Patents

Literature

659results about How to "Good resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

Aqueous high-performance monocomponent primer-topcoat anti-corrosion coating

The invention discloses an aqueous high-performance monocomponent primer-topcoat anti-corrosion coating, comprising aqueous modified acrylic acid emulsion, coloring pigment, antirust pigment, filling material, film forming auxiliary agent, thickening anti-settling agent, softened water, anti-flash rust agent, and auxiliary additive. The coating disclosed herein has excellent salt mist resistance, can resist salt mist for more than 1000h and resist weather for more than 200h, and has the characteristics of rapid drying, low content of VOC, no environmental pollution, and no harm to constructers' health. The coating disclosed therein is convenient for using, can be applied in high pressure airless spraying and ordinary air spraying, the thickness of single coating wet film can reach 200 mum without sagging or cracking, and the coating disclosed herein is widely suitable for anti-corrosion protection of locomotive, container, automobile, ship, bridge, iron tower, storage tank, pipeline and other steel structures.

Owner:中山大桥化工企业集团中山智亨实业发展有限公司

Environmentally-friendly barium-free thixotropic antirust oil

The invention discloses an environmentally-friendly barium-free thixotropic antirust oil, which is characterized by comprising the following components in percentage by weight: antirusting agent 4.0-25.0, thixotropic agent 0.1-5.0, antioxidant 0.1-3.0 and base oil 72.0-94.0. The preparation method of the environmentally-friendly barium-free thixotropic antirust oil comprises: firstly, adding the base oil into a reaction kettle, stirring the base oil, heating the base oil to 110 to 120 DEG C, adding the antirusting agent, stirring the mixture for continuous dehydration for 1 hour, and cooling the mixture to 50 to 60 DEG C; and secondly, adding the antioxidant, stirring the mixture for 3 hours at a constant temperature of 50 to 60 DEG C, adding the thixotropic agent, stirring the mixture for1 hour at 50 to 60 DEG C, cooling the resulting product to 40 DEG C, filtering the resulting product and discharging the resulting product. For obtaining antirust oil films that are insusceptible toflow and free from heavy metal barium, the antirust oil selects a proper barium-free corrosion inhibiter to ensure excellent antirust performance besides the thixotropic agent added for quickly forming stable oil films of antirust oil.

Owner:沈阳防锈包装材料有限责任公司

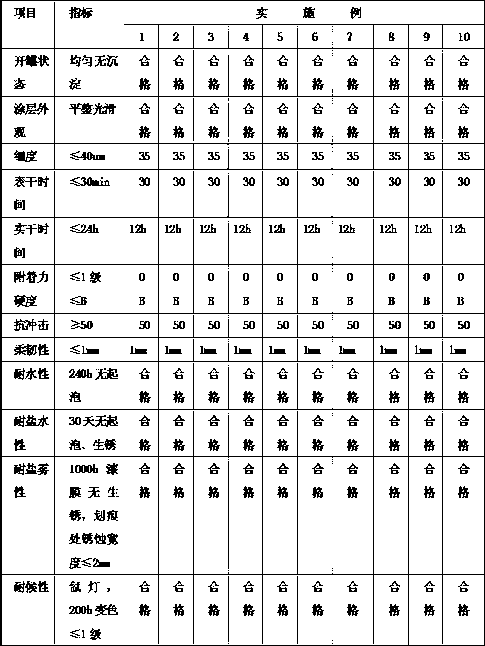

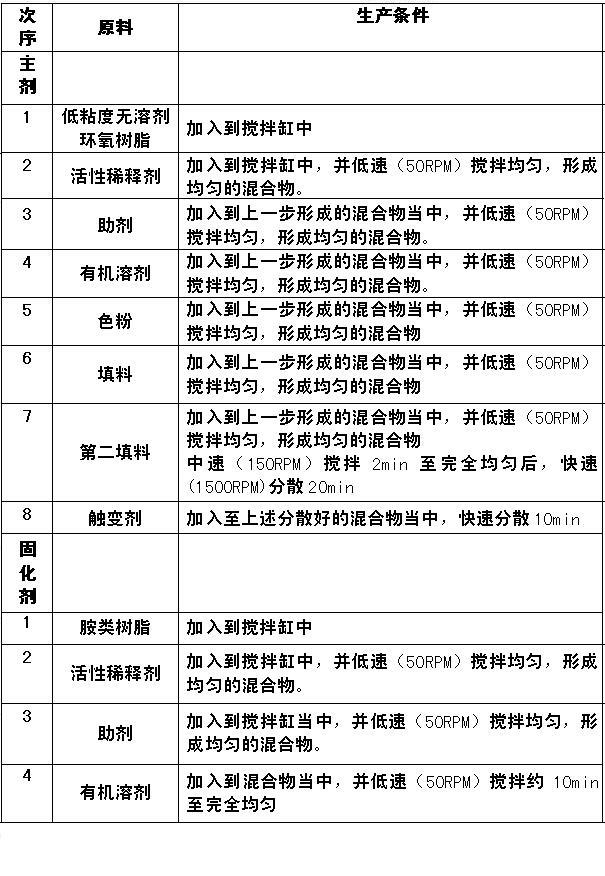

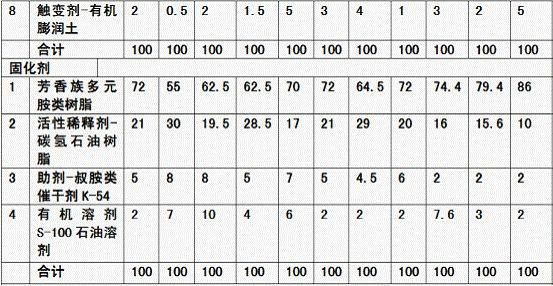

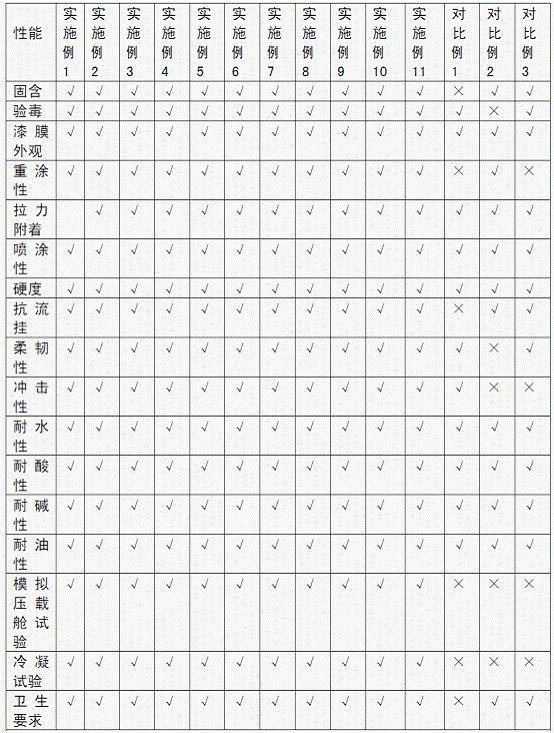

Novel environment-friendly coating with superhigh marine environment corrosion resistance and preparation method and application thereof

ActiveCN102352171AImprove anti-corrosion performanceGood resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyEnvironmental resistance

The invention discloses a novel environment-friendly coating with superhigh marine environment corrosion resistance and a preparation method and application thereof. The environment-friendly coating with superhigh marine corrosion resistance consists of the following components in part by weight: a main agent comprising 22 to 35 parts of low-viscosity solvent-free epoxy resin, 9 to 15 parts of activated thinner, 0.2 to 5 parts of aid, 5 to 8 parts of organic solvent, 0.5 to 15 parts of toner, 10 to 25 parts of first filler, 20 to 45 parts of second filler and 0.5 to 5 parts of thixotropic agent, and a curing agent comprising 60 to 90 parts of amine resin, 10 to 30 parts of activated thinner, 2 to 8 parts of aid and 2 to 10 parts of organic solvent. During use, the main agent and the curing agent are uniformly mixed, and the mixture is applied to the surface of a substrate. A film formed by the coating is high in corrosion resistance and low in content of volatile organic compounds (VOC), does not contain any toxic or harmful substance, can be universally used in a drinking water tank, and also can be used for a ship ballast tank, a ship bottom, a deck and each position of a marine platform.

Owner:CHINA PAINT MFG CO SHENZHEN

Special primer paint for medium and high grade automobile aluminum hubs and preparation method of primer paint

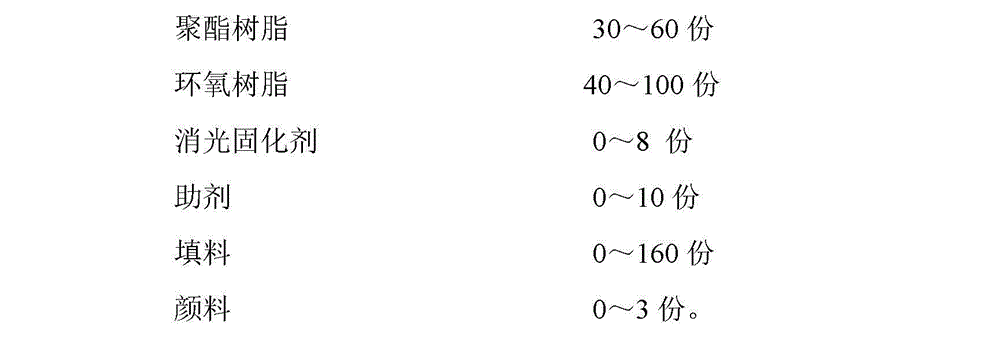

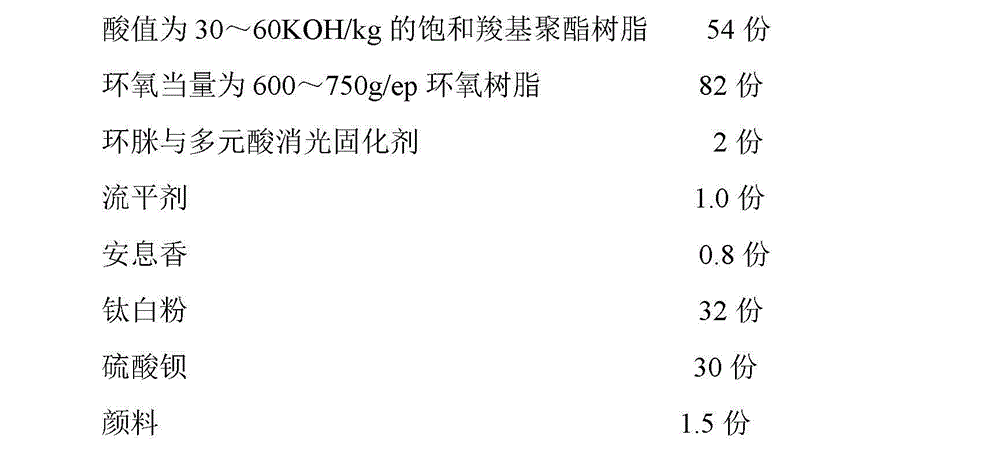

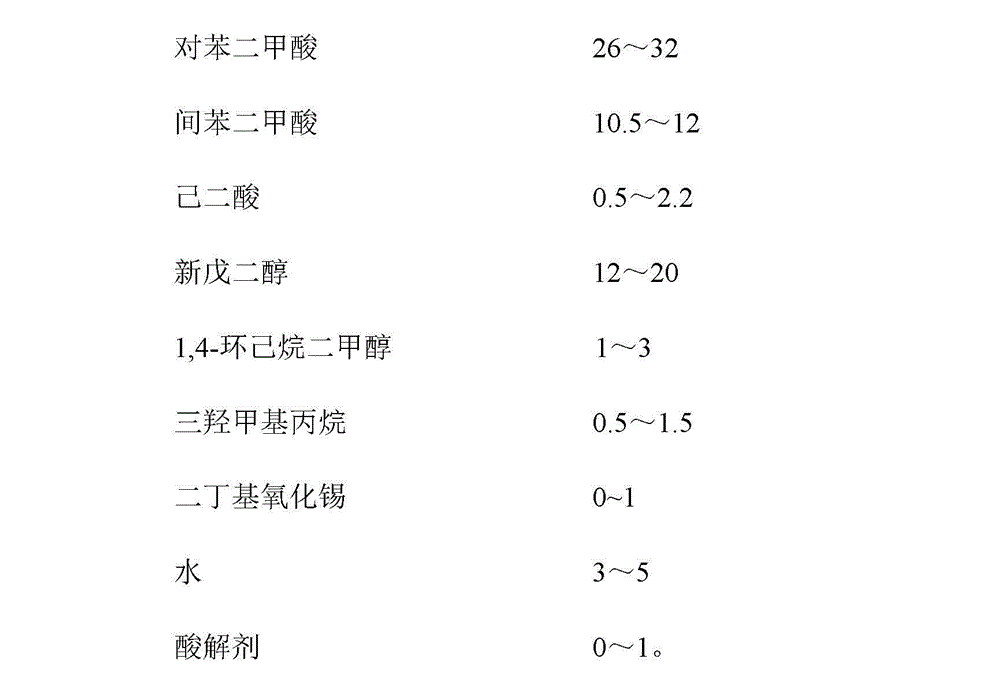

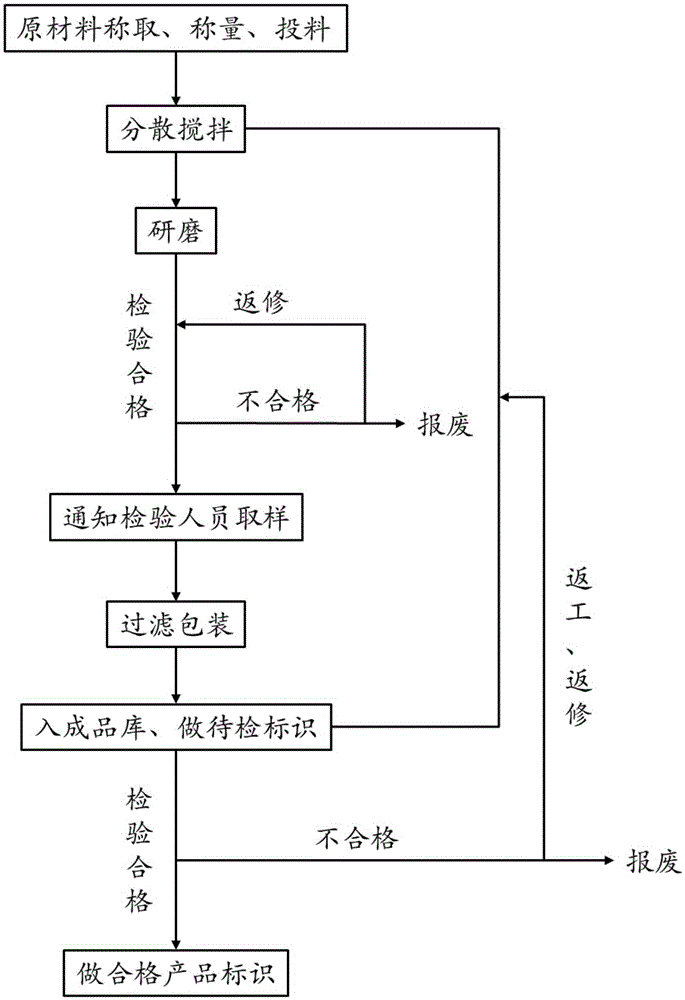

ActiveCN102911585ANon-toxic and environmentally friendlyImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses special primer paint for medium and high grade automobile aluminum hubs. The primer paint comprises, by weight, 30-60 parts of polyester resin, 40-100 parts of epoxy resin, 0-8 parts of matting and curing agents, 0-10 parts of additives, 0-160 parts of packing and 0-3 parts of pigment. The invention further discloses a preparation method of the paint. Once a coating of the paint is solidified, the paint has good leveling property, breathability and chemical resistance.

Owner:GUANGZHOU KINTE IND

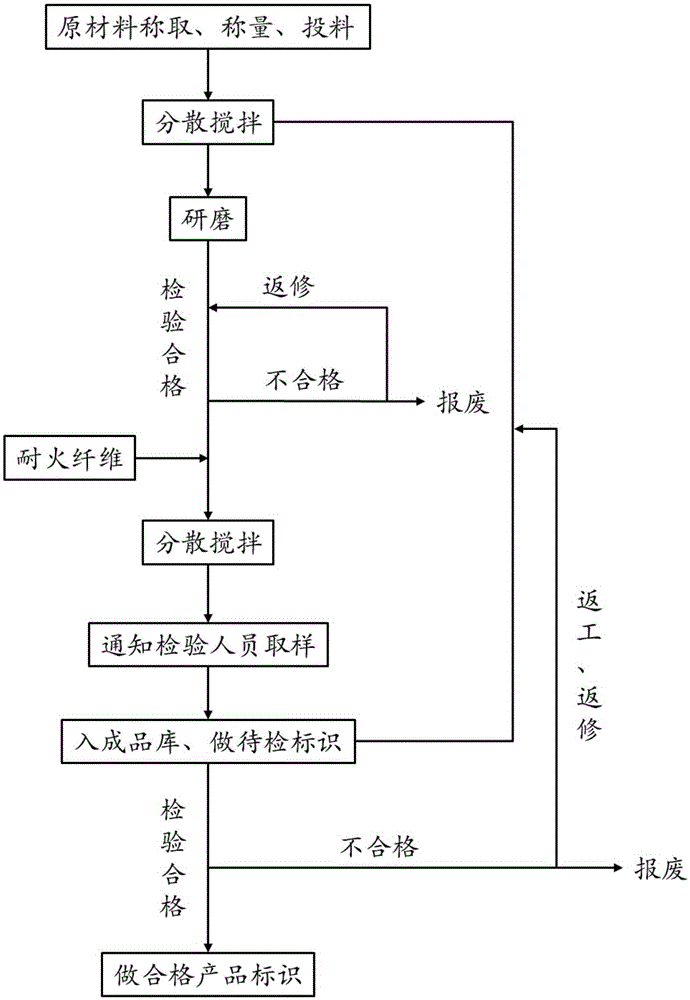

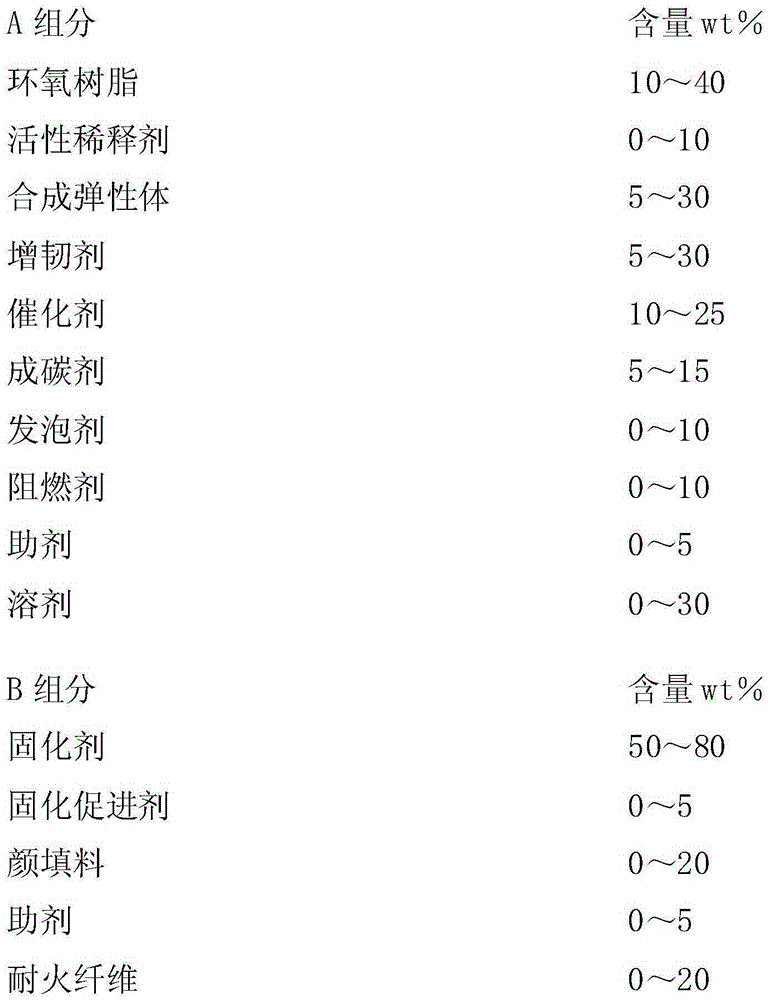

Flexible epoxy intumescence fire-retardant coating and preparation method thereof

InactiveCN105238221AImprove water resistanceExcellent medium resistanceFireproof paintsEpoxy resin coatingsElastomerFiber

The invention relates to a flexible intumescence fire-retardant coating and a preparation method thereof, and belongs to the field of functional coatings. The flexible intumescence fire-retardant coating is composed of a component A and a component B. The component A is prepared from epoxy resin, reactive diluent, synthetic elastomer, flexibilizer, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent. The component B is prepared from a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. The flexible epoxy intumescence fire-retardant coating prepared through the method has certain flexibility, and is particularly suitable for fire-retardant protection of the surface of a flexibility or deformation base material and the surface of a shapeless base material or the surface of light metal. In addition, the flexible epoxy intumescence fire-retardant coating prepared through the method has excellent water resistance, medium resistance, ageing resistance and salt-fog resistance and is suitable for fire-retardant protection of hydrocarbon fire potential risk areas in the ship, airplane and ocean environment and the petrochemical industry.

Owner:MARINE CHEM RES INST CO LTD

Antirust emulsion of self-crosslinked interpenetrating net polymer and its production

InactiveCN101029115AImprove stabilityExcellent calcium ion stabilityAnti-corrosive paintsCross-linkEpoxy

A self-cross-linked interpenetrating network polymer antirust emulsion and its production are disclosed. The emulsion consists of epoxy resin 2-50 proportion, unsaturated hydrocarbon monomer mixture 20-80 proportion, olefine hydroxyl-acid 0.5-8 proportion, functional organic silane 0.5-25 proportion, functional organic fluoride monomer 0.5-20 proportion, cross-linking agent 0.1-1.2 proportion, neutralizing agent 0.5-1.5 proportion, emulsifying agent 1-8 proportion, chain transfer agent 0.05-0.6 proportion, pH regulator 0.2-0.6 proportion, initiating agent 0.3-0.8 proportion, softened water 90-150 proportion and cross-linking curing agent 0.2-5 proportion. The process is carried out by dosing in the first, second and third reactors, mixing in the third reactor and discharging to obtain final product. It has excellent weather and water resistances, better anti-corrosive performance and storage stability.

Owner:HARBIN INST OF TECH

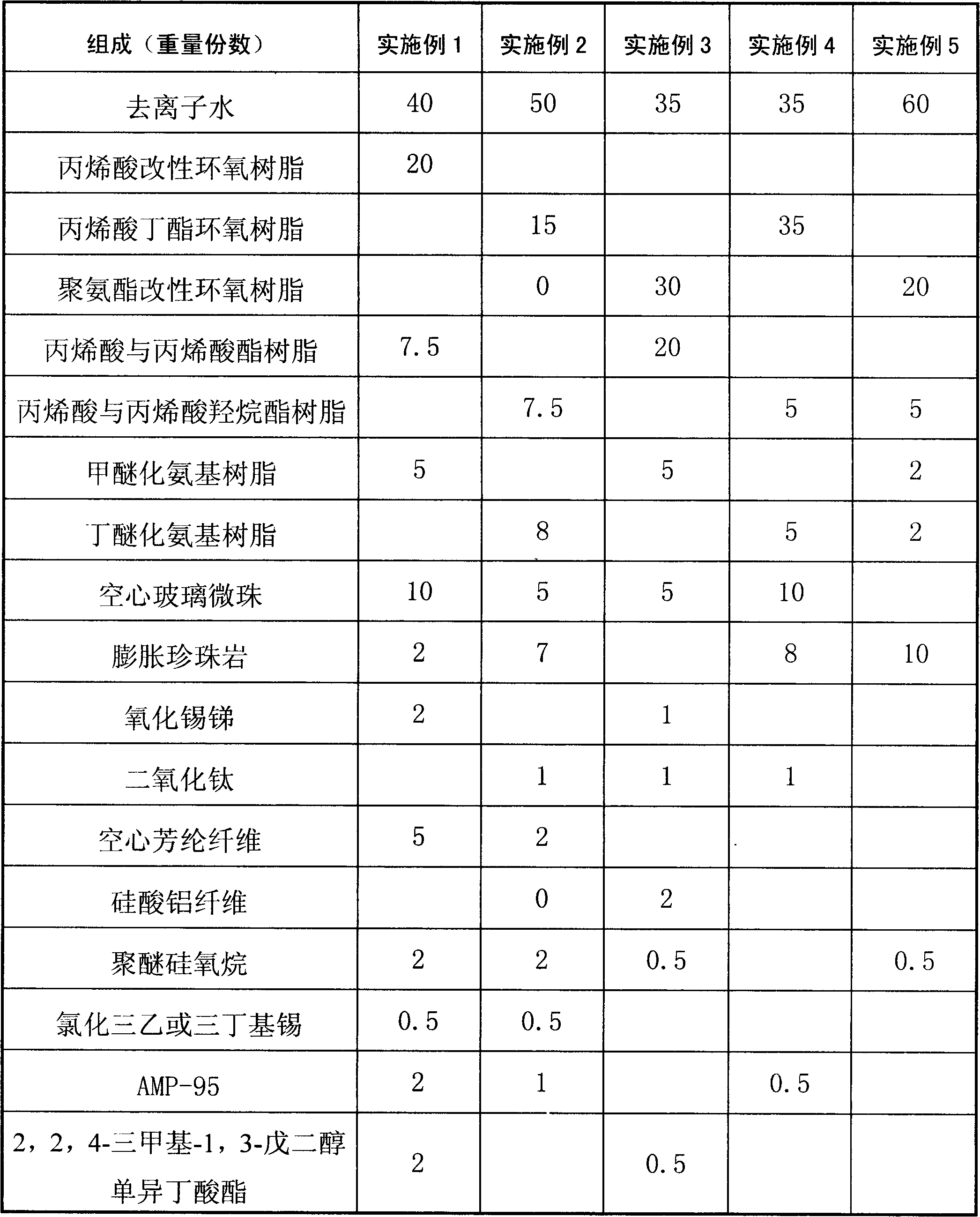

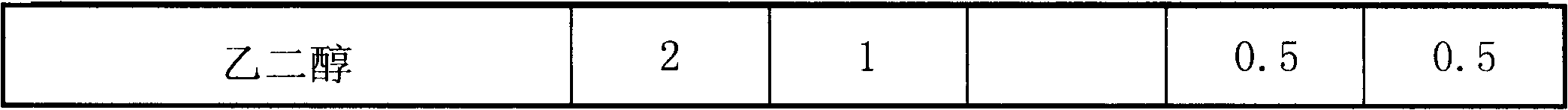

Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

InactiveCN103450773AStrong adhesionHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to a kind of heat insulation paint with a high anticorrosion performance and a preparation method thereof. The anticorrosion heat insulation paint is composed of following components in percentage by weight: 35 to 60% of deionized water, 20 to 40% of modified epoxy resin, 5 to 30% of modified acrylic resin, 1 to 8% of amino resin, 10 to 25% of heat insulation materials, 0 to 8% of strengthening materials, and 1 to 10% of auxiliary agent. The preparation method comprises following steps: orderly adding deionized water, modified epoxy resin, modified acrylic resin, and amino resin into a reactor, starting the stirrer, evenly mixing the materials, adjusting the pH value of the system to a range of 7 to 9, then orderly adding the auxiliary agent, the heat insulation materials, and the strengthening materials, stirring for 1 to 3 hours in a high speed, and evenly mixing so as to obtain the anticorrosion heat insulation paint. The preparation method has the advantages of simple technology, high production efficiency, and low energy consumption. The prepared paint does not contain any organic solvent, so no solvent will volatilize during the coating solidification process, so no pollution is generated to the environment. The paint has the advantages of excellent mechanical properties of bonding strength, hardness, scratch resistance, wear resistance, and water resistance, and good properties of anticorrosion, salt smog resistance, forming ability, heat resistance, and deflection resistance.

Owner:BOYIFEI EQUIP INST FOR NEW MATERIALS

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

Magnesium alloy non-chromium dacro solution paint and its preparation method

InactiveCN1786091AStrong adhesionGood weather resistanceLiquid surface applicatorsAnti-corrosive paintsCross-linkHeat resistance

The present invention discloses a magnesium alloy chrome-free dyclo solution coating and its production method. It is characterized by that the organic silicon and nano powder body undergone the process of nano dispersing liquor treatment are dispersed in the resin made up by using several resins through the process of polymerization and cross-linking reaction to make modification, and mixed with zinc powder and aluminium powder so as to obtain the invented acid-resistant, alkali-resistant, salt fog resistant, impact-resistant and corrosion-resistant magnesium alloy chrome-free dyclo solution coating.

Owner:长春吉大化学有限公司

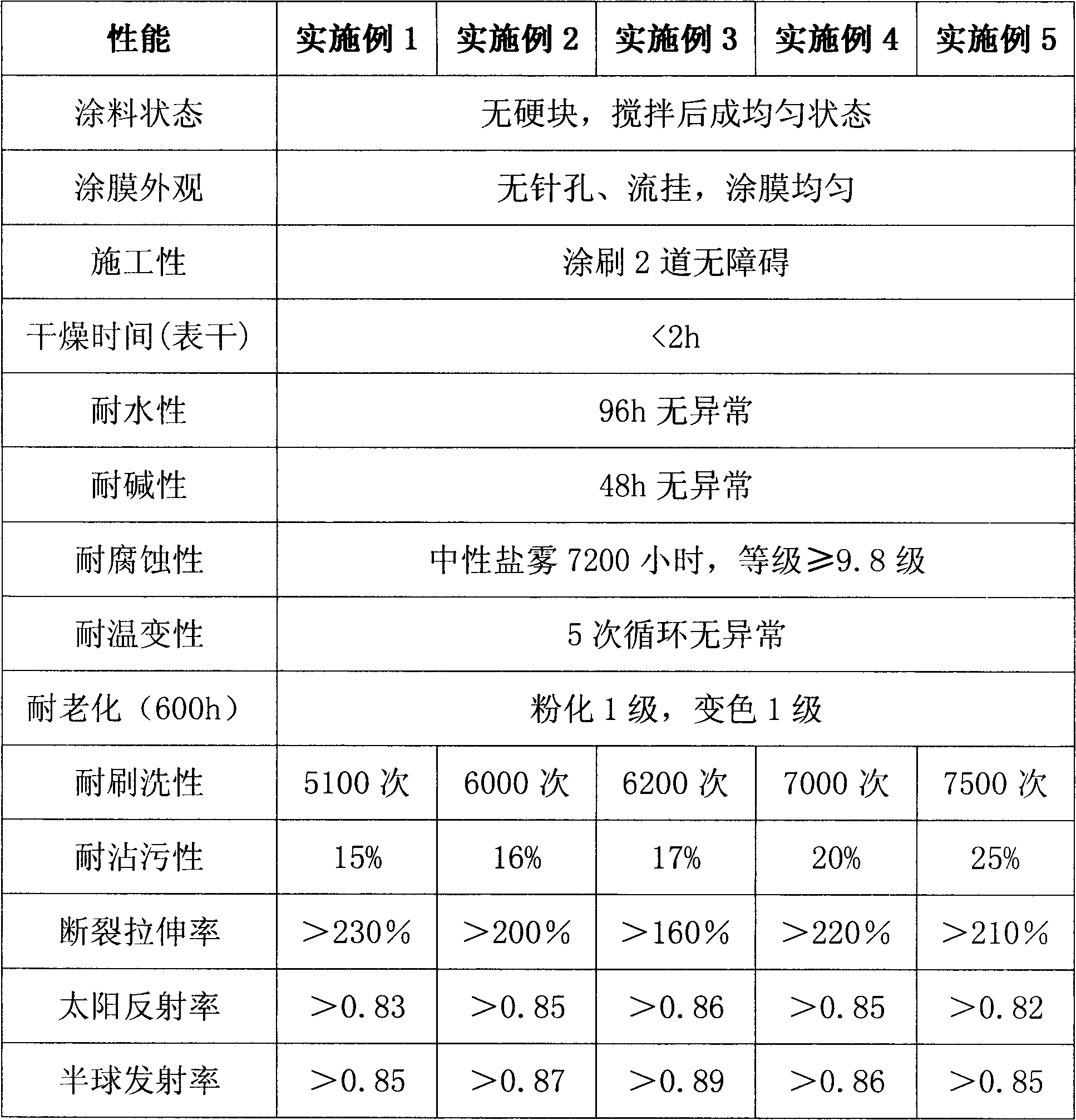

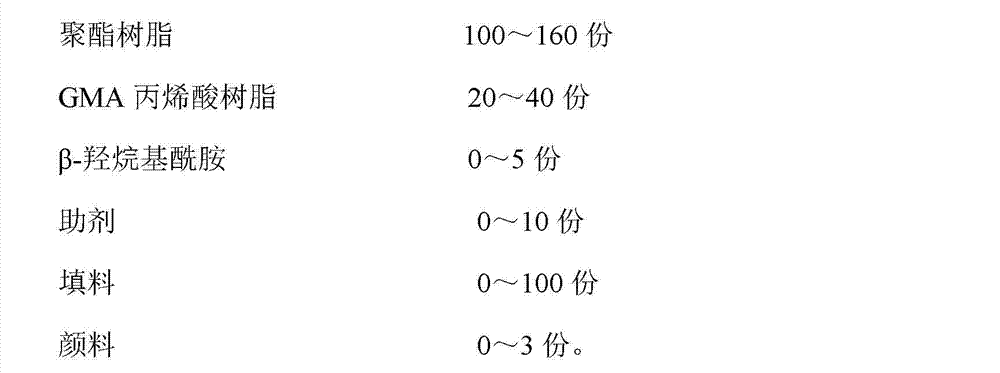

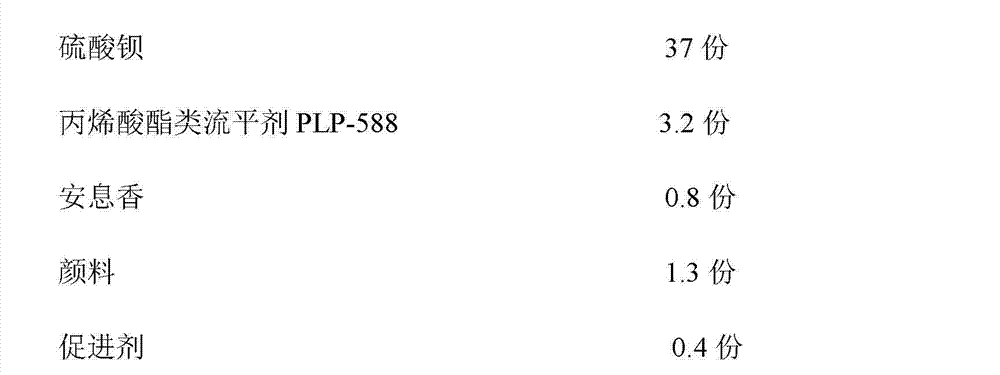

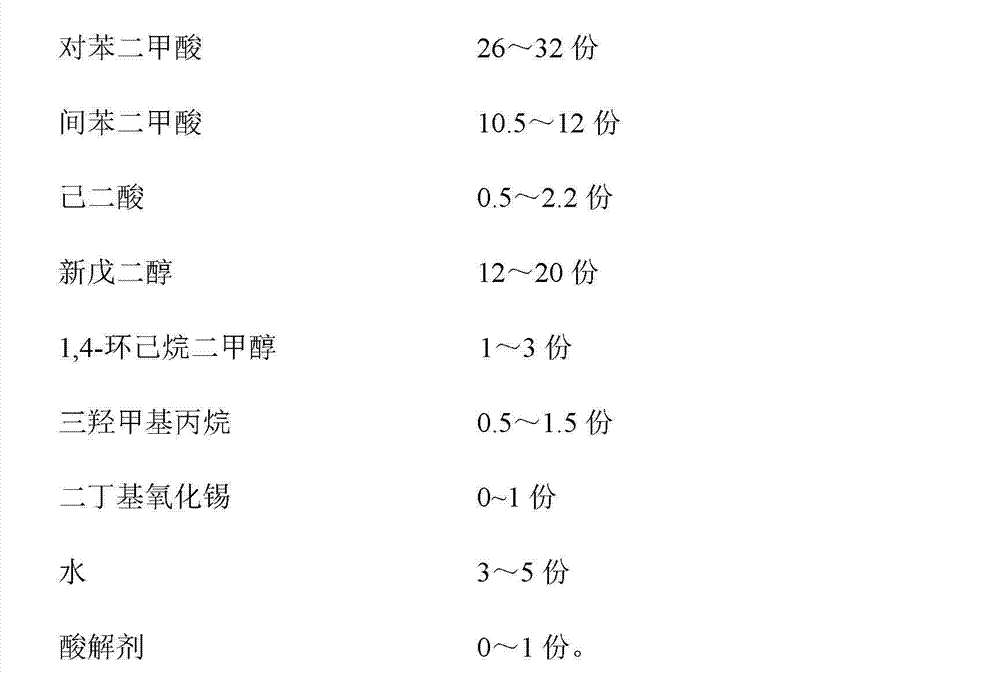

High weather-proof and corrosion-resistant powder paint for satellite earth antenna and preparation method thereof

ActiveCN102898933AGood electrificationShort curing timePowdery paintsPolyester coatingsAcrylic resinPolyester resin

The invention discloses a high weather-proof and corrosion-resistant powder paint for a satellite earth antenna. The paint comprises, by weight, 100-150 parts of polyester resin, 20-40 parts of GMA acrylic resin, 0-5 parts of beta-hydroxyalkylamide, 0-10 parts of assistants, 0-100 parts of paddings and 0-3 parts of pigments. The invention further discloses a preparation method for the powder paint. A coating after being coated by the paint and curing is good in mechanical properties, super-weather-proof, salt mist resistant, and provided with stable low gloss area.

Owner:GUANGZHOU KINTE IND

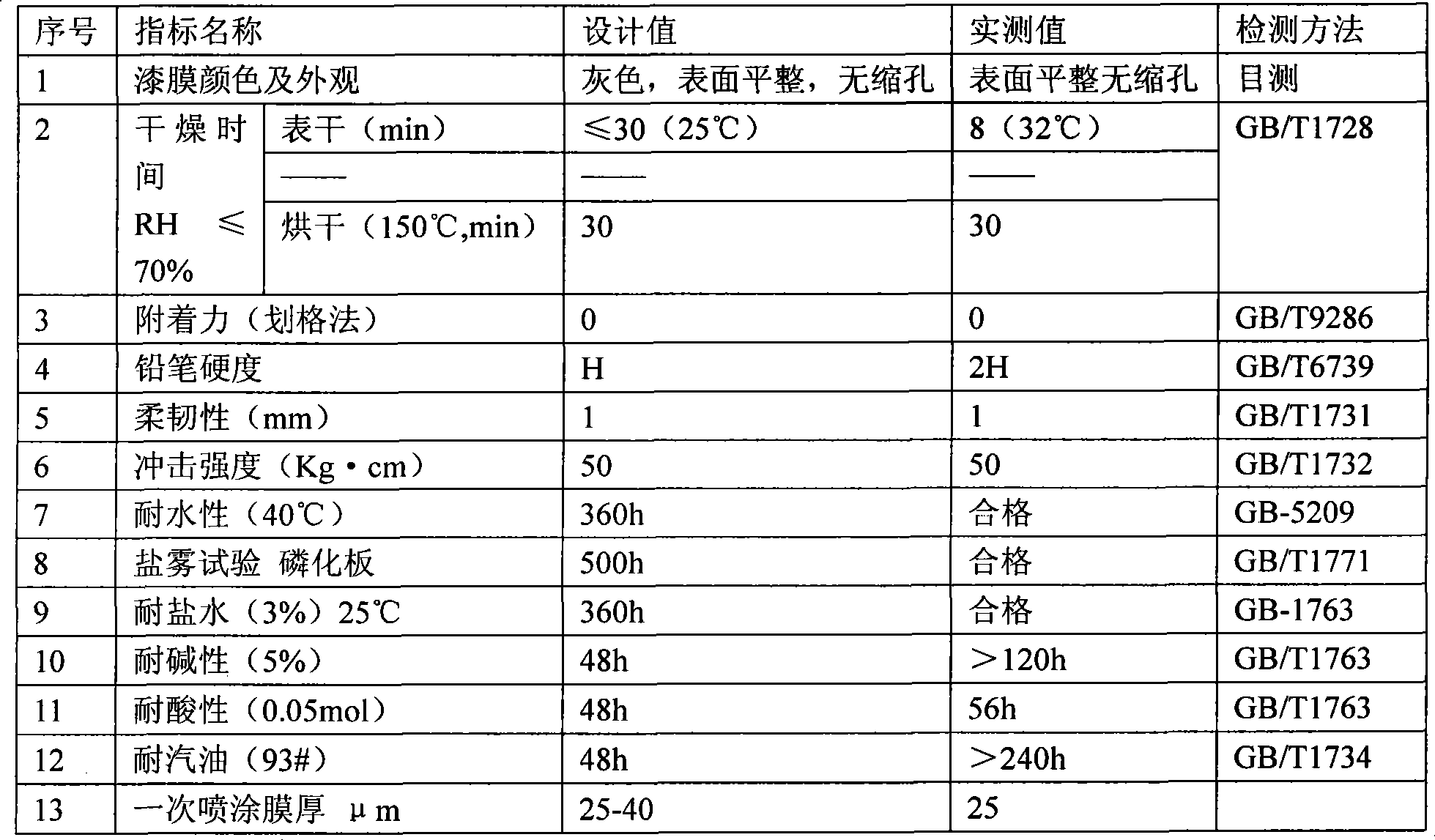

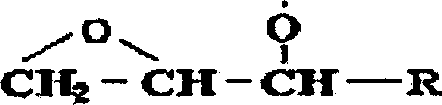

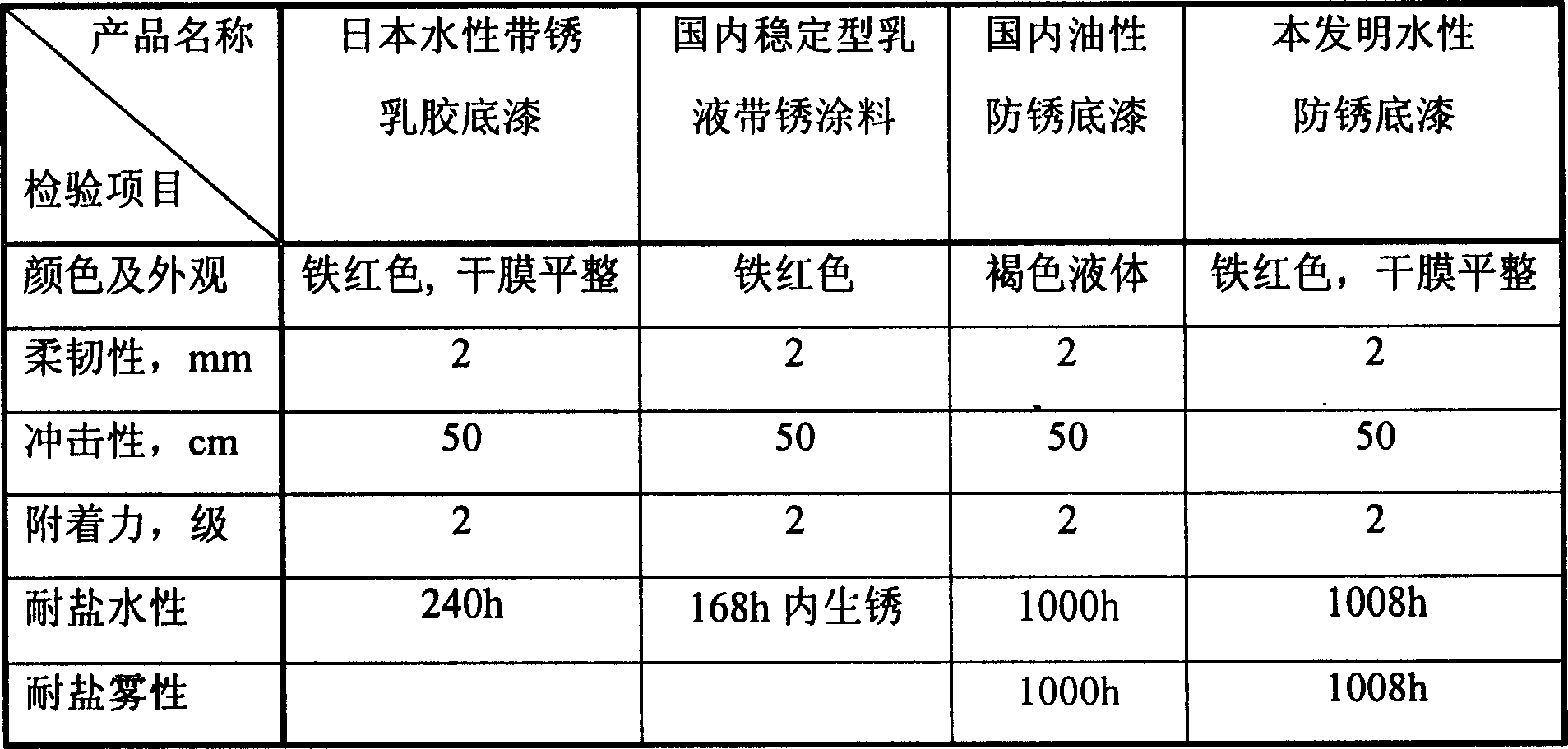

Single-component cationoid water-soluble epoxy-polyurethane anticorrosion primer system drying at 150 DEG C

InactiveCN101362919AGood solvent resistanceHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyElectrophoresis

The invention discloses a single-component (150DEG C) drying cation typed waterborne epoxy-polyurethane antisepsis primer system, comprising waterborne cation epoxy resin, pigment / filling material, nontoxic drier, dispersant and deionized water; all components of the invention are mixed and dispersed at high speed, statically arranged and grinded so as to prepare the single-component (150DEG C) drying cation typed waterborne epoxy-polyurethane antisepsis primer system. The single-component (150DEG C) drying cation typed waterborne epoxy-polyurethane antisepsis primer system has excellent construction performance, excellent alkali-resistance, waterproofing and salt spray resistance performance of film and good comprehensive performance. The single-component (150DEG C) drying cation typed waterborne epoxy-polyurethane antisepsis primer system can be applied to industrial antisepsis coating of automobiles, engineering machines, agricultural vehicles, and the like, antisepsis coating of hardware, electric apparatus industries, and paints used for repairing of electrophoresis.

Owner:江泽平 +1

Self-emulsified aqueous epoxy emulsion and method for preparing same

The present invention provides one kind of self-emulsifying water thinned epoxy emulsion and its production process. The self-emulsifying water thinned epoxy emulsion is produced through emulsion copolymerization with the polymer intermediate, which is obtained through polymerizing the mixed organosilicon monomer comprising alkenyl-containing trimethyl silane and octalkyl cyclotetrasiloxane and acrylic acid monomer, epoxy resin and acrylic acid monomer. The self-emulsifying water thinned epoxy emulsion has homogeneous particle size, high stability, and stable production process. The anticorrosive paint compounded with the self-emulsifying water thinned epoxy emulsion reaches the level of solvent type epoxy resin paint.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Water-soluble low surface energy paint and preparation method thereof

InactiveCN101712838ALow coating surface energyStrong hydrophobicAntifouling/underwater paintsPaints with biocidesAging resistancePreservative

The invention belongs to the technical fields of paint and paint production technology, in particular relates to water-soluble low surface energy paint. The paint is characterized in that the paint comprises latex for low surface energy paint, preservative, deforming agent, wetting dispersant, pH regulator, pigment and filler, nanometer fine powder, film- forming additive, thickener, flatting agent and water. The pigment, filler and nanometer fine powder can be added in the paint of the invention according to applications and demands. The technology process of the invention comprises the following steps: firstly adding water in a dispersion tank in a defined ratio, stirring, then successively adding wetting dispersant, film- forming additive and bactericide in the dispersion tank according to a defined ratio to stir evenly, and finally adding latex for low surface energy paint, pH regulator, film- forming additive, thickener and flatting agent according to a ratio to disperse evenly. The water-soluble low surface energy paint of the invention has the advantage of scrubbing resistance, acid and alkali resistance, salt water and salt spray resistance, aging resistance, safety and environmental protection and easy construction; and the surface energy of the paint of the invention is lower, the contact angle between the paint and water is over 100 degrees, and the contact angle between the paint and methylene diiodide is 70 degrees.

Owner:新元化学(山东)股份有限公司 +1

Fire-proof corrosive-resistant paint for superthin steel structure

A fireproof and corrosive-resistant pigment for super-thin steel construction is prepared by mixing acrylic modified resin with amino modified resin and epoxy resin proportionally to obtain mixed resin base materials and proportioning carbonizing catalyst polyphosphacid ammonium, carbonizing agent pentaerythrite, foaming agent cyanurotriamide with solvent 200# solvent oil, antiseptic zinc phosphate, butyrin acetate, titanium pigment, chlorinated paraffin, zinc oxide and auxiliaries. It has thin coating, excellent decorative function and adhesion. It can be used for hotels, shopping and enterprises

Owner:刘清龚

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Durable fresh-maintained preservative primer

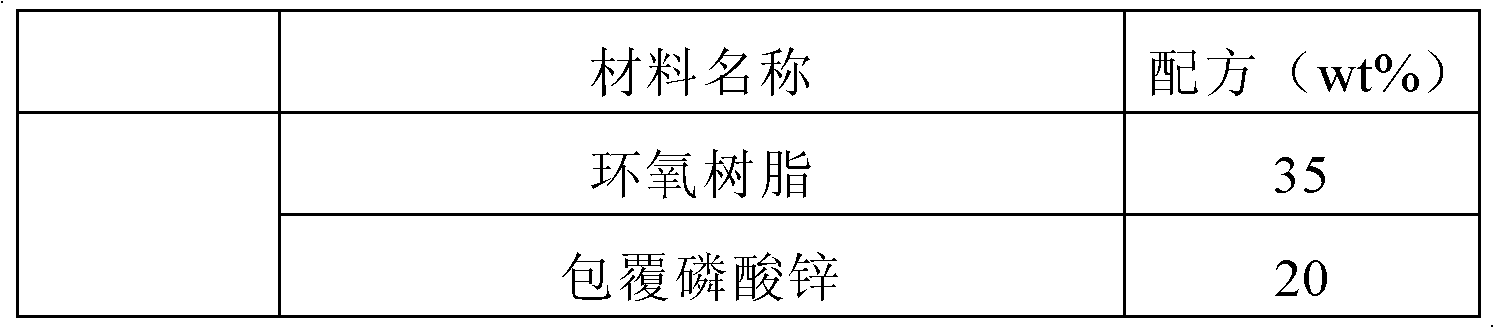

InactiveCN102643594AImprove adhesionStrong recoatability between layersAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention relates to a durable fresh-maintained preservative primer. Raw materials of the primer comprises a component A and a component B, wherein the consumption of the component B is 5-15 percent by weight that of the component A; the component A comprises the following components in percentage by weight: 20-50 percent of epoxy resin, 10-30 percent of phosphate, 1-10 percent of additive, 5-20 percent of diluting agent and 15-35 percent of solvent; and the component B comprises the following components in percentage by weight: 50-80 percent of curing agent and 20-50 percent of solvent. Compared with the prior art, the durable fresh-maintained preservative primer disclosed by the invention has the advantages of favorable adhesive force, strong laminated coating property, tough and tensile paint film, impact resistance, convenience in construction, long preservative effect cycle, favorable construction matching property and particularly excellent salt spray resistance.

Owner:项妙祥

Solvent-free epoxy coating

InactiveCN101705043AEasy constructionGood chemical stabilityEpoxy resin coatingsSolvent freeHardness

The invention provides a solvent-free epoxy coating, which is prepared by grinding and stirring the following components in part by weight: 30 to 70 parts of epoxy resin, 2 to 20 parts of toughening agent, 15 to 50 parts of color filler, and 0.2 to 5 parts of auxiliary agent. The solvent-free epoxy coating adopts the epoxy resin as a film-forming material, and because any reactive diluent is not added at all, the solvent-free epoxy coating is not volatile, has the water absorption of less than 0.6 percent, good chemical stability, strong adhesive force and high hardness. The solvent-free epoxy coating is very convenient in construction, can be used for brush painting after an initiator and a promoter is added in the solvent-free epoxy coating and the mixture is stirred evenly, and after the solvent-free epoxy coating is coated on a steel pipe and is solidified, the impact strength of the steel pipe can reach over 30 Kg.cm.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

High-temperature-resistant anticorrosive coating capable of being solidified at room temperature

InactiveCN109468065AGood three-proof performanceImprove moisture resistanceFireproof paintsAnti-corrosive paintsPetroleum productHeat resistance

The invention belongs to the technical field of coatings, and relates to a high-temperature-resistant anticorrosive coating capable of being solidified at a room temperature. The high-temperature-resistant anticorrosive coating capable of being solidified at the room temperature is characterized by comprising the following components in parts by weight: 20-60 parts of organic silicon resin, 0-30 parts of temperature-resistant powder, 5-40 parts of inorganic coloring pigment, 5-35 parts of temperature-resistant anticorrosive filler, 0.2-10 parts of a promoter and 20-50 parts of a solvent. The high-temperature-resistant anticorrosive coating capable of being solidified at the room temperature has the beneficial effects that (1) the coating both has temperature resistance and corrosion resistance, the tolerable temperature of the coating can reach 500 DEG C, and three-proofing performance (salt mist resistance, damp and heat resistance and mycete resistance) is excellent; (2) the coatingcan be solidified at the normal temperature, the problem that a common organic silicon resin coating needs to be heated for solidification is solved, and the processing property is good; and (3) medium resistance is excellent, and the coating material can resist petroleum products such as jet fuel RP-3.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

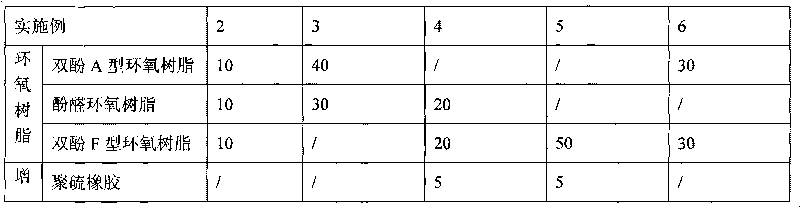

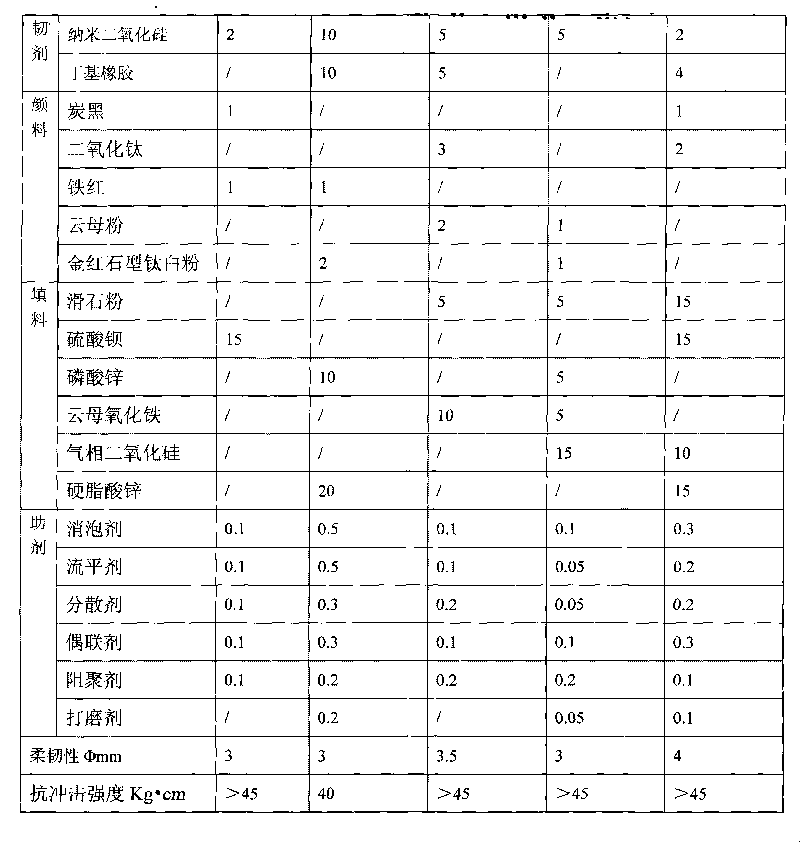

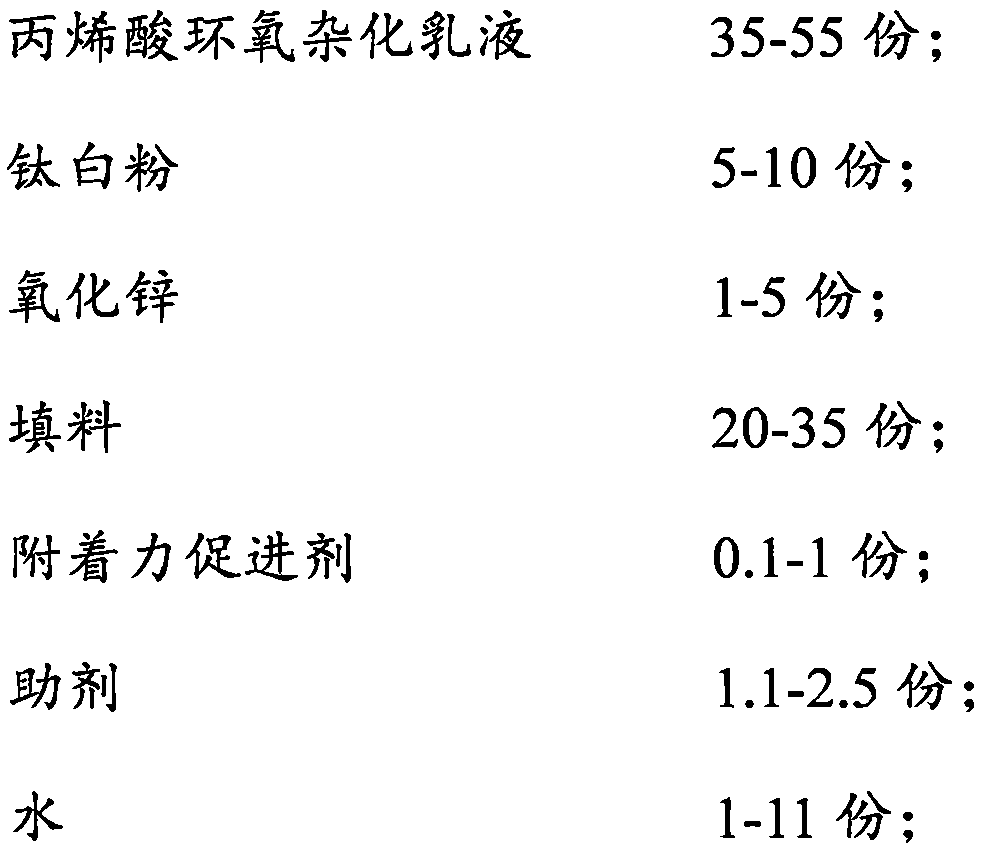

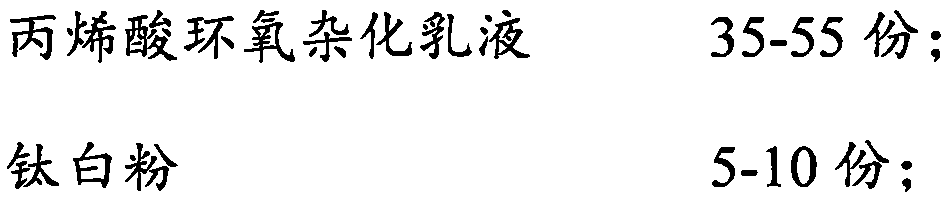

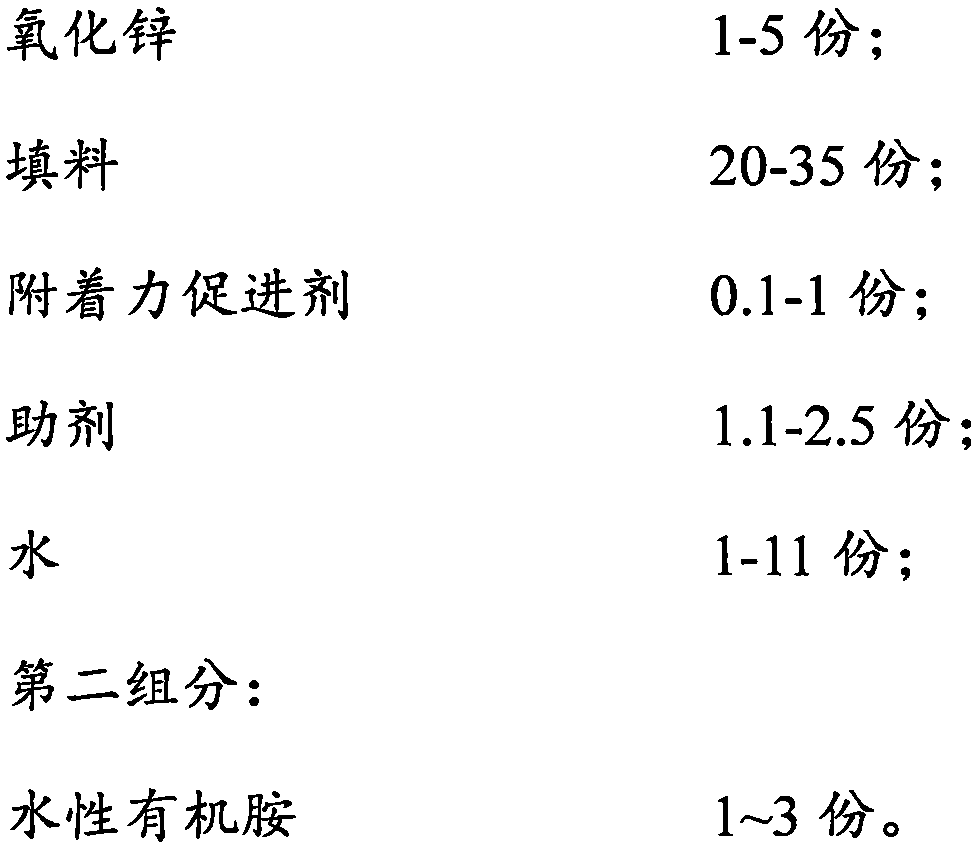

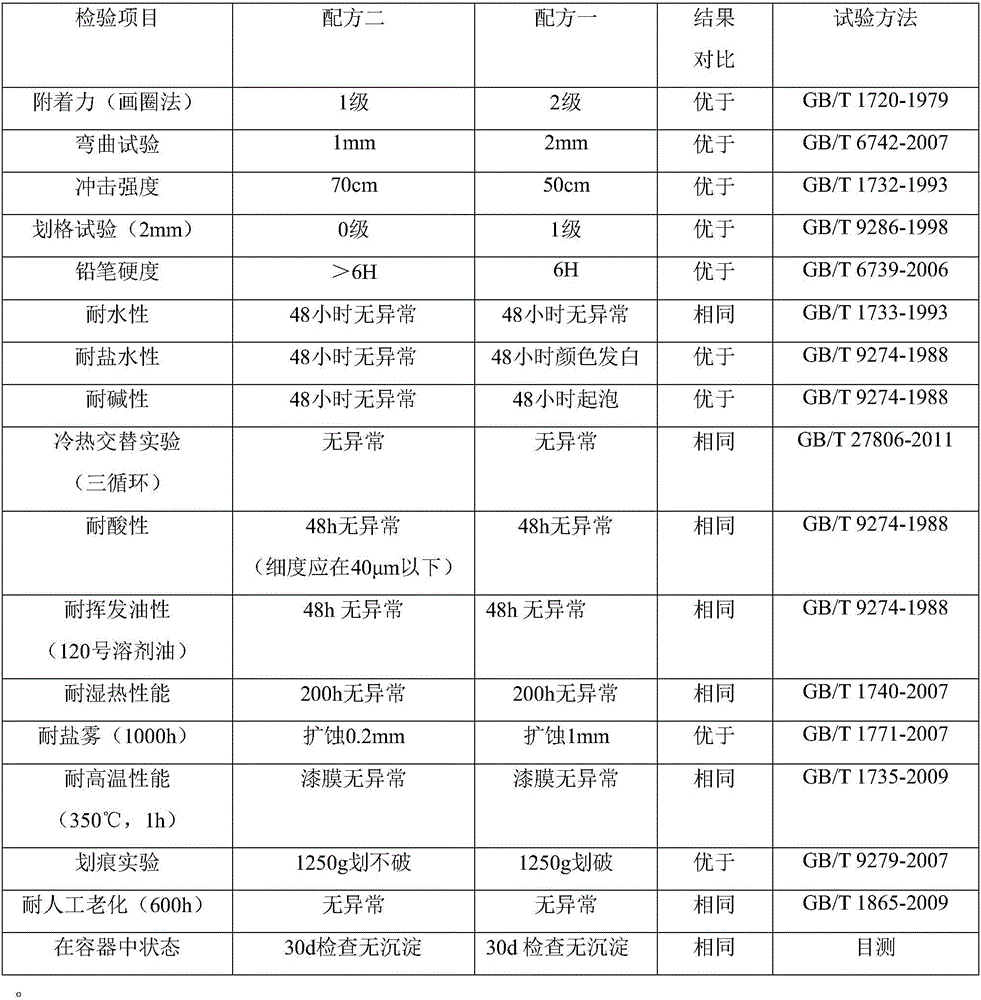

Two-component aqueous acrylate-epoxy resin hybrid coating

The invention discloses a two-component aqueous acrylate-epoxy resin hybrid coating. The epoxy resin part comprises 35-55 parts of an acrylate-epoxy resin hybrid emulsion, 5-10 parts of titanium dioxide, 1-5 parts of zinc oxide, 20-35 parts of a filler, 0.1-1 part of an adhesion promoter, 1.1-2.5 parts of an auxiliary agent and 1-11 parts of water. The curing agent part comprises 1-3 parts of aqueous organic amine. Through use of the hybrid system of an acrylate emulsion and epoxy resin, the anticorrosion coating with a fast drying rate, high film formation density, high weatherability and excellent salt mist resistance is prepared. Through formula optimization and curing agent mixing, the coating is a metal anticorrosion waterproof coating with a long service life, good application properties, good low temperature flexibility, good corrosion resistance, high hardness and good contamination resistance. The two-component aqueous acrylate-epoxy resin hybrid coating effectively prolongs a metal device usage time limit, can be used in terrace paint, saves a cost and provides a value for the society.

Owner:苏州匠品材料科技有限公司

Improved high-temperature resistant paint

ActiveCN105860790AImprove salt toleranceGood alkali resistanceFireproof paintsPolyurea/polyurethane coatingsSalt resistanceSlag

The invention discloses improved high-temperature resistant paint. The improved high-temperature resistant paint comprises solvent, organic silicon resin and / or modified organic silicon resin and high-temperature filler which is superfine slag powder. The high-temperature resistant paint is excellent in high temperature resistance, salt resistance, alkali resistance and salt spray resistance and has larger paint film adhesive force, higher paint film hardness and higher market application value.

Owner:NANJING INST OF PROD QUALITY INSPECTION

Titanium zirconium conversion liquid applied to surface of 2024 aluminum alloy and using method thereof

InactiveCN108070852AGood storage stabilityGood resistance to salt sprayMetallic material coating processesSolventIon

The invention relates to the field of aluminum alloy surface environment-friendly protection, in particular to titanium zirconium conversion liquid applied to the surface of a 2024 aluminum alloy anda using method thereof. The titanium zirconium conversion liquid comprises the following components including, by content, 3-15 g / L of fluorine titanic acid, 1-10 g / L of fluorine zirconium acid, 0.1-5g / L of accelerant, 0.1-4 g / L of corrosion inhibitor, 0.5-8 g / L of oxidizing agent, 0.01-1 g / L of pH modifier and the balance deionized water. The titanium zirconium conversion liquid applied to the surface of the 2024 aluminum alloy does not contain hexavalent chromium, lead, mercury and cadmium heavy metal ion compounds, does not contain volatile poisonous solvent like benzene and xylene, meetsthe requirement of environmental protection, and is simple in technology, industrialization is formed easily, and a conversion film has an excellent corrosion-resisting property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

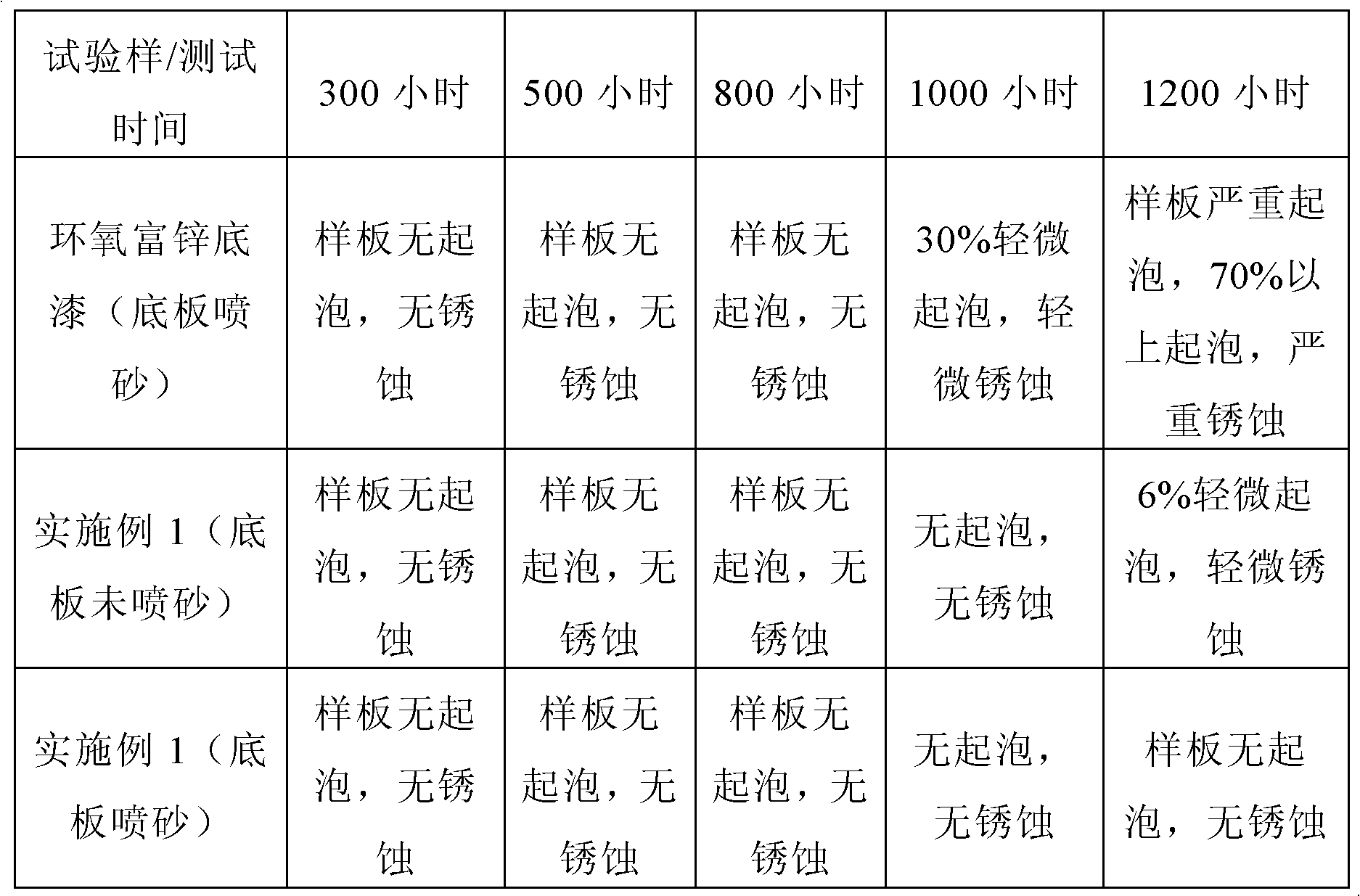

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

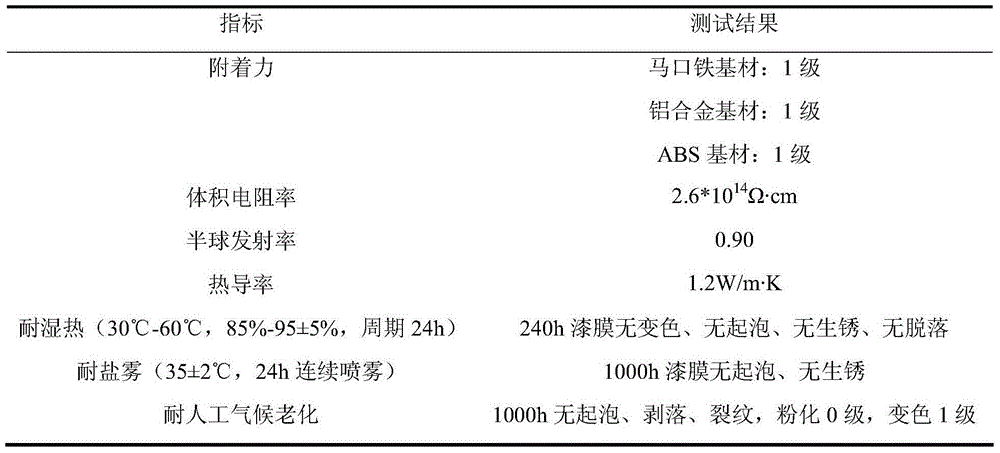

Preparation method of insulating high-thermal radiation coating suitable for various base materials

ActiveCN104610864AOvercome compatibilityImprove insulation performancePolyurea/polyurethane coatingsCross-linkHeat conducting

The invention relates to a preparation method of an insulating high-thermal radiation coating suitable for various base materials. The paint of the coating comprises the following ingredients by mass: 40 to 60 parts of a film-forming material, 30 to 50 parts of an insulating heat conducting filler, 40 to 70 parts of solvents, 0.3 to 2.0 parts of a wetting dispersant, 0.2 to 1.0 part of a foam killer, 0.1 to 0.8 part of a leveling agent, 0.02 to 0.1 part of a drier, 5 to 15 parts of a cross-linked curing agent adopting isocyanate. The preparation method comprises the following steps: uniformly spraying the paint on the surface of a device in such a manner that the sprayed layer is 0.01 to 0.03 mm in thickness each time and the total thickness is 0.13 to 0.18 mm. The coating prepared according to the method is high in hemispherical emissivity, thermal conductivity and volume resistivity, and has excellent salt spray resistance, moisture and heat resistance and aging resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

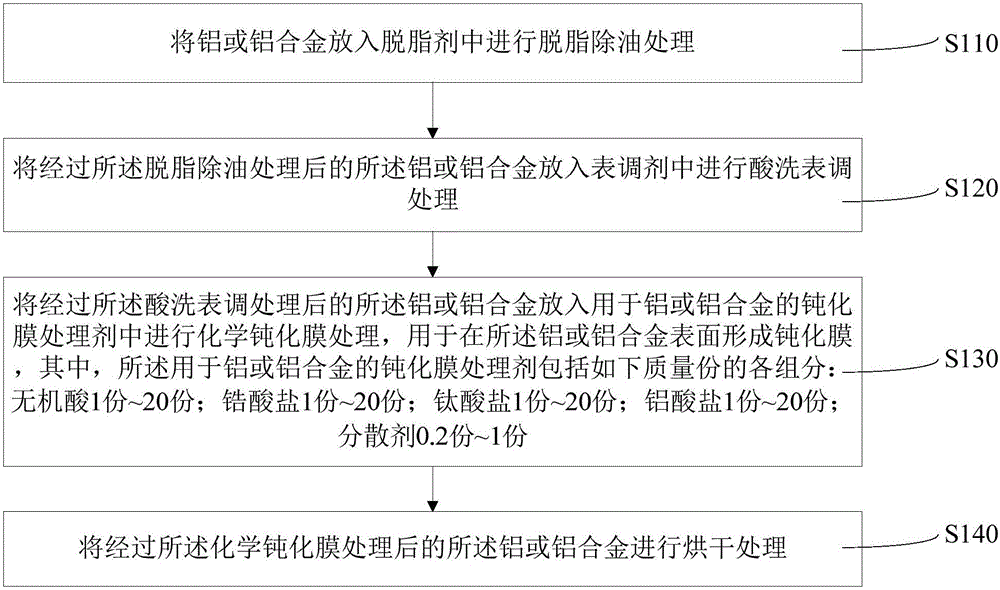

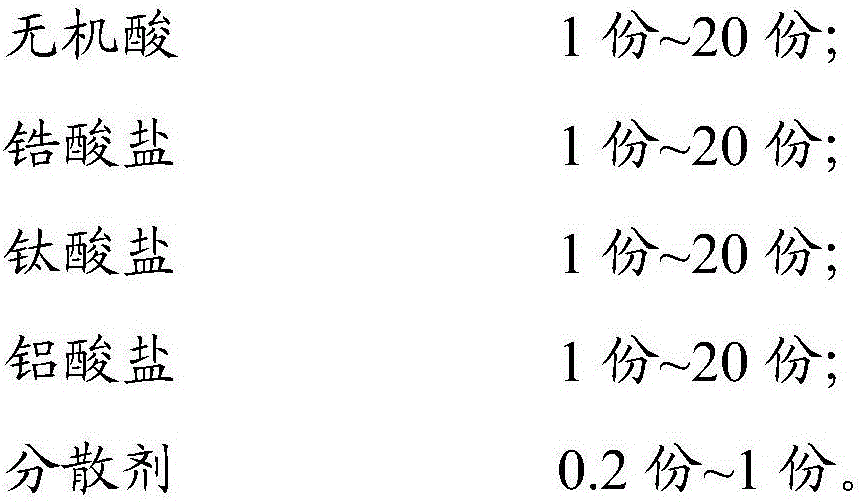

Zr-Ti passive film treating agent for aluminum or aluminum alloy and treating method thereof

InactiveCN105803442AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeAluminate

The invention relates to a passive film treating agent for aluminum or aluminum alloy and a treating method thereof. The passive film treating agent for aluminum or aluminum alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of titanate, 1 to 20 parts of aluminate and 0.2 to 1 part of a dispersing agent. According to the passive film treating agent for aluminum or aluminum alloy, relative to a traditional phosphorus-containing chromium-free passive film treating agent for aluminum or aluminum alloy which causes environmental pollution, the passive film treating agent for aluminum or aluminum alloy has the advantages that through 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of titanate, 1 to 20 parts of aluminate and 0.2 to 1 part of the dispersing agent, a phosphorus-free chromium-free Zr-Ti passive film can be formed on the surface of aluminum or aluminum alloy, the passive film is good in adhesive force, high in corrosion resistance degree and good in salt spray resistance property and film uniformity, and the obtained passive film can be guaranteed to maintain the same silver white metal appearance as aluminum or aluminum alloy.

Owner:广东东明新材科技有限公司

Solvent-resistant acrylic emulsion and preparation method thereof

InactiveCN108484811AStrong adhesionGood hardness and water resistanceSalt resistanceFunctional monomer

The invention discloses a solvent-resistant acrylic emulsion, belonging to the field of acrylic emulsions. The solvent-resistant acrylic emulsion comprises 180-260 parts of water, 50-60 parts of styrene, 40-50 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 1-5 parts of an anionic emulsifier, 1-5 parts of a functional monomer, 0.2-1 part of an initiator, 0.1-0.5 part of an oxidant and 0.1-0.5 part of a reducing agent. The preparation method for the solvent-resistant acrylic emulsion comprises the following steps: 1) pre-emulsification; 2) polymerization; and 3) post-elimination. The solvent-resistant acrylic emulsion provided by the invention is improved in scrub resistance and solvent resistance while having the basic performance of good adhesion, hardness, water resistance, salt water resistance, salt spray resistance, scrub resistance and the like, so the application scope of the acrylic emulsion is broadened, the application properties of the coating are enhanced, the basic performance of the emulsion is substantively improved, and the cost performance of the emulsion is greatly improved.

Owner:佛山市顺德区巴德富实业有限公司

Novel graphene slurry modified epoxy-zinc powder anticorrosion coating and preparation method thereof

InactiveCN109280457AReduce dosageGood dispersionAnti-corrosive paintsEpoxy resin coatingsAdhesion forceEpoxy

A novel graphene slurry modified epoxy-zinc powder anticorrosion coating and a preparation method thereof. The anticorrosion coating includes epoxy resin, graphene-epoxy resin slurry, metal zinc powder, functional filler, and other functional additives. By preparing the graphene-epoxy resin slurry having high dispersibility and electric-conductivity, a phenomenon of aggregation due to direct addition of graphene is effectively solved and usage amount of zinc powder is meanwhile reduced. By compounding the slurry with the epoxy resin and functional filler, dispersibility of graphene in the coating is improved. According to the preparation method, by combination of sand milling and high-speed dispersion, stable dispersion of the graphene in the coating is achieved, and fineness of the coating is guaranteed, so that the coating, compared with a conventional epoxy zinc-rich coating, the coating has good adhesion force, excellent anti-salt fog performance and outstanding anticorrosion performance. Compared with the conventional epoxy zinc-rich coating, the anticorrosion coating is greatly reduced in content of zinc powder, can reach 4000 h in anti-salt fog performance, is higher than 8MPa in adhesion force, and has extensive application prospect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

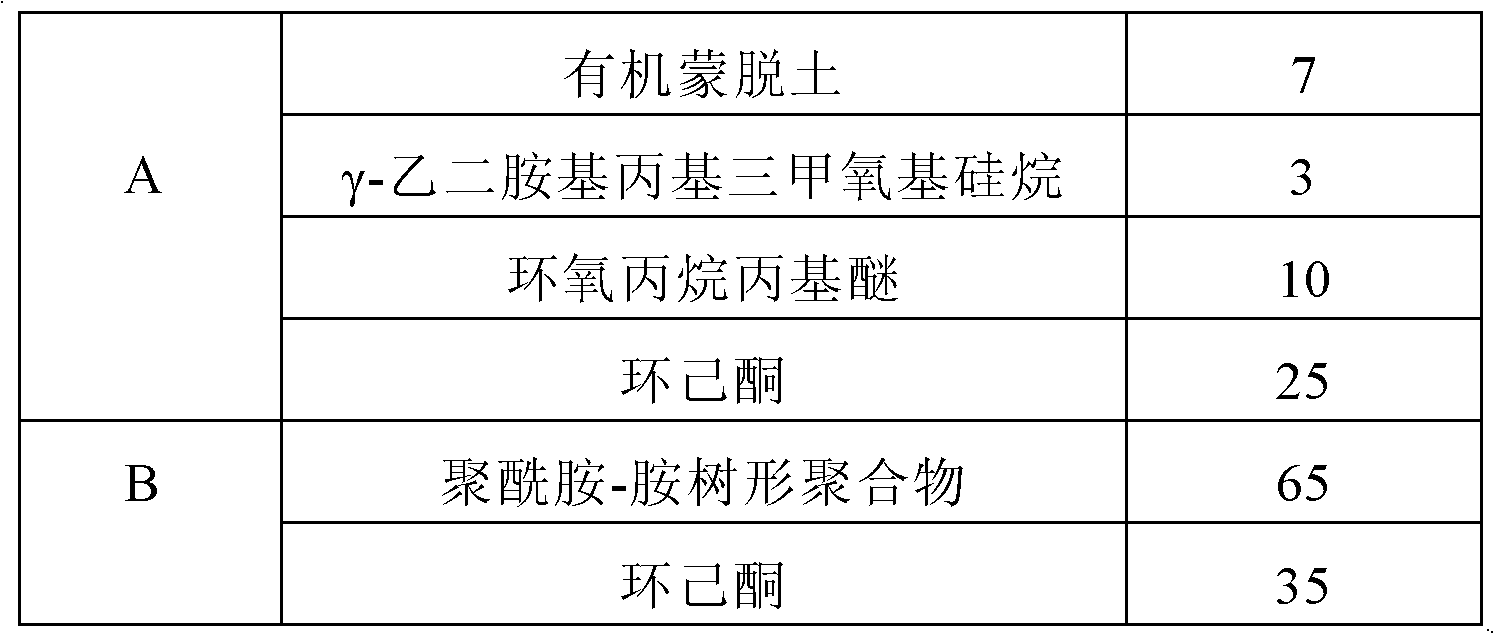

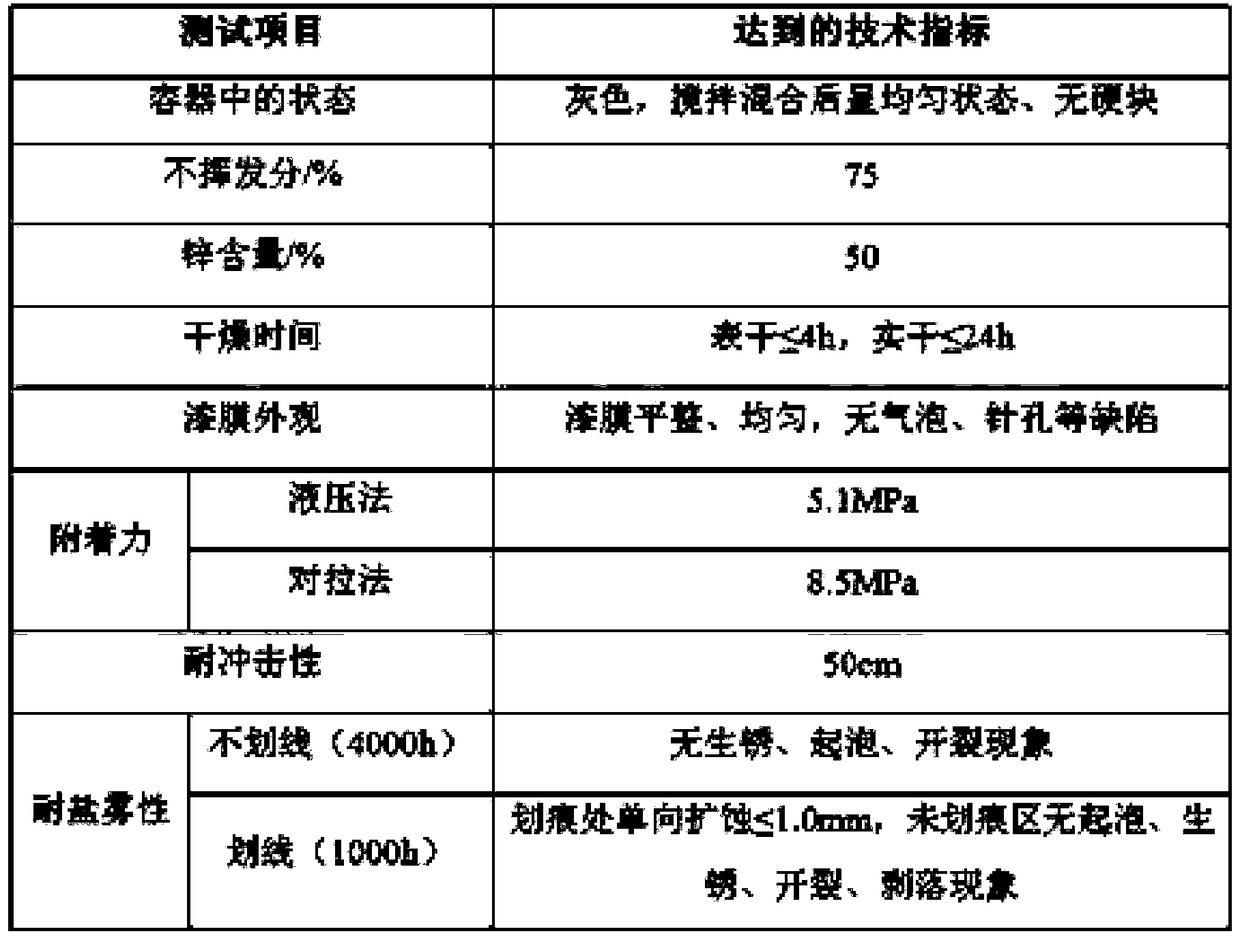

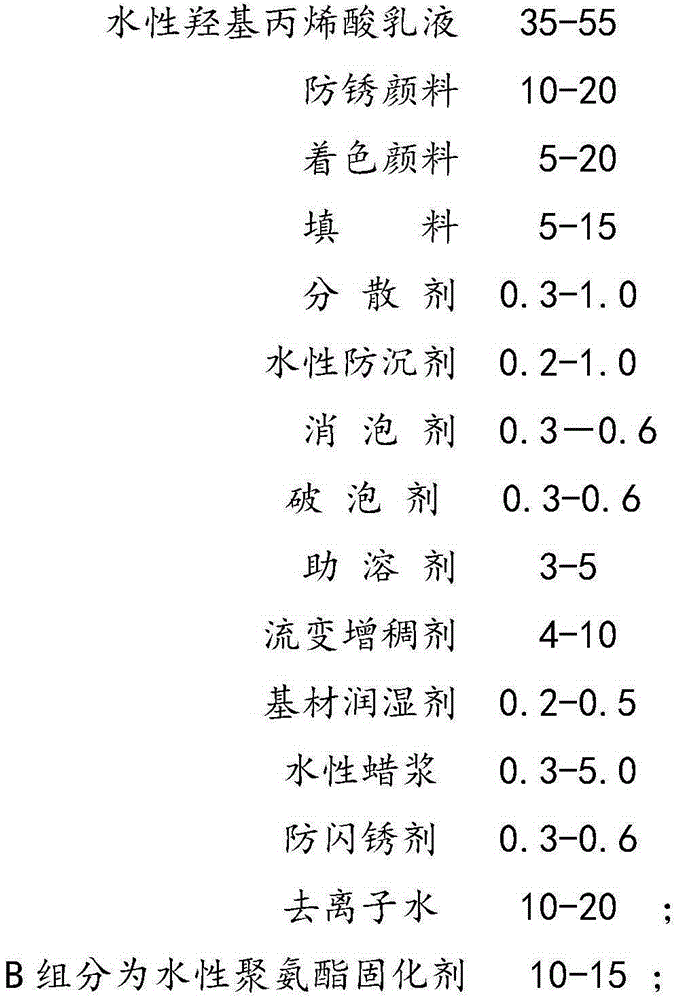

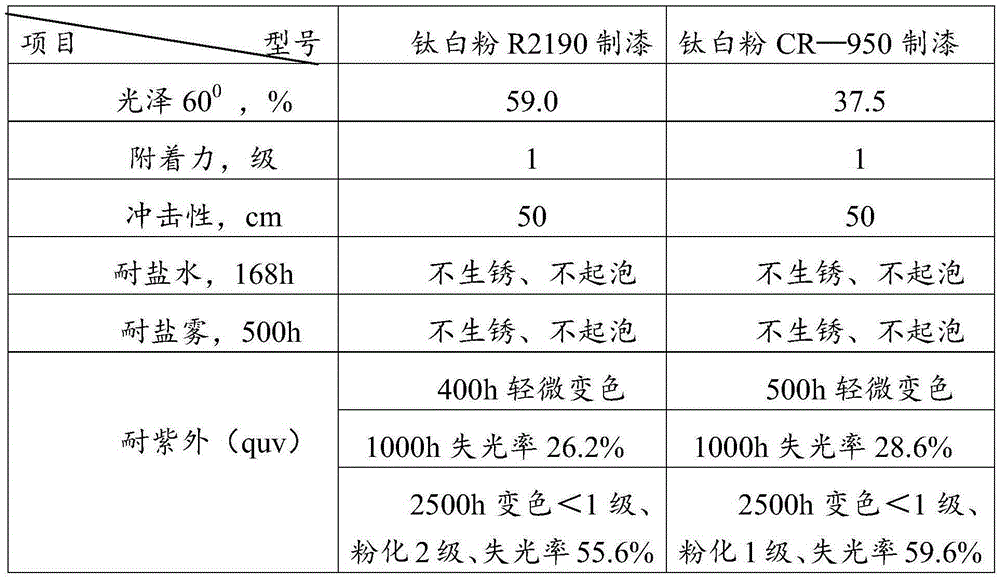

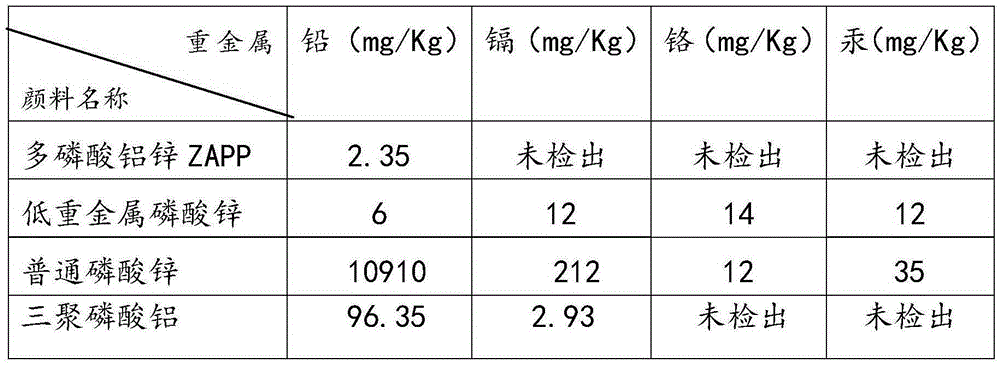

Water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components and preparation method of coating

InactiveCN105349019AGood outdoor weather resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating comprises a component A and a component B, wherein the component A comprises ingredients in parts by weight as follows: 35-55 parts of a water-borne hydroxyl acrylic acid emulsion, 10-20 parts of anti-rust pigments, 5-20 parts of coloring pigments, 5-15 parts of filler, 0.3-1.0 part of a dispersing agent, 0.2-1.0 part of a water-borne anti-settling agent, 0.3-0.6 parts of a defoaming agent, 0.3-0.6 parts of a foam breaker, 3-5 parts of a cosolvent, 4-10 parts of a rheological thickener, 0.2-0.5 parts of a substrate wetting agent, 0.3-5.0 parts of water-borne wax liquor, 0.3-0.6 parts of a flash rust preventing agent and 10-20 parts of deionized water; the component B comprises 10-15 parts by weight of a water-borne polyurethane curing agent. A preparation method comprises steps as follows: the raw materials are sequentially added to a container, are uniformly stirred at medium and high speeds and then are dispersed for 10 min respectively, a mixture is ground, the deionized water is added for uniform stirring, and the component A is prepared. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing the double components has the benefits of excellent outdoor weather fastness, adhesive force, water resistance, salt water resistance and salt fog resistance.

Owner:天津灯塔涂料工业发展有限公司

Asphalt concrete steel bridge pavement structure and pavement method thereof

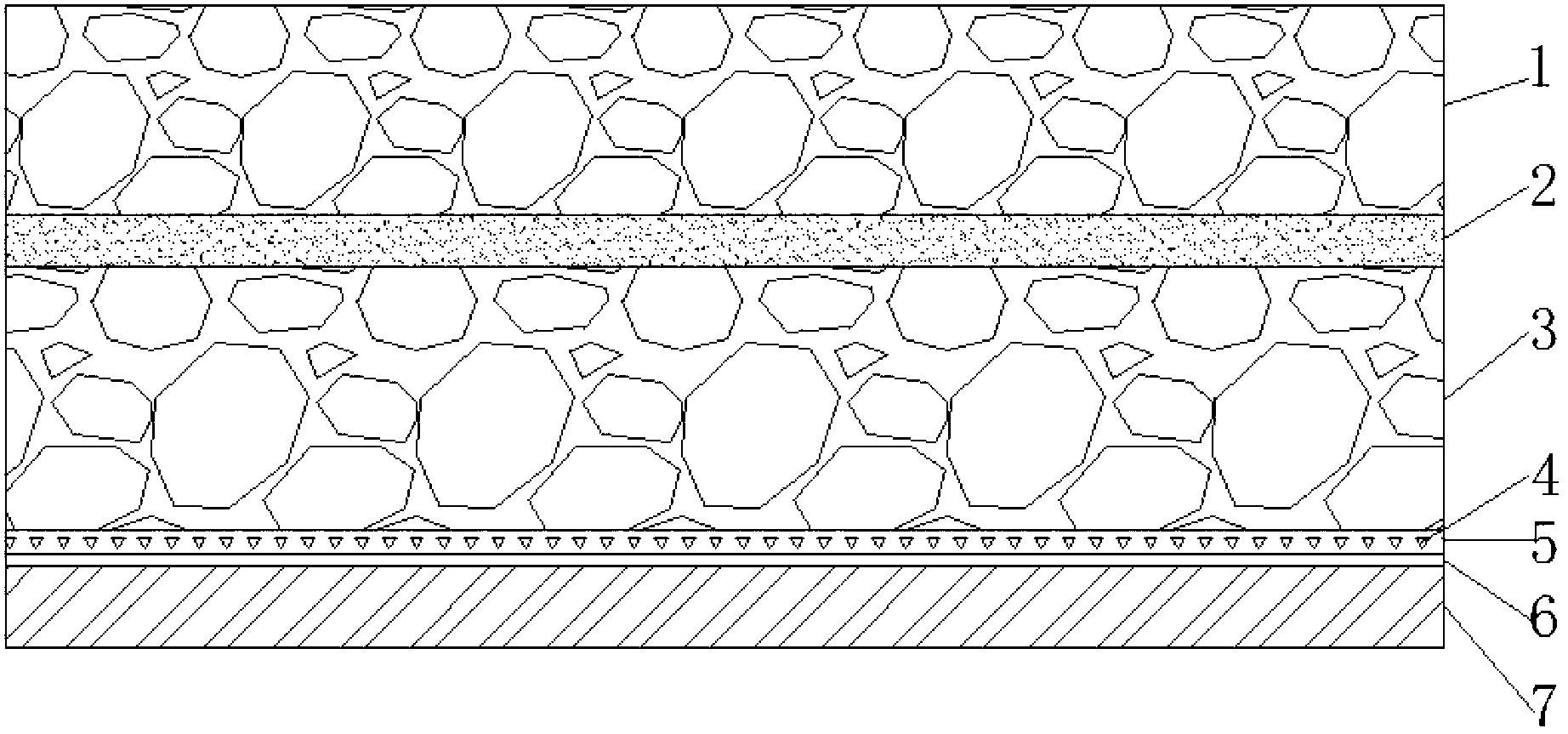

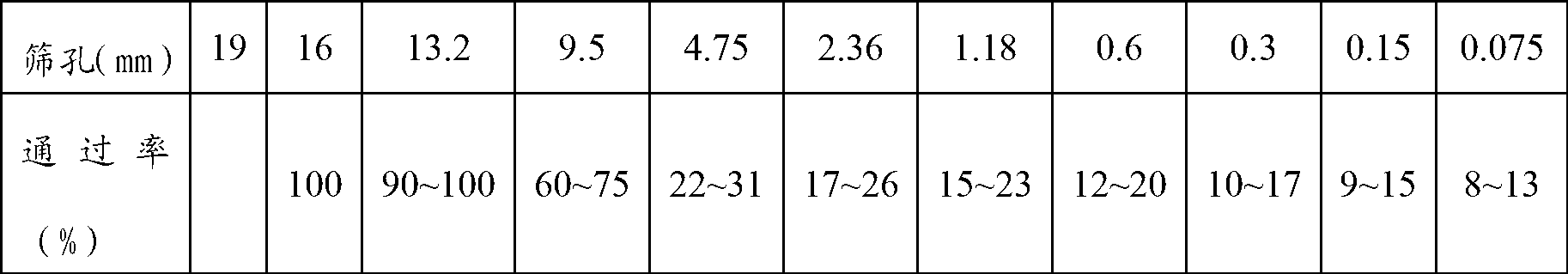

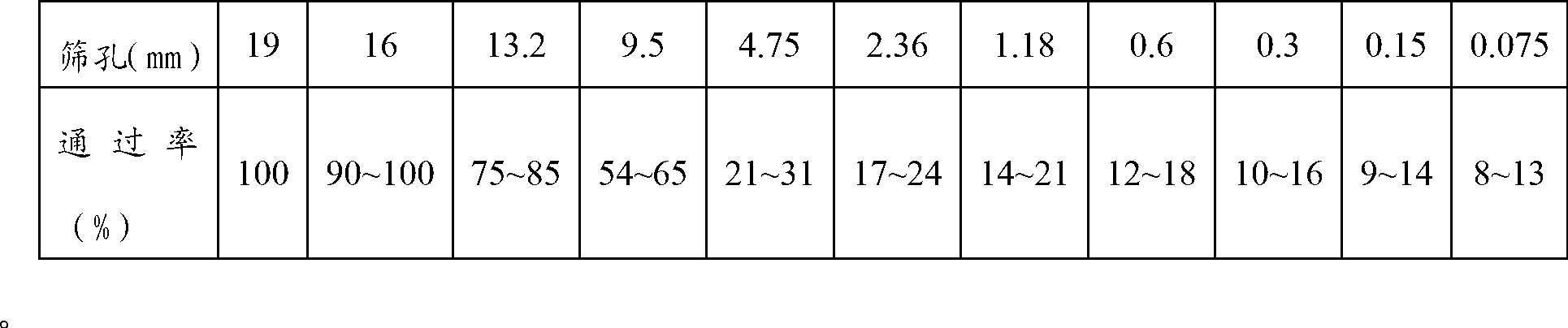

ActiveCN103015316ASolve the problem of permanent deformationStrong adhesionBridge structural detailsBridge erection/assemblySand blastingViscosity

The invention discloses an asphalt concrete steel bridge pavement structure comprising a steel bridge (7) derusted by sandblast, an anticorrosive coating (6), a binding layer (5), high-viscosity asphalt embedded compact granular composition concrete bottom layer (3), an oil sticking layer (2) and a high-viscosity asphalt embedded and compact granular composition concrete top layer (1) which are arranged from bottom to top; and furthermore, the invention also provides a pavement method of the asphalt concrete steel bridge pavement structure. According to the asphalt concrete steel bridge pavement structure, the high-viscosity asphalt embedded compact granular composition concrete layers are used as main pavement layers, so that concrete has favorable interlayer binding force and deformation following performance, the generation of cracks can be restrained, so that the whole steel bridge pavement structure has the advantages of favorable track resistance and water seepage resistance.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com