Intergrated process for in-field upgrading of hydrocarbons

a hydrocarbon and infield technology, applied in the cracking process, hydrocarbon oil cracking, water treatment, etc., can solve the problems of difficult to bring remote, heavy oil resources closer, and the oil produced from a significant number of oil reserves around the world is simply too heavy to flow under ambient conditions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

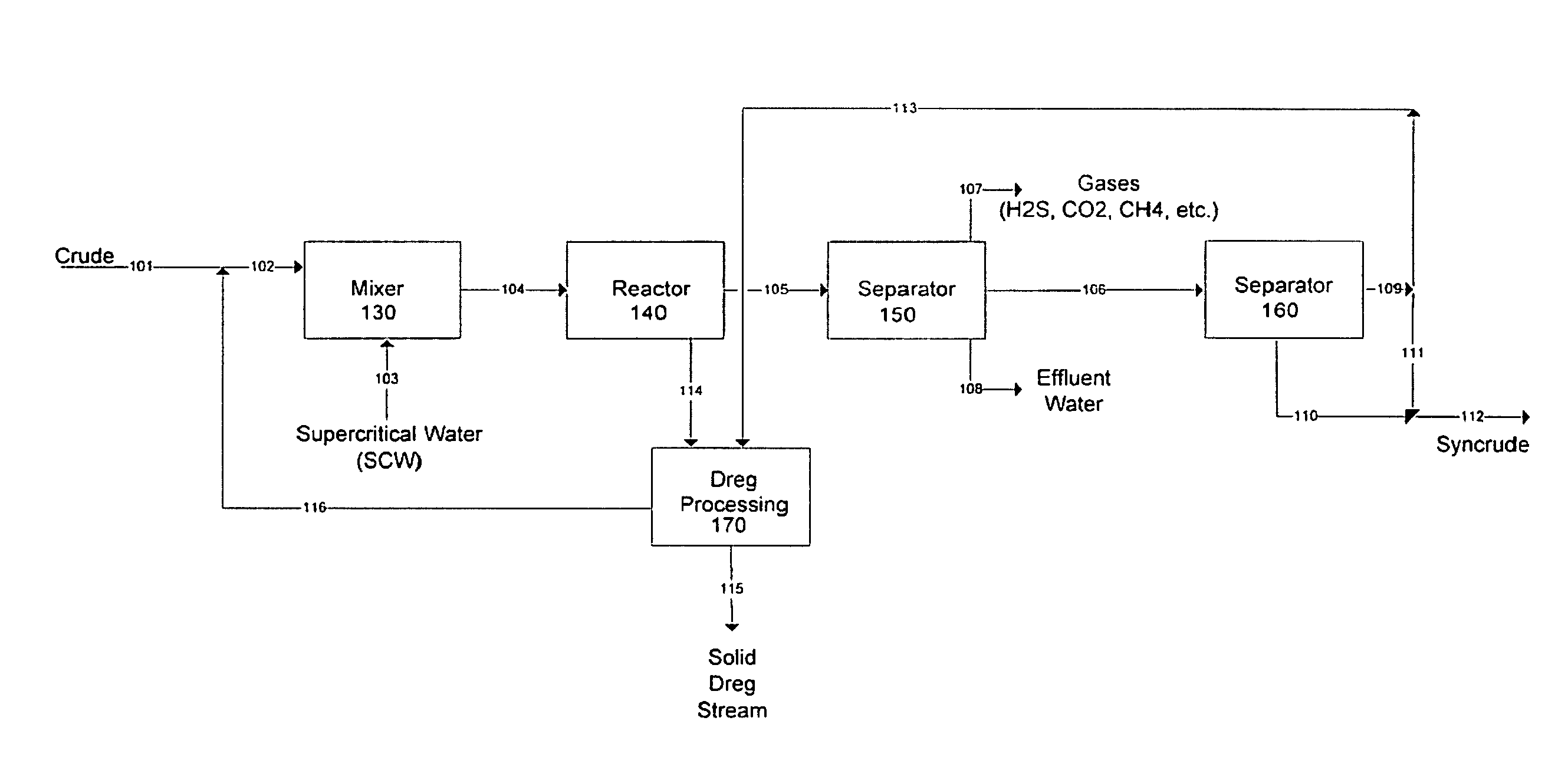

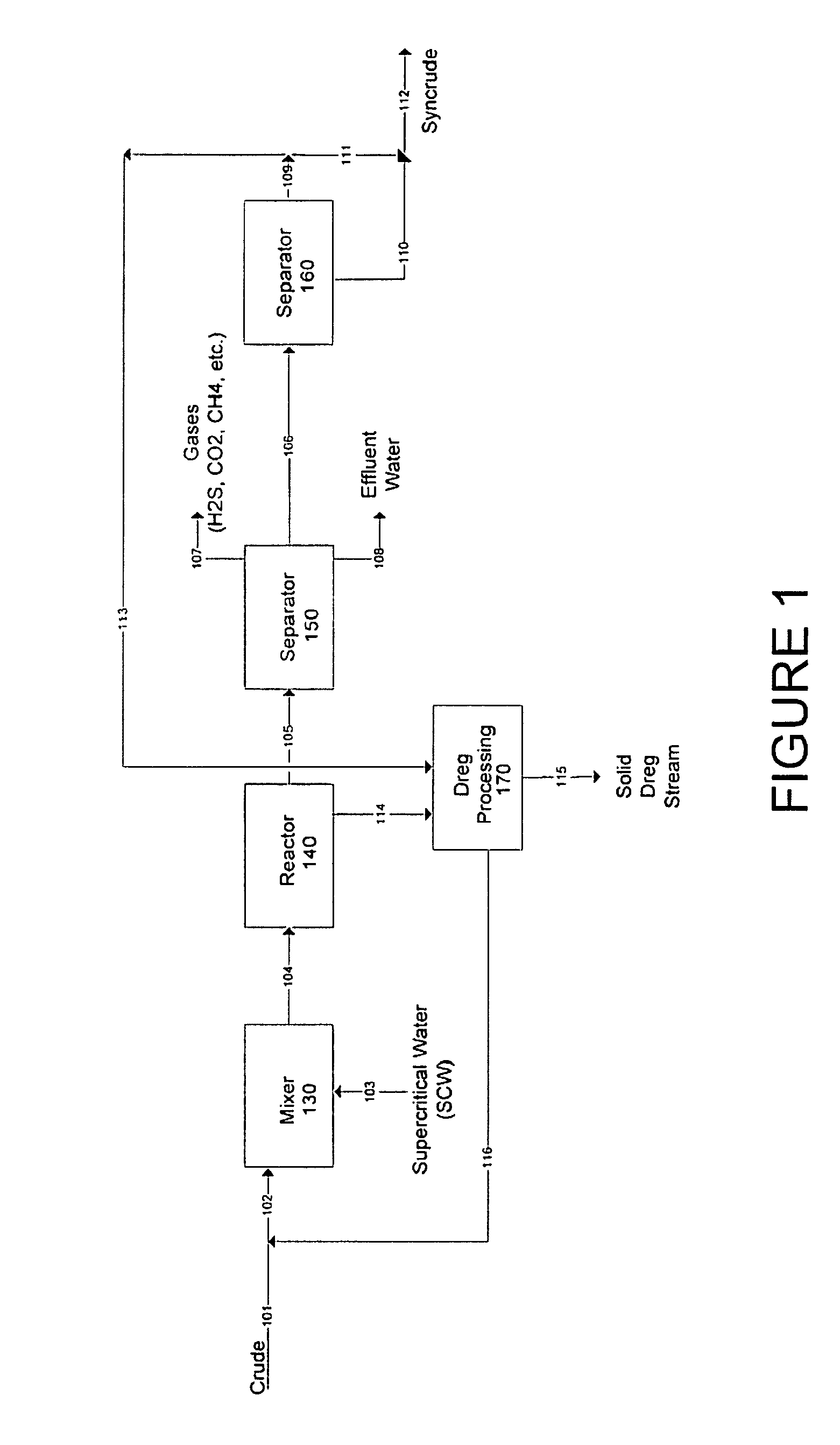

[0068]In an embodiment of the invention illustrated in FIG. 1, a heavy hydrocarbon feed stream 101 and a water feed stream 103, having compositions as shown in TABLES 1 & 2 (Simulated Example Data), are fed to a mixer 130. As described in more detail above, the mixer 130 may include, but is not limited to, static mixers, spray nozzles, and sonic or ultrasonic agitation. The heavy hydrocarbon feed stream 101 and the water feed stream 103 are mixed so that a combined stream 104 will reach supercritical water conditions. The operating pressure of the mixer 130 is in the range of about 3250 to about 3600 psia. The operating, temperature of the mixer 130 is in the range of about 385 to about 420° C. The oil / water mass mix ratio of the mixer 130 is in the range of about 1:0.5 to about 1:3.

[0069]The combined stream 104 is fed to a reactor 140. The combined stream 104 has a composition as shown in TABLES 1 & 2. As described in more detail above, the reactor 140 may include, but is not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com