Flame-retardant curing agent containing phosphorus and P-C key structure, preparation method of flame-retardant curing agent and flame-retardant epoxy resin with flame-retardant curing agent as raw materials

A technology of epoxy resin and curing agent, which is applied in the field of flame retardant epoxy resin, can solve the problems of easy hydrolysis, poor compatibility with epoxy resin matrix, poor thermal stability, etc., and achieve good compatibility and guarantee no Migration, durability, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

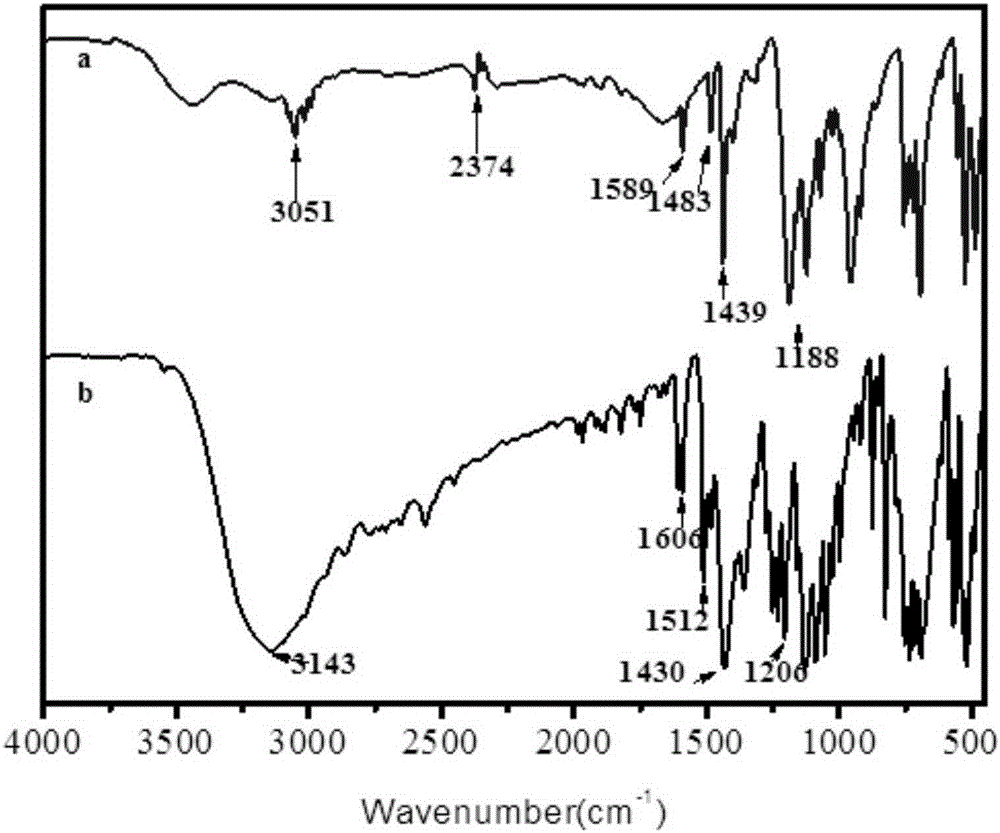

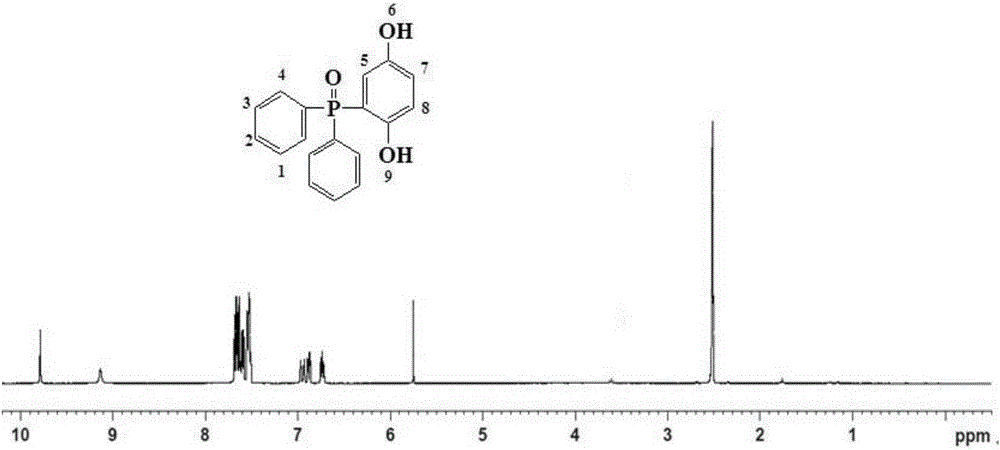

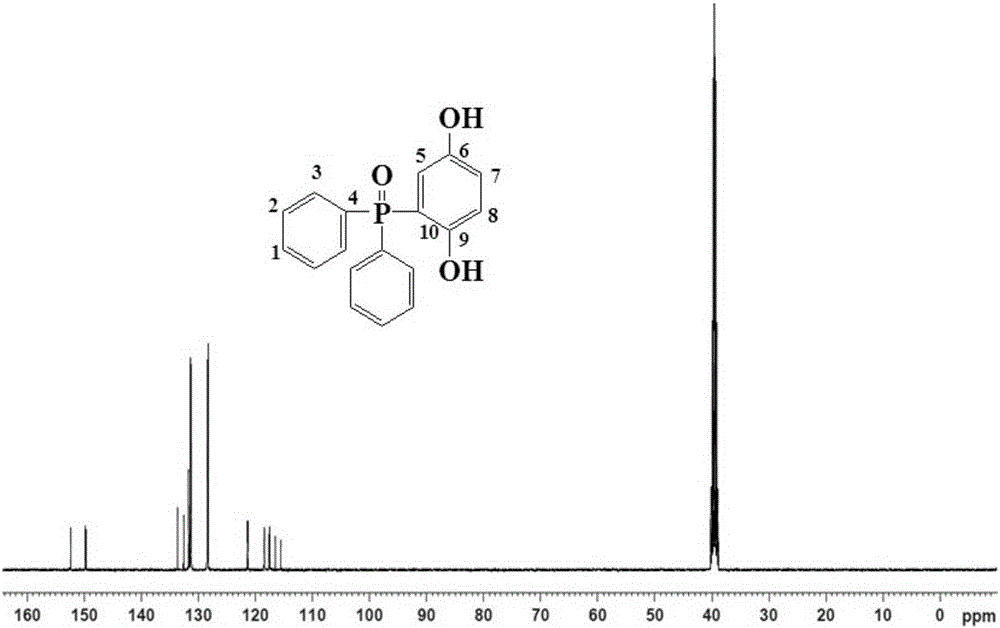

[0028] Specific implementation mode 1: The structural formula of the flame retardant curing agent containing phosphorus and P-C bond structure in this embodiment is:

[0029] where R is

specific Embodiment approach 2

[0030] Specific embodiment two: the preparation method of the flame retardant solidifying agent containing phosphorus and P-C bond structure of this embodiment, carries out according to the following steps:

[0031] 1. Add diphenylphosphine and raw material A into a four-neck round bottom flask equipped with a spherical condenser, thermometer, mechanical stirring device, constant pressure dropping funnel and gas protection device, and heat it into the flask under nitrogen protection The substance melts completely;

[0032] 2. Then add the solvent dropwise. Under the conditions of nitrogen flow and stirring, the reactant reacts in the reflux state for 2 to 3 hours, then cools to room temperature, and removes the solvent by rotary evaporation. The obtained precipitate is washed and dried to obtain a crude product. After the product is recrystallized, a white powdery product is finally obtained.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the raw material A in step 1 is p-quinone, maleic acid or itaconic acid. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com