Patents

Literature

248 results about "Glow plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface coating method for hydrophobic and superhydrophobic treatment in atmospheric pressure plasma

The present invention relates to a method of coating fluorocarbon or hydrocarbon on the surface of a workpiece using atmospheric pressure plasma. More particularly, the present invention relates to a method of coating hydrocarbon or fluorocarbon on the surface of a workpiece using plasma generated under atmospheric pressure such that the workpiece can have a hydrophobic or super-hydrophobic surface.The method of coating a surface of a workpiece with fluorocarbon to be hydrophobic or super-hydrophobic according to the present invention comprises the steps of generating first atmospheric pressure glow plasma by supplying a reaction gas into a discharge space formed between a first electrode and a second electrode, the reaction gas containing hydrogen gas, fluorocarbon gas and inert gas, the first and second electrodes being connected to an RF power supply of an atmospheric pressure plasma generator; and approaching the workpiece to the first electrode downstream of a reaction gas flow passing through the discharge space, such that the plasma created in the discharge space is transferred into a space between the first electrode and the workpiece to generate a second atmospheric pressure glow plasma therein, whereby a fluorocarbon coating layer can be formed on the surface of the workpiece.

Owner:KANG BANG KWON

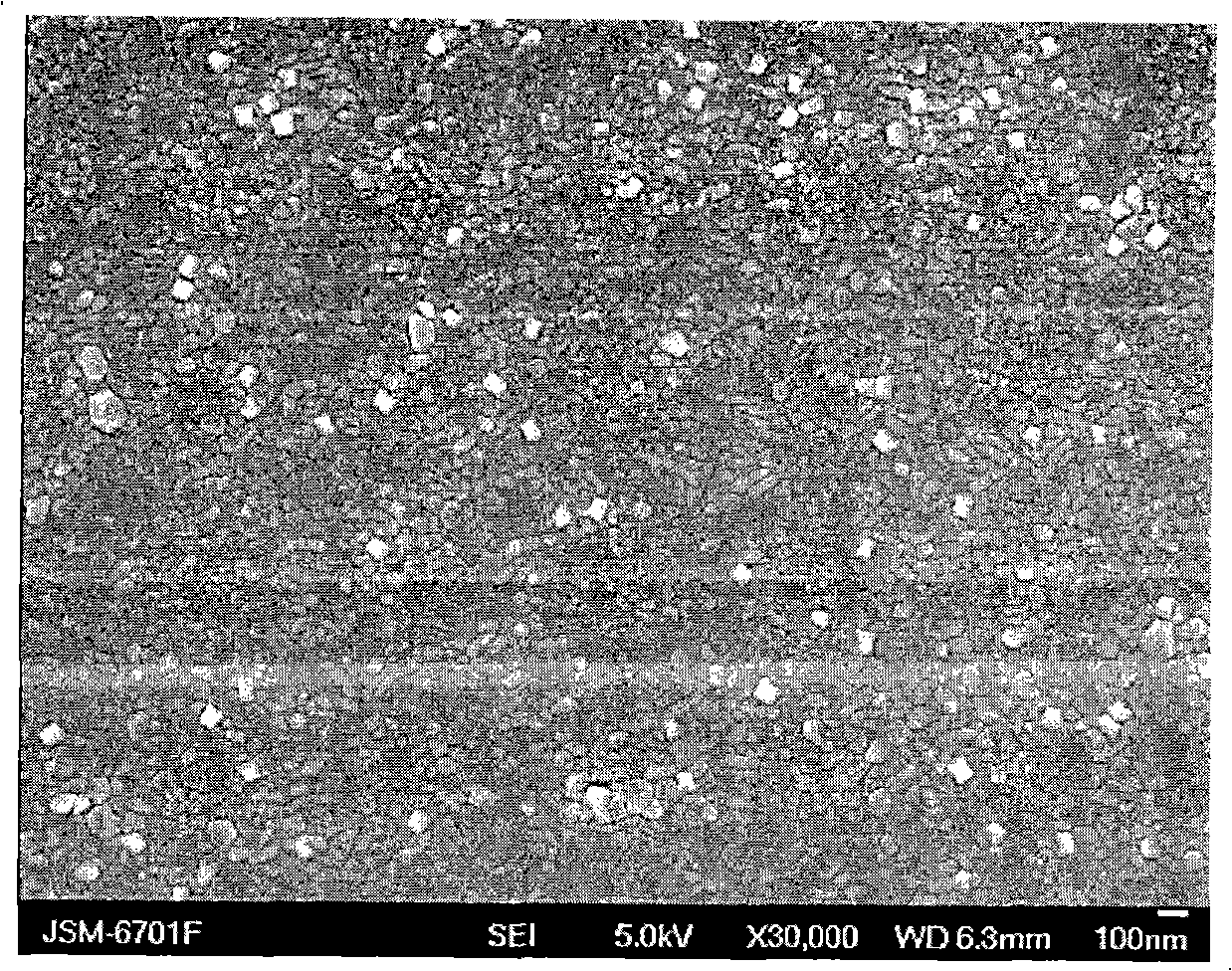

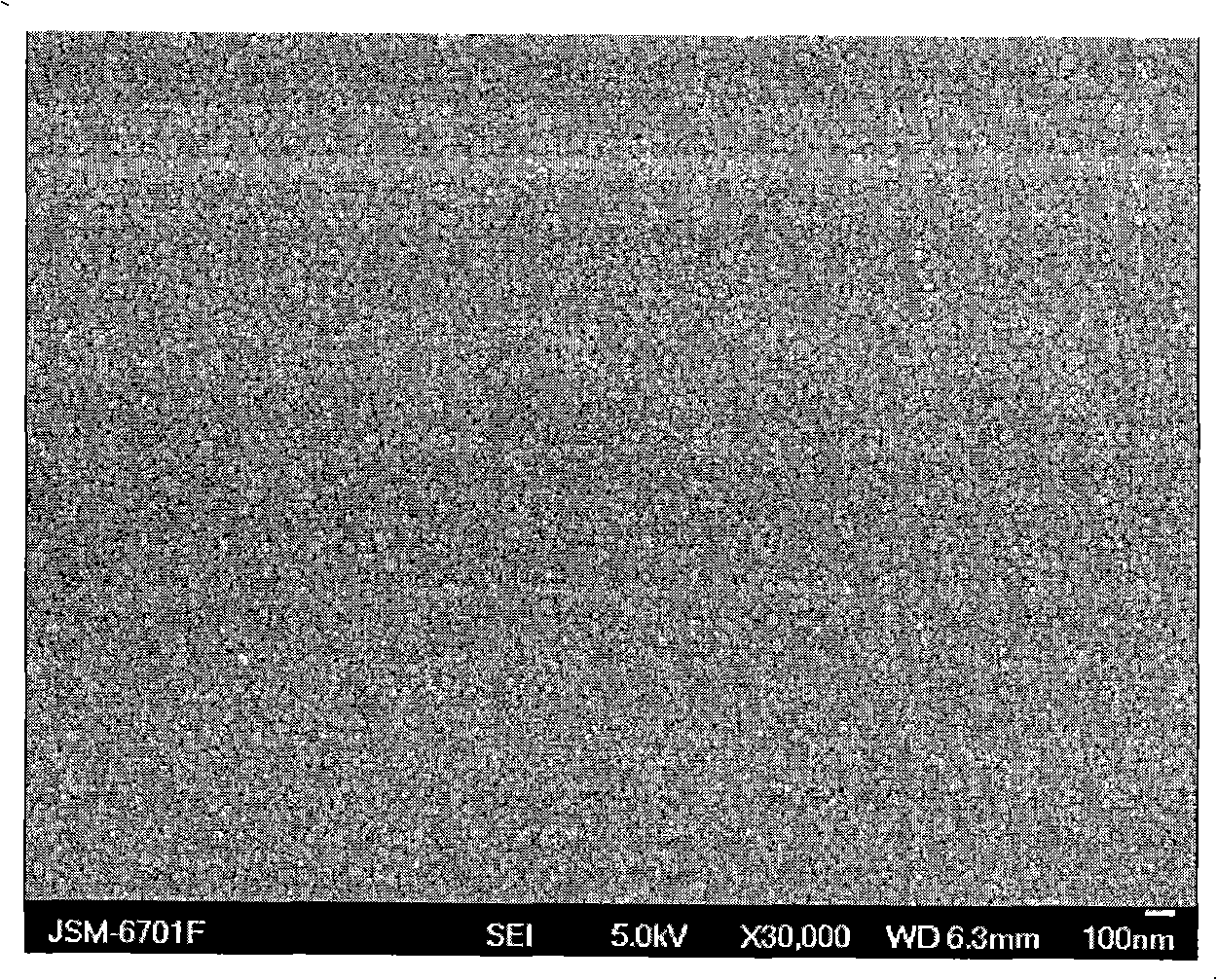

Surface functionalization of polymeric materials

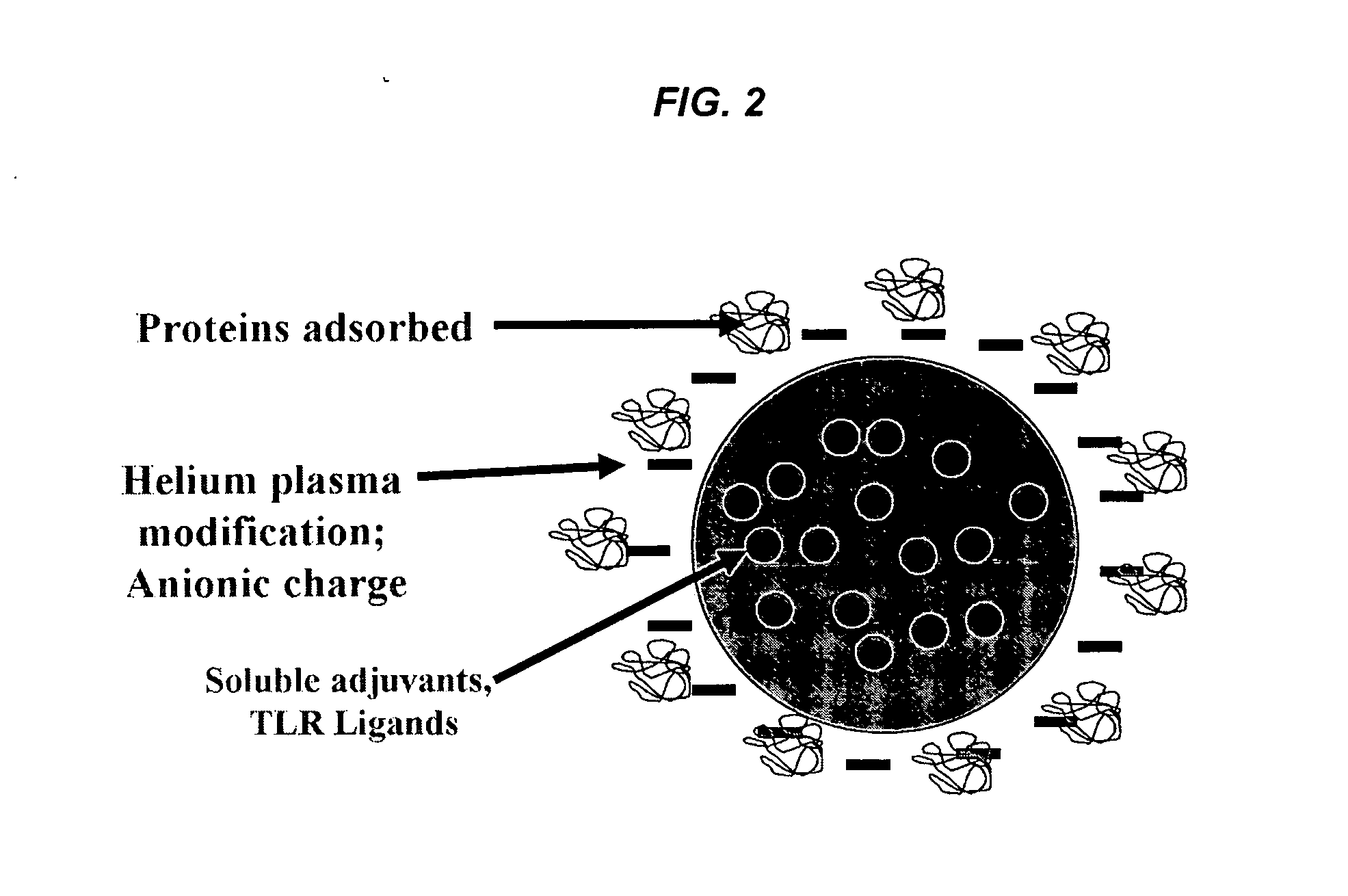

InactiveUS20070014752A1Safe vehicle for drug deliveryReduce structural damagePowder deliveryPharmaceutical non-active ingredientsActive agentGlow plasma

The present invention relates to methods for functionalizing a surface, comprising exposing a surface of a polymeric material to an atmospheric pressure glow plasma discharge, wherein exposure to the plasma discharge functionalizes the surface of the polymeric material. The present invention further provides for methods for functionalizing a polymeric material, wherein the functionalized surface has conjugated thereto bioactive agents. The present invention is also directed to compositions comprising a functionalized surface with attached bioactive agents.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

InactiveCN101403093AAvoid the disadvantages of brittlenessImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingComposite filmChemical plating

The invention relates to the technical filed of vacuum plating, in particular to a preparation method for conducting vacuum compound plating on the surface of a neodymium iron boron magnet, which is characterized in that the preparation method comprises the following steps: A. pre-treatment, the mixed liquor of washing liquid and purified water is used for conducting oil removal and parting medium washing to the magnet surface in an ultrasonic wave cleaner; B. ion cleaning and activation, the pre-treated neodymium iron boron magnet which is dried at 80-100 DEG C for 5-10 minutes undergoes bombardment activation of a glow plasma in vacuum environment, so as to increase surface activation energy; and C. vacuum plating, vacuum plating treatment is conducted to the neodymium iron boron magnet washed by ions in a vacuum chamber, and a metal plating is prepared on the surface. The deposited metal film on the surface of the neodymium iron boron magnet has the advantages of good stability, high bonding force and tightness, stronger anti-corrosion performance in cold and hot alternation environment. Furthermore, in the physical vapor deposition plating process, the plating thickness is affected much less by the magnet workpiece corner than in electroplating and chemical plating, and the pollution problem is avoided in the preparation process.

Owner:兰州大成科技股份有限公司

Double polar plates for fuel battery and method for making surface azote chromium thin film

InactiveCN101257117AChange surface propertiesImprove corrosion resistanceCell electrodesFinal product manufactureGlow plasmaMaterials science

The invention provides a bipolar plate for fuel cell and a surface nitric-chrome film preparation method which belong to fuel cell technique field. The bipolar plate is composed of a stainless steel thin plate substrate and its two sides nitric-chrome film; the nitric-chrome film thickness is micro-nanometer magnitude and is prepared by using electric arc ion filming method, therein, substrate passive film is removed by using ion sputtering method before filming, used ion comes from glow plasma of inert gases or electric arc plasma vaporized from metal target; a simple substance film with even component, a grads film with component changed continuously from inside to outside, or a multi-layer film with component changed alternately can be obtained by controlling filming parameter in film depositing process. The substrate provided by the invention is the stainless steel thin plate, and has a nitric-chrome film on surface. The stainless steel thin plate and intric-chrome film match connects in atom dimension because of ion film depositing, thereby, the bipolar plate has characteristics of low-cost besides complex characteristics, for example, corrosion resistance, electrical conduction, strengthen and hydrophobic etc. The bipolar plate and preparation method are mainly suitable for fuel cell manufacturing field.

Owner:DALIAN UNIV OF TECH

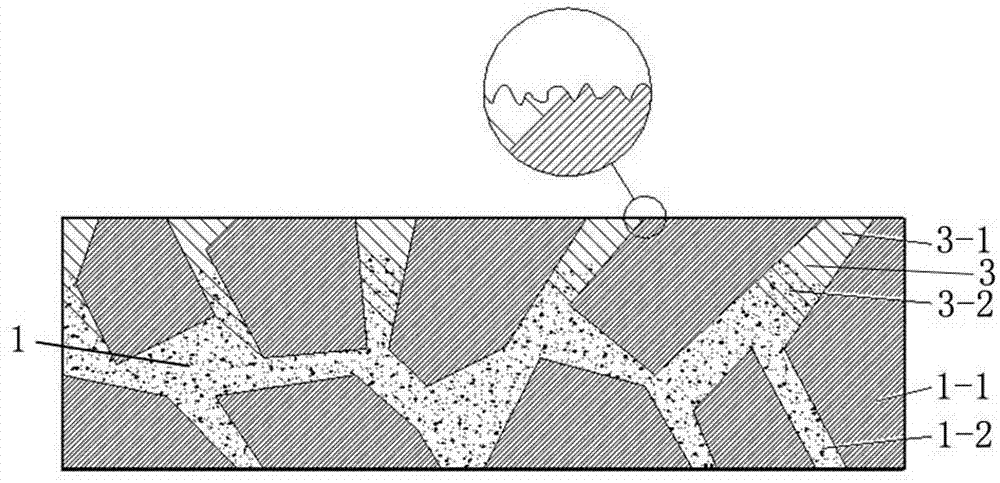

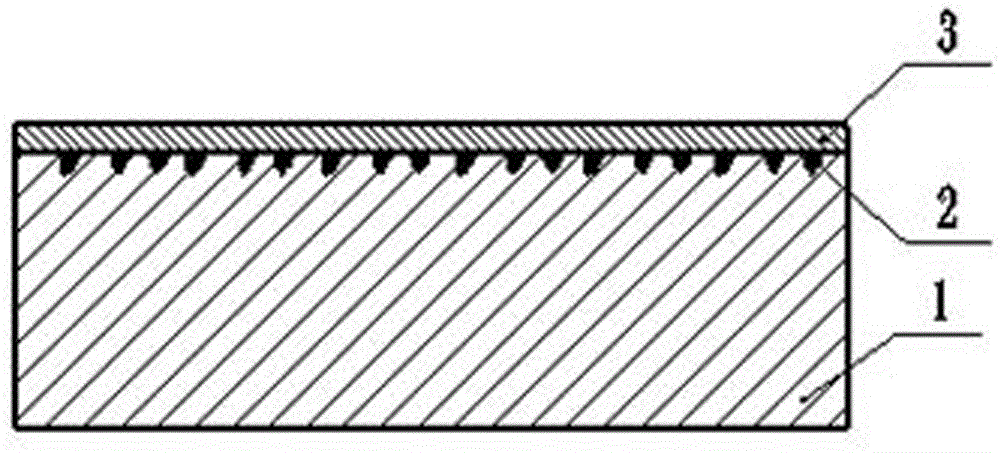

Method for improving bonding strength of hard alloy and diamond coating

ActiveCN104746030AAvoid the problem of interfacial stressHigh bonding strengthVacuum evaporation coatingSputtering coatingShielding gasGlow plasma

The invention relates to a method for improving the bonding strength of a hard alloy and a diamond coating. The method is realized by the technical scheme that by adopting a double glow plasma surface alloying technology, taking a metal carbide forming element material or a composite material of metal carbide forming elements as a target, inert gases as protecting gases, as well as carbon-containing gases as precursors, a diffusion barrier layer is prepared on the surface layer of the hard alloy, and then the diamond coating is deposited on the hard alloy surface on which the diffusion barrier layer is prepared by using a chemical vapor deposition method. By the use of the diffusion barrier layer prepared by the method disclosed by the invention, the diffusion of Co element to the surface layer of the hard alloy can be effectively stopped, the damage to a hard alloy matrix due to a surface Co removing treatment method is avoided, and the interface stress problem introduced by a transition layer applying method due to new interface addition can be avoided, so that the bonding strength between the diamond coating and the hard alloy matrix can be greatly improved.

Owner:TAIYUAN UNIV OF TECH

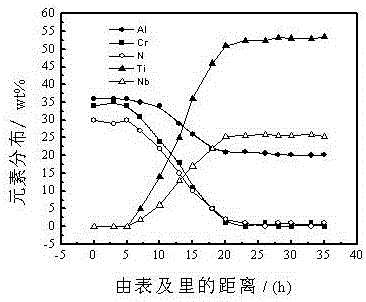

Titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat, and preparation method thereof

ActiveCN102732832ADense tissueSolve the problem of poor high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingAntioxidant capacityCoated surface

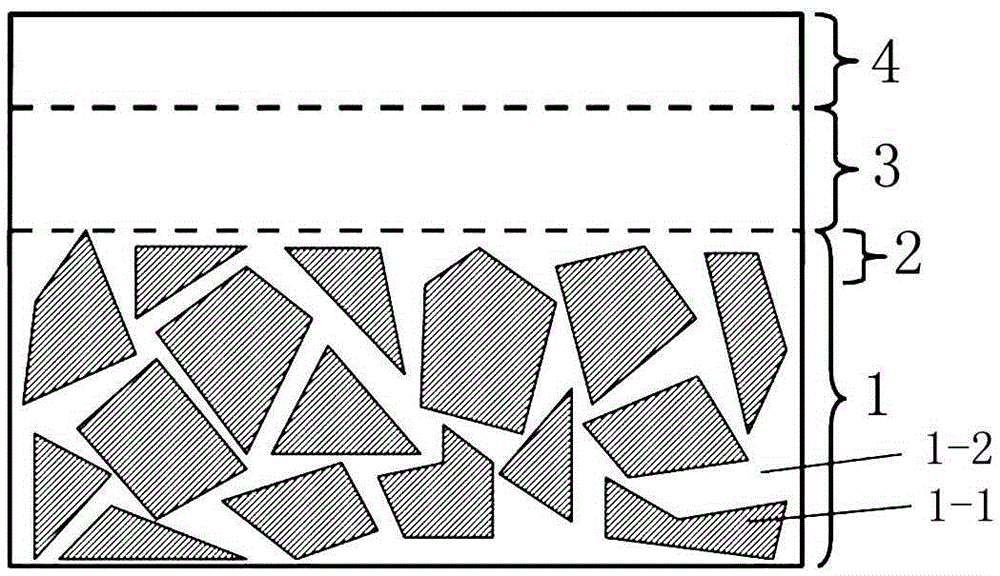

The invention relates to a titanium alloy surface high temperature oxidation resistance and wear resistance oxide gradient coat. According to the coat, the surface of the coat is an oxide film layer comprising Al2O3, Cr2O3 and NiO2, wherein the thickness is 4-6 mum; the middle of the coat is an Al-Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and an Al-Cr-Ni-Ti interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Al-Cr-Ni-Ti interdiffusion layer is 4-6 mum. According to the present invention, the oxide film layer on the surface of the coat has characteristics of compactness, flatness and strong antioxidant capacity; the Al-Cr-Ni alloy layer in the middle of the coat has characteristics of compact structure and high hardness so as to greatly improve wear resistance of the titanium alloy; the metallurgical collection of the coat and the substrate is achieved through the Al-Cr-Ni-Ti interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology is adopted to prepare the Al-Cr-Ni alloy layer on the surface of the titanium alloy, and then a plasma oxygen permeation treatment is performed on the Al-Cr-Ni alloy layer to prepare the high temperature oxidation resistance and wear resistance coat, such that the efficiency is high, and the process is simple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

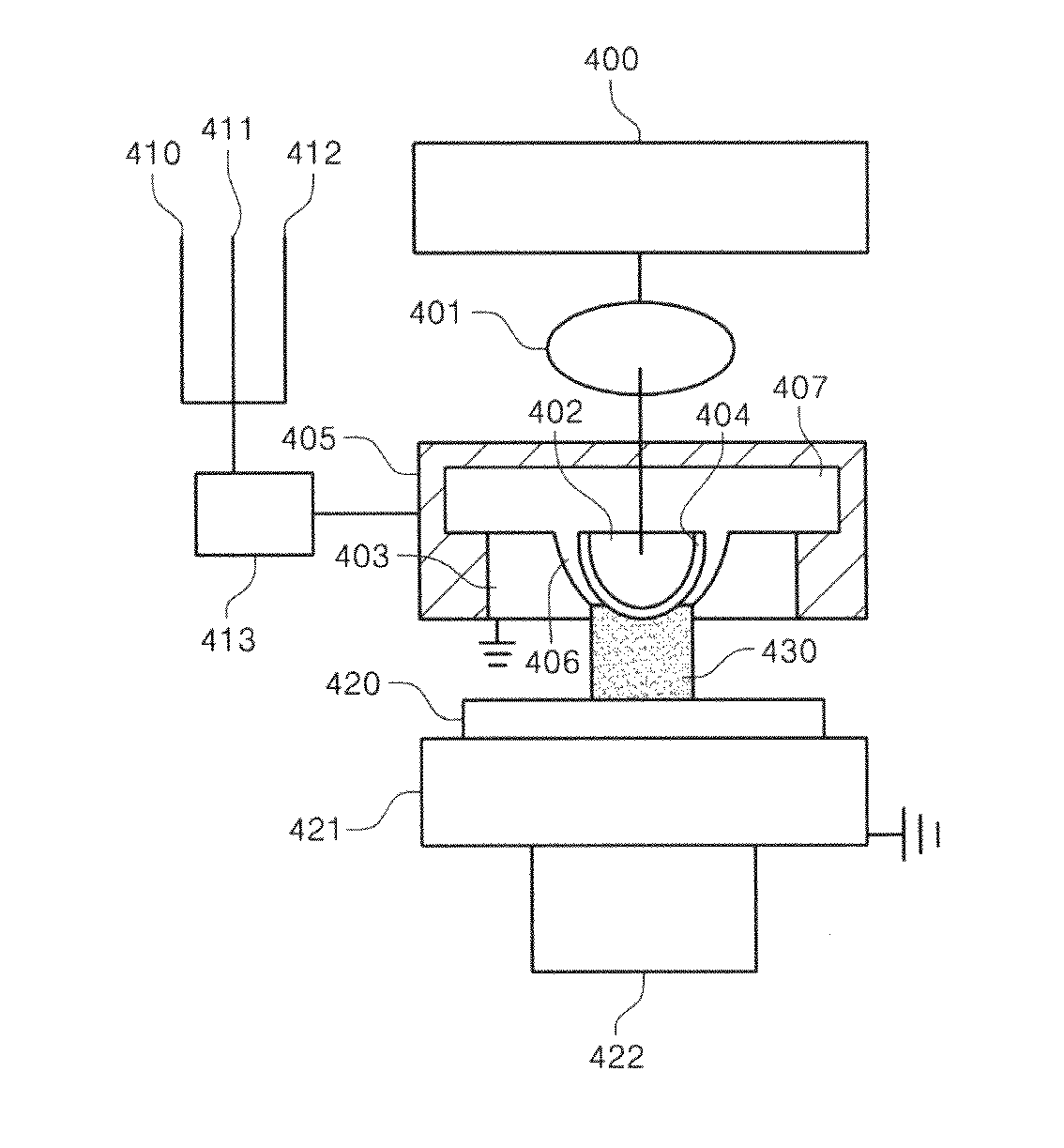

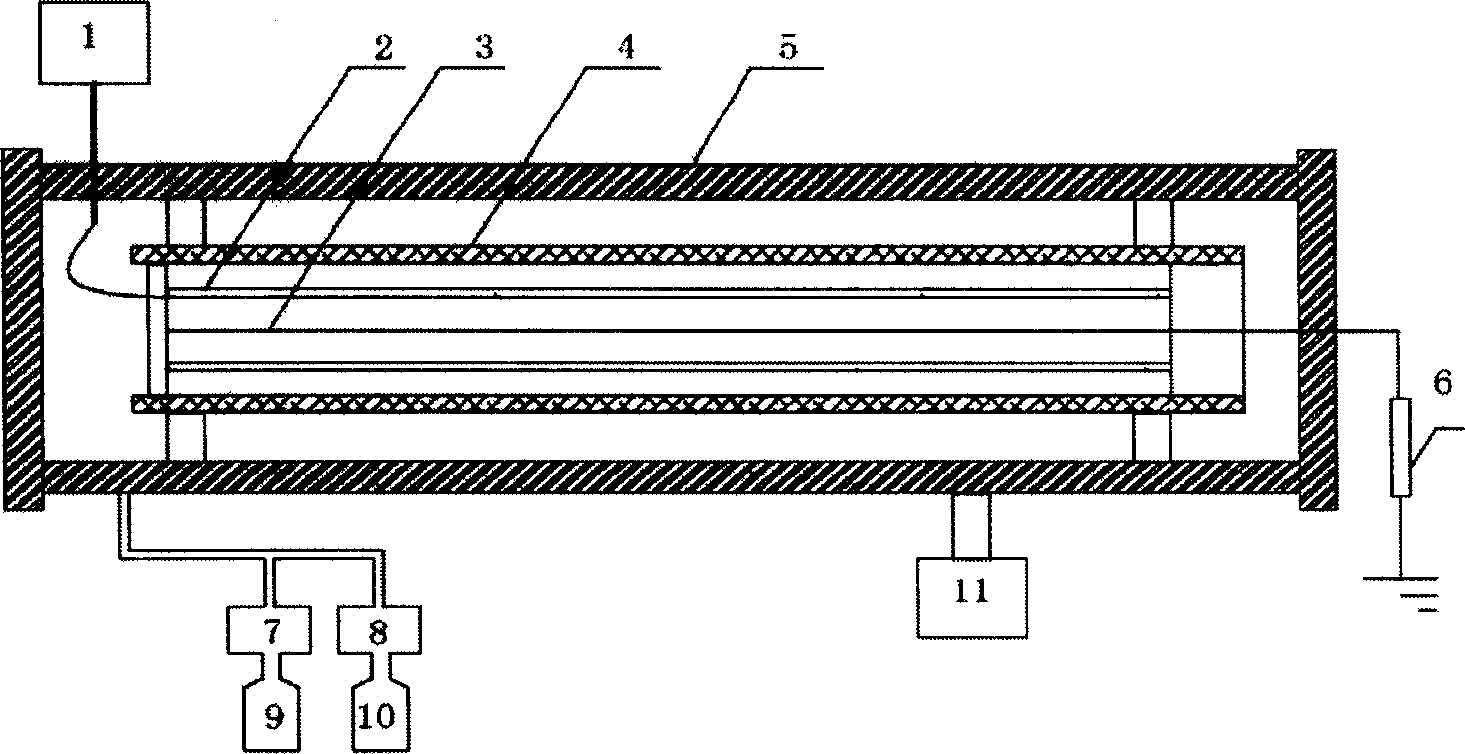

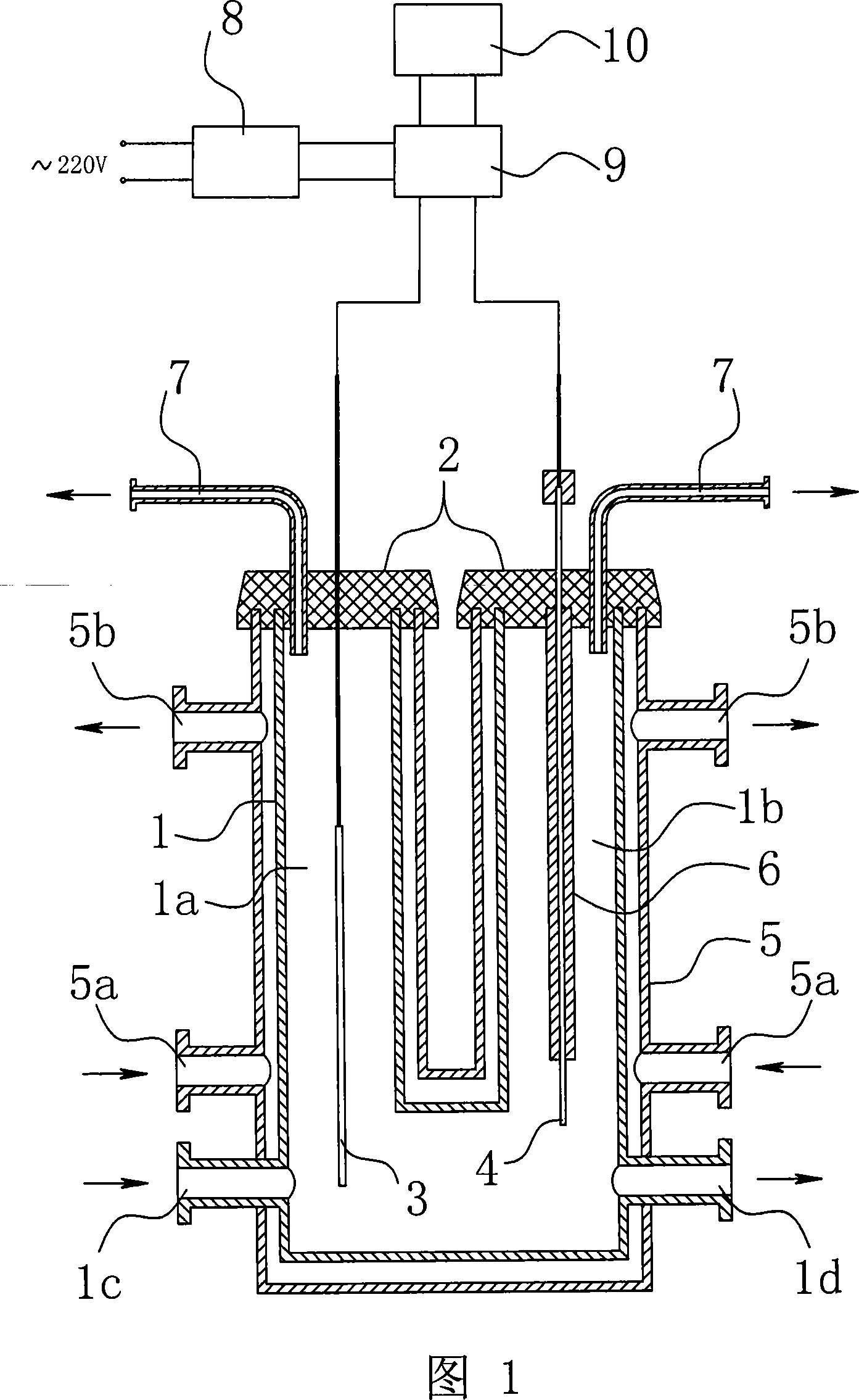

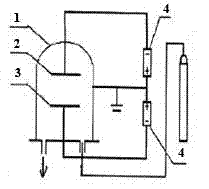

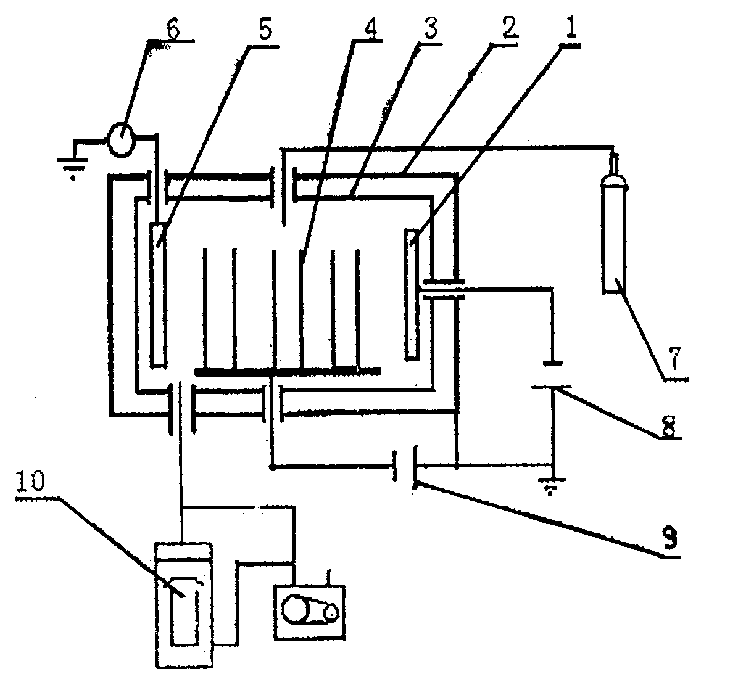

Apparatus for generating atmosphere pressure microwave glow plasma

InactiveCN101394705AIncrease energy densityHigh Active Particle ConcentrationElectric discharge tubesPlasma techniqueHigh energyEngineering

The invention relates to a device for generating atmospheric pressure microwave glow plasma. The device comprises a plasma reactor, a microwave regulating and monitoring system and a microwave source. The microwave source is connected with the left end of the microwave regulating and monitoring system through a coupling flange. The plasma reactor consists of a rectangular waveguide, a bar-shaped electrode, a flat electrode, a short-circuiting piston, a silica tube, a water-cooled jacket, an upper flange and a lower flange. Through holes are formed on the parts of the wide edges of the rectangular waveguide; the silica tube is installed on the rectangular waveguide by passing through the through holes; the water-cooled jacket is installed on the outer side of the silica tube; the silica tube is hermetically connected with the upper flange and the lower flange to form a working chamber; the bar-shaped electrode is hermetically connected with the upper flange through threads; the flat electrode is hermetically connected with the lower flange through threads; and the short-circuiting piston is arranged on the end part of the left side of the plasma reactor. The device can operate the microwave glow plasma at atmospheric pressure, thereby facilitating continuous production. The produced plasma has higher energy density, active particle concentration and efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Double polar plates for fuel battery and method for making surface carbon chromium thin film

ActiveCN101257118AChange surface propertiesImprove corrosion resistanceFinal product manufactureCell electrodesFuel cellsGlow plasma

The invention provides a bipolar plate for fuel cell and a surface carbon-chrome film preparation method which belong to fuel cell technique field. The bipolar plate is composed of a stainless steel thin plate substrate and its two sides carbon-chrome film; the carbon-chrome film thickness is micro-nanometer magnitude and is prepared by using electric arc ion filming method, therein, substrate passive film is removed by using ion sputtering method before filming, used ion comes from glow plasma of inert gases or electric arc plasma vaporized from metal target; a simple substance film with even component, a grads film with component changed continuously from inside to outside can be obtained by controlling filming parameter in film depositing process. The substrate provided by the invention is the stainless steel thin plate, and has a nitric-chrome film on surface. The stainless steel thin plate and carbon-chrome film match connects in atom dimension because of ion film depositing, thereby, the bipolar plate has characteristics of low-cost besides complex characteristics, for example, corrosion resistance, electrical conduction, strengthen and hydrophobic etc. The bipolar plate and preparation method are mainly suitable for fuel cell manufacturing field.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Discharge electrode structure of plasma air purification device

ActiveCN102548177ADifferent structureLimit processingDeodrantsPlasma techniqueGlow plasmaEngineering

The invention discloses a discharge electrode structure of a plasma air purification device. The electrode structure comprises a positive electrode group and a negative electrode group, wherein at least one of the positive electrode group and the negative electrode group is wrapped with insulating medium; and the two electrode groups contact directly, such that a contact point is formed. According to the invention, the discharge electrode structure is applied to the plasma air purification device, so a great amount of low temperature plasma is generated at an electrode intersection and a nearby area of the electrode intersection through the structure; the low temperature plasma has properties of glow-like plasma, wide sterilization range, high sterilization rate, short time consumption and low power consumption; in addition, the adopted net-like structure can not only ensure good air permeability but also enlarge the actual plasma function area, therefore, the sterilization rate is further improved.

Owner:BEIJING JIAOTONG UNIV

Method for manufacturing gradient hard composite coating on surface of hard alloy

ActiveCN105386049ASmall coefficient of thermal expansionHigh bonding strengthSuperimposed coating processGlow plasmaAlloy

The invention relates to a method for manufacturing a gradient hard composite coating on the surface of a hard alloy. A dual-layer glow plasma surface alloying device is used, argon serves as plasma stimulation gas, a composite target manufactured through a refractory metal wire and a graphite plate serves as a source electrode, and refractory metal and a carbide composite cementation layer of the refractory metal are manufactured on the surface of the hard alloy; then mixed gas of tetramethylsilane and hydrogen is led in, and the gradient composite coating comprising refractory metal carbide and silicon carbide is prepared by continuously increasing the flow of the tetramethylsilane; and finally methane is led in, the flow of the methane is gradually increased, the flow of the tetramethylsilane is reduced at the same time, and the silicon carbide and diamond gradient hard composite coating is prepared. The coating prepared with the method and a base body are in metallurgical bonding, the coefficients of thermal expansion from the base body to the coating are distributed in a gradient manner, and the method has the characteristics of being small in stress, high in binding intensity and the like. Meanwhile, the overall coating is continuously prepared in one device, the process is simple, and the cost is low.

Owner:TAIYUAN UNIV OF TECH

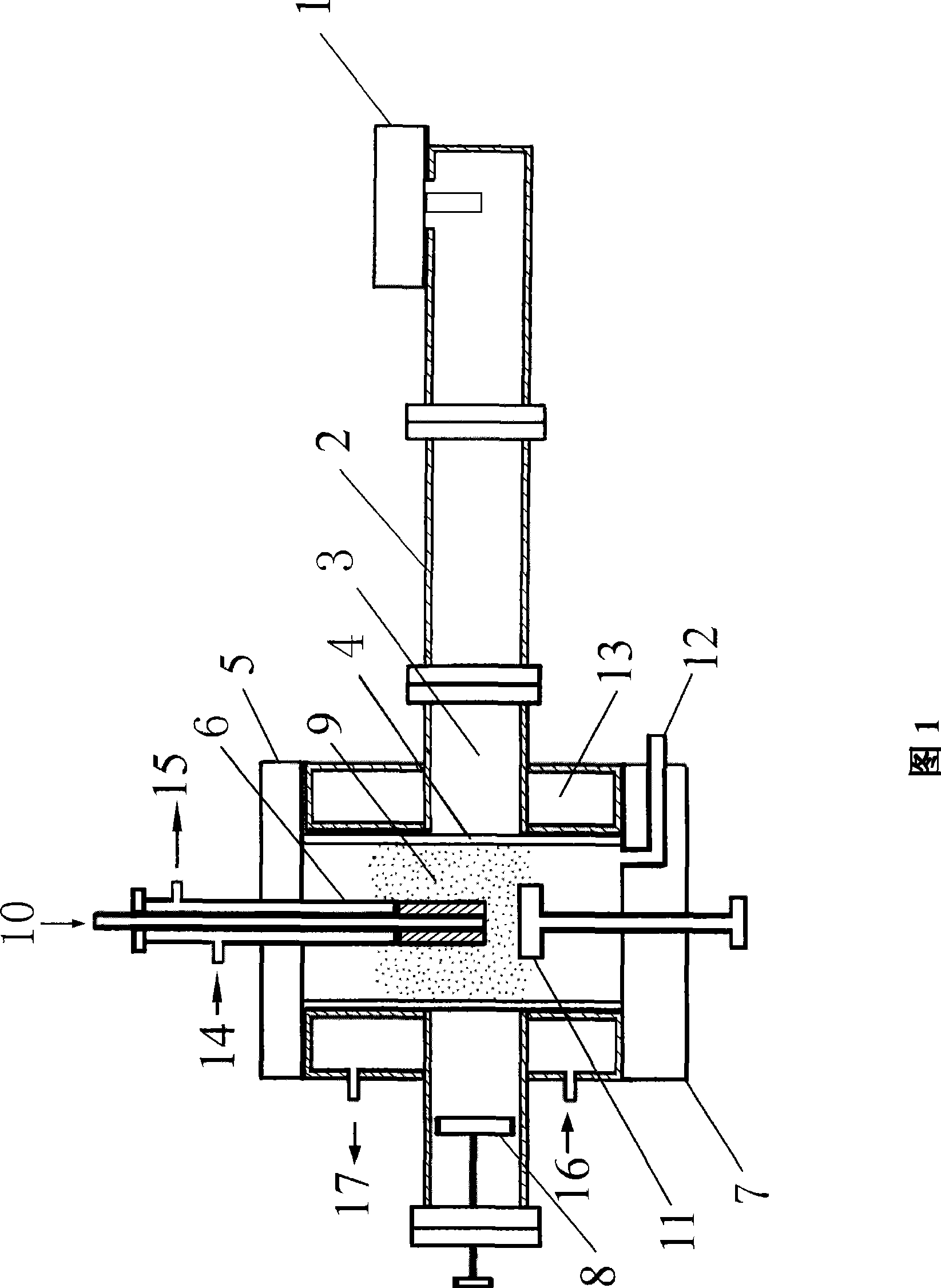

Atmospheric pressure glow plasma enhanced atom layer deposition device

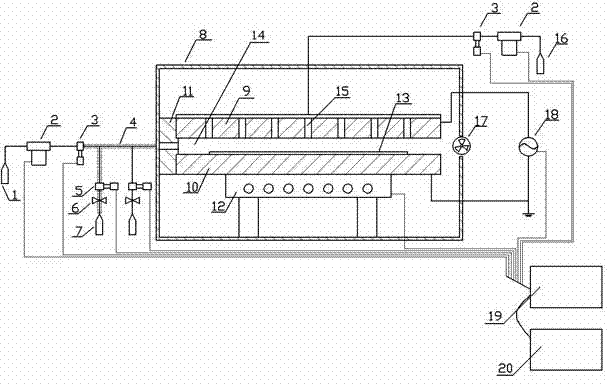

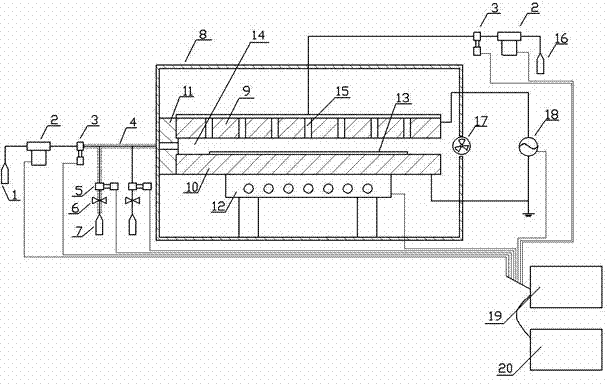

InactiveCN102534569AIncrease deposition rateAvoid damageChemical vapor deposition coatingGas cylinderProgrammable logic controller

The invention discloses an atmospheric pressure glow plasma enhanced atom layer deposition device, which comprises a main chamber, wherein a precursor body source air inlet pipeline opening, an upper electrode of a plasma generator and a lower electrode of the plasma generator are arranged inside the main chamber; a heater is arranged below the lower electrode of the plasma generator; an airstream channel is formed between the upper electrode of the plasma generator and the lower electrode of the plasma generator; an outlet of the precursor body source air inlet pipeline opening is opposite to the airstream channel and an inlet of the precursor body source air inlet pipeline opening is connected with a source air inlet heating pipeline; the source air inlet heating pipeline is connected with a carrier gas cylinder; a precursor body source bottle is connected to the source air inlet heating pipeline; both the upper electrode of the plasma generator and the lower electrode of the plasma generator are connected with a radio frequency power supply; a plurality of ventilating holes for introducing the plasma discharge gas are arranged on the upper electrode of the plasma generator; all the ventilating holes are connected with a plasma discharge gas bottle; both the heater and the radio frequency power supply are connected to a PLC (programmable logic controller) and the PLC is connected with a computer.

Owner:JIAXING KEMIN ELECTRONICS EQUIP TECH

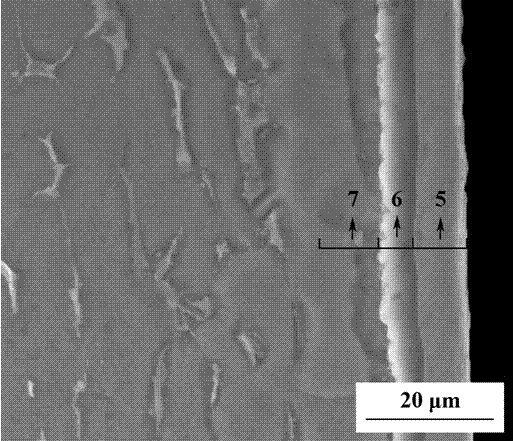

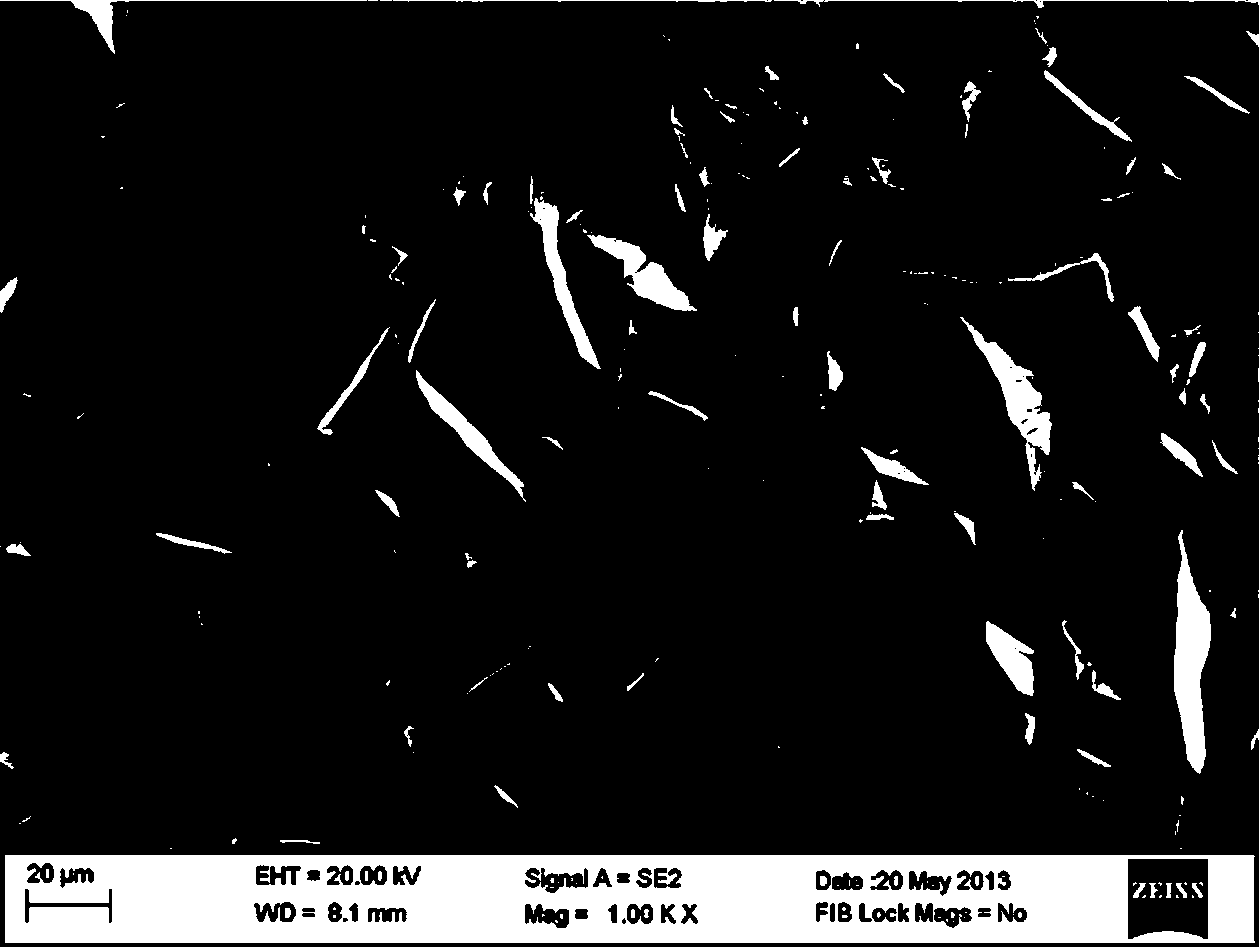

Slender metal pipe inner wall diamond-film-like deposition method using DC glow discharge

InactiveCN1851045AReduced vacuum requirementsLow costChemical vapor deposition coatingThin metalGlow plasma

The invention belongs to the surface transferring character of the low temperature plasma in the domain of the chemistry and the physics, the method of depositing the kind diamond. Film on the outer surface of the thin metal pipe using the direct current shining plasma is disclosed. Under the pressure of the same axes pole Pa, the several KV of the direct current even high voltage is used to produce the steady cylinder direct current plasma, the length of the cylinder direct current shinning plasma produced in the pipe can be controlled by the voltage of the voltage source, so the kind diamond film can be deposited on the whole inner surface of the thin metal pipe. The kind diamond film can be deposited evenly on the surface of the metal pipe with the diameter which is above 5mm and the length which is 5mm-2000mm, because of adopting the KV steady direct current power and the low needing of the vacuum degree, the cost of the setting is low and the using and the maintenance is easy.

Owner:DALIAN UNIV OF TECH

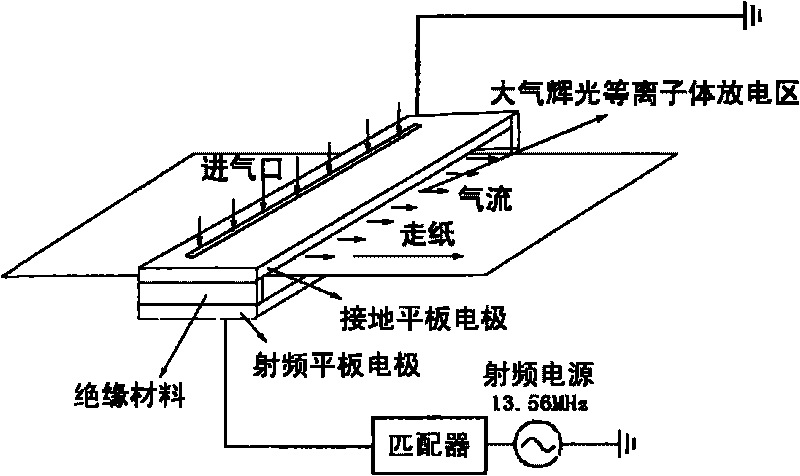

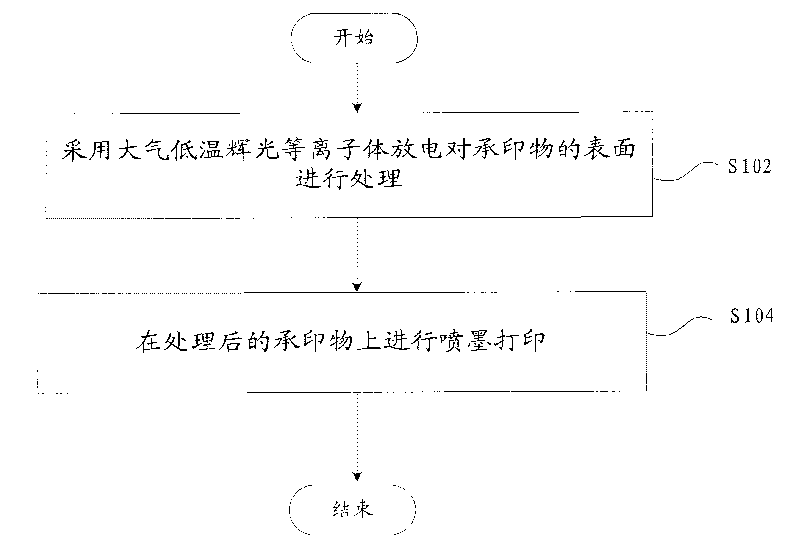

Inkjet printing method

The invention provides an inkjet printing method, comprising the following steps: process the surface of a printed material by adopting an atmosphere low-temperature glow plasma; carry out inkjet printing on the processed printed material. The temperature of an electric discharging gas is close to the room temperature, wherein, an electric discharging plasma contains a great amount of active materials which can etch the surface of the printed material, clean organic pollutants and activate material surface, thereby increasing the specific surface area of the material, enhancing the surface activity and cleaning the surface, an ink droplet is easy to spread, by adopting an surface processing method of the printed material before the inkjet printing, plasma electric discharging treatment is carried out to the printed material to be printed in the inkjet printing method, the surface characteristics of the printed material to be printed is changed, therefore, the ink droplet is easy to spread when the inkjet printing is carried out on the processed printed material, and the temperature of an electric discharging gas is close to the room temperature, therefore, the temperature of printed material surface is even.

Owner:中国印刷科学技术研究所

Method for treating industrial wastewater by low temperature using plasma and treating equipment

InactiveCN101050002AReduce consumptionLess investmentWater/sewage treatment by electrochemical methodsWater/sewage treatment by neutralisationIndustrial effluentGlow plasma

This invention discloses method and apparatus for treating industrial wastewater by using low-temperature plasma. The method comprises: adjusting the electric conductivity of wastewater, intermittently introducing wastewater into a plasma reactor, applying a voltage of 100-700 V to the plasma reactor to form glow plasma, treating wastewater with the glow plasma for 10-30 min, and discharging treated wastewater, standing, separating and discharging. The apparatus is composed of a power source and a plasma reactor. The surface area rati of the cathode and the anode in the plasma reactor is 1 :( 1.5-50), and the central distance between them is 4-5 cm. The method has such advantages as low energy consumption, short time and high efficiency.

Owner:广州精浦环保科技有限公司

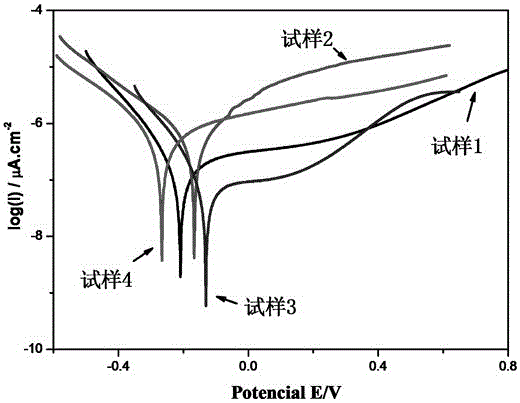

Preparation method of nitrogen (N)-doped titanium dioxide (TiO2) porous film on surface of stainless steel matrix

InactiveCN103276393AImprove light absorption efficiencyImprove adsorption capacitySuperimposed coating processGlow plasmaTitanium oxide

The invention discloses a preparation method of a nitrogen (N)-doped titanium dioxide (TiO2) porous film on the surface of a stainless steel matrix, belonging to the field of the preparation technology of photocatalytic materials. The method is characterized by a technical scheme for preparing a high film-based bonding strength anatase type N-doped TiO2 porous film on a stainless steel matrix, and comprises the following steps of: firstly preparing a Ti-N diffusion coating layer composed of a Ti-N diffusion layer in the matrix and a surface Ti-N compound film on the surface of a stainless steel workpiece by use of a double glow plasma surface alloying technology; then performing anode oxidation on the Ti-N film on the workpiece surface to generate an N-doped TiO2 porous film; and finally performing thermal treatment in the air to prepare an anatase type N-doped TiO2 porous film. By adopting the preparation method disclosed by the invention, the prepared N-doped TiO2 porous film has the advantages of large specific surface area and good film-based bonding strength, and also has visible light catalysis performance; and the stainless steel after the N-doped TiO2 surface modification can be applied to the fields of photocatalysis self-cleaning, photocatalysis sterilization and the like.

Owner:TAIYUAN UNIV OF TECH

Method for welding CVD diamond thick film and hard alloy

ActiveCN103894695AImprove surface wettabilityHigh bonding strengthSoldering apparatusChemical LinkageMetal device

The invention relates to a method for welding a CVD diamond thick film and hard alloy. The method comprises the steps that firstly, a double-glow plasma diffusion metal device metallizes a growth face of the CVD diamond thick film, and secondly, the double-glow plasma diffusion metal device is used for welding the metallized face and a hard alloy substrate in a brazing mode. According to the method, metal atoms are evenly diffused on the surface of the growth face of the diamond thick film according to the double-glow plasma diffusion metal technology, metal carbide is formed by the metal atoms and the diamond thick film, and superior bonding strength between a metal layer and the diamond thick film is guaranteed through chemical bonding. The metallized diamond thick film has good ground surface wettability, and a welding connector with high bonding strength can be formed through the metallized diamond thick film and the hard alloy under the heating action of plasma. The surface metallization of the diamond thick film and brazing can be finished through the same device, manufacturing production cost is greatly reduced, and industrialization can be achieved.

Owner:山西新碳超硬材料科技有限公司

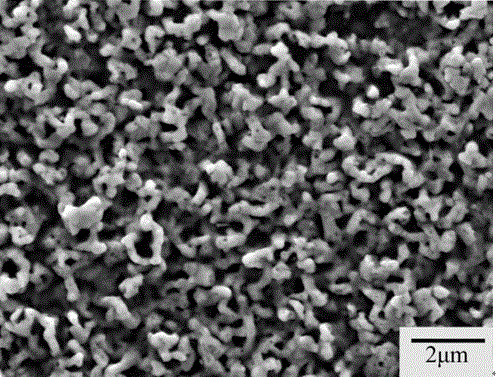

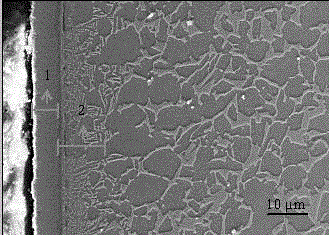

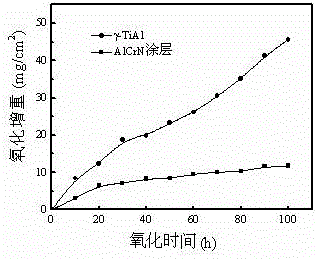

Gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat, and preparation method thereof

ActiveCN102732833AImprove high temperature oxidation resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingCoated surfaceGlow plasma

The invention relates to a gamma-TiAl alloy surface high temperature oxidation resistance and wear resistance coat. According to the coat, the surface of the coat is an oxide film layer comprising Cr2O3 and NiO2, wherein the thickness is 2-3 mum; the middle of the coat is a Cr-Ni alloy layer, wherein the thickness is 2-4 mum; and a Cr-Ni-Ti-Al interdiffusion layer is arranged between the coat and a substrate to achieve metallurgical collection, wherein the thickness of the Cr-Ni-Ti-Al interdiffusion layer is 4-6 mum. According to the present invention, the Cr2O3 and NiO2 oxide film on the surface of the coat has characteristics of compact structure and strong antioxidant capacity; the Cr-Ni alloy layer in the middle of the coat has characteristics of uniform structure and high hardness so as to greatly improve wear resistance of the gamma-TiAl alloy; the metallurgical collection of the coat and the substrate is achieved through the Cr-Ni-Ti-Al interdiffusion layer, and the combination strength is high; and a double glow plasma surface metallurgy technology and a plasma oxygen permeation technology are firstly combined in the coat preparation process of the present invention, special plasma oxygen permeation equipment is not required, the coat can be directly prepared in 5 hours by adopting double glow plasma surface metallurgy equipment, the process is simple, and the efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

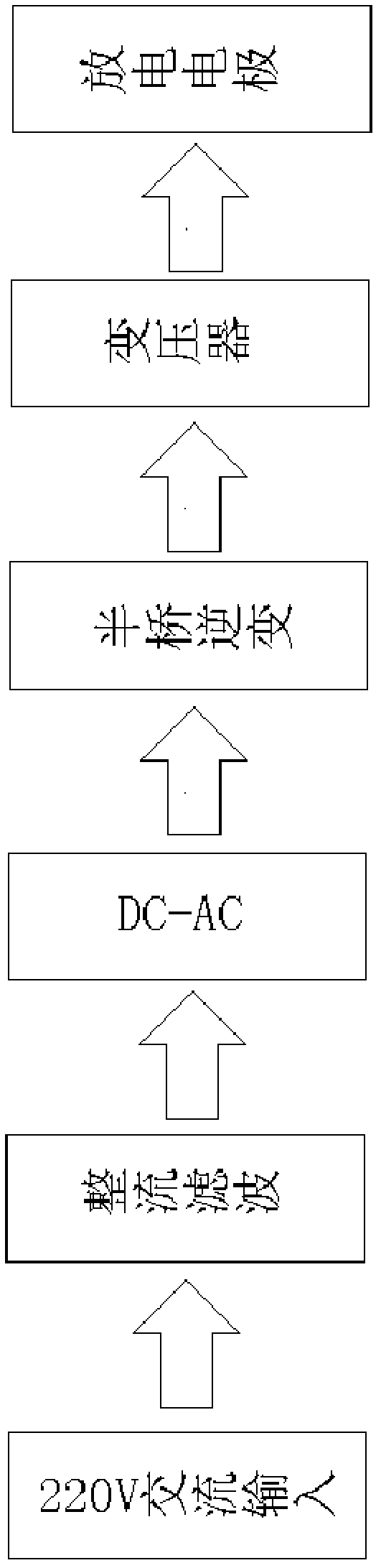

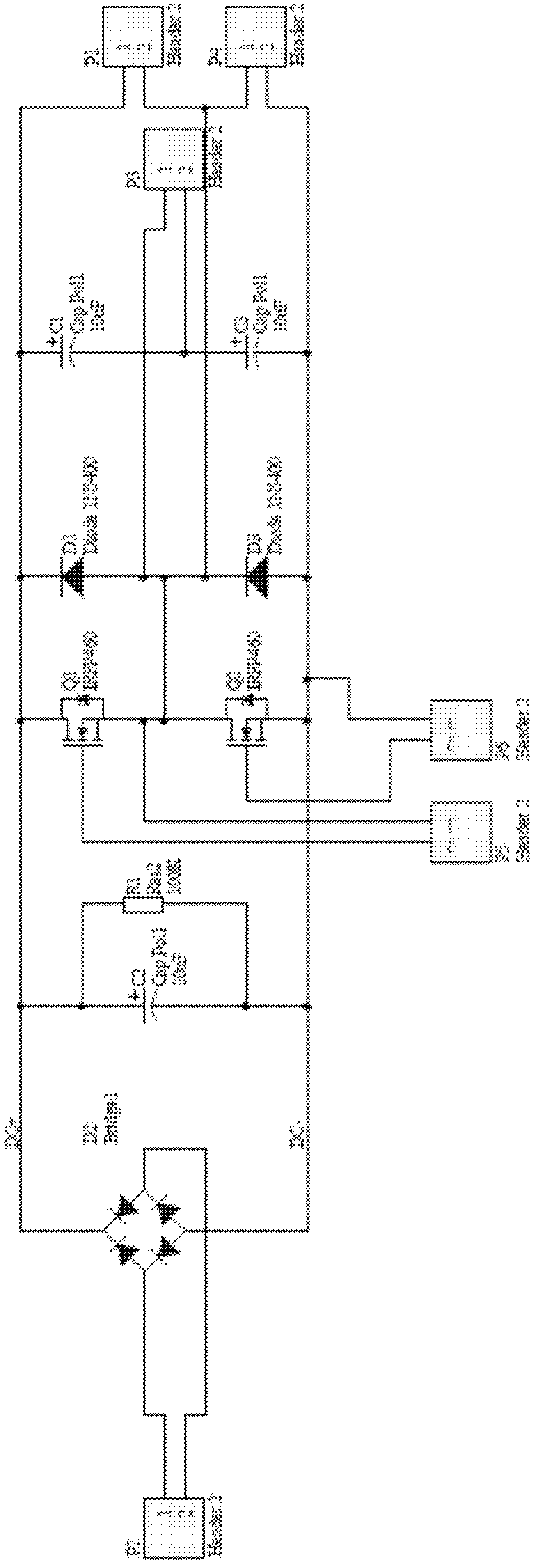

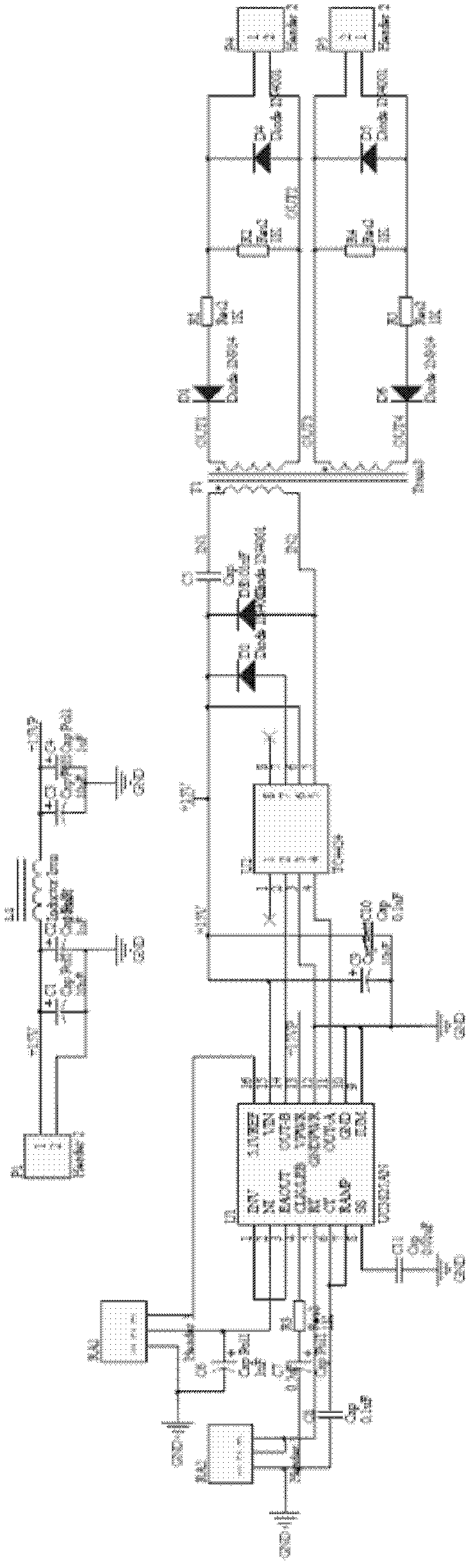

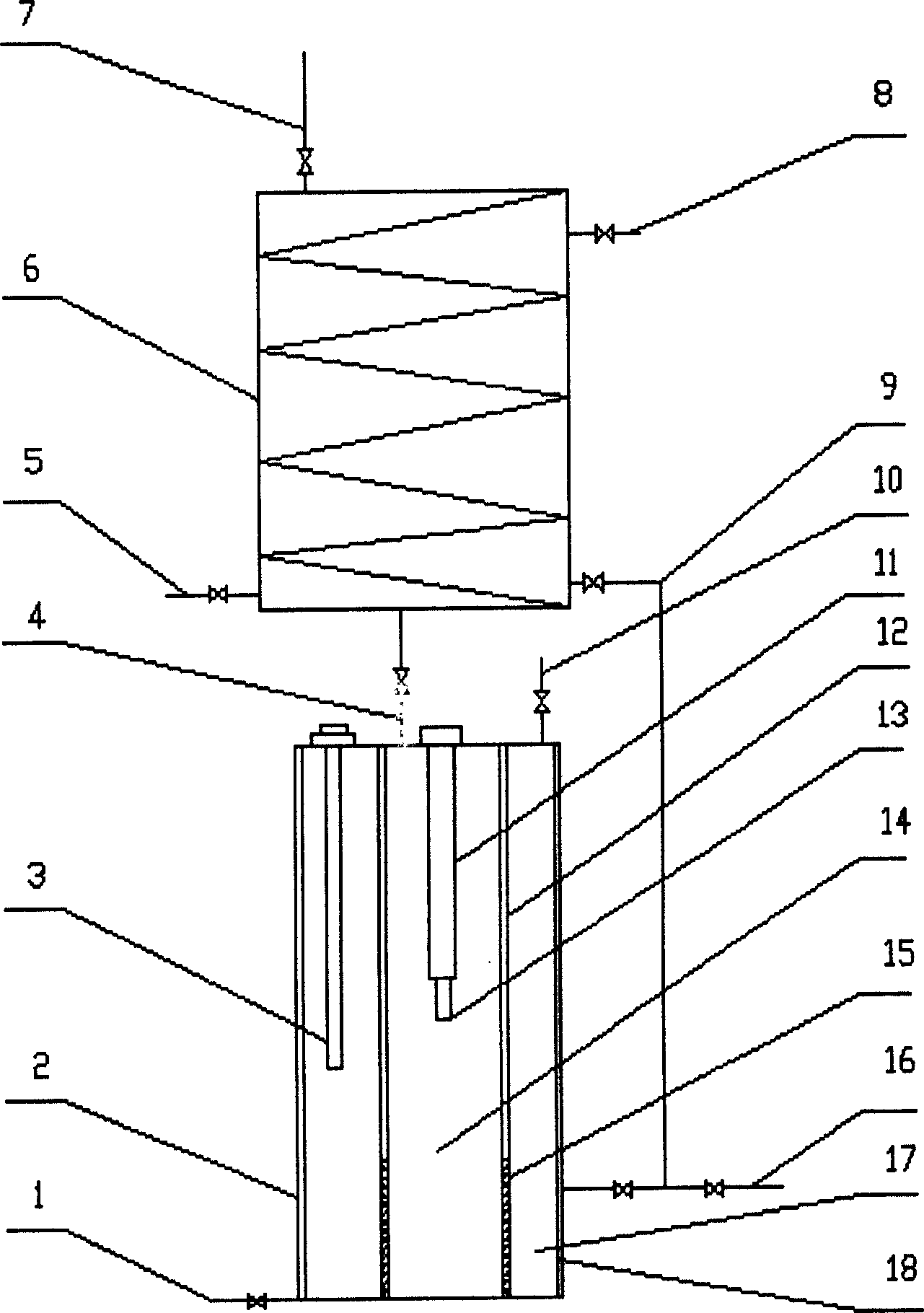

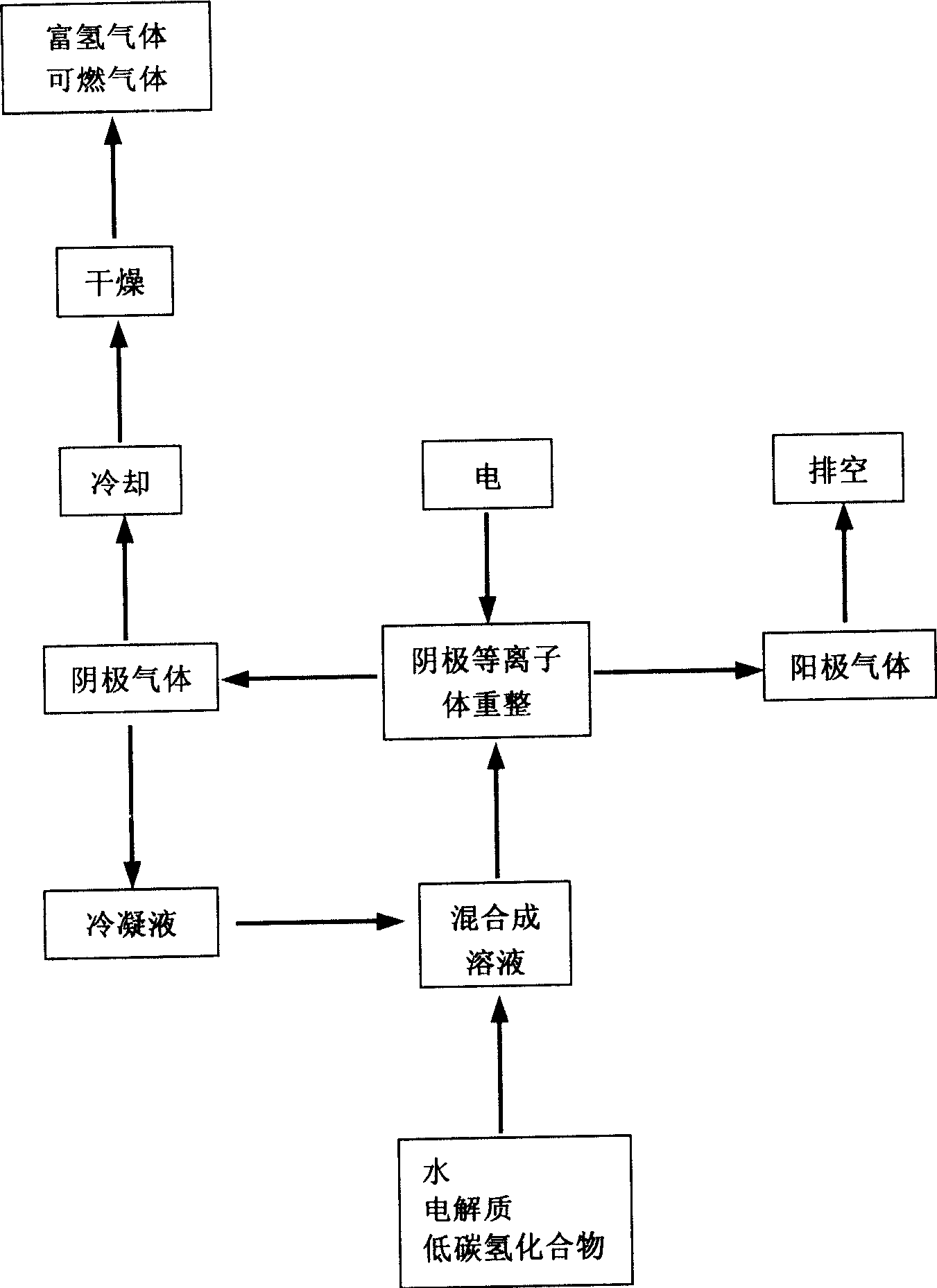

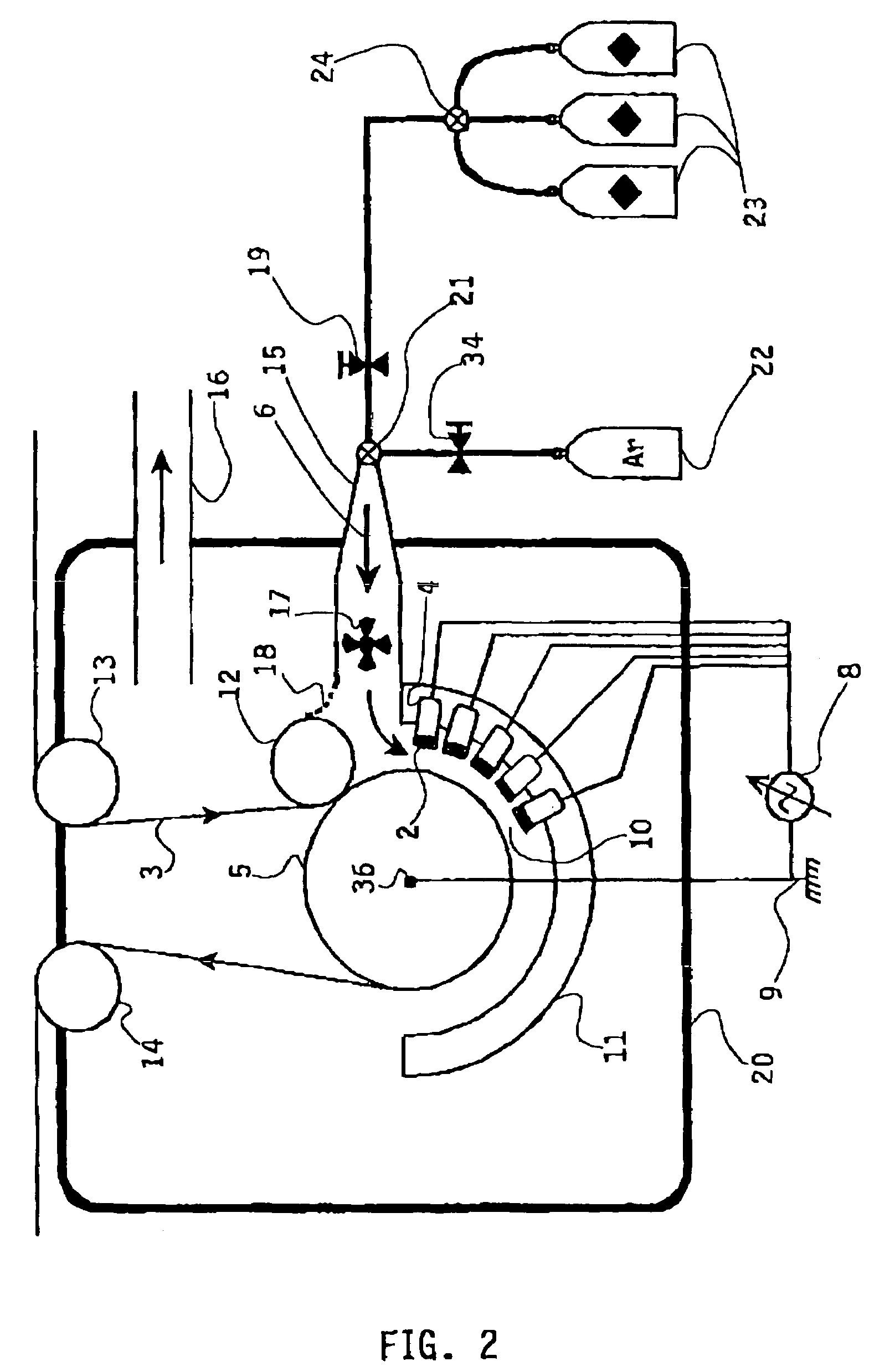

Method for preparing hydrogen rich gas through reforming plasma and equipment

InactiveCN1660693ASimple structureReduce volumeHydrogenEnergy based chemical/physical/physico-chemical processesAlcoholHydrogen

Owner:SOUTH CHINA UNIV OF TECH

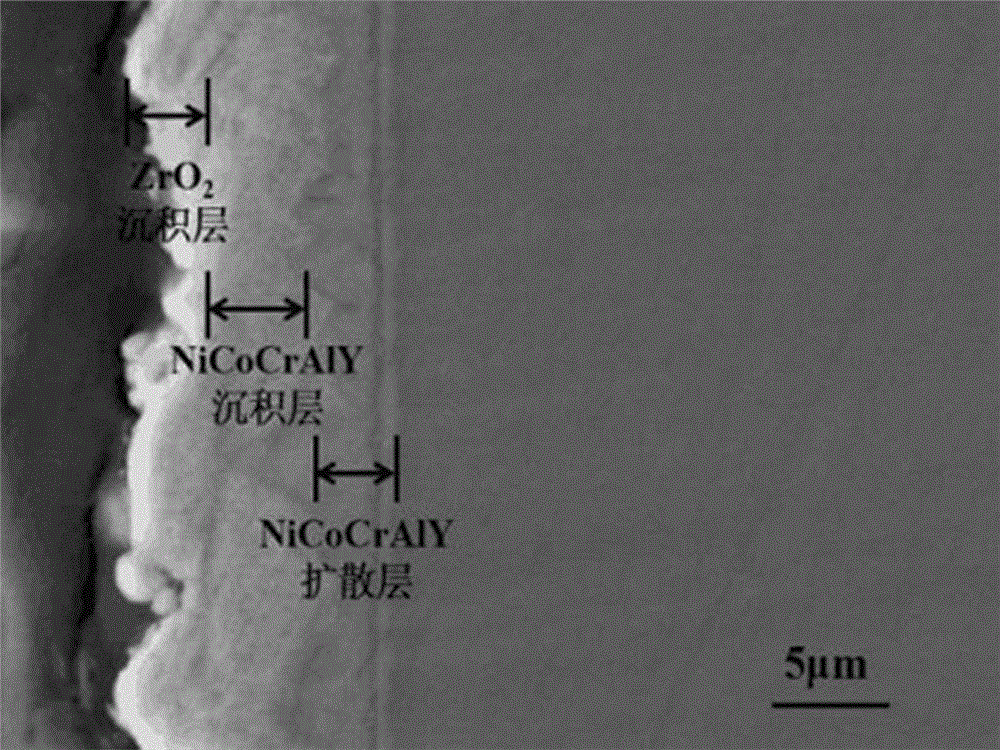

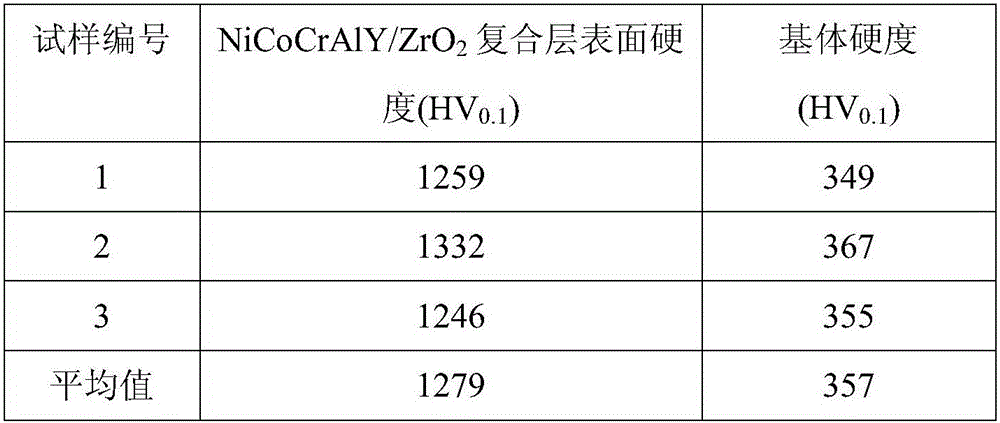

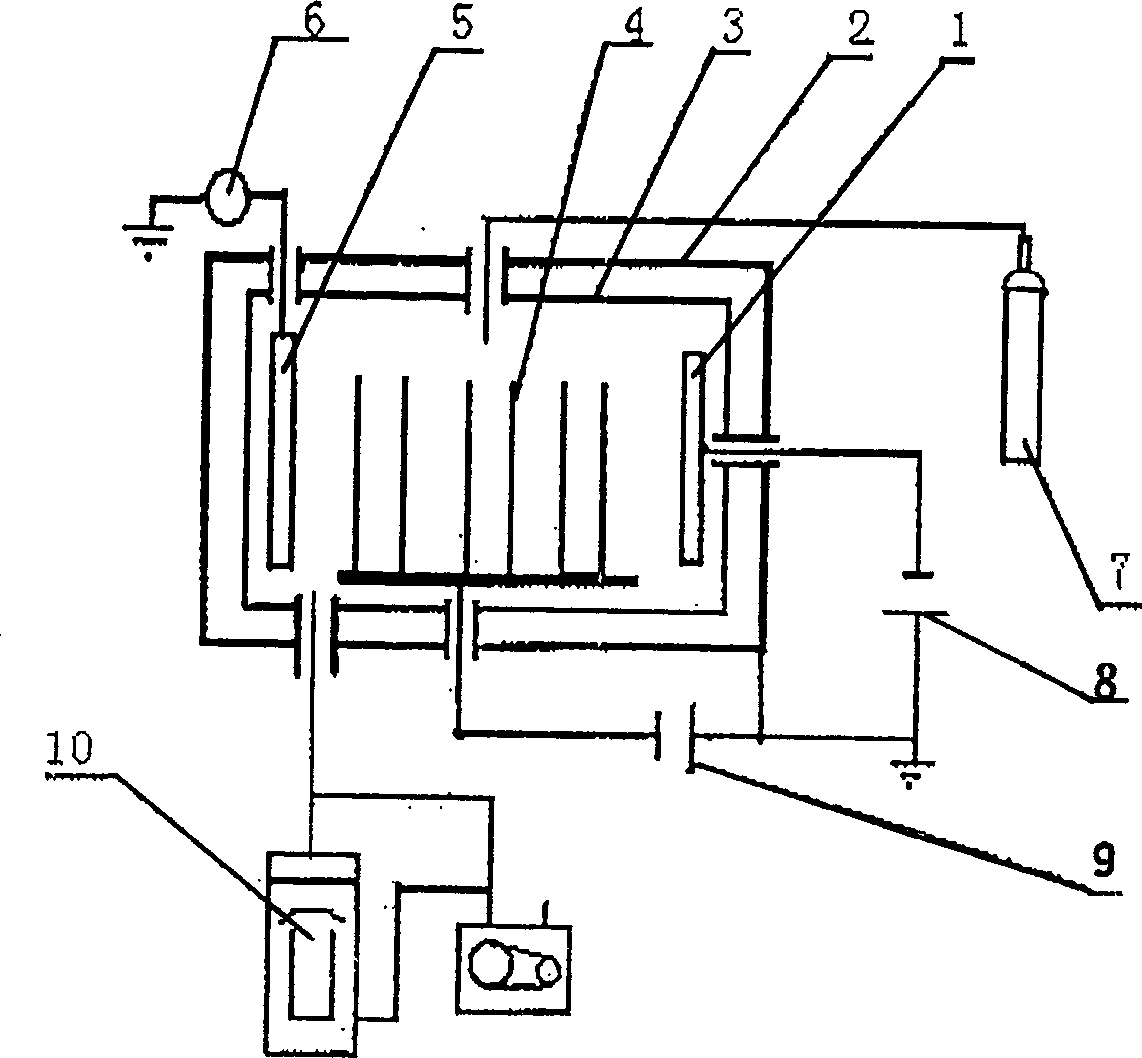

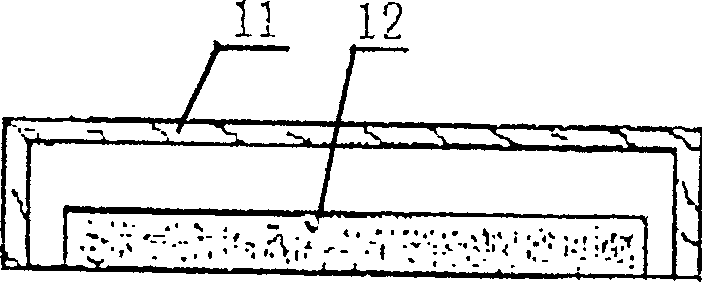

NiCoCrAlY / ZrO2 composite coating on gamma-TiAl alloy surface and preparation method thereof

InactiveCN105839061AHigh bonding strengthSufficient high temperature protectionVacuum evaporation coatingSputtering coatingSurface layerOxidation resistant

The invention belongs to the field of titanium alloy surface treatment. The NiCoCrAlY / ZrO2 composite coating comprises a ZrO2 alloying layer, a NiCoCrAlY layer and a NiCoCrAlY diffusion layer from a surface layer to an inner layer. The invention adopts the double glow plasma surface alloying technology to form the NiCoCrAlY alloying layer on the surface of gamma-TiAl alloy surface; then oxygen is introduced for ZrO2 co-alloying to form a ZrO2 alloying layer on the surface of NiCoCrAlY coating; finally a high temperature oxidation-resistant NiCoCrAlY / NiCoCrAlY composite layer is formed on the surface of gamma-TiAl titanium alloy. The ZrO2 alloying layer endows the gamma-TiAl titanium alloy with sufficient high temperature protection ability, the sub-surface NiCoCrAlY alloying layer can overcome the serious decomposition of ZrO2 coating under high temperature; and the NiCoCrAlY / ZrO2 multilayer structure realizes sufficient and reliable bonding strength between the alloy layer and a matrix, so as to improve the high temperature oxidation resistance and wear resistance of the gamma-TiAl alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process for glow ion hydrogen-free carbonizing titanium surface

A non-hydrogen glow ion process for carbonizing the surface of titanium (or Ti alloy) is characterized by that under the action of electric bias field and inert energy, the carbon ions (or atoms) sputted out from graphite electrode in glow plasmas reach to the surface of hot titanium workpiece, and under the action of thermal diffusion and ion bombardment the carbon ions (or atoms) come in the surface of titanium to form titanium carbide. Its advantages are high surface hardness (3000 HV) and antiwear nature, and deep carbonized layer.

Owner:太原理工大学表面工程研究所 +1

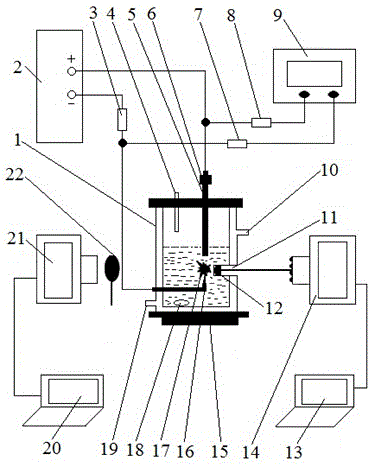

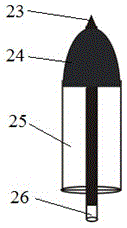

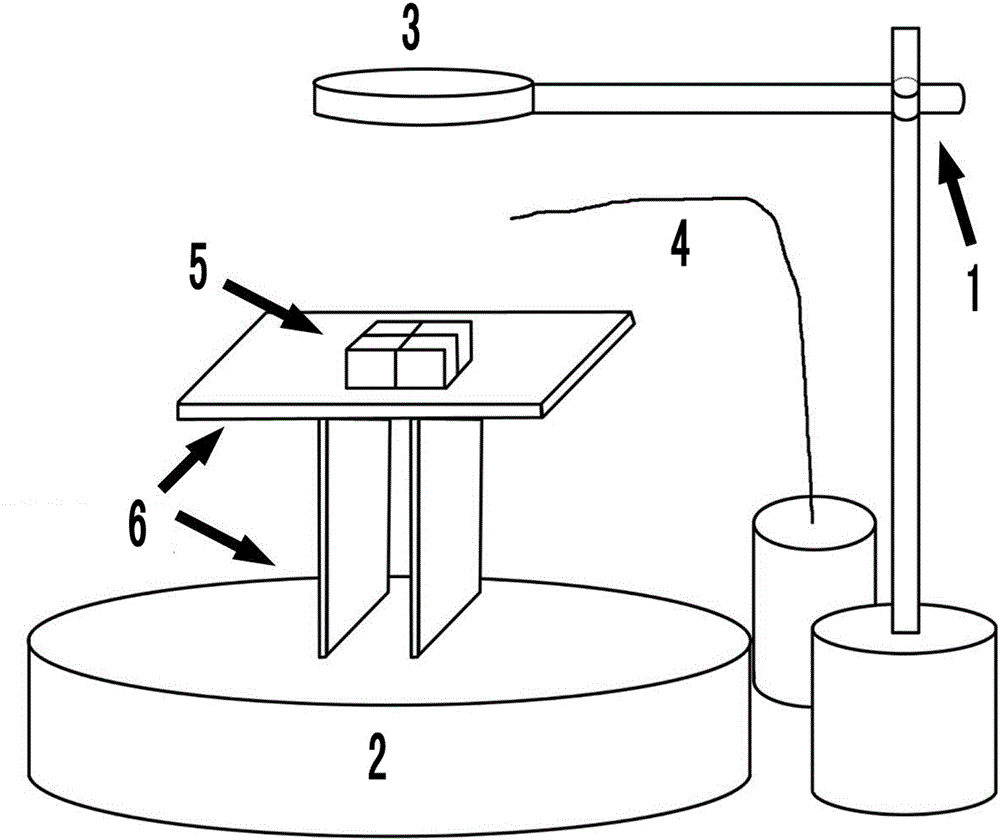

Metal element liquid phase cathode discharge plasma spectrum rapid detection system and detection method thereof

InactiveCN105115959AEasy to operateLow costAnalysis by electrical excitationGlow plasmaMaterials science

The invention relates to a metal element liquid phase cathode discharge plasma spectrum rapid detection system and a detection method thereof. The system comprises a plasma generation device, a fiber spectrometer and an ICCD camera. A needlelike platinum electrode cathode is arranged in the plasma generation device, the top of the plasma generation device is provided with an anode, the sidewall of the plasma generation device is provided with a fiber probe, and the needlelike platinum electrode cathode is respectively connected with a power supply negative electrode and an oscilloscope through two resistors; a graphite carbon rod is connected with a translation bench, a power supply positive electrode and a third resistor connected with the oscilloscope; and a condensing lens is arranged in front of the ICCD camera, and the fiber spectrometer and the ICCD camera are connected with a computer. In the detection process, voltage and current are increased, the needlelike platinum electrode cathode discharges to generate glow plasma, and the oscilloscope determines the current-voltage waveform; and the computer analyzes an optical signal to complete qualitative or quantitative detection of a metal element. The detection system uses no peristaltic pump, so loss caused by flow introduction of a sample in the determination process is avoided, and analysis detection of a trace quantity of the metal element in an environment sample is convenient.

Owner:NORTHWEST NORMAL UNIVERSITY

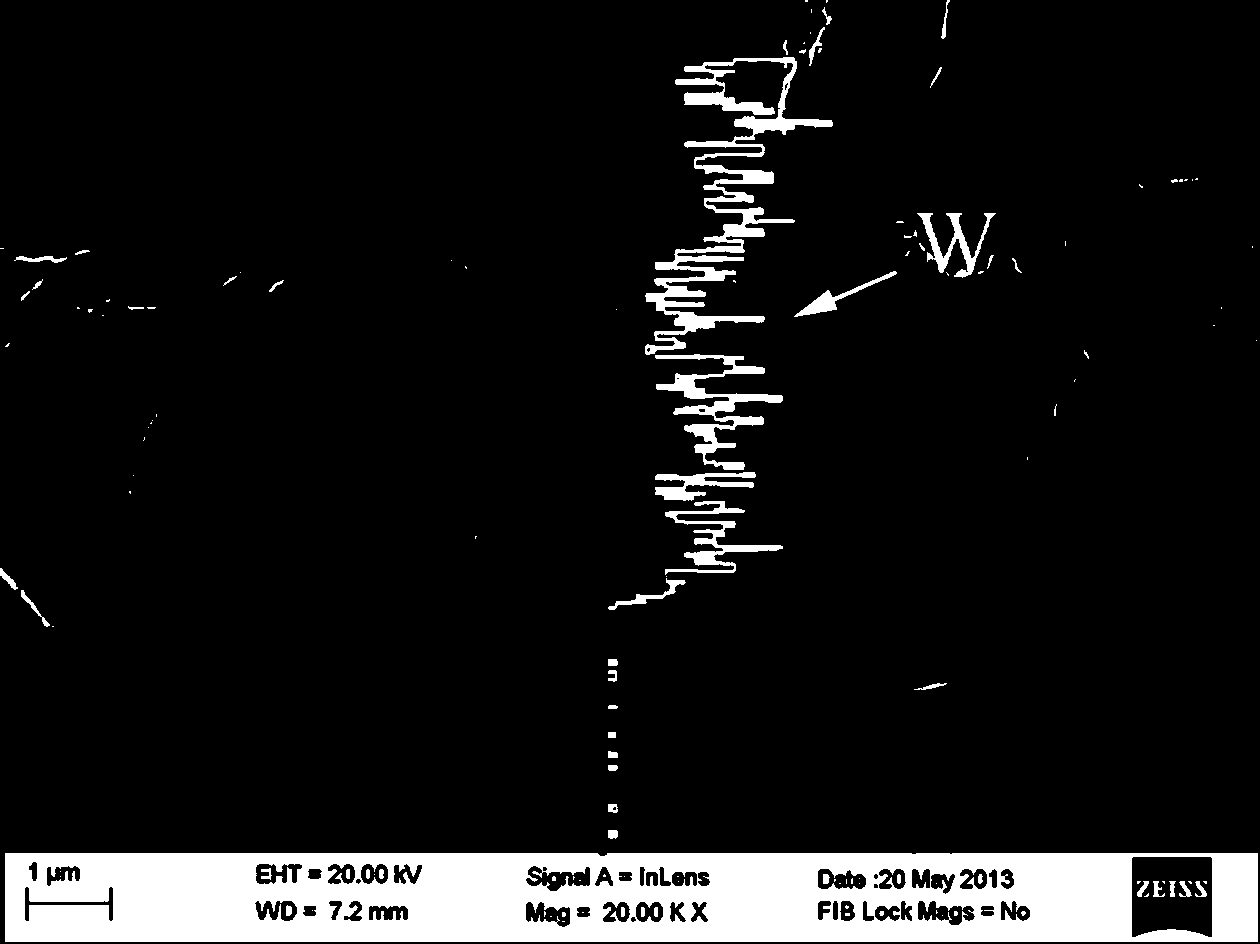

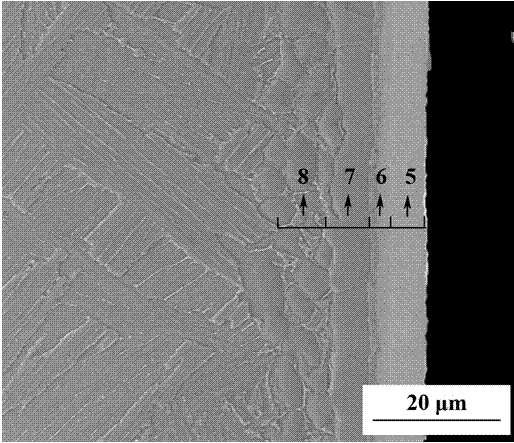

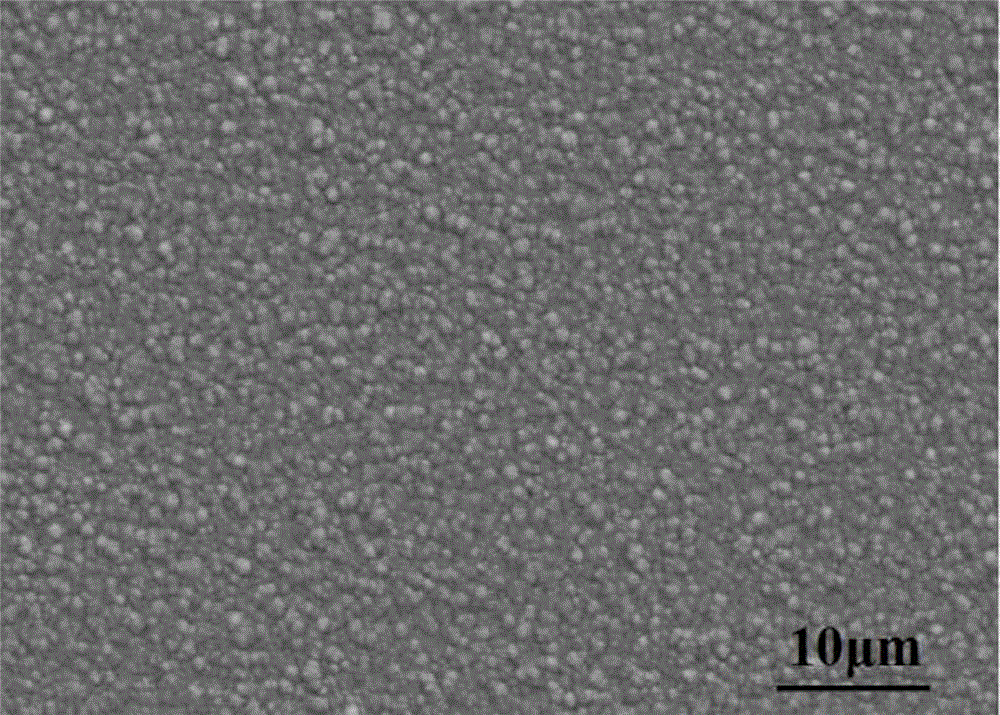

Diamond single crystal surface metallization treatment method

ActiveCN106835054AImprove the efficiency of graphitization transformationPromote the graphitization processVacuum evaporation coatingSputtering coatingEtchingIron group

The invention discloses a diamond single crystal surface metallization treatment method. The method comprises steps as follows: the surface of a diamond single crystal is bombarded and sputtered with Fe, Co or Ni as a source electrode target material with a double-glow plasma diffusion metallizing technique; the single crystal is soaked in an acid solution, so that remaining metal and graphite are removed; a metal diffusion coating is prepared on the surface of the diamond single crystal with strong carbide metal as a target material with a double-glow plasma diffusion metallizing technique. Uniformly distributed micro pits are formed in the surface of the single crystal under the bombardment and sputtering functions of the double-glow plasma and the graphitized catalytic function of Fe, Co, Ni and other iron group metals, surface roughening and activation are realized, strong carbide metallic elements react with a part of carbon atoms on the surface of the diamond so that chemical bond combination is realized, and the bonding strength of the surface metallization coating and the single-crystal diamond is improved. Bombardment etching and metallization treatment are realized with one device, the process is simple, the cost is low, and the method is suitable for industrial production.

Owner:山西国脉金晶碳基半导体材料产业研究院有限公司

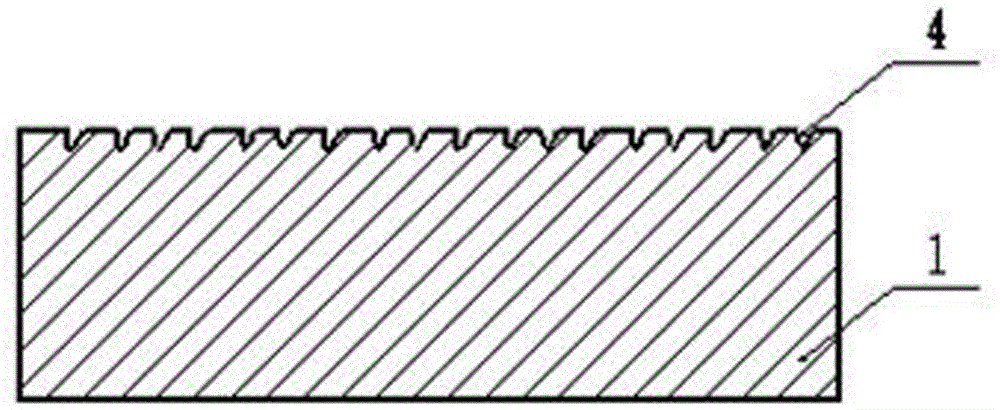

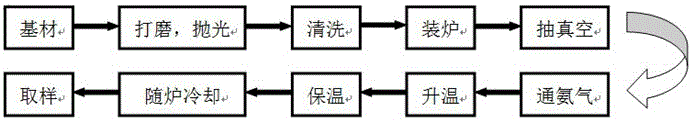

Method for preparing surface plasma nitrided layer of high-entropy alloy

InactiveCN106637062AHigh bonding strengthHigh hardnessSolid state diffusion coatingElectricityInternal pressure

The invention provides a method for preparing a surface plasma nitrided layer of a high-entropy alloy. The method comprises the steps that a high-entropy alloy base material is cleaned, a part is dried in a plasma nitriding furnace; and after the inner pressure and the outer pressure of the plasma nitriding furnace are identical, the part is placed on a cathode disk, vacuumizing is conducted on a furnace body, high-purity ammonia gas is fed into the furnace body, the temperature is raised and then kept, feeding of the ammonia gas is cut off, vacuumizing continues to be conducted, and the surface plasma nitrided layer of the high-entropy alloy is obtained after furnace cooling. According to the method for preparing the surface plasma nitrided layer of the high-entropy alloy, the LDMC-100A type pulse plasma nitriding furnace and the double glow plasma nitriding technology are utilized to conduct nitriding on the surface of the high-entropy alloy for the first time; the method for preparing the surface plasma nitrided layer of the high-entropy alloy has the advantages that the plasma nitrided layer is thick, high in combination strength and hardness and resistant to wear and corrosion; besides, the method for preparing the surface plasma nitrided layer of the high-entropy alloy has the advantages that the nitriding speed is high, the nitrided layer has good performance, technological deformation is small, and gas consumption and electricity consumption are small; and the method for preparing the surface plasma nitrided layer of the high-entropy alloy is a non-pollution nuisance-free ideal technology, and the surface plasma nitrided layer of the high-entropy alloy can be widely applied to the working conditions having a high wear resistance requirement and a high corrosion-resistance requirement.

Owner:TAIYUAN UNIV OF TECH

Preparation of high film substrate bond strength photocatalysis TiO2 film

InactiveCN101328574AHigh bonding strengthDoes not reduce UV activityPhysical/chemical process catalystsVacuum evaporation coatingGlow plasmaBond strength

A preparation method of a photocatalytic TiO2 film with high coating-substrate bonding strength belongs to the photocatalytic material preparation technical field, relating to a method for preparing a photocatalytic TiO2 film with high coating-substrate bonding strength on a metallic matrix. The method is characterized in that: firstly, by means of a double layer glow plasma metal impregnation technology, a titanium impregnation coating consisting of a diffused layer of titanium inside a matrix and a surface titanium settled layer is formed on the surface of the metal matrix at a high temperature of between 800 and 1,000 DEG C; the concentration of titanium inside a plating layer is increased from inside to outside and is in gradient distribution, thereby ensuring excellent bonding strength between a film and the matrix; then, a workpiece is placed inside an ordinary heating furnace, and undergoes heating treatment through making direct use of air within a temperature range of between 400 and 600 DEG C; therefore, the surface of the metal matrix is formed into a nitrogen-doped anatase-type TiO2 film with excellent photocatalytic performance. The preparation method has ideal process repeatability and easily controlled quality, and can be used in aspects such as water contaminant degradation and air purification.

Owner:TAIYUAN UNIV OF TECH

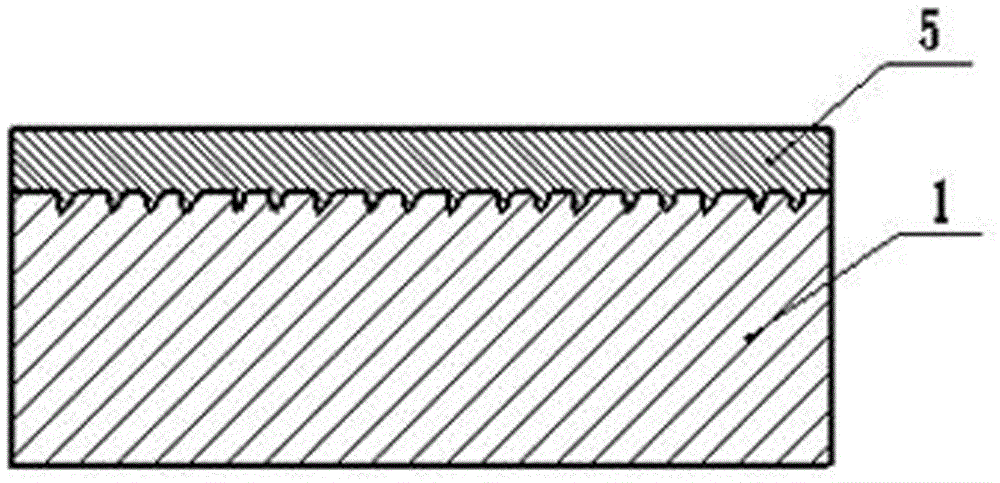

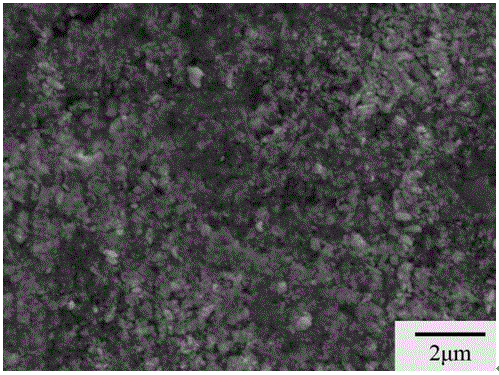

High-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on surface of titanium-aluminum alloy and preparation method thereof

InactiveCN105839049AImprove wear resistanceThe surface of the coating is smooth and denseVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention discloses a high-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on the surface of a titanium-aluminum alloy and a preparation method thereof. The coating is deposited on the surface of a titanium-aluminum alloy workpiece through the double glow plasma surface technology, an AlCrN deposited layer is located on the surface of the coating and is 5-10 micrometers thick, and a compact oxidized layer rich in Al2O3 and Cr oxide is formed by the AlCrN deposited layer at a high temperature; an AlCrN diffused layer is arranged in the coating and is 12-15 micrometers thick; the hardness of the obtained coating is 30-37 GPa, the room temperature friction coefficient of the coating is 0.3-0.33, and the high-temperature friction coefficient of the coating is 0.47-0.49. The preparation method includes the steps of charging, vacuumizing, workpiece surface activation, plasma permeation of the AlCrN coating, cooling and discharging. The obtained AlCrN coating solves the problem that the titanium-aluminum alloy is poor in high-temperature-oxidation resistance; meanwhile, the gradient structure of the diffused layer achieves metallurgical bonding of the coating and a substrate, and good high-temperature-oxidation resistance and good abrasion resistance are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Platinum group metal alloy coating with controlled alloying elements and preparation method thereof

InactiveCN102534290AComposition controllableEasy to makeVacuum evaporation coatingSputtering coatingIridiumNiobium

The invention relates to a method for preparing a platinum group metal alloy coating on the surface of a refractory metal material; and in the coating, iridium or platinum are main components, zirconium, hafnium, tantalum, niobium and aluminium are alloying elements, and oxides of the alloying elements are enhancing components. The preparation method of the coating comprises the following steps of: taking a number of platinum group metal wires and alloying metal wires, and leading the platinum group metal wires and alloying metal wires to pass through aluminium oxide ceramics and be fixed, thereby forming an alloying target; and placing the target and a workpiece in a vacuum chamber, wherein one end of the target faces towards the workpiece, the other end of the target is connected with a power source, the platinum group metal wires are connected with a group of power sources in parallel, and the alloying metal wires can be connected with two to five groups of power sources according to the distributional design. The alloy coating is deposited in a vacuum furnace by adopting a double-glow plasma method; in the deposition process, the electricity of a part of the alloying elements can be cut off, the electricity can be supplied again after the electricity is cut off, and after the electricity is cut off, the connected alloying wires are in the non-working state and do not sputter alloying atoms or ions, and therefore, the content of the alloying elements in the coating can be adjusted.

Owner:陈照峰

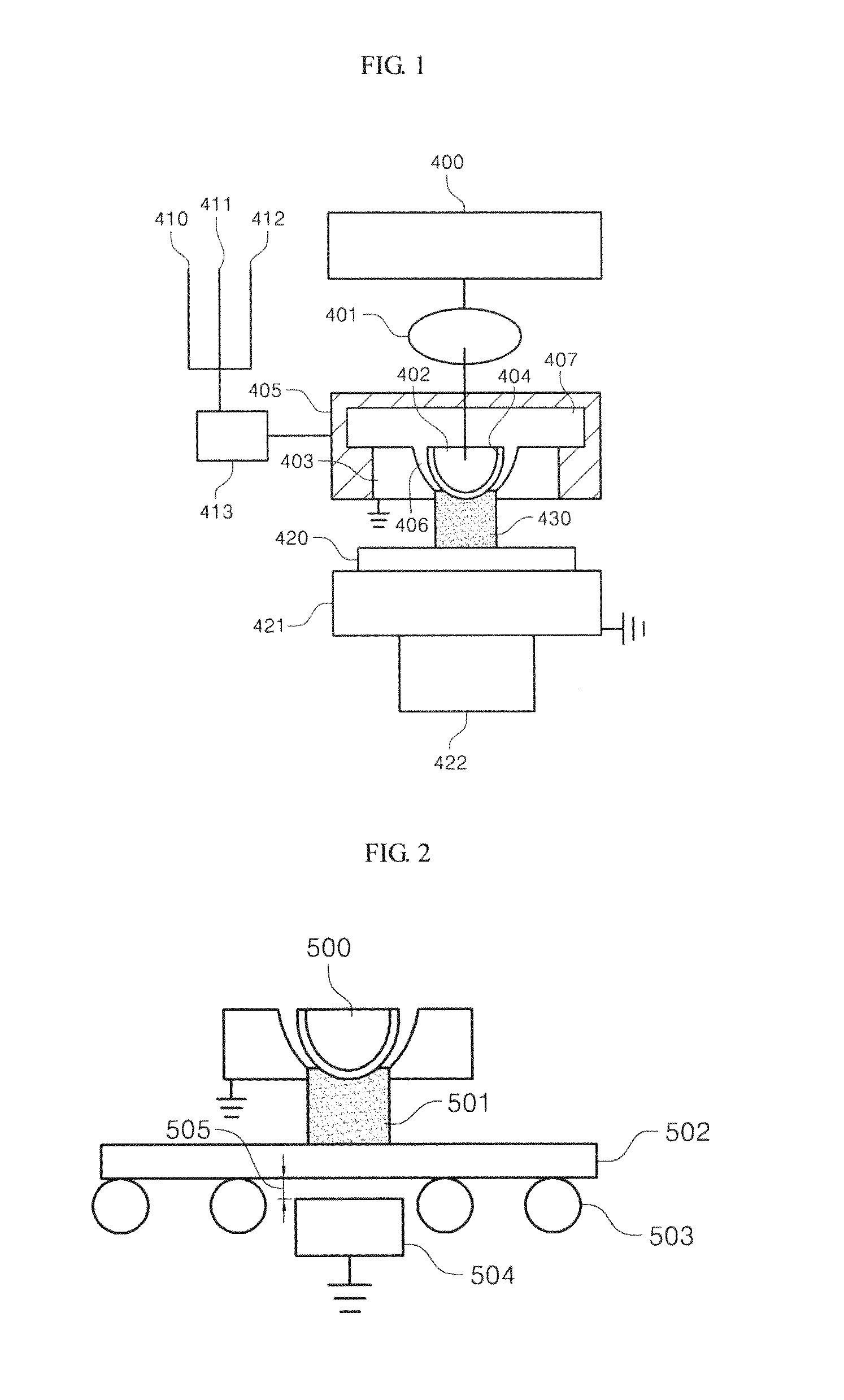

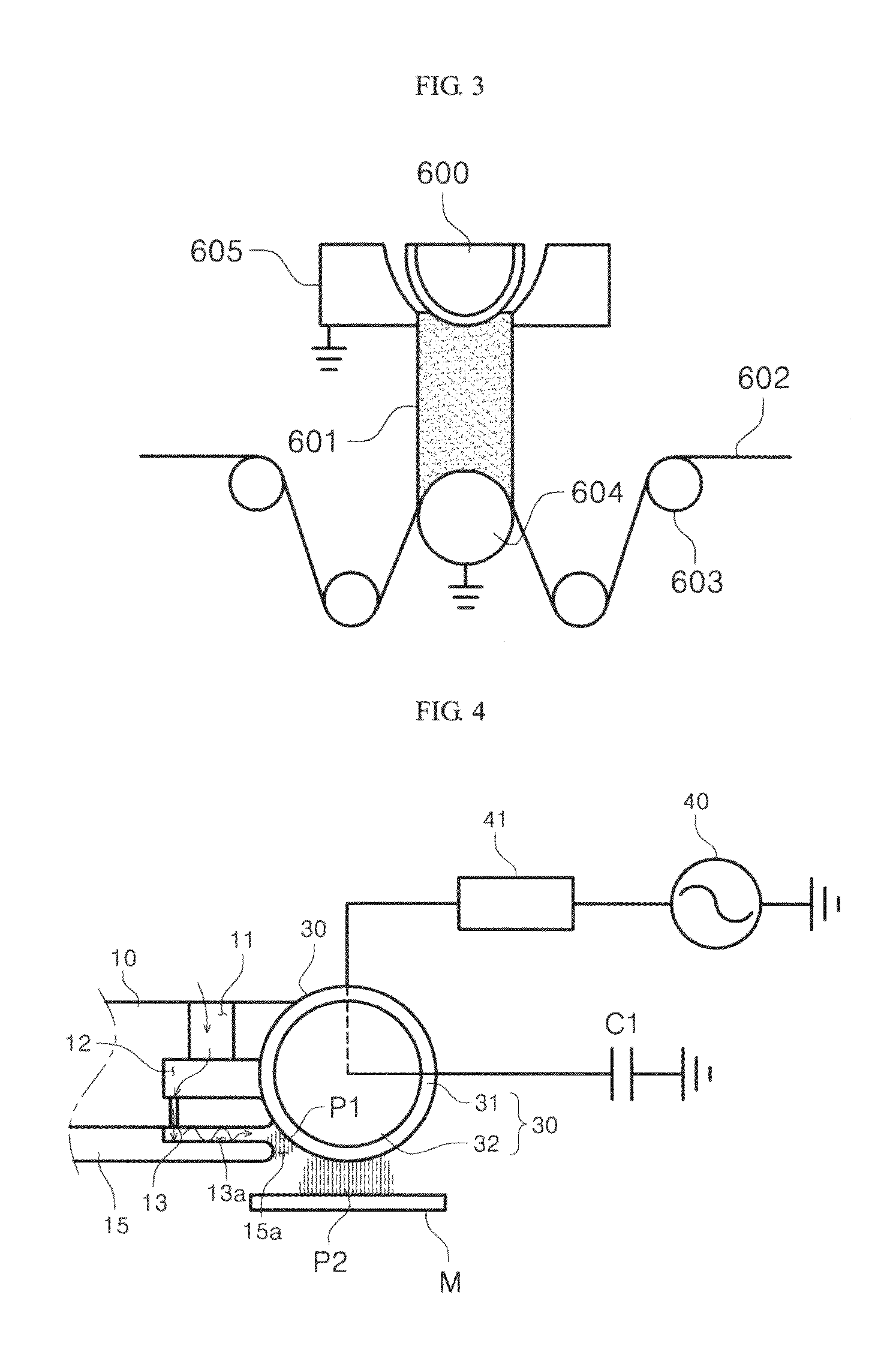

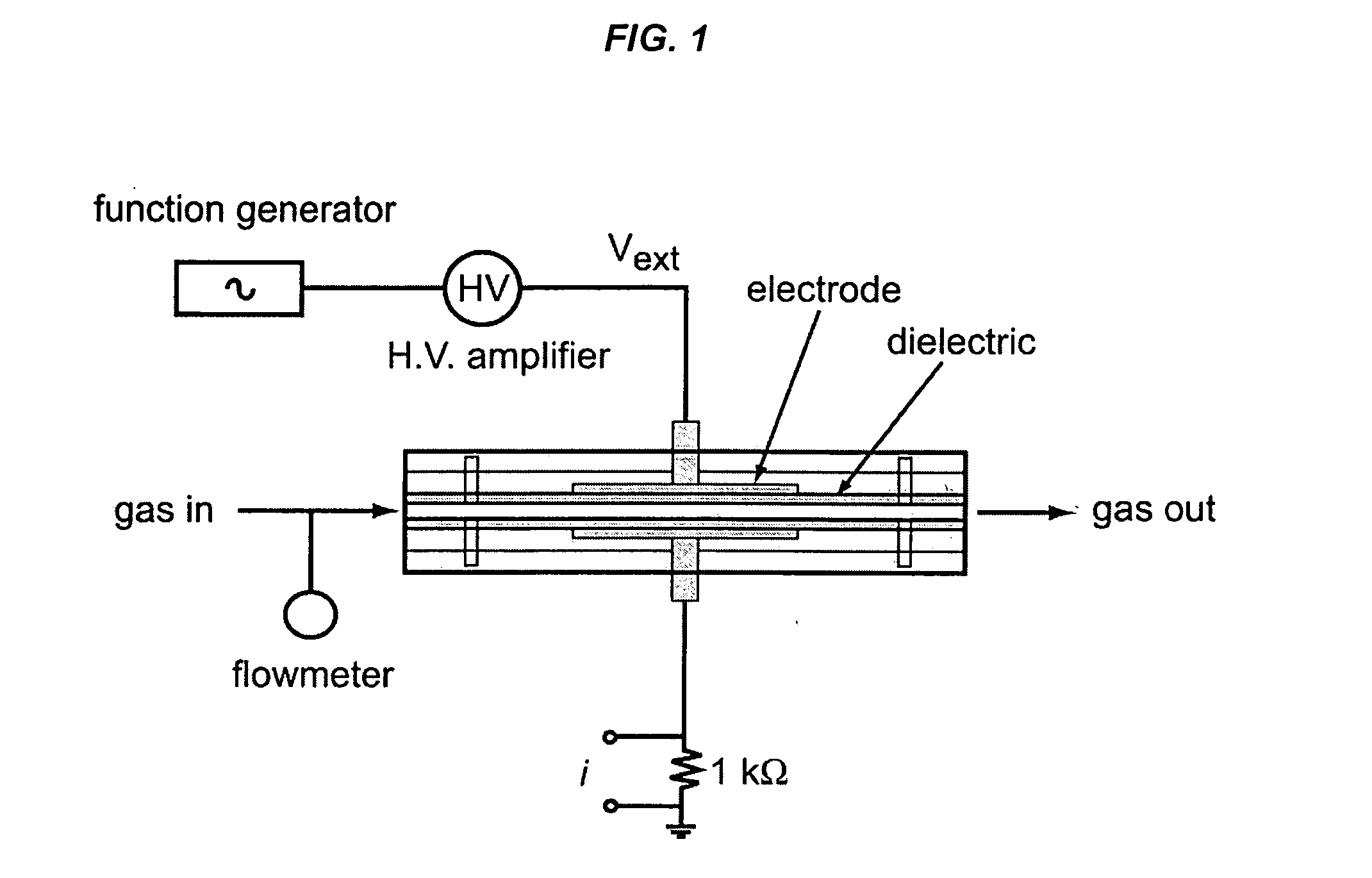

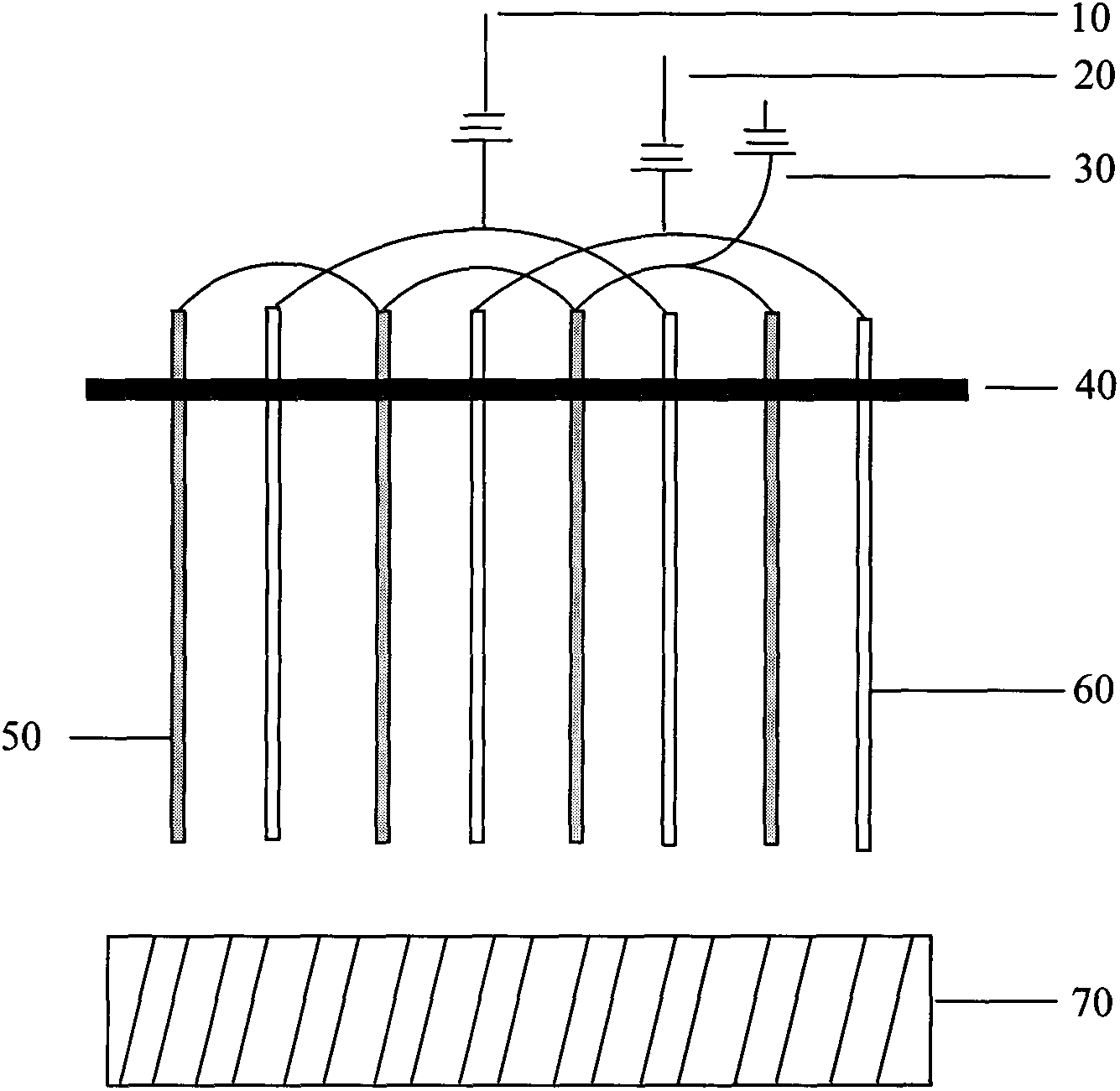

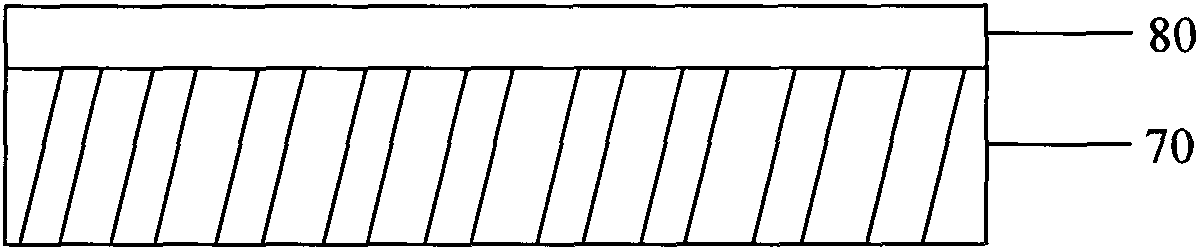

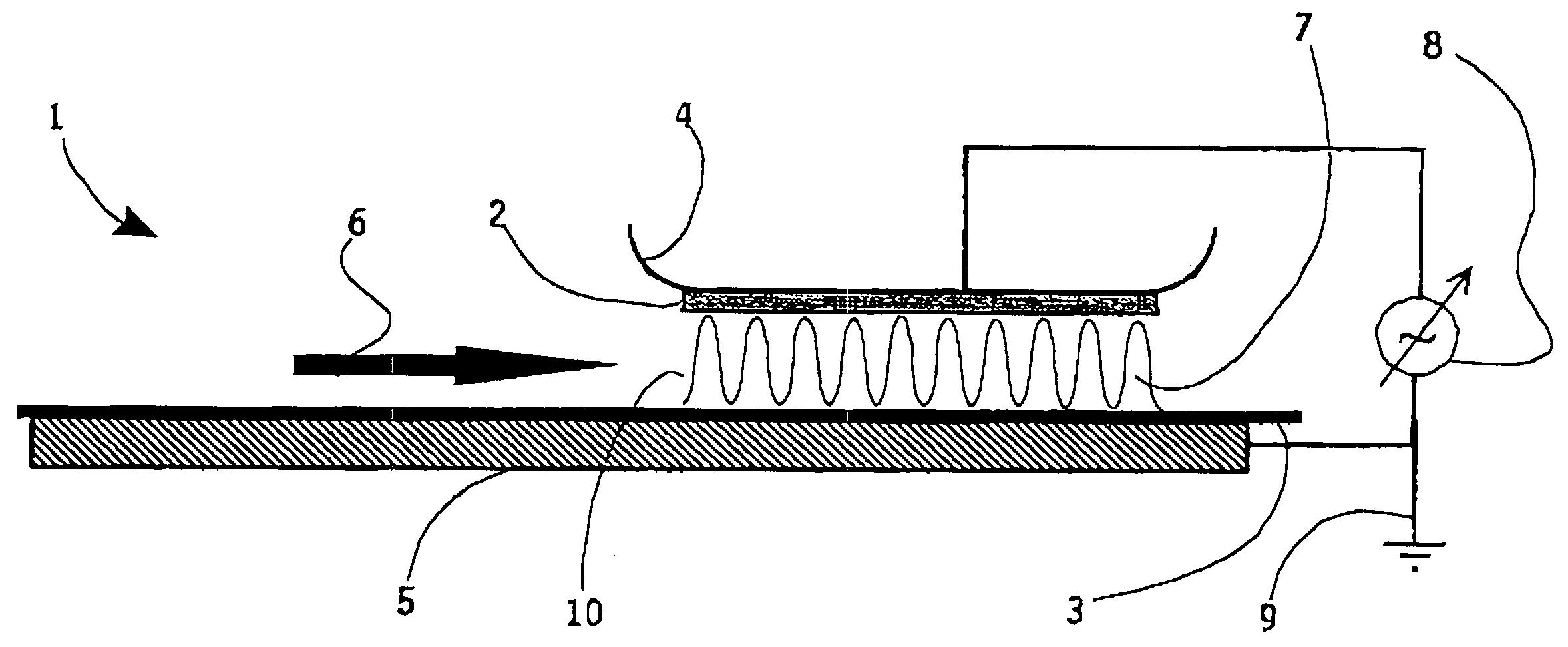

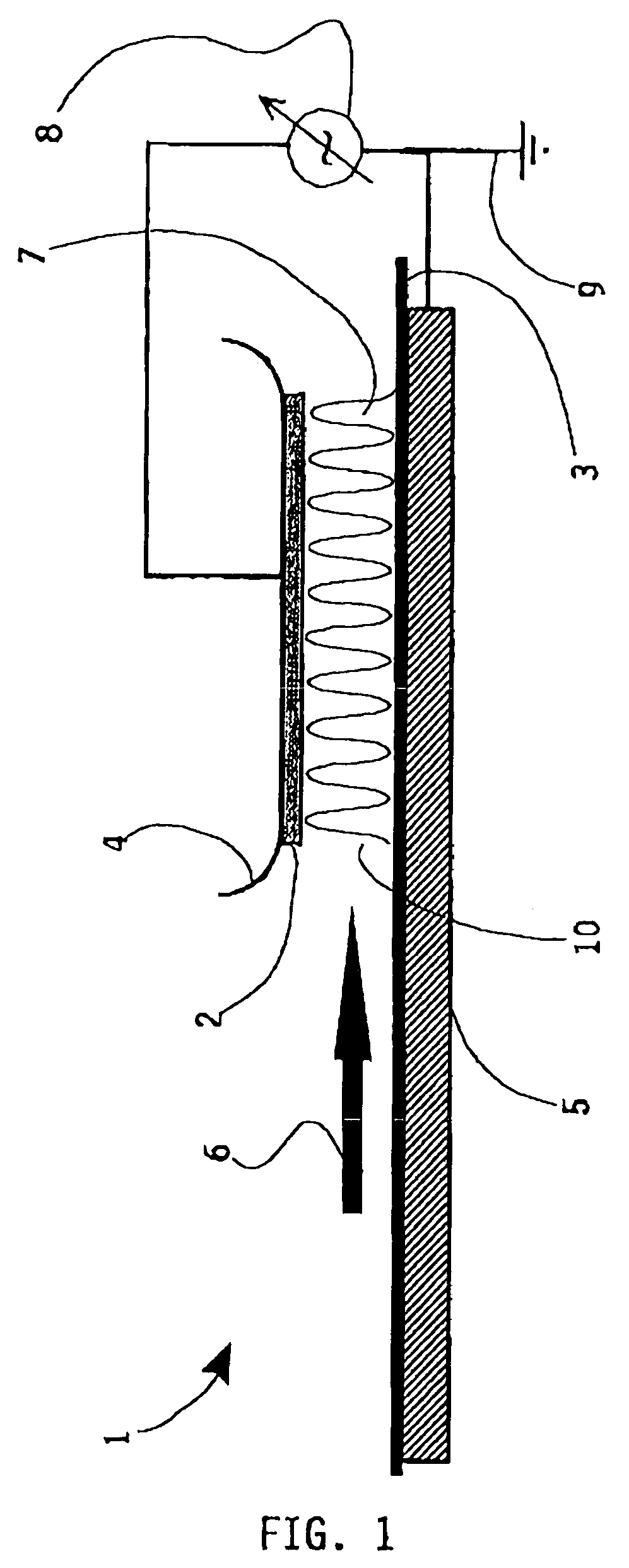

Method and arrangement for generating an atmospheric pressure glow discharge plasma (APG)

InactiveUS7491429B2Cost effectiveGood treatment effectElectric discharge tubesPretreated surfacesNitrogenGlow plasma

Method and arrangement (1) for generating an atmospheric pressure glow plasma APG (7), where in a plurality of electrodes, (4, 5) are arranged defining a discharge space (10) for forming said plasma (7). The electrodes (4,5) are connected to a power supply (8) providing an AC-voltage having a frequency of at least 50 kHz to the electrodes (4,5). A gaseous substance (6) is provided in said discharge space and comprises t least one of a group of argon, nitrogen and air.

Owner:FUJI PHOTO FILM BV

Titanium alloy surface ceramic/metal gradient high-temperature composite coating and preparing method thereof

ActiveCN105714244AHigh hardnessRaise room temperatureSolid state diffusion coatingGlow plasmaTitanium alloy

The invention relates to a titanium alloy surface ceramic / metal gradient high-temperature composite coating and a preparing technology. A titanium alloy serves as a matrix of the coating, an Al-Nb-Si alloy serves as a target material, and the gradient high-temperature composite coating is prepared through arc glow plasma. The gradient high-temperature composite coating is composed of two parts, an inner layer of the coating has the good high temperature oxidation resistance performance and is an aluminum-rich Ti-Al-Nb-Si multi-component alloying metal layer in good thermal physical performance cooperation with the matrix, an outer layer of the coating is a ceramic layer with titanium and aluminum nitride as the main part, the ceramic layer has the good high temperature oxidation resistance performance and the frictional wear performance, and chemical components of the coating are gradually changed in a gradient manner. The gradient high-temperature composite coating has the good high temperature oxidation resistance performance and also has the good room temperature resistance performance and the high-temperature dry sliding friction wear performance, the coating and the titanium alloy matrix are in typical metallurgy combination, and combination is firm.

Owner:QINGDAO BINHAI UNIV

Method for preparing alpha-Al2O3 coating by using double-glow plasma diffusion metalizing technology at low temperature

InactiveCN104988466AReduce the temperatureAccelerated corrosionVacuum evaporation coatingSputtering coatingRare-earth elementPhysical chemistry

The invention relates to a new method for preparing an alpha-Al2O3 coating by using a double-glow plasma diffusion metalizing technology at a low temperature. Firstly, a rare earth element Y and an alpha-Al2O3 seed crystal are added in an Al target, and an Al coating which is formed by doping of Y and alpha-Al2O3 seed crystal is prepared on a 316L stainless steel surface with the double-glow plasma diffusion metalizing technology; and then, under the low temperature of 580 DEG C, the coating is oxidized by plasmas, so that the coating with a high content of alpha-Al2O3 on the surface is obtained. The invention provides the new method for preparing the coating with the high content of alpha-Al2O3 on the 316L stainless steel surface at the low temperature; and the coating can be widely applied to the fields such as corrosion resistance, oxidation resistance and tritium resistance of stainless steel metals and the like.

Owner:江苏模影科技有限公司

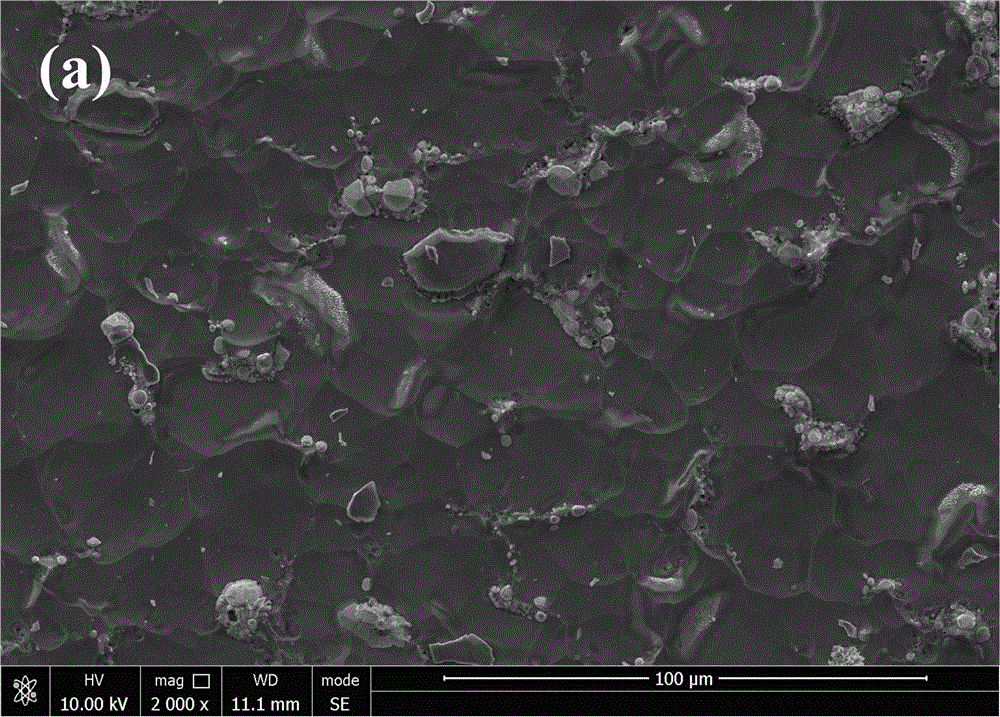

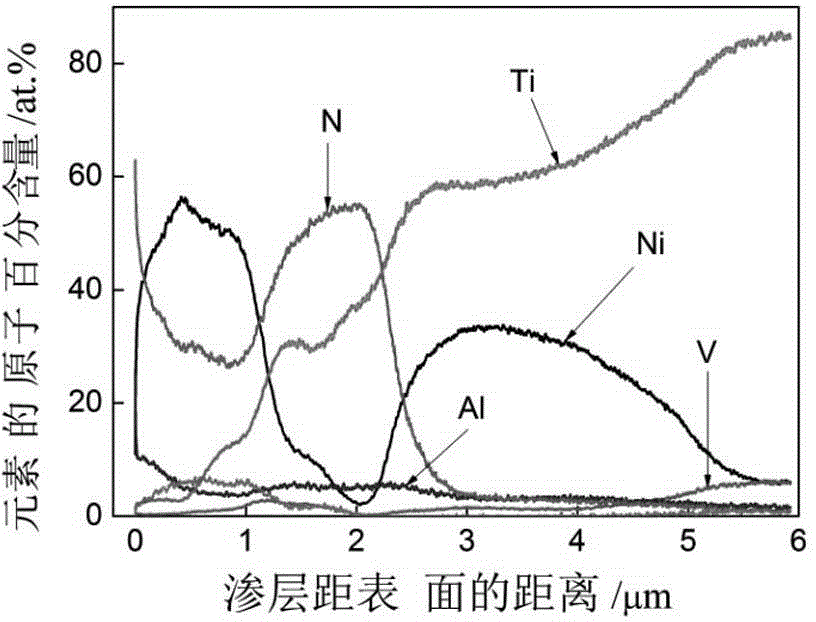

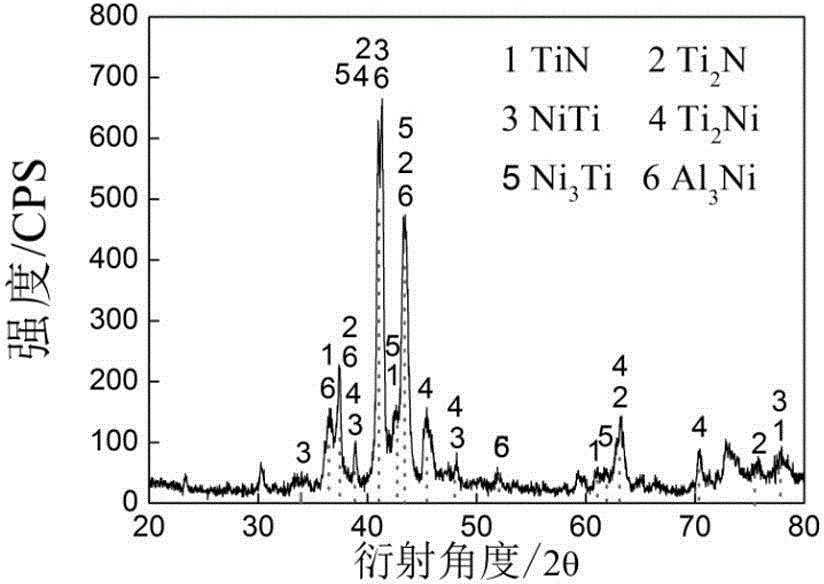

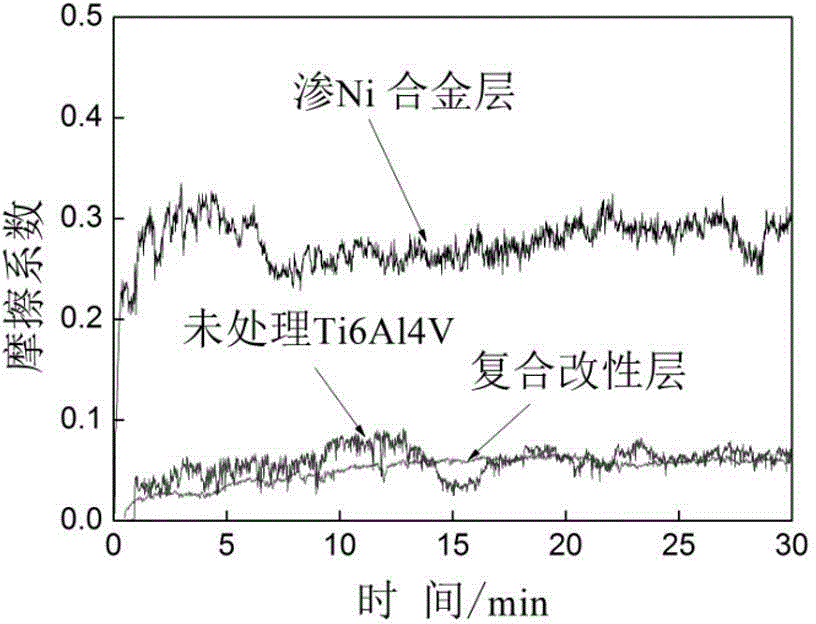

Preparation method for gradient titanium alloy-surface Ni/TiN composite modification layer

ActiveCN104862649ASolve the hardnessSolve wear resistanceVacuum evaporation coatingSputtering coatingSurface layerGlow plasma

The invention relates to the field of treatment of a surface layer, specifically to a preparation method for a titanium alloy-surface composite modification layer. The preparation method for the gradient titanium alloy-surface Ni / TiN composite modification layer comprises the following steps: carrying out nickelizing on the surface of titanium alloy by using double glow plasma diffusion metalizing technology so as to prepare a nickel alloy layer used as a transition layer; and then carrying out nitriding on the surface of a nickel alloyed sample so as to prepare a TiN film, wherein a prepared titanium alloy-surface modification layer is the Ni / TiN composite modification layer. The composite modification layer has the advantages of a thick diffusion metalizing layer, good compatibility of deformation, high hardness, resistance to sea water corrosion and good comprehensive mechanical properties and can be extensively applied to working conditions of high requirements on wear resistance, good toughness and resistance to sea water corrosion.

Owner:太原市赛斯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com