Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

A composite coating and vacuum coating technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems such as coating embrittlement, achieve strong anti-corrosion ability, improve coercive force, binding force and The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

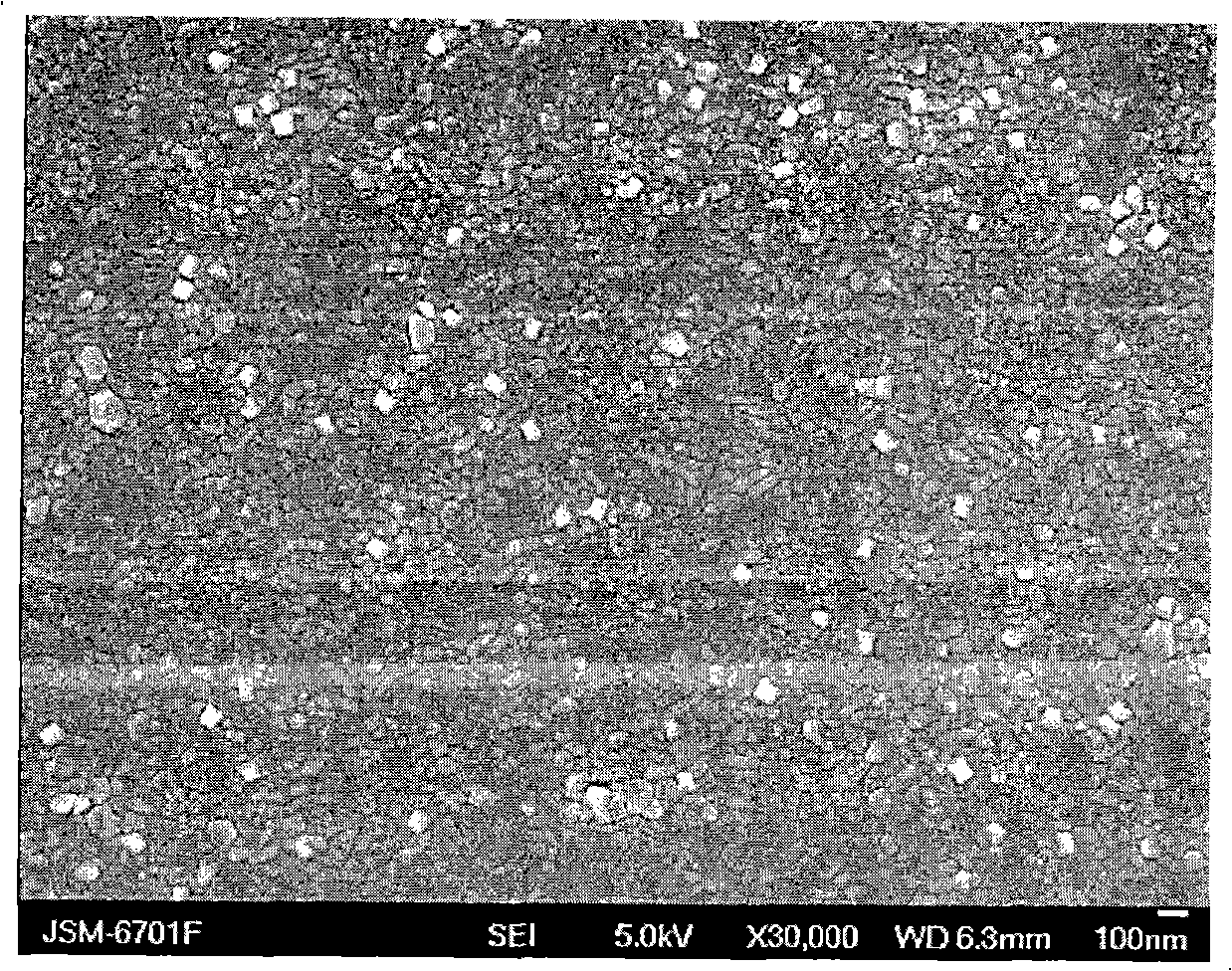

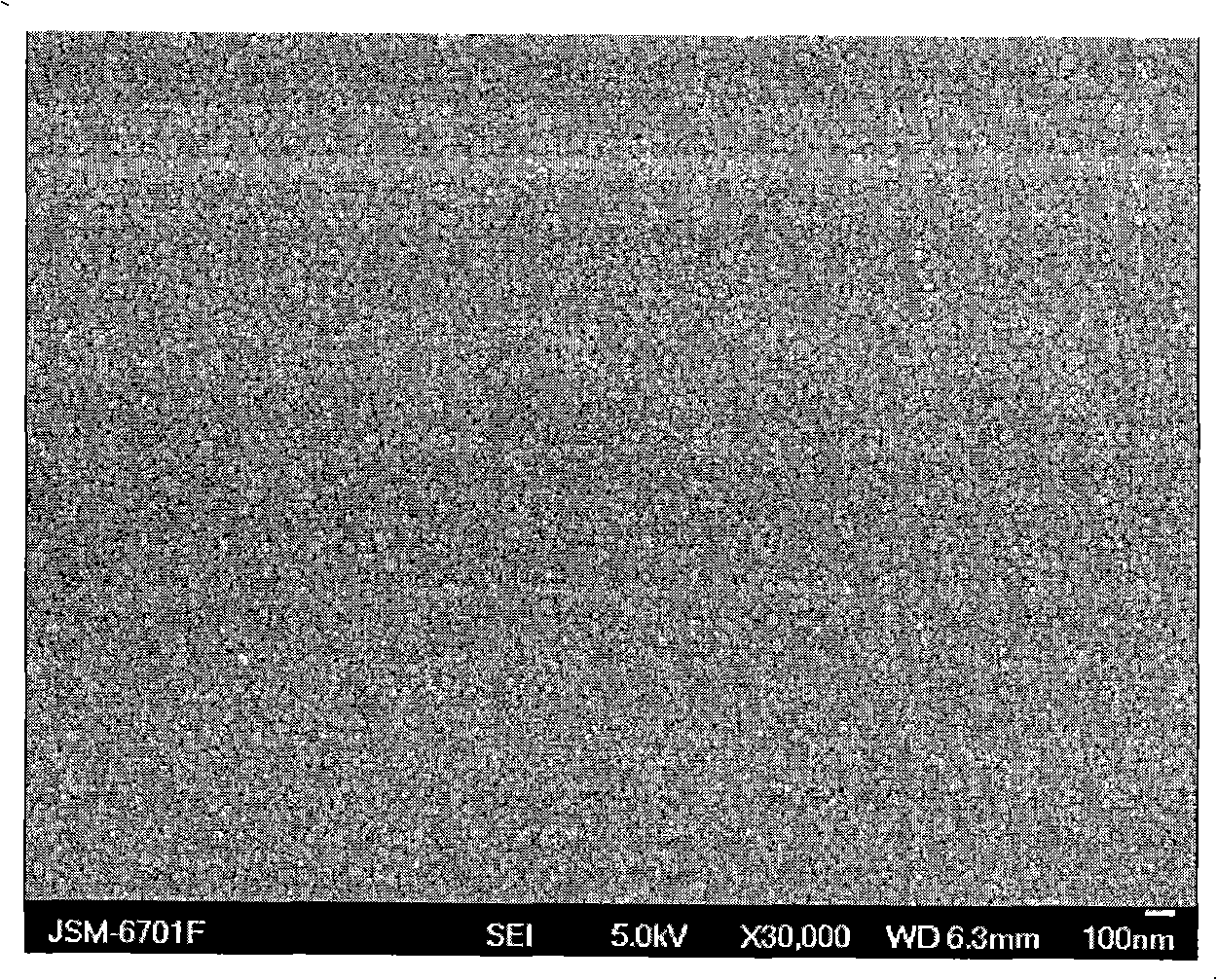

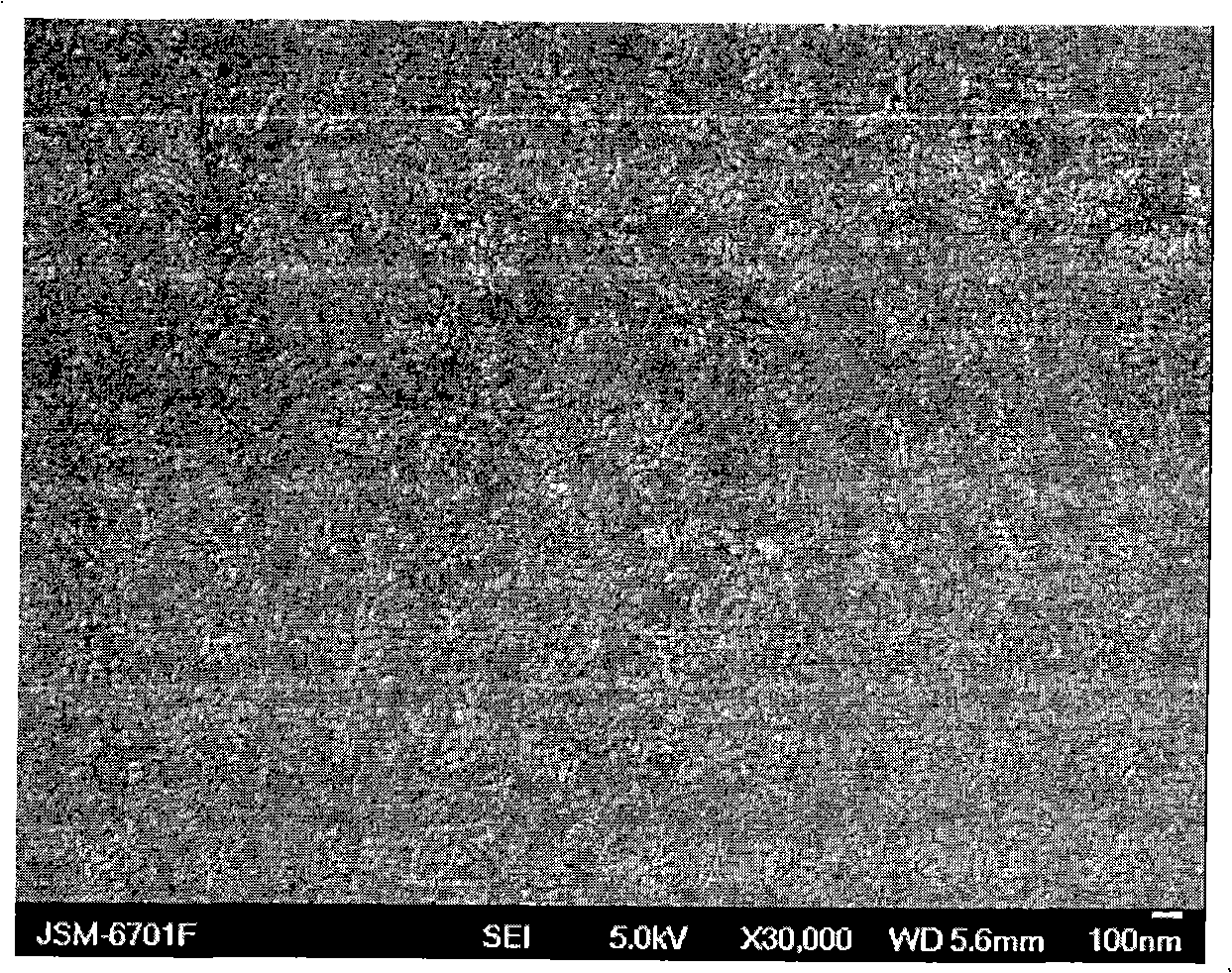

Image

Examples

Embodiment 1

[0028] Embodiment 1: a preparation method of vacuum composite coating on the surface of an NdFeB magnet, comprising the following steps:

[0029] A. Pretreatment, use a mixture of cleaning solution and pure water at a ratio of 1:1000 in an ultrasonic cleaning machine to remove oil and clean the surface of the magnet with a release agent;

[0030] B. Ion cleaning and activation, the pretreated NdFeB magnet is dried at a temperature of 80°C-100°C for 5-10 minutes, and then bombarded and activated by glow plasma in a vacuum environment to increase the surface activation energy; The steps of the glow plasma cleaning are: pre-evacuation, when the vacuum degree of the chamber is 8×10 -4 -3×10 -3 After Pa, the vacuum chamber body is filled with nitrogen through the flow control instrument to maintain the chamber body pressure at 4-5Pa; for the glow plasma, a voltage of 500-3000V is applied between the bombardment plate in the vacuum chamber body and the chamber body , the current i...

Embodiment 2

[0033] Embodiment 2: a preparation method of vacuum composite coating on the surface of an NdFeB magnet, comprising the following steps:

[0034] A. Pretreatment, use a mixture of cleaning solution and pure water at a ratio of 1:1000 in an ultrasonic cleaning machine to remove oil and clean the surface of the magnet with a release agent;

[0035] B. Ion cleaning and activation, the pretreated NdFeB magnet is dried at a temperature of 80°C-100°C for 5-10 minutes, and then bombarded and activated by glow plasma in a vacuum environment to increase the surface activation energy; The steps of the glow plasma cleaning are: pre-evacuation, when the vacuum degree of the chamber is 8×10 -4 -3×10 -3 After Pa, the vacuum chamber body is filled with argon gas through a flow control instrument to maintain the chamber body pressure at 4-5Pa; for the glow plasma, add 500-3000V between the bombardment plate and the chamber body in the vacuum chamber body Voltage, current 0.5-3A, produces pl...

Embodiment 3

[0038] Embodiment 3: a kind of preparation method of vacuum composite coating film on the surface of NdFeB magnet, comprises the following steps:

[0039] A. Pretreatment, use a mixture of cleaning solution and pure water at a ratio of 1:1000 in an ultrasonic cleaning machine to remove oil and clean the surface of the magnet with a release agent;

[0040] B. Ion cleaning and activation, the pretreated NdFeB magnet is dried at a temperature of 80°C-100°C for 5-10 minutes, and then bombarded and activated by glow plasma in a vacuum environment to increase the surface activation energy; The steps of the glow plasma cleaning are: pre-evacuation, when the vacuum degree of the chamber is 8×10 -4 -3×10 -3 After Pa, the vacuum chamber body is filled with nitrogen through the flow control instrument, and the chamber body pressure is maintained at 4-5Pa; for the glow plasma, a voltage of 500-3000V is applied between the high voltage rod in the vacuum chamber body and the chamber body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com