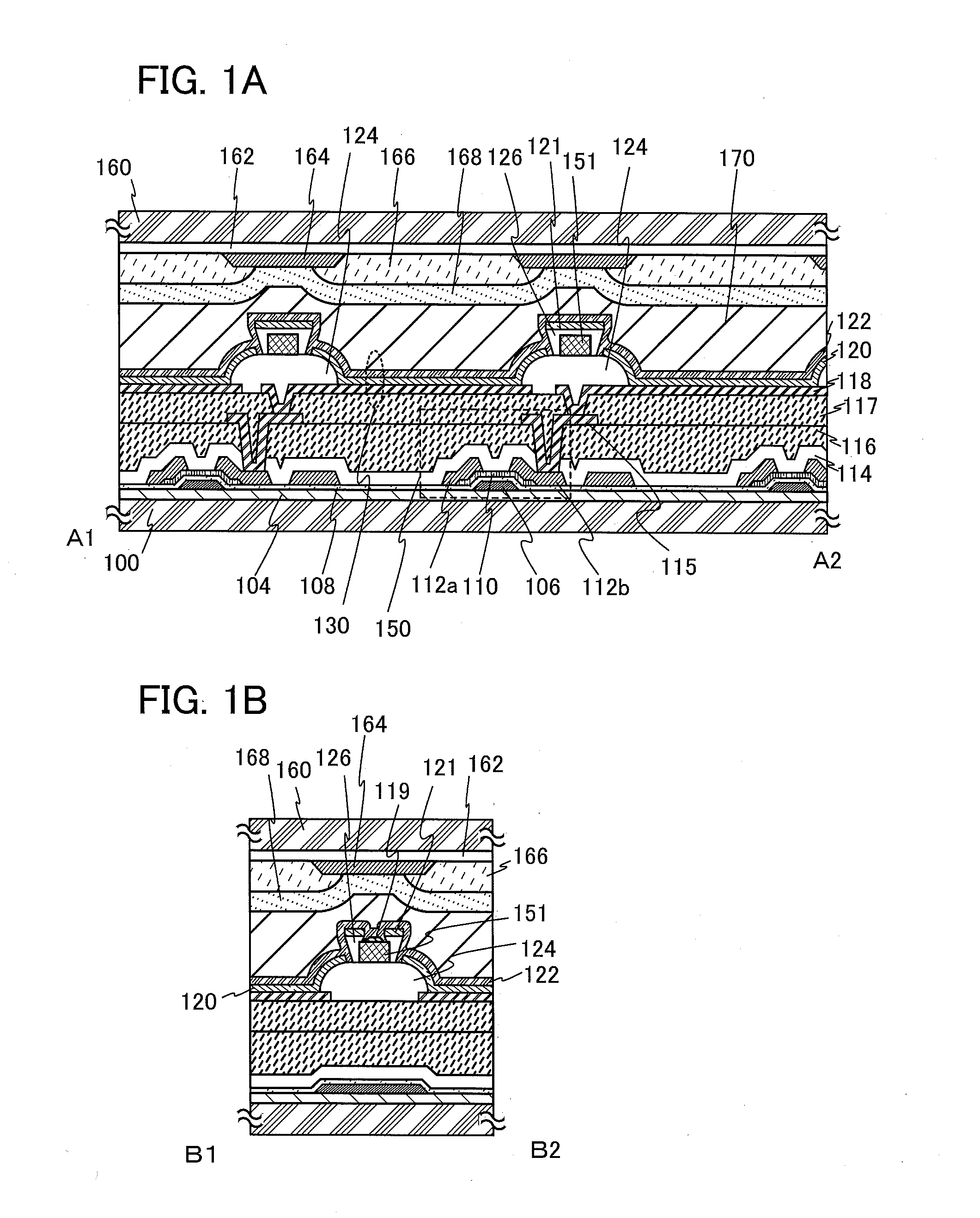

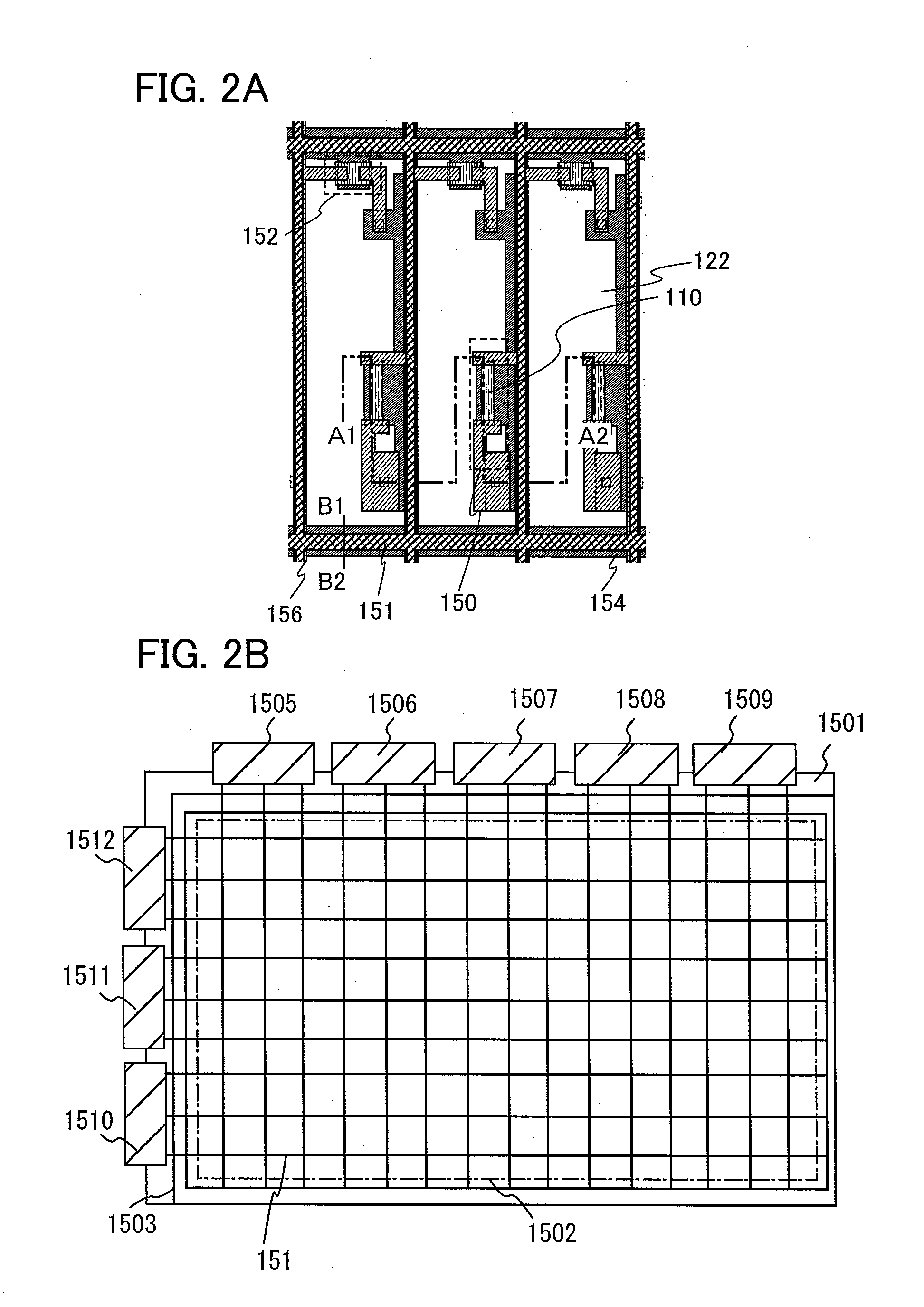

Display Device and Method for Manufacturing the Same

InactiveUS20130299791A1Increase the aperture ratioLarge-area displayElectroluminescent light sourcesSolid-state devicesDisplay deviceAuxiliary electrode

A structure of an EL display device which has an increased display area is provided. Further, a structure of an EL display device which has a high definition display is provided. An auxiliary electrode is formed over a first partition and side surfaces of the auxiliary electrode are covered with a second partition. A top surface of the auxiliary electrode is in contact with the conductive film which is one electrode of a light-emitting element and has a light-transmitting property, which enables a large-area display. Further, even the distance between the adjacent light-emitting elements is shortened, the auxiliary electrode can be provided between the adjacent light-emitting elements, which enables a high definition display.

Owner:SEMICON ENERGY LAB CO LTD

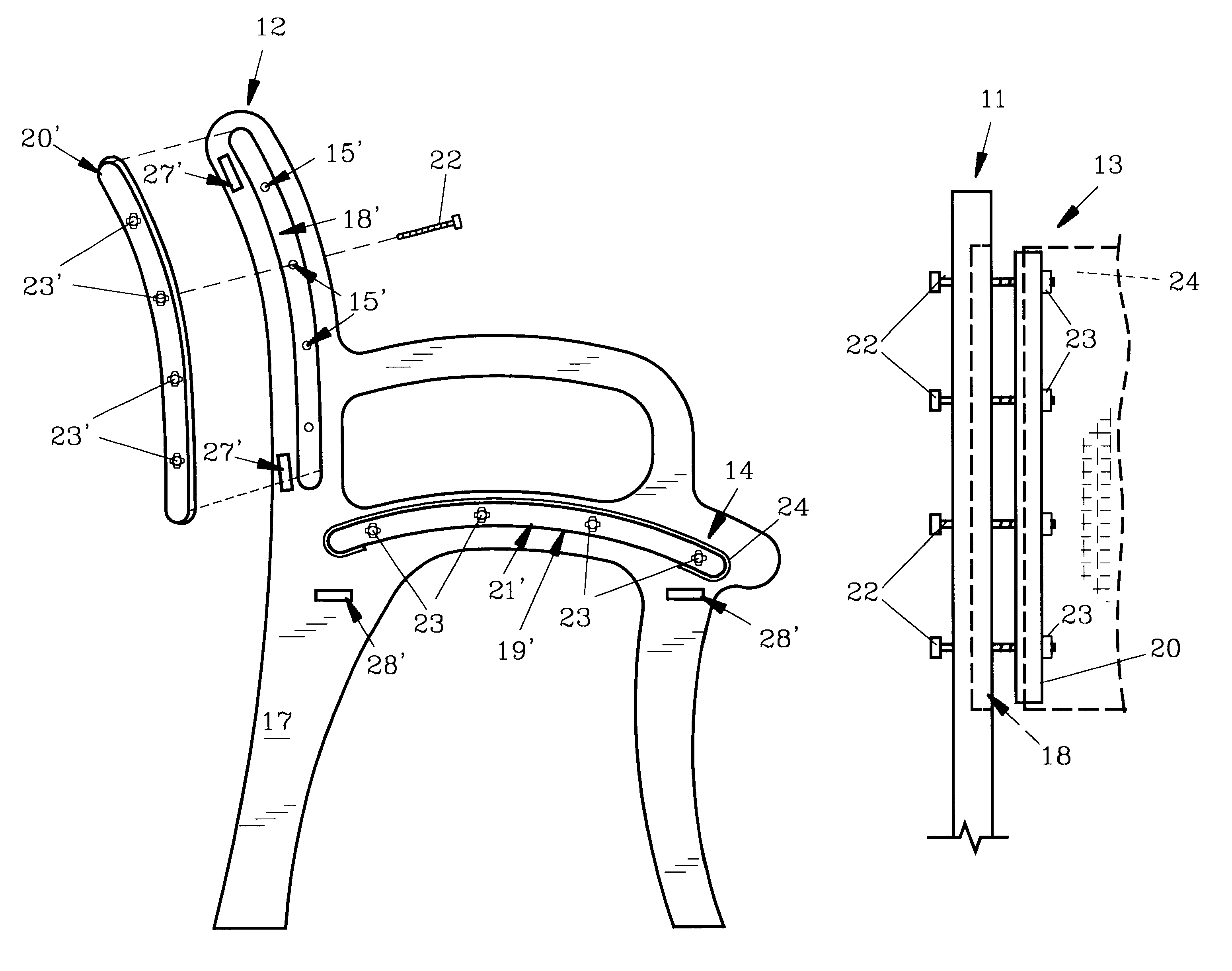

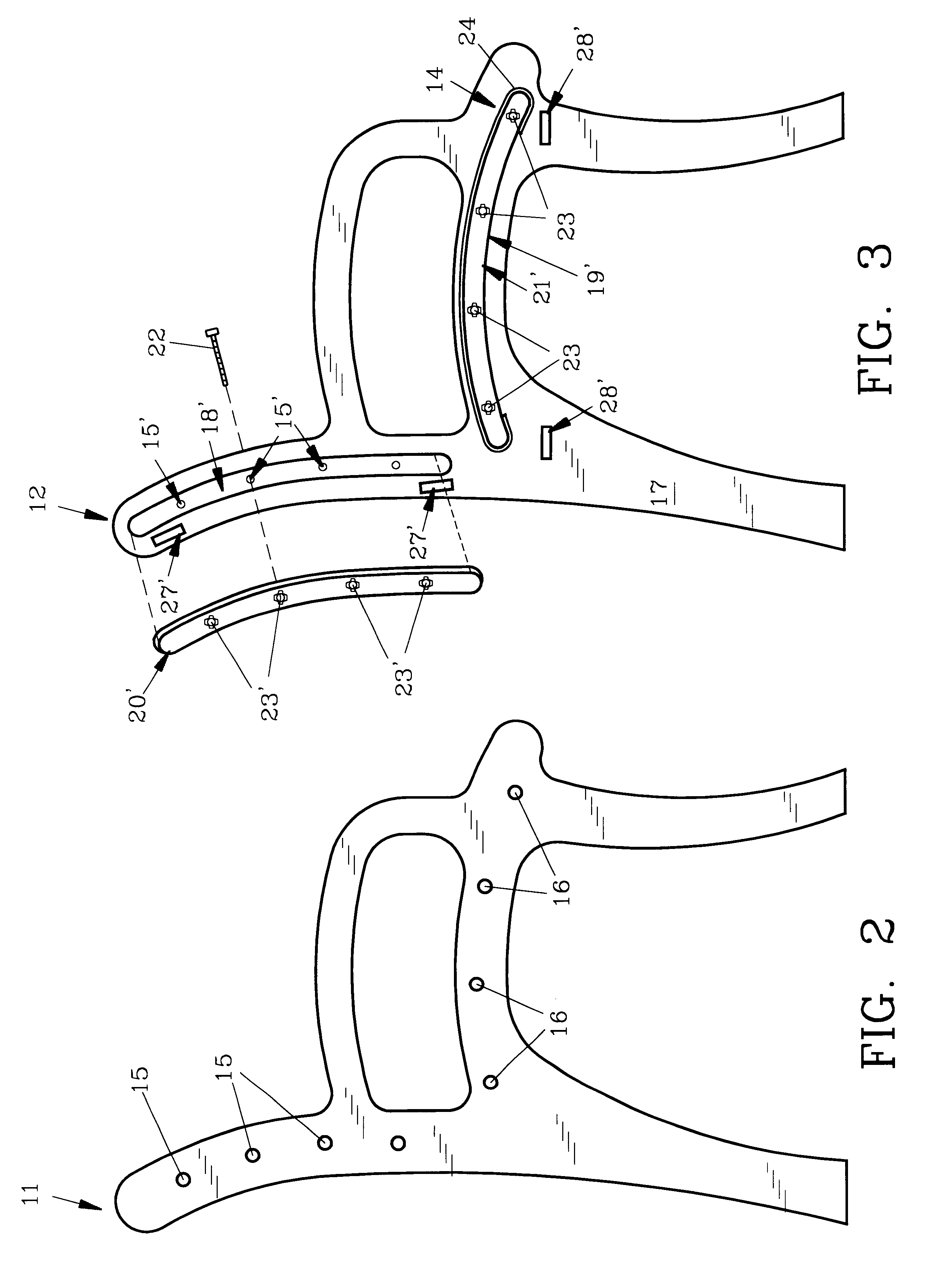

Furniture structure and method

A furniture structure and method are provided for chairs or other furniture as used in offices and homes. The structure provides an improved method of assembly using stretchable fabric spaced between opposing side frame members. Inserts attached to the fabric are used to selectively draw the fabric towards the side frames with threaded members so that a desirable tension can be applied to the fabric for comfort and aesthetic purposes. When worn the fabric can be easily replaced in the field by unskilled consumers.

Owner:TORNERO MARTA V

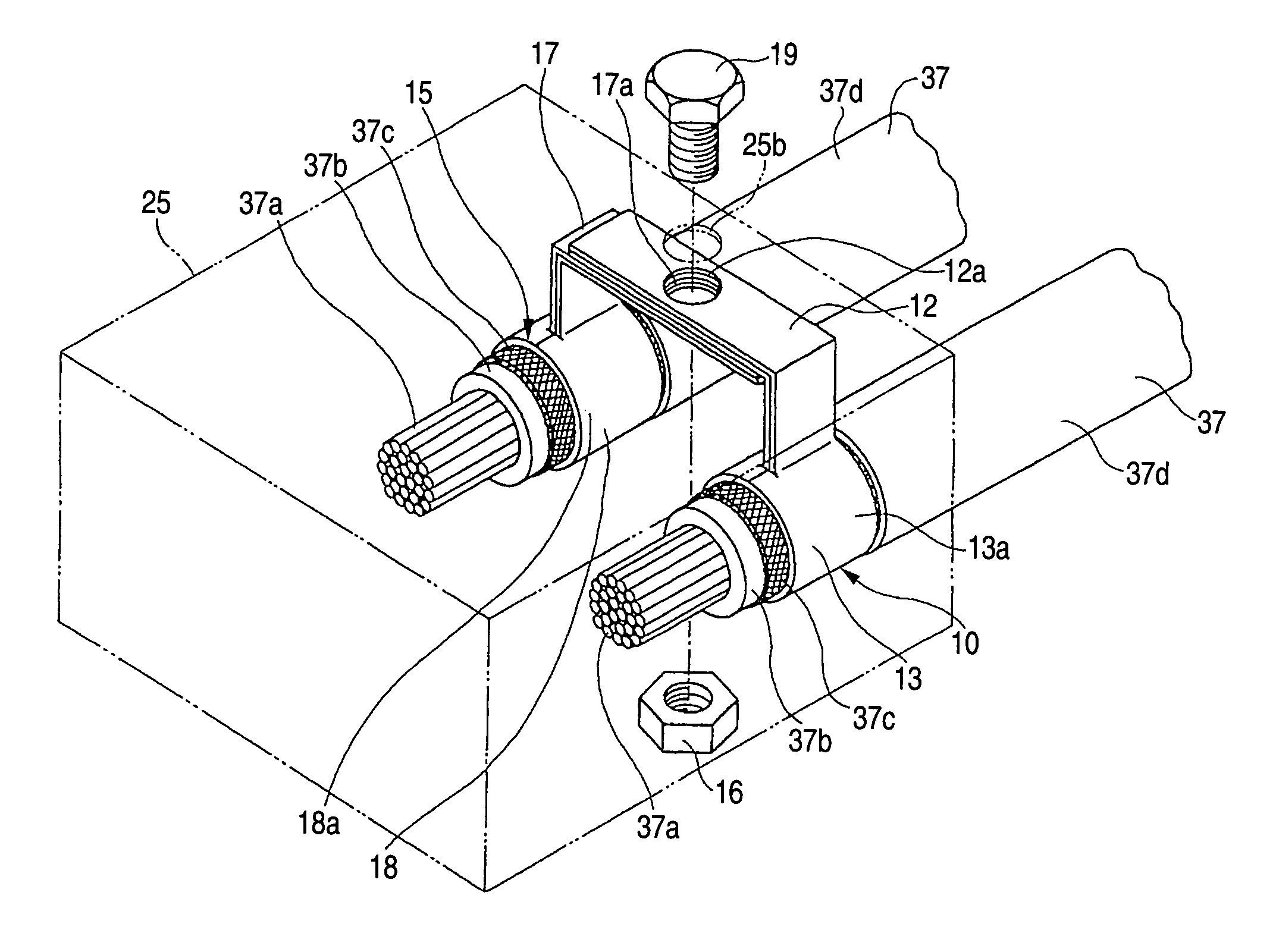

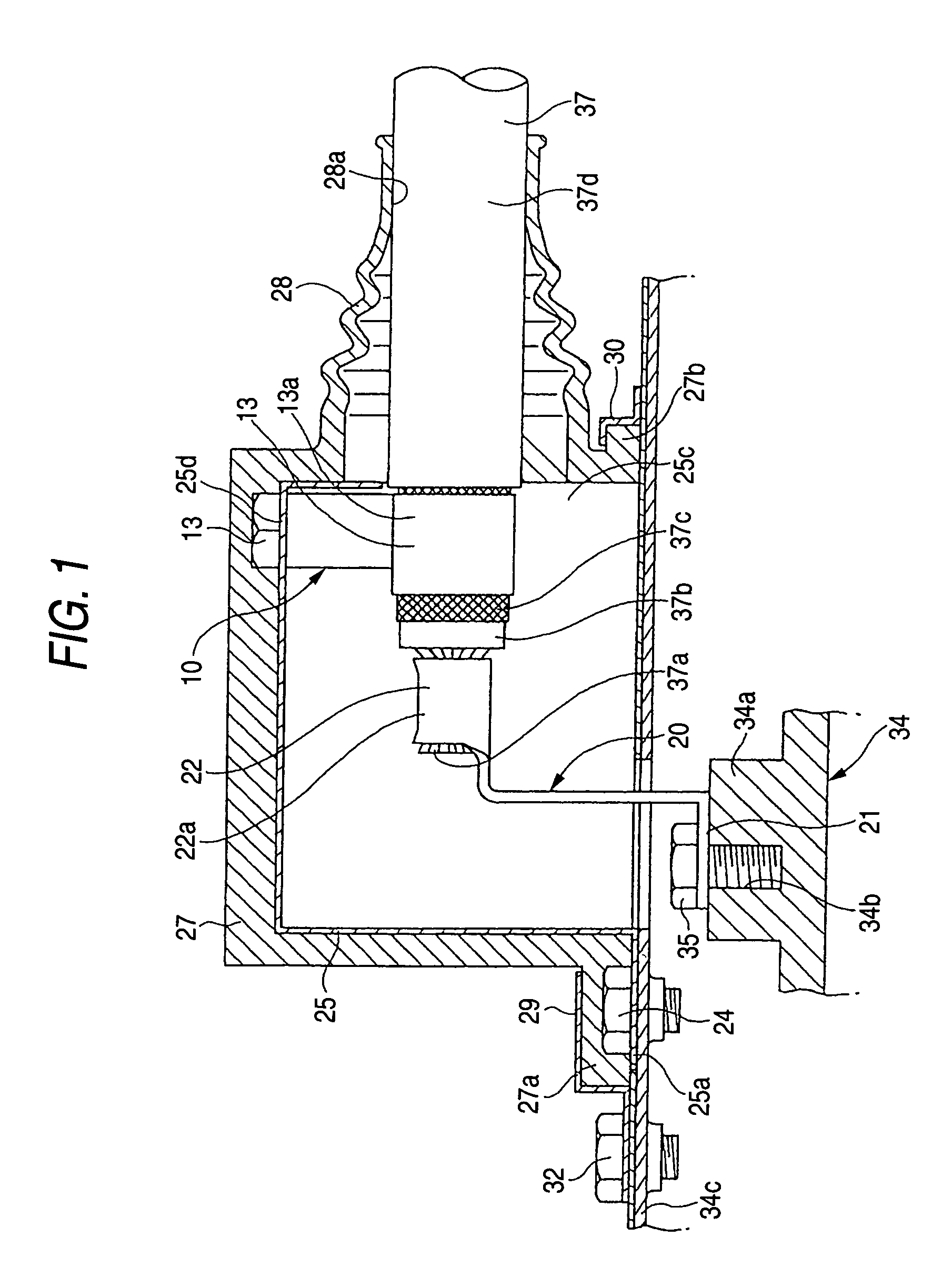

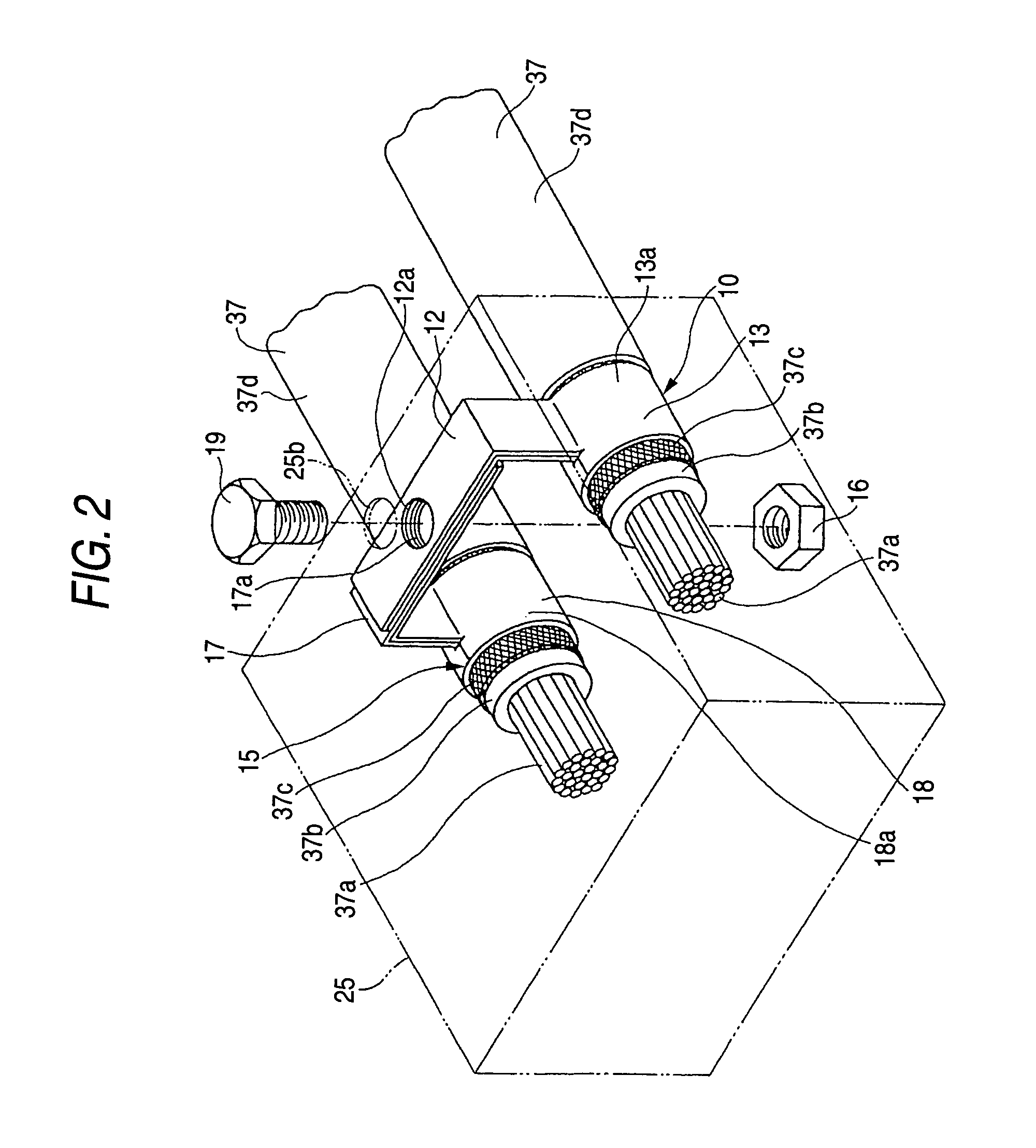

Shielded wire-connecting structure

InactiveUS6991493B2Waterproof performance of a connected portionAdd equipmentCouplings bases/casesConnections effected by permanent deformationEngineeringMechanical engineering

Owner:YAZAKI CORP

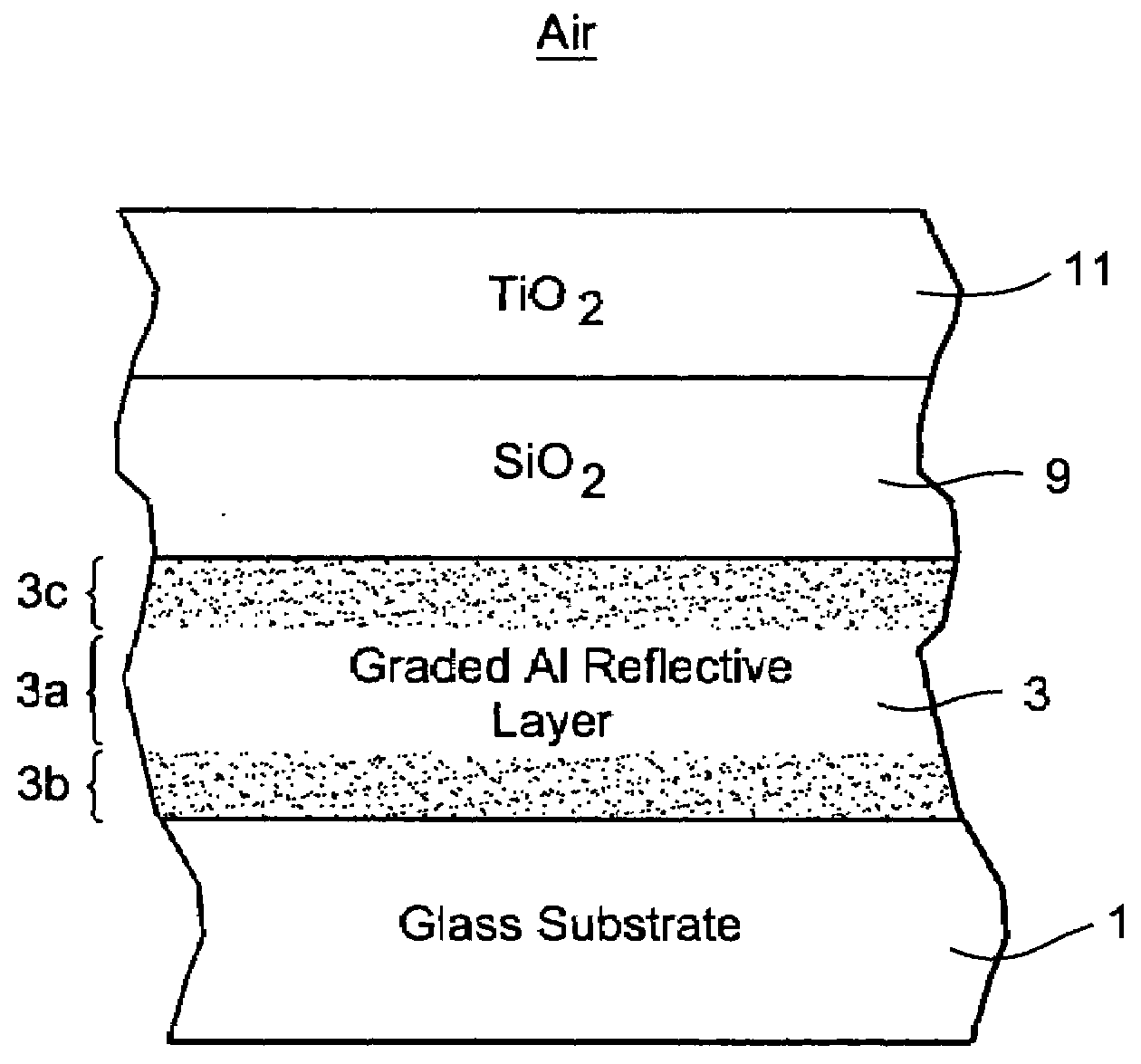

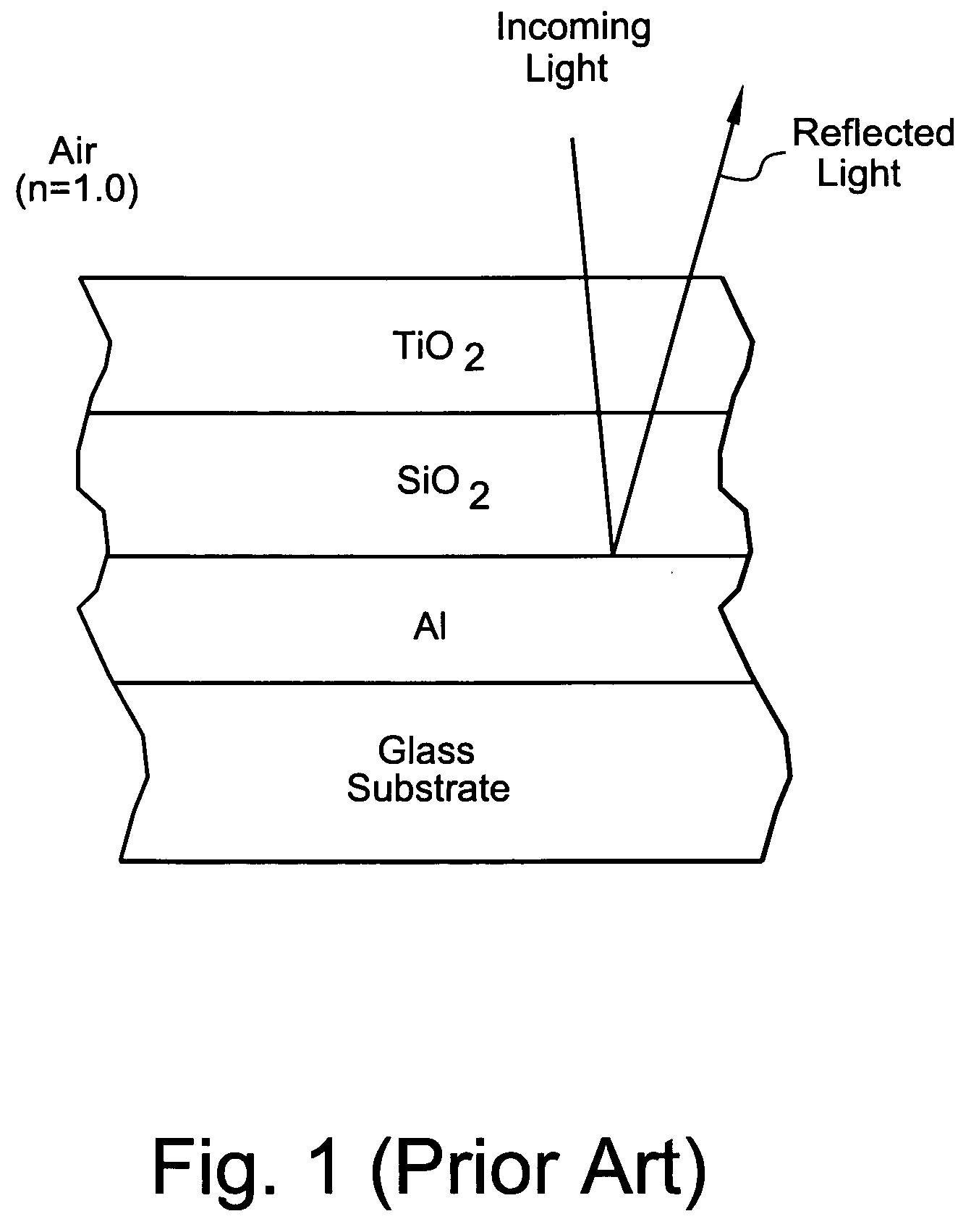

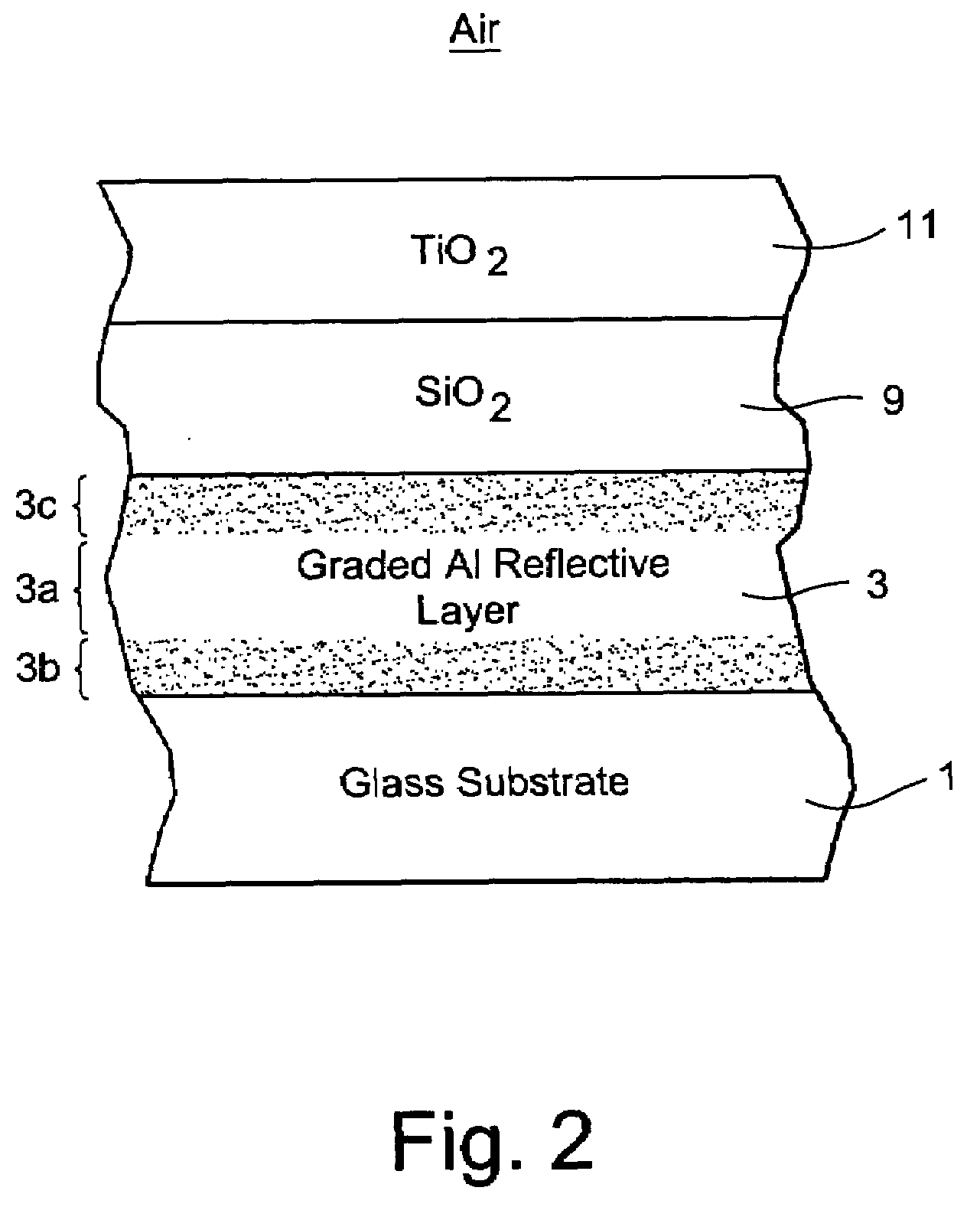

Method of making first surface mirror with oxide graded reflecting layer structure

InactiveUS20080073203A1Increased durabilityImprove manufacturabilityVacuum evaporation coatingSputtering coatingPartial reflectionMetal

A method of making a mirror such as a first-surface mirror (FSM) is provided. The mirror includes a reflecting layer structure made of a visible light reflecting material such as aluminum (Al) or the like. At least part of the reflecting layer structure is oxide graded, continuously or discontinuously, so as be more oxided at one or both sides of the layer structure. In other words, the reflecting layer structure is more or entirely metallic at a central portion thereof, and more oxided at the top and / or bottom side(s) thereof. In certain example embodiments, such first surface mirrors may be used in the context of projection televisions, or in any other suitable application.

Owner:GUARDIAN IND CORP

Sonotrode and anvil energy director grids for narrow/complex ultrasonic welds of improved durability

InactiveUS20120097339A1Great durabilityLess packaging materialLaminationLamination apparatusMesh gridEngineering

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

Preparation method of solvent-free sofa furniture microfiber synthetic leather

InactiveCN106381721AStrong leather effectResistant to hydrolysisFurniture partsPolyurea/polyurethane coatingsCarbon compositesSurface layer

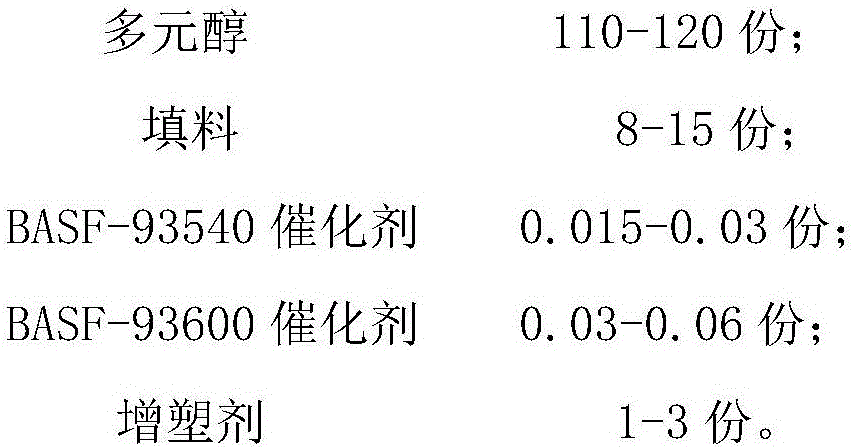

The invention discloses a preparation method of solvent-free sofa furniture microfiber synthetic leather, and is characterized in that an environmental-protection type polyether polymeric carbon composite type polyurethane resin is selected as a dry surface layer and a middle layer, a solvent-free layer is a foaming adhesive layer, a microfiber cloth base cloth pasted by a whole dry process and having good hand feeling and high chemical properties is selected for preparing the environmental-protection type sofa furniture leather having the excellent properties of strong real leather effect feeling, three-dimensional and full pattern, abrasion resistance, scratch resistance, hydrolysis resistance and the like; the solvent-free foaming layer is two-liquid type double-compound polyurethane and is composed of an isocyanate A component and a polyether polyol B component. The prepared solvent-free environmental-protection type sofa furniture leather has the advantages of simple leather preparation process, high efficiency and environmental protection, also has the characteristics of strong real leather effect feeling, three-dimensional and full pattern, full and soft hand feeling, wear resistance (wyzenbeek 400 thousand times), scratch resistance, hydrolysis resistance (8 years) and other high physical properties.

Owner:ANHUI ANLI MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com