Patents

Literature

520results about "Refining by water treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

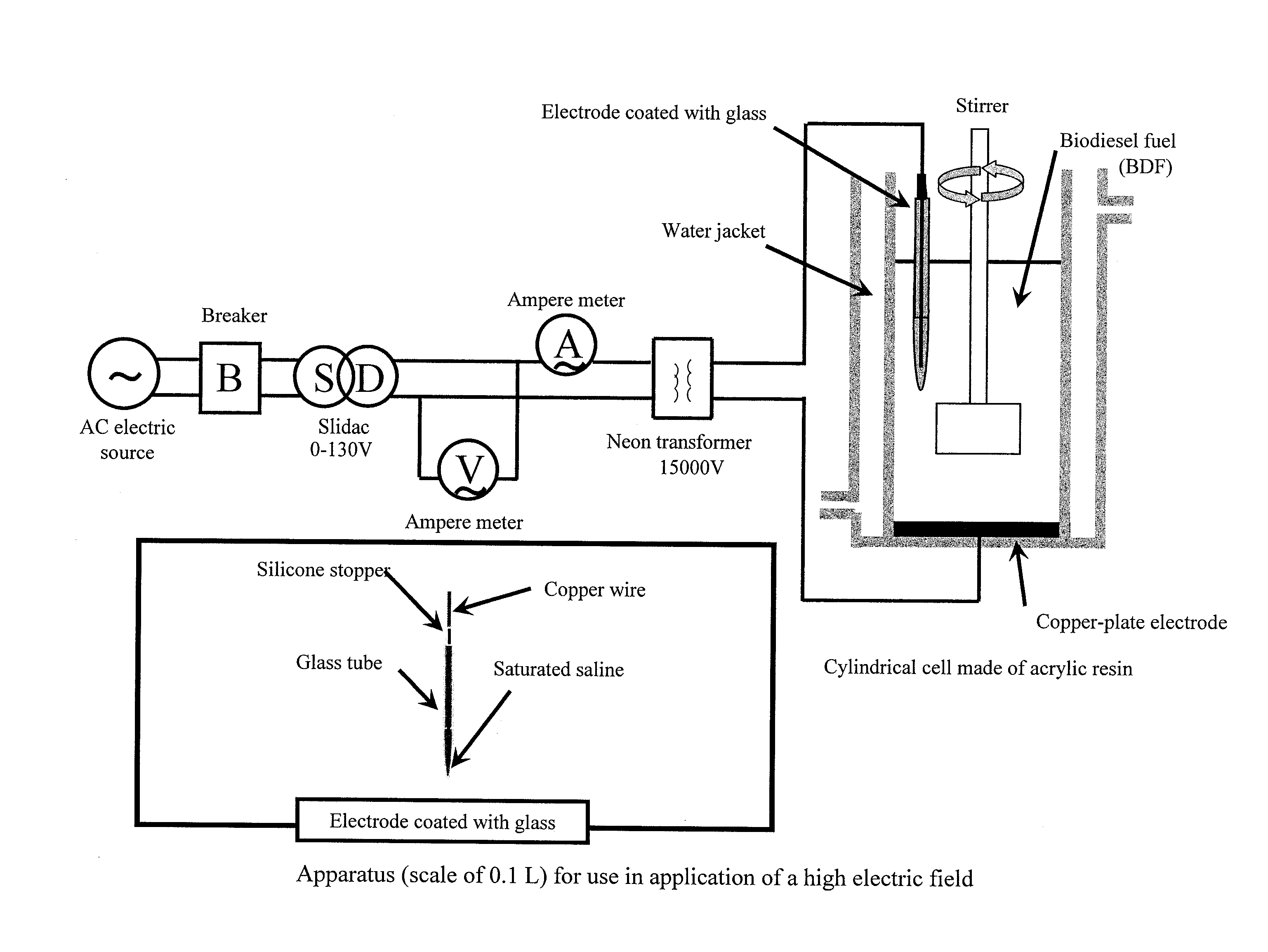

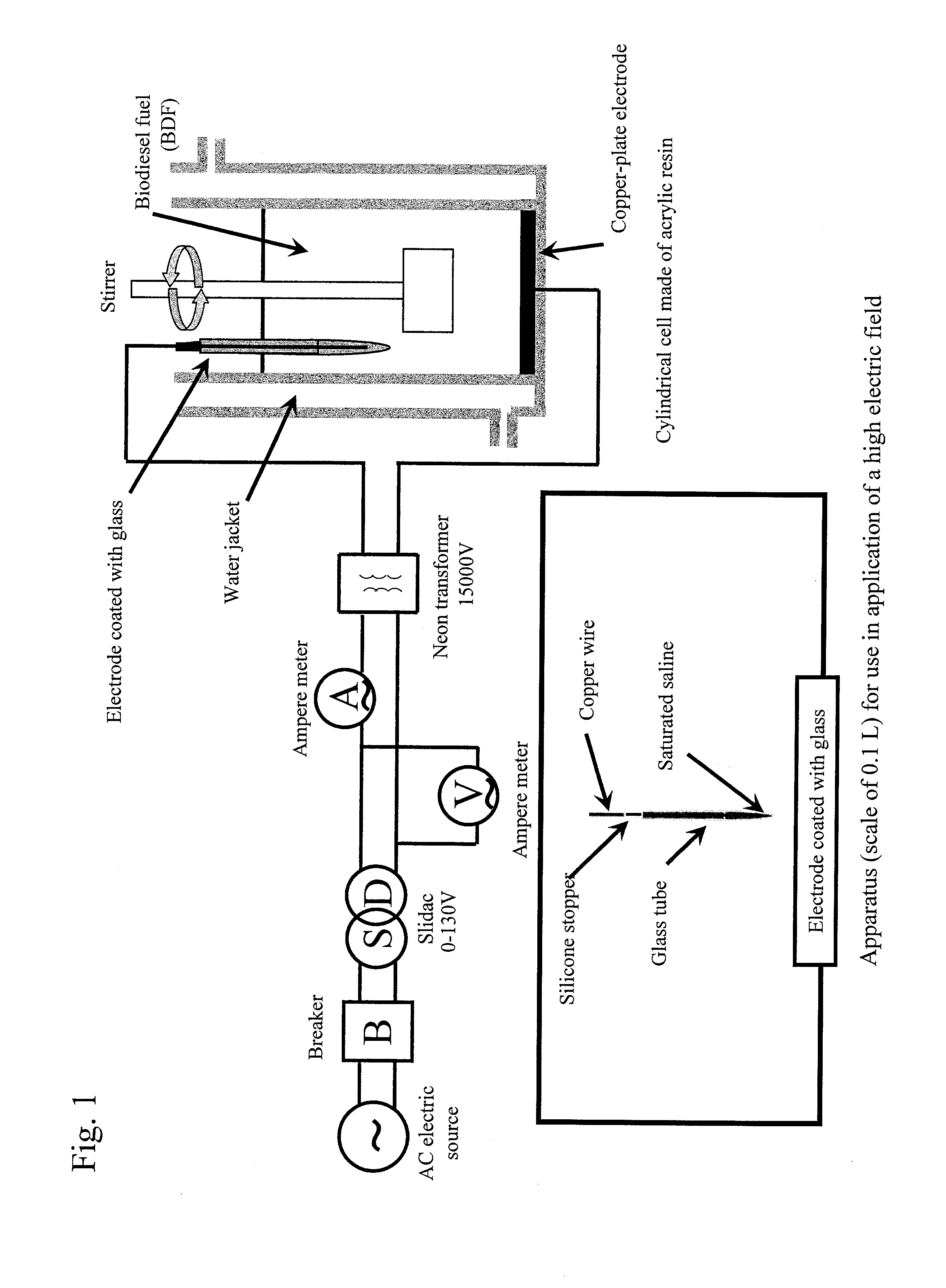

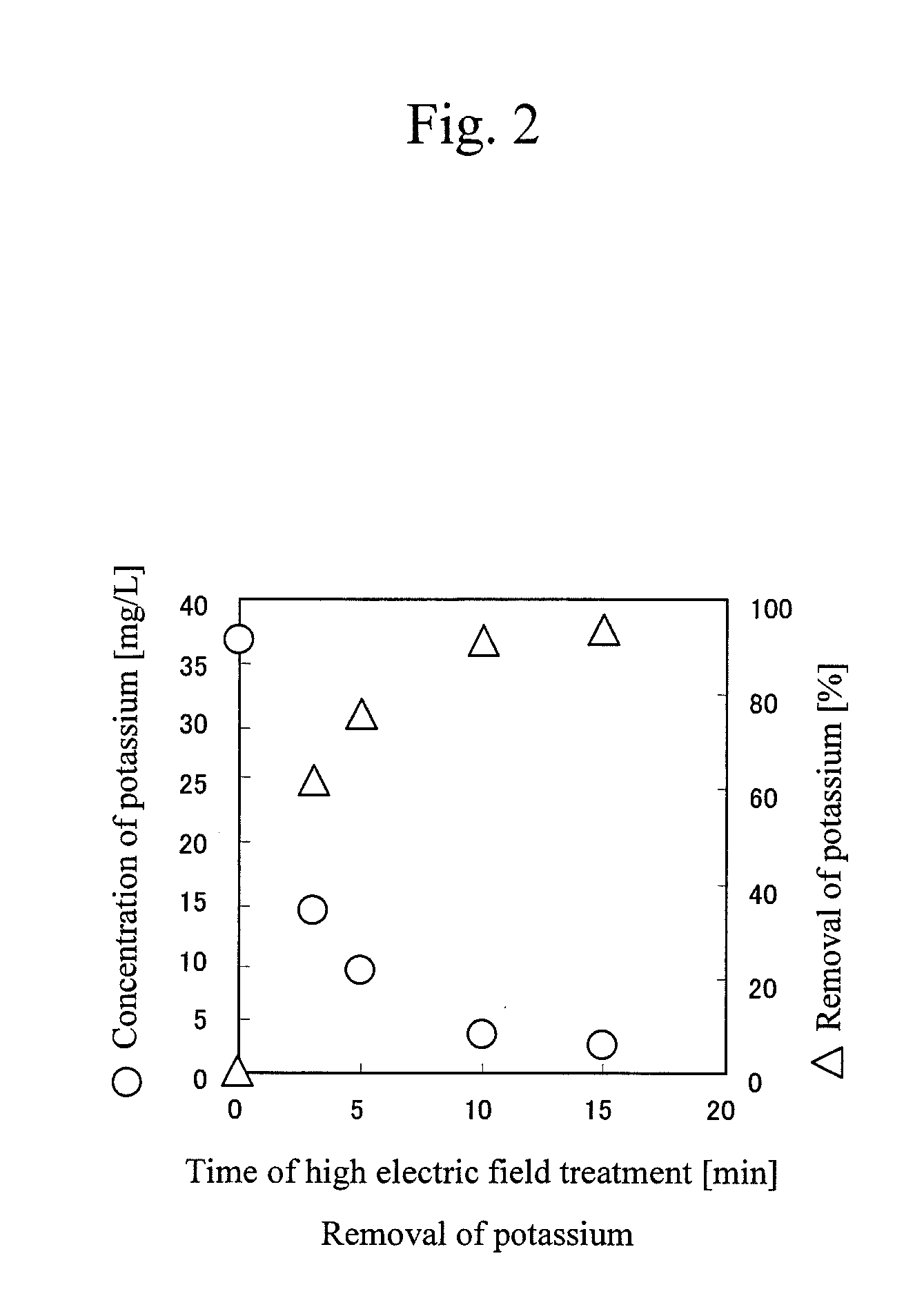

Method for purifying biodiesel fuel

InactiveUS20090025277A1Preventing and greatly reducing generationWater/sewage treatment by irradiationLiquid separation by electricityDemulsifierBiodiesel

Provided is a method for purifying a biodiesel fuel while completely preventing or greatly reducing generation of waste water. The present invention relates to a method for purifying a biodiesel fuel characterized by applying an electric field to or heating a crude biodiesel fuel and a method for purifying a biodiesel fuel characterized by adding water (preferably containing a demulsifier such as an inorganic calcium salt or a magnesium salt) to a crude biodiesel fuel to form W / O emulsion, and breaking the emulsion by application of an electric field or heating, etc.

Owner:KAGOSHIMA UNIV

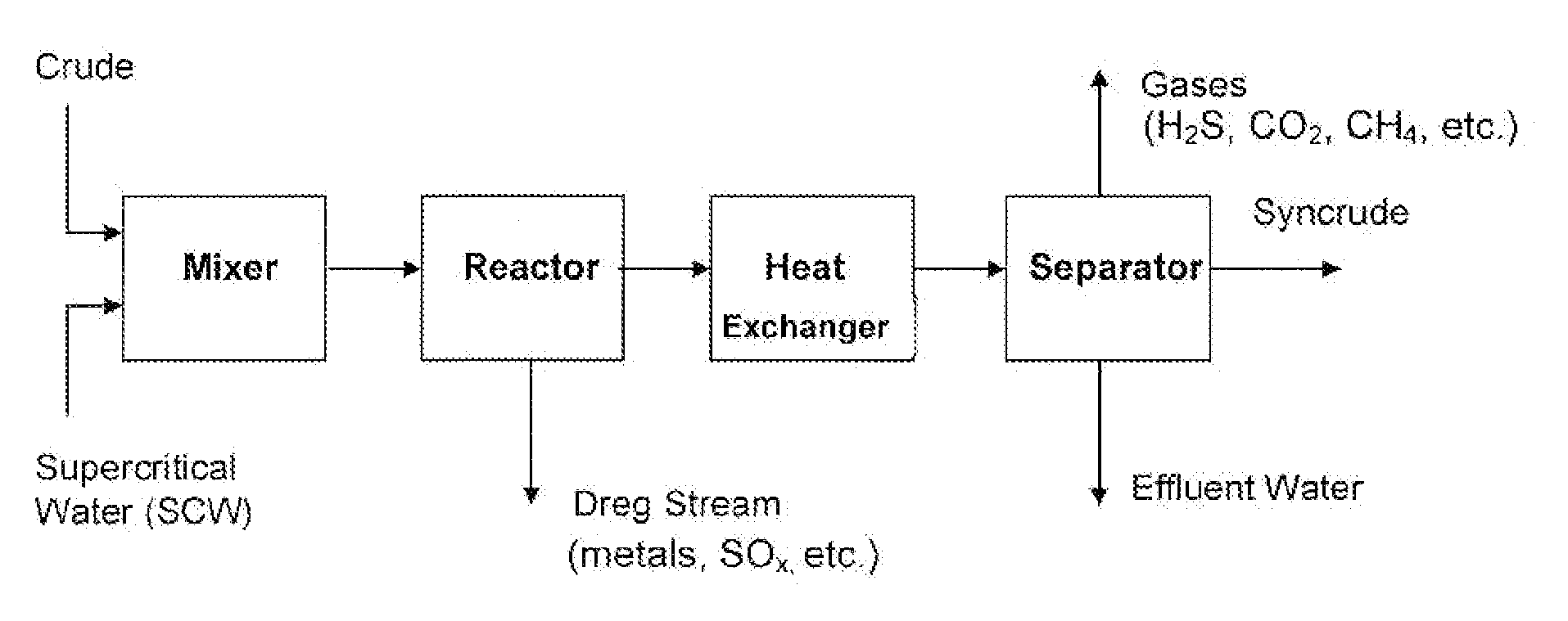

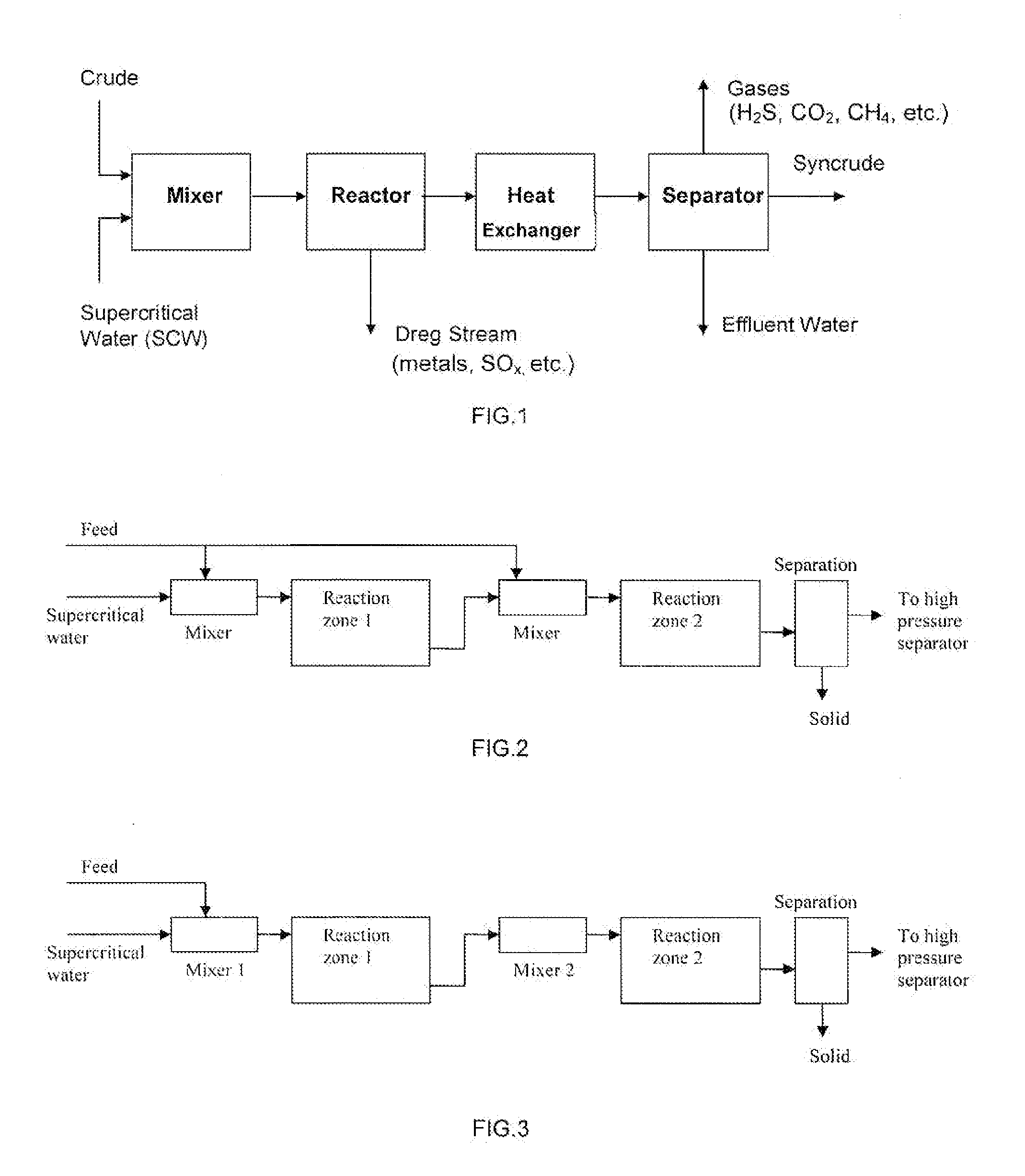

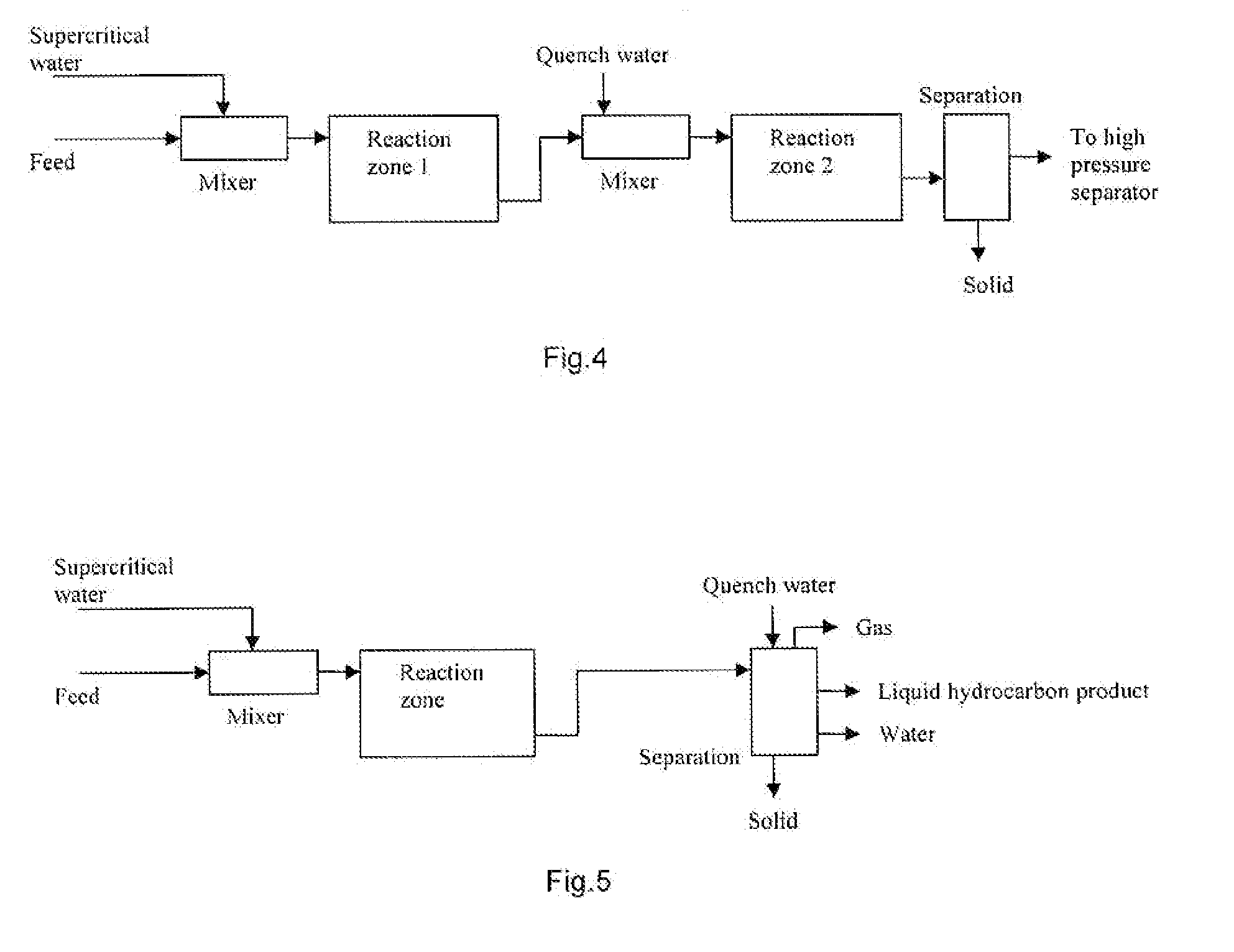

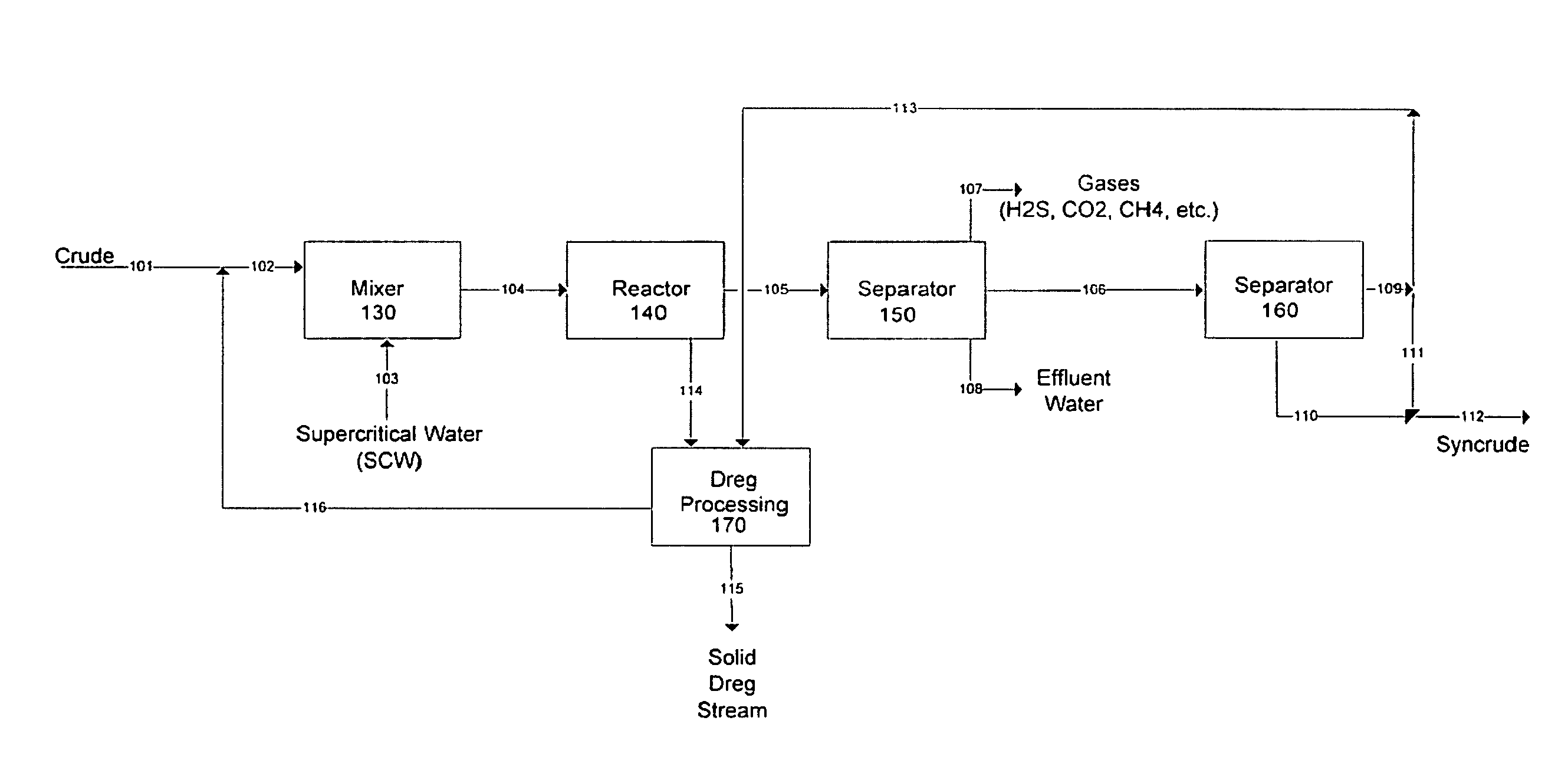

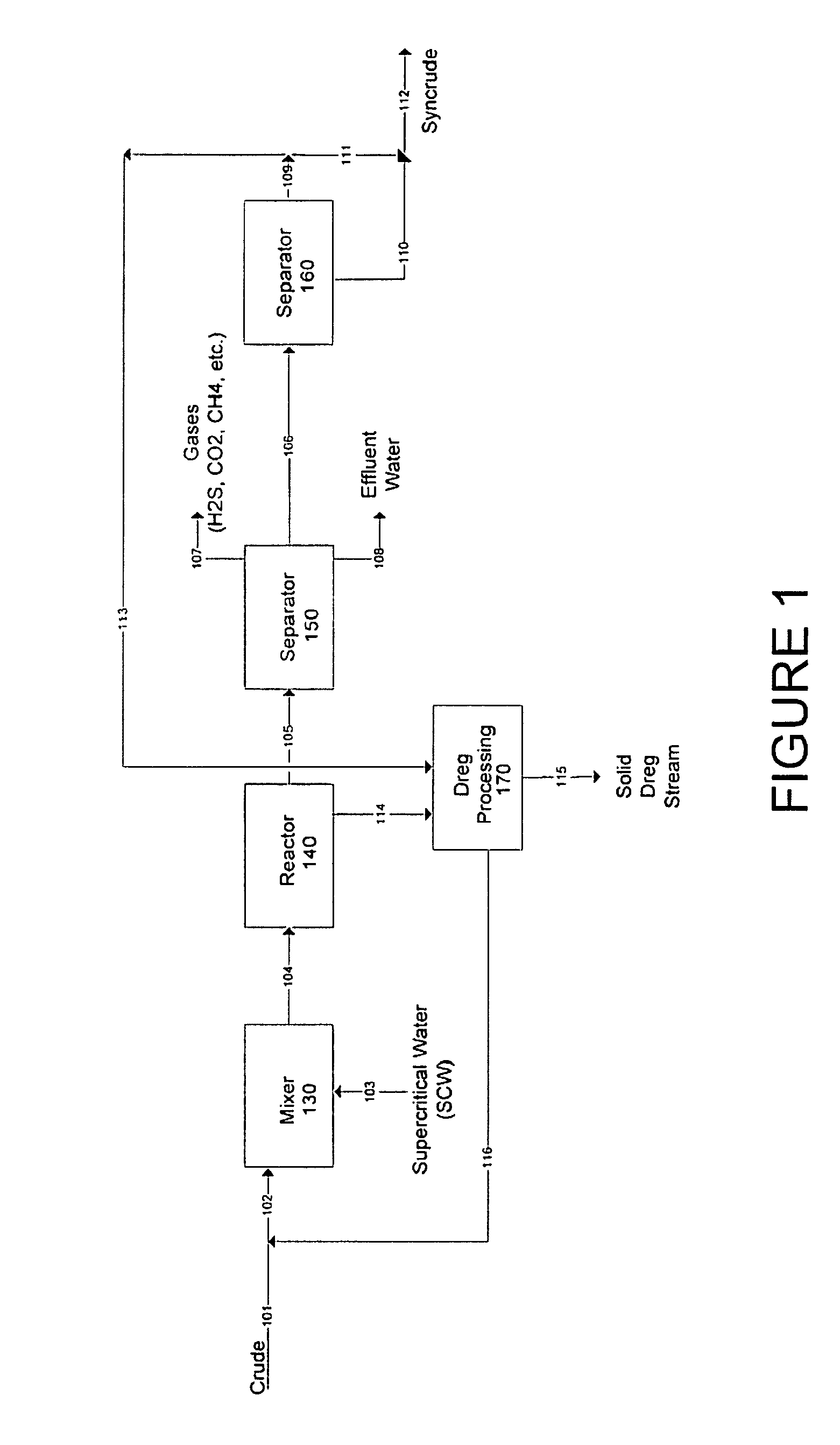

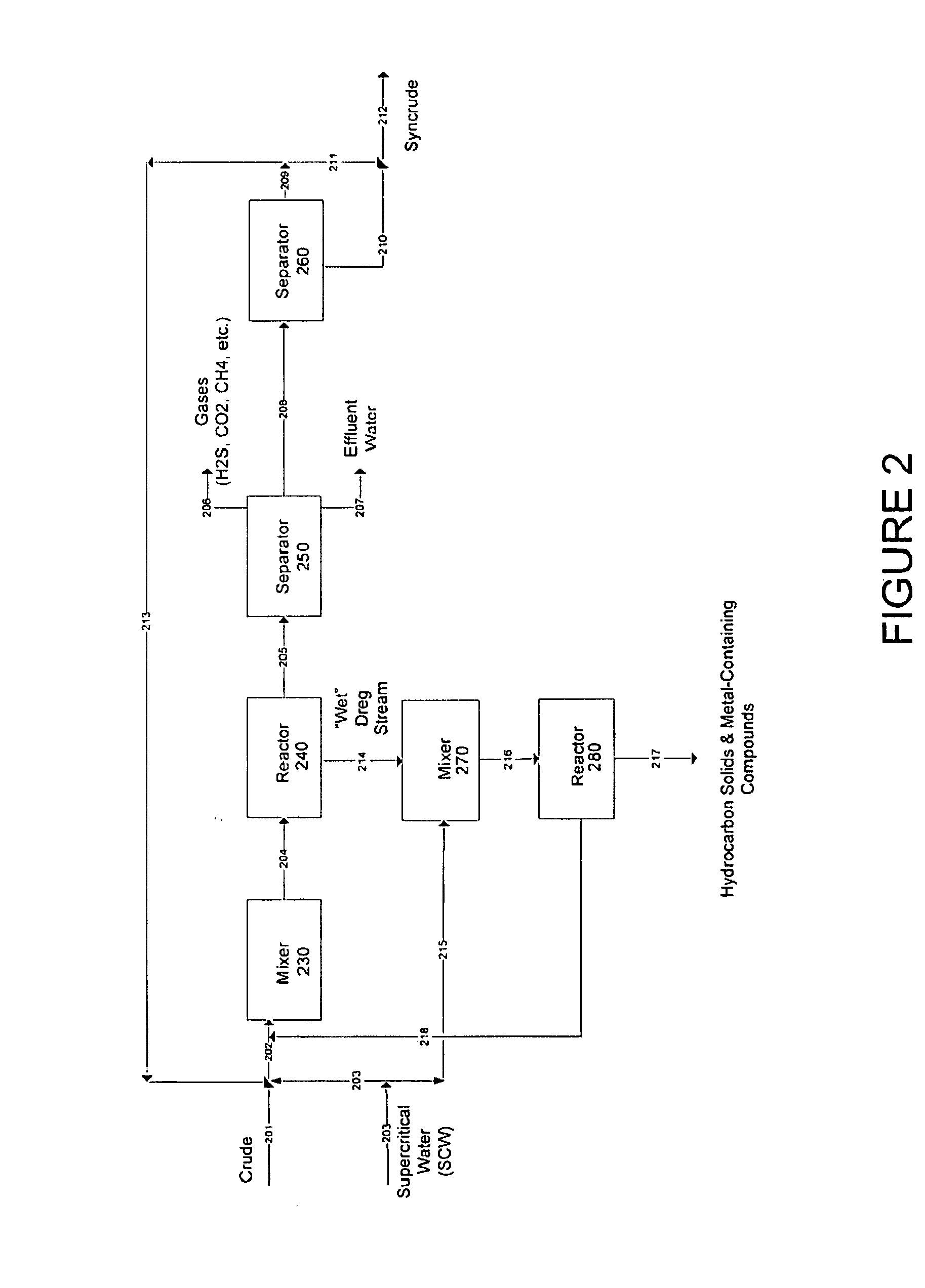

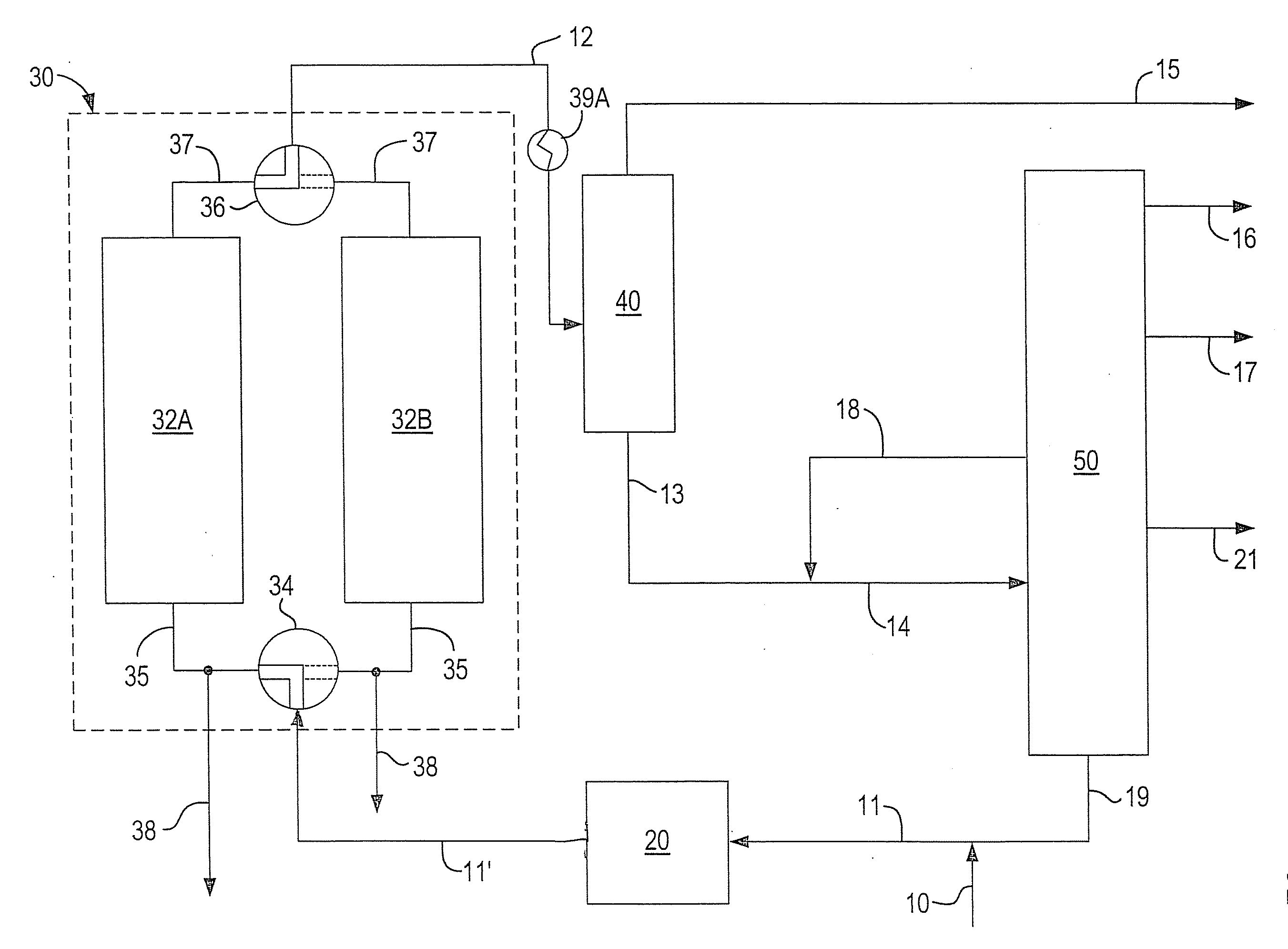

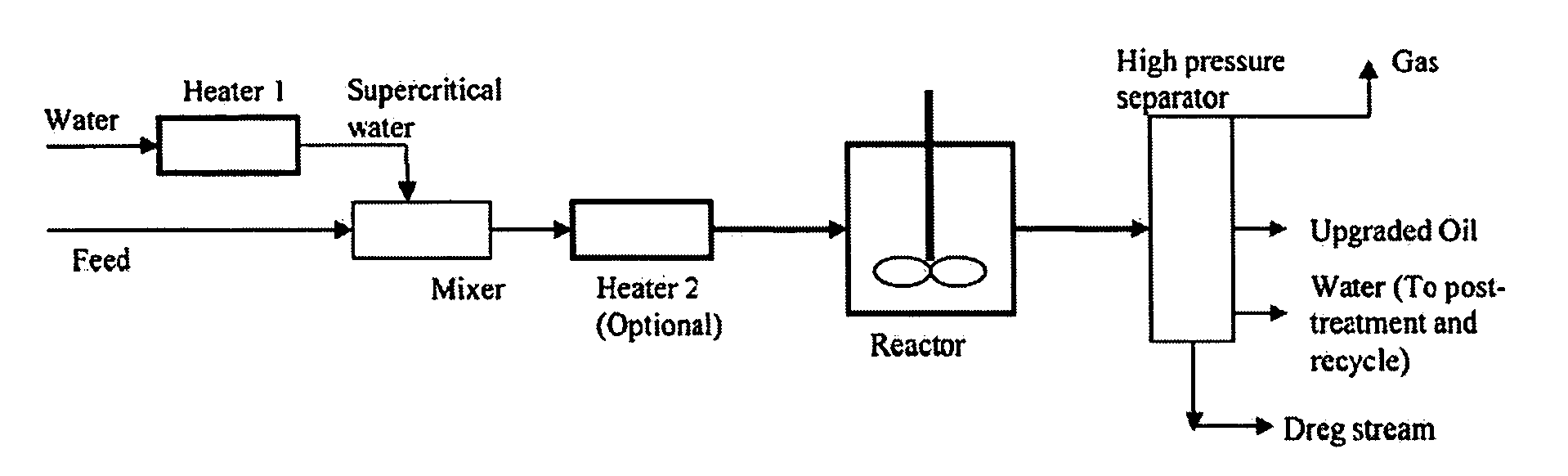

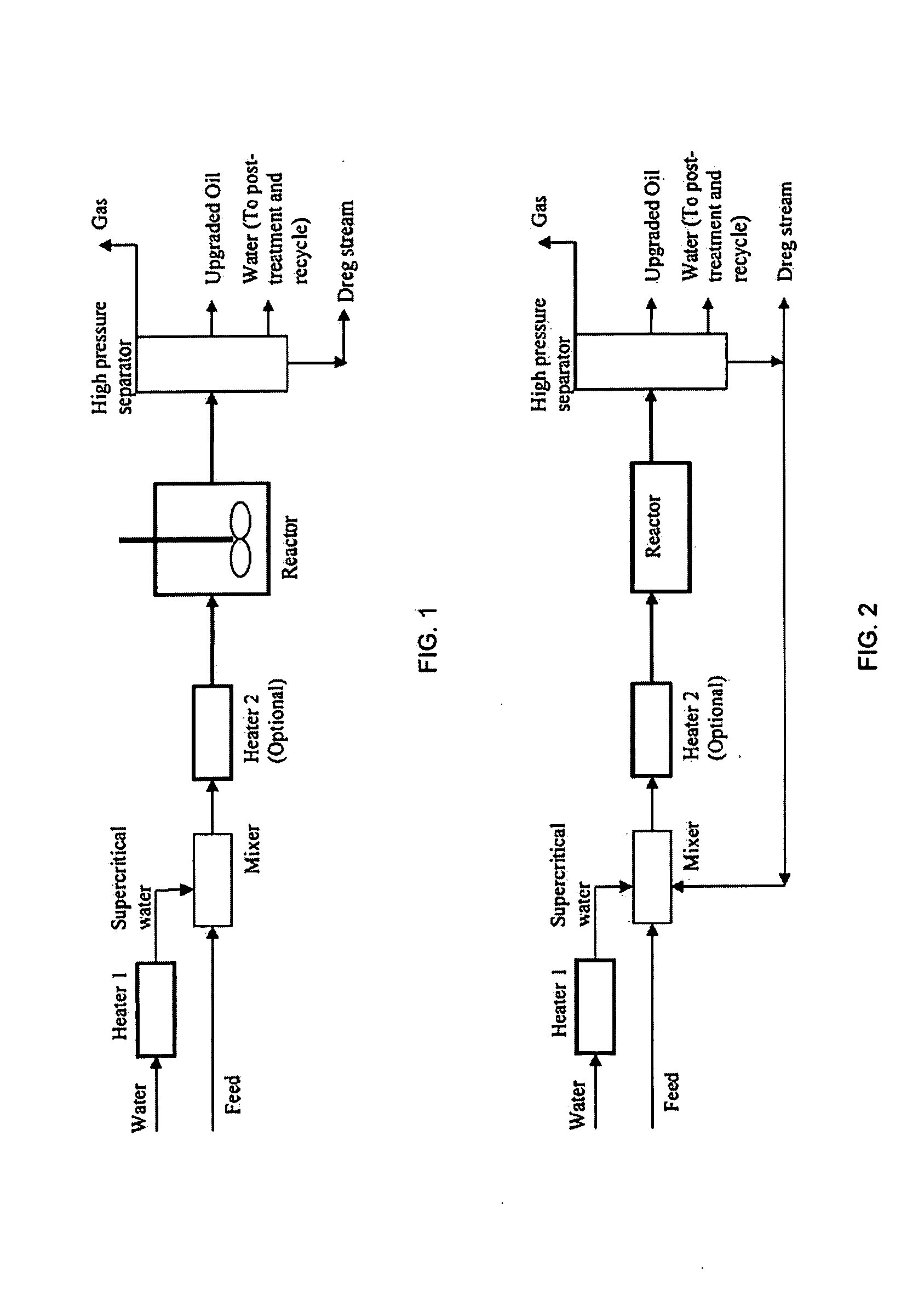

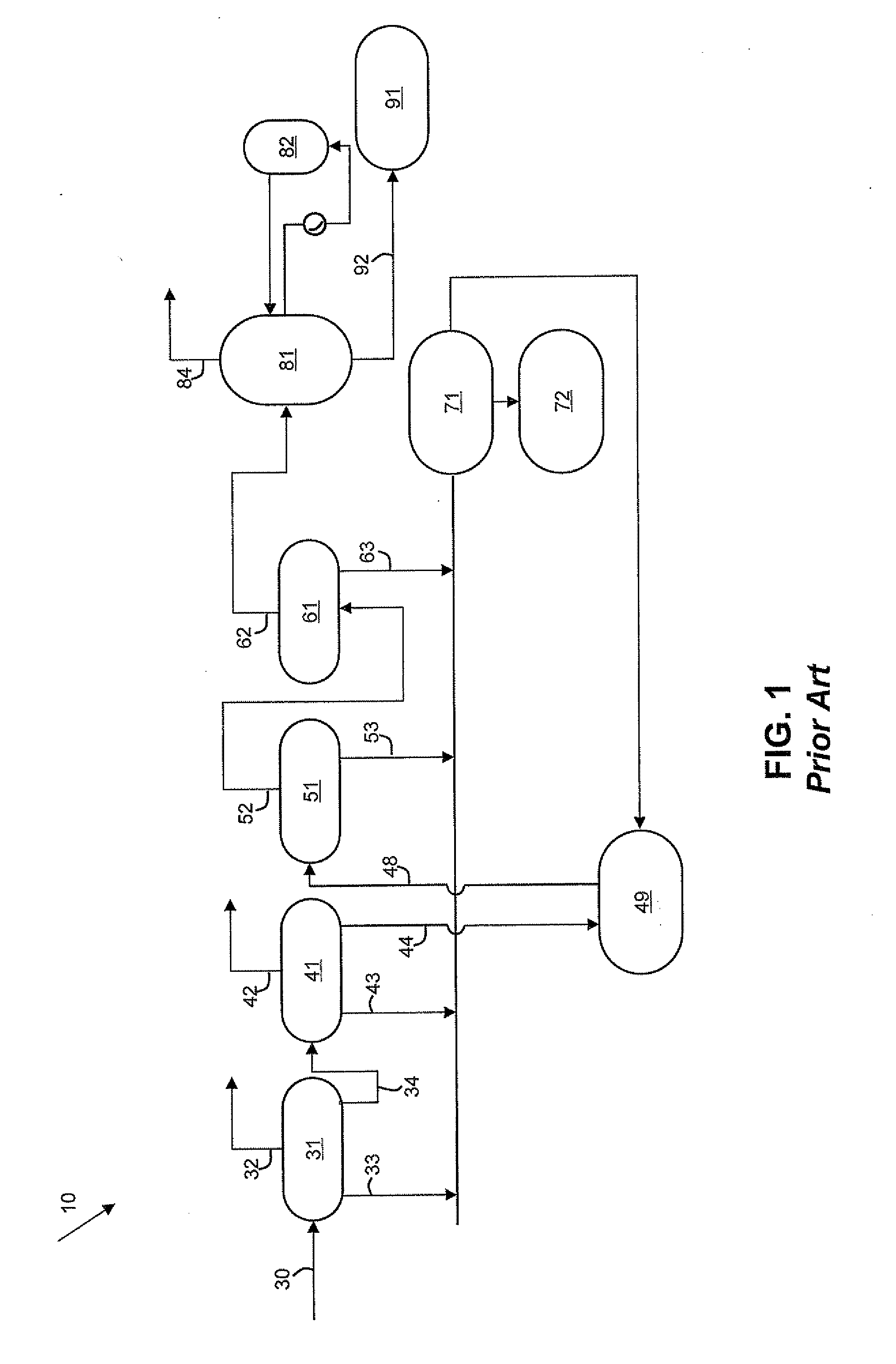

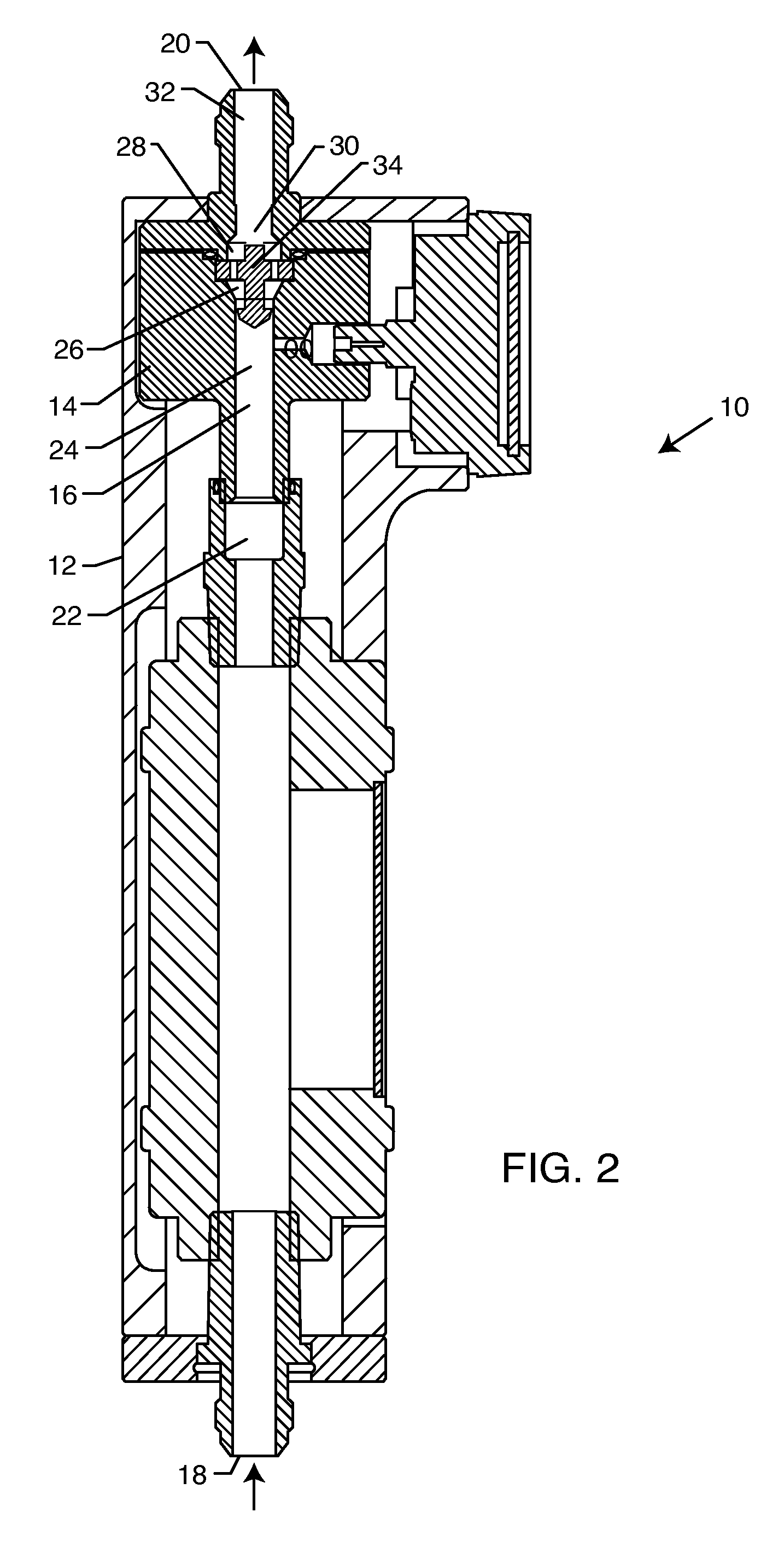

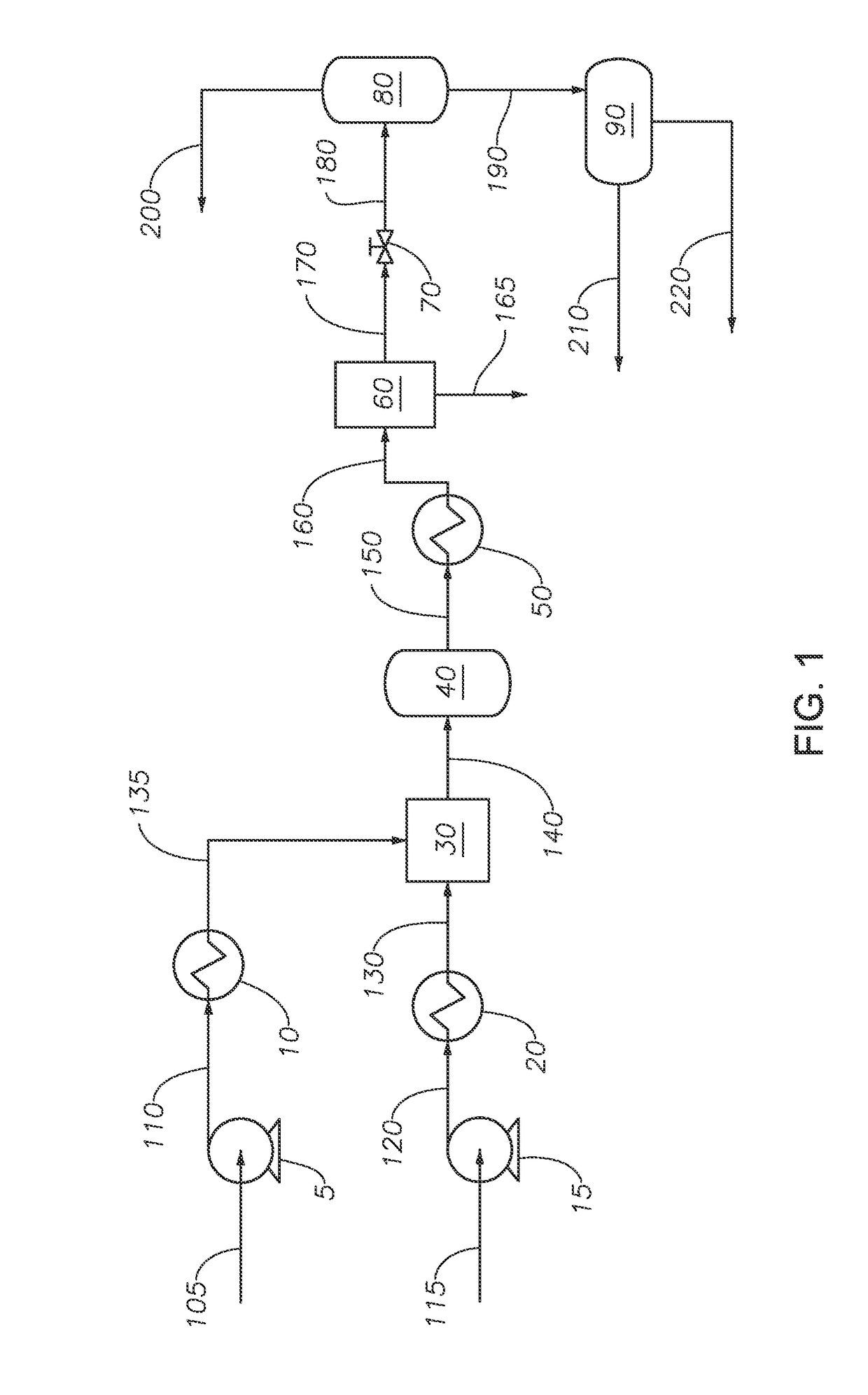

Reactor and process for upgrading heavy hydrocarbon oils

InactiveUS20080099374A1Prevent subsidenceRefining by water treatmentFeed devicesMomentumVolumetric Mass Density

A reactor for conducting a process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is described. The reactor is operable under continuous) semi-continuous or batch mode and is equipped with means to enable momentum, heat and mass transfer in and out of and within the reactor.

Owner:CHEVROU USA INC

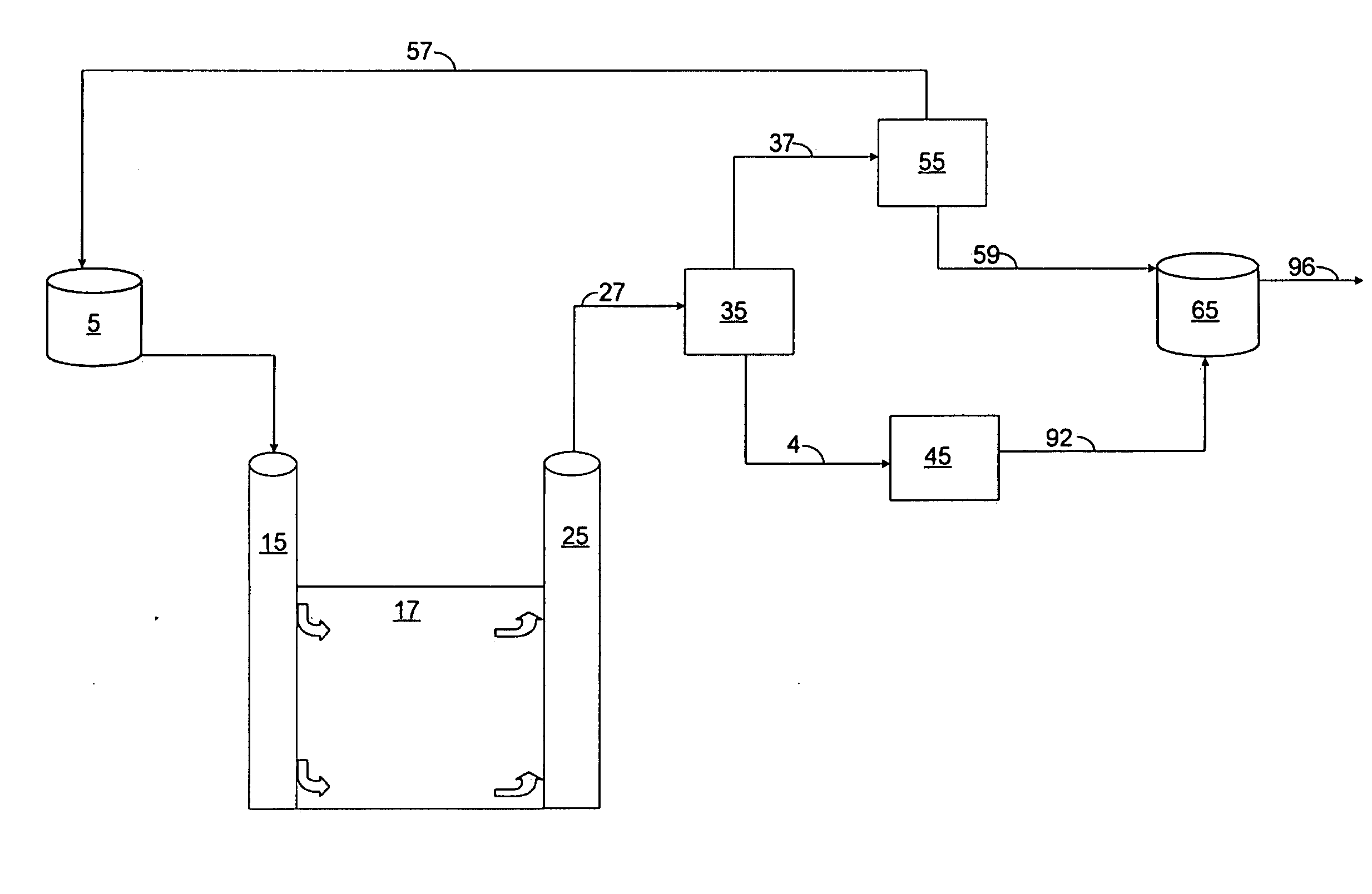

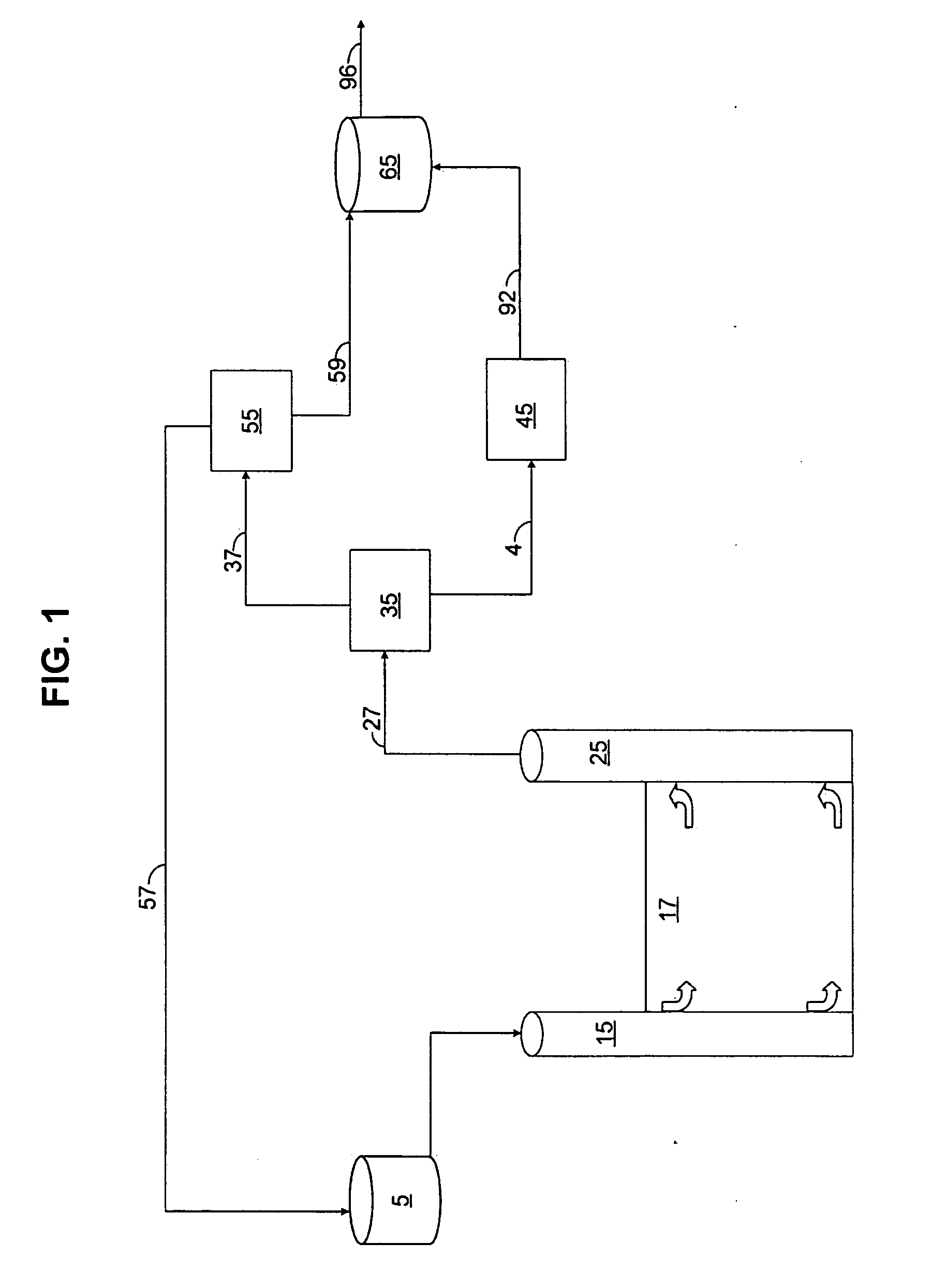

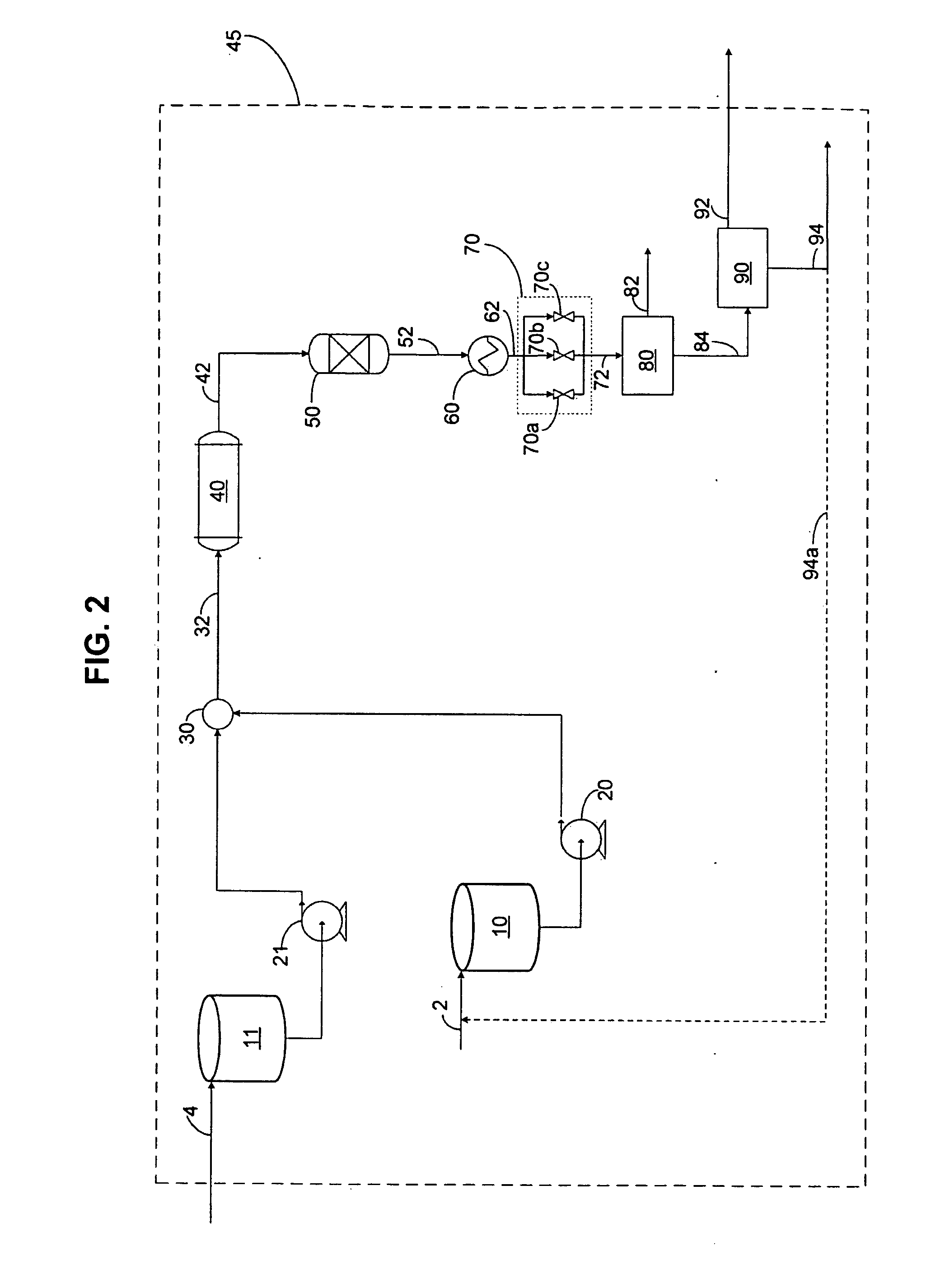

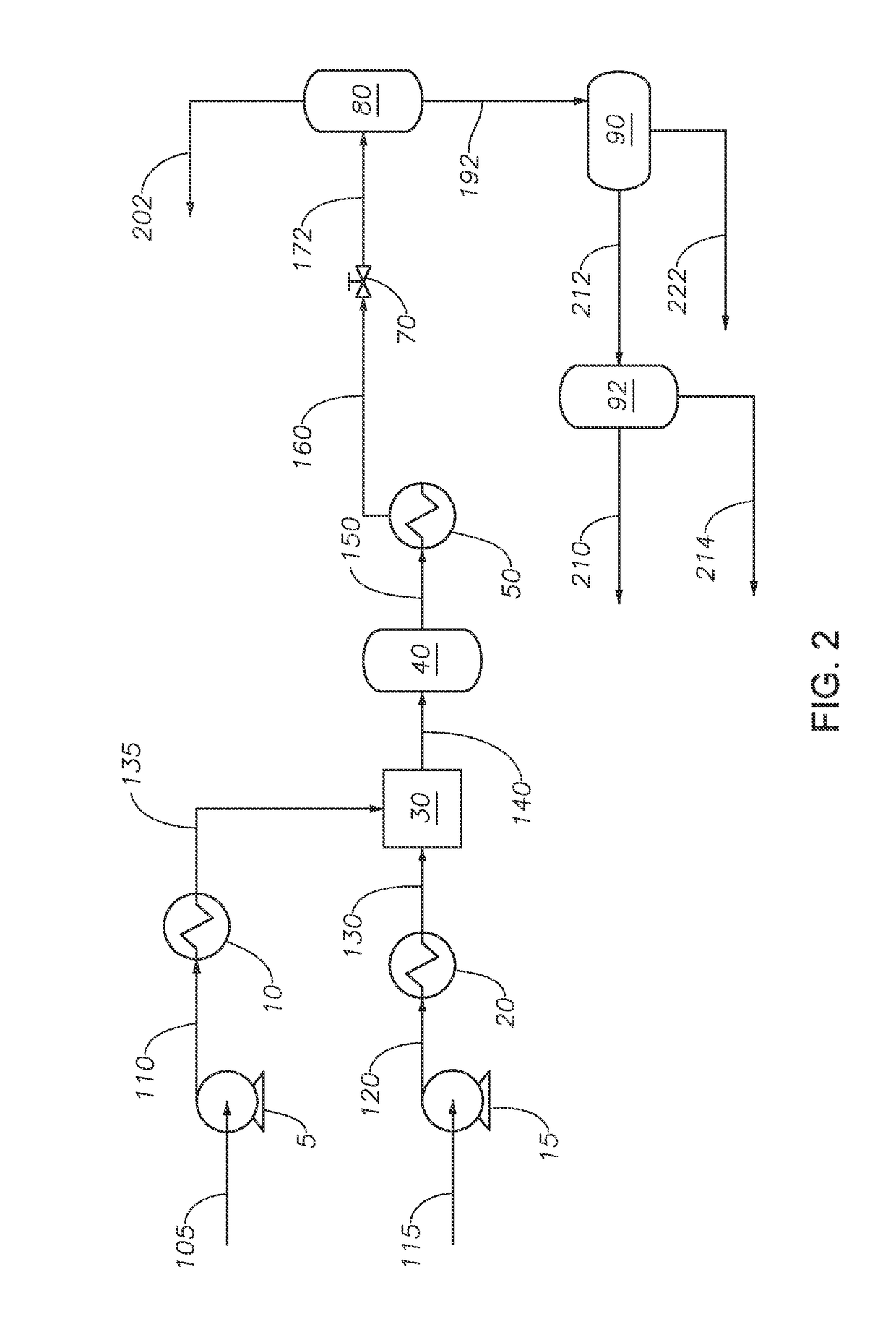

Intergrated process for in-field upgrading of hydrocarbons

InactiveUS20090159498A1Thermal non-catalytic crackingRefining by water treatmentHydrocarbonChemistry

Owner:CHEVROU USA INC

Supercritical water process to upgrade petroleum

ActiveUS20130140214A1Proceed efficientlyThermal non-catalytic crackingCatalytic crackingSludgePetroleum

Provided is a process for the supercritical upgrading of petroleum feedstock, wherein the process includes the use of a start-up agent, wherein the use of the start-up agent facilitates mixing of the petroleum feedstock and water, thereby reducing or eliminating the production of coke, coke precursor, and sludge.

Owner:SAUDI ARABIAN OIL CO

Process to upgrade whole crude oil by hot pressurized water and recovery fluid

ActiveUS20090139715A1Upgraded more easilyLess coke formationThermal non-catalytic crackingRefining by water treatmentSulfurLow nitrogen

A process for upgrading whole crude oil utilizing a recovery fluid, depressurizing an extracted whole crude oil / recovery fluid mixture in a step-wise fashion, and subsequently contacting at least a portion of the whole crude oil with supercritical water fluid to produce high value crude oil having low sulfur, low nitrogen, and low metallic impurities for use as hydrocarbon feedstock.

Owner:SAUDI ARABIAN OIL CO

Process for delayed coking of whole crude oil

ActiveUS20120298552A1Enhance thermal cracking reactionReduce coke yieldThermal non-catalytic crackingCatalytic crackingNaphthaFractionating column

An improved delayed coking process utilizing a coking unit and a coking unit product fractionating column which includes the steps of:heating a mixture of a fresh whole crude oil feedstream and the bottoms from the coking unit product fractionator in a furnace to a coking temperature in the range of 480° C. to 530° C. / 896° F. to 986° F.;introducing the heated mixed whole crude oil and bottoms feedstream directly into the delayed coking unit;optionally passing the vaporized liquid and gaseous coking unit product stream into a flash unit;recovering a light product gas stream that includes H2S, NH3 and C1 to C4 hydrocarbons from the flash unit;transferring the bottoms from the flash unit to the coking unit product fractionating column;recovering as separate side streams from the fractionating column naphtha, light gas oil and heavy gas oil;recycling a portion of the heavy gas oil by introducing it into the fractionating column optionally with the bottoms from the flash unit;mixing the fractionating column bottoms with the whole crude oil feedstream to form the mixed feedstream; andintroducing the mixed whole crude oil and fractionating column bottoms feedstream into the furnace.

Owner:SAUDI ARABIAN OIL CO

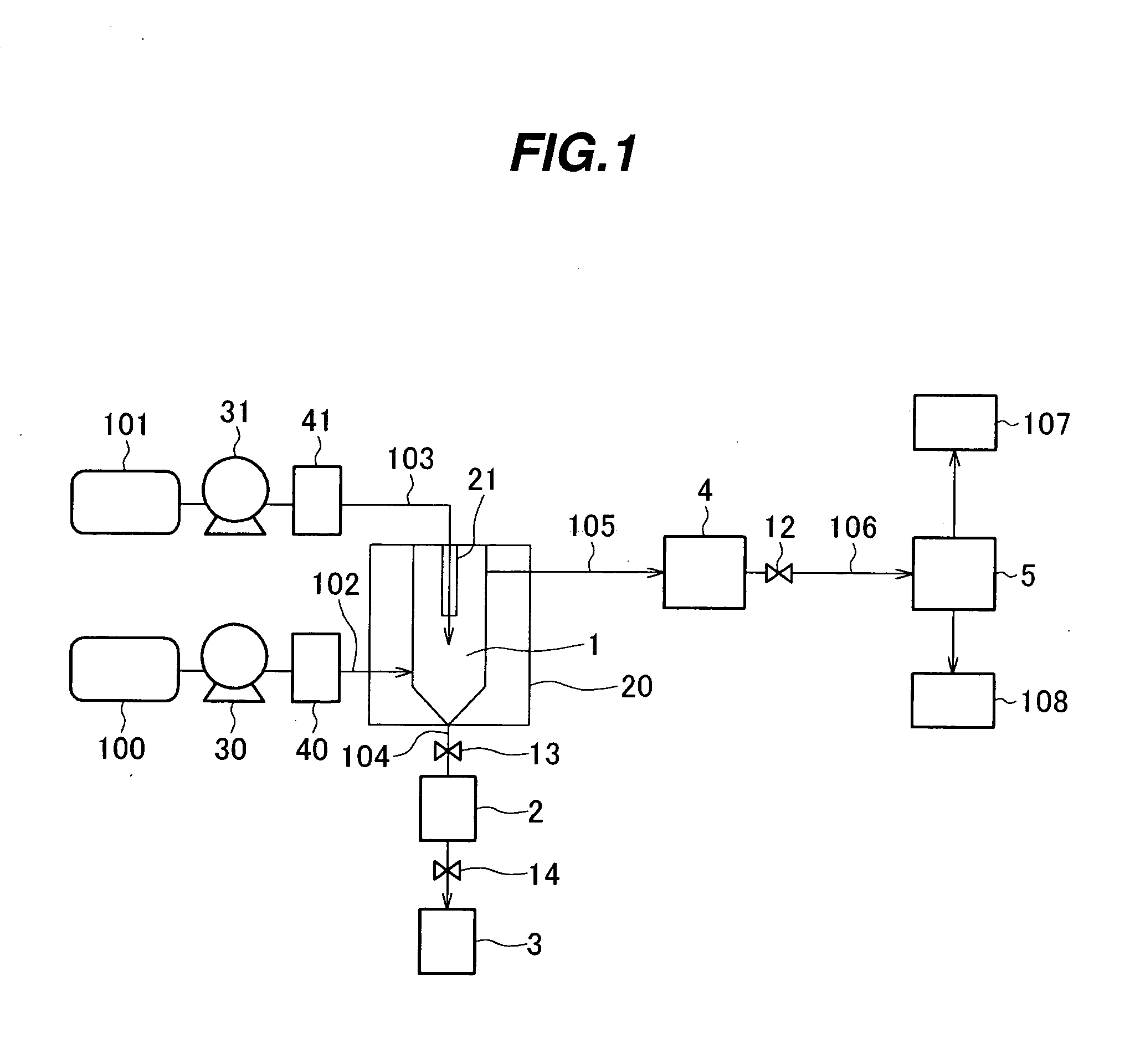

Petroleum Upgrading Process

ActiveUS20110147266A1Reduce the amount requiredIncrease gravityThermal non-catalytic crackingCatalytic crackingSulfurLow nitrogen

A process for upgrading a heavy oil stream by completely mixing the heavy oil stream with a water stream prior to the introduction of an oxidant stream. A mixture of the heavy oil stream and the water stream are subjected to operating conditions, in the presence of the oxidant stream, that are at or exceed the supercritical temperature and pressure of water. The resulting product stream is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the heavy oil stream.

Owner:SAUDI ARABIAN OIL CO

Simultaneous metal, sulfur and nitrogen removal using supercritical water

InactiveUS20090166262A1Reduce concentrationRefining by water treatmentLiquid carbonaceous fuelsNitrogen removalHydrogen

A process for removing metals, sulfur and nitrogen in the upgrading of hydrocarbons comprising: mixing hydrocarbons containing metals, sulfur and nitrogen with a fluid comprising water that has been heated to a temperature higher than its critical temperature in a mixing zone to form a mixture; passing the mixture to a reaction zone; reacting the mixture in the reaction zone under supercritical water conditions in the absence of externally added hydrogen for a residence time sufficient to allow upgrading reactions to occur while maintaining an effective amount of metals, derived from the hydrocarbon undergoing upgrading, in the reaction zone to catalyze the upgrading reactions; and recovering upgraded hydrocarbons having a lower concentration of metals, sulfur and nitrogen than the hydrocarbons before reaction is disclosed.

Owner:CHEVROU USA INC

Desalting adjunct chemistry

InactiveUS6120678AImproves separation of waterReduce decreaseDewatering/demulsification with chemical meansLiquid separation by electricityChemical treatmentMeth-

Improved performance in the phase separation of aqueous brines from hydrocarbons within an electrostatic desalter operation is obtained by the addition to the crude oil emulsions entering the desalter of an effective asphaltene dispersing amount of an alkyl phenol-formaldehyde liquid resin polymer, optionally in the presence of a lipophilic / hydrophilic vinylic polymer. The preferred resin is a nonyl phenol-formaldehyde resin having a molecular weight of from 1,000-20,000, and the preferred vinylic polymer is a copolymer of lauryl (meth)acrylate and hydroxyethyl (meth)acrylate. Best results from the electrostatic desalter are obtained when also using a demulsifier chemical treatment along with the asphaltene dispersing treatments. Desalter efficiency is increased and desalter brine effluent quality is greatly increased.

Owner:ECOLAB USA INC +1

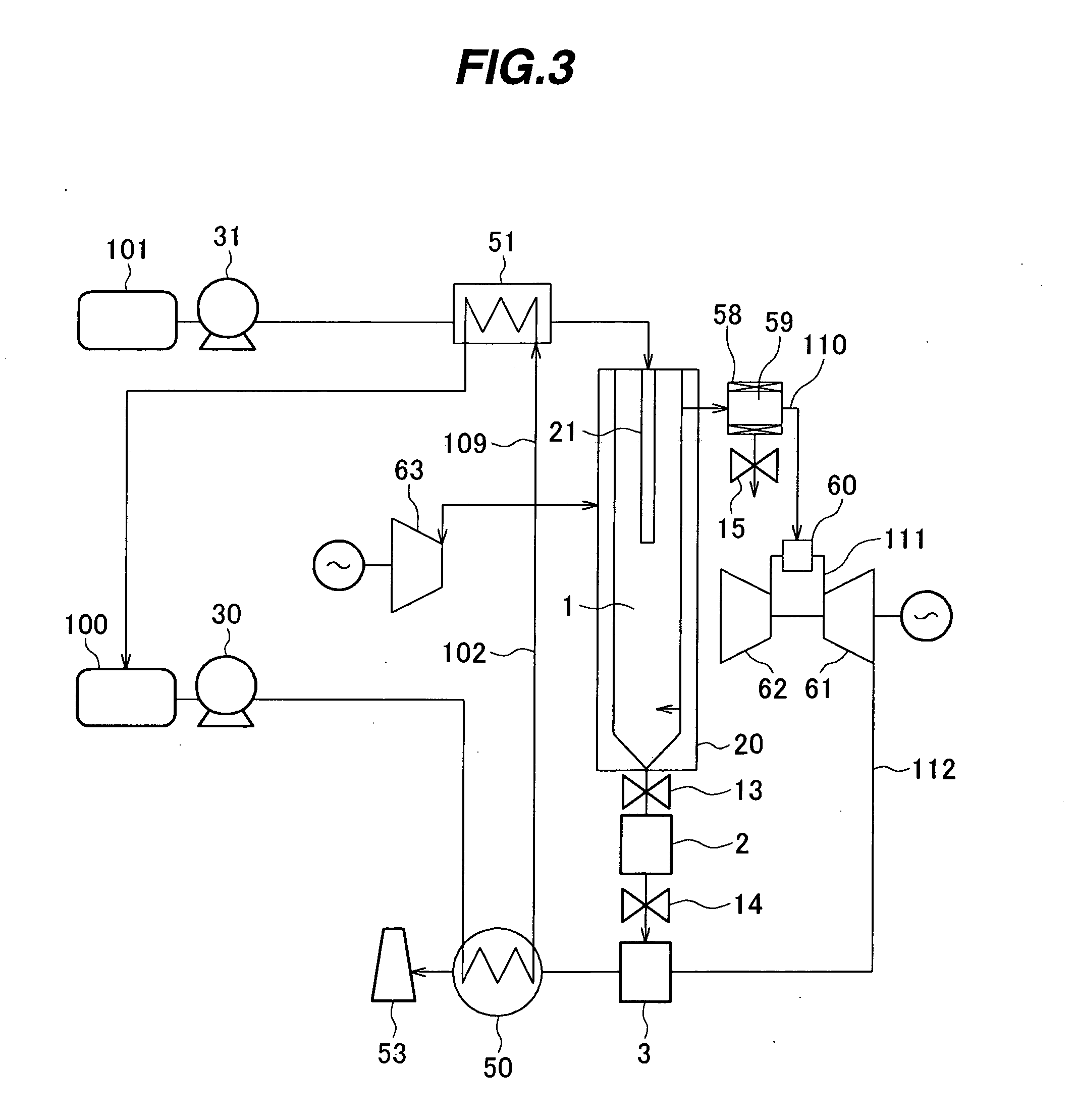

Heavy oil treating method and heavy oil treating system

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

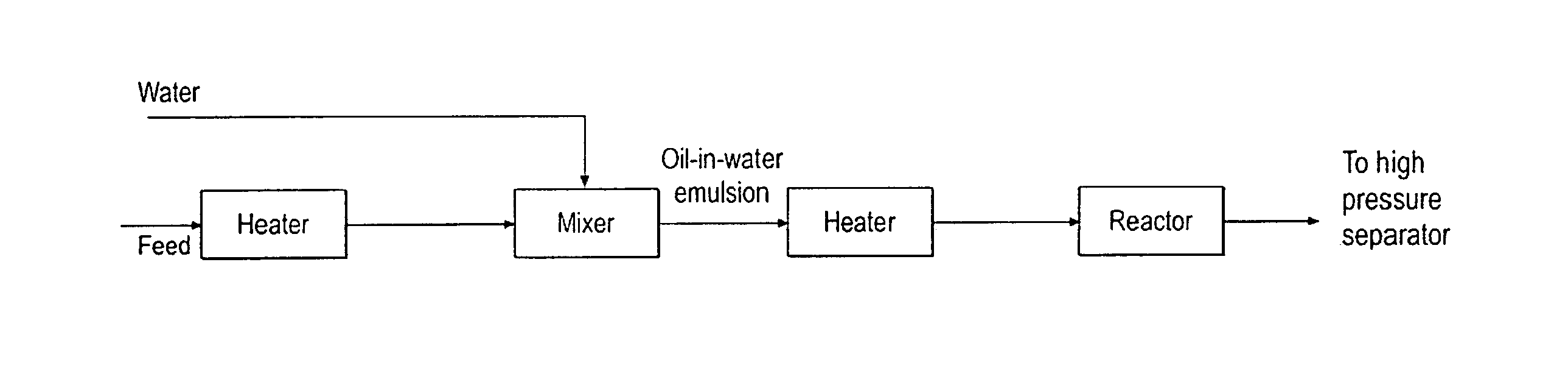

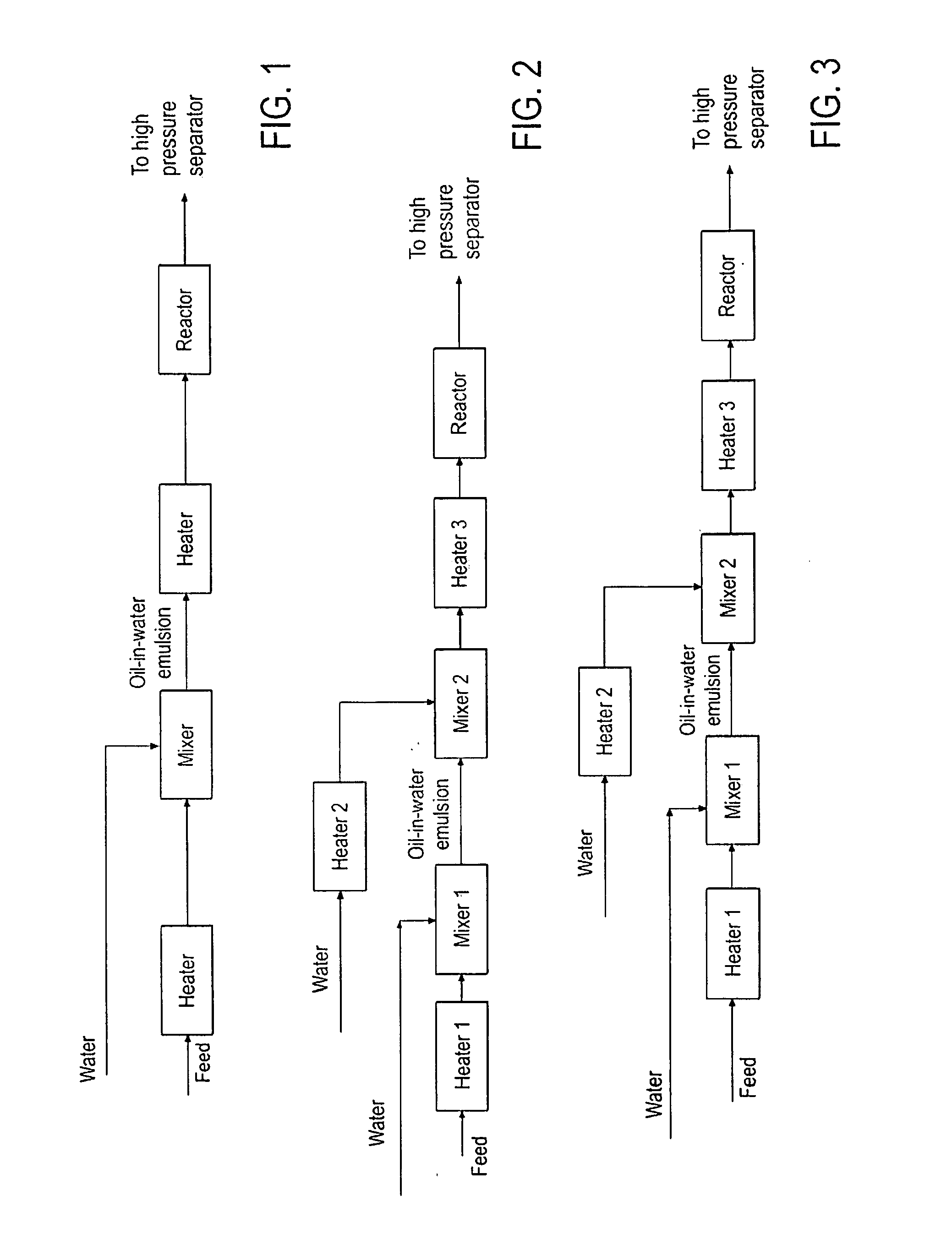

Upgrading heavy hydrocarbon oils

A process using supercritical water-oil emulsion to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts.

Owner:CHEVROU USA INC

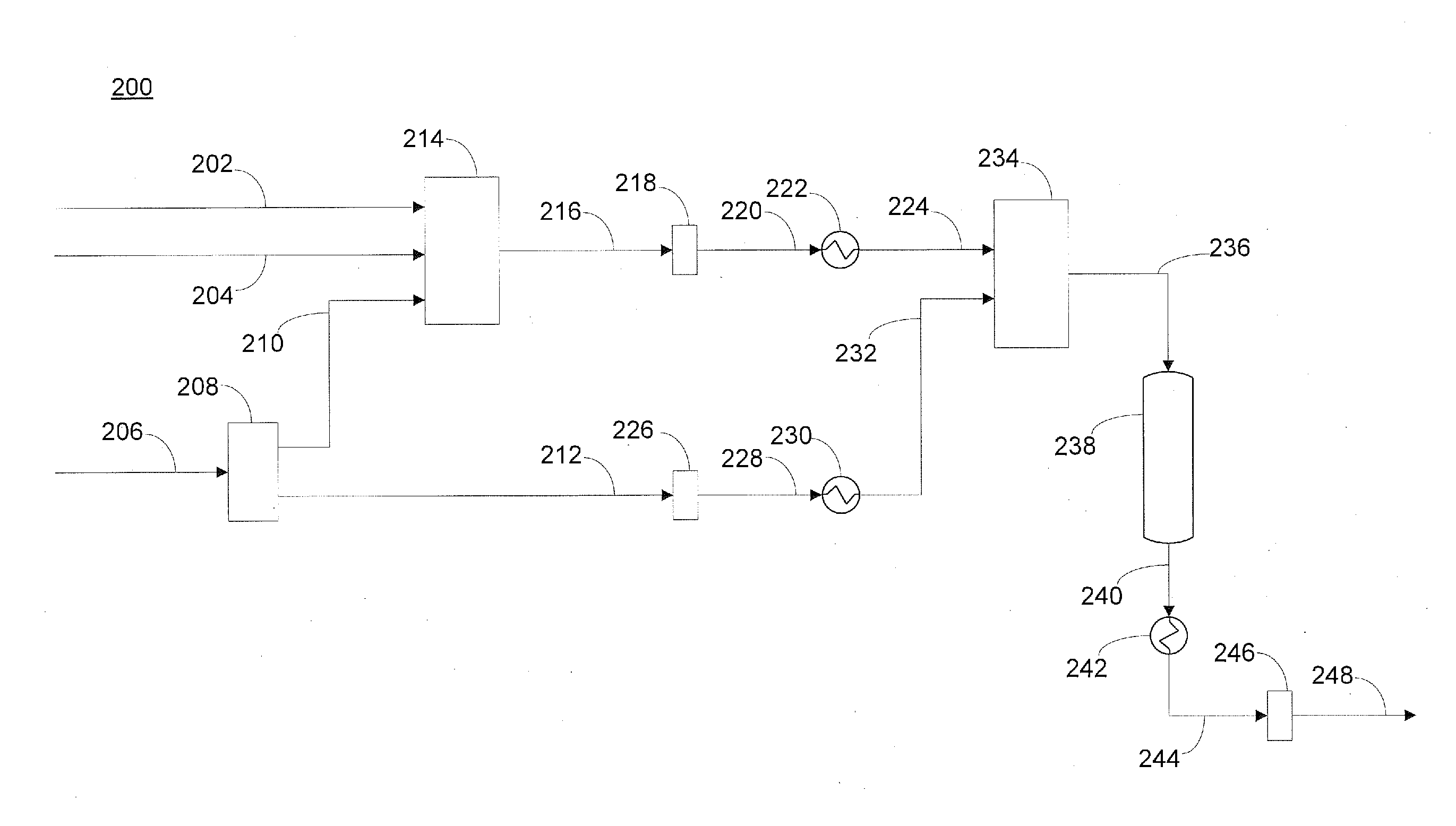

Upgrading of Hydrocarbons by Hydrothermal Process

ActiveUS20120061291A1Good physical propertiesLow costThermal non-catalytic crackingTreatment with plural serial cracking stages onlyHydrogenWater flow

A hydrocarbon feedstock upgrading method is provided. The method includes supplying the hydrocarbon feedstock, water and a pre-heated hydrogen donating composition to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream. The hydrogen donating composition is pre-heated and maintained at a temperature of greater than about 50° C. for a period of at least about 10 minutes. The modified stream includes upgraded hydrocarbons relative to the hydrocarbon feedstock. The modified stream is then separated into a gas stream and a liquid stream and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

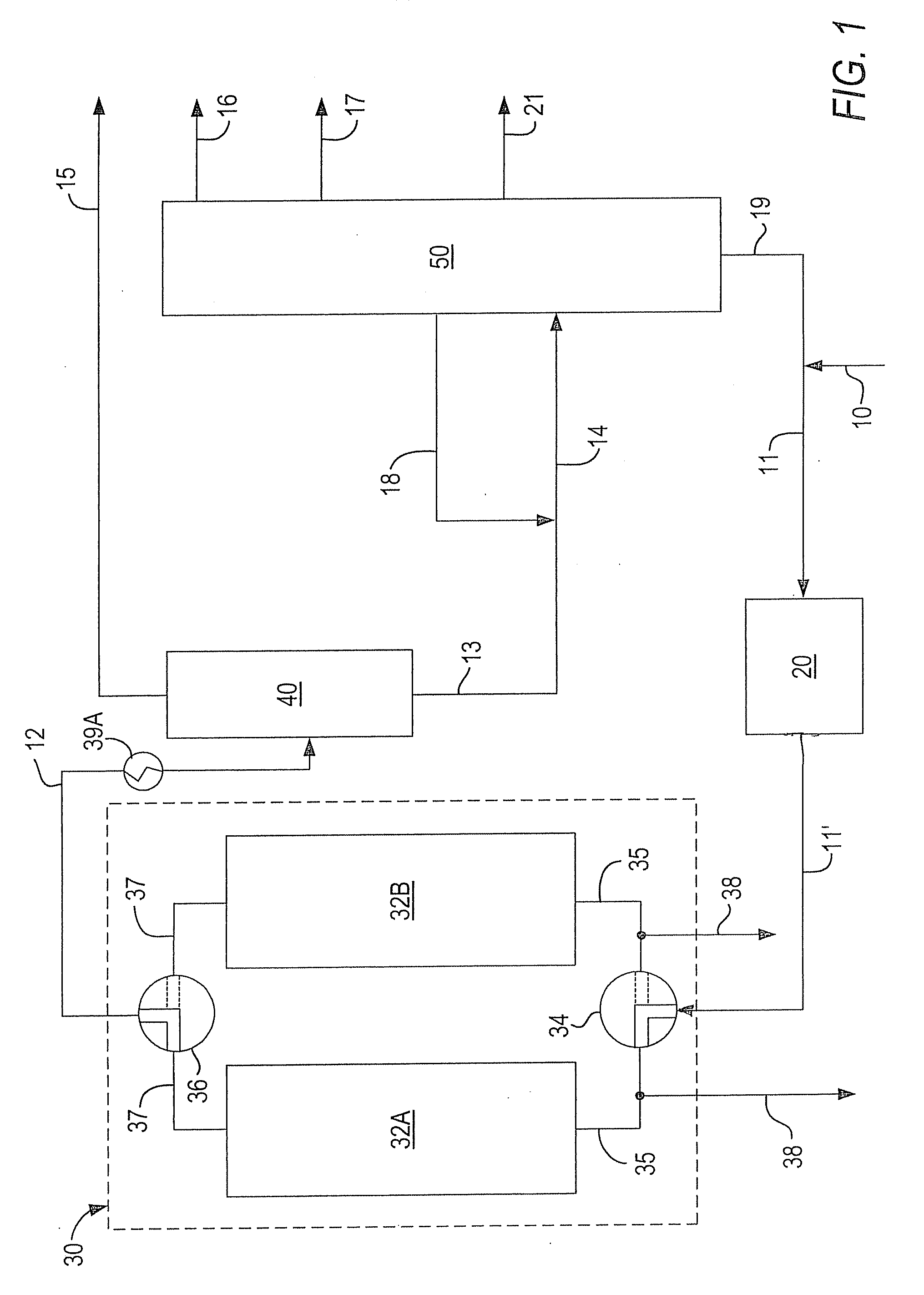

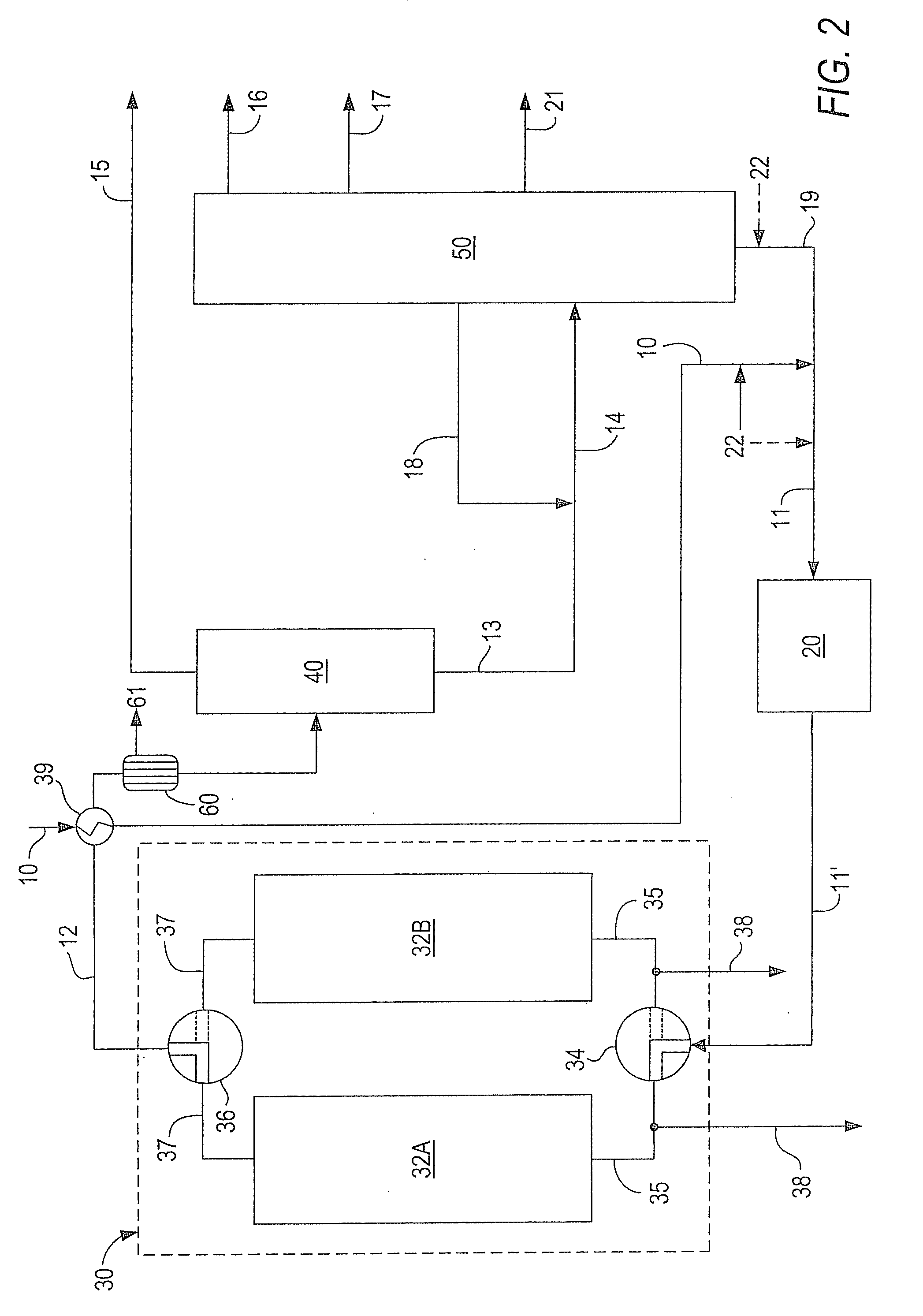

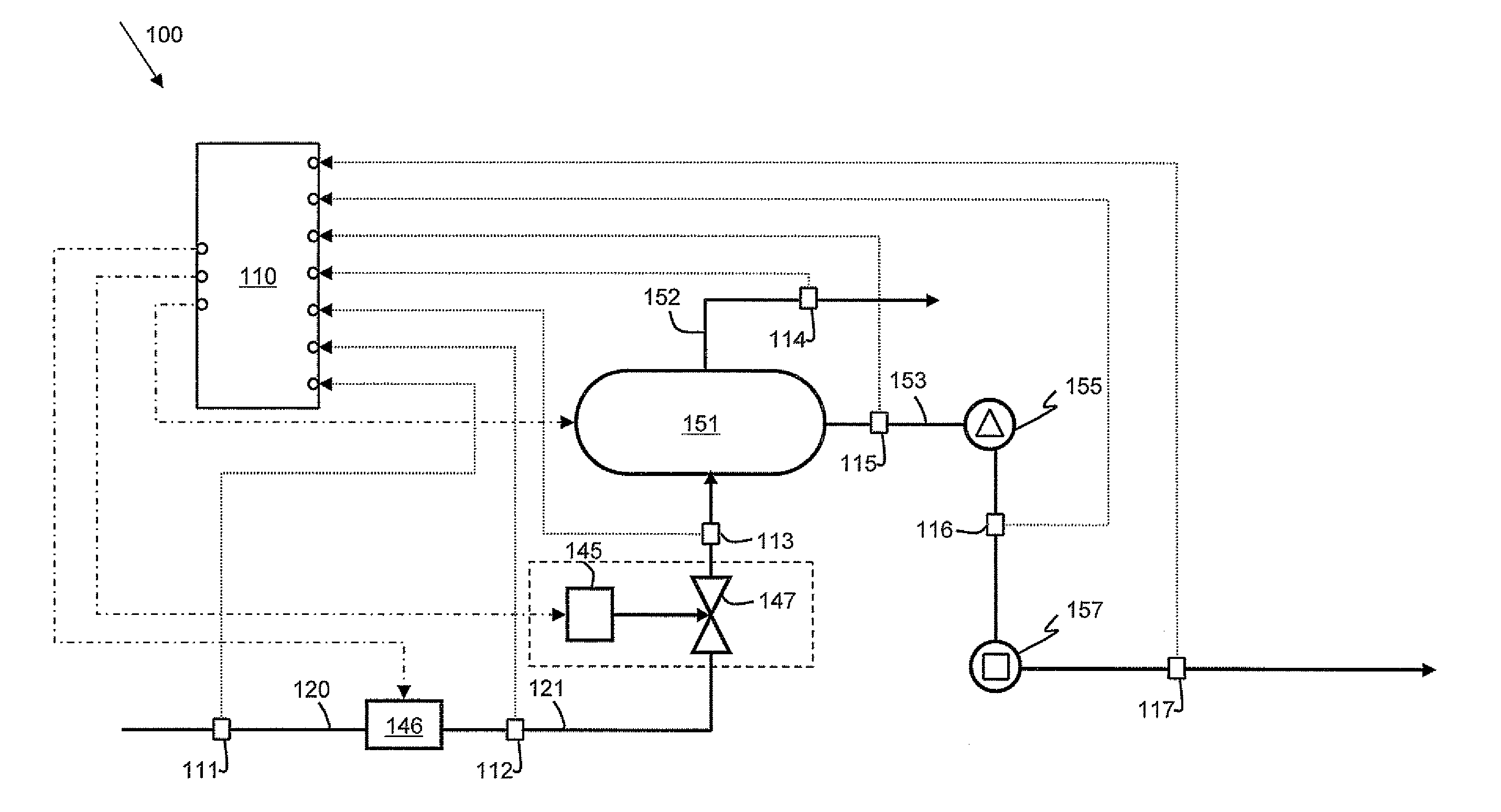

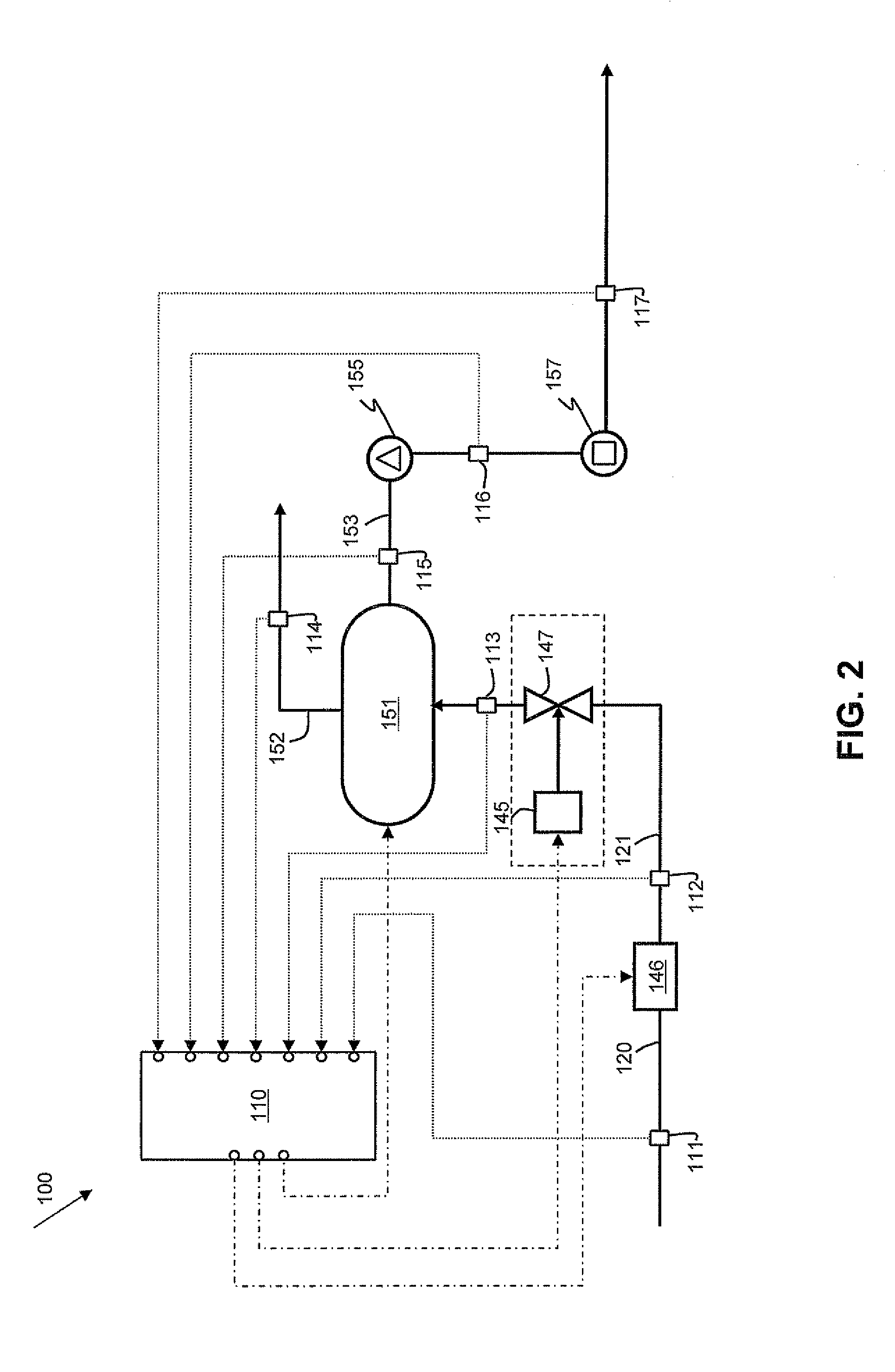

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS20130026082A1Low viscosityLiquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

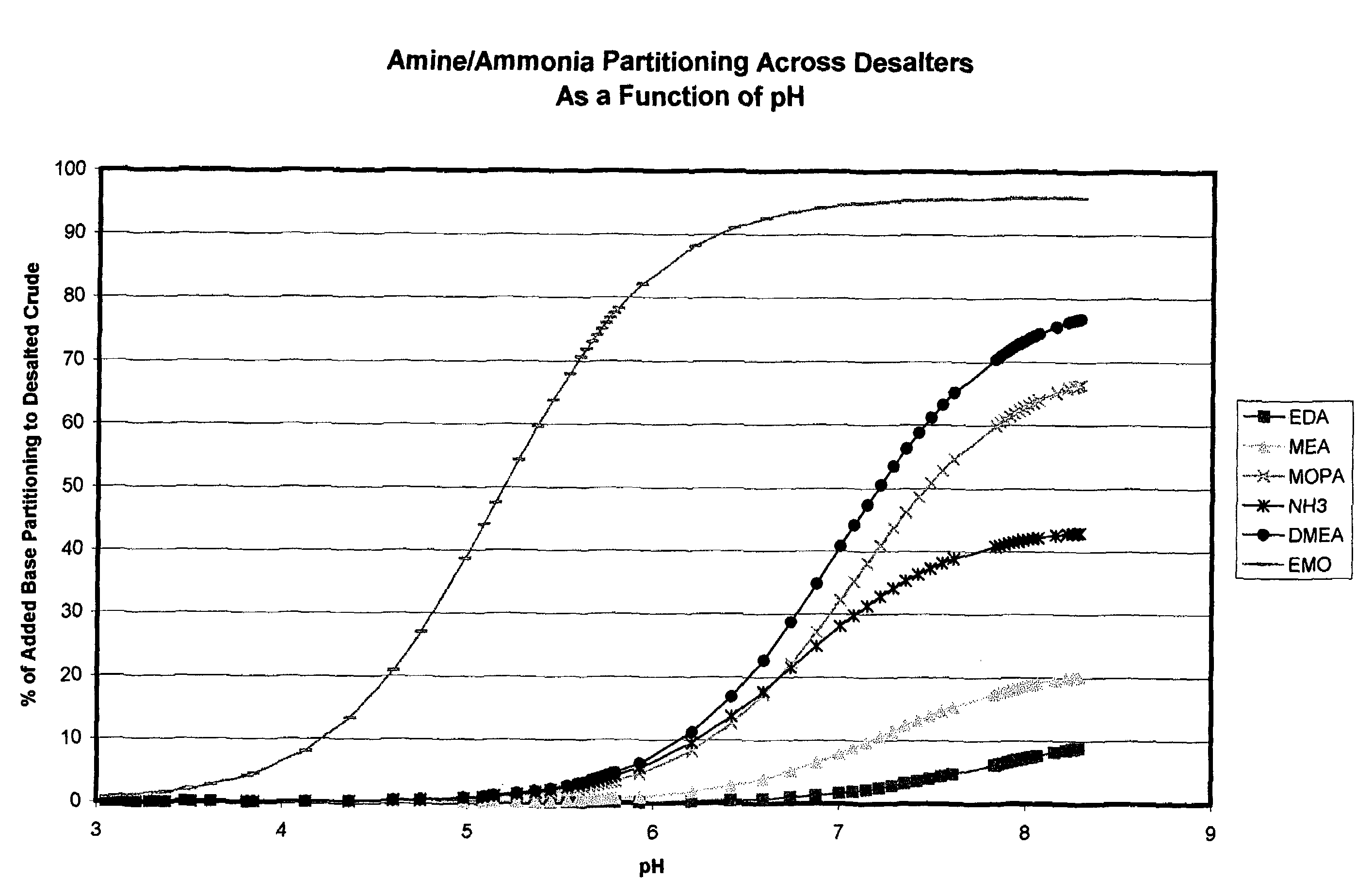

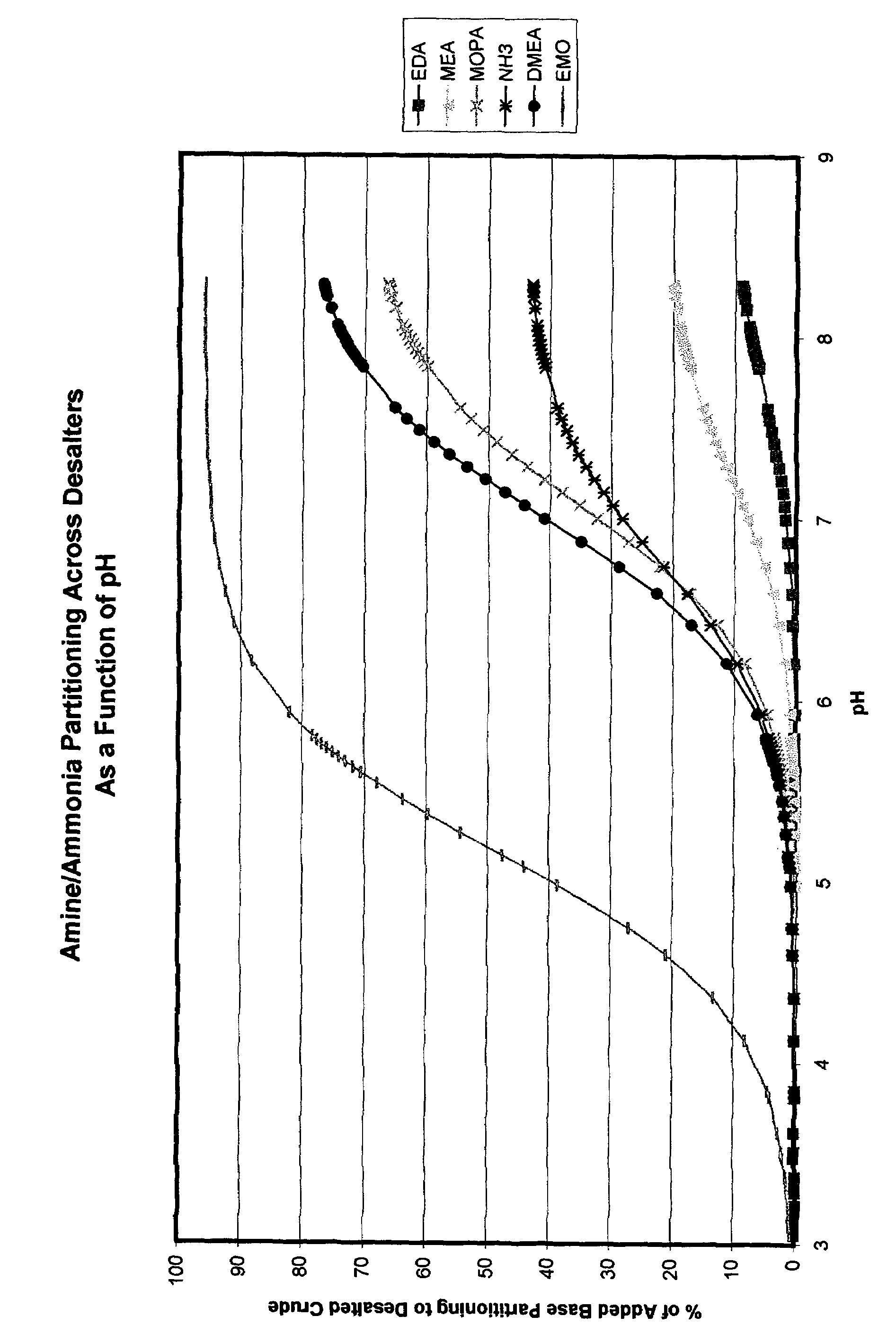

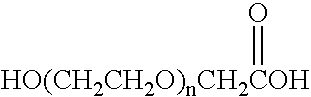

Additives to enhance metal and amine removal in refinery desalting processes

ActiveUS7497943B2Dewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansWash waterChloroacetic acids

It has been discovered that metals and / or amines can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxyacids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may also include at least one mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of metals and / or amines into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES INC

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

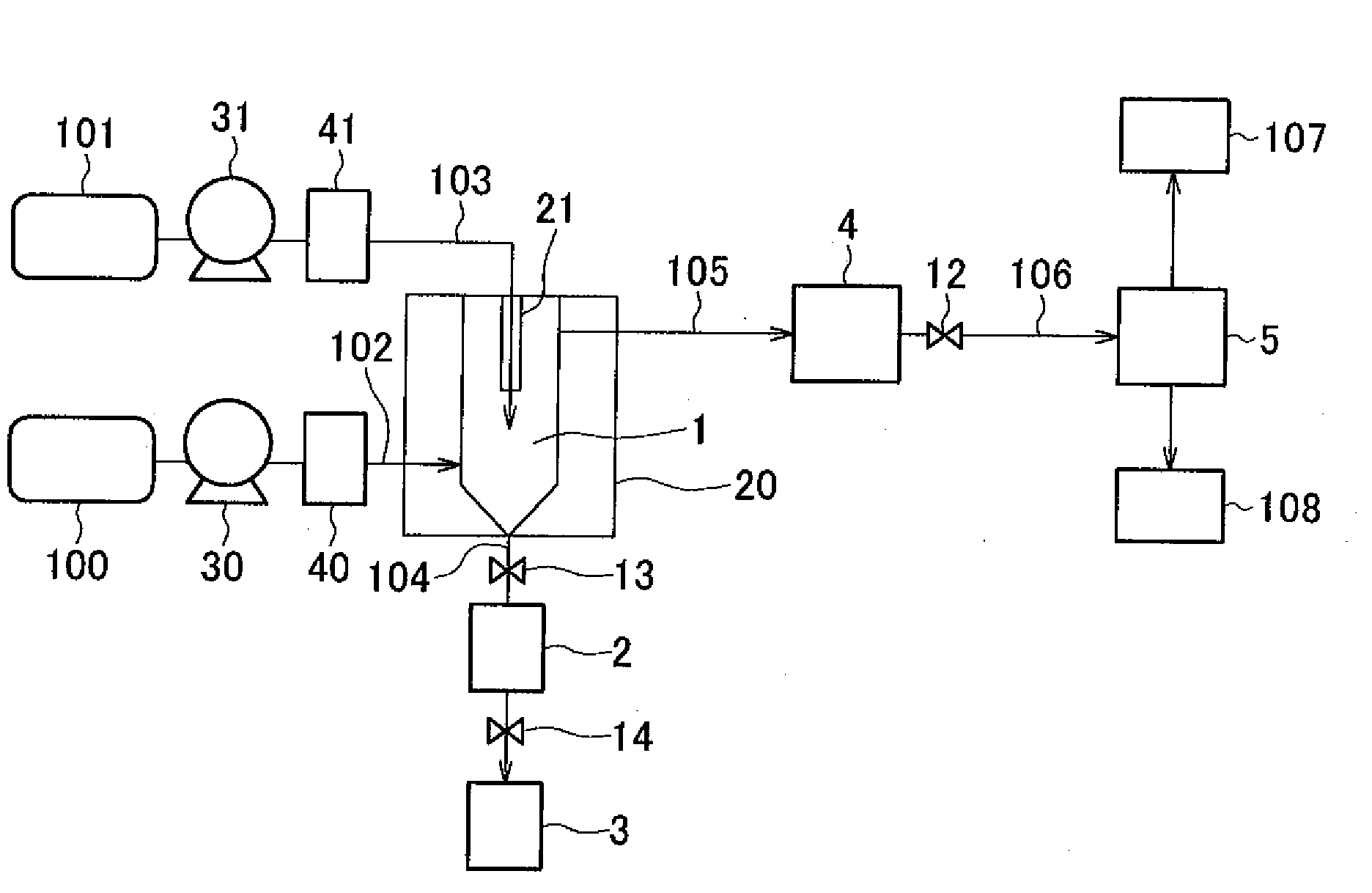

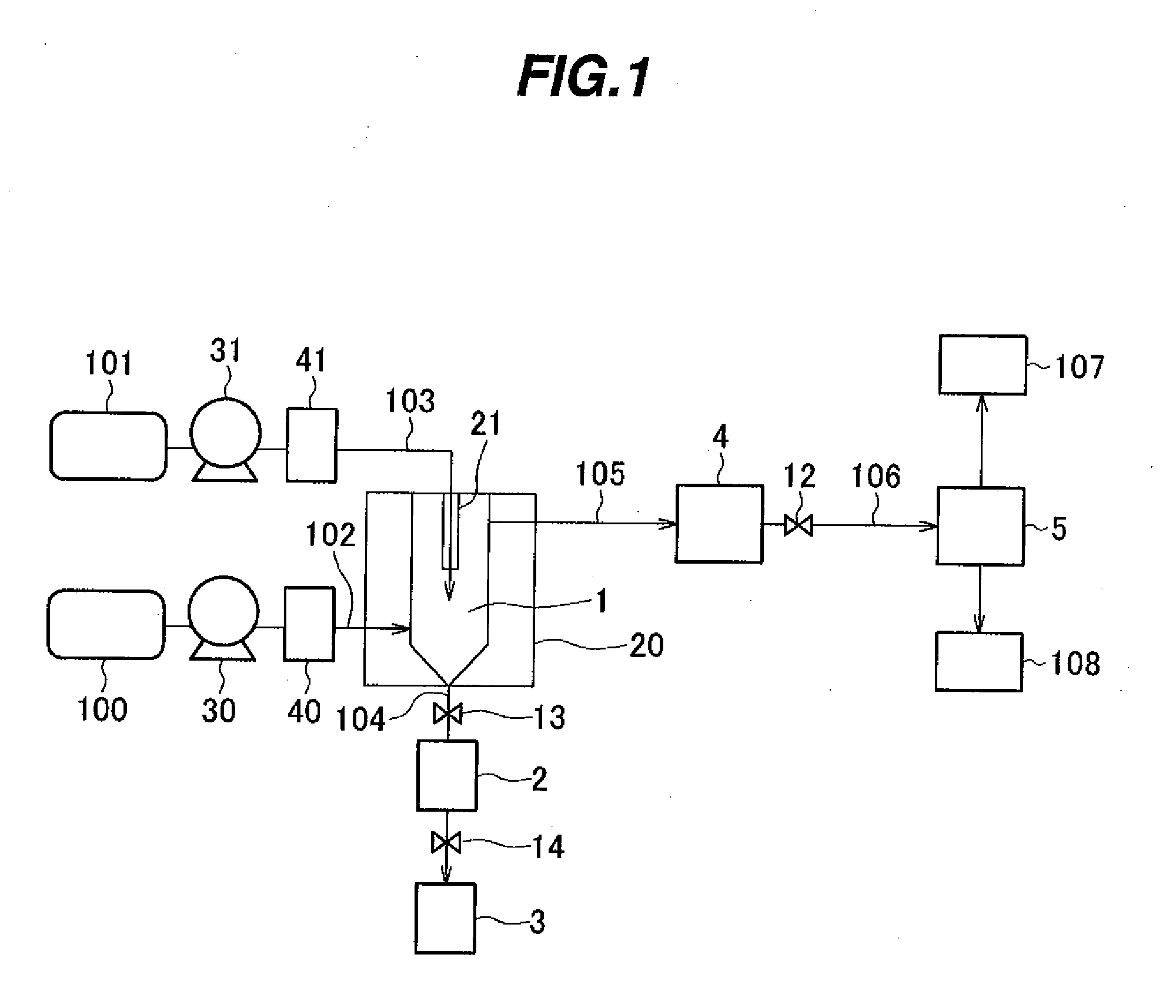

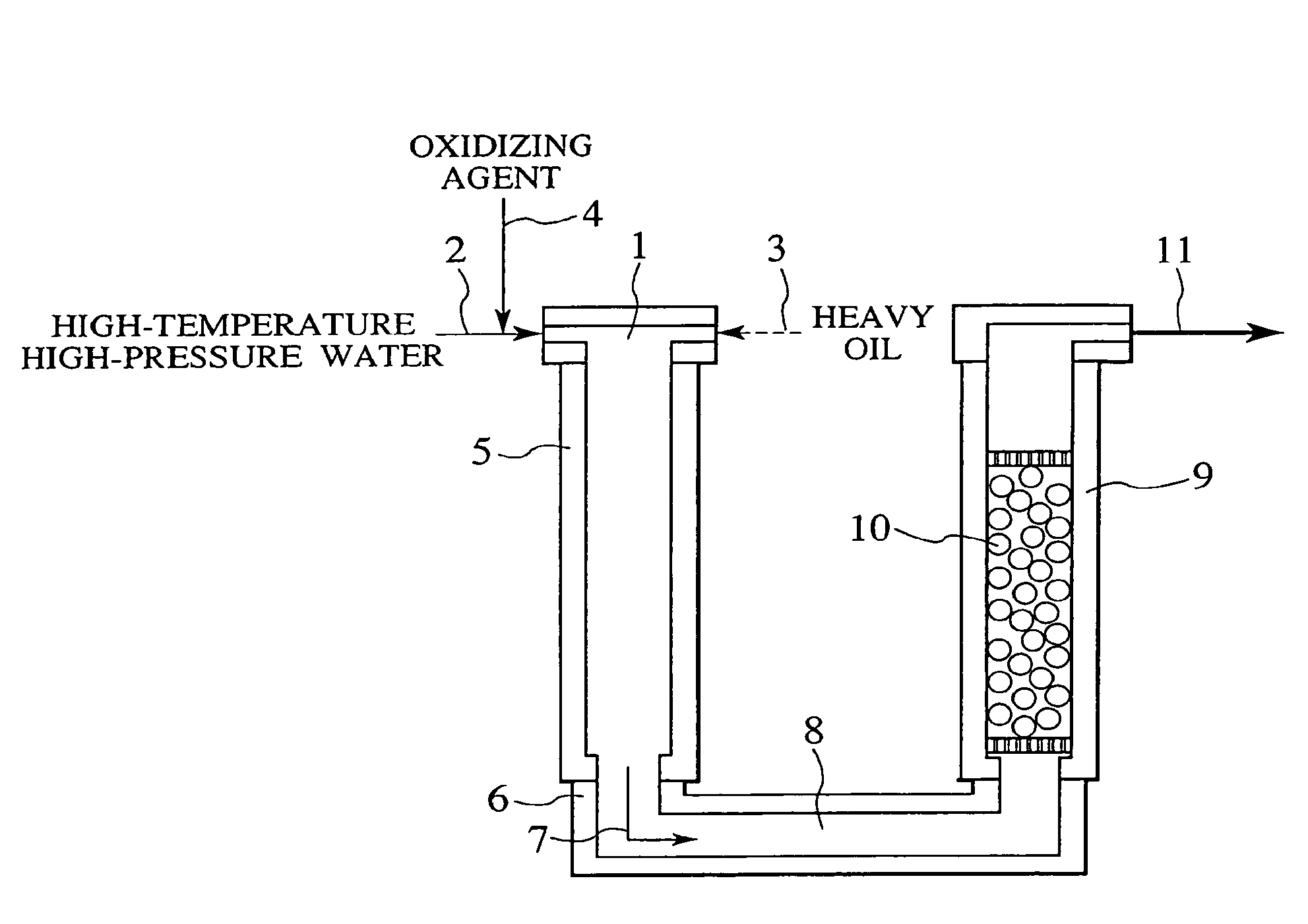

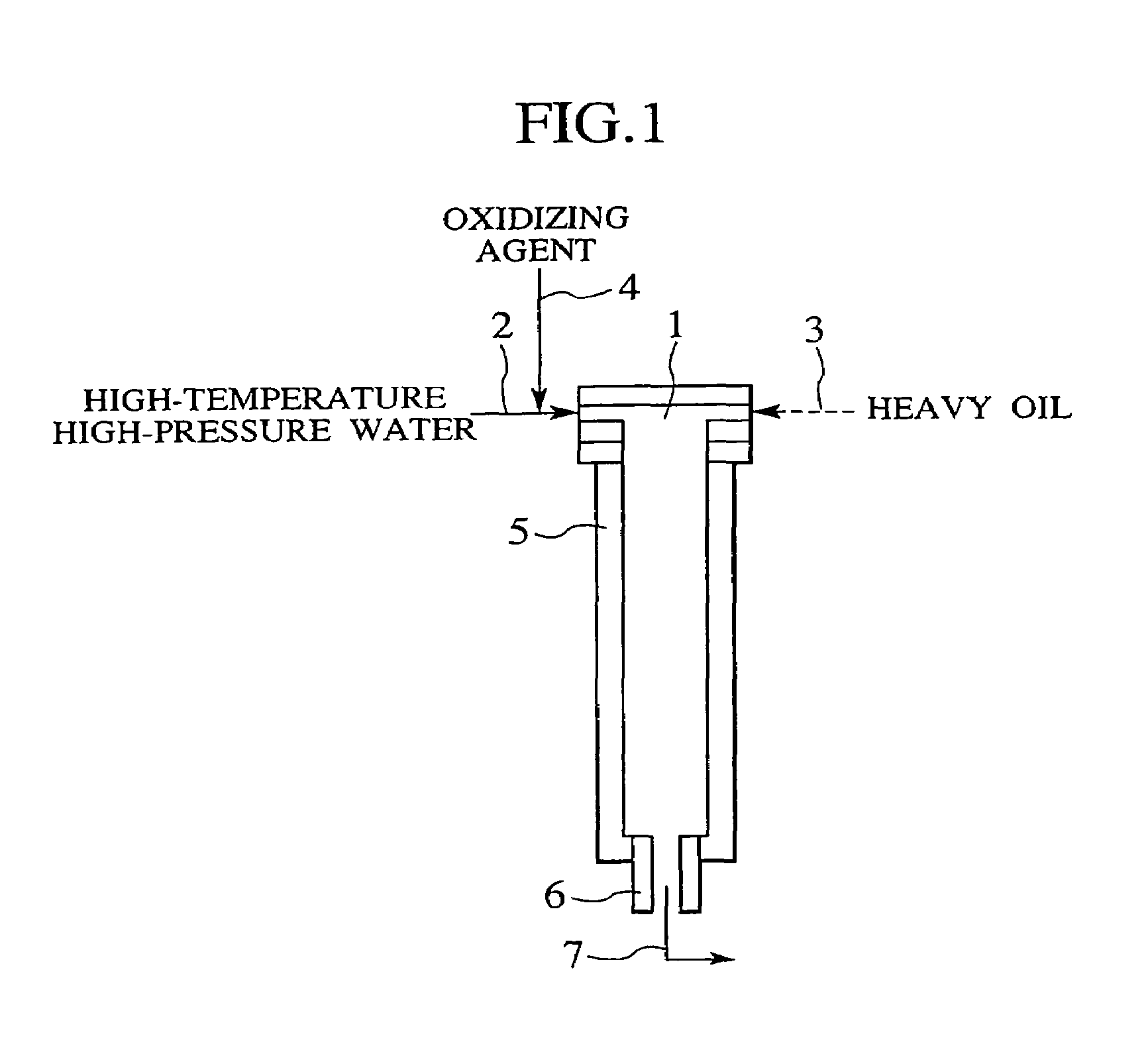

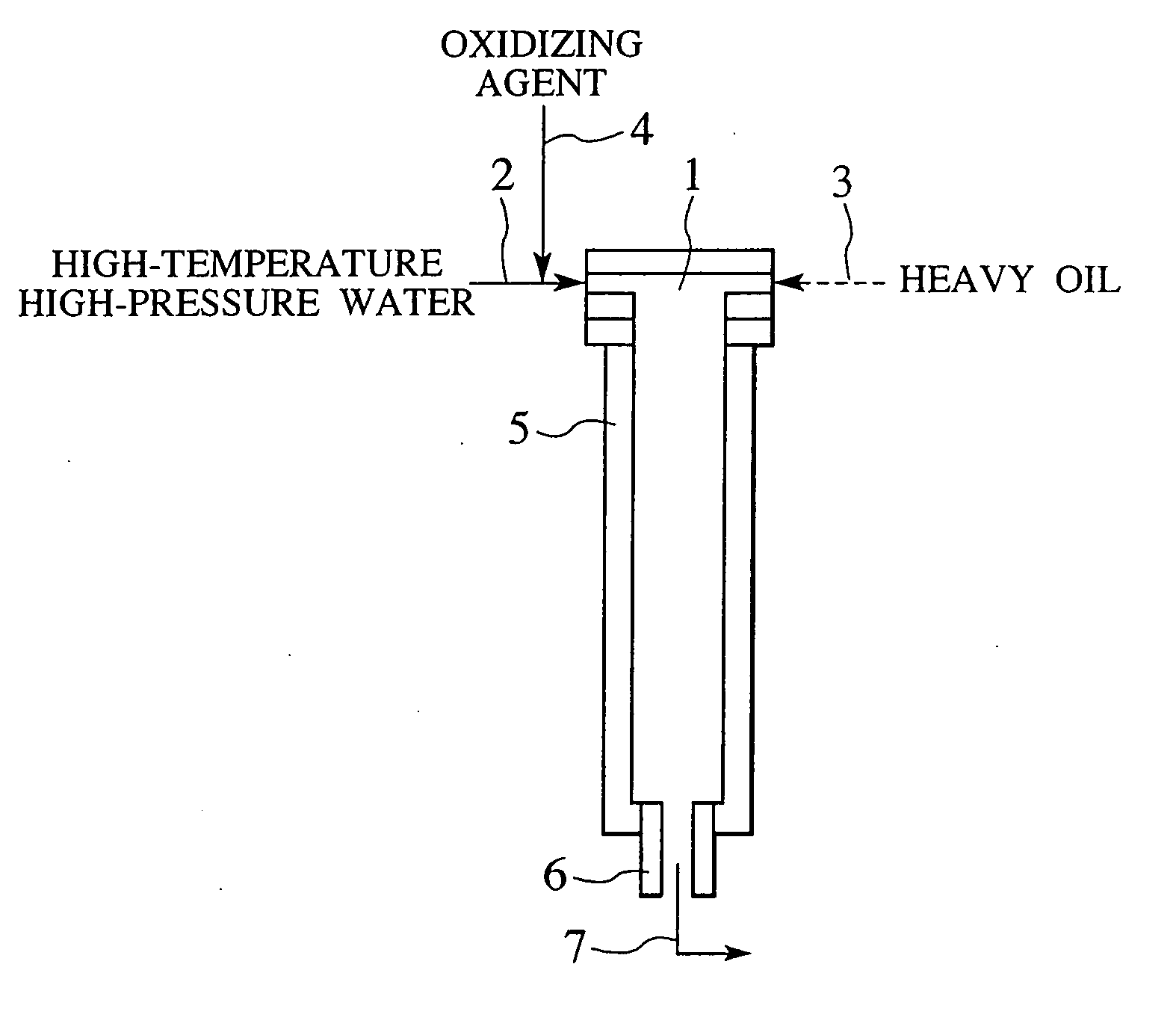

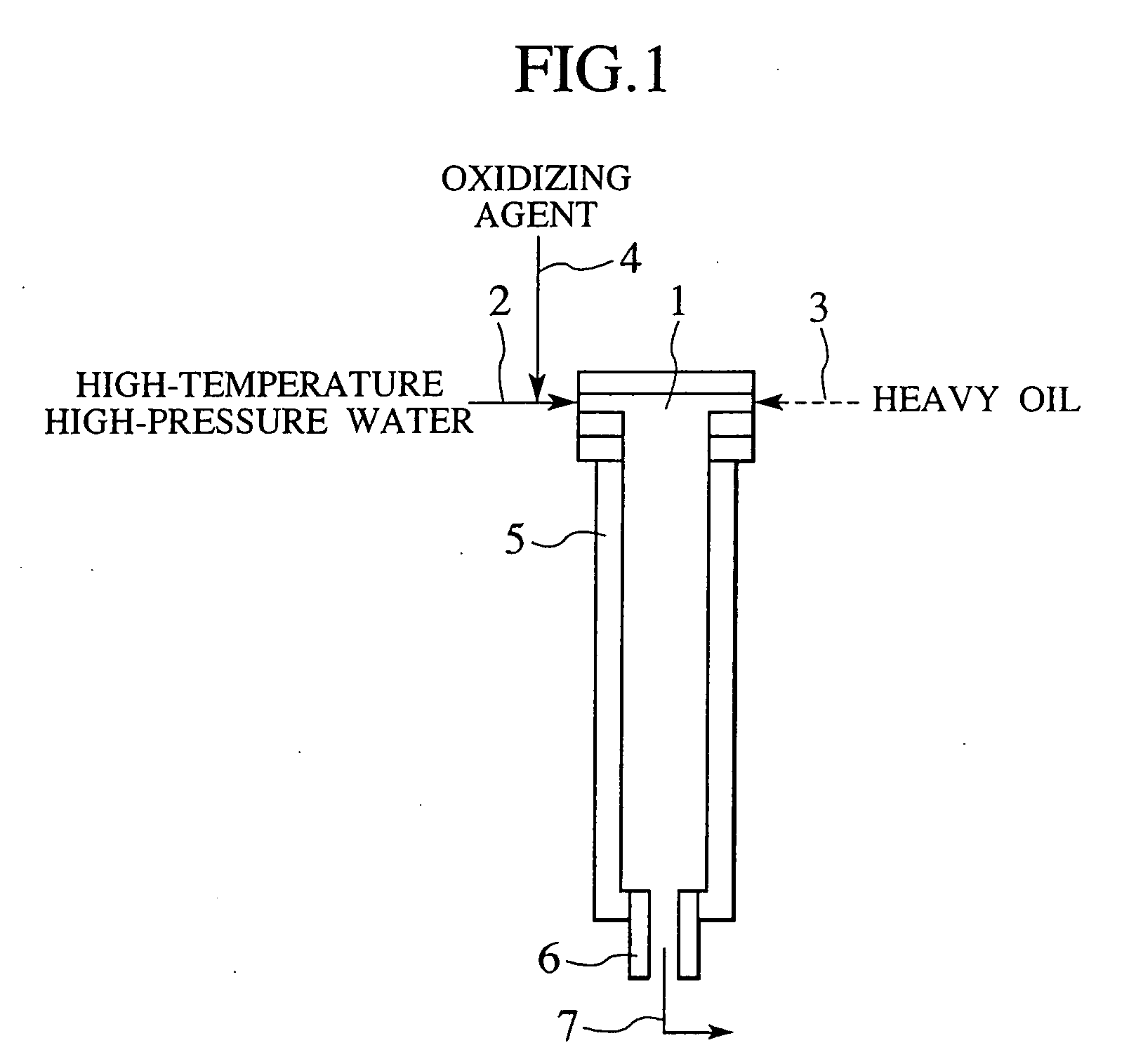

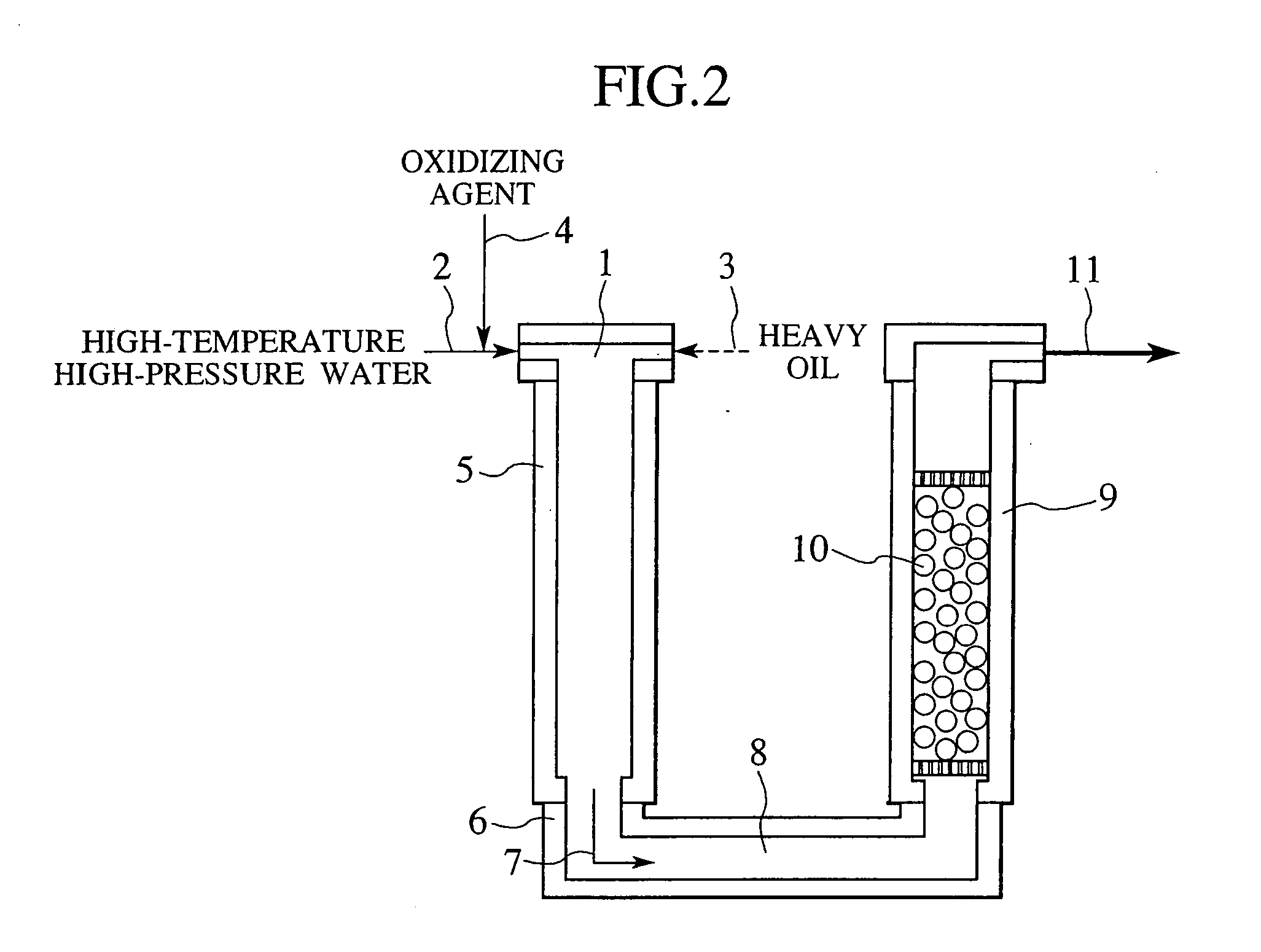

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

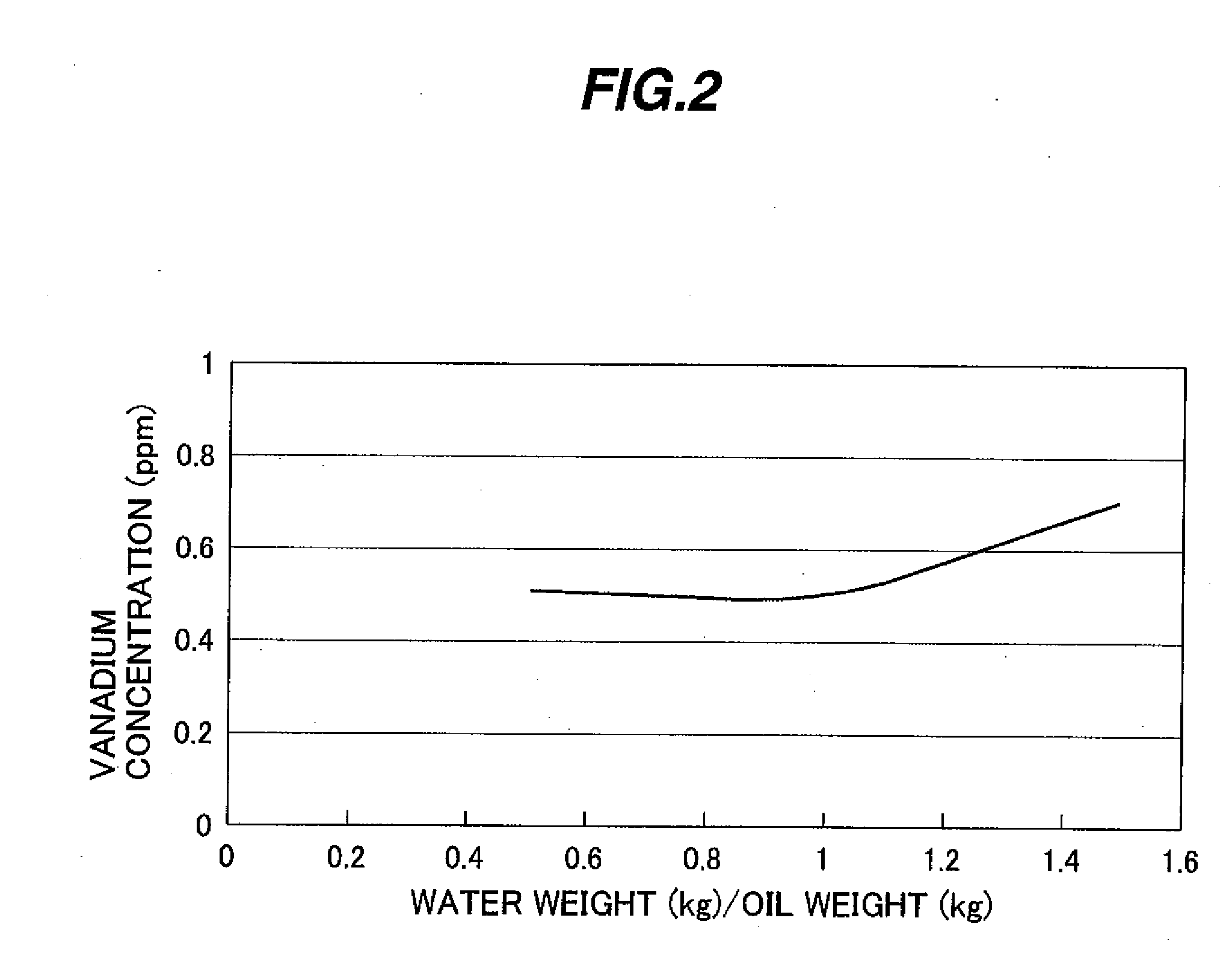

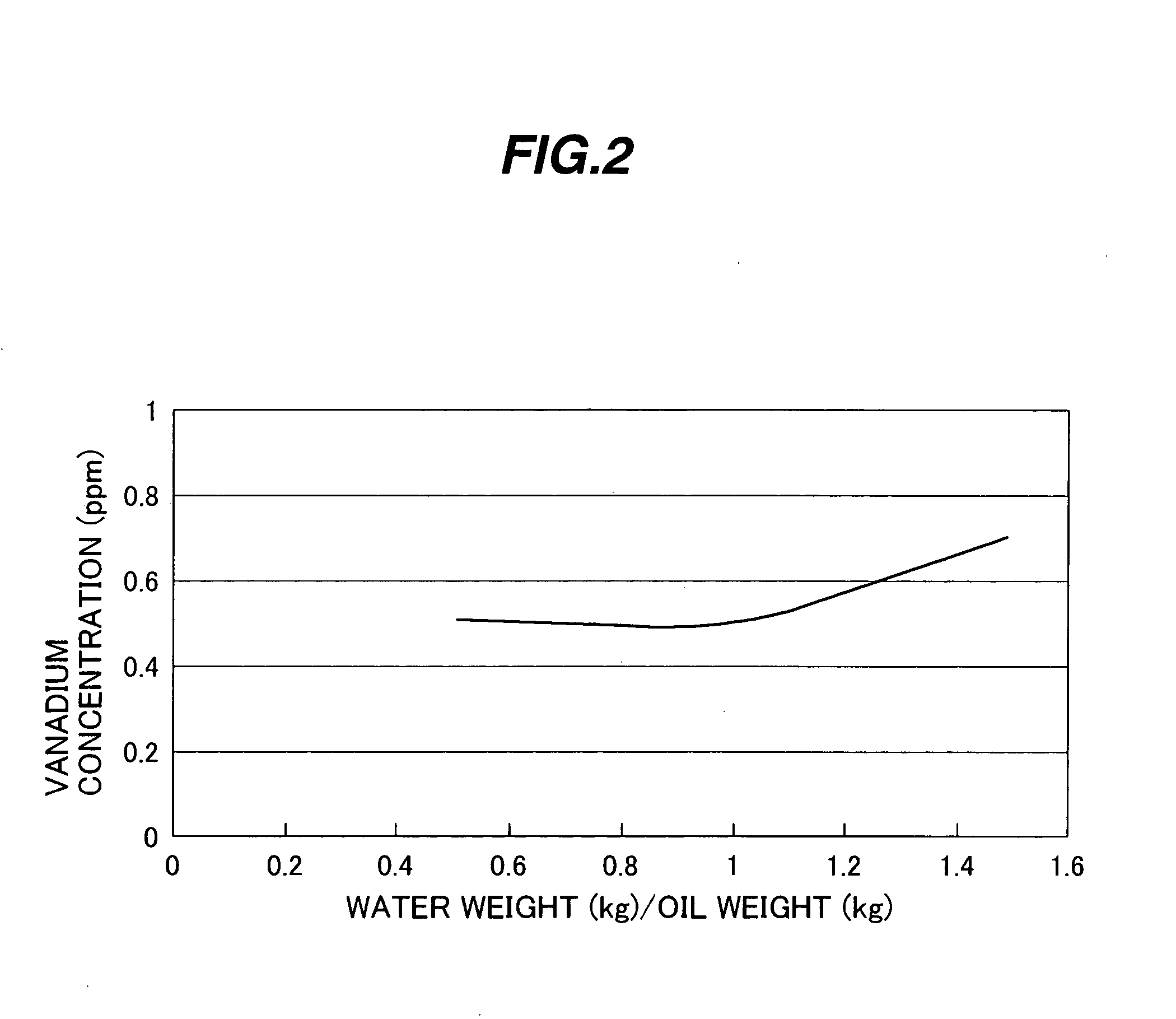

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

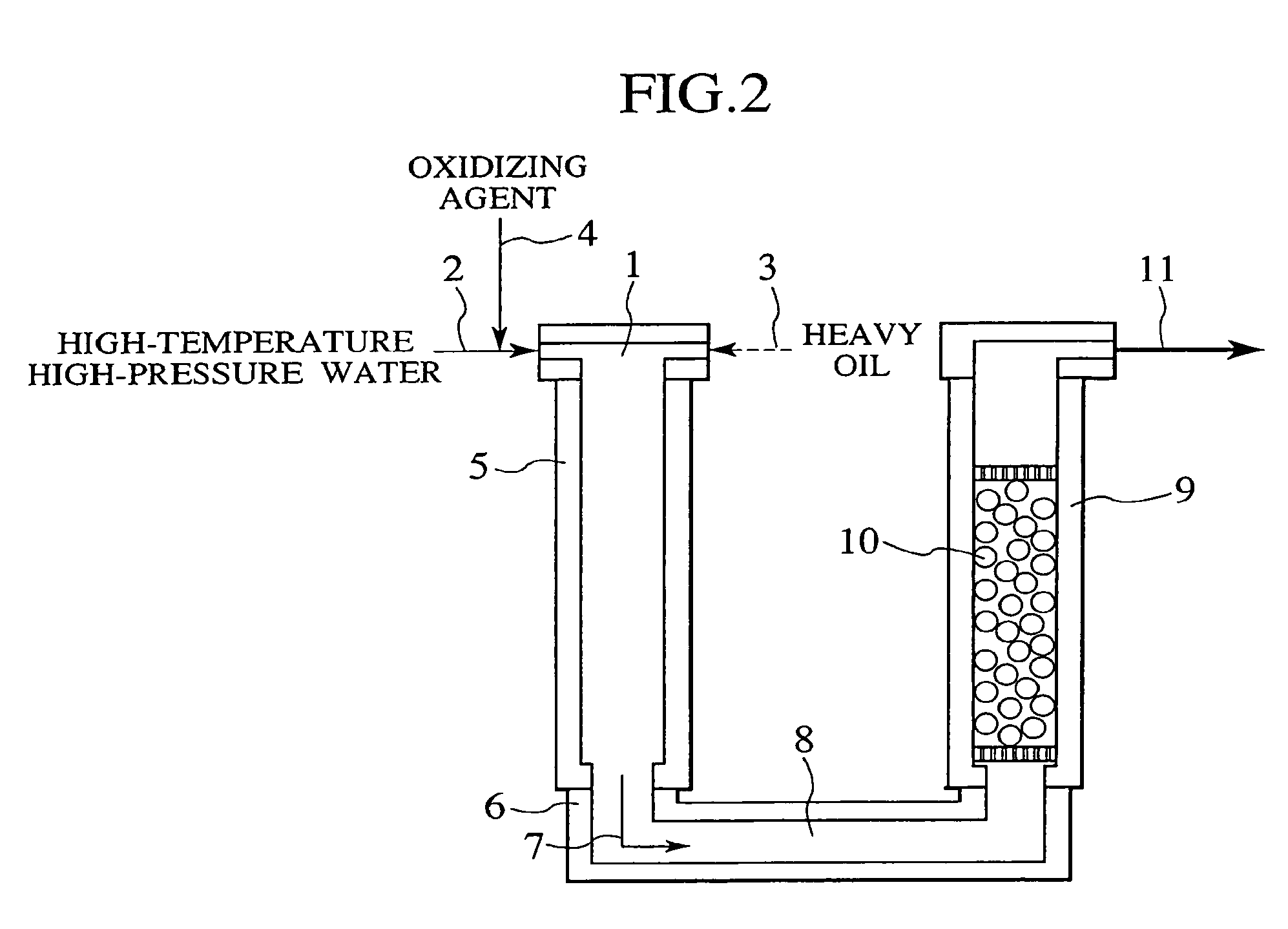

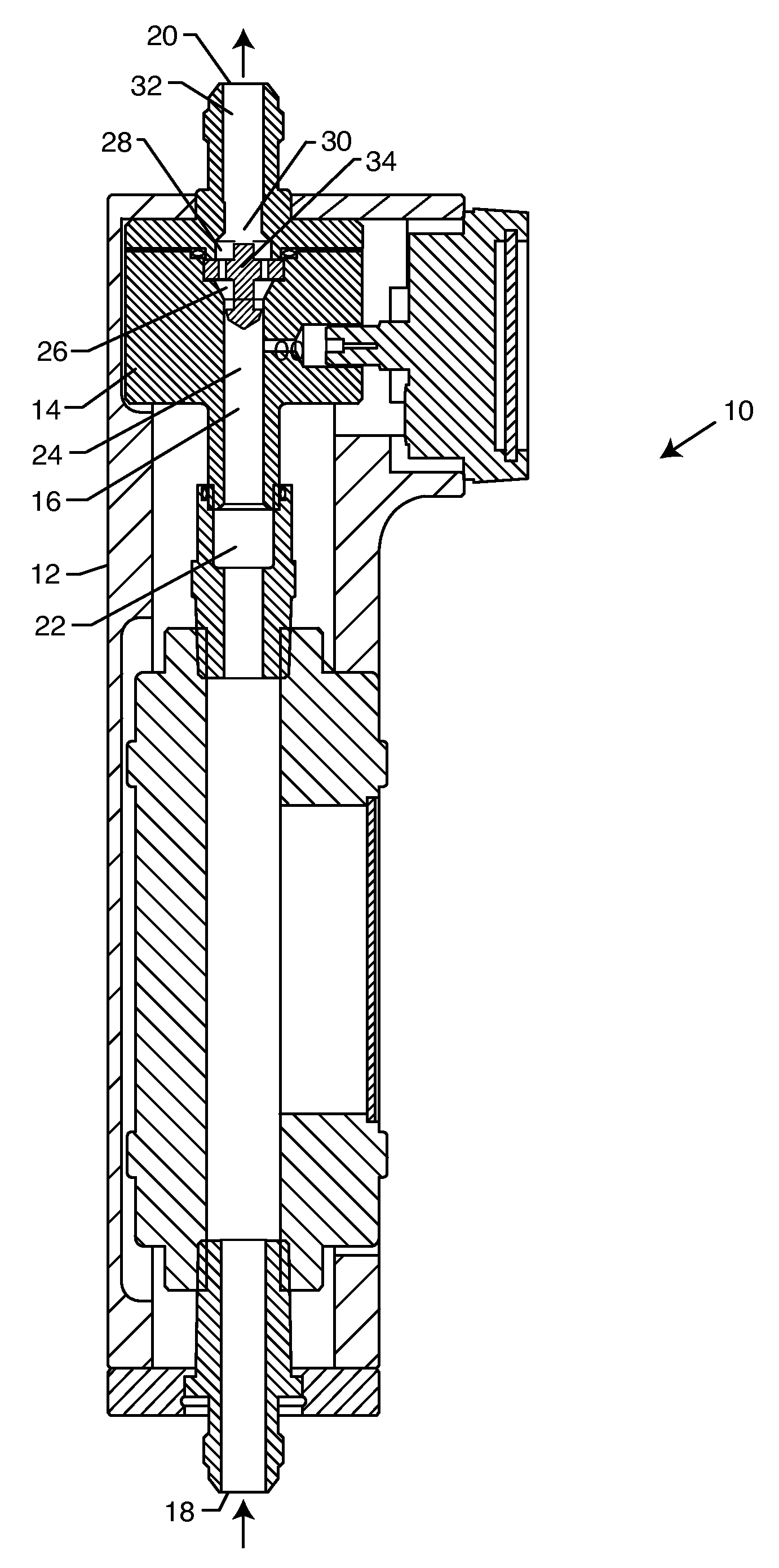

Method for cavitation-assisted refining, degumming and dewaxing of oil and fat

ActiveUS20090314688A1Improve throughputPrevent oxidationLiquid-gas reaction as foam/aerosol/bubblesFatty acid esterificationCavitationOil phase

A method for degumming and / or refining crude oil containing impurities involving mixing the crude oil with degumming agents, i.e., water or acid, and subjecting the mixture to flow-through, hydrodynamic cavitation processing. The cavitational processing transfers impurities in the crude oil to a water phase for easier separation. The water phase may be separated from the oil phase by commonly available separation methods.

Owner:CAVITATION TECH

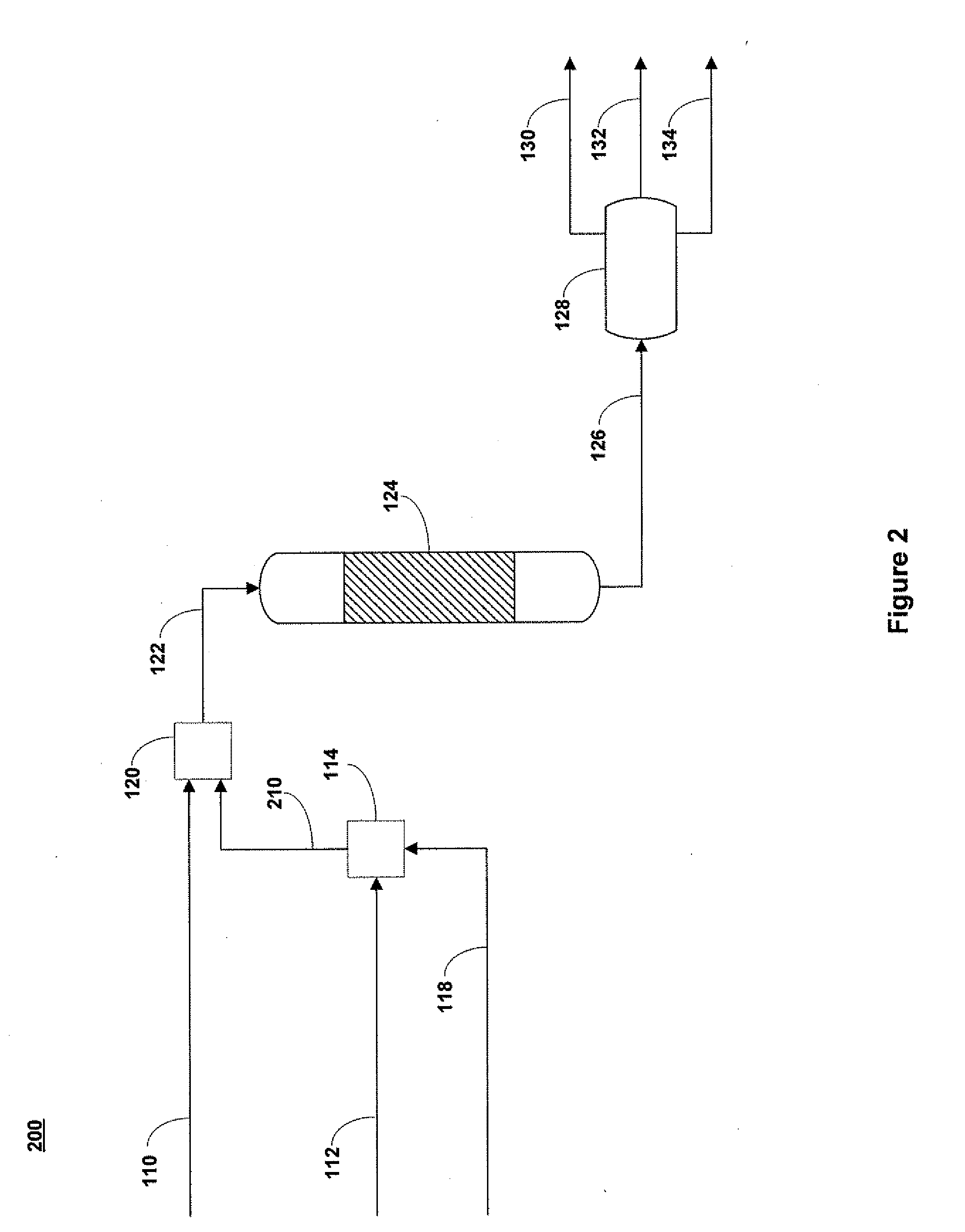

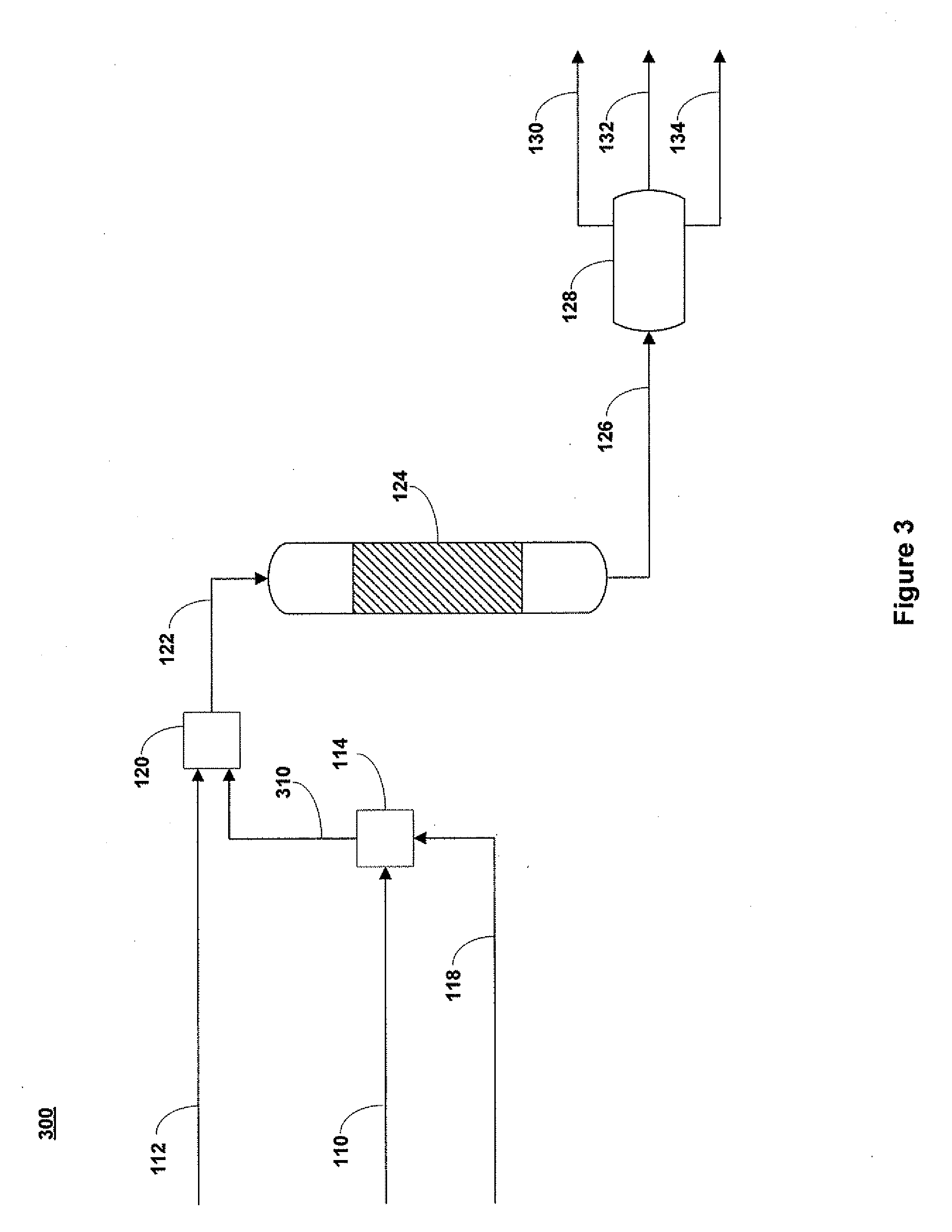

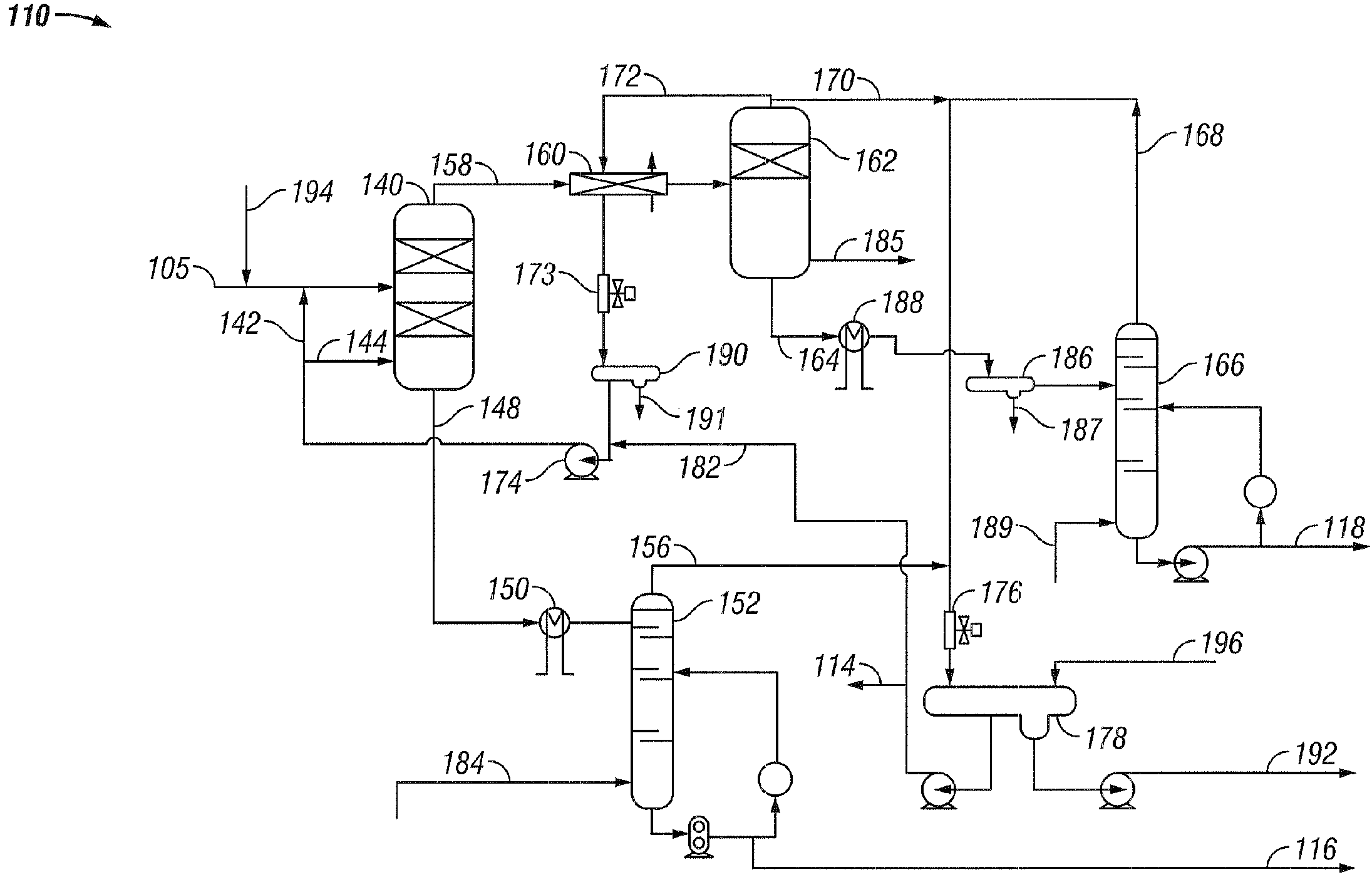

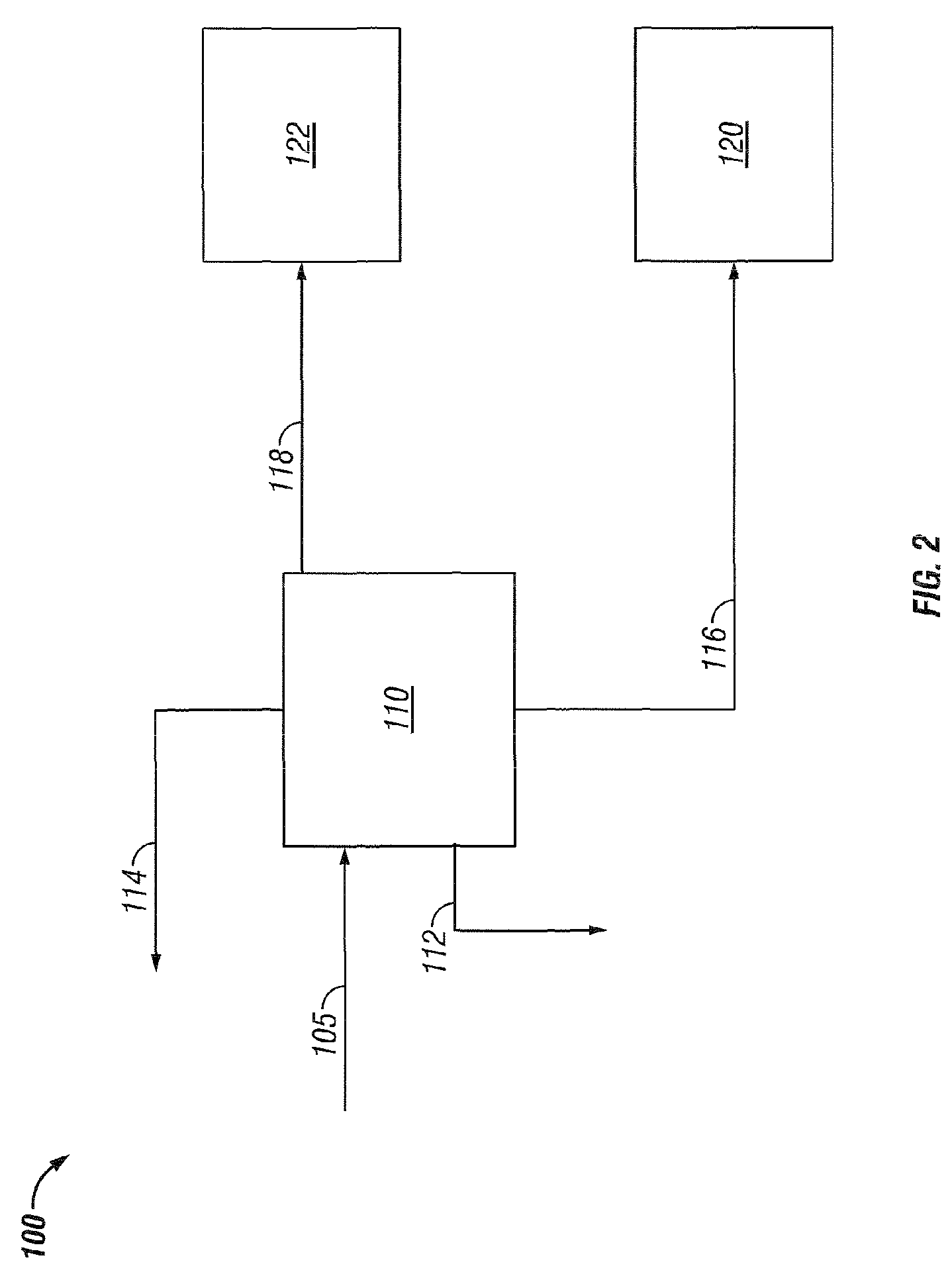

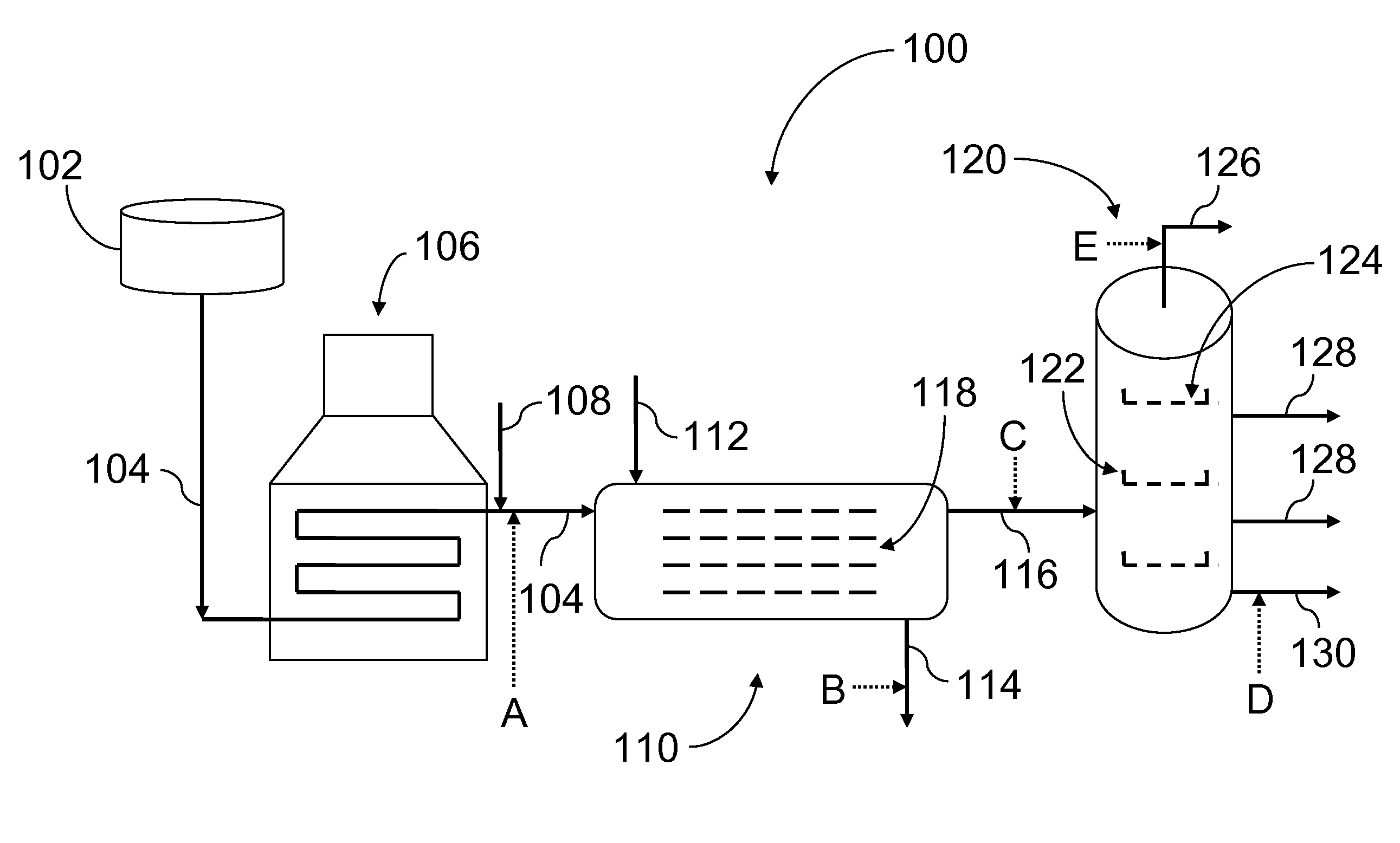

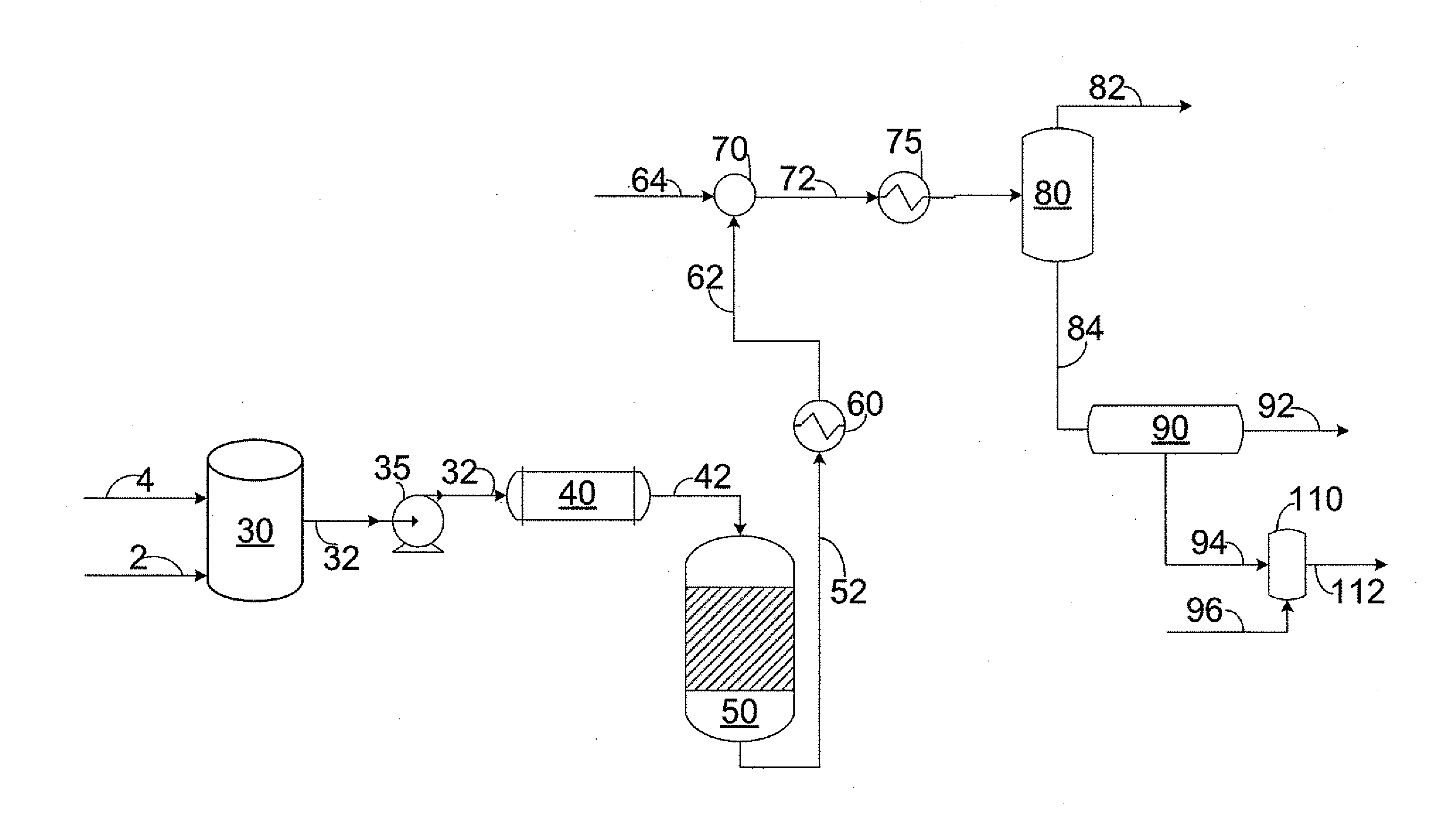

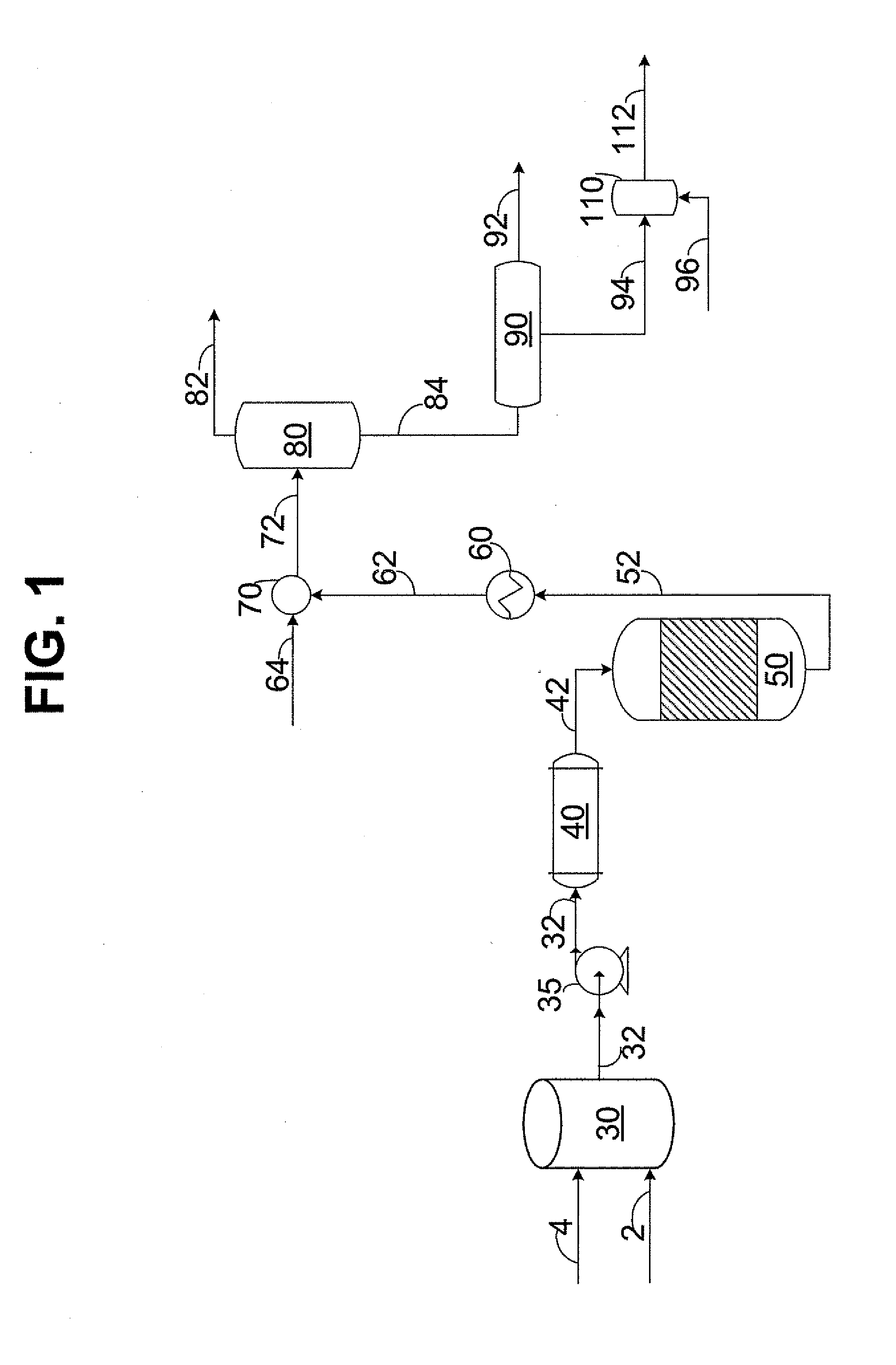

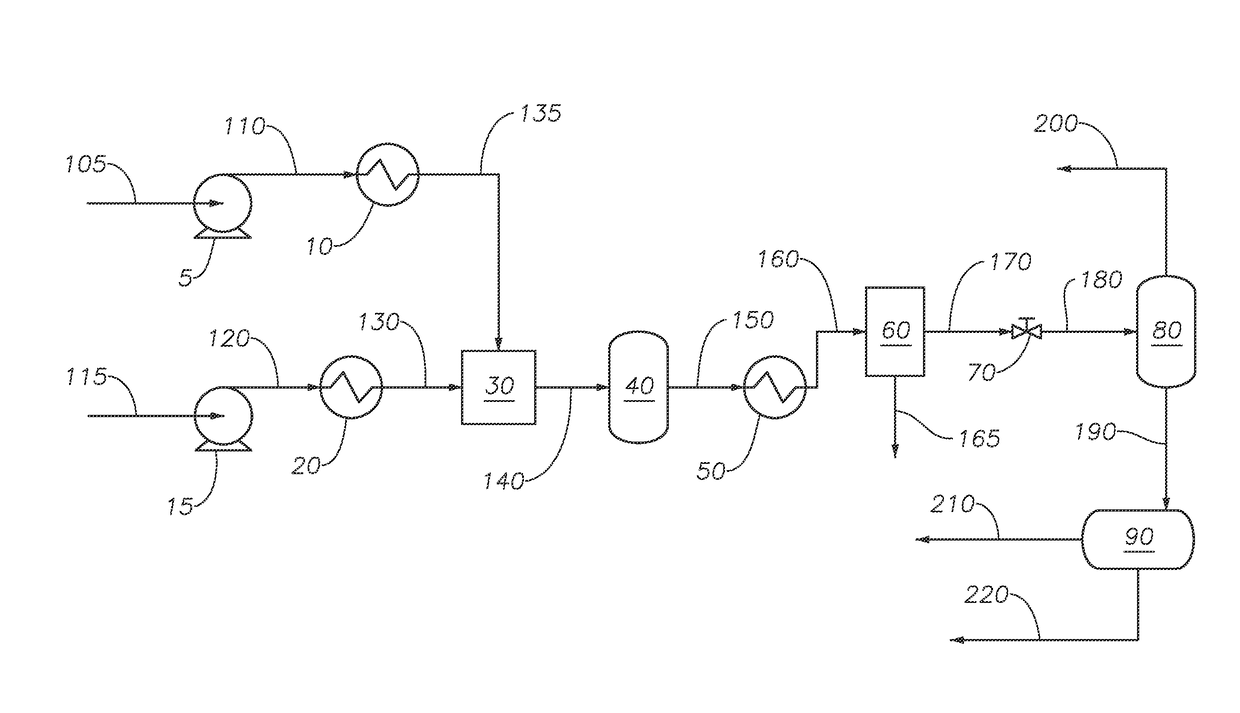

Bitumen production-upgrade with common or different solvents

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

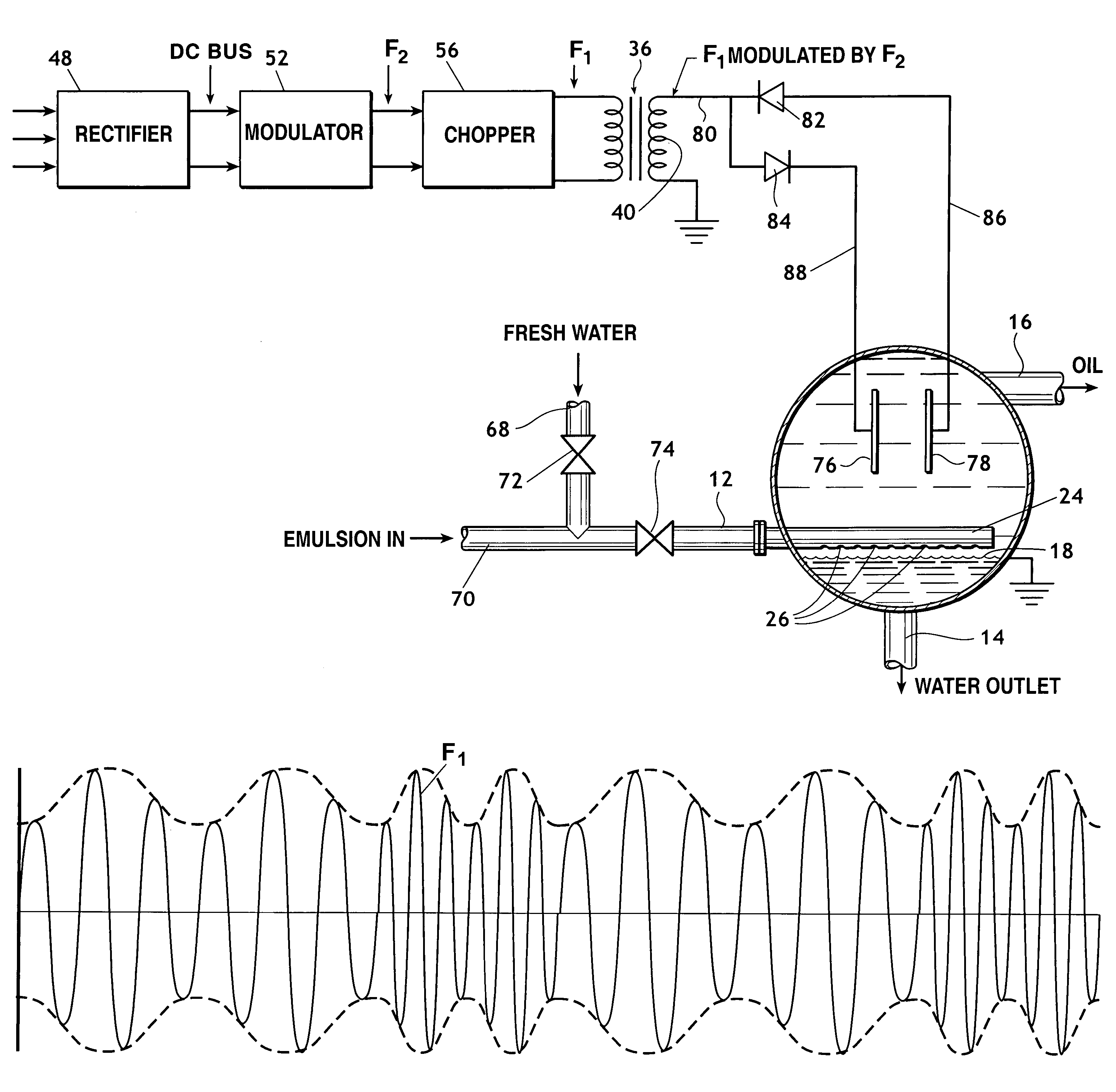

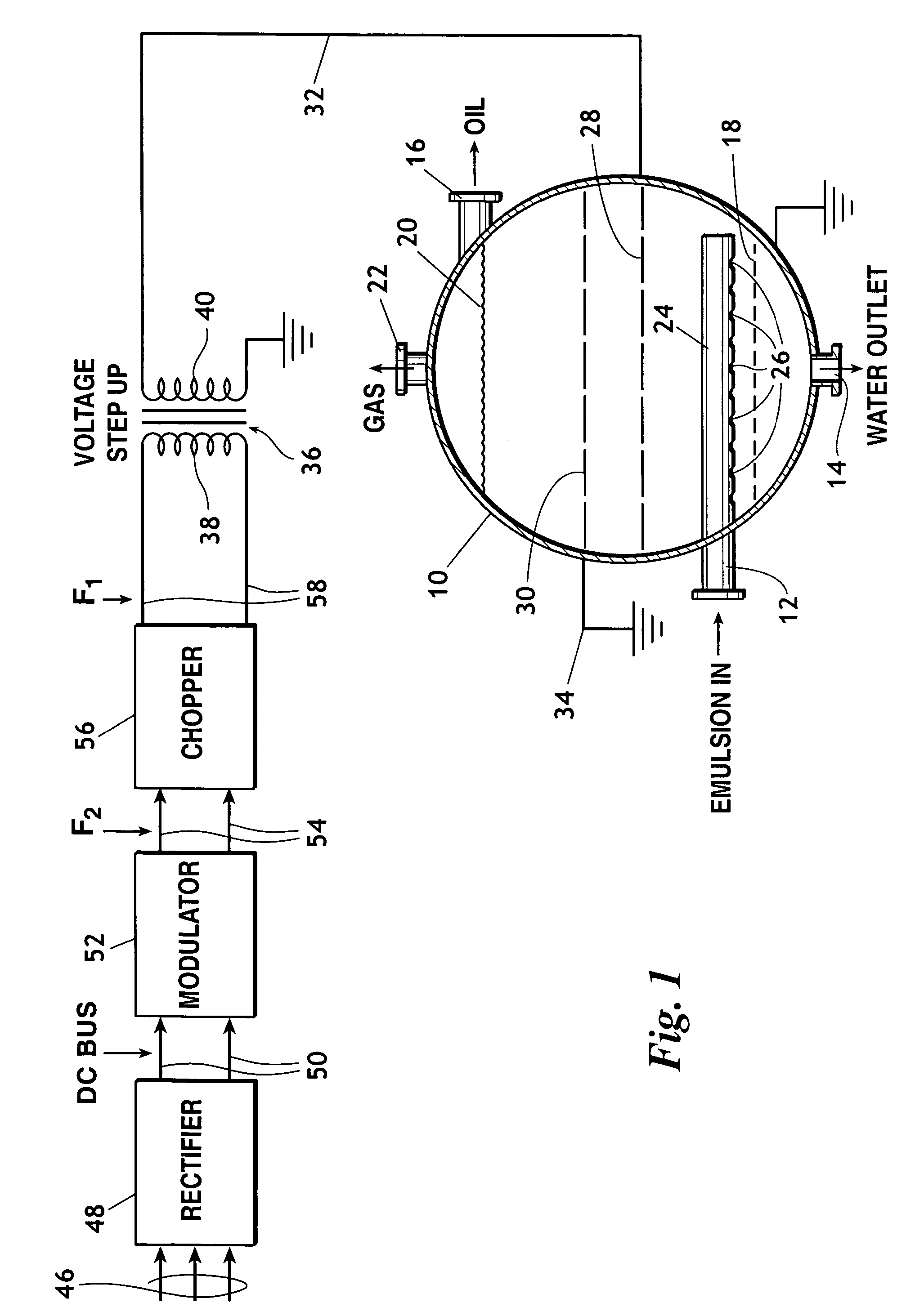

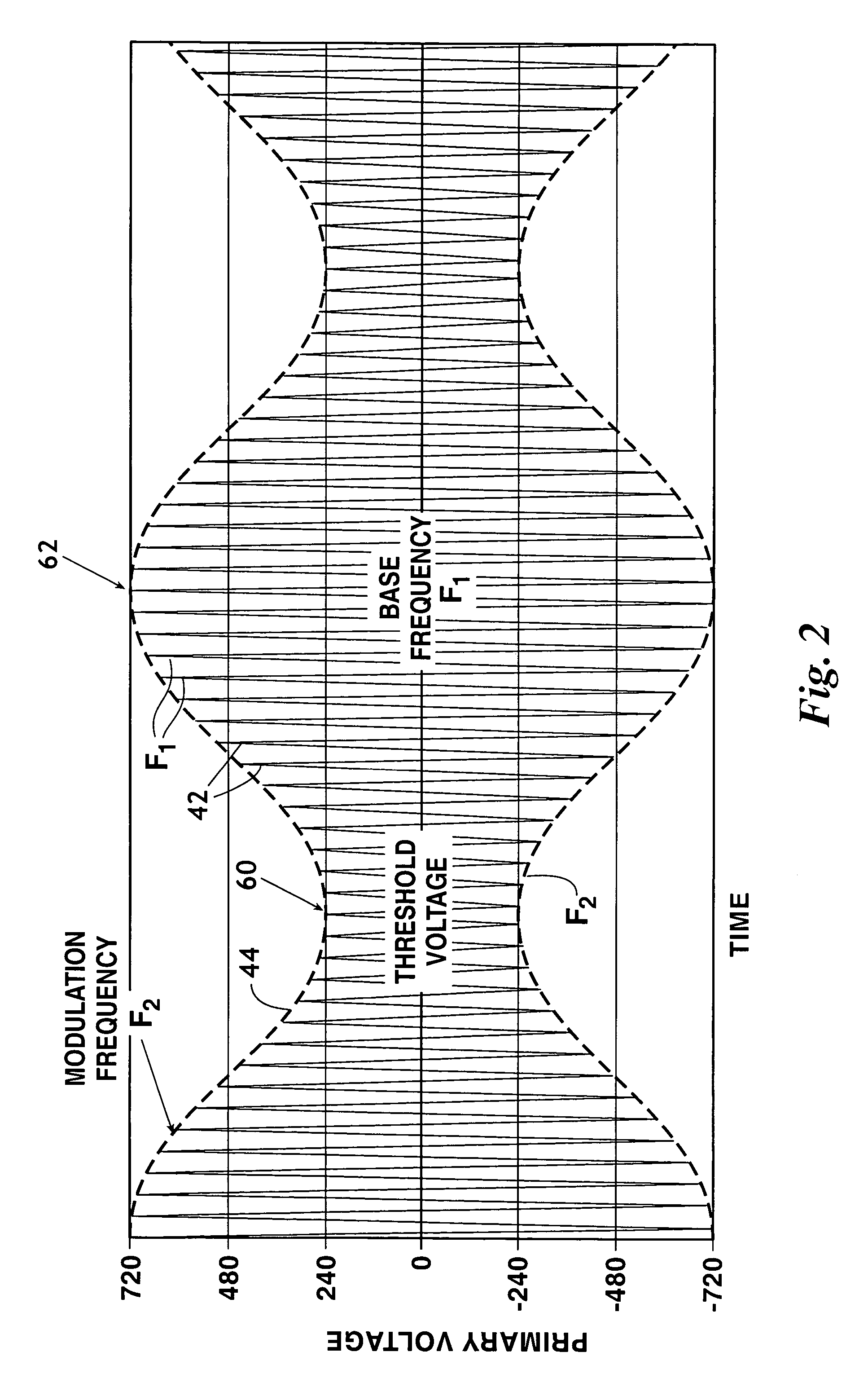

Multiple frequency electrostatic coalescence

A method of augmenting the separation of immiscible heavier and lighter components of an emulsion including the steps of conducting the emulsion into a treatment vessel, providing an AC voltage source, employing from the source an AC voltage of at least one selected frequency F1 to establish at least one electric filed within the vessel through which the emulsion passes, and cyclically modulating the AC voltage with a method of modulation selected from: (a) amplitude modulation; (b) frequency modulation; and (c) combined amplitude and frequency modulation.

Owner:NAT TANK

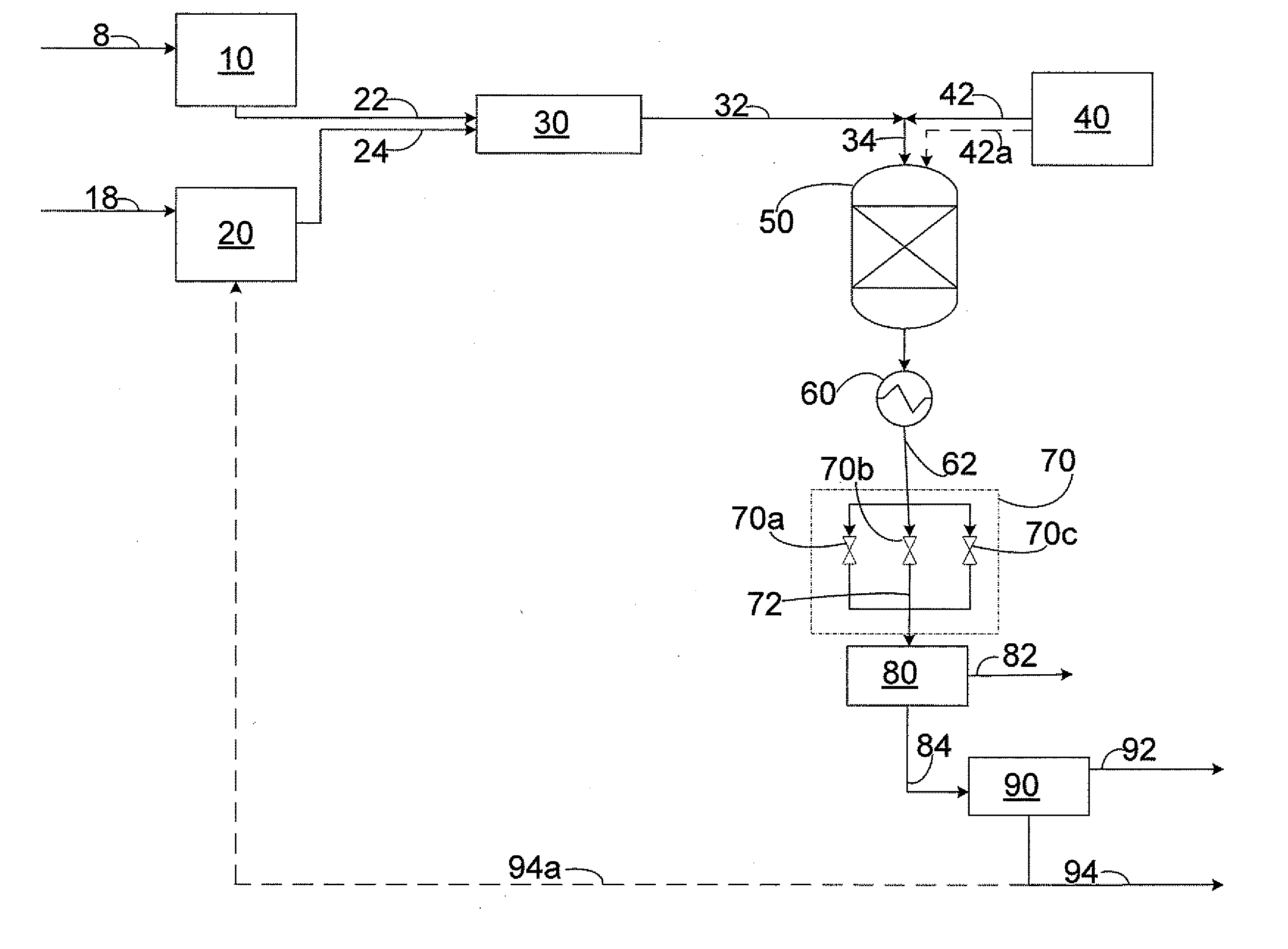

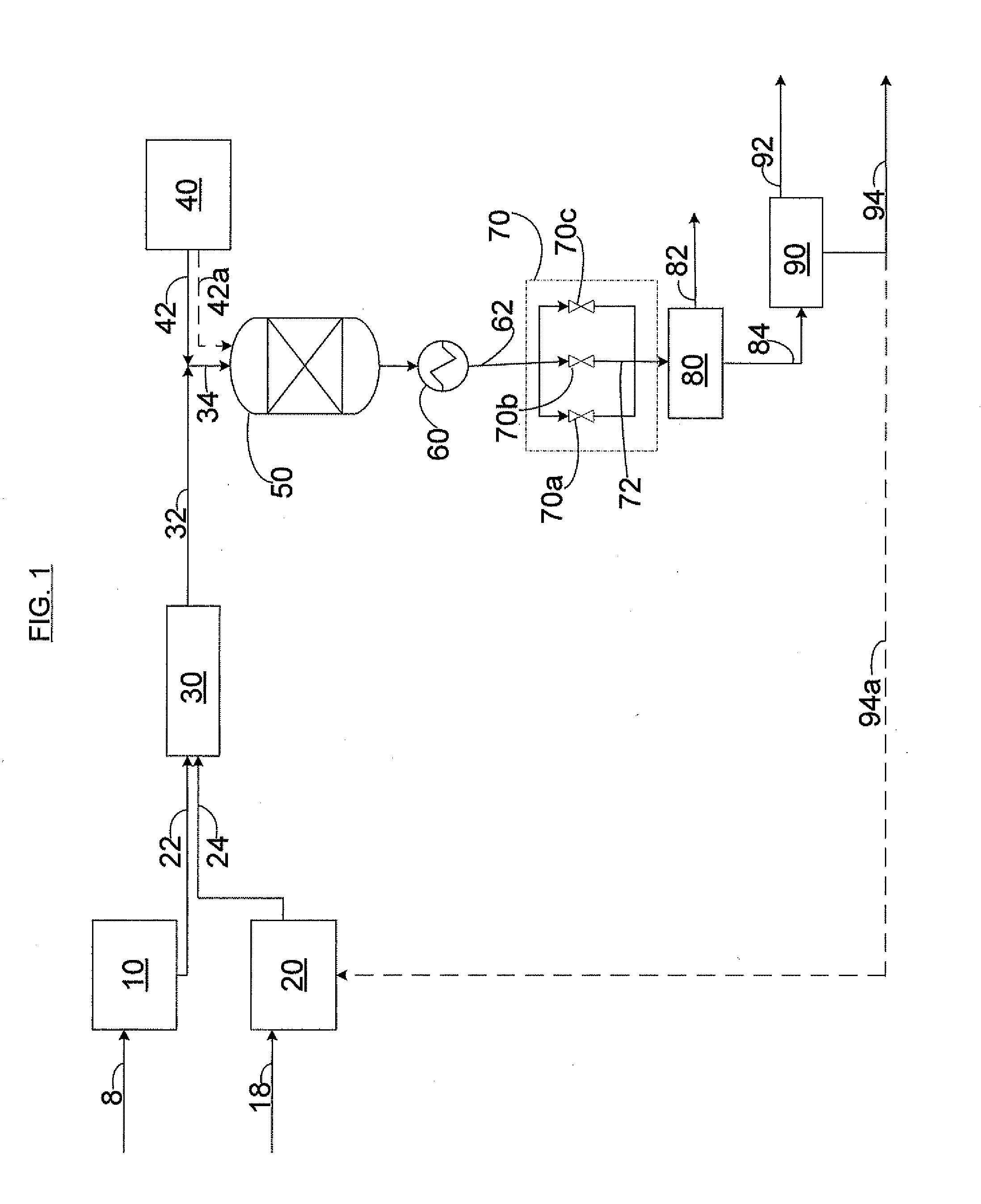

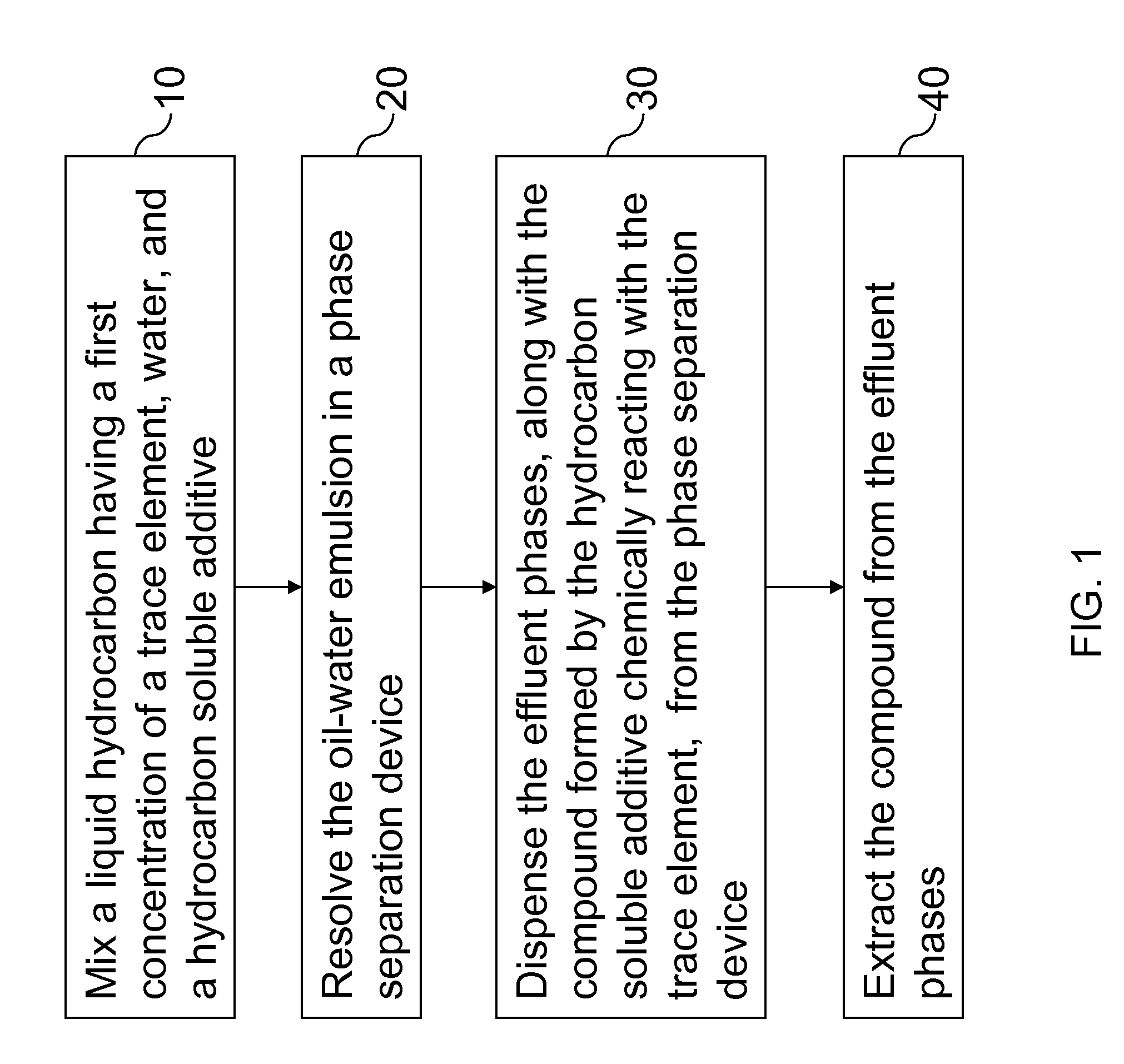

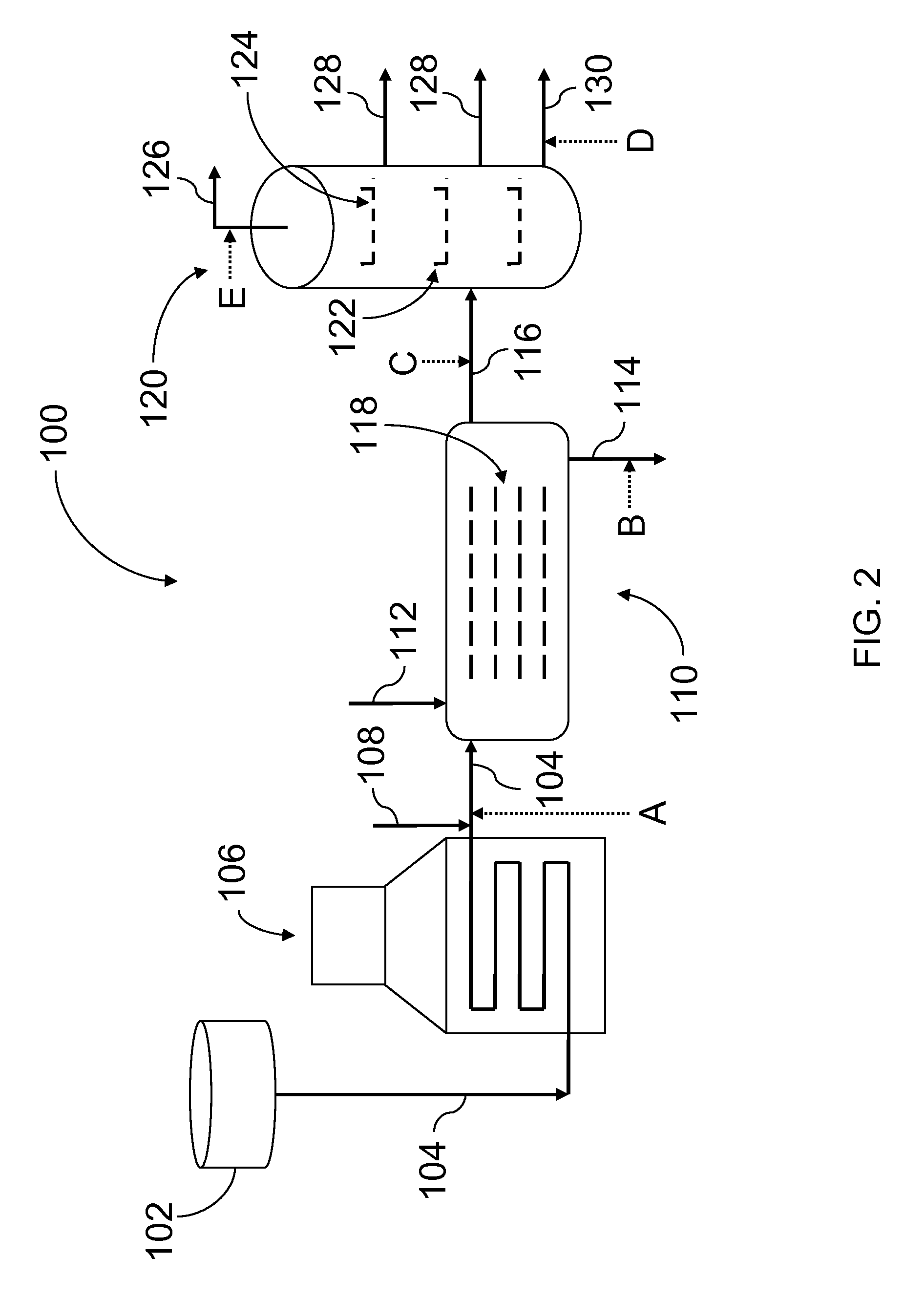

System and method for separating a trace element from a liquid hydrocarbon feed

InactiveUS20100000910A1Easy to removeEasy to separateTransportation and packagingRefining by water treatmentChemical reactionTrace element

The present invention is generally directed to removing a trace element from a liquid hydrocarbon feed. The liquid hydrocarbon feed, containing the trace element, is mixed with the water along with a hydrocarbon-soluble additive. While being mixed, a compound, which in some cases is preferably insoluble, is formed by the hydrocarbon-soluble additive chemically reacting with the trace element. A phase separation device, such as a desalter or an oil-water separator, receives the oil-water emulsion containing the compound and resolves the mixture to produce the compound, effluent brine, and effluent liquid hydrocarbon with a reduced concentration of the trace element as compared to the liquid hydrocarbon feed. In some embodiments, the present invention is directed to removing elemental mercury from a liquid hydrocarbon feed. A hydrocarbon-soluble sulfur-containing additive, typically an organic polysulfide, is mixed with the liquid hydrocarbon feed and water. The hydrocarbon-soluble, sulfur-containing additive reacts with the mercury, rapidly forming an agglomeration of mercuric sulfide which is then dispensed with the effluent brine or the effluent liquid hydrocarbon.

Owner:CHEVROU USA INC

Method of modifying biomass, modified biomass aqueous biomass sluryy and method of producing the same, modified biomass gas and method of gasifying biomass

InactiveUS20060112638A1Reduce the amount of oxygenImprove efficiencyPressurized chemical processSolid waste disposalCelluloseSolid component

This method of upgrading a biomass comprises: an upgrading step for performing upgrading treatment of a cellulose based biomass with an oxygen / carbon atomic ratio of at least 0.5, in presence of water and under a pressure of at least saturated water vapor pressure, and reducing said oxygen / carbon atomic ratio of said biomass to no more than 0.38, and a separation step for separating an upgraded reactant obtained from said upgrading step into a solid component and a liquid component.

Owner:JGC CORP +1

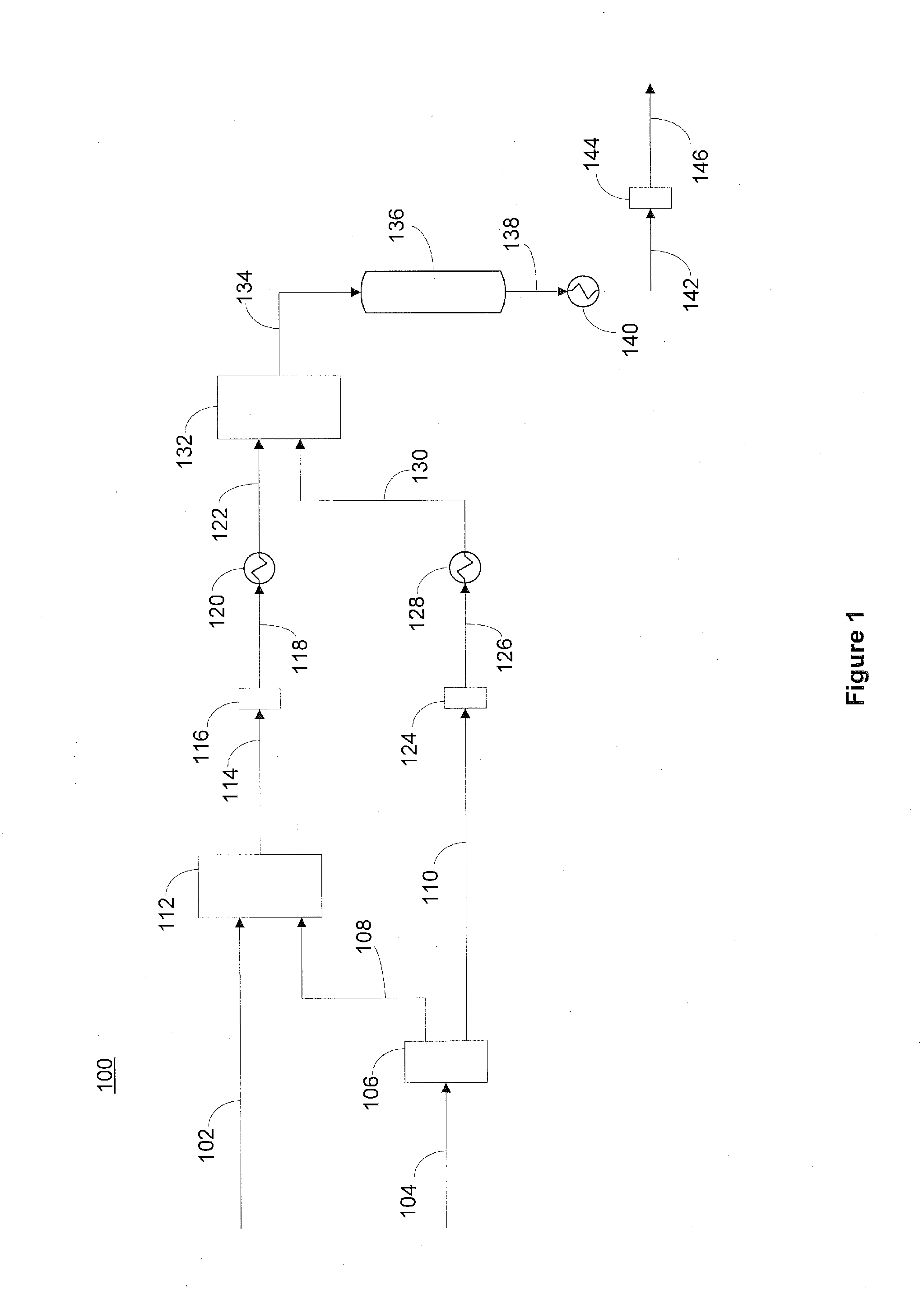

Removal of sulfur compounds from petroleum stream

ActiveUS20110315600A1Reduce the amount requiredIncreasing API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

Demulsifier composition and method of using same

ActiveUS20130261227A1Improve permeabilityImprove breathabilityDewatering/demulsification with chemical meansRefining by water treatmentDemulsifierActive agent

Disclosed and claimed is a microemulsion-based demulsifier composition and a method of demulsifying an emulsion comprising hydrocarbon and water. The demulsifier composition includes (i) an oil-like phase comprising at least one nonionic surfactant having a hydrophilic-lipophilic balance (HLB) of less than about 9; (ii) a coupling agent capable of stabilizing the demulsifier composition; (iii) at least one water-soluble or dispersible nonionic surfactant that is different from the at least one nonionic surfactant in the oil-like phase; (iv) at least one additional surfactant selected from anionic, cationic, amphoteric, and combinations thereof; (v) at least one nonionic demulsifier; and (vi) water.

Owner:CHAMPIONX USA INC

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS20070144941A1Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercritical water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Heavy oil treating method and heavy oil treating system

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

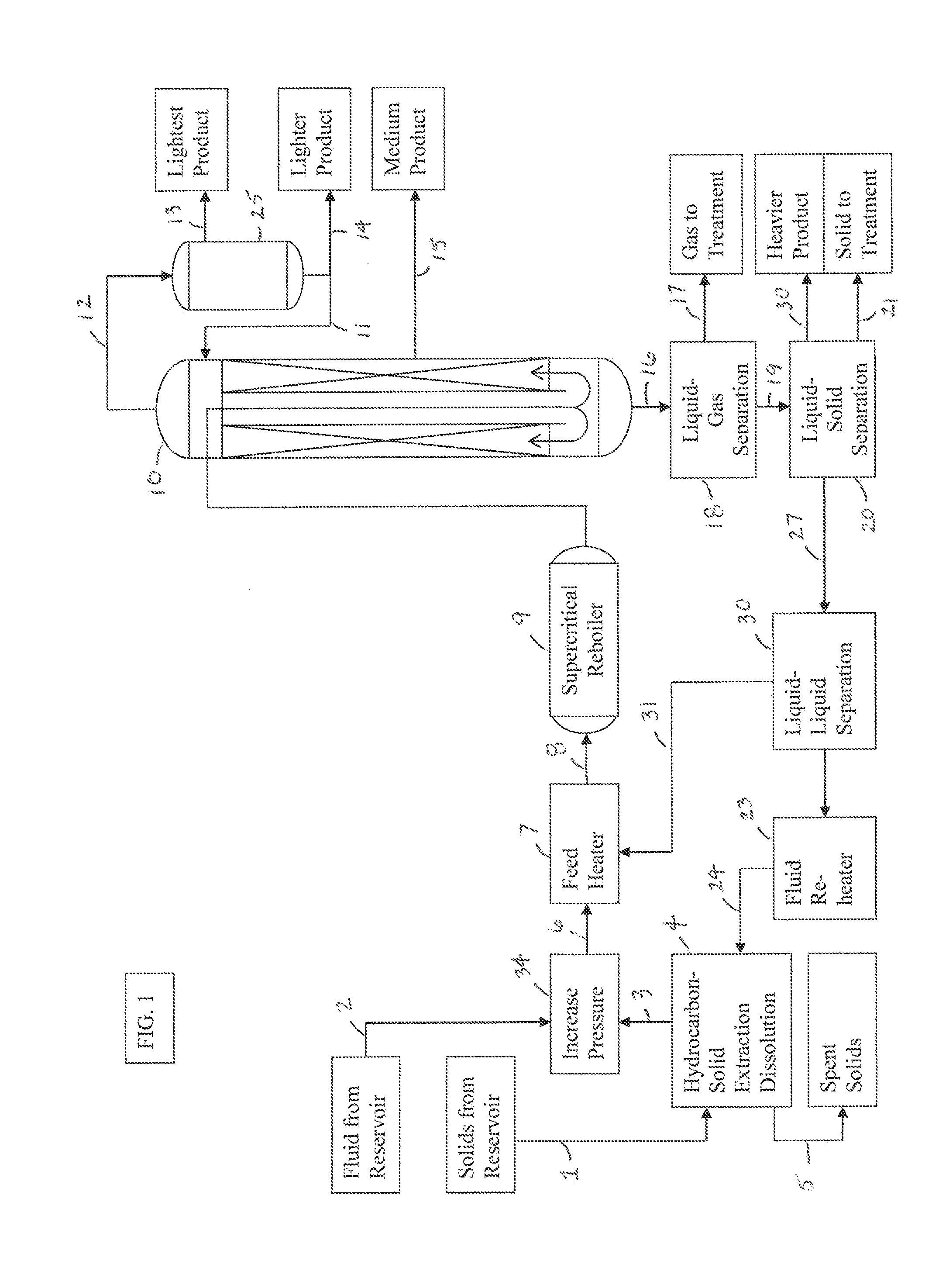

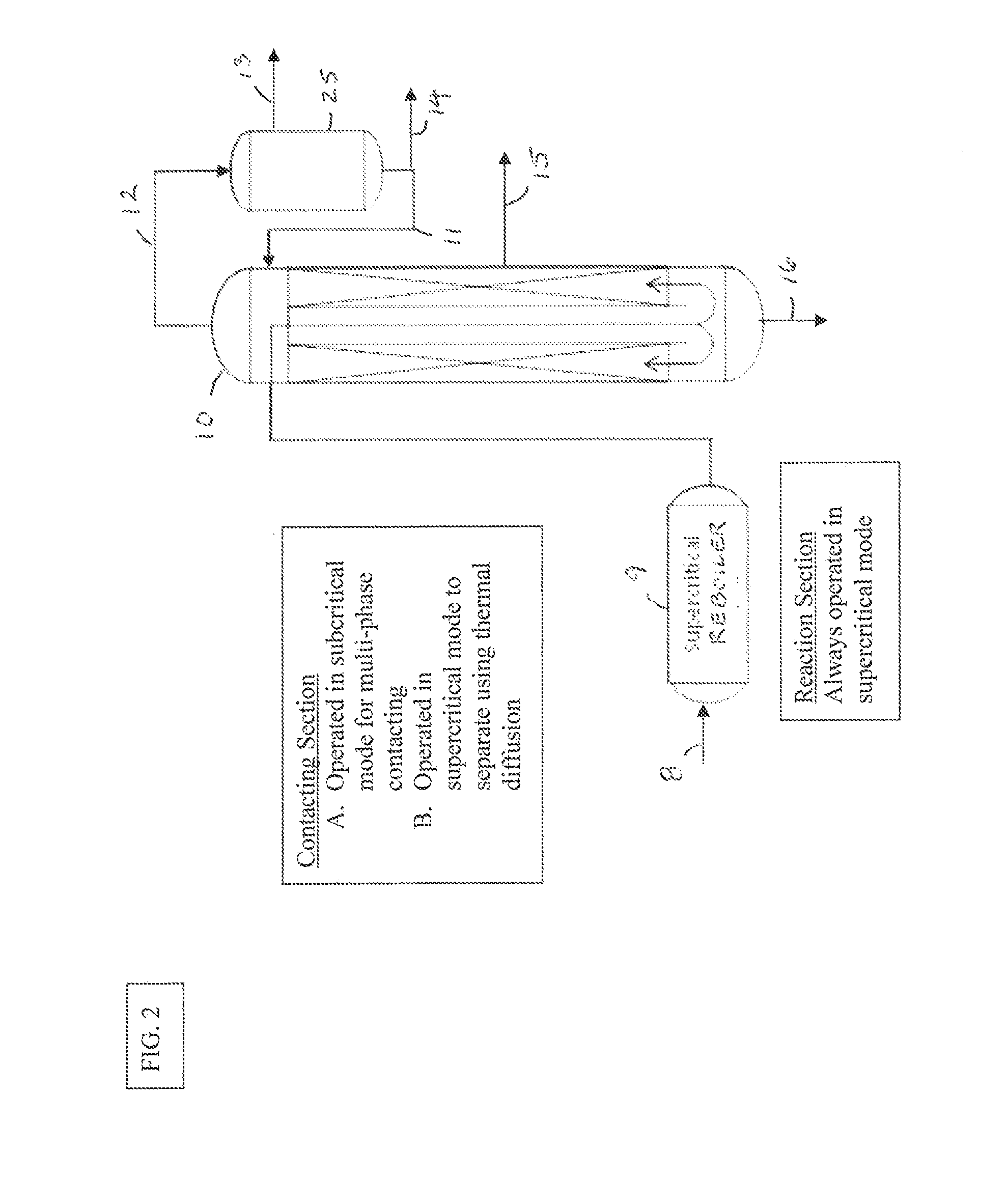

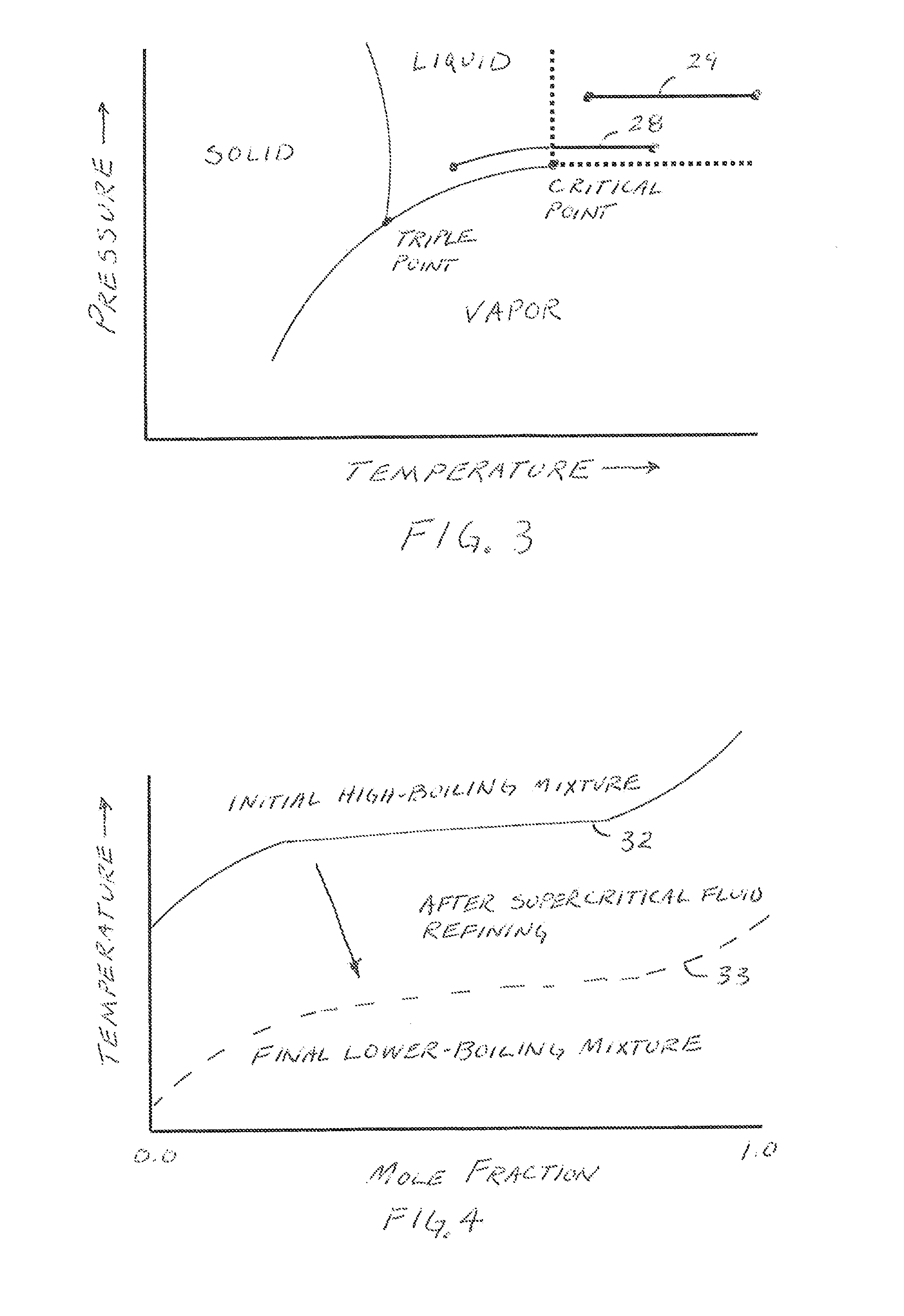

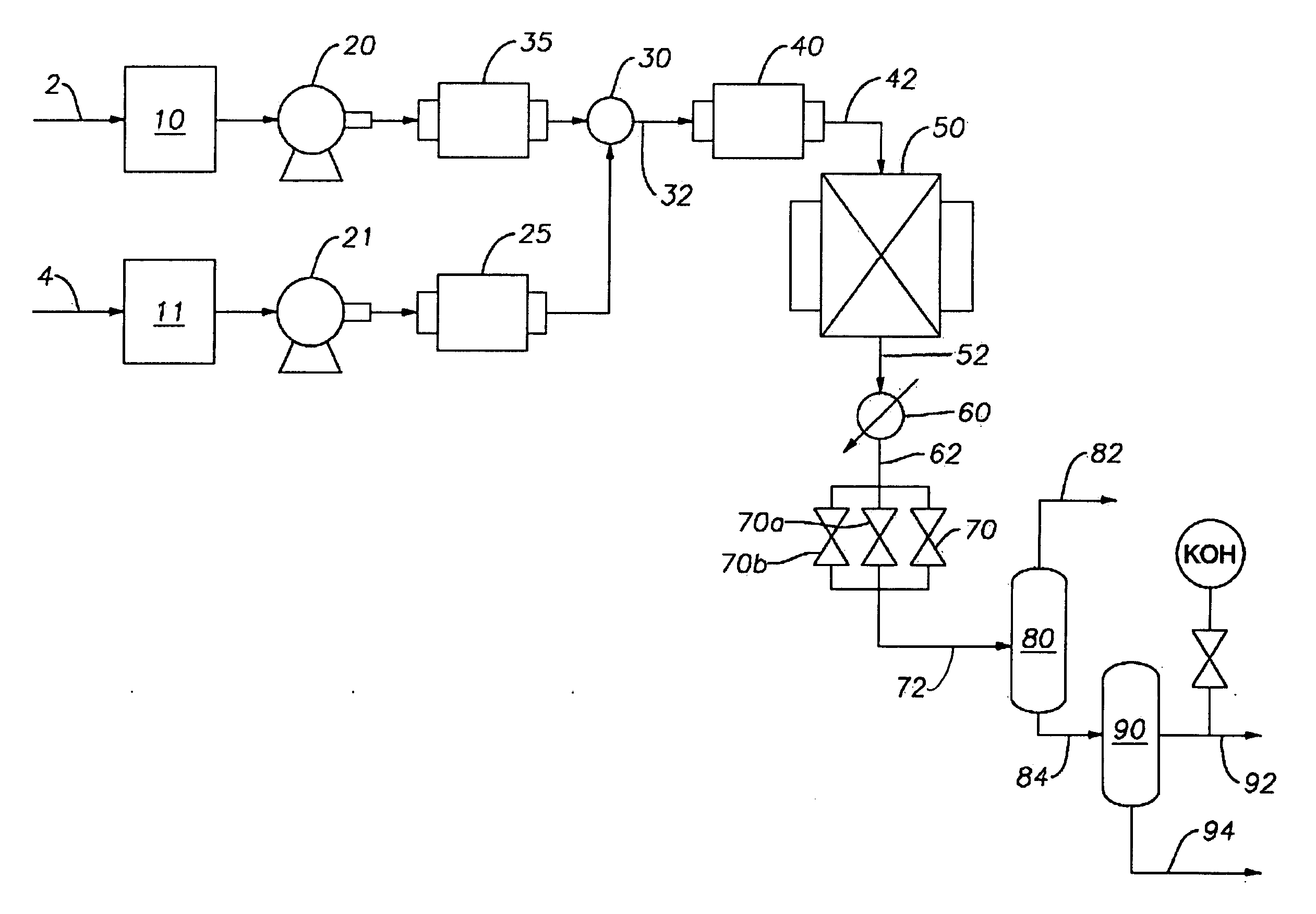

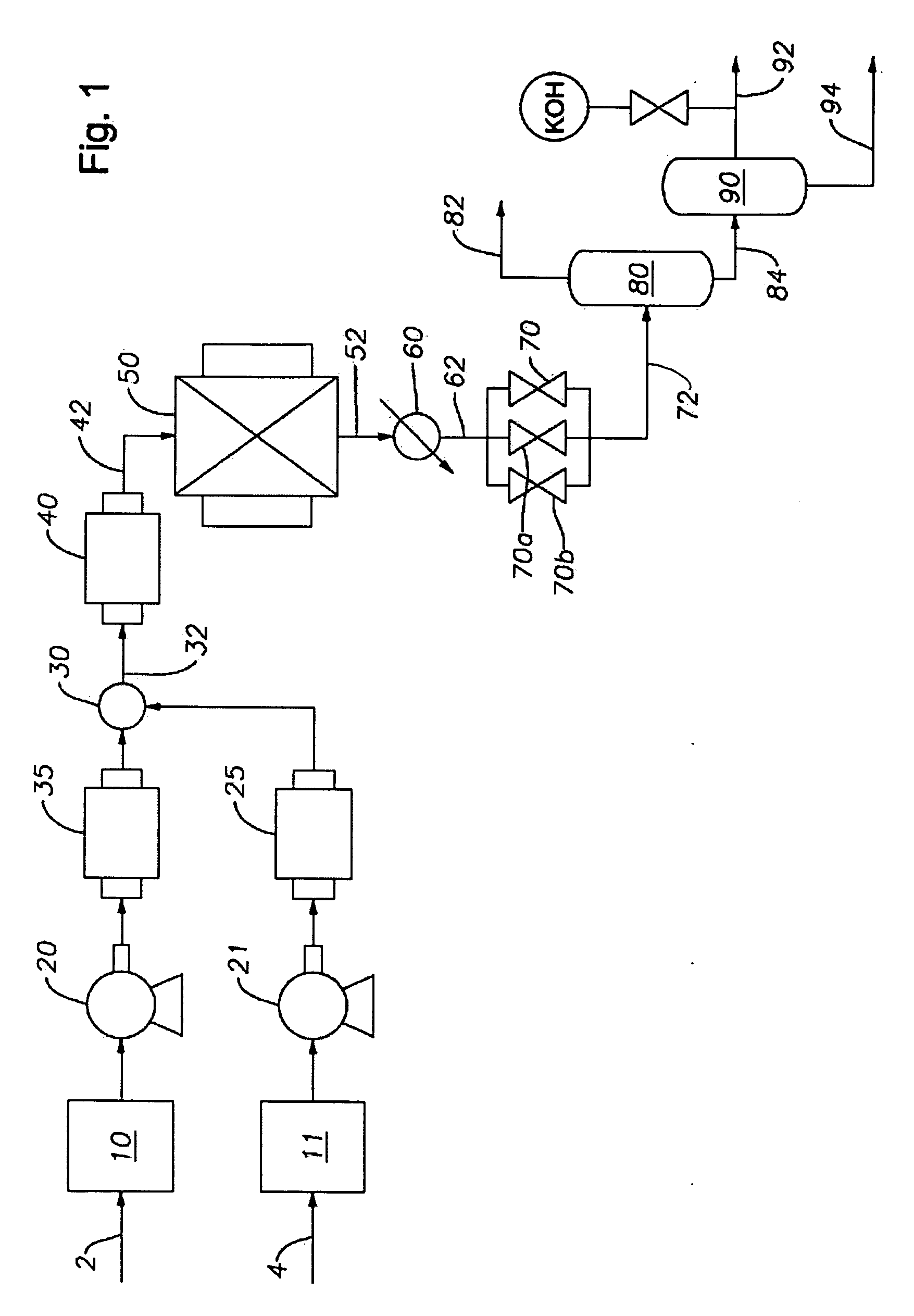

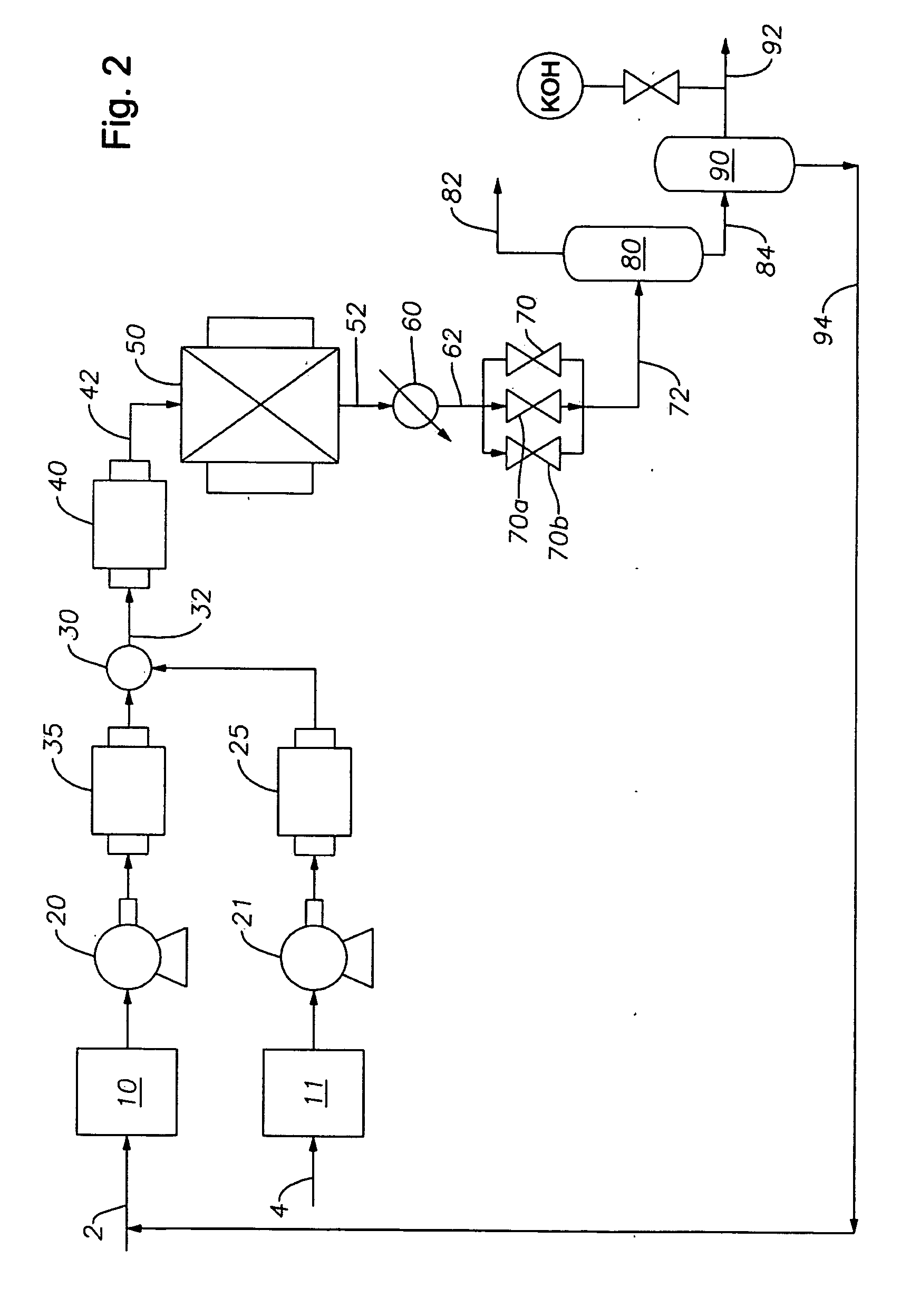

Using supercritical fluids to refine hydrocarbons

ActiveUS20110163011A1Light weightImprove securityRefining by water treatmentLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesAPI gravity

This is a method to reactively refine hydrocarbons, such as heavy oils with API gravities of less than 20° and bitumen-like hydrocarbons with viscosities greater than 1000 cp at standard temperature and pressure using a selected fluid at supercritical conditions. The reaction portion of the method delivers lighter weight, more volatile hydrocarbons to an attached contacting device that operates in mixed subcritical or supercritical modes. This separates the reaction products into portions that are viable for use or sale without further conventional refining and hydro-processing techniques. This method produces valuable products with fewer processing steps, lower costs, increased worker safety due to less processing and handling, allow greater opportunity for new oil field development and subsequent positive economic impact, reduce related carbon dioxide, and wastes typical with conventional refineries.

Owner:HEAVY OIL SOLUTIONS INC

Process to reduce acidity of crude oil

ActiveUS20090159504A1Reduce corrosionSimple methodThermal non-catalytic crackingRefining with metalsOrganic acidNaphthenic acid

Owner:SAUDI ARABIAN OIL CO

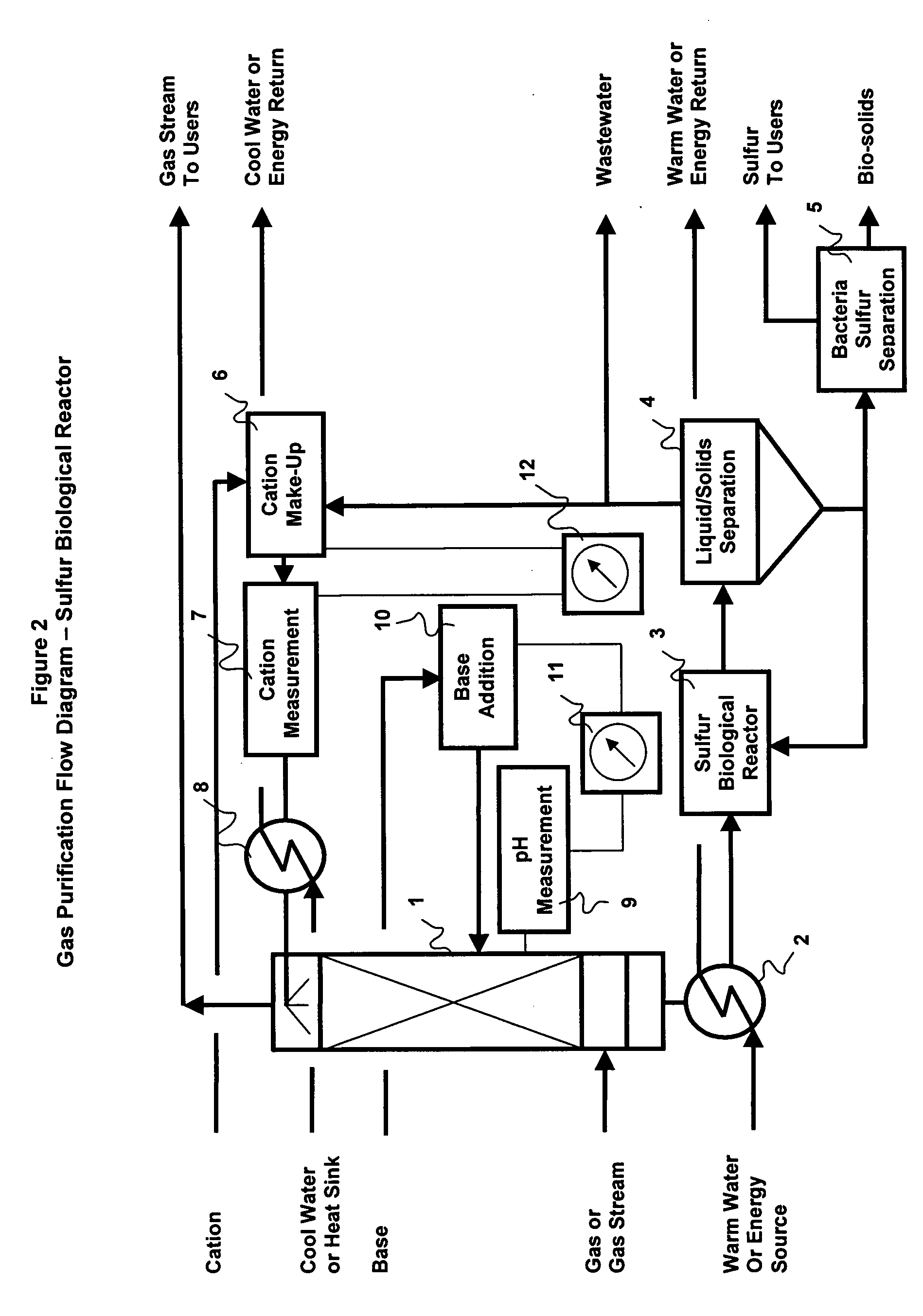

Methods, processes and apparatus for biological purification of a gas, liquid or solid; and hydrocarbon fuel from said processes

InactiveUS20080190844A1Effective and efficient and economically feasibleTreatment using aerobic processesWaste water treatment from gaseous effluentsPresent methodThiobacillus

This invention relates to improved methods, processes and apparatus for the removal of sulfides from a gas, liquid or solid (substance) wherein the substance is contacted with an aqueous solution. The instant invention presents methods and processes wherein at least one of H2S, SO2 and CS2 is chemically converted in an aqueous media to a salt and / or compound comprising sulfur and a cationic moiety. Said salt and / or compound comprising sulfur and a cationic moiety is herein termed a “Sulfur Salt”. After formation of the Sulfur Salt, the Sulfur Salt is converted to elemental sulfur with a bacterium capable of metabolizing sulfur. The preferred bacterium for metabolizing sulfur is a strain from the genus Thiobacillus. The most preferred strain from the genus Thiobacillus is Thiobacillus denitrificans. The instant invention prefers an aqueous operating pH of between 6.0 and 8.0, while the most preferred aqueous pH is between 6.0 and 7.0.

Owner:CLEARVALUE TECH

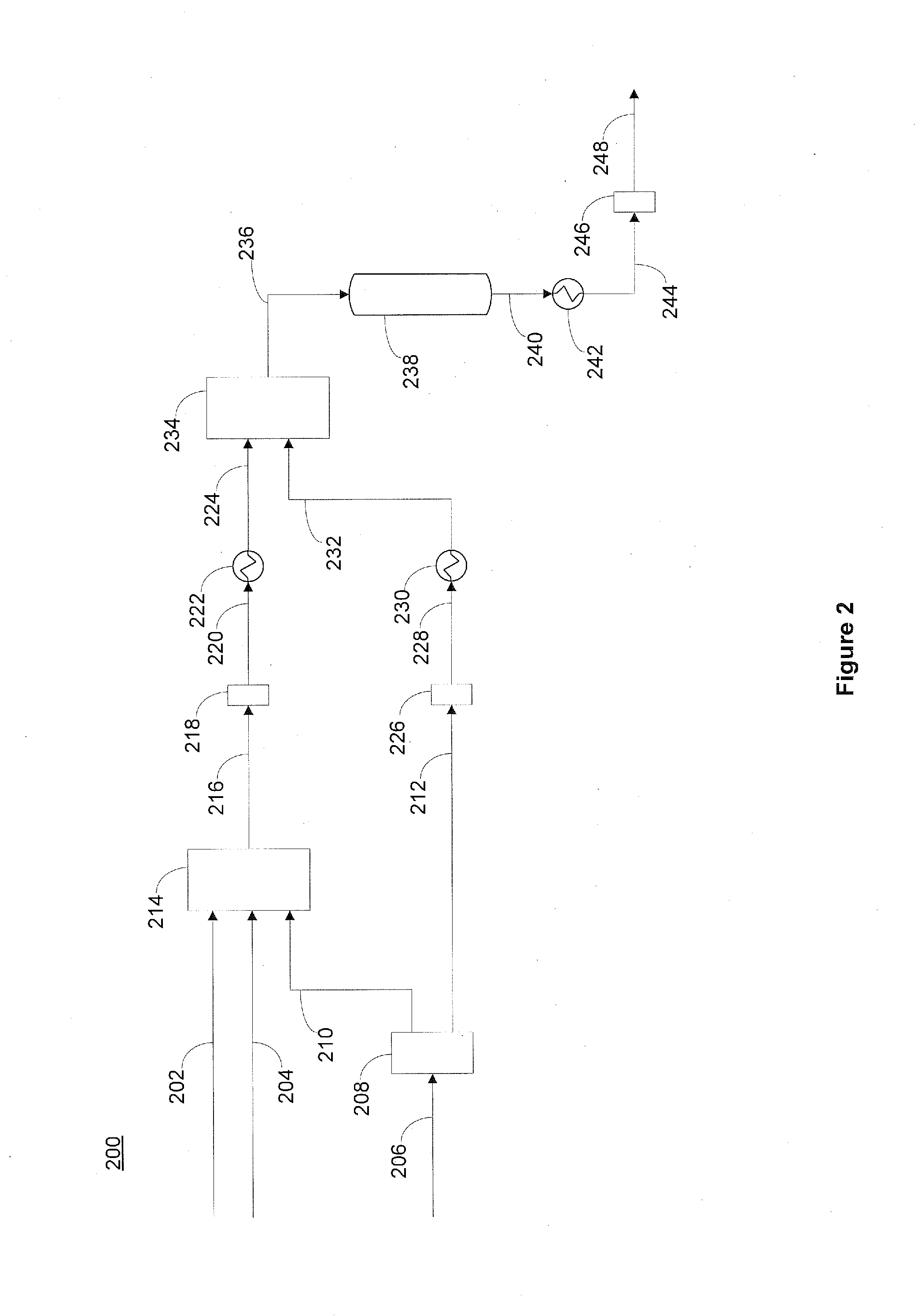

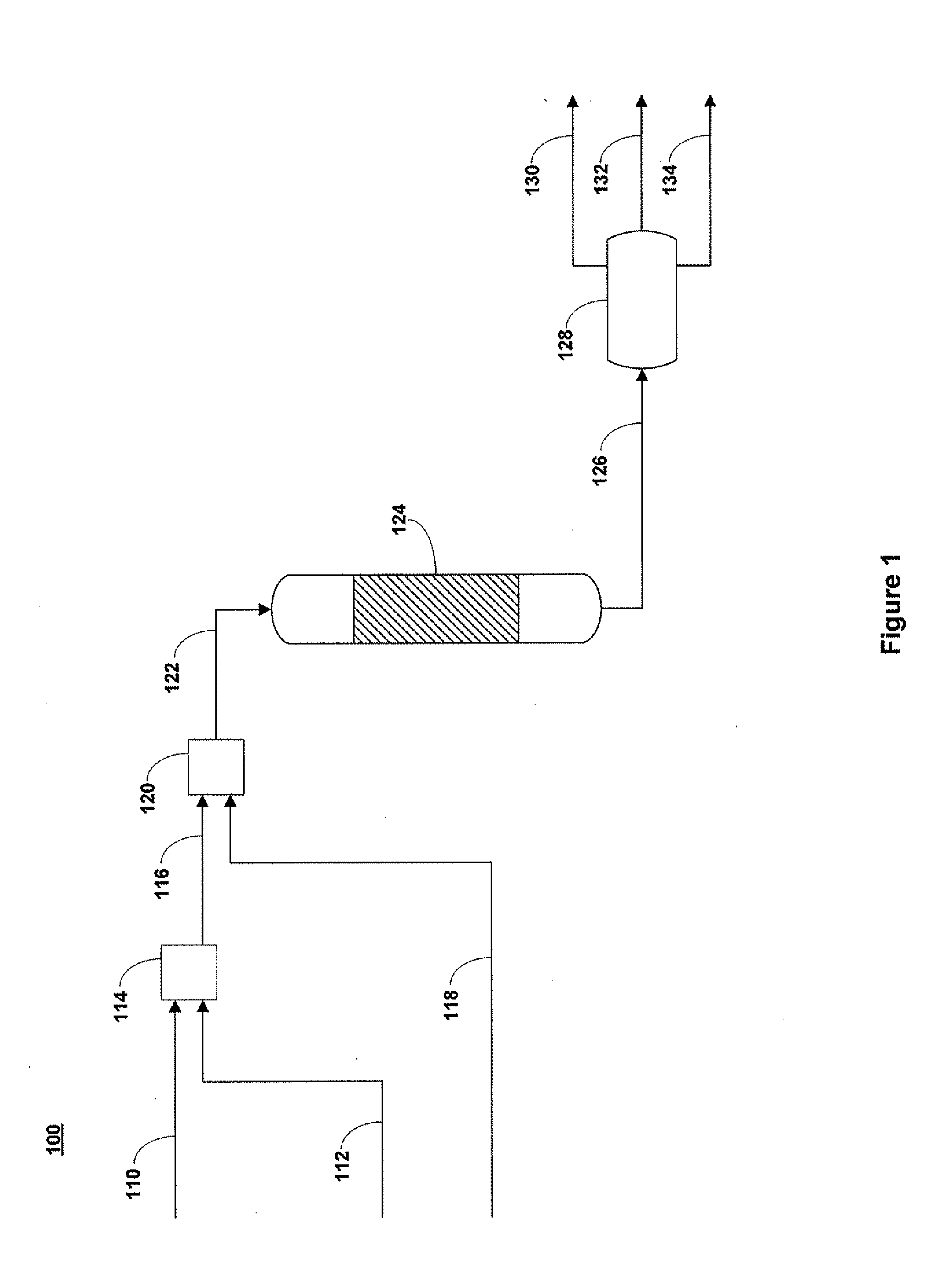

Method to remove metals from petroleum

ActiveUS20170107433A1Low sulfurThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productGas phase

A method to remove a metals impurity from a petroleum feedstock for use in a power generating process is provided. The method comprising the steps of mixing a heated feedstock with a heated water stream in a mixing device to produce a mixed stream; introducing the mixed stream to a supercritical water reactor in the absence of externally provided hydrogen and externally provided oxidizing agent to produce a reactor effluent comprising a refined petroleum portion; cooling the reactor effluent to produce a cooled stream; feeding the cooled stream to a rejecter configured to separate a sludge fraction to produce a de-sludged stream; reducing the pressure of the de-sludged stream to produce a depressurized product; separating the depressurized product to produce a gas phase product and a liquid product; separating the liquid product to produce a petroleum product, having a reduced asphaltene content, reduced concentration of metals impurity, and reduced sulfur.

Owner:SAUDI ARABIAN OIL CO

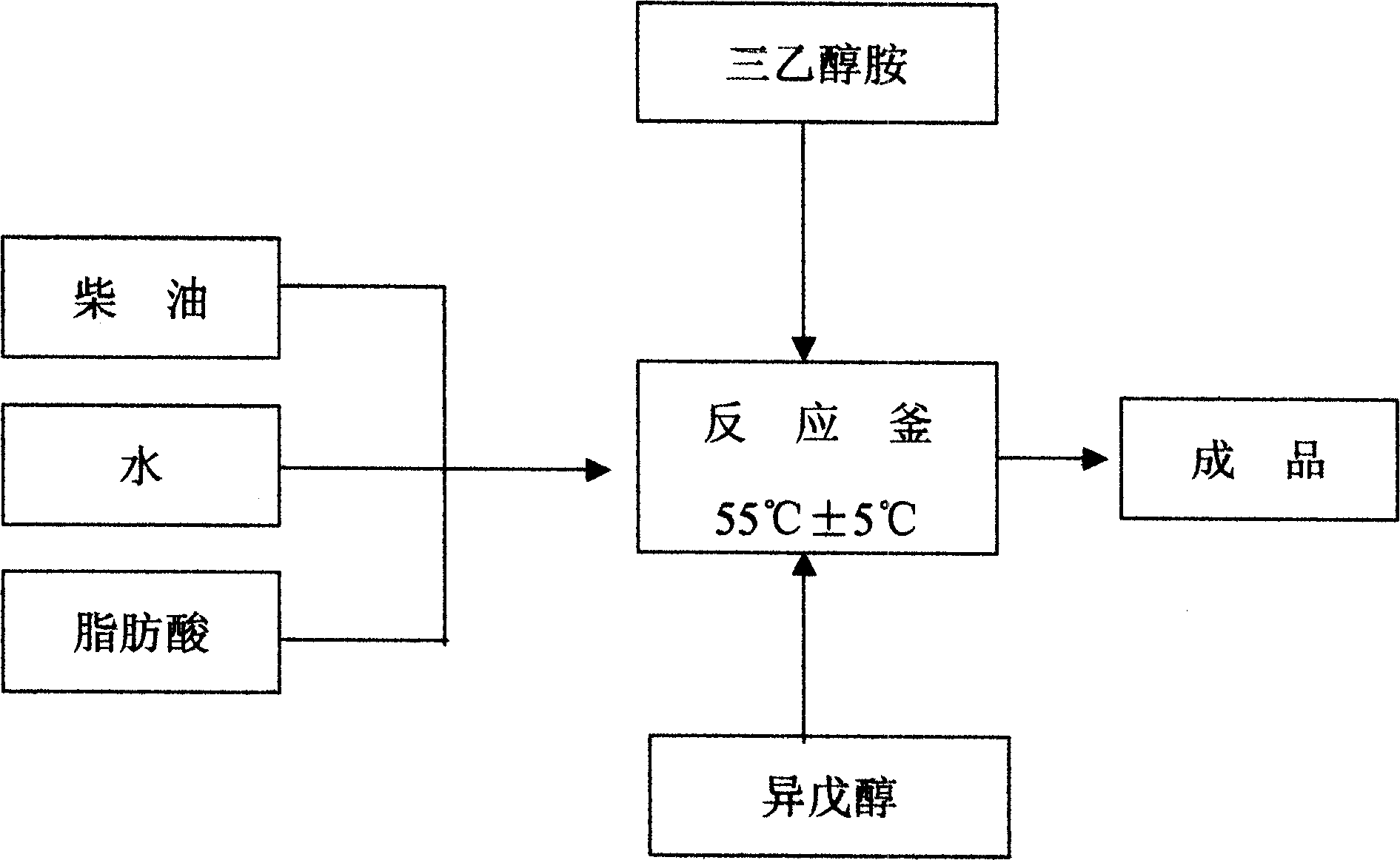

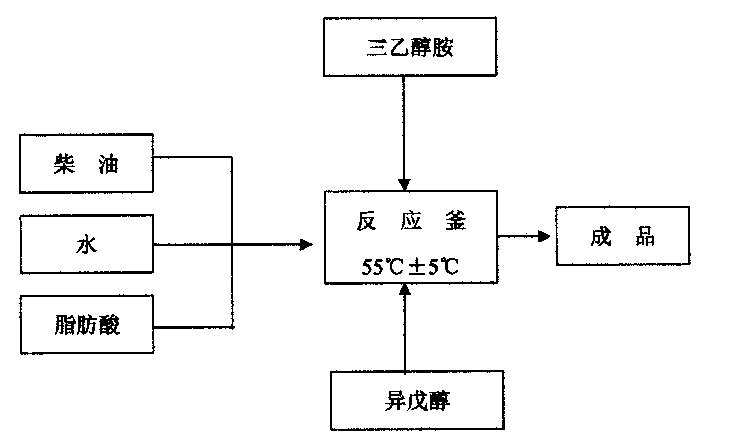

Production technology and formulation of microemulsion fuel oil

InactiveCN1410514AWide variety of sourcesTake advantage ofRefining by water treatmentFuel oilMicroemulsion

A microemulsified fuel oil is prepared from fatty acid (or oleic acid) (15 vol.%), triethanolamine (or biethanolamine) (2 vol.%), isopentanol (3 vol.%), water (20 vol.%) and diesel oil (60 vol.%). Its advantages are low cost, little harmful gas, and long service life of diesel engine.

Owner:季忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com