Preparation method of insulating high-thermal radiation coating suitable for various base materials

A heat-dissipating coating and high-radiation technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor electrical insulation and chemical resistance, little research on radiation heat dissipation characteristics, and poor radiation heat dissipation effect. Excellent resistance to salt spray, broad market prospects, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of insulating high radiation heat dissipation coating suitable for various substrates includes the following steps:

[0029] (1) Add the film-forming material, insulating and thermally conductive filler, solvent, wetting and dispersing agent, defoaming agent, leveling agent and drier into the container, and stir evenly to prepare a varnish slurry, each in parts by mass The group distribution is as follows:

[0030] 40-60 parts of film-forming material, 30-50 parts of insulating and thermally conductive filler, 40-70 parts of solvent

[0031] 0.3-2.0 parts of wetting and dispersing agent 0.2-1.0 parts of defoaming agent 0.1-0.8 parts of leveling agent

[0032] 0.02-0.1 parts of drier;

[0033] The film-forming substance is one or a combination of hydroxy acrylic resin, polyester modified hydroxy acrylic resin, or polyether modified hydroxy acrylic resin.

[0034] The insulating thermal conductive filler is a combination of a nitride thermal conductive filler...

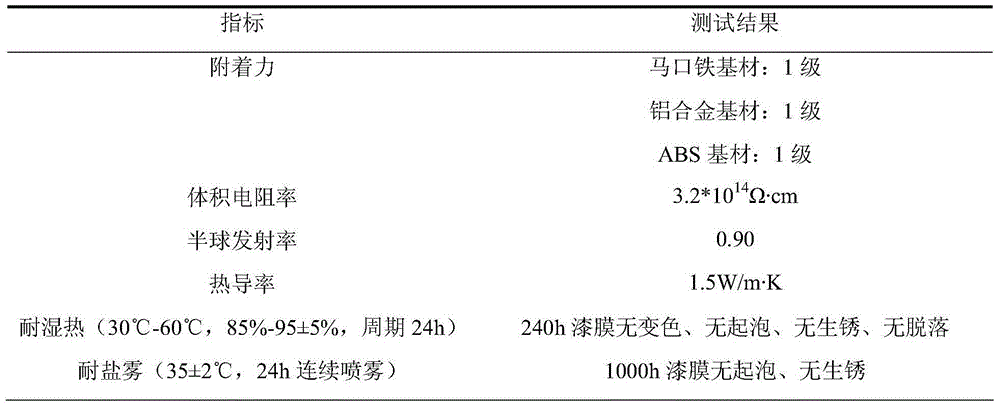

Embodiment 1

[0040] This embodiment includes the following steps:

[0041] (1) Add 100g of hydroxy acrylic resin, 64g of aluminum nitride, 16g of α-alumina, 65g of butyl acetate, 30g of ethyl acetate, 1.8g of wetting and dispersing agent (Disponer 9250), and defoaming agent ( Defom5300) 1.2g, leveling agent (Levelol839) 0.8g, drier (dibutyltin dilaurate) 0.06g, stir and mix with a glass rod to prepare a paint slurry.

[0042] (2) Pour the paint slurry in step (1) slowly into a ball mill tank, and use a planetary ball mill to grind and disperse for 2 hours to obtain a uniformly dispersed paint slurry.

[0043] (3) Filter the uniformly dispersed paint slurry in step (2) with a 100 μm filter, pour it into a jar, add 24 g of the cross-linking curing agent HDI biuret, and stir evenly.

[0044] (4), using aluminum alloy plate, red copper sheet, ABS plate and tinplate (tinning amount is E 4 , Hardness grade is T52), as the object to be sprayed, sand it with 240# sandpaper, and wipe the surface of the sam...

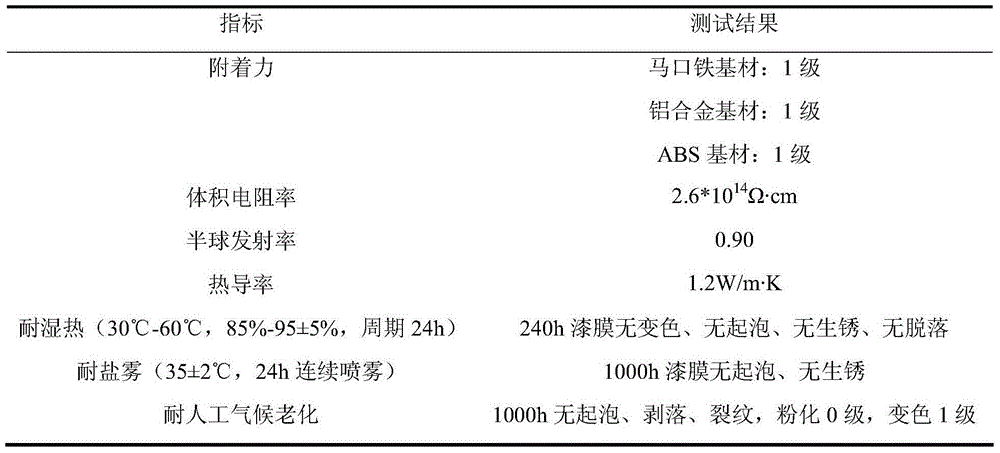

Embodiment 2

[0050] This embodiment includes the following steps:

[0051] (1) Add 80 g of hydroxy acrylic resin, 35 g of polyester modified hydroxy acrylic resin, 40 g of silicon nitride, 36 g of aluminum nitride, 19 g of α-alumina, 40 g of xylene, 60 g of butyl acetate, and ethyl acetate into the paint mixing tank. Ester 25g, wetting and dispersing agent (BYK-110) 2.5g, defoaming agent (BYK-052) 1.3g, leveling agent (BYK-358) 0.9g, drier (dibutyltin dilaurate) 0.06g, Stir and mix with a glass rod to prepare a paint slurry.

[0052] (2) Pour the paint slurry in step (1) slowly into a ball mill tank, and use a planetary ball mill to grind and disperse for 2 hours to obtain a uniformly dispersed paint slurry.

[0053] (3) Filter the uniformly dispersed paint slurry in step (2) with a 100 μm filter, pour it into a jar, add 28 g of the crosslinking curing agent HDI biuret, and stir evenly.

[0054] (4) Using aluminum alloy plate, red copper sheet, ABS plate and tinplate (the amount of tin plating is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com