Single-component self-phosphatizing antirust acrylic emulsion, and preparation method and application thereof

A technology of acrylic emulsion and epoxy monoacrylate, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of non-recyclable, lack of surface phosphating treatment process, etc., and achieve the effect of improving anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

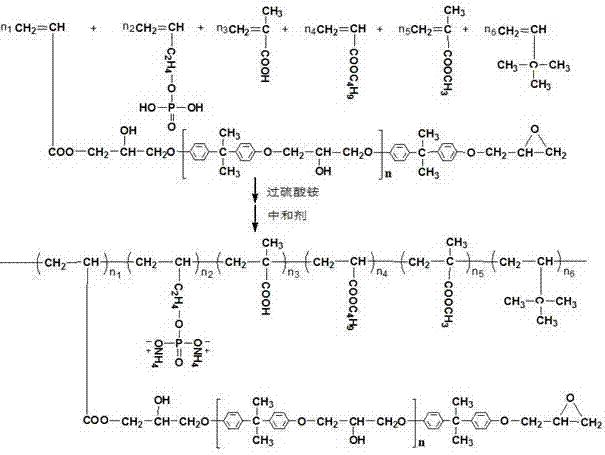

Method used

Image

Examples

Embodiment 1

[0048] Mix 400kg of epoxy resin E51 with 72kg of acrylic acid, add 0.36kg of hydroquinone, and carry out addition reaction at 98°C until the acid value is less than 5mgKOH / g, and then the epoxy monoacrylate is obtained.

[0049]

Embodiment 2

[0051] Mix 200kg of epoxy resin E51, 227kg of epoxy resin E44 with 43kg of methacrylic acid and 36kg of acrylic acid, add 0.39kg of p-methoxyphenol, and carry out addition reaction at 98°C until the acid value is less than 5mgKOH / g. Methyl methacrylate MMA 10kg, discharging, makes epoxy monoacrylate.

[0052]

Embodiment 3

[0054] Heat and dissolve 500kg of epoxy resin E20 in 100kg of ethylene glycol butyl ether, add 86kg of methacrylic acid and 0.43kg of p-methoxyphenol, and carry out addition reaction at 98°C until the acid value is less than 5mgKOH / g. Methyl methacrylate MMA 10kg, ethylene glycol butyl ether is distilled off under reduced pressure, and the remainder is epoxy monoacrylate.

[0055] serial number Viscosity (23°C) Example 1 15000mPa.s Example 2 1400mPa.s Example 3 1100mPa.s

[0056] The invention adopts the method of adding MMA to the product to reduce the viscosity, which can obviously reduce the viscosity of the epoxy monoacrylate, and is convenient for the operation of the reaction in the latter step.

[0057]

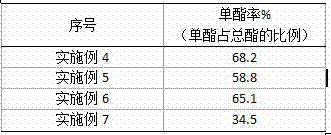

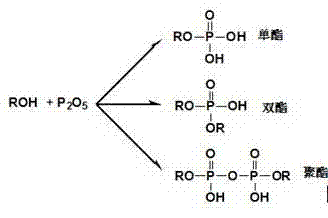

[0058] Two, the preparation embodiment of acrylic acid phosphate ester monomer

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com